Patents

Literature

296 results about "Kerogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kerogen is solid, insoluble organic matter in sedimentary rocks. Consisting of an estimated 10¹⁶ tons of carbon, it is the most abundant source of organic compounds on earth, exceeding the total organic content of living matter by 10,000 fold. It is insoluble in normal organic solvents and it does not have a specific chemical formula. Upon heating, kerogen converts in part to liquid and gaseous hydrocarbons. Petroleum and natural gas form from kerogen. Kerogen may be classified by its origin: lacustrine (e.g., algal), marine (e.g., planktonic), and terrestrial (e.g., pollen and spores). The name "kerogen" was introduced by the Scottish organic chemist Alexander Crum Brown in 1906, derived from the Greek for "wax birth" (Greek: κηρός "wax" and -gen, γένεση "birth").

Recovery of products from oil shale

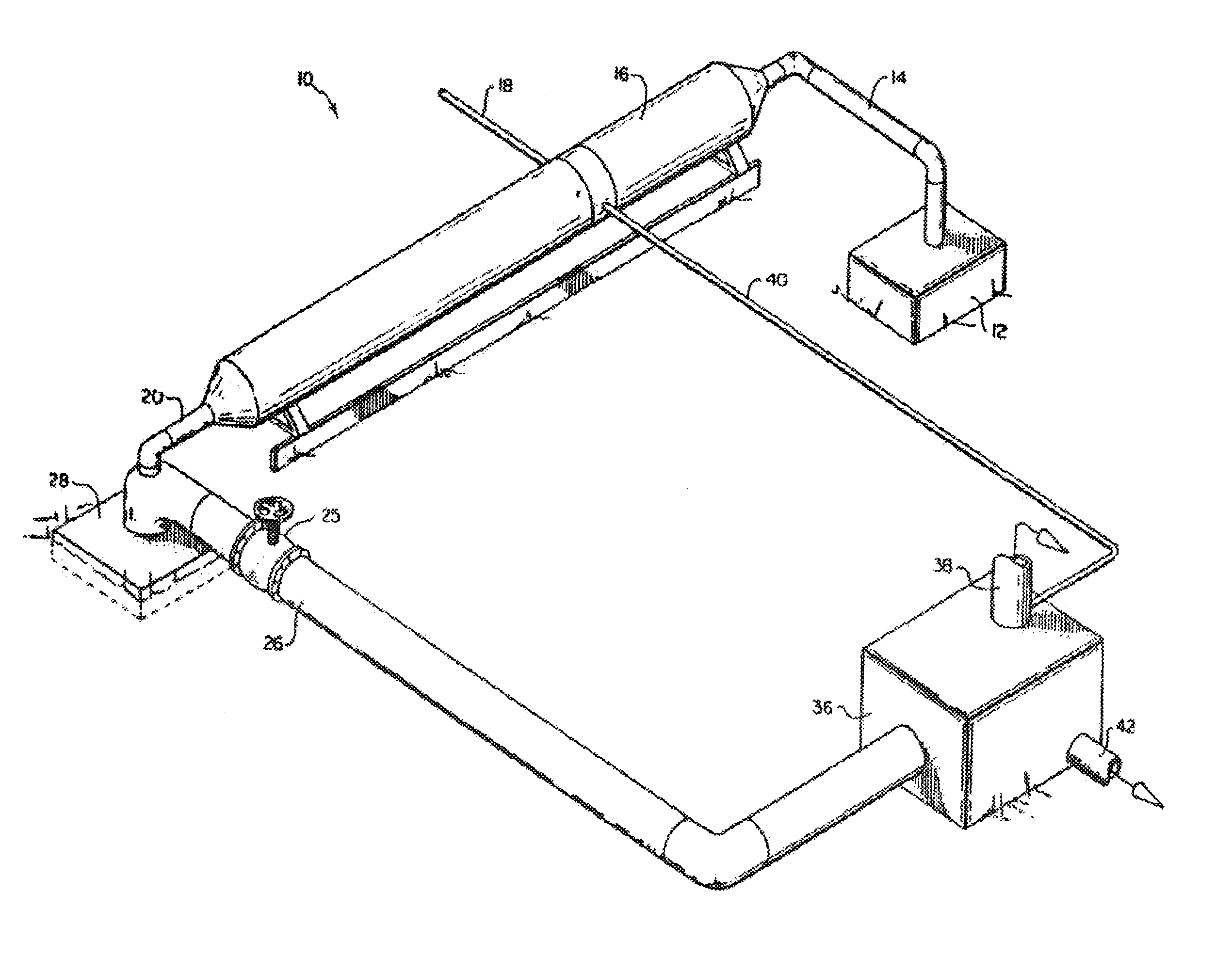

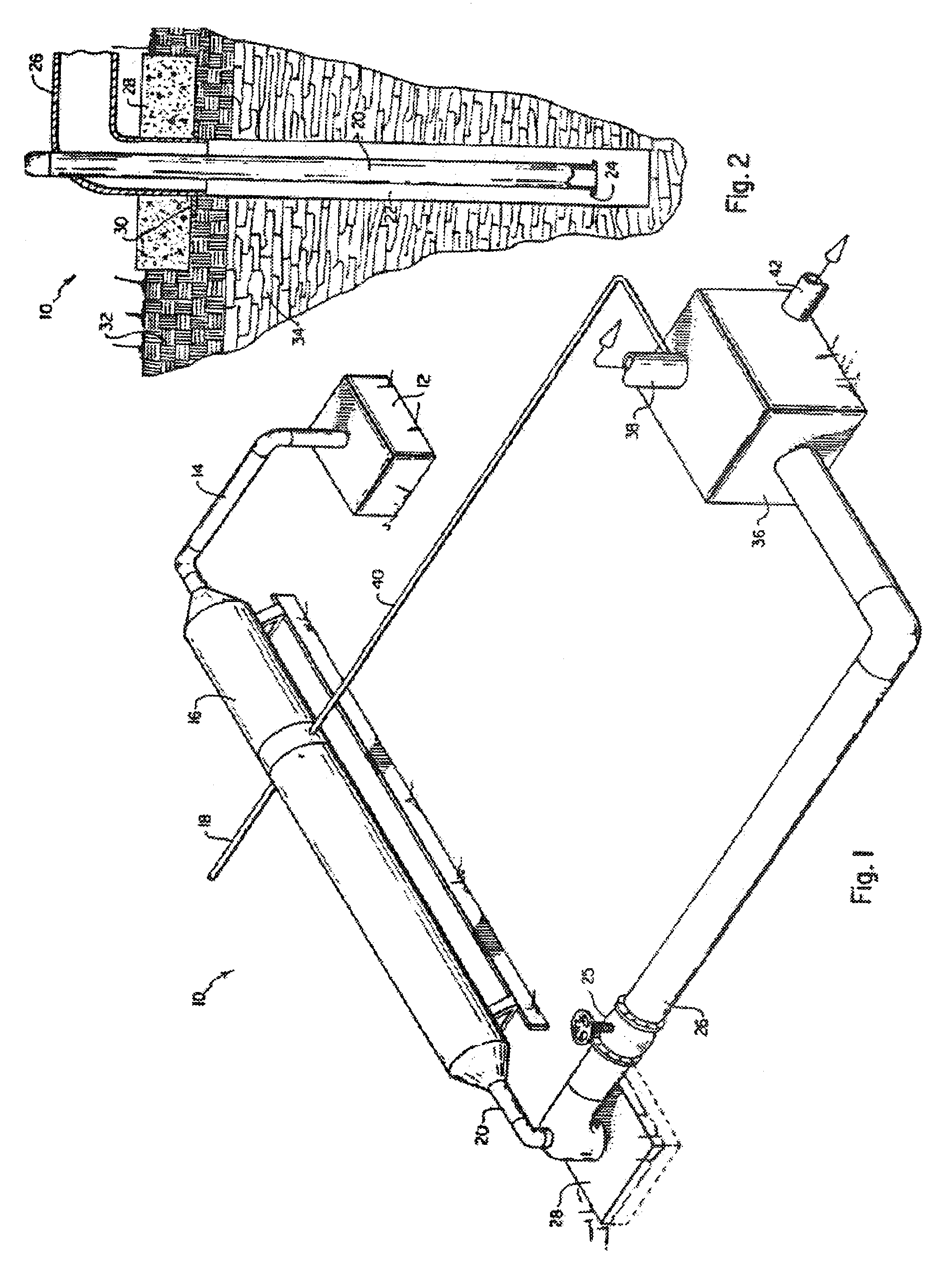

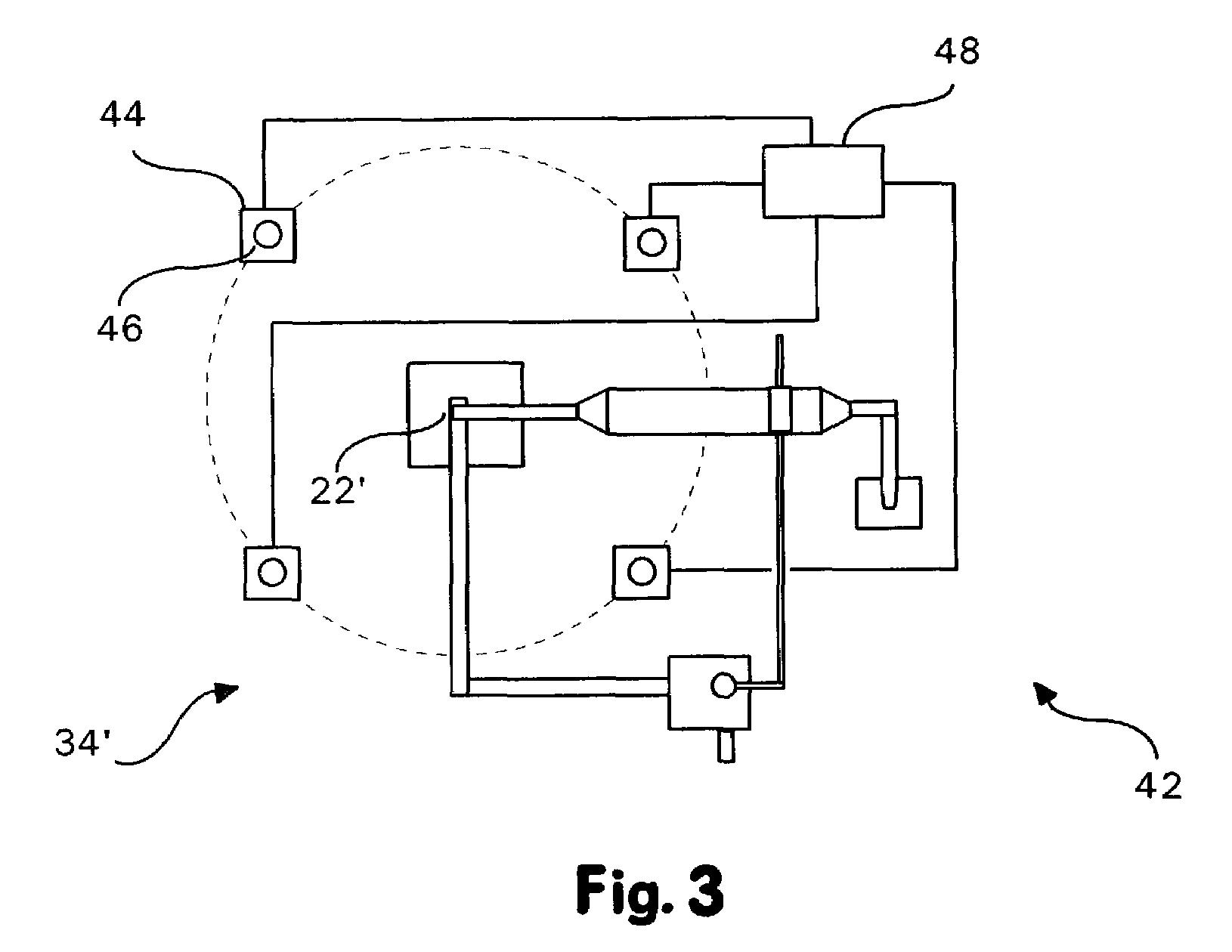

InactiveUS7048051B2Maximize recoveryProcedure is time-consume and expensiveFluid removalKerogenThermal energy

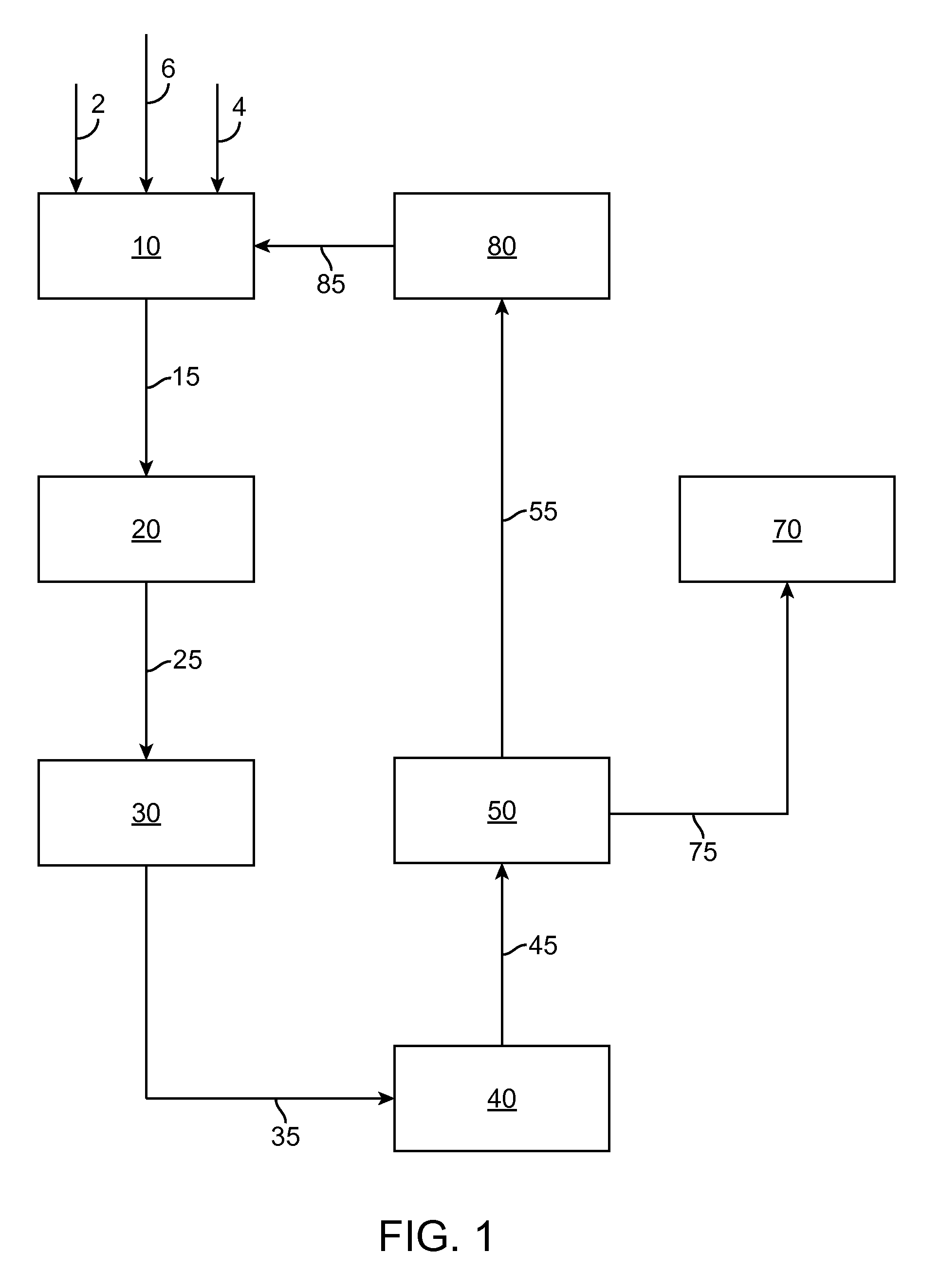

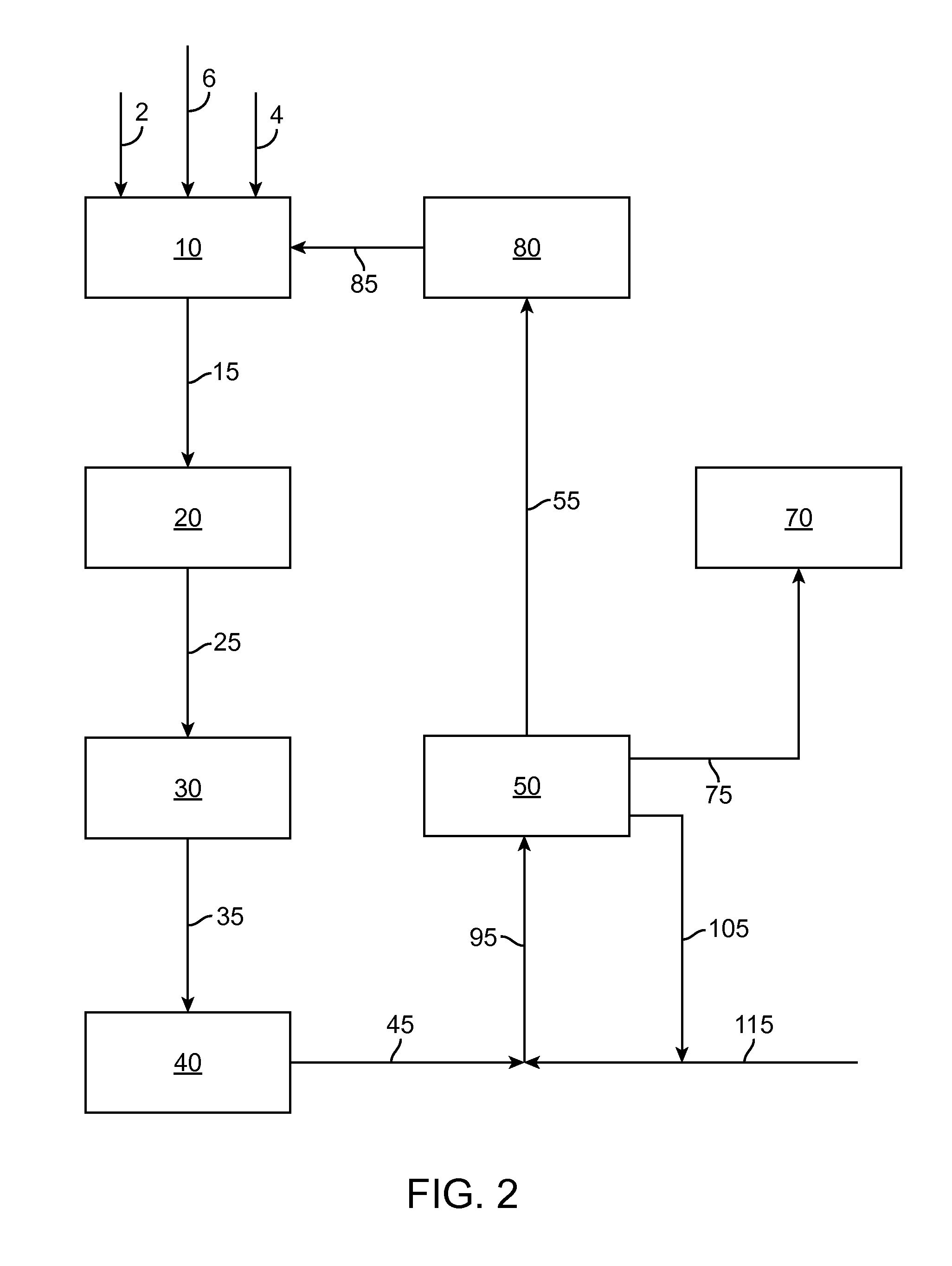

A process and system for recovering hydrocarbonaceous products from in situ oil shale formations. A hole is drilled in the oil shale formation and a processing gas inlet conduit is positioned within the hole. A processing gas is pressurized, heated, and introduced through the processing gas inlet conduit and into the hole. The processing gas creates a nonburning thermal energy front within the oil shale formation so as to convert kerogen in the oil shale to hydrocarbonaceous products. The products are withdrawn with the processing gas through an effluent gas conduit positioned around the opening of the hole, and are then transferred to a condenser wherein a liquid fraction of the products is formed and separated from a gaseous fraction.

Owner:GENERAL SYNFUELS INT

Method for production of hydrocarbons from organic-rich rock

A method for accelerating the conversion of kerogen to hydrocarbons in a subterranean formation containing organic-rich rock that is located in the vicinity of reservoir-quality strata. Sufficient heat is generated in the reservoir-quality strata such that it heats the organic-rich rock in the subterranean formation and accelerates the conversion of kerogen to hydrocarbons in the formation.

Owner:EXXONMOBIL UPSTREAM RES CO

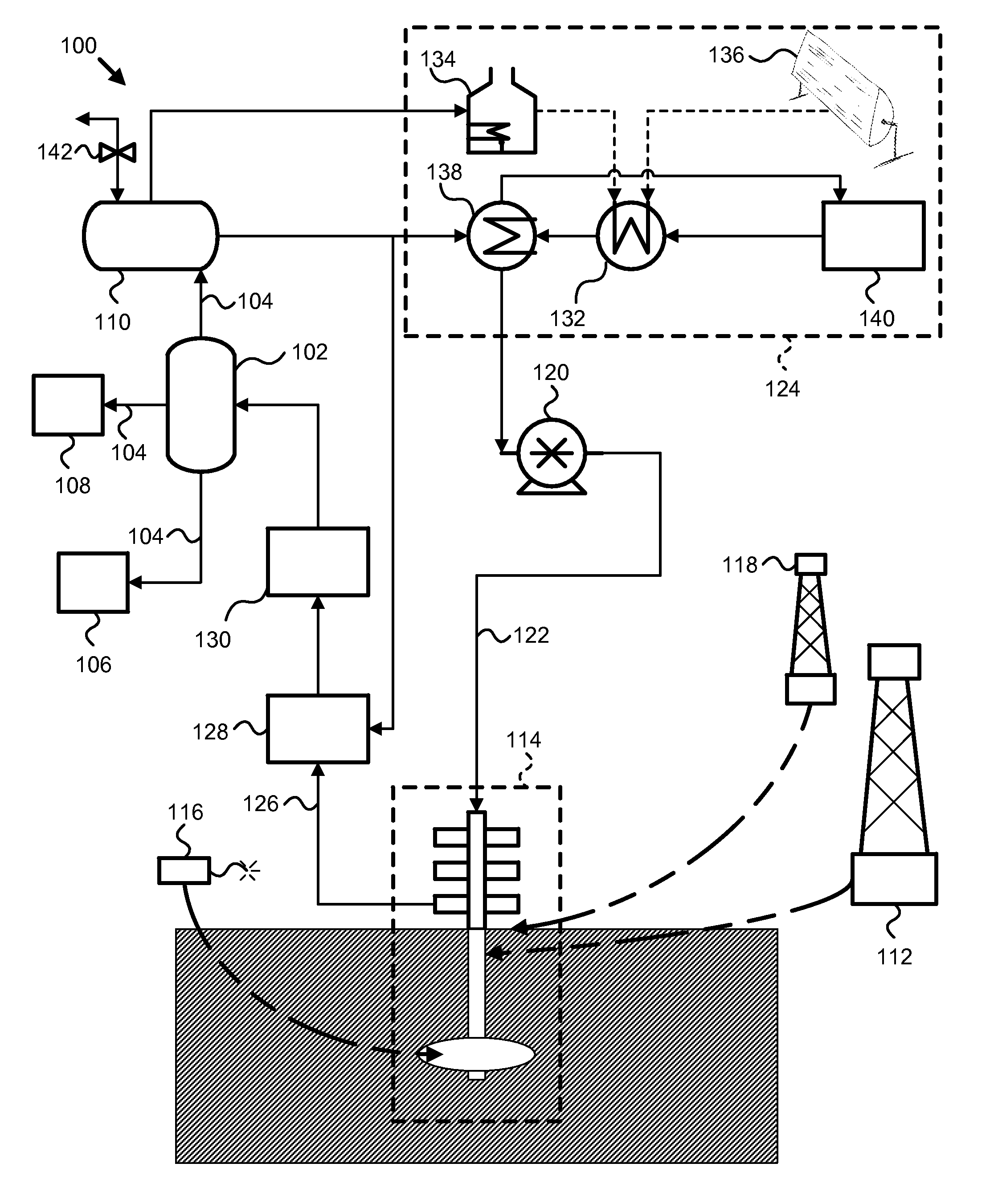

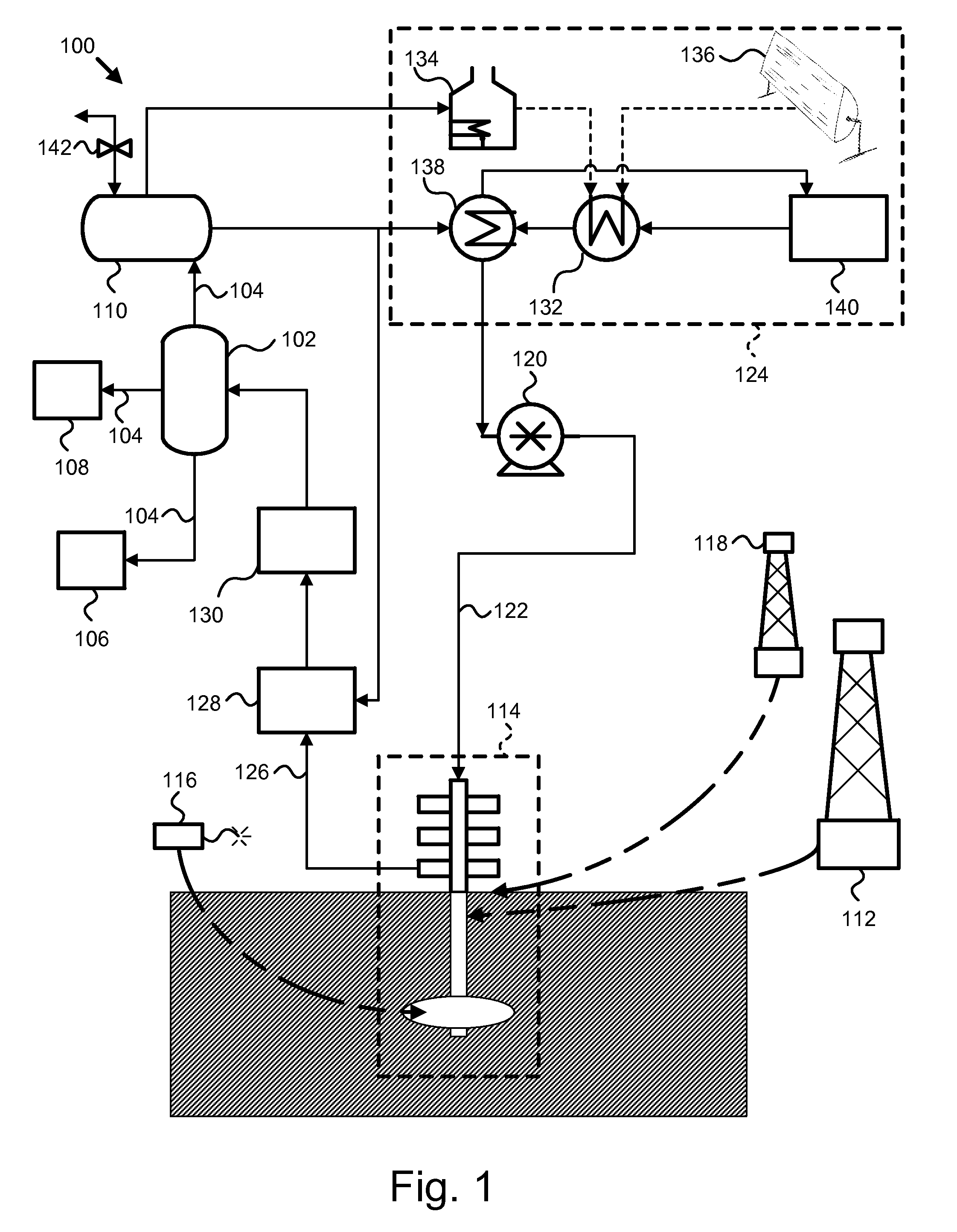

Process for producing Hydrocarbon fluids combining in situ heating, a power plant and a gas plant

An in situ method of producing hydrocarbon fluids from an organic-rich rock formation is provided. The method may include heating an organic-rich rock formation, for example an oil shale formation, in situ to pyrolyze formation hydrocarbons, for example kerogen, to form a production fluid containing hydrocarbon fluids. The method may include separating the production fluid into at least a gas stream and a liquid stream, where the gas stream is a low BTU gas stream. The low BTU gas stream is then fed to a gas turbine where it is combusted and is used to generate electricity.

Owner:KAMINSKY ROBERT D +4

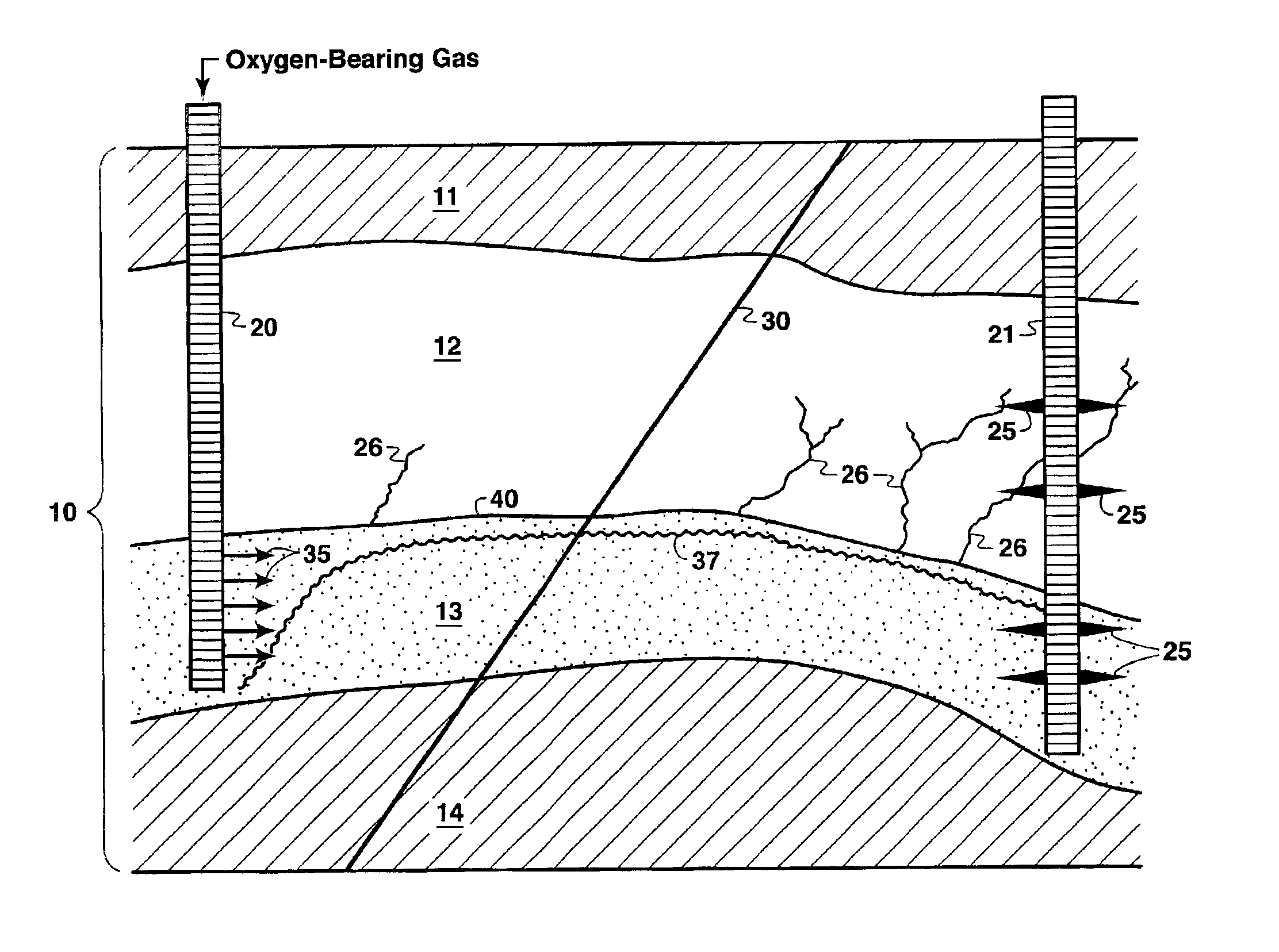

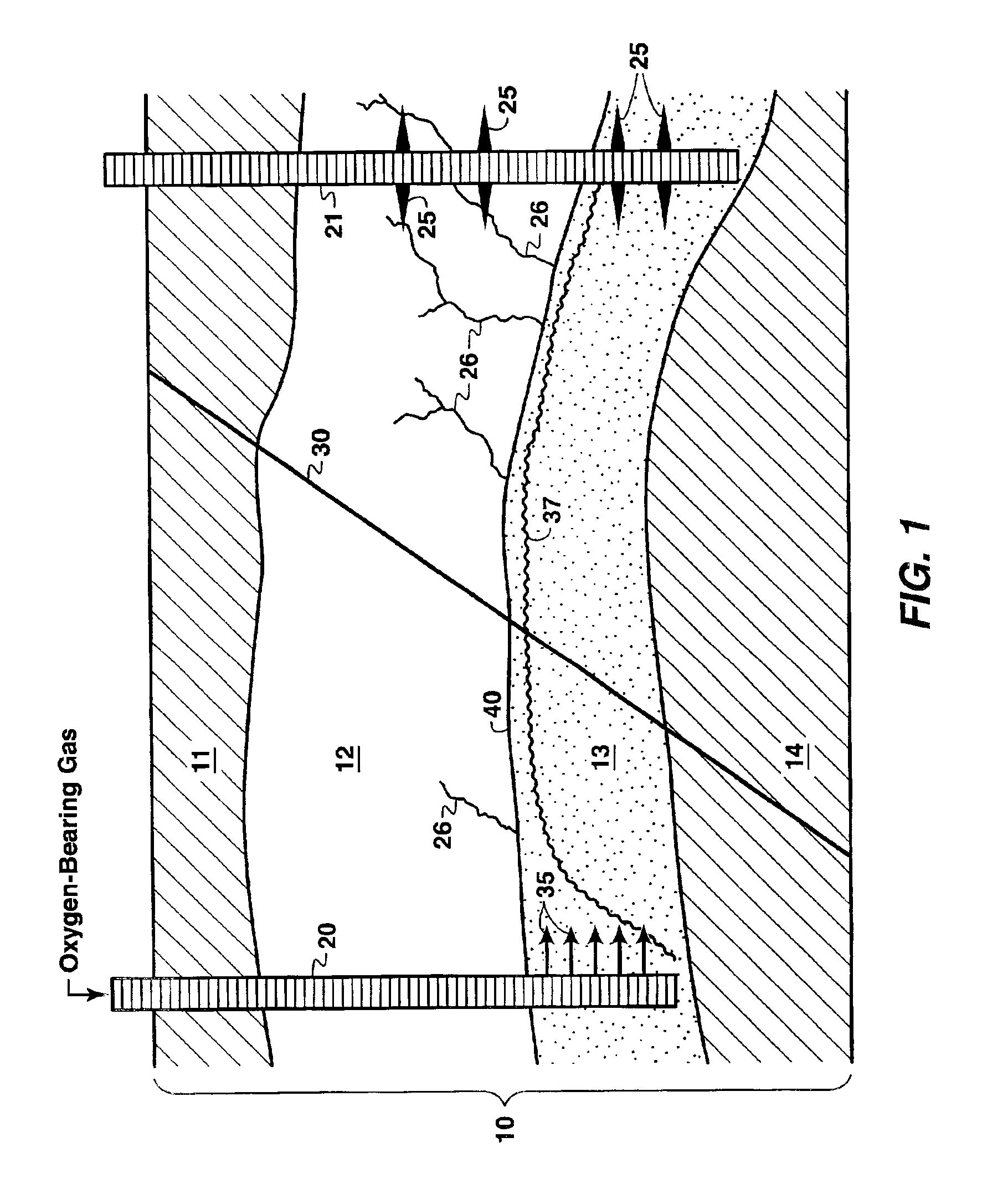

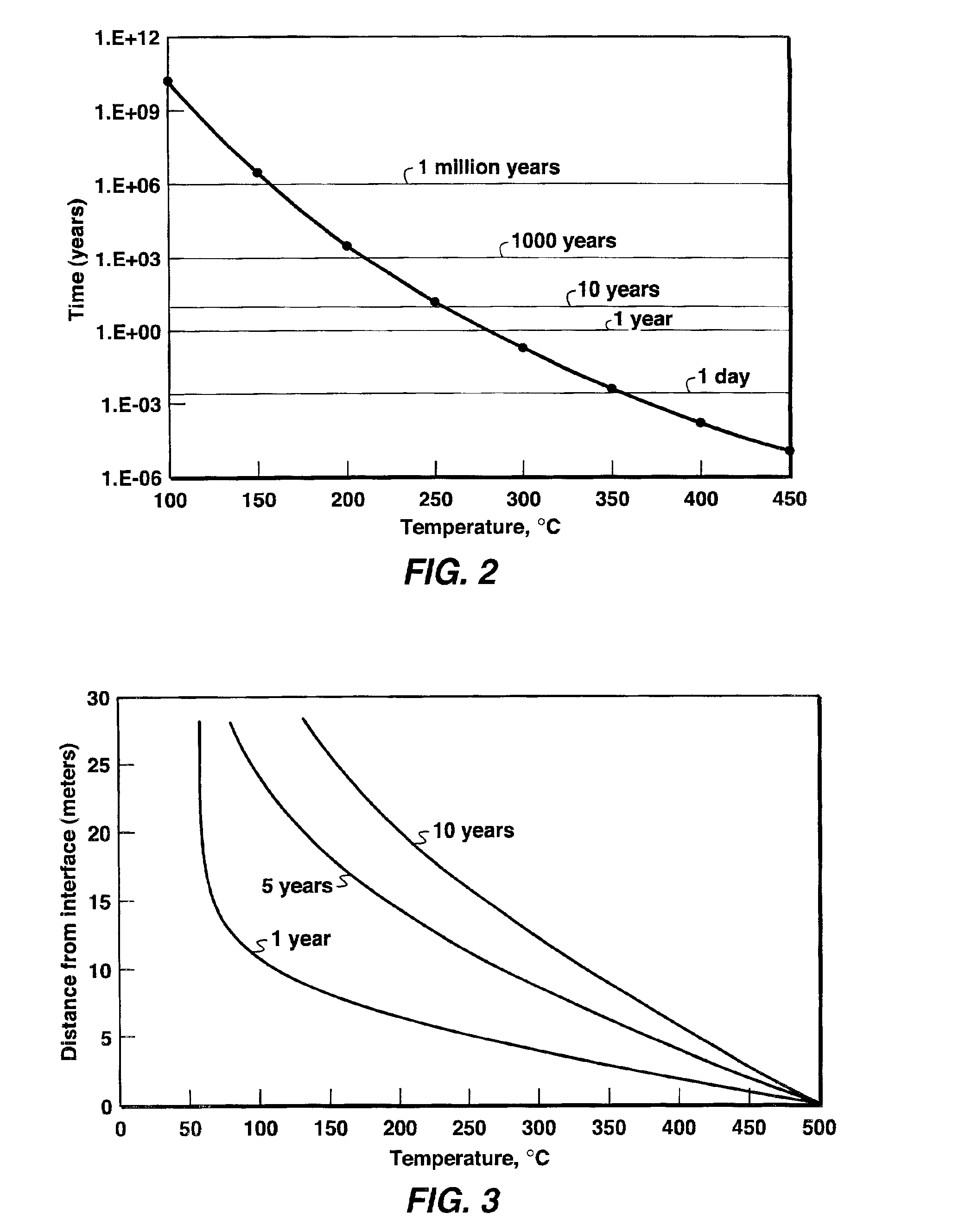

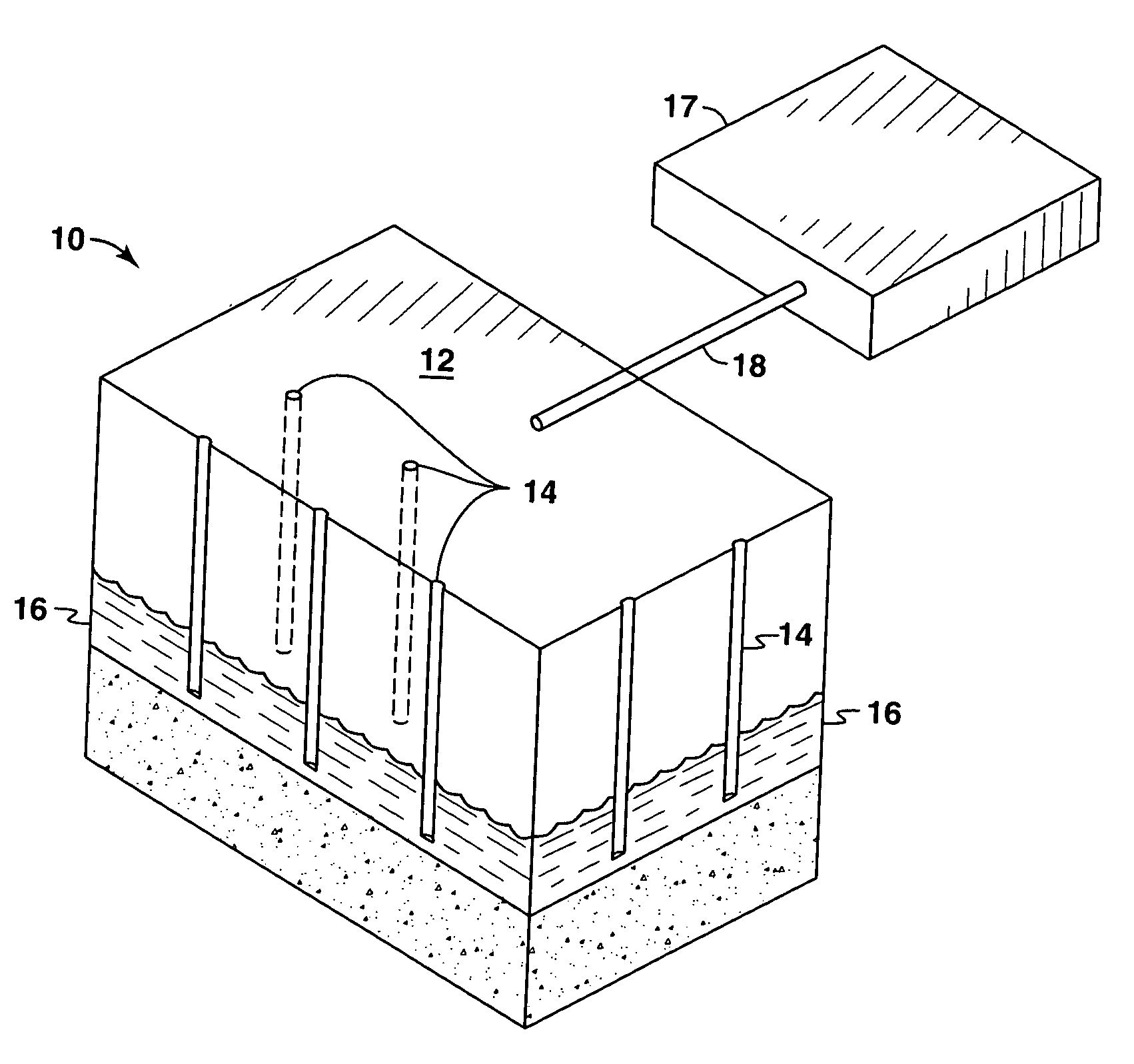

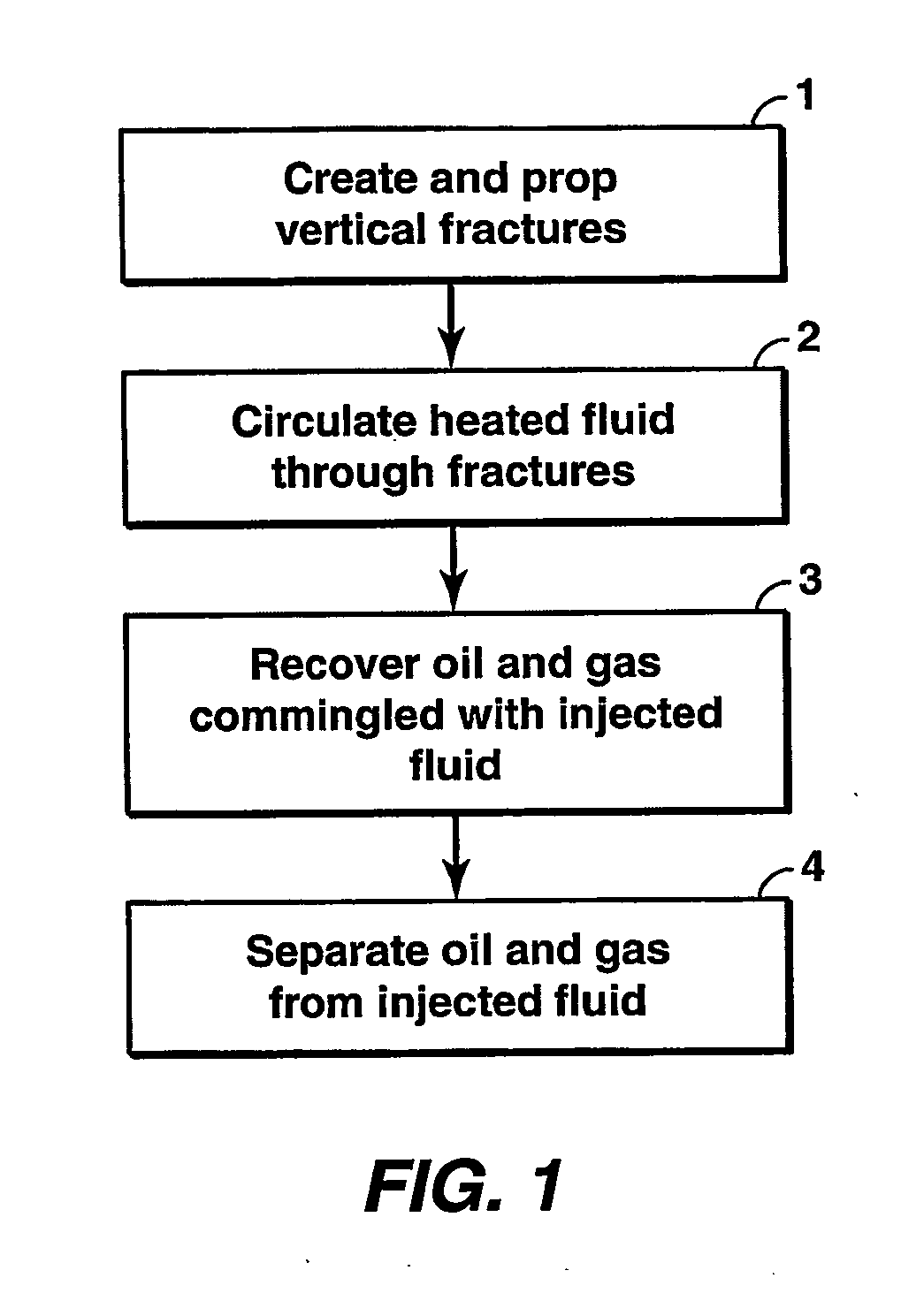

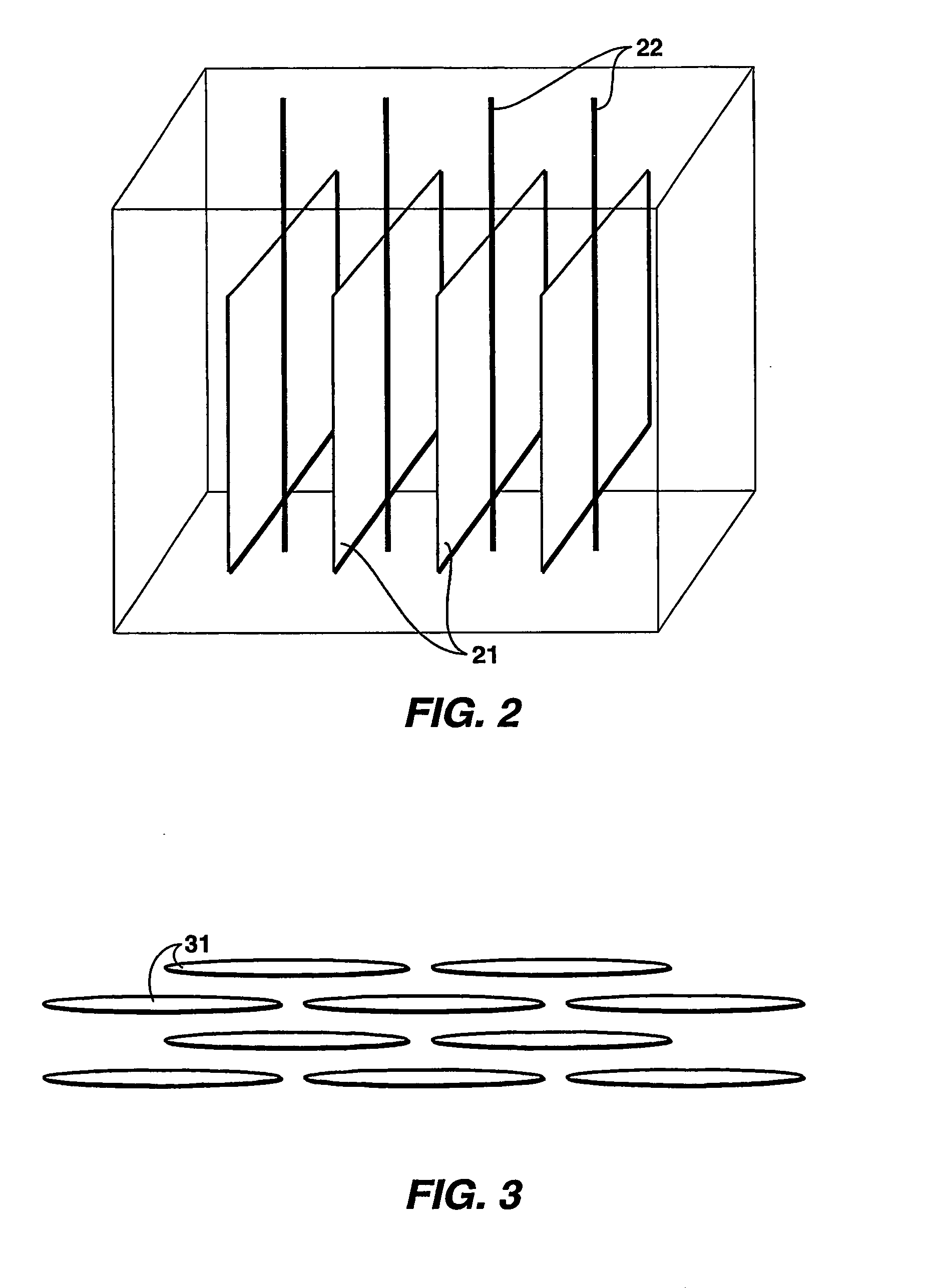

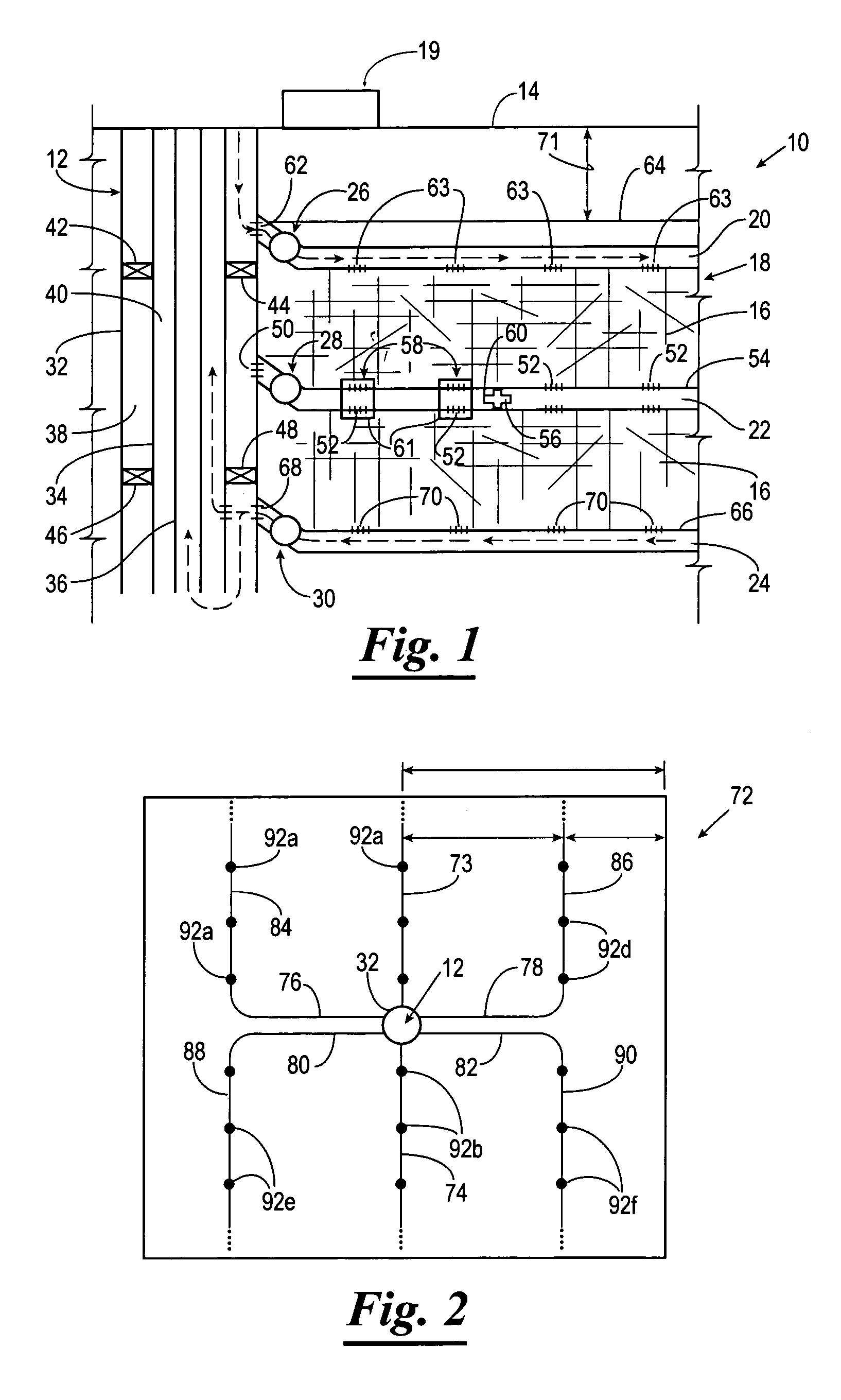

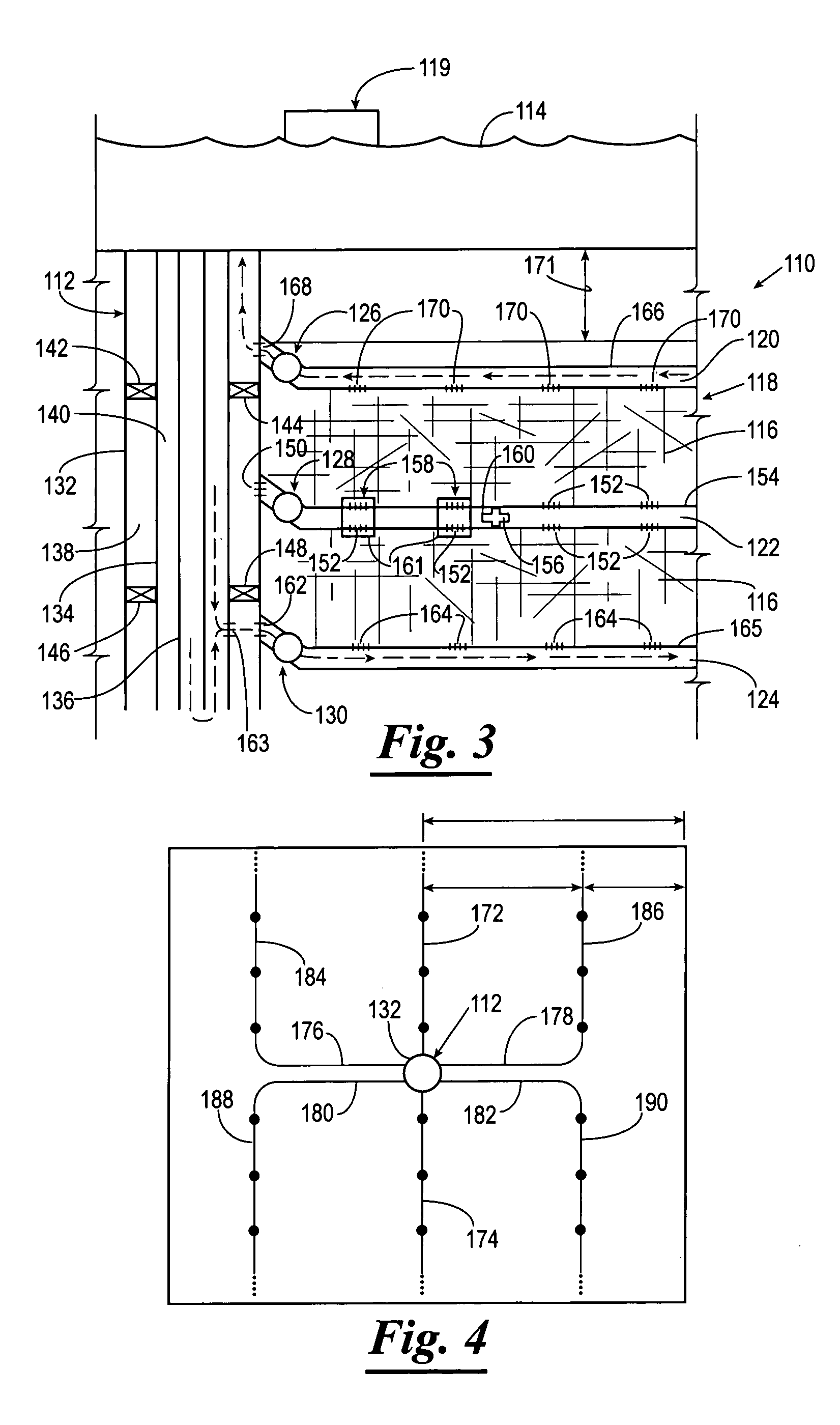

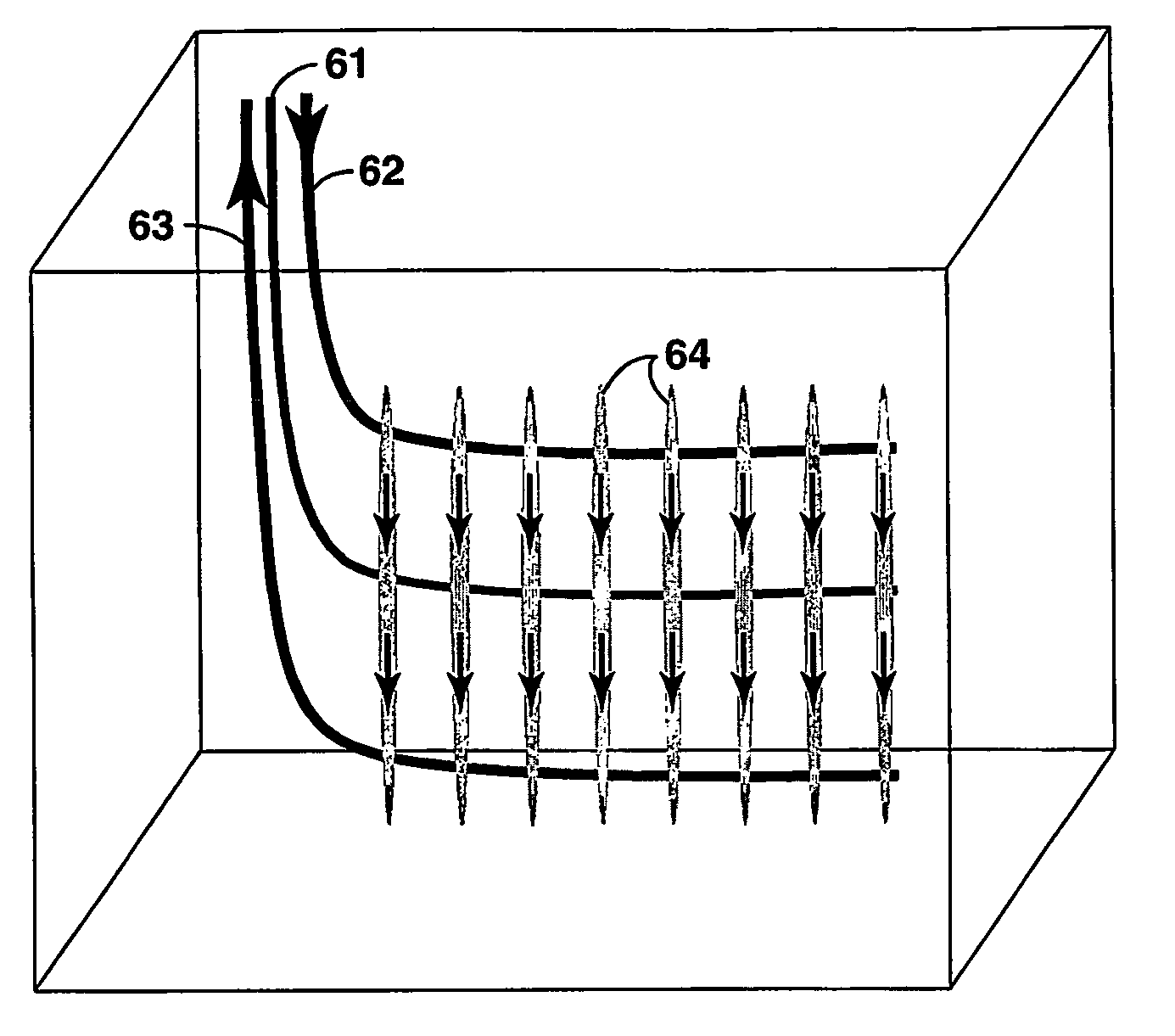

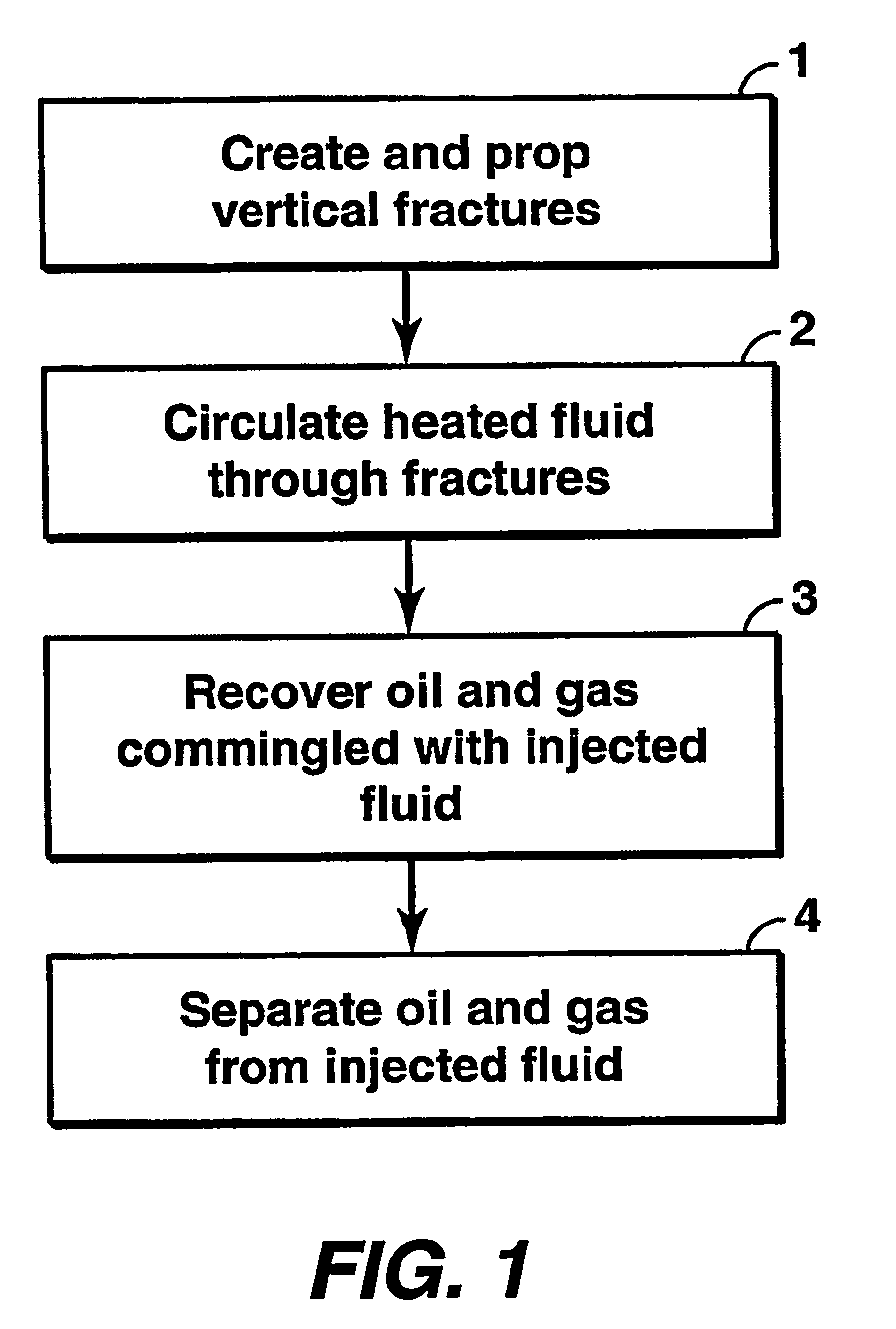

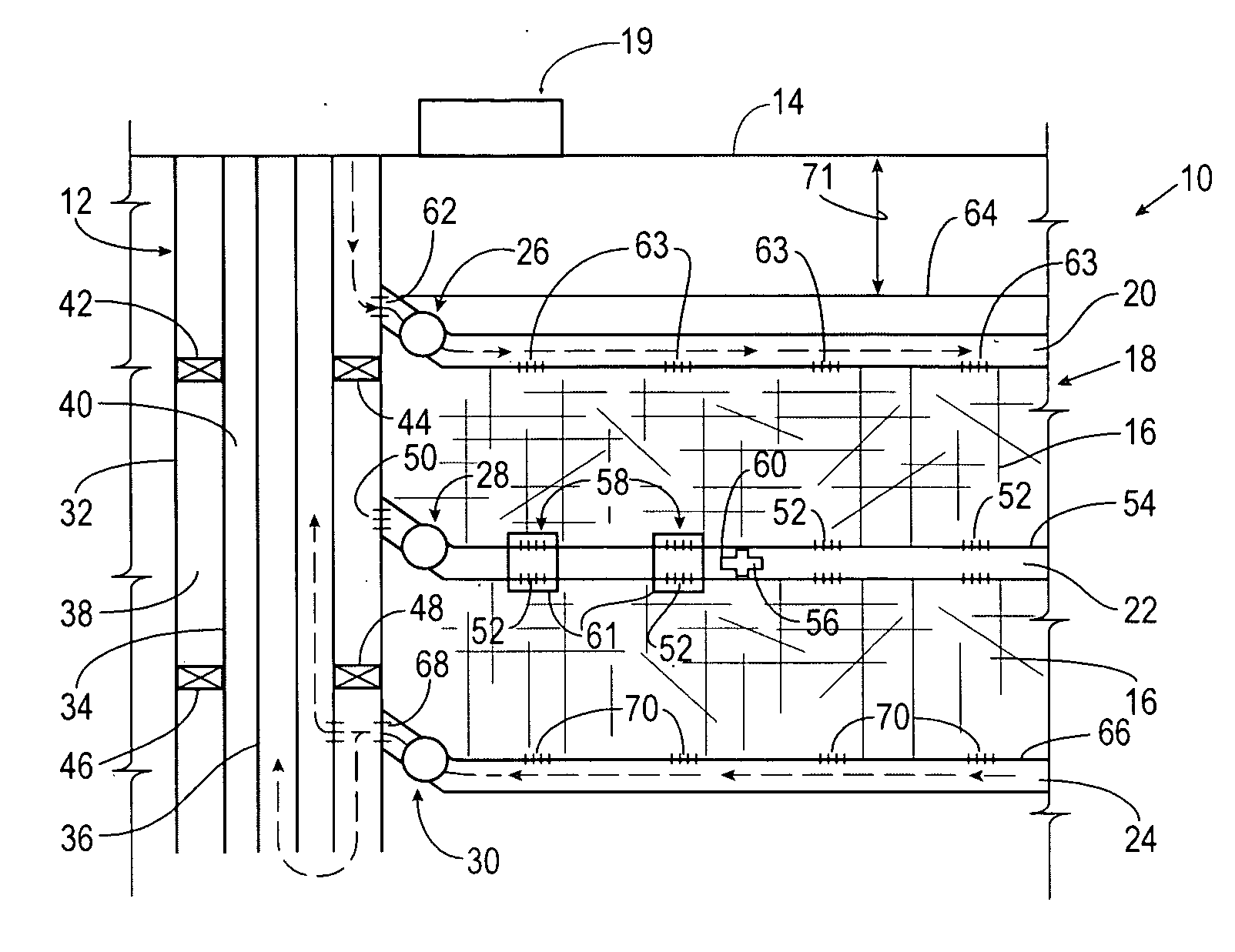

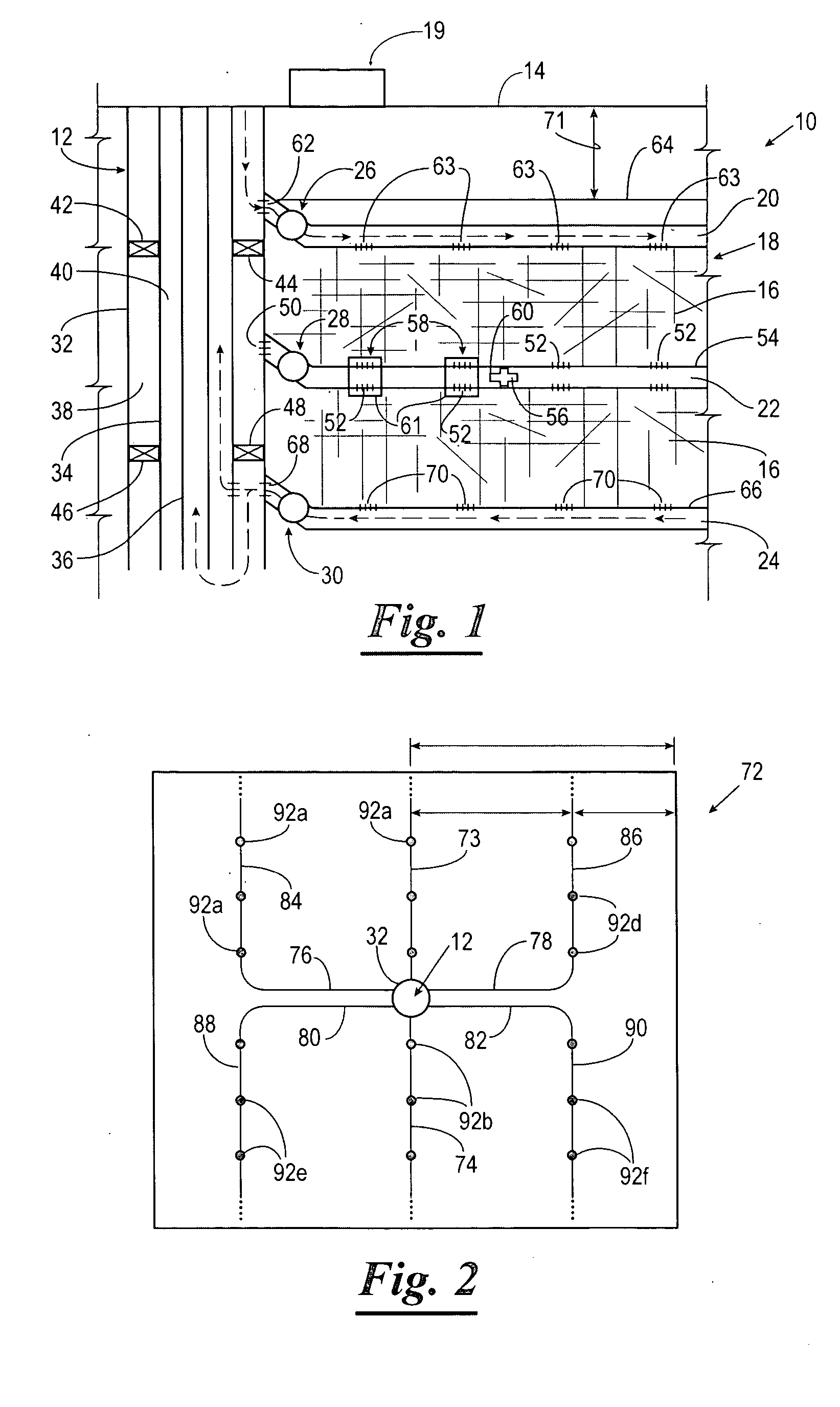

Hydrocarbon recovery from impermeable oil shales

InactiveUS20070023186A1Reduce penetrationAvoid insufficient heatingInsulationFluid removalKerogenCooling fluid

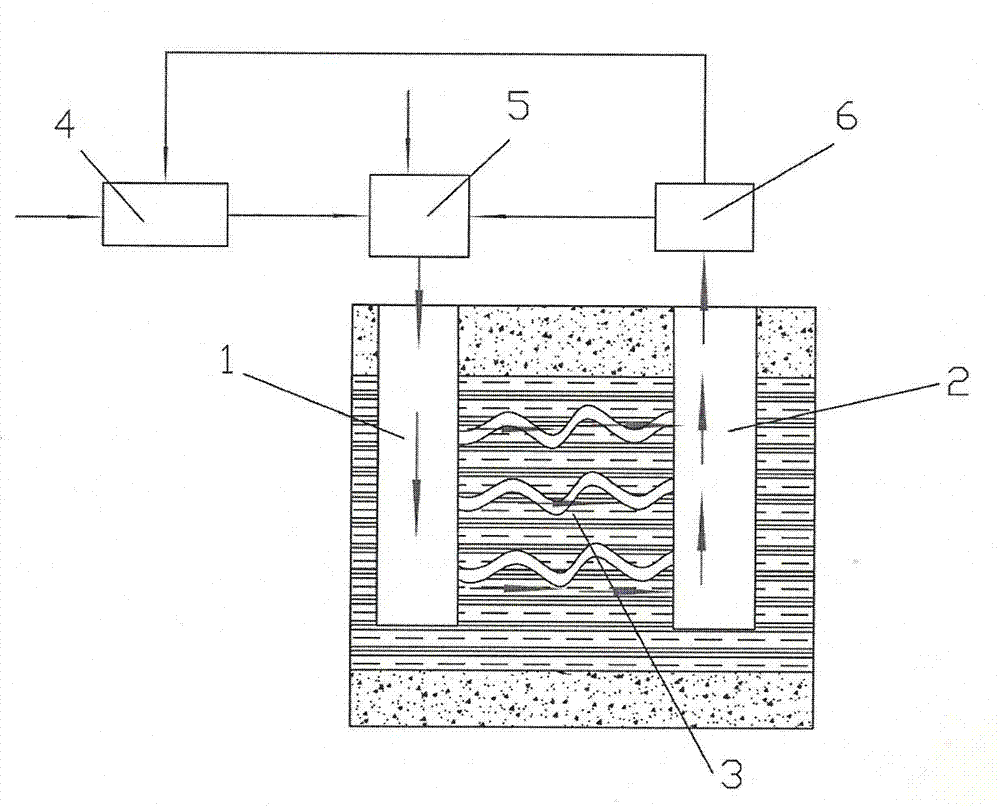

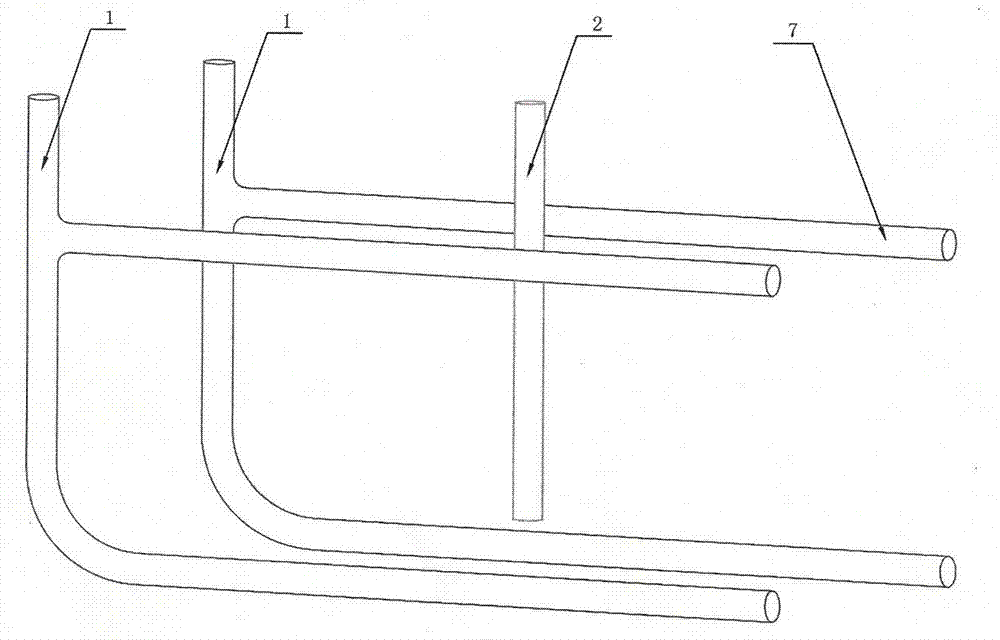

An economic method for in situ maturing and production of oil shale or other deep-lying, impermeable resources containing immobile hydrocarbons. Vertical fractures are created using horizontal or vertical wells. The same or other wells are used to inject pressurized fluids heated to less than approximately 370° C., and to return the cooled fluid for reheating and recycling. The heat transferred to the oil shale gradually matures the kerogen to oil and gas as the temperature in the shale is brought up, and also promotes permeability within the shale in the form of small fractures sufficient to allow the shale to flow into the well fractures where the product is collected commingled with the heating fluid and separated out before the heating fluid is recycled.

Owner:EXXONMOBIL UPSTREAM RES CO

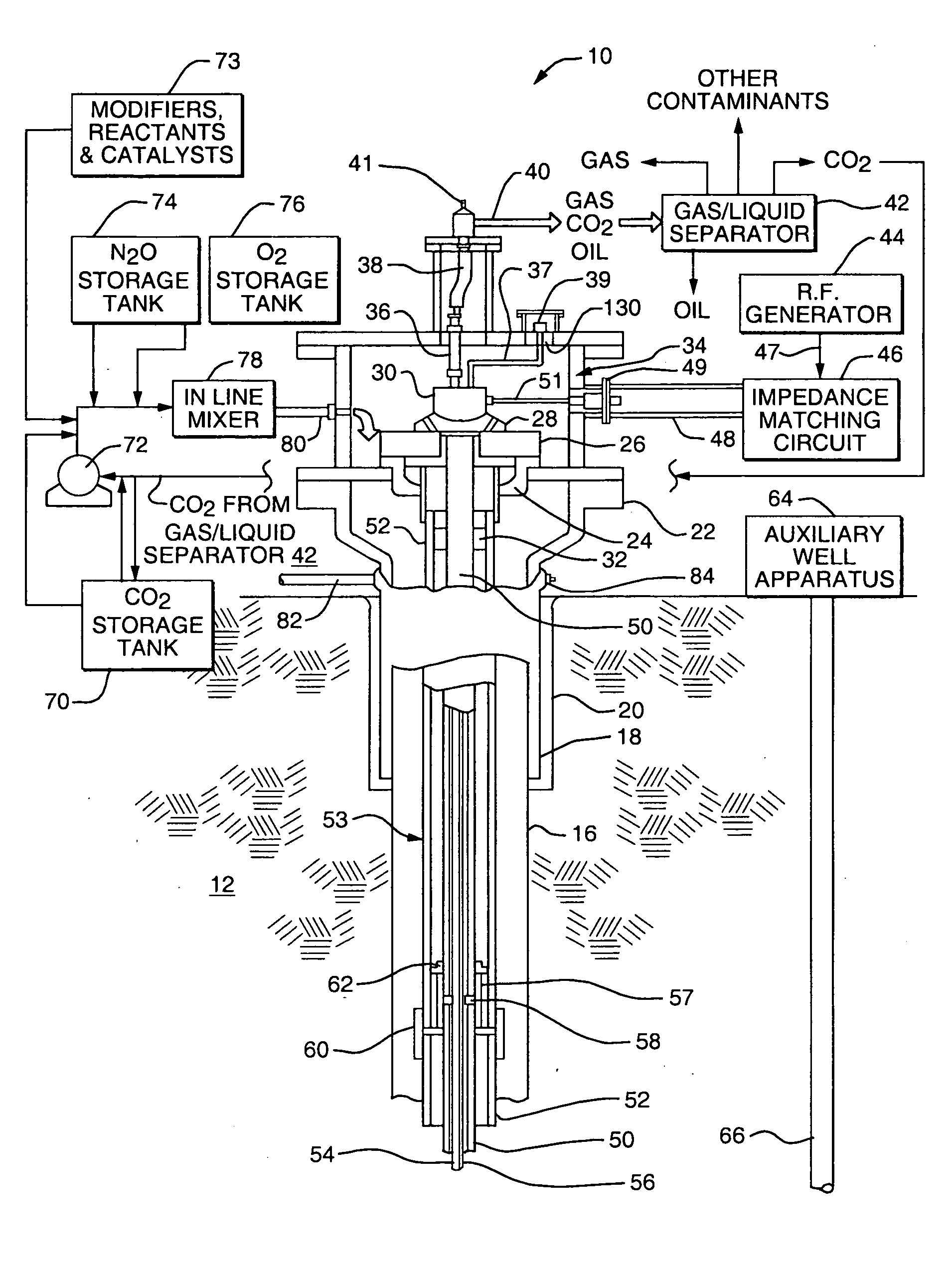

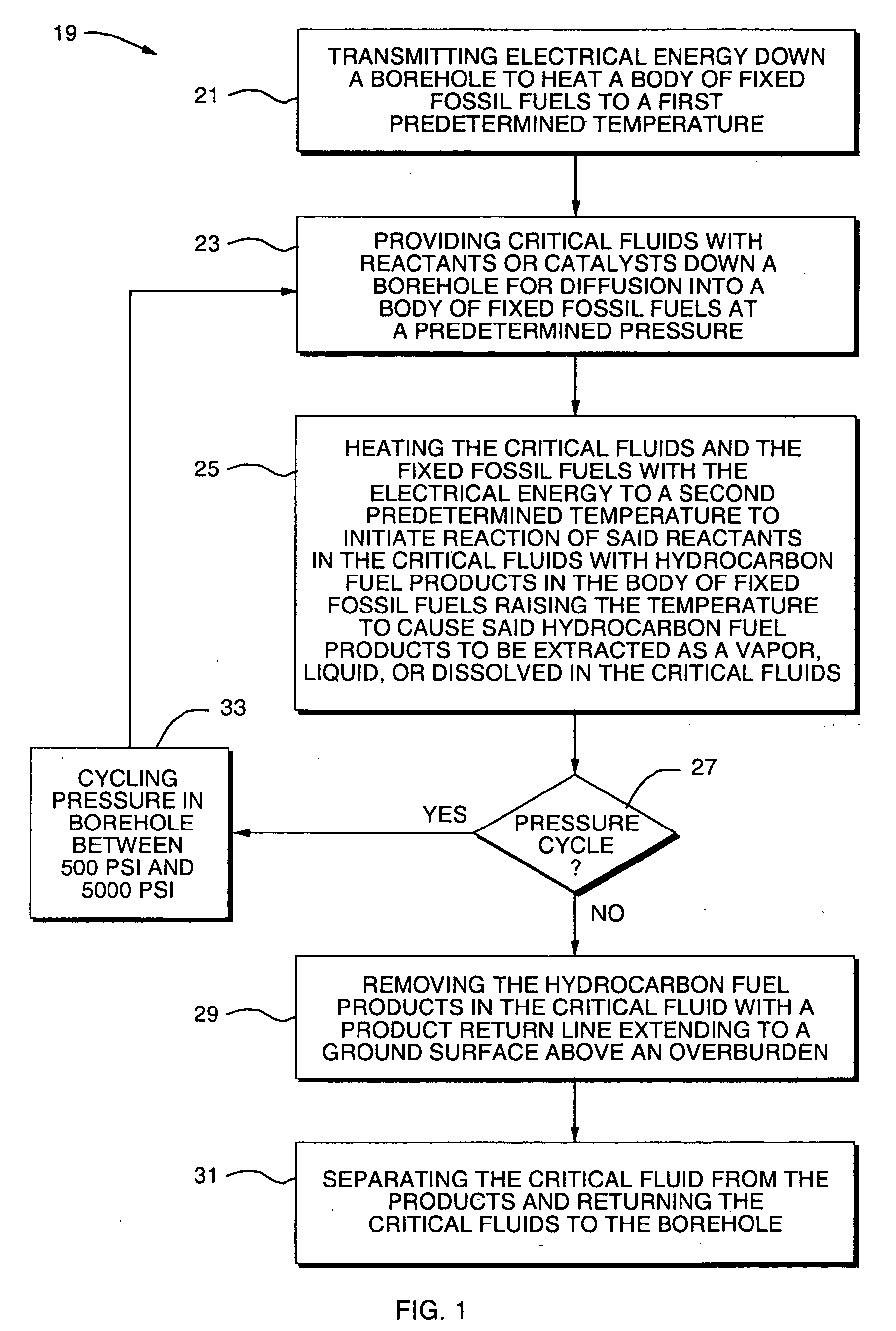

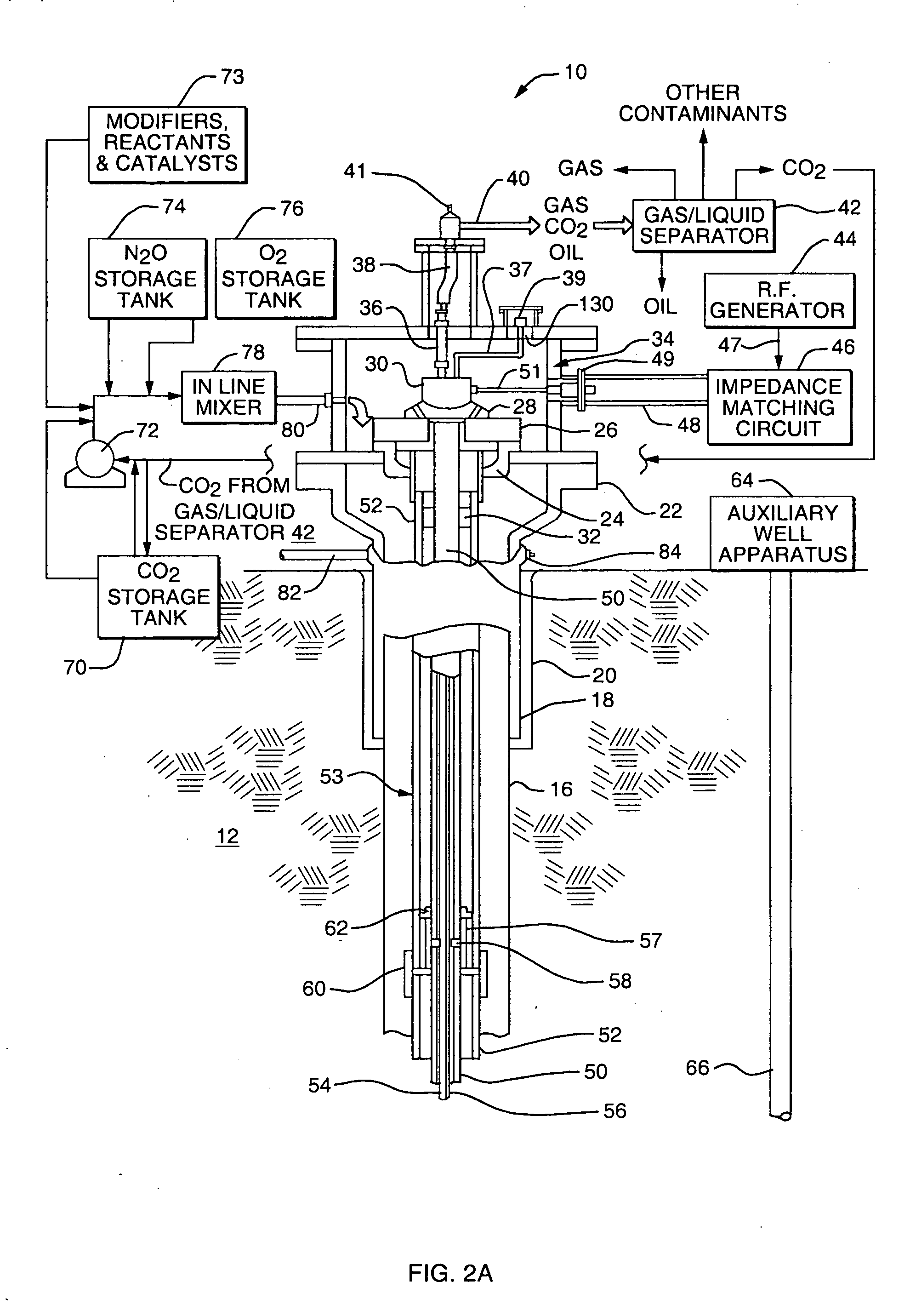

Method for extraction of hydrocarbon fuels or contaminants using electrical energy and critical fluids

ActiveUS20070137858A1Efficient heatingValid conversionSurveyHollow article cleaningVapor liquidHydrocotyle bowlesioides

The extraction of hydrocarbon fuel products such as kerogen oil and gas from a body of fixed fossil fuels such as oil shale is accomplished by applying a combination of electrical energy and critical fluids with reactants and / or catalysts down a borehole to initiate a reaction of reactants in the critical fluids with kerogen in the oil shale thereby raising the temperatures to cause kerogen oil and gas products to be extracted as a vapor, liquid or dissolved in the critical fluids. The hydrocarbon fuel products of kerogen oil or shale oil and hydrocarbon gas are removed to the ground surface by a product return line. An RF generator provides electromagnetic energy, and the critical fluids include a combination of carbon dioxide (CO2), with reactants of nitrous oxide (N2O) or oxygen (O2).

Owner:SCHLUMBERGER TECH CORP

In-situ method of producing oil shale and gas (methane) hydrates, on-shore and off-shore

A method is provided for in-situ production of oil shale and gas (methane) hydrates wherein a network of fractures is formed by injecting liquified gases into at least one substantially horizontally disposed fracturing borehole. Heat is thereafter applied to liquify the kerogen or to dissociate the gas (methane) hydrates so that oil shale oil and / or gases can be recovered from the fractured formations.

Owner:MAGUIRE JAMES Q

Hydrocarbon recovery from impermeable oil shales

Owner:EXXONMOBIL UPSTREAM RES CO

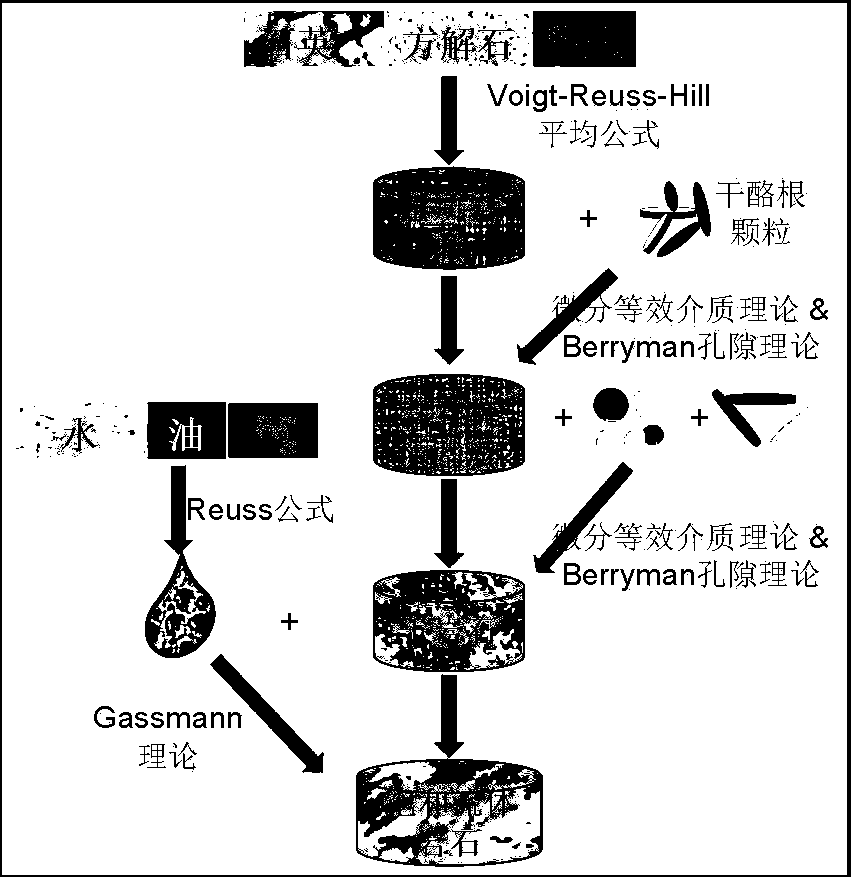

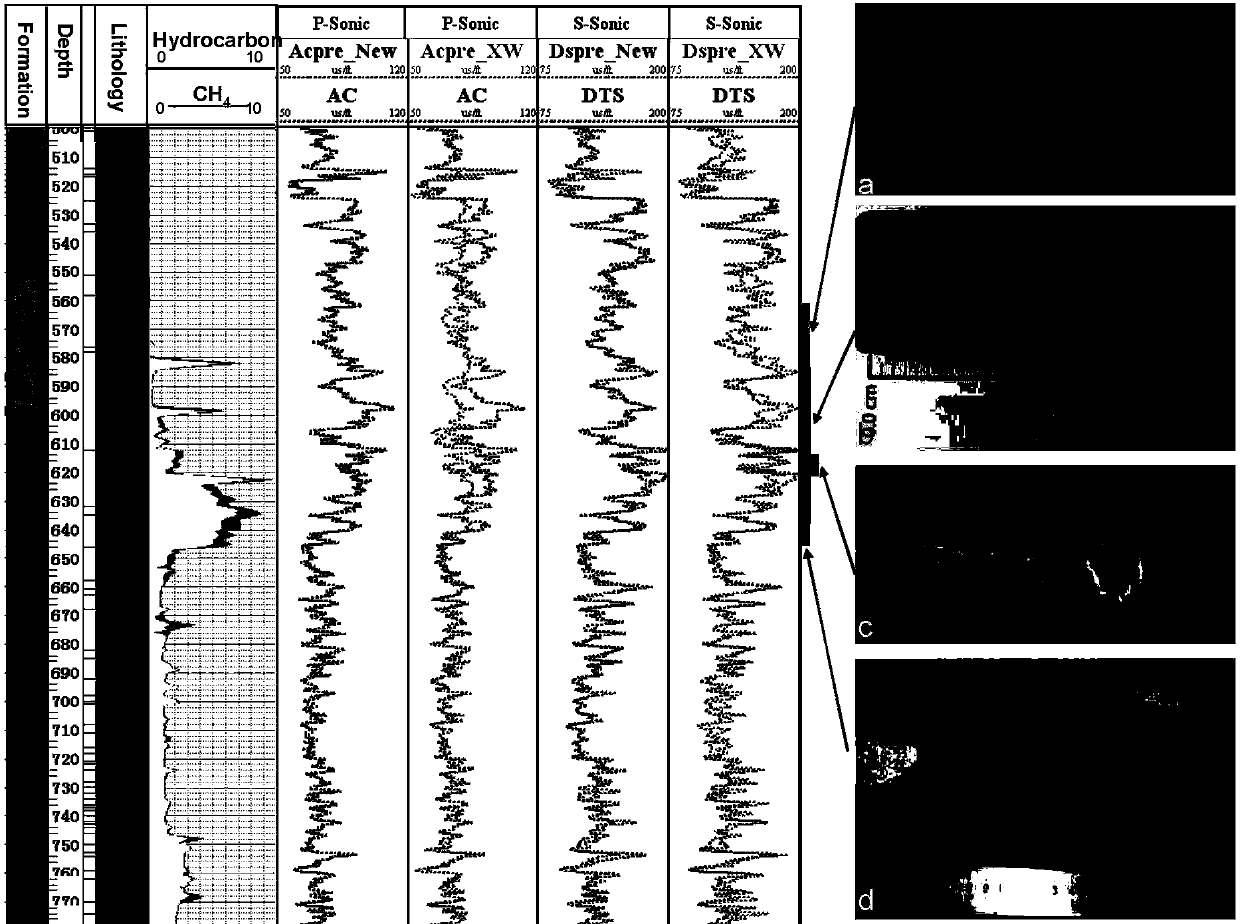

Shale gas reservoir crustal stress logging prediction method based on rock physics model

The present invention relates to a shale gas reservoir crustal stress logging prediction method based on a rock physics model. According to the method, a shale gas reservoir rock physics model which takes kerogen particles into consideration is established, so as to predict a longitudinal and transverse wave velocity of the logging; based on the above, a maximum and minimum horizontal principal stress and a fracture pressure of the reservoir are calculated; and an accurate stress assessment of a shale gas reservoir is carried out while a transverse wave logging is not provided. The beneficial effects of the invention are that: the rock physics model in line with characteristics of the shale gas reservoir is established to improve precision of the prediction velocity; and based on the rock physical model, the maximum and minimum horizontal principal stress and the fracture pressure are obtained, so that while the measured transverse wave logging data are not provided, the underground stress can be predicted on the basis of a conventional logging curve, and the prediction result is high in accuracy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

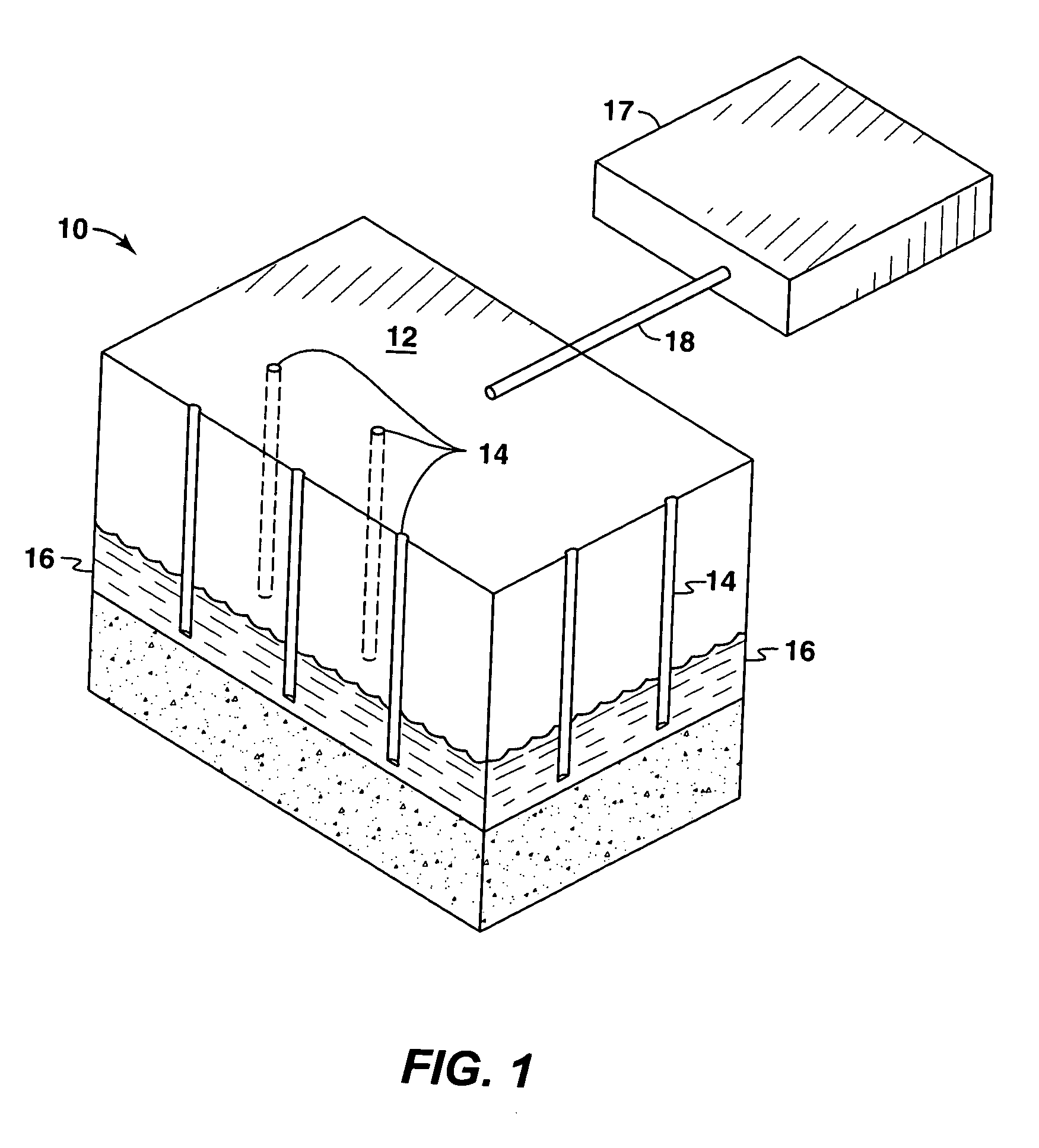

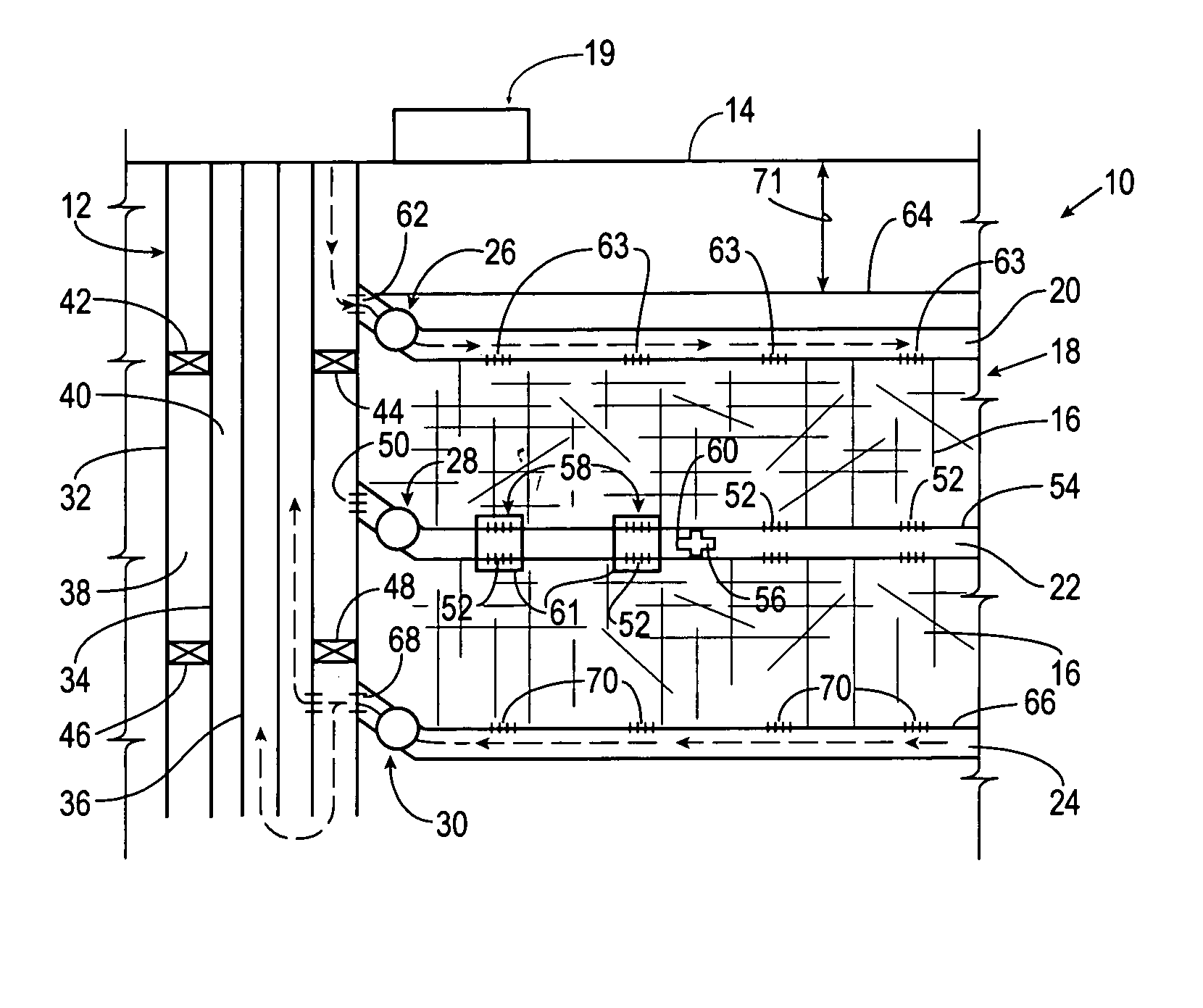

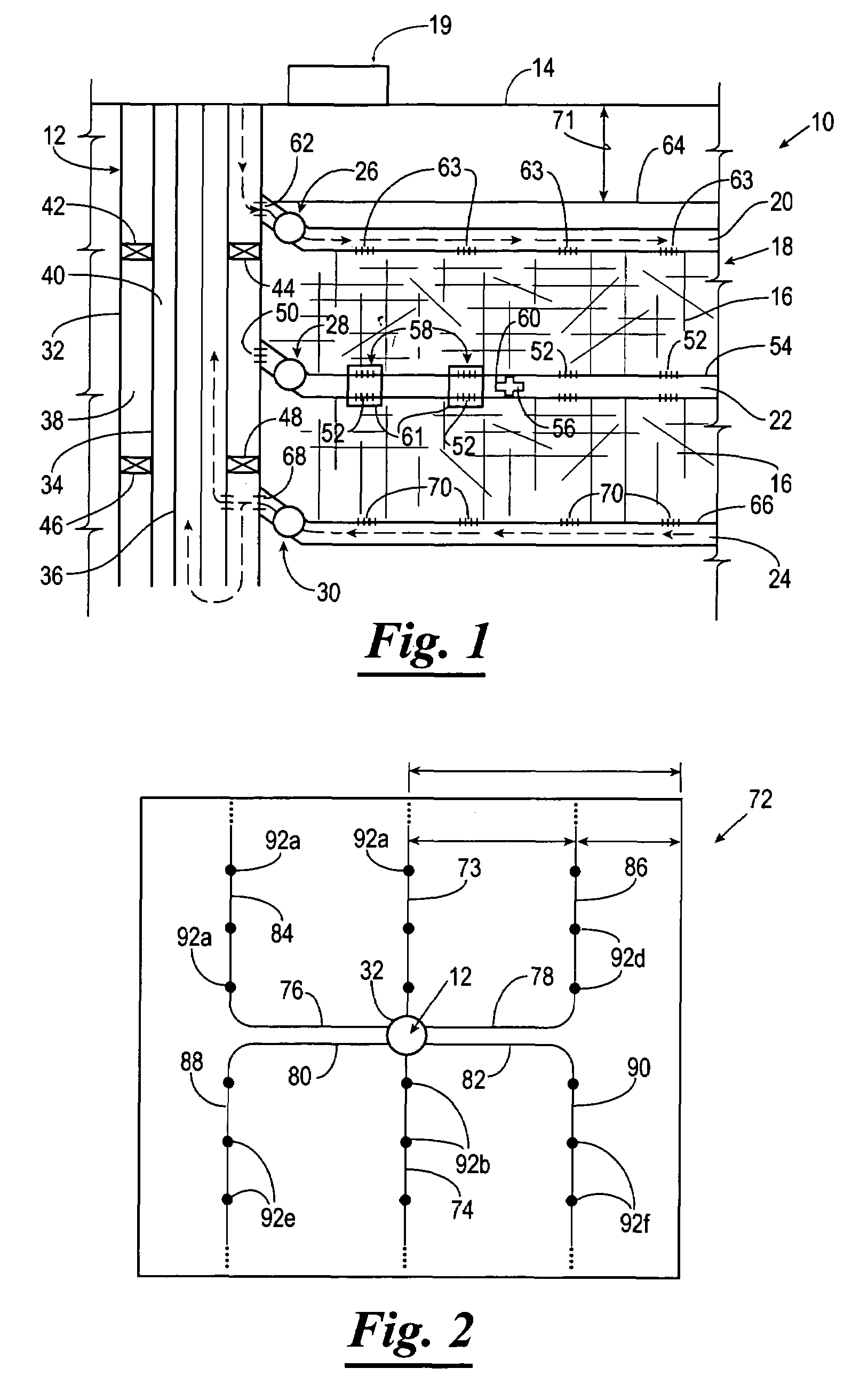

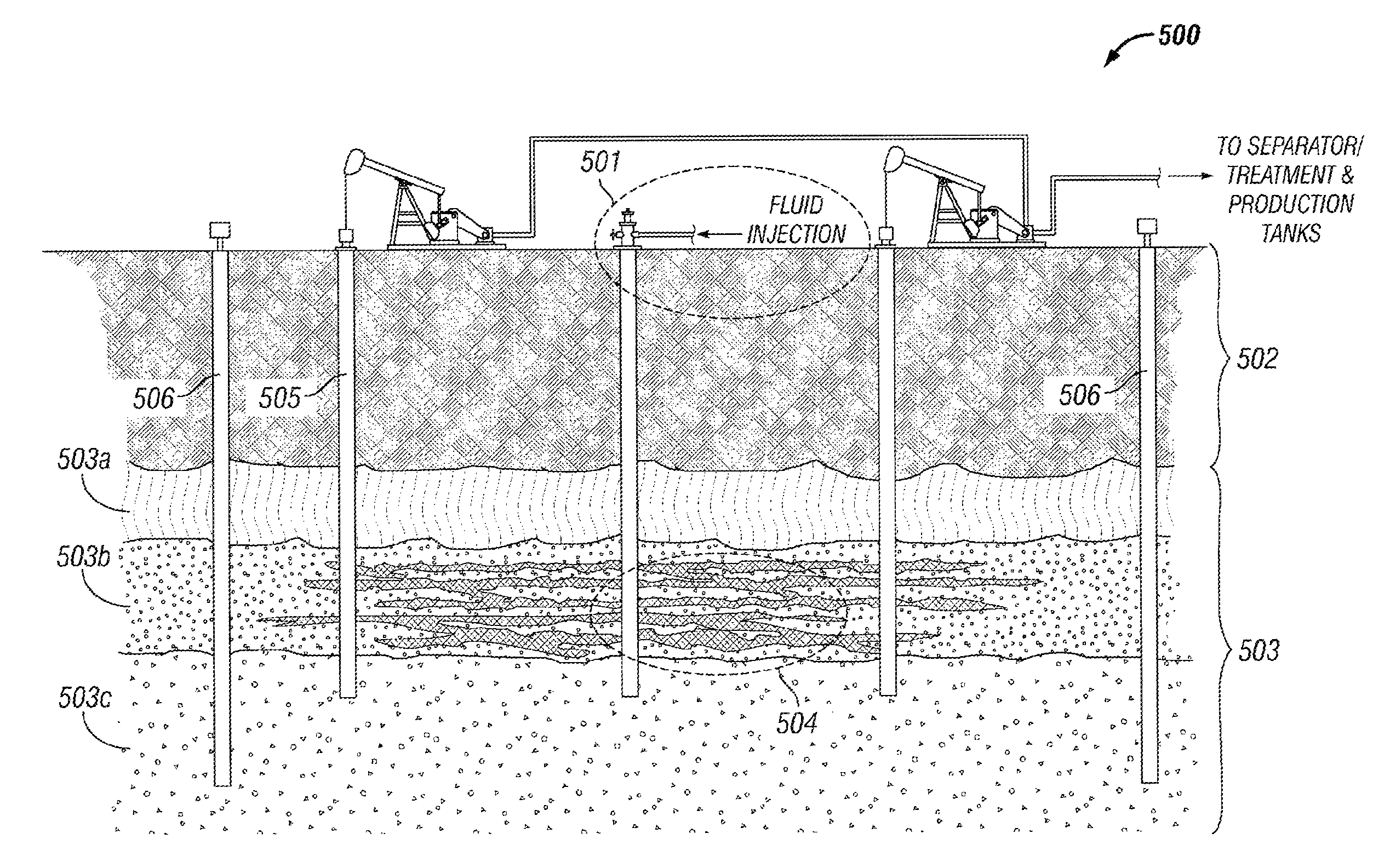

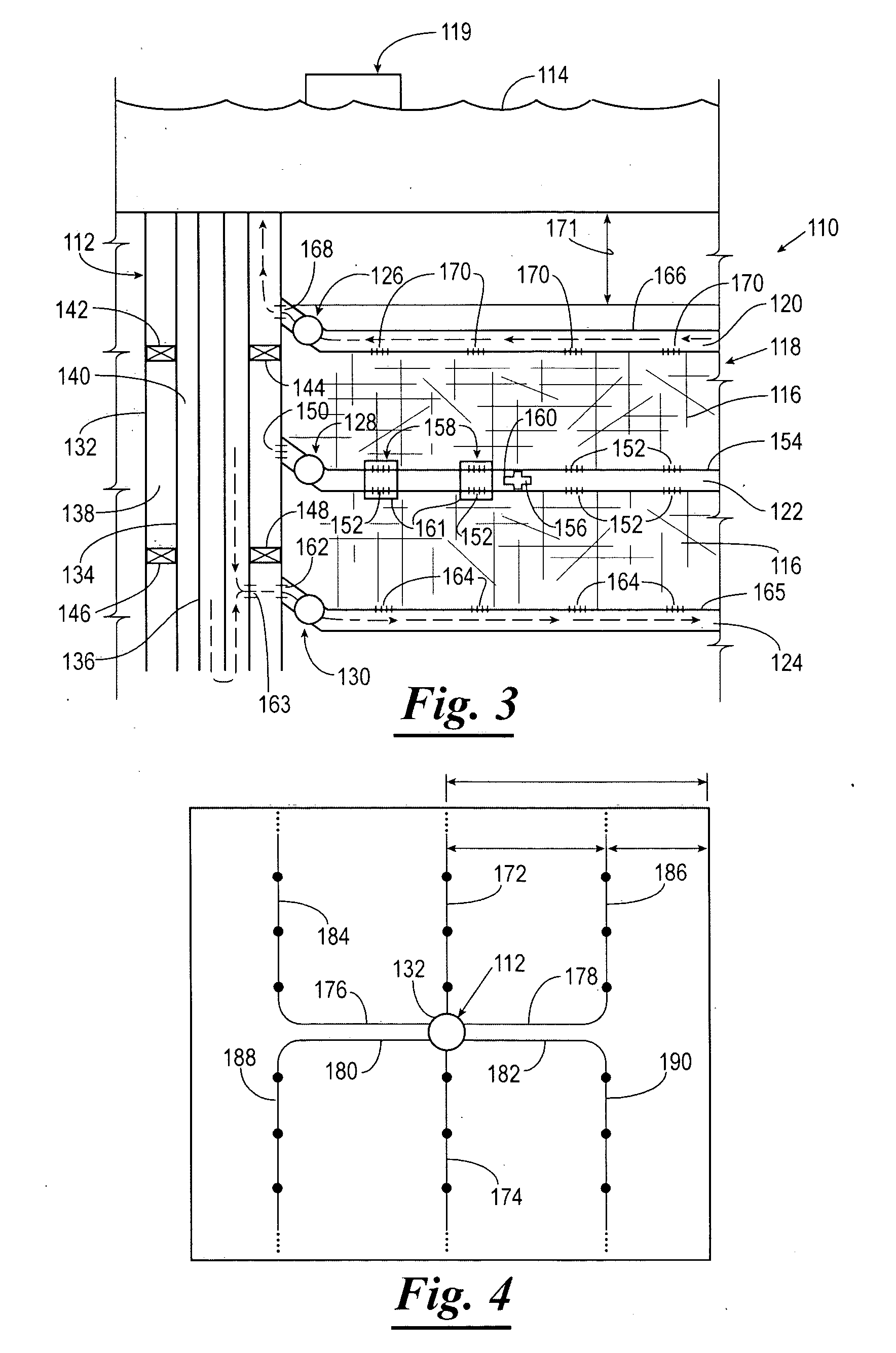

Optimized Well Spacing For In Situ Shale Oil Development

InactiveUS20110132600A1Minimize secondary crackingTravel efficientlySurveyInsulationThermal energyKerogen

A method for spacing heater wells for an in situ conversion process includes the steps of determining a direction along which thermal energy will travel most efficiently through a subsurface formation, and completing a plurality of heater wells in the subsurface formation, with the heater wells being spaced farther apart in the determined direction than in a direction transverse to the determined direction. In one aspect, the step of determining a direction along which thermal energy will travel most efficiently is performed based upon a review of geological data pertaining to the subsurface formation. The geological data may comprise the direction of least horizontal principal stress in the subsurface formation. Alternatively, the geological data may comprise the direction of bedding in the subsurface formation, the tilt of the subsurface formation relative to the surface topography, the organic carbon content of the kerogen, the initial formation permeability, and other factors.

Owner:EXXONMOBIL UPSTREAM RES CO

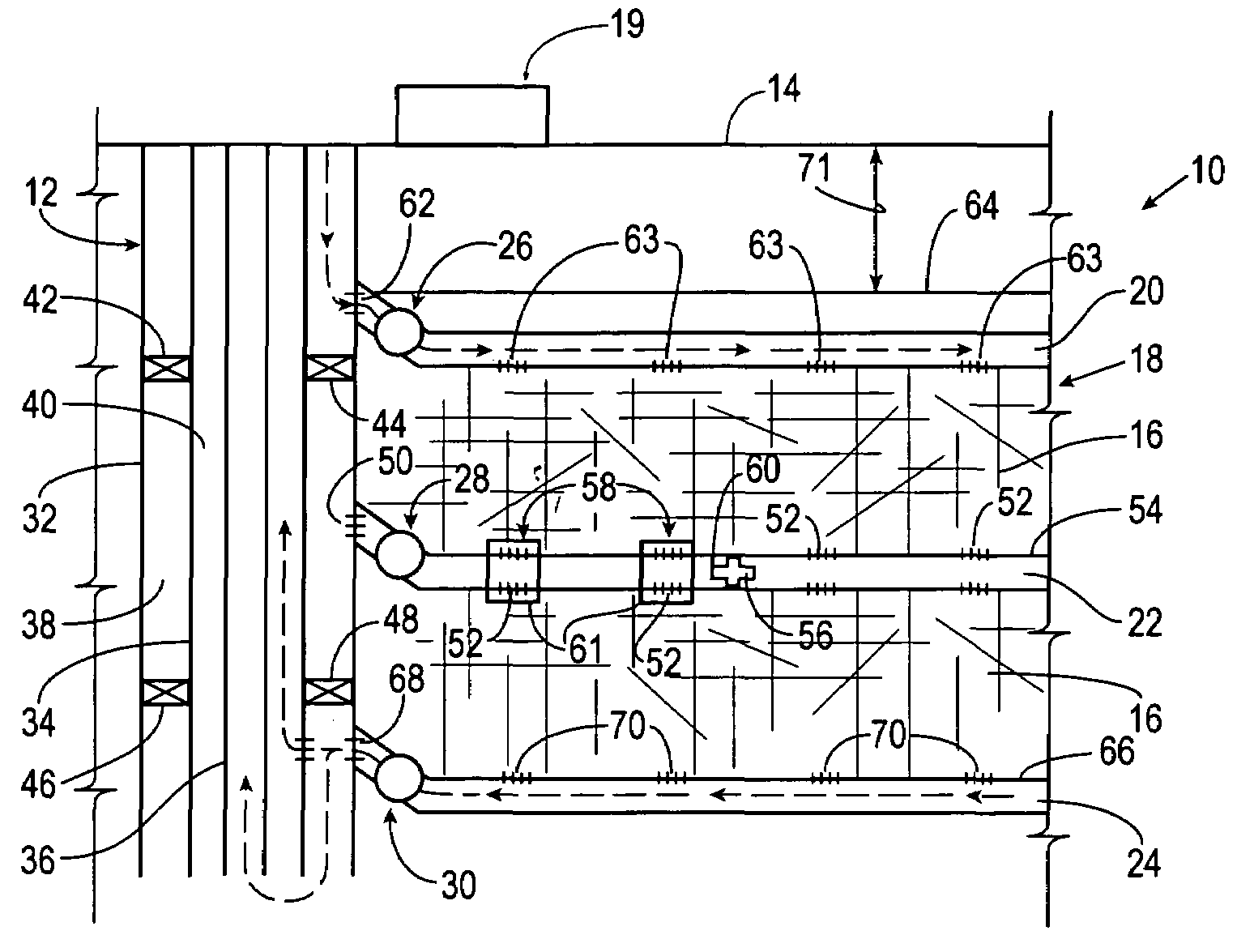

Optimized well spacing for in situ shale oil development

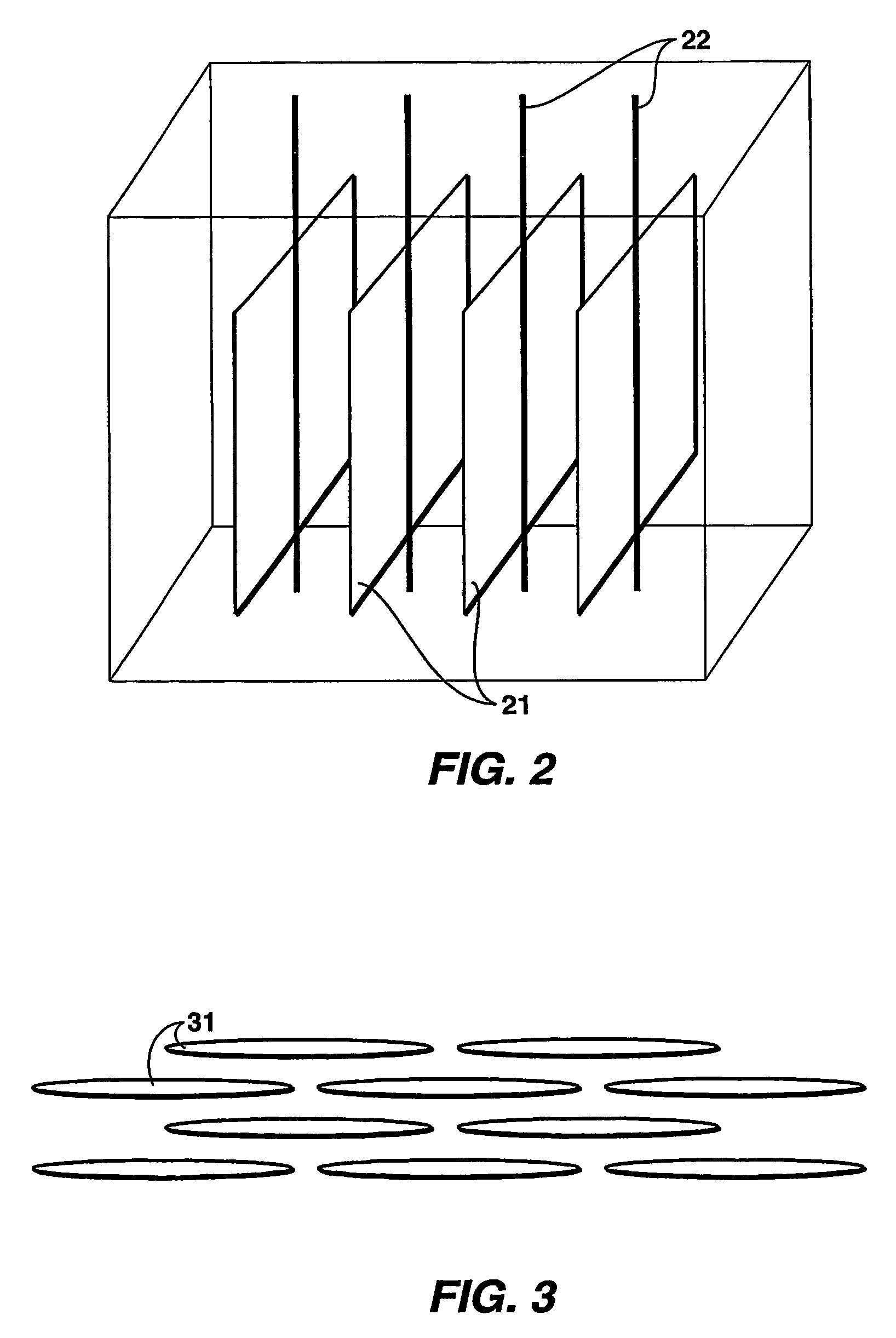

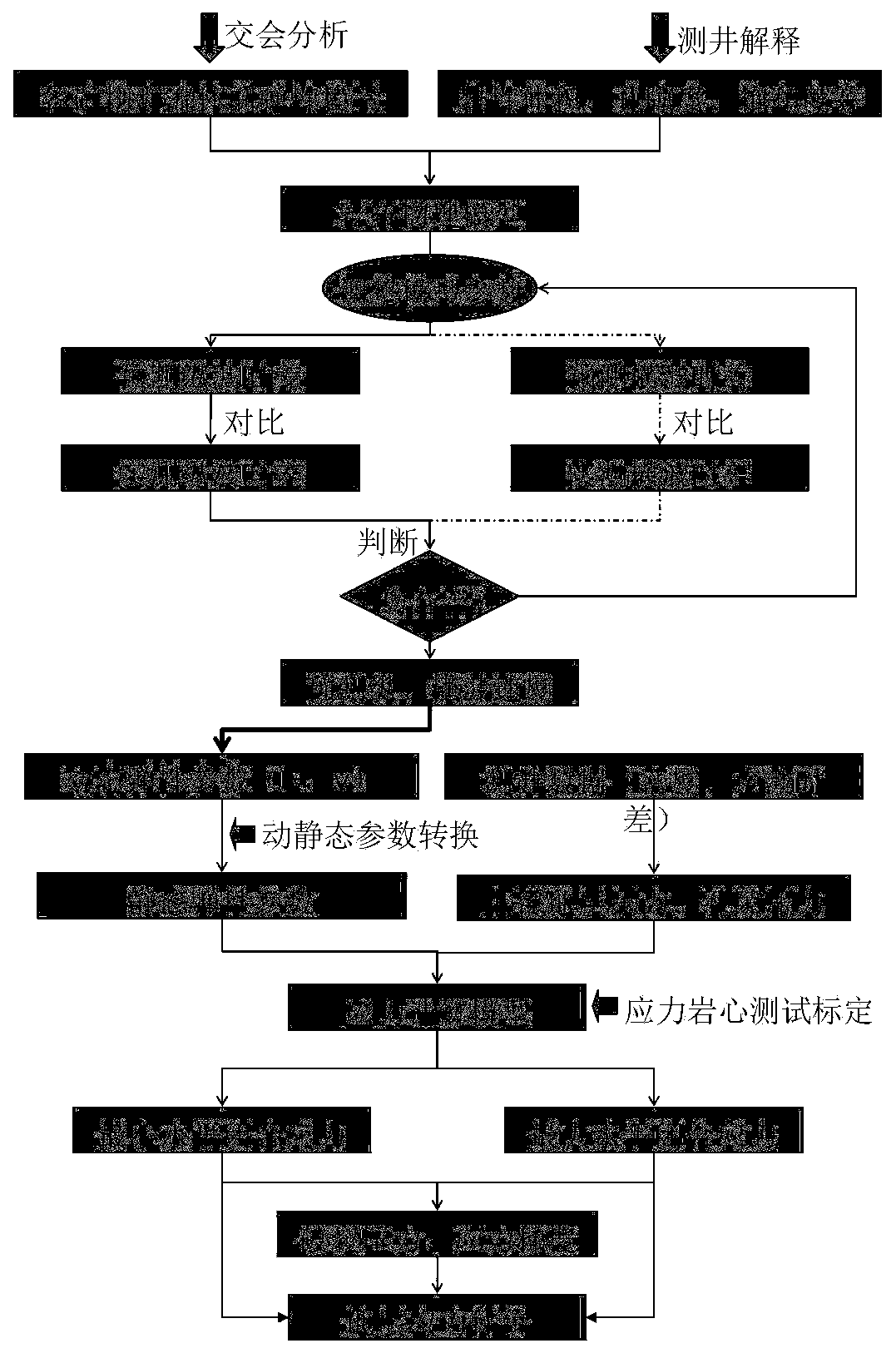

InactiveUS20080087420A1Minimize secondary crackingTravel efficientlyFluid removalCarbon-dioxide storageKerogenThermal energy

A method for spacing heater wells for an in situ conversion process is provided. The method includes the steps of determining a direction along which thermal energy will travel most efficiently through a subsurface formation, and completing a plurality of heater wells in the subsurface formation, with the heater wells being spaced farther apart in the determined direction than in a direction transverse to the determined direction. In one aspect, the step of determining a direction along which thermal energy will travel most efficiently is performed based upon a review of geological data pertaining to the subsurface formation. The geological data may comprise the direction of least horizontal principal stress in the subsurface formation. Alternatively, the geological data may comprise the direction of bedding in the subsurface formation, the tilt of the subsurface formation relative to the surface topography, the organic carbon content of the kerogen, the initial formation permeability, and other factors.

Owner:KAMINSKY ROBERT D +1

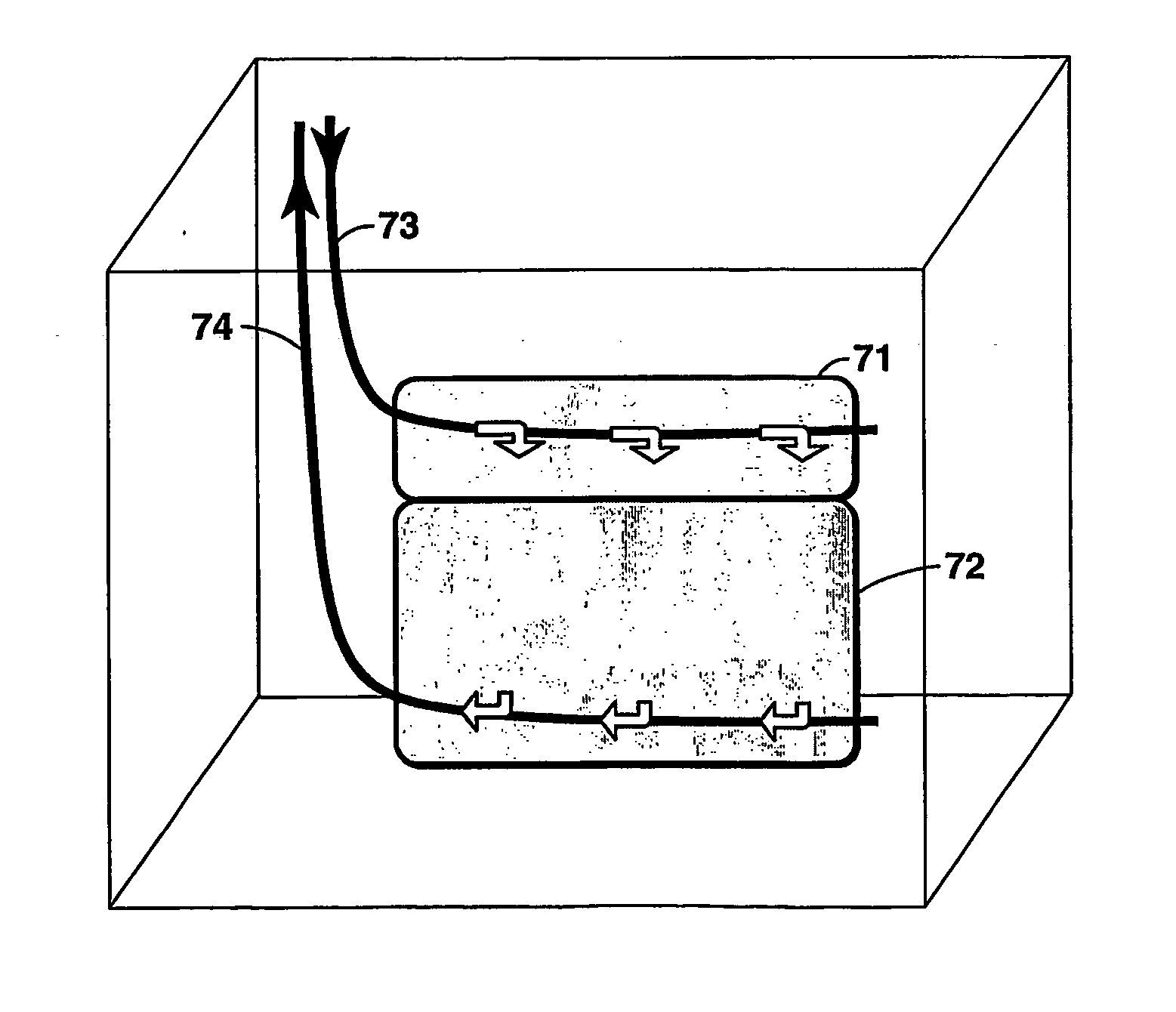

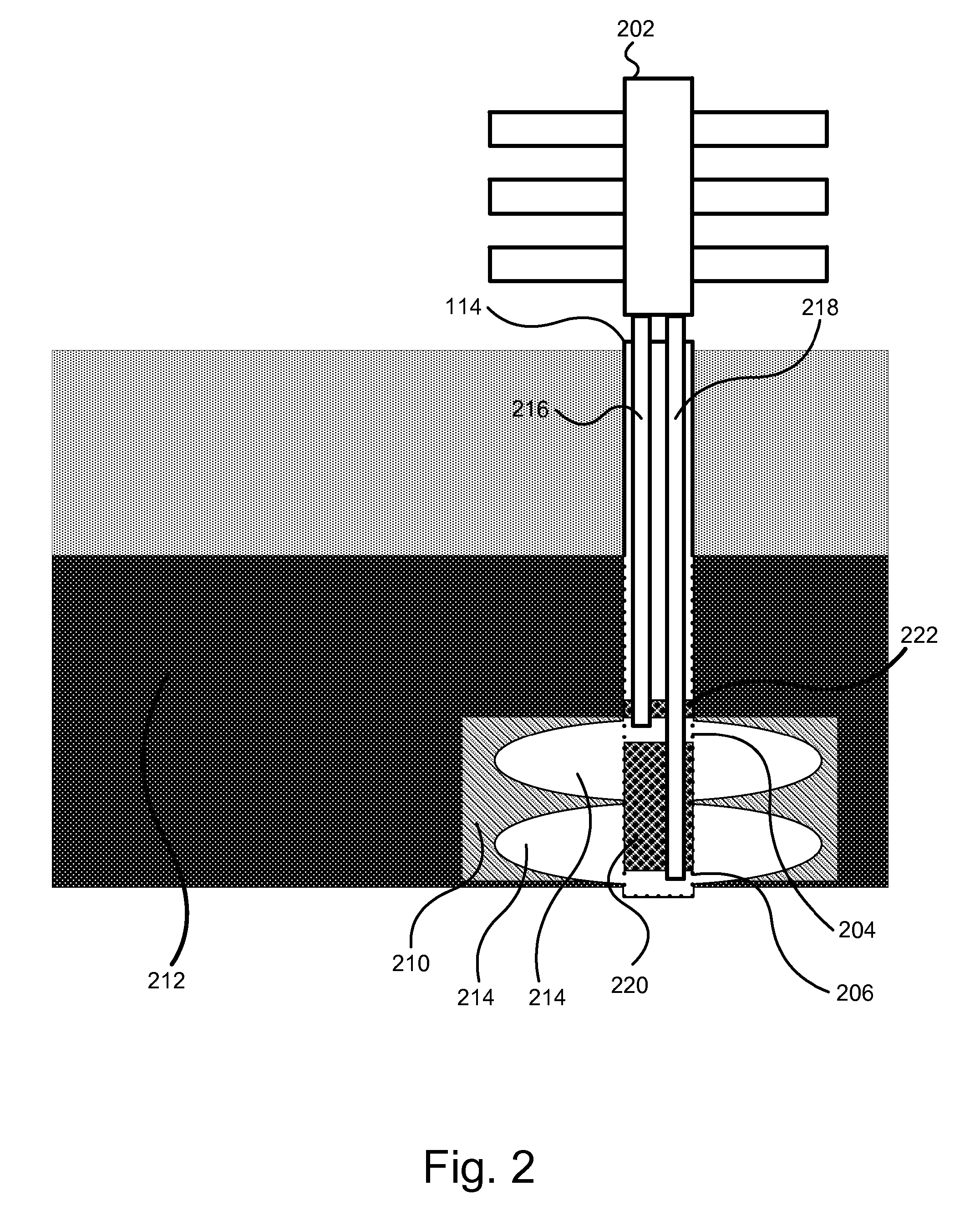

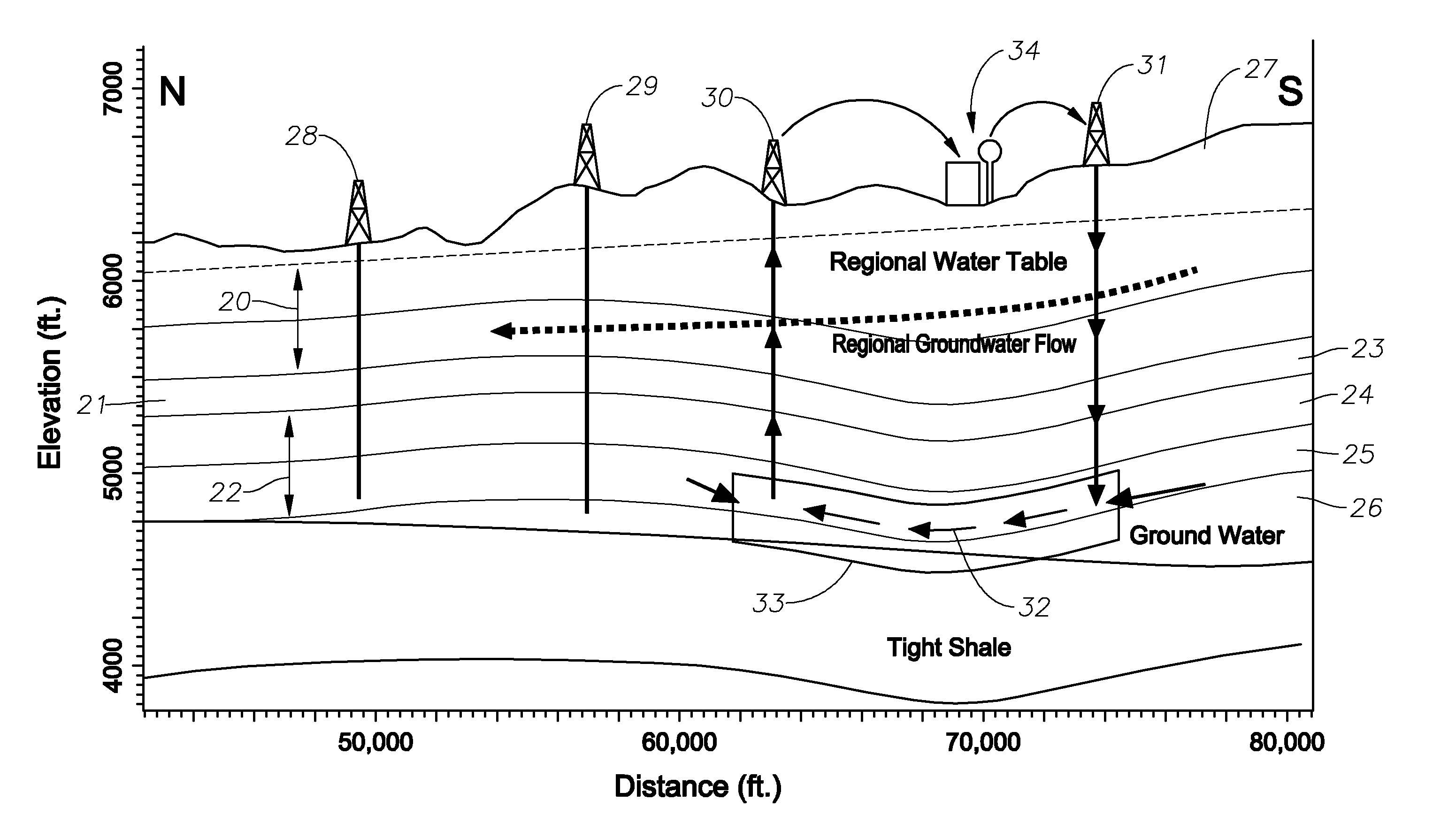

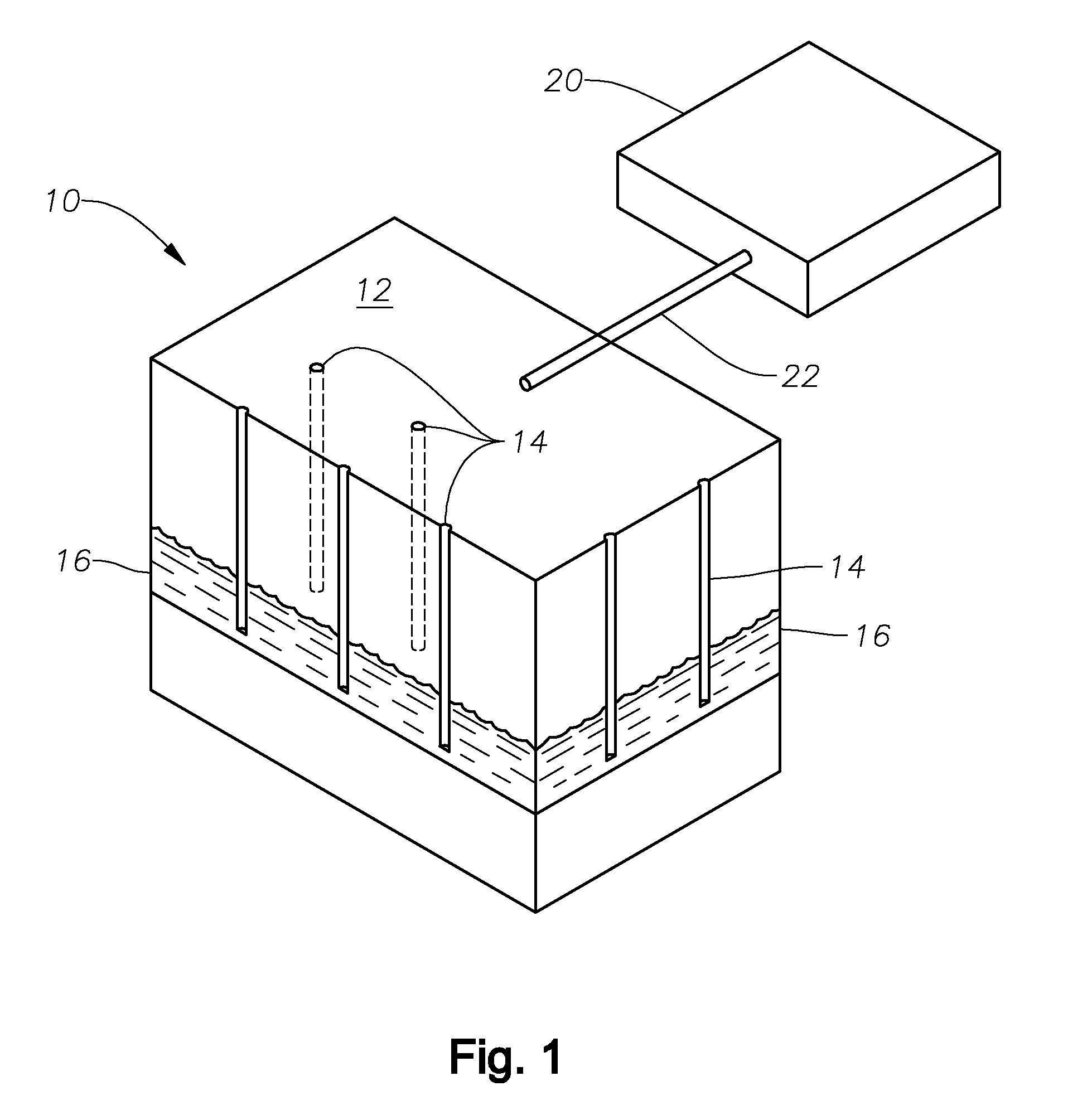

Apparatus, system, and method for in-situ extraction of oil from oil shale

An apparatus, system, and method are disclosed for in-situ extraction of oil from oil shale. The method comprises drilling a fluid conduit in fluid communication with a top and a bottom of a target zone within an oil shale formation. The method includes stimulating the target zone. The method further includes injecting a heated fluid into the bottom of the target zone such that the heated fluid entrains the kerogen within the target zone into the injected fluid to generate a production fluid. The method concludes with producing the production fluid, containing the in-situ kerogen, from the top of the target zone to the surface.

Owner:MOUNTAIN WEST ENERGY

In-situ method of producing oil shale and gas (methane) hydrates, on-shore and off-shore

A method is provided for in-situ production of oil shale and gas (methane) hydrates wherein a network of fractures is formed by injecting liquified gases into at least one substantially horizontally disposed fracturing borehole. Heat is thereafter applied to liquify the kerogen or to dissociate the gas (methane) hydrates so that oil shale oil and / or gases can be recovered from the fractured formations.

Owner:MAGUIRE JAMES Q

Heating an organic-rich rock formation in situ to produce products with improved properties

InactiveUS20080207970A1Carbon-dioxide storageLiquid hydrocarbon mixture productionKerogenHydrocarbon

A method of producing hydrocarbon fluids with improved hydrocarbon compound properties from a subsurface organic-rich rock formation, such as an oil shale formation, is provided. The method may include the step of heating the organic-rich rock formation in situ. In accordance with the method, the heating of the organic-rich rock formation may pyrolyze at least a portion of the formation hydrocarbons, for example kerogen, to create hydrocarbon fluids. Thereafter, the hydrocarbon fluids may be produced from the formation. Hydrocarbon fluids with improved hydrocarbon compound properties are also provided.

Owner:EXXONMOBIL UPSTREAM RES CO

Kerogen extraction from subterranean oil shale resources

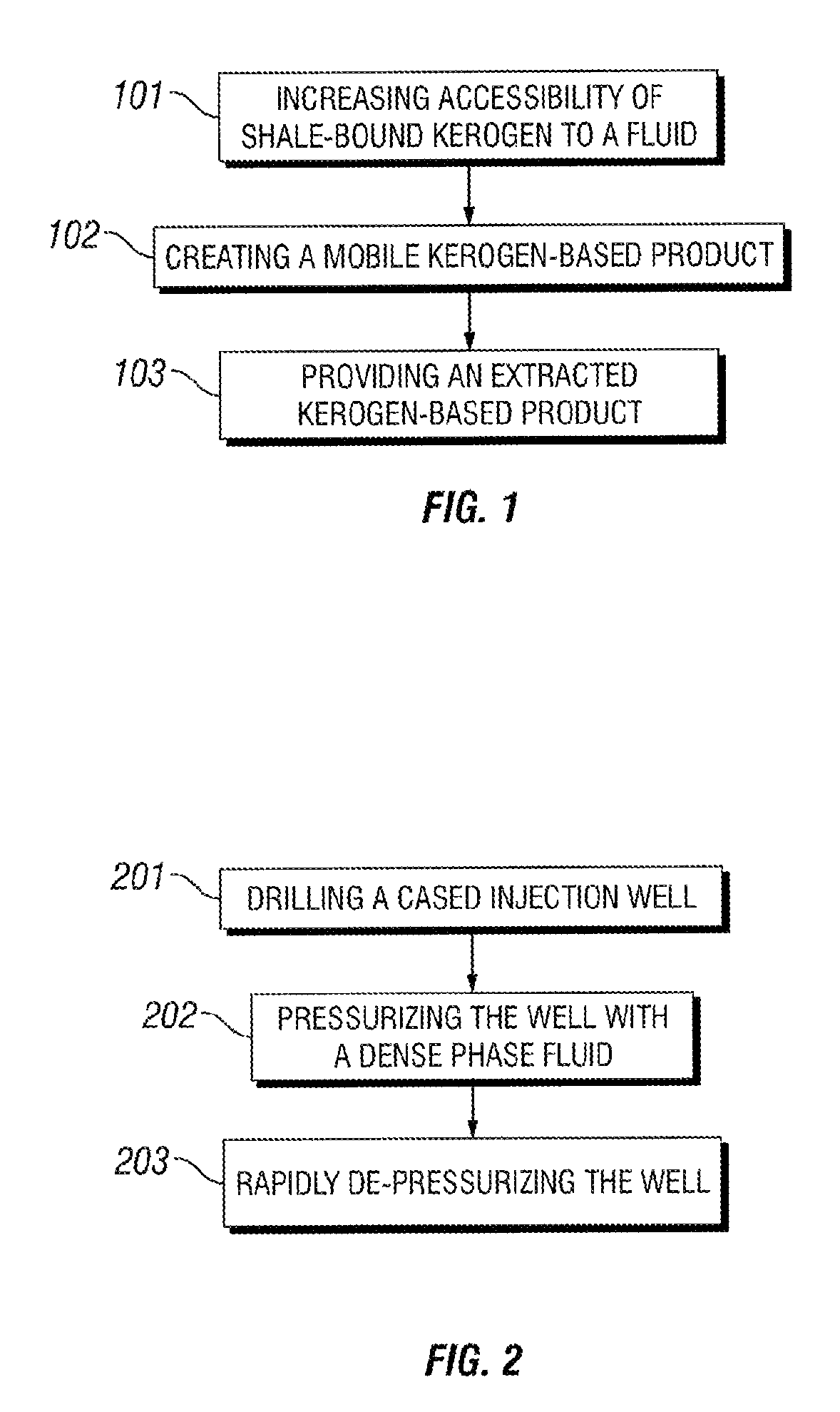

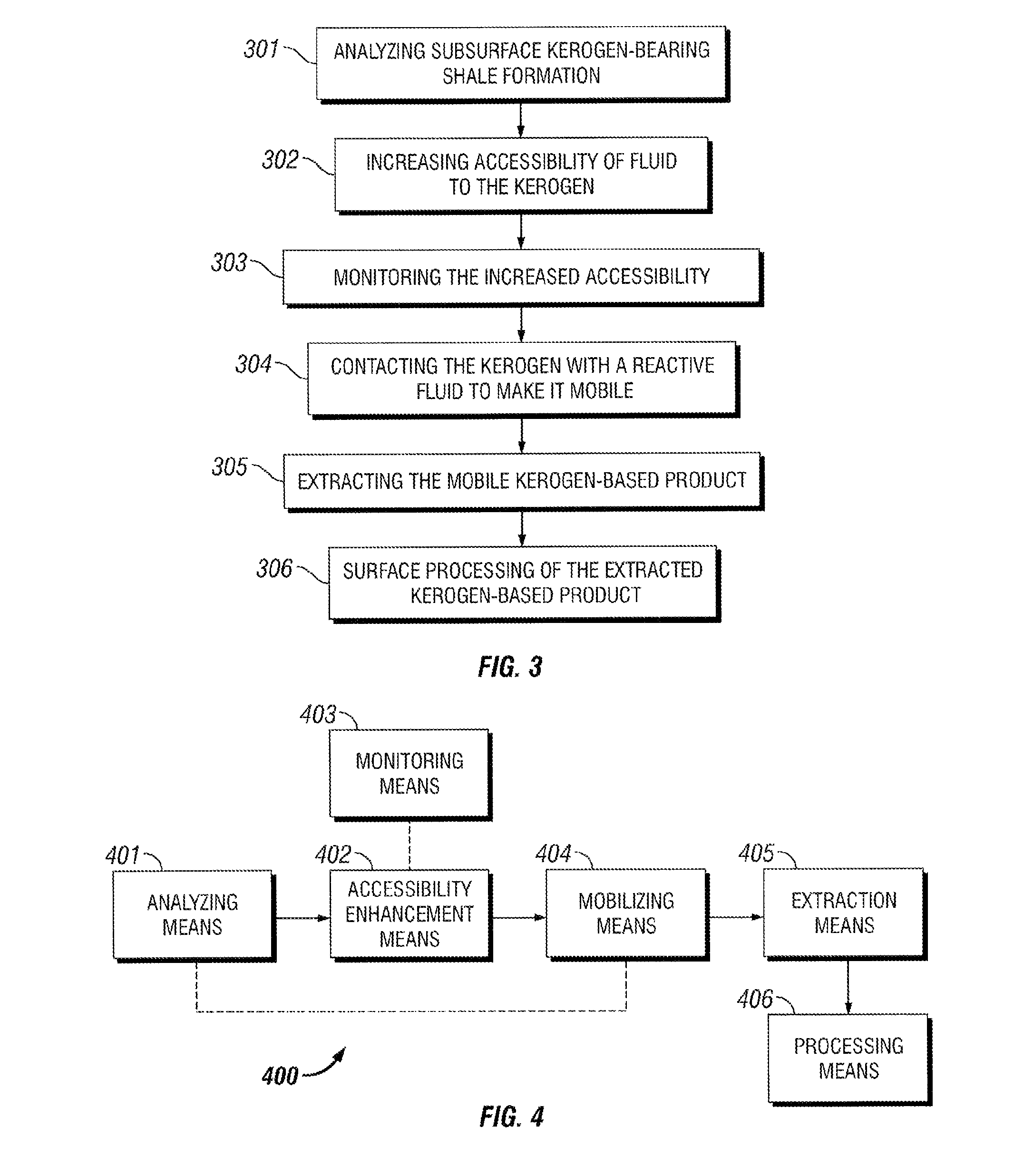

The present invention is directed to methods for extracting a kerogen-based product from subsurface (oil) shale formations, wherein such methods rely on fracturing and / or rubblizing portions of said formations so as to enhance their fluid permeability, and wherein such methods further rely on chemically modifying the shale-bound kerogen so as to render it mobile. The present invention is also directed at systems for implementing at least some of the foregoing methods. Additionally, the present invention is also directed to methods of fracturing and / or rubblizing subsurface shale formations and to methods of chemically modifying kerogen in situ so as to render it mobile.

Owner:CHEVROU USA INC +1

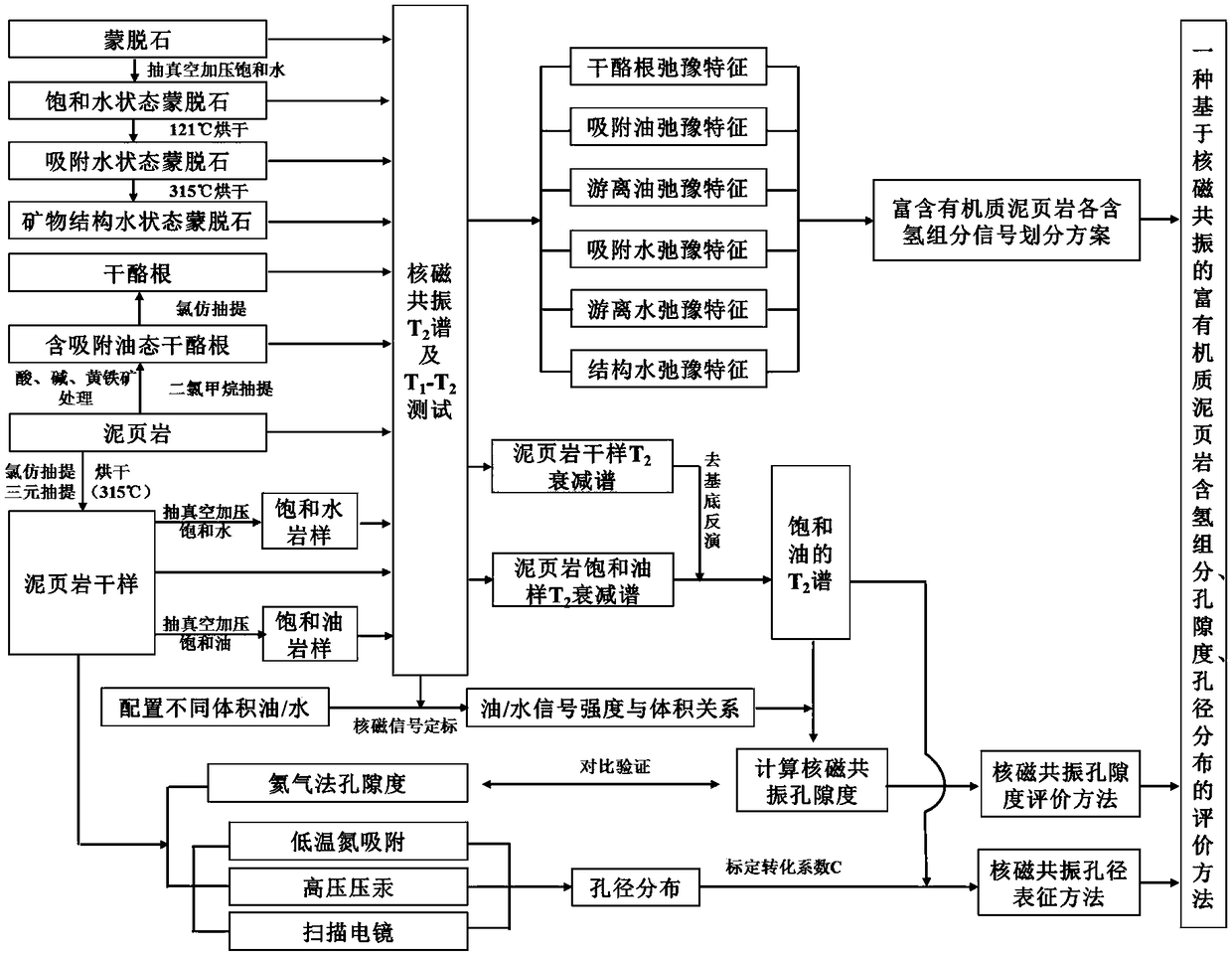

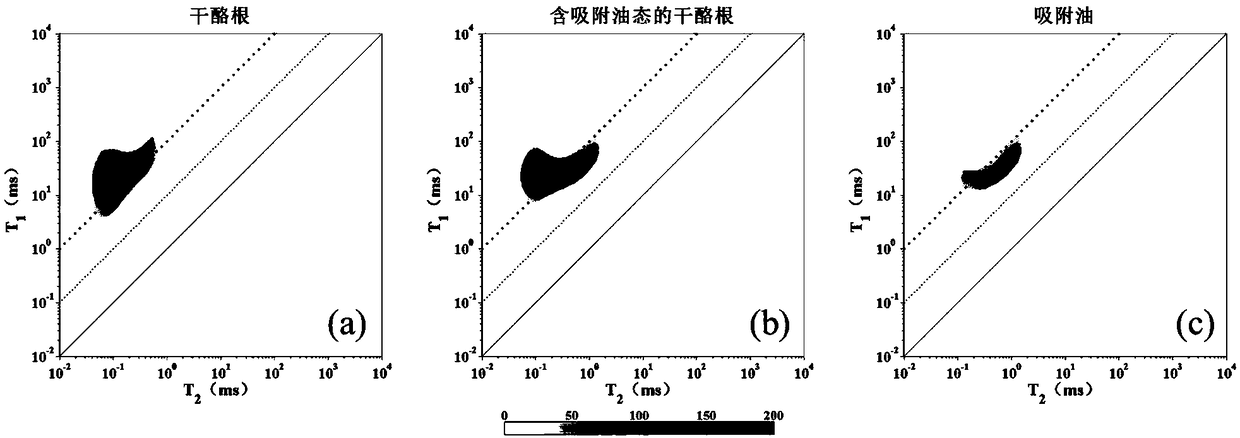

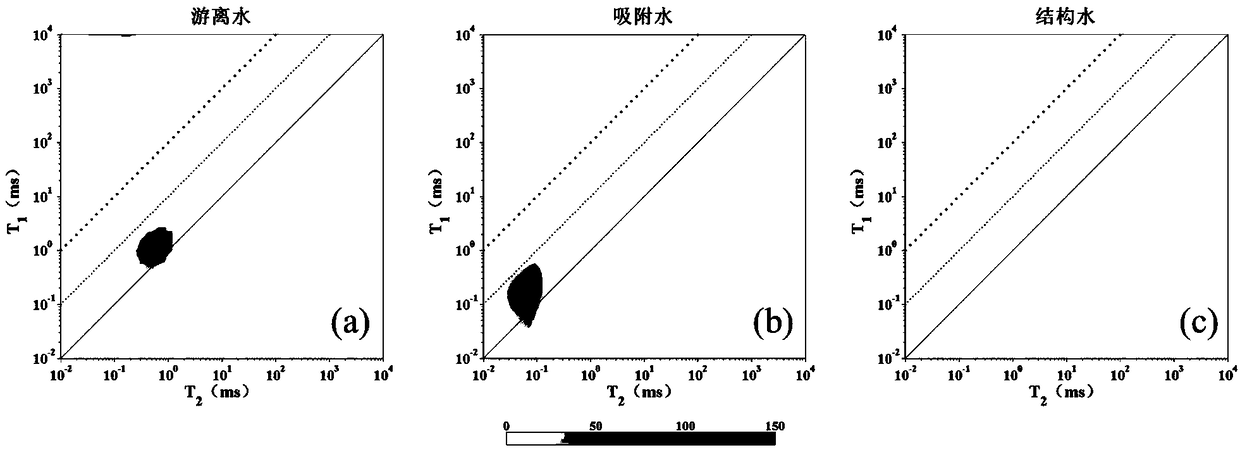

Evaluation method for hydrogen containing ingredient, porosity and aperture of shale rich in organic matters

ActiveCN108458960AResolve detectionImprove consistencyMagnetic measurementsEarth material testingClay mineralsAdditive ingredient

The invention belongs to the technical field of oil and gas development, and discloses an evaluation method for hydrogen containing ingredient, porosity and aperture of shale rich in organic matters.According to the magnetic resonance imaging T1-T2 spectrum differences of kerogen, kerogen containing adsorption oil, different minerals containing aqueous clay, shale, shale dry samples, saturated oil rock samples and saturated water rock samples, a division scheme of each hydrogen containing ingredient of the shale rich in organic matters, and a quantitative expression method of fluid ingredients is established; the T2 spectrum of the saturated shale rich in organic matters is taken as a target, the T2 spectrum of the shale dry sample is taken as a substrate, substrate inversion is carried out to obtain the T2 spectrum of oil in a hole, and on the basis of the T2 spectrum, the porosity and the pore diameter distribution of the shale rich in organic matters is evaluated. Compared with theconventional method, the evaluation method disclosed by the invention is characterized in that high innovation and credibility can be shown, and is favorable for improving the analysis of the magnetic resonance imaging on an aspect of shale rock physical measurement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

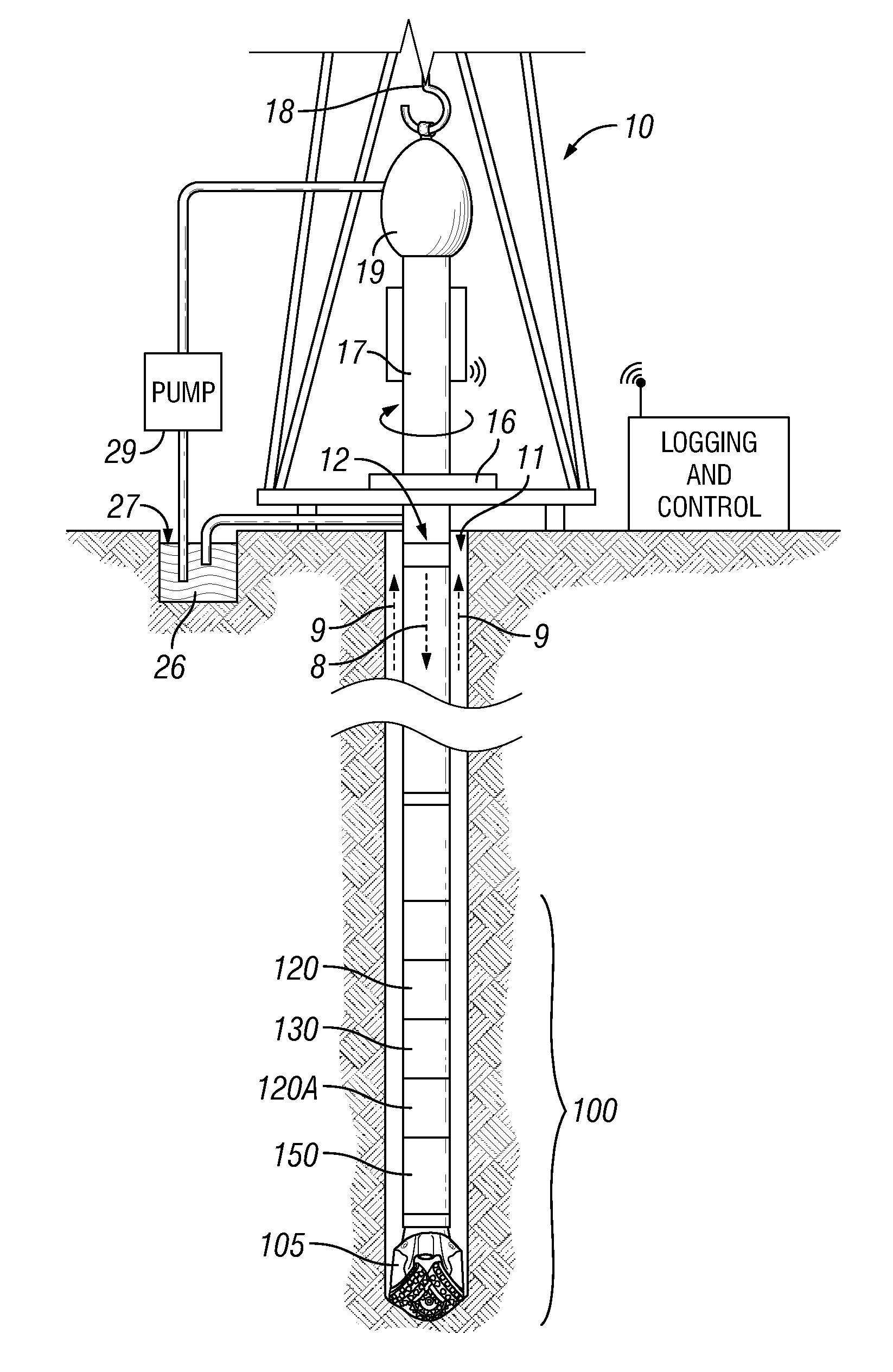

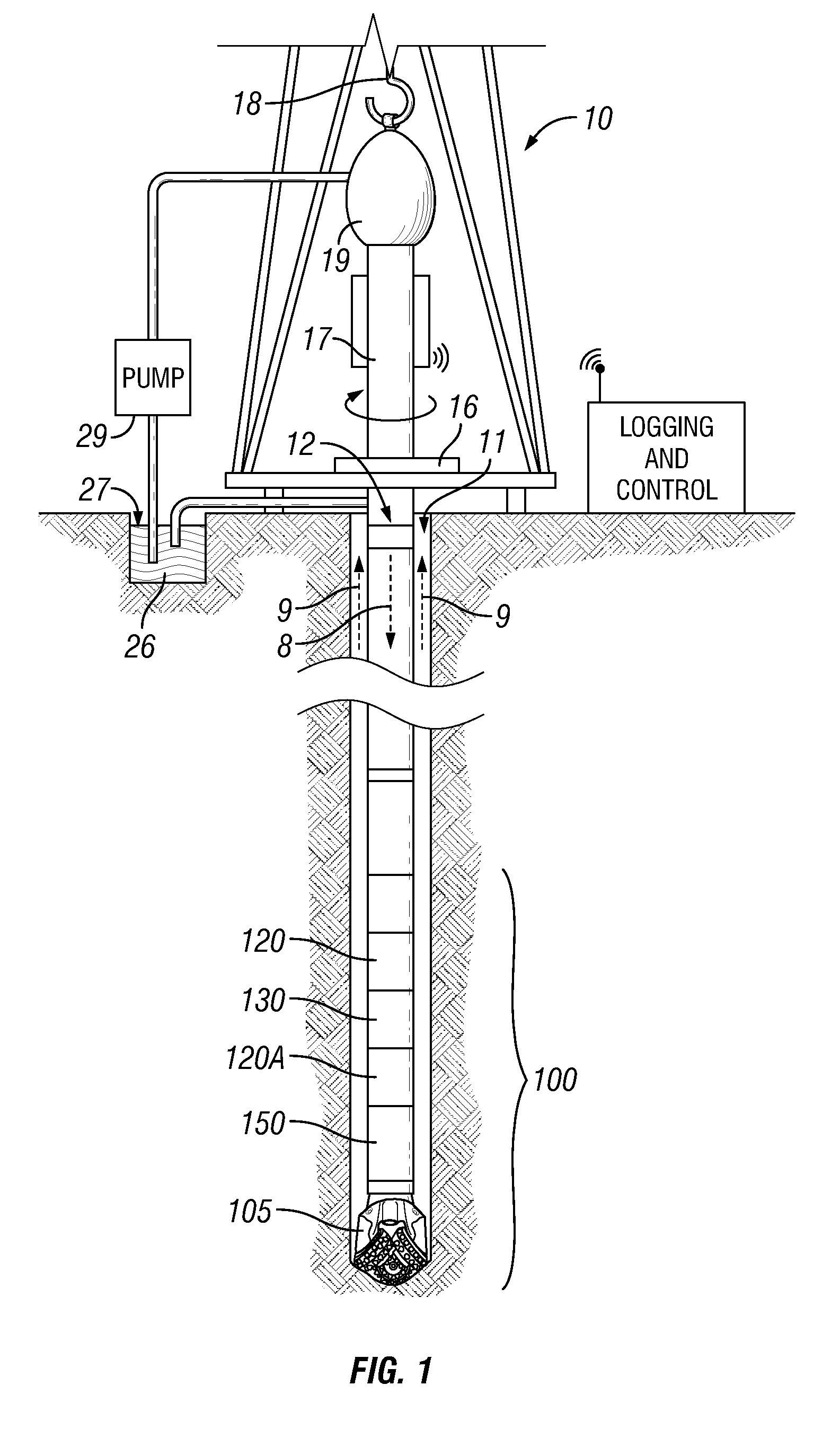

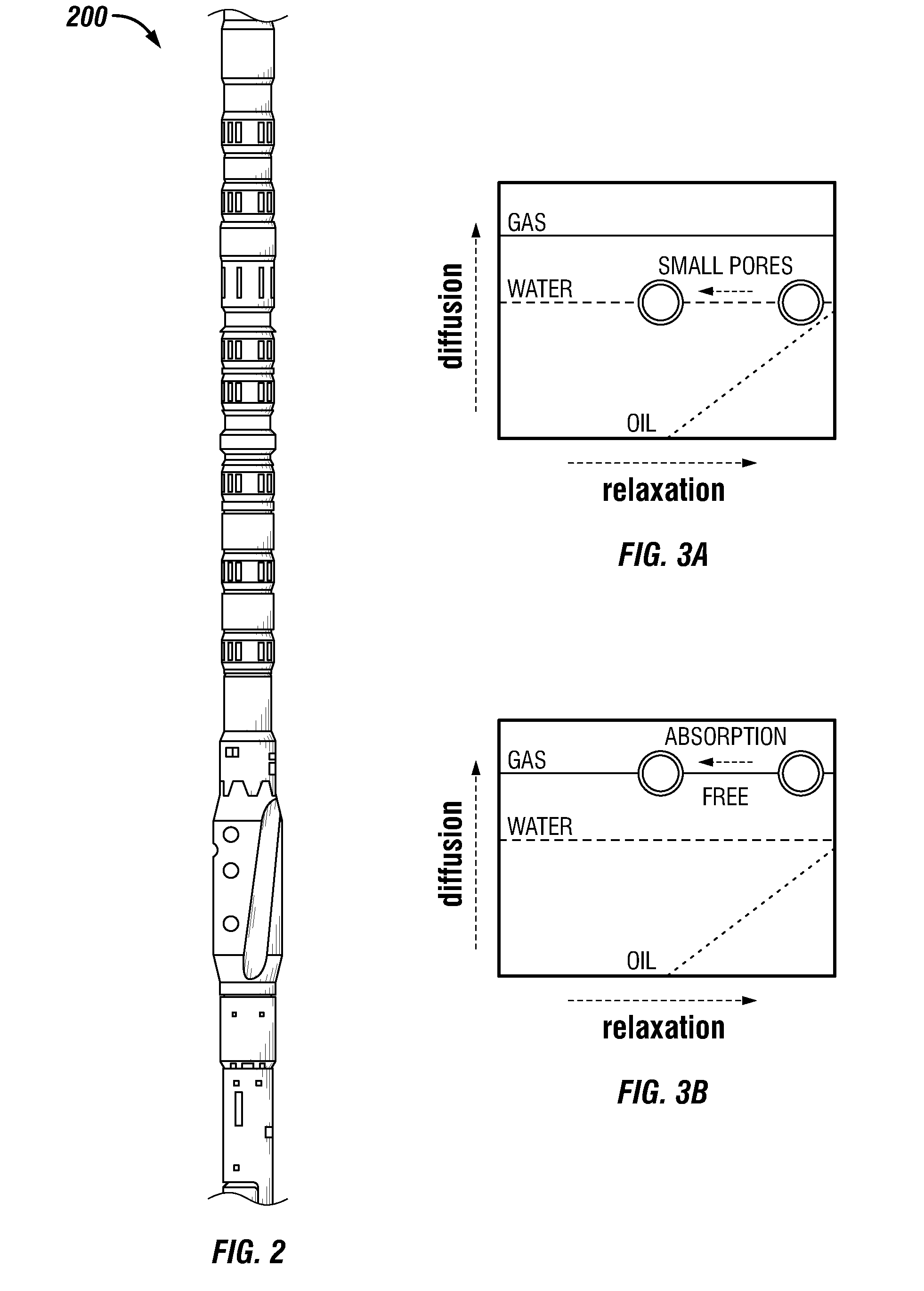

Estimating porosity and fluid volume

ActiveUS20110068788A1Improve signal-to-noise ratioEnhanced signalElectric/magnetic detection for well-loggingWater resource assessmentPorosityBound water

The present disclosure relates to a method to estimate a subsurface formation property. A downhole logging tool is provided and disposed in a wellbore. Multiple measurements of various measurement types are obtained at various depths of investigation using the downhole logging tool. The multiple measurements may include natural gamma ray measurements, density measurements, resistivity measurements, nuclear measurements, and nuclear magnetic resonance measurements. The signal-to-noise ratio of the measured signals is increased using, for example, lateral stacking and multi-shell inversion. The subsurface formation property is estimated using the increased signal-to-noise ratio signals. The subsurface formation property may include porosity, adsorbed gas volume, free gas volume, bound water volume, free water volume, oil volume, and kerogen volume. A fluid analysis may be performed using a multi-dimensional nuclear magnetic resonance technique. Fluids such as water, oil, gas, and oil-based mud in the wellbore may be identified and / or evaluated.

Owner:SCHLUMBERGER TECH CORP

Method for extracting shale oil and gas from oil shale in situ

The invention discloses a method for extracting shale oil and gas from oil shale in situ. The method comprises the steps that hot nitrogen is injected into an oil shale layer to crack kerogen in situ; after being extracted and separated, combustible gas which is generated initially is injected into a well together with the nitrogen by a certain proportion to have chemical reaction with the oil shale, so as to further crack organic substances in the oil shale, and extract shale oil and combustible gas; the hot nitrogen is an inert gas which is not only a carrier for transferring heat but also a carrier which carries shale oil and gas to above the ground; meanwhile, due to the pressure action of fluid, an oil and gas channel is favorably formed in the oil shale layer. The circulating combustible gas can have chemical reaction with the kerogen in the oil shale, so as to accelerate the reaction. According to the method for extracting shale oil and gas from the oil shale in situ, mining cost and risks are greatly reduced, the operability is greatly improved, problems caused by a surface dry distillation technology and an existing in-situ technology are fundamentally solved, the construction difficulty and cost are effectively reduced, and the method does not pollute underground water, is environment-friendly and is non-toxic.

Owner:JILIN UNIV +1

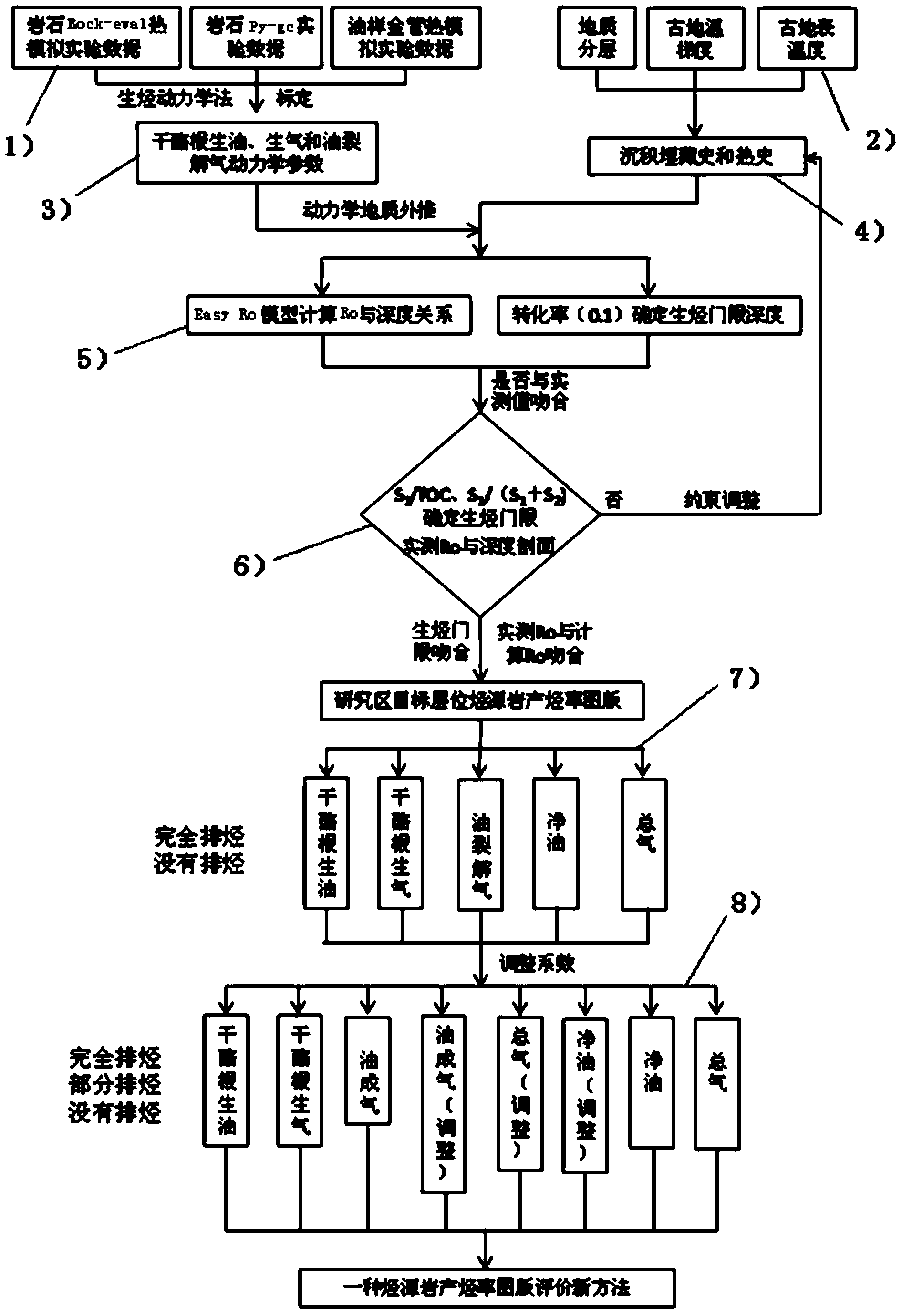

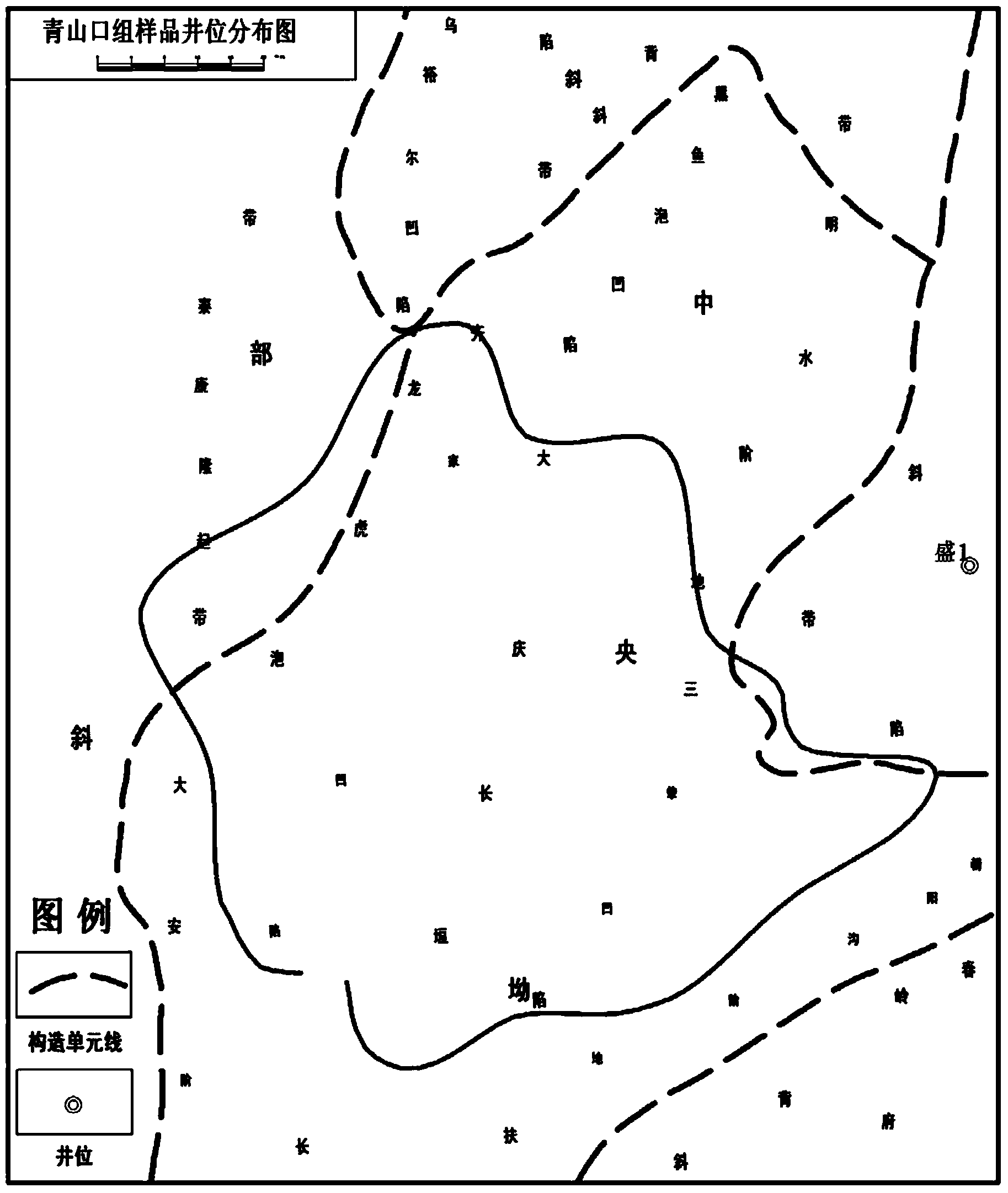

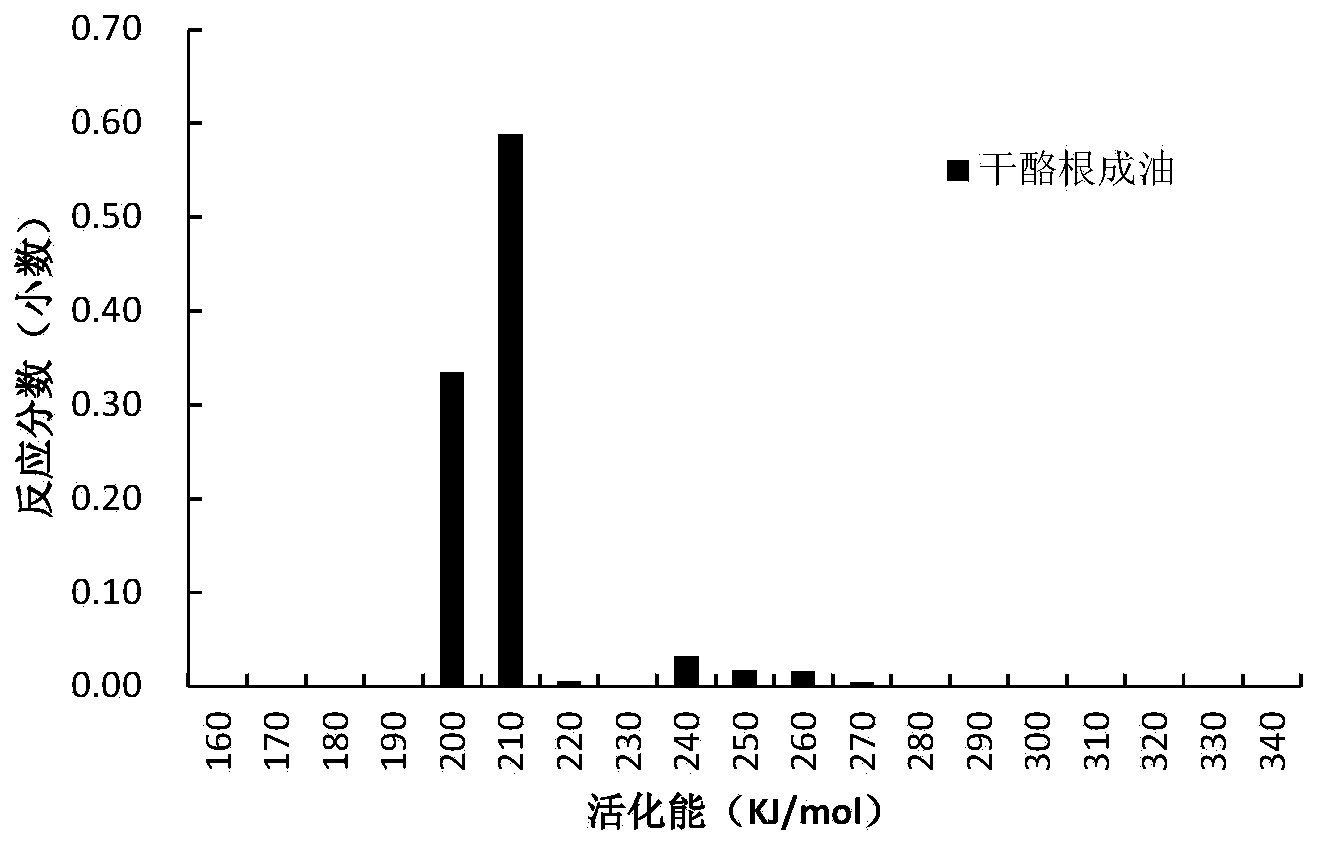

Establishment method for hydrocarbon source rock hydrocarbon production rate charts in petroleum resource assessment

InactiveCN104298883AIn line with the geological realitySolve the difficult problem of evaluating hydrocarbon production rateSpecial data processing applicationsProduction rateKerogen

The invention relates to an establishment method for hydrocarbon source rock hydrocarbon production rate charts in petroleum resource assessment. The establishment method includes the steps of 1), collecting experimental samples and determining thermal simulation experiment data through experiments; 2), collecting materials; 3), calibrating kerogen generated oil, generated gas and oil-cracking gas kinetic parameters; 4), establishing sedimentary burial history and thermal-history models of hydrocarbon source rocks on a target stratum of a research area; 5), establishing constraint condition of hydrocarbon source rock hydrocarbon production rate; 6), establishing kerogen generated oil, kerogen generated gas, oil generated gas, clean and total gas conversion profile charts on the target stratum of the research area; 7), checking whether dynamics geological extrapolation results meet requirements or not; 8), putting forwards part of hydrocarbon expulsion mode adjustment coefficients, evaluating hydrocarbon production rate curves of the partial hydrocarbon expulsion model, and establishing the hydrocarbon source rock hydrocarbon production rate charts including three modes, namely the mode of complete hydrocarbon expulsion, the mode of partial hydrocarbon expulsion and the mode of no hydrocarbon expulsion. The shortcoming in an original calculating method and experiment simulated data of the hydrocarbon source rock hydrocarbon production rate is overcome, and the hydrocarbon source rock hydrocarbon production rate at the target stratum can be accurately and reasonably determined according to oil field exploration practice by oil field workers.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

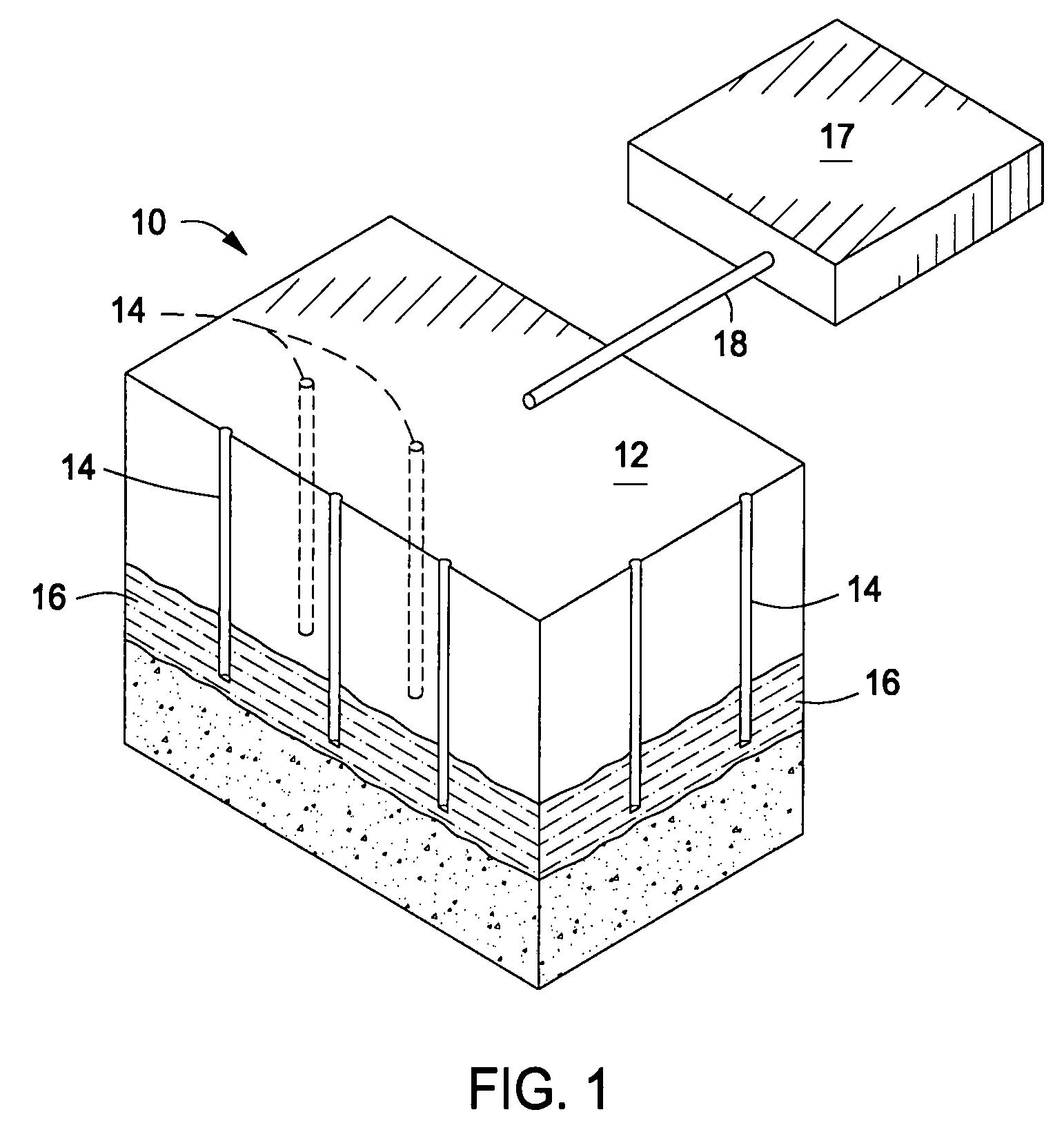

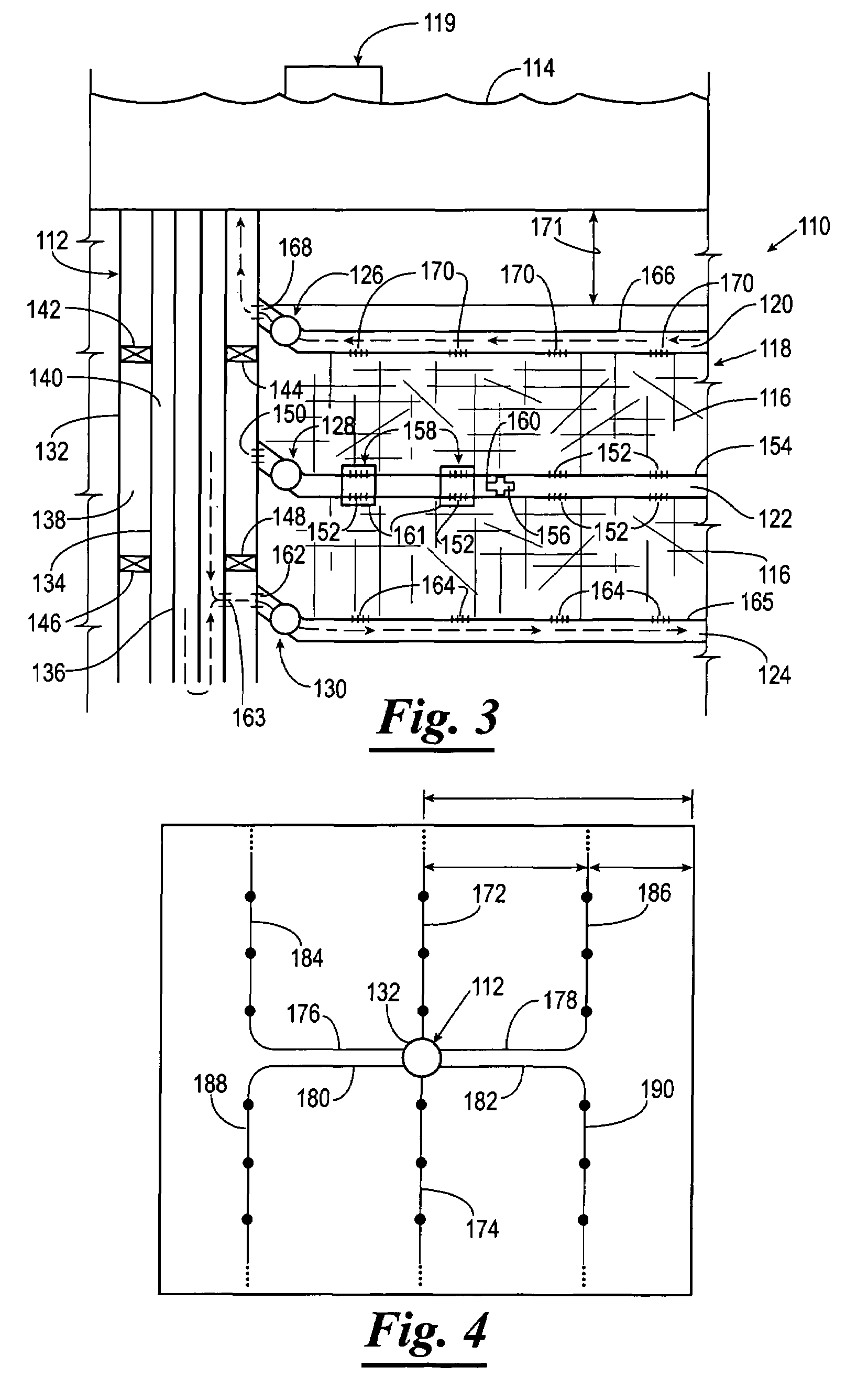

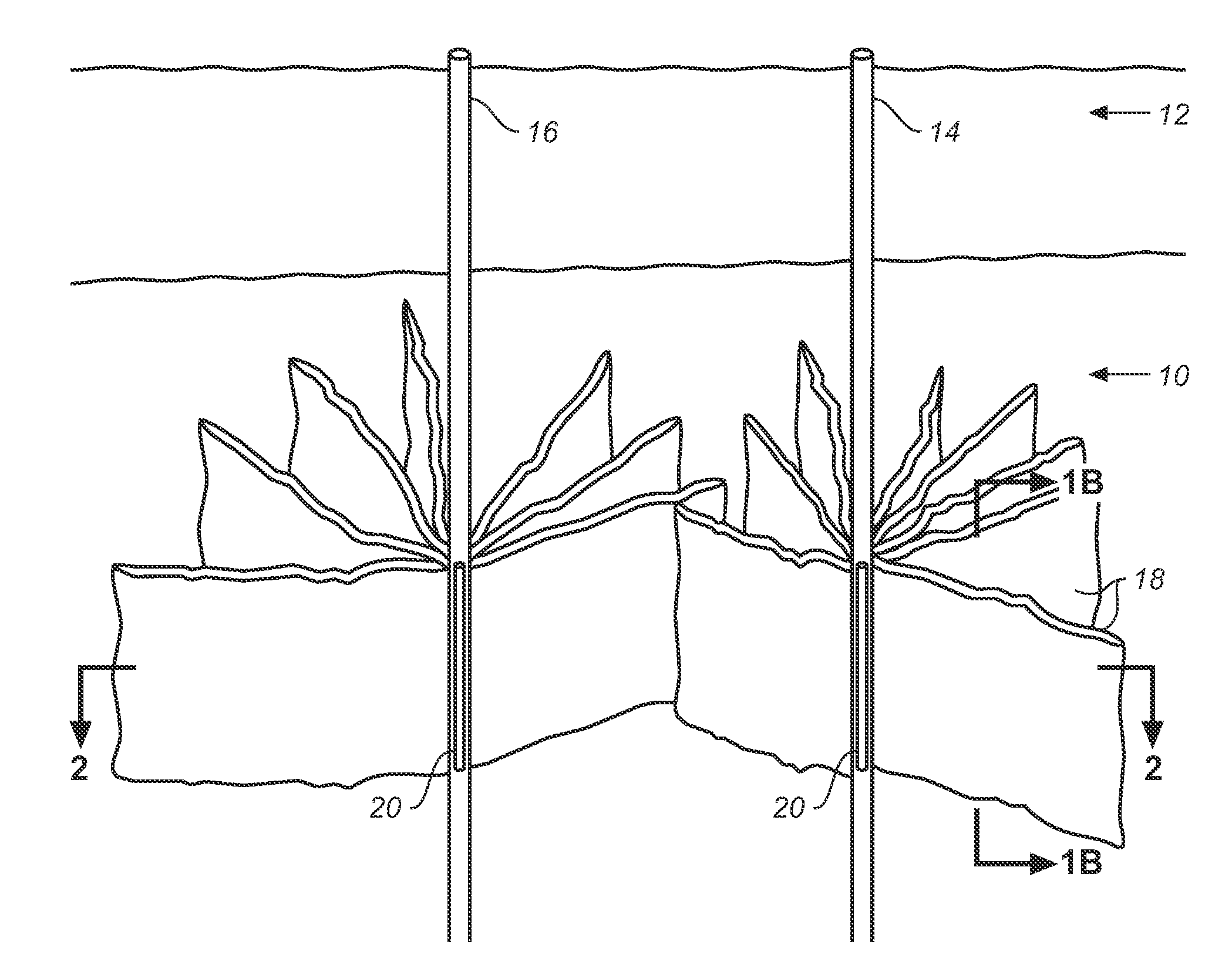

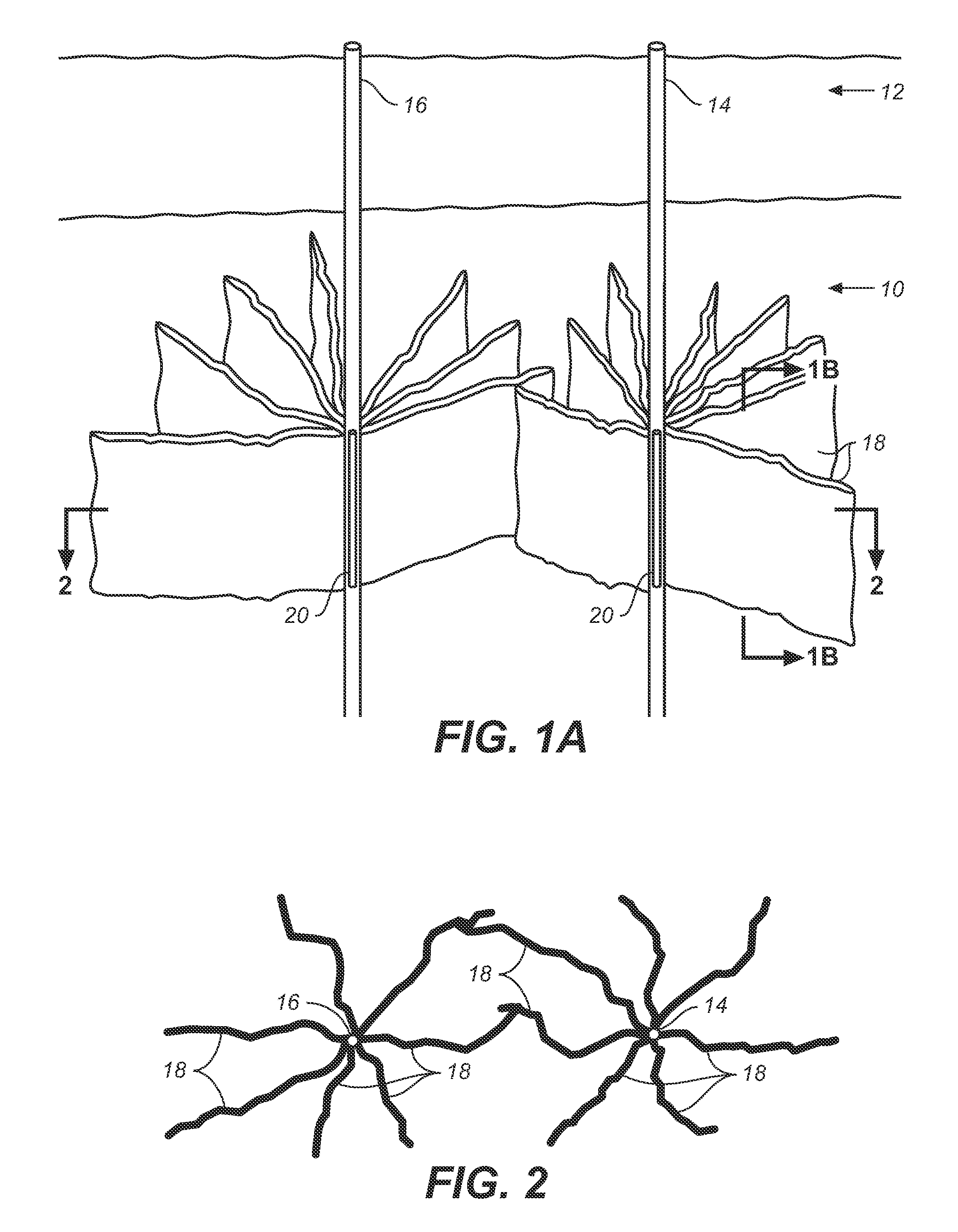

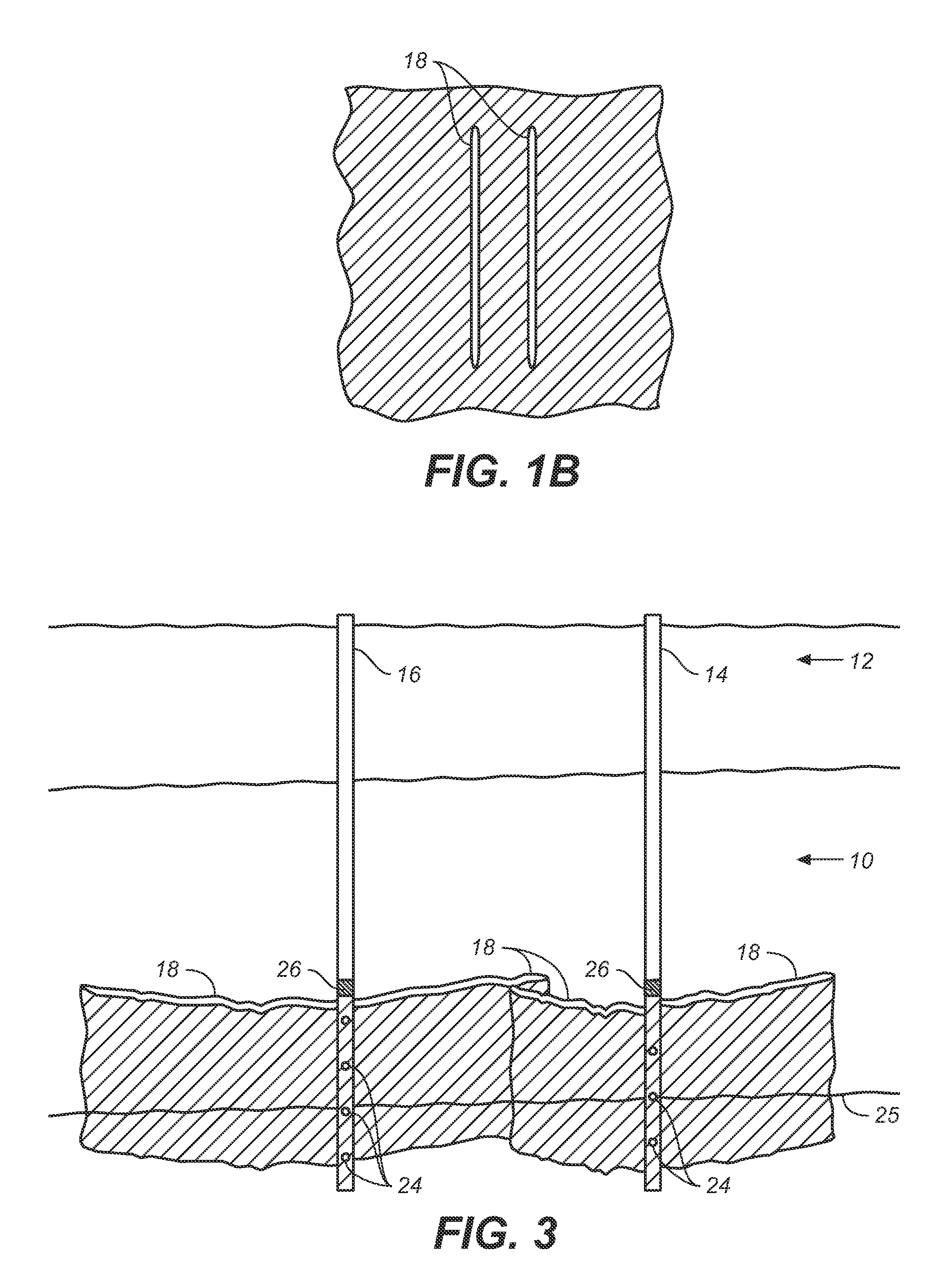

Process for two-step fracturing of oil shale formations for production of shale oil

A process for in situ production of shale oil comprises fracturing the target zone 10 of an shale oil formation using a two step approach. First, an initial set of fractures 18 is developed in the formation by using high pressure gas pulses. Second, a secondary set of fractures 28 extending and further fracturing the initial set of fractures 18 is created using a modified ANFO mix 22 wherein rubber particles acting as solid fuel are blended in with ammonium nitrate and fuel oil. The solid fuel enhances the fracturing characteristics of ANFO while minimizing its crushing and compacting tendencies. Hot high pour point oil is then injected into the formation and forced into the receptor well 16 where it is pumped to the surface. By circulating oil in the formation at carefully controlled temperatures, kerogen can be decomposed at the optimum rate to maximize the amount of oil recovered and yield high quality shale oil. High pour point oil reaching cooler extremities of the fractured formation will solidify creating an impermeable perimeter barrier 34 around the target zone 10.

Owner:YOUNG MICHAEL ROY

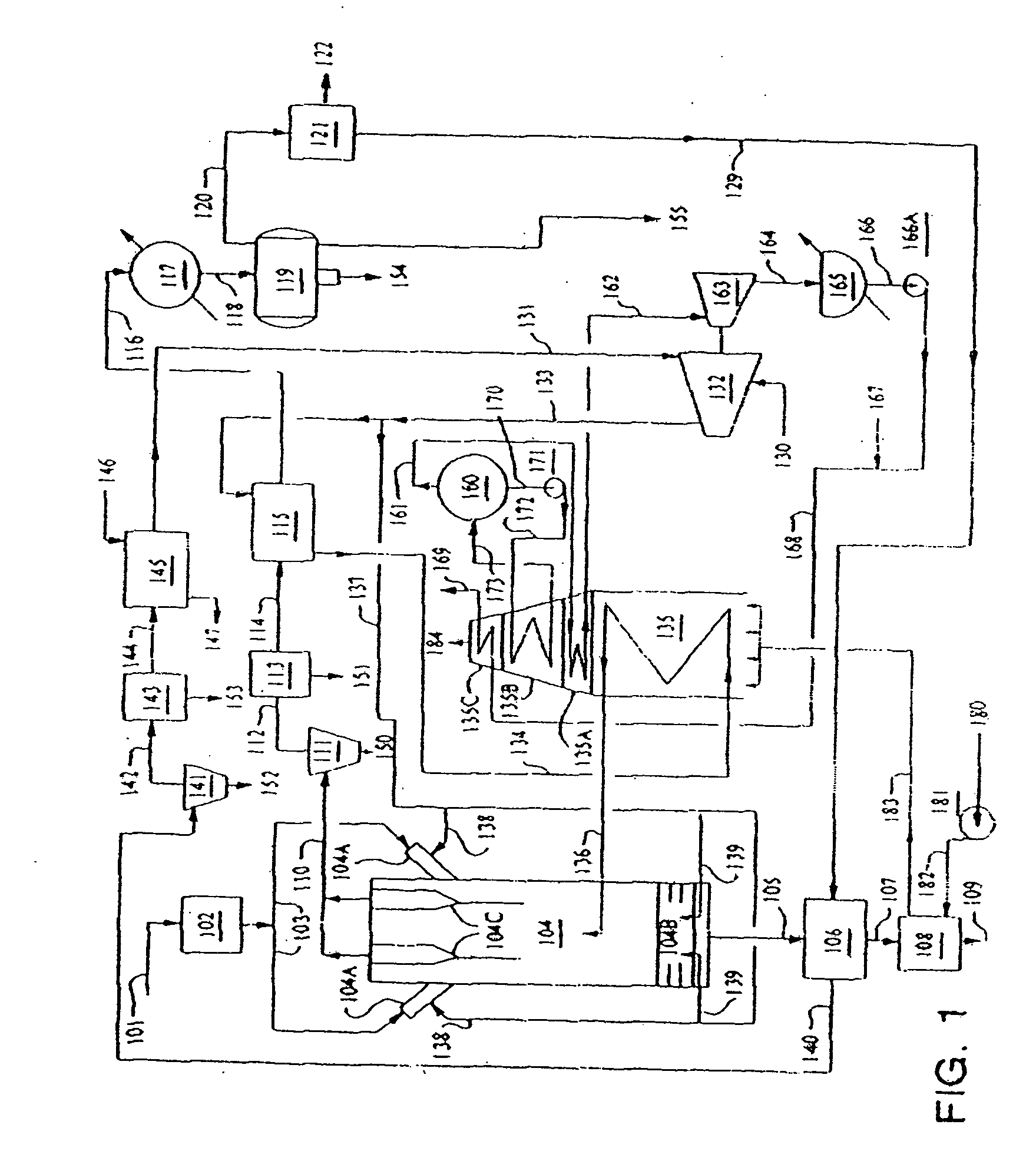

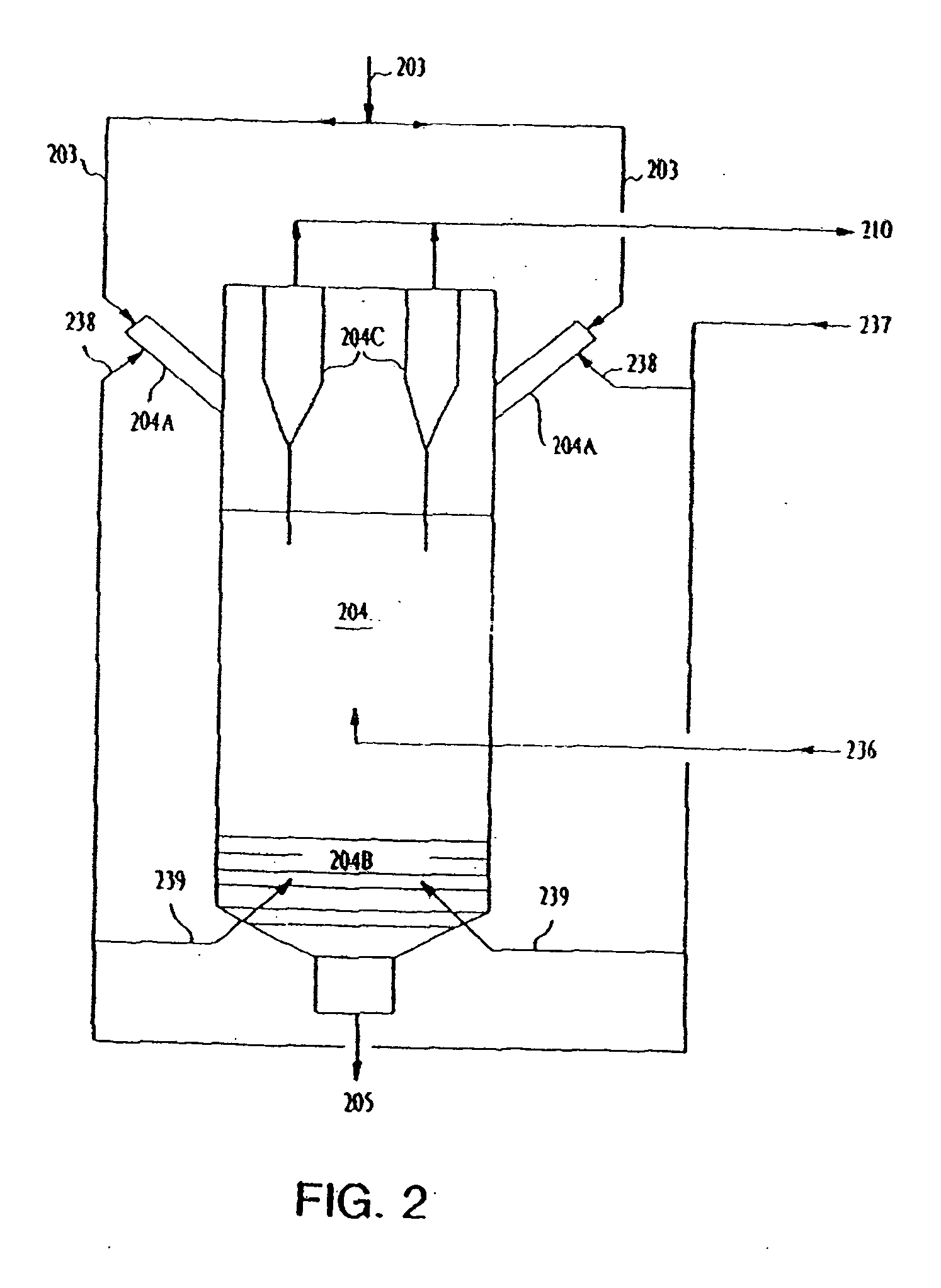

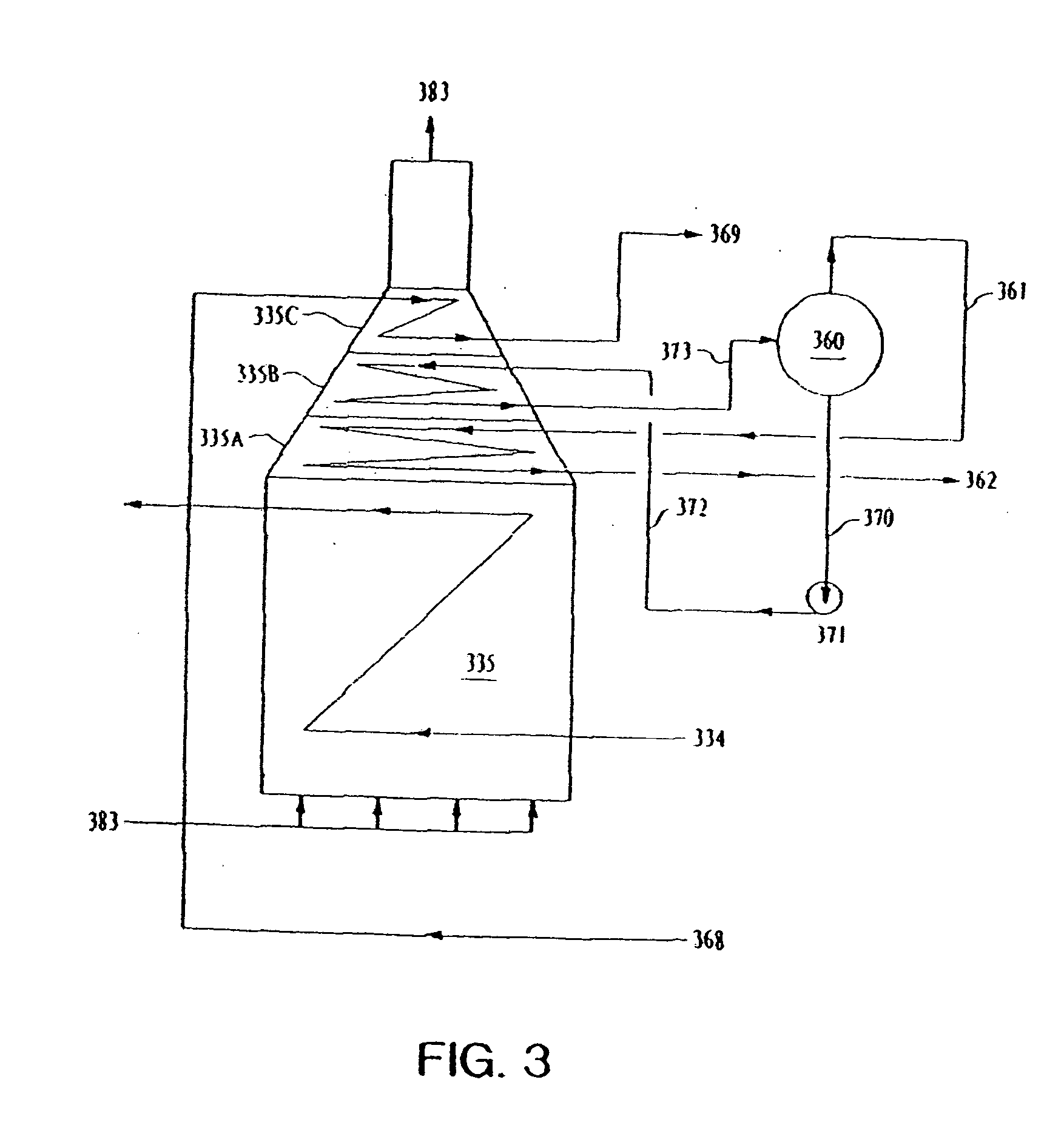

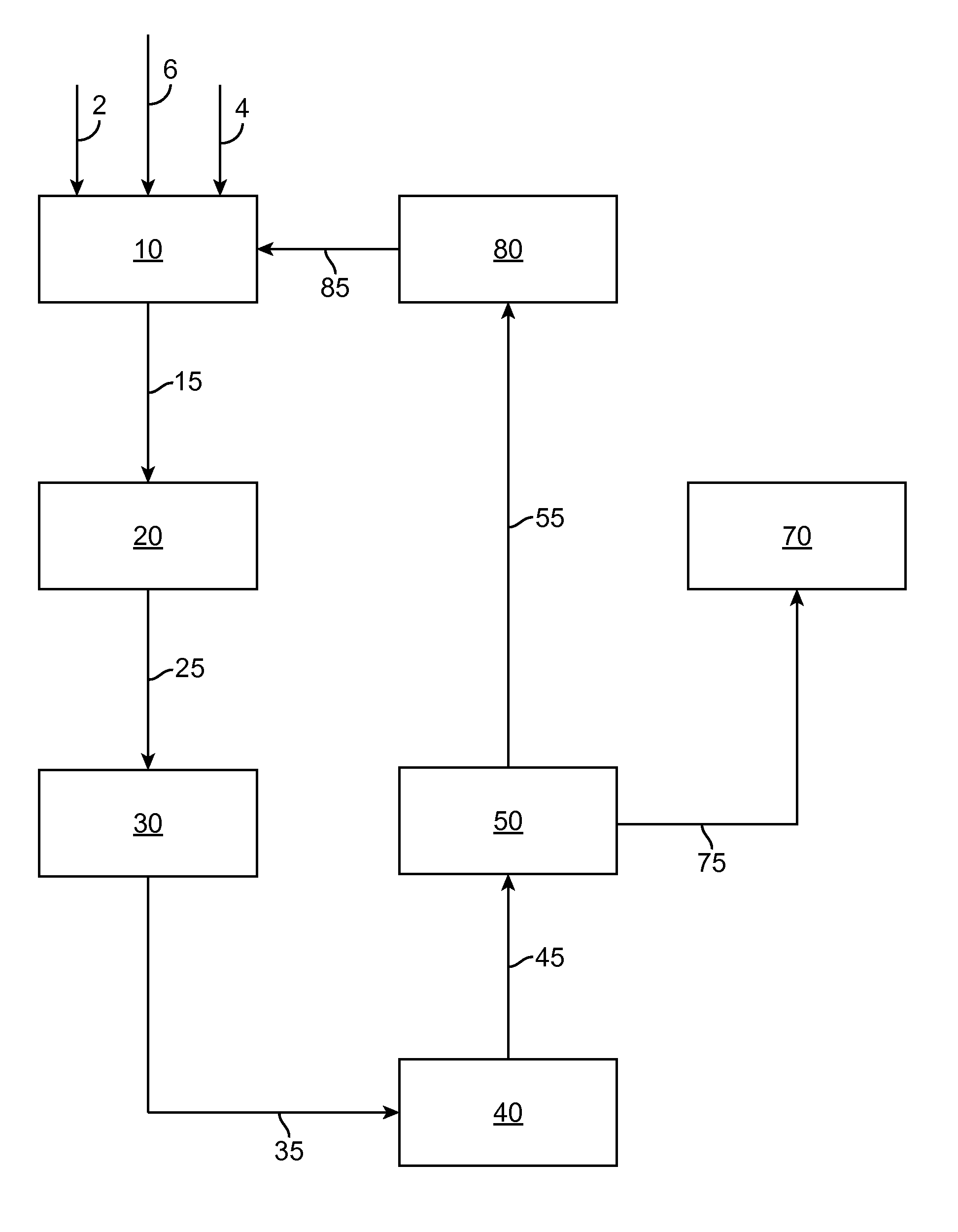

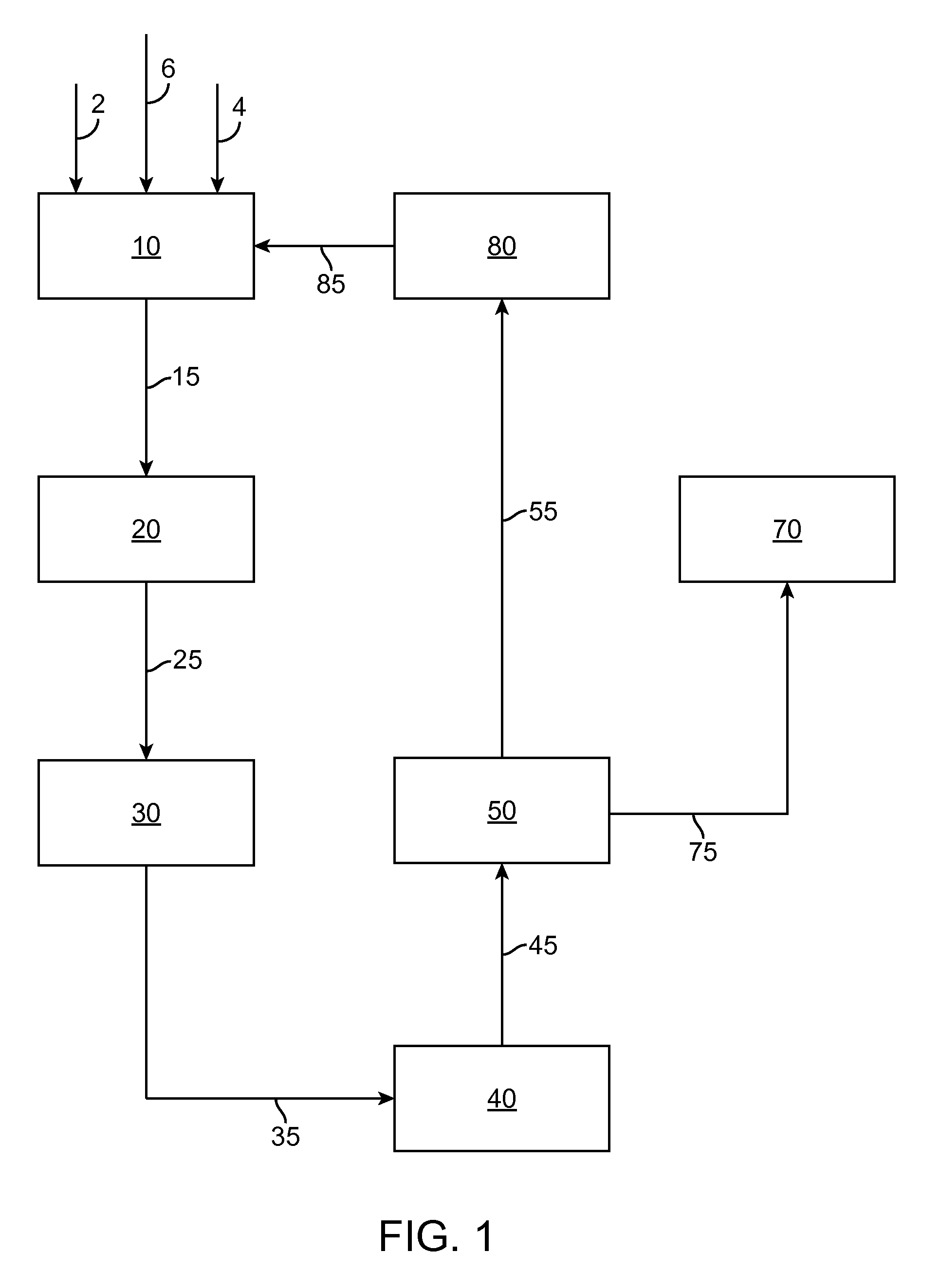

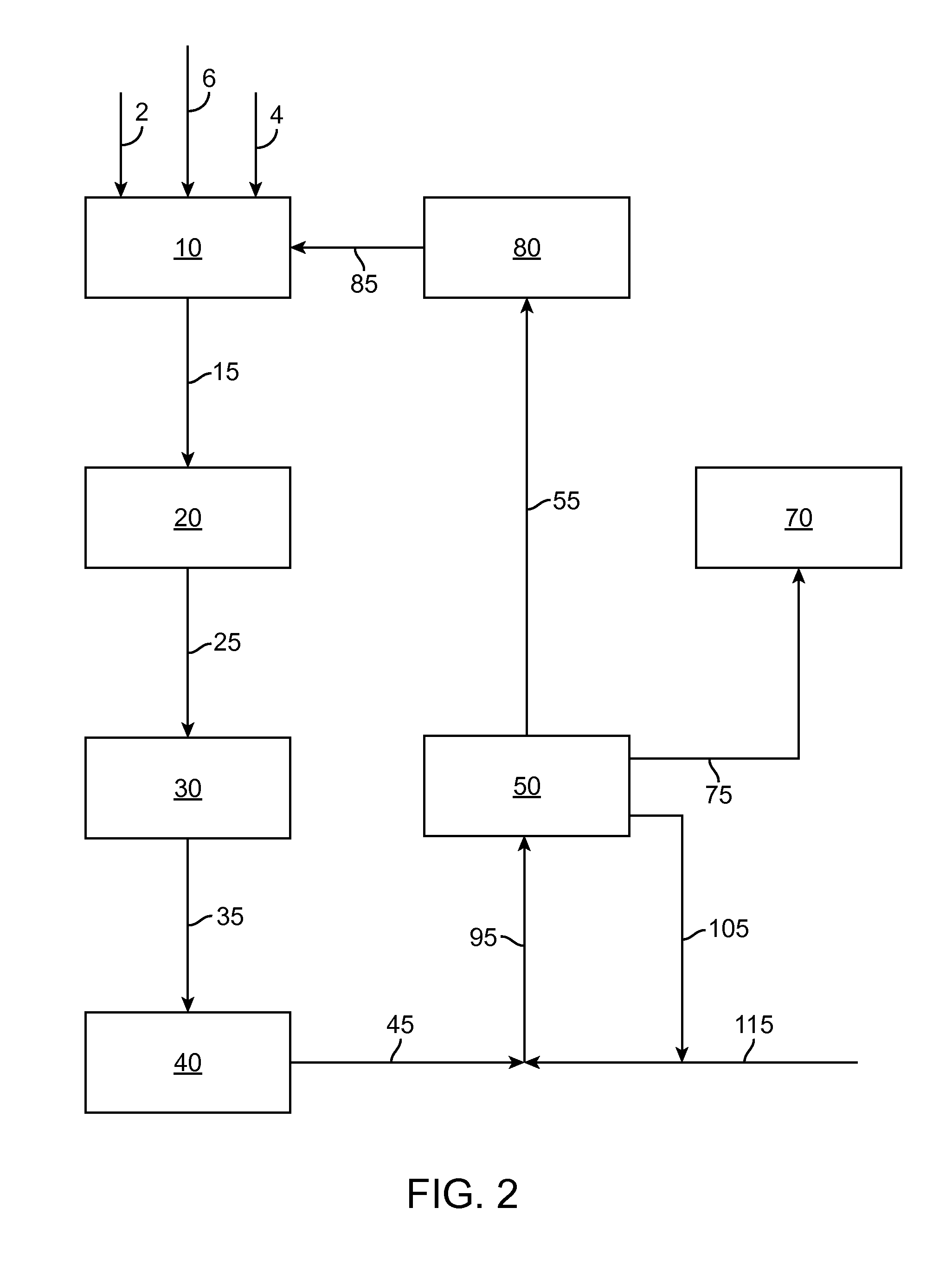

Process and apparatus for converting oil shale or oil sand (tar sand) to oil

InactiveUS20050252833A1Flexibility in processingLiquid hydrocarbon mixture productionHydrocarbon oil crackingOil shale gasPetroleum

Three new embodiments to the Chattanooga Process that convert or upgrade oil bitumen, a combination of oil sands and bitumen, a combination of sand and bitumen, and oil shale to high grade low sulfur (about 0.1 to 0.5 wt. % sulfur, or less) crude oil. The invention relates to a continuous process for producing synthetic crude oil (SCO) from oil sand bitumen which has been extracted from under ground via in situ processes, or strip mined and extracted via hot water extraction processes before upgrading. It can also apply to kerogen extracted in situ from shale underground. The process involves treating the hot bitumen with sand from an extraction process or the hot oil from kerogen with ground shale containing kerogen in a fluid bed reactor where the reactant and fluidizing medium is only hydrogen. The invention also relates to a continuous process for producing synthetic crude oil (SCO) from oil shale kerogen. The invention relates to a continuous process for producing synthetic crude oil from oil bearing material, e.g., oil shale or oil sand (tar sand), through continuous process for producing synthetic crude oil from bituminous oil sand (tar sand) or shale. The process includes treating the oil sand (tar sand) or shale to produce a fluidizable feed, feeding the fluidizable feed to a fluidized bed reactor, and fluidizing and reacting the fluidizable feed in the fluidized bed reactor with a feed of hydrogen provided by a feed stream having a stream containing hydrogen in a concentration greater than 90 vol % (90 vol %-100 vol % H2). In one embodiment, the invention relates to a continuous process which can recover methane and ethane from a recycle hydrogen stream. In one embodiment, the process can recover PSA tail gas as feed to a hydrogen plant. In one embodiment, the process can be operated to reduce or eliminate the requirement for externally provided methane feed to the hydrogen plant.

Owner:DOYLE JAMES A +1

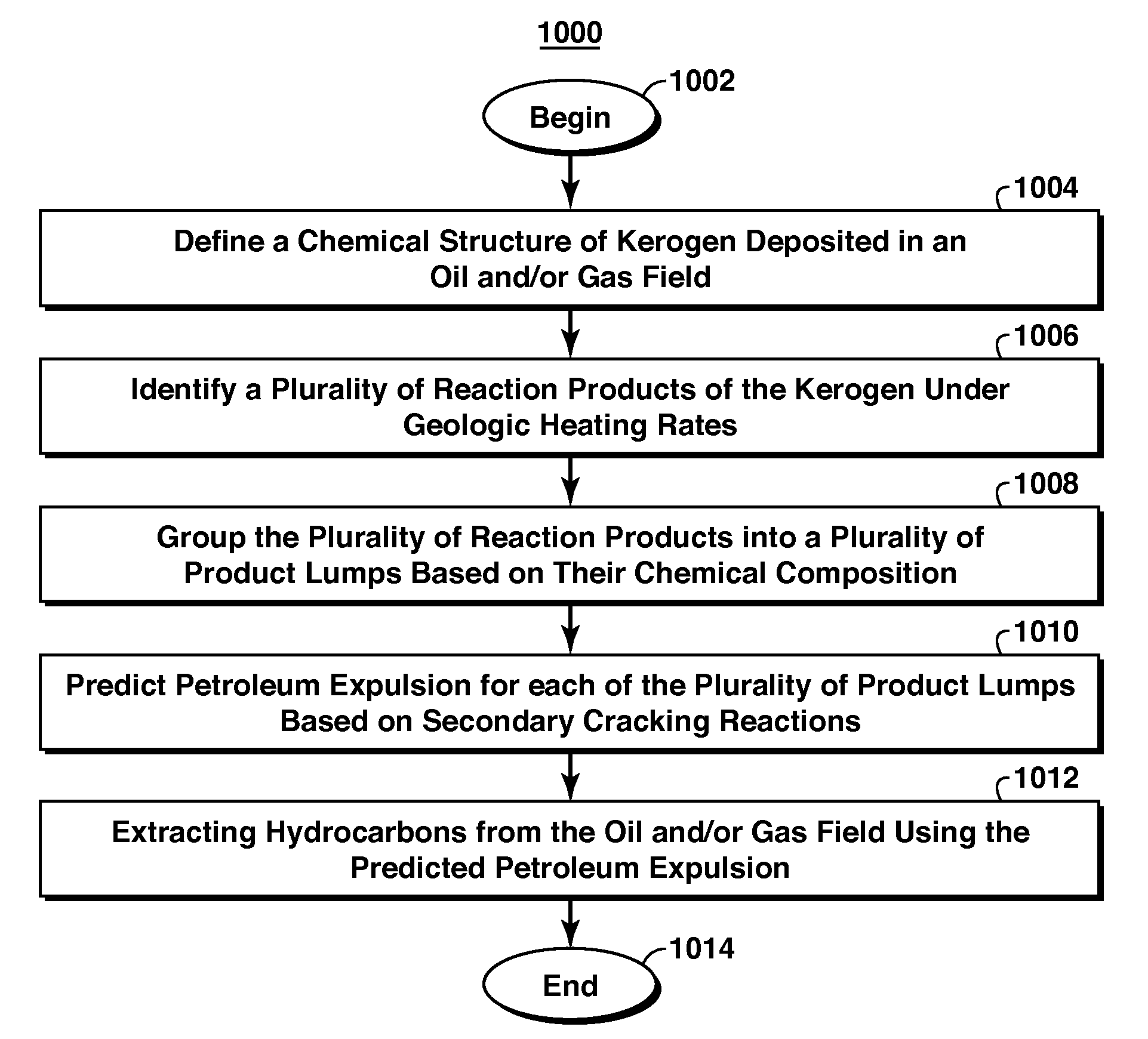

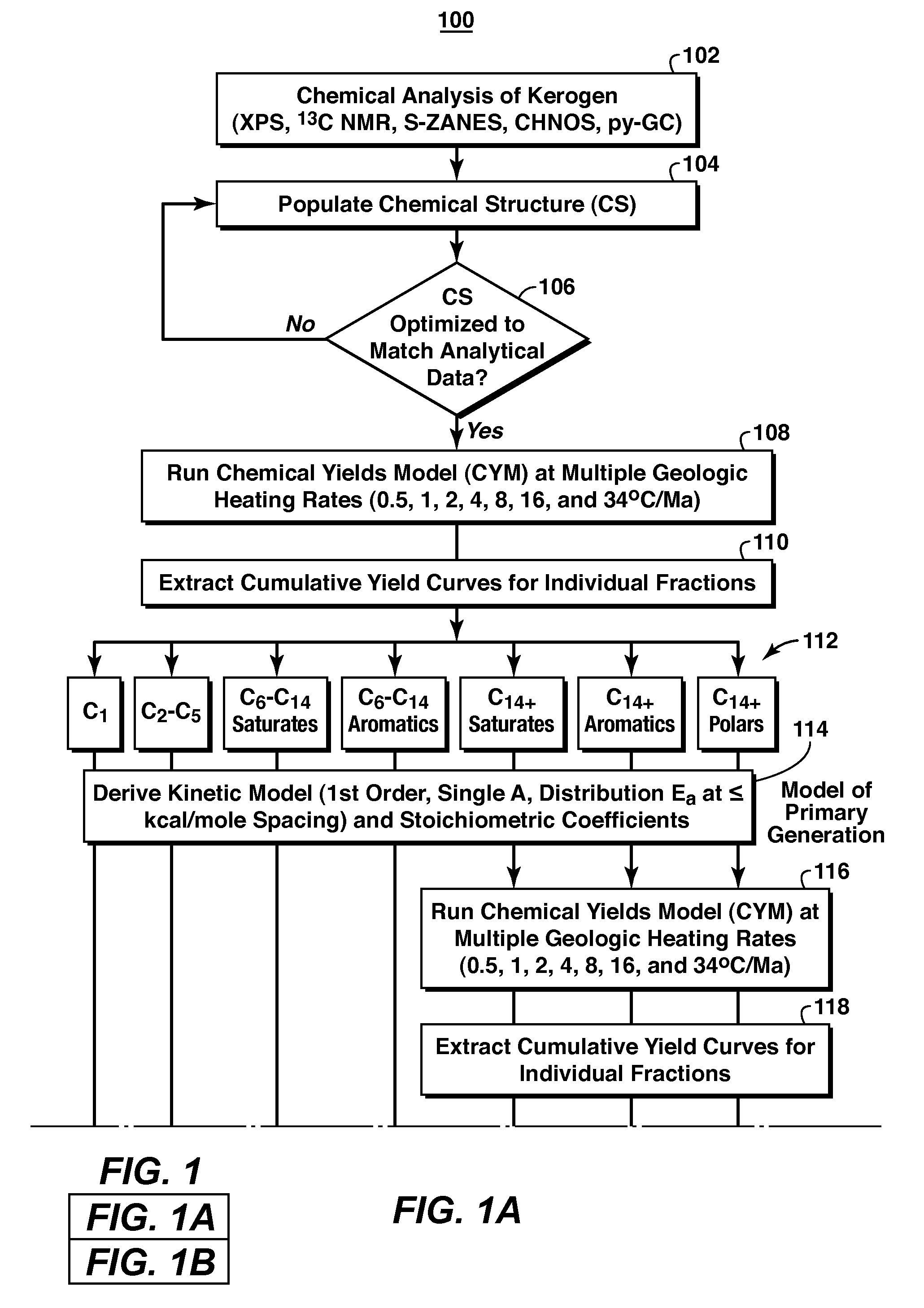

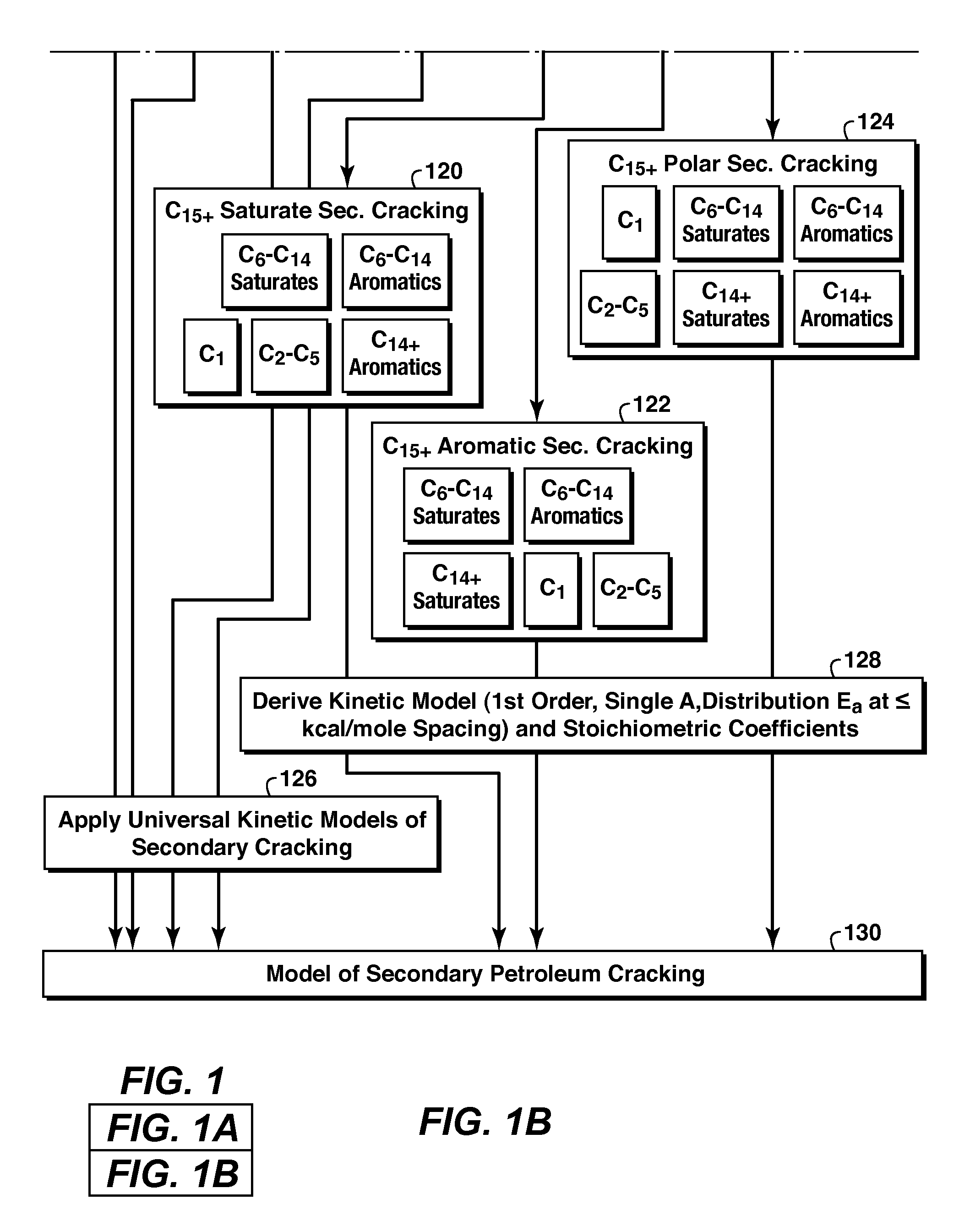

Method For Predicting Composition of Petroleum

A method for predicting petroleum expulsion is provided. An exemplary embodiment of the method comprises defining a chemical structure of a kerogen and identifying a plurality of reaction products of the kerogen under geologic heating rates. The exemplary method also comprises grouping the plurality of reaction products into a plurality of product lumps based on their chemical composition and predicting petroleum expulsion for each of the plurality of product lumps based on secondary cracking reactions.

Owner:EXXONMOBIL UPSTREAM RES CO

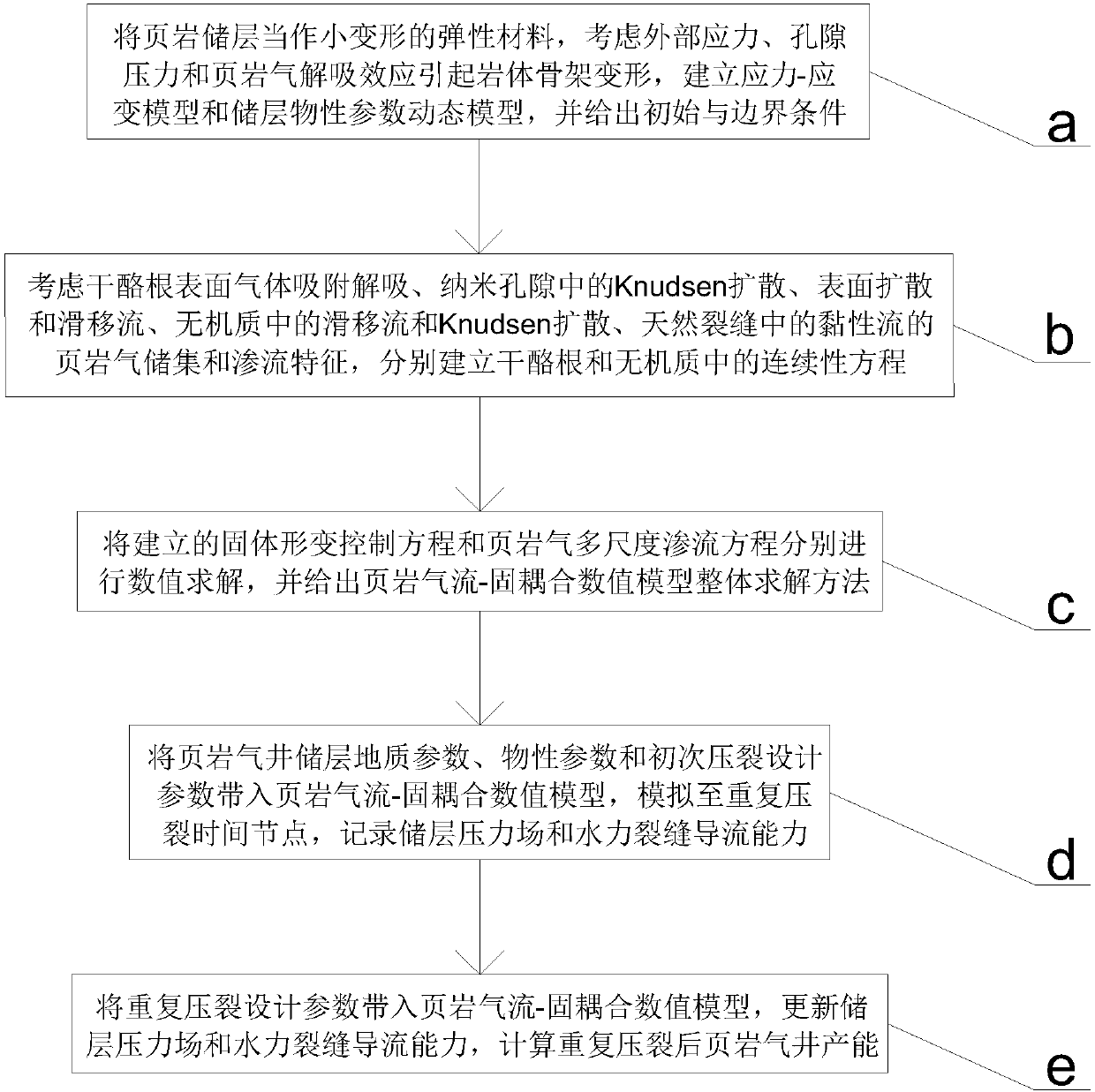

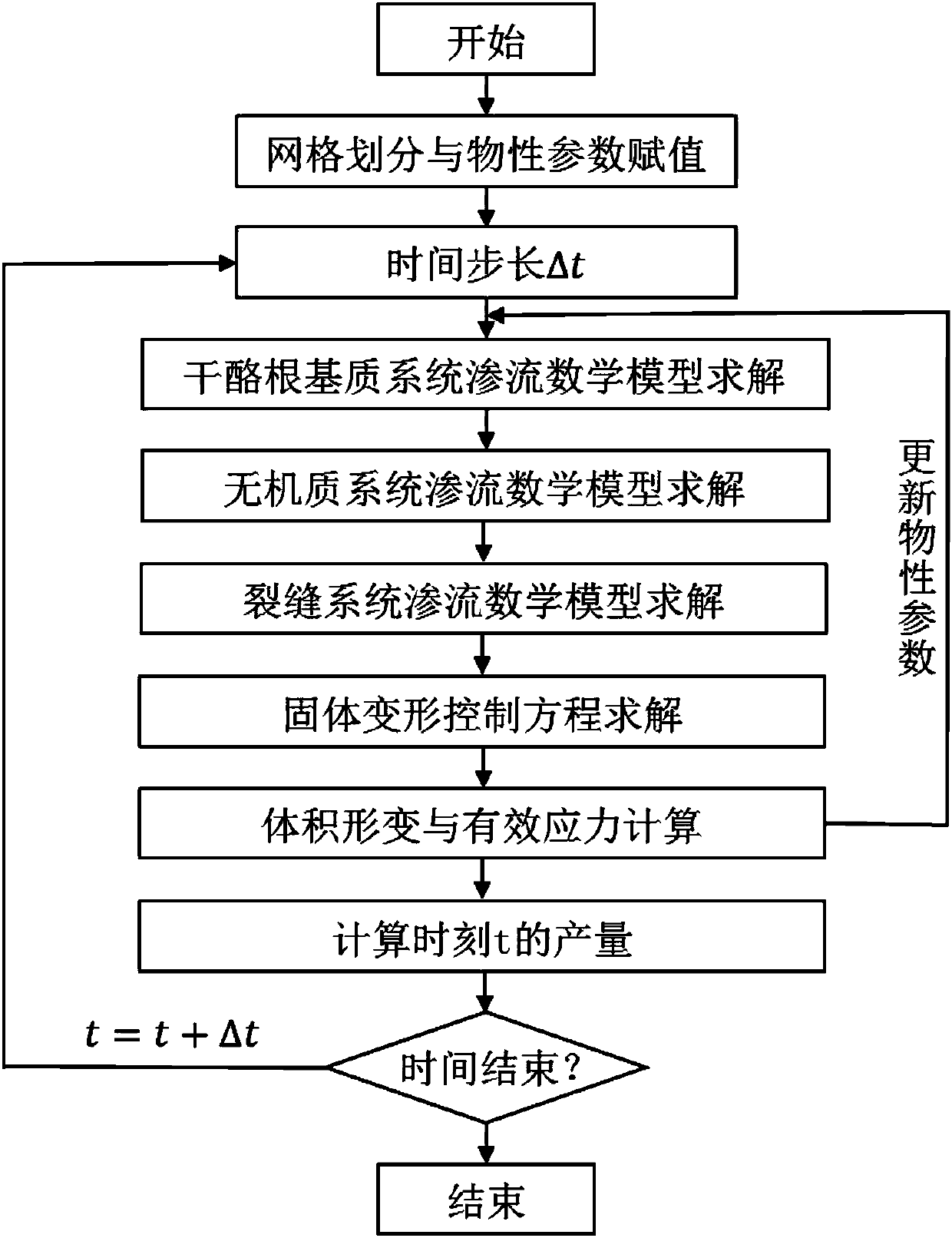

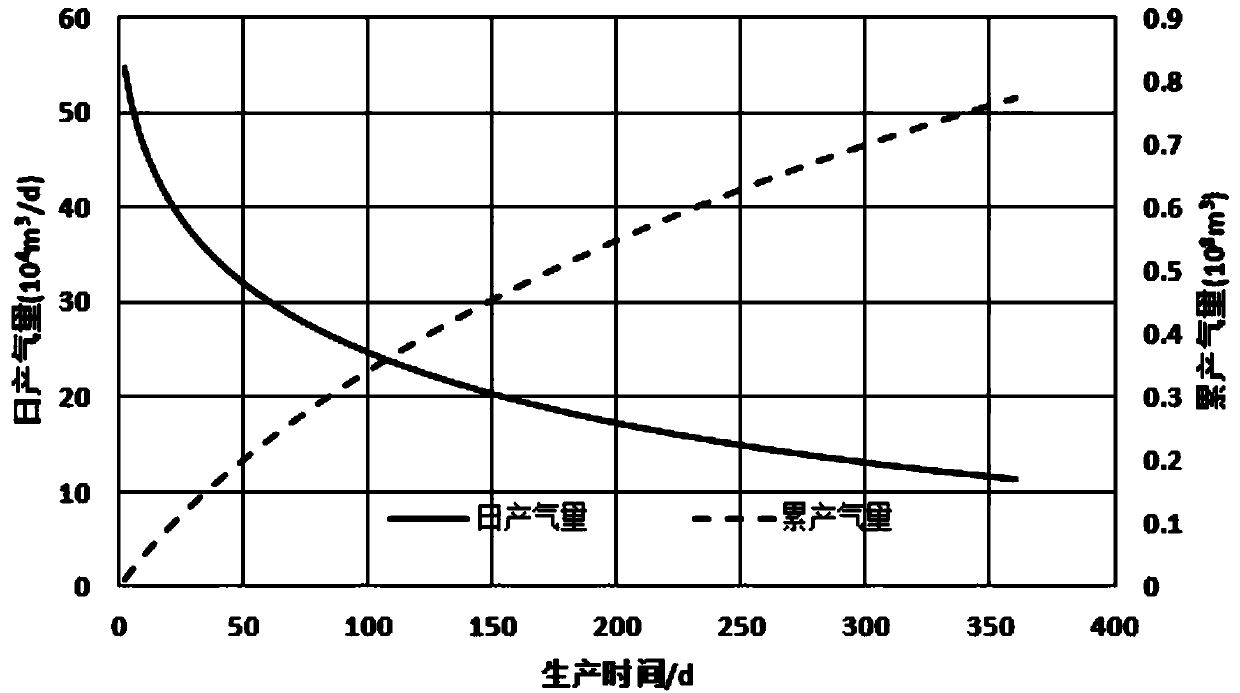

Shale gas horizontal well refracturing productivity calculation method

ActiveCN107622165ASolve the problem of inapplicable refracturing production capacity calculationFluid removalSpecial data processing applicationsKerogenDynamic models

The invention belongs to the technical field of unconventional oil gas production increasing transformation and particularly, relates to a shale gas horizontal well refracturing productivity calculation method. The method comprises the following steps of: by using a shale reservoir as an elastic material which is small in deformation, establishing a stress-strain model and a reservoir physical property parameter dynamic model; establishing a continuity equation in kerogen and an inorganic substance; respectively carrying out numerical solution on an established solid deformation control equation and shale gas multiscale seepage equation; bringing geological parameters, physical property parameters and primary fracturing design parameters of a shale gas well reservoir into a shale gas fluid-solid coupling numerical model, and recording a pressure field and hydraulic fracture flow conductivity of the reservoir; and bringing refracturing design parameters into the shale gas fluid-solid coupling numerical model, and calculating productivity of a shale gas well after refracturing. According to the method disclosed by the invention, seepage characteristics and stress-pressure field dynamic variations of the shale reservoir are considered, productivity and a recovery ratio of the shale reservoir after refracturing are predicted, and shale gas horizontal well refracturing optimizationdesign is guided.

Owner:SOUTHWEST PETROLEUM UNIV

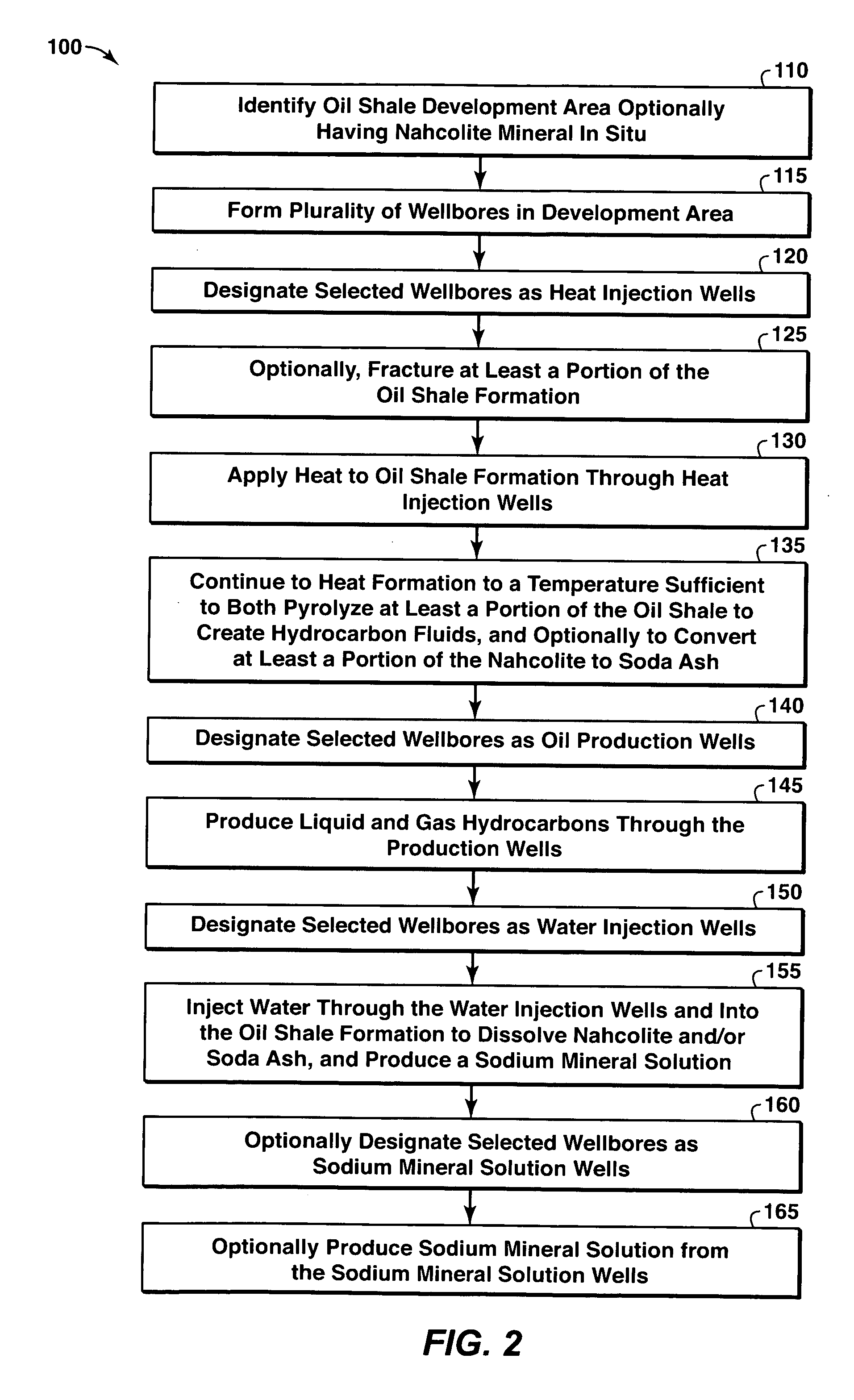

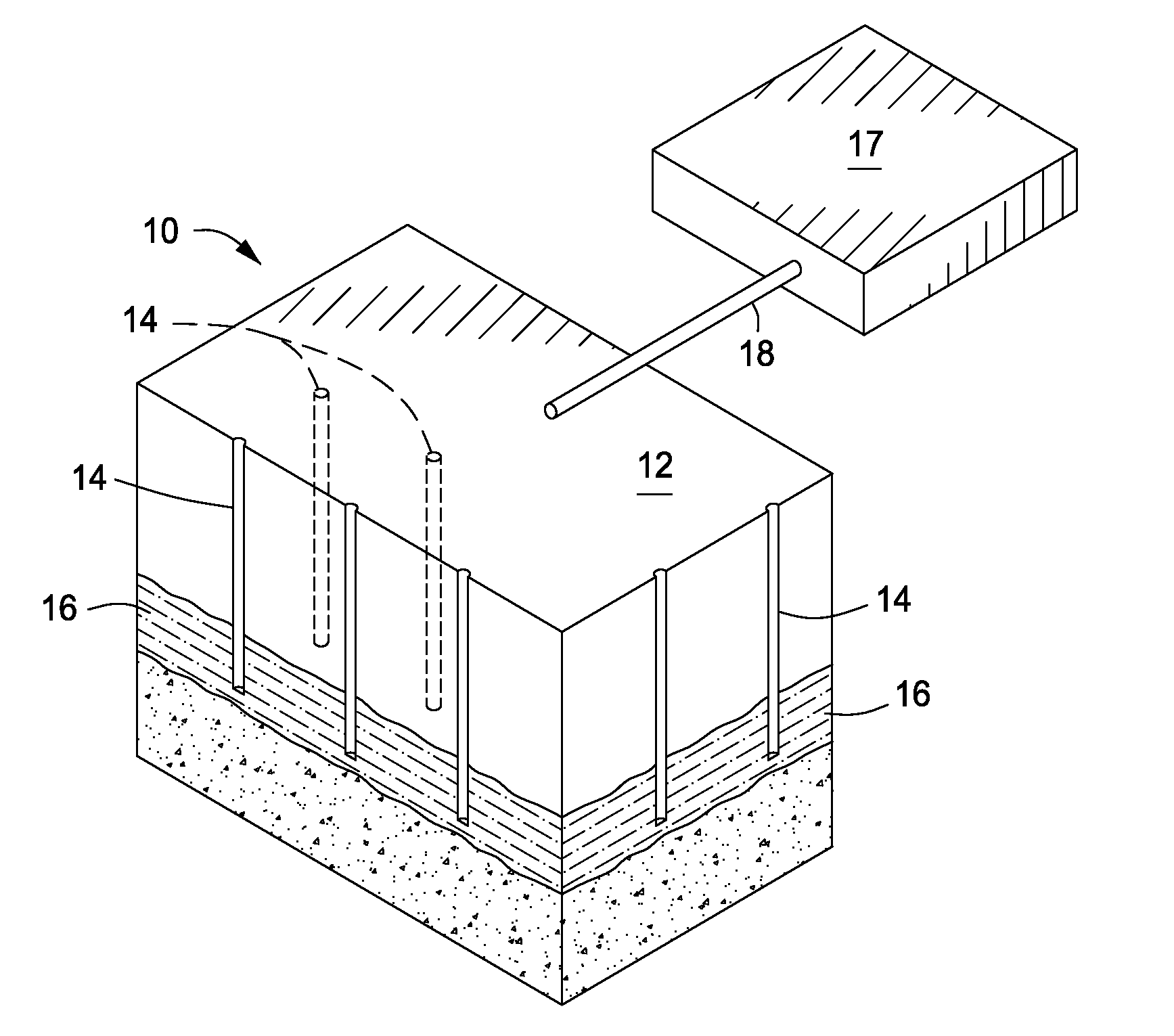

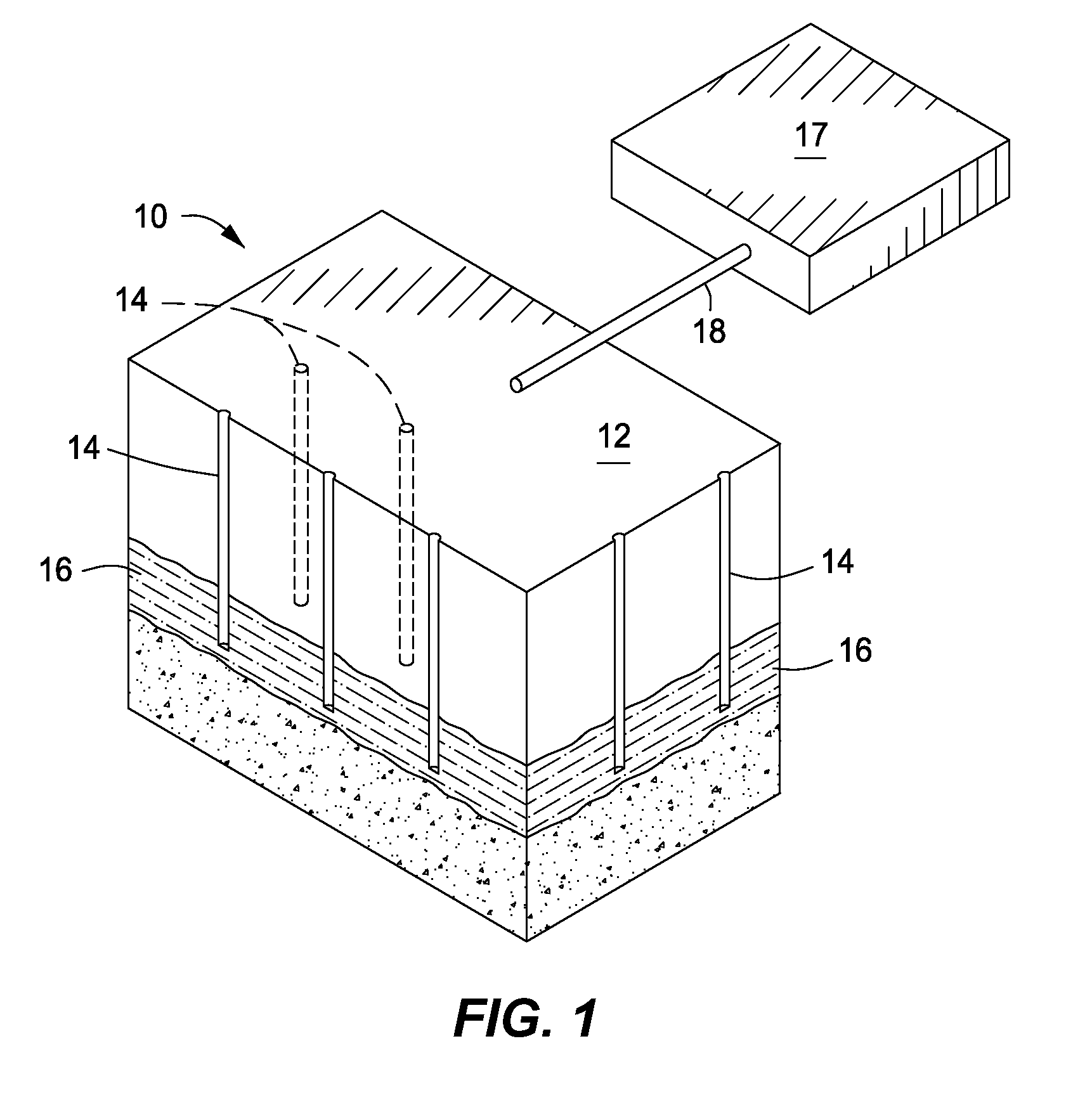

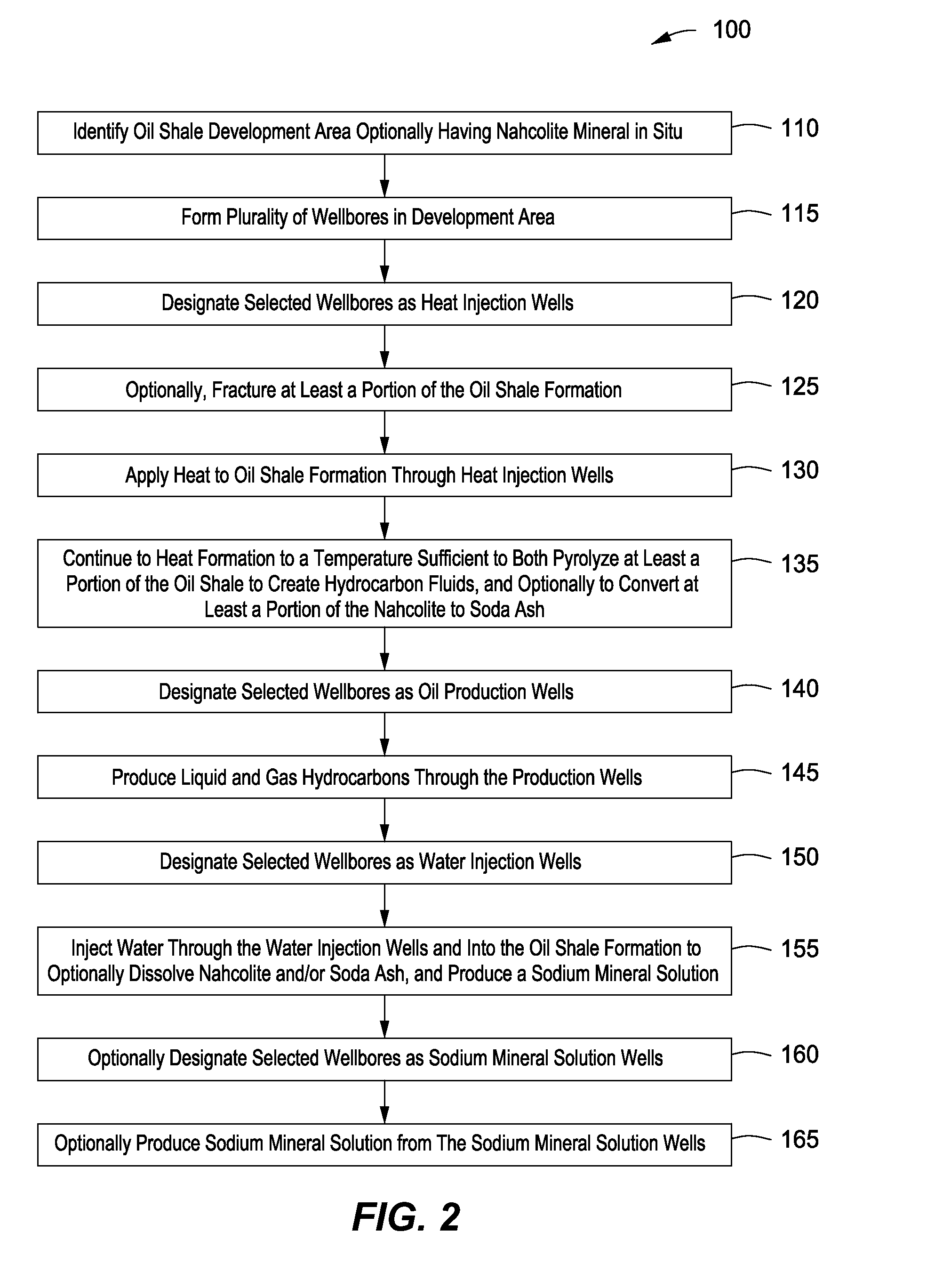

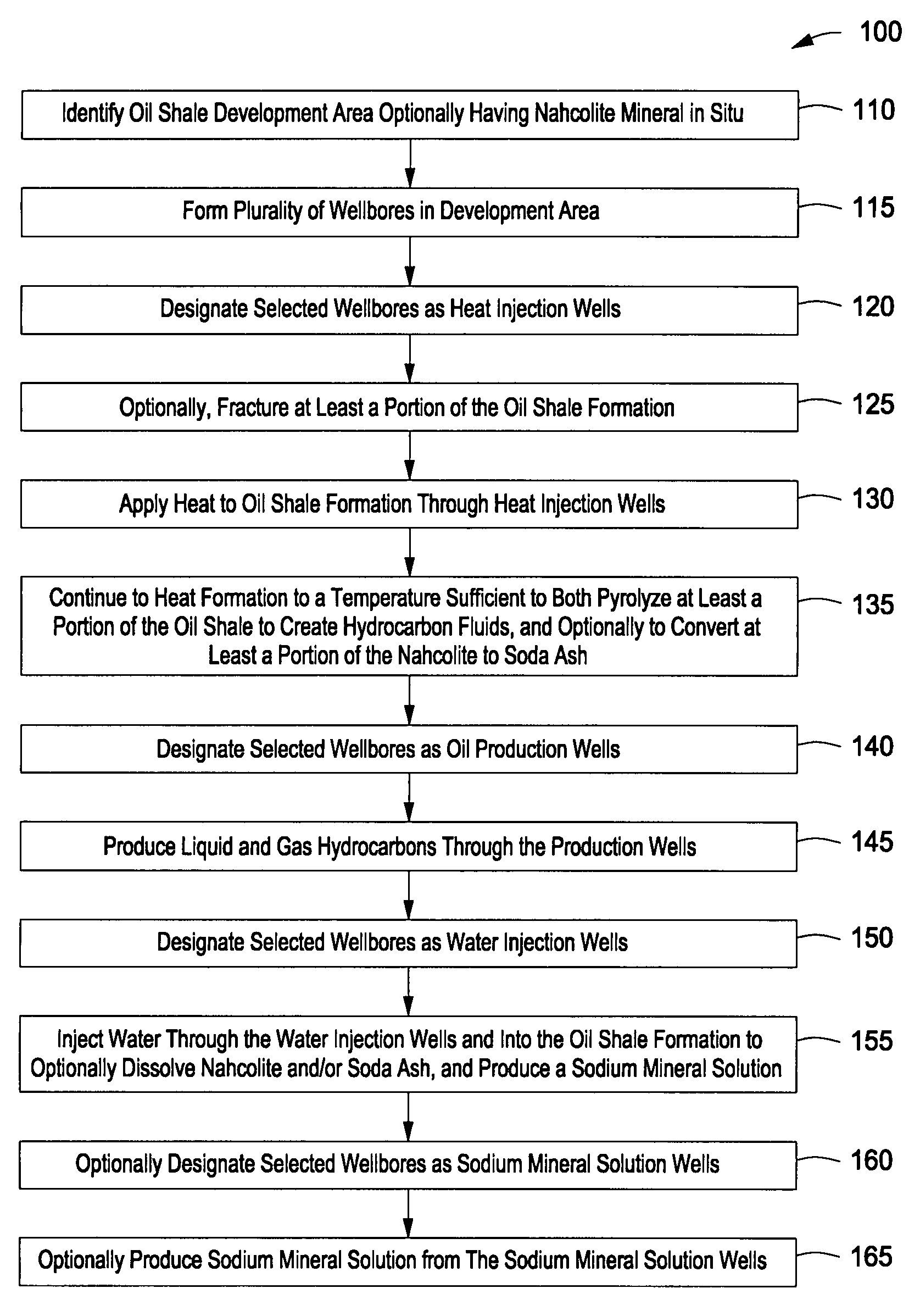

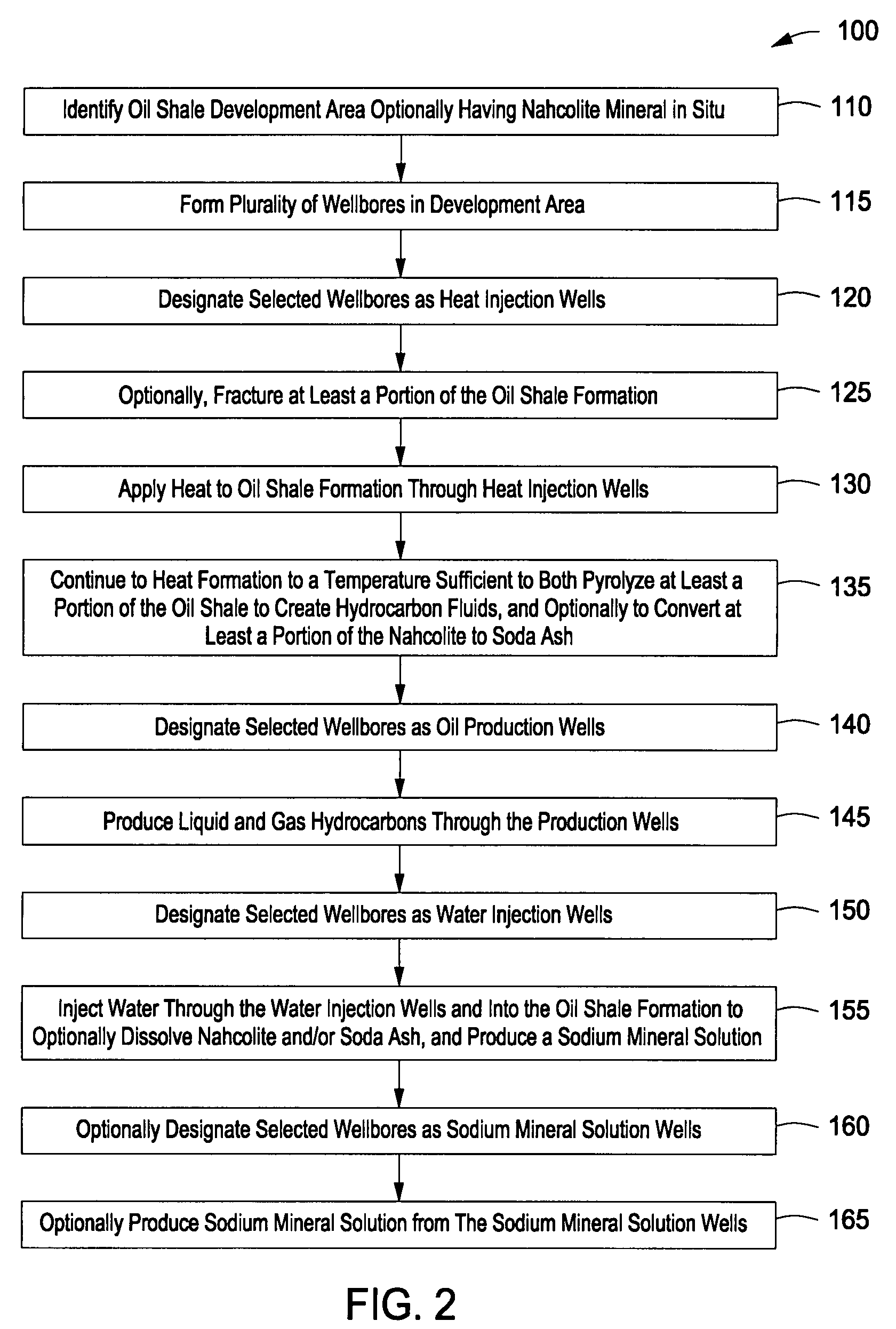

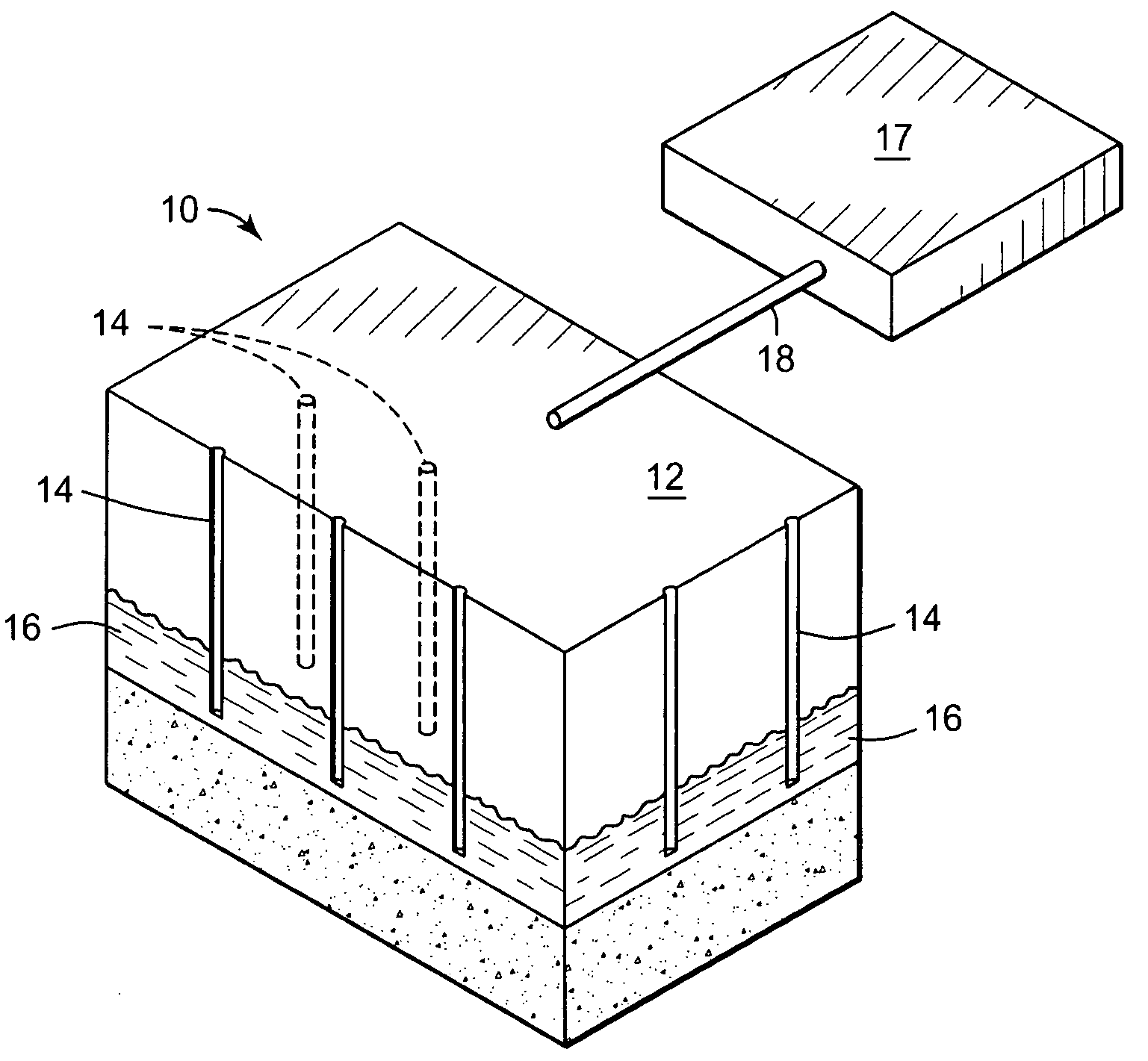

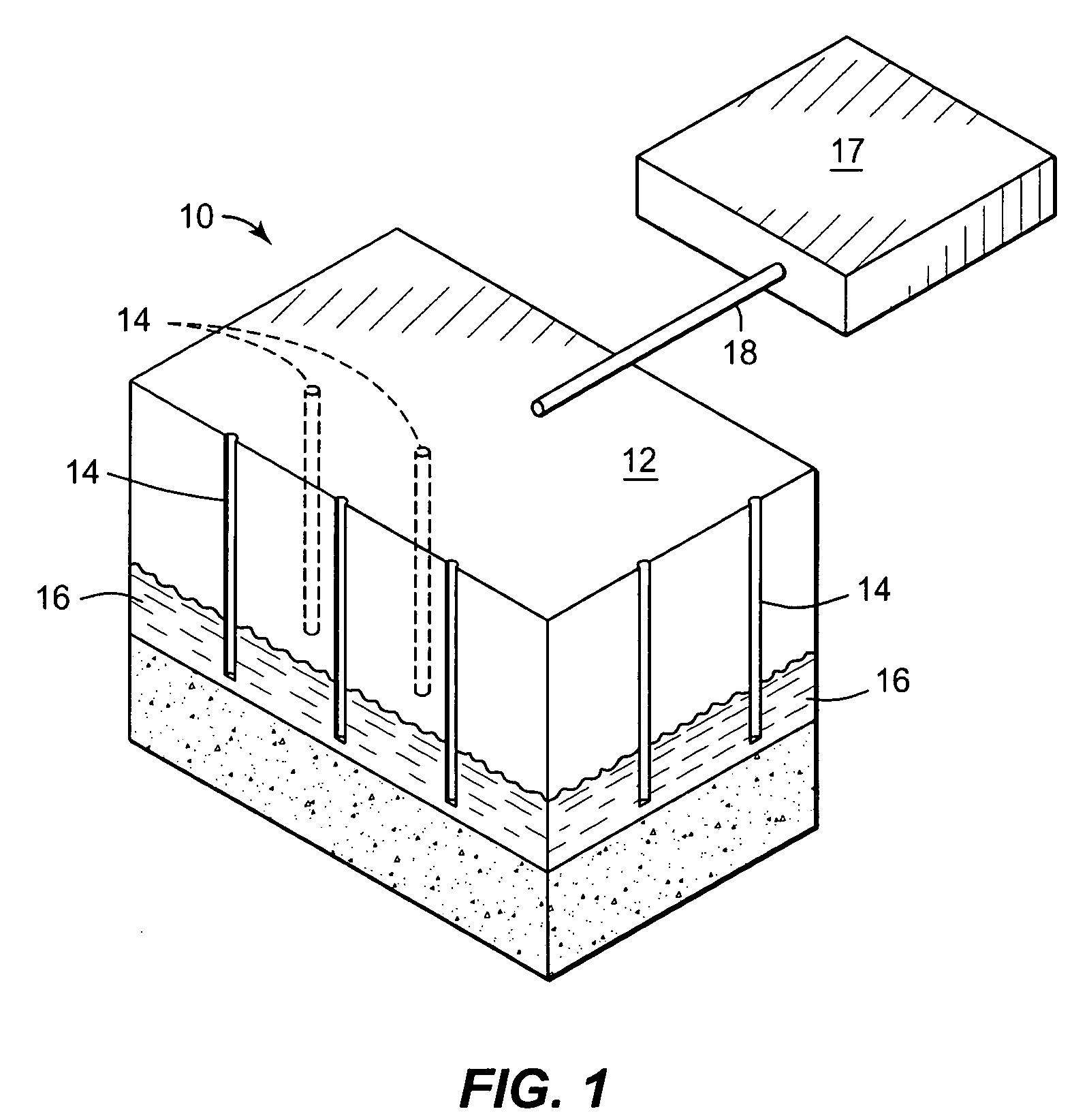

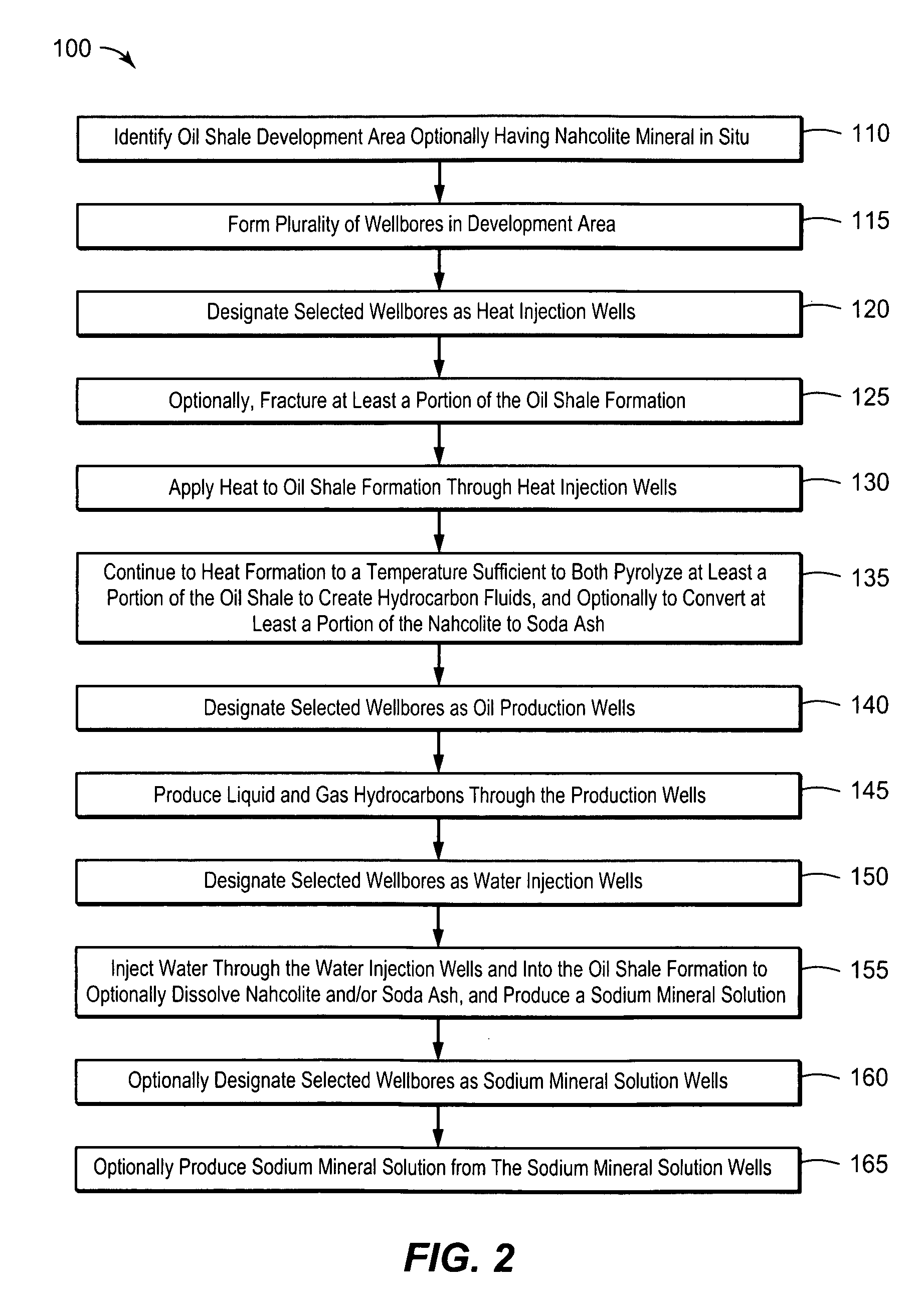

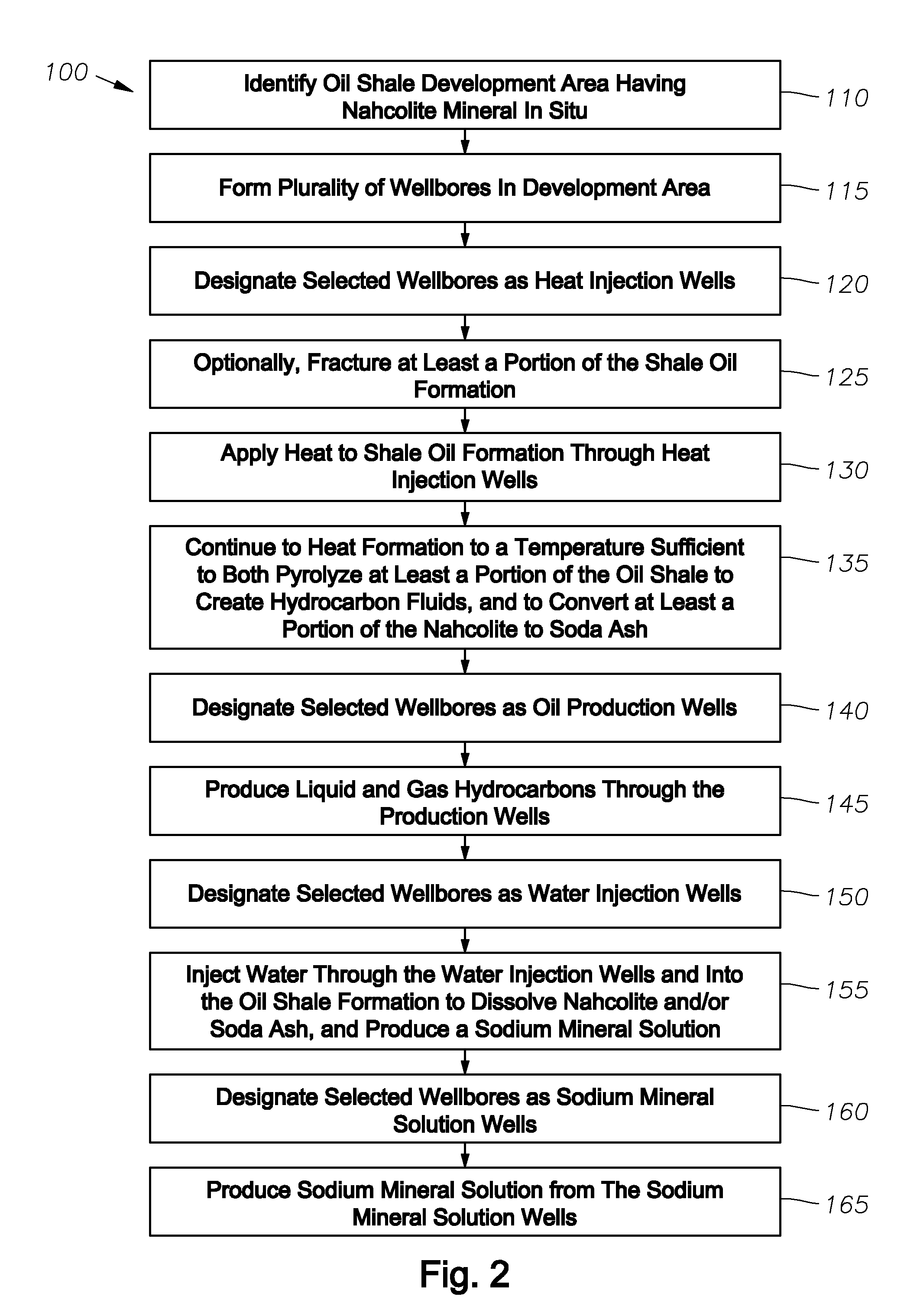

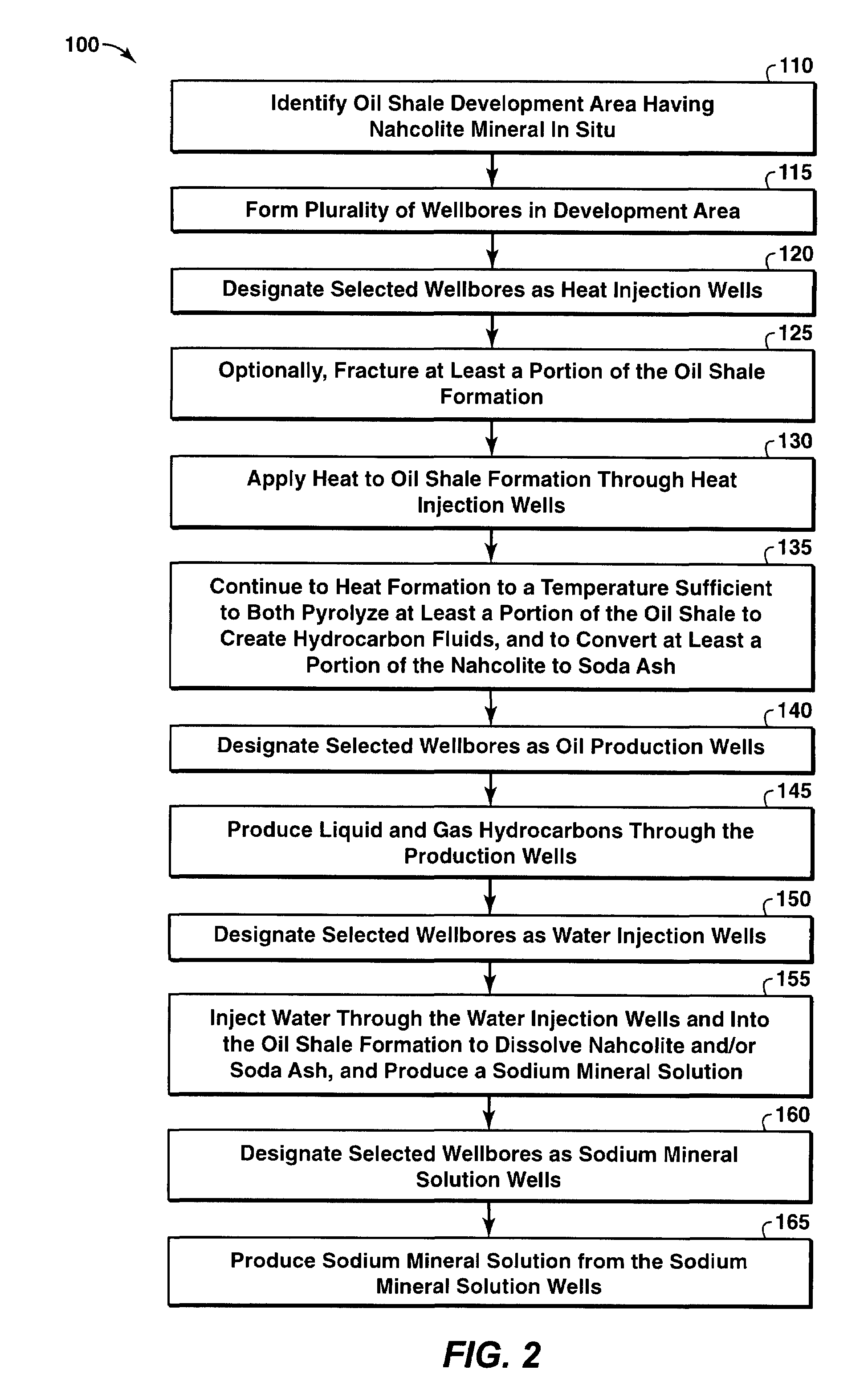

In Situ Co-Development of Oil Shale With Mineral Recovery

Owner:EXXONMOBIL UPSTREAM RES CO

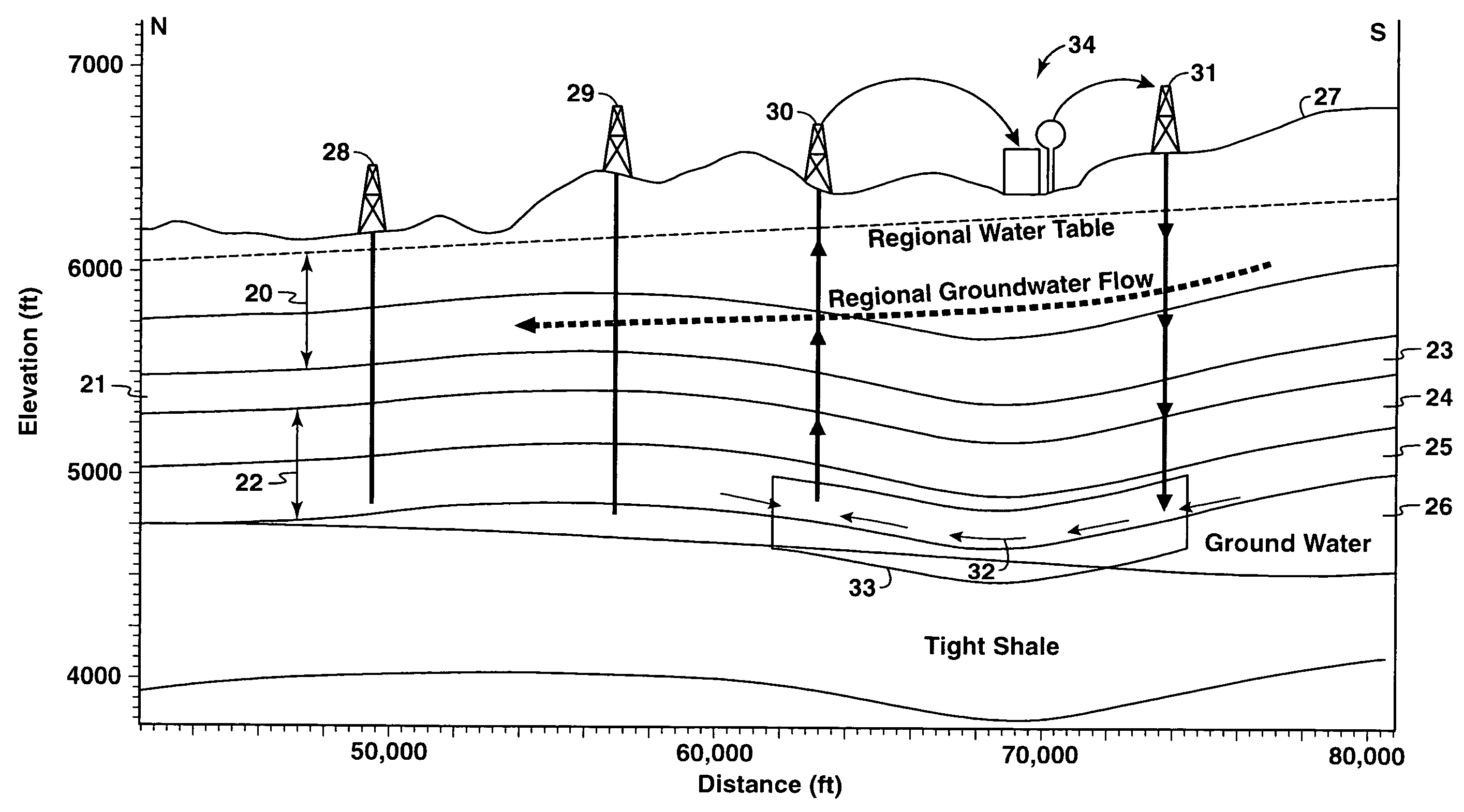

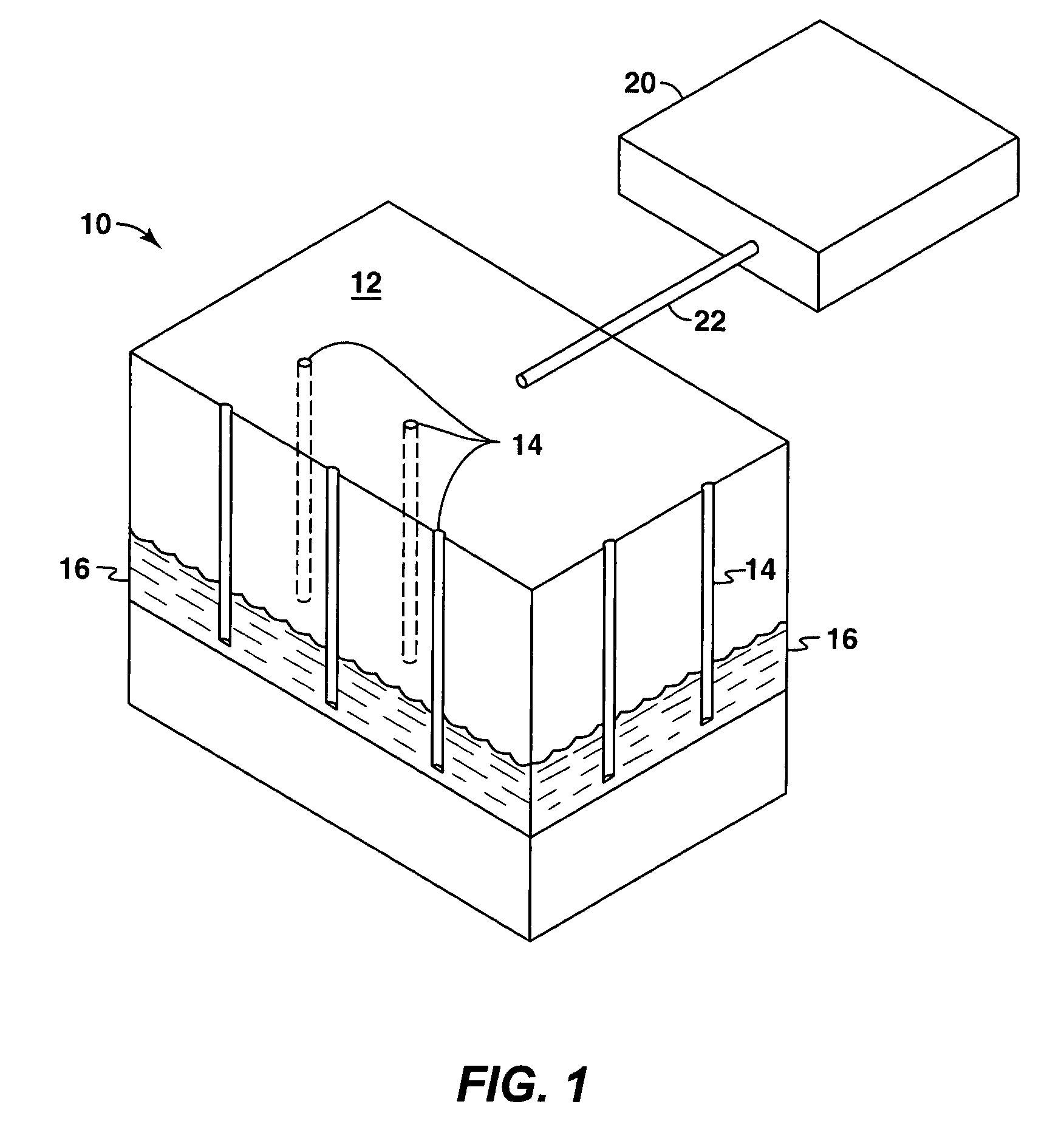

In situ co-development of oil shale with mineral recovery

A method of producing hydrocarbon fluids from a subsurface organic-rich rock formation, for example an oil shale formation, in which the oil shale formation contains water-soluble minerals, for example nahcolite, is provided. In one embodiment, the method includes the step of heating the organic-rich rock formation in situ. Optionally, this heating step may be performed prior to any substantial removal of water-soluble minerals from the organic-rich rock formation. In accordance with the method, the heating of the organic-rich rock formation both pyrolyzes at least a portion of the formation hydrocarbons, for example kerogen, to create hydrocarbon fluids, and converts at least a portion of the water-soluble minerals, for example, converts nahcolite to soda ash. Thereafter, the hydrocarbon fluids are produced from the formation.

Owner:EXXONMOBIL UPSTREAM RES CO

In-Situ Kerogen Conversion and Oxidant Regeneration

InactiveUS20130161002A1Process economyEfficient productionFluid removalDrilling compositionOrganic acidKerogen

Disclosed herein are methods for extracting a kerogen-based product from subsurface shale formations. The methods utilize in-situ reactions of kerogen involving liquid phase chemistry at formation temperatures and pressures. These methods rely on chemically modifying the shale-bound kerogen to render it mobile, using chemical oxidants. In the methods disclosed herein an oxidant is provided to the subsurface shale formation comprising kerogen in an inorganic matrix, the oxidant converting the kerogen to form organic acids, and forming a mobile kerogen-based product. The spent oxidant is regenerated in-situ to restore at least some of the original oxidation activity. At least a portion of the mobile kerogen-based product is recovered. The kerogen-derived product can be upgraded to provide commercial products.

Owner:CHEVROU USA INC

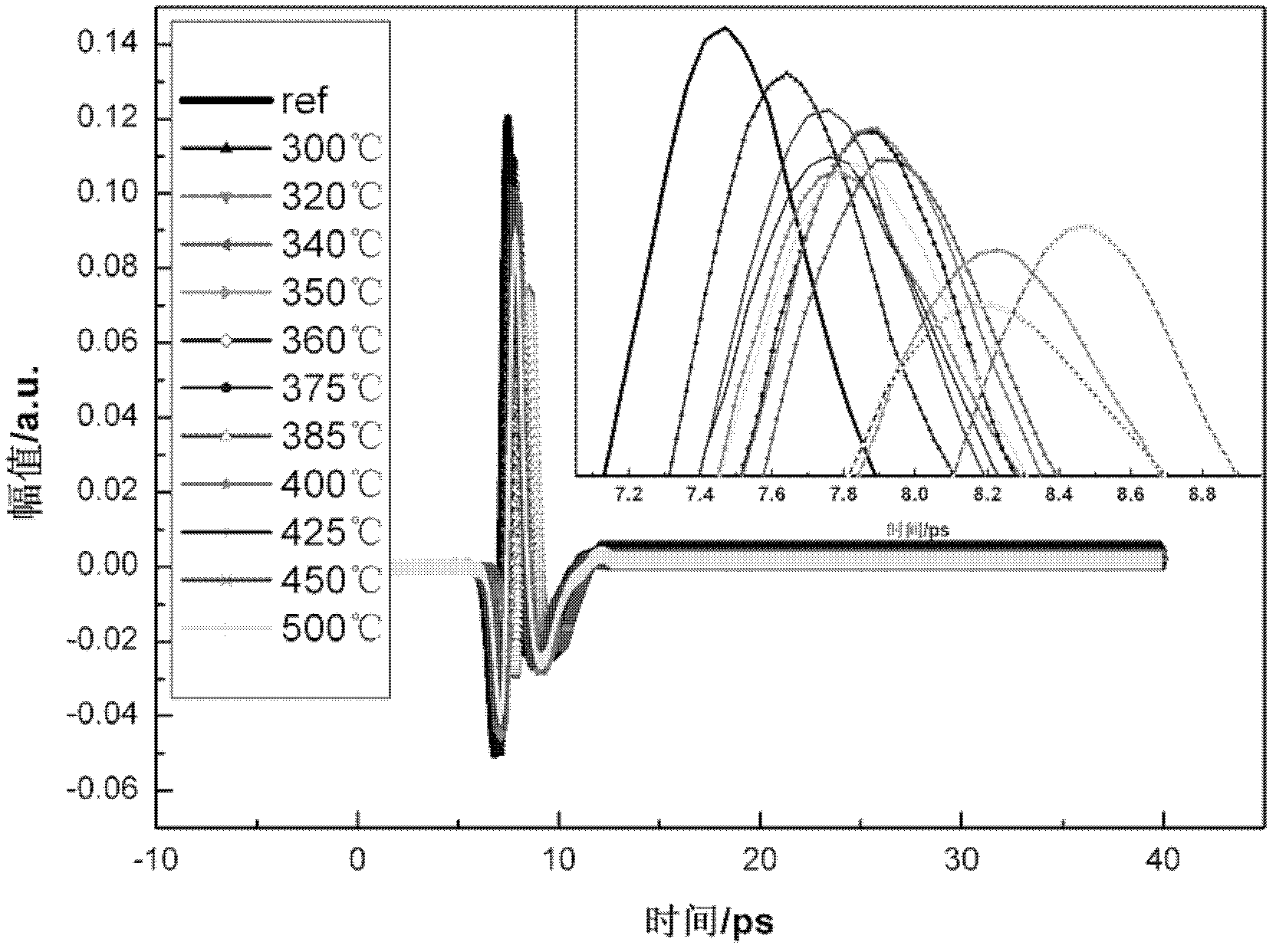

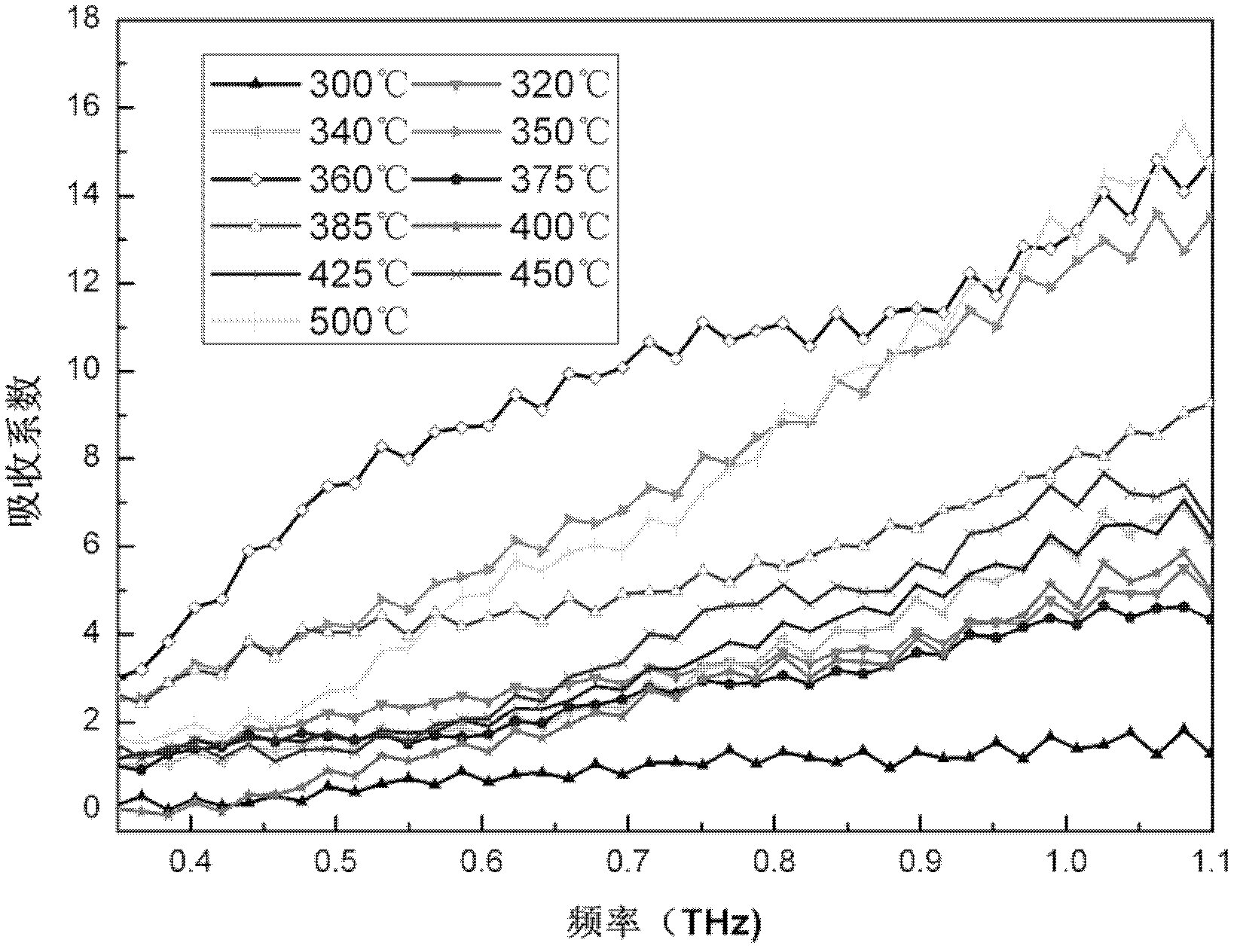

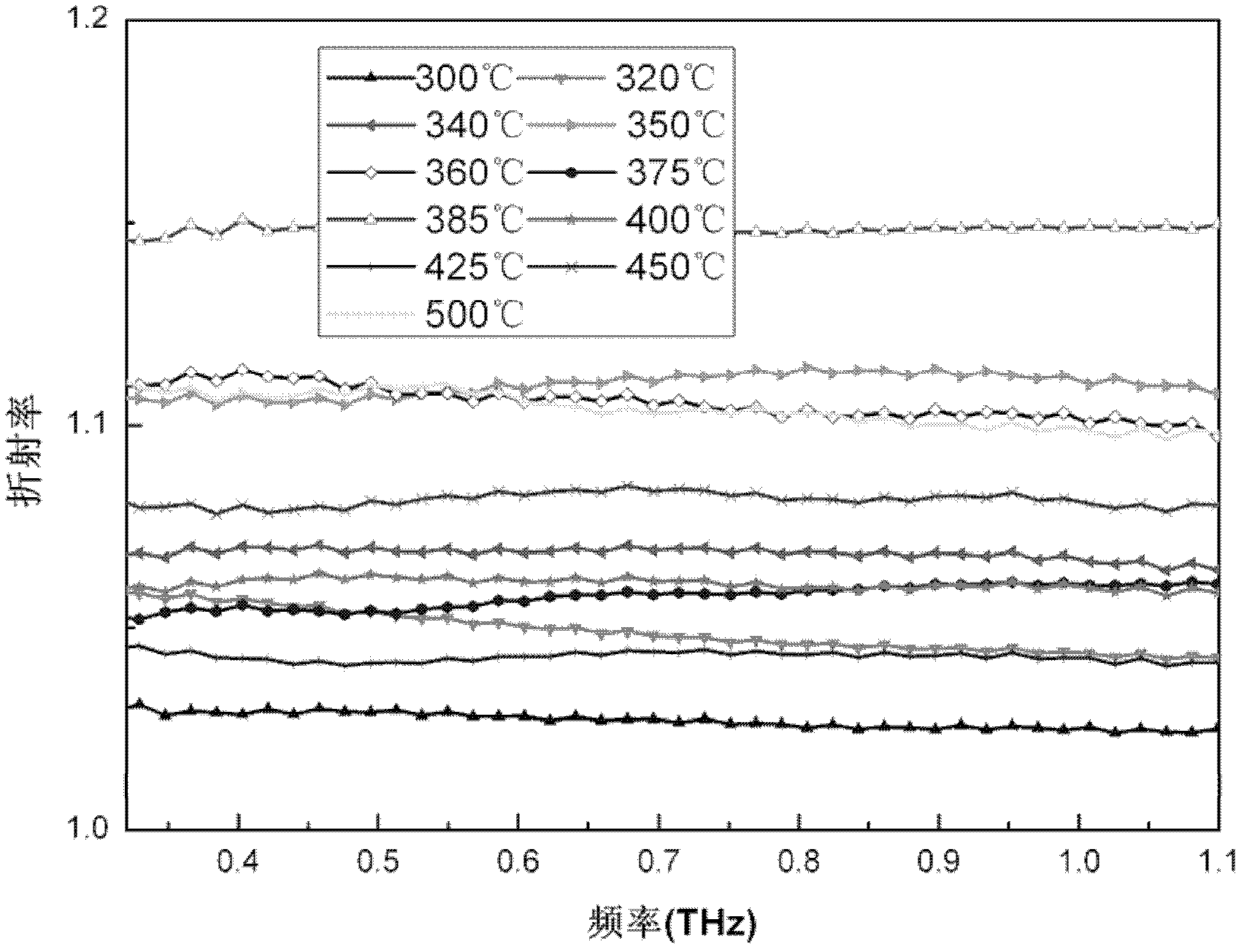

Nondestructive testing analytical method for kerogen based on terahertz time-domain spectroscopy

InactiveCN102353646AFast NDTEasy to operatePreparing sample for investigationColor/spectral properties measurementsKerogenTerahertz pulse

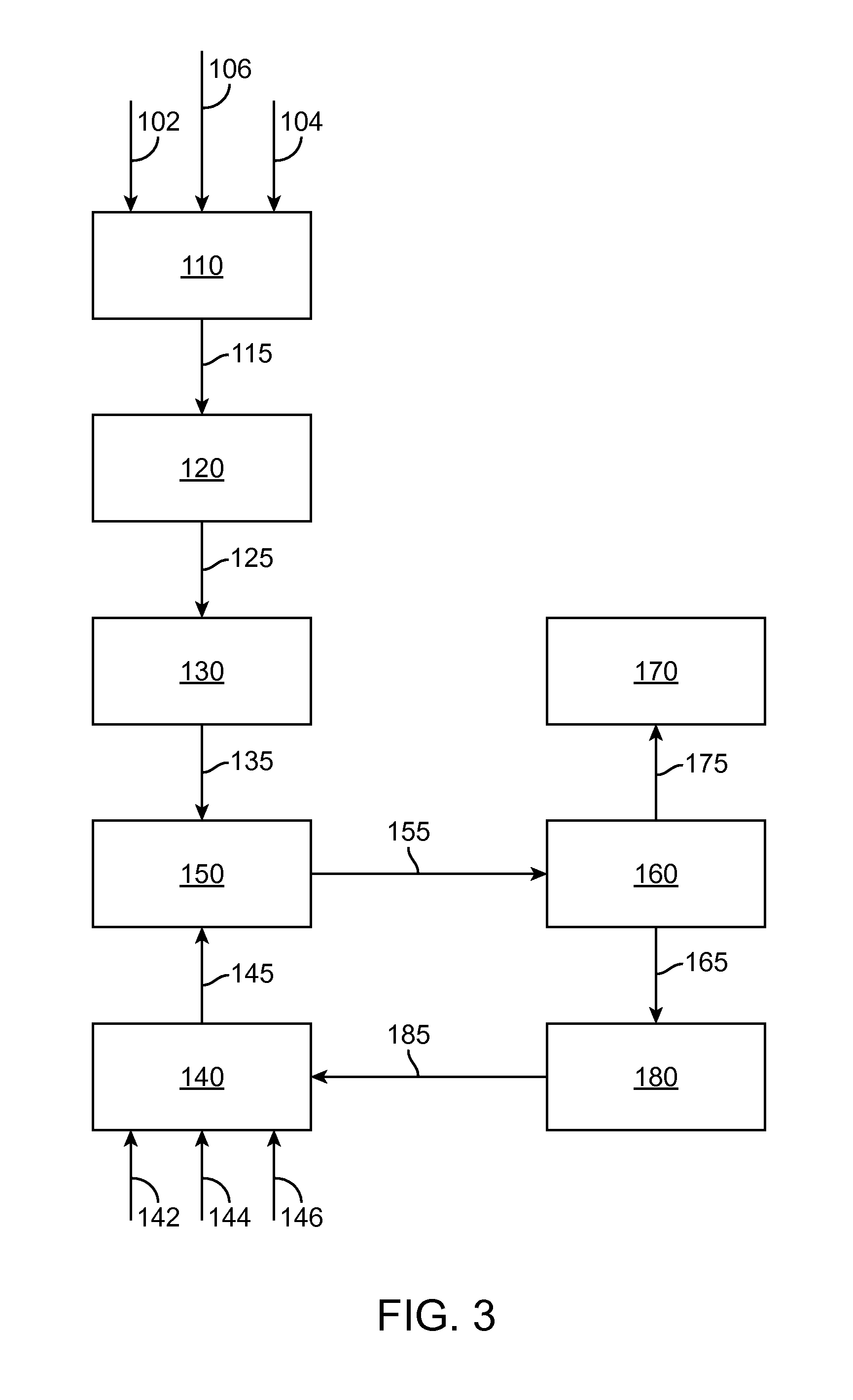

The invention relates to a nondestructive testing analytical method for kerogen based on terahertz time-domain spectroscopy. The method comprises the following steps of: firstly, selecting a sample cell; secondly, preparing a kerogen standard sample and accommodating the kerogen standard sample in the sample cell; thirdly, detecting the kerogen standard sample and the empty sample cell by using the terahertz time-domain spectroscopy to obtain a terahertz pulse time-domain waveform of the kerogen standard sample and a terahertz pulse time-domain waveform of the empty sample cell; fourthly, carrying out data processing on the terahertz pulse time-domain waveform of the kerogen standard sample and the terahertz pulse time-domain waveform of the empty sample cell to construct a standard fingerprint spectrum library; and fifthly, analyzing the thermal evolution and hydrocarbon generating capabilities of the kerogen standard sample according to optical parameters of the standard fingerprint spectrum library. The nondestructive testing analytical method for the kerogen based on the terahertz time-domain spectroscopy which is disclosed by the invention has the advantages of quick and nondestructive detection for the kerogen, easiness in operation, simpleness in data processing, favorable repeatability and relatively accurate measuring result.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

In-situ method of fracturing gas shale and geothermal areas

InactiveUS20070107901A1Promote recoveryOther heat production devicesGeothermal energy generationKerogenShale gas

A method is provided for in-situ production of oil shale, gas via gas (methane) hydrates and gas shale, and steam via geothermal formations wherein a network of fractures is formed by injecting liquified gases into at least one substantially horizontally disposed fracturing borehole. Thereafter, heat can be applied to liquefy the kerogen or to dissociate the gas (methane) hydrates so that oil shale oil and / or gases can be recovered from the fractured formations.

Owner:MAGUIRE JAMES Q

In-situ kerogen conversion and oxidant regeneration

InactiveUS8851177B2More environmentally benignProcess economyFluid removalDrilling compositionKerogenOrganic acid

The invention relates to methods for extracting a kerogen-based product from subsurface shale formations. The methods utilize in-situ reactions of kerogen involving liquid phase chemistry at formation temperatures and pressures. These methods rely on chemically modifying the shale-bound kerogen to render it mobile, using chemical oxidants. In one embodiment, an oxidant is provided to the subsurface shale formation comprising kerogen in an inorganic matrix, the oxidant converting the kerogen to form organic acids, and forming a mobile kerogen-based product. The spent oxidant is regenerated in-situ to restore at least some of the original oxidation activity. At least a portion of the mobile kerogen-based product is recovered. The kerogen-derived product can be upgraded to provide commercial products.

Owner:CHEVROU USA INC

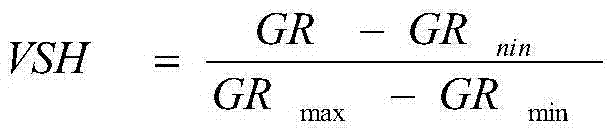

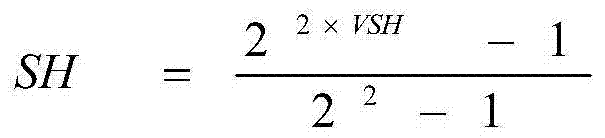

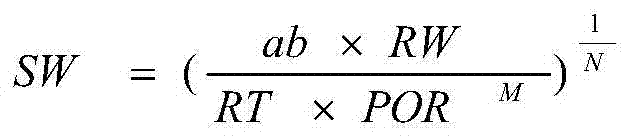

Shale gas physical geography quick evaluation method

InactiveCN104500049AEasy to mineSolve the very inconvenient problem of miningInformaticsInstrumentsKerogenWell logging

The invention discloses a shale gas physical geography quick evaluation method. The geologic factors of production of shale gas are as follow: clay, kerogen, porosity, water saturation and permeability, and according to the above geologic factors, evaluation calculation with different models is performed: in the conventional well logging interpretation, the content of clay is calculated by a uranium-free gamma ray curve; the formation of kerogen is mostly in the reduction environment with relatively high content of the radioactive element U, so that a peak appears in the natural gamma ray curve, and as the density of kerogen is relatively low, TOC is integrally calculated with several methods; the value of porosity is calculated by a neutron-density crossplot, and the amount of minerals in rock can also be calculated through correction of the crossplot; the water saturation is calculated by the Archie's formula; and the permeability is calculated according to regression of porosity, and only the shale segment reservoir bed is subjected to regression. The shale gas physical geography production factors can be quickly and accurately calculated, and the results are accurate.

Owner:CHENGDU CHUANGYUAN OIL & GAS TECH DEV

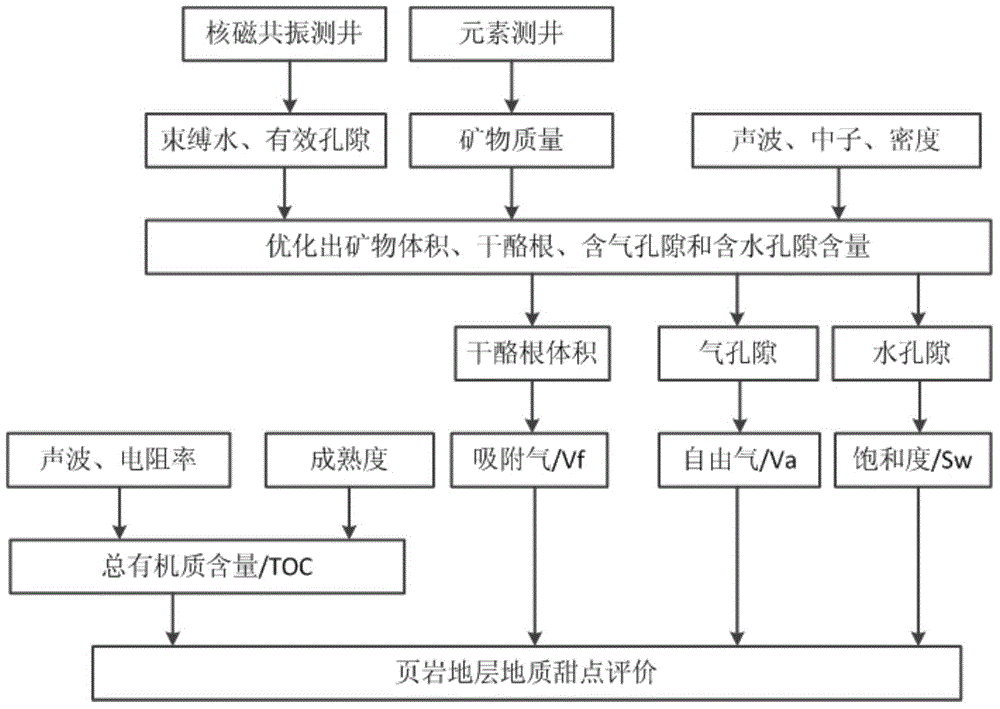

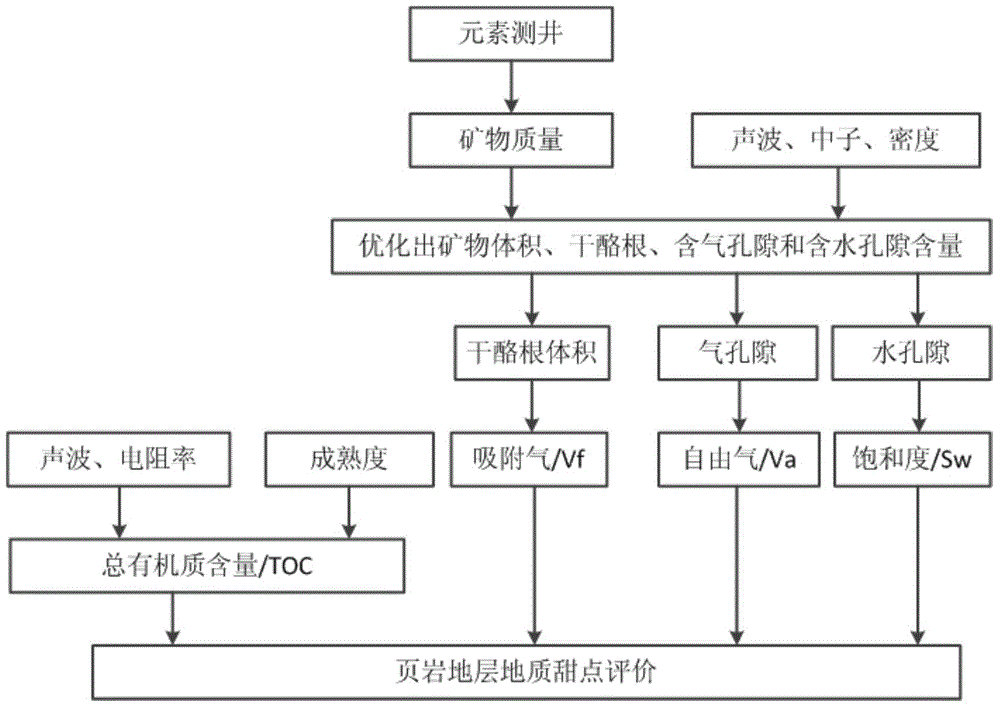

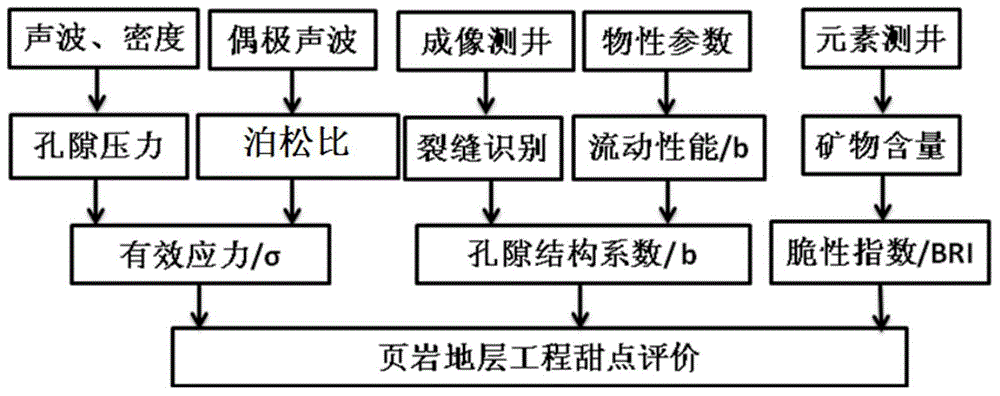

Method for recognizing sweet spots in shale stratum

ActiveCN105986816AFull consideration of integrityConsider completenessBorehole/well accessoriesPorosityKerogen

The invention discloses a method for recognizing sweet spots in a shale stratum. The method includes the following steps that the kerogen volume content, the gas-bearing porosity, the gas saturation and the total organic content of the shale stratum are determined according to logging information, and the geological sweet spot coefficient of the shale stratum is obtained through a radar map analyzing method; the maximum horizontal effective stress value, the pore structure index and the brittleness index of the shale stratum are determined according to the logging information, and the engineering sweet spot coefficient of the shale stratum is obtained through the radar map analyzing method; and the sweet spots in the shale stratum are recognized according to the geological sweet spot coefficient and the engineering sweet spot coefficient. According to the method, the geological sweet spots and the engineering sweet spots in the shale stratum are quantitatively represented according to the geological sweet spot coefficient and the engineering sweet spot coefficient, and the sweet spots in the shale stratum can be determined through comprehensive analysis of the two coefficients; and the development cost can be lowered by exploration and development in sweet spot areas, and the development efficiency of shale gas is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com