Patents

Literature

606 results about "Cycle oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cycle oil is a light lubricating oil suited for use on bicycles and similar devices. It is a liquid residue produced in the petroleum industry when catalytic cracking is employed to convert heavy hydrocarbon fractions remaining from earlier stages of crude oil refining into more valuable lighter products.

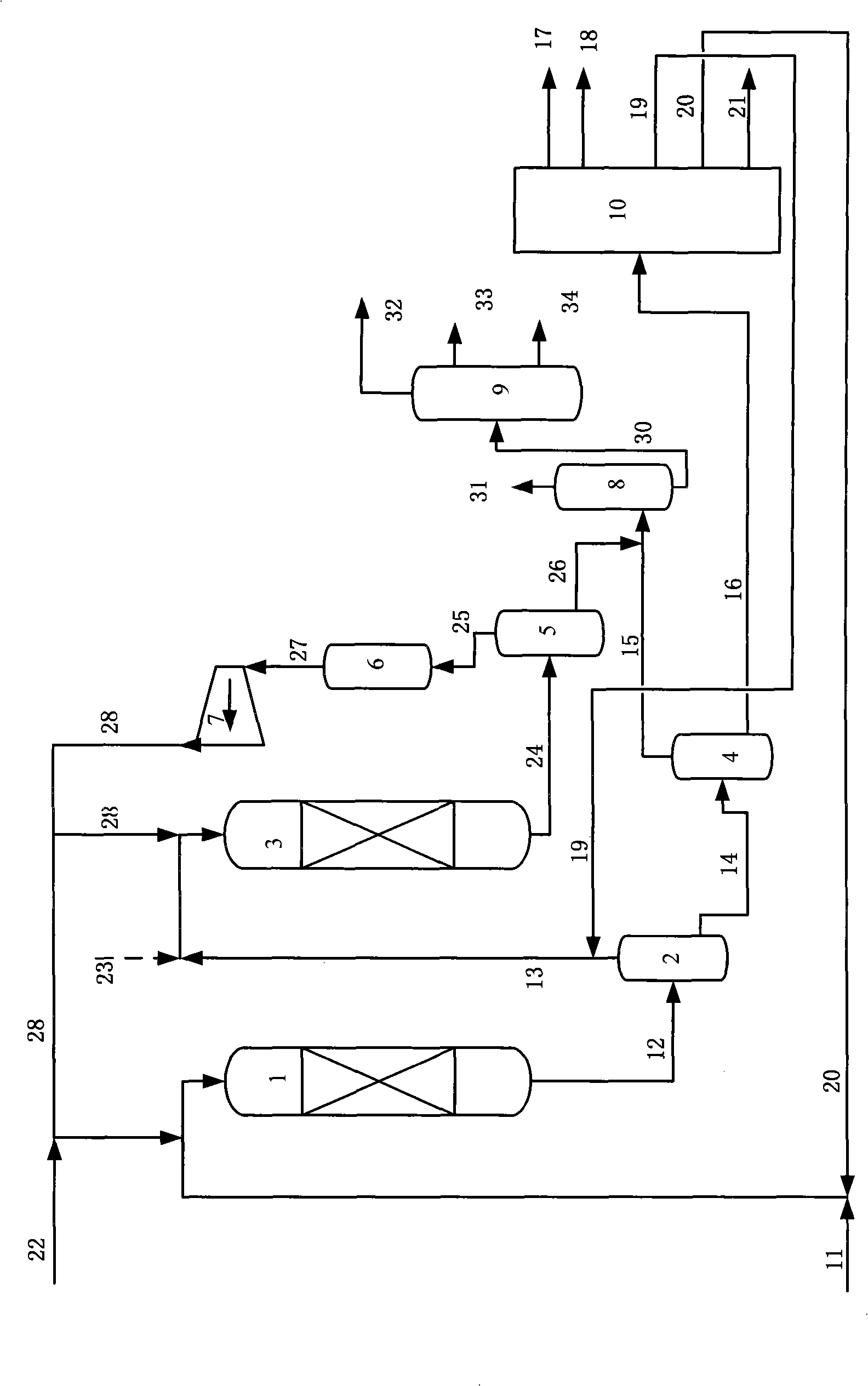

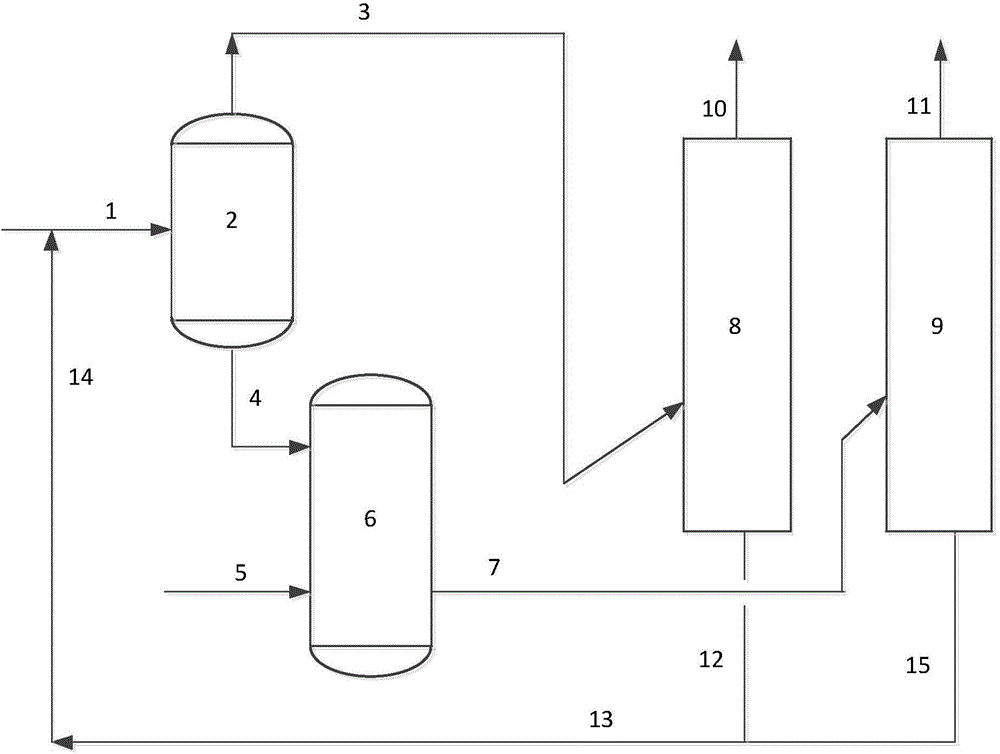

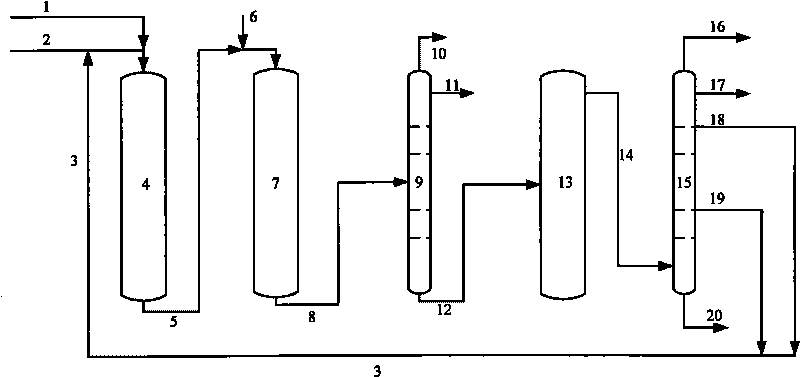

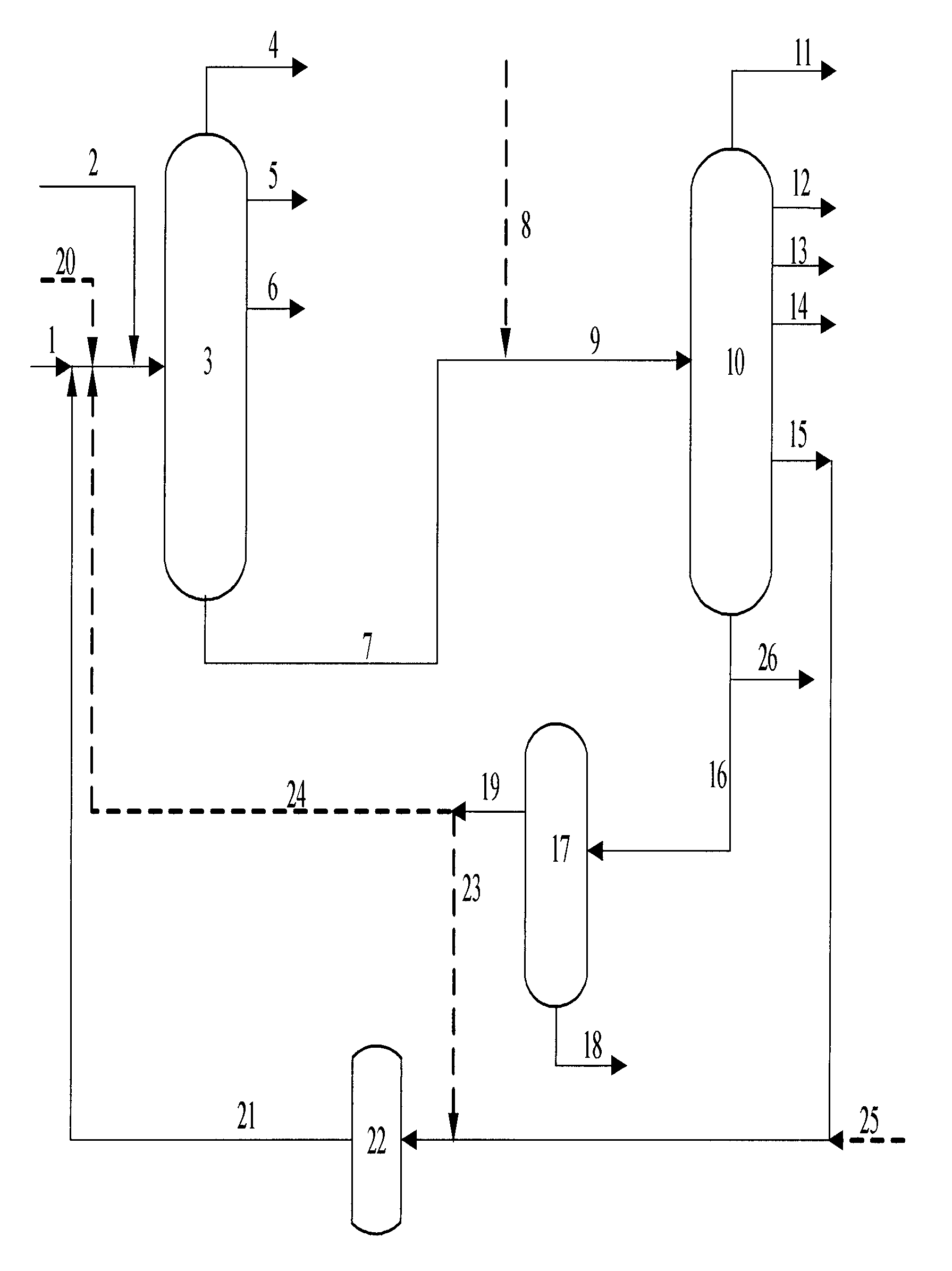

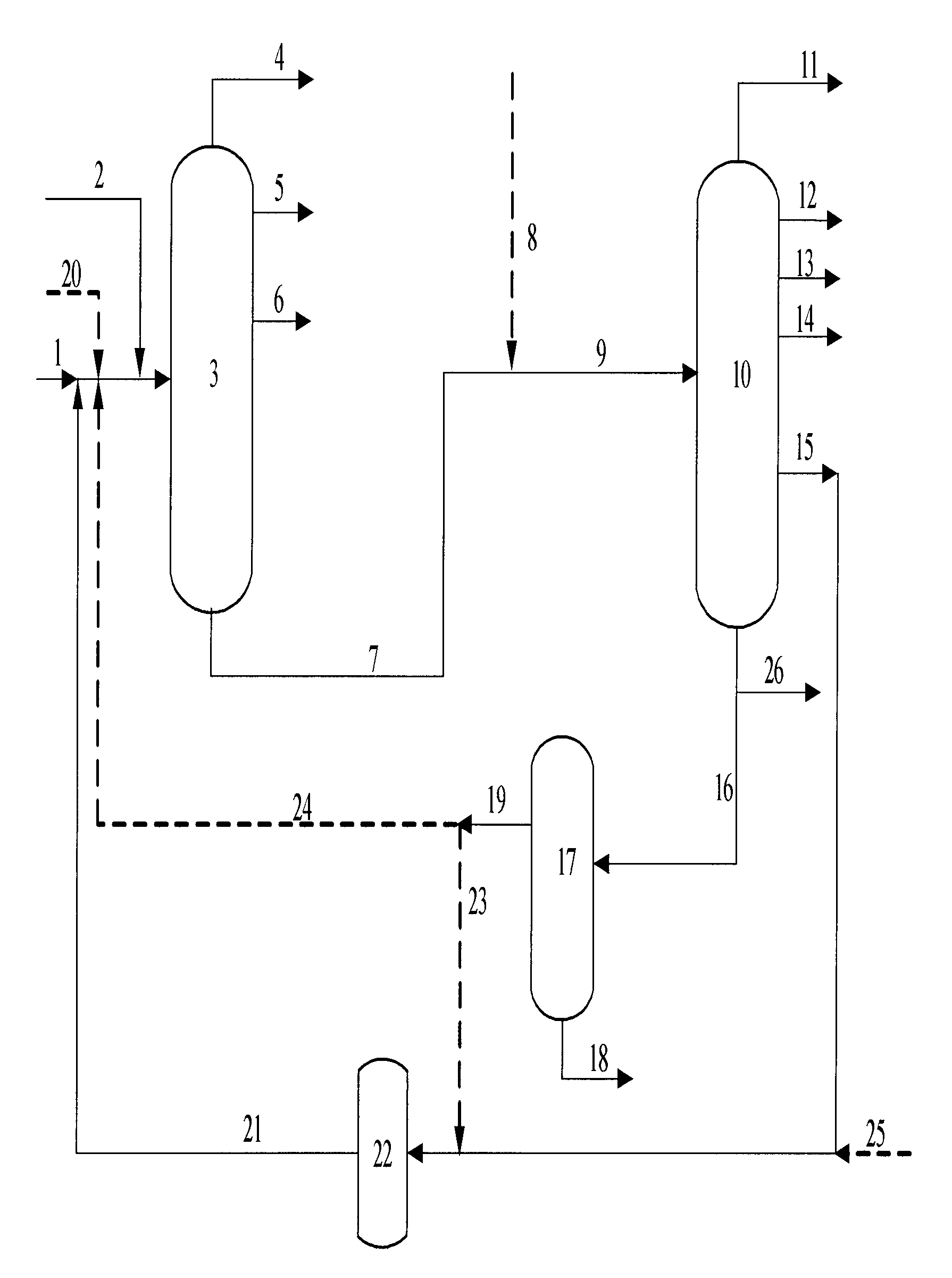

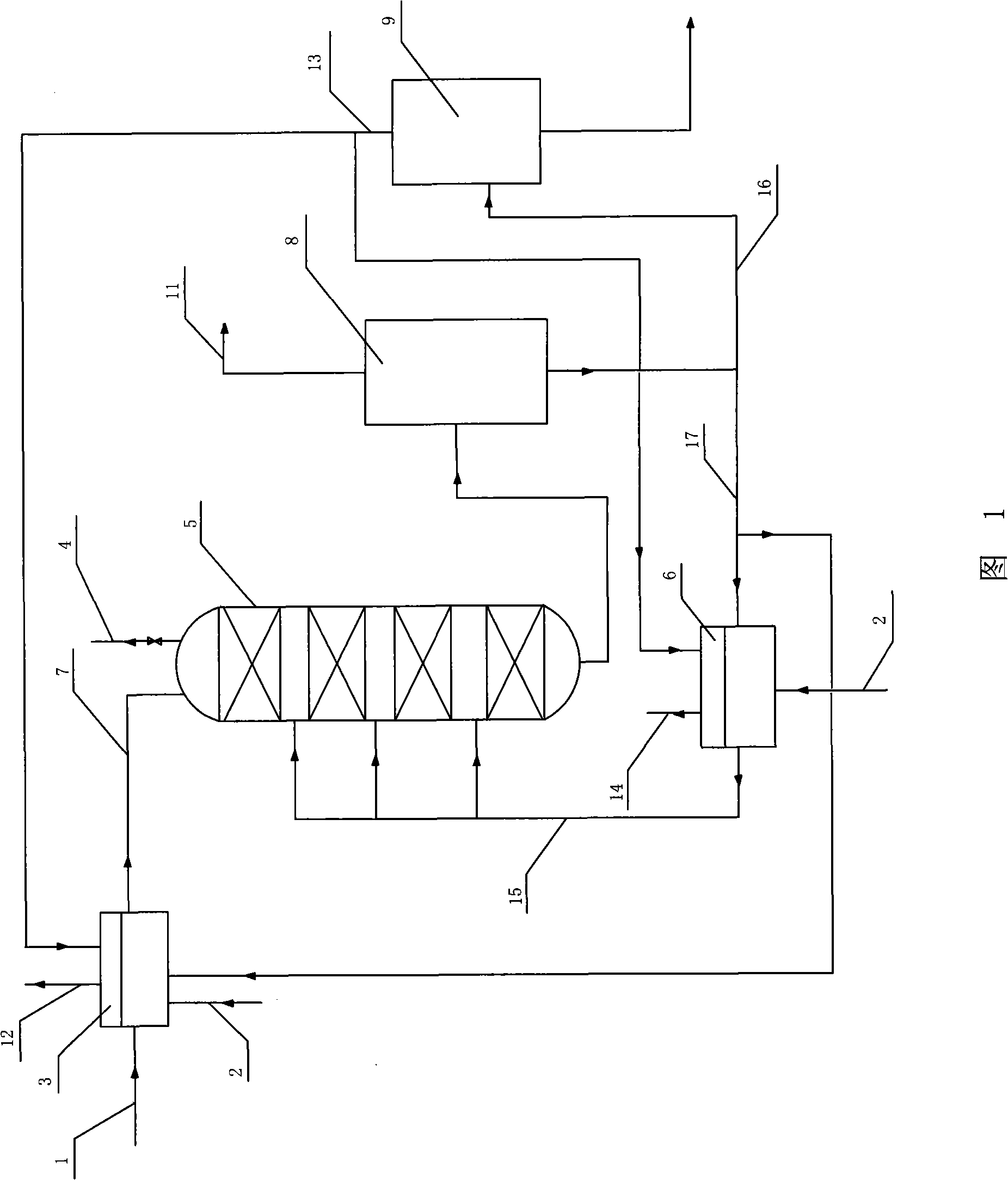

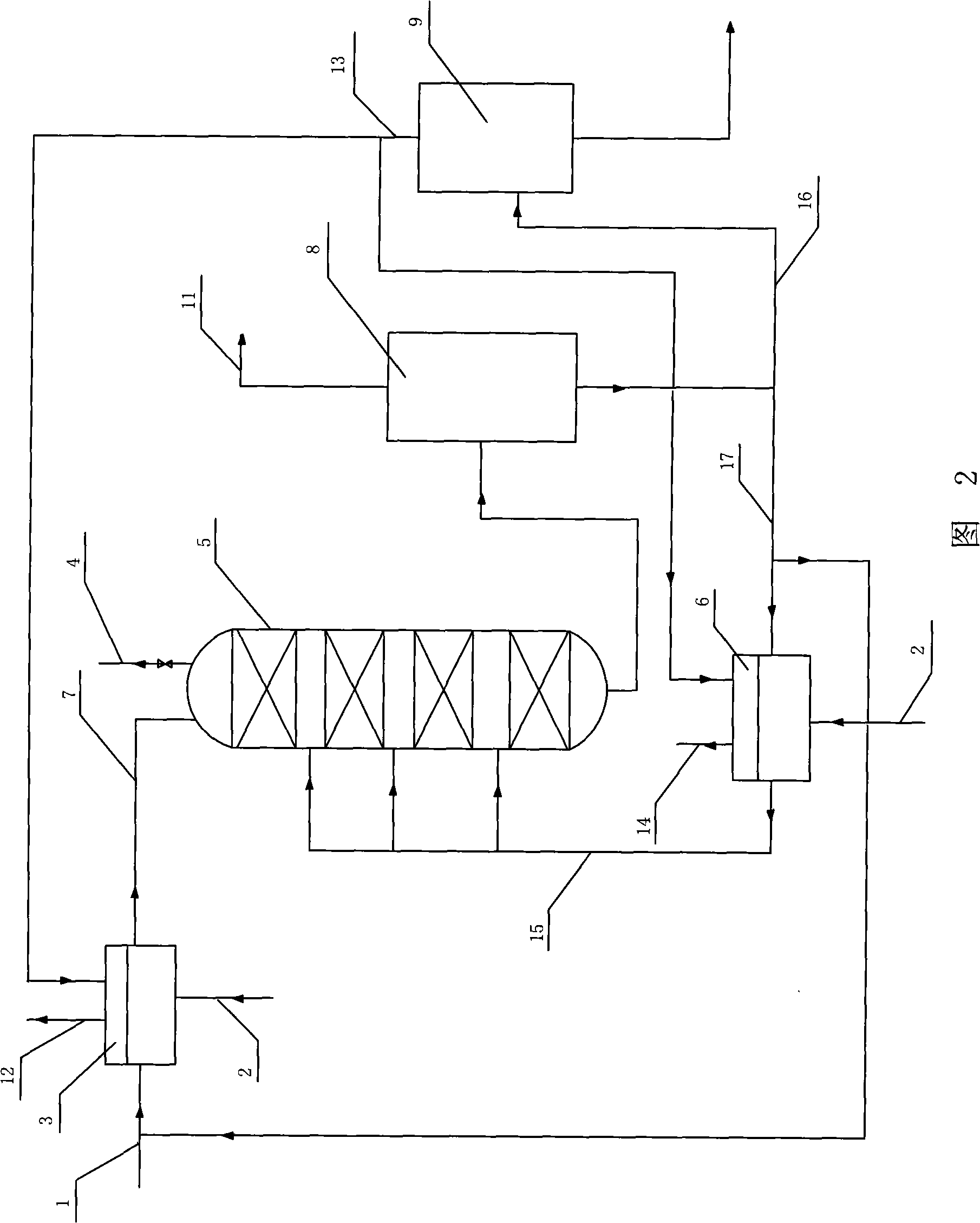

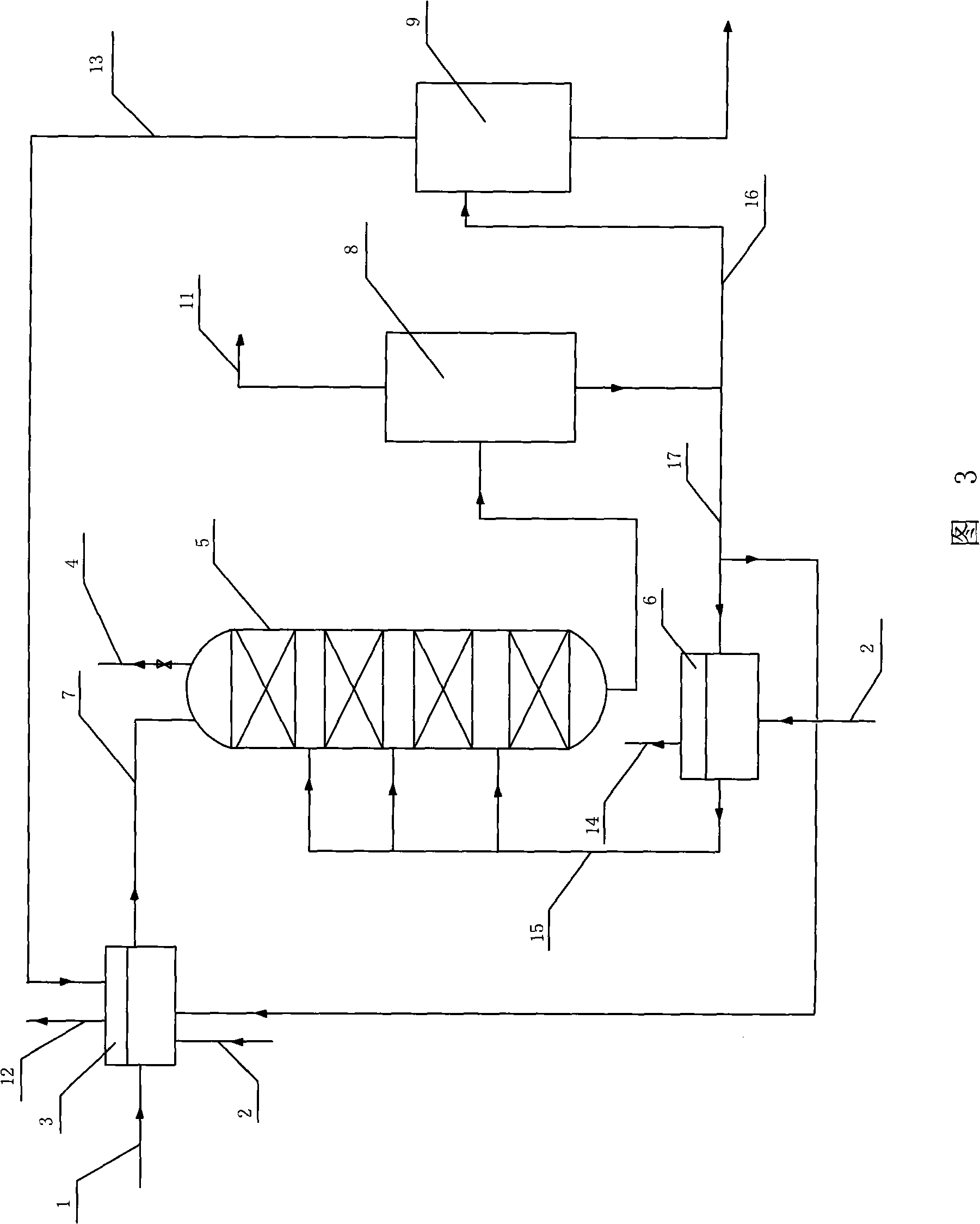

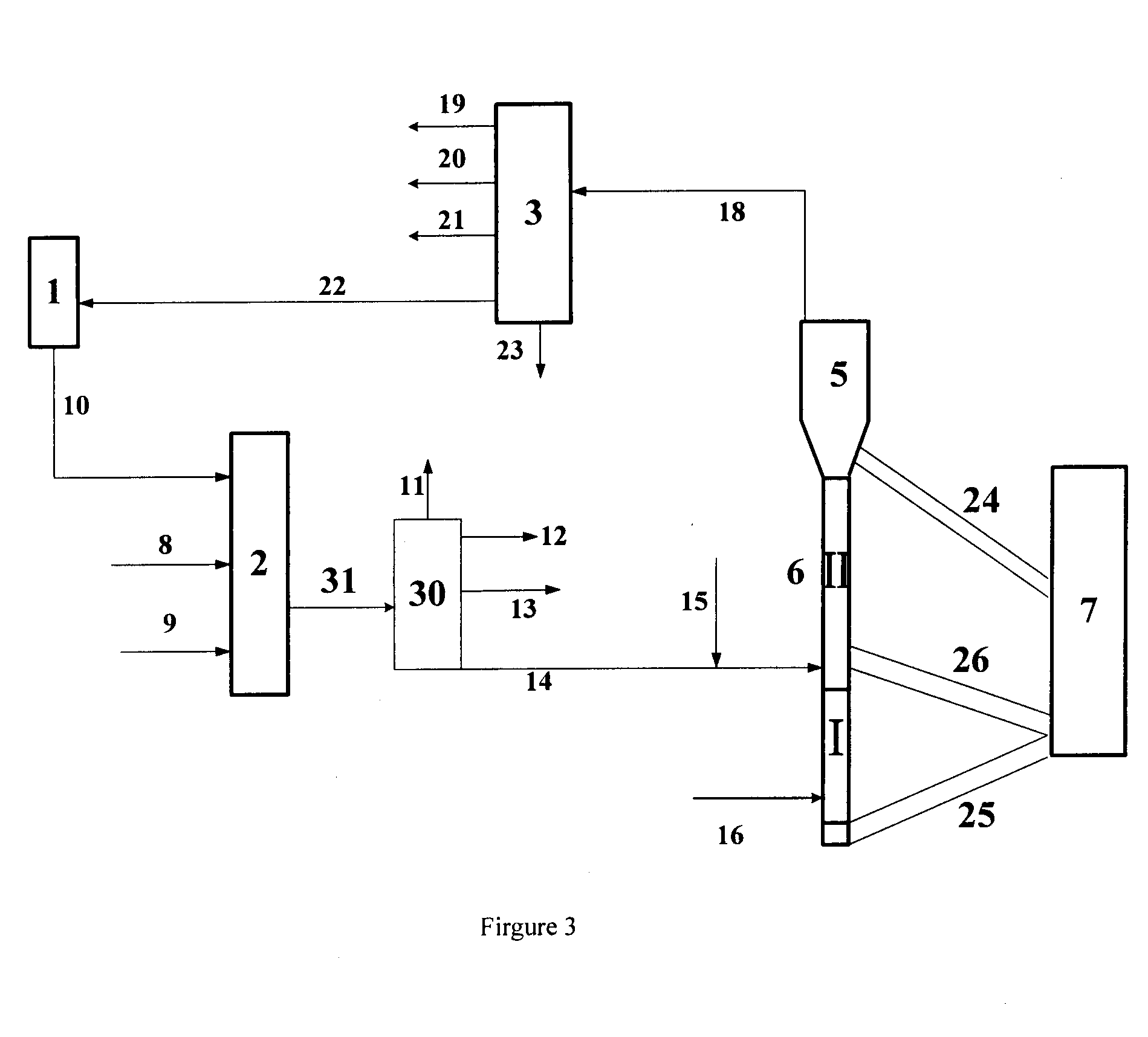

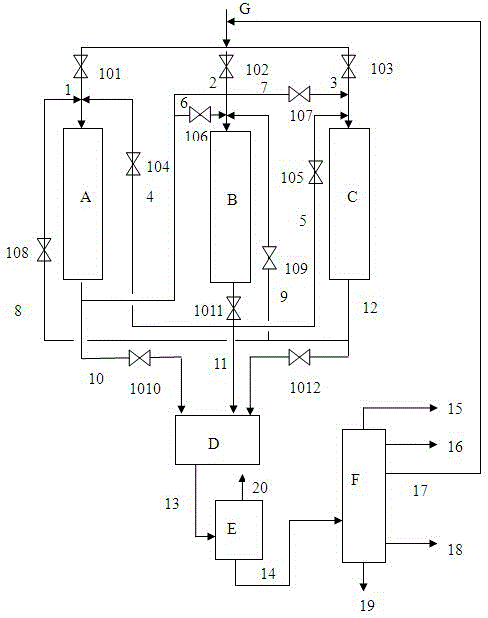

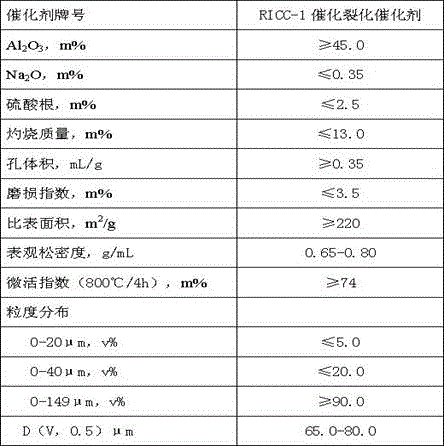

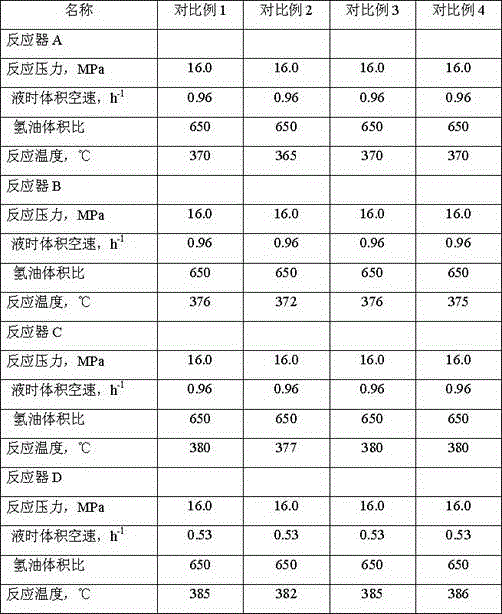

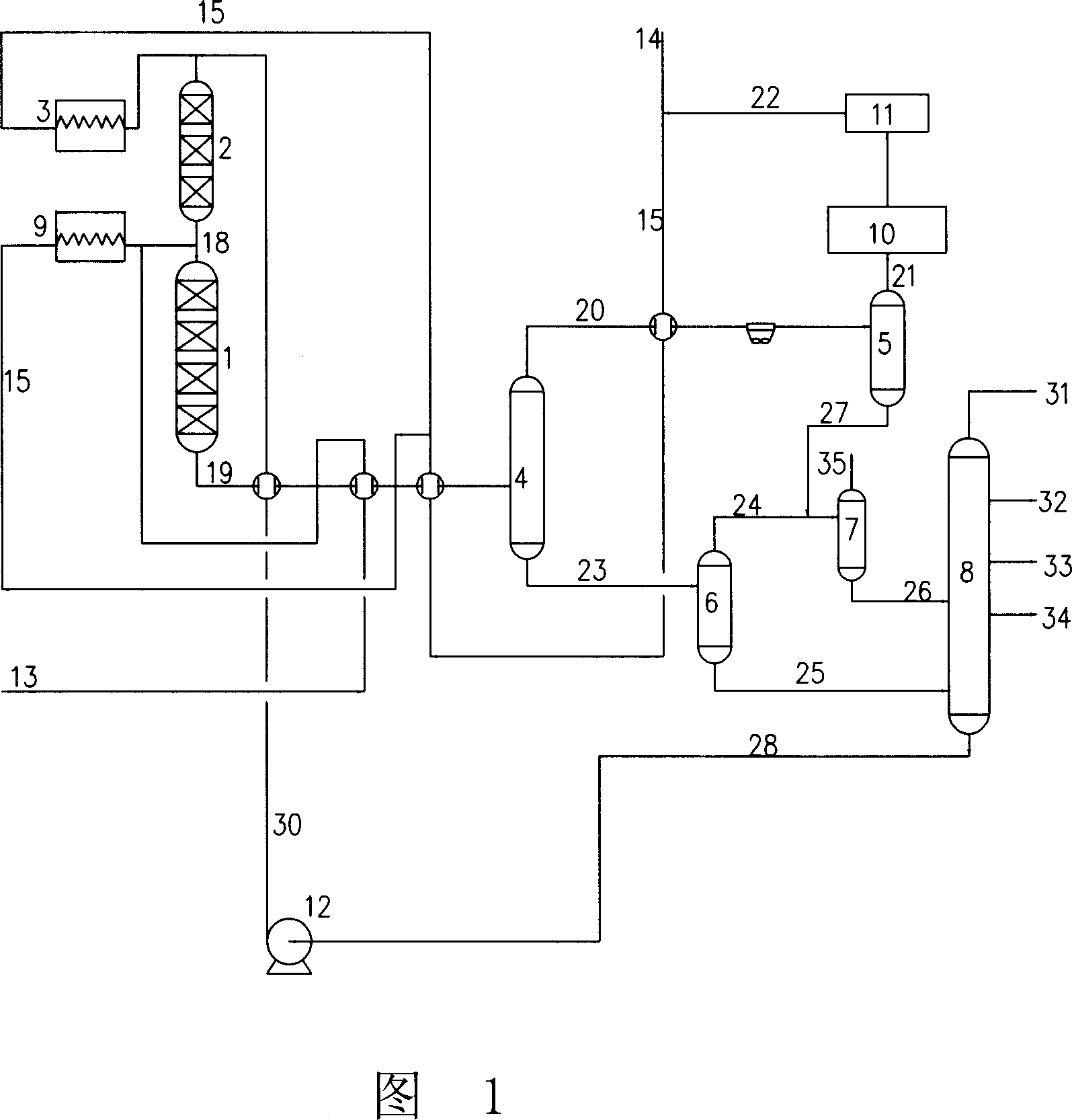

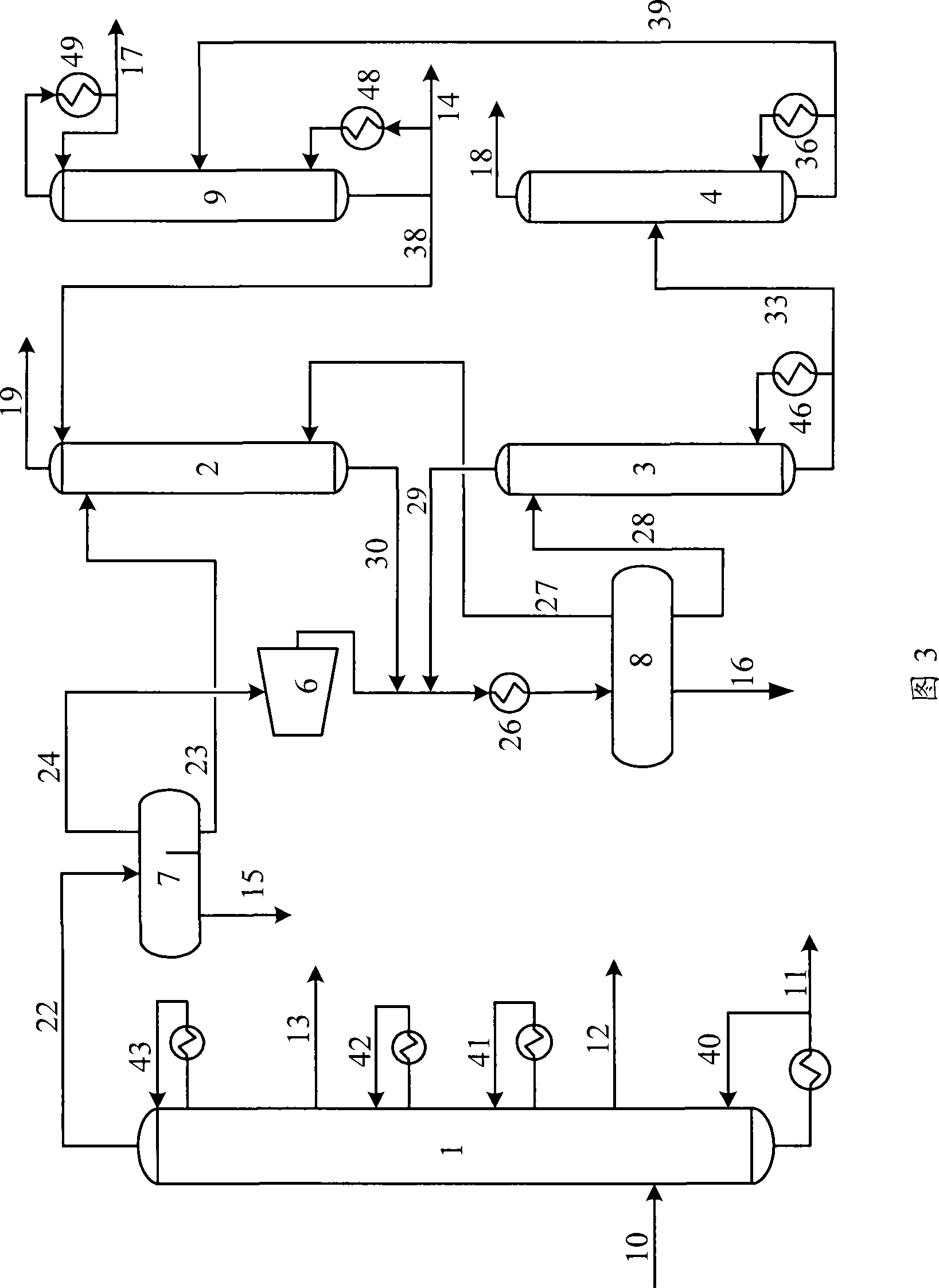

Optimized hydrogenation-catalytic cracking combination process

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced atthe same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

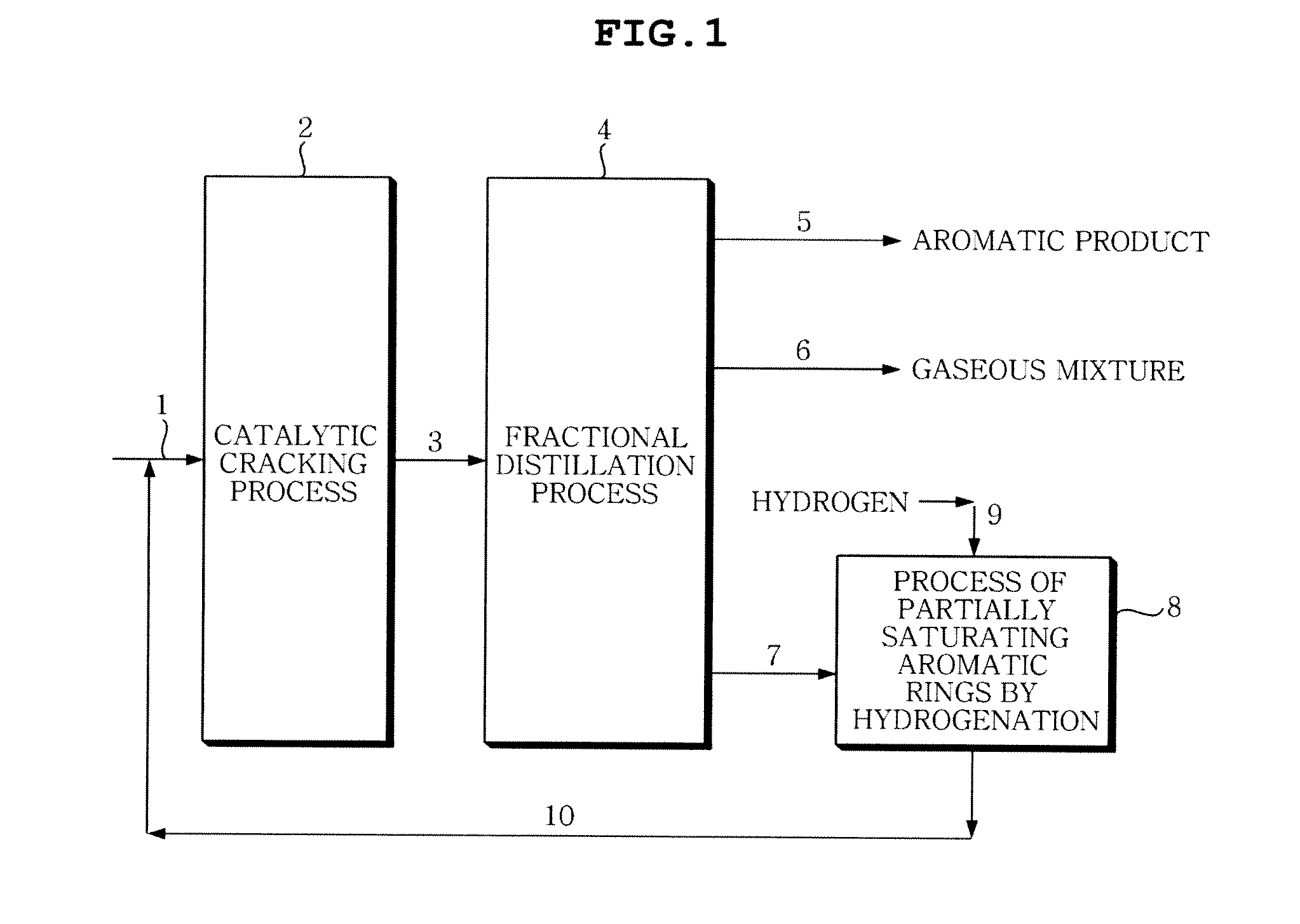

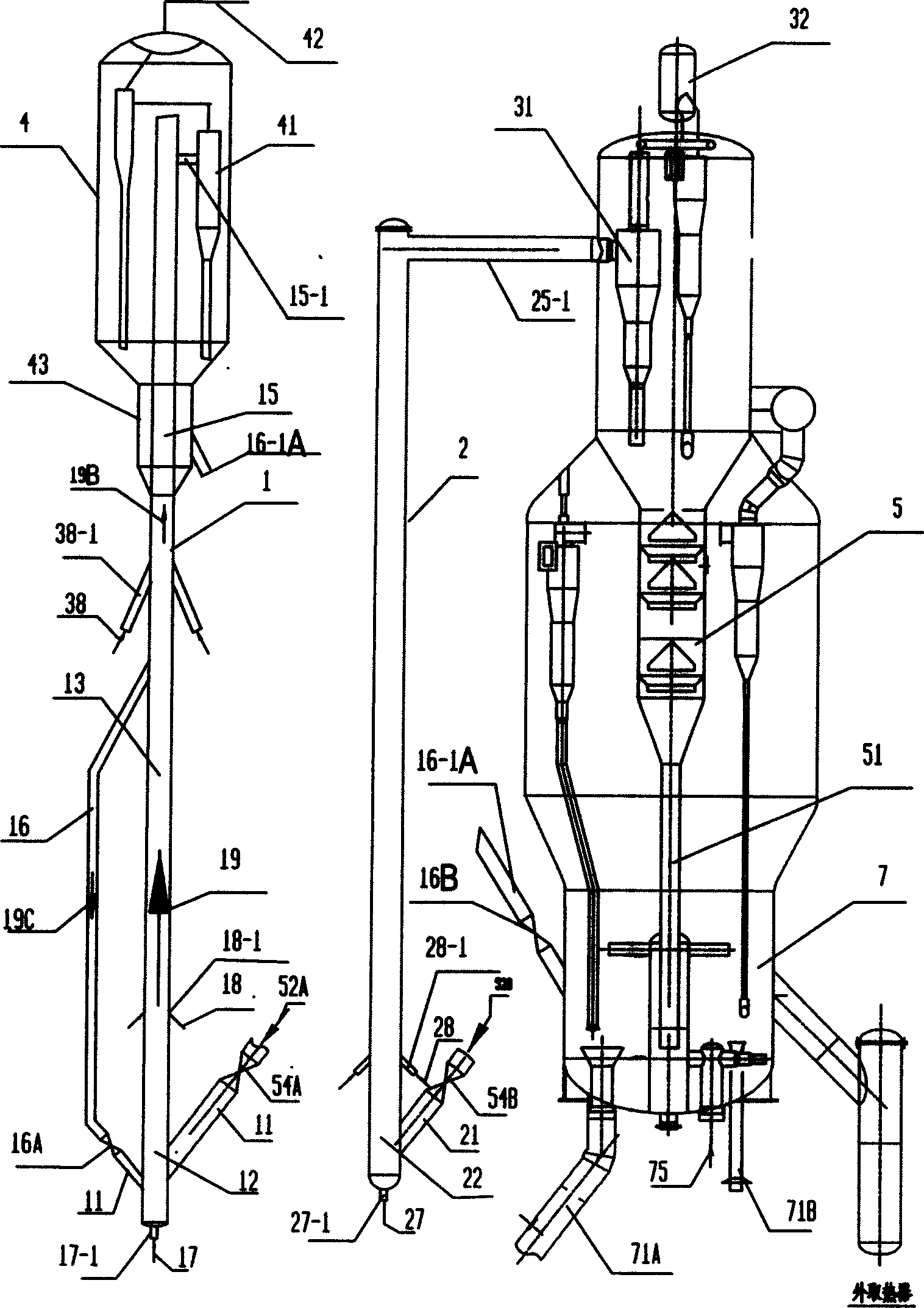

Catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon

ActiveCN104560187AReduce hydrogen consumptionImprove harsh conditionsTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonGasoline

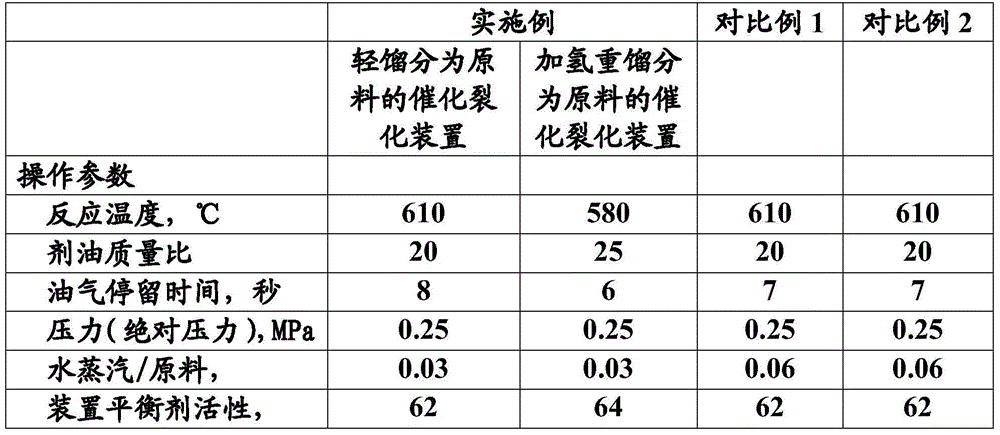

The invention provides a catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon. The catalytic conversion method comprises the following steps: cutting catalytic cracking light cycle oil to obtain a light fraction and a heavy fraction, performing hydrogenation treatment on the heavy fraction to obtain a hydrogenated heavy fraction, singly and respectively conveying the light fraction and the heavy fraction into different riser reactors of catalytic cracking devices, performing a cracking reaction in the presence of a catalytic cracking catalyst, and separating reaction products to obtain a product containing the gasoline which contains rich aromatic hydrocarbon and the light cycle oil. According to the method, single catalytic cracking devices are used for processing the light fraction and the hydrogenated heavy fraction of the light cycle oil to satisfy harsh conditions necessary for the catalytic cracking reaction of different fractions of the light cycle oil to the maximum, so as to produce catalytic gasoline containing rich benzene, toluene and xylene to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

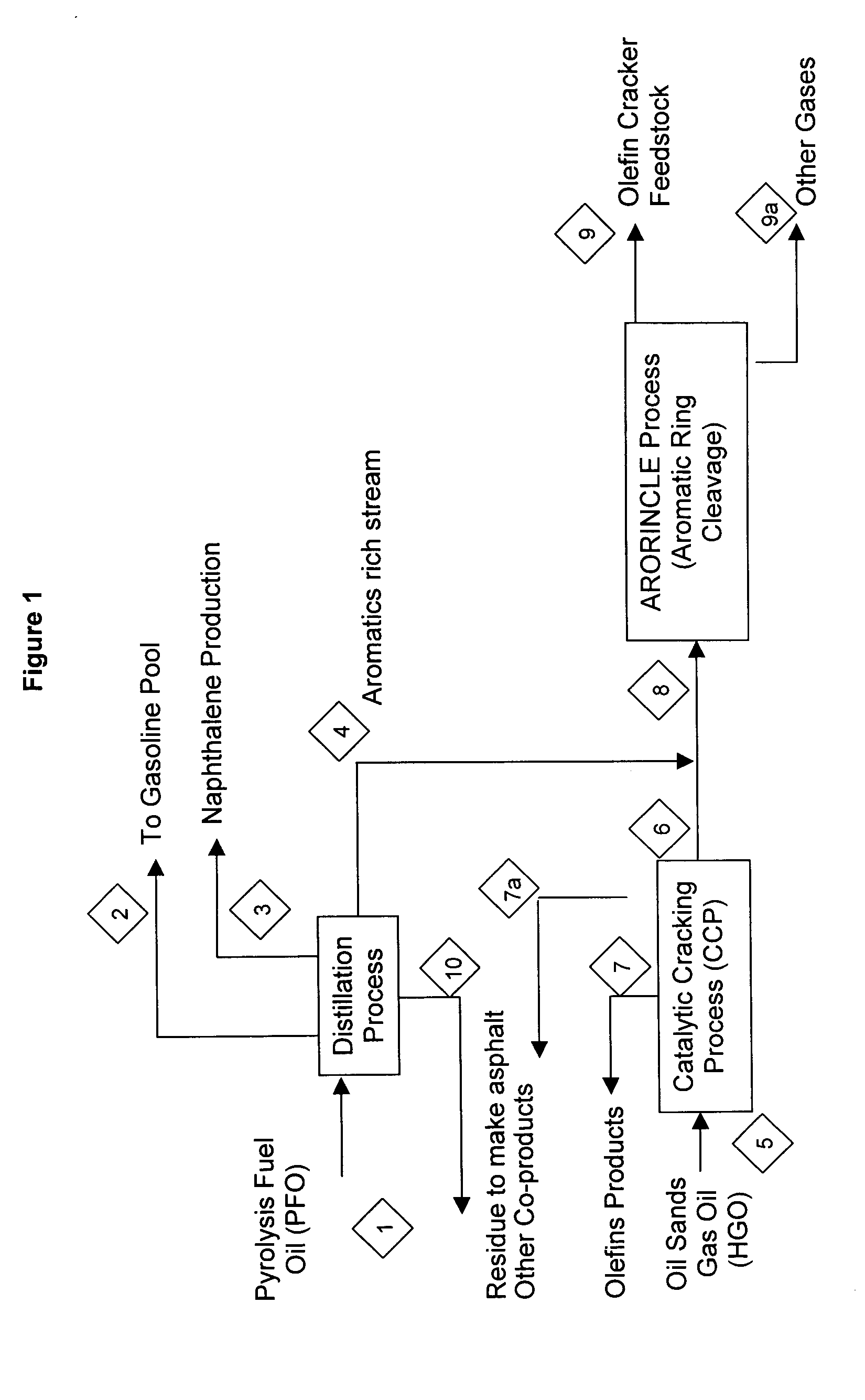

Integrated process to convert heavy oils from oil sands to petrochemical feedstock

ActiveUS20050258073A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkaneFuel oil

An aromatics / naphthalene rich stream obtained by processing heavy gas oil derived from tar sands and cycle oils derived from cracking heavy gas oil may optionally be blended and subjected to a hydrogenation process and a ring opening reaction typically in the presence of a zeolite, alumina, or silica alumina based catalyst which may contain noble metals and or copper or molybdenum to produce paraffinic feedstocks for further chemical processing.

Owner:NOVA CHEM (INT) SA

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

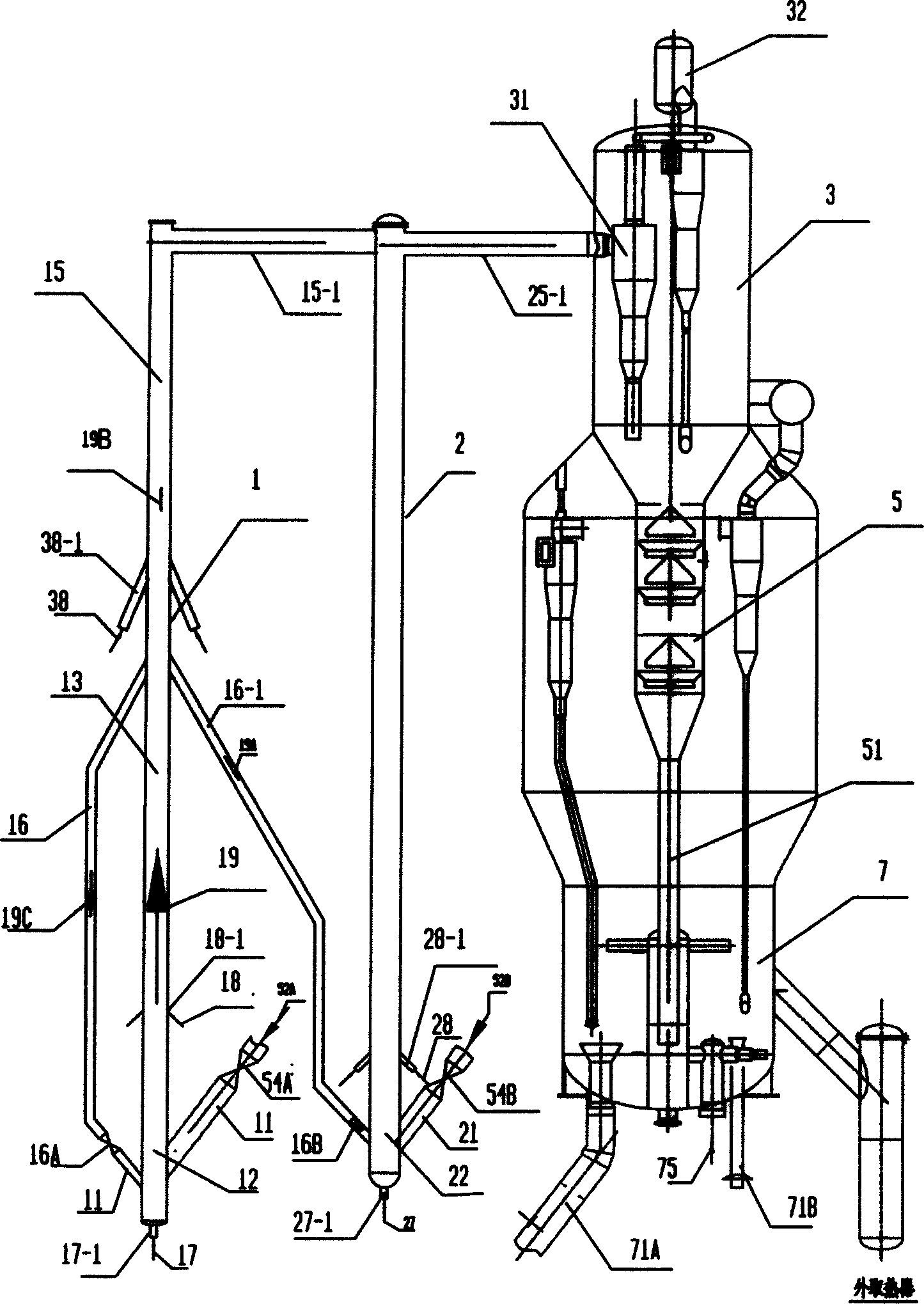

Catalytic conversion method for producing gasoline containing rich aromatic compounds

ActiveCN104560185AReduce hydrogen consumptionImprove harsh conditionsTreatment with hydrotreatment processesGasolineCracking reaction

The invention provides a catalytic conversion method for producing gasoline containing rich aromatic compounds. The catalytic conversion method comprises the following steps: cutting catalytic cracking light cycle oil to obtain a light fraction and a heavy fraction, performing hydrogenation treatment on the heavy fraction to obtain a hydrogenated heavy fraction, singly conveying the light fraction and the hydrogenated heavy fraction into catalytic cracking devices from different nozzles in a layering manner, performing a cracking reaction in the presence of a catalytic cracking catalyst, and separating reaction products to obtain a product containing the gasoline which contains rich aromatic compounds and the light cycle oil. According to the method, single catalytic cracking devices are used for processing the light fraction and the hydrogenated heavy fraction of the light cycle oil, and the light fraction and the heavy fraction enter the catalytic cracking devices in the layering manner, so that the harsh conditions necessary for the catalytic cracking reaction of different fractions of the light cycle oil can be optimized and satisfied to the maximum, so as to produce catalytic gasoline containing rich benzene, toluene and xylene to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

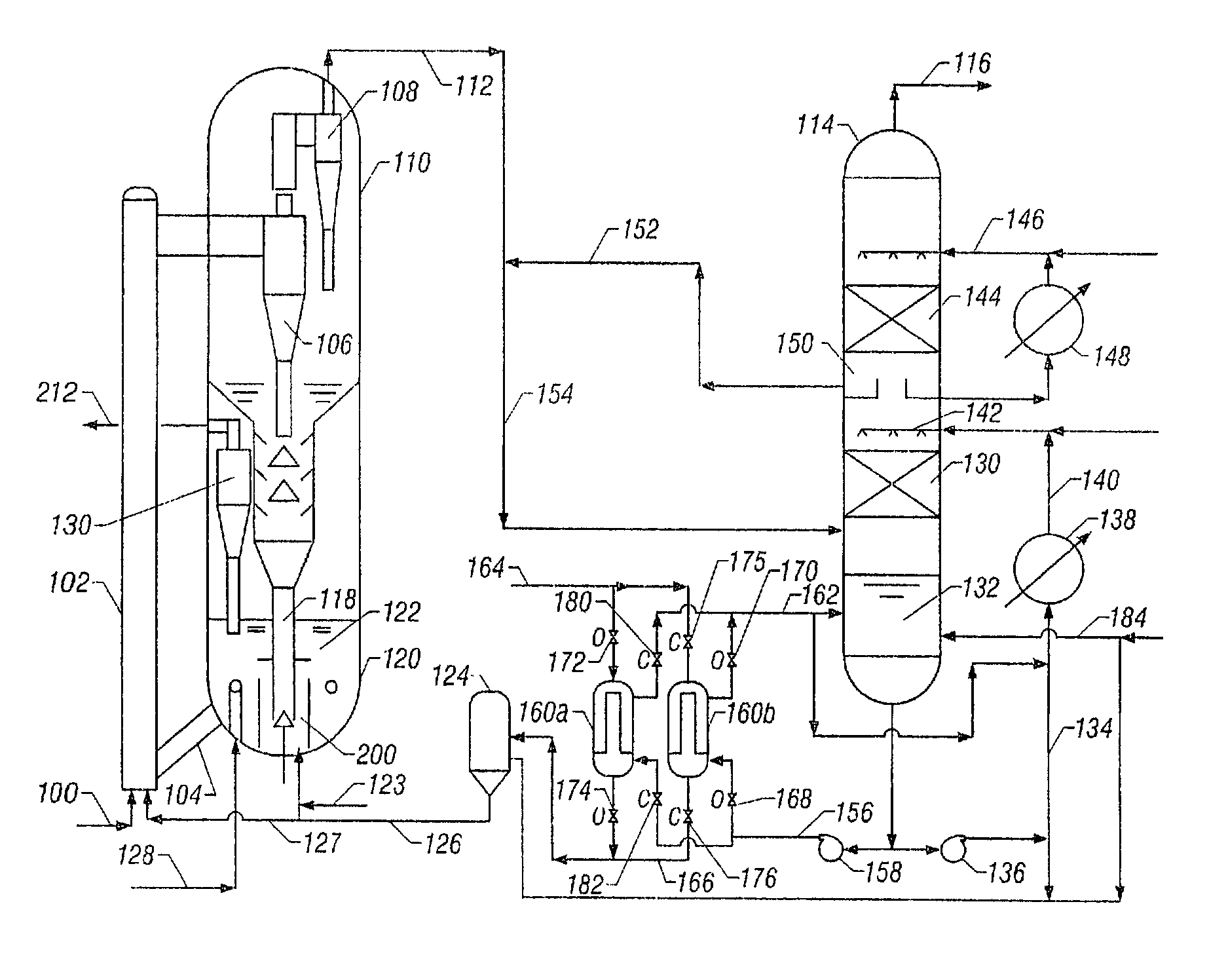

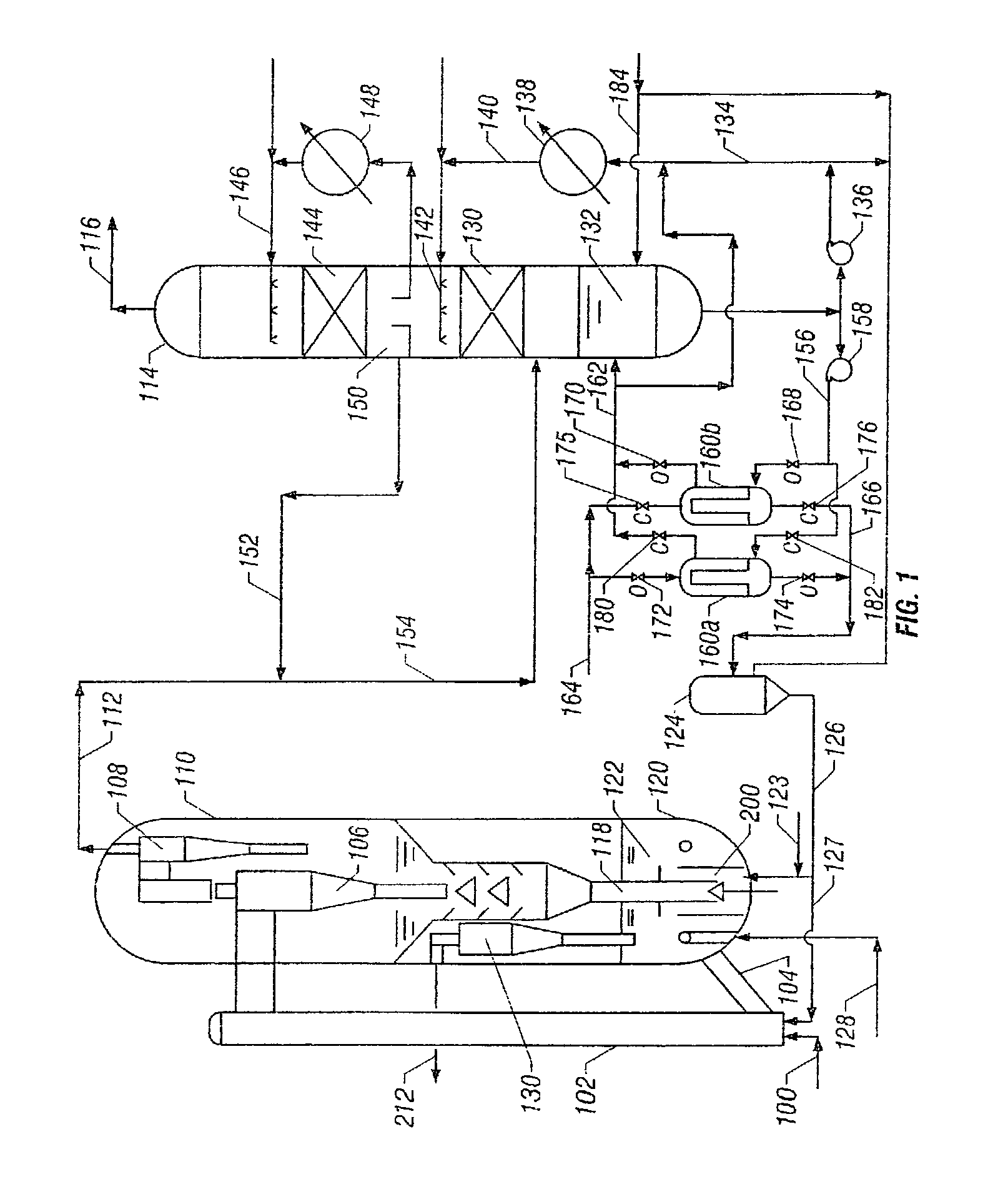

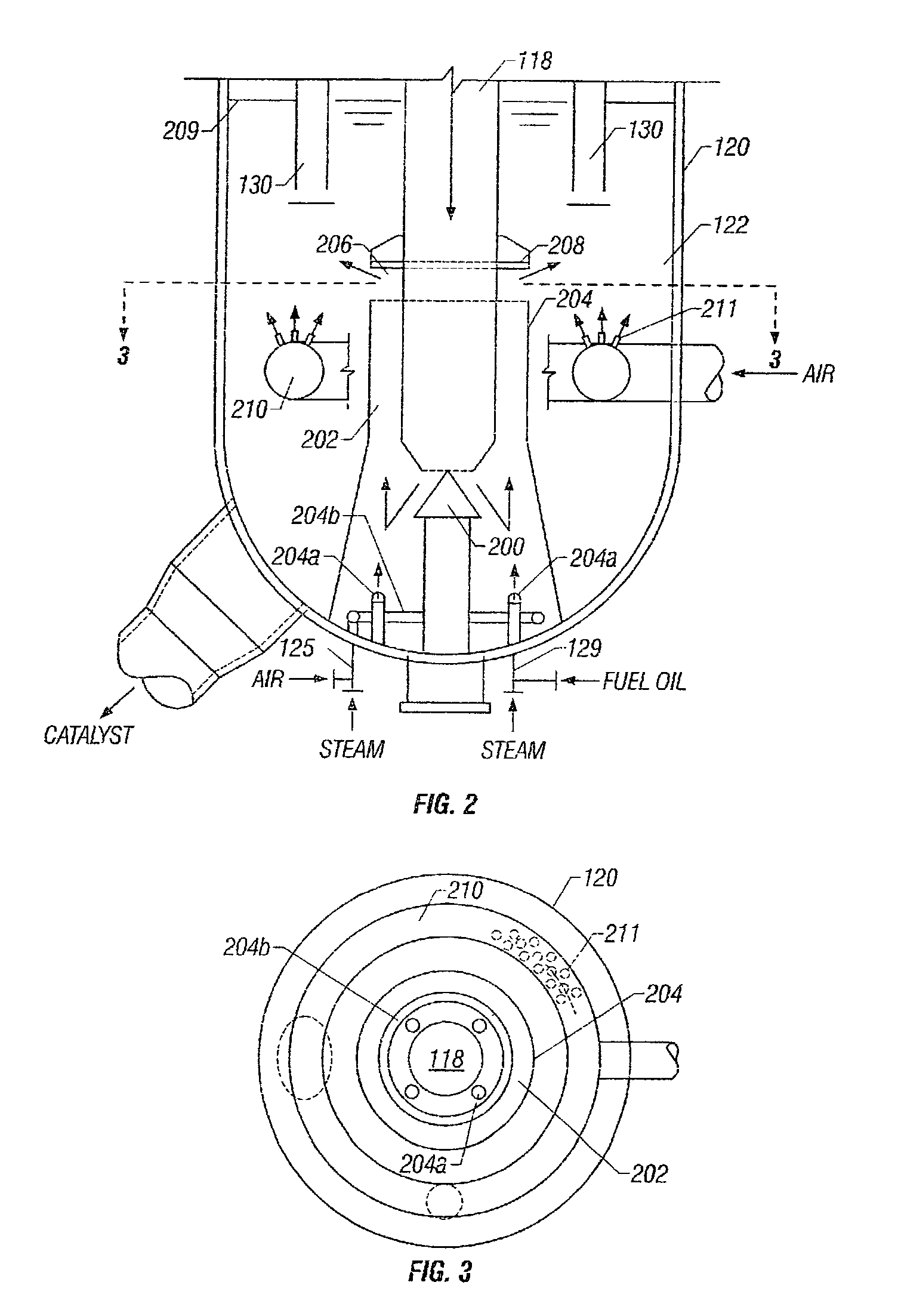

Catalyst recovery from light olefin FCC effluent

ActiveUS7011740B2Eliminate catalyst lossThermal non-catalytic crackingCatalytic crackingCycle oilFuel oil

A method and system for recovering fines from a light FCC-type effluent gas. Cracked gases from the reactor are cooled by direct contact with circulating oil in an oil quench tower. The circulating oil also washes out the catalyst fines carried with the reactor effluent gas. A flow of the oil from the quench tower bottoms is sent through one of a pair of filters to remove fines and recycled to the tower. The other filter is in backwash operation using a compressed gas to remove the fines therefrom and into a surge drum. Fuel oil or quench oil is added to the drum to form a slurry, which carries the catalyst fines to the regenerator where the oil is combusted to supply the FCC system heat requirements. Since a minimum amount of fuel oil is generated in the FCC, fuel oil is imported to inventory the quench tower.

Owner:KELLOGG BROWN & ROOT INC

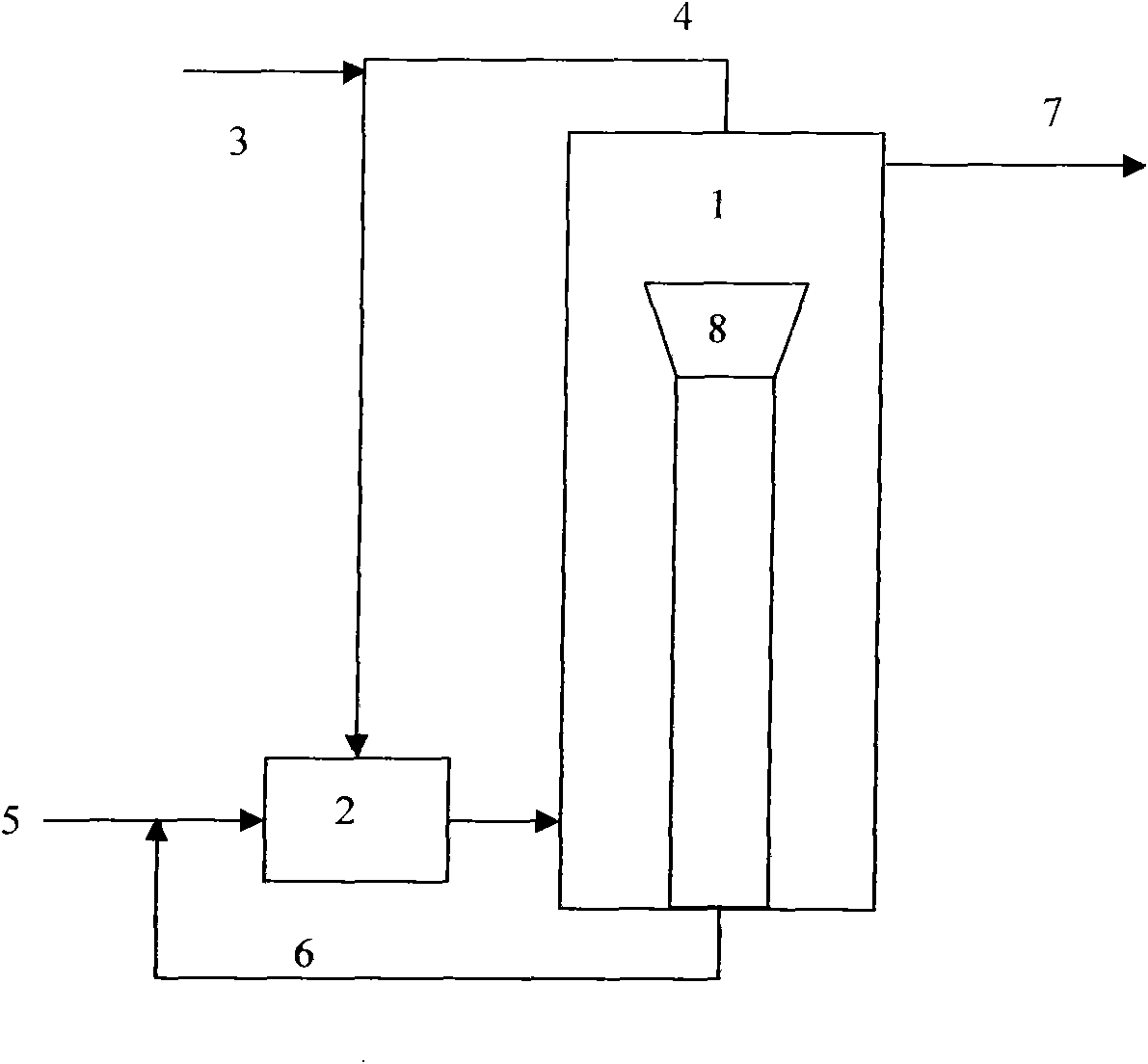

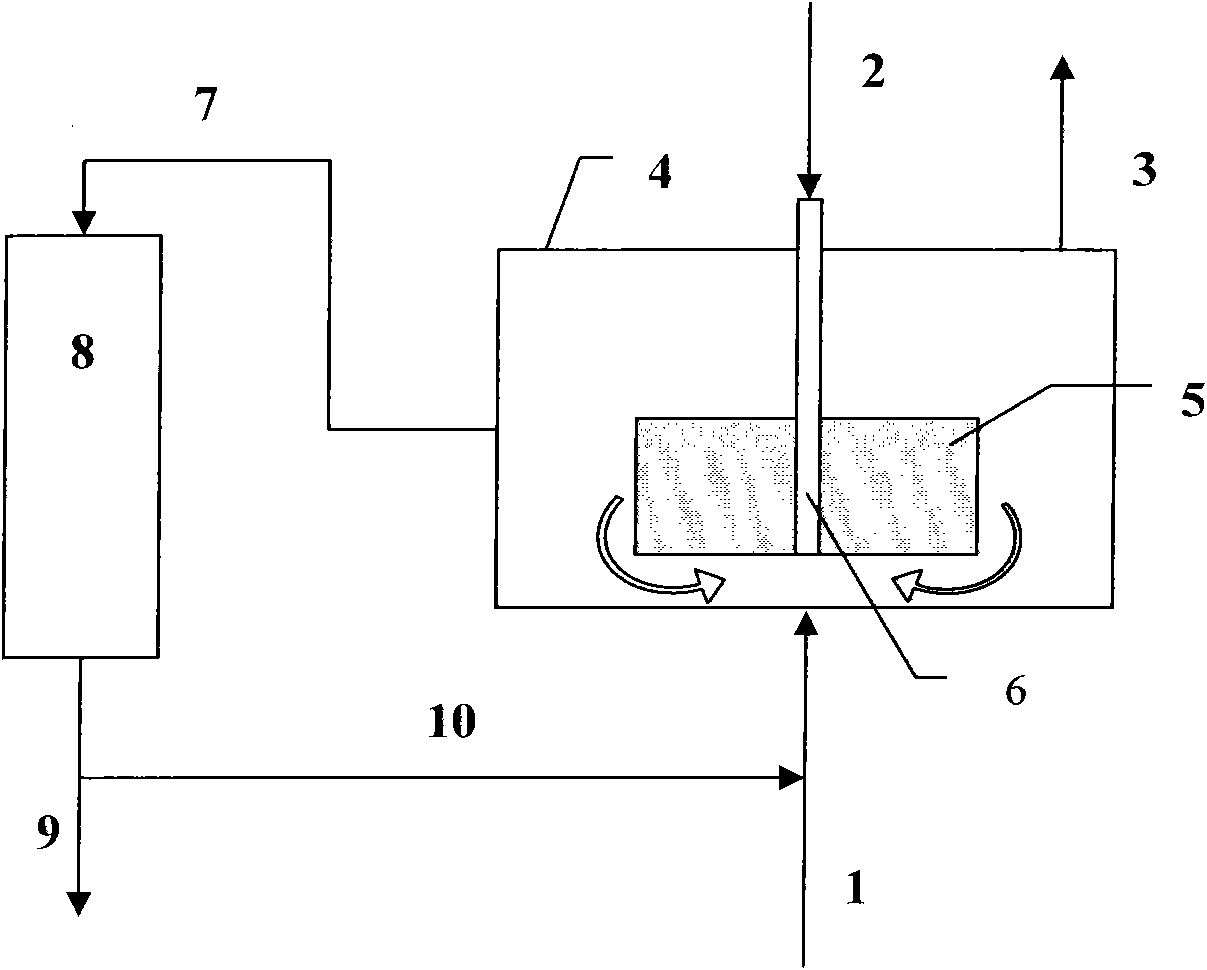

Method for enhancing gas-liquid mass transfer of ebullated bed hydrogenation reactor

ActiveCN102049220AIncreased contact surface areaImprove mass transfer efficiencyChemical/physical processesMicrobubblesHydrogenation reaction

The invention discloses a method for enhancing the gas-liquid mass transfer of an ebullated bed hydrogenation reactor, which comprises the following processes of: introducing fresh raw oil, circulating oil and hydrogen into a microbubble generator arranged in front of the reactor, fully mixing to make the hydrogen dispersed in a liquid-phase material in the form of microbubbles, and performing hydrogenation and cracking reaction in the ebullated bed reactor. The method can improve the utilization rate of the hydrogen, reduce the volume ratio of the hydrogen to the oil, save operating cost andpromote the depth of the hydrogenation and cracking reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

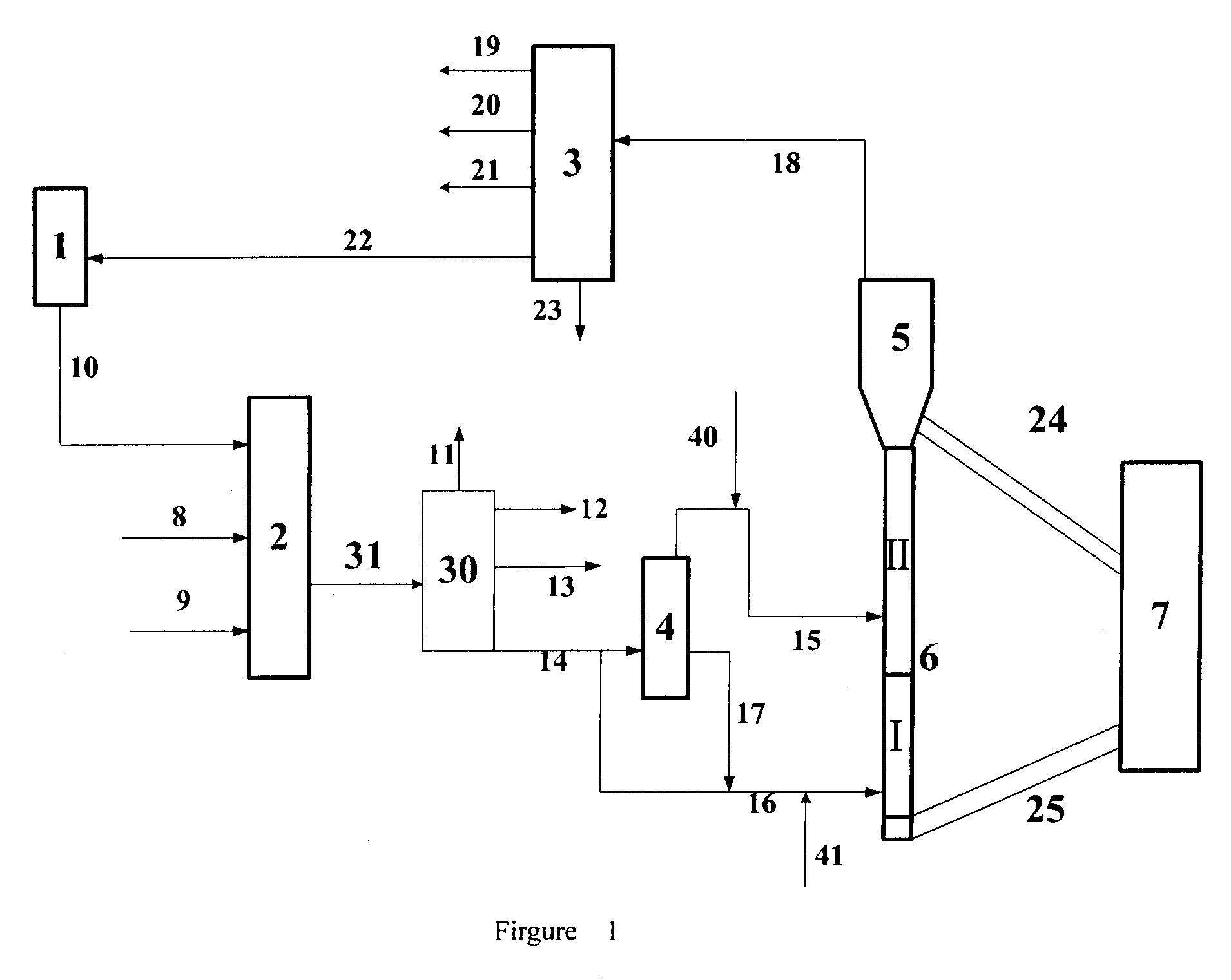

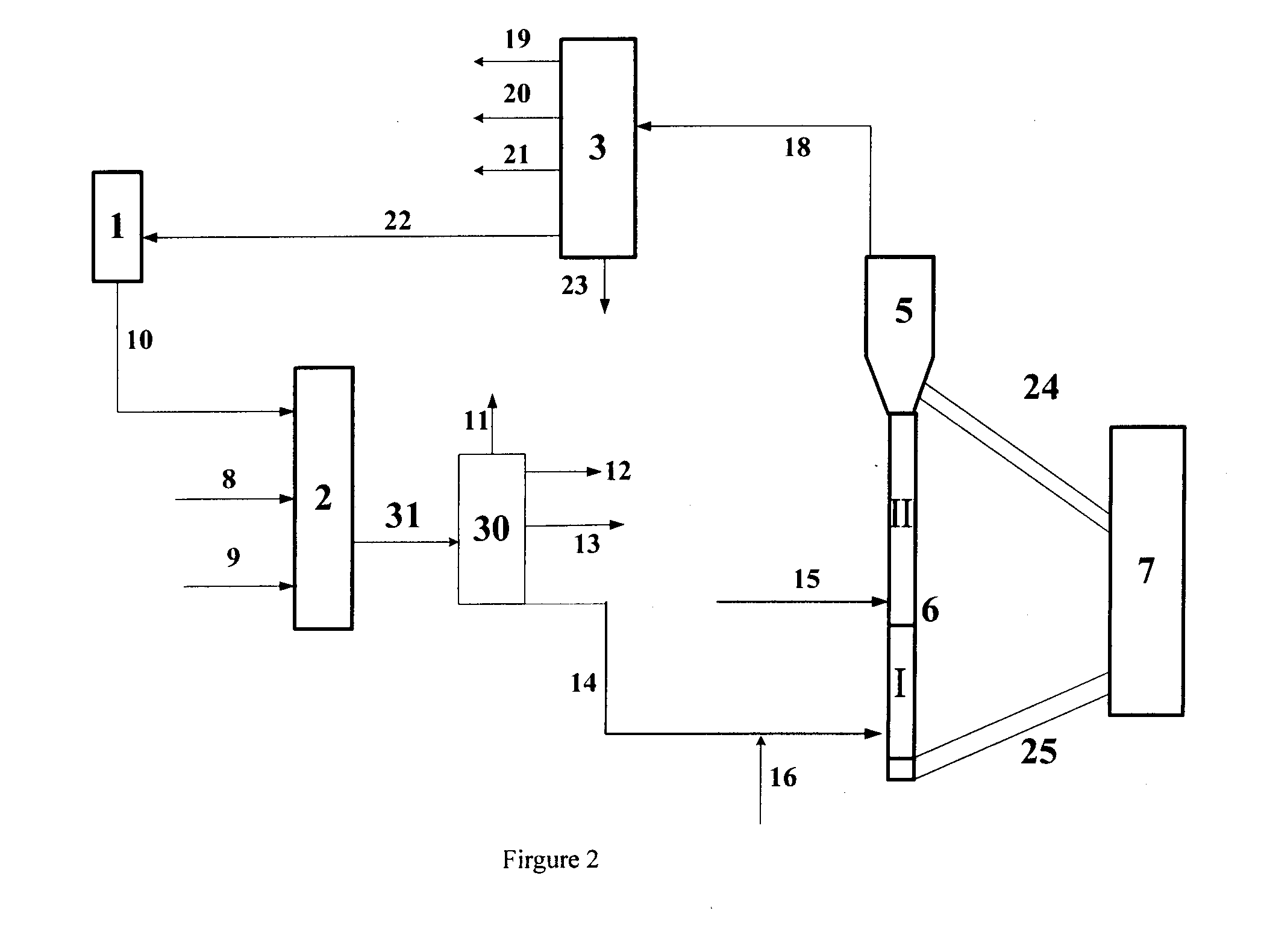

Method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons

ActiveCN101747935AImprove propertiesDoes not affect activityTreatment with hydrotreatment processesWaxResidual oil

The invention provides a method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons. The method produces qualified catalytic cracking raw materials through hydrogenation by taking wax oil and residual oil as raw materials, returns light cycle oil and heavy cycle oil which are catalytic cracking by-products to a hydrogenation unit for the catalytic cracking rawmaterials at the same time, hydrogenates the catalytic cracking by-products together with the catalytic cracking raw materials, and then takes the obtained product as the catalytic cracking raw materials to produce light olefins and monocyclic aromatic hydrocarbons. By introducing the residual oil before a second reaction zone of hydrogenation, the method widens the sources of the catalytic cracking raw materials, increases the processing amount of low-value residual oil, and solves the problem of the heat balance of catalytic cracking units. The light and heavy cycle oil of catalytic cracking is introduced into the hydrogenation unit, hydrogenated and then taken as the catalytic cracking raw materials, so that the yield of high-value products of the catalytic cracking units can be increased, and the deactivation of hydrogenation catalysts is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

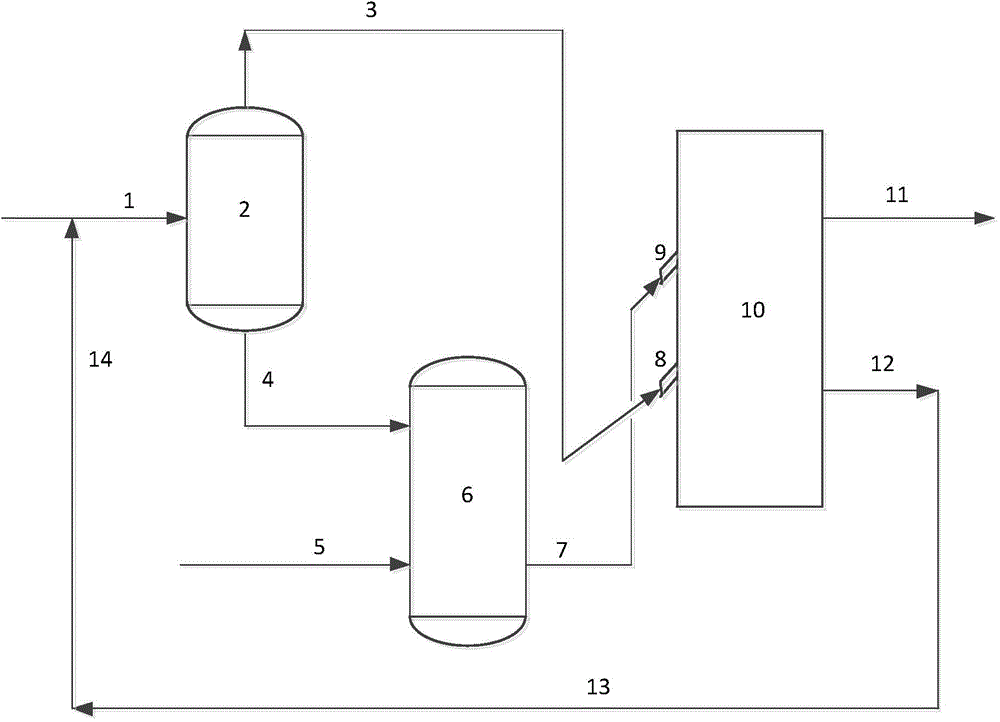

Catalytic conversion method for hydrocarbon oil raw material

ActiveCN101191081AReduce olefin contentBoost octaneTreatment with hydrotreatment processesLiquid gasRaw material

The invention discloses a catalytic conversion method for a hydrocarbon oil raw material. The hydrocarbon oil raw material contacts the catalytic cracking catalyst in a catalytic cracking reactor, the reaction oil gas and a spent catalyst are separated, then the spent catalyst is made steam stripping and regeneration and then returns to the catalytic cracking reactor for repeated use, the reaction oil gas is fractionated to obtain dry gas, liquefied gas, gasoline, light circulating oil, heavy circulating oil and heavy oil; the light circulating oil and any diesel fraction are cut into the light fraction of the light circulating oil and the heavy fraction of the light circulating oil; the heavy fraction of the light circulating oil is mixed with the heavy circulating oil and contacts the hydrogen and the hydrorefining catalyst, the reaction effluent is separated to obtain gas, naphtha and hydrogenated diesel, the hydrogen is reclaimed and then is circularly used; the light fraction of the light circulating oil independently or the light fraction of the light circulating oil along with the hydrogenated diesel returns to the catalytic cracking reactor. The method converts the catalytic cracking circulating oil into the gasoline with low olefin content and high octane value, and improves the yield of the gasoline and the yield of the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high value aromatics and olefin from light cycle oil produced by a fluidized catalytic cracking process

ActiveUS20110207979A1Increase productionMaximize processing efficiencyCatalytic crackingHydrocarbonsHigh concentrationPetroleum

The present invention relates to a method of producing aromatic products (benzene / toluene / xylene) and olefin products from petroleum fractions obtained by fluid catalytic cracking, and, more particularly, to a method of producing products comprising high-concentration aromatic products and high value-added light olefin products from light cycle oil obtained by fluid catalytic cracking.

Owner:SK INNOVATION CO LTD

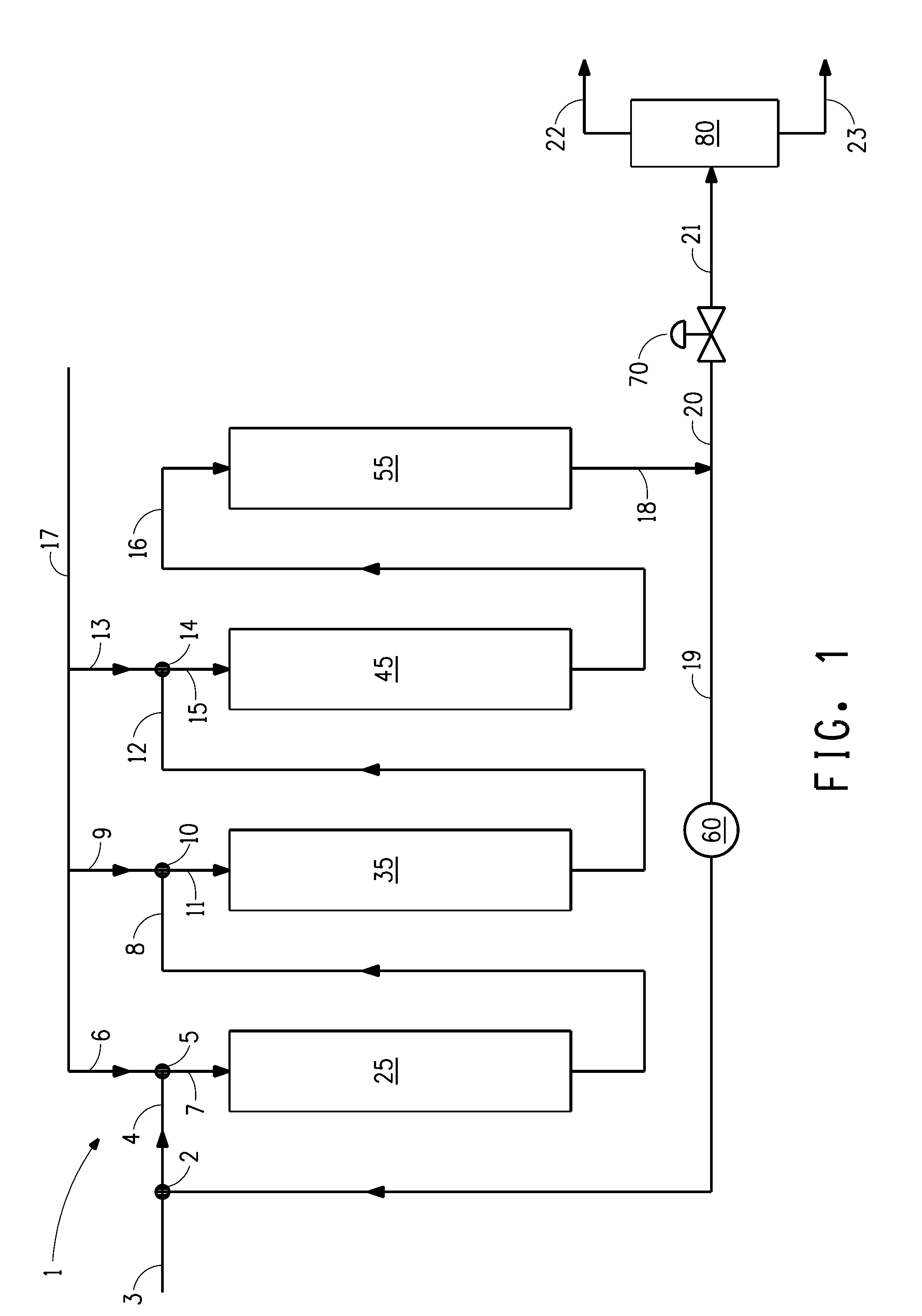

Targeted pretreatment and selective ring opening in liquid-full reactors

ActiveUS20120205285A1Reduce its nitrogen, sulfur and aromaticsIncrease valueTreatment with plural serial cracking stages onlyRefining to change hydrocarbon structural skeletonLiquid productHydrogen

A process for hydroprocessing hydrocarbons in a combined targeted pretreatment and selective ring-opening unit wherein the targeted pretreatment comprises at least two stages in a single liquid recycle loop. The process operates as a liquid-full process, wherein all of the hydrogen dissolves in the liquid phase. Heavy hydrocarbons and light cycle oils can be converted in the process to provide a liquid product having over 50% in the diesel boiling range, with properties to meet use in low sulfur diesel.

Owner:REFINING TECH SOLUTIONS LLC

Process and Apparatus for Upgrading Steam Cracker Tar Using Hydrogen Donor Compounds

ActiveUS20110005970A1Efficiently managing introductionSelf containedThermal non-catalytic crackingTreatment with plural serial cracking stages onlyCycle oilTar

A process and apparatus are provided for upgrading steam cracker tars from steam crackers. The invention also relates to a steam cracking process and apparatus for reducing yields of tars produced from steam cracking while increasing yields of higher value products by heating steam cracker tar, in the presence of hydrogen donor compounds, e.g., tetralin. The hydrogen donor compounds can be provided in a hydrogen donor-rich hydrocarbon stream, e.g., light cycle oils, or low sulfur vacuum tower bottoms. The treated tar can be separated into gas oil, fuel oil and tar streams.

Owner:EXXONMOBIL CHEM PAT INC

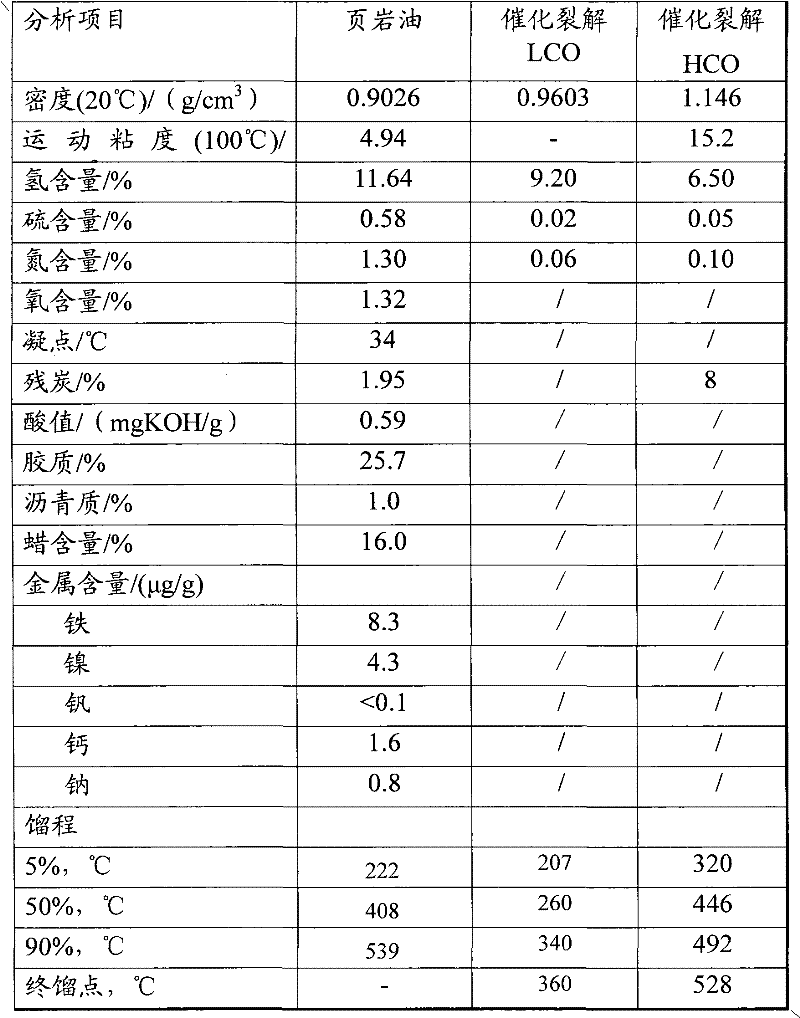

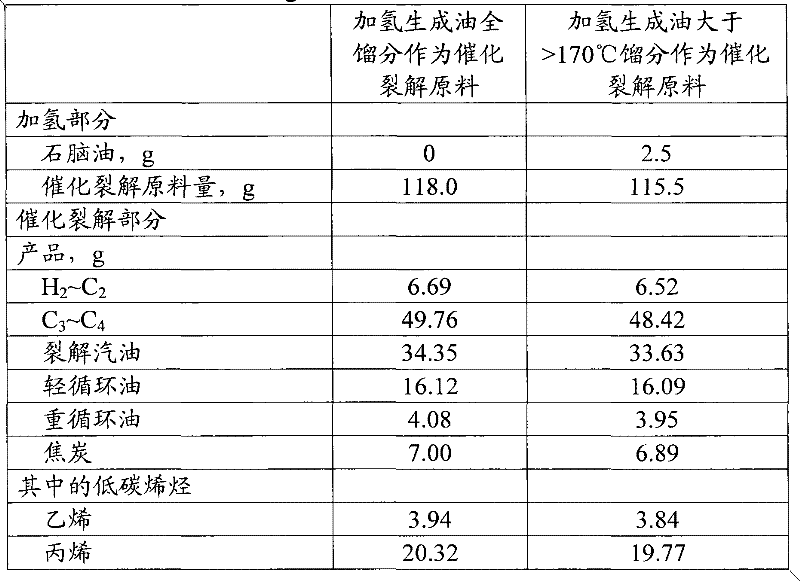

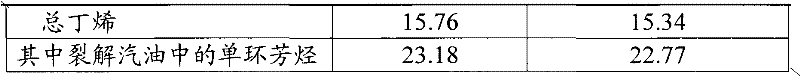

Deep processing method for shale oil

ActiveCN102453546ASave resourcesOvercome expensiveTreatment with hydrotreatment processesHydrogen treatmentLiquid gas

The invention relates to a deep processing method for shale oil, which comprises the following steps: placing shale oil, catalytic cracking light cycle oil and catalytic cracking heavy cycle oil into a shale oil hydrotreatment apparatus; placing the obtained hydrogenation generation oil and optional vacuum gas oil in a catalytic cracking apparatus, separating the reacted product to obtain ethane-containing dry gas, propylene and butylene-containing liquefied gas, monocyclic aromatics-rich catalytic cracking gasoline, catalytic cracking light cycle stock oil, catalytic cracking heavy cycle oil and catalytic cracking oil slurry; circulating catalytic cracking light cycle stock oil and catalytic cracking heavy cycle oil to the shale oil hydrotreatment apparatus. The deep processing method of shale oil is used for high value substances like ethane, propylene, butylene, benzene, toluene, xylene and the like, so that added value of the product can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

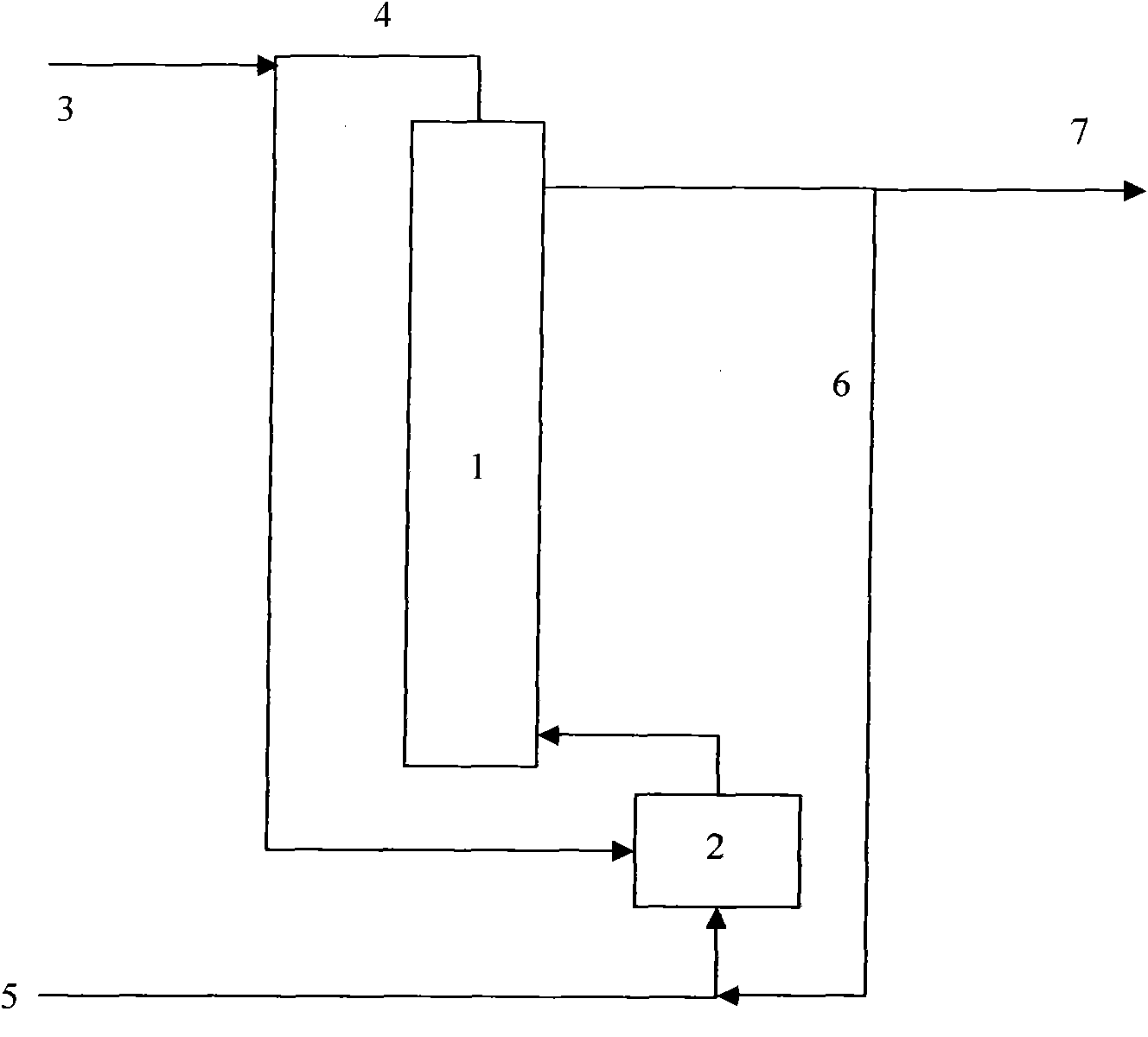

Liquid phase circular hydrogenation treatment method capable of improving mixed amount of hydrogen

ActiveCN102311790AImprove efficiencyEasy to operateTreatment with hydrotreatment processesHydrocarbon oils refiningGas phaseHydrodesulfurization

The invention discloses a liquid phase circular hydrogenation treatment method capable of improving mixed amount of hydrogen. The process flow adopted by the method comprises that: a liquid-phase material ( including fresh raw material oil, after-reaction circulating oil and circulating oil in a supergravity hydrogen mixing equipment) and hydrogen are filled into the supergravity hydrogen mixing equipment at the same time; and the hydrogen is torn and cut into lots of micro air bubbles through the high-speed rotation of a gas-liquid mixing impeller, a gas-liquid mass transfer efficiency is increased greatly, hydrogen is dissolved in the liquid-phase material in a saturated state, and the lots of micro air bubbles are dispersed in the liquid-phase material in an emulsified state so as to be brought into a reactor to undergo a hydrogenation reaction. In the method disclosed by the invention, the adoption of the supergravity hydrogen mixing equipment greatly promotes the dissolution of hydrogen and more effectively removes gas-phase impurities such as hydrogen sulfide and ammonia, so as to promote reactions such as hydrodesulfurization, denitrification, aromatic saturation and cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

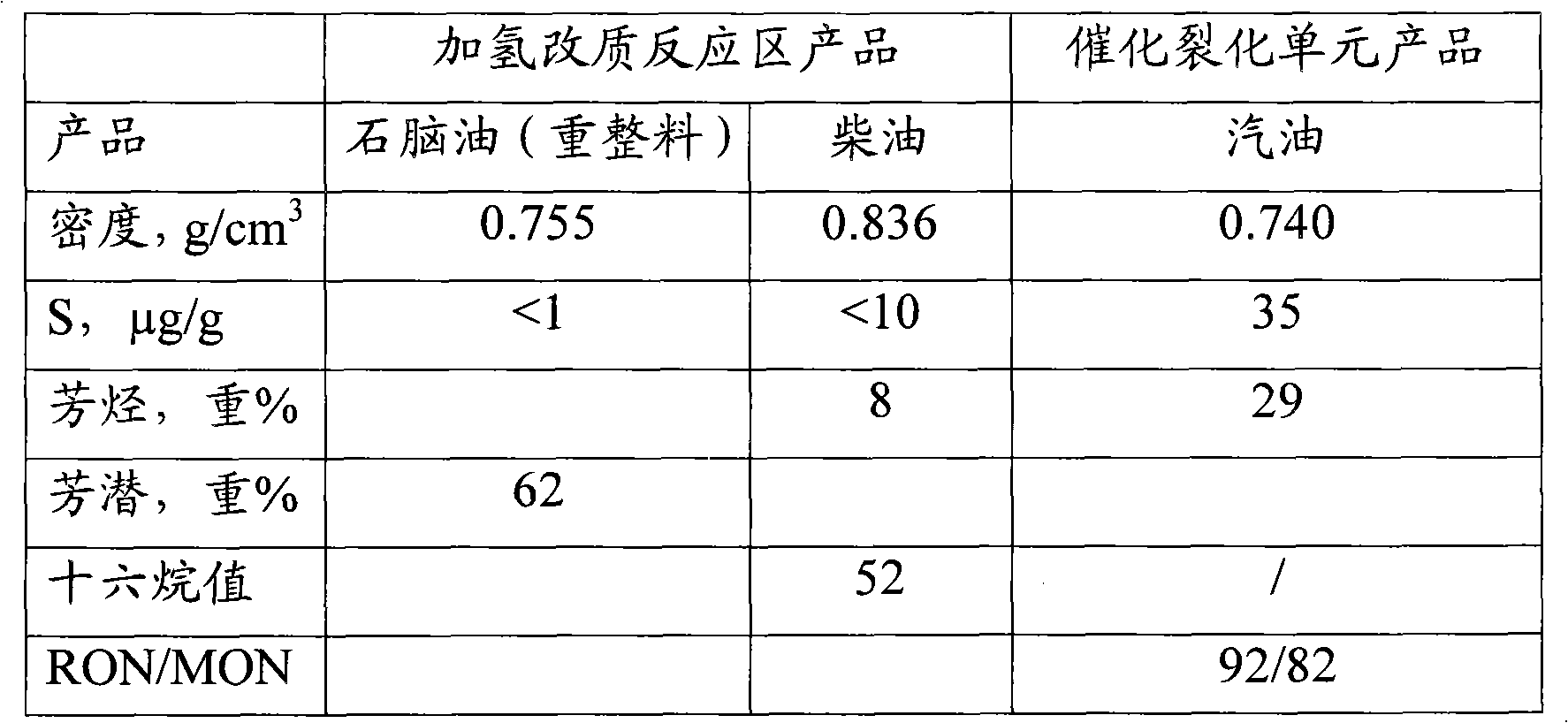

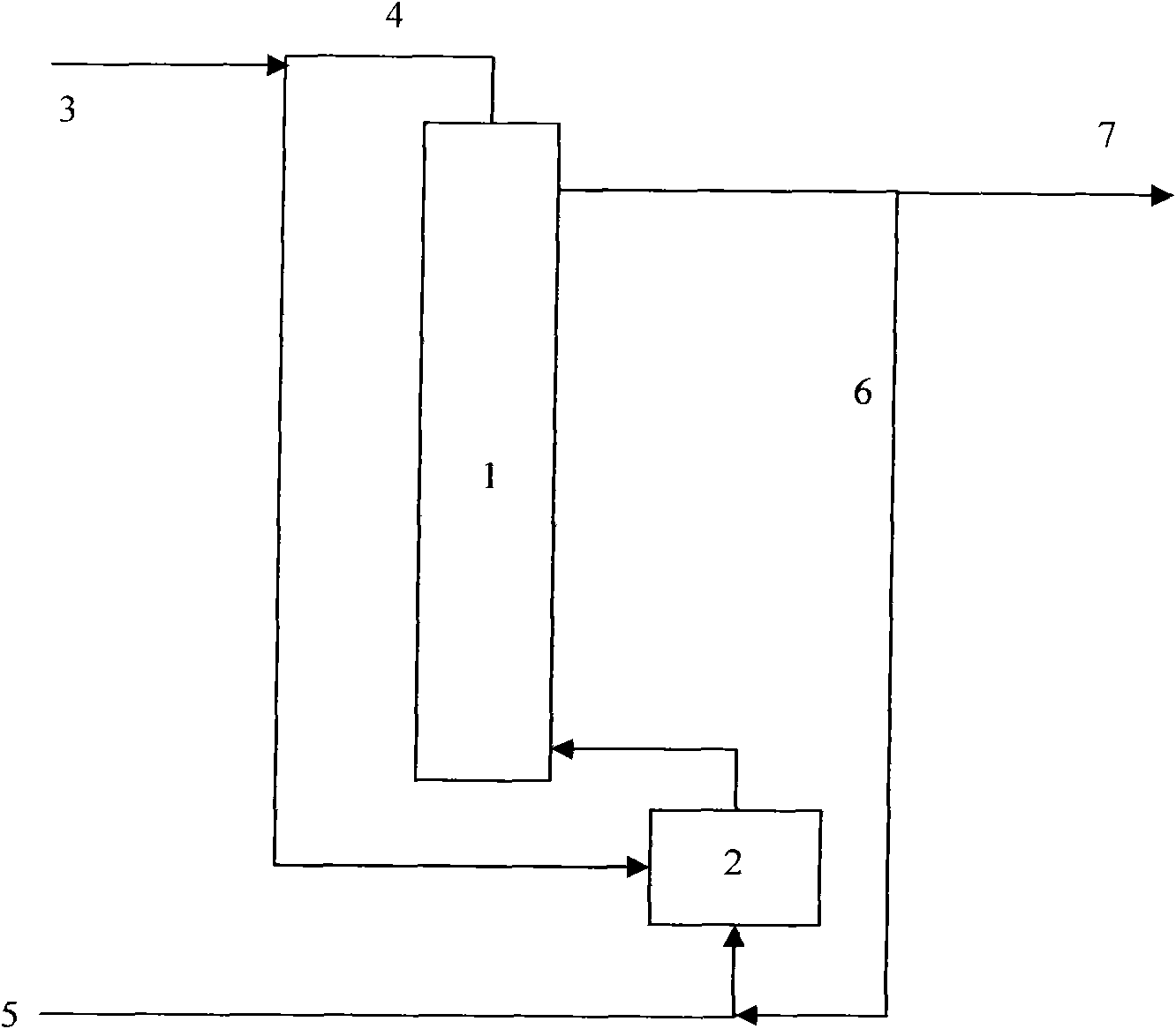

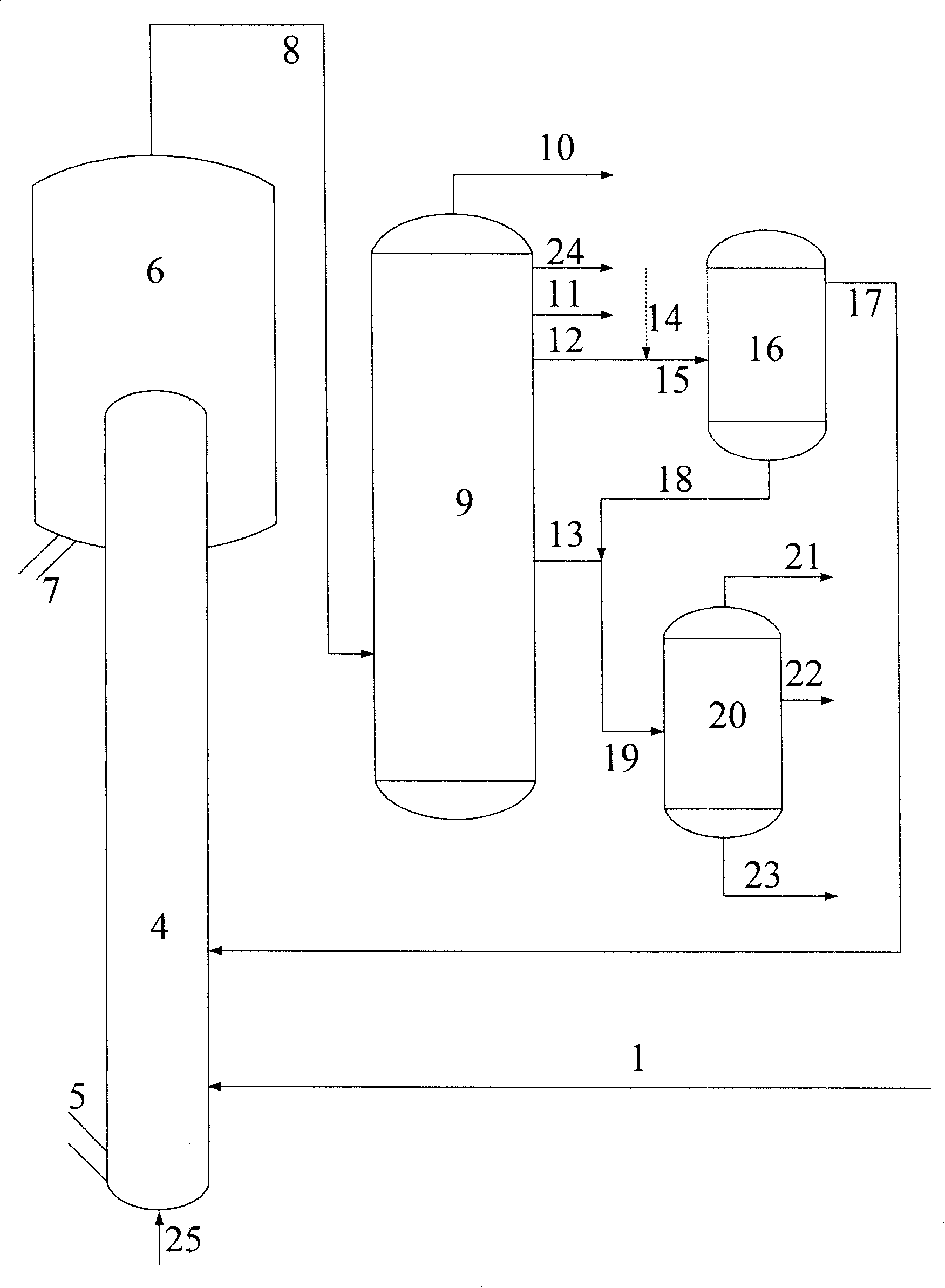

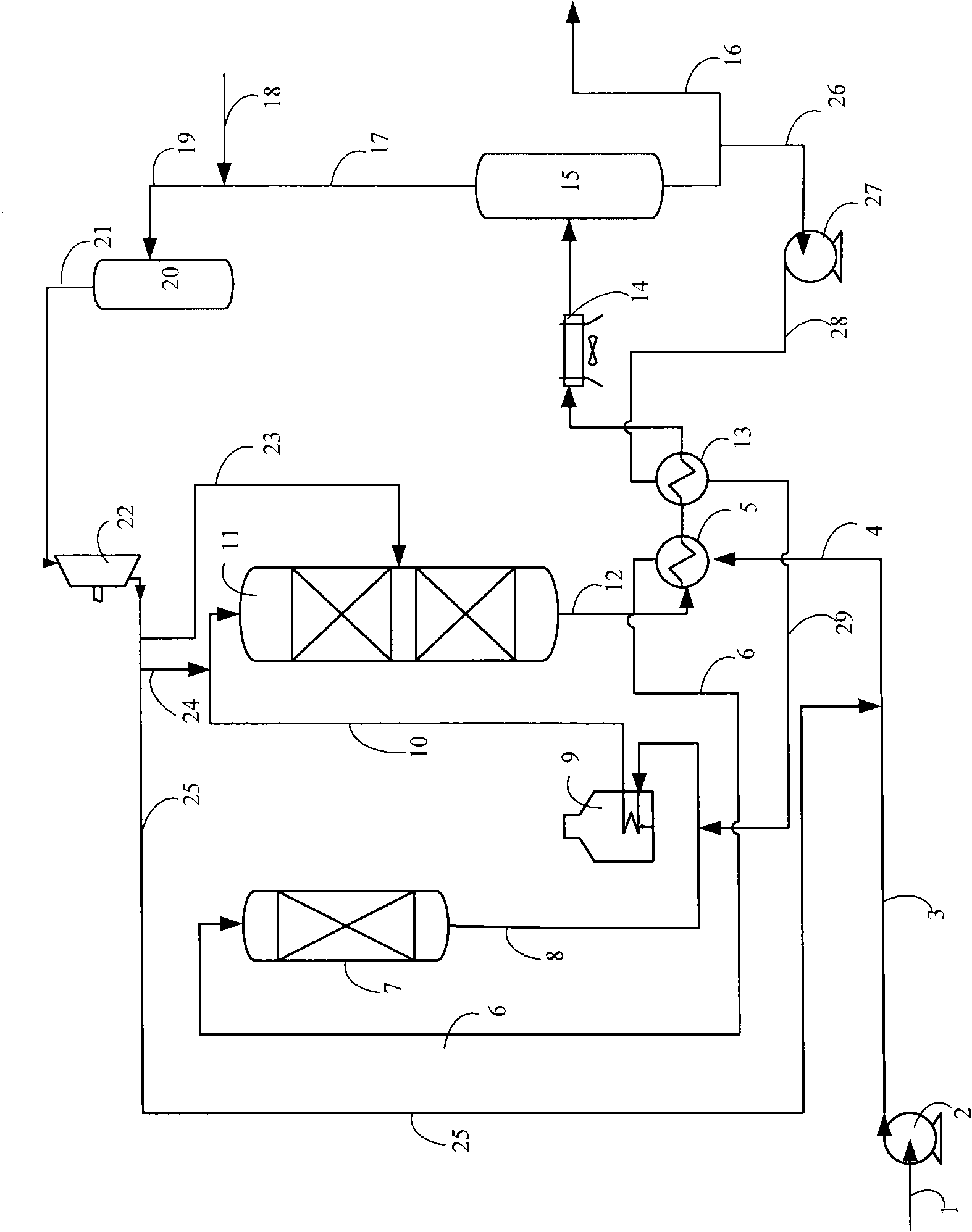

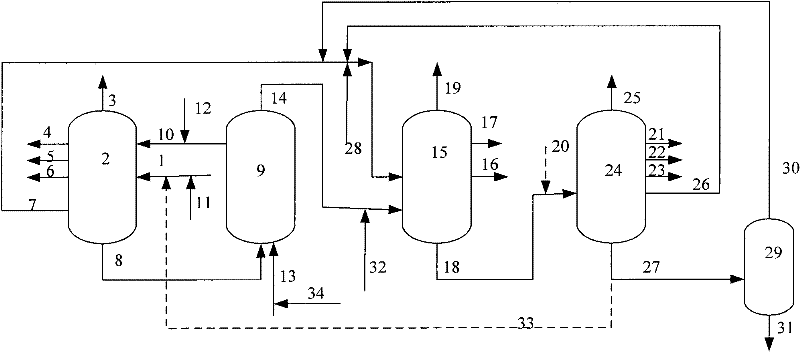

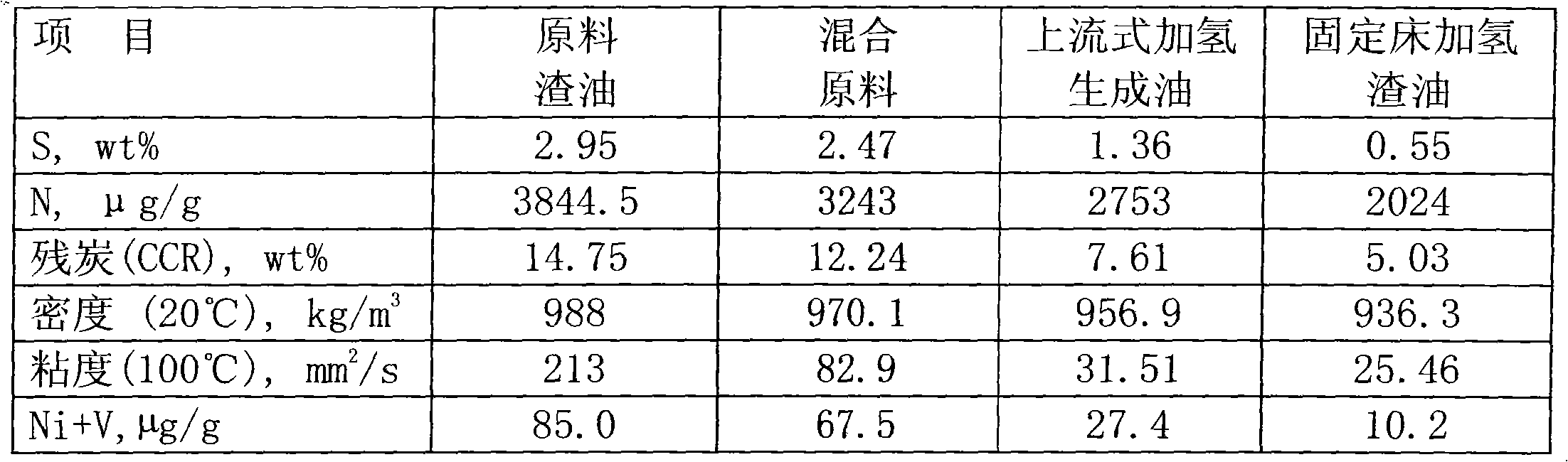

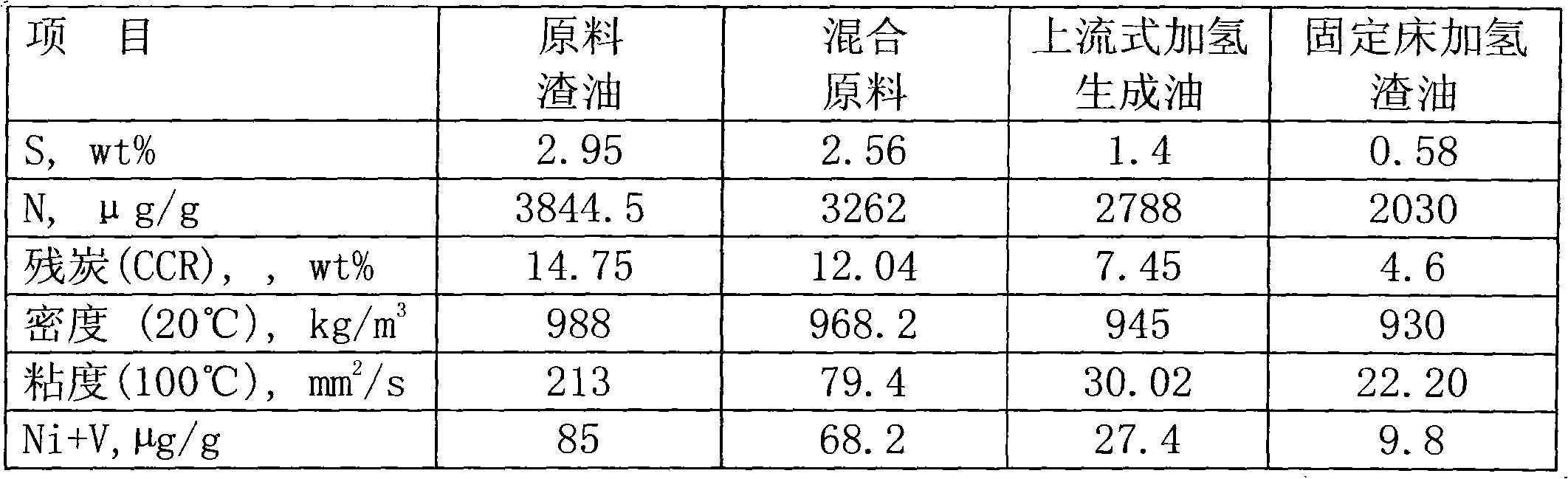

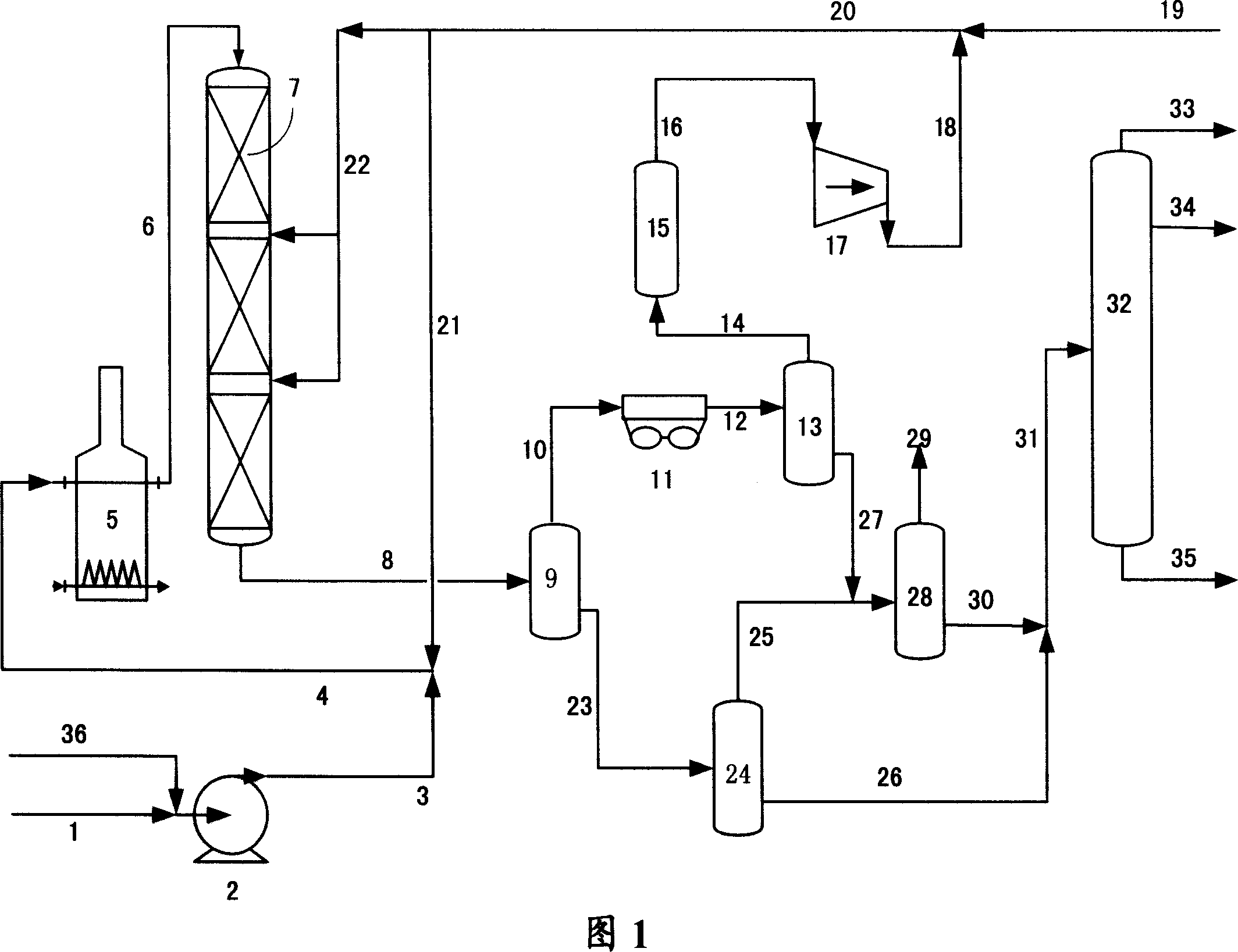

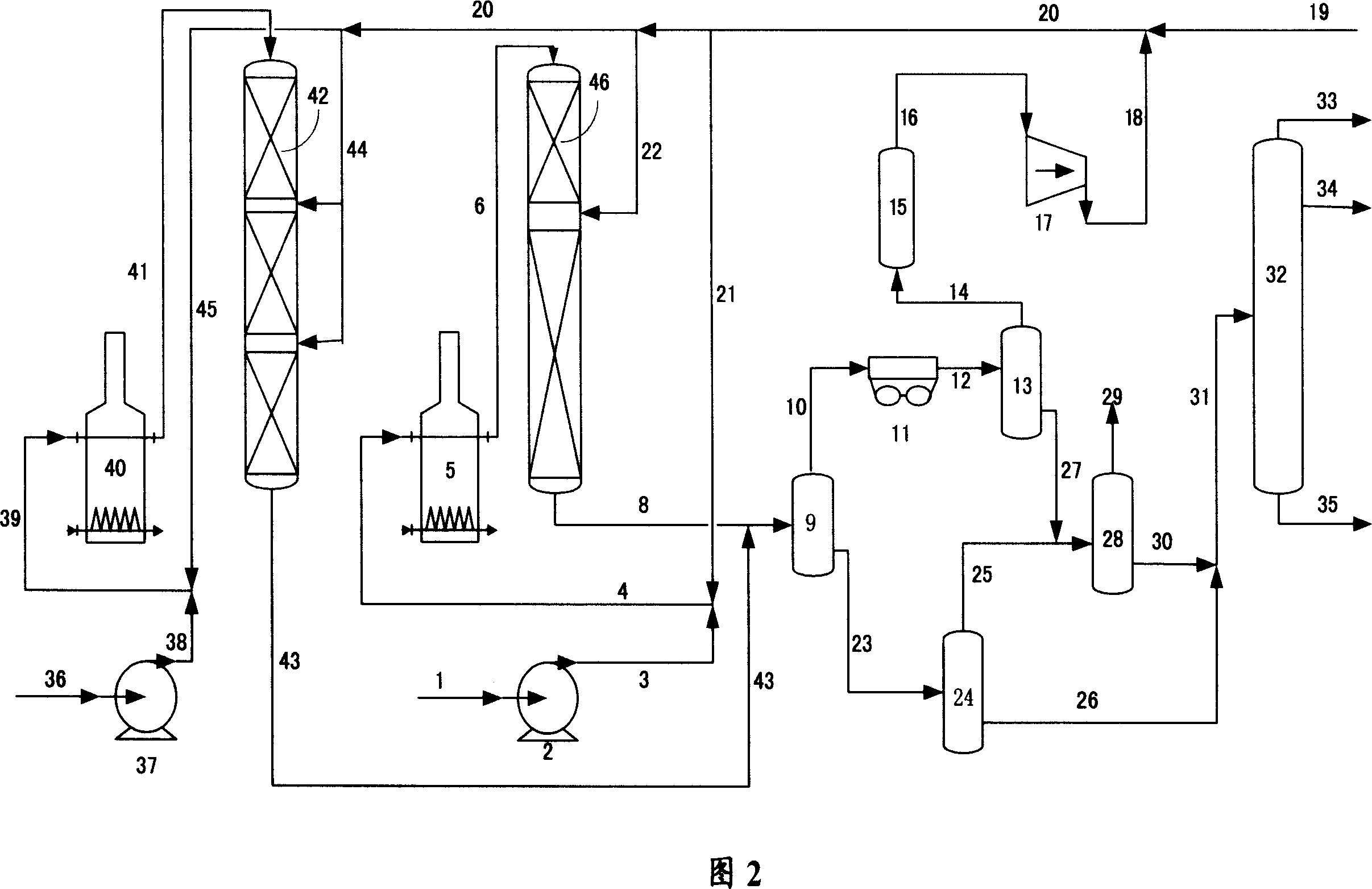

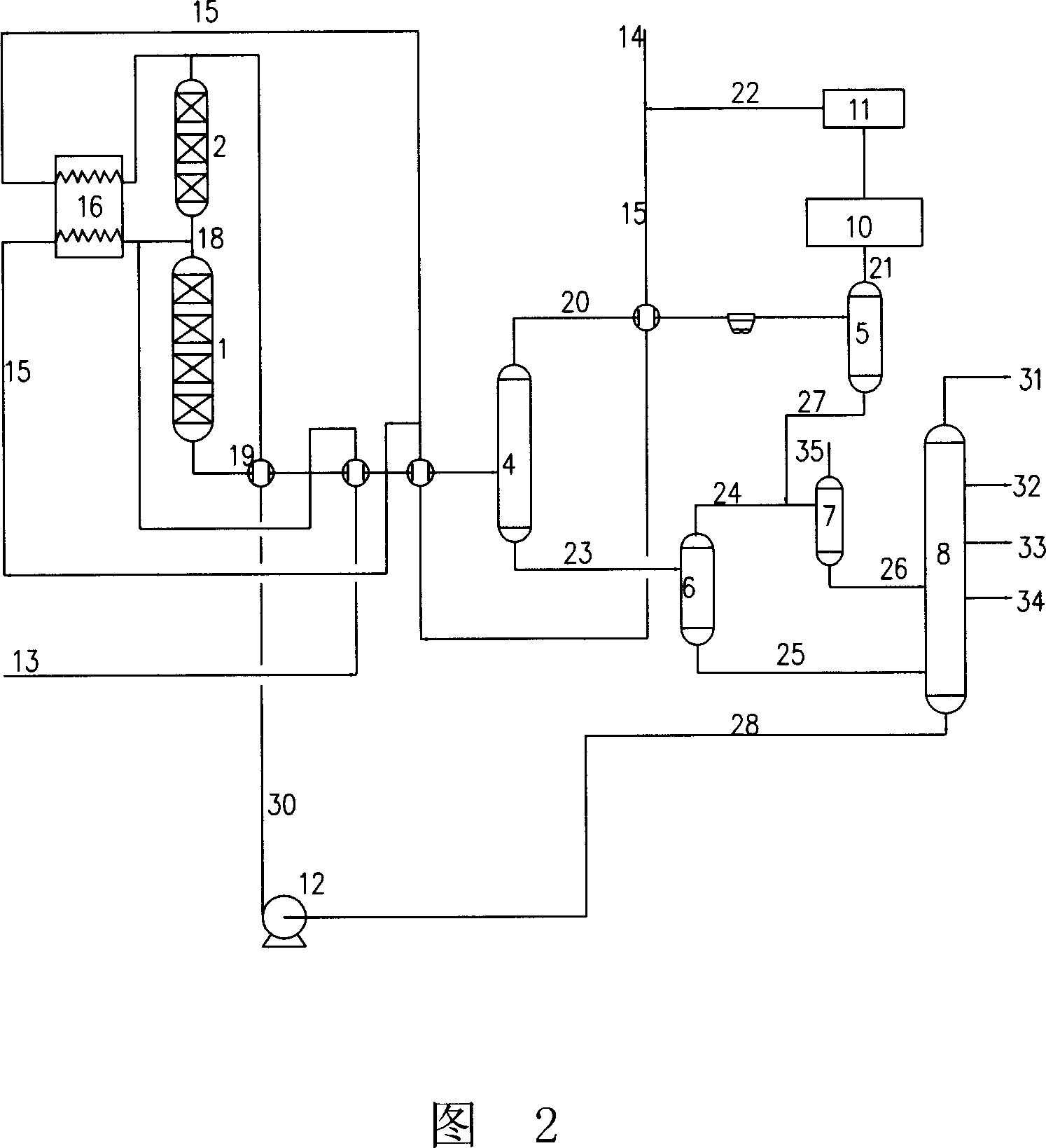

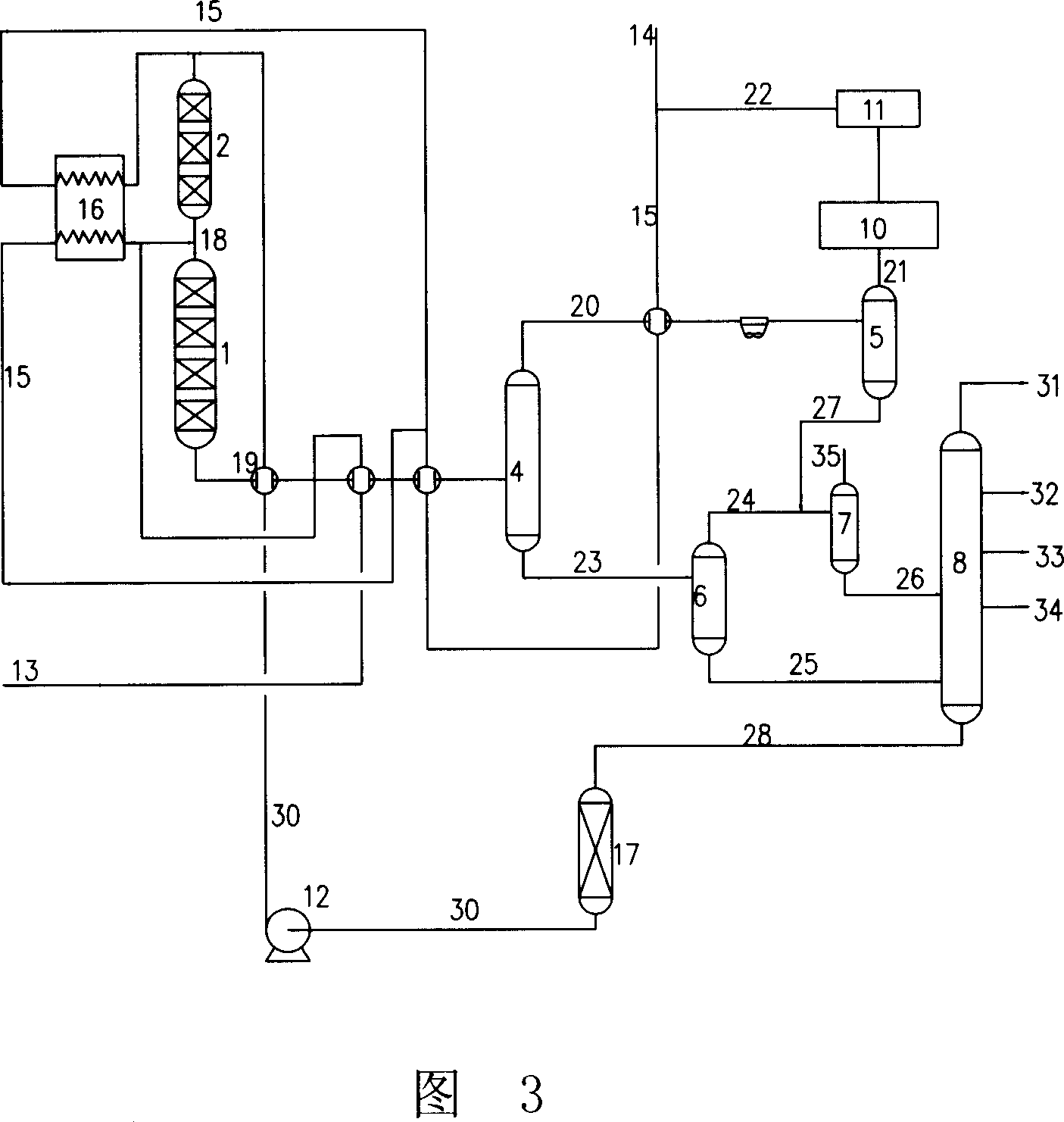

Combined process for hydrotreating and catalytic cracking of residue

ActiveUS8529753B2Improve efficiencyLow costThermal non-catalytic crackingCatalytic crackingSlurryImpurity

Owner:CHINA PETROCHEMICAL CORP +1

Liquid-solid two-phase hydrogenation method for hydrocarbon oil

The invention discloses a method of hydrocarbon oil liquid-solid two-phase hydrogenation; the method avoids the recycle hydrogen and the recycle hydrogen compressor; hydrogen is mixed with fresh raw oil and a part of recycle oil under the existence of solvent or diluent; after the gas is separated in the mixer, the mixture is fed into the reactor and is contacted with the catalyst for reaction after the gas is separated on top of the reactor; the other part of the recycle oil is mixed with hydrogen and solvent or diluent and the gas is separated; the mixture is all or partially fed into the bed of the catalyst; the effluent of the reaction is discharged from the bottom of the reactor for separation; the separated solvent or the diluent is used for recycle use; the liquid product is used as the product or the recycle oil; the solubility of hydrogen in solvent or diluent is more than the solubility of hydrogen in the mixture of fresh raw oil and solvent or diluent.

Owner:CHINA PETROCHEMICAL CORP +1

Hydrogenation and refining method of gasoline with poor quality

ActiveCN101591565AThe method flow is simpleEasy and flexible operationTreatment with hydrotreatment processesSolventPoor quality

The invention discloses a hydrogenation and refining method of gasoline with poor quality, comprising the following steps: the base oil of gasoline contacts and reacts with hydrogenation protective agent at low temperature; after reaction effluent is mixed with circulation oil, the mixture sequentially contacts and reacts with hydrogenation desilication solvent and hyrorefining catalyst at high temperature; the reaction product is cooled and separated to obtain hydrogen-rich gas and refined gasoline fraction; and parts of refined gasoline fraction serves as circulation oil to return to the outlet of a first hydrogenation reaction area. The method can handle coker gasoline with high content of sulphur, nitrogen and olefin, and refined gasoline fraction can satisfy charging requirements of reforming pre-hydrogenation devices and steam cracking ethene preparing devices. The method of the invention can effectively slow coking speed of heating furnace tubes, greatly lowers pressure drop generation frequency of a main hydrogenation reactor, improves the operating severity of the main hydrogenation reactor and retards the deactivation speed of catalyst at the bottom of a refined reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and composition for using organic, plant-derived, oil-extracted materials in two-cycle oil additives for reduced emissions

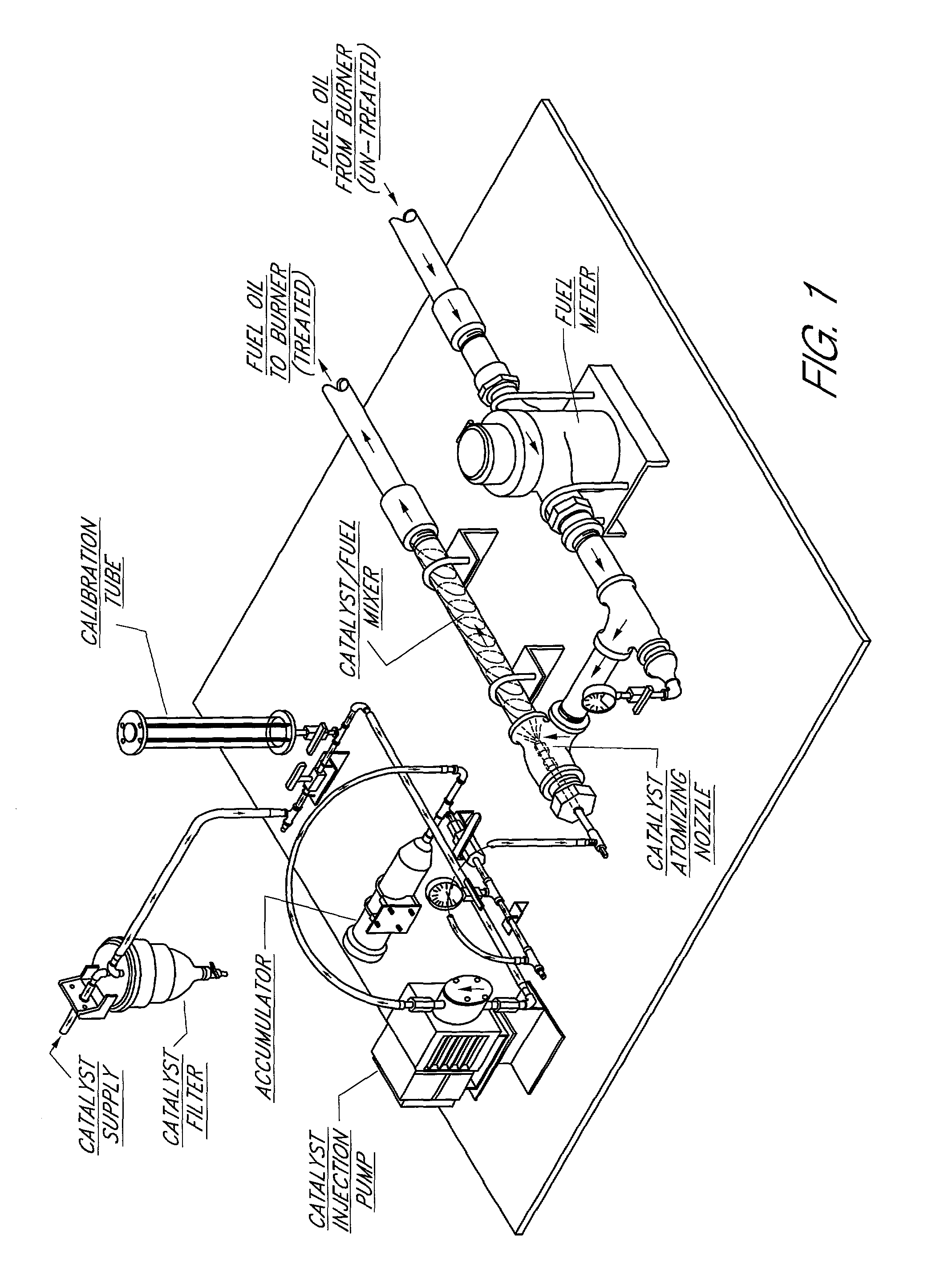

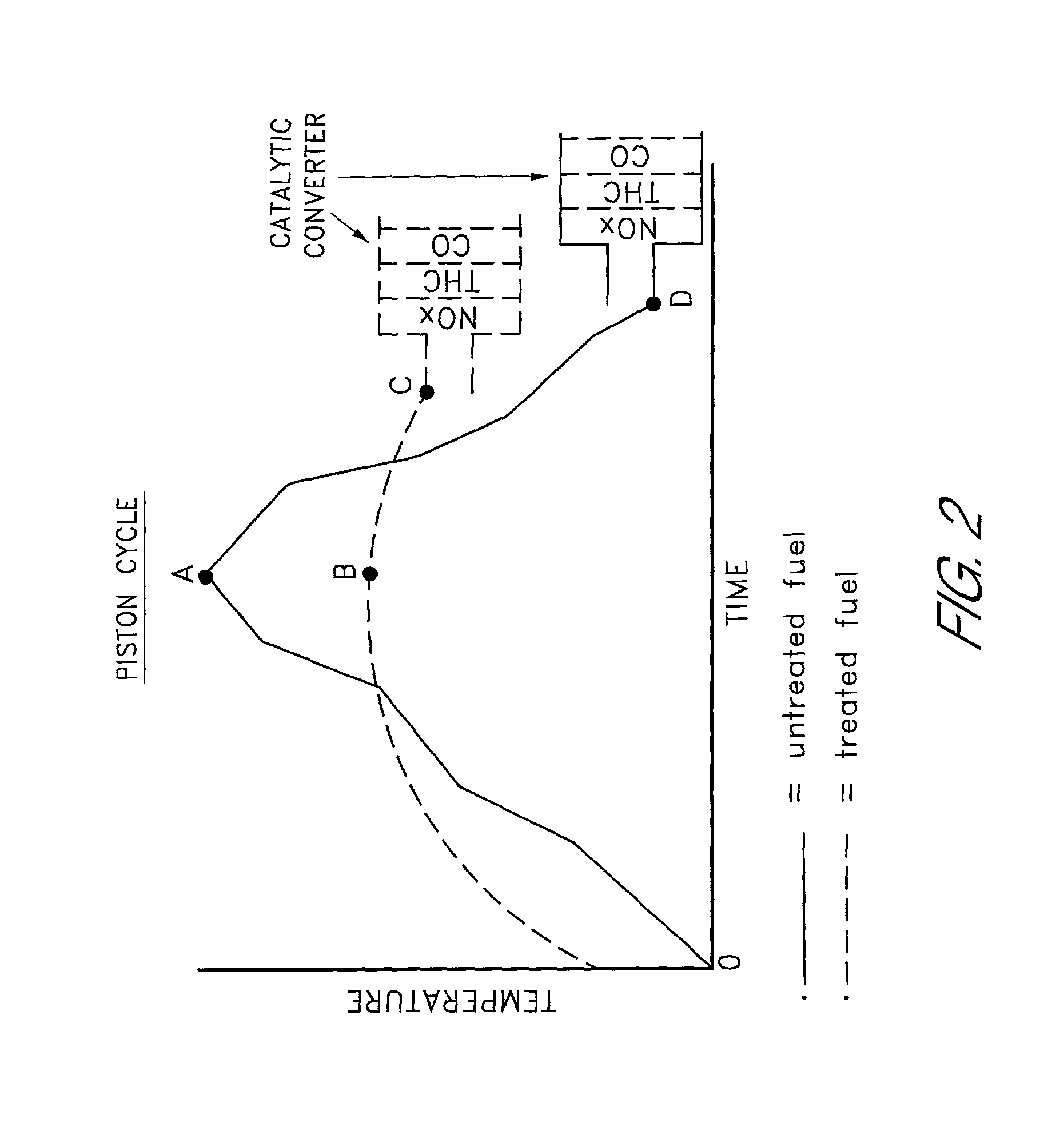

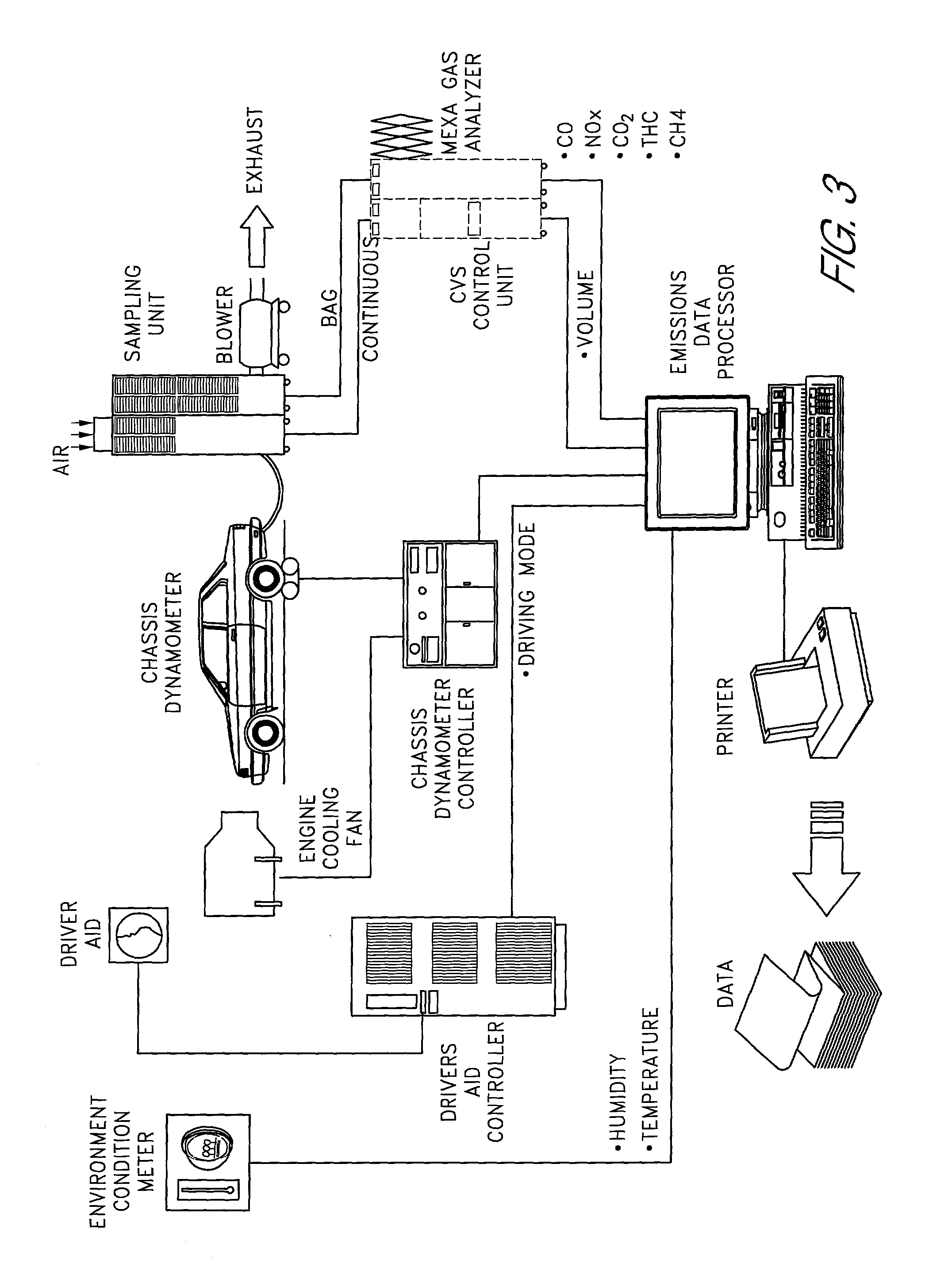

InactiveUS7144435B2Reduce pollutant emissionsAvoid equipmentSolid fuelsLiquid carbonaceous fuelsCombustionOil additive

A two-cycle oil additive is provided that includes a plant oil extract, β-carotene, and jojoba oil. The additive may be added to any two-cycle oil or fuel to reduce emissions of undesired components during combustion of the fuel. A method for preparing the additive is also provided.

Owner:AQ

A combined method for processing inferior heavy oil

ActiveCN102260529AAchieve hydrogen balanceEconomic routeHydrogenTreatment with hydrotreatment processesOil processingCombined method

The invention relates to a combined method for processing inferior heavy oil. The method comprises the following steps: a heavy oil raw material is reacted in a contacted cracking unit, an obtained heavy oil fraction I enters into a hydrotreating unit, a contact agent with charcoal enters into a gasification unit for a gasification reaction, the generated hydrogen enters into the hydrotreating unit, a heavy oil fraction II is obtained by a reaction in the hydrotreating unit and enters into a catalytic cracking unit, heavy cycle oil obtained by reacting is returned to the hydrotreating unit, an oil slurry is returned to the contacted cracking unit, regeneration flue gas used as a gasifying agent is returned to the gasification unit. The method of the invention is used for processing inferior heavy oil, and integrates two functions of deep processing of inferior heavy oil and reasonable utilization of excessive carbonaceous residue, so that the hydrogen balance of heavy oil processing can be realized. The combined method of the invention is capable of effectively improving the catalytic cracking raw materials and reasonably utilizing heavy cycle oil, the oil slurry and regeneration flue gas generated by the catalytic cracking apparatus, thereby the treating capacity and economic benefit of the heavy oil catalytic cracking apparatus can be enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

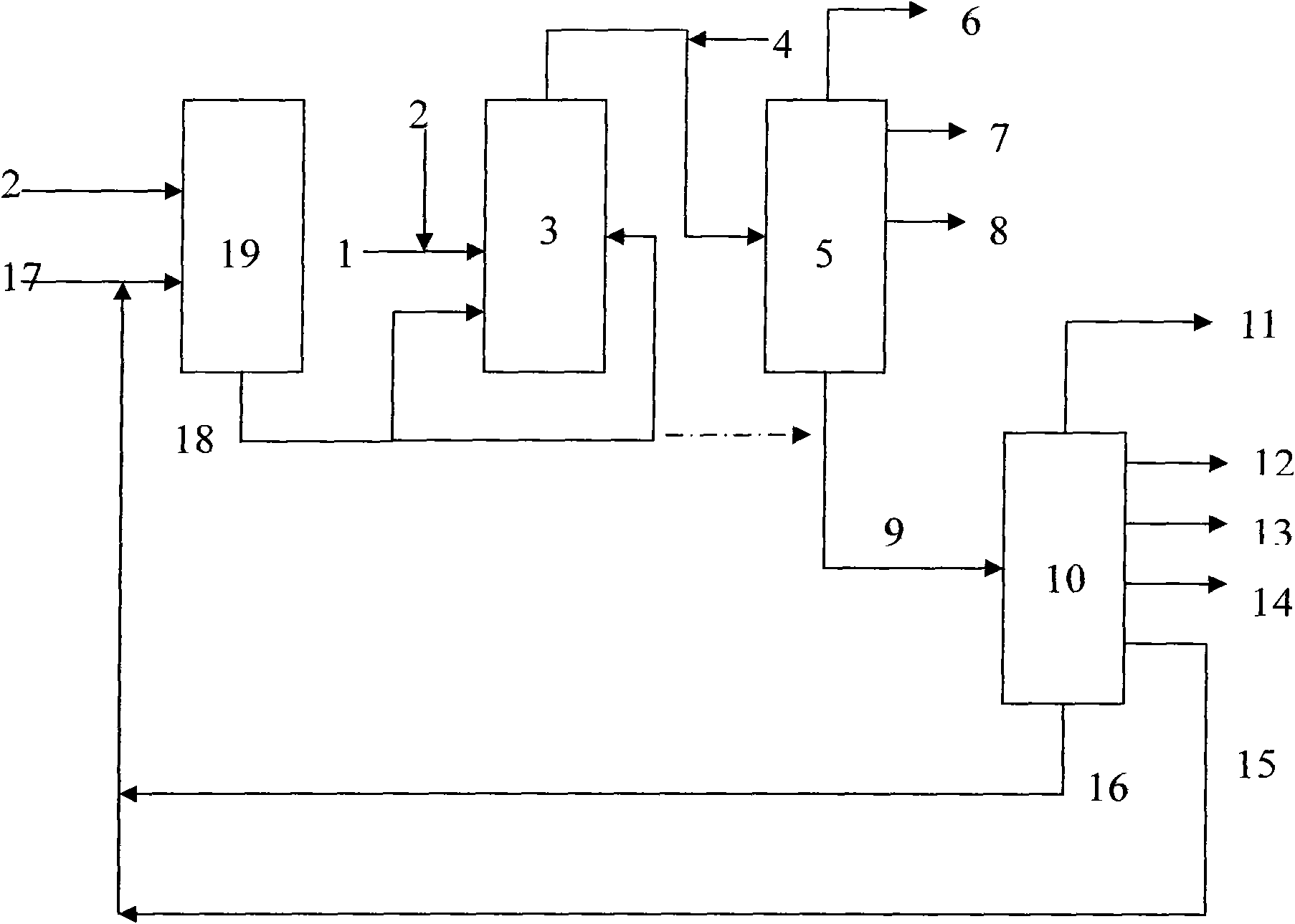

Method for hydrotreating heavy hydrocarbon

InactiveCN101942332AExtended service lifeImprove operational stabilityTreatment with hydrotreatment processesHydrogenation reactionReaction zone

The invention discloses a method for hydrotreating heavy hydrocarbon. A hydrotreatment process comprises a pre-hydrogenation reaction zone, an up-flow hydrogenation reaction zone and a fixed bed-trickle bed reaction zone. The method comprise the following steps that: catalytic cracking slurry oil and / or catalytic cracking heavy cycle oil pass / passes through the pre-hydrogenation reaction zone; the pre-hydrogenation reaction zone adopts a fixed bed-trickle bed operation mode; both the reaction effluent of the pre-hydrogenation reaction zone and a residual oil raw material are jointly introduced into the up-flow hydrogenation reaction zone and the fixed bed-trickle bed reaction zone in turn; and the final reaction effluent is separated. The method of directly taking the catalytic cracking residual oil, the catalytic cracking heavy cycle oil and the like as fluxing oil of the residual oil raw material is changed, and the catalytic cracking residual oil and the catalytic cracking heavy cycle oil are pretreated to retard the coking of a catalyst and effectively prevent the generation of a bed layer hot point, so that stable operation of an up-flow reactor is guaranteed, the service life of the catalyst is prolonged, simultaneously the product quality is improved.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

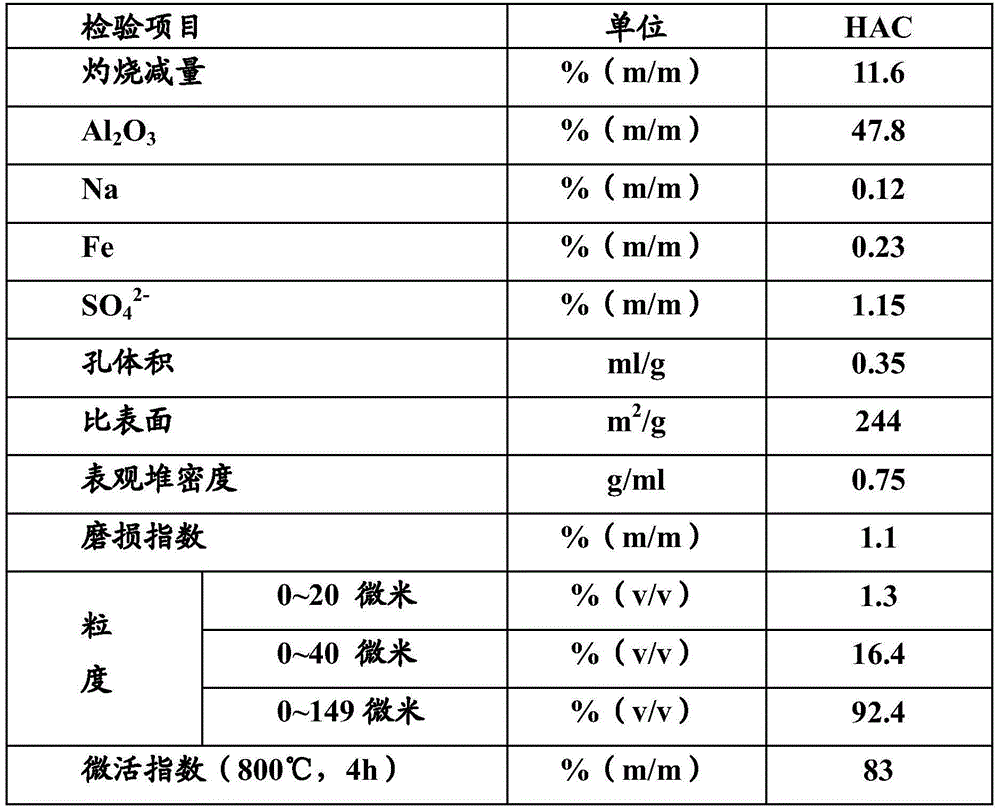

Method of dense raw material hydrotreatment-catalytic cracking for improving propylene productivity

ActiveCN101063047AHigh yieldTreatment with hydrotreatment processesHydrogenation reactionCutting oil

The invention discloses a heavy raw material hydrotreating-catalytic cracking method to increase propone productivity, which comprises the following steps: choosing light circling oil and or weight circling oil from catalytic cracking unit; adding into hydrogenation reaction zone with heavy cut oil; or adding into two hydrogenation reaction zone with different hydrogenation catalyst to react; getting effluent; cooling; separating; fractionating; getting heavy liquid phase fraction; moving catalytic cracking unit; separating the catalytic cracking reacting product; getting the final product. This invention can dispose cycloalkyl heavy raw material, which propone receiving ratio can increase by 5-7 percent dot.

Owner:CHINA PETROLEUM & CHEM CORP +1

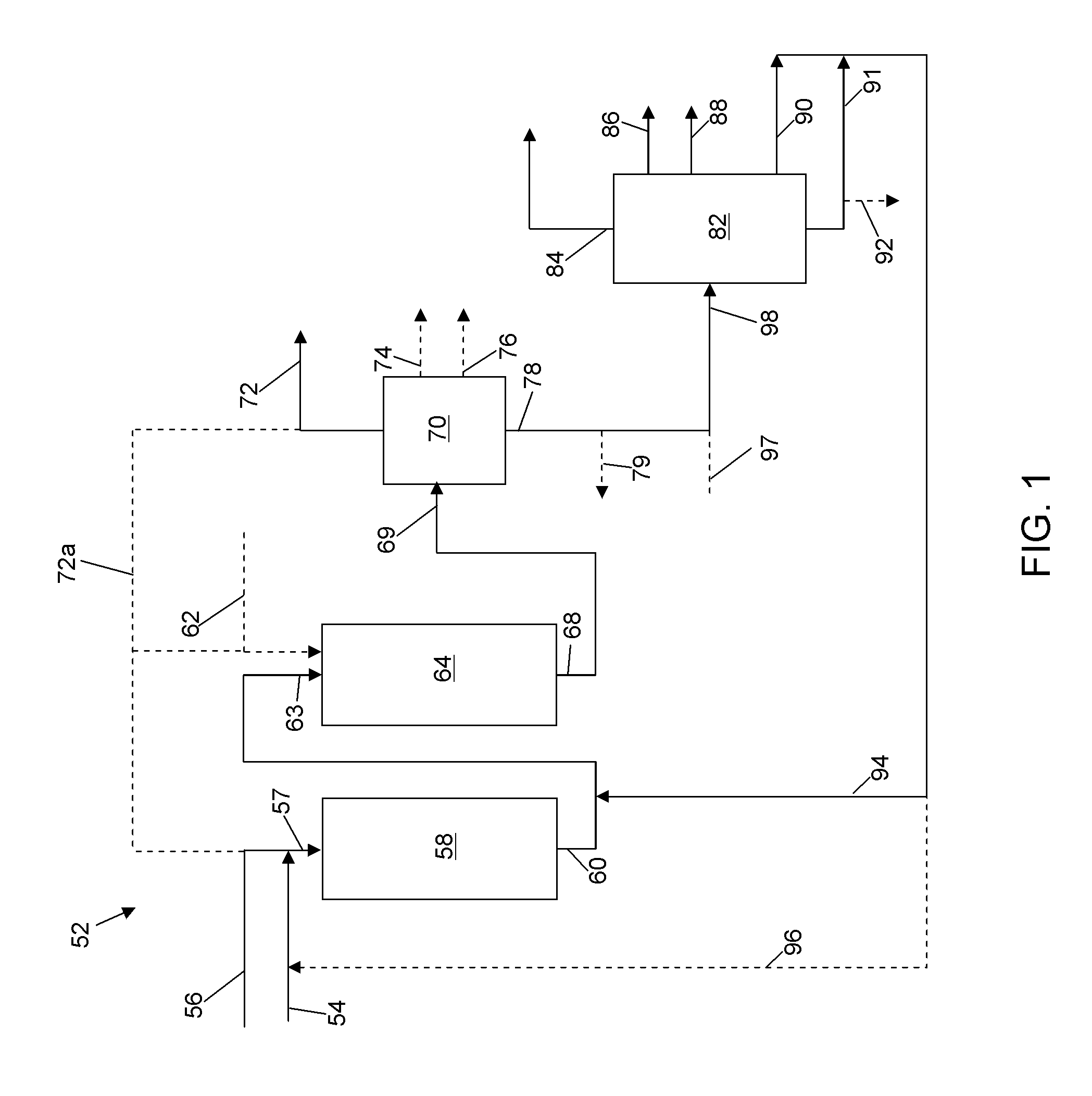

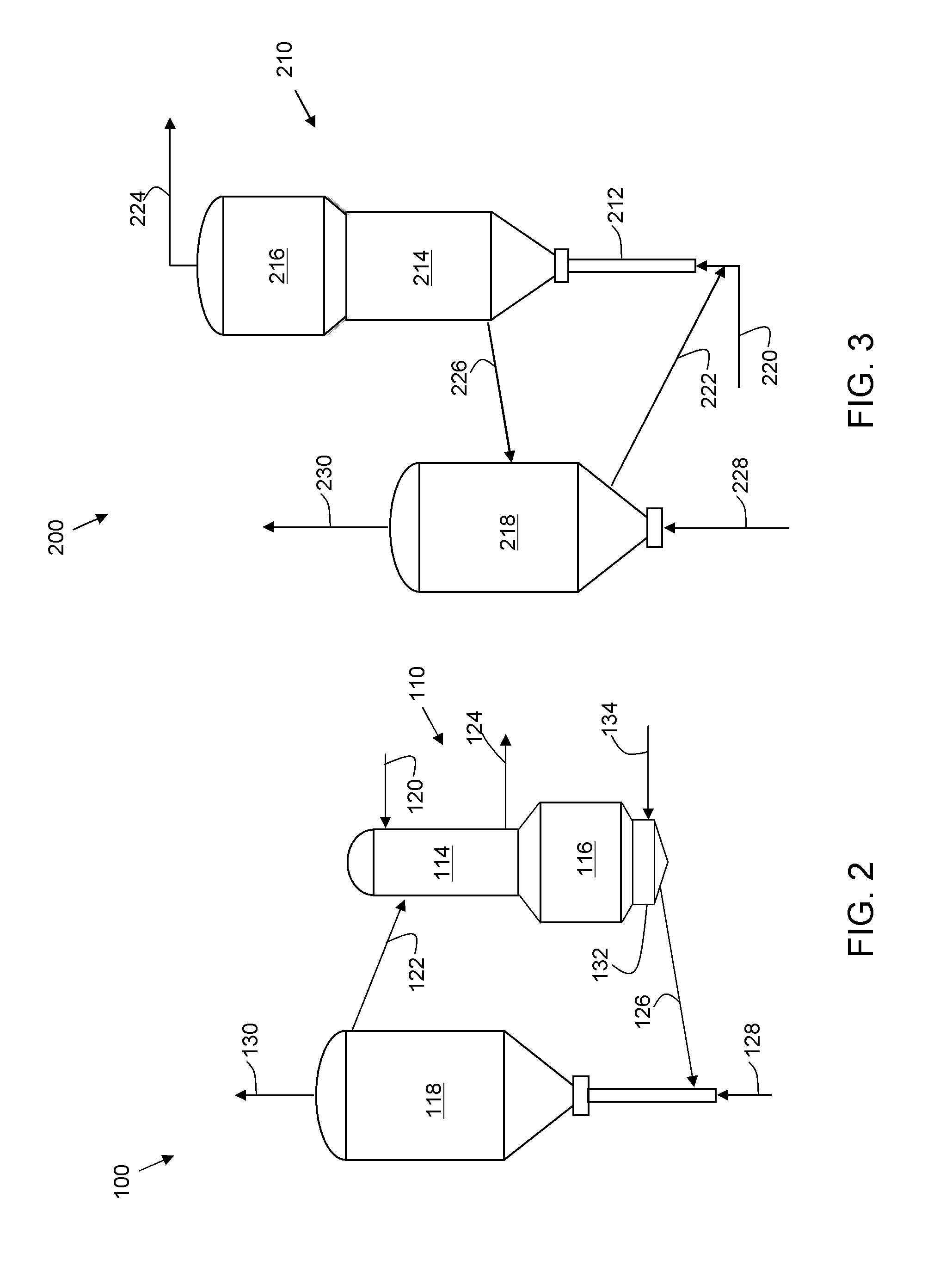

Cracking system and process integrating hydrocracking and fluidized catalytic cracking

ActiveUS20120241359A1Maximum flexibilityCatalytic crackingMolecular sieve catalystsHydrogenBoiling point

A system and method of cracking hydrocarbon feedstocks is provided that allows for significant flexibility in terms of the desired product yield. An integrated process includes introducing the feedstock and hydrogen into a first hydrocracking reaction zone containing a first hydrocracking catalyst to produce a first zone effluent. The first zone effluent and optionally additional hydrogen are passed to a second hydrocracking reaction zone containing a second hydrocracking catalyst to produce a second zone effluent. The second zone effluent is conveyed to a fractionating zone to at least a low boiling fraction and a high boiling fraction, and optionally one or more intermediate fractions. The bottoms fraction is passed to a fluidized catalytic cracking reaction and separation zone, from which olefins and gasoline are recovered. At least a portion of remaining cycle oil is passed from the fluidized catalytic cracking reaction and separation zone to the first and / or second hydrocracking reaction zone.

Owner:SAUDI ARABIAN OIL CO

Conversion method for low-grade heavy and residual oil

ActiveCN1654603AExpand sourceQuality improvementTreatment with hydrotreatment processesHydrogenLower grade

The present invention discloses a sort of method for converting the inferior heavy oil and residual oil, the deasphalted oil and deoiled asphalt is fractionated by the solvent from the raw material of heavy oil and residual oil, wherein the deasphalted oil is delivered to the hydrotreating arrangement of the fixed bed, modifies the matter with the reaction of hydrogen and hydrogenation catalysts, the separated production includes the lightweight cut fraction and hydrocracking tail oil, the hydrocracking tail oil is delivered to the catalytic cracking unit, and cracked with the function of the cracking catalyst, the separated production includes light-weighted cut fraction, heavy recycle oil and slurry oil. The deoiled asphalt which is fractionated by solvent and catalytic slurry oil are delivered to the hydrogenation equipment of the suspension bed together, and are farther produced to get various of light-weighted cut fractions with the function of hydrogen and decentralized energizing agent. This method can effectively reduce the operation severity of the hydrotreating arrangement in the fixed bed and the hydrogenation plant in the suspension bed, and can improve the creation rate and the quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

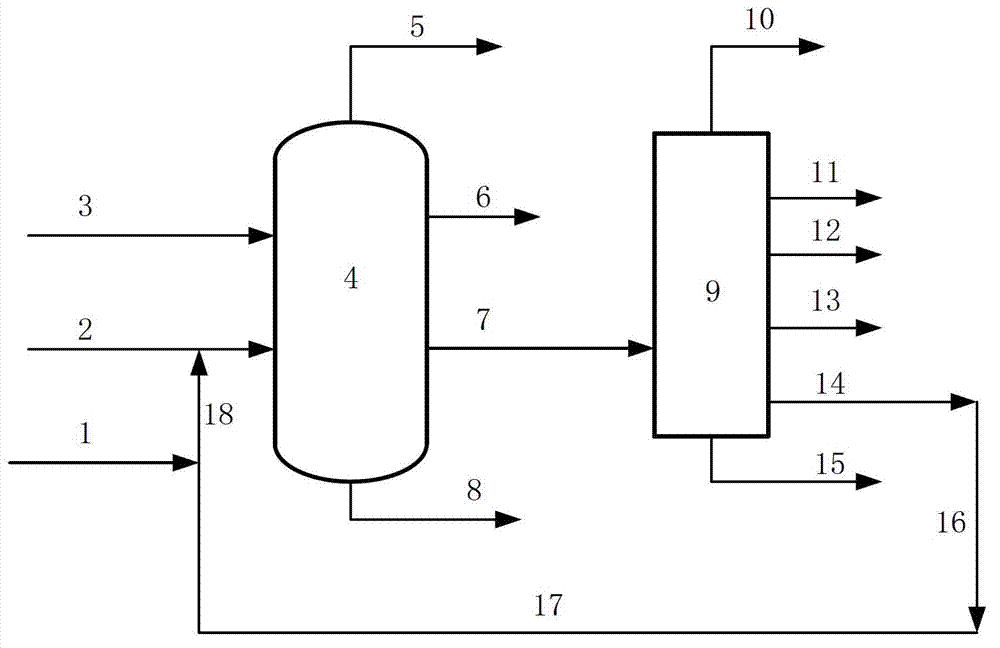

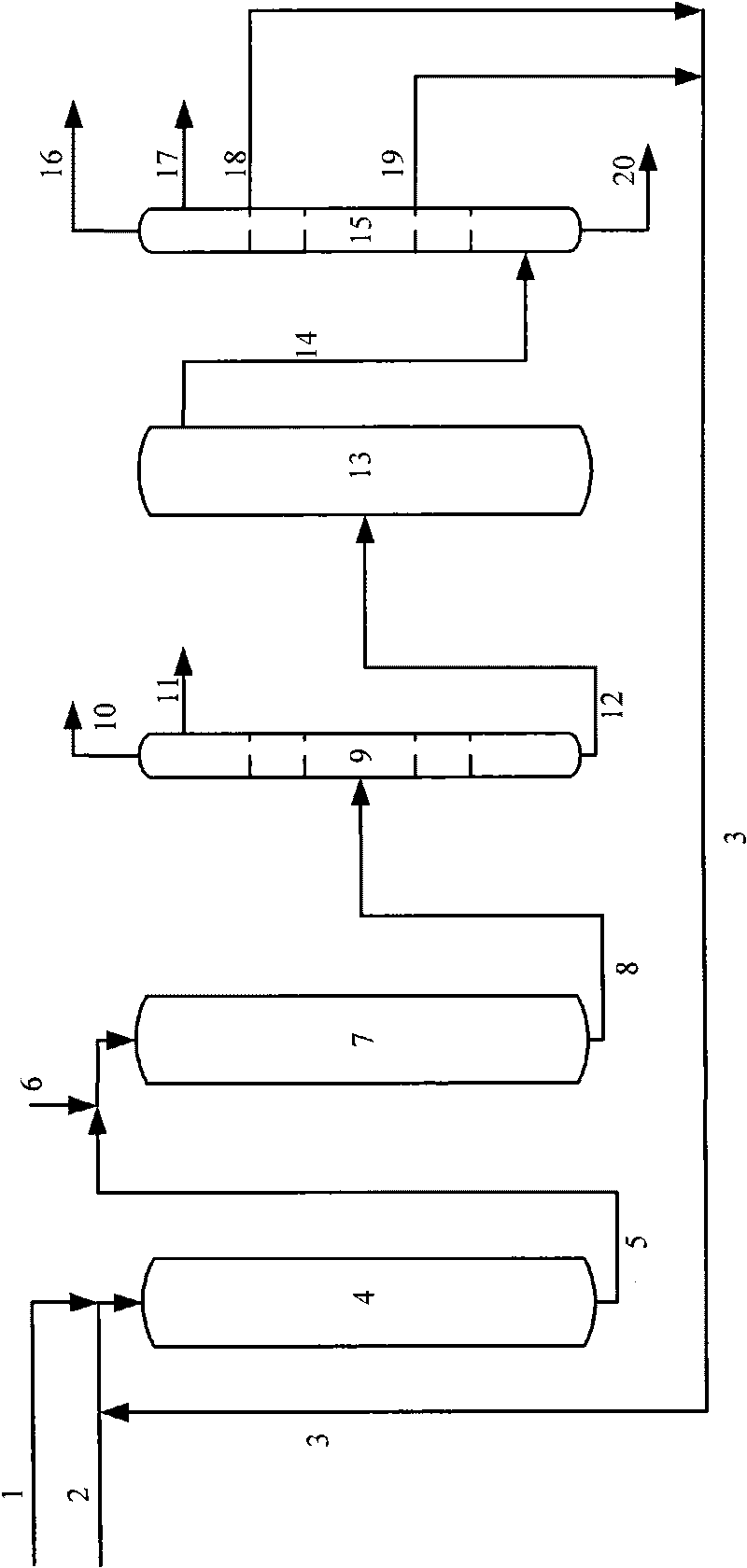

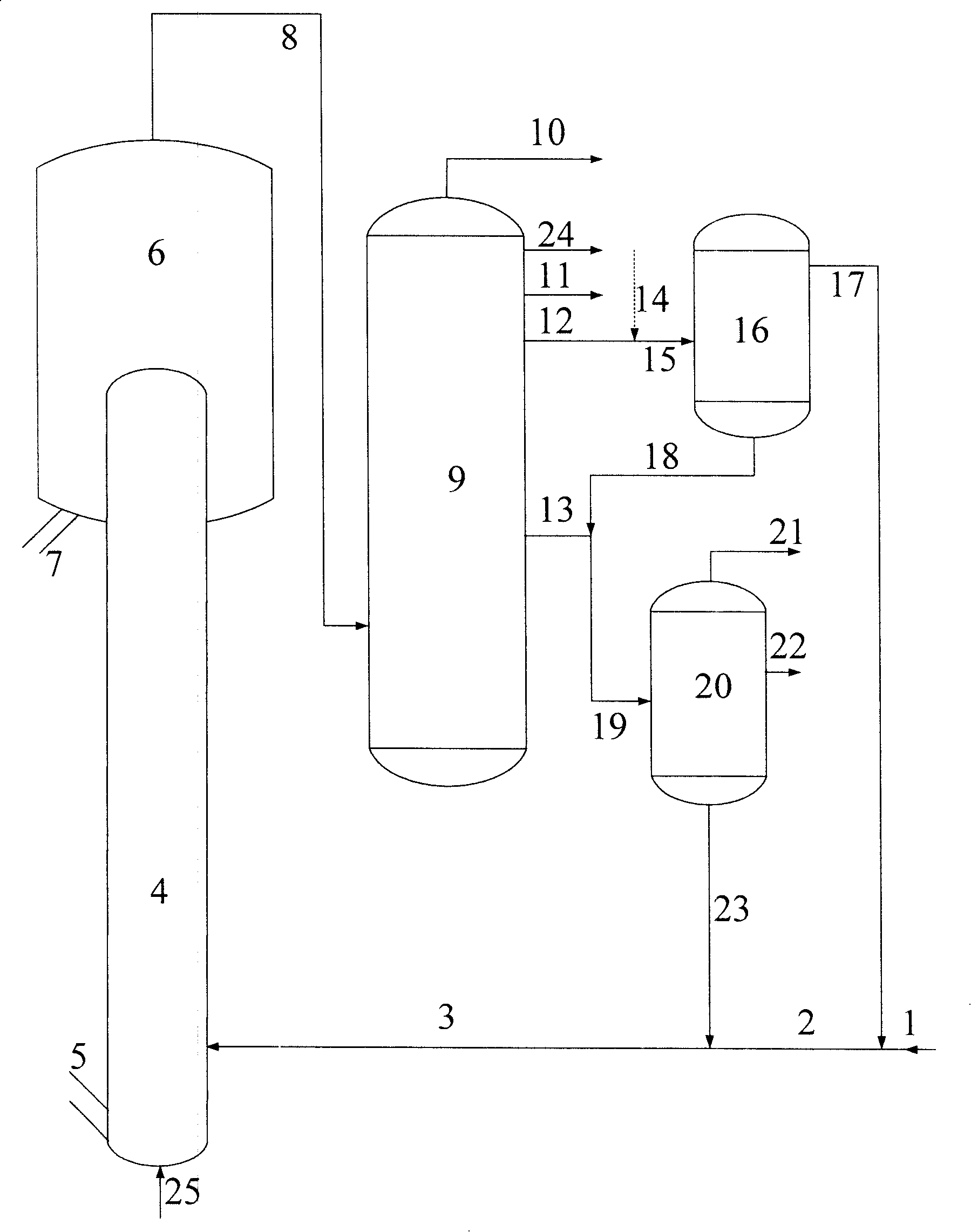

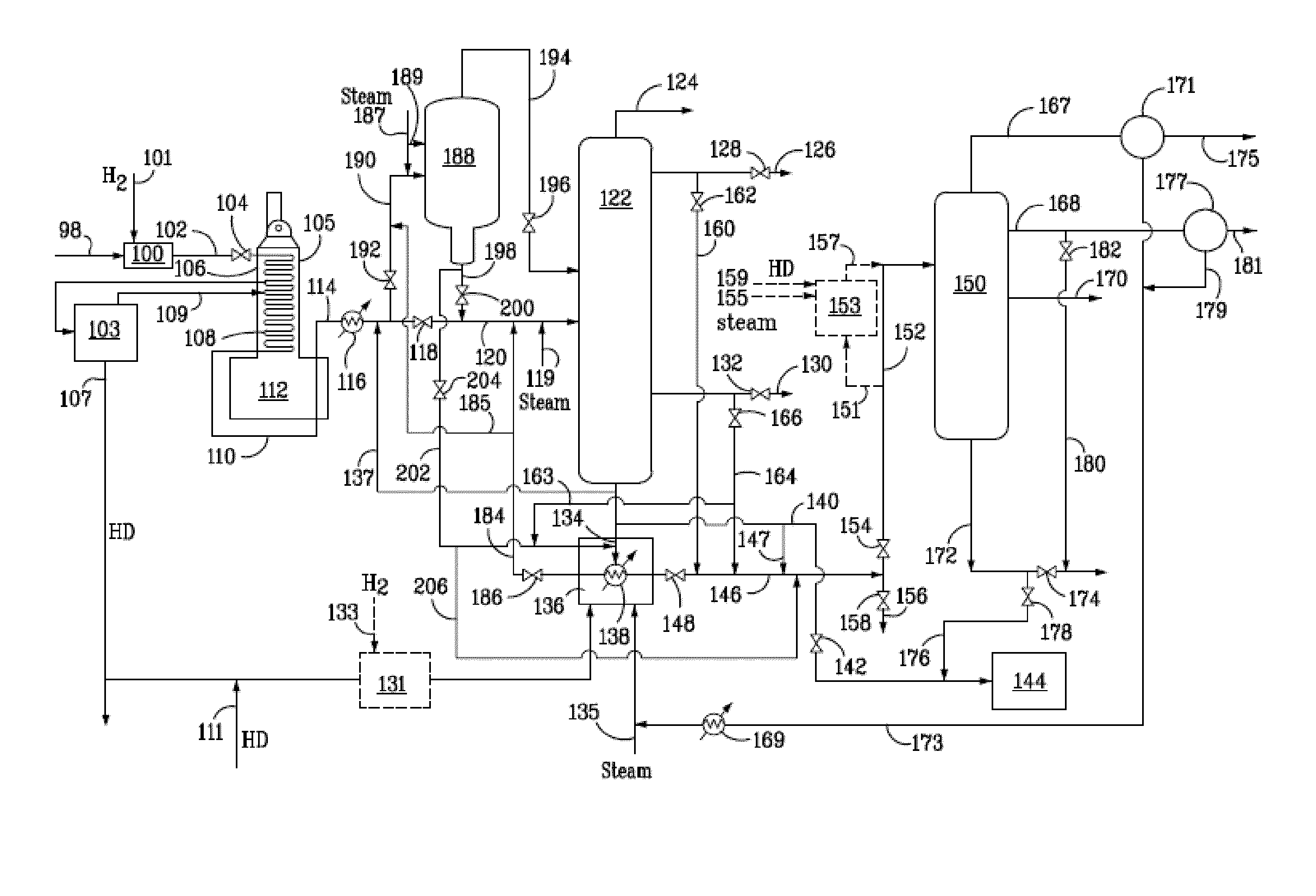

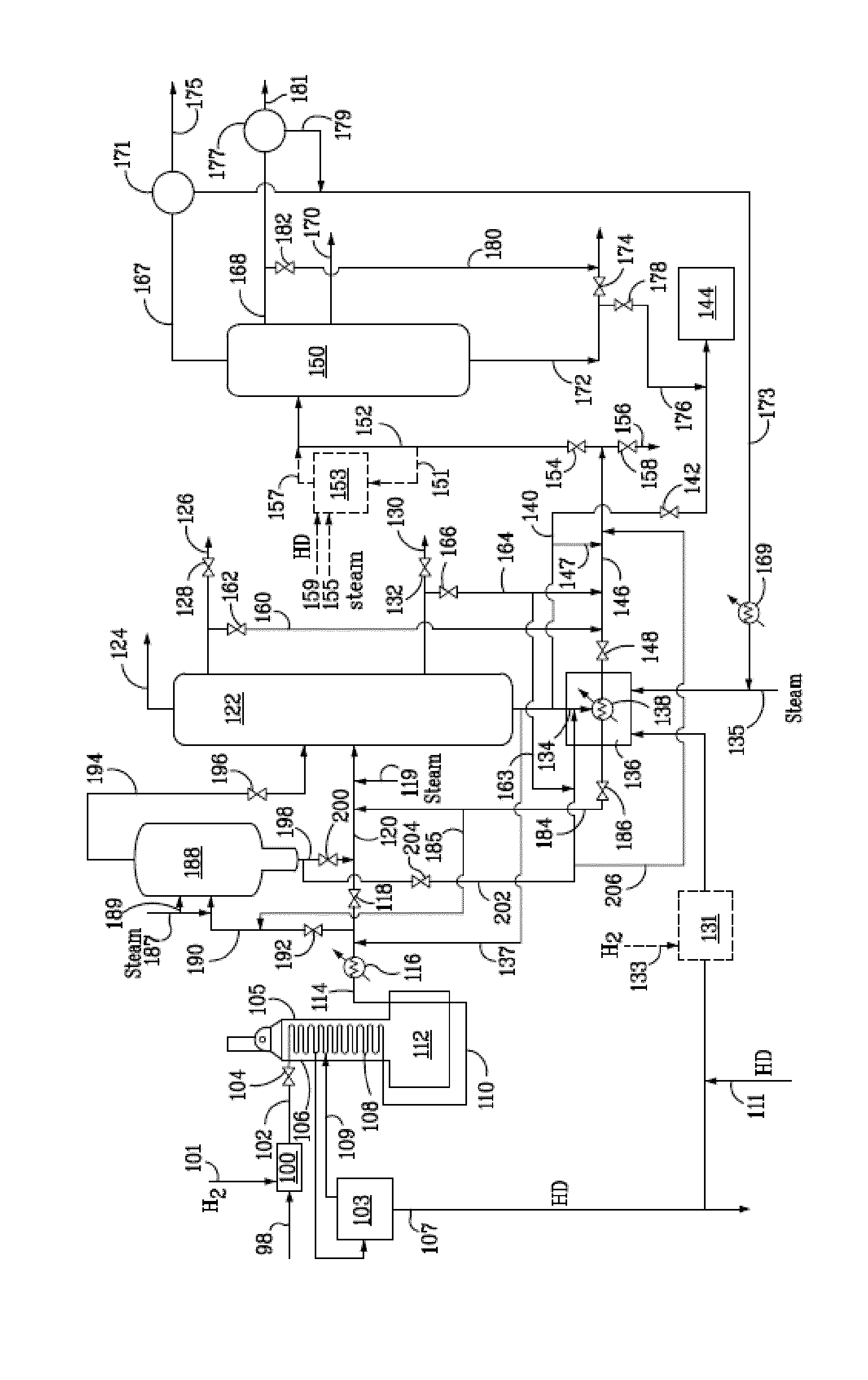

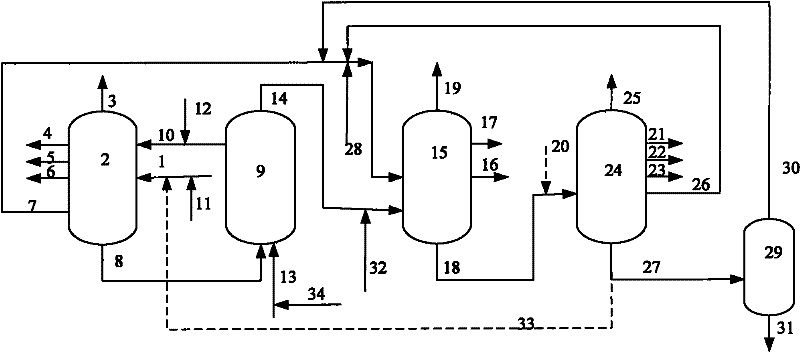

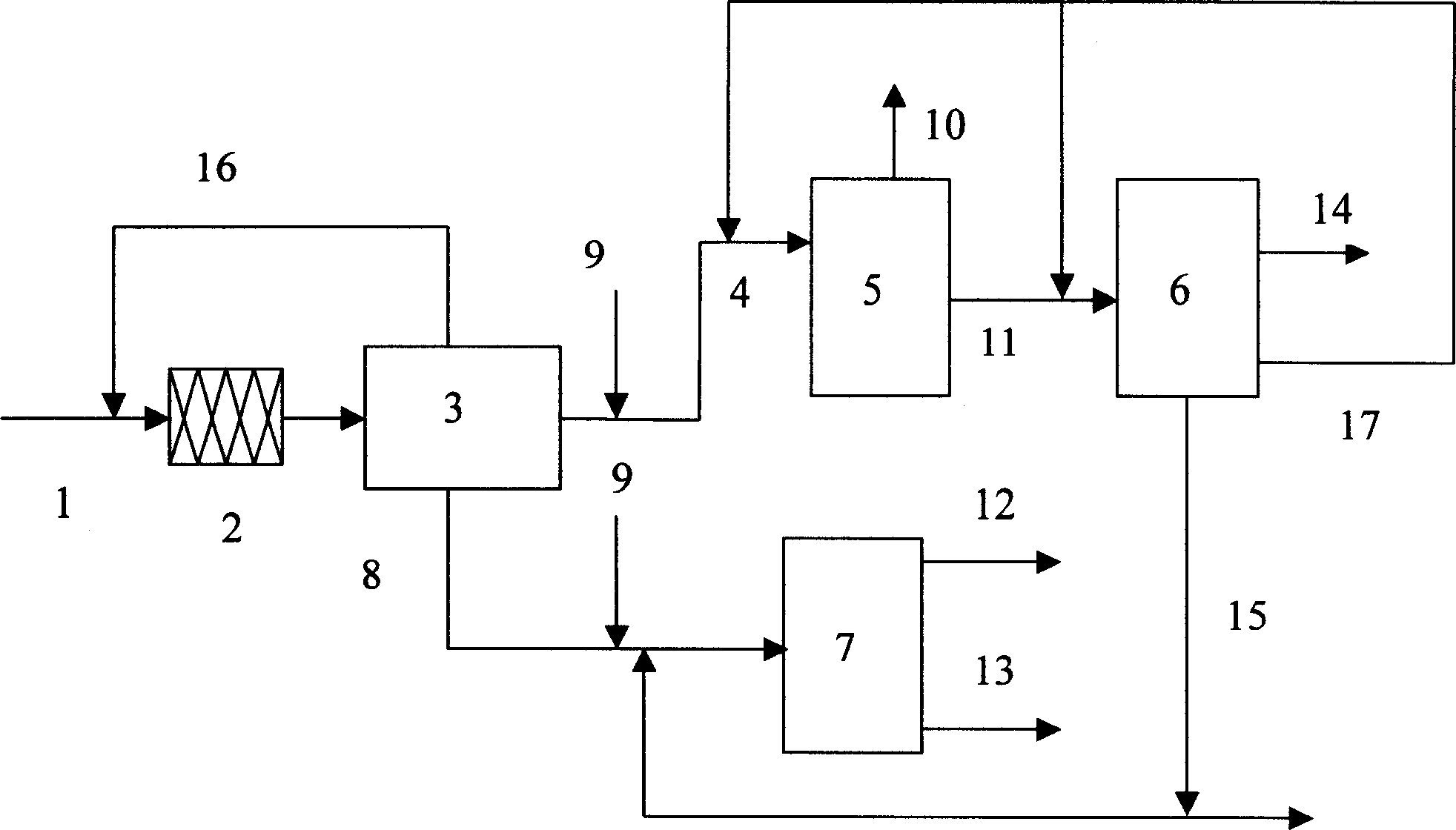

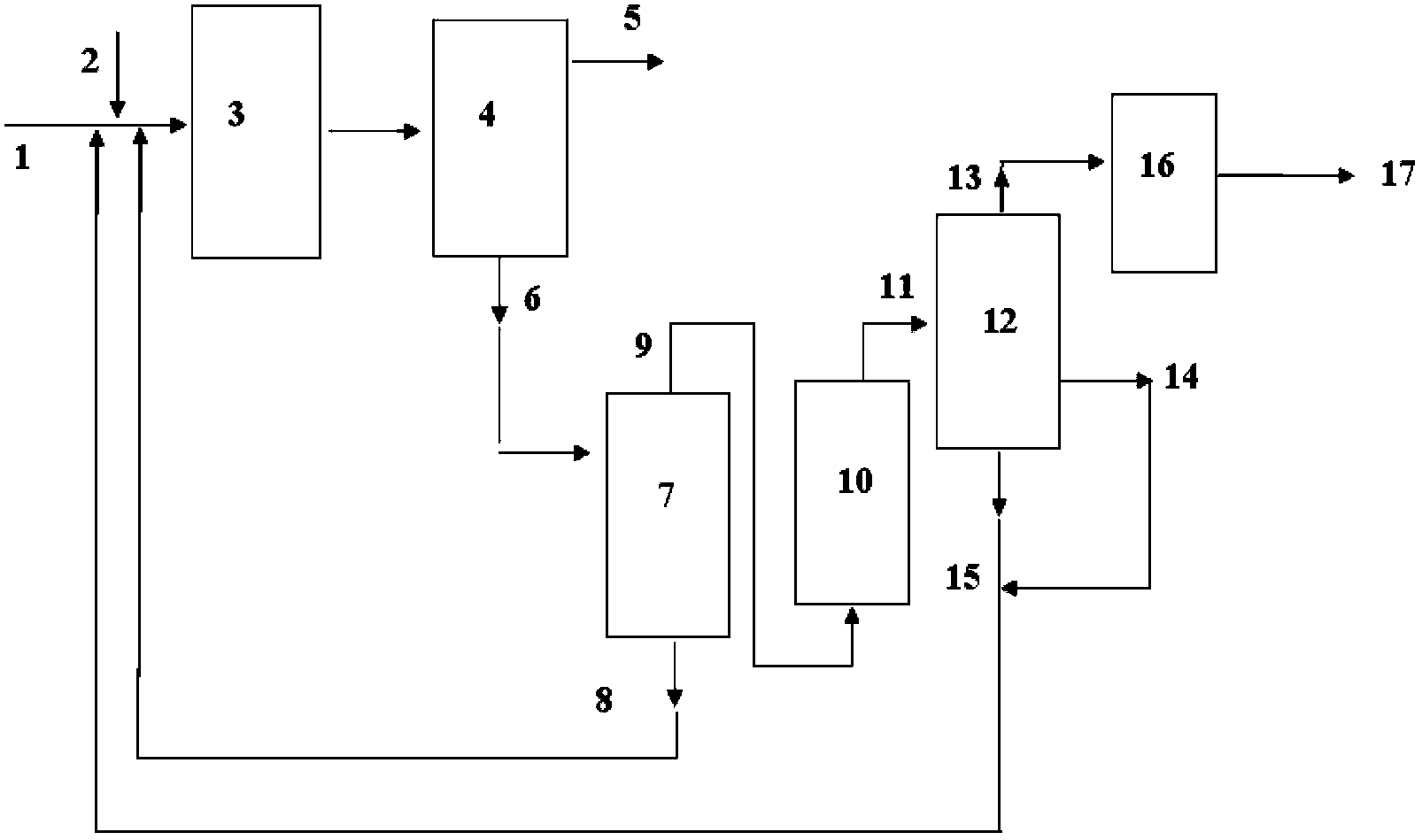

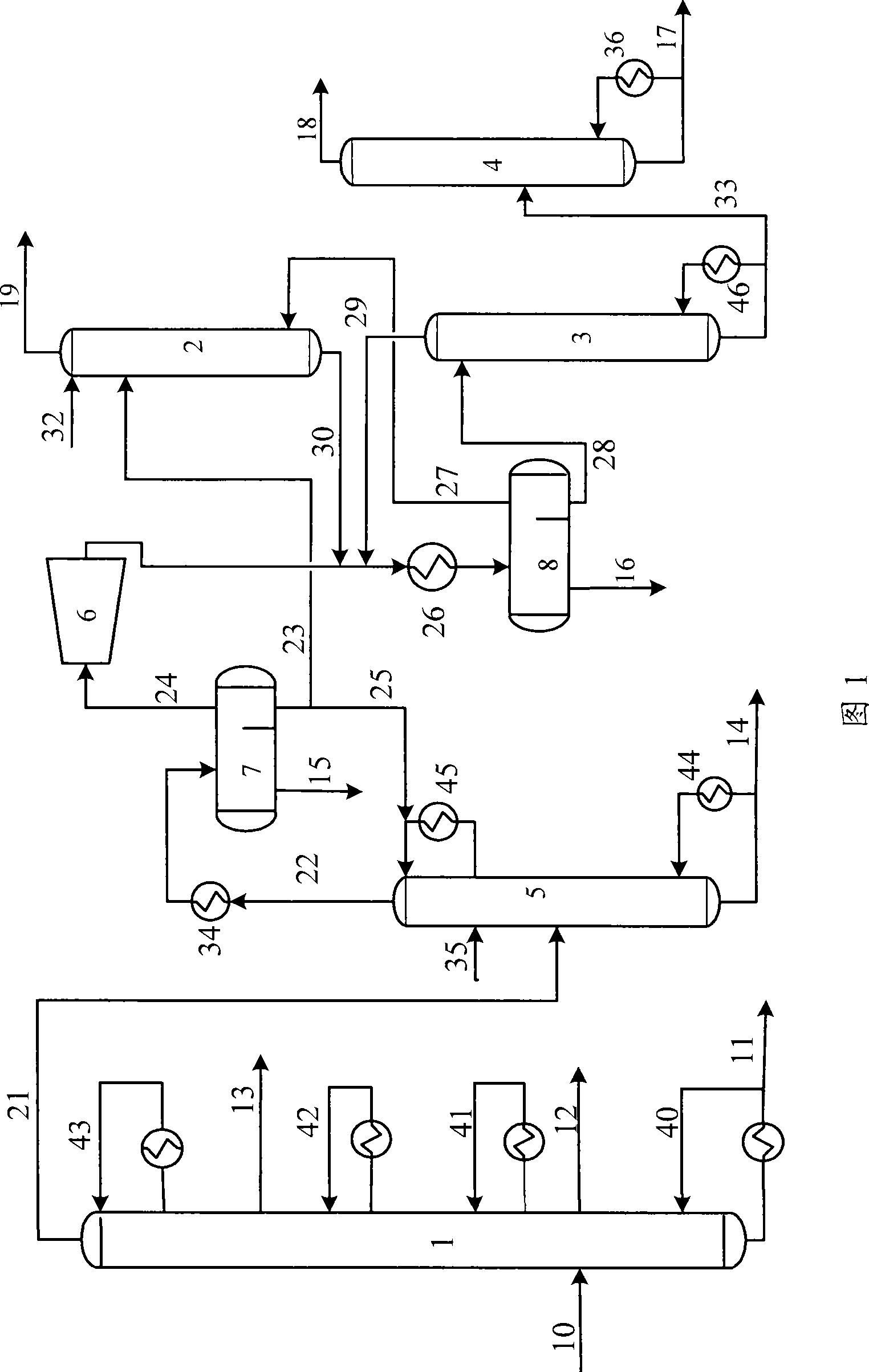

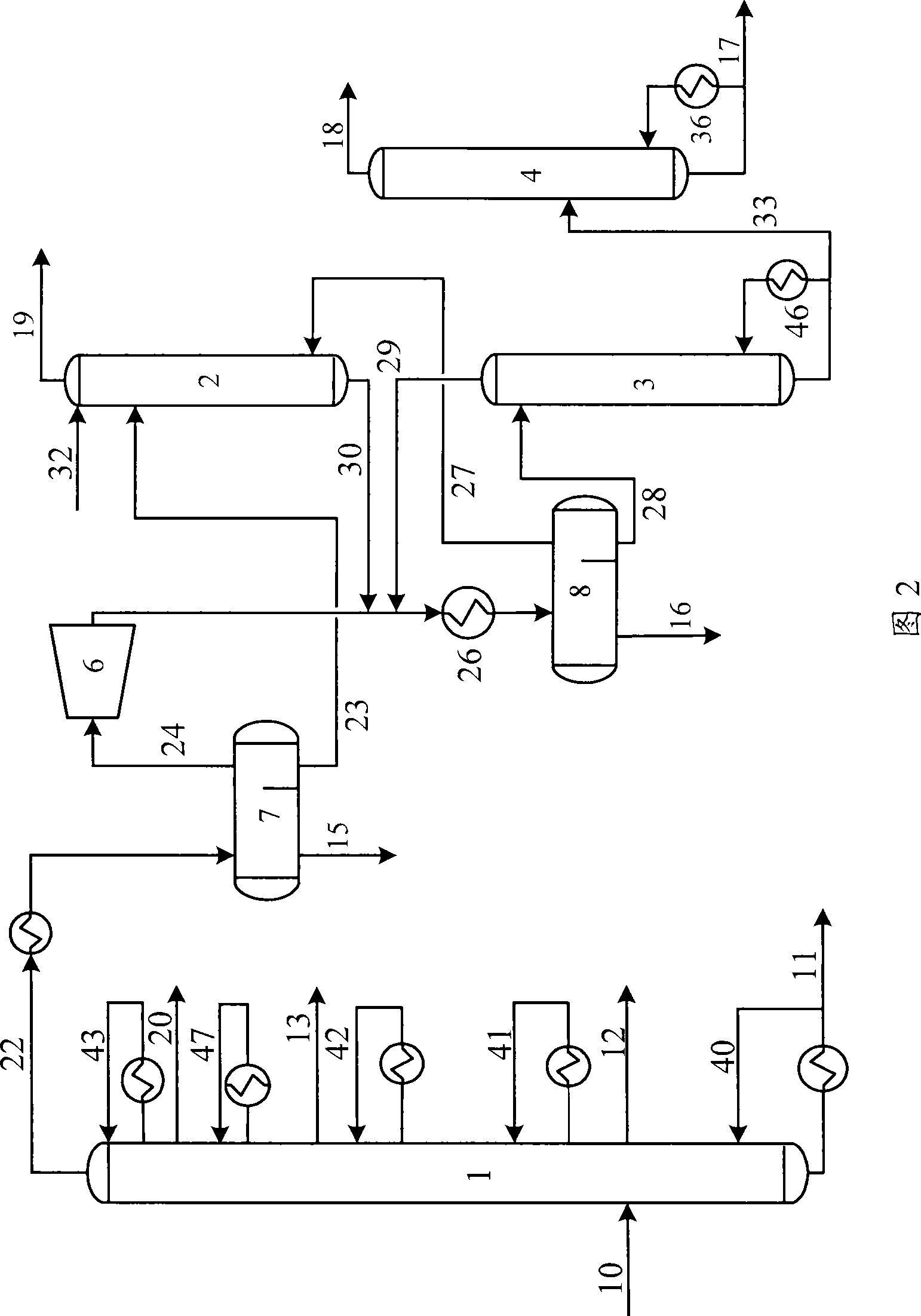

Improved integrated process for hydrogenation and catalytic cracking of hydrocarbon oil

ActiveUS20110062054A1Improve conversion depthIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyQuantum gasNatural gas

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated tail oil; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products to obtain dry gas, hydrogenated naphtha, liquefied petroleum gas, catalytic cracked gasoline, catalytic cracked diesel oil, and catalytic cracking cycle oil; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions, the light and the heavy fractions or normal catalytic cracking heavy feedstock oil and normal catalytic cracking light feedstock oil, prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst. The process according to the present invention is especially suitable for conversion of hydrocarbon oils to produce more products of gasoline or diesel oil.

Owner:CHINA PETROCHEMICAL CORP +1

Combination processing method of inferior heavy oil

ActiveCN103789036AHigh yieldHigh residual carbon valueTreatment with hydrotreatment processesHydrogenGasoline

A combination processing method of inferior heavy oil comprises the following steps that: A, a heavy oil feedstock enters into a liquid flow bed reactor for hydrocracking in the effects of hydrogen and a dispersible hydrocracking catalyst; B, the obtained hydrogenation product is fractionally distilled to obtain light oil and heavy oil, the cutting point is 320-380 DEG C, and the light oil is led out of the device; C, the heavy oil obtained by fractional distillation is extracted by a solvent to obtain deasphalted oil and deoiled asphalt; D, the deoiled asphalt is contacted with a catalytic cracking catalyst for cracking reaction in catalytic cracking conditions, and light oil, heavy cycle oil and slurry oil are obtained by fractional distillation; E, the deoiled asphalt obtained by the step C is recycled into the liquid flow bed reactor in the step A. According to the combination processing method provided by the invention, a variety of processes are integrated for processing of the inferior heavy oil, full transformation of the heavy oil can be realized, and more gasoline and diesel oil which are excellent in performances can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

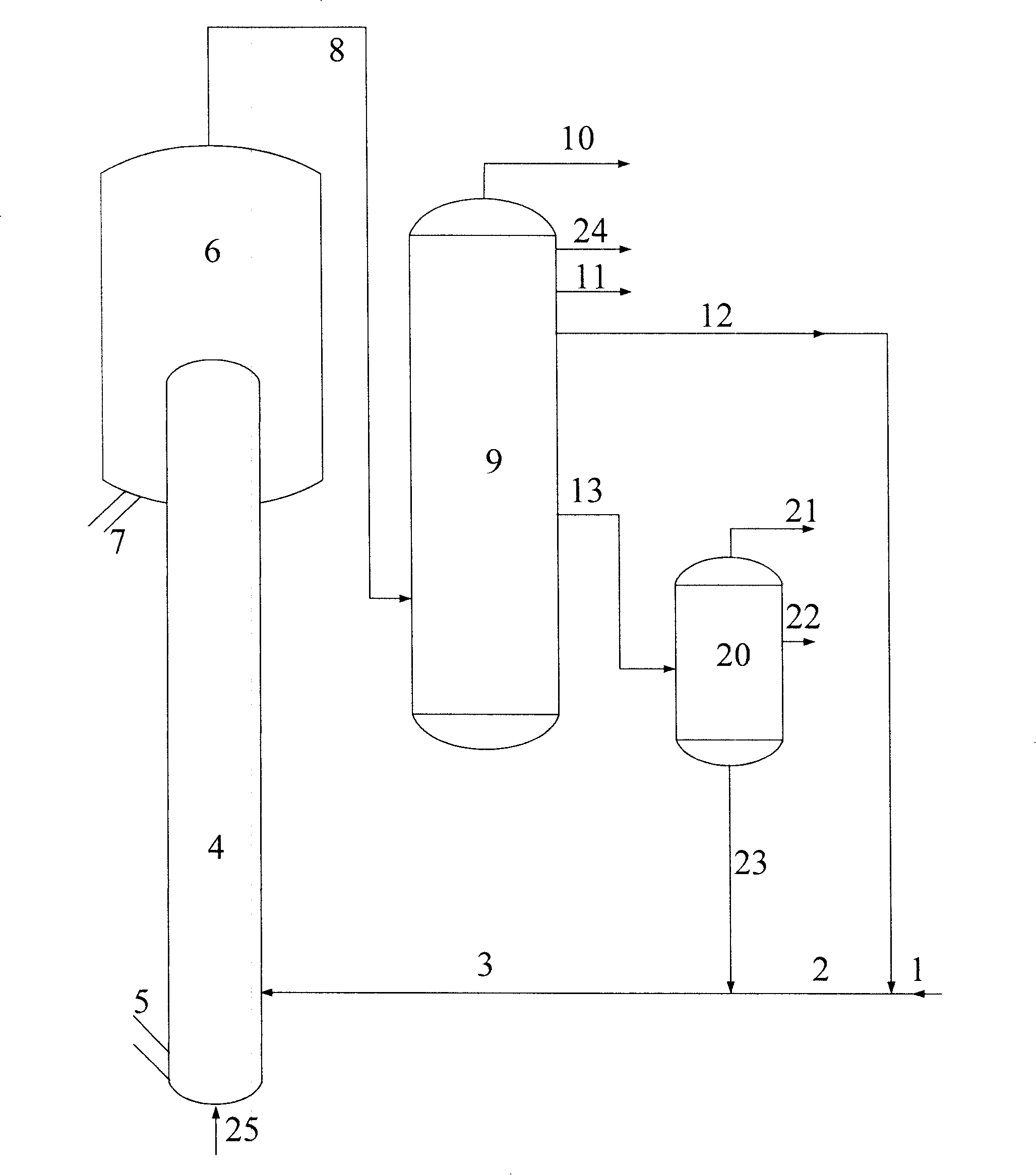

Residual oil hydrotreating-catalytic cracking combined process method

ActiveCN106701189AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a residual oil hydrotreating-catalytic cracking combined process method which includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process method includes the following contents: a residual oil raw material, at least part of a catalytic cracking diesel oil fraction and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel oil is partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbons hydrocracking method

ActiveCN1923972AReduce the amount of cold hydrogenControl the amount of cold hydrogenTreatment with hydrotreatment processesHydrogenCracking reaction

The invention discloses a hydrogenation cracking method of hydrocarbon, which consists of first reactor and second reactor, wherein the first reactor is refined hydrogen reactor or hydrogenation refining and hydrogenation cracking reactor; the second reactor is hydrogenation cracking reactor; the crude oil and flow material from second reactor enters in the first reactor with hydrogen to do hydrogenation refining reaction or hydrogenation refining and hydrogenation cracking reaction; the effluent from the first reactor is separated to obtain circulated hydrogen, object product and non-conversing oil; all or partial non-conversing oil can be circulating oil in the second reactor with hydrogen, which proceeds hydrogenation cracking reaction; the effluent from the second reactor enters in the first reactor; the composite hydrogen can be new hydrogen to supplement, which mixes gas with circulating hydrogen.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Heavy oil reservoir artificial bubble oil throughput exploiting method

ActiveCN104213886AImprove stabilityImprove liquidityFluid removalDrilling compositionFoaming agentGas oil ratio

The invention provides a heavy oil reservoir artificial bubble oil throughput exploiting method. The method comprises the following steps of step 1, injecting solvent type foam liquid into an oil well; step 2, after the well is covered for proper time, opening the well to produce oil; step 3, when the daily oil yield is 1m<3> / d to 2 m<3> / d, stopping throughput production of the period, and repeating the step 1 to step 3, and when the gas yield is gradually reduced and the cycle produced gas-oil ratio is smaller than 5, performing step 4; step 4, injecting an oil-soluble viscosity reducer into the oil well; step 5, injecting a solvent type foaming agent into the oil well; step 6, after the well is covered for proper time, opening the well to produce oil; step 7, when the daily oil yield is 1m<3> / d to 2 m<3> / d, stopping throughput production of the period, and repeating the step 4 to step 6; step 8, when the cycle oil yield is smaller than 100 to 200m<3>, stopping production. By the exploiting method provided by the invention, the viscosity of crude oil can be greatly reduced, and the aim of greatly improving the primary gas-containing heavy oil reservoir recovery ratio is fulfilled due to the fact that bubble oil flow is artificially produced.

Owner:PETROCHINA CO LTD

Catalytic cracking oil and gas separation method

ActiveCN101418235AImprove separation efficiencyAvoid revaporizationCatalytic crackingGaseous mixture working upReboilerSlurry

The invention discloses a method for separating catalytic cracking oil gas. The method comprises the following steps: oil gas produced by catalytic cracking reaction is introduced into a main fractionating tower; after distillation, materials discharged from a tower top are gasoline and gases with a molecular structure having less than 4 carbon atoms, and diesel, cycle oil and / or heavy diesel and slurry oil are separated sequentially by the main fractionating tower from top down; the gasoline and the gases with a molecular structure having less than 4 carbon atoms are introduced into a gasoline splitter and heavy naphtha are discharged from the bottom of the tower; light gasoline and gases with a molecular structure having less than 4 carbon atoms discharged from the top of the gasoline splitter are introduced into an FCC absorption and stabilization system to separate light gasoline light naphtha, liquid gas and dry gases. The method injects gases discharged from the tower top of the main fractionating tower into a middle part of the gasoline splitter, and arranges reflux on the top of the gasoline splitter and a reboiler at the bottom to improve the gasoline separation efficiency. The method uses the low-temperature energy of gases discharged from the top of the main fractionating tower to prevent the revaporization of directly cooled and liquefied gases and reduces energy consumption of the reboiler and cooling water of gasoline splitter.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com