Patents

Literature

138results about How to "Rapid condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

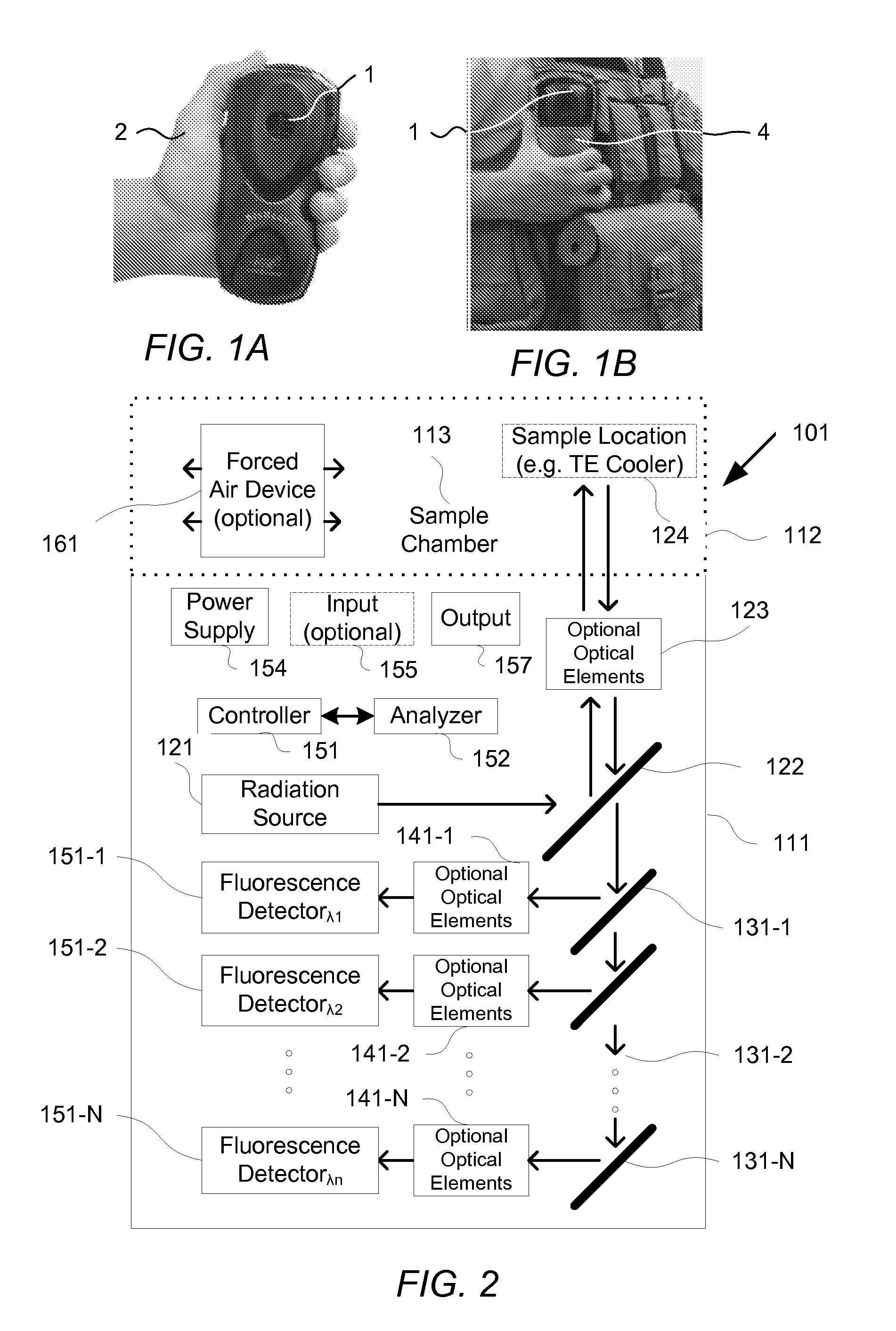

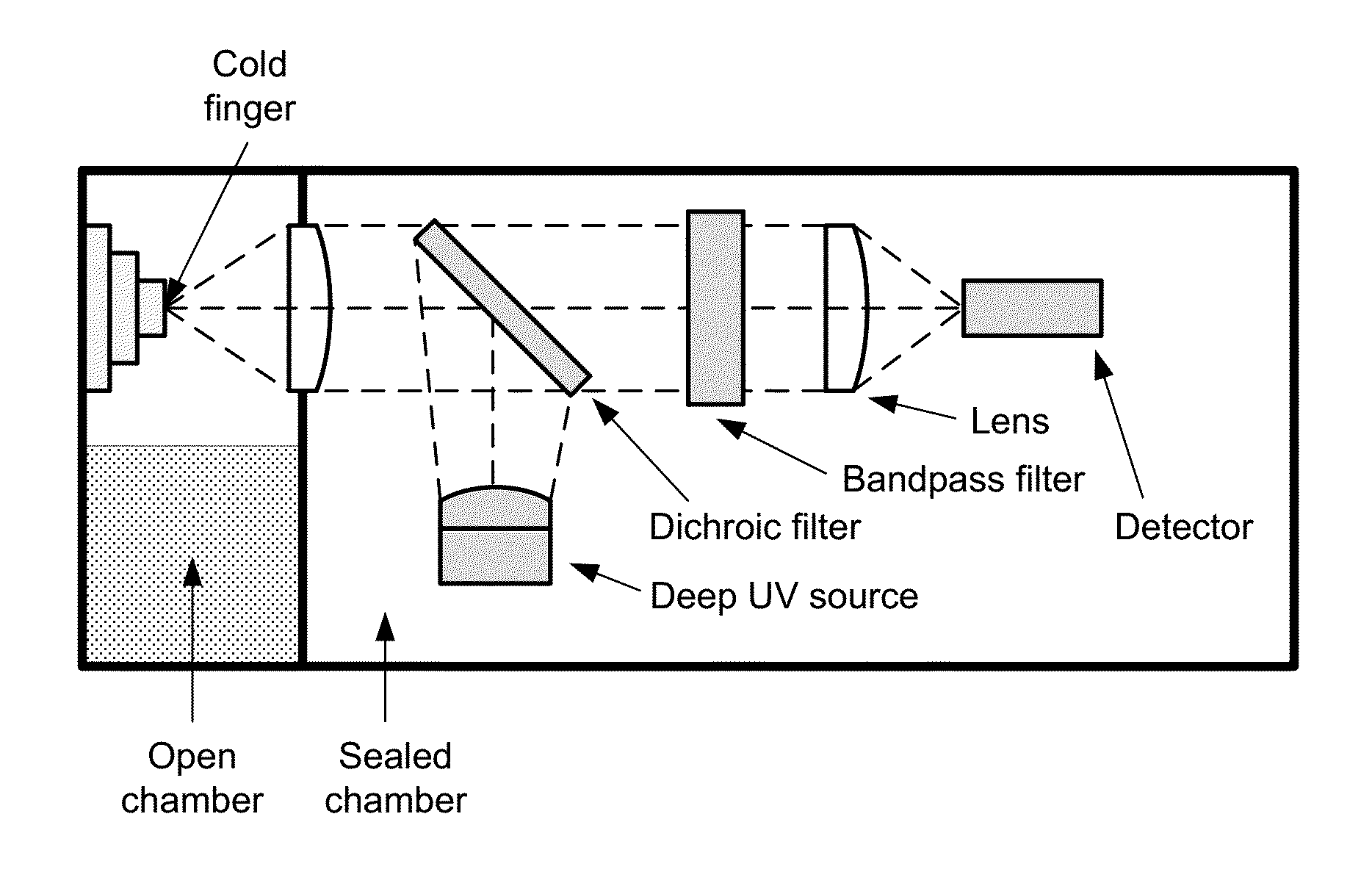

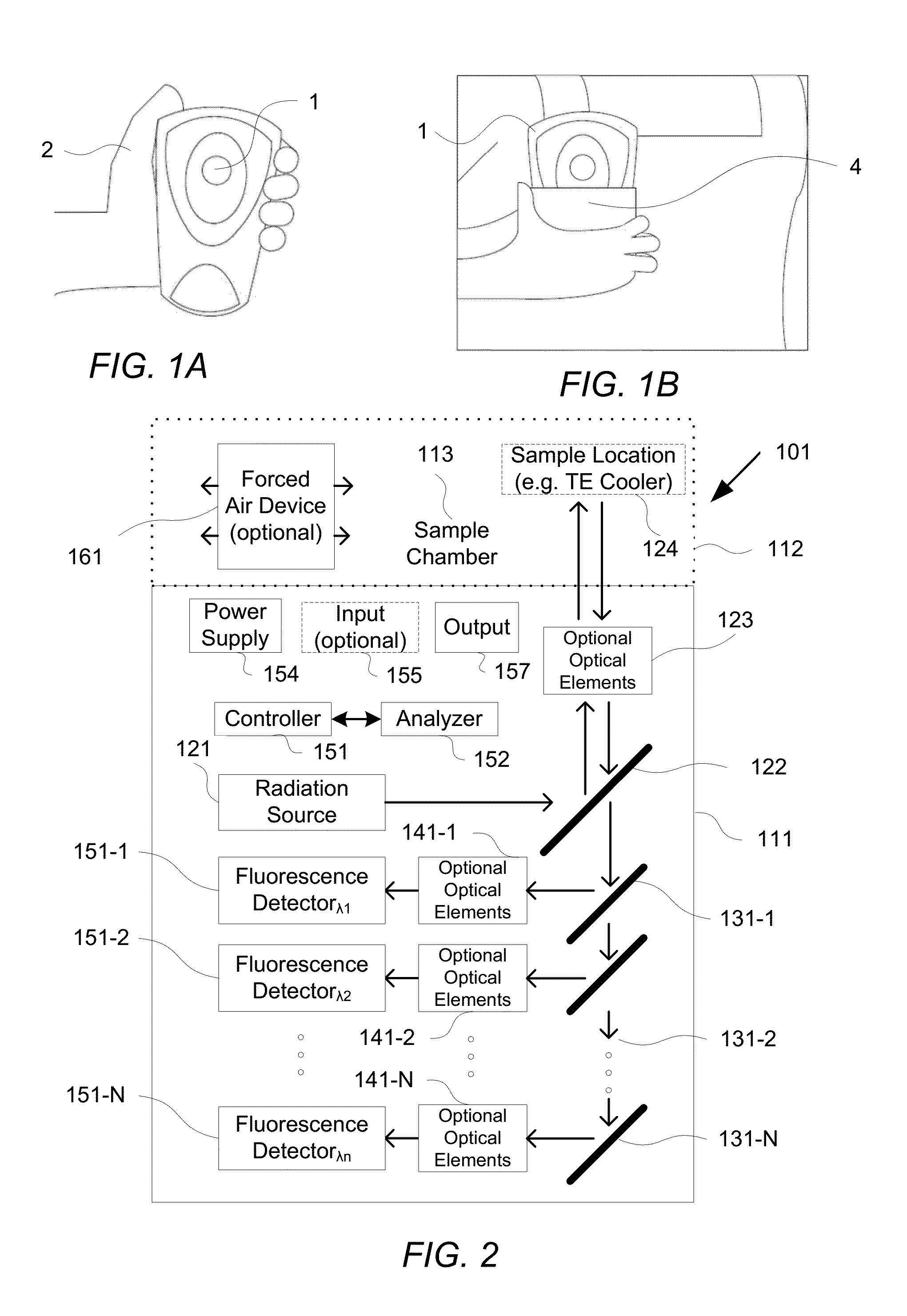

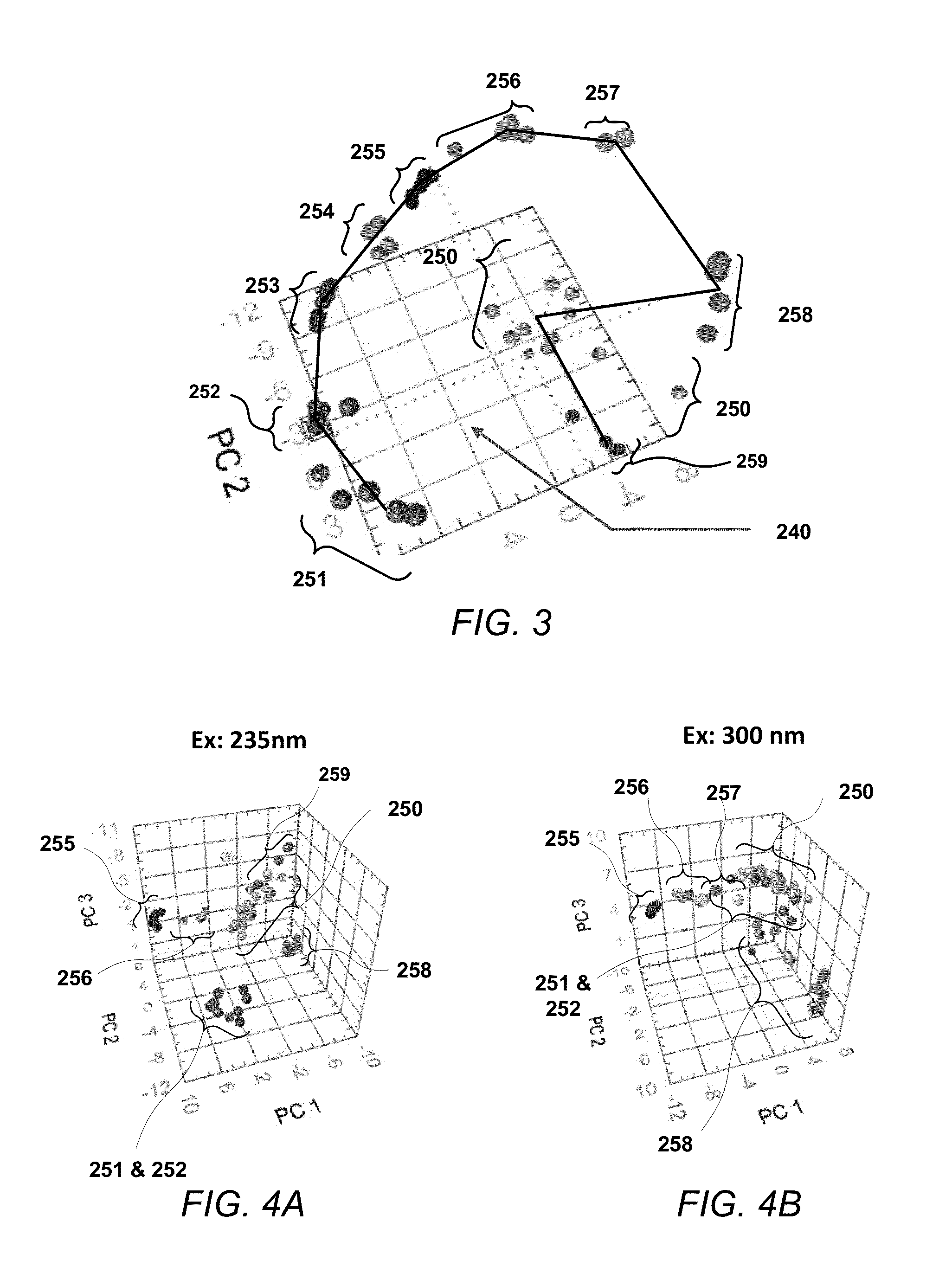

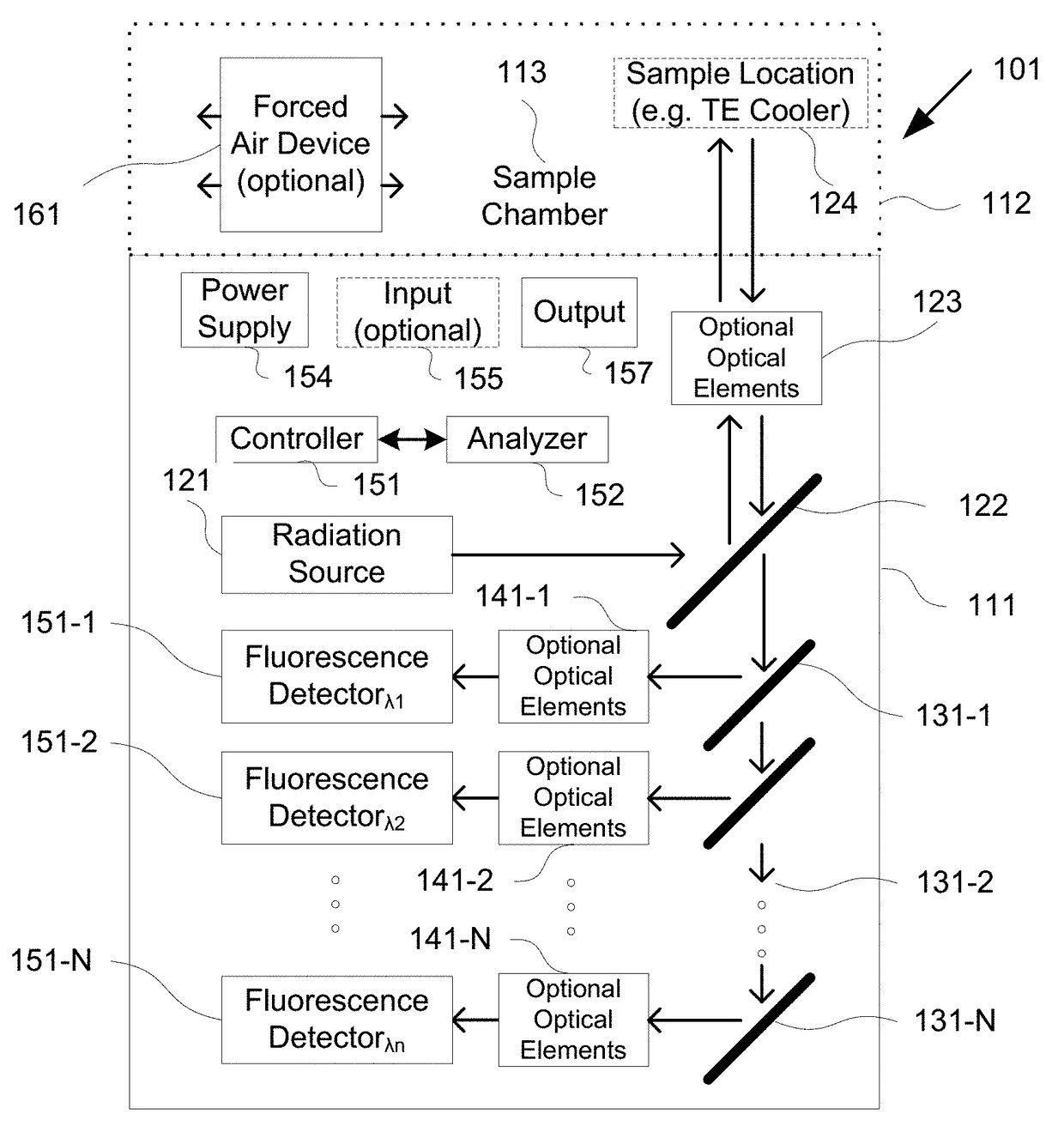

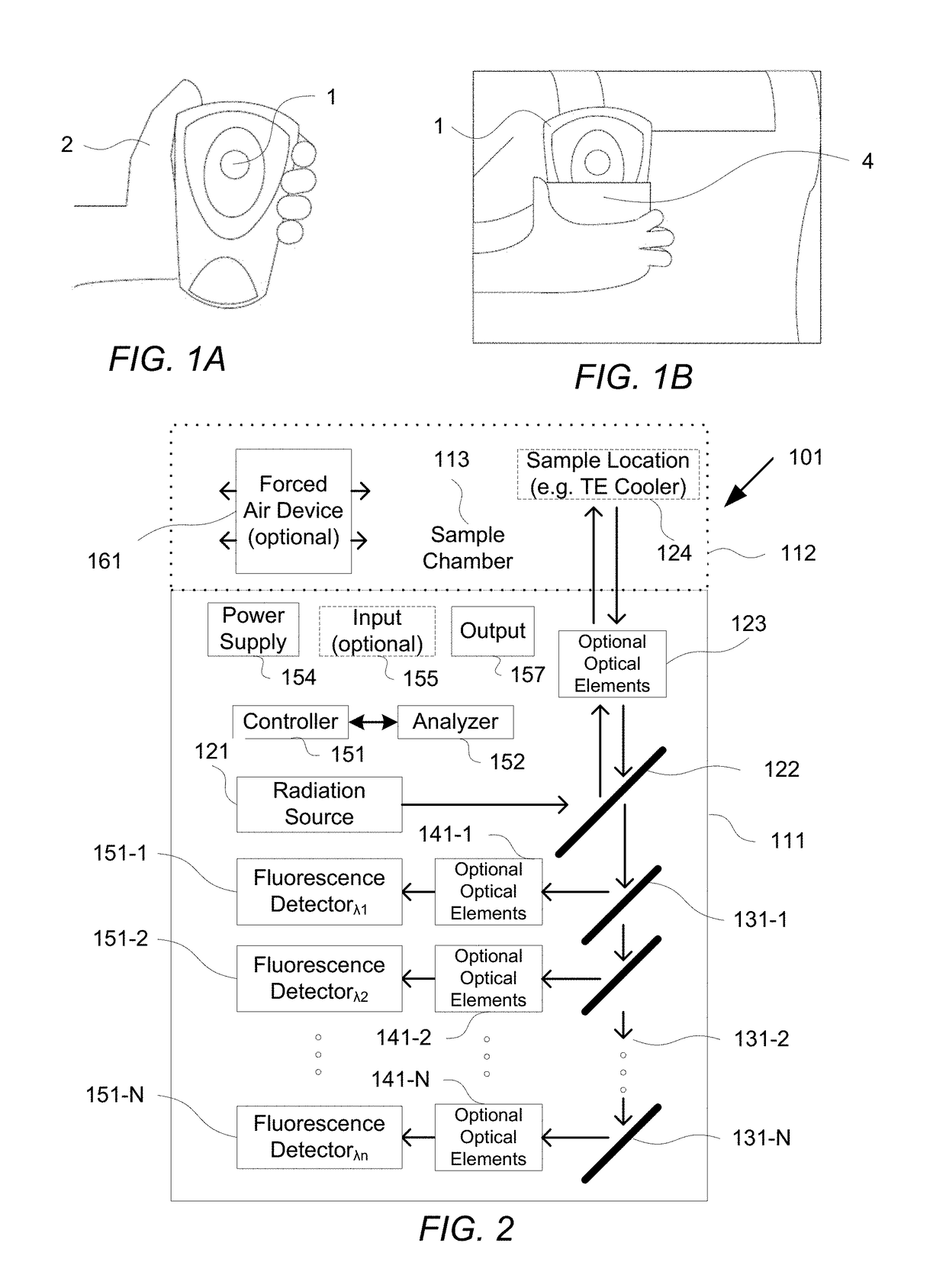

Native fluorescence detection methods and detectors for naphthalene and/or other volatile organic compound vapors

ActiveUS8759791B1Rapid condensationRapid vaporization of VOCsTime-of-flight spectrometersSpectrum investigationDosimeterUltraviolet

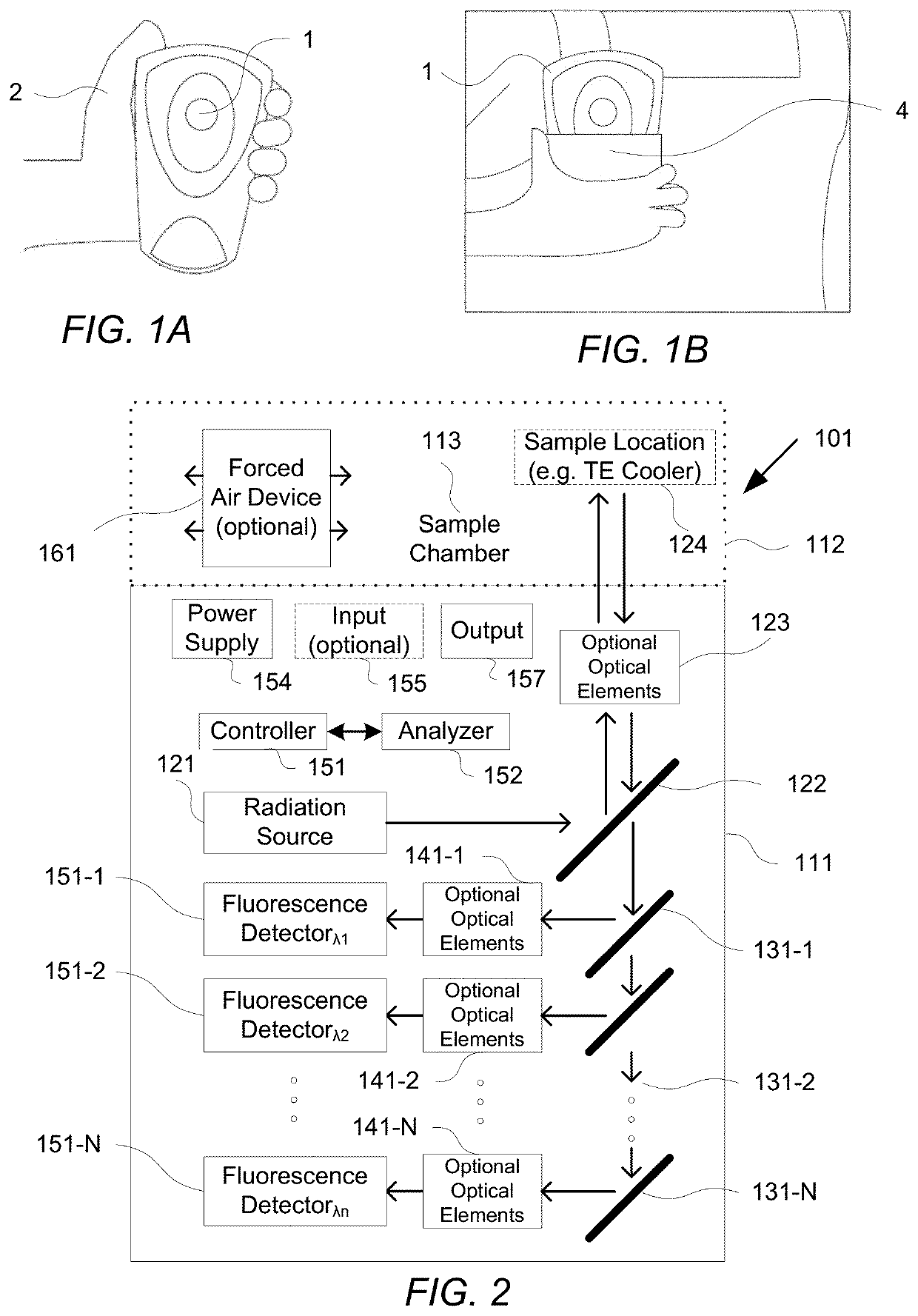

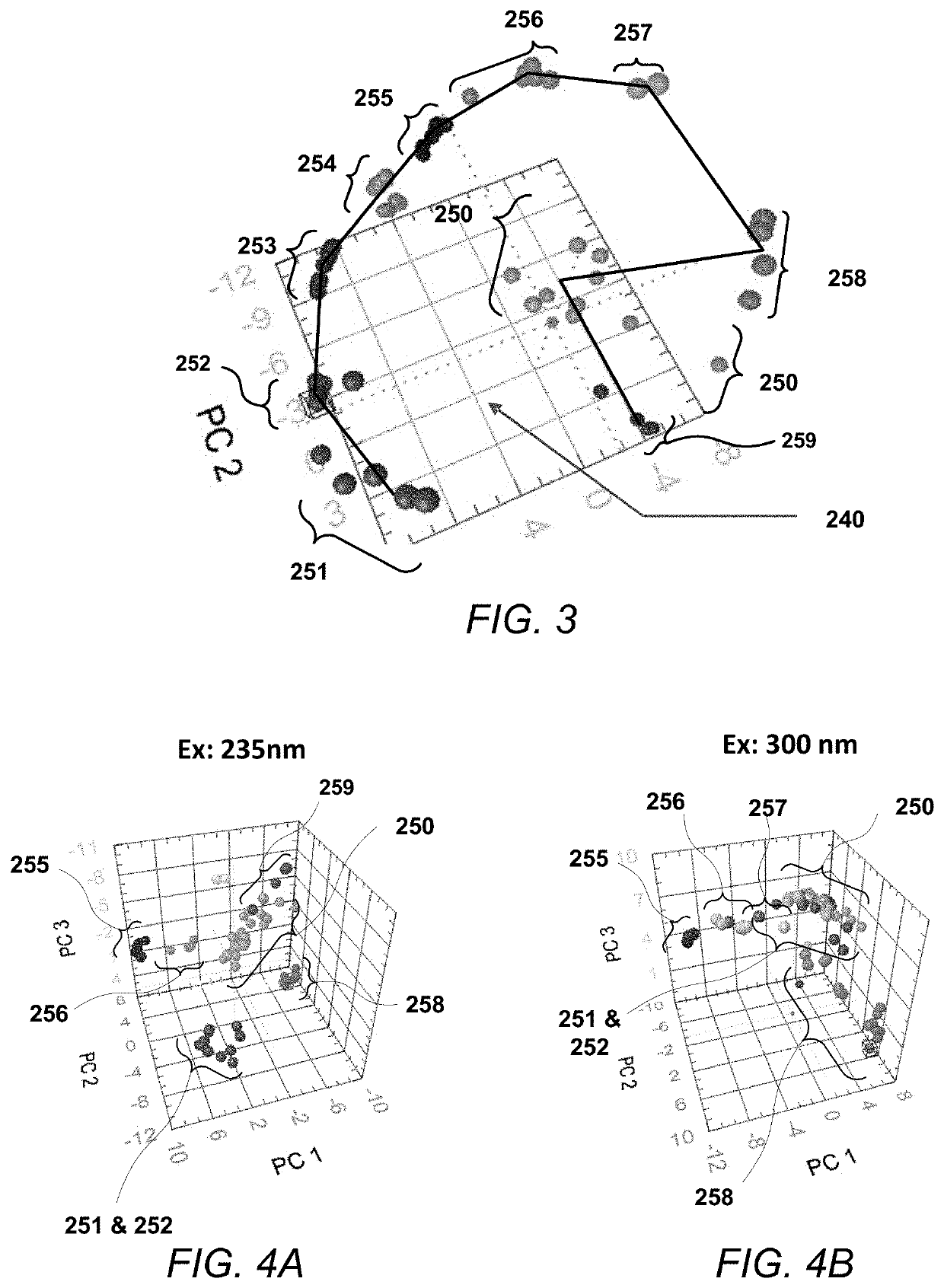

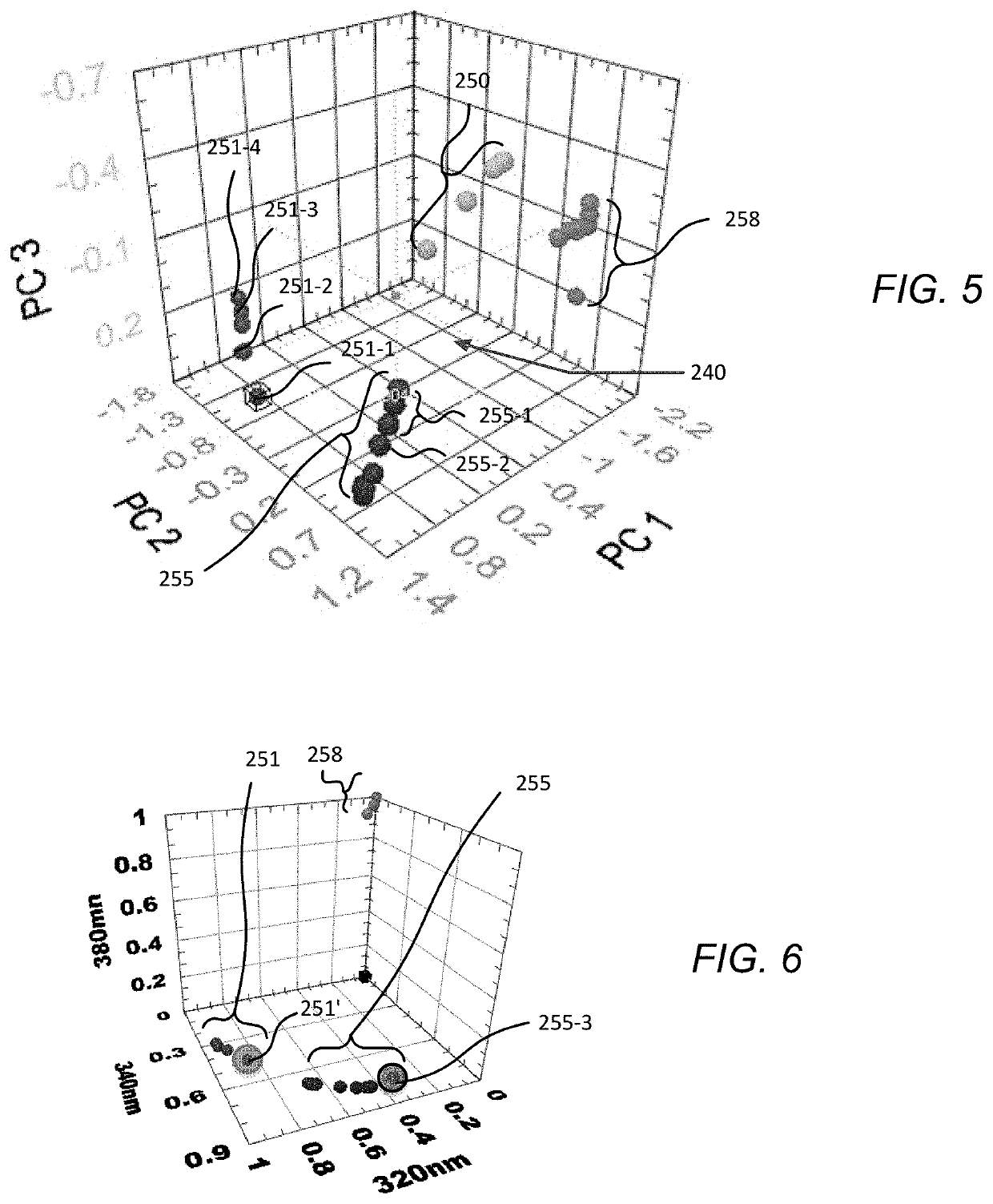

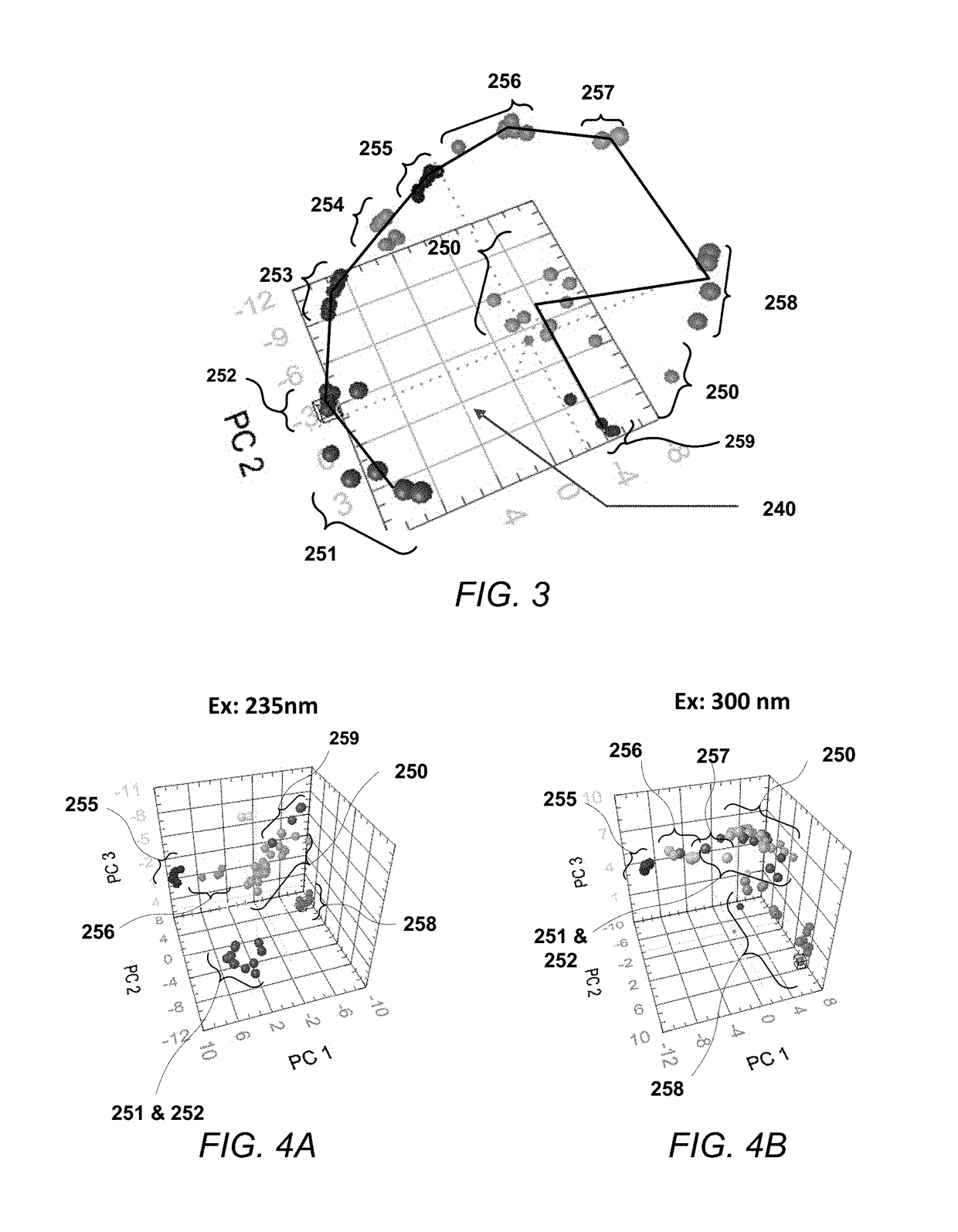

Naphthalene, benzene, toluene, xylene, and other volatile organic compounds have been identified as serious health hazards. This is especially true for personnel working with JP8 jet fuel and other fuels containing naphthalene as well as other hazardous volatile organic compounds (VOCs). Embodiments of the invention are directed to methods and apparatus for near-real-time in-situ detection and accumulated dose measurement of exposure to naphthalene vapor and other hazardous gaseous VOCs. The methods and apparatus employ excitation of fluorophors native or endogenous to compounds of interest using light sources emitting in the ultraviolet below 300 nm and measurement of native fluorescence emissions in distinct wavebands above the excitation wavelength. The apparatus of some embodiments are cell-phone-sized sensor / dosimeter “badges” to be worn by personnel potentially exposed to naphthalene or other hazardous VOCs. The badge sensor of some embodiments provides both real time detection and data logging of exposure to naphthalene or other VOCs of interest from which both instantaneous and accumulated dose can be determined. The badges employ a new native fluorescence based detection method to identify and differentiate VOCs. The particular focus of some embodiments are the detection and identification of naphthalene while other embodiments are directed to detection and identification of other VOCs like aromatic hydrocarbons such as benzene, toluene, and xylene.

Owner:PHOTON SYST

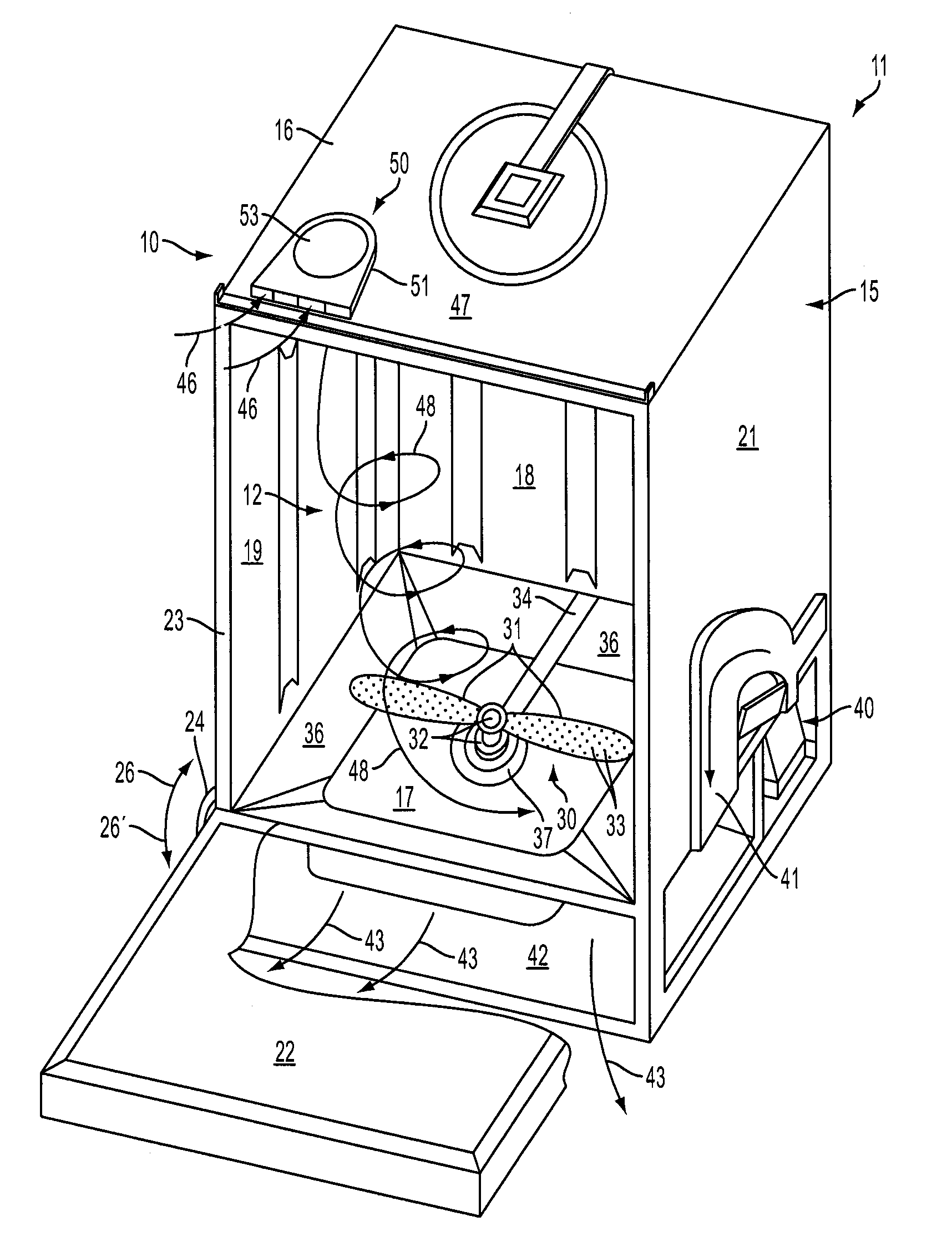

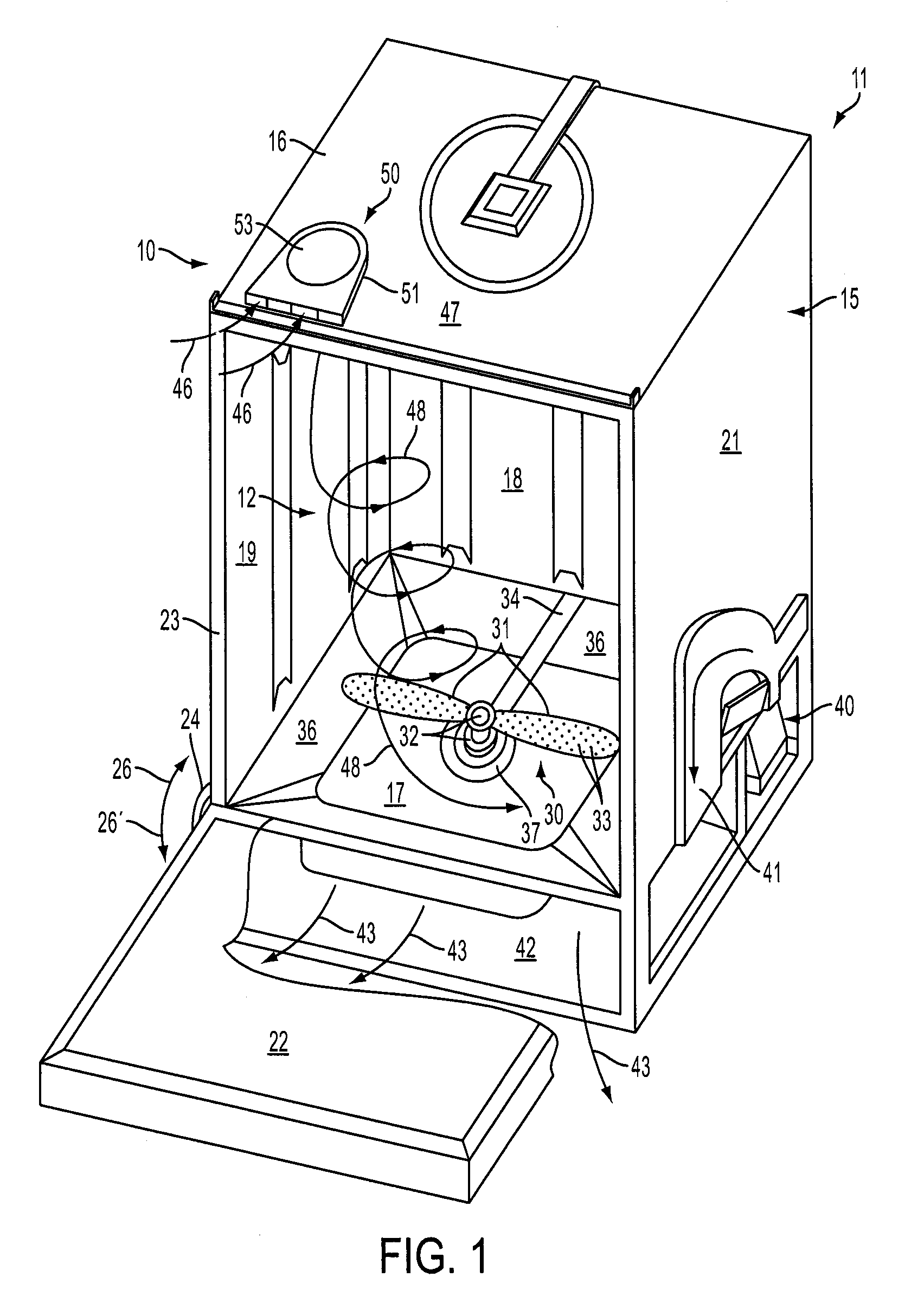

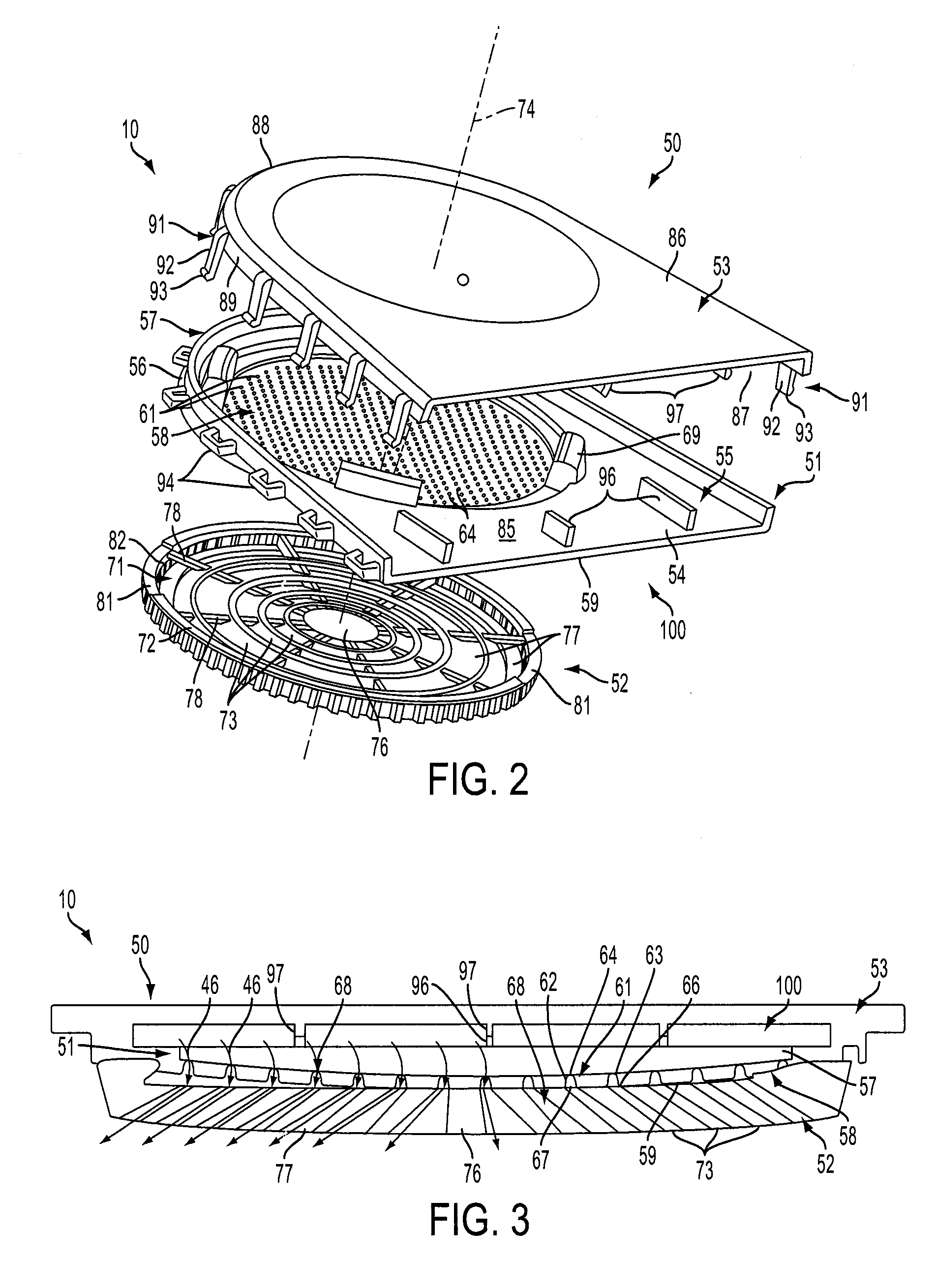

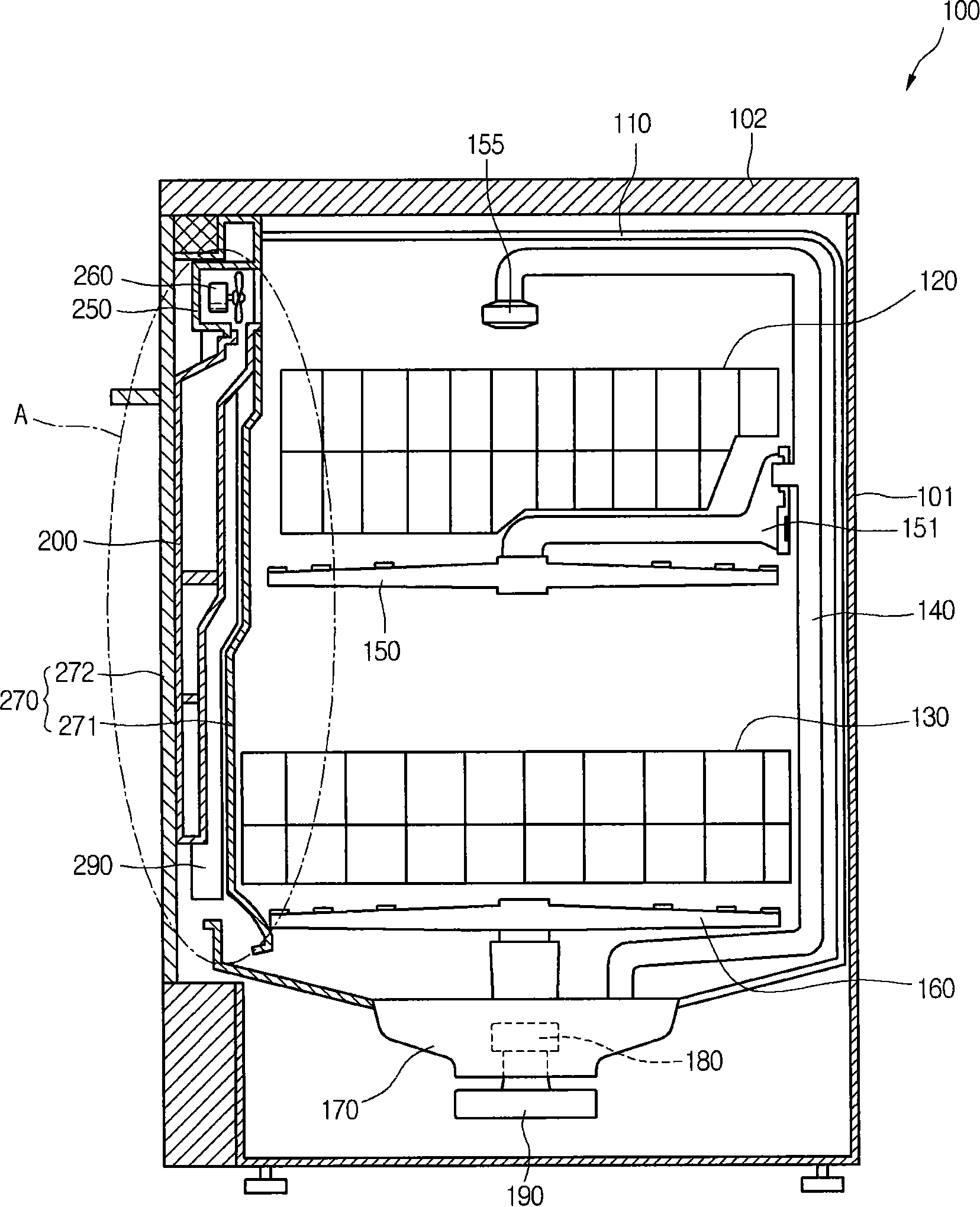

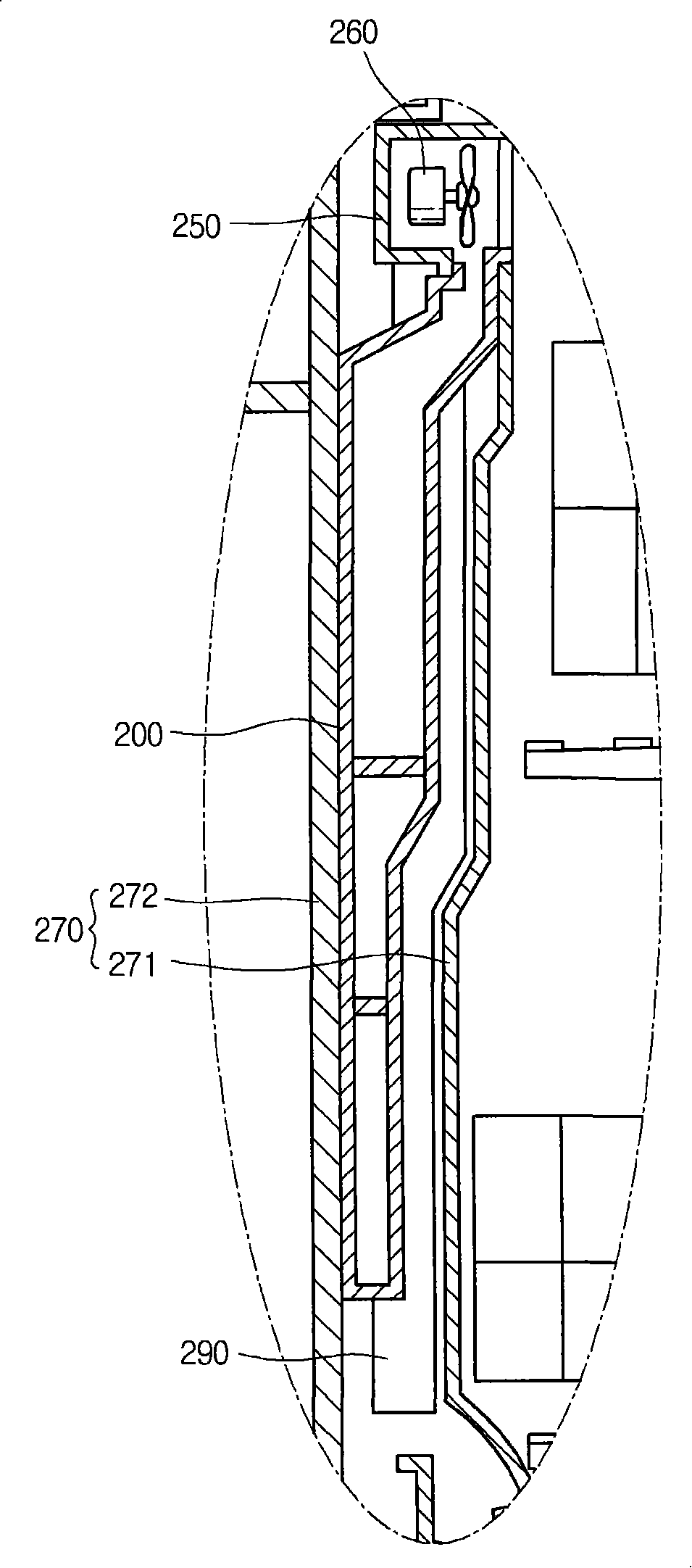

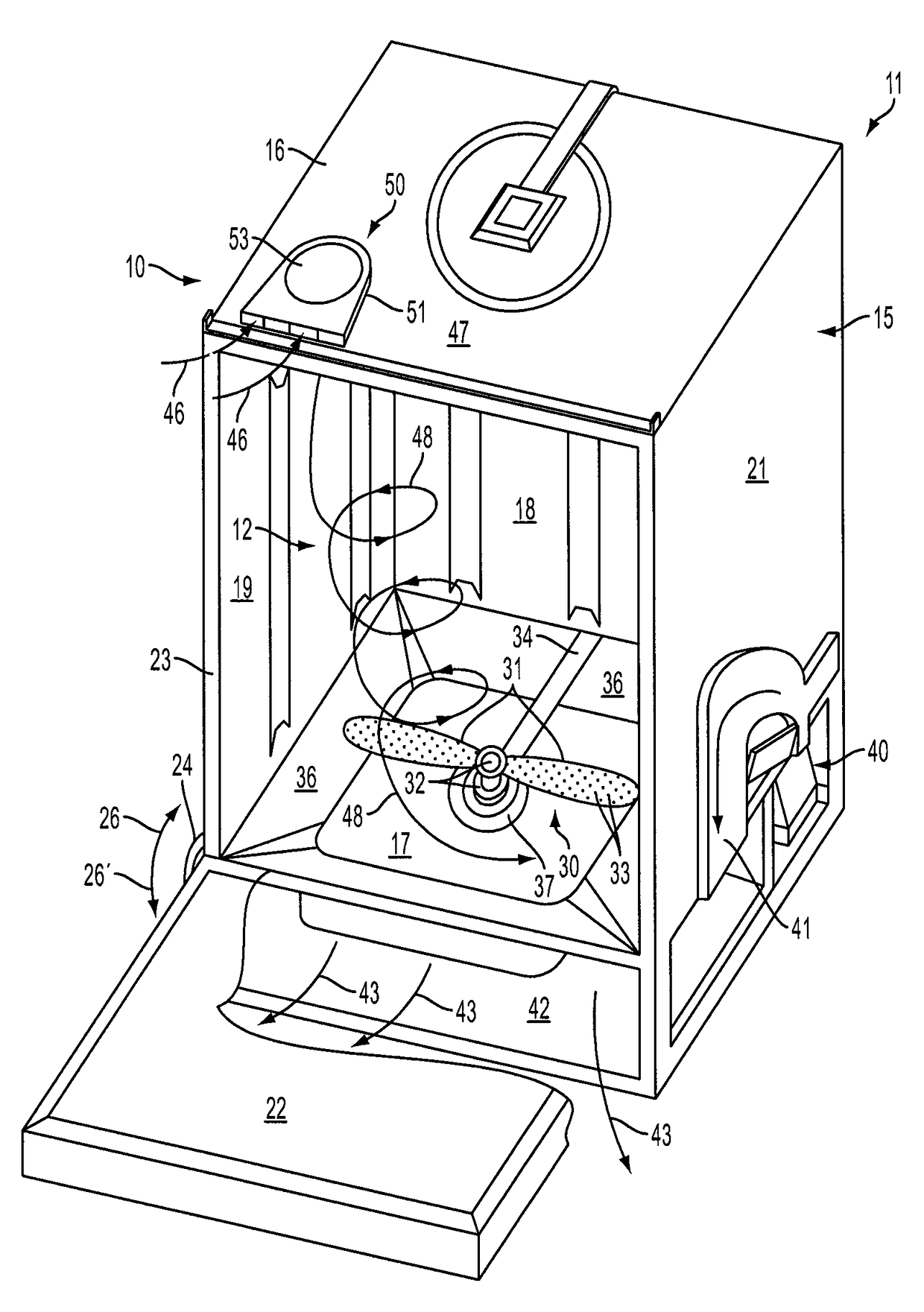

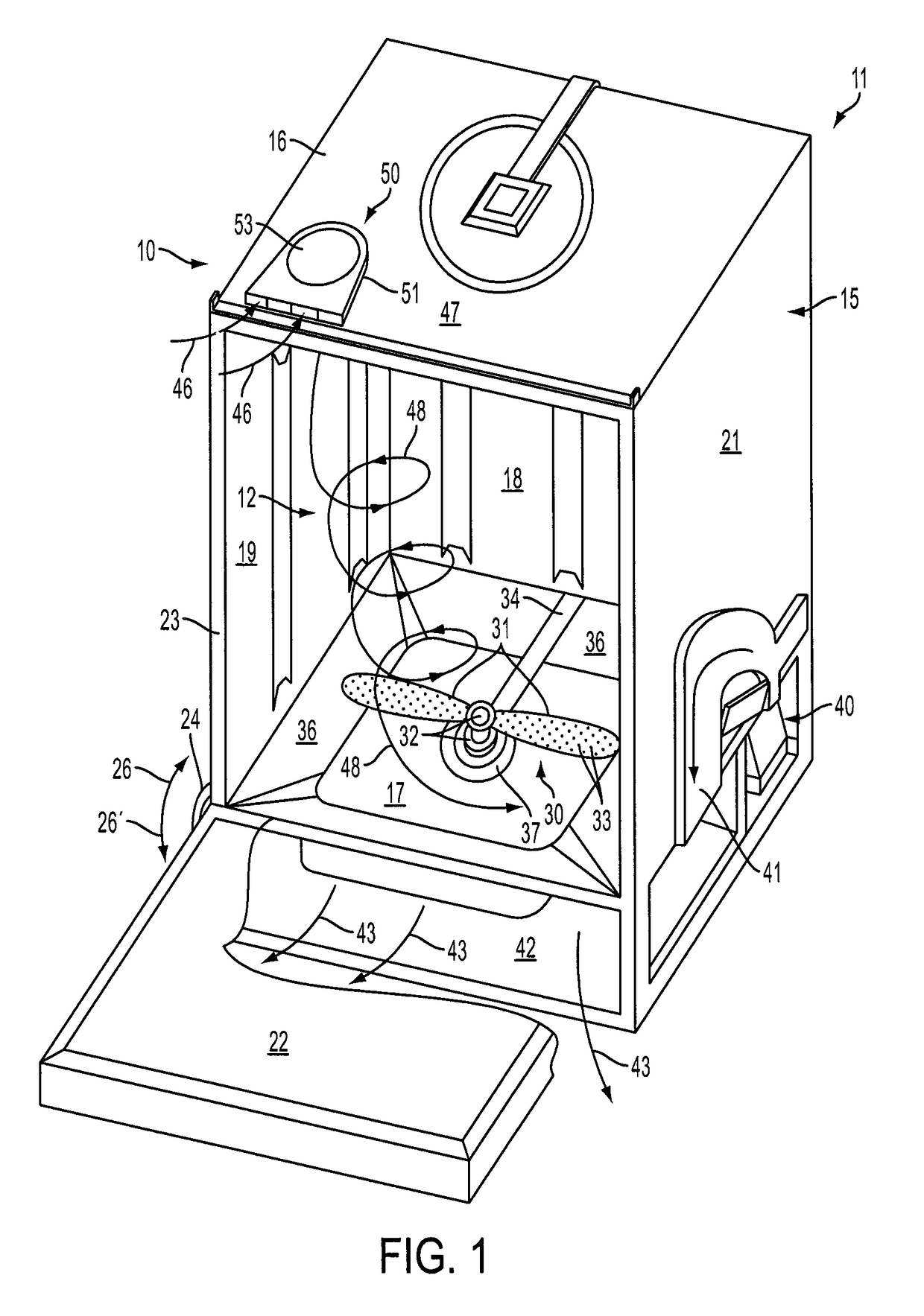

Drying system for a dishwasher

InactiveUS20130008474A1Much turbulenceFast condensation of moistureTableware washing/rinsing machine detailsDrying chambers/containersEngineeringMoisture

A drying system for a dishwasher including a passive vent assembly mounted to a top portion of the dishwasher. The passive vent assembly includes a passive vent structure having a series of air vents defined therein and through which drying air flows are drawn into the wash chamber of the dishwasher, a diffuser mounted over the air vents and including a series of fins for spreading the drying air flows across the wash chamber, and a moisture trap hood mounted over an upper surface of the passive vent structure.

Owner:VIKING RANGE

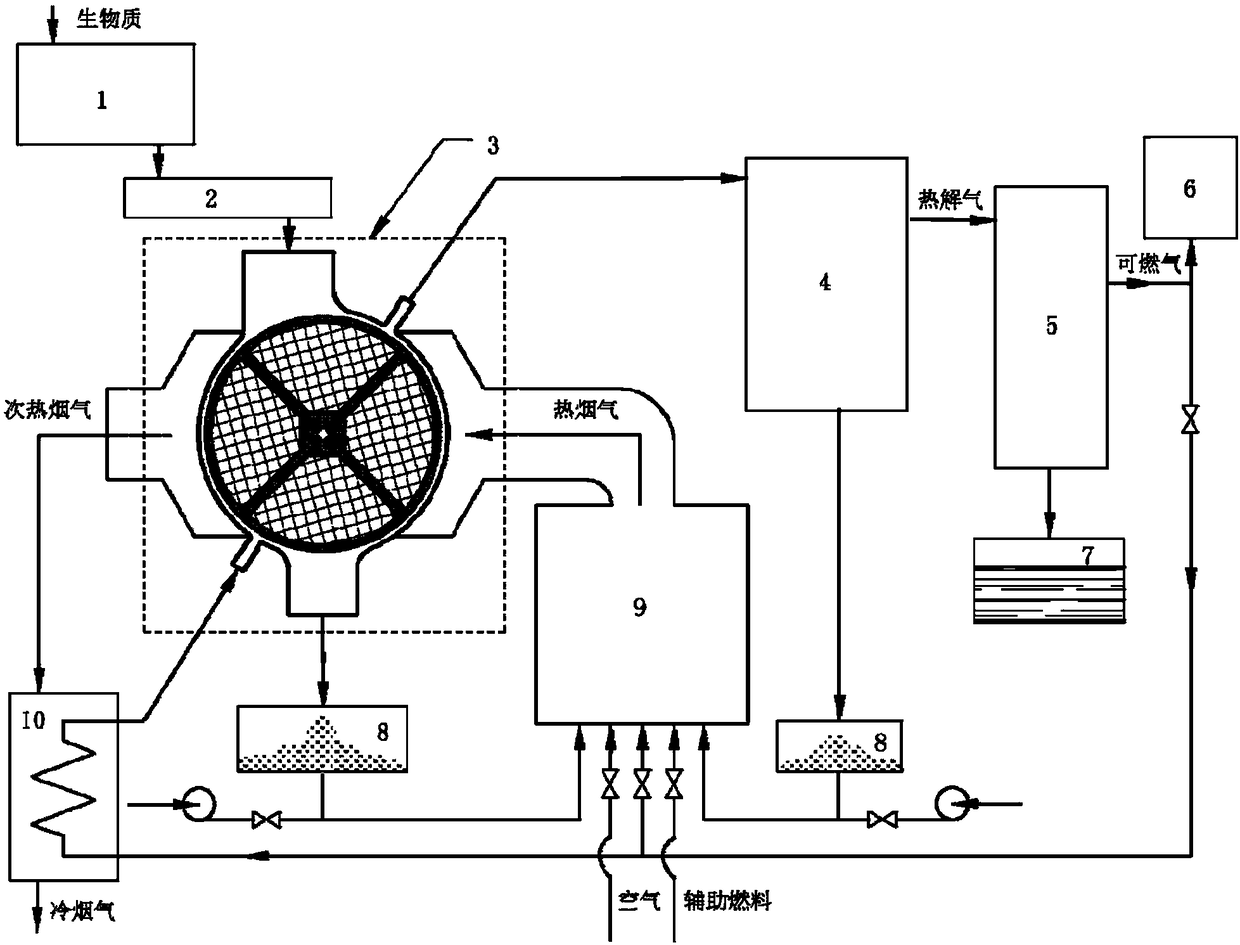

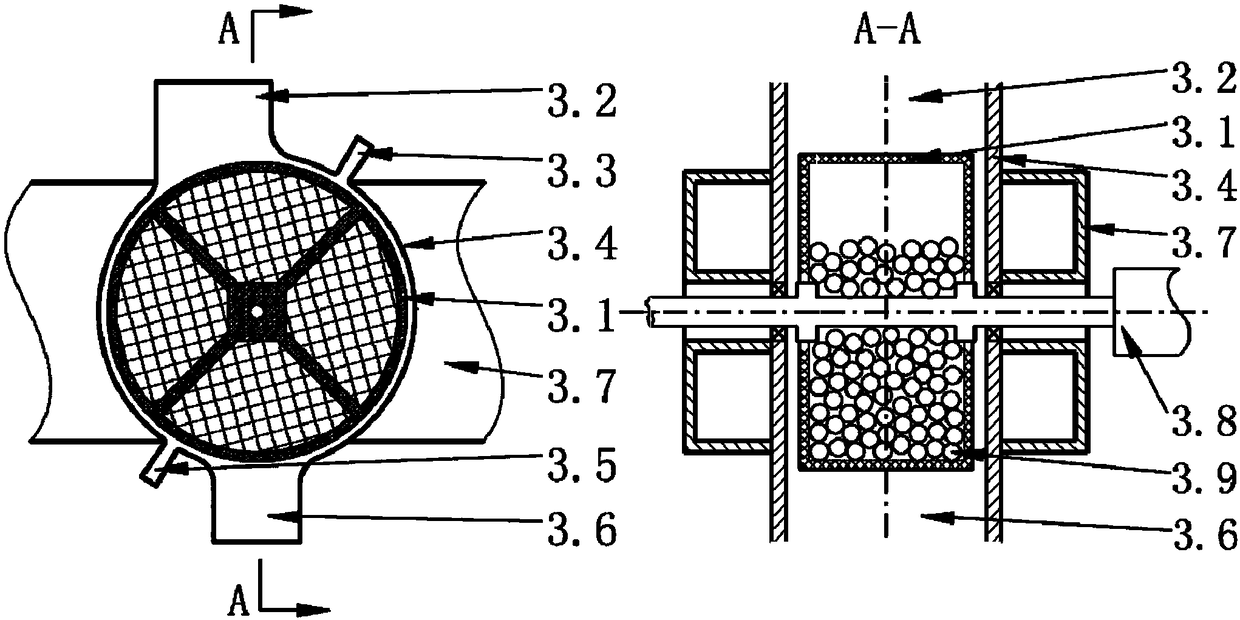

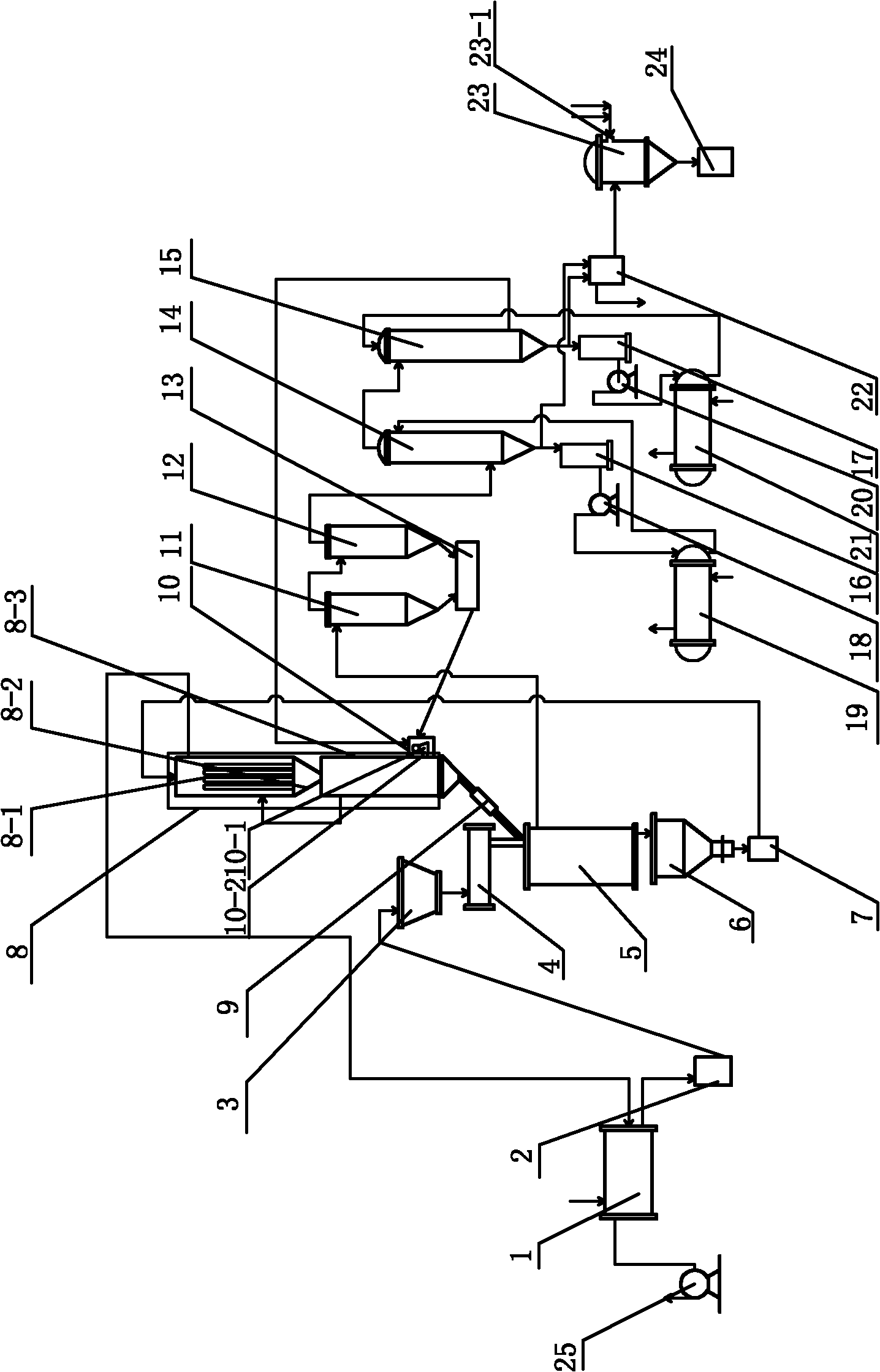

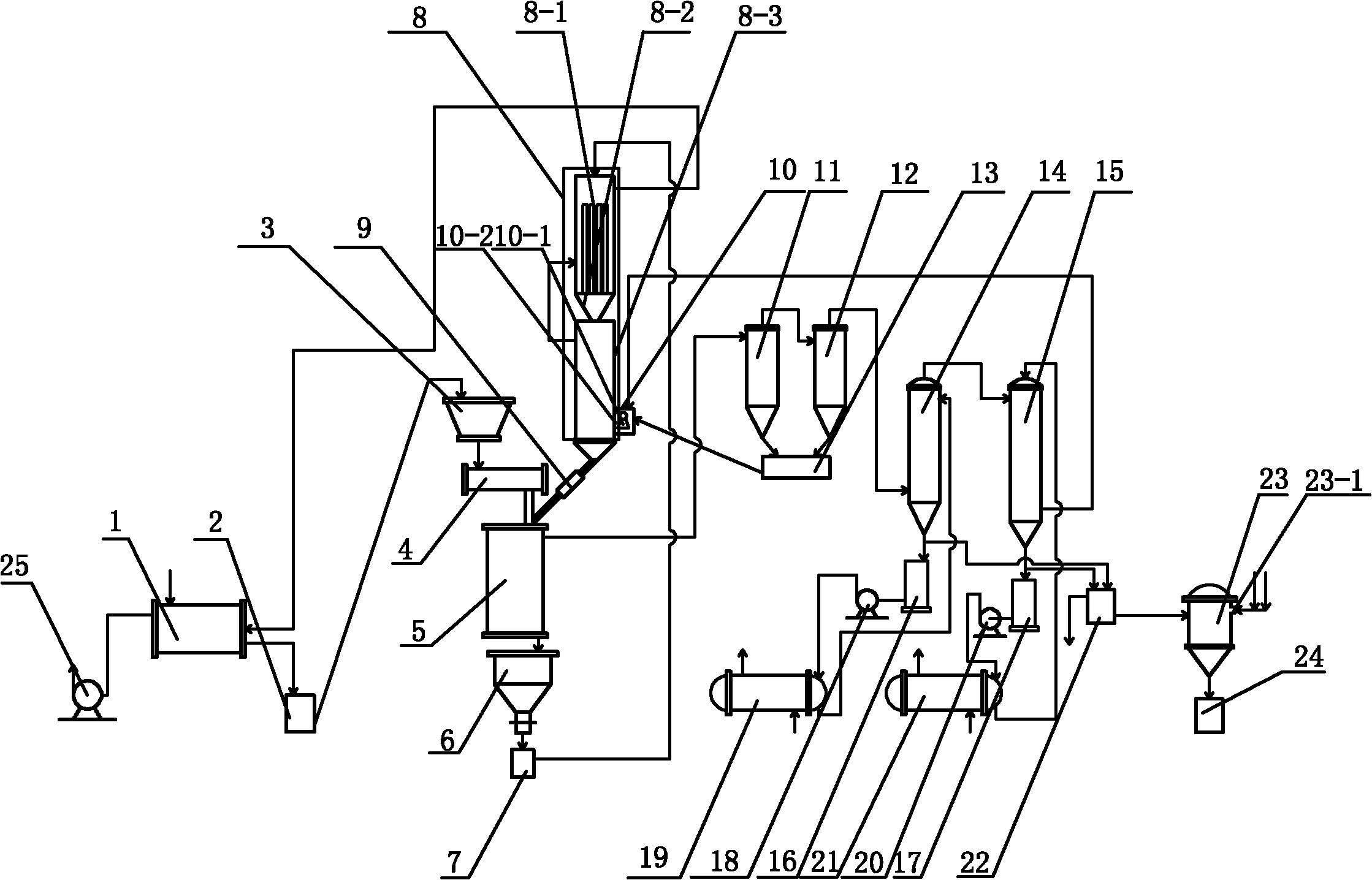

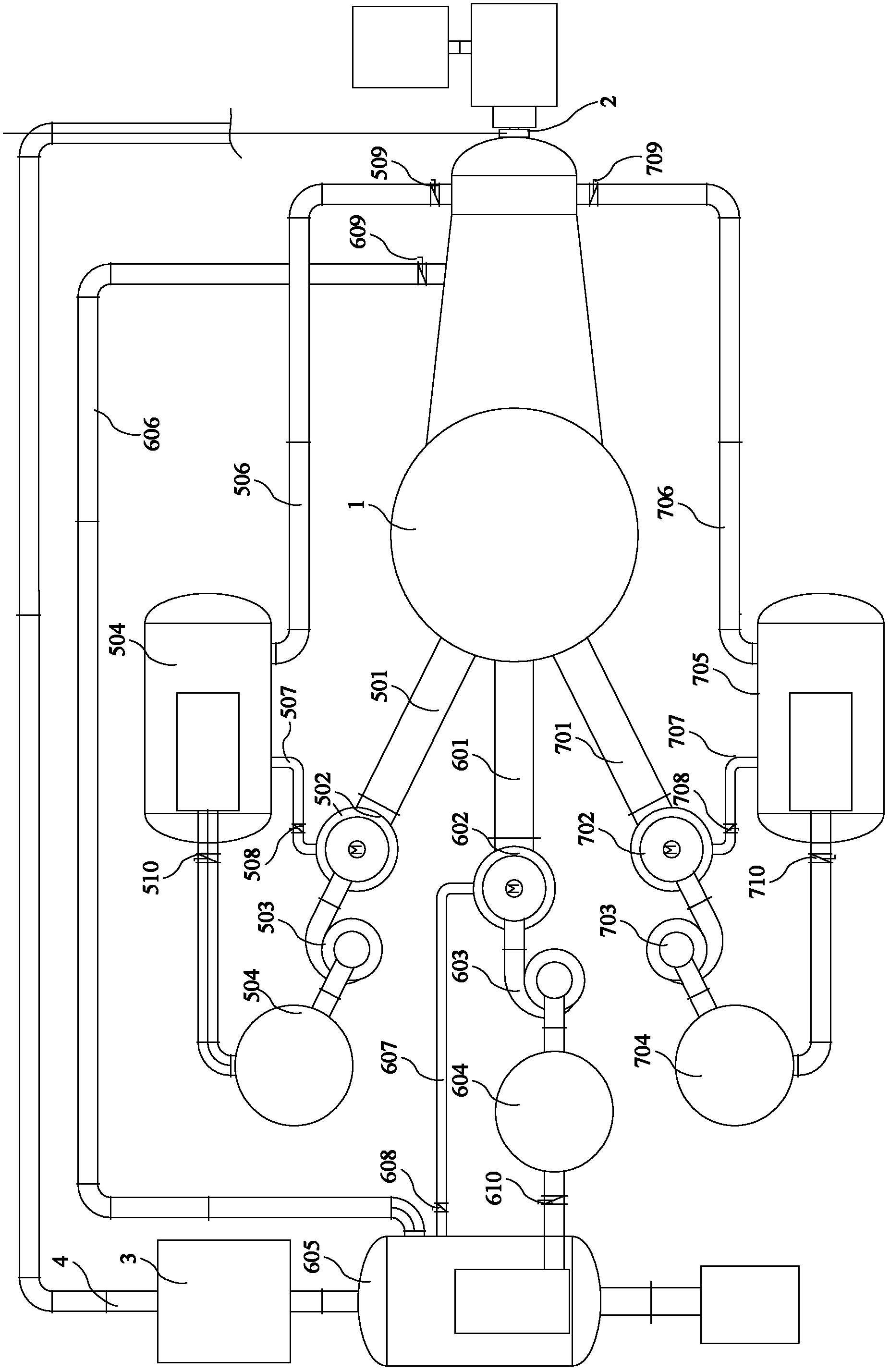

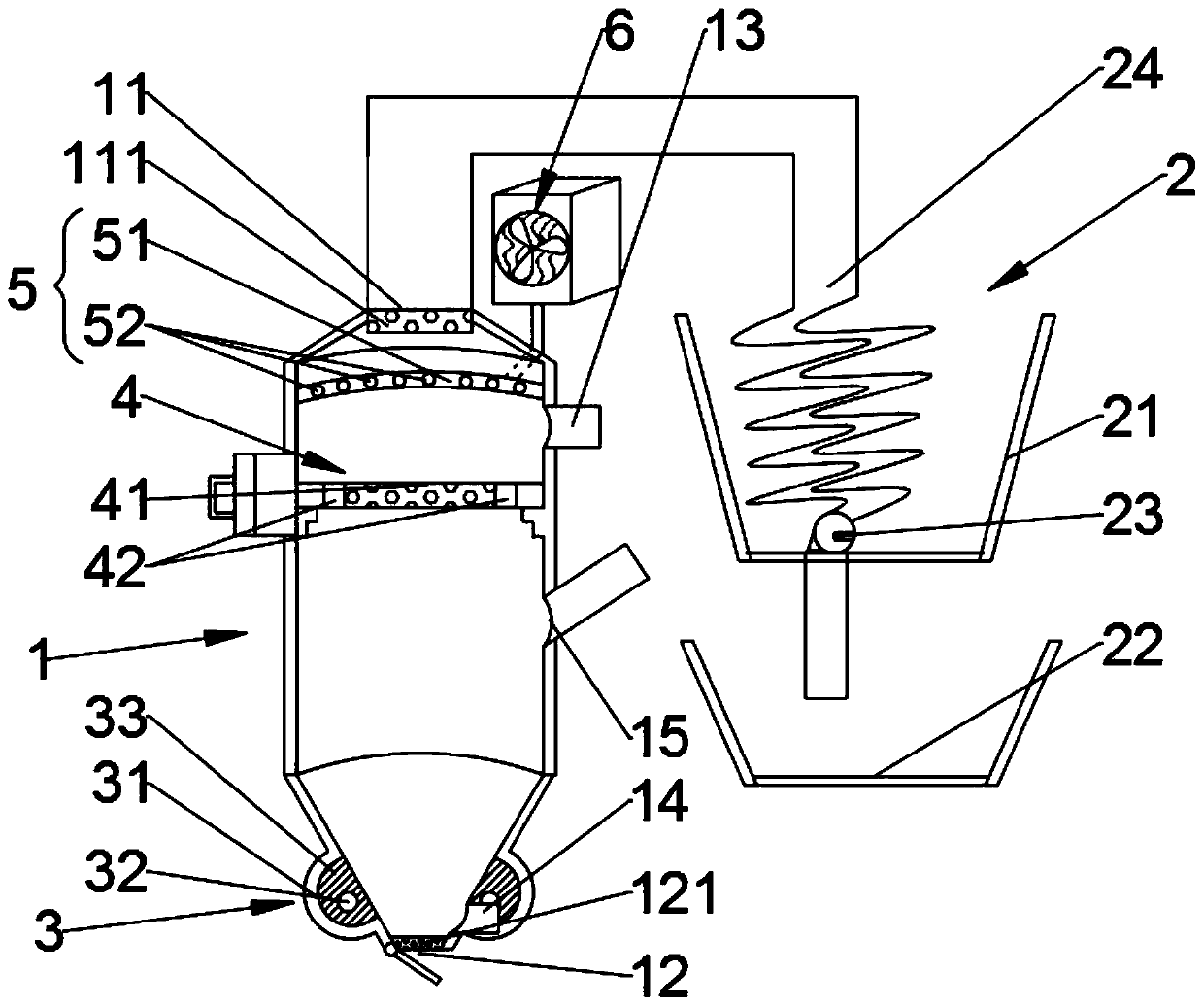

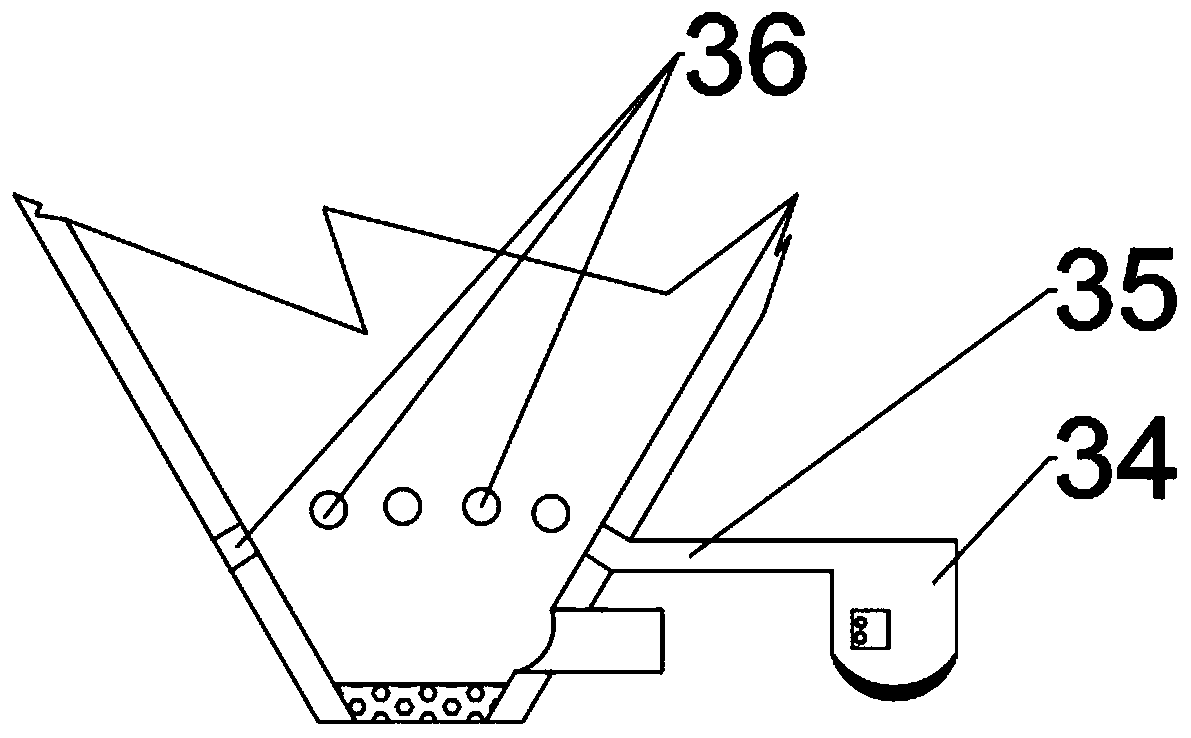

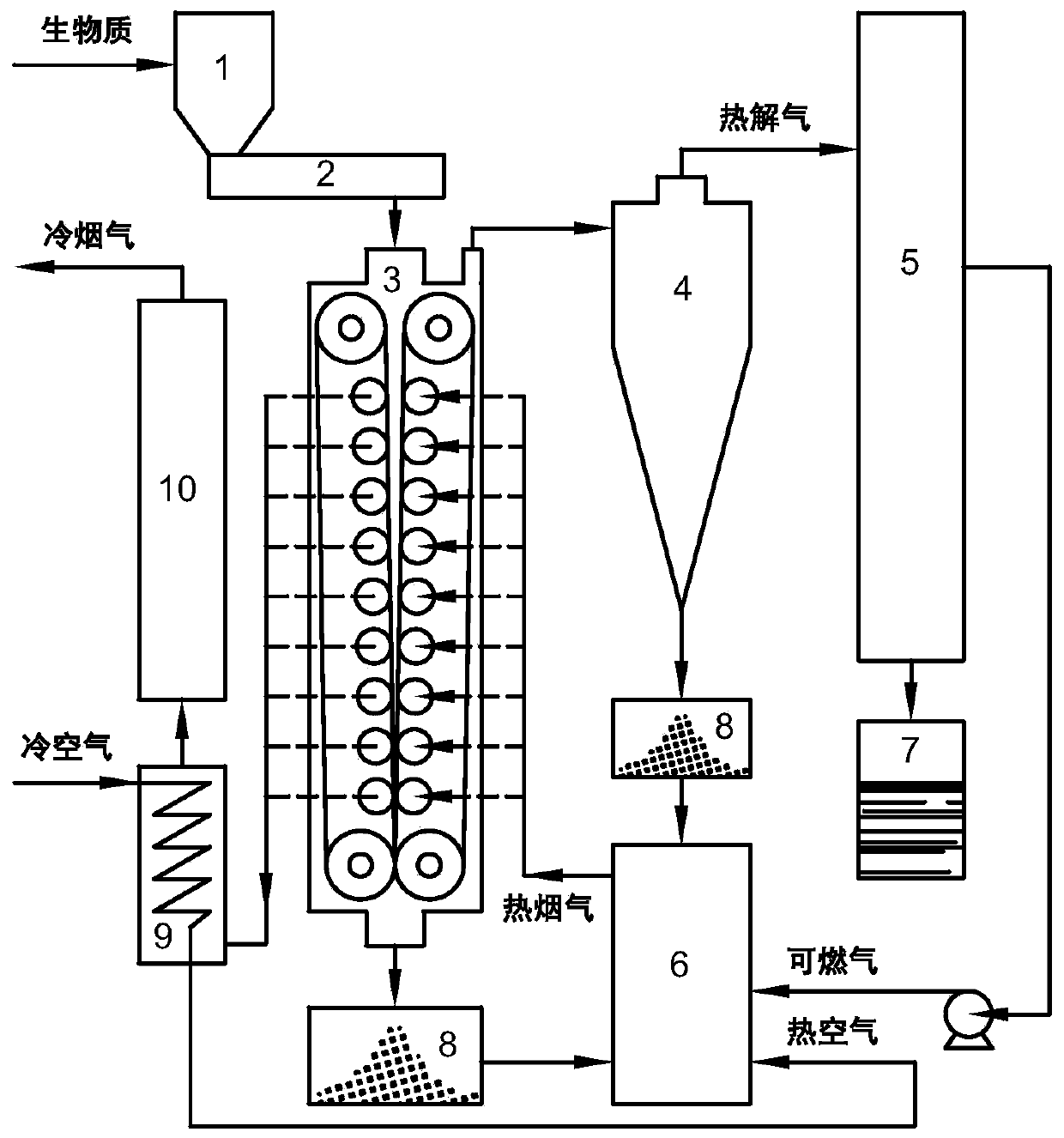

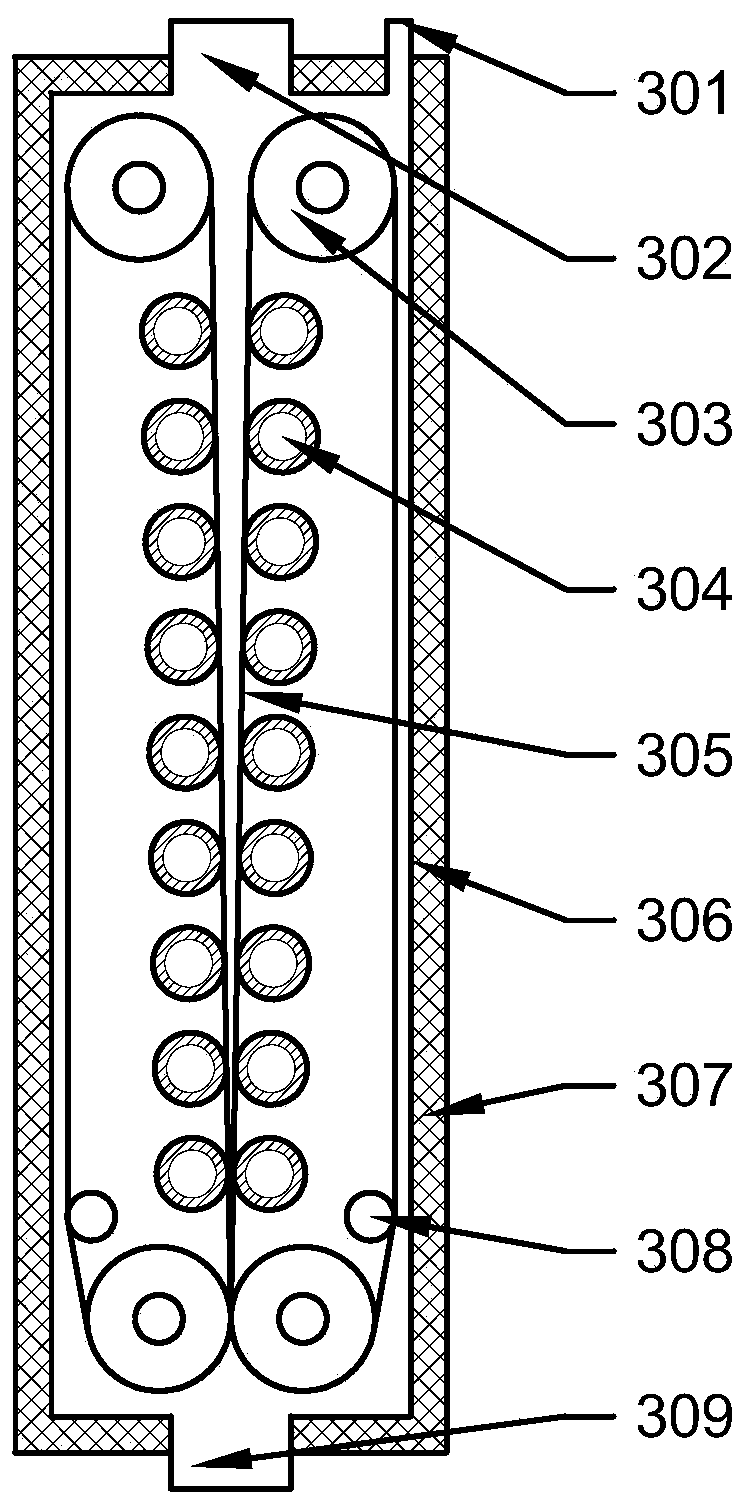

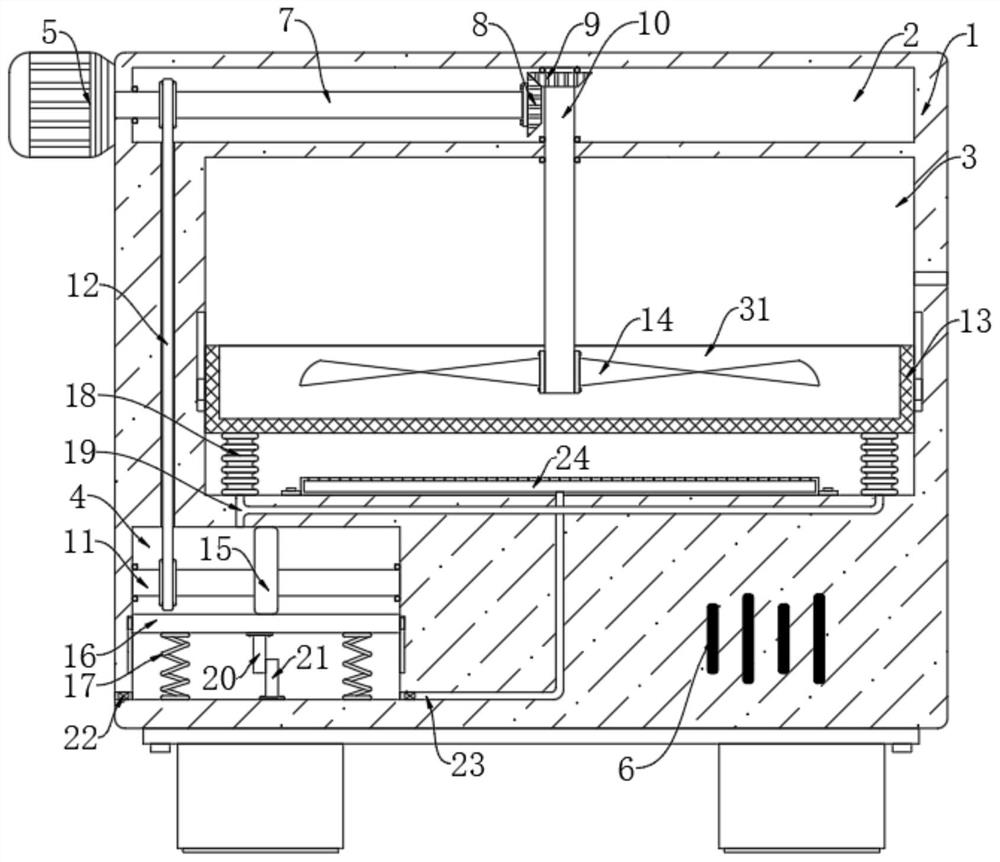

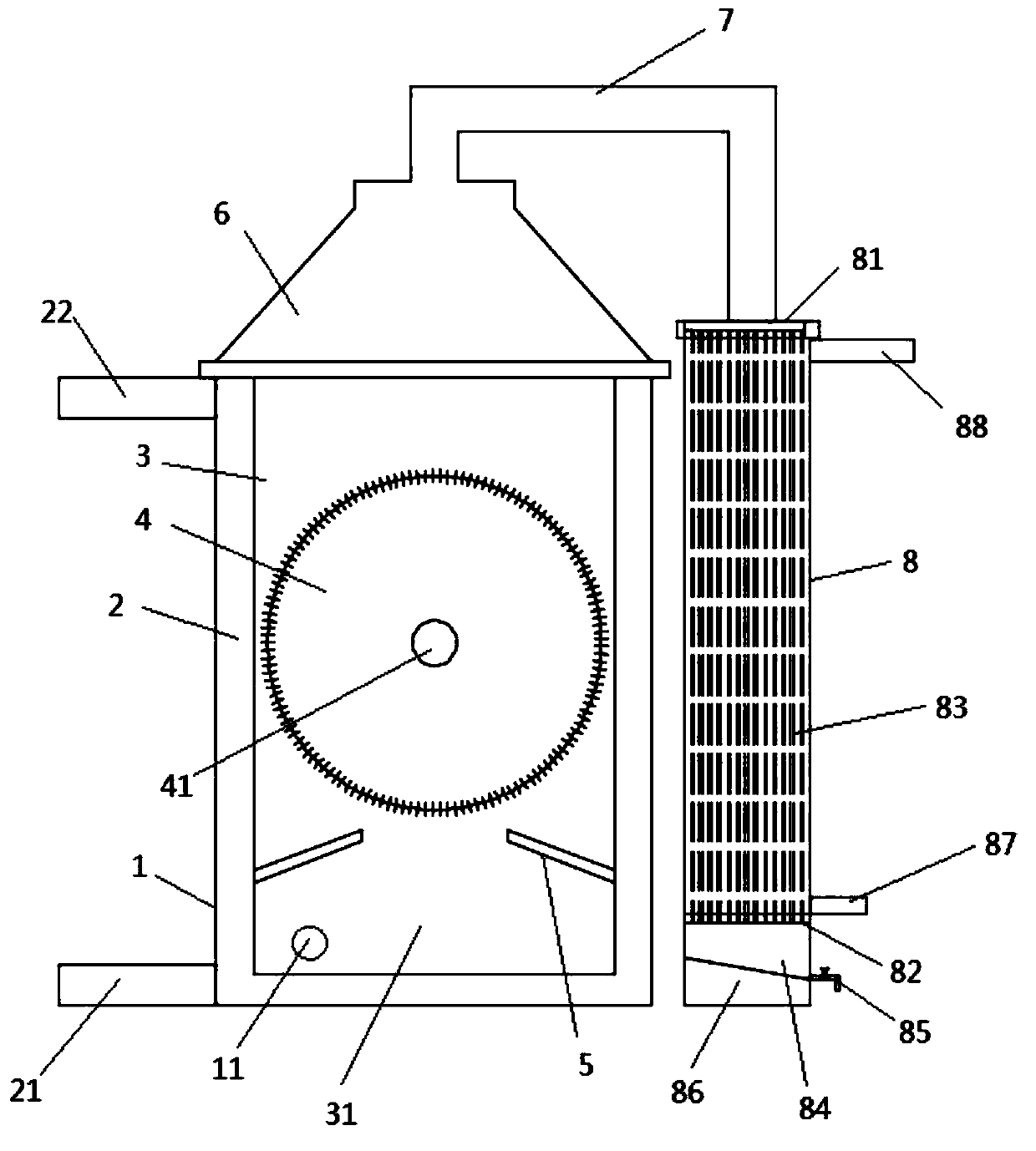

Biomass quick catalytic pyrolysis device and method

ActiveCN108587671AEvenly heatedHeating up fastBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisCombustion system

The invention belongs to the technical field of biomass energy utilization, and particularly relates to a biomass quick catalytic pyrolysis device and method. The device comprises a hopper, a feed system, a revolving bed pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a flammable gas storage tank, a liquid collecting box, a solid coke collecting box, a burning system and a gas carrying and heat exchanging system, wherein the revolving bed pyrolysis reactor is composed of a revolving bed body, an airtight shell, a heat exchanging flue passage, a drive system, a spherical carrier and the like. After pretreatment, biomass particles enter into the revolving bed body and are subjected to quick catalytic pyrolysis under the effect of a catalyst, and generated pyrolysis gas is subjected to quick condensation to obtain certain bio-oil; non-condensing flammable gas and coke are collected and are used for burning and heat supply to achieve self-heating pyrolysis. The device can prepare high-grade liquid fuel or bio-oil containing rich high value-added chemicals by adjusting reaction working conditions and catalyst types.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

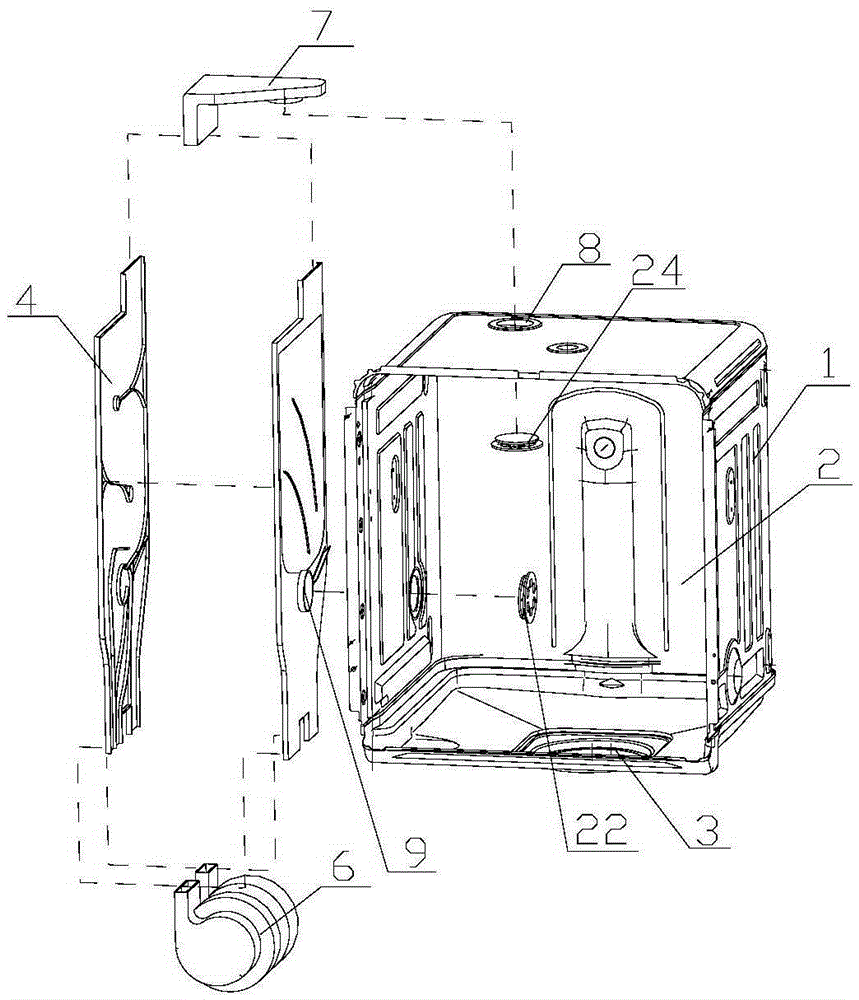

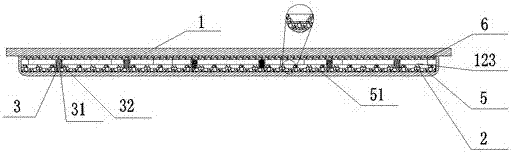

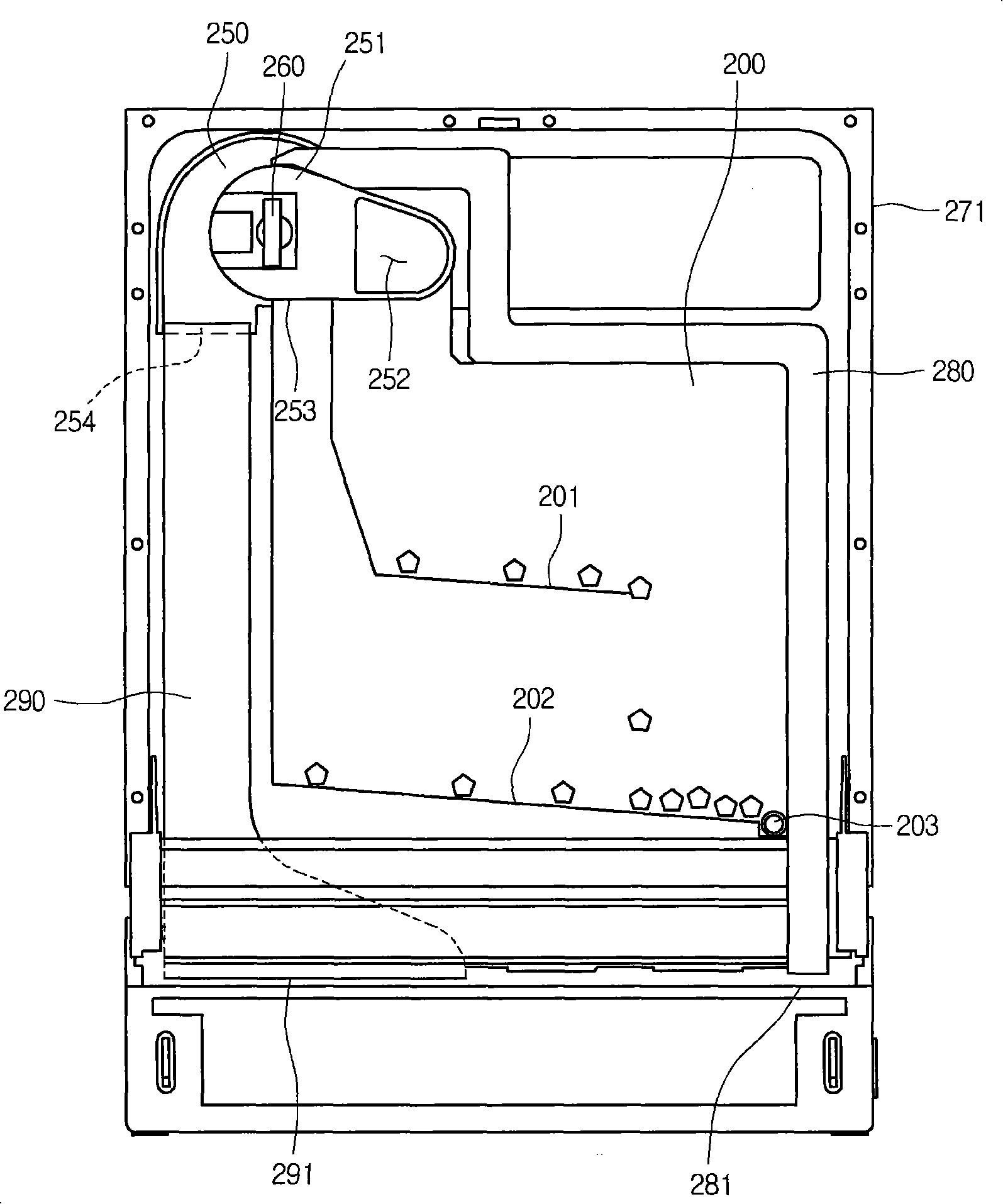

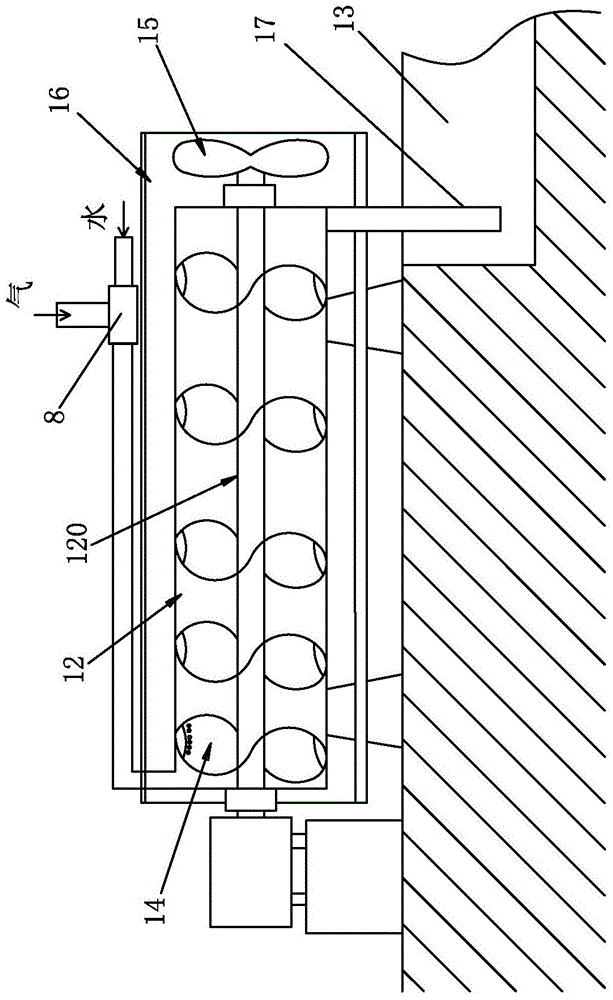

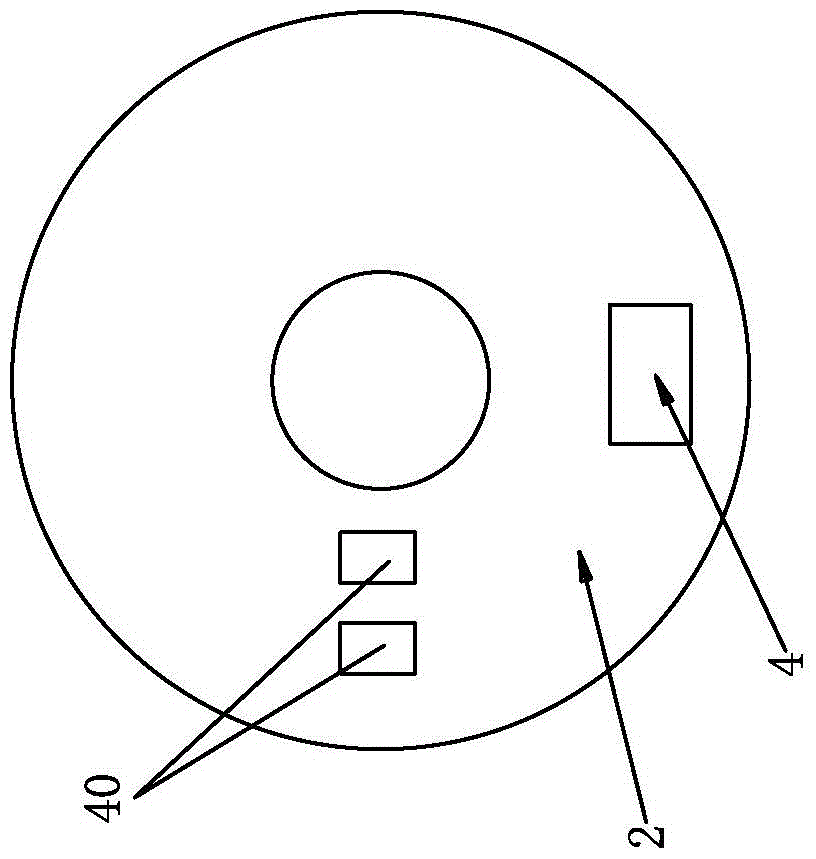

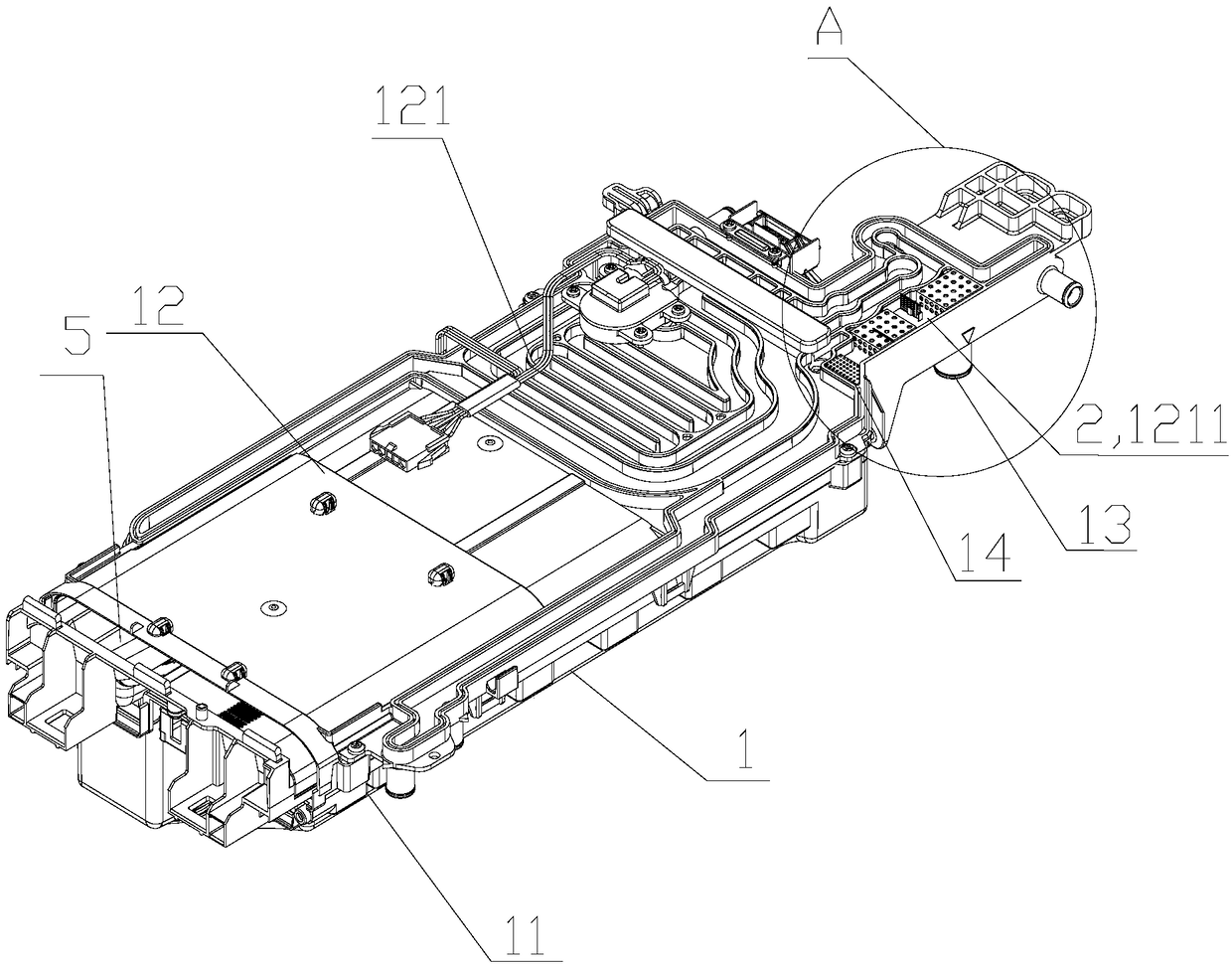

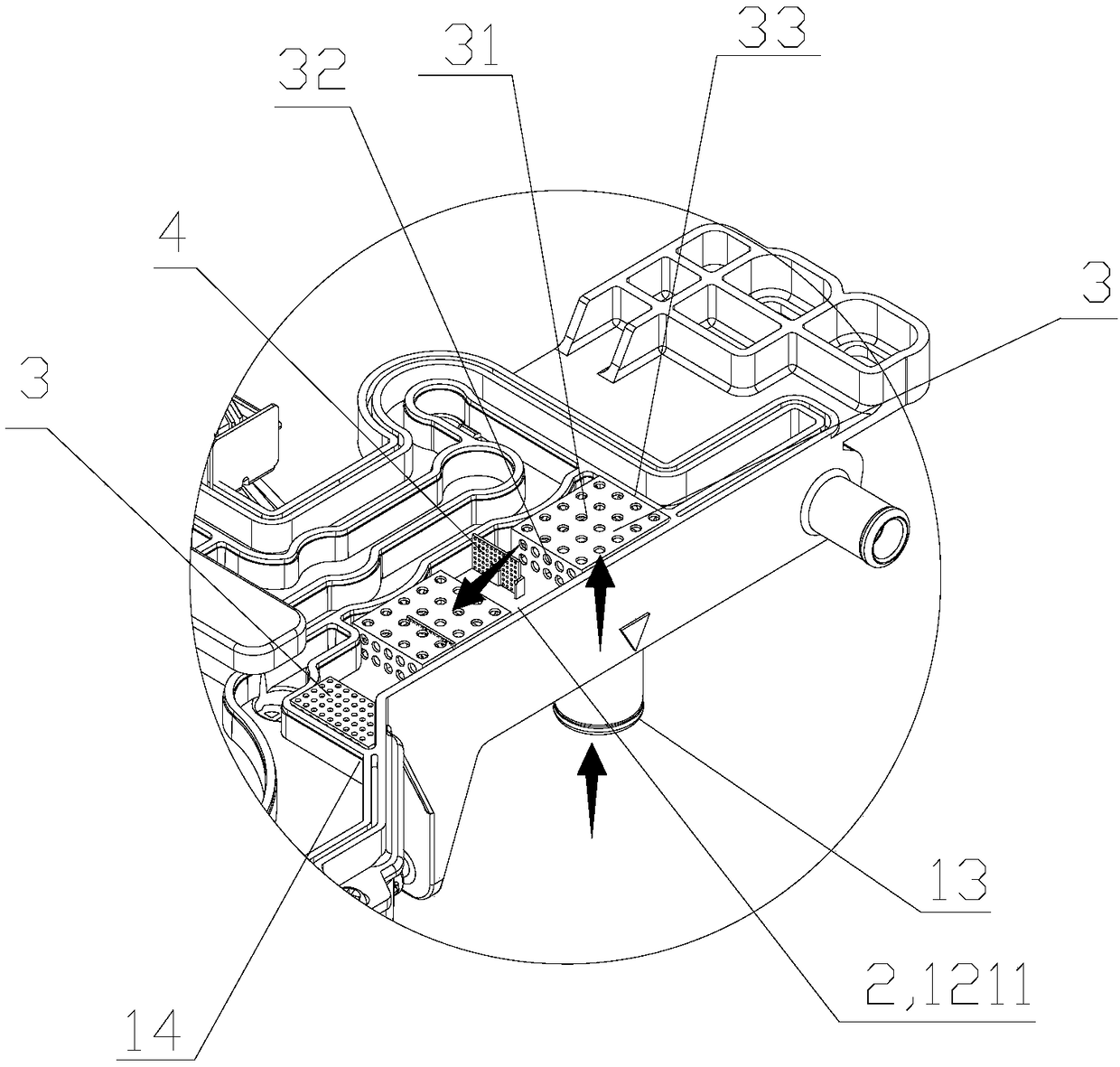

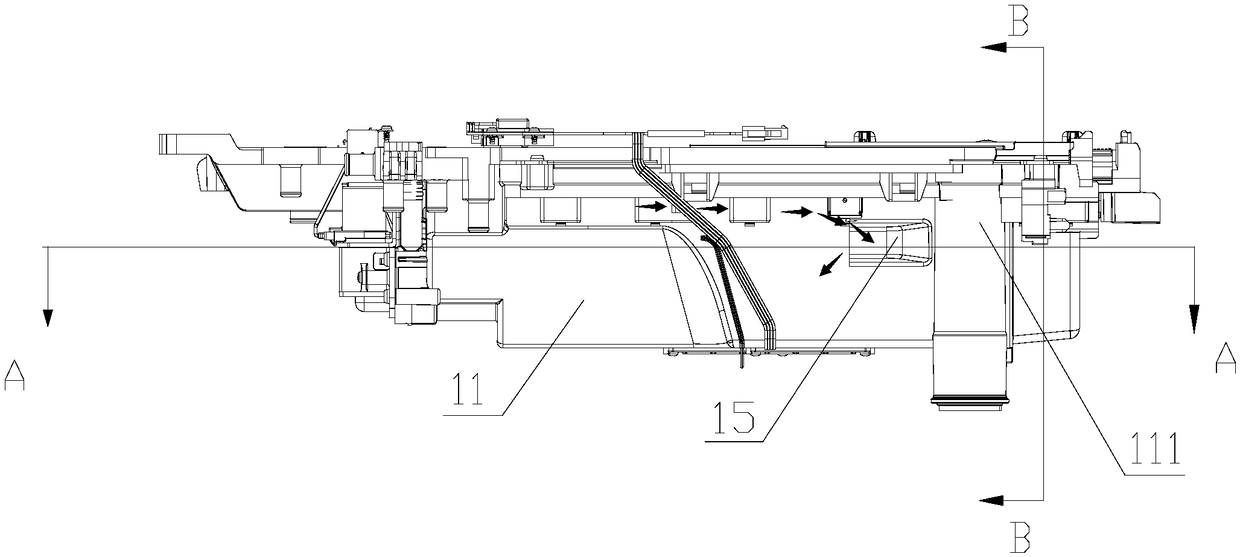

Condensing device for dish-washing machine and dish-washing machine provided with condensing device

ActiveCN106551666ARapid condensationSpeed up the flowTableware washing/rinsing machine detailsWater vaporEngineering

The invention relates to a condensing device for a dish-washing machine and the dish-washing machine provided with the condensing device. The condensing device comprises an inner container, a condenser and draught fans. One end of the condenser communicates with the inner container through an air inlet, and the other end of the condenser is connected with the draught fans. An air supply opening communicating with the inner container is formed in one side plate of the condenser. Airflow is conveyed into the condenser and supplied into the inner container through the air supply opening so that water vapor can enter the condenser through the air inlet to form inner airflow circulation, meanwhile, cooling airflow is conveyed to the outer surface of the condenser to form outer airflow circulation, and power is provided for inner airflow circulation and outer airflow circulation through the two draught fans correspondingly or through one draught fan at the same time. The condensing device has inner airflow circulation and outer airflow circulation at the same time, the flowing speed of airflow on the outer surfaces of the side plates of the condenser can be increased, the surface temperature of the condenser can be reduced, fast condensation of the water vapor in the condenser can be facilitated, and the condensation efficiency can be greatly improved.

Owner:QINGDAO HAIER DISHWASHER +1

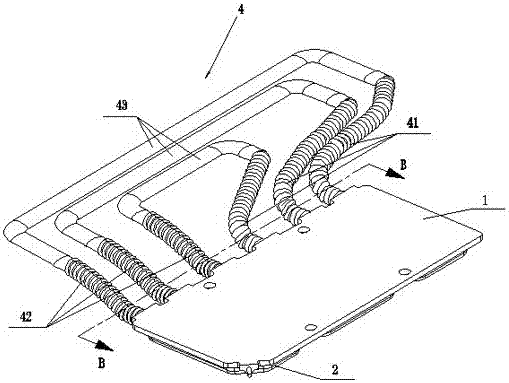

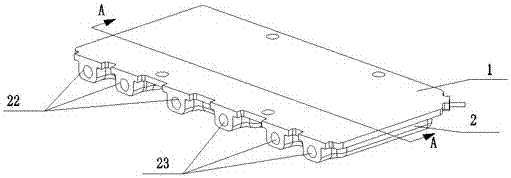

Loop soaking plate

InactiveCN106949764AAccelerate evaporationRelieve heat loadIndirect heat exchangersLiquid stateEvaporation

The invention discloses a loop soaking plate, and aims to provide the loop soaking plate with simple structure, low cost and higher generality and particularly suitable for high-heat-flux places. The loop soaking plate comprises a cover plate and a baseplate; the cover plate is fixed on the baseplate; a closed vacuum plate shell is formed between the cover plate and the baseplate; a first capillary structure layer and a second capillary structure layer are arranged in the plate shell; an evaporation cavity is formed between the first capillary structure layer and the second capillary structure layer; multiple support structures are vertically arranged between the first capillary structure layer and the second capillary structure layer; the first capillary structure layer is permeated with a liquid-state working medium; the plate shell is provided with at least one loop module for accommodating the working medium to flow; and the loop module communicates with the evaporation cavity.

Owner:GUANGZHOU HUAZUAN ELECTRONICS TECH

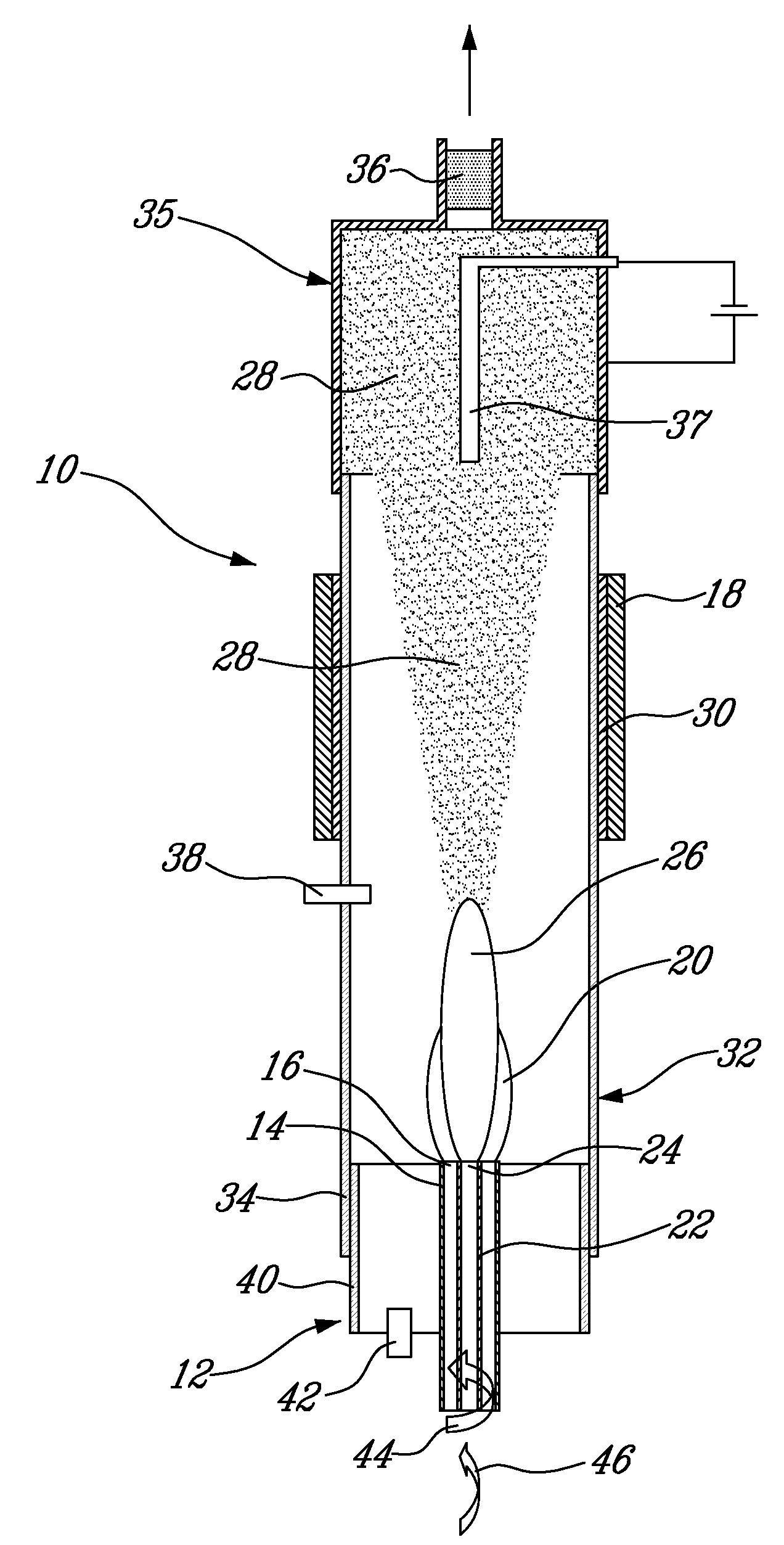

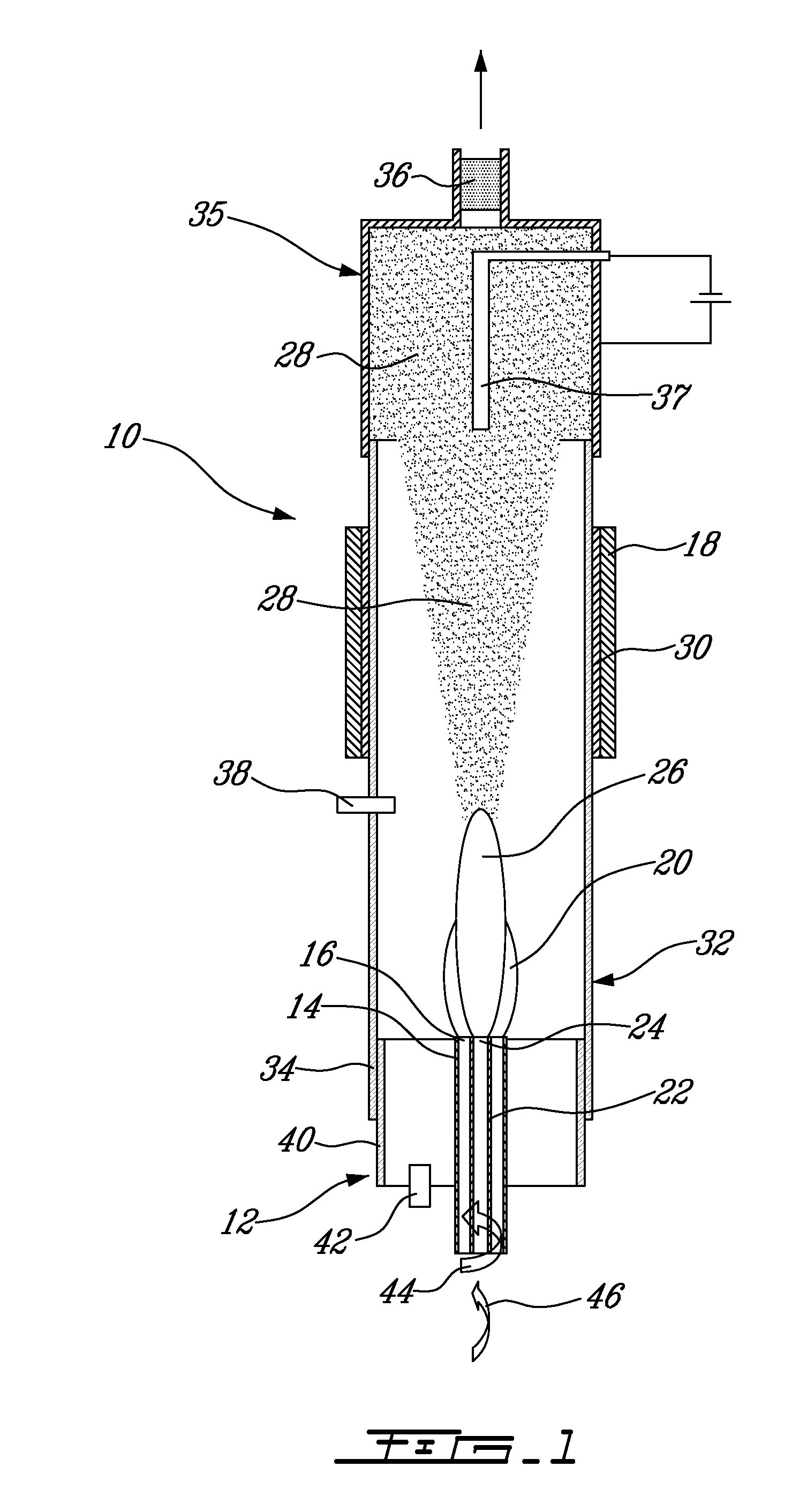

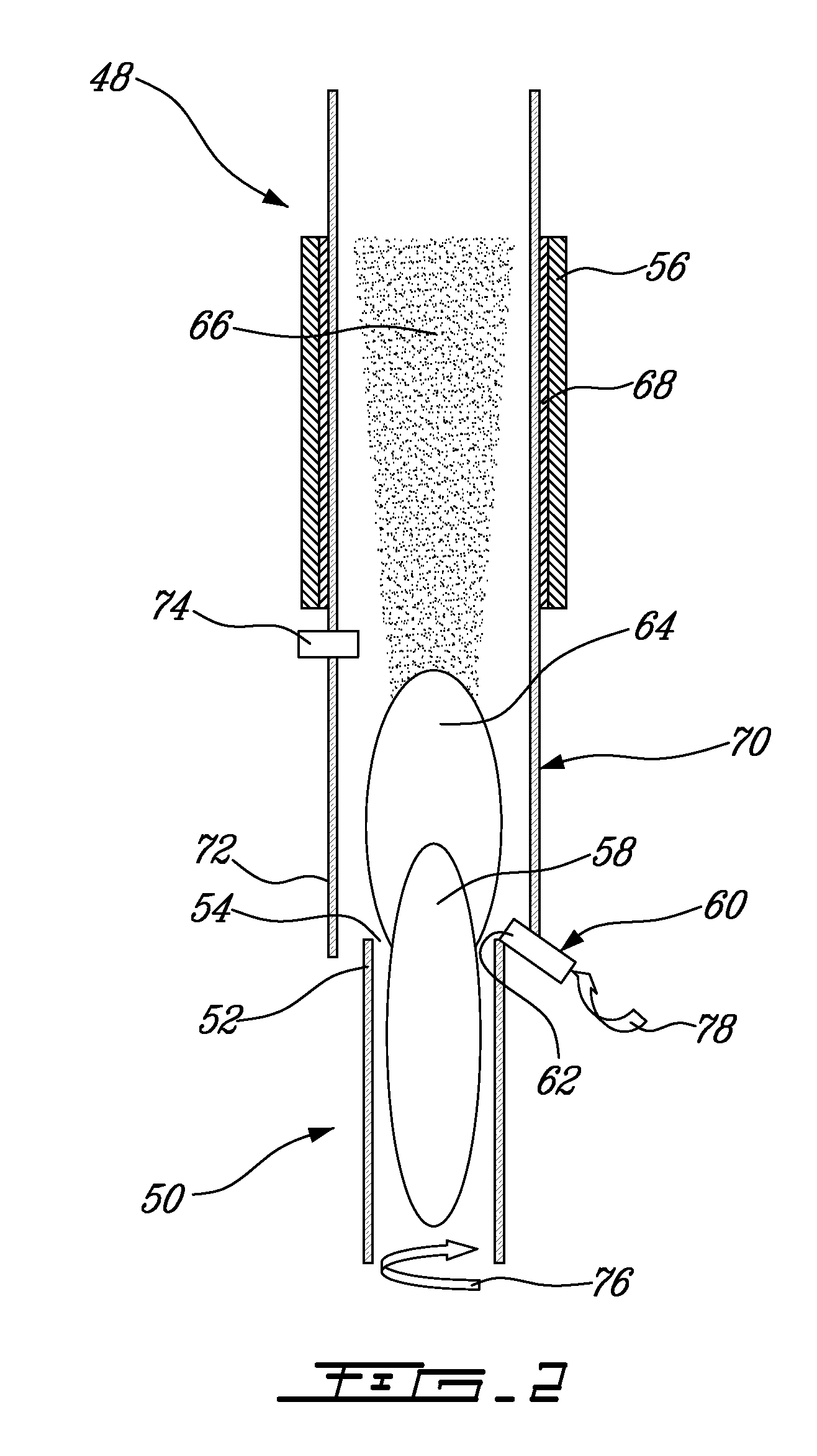

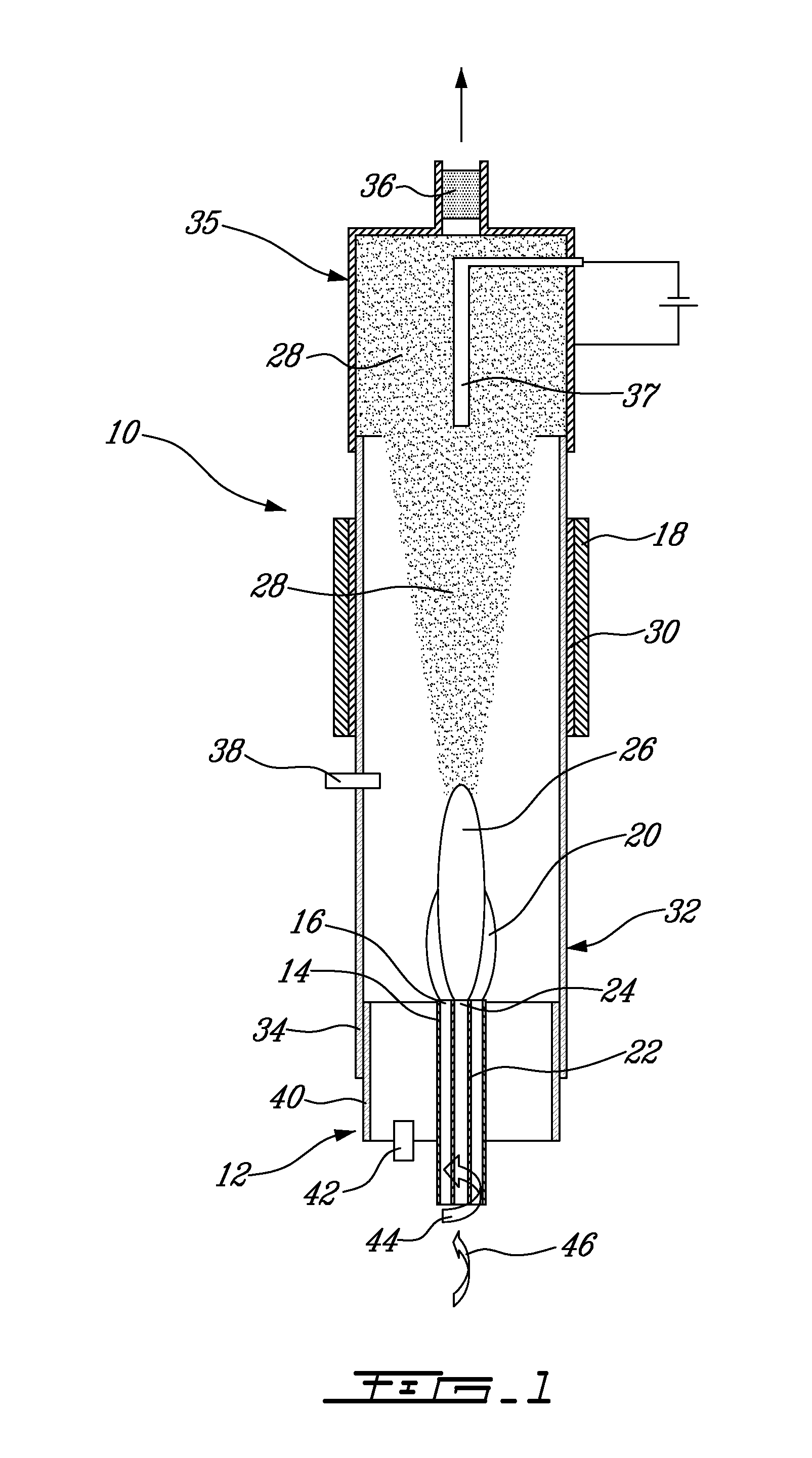

Method and apparatus for producing single-wall carbon nanotubes

InactiveUS20080124482A1Rapid condensationAvoid emissionsMaterial nanotechnologyFibre chemical featuresPower flowCarbon nanotube

There is provided a method for producing single-wall carbon nanotubes comprising condensing a plasma comprising atoms or molecules of carbon and atoms of a metal suitable for catalyzing the formation of single-wall carbon nanotubes in an oven at a predetermined temperature so as to provide a temperature gradient, thereby forming single-wall carbon nanotubes; and collecting the so-formed single-wall carbon nanotubes by passing them through an electrostatic trap comprising a pair of electrodes generating an electrical current so as to deposit at least a portion of the single-wall carbon nanotubes on one of the electrodes.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

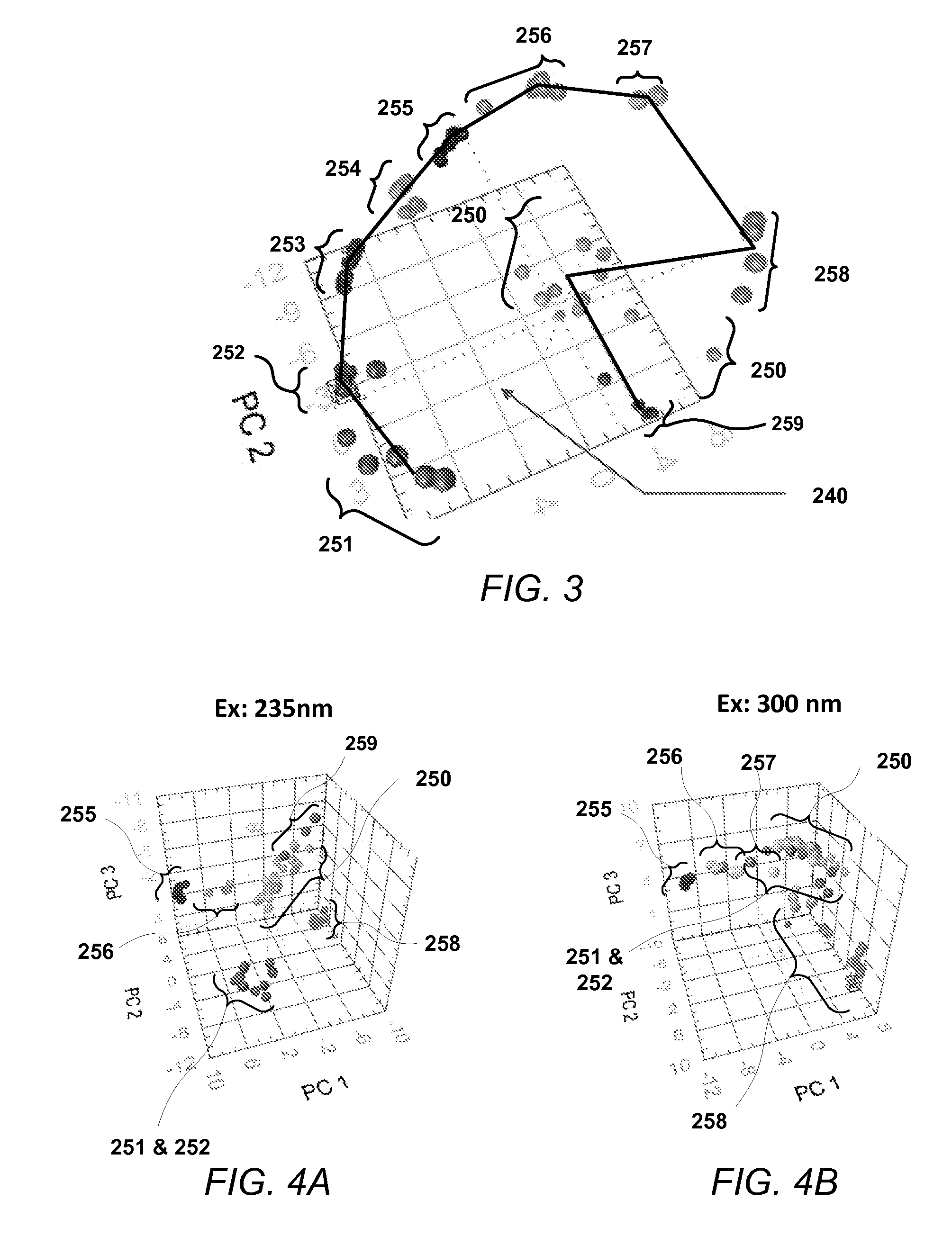

Native fluorescence detection methods, devices, and systems for organic compounds

ActiveUS9442070B1Rapid condensationRapid vaporization of VOCsSpectrum investigationMaterial analysis by electric/magnetic meansDosimeterUltraviolet

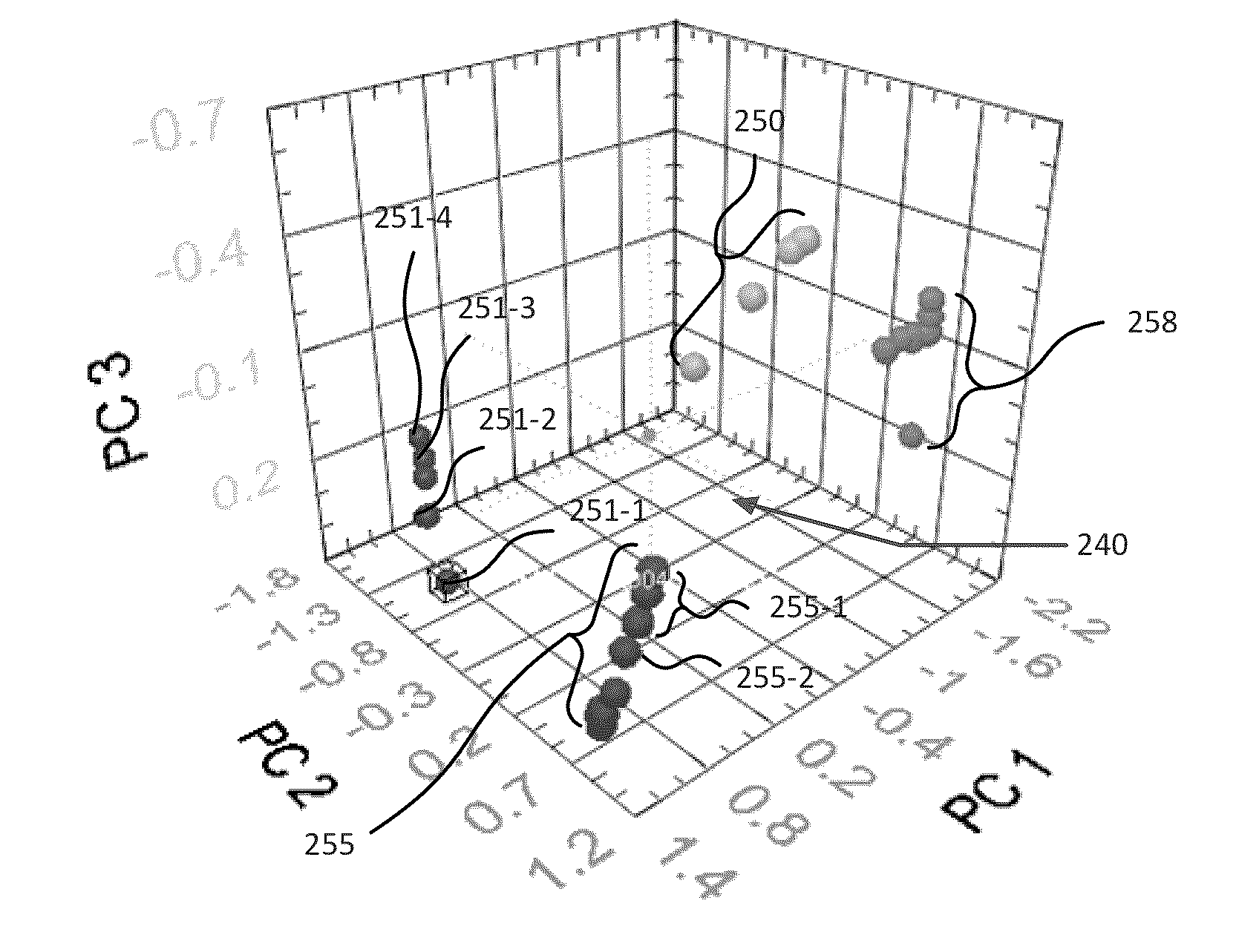

Naphthalene, benzene, toluene, xylene, and other volatile organic compounds VOCs have been identified as serious health hazards. Embodiments of the invention are directed to methods and apparatus for near-real-time in-situ detection and accumulated dose measurement of exposure to naphthalene vapor and other hazardous gaseous VOCs. The methods and apparatus employ excitation of fluorophors native or endogenous to compounds of interest using light sources emitting in the ultraviolet below 300 nm and measurement of native fluorescence emissions in distinct wavebands above the excitation wavelength. The apparatus of some embodiments are cell-phone-sized sensor / dosimeter “badges” to be worn by personnel potentially exposed to hazardous VOCs. The badge sensor of some embodiments provides both real time detection and data logging of exposure to naphthalene or other VOCs of interest from which both instantaneous and accumulated dose can be determined.

Owner:PHOTON SYST

Device and method for producing biological fuel oil by quickly cracking biomass

InactiveCN102031133AStable temperature controlFully condensedDirect heating destructive distillationBiofuelsThermal energyTemperature control

The invention discloses a device and a method for producing biological fuel oil by quickly cracking biomass, relates to a device and a method for producing biological fuel oil and aims to solve the problems of low energy utilization ratio, high operating cost and poor practical production continuity existing in the conventional biomass thermal cracking process and the problem of the absence of accurate heat carrier heating temperature regulating function in the conventional biomass thermal cracking process device. In the scheme of the device, the bottom of a heat carrier heating device is communicated with a heat carrier inlet end of a cracking reactor through an accurate heat carrier temperature control device; the cracking reactor is communicated with a separator; the separator is communicated with a condenser; the condenser is communicated with a heat energy supply device; and the heat energy supply device is communicated with the heat carrier heating device. In the scheme of the method, products produced by the thermal cracking reaction of biomass powder comprise thermal cracking gas and carbon; a heat carrier enters a heat carrier collecting box; and uncondensed thermal cracking gas enters a non-condensable gas burner to burn, and then smoke gas is produced and enters the heat carrier heating device. The device and the method are used for producing biological fuel oil.

Owner:NORTHEAST FORESTRY UNIVERSITY

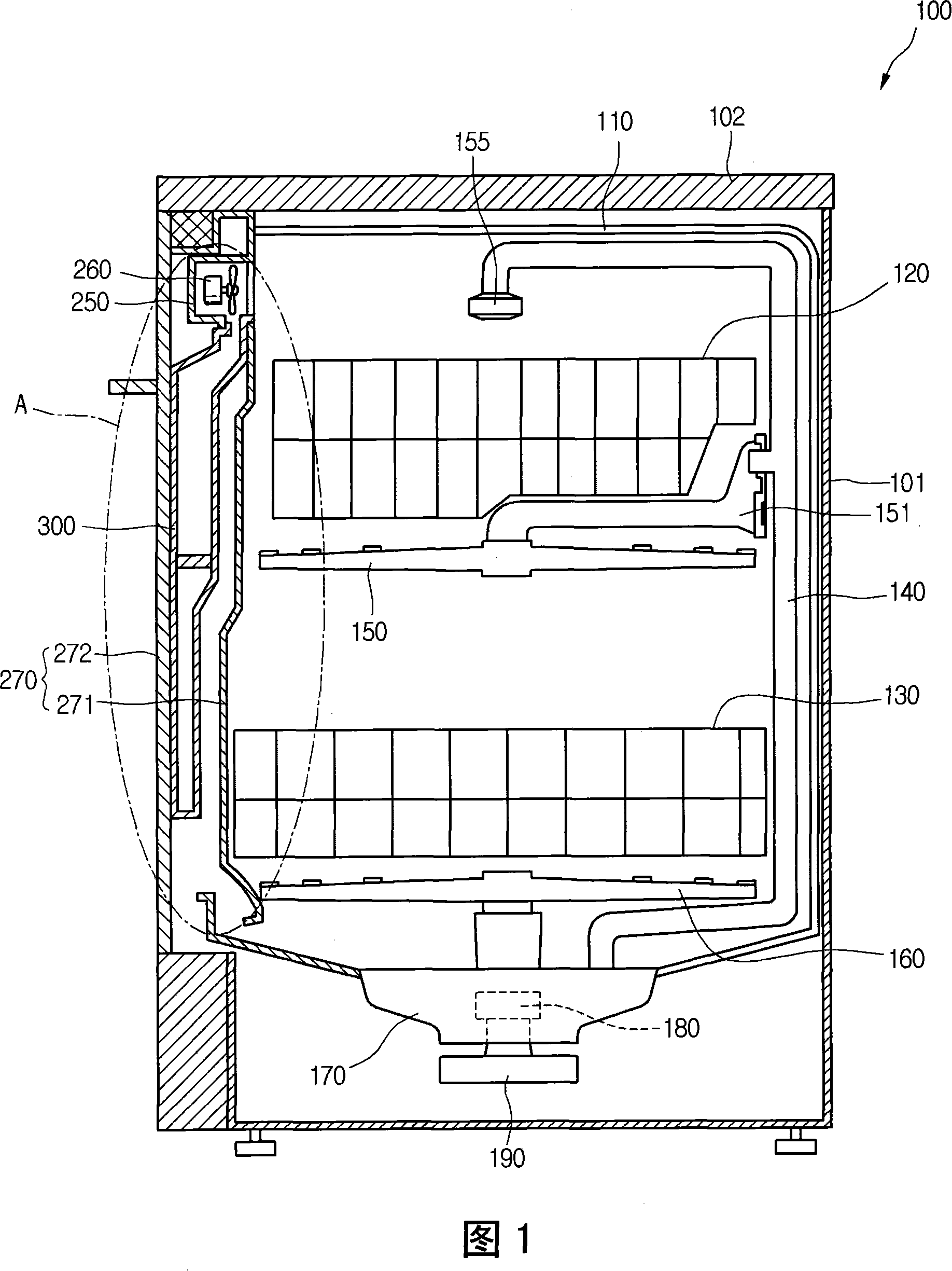

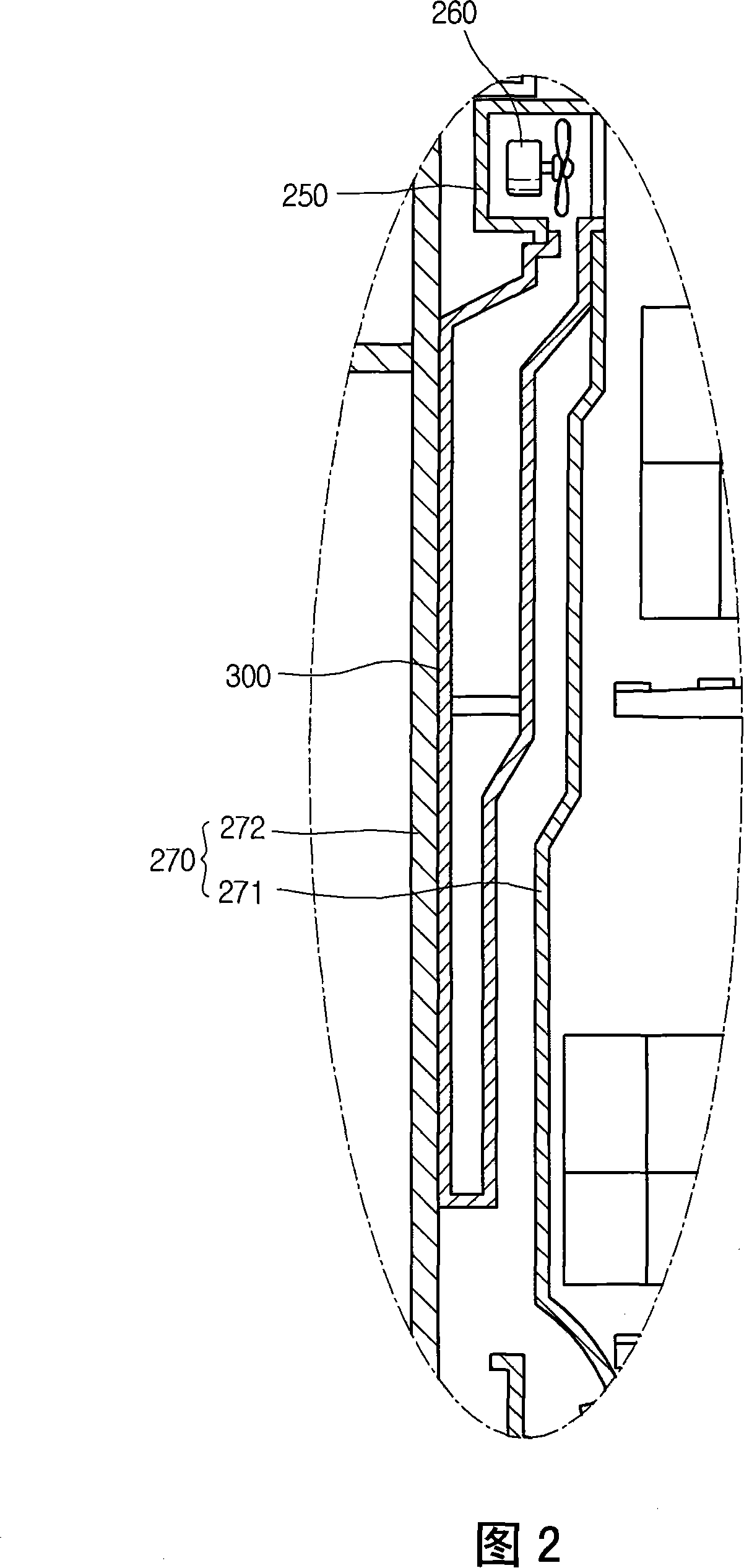

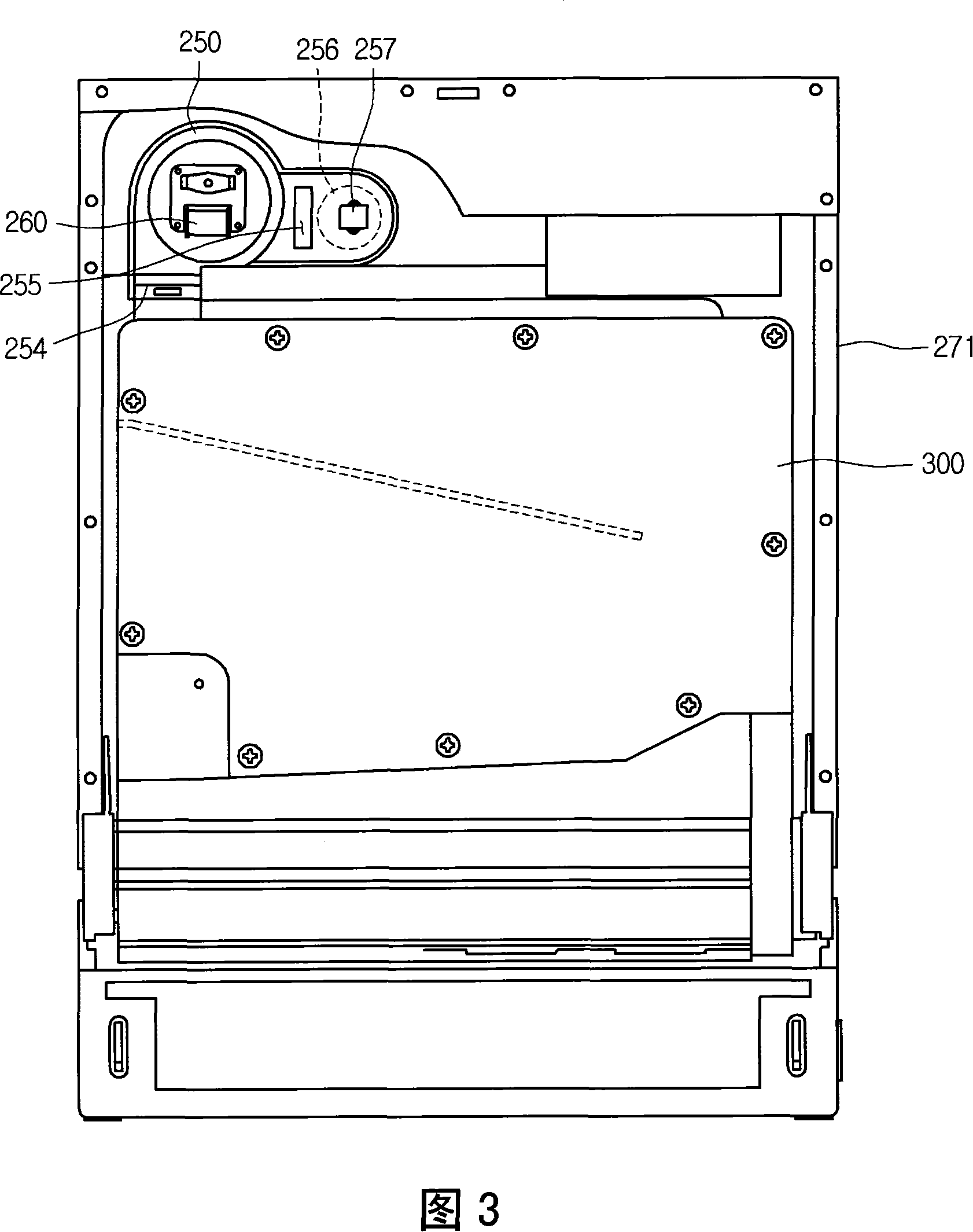

Dishwasher

InactiveCN101164491ARapid condensationShorten drying timeTableware washing/rinsing machine detailsEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

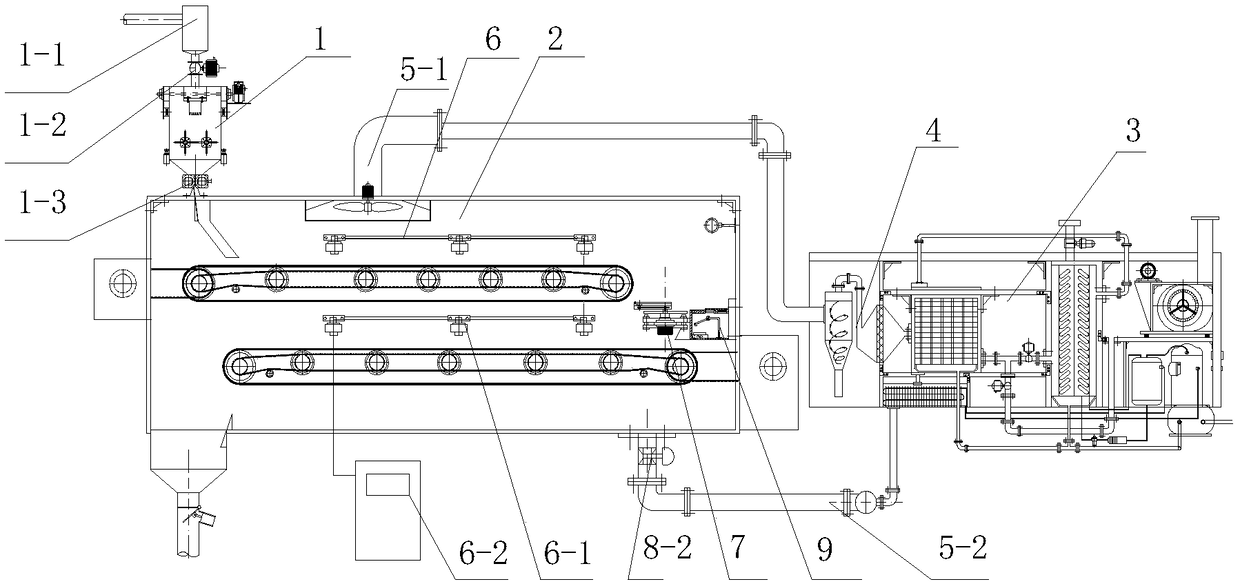

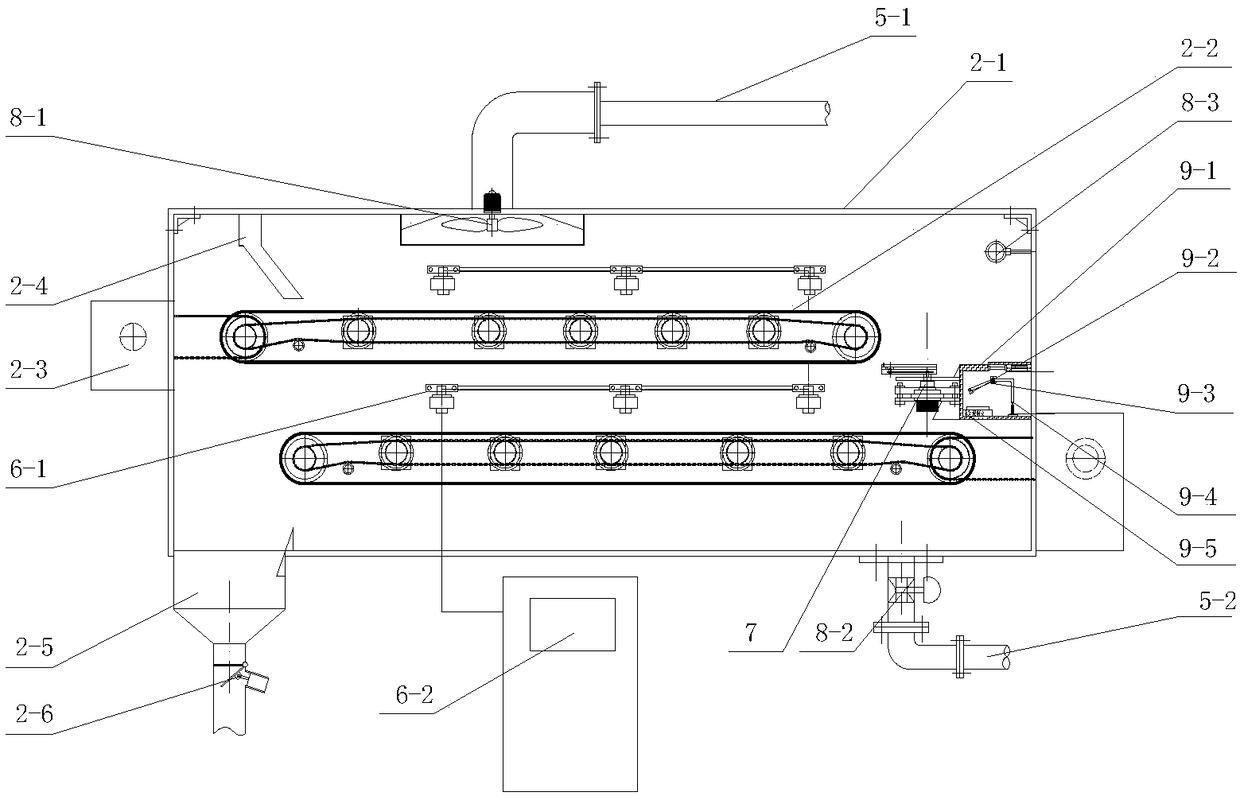

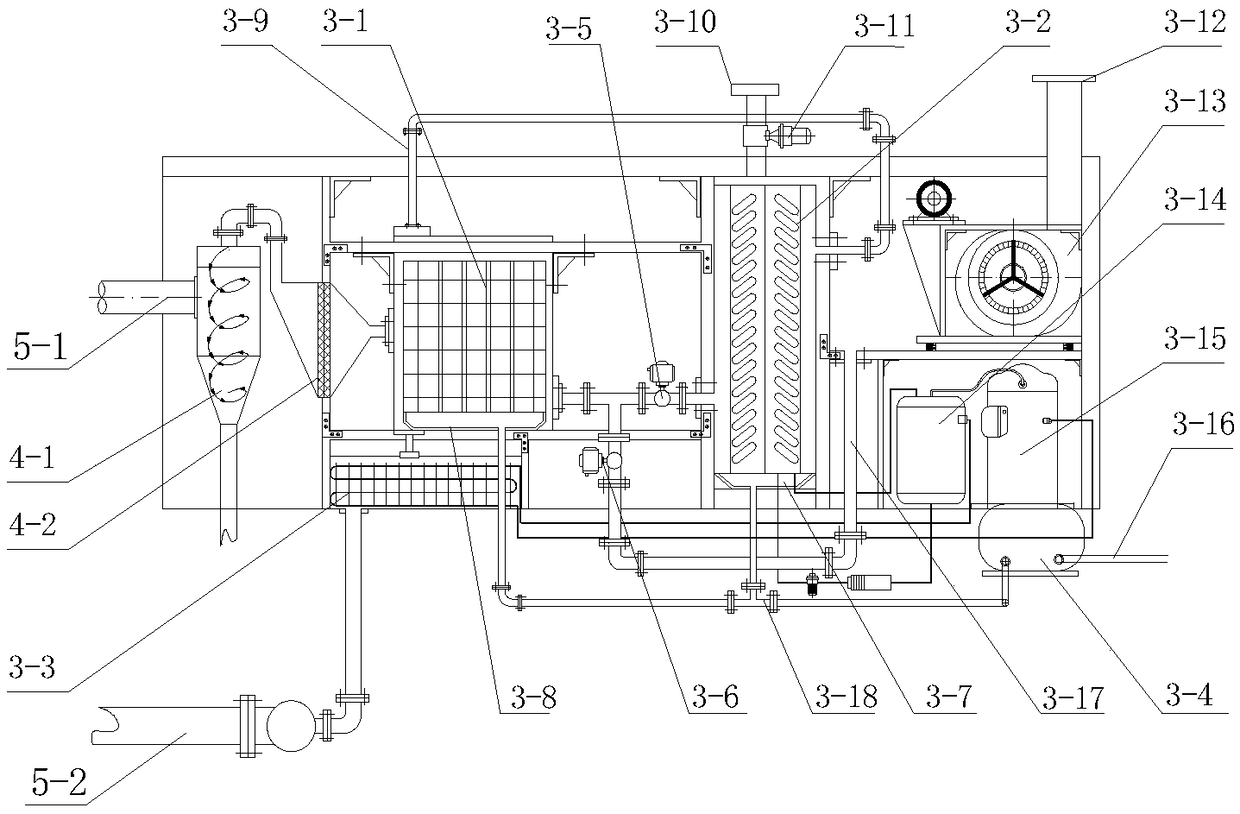

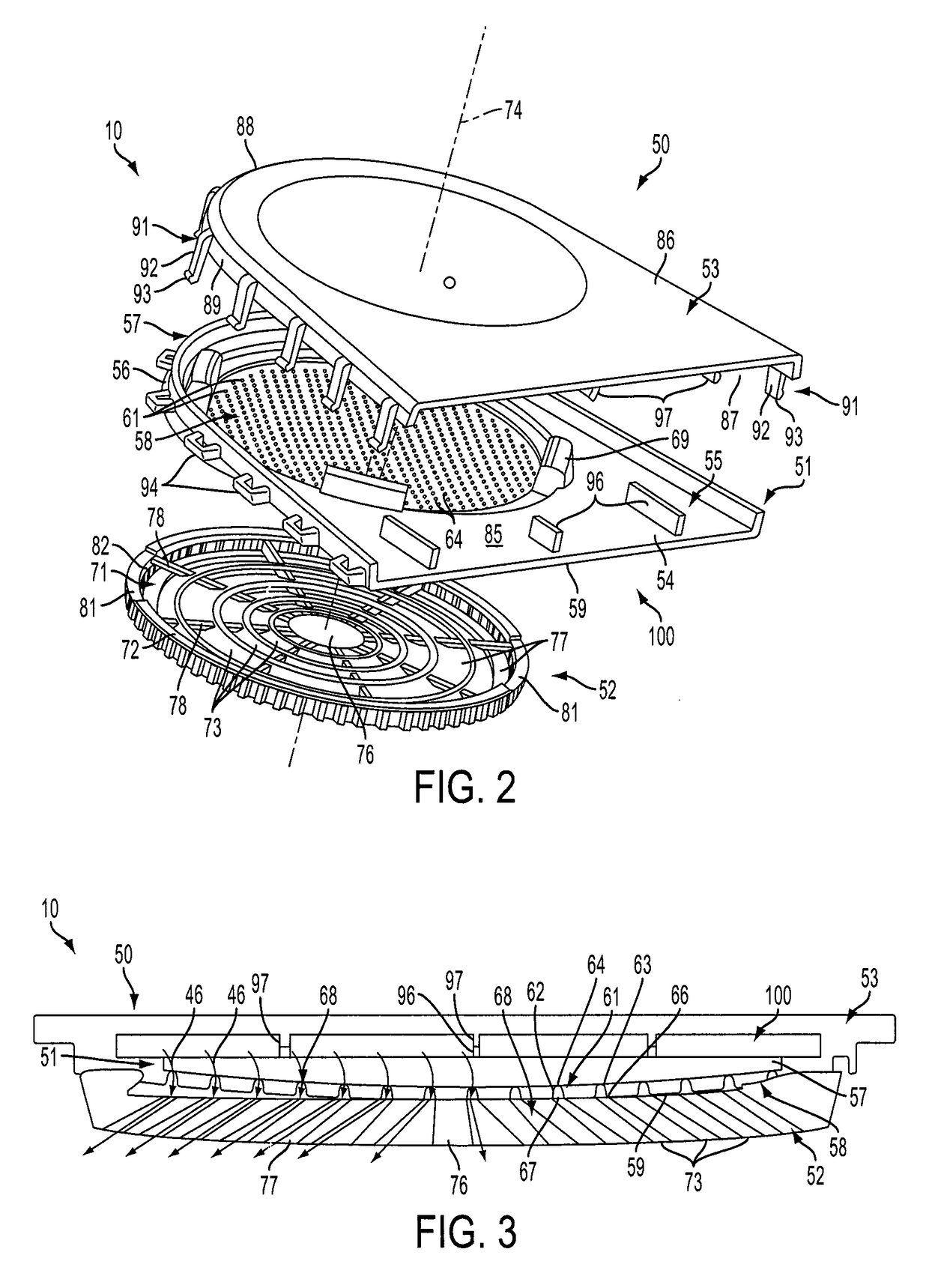

Intelligent low energy consumption sludge low-temperature drying system

PendingCN109231780AImprove drying efficiencyHeating fastSludge treatment by de-watering/drying/thickeningSludgeHigh energy

The invention discloses an intelligent low energy consumption sludge low-temperature drying system. The system comprises a sludge feed device (1), a drying tank (2), a dehumidifying and heating device(3), a dust removing device (4) and a gas pipeline, wherein the sludge feed device (1) is arranged on the drying tank (2) and is connected with the drying tank (2); the drying tank (2) is connected with the dehumidifying and heating device (3) through the gas pipeline; the dust removing device (4) is arranged between the drying tank (2) and the dehumidifying and heating device (3); a sludge outlet (2-5) is formed in the bottom of the drying tank (2); an automatic sampling device (7) is used for automatically sampling sludge in the drying tank (2); a water content online detection device (9) is used for detecting the water content of sampled sludge, and the sludge conveying speed of the drying tank (2) is adjusted according to the detection result of the water content. The intelligent lowenergy consumption sludge low-temperature drying system has the advantages of high energy utilization, and real-time detection on sludge water content variation through the water content online detection device.

Owner:浙江诺曼环保工程技术有限公司

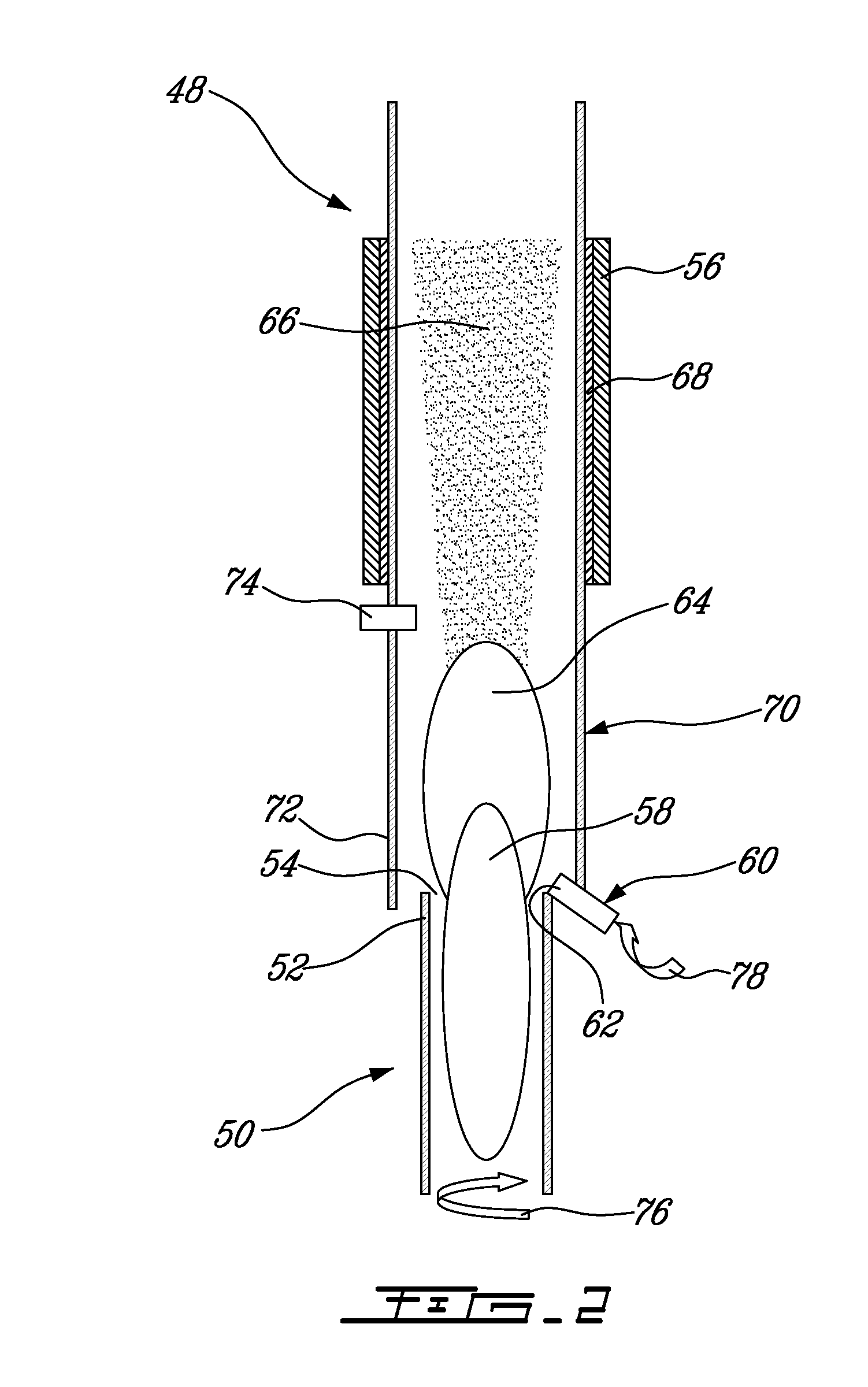

Method and apparatus for producing single-wall carbon nanotubes

InactiveUS20080226536A1Rapid condensationAvoid emissionsMaterial nanotechnologyFibre chemical featuresMetal catalystCarbon nanotube

The invention relates to a method for producing single-wall carbon nanotubes. The method of the invention comprises the steps of (a) providing a plasma torch having a plasma tube with a plasma-discharging end; (b) feeding an inert gas through the plasma tube to form a primary plasma; (c) contacting a carbon-containing substance and a metal catalyst with the primary plasma at the plasma-discharging end of the plasma tube, to form a secondary plasma containing atoms or molecules of carbon and atoms of the metal catalyst; and (d) condensing the atoms or molecules of carbon and the atoms of the metal catalyst to form single-wall carbon nanotubes. Alternatively, steps (b) and (c) can be carried out by feeding an inert gas and an inorganic metal catalyst through the plasma tube to form a primary plasma containing atoms of the inorganic metal catalyst and contacting a carbon-containing substance with the primary plasma at the plasma-discharging end of the plasma tube, to form a secondary plasma containing atoms or molecules of carbon and the atoms of metal catalyst. An apparatus for carrying out the method according to the invention is also disclosed.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

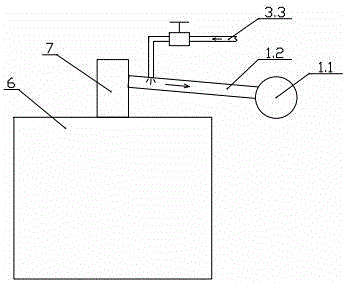

Cleaning method for tunnel dry ice

The invention discloses a cleaning method for tunnel dry ice. The method comprises the following steps: 1) respectively connecting an air compressor, a liquid carbon dioxide storage tank and a dry ice cleaning device, and checking gas tightness; 2) connecting the dry ice cleaning device and interfaces of each nozzle set on a cleaning nozzle machine bogie; 3) driving an engineering truck into a tunnel inlet to be cleaned, and adjusting the cleaning nozzle machine bogie; 4) opening the air compressor, opening a valve connected with the dry ice cleaning device after the pressure of the air compressor reaches set value; 5) opening the carbon dioxide storage tank valve; 6) uniformly progressing the engineering truck with low speed, assuring the cleaning time of each cleaned surface for 1-2 seconds; 7) closing the liquid carbon dioxide storage tank valve after finishing cleaning. The cleaning method develops a device suitable for cleaning the tunnel dry ice according to physico-chemical property of carbon dioxide, thermodynamic principle and dry ice cleaning characteristics; according to the cleaning method for tunnel dry ice, the ejected dry ice is dry ice sand which has soft texture, small grain diameter and low density, so that the surface of cement is favorable for cleaning and has no injury to the cement, thereby reducing the influence of void and fissuring of the cement surface caused by dry ice micro detonation.

Owner:CHONGQING UNIV

Chlorine-free type high-strength high-performance sprayed concrete accelerator

The invention discloses a chlorine-free type high-strength high-performance sprayed concrete accelerator which comprises aluminate, carbonate, alkali metal hydroxide, alkanolamine, cellulose and water. Through the invention, the setting time of cement slurry and concrete can be greatly shortened, the cement slurry and the concrete are initially set within 5 minutes and finally set within 10 minutes, and the strength is rapidly improved after the slurry is set. The rusting harm of chlorine ions to reinforcing bars inside the concrete can be effectively avoided by using the invention.

Owner:浙江五龙新材股份有限公司

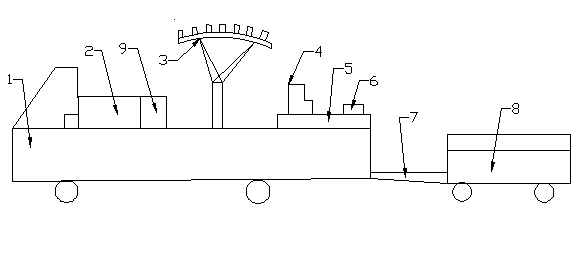

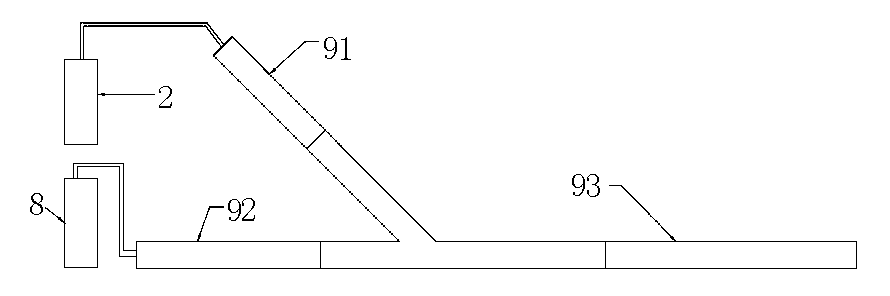

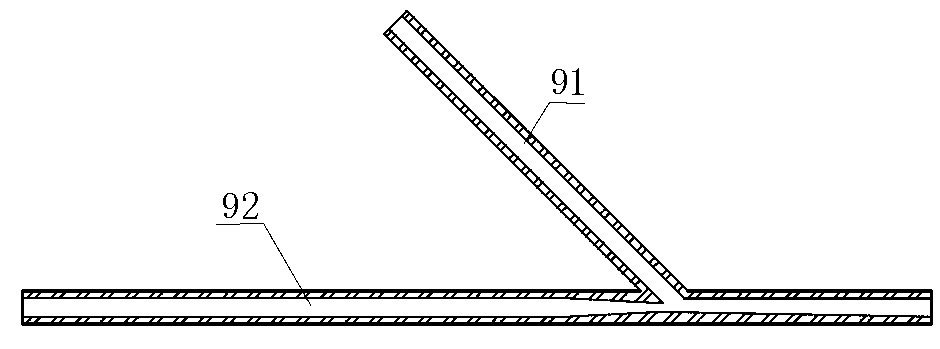

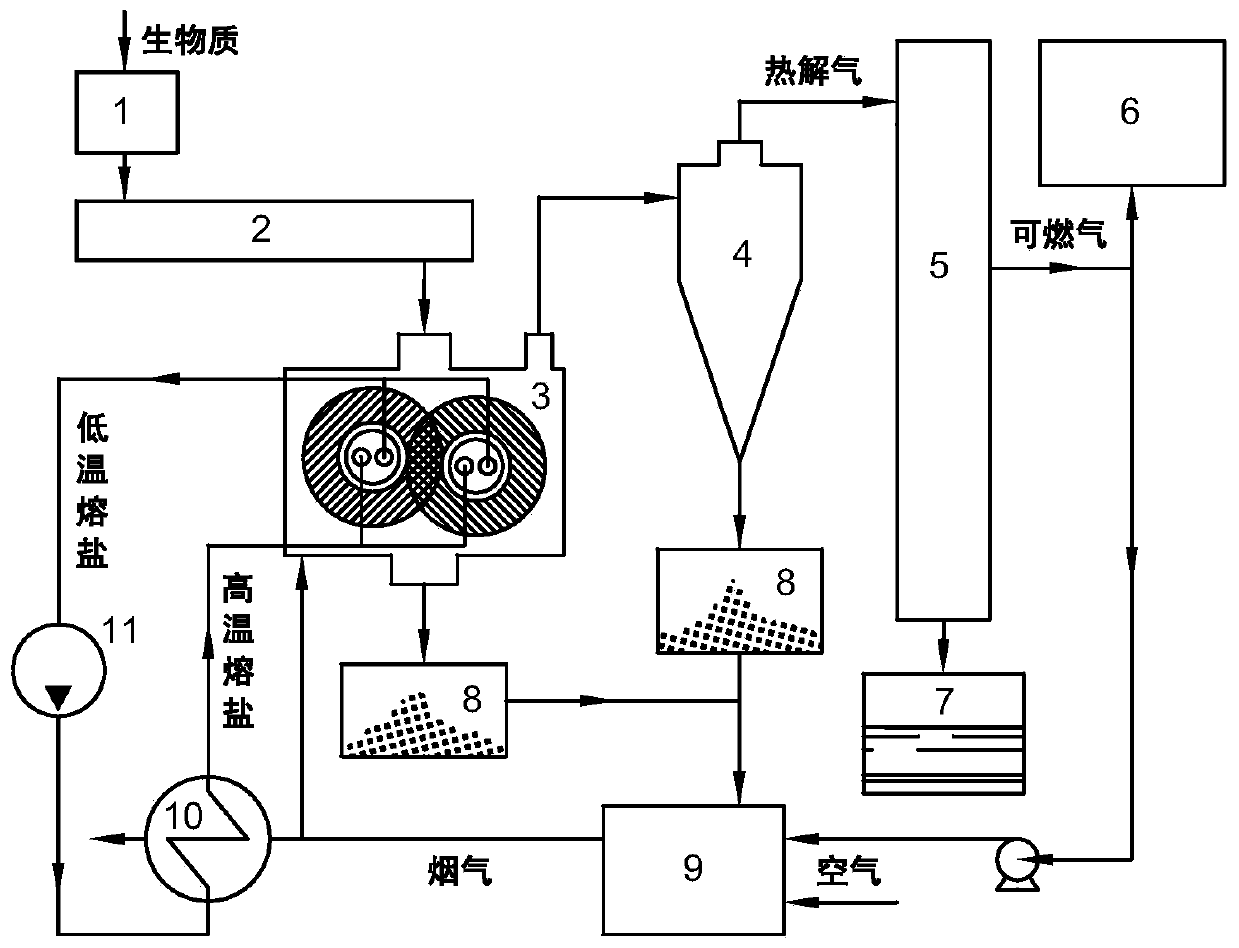

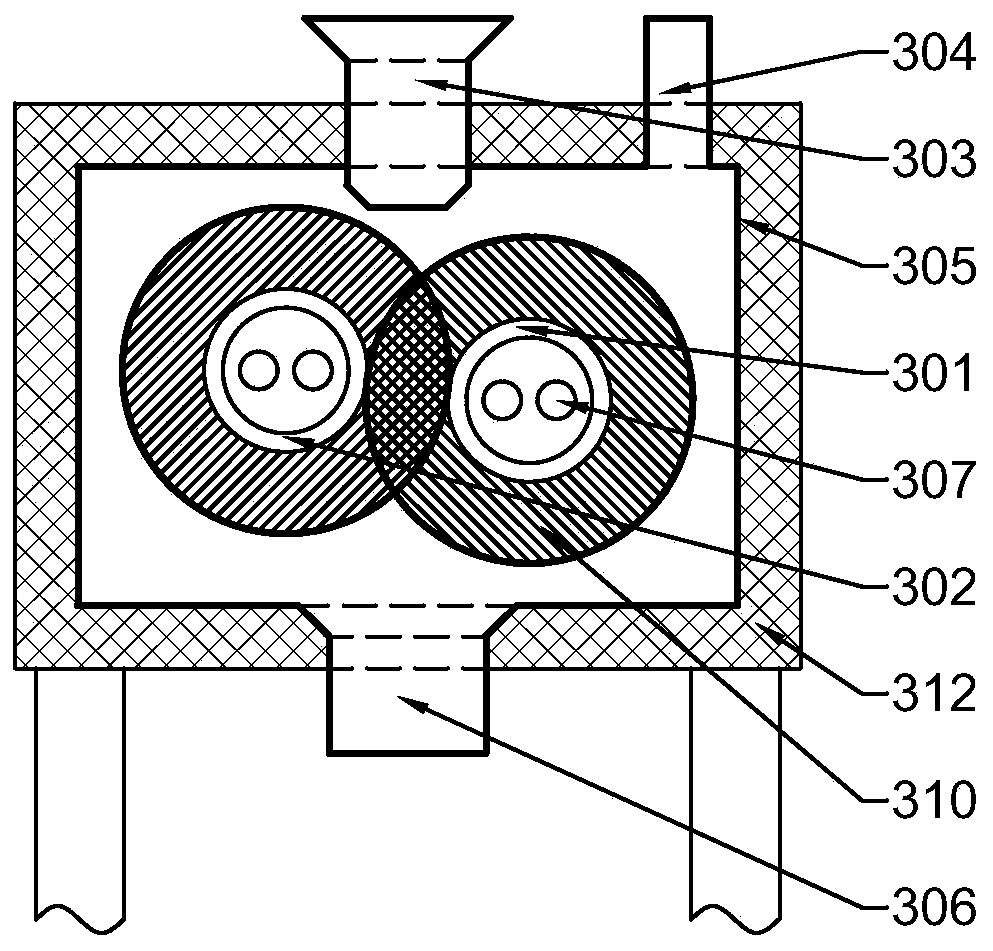

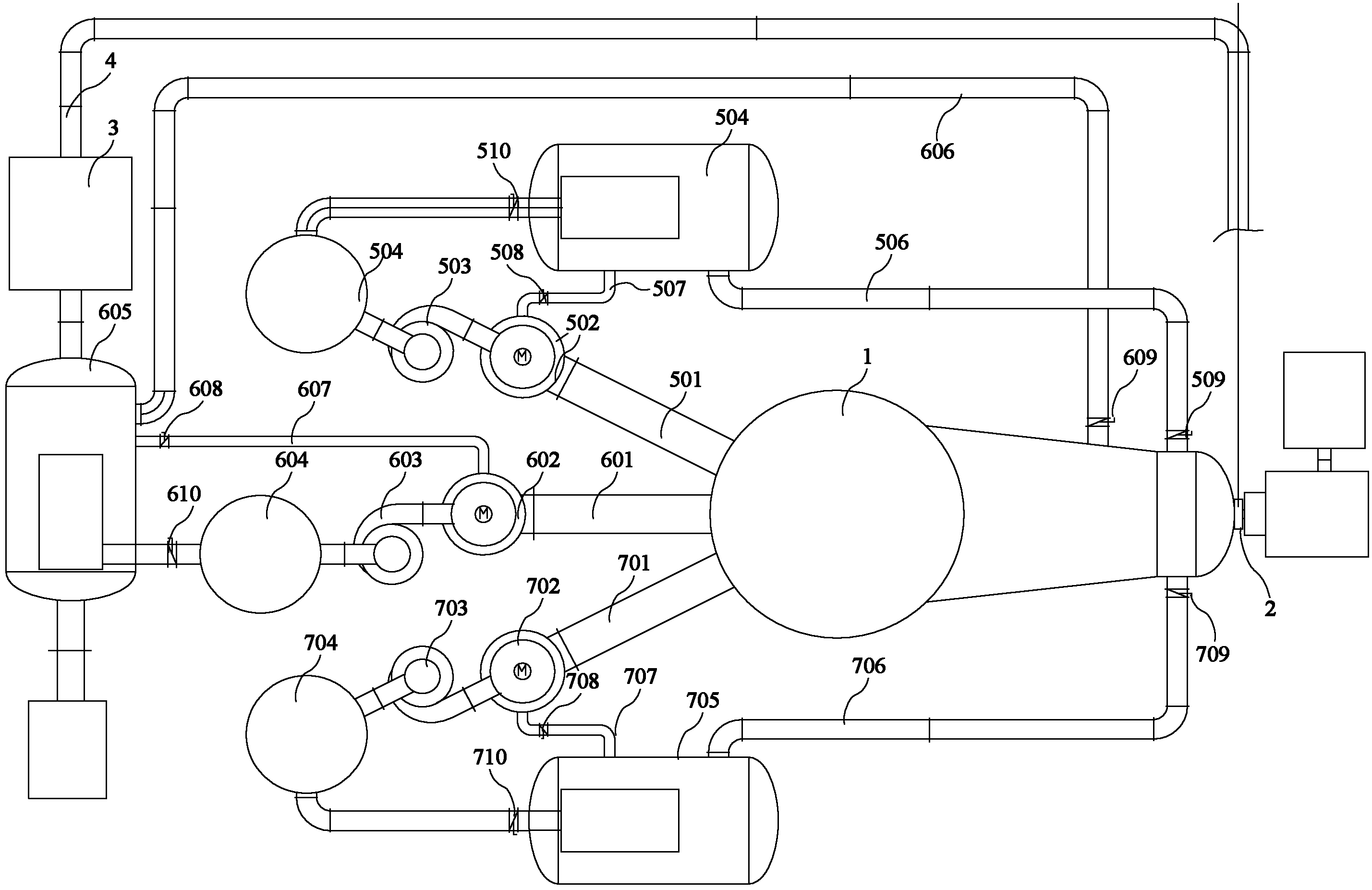

Differential grinding roller type rapid biomass catalytic pyrolysis device and method

ActiveCN110003926AImprove heat transfer efficiencyEfficient heat transferBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisThermal insulation

The invention relates to a differential grinding roller type rapid biomass catalytic pyrolysis device and method. The device comprises a hopper, a feed system, a differential grinding roller type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a bio-oil collection tank, a carbon collection box, a combustion system, a heat exchange system and a fused salt circulation system. The differential grinding roller type pyrolysis reactor comprises a pair of differential grinding rollers, a closed casing, a high-temperature fused salt heat exchange tube, a materialinlet / outlet, a gas outlet, a drive and transmission device and a thermal insulation system. The pretreated biomass raw materials are subjected to heating and shearing friction of cross high-temperature millstones, the surface carbon residues are continuously peeled off, and effective catalytic pyrolysis inside raw material particles is ensured; the pyrolysis gas is rapidly condensed after gas-solid separation so as to obtain high-grade bio-oil fuel or bio-oil enriched in specific high value-added products; meanwhile, the combustible gas and coke are collected and combusted to produce high temperature flue gas, and the flue gas is used for heating the fused salt and conducting heat and further heating the millstone, so that a self-heating pyrolysis process is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Native fluorescence detection methods, devices, and systems for organic compounds

ActiveUS10598596B1Rapid condensationRapid vaporization of VOCsRadiation pyrometrySpectrum investigationWave bandEnvironmental chemistry

Naphthalene, benzene, toluene, xylene, and other volatile organic compounds VOCs have been identified as serious health hazards. Embodiments of the invention are directed to methods and apparatus for near-real-time in-situ detection and accumulated dose measurement of exposure to naphthalene vapor and other hazardous gaseous VOCs. The methods and apparatus employ excitation of fluorophors native or endogenous to compounds of interest using light sources emitting in the ultraviolet below 300 nm and measurement of native fluorescence emissions in distinct wavebands above the excitation wavelength. The apparatus of some embodiments are cell-phone-sized sensor / dosimeter “badges” to be worn by personnel potentially exposed to hazardous VOCs. The badge sensor of some embodiments provides both real time detection and data logging of exposure to naphthalene or other VOCs of interest from which both instantaneous and accumulated dose can be determined.

Owner:PHOTON SYST

Drying system for a dishwasher

InactiveUS9872598B2Rapid and efficientReduce morbidityTableware washing/rinsing machine detailsDrying chambers/containersEngineeringMoisture

Owner:VIKING RANGE

Self-purification method for machine-made charcoal kiln smoke collecting pipe and kiln smoke collecting system for self-purification method

InactiveCN106424030AImprove purification effectAvoid cloggingUsing liquid separation agentHollow article cleaningCollection systemSelf purification

The invention relates to a self-purification method for a machine-made charcoal kiln smoke collecting pipe and a kiln smoke collecting system for the self-purification method. The method comprises the steps that bamboo and wood vinegar liquor in a liquor collecting pool flows back to the portion near the air inlet end of the kiln smoke collecting pipe through a circulating liquor supply pipeline, and the bamboo and wood vinegar liquor is used for spraying and purifying kiln smoke newly entering the kiln smoke collecting pipe; the kiln smoke collecting pipe has a certain degree of inclination, and the liquor in the kiln smoke collecting pipe is guided out from the low end and flows to the liquor collecting pool; and the smoke in the kiln smoke collecting pipe is guided out from the high end and flows to a water-gas separation device. According to the self-purification method for the machine-made charcoal kiln smoke collecting pipe and the kiln smoke collecting system, the bamboo and wood vinegar liquor flows back to the air inlet end of the kiln smoke collecting pipe through the circulating liquor supply pipeline; on the one hand, kiln smoke purification is facilitated, vaporific gas in the kiln smoke is condensed quickly, the smoke is set quickly, and the vaporific gas and the smoke flow to the liquor collecting pool along with the bamboo and wood vinegar liquor; and on the other hand, due to the fact that the bamboo and wood vinegar liquor flows in the kiln smoke collecting pipe in a circulating manner, the flushing function on the inner wall of the kiln smoke collecting pipe is achieved, and thus the kiln smoke collecting pipe can be prevented from being blocked, and the ventilatory capacity of the pipe and the pipe gas delivery safety are increased.

Owner:BLUE MACHINERY & ELECTRONICS

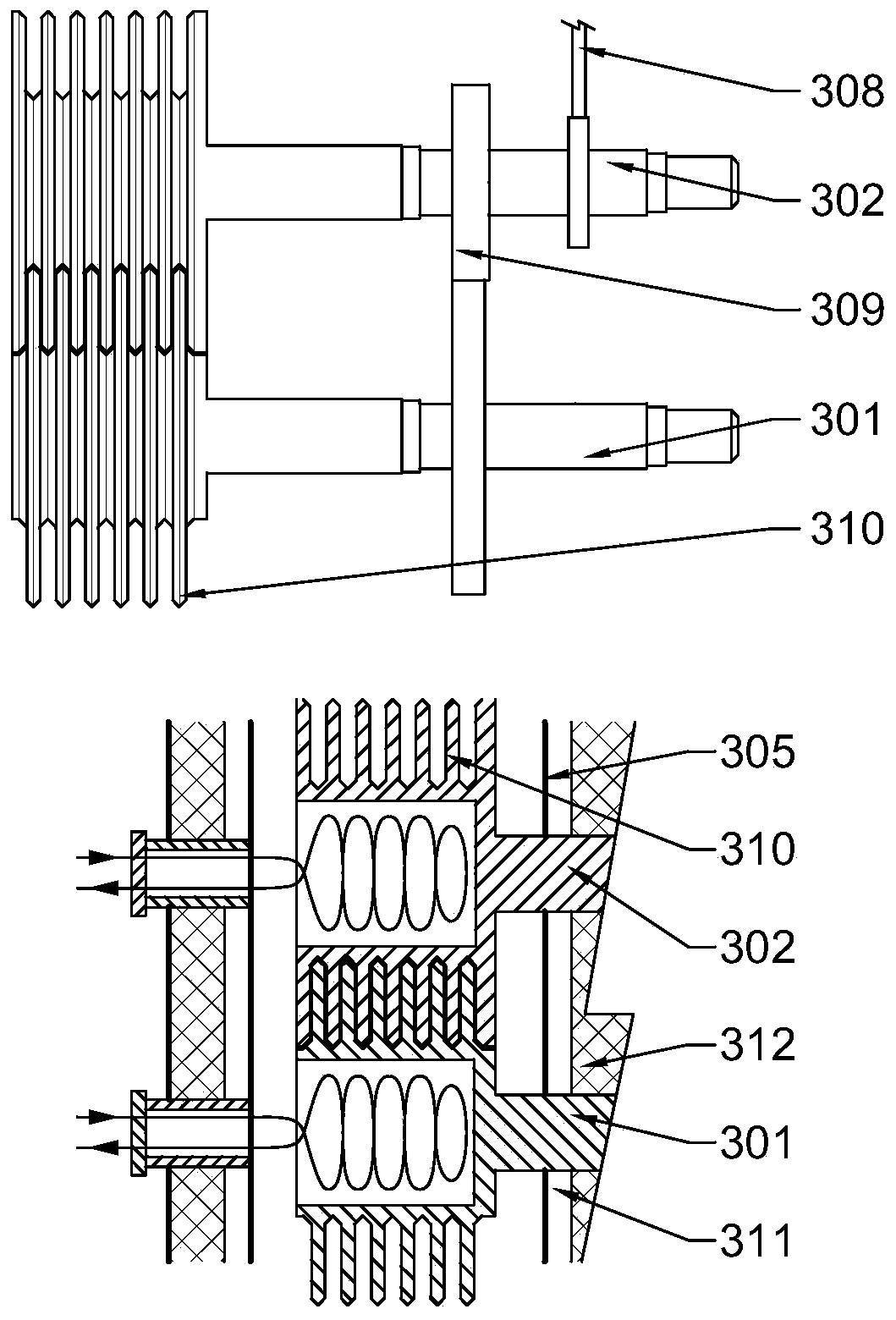

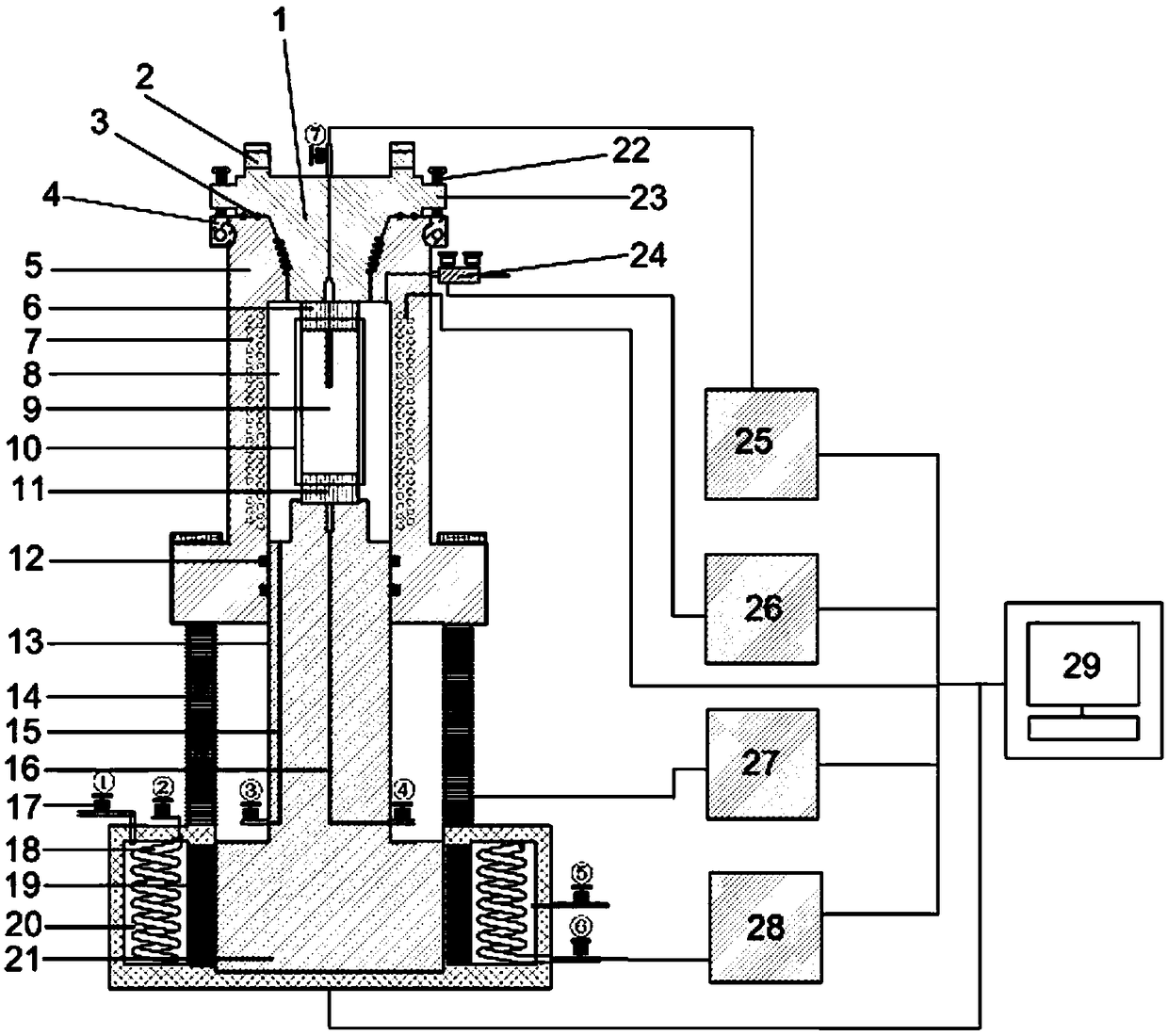

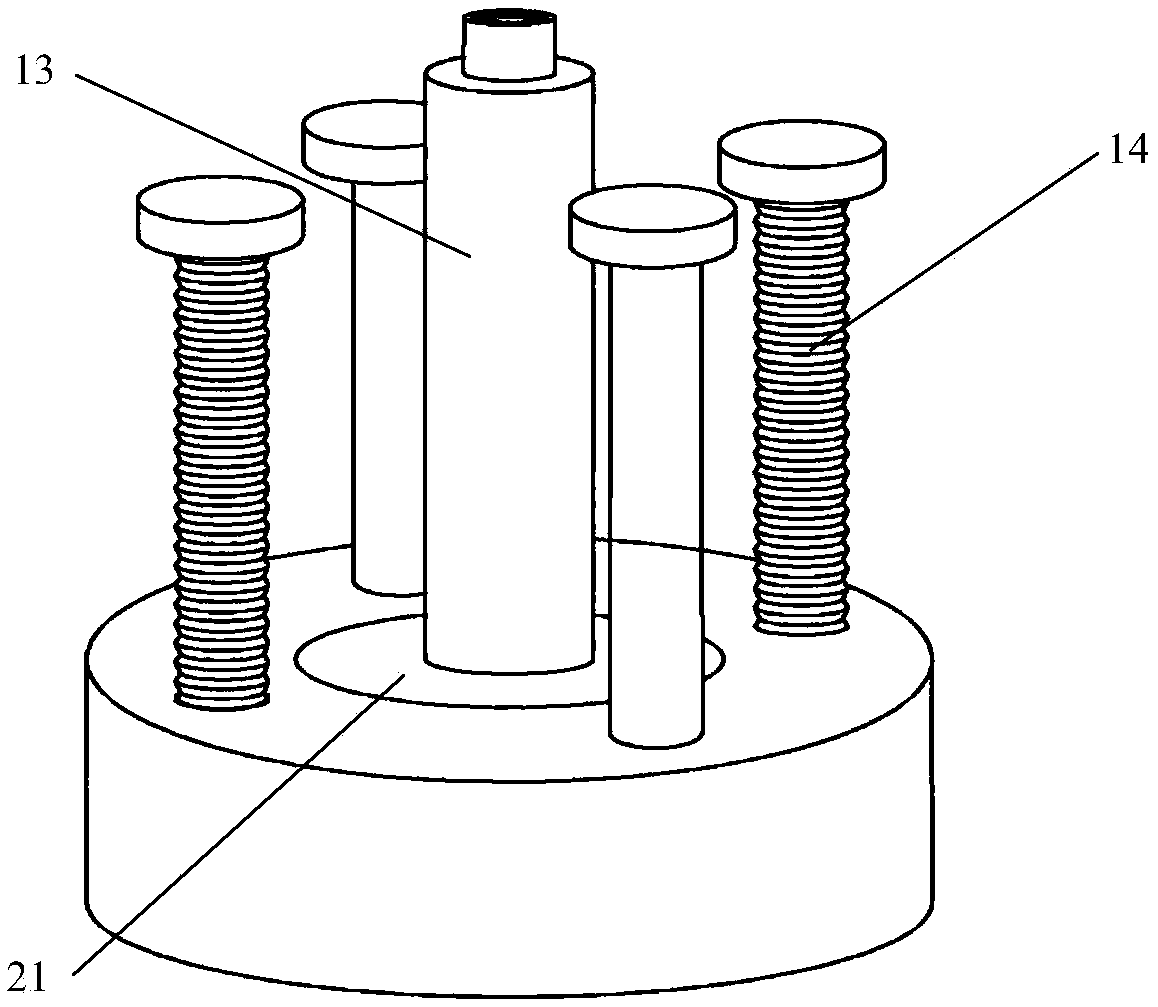

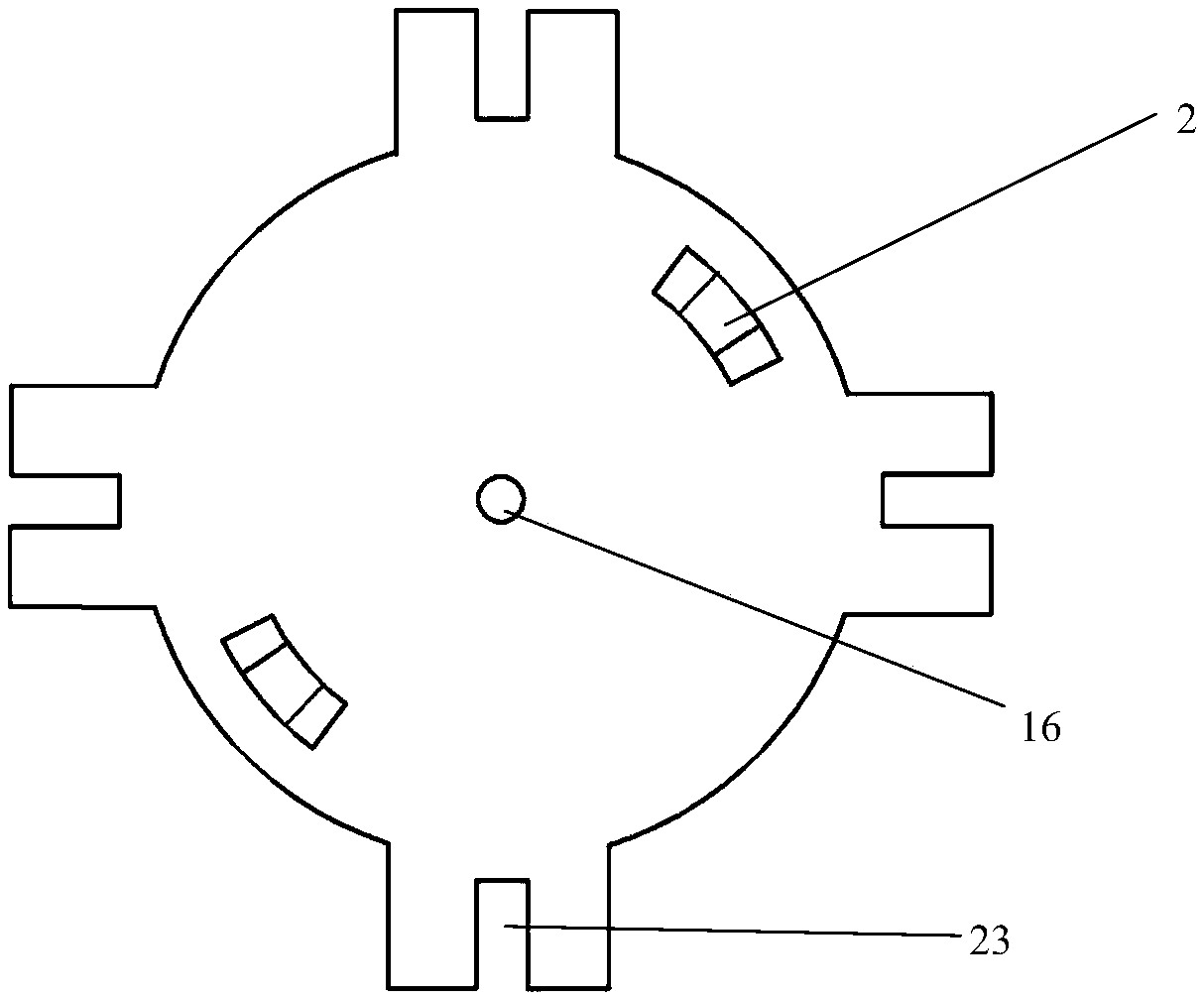

Core test device for high temperature and high pressure hydraulic fracturing and triaxial test

PendingCN109357953ASimple structureEasy to assemble and disassembleMaterial strength using tensile/compressive forcesFour-way valveThermal insulation

The invention relates to a core test device for high temperature and high pressure hydraulic fracturing and triaxial test. The core test device is composed of a top conical thread plug, a dismountingauxiliary hole, an O-shaped sealing ring, a movable bolt ring, a cylinder body, a top cushion block, a heating resistance wire, a cavity, a rock sample, a high elastic rubber sleeve, a bottom cushionblock, a stepseal, an axial direction plunger, an axial direction bolt guide rail, an oil guide hole, a central water guide hole, a condensing pipe, a thermal insulation protective layer, a heat transfer of cooling chamber, a servo hydraulic press, a bolt, a constraint slot, a high-voltage four-way valve, a hydraulic pump, a confining pressure pump, a lifting controller, an oil box, a computer system, and a high-voltage ball valve. The test device is simple in structure, convenient to detach, good in sealing performance, capable of rapidly replacing rock cores, and capable of performing different core mechanical property tests under various temperatures and pressure conditions according to scientific research and production requirements, the system comprises a core triaxial test and a hydraulic fracturing test, and the working efficiency is high and reliable.

Owner:JILIN UNIV

Atomized production system

InactiveCN102398039AImprove atomization energy conversion rateIncrease production capacityGrade systemEngineering

The embodiment of the invention discloses an atomized production system, which comprises a spraying device, an atomizing chamber, a nitrogen gas compression system, a nitrogen producing system, a cooling system, grading systems and ventilators, wherein the spraying device is communicated with the atomizing chamber which is communicated with a plurality of sets of grading systems; each set of grading system is respectively connected with one ventilator; the nitrogen gas compression system is communicated with a gas balancing tank and the spraying device; and the nitrogen producing system is communicated with the gas balancing tank. In the atomized production system, a cooling tube array is arranged on a ventilation pipeline; and a water-cooling jacket is arranged on equipment. In the embodiment of the invention, one spraying device corresponds to the plurality of sets of grading systems and each set of grading system is provided with one ventilator; through a plurality of tests by an inventor, the pressure of the atomized production system can reach as high as 6-12MPa and the cooling speed can reach 103-104k / s; and in addition, high-pressure gas of the atomizing device is centrally used, and thereby the conversion rate of atomizing energy is improved and further the production capacity of the atomized production system is improved.

Owner:米成群

Native fluorescence detection methods, devices, and systems for organic compounds

ActiveUS9909990B1Rapid condensationRapid vaporization of VOCsSpectrum investigationMaterial analysis by electric/magnetic meansDosimeterUltraviolet

Naphthalene, benzene, toluene, xylene, and other volatile organic compounds VOCs have been identified as serious health hazards. Embodiments of the invention are directed to methods and apparatus for near-real-time in-situ detection and accumulated dose measurement of exposure to naphthalene vapor and other hazardous gaseous VOCs. The methods and apparatus employ excitation of fluorophors native or endogenous to compounds of interest using light sources emitting in the ultraviolet below 300 nm and measurement of native fluorescence emissions in distinct wavebands above the excitation wavelength. The apparatus of some embodiments are cell-phone-sized sensor / dosimeter “badges” to be worn by personnel potentially exposed to hazardous VOCs. The badge sensor of some embodiments provides both real time detection and data logging of exposure to naphthalene or other VOCs of interest from which both instantaneous and accumulated dose can be determined.

Owner:PHOTON SYST

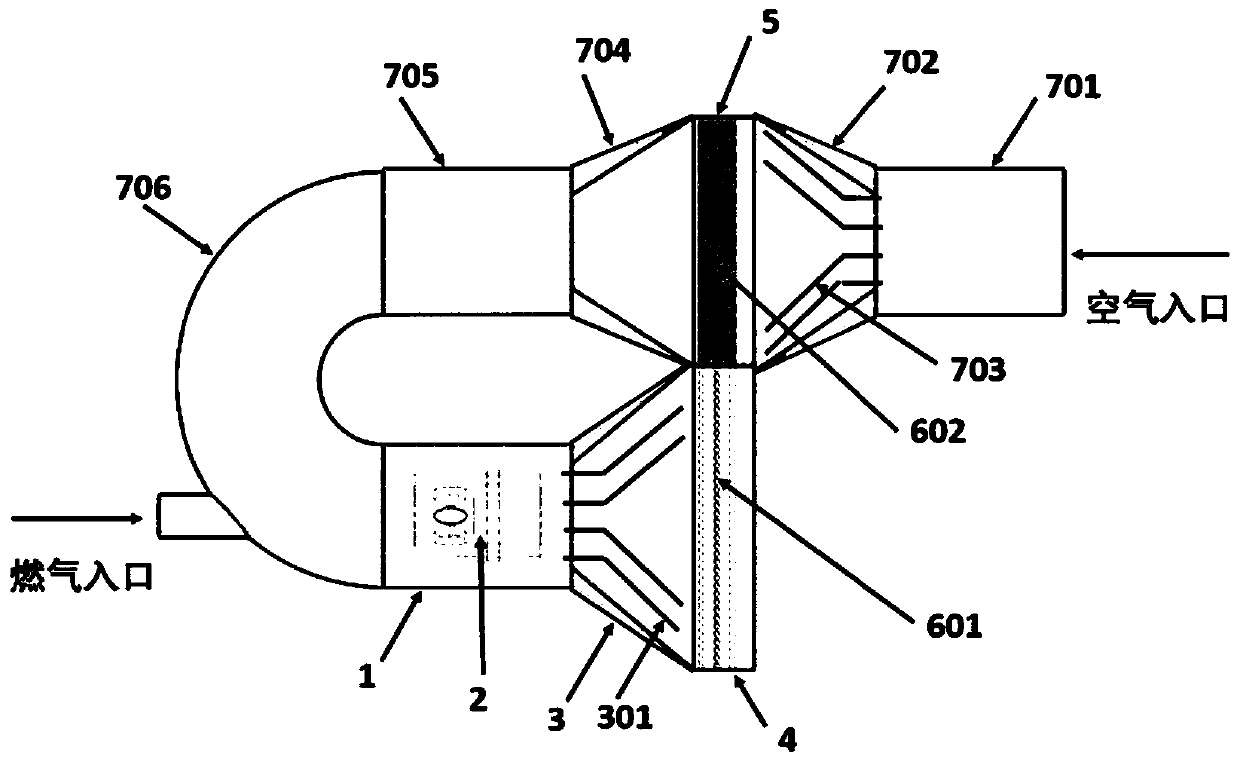

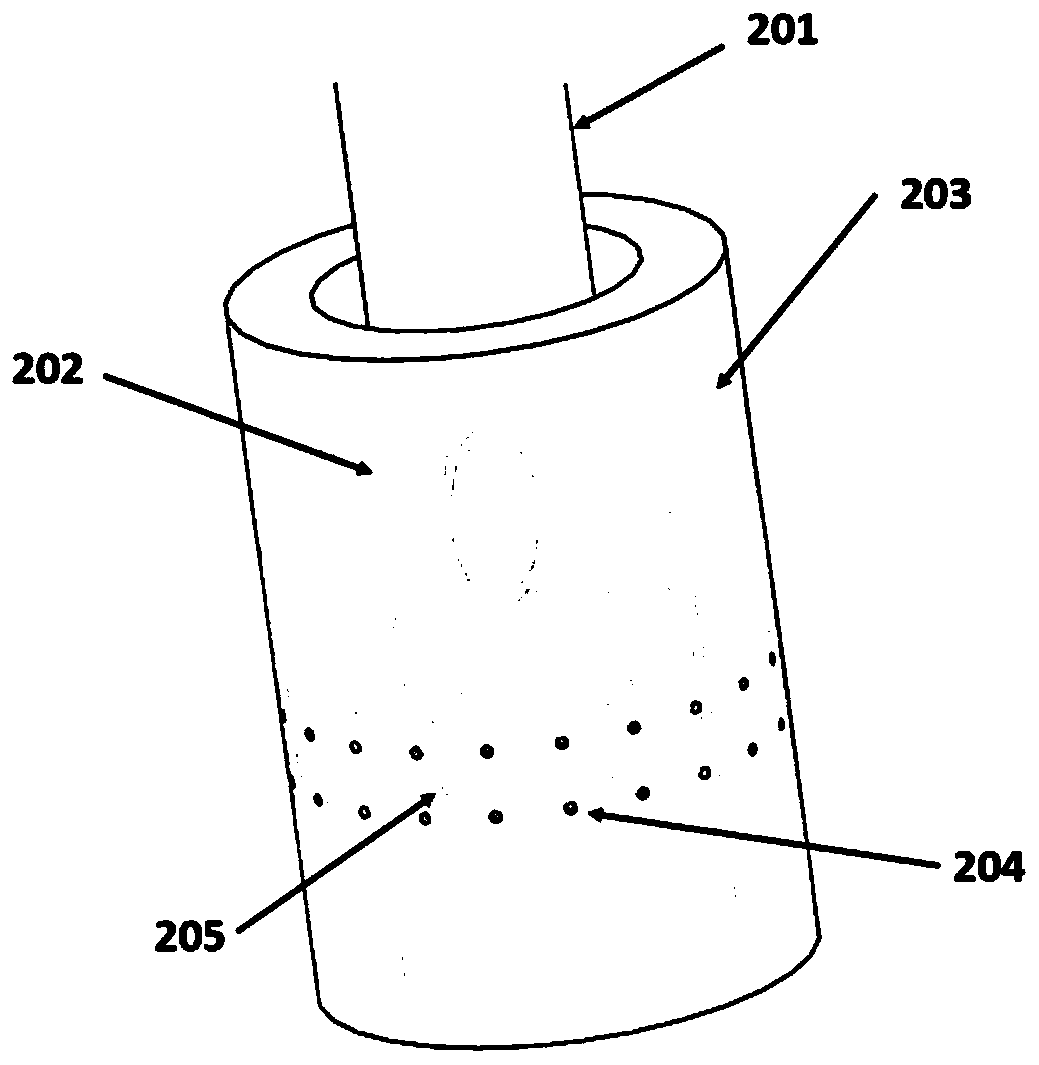

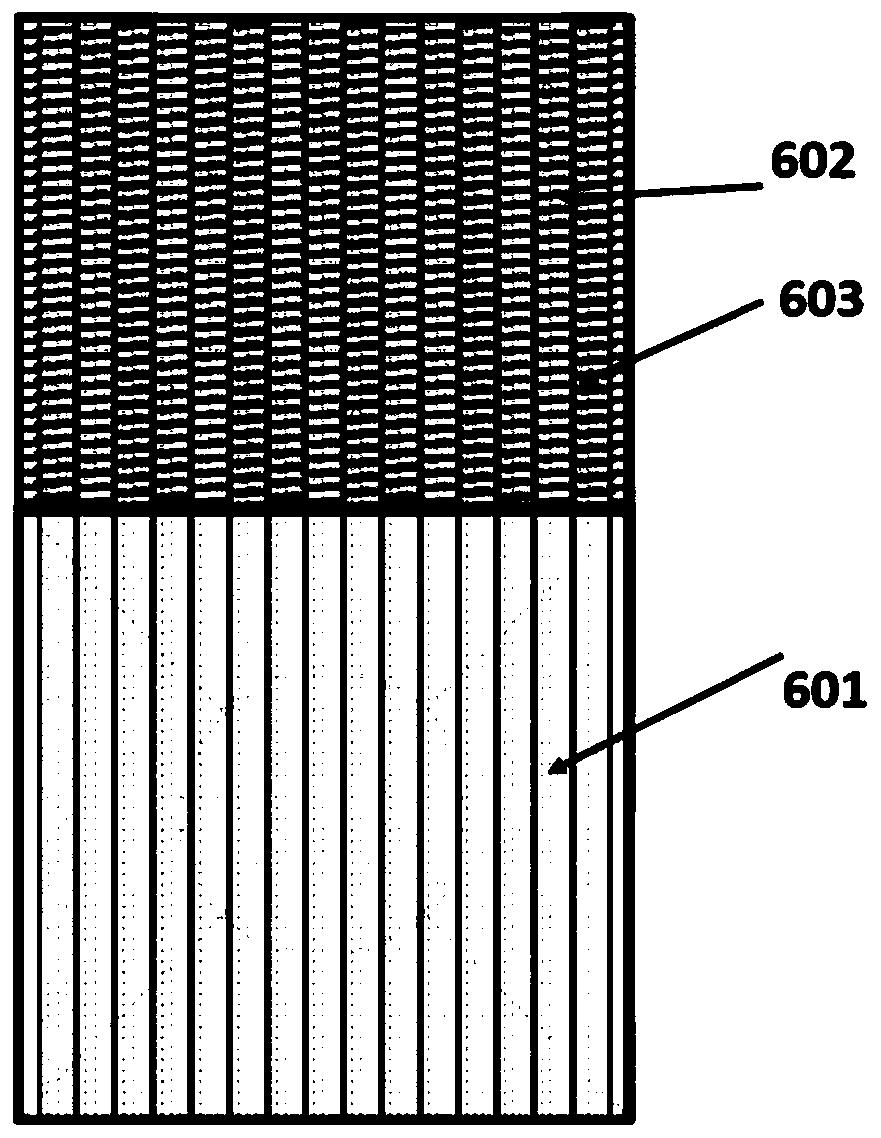

Heat-pipe-based heat exchange low-nitrogen gas burner

ActiveCN111121022AEmission reductionAvoid destructionIndirect heat exchangersIndirect carbon-dioxide mitigationWater circulationNitrogen gas

The invention discloses a heat-pipe-based heat exchange low-nitrogen type gas burner. The burner comprises an air-fuel mixing section and a combustion head which are sequentially connected in a gas flow direction, wherein a gas nozzle is arranged in the air-fuel mixing section, the combustion head comprises a plurality of heat pipes arranged in a pipe bundle mode, a heat pipe evaporation heat absorption section in the pipe bundle is arranged to form a combustion gap as the combustion head, and a heat pipe condensation heat release section is provided with a condensing device and is arranged outside a furnace. According to the burner, the combustion head formed through intermittent arrangement of the plurality of heat pipes is arranged between the furnace and the air-fuel mixing section, two phase-change heat exchange processes of evaporation heat absorption and condensation heat release in a heat pipe heat transfer process have the advantages of good heat conductivity, isothermal property and the like, so that pipe inner working media in the heat pipes are evaporated into steam when the heat pipe evaporation heat absorption section absorbs heat of a combustion zone of the furnace,the condensation device of air cooling, water cooling and the like is adopted for condensation and heat releasing, liquid after the steam in the pipes is subjected to heat releasing and condensation flows back the heat absorption section under the action of gravity, and the damage caused to a boiler hydrodynamic cycle of a water-cooled combustor water cycle is effectively solved.

Owner:XI AN JIAOTONG UNIV +1

Medicinal material processing device

InactiveCN110170486ARapid condensationActs as a cooling substanceFlow mixersTransportation and packagingEngineeringMaterials processing

The invention discloses a medicinal material processing device which comprises a cylinder body, a condensing assembly and a heating assembly. The heating assembly is located on the bottom of the cylinder body. The condensing assembly is located vertically above the cylinder body. The cylinder body is further provided with a first outlet, a first liquid inlet, a second liquid inlet, a feeding portand a discharging port. The body of the cylinder body is of a cylinder shape. The bottom is of a shape gradually expanded in the direction away from the discharging port from the discharging port. Theheating assembly is located at the position, close to the bottom, of the periphery wall of the cylinder body. The first outlet is formed in the top of the cylinder body and communicates with the condensing assembly. The discharging port is formed in the bottom of the cylinder body and provided with a first screening and filtering part. The feeding port is formed in the periphery wall of the cylinder body. The first liquid inlet and the second liquid inlet are formed in positions, of different heights, of the periphery wall of the cylinder body in the vertical direction. The flow guide direction of the first liquid inlet and the second liquid inlet is tangent with the inner wall of the cylinder body. According to the medicinal material processing device, the medicinal materials can be washed and extracted, the medicinal material processing steps are integrated, and the equipment utilization rate is increased.

Owner:古浪县康泰中药材种植专业合作社

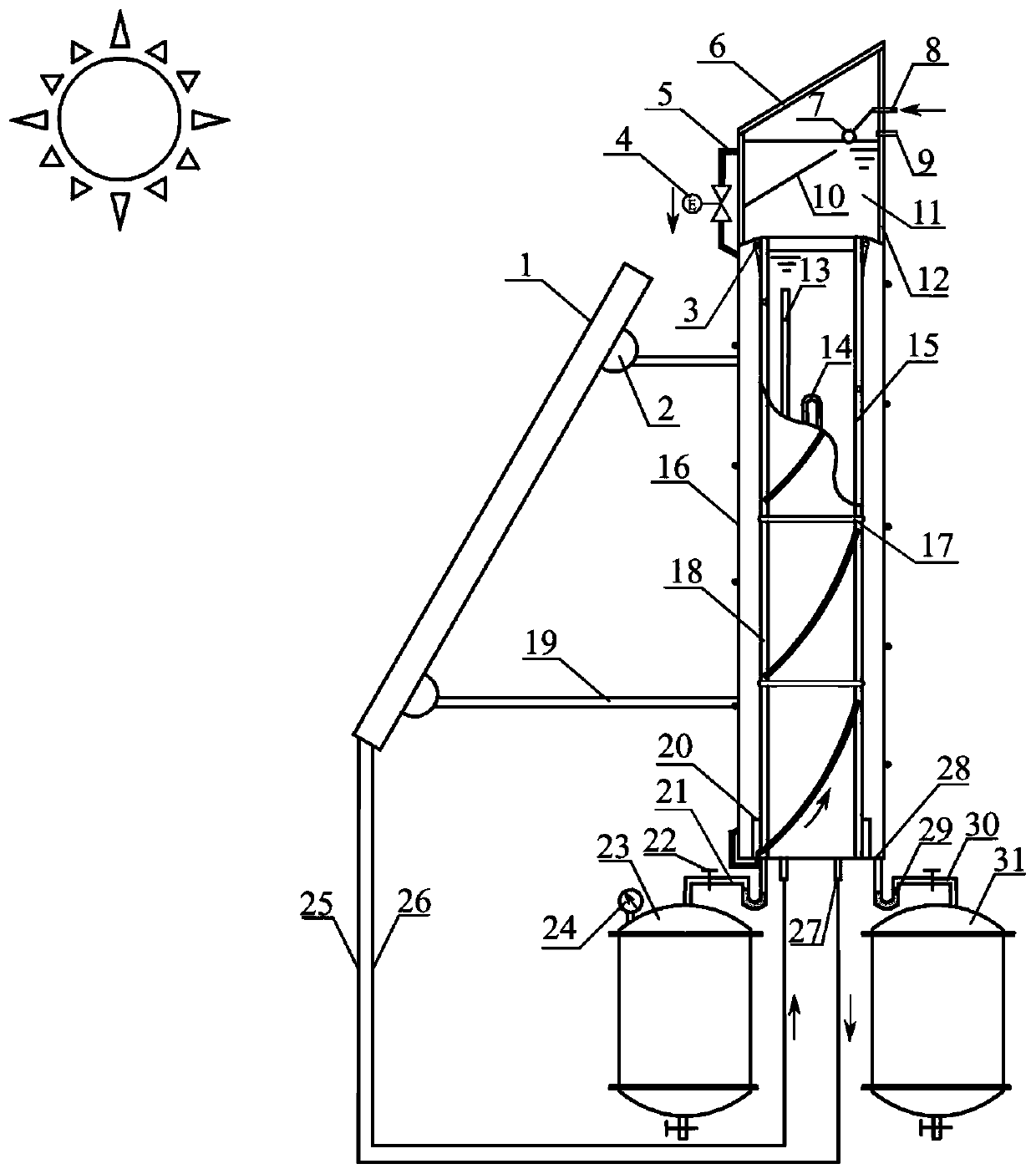

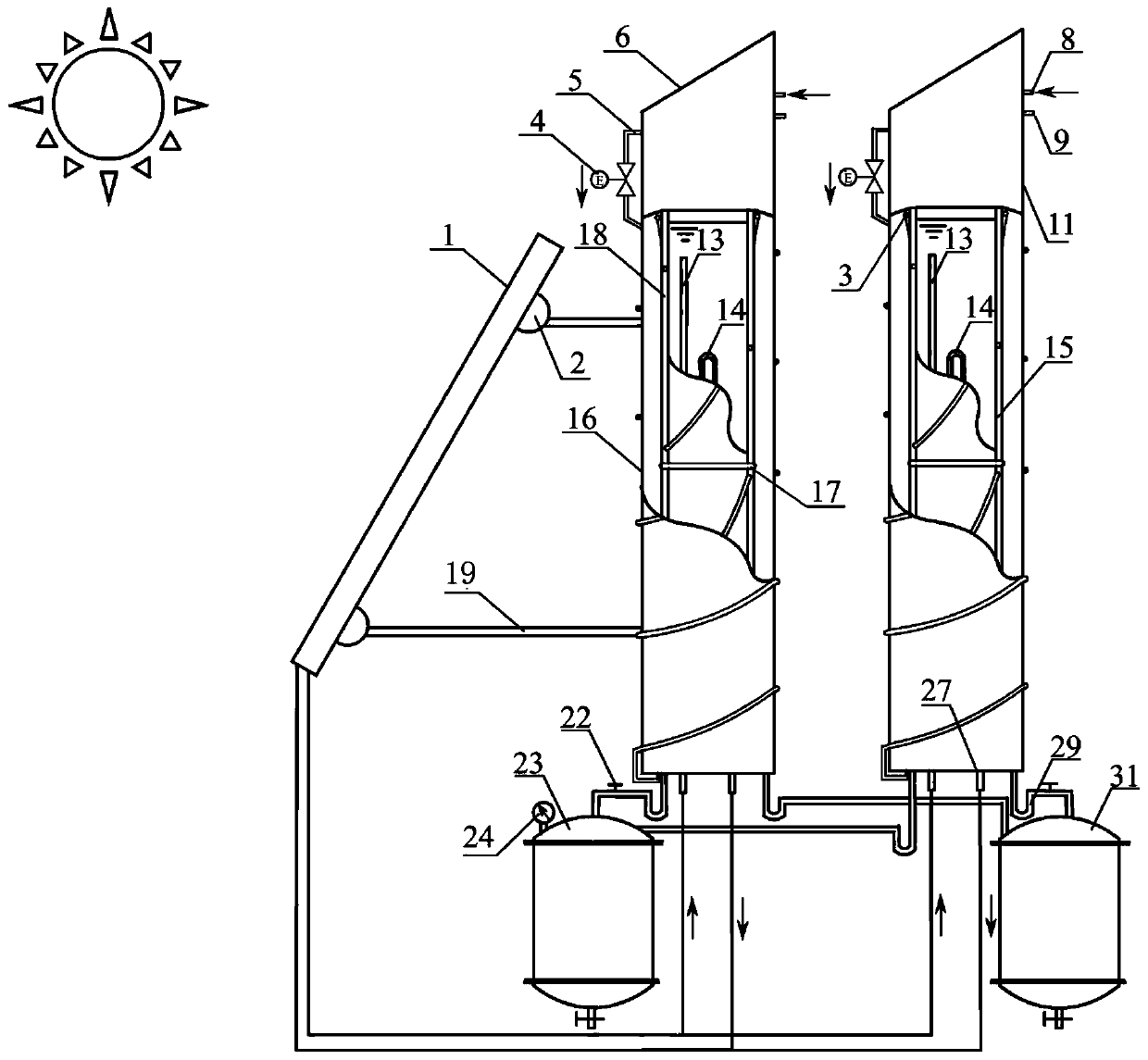

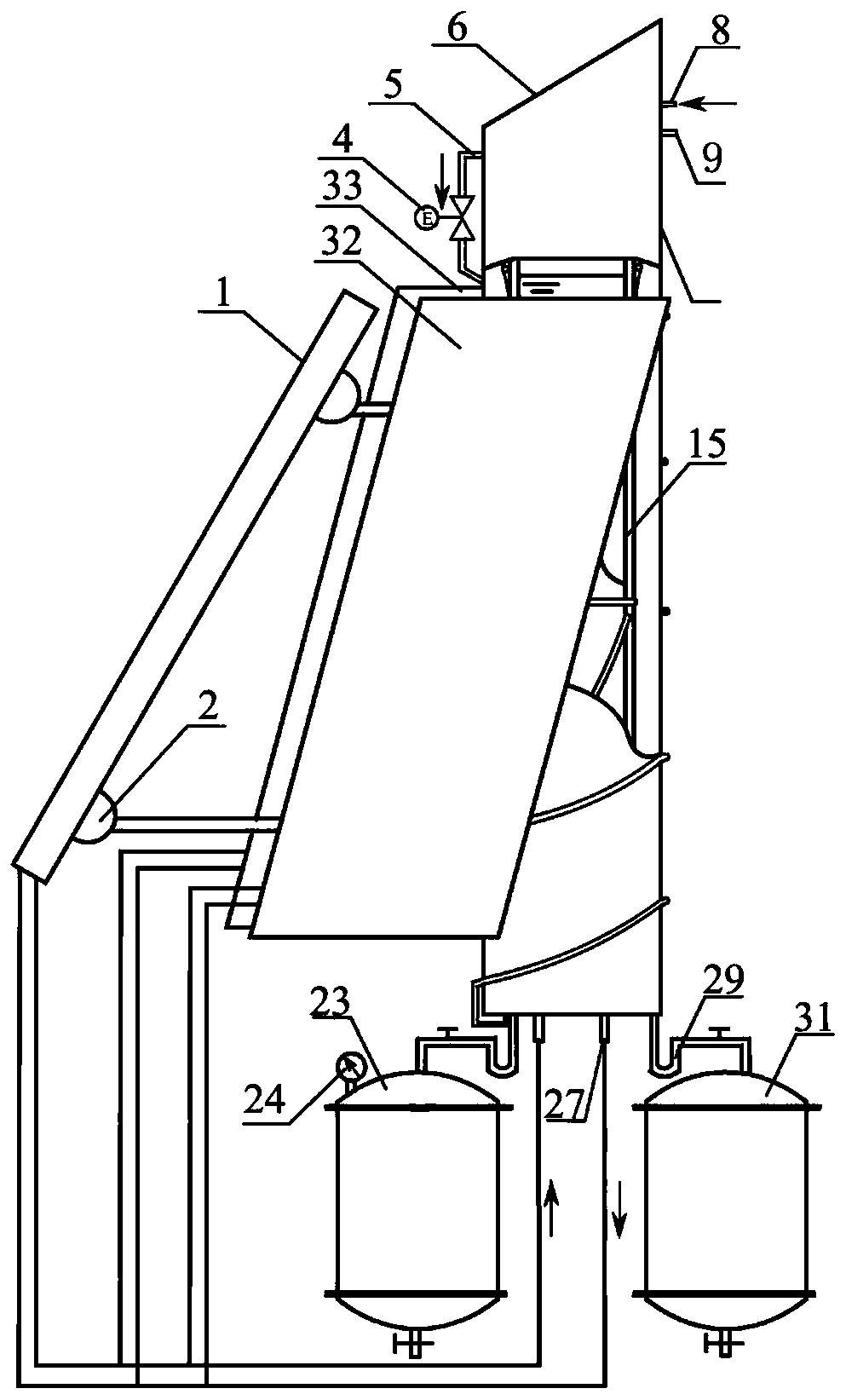

Self-gravity water inlet heat regeneration type liquid film evaporation type solar seawater distillation device

PendingCN111204832ACongeal fastIncrease water production rateGeneral water supply conservationSeawater treatmentGlass coverWater vapor

The invention discloses a self-gravity water inlet heat regeneration type liquid film evaporation type solar seawater distillation device. The device comprises a flat-plate solar collector A, a concentrated seawater collection tank, a fresh water collection tank, a water distributor, a flow control valve, a seawater feeding pipe, a glass cover plate, an overflow pipe, a preheated seawater cylinder, a hot water inlet pipe A, a heating water tank, a condensation sleeve A, a water absorption material, a water baffle, a concentrated seawater collection pipe, a water return pipe, a hot water inletpipe B, a bottom plate and a fresh water collection pipe. According to the invention, the preheated seawater cylinder and a saline water separation part are combined into one, self-gravity water feeding of seawater can be realized by utilizing potential energy of the seawater to save the power driving energy consumption, the solar energy absorbed by the preheating seawater cylinder is absorbed byseawater, the water inlet temperature is increased, latent heat of condensation released by water vapor in the seawater feeding pipe during condensation is also absorbed by seawater in the seawater feeding pipe, condensation of the water vapor is promoted, and the water production rate of the seawater distillation device is increased.

Owner:内蒙古天之风科技有限责任公司

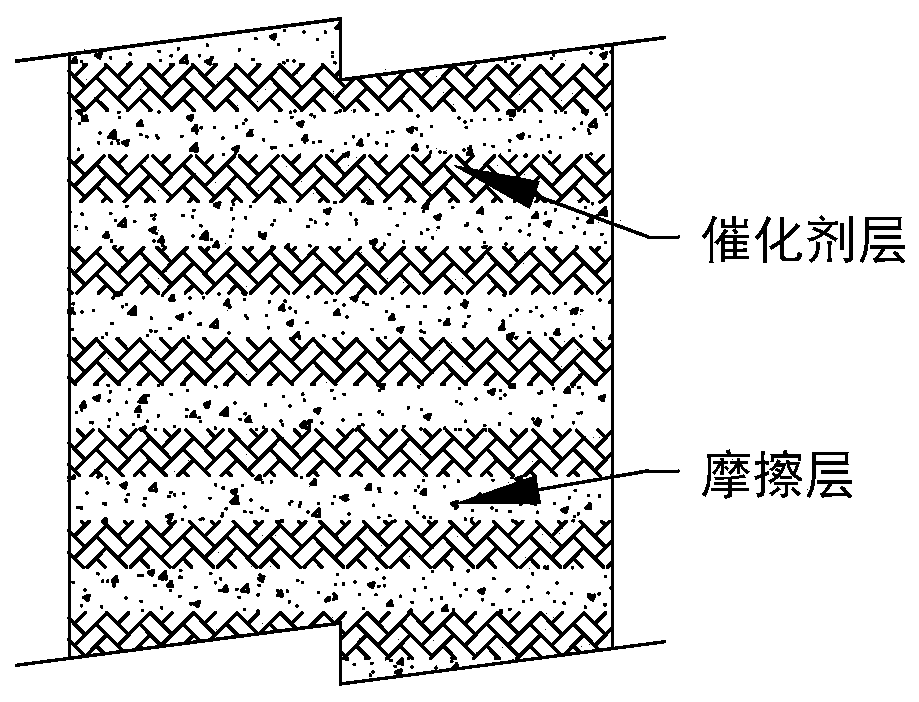

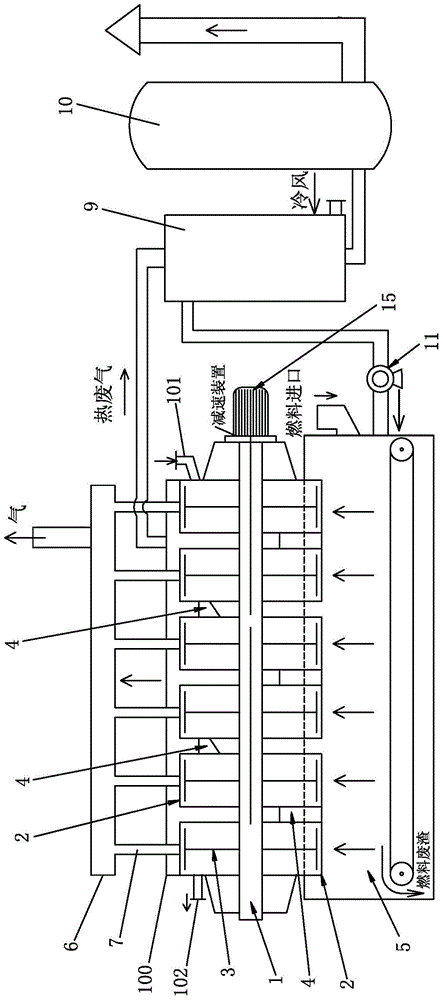

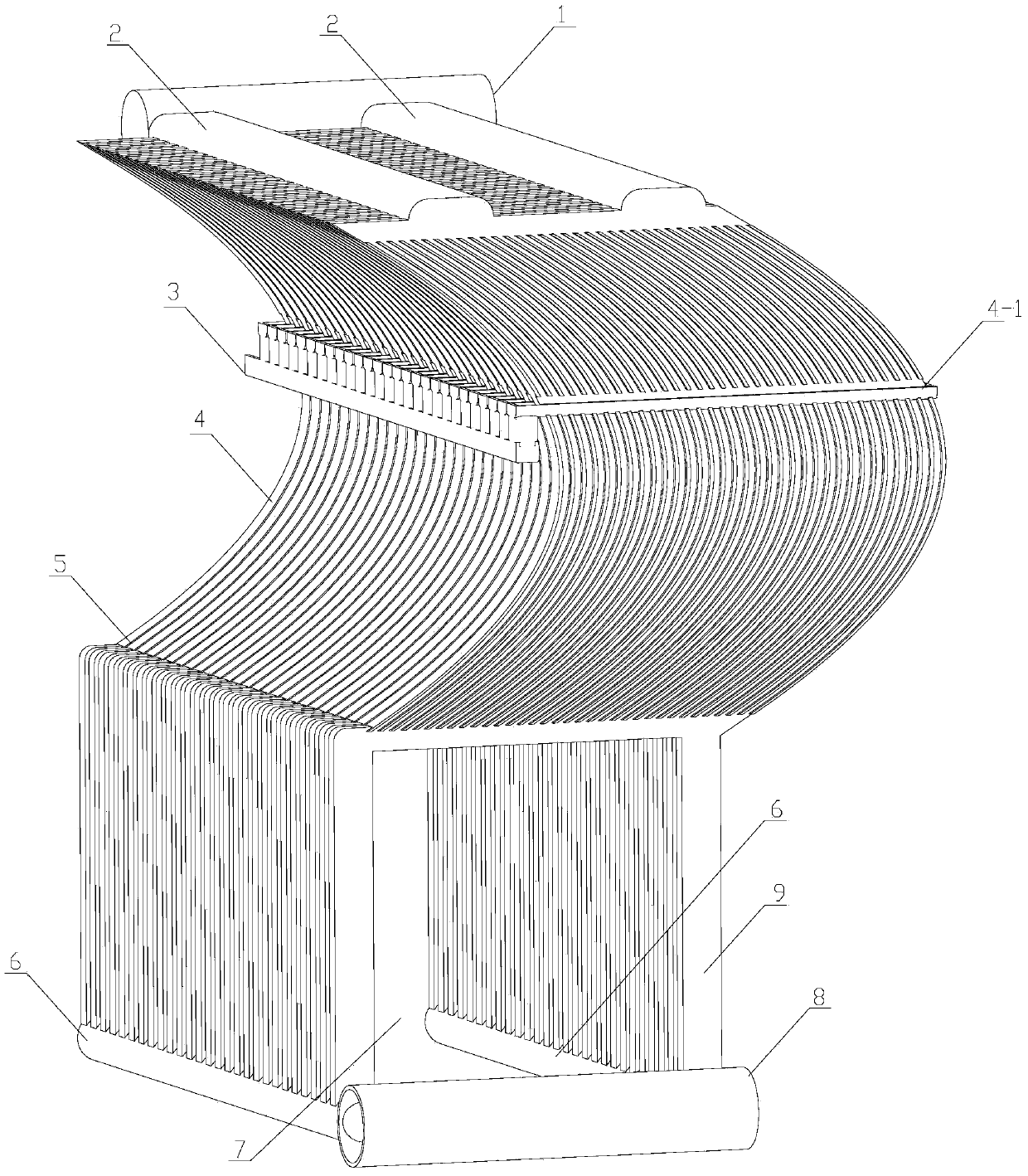

Grinding belt-type device for rapid catalytic pyrolysis of biomass and method

ActiveCN110003927ARapid condensationFully condensedBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisCombustion system

The invention belongs to the field of biomass energy utilization, and relates to a grinding belt-type device for rapid catalytic pyrolysis of biomass and a method. The device comprises a hopper, a feed system, a grinding belt-type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a combustion system, a bio-oil collection tank, a charcoal collection tank, an airpreheating system and a flue gas purification system, wherein the grinding belt-type pyrolysis reactor comprises grinding belts, heating tubes, driving drums, tensioning devices, a sealed casing, a feed inlet, a discharge opening and a gas outlet. Pretreated material particles are continuously sheared and rubbed by the grinding belts with speed difference on two sides, and are heated by the multi-layer heating tubes to continuously pyrolyze on the surface while stripping the residual charcoal, so that a catalyst and heat can be fully fed inside the particles; the pyrolysis gas is rapidly condensed by gas-solid separation to obtain high-grade bio-oil fuel or bio-oil rich in specific high value-added products; combustible gas and coke produced by combustion generate high-temperature flue gas for heating the heating tubes, so as to achieve an autothermal pyrolysis process.

Owner:北京博霖环境科技有限公司

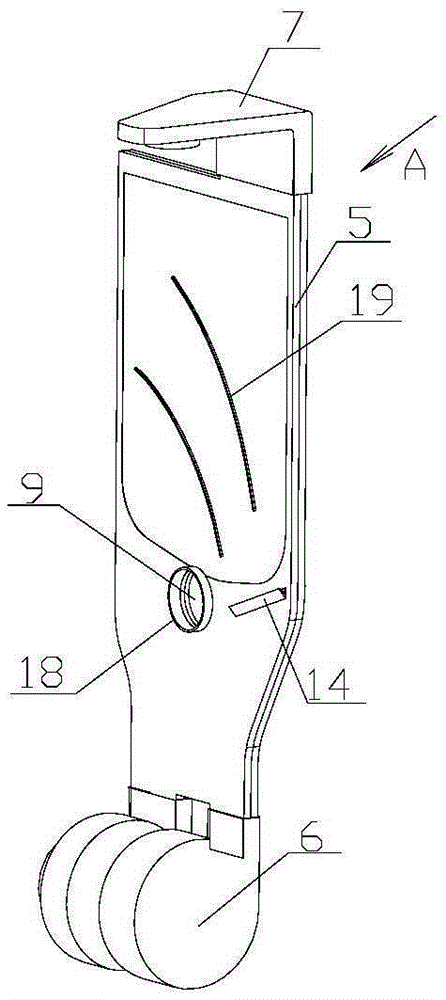

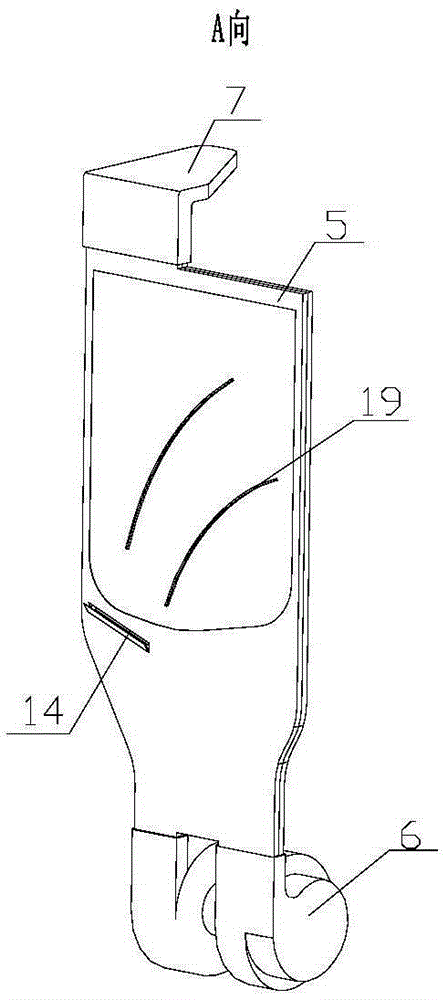

Dishwasher

InactiveCN101152070ARapid condensationShorten drying timeTableware washing/rinsing machine detailsEngineeringMechanical engineering

A dishwasher includes a tub defining a washing chamber, and a door rotatably connected to the tub. The door includes a door cover and a door liner connected to a rear side of the door cover. A condenser is disposed between the door cover and the door liner to condense stream, and a fan assembly sucks steam inside the tub and supplies the sucked steam to the condenser.

Owner:LG ELECTRONICS INC

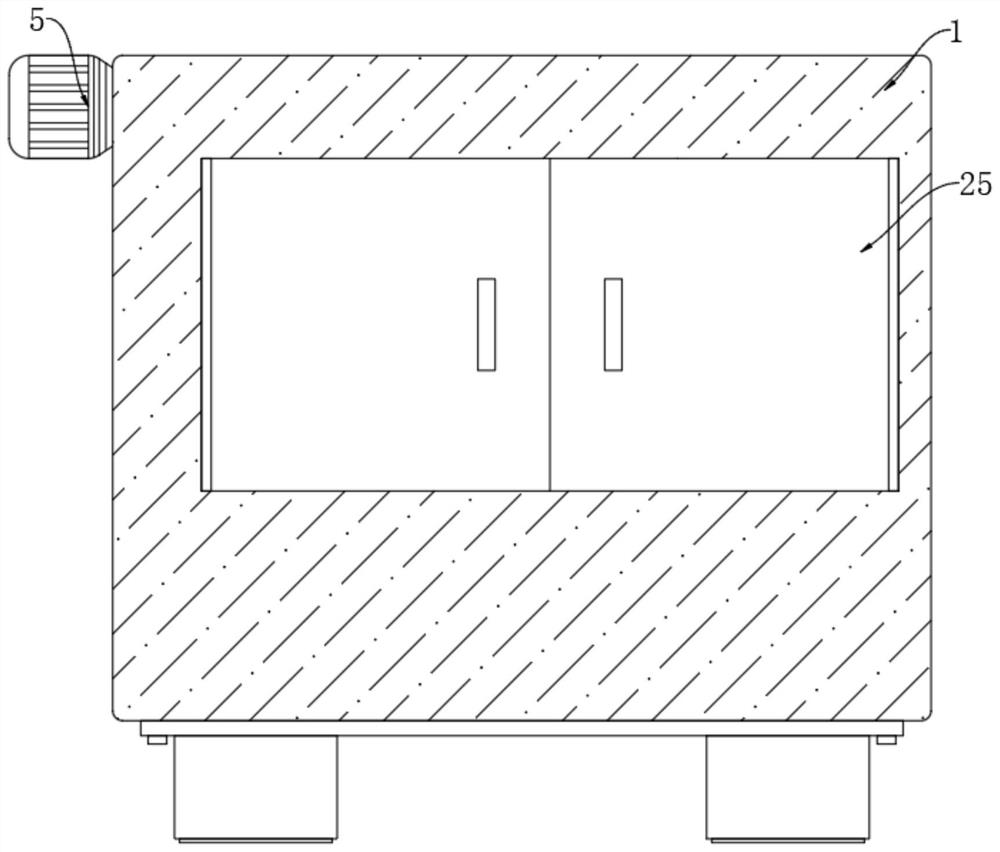

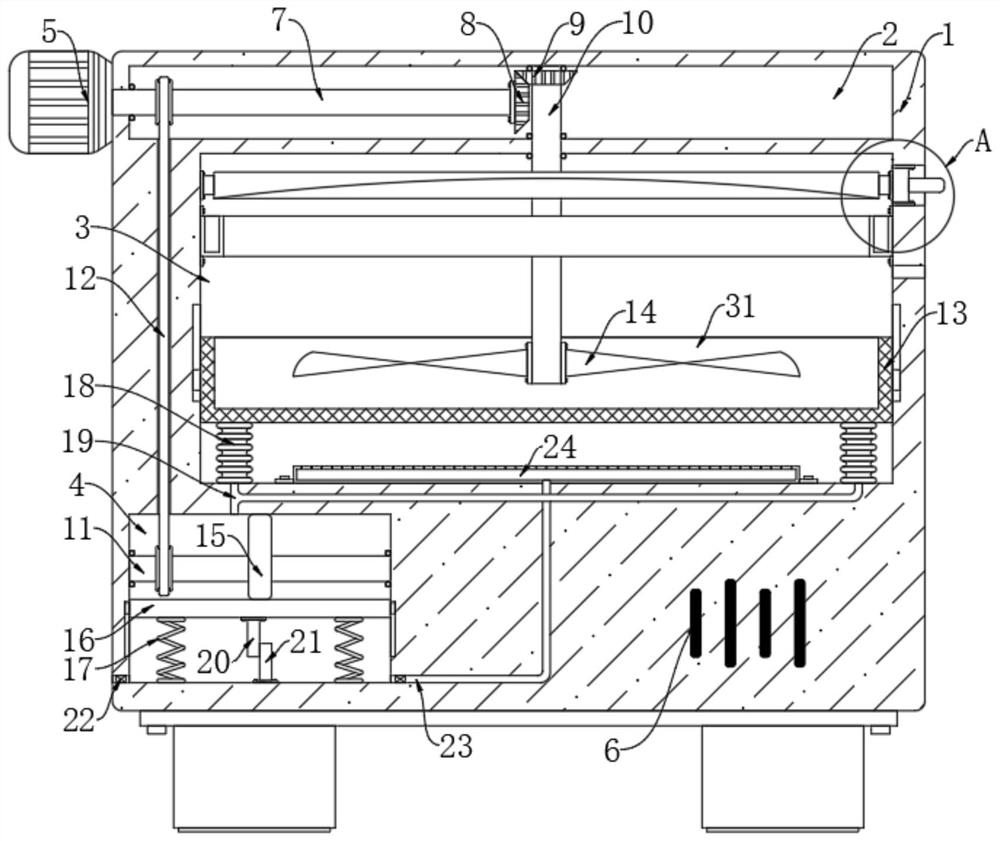

Crop drying device with rapid drying function

InactiveCN112696901APromote disturbanceEasy to dryDrying gas arrangementsSteam/vapor condensersAgricultural scienceAgricultural engineering

The invention discloses a crop drying device with a rapid drying function. The crop drying device comprises a box body and a triggering mechanism. The box body is sequentially provided with a rotating cavity, a working cavity and a moving cavity from top to bottom, an opening communicating with the outside is formed in the inner wall of the front side of the working cavity, and a sliding door is installed on the opening. The triggering mechanism comprises a first rotating rod horizontally arranged in the rotating cavity, a motor is installed on the left side wall of the box body, and the tail end of an output shaft of the motor extends into the rotating cavity. The device stirs and shakes crops, so that the crops are always in a flowing state, when hot air is sprayed to the crops, the crops can be dried in all directions, the drying effect is better, water vapor is condensed into water drops, the water drops are thrown into a collecting tank through centrifugal force to be collected, and the water drops are prevented from falling into the crops again.

Owner:吴丹丹

Continuous drying system for slurry or powder and its working method

ActiveCN104976873BFully dryHigh recovery rateEvaporator accessoriesDrying gas arrangementsSlagBenzoyl chloride

The invention relates to a continuous drying system of slurry or powder. The continuous drying system comprises a drying host; the drying host comprises a plurality of closed cavities that are arranged vertically and arrayed at intervals front and back, and a heating device heating the cavities; the cavities are internally provided with material scraping plates suitable for rotation; the adjacent cavities are in sealing connection with each other by at least one material passing channel; at least one pair of adjacent cavities exists; inlets of the material passing channels formed between the adjacent cavities are positioned at the middle parts and / or the middle upper parts and / or the tops of the cavities in the height direction; an exhaust channel is arranged on at least one cavity; a material inlet is formed at the cavity at the front end; a material outlet is formed at the cavity at the rear end; and during working, under rotational action of the various material scraping plates, the slurry or the powder moves from the cavity at the front end to the cavity at the rear end sequentially. The continuous drying system can be applied to evaporation collection of phosphorus in phosphorus mud and phosphorus slag, residual liquid treatment of calcium oxide or calcium chloride and benzoyl chloride, drying of finished chemicals, comprehensive recovery processing of the three wastes, etc.

Owner:邹岳明

Washing machine

ActiveCN109440402ARapid condensationAvoid inconvenienceOther washing machinesTextiles and paperWaste managementWater tanks

The invention provides a washing machine which comprises a water tank and an outer tub. A vapor channel communicated with the outer tub is arranged on the water tank, the vapor channel is internally provided with a condensing device for condensing vapor, and / or the water tank is internally provided with a flow guide device for guiding the vapor to be discharged from one side of the water tank. Inthe washing machine, by arranging the condensing device in the vapor channel, hot vapor flowing from the outer tub to the water tank is rapidly condensed, and therefore it is avoided that the vapor iscondensed on a distribution box handle at an opening end of the water tank and user experience is affected; in addition, the vapor is discharged from one side of the water tank, and it is avoided that the vapor flows to the opening end of the water tank and is condensed on the distribution box handle and inconvenience is brought to a user.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Solid-liquid dual-purpose wine brewing equipment

InactiveCN110591851AEasy to take outHigh yieldAlcoholic beverage preparationInsulation layerBiochemical engineering

The invention discloses solid-liquid dual-purpose wine brewing equipment. The equipment comprises a tank body, a heating and heat insulation layer, an inner tank, a fermentation stirring cylinder, a partition plate, a tank cover, an air passing pipe and a rapid condensation tank; a heating and heat insulation layer is arranged on the side wall of the tank body, the inner tank is arranged in the heating and heat insulation layer, the fermentation stirring cylinder is arranged in the inner tank, and the partition plate is arranged on the side wall of the inner tank below the fermentation stirring cylinder; the tank cover is mounted on the top side of the tank body, the air passing pipe is arranged at the top of the tank cover, and the air passing pipe is connected to the rapid condensation tank on one side of the tank body; a shunting plug is arranged at the top end of the rapid condensationtank, and a condensation branch pipe is arranged below the shunting plug; the bottom end of the condensation branch pipe is mounted on a condensate plug; a liquid collecting tank is arranged below the condensate plug, and a support is arranged below the liquid collecting tank; and a rapid condensation liquid inlet pipe and a rapid condensation liquid outlet pipe are arranged on the side wall of the rapid condensation tank. The equipment has the characteristics of wine product improvement, uniform fermentation and heating, dual purposes for liquid and solid raw materials, softness and air permeability of solid raw materials, rapid condensation and strong yield improvement capability.

Owner:ANHUI LETIAN BREWING

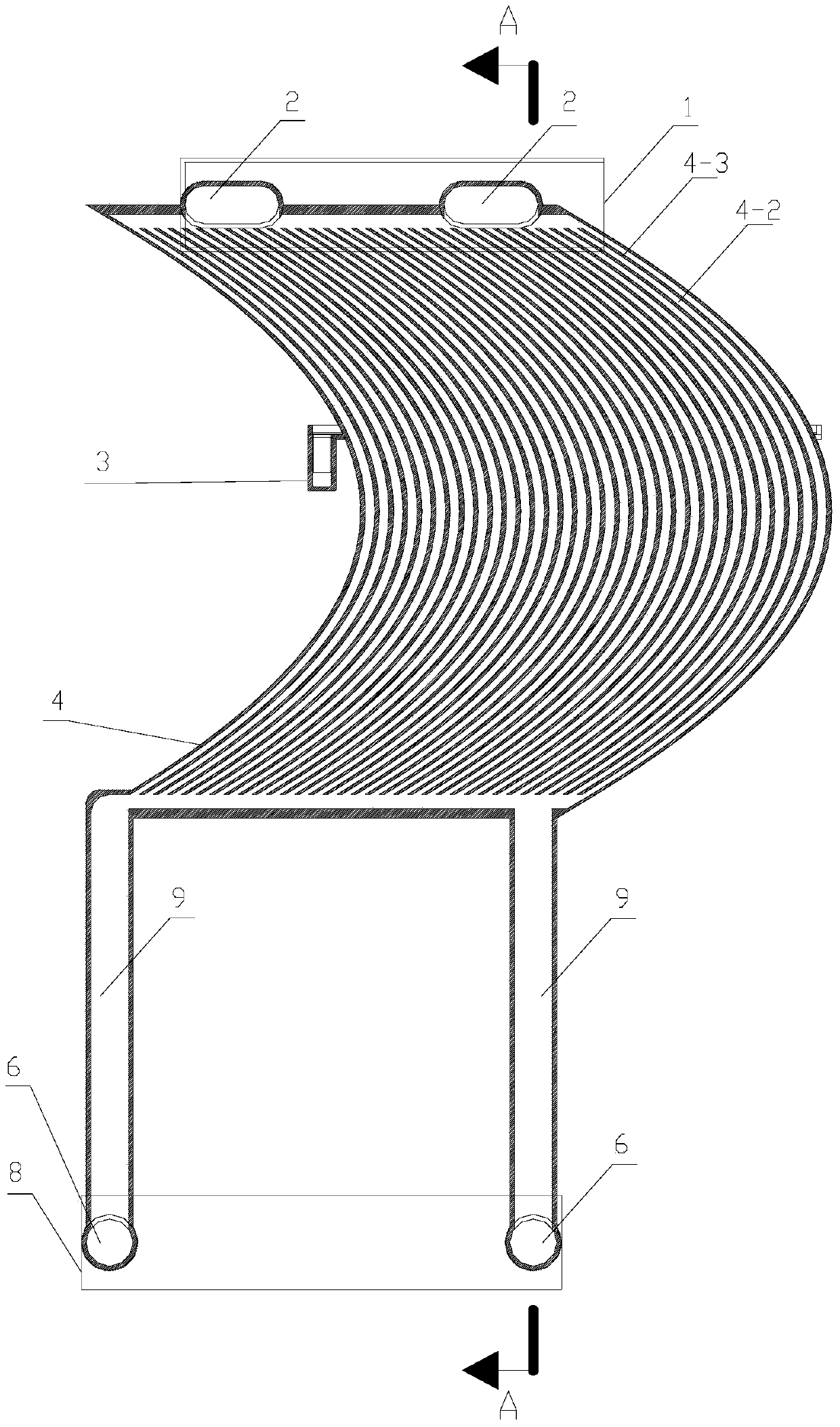

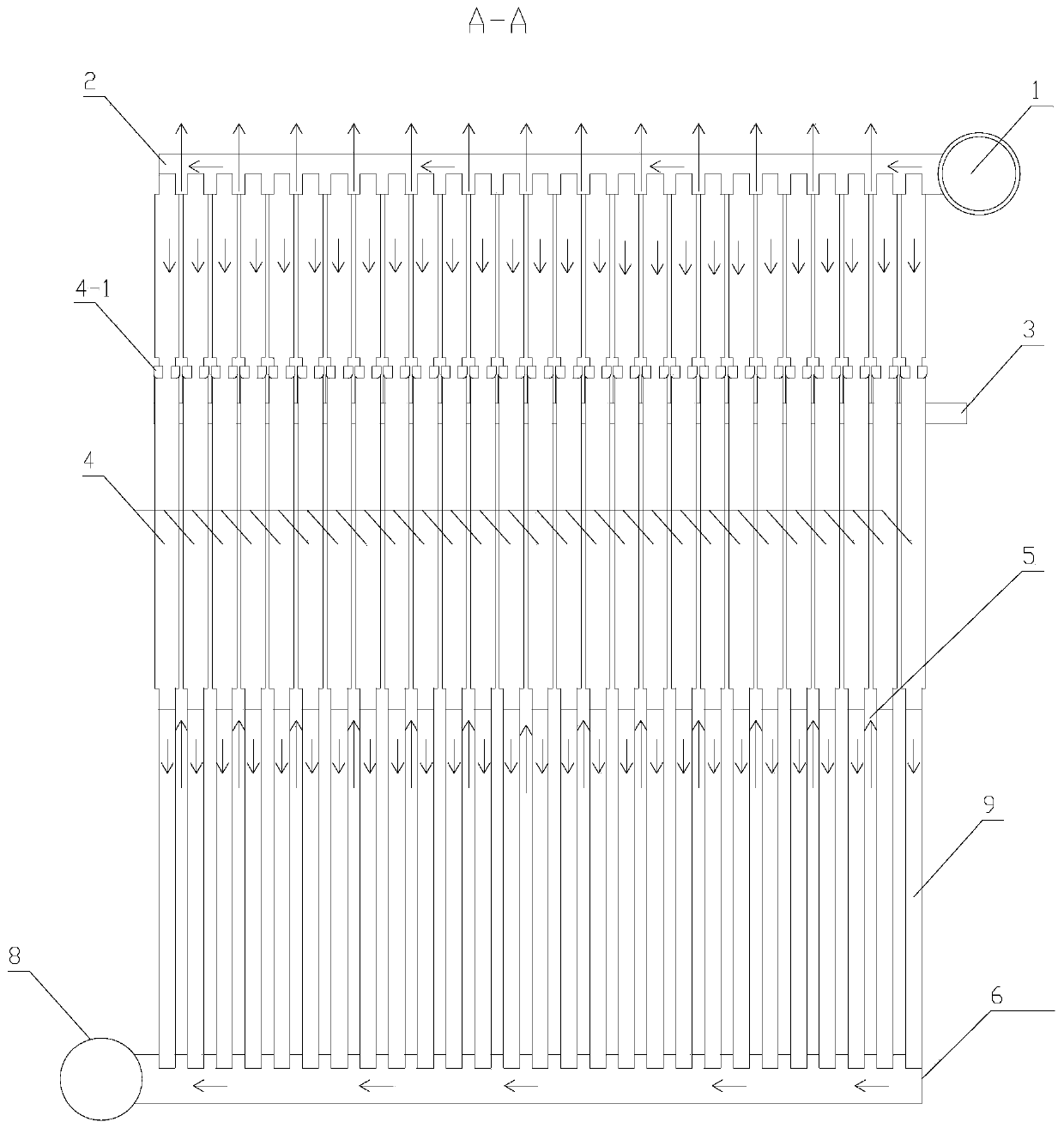

Condensation type heat exchange plate and condensation type heat exchanger with same

InactiveCN104006699AIncrease disturbanceReduce heat lossFluid heatersLaminated elementsCombustion chamberManufacturing technology

The invention discloses a condensation type heat exchange plate and a condensation type heat exchanger with the condensation type heat exchange plate. The interior of the heat exchange plate is divided into a plurality of arc-shaped water flowing channels which are parallel to one another, pipe connecting ports which are connected with a water inlet pipe and a water outlet pipe respectively are formed in the upper end and the lower end of the interior of the heat exchange plate respectively, water holes are formed in the positions of the pipe connecting ports, the two ends, communicated with the water holes, of an inner cavity of the heat exchange plate are provided with water collecting spaces respectively, the water collecting spaces are communicated with all the water flowing channels, and fins are arranged on the two outer sides of the heat exchange plate respectively. The condensation type heat exchanger is formed by combining a plurality of heat exchange plates in parallel, a smoke pipeline of the condensation type heat exchanger is an inter-plate gap defined by the ribs outside every two adjacent heat exchange plates, the water flowing channels inside the heat exchange plates serve as water flowing pipelines of the condensation type heat exchanger, and the space defined by down pipes on the bottoms of the heat exchange plates serves as a combustion chamber. The condensation type heat exchange plate is made of cast aluminum alloy through die casting and has the advantages that the heat resistance is high, the sealing performance is high, and the balance among the corrosion resistance, the good head conductivity and the manufacturing technology is well considered, heat loss is effectively reduced, and heat exchange efficiency is improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com