Patents

Literature

143 results about "Benzene toluene xylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toluene and xylene are aromatic hydrocarbons, derivatives of benzene, with its chemical formula C 6 H 6. Skeletal carbon atoms in benzene form what resembles a Ferris wheel, with the six hydrogen atoms corresponding to the cars. Benzene changes into toluene and xylene through substitution of hydrogen atoms by methyl groups (CH 3 -).

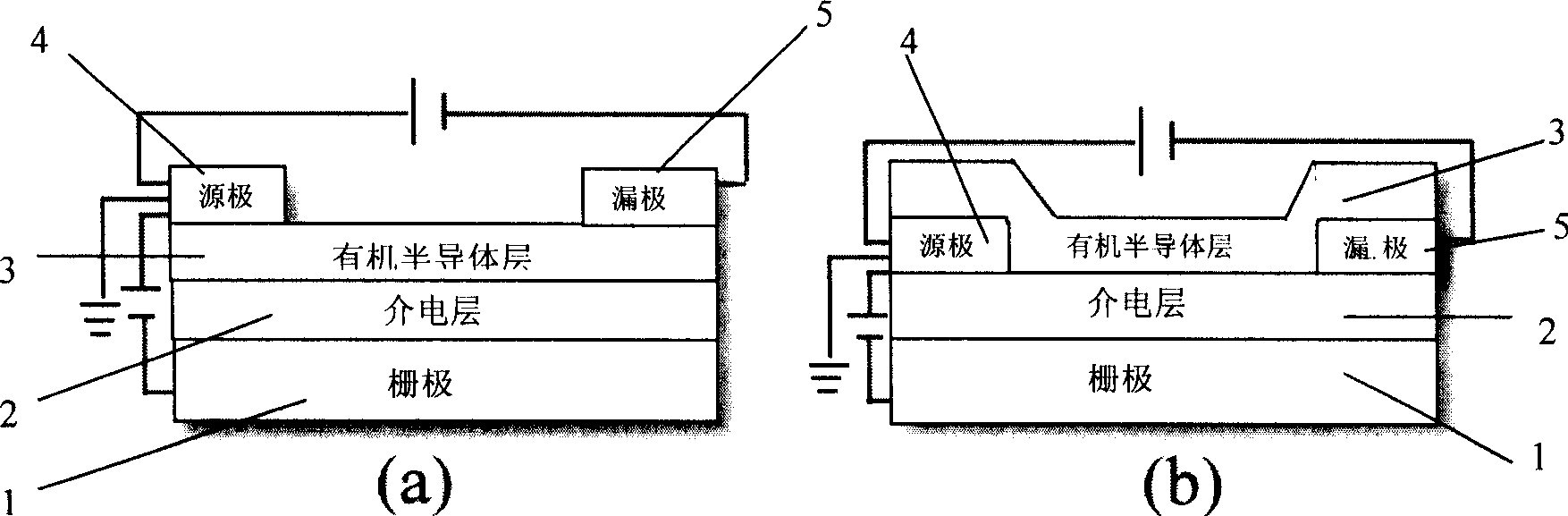

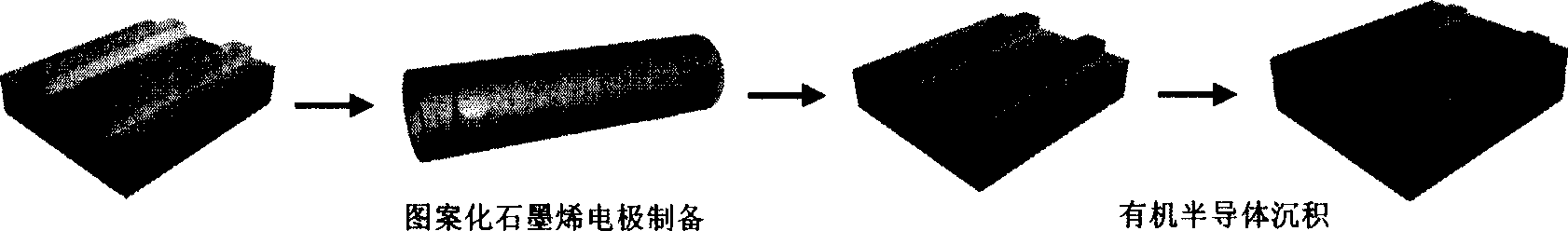

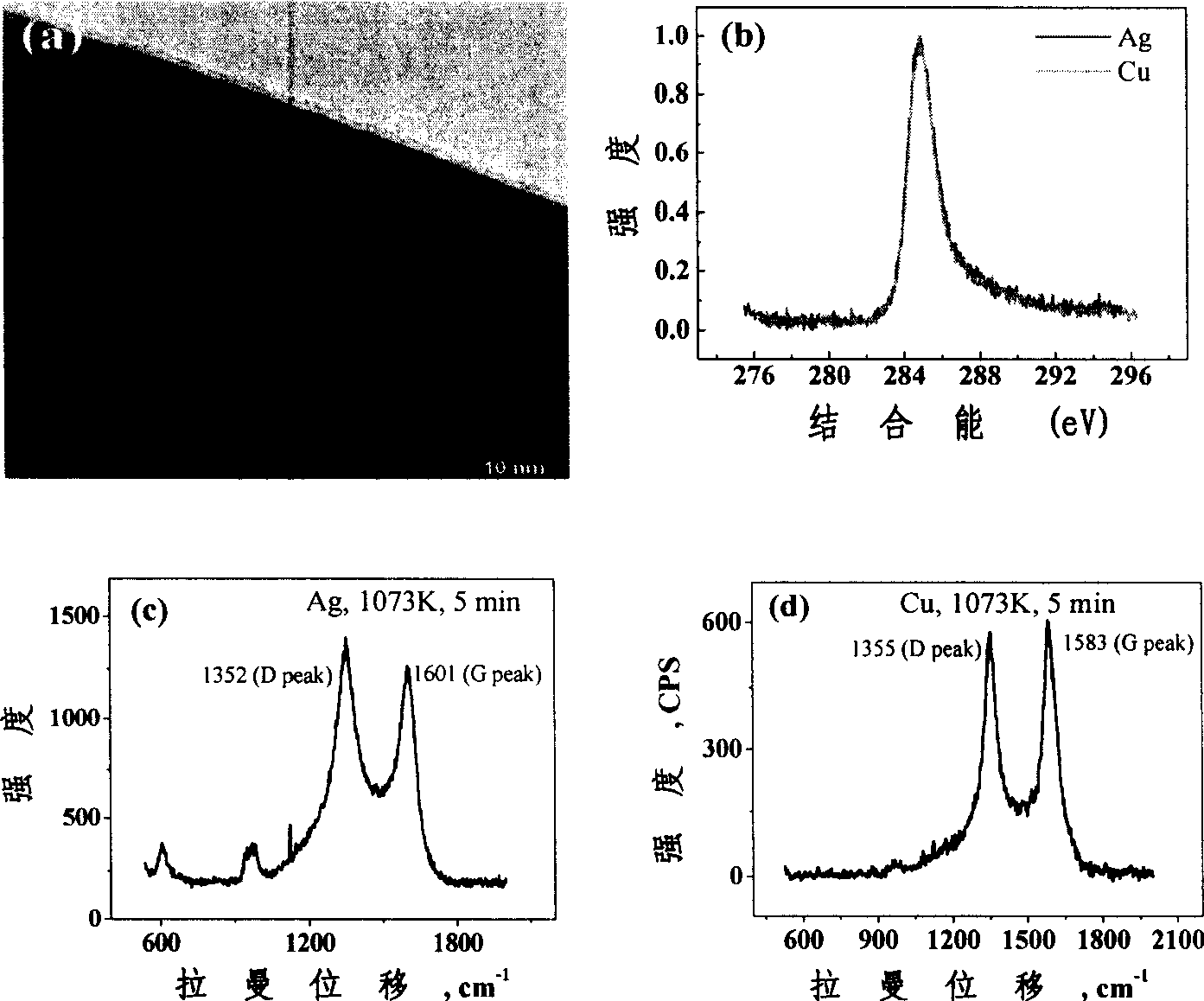

Organic field effect transistor and special source/drain electrode and preparation method thereof

InactiveCN101442105ALow costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorGas phase

The invention discloses an organic field effect transistor (FET), as well as a special source-drain electrode and a preparation method thereof. The organic FET with an electrode structure comprises a gate electrode, a dielectric layer, an organic semiconductor layer, a source electrode and a drain electrode, wherein the source electrode and the drain electrode are patterned Graphene electrodes. The method for preparing the patterned Graphene electrodes comprises the following steps: 1) a metal film is deposited on a substrate and is patterned; and 2) the substrate on which the patterned metal film is deposited is placed in a chemical vapor deposition system, and chemical vapor Graphene deposition is performed on the surface of a patterned metal electrode material, so as to obtain the patterned Graphene electrodes, wherein a carbon source used in chemical vapor deposition is methanol, ethanol, propanol, pentanol, benzene, toluene, xylene, methane and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

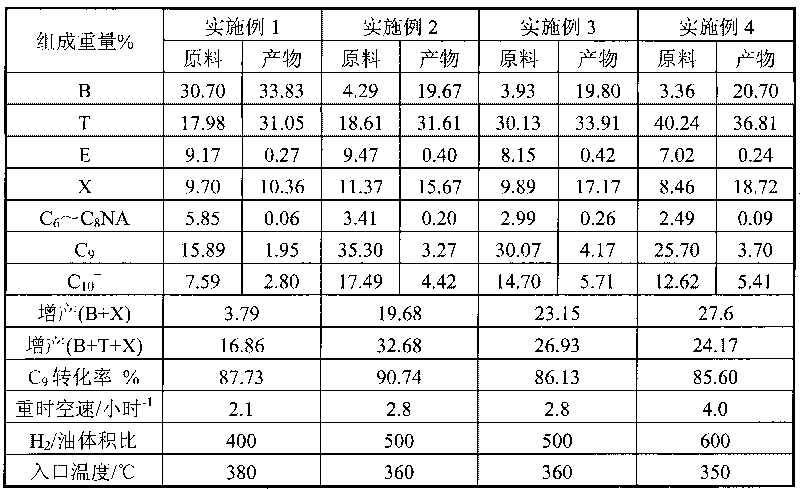

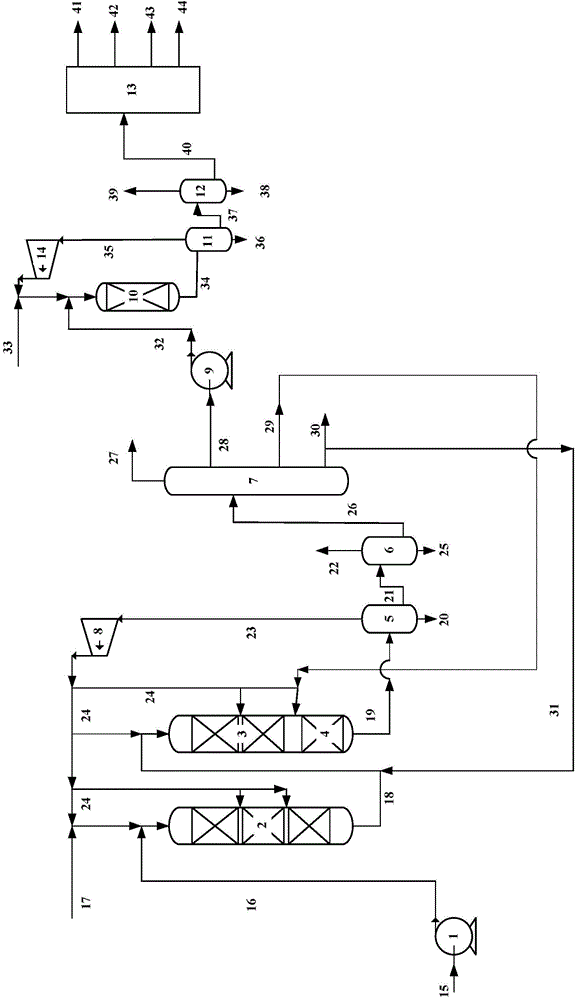

Method for hydrogenation pyrolysis of prolific benzene and xylene by using pyrolysis gasoline

InactiveCN101734986AModerate hydrogenation performanceIncrease added valueHydrocarbon by hydrocarbon crackingNaphtha reformingAlkaneIsomerization

The invention relates to a method for hydrogenation pyrolysis of prolific benzene and xylene by using pyrolysis gasoline. The method mainly solves the problems that only BTX (B is benzene, T is toluene and X is xylene) arene is separated in the traditional process of the pyrolysis gasoline, and the light arene output contains a great amount of toluene with lower utilization value with the separated heavy arene. In the invention, alkyl transfer reaction is carried out among the pyrolysis gasoline material of C7+, the heavy arene hydrogenation and the light arene are in the presence of catalyst, and isomerization reaction is carried out on the light arene into the component rick in BTX light arene; and the liquid-phase is separated into benzene, toluene, xylene and C9+ distillate according to different boiling points, wherein the toluene and the C9+ distillate can be returned for further processing as the feedstock and the light alkane can be separated from gas-phase output, thereby favorably solving the technical problem. The method can be used for the industrial production of light arene.

Owner:CHINA PETROLEUM & CHEM CORP +1

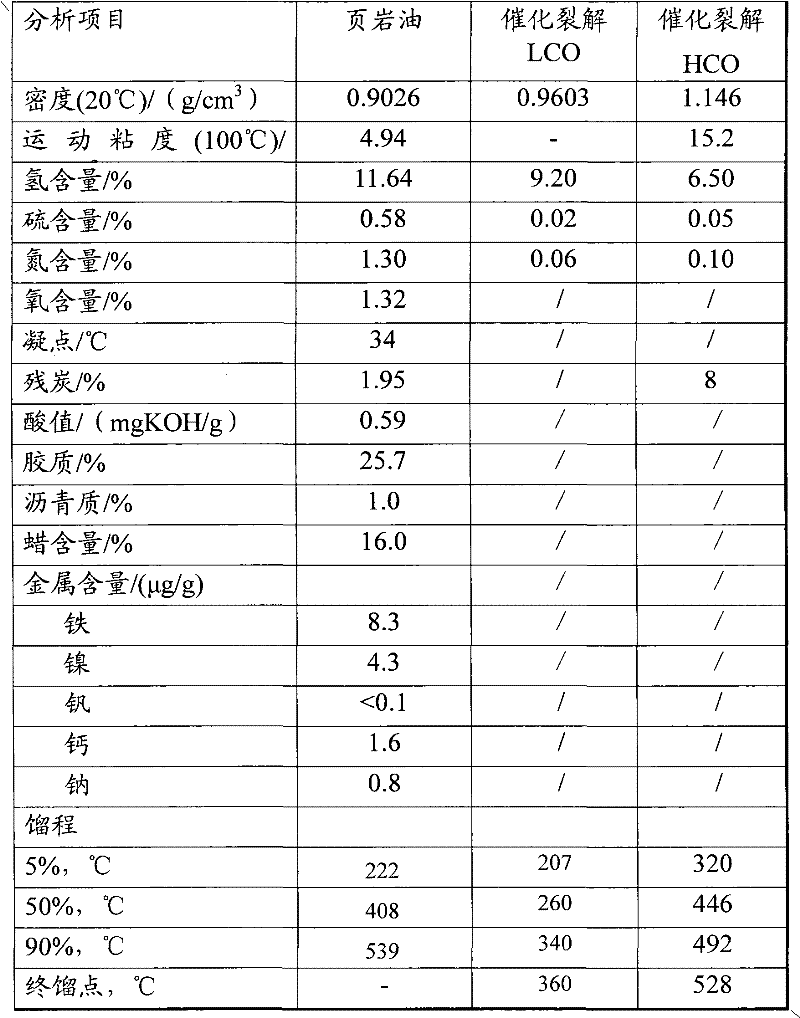

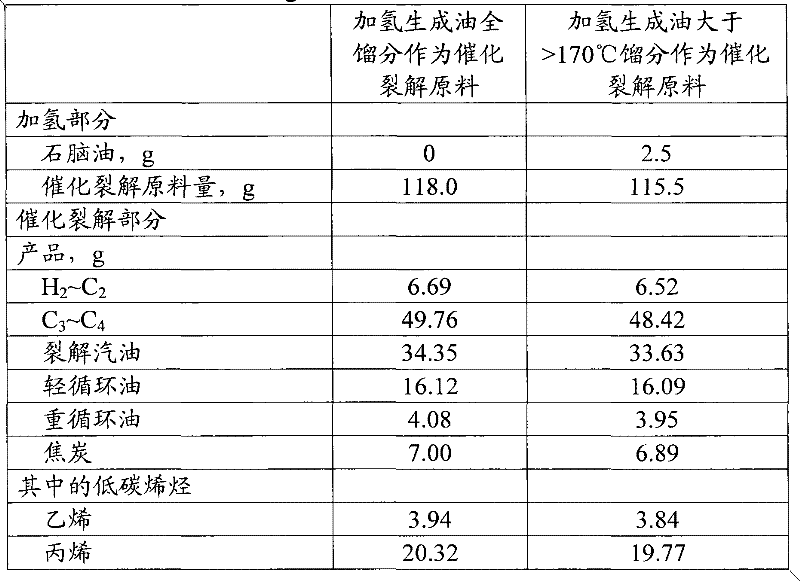

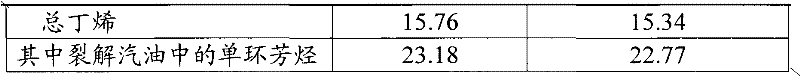

Deep processing method for shale oil

ActiveCN102453546ASave resourcesOvercome expensiveTreatment with hydrotreatment processesHydrogen treatmentLiquid gas

The invention relates to a deep processing method for shale oil, which comprises the following steps: placing shale oil, catalytic cracking light cycle oil and catalytic cracking heavy cycle oil into a shale oil hydrotreatment apparatus; placing the obtained hydrogenation generation oil and optional vacuum gas oil in a catalytic cracking apparatus, separating the reacted product to obtain ethane-containing dry gas, propylene and butylene-containing liquefied gas, monocyclic aromatics-rich catalytic cracking gasoline, catalytic cracking light cycle stock oil, catalytic cracking heavy cycle oil and catalytic cracking oil slurry; circulating catalytic cracking light cycle stock oil and catalytic cracking heavy cycle oil to the shale oil hydrotreatment apparatus. The deep processing method of shale oil is used for high value substances like ethane, propylene, butylene, benzene, toluene, xylene and the like, so that added value of the product can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

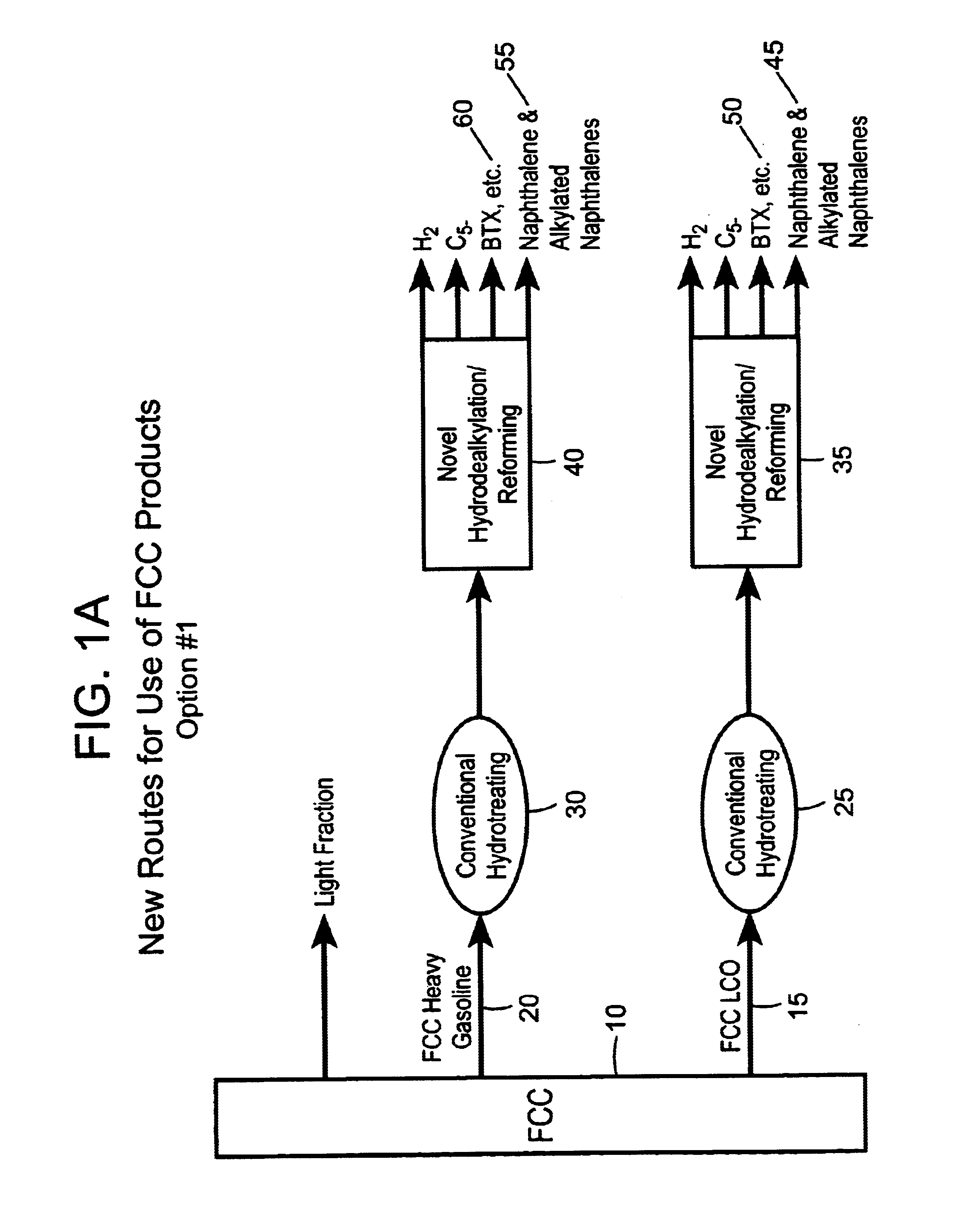

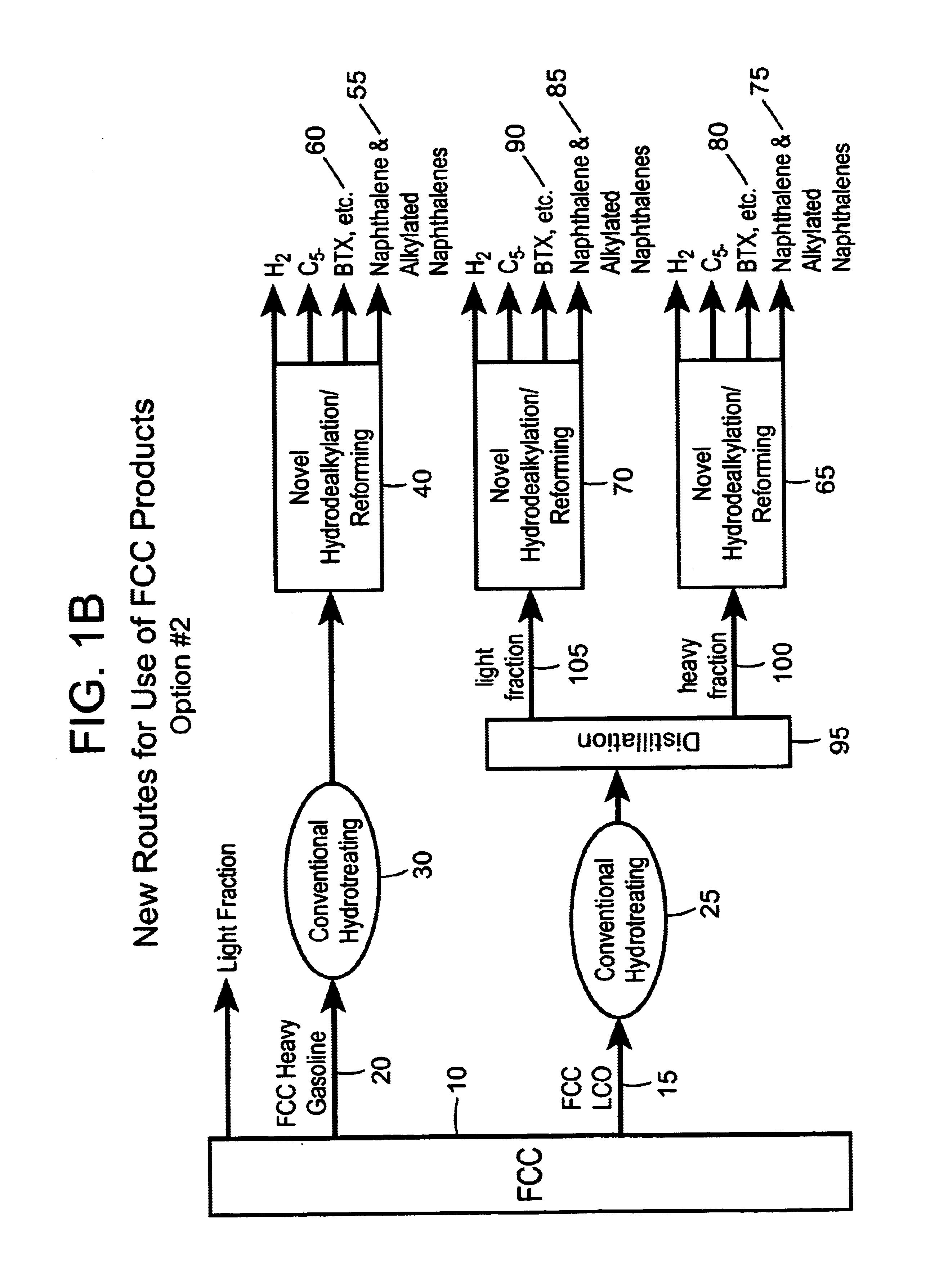

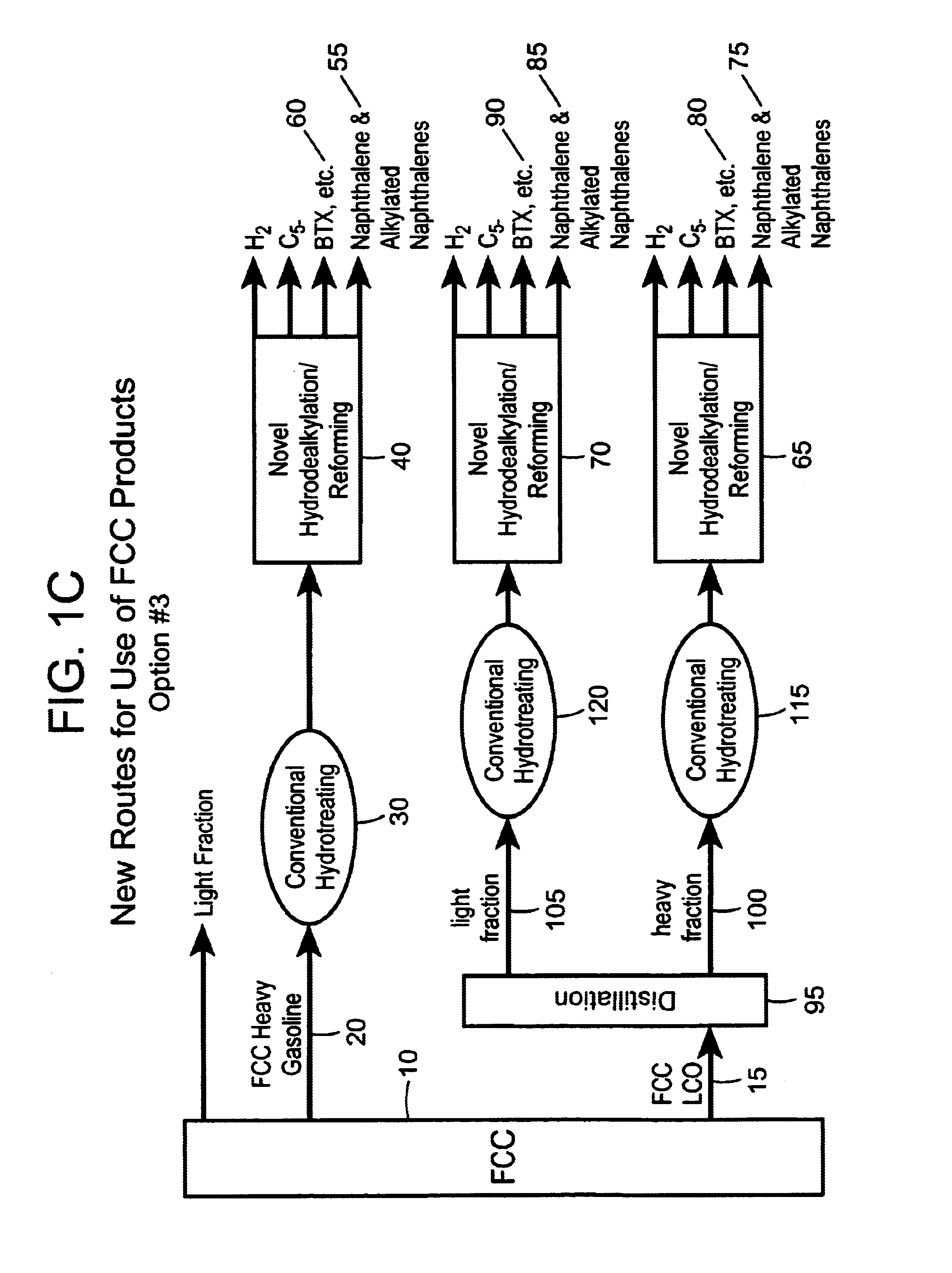

Process for converting heavy hydrocarbon feeds to high octane gasoline, BTX and other valuable aromatics

InactiveUS6900365B2High yieldOutstanding propertyCatalytic naphtha reformingHydrocarbonsMolecular sieveDehydrogenation

A catalytic hydrodealkylation / reforming process which comprises contacting a heavy hydrocarbon feedstream under catalytic hydrodealkylation / reforming conditions with a composition comprising borosilicate molecular sieves having a pore size greater than about 5.0 Angstroms and a Constraint Index smaller than about 1.0; further containing a hydrogenation / dehydrogenation component; wherein at least a portion of the heavy hydrocarbon feedstream is converted to a product comprising benzene, toluene, xylenes and ethylbenzene.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

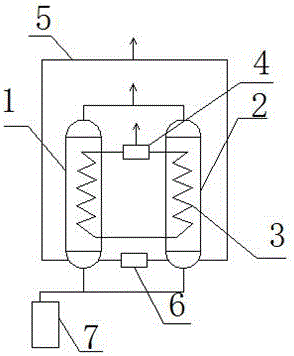

Method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms

ActiveCN102059047AAchieve purificationMeet emission requirementsDispersed particle separationAtmospheric airHigh energy

The invention discloses a method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms. After being collected, organic waste gas is sequentially treated through a low-temperature plasma reactor and a biological treatment reactor and finally exhausted to the atmosphere through a chimney. In the low-temperature plasma reactor, polycyclic aromatichydrocarbon, halogenated hydrocarbon, heterocycle compounds and an organic nitrile compound which are insoluble in water and nonbiodegradable are oxidized into low-carbon organic acid, alcohol, esterand other organic compounds which are soluble in water and biodegradable by utilizing substances with strong oxidizing property, such as O3, OH., H2O2, O. and high-energy electrons generated by high voltage discharge. In the biological treatment reactor, the organic acid, the alcohol, the ester and other organic compounds are further converted into CO2, H2O and other inorganic compounds under theaction of microorganisms. Through the treatment, the total purification efficiency of nondegradable organic compounds containing benzene, methylbenzene, dimethylbenzene, phenol and the like in waste gas can be up to over 90 percent.

Owner:山东航源环境科技有限公司

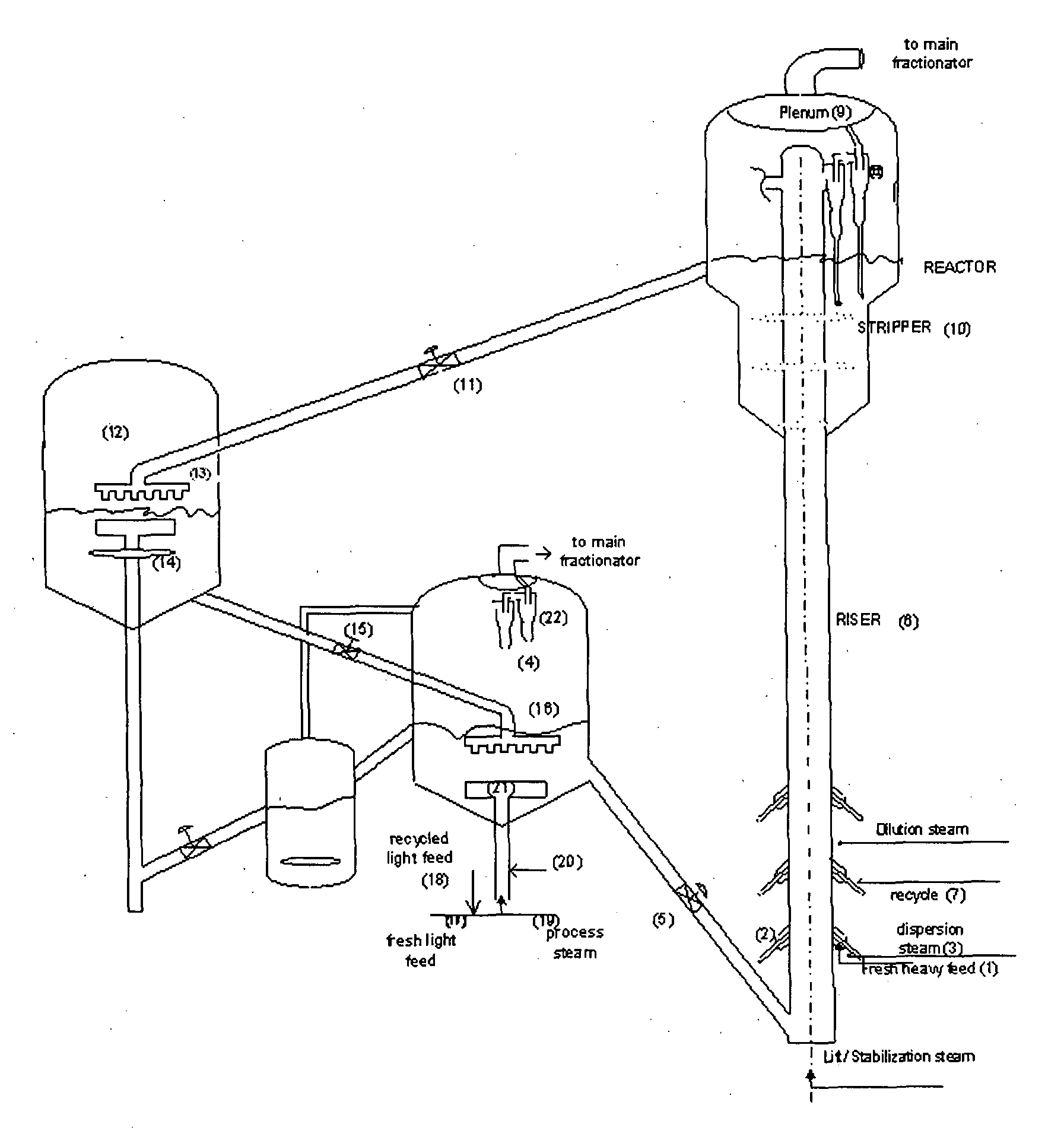

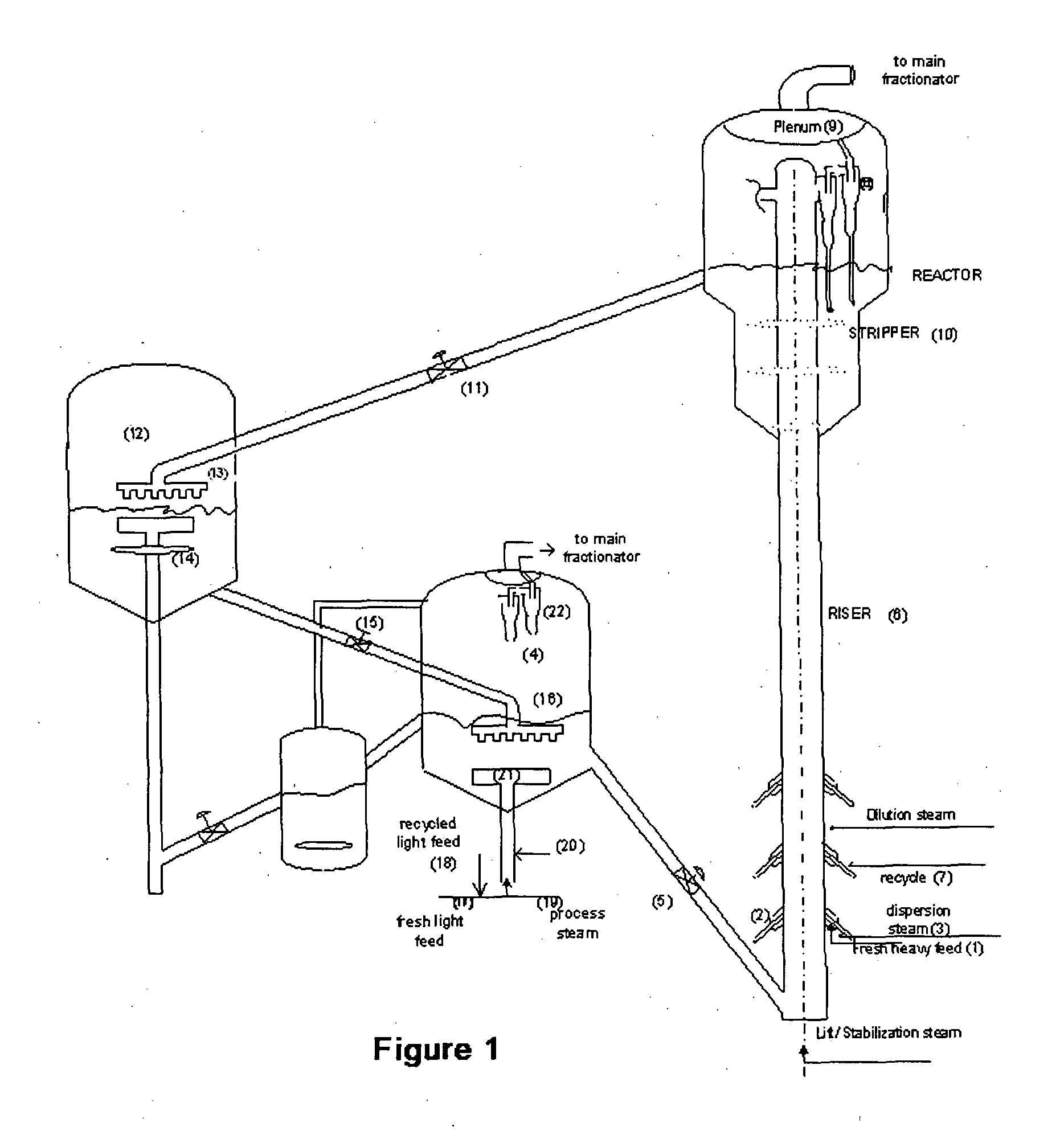

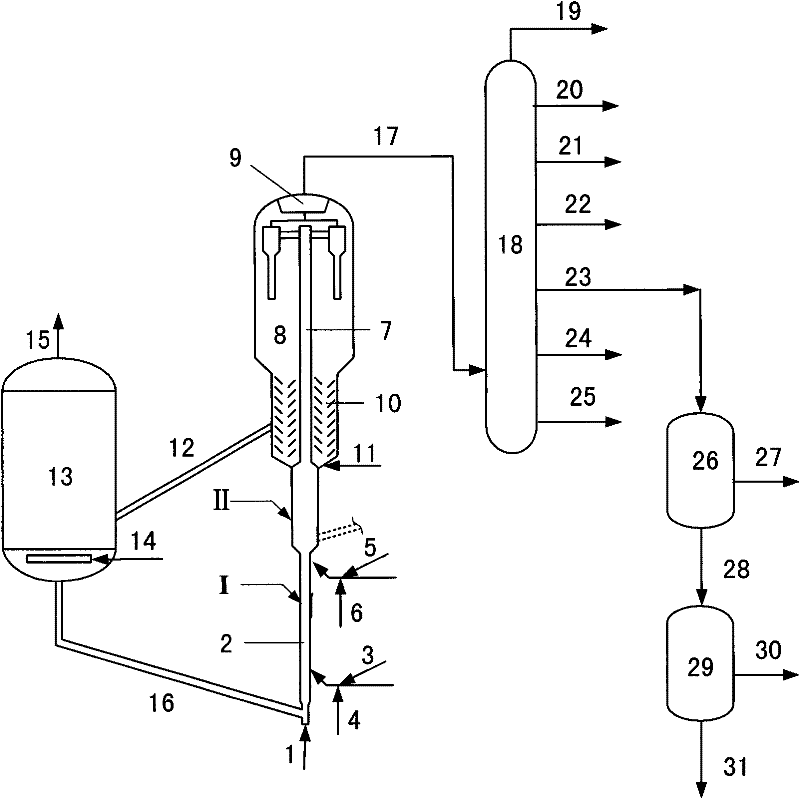

Process for simultaneous cracking of lighter and heavier hydrocarbon feed and system for the same

ActiveUS20130056393A1Reduce sulfur contentEfficient use ofTreatment with plural serial cracking stages onlyCatalytic crackingProcess conditionsHydrocarbon

The invention provides for a process and apparatus for simultaneous conversion of lighter and heavier hydrocarbon feedstocks into improved yields of light olefins in the range of C2 to C4, liquid aromatics in the range C6 to C8 mainly benzene, toluene, xylene and ethyl benzene and other useful products employing at least two different reactors operated in series with respect to catalyst flow and parallel with respect to feed flow under different regimes and process conditions with same catalyst system.

Owner:INDIAN OIL CORPORATION

Process of preparing aromatic hydrocarbons and liquefied petroleum gas from hydrocarbon mixture

Disclosed is a process of preparing aromatic hydrocarbons and liquefied petroleum gas (LPG) from a hydrocarbon mixture, in which a non-aromatic compound in the hydrocarbon feedstock mixture is converted into a gaseous material having a large amount of LPG through hydrocracking, and an aromatic compound therein is converted into an oil component having large amounts of benzene, toluene, and xylene (BTX) through dealkylation and transalkylation, in the presence of a catalyst obtained by supporting platinum / bismuth onto a mixture support having zeolite and an inorganic binder. The gaseous product is separated into LPG and a mixture of methane and ethane depending on differences in boiling point through distillation, while the liquid product is separated into benzene, toluene, xylene, and C9+ aromatic compounds depending on differences in boiling point through distillation.

Owner:SK INNOVATION CO LTD

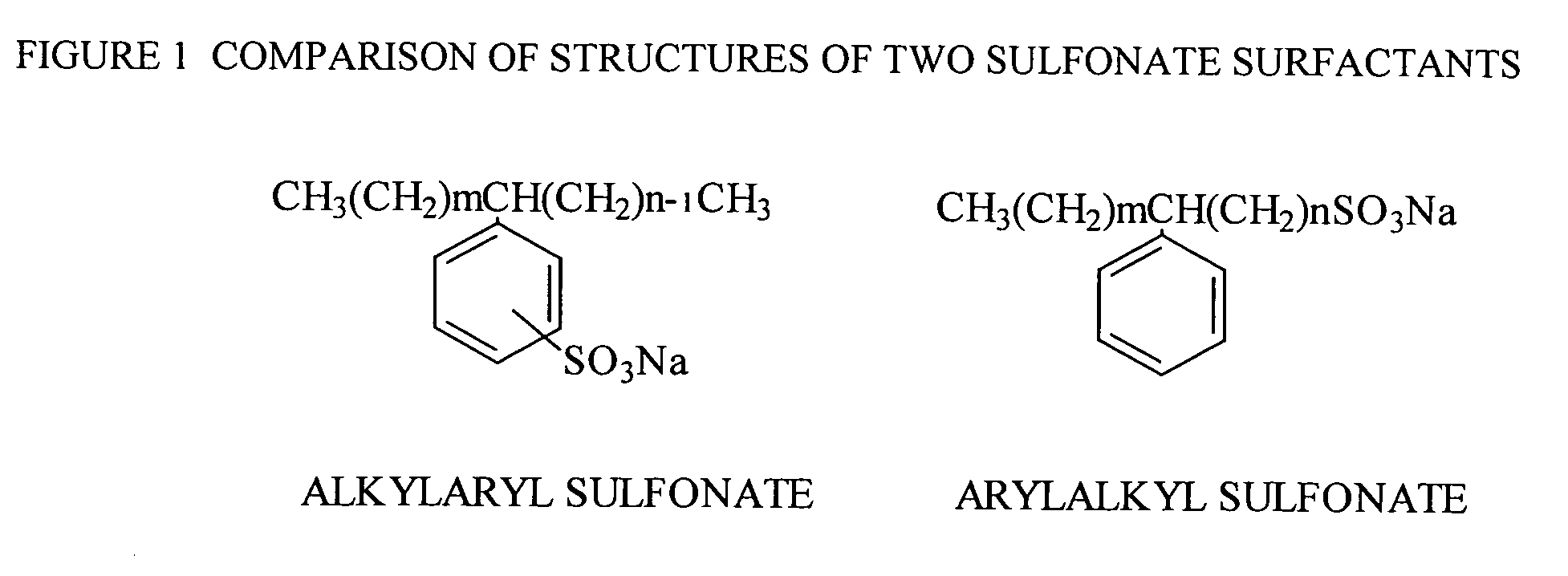

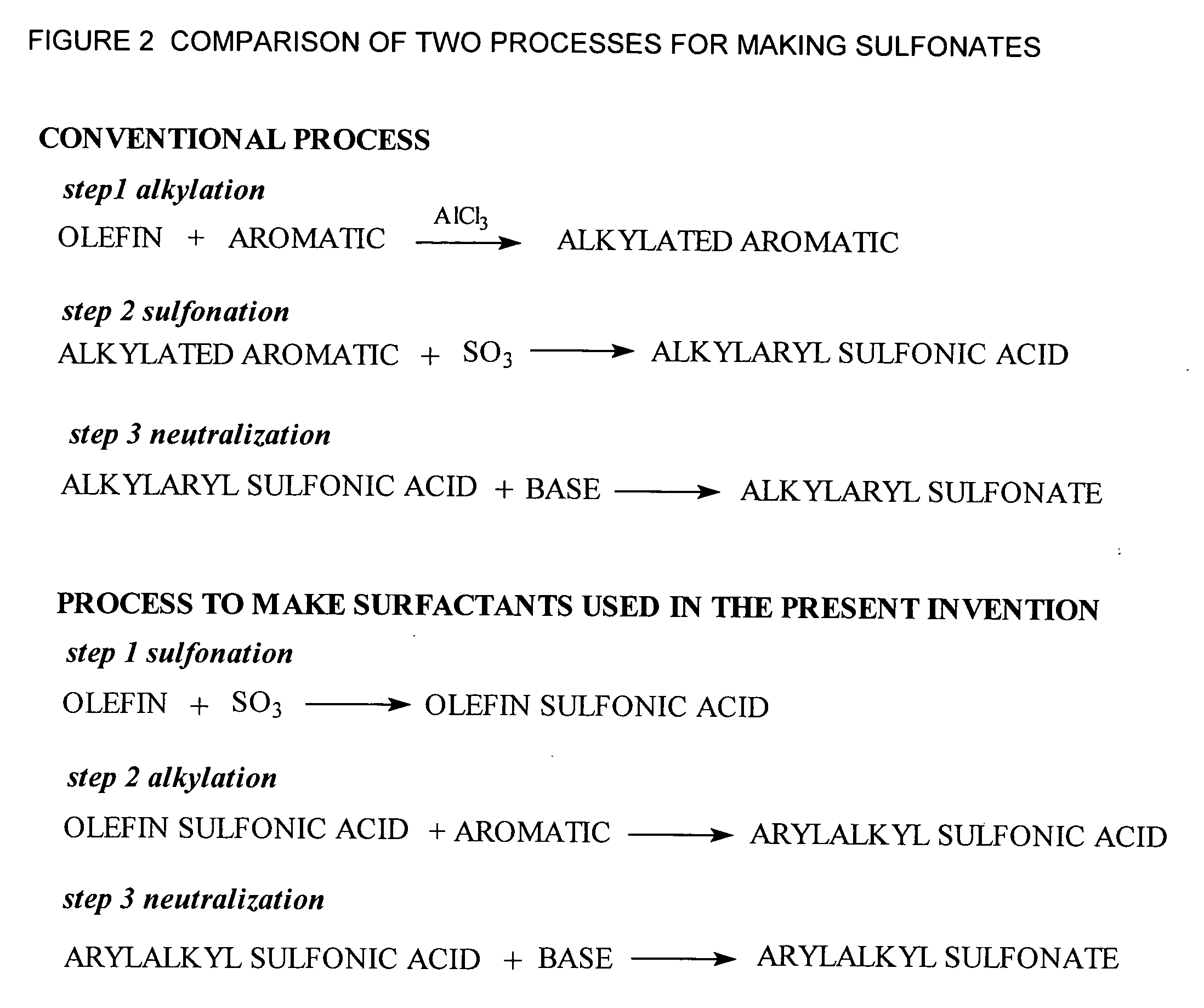

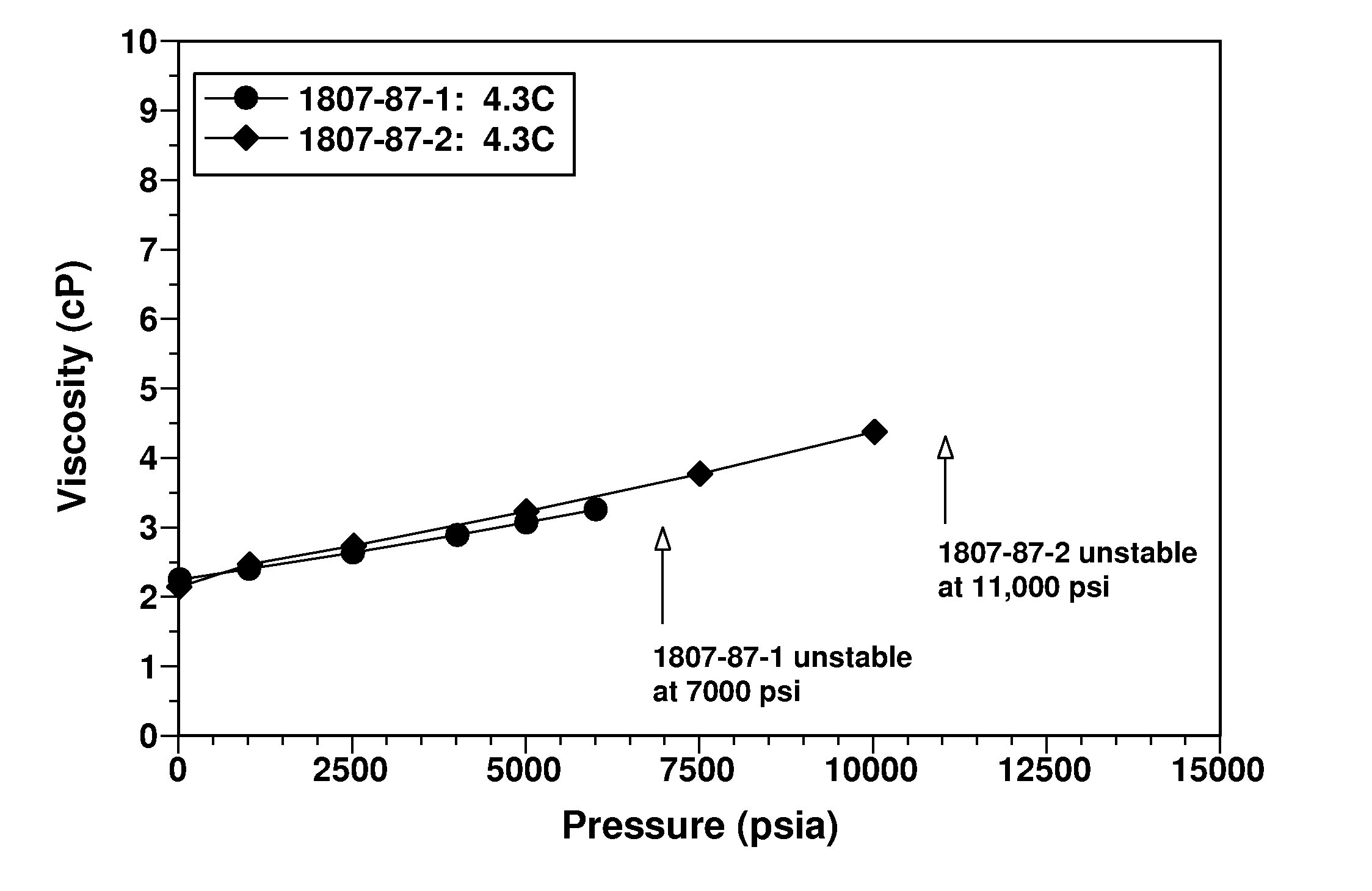

Oil recovery composition and method using arylalkyl sulfonate surfactants derived from broad distribution aplha-olefins

An oil recovery method is disclosed which uses injection fluids containing a particular class of arylalkyl sulfonate surfactants that are derived from an alpha-olefin stream having a broad distribution of carbon numbers ranging from more than 10 to greater than 30. The alpha-olefin stream is reacted with sulfur trioxide to form the olefin sulfonic acids, and then these are reacted with aromatic feedstock, such as benzene, toluene, xylene, ethylbenzene, phenol, substituted phenol, naphthalene or substituted naphthalene, or a mixture thereof, and neutralized to form arylalkyl sulfonate surfactants. The resulting surfactants have high solubility in a wide range of brines and provide ultra low interfacial tension with crude oils. The resulting surfactants also have economical advantages over the conventional alkylaryl sulfonate surfactants derived from a broad distribution of alpha-olefin stream due to the elimination of the costly alkylation process and the toxic catalyst used in the process.

Owner:BERGER PAUL DANIEL +1

Paraffin Inhibitor Compositions and Their Use in Oil and Gas Production

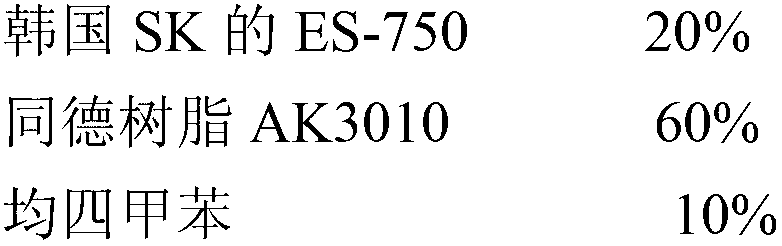

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

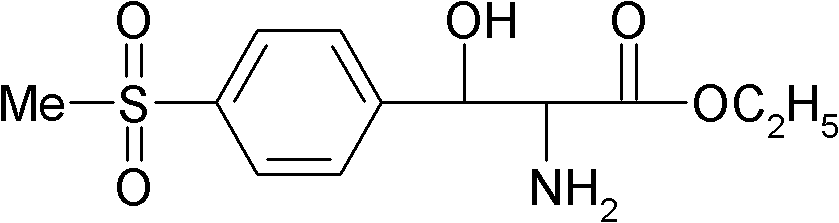

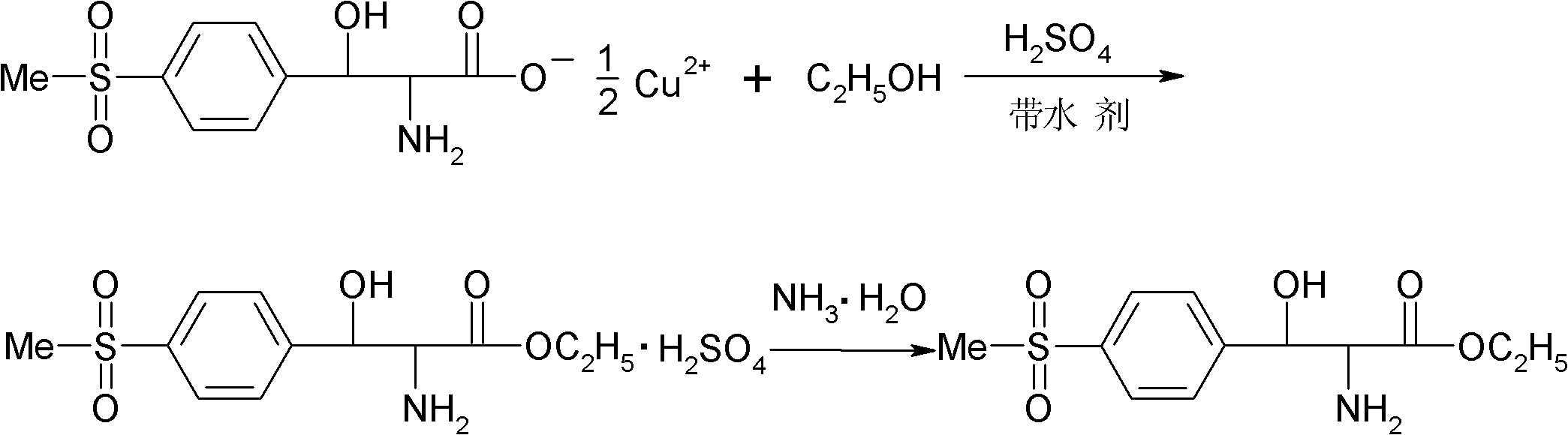

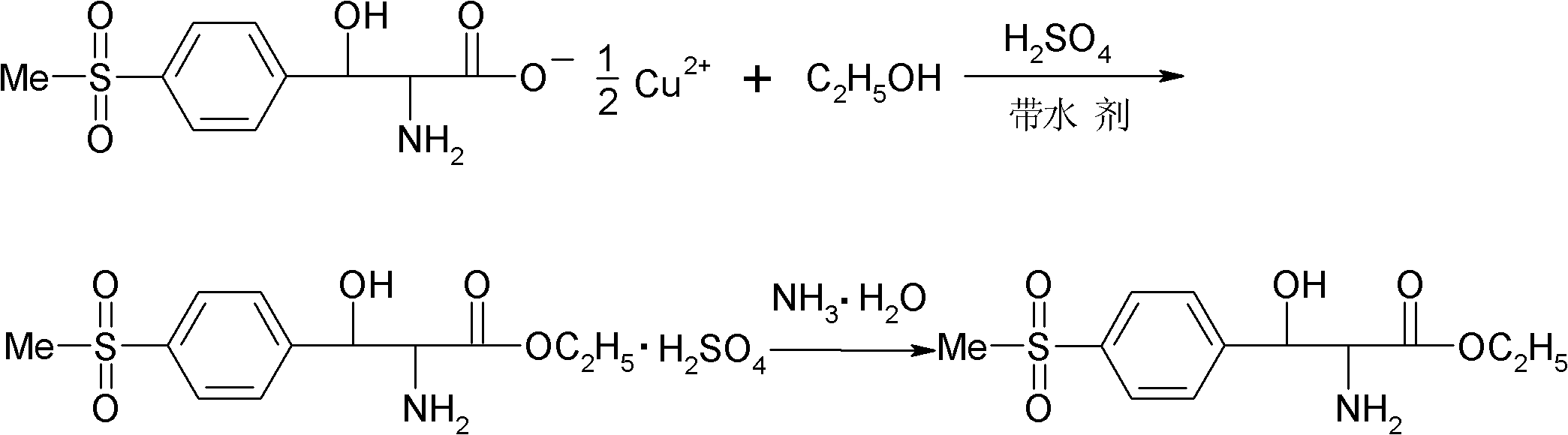

Preparation method of DL-p-methylsulfonylphenyl serine ethyl ester

InactiveCN102442930AHigh yieldMild reaction conditionsOrganic chemistryOrganic compound preparationEthyl esterCopper salt

The invention provides a preparation method of DL-p-methylsulfonylphenyl serine ethyl ester. A main initial raw material of p-methylsulfonylphenylserine copper salt is successively treated with esterification, dissociation and neutralization to prepare the DL-p-methylsulfonylphenyl serine ethyl ester. Benzene, toluene, xylene, hexane and cyclohexane are used as water carrying agents in the esterification reaction to promote progressing of the esterification reaction. The synthetic method of the invention has mild reaction conditions, simple technical operations and a total yield higher than 90%.

Owner:JIANGSU YUXIANG CHEM +1

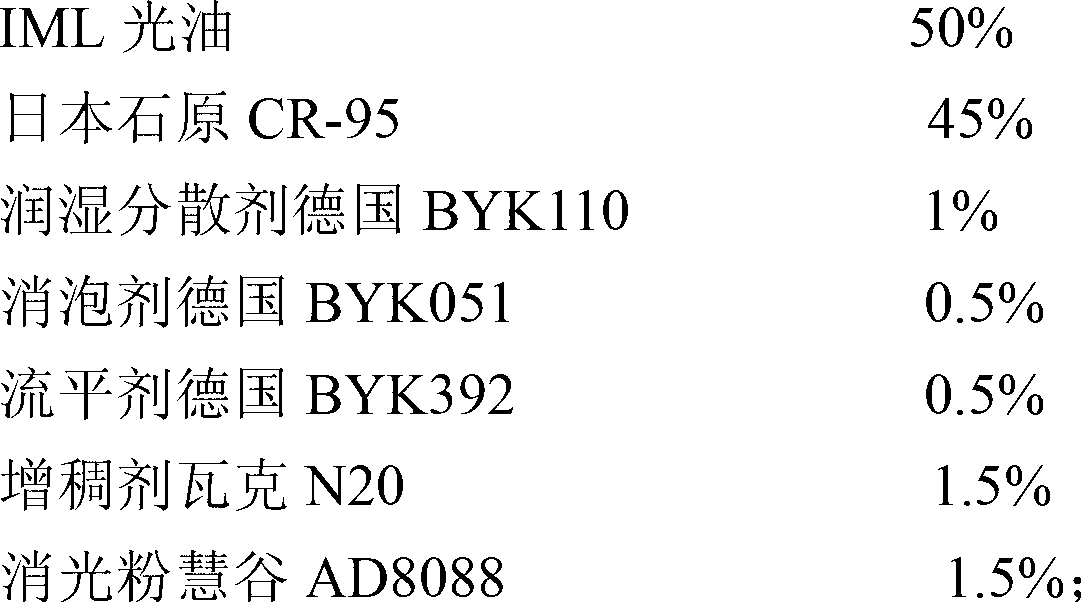

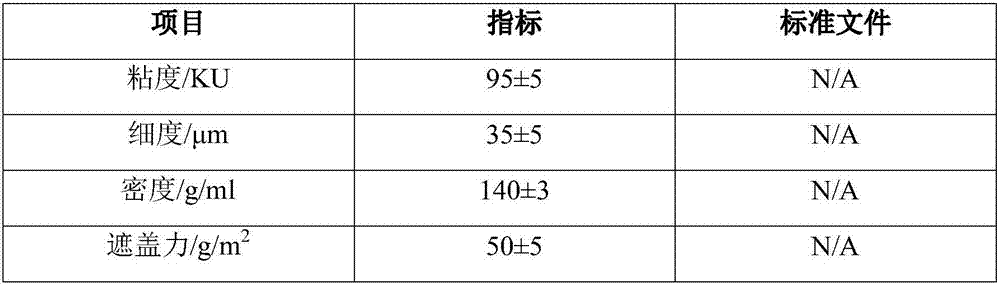

IML gloss oil and IML printing ink and preparation method and application thereof

The invention discloses IML gloss oil and IML printing ink, a preparation method and an application thereof. The IML gloss oil is obtained by dissolving saturated polyester resin in an organic solvent. The IML printing ink comprises an A component and an isocyanate curing agent with a mass ratio of 10:0.9-2; the A component comprises the following components: 40-89% of the IML gloss oil, 8-55% of pigment, 0.5-2% of a wetting dispersant, 0.5-1% of a defoamer, 0.5-1% of a levelling agent, 0.5-2% of a thickening agent, and 0-1.5% of extinction powder. The IML printing ink does not contain harmful or toxic substances for human body, such as benzene, toluene, xylene, isophorone and the like, and has the advantages of low odor environment and low environmental load; the IML printing ink has good adhesion performance, high-temperature ink-sweeping resistance, and tensile property, is widely applicable to fields of panels of household appliances, display screens and control panels, 3C product buttons, housing, and large-scale casings, automotive upholstery, and the like.

Owner:清远慧谷新材料技术有限公司

Method for synthesizing liquefied petroleum gas and BTX aromatics by butyl alcohol

InactiveCN103131456AReduce dependenceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsNitrogen gasPolymerization

The invention provides a method for synthesizing liquefied petroleum gas and BTX aromatics by butyl alcohol. The method for synthesizing the liquefied petroleum gas and the BTX aromatics by the butyl alcohol comprises the steps that butyl alcohol raw materials or mixed reaction raw materials of butyl alcohol raw materials and nitrogen are put into a reaction area; the reaction raw materials are converted into a liquid-phase aromatic hydrocarbon compound rich in benzene, methylbenzene and dimethylbenzene under the action of catalytic agents and through dehydration reaction and polymerization and aromatization reaction; the liquid-phase aromatic hydrocarbon compound is converted into a liquefied petroleum gas component rich in dimethylmethane, hydride butyl and iso-butane through hydrogen transfer and cleavage reaction; and the liquid-phase aromatic hydrocarbon compound and the liquefied petroleum gas component are recovered through gas-liquid separation. According to the method for synthesizing the liquefied petroleum gas and the BTX aromatics by the butyl alcohol, non-fossil resources are adopted as raw materials, the aromatic hydrocarbon compound (the benzene, the methylbenzene and the dimethylbenzene) is produced under the condition that the catalytic agents exist, and dependence on disposable consumption of fossil raw materials (hydrocarbon, naphtha, and diesel oil) is reduced for the production of the aromatic hydrocarbon compound.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

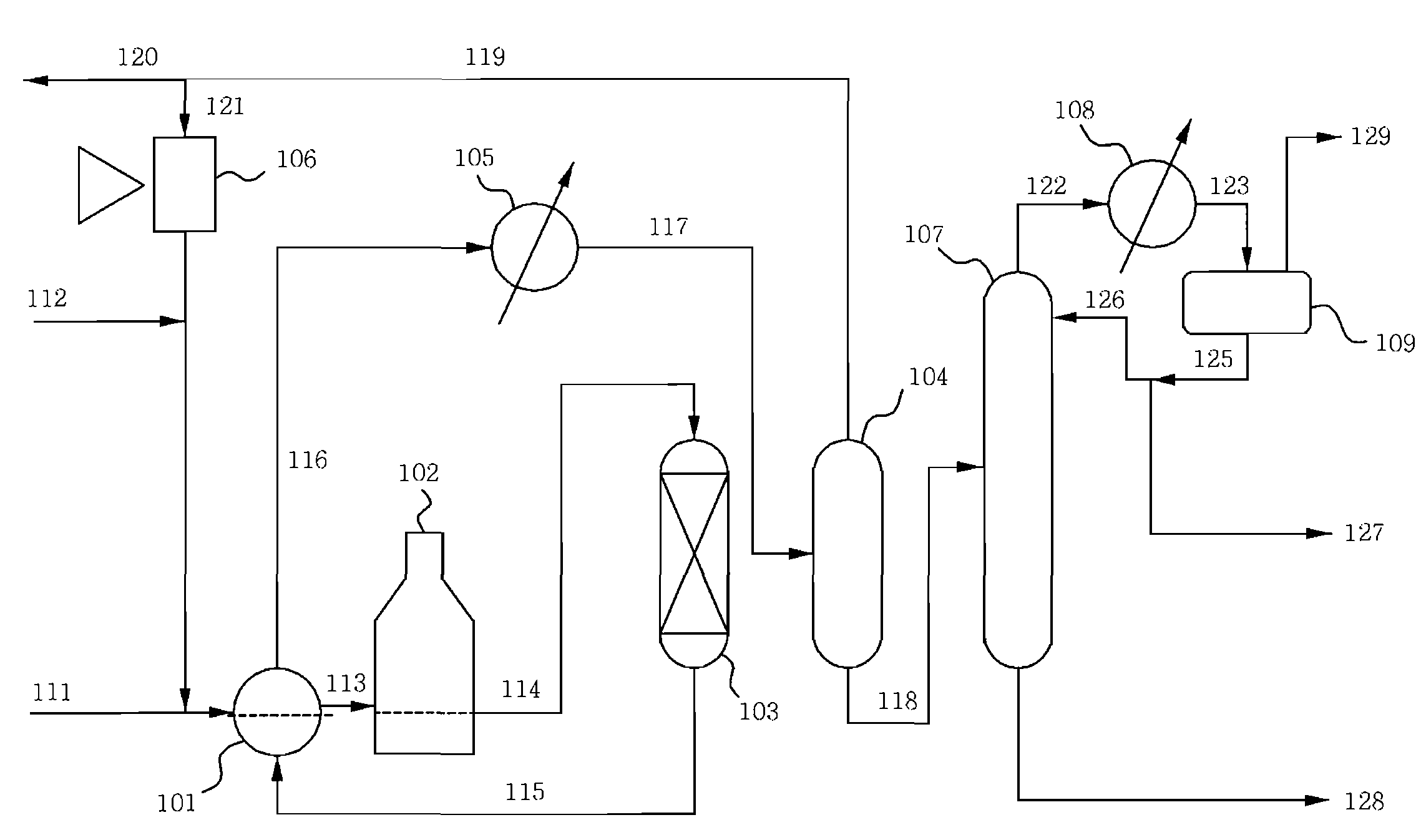

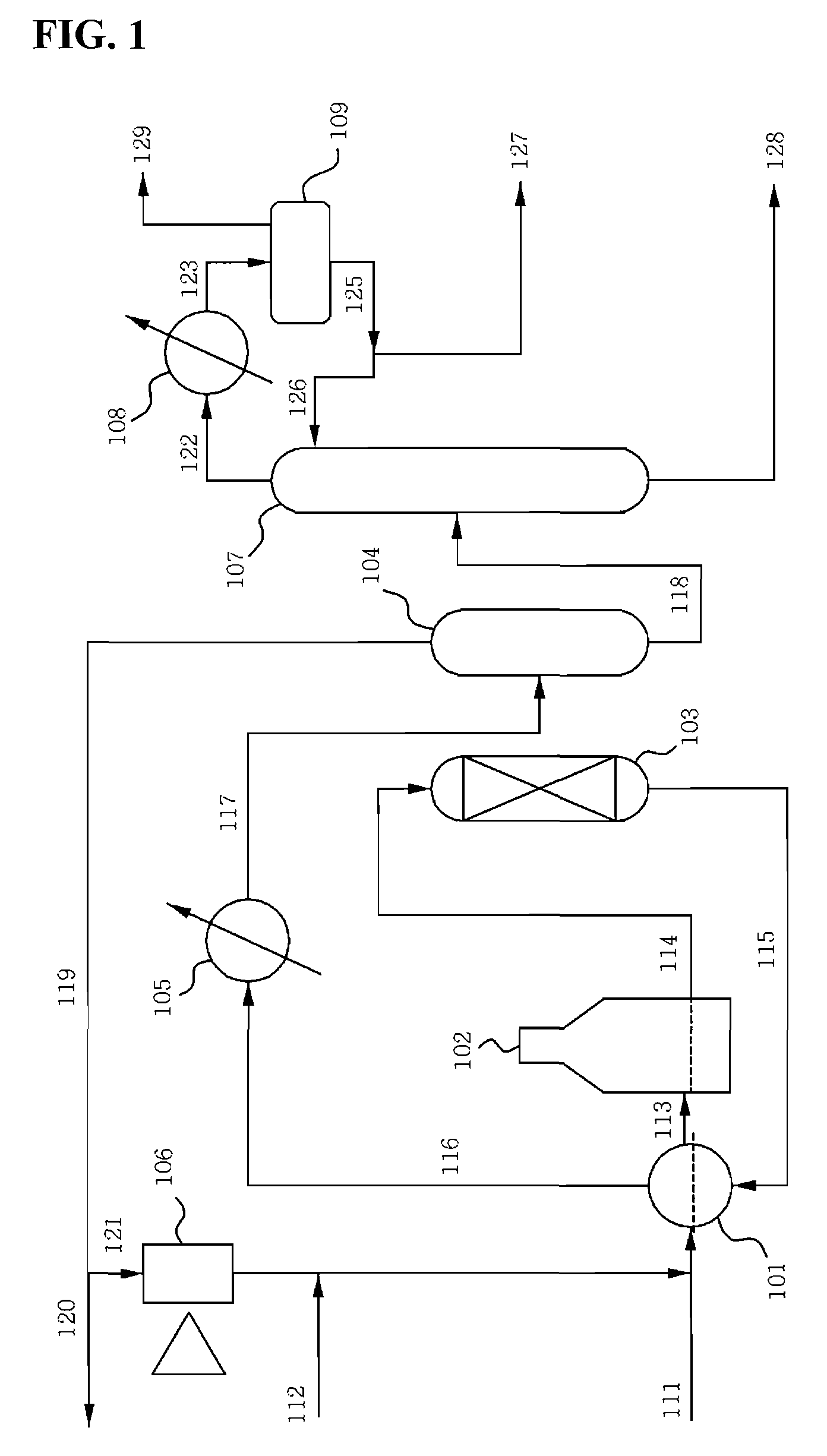

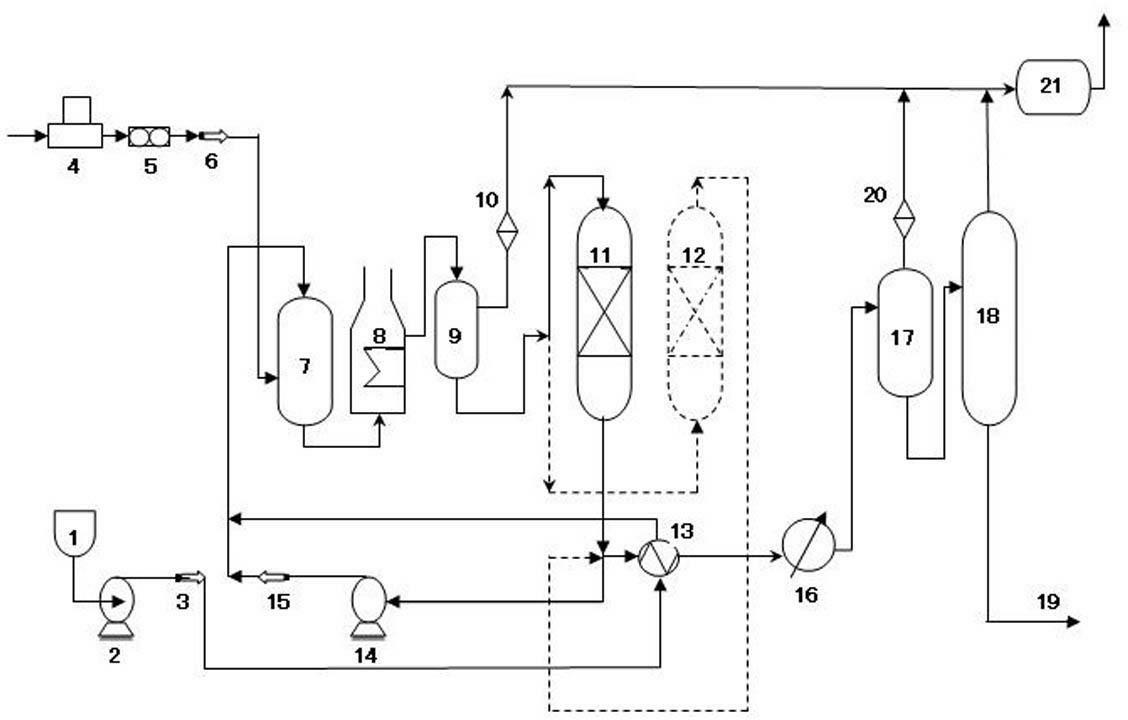

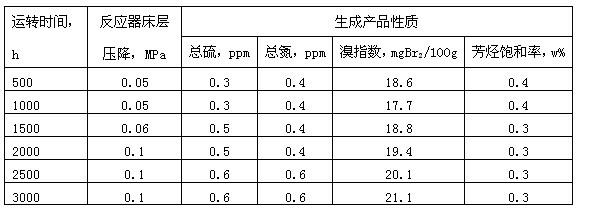

Method for producing benzene, toluene and xylene from poor-quality diesel oil raw material

ActiveCN105316040AGood choiceWeakened hydrogenationHydrocarbonsTreatment with hydrotreatment processesThiolSulfur

The invention relates to a method for producing benzene, toluene and xylene from a poor-quality diesel oil raw material. According to the method, a poor-quality diesel oil raw material reacts in a hydrorefining zone, a hydrocracking reaction zone I and a hydrocracking reaction zone II to generate a stream being rich in benzene, toluene and xylene, the reaction products of the hydrocracking reaction zone I are subjected to fractionation to separate so as to obtain the light gasoline distillate, the heavy gasoline distillate, the middle distillate and the tail gasoline distillate, thiophene, mercaptan and the like are removed from the heavy gasoline through a desulfurization reaction zone, and separation is performed to obtain the high added value products such as benzene, toluene and xylene, raffinate oil, and the like. With the method of the present invention, the poor-quality diesel oil raw material can be effectively converted into the high added value products such as benzene, toluene, xylene and the like while the partial light gasoline and the low sulfur diesel oil blending component can be concurrently produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

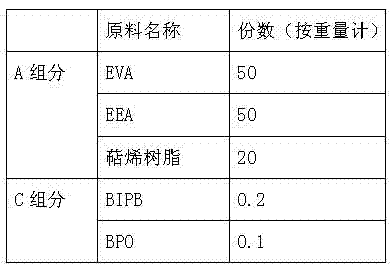

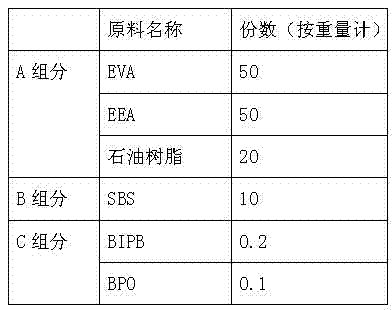

Hot melt adhesive film for adhering sole, and preparation method thereof

ActiveCN103756576APolymerization ControlImproved color stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceBenzoyl peroxide

The present invention relates to a hot melt adhesive film for adhering a sole. The hot melt adhesive film comprises the following raw materials by weight: 50-60 parts of ethylene-vinyl acetate (EVA), 30-60 parts of modified ethylene-ethyl acrylate (EEA), 15-35 parts of a styrene-butadiene block copolymer (SBS), 5-20 parts of a terpene resin, 0.1-0.5 part of bis-(tertbutylperoxy isopropyl)benzene (BIPB), and 0.1-0.5 part of benzoyl peroxide (BPO). According to the present invention, the hot melt adhesive film does not contain benzene, toluene, xylene and other harmful solvents, the sole does not require the primer treatment, the operation process is simple, and the environmental requirement requirements are met.

Owner:江阴伟韬塑料新材料有限公司

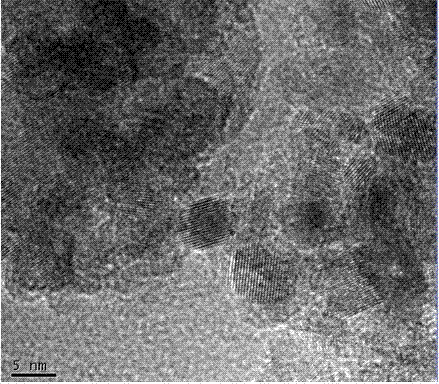

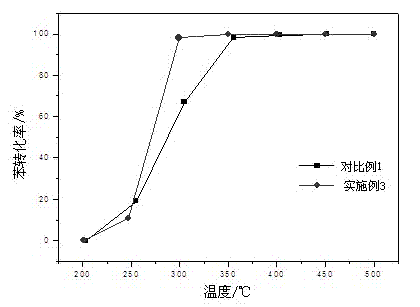

Catalyst for low-temperature catalytic combustion of volatile organic compounds and preparation method thereof

InactiveCN102824909AImprove low temperature catalytic activitySimple preparation processIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEngineering

The invention discloses a catalyst for low-temperature catalytic combustion of volatile organic compounds and a preparation method thereof, belonging to the technical fields of chemical catalyst and preparation technology thereof. The catalyst contains, by mass percent, 0.1 to 1 % of an active ingredient Pb, 74 to 99.4 % of a carrier Al2O3 and 0.5 to 25% of an auxiliary agent RE2O3, wherein a specific surface area of a composite oxide RE2O3- Al2O3 is 80 to 326 m<2> / g. The catalyst provided by the invention is simple in preparation technology, easy to produce in large scale, and has a very high catalytic activity for low-temperature complete oxidation reactions of benzene, toluene, xylene, ethyl acetate, ethanol and propane. Provided is a novel and high-efficiency catalyst which can be used for purification treatment of the volatile organic compounds in fields of industrial exhaust or indoor pollution.

Owner:FUZHOU UNIV

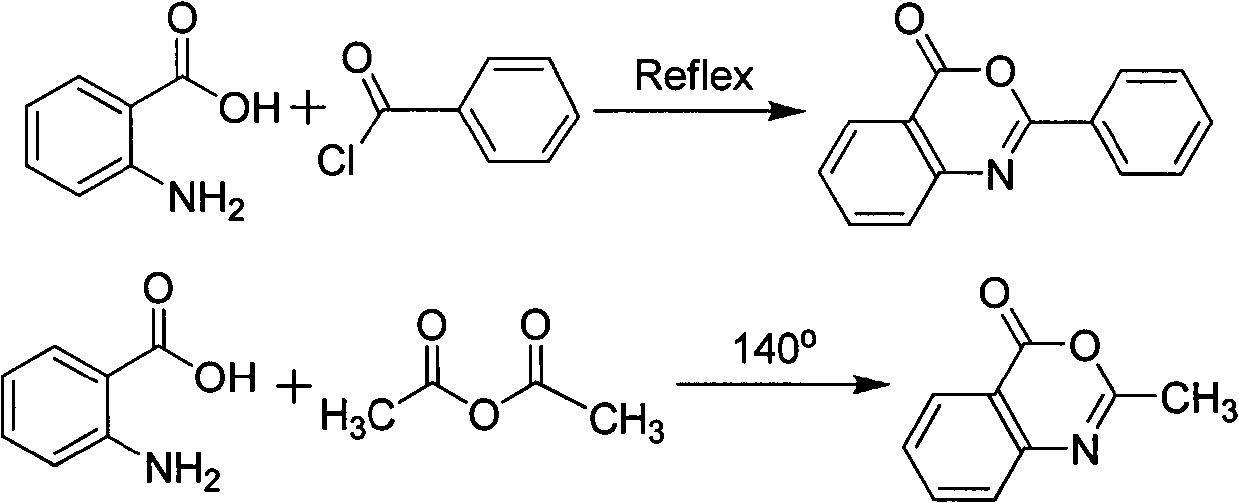

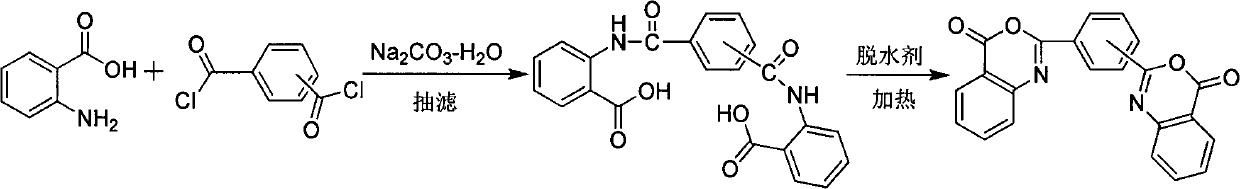

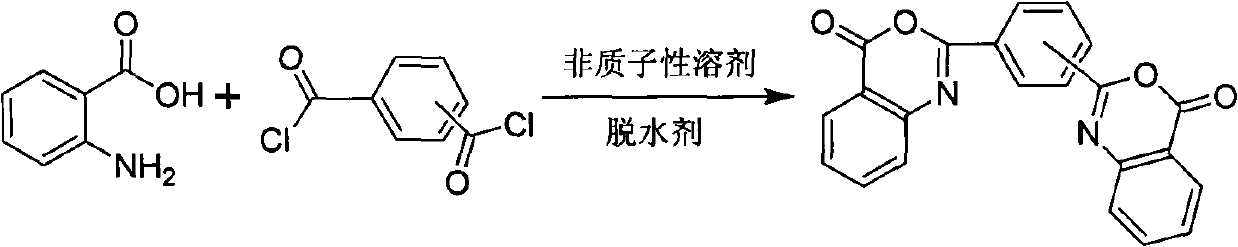

Novel synthetic method of bis-benzoxazine ketone ultraviolet absorbent

The invention provides a novel synthetic method of a bis-benzoxazine ketone ultraviolet absorbent, and belongs to the technical field of fine chemical engineering. The method comprises the following steps: A, stirring, anhydrides, used as raw materials, of o-aminobenzoic acid and (o-, m-, p-) phthaloyl dichloride or (o-, m-, p-)phthalic acid for a certain time in a non-polar solvent; B, adding chemical dehydrating agent or physical dehydrating agent in a reaction system without separating, slowly heating and refluxing for a certain time to obtain (o-, m-, p-)substituted bis-benzoxazine ketone ultraviolet absorbent; wherein the stirring time in the step A is not less than 1 hour, the refluxing time is 5-10 hours in the step B, the chemical dehydrating agent used in the step B is various dehydrating agents reacted with the water, including but not limited to alkaline calcium oxide, soda lime, acidic concentrated sulfuric acid, concentrated phosphoric acid, polyphosphoric acid, phosphorus pentoxide, thionyl chloride, acetic anhydride and the like, neutral molecular sieve, water-absorbent, anhydrous cupric sulfate and the like; the physical dehydrating agent comprises but not limited to non-protonic solvent such as benzene, methylbenzene, xylene and the like. The method provided by the invention has the advantages of being simple in operation flow, low in cost, simple in equipment, and suitable for the scale industrial production.

Owner:SHANDONG UNIV OF SCI & TECH

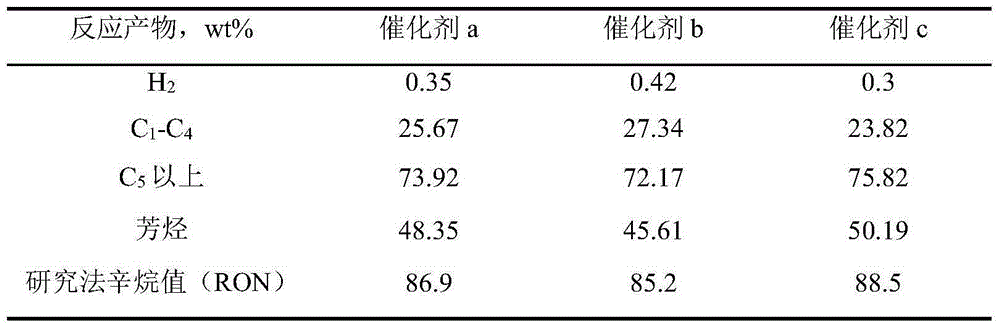

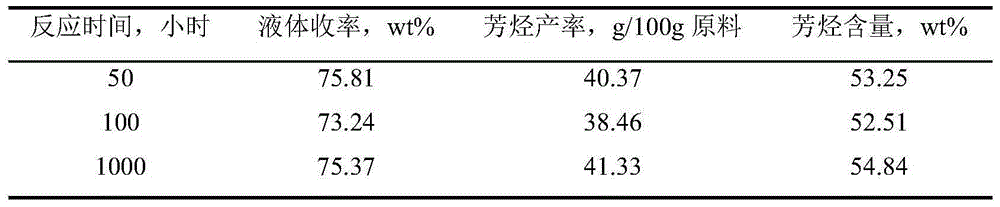

Catalyst for straight-run naphtha aromatization and preparation method thereof

InactiveCN106552663ARegular skeleton structureFast responseMolecular sieve catalystsHigher alkanesNaphtha

The invention discloses a catalyst for straight-run naphtha aromatization and a preparation method thereof. The catalyst for straight-run naphtha aromatization is prepared by modifying a nano ZSM-5 molecular sieve, preparing a carrier and preparing the catalyst. The catalyst is suitable for treating raw materials with high alkane content. And the catalyst has high catalytic activity and high arene selectivity. So the catalyst can be applied to more mild process conditions and can be applied to production of high-octane gasoline blending components and chemical raw materials like benzene, toluene, xylene, etc.

Owner:PETROCHINA CO LTD

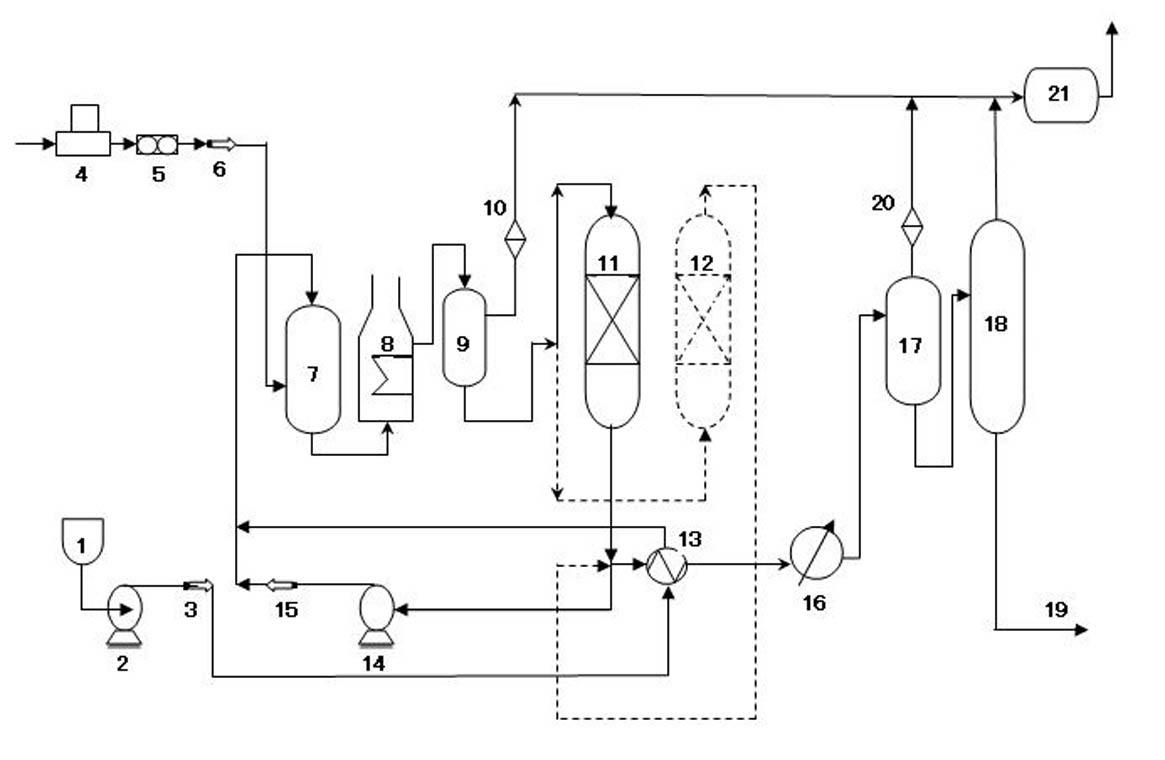

Crude benzene hydrogenation method

ActiveCN102320910AGuarantee quality requirementsInhibit cokingHydrocarbon purification/separationHydrocarbonsFluid phaseHydrogenation reaction

The invention discloses a crude benzene hydrogenation method, which comprises the steps that: crude benzene full-fractional raw materials, hydrogen and cyclic products generated through hydrogenation are fully mixed in a hydrogen mixing tank so that the hydrogen is dissolved in hydrogenation raw materials to the maximum degree; then, the crude benzene full-fractional hydrogenation raw materials with rich dissolved hydrogen enter one section of hydrogenation reactor in a full liquid phase form; and in addition, the whole hydrogenation reaction is carried out under the full liquid phase condition through controlling the pressure of a system. After the crude benzene hydrogenation method is adopted, the coking problem in the crude benzene hydrogenation process can be perfectly solved, the long-term operation of a crude benzene hydrogenation device is realized, the crude benzene full-fractional hydrogenation refining can also be realized, crude benzene is completely converted into important chemical products such as clean benzene, toluene, dimethylbenzene and the like, and the comprehensive utilization value of the crude benzene is improved. In addition, the hydrogenation reaction in the method is liquid phase reaction, the hydrogen circulation process and the adoption of a hydrogen circulation compressor are not needed, in addition, the raw material pretreatment link is omitted, and simultaneously, one section of hydrogenation reactor is used, so the energy consumption and the investment can be effectively reduced.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Process for liquid phase aromatics alkylation comprising in-situ catalyst reactivation with polar compounds

The catalyst becomes at least partially deactivated by sorbing catalyst poisons present in the feed during a process for alkylating aromatics by contacting a feed containing benzene, toluene, xylenes, alkylbenzenes, naphthalene or substituted naphthalenes under liquid phase alkylating conditions with C2-C16 olefins in the presence of MCM-22, MCM-36, MCM-49, MCM-56, ZSM-5, ZSM-11, ZSM-12, ZSM-23, ZSM-35, ZSM-48, ZSM-50, ZSM-4, ZSM-18, ZSM-20, Zeolite X, Zeolite Y, USY, mordenite or offretite to provide an alkylated aromatic product. The at least partially deactivated catalyst can be treated in situ by contacting with at least one polar compound having a dipole moment of at least 0.05 Debyes and selected from the group consisting of acetic acid, formic acid, water, and carbon monoxide, under conditions of temperature and pressure employed in the liquid phase alkylating conditions which are sufficient to at least partially desorb the catalyst poison from the catalyst.

Owner:EXXONMOBIL CORP (US)

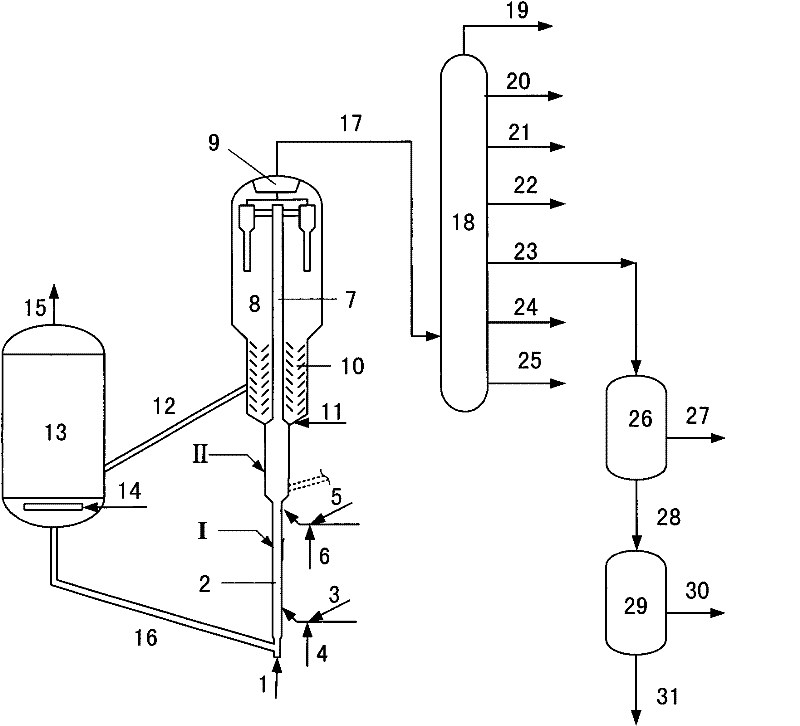

Petroleum hydrocarbon catalytic conversion method

ActiveCN102344831AHigh yieldHigh selectivityTreatment with hydrotreatment processesChemical recyclingCatalytic transformationGasoline

The invention discloses a petroleum hydrocarbon catalytic conversion method. The petroleum hydrocarbon catalytic conversion method comprises the following steps that raw oil contacts a mesoporous zeolite-rich catalyst in a first reaction zone of a reactor and undergo a cracking reaction; a reactant flow and a part of the raw oil are fed into a second reaction zone of the reactor and further undergo a cracking reaction; reaction oil gas and a catalyst needing to be regenerated are separated out, wherein the catalyst needing to be regenerated is subjected to steam stripping and burning regeneration and then is fed back to the reactor; the reaction oil gas is subjected to separation to form a desired ethane product, propylene and aromatic hydrocarbon-rich catalytic gasoline; the aromatic hydrocarbon-rich catalytic gasoline is subjected to selective hydrogenation and then is fed into a aromatic hydrocarbon extraction device to produce a desired light aromatic hydrocarbon product by separation; and the extract oil obtained by the previous step is fed back to the first reaction zone of the reactor. Through petroleum hydrocarbon catalytic conversion method, an ethene yield is 22.43 wt%; a propylene yield is 33.22 wt%; and a benzene-toluene-xylene mixture yield is 25.28 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

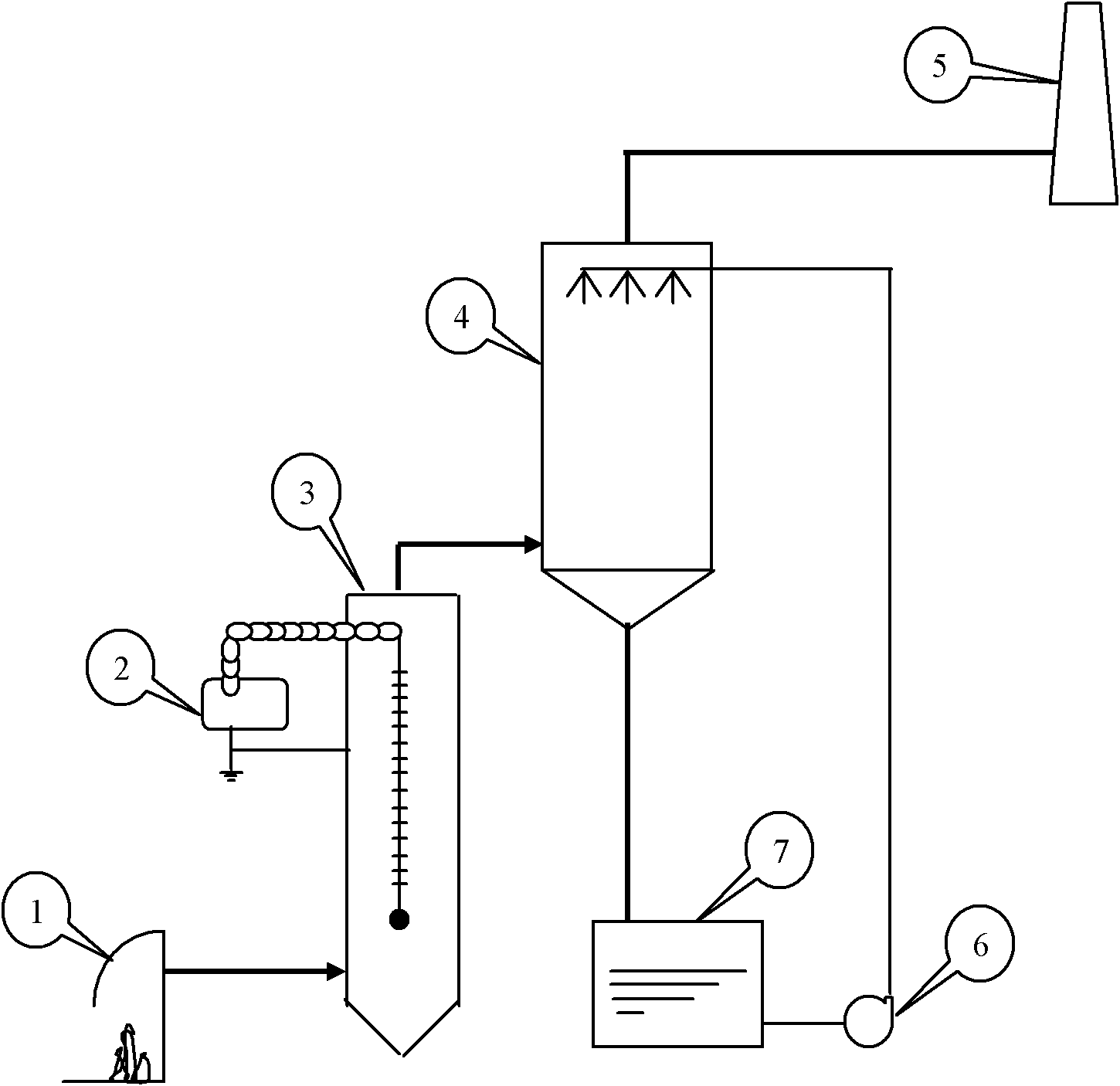

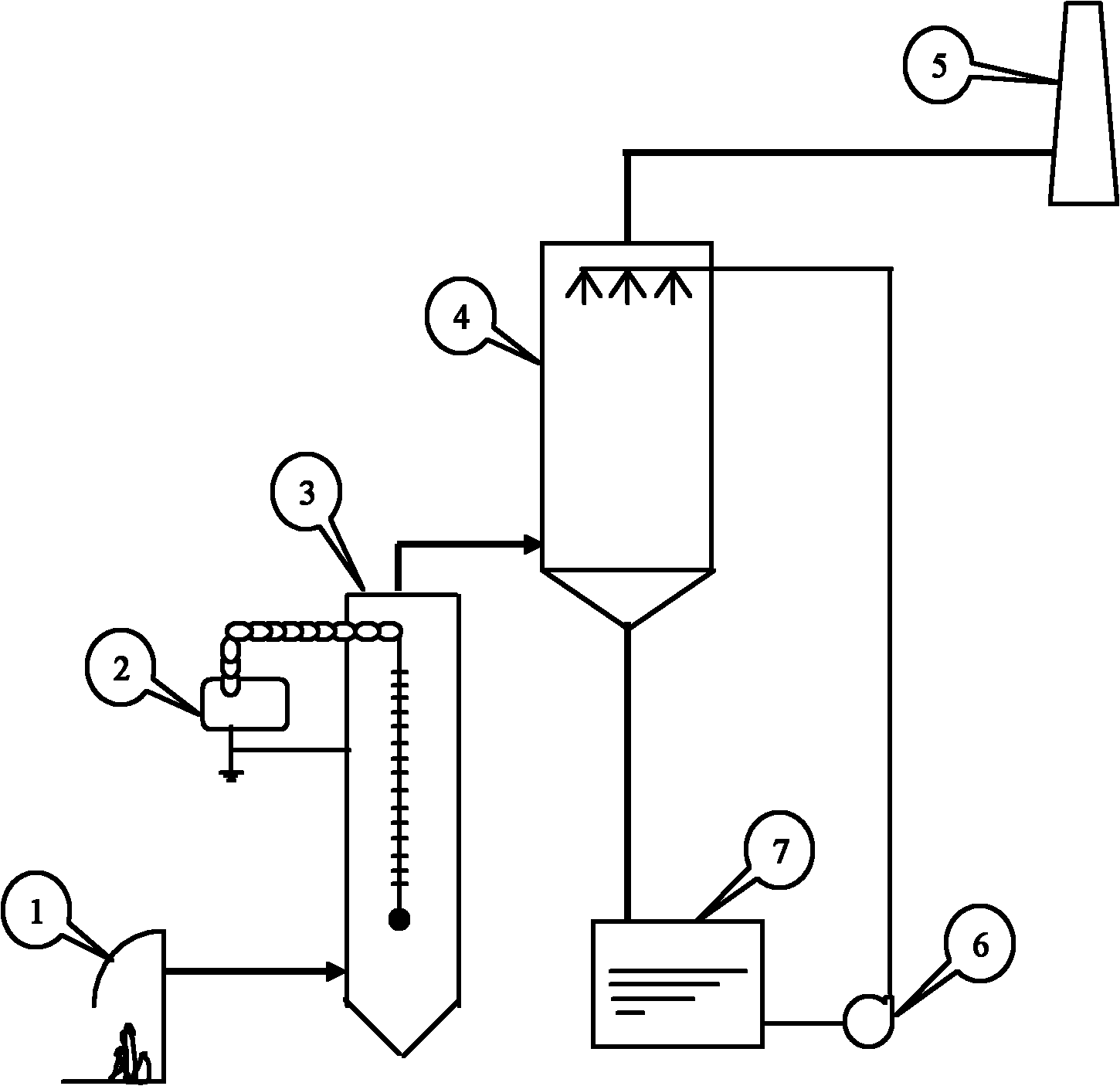

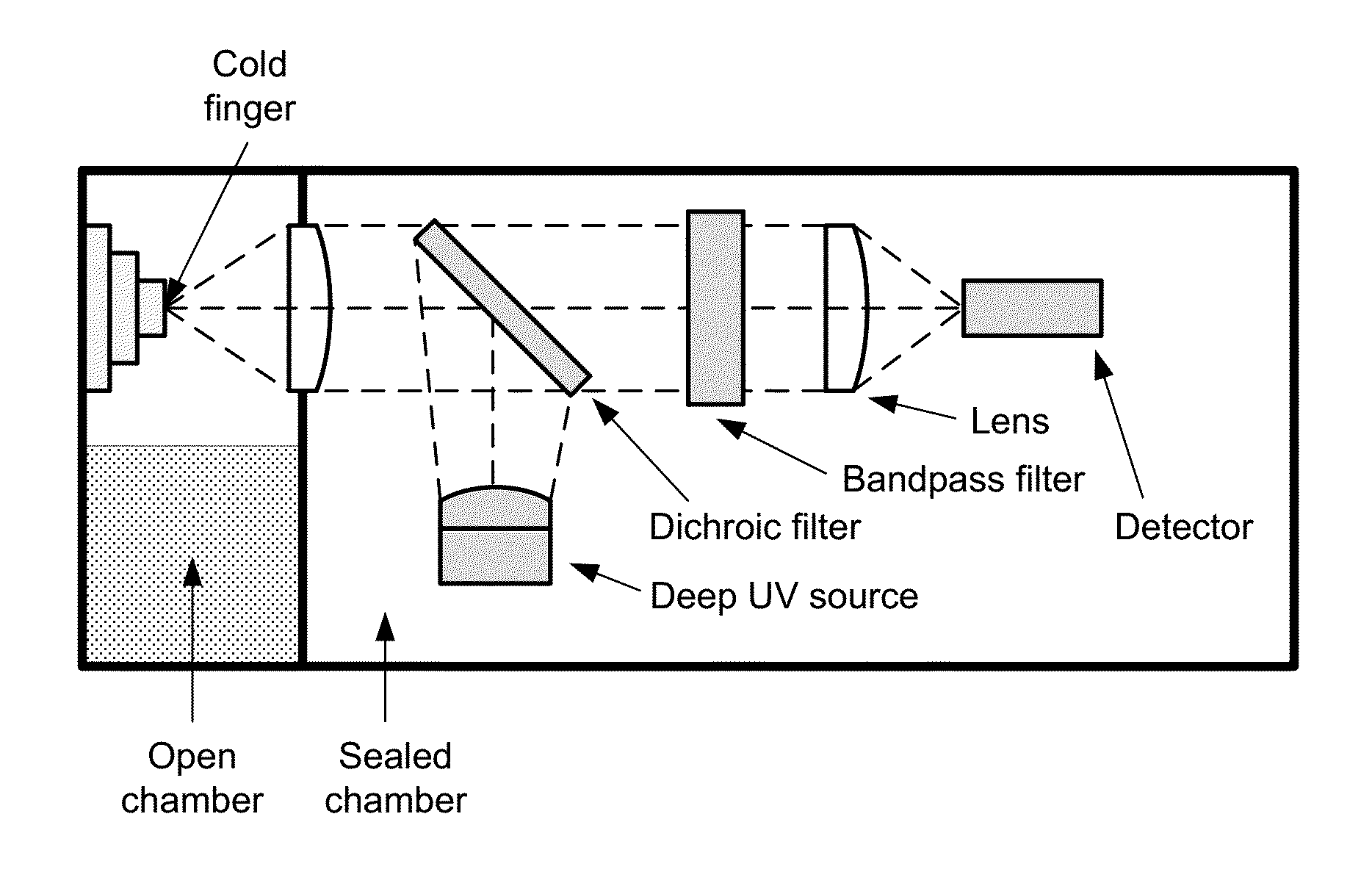

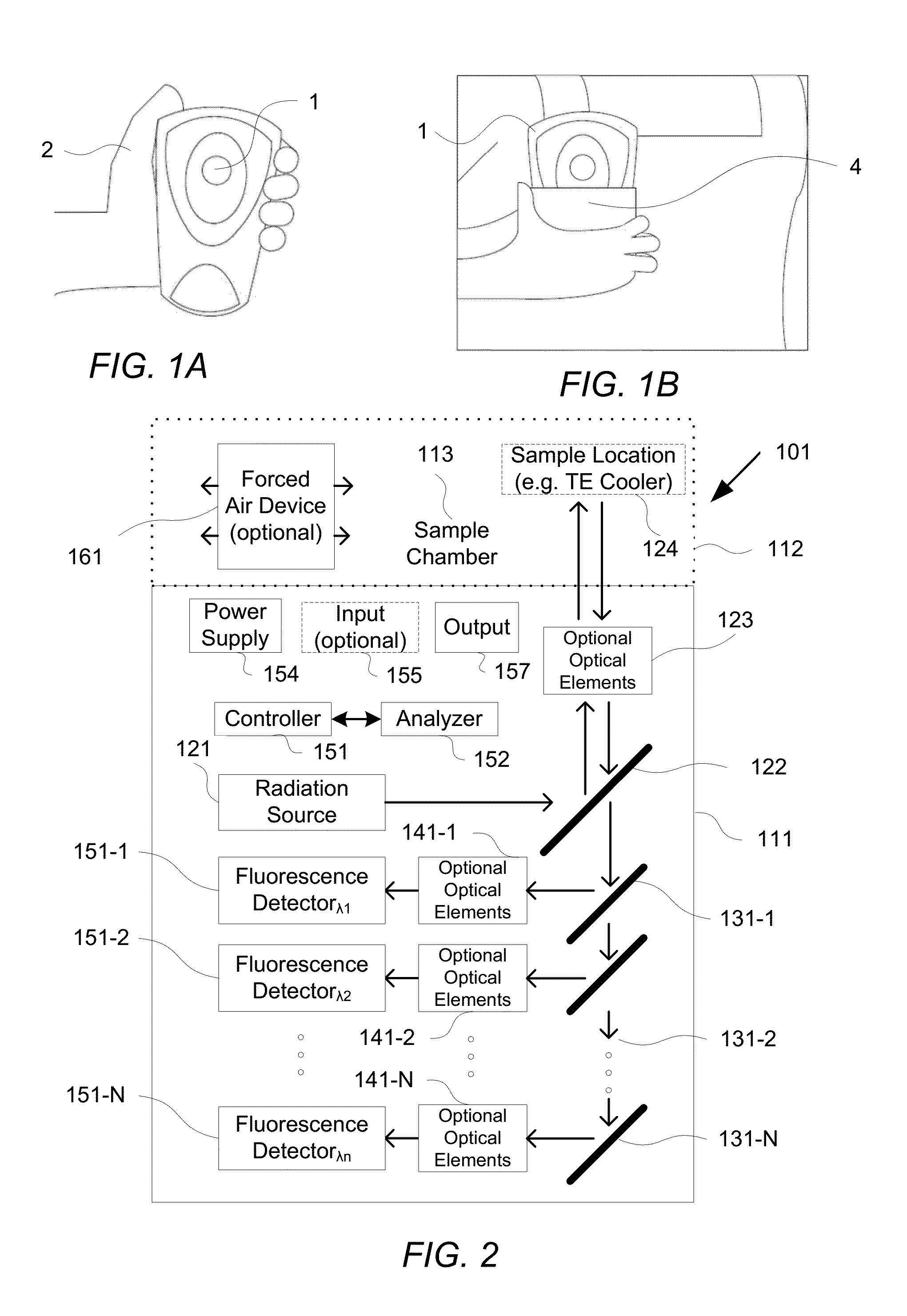

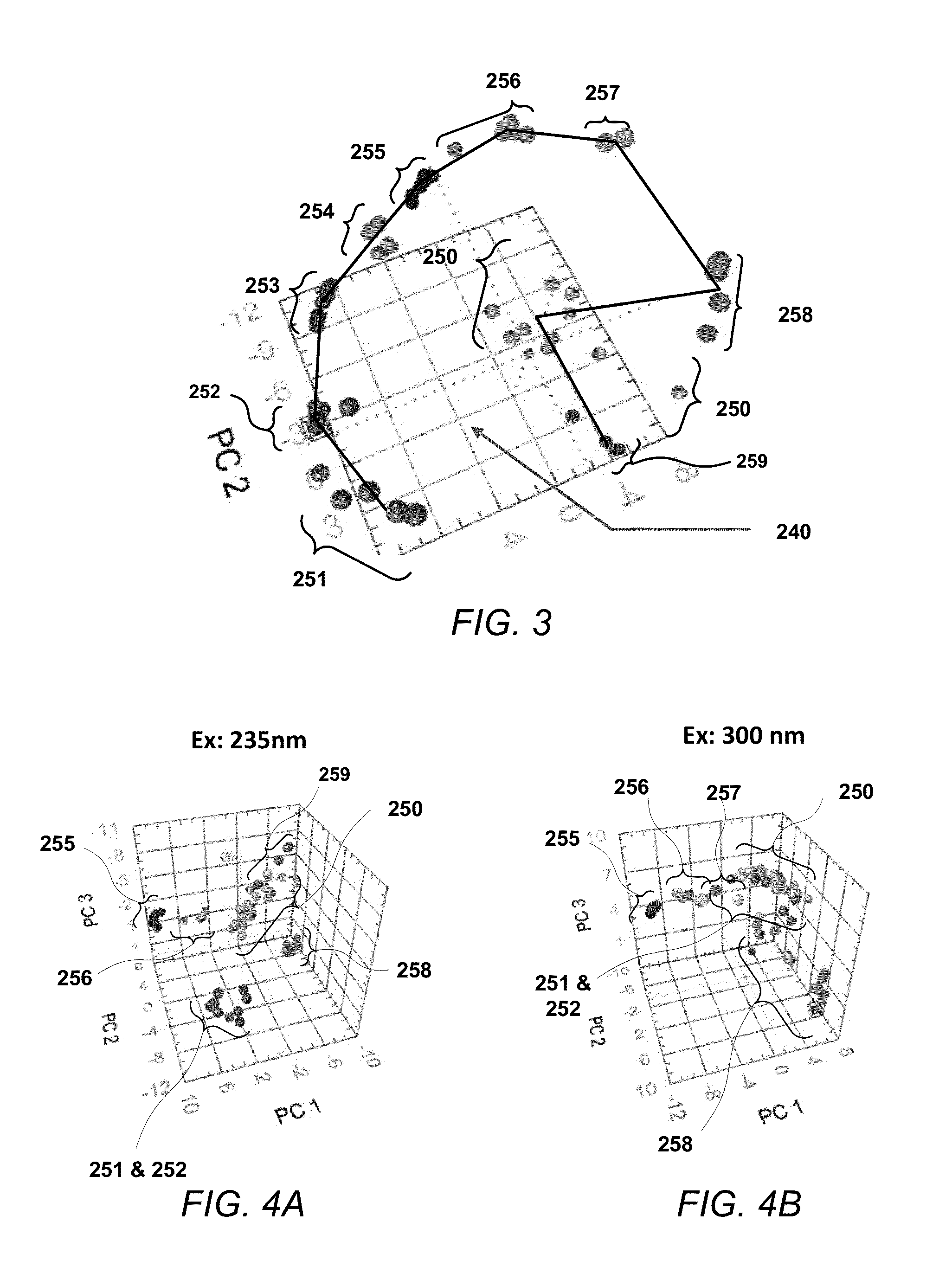

Native fluorescence detection methods, devices, and systems for organic compounds

ActiveUS9442070B1Rapid condensationRapid vaporization of VOCsSpectrum investigationMaterial analysis by electric/magnetic meansDosimeterUltraviolet

Naphthalene, benzene, toluene, xylene, and other volatile organic compounds VOCs have been identified as serious health hazards. Embodiments of the invention are directed to methods and apparatus for near-real-time in-situ detection and accumulated dose measurement of exposure to naphthalene vapor and other hazardous gaseous VOCs. The methods and apparatus employ excitation of fluorophors native or endogenous to compounds of interest using light sources emitting in the ultraviolet below 300 nm and measurement of native fluorescence emissions in distinct wavebands above the excitation wavelength. The apparatus of some embodiments are cell-phone-sized sensor / dosimeter “badges” to be worn by personnel potentially exposed to hazardous VOCs. The badge sensor of some embodiments provides both real time detection and data logging of exposure to naphthalene or other VOCs of interest from which both instantaneous and accumulated dose can be determined.

Owner:PHOTON SYST

Volatile organic waste gas treatment process and treatment equipment used in treatment process

InactiveCN105709559AReduce the content of harmful substancesLow running costGas treatmentDispersed particle separationHazardous substanceDirect combustion

The invention discloses a volatile organic waste gas treatment process and treatment equipment used in the treatment process. Deep-cool nitrogen released from a liquid nitrogen storage tank exchanges heat with organic waste gas in a first treater and a second treater, the temperature of organic waste gas can be reduced to be lower than the freezing point due to low temperature of nitrogen, the organic waste gas is attached to the inside of condensing equipment, volatile organic compounds such as benzene, methylbenzene, xylene and the like in the organic waste gas are liquefied to flow out through switching of ventilation and heating and are combusted as fuel, and the purpose of removal of harmful substances in the organic waste gas is achieved. The treatment process has the advantages as follows: 1, the investment is small, and the operation cost is low; 2, the content of harmful substances in exhausted gas is reduced, and the effect of up-to-standard release is realized; 3, in combination of direct combustion, condensed substances can be combusted without other fuel, the energy is saved, and the operation cost is effectively reduced.

Owner:惠州市盛和化工有限公司

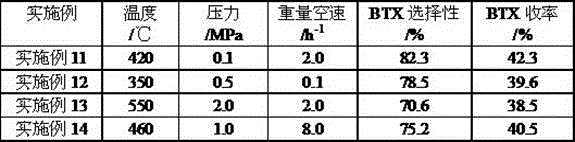

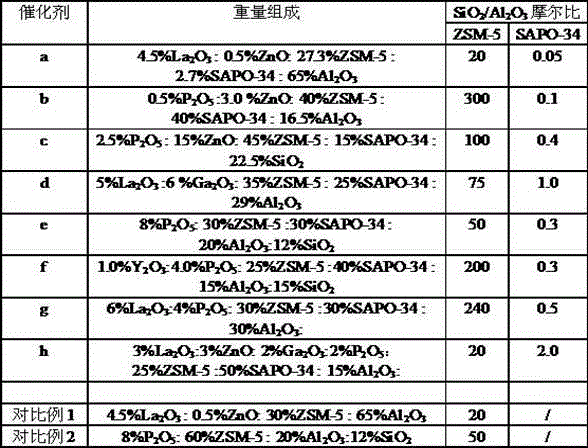

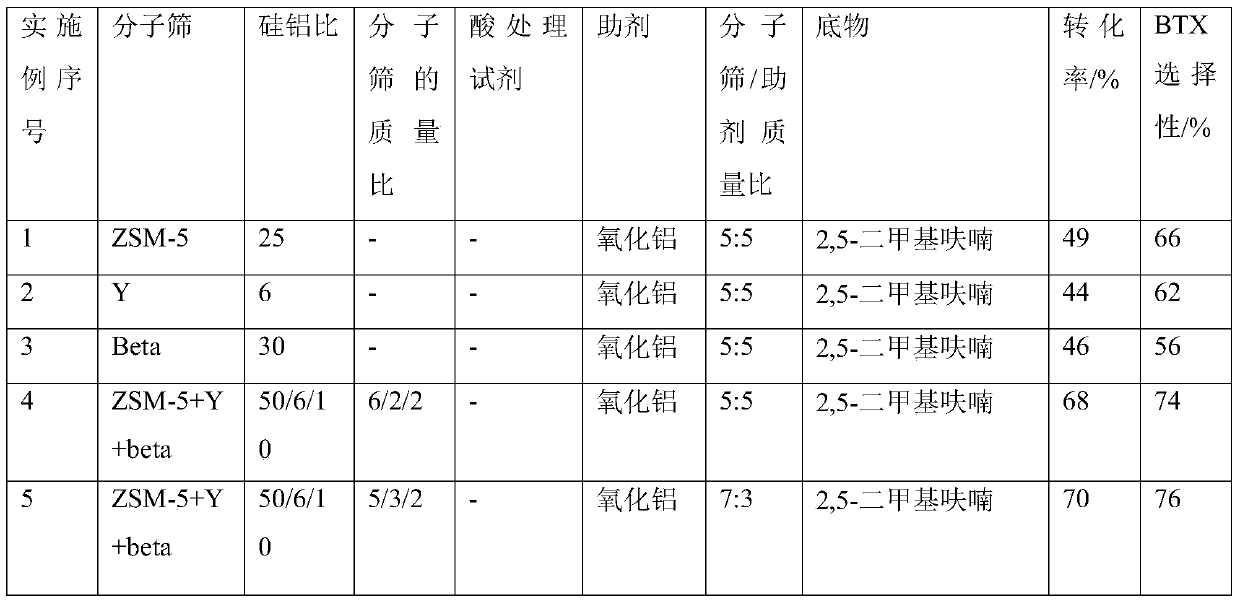

Composite molecular sieve catalyst for preparing aromatics by use of methanol

ActiveCN104549481AImprove technical effectReduced activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsSilicon oxideZSM-5

The invention relates to a composite molecular sieve catalyst for preparing aromatics by use of methanol, aiming at solving the problems that the BTX (Benzene-Toluene-Xylene) has low selectivity and the BTX has low yield when the existing catalyst is used for preparing aromatics by use of methanol. The catalyst is prepared from the following components in percentage by weight: 0.5-8% of P2O5, 0.5-15% of at least one of ZnO, Ga2O3 or MoO3, 0-6% of at least one of La2O3 or Co2O3, 30-80% of mixture of ZSM-5 molecular sieve and SAPO-34 molecular sieve, and 15-65% of at least one of aluminum oxide or silicon oxide, wherein the weight ratio of the ZSM-5 to the SAPO-34 is 10:1 to 0.5:1. The composite molecular sieve catalyst can solve the problem and can be used for industrial production for preparing aromatics by use of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

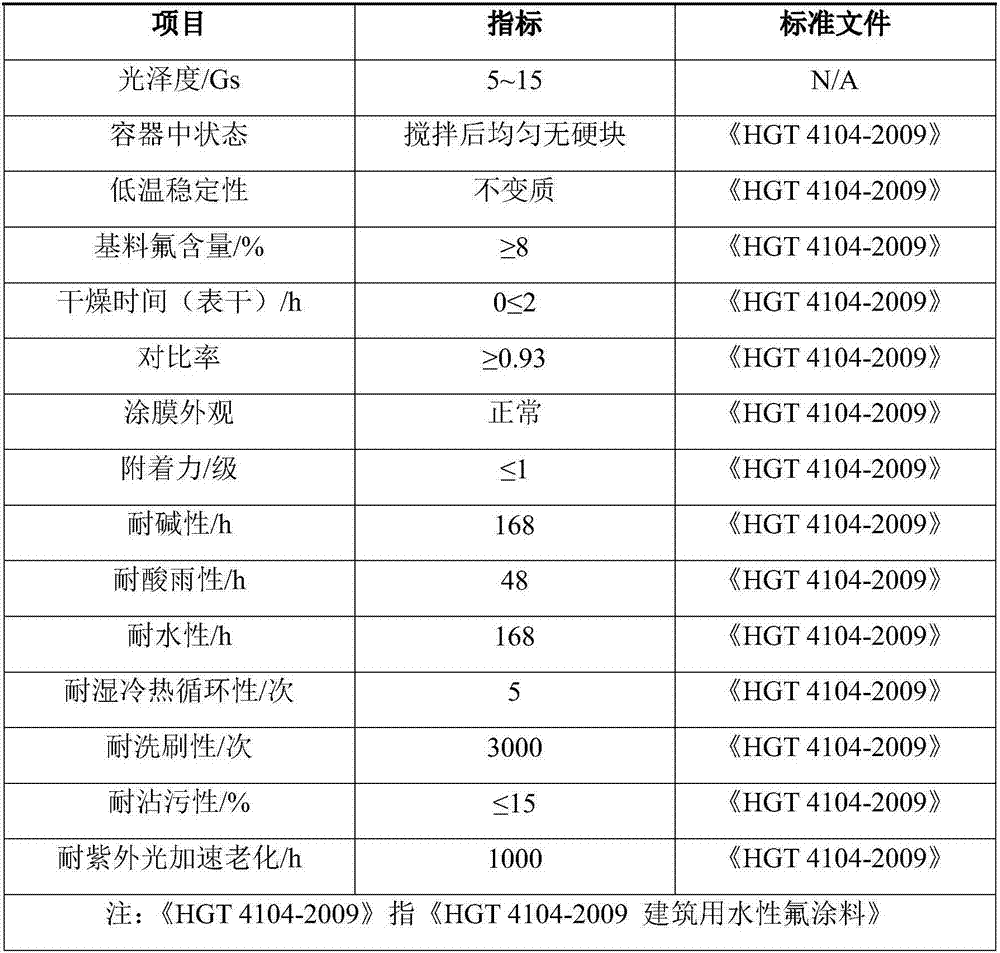

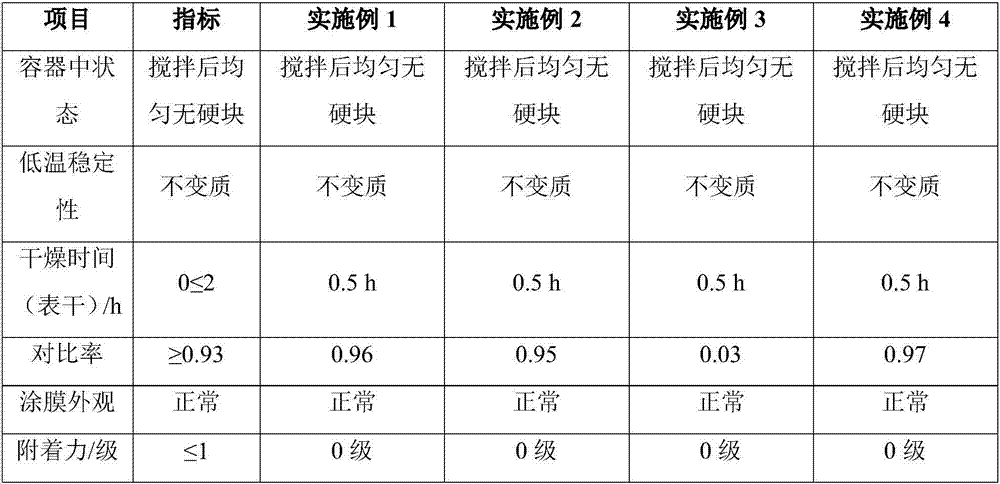

Environment-friendly FEVE (trifluorochloroethylene copolymer) fluorocarbon coating and preparation method thereof

InactiveCN106893414AImprove wear resistanceGood alkali resistanceAntifouling/underwater paintsPaints with biocidesEpoxyCopolymer

The invention particularly relates to an environment-friendly FEVE (trifluorochloroethylene copolymer) fluorocarbon coating and a preparation method thereof. The environment-friendly FEVE fluorocarbon coating is prepared from, by weight, 20-30 parts of an FEVE emulsion, 20-30 parts of epoxy-based silane modified silica sol, 1.0-2.0 parts of a coalescing agent, 0.1-1.0 part of a viscosifier, 0.2-1.0 part of a polyurethane thickening agent and 30-60 parts of color paste; the color paste is prepared from, by weight, 33% of water, 0.3% of a multifunctional agent, 0.3% of a cellulosic thickener, 0.4% of a wetting agent, 0.9% of a dispersing agent, 0.1% of a defoamer, 47% of titanium dioxide, 9% of mica powder and 9% of wollastonite powder. The environment-friendly FEVE fluorocarbon coating is free from organic solvents of benzene, methylbenzene, xylene, ethylbenzene and the like and harmful substances like free diisocyanate to human bodies and environment, excellent in alkali resistance, water resistance, aging resistance, corrosion resistance, washability, adhesive force and strain resistance and broad in market prospect.

Owner:湖南中智优库科技有限公司

Water-based coating varnish for door industry

The invention discloses a water-based coating varnish for door industry, which is prepared from the following components in percentage by mass: 60 to 80 percent of water-based resin, 6 to 12 percent of amino resin, 1 to 5 percent of flowing deformation modification assistant, 0.1 to 1 percent of wetting dispersing assistant, 2 to 6 percent of cosolvent, 8 to 20 percent of deionized water, 0.1 to 0.5 percent of antifoaming agent, 0.2 to 1.0 percent of pH regulation agent and 0.2 to 1.0 percent of flatting agent. The water-based coating varnish for door industry disclosed by the invention has the advantages of being single-component water-based stoving varnish, having no organic solvent such as benzene, toluene, xylene and the like and heavy metals, being non-flammable and non-explosive, andbelonging to environment-friendly products; the adhesive force is good, and the hardness is high; the varnish film is rich, and has high gloss; the construction performance is great and the construction requirements of door industry production can be met; the VOC (volatile organic compounds) is extremely low, and can be completely diluted by water; the product has the advantages of high performance, low cost and low pollution.

Owner:CHONGQING SANXIA PAINTS CO LTD

Method and device for hydrogenating whole-fraction medium and low-temperature coal tar to prepare mononuclear aromatics

ActiveCN106701181AThe equipment runs stablyGood product yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsEngineeringCoal tar

Owner:NORTHWEST UNIV

Macroporous crosslinked antibacterial macromolecular resin containing halamine functional group, as well as preparation and application thereof

InactiveCN105111367AImprove surface hydrophilicityThe synthesis process is green and environmentally friendlyBiocideDisinfectantsFoaming agentMacromolecule

The invention relates to a macroporous crosslinked antibacterial macromolecular resin containing a halamine functional group, as well as preparation and application thereof. According to the preparation, acrylic acid, acrylate, acrylamide and the like serving as monomers of polymerization, an amide crosslinking agent serving as a crosslinking agent of polymerization, and benzene, methylbenzene, xylene and the like serving as a pore-foaming agent perform a polymerization reaction under the action of an initiator to generate a macroporous crosslinked copolymer resin containing a halamine functional group; and the macroporous crosslinked antibacterial macromolecular resin containing a halamine functional group is generated by means of a halogenating reaction of the halamine functional group. Compared with the prior art, the antibacterial macromolecular resin has a quick, effective and broad-spectrum antibacterial effect, can be widely applied to sterilization and disinfection treatment of various water bodies and air and control of harmful unpleasant gases, and can be subjected to certain mixing treatment with other materials to prepare various sanitary antibacterial products, such as antibacterial mattress protectors, antibacterial carpets, antibacterial diapers and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of xylene by alkylation of mixed crude benzene and methanol

InactiveCN103980080ALow costReduce energy consumptionHydrocarbon by hydrocarbon and non-hydrocarbon condensationPtru catalystFluidized bed

The invention relates to a preparation method of xylene by alkylation of mixed crude benzene and methanol. The method uses mixed crude benzene and methanol in the molar ratio of 1-6:1 as raw materials, and the mixed crude benzene comprises 30-94% of benzene, 5-60% of toluene b, 1-6% of xylene, 0-10% of non-aromatic hydrocarbons and 0-10% of C9 aromatic hydrocarbons. The raw materials are subjected to an alkylation reaction in the presence of an acidic zeolite catalyst in a fixed bed or fluidized bed reactor under the conditions of reaction temperature at 360-460 DEG C, reaction pressure of 0-5.0 MPa, carrier gas of H2, H2O steam or CO2, so as to prepare xylene. This method can utilize coking-source benzene with surplus capacity and cheap methanol to produce xylene with high industrial added value, greatly reduces the production cost of raw materials, reduces the energy consumption and material consumption, and significantly improves the economic and social benefits of xylene production by alkylation of benzene and methanol.

Owner:TONGJI UNIV

Method for efficient preparation of biomass based aromatic hydrocarbon

ActiveCN105498827AHigh structural efficiencyLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsFuranMolecular sieve

The invention relates to a method for efficient preparation of biomass based aromatic hydrocarbon, and mainly solves the problem of low aromatization efficiency in the process of preparing aromatic hydrocarbon from biomass based furan derivatives. According to a technical scheme, a multicomponent composite molecular sieve with synergistic effect is employed for aromatization of a furan compound, the reaction temperature is 300-800DEG C, the hydrogen pressure is 0.1-5MPa, and the weight space velocity is 0.3-10h<-1>. Catalytic aromatization is carried out on the furan compound to perform high selectivity preparation of benzene, toluene, xylene and other aromatic compounds, the raw material conversion rate and the selectivity of benzene, toluene and xylene all reach more than 80%. Through the synergistic effect of the molecular sieve in the catalyst, the method improves the aromatization efficiency of the furan compound, well solves the problem of low efficiency in preparation of benzene, toluene and xylene from biomass based furan compounds, and can be used for the field of preparation of aromatic hydrocarbon from non-fossil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

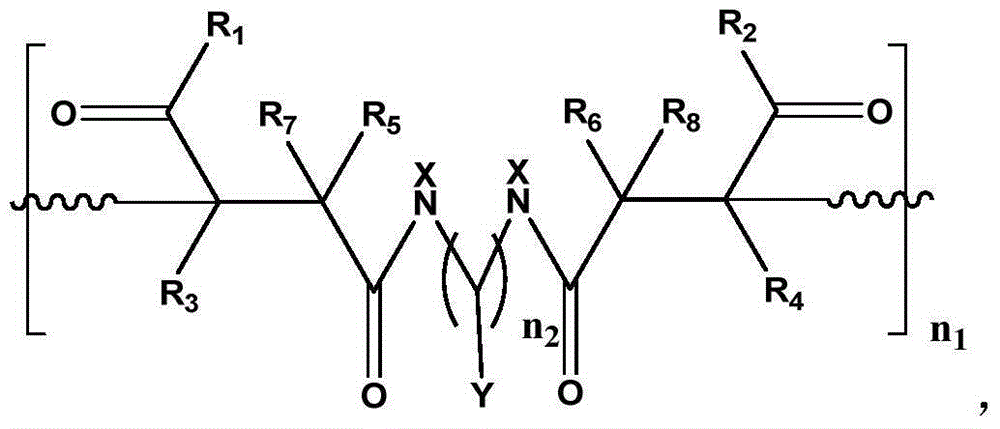

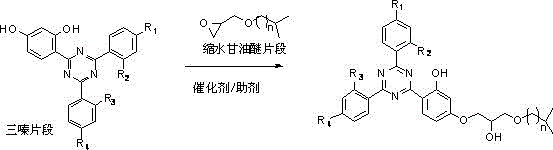

Long-branched-carbon-chain triazine ultraviolet absorbent compound and preparation method thereof

The invention provides a long-branched-carbon-chain triazine ultraviolet absorbent compound and a preparation method thereof. The reaction of the preparation method is as shown in the specification, wherein n is 10-15, R1 is H or CH3, R2 is H or CH3, R3 is H or CH3 and R4 is H or CH3. A synthesizing method of the long-branched-carbon-chain triazine ultraviolet absorbent compound includes: dissolving triazine fragments into an organic solvent such as benzene, toluene, xylene, tetrahydrofuran and 1, 2-dichlorobenzene; adding C13-C18 long-branched-carbon-chain glycidyl ether, adding a catalyst such as iodine and potassium iodide, and adding a cocatalyst such as 18-crown-6, PEG400, tetrabutyl ammonium bromide, tetrabutyl ammonium chloride and benzyl triethyl ammonium chloride; slowly heating to 60-140 DEG C, keeping the reaction for 12-24 hours; cooling after the reaction, washing with water, concentrating and crystalizing to obtain the long-branched-carbon-chain triazine ultraviolet absorbent compound. The long-branched-carbon-chain triazine ultraviolet absorbent compound is novel in structure, simple in preparation operation and extremely high in commercial application value.

Owner:郑绍军 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com