Self-adaption intelligent system for monitoring abnormal conditions of turning tool and method thereof

A technology for intelligent monitoring and abnormal status, applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as low energy consumption and high monitoring convenience, reduce complexity, and reduce the difficulty of mastering and application by workers , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

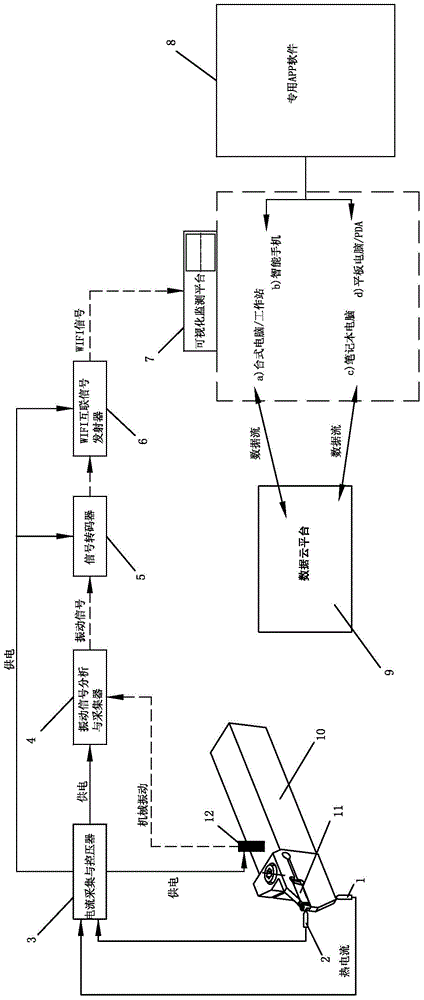

[0030] See figure 1 As shown, an adaptive intelligent monitoring system for abnormal state of a turning tool of the present invention includes:

[0031] A low-temperature end thermoelectric sensor 1 installed at the turning tool body 10 directly below the turning insert 11;

[0032] A thermoelectric sensor 2 at the high temperature end installed on the flank face of the turning insert 11 close to the cutting area;

[0033] A vibration sensor 12 installed at the overhang of the turning tool body 10 on the same plane as the turning insert 11;

[0034] A current acquisition and voltage control device 3, used to collect current signals and supply power to the components of the system; the current acquisition and voltage control device 3 includes transformers, voltage stabilizers, etc.;

[0035] A vibration signal analysis and collector 4 for collecting and analyzing vibration signals;

[0036] A signal transcoder 5, used to analyze and convert the input signal into an electronic signal that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com