Pressure sensor based on friction power generation and pressure sensing system

A pressure sensor, triboelectric power generation technology, applied in the field of sensors, can solve the problem of no occurrence, and achieve the effect of overcoming susceptibility to static electricity, high precision, and wide application environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

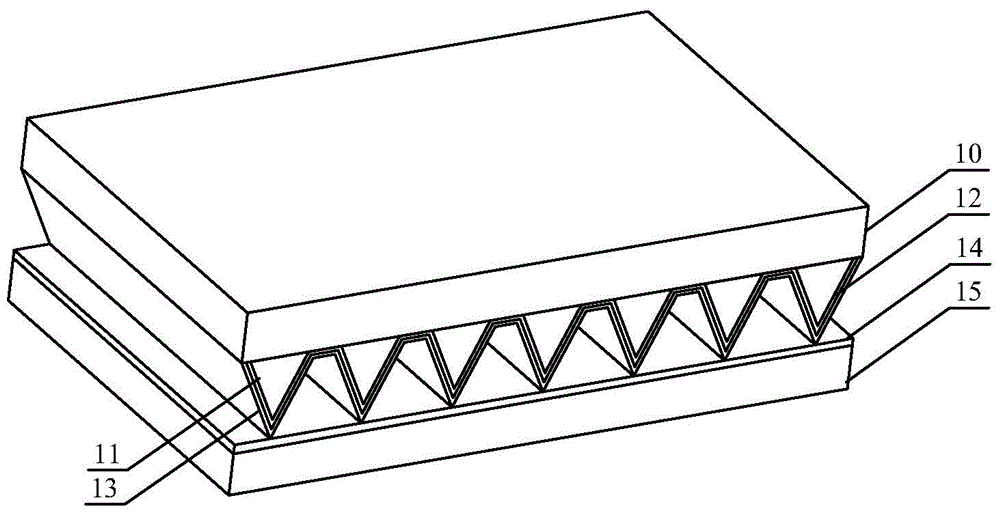

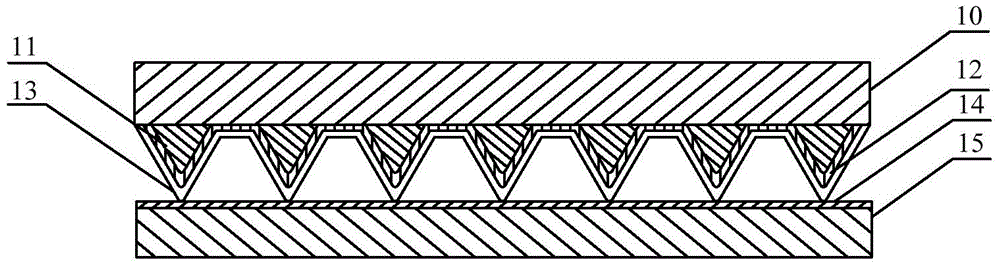

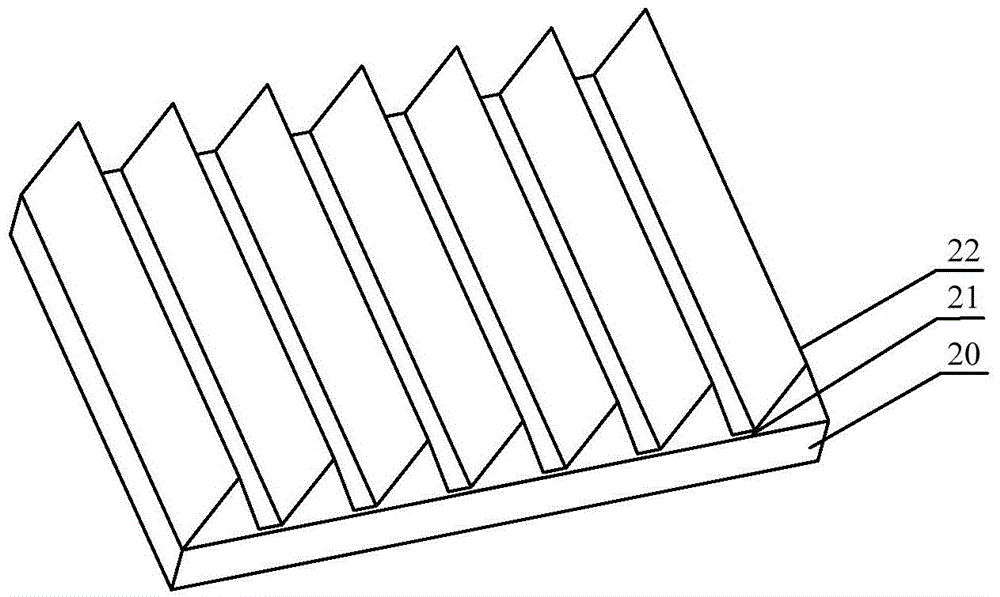

[0051] Aiming at the problems existing in the prior art, the present invention provides a pressure sensor based on triboelectric power generation. The pressure sensor at least includes a pressure bearing part, an elastic matrix, a base, and a friction generator located between the elastic matrix and the base. In a structure provided by the present invention, an elastic matrix with a regular convex structure is arranged on one side surface of the pressure-bearing part and / or the base; in another structure of the present invention, between the friction generator An elastic matrix with a regular raised structure is formed in the layer. One function of the elastic matrix is to enable the friction generator to form a friction interface with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com