Patents

Literature

1275 results about "Pressure - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

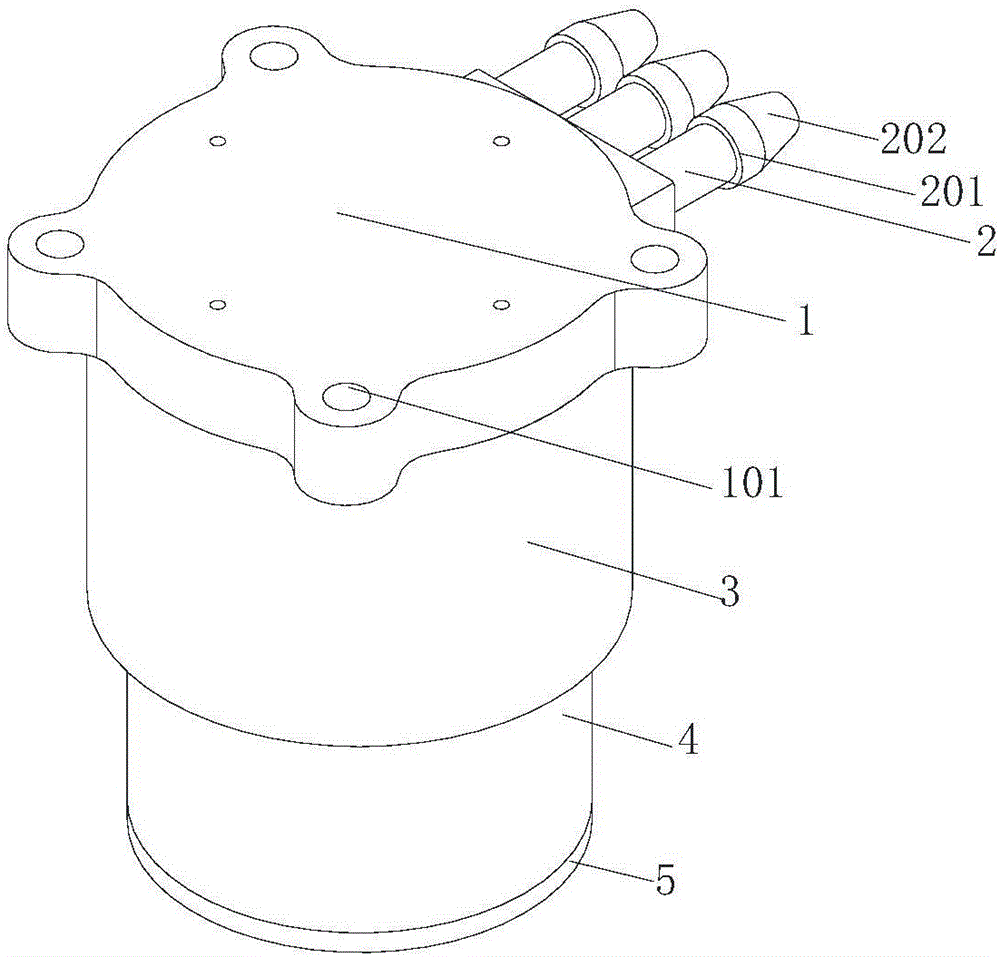

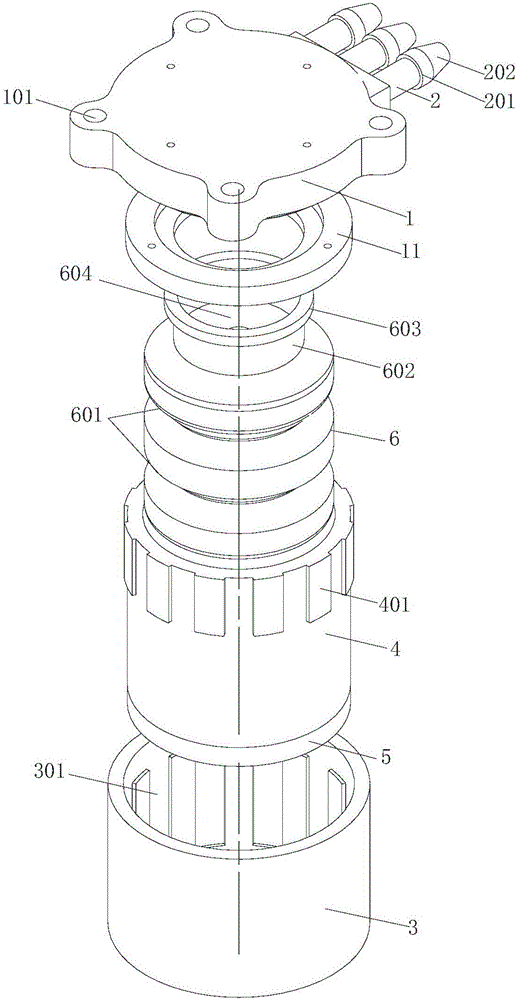

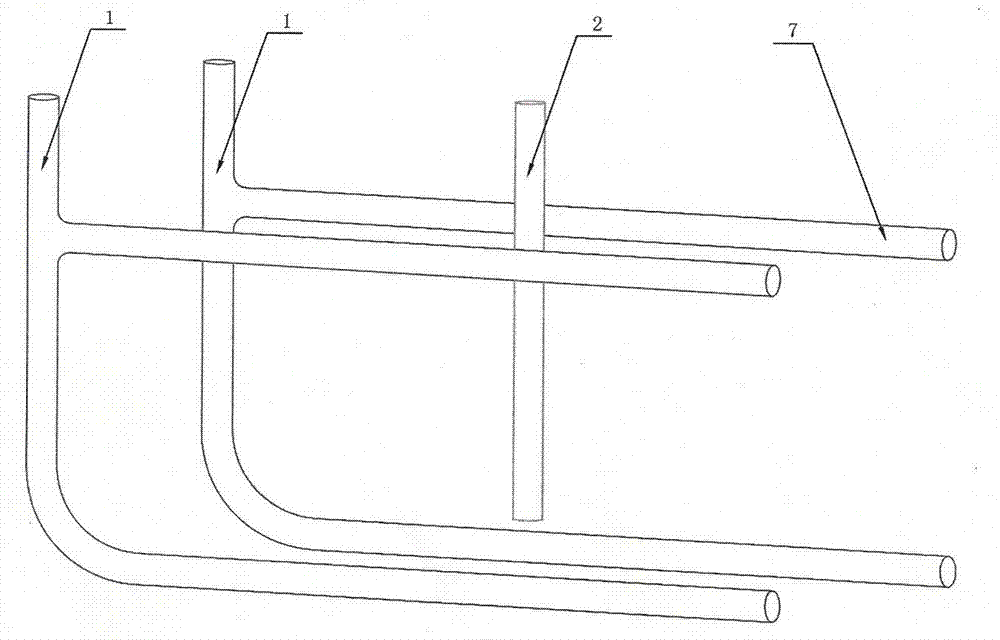

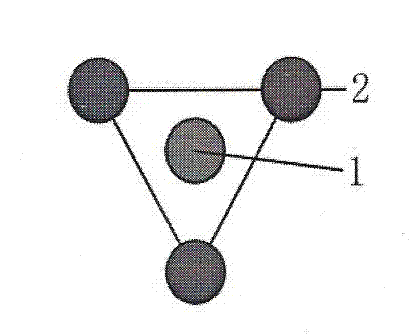

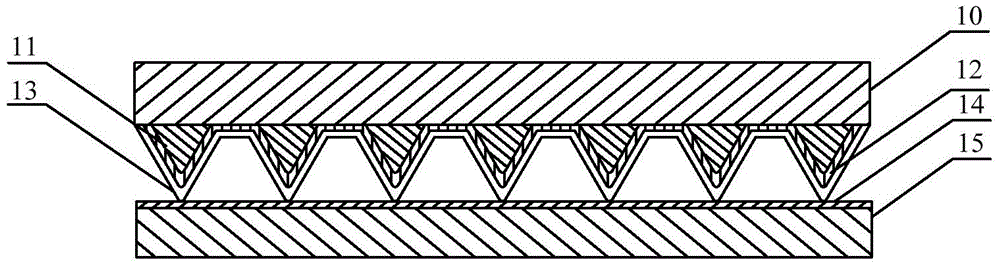

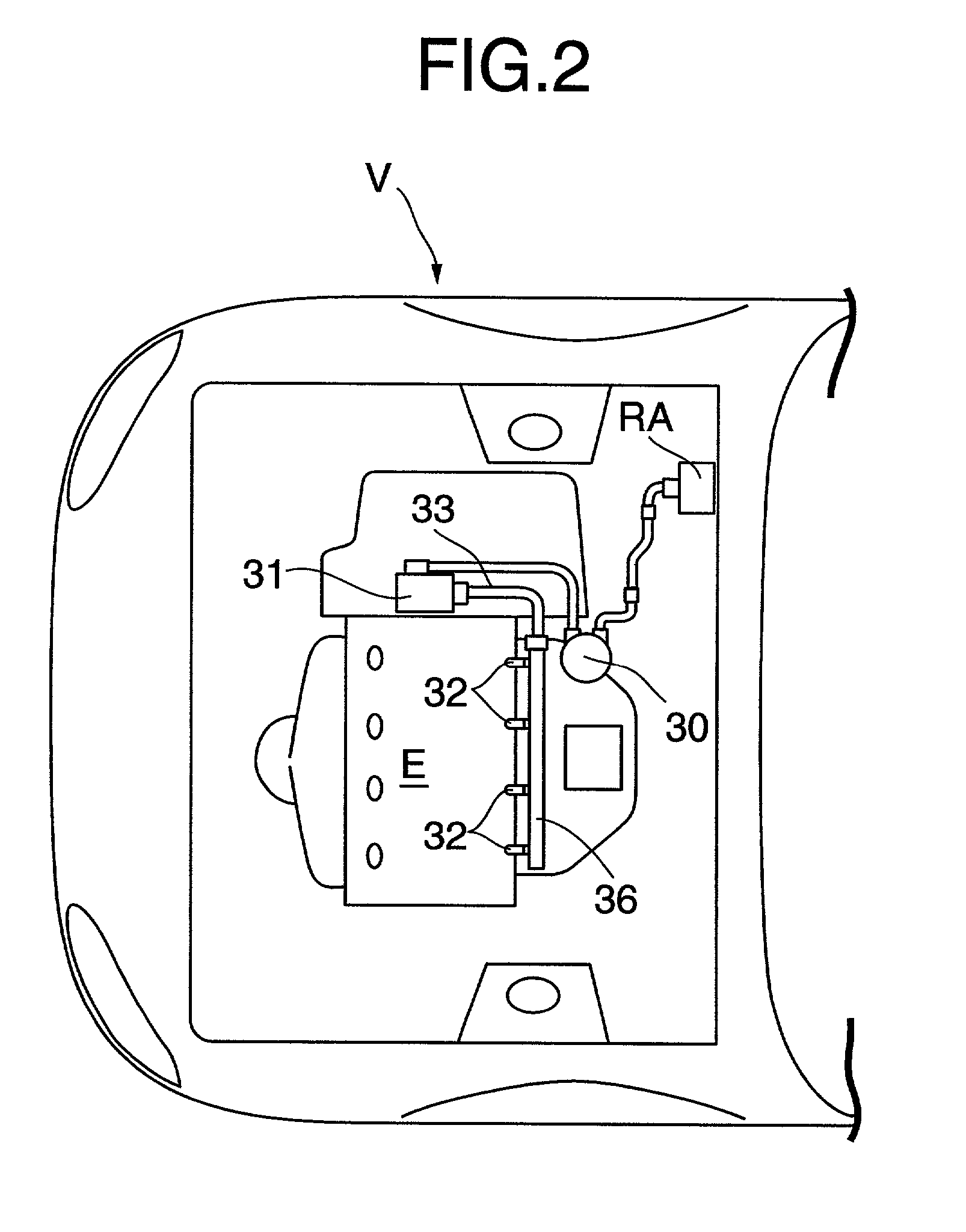

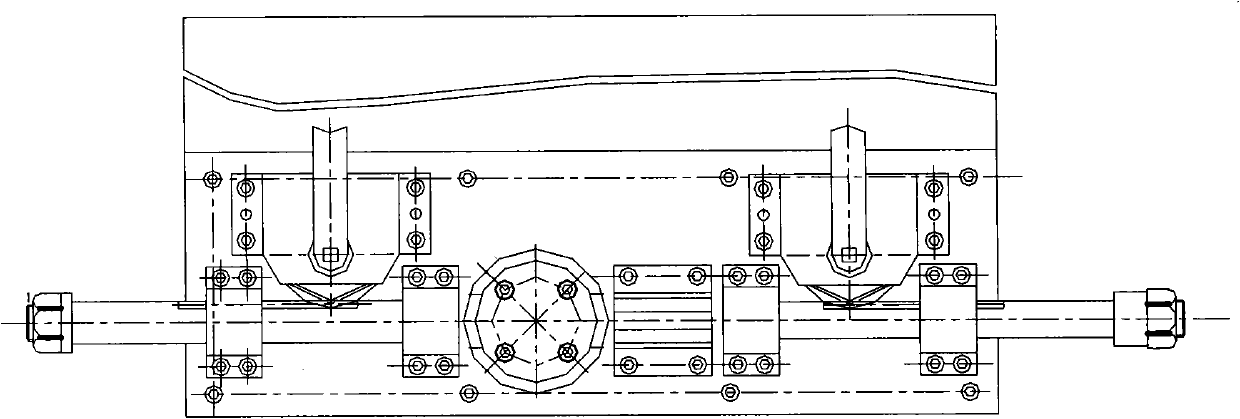

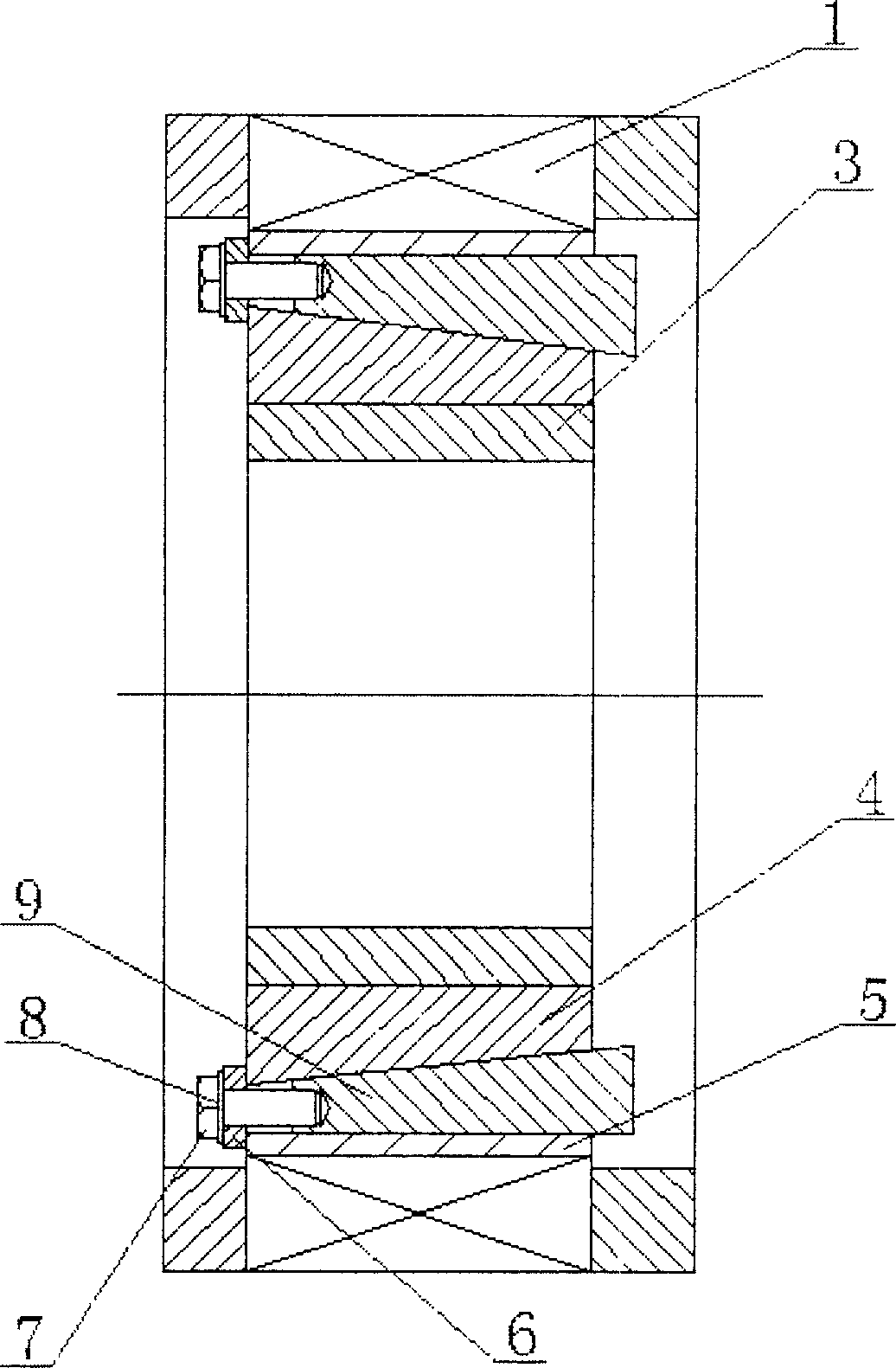

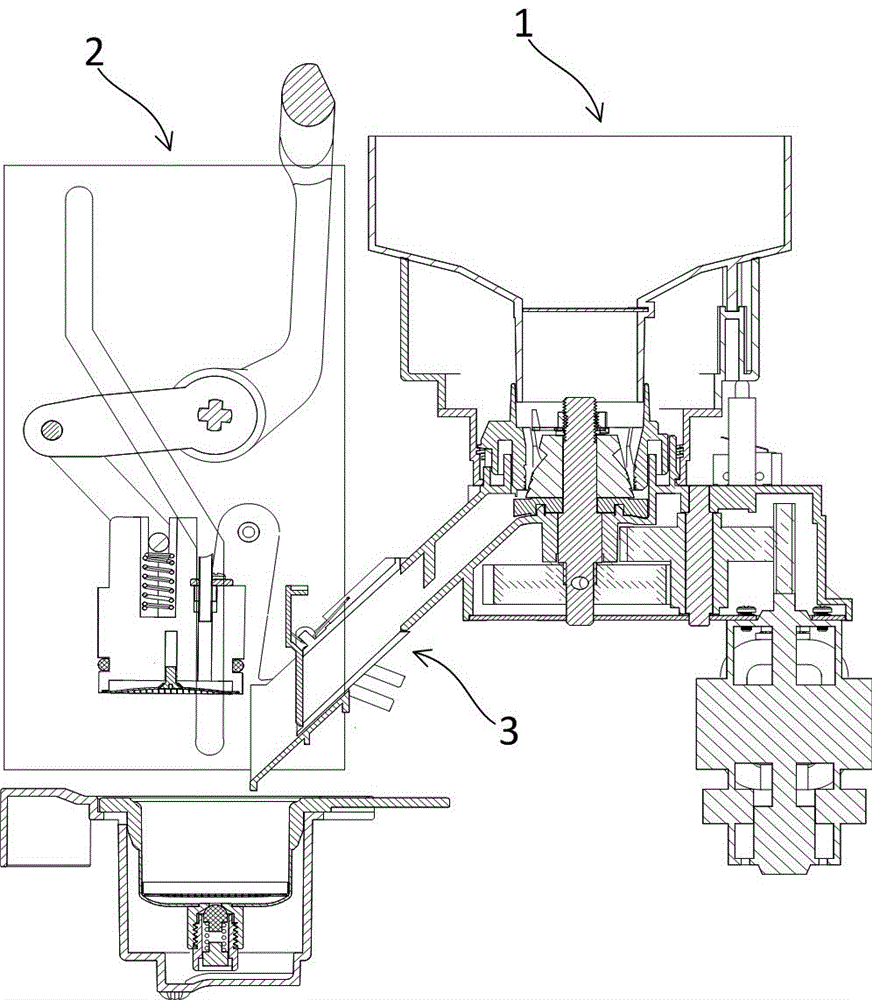

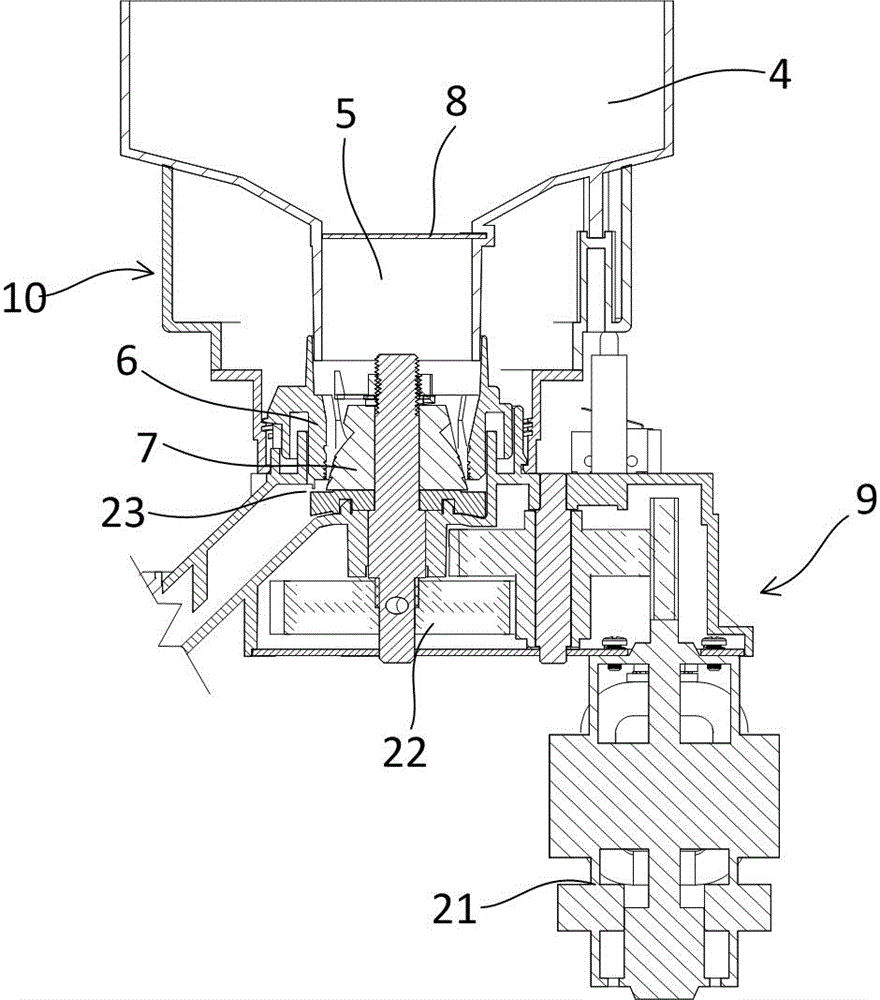

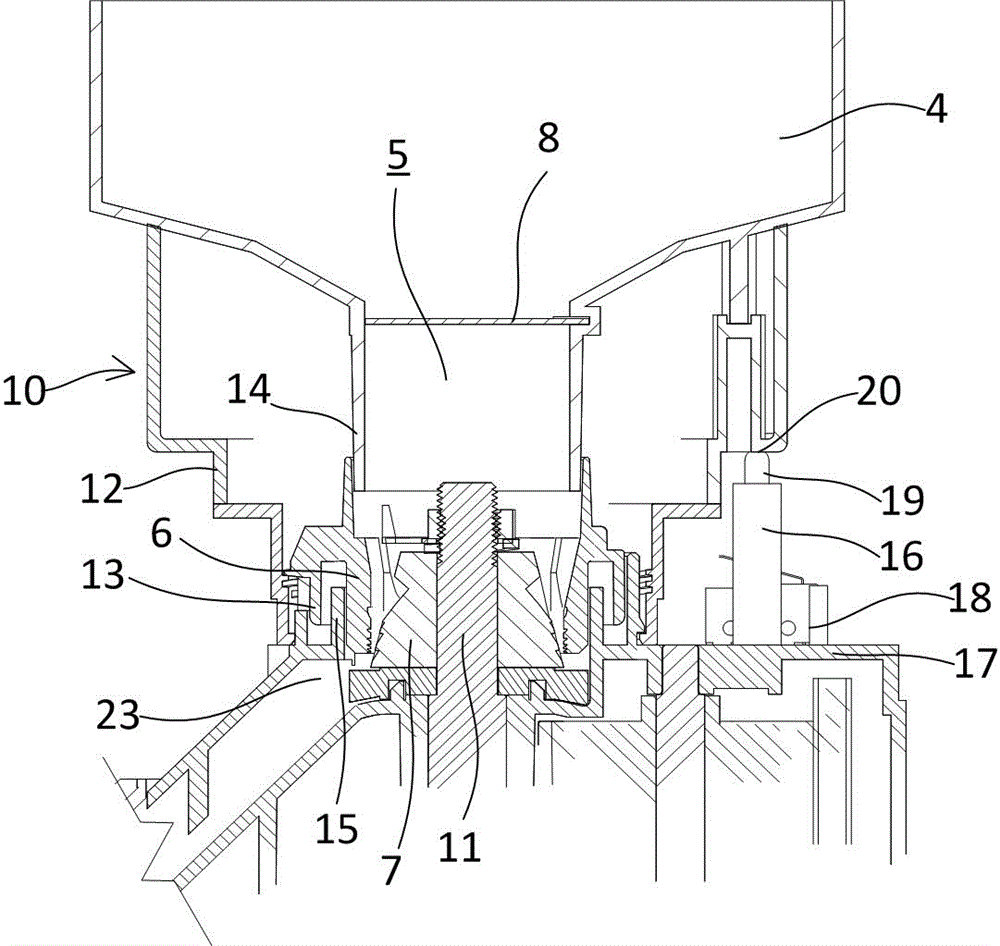

Washing machine feet with automatic levelling function and washing machine

ActiveCN105755757ALarge adjustment rangeEasy to adjustMachine framesOther washing machinesLaundry washing machineLiquid medium

The invention provides washing machine feet with an automatic levelling function and a washing machine. The bottom of the washing machine is provided with the multiple feet; each foot comprises a fixed part and a moving part, a hollow chamber is formed between each fixed part and the corresponding moving part, and each hollow chamber is filled with a hydraulic medium; every two related feet are mutually connected by a high-pressure oil pipe, so that the hollow chambers of the two feet are mutually communicated, or all the feet are respectively connected to a communicating device by high-pressure oil pipes, so that the hollow chambers of all the feet are mutually communicated; under the action of pressure, the hydraulic medium can flow among the mutually-communicated hollow chambers of the feet to enable the moving parts to stretch and retract, and automatic levelling is performed. The washing machine feet with the automatic levelling function has the advantages that according to a hydraulic principle, each foot is filled with the hydraulic medium, and is enabled to perform adaptive adjustment because of the fluidity of the hydraulic medium under different pressures, the hydraulic medium can flow among the feet, the adjustment range is bigger, and the effect is better.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

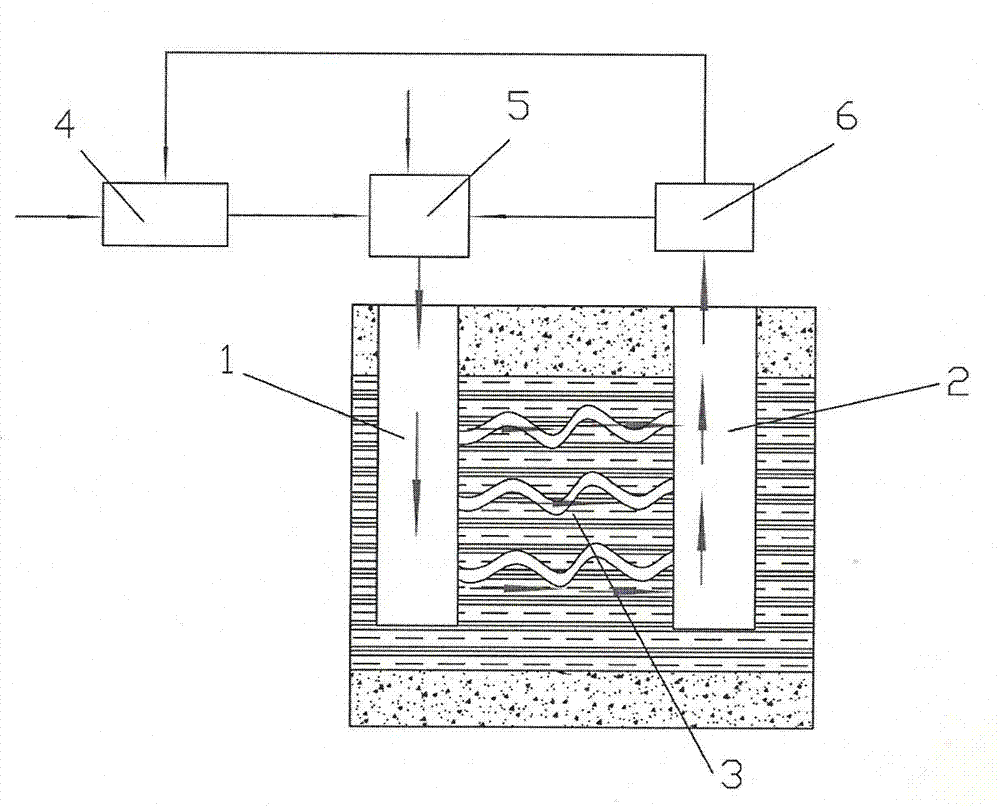

Method for extracting shale oil and gas from oil shale in situ

The invention discloses a method for extracting shale oil and gas from oil shale in situ. The method comprises the steps that hot nitrogen is injected into an oil shale layer to crack kerogen in situ; after being extracted and separated, combustible gas which is generated initially is injected into a well together with the nitrogen by a certain proportion to have chemical reaction with the oil shale, so as to further crack organic substances in the oil shale, and extract shale oil and combustible gas; the hot nitrogen is an inert gas which is not only a carrier for transferring heat but also a carrier which carries shale oil and gas to above the ground; meanwhile, due to the pressure action of fluid, an oil and gas channel is favorably formed in the oil shale layer. The circulating combustible gas can have chemical reaction with the kerogen in the oil shale, so as to accelerate the reaction. According to the method for extracting shale oil and gas from the oil shale in situ, mining cost and risks are greatly reduced, the operability is greatly improved, problems caused by a surface dry distillation technology and an existing in-situ technology are fundamentally solved, the construction difficulty and cost are effectively reduced, and the method does not pollute underground water, is environment-friendly and is non-toxic.

Owner:JILIN UNIV +1

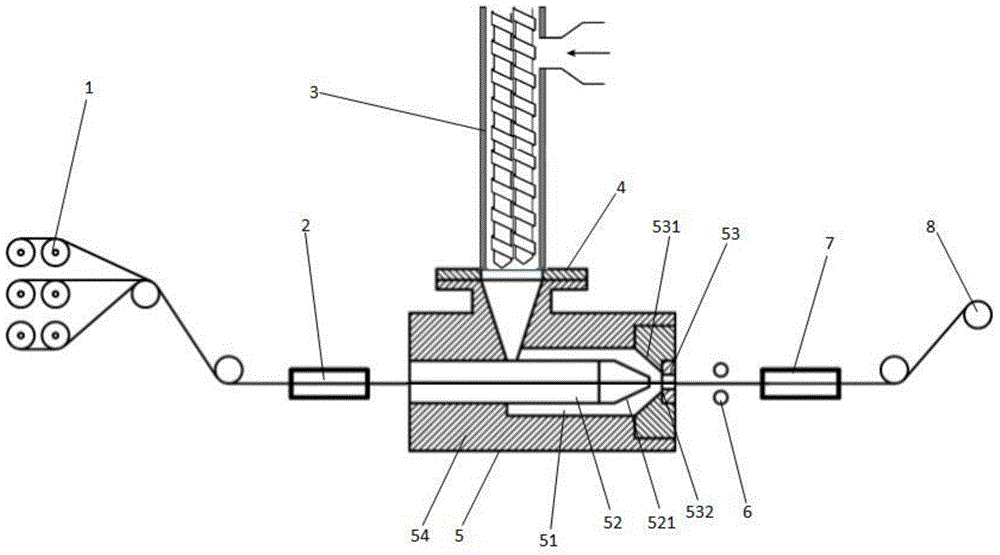

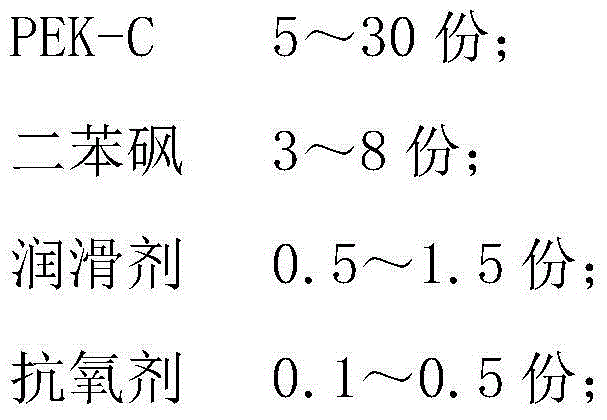

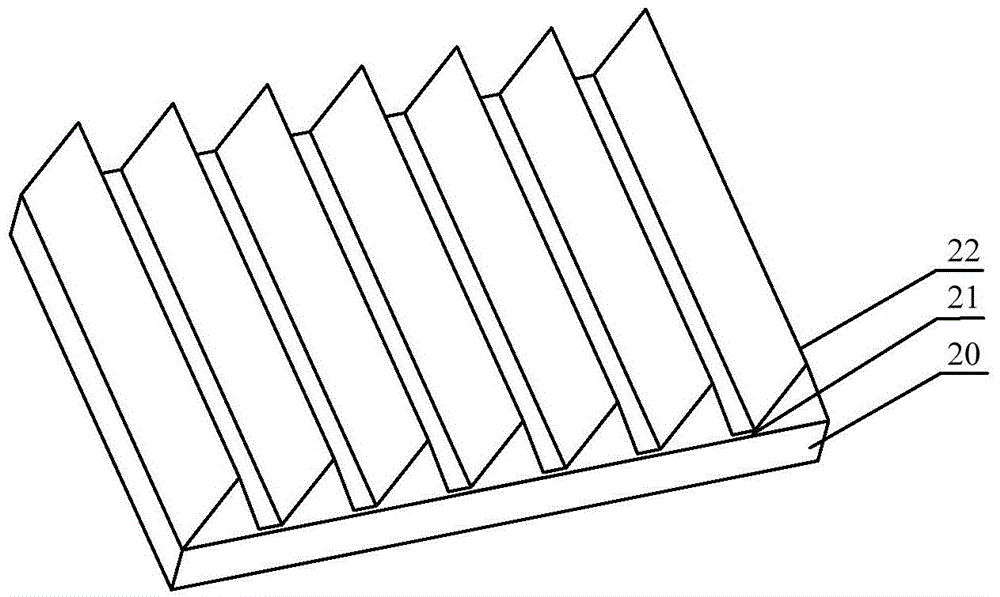

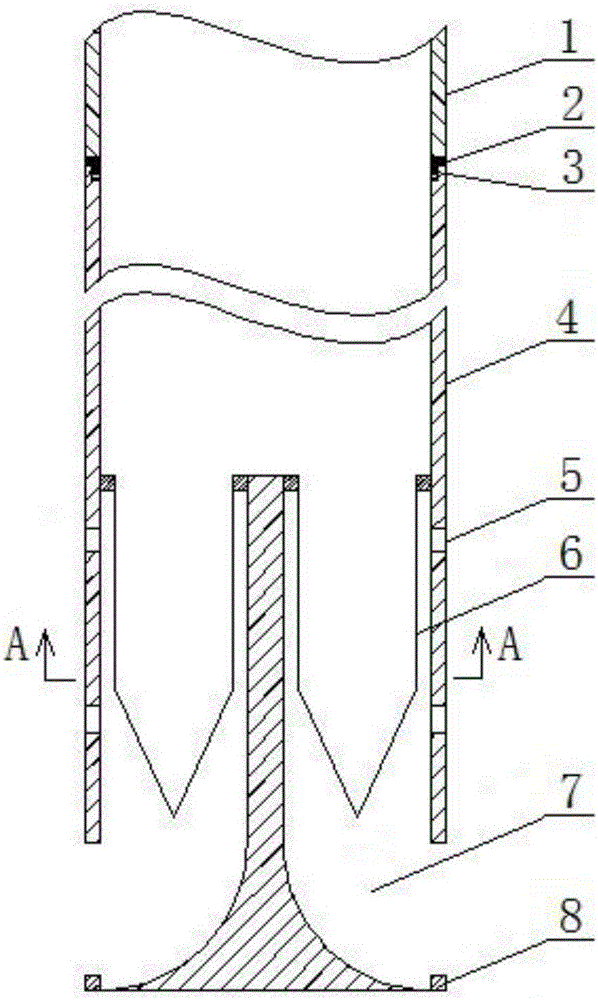

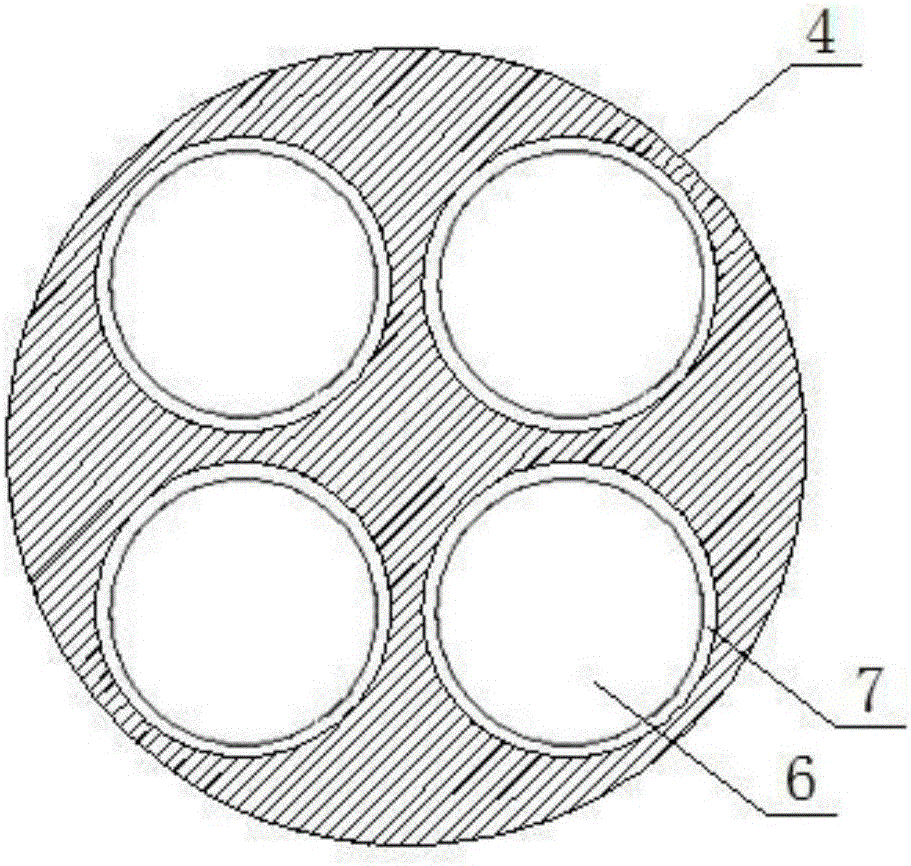

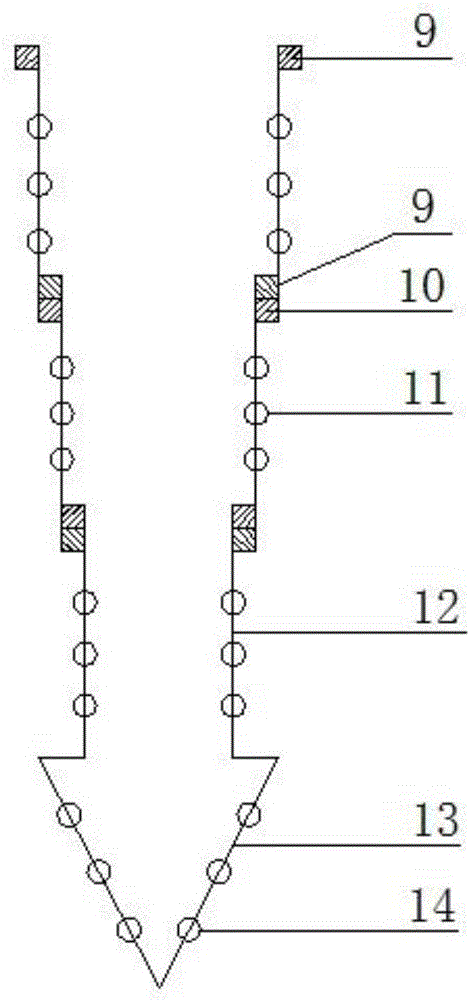

Method and equipment for preparing continuous fiber-reinforced polyether-ether-ketone composite material prepreg tape

ActiveCN104629254AGuaranteed continuous productionImprove performanceFiber bundlePolyether ether ketone

The invention discloses a method and equipment for manufacturing a continuous fiber-reinforced polyether-ether-ketone composite material prepreg tape. The method comprises the following steps: (1) splitting; (2) preheating; (3) cladding, namely, feeding the preheated continuous fiber bundle into a dipping mold to be mixed with modified PEEK resin melt extruded from a twin-screw extruder in the dipping mold, and cladding the modified PEEK resin melt on the continuous fiber bundle under the pressure action; and (4) winding. The equipment comprises a splitting device, a heating box, a material mixing device and a winding device which are arranged from left to right, wherein the material mixing device comprises the twin-screw extruder and the dipping mold; the dipping mold is connected with the twin-screw extruder and is used for cladding the resin melt flowing from a resin runner on the continuous fiber bundle under the pressure action; and the winding device is used for winding the prepreg tape which is discharged from the dipping mold. According to the method and the equipment, continuous production of the prepreg tape is ensured; blending modification and fiber dipping are integrated; the technological processes are reduced; and the efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

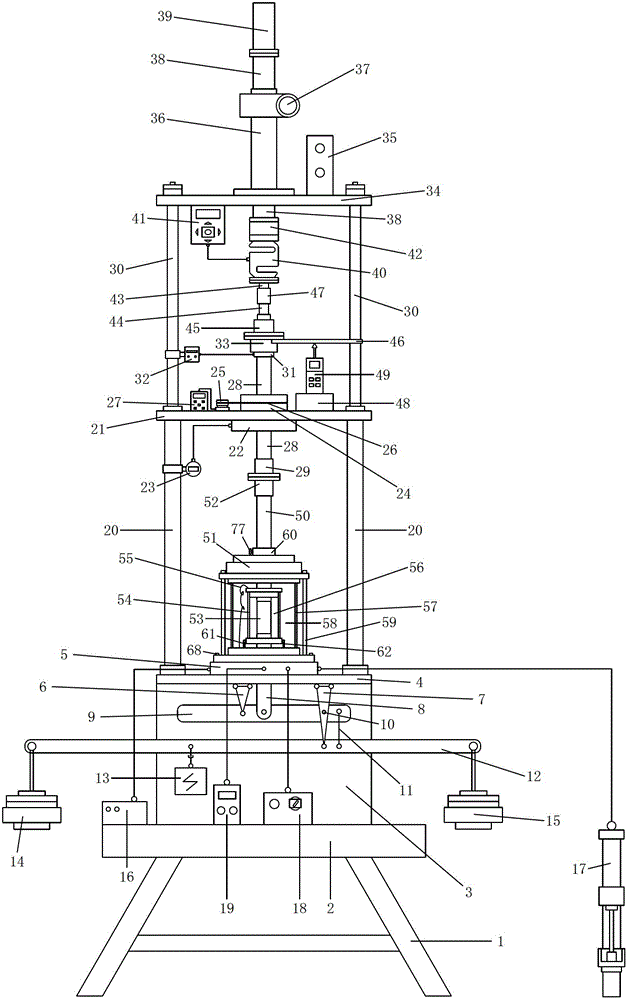

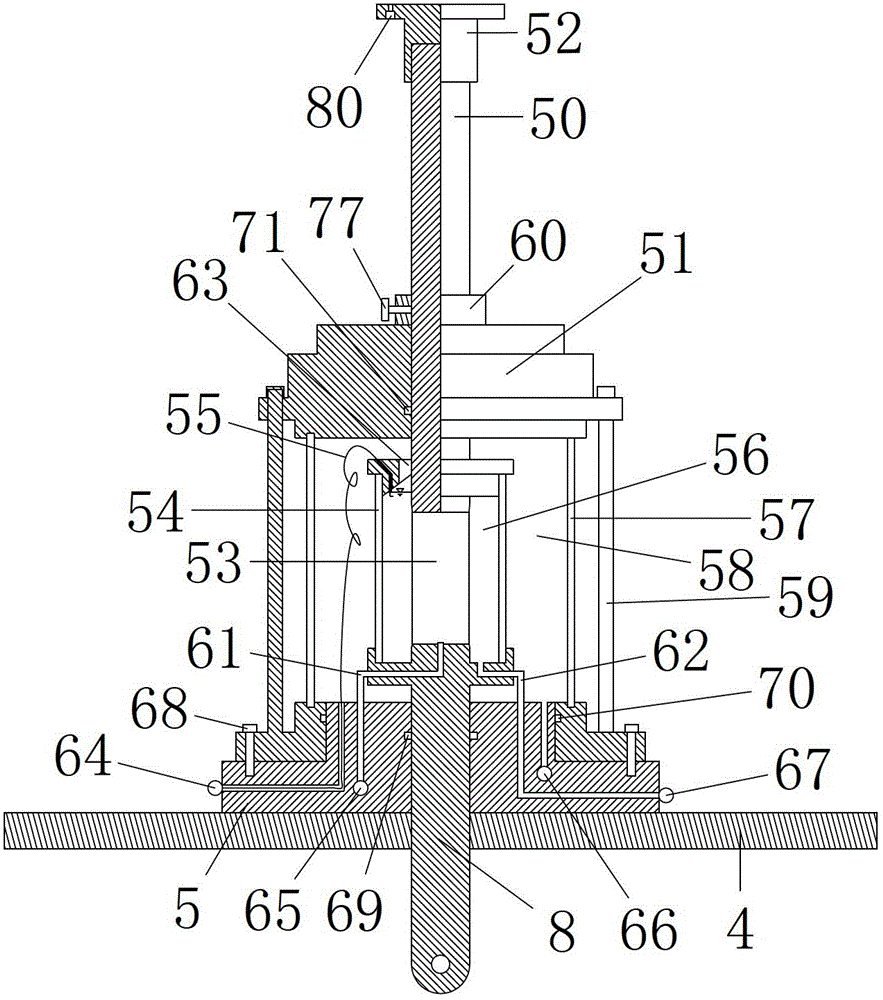

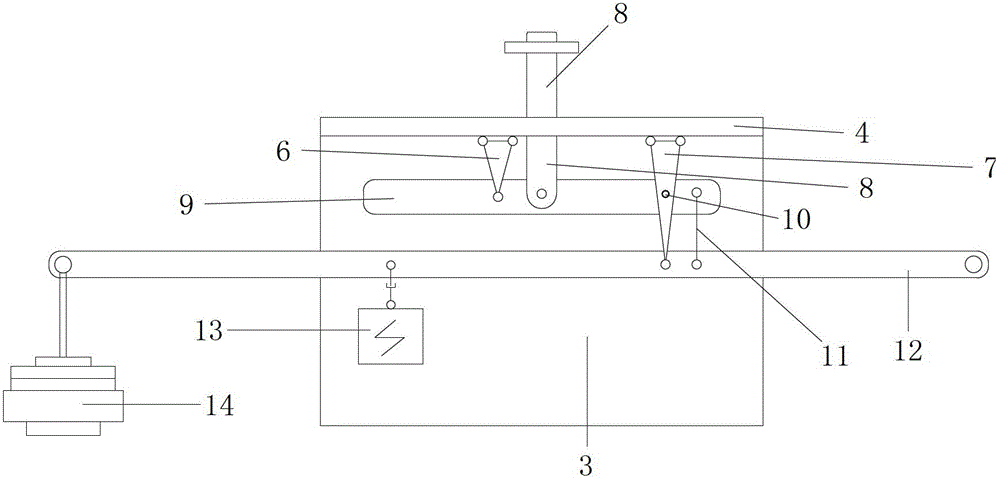

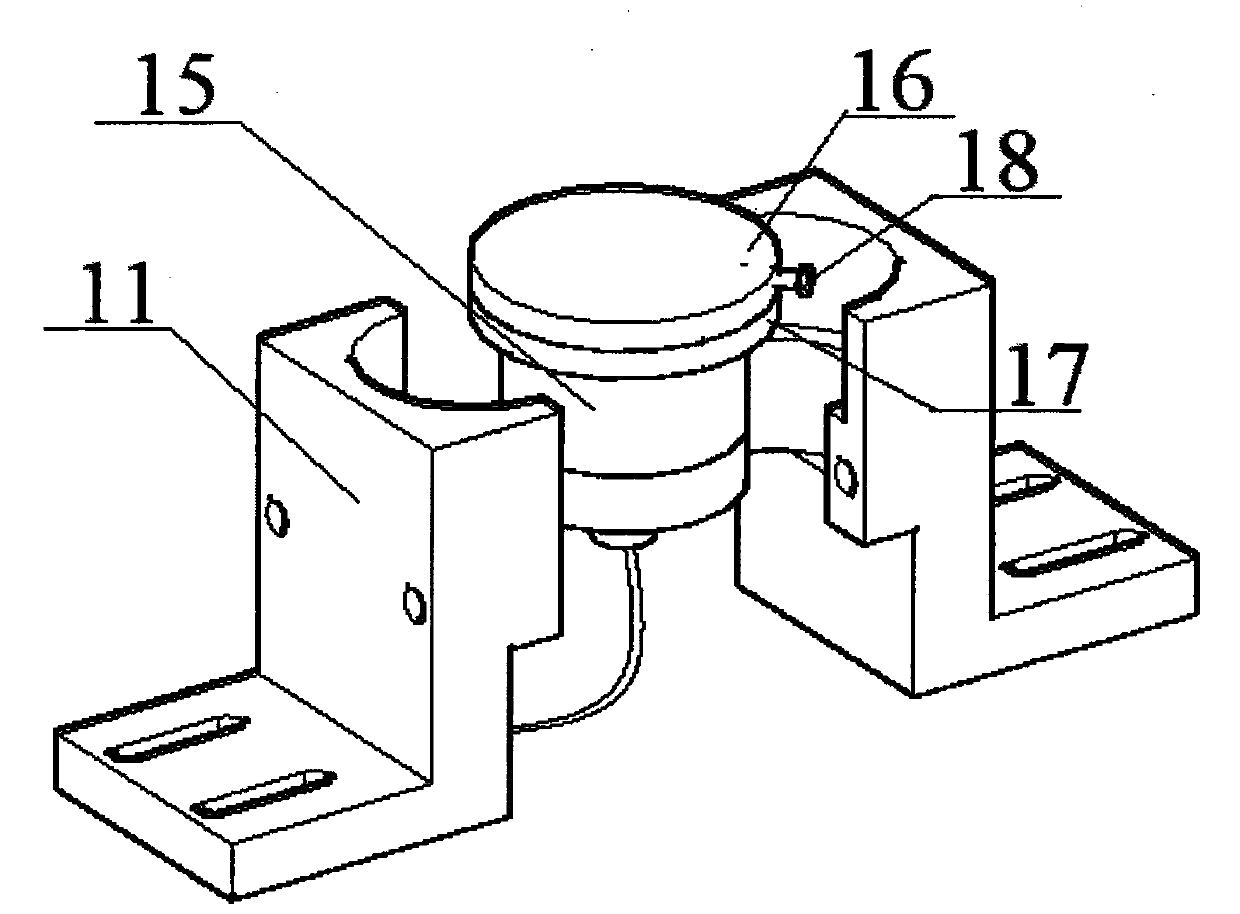

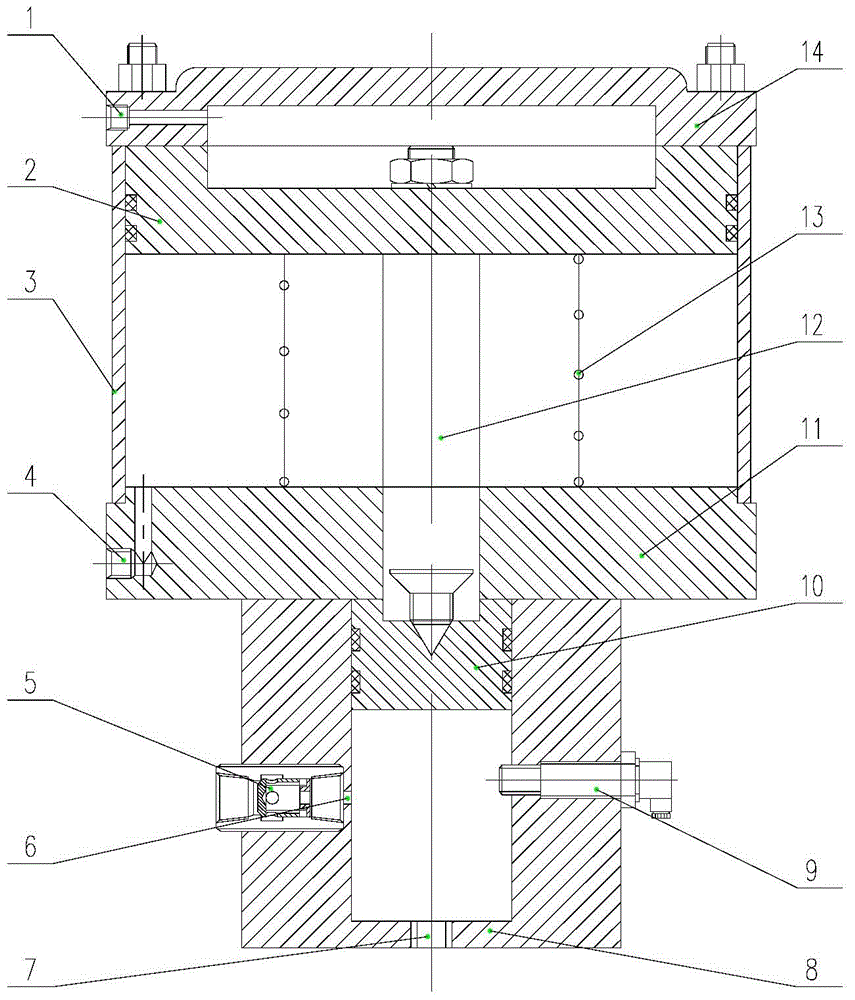

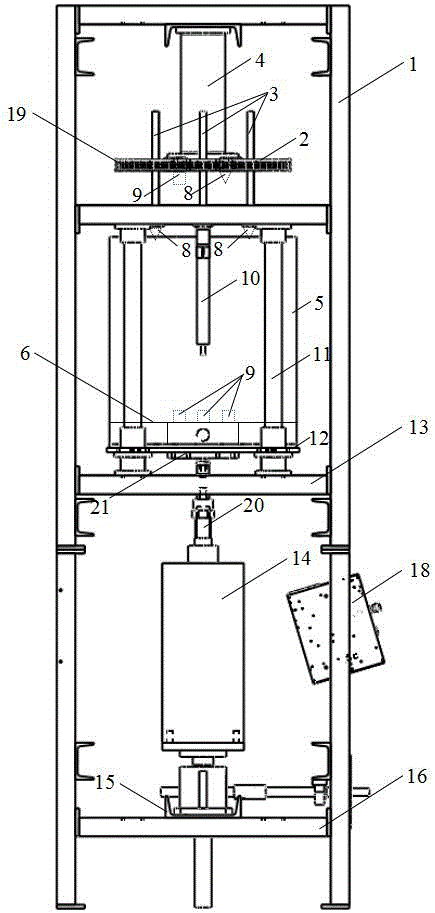

Multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions

InactiveCN103149101AStable controlCode of PracticeInvestigating material ductilityAxial displacementAmbient pressure

The invention discloses multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions, which structurally comprises a main body part, power supply equipment, an axial loading and measuring mechanism, a torque loading and measuring mechanism, a volume-changed water level controlling and measuring mechanism, an ambient pressure loading and measuring mechanism, a pore pressure measuring mechanism, a creeping and loading mechanism, an axial displacement measuring mechanism and a lubricating mechanism. A torque separator can apply any combined axial action and torque action; a multifunctional lever part not only can apply a tension action to a sample through a lever, but also can apply a pressure action to the sample through the lever; and a detachable split volume-changed measuring water jacket structure is remarkably changed on the aspect of soil body sample body-changed measurement. The machine provided by the invention is simple in structure, convenient to operate and high in accuracy rate and success rate.

Owner:XIAN UNIV OF TECH

Mixed bonding structure for three-dimension integration and bonding method for mixed bonding structure

ActiveCN102593087AAvoid circuit breakingAvoid reliabilitySemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsInterconnection

The invention relates to a mixed bonding structure for three-dimension integration and a bonding method for the mixed bonding structure. The mixed bonding structure for the three-dimension integration comprises a first substrate. The first substrate is provided with bonding interconnection metal electrically connected with the first substrate; the other end part of the bonding interconnection metal, which is correspondingly connected with the first substrate, is sunk to form a cavity; a first dielectric adhesion layer covers at the periphery of the bonding interconnection metal on the first substrate; the bonding interconnection metal is encircled by the first dielectric adhesion layer; and the first dielectric adhesion layer is lower than the edge of the bonding interconnection metal. According to the mixed bonding structure for the three-dimension integration, the first dielectric adhesion layer is lower than the edge of the top part of a salient point, and when bonding is performed under the pressure action, the edge of the top part of the salient point is bonded with a pad of a second substrate, and thereby, the dielectric adhesion layer can be stopped entering the surface of the bonding interconnection metal, which is bonded with the pad, and the open circuit problem and the reliability problem can be avoided. The mixed bonding structure for the three-dimension integration is compact in structure and is convenient in process operation.

Owner:NAT CENT FOR ADVANCED PACKAGING

Pressure sensor based on friction power generation and pressure sensing system

ActiveCN104374498ASelf-poweredHigh precisionFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesElectromagnetic interferenceEngineering

The invention discloses a pressure sensor based on friction power generation and a pressure sensing system. The pressure sensor based on friction power generation comprises a pressure bearing component, a first elastic base body, a first structural layer, a base and a second structural layer, wherein the first elastic base body is arranged on a first side surface of the pressure bearing component and is provided with a regular protruding structure, the first structural layer covers the first elastic base body and forms a corresponding structure matched with the protruding structure of the first elastic base body, and the second structural layer is arranged on a first side surface of the base. When pressure is acted on the pressure bearing component, the first elastic base body and the first structural layer deform so as to enable the contacting area of a friction interface to be increased along with the increase of pressure, and a corresponding relation between the contacting area and output signals is utilized to enable the output signals of a signal output end to represent the intensity of pressure. The pressure sensor based on friction power generation overcomes the defect that a traditional pressure sensor is easily interfered by static electricity and electromagnetism, and has the advantages of being high in accuracy, wide in measurement range and wide in application environment.

Owner:NEWNAGY TANGSHAN

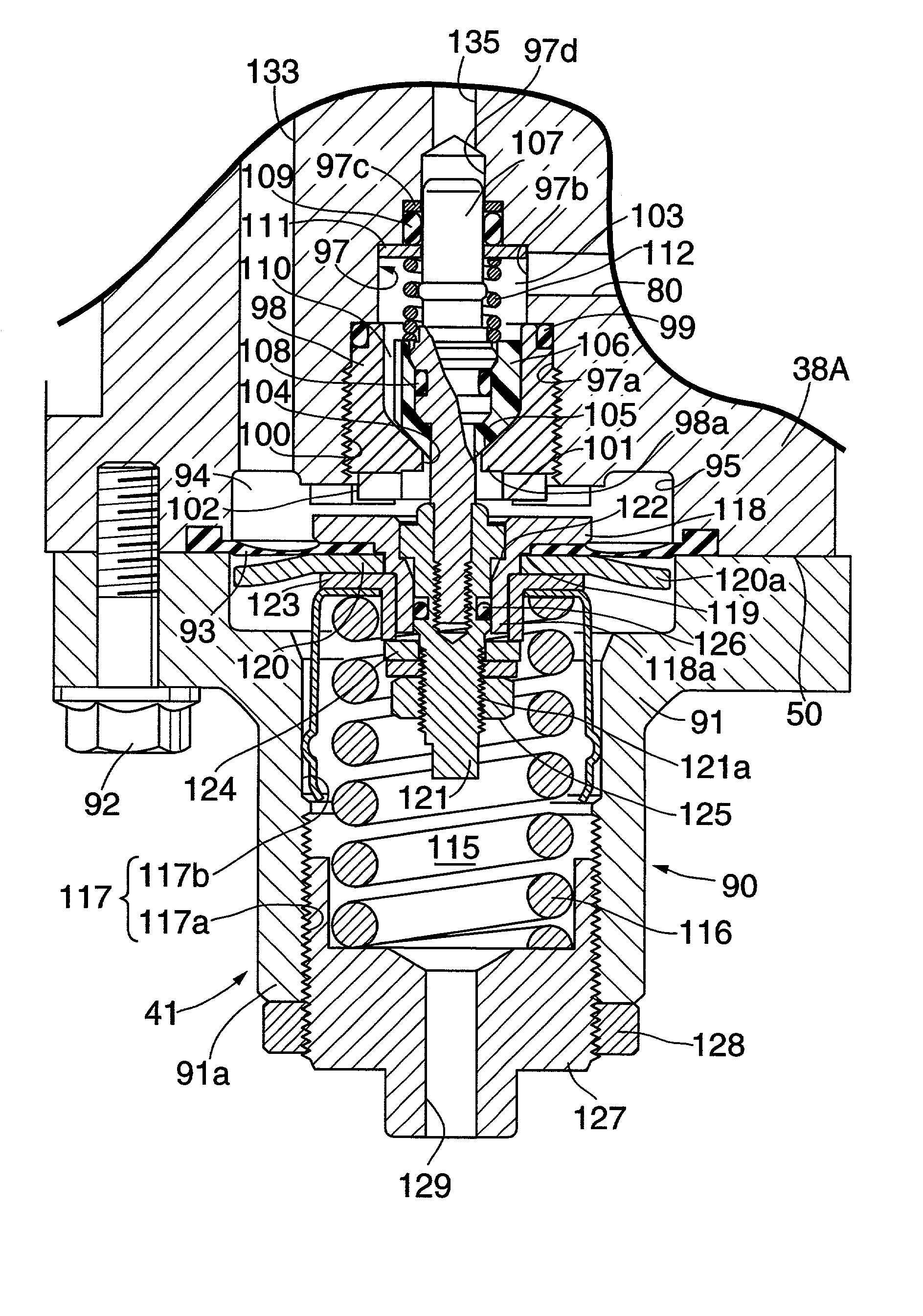

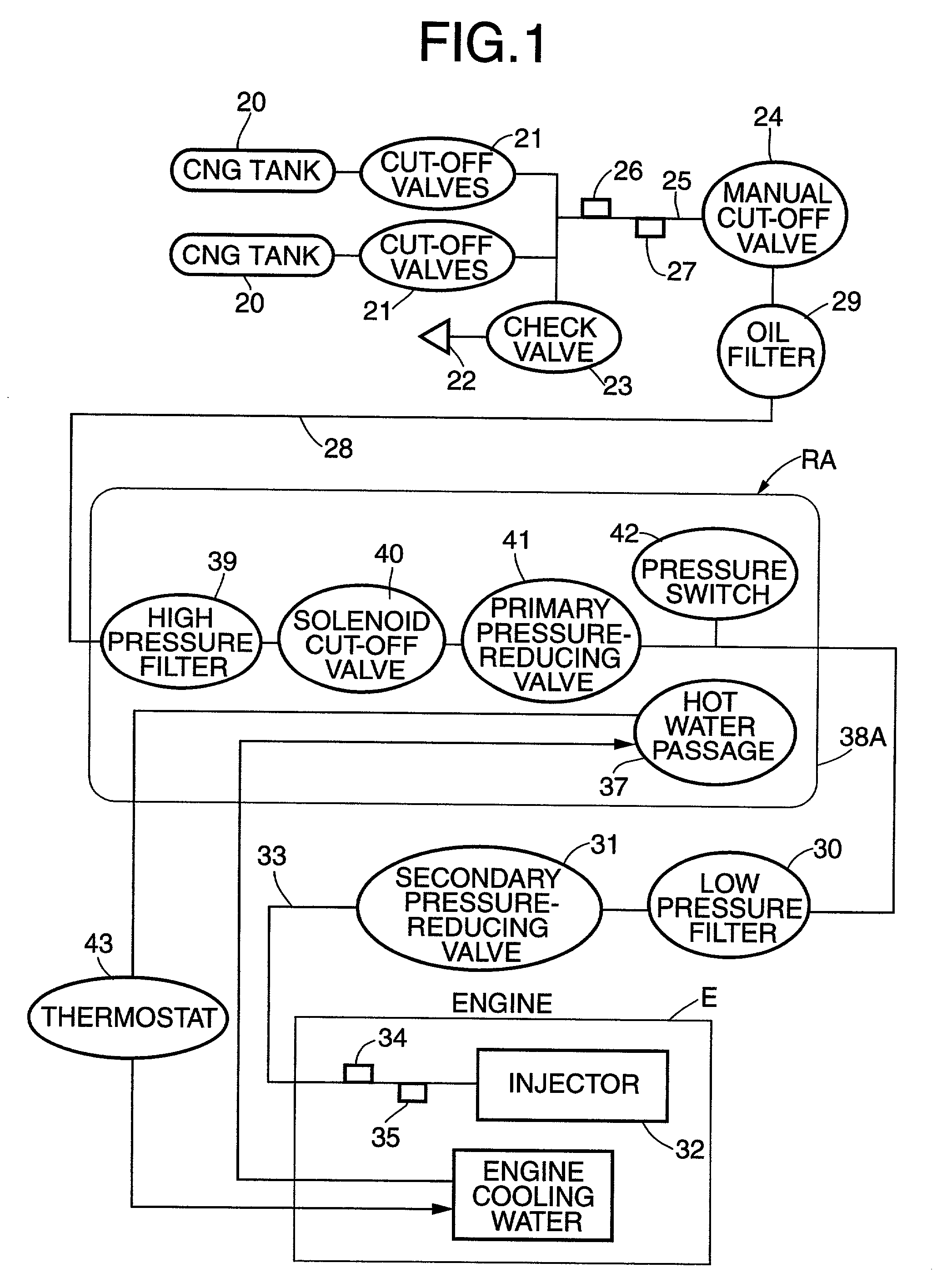

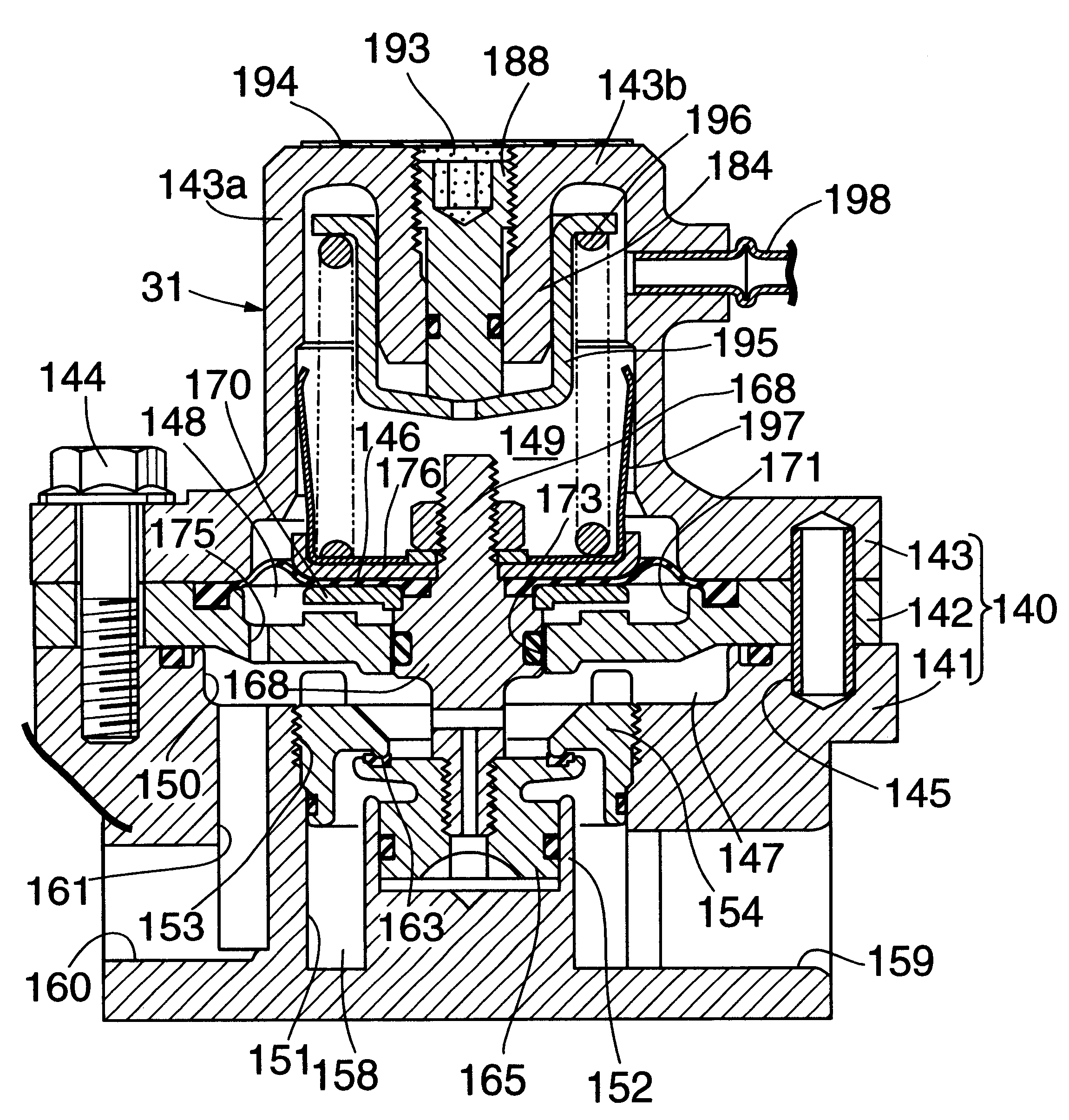

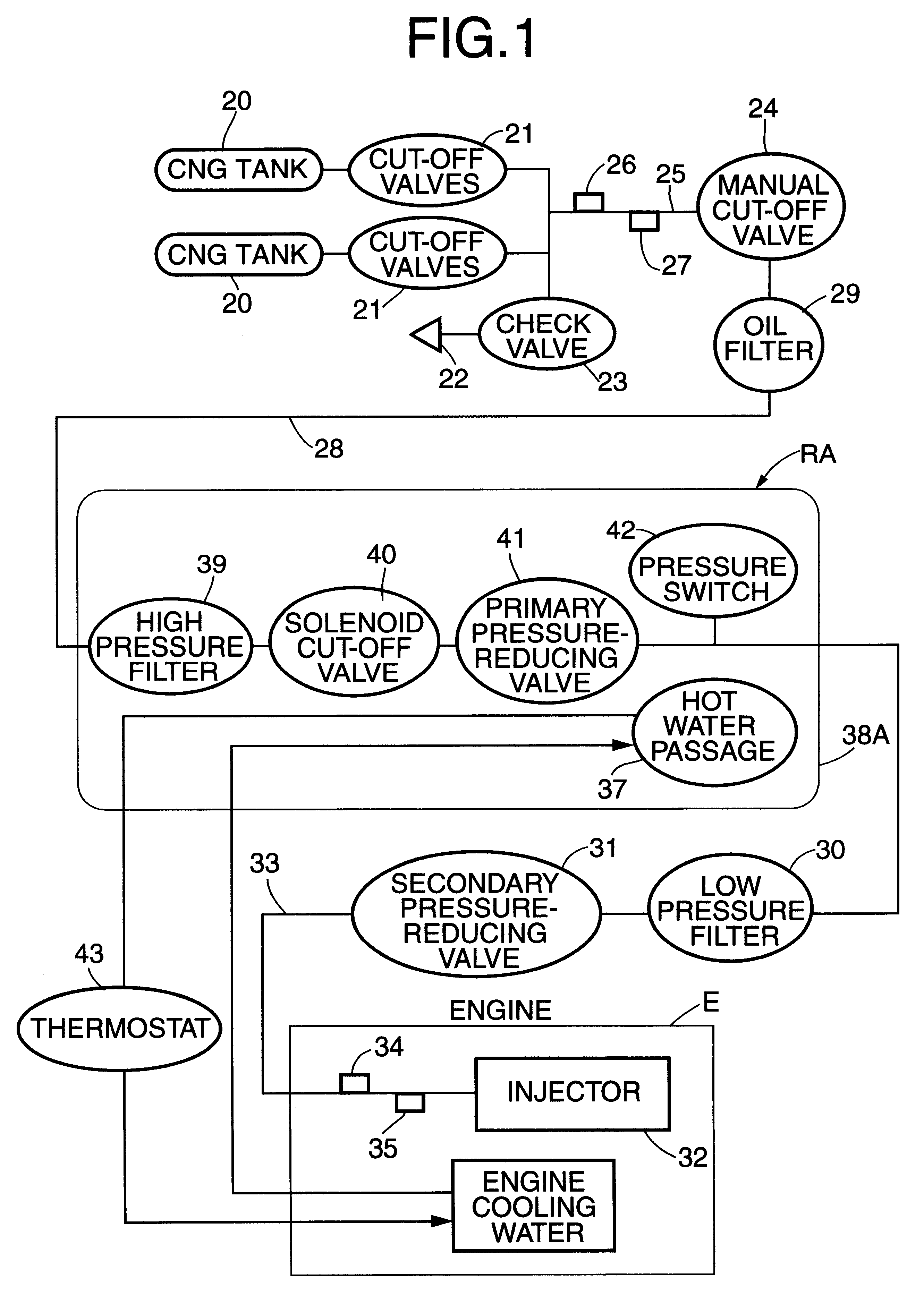

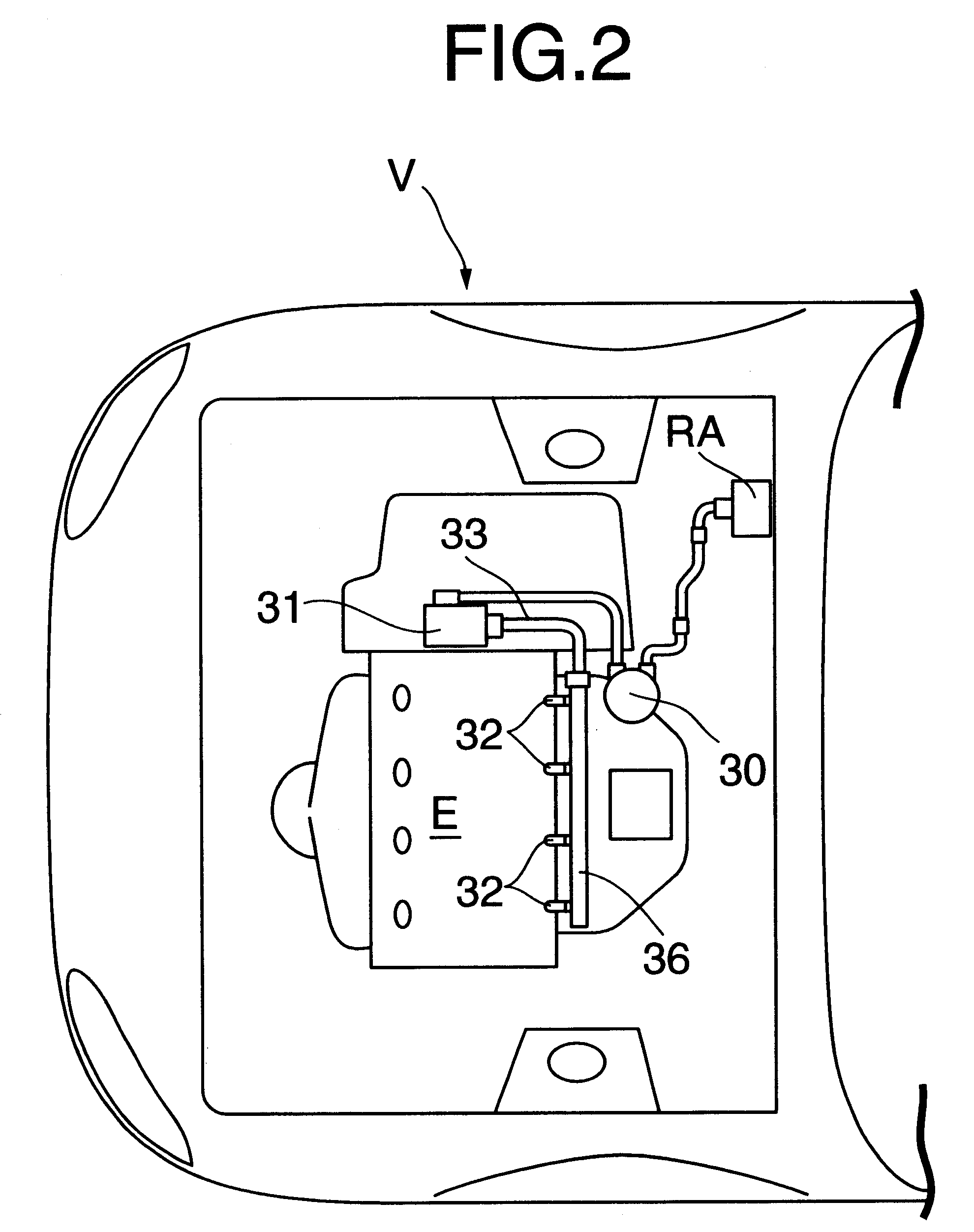

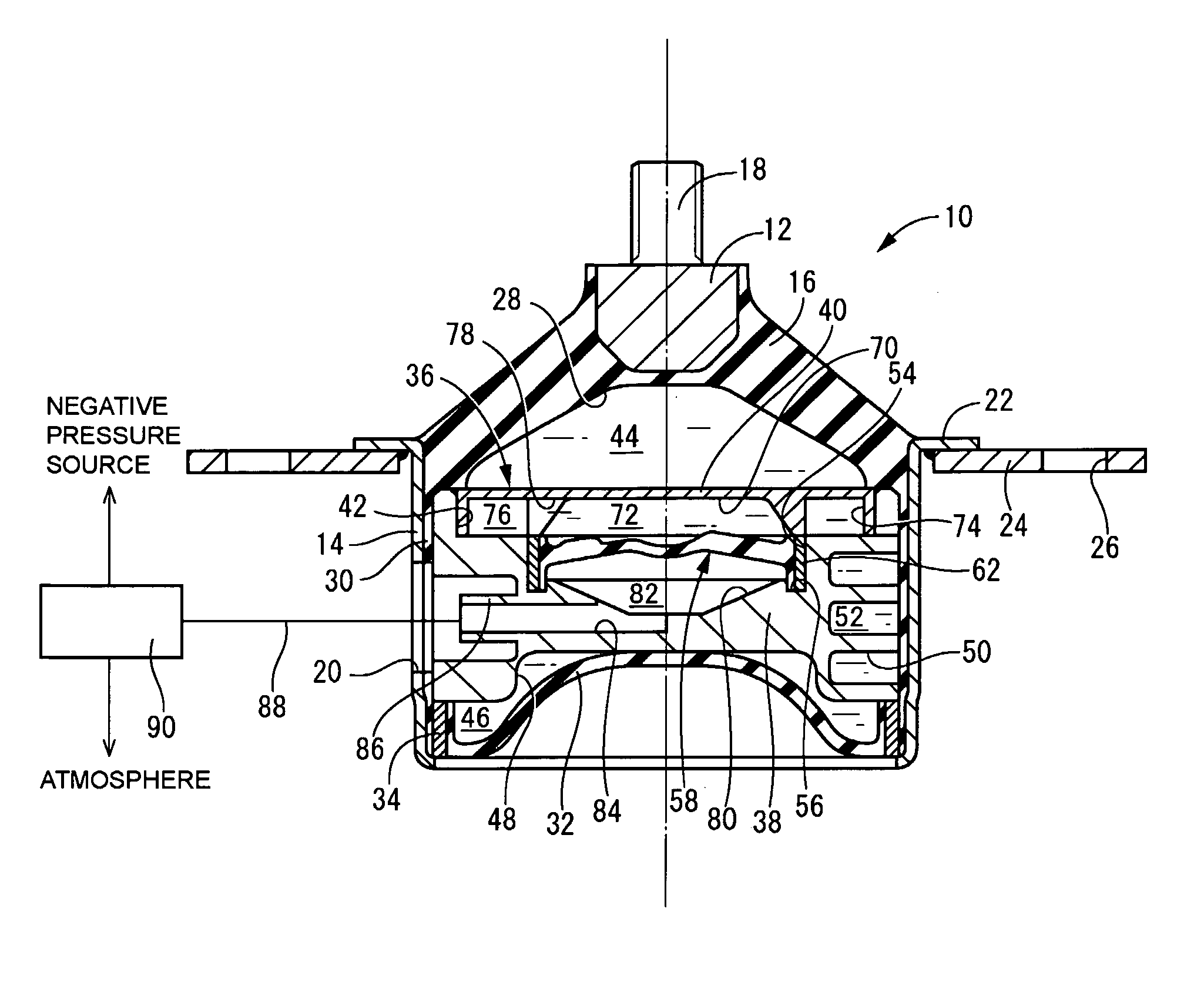

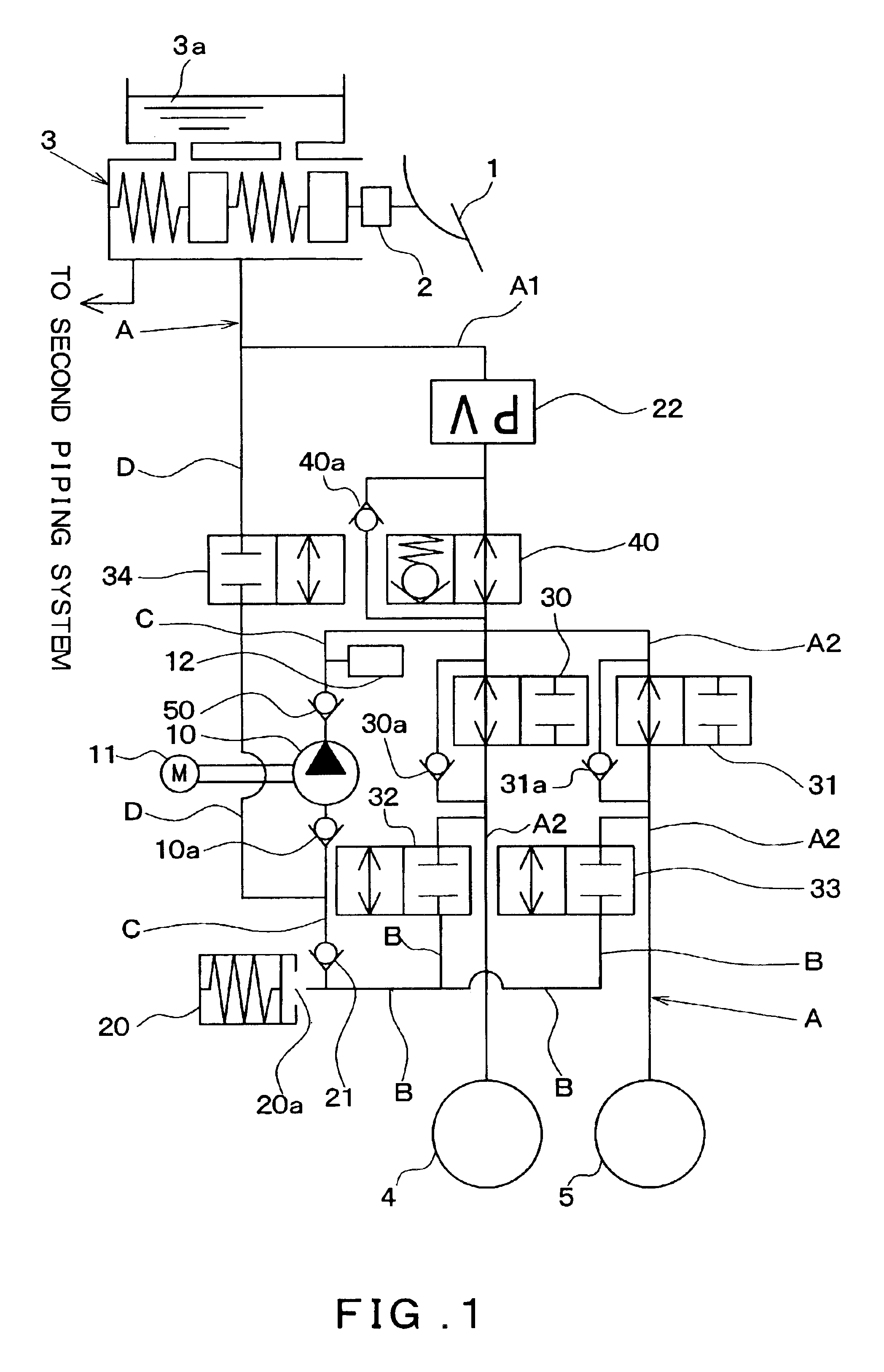

Gas pressure-reducing valve

InactiveUS20020083980A1Simple structureHigh precisionOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringPressure - action

A gas pressure-reducing valve includes a pressure-reducing chamber for generating a gas pressure that acts on one surface of a diaphragm, a valve body that can sit on a valve seat having in its central part a valve hole communicating with the pressure-reducing chamber, and a spring biasing the diaphragm in a direction that detaches the valve body from the valve seat. A valve housing is formed by conjoining a body, a partition, and a cover. The partition forms the pressure-reducing chamber between itself and the body and forms a pressure action chamber between itself and the diaphragm. The cover forms the spring chamber between itself and the other surface of the diaphragm and has the peripheral edge of the diaphragm clamped between itself and the partition. The partition has a through hole for allowing the valve stem to run through in an airtight and axially slidable manner and a communicating hole for providing communication between the pressure action chamber and the pressure-reducing chamber. The structure of the body can thus be simplified thereby enhancing the machining precision, and the diameter of the pressure-reducing chamber can be determined regardless of the diameter of the diaphragm.

Owner:KEIHIN CORP

Method and equipment for atomizing, cooling and granulating nylon polymer

The invention relates to a method for spraying, cooling and granulating a nylon polymer. The method comprises the following steps of: conveying a nylon polymer melt in a reaction kettle to a pressure sprayer on the top of a spraying tower by a heat-insulating pipeline under the pressure action, spraying the nylon polymer melt from the pressure sprayer, dispersing into fine fog drips, flashing moisture in the fog drips at high temperature, and drying quickly; cooling the high-temperature fog drips by cooling gas which enters the spraying tower to form uniform nylon solid granules, and settling the nylon solid granules in the tower; opening a gas outlet of the spraying tower, starting a draught fan, leading mixed gas in the spraying tower out of the gas outlet, and maintaining pressure of -100 to 20 Pa in the spraying tower; and collecting the nylon solid granules which drop to the bottom of the spraying tower, grading, and packaging to form a finished product. The invention also provides equipment for spraying, cooling and granulating the nylon polymer. By the method and the equipment, the discharge speed is improved, the granularity is increased, and discharged materials can be protected by nitrogen to prevent the materials from being oxidized; and the device is high in controllability and regulation performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

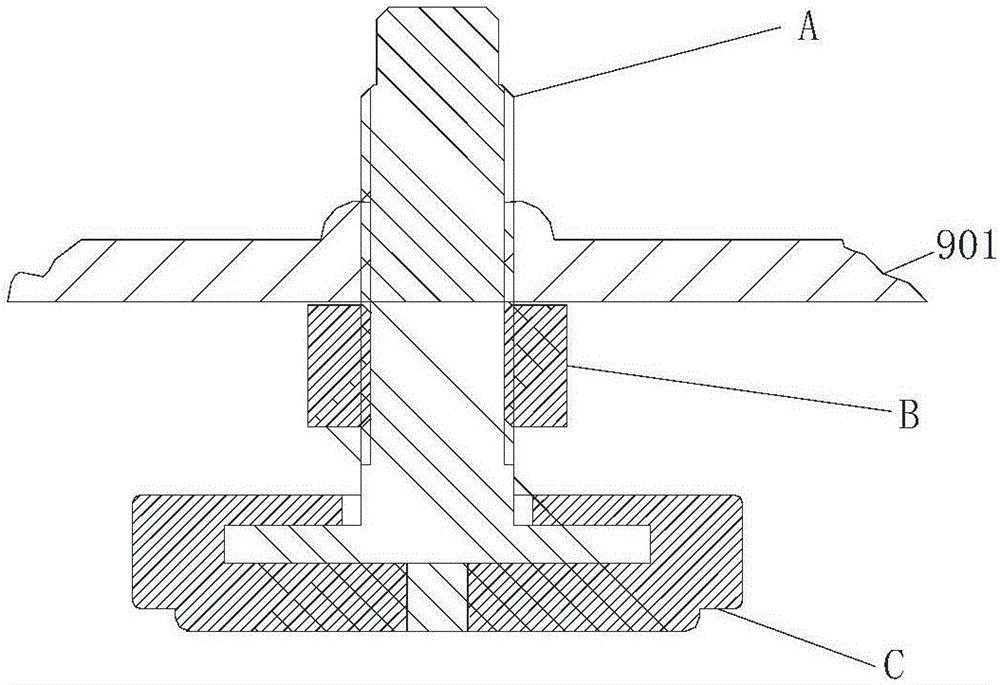

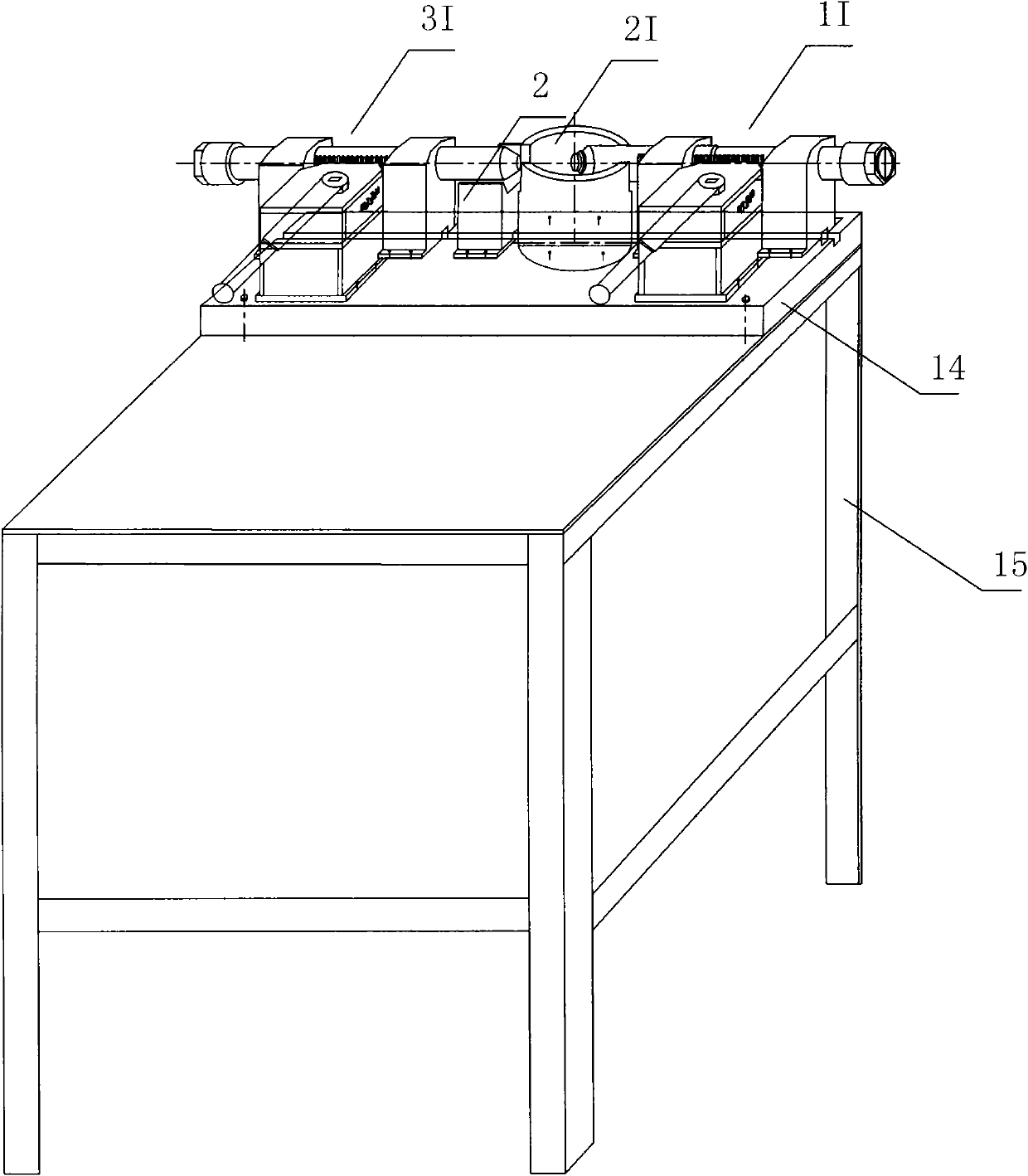

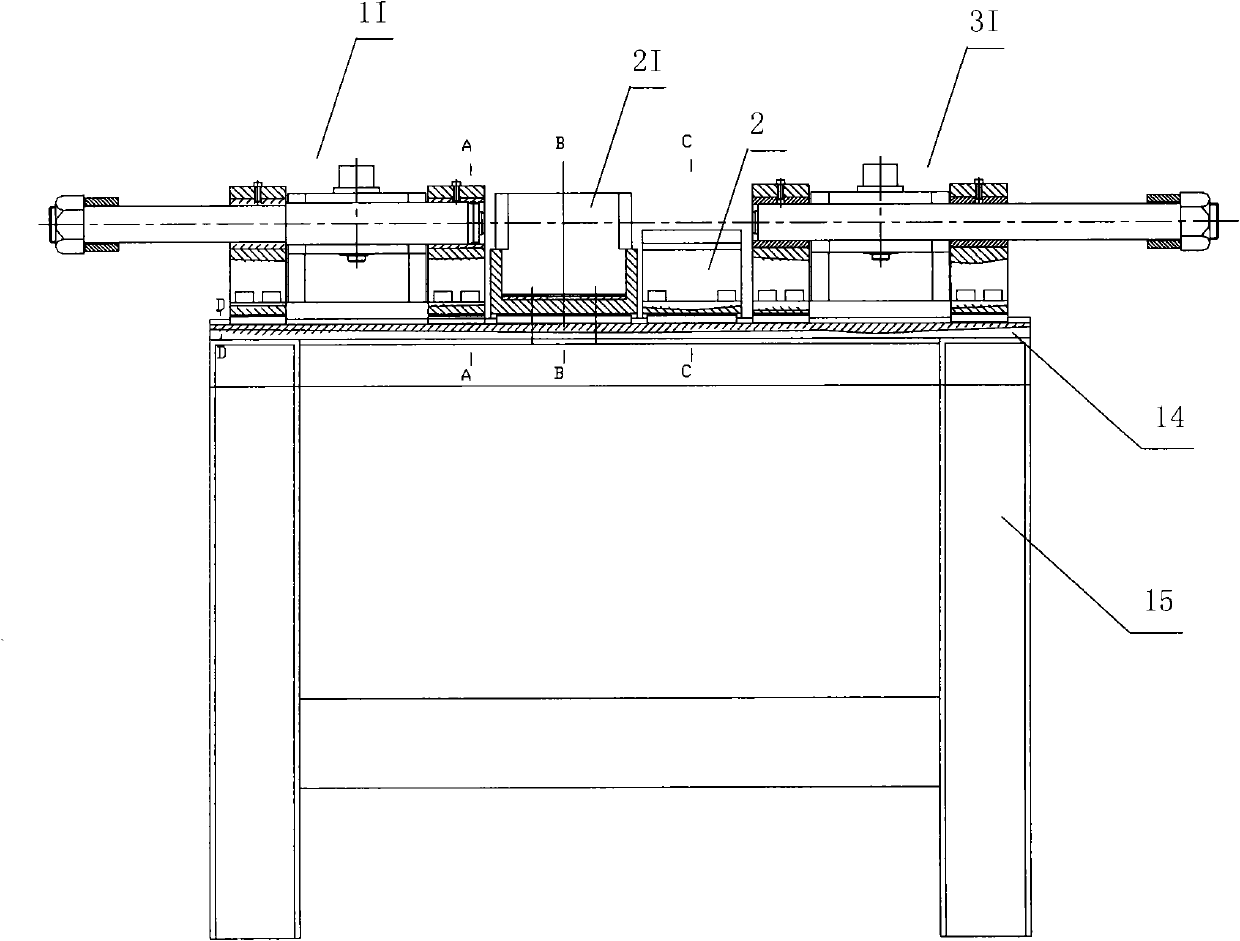

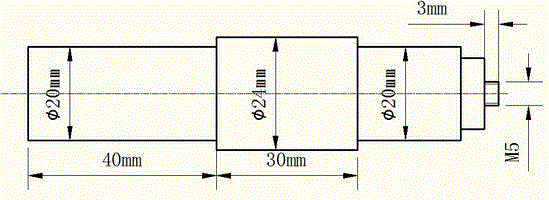

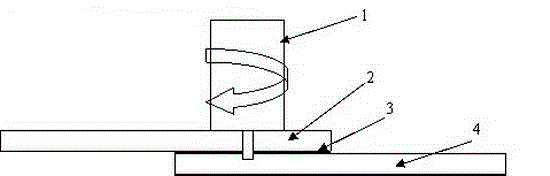

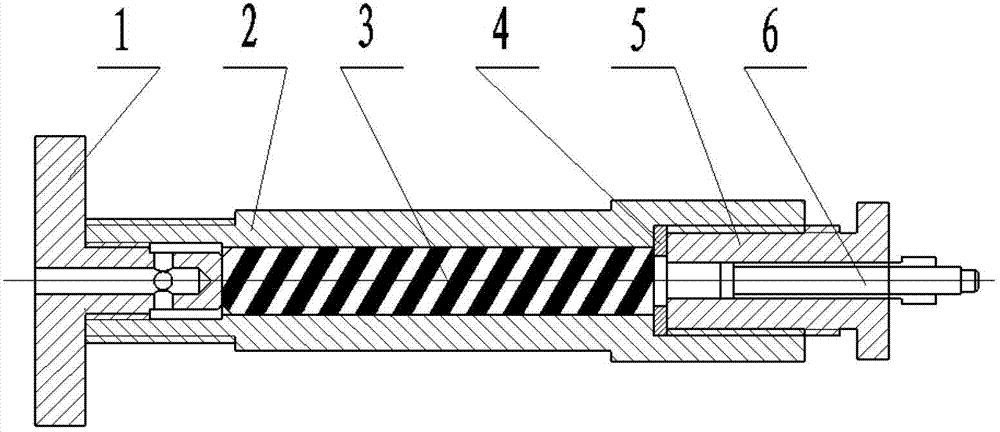

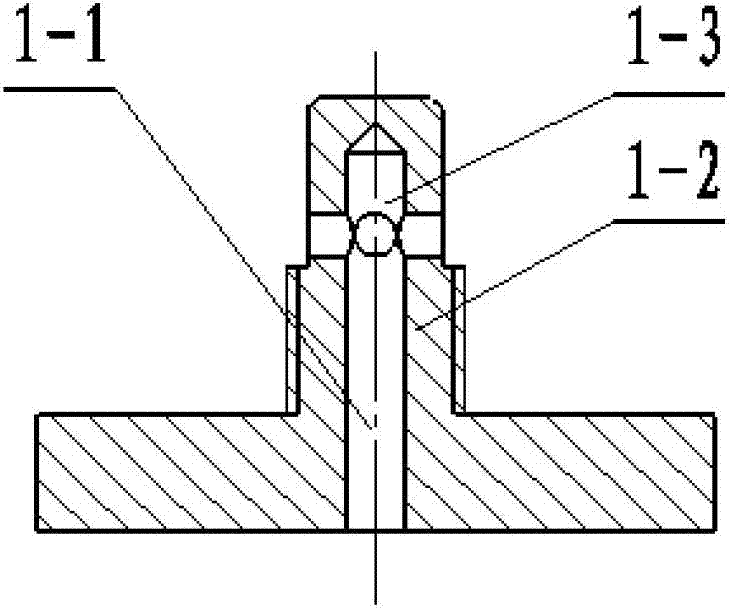

Assembly device and method for diesel engine piston pin

ActiveCN102198585AAvoid damageImprove labor efficiencyMetal working apparatusEngineeringDiesel engine

The invention discloses an assembly device for a diesel engine piston pin. The assembly device comprises a piston pin guide assembly, a piston sleeve assembly, a piston pin supporting block and a piston pin pressing assembly which are positioned at corresponding positions of a slot on a bottom plate, wherein a piston pin is placed on the piston pin supporting block; the piston sleeve assembly comprises a piston sleeve, and notches are formed at two sides of the piston sleeve; the piston pin guide assembly comprises a positioning core shaft; the piston pin pressing assembly comprises a push rod; and the push rod is coaxial with the positioning core shaft. When being assembled, the piston pin is penetrated into the notch at the other side of the piston sleeve, a pin hole in a piston and a hole at a small end of a connecting rod in sequence under the positioning action of the positioning core shaft and the pressure action of the push rod, so that the piston pin is pressed into the pin hole in the piston and the hole at the small end of the connecting rod and are in close fit with the pin hole in the piston and the hole at the small end of the connecting rod respectively. Through the assembly device, assemblies can be prevented from being damaged, cylinder holes can be prevented from being pulled, and production efficiency can be greatly increased.

Owner:GUANGXI YUCHAI MASCH CO LTD

Gas pressure-reducing valve

InactiveUS6629544B2Simple structureHigh precisionOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringPressure - action

A gas pressure-reducing valve includes a pressure-reducing chamber for generating a gas pressure that acts on one surface of a diaphragm, a valve body that can sit on a valve seat having in its central part a valve hole communicating with the pressure-reducing chamber, and a spring biasing the diaphragm in a direction that detaches the valve body from the valve seat. A valve housing is formed by conjoining a body, a partition, and a cover. The partition forms the pressure-reducing chamber between itself and the body and forms a pressure action chamber between itself and the diaphragm. The cover forms the spring chamber between itself and the other surface of the diaphragm and has the peripheral edge of the diaphragm clamped between itself and the partition. The partition has a through hole for allowing the valve stem to run through in an airtight and axially slidable manner and a communicating hole for providing communication between the pressure action chamber and the pressure-reducing chamber. The structure of the body can thus be simplified thereby enhancing the machining precision, and the diameter of the pressure-reducing chamber can be determined regardless of the diameter of the diaphragm.

Owner:KEIHIN CORP

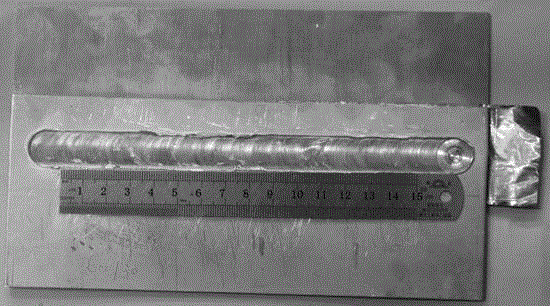

Friction stir welding-braze welding composite welding method for dissimilar metal bonding structure

InactiveCN104923927AAvoid problems with brittle intermetallic compoundsIncrease widthWelding/soldering/cutting articlesWelding apparatusStress concentrationHardness

A friction stir welding-braze welding composite welding method for a dissimilar metal bonding structure is provided. The operation process of the method is as follows: before welding, a material with low hardness is placed on the upper layer, a material with high hardness is placed on the lower layer, and a soft solder with a low melting point, such as pure Zn or a Zn-matrix solder, is placed between two plates; a stirring head which rotates at a high speed is inserted into the metal in the upper layer, a stirring pin enters the metal in the lower layer, and the solder which is clamped between two types of metal is melted by stirring friction heat; and finally excess melted solder is extruded under the pressure action of a shaft shoulder, the purification of the interface is realized, diffusion bonding is formed, and the purpose of welding is achieved. According to the method, composite welding seams can be obtained; the effective bonding width of the bonding structure can be increased; stress concentration and the interface effect of the bonding interface are reduced; and the service performance of joints is improved.

Owner:NANCHANG HANGKONG UNIVERSITY

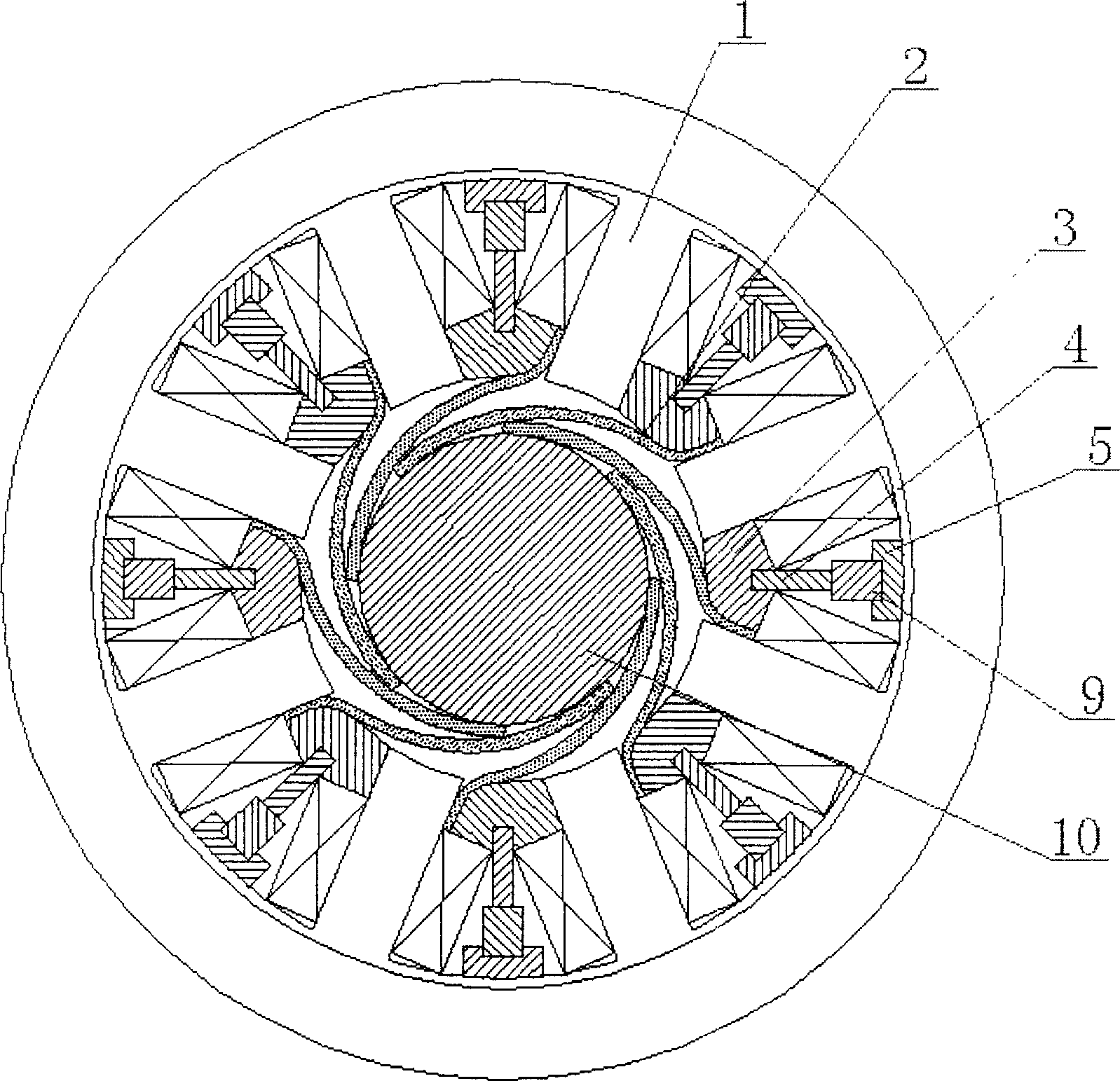

Magnetic-gas bearing and method for making compliant foil

InactiveCN1730959AShorten the axial lengthImprove performanceBearing componentsMagnetic bearingsMagnetic tension forceMagnetic poles

The mixed magnetic air journal bearing is mixed bearing of active magnetically suspension bearing and dynamic pressure air journal bearing, and includes active magnetically suspension radial bearing, elastic foil embedded between magnetic poles of the magnetically suspension radial bearing, and locking mechanism comprising locking wedge block, inclined blocks, bearing block, gag, screw and stop washer. The elastic foil with pre-wedged angle, has one end held onto the magnetic pole and has higher static and dynamic performance than rigid bearing. Owing to the magnetic force to suspend the rotor in the balance position and fluid force to deform the foil for coupling the interval of the air film, the rotor-bearing reaches ultimate stable balance. The bearing has simple structure, has the advantages of both active magnetically suspension bearing and foil bearing, excellent damping characteristic and improved structure rigidity and dynamic characteristic.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

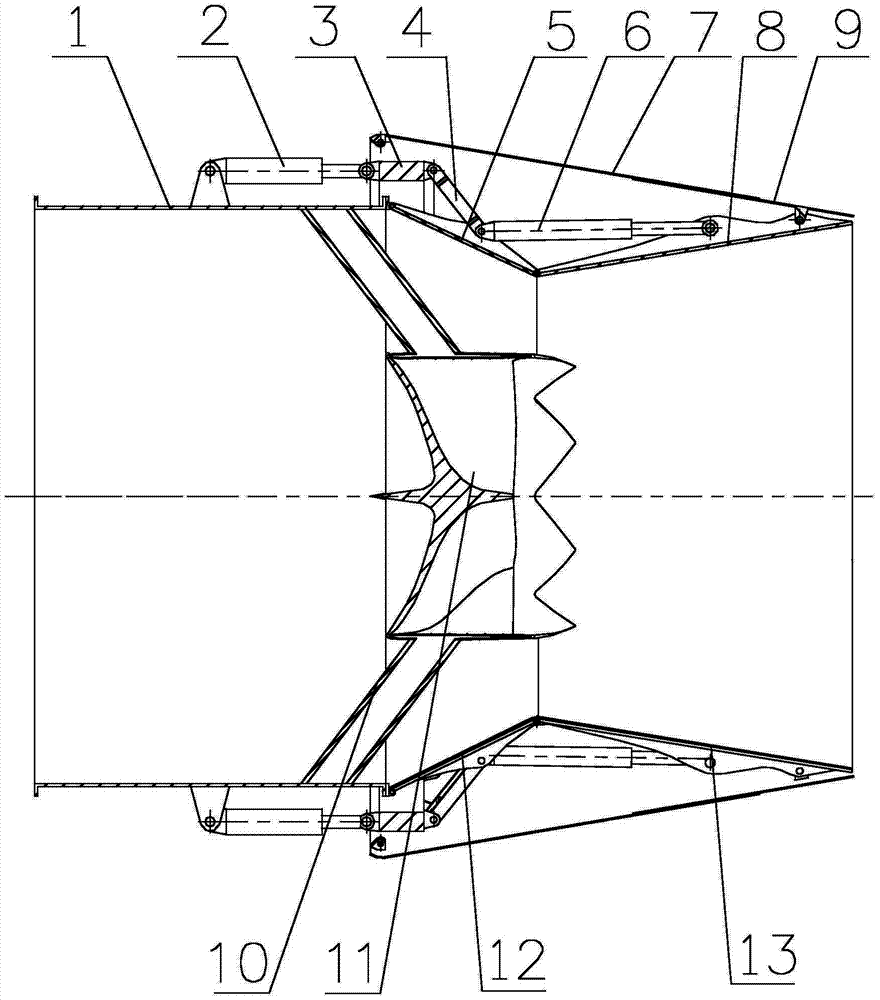

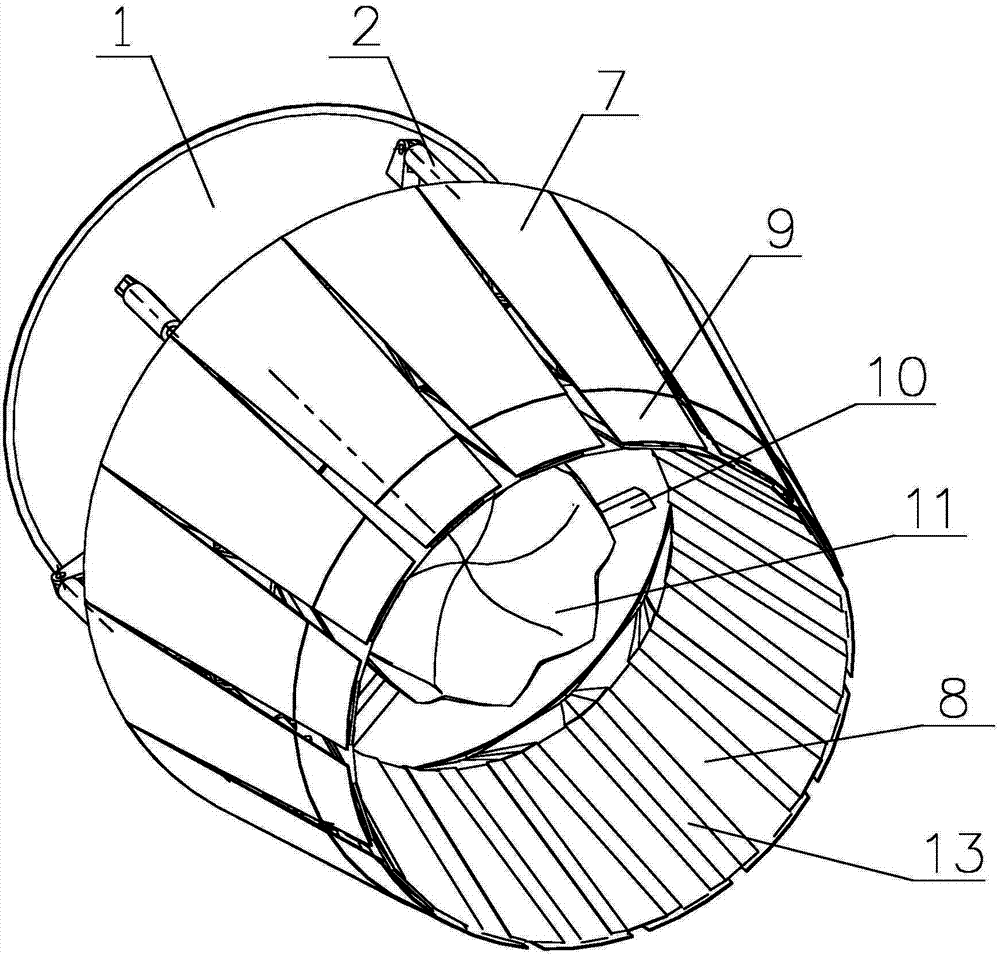

Axisymmetric convergent and divergent exhaust nozzle

ActiveCN103696878AMake up for the stealth function defectImprove stealth performanceJet propulsion plantsEngineeringAtmospheric pressure

The invention relates to an axisymmetric convergent and divergent exhaust nozzle. The exhaust nozzle is characterized by mainly consisting of a cylinder, a driving adjusting mechanism, a sealing component, a center shielding component and an outer fairing component, wherein the front end of the cylinder is connected with an engine to serve as a support component of the whole exhaust nozzle, the driving adjusting mechanism mainly consists of action cylinders, a synchronous adjusting ring, pull rods, convergent flaps, air pressure action cylinders, and divergent flaps, the sealing component mainly consists of a convergent sealing sheet and an divergent sealing sheet, and is mainly used for sealing the air flow in the exhaust nozzle, and the divergent sealing sheet is positioned in the inner sides of the circumferentially distributed divergent flaps and between the circumferentially distributed divergent flaps, and is connected with the divergent flaps at the two adjacent sides through a conventional cooperation pressing mechanism. The axisymmetric convergent and divergent exhaust nozzle has the advantages that the influence on the area adjusting range of a throat pipe of the conventional axisymmetric convergent and divergent exhaust nozzle is avoided, the good hiding capability is realized, the defect of hiding function of the conventional axisymmetric convergent and divergent exhaust nozzle is overcome, meanwhile, the structure is simple, and the reliability is high.

Owner:AECC SHENYANG ENGINE RES INST

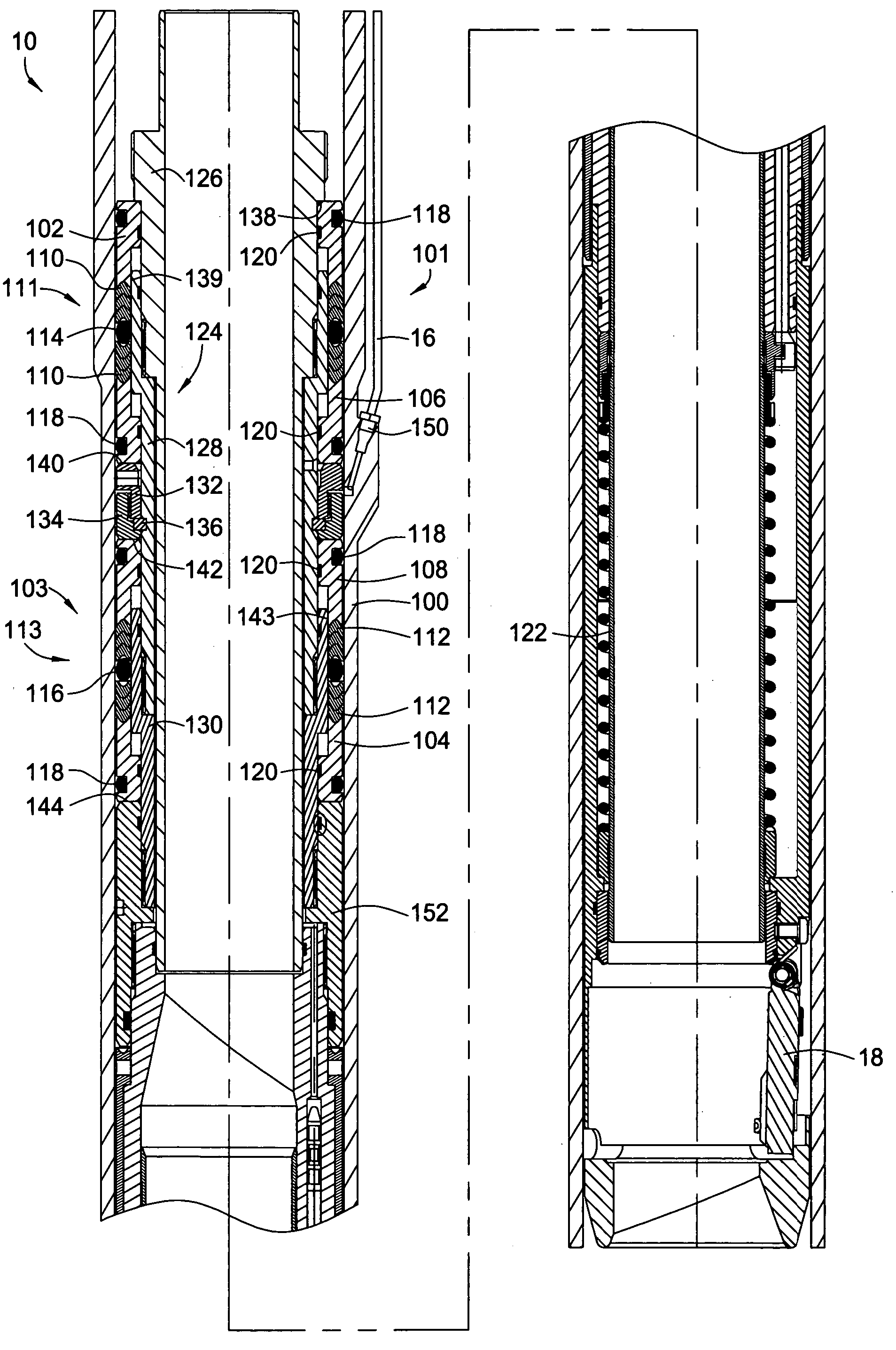

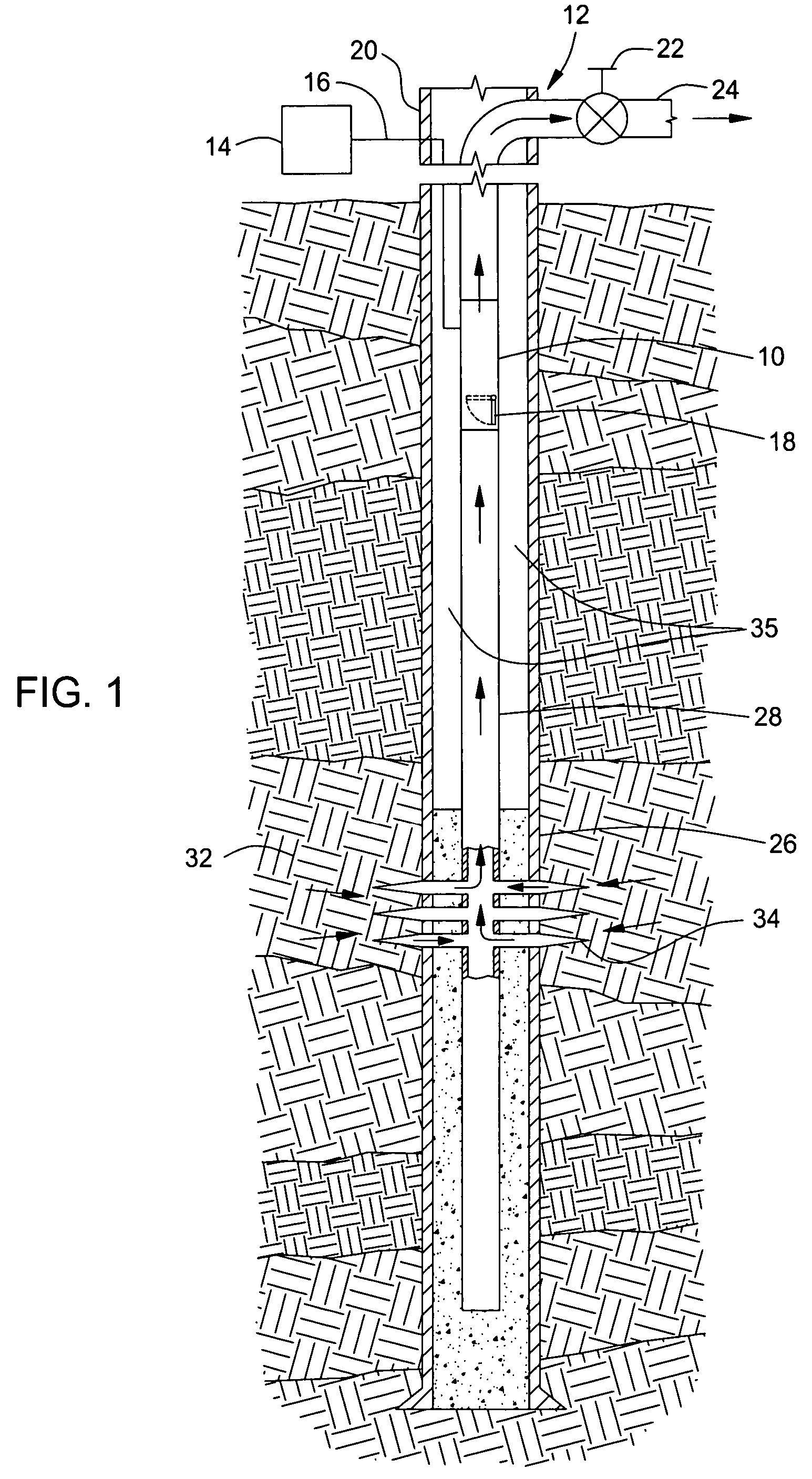

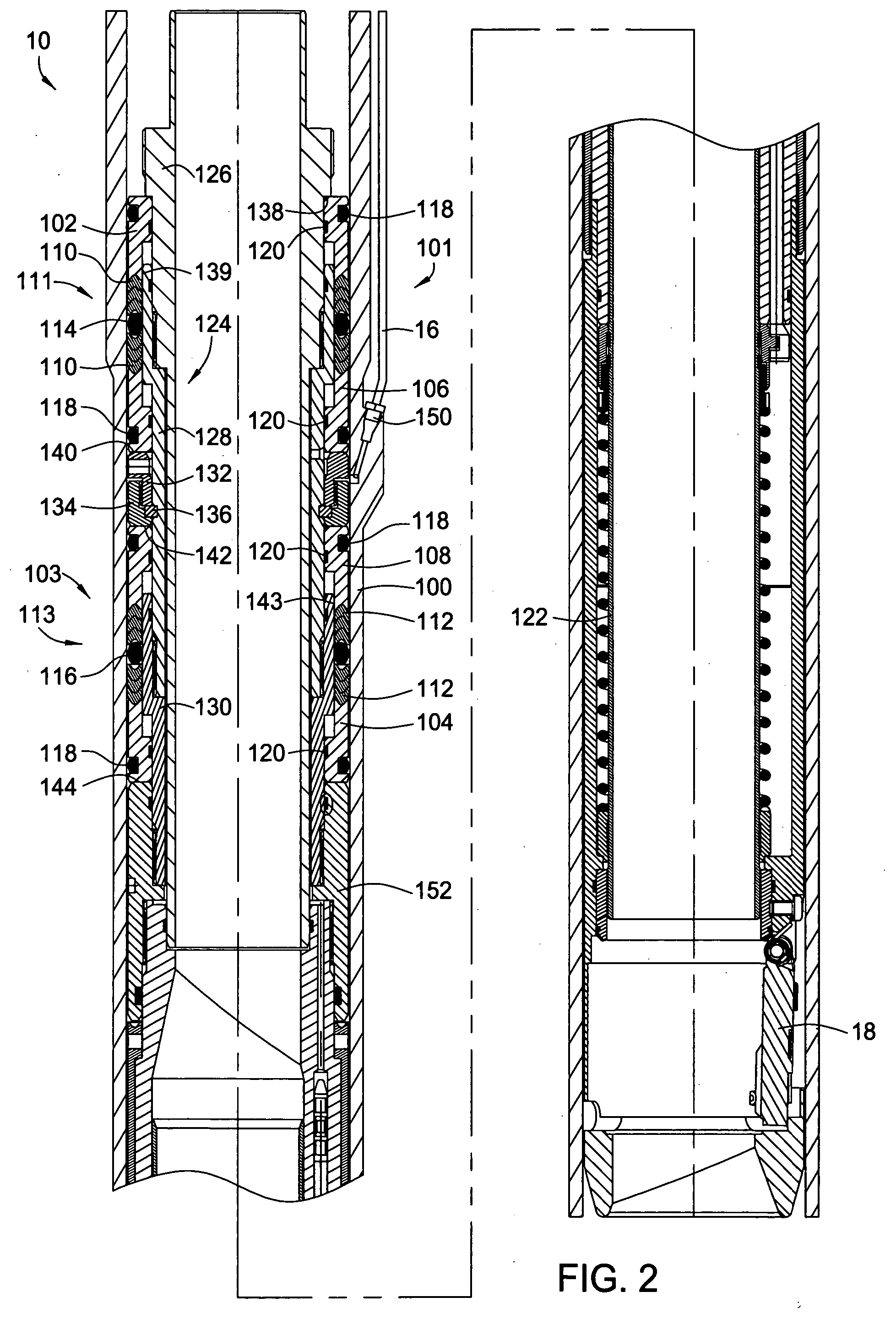

Seal assembly for a safety valve

Methods and apparatus for sealing a safety valve within a tubular that the safety valve is designed to be landed and set in are disclosed. The valve includes a seal assembly having a seal on the valve that is acted on by a first piston disposed on a first side of the seal and / or a second piston disposed on a second side of the seal. Wellbore fluid pressure acts on the first piston when the valve is closed, thereby moving the first piston to force the seal into sealing contact with an inside surface of the tubular. When the safety valve is actuated open, fluid pressure from a control line acts on the second piston and moves the second piston to force the seal into sealing contact with the inside surface of the tubular. The seal may include a plurality of chevron seals on each side of a sealing element.

Owner:WEATHERFORD TECH HLDG LLC

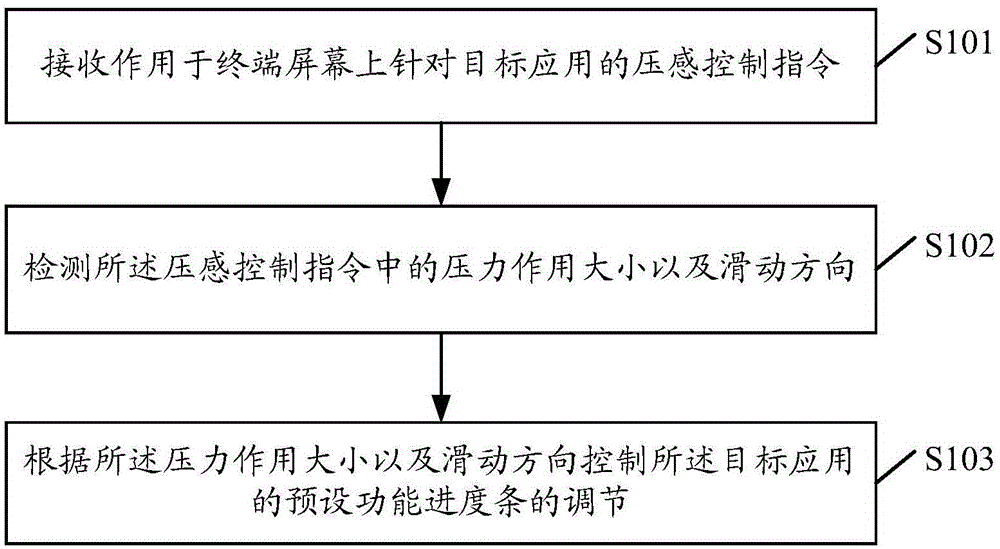

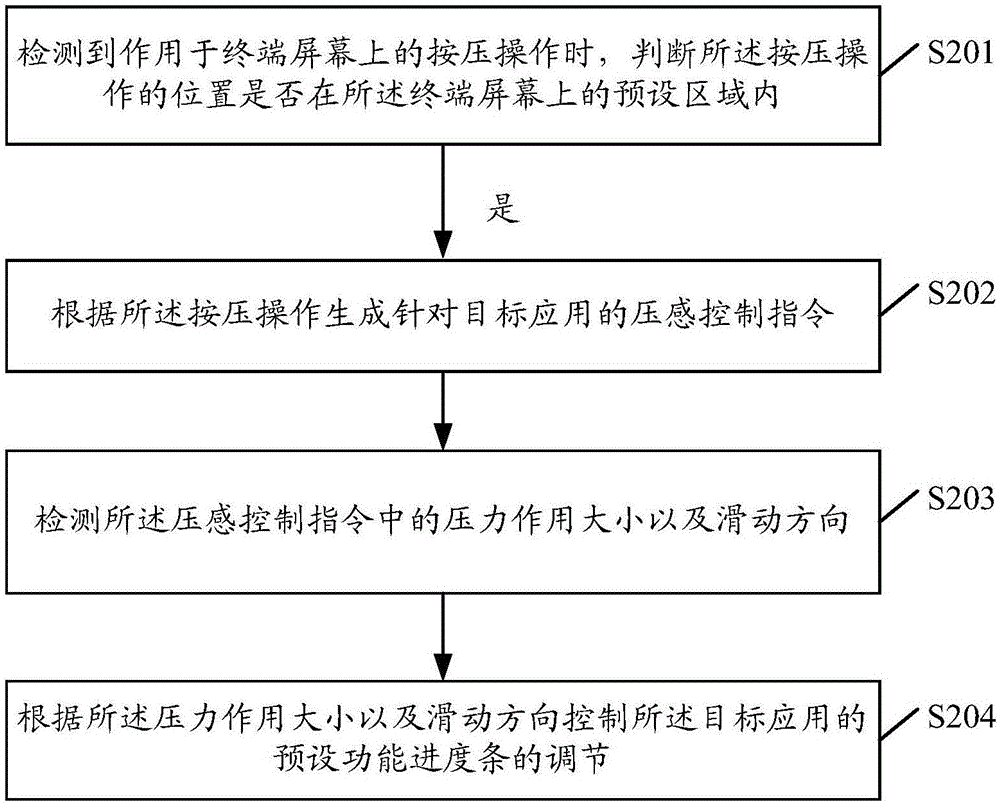

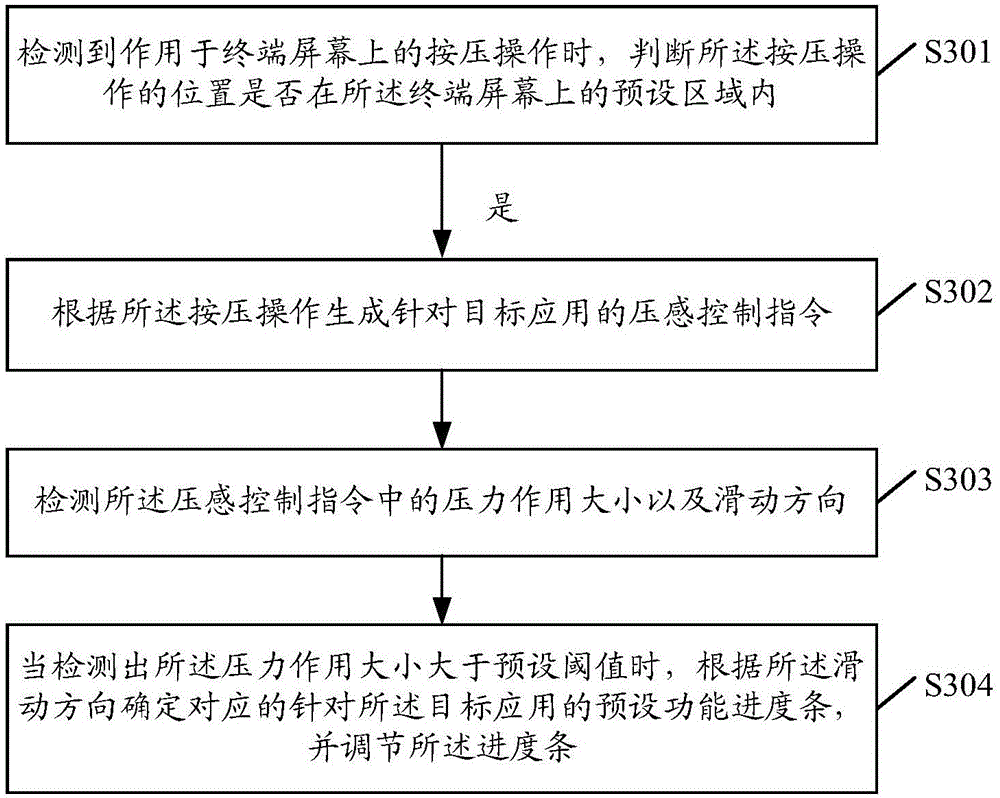

Progress bar control method and apparatus

ActiveCN105117131AEasy to operateImprove experienceInput/output processes for data processingProgress barPressure - action

An embodiment of the invention discloses a progress bar control method and apparatus. The method can comprise: receiving a pressure-sensitive control instruction that is acted on a terminal screen and aims at a target application; detecting a pressure action size and a sliding direction in the pressure control instruction; and according to the pressure action size and the slide direction, controlling adjustment of a preset function progress bar of the target application. According to the invention, the terminal can be enabled to carryout pressure-sensitive control on the preset function progress bar of the application according to the pressure-sensitive control instruction acted by the user on the terminal screen; the progress bar control method and apparatus are convenient in operation; andthe user experience is effectively improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

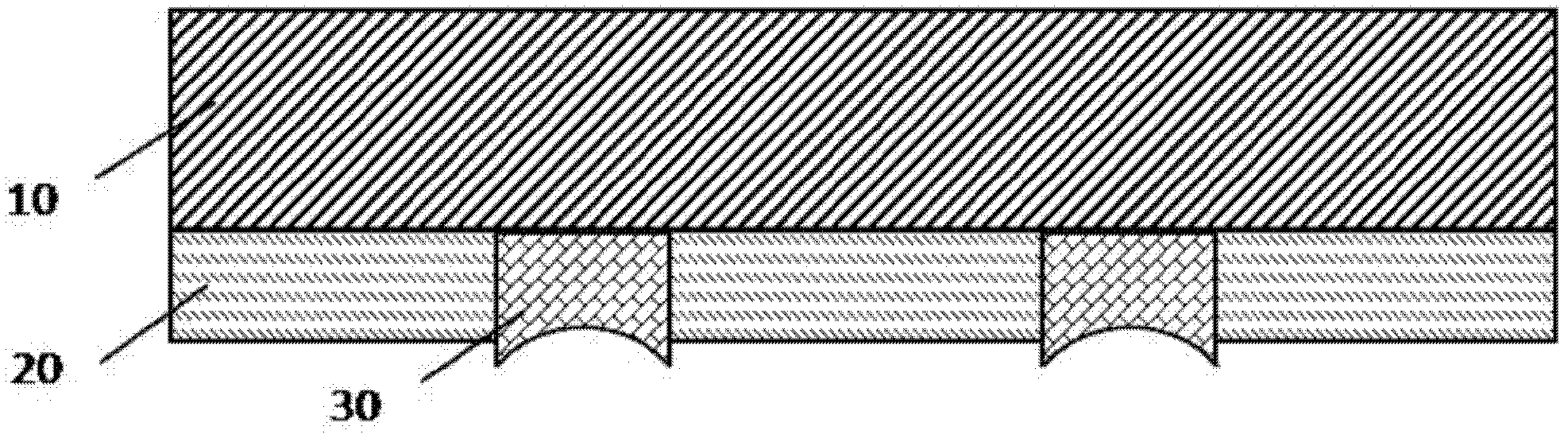

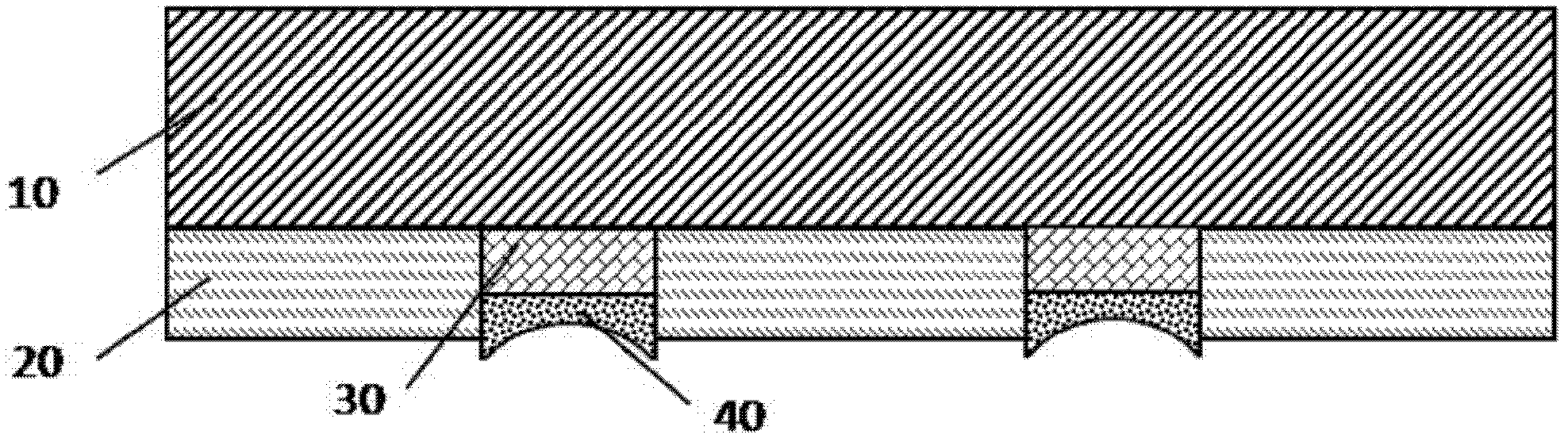

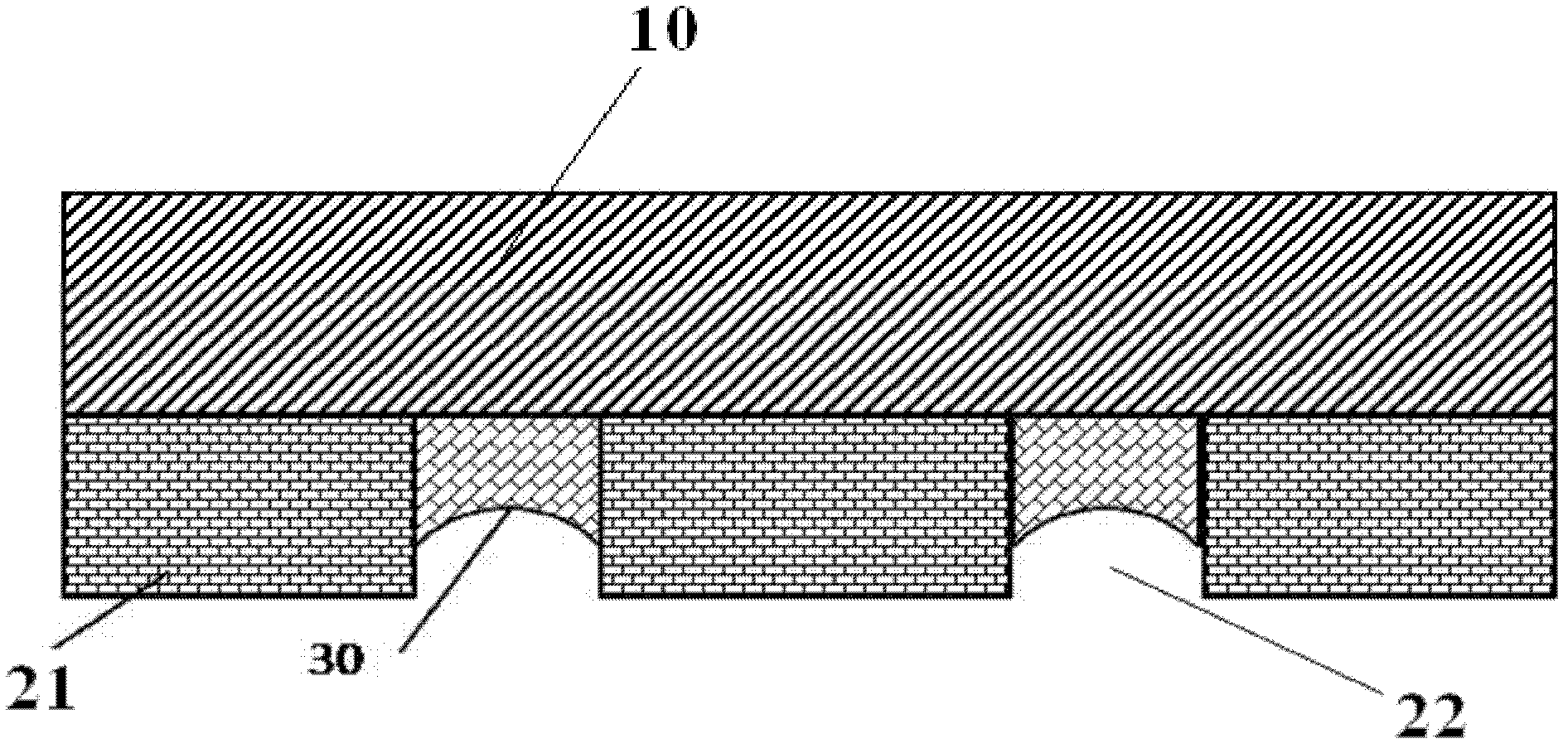

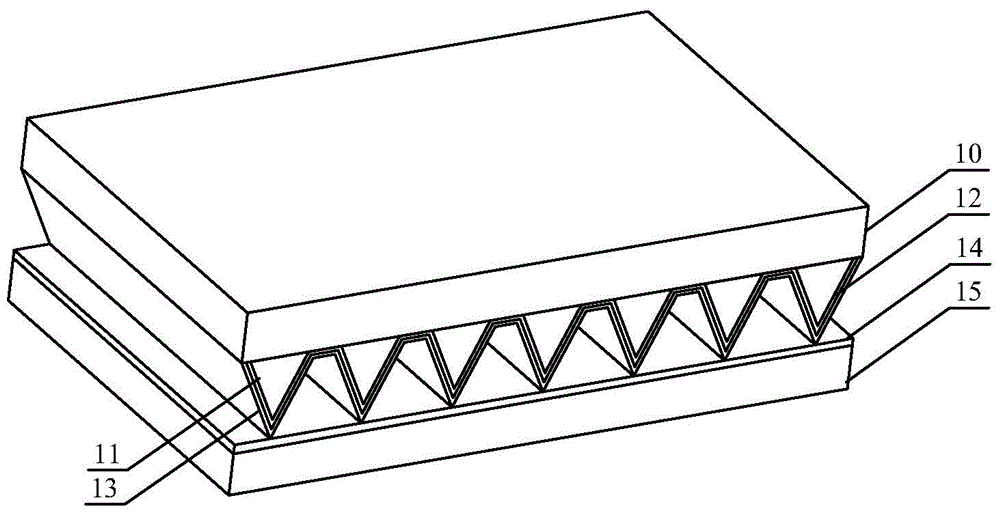

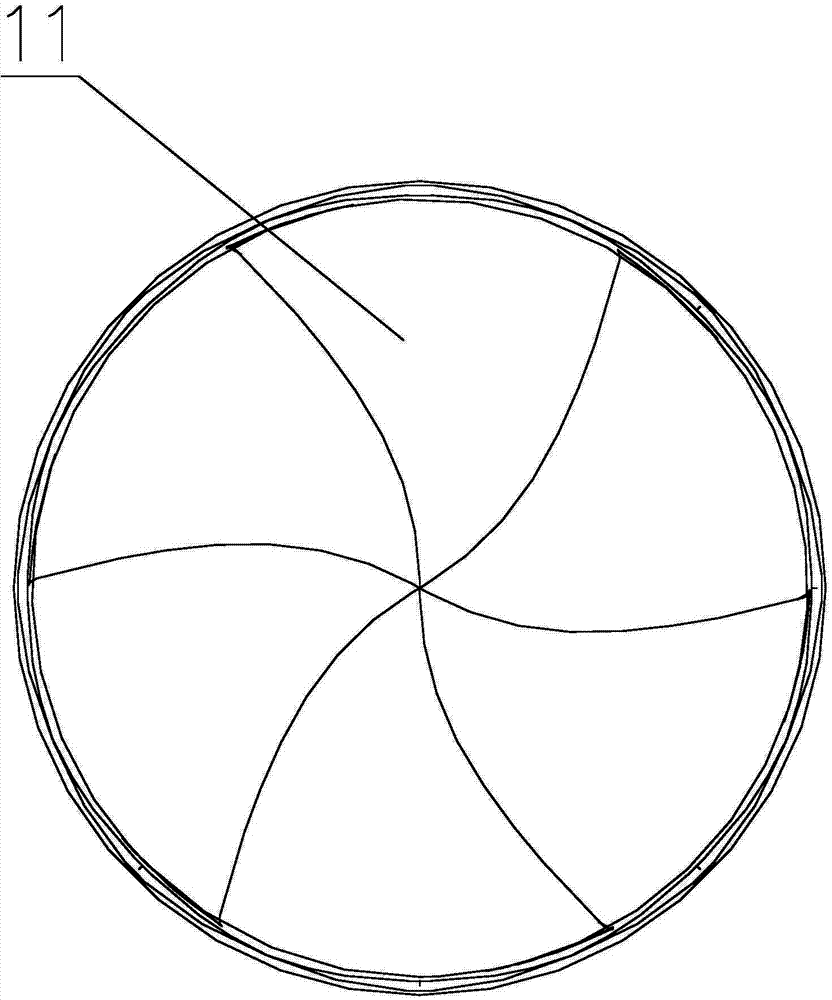

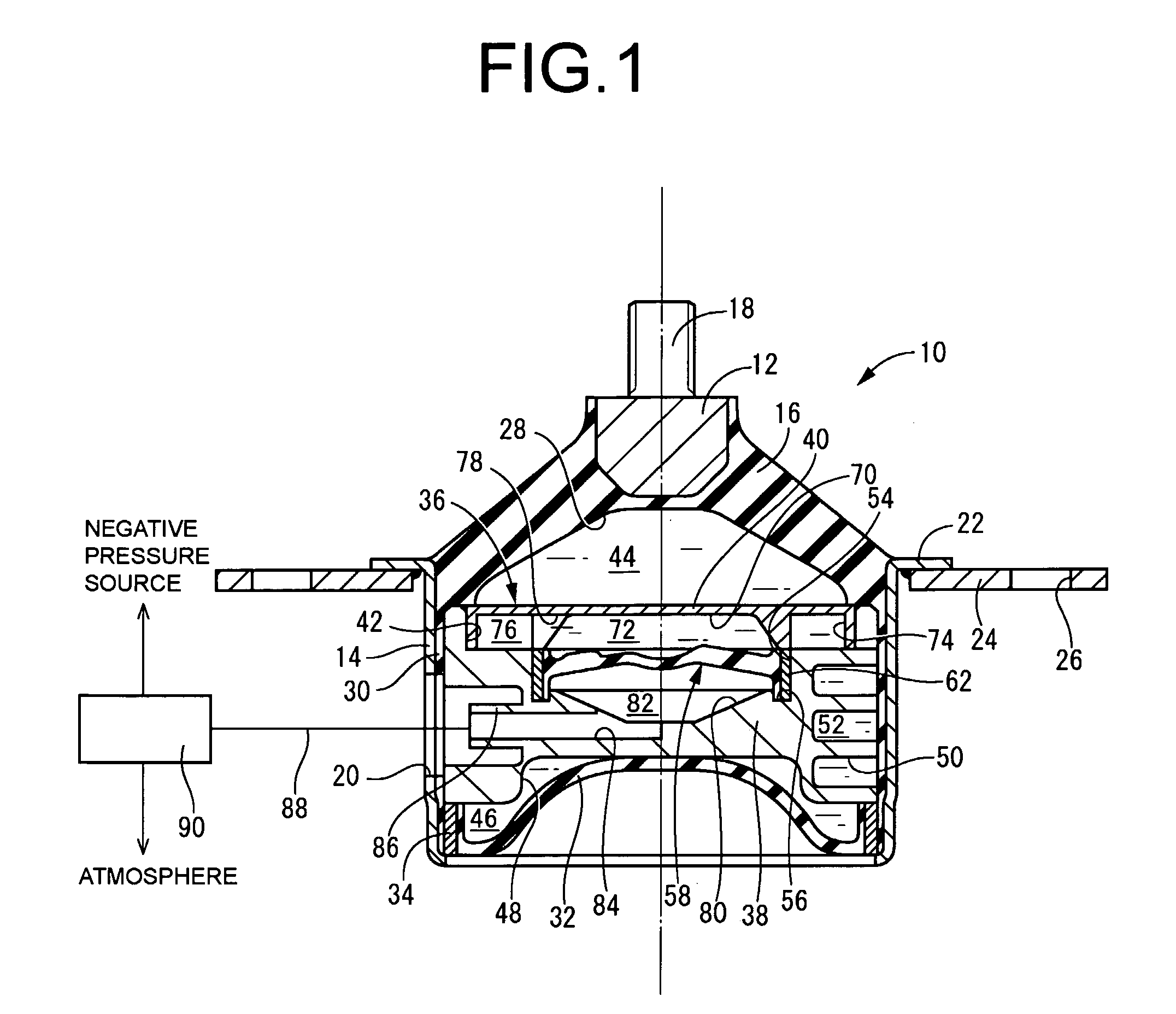

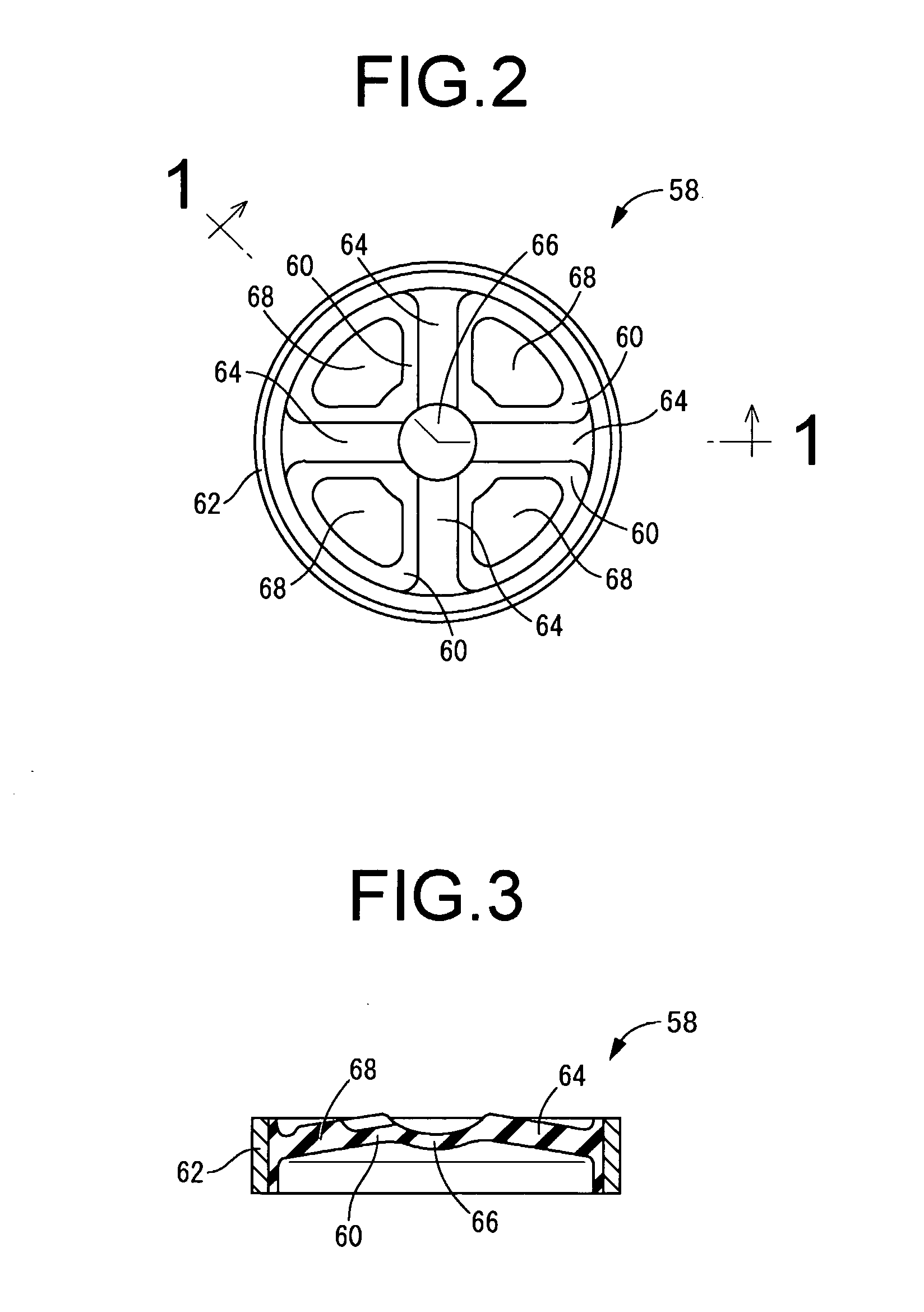

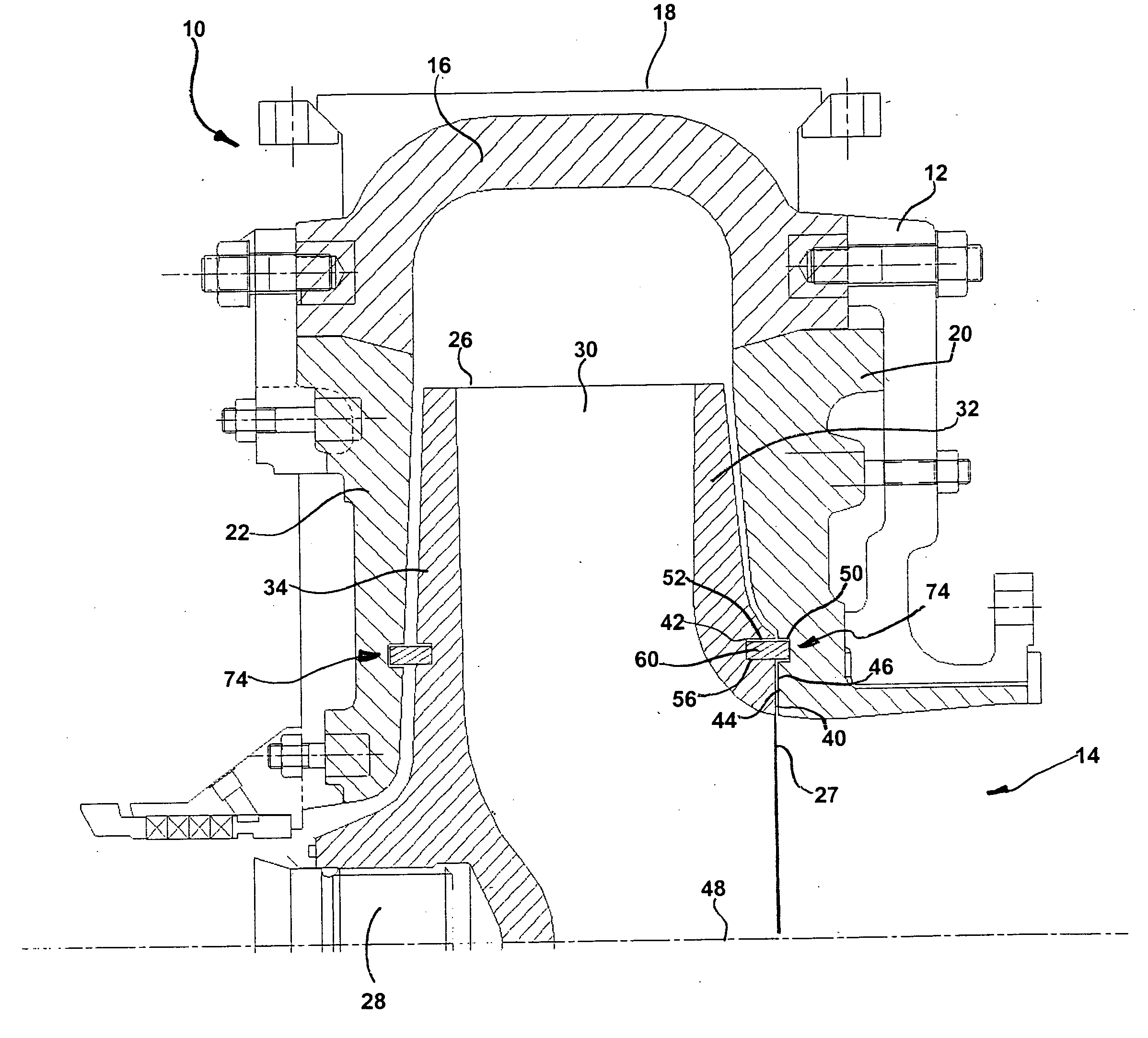

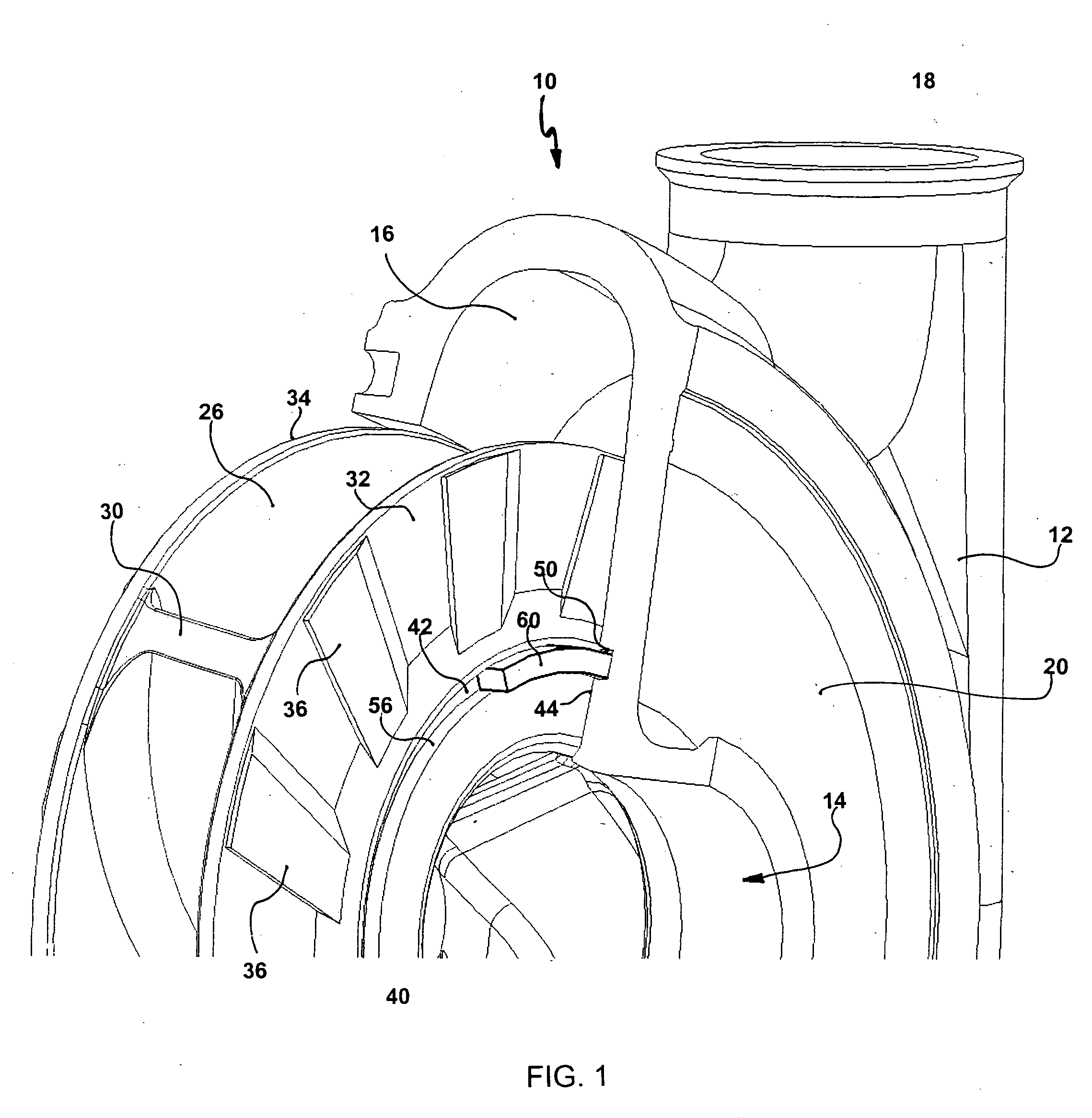

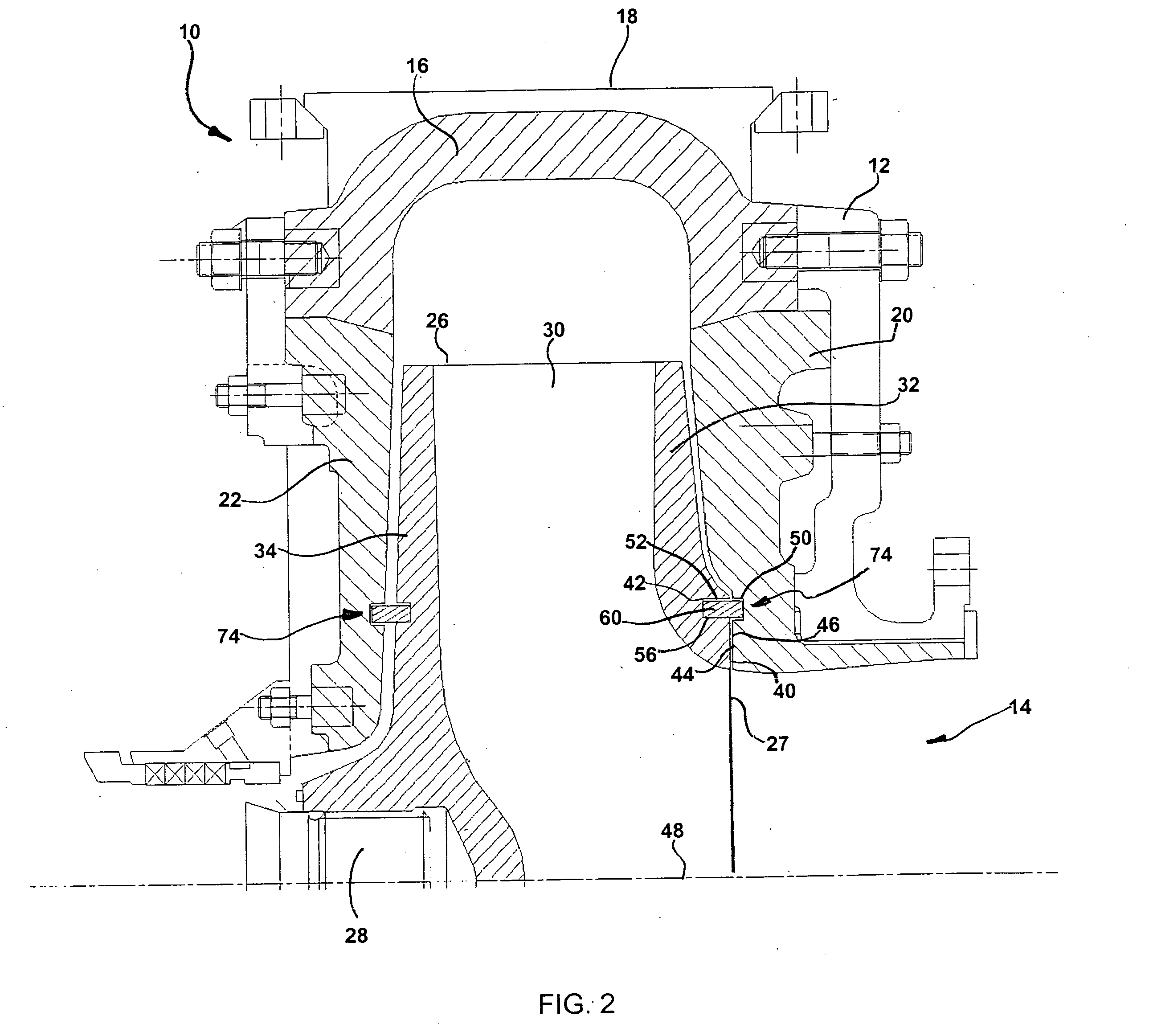

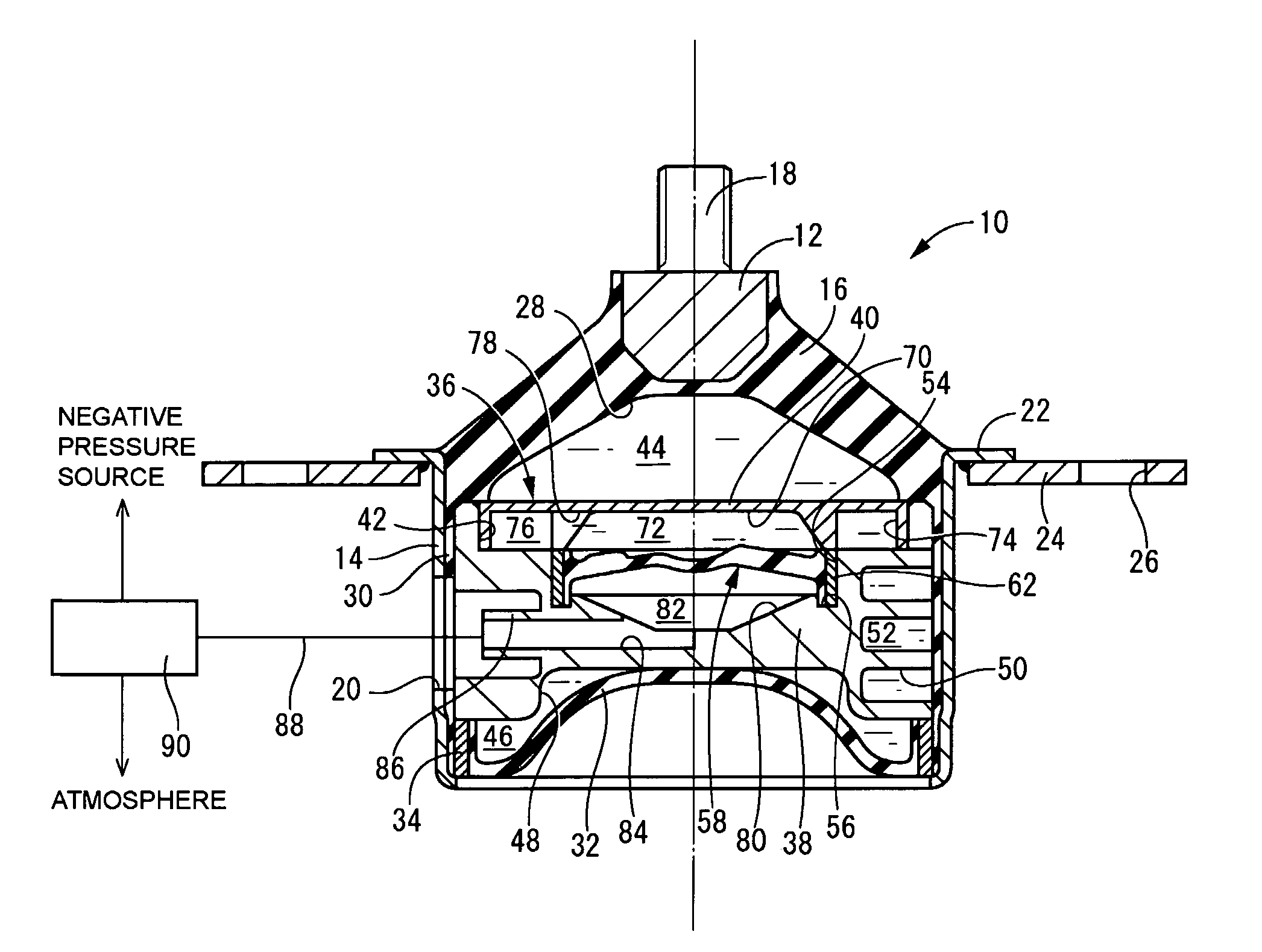

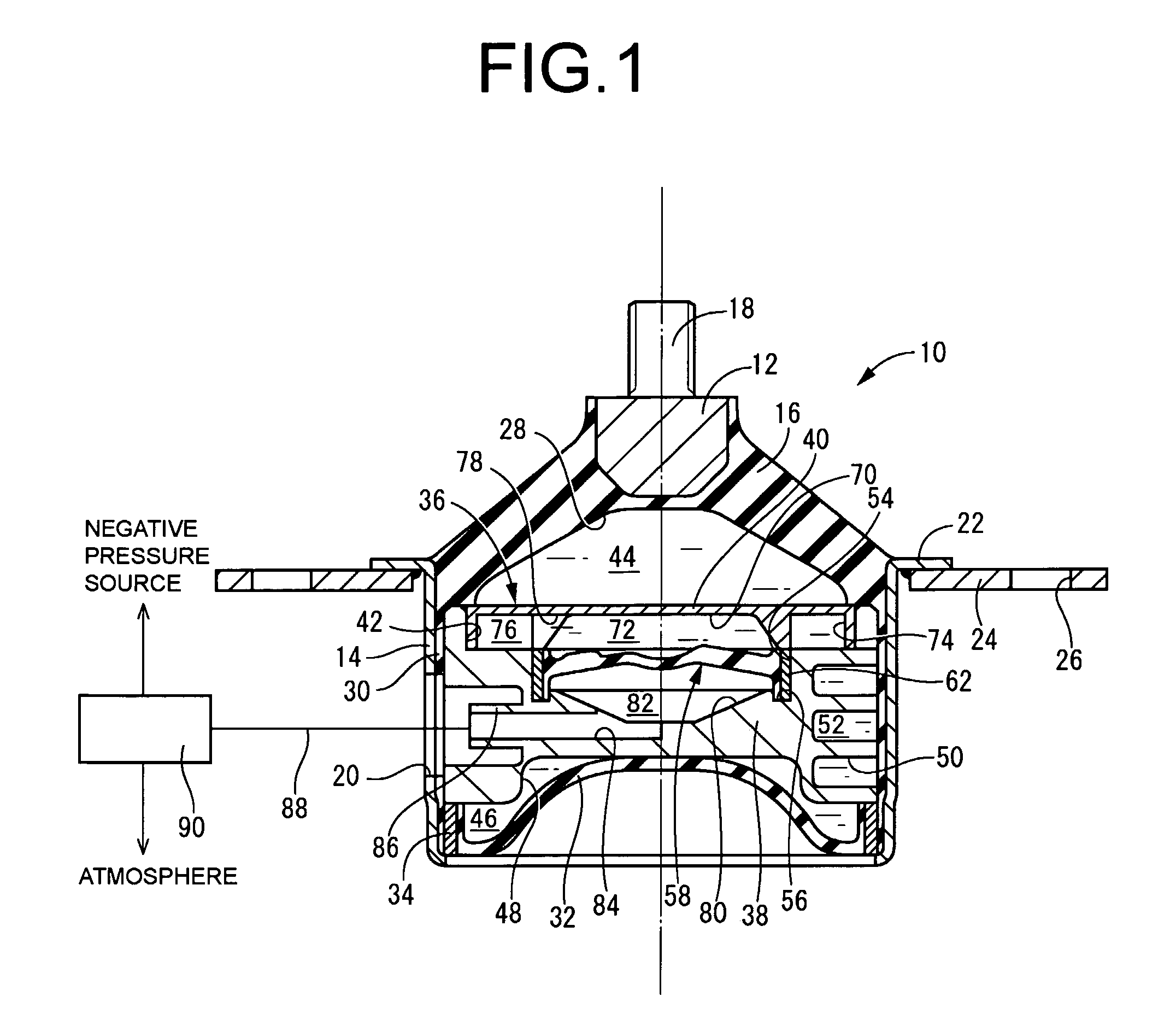

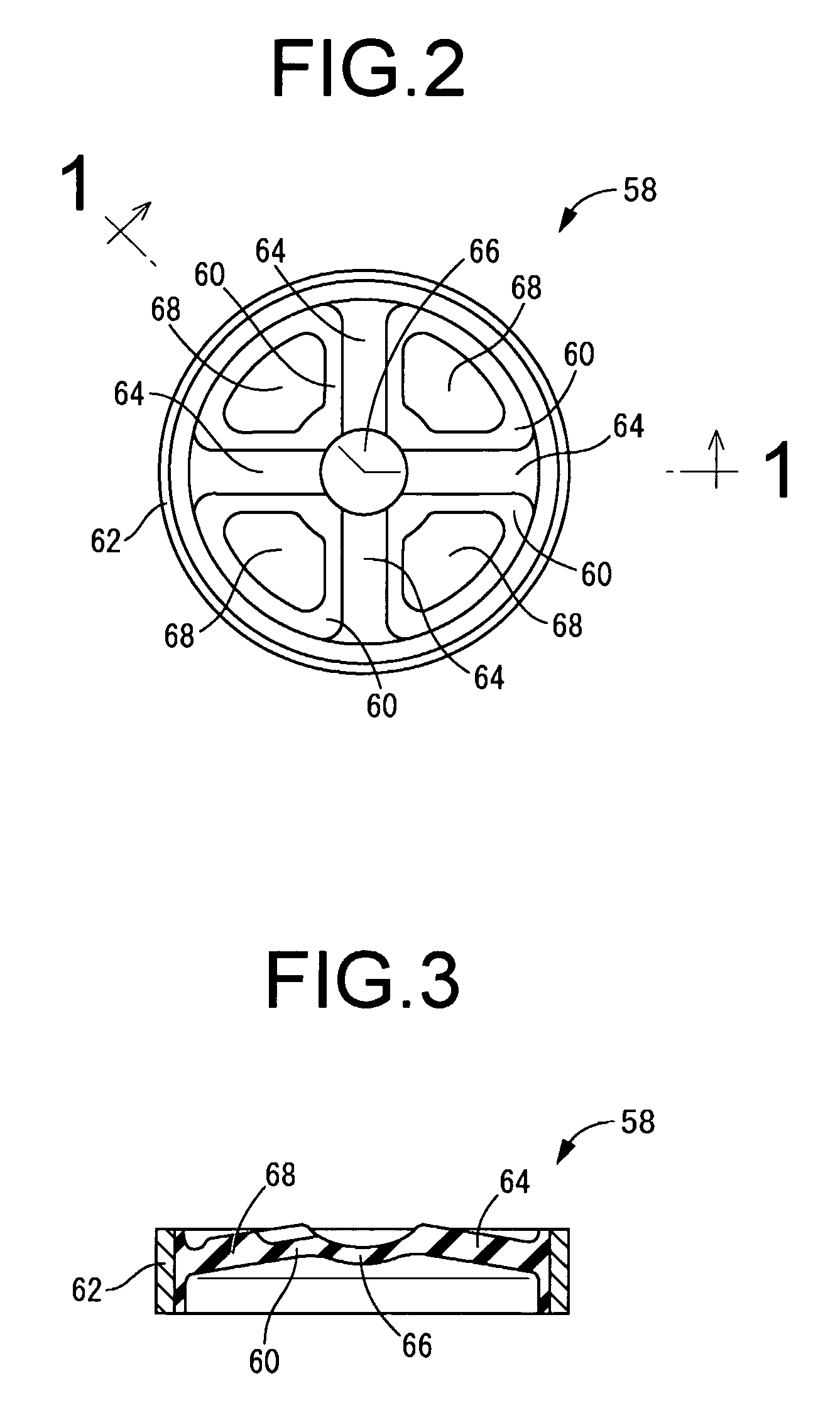

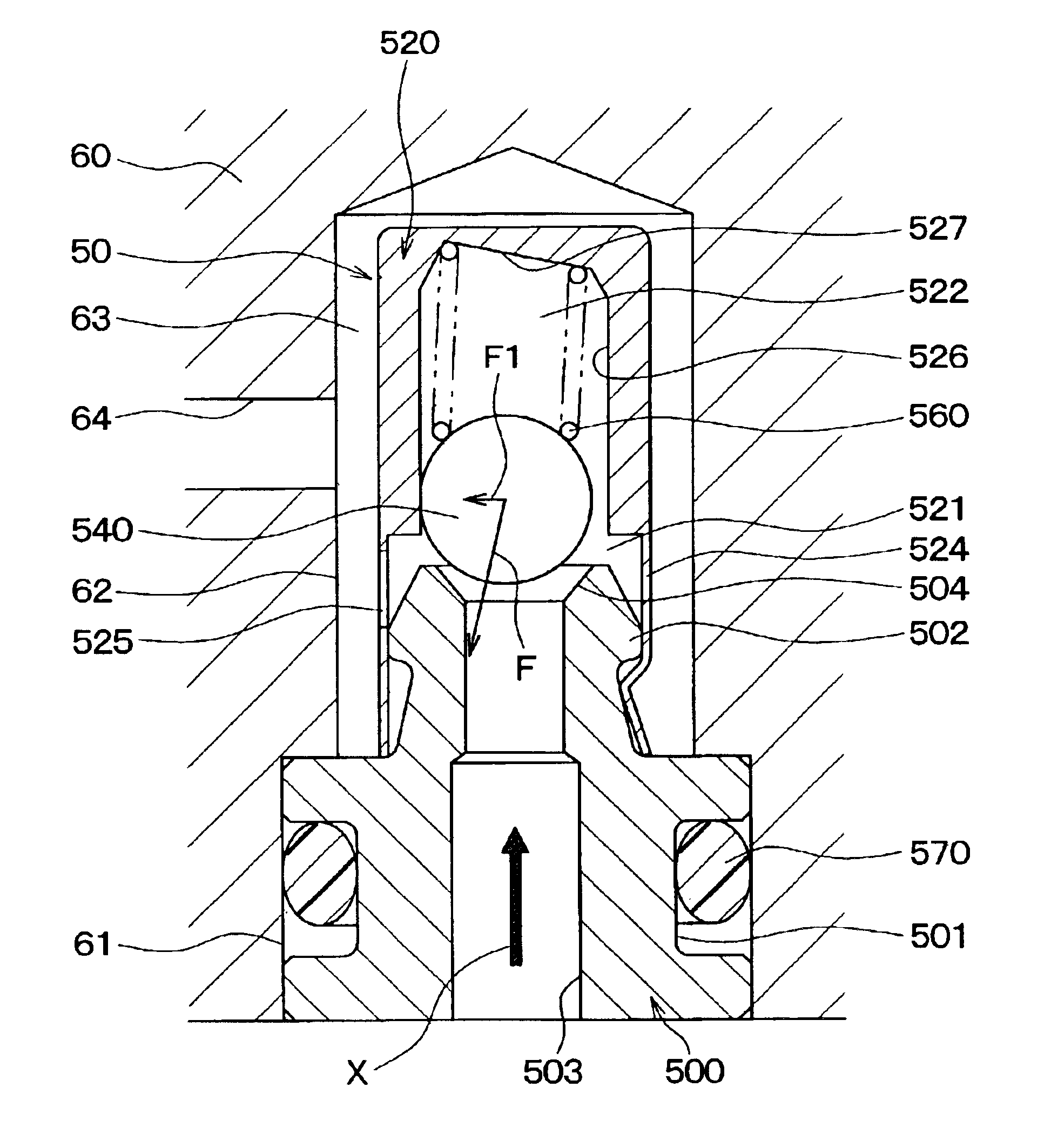

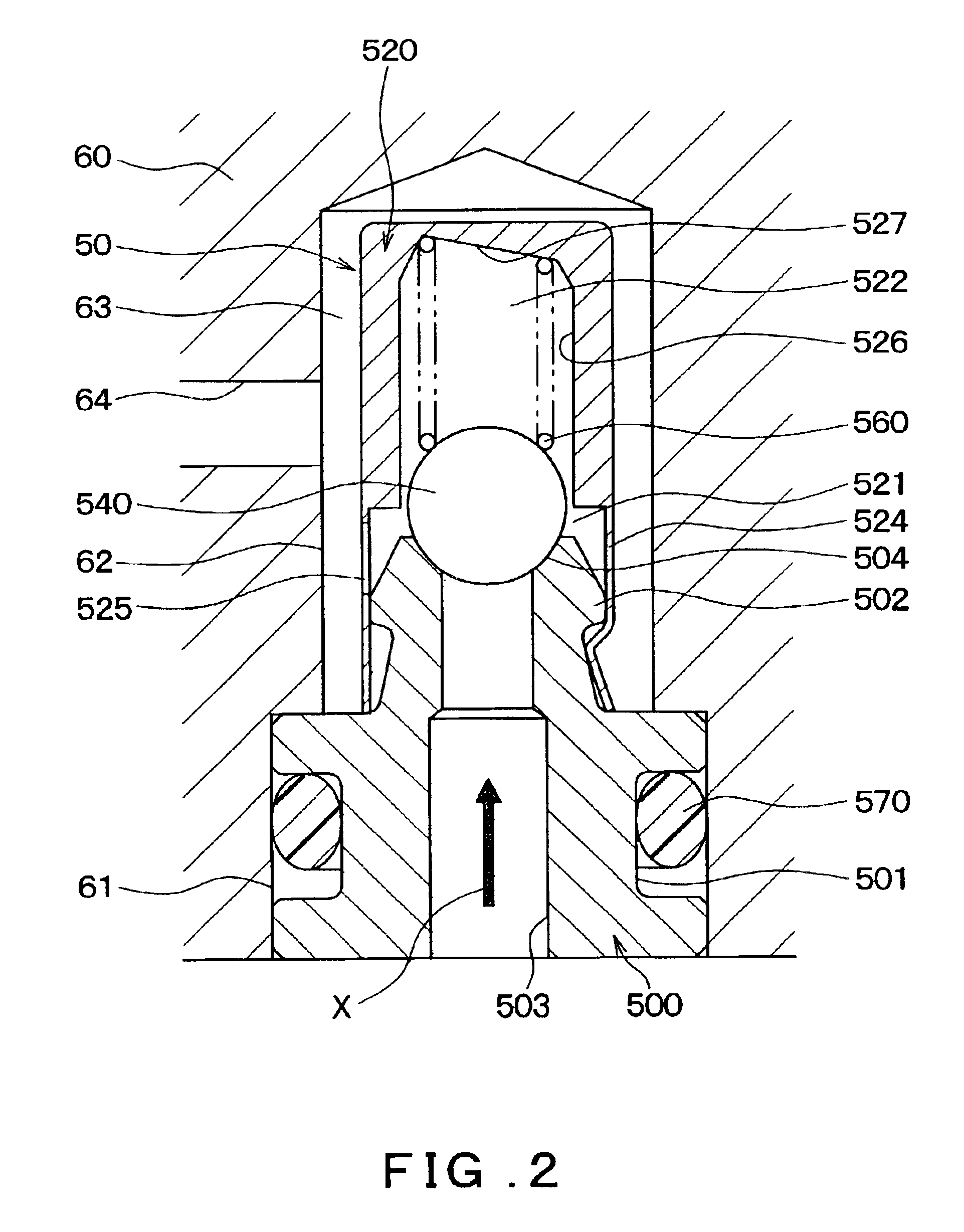

Fluid-filled type vibration-damping device

ActiveUS20060208405A1Increase flexibilitySolve the lack of durabilityMachine framesLiquid springsElastomerEngineering

A fluid-filled type vibration-damping device having an elastic rubber film partially defining a primary fluid chamber at one surface and partially defining a pressure action chamber. The pressure action chamber varies its pressure under control so that the elastic rubber film changes its elasticity to change damping characteristics of the device. To give sufficient recovery force for the elastic rubber film, the elastic rubber film includes a plurality of thick reinforcing ribs circumferentially spaced apart from one another and extending in a radial direction from an outside peripheral edge over a length not reaching a center so that areas situated between pairs of adjacent reinforcing ribs constitutes thin portions formed by a thin rubber elastic body, while the center portion of the elastic rubber film situated between distal ends constitutes a bowed center portion thinner than the reinforcing ribs and convex towards the pressure action chamber.

Owner:SUMITOMO RIKO CO LTD

Explosion-field shock wave overpressure filter

InactiveCN102818670ARequirements for Accurate Measurement of Quasi-static PressureAchieving Accurate Measurement RequirementsApparatus for force/torque/work measurementShock waveEngineering

The invention discloses an explosion-field shock wave overpressure filter, which is composed of a cover plate, a tube cavity, a screw rod, a buffer gasket, a sensor installing base and a pressure sensor, wherein one end of the tube cavity is connected with the cover plate, and the other end of the tube cavity is connected with the sensor installing base; the piezoresistive pressure sensor is installed in the sensor installing base; and the inner part of the tube cavity is provided with the screw rod. Explosive is exploded in a closed environment, and shock waves enter from a blind hole in the cover plate, penetrate through cross through holes, and enter into a groove of the screw rod in the tube cavity from gaps around a boss. The shock waves are transmitted along with the screw groove to be weakened, and finally the shock waves are transmitted to the sensitive surface of the pressure sensor. The pressure sensor is subjected to a pressure action and then outputs pressure signals, the pressure signals are amplified through a front adapter, and then a quasi static pressure curve is obtained.

Owner:XIAN MODERN CHEM RES INST

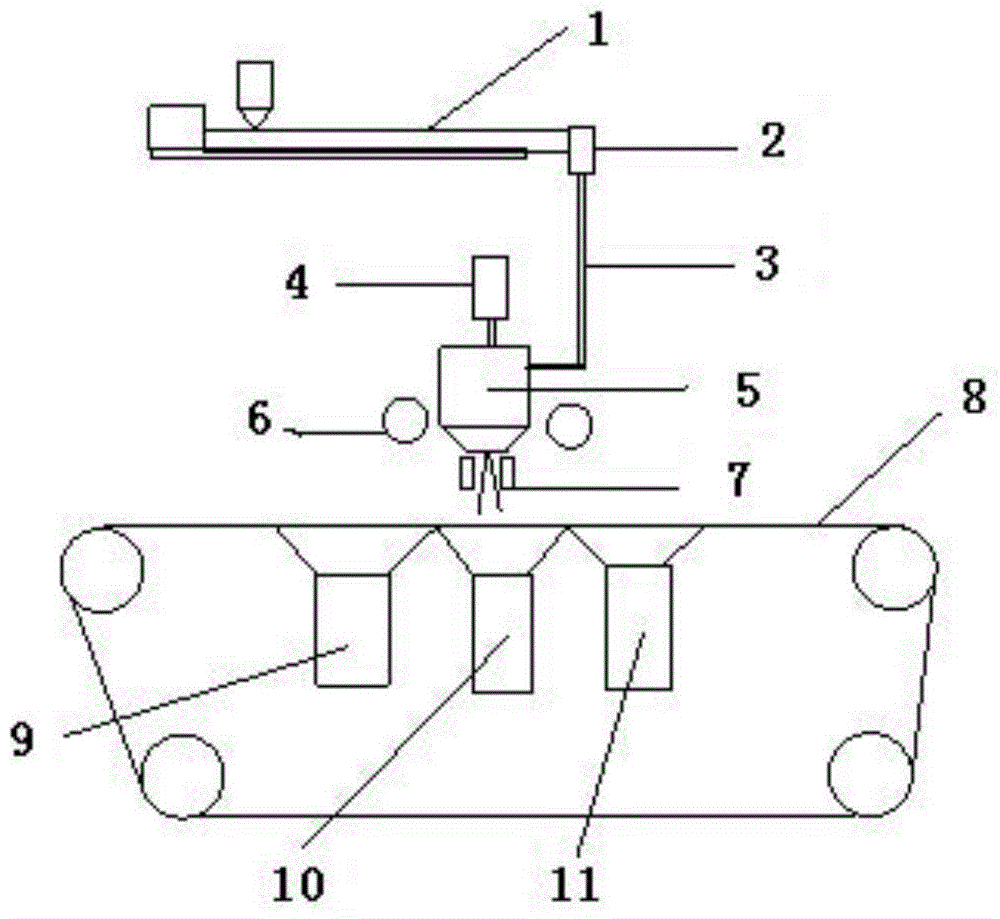

Automatic feeding device for nondestructive testing of leafy vegetables

The invention relates to the field of testing equipment, and discloses an automatic feeding device for nondestructive testing of leafy vegetables. The automatic feeding device for nondestructive testing of the leafy vegetables comprises a rotation transportation unit, a suction unit, a material storage unit, a power output unit and a motor control unit. The rotation transportation unit comprises a roller, the circumference of the roller is provided with multiple sets of suction holes, and a sealing unit used for blocking one set of the suction holes in the roller is fixedly arranged in the roller; the suction unit comprises a suction pump which is used for sucking air in the roller to form negative pressure on the inner side of the roller; the material storage unit comprises a material tank used for containing the leafy vegetables, the material tank is located below the roller, and when the automatic feeding device works, the leafy vegetables in the material tank are adsorbed on the outer wall of the roller under the negative pressure action of the roller; the power output unit is used for driving the roller to rotate and conveying the leafy vegetables to the corresponding position blocked by the sealing unit to fall; the motor control unit is used for controlling the rotation speed of the roller. According to the automatic feeding device for nondestructive testing of the leafy vegetables, continuous, even and automatic feeding can be achieved, and necessary conditions are supplied to optical nondestructive testing of the leafy vegetable quality.

Owner:CHINA AGRI UNIV

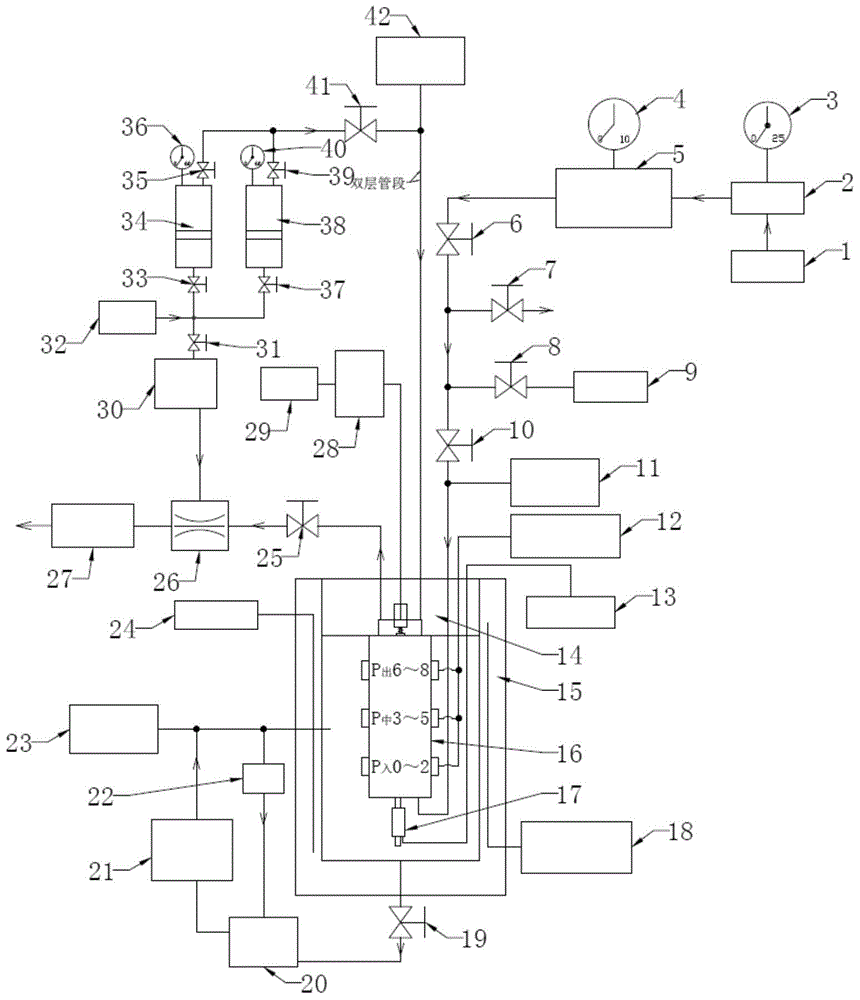

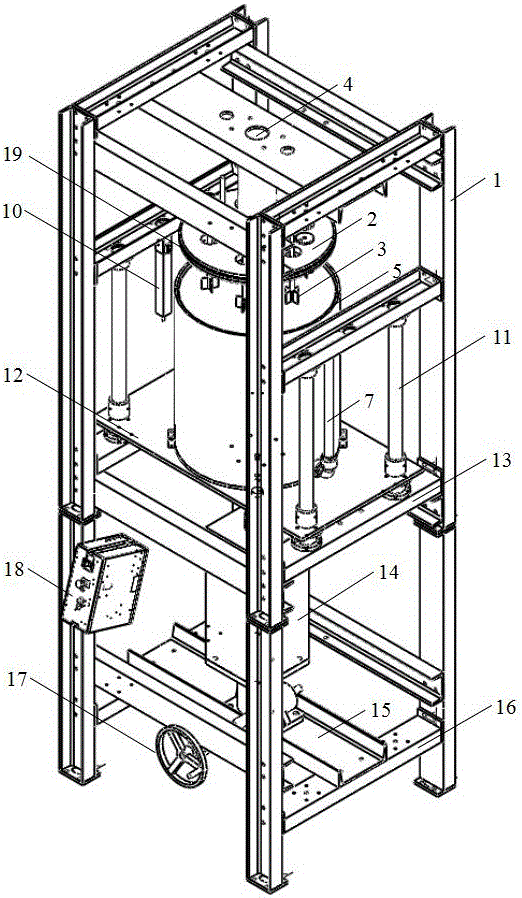

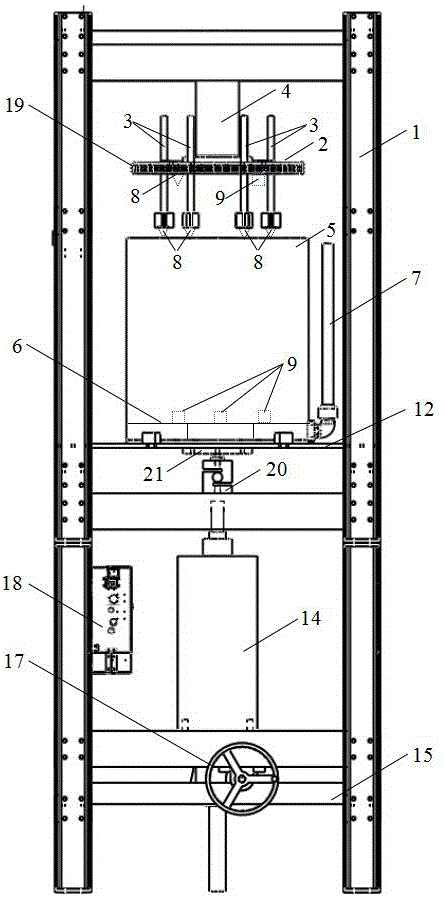

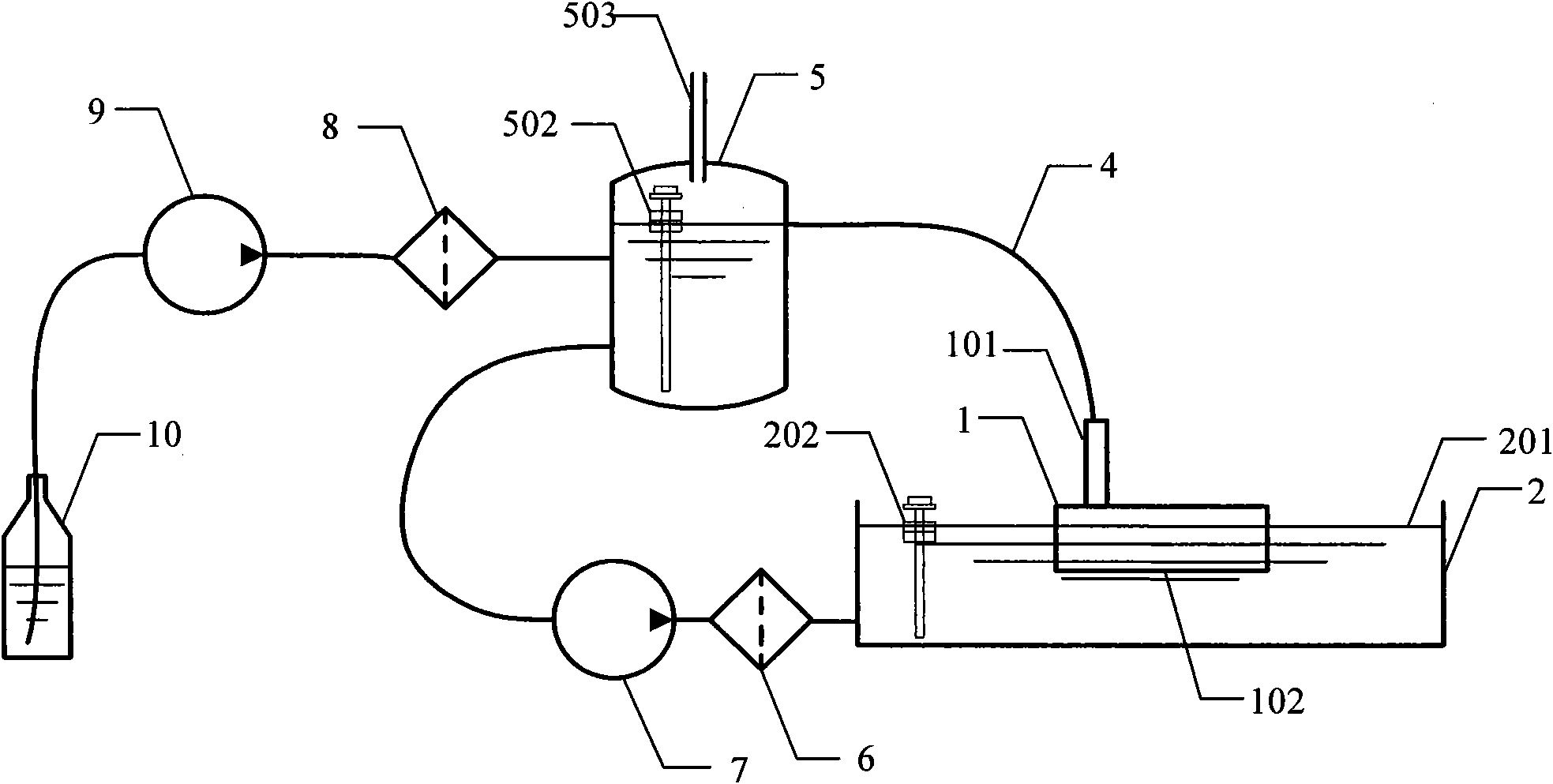

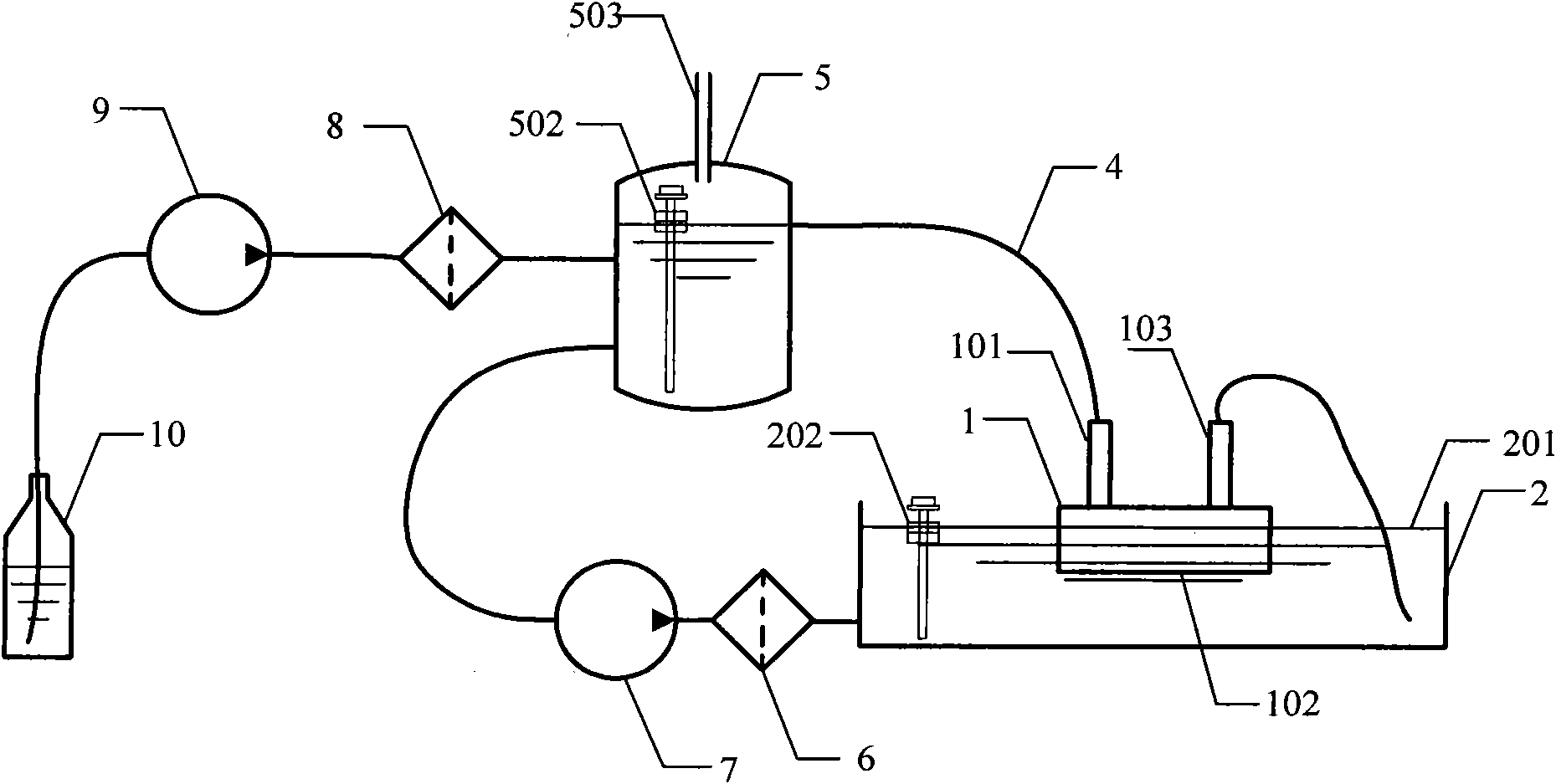

Crack-containing shale stability evaluation device and method

ActiveCN106153856ARealize stability evaluationRealize evaluationEarth material testingEngineeringPressure - action

A crack-containing shale stability evaluation device mainly comprises a kettle, a temperature control assembly connected with the kettle, a pressure assembly connected with the kettle, a back pressure control assembly, a gas source supply control assembly, a liquid medium assembly connected with the kettle, a core deformation measuring assembly connected with the kettle, and a data measuring and collecting assembly, wherein the kettle is used for fixing a core and simulating the environment around the core; the temperature control assembly is controlled to heat the core, control the temperature and simulate the actual temperature of a stratum; the pressure assembly is used for exerting confining pressure, required by experiments, on the core to simulate stratum burden pressure; the back pressure control assembly is used for back pressure control of the core; the gas source supply control assembly is used for providing a constant-pressure gas source on a core inlet end; the liquid medium assembly is used for providing clean water or slurry for the core and simulating the pressure action of drilling fluid circulation; the core deformation measuring assembly is used for measuring core deformation; the data measuring and collecting assembly is connected with the assemblies and used for obtaining expansion strain, the crack core pore pressure propagation rule and pressure penetration period monitoring results.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible floating ring seal arrangement for rotodynamic pumps

InactiveUS20070160465A1Effective limitResistant to wearSpecific fluid pumpsPropellersCentrifugal forceRotodynamic pump

A floating ring seal arrangement for rotodynamic pumps comprises a flexible ring that is structured to fit within a circular channel formed by generally concentric grooves in the rotating and non-rotating elements of the pump, the ring further being sized to rest against the inner diameter of the groove of the rotating element when static, and capable of radially expansion under centrifugal forces to cause the flexible ring to float in the circular channel during operation of the pump, or deformation under centrifugal or pressure forces such that gaps between the flexible ring and groove in the non-rotating element are minimized or eliminated.

Owner:WEIR SLURRY GRP INC

Fluid-filled type vibration-damping device

ActiveUS7350776B2Satisfactory low dynamic spring characteristicGood vibration reduction effectMachine framesLiquid springsElastomerEngineering

A fluid-filled type vibration-damping device having an elastic rubber film partially defining a primary fluid chamber at one surface and partially defining a pressure action chamber. The pressure action chamber varies its pressure under control so that the elastic rubber film changes its elasticity to change damping characteristics of the device. To give sufficient recovery force for the elastic rubber film, the elastic rubber film includes a plurality of thick reinforcing ribs circumferentially spaced apart from one another and extending in a radial direction from an outside peripheral edge over a length not reaching a center so that areas situated between pairs of adjacent reinforcing ribs constitutes thin portions formed by a thin rubber elastic body, while the center portion of the elastic rubber film situated between distal ends constitutes a bowed center portion thinner than the reinforcing ribs and convex towards the pressure action chamber.

Owner:SUMITOMO RIKO CO LTD

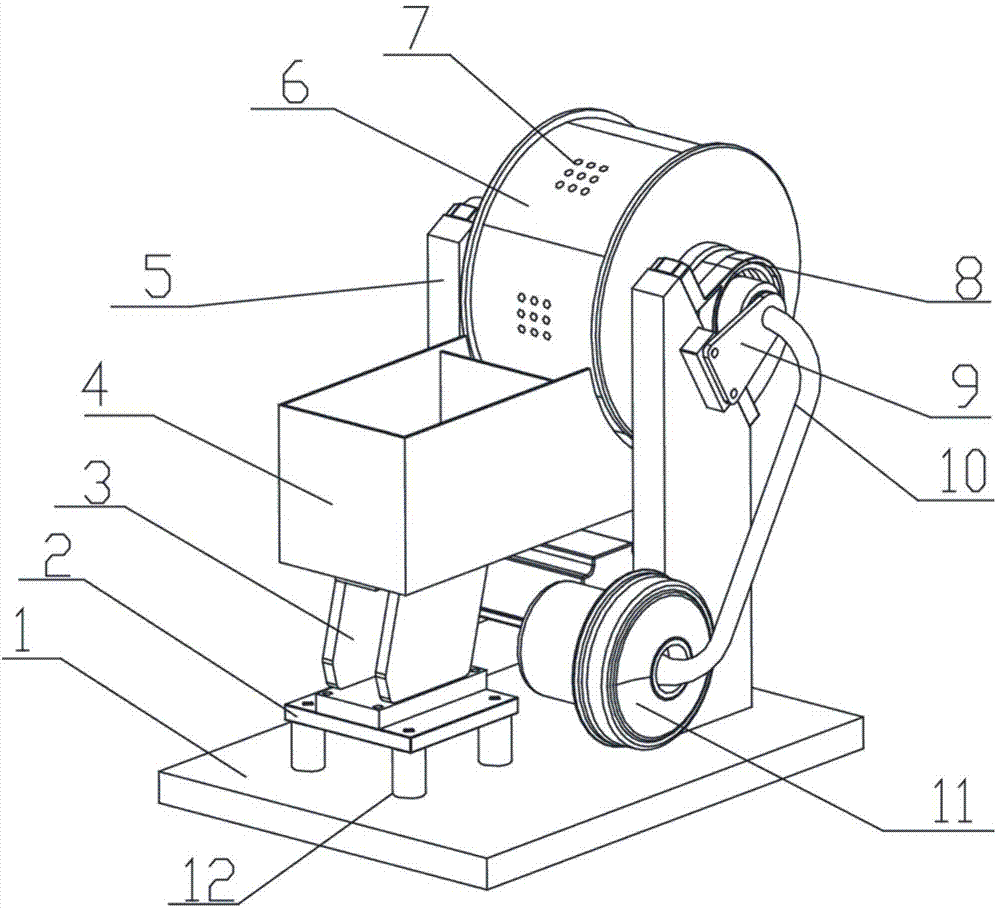

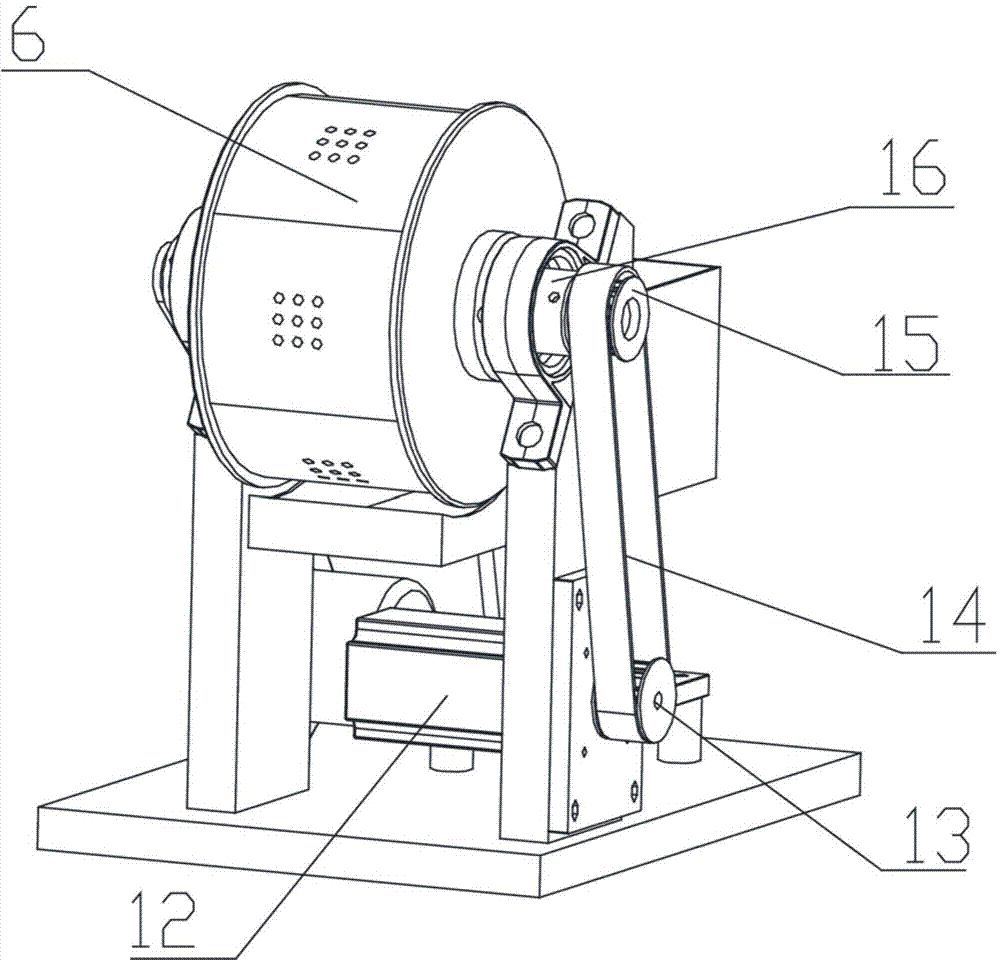

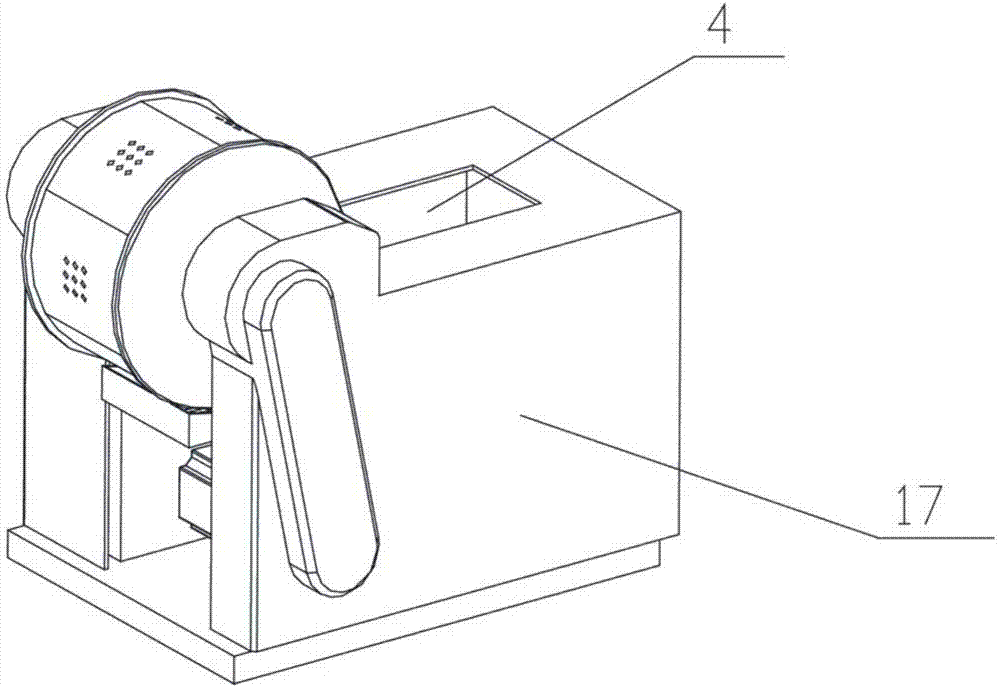

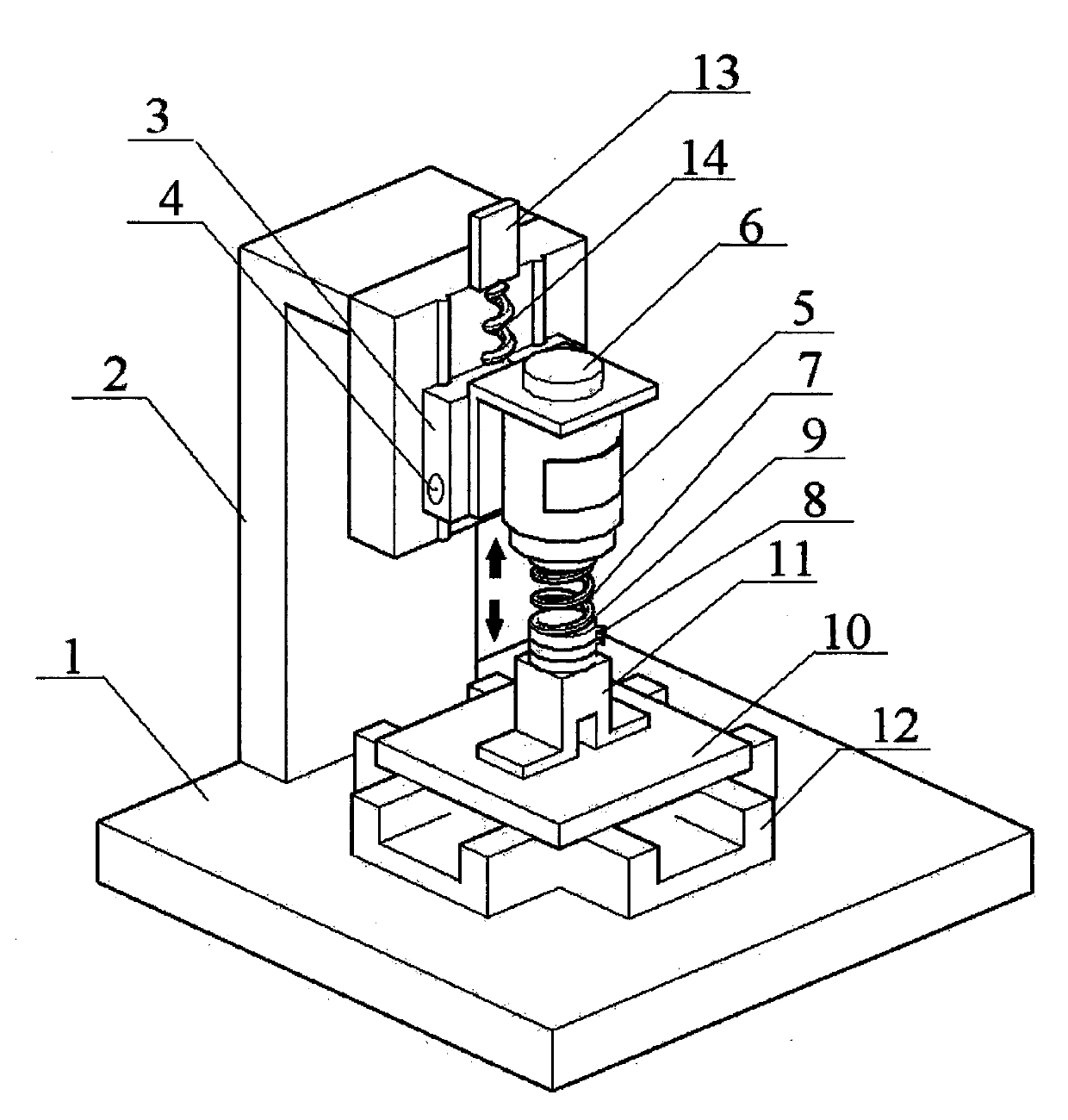

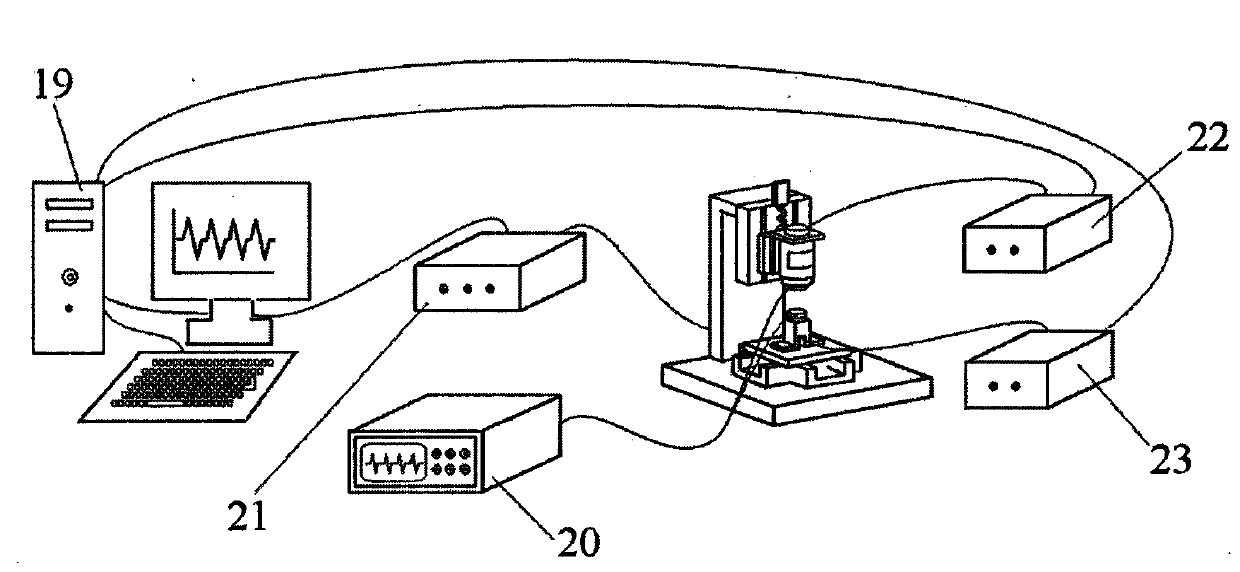

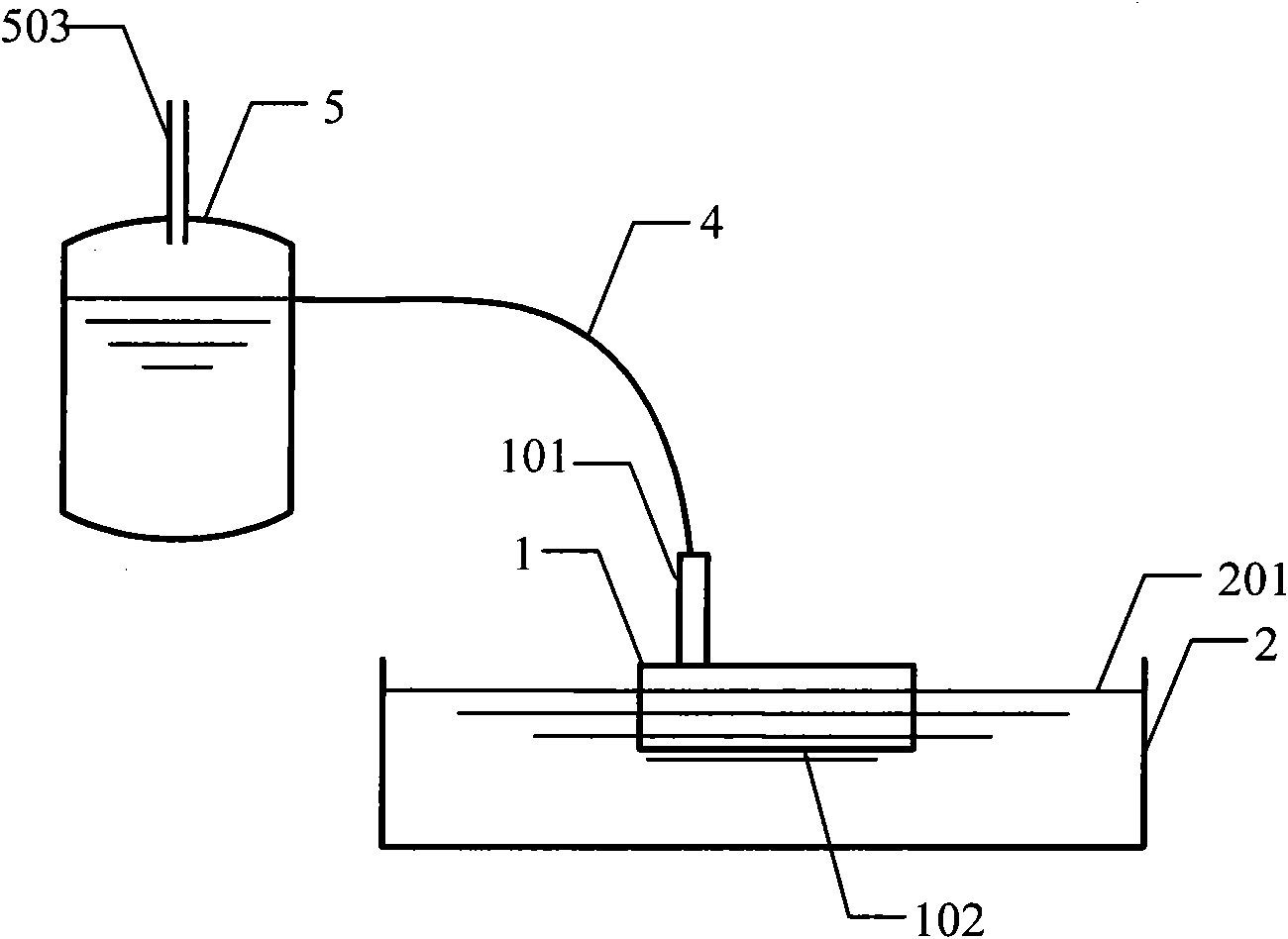

Device and method for testing piezoelectric property of electrostatic spinning PVDF (polyvinylidene fluoride) piezoelectric fiber membrane

The invention discloses a device for testing piezoelectric property of an electrostatic spinning PVDF (polyvinylidene fluoride) piezoelectric fiber membrane. A vertical seat is fixed in the rear of a base, a vertical panel capable of moving up and down is arranged on the front side of the vertical seat, one end of the vertical panel is connected with one end of a stepping motor, a motor fixing device is arranged on the vertical panel, one end of the motor fixing device is connected with the upper end of a motor, a spring is fixed to the lower end of the motor, the lower end of the spring is connected with a contactor, a first insulation layer is arranged between the contactor and the spring, a force transducer is arranged under the contactor, a second insulation layer and a conductive layer are arranged on the force transducer which is arranged in the middle of a clamp, and the clamp is arranged on the base through a horizontal panel. The device can measure piezoelectric signals generated by a flexible piezoelectric material under different-size and different-frequency pressure actions so as to characterize the piezoelectric property of the piezoelectric material, and measuring results can be computed to obtain piezoelectric strain constants; the electric signal measurement device is high in precision, good in repeatability and comparability and high in measurement efficiency.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Check valve with vibration prevention function

In a check valve of the present invention, when a pressure action direction of a fluid on a valve body is assumed to be X, a spring receiving surface that abuts with a seat surface that is at one end in an axial direction of the helical compression spring is made to incline with respect to a surface perpendicular to the pressure action direction X. Accordingly, an urging force of the helical compression spring on the valve body acts obliquely with respect to the pressure action direction X. Thus the valve body is pressed to a side wall surface when the valve is opened, and vibration of the valve body is inhibited. Accordingly, it is possible to embody the invention with an extremely simple structure in which the spring receiving surface is inclined with respect to the surface perpendicular to the pressure action direction X.

Owner:ADVICS CO LTD

Gas-liquid pressure cylinder

InactiveCN104314912ACompact structureEasy maintenanceFluid-pressure actuator testingServometer circuitsLow speedFuel tank

The invention discloses a gas-liquid pressure cylinder. The gas-liquid pressure cylinder is not provided with an oil storage cavity and is simple and compact in structure, convenient to maintain, high in efficiency, and saves energy. An oil inlet is formed in a liquid cylinder body and communicated with an oil storage tank of a braking system through a one-way valve. When the pressure cylinder does not have pressure air, the one-way valve is opened, and the oil storage tank is communicated with the pressure cylinder. After the pressure cylinder is filled with compressed air, due to the pressure action, the one-way valve is closed, and the passage between the oil storage tank and the pressure cylinder is cut off. The gas-liquid pressure cylinder can realize automatic oil supplement, lowers the labor intensity, and is low in maintenance cost. As a hydraulic sensor is arranged in the liquid cylinder body, the gas-liquid pressure cylinder has a real-time pressure monitoring function, can quickly and accurately feedback and display hydraulic pressure information, can carry out an early-warning prompt for abnormal pressure, and is convenient for a hydraulic system to maintain and find faults. The gas-liquid pressure cylinder is convenient to add oil and can monitor and feedback the hydraulic pressure in real time, all the operations are automatically completed during working, and the practicality is strong. The gas-liquid pressure cylinder is used together with low-speed and middle-speed maglev train braking systems, lowers the labor intensity of workers, and is convenient to maintain and reliable in work.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Testing device for measuring shearing strength parameter changes in solidifying process of soft clay

ActiveCN106290006AVarious types of experimentsUniversalEarth material testingMaterial strength using steady shearing forcesSoft clayPore water pressure

The invention relates to a testing device for measuring the shearing strength parameter changes in the solidifying process of soft clay and belongs to the technical field of soft clay analyzing devices. The testing device comprises a frame, a loading plate, miniature vane shearing instruments with a pore pressure testing function, a torsion meter, a sample chamber, a measuring unit and a lifting mechanism. The loading plate is arranged above the sample chamber, and the loading plate or the sample chamber is arranged on the frame through the lifting mechanism. The measuring unit comprises sensors used for collecting pore water pressure, soil pressure, displacement and other information. By means of the testing device, a shearing failure mechanism without volume change action or a shearing failure mechanism without pore pressure action can be independently studied, a shearing failure mechanism under volume change and pore pressure coupled action can be studied at the same time, and more testing types are achieved; shearing strength changes caused by soil body changes and pore pressure changes in the loading and solidifying process of soft clay can also be studied, and the changing rules of the shear strength parameters in the whole study process along with the solidifying process can be studied.

Owner:HOHAI UNIV

Road foundation or base and building soft foundation grouting reinforcement method

The invention discloses a road foundation or base and building soft foundation grouting reinforcement method. The method comprises the following steps: setting a reinforcement position, and drilling to form a grouting hole; making a grouting pipe with the length being greater than the depth of the grouting hole according to the depth of the grouting hole, and connecting the grouting pipe to a grouting pump; arranging the grouting pipe and starting the grouting pump to make a slurry flow into the grouting pipe, and allowing the slurry to be shunted when the slurry flows to the tail end of the casting pipe in order to make the slurry flow to a flow guiding pipe, and allowing the flow guiding tube to downward slide along a flow guiding slot under the pressure action of the slurry and to outward extend in a cruciform manner in order to make the nested flow guiding tube extend step by step; allowing the slurry to be discharged from slurry outlet holes arranged on the grouting pipe and the flow guiding pipe and to diffuse to a predetermined grouting reinforcement position and range; and stopping grouting, and pulling out the grouting pipe. The method has the advantages of wide diffusion range of the slurry, uniform distribution in the soft foundation, fast slurry discharging speed, good grouting reinforcement effect, and avoiding of secondary grouting.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Italian coffee machine

The invention discloses an Italian coffee machine which comprises a quantified grinding device and a coffee extraction device. A linkage powder discharging groove mechanism is arranged between the quantified grinding device and the coffee extraction device. The Italian coffee machine has the advantages that coffee powder is subjected to multi-grade pressurizing deep extraction, effective components which are hard to extract under the normal pressure action can be extracted out, and the flavor and taste of coffee are improved.

Owner:宁波夏纳电器有限公司

Fluffy melt-blow cloth preparation method

The invention relates to a fluffy melt-blow cloth preparation method. The method comprises the following steps that raw material is heated and melt via a screw extruder and then extruded to be filtered via a filter; then the melt and filtered raw material is conveyed to a metering pump for melt measurement via a pipeline; the melt is sent to a die head and forms fine fibers due to a traction action of high-speed hot air; and the fibers are cooled via cross air blasting and are then lapped on a net forming bench to form a non-woven fabric due to a negative pressure action of a front overflow draught fan, a pumping draught fan and a back overflow draught fan. By the use of the fluffy melt-blow cloth preparation method, problems of hard cloth surface hand feeling and poor fluffy performance of the fibers as well as thin cloth surface can be solved; and the fluffy melt-blow cloth is fluffy, has great tenacity and soft hand feeling.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

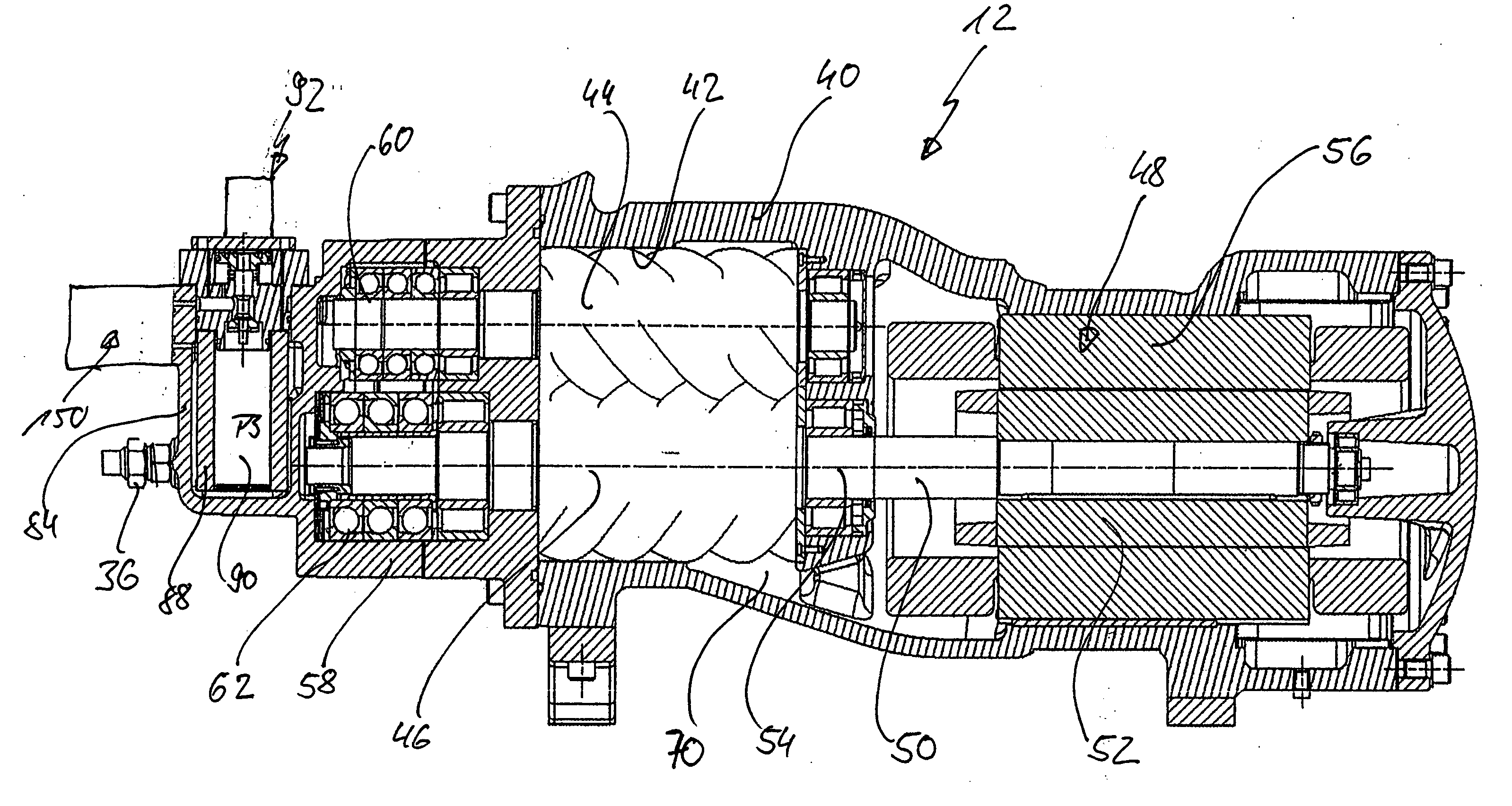

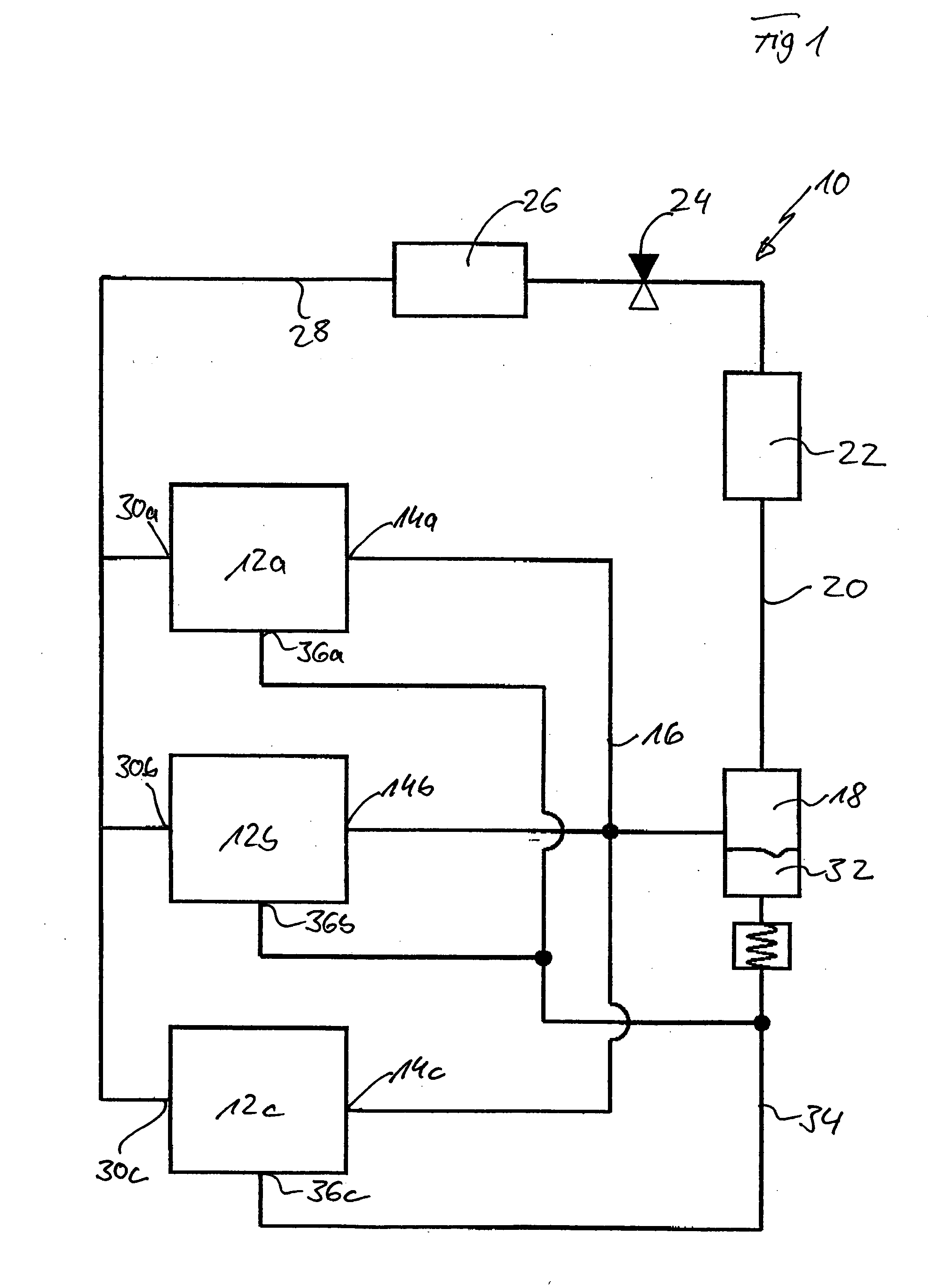

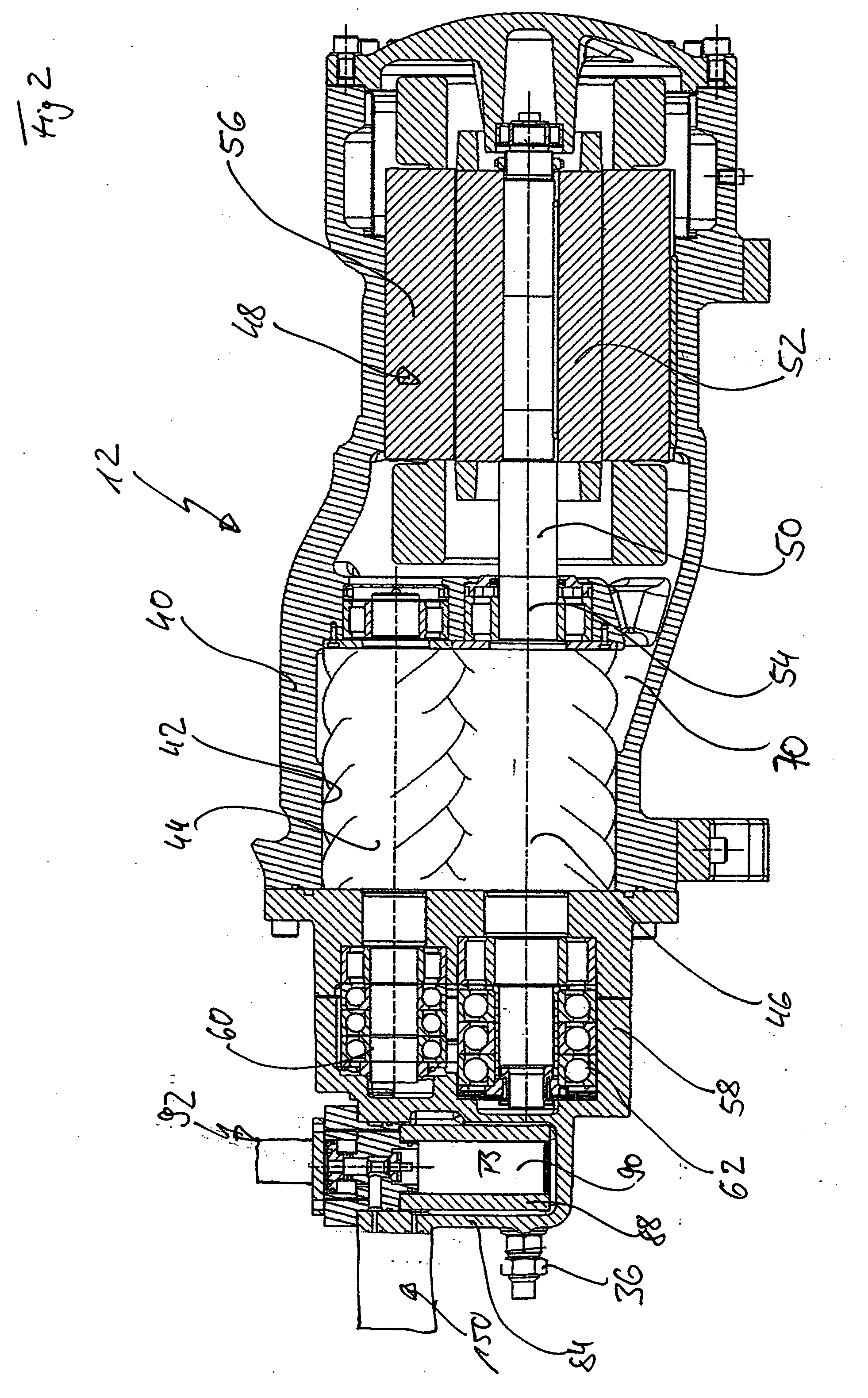

Screw compressor

ActiveUS20060117790A1Sufficient supplyPressure dropOscillating piston enginesSealing arrangement for pumpsEngineeringRefrigerant

In order to improve a screw compressor for compressing refrigerant in a refrigerant circuit, comprising a compressor housing, in which a screw rotor receiving means and an inlet channel as well as an outlet channel for the refrigerant to be compressed are provided, at least one screw rotor arranged in the screw rotor receiving means, a drive for the at least one screw rotor and a lubricant supply which conveys lubricant from a lubricant reservoir acted upon by pressure via a line system at least to the at least one screw rotor during operation, in such a manner that the operation and the monitoring of the screw compressor are reliable it is suggested that a valve be provided in the line system of the lubricant supply, this valve being controllable by way of a difference in pressure between the pressure in the outlet channel and a reference pressure influenced by a pressure in the refrigerant circuit and opening when the screw rotor is compressing refrigerant as well as closing when the screw rotor is not compressing refrigerant.

Owner:BITZER KUEHLMASCHINENBAU GMBH

Device and method for cleaning spray head

The invention discloses a device and a method for cleaning a spray head. The device comprises a cleaning tank and a negative pressure device, wherein the cleaning tank is filled with a cleaning solution for soaking a nozzle of the spray head, and the ink port of the spray head is communicated with the negative pressure device; and under the negative pressure action of the negative pressure device, the cleaning solution is sucked from the nozzle of the spray head and flows to the negative pressure device from the ink port. By adopting the device in the embodiment, the cleaning solution reversely flows in the spray head by using negative pressure, so that solidified ink and other impurities can be prevented from blocking the spray head, and the purpose of cleaning the spray head more thoroughly is fulfilled.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com