Deep processing method for shale oil

A technology for shale oil and raw oil, which is applied in the deep processing field of shale oil, can solve the problems of low production of low-carbon olefins such as propylene, etc., and achieve the effects of increasing the amount of raw materials, improving product efficiency and saving oil resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

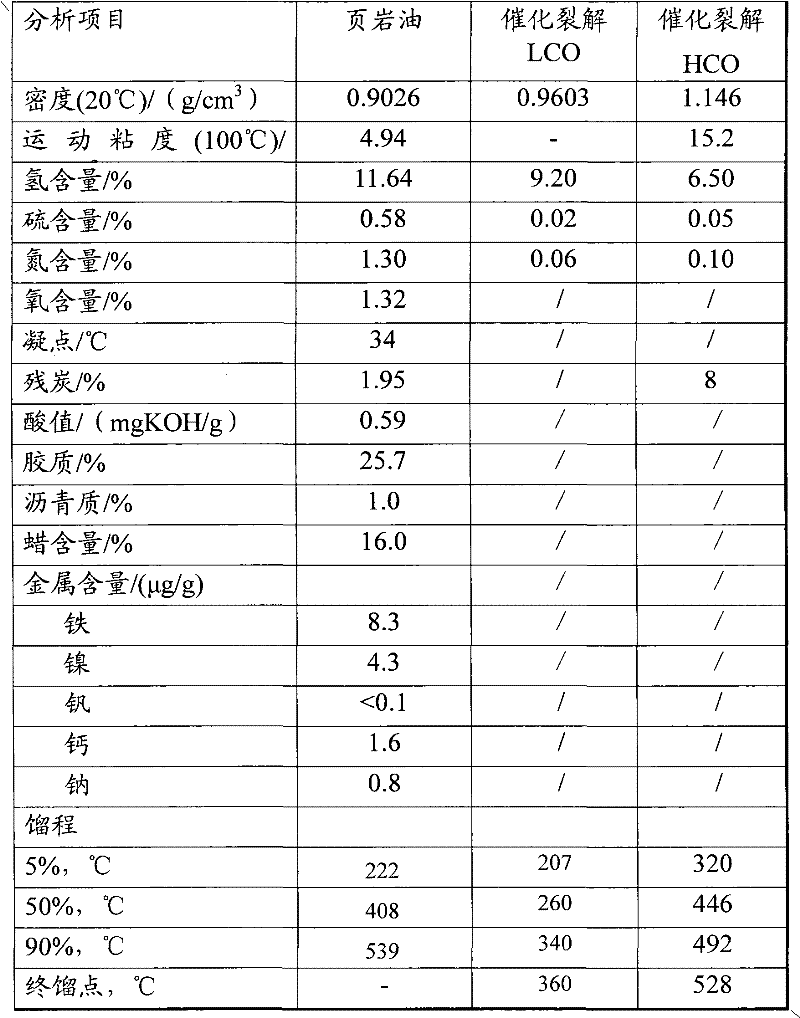

[0052] Shale oil, catalytic cracking LCO, catalytic cracking HCO (mass ratio 100:16:4) at a pressure of 15.5MPa, a reaction temperature of 380°C, in 0.625h -1 The hydrogenation reaction was carried out under the conditions of space velocity and hydrogen-to-oil ratio of 800 (v / v), and the properties of the resulting oil are shown in Table 2.

[0053] The resulting oil is distilled, and the properties of the hydrogenated tail oil after the distilled naphtha, that is, the raw material for catalytic cracking, are shown in Table 2.

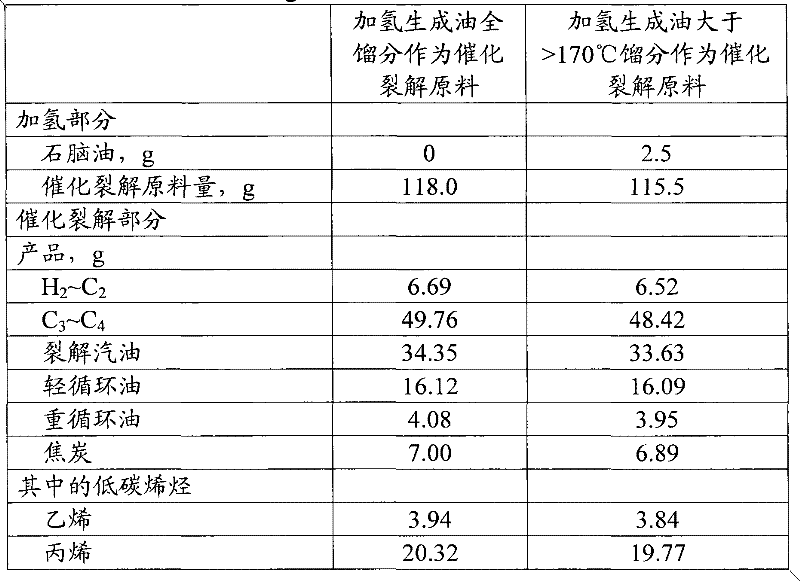

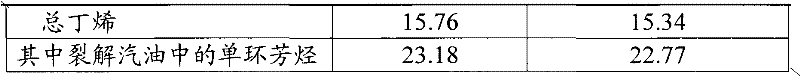

[0054] Catalytic cracking of the whole distillate of the hydrogenated oil, and catalytic cracking of the hydrogenated tail oil after distilling naphtha, the reaction conditions are normal pressure, one-way, the reaction temperature is 565 ° C, the amount of atomized water is 25%, and the agent-oil ratio is 11. The material distribution of the obtained product is shown in Table 3.

[0055] Table 1 Properties of shale oil and catalytic cracking LCO and ...

Embodiment 2

[0073] Shale oil, catalytic cracking LCO, catalytic cracking HCO (mass ratio 100:5.5:1.5) at a pressure of 10.0MPa, a reaction temperature of 390°C, in 0.32h -1 The hydrogenation reaction was carried out under the conditions of space velocity and hydrogen-oil ratio of 1000 (v / v). The hydrogenated oil is distilled to distill naphtha, 170-350°C diesel oil and >350°C tail oil, the properties of which are shown in Table 6. The product distribution is shown in Table 7.

[0074] Hydrogenated tail oil was subjected to catalytic cracking, the reaction conditions were atmospheric pressure, one pass, the reaction temperature was 565°C, the amount of atomized water was 25%, and the ratio of agent to oil was 11. The material distribution of the obtained products is shown in Table 7.

Embodiment 3

[0085]Shale oil, catalytic cracking LCO, catalytic cracking HCO (mass ratio 100:11:2) at a pressure of 14.0MPa, a reaction temperature of 385°C, in 0.50h -1 The hydrogenation reaction was carried out under the conditions of space velocity and hydrogen-oil ratio of 1000 (v / v). The resulting oil is distilled to distill naphtha, low-point diesel oil and tail oil, the properties of which are shown in Table 8, and the product distribution is shown in Table 9.

[0086] Hydrogenated tail oil was subjected to catalytic cracking, the reaction conditions were normal pressure, one pass, the reaction temperature was 565°C, the amount of atomized water was 25%, and the ratio of agent to oil was 11. The material distribution of the obtained products is shown in Table 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com