Patents

Literature

650 results about "Brittle fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brittle fracture is the fracture of a metallic object or other material without appreciable prior plastic deformation. It is a break in a brittle piece of metal that failed because stress exceeded cohesion. The brittle fracture of normally ductile steels occurs primarily in large, continuous, box-like structures such as: Box beams.

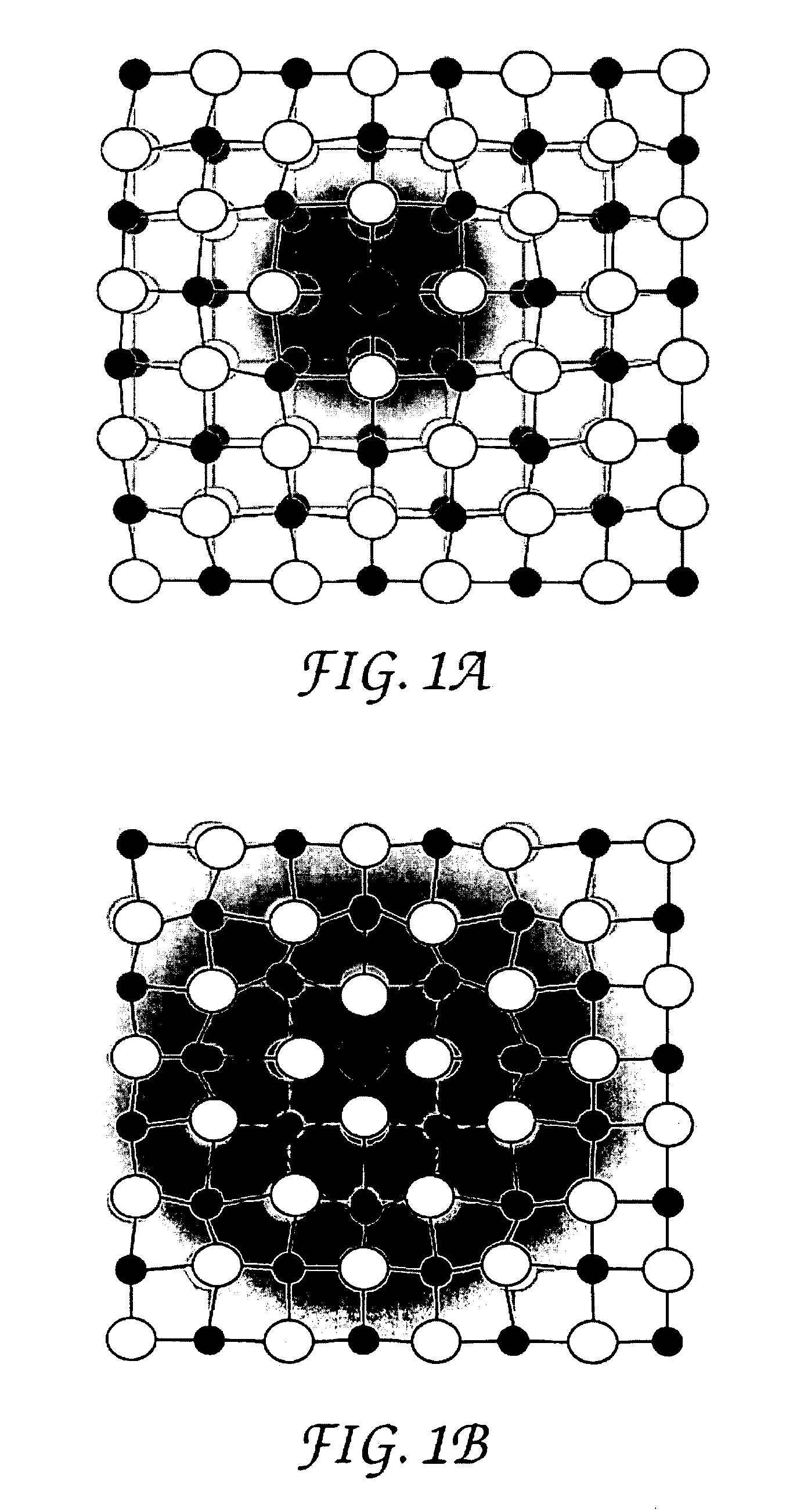

Bright metal flake based pigments

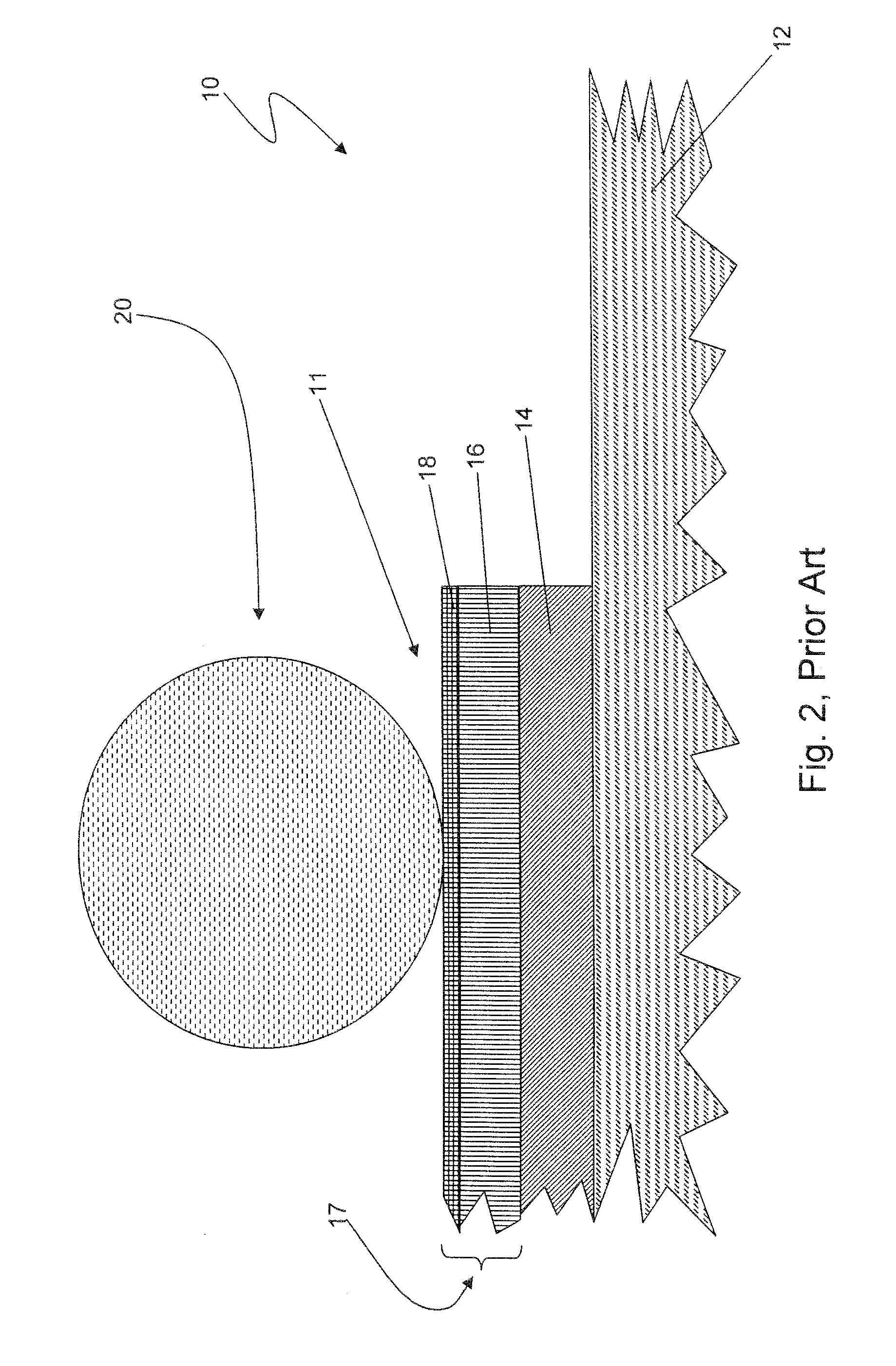

InactiveUS6150022AGood specular reflectance characteristicPigment preparation by PVD/CVD methodsSynthetic resin layered productsDielectricReflectivity

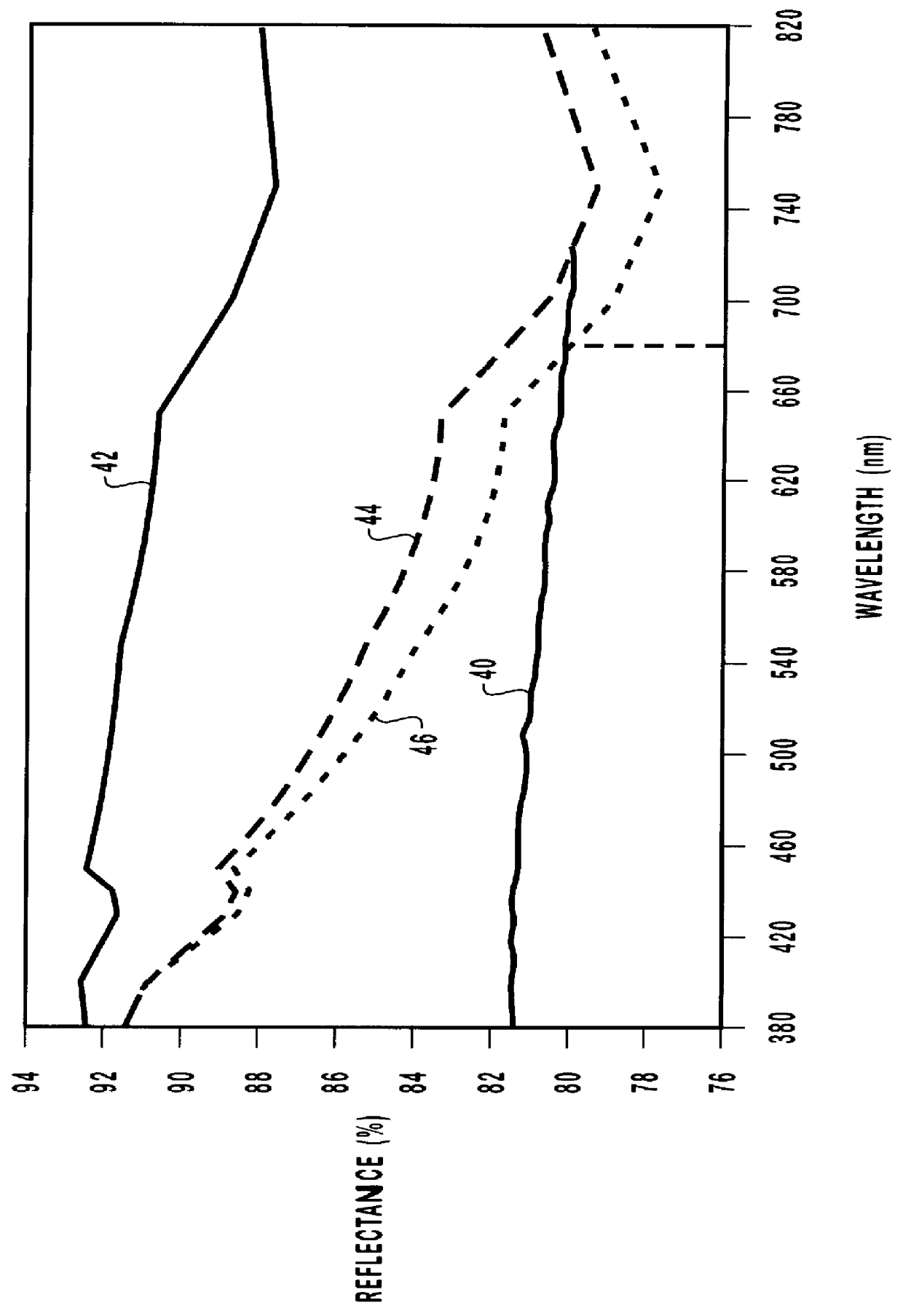

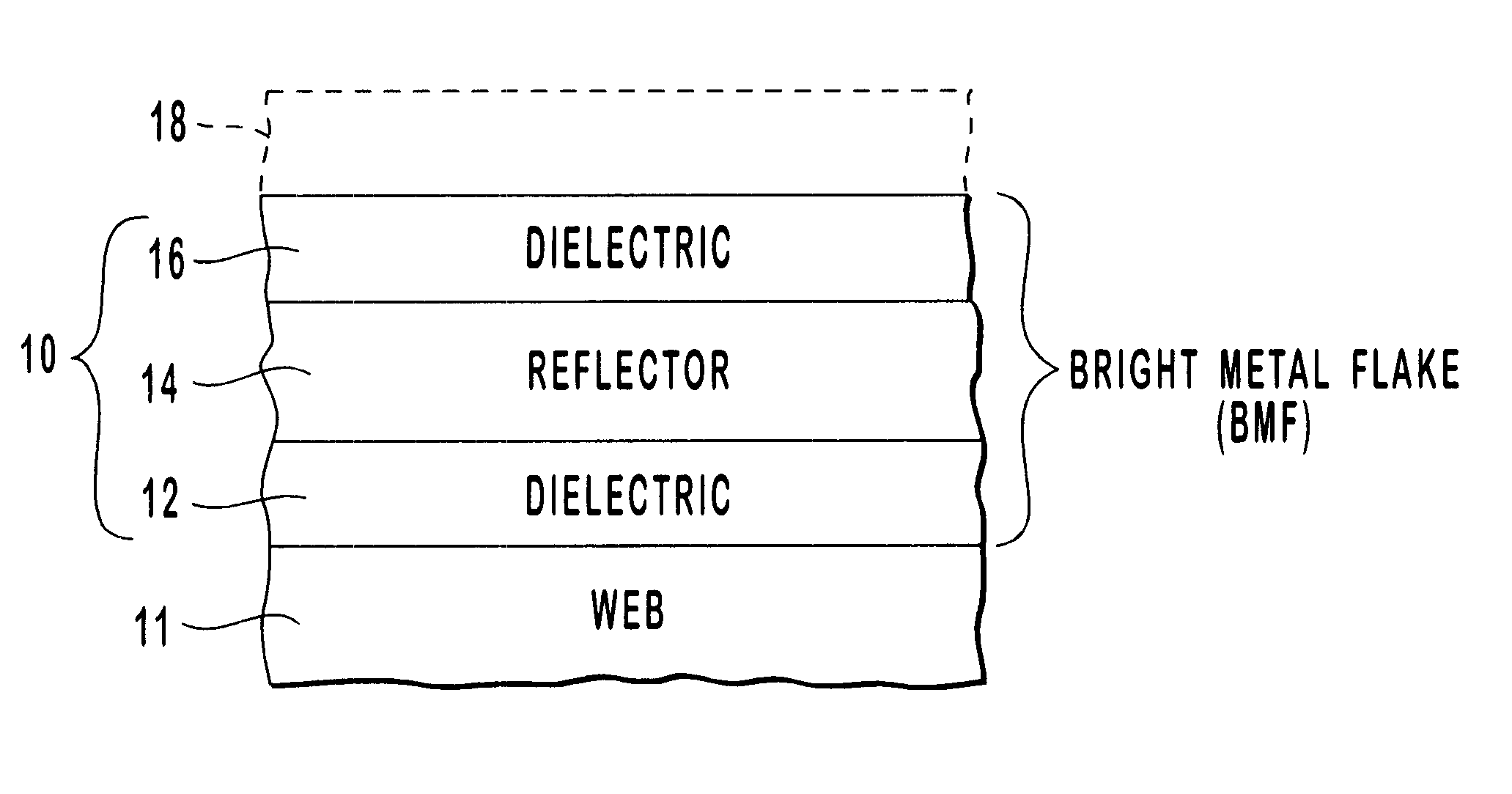

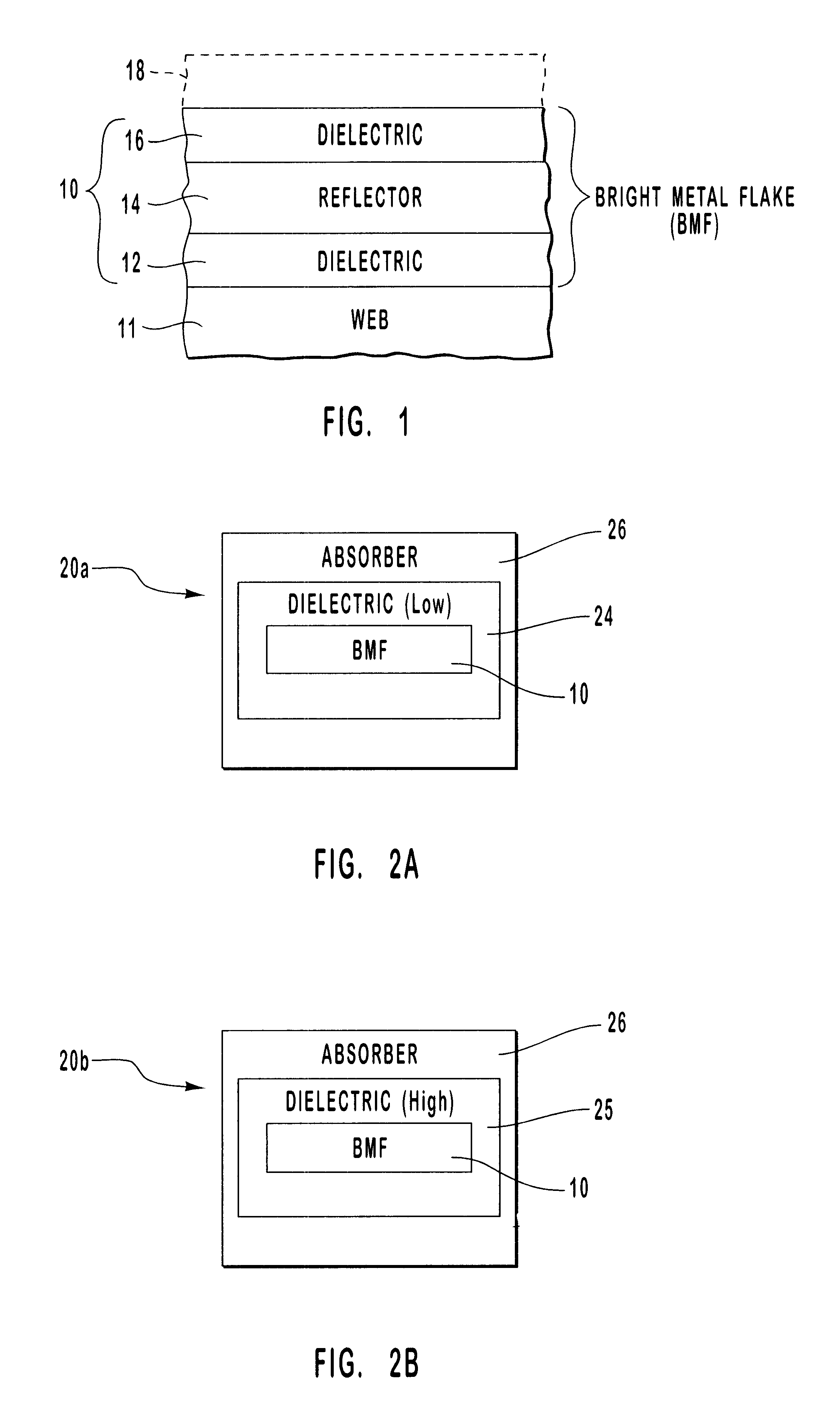

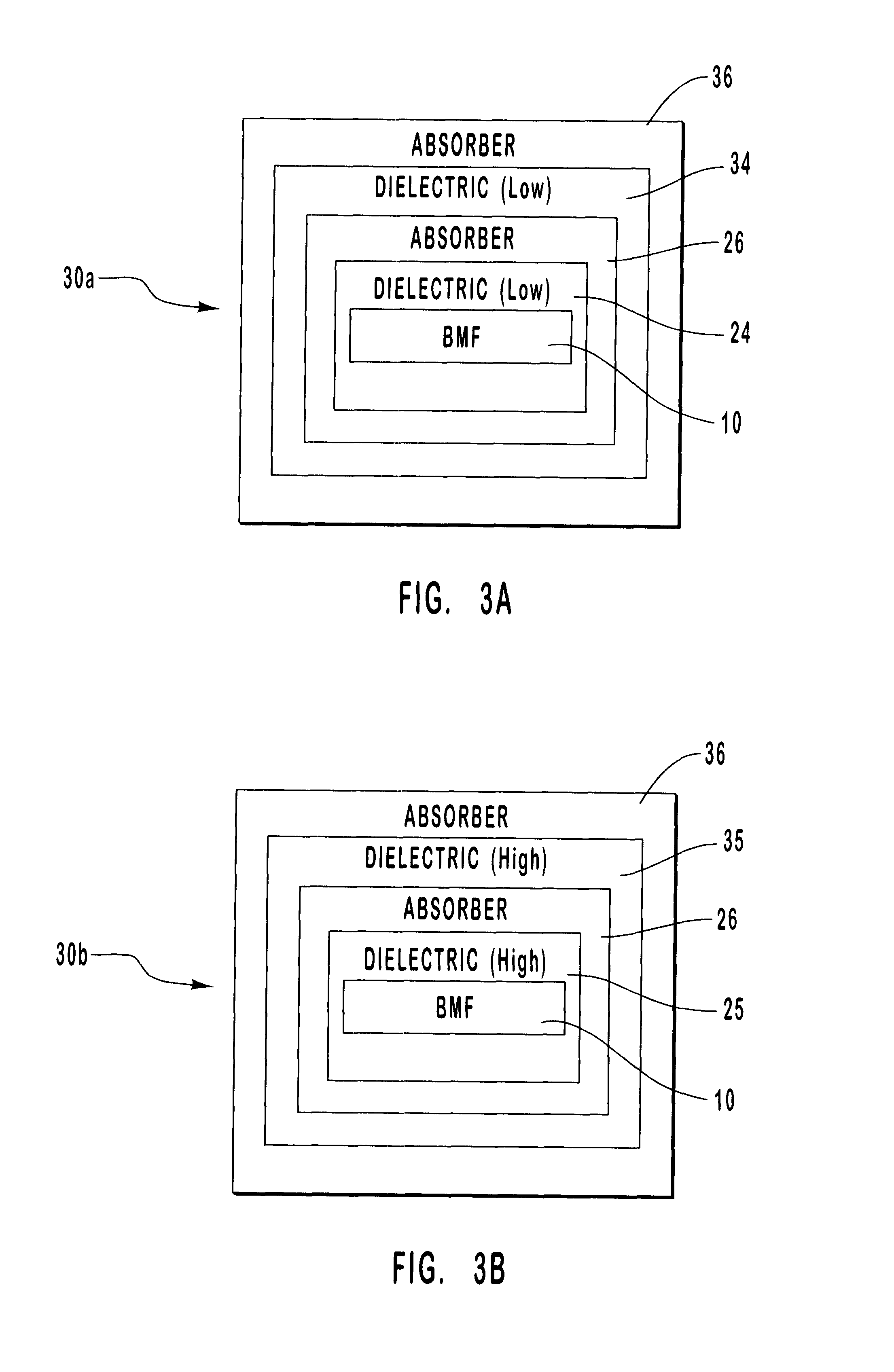

A flake-based pigment is provided having improved specular reflectance characteristics in the visible wavelength range. The flake-based pigment has a plurality of core flake sections each formed of a central reflector layer and dielectric support layers on opposing sides of the reflector layer. The resulting core flake section is a very thin three-layered structure that exhibits a uniaxial compressive strength much greater than a corresponding uniaxial tensile strength. This structure provides the benefits of rigidity and brittle fracture during manufacturing and application processes, which ultimately provides favorable planar and specular reflectance characteristics for the pigment in the visible wavelength range. A variety of outer coating layers can be formed around the core flake sections, such as various dielectric and absorber layers having thicknesses dependent upon the desired optical characteristics of the pigment.

Owner:JDS UNIPHASE CORP

Bright metal flake

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

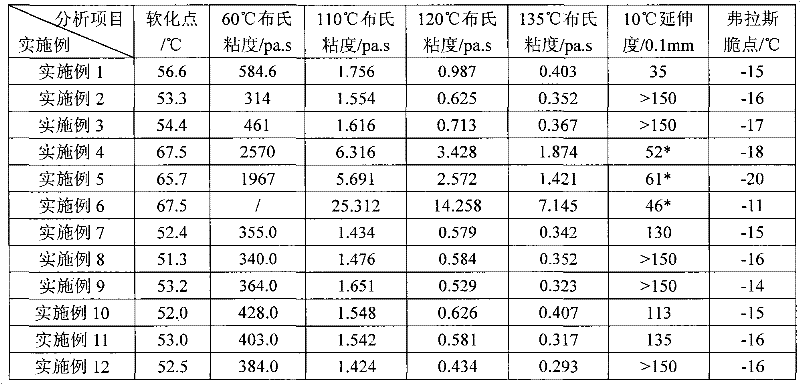

Warm mixed asphalt cement and preparation method thereof

ActiveCN102532920AWith viscosity reducing effectHas a lubricating effectIn situ pavingsClimate change adaptationEnvironmental resistanceChemical industry

Owner:PETROCHINA CO LTD +1

Bright metal flake based pigments

InactiveUS6383638B1Good specular reflectance characteristicPigment preparation by PVD/CVD methodsSynthetic resin layered productsDielectricReflectivity

A flake-based pigment is provided having improved specular reflectance characteristics in the visible wavelength range. The flake-based pigment has a plurality of core flake sections each formed of a central reflector layer and dielectric support layers on opposing sides of the reflector layer. The resulting core flake section is a very thin three-layered structure that exhibits a uniaxial compressive strength much greater than a corresponding uniaxial tensile strength. This structure provides the benefits of rigidity and brittle fracture during manufacturing and application processes, which ultimately provides favorable planar and specular reflectance characteristics for the pigment in the visible wavelength range. A variety of outer coating layers can be formed around the core flake sections, such as various dielectric and absorber layers having thicknesses dependent upon the desired optical characteristics of the pigment.

Owner:JDS UNIPHASE CORP

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

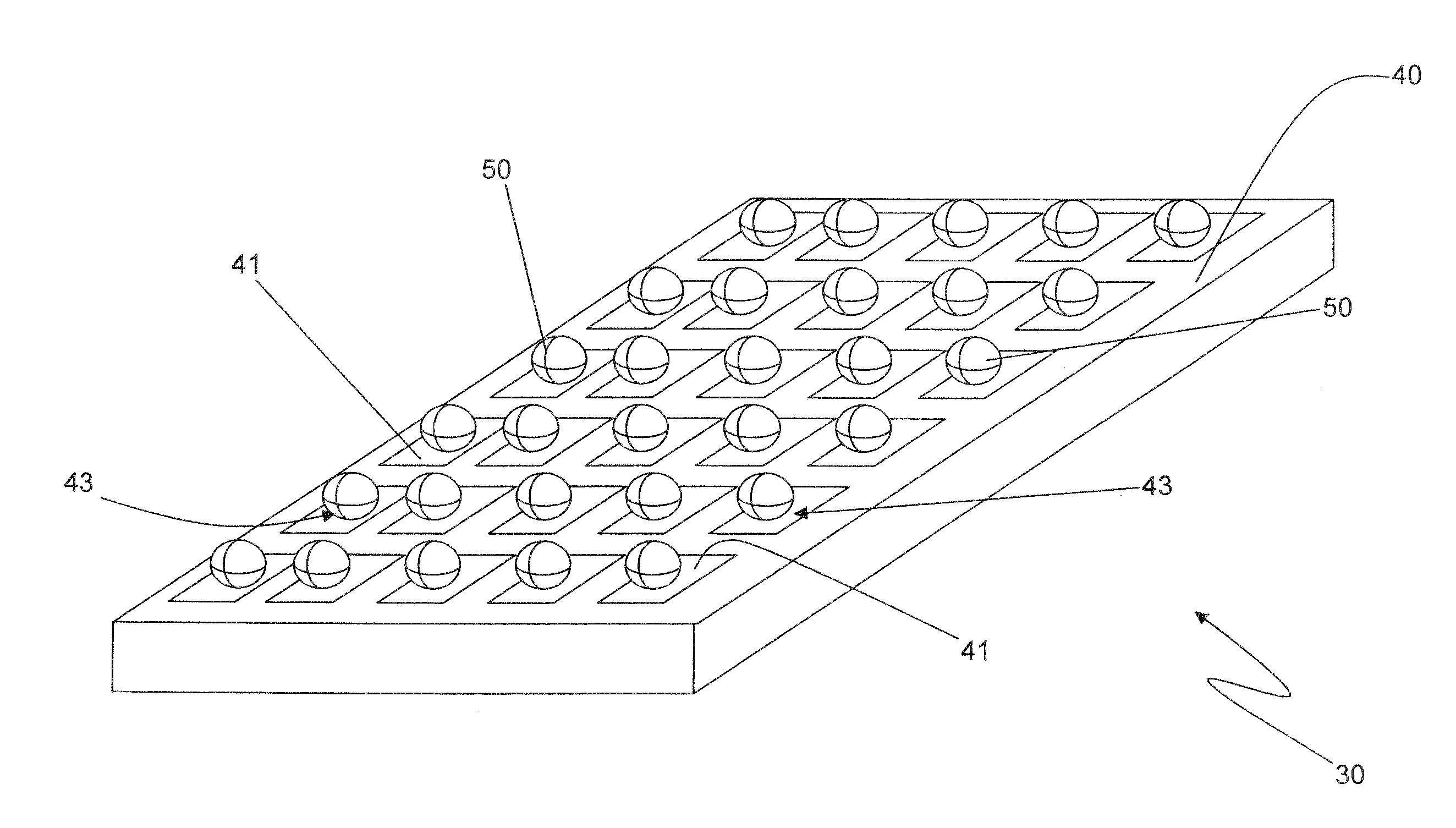

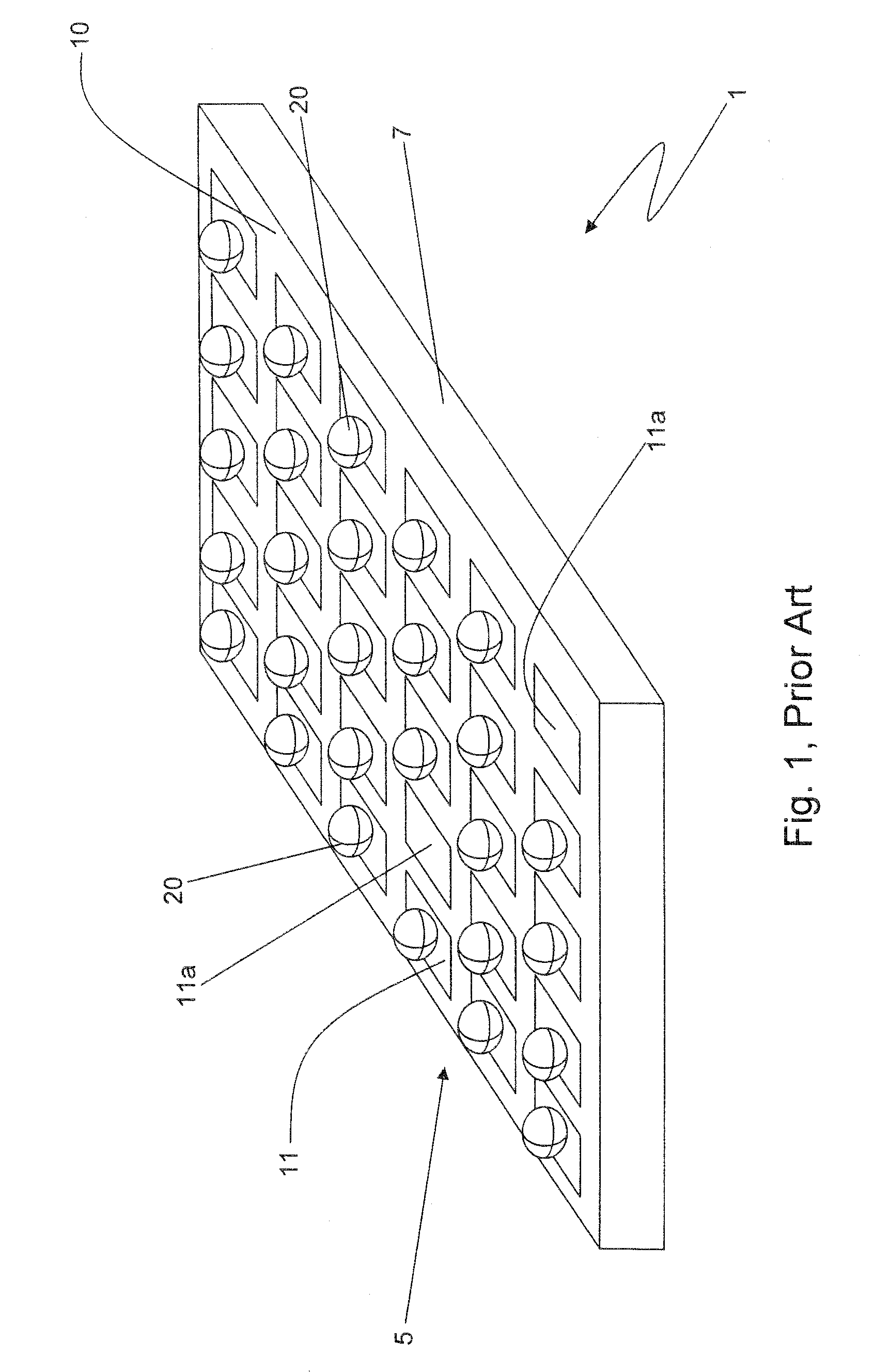

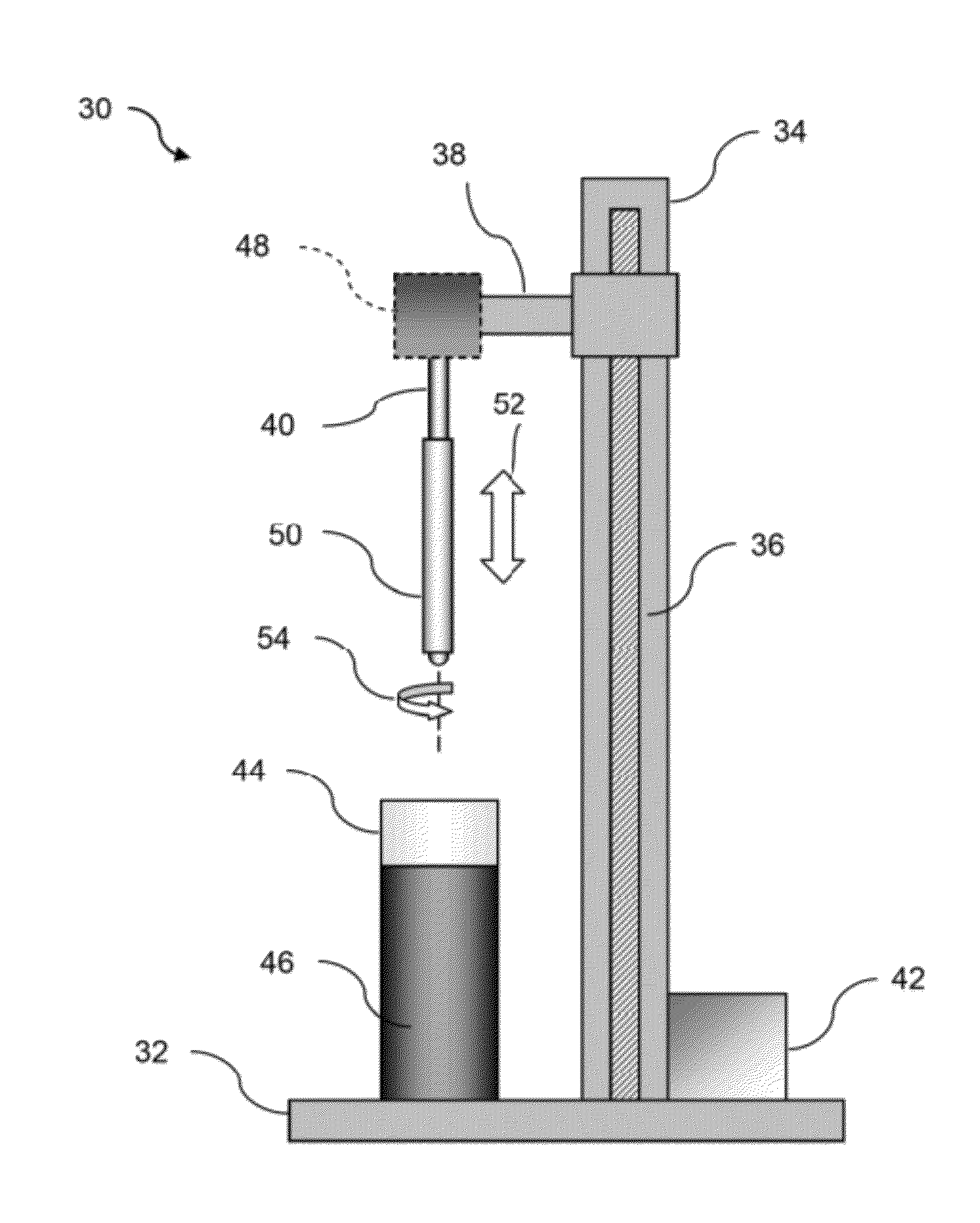

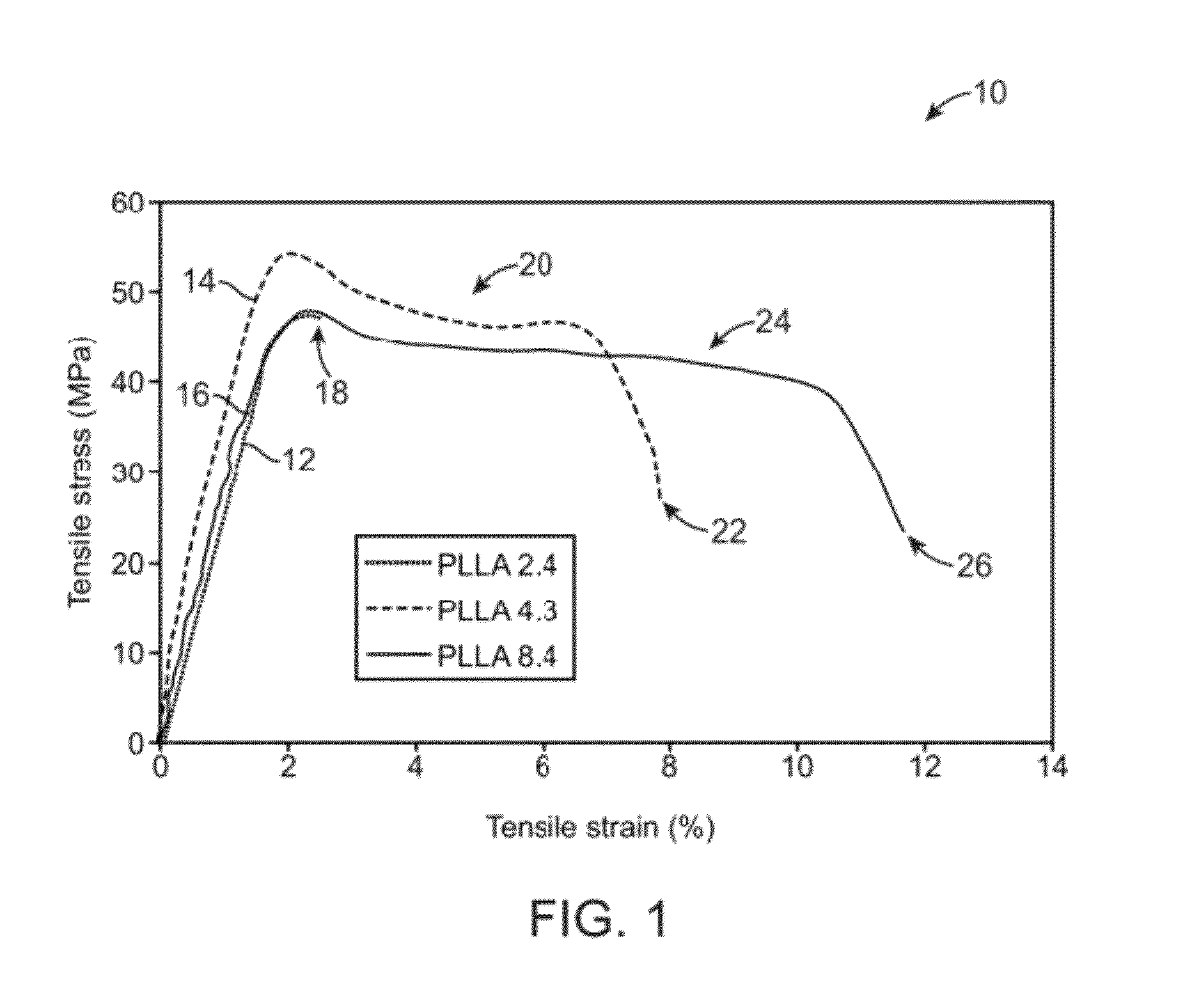

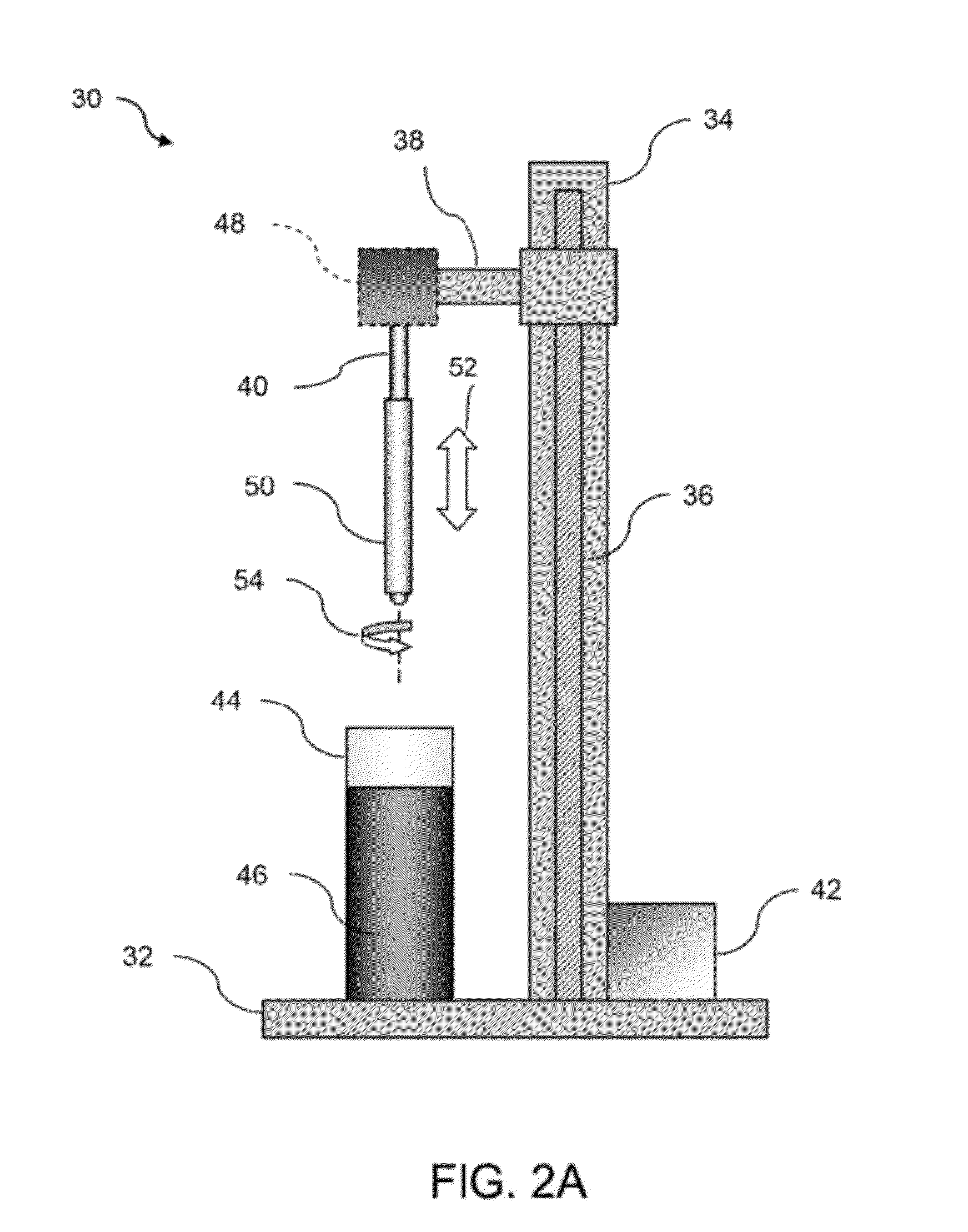

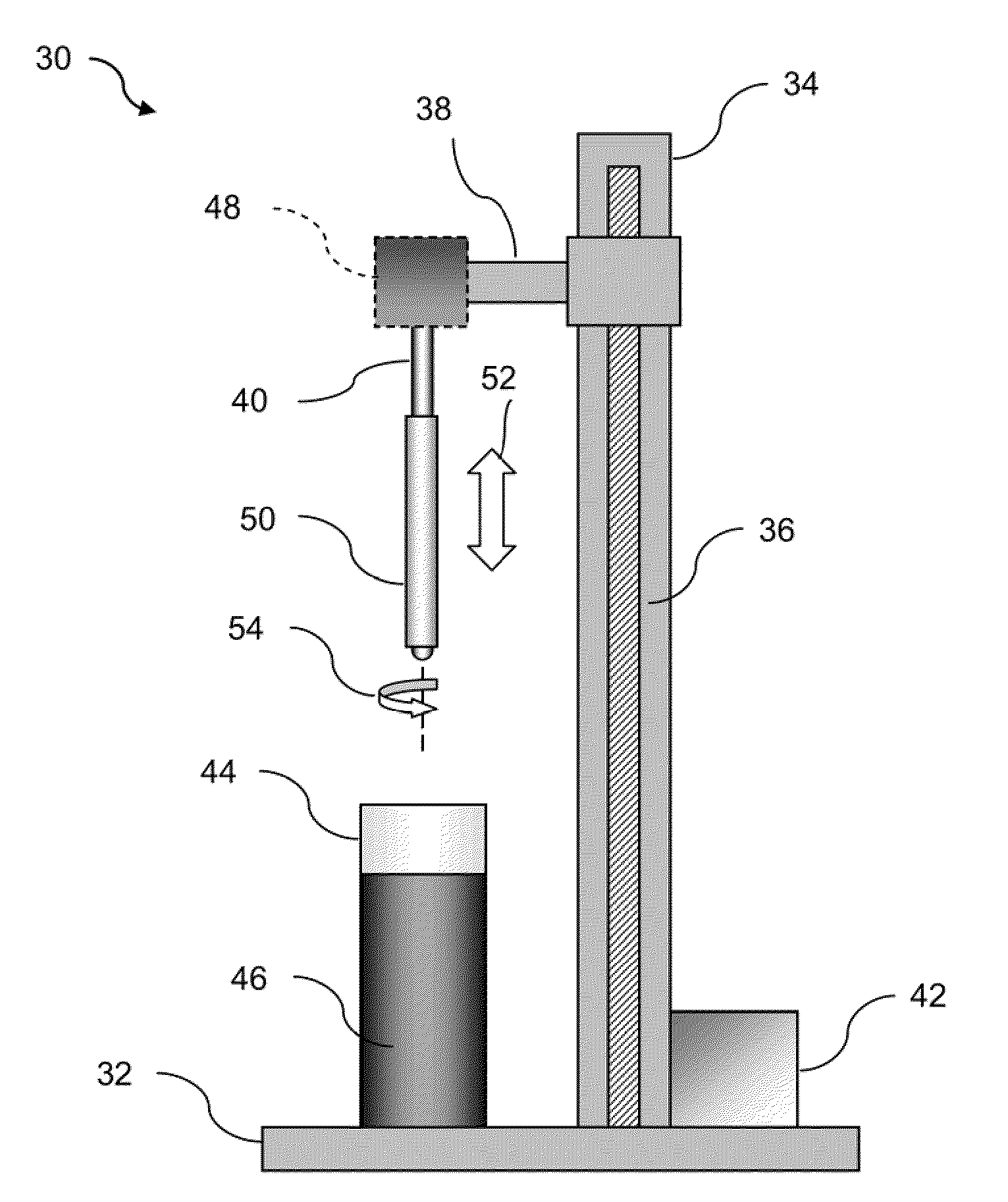

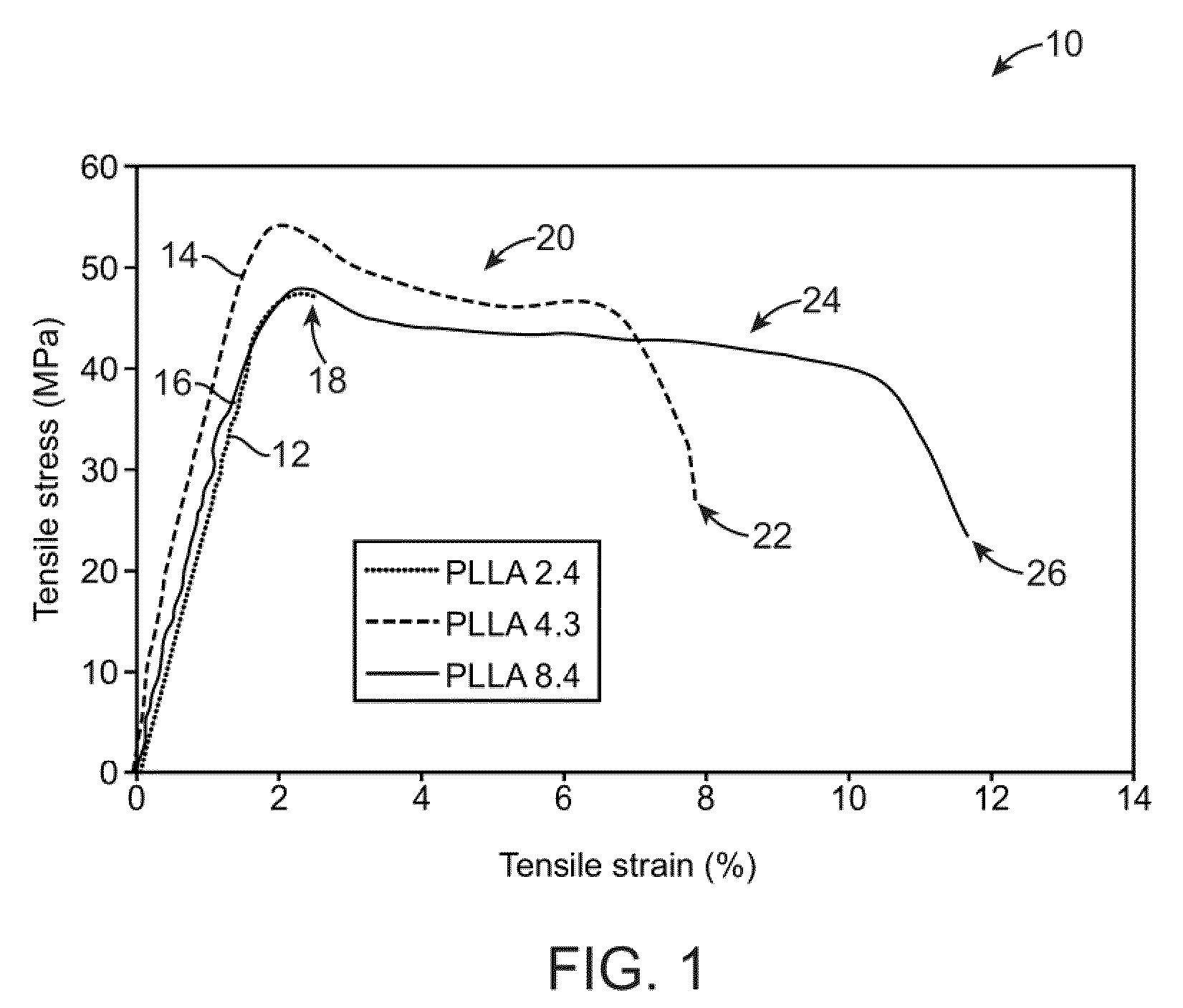

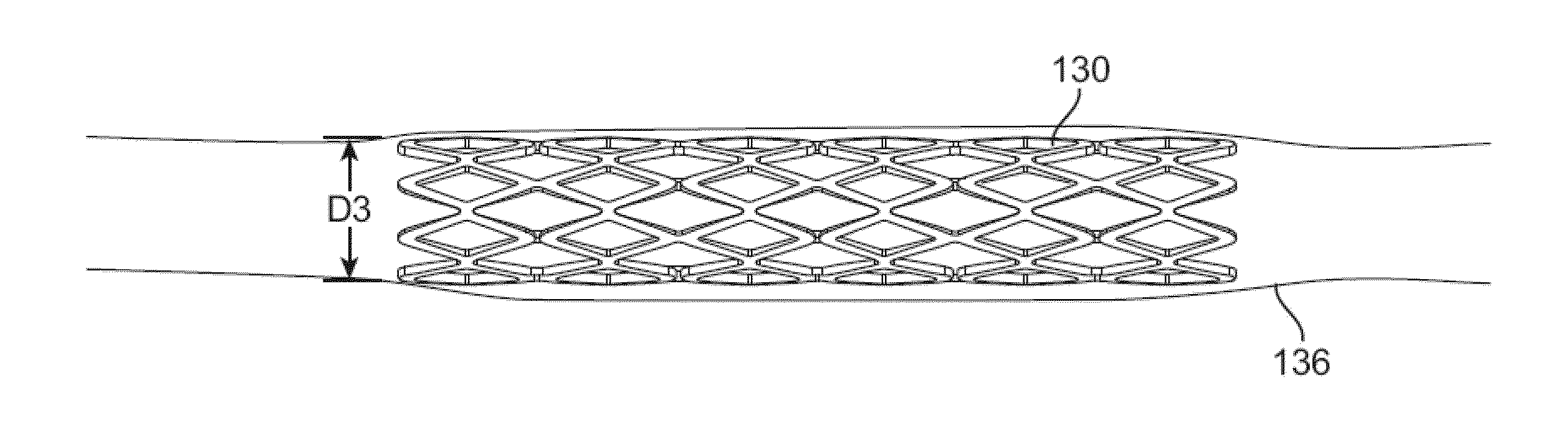

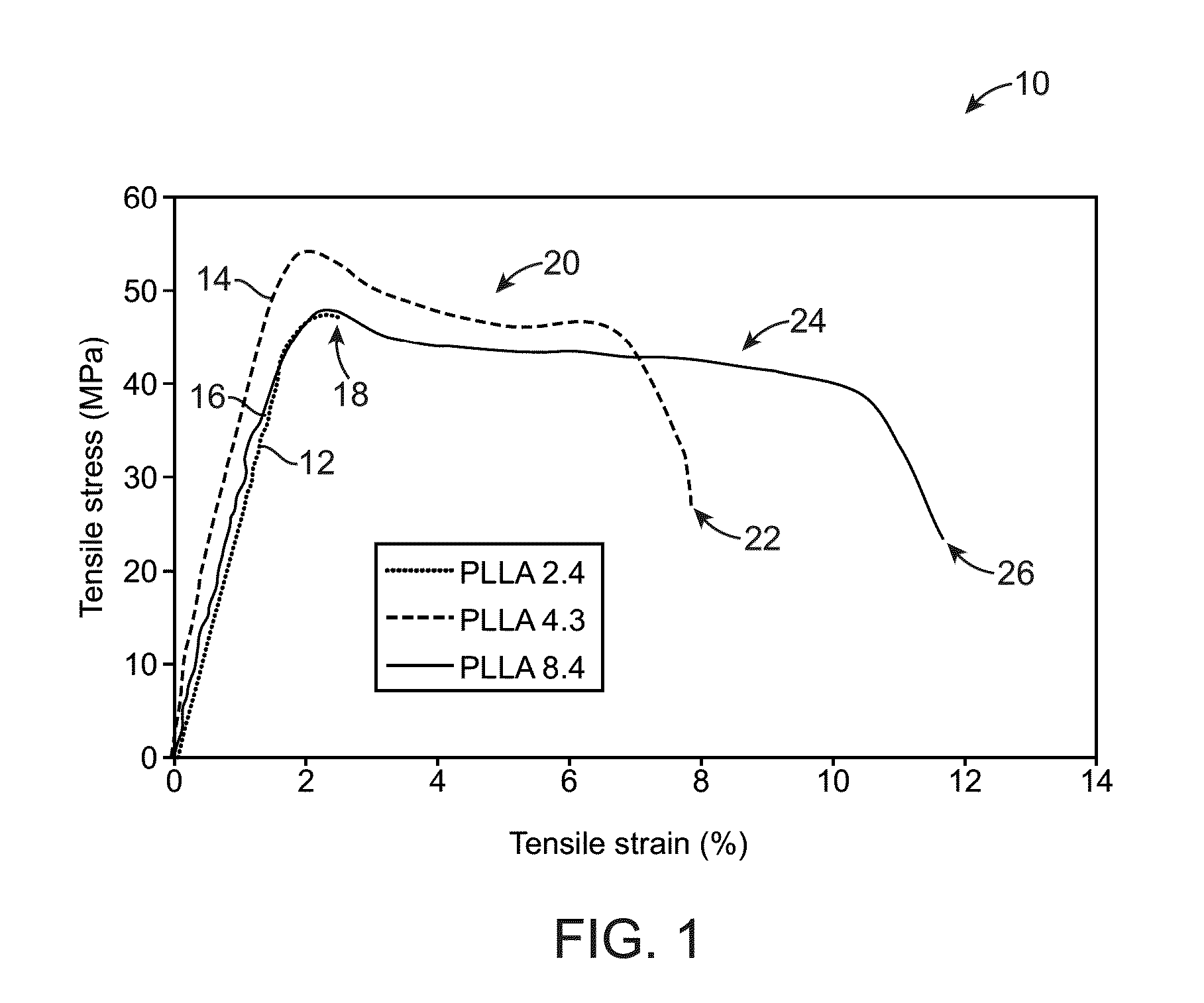

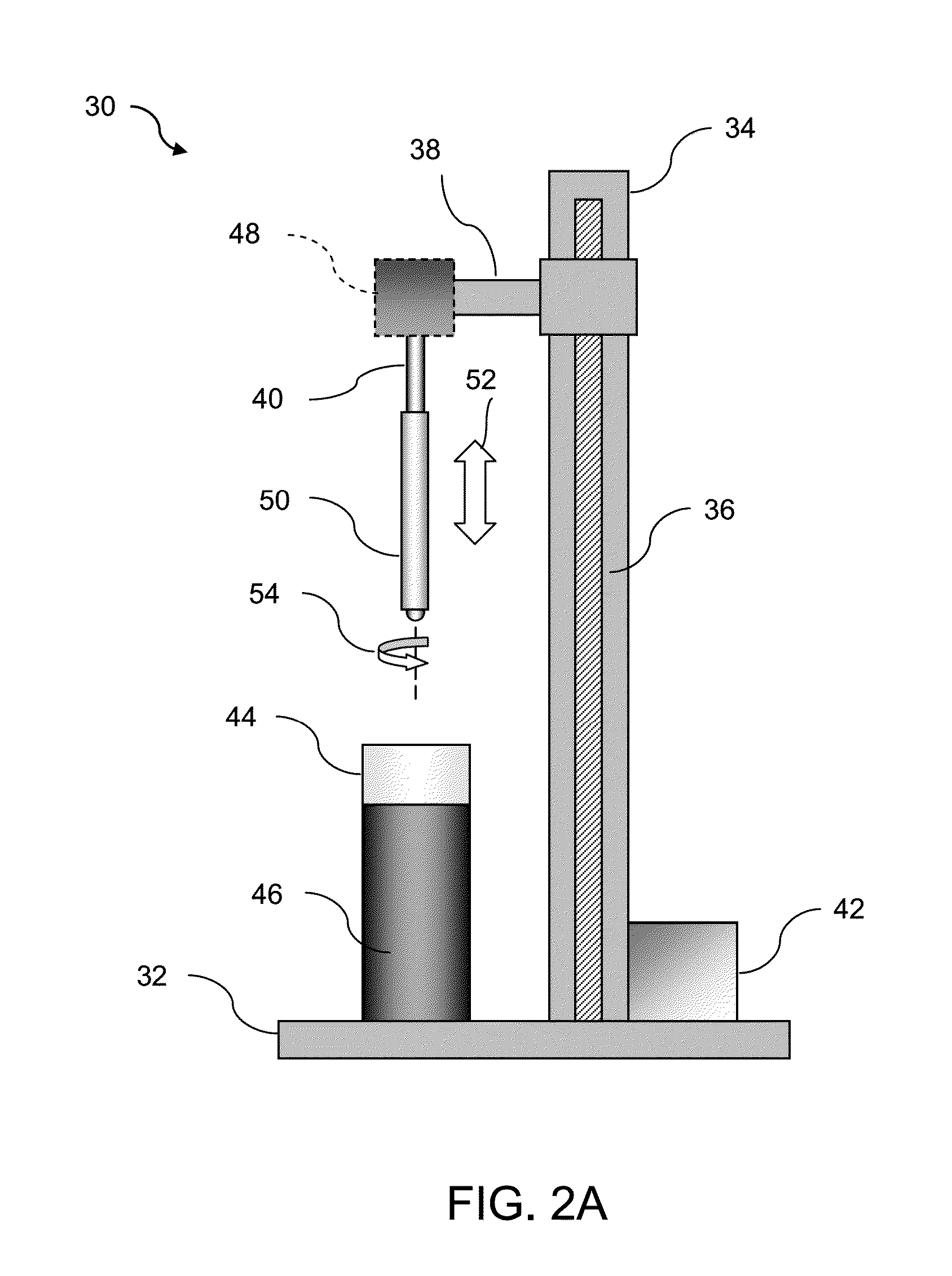

Stent fabrication via tubular casting processes

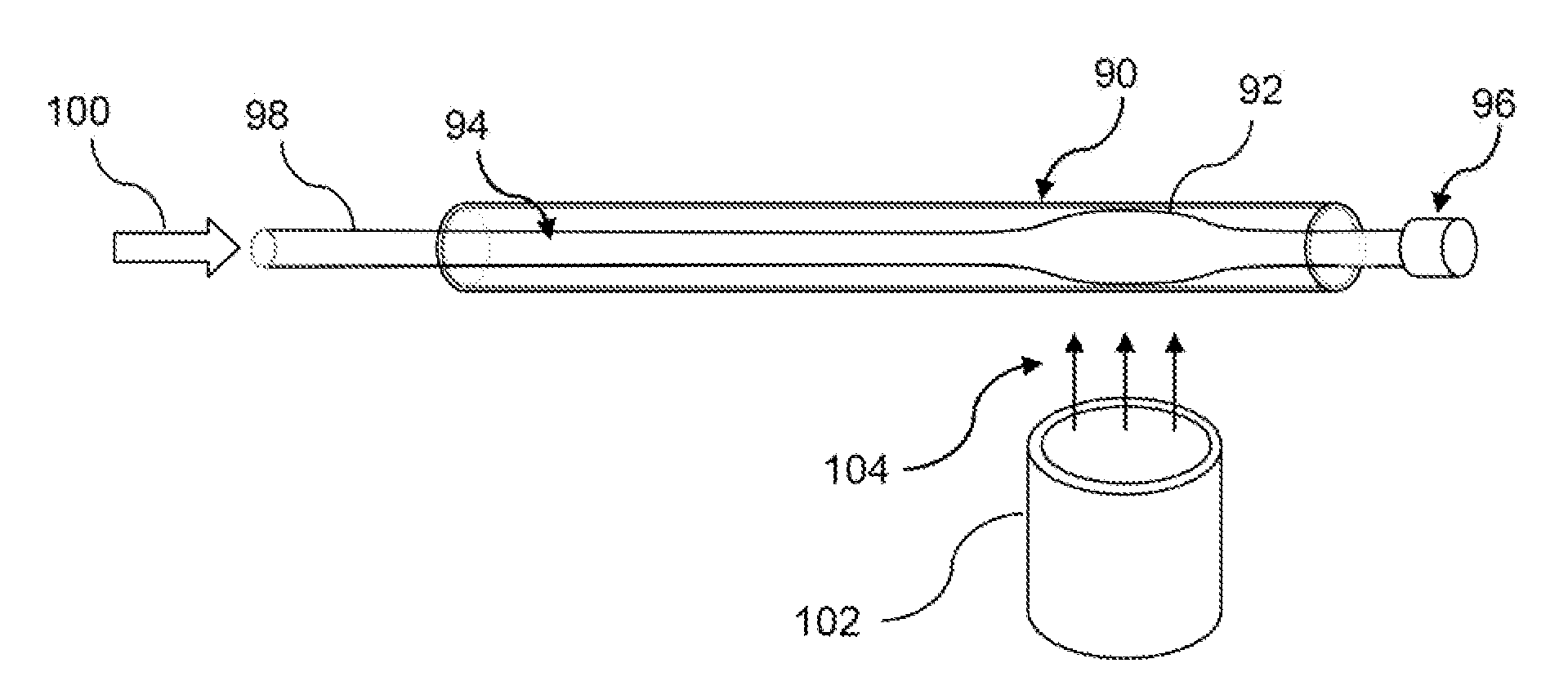

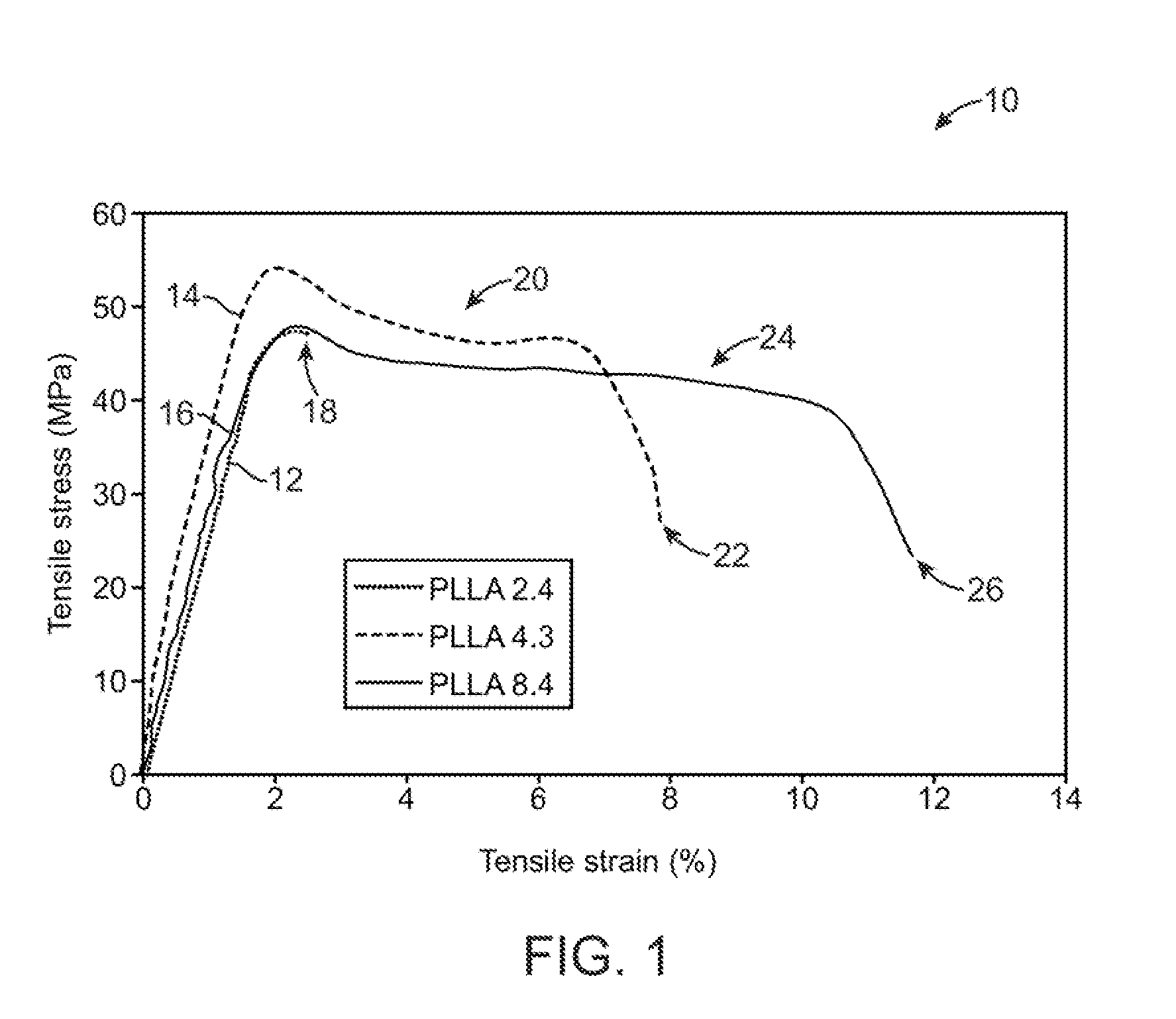

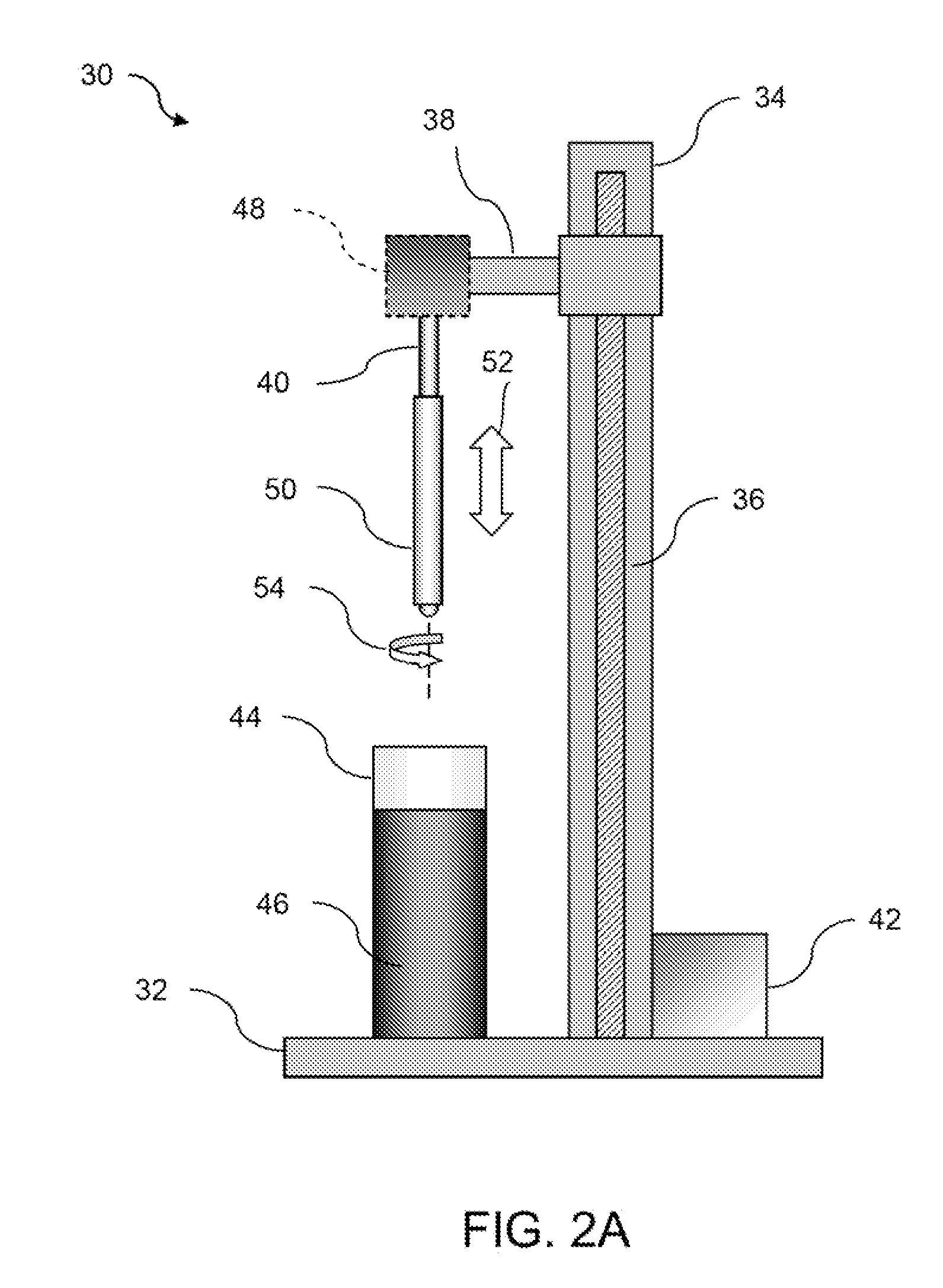

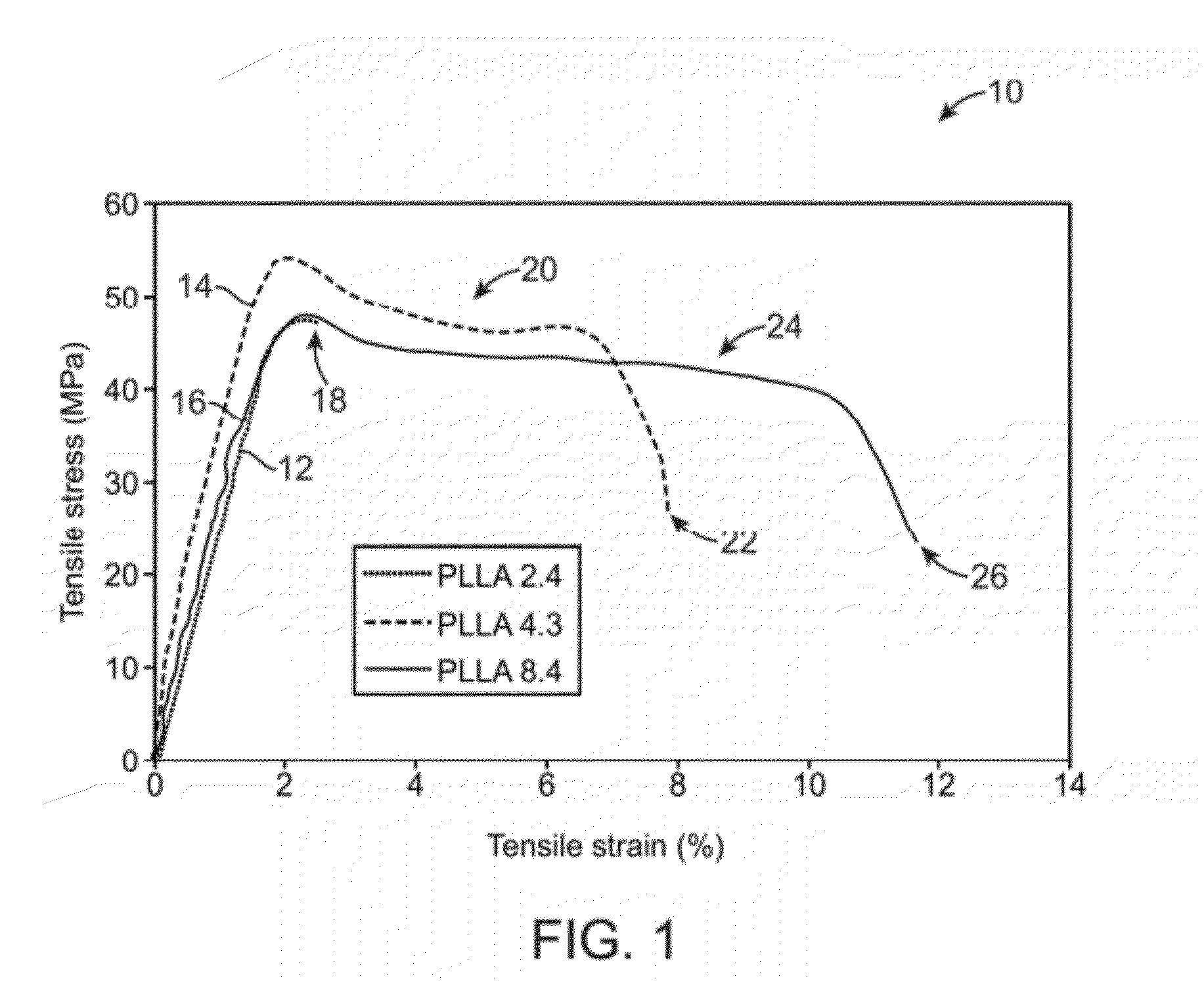

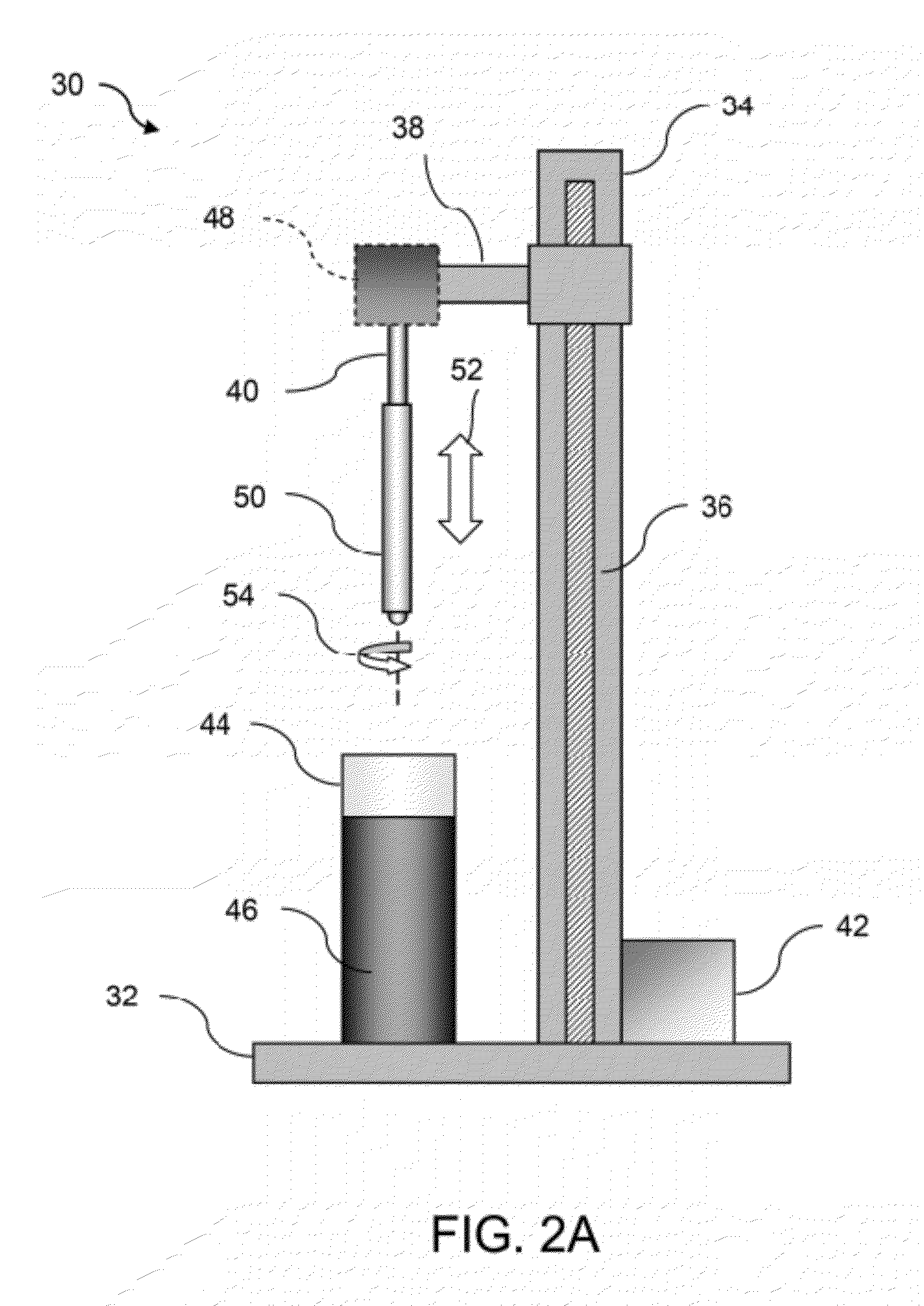

ActiveUS20100004734A1Improve mechanical propertiesReduced flexibilityOrganic active ingredientsStentsDip-coatingPolymer solution

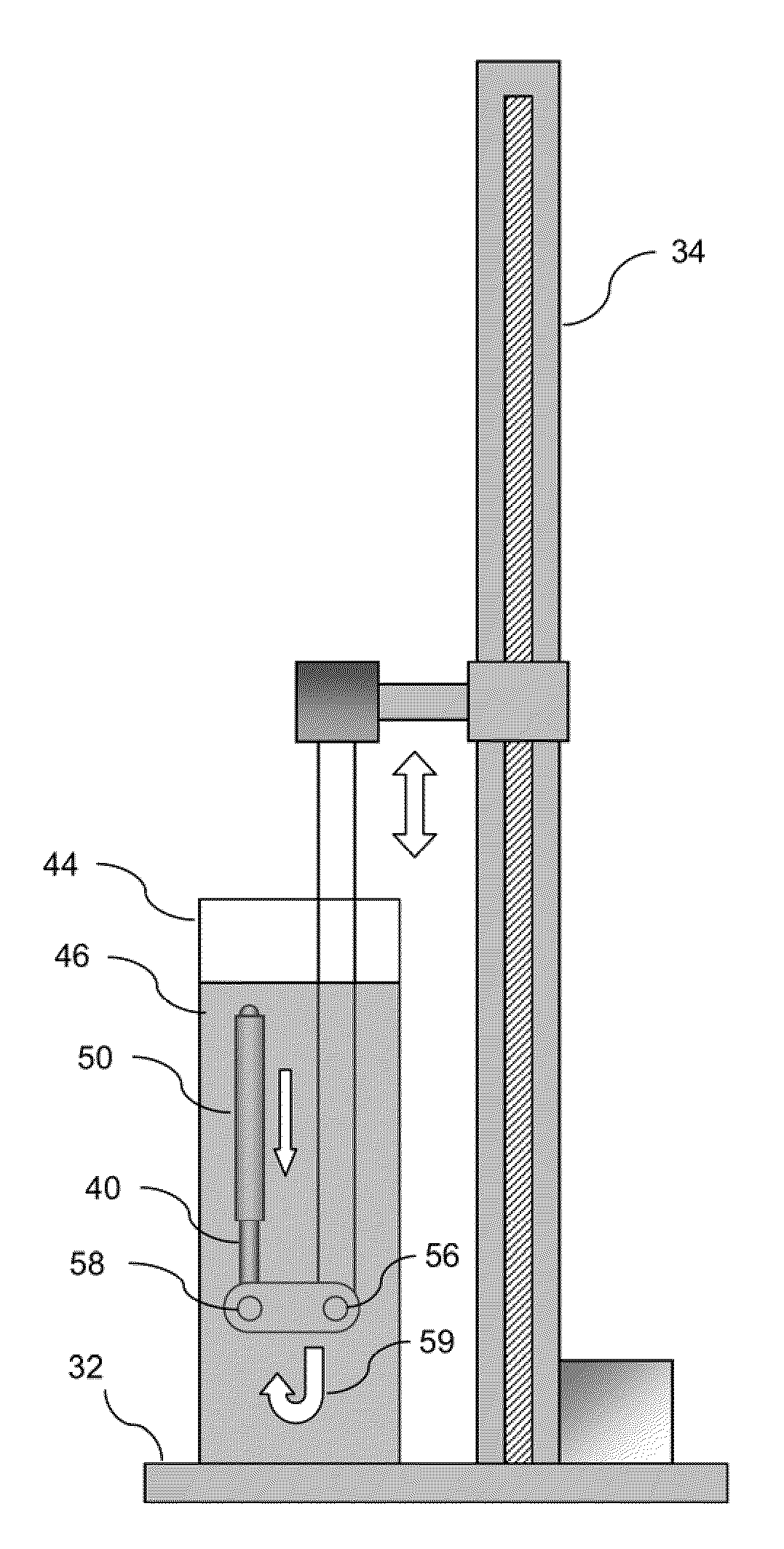

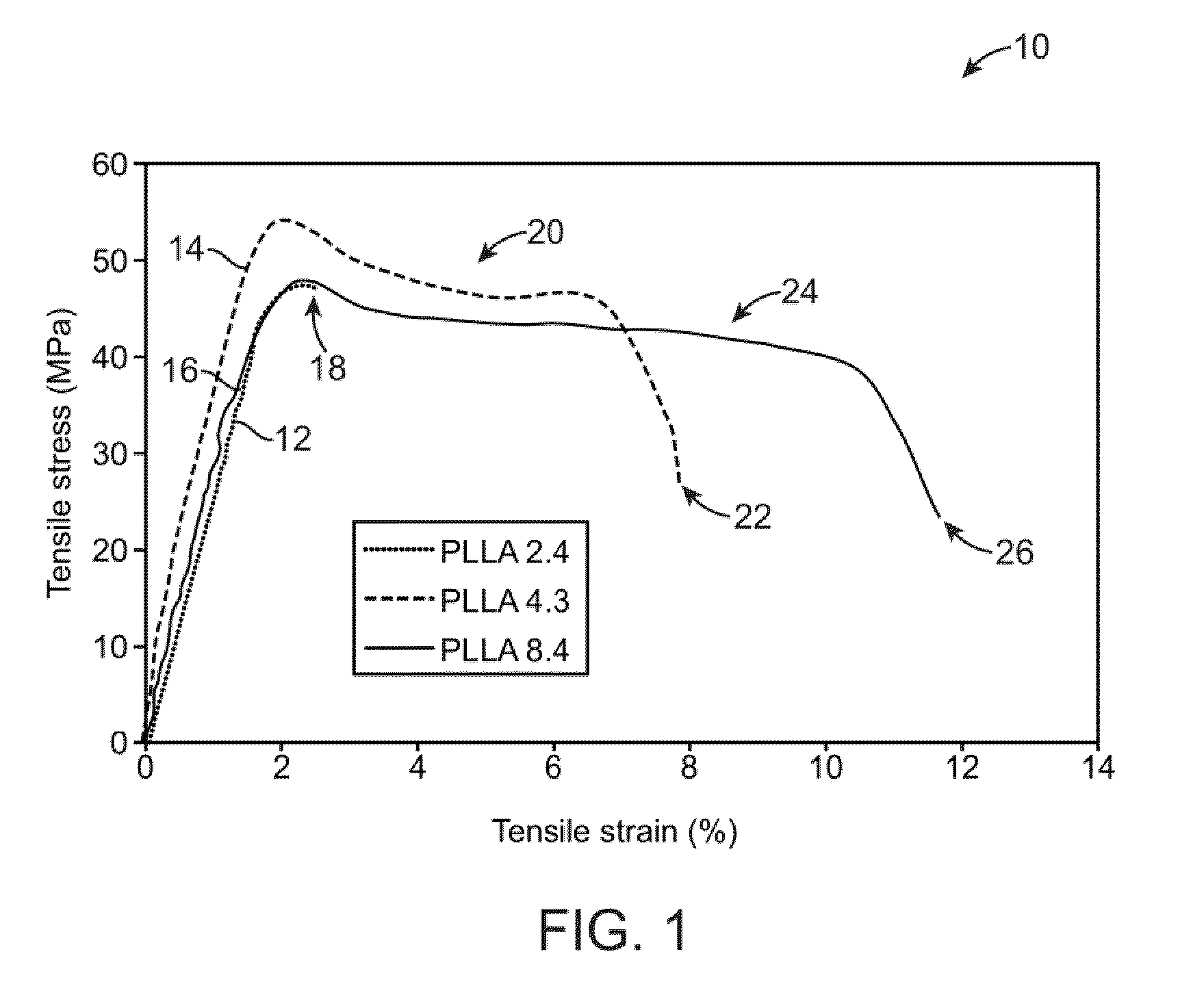

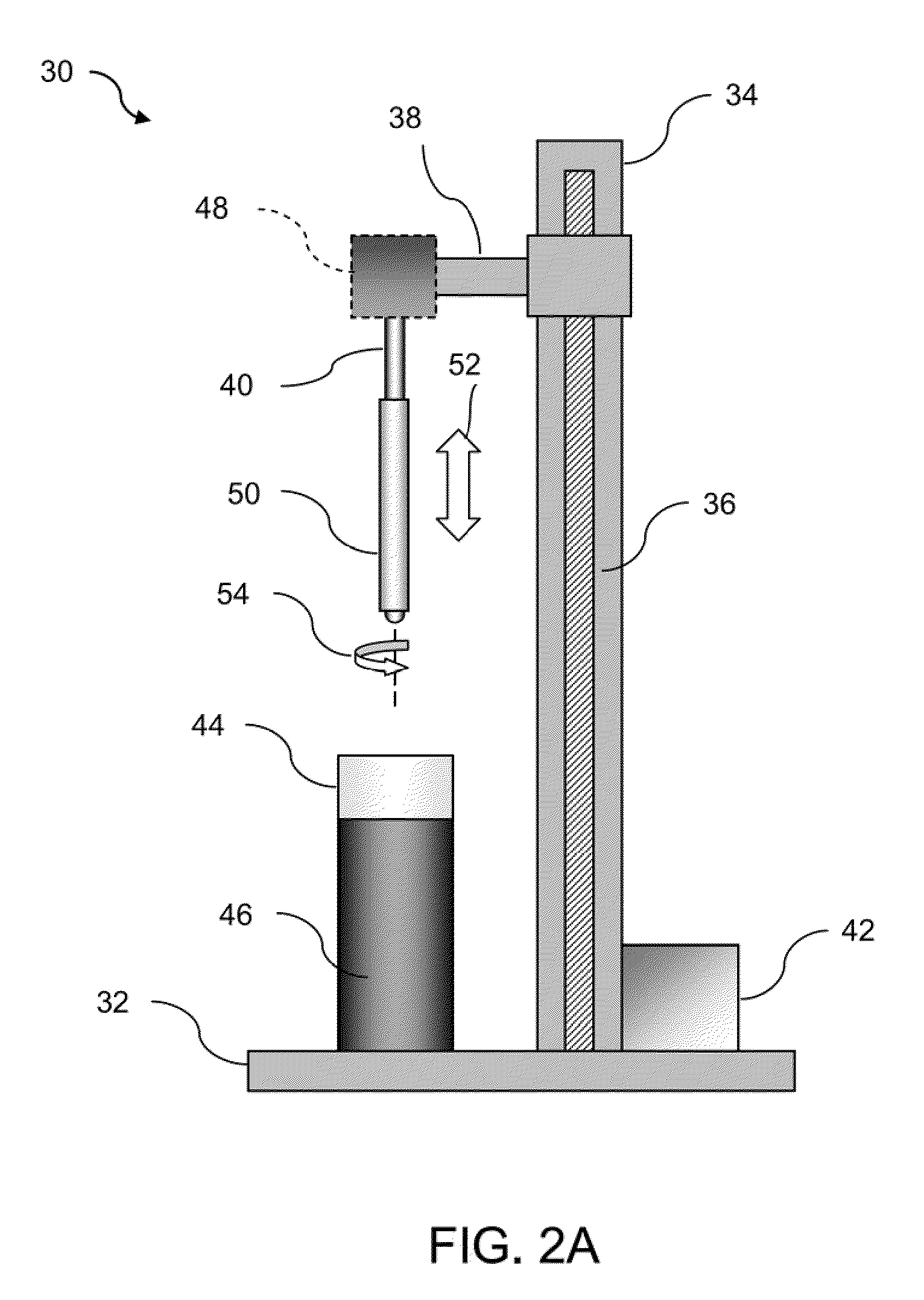

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

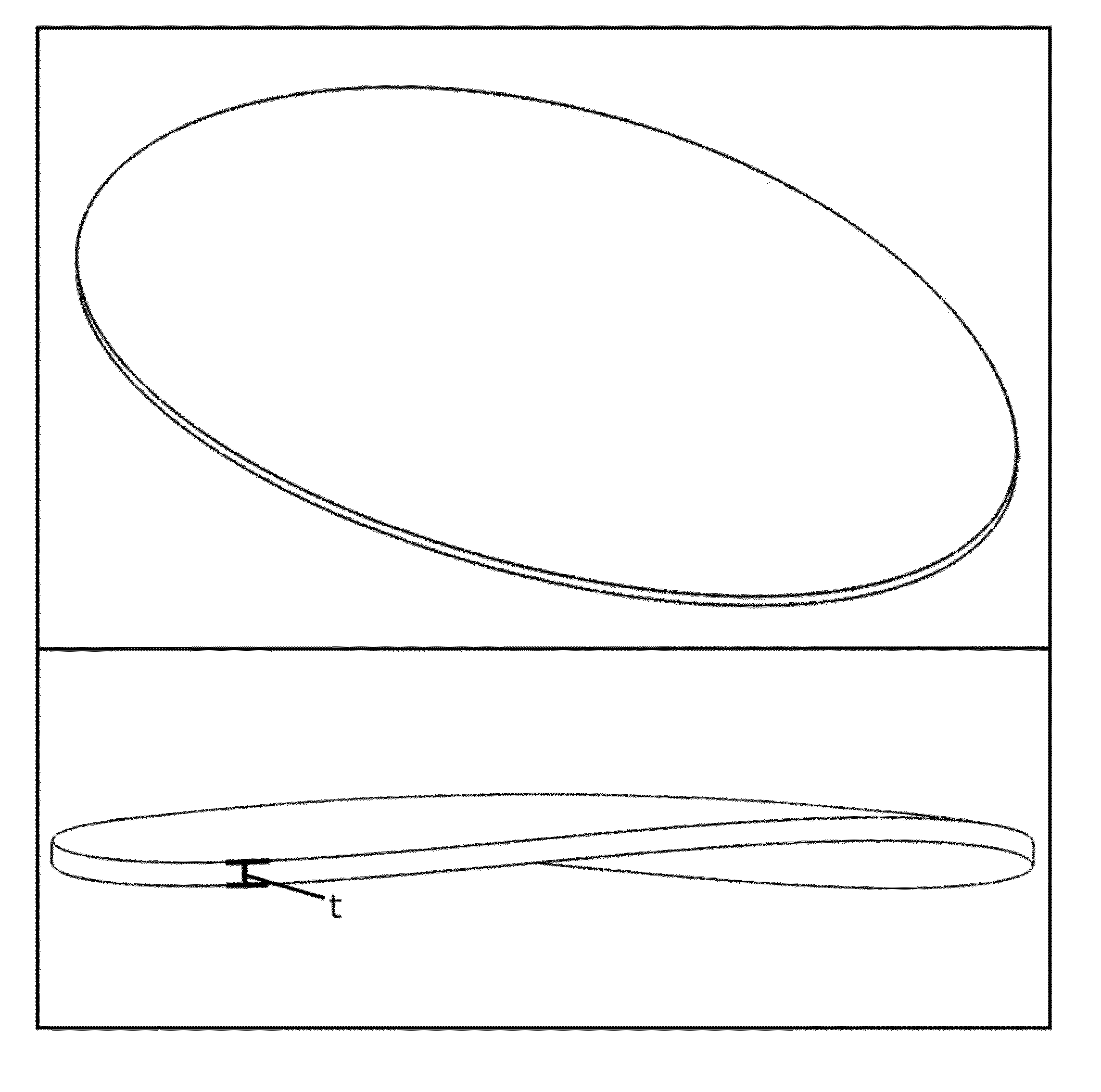

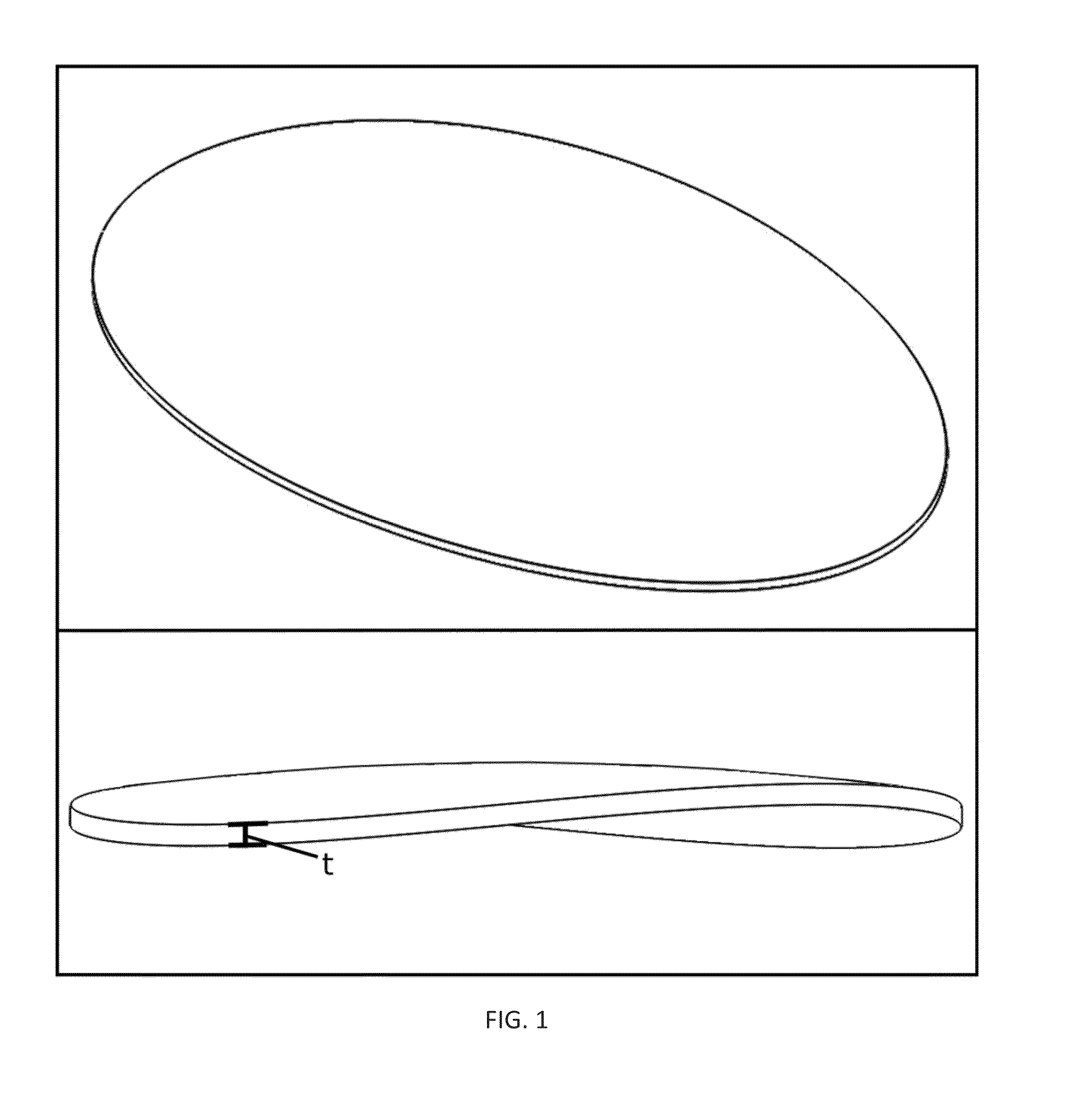

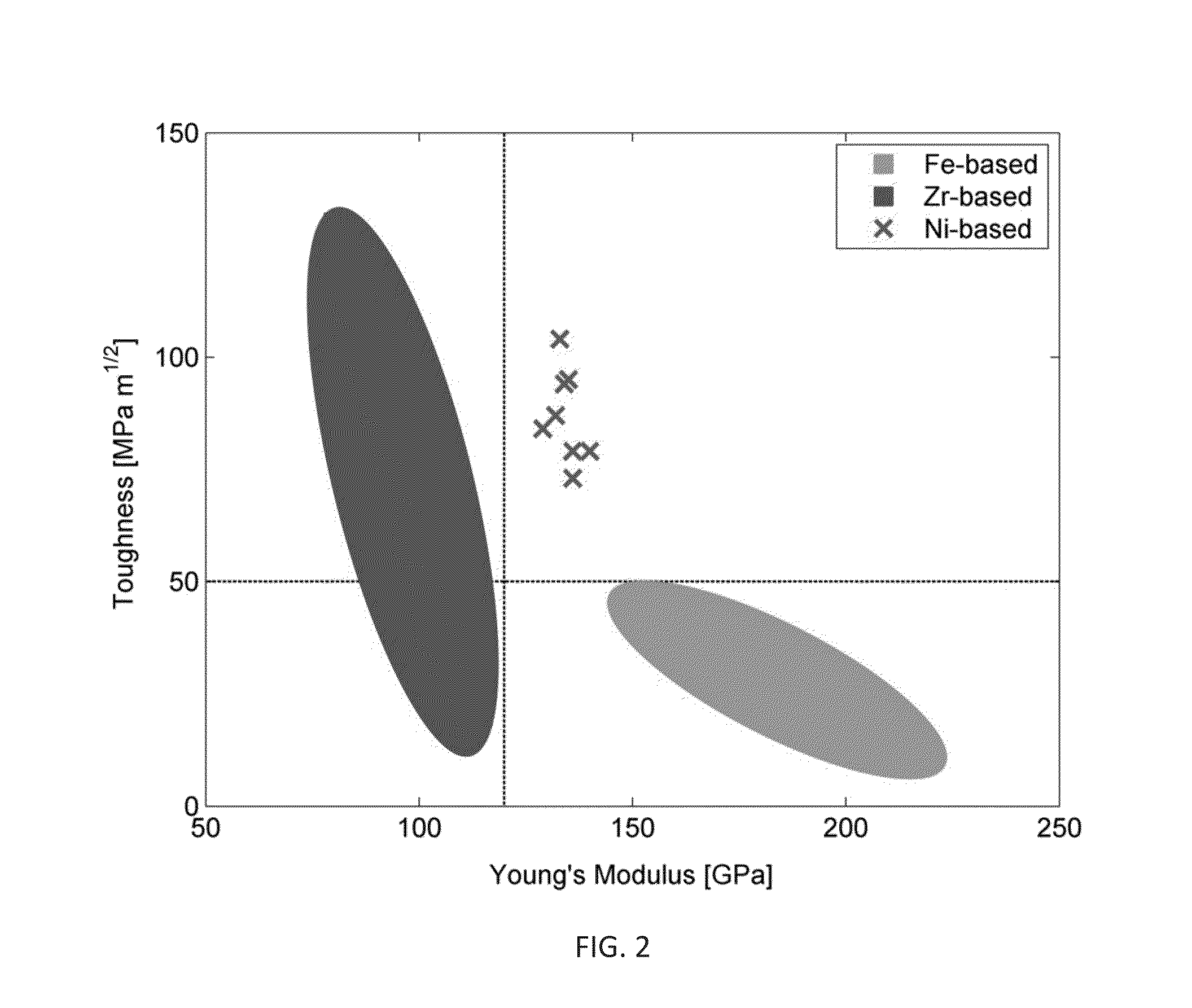

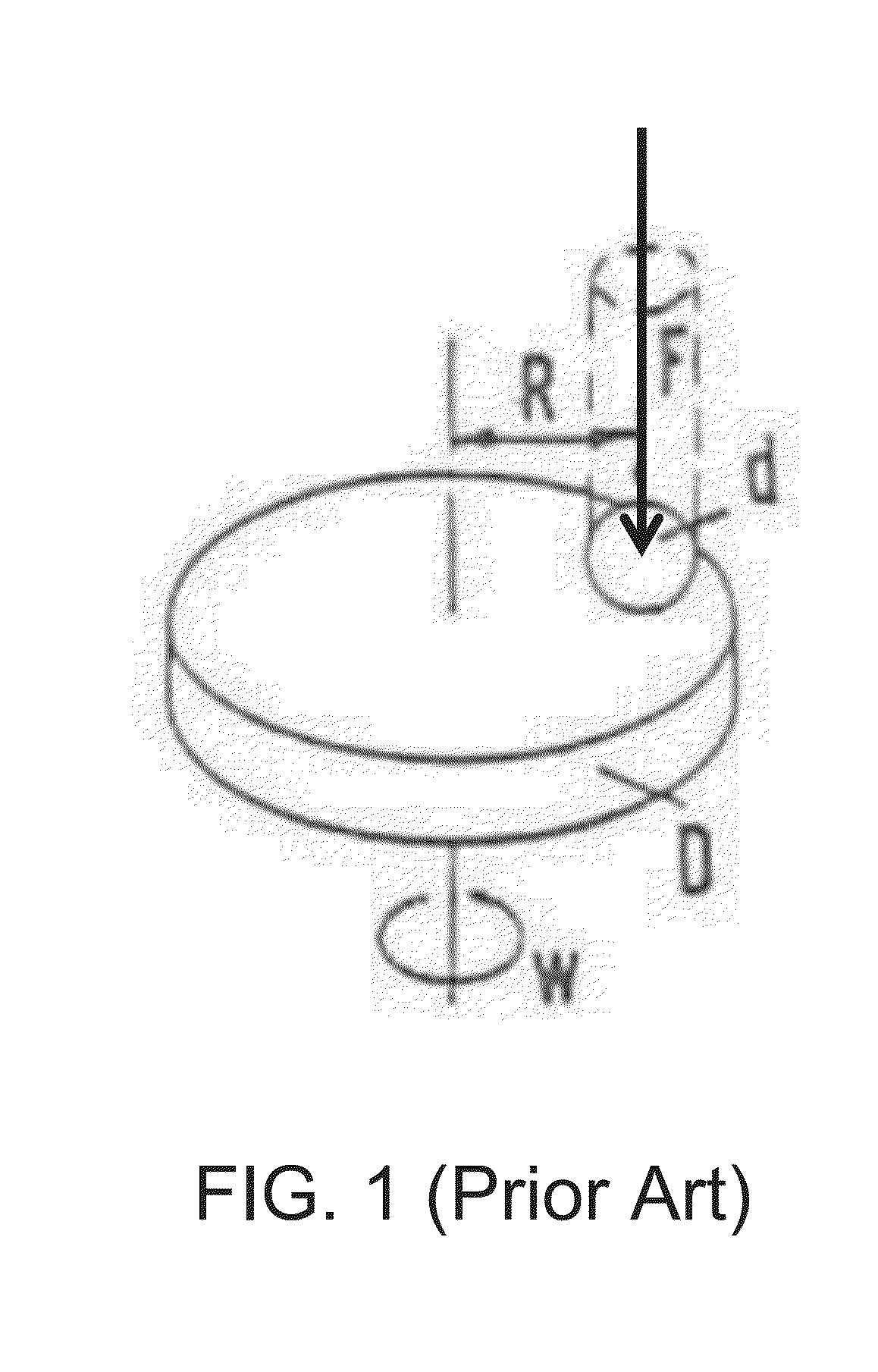

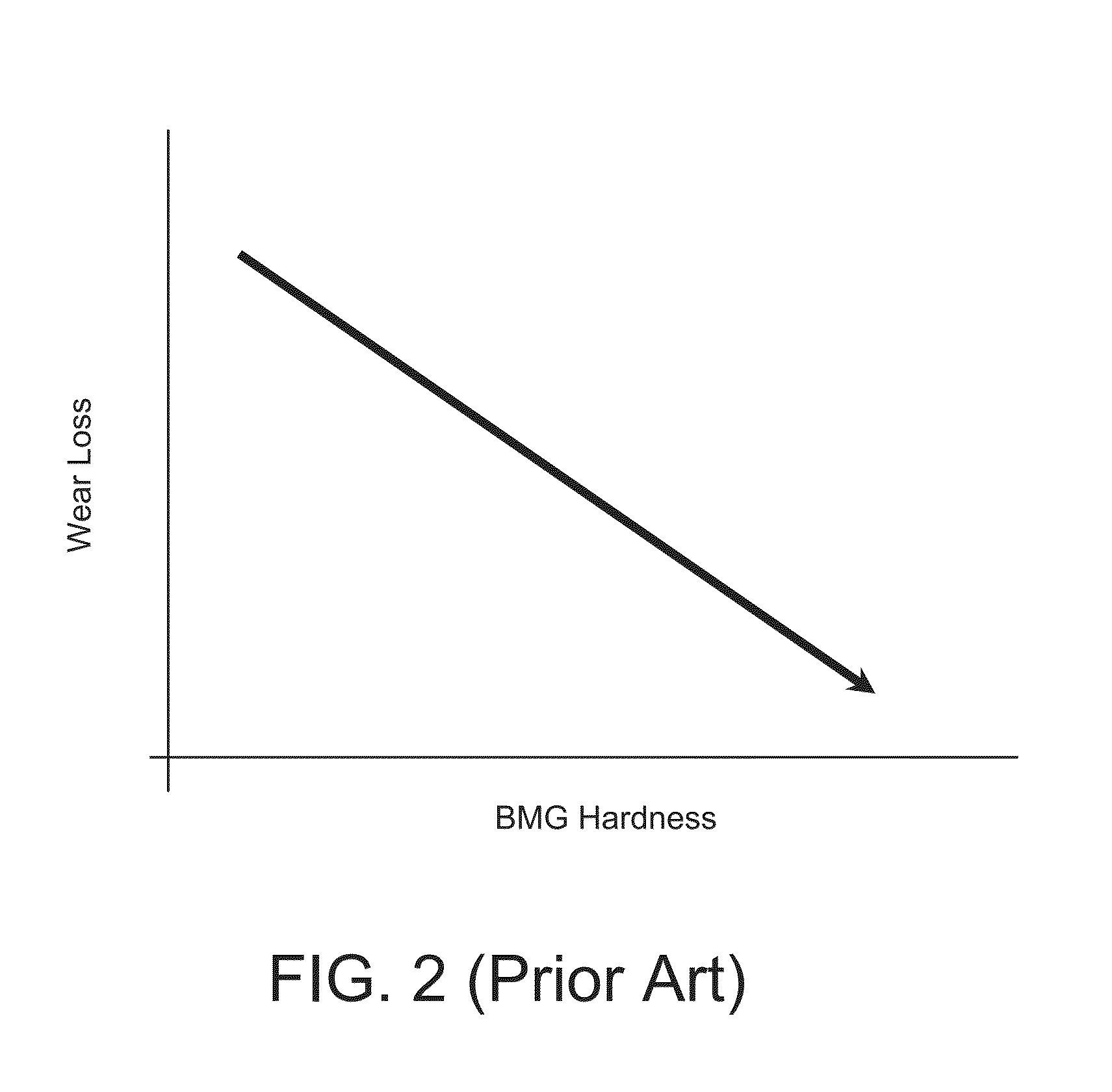

Golf club fabricated from bulk metallic glasses with high toughness and high stiffness

Golf clubs formed from bulk-solidifying amorphous metals (i.e., metallic glasses) having high elastic modulus and fracture toughness, and to methods of forming the same are provided. Among other components, the golf club materials disclosed enable fabrication of flexural membranes or shells used in golf club heads (drivers, fairways, hybrids, irons, wedges and putters) exhibiting enhanced flexural or bending compliance together with the ability to deform plastically and avoid brittle fracture or catastrophic failure when overloaded under bending loads. Further, the high strength of the material and its density, comparable to that of steel, enables the redistribution of mass in the golf club while maintaining a desired overall target mass.

Owner:GLASSIMETAL TECH

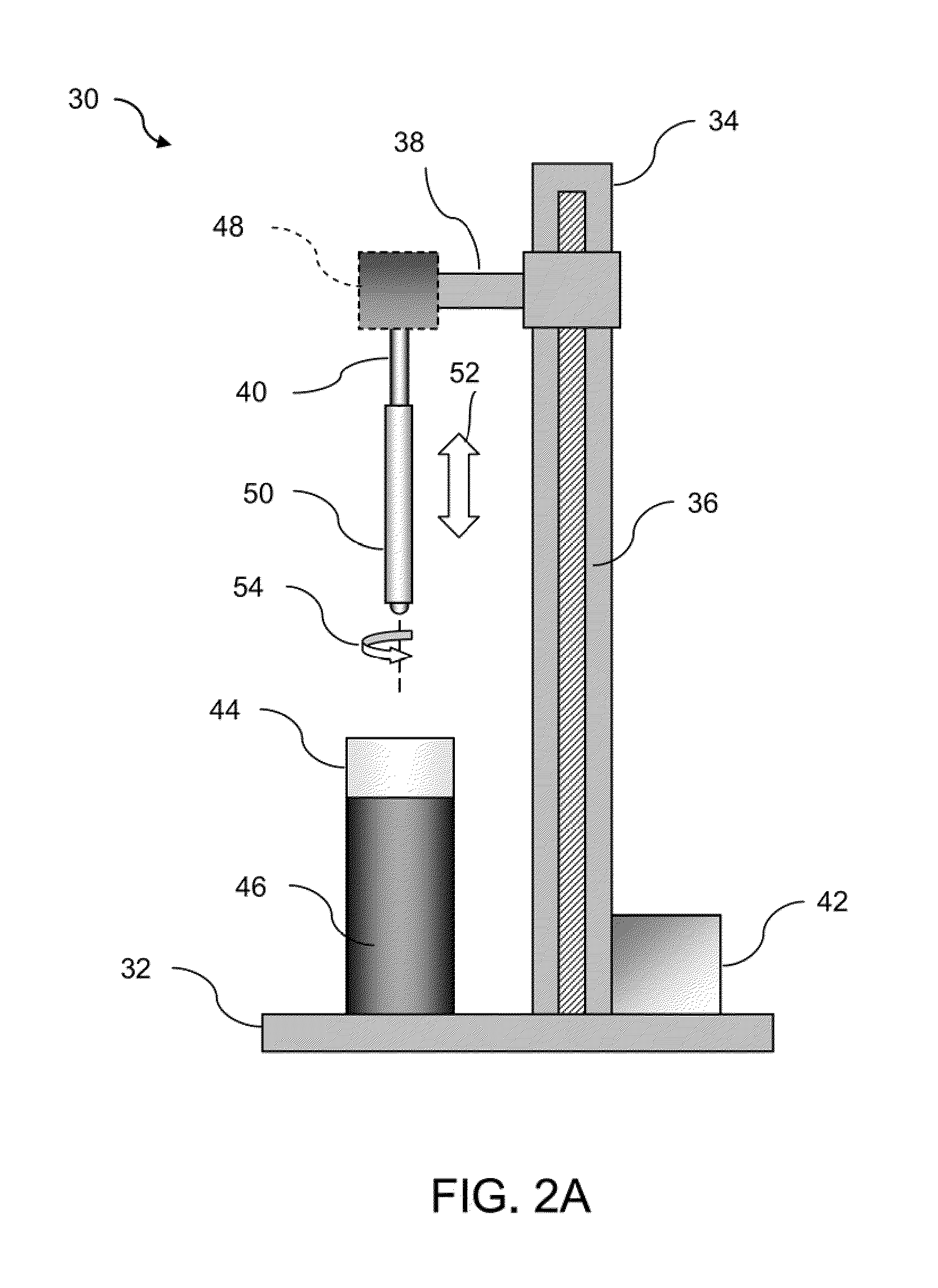

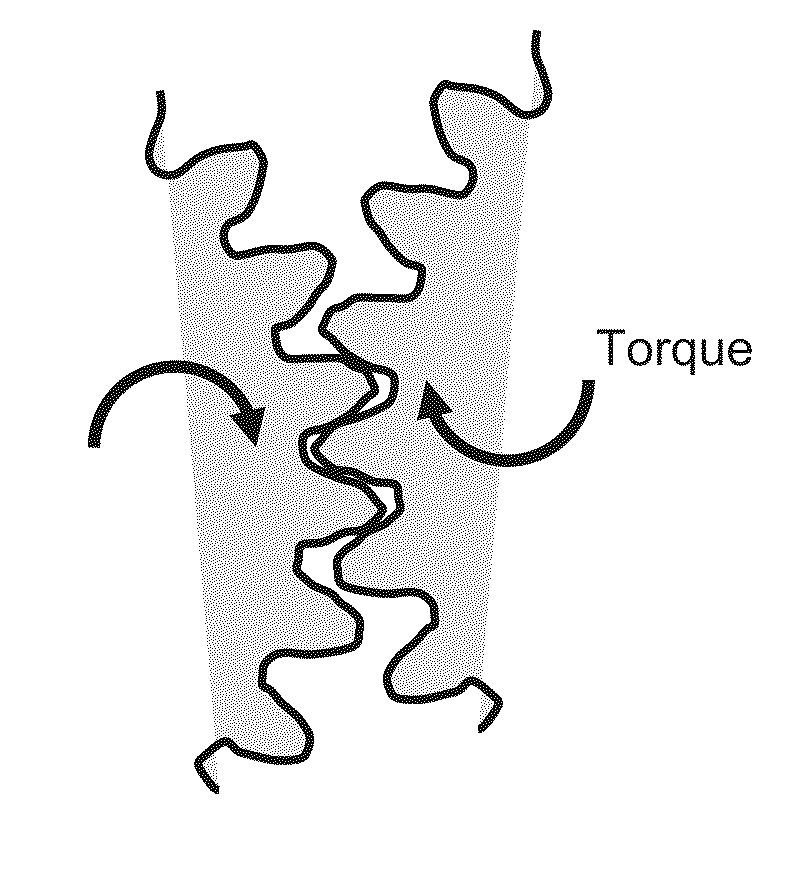

Systems and methods for implementing bulk metallic glass-based macroscale gears

Systems and methods in accordance with embodiments of the invention implement bulk metallic glass-based macroscale gears. In one embodiment, a method of fabricating a bulk metallic glass-based macroscale gear, where at least either the thickness of the gear is greater than 3 mm or the diameter of the gear is greater than 9 mm, includes: obtaining design parameters of the gear to be formed; selecting a bulk metallic glass from which the gear will be formed based on the obtained design parameters, where the selected bulk metallic glass is characterized by a resistance to standard modes of wear and a resistance to brittle fracture such that a gear can be formed from the selected bulk metallic glass that accords with the obtained design parameters; and fabricating the gear from the selected bulk metallic glass that accords with the obtained design parameters.

Owner:CALIFORNIA INST OF TECH

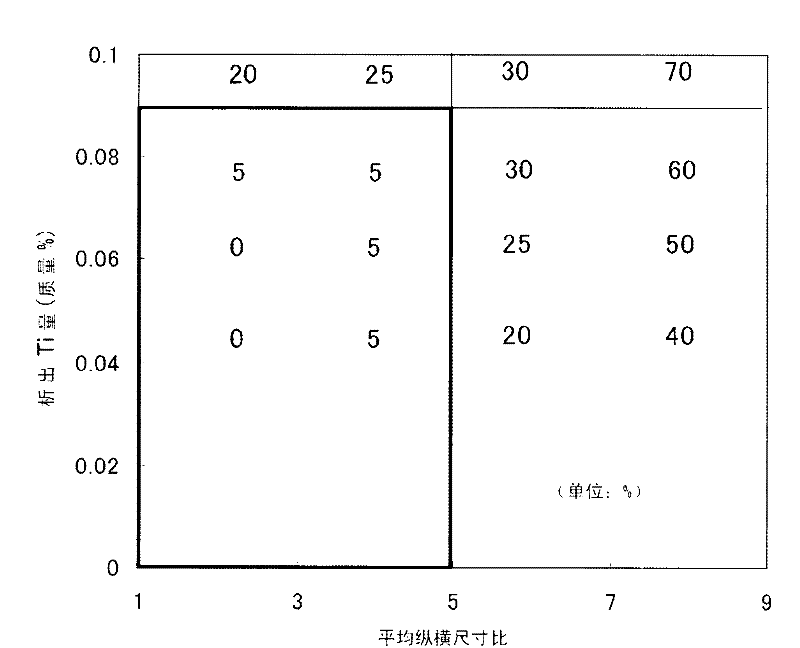

Hot rolled steel sheet having excellent punching workability and fatigue properties, hot dip galvanized steel sheet, and method for producing the same

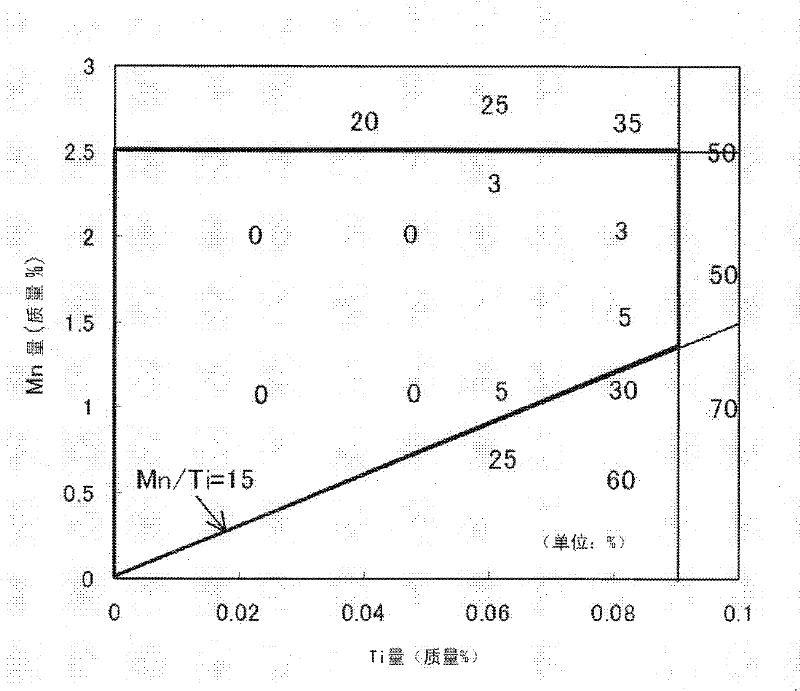

ActiveCN102333899ALess end face damageExcellent fatigue propertiesFurnace typesMetal rolling arrangementsCarbideBrittle fracture

Provided is a hot rolled steel sheet comprising, by mass%, 0.025 to 0.15% of C, 0.01 to 1.0% or less of Si, 1.0 to 2.5% of Mn, 0.02% or less of P, 0.005% or less of S, 0.5% or less of Al, 0.04 to 0.10% of Ti, and 0.007% or less of N, as well as Fe and inevitable impurities as the balance, wherein the Mn / Ti ratio is 15 or greater; Nb is not added; the ferrite volume percentage is 30% or greater and the balance comprises one of or both pearlite and bainite; the average aspect ratio of the crystal grain corresponding ellipsoid is 5 or less; the average distribution density on the ferrite grain boundary surface of Ti carbide having a grain size of 20 nm or greater is 10 grains / [mu]m or less; the brittle fracture rate of surface fractured by punching is less than 20%; and the maximum tensile strength is 590 MPa or greater.

Owner:NIPPON STEEL CORP

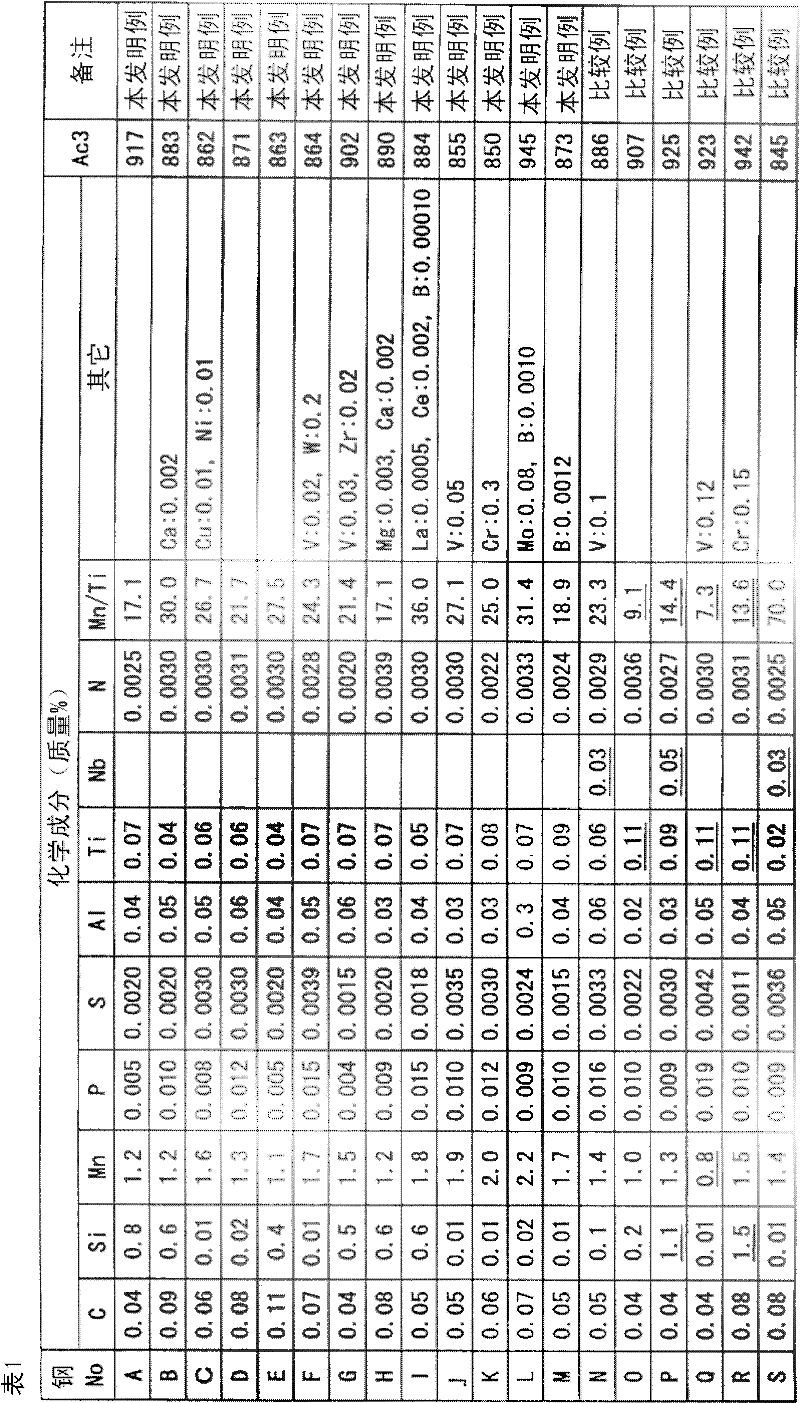

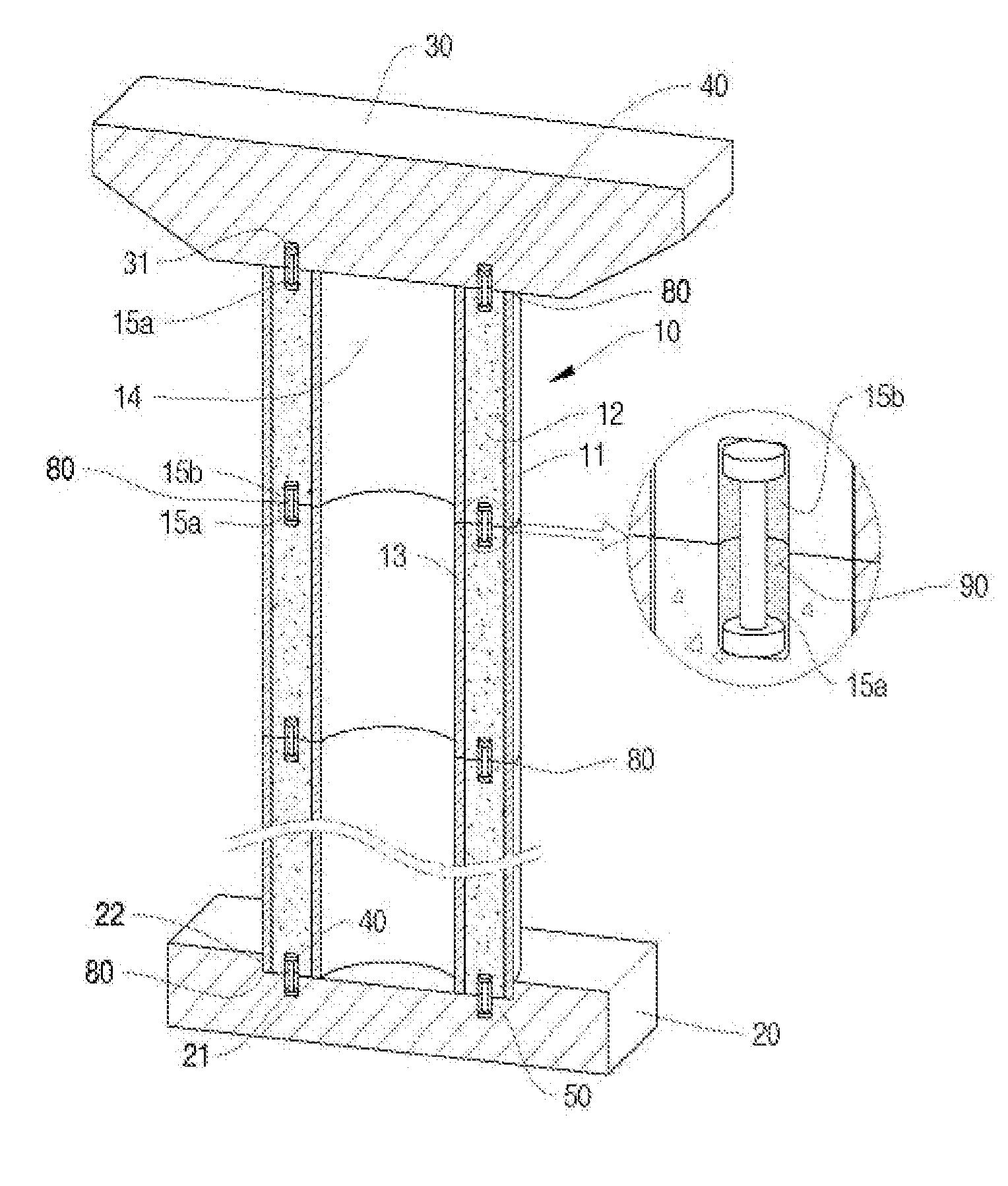

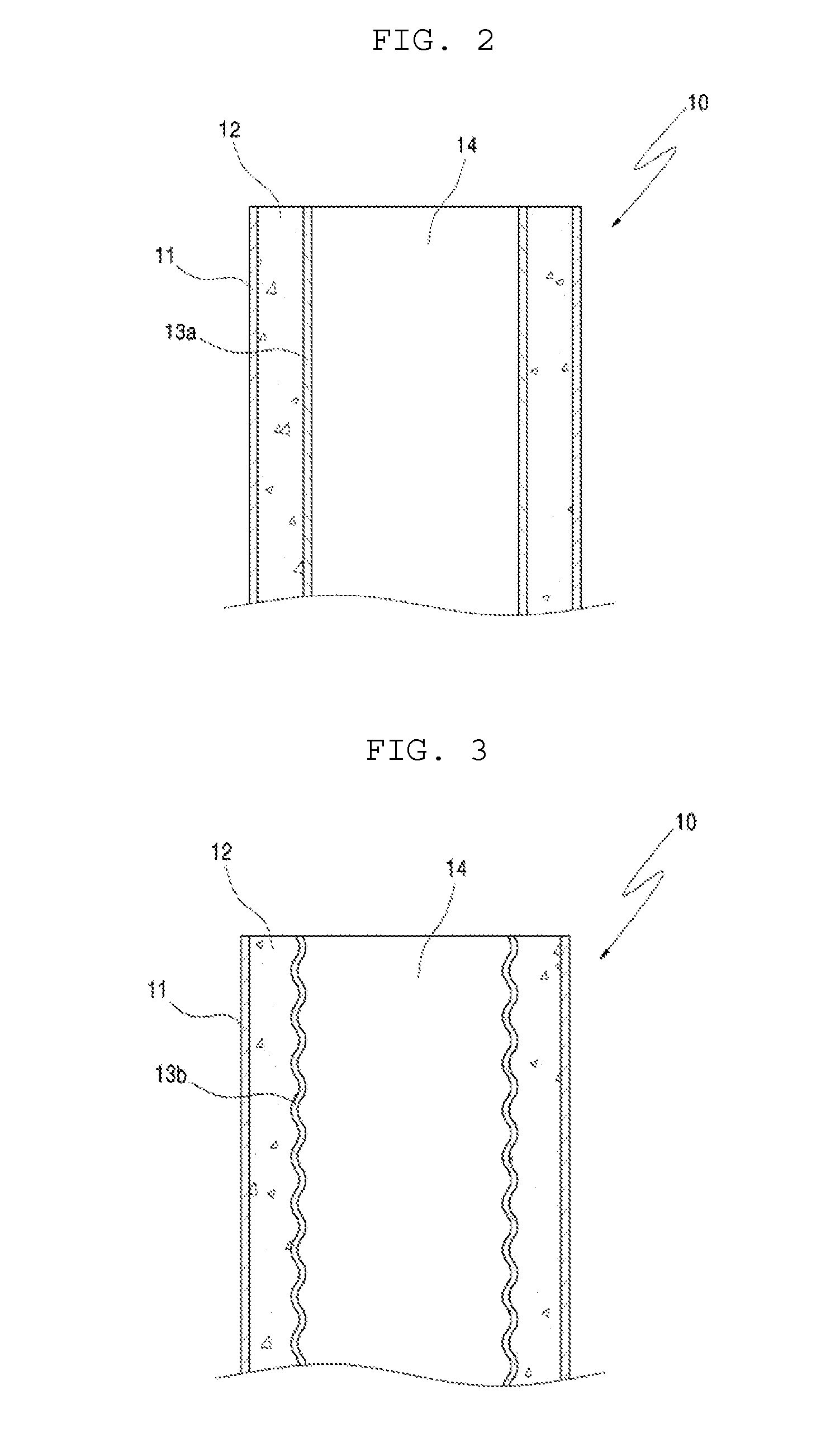

Modular Column System Using Internally Confined Hollow Column Unit and Method of Constructing the Same

A modular column system and a method of constructing the same are constructed by stacking at least one precast unit between a foundation section and a coping section. The precast unit makes use of an internally confined hollow column unit fabricated in advance, and joint sections between the precast units are firmly formed. Thereby, the modular column system can realize a short construction period and economy because reinforcement bars and forms are not used, as well as high resistance to bending moment and reduction in cross section and self-weight of the precast unit, and thus the modular column system can provide easier and more economical assembly, and prevent brittle fracture of the joint section between the precast units.

Owner:HANBAT NAT UNIV IND ACADEMIC COOPERATION FOUND

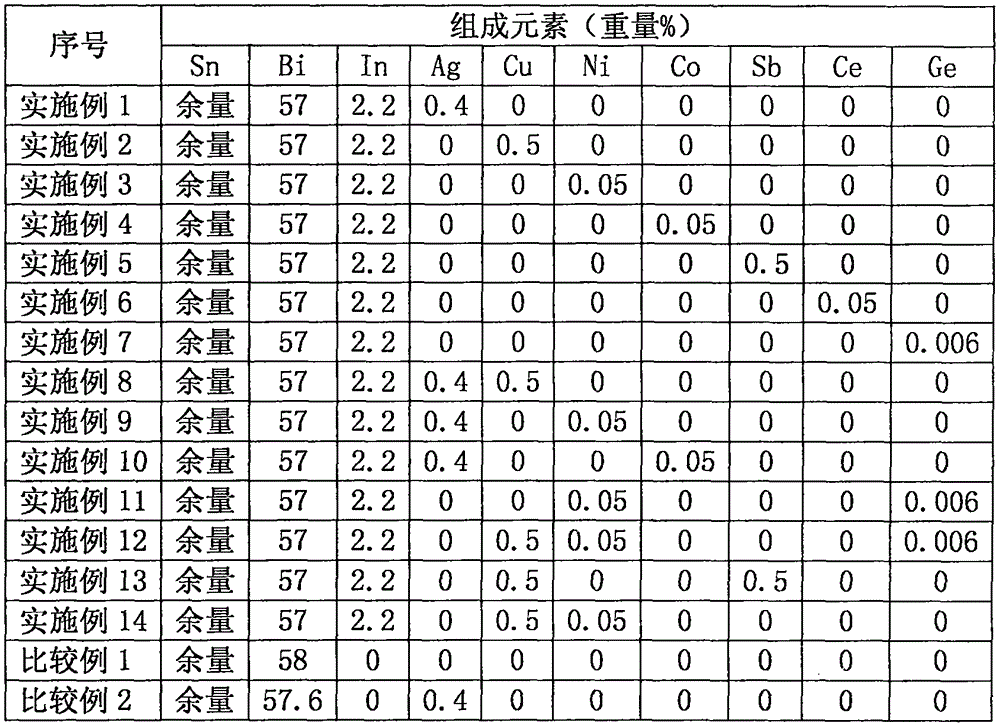

Lead-free solder alloy

InactiveCN105215569ALow melting pointReduce overheating warpageWelding/cutting media/materialsSoldering mediaRare-earth elementBrittle fracture

The invention discloses a lead-free solder alloy. The lead-free solder alloy contains Bi of greater than or equal to 30% and less than or equal to 60%, In of greater than 2% and less than or equal to 5%, a microalloy element (a modificator), a rare-earth element, an anti-oxidization element, and the balance of Sn and inevitable impurities. The lead-free solder alloy is used for effectively improving the reliability problem of brittle fracture of a welded joint due to that Bi-phase crystalline grains in a traditional Sn-Bi alloy system are large and Bi is segregated at a Cu / Cu3Sn interface in the form of particles in the long-term service process of traditional Sn-Bi series alloys; as a result, the mechanical shock and the anti-dropping performance of the traditional Sn-Bi series alloys can be greatly improved.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

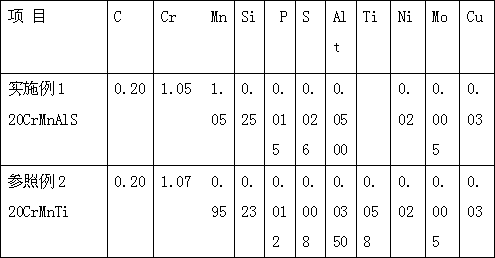

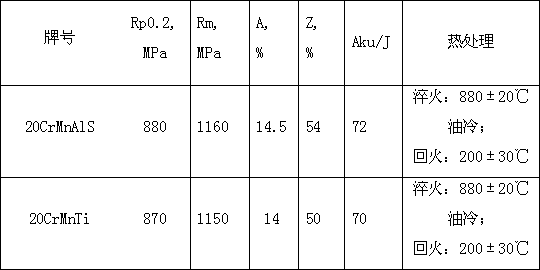

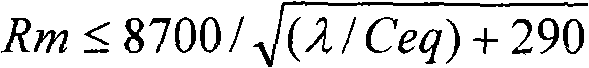

Free-machining pinion steel and production technique thereof

The invention discloses a free-machining pinion steel and a production technique thereof. The pinion steel comprises the following components in percentage by weight: 0.14-0.22% of C, 0.20-0.35% of Si, 0.95-1.15% of Mn, 0.95-1.15% of Cr, 0.020-0.060% of Al, at most 0.035% of P, 0.012-0.030% of S, and the balance of Fe and inevitable impurities. The technique comprises the following steps: smelting, continuous casting and rolling. In the invention, the Cr-Mn-Al-S pinion steel is used instead of the original Cr-Mn-Ti pinion steel, Al and S elements are added, and the intracrystalline ferrite is sufficiently utilized to refine the crystalline grains. The invention can stabilize the Jominy hardenability, reduce the pinion deformation after heat treatment, enhance the brittle fracture resistance and crack propagation resistance, and improve the free machining capacity of the pinion in the machining process. The invention is applicable to pinion steel as a substitute of 20CrMnTi.

Owner:ZENITH STEEL GROUP CORP +1

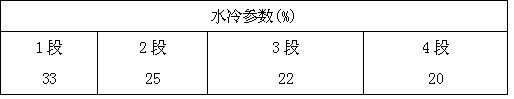

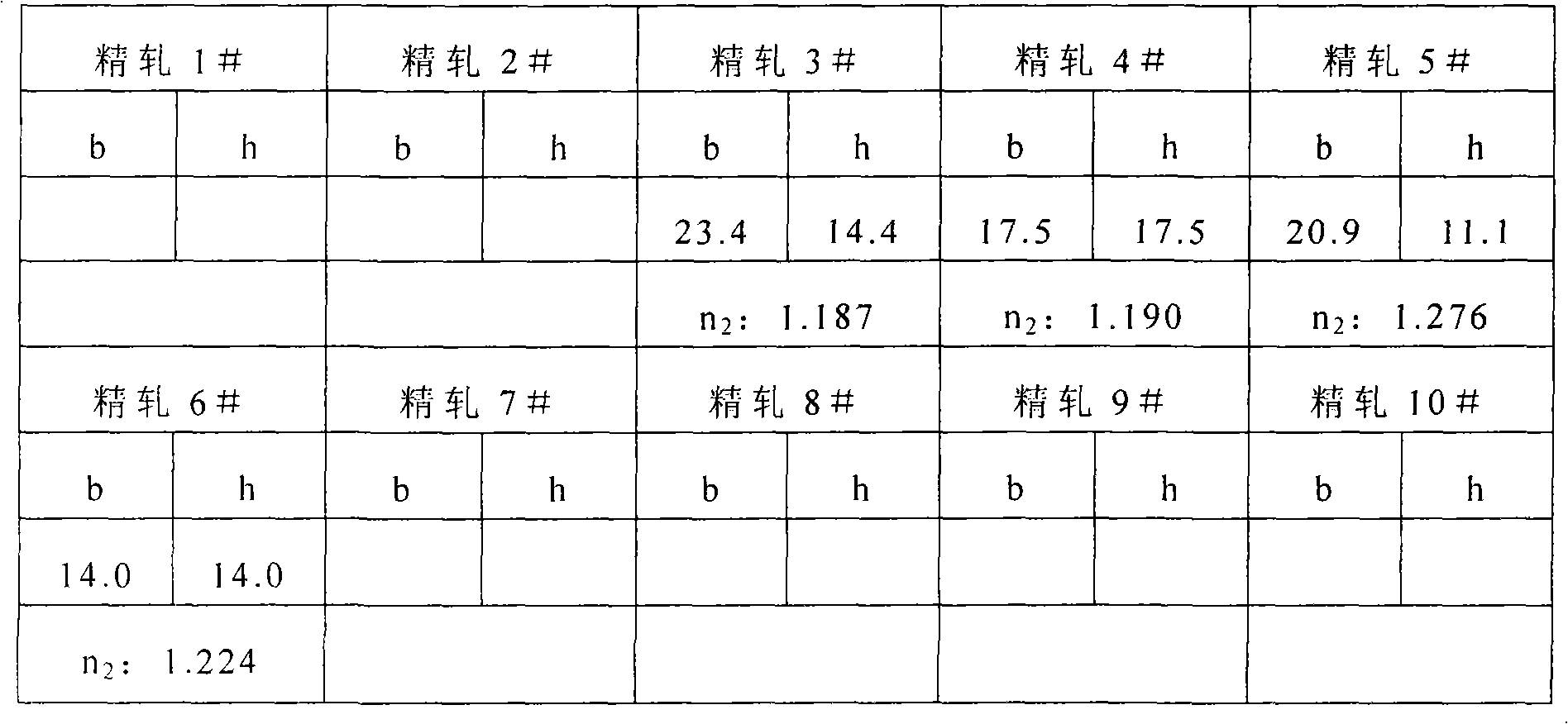

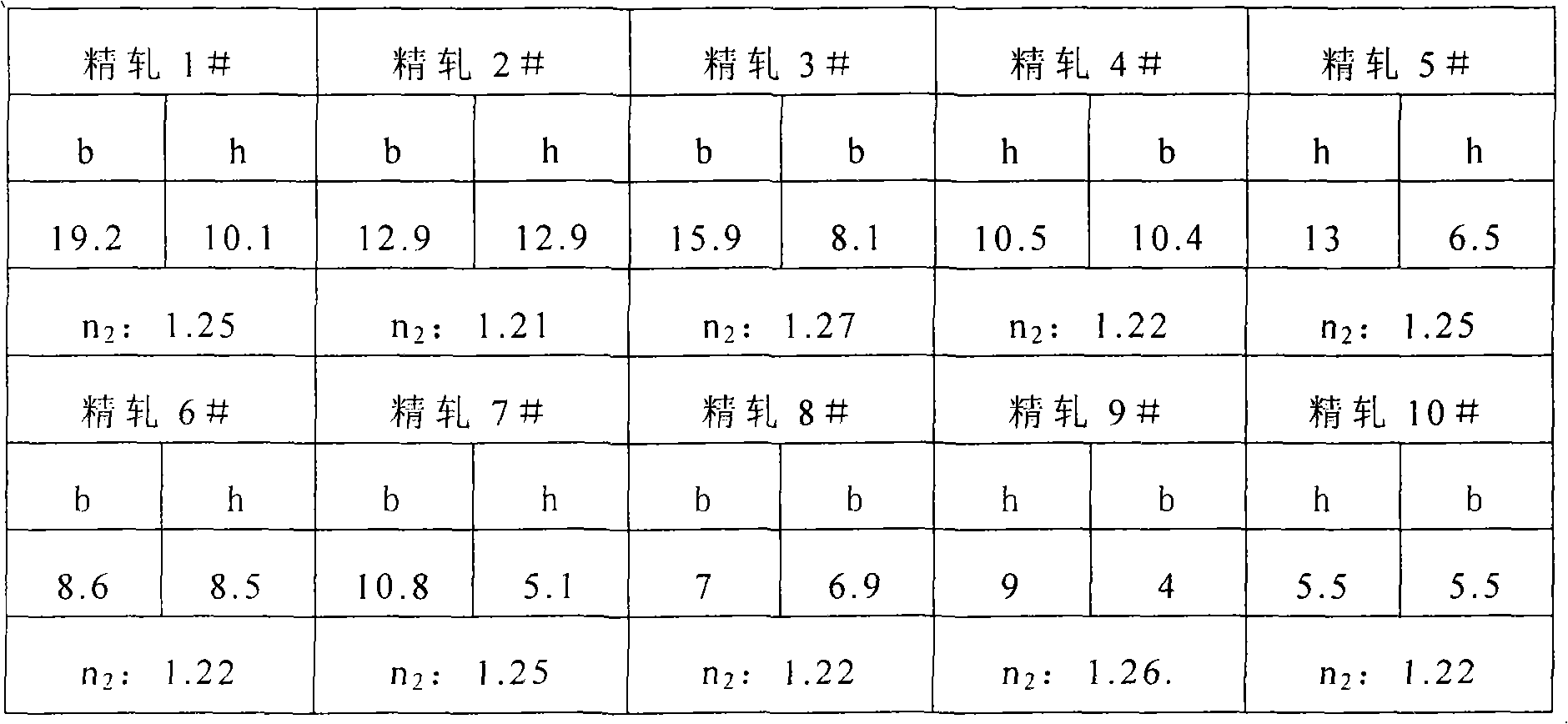

Method for producing good-quality high-carbon steel green rod for drawing

InactiveCN101327490AImprove organizational structure ratioRefine the grain sizeTemperature control deviceWork treatment devicesHigh carbonRoom temperature

The invention discloses a production method to draw high-quality high-carbon steel green rod, which includes the following steps: firstly, the high-carbon continuous cast steel is heated, and then goes through the treatment processes of rough rolling, medium rolling and prefinishing rolling so that the cumulative rolling elongation n1 equals 65 to 120 times; secondly, the rolled pieces are prewatercooled; and then the rolled pieces go through the prefinishing rolling process for 4 to 10 times, wherein, the elongation n2 equals to 1. 1 to 1. 3 times each time and the finishing temperature is 920 to 1090 degrees centigrade; and then the rolled pieces are prewatercooled for a second time, wherein, the rolled pieces reach a drawing out temperature of 830 to 900 degrees centigrade and are made into scattered rolls; in the end, the scattered rolls are air-cooled, wherein, the temperature of the scattered rolls at the outlet of the air cooling roll table is 330 to 450 degrees centigrade; the rolls are cooled in the air environment to room temperature to produce high quality high-carbon steel green rods for drawing, which have large numbers of sorbites, small interlamellar spacing and stable mechanical properties and are not apt to brittle fracture in the production process.

Owner:WUHAN IRON & STEEL (GROUP) CORP

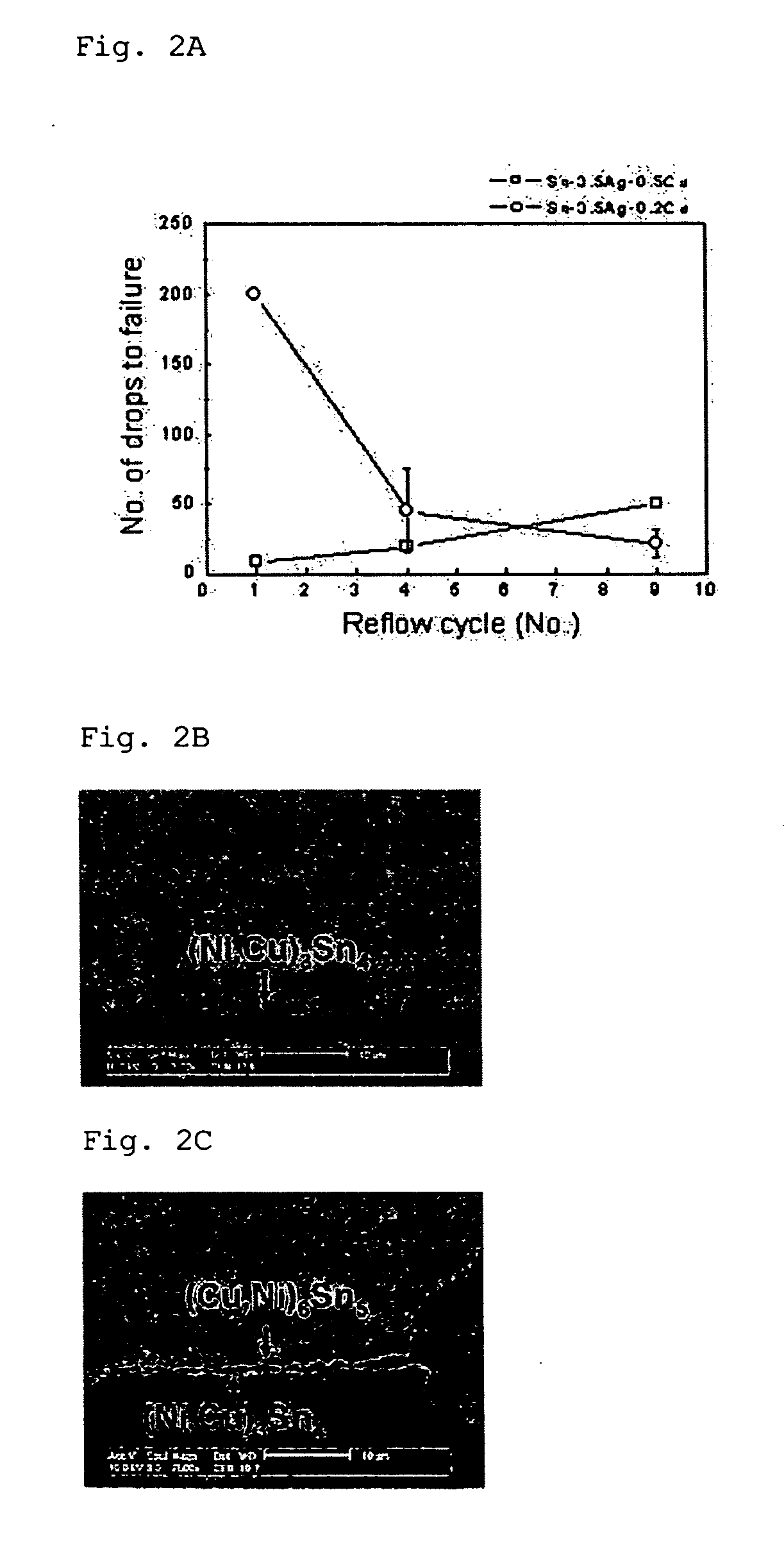

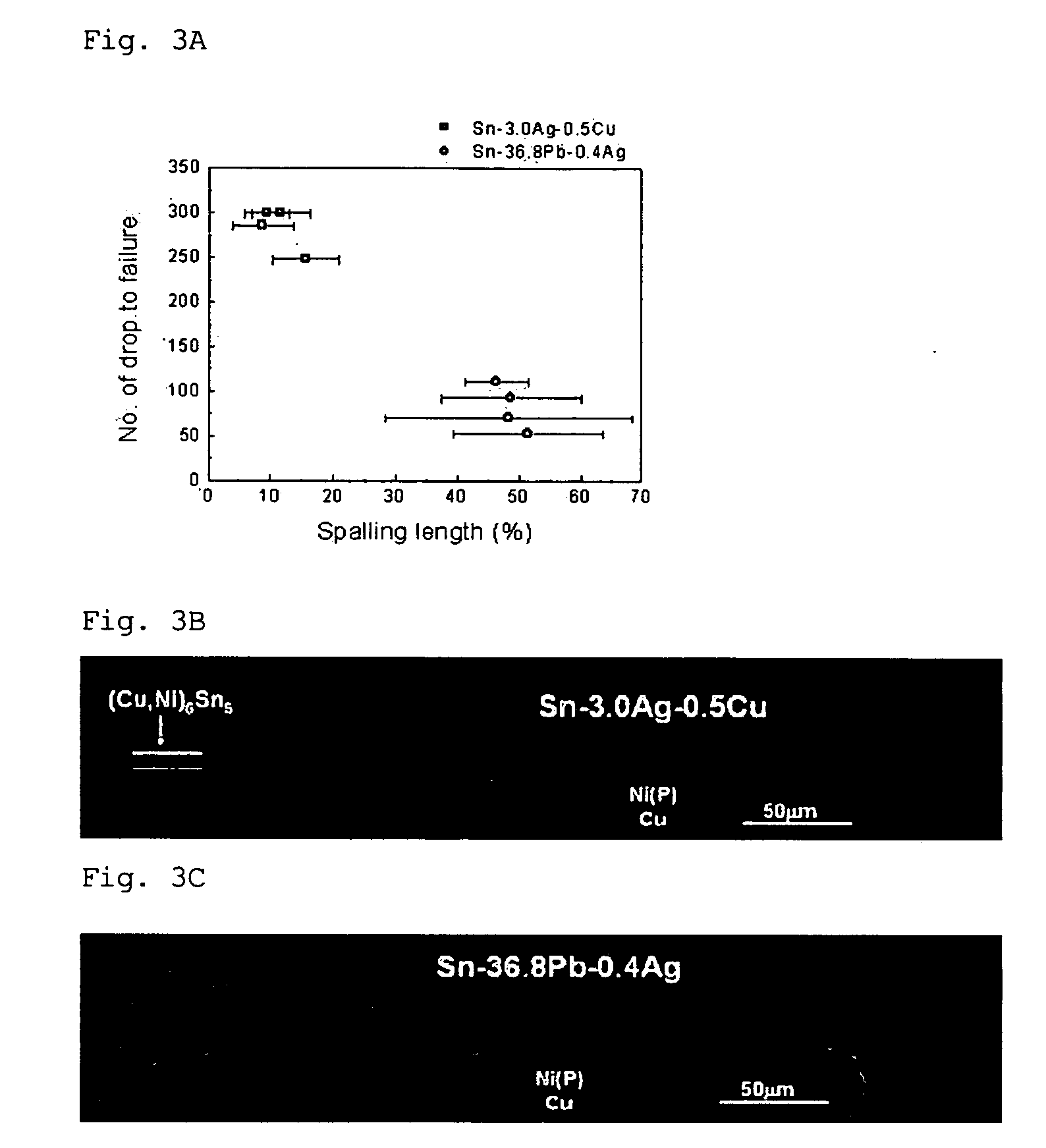

Soldering Method and Related Device for Improved Resistance to Brittle Fracture

ActiveUS20100243300A1Easy to optimizeLess-prone to brittle failureSolid-state devicesComponent plug-in assemblagesTin-silver-copperBrittle fracture

A lead-free solder joint is formed between a tin-silver-copper solder alloy (SAC), SACX, or other commonly used Pb-free solder alloys, and a metallization layer of a substrate. Interaction of the SAC with the metallization layer forms an intermetallic compound (IMC) that binds the solder mass to the metallization layer. The IMC region is substantially free of any phosphorous-containing layers or regions.

Owner:BELL SEMICON LLC

Stent fabrication via tubular casting processes

ActiveUS20090319028A1Improve mechanical propertiesReduced flexibilityOrganic active ingredientsHeart valvesPolymer solutionDip-coating

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

Stent fabrication via tubular casting processes

ActiveUS8206635B2Improve radial strengthImprove overall strength levelsOrganic active ingredientsPeptide/protein ingredientsPolymer solutionDip-coating

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

Cross-linking agent modified polyethylene geogrid and manufacturing method thereof

InactiveCN103131071ASingle Rib Tensile Length IncreaseImprove single rib strengthSoil preservationCross-linkLinear low-density polyethylene

Disclosed is cross-linking agent modified polyethylene geogrid. Components with percentage content of the cross-linking agent modified polyethylene geogrid are 65% to 70% of high-density polyethylene (HDPE), 21% to 26% linear low density polyethylene (LLDPE), 0.5 % to 1% of dicumyl peroxide (DCP), 0.5% to 2% A-151, 0.5% to 1% dibutyltion dilautate (DBTDL) and 4.5% to 5% color master with carbon black content more than 45 %. The manufacturing method of the cross-linking agent modified polyethylene geogrid comprises steps as below: 1) master batch manufacturing: mixing part of HDPE, LLDPE, DCP, A-151 and DBTDL together, enabling the blend to pass through a screw extruder to be fused at the temperature of 160 DEG C to 200 DEG C to manufacture the master batch in a melting mode; 2) mixing of the master batch, the color master and remaining HDPE; 3) molding of sheet materials; 4) punching; 5) stretching. The cross-linking agent modified polyethylene geogrid improves toughness, significantly relieves the phenomenon of rib portion brittle fractures, and effectively lowers cost. Stretching length of a single rib is increased by 10 % to 20 %, strength is improved by 5 % to 10 %, and gram weight of a product is reduced by 20 % to 30 %.

Owner:NANCHANG TIANGAO ENVIRONMENTAL PROTECTION TECH CO LTD

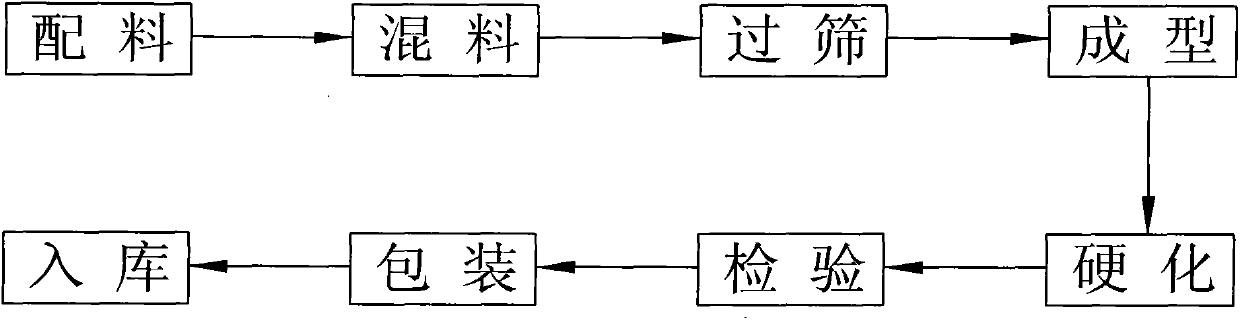

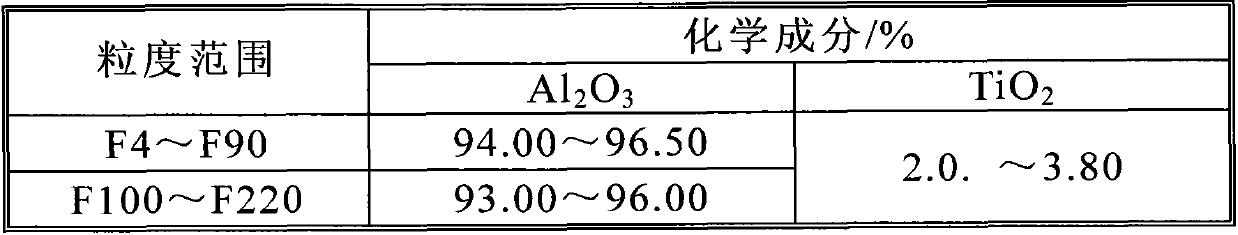

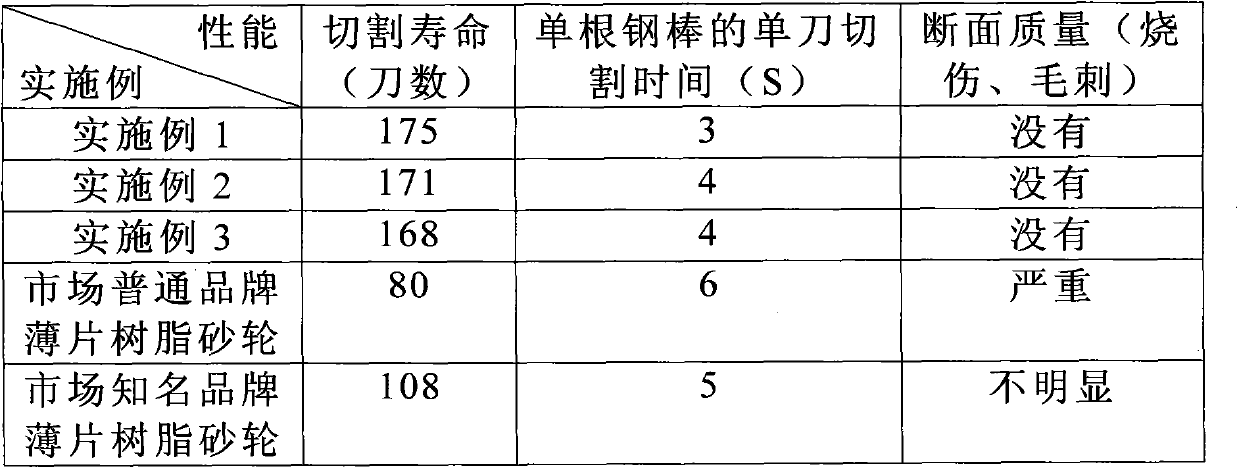

Slice resin grinding wheel and preparation method thereof

InactiveCN103465180AHigh strengthImprove wear resistanceAbrasion apparatusGrinding devicesEngineeringBrittle fracture

The invention provides a slice resin grinding wheel and a preparation method thereof and belongs to the field of grinding tools. The slice resin grinding wheel solves the problems that existing slice resin grinding wheels are easily subjected to brittle fracture and damage and are short in service lives and not ideal enough in rigidity and self-sharpening performance. The slice resin grinding wheel comprises a grinding body and a reinforcing piece placed in the grinding body so as to enhance rotation strength of the grinding body. The grinding body comprises, by weight, 30-40 parts of white fused alumina, 65-75 parts of microcrystal fused alumina, 5-20 parts of green silicon carbide, 5-10 parts of resorcin-formalin, 10-20 parts of phenolic resin powder, 8-15 parts of cryolite powder and 10-20 parts of pyrite powder. The invention further provides the preparation method of the slice resin grinding wheel. The slice resin grinding wheel has the advantages of being low in production cost, high in rigidity, good in self-sharpening performance and long in service life.

Owner:NINGBO DAHUA GRINDING WHEEL

Cold rolling method capable of preventing edge crack and brittle fracture of silicon steel with Si content more than or equal to 3.5 percent

ActiveCN104399749AImprove magnetismSave rolling timeTemperature control deviceMetal rolling arrangementsSheet steelEmulsion

The invention relates to a cold rolling method capable of preventing edge crack and brittle fracture of silicon steel with Si content more than or equal to 3.5 percent. The cold rolling method comprises the steps of firstly preheating an uncoiled steel plate; spraying emulsion and fully closing the flow of the emulsion on the outlet sides of former 1-4 passes; conducting cold rolling by adopting a one-step cold rolling method; coiling, wherein the tension at the starting stage is enabled to be 60-80 percent smaller than the tension under set coiling speed to conduct tension control; conducting subsequent processes according to conventional steps. The cold rolling method capable of preventing edge crack and brittle fracture of silicon steel with Si content more than or equal to 3.5 percent has the advantages that not only can the silicon content be enabled to be more than 3.5 percent to improve the magnetic performance of the silicon steel plate, but also the steel plate can be free of edge cracks during cold rolling, the brittle fracture and reject rate is decreased to 0.15 percent, the rolling time of a single coil can be shortened by no less than 10 minutes, and compared with the prior art, the yield is improved by 28.64 percent.

Owner:武汉钢铁有限公司

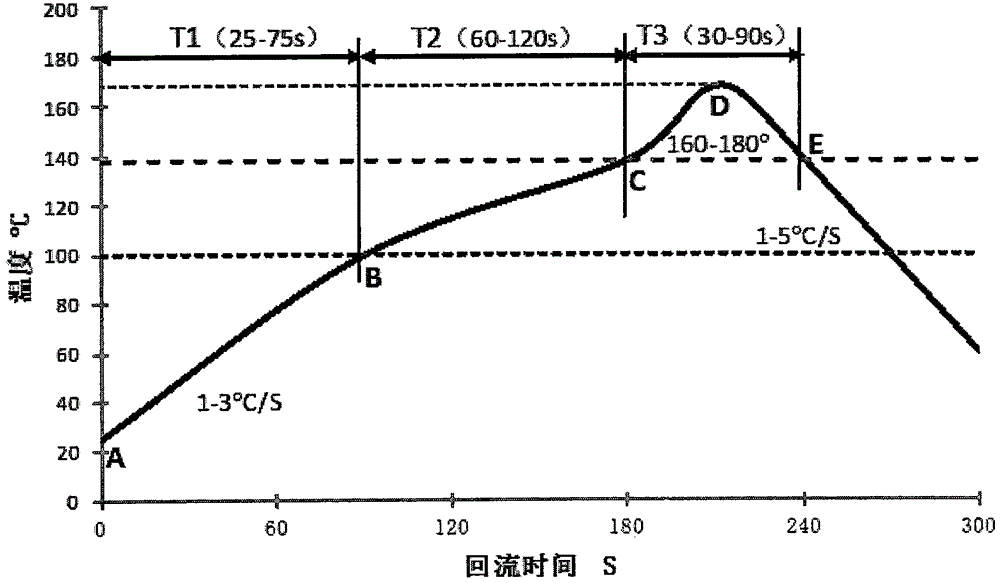

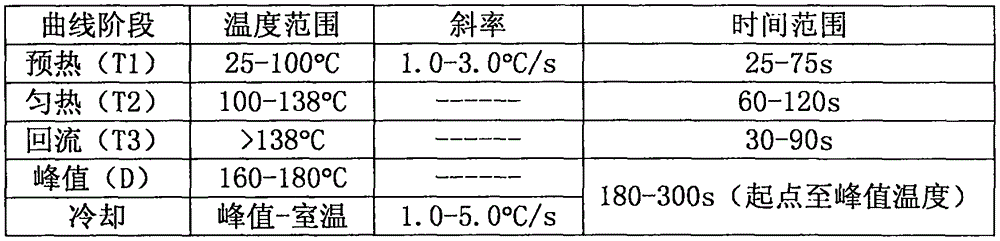

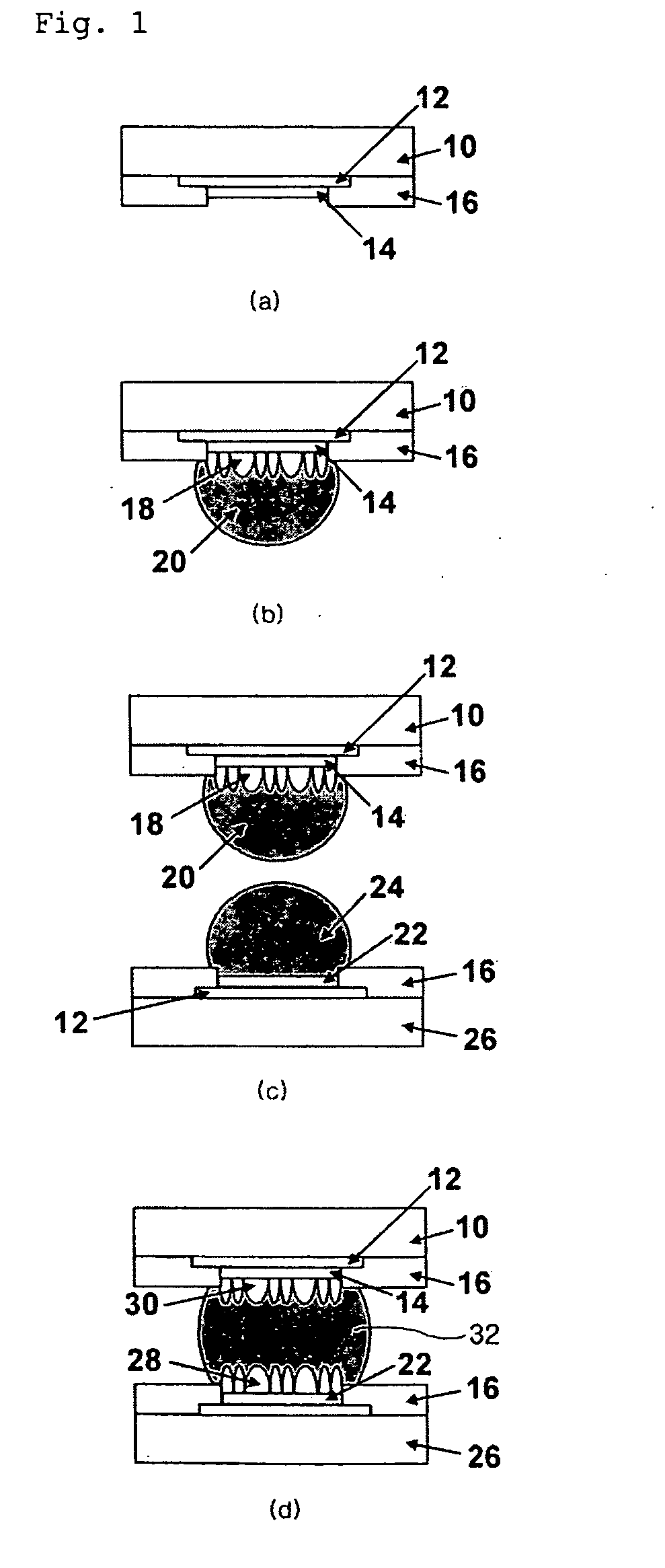

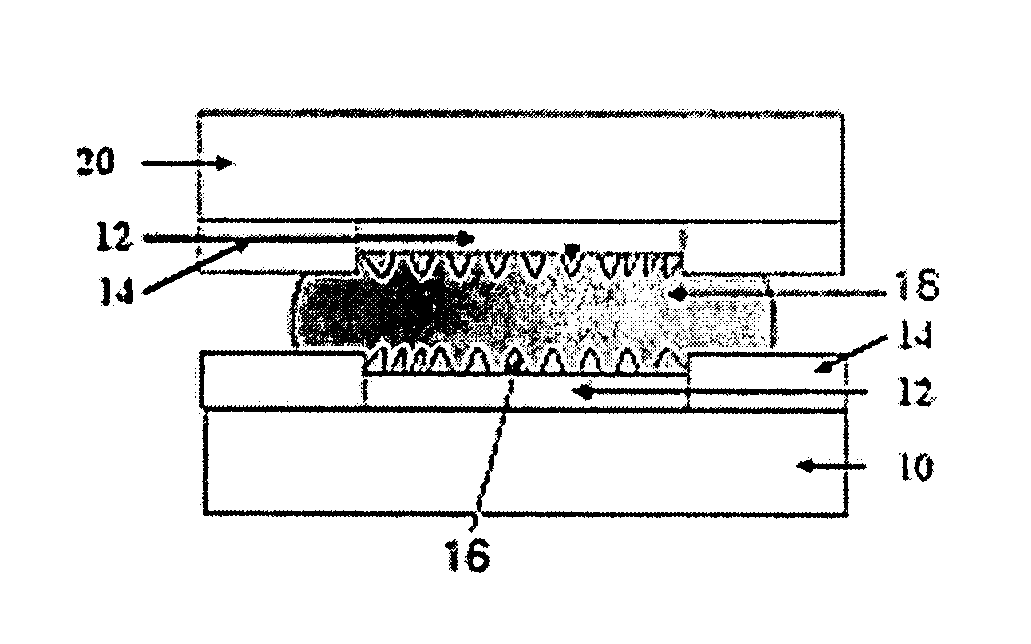

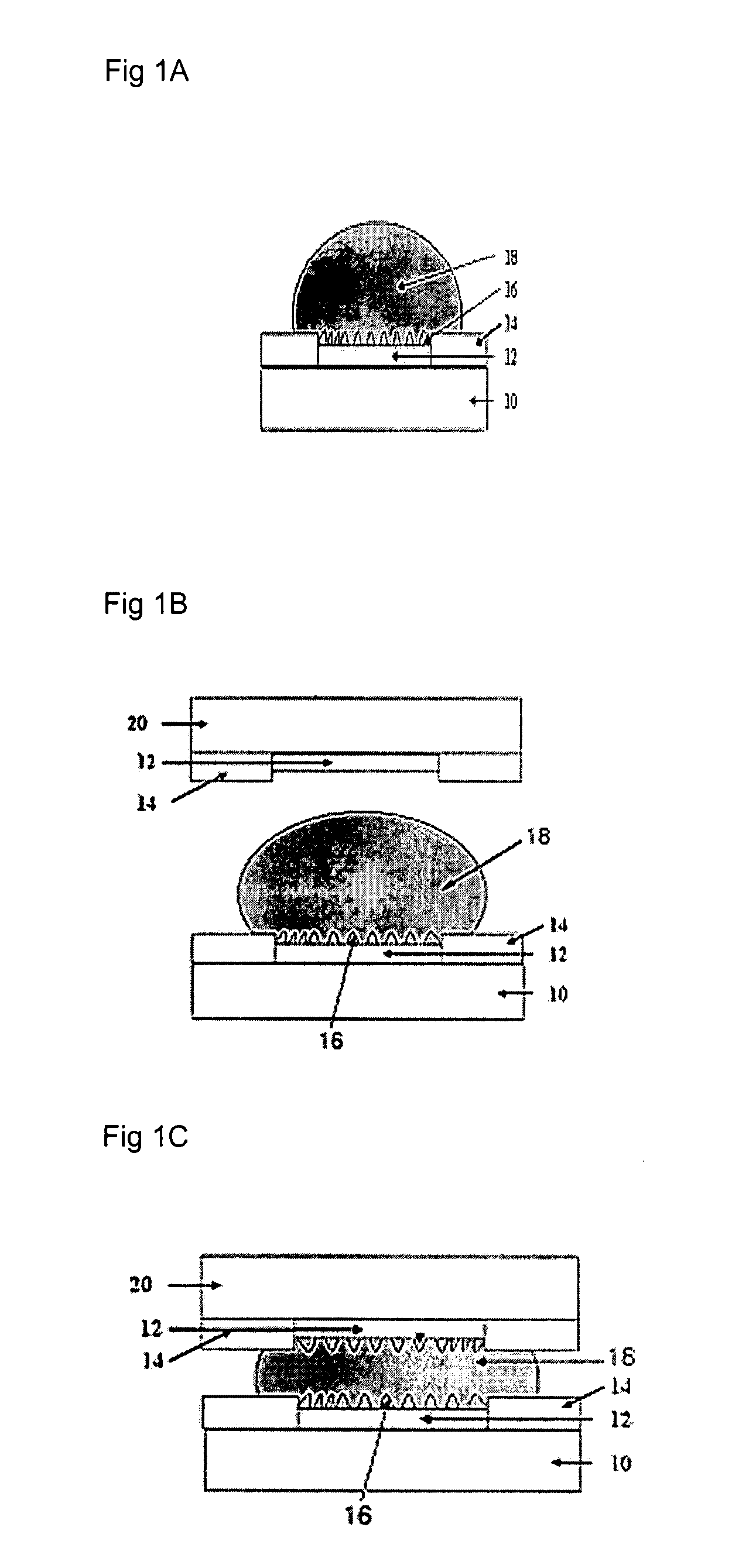

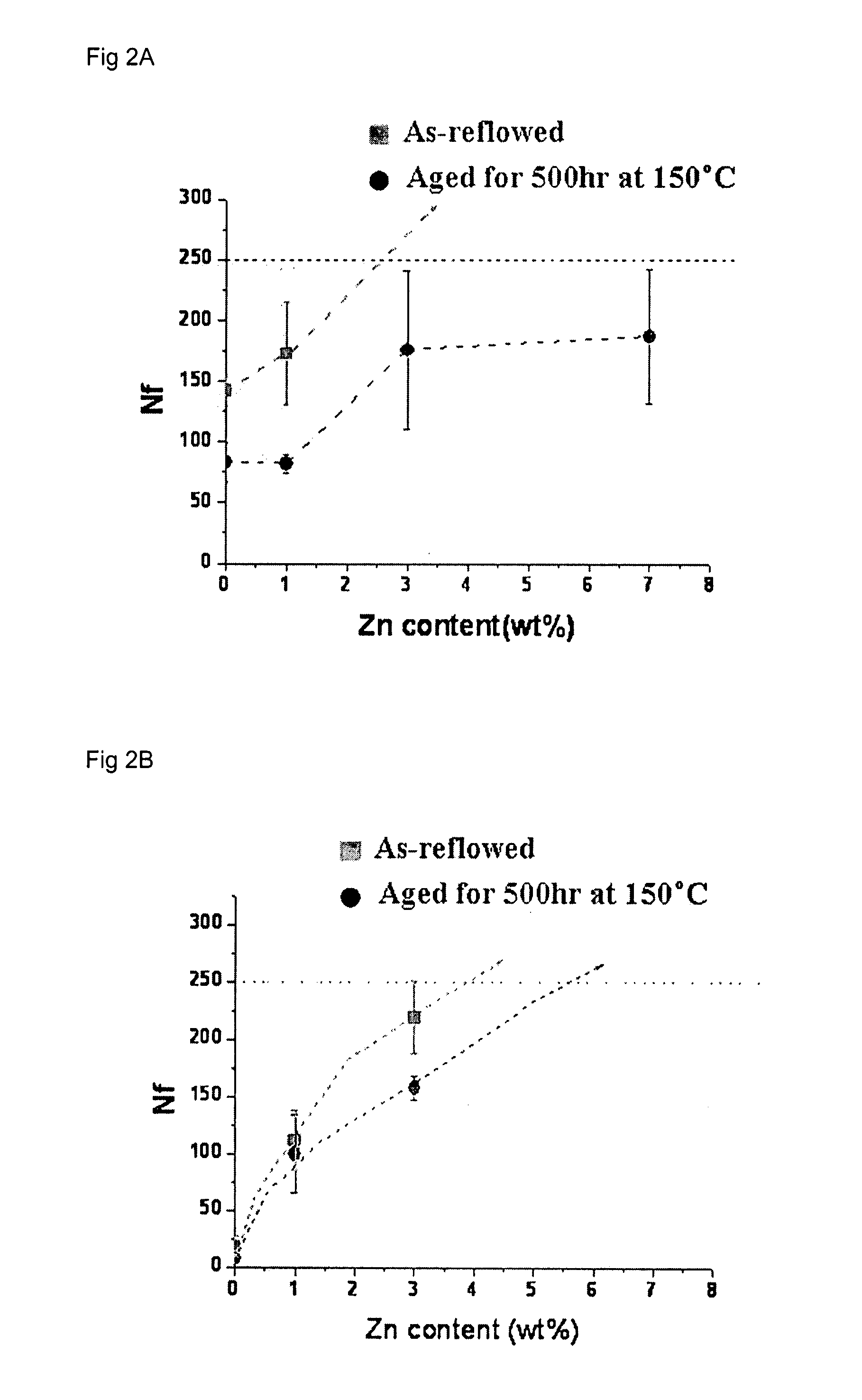

Method for joining electronic parts finished with nickel and electronic parts finished with electroless nickel

InactiveUS20070158391A1Preventing brittle fractureBrittle fractureCooking-vessel materialsSolid-state devicesElectroless nickelBrittle fracture

The present invention relates, generally, to methods for joining an electronic part finished with nickel and an electronic part finished with electroless nickel, which can prevent a brittle fracture, more particularly, to a method for joining an electronic part finished with nickel and an electronic part finished with electroless nickel with a solder by controlling the composition of the solder to prevent a brittle fracture occurring at the solder joining portion.A method for joining an electronic part finished with nickel and an electronic part finished with electroless nickel, comprising: (1) reflowing solder to a nickel portion of an electronic part finished with nickel to obtain an electronic part where an intermetallic compound and a solder are formed; (2) obtaining an electronic part finished with an eletroless nickel, of which the nickel portion is connected with the solder; and (3) solder-joining an electronic part finished with nickel obtained in the step (1) and the electronic part finished with electroless nickel obtained in the step (2).

Owner:KOREA ADVANCED INST OF SCI & TECH

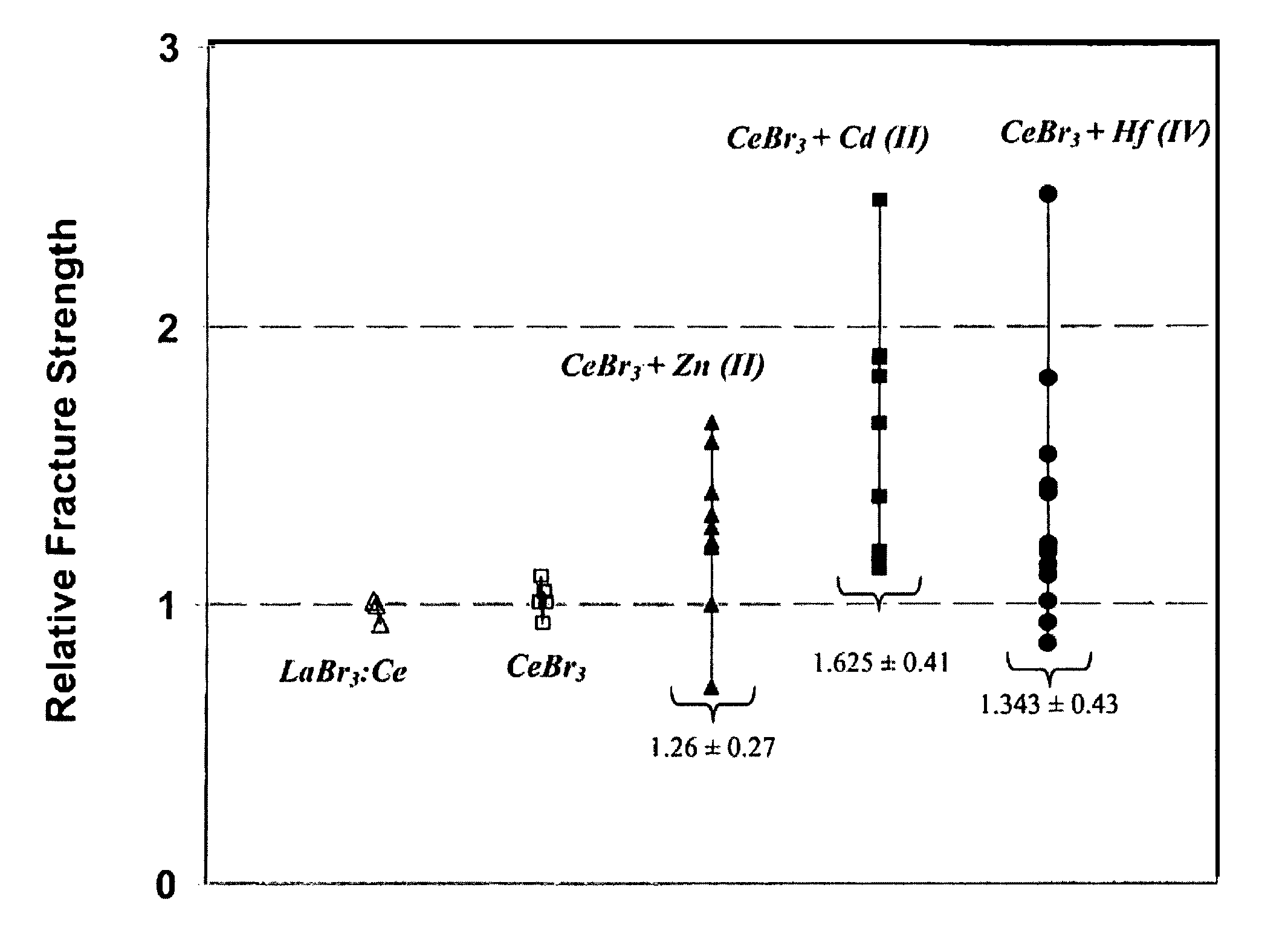

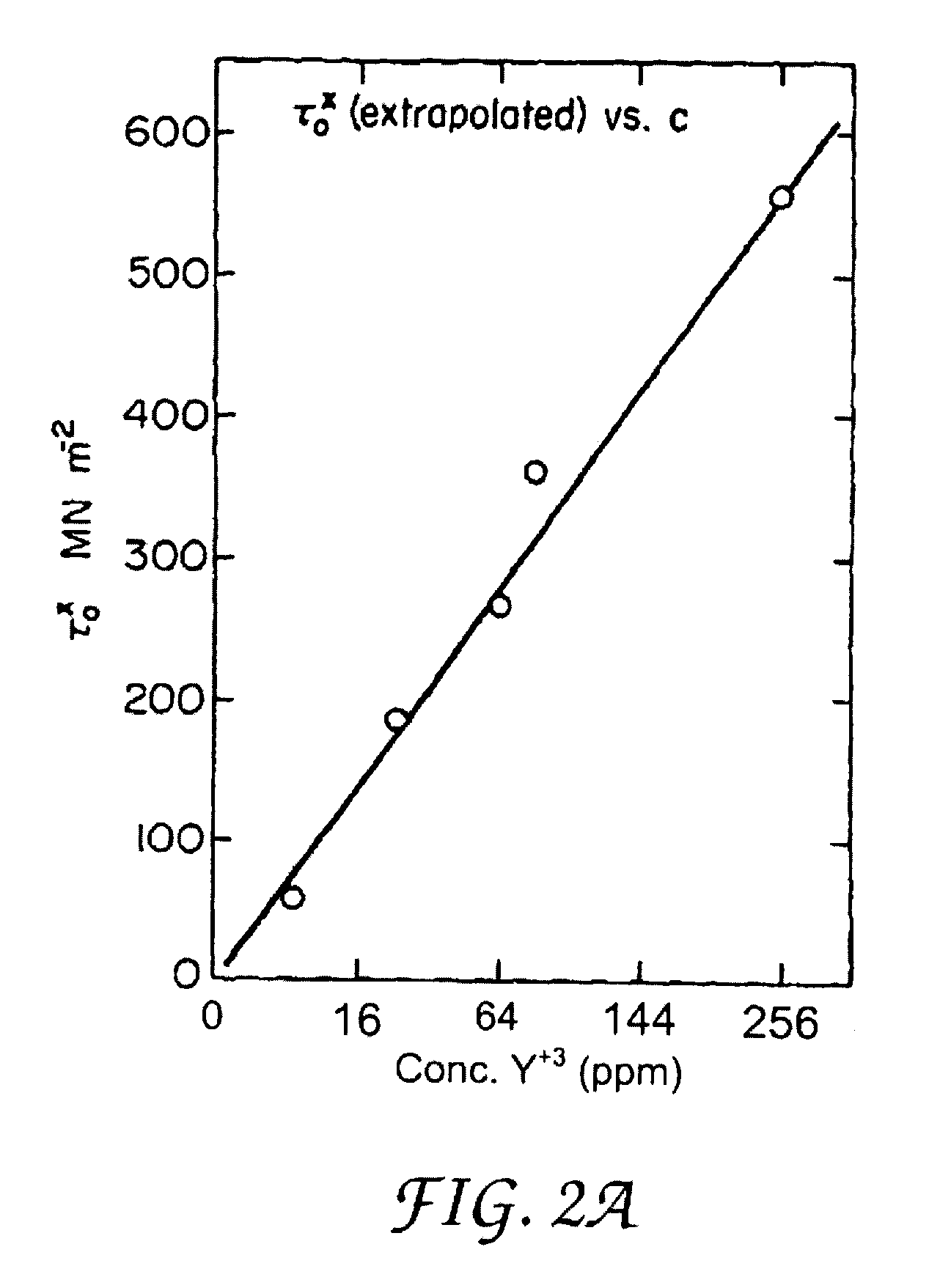

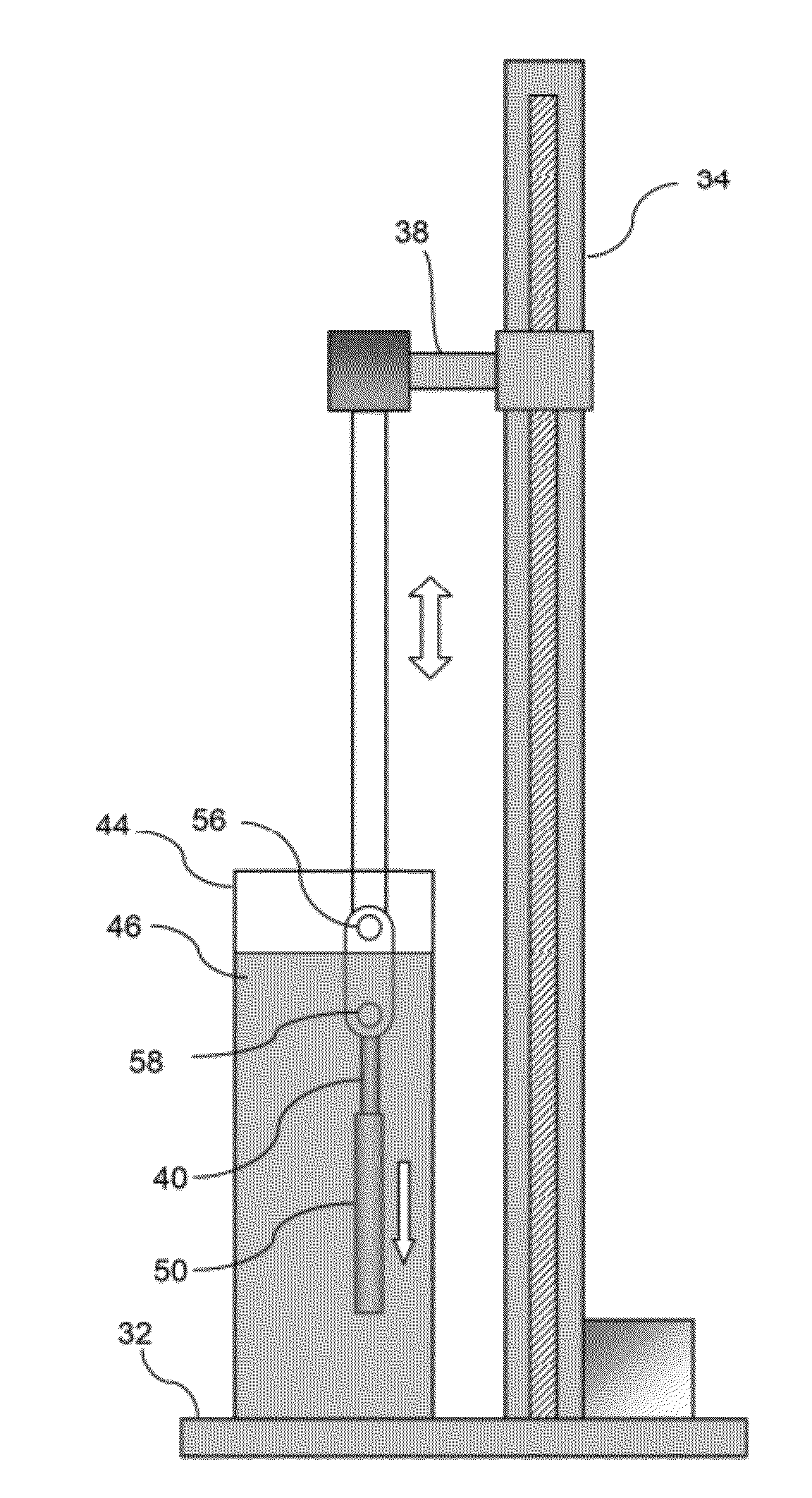

Fracture-resistant lanthanide scintillators

ActiveUS7863572B1Sufficient strainReduce slippageMaterial analysis by optical meansRadiation intensity measurementFluorescenceLanthanide

Lanthanide halide alloys have recently enabled scintillating gamma ray spectrometers comparable to room temperature semiconductors (<3% FWHM energy resolutions at 662 keV). However brittle fracture of these materials upon cooling hinders the growth of large volume crystals. Efforts to improve the strength through non-lanthanide alloy substitution, while preserving scintillation, have been demonstrated. Isovalent alloys having nominal compositions of comprising Al, Ga, Sc, Y, and In dopants as well as aliovalent alloys comprising Ca, Sr, Zr, Hf, Zn, and Pb dopants were prepared. All of these alloys exhibit bright fluorescence under UV excitation, with varying shifts in the spectral peaks and intensities relative to pure CeBr3. Further, these alloys scintillate when coupled to a photomultiplier tube (PMT) and exposed to 137Cs gamma rays.

Owner:SANDIA NAT LAB

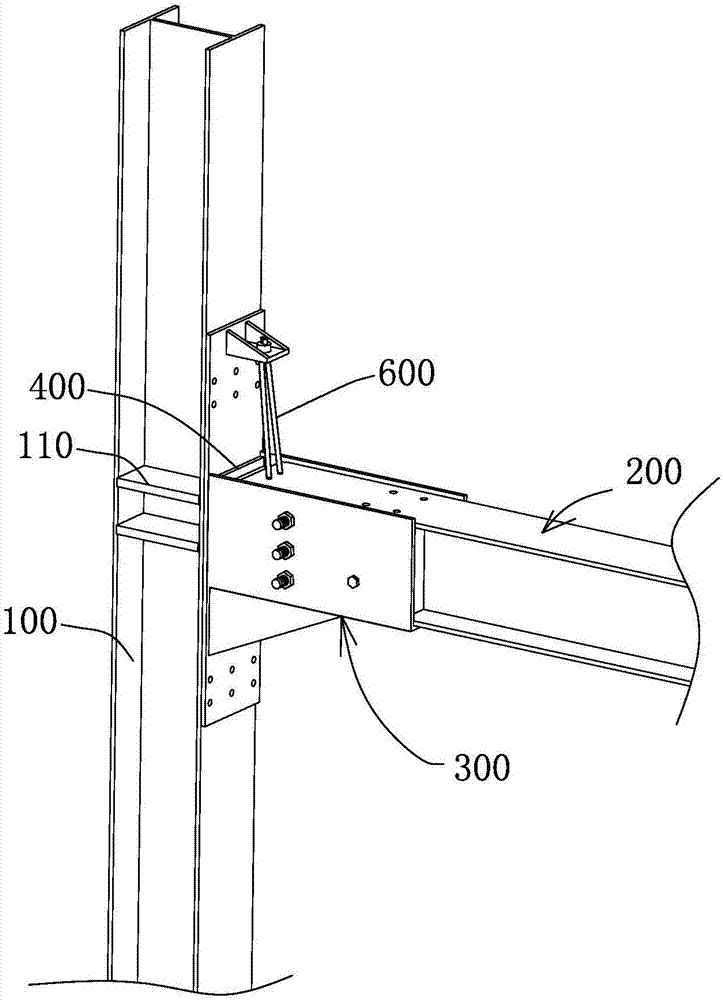

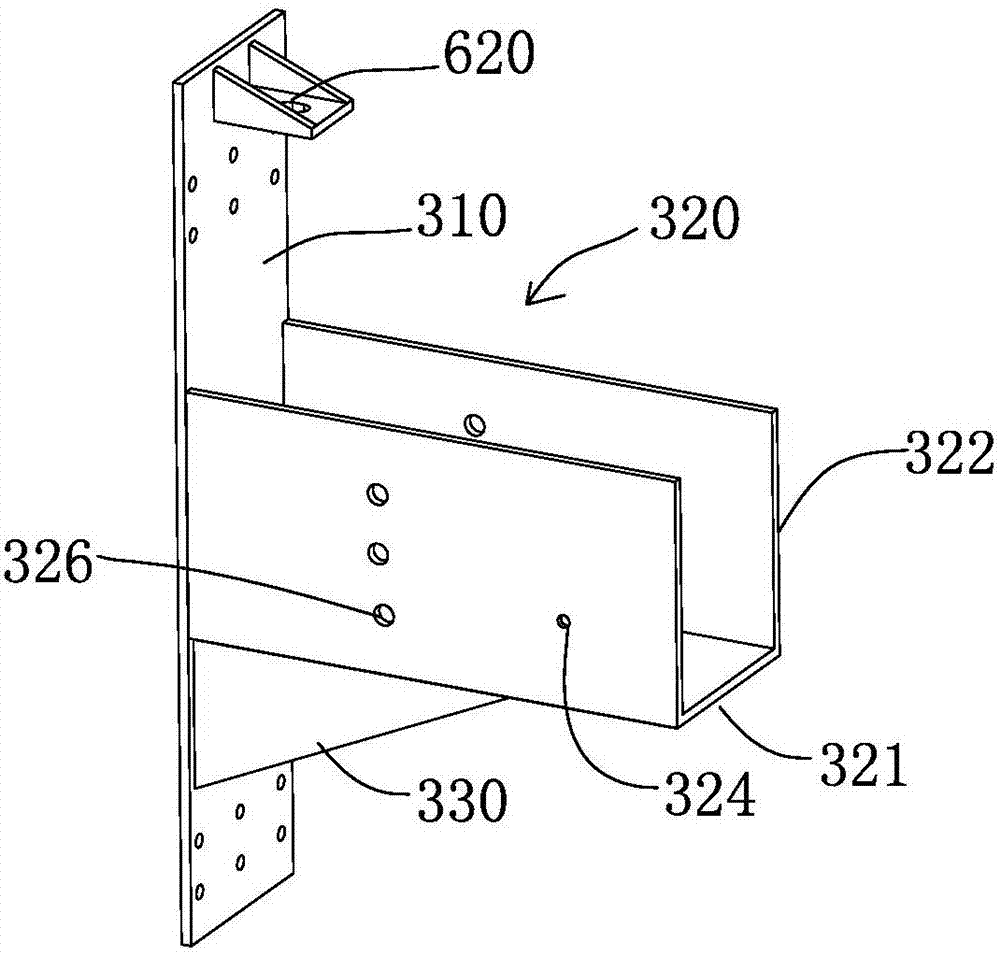

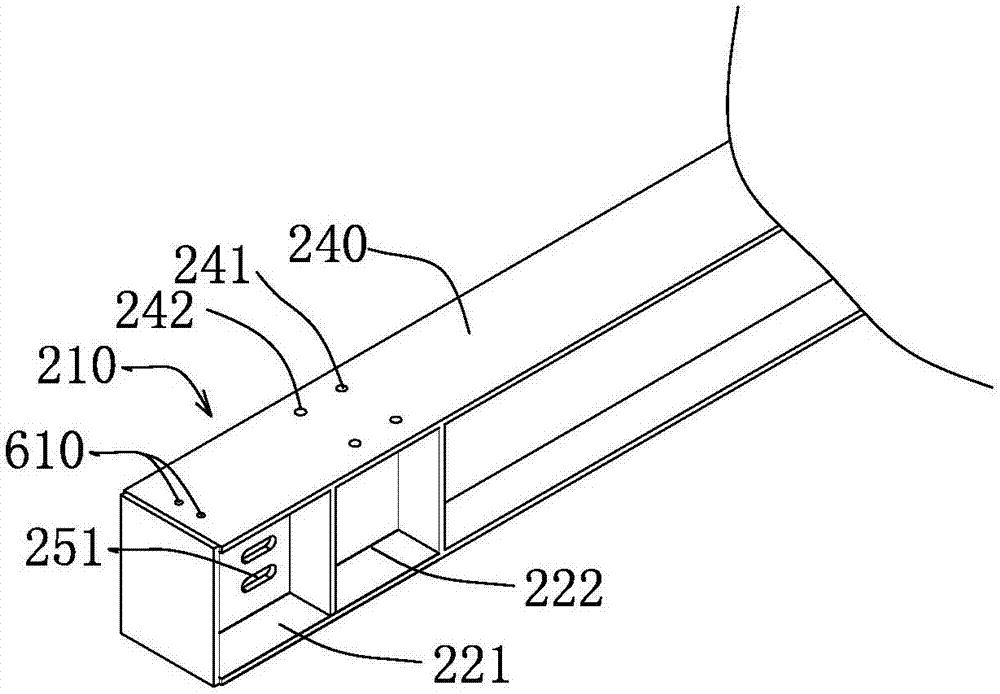

Beam-column anti-seismic connecting joint and connecting method thereof

ActiveCN107476434AGuaranteed rigid connectionConsumes seismic energyProtective buildings/sheltersBuilding material handlingStructural engineeringSteel columns

The invention discloses a beam-column anti-seismic connecting joint and a connecting method thereof, and the problem of brittle fracture is solved. The beam-column anti-seismic connecting joint is used for connecting of a steel column and an I-shaped steel beam, and a first space and a second space are arranged on connecting parts of the two ends of the steel beam; a laminated component is arranged in the first space, and a grouting groove is formed in the second space; a transition connecting piece is fixed on the steel column, and an inserting groove of the transition connecting piece is a U-shaped groove structure with upward opening and is composed of a bottom plate and side plates on the two sides; a connecting part is connected with the inserting groove in an inserted mode, and high strength long bolts are fixed on the two side walls of the inserting groove; and high strength long bolts pass through a strip hole I in a steel sheet, a strip hole II in a beam web and a pin hole in a friction slice. By means of grouting, rigid connecting is formed between the steel beam and the transition connecting piece. Under the action of an strong earthquake, concrete blocks are damaged and crushed, then flexible connecting is formed between the steel beam and the transition connecting piece through the laminated component and the concrete blocks.

Owner:广东省正联钢构工程有限公司

Preparation method for alumina coat on quartz fibre surface

The invention relates to a preparation method for an alumina coat on quartz fibre surfaces, and belongs to the technical field of special functional ceramics. The preparation method comprises the following steps: respectively adding aluminum ion, nitric acid and chelating agent in solvent according to the molar ratio of 1: (0.03-0.28): (0.5-1) till all the materials are hydrolyzed to generate sediments; then, adding peptizator to carry out peptization; carrying out reflux heating and stirring for 8 to 24h at a temperature of between 50 and 100 DEG C to obtain transparent and stable Al2O3 sol; putting quartz fibre into a steeping vat of Al2O3 sol for steeping and then heating up and gradually drying the quartz fibre at a temperature of between room temperature and 80 DEG C; and finally, carrying out heat treatment at a temperature of between 450 and 850 DEG C to obtain the quartz fibre coated with the alumina coat. The preparation method is scientific, reasonable and easy to implement; moreover, the Al2O3 coat coated on the surface of the quartz fibre increases material mechanical property and reduces material brittle fracture.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Stent fabrication via tubular casting processes

ActiveUS20120232643A1Improve radial strengthImprove overall strength levelsStentsHeart valvesDelayed timePolymer solution

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

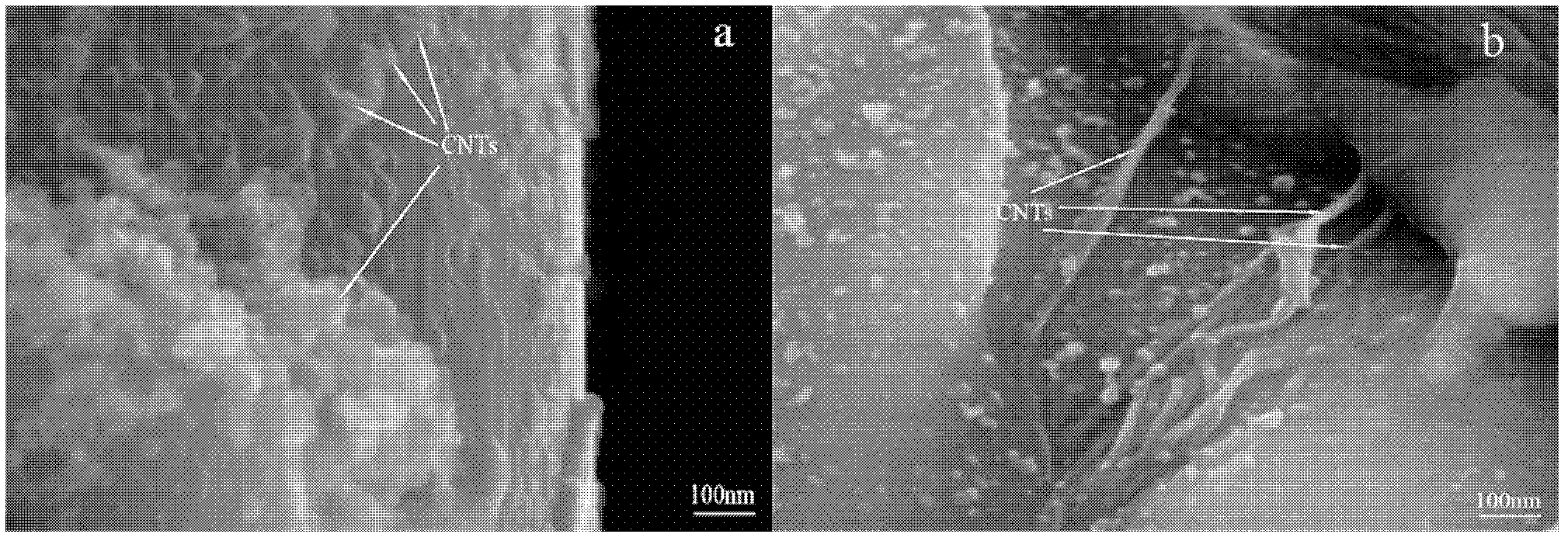

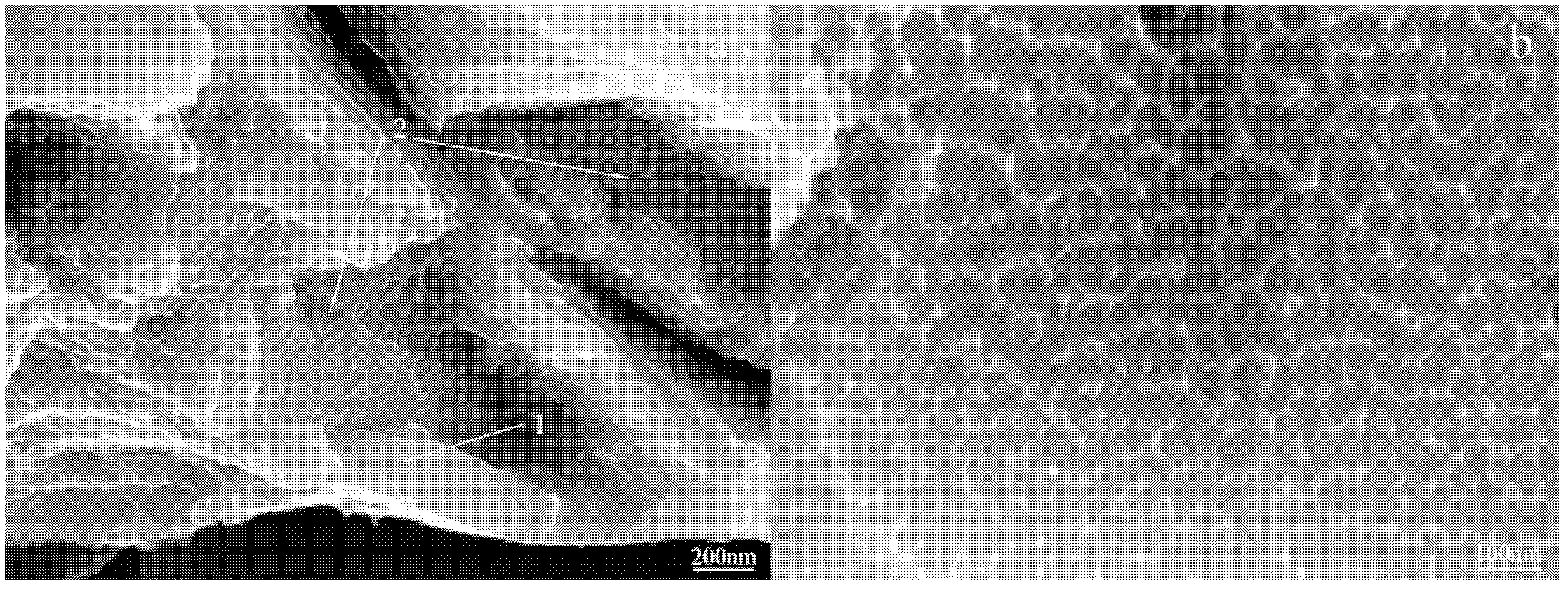

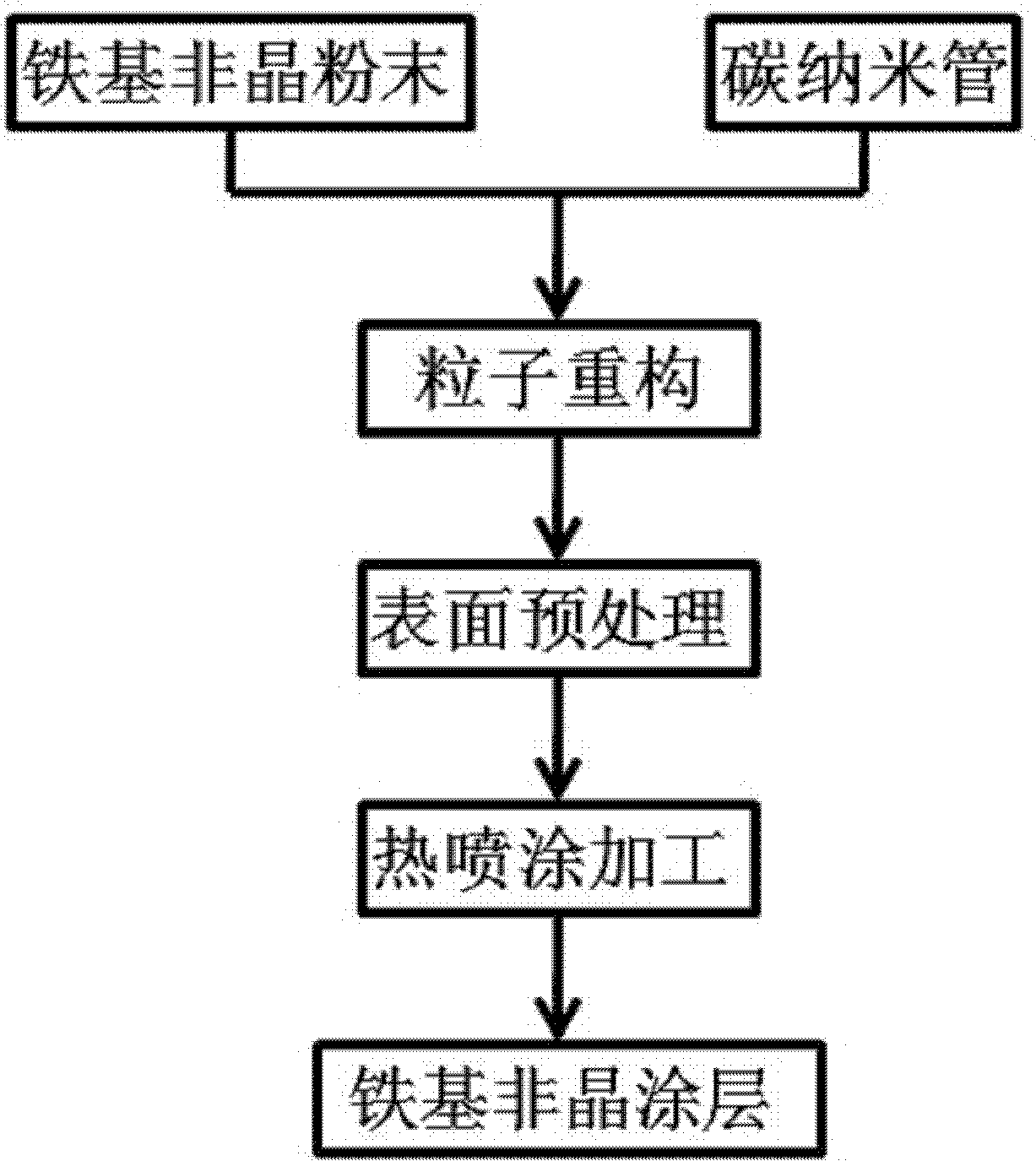

Production of carbon nanotube reinforced Fe-based amorphous alloy thermal spray coating and method

InactiveCN102650027AImprove toughnessPlay a reinforcing roleMolten spray coatingSpray GranulationThermal spraying

The invention provides the production of a carbon nanotube reinforced high tenacity Fe-based amorphous alloy thermal spray coating and a method. A mechanical ball-milling method or a spray granulation method is utilized to reconstruct Fe-based amorphous powder and a carbon nanotube to form Fe-based amorphous-carbon nanotube composite powder; a spraying material surface is pretreated; and the thermal spraying process is carried out, a plasma spraying technology is adopted to spray the Fe-based amorphous-carbon nanotube composite powder, so the high strength and tenacity Fe-based amorphous coating is produced. The Fe-based amorphous alloy powder comprises components of C, B, Ni, Si, Mo, Cr, W and Fe; and the granularity is 1-100mum. The carbon nanotube is a multi-wall carbon nanotube which has the purity larger than 95%, the external diameter of 8-70nm and the length of 100nm-20mum. The carbon nanotube and the Fe-based amorphous are well combined in the coating, so the reinforcing effect is obvious; and the coating fracture surface presents an appearance of total brittle fracture and local ductile fracture, both the tenacity and strength of the Fe-based amorphous are improved, so a practicable and feasible method for applying the Fe-based amorphous coating in a project is provided.

Owner:TIANJIN UNIV

Method of joining electronic package capable of prevention for brittle fracture

InactiveUS20080237314A1Prevention of brittle fractureAvoid fracturesSemiconductor/solid-state device detailsSolid-state devicesCopperBrittle fracture

Disclosed is a method of joining electronic package parts, comprising the steps of: reflowing lead-free solders containing alloy elements on top of each of the electronic package parts having a surface treated with copper or nickel; and mounting the surface treated electronic parts on the lead-free solders then reflowing the lead-free solders to generate intermetallic compound between the lead-free solders and the surface treated portion of each of the electronic parts.Alternatively, the method of joining the electronic package parts according to the present invention comprises the steps of: forming a plating layer made of alloy elements on top of each of the electronic parts having a surface treated with copper or nickel and reflowing lead-free solders; and mounting the surface treated electronic parts on the lead-free solders then reflowing the lead-free solders to allow the alloy elements contained in the plating layer to be diffused into the lead-free solders and generate intermetallic compound between the lead-free solders and the surface treated portion of each of the electronic parts.The present invention can prevent brittle fracture of the electronic package parts by deriving alteration of the intermetallic compounds generated from existing lead-free solders when the electronic package parts of electronic devices are solder joined together, thereby ensuring reliability of the electronic devices.

Owner:KOREA ADVANCED INST OF SCI & TECH

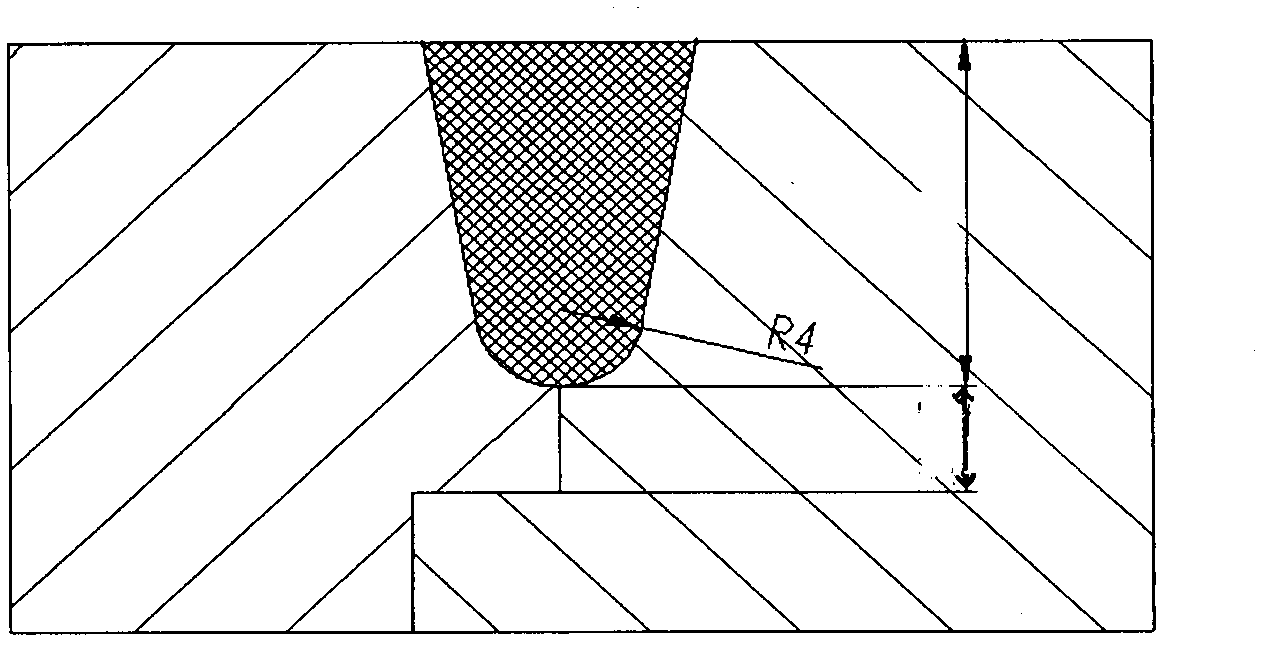

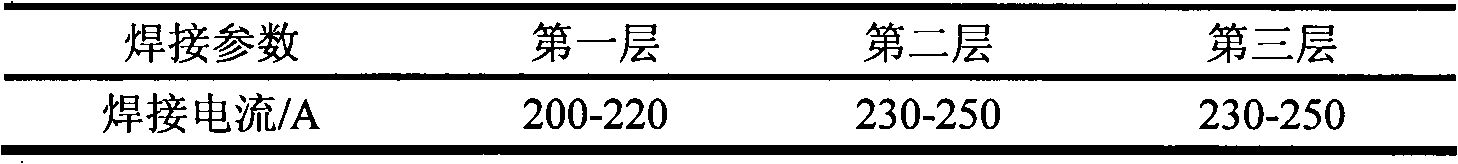

Cylinder barrel of oil cylinder of crane and processing process thereof

ActiveCN102517491AReduce welding defectsImprove safety and reliabilityArc welding apparatusCylindersHydraulic cylinderWelding defect

The invention discloses a cylinder barrel of an oil cylinder of a crane and a processing process thereof. The invention belongs to the field of hydraulic cylinders. The material of a cylinder barrel body is Q345B. The material contains alloy elements, such as Cr, Nb, Ni, V and the like, and the mechanical property and the welding property are both better than those of 45# steel. The processing process comprises the following steps: (1) using a hot rolling steel pipe: selecting on a pipe blank, blanking, aligning, rough turning on an outer circle, welding on a flange, scraping on an inner hole, rough turning and finish turning; and (2) using a high-accuracy cold drawing steel pipe: cold drawing, aligning, blanking, welding on a flange, scraping on an inner hole, rough turning and finish turning; and the cylinder barrel of the oil cylinder of the crane and the processing process thereof are characterized by the technological parameter of welding, the technological parameter of cold-drawing processing and the technological parameter of scraping processing. The cylinder barrel of the oil cylinder of the crane and the processing process thereof have the beneficial effects that the welding defect of the oil cylinder is lowered by more than 50 percent; and moreover, the after-fracture elongation rate of the material of the cylinder barrel is enhanced, the toughness of the cylinder barrel is ensured, and the danger of the occurrence of brittle fracture of the cylinder barrel is decreased, so that the safety reliability of the oil cylinder is greatly enhanced.

Owner:XCMG HYDRAULICS CO LTD

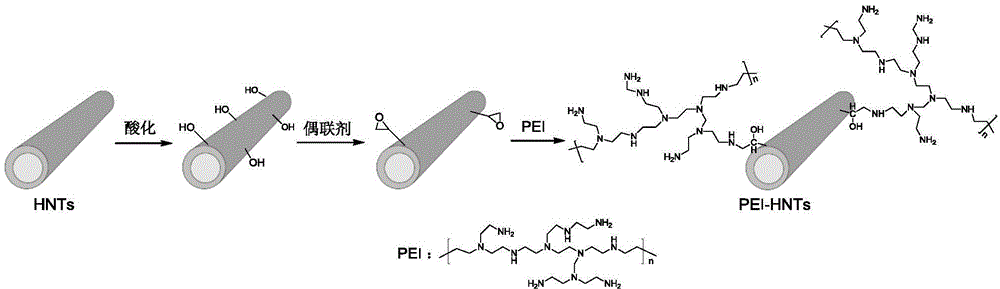

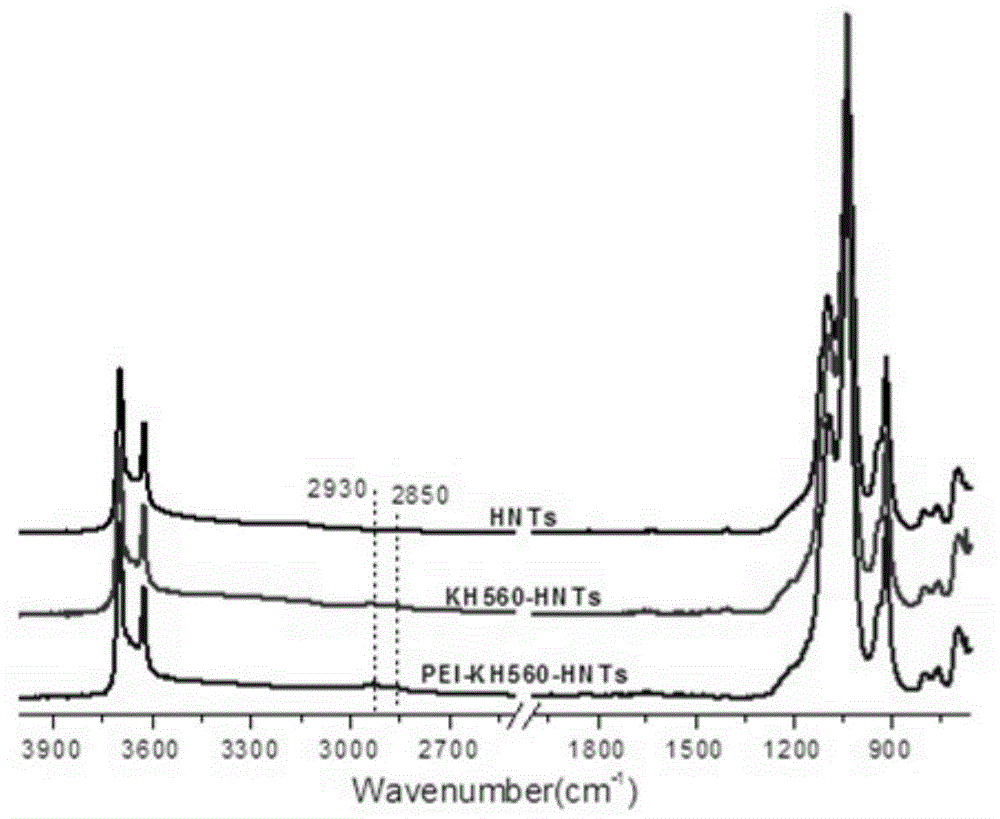

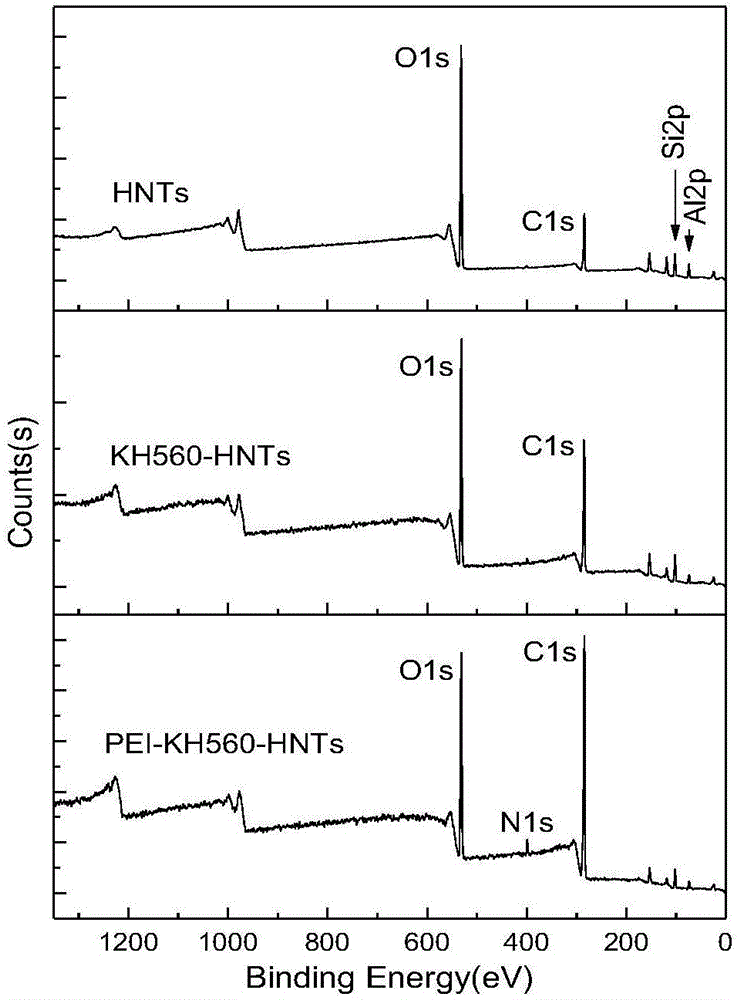

Halloysite nanotube / epoxy nanocomposite

The present invention relates to the field of nano-composite materials, and specifically relates to a halloysite nanotube / epoxy nanocomposite. The halloysite nanotube is a branched polymine grafted halloysite nanotube; the branched polymine grafted weight halloysite nanotube and epoxy resin are in the weight ratio of 0.2-20:100, preferably 0.5-5:100. The hyperbranched polymine is grafted onto epoxidized HNTs, so that the branched structure has rich amino groups to generate stronger chemical bonds or hydrogen bonds between the halloysite nanotube and an epoxy matrix and to enhance the interface effect. The prepared modified halloysite nanotube can effectively improve the impact resistance of epoxy resin and reduce brittle fracture of epoxy resin, and has broad application prospects in the fields of automotive, electronics, functional materials and aerospace.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Stent fabrication via tubular casting processes

ActiveUS8206636B2Improve ductilityHigh strengthOrganic active ingredientsPeptide/protein ingredientsPolymer solutionDip-coating

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

Bioabsorbable stents

InactiveUS20150342764A1Improve mechanical propertiesReduced flexibilityStentsSurgeryDelayed timeEngineering

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com