Patents

Literature

221results about How to "Fast condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Konjac jelly powder and method for making jellies by using same

InactiveCN102106495AGood physical and chemical propertiesImprove water holding capacityFood preparationLocust bean gumFiltration

The invention discloses konjac jelly powder. The konjac jelly powder comprises the following components in part by weight: 30 to 40 parts of konjac powder, 10 to 25 parts of carrageenin, 0 to 10 parts of xanthan gum, 0 to 15 parts of locust bean gum, 0 to 20 parts of guar gum, 5 to 12.5 parts of sodium citrate, 8 to 15 parts of potassium chloride, 0 to 7 parts of xylitol and 2 to 5 parts of citric acid. A method for preparing jellies by using the konjac jelly powder comprises the following steps of: mixing the konjac jelly powder and white granulated sugar uniformly; pouring the mixed white granulated sugar and konjac jelly powder into a stirred cold water proportioning cylinder; continuously adding the white granulated sugar or syrup, opening steam and heating; and performing filtration, packing and sterilization to obtain konjac jelly finished products. The konjac jelly powder provided by the invention has low production cost, adjustable taste and high dietary fiber content; the prepared konjac jellies do not need to be treated by alkali; and the method for preparing the jellies by using the konjac jelly powder has simple making process and low making cost.

Owner:HUBEI YIZHI KONJAC BIOTECH

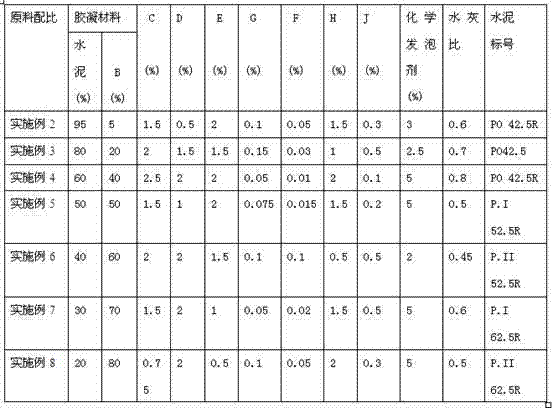

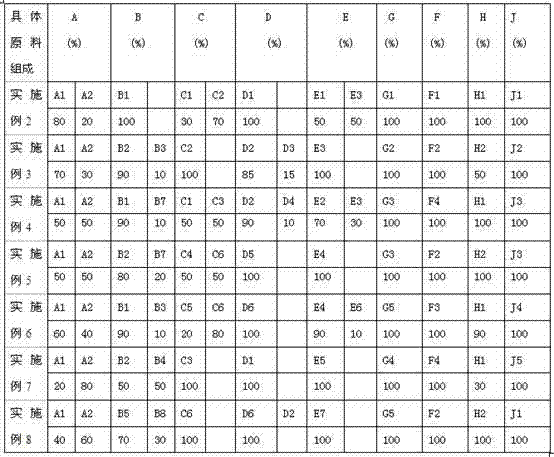

Inorganic foaming thermal-insulation mortar and preparation method thereof

The present invention provides an inorganic foaming thermal-insulation mortar and a preparation method thereof, and belongs to the technical field of building material preparation. The thermal-insulation mortar comprises a cementing material, expanded perlite particles, a macromolecule polymer, a coagulant, an early strength agent, a physical foaming agent, a chemical foaming agent hydrogen peroxide, a chemical foaming agent foaming catalyst, a hydrophobic agent, reinforced short fibers and water. According to the present invention, the inorganic foaming thermal-insulation mortar can be directly coated on the wall and the roof requiring the thermal-insulation treatment, the thickness of the inorganic thermal-insulation mortar layer can be adjusted within 10-100 mm, screeding finishing construction is performed before the cementing material is subjected to final setting, and hardening is performed to obtain the inorganic thermal-insulation mortar layer with characteristics of good durability, good water resistance and good heat insulation, wherein the inorganic thermal-insulation mortar layer never sheds, and has the same service life as the building being subjected to thermal-insulation by the inorganic thermal-insulation mortar layer; and the raw material cost is low, and significant economic benefits and environmental benefits are provided.

Owner:安徽融博科技有限公司

Anti-freeze aerated concrete brick

The invention discloses an anti-freeze aerated concrete brick. The anti-freeze aerated concrete brick is prepared from the following raw materials in parts by weight: 35-40 parts of fly ash, 15-20 parts of cement, 15-20 parts of wollastonite powder, 5-10 parts of modified straw ash, 2-4 parts of gypsum, 0.05-0.1 part of aluminum powder, 2-4 parts of urea, 0.01-0.03 part of oxyparaffin soap, 1-2 parts of sugar calcium, 4-6 parts of calcium formate, 0.1-0.5 part of polyethylene wax powder, 4-6 parts of calcium carbonate, 0.2-0.4 part of calcium nitrate, 0.1-0.2 part of sodium acetate and right amount of water.

Owner:潘逸东

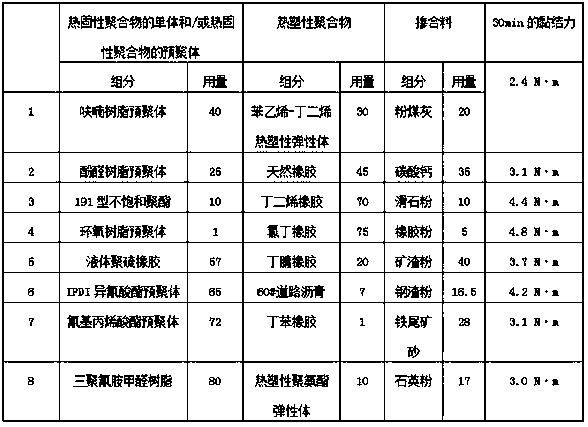

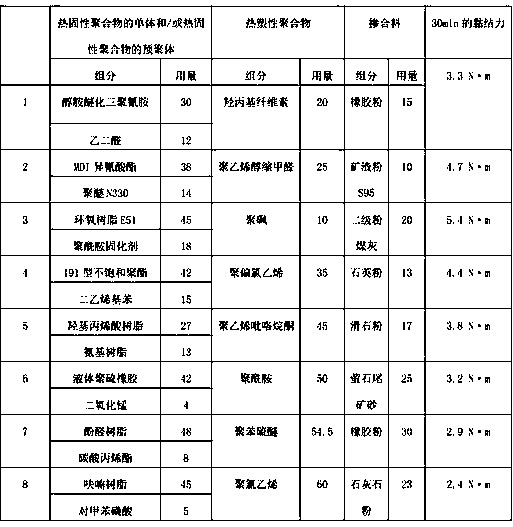

Asphalt pavement repair material

ActiveCN109401519AEasy to fixPromote repairConjugated diene hydrocarbon coatingsNatural rubber coatingsPrepolymerAntioxidant

The invention discloses an asphalt pavement repair material, and belongs to the field of engineering materials. The asphalt pavement repair material is prepared from 20-60 parts of monomers of thermosetting polymers and / or prepolymers of the thermosetting polymers, 2-8 parts of an antioxidant, 1-8 parts of an accelerant, 10-30 parts of an admixture, 5-60 parts of the thermosetting polymers, 10-40parts of an initiator, 10-20 parts of a reinforcing agent, 1-60 parts of a diluent and 10-40 parts of aggregates. The asphalt pavement repair material has the advantages of being high in condensationrate, strength, waterproofness and abrasion performance and capable of repairing pavement and getting the traffic to move again in 30 minutes and making construction easy. According to a pavement repaired with the asphalt pavement repair material, the compressive strength can reach 100 MPa, the wet wheel abrasion value is smaller than 800 g*m<-2>, and the load wheel adhesion sand amount water immersion 1d is smaller than 450 g*m<-2>.

Owner:DALIAN UNIV OF TECH

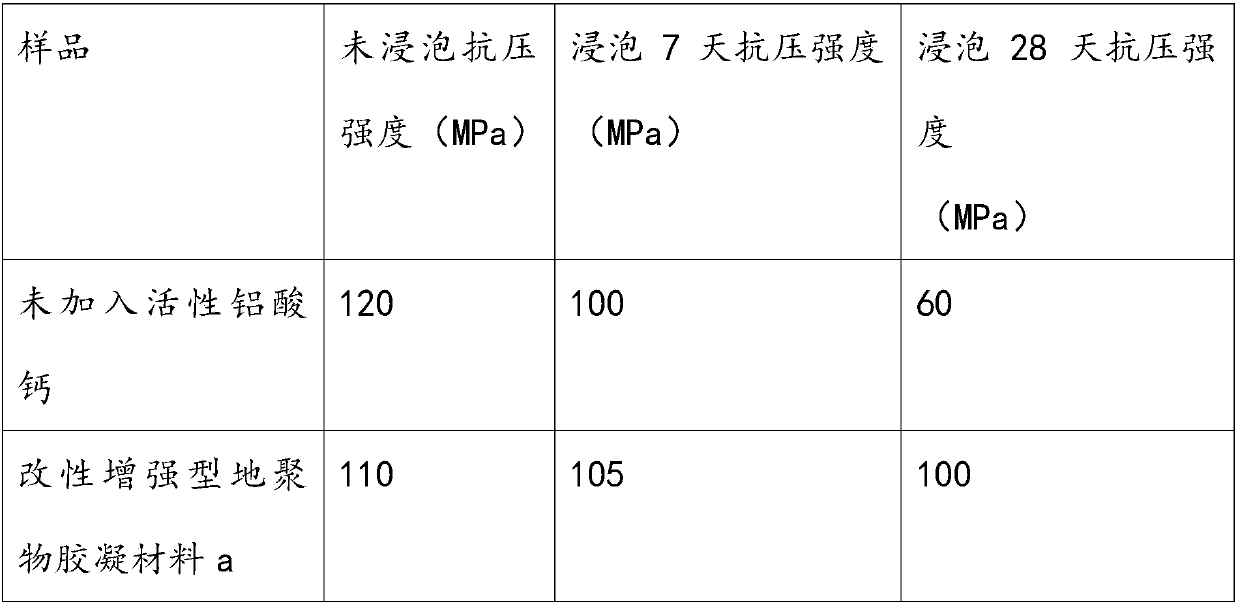

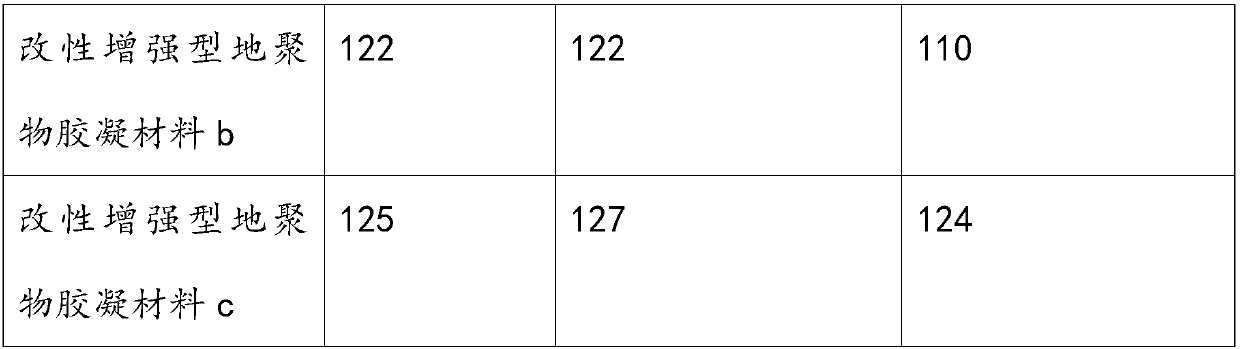

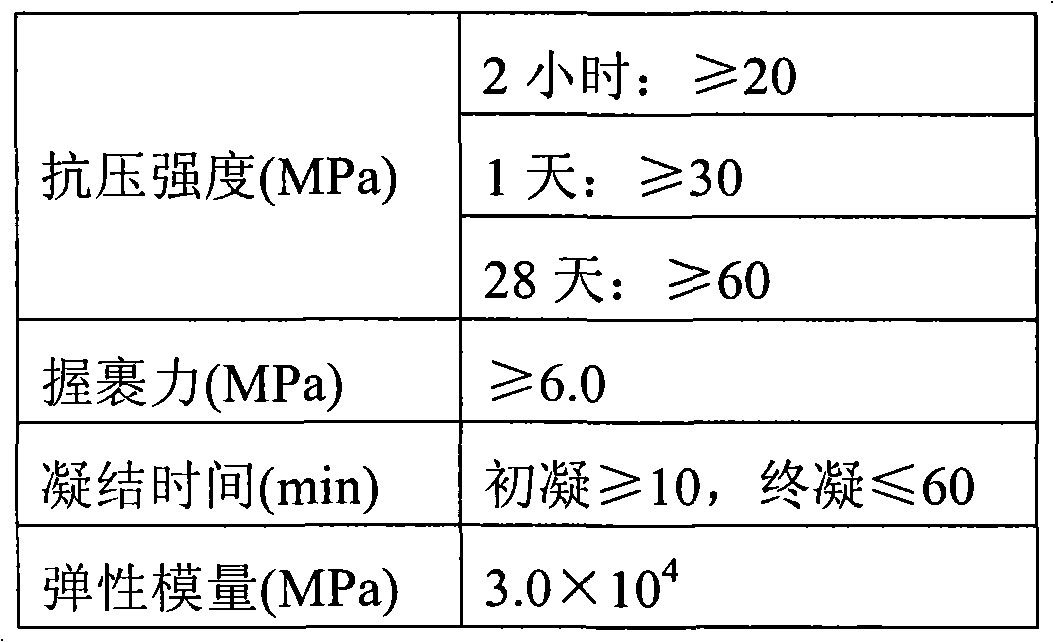

Modified reinforced geopolymer gelling material and preparation method thereof

The invention discloses a modified reinforced geopolymer gelling material. The modified reinforced geopolymer gelling material comprises 40-60 parts of compounded silicon-aluminum powder, 70-90 partsof a compounded alkali activator, 5-15 parts of a modifier and 2-6 parts of a condensed phosphate promoter, and the compounded silicon-aluminum powder includes 20-30 parts of metakaolin, 10-20 parts of fly ash, 5-10 parts of mineral slag, 5-10 parts of steel slag, 4-6 parts of silica fume and 1-2 parts of nano-silica. The invention also discloses a preparation method of the modified reinforced geopolymer gelling material. The above product has a high chemical stability and a high mechanical strength in an acid and alkali erosion environment.

Owner:ZHEJIANG UNIV

Self-flow hard grouting material and using method thereof

The invention relates to the field of silicate cement, in particular to a self-flow hard grouting material and a using method thereof. The self-flow hard grouting material consists of cement, an expanding agent, a thickening time control agent, a retarder, a water reducer, sand, an antifoaming agent and macadam, and is characterized by comprising the following components in part by mass: 0.5 to 1.5 parts of cement, 0.05 to 0.20 part of expanding agent, 0.2 to 0.3 part of thickening time control agent, 0.004 to 0.006 part of retarder, 0.01 to 0.02 part of water reducer, 0.6 to 0.7 part of sand, 0.001 to 0.002 part of antifoaming agent and 0.7 to 1 part of macadam. The self-flow hard grouting material has the advantages of high mechanical strength and high coagulation speed.

Owner:MCC5 GROUP CORP SHANGHAI

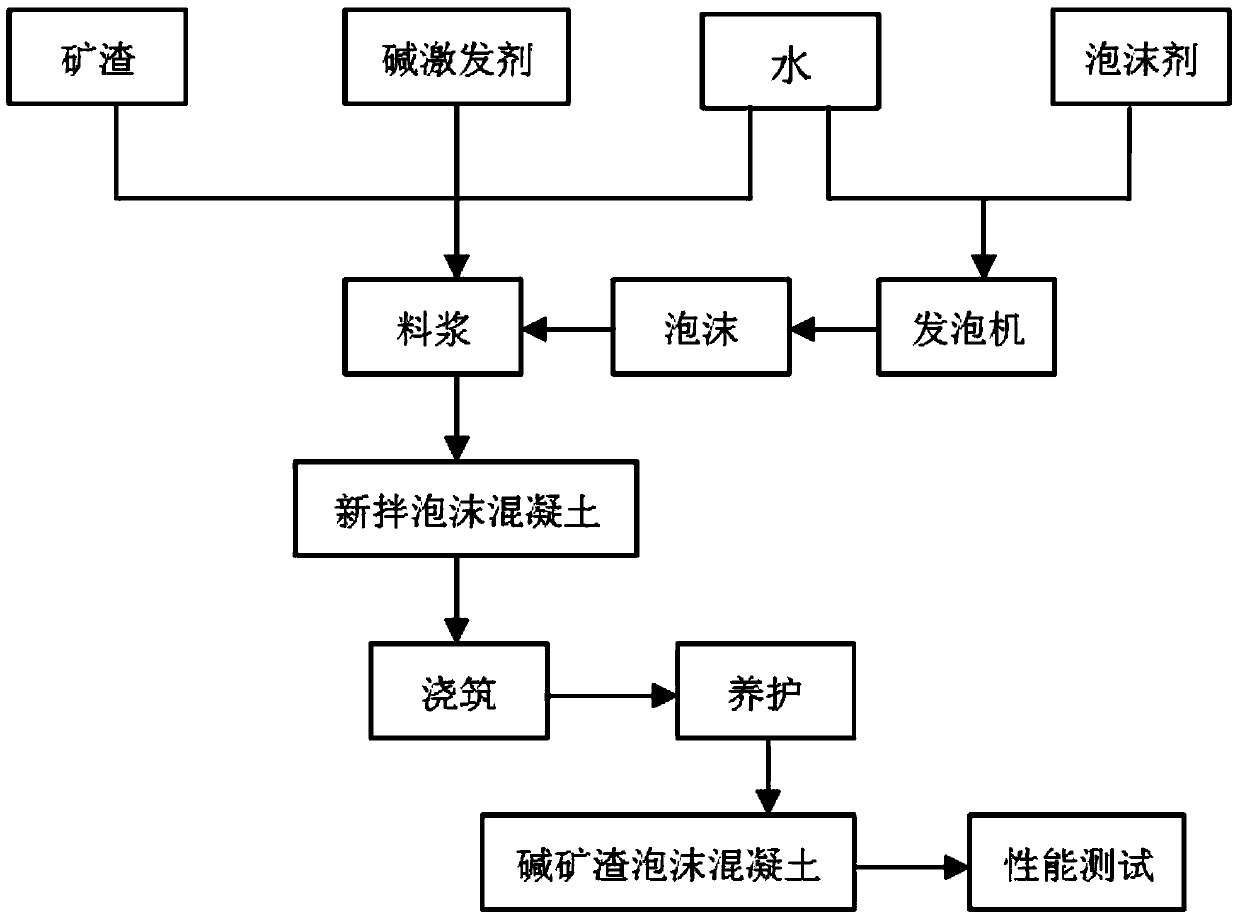

Alkali slag foamed concrete

The invention discloses an alkali slag foamed concrete which comprises slag and an alkali activator, wherein the alkali activator is sodium hydroxide or water glass. When the alkali activator is sodium hydroxide, the alkali slag foamed concrete is composed of the following components in parts by mass: 59-65 parts of slag, 5-6% of NaOH, 23-26 parts of water and 4.8-12.2 parts of foaming agent. When the alkali activator is water glass, the alkali slag foamed concrete is composed of the following components in parts by mass: 56-61 parts of slag, 9-11 parts of water glass, 21-25 parts of water and 5.0-12.2 parts of foaming agent. The volume weight of the foamed concrete is 290-610 kg / m<3>. The alkali slag foamed concrete has the advantages of short setting time, quick strength development, higher later strength, excellent water resistance and excellent weather resistance, and can be used for a long time.

Owner:CHONGQING UNIV

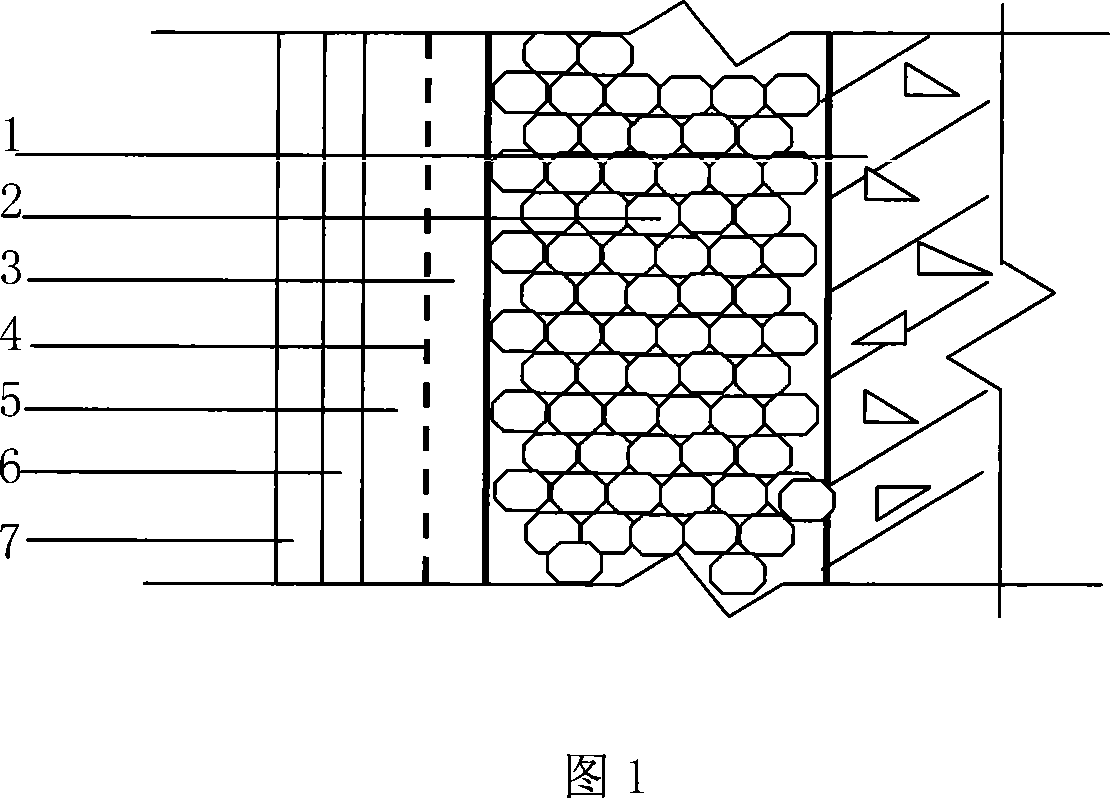

Plant fiber reinforced inorganic light composite and preparation method thereof

InactiveCN106747031APrevent shrinkageFast condensationSolid waste managementCeramicwareMagnesium chloride hexahydrateFlexural strength

The invention discloses a plant fiber reinforced inorganic light composite which is mainly prepared from magnesium chloride hexahydrate, magnesium sulfate heptahydrate, light calcined magnesia, water, a water reducer, a reinforcing agent, reinforcing fibers, a foaming agent, an exciting agent, a stabilizer and adjusting admixture. The preparation method comprises steps as follows: magnesium chloride hexahydrate, magnesium sulfate heptahydrate and water are mixed to be made into a saline solution; light calcined magnesia, the water reducer and the reinforcing agent are added to the saline solution, the mixture is stirred at a constant speed, and an inorganic sizing material is obtained; the reinforcing fibers are added to the inorganic sizing material and stirred at a constant speed, the adjusting admixture, the stabilizer and the exciting agent are dropwise added slowly, finally, the foaming agent is added quickly, the mixture is stirred at a high speed, and a foamed inorganic sizing material is obtained; the foamed inorganic sizing material is poured into a die, left to stand for foaming, removed from the die and maintained, and the plant fiber reinforced inorganic light composite is obtained. The composite has the advantages of high pressure resistance, high bending resistance, low density, no formaldehyde, aging resistance, mildew resistance, termite resistance, moisture-proof performance, no deformation, sound and heat insulation, good heat preservation and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

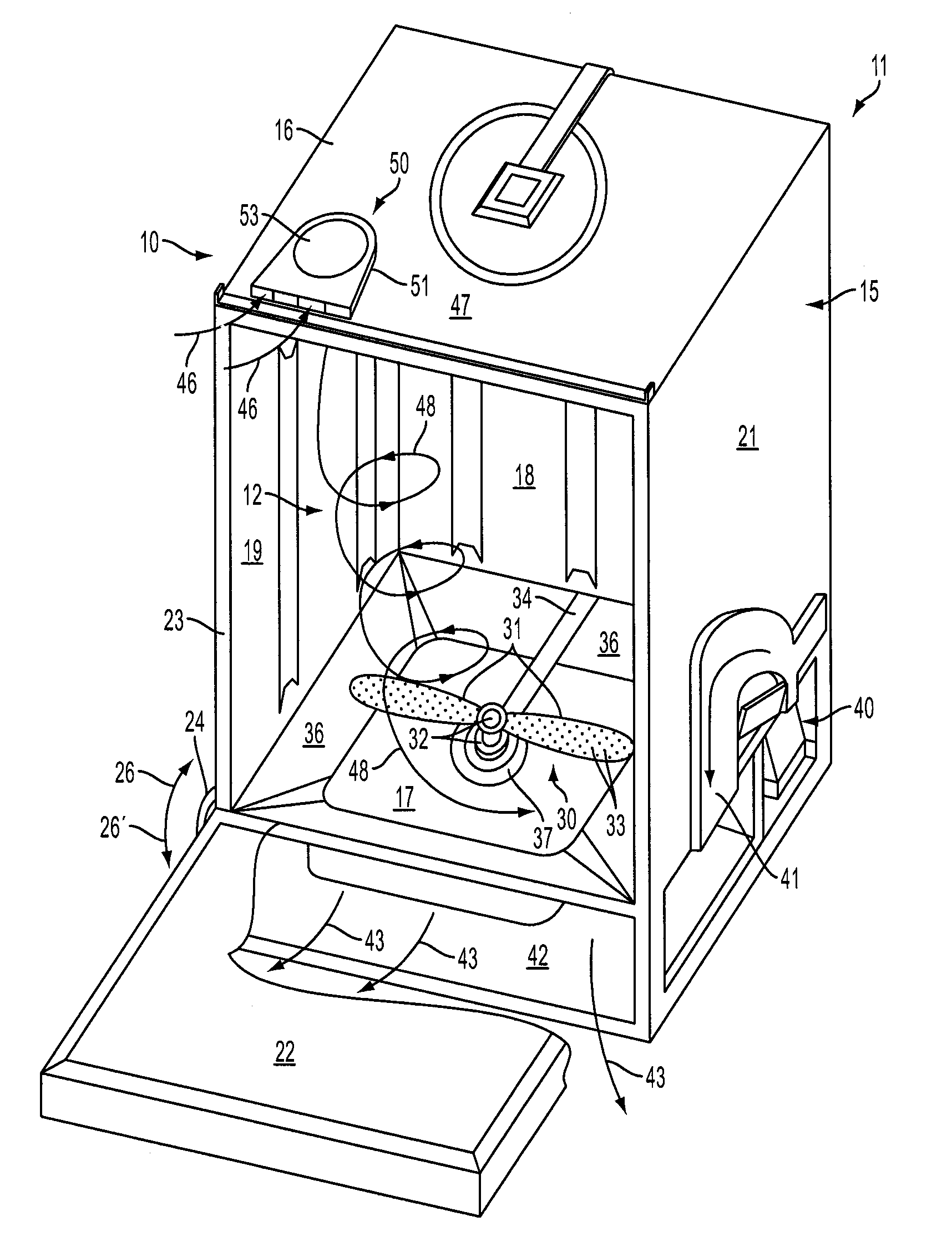

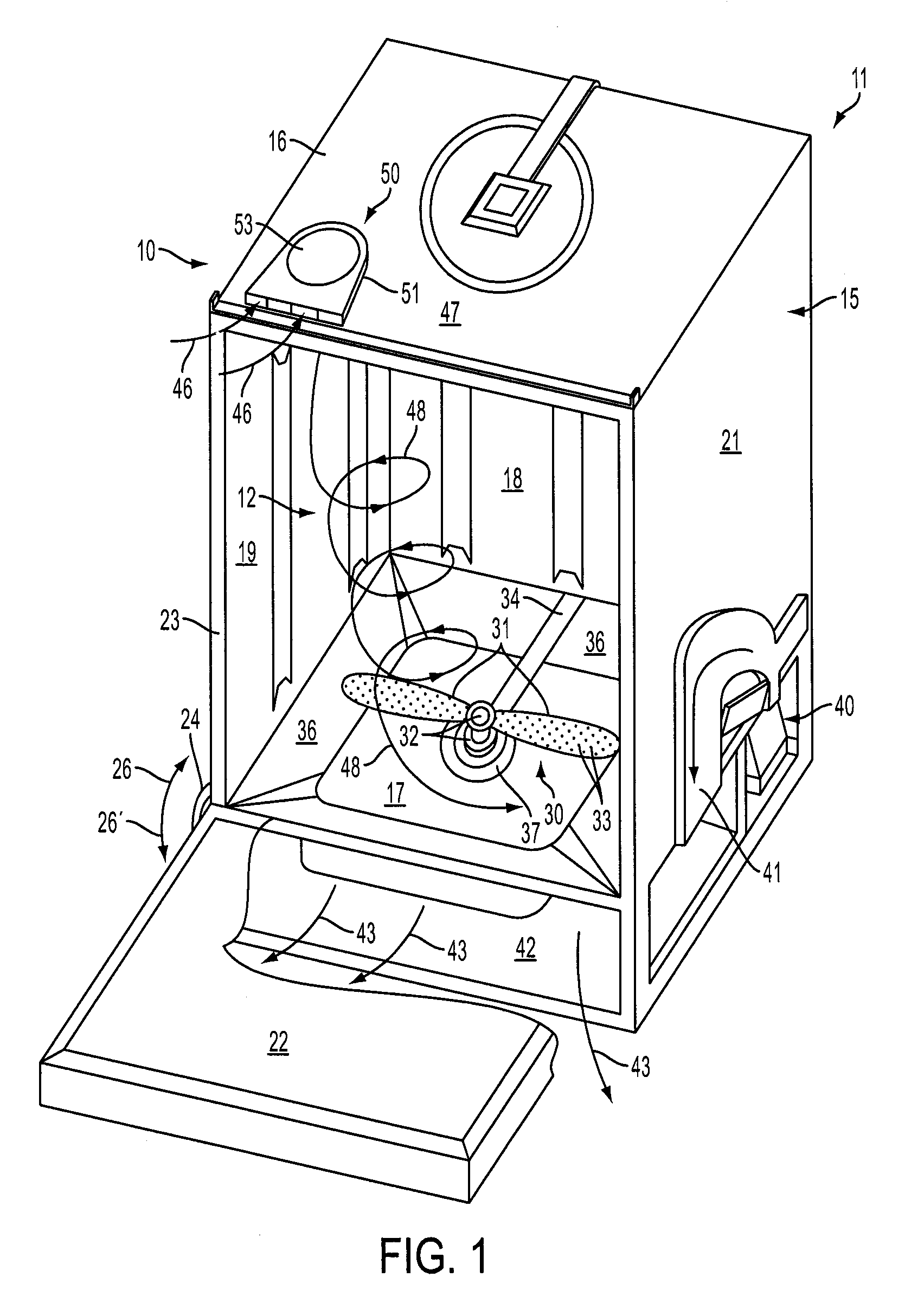

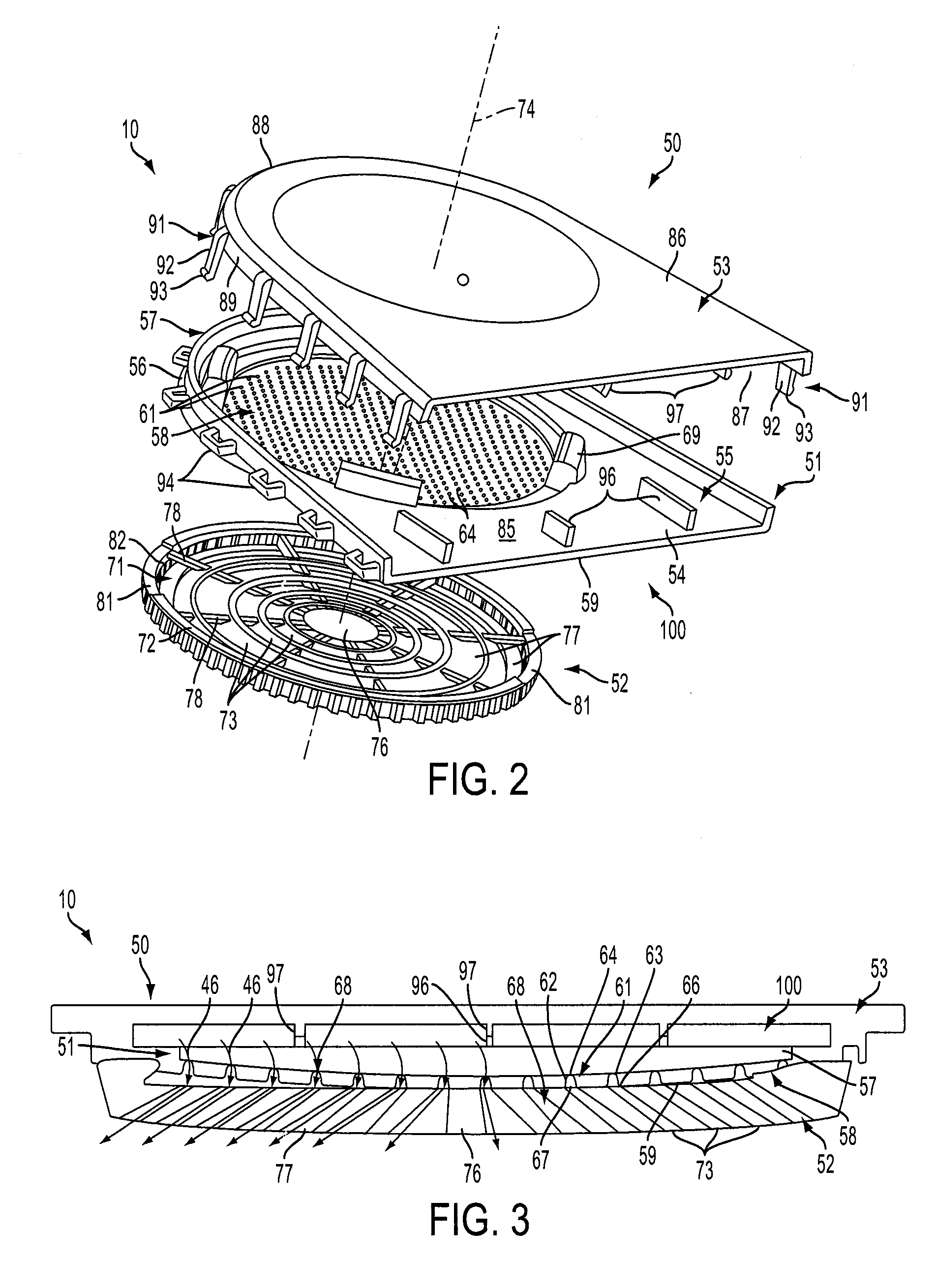

Drying system for a dishwasher

InactiveUS20130008474A1Much turbulenceFast condensation of moistureTableware washing/rinsing machine detailsDrying chambers/containersEngineeringMoisture

A drying system for a dishwasher including a passive vent assembly mounted to a top portion of the dishwasher. The passive vent assembly includes a passive vent structure having a series of air vents defined therein and through which drying air flows are drawn into the wash chamber of the dishwasher, a diffuser mounted over the air vents and including a series of fins for spreading the drying air flows across the wash chamber, and a moisture trap hood mounted over an upper surface of the passive vent structure.

Owner:VIKING RANGE

Geopolymer foamed light aggregate concrete and preparation method thereof

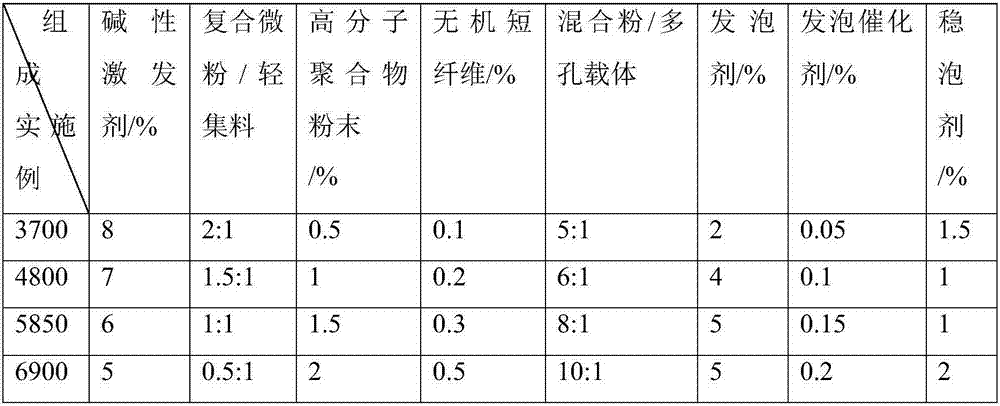

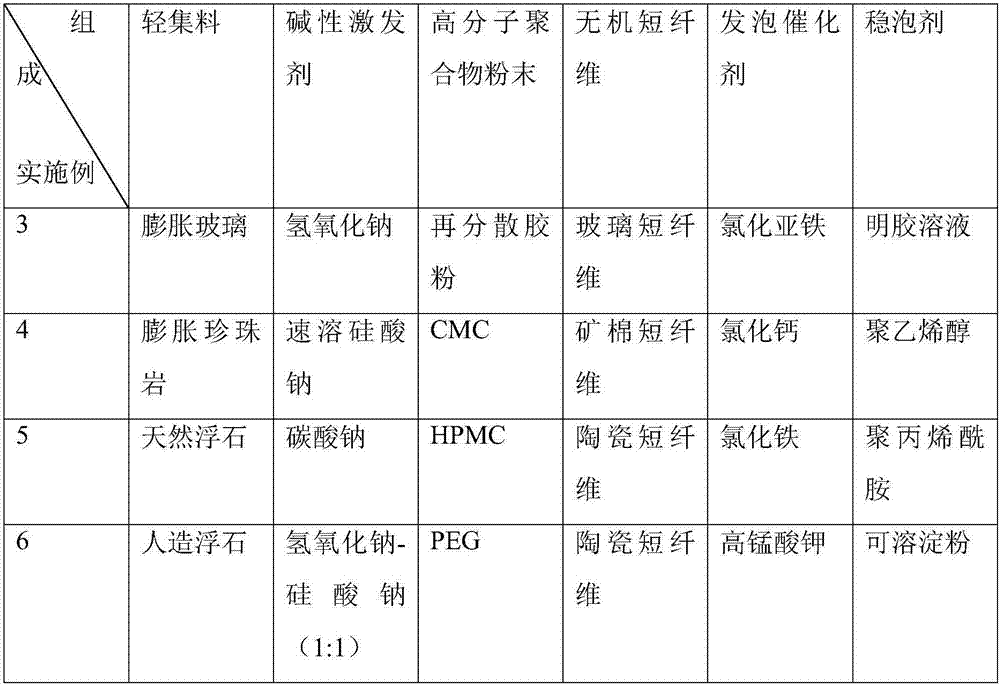

The invention discloses geopolymer foamed light aggregate concrete. The material is composed of slag-fly ash composite micro powder, an alkali activator, inorganic super-light aggregate, high-molecular polymer powder, inorganic staple fibers, a hydrogen peroxide chemical foaming agent, a foaming catalyst, an inorganic porous carrier and a foam stabilizer. The method for preparing the geopolymer foamed light aggregate concrete comprises the following steps: mixing and manufacturing various components according to a certain ratio. The problems that the strength of the conventional cement-based foam concrete material is greatly decreased when used for high-temperature insulation and foams and bubbles difficultly grow due to too fast setting of slag-based geopolymer foamed cement and the like can be effectively solved. Therefore, the durability of the foamed light aggregate geopolymer concrete layer is obviously improved, and the light aggregate concrete can be used for promoting energy-saving insulation of low-temperature and normal-pressure building envelopes, decreasing the dead weight of walls and reducing CO2 emission, contributes to improving ecological and economic benefits and is extremely convenient in construction. The construction cost and material cost can be greatly reduced.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Quick leakage-stopping agent

InactiveCN1434093AFast condensationHigh strengthOther chemical processesUltimate tensile strengthDefoaming Agents

The present invention discloses a quick leakage-stopping agent. It uses hydraulic binding cement base material, anchoring agent, hardening accelerator, solidifying agent, water-reducing agent, powdered defoaming agent and strengthening filling material as raw material, and adds these raw materials into mixing machine according to a certain order, uniformly mixes them and grinds them into 325 meshes to 400 meshes in grain size in grinding machine so as to obtain the invented product. Said product has the advantages of quick setting speed, high strength and good binding performance, so that it has good leakage-stopping and water-proofing function, and has extensive application.

Owner:刘玉军

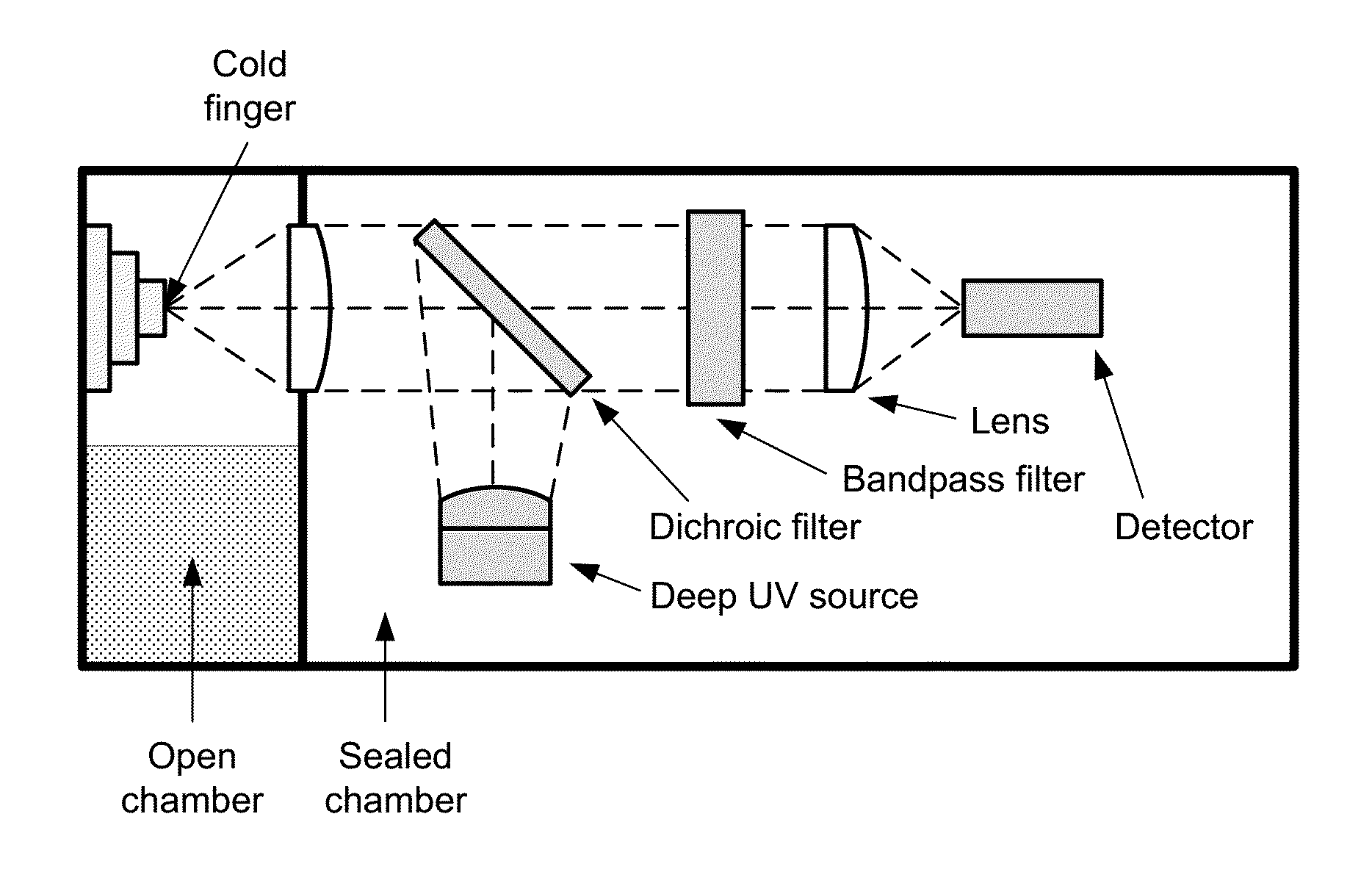

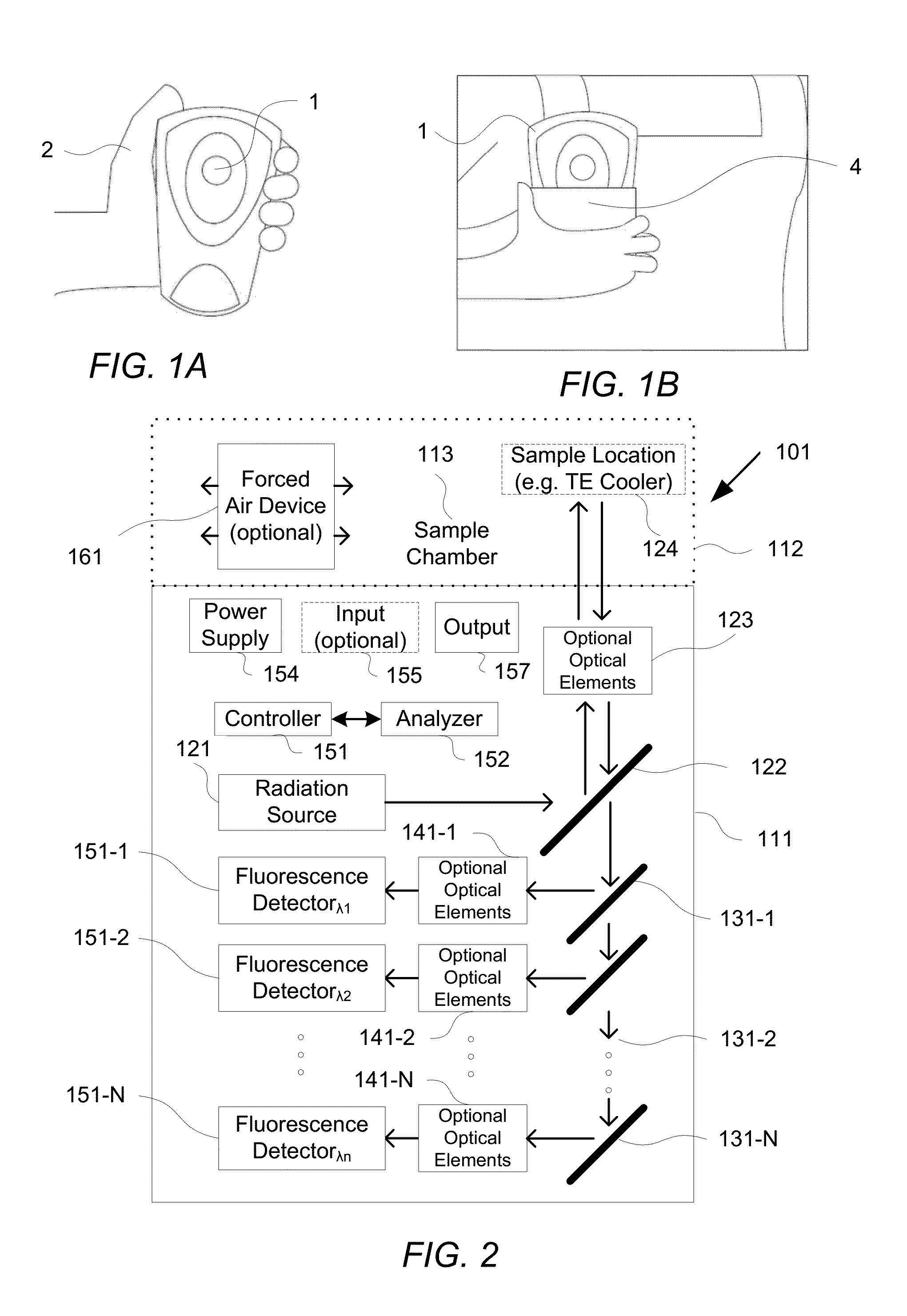

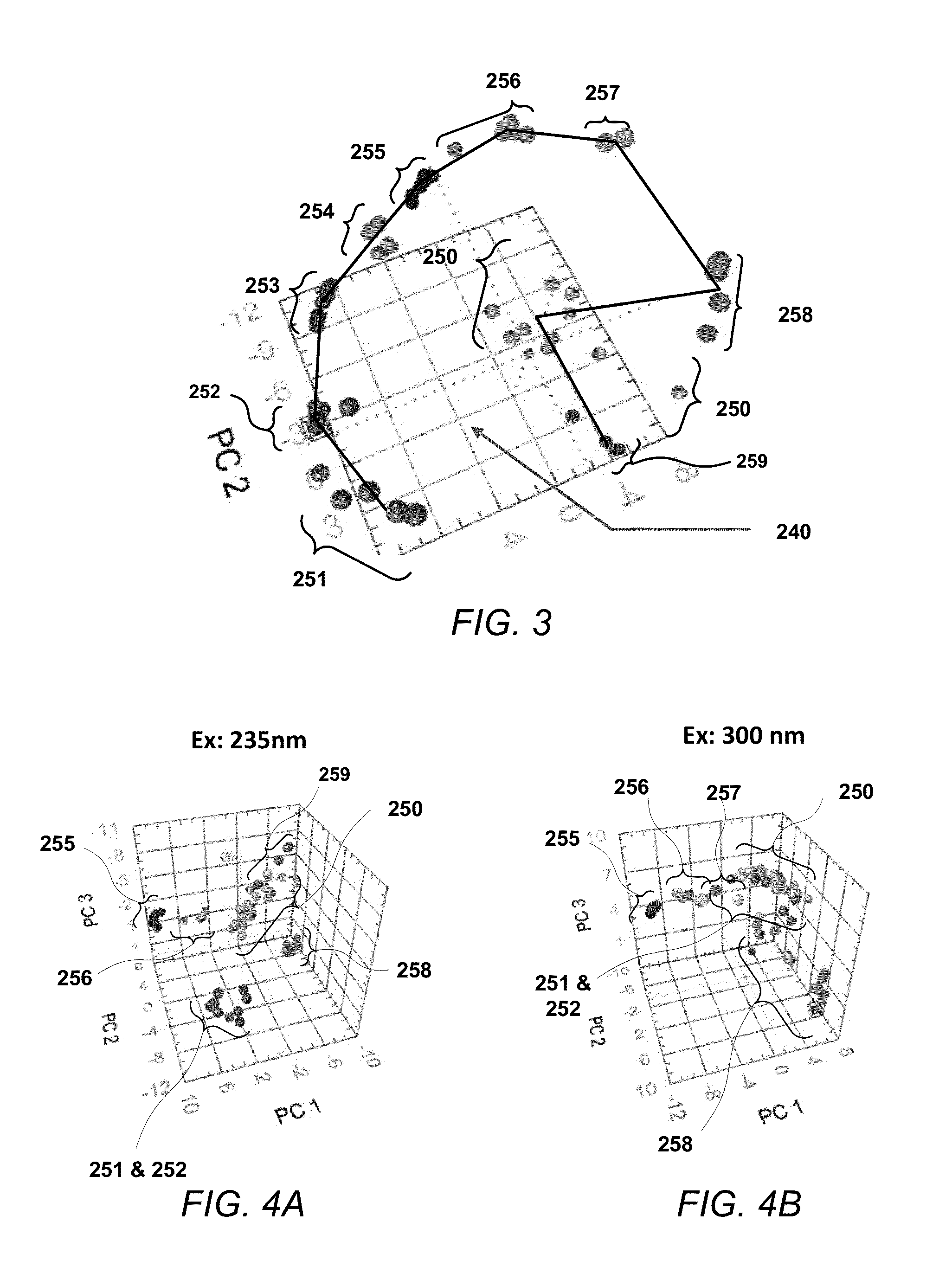

Native fluorescence detection methods, devices, and systems for organic compounds

ActiveUS9442070B1Rapid condensationRapid vaporization of VOCsSpectrum investigationMaterial analysis by electric/magnetic meansDosimeterUltraviolet

Naphthalene, benzene, toluene, xylene, and other volatile organic compounds VOCs have been identified as serious health hazards. Embodiments of the invention are directed to methods and apparatus for near-real-time in-situ detection and accumulated dose measurement of exposure to naphthalene vapor and other hazardous gaseous VOCs. The methods and apparatus employ excitation of fluorophors native or endogenous to compounds of interest using light sources emitting in the ultraviolet below 300 nm and measurement of native fluorescence emissions in distinct wavebands above the excitation wavelength. The apparatus of some embodiments are cell-phone-sized sensor / dosimeter “badges” to be worn by personnel potentially exposed to hazardous VOCs. The badge sensor of some embodiments provides both real time detection and data logging of exposure to naphthalene or other VOCs of interest from which both instantaneous and accumulated dose can be determined.

Owner:PHOTON SYST

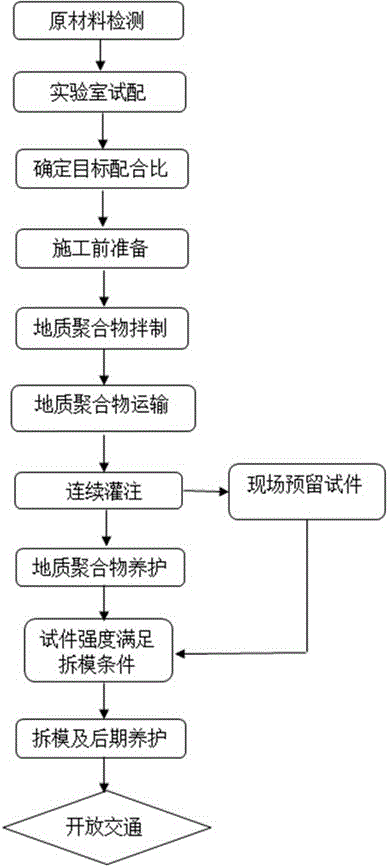

Geopolymer-based heavy load pavement paving material and preparation method thereof

InactiveCN106495585AShort setting timeFast condensationSolid waste managementCement productionSlagRoad surface

The invention relates to the technical field of building materials, in particular to a geopolymer composite, a geopolymer-based heavy load pavement paving material and a preparation method of the material. The geopolymer composite comprises a first component with particle size of 15-25 micrometers, a fine aggregate component with particle size of 0.3-0.5 millimeter, a coarse aggregate component with particle size of 5-31 millimeters and an alkali activator, wherein the first component comprises metakaolin, slag and fly ash. The provided composite comprises metakaolin, slag, fly ash, the fine aggregate component and the coarse aggregate component, and is polymerized under excitation of the alkali activator to form the concrete type geopolymer-based heavy load pavement paving material. The geopolymer-based heavy load pavement paving material is suitable for paving a heavy load pavement, and has the advantages of being short in setting time, high in strength, low in contractibility rate, cracking resistant and the like. The paving material is prepared from solid waste raw materials, the preparation technology is simple, construction is convenient, operation is convenient, cost is low, and the paving material is suitable for large-scale application and popularization.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

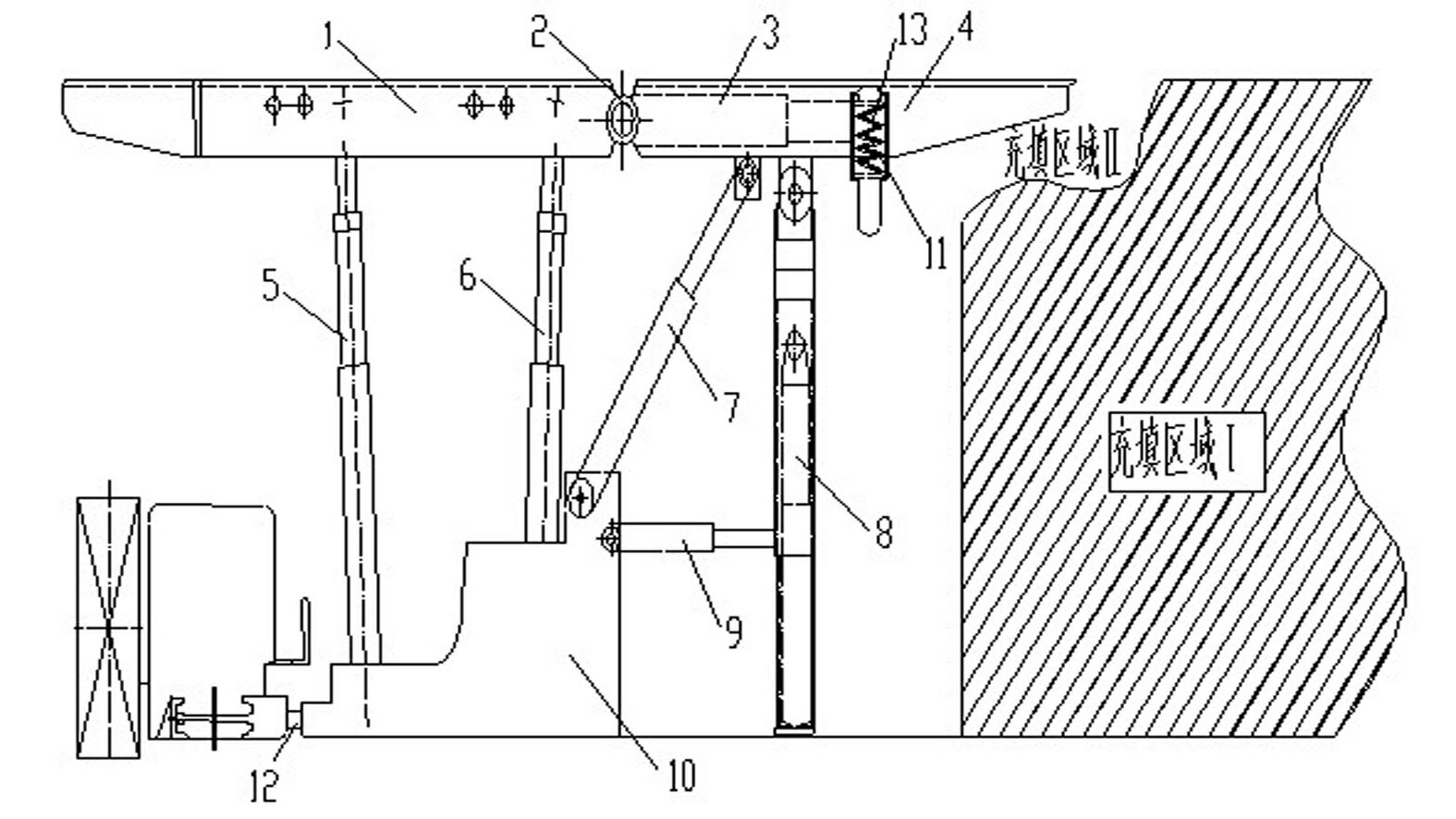

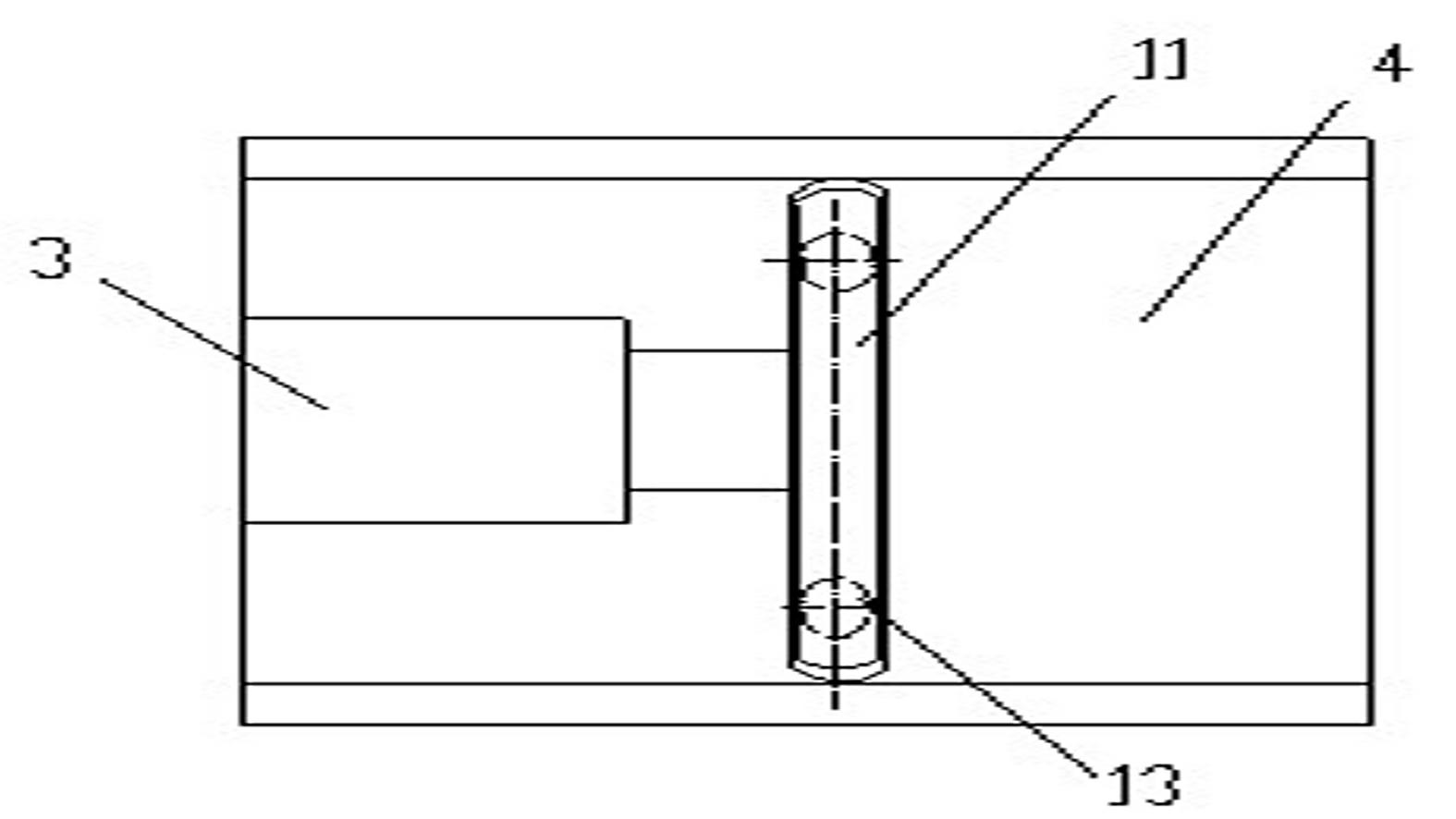

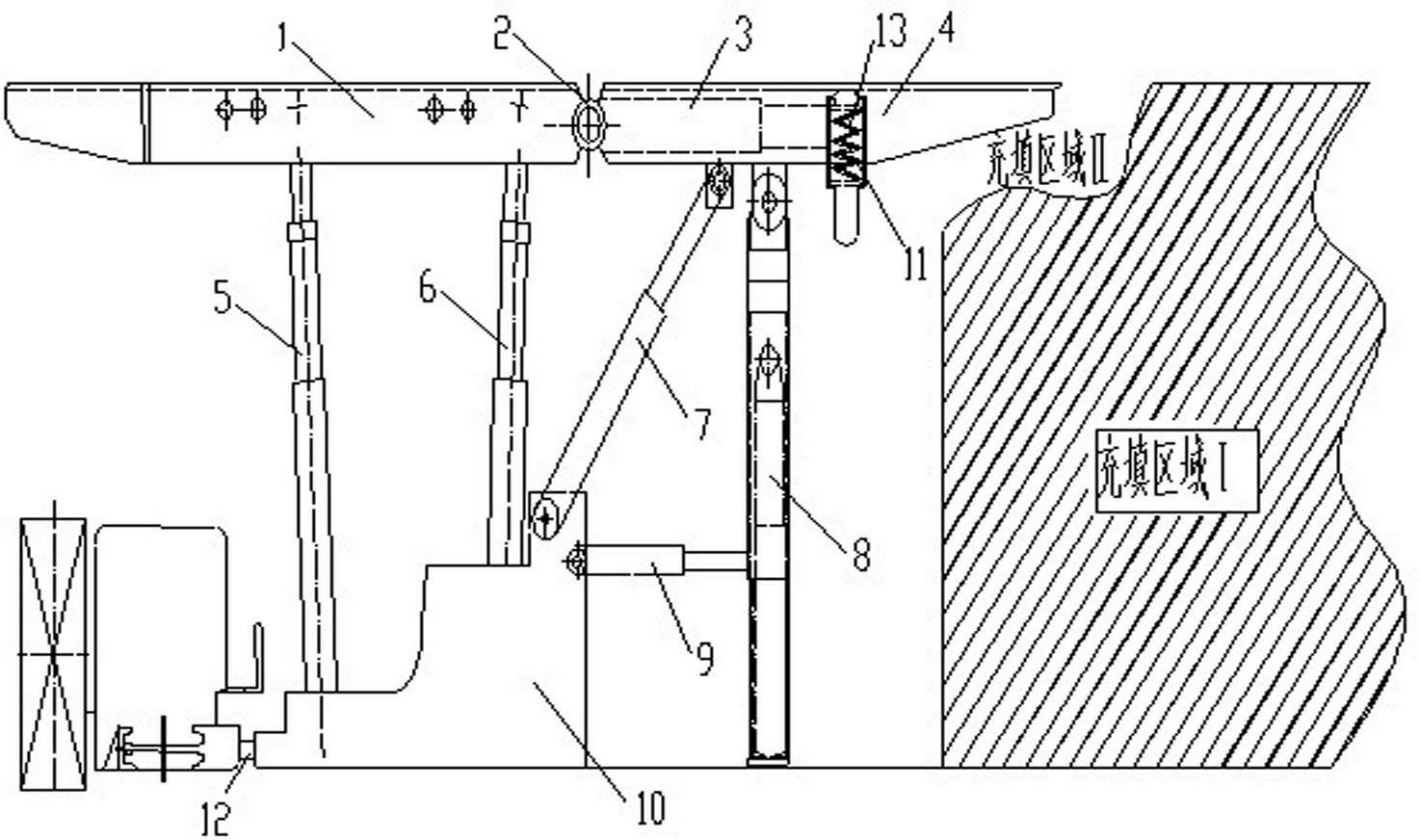

Method for filling gob

ActiveCN102493839AReduce sinkageSimple structureMaterial fill-upMine roof supportsPush and pullJackscrew

The invention provides a method for filling a gob. In the filling process, when filling paste arrives at the position of an elastic baffle, a pushing device which is arranged on a tail beam of a hydraulic support pushes and pulls the elastic baffle back and forth to ensure that the filling paste refills the gob after being pushed to the gob which is not filled fully behind the hydraulic support; the pushing device is hinged with a pushing jack at the left end of the tail beam of the hydraulic support; the right end of the pushing jack is connected with the elastic baffle; and the filling paste is formed by uniformly mixing coal gangue, coal ash, a cementing material and water in the mass percent ratio of 45:20:15:20. According to the method, the pushing device which is arranged on the tail beam of the hydraulic support has a simple structure and is convenient to operate; and according to particle sizes and different ratios of components, the materials of the filling paste are convenient to transport and control, are condensed quickly and have certain expansibility and a good roof-contacting effect to ensure that surface subsidence can be effectively controlled.

Owner:TAIYUAN UNIV OF TECH

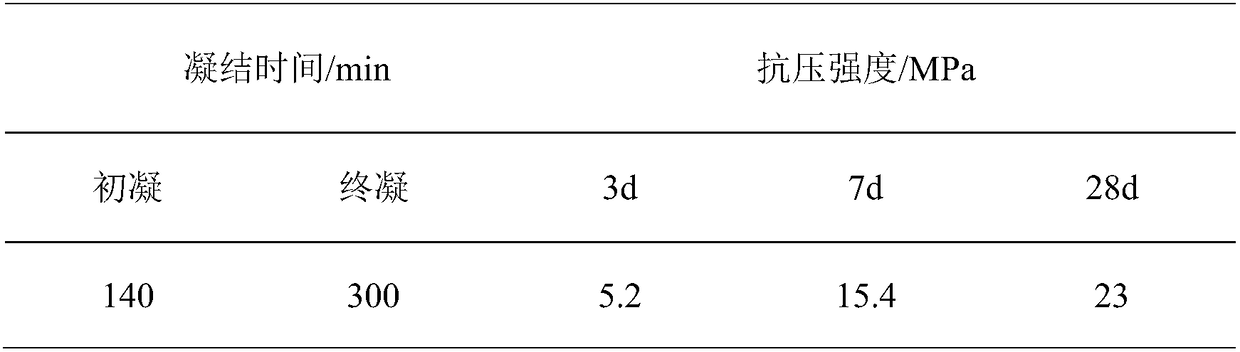

Method for preparing grouting material by using water-containing red mud synergistic blast furnace slag

The invention provides a novel red mud-based grouting material and preparation method thereof. The grouting material is prepared from the following components by weight percent: 70-80% of red mud liquid, 15-25% of blast furnace slag powder, 5-10% of compound alkali-activator, 2-10% of water reducing agent and 1-2% of early strength agent. The novel red mud-based grouting material prepared from redmud and the blast furnace slag powder is good in fluidity, high in early strength and short in time of coagulation, and does not shrink. The preparation method provided by the invention reasonably utilizes industrial waste, can reduce the influence of the waste on the environment, and is easy in preparation; the method is simple in steps, convenient to operate and high in practicability.

Owner:SHANDONG UNIV

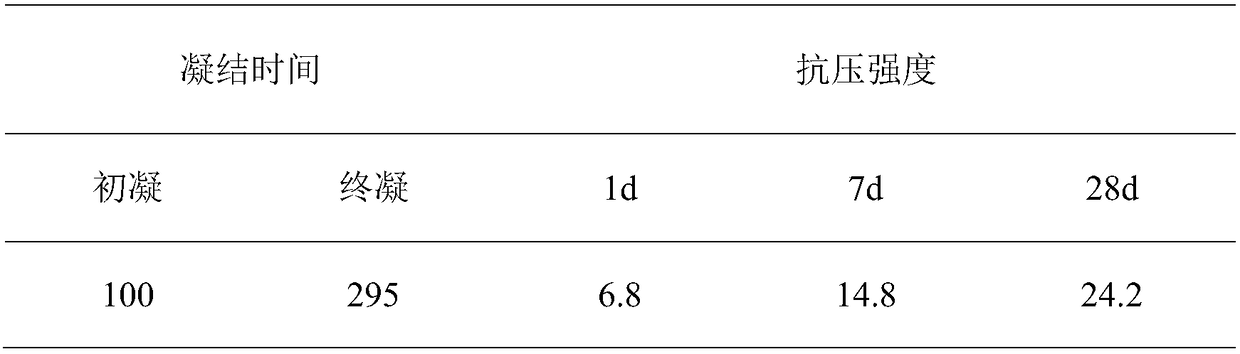

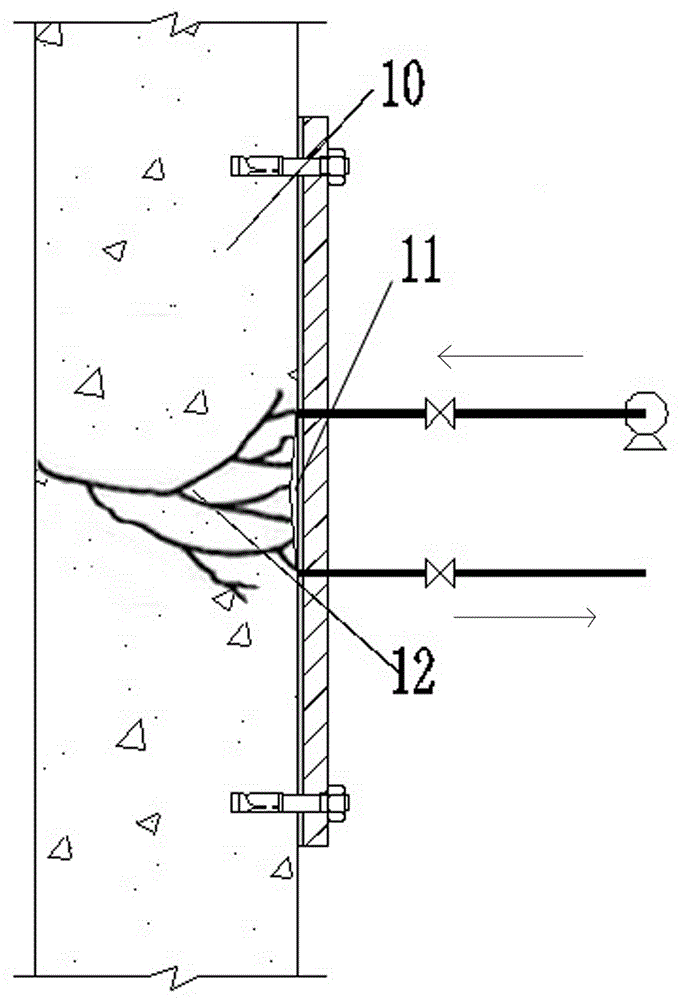

Leakage repairing device for pressure-bearing reinforced concrete structure and construction method thereof

ActiveCN104088254AFacilitate communicationImprove sealingMarine site engineeringReinforced concreteRebar

A leakage repairing device for a pressure-bearing reinforced concrete structure comprises a double-layer sealing and reinforcing plate and a crack grouting and draining device, wherein the outer wall surface of a seepage crack portion is fixedly covered with the double-layer sealing and reinforcing plate. The double-layer sealing and reinforcing plate is composed of a rubber sealing backing plate on the inner side and a reinforcing steel plate on the outer side and is anchored to structure concrete around the seepage crack portion through expansion bolts around a plate body. The crack grouting and draining device is separately arranged on the upper side and the lower side of the seepage crack portion and comprises a grouting pipe at the upper portion and a first draining pipe at the lower portion. The outer wall surface of the seepage crack portion is provided with a flow guide groove through which a plurality of cracks are communicated. The grouting pipe, the flow guide groove and the first draining pipe are communicated. The leakage repairing device can be quickly manufactured at the construction site, the whole structure repairing process only takes several minutes, the leakage repairing device can be conveniently disassembled in the later stage without influencing the appearance of the concrete structure, and the solution method high in efficiency and fast to implement in a limited construction period is achieved.

Owner:泛华建设集团有限公司

Rare-earth composite wall heat-insulating layer and heat-insulating layer material preparation method

InactiveCN101215858AHigh strengthImprove insulation effectCovering/liningsClimate change adaptationInfraredRare earth

The invention relates to a heat-insulating layer of a rare earth complex wall body and the manufacturing method of heat-insulating layer material, which belongs to the field of architectural materials. The invention is characterized in that the process for preparation comprises mixing rare earth rubber powder by weight ratio that rubber powder: water = 1:1 to 1.5, adding polyphenyl particles into material which is mixed, the proportion is that rubber powder: EPS particles = 1 kg: 8 L, continuously mixing for 5-10 min to make rare earth rubber powder EPS particle heat-insulating material, mixing rare earth trowel finish sand with water according to the proportion that rare earth trowel finish sand: water = 1: 1 into slurry, making rare earth trowel finish sand slurry, and brushing rare earth rubber powder EPS particle heat-insulating material, trowel finish sand slurry, standard net cloth, rare earth trowel finish sand slurry, flexible putty and face coat on the base layer of the wall body in turn. The invention has good heat-insulating property, strong binding power, high compression strength, good water resistance and flame proof, which is antiseptic, noncorrosive, nontoxic, tasteless and pollution-free, has the function of absorbing ultraviolet ray and infrared ray, and has quick coagulate speed, rapid increase of the strength of materials, and the construction procedure is rapid, timesaving and laborsaving.

Owner:包头市科强新型材料有限公司

Deep dedusting and defogging device

ActiveCN105854425AIncrease flow rateIncrease centrifugal forceDispersed particle separationDual actionFlue gas

The invention relates to a deep dedusting and defogging device which comprises flow guide cylinders arranged in an absorption tower, wherein airflow passages are formed in the flow guide cylinders; spiral passages communicated with the airflow passages are further formed above the air flow passages; outlets of the spiral passages are inclined; the cylinder walls of the flow guide cylinders are higher than the outlets of the spiral passages, and volume-enlarged chambers with openings are formed in the position above the spiral passages. According to the device, the spiral passages are additionally formed in the position above the airflow passages, and in a rising process of flue gas, the effect of absorbing dust and removing liquid drops is achieved by virtue of continuous rotation and collision movement between water drops in the flue gas, the water drops and the dust as well as the water drops and the walls of the passage walls under double actions of centrifugal force and inertial collision, so that defogging and dedusting efficiency is effectively improved; in the volume-enlarged chamber, the speed of the flue gas is reduced, the separated liquid drops fall, and the liquid drops are discharged through the downward passages separated from the flue gas, so that secondary carrying is prevented.

Owner:TIANJIN XIANGYUANXI ENVIRONMENTAL PROTECTION EQUIP CO LTD +1

Alkali-free liquid setting accelerator containing cellulose and preparation method of alkali-free liquid setting accelerator

The invention discloses an alkali-free liquid setting accelerator containing cellulose and a preparation method of the alkali-free liquid setting accelerator. The alkali-free liquid setting accelerator comprises components in parts by mass as follows: 30-60 parts of aluminum sulfate, 5-10 parts of calcium formate, 5-10 parts of calcium fluoride, 0.8-1.6 parts of sulfosalicyclic acid, 1.0-3.5 parts of hydroxyethyl cellulose, 0.8-1.5 parts of polyacrylamide, 0.2-1.0 part of ethylenediamine tetraacetic acid, 1-3 parts of triisopropanolamine, 0.15-1.2 parts of polypropylene glycol, 0.10-1.12 parts of dimethyl silicone, 0.5-1.5 parts of phosphoric acid, 0.5-1.5 parts of hydrofluoric acid, 3-8 parts of magnesium sulfate, 1-3 parts of sodium fluoride, 1-4 parts of trimethylolethane, 2-6 parts of aluminum hydroxide and 30-60 parts of water.

Owner:徐明

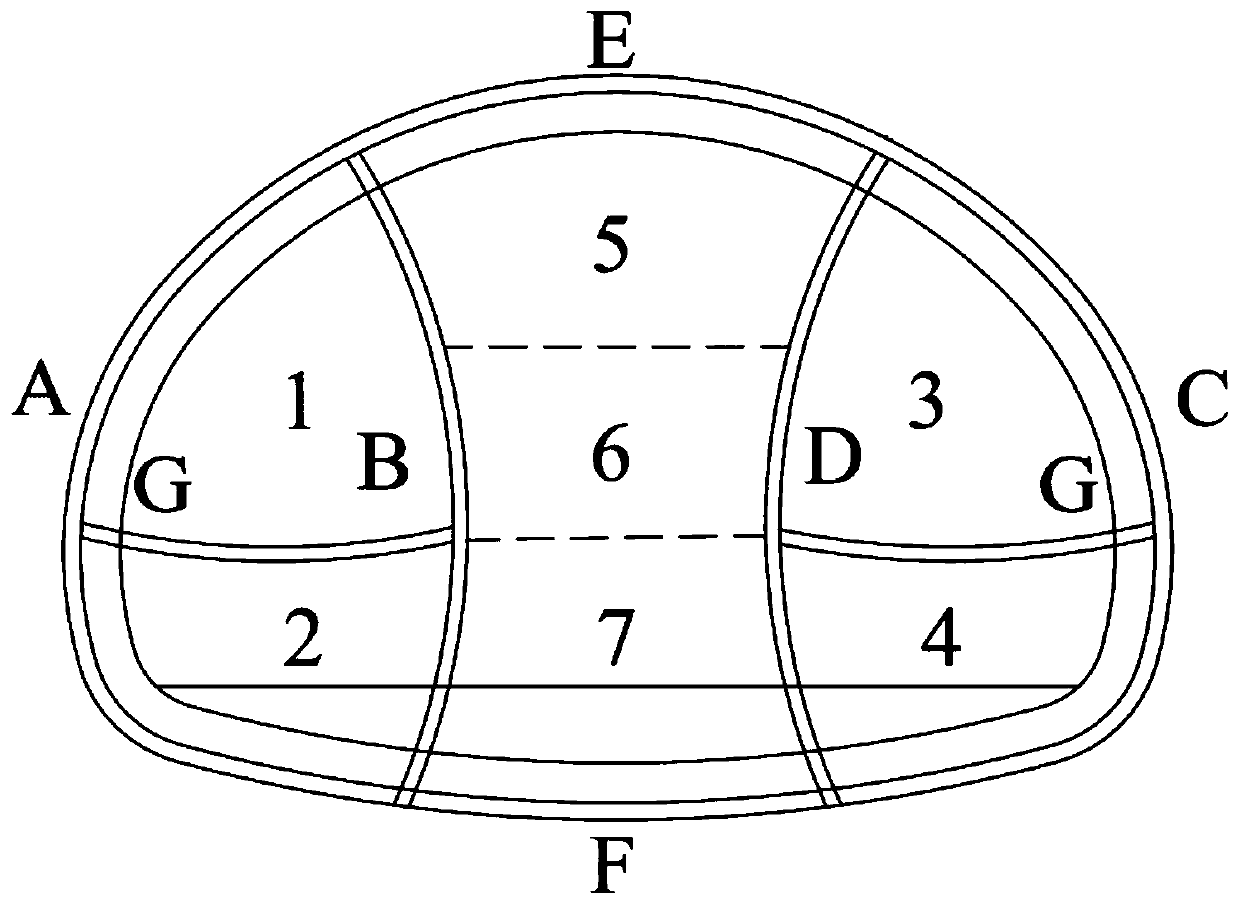

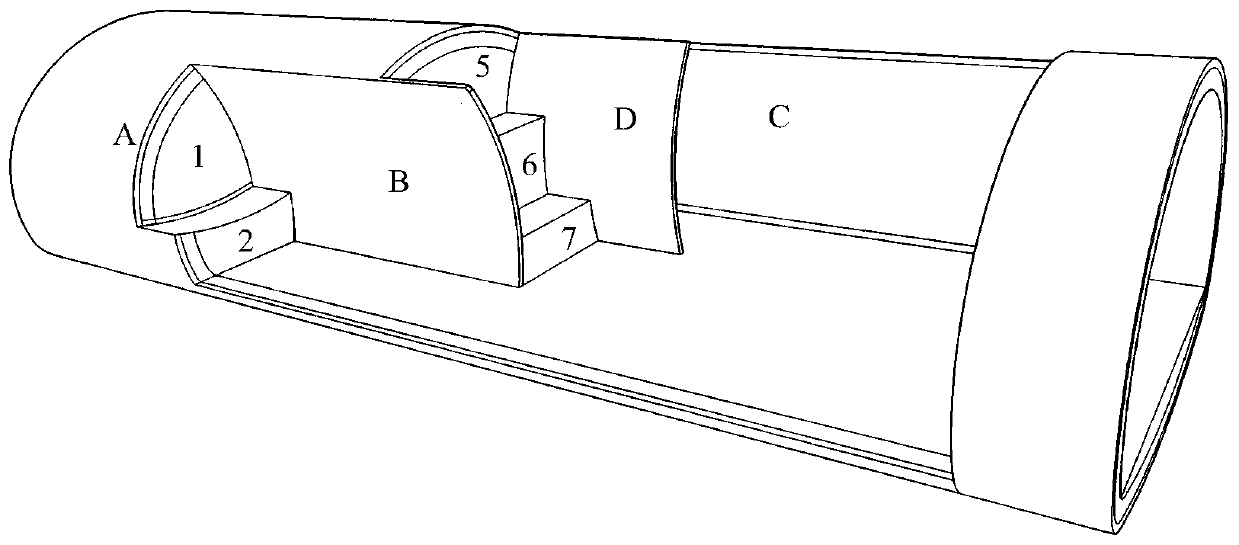

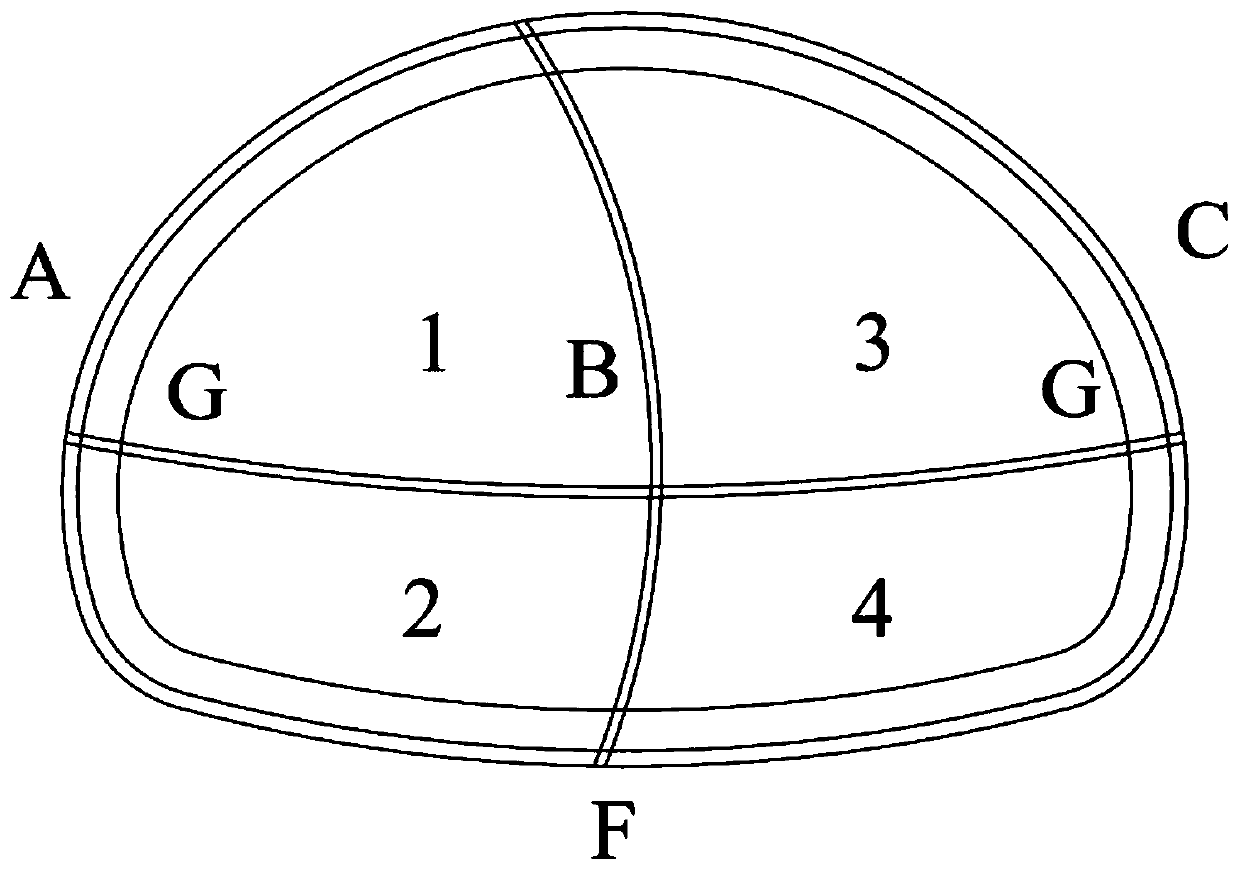

Construction method conversion construction method of super-large-span tunnel in V-level to IV-level surrounding rock section

ActiveCN109989757AReduce disturbanceAvoid intervalsUnderground chambersTunnel liningTunnel constructionBuilding construction

The invention discloses a construction method conversion construction method of a super-large-span tunnel in a V-level to IV-level surrounding rock section. The elevation of an excavation arching lineis controlled to be consistent; in transition section construction, a left pilot tunnel temporary middle wall and a right pilot tunnel temporary middle wall on the two sides of a pilot and a rear pilot in a surrounding rock double-side-wall pilot tunnel method simultaneously move towards the middle of the tunnel until the left pilot tunnel temporary middle wall is in contact with the right pilottunnel temporary middle wall, and foot locking anchor rods are applied to the two sides of a temporary inverted arch; and then the right pilot tunnel temporary middle wall is removed, and the left pilot tunnel temporary middle wall is reserved as a middle temporary middle wall of a CRD method. According to the method, a double-side-wall pilot tunnel method is transversely transited to the CRD method through a gradual change method, the time interval between construction method conversion is avoided, and disturbance of later removal of temporary supports of the double-side-wall pilot tunnel method to surrounding rock is reduced; and therefore the construction speed is increased, the construction period is shortened, enforced idleness due to poor organization of work is avoided, and economicbenefits of tunnel construction are improved.

Owner:CHANGAN UNIV

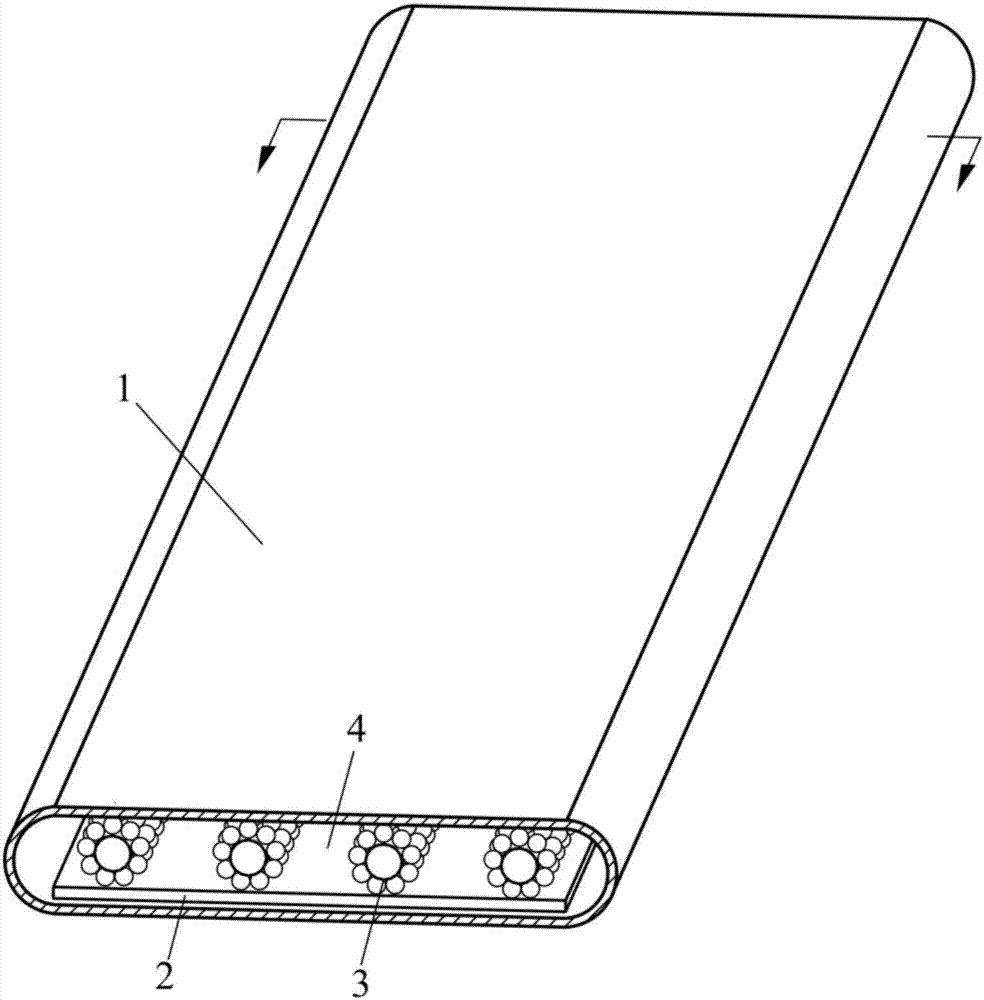

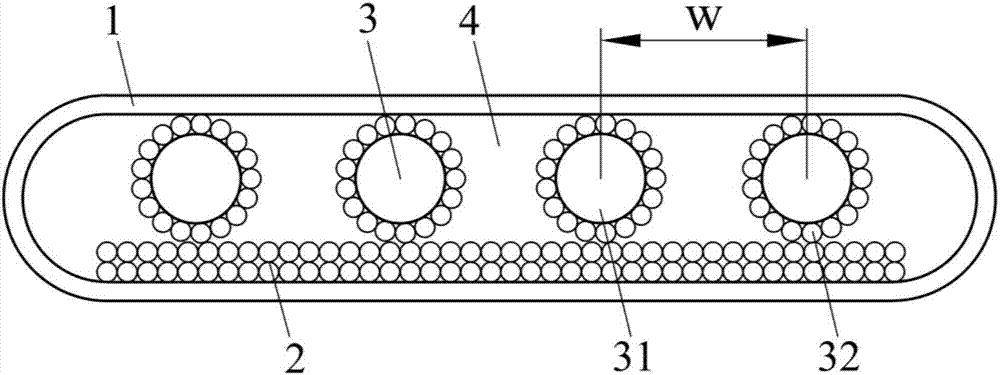

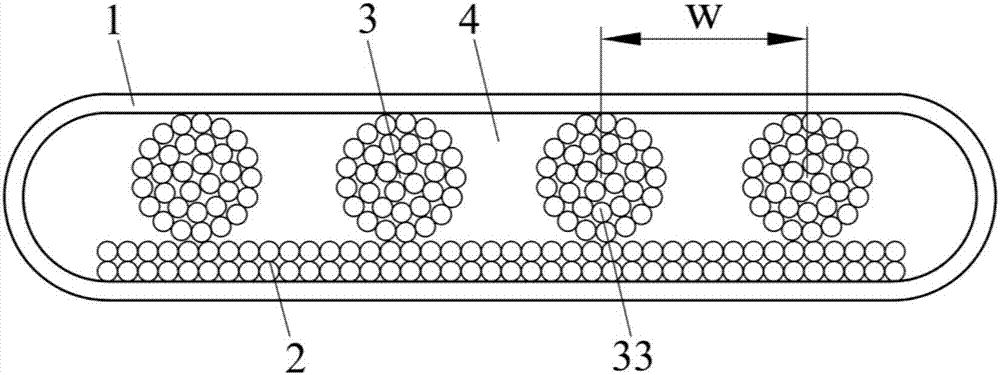

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High polymer water stopping material for crack repair and preparation method thereof

The invention belongs to the technical field of road maintenance materials, and particularly relates to a high polymer water stopping material for crack repair and a preparation method thereof. The high polymer water stopping material has excellent characteristics like good bonding performance, high water absorbability, high fluidity, short coagulation time, high impermeability, high seasonal adjustability, high durability and simplicity and convenience in construction operation. The high polymer water stopping material comprises, by weight, 10-30 parts of vinyl monomer, 20-60 parts of cementbase material, 10-30 parts of moisturizing agent, 1-2 parts of initiator, 1-2 parts of co-initiator, 1-10 parts of crosslinking agent and 1-2 parts of water reducer. The high polymer water stopping material is prepared through a certain preparation method.

Owner:西安长大公路养护技术有限公司

Novel high-strength high-water-retention coal ash high-water material

The invention discloses a novel high-strength high-water-retention coal ash high-water material. The materials is prepared from a first major part and a second major part, wherein the first major part consists of 65%-75% of water, a material A (15%-20% of sulphoaluminate cement clinker), a material B (4%-6% of lime and 10%-15% of gypsum), a material A-A (1%-2% of a retarder and 2%-4% of a suspending agent), and a material B-B (0.1%-0.5% of a setting accelerator, 1%-2% of an early strength agent and 1%-2% of a dispersing agent), and the material A, the material A-A, the material B-B and the material B meet a relationship of A:(A-A):(B-B):B= 1:0.1:1:0.04. The coal ash weight of the second major part can reach 30% of the total weight of all the components except water of the first major part. The novel high-strength high-water-retention coal ash high-water material has the advantages of high later-stage strength, good water retention during a stress process, recycle of resources, environment protection and cost saving, and can be applied on a large scale to the field of long-term stable supporting and filling in mining areas

Owner:SICHUAN UNIV

Cement calcine-free quick coagulator and its production process

The invention discloses a cement baking-free quick-setting agent and the process for preparation, wherein the quick-setting agent is prepared from the raw materials (by weight ratio) of alkaline metal hydroxide 1-10%, soluble carbonates 10-30%, aluminates 15-40%, lemon acid 2-7%, fly ash 20-35% and bone coal 20-35% through steps of mixing raw materials, disintegrating, grinding and sieving.

Owner:张洪伟

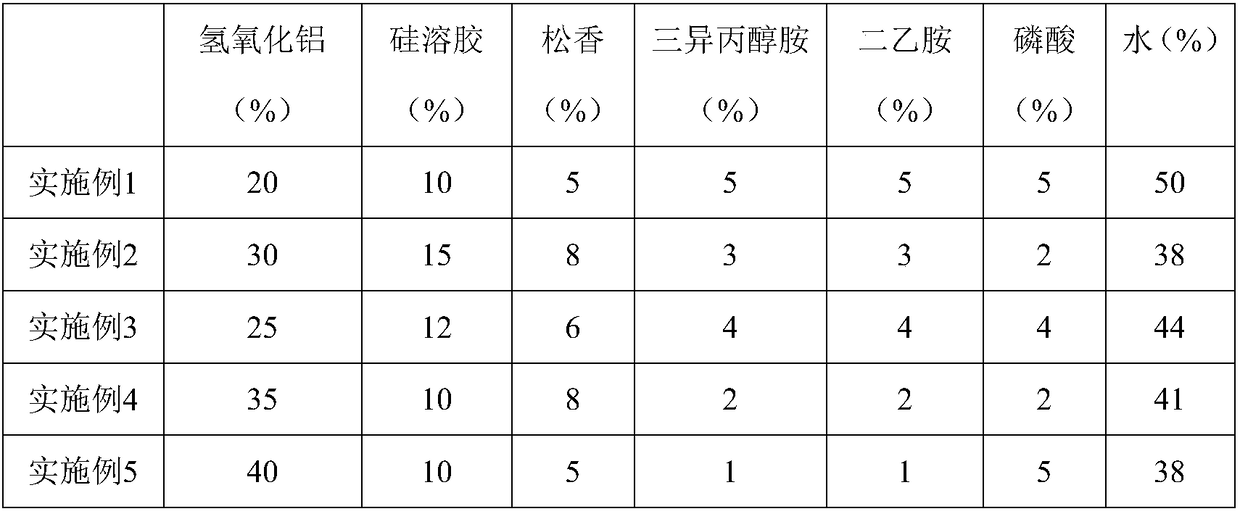

Novel foundation pit waterproof curtain additive material alkali-free liquid accelerator and preparation method thereof

The invention relates to a novel foundation pit waterproof curtain additive material alkali-free liquid accelerator and a preparation method thereof. The novel foundation pit waterproof curtain additive material alkali-free liquid accelerator comprises the following components in percentage by mass: 20-40% of aluminium hydroxide, 10-15% of silica sol, 3-10% of rosin, 1-5% of triisopropanolamine, 1-5% of diethylamine, 1-5% of phosphoric acid and 35-55% of water. The silica sol is silica sol modified by a silane coupling agent; the silane coupling agent is an alkyl alkoxy silane coupling agent and has a structural formula of YRnSiX3. The novel foundation pit waterproof curtain additive material alkali-free liquid accelerator has a stable solution system, does not contain any sulfate ion, alkali metal ion, chloride ion or any other corrosive substance and is stable in quality, excellent in adaptability, low in doping amount, high in condensation rate and high in strength; even if stored at a normal temperature for six months, the accelerator does not have a layering phenomenon.

Owner:江苏地基工程有限公司

Hole sealing material of potassium-magnesium salt mine drilling holes and hole sealing method thereof

InactiveCN102516962AHigh strengthFast condensationDrilling compositionSealing/packingMagnesium saltPotassium

The invention relates to a hole sealing material of potassium-magnesium salt mine drilling holes. The material is prepared by stirring and mixing the following raw materials in percentage by weight: 60-85% of drilling circulation liquid used by the potassium-magnesium salt mine drilling hole, 10-30% of aggregate, 5-20% of magnesium oxide, and 0.01-0.1% of water-repellent agent. The invention further provides a hole sealing method using the hole sealing material. The hole sealing material provided by the invention fully uses the wasted drilling circulation liquid, saves energy and is environment-friendly; the hole sealing material has a fast condensation speed, and has certain plasticity and expansion performance at the early period; the hole sealing material can be closely combined with a well wall, and can prevent the water from infiltrating to corrode the well wall; and the material has high later strength, and has excellent corrosion resistant performance of resisting halite and brine.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

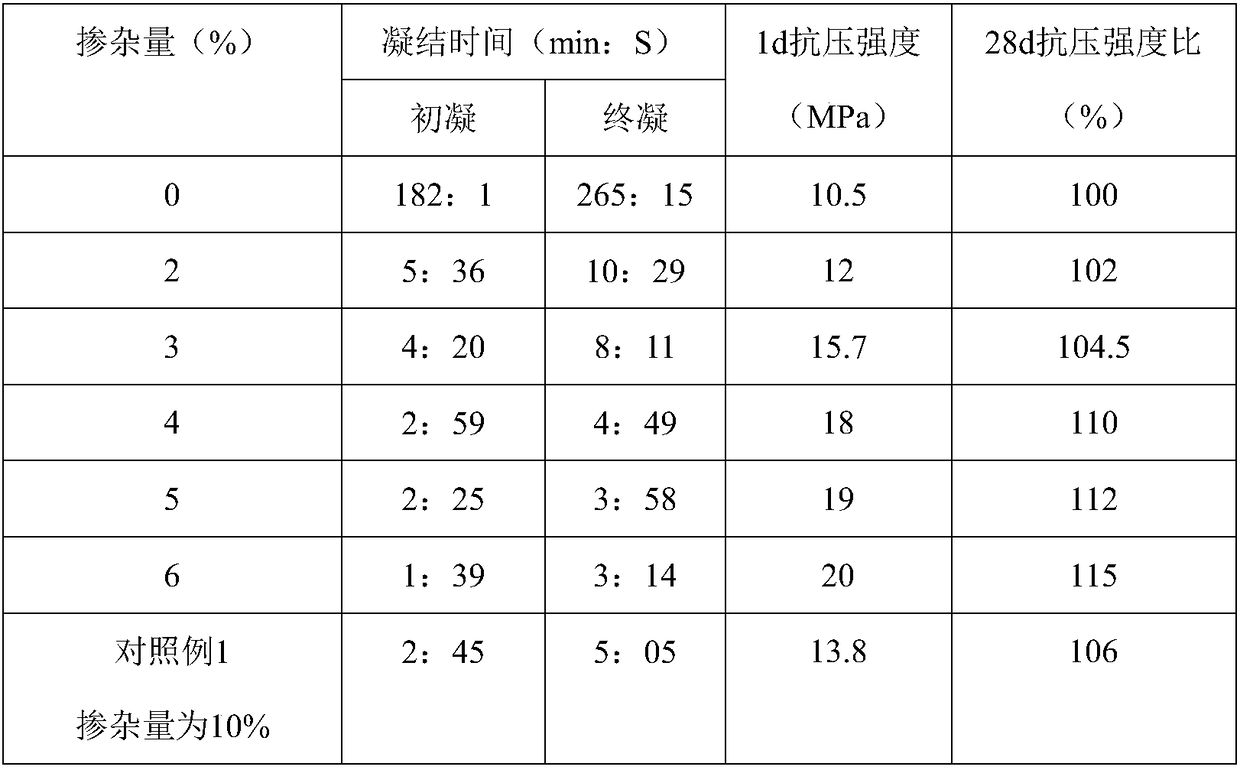

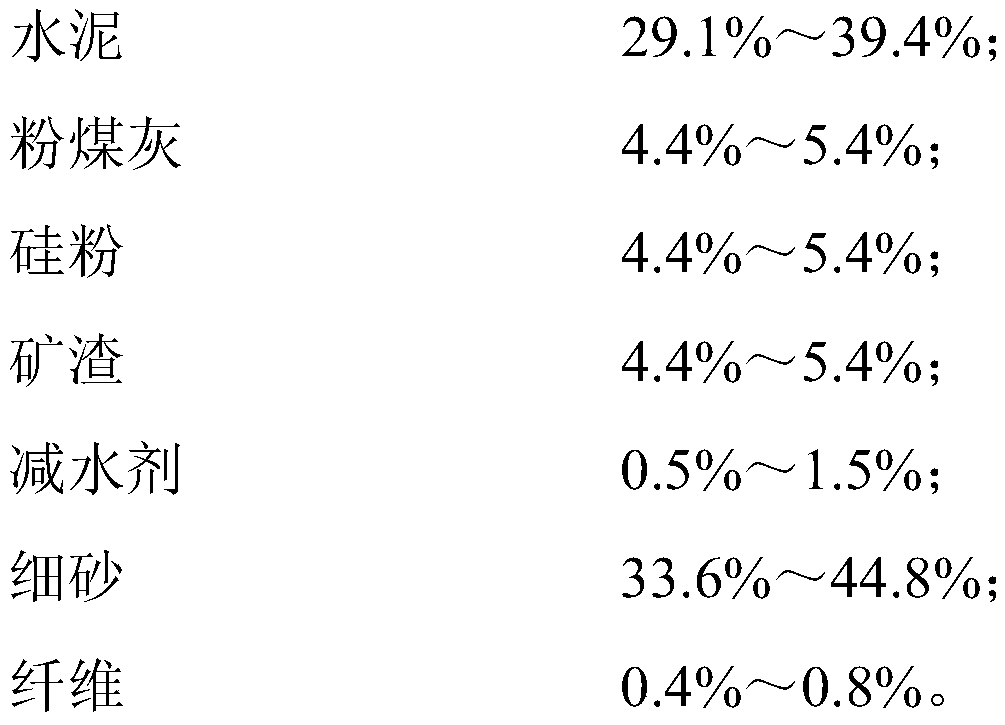

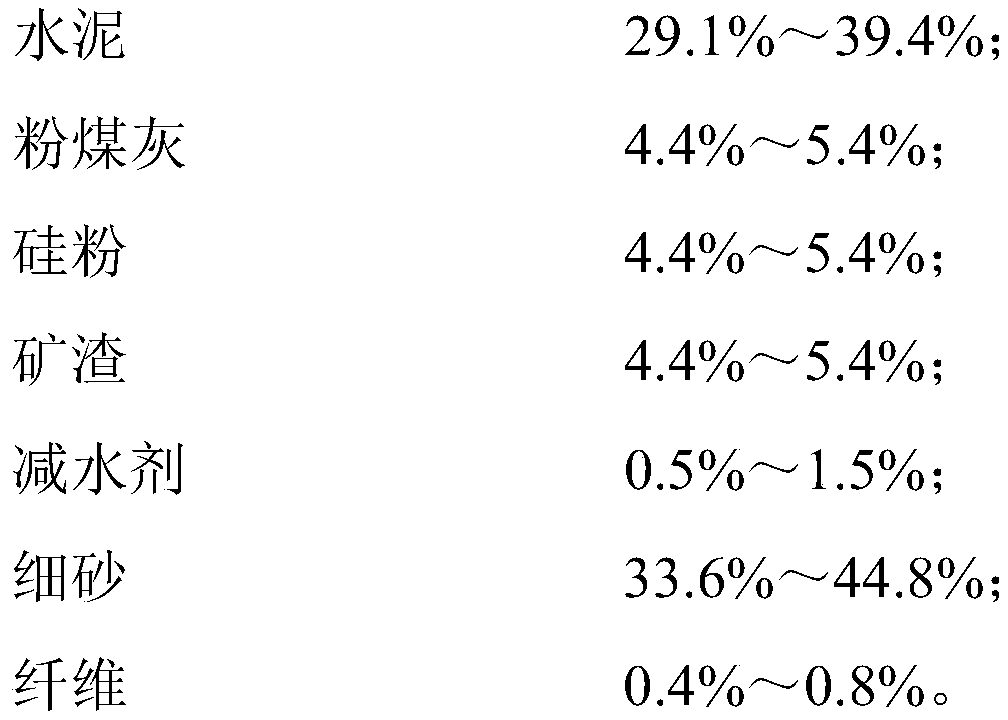

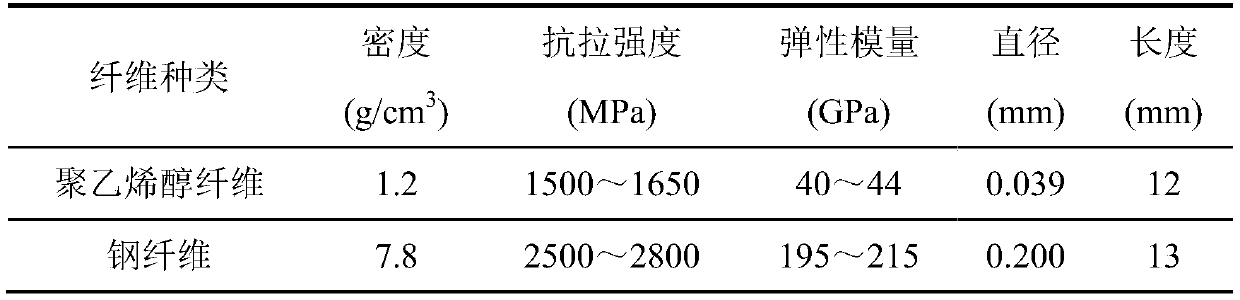

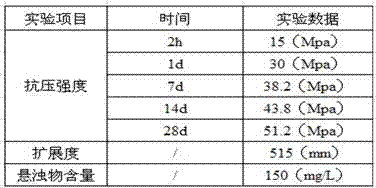

High-strength fiber-reinforced cement-based composite material as well as preparation method and application thereof

The invention belongs to the technical field of building materials, and discloses a high-strength fiber-reinforced cement-based composite material as well as a preparation method and application thereof. The composite material is formed by mixing, by mass, 85%-92% of a dry material and 8%-15% of water and is applied to steel bridge deck pavement, and the dry material comprises cement, fly ash, silicon powder, slag, a water reducing agent, fine sand and fibers. The material provided by the invention has the performance characteristics of high setting speed, high strength, high ductility, low shrinkage and high temperature resistance, and has good cooperative workability with steel.

Owner:CHINA JINGYE ENG +2

Underwater non-dispersive quick-setting and rapid-hardening cement-based composite material and preparation method and application thereof

The invention belongs to the field of composite materials and particularly relates to an underwater non-dispersive quick-setting and rapid-hardening cement-based composite material and a preparation method and application thereof. The underwater non-dispersive quick-setting and rapid-hardening cement-based composite material is prepared from the following raw materials in percentages by weight: 32-34% of portland cement, 8.8-9% of calcium aluminate, 5-7% of magnesium oxide, 0.5-2% of sulfur trioxide, 0.2-0.3% of a polycarboxylate concrete admixture, 0.3-0.7% of a flocculating agent, 0.05-0.2% of an accelerator, 0.05-0.2% of an air entraining agent, 0.05-0.3% of a corrosion inhibitor, 26-31% of a fine aggregate, 13-18% of a coarse aggregate and 8.4-8.5% of water. The material can be used for quickly repairing a concrete building in a water conservancy project, and the repair material is capable of quickly setting and ensuring the early strength.

Owner:俞家欢

Method for high temperature quick synthesizing blender or compound titanate ceramic powder

The present invention provides high temperature synthesizing process of blended or compound titanate ceramic powder. The method includes fully mixing titanate synthesized in advance and blended elements, grinding and tabletting, fast reaction of the mixture in argon atmosphere inside vacuum arc furnace, and grinding the reacted solid into the blended titanate ceramic powder. The present invention has simple technological process, easy operation, short reaction period, low cost, and high quality and performance of prepared blended titanate ceramic powder.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

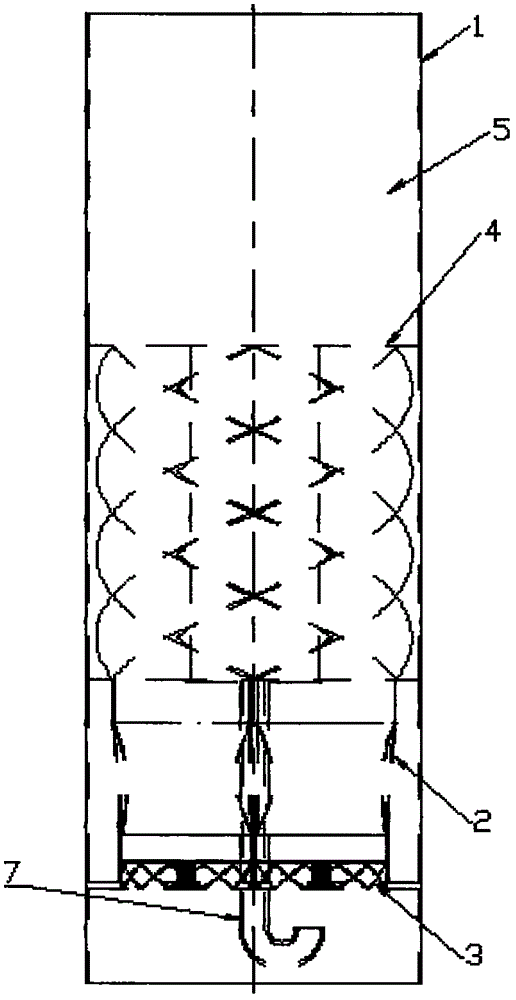

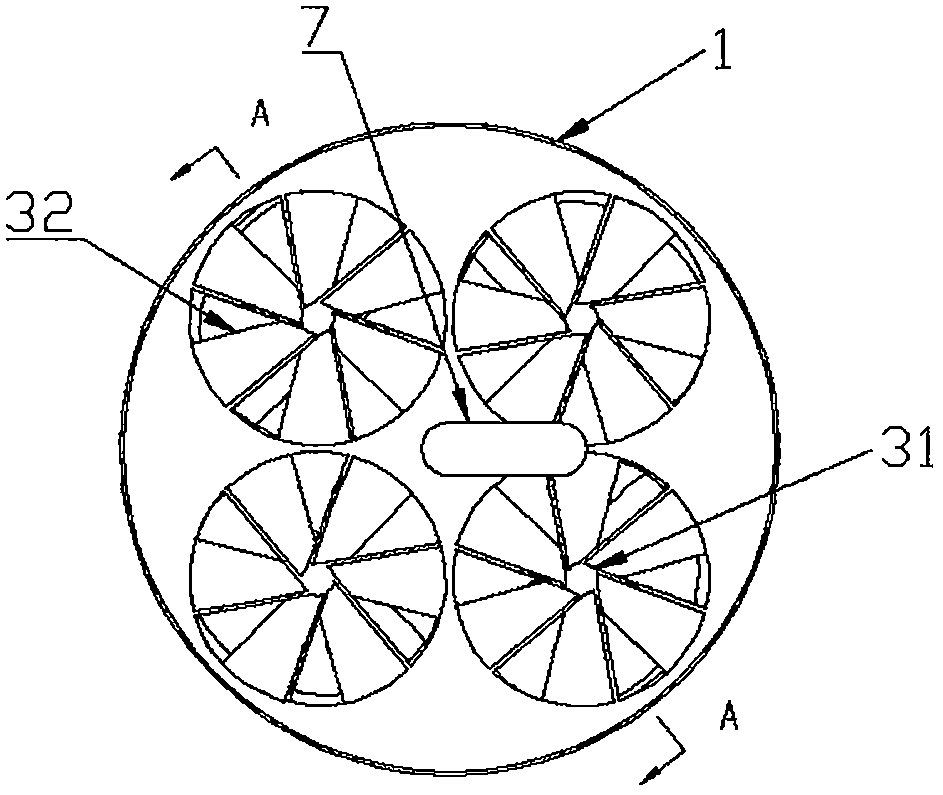

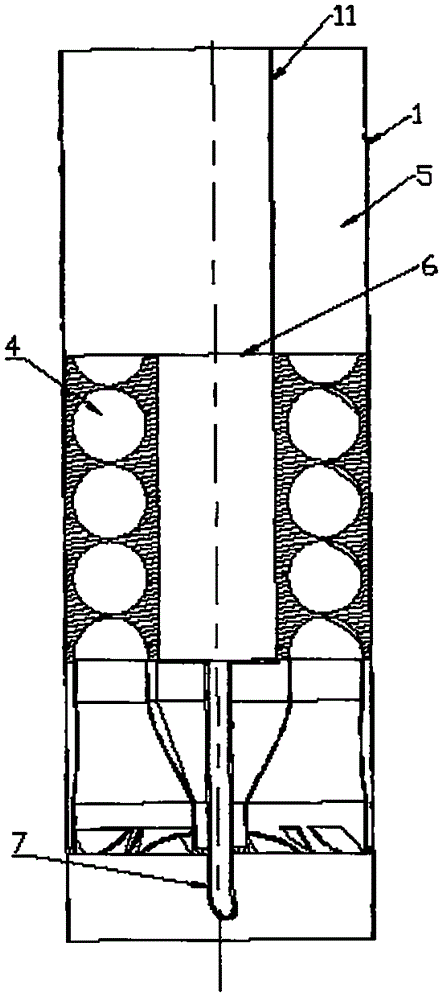

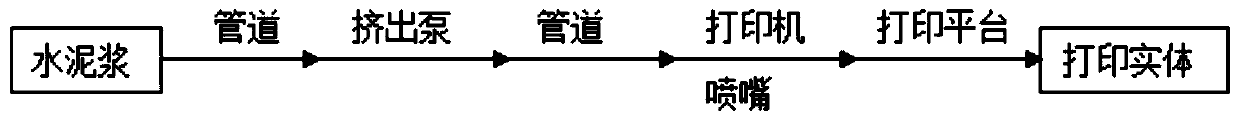

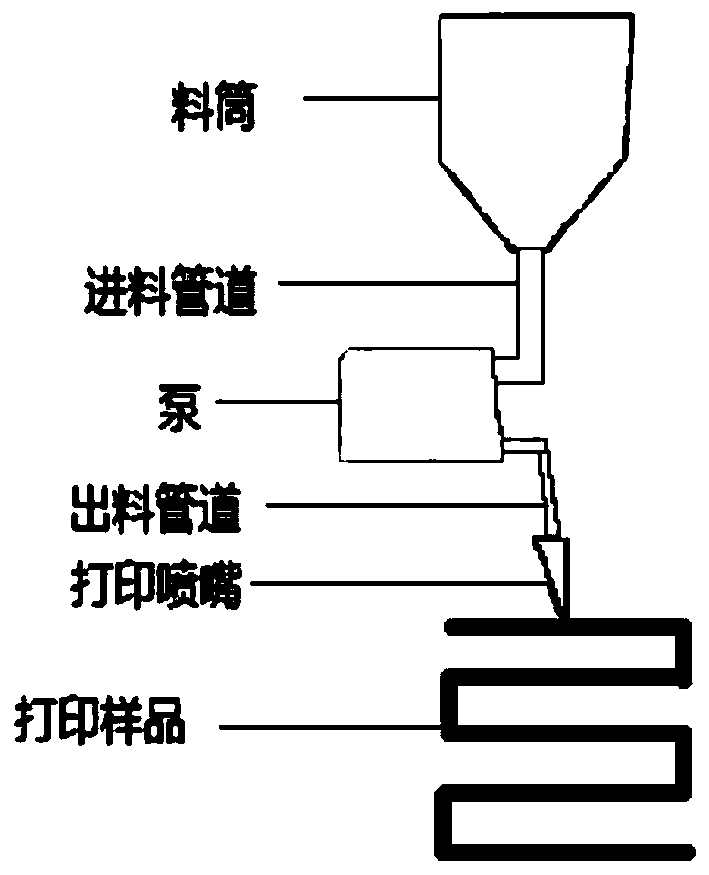

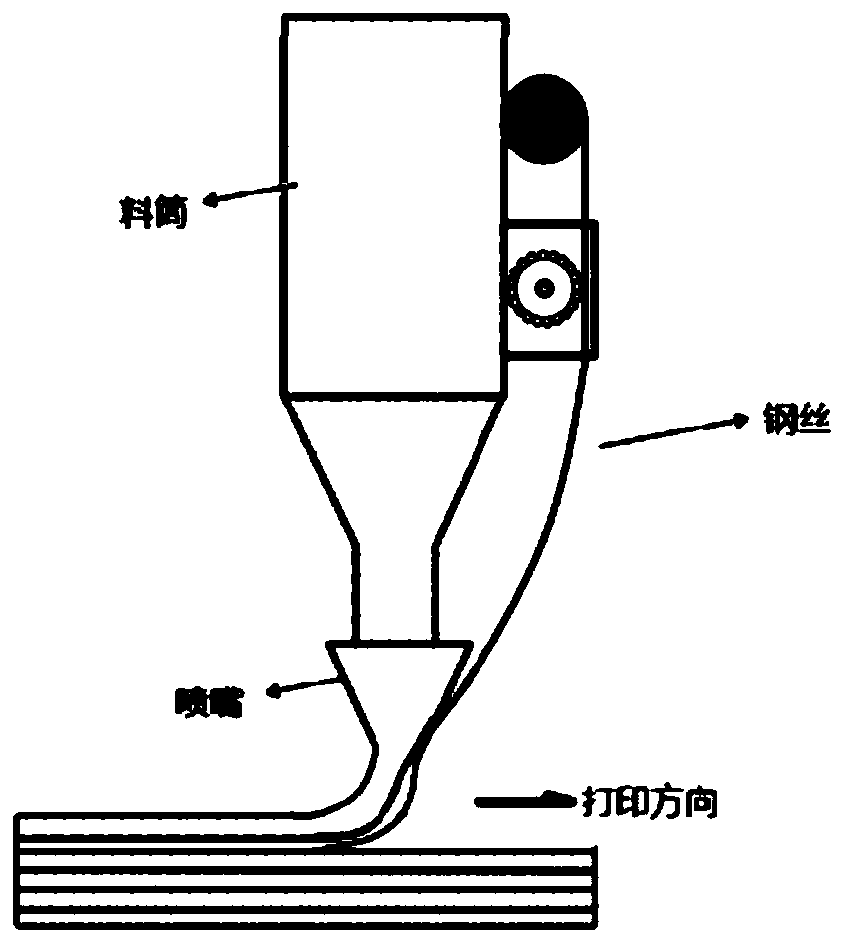

3D printing nozzle for continuous material stirring and extruding and continuous spiral wire feeding

ActiveCN110883901AEfficient printingEasy to assemble and disassembleAdditive manufacturing apparatusCeramic shaping apparatus3d printFiber

The invention discloses a 3D printing nozzle for continuous material stirring and extruding and continuous spiral wire feeding. The 3D printing nozzle comprises a motor, a cylinder, a rotating drum, an upper transmission shaft pipe, a lower transmission shaft pipe, a material equalizing device, a spatula nozzle and a supporting frame, wherein the upper transmission shaft pipe and the lower transmission shaft pipe are arranged on the central axis of the rotating drum. According to the 3D printing nozzle, dry powder enters a spray nozzle and is mixed with liquid to be extruded, so that the usageamount of retarder of traditional 3D concrete can be greatly reduced, and various performance indexes of the 3D concrete can be beneficially improved. Area requirements of a concrete 3D printing siteare reduced. Energy is saved, and the environment is protected. A liquid inlet port has strong flow and slow flow interfaces, and strong water flow can be used for flushing after use. Parts are modular components which are convenient to maintain and replace. An outlet spatula nozzle rotates clockwise to realize the function of smoothing the profile side wall and obtain a smooth lateral side. According to the 3D printing nozzle, a spirally wound steel wire (or long fiber wire) is internally arranged, so that the strength and toughness of 3D concrete materials is effectively enhanced, and the crack resistance of members is obviously improved.

Owner:大连学庆铭锋数控技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com