Synchronous rectification driving circuit suitable for central tapped structure rectifying circuit

A drive circuit and rectifier circuit technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the problems of increasing online loss, reducing efficiency, voltage spikes, etc., and achieve power consumption The effect of reducing, reducing costs and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

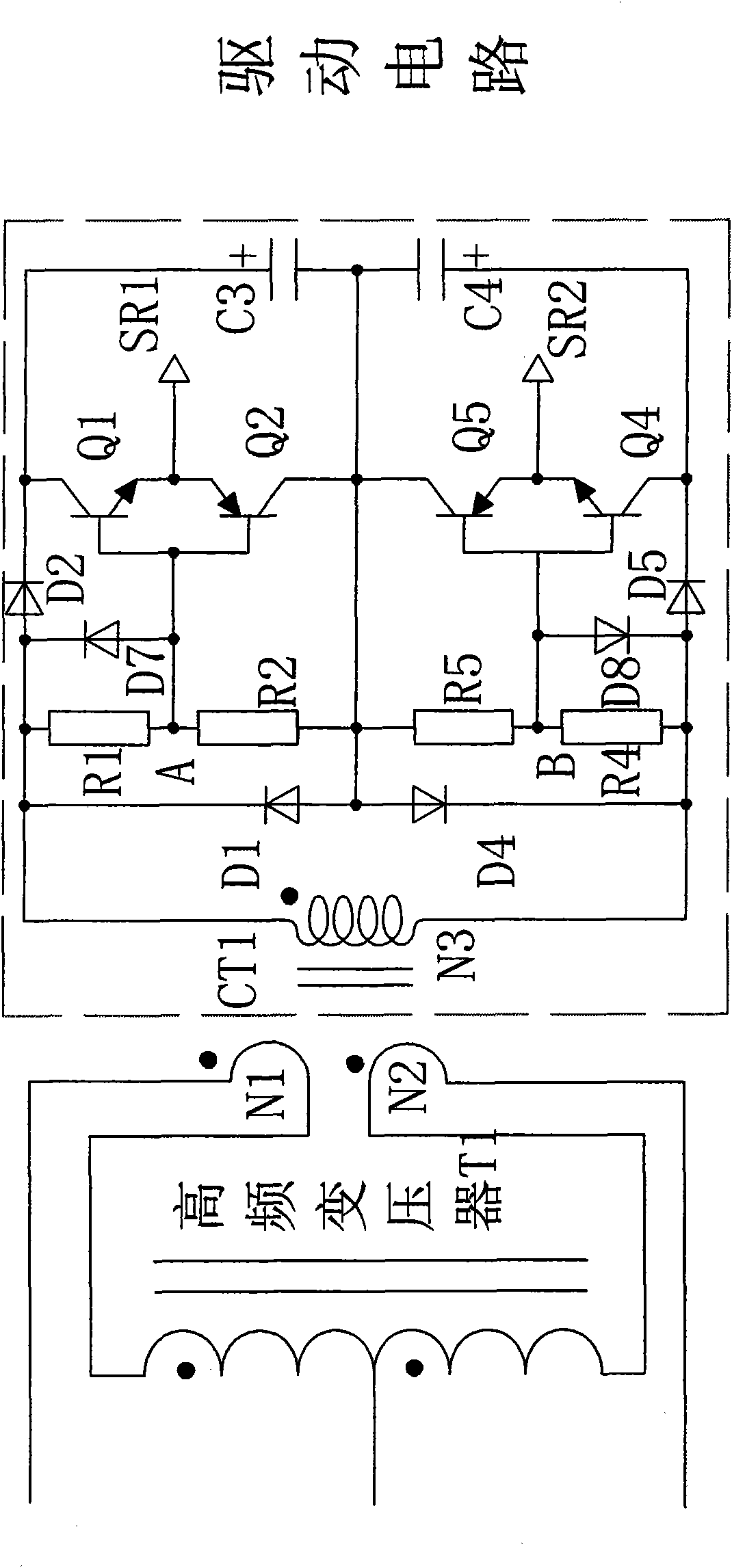

[0046] Refer to attached Figure 7 , The present invention is applied to Embodiment 1 of a center-tap structure rectifier circuit with misdrive protection, including a main circuit, a drive circuit, a current transformer CT1 and two misdrive protection circuits.

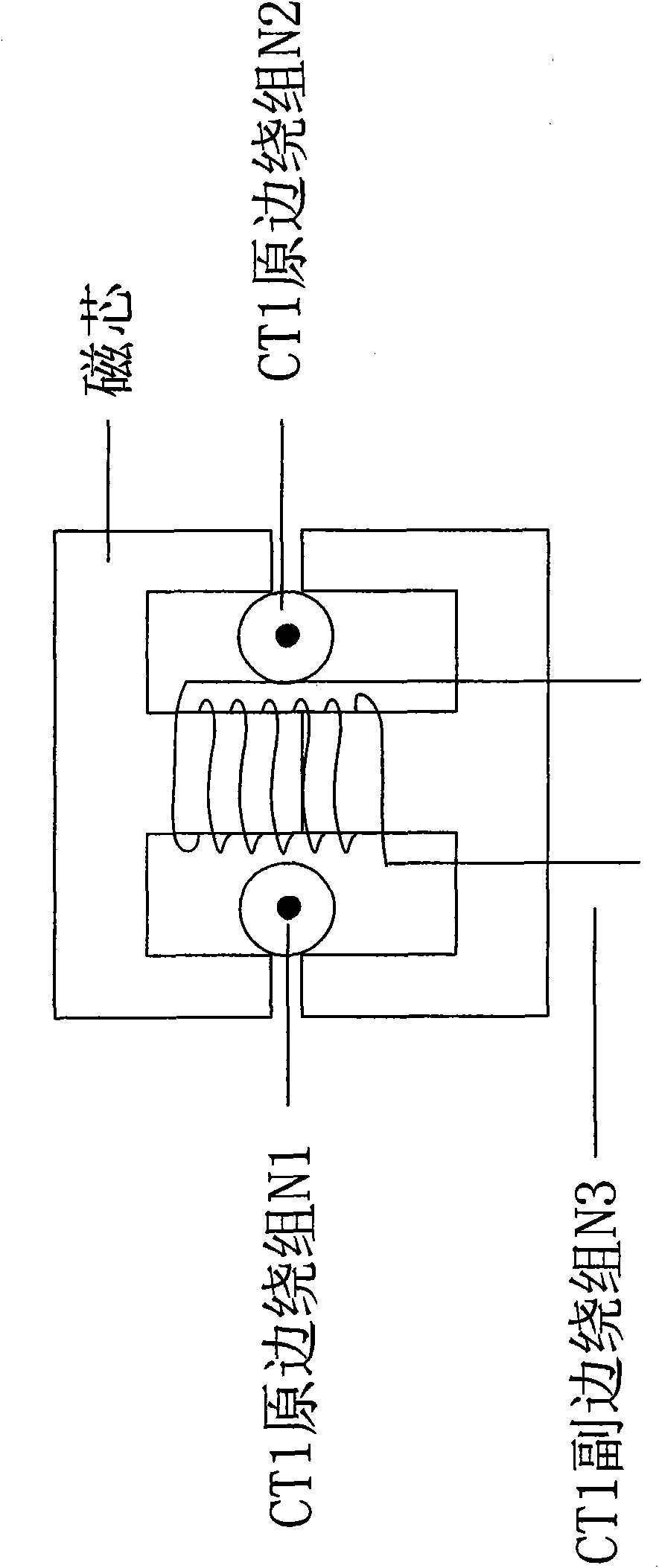

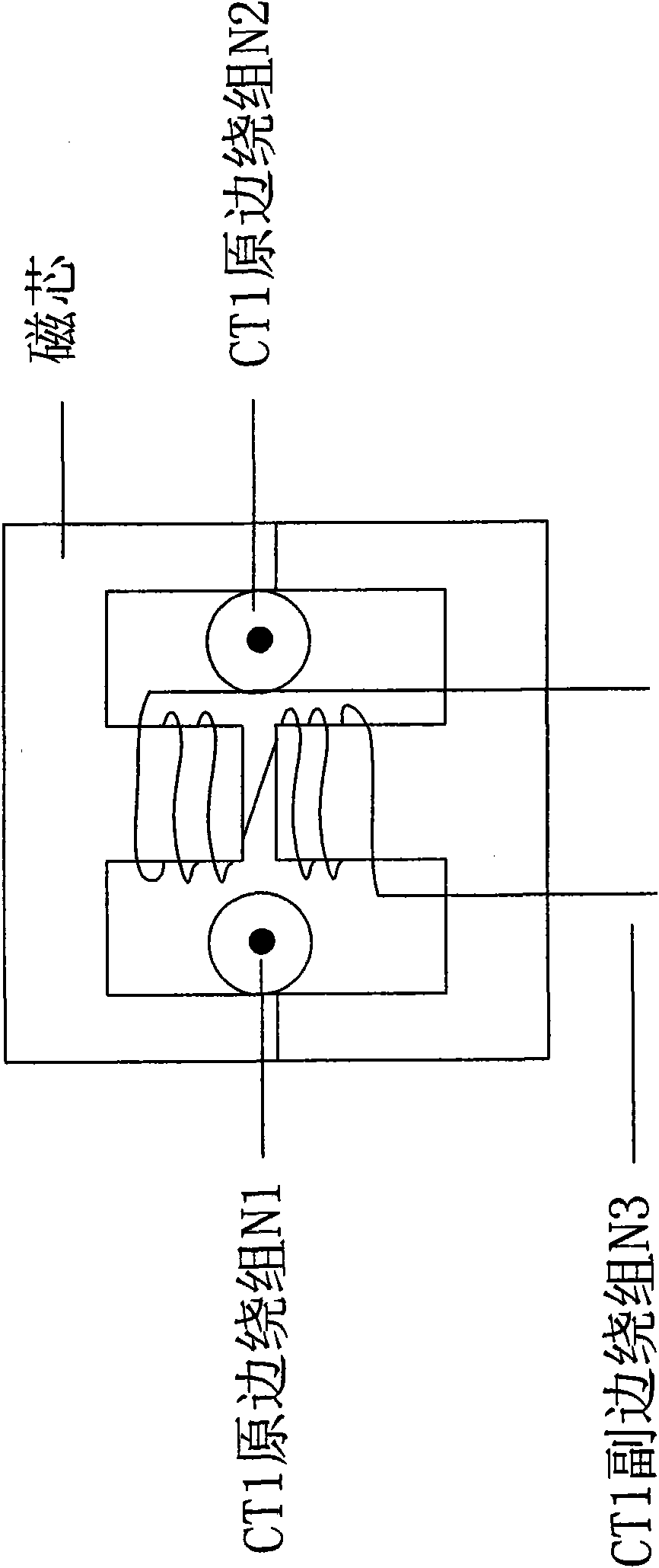

[0047] The main circuit is composed of a high-frequency transformer T1, a primary winding of a current transformer CT1, an output capacitor C1, an output capacitor C2, a synchronous rectifier SR1, and a synchronous rectifier SR2. The terminal with the same name of high-frequency transformer T1 is connected to the non-identical terminal of primary winding N1 of current transformer CT1, the non-identical terminal of high-frequency transformer T1 is connected to the terminal of the same name of primary winding N2 of current transformer CT1, and the center tap of high-frequency transformer T1 Connect to the positive poles of output capacitor C1 and output capacitor C2; the same-named terminal of the primary winding N1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com