Patents

Literature

76 results about "Crystal rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate

InactiveCN102051685APolycrystalline material growthFrom melt solutionsCrystal rotationSingle crystal

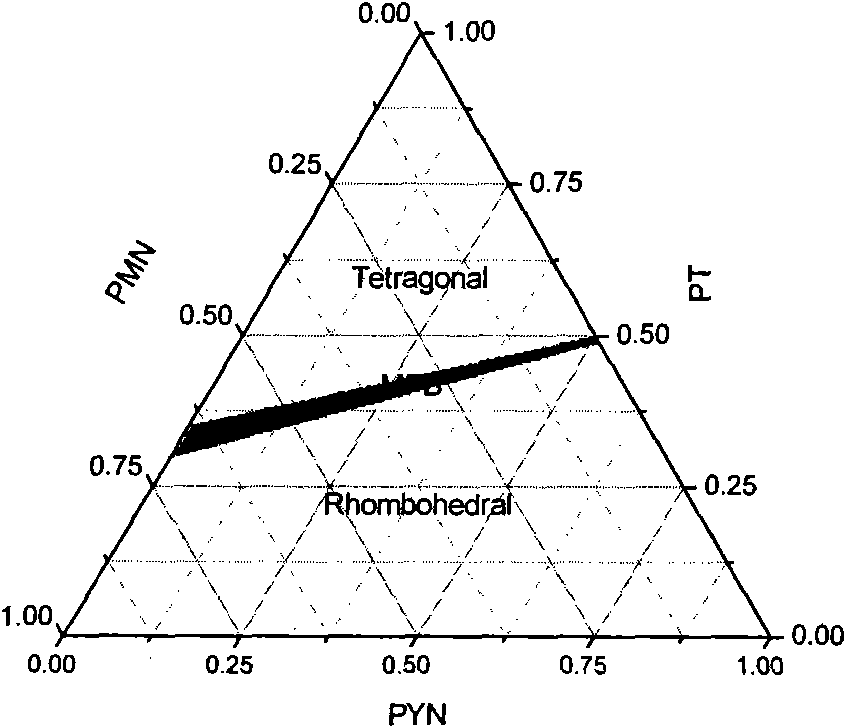

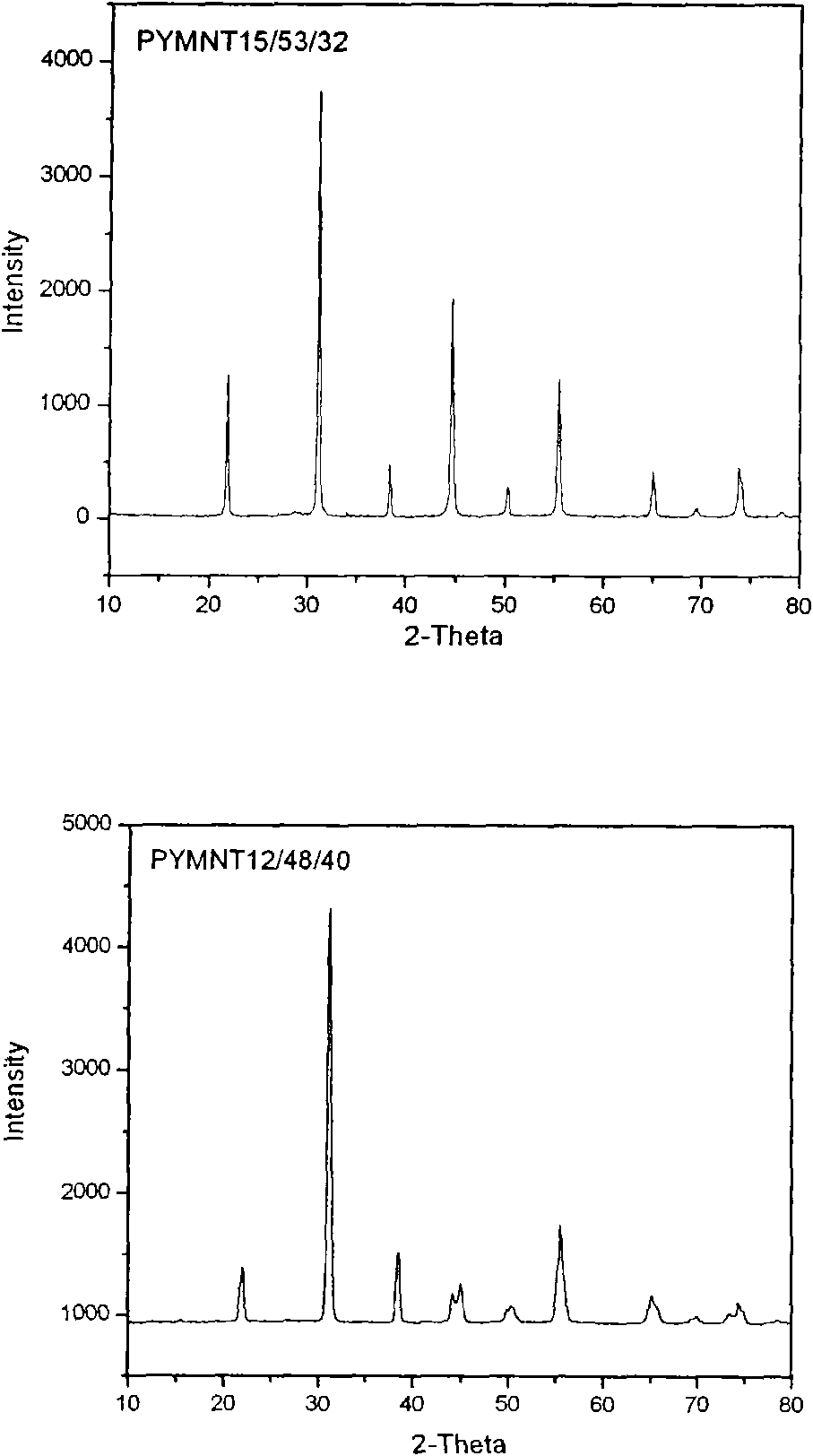

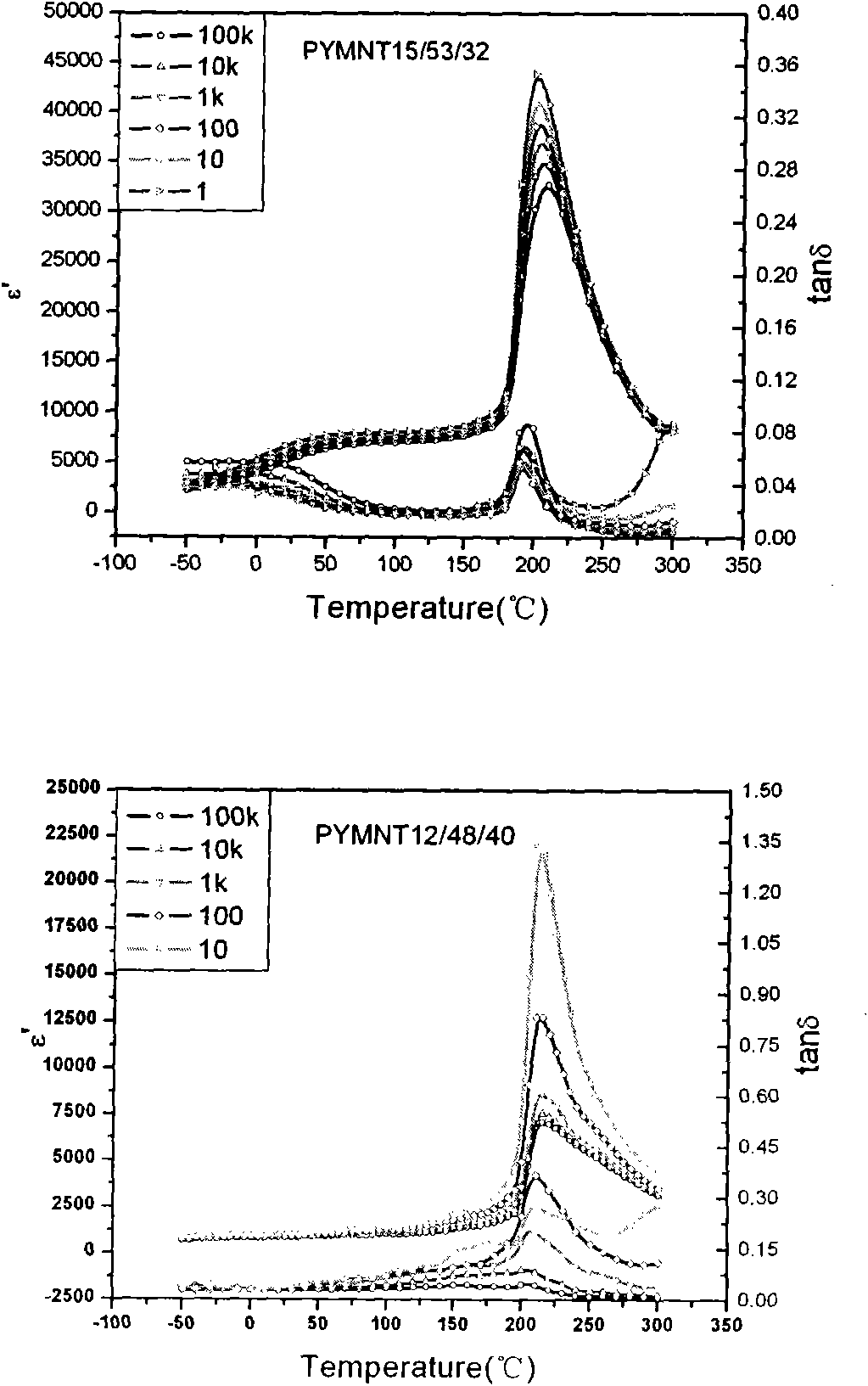

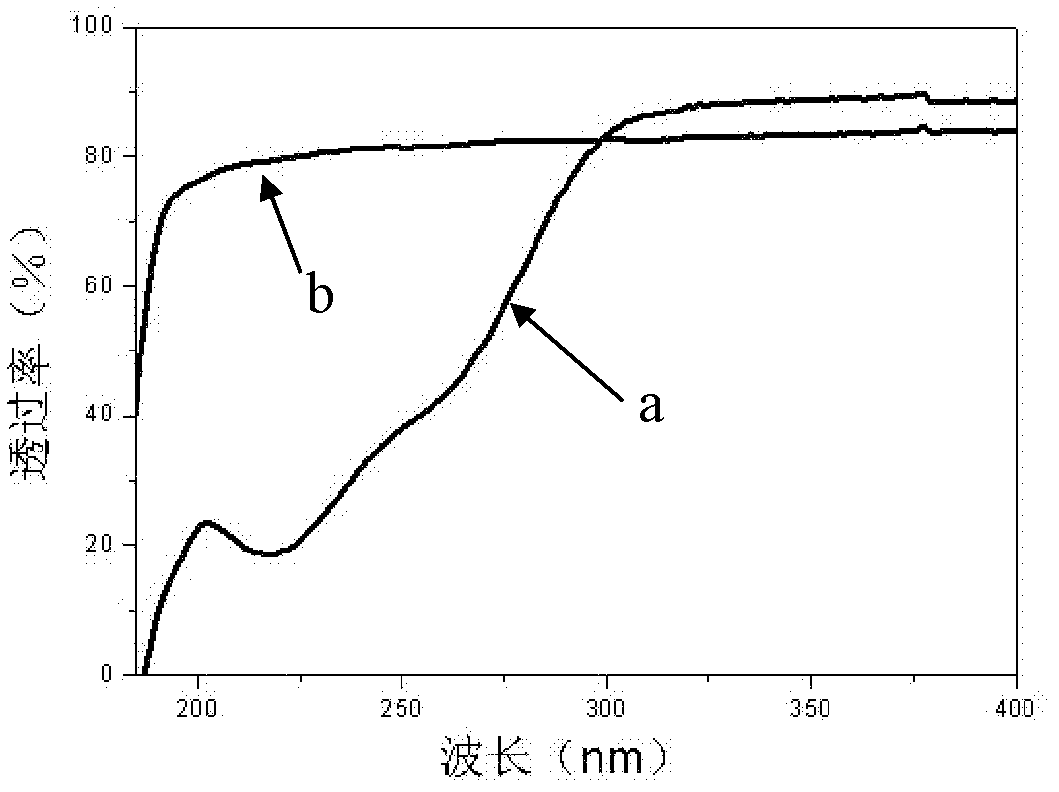

The invention relates to the growth, the structures and the properties of novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate. The crystal belongs to a perovskite structure, has an MPB region and has a chemical formula of (1-x-y)Pb(Yb1 / 2Nb1 / 2)O3-xPb(Mg1 / 3Nb2 / 3)O3-yPbTiO3 which is short for PYMNT or PYN-PMN-PT. By adopting a top crystal-seeded method, the crystal with large size and high quality can grow under the conditions that the growth temperature of the crystal is 950-1100 DEG C, the crystal rotation speed is 5-30rpm, and the cooling speed is 0.2-5 DEG C / day, and the grown crystal exposes a 001 natural growth surface. Through X-ray powder diffraction, the system is confirmed as the perovskite structure; and through ferroelectric, dielectric and piezoelectric measurement, the ferroelectricity, the dielectric property and the piezoelectricity of the crystal are analyzed. The crystal has high Curie temperature and trigonal-tetragonal phase transition temperature, large piezoelectric constant and electromechanical coupling factor, high dielectric constant and low dielectric loss and better heat stability. The crystal can be widely applied to devices in the piezoelectric fields of ultrasonically medical imaging, sonar probes, actuators, ultrasonic motors, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

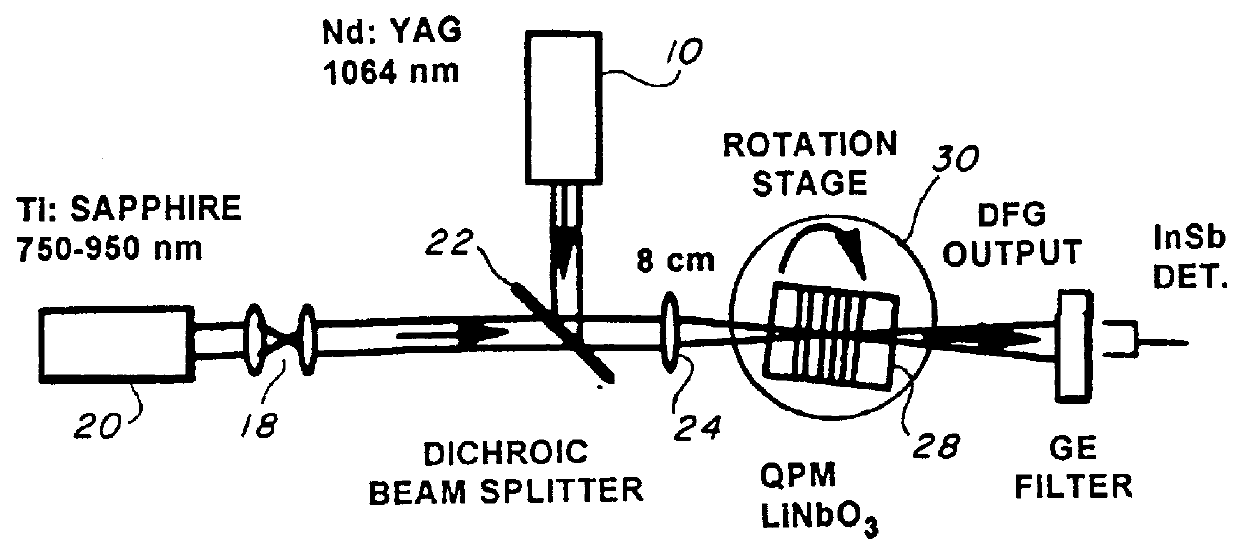

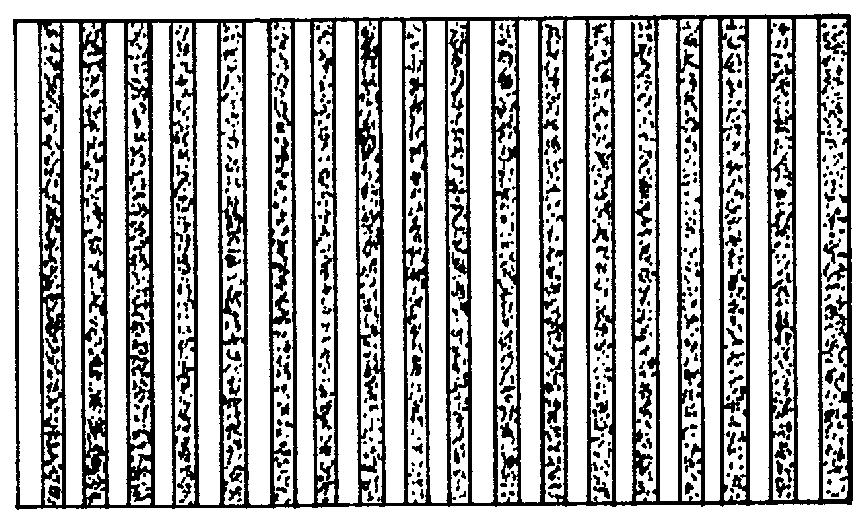

Compact continuous wave tunable infrared lasers and method therefor

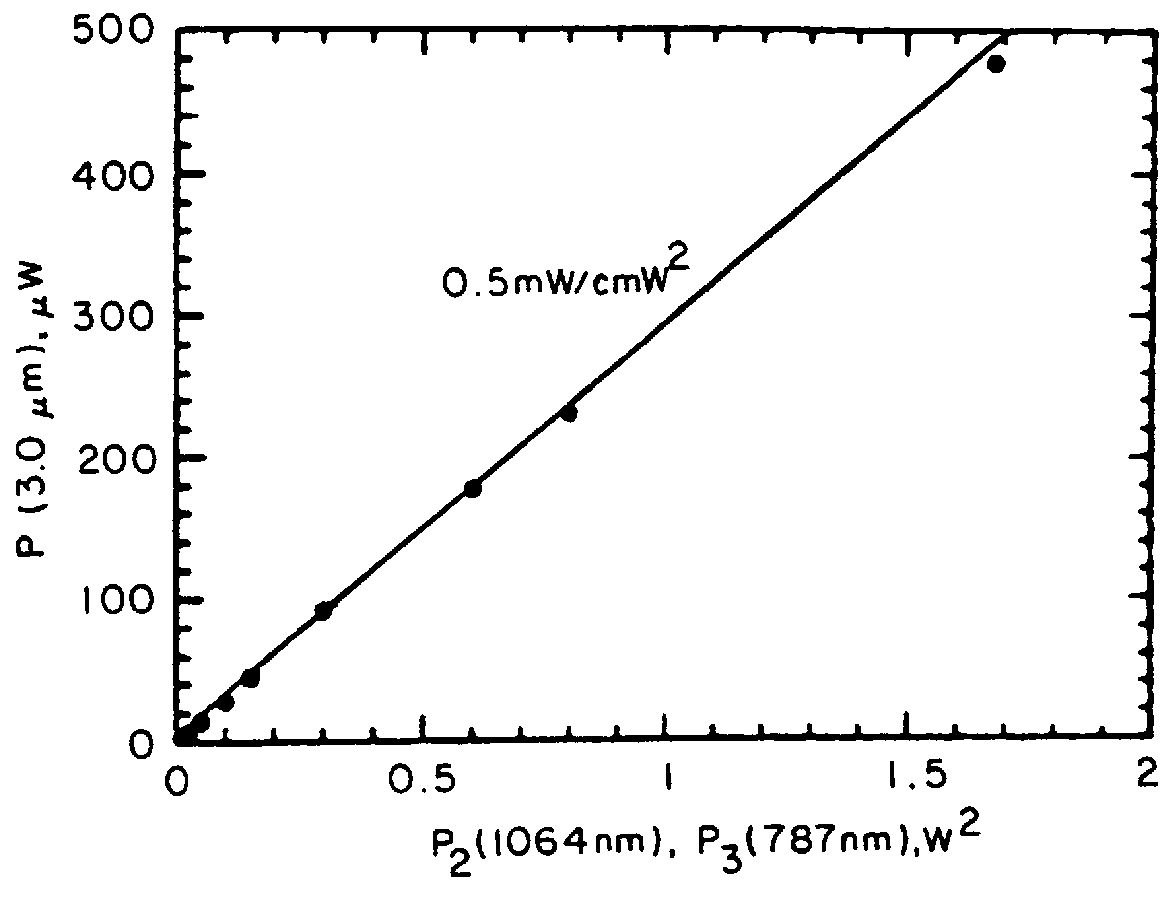

A bulk, quasi-periodic phase-matched difference-frequency (DFG) process in field-poled LiNbO.sub.3 bulk crystal permits continuous tunability of the output radiation in the 3.0-4.1 .mu.m wavelength range through grating rotation. DFG in QPM-LiNbO.sub.3 crystal, carried out using a Nd:YAG laser and a high power semiconductor laser at the quasi-phased matching (QPM) degeneracy point, results in an ultra wide 0.5 .mu.m acceptance bandwidth, permitting crystal rotation-free wavelength tuning of 4.0-4.5 .mu.m, with 0.2 mW output power at 4.5 .mu.m.

Owner:BURNS WILLIAM K +2

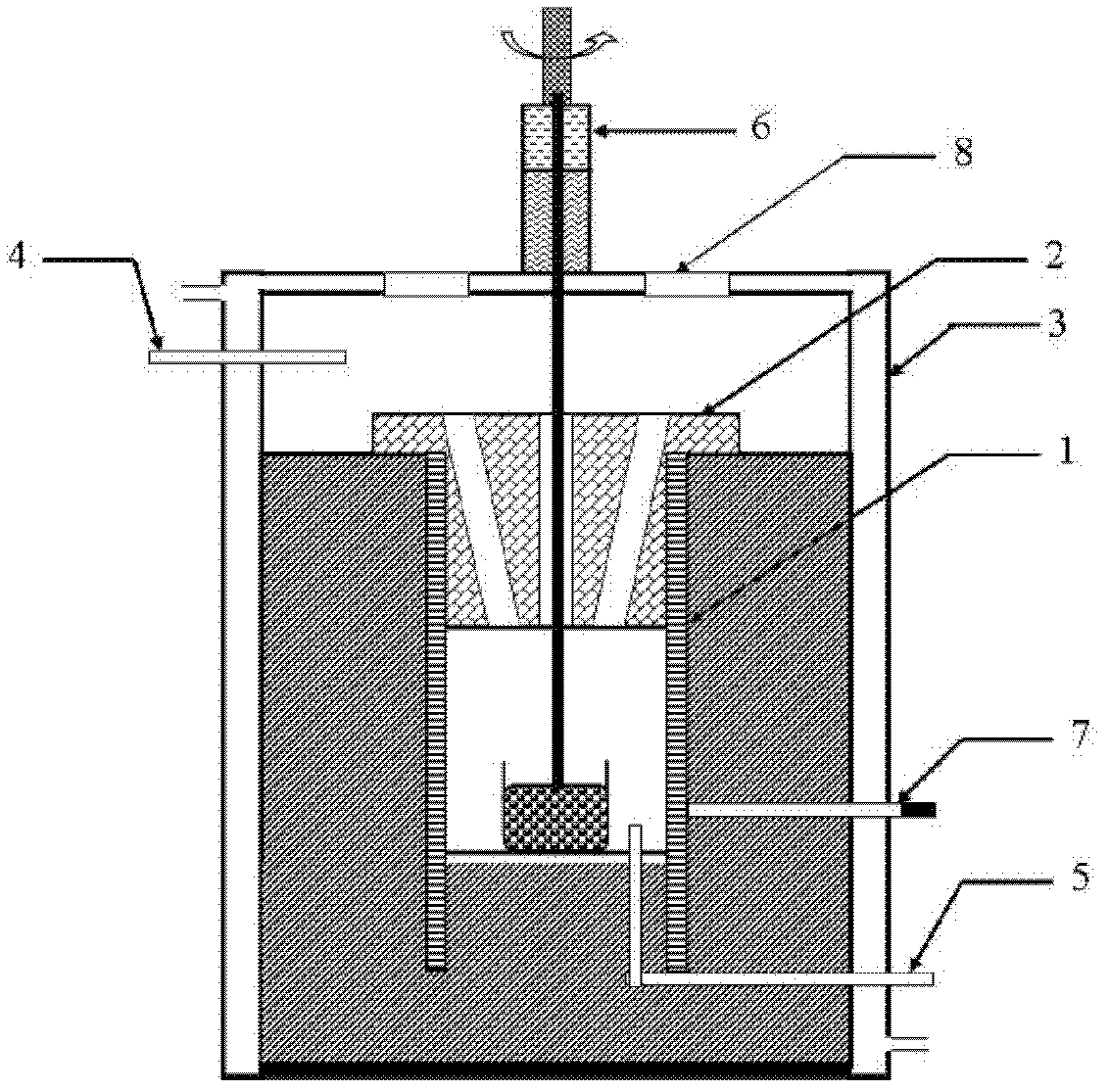

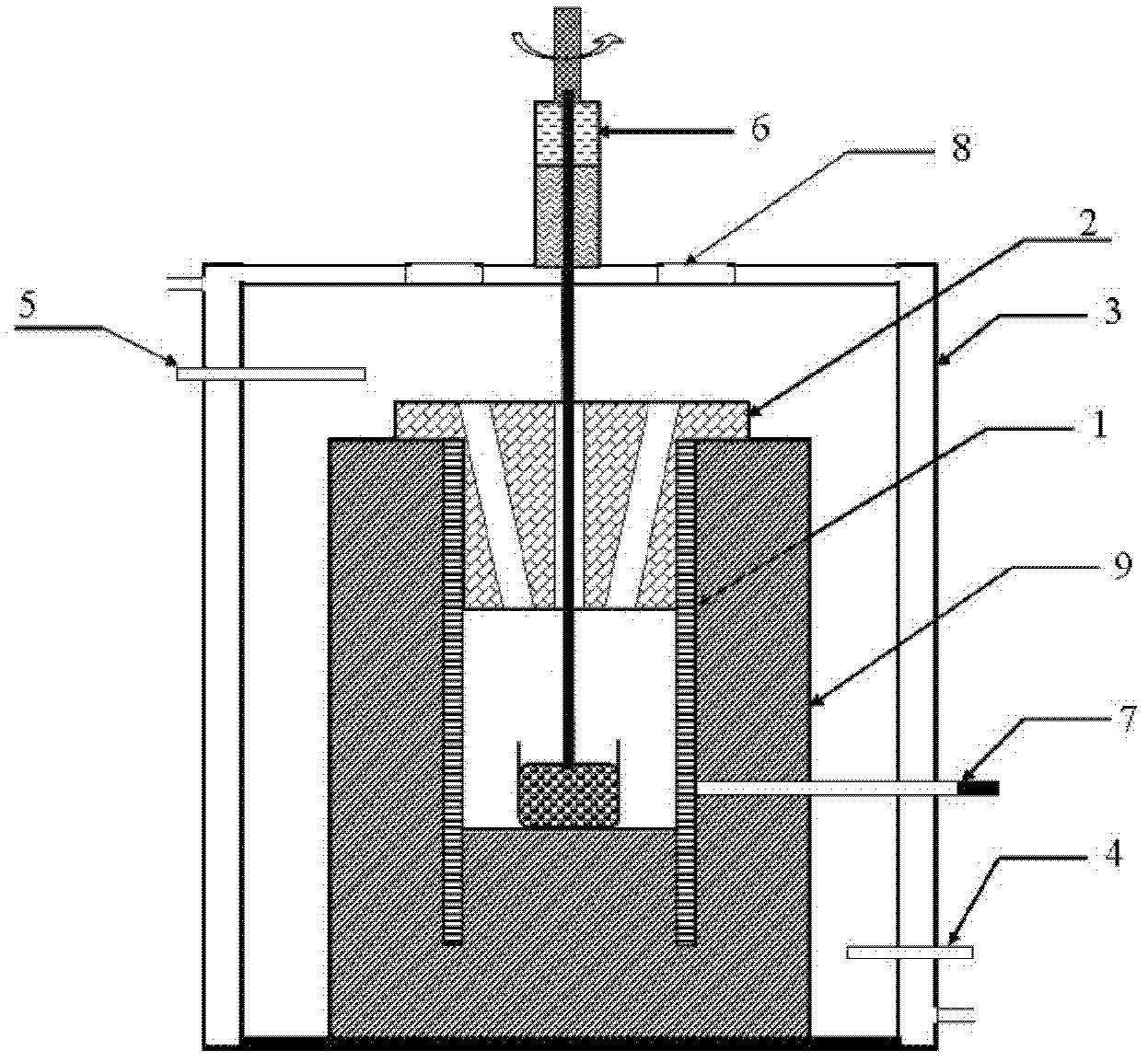

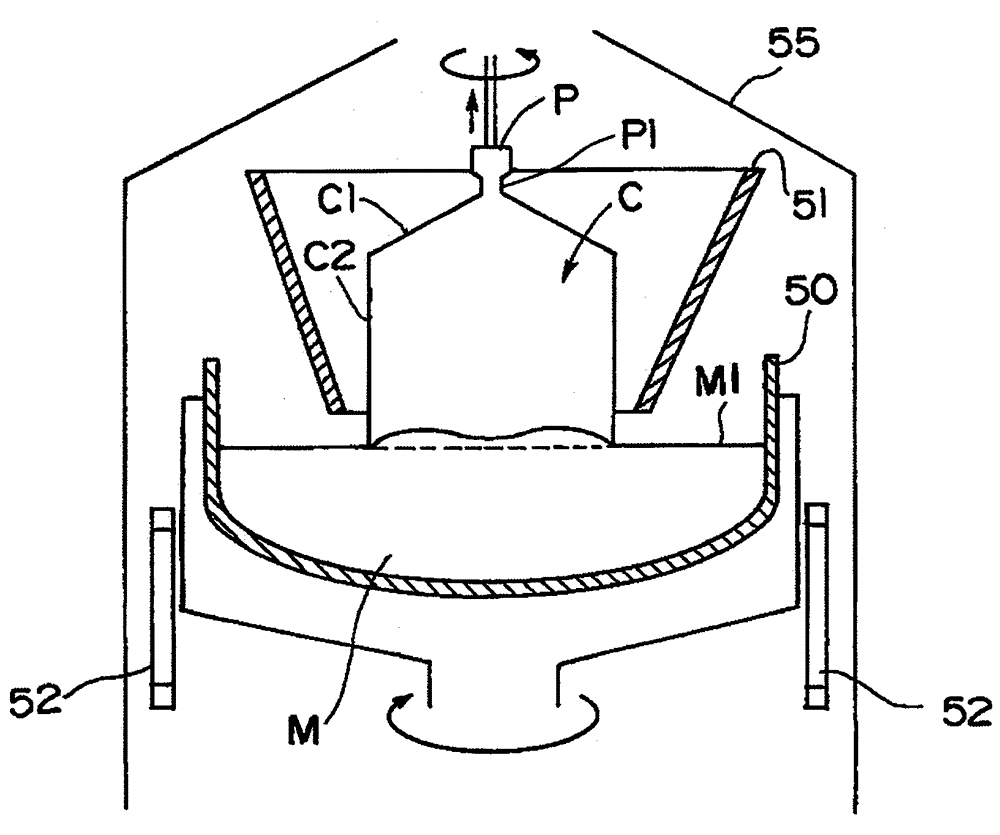

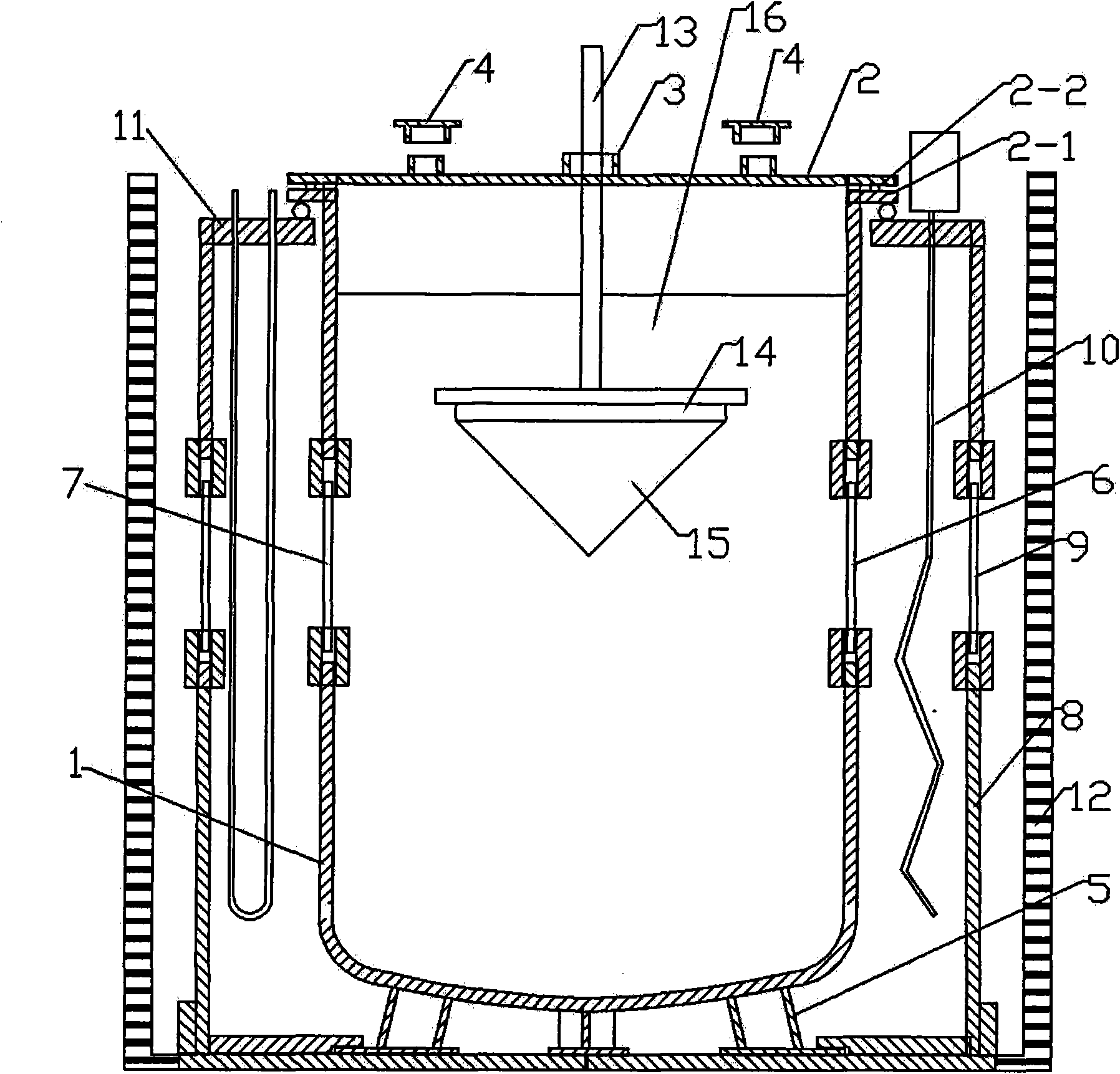

Closed monocrystalline growth furnace for molten salt method crystal growth

ActiveCN102877116AGood optical performanceChange ionic radiusFrom melt solutionsBrickCrystal rotation

A closed monocrystalline growth furnace for the molten salt method crystal growth comprises a ceramic bushing hearth wound with a resistance wire, a closed barrel-shaped hollow double-layer stainless steel outer furnace shell positioned outside the hearth, fireproof heat-insulation bricks / cotton arranged between the furnace shell and the hearth, a thermocouple traversing the furnace shell and extending to the outer wall of the hearth, and a fireproof heat-insulation brick furnace cover covering the upper port of the hearth, wherein the center and two sides of the furnace cover are provided with a first vertical central through hole and observation holes respectively; cooling water which flows in a circulating manner is contained in the furnace shell; the wall of the furnace shell is provided with an aspirating hole and an air inlet; the center of the cover of the furnace shell is provided with a second vertical central through hole opposite to the first vertical central through hole, and quartz glass windows; an atmospheric gas is filled to the inside of the furnace shell; a magnetofluid is arranged over the furnace shell and is connected with the furnace shell through a bellow; and a seed crystal rod traverses the magnetofluid, is connected with a universal knot, and is fixed on a crystal rotation head through the universal knot. The furnace enables crystals to grow under the atmospheric gas, the entry of impurities into the crystals to be reduced, the optical properties of the crystals to be improved, the extrinsic absorption generated by the crystals in an ultraviolet spectrum region to be removed, and the ultraviolet laser output power to be improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Rapid ending method for Czochralski silicon

ActiveCN107761163AAvoid breakingShorten closing timePolycrystalline material growthBy pulling from meltCrystal rotationIntermediate stage

The invention discloses a rapid ending method for Czochralski silicon. The rapid ending method for Czochralski silicon comprises the following steps: in an early stage, stopping rising of a crucible,increasing the temperature of a thermal field, maintaining a crystal growth speed, a crystal rotation speed and a crucible rotation speed unchanged, and allowing a crystal diameter to decrease; in a middle stage, reducing the crystal growth speed, driving the crucible to rise, then reducing heating power, increasing the crystal rotation speed and the crucible rotation speed, and allowing the risetrend of the temperature of the thermal field to slow down; and in a later stage, stopping rising of the crucible, maintaining the crystal rotation speed and the crucible rotation speed unchanged, increasing the crystal growth speed, and lifting crystal out of the liquid level of molten silicon when the crystal diameter decreases to 25 to 30 mm so as to complete ending. The rapid ending method forCzochralski silicon can rapidly decrease the crystal diameter on the premise of maintaining the growth speed of monocrystal silicon crystals unchanged; then the method reduces the crystal growth speed, increases the crystal rotation speed and the crucible rotation speed, and decreases heating power to slow down the temperature rising trend of the thermal field, so the tail part of a crystal is prevented from break-off; and finally, a crystal pulling speed is rapidly increased to complete ending, so ending time is greatly shortened, and yield is substantially increased.

Owner:YINCHUAN LONGI SILICON MATERIALS

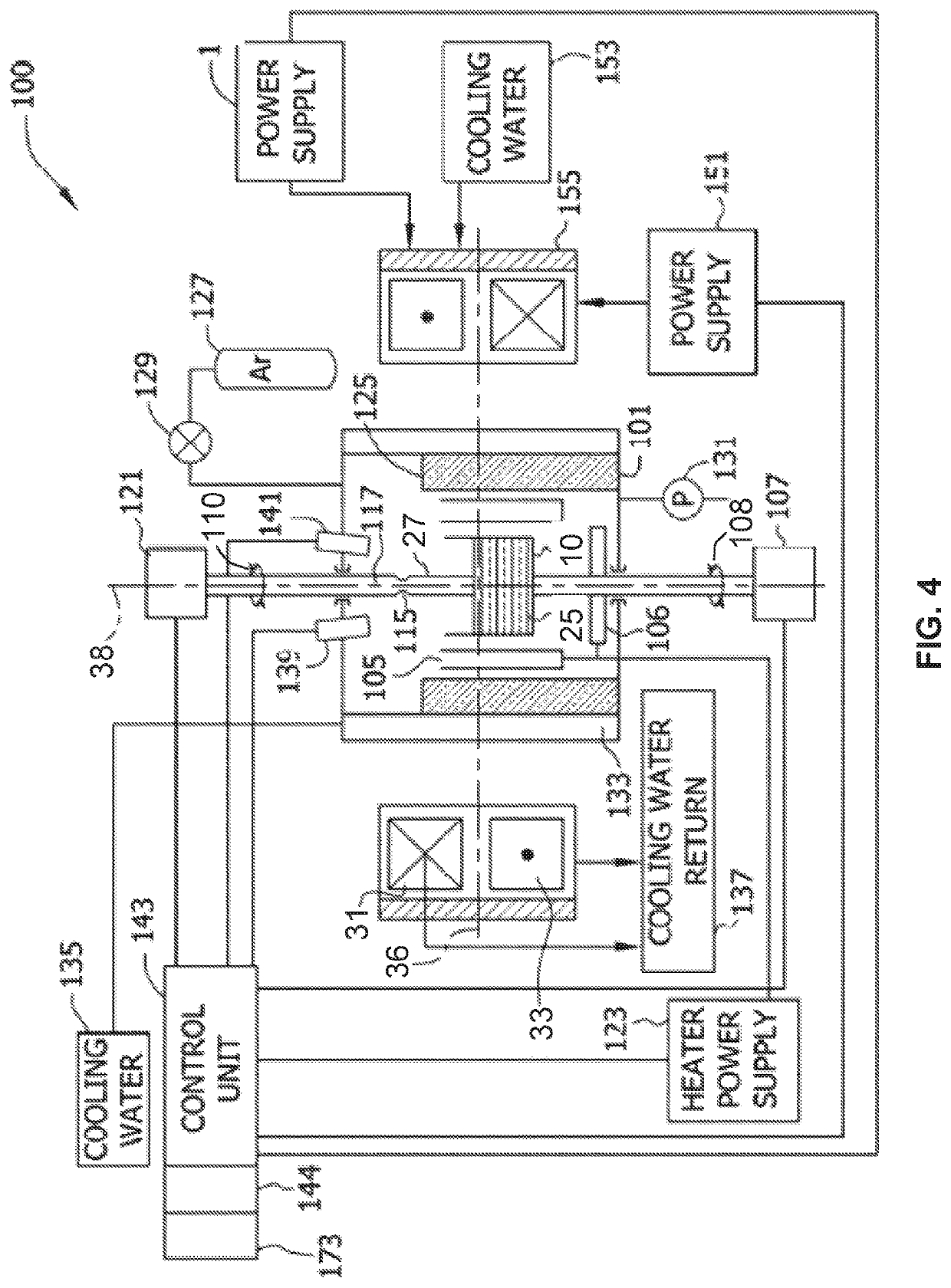

Systems and methods for production of low oxygen content silicon

ActiveUS20180355509A1Increase the magnetic field strengthPolycrystalline material growthBy pulling from meltCrucibleCrystal rotation

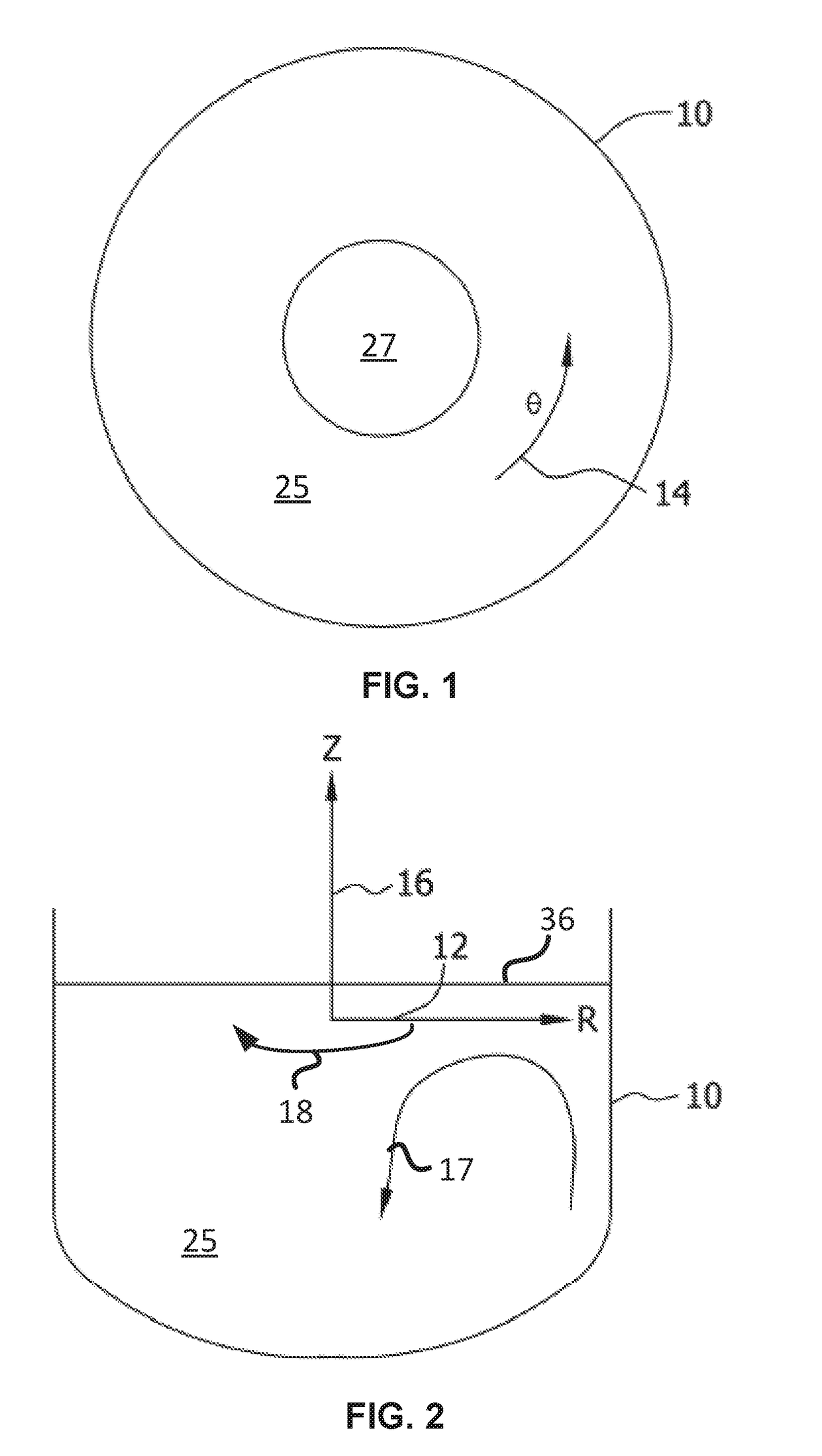

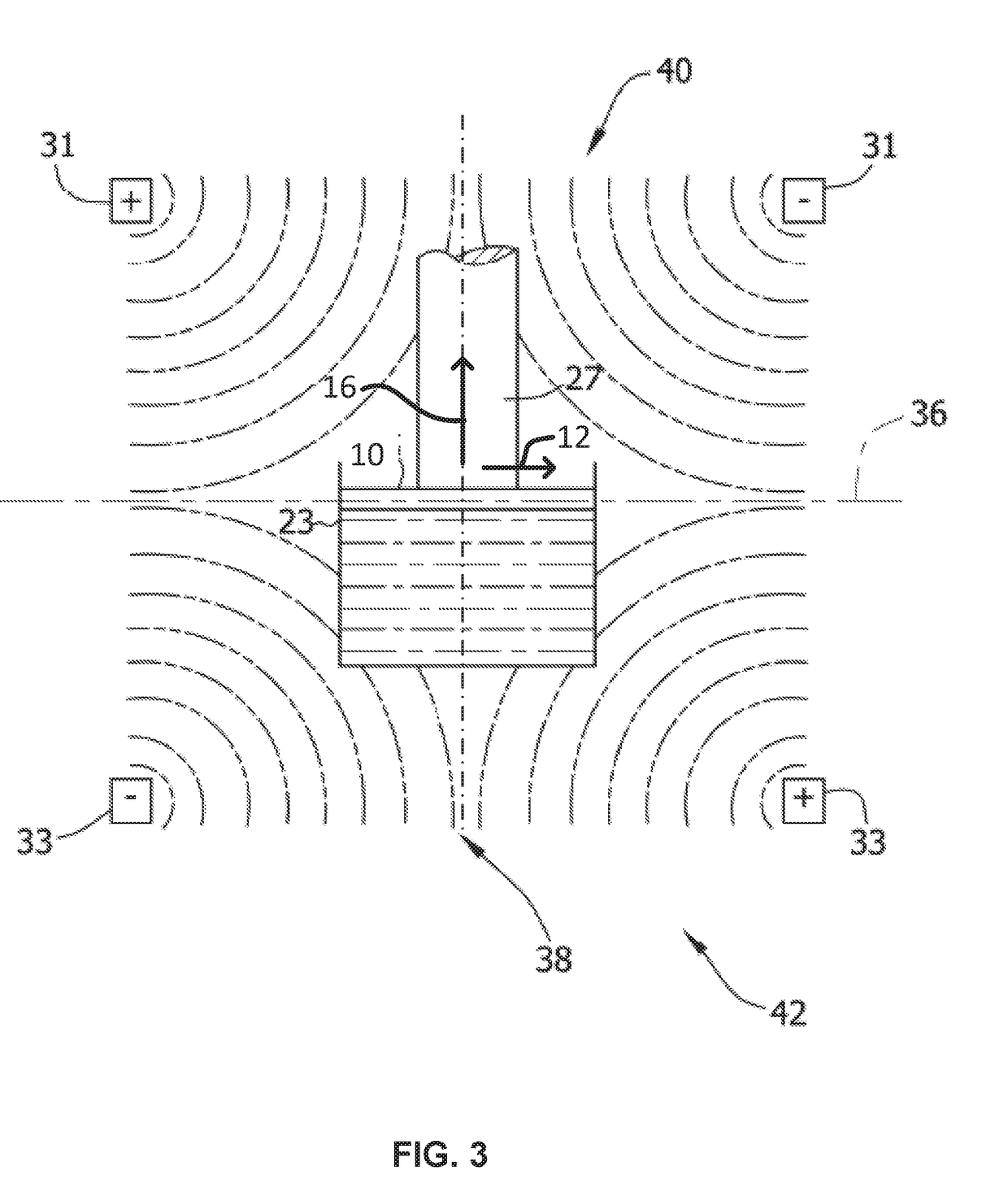

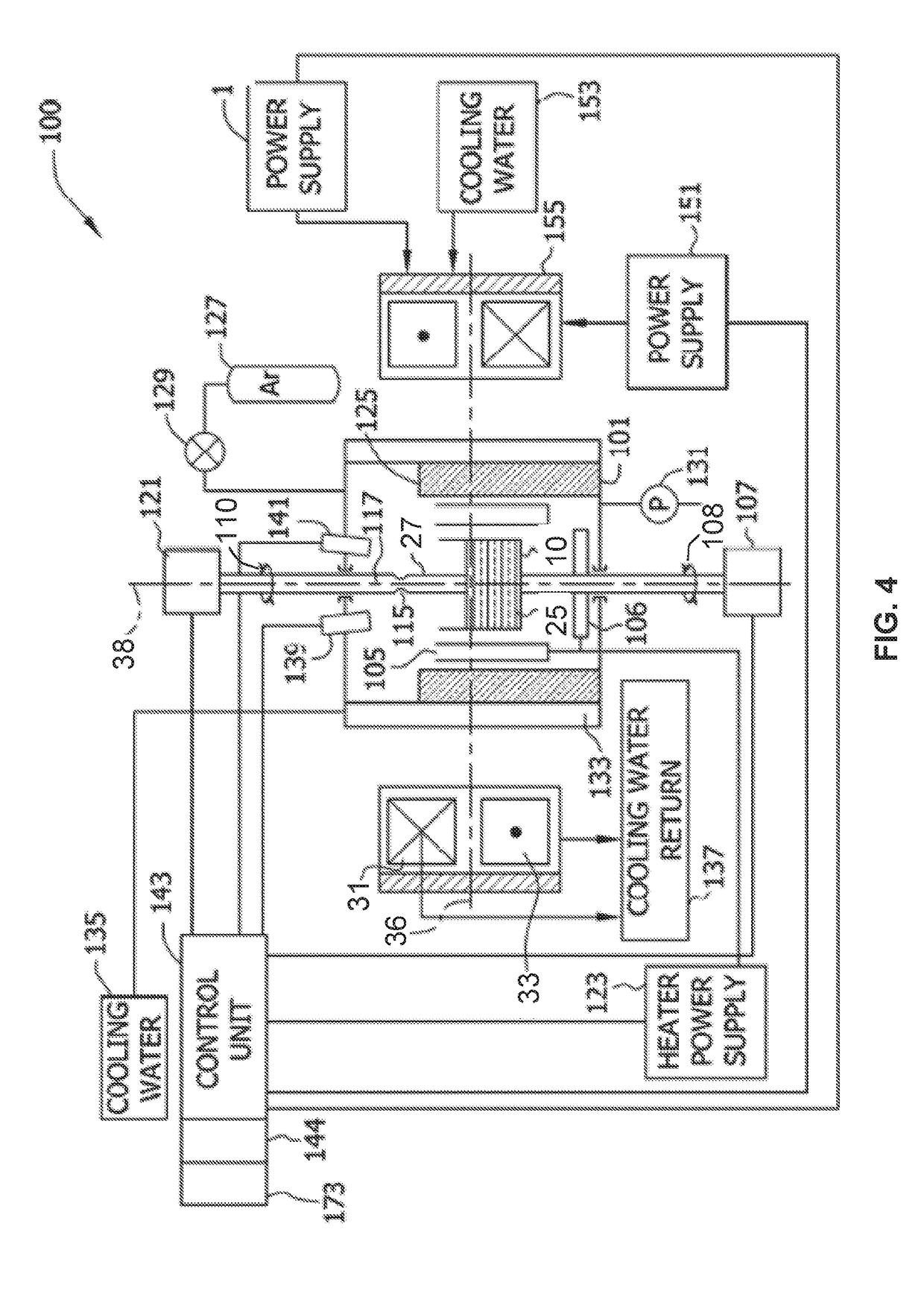

A method for producing a silicon ingot includes withdrawing a seed crystal from a melt that includes melted silicon in a crucible that is enclosed in a vacuum chamber containing a cusped magnetic field. At least one process parameter is regulated in at least two stages, including a first stage corresponding to formation of the silicon ingot up to an intermediate ingot length, and a second stage corresponding to formation of the silicon ingot from the intermediate ingot length to the total ingot length. During the second stage process parameter regulation may include reducing a crystal rotation rate, reducing a crucible rotation rate, and / or increasing a magnetic field strength relative to the first stage.

Owner:GLOBALWAFERS CO LTD

Production method of solar-grade czochralski silicon

InactiveCN104451872AReduce black chipsReduce the problem of dark cornersPolycrystalline material growthBy pulling from meltCrystal rotationSingle crystal

The invention discloses a production method of solar-grade czochralski silicon, and relates to the technical field of czochralski silicon. The production method comprises the following eight steps of charging, melting, stabilizing the temperature, seeding, shouldering, performing equal-diameter growth and ending. According to the production method disclosed by the invention, in the seeding process, the crystal rotation and the crucible rotation are set to be 8 revolutions per minute. The production method is simple and convenient to operate, easy to realize, capable of effectively reducing crystal defects which possibly appear in a crystallization process, lowering a problem of producing black chips and black angle plates in the czochralski silicon, remarkably improving the quality of the single crystal and prolonging the service life of the single crystal, avoiding returned goods due to product quality defects and saving unnecessary fund waste for the enterprises.

Owner:XINGTAI JINGLONG ELECTRONICS MATERIAL

Chromium-doped calcium magnesium silicate tunable laser crystal and preparation method thereof

ActiveCN103173862APromote growthEasy qualityPolycrystalline material growthBy pulling from meltChromium dopingSpace group

The invention provides a chromium-doped calcium magnesium silicate tunable laser crystal and a preparation method thereof. The crystal has a molecular formula of Cr<3+>:CaMgSi2O6. The crustal belongs to a monoclinic system, and a space group of C12 / c1. Cell parameters of the crystal are that a=9.741 angstrom, b=8.901 angstrom, c=5.257 angstrom, beta=105.97 DEG, V=439.1 angstrom<3>, Z=4, and Dc=3.271 g / cm3. Cr<3+>:CaMgSi2O6 is a same-composition molten compound. High-optical-quality and large-size crystals can be grown with a Czochralski method. Growth conditions comprise that: a growth temperature is 1500 DEG, a pulling speed is 0.2-0.8mm / h, and a crystal rotation speed is 10-20rpm. A tunable range is 700-1350nm. The crystal is possible to become a novel tunable laser crystal, and can be practically applied.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Ytterbium doped gadolinium lanthanum calcium oxoborate laser crystal, producing method, and purpose

The invention discloses a method for preparing and using laser crystal mixed with the ytterbium doped gadolinium lanthanum calcium oxyborate, which relate to the field of the intraocular lens. At a temperature of about 1470 DEG C, the invention, at a crystal rotation speed of 5 to 20 rotations per minute and a pulling rate of 0.5 to 2mm per hour, produce the crystal of Yb<3+>:Gd<1-X>La<X>Ca<4>O(BO3)3 of high quality and larger dimension though a czochralski method. The crystal is a novel laser crystal, which can generate a laser output with a wavelength of about 1 Mum. The crystal also has the frequency-doubled effect and can get blue-green laser output through a self-frequency-doubling or self-mixing nonlinear optical method. A solid laser made from the crystal can be applied in the fields such as spectroscopy, biomedicine, military science and etc.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Monocrystalline silicon growth ultrasonic wave oxygen control method

ActiveCN105483817AReduce sound intensityReduce the ultrasonic amplitudePolycrystalline material growthBy pulling from meltSolubilityCrystal rotation

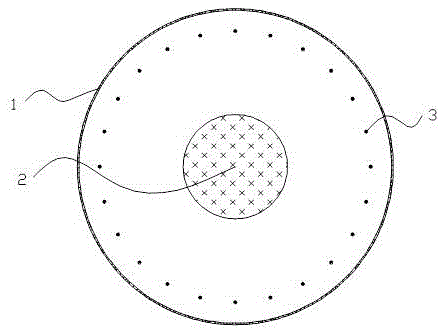

The invention discloses a monocrystalline silicon growth ultrasonic wave oxygen control method. In a device of the monocrystalline silicon growth ultrasonic wave oxygen control method, the surface of silicon melt is provided with a set of ultrasonic wave, and a set of ultrasonic wave vibration heads are uniformly distributed on a circle coaxial to silicon single crystal rods and a crucible; the distance between each pair of ultrasonic wave vibration heads is controlled to be 1.5 to 2 times of the distance from a corresponding ultrasonic wave vibration head to the crucible wall; the ultrasonic wave vibration heads are made of a high-purity quartz material, and are stretched to be 10 to 15mm below the surface of the silicon melt; and the depth is maintained in the process of crystal growth. In silicon single crystal equal-diameter growth process, ultrasonic wave oscillation is introduced so as to inhibit heat natural convection in a high oxygen concentration zone around the crucible, accelerate flow of the silicon melt from the center to the surrounding caused by crystal rotation, promote volatilization of oxygen on a free surface, reduce solubility of Si-O gas in the silicon melt, promote volatilization of Si-O on the surface of the silicon melt, and control oxygen content of obtained crystals.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

Processing process for preparing single crystal silicon through Czochralski method

InactiveCN107794563ALow oxygenInhibit entryPolycrystalline material growthBy pulling from meltCrystal rotationCzochralski method

The invention discloses a processing technology for preparing single crystal silicon by the Czochralski method, which comprises the following steps: necking growth: when the temperature of the silicon melt is stabilized to a certain temperature, the seed crystal is immersed in the silicon melt, and the seed crystal is Increase the pulling speed at a certain rate to reduce the diameter of the seed crystal to 3-7mm; shoulder growth: after the necking growth is completed, reduce the crucible temperature and pulling speed, adjust the crucible rotation speed and crystal rotation speed, and increase the crystal to the required diameter; equal-diameter growth: after the shoulder growth is completed, adjust the crucible temperature, pulling speed, crucible rotation speed and crystal rotation speed, so that the diameter of the ingot is maintained between plus and minus 2mm; the present invention adds pure boron to the single crystal silicon raw material, The mass ratio of pure boron to monocrystalline silicon raw materials is 5%-15%, so that the resistivity of monocrystalline silicon can reach 300Ω / CM, and the radial uniformity of resistivity is within 3%; reduce the oxygen content in silicon melt It effectively inhibits the entry of oxygen from the silicon melt into the silicon crystal, improves work efficiency, and reduces the oxygen content of the silicon crystal.

Owner:JIANGSU YONGJIA ELECTRONICS MATERIALS

Method for adjusting growth temperature of silicon carbide monocrystal

InactiveCN105970285AImprove operational safetyImprove product qualityPolycrystalline material growthBy pulling from meltCrystal rotationCrucible

The invention relates to a method for adjusting the growth temperature of a silicon carbide monocrystal. The method comprises the following steps: enabling a seed crystal and a crucible to be coaxial and to rotate in opposite directions; controlling the temperature field and temperature distribution of a melt by controlling the crystal rotation speed and the crucible rotation speed; enabling an induction coil to be fixed; adjusting the silicon carbide subliming plane to be in the highest point of an induction coil magnetic field all the time by lifting the crucible. The method is stable in temperature change and high in product quality.

Owner:JIANGSU BAIR PHOTOELECTRIC EQUIP CO LTD

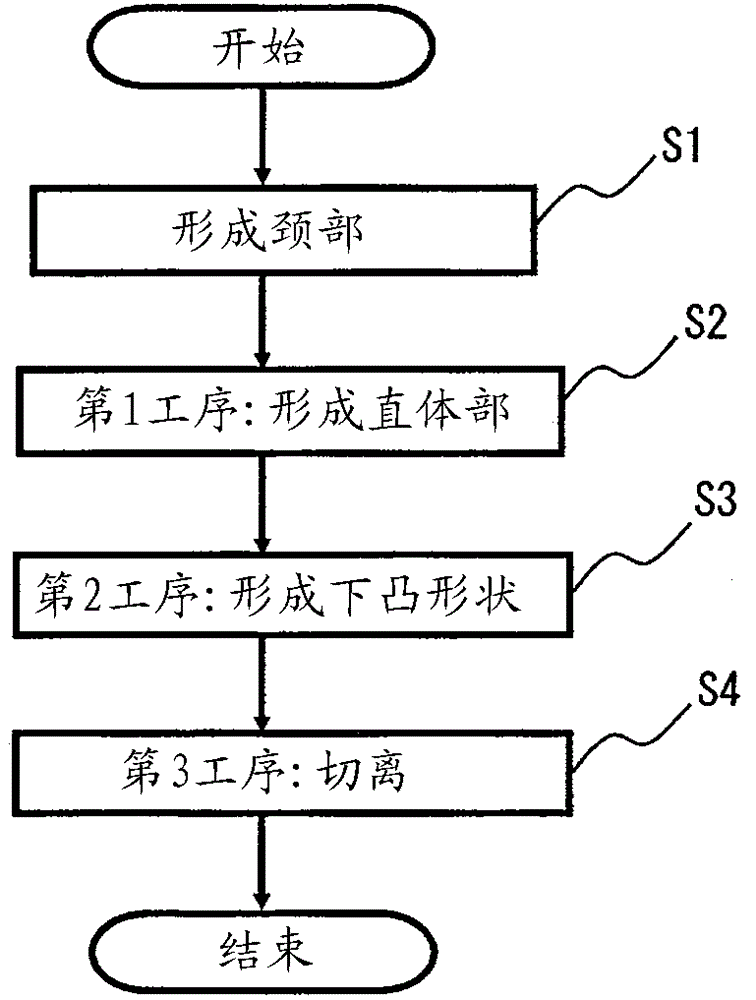

Single crystal extraction method

ActiveCN105040099AReduce extraction timeImprove yieldPolycrystalline material growthBy pulling from meltCrystal rotationCunife

The single crystal extraction method is used for shortening the extraction time from the forming of a straight body part to crystal excision from a meltwater, extracting single crystal and improving a rate of finished products. The method comprises a first process, a second process and a third process. The first process forms the straight body part (C2), and the second process is behind the first process. In the final process of forming the straight body part, a lower protruded shape (C3) protruded downwards is formed at the lower end of the crystal, and the third process is configured to cut the lower protruded shape formed in the second process from the silicon meltwater. In the second process, the field density of the horizontal magnetic field is controlled lower than the first process in the range of 800 to 1000 gausses, the crystal extract speed is controlled lower than the first process in the range of 0.2 to 0.5 mm / min, the crystal rotation speed is controlled lower than the first process in the range of 1 to 3 rpm, and the crucible rotation speed is controlled in the range of 0.5 to 5 rpm.

Owner:GLOBALWAFERS JAPAN

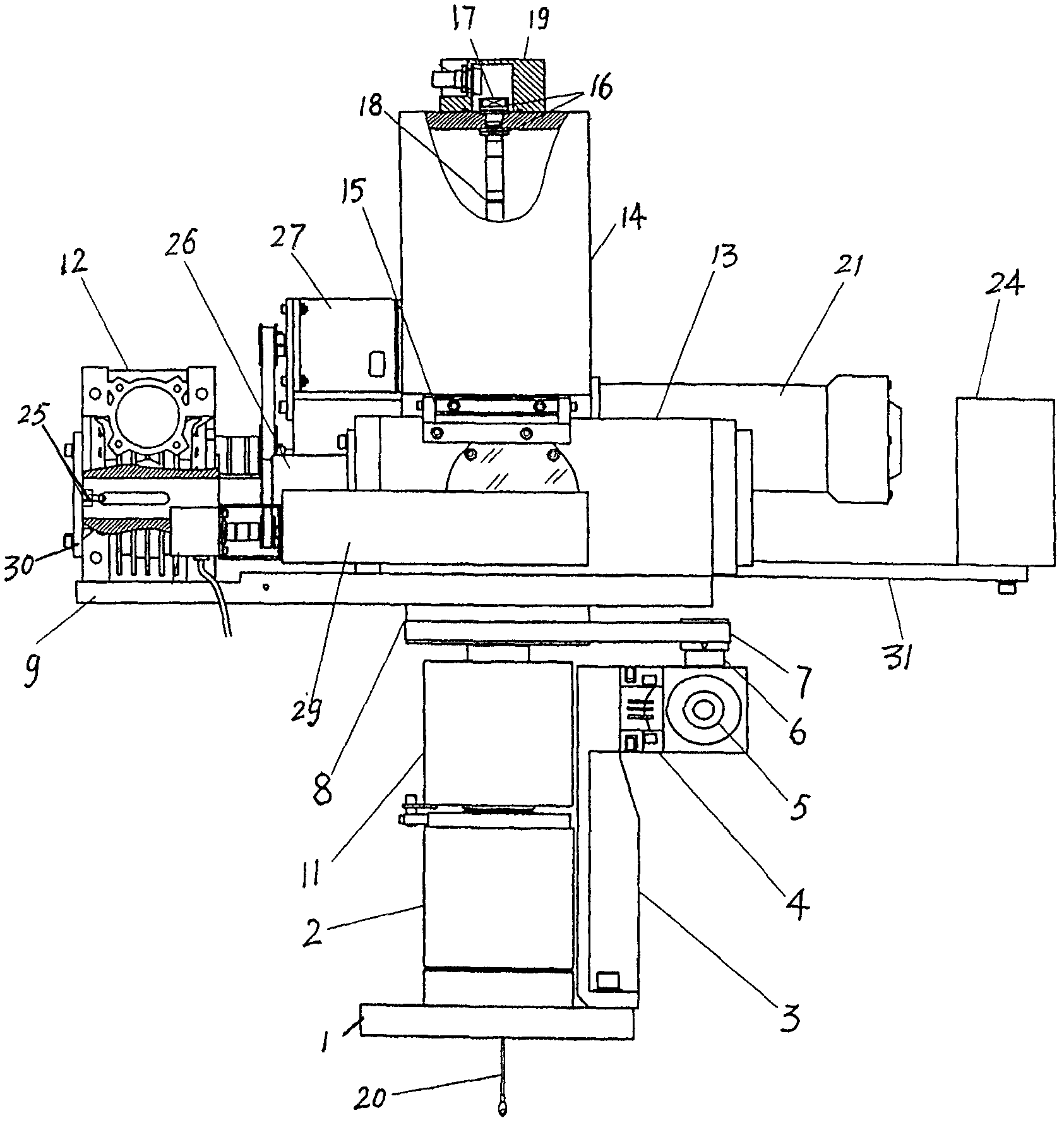

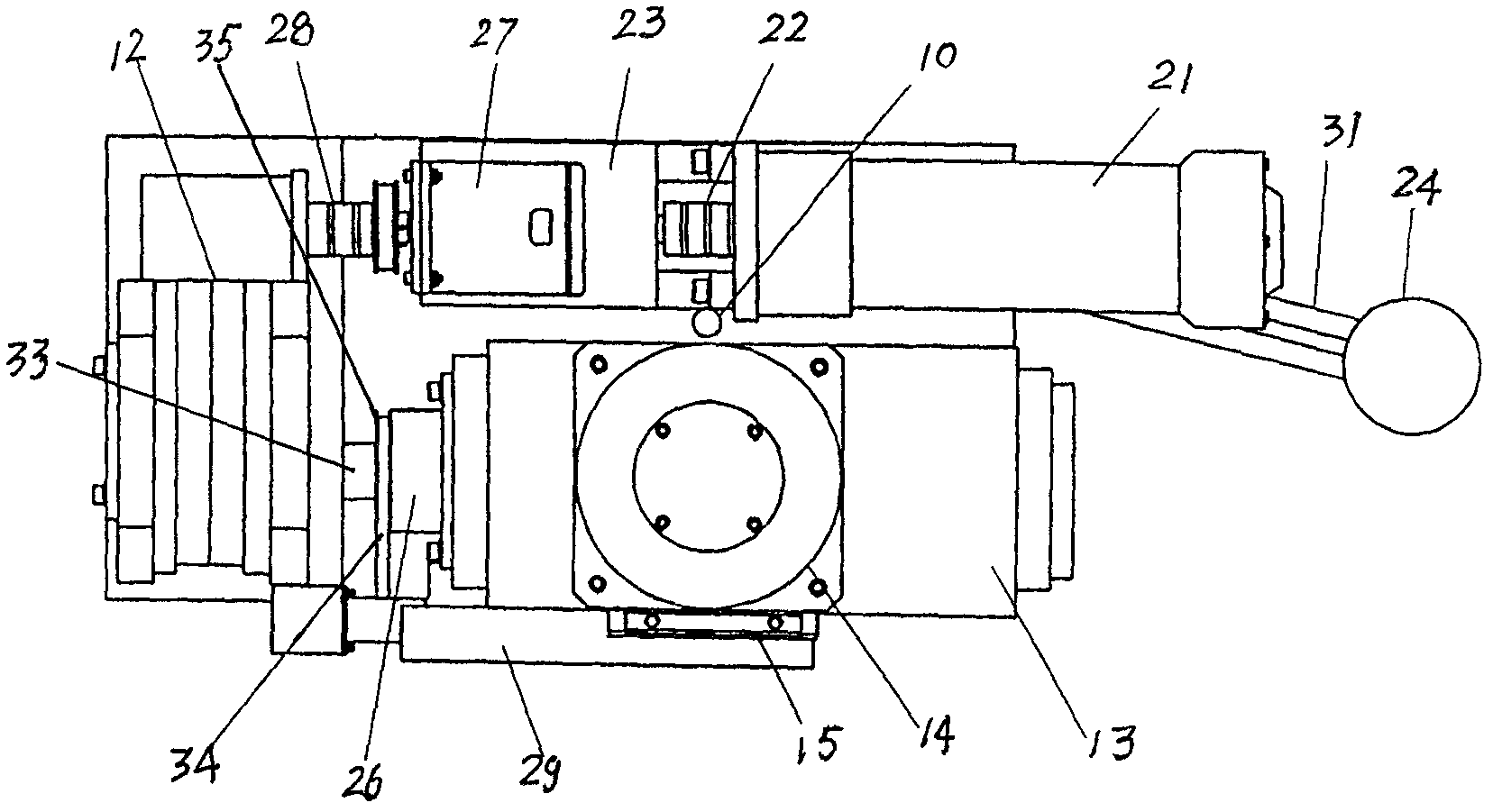

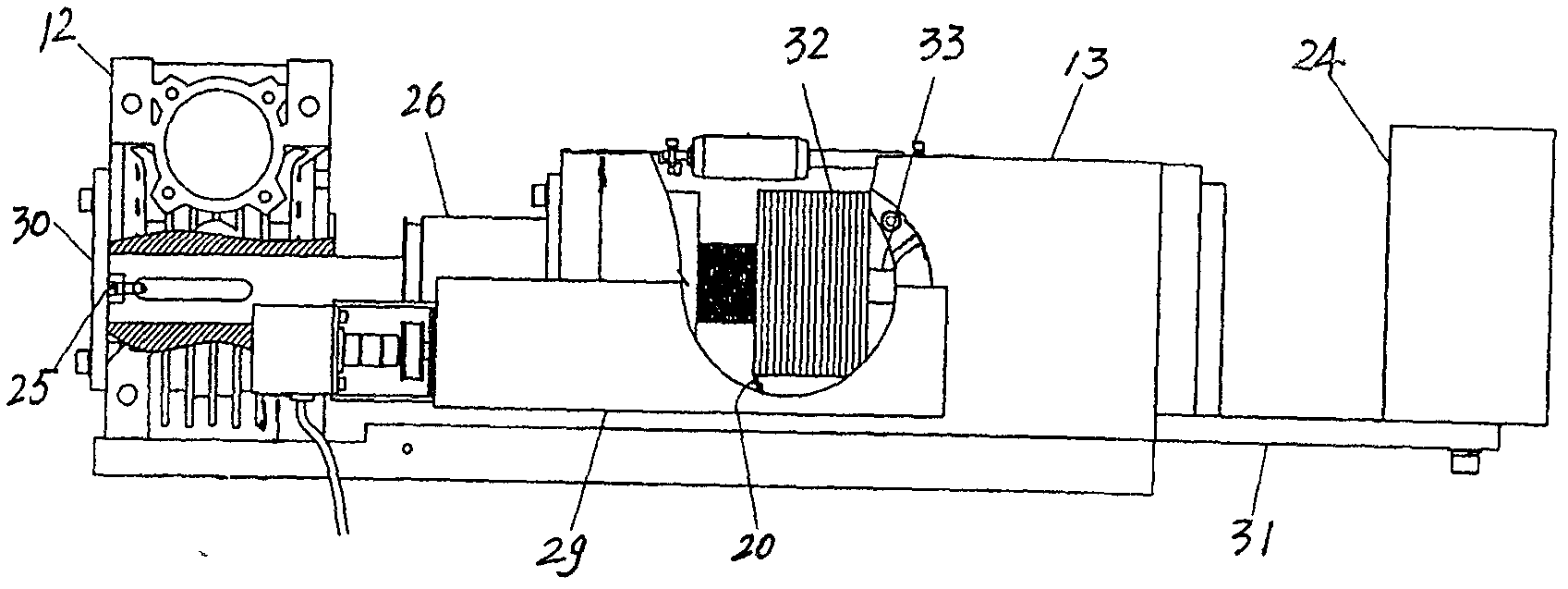

Seed crystal lifting device for Czochralski monocrystal furnace

InactiveCN102220635AReasonable structureEasy maintenanceBy pulling from meltCrystal rotationDrive shaft

A seed crystal lifting device for a Czochralski monocrystal furnace consists of a top cavity component, a lifting cavity component, a bipolar transmission and pulling transmission shaft, a clutch component, a quick motor, a slow motor, a Czochralski head limiting mechanism and a rotary component; the top cavity component comprises a top cavity, a top cover flange, a bearing pin, a surface bearing and a pulley component; the lifting cavity component comprises a lifting cavity, a clue pipe, a splined shaft and a crystal lifting magnetofluid; and the rotary component comprises a crystal lifting soleplate, a heavy punch, a slip ring, a crystal rotation drive motor, a worm and gear crystal rotation speed reducer and a crystal rotation magnetofluid. The seed crystal lifting device for a Czochralski monocrystal furnace has the advantages of reasonable structure, good seed crystal lifting stability and convenience for maintenance and use, and the like.

Owner:WENZHOU YONGTAI ELECTRIC

Ytterbium doped yttrium lanthanum calcium oxoborate laser crystal, producing method, and purpose

The invention discloses a laser crystal of ytterbrium doped calcium oxygen borate yttrium lanthanum, a preparation method and an application thereof. The invention relates to the field of an artificial crystal, in particular to a laser crystal of ytterbrium doped calcium oxygen borate yttrium lanthanum (Yb3+:Y<1-X>LaXCa4O(BO3)3), the preparation method and the application thereof. At a temperature of about 1500 DEG C, the invention, at a crystal rotation speed of 5 to 20 rotations per minute and a pulling rate of 0.5 to 2mm per hour, produce the crystal of Yb3+:Y<1-X>LaXCa4O(BO3)3 of high quality and larger dimension though a czochralski method. The crystal is a novel laser crystal, which can generate a laser output with a wavelength of about 1 micrometer. The crystal also has the frequency-doubled effect and can get blue-green laser output through a self-frequency-doubling or self-mixing nonlinear optical method. A solid laser made from the crystal can be applied in the fields such as spectroscopy, biomedicine, military science and etc.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

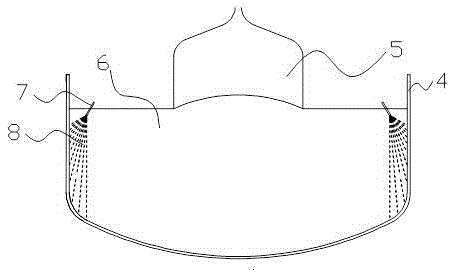

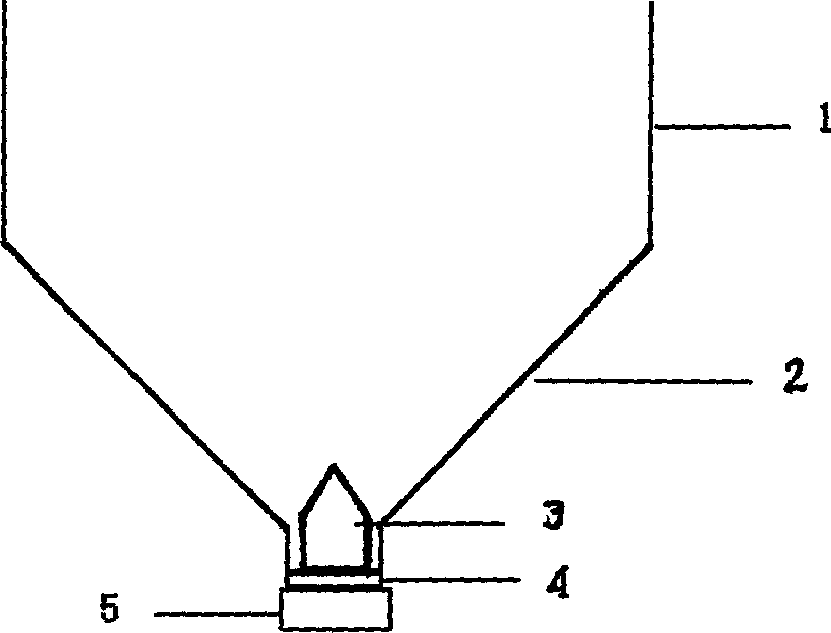

Crystal quick growth device using solution method

InactiveCN1884632ATemperature has no effectFast growthFrom normal temperature solutionsSolution crystallizationAutomatic controlCrystal rotation

This invention relates to a kind of rapid growth device of crystal by solution method. It composed of side Infra- red heating light, growth container, crystal rotation device and temperature automatic control system. The growth container includes column wall, taper wall, taper top glass column, round bottom, and bottom heating plate. On bottom of growth container or taper top, there is flat-bottomed round bottom, on which is the solid taper glass column which is located at the center of flat bottom. The crystal is grew on lower part of growth container. The outside of bottom is the heating board with same area and shape. On the bottom of growth container is the taper wall that concentrate the secondary nucleation of crystal during its growth to its bottom under the influence of gravitation and solution convection. On top of the taper wall is the column wall connected and sealed with it. It is simple, cheap, and easy to use and the crystal is fast grew and has good quality.

Owner:QINGDAO UNIV

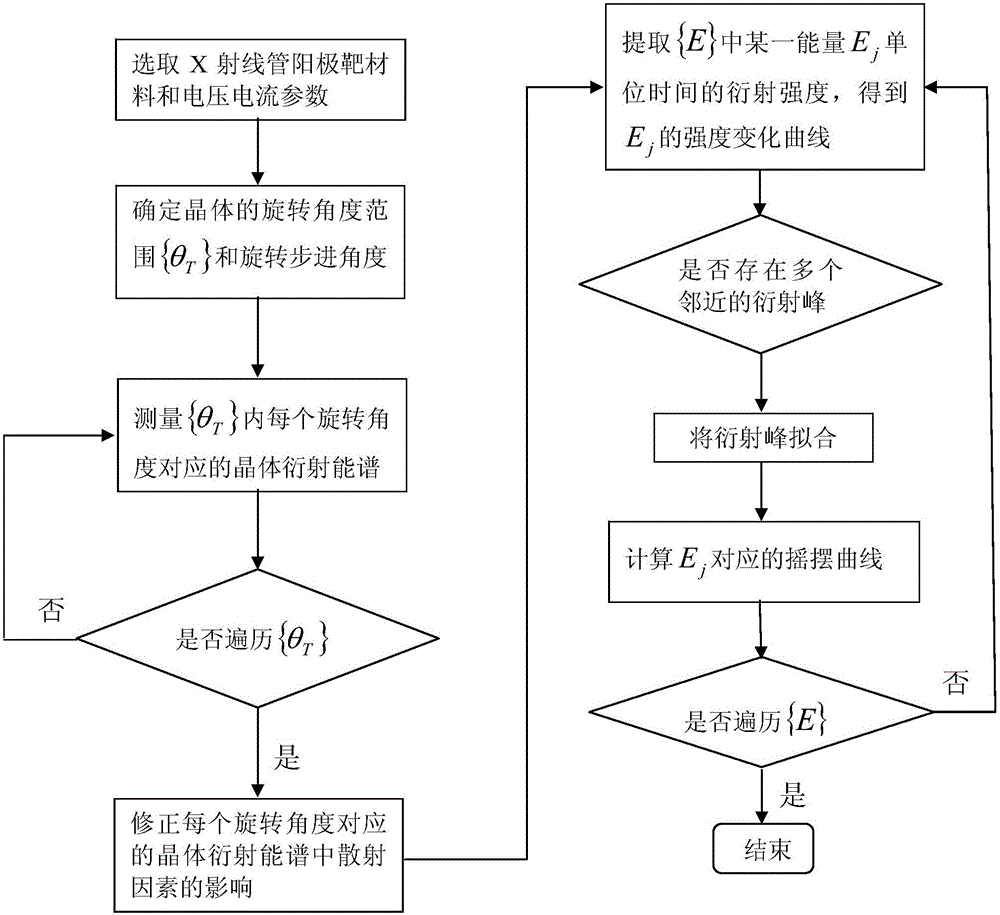

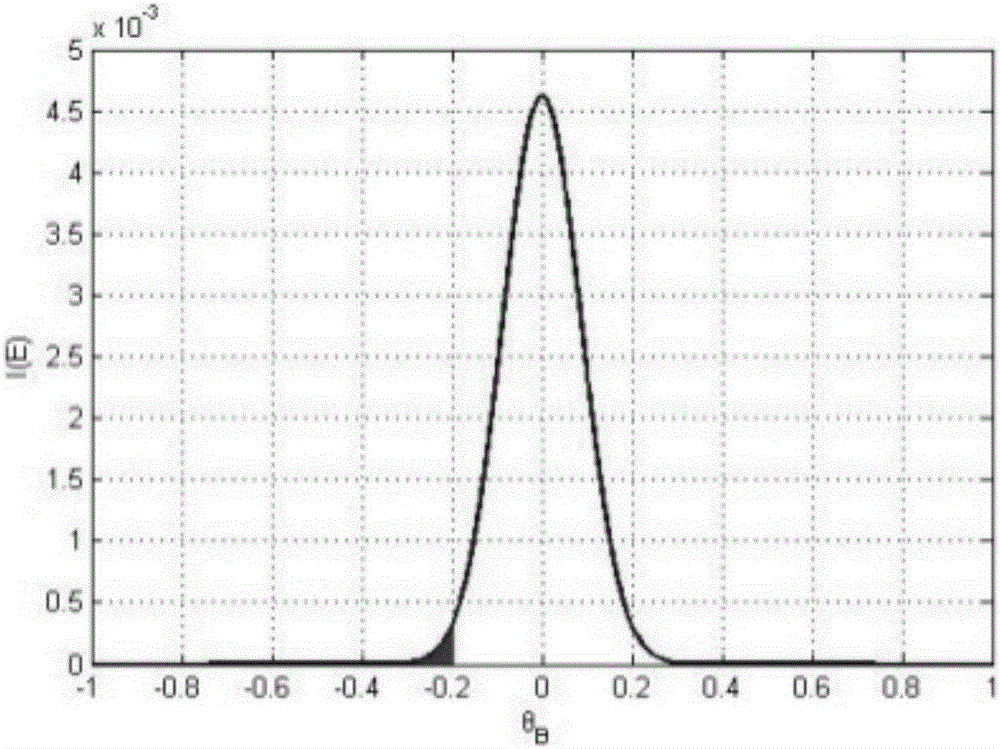

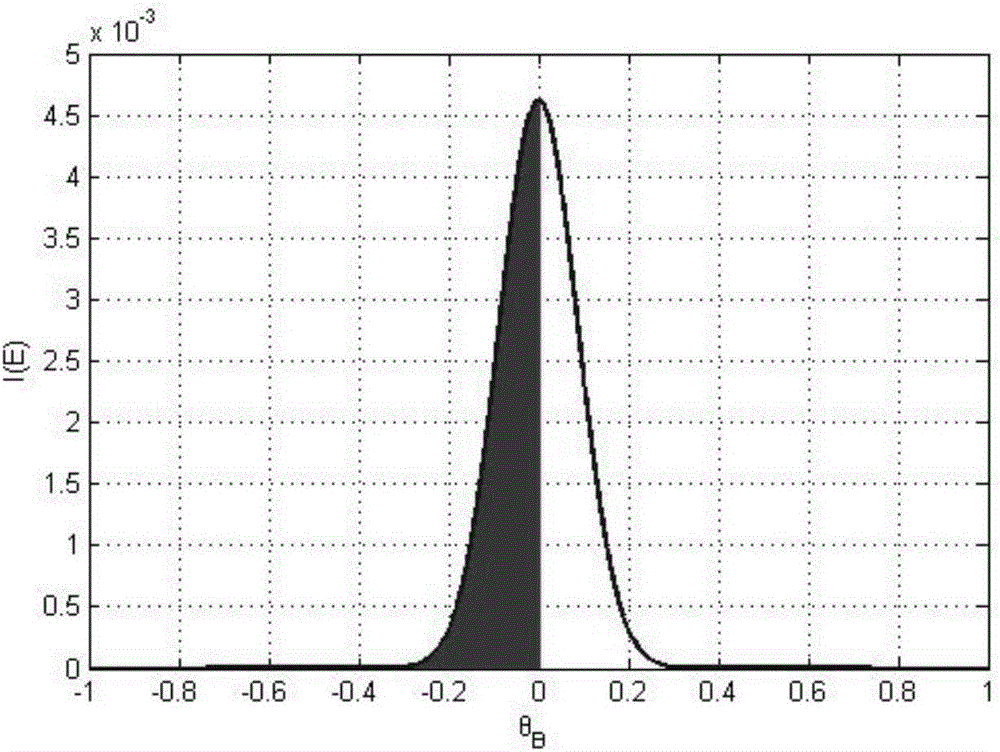

Crystal rocking curve measurement method based on energy resolution detector

InactiveCN105866151AExtended energy rangeRealize measurementMaterial analysis using wave/particle radiationRocking curveLattice plane

The invention relates to a crystal rocking curve measurement method based on an energy resolution detector, comprising the steps of 1, selecting an X-ray tube anode target material and voltage / current parameters based on an X-ray energy range {E} for measurement; 2, determining a Bragg diffraction angle range {theta B}, a crystal rotation angle range {theta T} and a rotation stepping angle; 3, measuring a crystal diffraction energy spectrum of each rotation angle within the {theta T}; 4, correcting the effect of scattering factors in the crystal diffraction energy spectrums; 5, extracting the diffraction strength of X-ray of energy Ej in {E} within a unit interval when theta Ti = theta Bi, so as to obtain a strength variation curve of Ej; 6, performing diffraction peak fitting on the strength variation curve; 7, figuring out a first-order derivative of a fitted diffraction peak, selecting absolute values of a part of the diffraction peak where the slope of the first-order derivative is not less than 0, i.e., the left and right branches of a rocking curve, and splicing to obtain the rocking curve of Ej; 8, repeating steps 5-7 until {E} is traversed, thereby obtaining the rocking curve of the X ray of all energies in {E} to a certain lattice plane of a crystal.

Owner:NORTHWEST INST OF NUCLEAR TECH

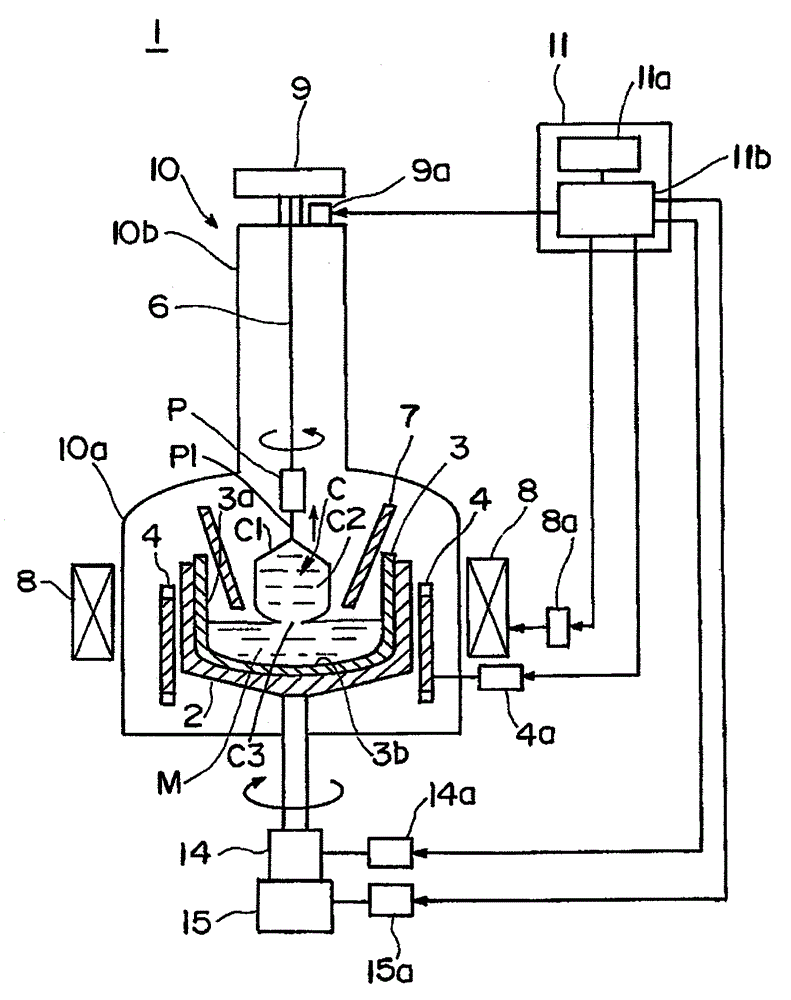

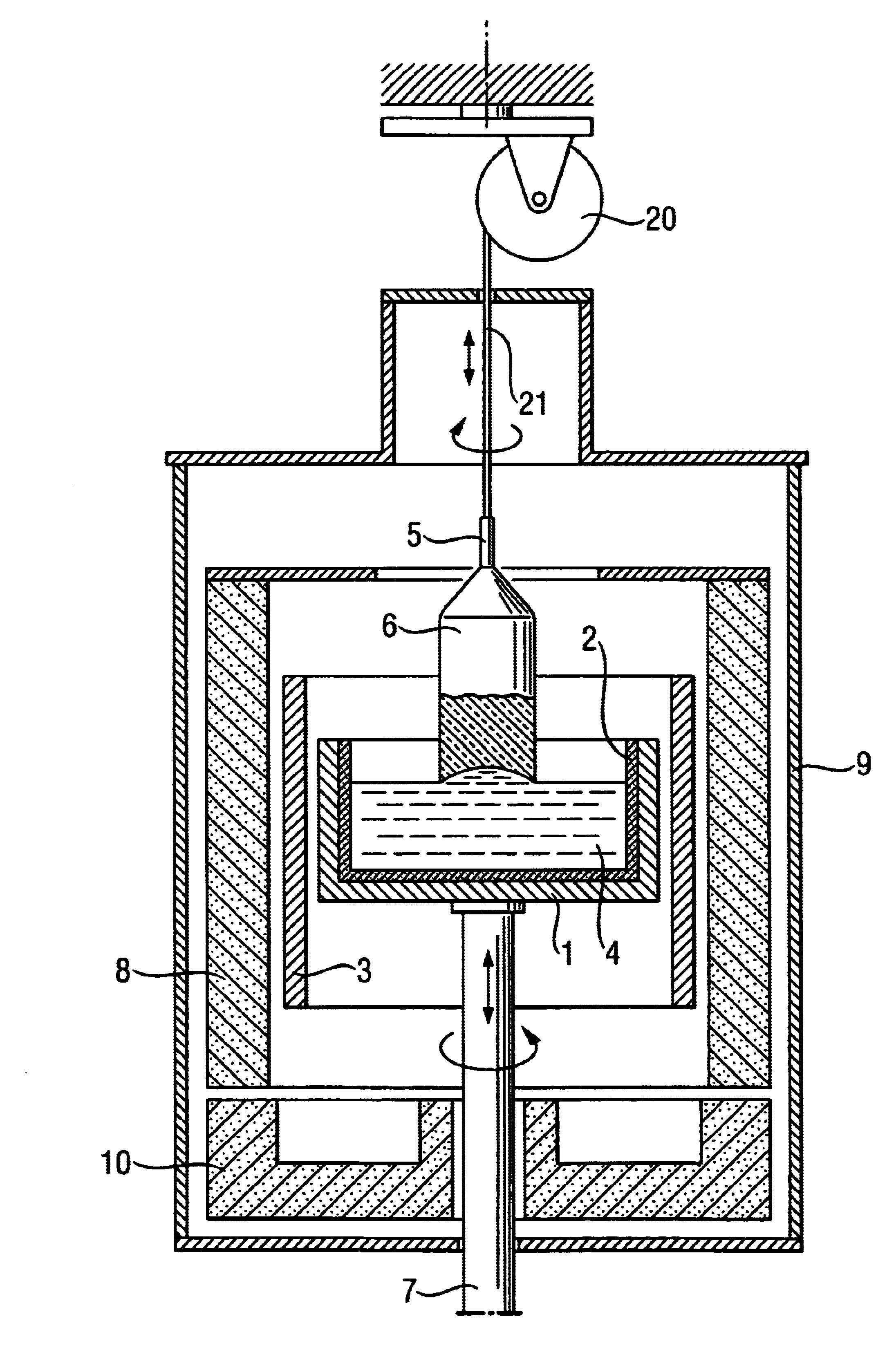

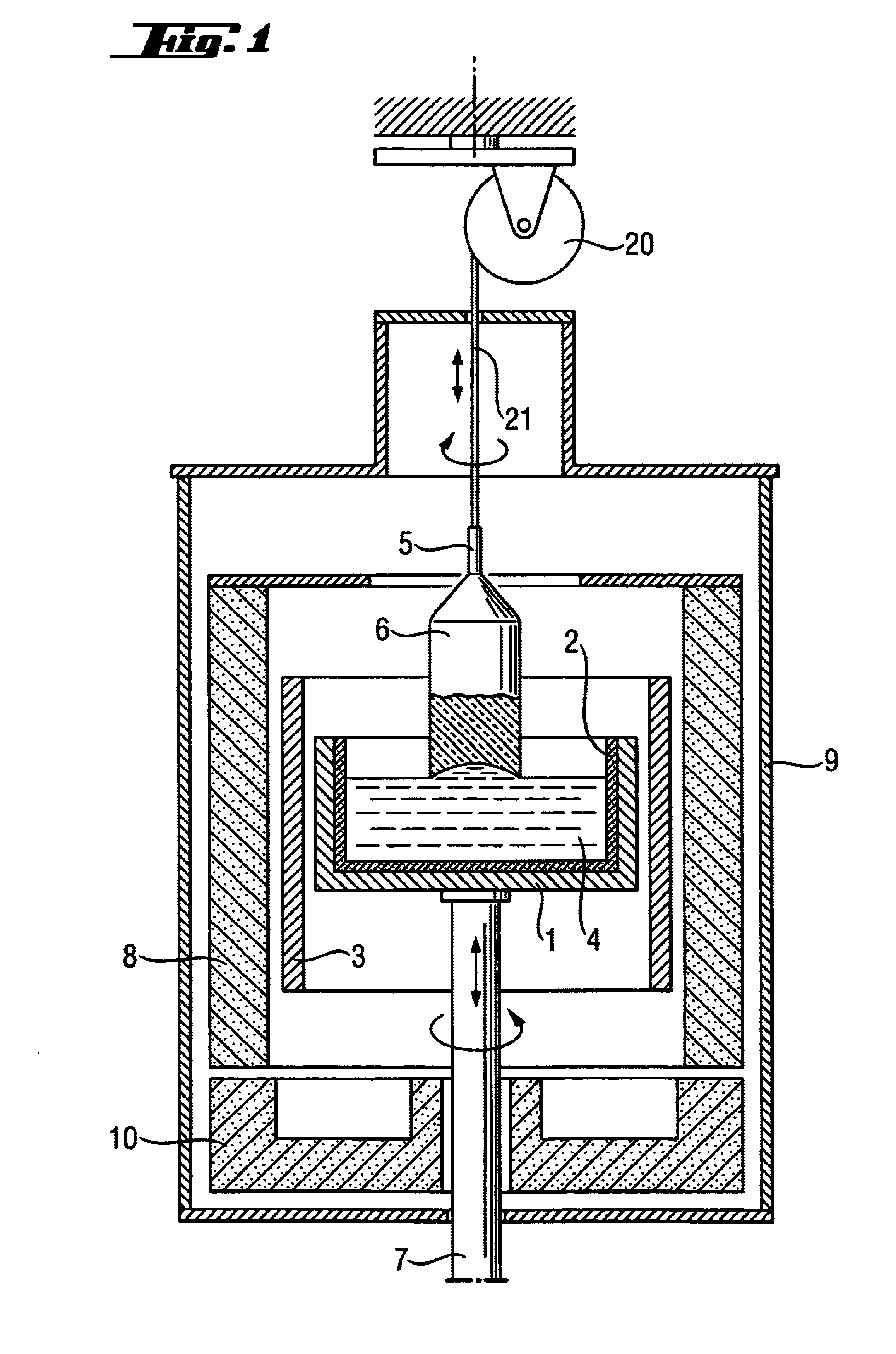

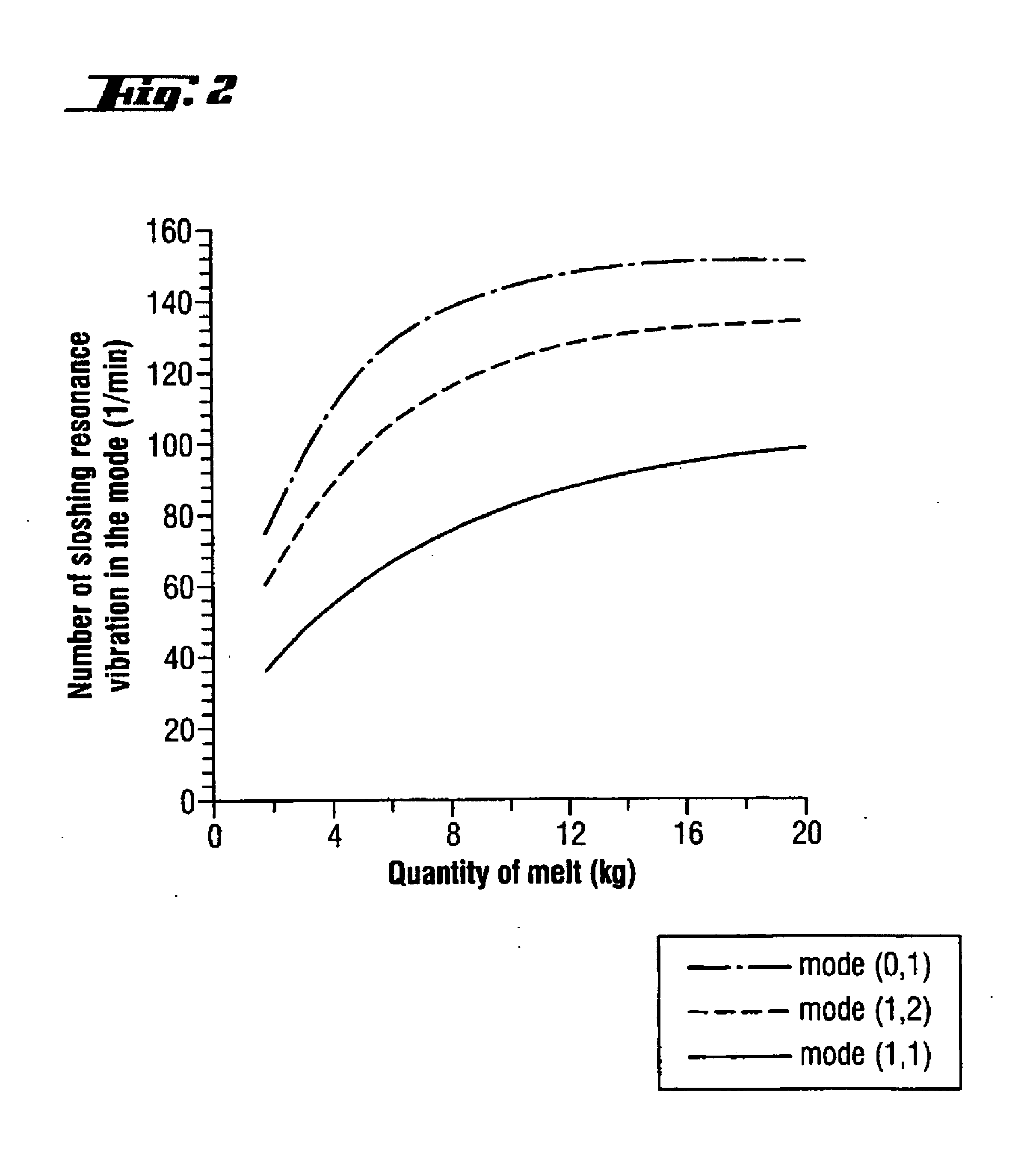

Single crystal production method

InactiveUS6899759B2Improve production yieldPreventing numberPolycrystalline material growthBy pulling from meltCrystal rotationCrucible

A single crystal production method based on the Czochralski method comprises controlling a number of crucible rotations and crystal rotations so that a number of vibrations for driving a melt, determined on the basis of the number of crucible and crystal rotations during a single crystal growing procedure, is outside a range from 95% to 105% of a number of sloshing resonance vibrations of the melt. In another embodiment, the method comprises controlling a number of rotations of a crystal and crucible, so that when a number of vibrations for driving a melt, determined by the number of crucible and crystal rotations during a single crystal growing procedure, is within a range from 95% to 105% of a number of sloshing resonance vibrations of the melt, the number of vibrations of the melt due to sloshing does not exceed 2000 times during a period when the number of vibrations is within that range.

Owner:SILTRONIC AG

Shoulder-lifting edulcoration method in monocrystal production process

InactiveCN102212872AEasy to stickIncrease surface areaPolycrystalline material growthBy pulling from meltCrystal rotationSingle crystal

The invention relates to a shoulder-lifting edulcoration method in a monocrystal production process, and the method comprises the following steps: after one or two shoulders are lifted in the monocrystal production process, keeping the power value of a monocrystal furnace at shouldering power; amplifying the shoulder of which the edge is removed; automatically equalizing the diameter of 4-9cm; then, exiting an automatic isodiametric state, and changing into a manual state; increasing the power value to 60-90 kilowatts; keeping crystal rotation at 1-3 revolutions per minute and crucible rotation at 1-3 revolutions per minute; carrying out back melting on isodiametric polycrystal of which the length is 4-9 cm; after melting 50-70% of crystal, lowering the power value to 40-60 kilowatts; and slowly melting the crystal into a 'peach shape'. According to the shoulder-lifting edulcoration method, the crystal is melted from top to bottom so as to be slowly melted into a 'peach shape' which is easy to adsorb a great quantity of impurities, thereby playing a role in purifying a silicon fusant. According to the shoulder-lifting edulcoration method, shoulder lifting times are reduced, and the purposes of improving the monocrystal finished product rate and improving the production efficiency are achieved.

Owner:ZHEJIANG XINGYU ENERGY TECH

Blended ytterbium boric acid Gd yttrium oxygen calcium self-frequency doubling laser crystal

InactiveCN1609287AQuality improvementHigh quality high qualityPolycrystalline material growthActive medium materialCrystal rotationRefractive index

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

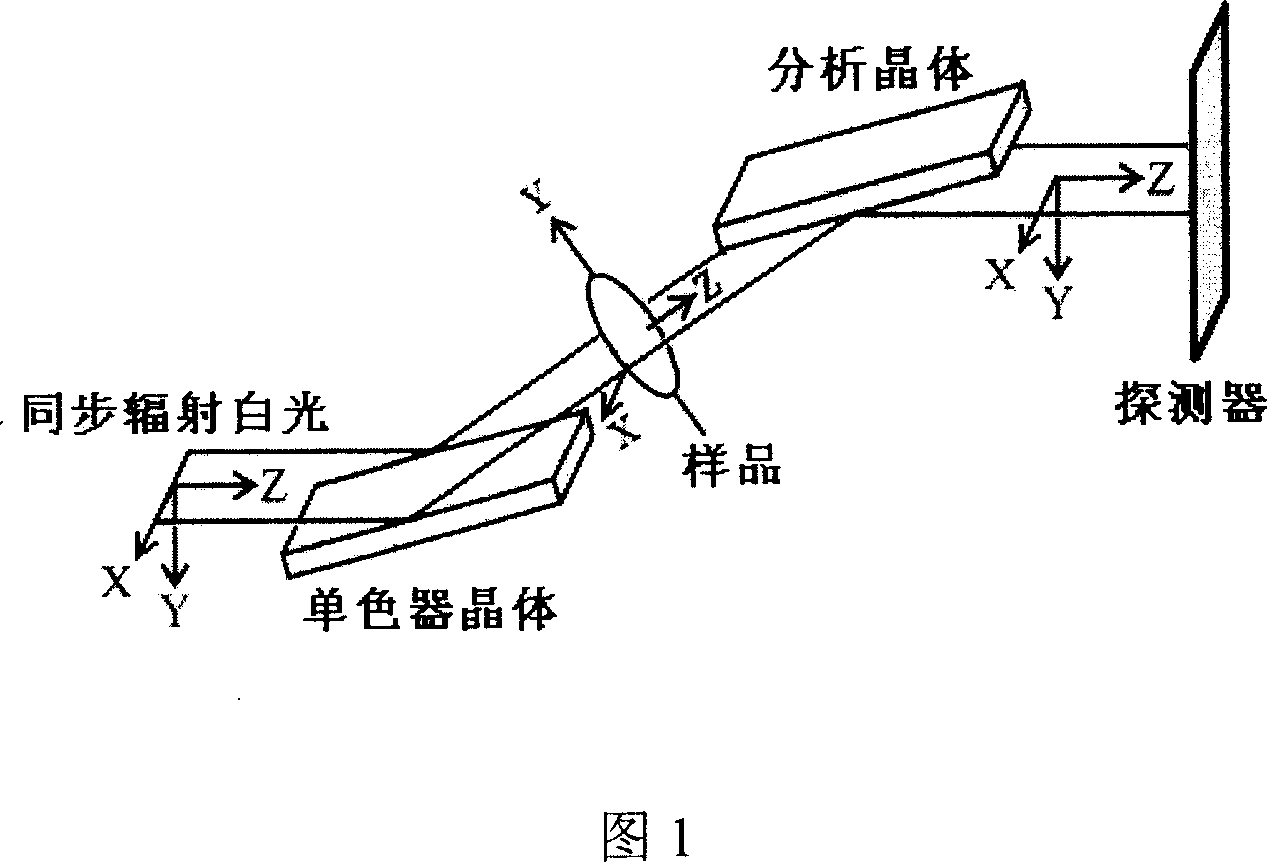

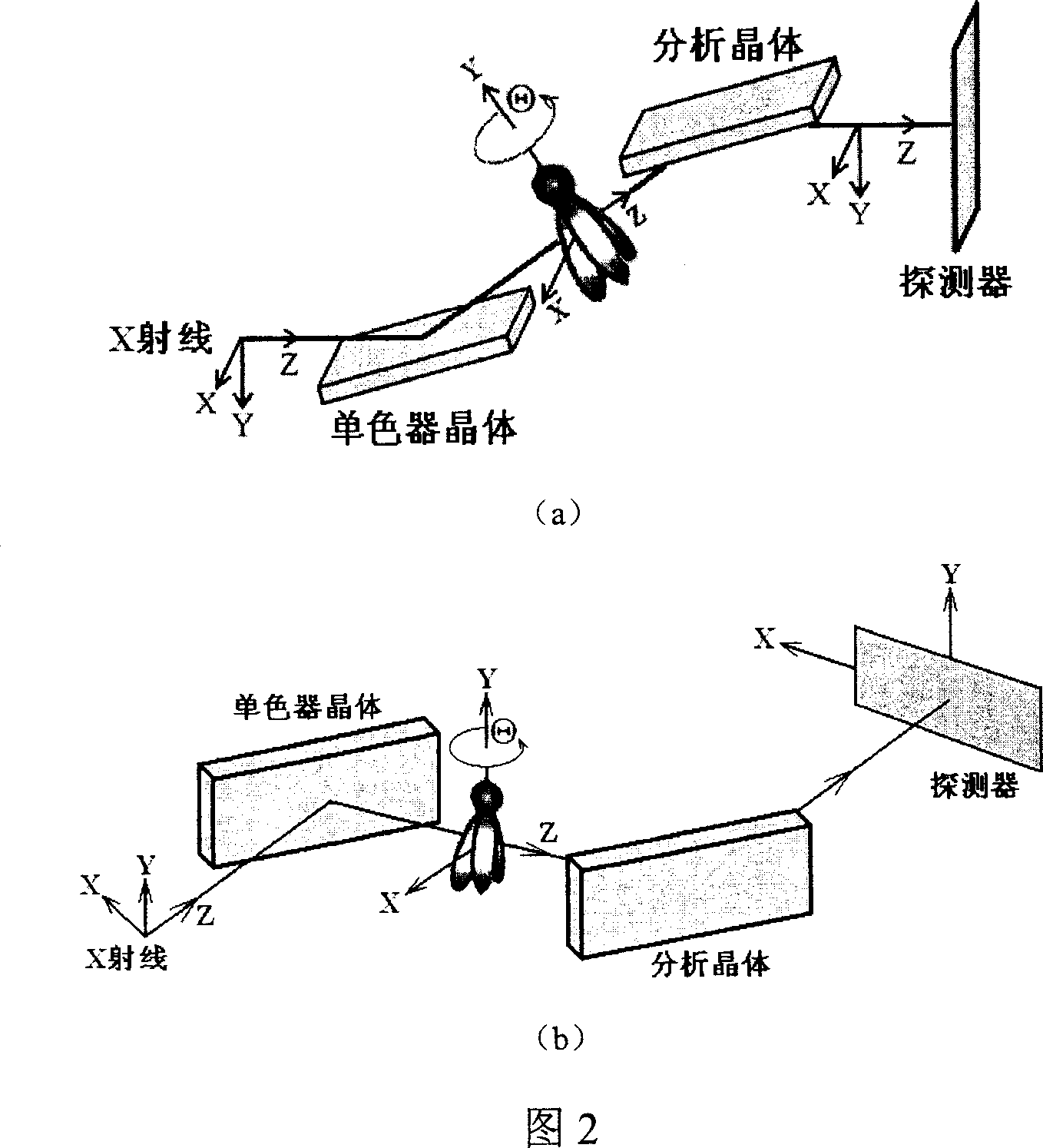

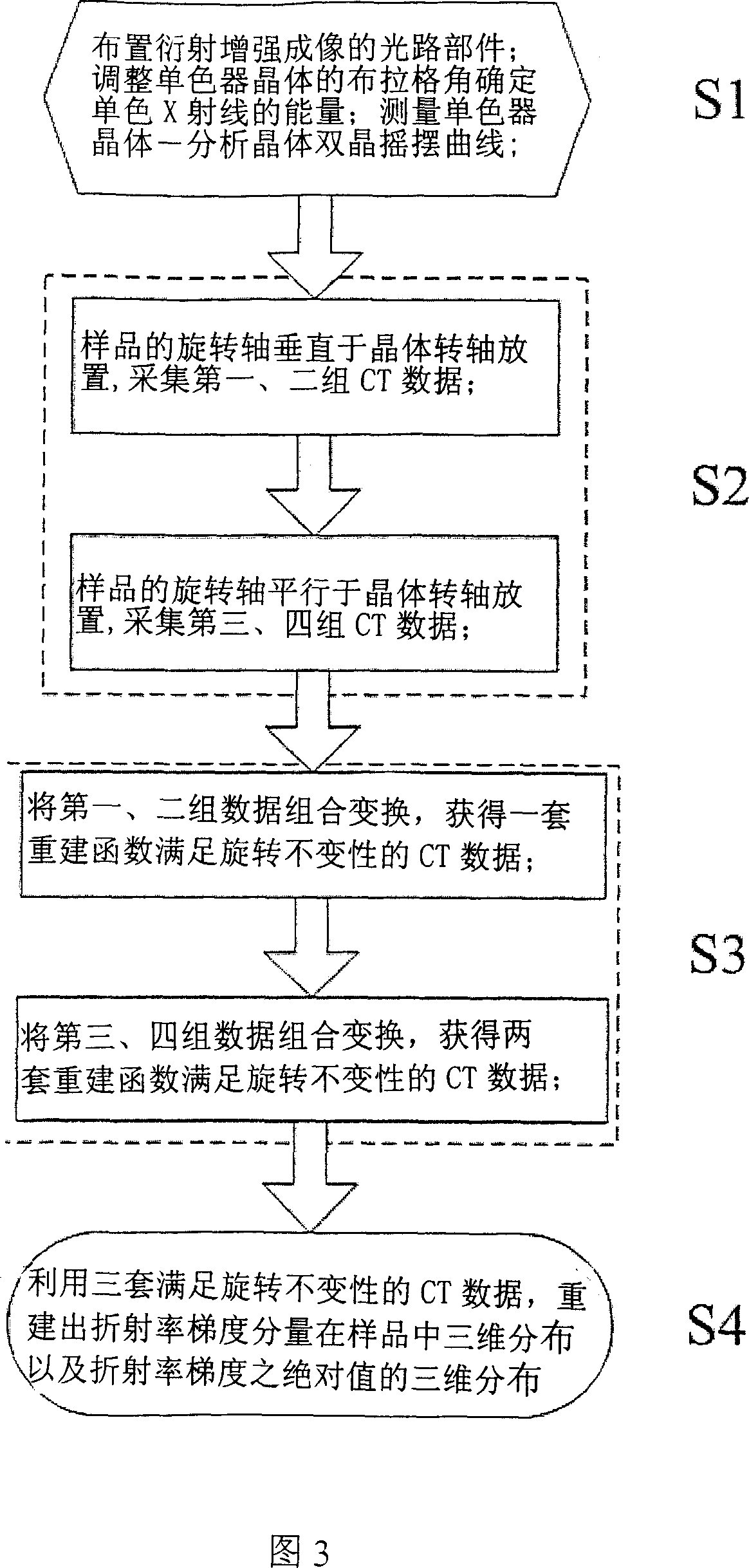

X-ray refractive-contrasting CT data collection method and reconstruction method

InactiveCN1965761AMaterial analysis using wave/particle radiationComputerised tomographsImaging conditionCrystal rotation

The invention relates to a computer imaging technique, especially an X-ray CT data collecting method and rebuilding method, wherein the invention uses diffraction strengthen waist imaging method to use two methods that sample rotation axle is vertical to crystal rotation axle and sample rotation axle is parallel to the crystal rotation axle, to combine and convert collected four groups of CT data, to make rebuild function meet rotation constant property, and use traditional CT method to rebuild the three-dimension distribution of three refractive indexes. And said method comprises that: S1, finding the conditions of X-ray diffraction strengthen waist image; S2, collecting four groups of CT data; S3, combining and converting CT groups, to meet rotation constant property; S43, using traditional CT method to rebuild the three-dimension distribution of refractive indexes in sample.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Continuous pulling monocrystalline silicon growth method

ActiveCN109972200AReduce uninterrupted feedingImprove continuityPolycrystalline material growthBy pulling from meltSemiconductor materialsCrucible

The invention provides a continuous pulling monocrystalline silicon growth method, and belongs to the field of semiconductor material preparation, wherein the method comprises the steps of material melting, stabilization, neck guiding, shoulder releasing, shoulder rotating, equal diameter and tail ending, wherein the material melting power is gradually increased and heated in the early stage, thematerial melting power in the medium stage is kept at the stable power, and the material melting power is reduced in the later stage; the rotating directions of crystal rotation and pan rotation are opposite in the stabilization process, the temperature of a thermal field is adjusted to the neck guiding temperature, and a feeding device is kept in a feeding state; the crystal growth speed is reduced in the shoulder releasing process, the feeding device is in the feeding state, and the feeding amount is gradually increased; the shoulder rotating process is increased on the basis of the shoulderreleasing; the given temperature in the early stage of the equal diameter process, and the temperature is controlled, and the temperature is reduced in the early stage. According to the continuous pulling monocrystalline silicon growth method, the feeding amount in the crystal growth crucible can be reduced, the continuous feeding of the monocrystalline furnace is achieved, the secondary feedingtime is reduced, the synchronous feeding and crystal growth are achieved, the initial crystal growth crystal source in the crucible is less, and the resistivity distribution is more uniform.

Owner:XINGTAI JINGLONG ELECTRONICS MATERIAL +1

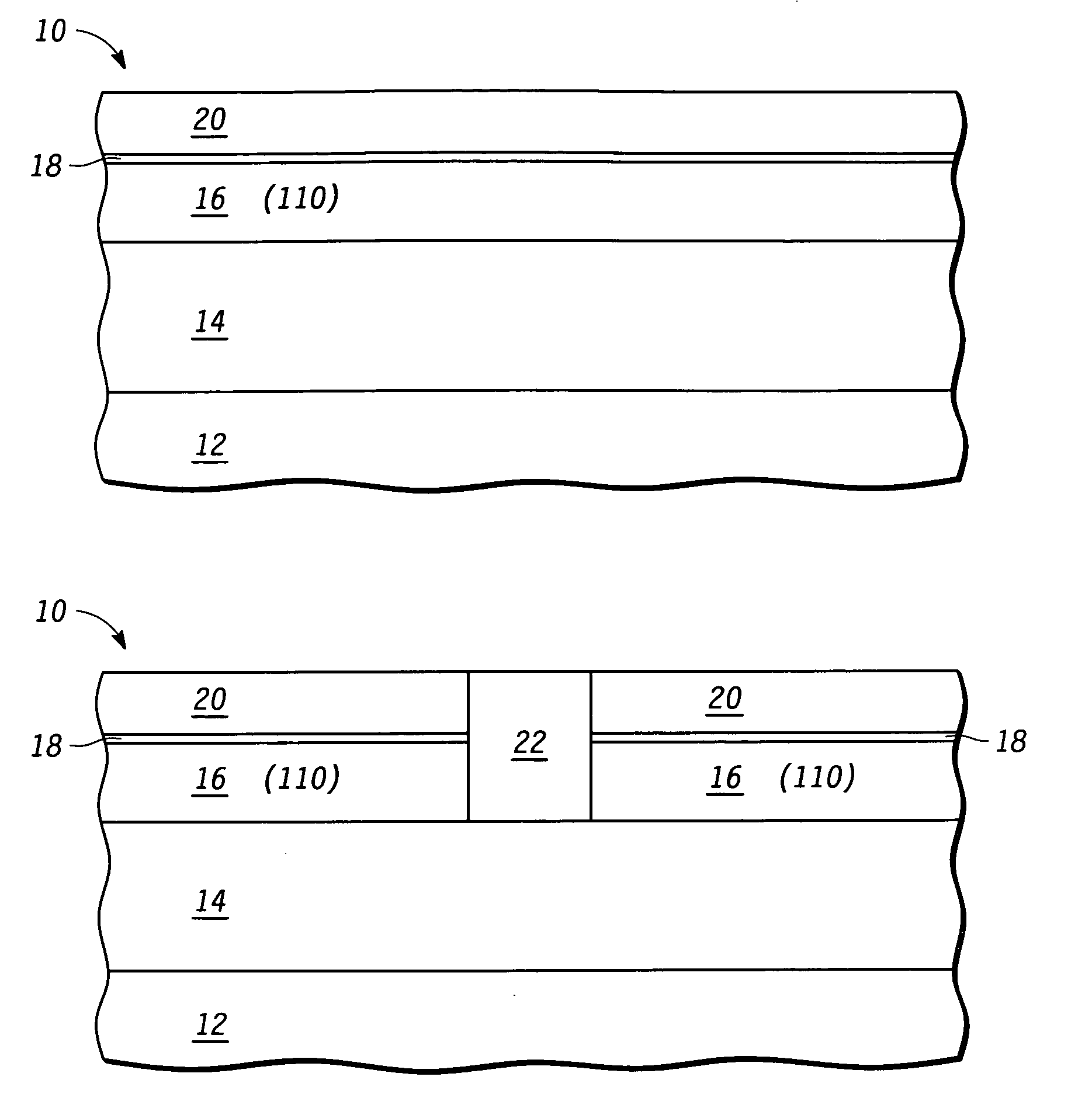

Method to selectively form regions having differing properties and structure

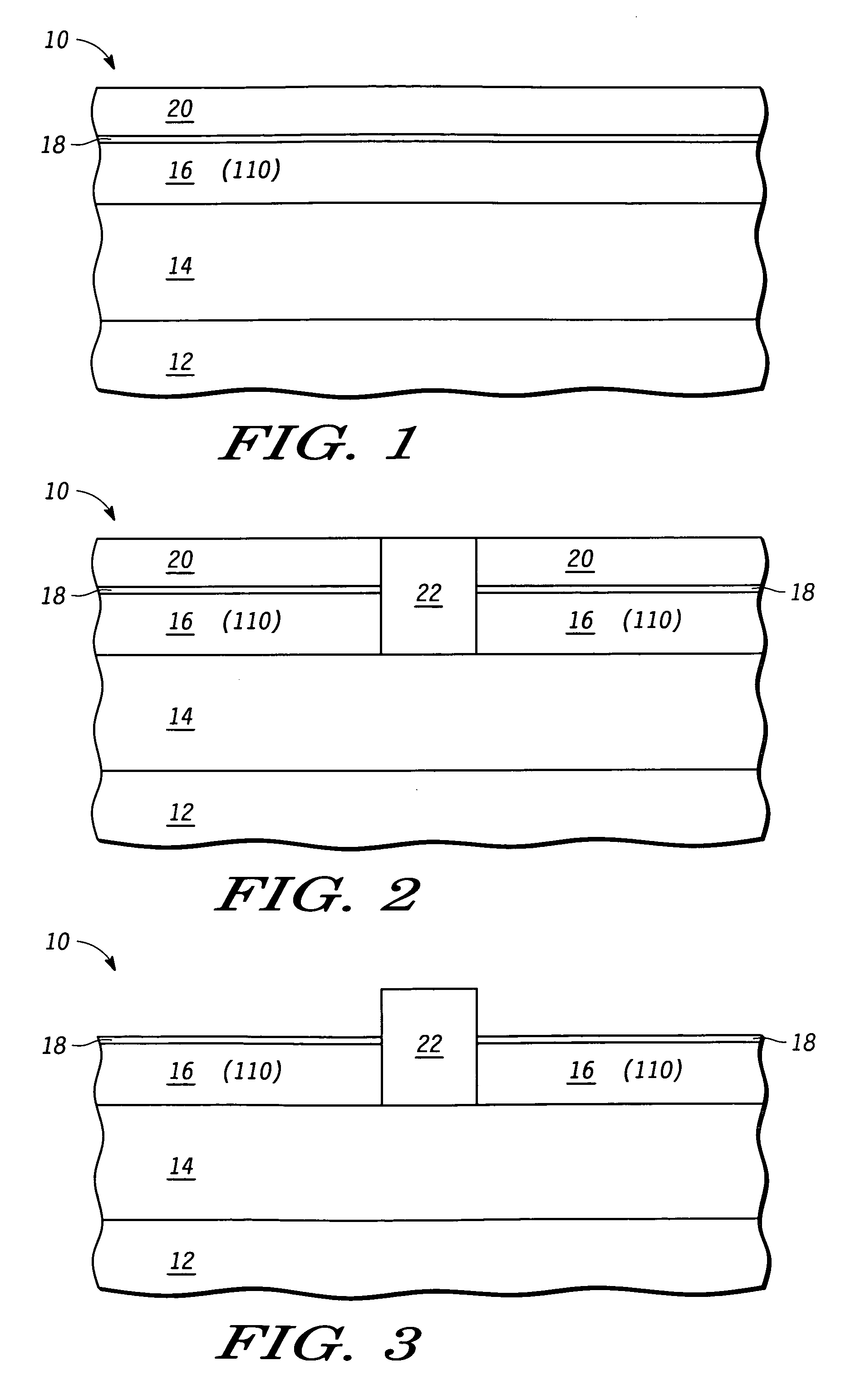

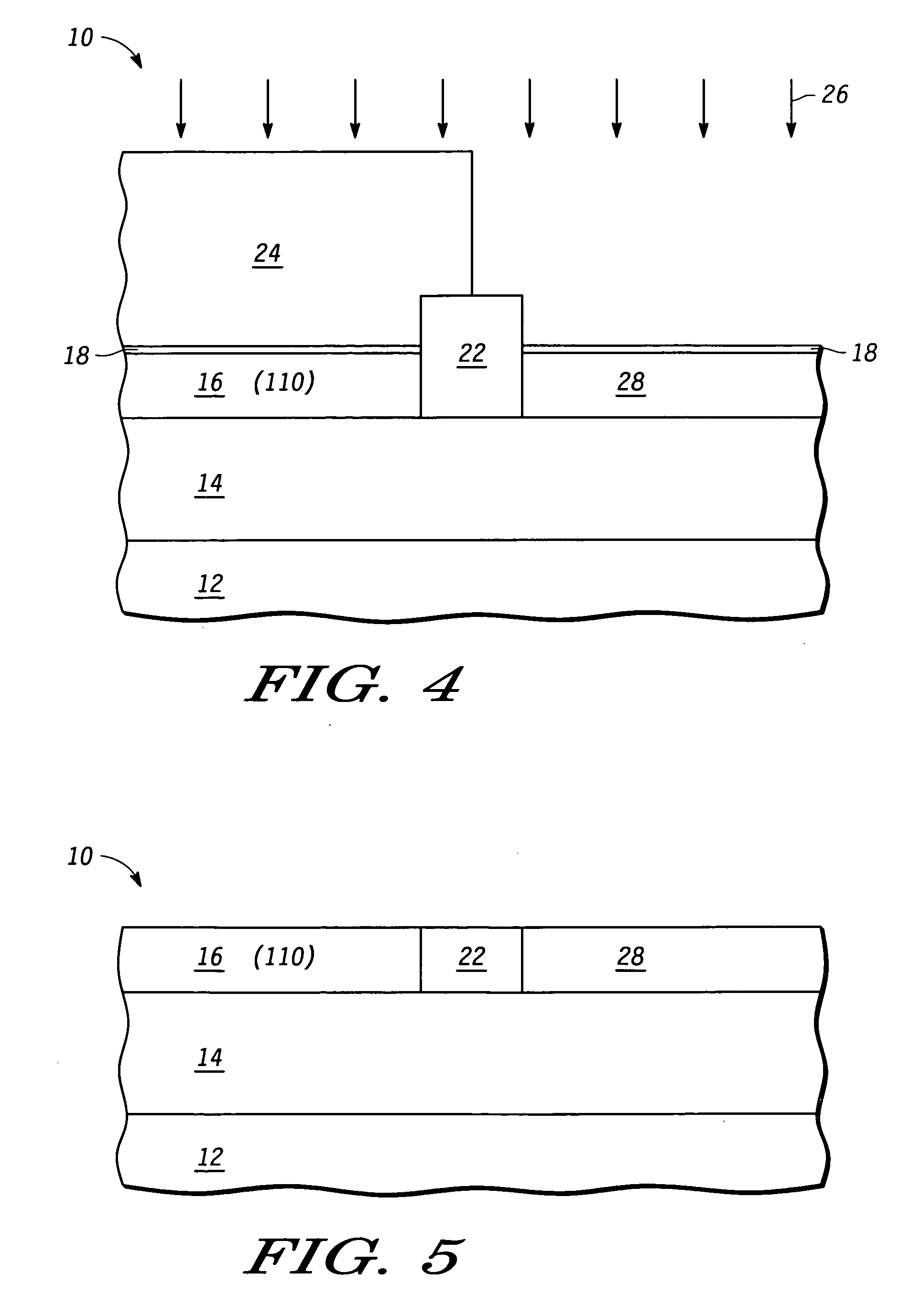

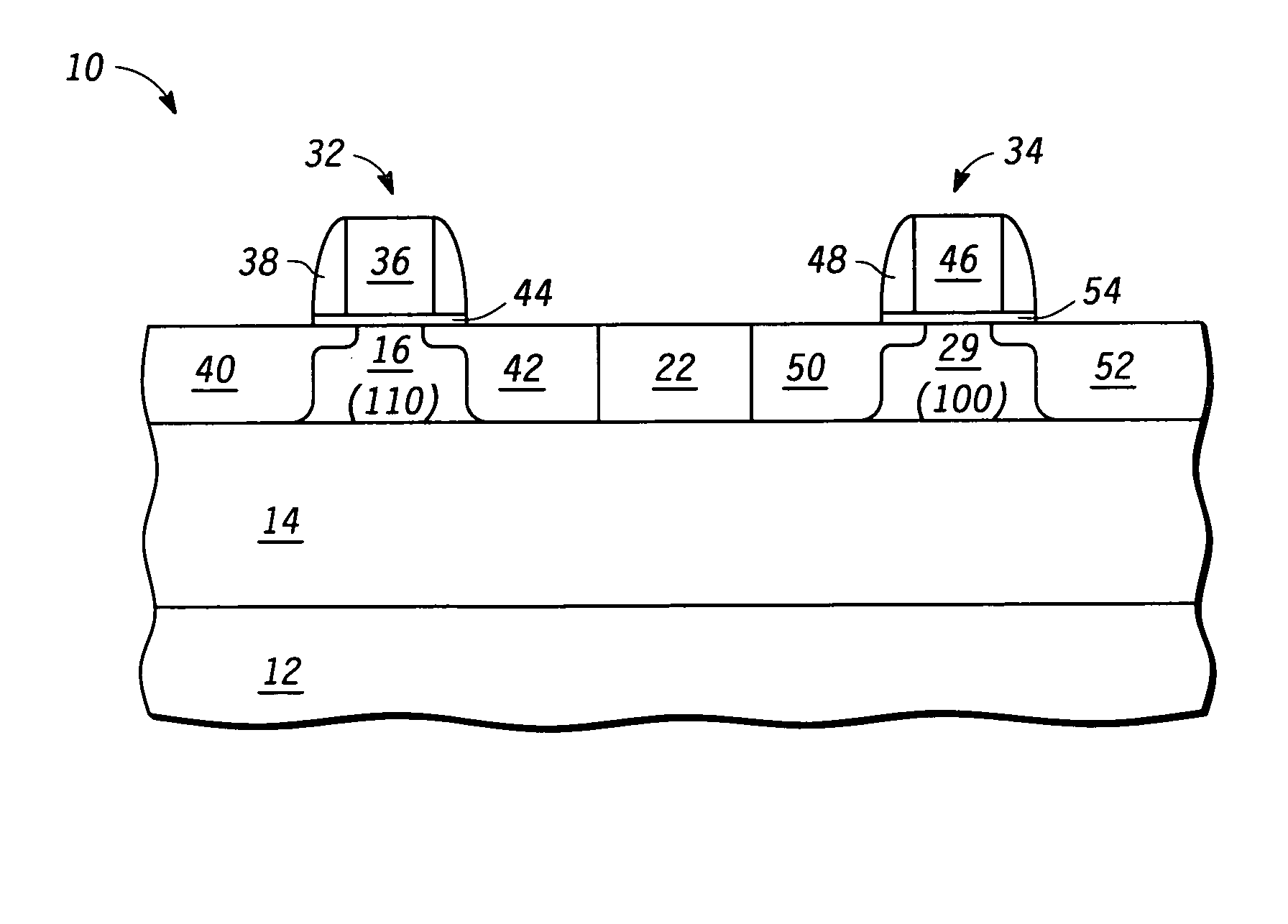

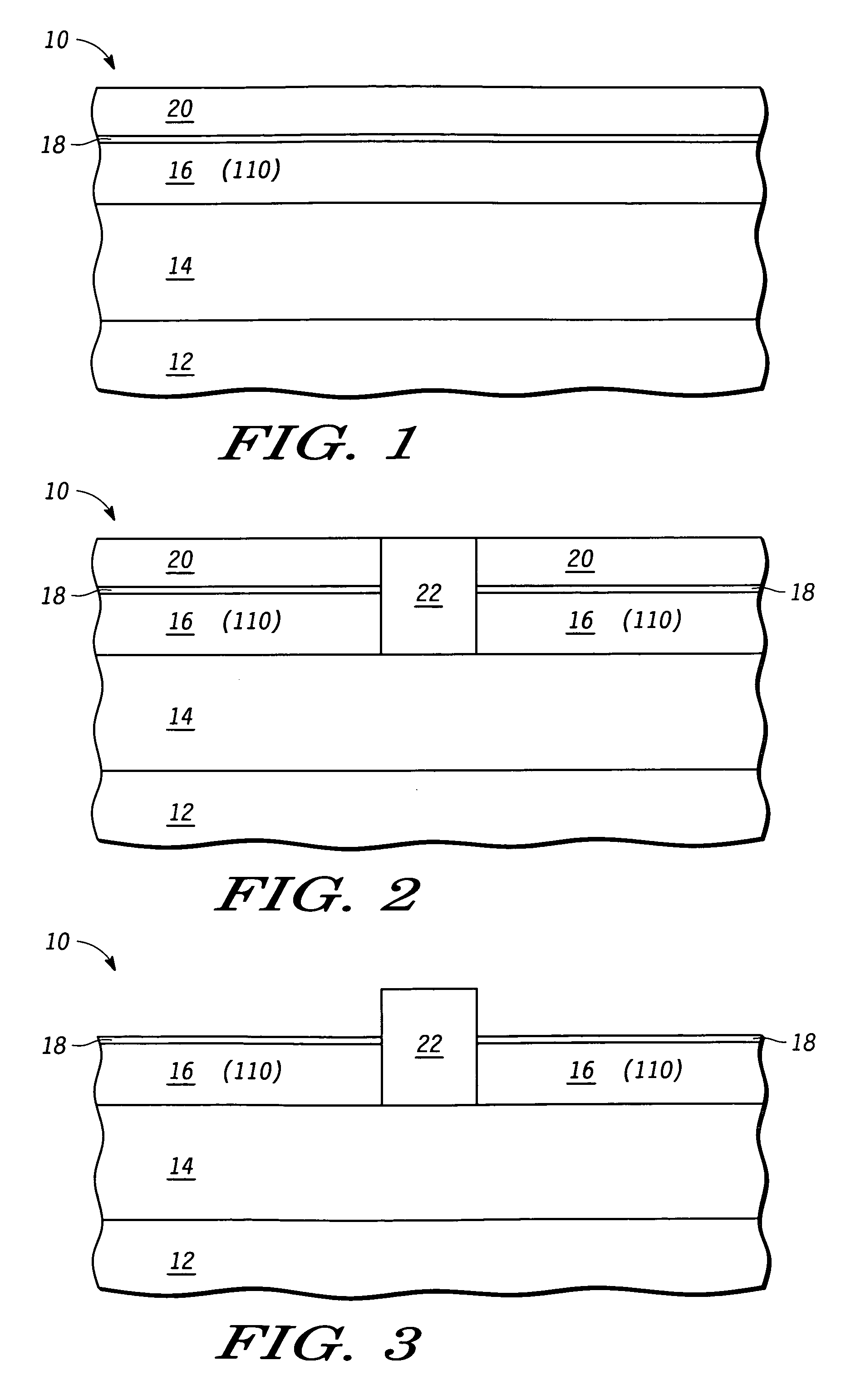

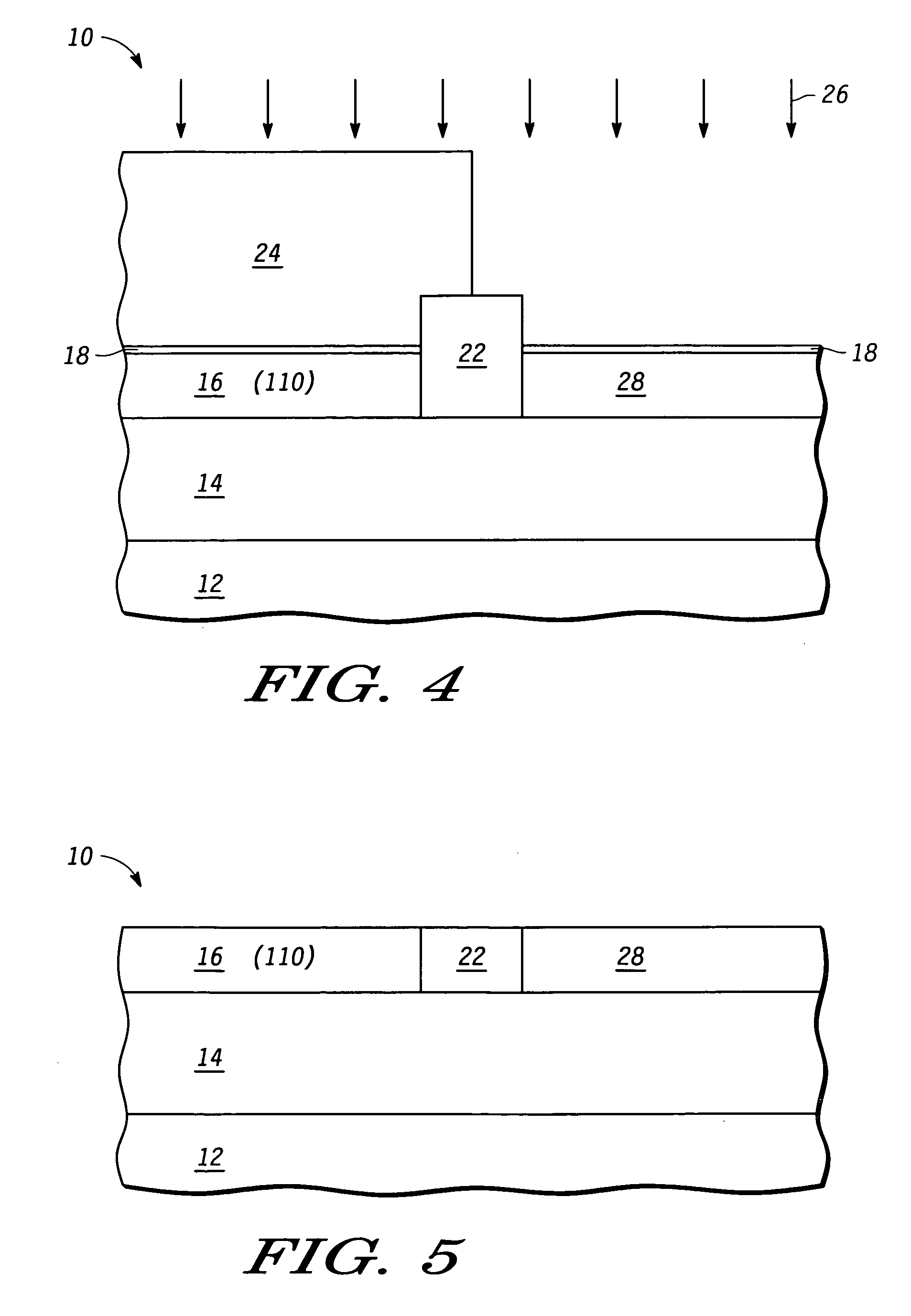

InactiveUS20070190745A1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureCrystal rotation

A semiconductor device is formed having two physically separate regions with differing properties such as different surface orientation, crystal rotation, strain or composition. In one form a first layer having a first property is formed on an insulating layer. The first layer is isolated into first and second physically separate areas. After this physical separation, only the first area is amorphized. A donor wafer is placed in contact with the first and second areas. The semiconductor device is annealed to modify the first of the first and second separate areas to have a different property from the second of the first and second separate areas. The donor wafer is removed and at least one semiconductor structure is formed in each of the first and second physically separate areas. In another form, the separate regions are a bulk substrate and an electrically isolated region within the bulk substrate.

Owner:NXP USA INC

Method to selectively form regions having differing properties and structure

InactiveUS7285452B2Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureCrystal rotation

A semiconductor device is formed having two physically separate regions with differing properties such as different surface orientation, crystal rotation, strain or composition. In one form a first layer having a first property is formed on an insulating layer. The first layer is isolated into first and second physically separate areas. After this physical separation, only the first area is amorphized. A donor wafer is placed in contact with the first and second areas. The semiconductor device is annealed to modify the first of the first and second separate areas to have a different property from the second of the first and second separate areas. The donor wafer is removed and at least one semiconductor structure is formed in each of the first and second physically separate areas. In another form, the separate regions are a bulk substrate and an electrically isolated region within the bulk substrate.

Owner:NXP USA INC

Single crystal growth method of monopotassium phosphate with large caliber and high quality

InactiveCN101775651AIncrease growth successFast downward growthPolycrystalline material growthFrom normal temperature solutionsCrystal rotationRoom temperature

The invention relates to a single crystal growth method of monopotassium phosphate with large caliber and high quality, comprising the following steps: when seed crystal forms a cone, initial growth temperature lowers to the temperature of 0.5 DEG C below solution saturating point, and cone forming begins; cooling rate is controlled at 0.05 DEG / day; the mode of cooling by stage is adopted after the seed crystal is in phragmocone; the crystal is in phragmocone until 50 DEG C; cooling rate is kept to 0.05 DEG C / day; at the temperature of 50-35 DEG C, cooling rate is kept to 0.1 DEG C / day; at the temperature of 35 DEG C to room temperature, cooling rate is kept to 0.15 DEG C / day; a crystal rotation mode adopts the following circulation sequence: quickening, positive rotating, slowing down, stalling, quickening, reverse rotating, slowing down and stalling; seed crystal rotates at time interval as follows: 20 seconds, 60 seconds, 20 seconds, 20 seconds, 20 seconds, 60 seconds, 20 seconds and 20 seconds; and the positive rotating rate and the reversal rate are kept to 40-60 turns / minute.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

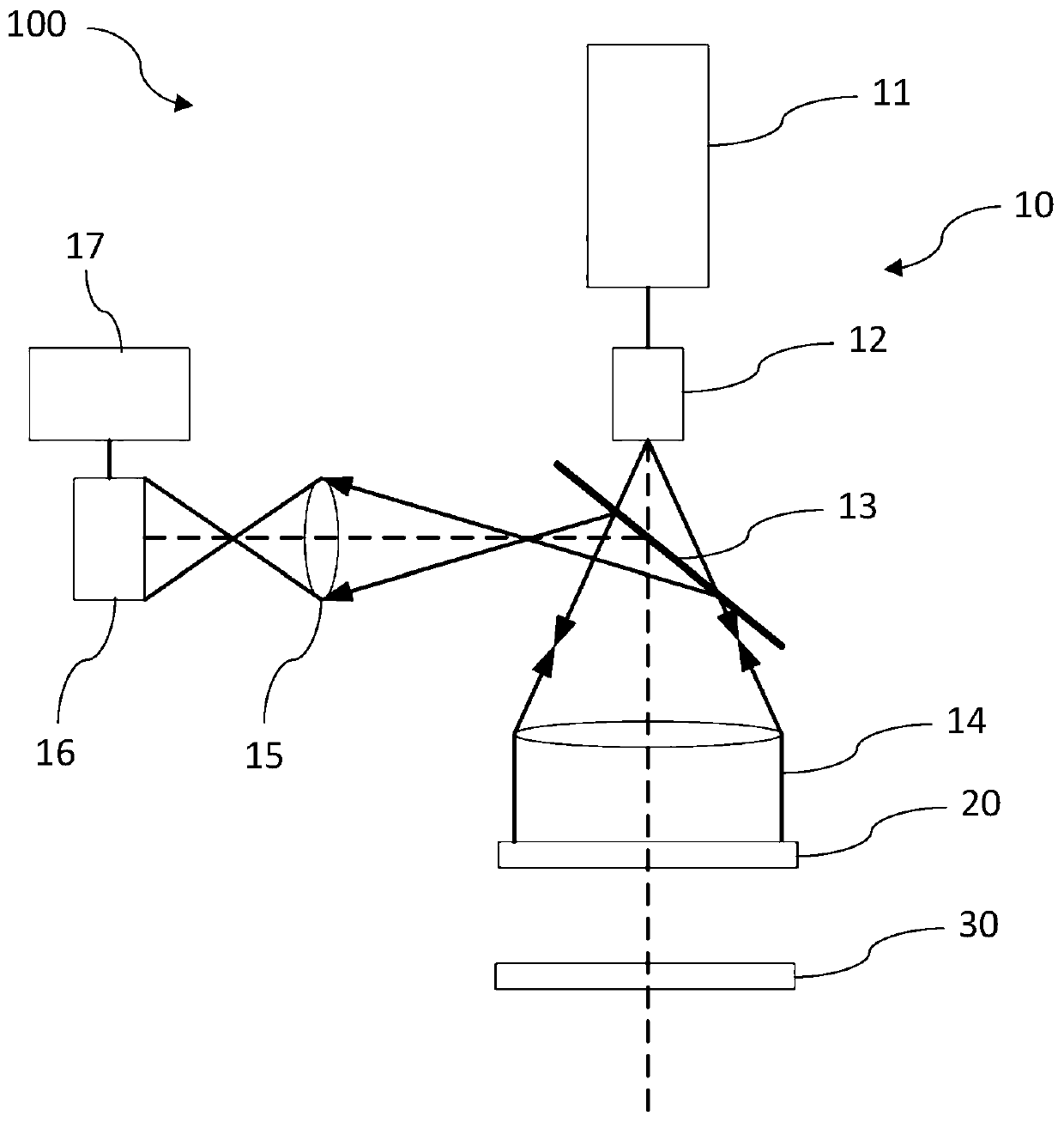

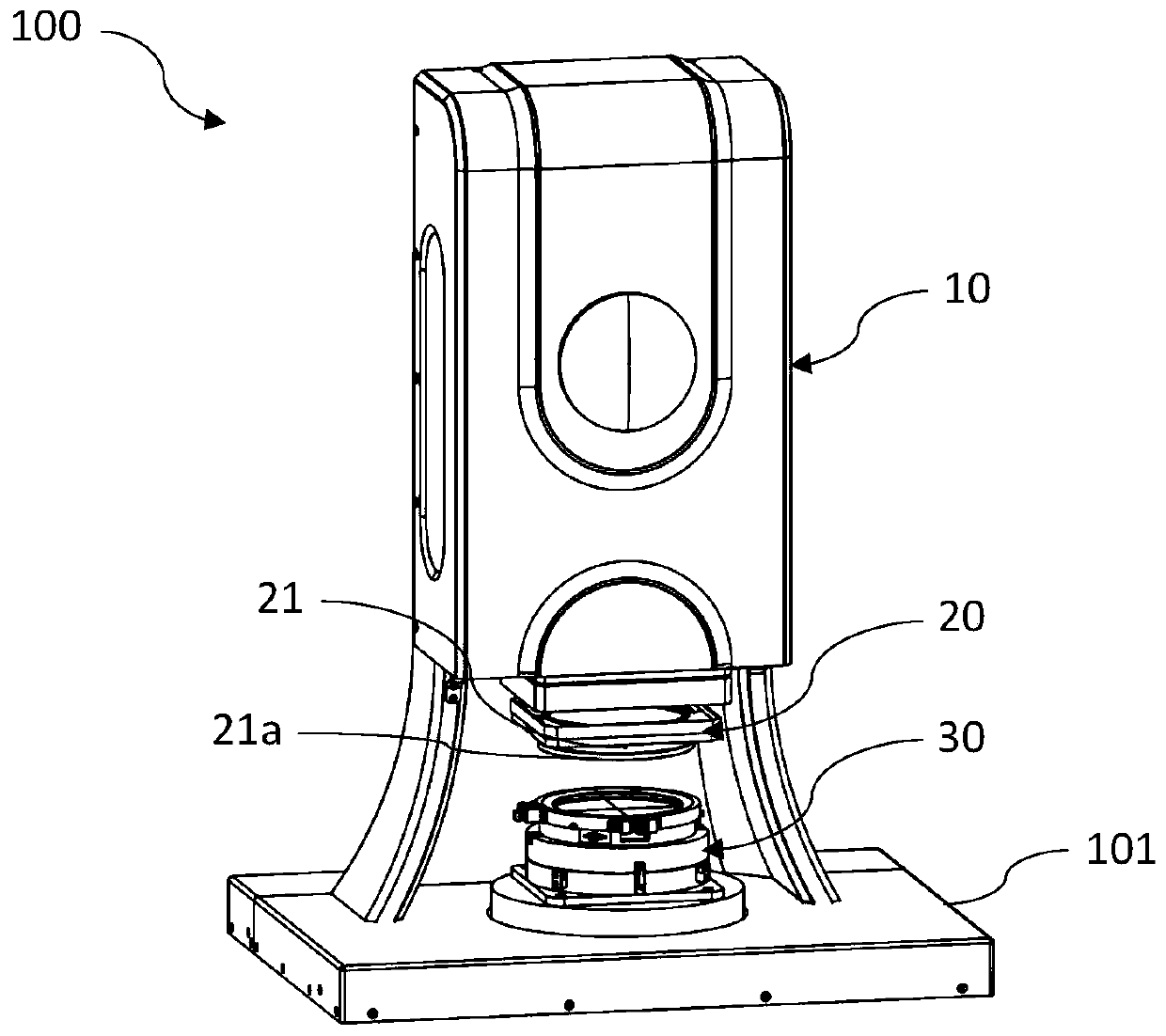

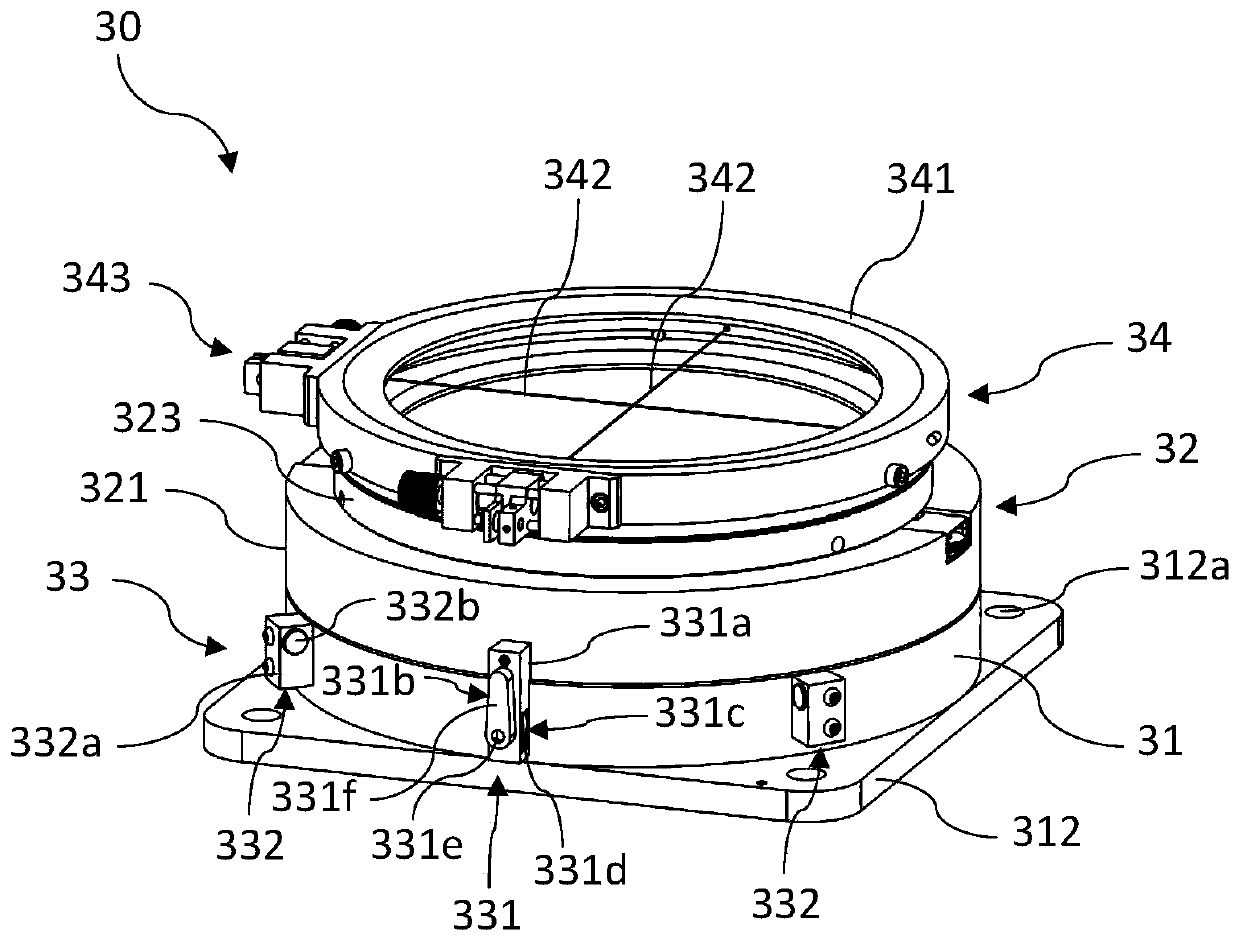

Vertical laser interferometry device and method for measuring flat crystal absolute surface shape

ActiveCN110030948APrecise positioningEasy loading and unloadingUsing optical meansLaser transmitterBeam splitter

The invention provides a vertical laser interferometry device and method for measuring a flat crystal absolute surface shape, and adopts a method of three-plane mutual inspection to measure the absolute surface shape of three flat crystal working faces. The device comprises the following parts of a device main body containing a laser emitter, a filter, a beam splitter, a collimating lens, an imaging objective lens, an image detector and a processing portion; a reference flat crystal carrying device located directly under the collimating lens and disposed with the same optical axis of the collimating lens for carrying the flat crystal as a reference flat crystal; and a flat crystal rotation carrying device located directly under the reference flat crystal carrying device and disposed with the same optical axis of the reference flat crystal carrying device for carrying the flat crystal as the flat crystal to be tested, wherein the flat crystal rotation carrying device has a fixed disk, arotation carrying portion and a defining portion, and the defining portion is used for limiting the rotating disk to the first position when the rotating disk is switched to a first position and limiting the rotating disk to the second position when the rotating disk is switched to a second position.

Owner:苏州慧利仪器有限责任公司

Ce3xGy3(1-x-y)Y3yAl5O12 doped garnet high-temperature scintillation crystal and preparation method thereof

InactiveCN106149054AGood lookingGood opticsPolycrystalline material growthBy pulling from meltHigh concentrationIridium

The invention relates to a Ce3xGy3(1-x-y)Y3yAl5O12 doped garnet high-temperature scintillation crystal and a preparation method thereof. The chemical formula of the crystal is Ce3xGy3(1-x-y)Y3yAl5O12, the processing steps are as below: the Ce3xGy3(1-x-y)Y3yAl5O12 crystal is grown with a medium-frequency induction heating pulling method, a heating unit is an iridium crucible, the raw materials are weighed according to proportion after calcination, the raw materials are pressed into blocks by a static pressure machine after weighing, matching and uniform grinding and mixing, sintering is performed at the temperature of 1,300 DEG C and solid-phase reaction happens, and the sintered raw materials are preserved in a drying cabinet; zirconium oxide and aluminum oxide are used as an insulation cover and an insulation material respectively, an observation hole is sealed by a gem piece, the inside of a hearth is protected by inert gas, the crystal growth temperature is about 1,950 DEG C, the pulling rate is 0.5-5 mm / h, and the crystal rotation speed is 10-30 rpm. The crystal has the advantages that the crystal growth cost is low, large size is easy to prepare, high-concentration doping is realized, the scintillation property is excellent and the like.

Owner:SUZHOU SIHAI CHANGJING PHOTOELECTRIC MATERIAL

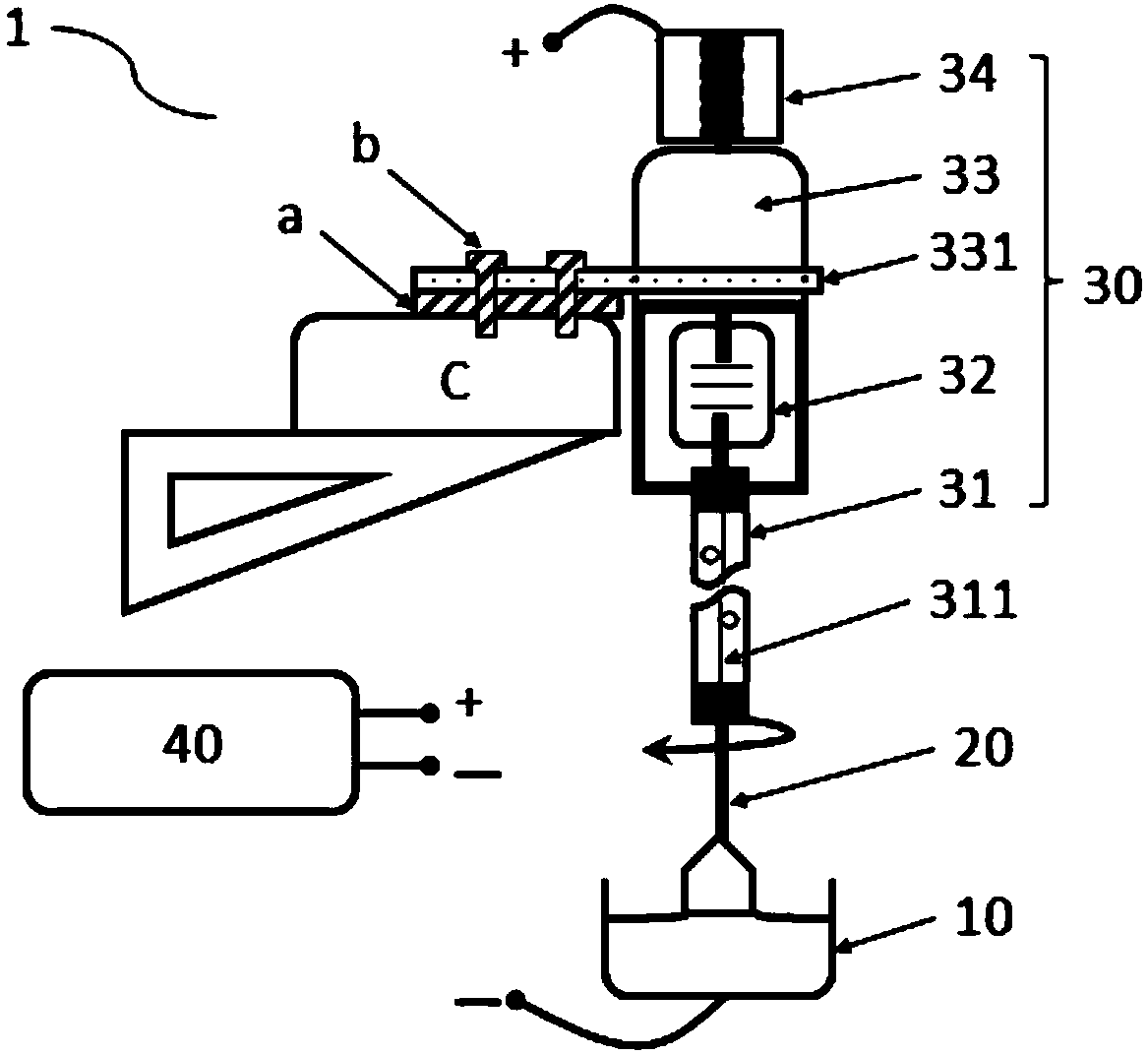

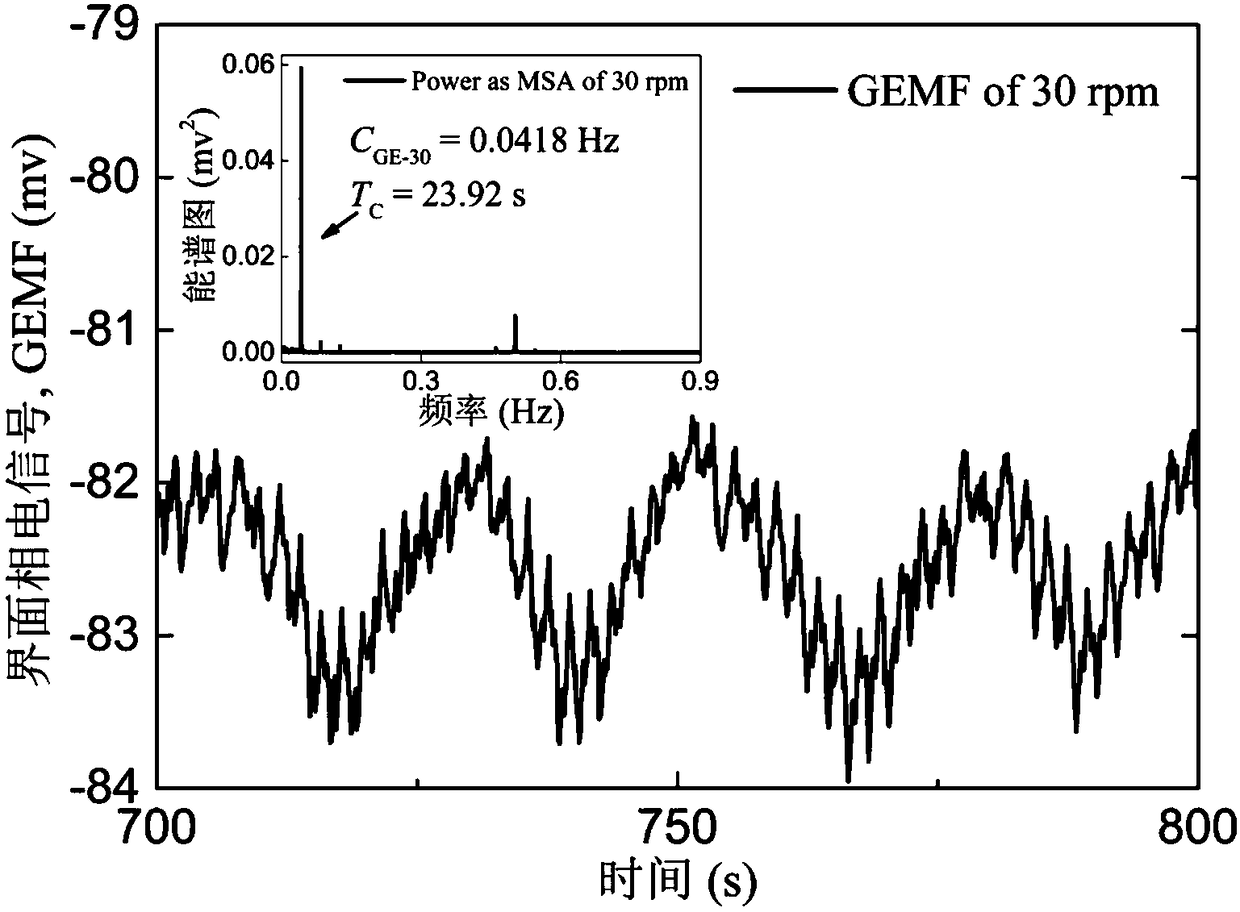

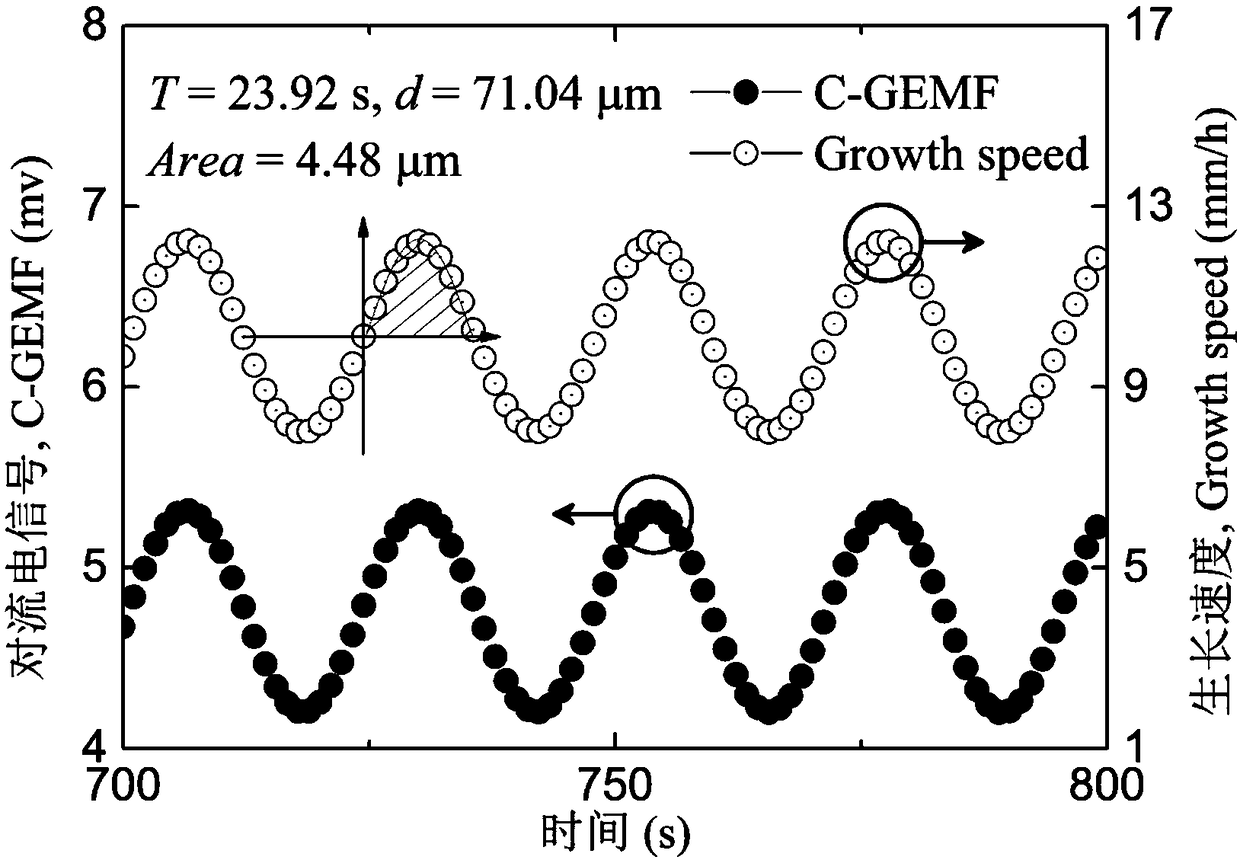

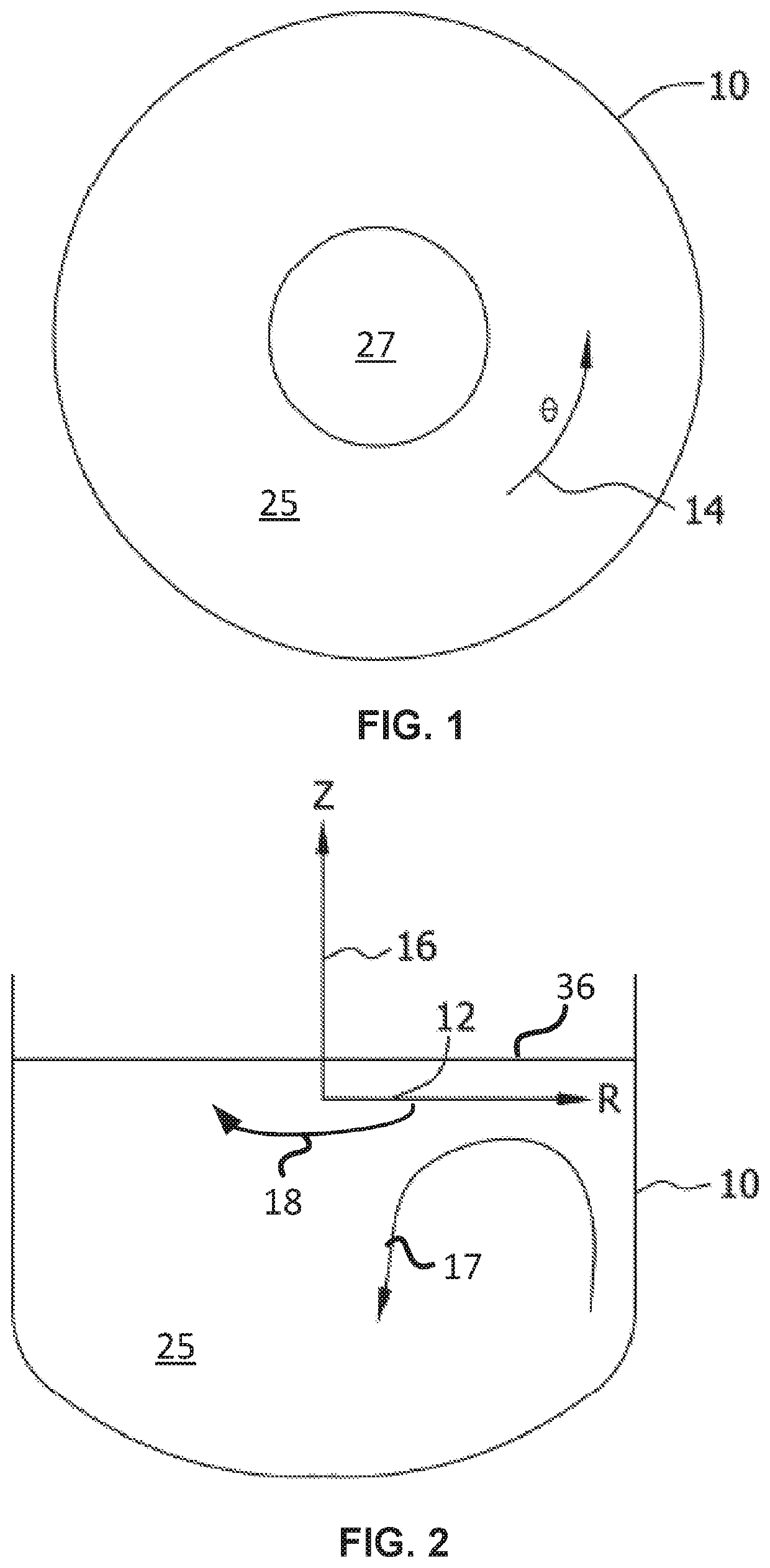

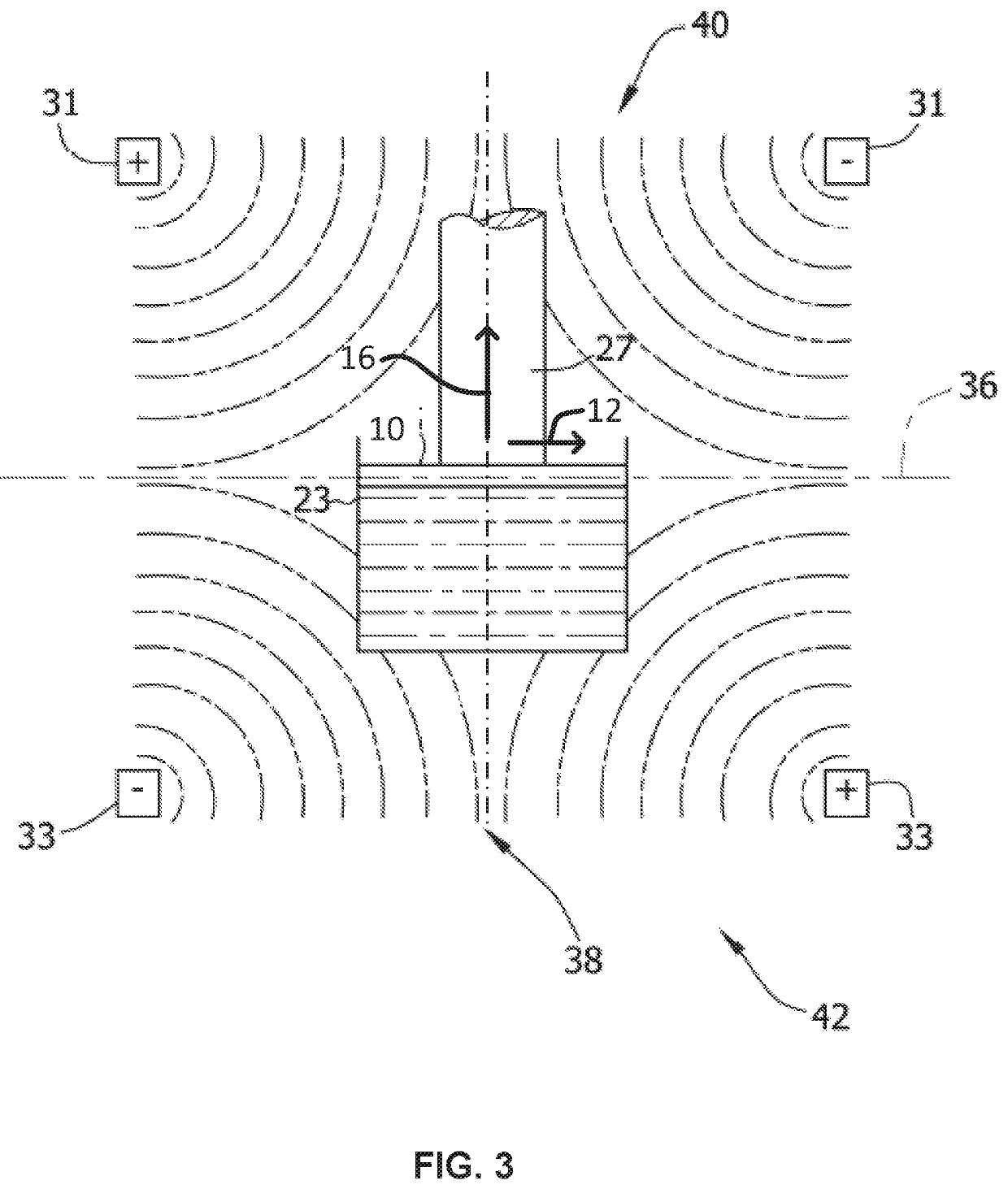

Crystal growth interface electrical signal acquisition system

The invention relates to a crystal growth interface electrical signal acquisition system which comprises a crucible, a seed rod, a crystal rotation mechanism and an electrical signal acquisition unit;the crystal rotation mechanism is isolated with an outside furnace body and comprises a crystal rotation rod, a coulpler, a double-shaft motor and an electrical slip ring; the crystal rotation rod iselectrically connected with the seed rod and in a hollow structure, and a conductive core is arranged in the crystal rotation rod; the lower end of the coupler is connected with the conductive core;the double-shaft motor comprises a motor bracket, a motor main shaft and a motor auxiliary shaft, and the motor main shaft is connected with the upper end of the coupler; the fixed end of the electrical slip ring is fixed on the motor bracket, and the free end of the electrical slip ring is electrically connected with the motor auxiliary shaft; the two ends of the electrical signal acquisition unit are electrically connected with the crucible and the fixed end of the electrical slip ring respectively. According to the crystal growth interface electrical signal acquisition system, high-speed acquisition and stable transmission of interface electrical signals can be realized.

Owner:SUN YAT SEN UNIV

Systems and methods for production of low oxygen content silicon

ActiveUS10745823B2Increase the magnetic field strengthPolycrystalline material growthBy pulling from meltCrystal rotationIngot

A method for producing a silicon ingot includes withdrawing a seed crystal from a melt that includes melted silicon in a crucible that is enclosed in a vacuum chamber containing a cusped magnetic field. At least one process parameter is regulated in at least two stages, including a first stage corresponding to formation of the silicon ingot up to an intermediate ingot length, and a second stage corresponding to formation of the silicon ingot from the intermediate ingot length to the total ingot length. During the second stage process parameter regulation may include reducing a crystal rotation rate, reducing a crucible rotation rate, and / or increasing a magnetic field strength relative to the first stage.

Owner:GLOBALWAFERS CO LTD

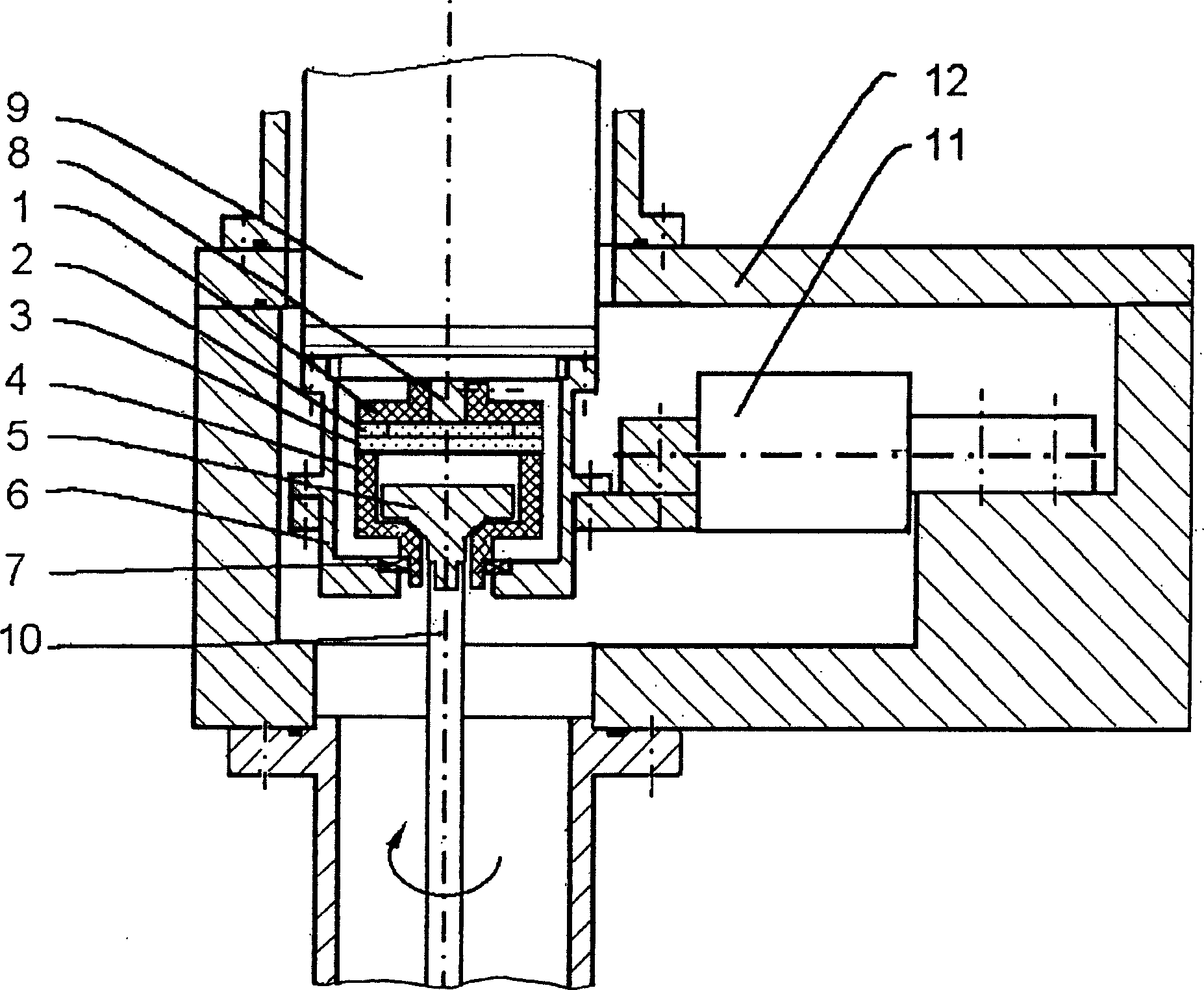

Apparatus for rotating and drawing of crystal with damping

InactiveCN1598079AEasy to realize automatic positioningGuaranteed verticalityBy pulling from meltCircular discCrystal rotation

This invention provides a crystal rotation lift and pulls equipment that has damping. It is consisted of flanged shaft, flexibie disc, conical surface rotary table, friction cone, seed rod, supporting enclosure and motor. Two flexible discs are fixed between the lower end of the flanged shaft and the upper end of the conical surface rotary table separately, the keep a certain pressure. The friction cone is fixed at the place of conical surface of conical surface roa\tary table, the lower end of the friction cone is connecdted with seed rod, the conical surface rotary table is fixed on the supporting enclosure by bearing, and it can rotate freely. The supporting enclosure is fixed on the motor. This invention transforms the fixed coupling direct drive between the motor and the seed rod into friction drive. It can bring relative slip, so it can eliminate the torque caused by inertia of the motor, and then it will work as active protecion equipment.

Owner:SHANDONG UNIV

Ytterbium doped kalium-lanthanum molybdate laser crystal, producing method, and purpose

A laser crystal mixed with the ytterbium doped lanthanum potassium molybdate and the preparation method as well as the use thereof relate to the field of the intraocular lens.At a temperature of about 1070 DEG C, the invention, at a crystal rotation speed of 5 to 20 rotations per minute and a pulling rate of 0.5 to 2mm per hour, grows the crystal of Yb<3>:KLa(MoO4)2 of high quality and larger dimension through the czochralski method. The crystal is a novel laser crystal, which can generate a laser output with a wavelength of about 1 Mum. A solid laser made from the crystal can be applied in the fields such as spectroscopy, biomedicine, military science and etc.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com