Method for preparing vacuum zone melting high resistant silicon single crystal

A vacuum zone, high-resistance silicon technology, applied in the self-zone melting method, single crystal growth, single crystal growth and other directions, can solve the problems of high cross-sectional uniformity, high "minority carrier lifetime, and inability to produce ultra-high purity. Achieve the effect of increasing resistivity, improving device performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation method of vacuum zone melting high resistance silicon single crystal with Φ53±2mm

[0037] Using the QR 400 domestic vacuum zone melting single crystal furnace produced by Beijing Jingyuntong Technology Co., Ltd., the method of the present invention is used to produce Φ53mm±2mm high-resistance silicon single crystal, and its quality reaches SEMI standards.

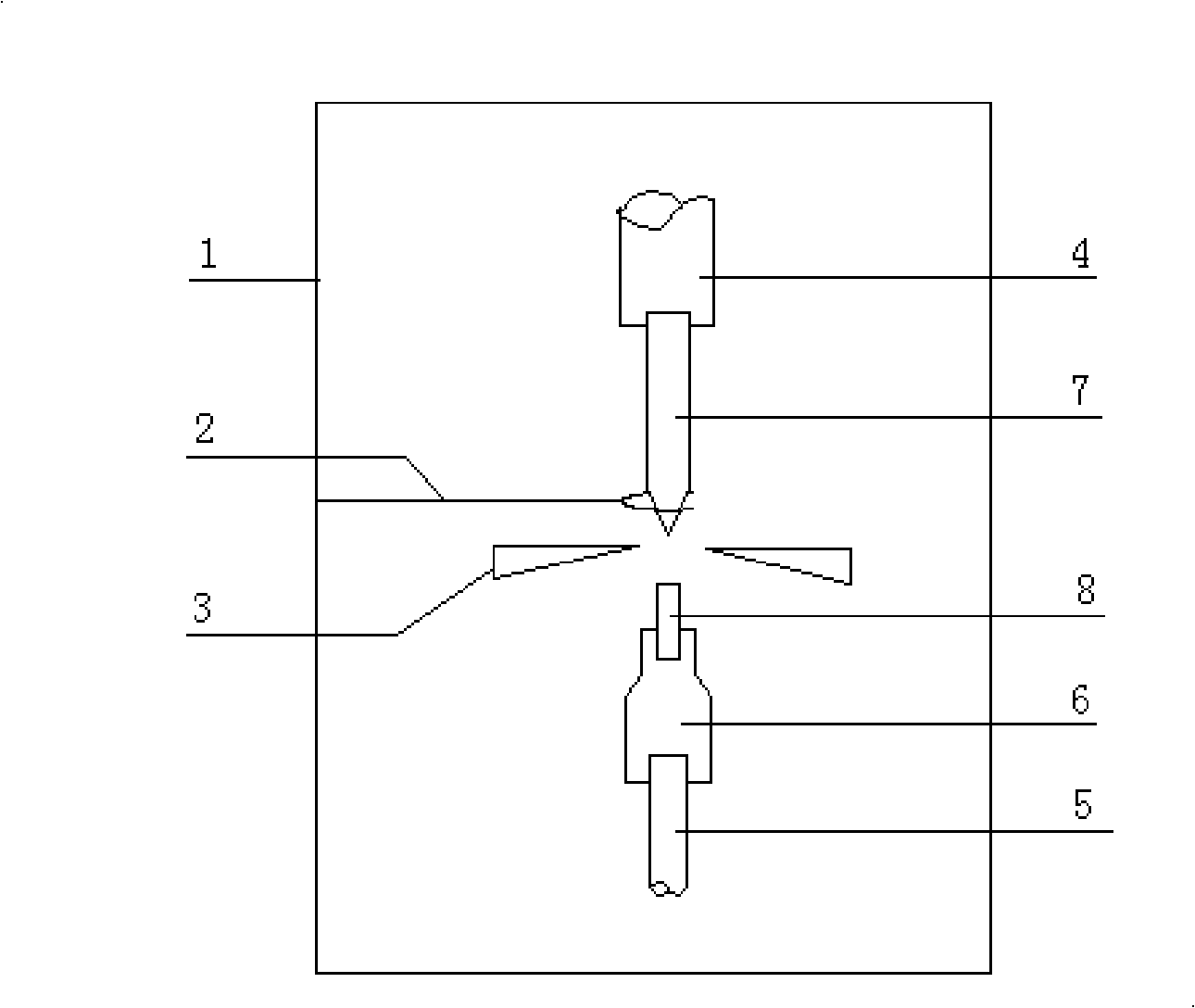

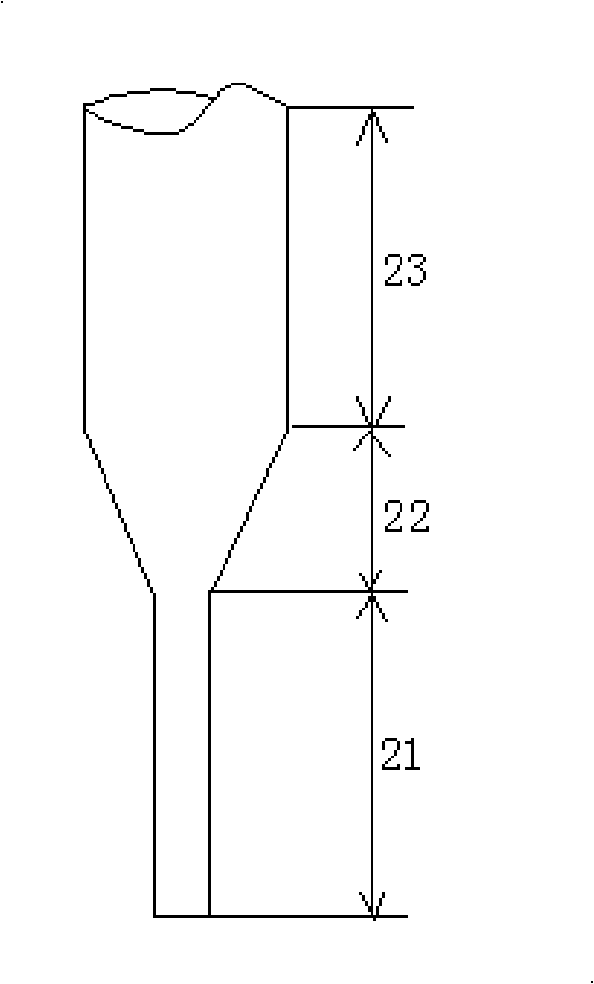

[0038] Combine now figure 1 and figure 2 To further describe this method:

[0039] The preparation method of the high-resistance silicon single crystal melted in the vacuum zone includes two major processes of polysilicon purification and silicon single crystal crystallization in sequence, and is operated according to the following steps:

[0040] A. Polysilicon purification process: the purpose is to purify polysilicon materials to obtain 11N (that is, the purity reaches 0.99999999999 and above) high-purity polysilicon. The operation steps are:

[0041] (a) Furnace cleaning and furnace loa...

Embodiment 2

[0063] Example 2 Preparation method of vacuum zone melting high-resistance silicon single crystal with Φ53±2 mm

[0064] Using the same vacuum zone melting single crystal furnace and operation method as in Example 1, a high-resistance silicon single crystal of Φ53mm±2mm was produced, and its quality reached the SEMI standard.

[0065] The difference with embodiment 1 mainly lies in the difference of each parameter condition, specifically as follows (unspecified places are identical with embodiment 1):

[0066] A. Polysilicon purification process:

[0067] (b) Evacuation and preheating process:

[0068] (6) Start the mechanical pump to evacuate the melting single crystal furnace in the vacuum zone. When the vacuum degree in the furnace chamber reaches 10 -2 Pa, turn on the molecular pump, and pump the vacuum in the furnace chamber to 3×10 -4 pa;

[0069] Use the quartz fork 2 to preheat the polysilicon rod 7 by indirect radiation. The preheating time is 20 minutes. After th...

Embodiment 3

[0082] Example 3 Preparation method of vacuum zone melting high resistance silicon single crystal with Φ53±2mm

[0083] Using the same vacuum zone melting single crystal furnace and operation method as in Example 1, a high-resistance silicon single crystal of Φ53mm±2mm was produced, and its quality reached the SEMI standard.

[0084] The difference with embodiment 1 mainly lies in the difference of each parameter condition, specifically as follows (unspecified places are identical with embodiment 1):

[0085] A. Polysilicon purification process:

[0086] (b) Evacuation and preheating process:

[0087] (6) Start the mechanical pump to evacuate the melting single crystal furnace in the vacuum zone. When the vacuum degree in the furnace chamber reaches 10 -2 At Pa, turn on the molecular pump and pump the vacuum in the furnace chamber to 1×10 -3 Pa;

[0088] Use the quartz fork 2 to preheat the polysilicon rod 7 by indirect radiation. The preheating time is 25 minutes. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com