Patents

Literature

225 results about "Resistivity distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

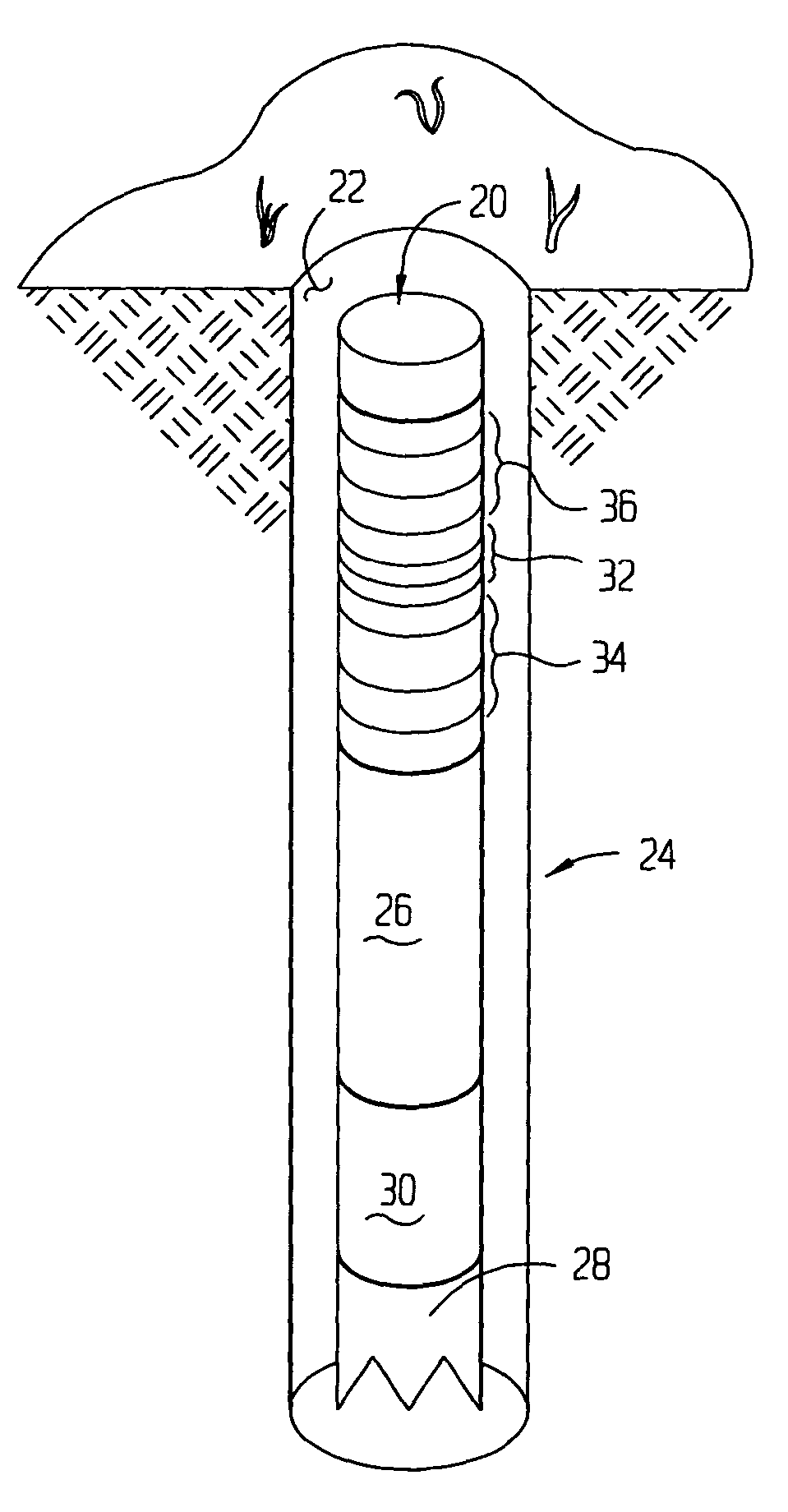

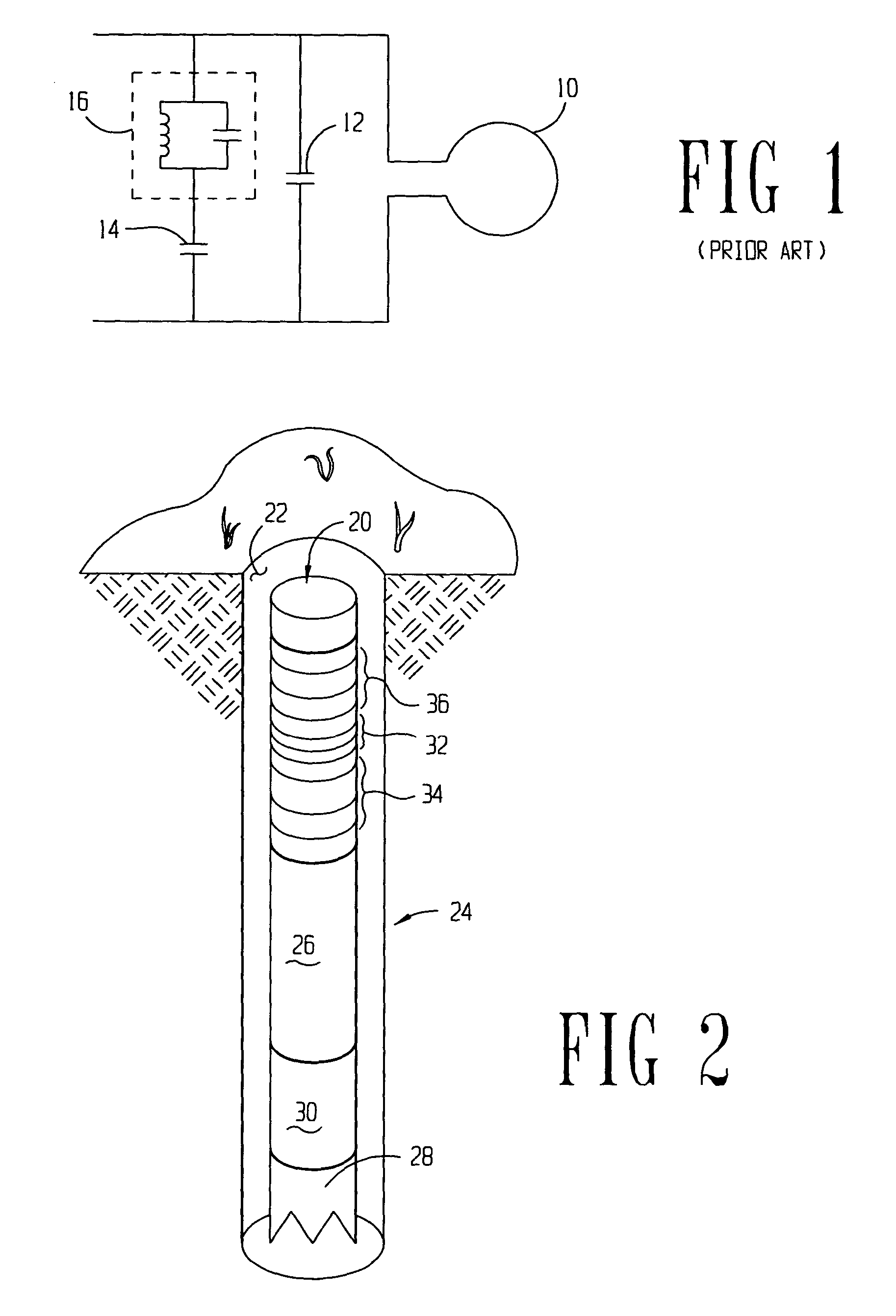

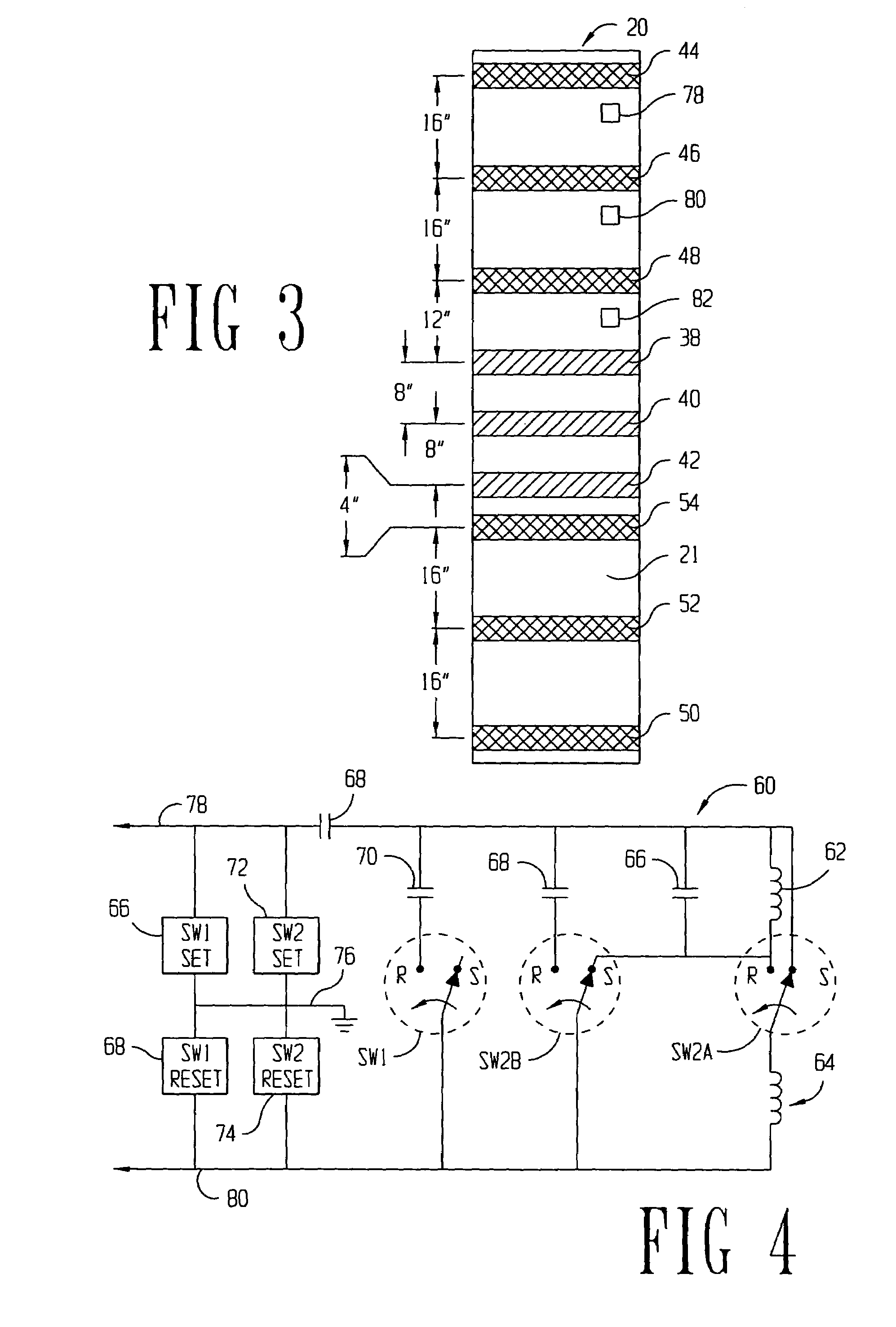

Electromagnetic wave resistivity tool

InactiveUS7038455B2Electric/magnetic detection for well-loggingSurveyEngineeringResistivity distribution

Owner:HALLIBURTON ENERGY SERVICES INC

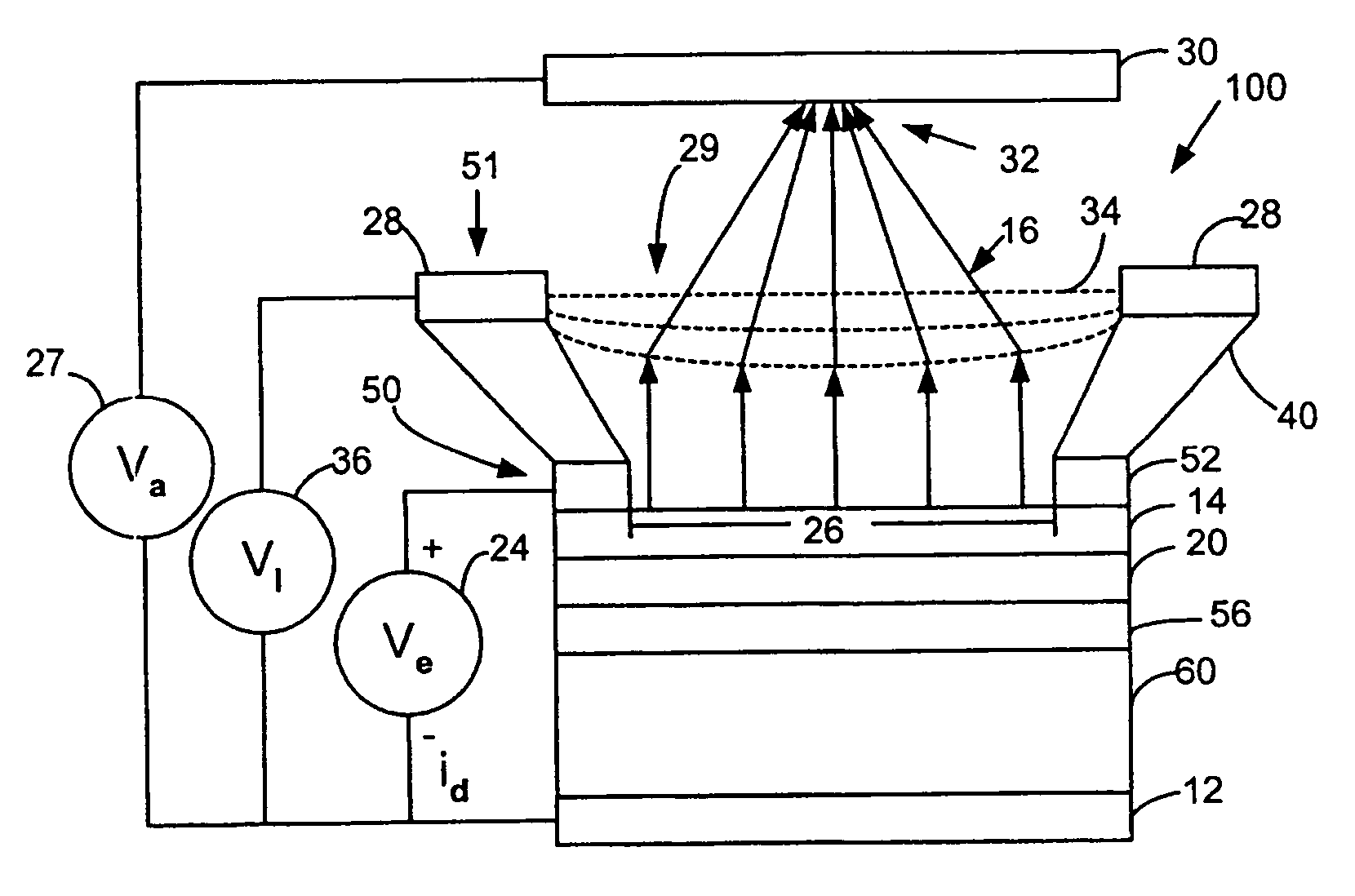

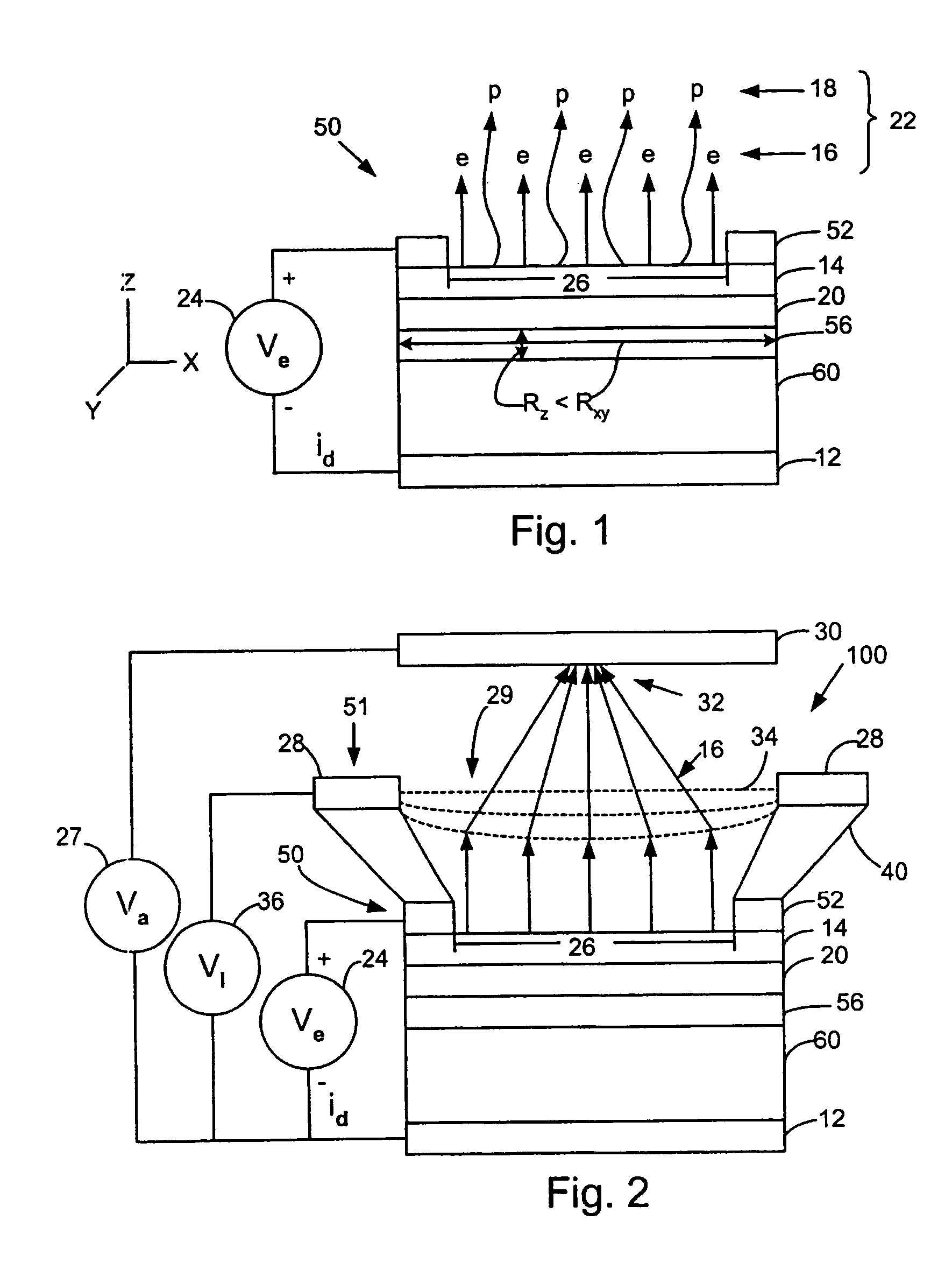

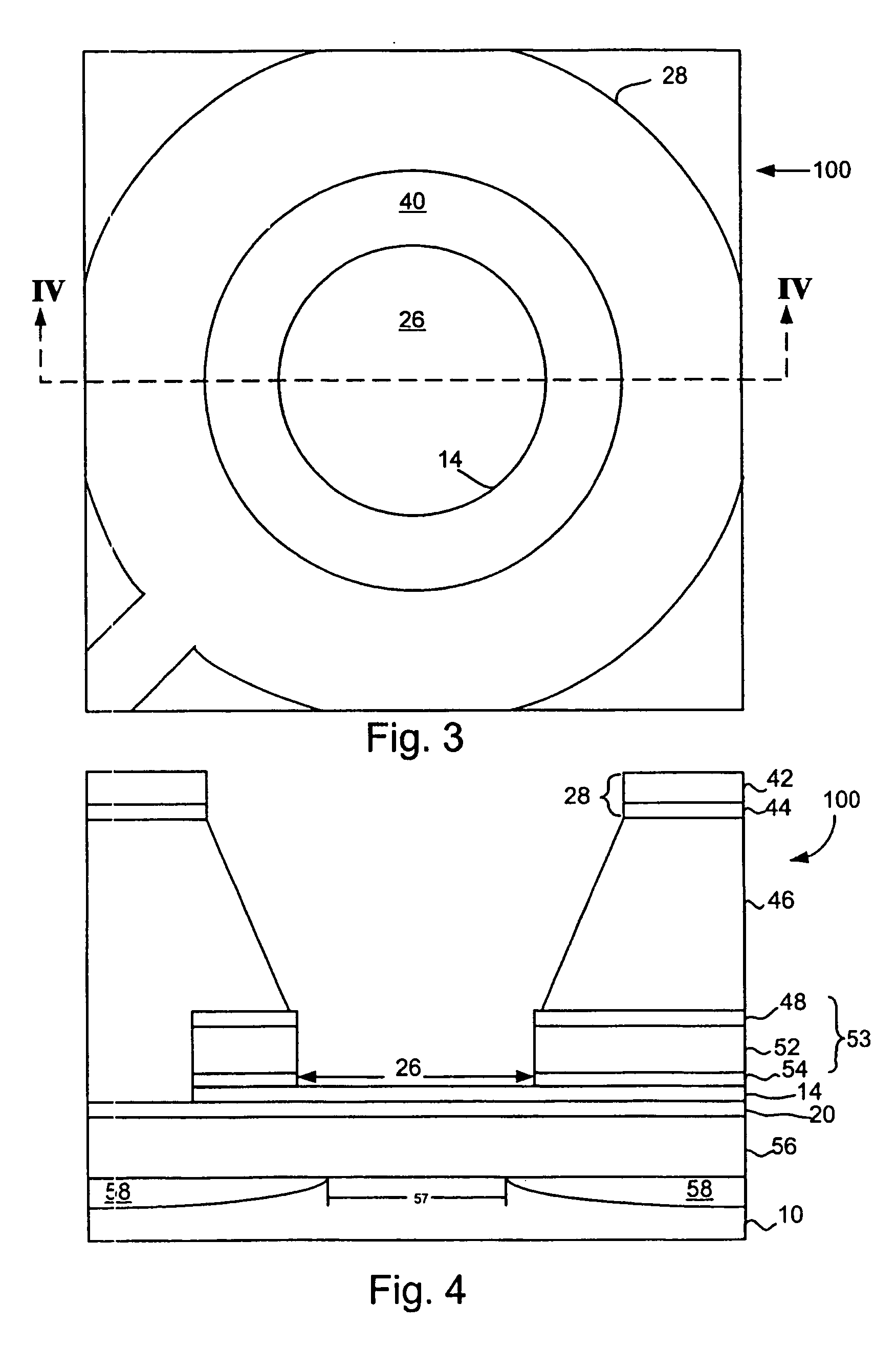

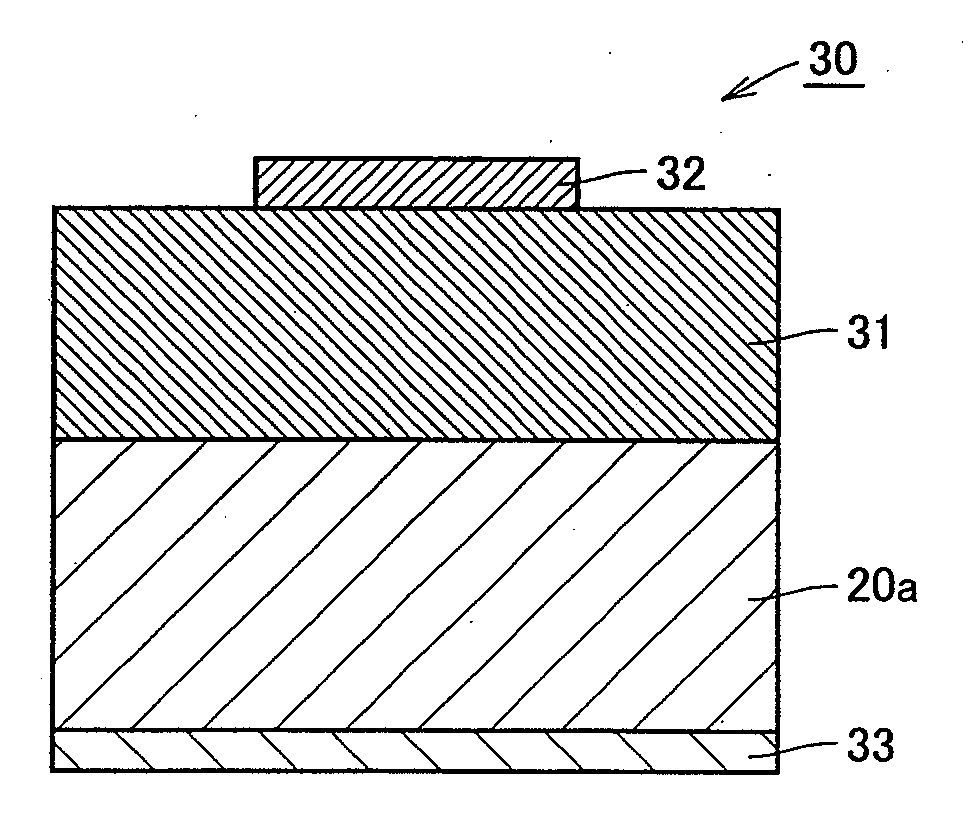

Emitter and method of making

InactiveUS7118982B2NanoinformaticsElectrode and associated part arrangementsElectron sourceOptoelectronics

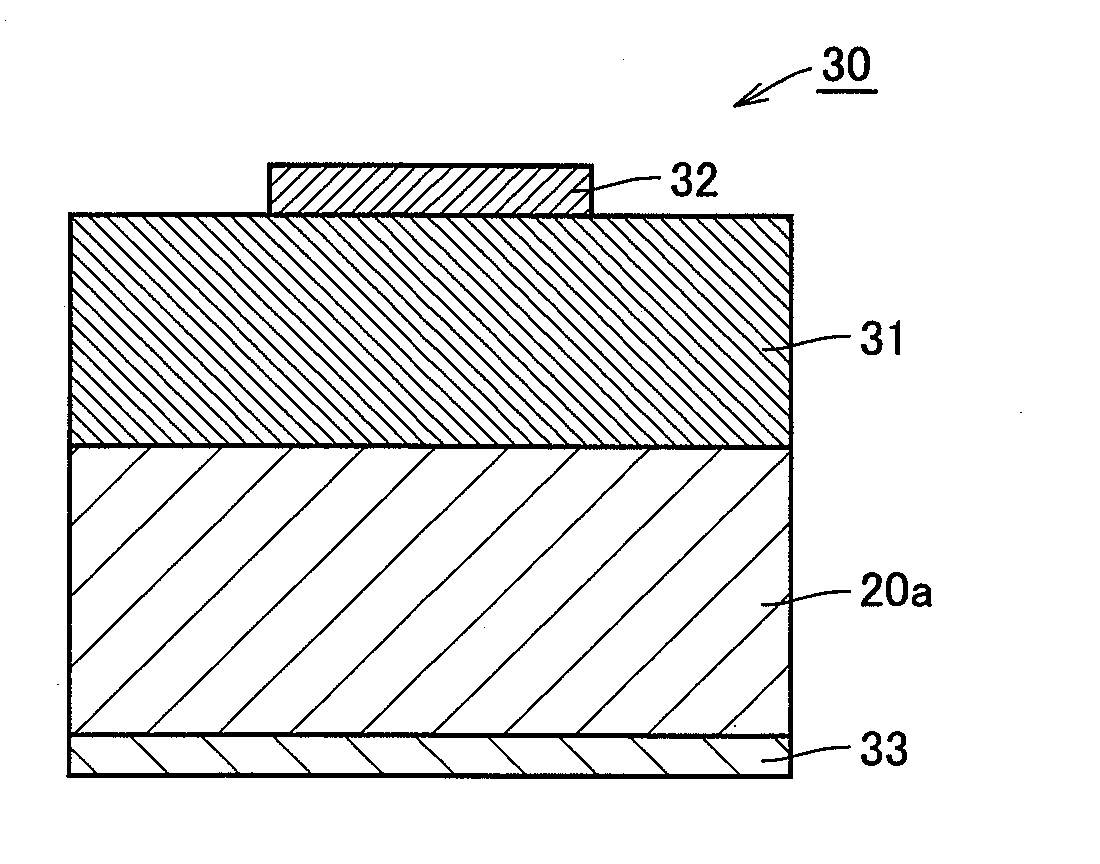

An emitter includes an electron source and a cathode. The cathode has an emissive surface. The emitter further includes a continuous anisotropic conductivity layer disposed between the electron source and the emissive surface of the cathode. The anisotropic conductivity layer has an anisotropic sheet resistivity profile and provides for substantially uniform emissions over the emissive surface of the emitter.

Owner:SAMSUNG ELECTRONICS CO LTD

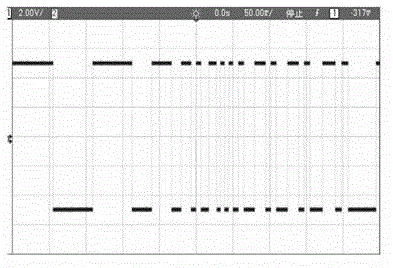

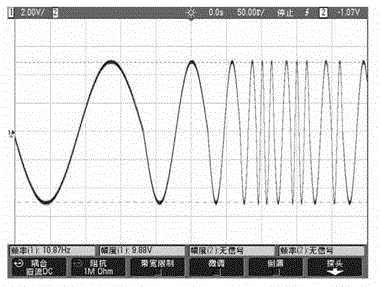

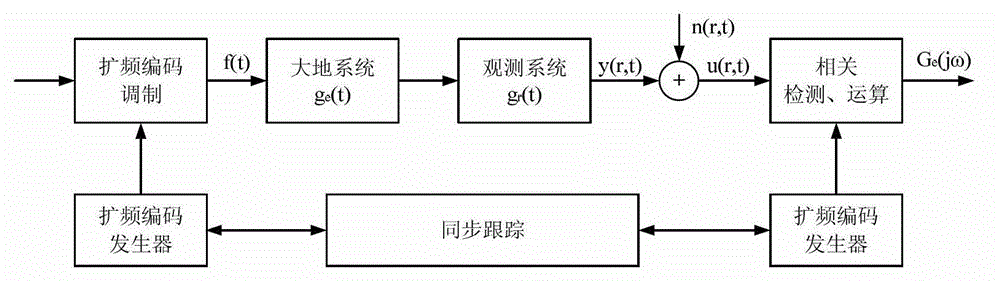

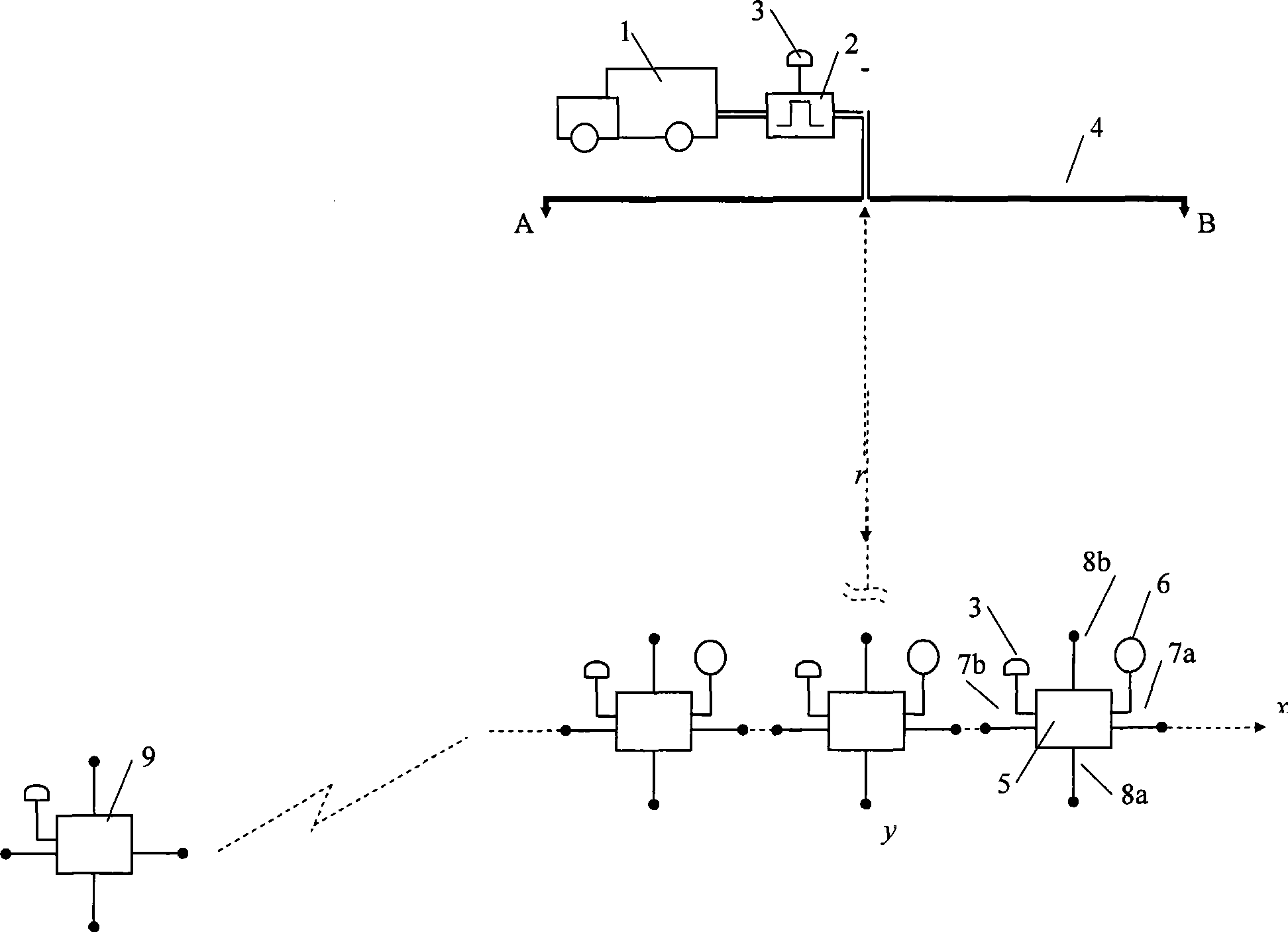

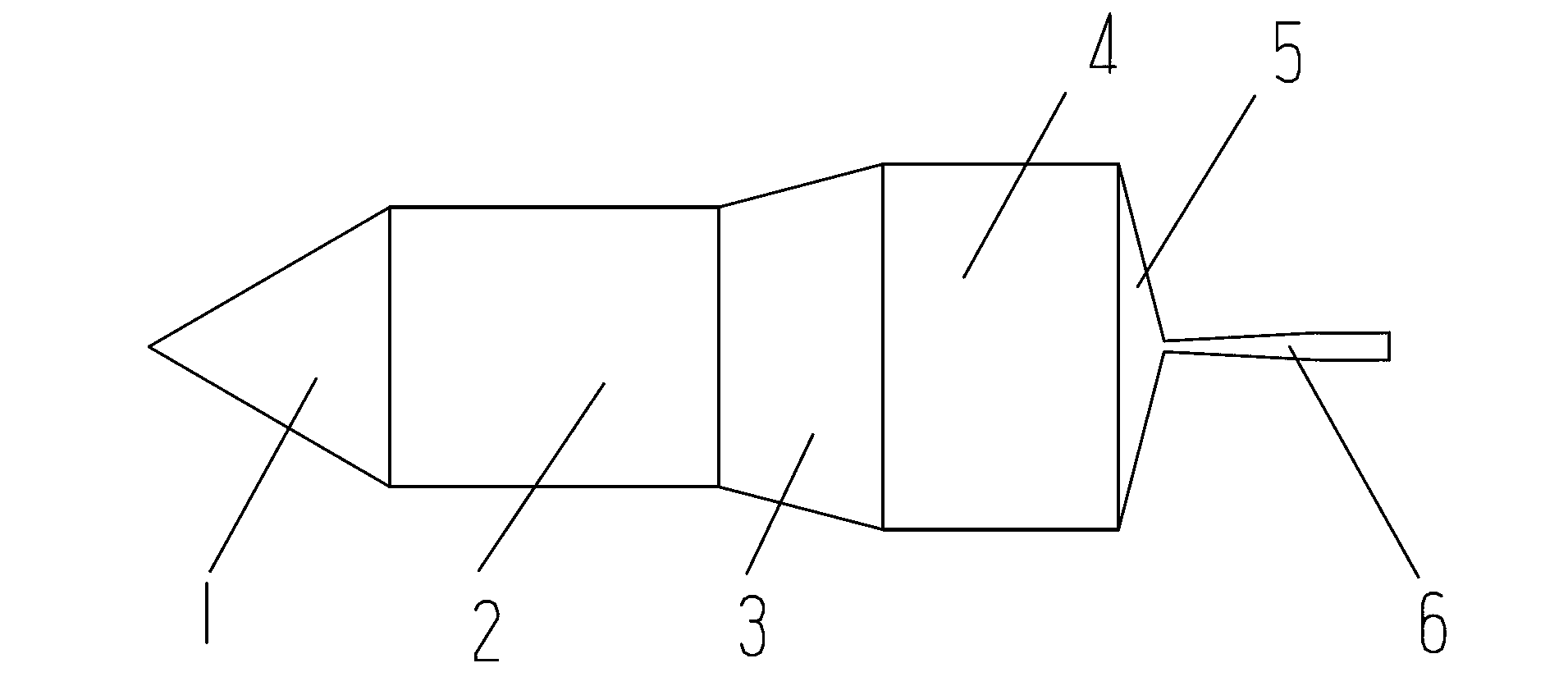

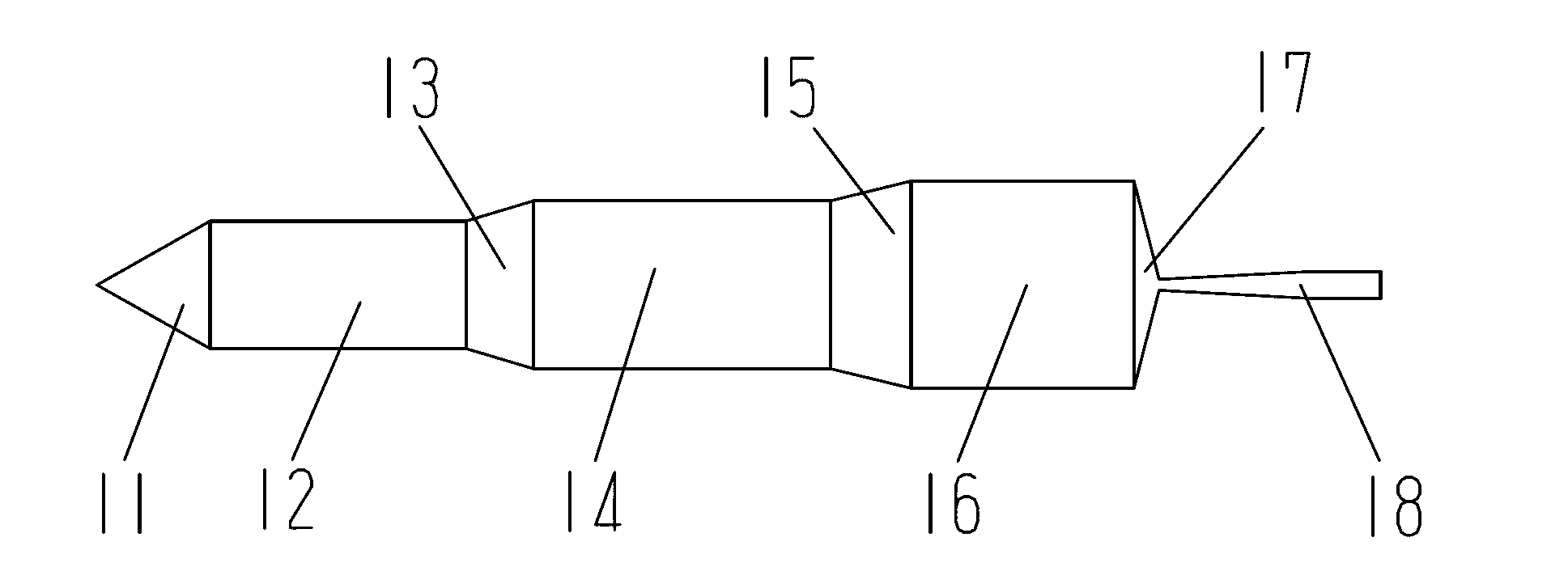

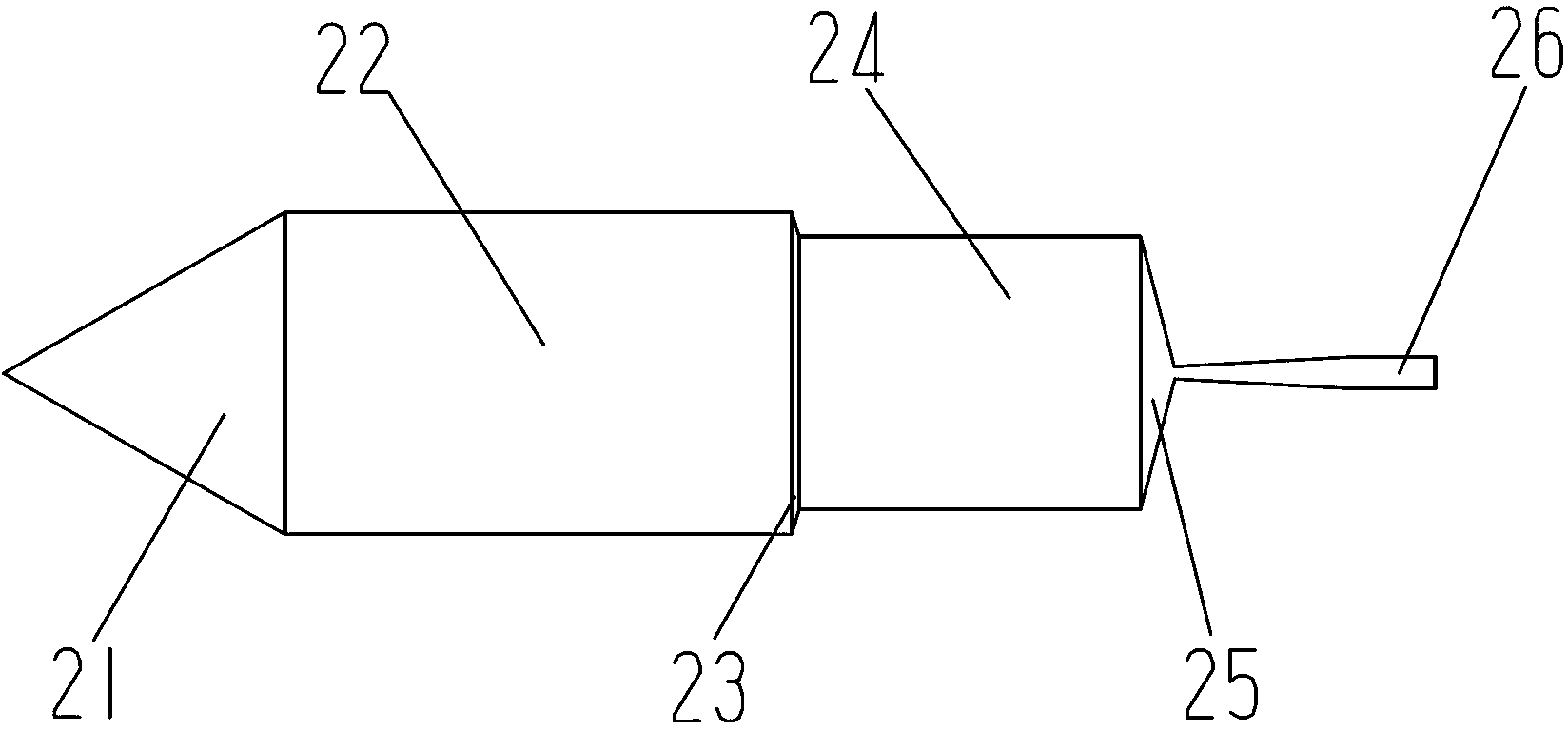

Ground electromagnetic prospecting method based on SPSP (Spread Spectrum) coding technology and detection system thereof

ActiveCN102721982AIncreased complexityImprove featuresDetection using electromagnetic wavesGround systemDistribution characteristic

The invention discloses a ground electromagnetic prospecting method based on an SPSP (Spread Spectrum) coding technology and a detection system thereof. The ground electromagnetic prospecting method based on the SPSP coding technology comprises the following steps of: supplying a current signal hopping according to a certain coded sequence to underground by a sending electrode, and using the current signal as a manual excitation source; receiving an electromagnetic field response message by a receiver, and meanwhile, synchronously recording the sent current signal and the geoelectrical response message of the position where the receiver is located by the receiver; and obtaining ground system response comprising the geoelectrical resistivity through a correlated identification method, and finally obtaining the distribution characteristics of the geoelectrical resistivity. According to the detection system applying the ground electromagnetic prospecting method disclosed by the invention, a sine-wave or square-wave signal in unipolarity or bipolarity in the whole preset frequency range can be sent by a transmitter, a sending sequence can hop according to a preset frequency pattern, and uncorrelated noise can be removed through a correlated identification detection method.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

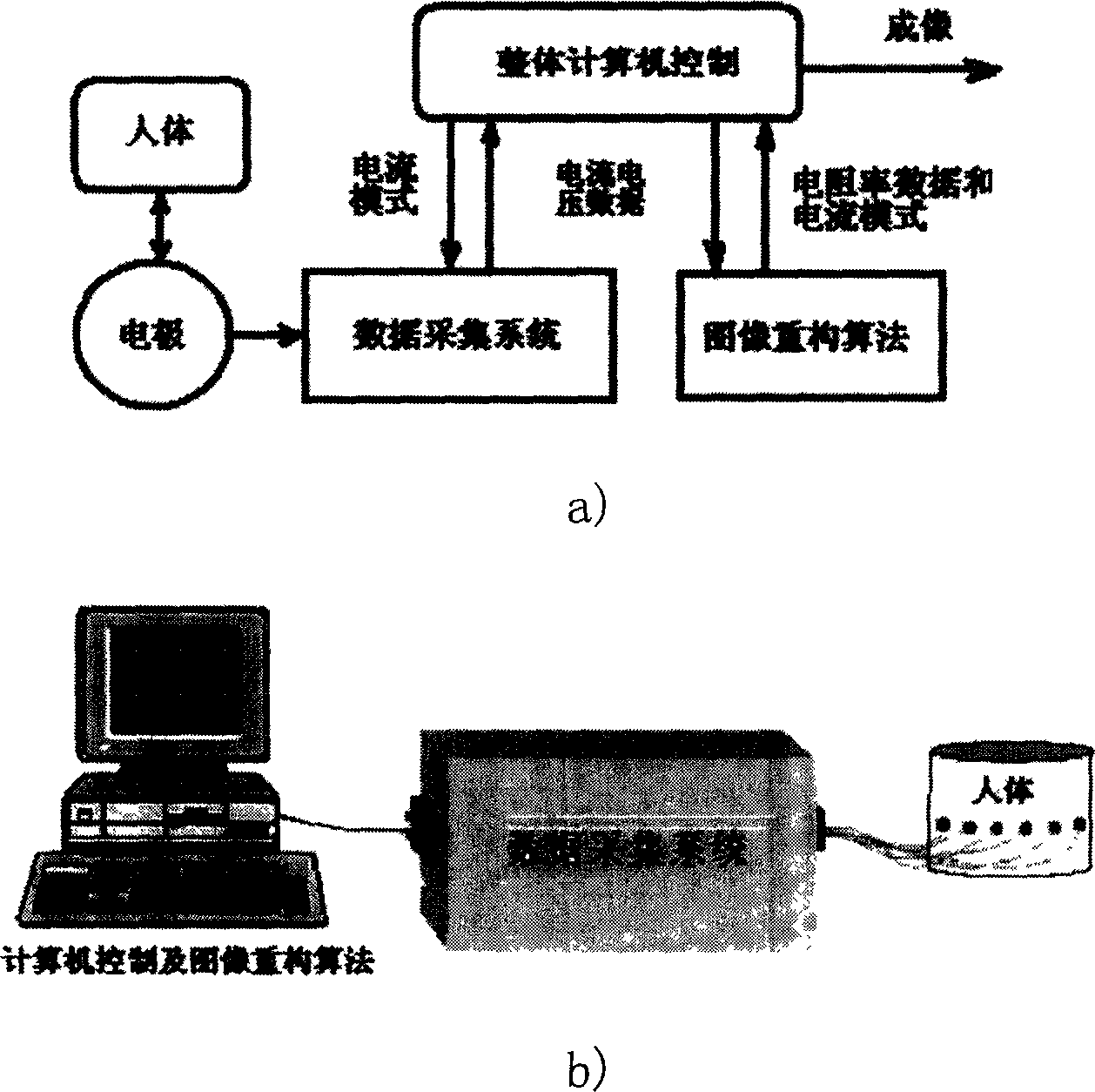

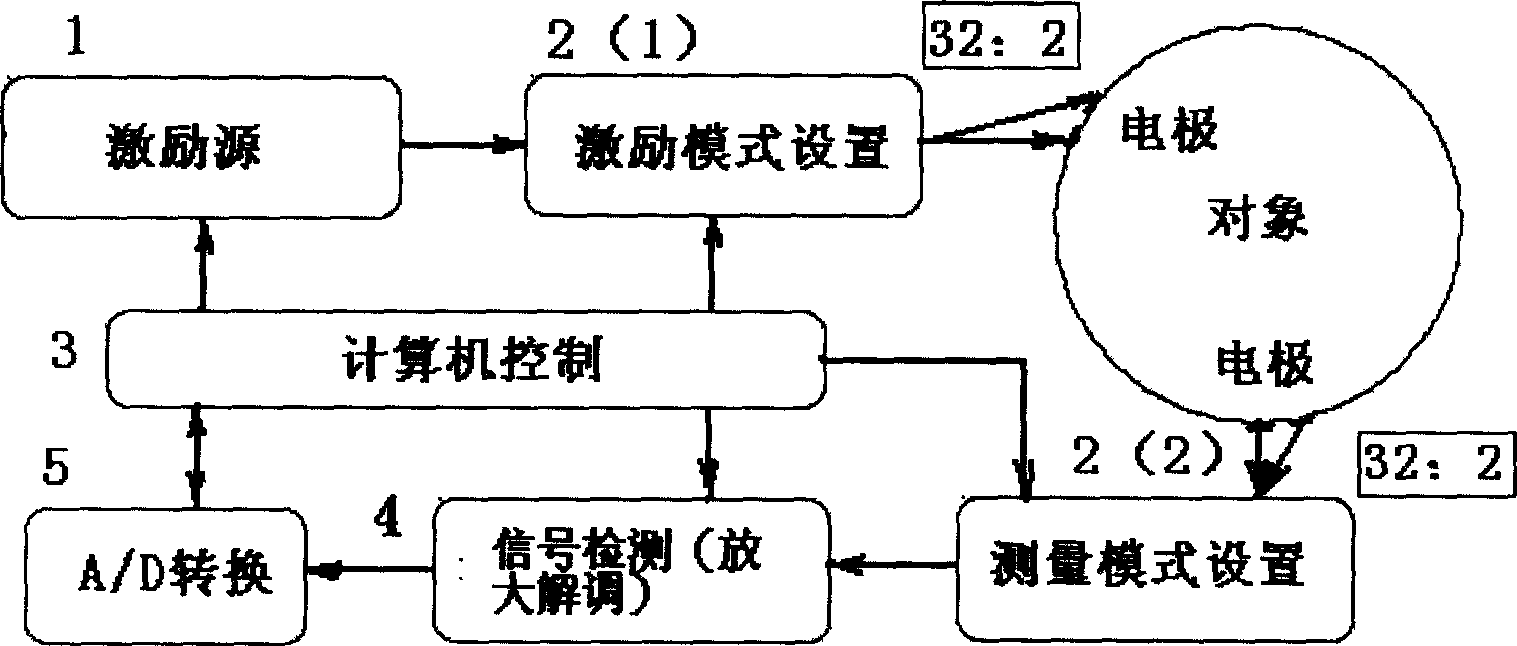

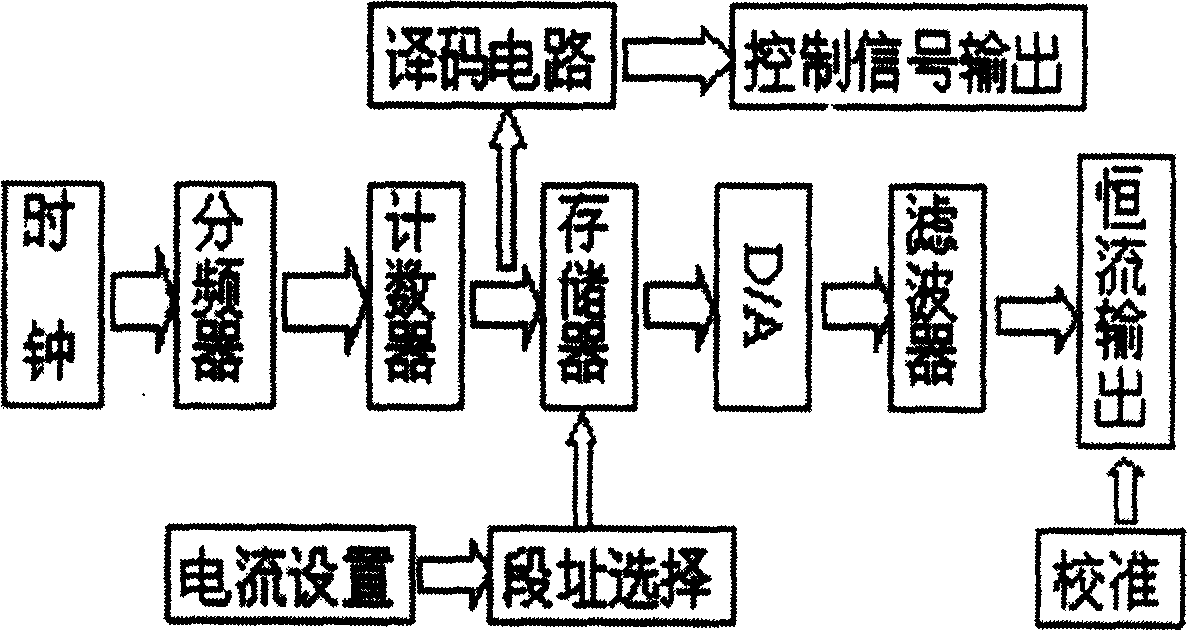

Electric impedance tomographic imaging method and apparatus for imaging monitoring beside sickbed

InactiveCN1526358ADiagnostic recording/measuringSensorsElectrical resistance and conductancePower flow

The present invention discloses electric impedance tomographic imaging method and apparatus for imaging nursing beside sickbed. The integral computerized data collecting system and the re-construction algorithm provides the interface and controls the imaging nursing process. The apparatus includes one computer and one connected data collecting system, the computer is equipped with program for controlling the data collecting system and algorithm for re-constructing image, and the data collecting system has also control module to apply excitation current to body signal collecting electrodes. The present invention features the several pairs of electrodes for applying excitation current and collecting body signals, the data collecting system providing constant AC excitation, high precision signal detection and programmed driving and measuring mode, and the calculation of body resistivity distribution and image display.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

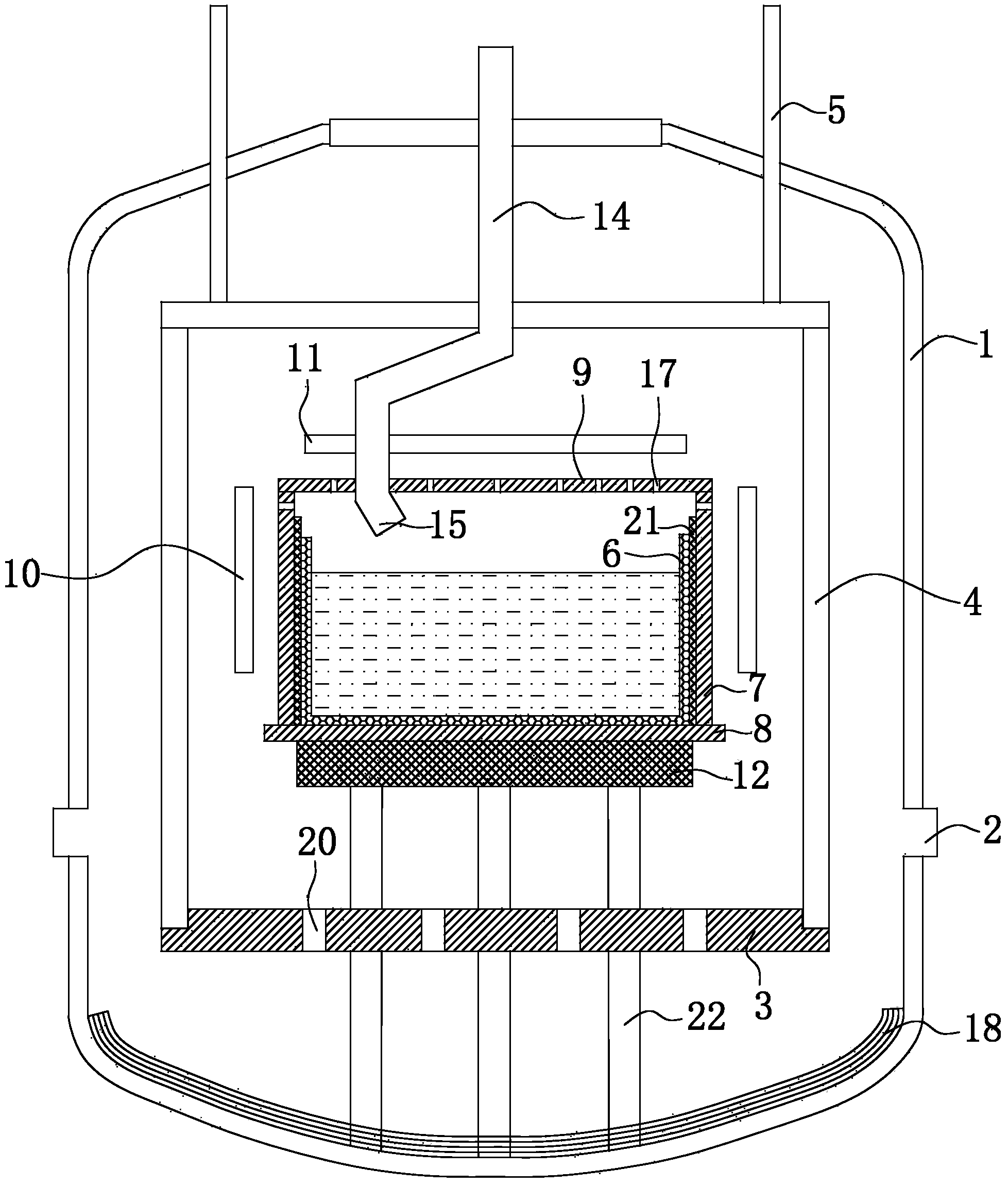

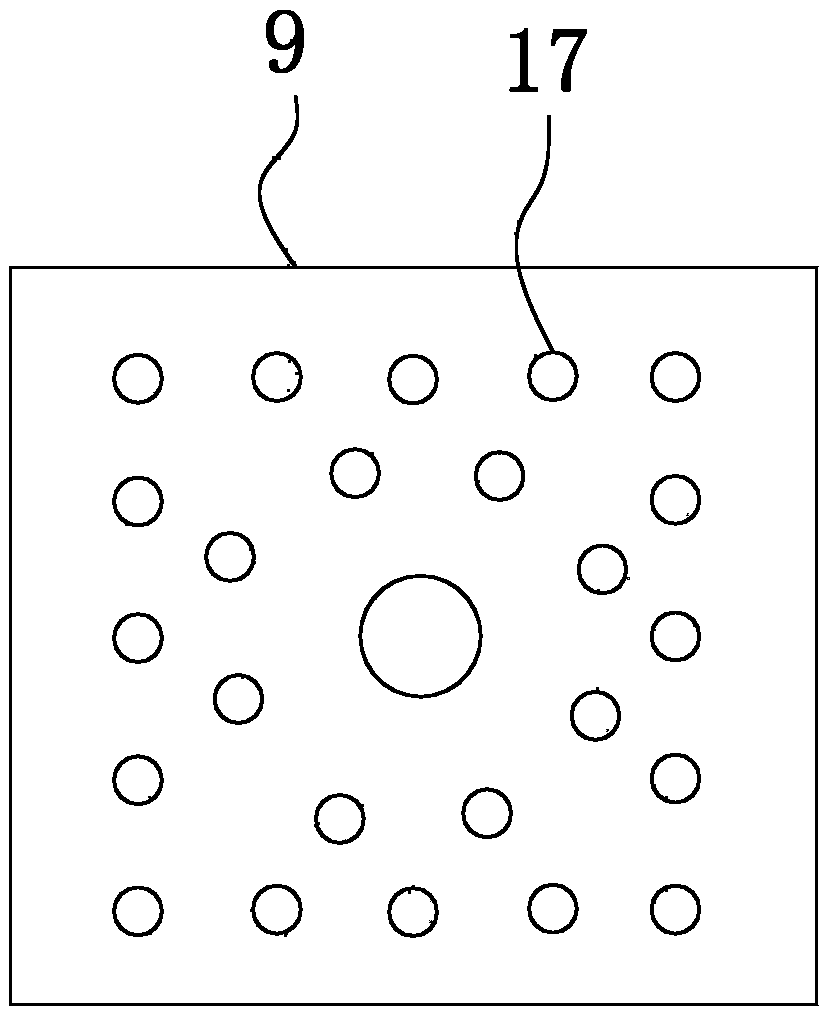

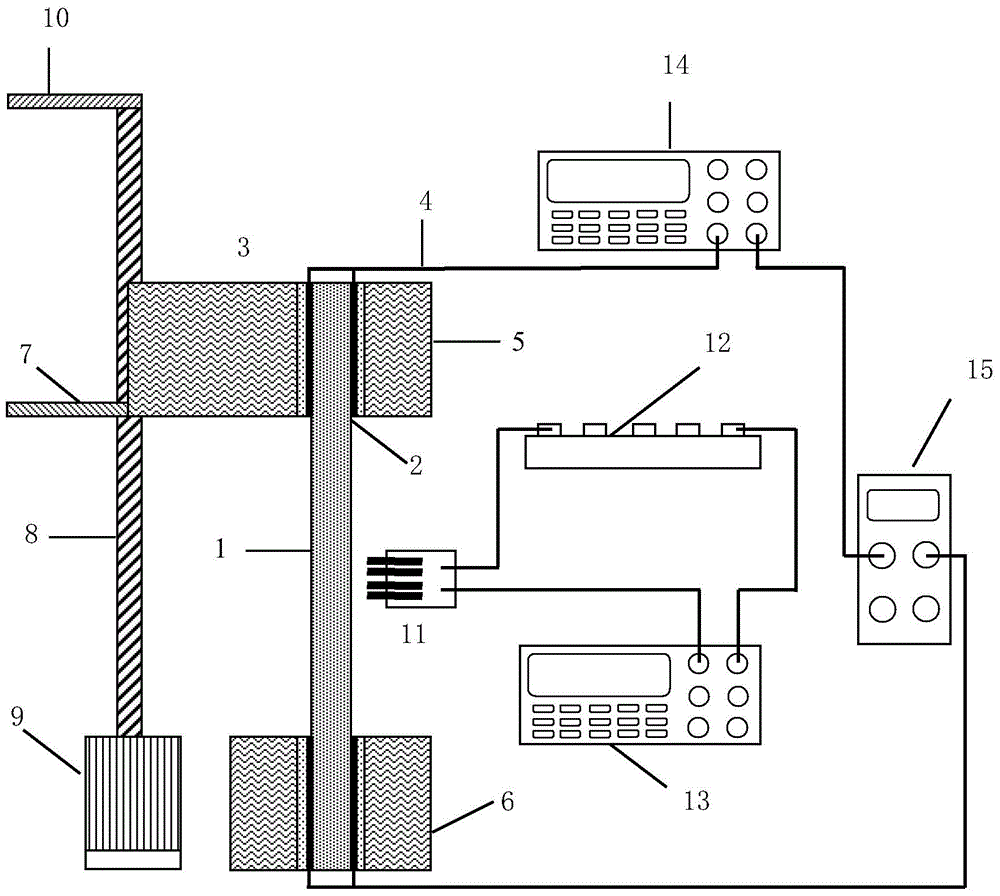

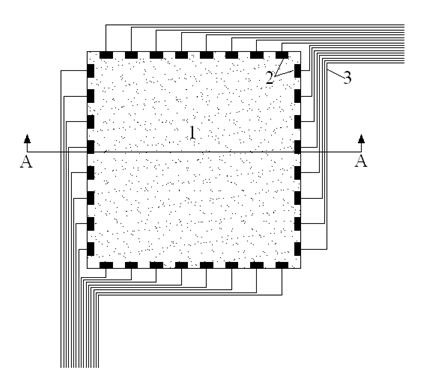

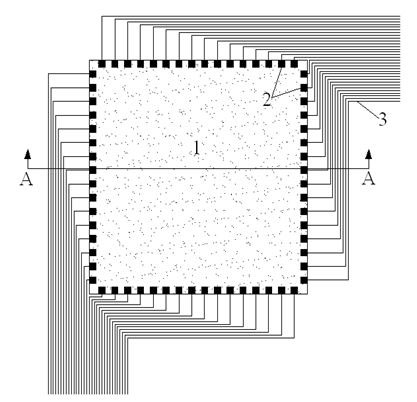

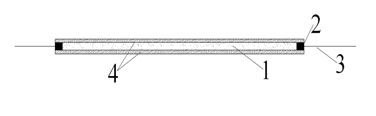

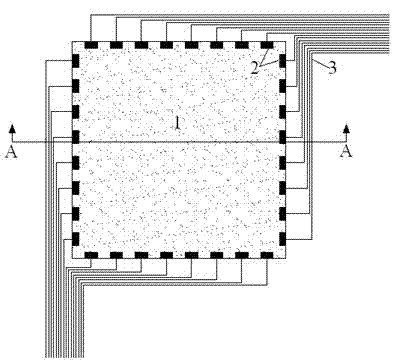

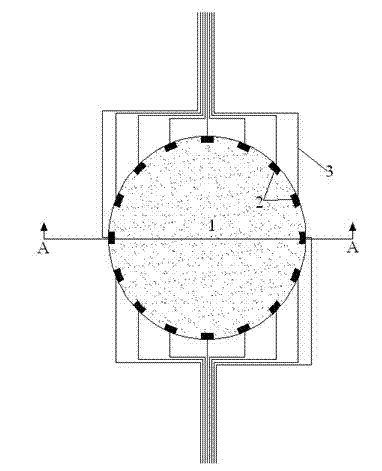

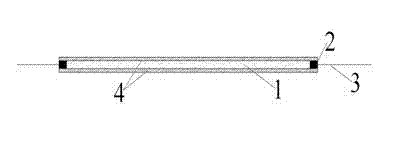

Piezoresistive-material-based resistivity imaging flexible pressure detection system and detection method

ActiveCN103267597AImprove flexibilitySimple structureForce measurementElectrical resistance and conductanceElectrical impedance tomography

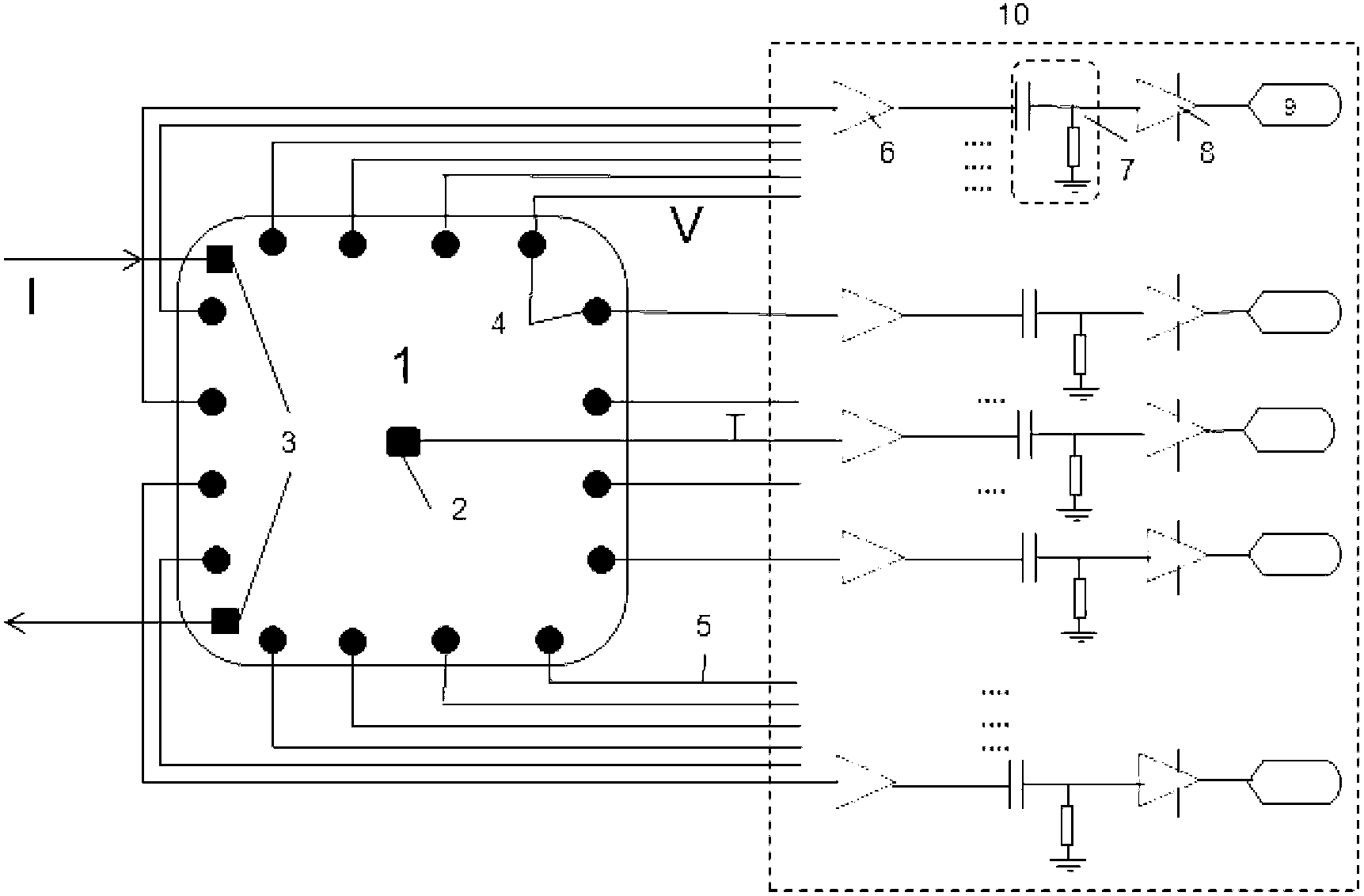

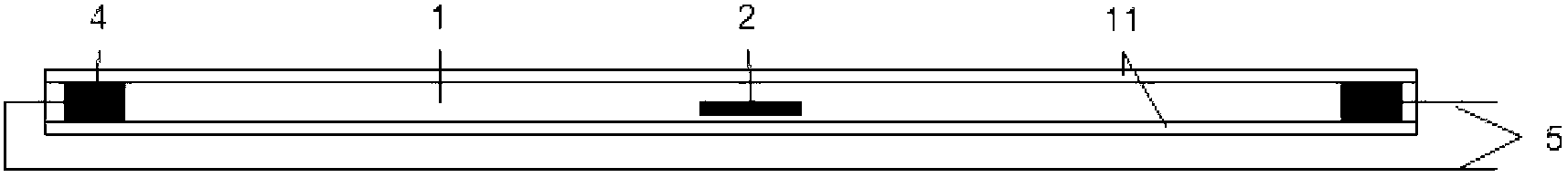

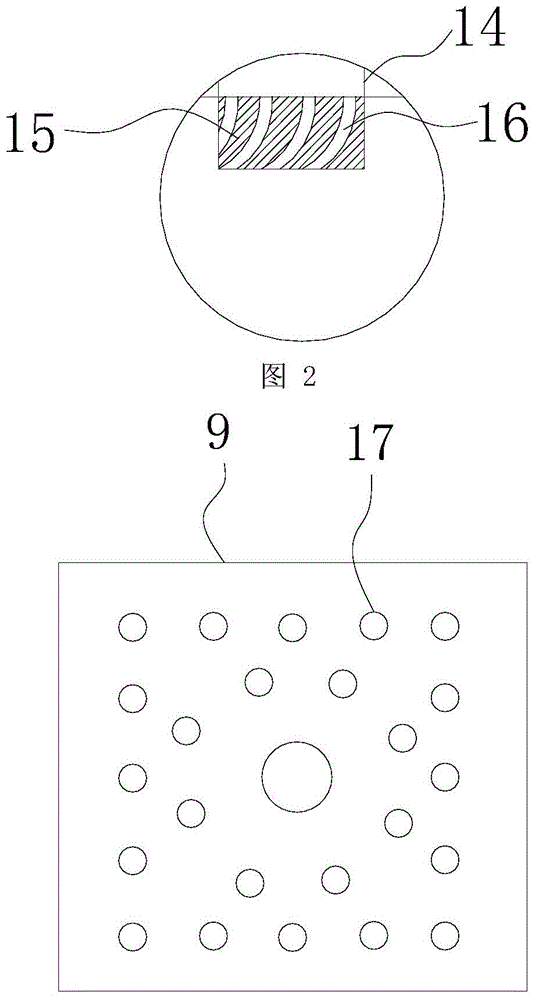

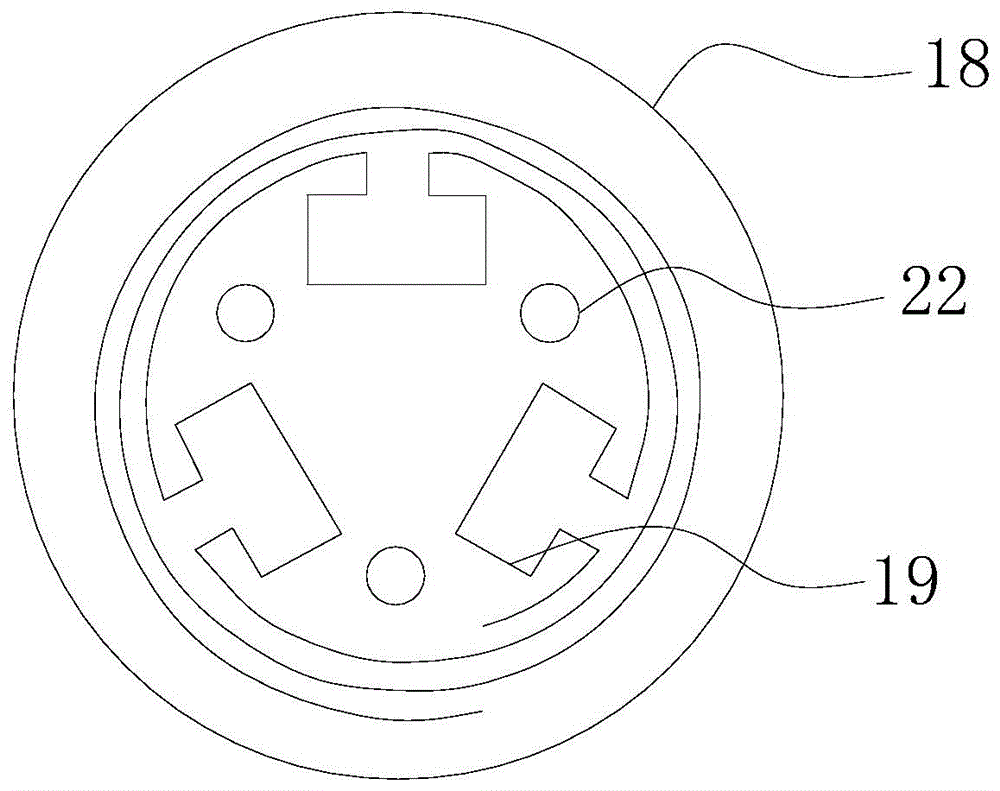

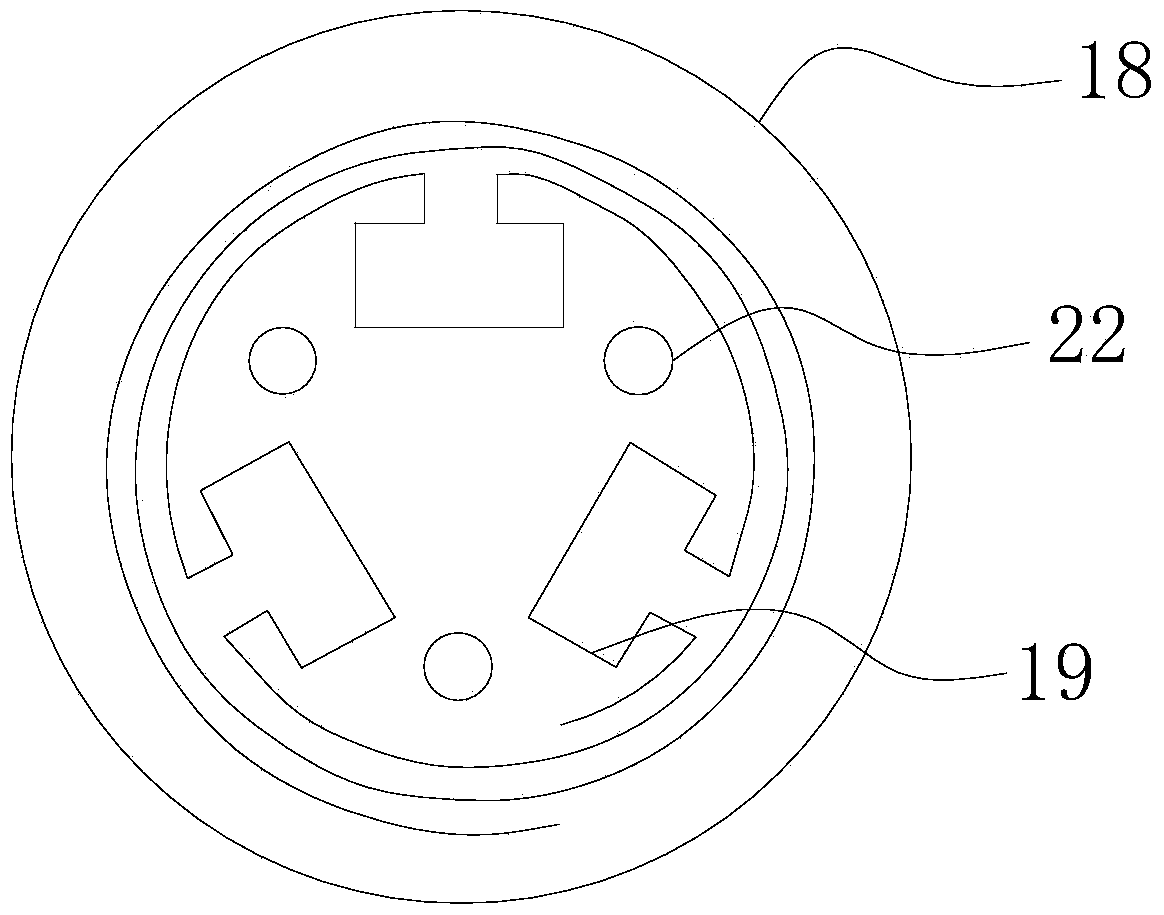

The invention discloses a piezoresistive-material-based resistivity imaging flexible pressure detection system, which comprises a pressure detection pad (1), a temperature sensor (2) buried in the pressure detection pad (1), injection electrodes (3) connected to the edge of the pressure detection pad (1), a plurality of uniformly distributed receiving electrodes (4) connected to the periphery of the pressure detection pad (1), wires (5) connected to the receiving electrodes (4) and the temperature sensor (2) and a signal acquisition circuit (10) connected with the wires (5), wherein the pressure detection pad (1) is made from a piezoresistive material; and when certain pressure is applied to the pressure detection pad, the resistivity of the material in the pressure detection pad can be changed. The injection electrodes connected to the pressure detection pad are used for injecting current into the pressure detection pad, the receiving electrodes arranged around the detection pad are used for receiving detected voltage signals, and an electrical impedance tomography principle is used for calculating resistivity distribution in the pressure detection pad to further invert the distribution of the pressure born by the pressure detection pad.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

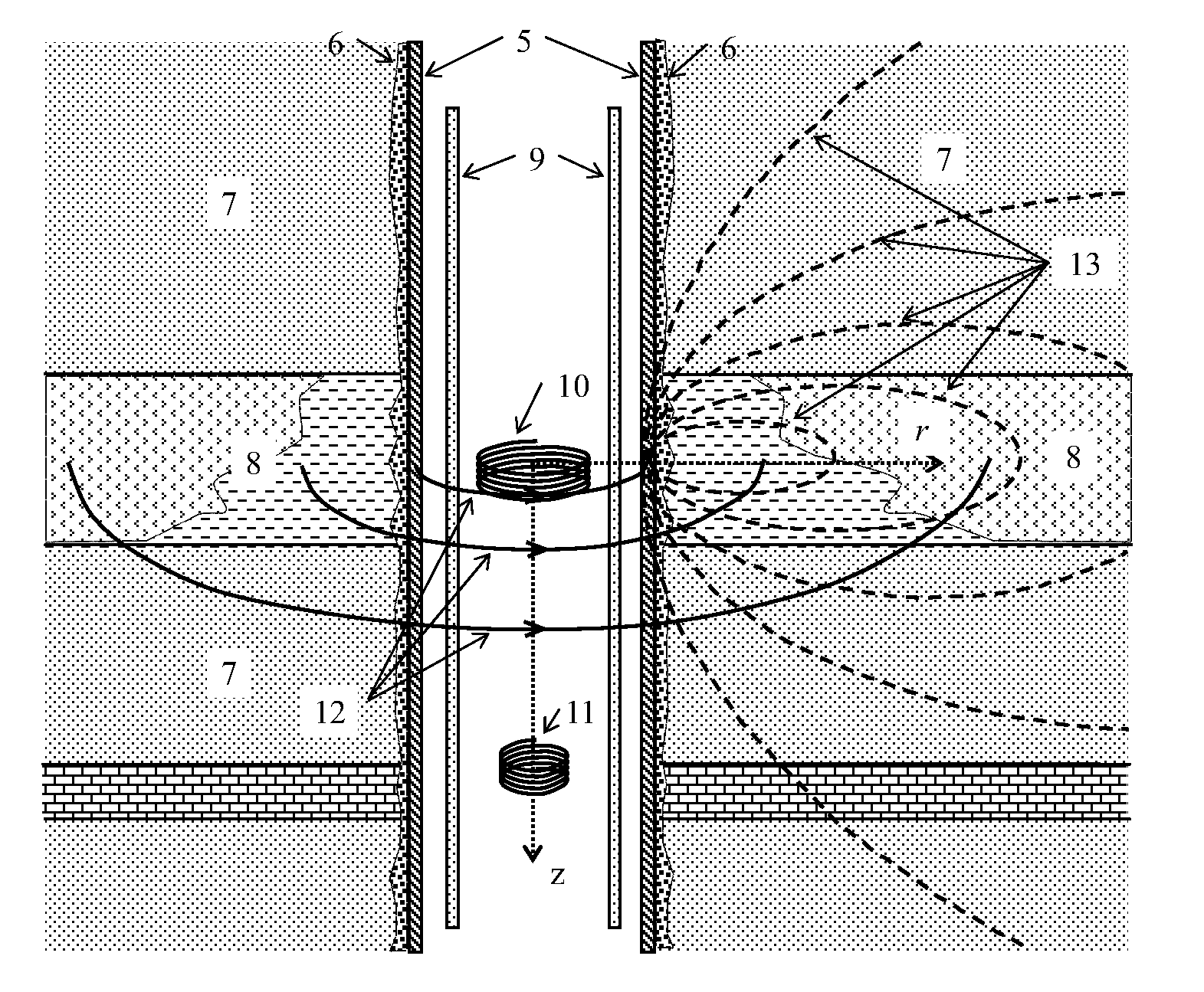

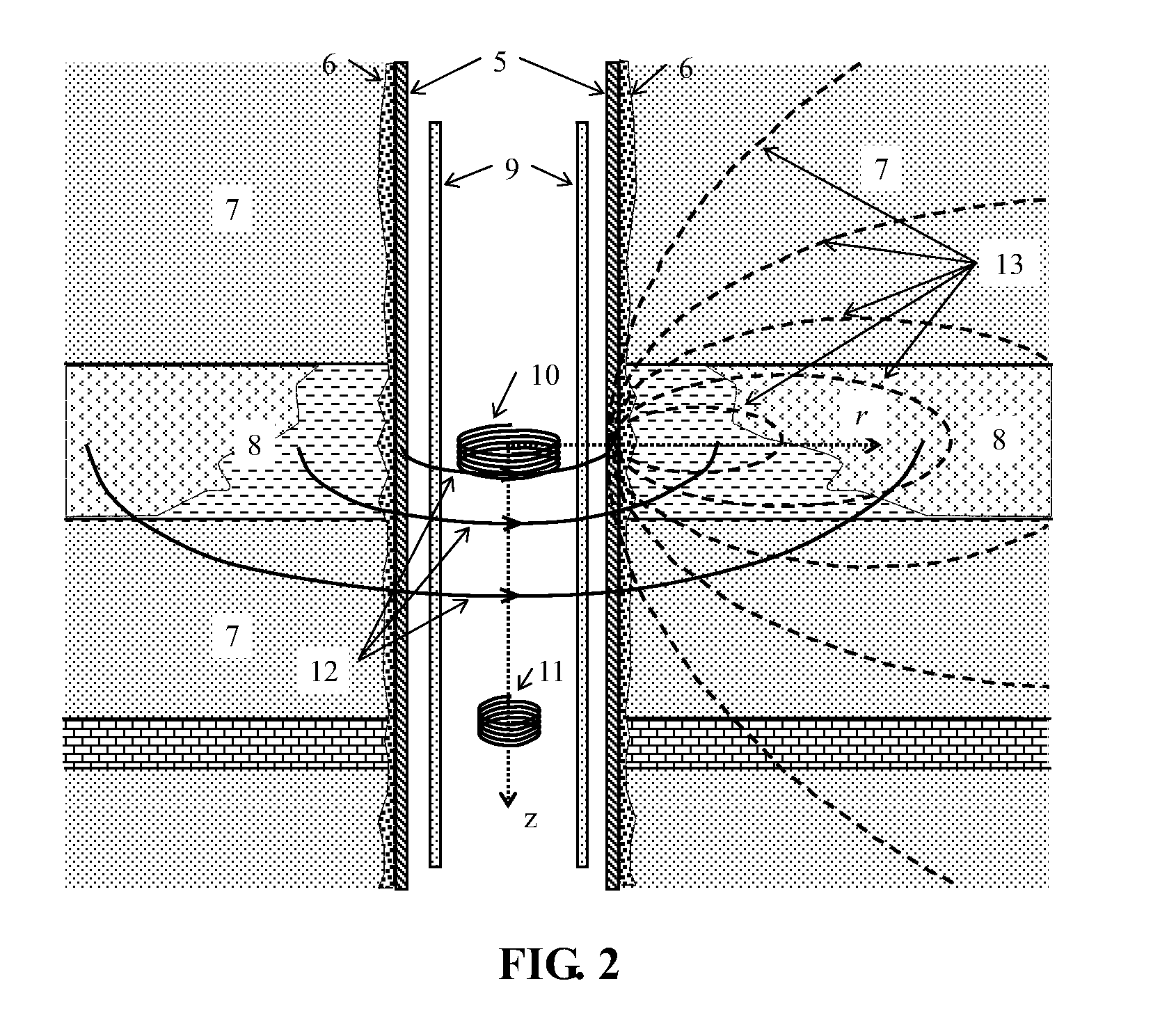

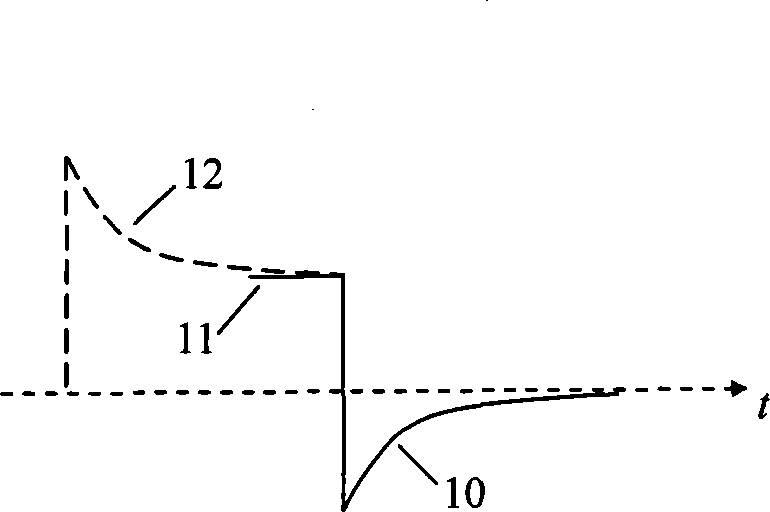

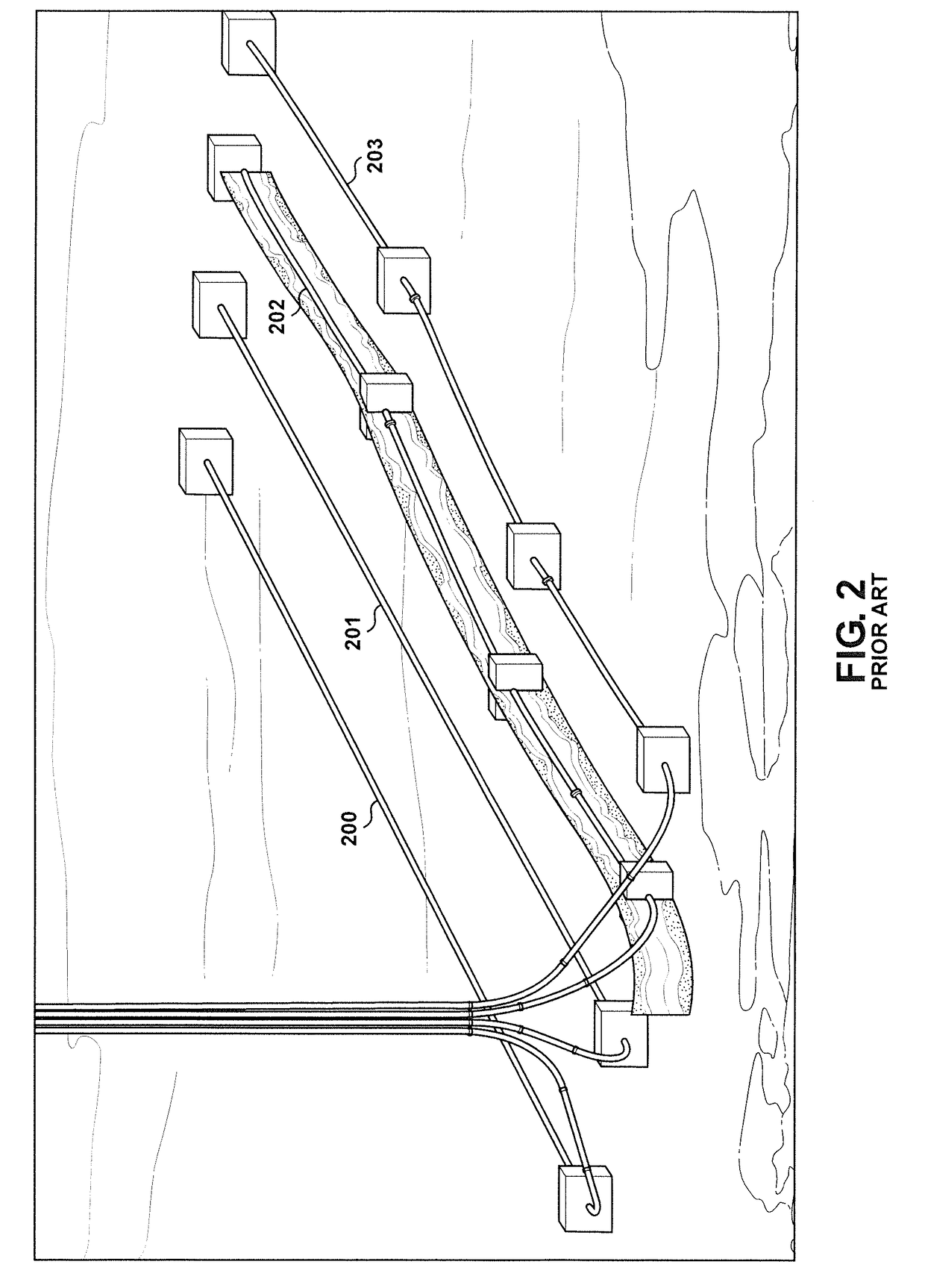

Method for detecting formation resistivity outside of metal casing using time-domain electromagnetic pulse in well

InactiveUS20120215448A1Power consumption of power supply is notReduce use costElectric/magnetic detection for well-loggingSeismology for water-loggingDigital recordingElectromagnetic pulse

A method for detecting formation resistivity outside of metal casing using time-domain electromagnetic pulse in a borehole, the method including steps of a) providing a borehole large power pulse transmitting source, recording an induced electromotive force ε, and full time digital recording a transmitted waveform and a received signal; b) conducting transmission-reception and superimposing received signals to improve signal to noise ratio; c) calculating corresponding casing response according to known casing parameters and recorded current waveform of the transmitting source to obtain a relative induced electromotive force Δεf; d) correcting relative induced electromotive force value; e) carrying out one-dimensional inversion and converting the observation signal into radial variation information of the formation resistivity; f) obtaining a two-dimensional image of the longitudinal and radial resistivity distribution of outer cased formation resistivity for measured well sections; and g) determining residual oil distribution in a reservoir from outer cased reservoir resistivity distribution.

Owner:YANGTZE UNIVERSITY

Method for preparing vacuum zone melting high resistant silicon single crystal

ActiveCN101525764AHigh resistivityEnhanced ultra-high purityPolycrystalline material growthBy zone-melting liquidsZone meltingSingle crystal

The invention discloses a method for preparing vacuum zone melting high resistant silicon single crystal, comprising the two sequential major processes: polysilicon purification and crystal forming of silicon single crystal, wherein, the process of polysilicon purification comprises the steps of cleaning fire, charging, evacuating, preheating, melting materials heat sealing, growing narrow necks, shouldering, shoulder circuiting, equating diameter, ending and repeating; the process of crystal forming of silicon single crystal comprises the steps of cleaning fire, charging, evacuating, preheating, processing of chemicals, crystal seeding, shouldering, shoulder circuiting, equating diameter, ending and blowing out. With the method of the invention adopted to prepare silicon single crystal, electric resistivity, ultra-high purity, resistivity profile, uniformity of cross-section electric resistivity and minority carrier lifetime are greatly improved; purity of the silicon single crystal is above 11N, electric resistivity reaches 8000 omega / cm-30000omega / cm, uniformity of cross-section electric resistivity is less than 15%, and minority carrier lifetime is more than 600-1000Mus, thus greatly improving performance, stability and safety of the devices while realizing mass production of vacuum zone melting high resistant silicon single crystal.

Owner:峨嵋半导体材料研究所

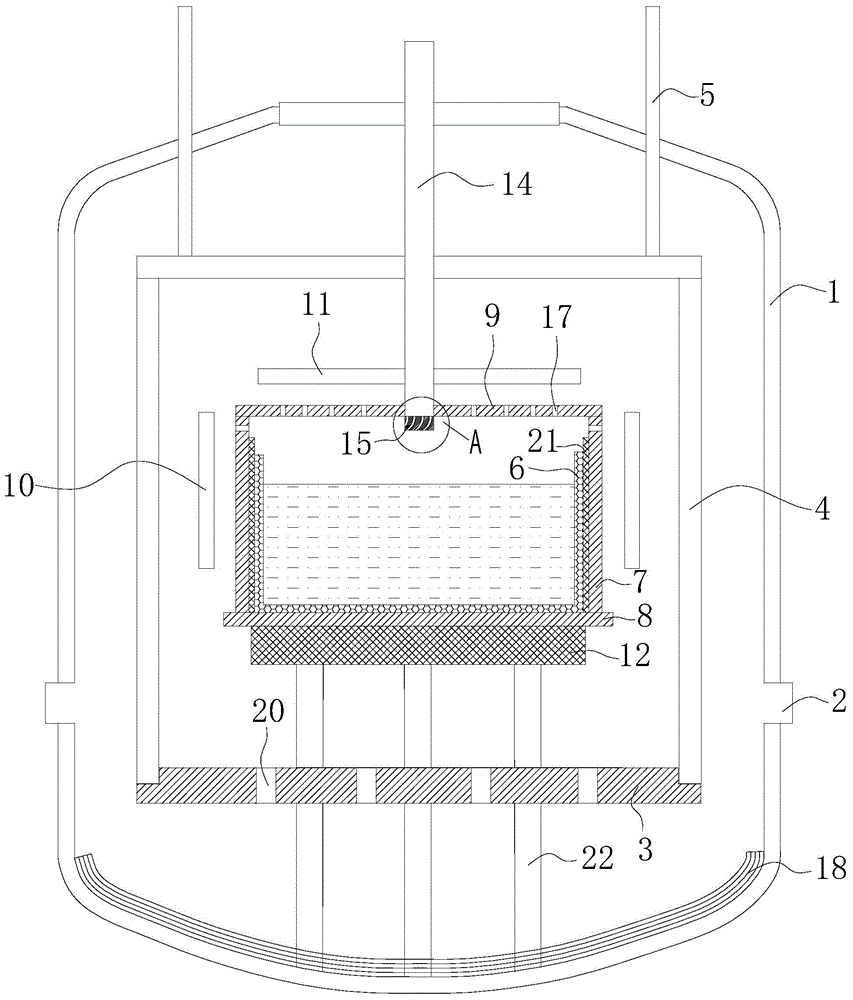

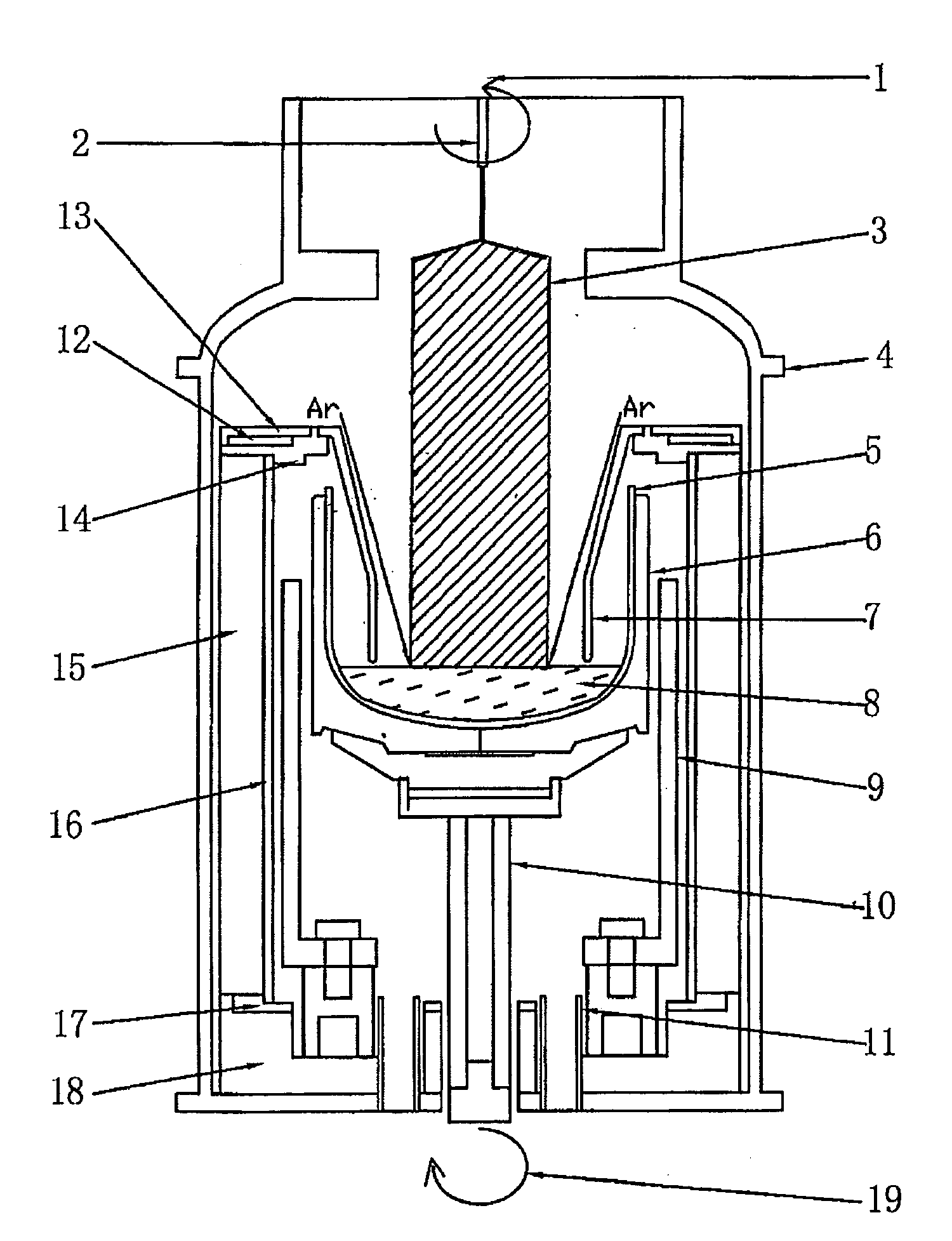

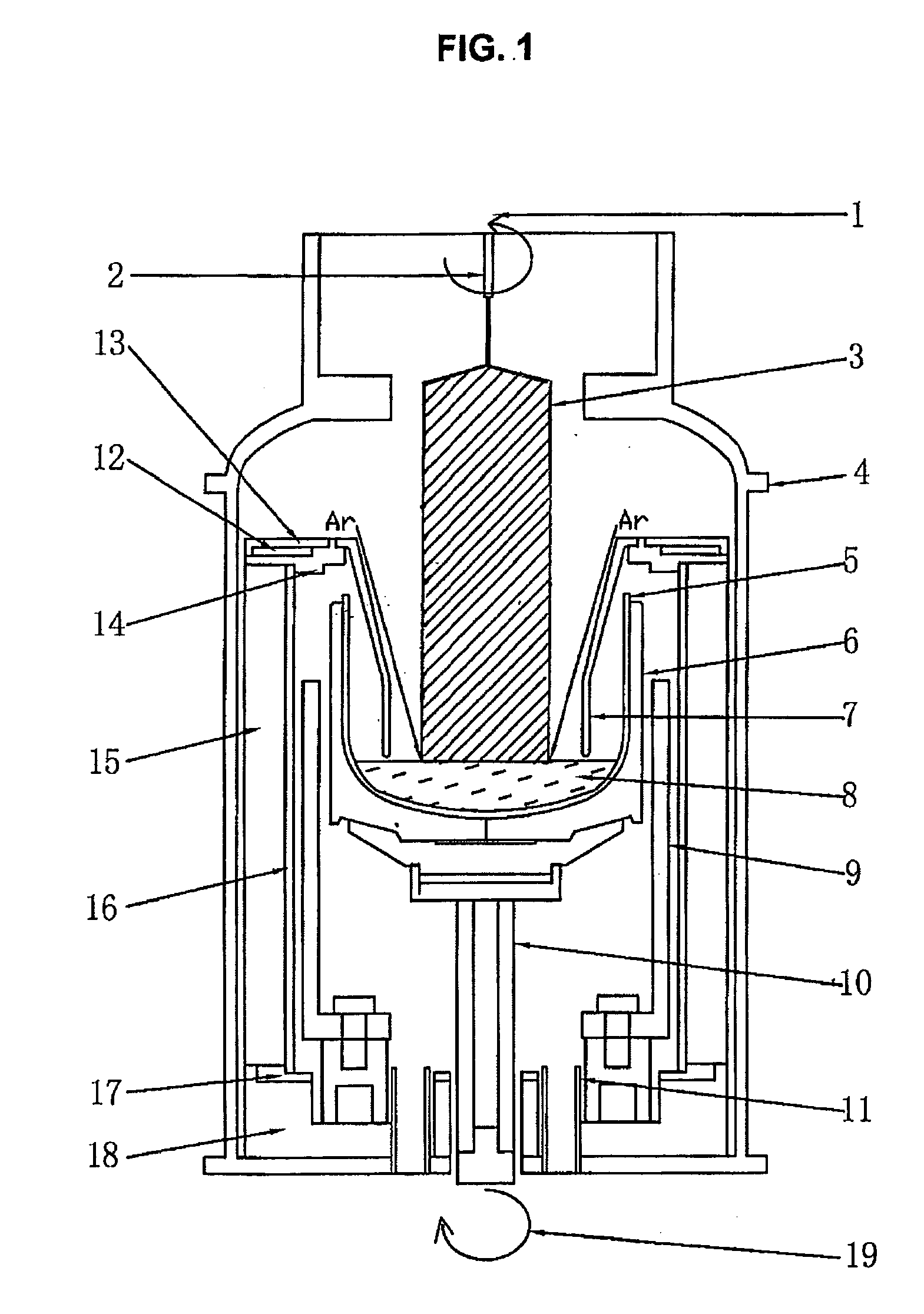

Polycrystalline silicon ingot furnace

ActiveCN103556220ADiffuse fullyAvoid enriched regionsPolycrystalline material growthSingle crystal growth detailsCrucibleIngot

The invention discloses a polycrystalline silicon ingot furnace which can enable the resistivity of a cast ingot to be distributed uniformly. A stop block for sealing a gas outlet is arranged at the gas outlet of a gas inlet pipe of the polycrystalline silicon ingot furnace, a plurality of spiral holes with the same helical direction are formed in the stop block, the plurality of the spiral holes are arranged around the central axis of the gas inlet pipe, inlets of the spiral holes are positioned on the upper surface of the stop block, and outlets of the spiral holes are positioned on the lower surface of the stop block. After argon gas passes through the spiral holes, the gas outlet way of the argon gas is changed from original direct blowing to rotating gas outlet, and the argon gas which is sprayed out of the spiral holes in a rotating manner can drive a silicon solution in a crucible to rotate, so that impurities contained in the silicon solution can be fully diffused in the silicon solution, the distribution of liquid-phase components is uniform, and the uniform distribution of the resistivity of the cast ingot is ensured; furthermore, the stirring of the silicon solution in the crucible can enable the volatile impurities contained in the silicon solution to be volatilized as soon as possible so as to ensure the quality and performance of the cast ingot. The polycrystalline silicon ingot furnace is suitable for popularization and application in the field of polycrystalline silicon production equipment.

Owner:LESHAN TOPRAYCELL

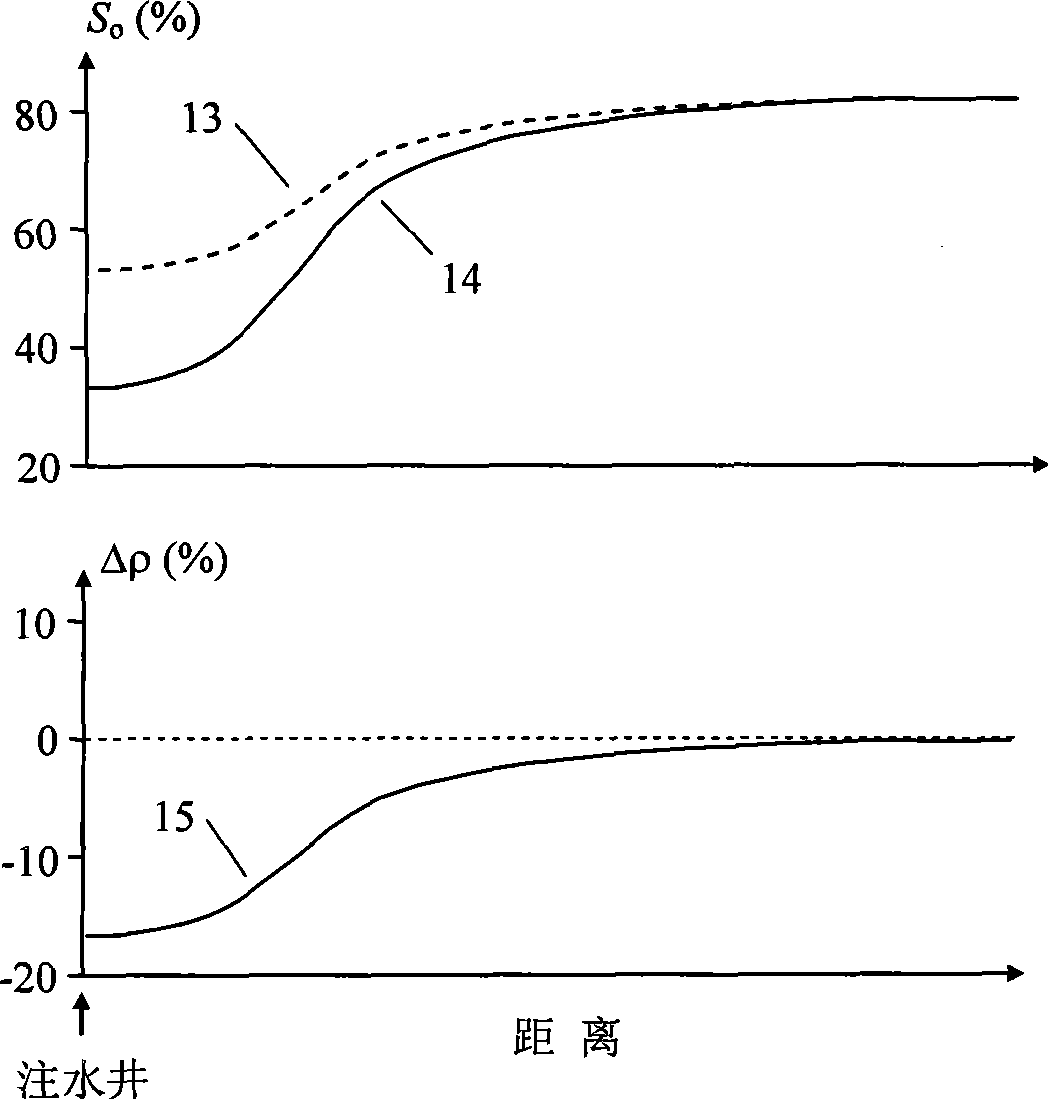

Electromagnetical method for dynamically monitoring oil reservoir injection-production

ActiveCN101382070AElectromagnetic method for dynamic monitoringBorehole/well accessoriesPorosityDynamic monitoring

The invention provides an electromagnetic method for dynamically monitoring the injection-production of oil pool in the geophysical exploration and the oilfield development technologies, particularly comprising the steps of: measuring transient electromagnetic for the first time in a work area, recording and handling the time variable data of horizontal components of Ex and Ey of electric field and a vertical component of the magnetic field Bz; obtaining the resistivity distribution of the measured area with the depth according to the reversion of an apparent resistivity value; measuring the transient electromagnetic for the second time in the work area on ground; calculating difference between the data obtained in two different times to obtain a plane distribution diagram of the field value of a reservoir bed or the difference value of the resistivity; according to the features of a facies zone of the reservoir in work area in water driving and steam driving, the plane distribution diagram of the resistivity and the difference value is used to reflect the porosity and permeability distribution in work area reservoir and determine the proliferation of the injection agent and the position of the remaining oil. The electromagnetic method improves the signal to noise ratio for observing data under a strong interference environment, enhances the capability of extracting weak signals, increases the accuracy and resolution of reversion and can realize dynamic monitoring of oil pool developing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

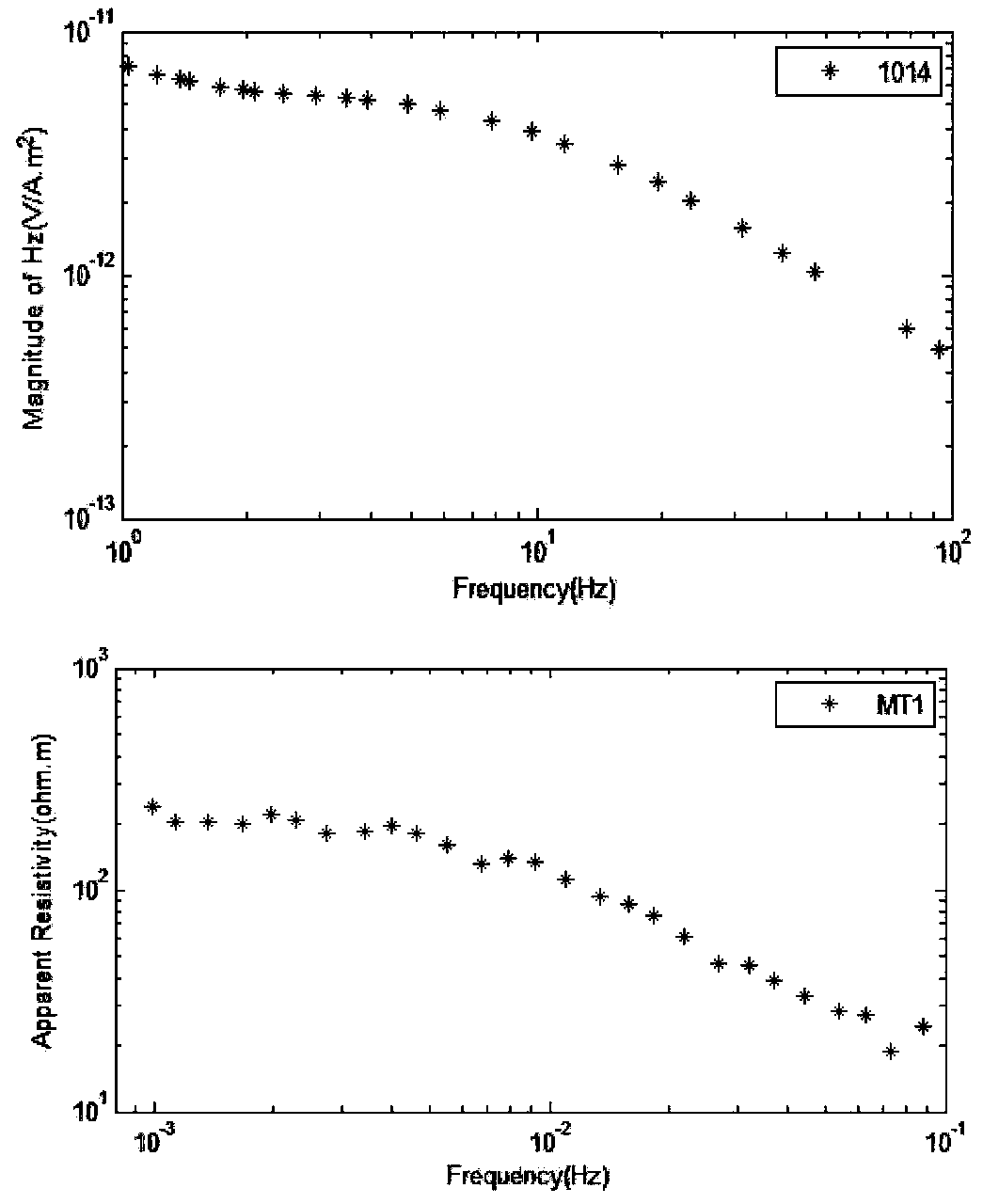

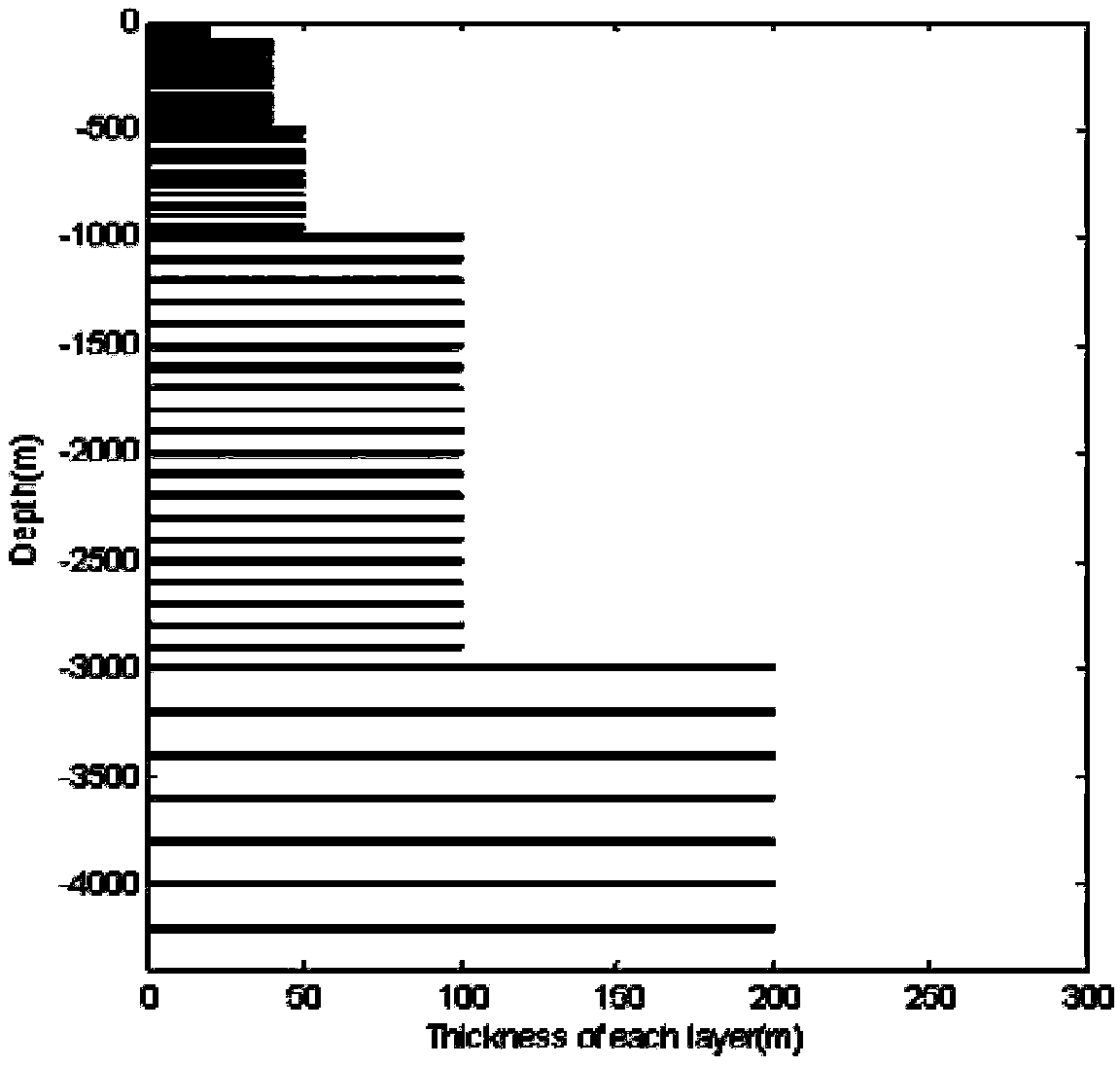

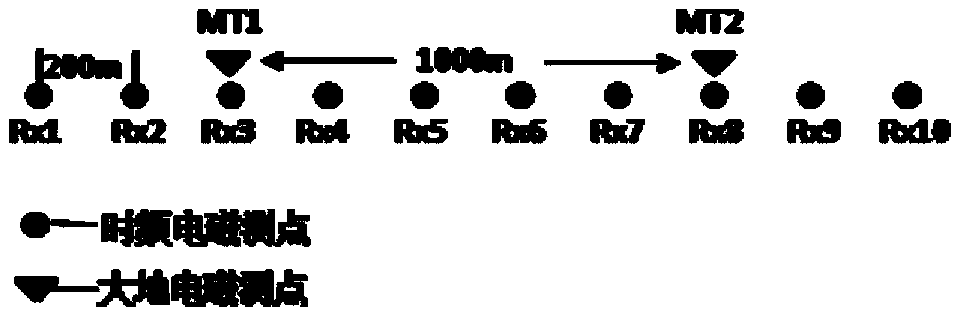

One-dimensional joint inversion method for time-frequency electromagnetic data and magnetotelluric data

ActiveCN104280782AElectric/magnetic detectionAcoustic wave reradiationImage resolutionInversion Time

The invention discloses a one-dimensional joint inversion method for time-frequency electromagnetic data and magnetotelluric data. The transmitting frequency of the joint inversion time-frequency electromagnetism ranges from 0.025 Hz to 100 Hz, the frequency of the magnetotelluric sounding ranges from 0.0005 Hz to 320 Hz, the distances between all time-frequency electromagnetic measuring points and all magnetotelluric measuring points are calculated, the nearest magnetotelluric measuring point is obtained, data of the magnetotelluric measuring point are extracted, a joint inversion Jacobian partial derivative matrix of the time-frequency electromagnetism and the magnetotelluric sounding is calculated, a target function is calculated according to the regularization inversion principle, the target function is minimized through the conjugate gradient iterative algorithm, and when the fitting error of the target function reaches the set error standard or the iterations exceed the set maximum iteration number, the joint inversion is finished. According to the one-dimensional joint inversion method, the underground dielectric resistivity distribution below a measuring line can be obtained, the interpretation requirements for structures, faults and entrapments can be met, and the joint inversion result shows that the resolution from shallow to deep is higher than the resolution of the inversion result obtained by independently using time-frequency electromagnetic data.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

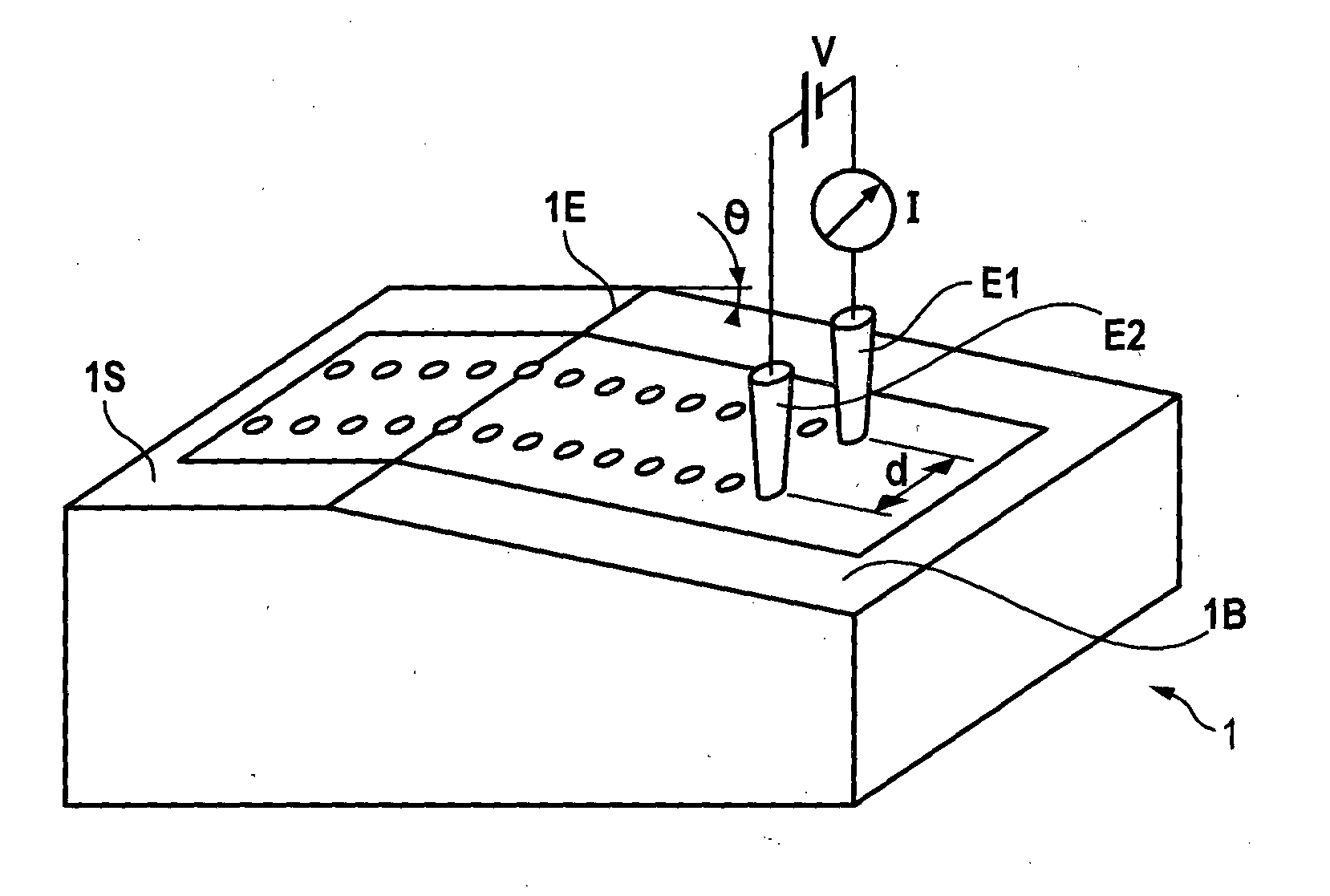

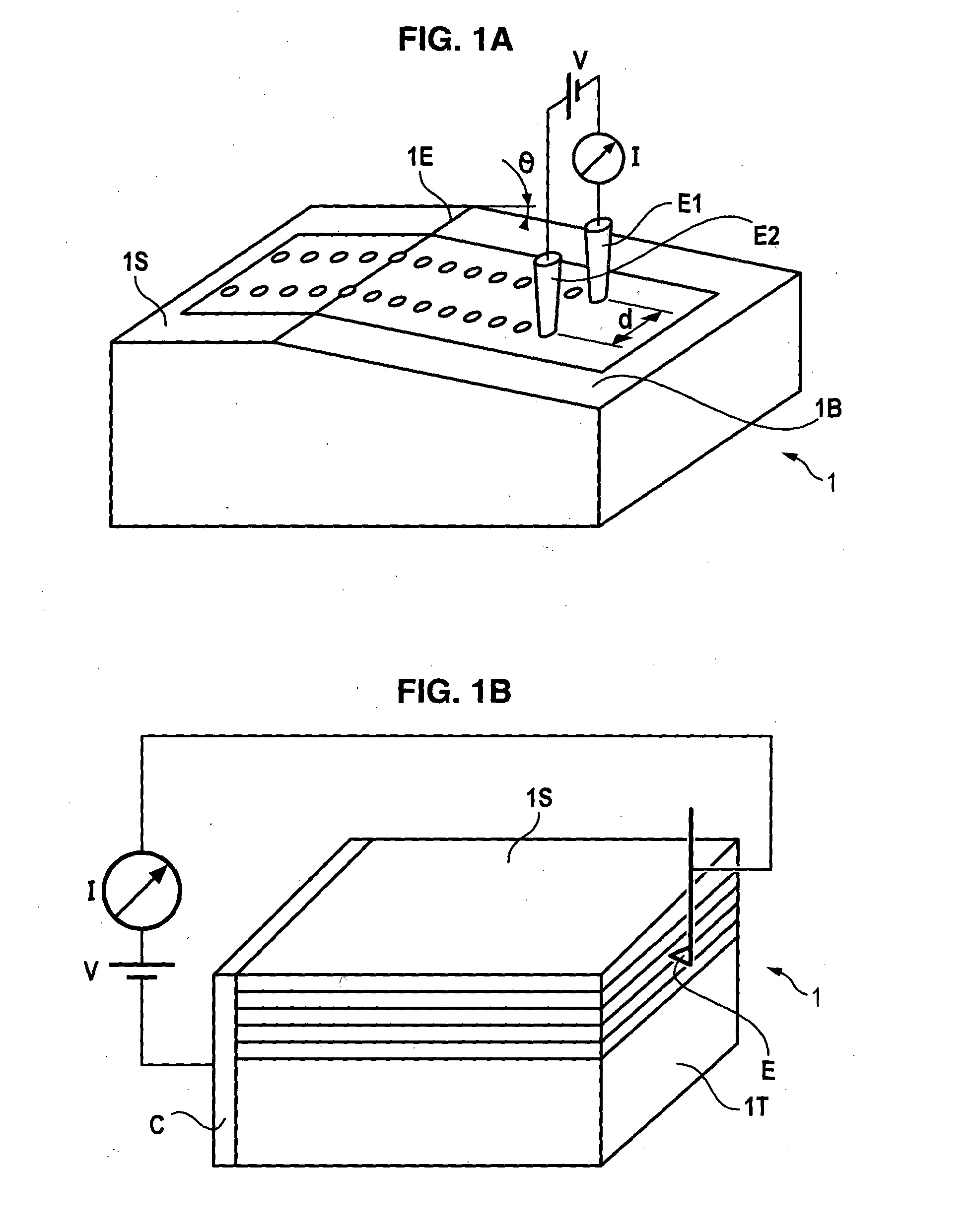

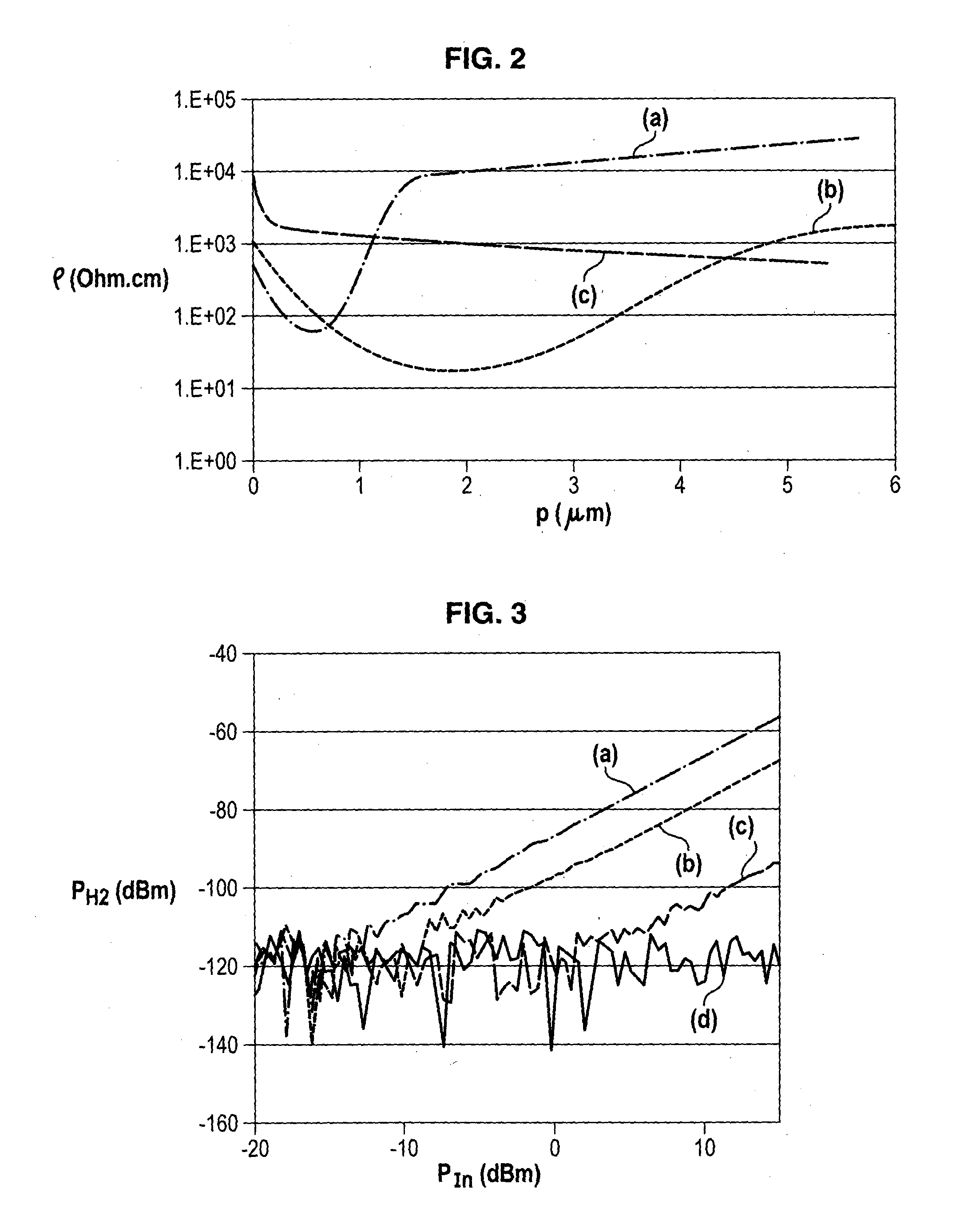

Method and device for testing semiconductor subtrates for radiofrequency application

InactiveUS20150168326A1Improve performanceResistance/reactance/impedenceVoltage-current phase angleSemiconductorElectric field

The invention relates to a method for testing a semiconductor substrate (1) for radiofrequency applications, characterized in that the electrical resistivity profile of the substrate as a function of depth, is measured and, using the profile, a criterion is calculated, defined by the formula (I): where D is the integration depth, σ(x) is the electrical conductivity measured at a depth x in the substrate, and L is a characteristic attenuation length of the electric field in the substrate. The invention also relates to a method for selecting a semiconductor substrate (1) for radiofrequency applications and to a device for implementing these methods.

Owner:SOITEC SA

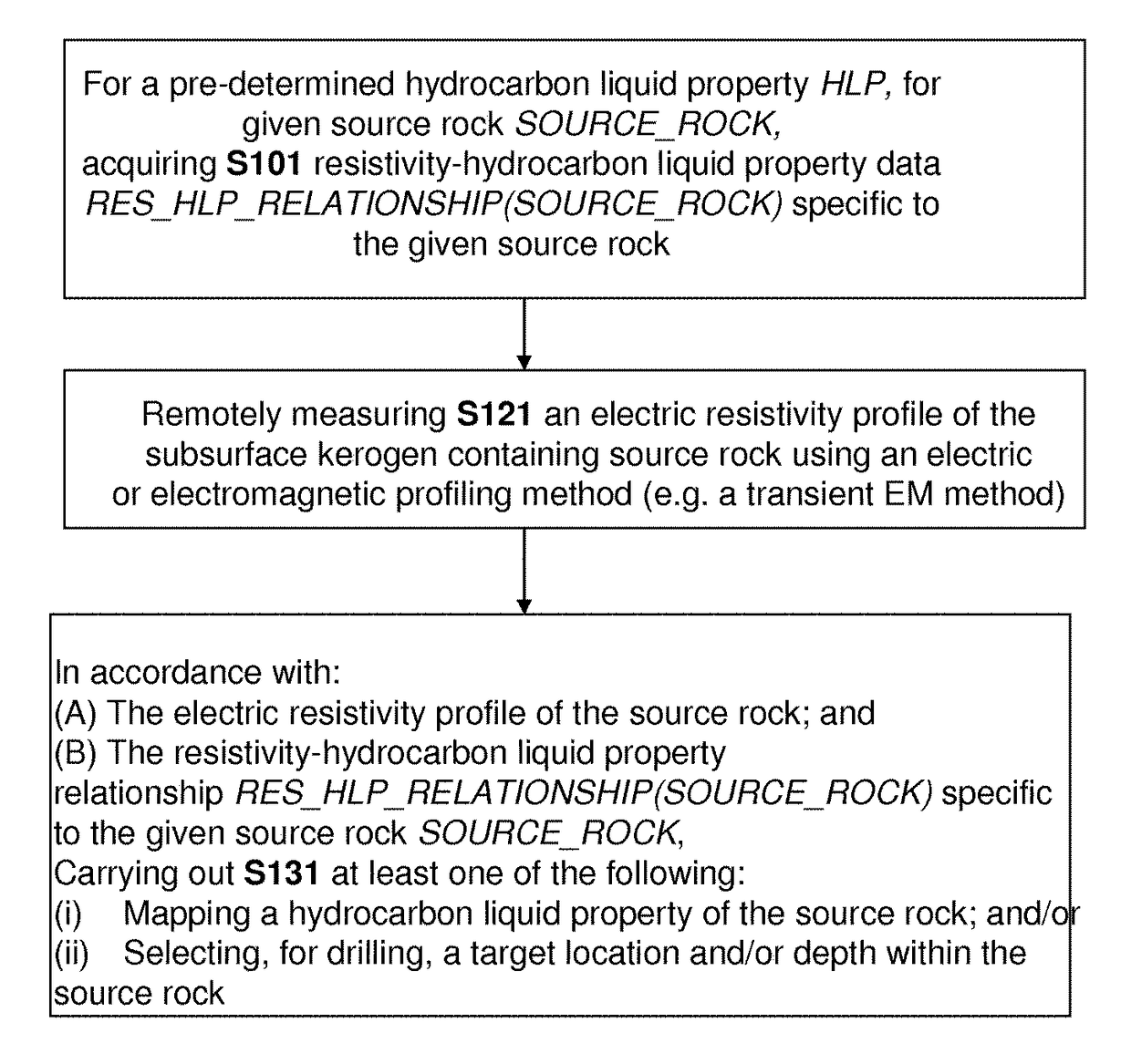

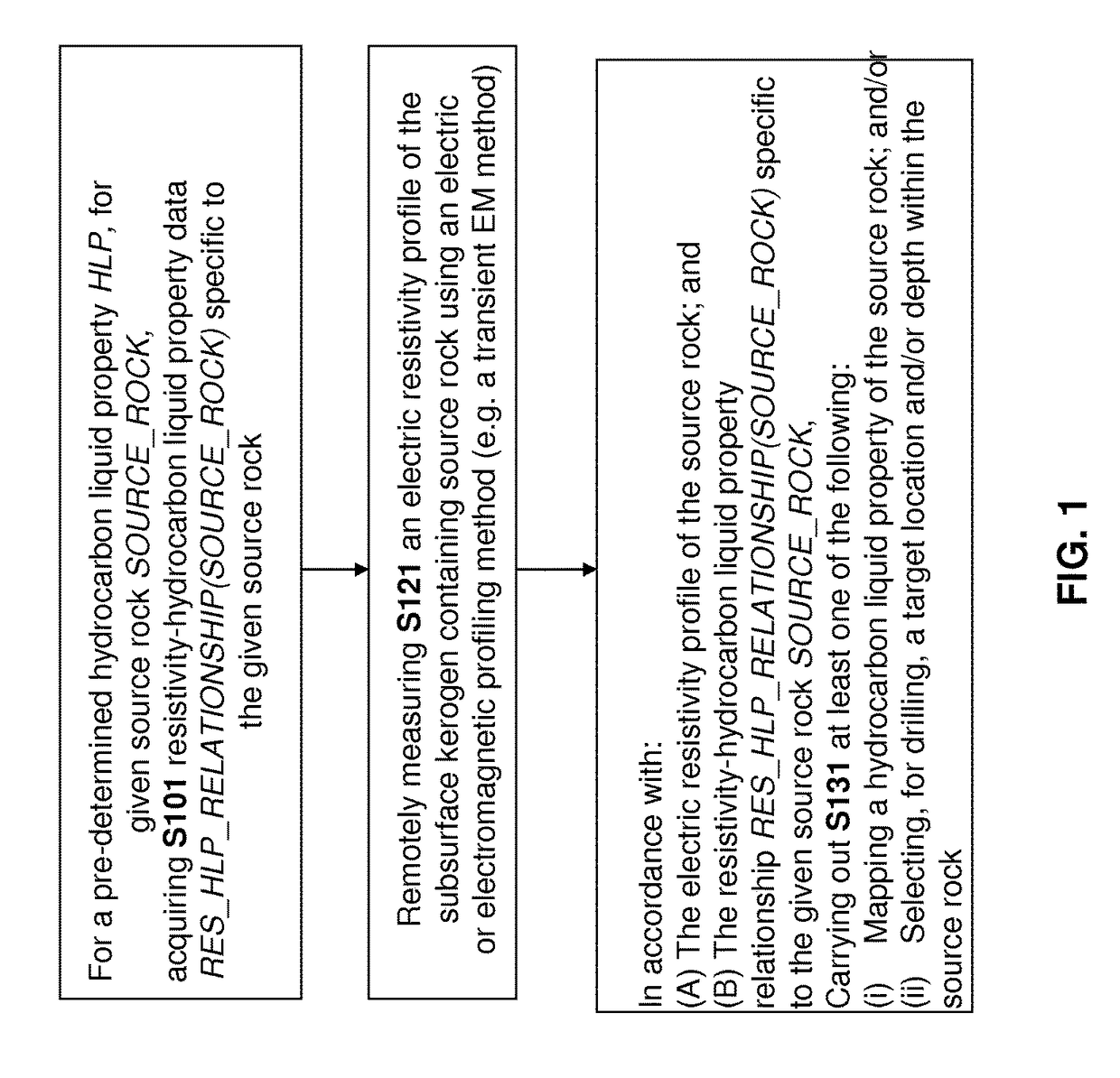

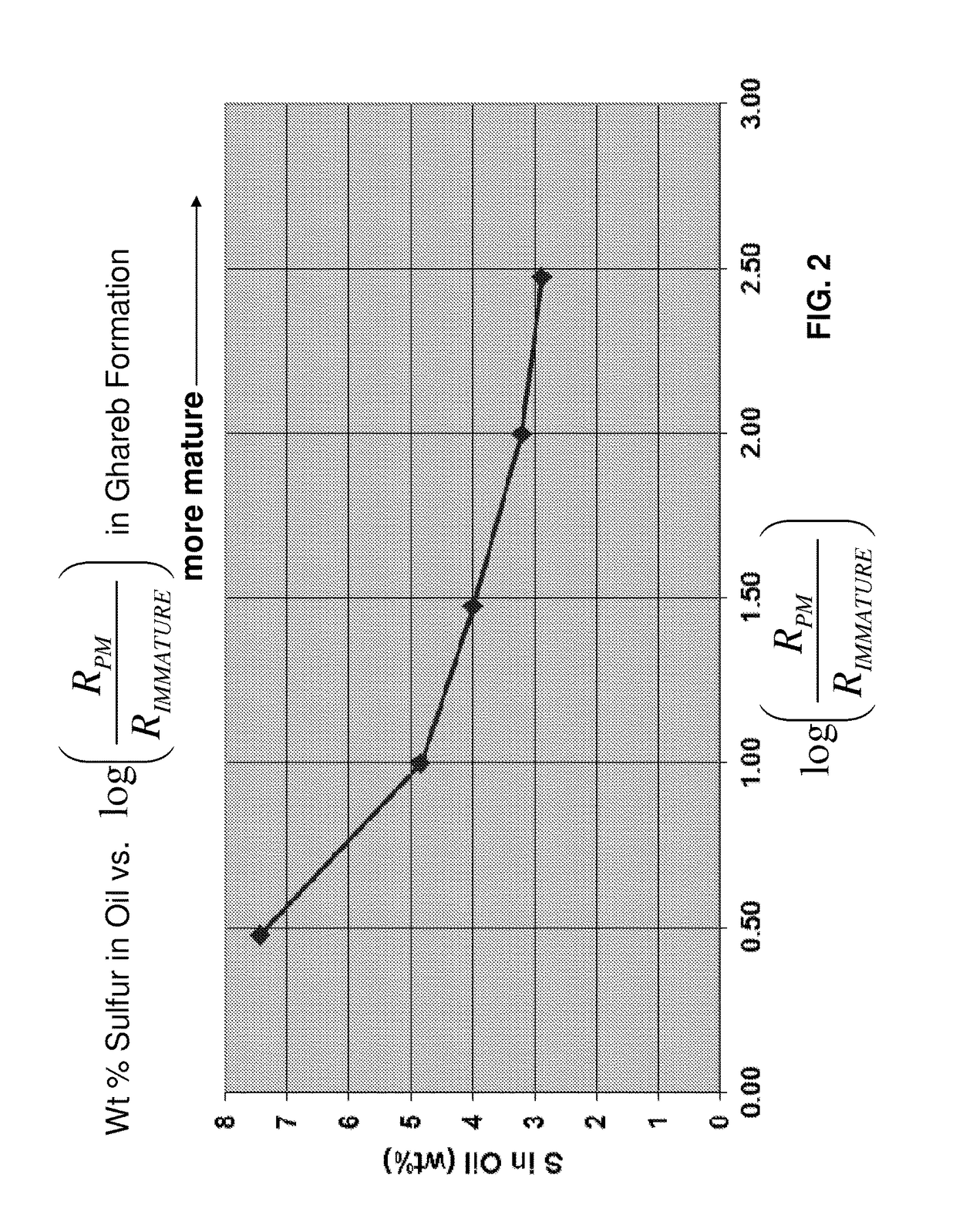

Mapping hydrocarbon liquid properties of a kerogencontaining source rock

ActiveUS9784882B2Electric/magnetic detection for well-loggingAcoustic wave reradiationKerogenTight oil

A method is disclosed for generating an areal map of a pre-determined hydrocarbon liquid property of a subsurface kerogen-containing source rock from an electromagnetic resistivity profile. Preferably, the profile is generated by a transient EM method such as a long-offset transient electromagnetic (LOTEM) method. In some embodiments, the areal map is generated by employing resistivity-hydrocarbon liquid-quality relationship data describing a relationship between (i) a property of hydrocarbon liquid generated within the source rock pore space to (ii) an electrical resistivity of the source rock. In some embodiments, it is possible to acquire such data even in the absence of source rock samples where the hydrocarbon liquids within the samples has been preserved. The areal map is useful for determining a target location and / or depth in the source rock to drill for oil. The presently-disclosed techniques are particularly relevant to tight oil formations.

Owner:GENIE IP

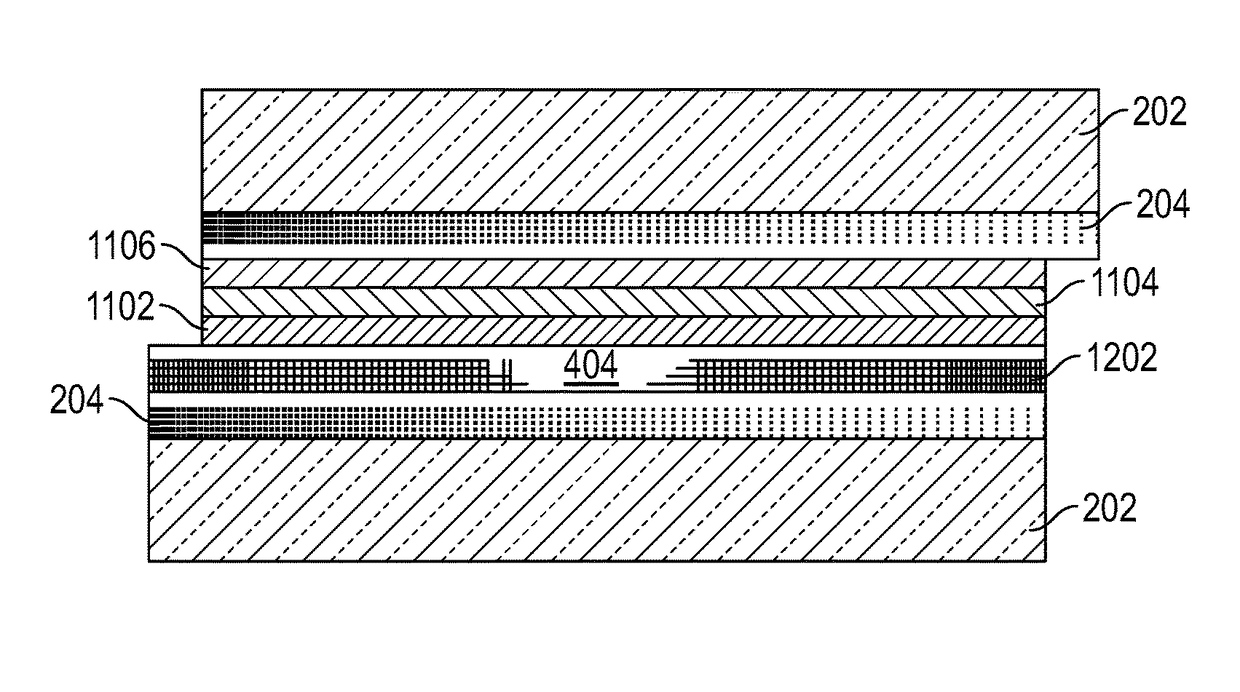

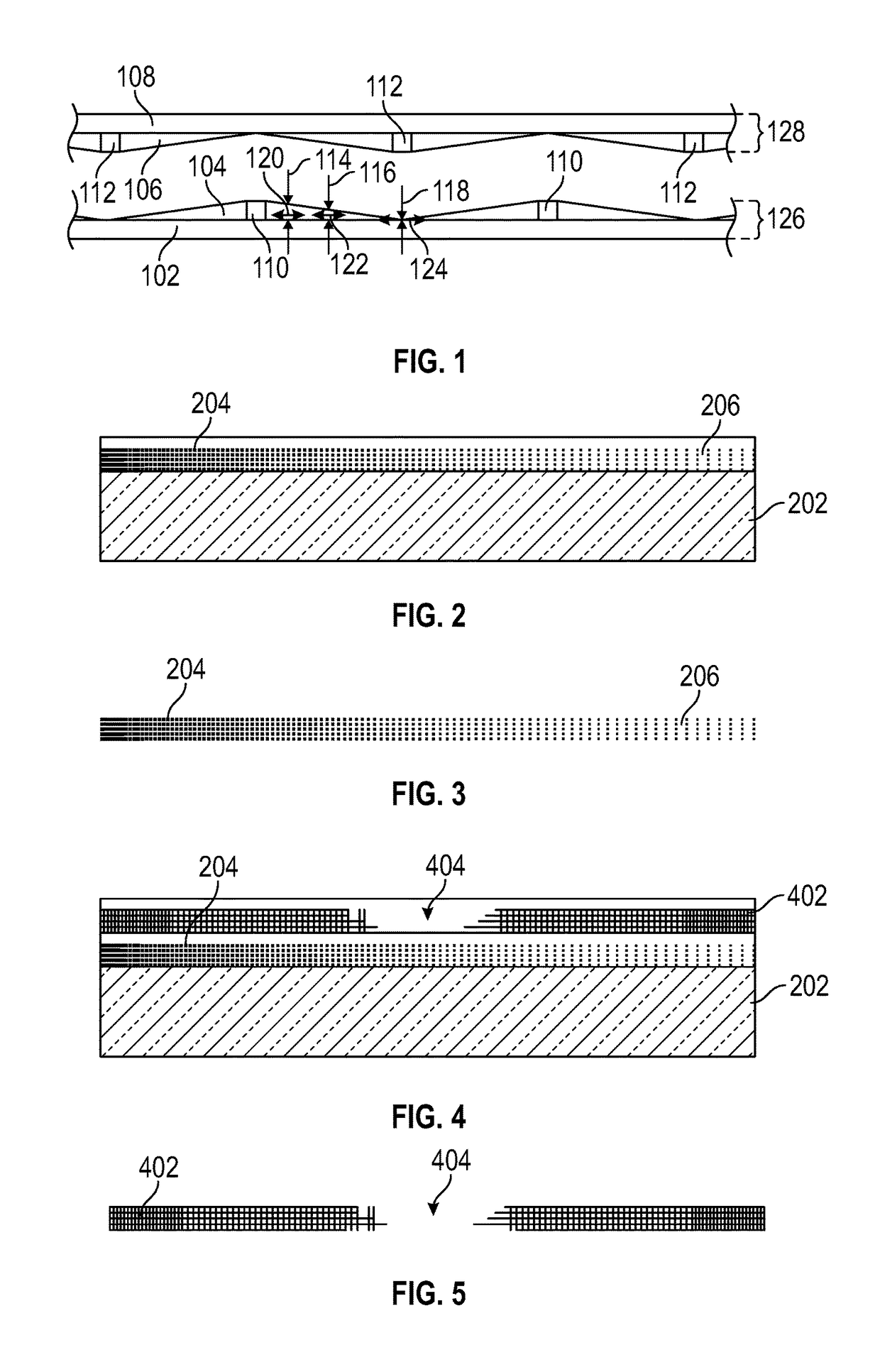

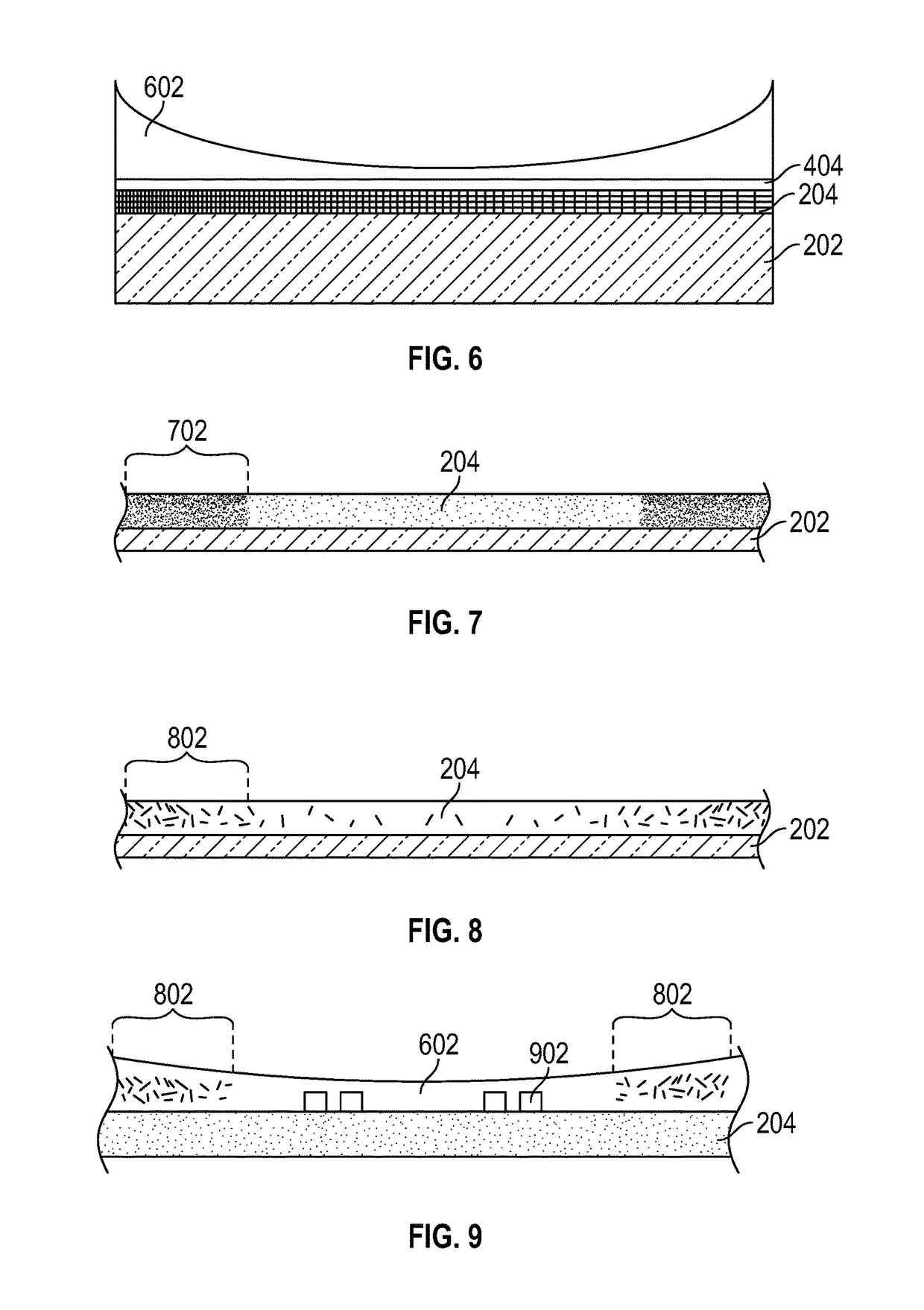

Manufacturing methods for a transparent conductive oxide on a flexible substrate

ActiveUS9658508B1Lower resistanceImprove transmittanceNon-linear opticsElectrical resistance and conductanceElectrochromism

An electrochromic device is provided. The device includes a substrate and an electrochromic stack on the substrate. The stack includes a first set of bus bars, a first transparent conductive layer, at least one electrochromic layer, a second transparent conductive layer, and a second set of bus bars, wherein at least one of the first transparent conductive layer or the second transparent conductive layer includes resistivity that varies by horizontal location according to a resistivity profile. In some embodiments the resistivity profile has a vertical component that may or may not be in addition to the horizontal component. Various embodiments of these materials can be tuned as to profiles of vertical resistance and horizontal sheet resistance.

Owner:KINESTRAL TECH

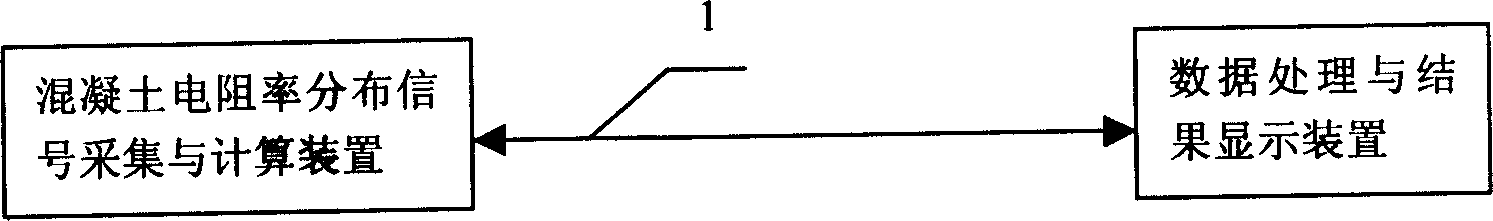

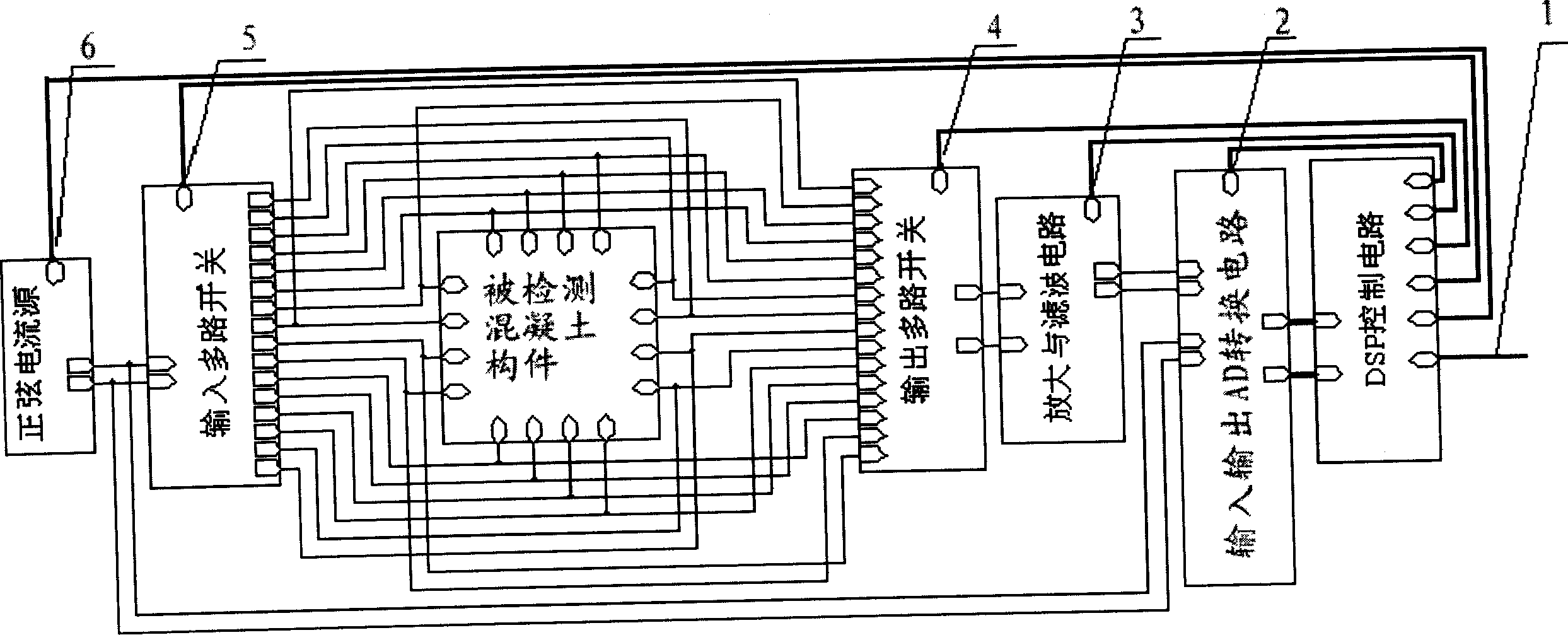

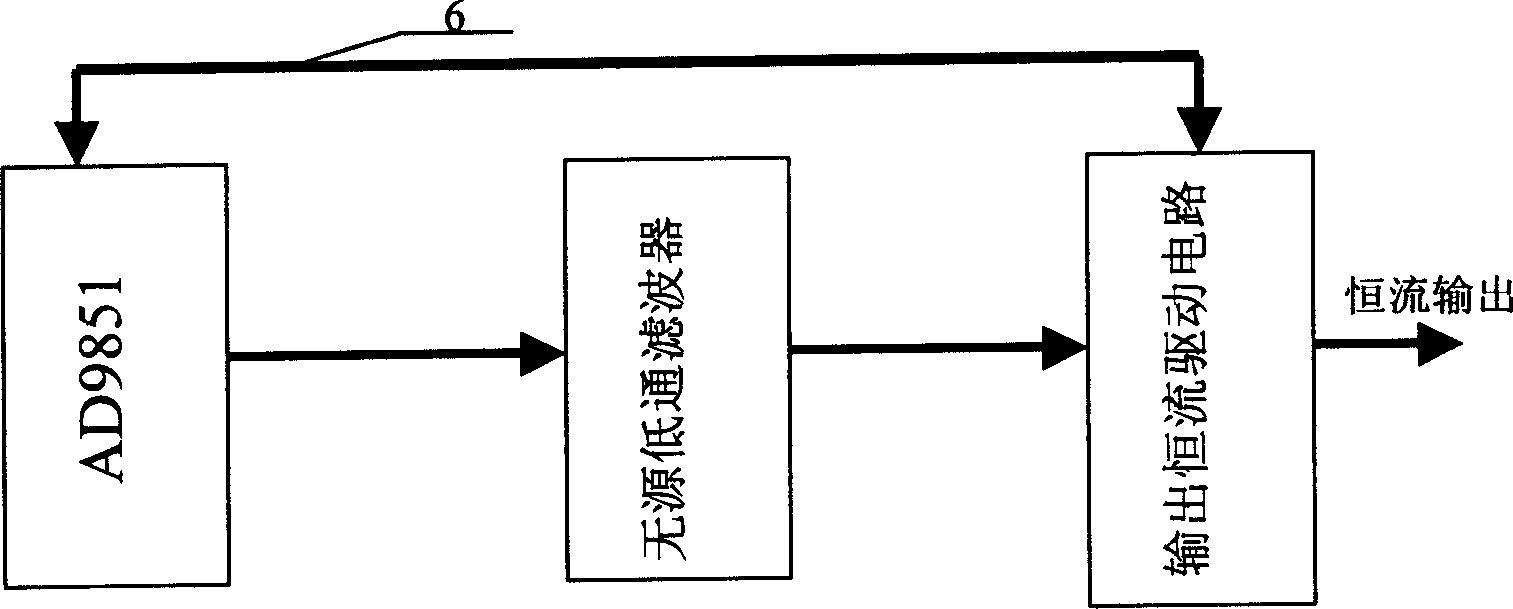

Method and apparatus for concrete damage detection based on impedance imaging

InactiveCN1837805AReal-time monitoring of injury developmentMaterial resistanceElectrical resistance and conductanceMultiway switching

This invention relates to a method and apparatus for concrete damage detection based on impedance imaging, which comprises the following steps: (1) setting multiple electrodes on target; (2) connecting the excitation input ports of former electrodes to the multi-way input switch; (3) forcing the drive sine current to every two electrodes by turns, measuring the current amplitudes and phases; (4) computing resistance distribution in the concrete; (5) acquiring and storing computation data to compare with given data for analysis.

Owner:SICHUAN UNIV

Crystalline silicon preparation method and crystalline silicon

InactiveCN105755532ALow resistivityIncrease concentrationPolycrystalline material growthBy pulling from meltDopantCrucible

The invention provides a crystalline silicon preparation method.The crystalline silicon preparation method includes that polycrystalline silicon and a dopant are added into a crucible of a crystalline silicon ingot furnace or a single crystal furnace; in presence of protective gas, the polycrystalline silicon and the dopant are heated to melt completely to form silicon melts, crystalline silicon growth parameters are adjusted to enable the silicon melts to start to grow crystals, and in a crystal growing process, when resistivity of the crystals reaches clinical resistivity, new silicon melts formed by the polycrystalline silicon are replenished into residual silicon melts in the crucible to enable the resistivity of the crystals to be adjusted to target resistivity, and the new silicon melts continue growing crystals so as to obtain crystalline silicon with target yield after crystallization of the silicon melts in the crucible is completed.The crystalline silicon preparation method is capable of solving the problems of too many low-resistivity regions, scattered resistivity distribution and low crystalline silicon yield in the prior art.The invention further provides the crystalline silicon.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

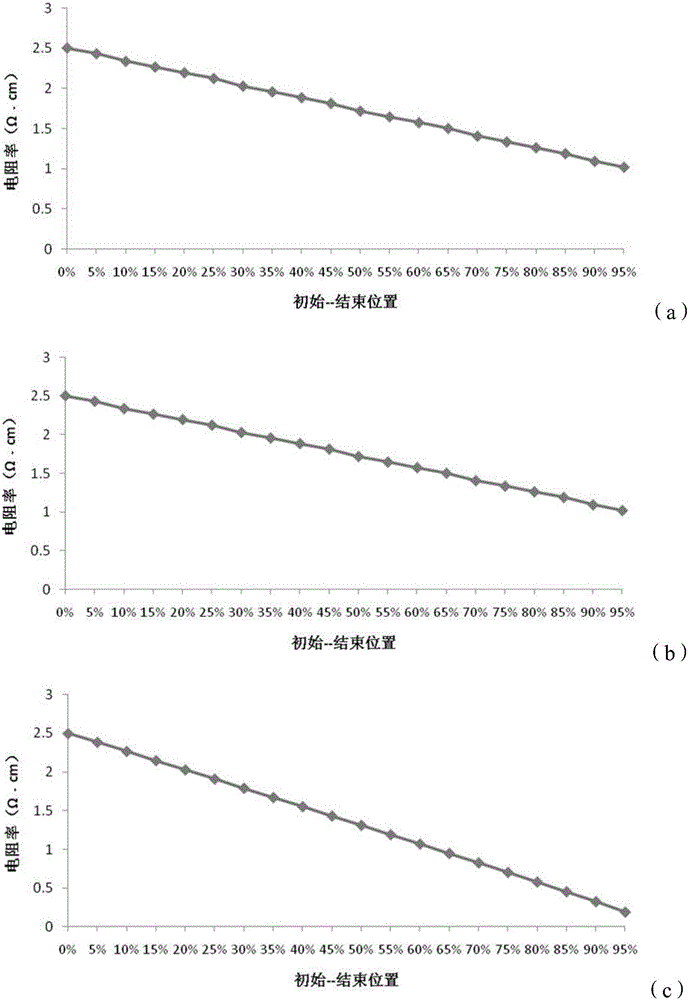

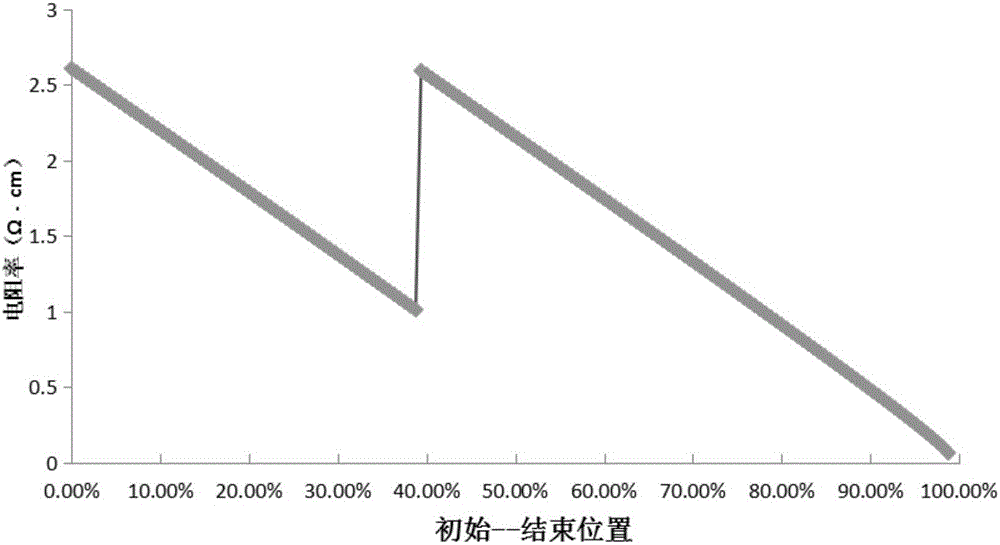

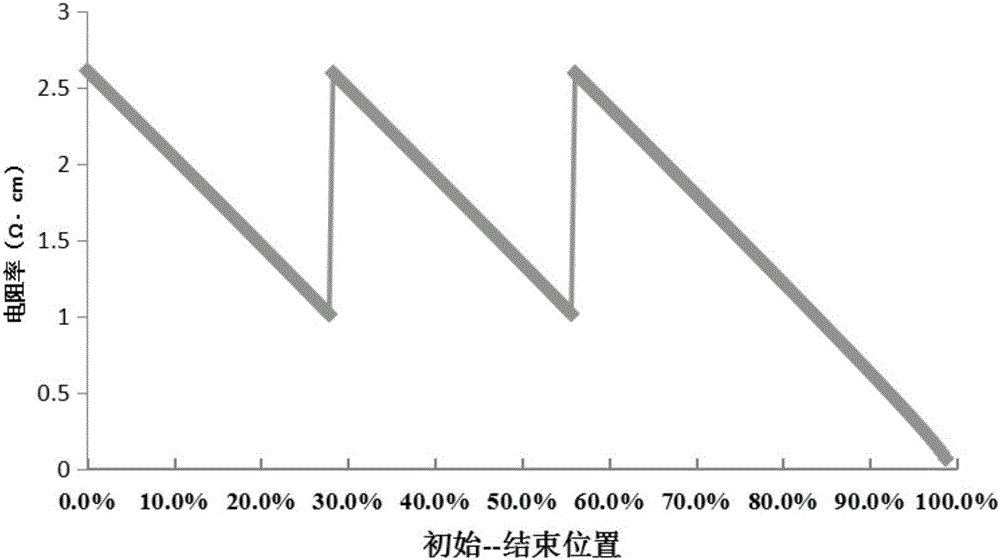

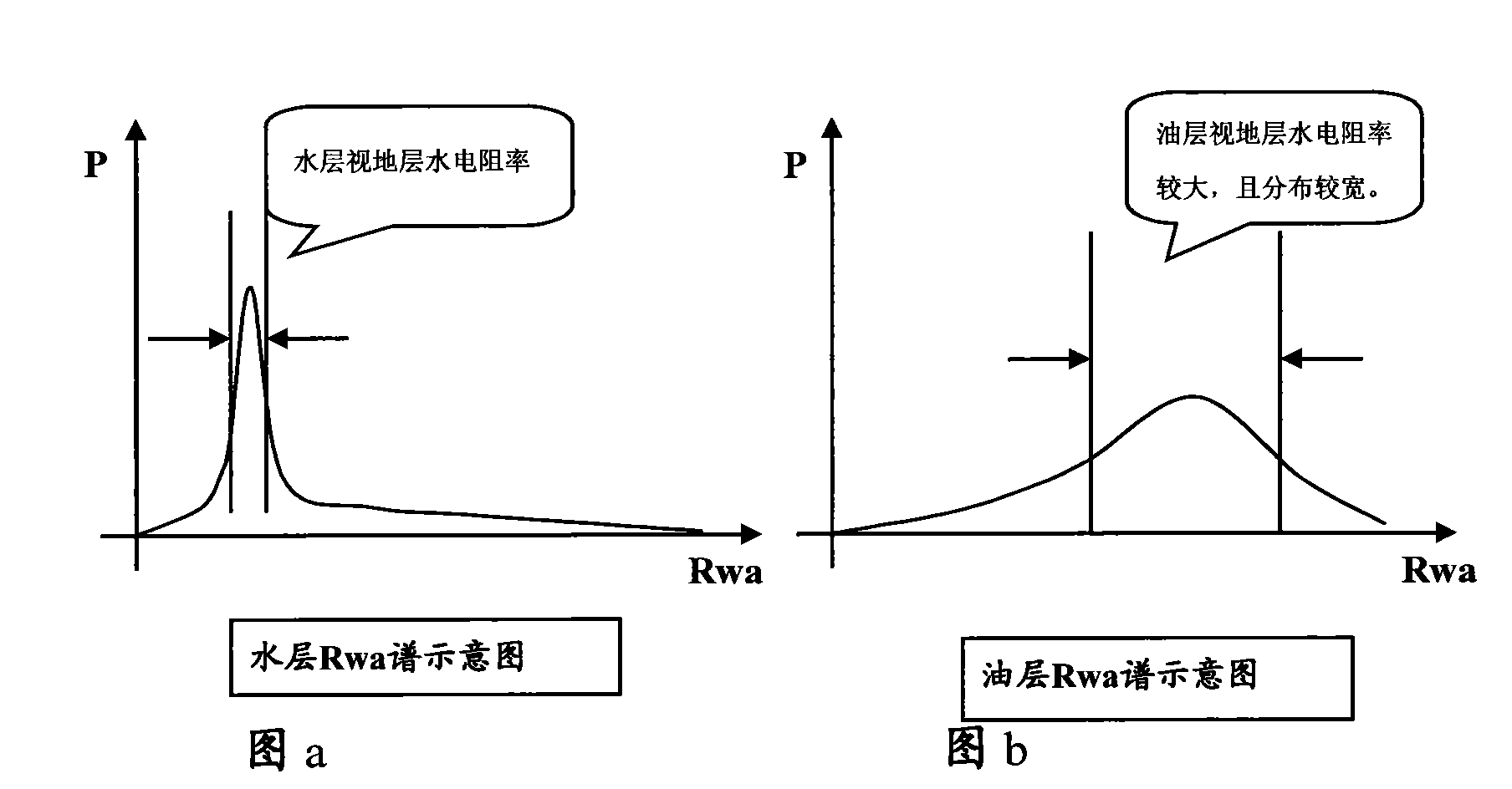

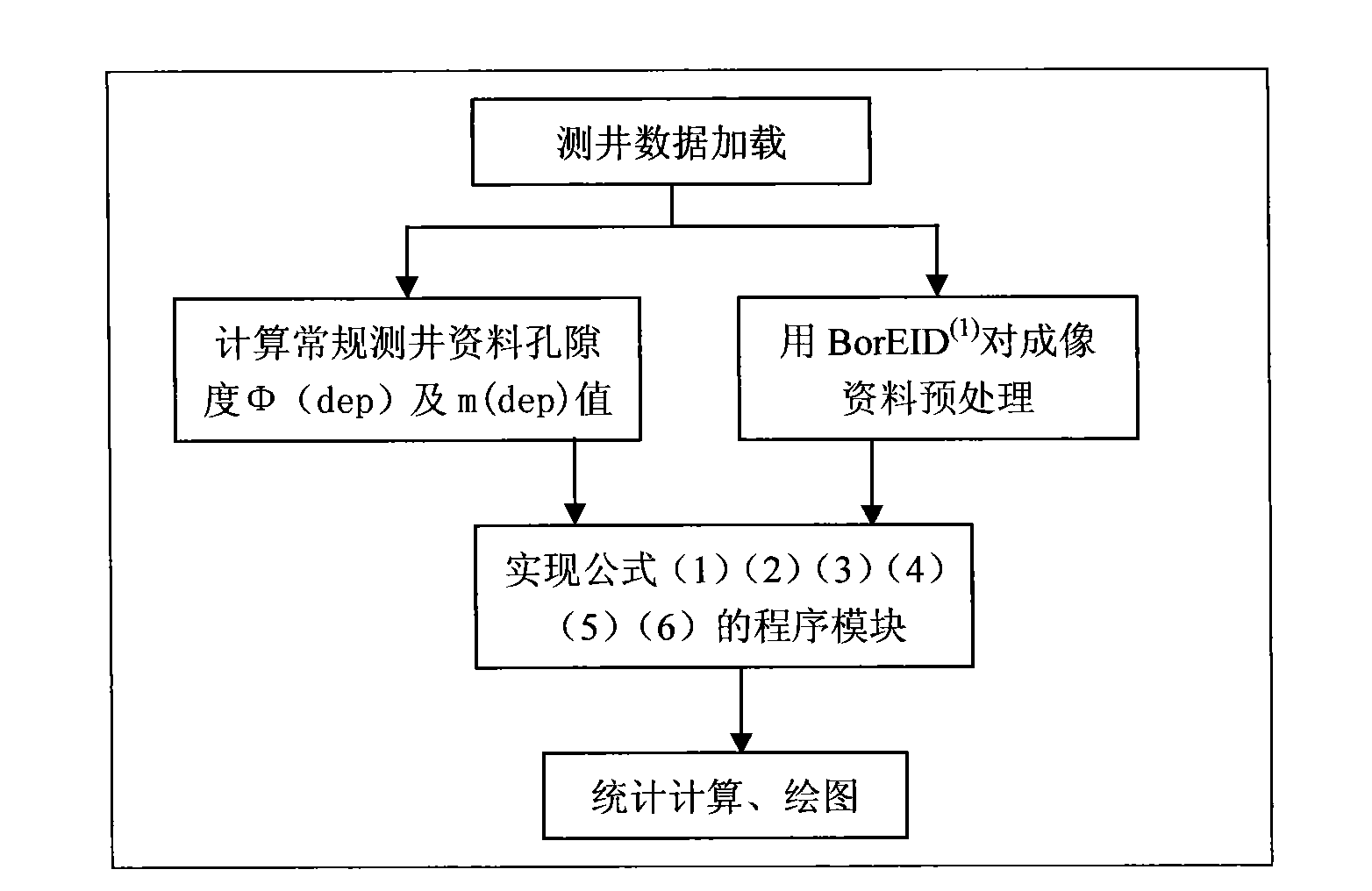

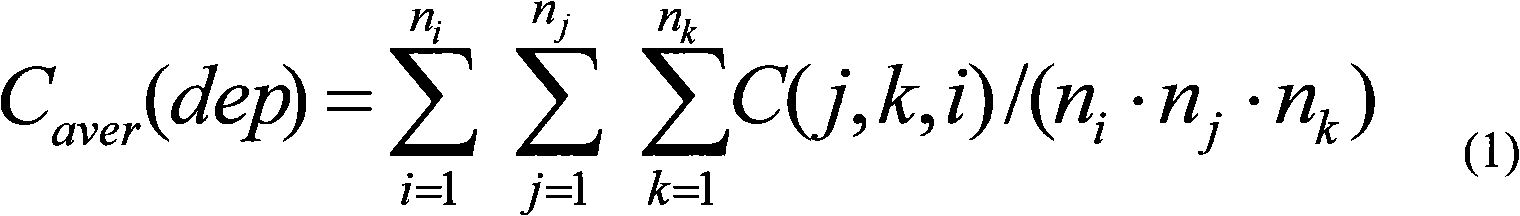

Method for calculating apparent formation water resistivity spectrum and parameters by applying electric imaging data of point-by-point calibration

ActiveCN102033247AElectric/magnetic detection for well-loggingWater resource assessmentElectricityAverage current

The invention relates to a method for calculating apparent formation water resistivity spectrum and parameters by applying electric imaging data of point-by-point calibration. The point-by-point calibration comprises the following steps: using a logging data editing tool to lead the electric imaging data to be consistent with the shallow resistivity depth; calculating the average current value of images of the electric imaging data; for each image frame, calculating a calibration coefficient by a conductivity value corresponding to the shallow resistivity value at the same depth point; carrying out calculation of the apparent formation water resistivity spectrum by applying the electric imaging data; according to the fact that the electric imaging of the shallow resistivity calibration is substantially a conductivity image of a well-wall flushed zone, defining the apparent formation water resistivity of one pixel point of the electric imaging data; calculating the apparent formation water resistivity spectrum parameters by applying the electric imaging data; introducing the average value to express the deviation degree of a main peak from a base line in the apparent formation water resistivity spectrum; using variance to express the width of the apparent formation water resistivity distribution spectrum; carrying out point-by-point calibration on the electric imaging data by applying shallow resistivity, calculating the apparent formation water resistivity spectrum of the electric imaging data, wherein the extracted average value and extracted variance of the apparent formation water resistivity spectrum have obvious application effect on evaluating the performance of reservoir fluid.

Owner:PETROCHINA CO LTD

Polysilicon ingot furnace

ActiveCN103541003AEvenly distributedUniform resistivity distributionPolycrystalline material growthSingle crystal growth detailsCrucibleIngot

The invention discloses a polysilicon ingot furnace capable of uniformly distributing the resistivity of ingots. The gas outlet of a gas inlet pipe of the polysilicon ingot furnace is extended to a position close to the inner wall of a crucible, the included angle between the central axis of gas flow ejected from the gas outlet and the central axis of the crucible is 20-30 degrees, when being ejected from the gas outlet of the gas inlet pipe, argon is ejected to the surface of silicon liquid obliquely downwards, the original direct blowing manner is changed into an oblique blowing manner, and the central axis of gas flow ejected from the gas outlet and the central axis of the crucible are skew lines, so that the gas flow ejected obliquely downwards can drive the silicon liquid in the crucible to rotate to fully disperse impurities contained in the silicon liquid in a silicon solution to uniformly distribute the liquid phase components so as to avoid the existence of impurity enrichment regions in the ingots and ensure the uniform distribution of the resistivity of the ingots, and the silicon liquid in the crucible is stirred to promote the volatilizable impurities contained in the silicon liquid to be volatilized as soon as possible. The polysilicon ingot furnace is suitable for popularization and application in the field of polysilicon production equipment.

Owner:LESHAN TOPRAYCELL

Resistivity log correction method

InactiveUS6098019AElectric/magnetic detection for well-loggingSeismology for water-loggingGeomorphologyElectric resistivity

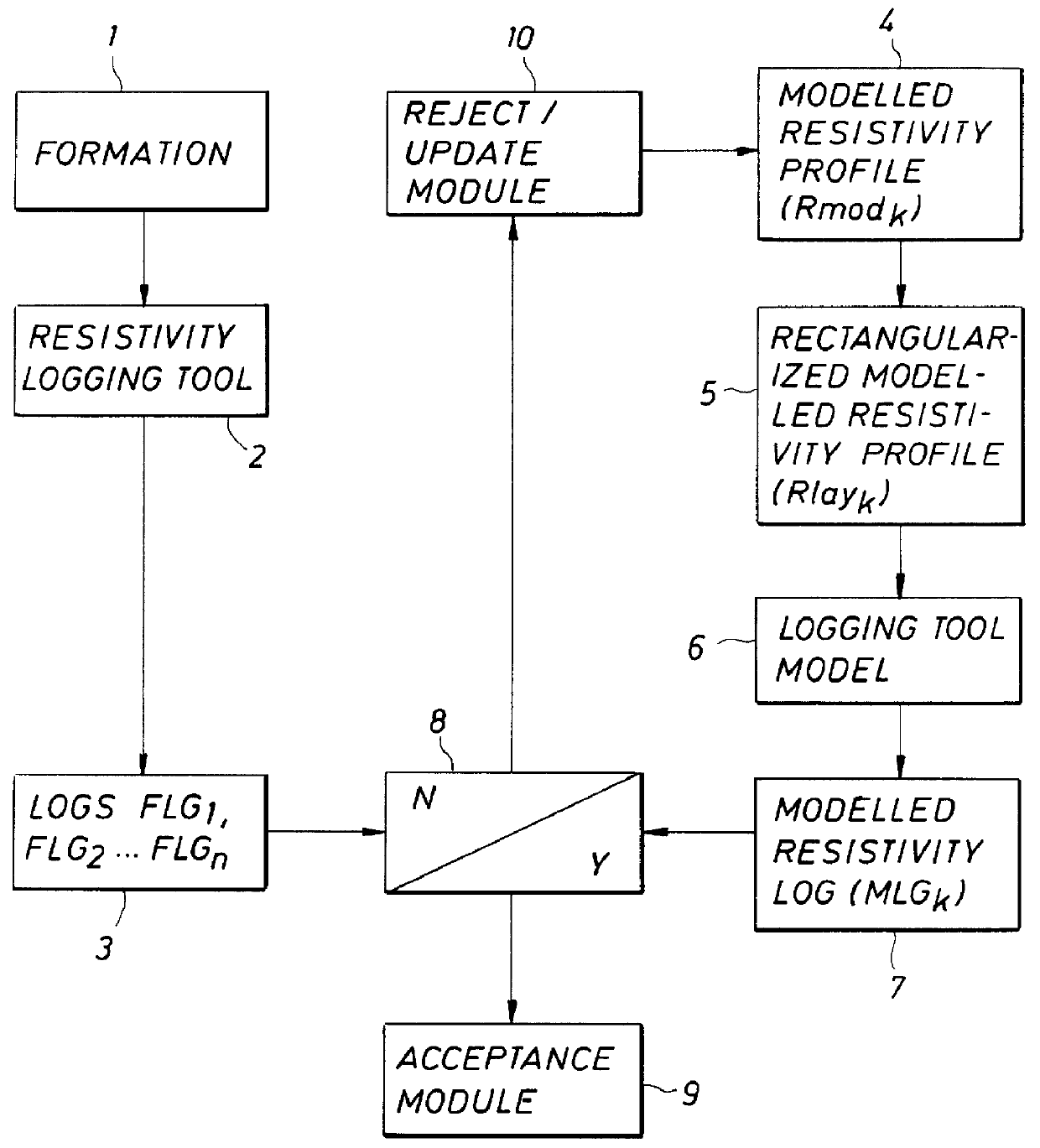

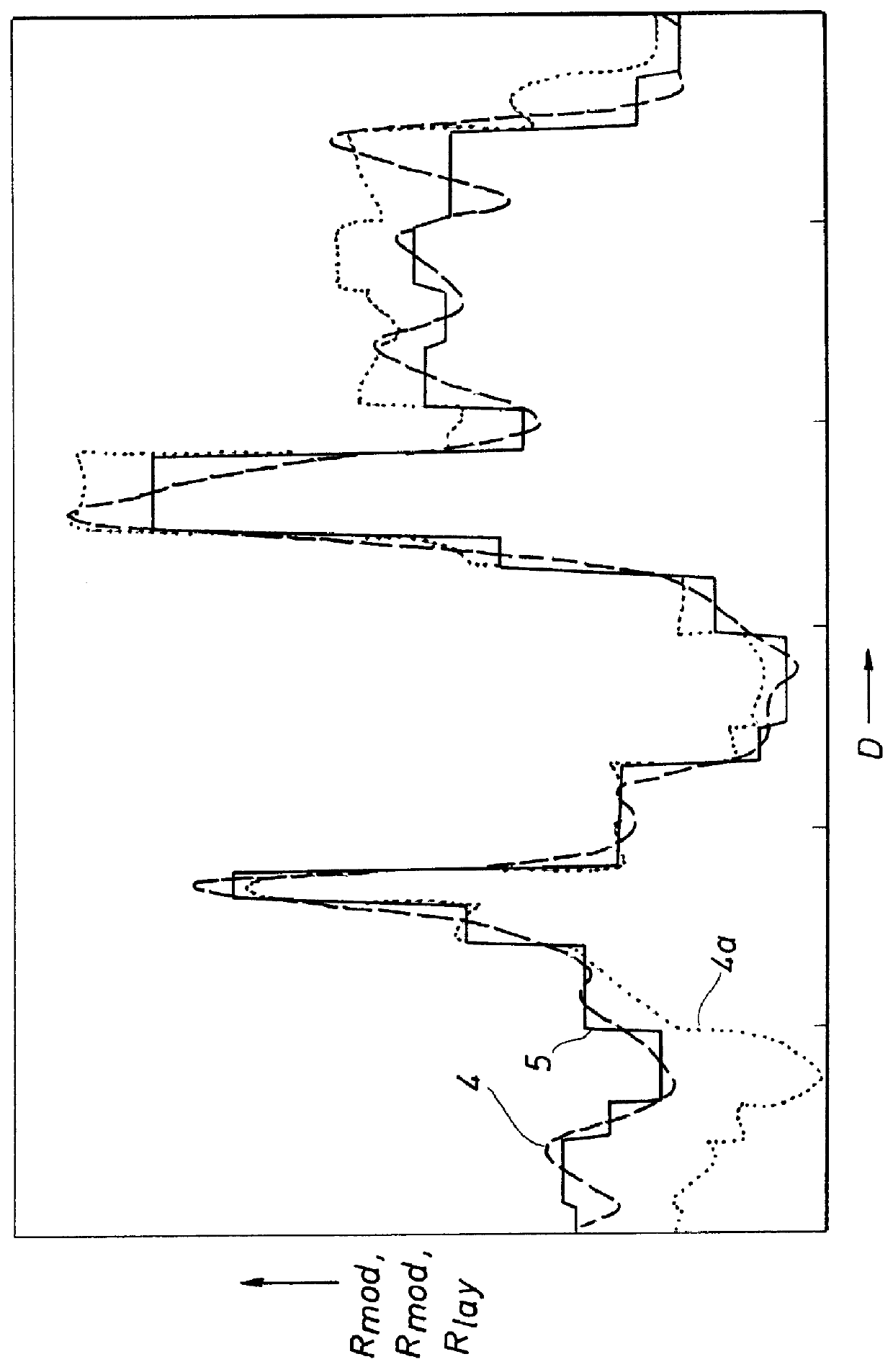

A method of determining electric resistivity of an earth formation (1) surrounding a wellbore filled with a wellbore fluid, is provided, which method comprises: operating a resistivity logging tool (2) in the wellbore so as to provide a plurality of resistivity logs (FLG1, . . . , n) (3) of the earth formation (1) for different radial intervals (1, . . . , n) relative to the wellbore; for each radial interval (k), selecting a modelled resistivity profile (Rmodk) (4); inputting the modelled resistivity profiles (Rmod1, . . . , n) (4) to a logging tool simulator (6) so as to provide for each radial interval (k) a modelled resistivity log (MLGk) (7) having a depth of investigation corresponding to the radial interval (k); for each radial interval (k) updating the modelled resistivity profile (Rmodk) (7) in dependence of an observed deviation of the resistivity log (FLGk) (3) from the modelled resistivity log (MLGk) (7); and repeating steps c)-d) until for each radial interval (k) the difference between the resistivity log (FLGk) (3) and the corresponding modelled resistivity log (MLGk) (7) is below a selected threshold value (8).

Owner:SHELL OIL CO

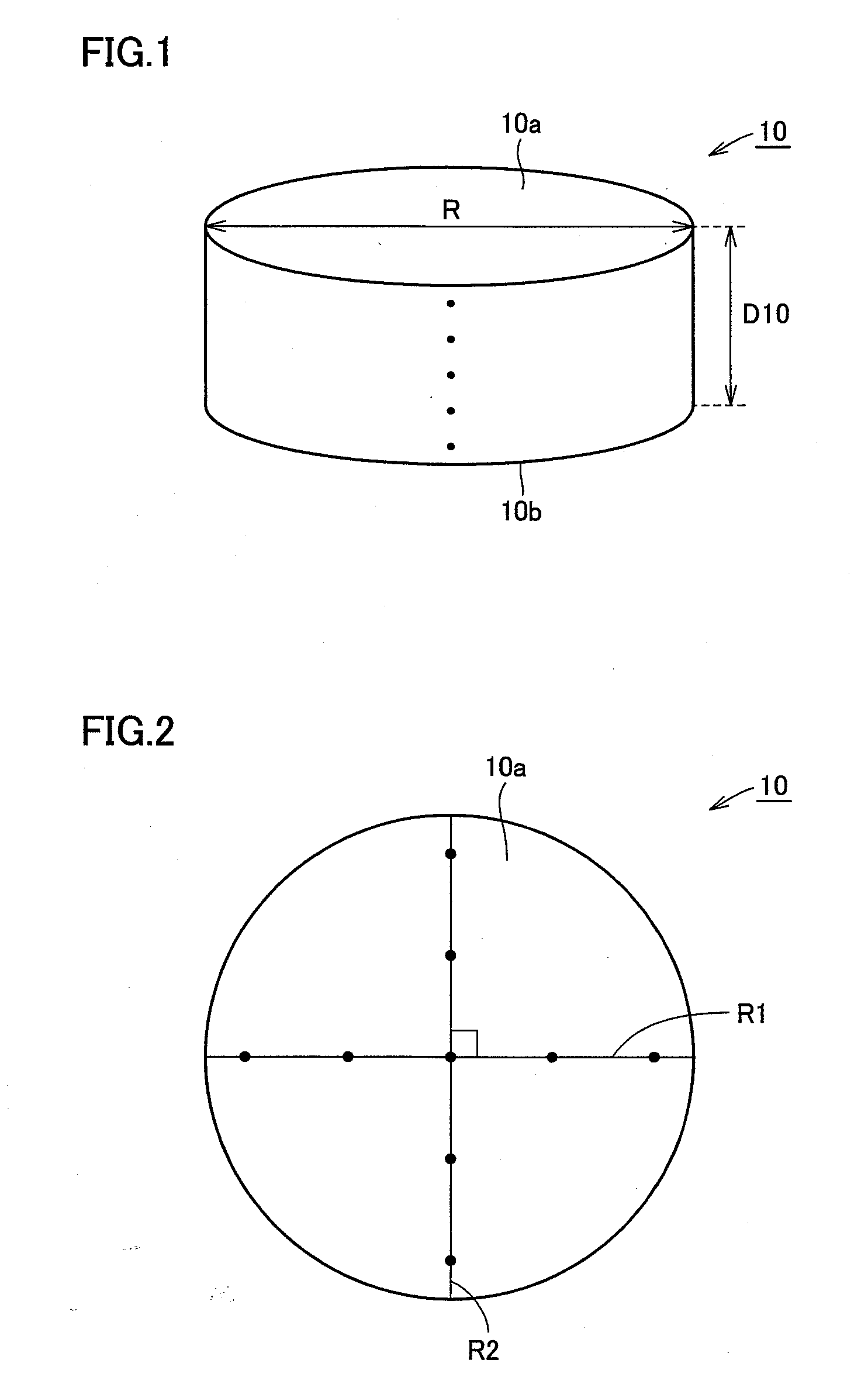

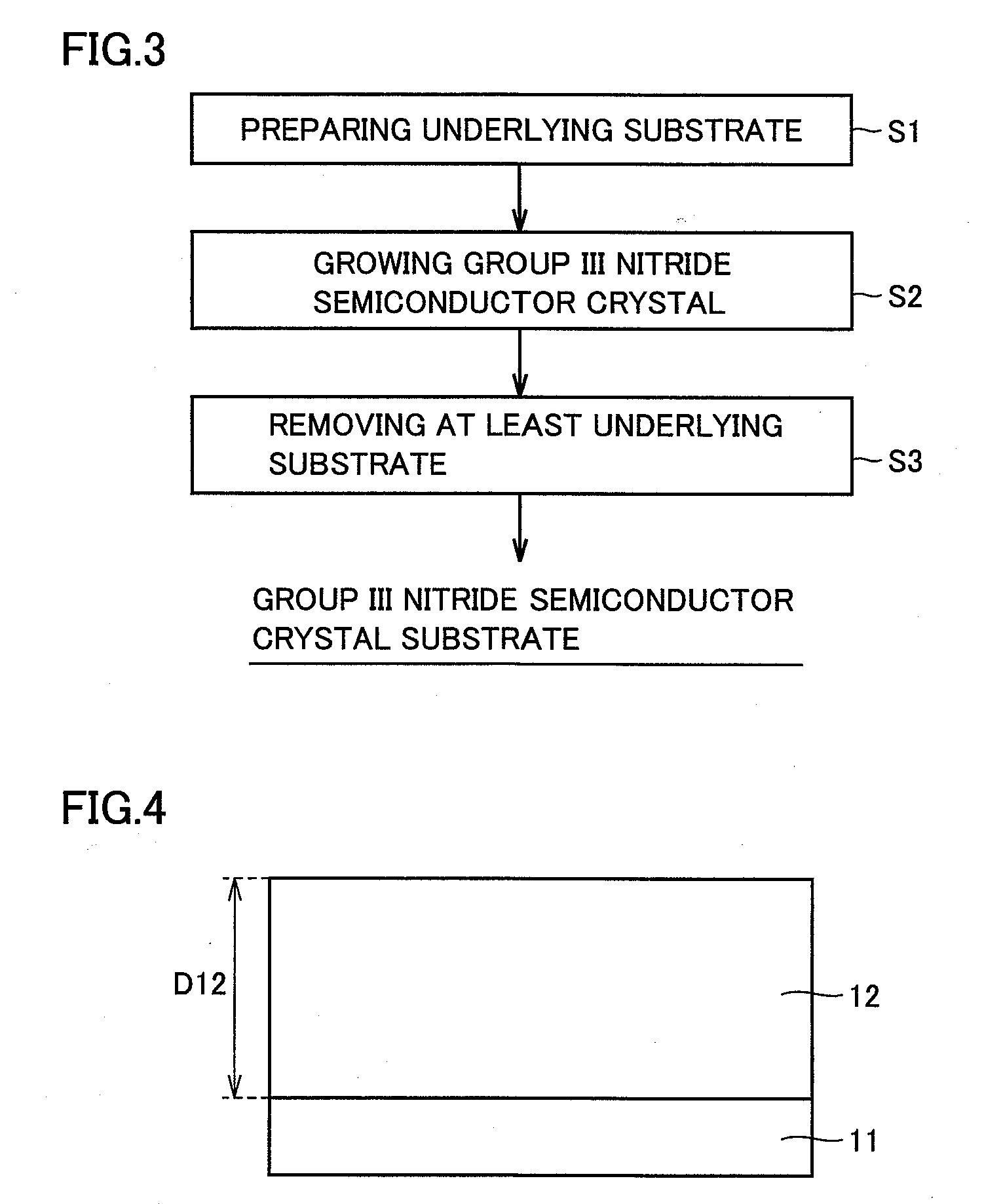

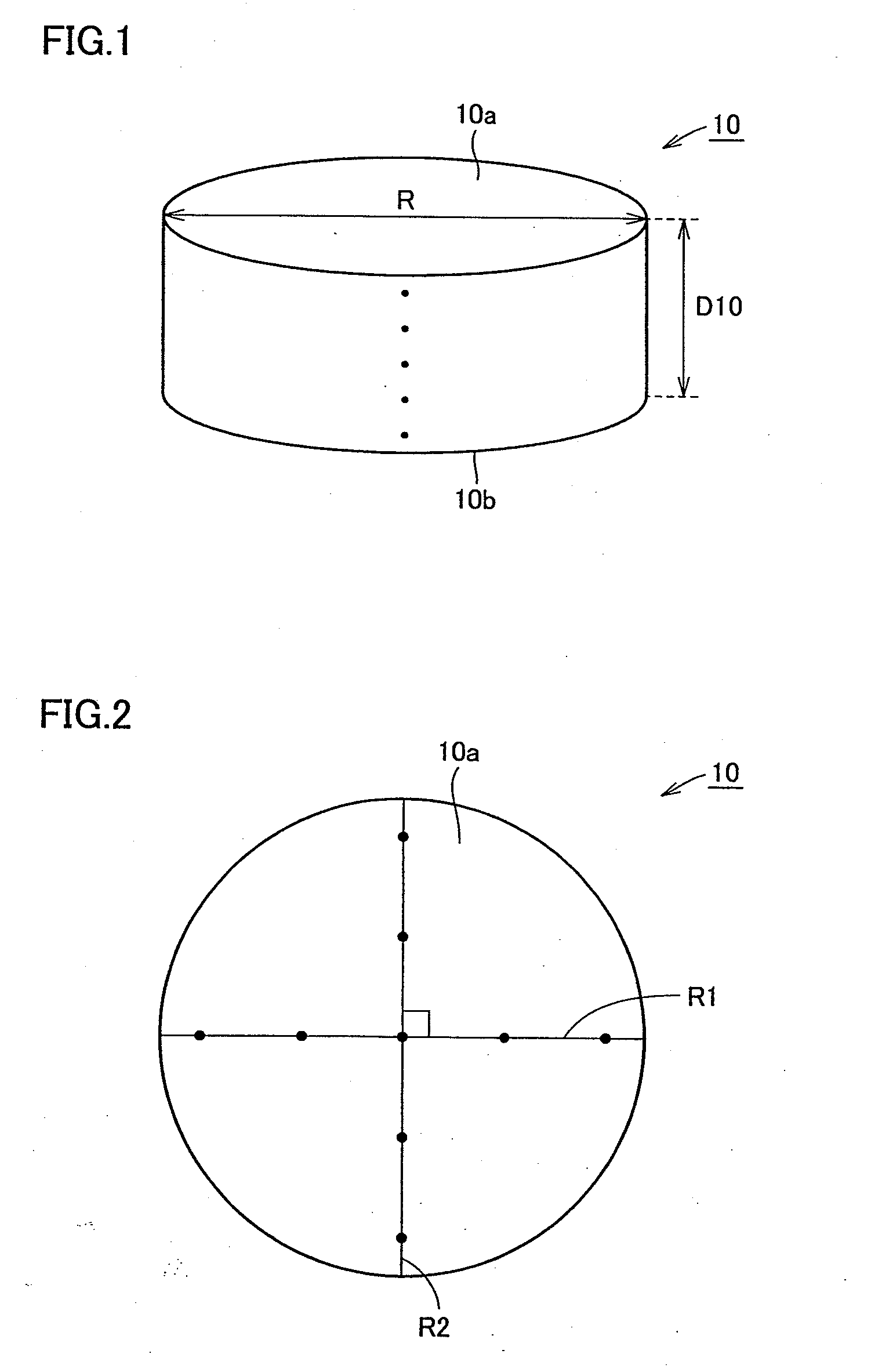

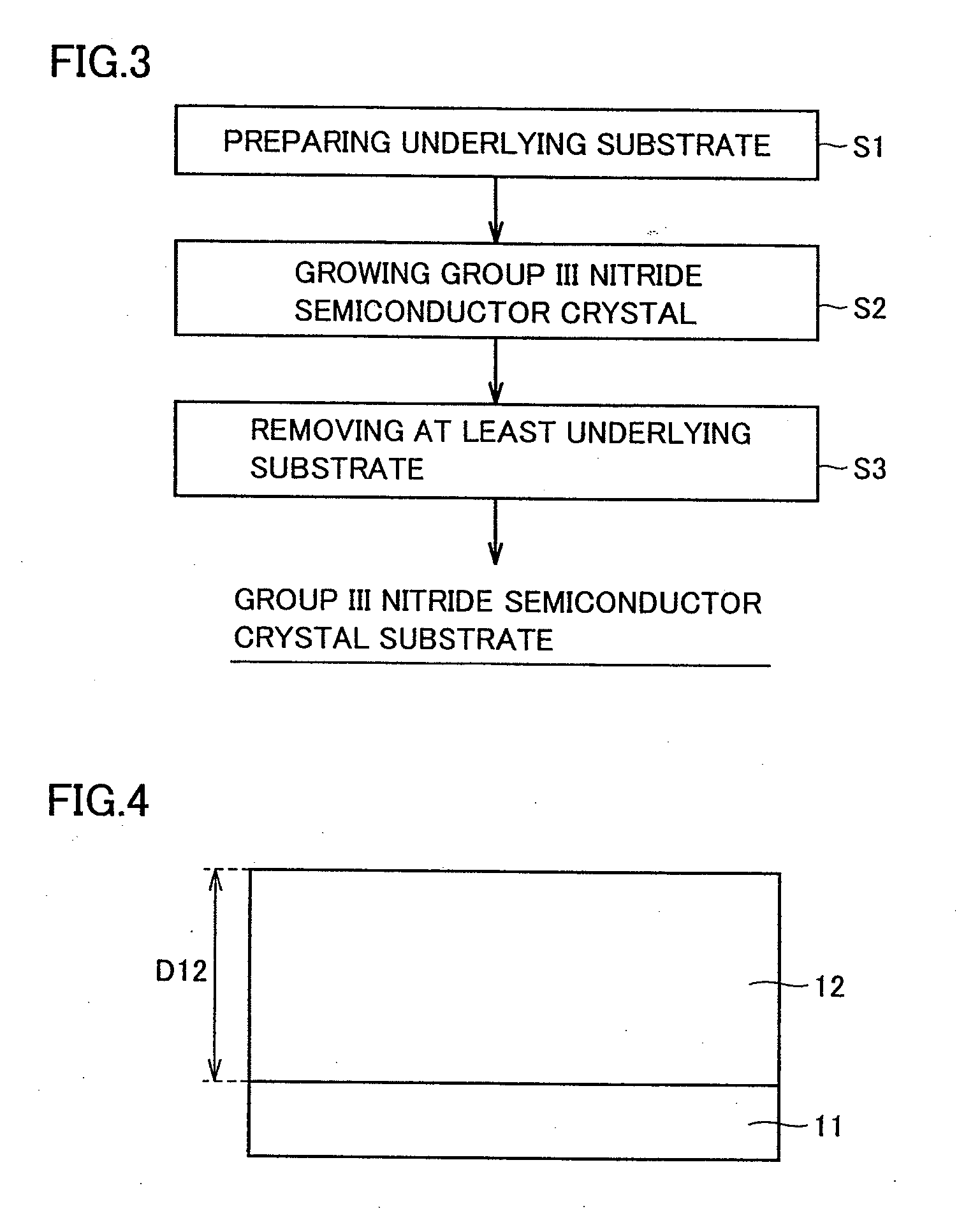

Group iii nitride semiconductor crystal substrate and semiconductor device

ActiveUS20090127662A1Prevent degradationLow resistivityPolycrystalline material growthFrom chemically reactive gasesNitride semiconductorsSemiconductor device

A group III nitride semiconductor crystal substrate has a diameter of at least 25 mm and not more than 160 mm. The resistivity of the group III nitride semiconductor crystal substrate is at least 1×10−4 Ω·m and not more than 0.1 Ω·cm. The resistivity distribution in the diameter direction of the group III nitride semiconductor crystal is at least −30% and not more than 30%. The resistivity distribution in the thickness direction of the group III nitride semiconductor crystal is at least −16% and not more than 16%.

Owner:SUMITOMO ELECTRIC IND LTD

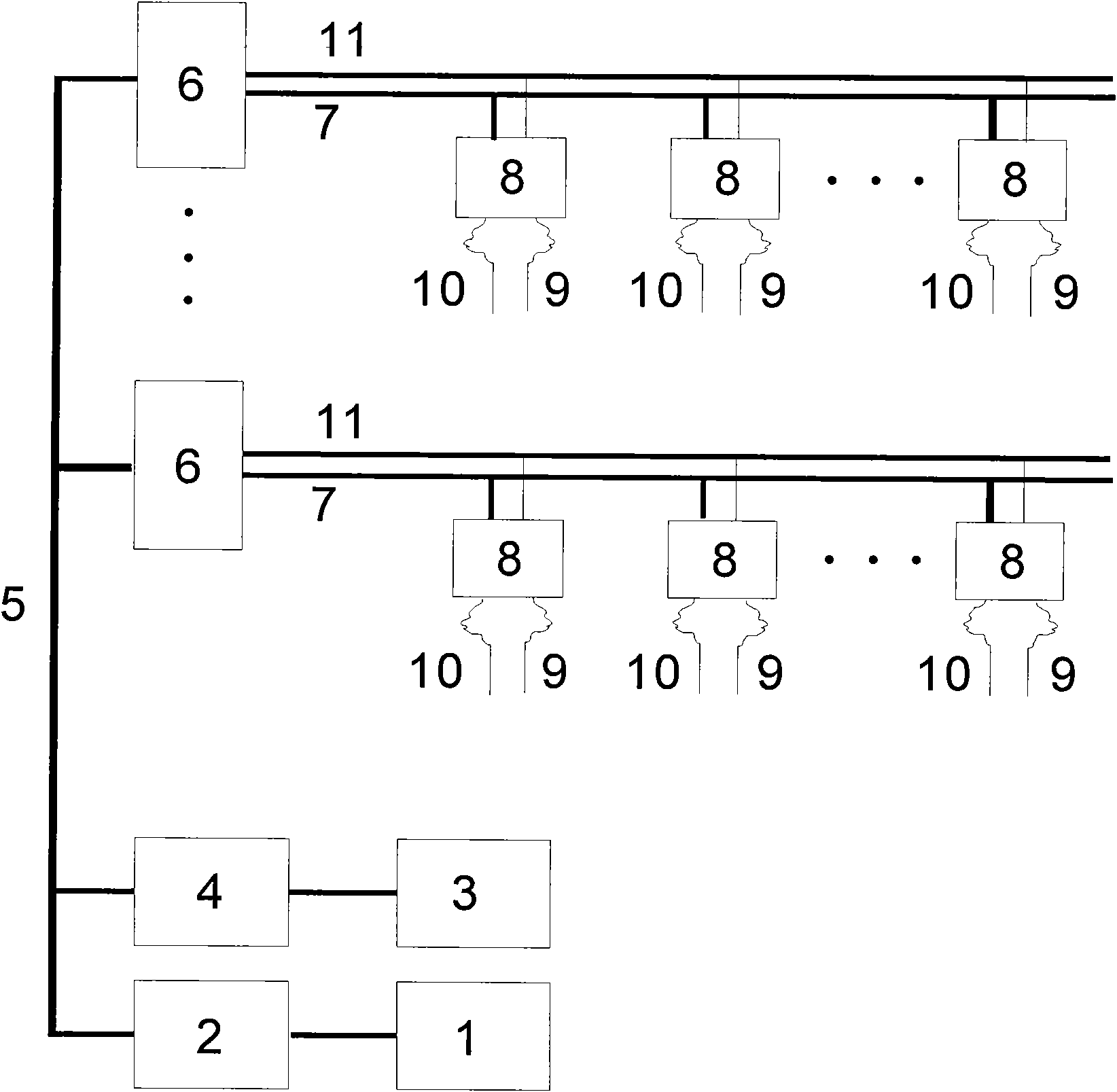

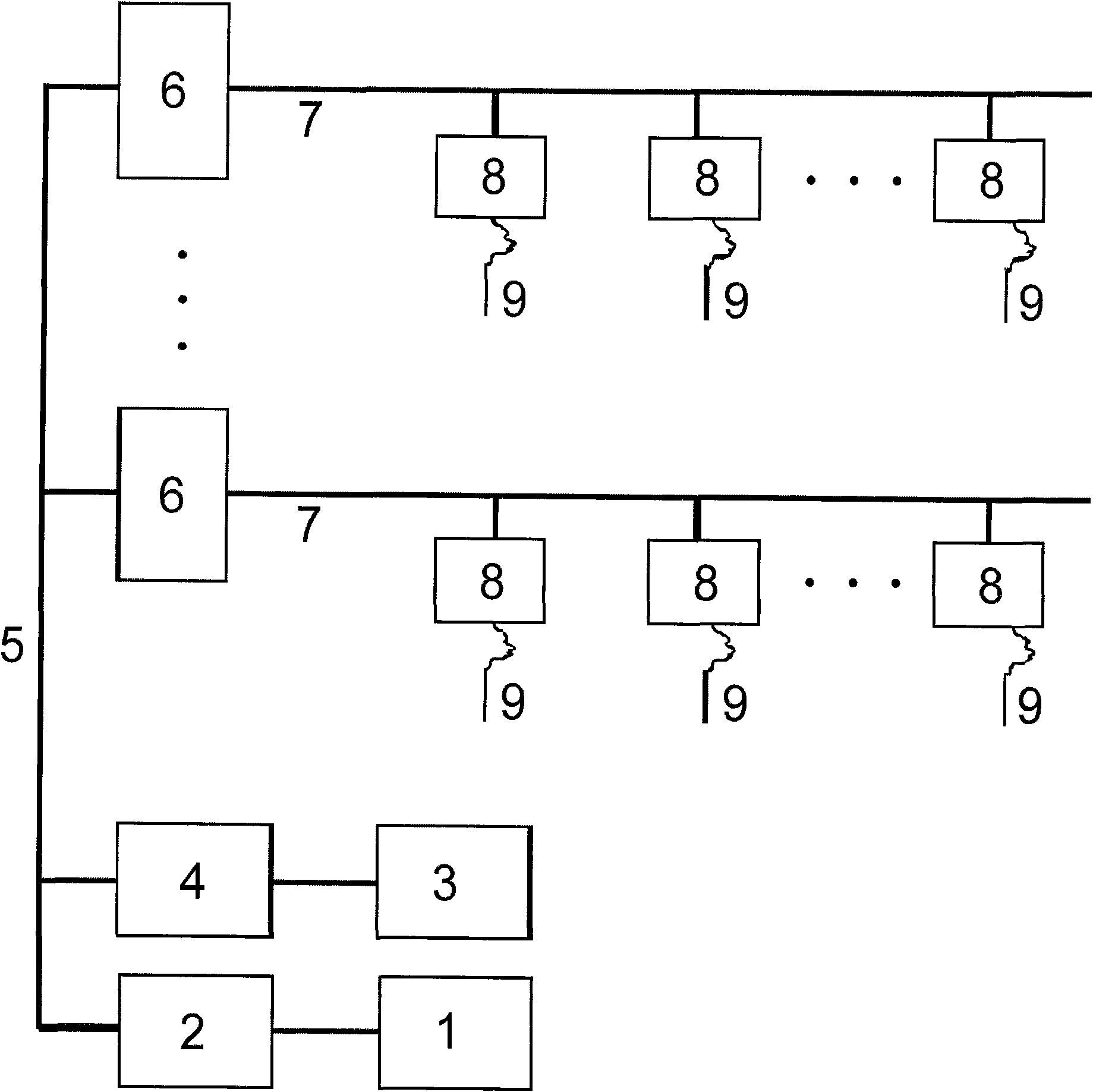

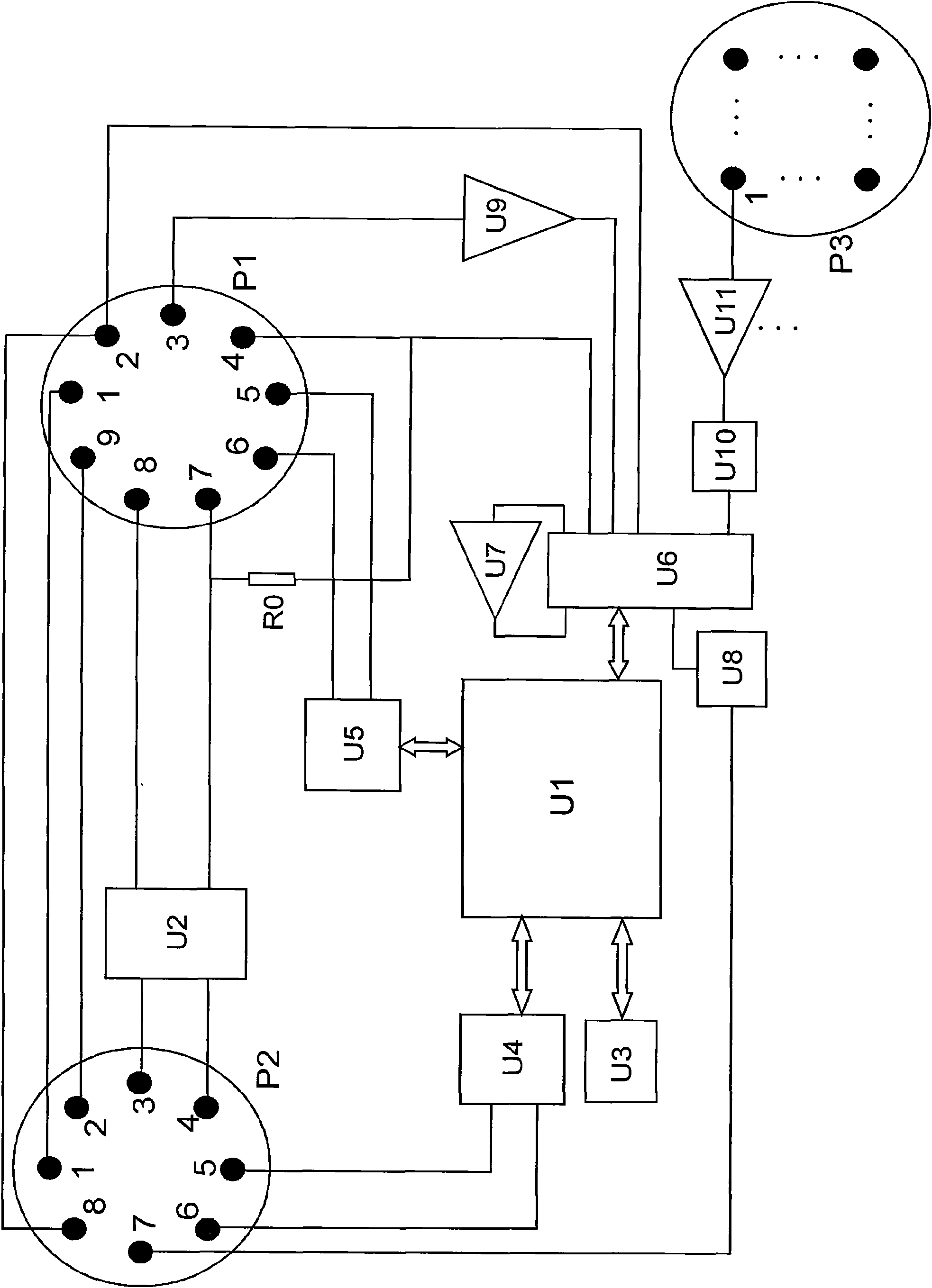

Hardware composition proposal of three-dimensional resistivity imaging system

InactiveCN101581797AImprove signal-to-noise ratioImprove efficiencyElectric/magnetic detection for well-loggingData acquisitionData transmission

The invention belongs to the technical field of geophysical exploration and relates to a hardware composition proposal of a three-dimensional resistivity imaging system. The invention comprises a hardware composition proposal applied in the scientific research application and a hardware composition proposal applied to engineering application; under the control of a notebook computer, a control command, a state data and a measurement data are transmitted by a mixed network composing of a CAN bus and a RS485 bus; an electrode switching device is adopted to select the communication of a power supply anode (A), a power supply cathode (B), a measurement common electrode (N), a measurement collecting electrode (M) and a polarization electrode or non-polarization electrode; a data collecting sub-station device carries out data collecting and data pre-processing; the pre-processed data is transmitted to the notebook computer for memory, analysis and calculation; and the resistivity distribution image is imaged and displayed at the measurement region.

Owner:EAST CHINA UNIV OF TECH

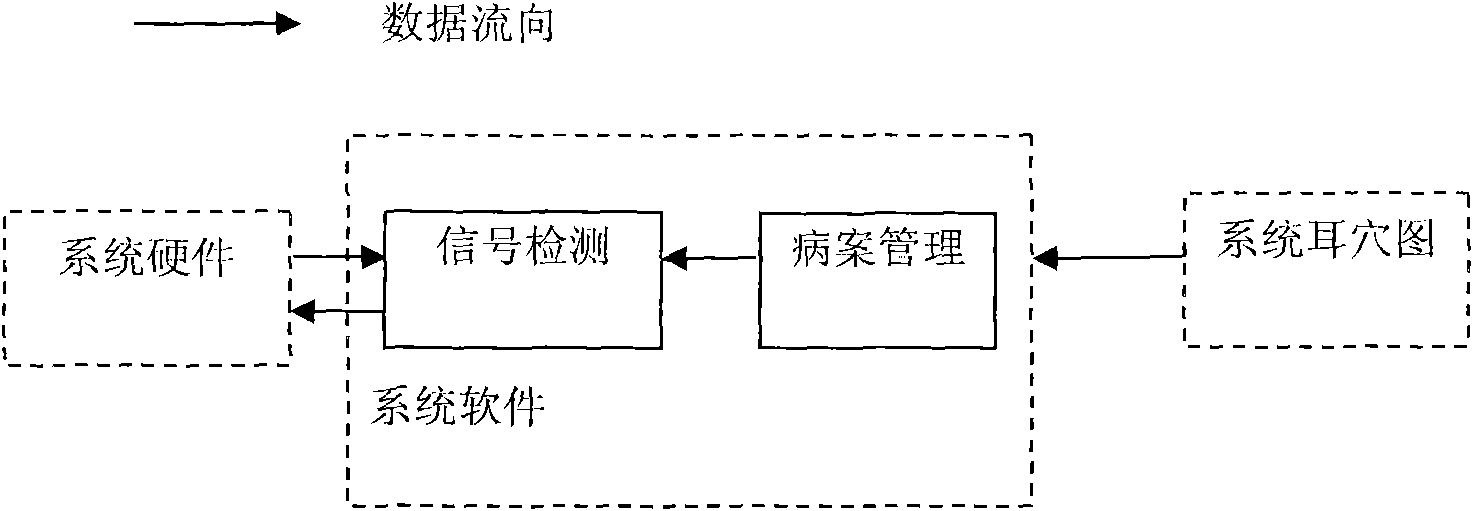

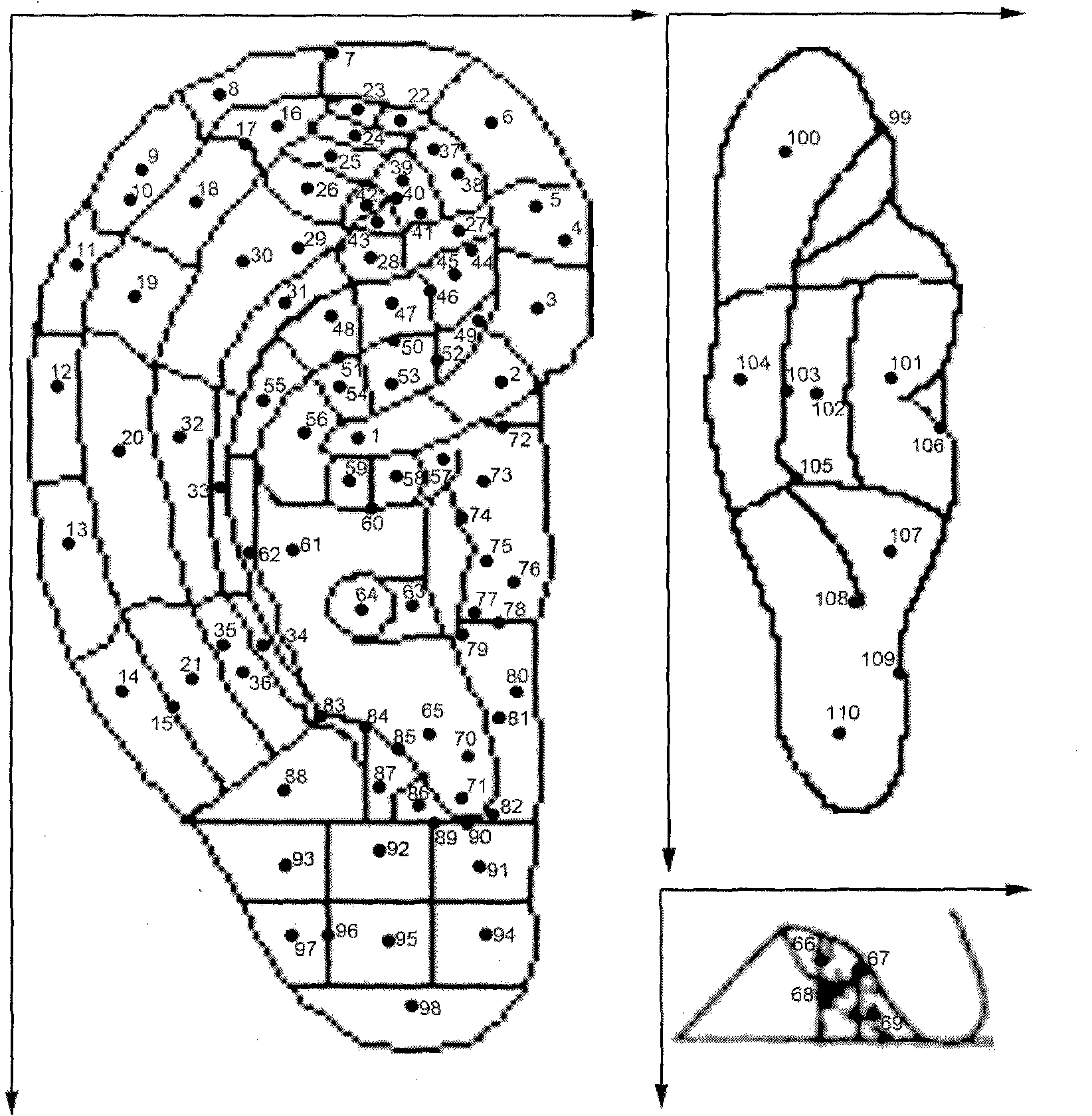

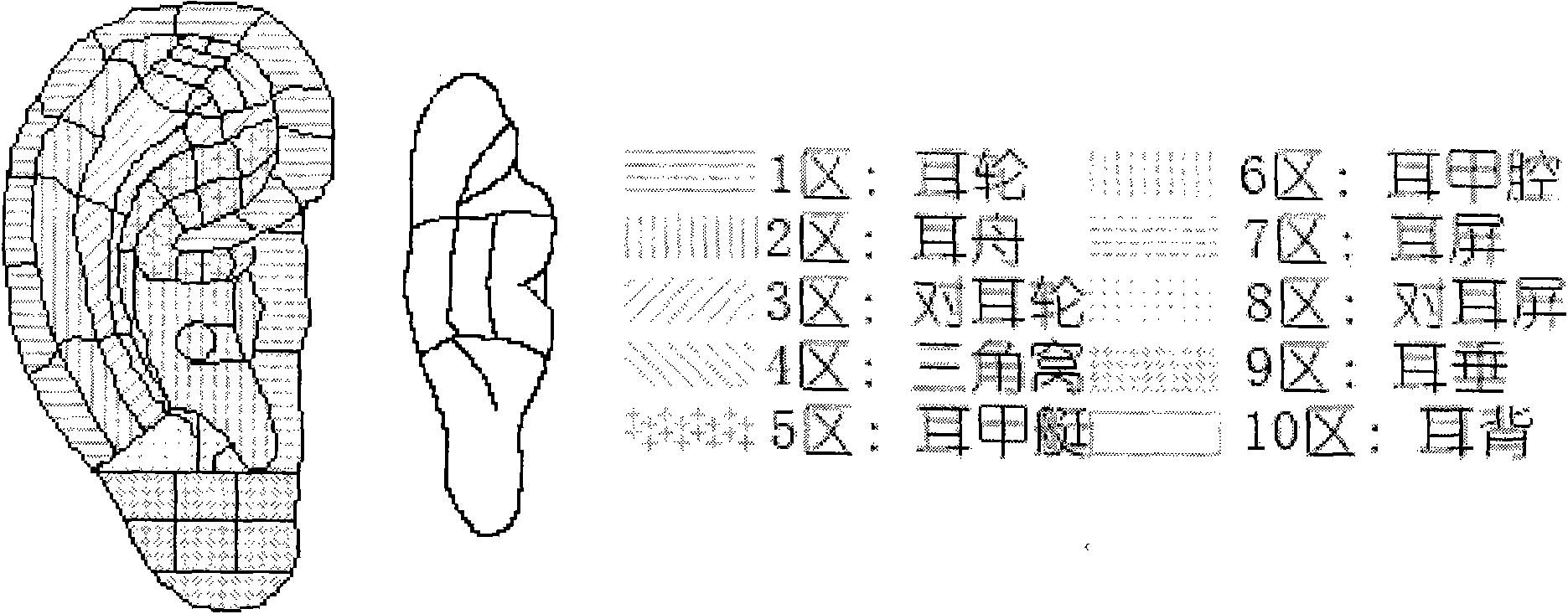

Computer method for realizing auricular point pseudo-color distribution graph

InactiveCN101877030ADiagnostic recording/measuringSensorsElectrical resistance and conductanceColor mapping

The invention discloses a computer method for realizing an auricular point pseudo-color distribution graph and the method is characterized by comprising the following steps: initializing in the computer and inputting a system auricular point graph; setting a signal detecting module which consists of a test interface sub-module, a measuring control sub-module and a result analysis sub-module; carrying out pseudo-color mapping according to auricular point resistivity and giving colors to the region except the auricular points by an interpolation method, and carrying out image processing to obtain the auricular point pseudo-color distribution map with an auricle contour and partition information. Then, acupoints are measured according to standard steps. By adopting the method, the auricular point resistivity can be visually displayed in the pseudo-color form, and an auricle pseudo-color resistivity distribution graph can be drawn, thus being convenient for positioning a lesion region, and simultaneously, three measuring modes which are overall measurement, partial measurement and random measurement can be adopted according to actual requirements, thus improving the adaptation range of the auricular point detection.

Owner:TSINGHUA UNIV

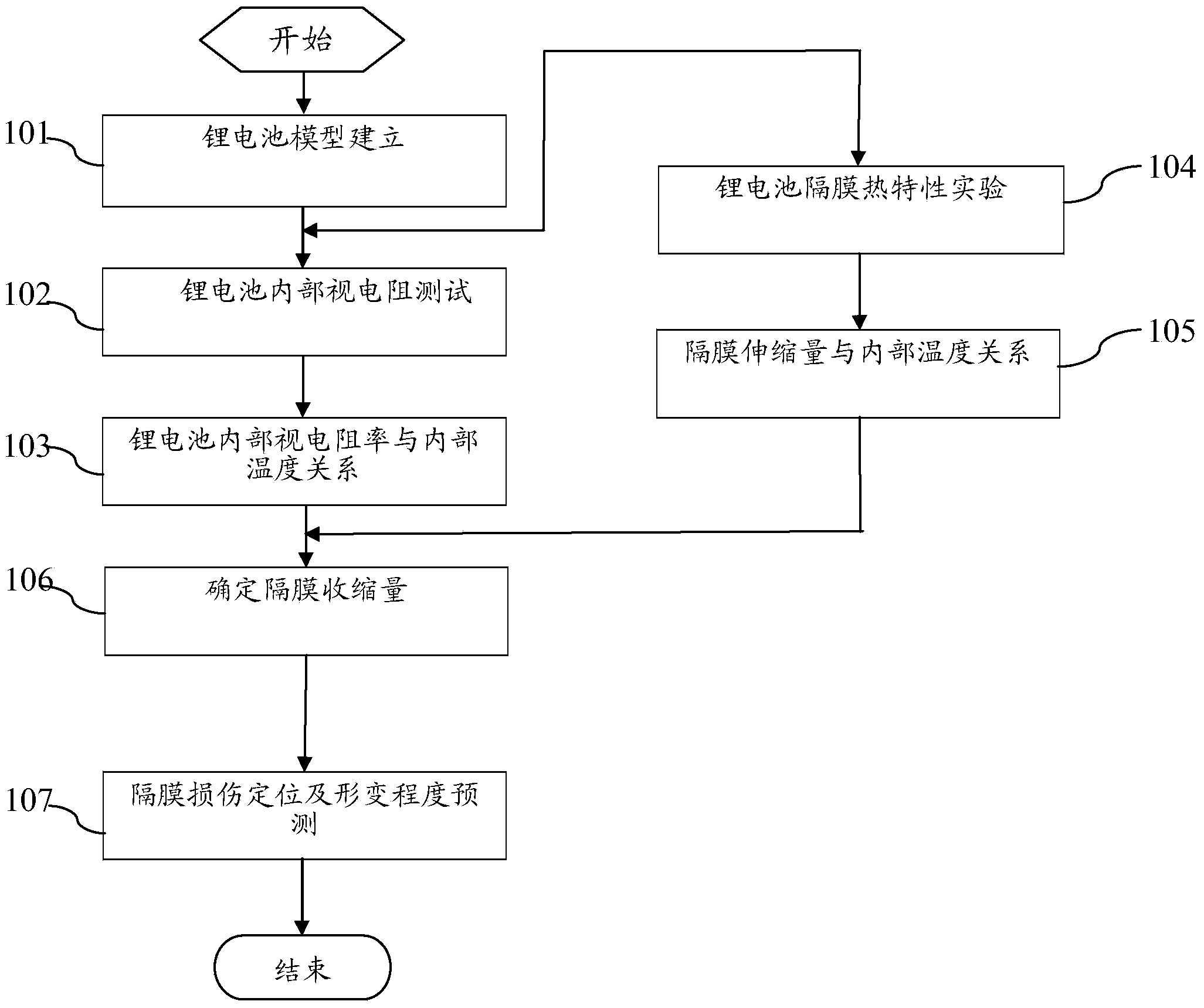

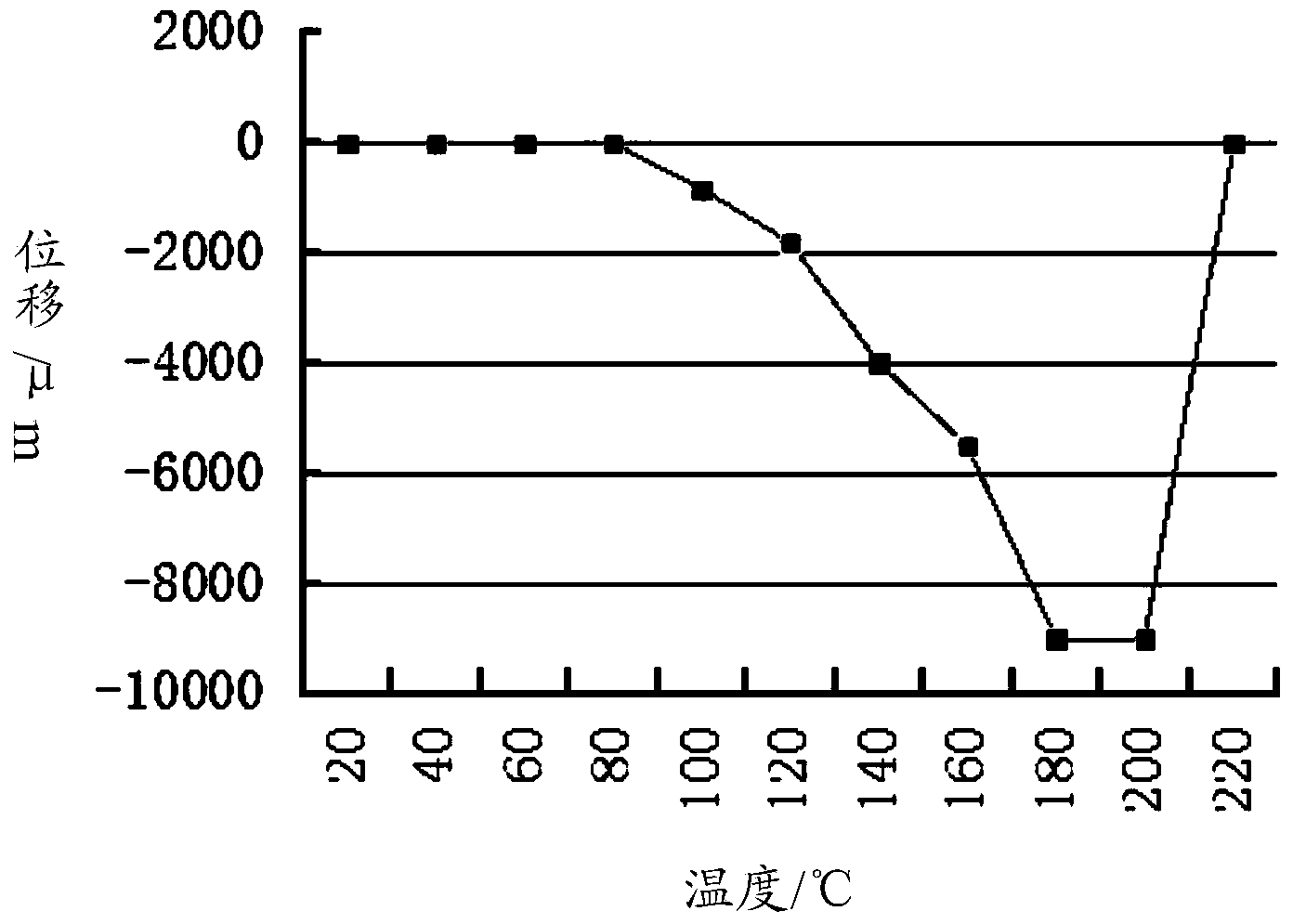

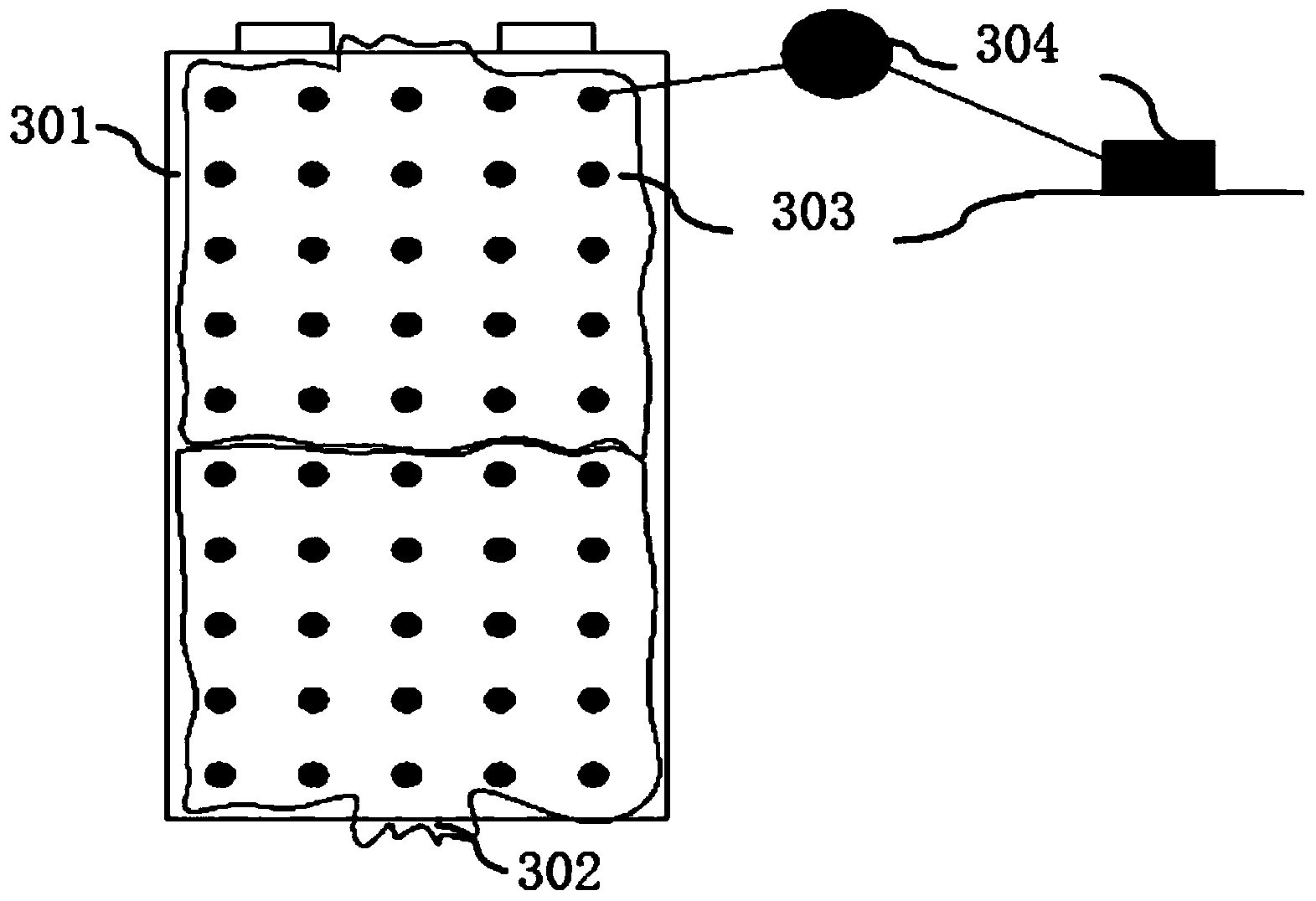

Safety monitoring method for internal diaphragm of lithium-ion power battery

InactiveCN104280418AReal-time online monitoring of security situationOnline monitoring of security situationInvestigating phase/state changePower batteryElectrical battery

The invention discloses a safety monitoring method for an internal diaphragm of a lithium-ion power battery. The safety monitoring method comprises the following steps: testing the internal apparent resistivity of the lithium-ion power battery to obtain the internal resistivity distribution of the lithium-ion power battery; determining an internal temperature field according to the internal resistivity distribution of the lithium-ion power battery and tracking a high temperature variation region; obtaining the change of the stretching quantity of the diaphragm at different temperatures inside the lithium-ion power battery and determining the relation between the internal temperatures and the stretching quantity; determining the stretching quantity of the diaphragm and assessing the internal performance condition of the lithium-ion power battery according to the stretching quantity; locating the damage of the diaphragm and predicting the deformation degree of the diaphragm. The safety monitoring method for the internal diaphragm of the lithium-ion power battery has the advantages that the damage condition of the internal diaphragm is deduced according to the change of the internal apparent resistivity of the lithium-ion power battery, the thermal loss location and the deformation degree prediction on the internal diaphragm of the lithium-ion power battery in a high temperature environment are realized, and the technical bottleneck of the safety monitoring mode of a traditional battery is broken through; besides, the safety monitoring method plays a directing role in research in the fields of life prediction and load control of the lithium-ion power batteries, and new energy resources.

Owner:广东省标准化研究院 +1

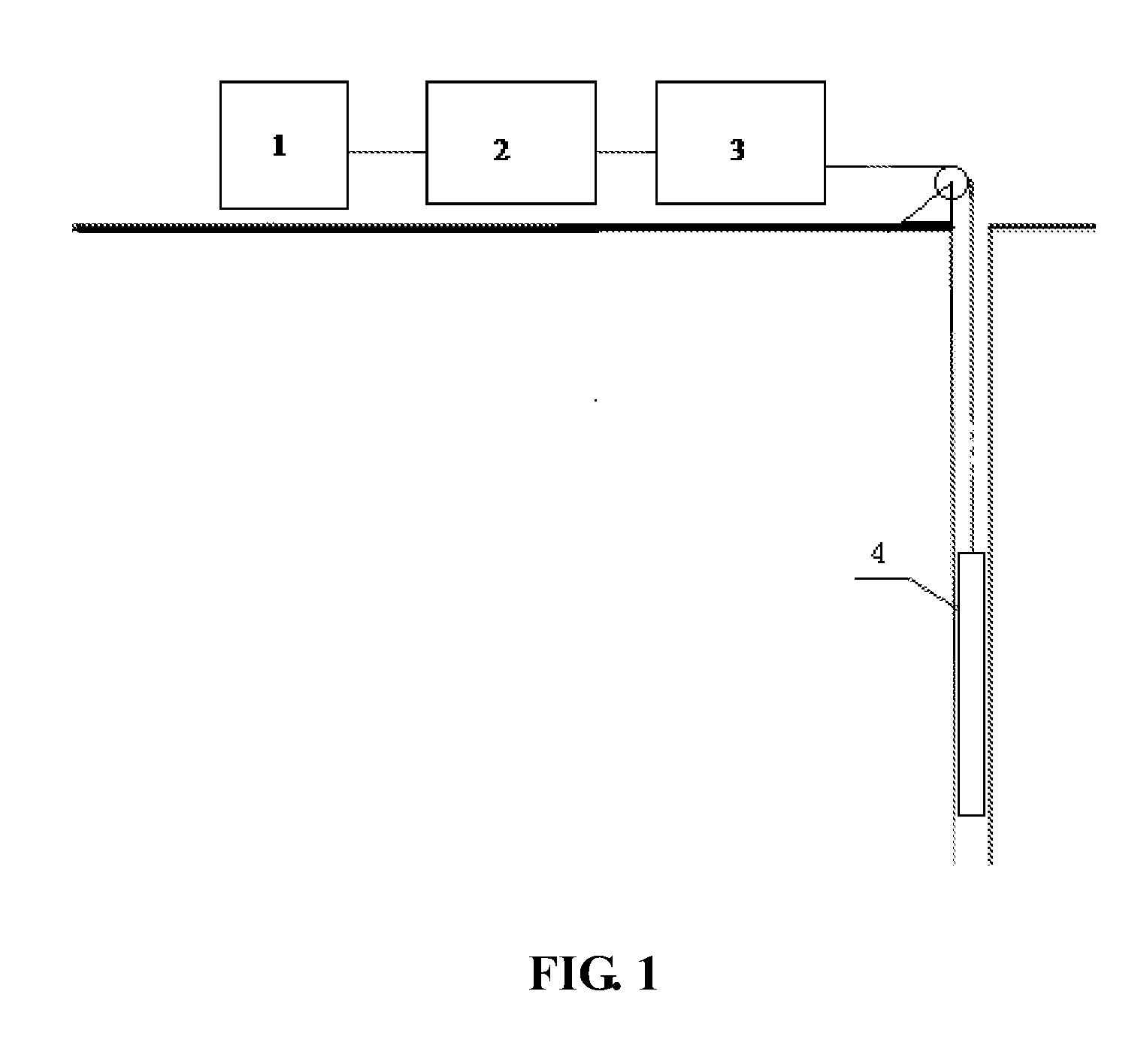

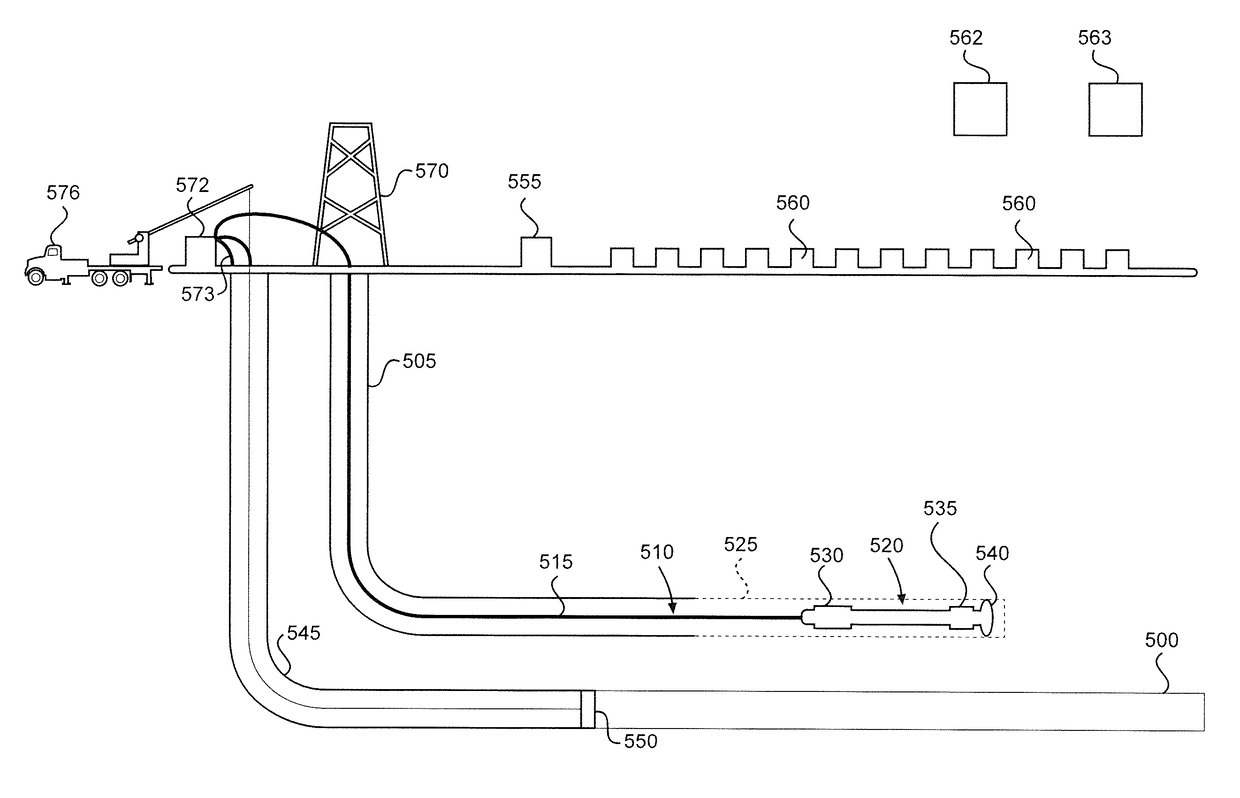

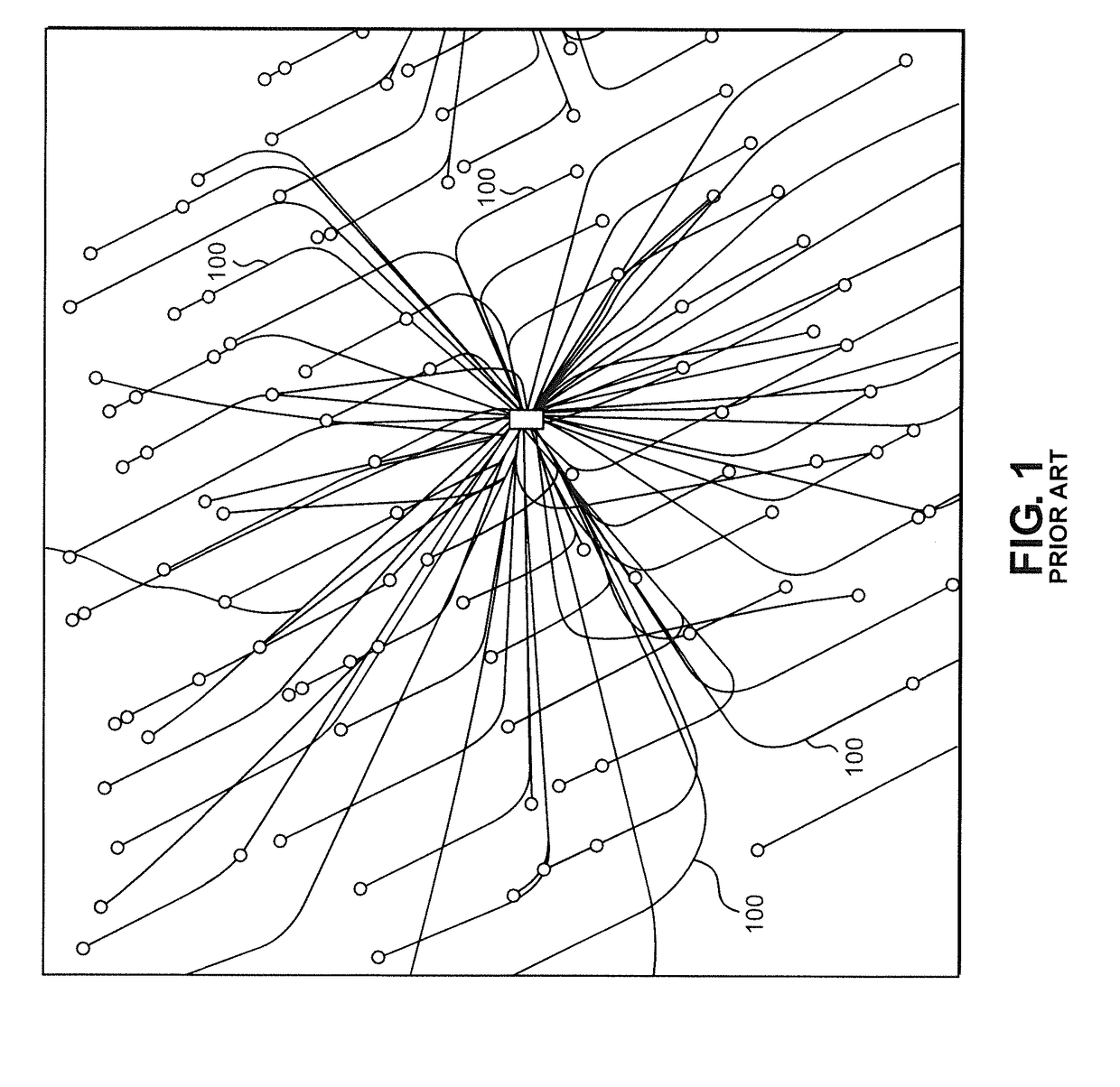

System and Method for Performing Distant Geophysical Survey

ActiveUS20170097441A1Improve understandingImprove accuracyElectric/magnetic detection for well-loggingSurveyElectromagnetic fieldGeophysical survey

A downhole drilling tool is adapted to be placed in a borehole formed in the earth. The downhole drilling tool has mounted thereto at least one of a transmitter for generating and a receiver for sensing at least one component of an electromagnetic field within a distant earth region. The tool also has a device configured to acquire subsurface data from the at least one component of the electromagnetic field; and a device configured to calculate a resistivity distribution of the distant earth region from the subsurface data. A geophysical survey is performed with a downhole drilling tool by transmitting at least one component of an electromagnetic field through the distant earth region; acquiring subsurface data from the at least one component of the electromagnetic field; and calculating a resistivity distribution of the distant earth region from the subsurface data.

Owner:GROUNDMETRICS

Diameter transitional czochralski silicon growing method

ActiveCN103290470AReduce wasteReduce manufacturing costPolycrystalline material growthBy pulling from meltSingle crystalOptoelectronics

The invention discloses a diameter transitional czochralski silicon growing method. The method comprises the following steps of: A, setting a required transitional single crystal diameter and an initial diameter transitional single crystal equal diameter length L according to the axial resistance distribution condition from the head to the tail of a crystal bar; B, carrying out normal czochralski silicon production including steps of melting, temperature stabilizing, guiding the crystal, shouldering, shoulder rotating and the like; C, setting the diameter transitional size and the diameter transitional length according to step A, carrying out a first equal diameter growing step, and when the single crystal equal diameter of the first equal diameter growing step grows to the designated length L, starting the diameter transition; D, after the diameter of the single crystal is turned into the required diameter, carrying out the next equal diameter growing step; and E, completing a closing process after the length of a silicon single crystal bar meets a production requirement.

Owner:ZHEJIANG HAINA SEMICON CO LTD

System and method for testing mechanical-electrical coupling effect of electrical conducting functional material

InactiveCN104931335ARealize measurementRealize analysisResistance/reactance/impedenceStrength propertiesHand heldDrive motor

The invention discloses a system and a method for testing the mechanical-electrical coupling effect of an electrical conducting functional material . The system comprises an electrical conducting functional material sample, a sample electrode, an insulation tape, an external wire on the electrode, a sample clamping device, a displacement sensor, a transmission shaft, a driving motor, a force sensor, a handheld four-point probe, a digital source meter B, a digital source meter A and a DC power supply, wherein an integral load-displacement curve can be obtained through accurate control of parameters such as voltage strength, conduction time and loading speed; mechanical and electrical properties such as elasticity modulus, tensile strength, elongation at break, yield strength, integral volume resistivity and micro-area volume resistivity distribution of a material under the action of different force fields and electric fields can be obtained through further calculation. Therefore, measurement and analysis of the mechanical-electrical coupling effect of the electrical conducting functional material can be realized accurately and reliably, and the system and the method are suitable for electrical conducting functional materials such as conductive macromolecule, piezoceramics, a polymer-matrix composite, a ceramics-matrix composite, and a metal-matrix composite.

Owner:PEKING UNIV

Group III Nitride Semiconductor Crystal Substrate and Semiconductor Device

InactiveUS20100164070A1Prevent degradationLow resistivityPolycrystalline material growthFrom chemically reactive gasesMaterials scienceNitride semiconductors

A group III nitride semiconductor crystal substrate has a diameter of at least 25 mm and not more than 160 mm. The resistivity of the group III nitride semiconductor crystal substrate is at least 1×10−4 Ω·cm and not more than 0.1 Ω·cm. The resistivity distribution in the diameter direction of the group III nitride semiconductor crystal is at least −30% and not more than 30%. The resistivity distribution in the thickness direction of the group III nitride semiconductor crystal is at least −16% and not more than 16%.

Owner:SUMITOMO ELECTRIC IND LTD

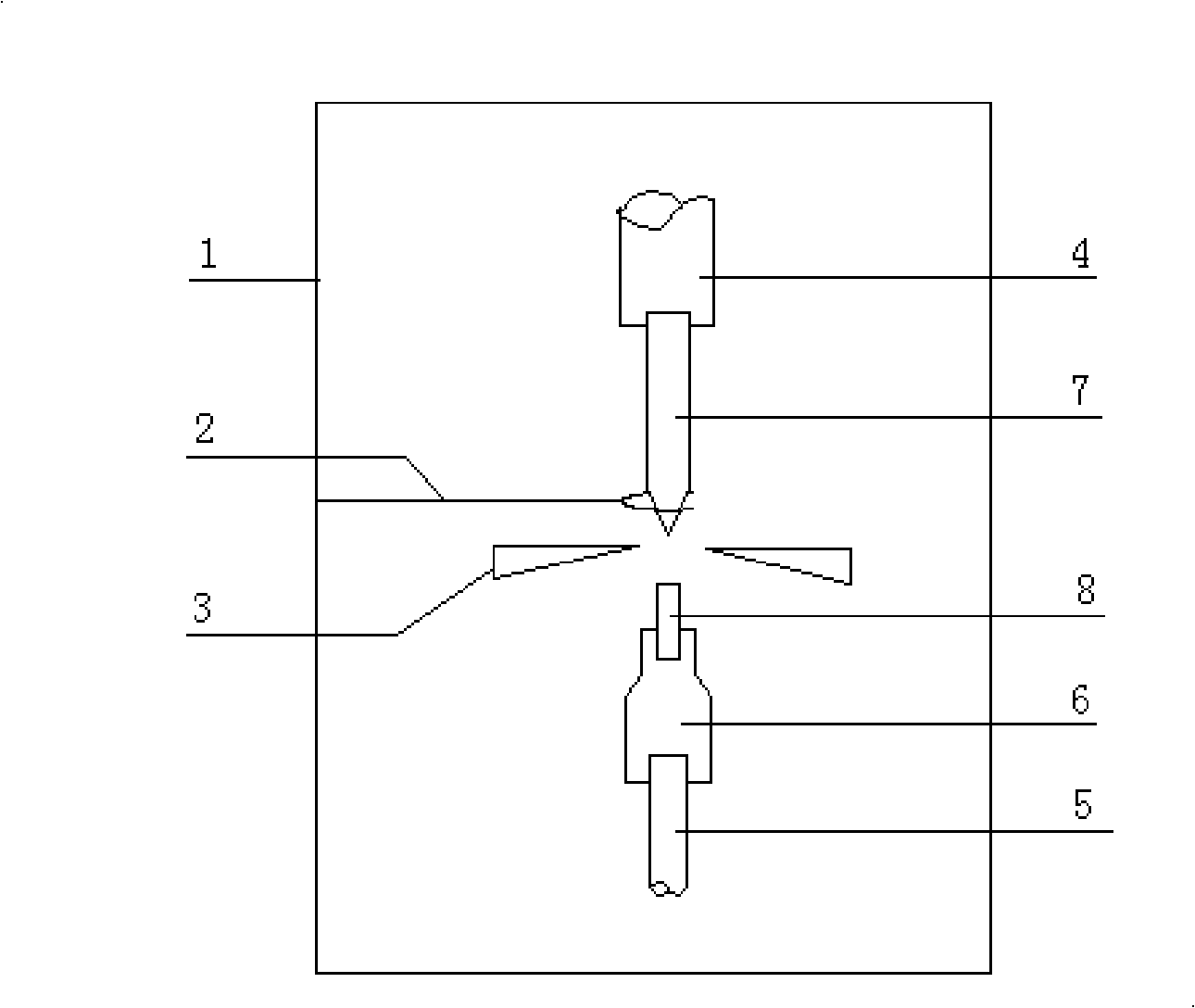

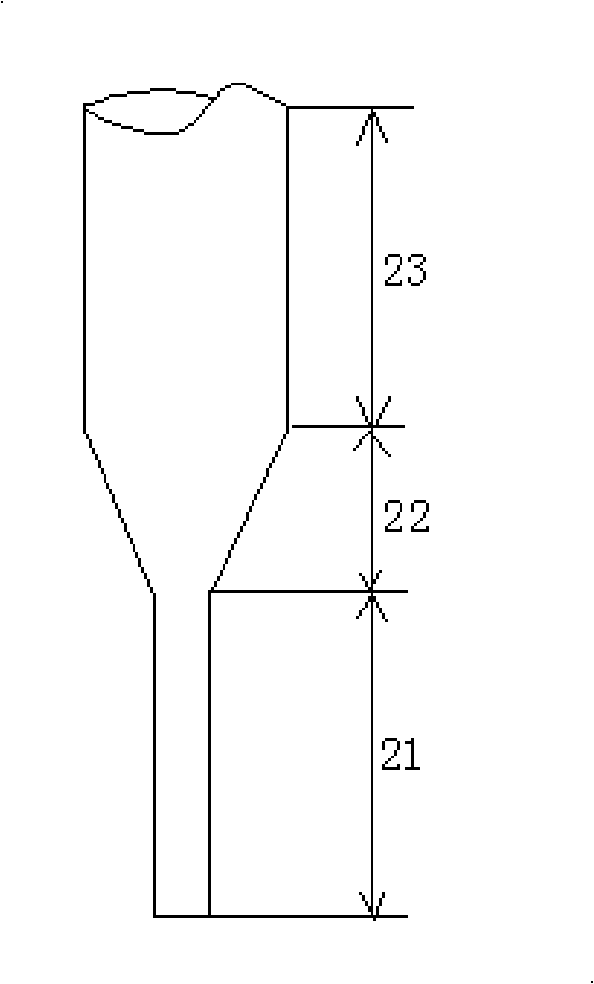

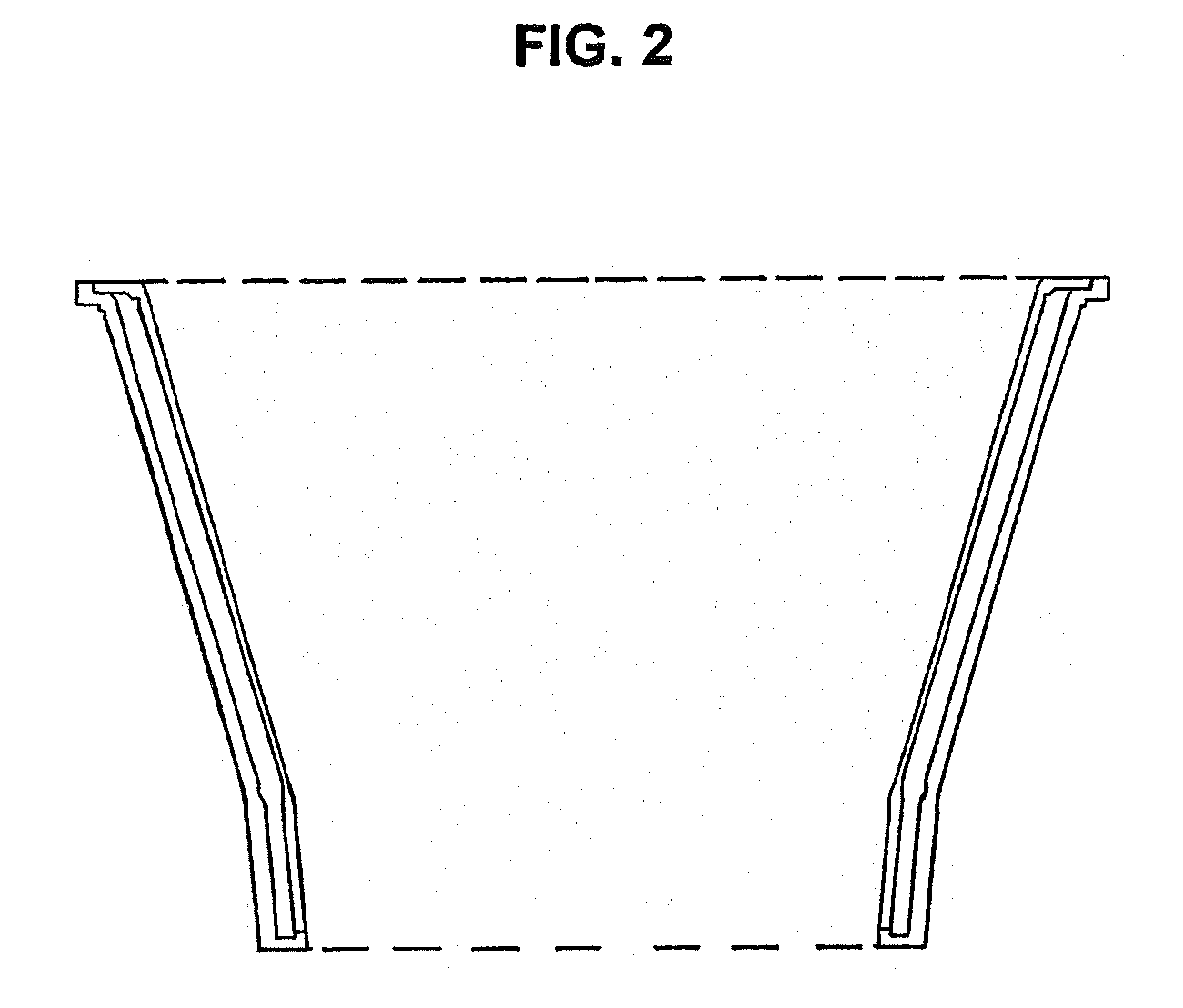

Device and process for growing ga-doped single silicon crystals suitable for making solar cells

InactiveUS20090072202A1Simple procedureLow production costPolycrystalline material growthBy pulling from meltMetallurgySolar cell

A device and method for producing Ga doped silicone single crystal with a diameter between 150 and 165 mm and a narrow resistivity distribution range (from 3 Ω·cm to 0.5 Ω·cm). The device is characterized by the use of a shorter heater and a funnel shaped gas flow guide capable of blowing an inert gas such as Ar straight to the crystallization frontier at the interface between outer surface of the nascent single crystal ingot and the surface of the melt of polycrystalline silicone raw materials in a quartz crucible.

Owner:REN BING YAN +1

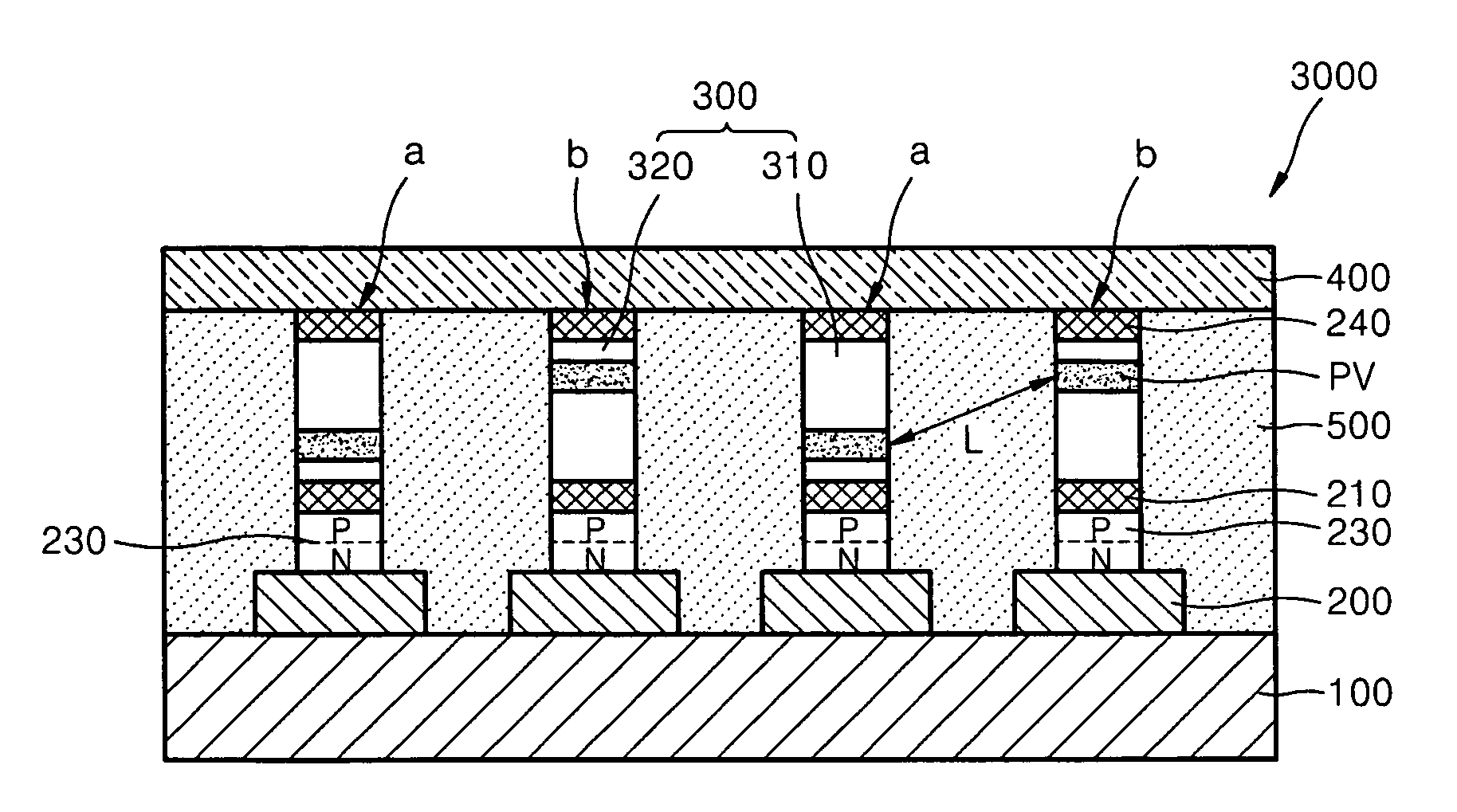

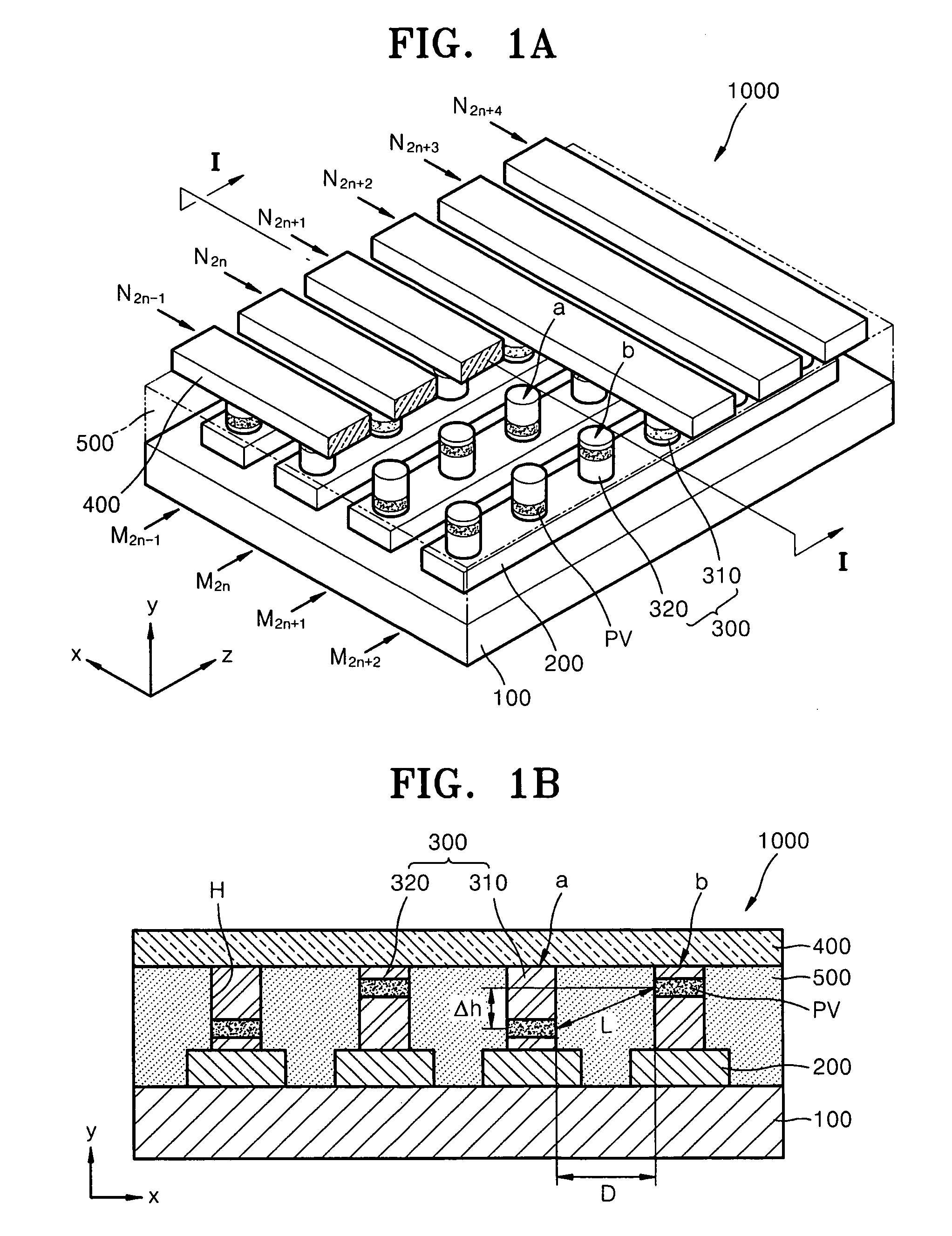

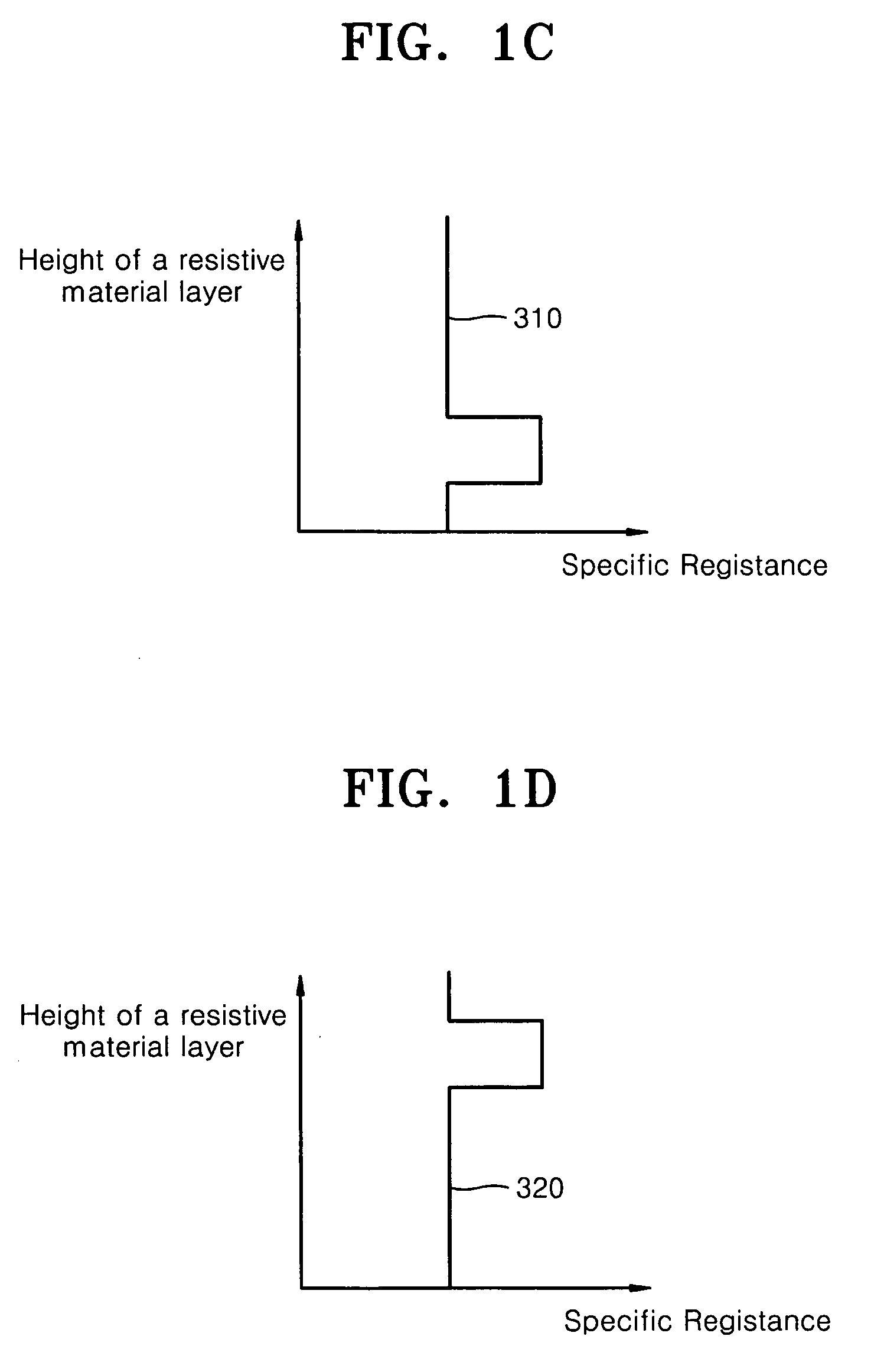

Semiconductor memory device and method of manufacturing the same

ActiveUS20080283813A1Reduce thermal interferenceErroneous operationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor memory device includes first conductive lines on a substrate, an interlayer insulating layer with a plurality of via holes on the substrate, second conductive lines on the interlayer insulating layer, and a resistive memory material in the via holes and electrically connected to the first and second conductive lines, the resistive memory material having a vertically non-uniform specific resistance profile with respect to the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Surface deformation distribution test sensing element

InactiveCN102305587AAchieve ultra-thinStrain sensitiveElectrical/magnetic solid deformation measurementElectrical resistance and conductanceInsulation layer

The invention discloses a surface deformation distribution test sensing element which comprises a flexible sensing thin film, electrodes arranged at the periphery of the flexible sensing thin film uniformly at intervals, lead wires which are connected with the electrodes, an upper flexible insulation layer and a lower flexible insulation layer. Composite materials with strain sensitivity characteristics are utilized to prepare the flexible sensing thin film; and the electrodes and the lead wires are used for outputting specific resistivity information at different positions of the flexible sensing thin film. When in test, the lead wires and a testing instrument are connected; collection test and calculation are carried out by utilizing the electrical impedance imaging technology, the specific resistivity distribution at different positions of the flexible sensing thin film is obtained, and the strain size distribution is obtained through the specific relationship between the strain size of the sensing thin film and the size of the specific resistivity again. The test of two-dimensional deformation field quantity can be realized by the sensing element disclosed by the invention, and the sensing element has the characteristics of simple and ultrathin structure, flexibility, high resolution ratio and precision, great strain range and low cost.

Owner:CHINA UNIV OF MINING & TECH

Interface pressure distribution testing sensing element

InactiveCN102410894AThin structureHigh precision of force sensitivityForce measurement using piezo-resistive materialsElectrical resistance and conductanceConductive polymer composite

The invention discloses an interface pressure distribution testing sensing element. The interface pressure distribution testing sensing element comprises a sensing film, electrodes uniformly arranged around the sensing film at intervals, a lead connected with the electrodes and an upper and lower insulating paint layer. The sensing film is made from a conductive polymer composite material provided with a piezo-resistive sensitivity characteristic, and the electrodes and the lead are used for outputting resistivity information of the sensing film in different positions. When in testing, the lead is connected with a testing instrument, the electrical impedance imaging technology is used for acquiring, testing and computing so as to obtain the resistivity distribution of the sensing film in different positions, and then the pressure distribution can be obtained through the relationship between the sensing film pressure and the resistivity. The interface pressure distribution testing sensing element can be used for measuring the interface pressure distribution and change, and has the advantages of simple structure, ultra-thin film, strong flexibility, high resolution and precision, large measuring range and low cost.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com