Patents

Literature

53results about How to "Less catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Starter feed stream acidification in DMC-catalyzed process

InactiveUS20050209438A1Easy to optimizeLess catalystPhysical/chemical process catalystsElastomerPolyol

The process of the present invention provides for the manufacture of lower molecular weight DMC-catalyzed polyols than is possible using non-acidified continuous addition of starter (CAOS) feeds, by adding excess acid to a starter feed stream over that required for mere neutralization of the basicity of the starter. The benefits of the invention also extend to starters which do not contain basicity. Polyether polyols made by the inventive process may be used to produce improved polyurethane products such as coatings, adhesives, sealants, elastomers, foams and the like.

Owner:BAYER MATERIALSCIENCE AG

Method for preparing 2,5-diformyl furan by catalyzing 5-hydroxy methyl furfural

ActiveCN101619050AHigh separation yieldLess catalystOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFuranNitrite

The invention provides a method for preparing 2,5-diformyl furan by catalytic oxidation of 5-hydroxy methyl furfural. The method comprises the following steps: taking air or oxygen as an oxygen source, taking a mixture of inorganic vanadium oxides, 2,2,6,6-4-pipecolate-oxygen radicals and derivatives and nitrites of the 2,2,6,6-4-pipecolate-oxygen radicals as a compound catalyst system, and oxidizing the 5-hydroxy methyl furfural into the 2,5-diformyl furan at a temperature of between 50 and 120 DEG C. The method has the advantages of high oxidizing efficiency, few byproducts, mild reaction conditions, easy separation and purification of products and quite high practicability.

Owner:中科化物(大连)科技实业有限公司

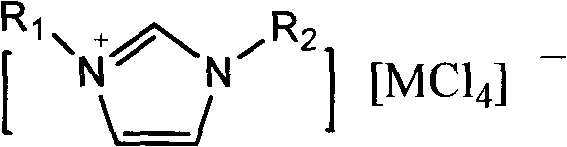

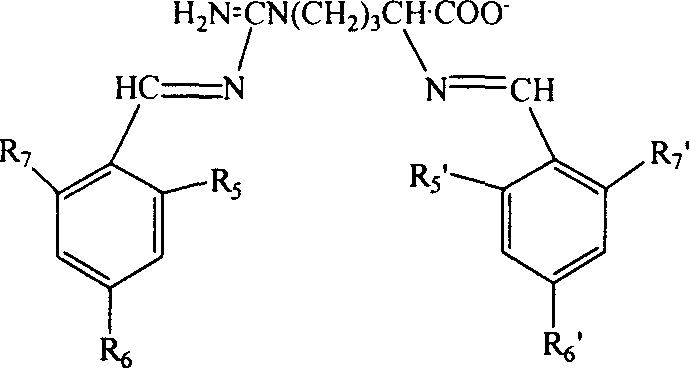

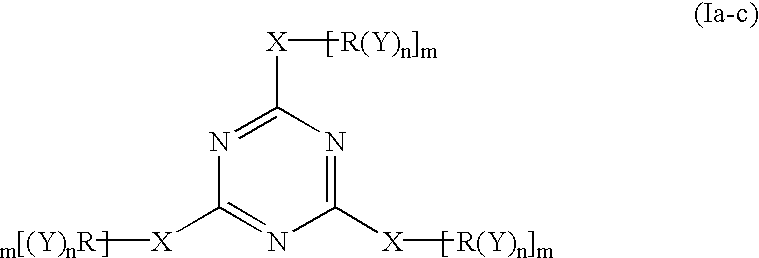

Novel disulfonic acid type alkyl imidazole ionic liquid, preparation and uses thereof

ActiveCN101508675AGood catalytic activityReduce dosageOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventIon

The invention discloses a novel disulfonate type alkyl imidazole ionic liquid as well as a preparation method and application thereof. Structure of the ionic liquid is shown as formula (I), and the preparation method of the ionic liquid comprises the followings steps: trimethylsilylimidazole with structure shown as formula (II) is dropwise added to sultones with the structure shown as formula (III) for heat insulation reaction at the temperature of minus 20 DEG C to 30 DEG C, then water is dropwise added for continuing the heat insulation reaction to obtain an intermediate product (a zwitterionic compound) with the structure shown as formula (IV); an HY acid is dropwise added to aqueous solution of the zwitterionic compound to obtain a target product after full reaction at the temperature of 60-100 DEG C. The designed ionic liquid is hydrostable, almost has no steam pressure, especially has strong acidic properties, exhibits good catalytic activity when being applied to pechmann reaction, and a synthetic method thereof has environment-friendly feature, thus being expected to be applied to organic synthesis and catalysis fields as an environment-friendly solvent and catalyst.

Owner:ZHEJIANG UNIV OF TECH

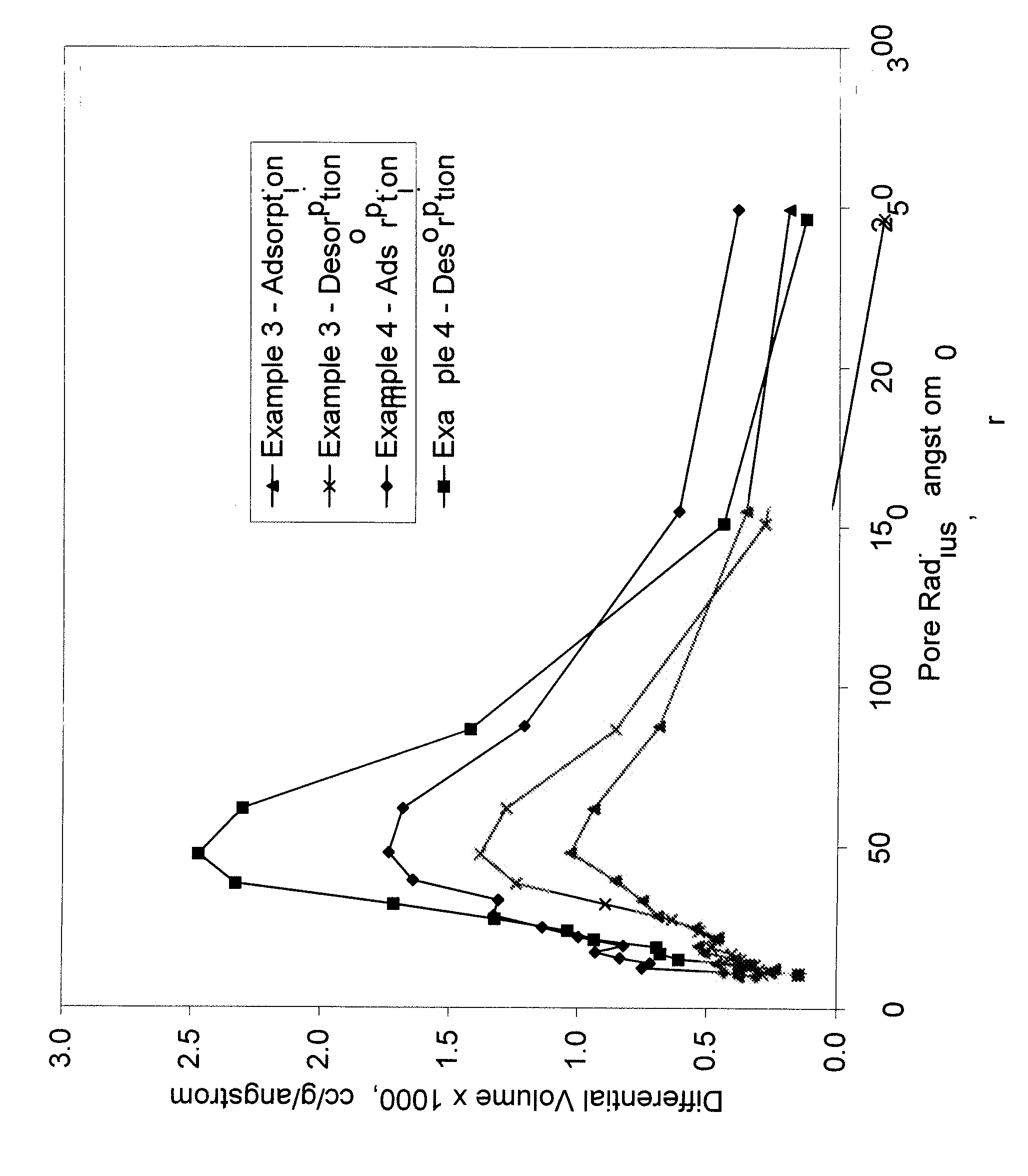

Selective Hydrogenation Process Using Layered Catalyst Composition and Preparation of Said Catalyst

InactiveUS20080248199A1High airspeedLower cost of capitalMolecular sieve catalystsPretreated surfacesHydrogenation processOrganic chemistry

A selective hydrogenation process and a layered catalyst composition for use in the selective hydrogenation process are disclosed. The process is useful for the selective hydrogenation of diolefins having from about 8 to about 19 carbon atoms per molecule to monoolefins.

Owner:UOP LLC

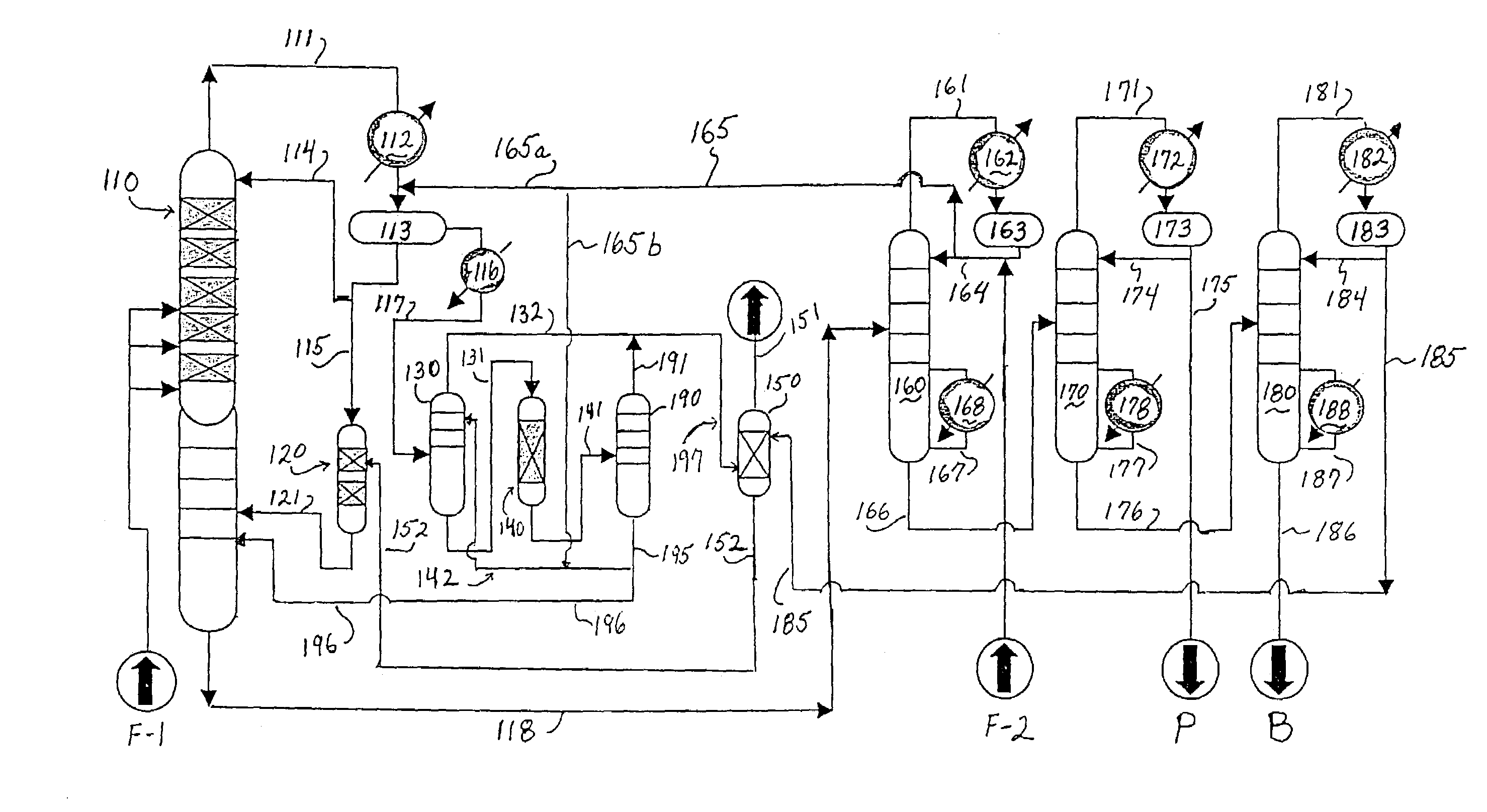

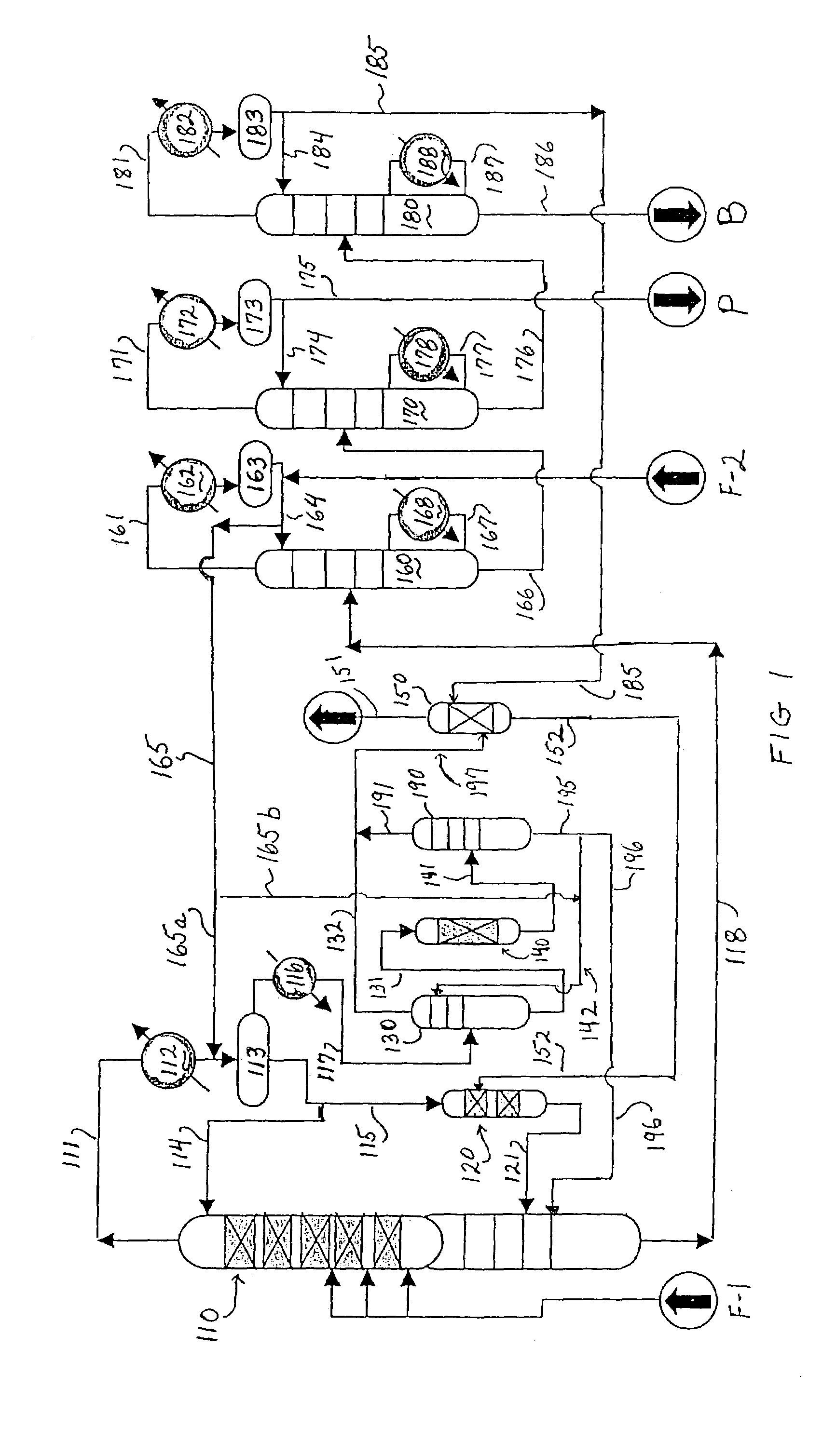

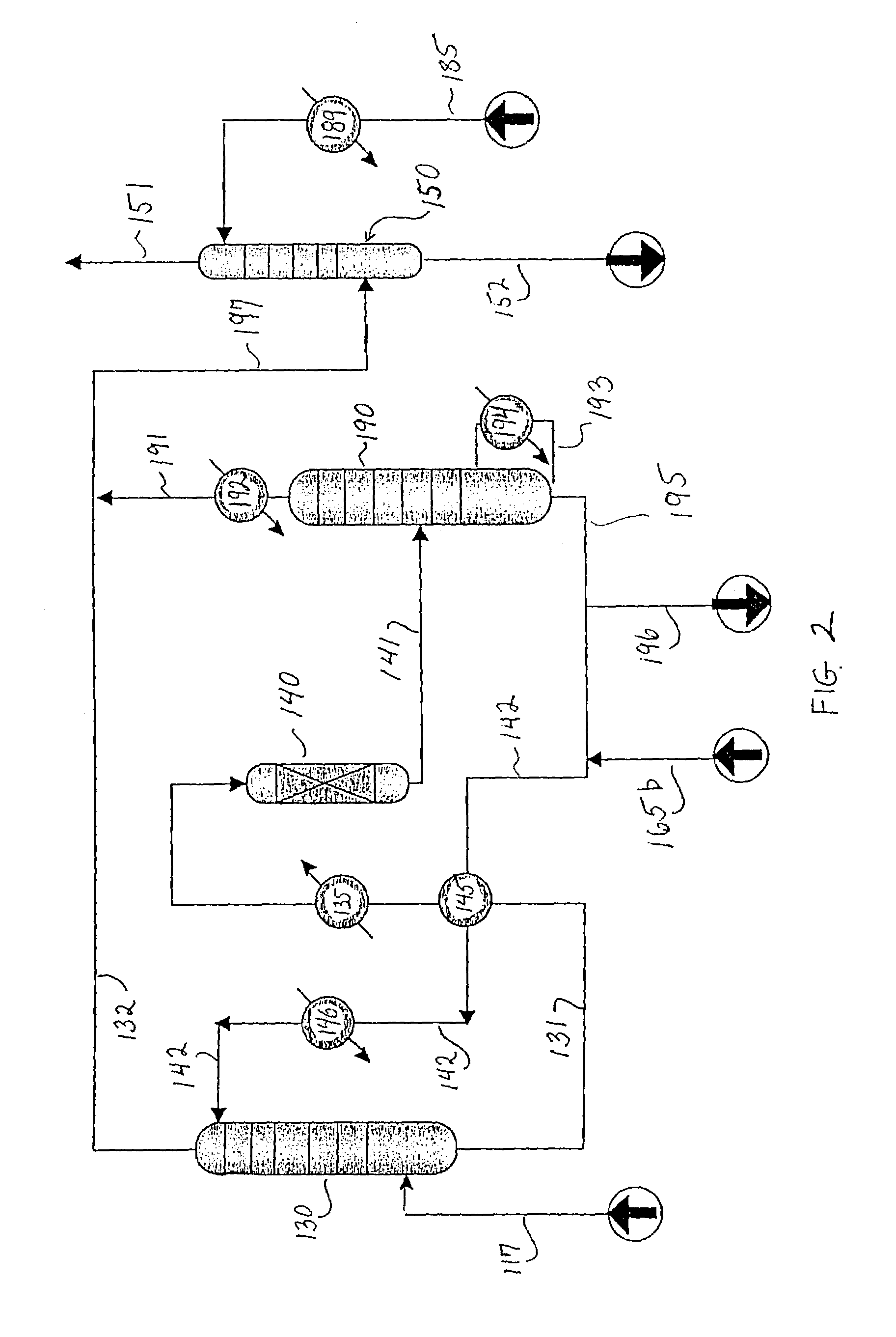

Process for the production of alkylbenzene with ethane stripping

ActiveUS7071369B2Increase conversionsLess catalystMolecular sieve catalystsHydrocarbonsAlkyl transferReaction zone

A process for the production of alkylbenzene includes introducing benzene and an olefin feed into a first alkylation reaction zone in the presence of a first alkylation catalyst under first alkylation reaction conditions to produce a first alkylation effluent containing alkylbenzene and a first alkylation overhead stream. The first alkylation overhead stream is separated into a liquid portion containing benzene and a vapor portion containing unconverted olefin and ethane. A major portion of the unconverted olefin in the vapor portion of the first alkylation overhead stream is absorbed into a de-ethanized aromatic lean oil stream containing benzene and alkylbenzene in an absorption zone to produce a rich oil stream containing olefins and at least some of the ethane. The rich oil stream is sent to a second alkylation reaction zone containing a second alkylation catalyst under second alkylation reaction conditions to produce a first aromatic lean oil stream, which is fractionated in a de-ethanizer to produces a de-ethanizer vapor overhead containing a major portion of the ethane and a liquid bottoms containing the de-ethanized aromatic lean oil.

Owner:ABB LUMMUS GLOBAL INC

Uses of benzoic acid stannous as catalyst

ActiveCN101492441ALess catalystHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemistryOligomer

The invention mainly relates to the usage of benzoic acid stannous, in particular to the usage of the benzoic acid stannous as a catalyst for the oligomer pyrolysis. The oligomer is one of lact-acid oligomer or oligomeric hydroxyacetic acid. The lact-acid oligomer cracks to generate lactide, and the oligomeric hydroxyacetic acid cracks to generate glycolide.

Owner:ZHEJIANG HISUN BIOMATERIALS +1

New method for preparing p-chlorotoluene through selective chlorination of toluene

InactiveCN102731246ALess catalystHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationIonAluminium

The invention provides a new method for preparing p-chlorotoluene through selective chlorination of toluene. The new method comprises the steps as follows: 1) mixing alkylimidazolium chloride ionic liquid with lewis acid to obtain lewis acid type ionic liquid, wherein R1 and R2 are C1 to C8 alkyl group, and MCln is lewis acid such as ferric trichloride, aluminium trichloride and antimony trichloride; 2) taking the lewis acid type ionic liquid as catalyst to be added in toluene solution, introducing chlorine gas in dark, controlling the temperature at 0-50 DEG C in the whole chlorination process, and controlling the chlorine introduction amount so as to enable the conversion percent of the toluene to be larger than 85%; and (3), cooling, and then filtering the ionic liquid to obtain the toluene monochloride mixture solution. After being applied for toluene ring chlorination as the catalyst, the advantages of small catalyst use amount, high selectivity to p-chlorotoluene, easy separation, and applicability are provided.

Owner:常州新东化工发展有限公司

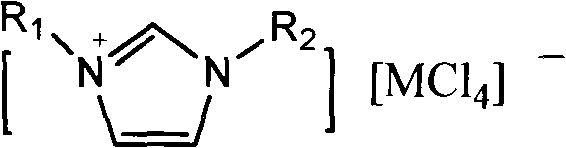

Process for preparing ketoisophorone

InactiveCN1865210AFast responseLess catalystOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventIsophorone

Owner:ZHEJIANG UNIV +1

Method for preparing p-hydroxyphenyl ethanol

InactiveCN103232328ALess catalystCatalyst dosage can be reusedOrganic chemistryOrganic compound preparationSolventNitrogen gas

The invention provides a method for preparing p-hydroxyphenyl ethanol, relating to a preparation method of a compound. The method for preparing the p-hydroxyphenyl ethanol, provided by the invention, has the advantages of simplicity in operation, environmental friendliness, high yield, reusable catalyst and applicability to industrial production. The method comprises the steps of: putting p-hydroxyphenyl acetate serving as a raw material, a copper-based catalyst serving as a hydrogenation catalyst, and a reaction solvent in a reaction vessel, replacing air in the reaction vessel with nitrogen gas and hydrogen gas respectively, and then, reacting; and carrying out depressurized spin drying on a solution after reacting, recovering the reaction solvent so as to obtain white solids, recrystallizing by using chloroform so as to obtain colorless needle-like crystals, filtering out precipitated crystals, washing filter cakes with water, and then, carrying out vacuum drying, thereby obtaining the p-hydroxyphenyl ethanol. The copper-based catalyst is used, so that the catalyst is little in consumption and can be reused; used solvents can be all recovered, so that the environmental protection and cost reduction are benefited; and the yield of the p-hydroxyphenyl ethanol is high and can reach over 80% at highest.

Owner:XIAMEN UNIV +1

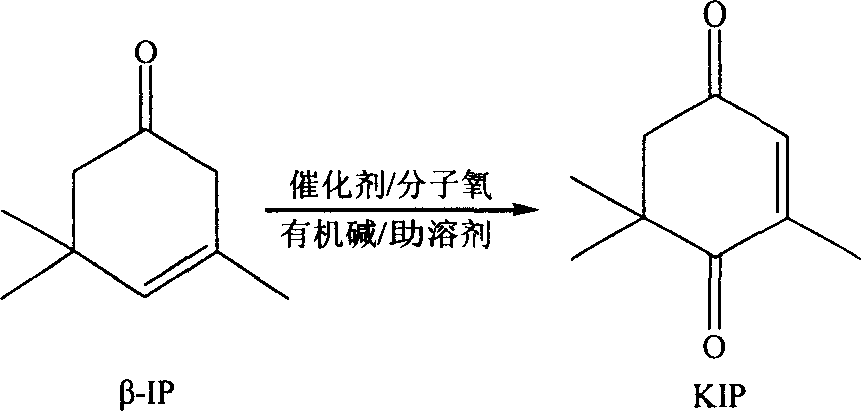

Solid base catalyst and method for making and using the same

ActiveUS20130079560A1Efficient and predictableReduce the amount requiredMolecular sieve catalystsOrganic compound preparation4-aminodiphenylamineInorganic chemistry

A solid base catalyst having a carrier, an organic base, and an inorganic base. Both of the organic base and inorganic base are loaded on the carrier. The solid base catalyst is especially suitable for the synthesis of 4-Aminodiphenylamine (4-ADPA).

Owner:SENNICS CO LTD

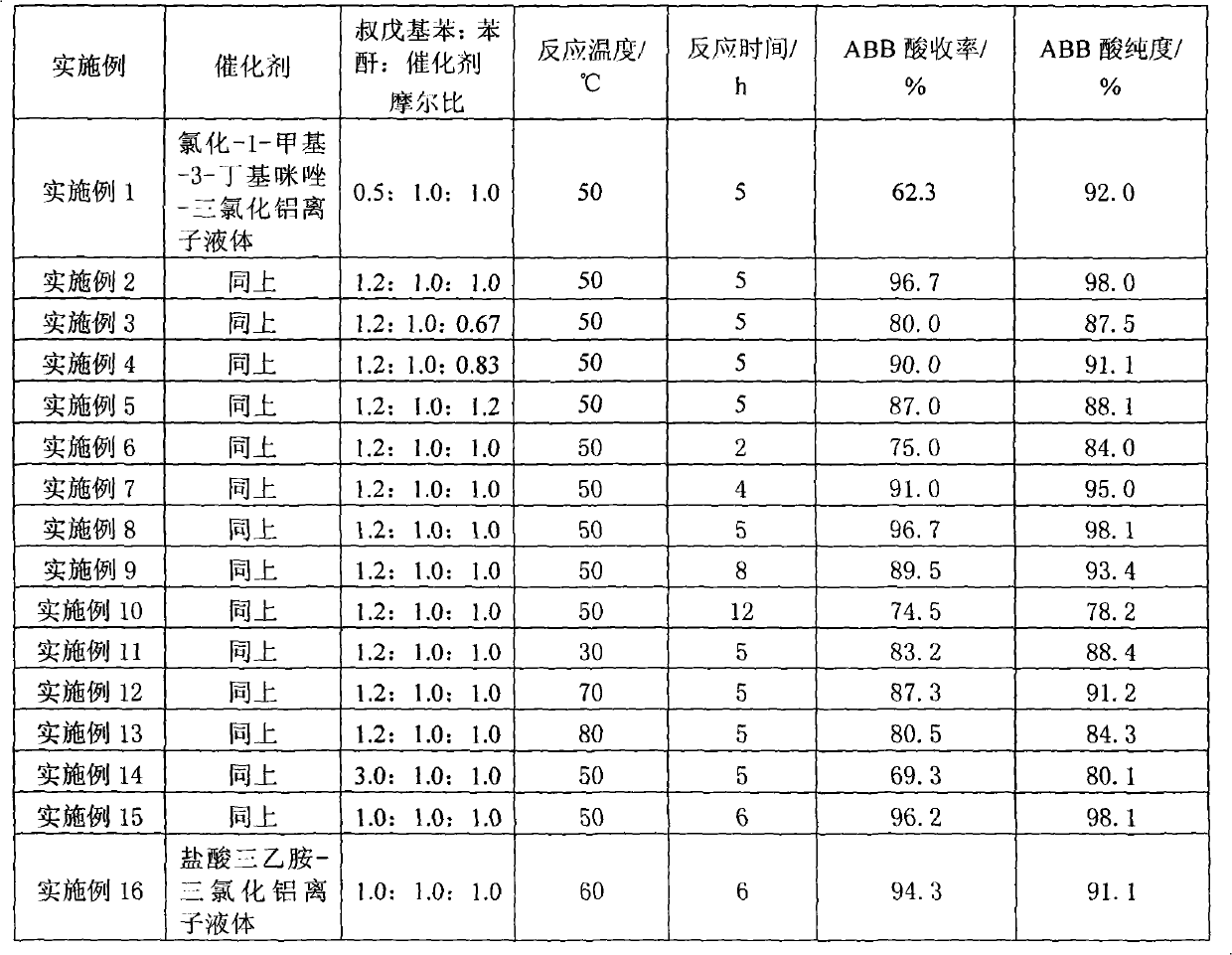

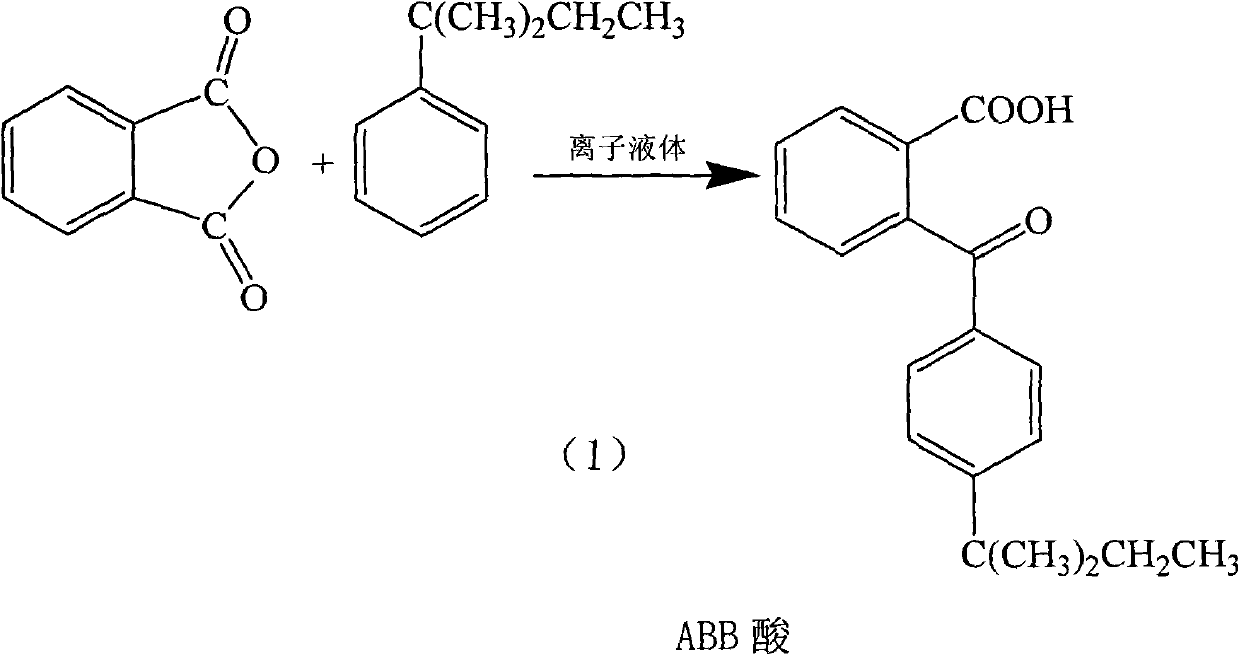

Preparation method of 2-(4'-amyl-benzoyl) benzoic acid

InactiveCN101921189ALess catalystNo wasteOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIonBenzene

The invention discloses a preparation method of 2-(4'-amyl-benzoyl) benzoic acid. The 2-(4'-amyl-benzoyl) benzoic acid is synthesized by taking tert-amyl benzene and phthalic anhydride as raw materials and taking chlorination-1-methyl-3-butyl imidazole-aluminum chloride or triethylamine hydrochloride-aluminum chloride ion liquid as a catalyst, wherein the feeding molar ratio of the tert-amyl benzene to the phthalic anhydride to the ion liquid catalyst is 0.5-3.0:1.0:0.67-1.2; the optimal feeding ratio is 1.0-1.2:1.0:1.0; the reaction temperature is 20-80 DEG C, and the optimal reaction temperature is 40-60 DEG C; the reaction time is 2-12h, and the optimal reaction time is 6-8h; and after reaction, water is added for carrying out suction filtration to obtain solid ABB acid. By adopting the method, the reaction yield can reach 98%.

Owner:LIMING RES INST OF CHEM IND

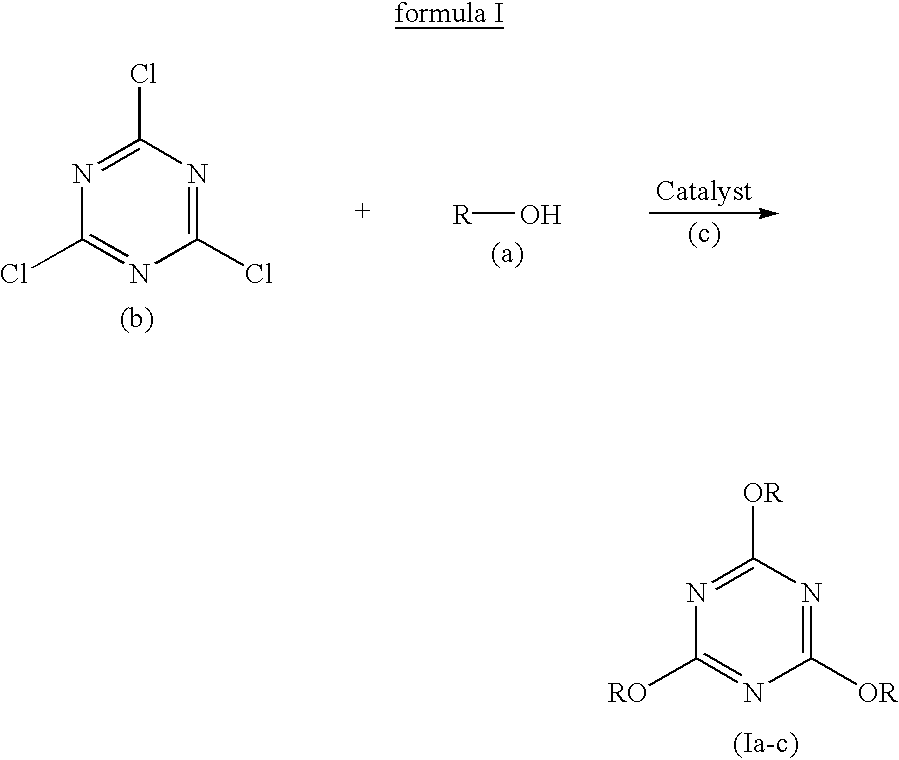

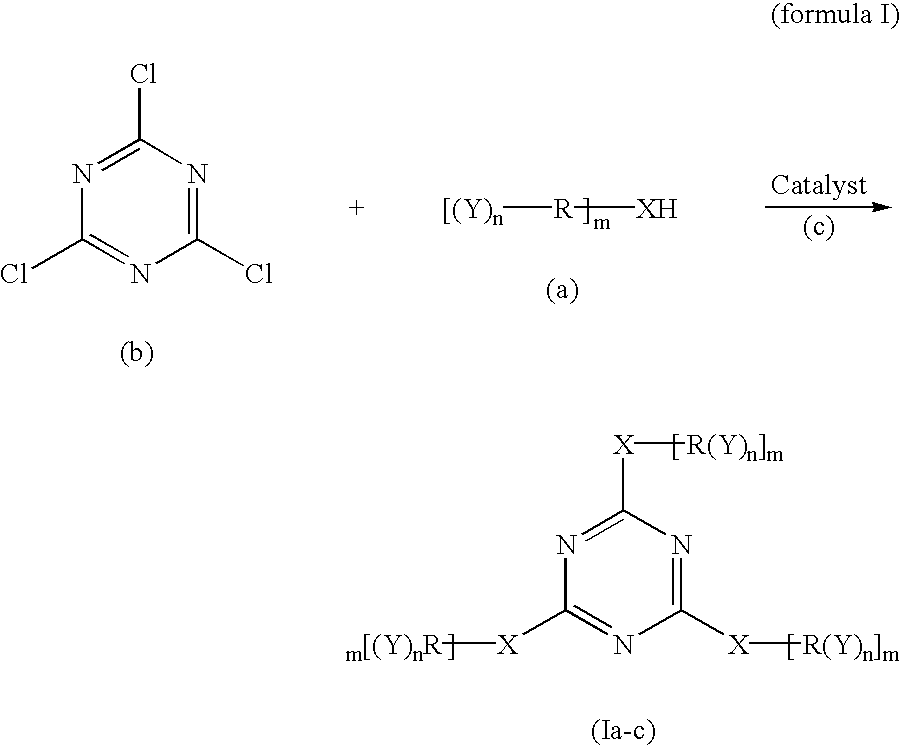

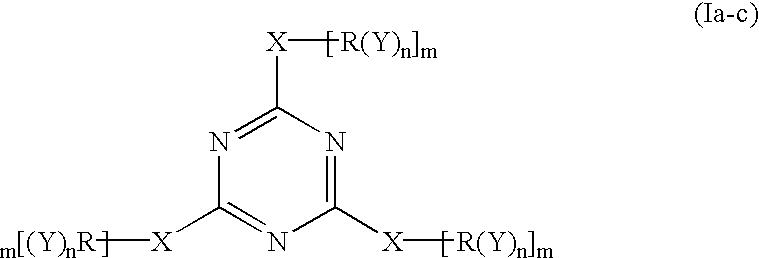

Polyether polyols with increased functionality

InactiveUS6548564B1Mild conditionsFunction increaseOrganic chemistryOther chemical processesPolymer sciencePolyol

This invention relates to a process for the preparation of a polyether polyol having a functionality of at least about 3, a molecular weight of from about 560 to about 35,000 and an OH number of from about 10 to about 1,100. This process comprises reacting (a) a polyether polyol containing one or more ether groups, having a functionality of about 2 to about 8, a molecular weight of about 106 to about 12,000, and an OH number of about 28 to about 1,400, with (b) cyanuric chloride, optionally, in the presence of (c) one or more catalysts; wherein the functionality of the resultant polyether polyols equals three times the functionality of (a) said polyether polyol, minus three. This invention also relates to the process of reacting a polyether polyol, formed by the stated reaction with cyanuric chloride, with an alkylene oxide, optionally in the presence of a catalyst, to form a polyether polyol that has a higher molecular weight and a functionality greater than or equal to the functionality of the polyether polyol used as the starter in this process.

Owner:BAYER POLYMERS LLC

Hydrogenation method for hydrocarbon oils

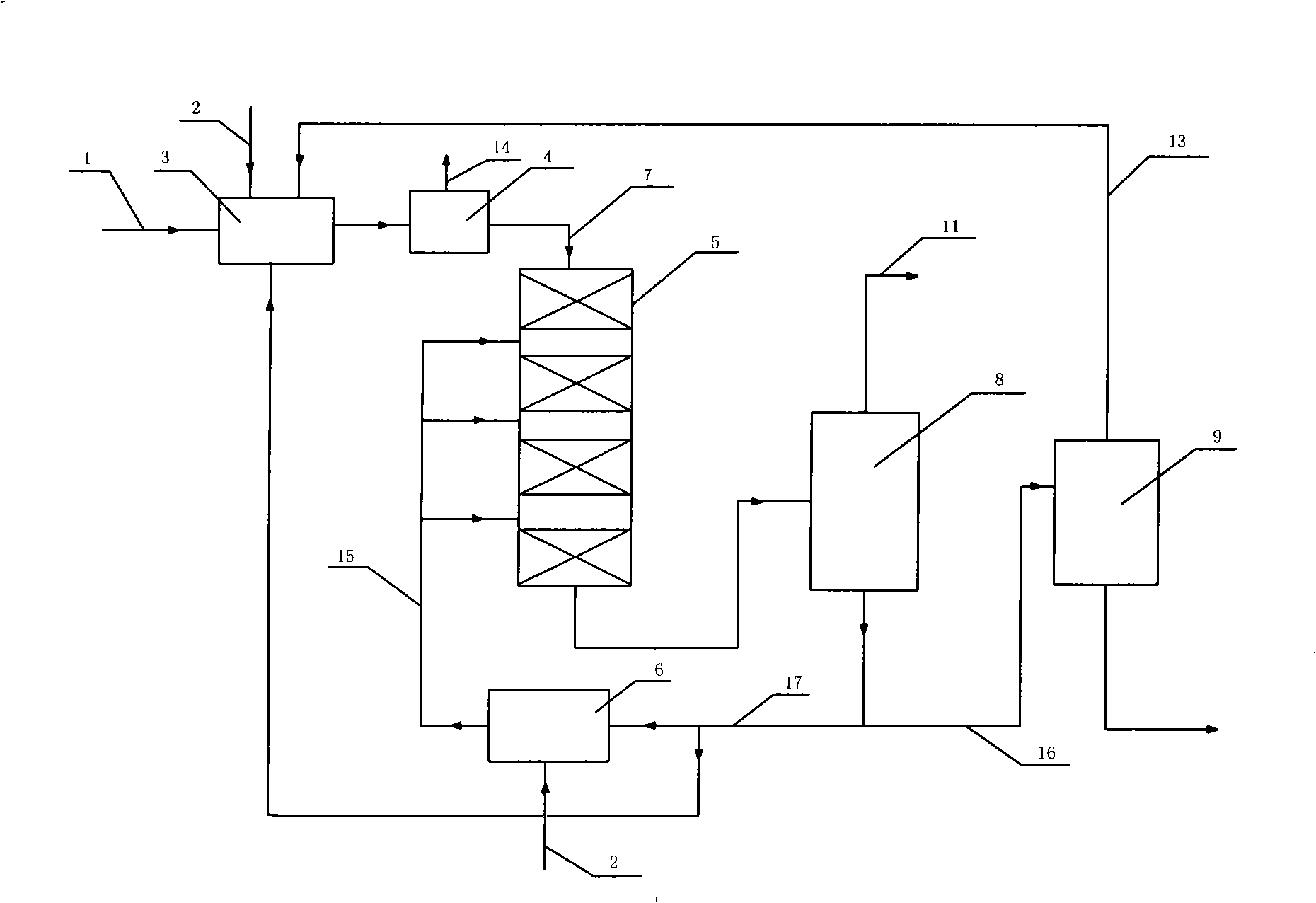

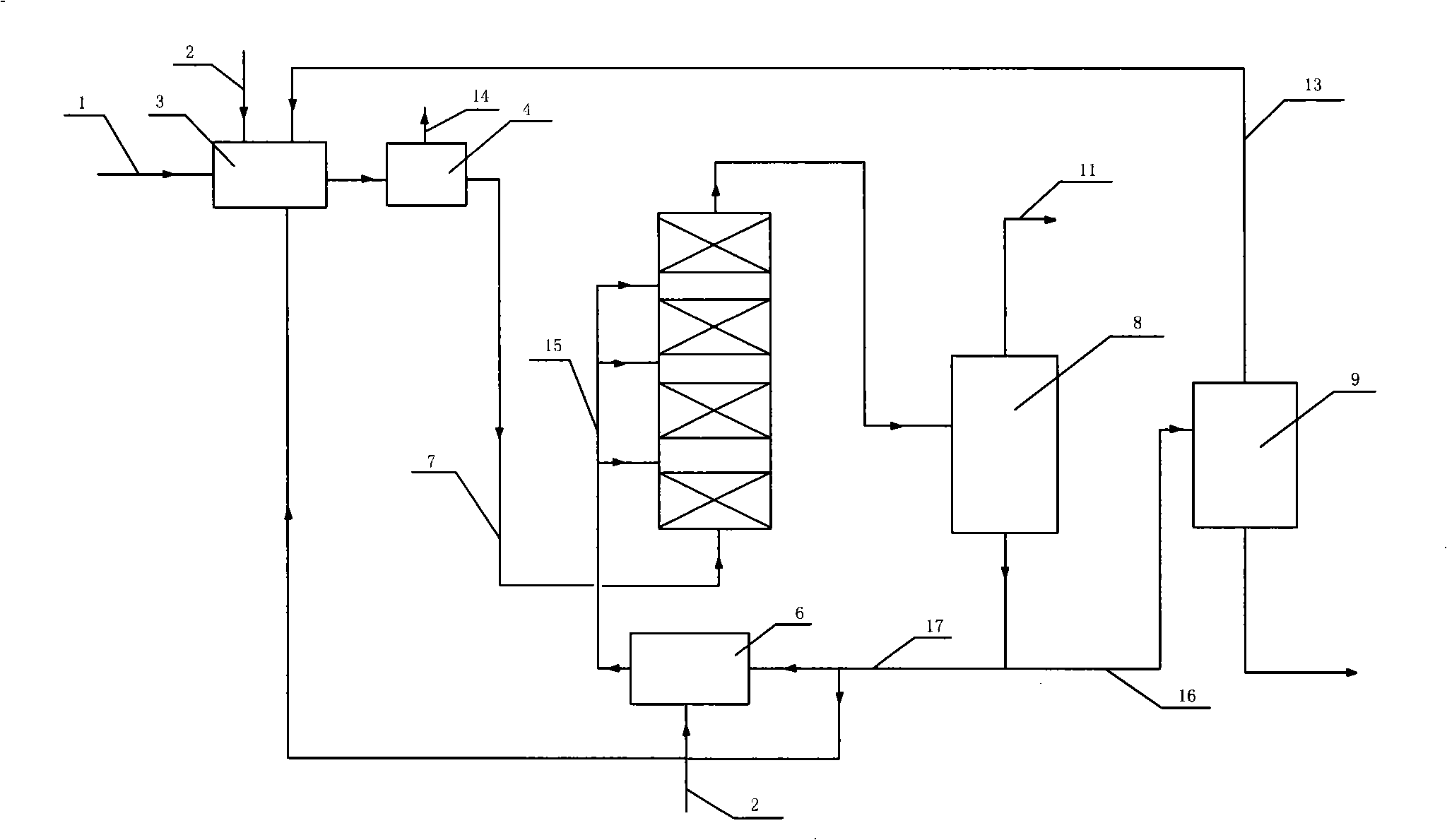

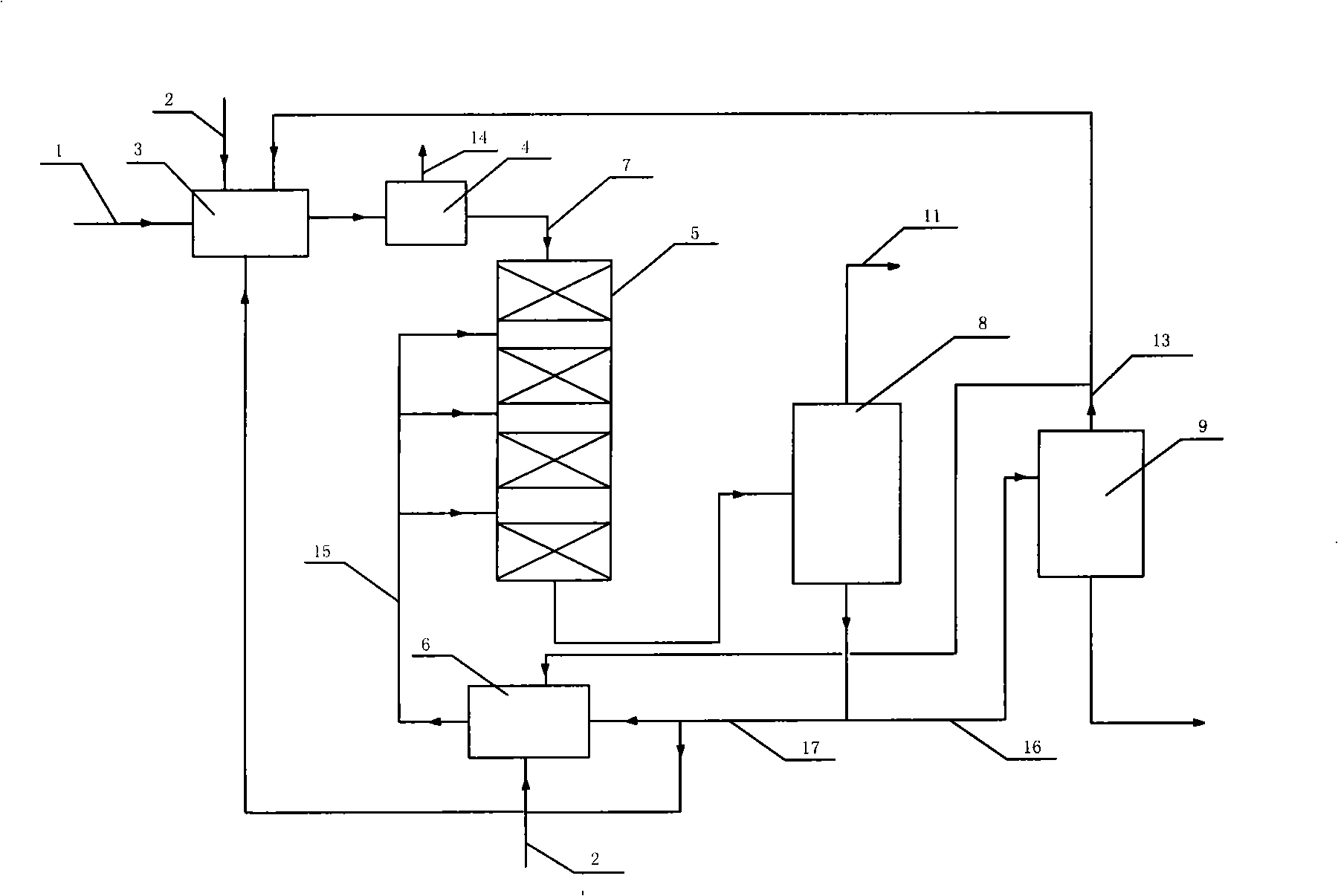

ActiveCN101338220ALess catalystLittle loss of hydrogenRefining to eliminate hetero atomsSolventCycle oil

The present invention discloses a hydrocarbon oil hydrogenation method, which cancels circulating hydrogen and a circulating hydrogen compressor. Hydrogen is mixed with fresh crude oil and part of circulating oil under the existence of a solvent or a diluting agent so as to form a mixture flow; the mixture flows into a reactor to contact a catalyst; after the other part or the whole of the circulating oil is mixed with hydrogen, a circuit or a shunt circuit enters the reactor between reactor catalyst bed layers; the reacted effluent is used for gas-liquid separation and the liquid phase further separates the solvent or the diluting solvent for recycling use; a part of the separated liquid product is used as the product and the other part is used as the circulating oil. The hydrogen solubility in the solvent or the diluting solvent is larger than the hydrogen solubility in the mixture of fresh crude oil and the solvent or the diluting agent.

Owner:CHINA PETROCHEMICAL CORP +1

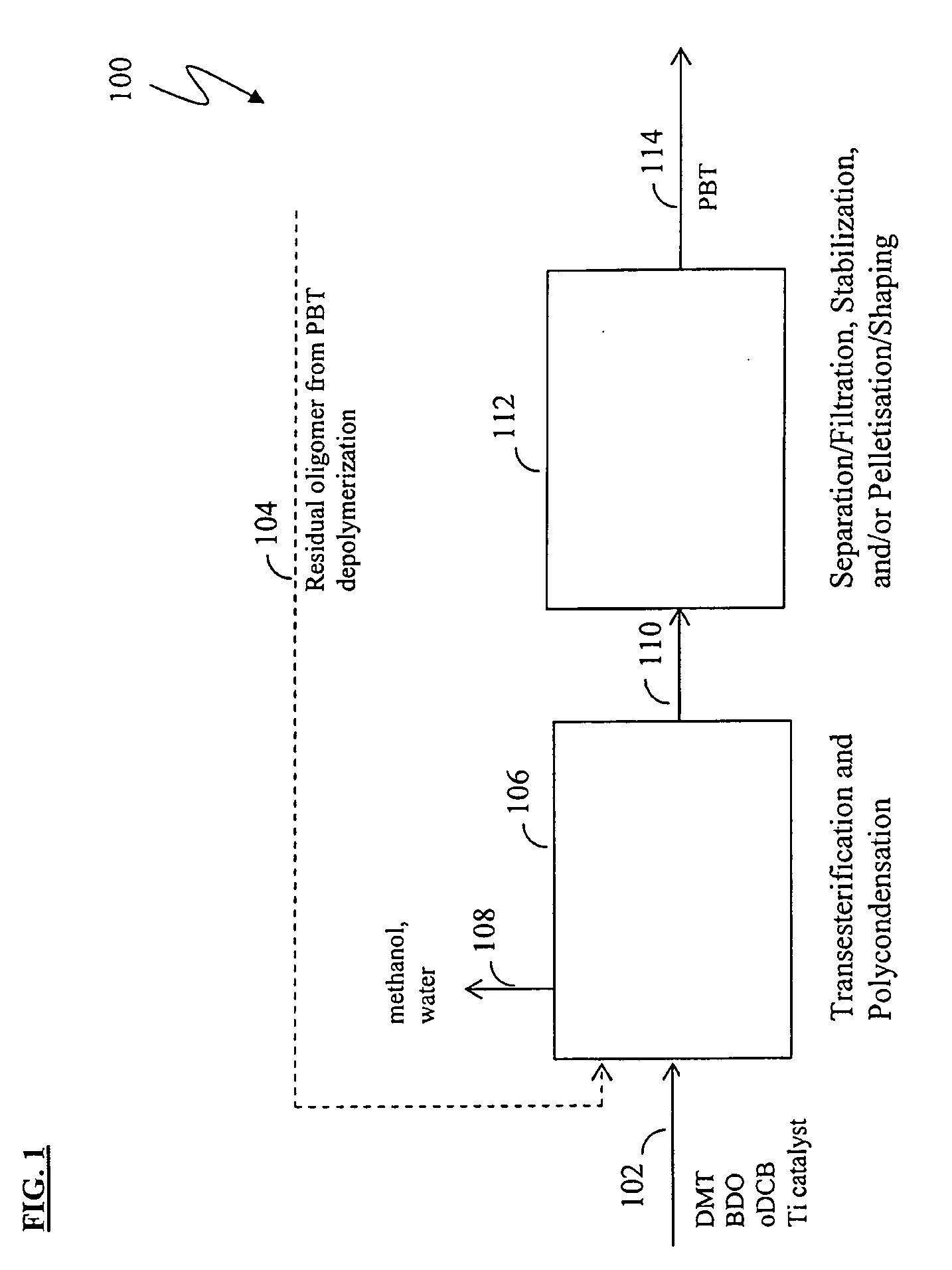

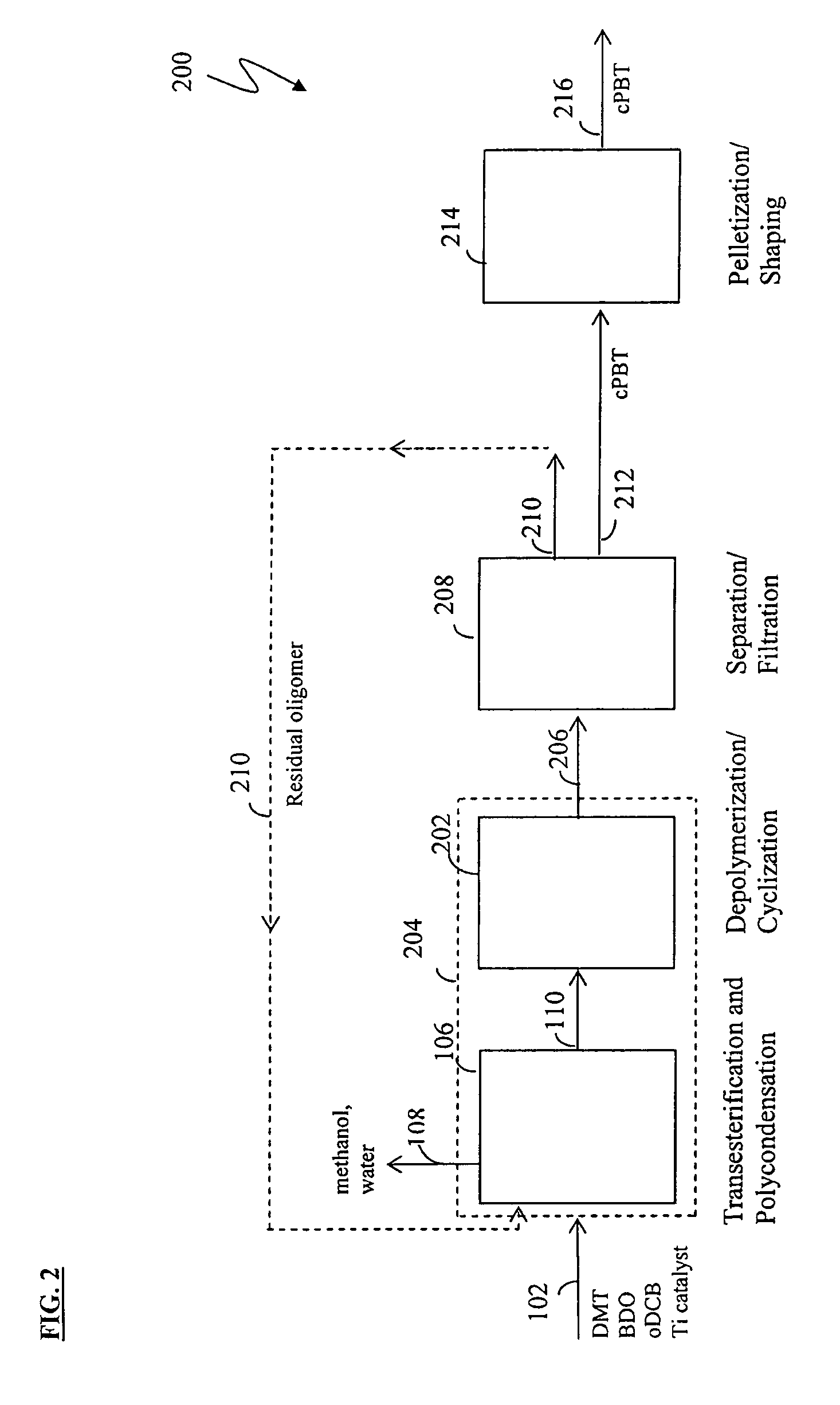

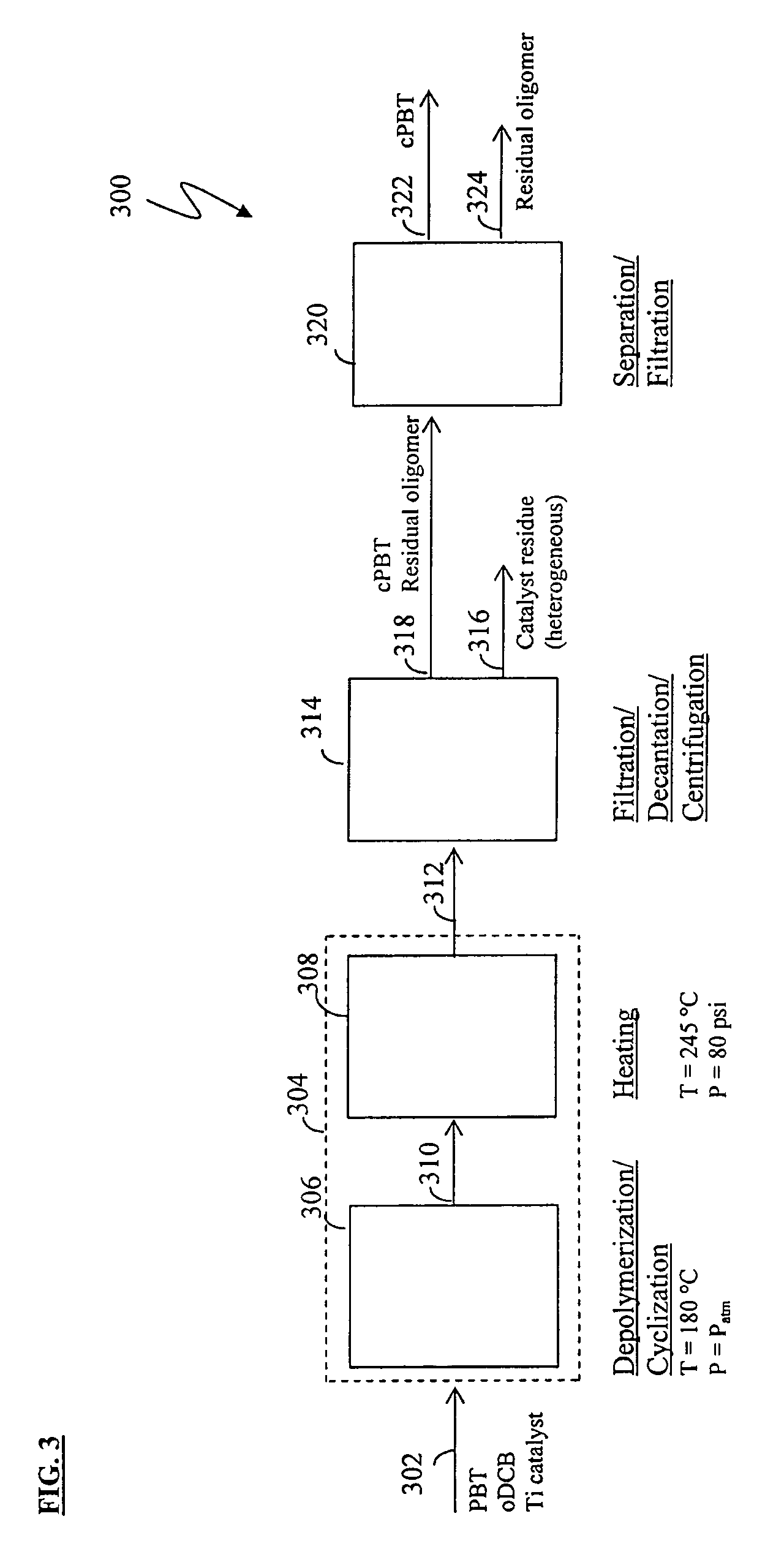

Methods for removing catalyst residue from a depolymerization process stream

InactiveUS20060235233A1Reduce purification costsReduce residue levelsOrganic compound preparationCarboxylic acid esters preparationPolyesterDepolymerization

The invention relates to methods and systems for selective removal of catalyst residue from a depolymerization product stream without a water quench, as well as methods and systems for subsequent recovery of residual linear oligomer. The substantially metal-free and substantially water-free residual oligomer byproduct can then be advantageously used as recyclate in a process for preparing MPO. For example, the residual oligomer recyclate can be used as a reactant in the polymerization and subsequent depolymerization (cyclization) of low-acid polyester to form MPO.

Owner:LIQUID THERMO PLASTICS

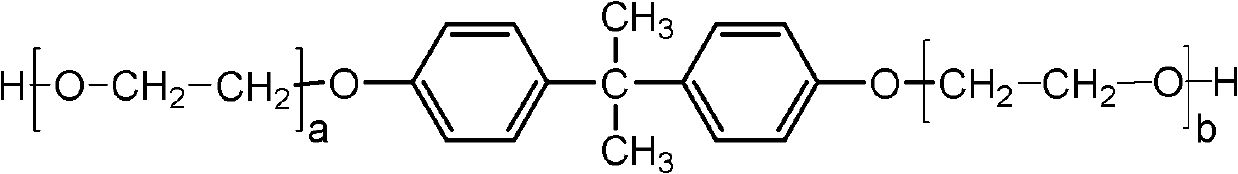

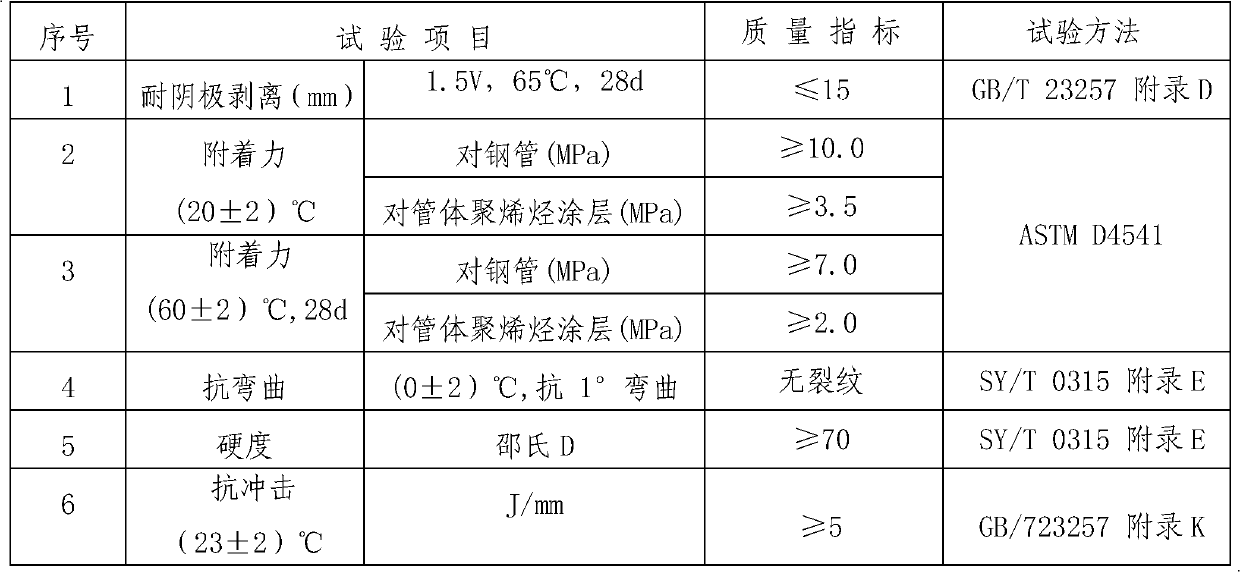

Solvent-free polyurethane joint coating anticorrosive paint for pipelines

ActiveCN103374293AReduces coating bubble problemsLess catalystAnti-corrosive paintsPolyurea/polyurethane coatingsSolventCorrosion prevention

The invention provides solvent-free polyurethane joint coating anticorrosive paint for metal pipelines, relating to the technical field of general corrosion prevention of metal materials and pipeline systems. The solvent-free polyurethane joint coating anticorrosive paint comprises a component A and a component B, wherein the component A contains a hydroxyl component with the average equivalent weight in the range from 200 to 2000, the hydroxyl component takes bisphenol A as a starting agent and contains a polyethylene oxide addition product with a molecular structure shown in descriptions, in the molecular structure, a and b are identical or different integers in the range from 1 to 20, and the component B is polyisocyanate. The solvent-free polyurethane joint coating anticorrosive paint has low water absorption and high reaction activity; a film forming matter has excellent cathodic disbonding resistance and hot water adhesive force resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

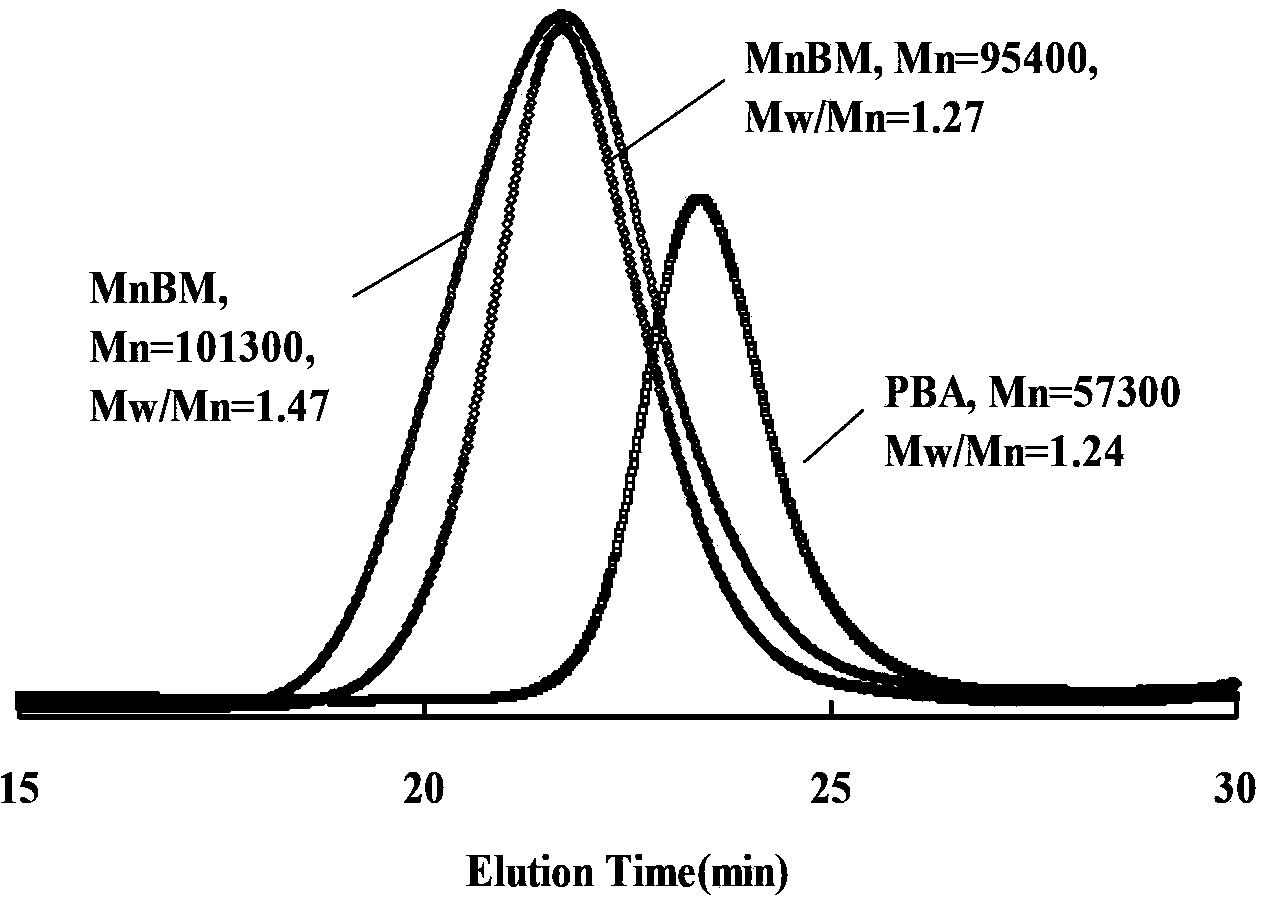

Preparation method of triblock acrylic acid ester thermoplastic elastomer

The invention relates to a preparation method of a triblock acrylic acid ester thermoplastic elastomer. The method is as below: first preparing poly butyl acrylate monomer; initiating polymerization of methyl methacrylate monomers by using the poly butyl acrylate monomer as a macro-molecular initiator to obtain poly(methyl methacrylate-b-butyl acrylate monomer-b-methyl methacrylate). The method can reduce the usage amount of a catalyst, reduce sensitivity to oxygen during a polymerization process; an environment-friendly reducing agent is employed; and the post-treatment is simple to reduce cost of industrial production.

Owner:CHANGZHOU UNIV

Starter feed stream acidification in dmc-catalyzed process

ActiveUS20100234647A1Reduce molecular weightLess catalystPhysical/chemical process catalystsOrganic compound preparationElastomerPolyol

The process of the present invention provides for the manufacture of lower molecular weight DMC-catalyzed polyols than is possible using non-acidified continuous addition of starter (CAOS) feeds, by adding excess acid to a starter feed stream over that required for mere neutralization of the basicity of the starter. The benefits of the invention also extend to starters which do not contain basicity. Polyether polyols made by the inventive process may be used to produce improved polyurethane products such as coatings, adhesives, sealants, elastomers, foams and the like.

Owner:COVESTRO LLC

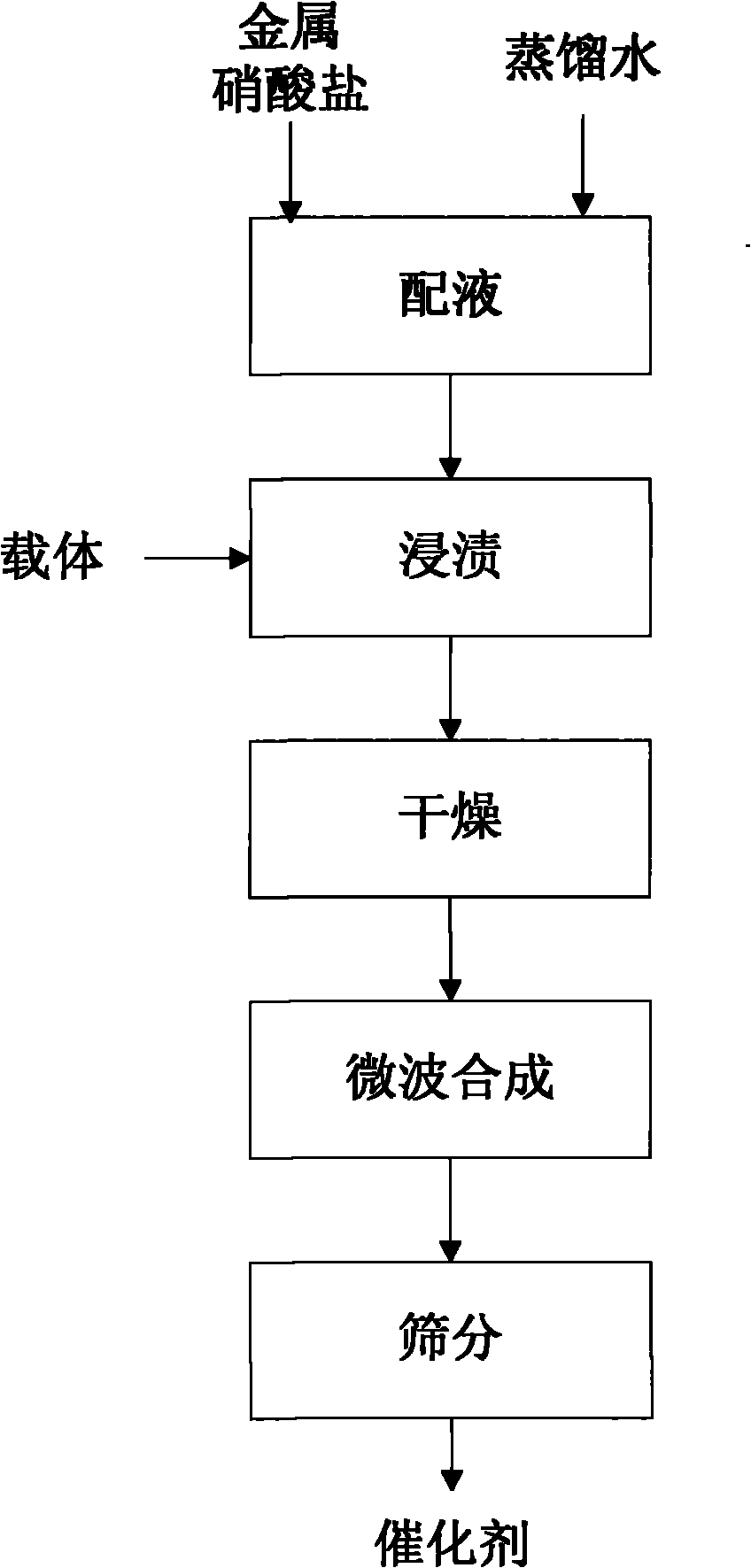

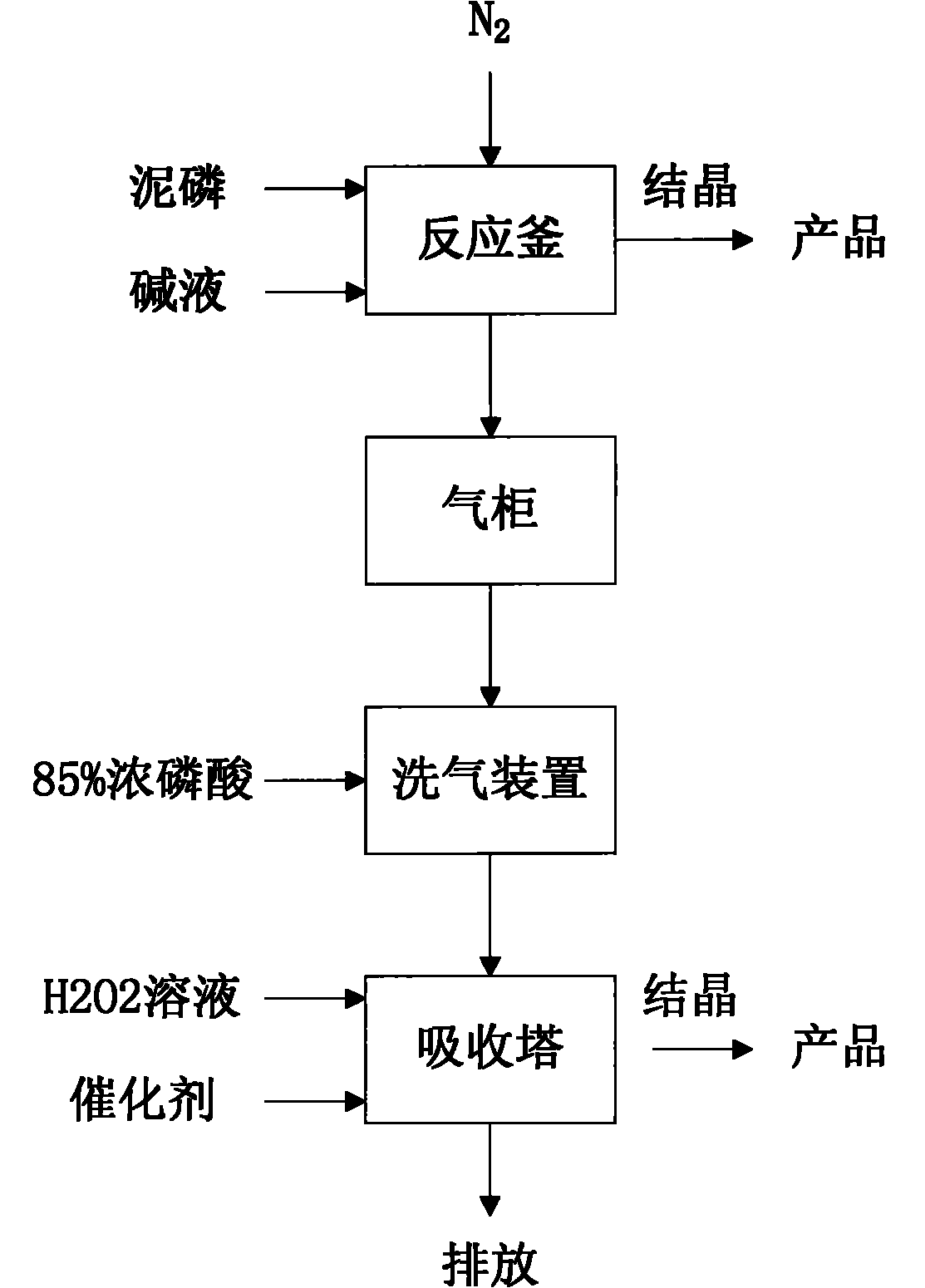

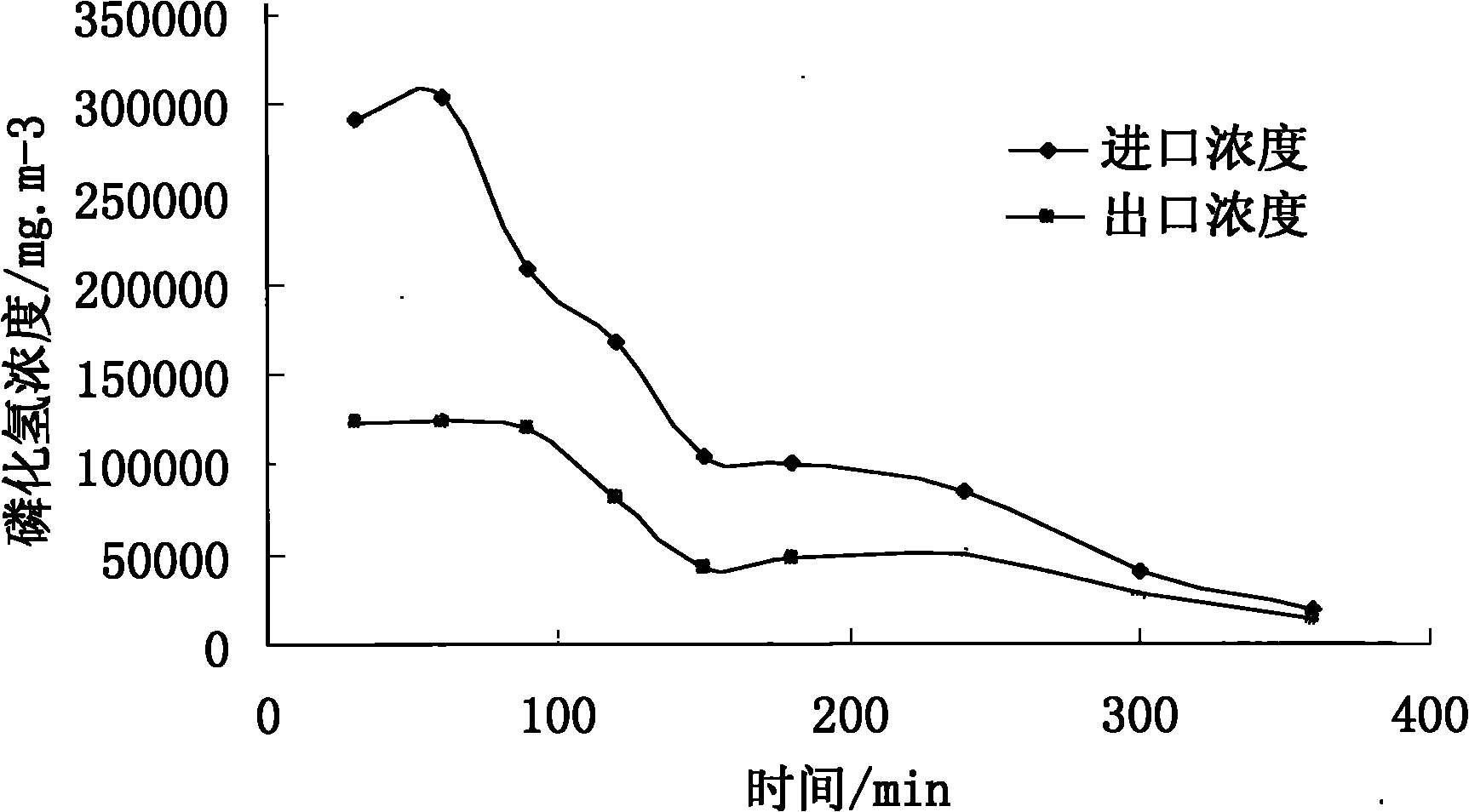

Microwave synthesis method used for multi-phase oxidation catalyst of hydrogen phosphide

InactiveCN101804362AImprove absorption efficiencyLess catalystDispersed particle separationCatalyst activation/preparationHydrogen phosphideIon

The invention relates to a microwave synthesis method used for a multi-phase oxidation catalyst of hydrogen phosphide, which belongs to the technical field of industrial waste gas purification treatment. The method comprises the following steps: dissolving nitrate in distilled water to prepare a metal ion solution; firstly, carrying out pretreatment on a carrier; then dipping in the metal ion solution under stirring, filtering to obtain a filter cake and then baking; putting the dried filter cake in a microwave synthesizer for synthesis to obtain a catalyst product. The synthesis method is convenient and rapid, and the prepared catalyst can obviously improve the absorption efficiency of a hydrogen dioxide solution on hydrogen phosphide; the catalyst has better stability and lower use level, does not contain impurities and can be repeatedly used.

Owner:KUNMING UNIV OF SCI & TECH

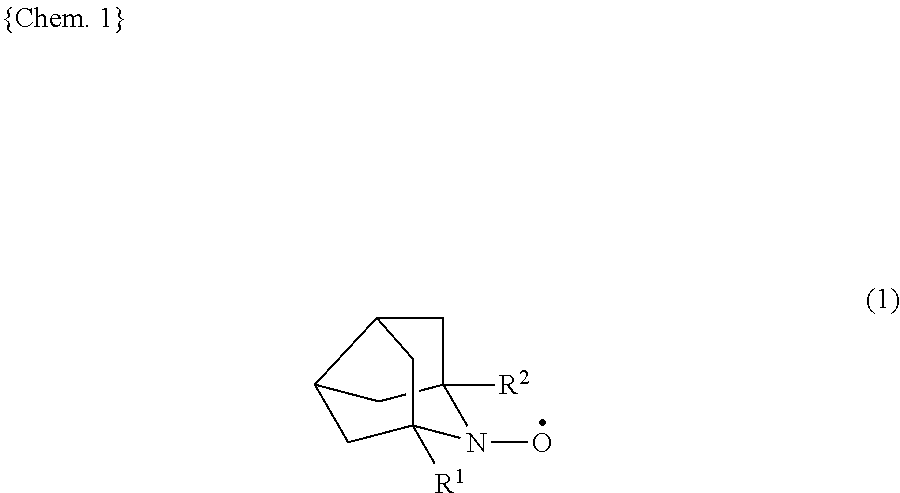

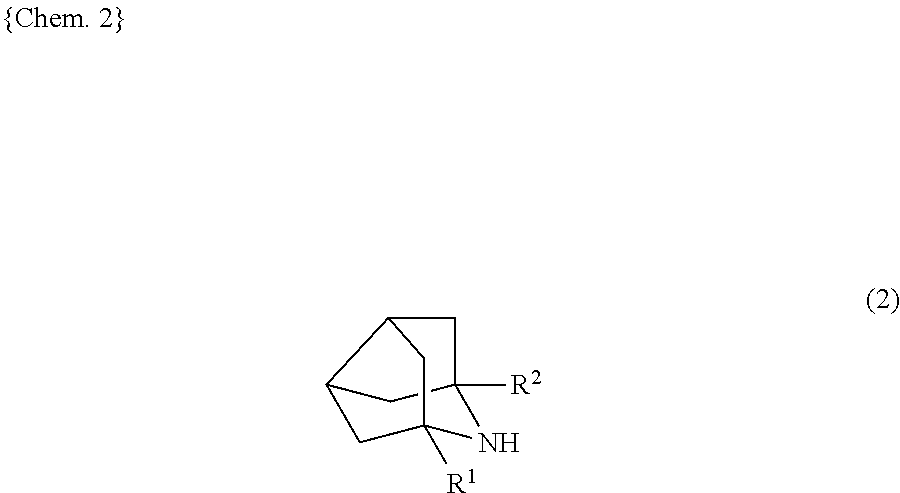

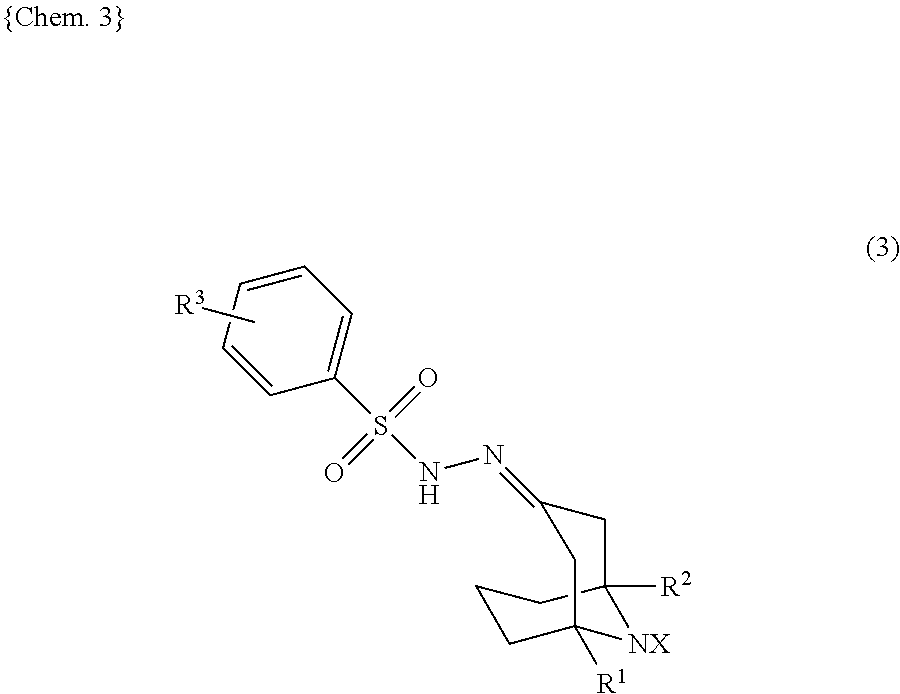

9-azanoradamantane n-oxyl compound and method for producing same, and organic oxidation catalyst and method for oxidizing alcohols using 9-azanoradamantane n-oxyl compound

InactiveUS20150031887A1Less catalystShort reaction timeOrganic compounds purification/separation/stabilisationOrganic compound preparationPolyolAlcohol

An organocatalyst for oxidizing alcohols in which a primary alcohol is selectively oxidized in a polyol substrate having a plurality of alcohols under environmentally-friendly conditions. The organic oxidation catalyst has an oxygen atom bonded to a nitrogen atom of an azanoradamantane skeleton and at least one alkyl group at positions 1 and 5. The oxidation catalyst has higher activity than TEMPO, which is an existing oxidation catalyst, in the selective oxidation reaction of primary alcohols, and better selectivity than AZADO and 1-Me-AZADO. This DMN-AZADO can be applied to the selective oxidation reaction of primary alcohols that contributes to shortening the synthesizing process for pharmaceuticals, pharmaceutical raw materials, agricultural chemicals, cosmetics, organic materials, and other such high value-added organic compounds.

Owner:TOHOKU UNIV

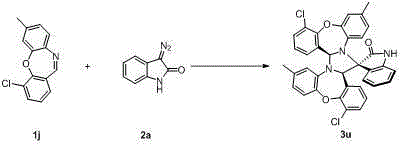

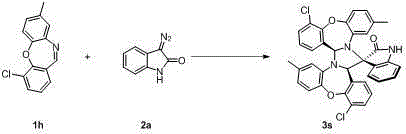

Spiro oxindole imidazolinyl oxazepine compound and synthesis method thereof

The present invention discloses a spiro oxindole imidazolinyl oxazepine compound and a synthesis method thereof, wherein particularly diazo oxindole and dibenzoxazepine are adopted as reactants, and synthesis is performed in a solvent under catalysis of iron trifluomethanesulfonate (II) or a p-toluenesulfonic acid monohydrate to obtain the product. According to the present invention, the method has characteristics of simple and easily-available raw materials, mild reaction conditions, simple and convenient post-treatment, wide substrate application range, high yield and high diastereoselectivity; and the synthesized product can be used for synthesizing the intermediate of drugs and insecticides.

Owner:SUZHOU UNIV

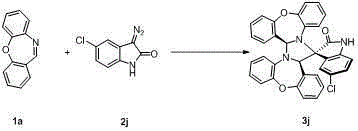

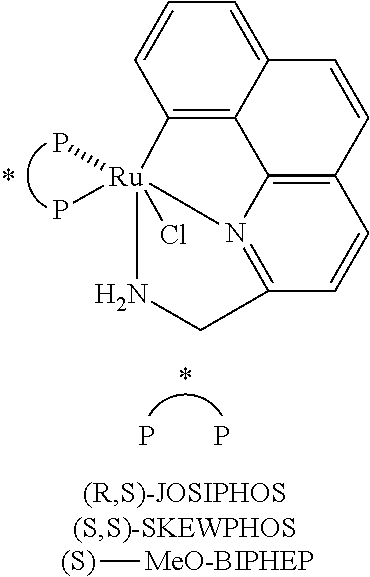

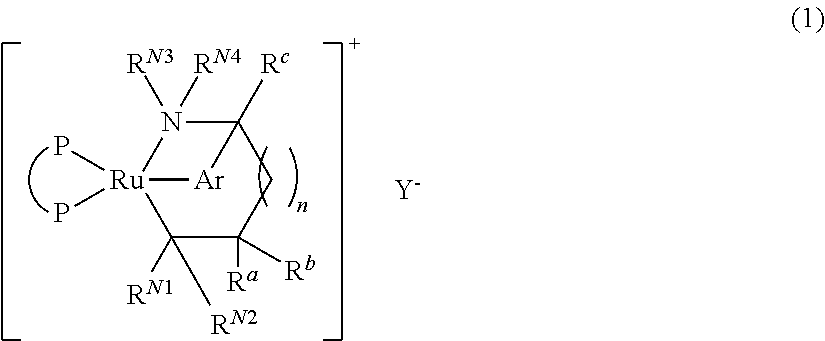

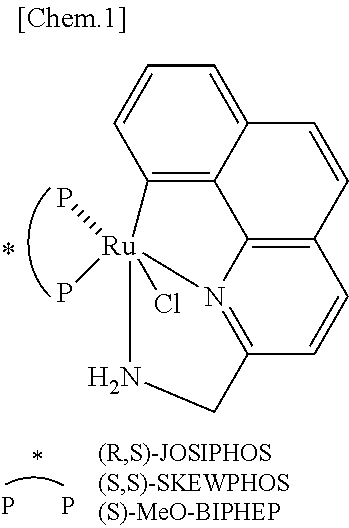

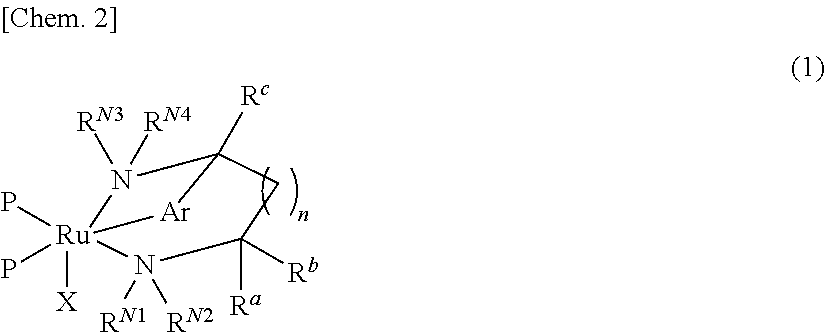

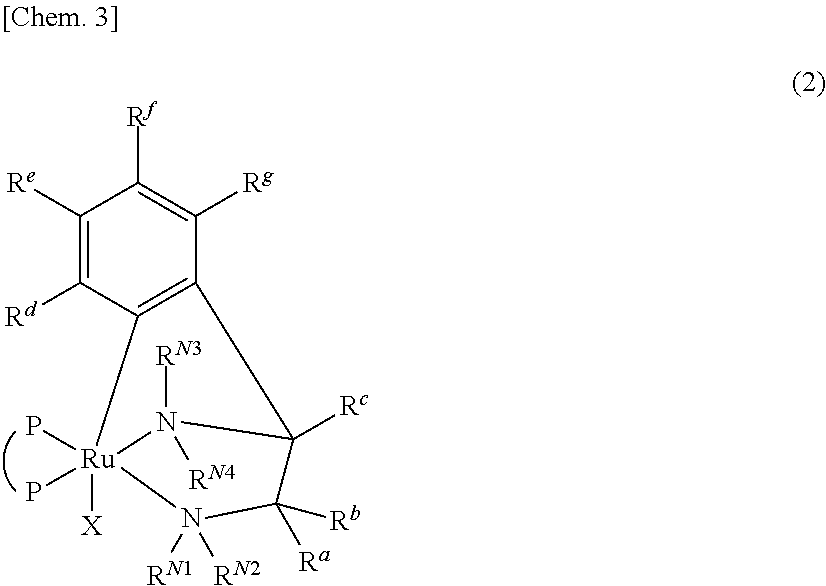

Novel ruthenium complex and process for producing optically active alcohol compound using same as catalyst

ActiveUS20140187809A1Good reactivityConversion rate and selectivityRuthenium organic compoundsOrganic compound preparationCoordination complexEnantio selectivity

The present invention provides a novel ruthenium complex which has an excellent catalytic activity in terms of reactivity for an asymmetric reduction of a carbonyl compound and enantioselectivity, a catalyst using the ruthenium complex, and a method for preparing optically active alcohol compounds using the ruthenium complex. The present invention relates to a ruthenium complex having a ruthenacycle structure, a catalyst for an asymmetric reduction consisting of the ruthenium complex, and a method for preparing optically active alcohol compounds using the ruthenium complex.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Ruthenium complex and method for preparing optically active alcohol compound

ActiveUS20130041151A1Good reactivityConversion rate and selectivityRuthenium organic compoundsTin organic compoundsChemistryCoordination complex

The present invention provides a novel ruthenium complex which has an excellent catalytic activity in terms of reactivity for asymmetric reduction of a carbonyl compound and enantioselectivity, a catalyst using the ruthenium complex, and a method for preparing optically active alcohol compounds using the ruthenium complex. The present invention relates to a ruthenium complex having ruthenacycle structure, a catalyst for asymmetric reduction consisting of the ruthenium complex, and a method for preparing optically active alcohol using the ruthenium complex.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Process of catalytic ammoxidation for hydrogen cyanide production

ActiveUS7763225B2Improve performanceGood choiceHeterogenous catalyst chemical elementsCatalyst activation/preparationOxidation stateOxygen

A process for the ammoxidation of an alcohol feed, such as methanol, or a nitrile feed, such as propionitrile, or a mixture thereof, to form hydrogen cyanide uses a modified Mn—P catalyst having the following empirical formula:MnaP1AbOx where A=one or more of K, Ca, Mo, Zn, Fe or mixtures thereof; a=1 to 1.5; b=0.01 to 1.0 and x is a total number of oxygen atoms determined by the oxidation states of the other elements present.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

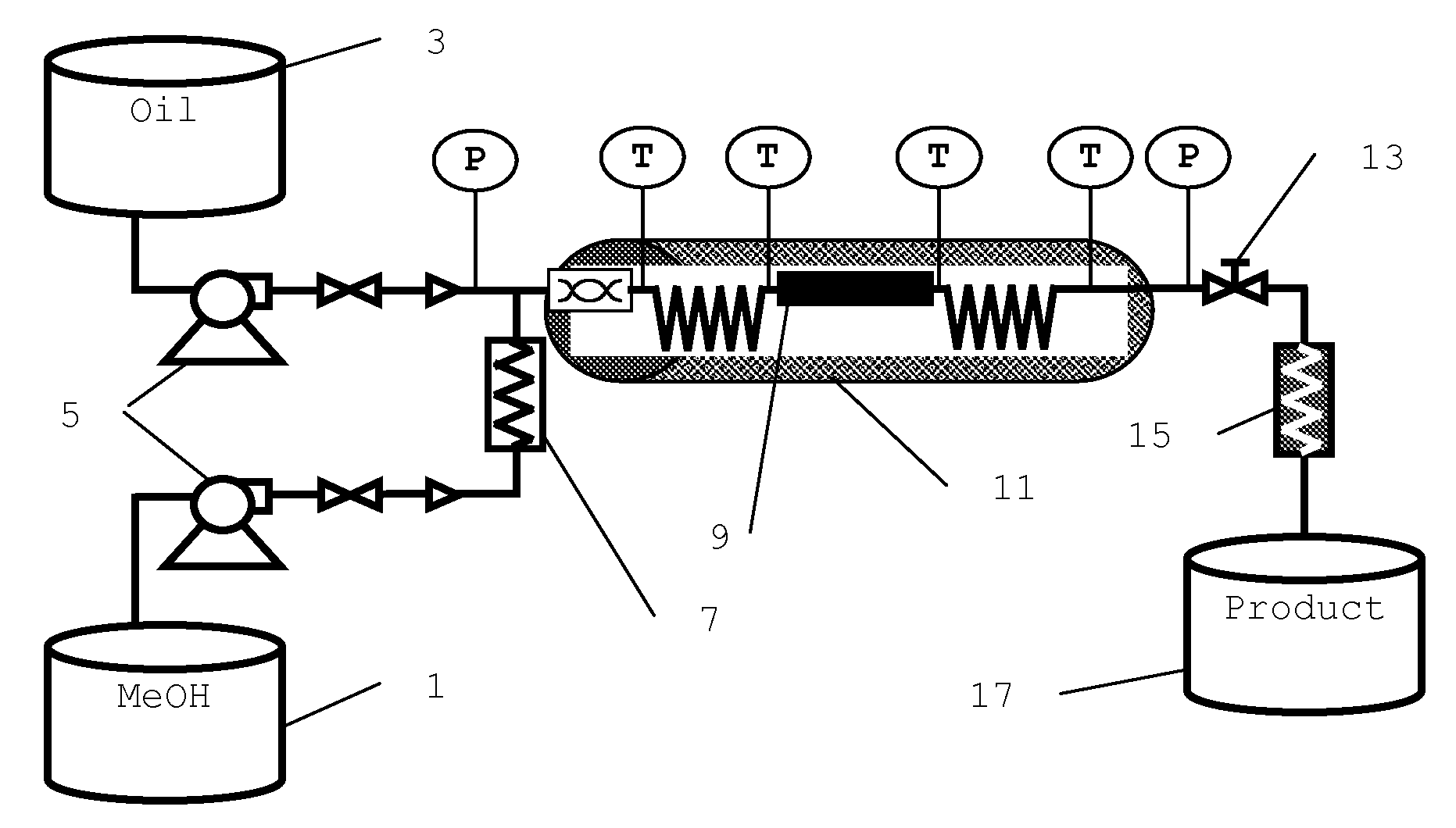

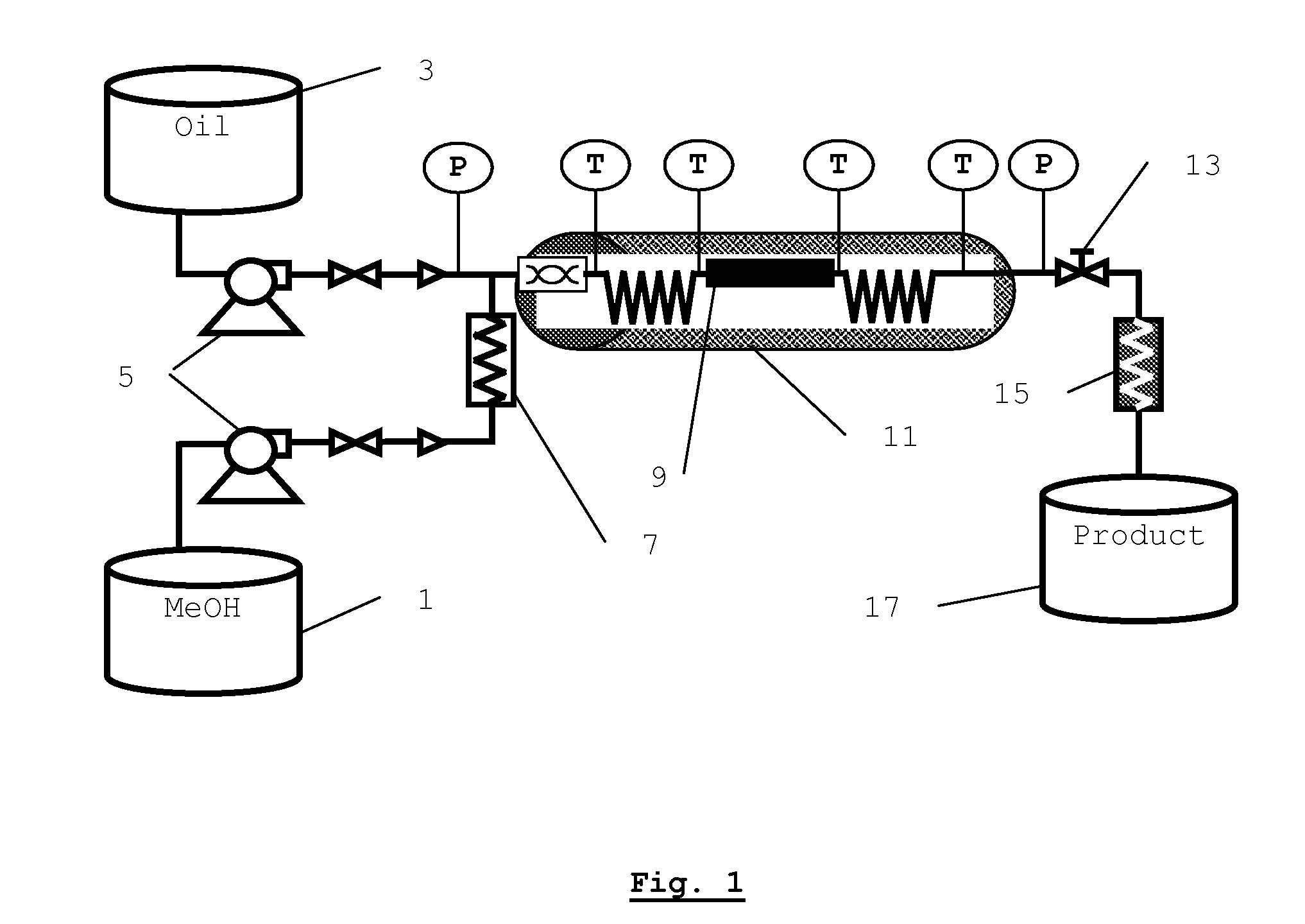

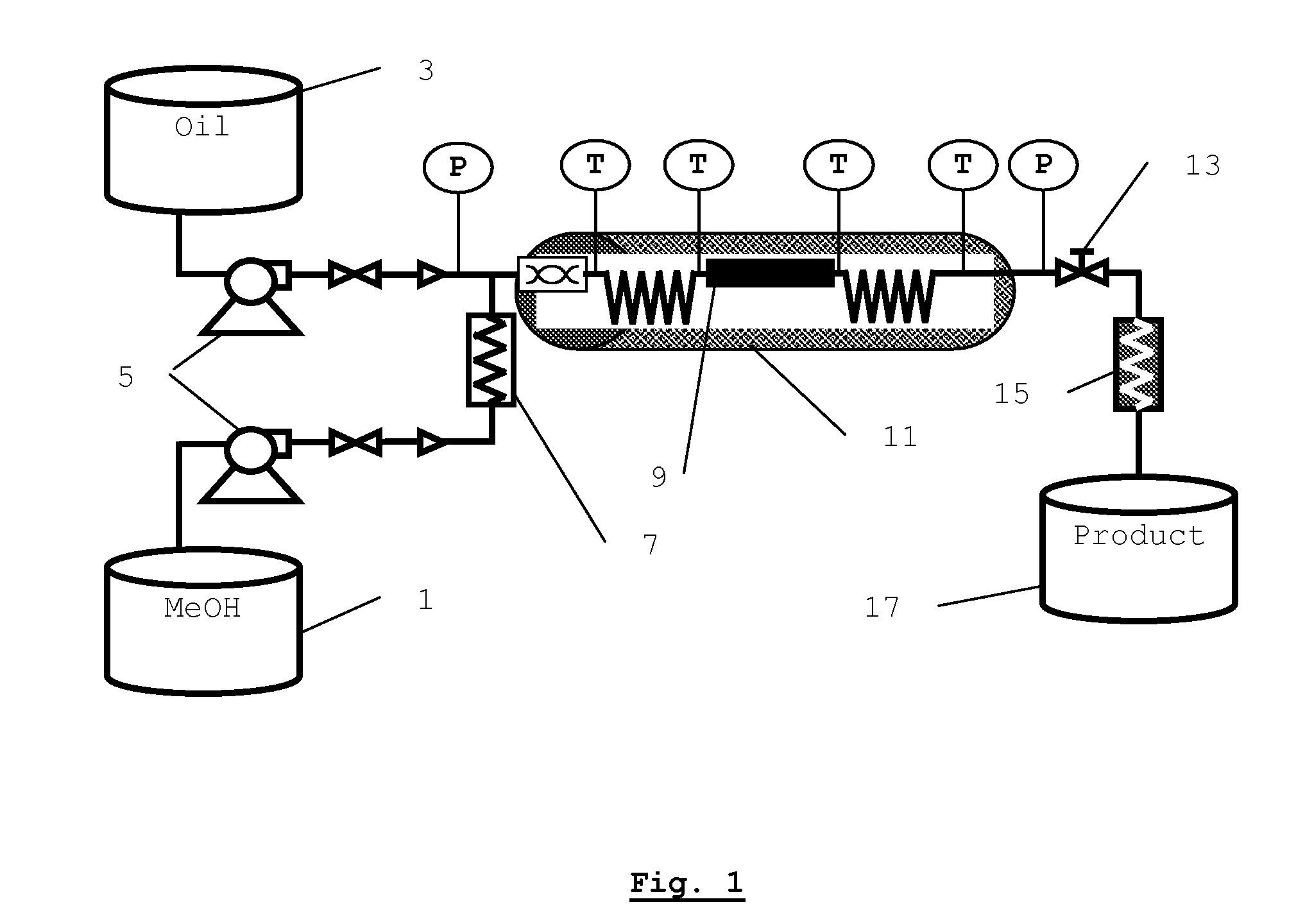

Method for producing biodiesel using an immobilised catalyst

ActiveUS8067624B2Increase chanceLess catalystFatty oils/acids recovery from wasteFatty acid esterificationAlkaline earth metalAlcohol

A method produces a fatty acid alkylester by transesterification of a fat or oil and an alcohol. The reaction is catalysed by a heterogeneous catalyst immobilized in a tubular reactor at a temperature between 260 and 420° C. and at a pressure higher than 5 bar. A mixture of the fat or oil and the alcohol is led in a continuous flow through the tubular reactor. The catalyst is preferably a metal oxide or a metal carbonate including an alkaline earth metal. The reaction takes place at reduced residence times and contact times compared to the prior art.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

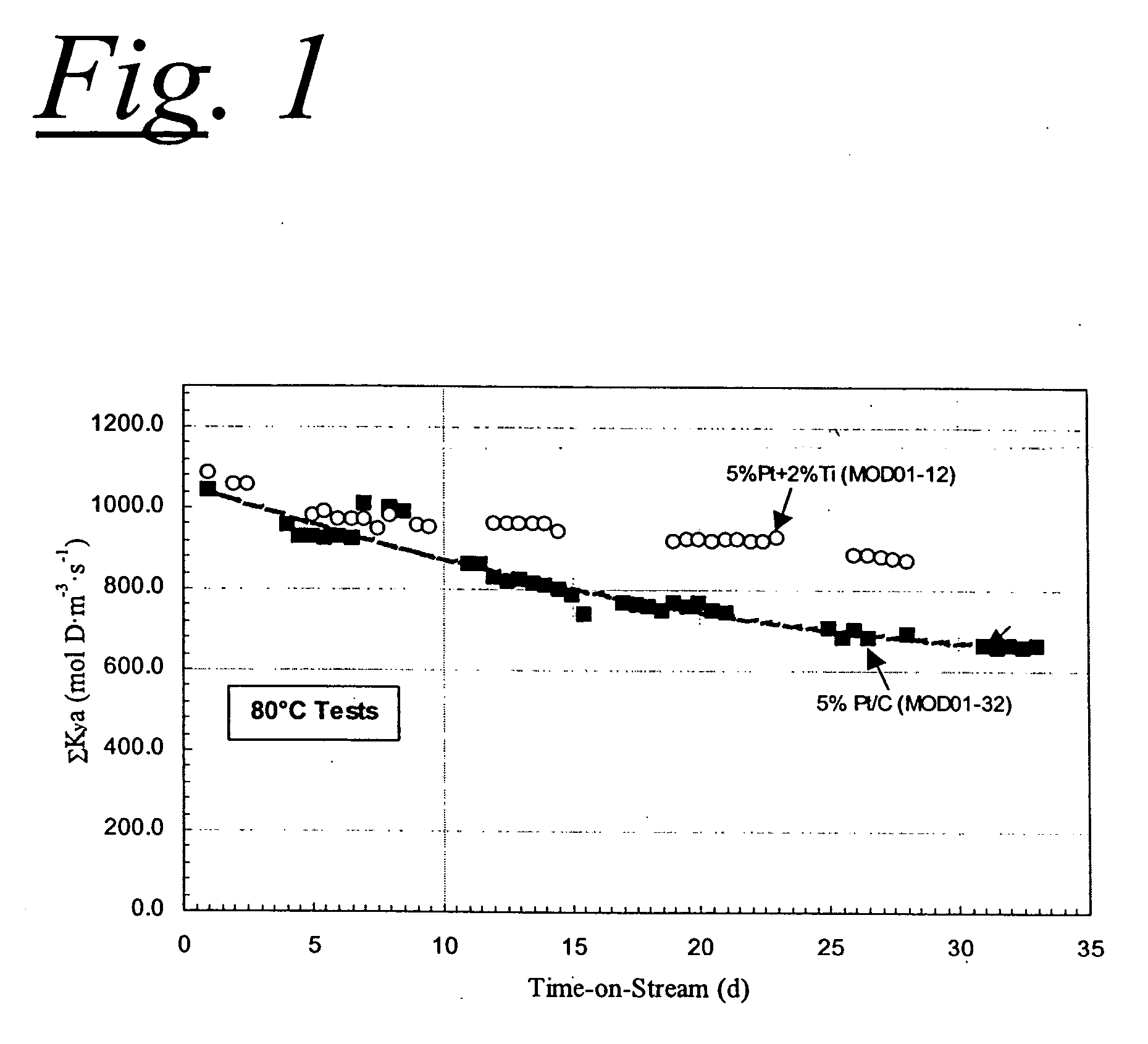

Wetproofed catalysts for hydrogen isotope exchange

A method to catalyze hydrogen isotope exchange between water and hydrogen in which the water and hydrogen are contacted with a wetproofed catalyst, the catalyst having a hydrophobic porous matrix which has dispersed therein catalytically active platinum and at least one other metal which is chromium or titanium.

Owner:ATOMIC ENERGY OF CANADA LIMITED +1

Preparation method of 1,3-dioxolane

The invention discloses a preparation method of 1,3-dioxolane. The preparation method comprises the steps of carrying out a reaction by taking ethylene glycol and polyformaldehyde as raw materials and adding right amount of N86 type ionic liquid catalyst; drying the obtained product with solid caustic soda, rectifying, adding right amount of antioxidant and evenly mixing to obtain the target product 1,3-dioxolane. The preparation method has the advantages of being less in consumption of the catalyst, short in reaction time, low in reaction temperature, high in product purity, and the like.

Owner:NEUFTECH BIOTECH HEFEI

Novel method for producing biodiesel using an immobilised catalyst

ActiveUS20100010247A1Extended reaction timeRaise the reaction temperatureFatty oils/acids recovery from wasteFatty acid esterificationAlkaline earth metalContinuous flow

A method produces a fatty acid alkylester by transesterification of a fat or oil and an alcohol. The reaction is catalysed by a heterogeneous catalyst immobilised in a tubular reactor at a temperature between 260 and 420° C. and at a pressure higher than 5 bar. A mixture of the fat or oil and the alcohol is led in a continuous flow through the tubular reactor. The catalyst is preferably a metal oxide or a metal carbonate including an alkaline earth metal. The reaction takes place at reduced residence times and contact times compared to the prior art.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

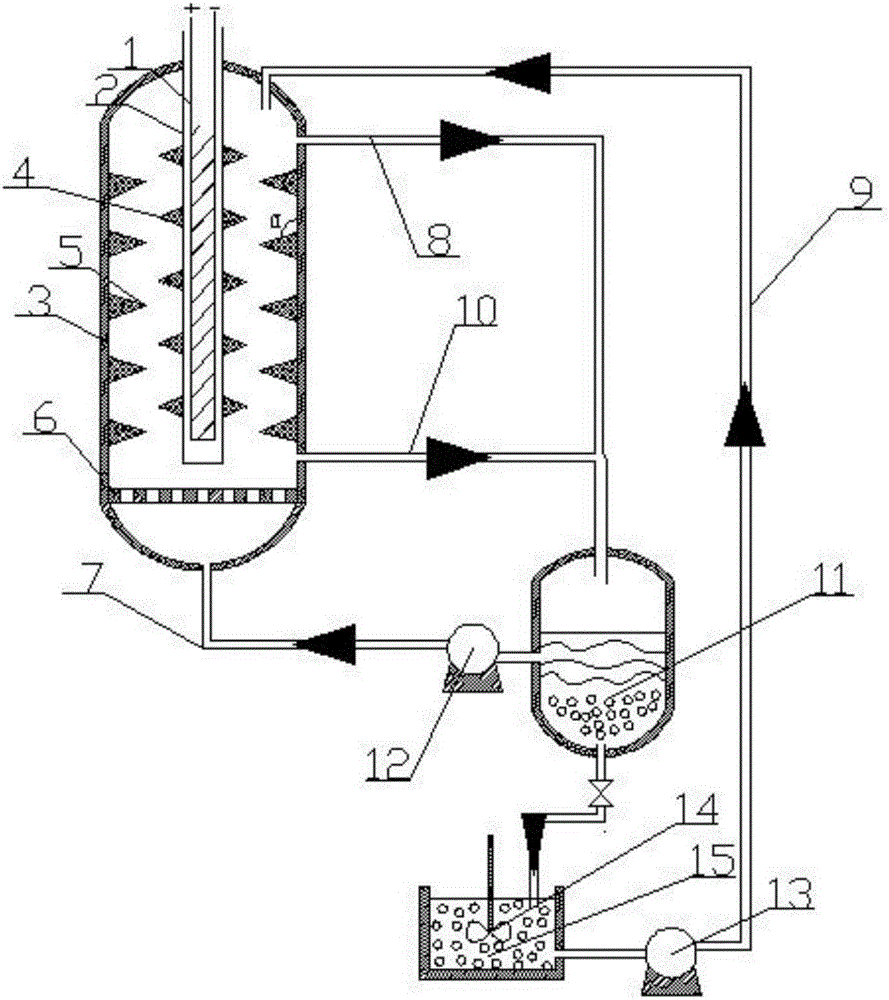

Multi-baffle counterflow photo-catalytic reaction device

ActiveCN106512888ALess catalystImprove light energy utilizationChemical/physical/physico-chemical reactor detailsEnergy based chemical/physical/physico-chemical processesEngineeringLight source

The invention discloses a multi-baffle counterflow photo-catalytic reaction device. A light source is fixedly arranged on the central position of a cylindrical tapered reactor; a light source outer isolating sleeve is matched with the light source; a fixed tapered baffle on the isolating sleeve is distributed on the light source outer isolating sleeve; a tapered baffle of a fixed tower wall is distributed on the cylindrical tapered reaction tower; a distributing plate is fixedly arranged on the bent position of the cylindrical tapered reaction tower; a reaction liquid inlet is connected with the bottom of the cylindrical tapered reaction tower; a reaction liquid outlet is connected with the top of the cylindrical tapered reaction tower; the reaction liquid inlet is connected with the upper part of a catalyst settling tank; a pump a is used for conveying a reaction liquid; the reaction liquid outlet and the catalyst turbid liquid outlet enter the catalyst settling tank; the bottom of the catalyst settling tank is matched with a catalyst turbid liquid storage slot; a blade stirrer is fixedly arranged on the center of the catalyst turbid liquid storage slot; the catalyst turbid liquid inlet is connected with the bottom of the catalyst turbid liquid storage slot; and a pump b is used for conveying the catalyst turbid liquid.

Owner:INNER MONGOLIA NORMAL UNIVERSITY

Polyether polyols with increased functionality

InactiveUS20030119930A1Function increaseQuick responseOrganic chemistryOther chemical processesSimple Organic CompoundsPolymer science

This invention relates to a process for the preparation an epoxide-reactive compound having a functionality of at least 3, a molecular weight of from about 250 to about 1,900, and an OH number of from about 85 to about 1,400. This process comprises reacting (a) an organic compound which is free of ether groups, having a molecular weight of from about 60 to about 600, and containing from about 2 to about 8 reactive sites; with (b) cyanuric chloride; optionally, in the presence of (c) one or more catalysts; wherein the functionality of the resultant epoxide-reactive compound equals three times the functionality of (a) said organic compound minus three. This invention also relates to further reacting the epoxide-reactive compound produced by the above process with an alkylene oxide, optionally in the presence of a catalyst to form a polyether polyol having a functionality of at least about 3, a molecular weight of from about 300 to about 18,000, and an OH number of from about 10 to about 565.

Owner:BAYER POLYMERS LLC

Clean chlorobenzene liquid phase nitration method having superior para-selectivity

InactiveCN101412677AGood para selectivityLess catalystChemical recyclingNitro compound preparationSolventLiquid phase

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com