Self-power distributed wireless current sensor

A current sensor, distributed technology, applied in current collectors, battery circuit devices, instruments, etc., can solve the problem of current sensors occupying additional space for separate power supply, and achieves the effect of saving wiring space, compact structure, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

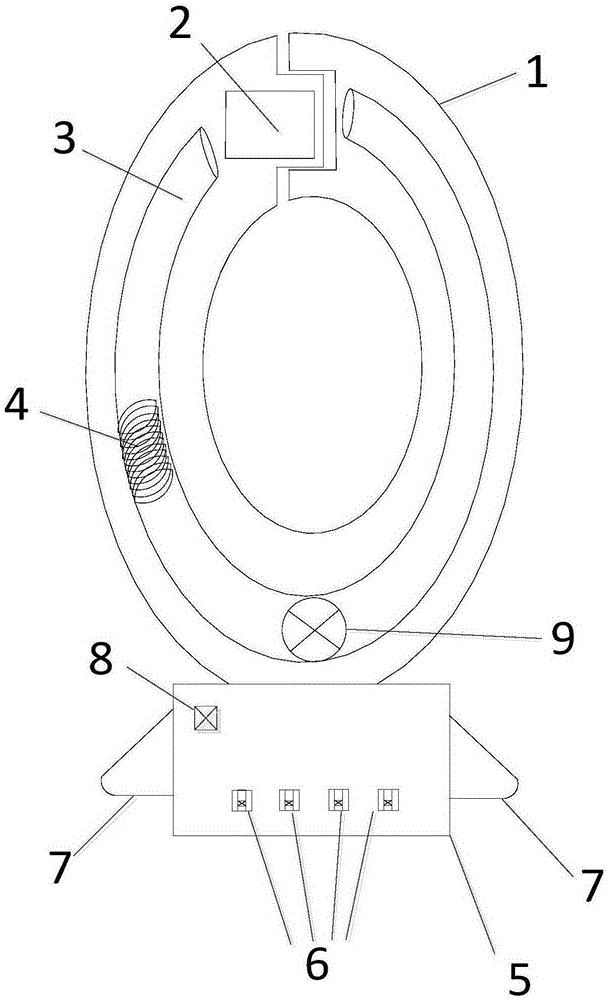

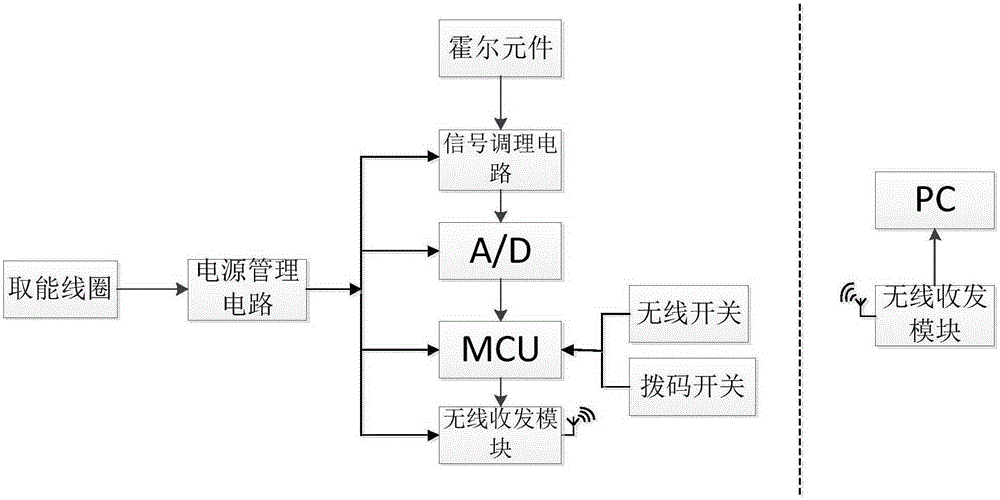

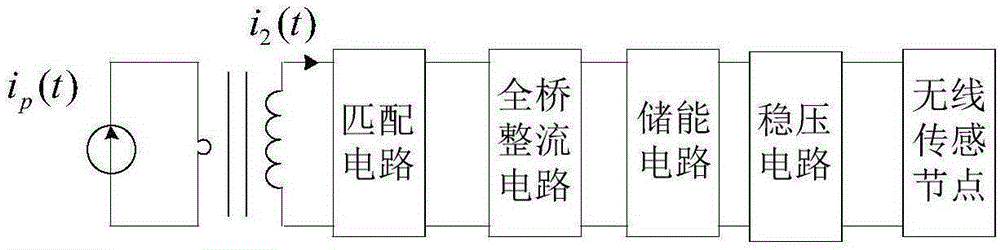

[0044] A self-powered distributed wireless current sensor, which is mainly buckled on the outside of the three-phase wires. When the wires are connected and current flows through, the energy harvesting coil 4 starts to work. The working principle of the energy harvesting coil 4 is similar to that of a transformer, but there are differences. The transformer uses the principle of mutual inductance of the coil to change the AC voltage of the front stage. The primary side of the energy-taking coil 4 is controlled by alternating current rather than voltage, and the primary side is a single-turn winding, and the secondary side is a multi-turn winding. , when the primary side is fed with a sinusoidal alternating current, the voltage induced by the secondary side of the energy-taking coil 4 is sorted out as follows: E = 4.44 2 fN 2 μSI μ / l ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com