Systems and methods for implementing bulk metallic glass-based macroscale gears

a macroscale gear and metallic glass technology, applied in the direction of gearing, hoisting equipment, other domestic articles, etc., can solve the problems of limited viability of metallic glasses, limited manufacturing of metallic glasses, and limited viability of engineering materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

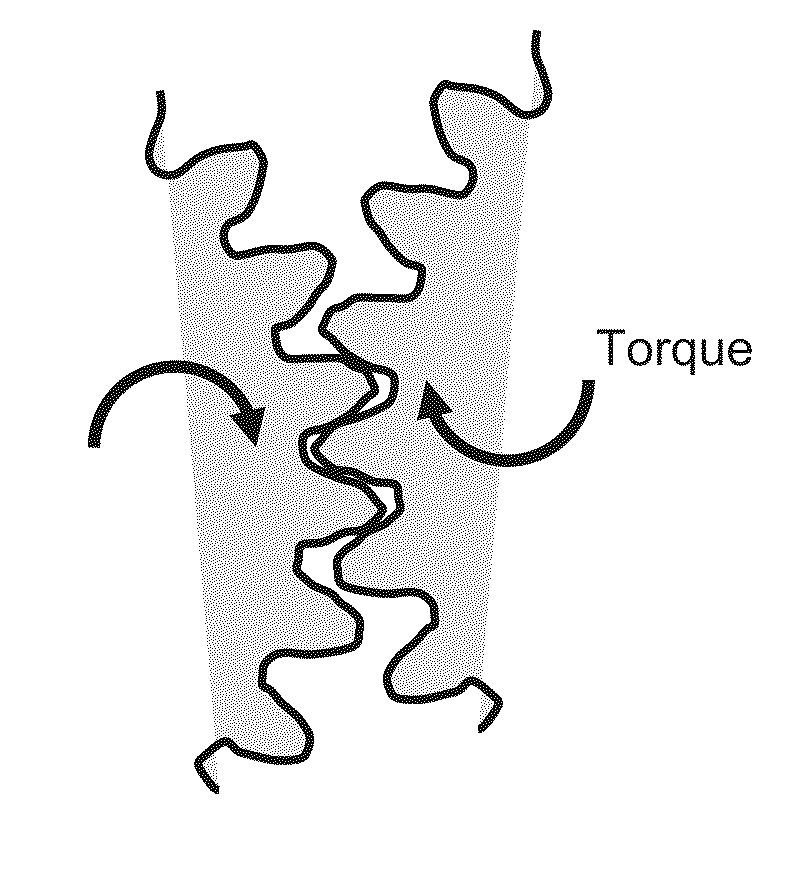

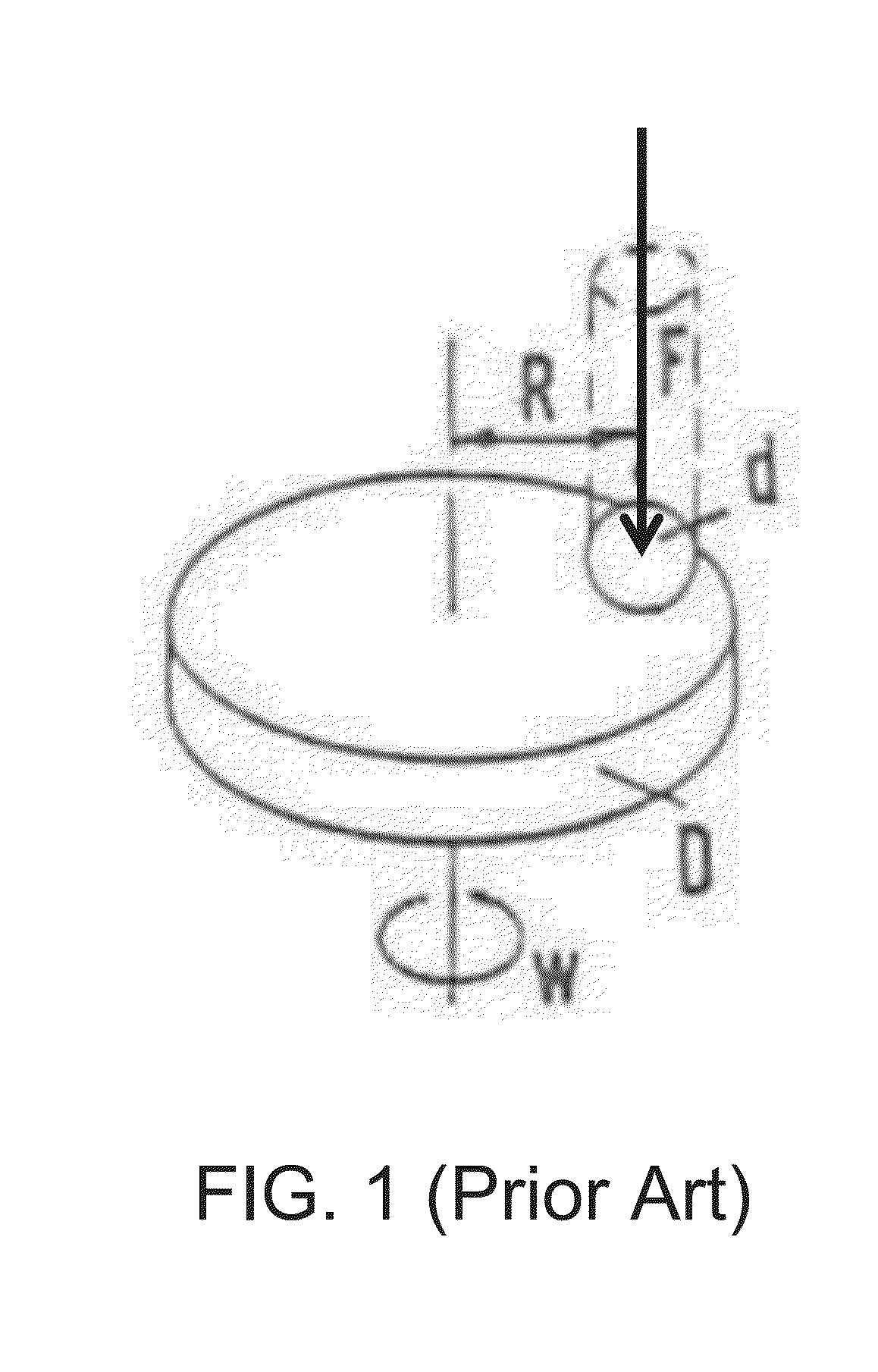

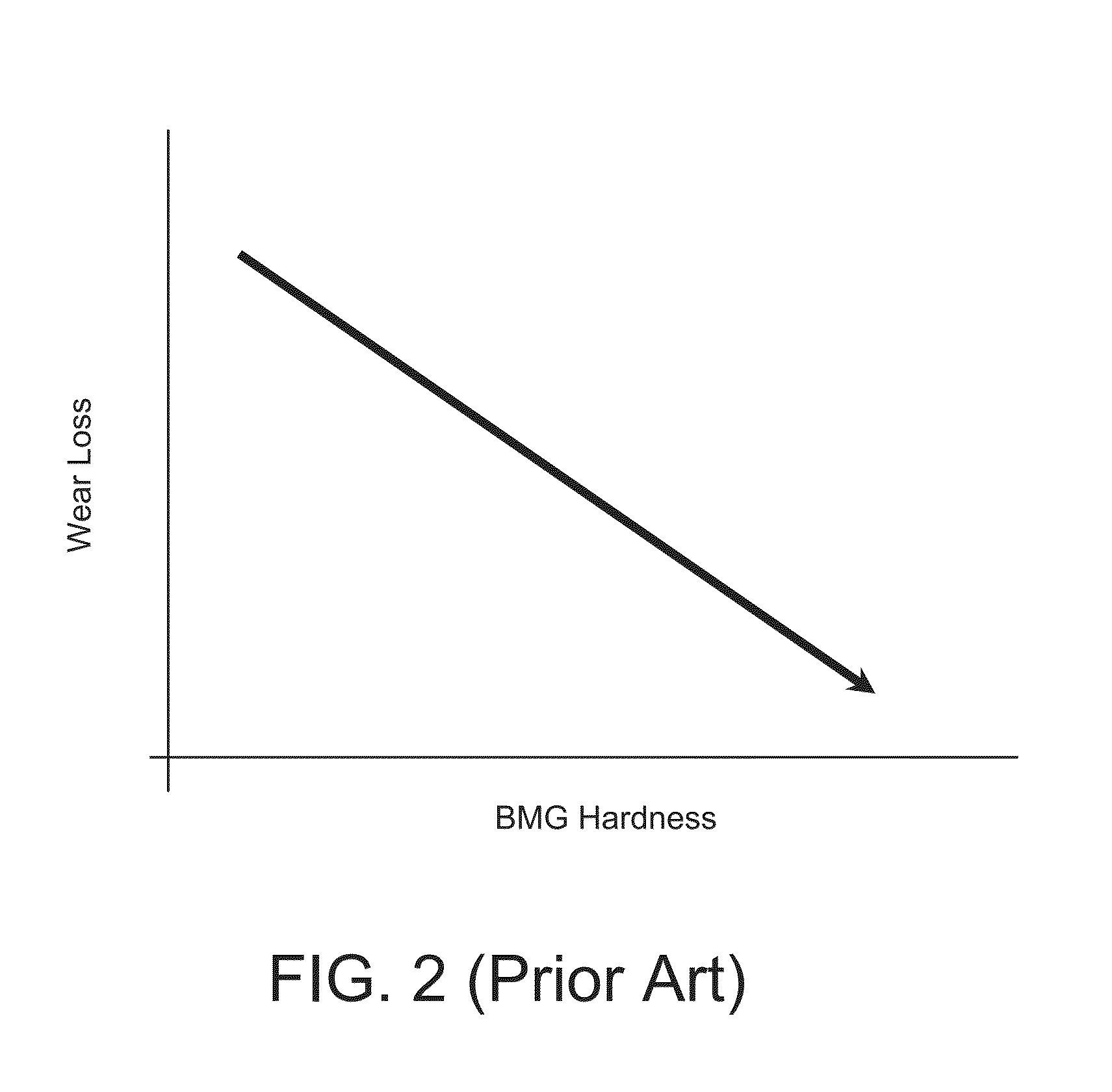

[0049]Turning now to the drawings, systems and methods for implementing bulk metallic glass-based macroscale gears are illustrated. Bulk metallic glasses (BMGs) possess a number of useful materials properties (e.g., high tensile strength, corrosion resistance, electrical conductivity, processability), and have been well studied for their potential as advanced engineering materials. In particular, BMGs have been extensively studied for their potential implementation in applications that require wear resistance. (see e.g., Wu, Trans. Nonferrous Met. Soc. China 22 (2012), 585-589; Wu, Intermetallics 25 (2012) 115-125; Kong, Tribal Lett (2009) 35:151-158; Zenebe, Tribol Lett (2012) 47:131-138; Chen, J. Mater. Res., Vol. 26, No. 20, Oct. 28, 2011; Liu, Tribol Lett (2012) 46:131-138; the disclosures of which are hereby incorporated by reference.) To be clear, “wear” conventionally refers to the displacement of the surface of a material as a direct result of its mechanical interaction with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com