Patents

Literature

161 results about "Dysprosium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dysprosium titanate (Dy₂Ti₂O₇) is an inorganic compound, a ceramic of the titanate family, with pyrochlore structure. Its CAS number is 68993-46-4. Dysprosium titanate, like holmium titanate and holmium stannate, is a spin ice material. In 2009, quasiparticles resembling magnetic monopoles were observed at low temperature and high magnetic field.

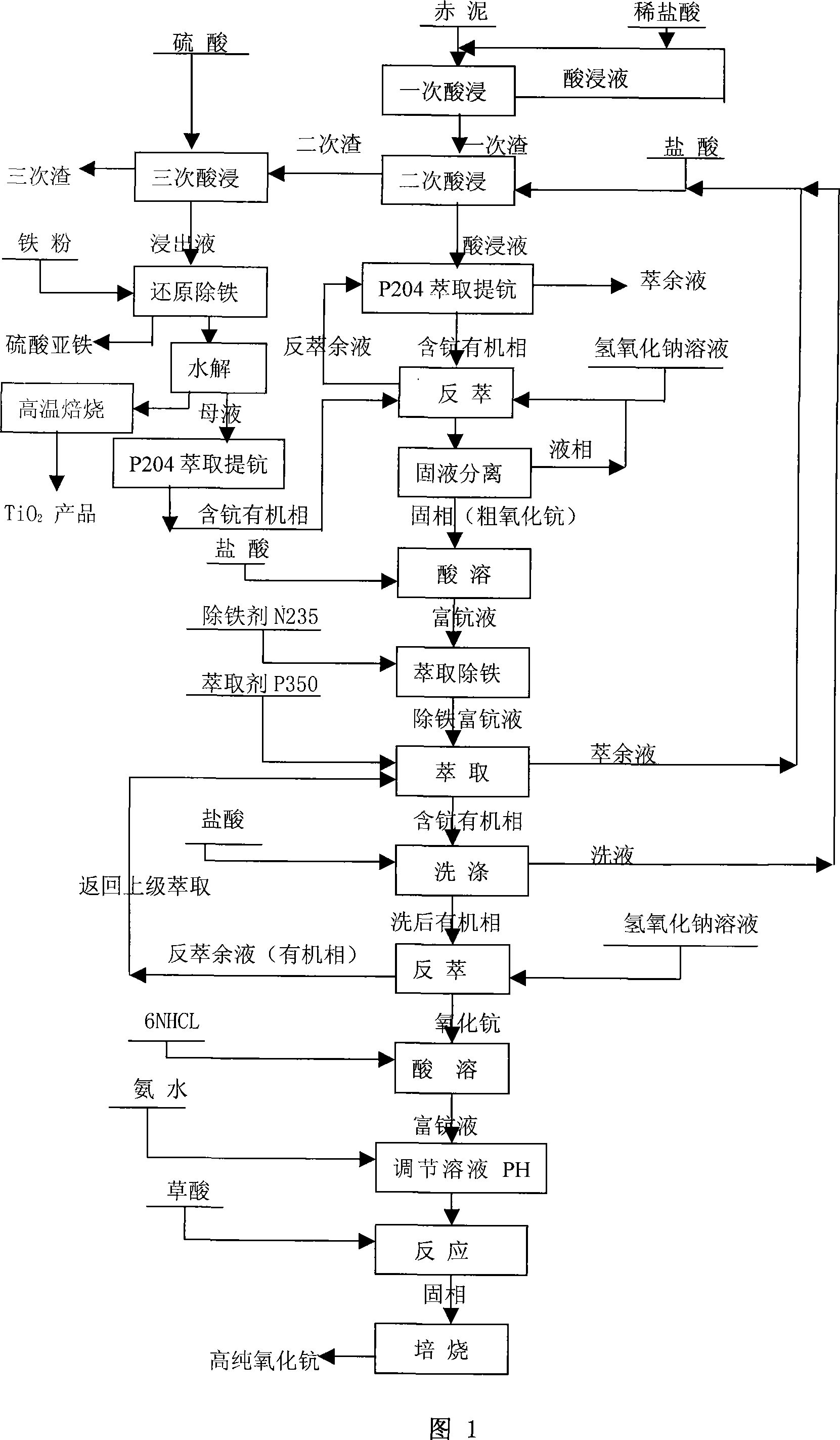

Method for extracting metal scandium and titanium from red mud

ActiveCN101182601AReduce processing costsEfficient use ofProcess efficiency improvementRed mudHydrolysate

The invention relates to a method for extracting metal scandium and titanium from red mud; the method is used for extracting scandium and titanium from the red mud; the method takes the red mud which is produced through the sinter process of the high-grade ore two portion of clinker in alumina plant as the raw material; the hydrochloric acid with a concentration of 2 percent to 6 percent is used for leaching the calcium and sodium from the red mud to increase the content of the scandium and titanium in the red mud; and then the hydrochloric acid with a concentration of 16 percent to 22 percent is used for a second acid dipping of the red mud and the product of scandium oxide is obtained after the leaching liquid passes the processes of extraction, reverse extraction and baking; the hydrochloric acid with a concentration of 80 percent to 90 percent is used for a third acid dipping of the red mud after the second one and the leaching liquid is added with iron powder for reduction and then the temperature is reduced to crystallize and separate out iron in the pattern of FeSO<4>.7H<2>O; the acid liquid which contains titanium after the iron is removed is added with alkali and heated for hydrolysis; the product of titanium oxide is obtained after the hydrolysate is baked. The method is simple and easy to be carried out and most metal elements in the red mud can be recovered and the cost for processing the red mud is low, all of which are beneficial to the comprehensive utilization of the red mud.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

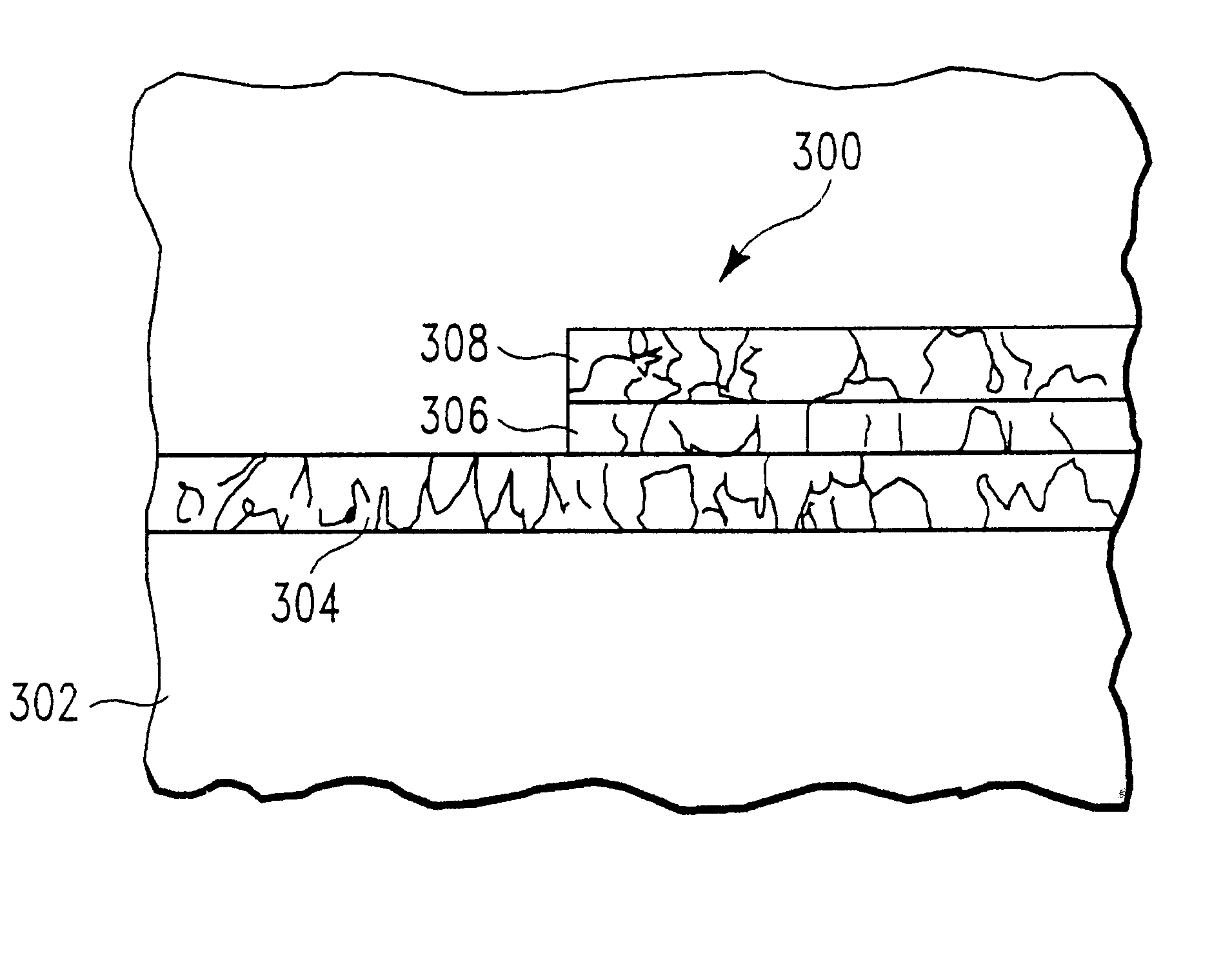

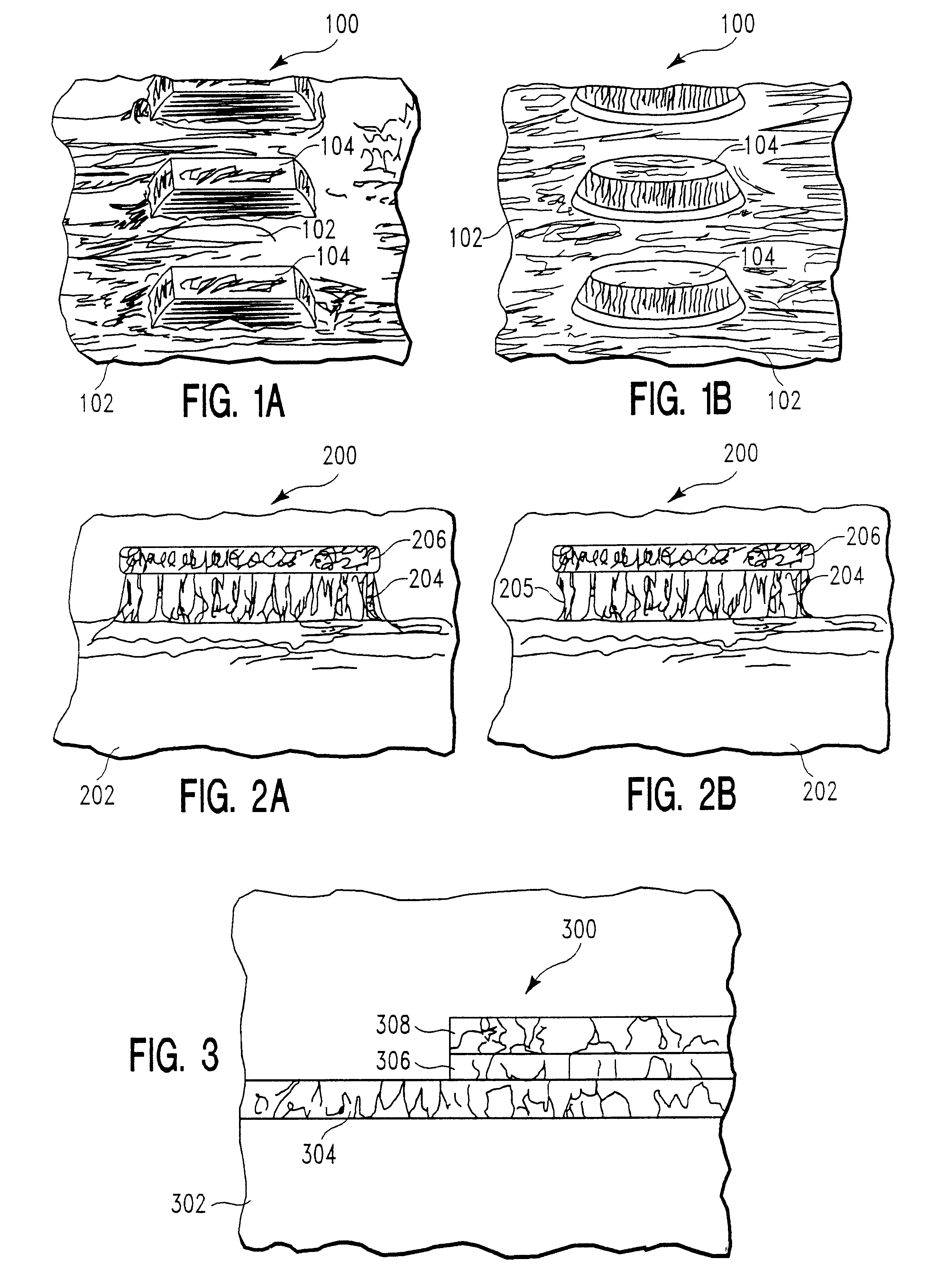

Method of patterning lead zirconium titanate and barium strontium titanate

In an embodiment of the present invention, a method is provided of patterning PZT layers or BST layers. For example, a PZT layer or a BST layer is plasma etched through a high-temperature-compatible mask such as a titanium nitride (TiN) mask, using a plasma feed gas comprising as a primary etchant boron trichloride (BCl3) or silicon tetrachloride (SiCi4). Although BCl3 or SiCl4 may be used alone as the etchant plasma source gas, it is typically used in combination with an essentially inert gas. Preferably the essentially inert gas is argon. Other potential essentially inert gases which may be used include xenon, krypton, and helium. In some instances O2 or N2, or Cl2, or a combination thereof may be added to the primary etchant to increase the etch rate of PZT or BST relative to adjacent materials, such as the high-temperature-compatible masking material. A TiN masking material can easily be removed without damaging underlying oxides. The selectivity of PZT or BST relative to TiN is very good, with the ratio of the etch rate of the PZT film to the etch rate of the TiN mask typically being better than 20:1. In addition, the etch rate for PZT using a BCl3-comprising plasma source gas is typically in excess of 2,000 Å per minute. A substrate bias power is applied to direct ions produced from the BCl3 or SiCl4 toward the surface to be etched. The bias power is controlled to avoid sputtering of a conductive layer or layers in contact with the PZT layer, so that the surface of the etched PZT is not contaminated by a conductive material, which can cause the semiconductor device which includes the patterned PZT to short out.

Owner:APPLIED MATERIALS INC

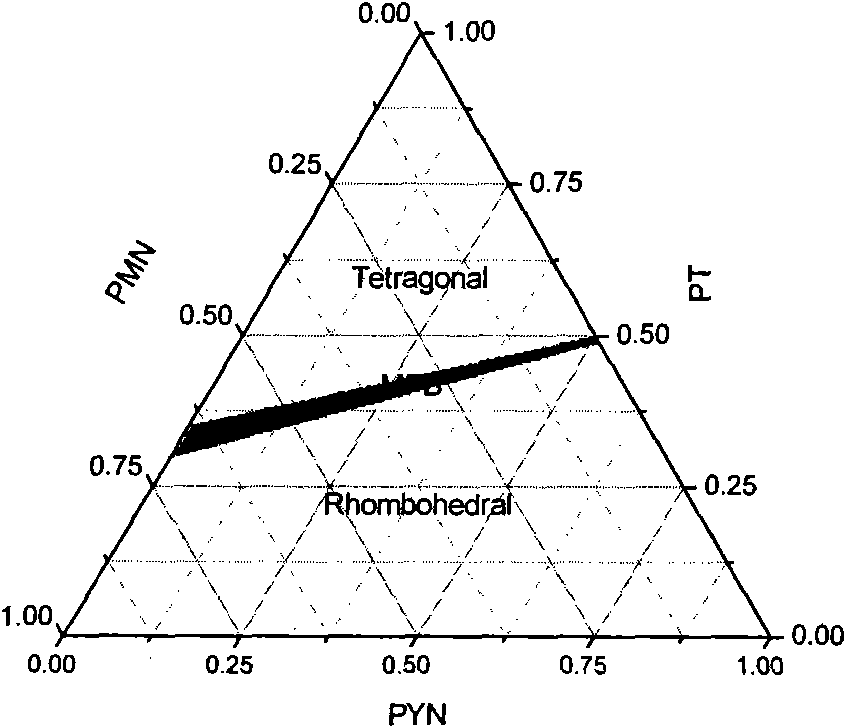

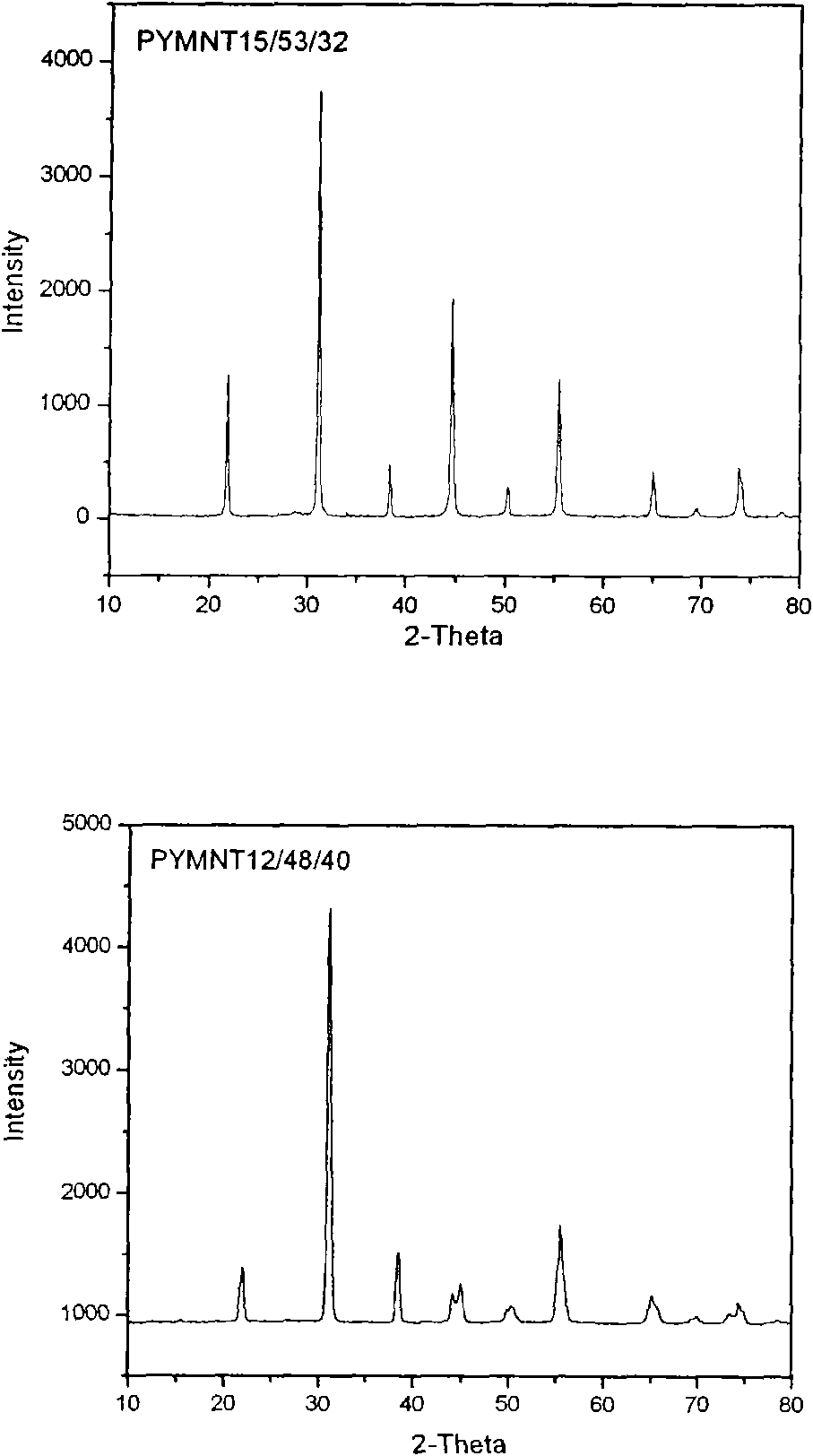

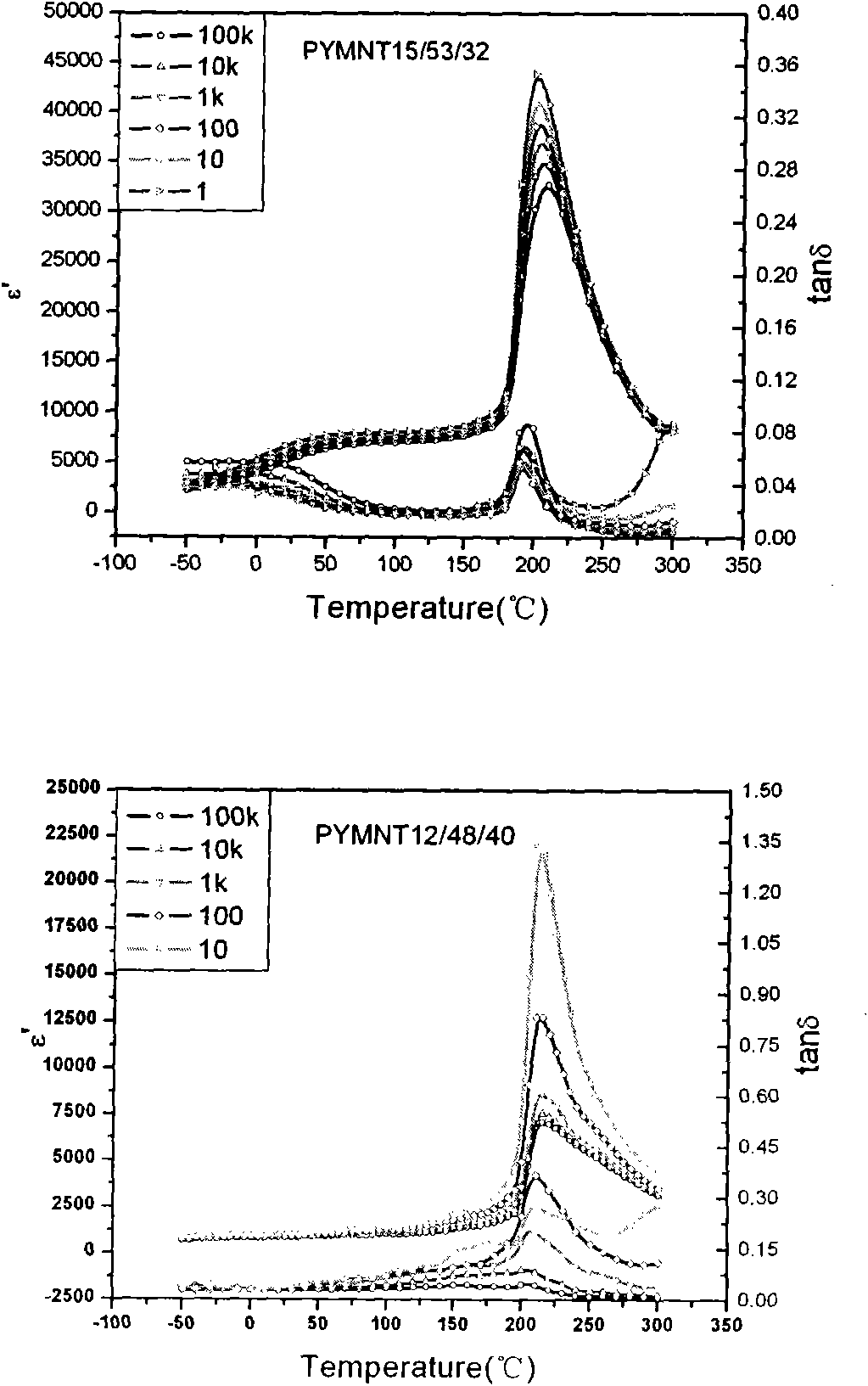

Novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate

InactiveCN102051685APolycrystalline material growthFrom melt solutionsCrystal rotationSingle crystal

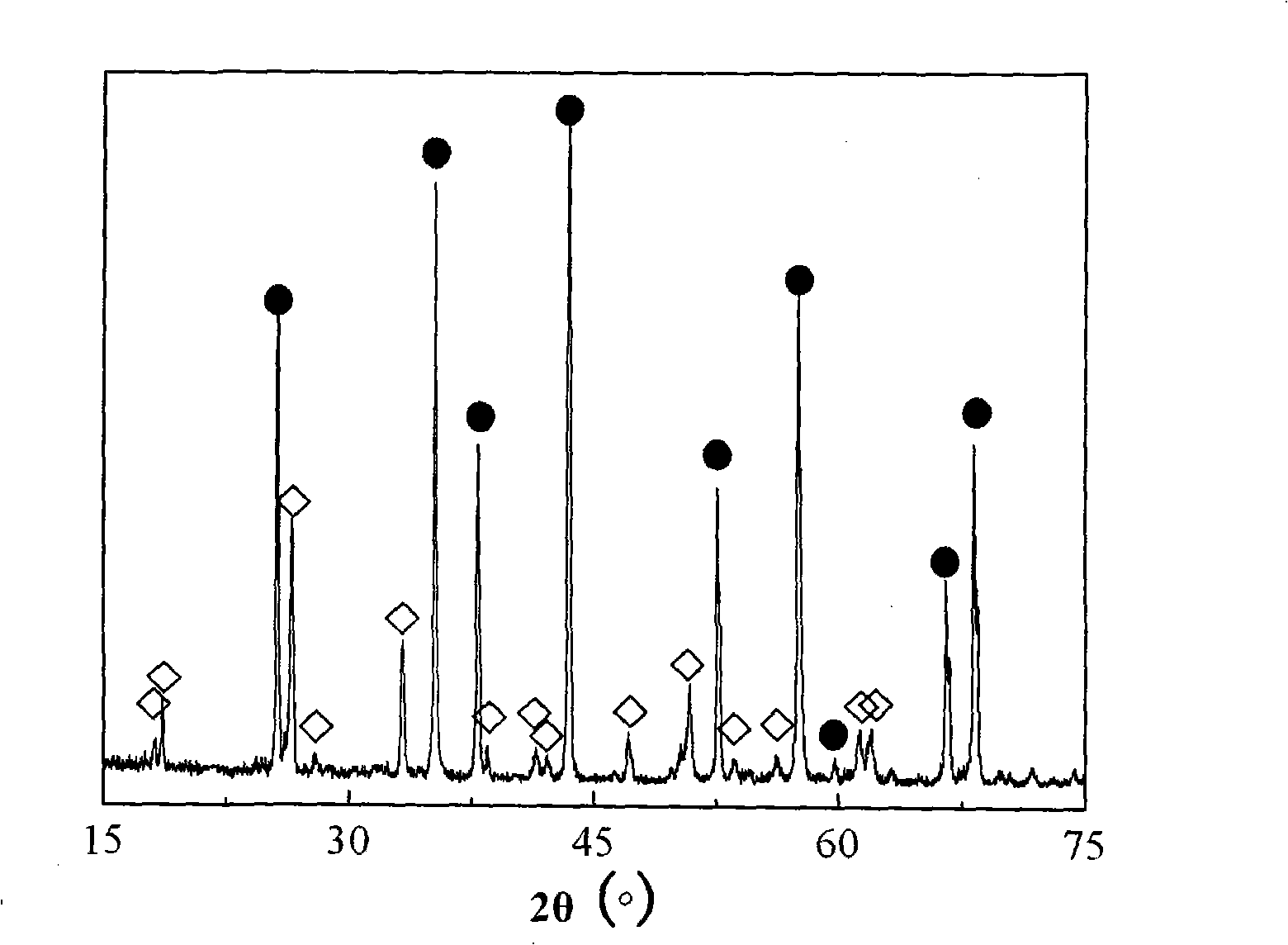

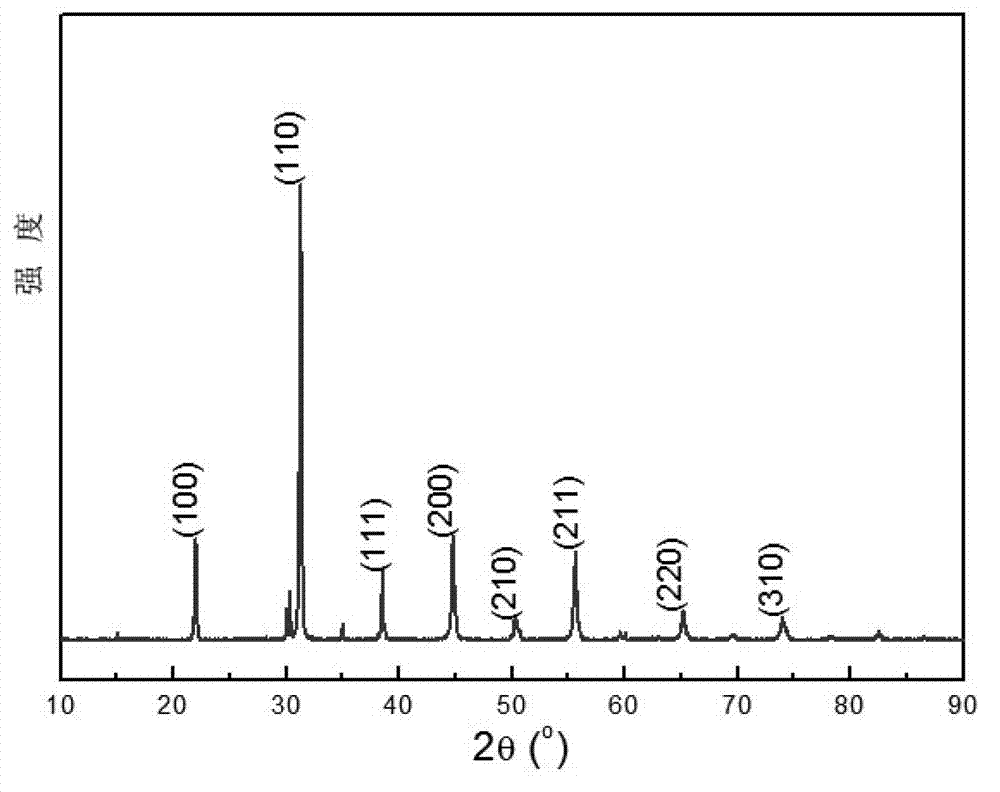

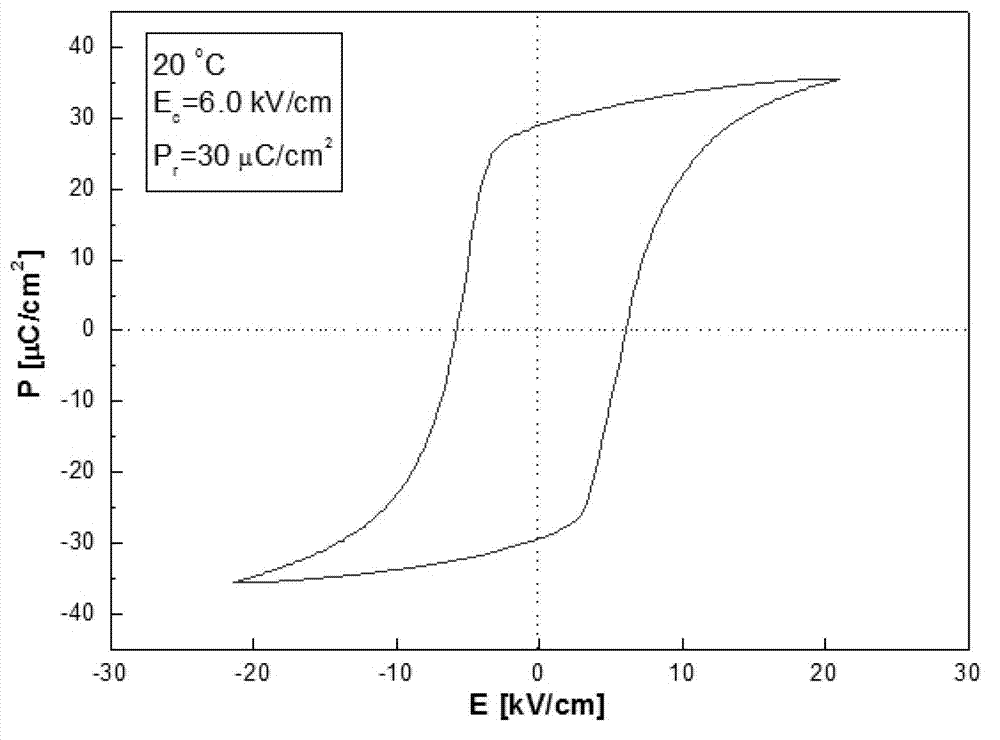

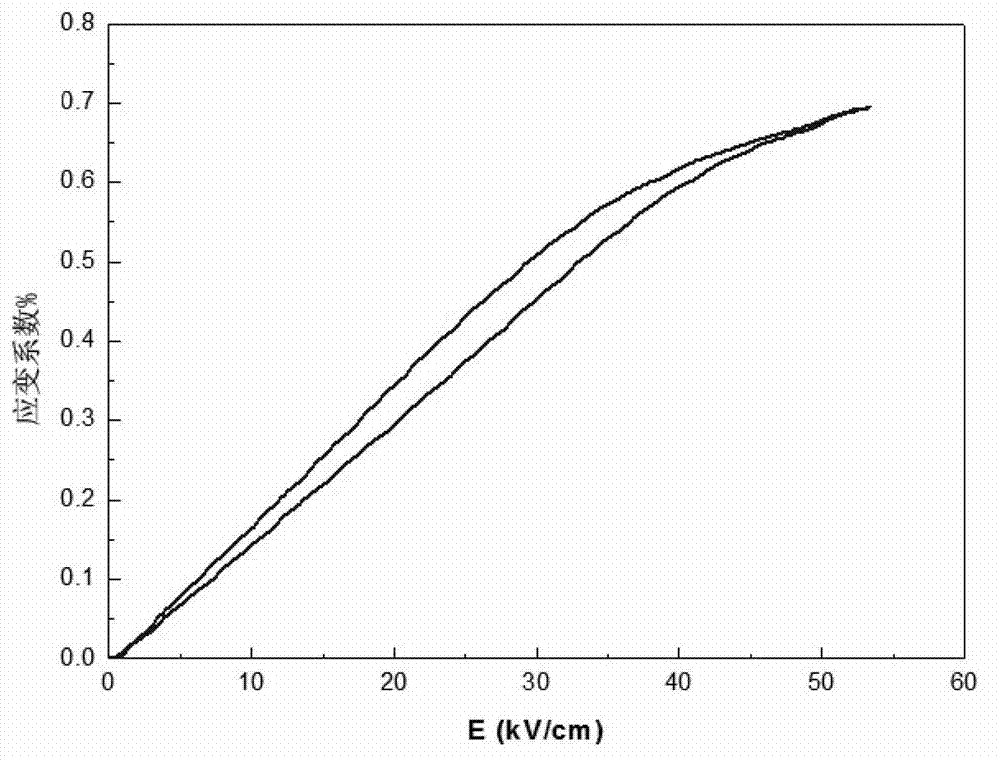

The invention relates to the growth, the structures and the properties of novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate. The crystal belongs to a perovskite structure, has an MPB region and has a chemical formula of (1-x-y)Pb(Yb1 / 2Nb1 / 2)O3-xPb(Mg1 / 3Nb2 / 3)O3-yPbTiO3 which is short for PYMNT or PYN-PMN-PT. By adopting a top crystal-seeded method, the crystal with large size and high quality can grow under the conditions that the growth temperature of the crystal is 950-1100 DEG C, the crystal rotation speed is 5-30rpm, and the cooling speed is 0.2-5 DEG C / day, and the grown crystal exposes a 001 natural growth surface. Through X-ray powder diffraction, the system is confirmed as the perovskite structure; and through ferroelectric, dielectric and piezoelectric measurement, the ferroelectricity, the dielectric property and the piezoelectricity of the crystal are analyzed. The crystal has high Curie temperature and trigonal-tetragonal phase transition temperature, large piezoelectric constant and electromechanical coupling factor, high dielectric constant and low dielectric loss and better heat stability. The crystal can be widely applied to devices in the piezoelectric fields of ultrasonically medical imaging, sonar probes, actuators, ultrasonic motors, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

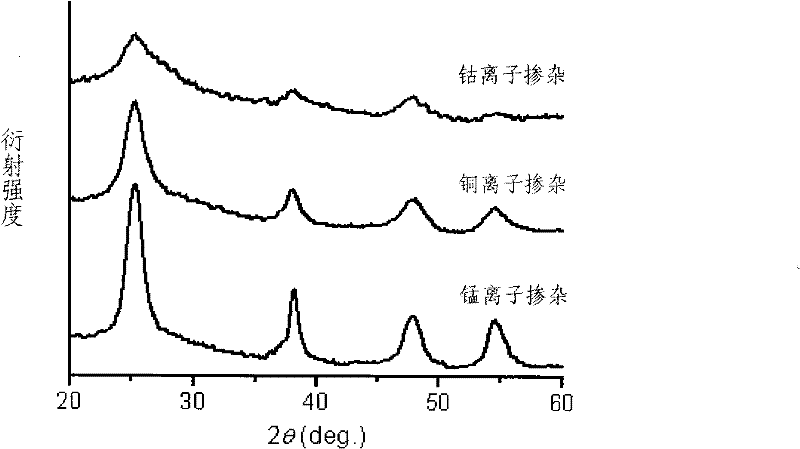

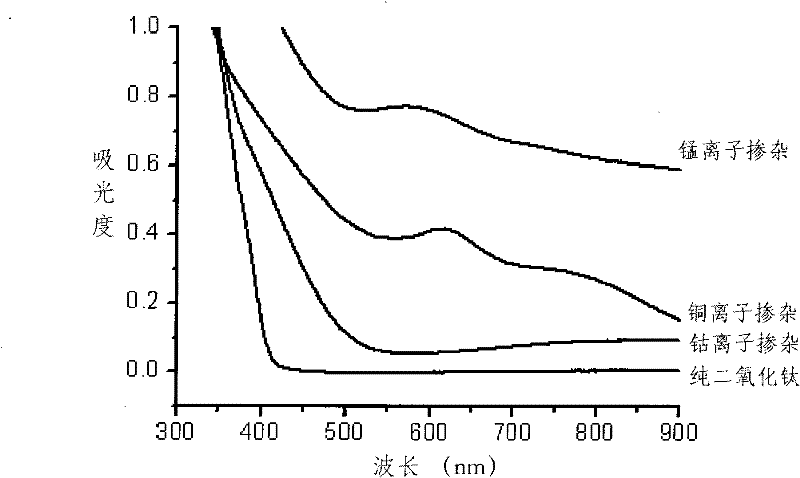

Preparation method of titanium dioxide transparent aqueous sol doped with metal ions

PendingCN102295310AImprove photocatalytic efficiencySolve pollutionTitanium dioxideMetal/metal-oxides/metal-hydroxide catalystsTitanium metalHYDROSOL

The invention relates to a class of titanium dioxide photocatalysts, in particular to a low-temperature preparation method of visible light-responsive titanium dioxide transparent aqueous sol doped with metal ions. The titanium inorganic salt and the metal inorganic salt as a dopant are dissolved in water together to form a mixed solution; wherein, the molar ratio of the metal ion in the metal inorganic salt as a dopant to the titanium ion in the titanium inorganic salt is 0.001~ 0.2; then dropwise add inorganic lye until the pH of the mixed solution is about 7-11 to obtain a composite titanic acid precipitate, wash the composite titanic acid precipitate with water and filter, then disperse with hydrogen peroxide aqueous solution, at a temperature of 50-100 Heating at ℃ for 1-24 hours to obtain a transparent aqueous sol of titanium dioxide doped with metal ions. The low-temperature preparation method of the metal ion-doped titanium dioxide transparent water-based sol avoids the problem of environmental pollution, and the obtained sol is transparent, neutral and water-based, and has good photocatalytic effect under visible light.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

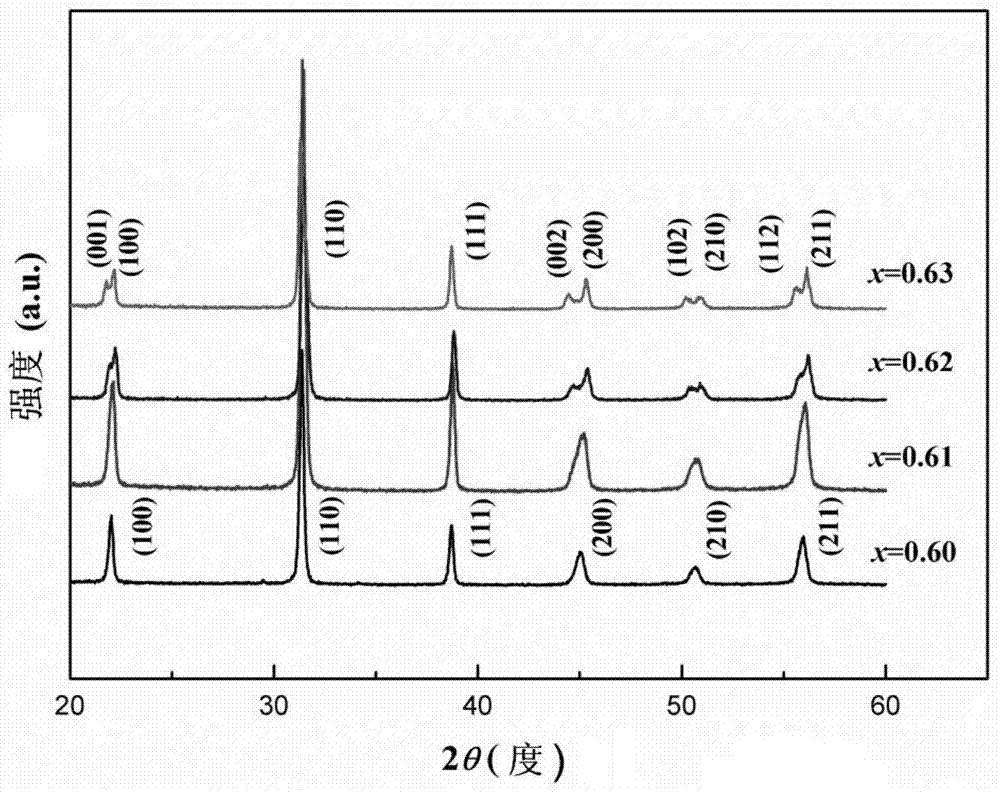

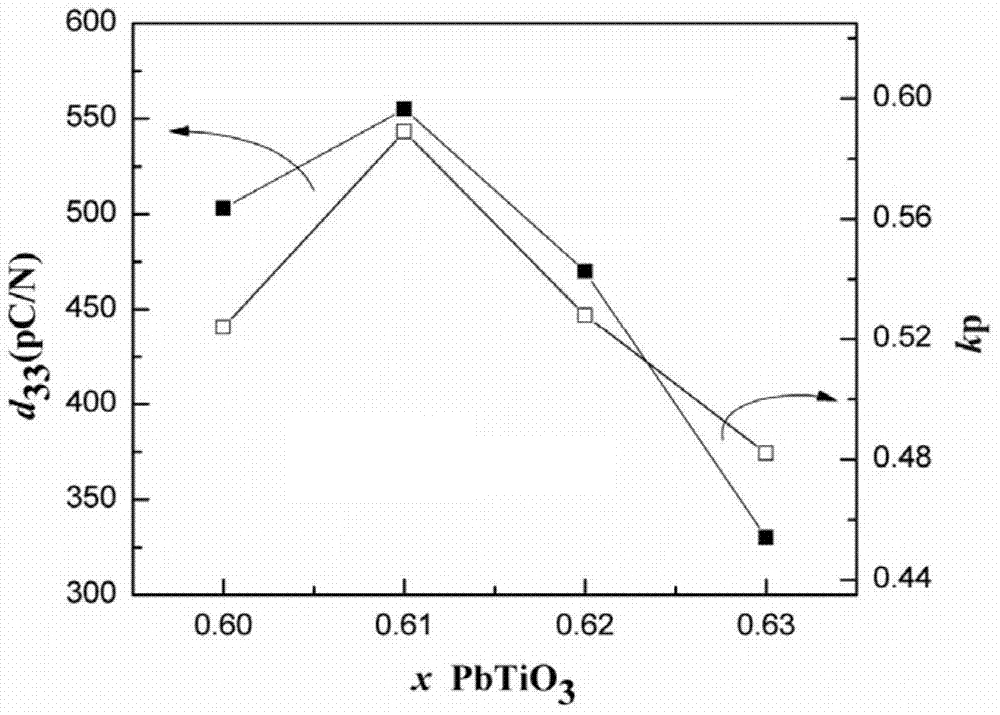

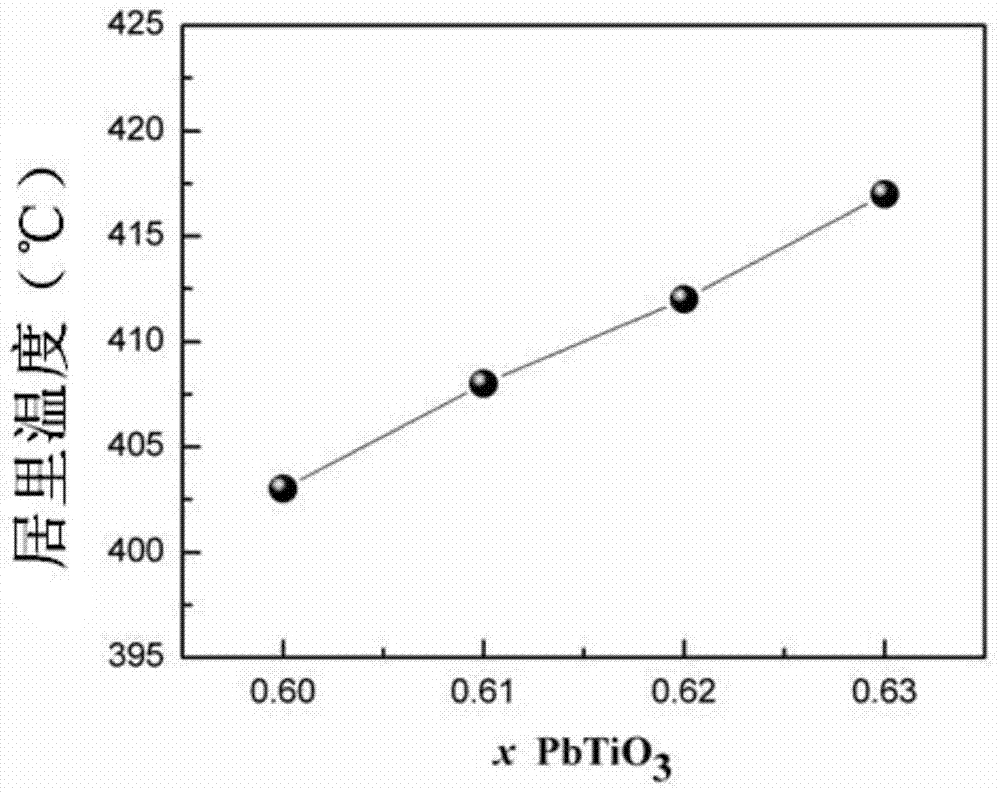

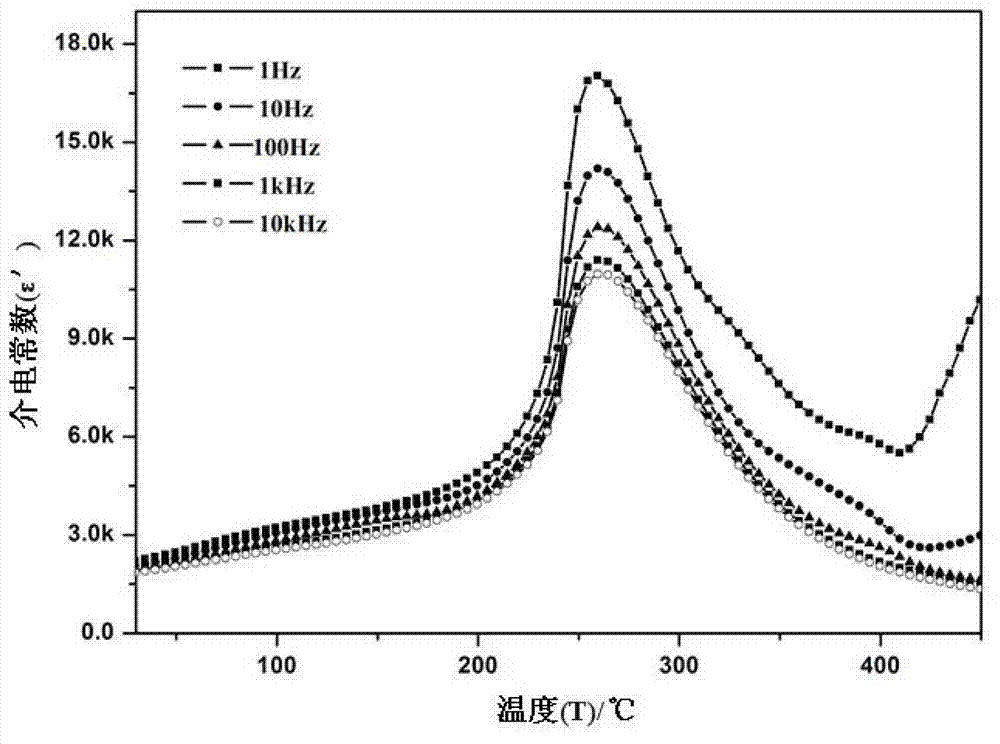

Lead tin niobate-bismuth scandate-lead titanate ternary system high temperature piezoceramic material and preparation method thereof

The invention provides a lead tin niobate-bismuth scandate-lead titanate ternary system high temperature piezoceramic material and a preparation method thereof. The structure of the material is as shown in the following general formula: 0.05Pb(Sn1 / 3Nb2 / 3)O3-(0.95-x)BiScO3-xPbTiO3, wherein x and 0.95-x respectively represent the mole percentages of PbTiO3 and BiScO3; x ranges from 0.60-0.63. The invention further provides a preparation method of the high temperature piezoceramic material. According to the lead tin niobate-bismuth scandate-lead titanate ternary system high temperature piezoceramic material provided by the invention, by changing the material system, the use amount of Sc is reduced compared with that of an existing piezoceramic material BiScO3-PbTiO3, the cost of industrial production is lowered, and under the condition that a relatively high Curie temperature is kept, the piezoelectric property of the material is further improved.

Owner:PEKING UNIV

Layered perovskite structural ceramic and preparation method thereof

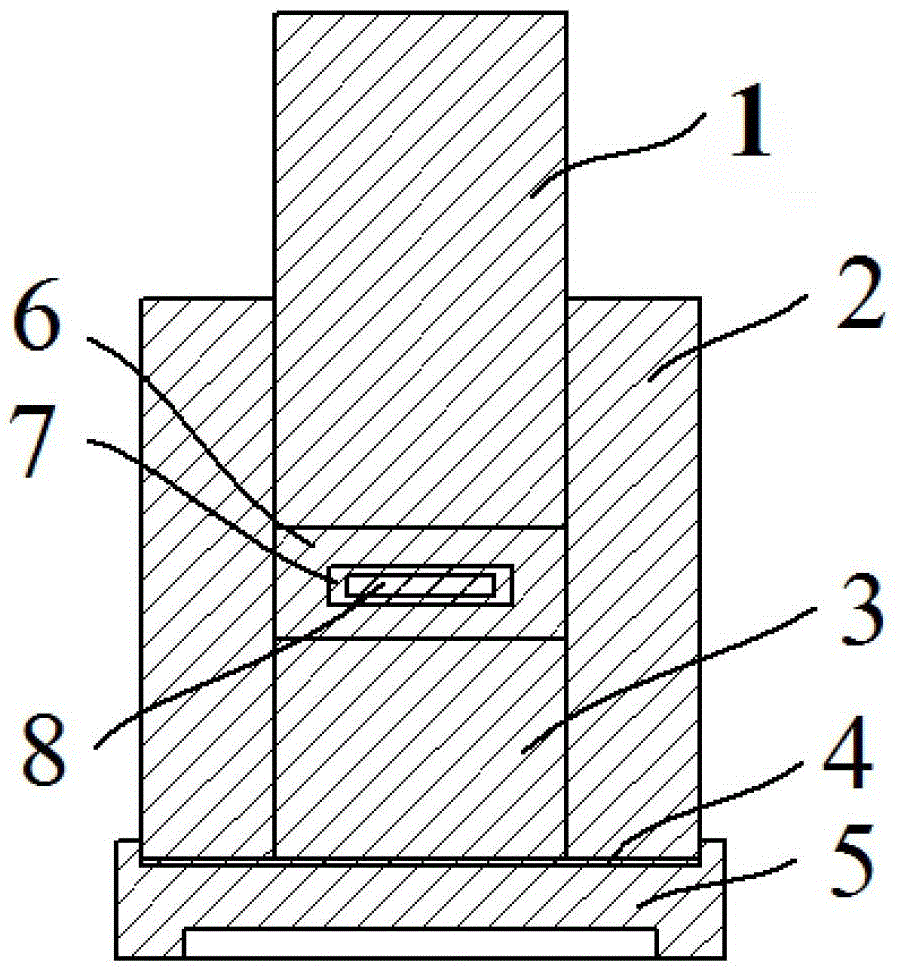

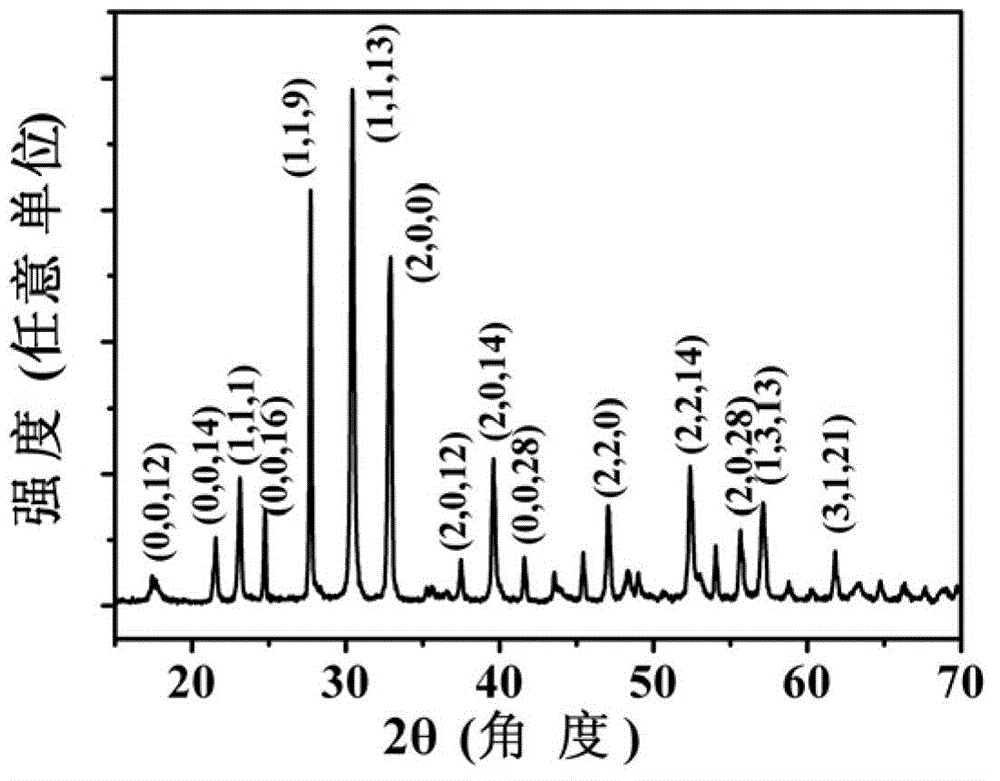

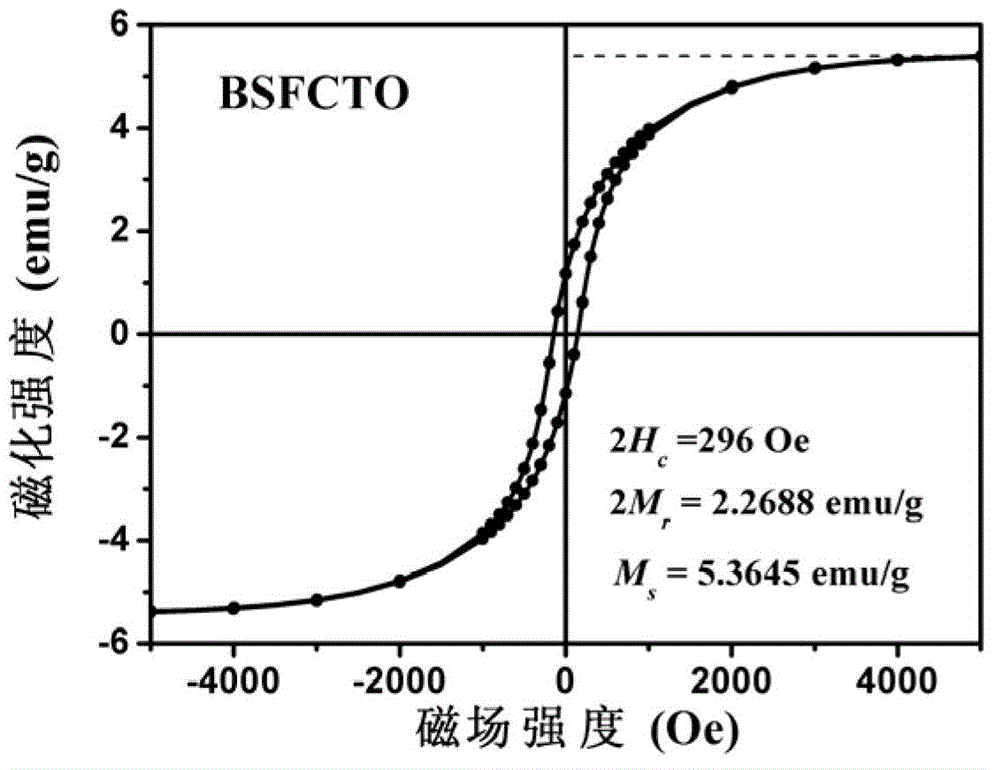

The invention provides layered perovskite structural ceramic and a preparation method thereof. The preparation method includes mixing well titanate compounds, bismuth compounds, strontium compounds, iron compounds, cobalt compounds and complexing agent in solvent, heating, drying and combusting to obtain powder, and presintering to obtain powder; performing the powder, and performing hot-pressing sintering to obtain the structural ceramic in in a formula (I). Compared with ceramics prepared in the prior art by solid phase sintering process, the structural ceramic in the formula (I) is prepared by solution process and hot pressing sintering. The preparation method has the advantages that less volatile low-valence strontium ions are introduced, increased leakage current due to volatilization of the strontium ions is improved, and ferroelectric properties are improved; the raw materials are evenly spread by the solution process, the power is even in component and has high reactivity, and Fe-Co ions are coupled fully; and the materials processed by hot pressing sintering are high in density and orientation, and the layered perovskite structural material can be obtained, namely Bi(n+1-x)SrxF3(n-3) / 2Co(n-3) / 2Ti3O3(n+1) (I).

Owner:UNIV OF SCI & TECH OF CHINA

Aluminum oxide/alumina titanate ceramica composite material and preparation thereof

Disclosed is an alumina / aluminum titanate ceramic composite material and a preparation method thereof, relating to a ceramic composite material and a preparation method thereof. The preparation method solves the problems that the preparation process of the present alumina / aluminum titanate ceramic composite material is complicated, the sintering temperature is high, long time is consumed, the density of the product is low, the performance of the product is poor and the aluminum titanate is decomposed easily. The alumina / aluminum titanate ceramic composite material is prepared by mixed powders, deionized water and a binder, wherein, the mixed powders are composed of nanometer alumina and nanometer titanium oxide. The preparation method is as follows: firstly, weighting raw materials, and mixing the materials to obtain a slurry; secondly, re-granulation to the slurry for obtaining a nano-composite powder; thirdly, heat treatment to the nano-composite powder; and fourthly, insulating and sintering the nano-composite powder obtained after the heat treatment to gain the alumina / aluminum titanate ceramic composite material. The preparation method is simple, the sintering temperature is low, short time is consumed, aluminum titanate in the product is not decomposed, the density of the product is high and the performance of the product is good.

Owner:HARBIN INST OF TECH

Process for preparing aluminum titanate powder and sintered body

InactiveUS6197248B1High yieldShort timeCeramic shaping apparatusTitanium compoundsShell moldingDysprosium titanate

A process for preparing a powder of aluminum titanate, including the steps of subjecting to pressure molding a mixture of 100 parts by weight of a mixture of Al2O3 and TiO2 at a molar ratio of the former: the latter of 1:0.95-1.05, 2 to 5 parts by weight of SiO2, 2 to 5 parts by weight of iron oxide calculated as Fe2O3 and 1 to 3 parts by weight of a powder of an organic substance; sintering the molded product at a temperature of 1600 to 1700° C. in a closed container; and pulverizing the molded product. A further process for preparing a sintered body of aluminum titanate includes the steps of molding the powder of aluminum titanate obtained by the above-mentioned process and sintering the molded product at 1450 to 1550° C.

Owner:OHCERA CO LTD

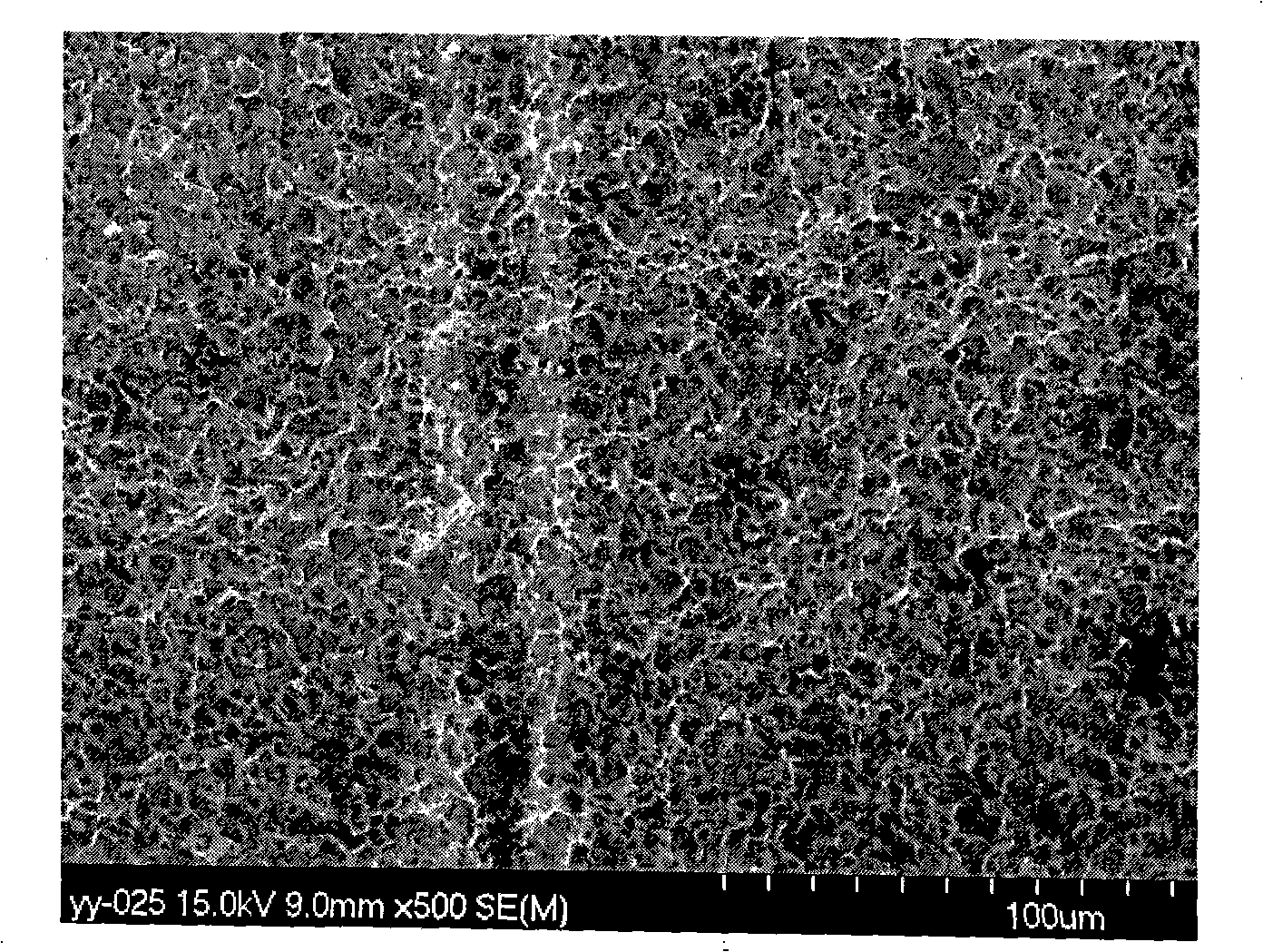

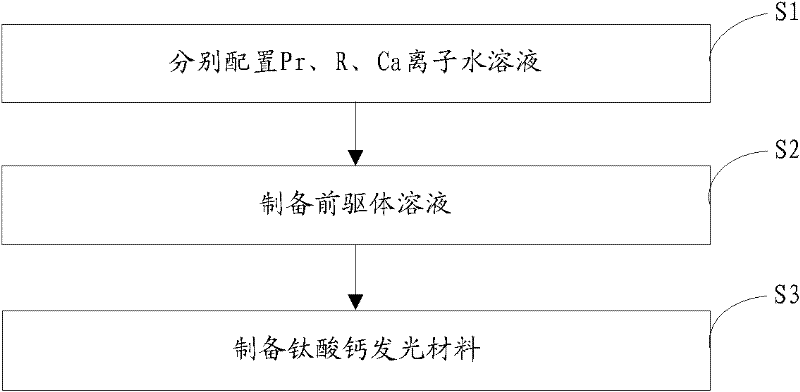

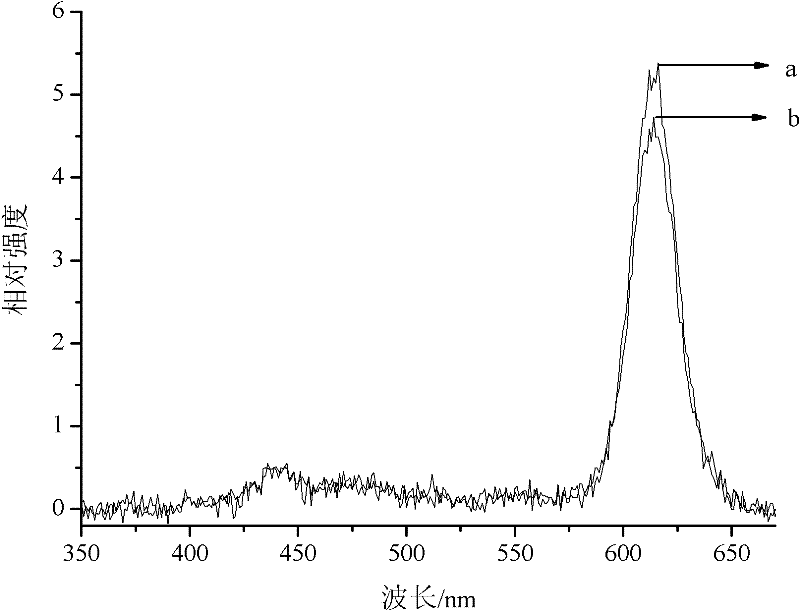

Calcium titanate luminescent material and preparation method thereof

InactiveCN102477294ASimple preparation processLow equipment requirementsLuminescent compositionsLuminous intensityDysprosium titanate

The invention belongs to the field of luminescent materials, and discloses a calcium titanate luminescent material and a preparation method thereof. The chemical general formula of the calcium titanate luminescent material is Ca1-xTi1-yO3: xPr, yR, M, wherein 0.001<=x<=0.01, 0.005<=y<=0.03, R refers to at least one of Al and Ga, and M refers to at least one of nano particles of Ag, Au, Pt and Pd. The calcium titanate luminescent material is simple in preparation process, low in equipment requirement and short in preparation period. A small quantity of metallic nano particles is added into the luminescent material to enhance luminescence of the luminescent material, and the luminous intensity can be enhanced under excitation of cathode rays.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

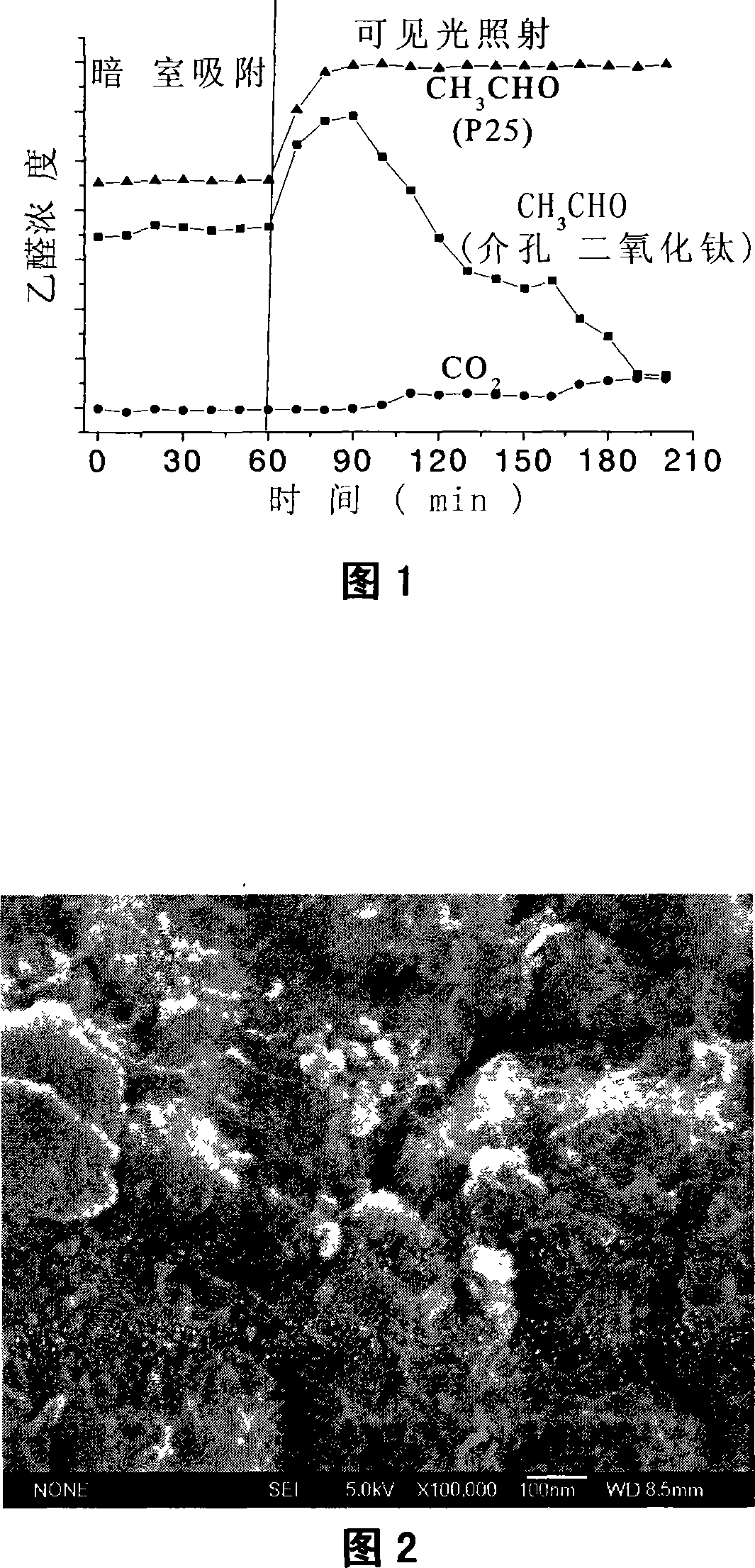

Method for preparing mesoporous crystal titanium dioxide using light-sensitive active matter as formboard

ActiveCN101024169ALarge specific surface areaFacilitated DiffusionPhysical/chemical process catalystsActive matterCarbon nanotube

The invention relates to a mesoporous TiO2 Crystal Preparation method with a photosensitive activity as template, it belongs to chemical engineering technology. Use of titanium alkoxides or ion-containing titanium ions titanate or salts or mixtures of these substances as TiO2 precursor, ethanol or acetone or a mixture of both as the diluents, used ethylene glycol or isopropyl alcohol or a mixture of both as dispersant, used Perylenequinone derivatives or other natural extract with photosensitive activity as the photosensitive activity object; the titanium dioxide precursor hydrolysis and crystal to get the mesoporous TiO2 precursor; mesoporous TiO2 precursor was sintering to get mesoporous TiO2 Crystal with photosensitive activity as template. The mesoporous materials of this invention through sol-gel method and the high-temperature burning, do visible catalyst, or get carbon nm tube by the separation and purification. The invention has low cost of production, product higher catalytic activity, stable performance, simple process.

Owner:YUNNAN UNIV

Method for producing aluminum titanate sintered object

InactiveUS7011788B2Reduction factorImprove corrosion resistanceCeramic shaping apparatusTitanium compoundsThermal expansionAlkali feldspar

Owner:OHCERA CO LTD

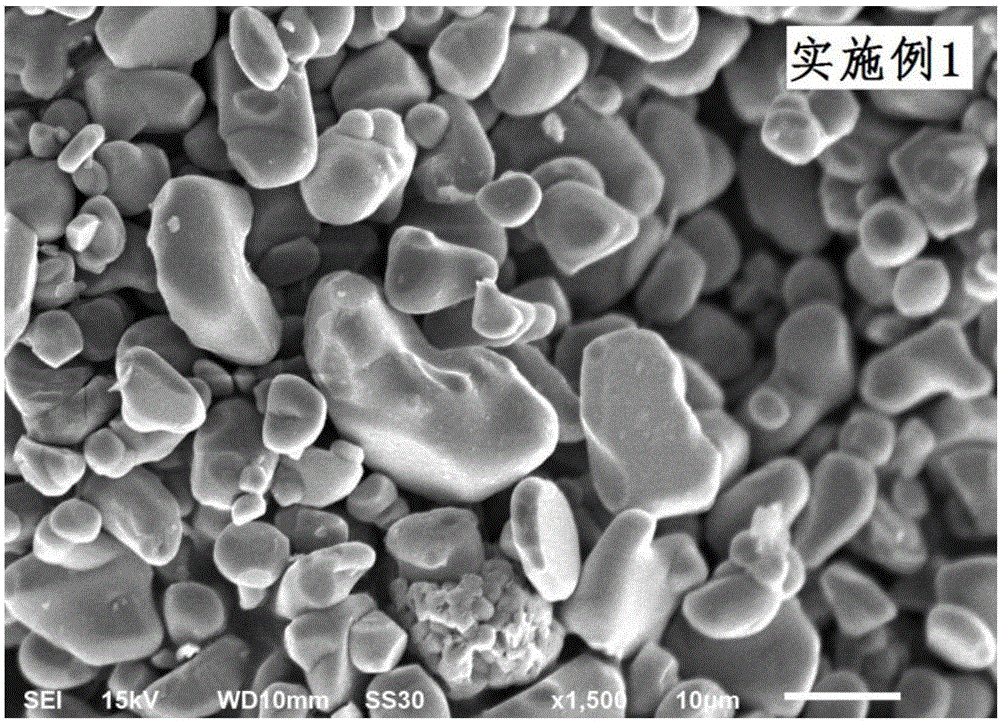

Method for preparing titanate lamella

ActiveCN1978715ALow reaction temperatureLow costPolycrystalline material growthFrom solid stateManufacturing technologyPotassium

The invention relates to titanate platelet manufacturing method. Its main features are as follows: using titanium and potassium bearing compound as raw material; mixing as 3.5-4.5 Mol rate of the TiO2 / K2O; adding certain magnesium bearing compound and composing at 900-1300 degree centigrade for 30min-10h; adding metal magnesium metal powder as accelerator to generate titanate platelet with average 1-20mum length width, 1-5 aspect ratio, and 0.4-2munm thickness which has high strength, high temperature resistant, good frictional properties etc, can be used as reinforcing agent for plastics composite, as friction control agent in car, train, airplane brake disks. The manufacturing technology of the invention has the advantages of simple, high yield, low cost, no environment pollution, and acceptable for commercial scale production.

Owner:隗学礼

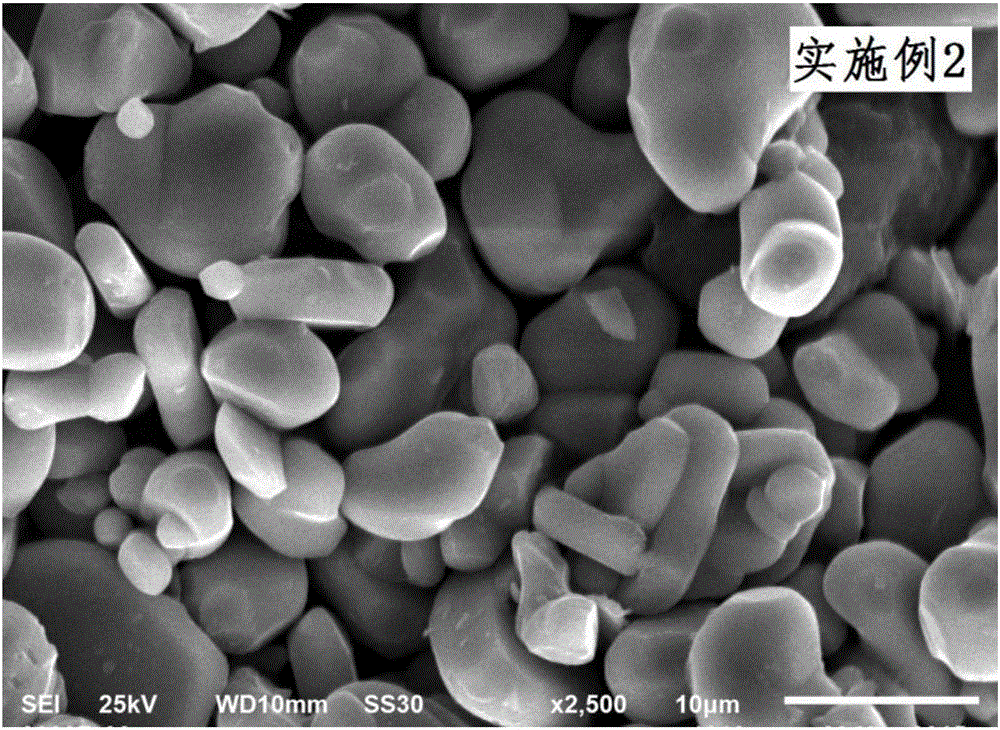

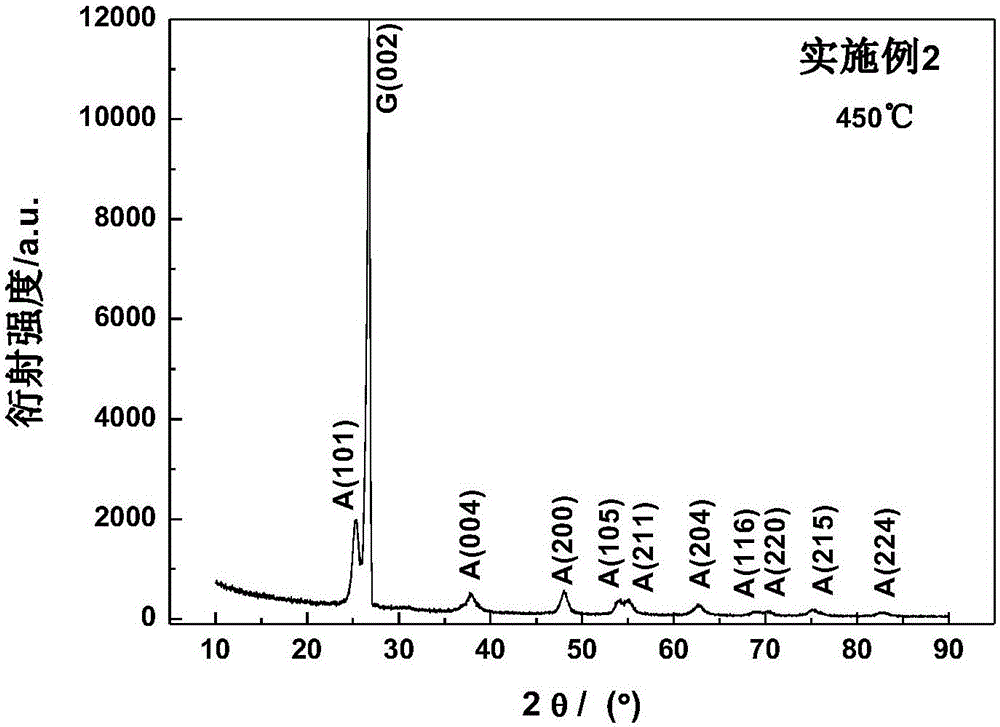

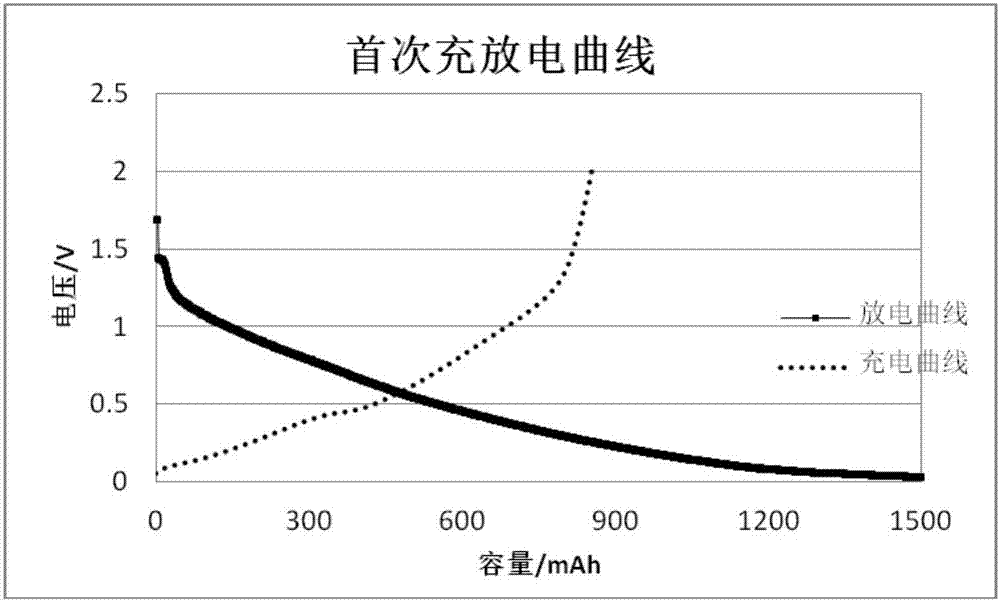

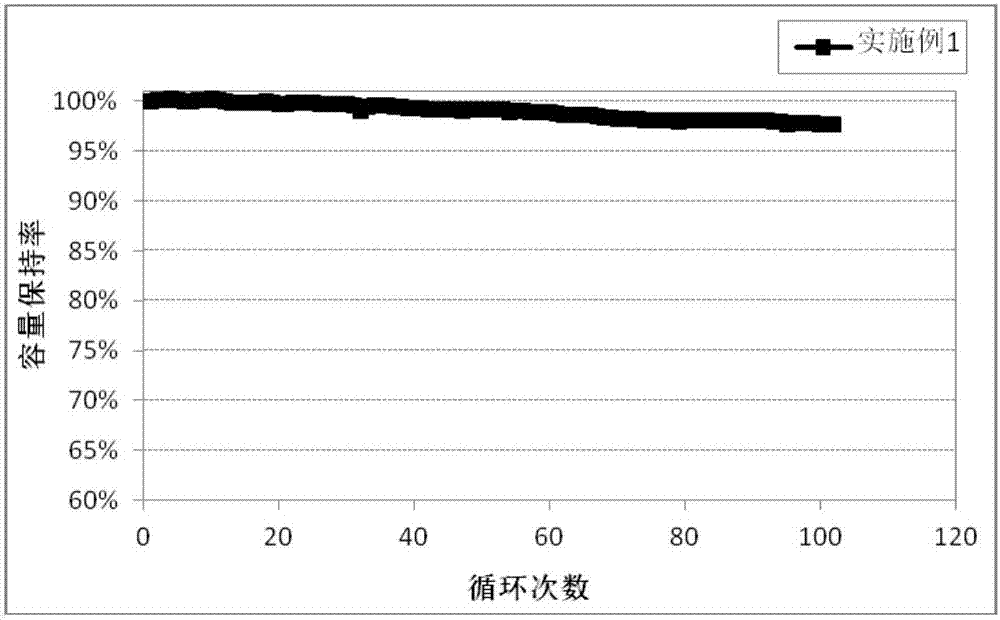

Method for preparing nanometer titania coated graphite cathode material

InactiveCN106711417AImprove mechanical propertiesGood physical and chemical stabilityCell electrodesSecondary cellsHigh rateDysprosium titanate

The invention discloses a method for preparing a nanometer titania coated graphite cathode material. The method comprises the steps that A, graphite is added into a mixed solution of glacial acetic acid, water and absolute ethyl alcohol at room temperature under the stirring condition, the materials are fully mixed, and a mixture is obtained; B, a titanate and absolute ethyl alcohol mixed solution is dropwise added into the mixture obtained in the step A within a certain time at room temperature under the stirring condition, standing is carried out for several hours, drying is carried out, and metatitanic acid gel coated powdered graphite is obtained; C, the metatitanic acid gel coated powdered graphite obtained in the step B is placed in a program temperature control furnace, the temperature is raised to 350 DEG C to 850 DEG C at a certain heating rate, the constant temperature is kept for several hours under the vacuum condition, the product is naturally cooled to room temperature, and the anatase and rutile type nanometer titania coated graphite material is obtained. The grain size of the nanometer titania coated graphite cathode material ranges from 1 micrometer to 35 micrometers, and high specific discharge capacity, good cycle performance and high high-rate charge and discharge performance are achieved.

Owner:HUBEI UEE ENERGY TECH CO LTD

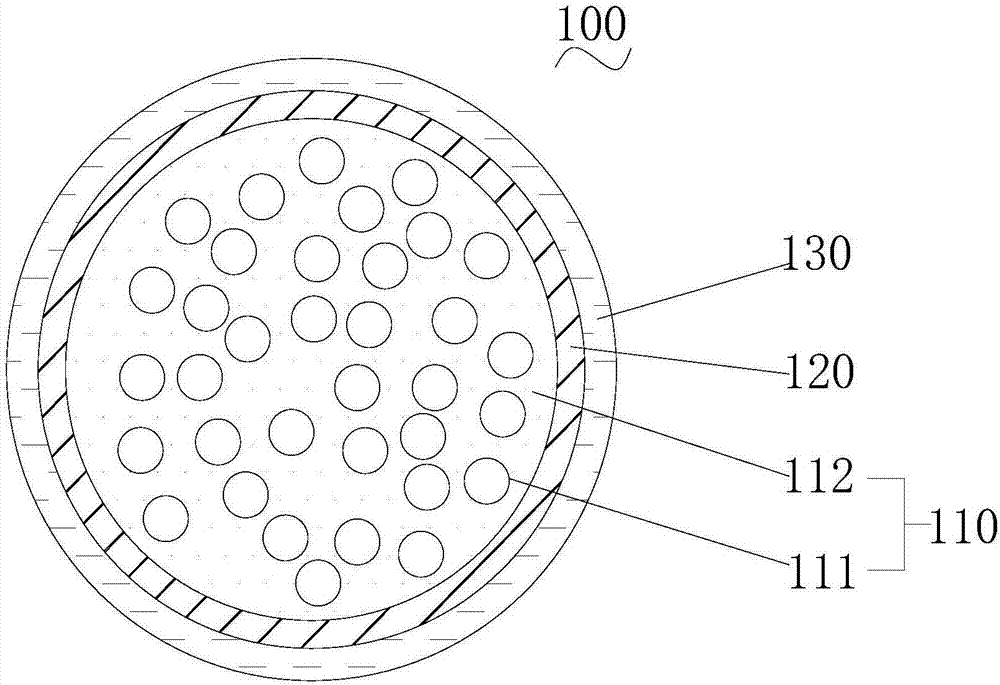

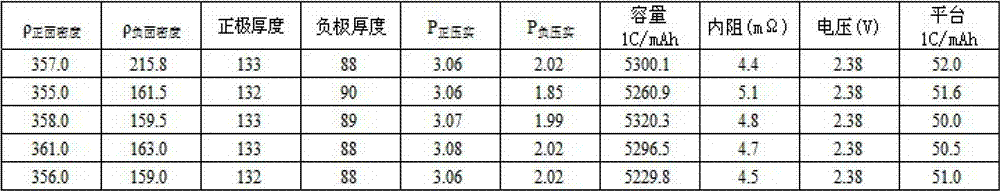

Single-layer/double-layer coated silicon oxide composite anode material and preparation method thereof

ActiveCN107959012AImprove cycle stabilityAlleviate the volume expansion effectCell electrodesCarbon layerSilicon oxide

The invention provides a single-layer / double-layer coated silicon oxide composite anode material and a preparation method thereof. The single-layer coated silicon oxide composite anode material is a two-layer composite material which has a core-shell structure, an inner core is a silica precursor, an outer layer is a lithium titanate layer, and the silica precursor is a material which is formed byuniformly dispersing and distributing silicon on silica. The double-layer coated silicon oxide composite anode material is a three-layer composite material which has a core-shell structure, an innercore is a silica precursor, a middle layer is a lithium titanate layer, and the outermost layer is a carbon layer which coats the outer surface of the lithium titanate layer. The double-layer coated silicon oxide composite anode material has the three-layer structure, the inner core is the silica precursor, the middle layer is the lithium titanate layer, the outermost layer is the carbon layer, the volume effect of silicon oxide can be buffered well, and thus, the double-layer coated silicon oxide composite anode material has high specific capacity and excellent cycle performance.

Owner:ETRUST POWER ETP GRP LTD

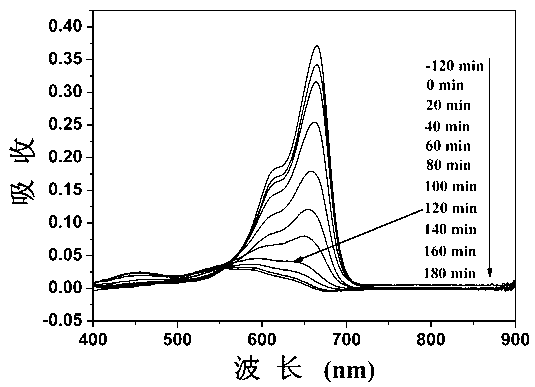

Titanium dioxide/lead titanate compounded nanometer photocatalyst and preparation method thereof

InactiveCN103263907AEasy to prepareEasy to controlMetal/metal-oxides/metal-hydroxide catalystsUltraviolet lightsRoom temperature

The invention discloses a titanium dioxide / lead titanate compounded nanometer photocatalyst and a preparation method thereof. The titanium dioxide / lead titanate compounded nanometer photocatalyst is a heterogeneous structure material formed by distributing titanium dioxide nano particles on the surface of lead titanate nano sheets. The preparation method comprises the following steps of dispersing lead titanate nano sheets synthetized through a hydrothermal method into deionized water; preparing a titanium source water solution; and dropwise adding the titanium source water solution into the lead titanate nano sheet water solution, then transferring into a hydrothermal reaction kettle, after hydrothermal reaction, cooling to room temperature, filtering, washing, and drying. The preparation method is simple and easy to control, and has low requirement on equipment; and the prepared titanium dioxide / lead titanate compounded nanometer photocatalyst can be used for regulating the ultraviolet light catalysis of the titanium dioxide into visible light catalysis.

Owner:ZHEJIANG UNIV

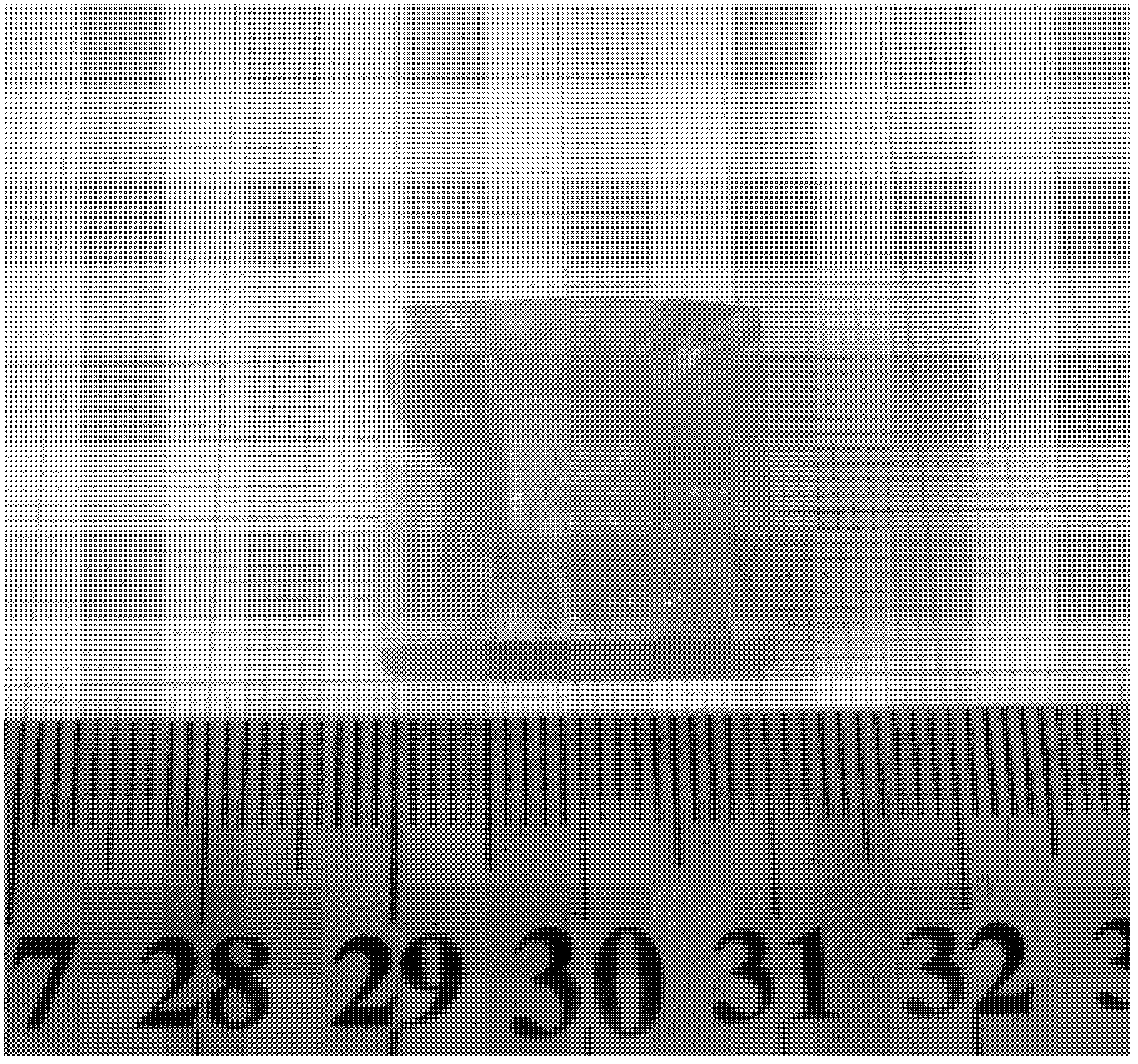

Lead lutetioniobate-lead magnesioniobate-lead titanate ternary-system relaxation ferroelectric monocrystal and preparation method thereof

InactiveCN102817080AExcellent piezoelectric propertiesGood electric field stabilityPolycrystalline material growthFrom frozen solutionsMass growthSingle crystal

The invention discloses a lead lutetioniobate-lead magnesioniobate-lead titanate ternary-system relaxation ferroelectric monocrystal and a preparation method thereof. The chemical general formula of the monocrystal is xPb(Lu1 / 2Nb1 / 2)O3-yPb(Mg1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein 0.1<=x<=0.4, 0.2<=y<=0.6, but 1-x-y is not equal to 0. The PLMNT monocrystal is prepared by a crucible descent method. The invention effectively overcomes the defect of overlow Curie temperature in the PMNT monocrystal and the defects of difficulties in crystallization and mass growth in the PLNT monocrystal in the prior art. The PLMNT monocrystal disclosed by the invention has great application potential at room temperature, is very applicable to high-temperature devices, has wide application temperature range, and can completely satisfy the application requirements in high technologies, such as ultrasonic imaging, ultrasonic motors and the like, thereby having very wide application prospects.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

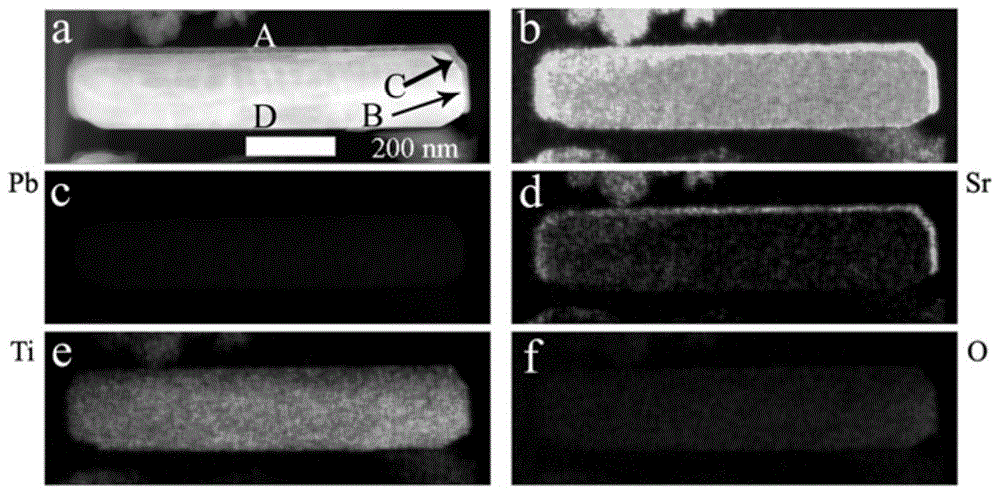

Preparation method of lead titanate-strontium titanate monocrystal nanometer material with core-shell structure

ActiveCN105040090ASimple processEasy to controlPolycrystalline material growthFrom normal temperature solutionsStrontium titanateSingle crystal

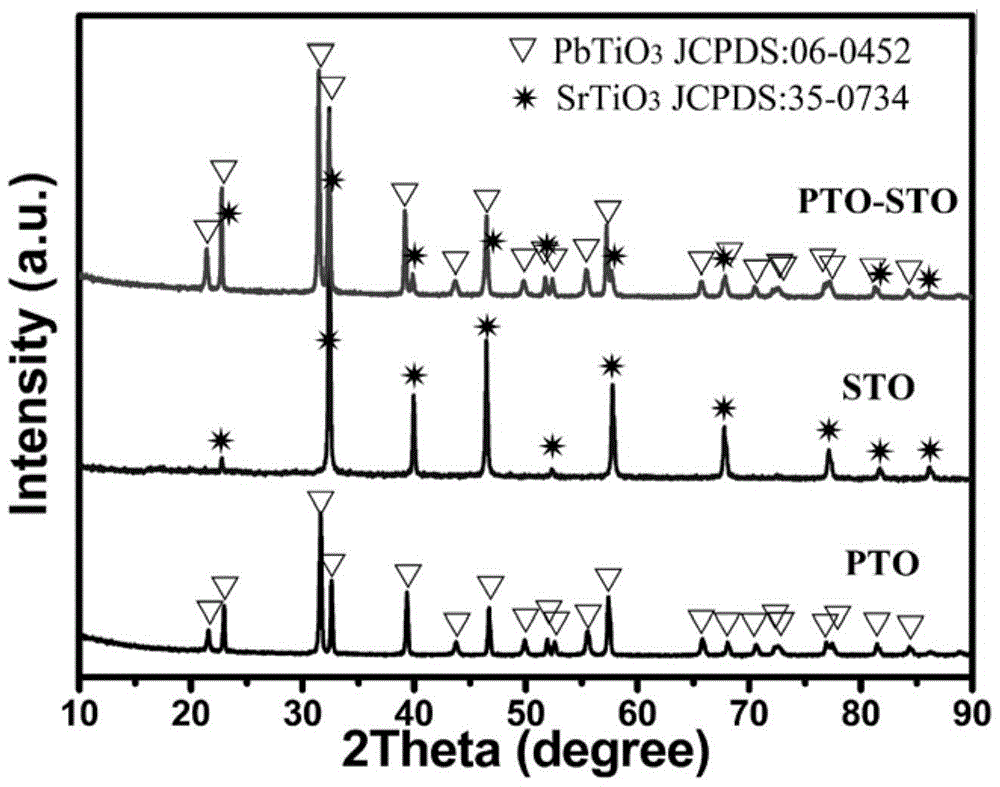

The invention relates to a preparation method of a perovskite phase lead titanate-strontium titanate monocrystal nanometer material with a core-shell structure. The preparation method comprises the steps of taking a monocrystal single-domain perovskite phase lead titanate nanosheet as a template and a raw material, taking tetrabutyl titanate as a titanium source, taking strontium nitrate as a strontium source, taking sodium hydroxide as a precipitant and a mineralizing agent, and preparing precursor mixed turbid liquid for a hydrothermal reaction under the condition of magnetic stirring; sealing the precursor mixed turbid liquid into a stainless steel reaction still having a teflon liner, and obtaining a core-shell structure perovskite phase lead titanate-strontium titanate monocrystal nanometer composite structure through subjecting to hydro-thermal treatment at the temperature of 160 to 220 DEG C for 4 to 24 hours. The preparation method provided by the invention is simple in technical process, easy to control, free of pollution, low in cost, and easy for mass production. The prepared perovskite phase lead titanate-strontium titanate monocrystal nanometer composite structure has a clear core-shell structure, and has an interface with atomic resolution.

Owner:ZHEJIANG UNIV

Method for preparing high strength aluminum titanate ceramic

InactiveCN101456729AImprove mechanical propertiesHigh mechanical strengthHigh intensityDysprosium titanate

The invention belongs to a method for preparing high-strength aluminum titanate ceramic, which comprises the steps: (1) material distribution; (2) ball milling; (3) drying; (4) granulation; (5) molding by semidry pressing; (6) measurement and sintering; and (7) testing. The method accelerates the sintering by adding an appropriate additive, greatly improves the sintering property of aluminum titanate, inhibits the decomposition of the aluminum titanate, and ensures that the aluminum titanate has the characteristics of excellent thermal shock resistance and thermal impact resistance and so on, thereby ensuring that the aluminum titanate ceramic is practically applied and can be widely applied to industrial production.

Owner:王碧君

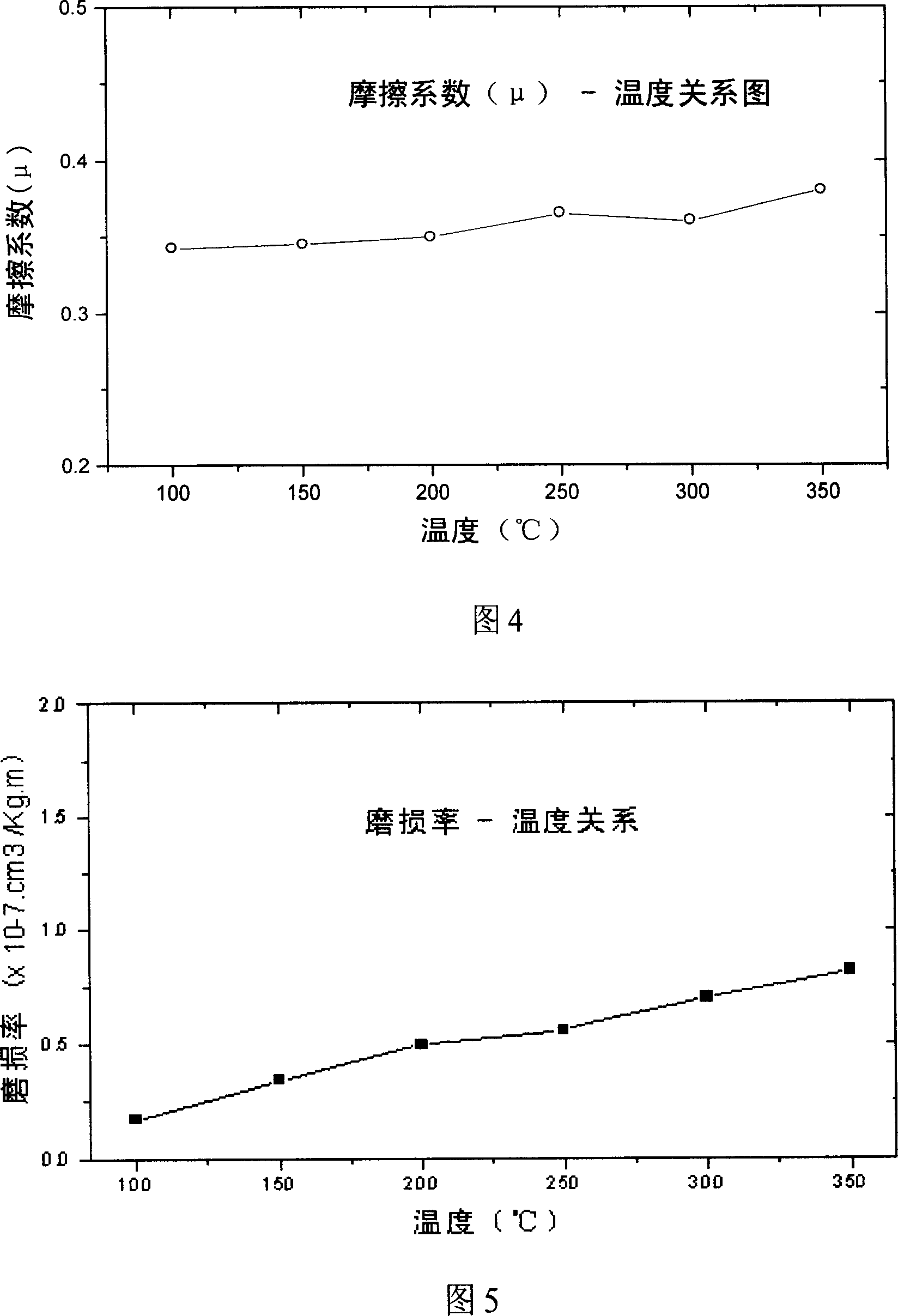

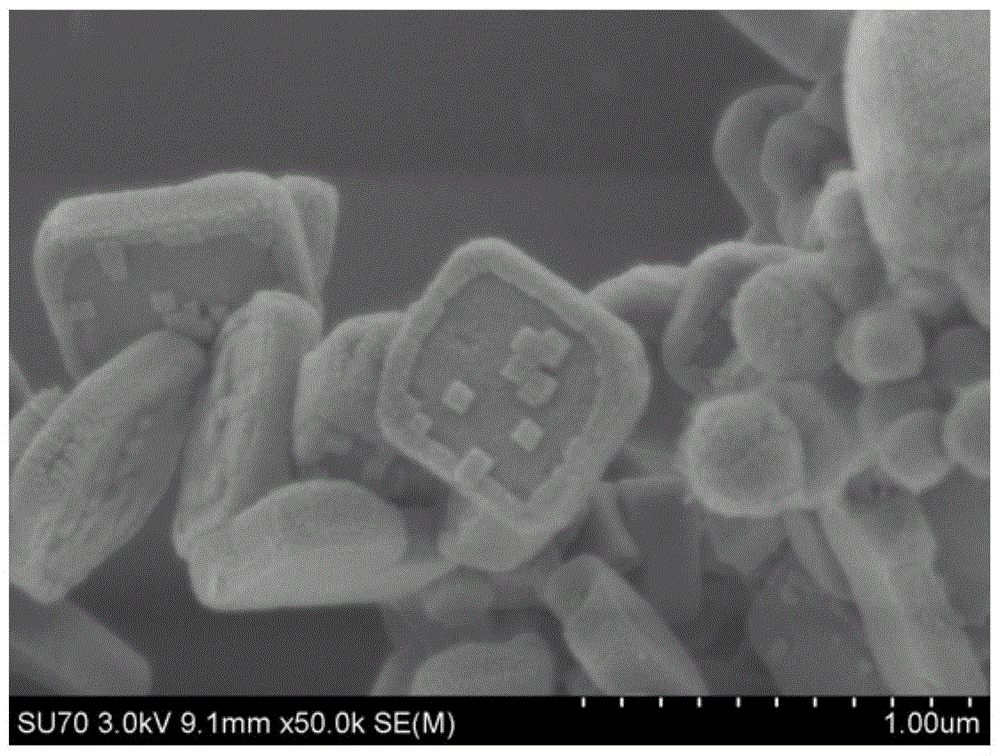

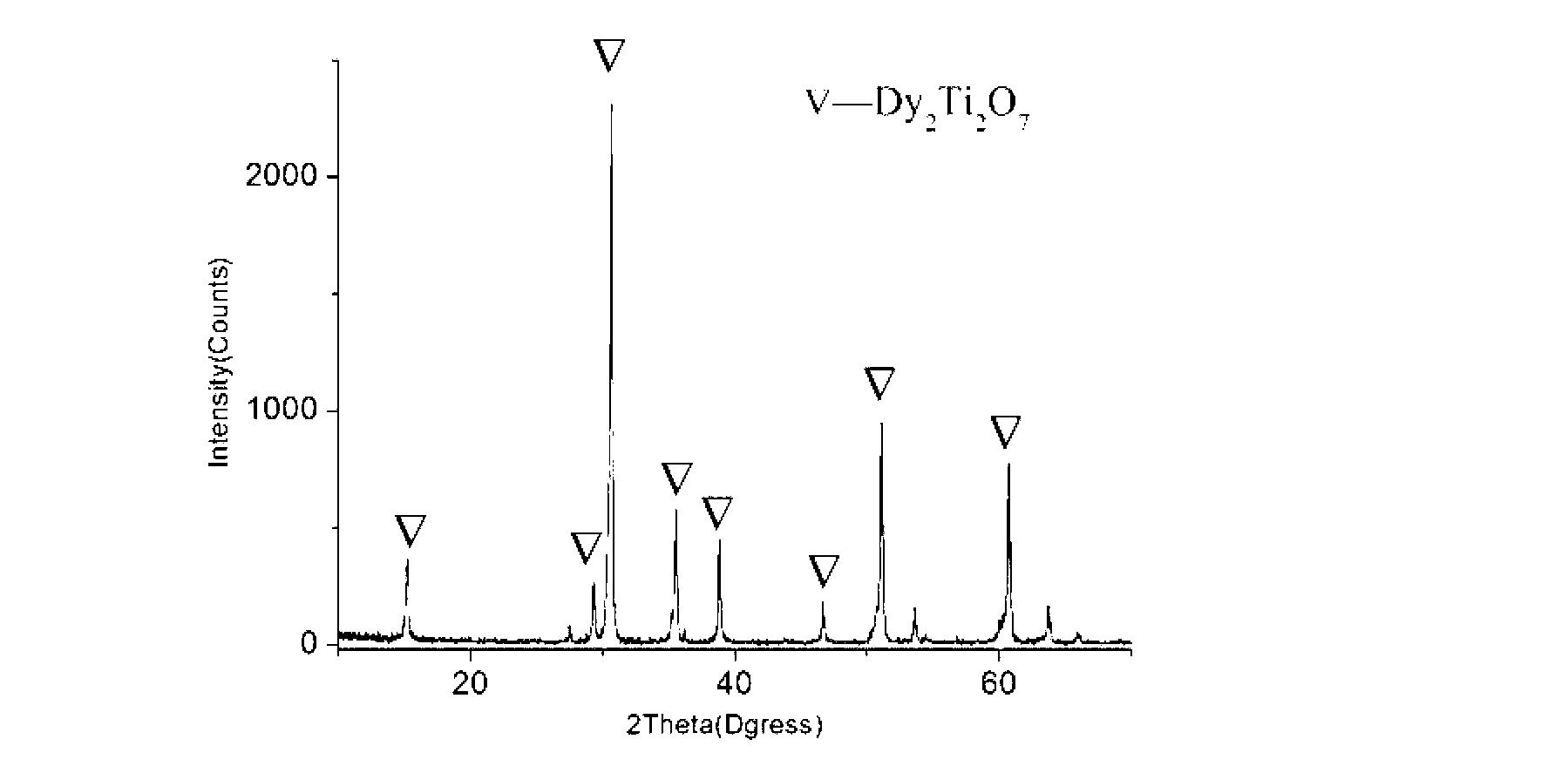

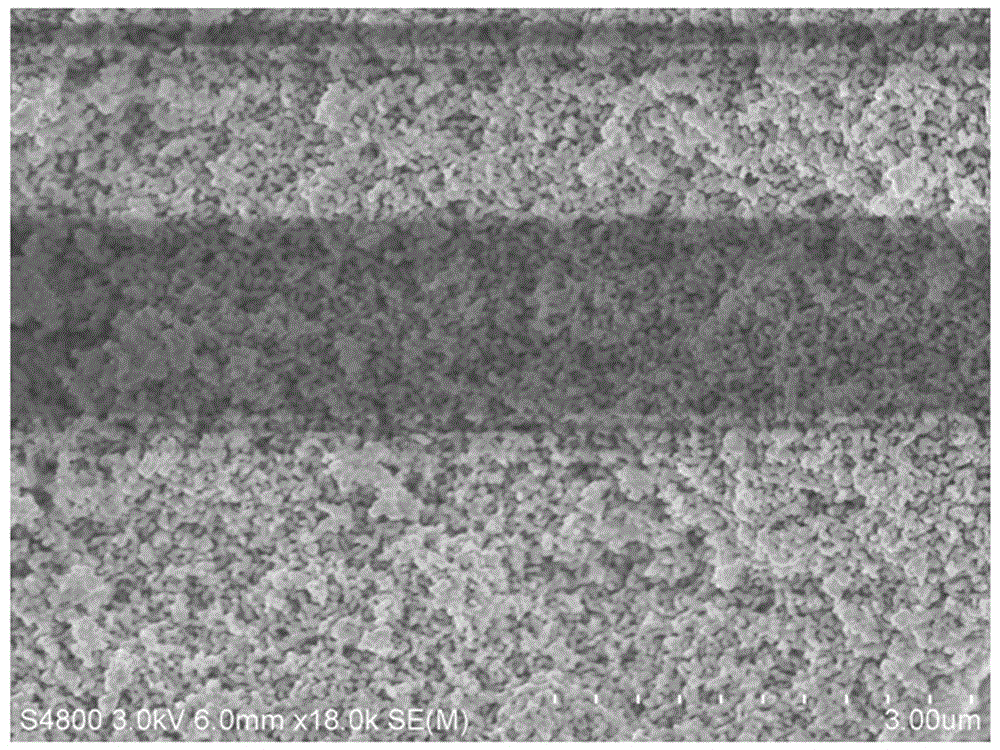

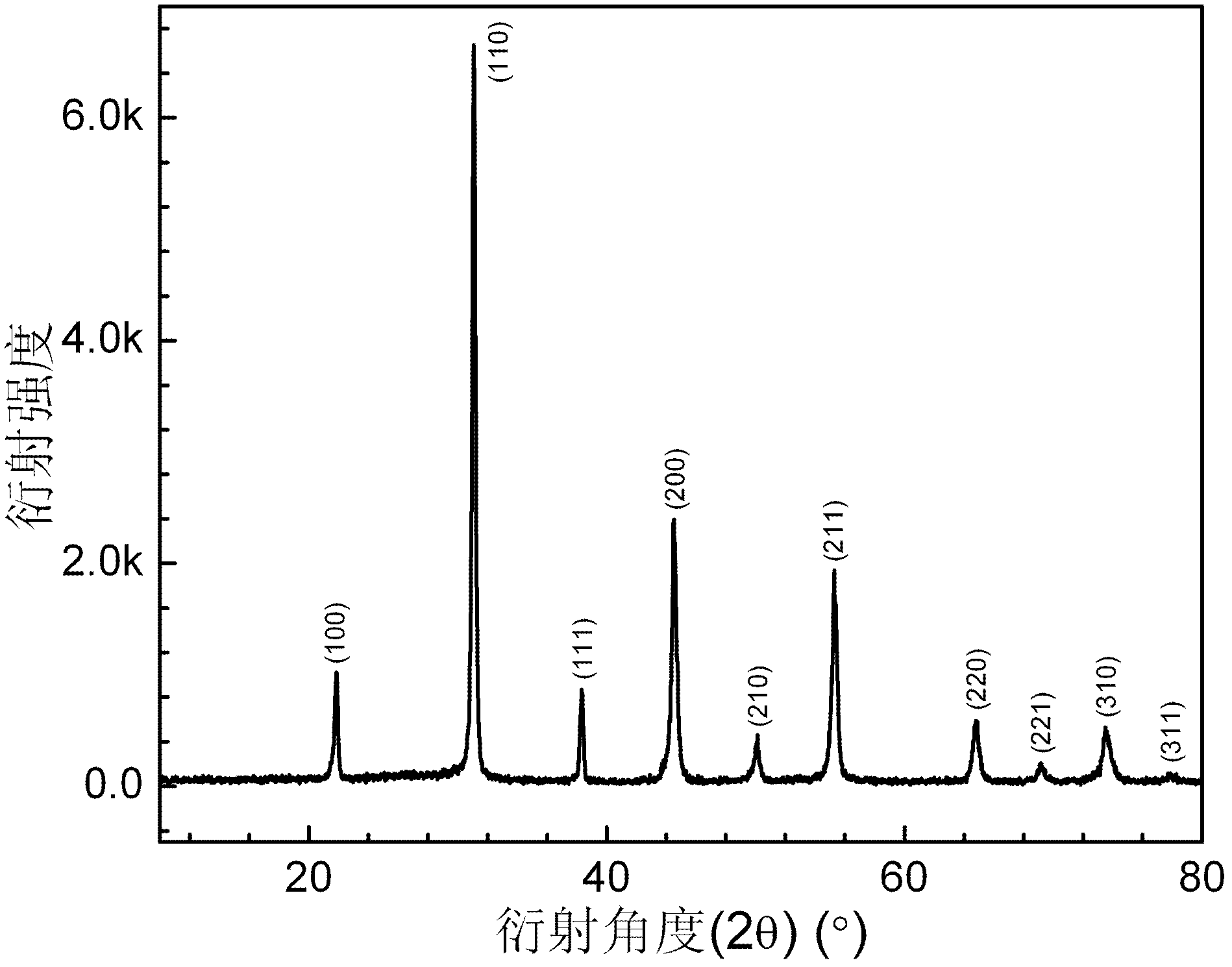

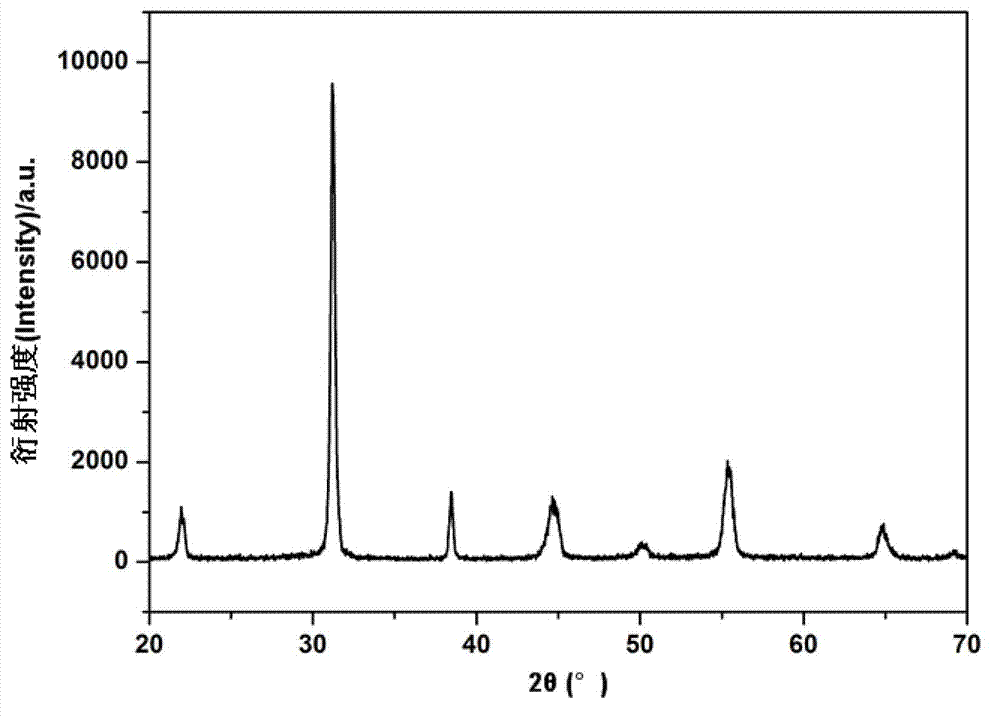

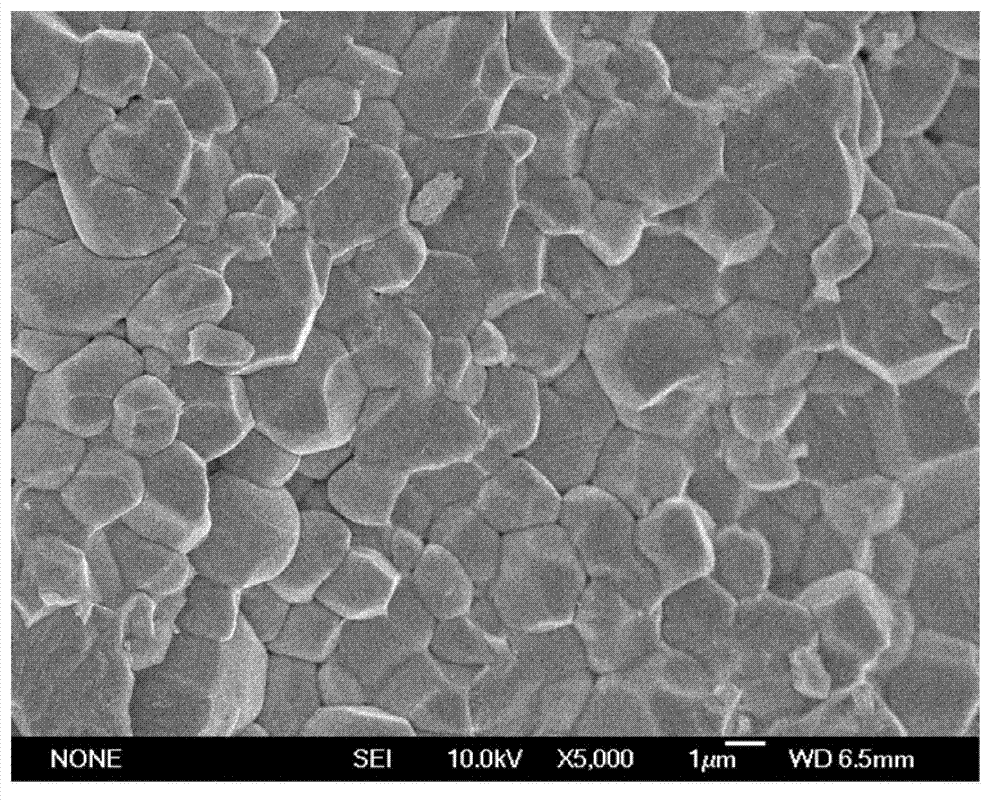

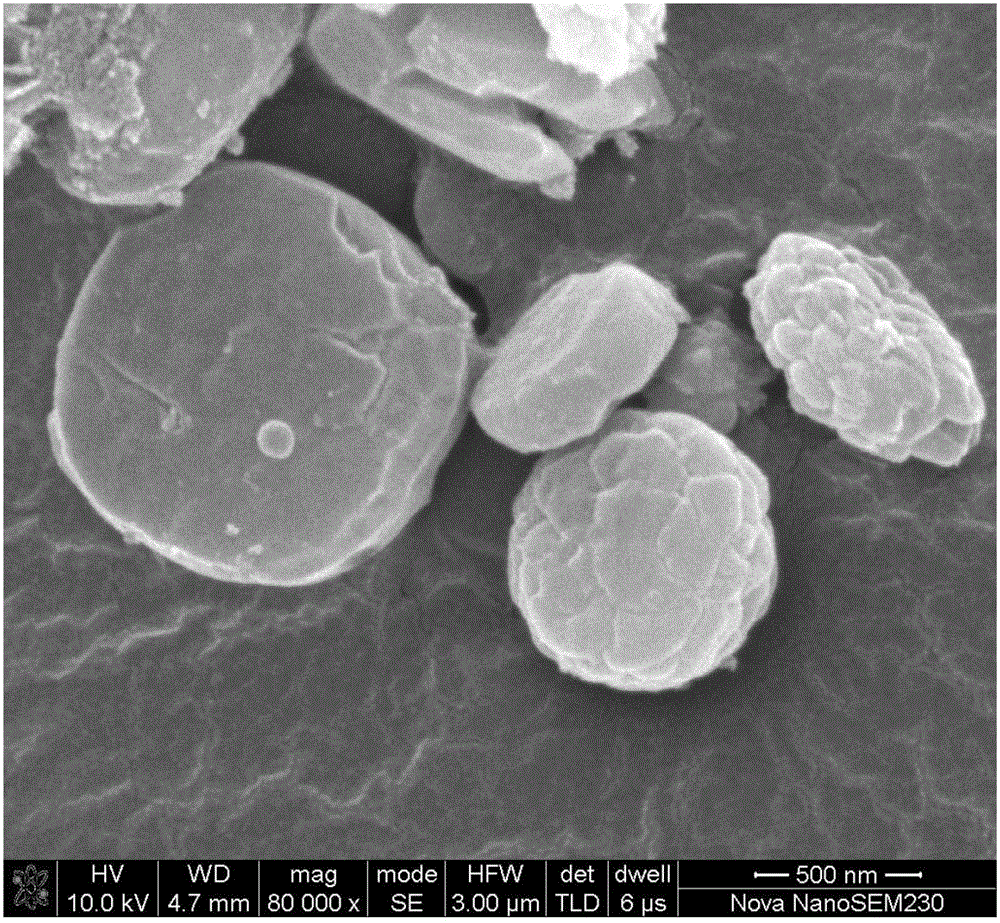

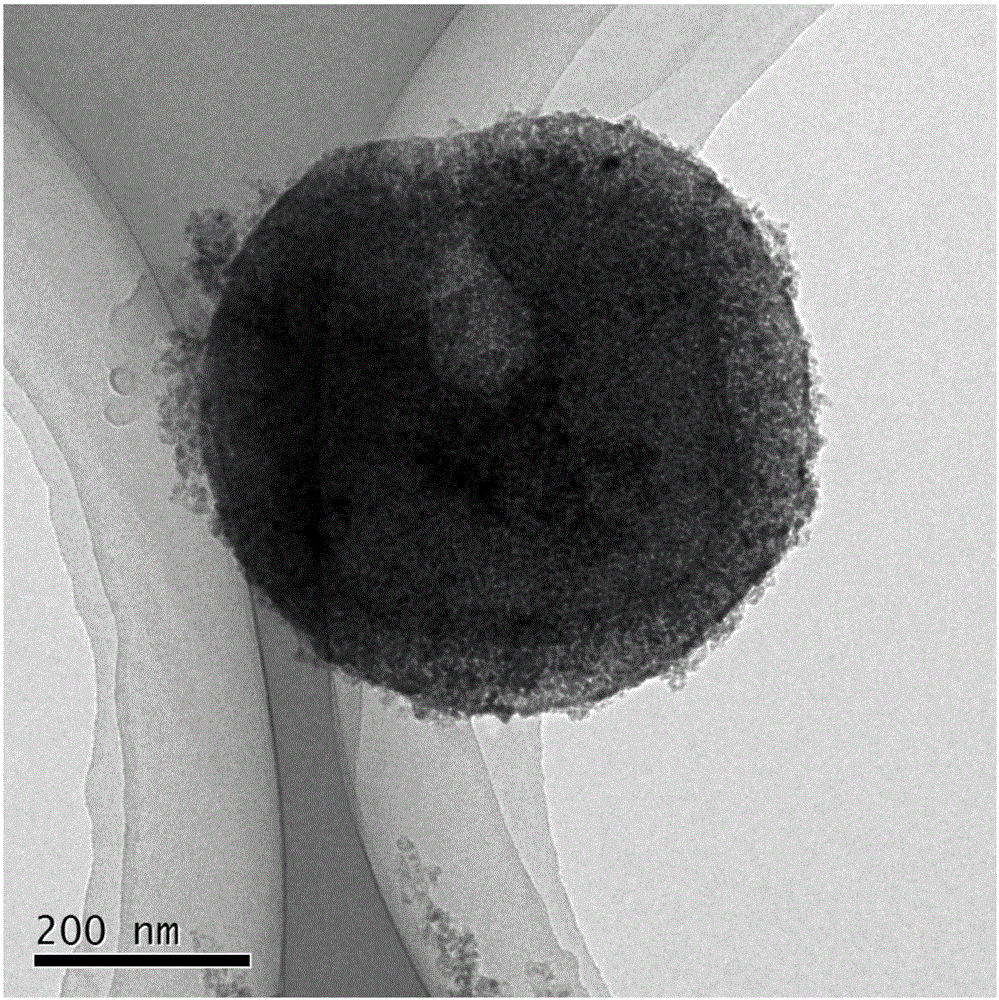

Preparation method of nano dysprosium titanate powder

InactiveCN102701273AReduce hydrolysisSlow down aggregationNanotechnologyTitanium compoundsAcetic acidAlcohol

The invention relates to a preparation method of nano dysprosium titanate powder. The method comprises the steps of dropping alcohol / water / glacial acetic acid mixed solution containing dysprosium nitrate into titanium acid butyl ester alcohol solution according to the molar ratio of Dy:Ti=(1-2:1); ageing obtained colloidal sol at the room temperature so as to obtain gel; drying and crushing the gel, arranging the gel into an aluminum oxide crucible, sintering the gel at 8001100 DEG C so as to obtain the nano dysprosium titanate powder. The nano dysprosium titanate powder preparation process is simple, the grain size of the powder is even and small, and the purity is high; and the powder can be used as neutron absorbing materials.

Owner:SHANDONG UNIV

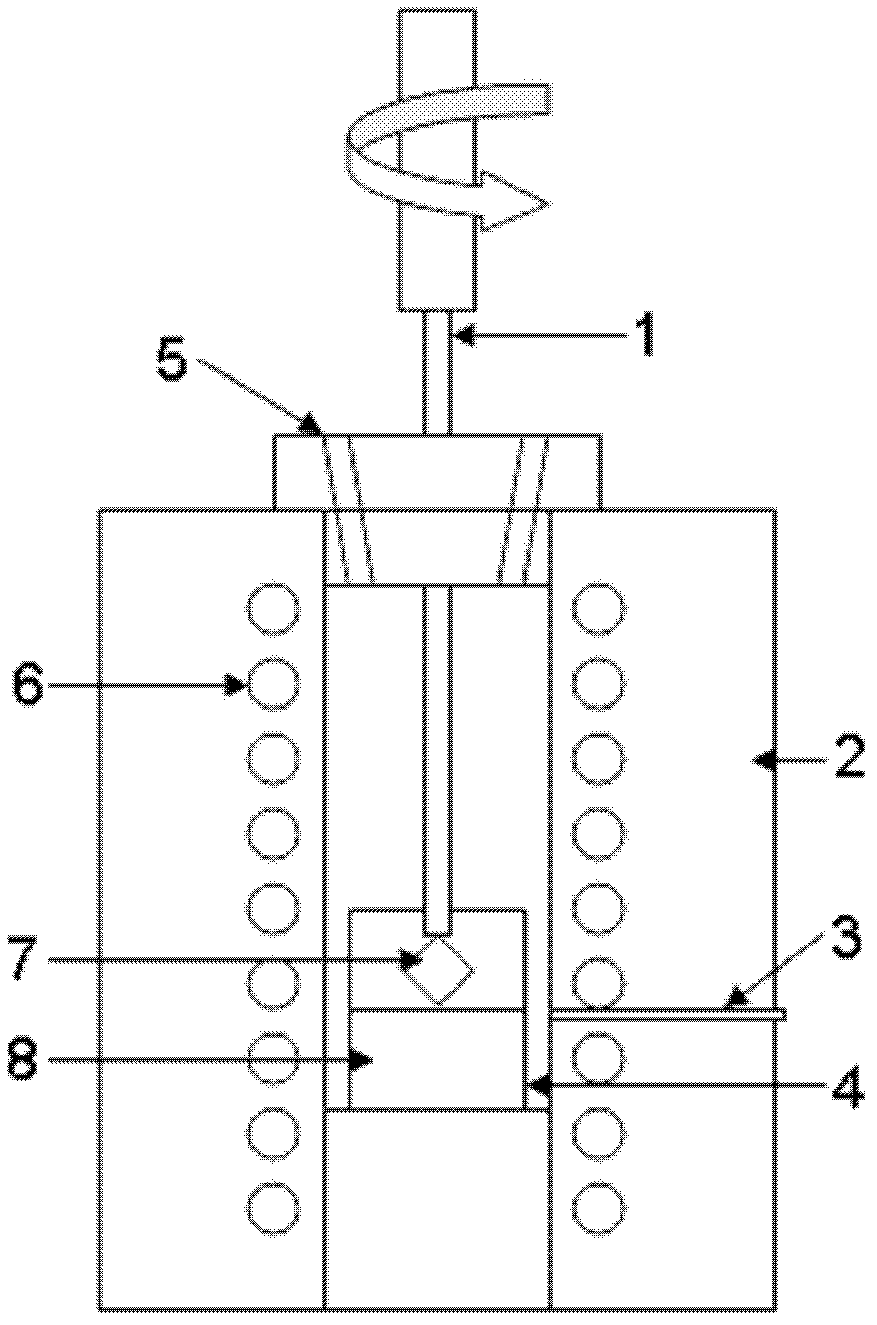

Preparation of high-catalytic activity Ti-based electrodes, Ti/nanoTiO2-RE2O3 and Ti/nanoTiO2-ZrO2

The invention relates to a convenient and fast method for preparation of high-catalytic activity Ti-based electrodes, Ti / nanoTiO2-RE2O3 and Ti / nanoTiO2-ZrO2, and a related key problem in the method is preparation of a modification material having high catalytic activity and stability. According to the invention, the process of sacrificial anodes is adopted, an inert electrode is used as a cathode, metallic Ti is used as a sacrificial anode, and a small amount of tetrabutylammonium bromide (Bu4NBr) is added into anhydrous ethanol as a conductive salt; ethyl titanate (Ti(OEt)4), a precursor of TiO2, is prepared through electrolysis; salt compounds of rare earth metals and zirconium metal are respectively added into ethyl titanate, and ethyl titanate is directly subjected to hydrolysis so as to respectively obtain rare earth metal doped composite nanometer TiO2 sol and zirconium metal doped composite nanometer TiO2 sol; pure titanium metal is used, the rare earth metal doped composite nanometer TiO2 sol and the zirconium metal doped composite nanometer TiO2 sol are respectively coated on Ti substrates having clean surfaces by using the Czochralski method, and electrodes modified by films doped with different metal oxides, i.e., Ti / nanoTiO2-RE2O3 and Ti / nanoTiO2-ZrO2 electrodes, are prepared after calcination.

Owner:HUAINAN NORMAL UNIV

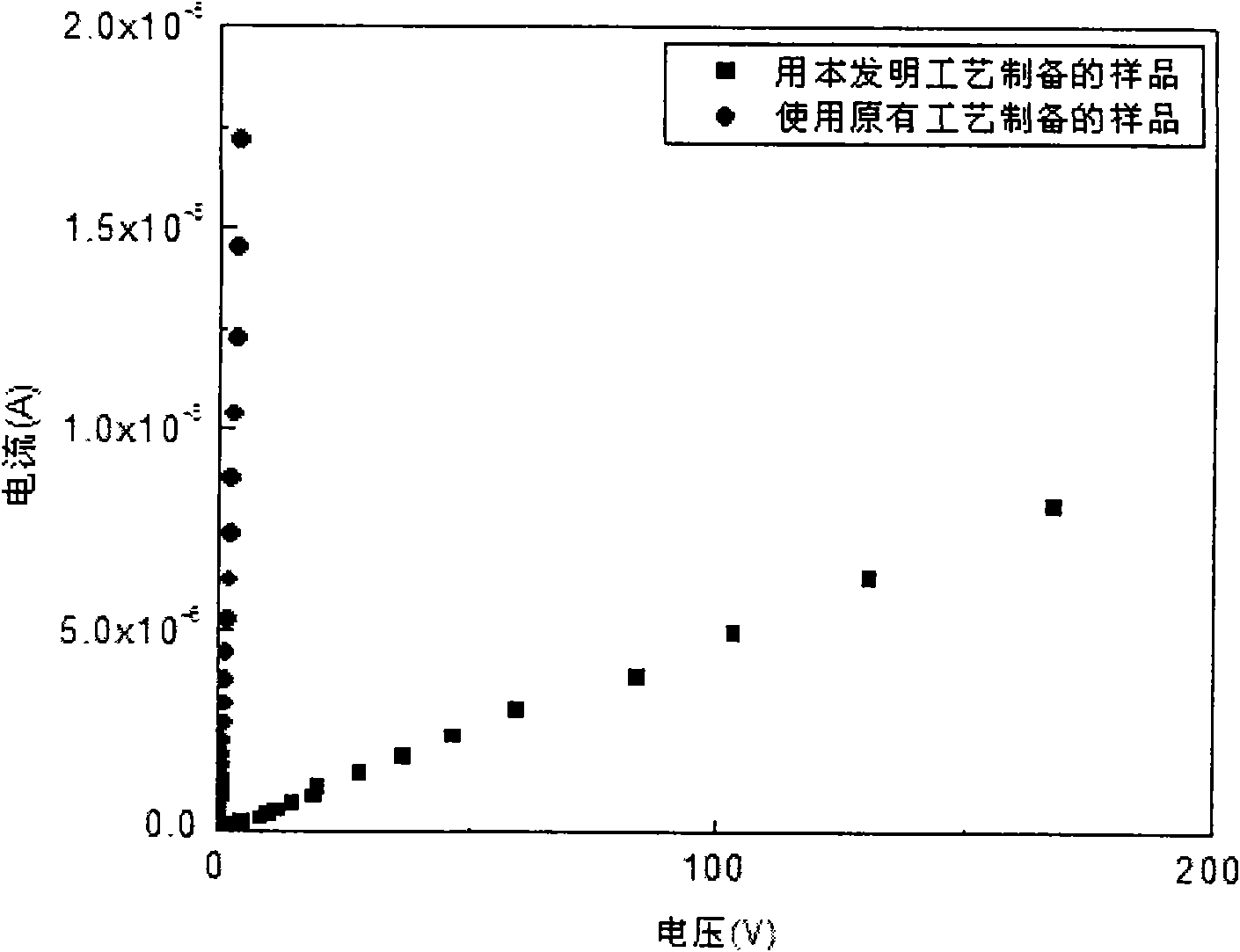

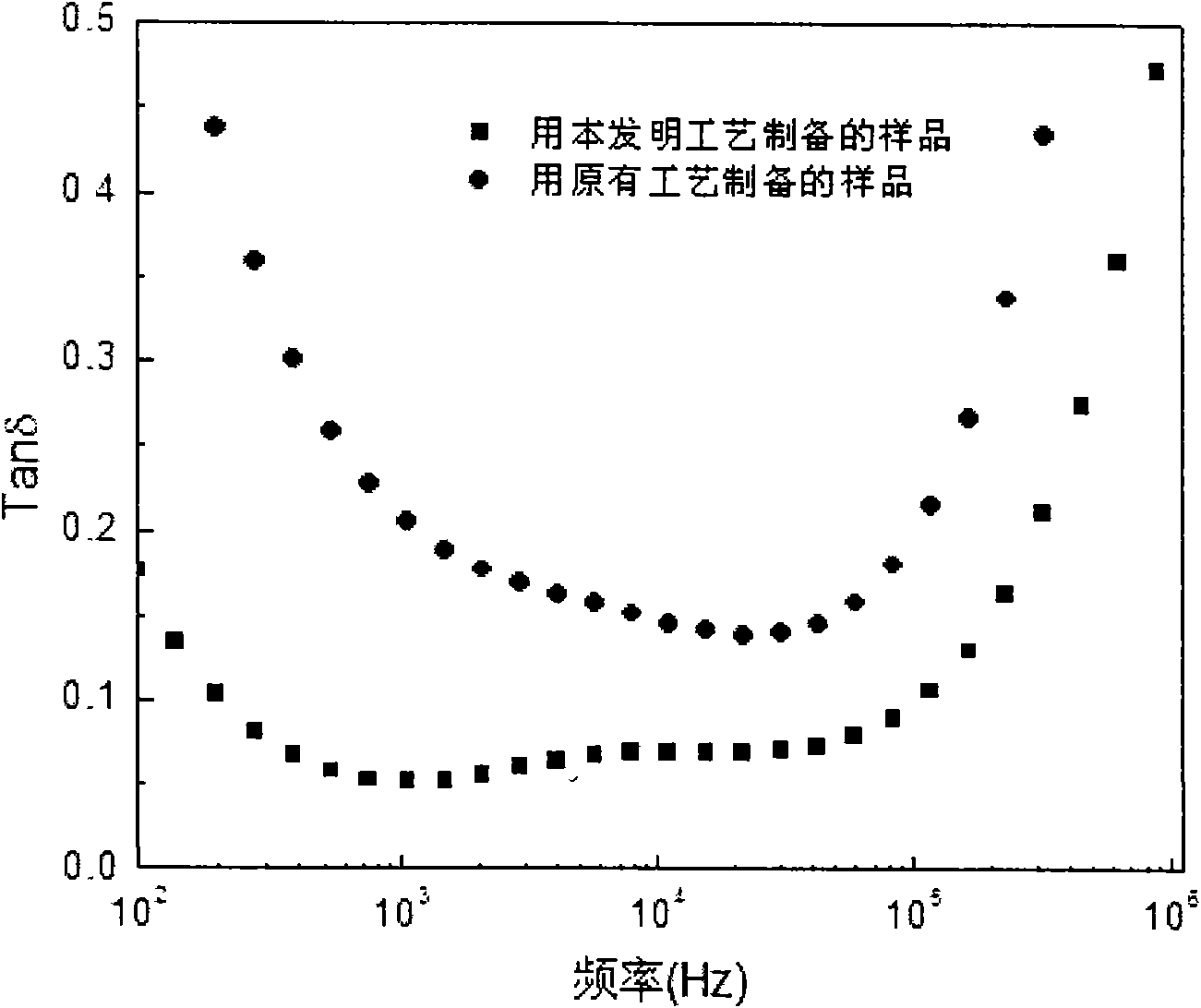

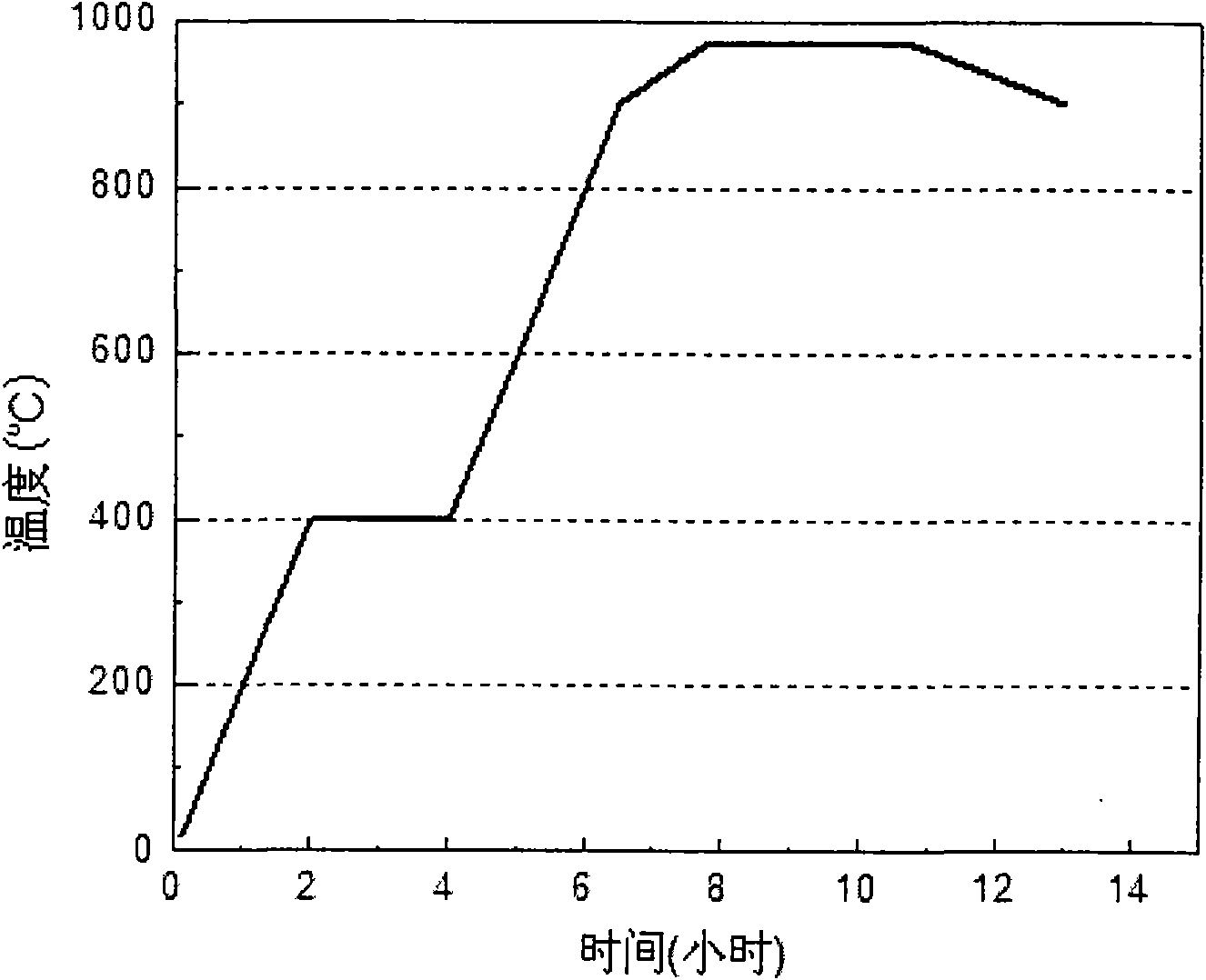

Method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics

ActiveCN101671174ASolve the problem of too much conductivitySuitable for industrial applicationsCeramic sinteringChemical reaction

The invention relates to a method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics, belonging to the technical field of high dielectric ceramic materials. The calcium copper titanate ceramics are prepared from initial raw materials of CaCO3 or CaO, CuO and TiO2, wherein after being mixed, the raw materials are processed by mix grinding and then processed by presintering at the temperature from 800 DEG C to 950 DEG C after mix grinding, hard blocks after presintering are cracked to be ground, and the powdered materials after presintering and grinding are prepared into green bodies with predetermined shapes; and the green bodies are heated to the sintering temperature ranging from 960 DEG C to 990 DEG C from room temperature, and heat preservation is carried out for 1 to 24 hours at the sintering temperature, thereby realizing the sintering densification of the ceramics. The preparation method controls performance parameters by controlling technological parameters, and structural changes and chemical reactions in a sintering process. The ceramic materials prepared by the method can meet the requirement on industrial application; and simultaneously, compared with the prior art, the preparation method can obviously reduce the energy consumption, is environment-friendly and reduces the production cost.

Owner:TSINGHUA UNIV

Preparation method of cathode slurry for aquo-lithium titanate dynamical type battery

The invention discloses a preparation method of a cathode slurry for an aquo-lithium titanate dynamical type battery. The method comprises the following steps: first, weighting raw materials according to the following mass percentage: 1-13% of a conductive agent, 1-5% of a dispersant sodium carboxymethyl cellulose, 2-5% of a binder styrene-butadiene latex, 81-93% of an active substance lithium titanate and water accounting for 50-65% of the total weight of the above materials; after the weighing, adding the dispersant sodium carboxymethyl cellulose into water, stirring for 2-6 h and shelving for 20-24h to obtain a sodium carboxymethyl cellulose mother liquor; then adding the conductive agent into the sodium carboxymethyl cellulose mother liquor, and stirring for 2-3 h; adding the active substance lithium titanate, stirring for 3-4 h, and adjusting viscosity; and finally adding the styrene-butadiene latex and stirring for 1-1.5h in vacuum to obtain the slurry. According to the invention, traditional PVDF is substituted by styrene-butadiene latex, so as to realize application of water-based binder as the cathode in lithium titanate; the invention has the advantages of no toxicity or pollution; besides, the aqueous binder solves the phenomenon of plate shedding caused by water absorption.

Owner:青岛瀚博电子科技有限公司

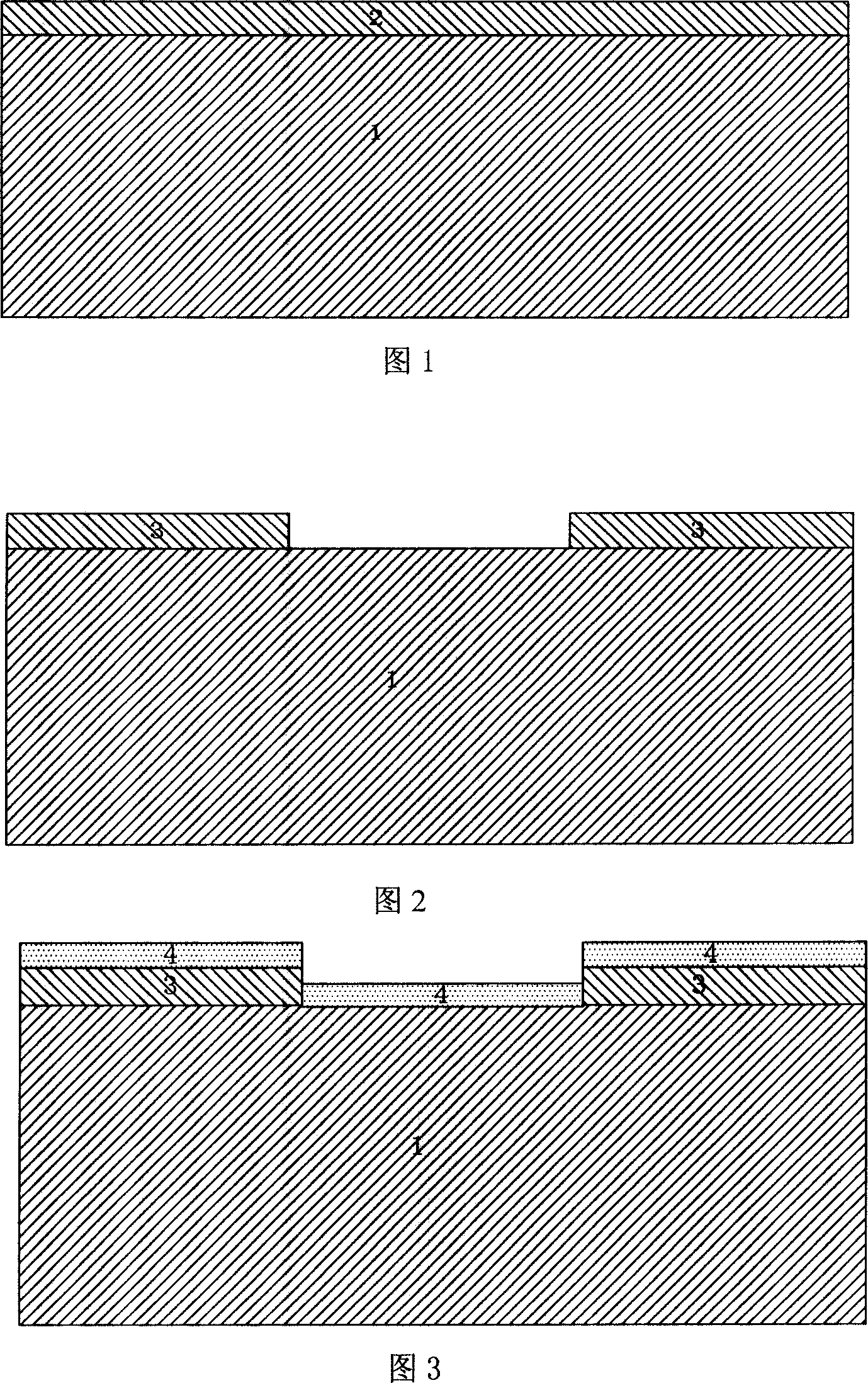

Strip preparation method of graphics ferroelectric lead zirconate titanate film

InactiveCN101135865AQuality improvementCause damageSemiconductor/solid-state device manufacturingPhotosensitive material processingLead zirconate titanateDysprosium titanate

The method comprises: coating a 0.01-10000 mu m thick zinc oxide sacrificial layer on the baseplate; using the photo etching and corrosion technology to pattern the sacrificial material; at the area where the PZT film will be reserved, the sacrificial layer will be etched; at the area where the PZT film will be stripped, the sacrificial layer will be reserved; after patterning, the PZT film is be coated on the sacrificial material; releasing the sacrificial layer; expose the PZT film pattern.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Low-temperature sintered zinc titanate high-frequency dielectric ceramic and preparation method thereof

The invention relates to a low-temperature sintered zinc titanate high-frequency dielectric ceramic and preparation method, wherein the ceramic comprises zinc oxide produced by decomposing one portion of basic zinc carbonate, one portion of anatase nano-TiO2 and 0.75-1.00 wt% of vanadium pentoxide and diboron trioxide additive, wherein the basic zinc carbonate is used for producing zinc oxide, the preparation comprises ball grinding, drying, grinding, forming, pre-calcination, sintering and silvering.

Owner:西安广芯电子科技有限公司

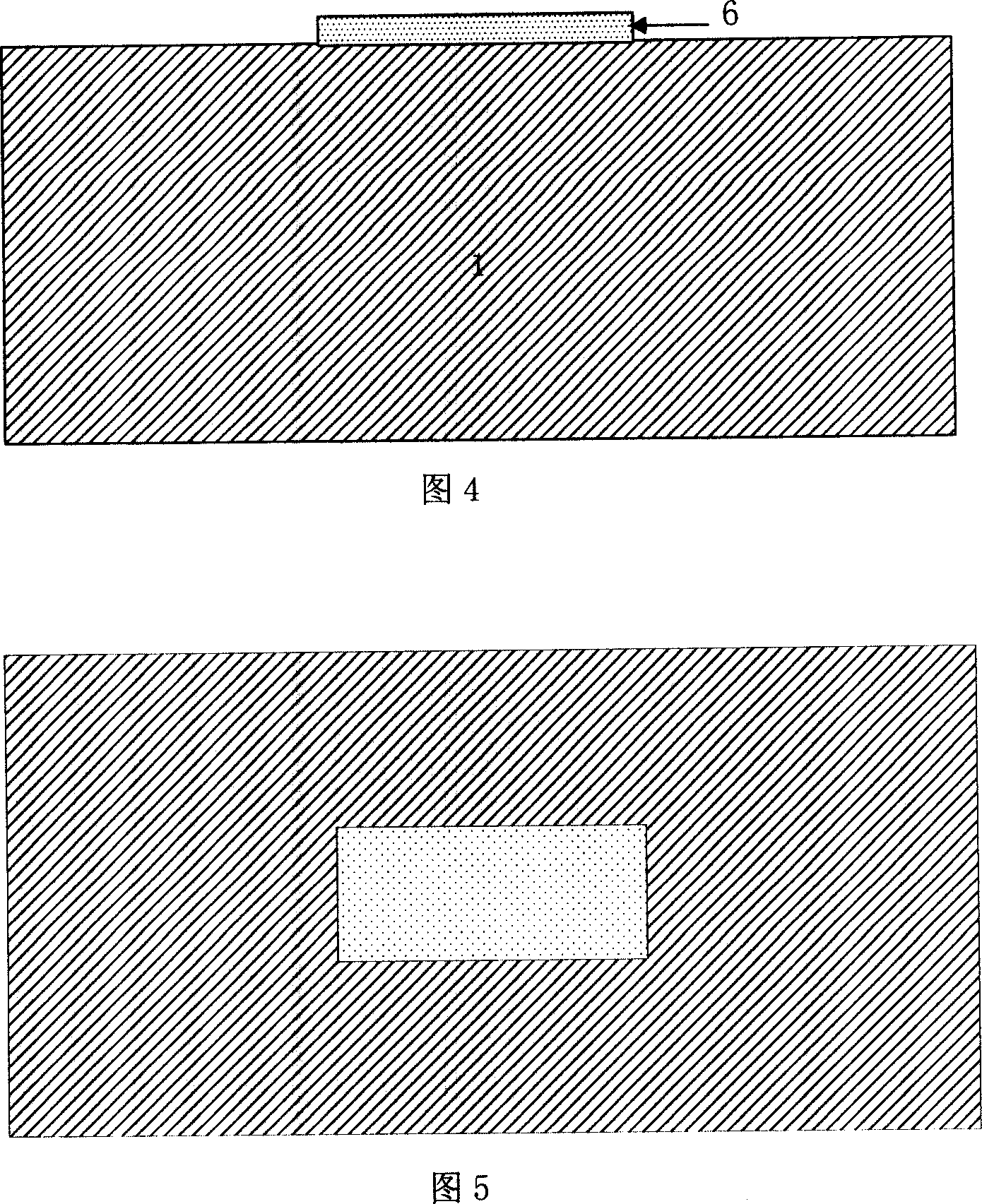

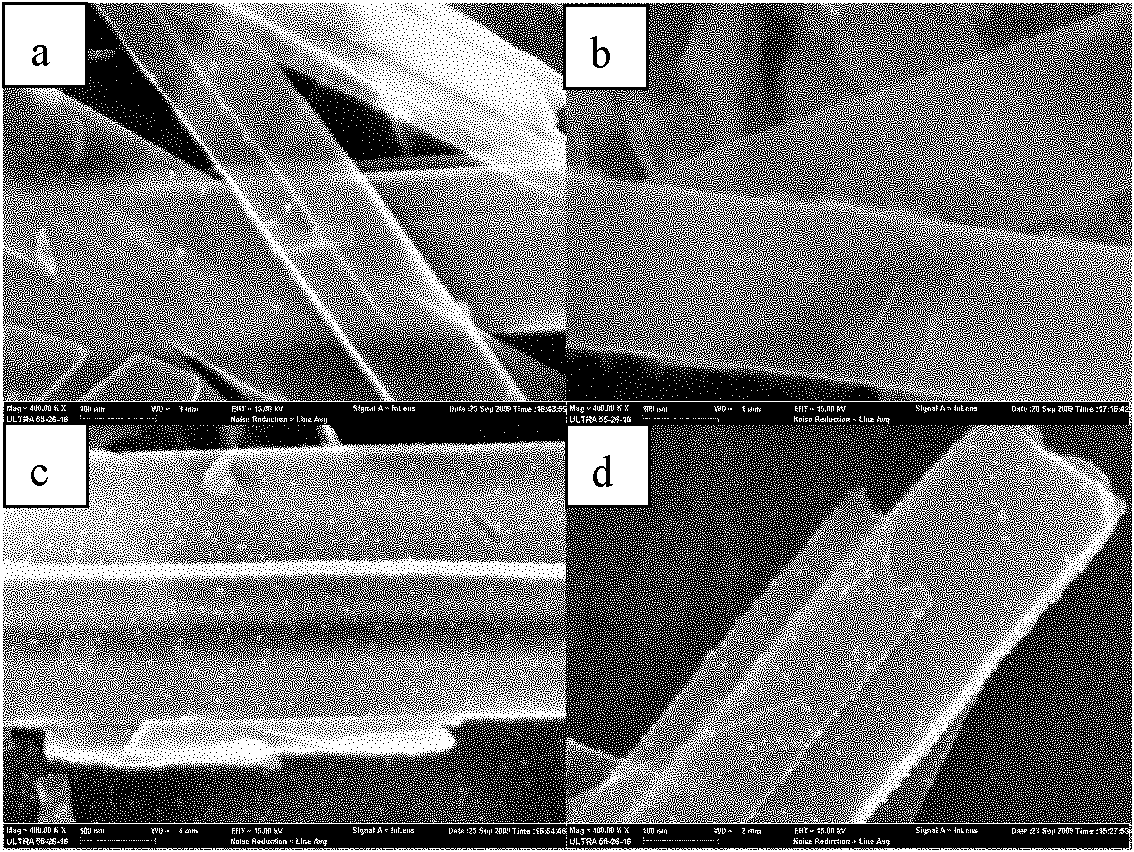

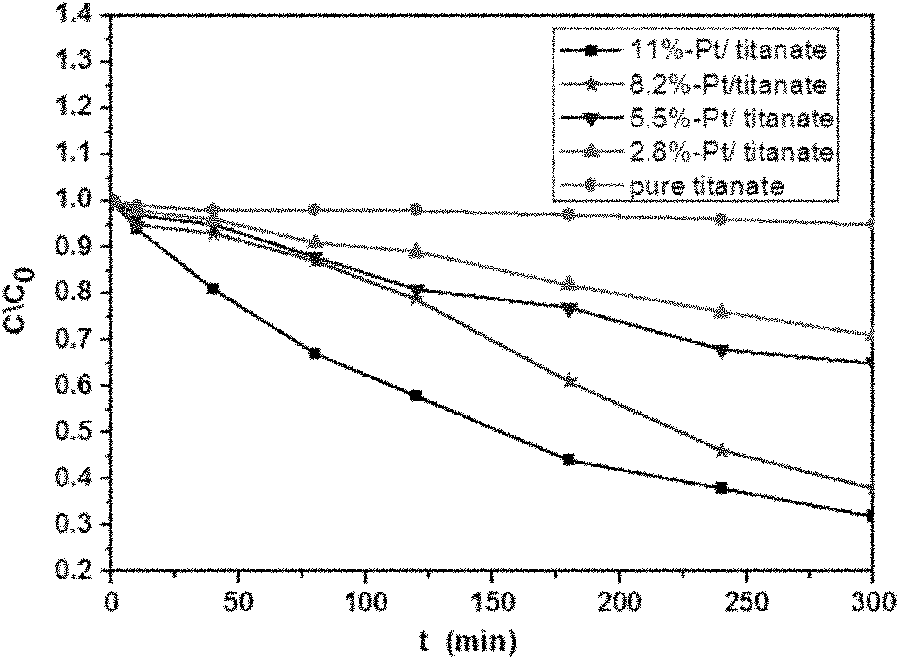

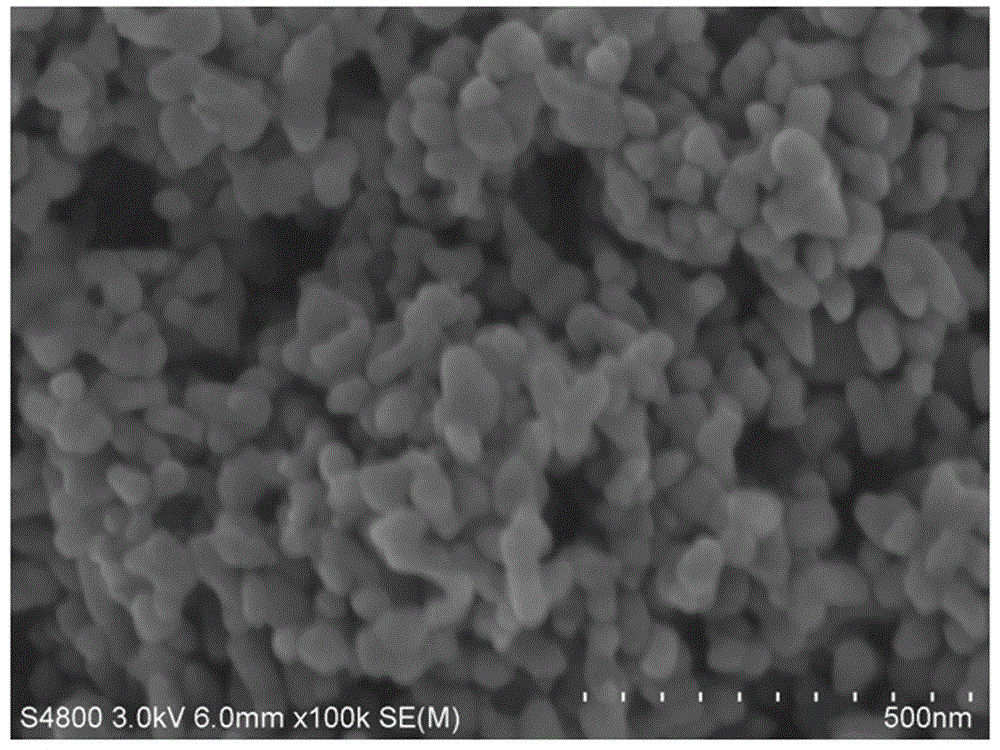

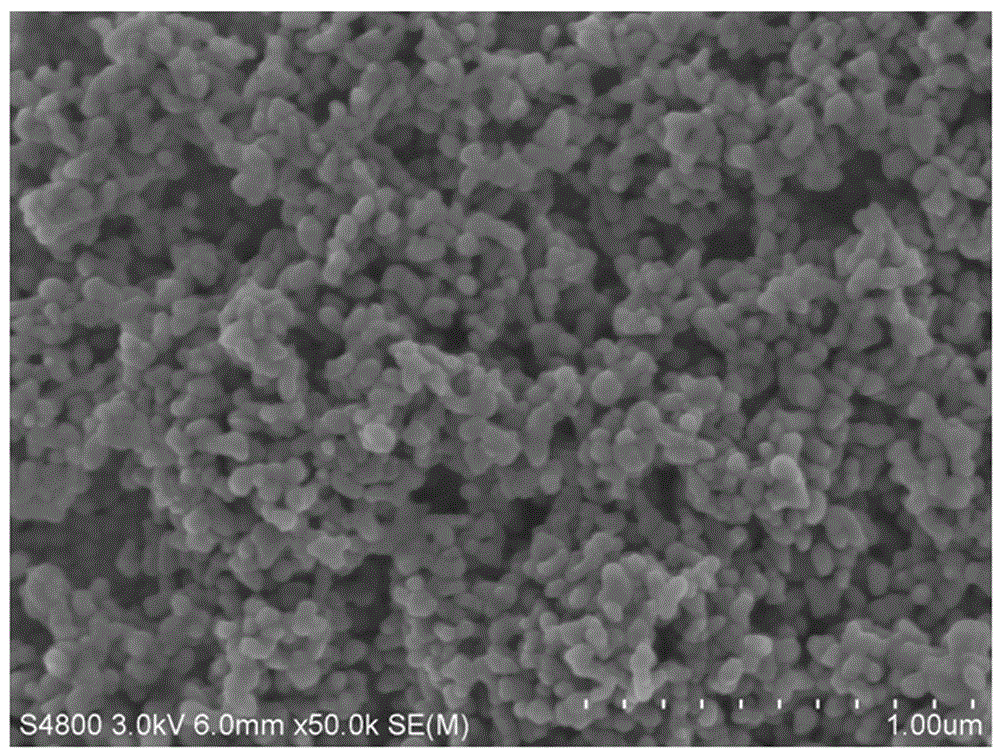

Self-assembly method of precious metal quantum dot/one-dimensional titanate nanoribbon heterojunction material

ActiveCN102039149ASignificant photocatalytic enhancement effectImprove bindingMaterial nanotechnologyCatalyst activation/preparationHeterojunctionPhysical chemistry

The invention relates to a self-assembly method of a photocatalyst material, and relates to a self-assembly method of a precious metal quantum dot / one-dimensional titanate nanoribbon heterojunction material, which is characterized by comprising the following steps of: (1) preparing a phosphonic acid surfactant solution with the concentration of not less than 10mg / mL; (2) obtaining the one-dimensional titanate nanoribbon processed with a phosphonic acid surfactant according to the mass ratio of the one-dimensional titanate nanoribbon to the phosphonic acid surfactant solution being 1:1-1:10; (3) preparing a precious metal quantum dot solution with the concentration of not less than 10mg / mL according to the mass ratio of the precious metal quantum dot to the one-dimensional titanate nanoribbon being 0.1-12 percent; (4) immersing the one-dimensional titanate nanoribbon processed with the phosphonic acid surfactant in the precious metal quantum dot solution to obtain the precious metal quantum dot / one-dimensional titanate nanoribbon heterojunction material with different precious metal contents in a self-assembly mode. The method has simple process and low cost. Moreover, the obtainedphotocatalyst material has prominent photocatalytic enhancement effect.

Owner:WUHAN UNIV OF TECH

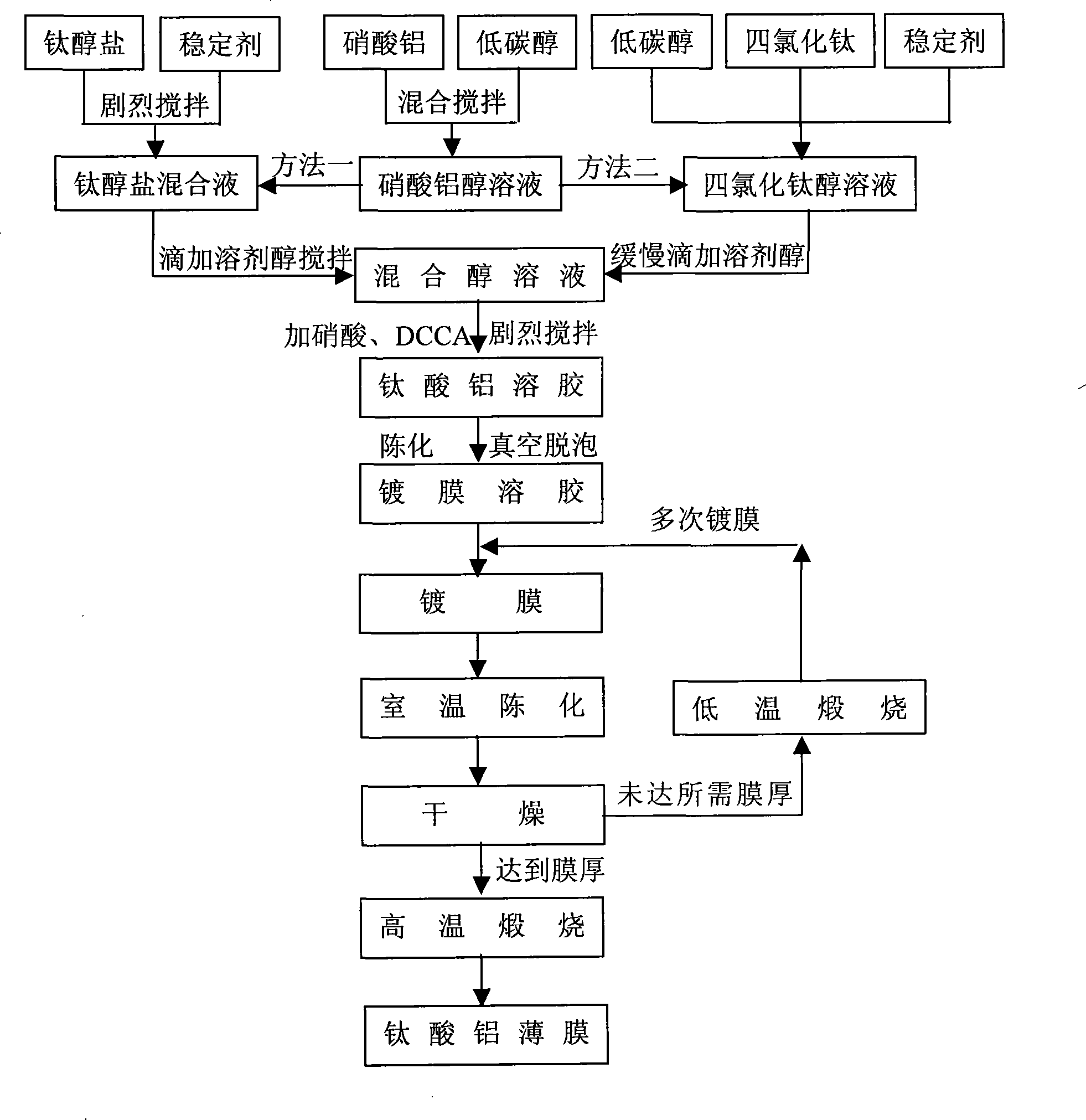

Method for producing aluminium titanates film by using colloidal sols-gel rubber technique

The invention discloses a method adopting sol-gel technique to prepare aluminum titanate film. The method comprises the steps as follows: adopting aluminum nitrate as the aluminium source, inducting titanium through titanium alkoxide or titanium tetrachloride, utilizing lower alcohol as the solvent, and applying acetylacetone, acetic acid or glycol as the stabilizer to control the hydrolyzing speed of the titanium precursor, wherein, the PH value is adjusted by nitric acid; the aluminum titanate sol is prepared by utilizing glycerin, butanediol or formamide as the dryness control chemical additive; after aging and vacuum defoaming of the sol, the dipping lifting method is adopted to coat film, and the film is processed by room temperature aging, room temperature drying and drying under 50 DEG C to get dry gel film. The film can be coated repeatedly till the necessary thickness of film. Before repeated coating, a low temperature calcine disposal of 450 DEG C is necessary, and finally the even and compact aluminum titanate film is formed by calcinations under 1350 DEG C. The invention has the advantages of simple process, low cost of raw material, etc.

Owner:JINGDEZHEN CERAMIC INSTITUTE

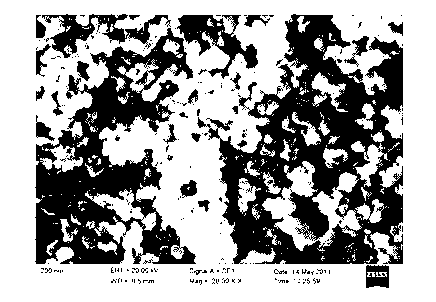

Preparation method of nickel titanate/titanium dioxide composite nanomaterial

InactiveCN105905940AReduce craft production costControllableTitanium dioxideMetal/metal-oxides/metal-hydroxide catalystsCross-linkDyeing wastewater

The invention belongs to the technical field of functional materials, and relates to a preparation method of a nickel titanate / titanium dioxide composite nanomaterial. The method comprises the following steps: dissolving and uniformly mixing nickel acetylacetonate and titanium acetylacetonate in an alcohol solution, carrying out a cross-linking reaction at a certain temperature, and carrying out heat treatment in a muffle furnace to obtain the nickel titanate / titanium dioxide composite nanomaterial. The preparation method is simple and easy, and the nickel titanate / titanium dioxide composite nanomaterial has the advantages of high purity, low content of impurities, low preparation cost, excellent performances, and realization of industrial batch production. The nickel titanate / titanium dioxide composite nanomaterial prepared in the invention has high catalysis activity as a photocatalytic material, and has wide application prospects in the field of degradation of dye wastewater and indoor harmful gases and the field of photocatalytic disinfection.

Owner:BOHAI UNIV

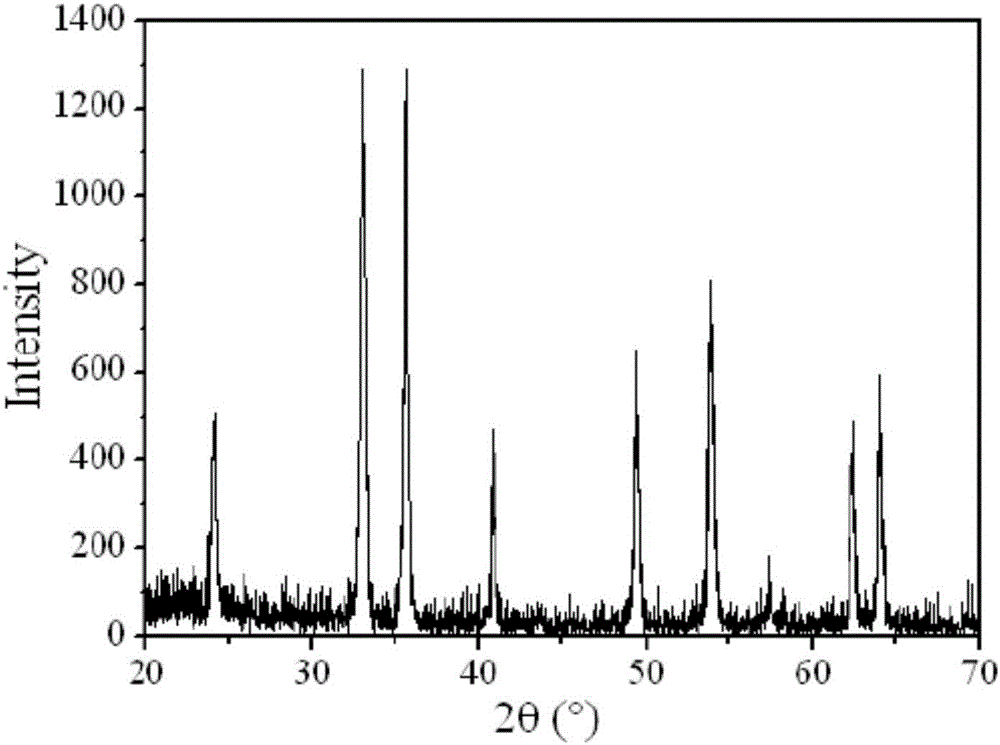

Method for preparing ferroelectric single crystal lead indium niobate-lead titanate

InactiveCN102560617AQuality improvementMeet application requirementsPolycrystalline material growthFrom melt solutionsIndiumX-ray

The invention relates to a method for preparing a ferroelectric single crystal lead indium niobate-lead titanate, and belongs to the field of crystal growth. The preparation method comprises the following steps of: mixing raw materials, dissolving, growing, and the like, namely a PIN-PT crystal is successfully grown by a top seeded solution growth (TSSG) method. The structure and ferroelectric, dielectric and piezoelectric properties of the crystal are analyzed through X-ray powder diffraction and ferroelectric, dielectric and piezoelectric measurement. Preferably, the 0.655PIN-0.345PT crystal has high Curie temperature and rhombohedral-tetragonal phase change temperature, high piezoelectric property and electromechanical coupling property and a wide application prospect. The method is convenient to operate and suitable for batch growth, equipment is simple, and a high-quality large-size PIN-PT crystal can be stably provided.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Ternary ferroelectric solid solution lead niobate ytterbate-lead zinc niobate-lead titanate

The invention relates to a ternary ferroelectric solid solution lead niobate ytterbate-lead zinc niobate-lead titanate. The chemical formula of the solid solution is xPb(Yb1 / 2Nb1 / 2)O3-yPb(Zn1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein x is more than 0 and less than 1, and y is more than 0 and less than 1, and the solid solution belongs to a typical composite perovskite structure. The system is good in piezoelectric and electromechanical performance, high in Curie temperature and good in thermal stability, and has a wide application prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

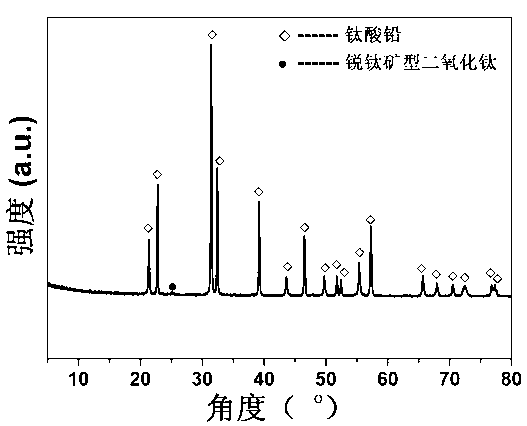

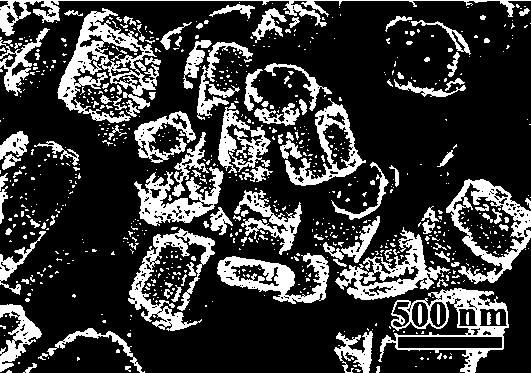

Sodium-ion battery nickel titanate cathode material and preparation method thereof

ActiveCN106299344AIncreased wetted contact areaImprove cycle stabilityCell electrodesSecondary cellsMicro structureSodium-ion battery

The invention discloses a sodium-ion battery nickel titanate cathode material and a preparation method thereof. The nickel titanate material has a loose and porous structure and a disc-shaped micro-structure, and has low potential, high specificity and excellent circulation performance when used as a sodium-ion battery cathode material. The preparation method of the sodium-ion battery nickel titanate cathode material is simple, cost is low, and wide industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com