Patents

Literature

543results about How to "Excellent machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper alloy with no lead

This invention relates to a Pb-free Cu alloy, especially a Pb-free machinable Cu alloy, which is composed of: Cu 55.0-89%, Zn 3.0-45%, Sn 0.1-10%, Ni 0.1-2.0%, Si 0-5.0%, Bi 0.1-5.0%, Se 0-3.0%, Al 0.01-1.0%, P 0.05-0.15%, and RE 0.01-0.5%. RE, Bi, Se and P are added respectively in the forms of RE-Cu intermediate alloy, Cu-Bi intermediate alloy, Cu-Se intermediate alloy and P-Cu intermediate alloy, or RE, Bi, Se and P are added respectively in the forms of Bi-Se alloy and P-Cu alloy. This invention can eliminate harmful effects on environment and human bodies caused by Pb during production and recovery process. The Cu alloy has good machinability, mechanical properties, processability and fluidity, and has no thermal splitting. The production method is simple, and can produce the Cu alloy by using the present apparatus for producing lead-brass alloy. Besides, the contents of Se, Bi and RE are low,.

Owner:JIANGXI UNIV OF SCI & TECH

Medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and production technological method thereof

ActiveCN107287504AExcellent machinabilityReduce precipitationProcess efficiency improvementSulfurImpurity

The invention discloses medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and a production technological method thereof. The non-quenched-and-tempered steel mainly comprises 0.35%-0.50% of C, 0.10%-0.80% of Si, 0.75%-1.60% of Mn, 0-0.03% of P, 0.02%-0.08% of S, 0-0.08% of Mo, 0-0.025% of Nb, 0.02%-0.12% of V, 0.012%-0.016% of N, 0.02%-0.08% of Te, 0.001%-0.003% of Ca, and the balance Fe and inevitable impurities. The ratio of the tellurium to the sulfur is 0.25-2.5. According to the free-cutting non-quenched-and-tempered steel disclosed by the invention, occluded foreign substances in the steel can be subjected to modifying treatment by adding the tellurium, the cutting properties, fatigue resistance and the like of the non-quenched-and-tempered steel can be improved obviously, and pollution to the environment can be avoided.

Owner:SHANGHAI UNIV

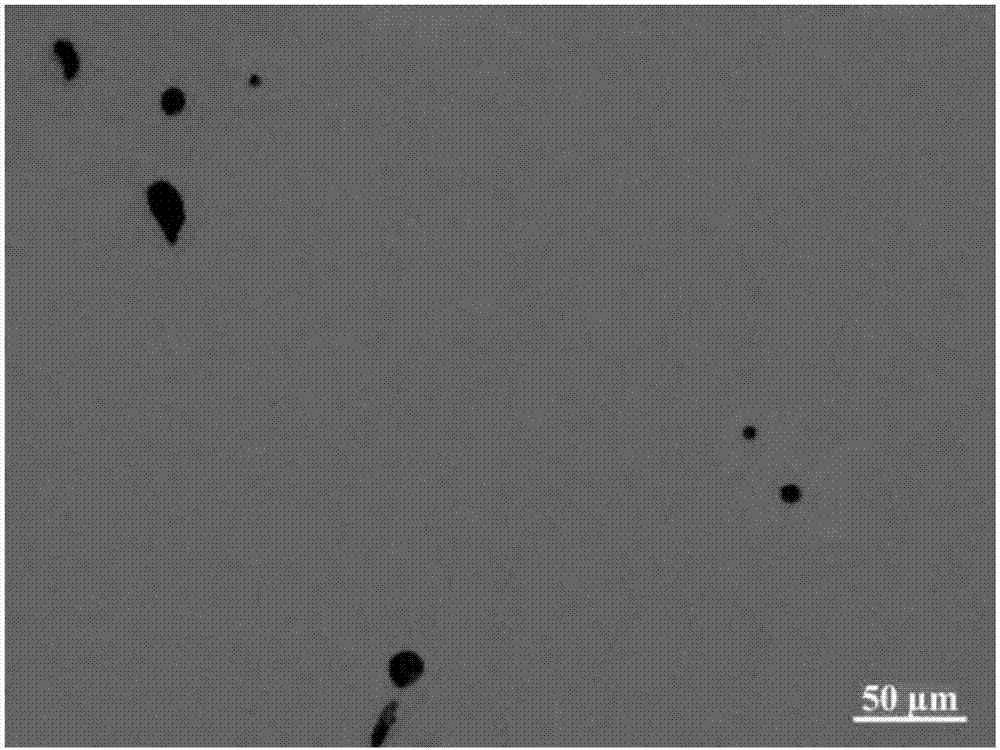

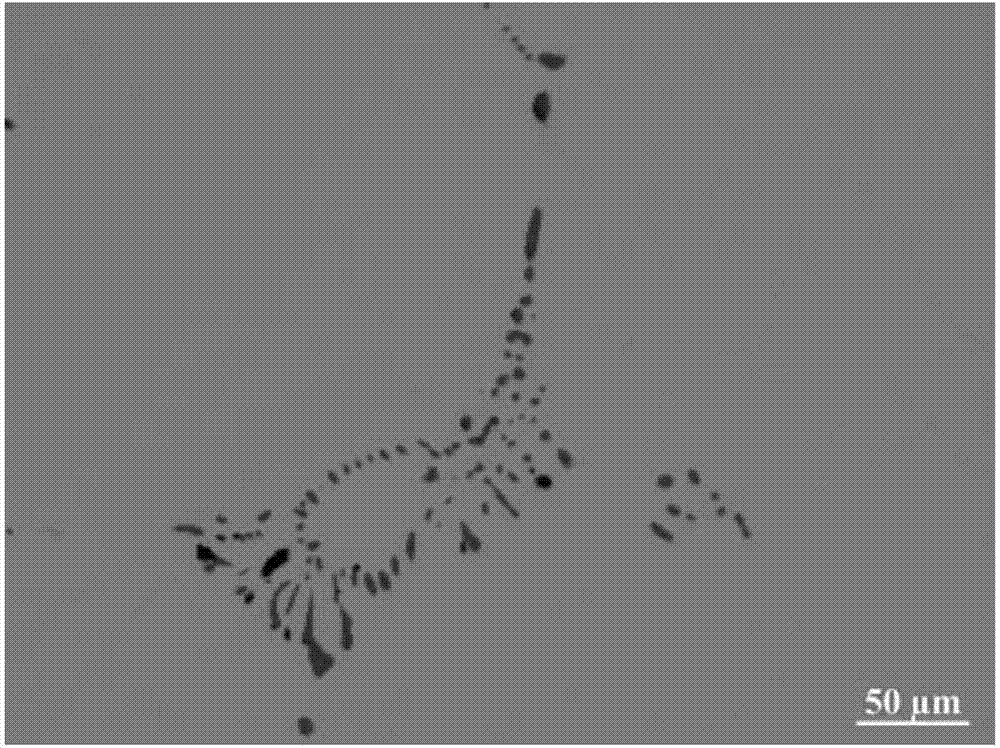

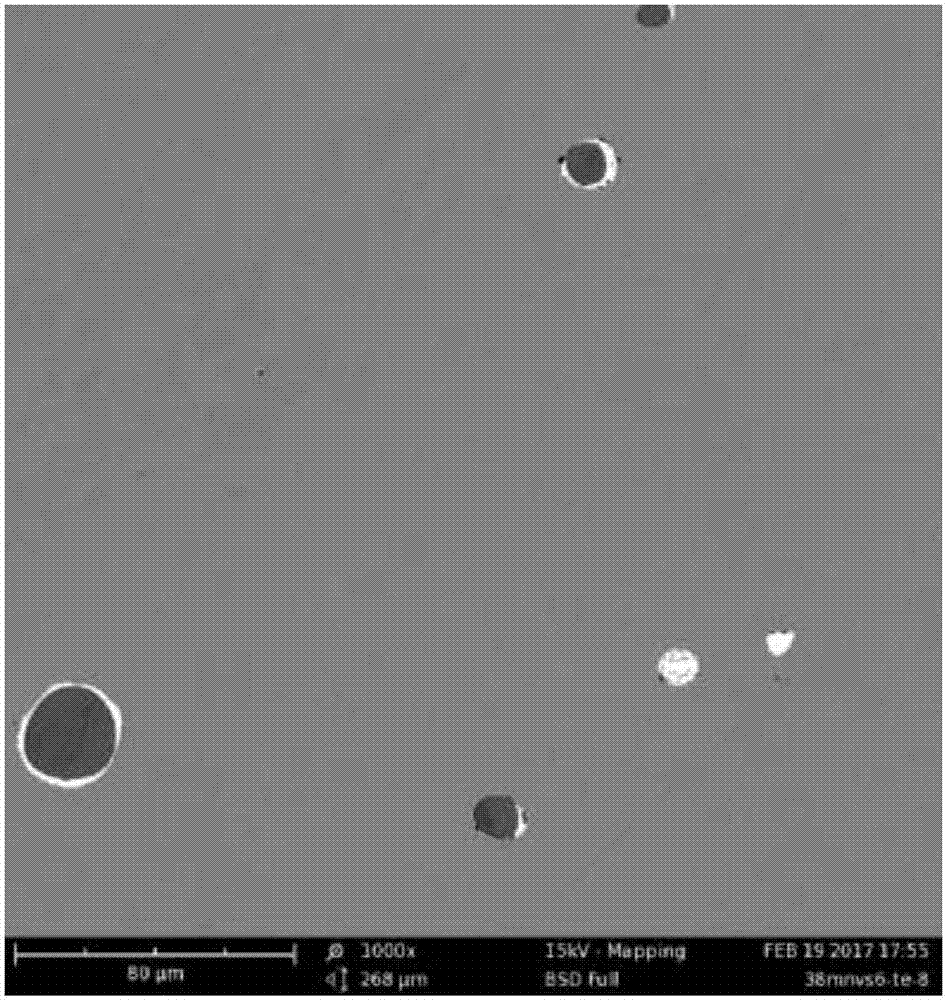

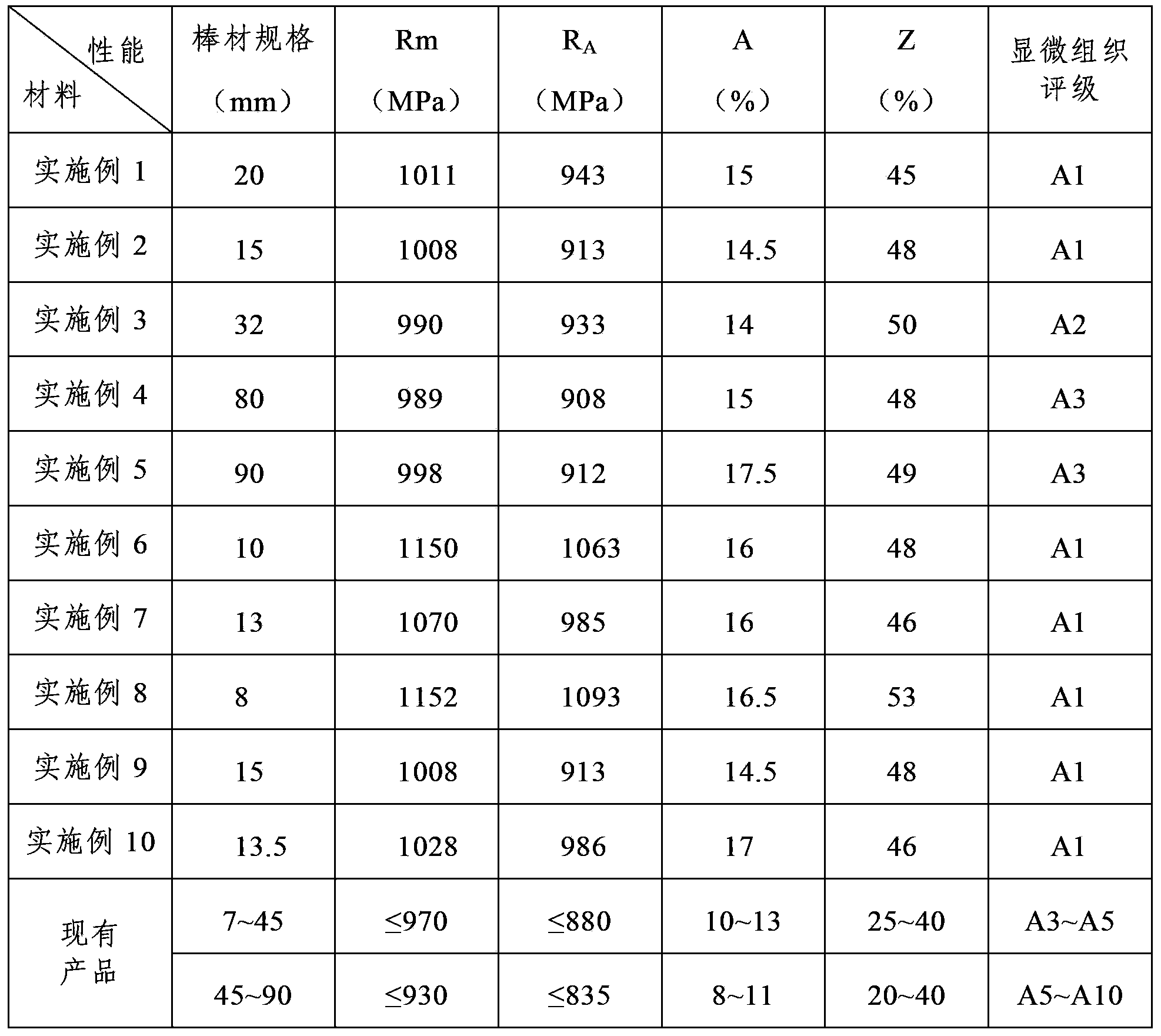

Preparation method of TC4ELI titanium alloy bar

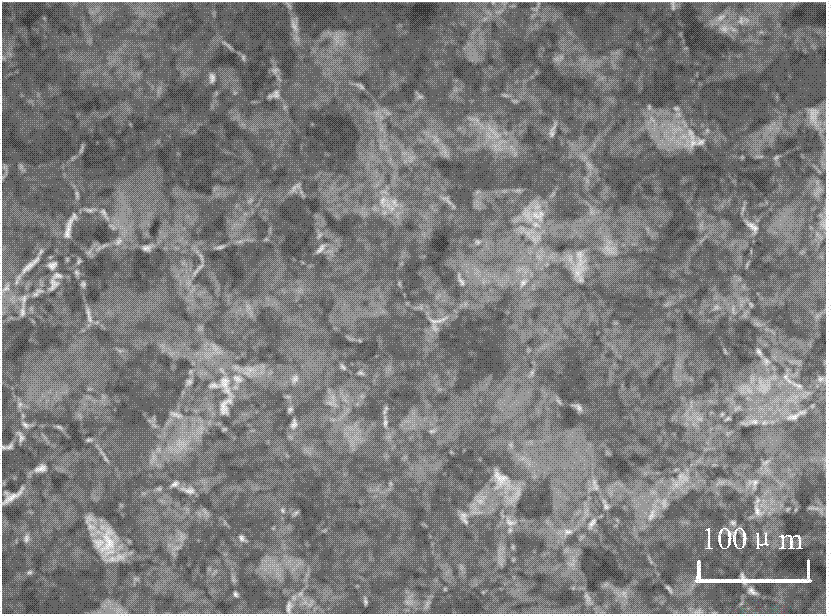

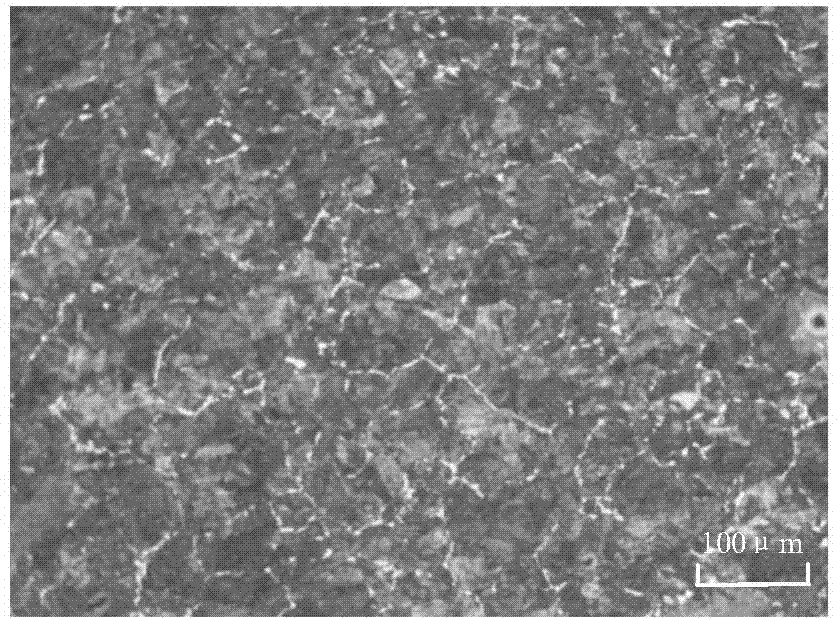

The invention provides a preparation method of a TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 15mm-90mm. The invention also provides a preparation method of the TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) rolling; (5) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 8mm-15mm. The preparation method is simple in process, strong in repeatability and suitable for large-scale industrial production; the TC4ELI titanium alloy bar prepared by adopting the preparation method is uniform and fine in structure, high in microscopic structure level and excellent in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

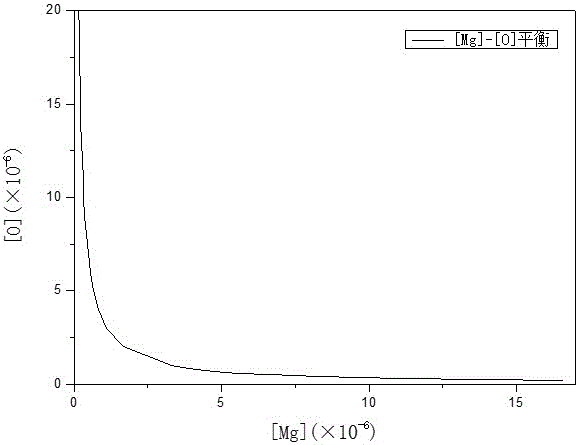

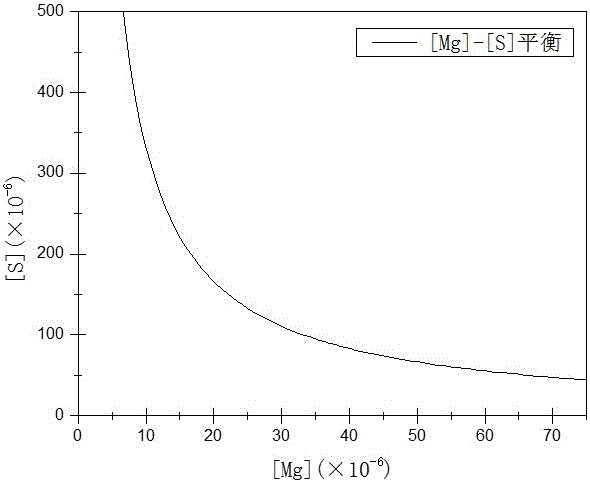

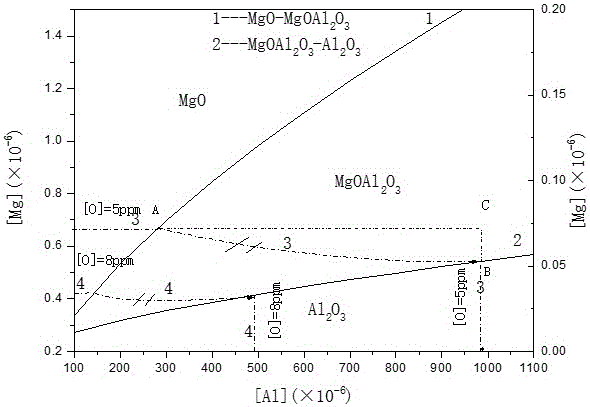

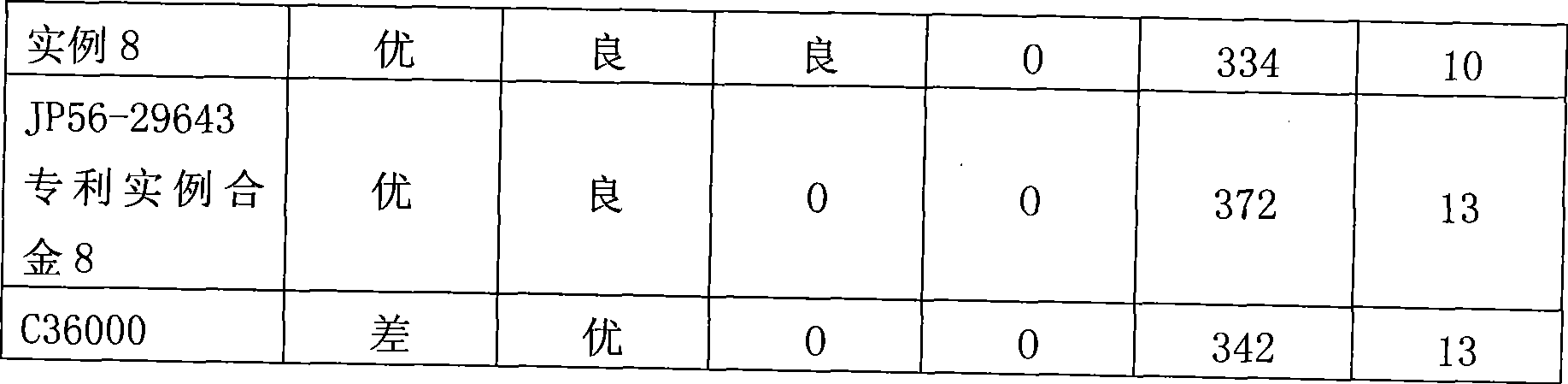

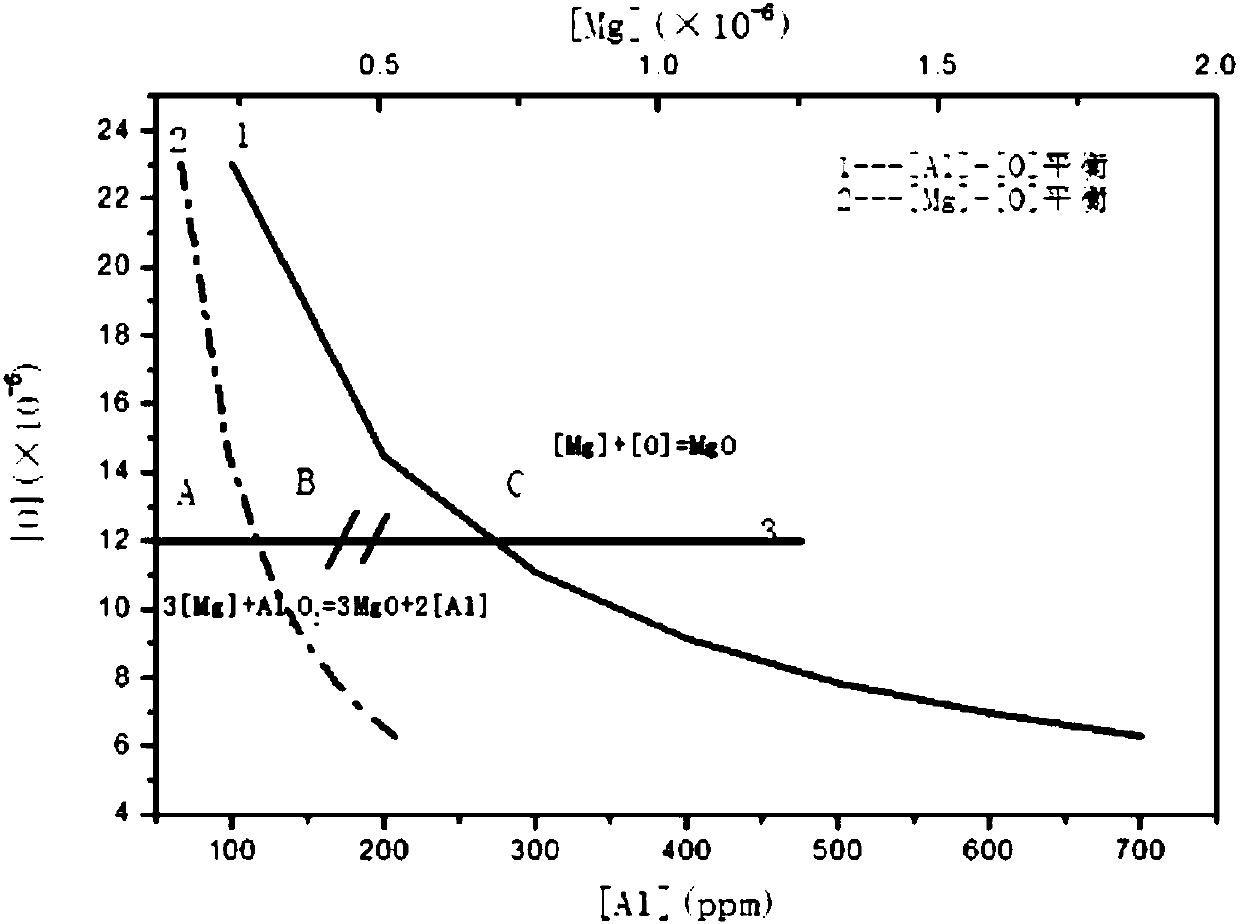

Magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and preparation method thereof

The invention discloses magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and a preparation method thereof. The steel is prepared from, by weight percent, 0.15%-0.25% of C, not larger than 0.12% of Si, 0.80%-1.50% of Mn, not larger than 0.035% of P, 0.02%-0.055% of S, 0.80%-1.30% of Cr, 0.015%-0.055% of Al, 0.004%-0.015% of N, 0.0006%-0.004% of Mg, 0.0006%-0.005% of Ca, not larger than 0.0025% of [O] and the balance iron and inevitable impurities. Composite modification is carried out on inclusion by adding a small quantity of calcium and magnesium elements in the refining process, and the composite inclusion with oxide (including multiple oxide) as a core is formed, wherein the core of the composite inclusion is wrapped by sulfide; splitting of the oxide to a steel substrate can be relieved, the anti-fatigue performance can be improved, and the transverse mechanical property of the steel can be improved; and the magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel both good in mechanical performance and cutting performance is produced, and has large economic benefits.

Owner:SHANGHAI UNIV

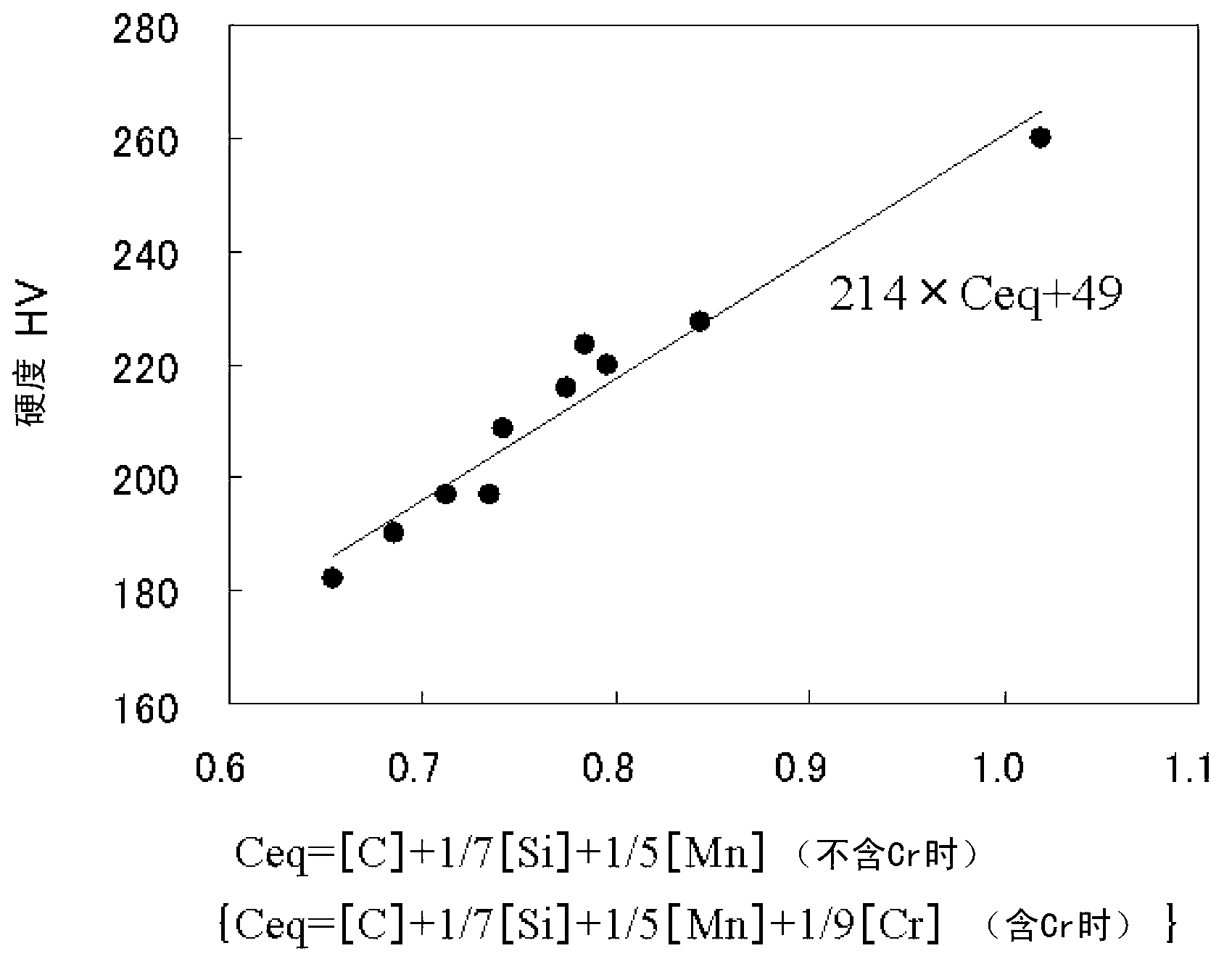

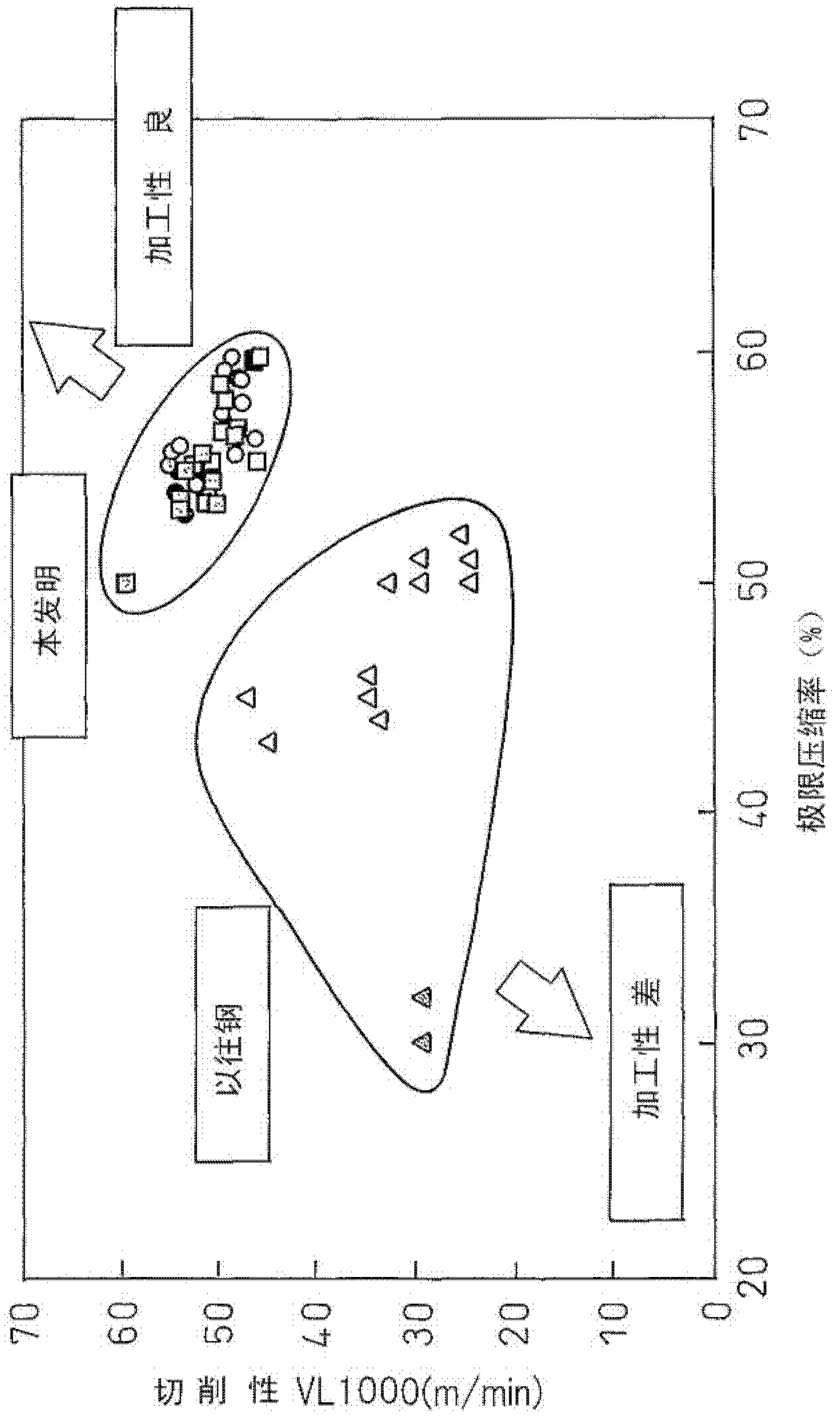

Steel having excellent machinability for mechanical structure

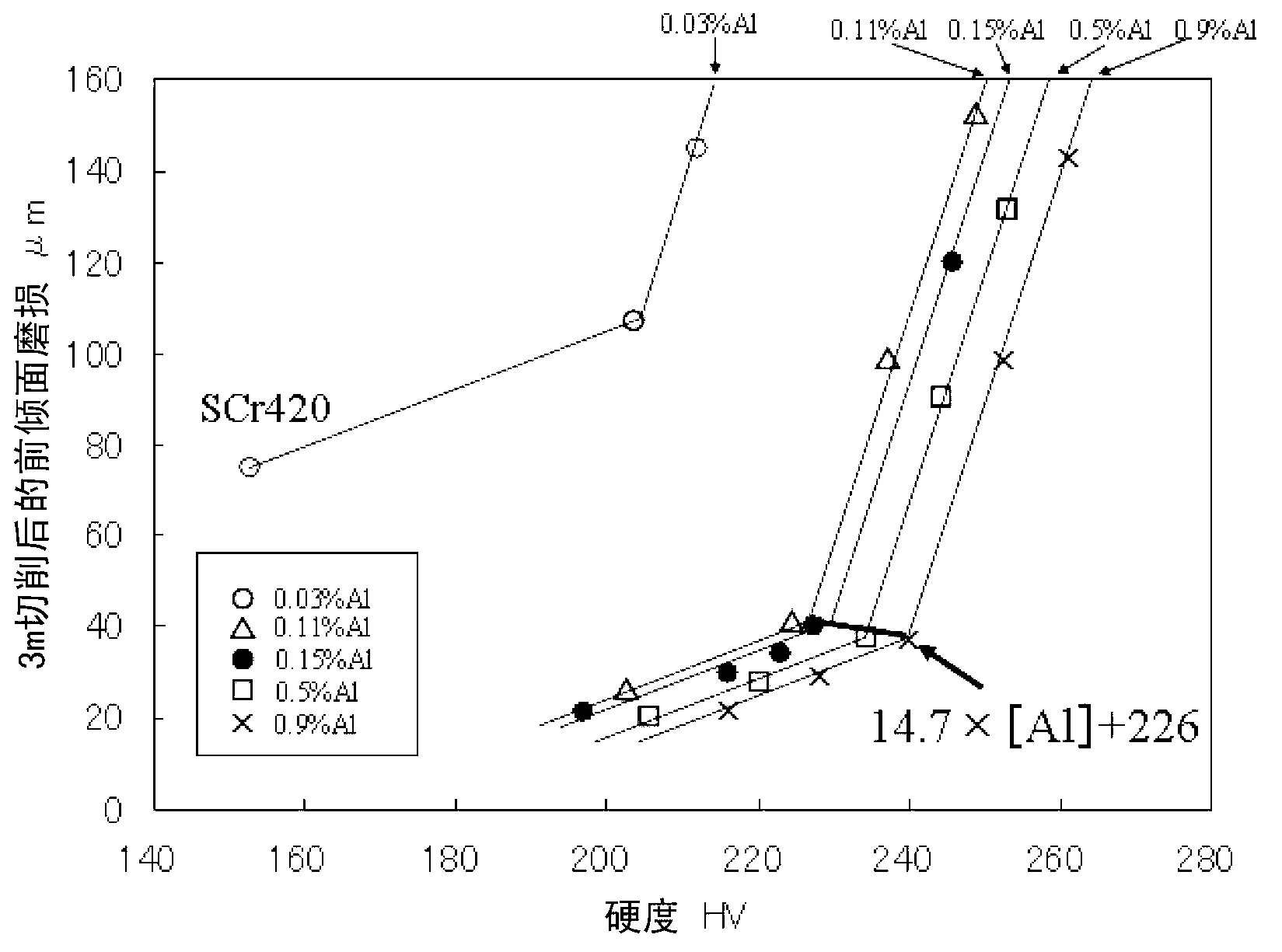

InactiveCN102985577AImprove fatigue strengthExcellent machinabilityIncreasing energy efficiencyMetallurgyMachinability

Provided is a steel for a mechanical structure, which comprises, by mass%, 0.40% to less than 0.75% of C, 0.01% to 3.0% of Si, 0.1% to 1.8% of Mn, 0.001% to 0.1% of S, greater than 0.1% to 1.0% of Al, 0.001% to 0.02% of N, no more than 0.05% of P, and residual Fe and inevitable impurities as the balance, and which satisfies 139.38<=214[C]+30.6[Si]+42.8[Mn]-14.7[Al]<=177 and 0.72<=[C]+1 / 7[Si]+1 / 5[Mn]<1.539.

Owner:NIPPON STEEL CORP

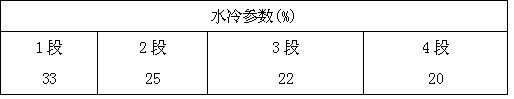

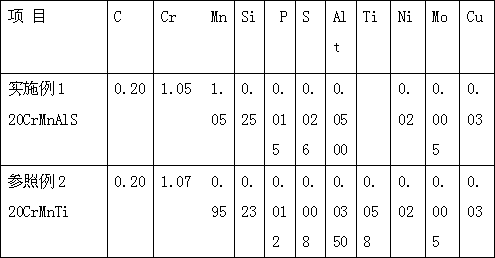

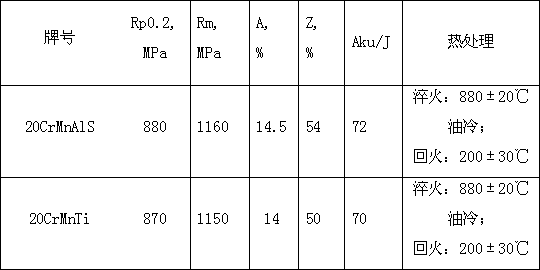

Free-machining pinion steel and production technique thereof

The invention discloses a free-machining pinion steel and a production technique thereof. The pinion steel comprises the following components in percentage by weight: 0.14-0.22% of C, 0.20-0.35% of Si, 0.95-1.15% of Mn, 0.95-1.15% of Cr, 0.020-0.060% of Al, at most 0.035% of P, 0.012-0.030% of S, and the balance of Fe and inevitable impurities. The technique comprises the following steps: smelting, continuous casting and rolling. In the invention, the Cr-Mn-Al-S pinion steel is used instead of the original Cr-Mn-Ti pinion steel, Al and S elements are added, and the intracrystalline ferrite is sufficiently utilized to refine the crystalline grains. The invention can stabilize the Jominy hardenability, reduce the pinion deformation after heat treatment, enhance the brittle fracture resistance and crack propagation resistance, and improve the free machining capacity of the pinion in the machining process. The invention is applicable to pinion steel as a substitute of 20CrMnTi.

Owner:ZENITH STEEL GROUP CORP +1

Production method of Mn-Cr high-performance gear steel

The invention belongs to the technical field of alloy steel, and in particular, relates to a manufacturing method of Mn-Cr gear steel. The gear steel comprises the following components: 0.17-0.22% of C, 0.15-0.25% of Si, 1.10-1.40% of Mn, 1.00-1.30% of Cr, Mo not more than 0.08%, B not more than 0.0005%, Cu not more than 0.02%, Ni not more than 0.02%, 0.025-0.055% of Al, P not more than 0.015%, 0.020-0.035% of S, N not more than 130 ppm, and the balance of iron. The method improves the cleanness of molten steel through optimizing the refining process and the slag system control, performs the nitrogen adding treatment through a wire feeding procedure to effectively refine grains of the aluminum deoxidation gear steel, realizes precise control of hardenability alloy elements, solves the deoxidation and sulfur maintaining contradiction, and guarantees excellent pouring performance of the molten steel and excellent cutting performance of the gear steel.

Owner:ZENITH STEEL GROUP CORP +1

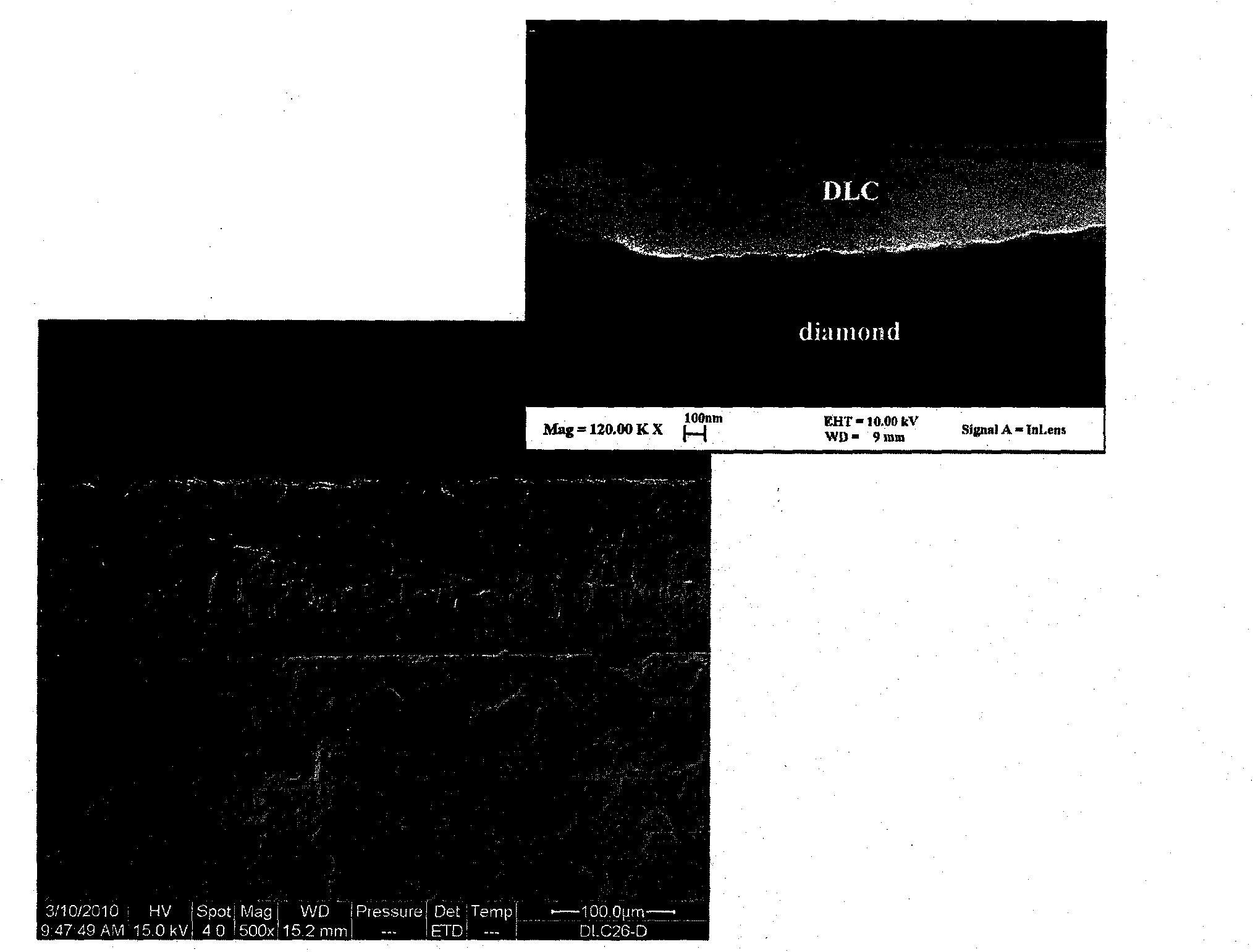

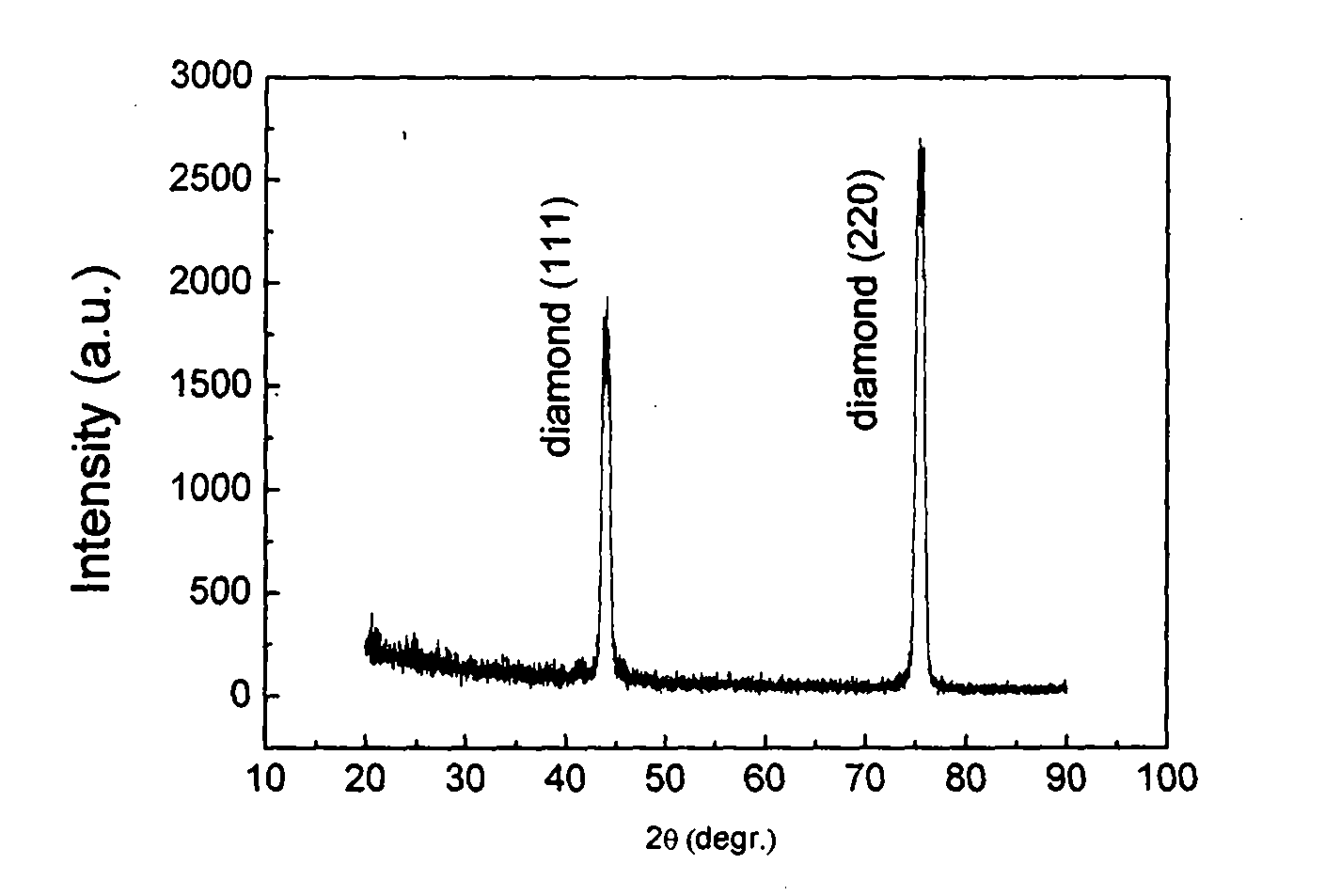

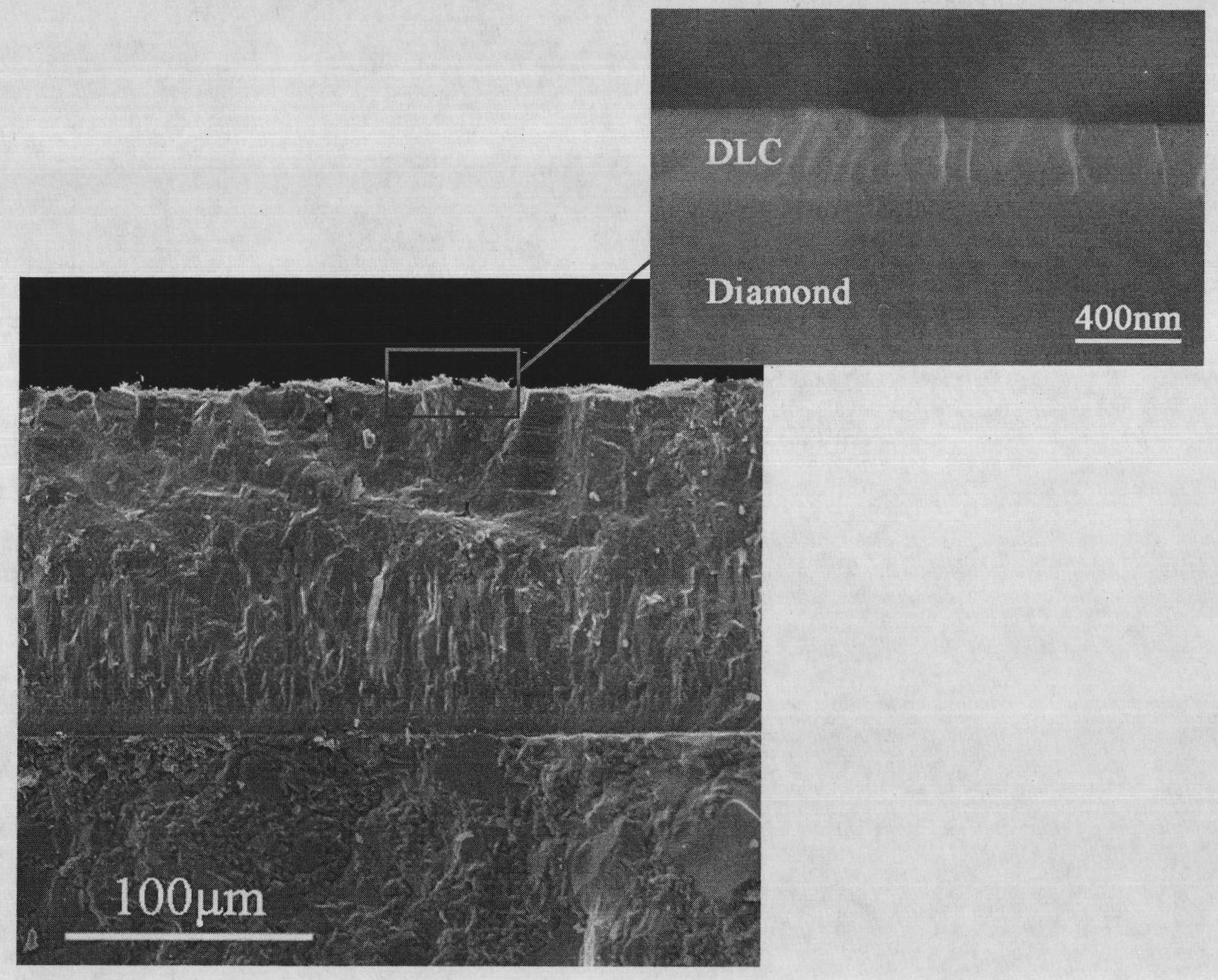

Super-hard self-lubricating diamond/diamond-like composite laminated coating material and preparation method thereof

ActiveCN101818332AThe process steps are simplePrecise and controllable synthesis conditionsChemical vapor deposition coatingPolymer scienceMagnetic filtration

The invention relates to a tool coating material and a preparation method thereof, and belongs to the technical field of material preparation and application. The material is a diamond / diamond-like composite laminated coating material with super-hard self-lubricating property. The method for preparing the diamond / diamond-like composite laminated coating material is characterized by comprising the following steps of: firstly, pretreating a matrix by using mixed solution of acid and alkali respectively; secondly, synthesizing diamond with ultrahigh hardness and good crystalline form on the matrix, which serves as the main body of the composite coating, by adopting hot filament chemical vapor deposition; and finally, depositing a high-hardness diamond-like thin film on the main body of the diamond, which serves as a self-lubricating surface layer, by using magnetic filtration cathodic vacuum arc. In order to improve the binding force between the diamond thin film and the matrix and between the diamond-like thin film and the diamond thin film, a transition layer is coated between adjacent layers respectively. The method has the advantages of simple process, precise and controllable synthesis conditions, high film-forming quality, high product yield, low cost, and the like. The obtained diamond / diamond-like composite laminated coating material has ultrahigh hardness, extremely low friction factor and extremely low wear rate, shows excellent self-lubricating friction and wear resistance, and has significance for application of tools or molds under rigorous service conditions.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

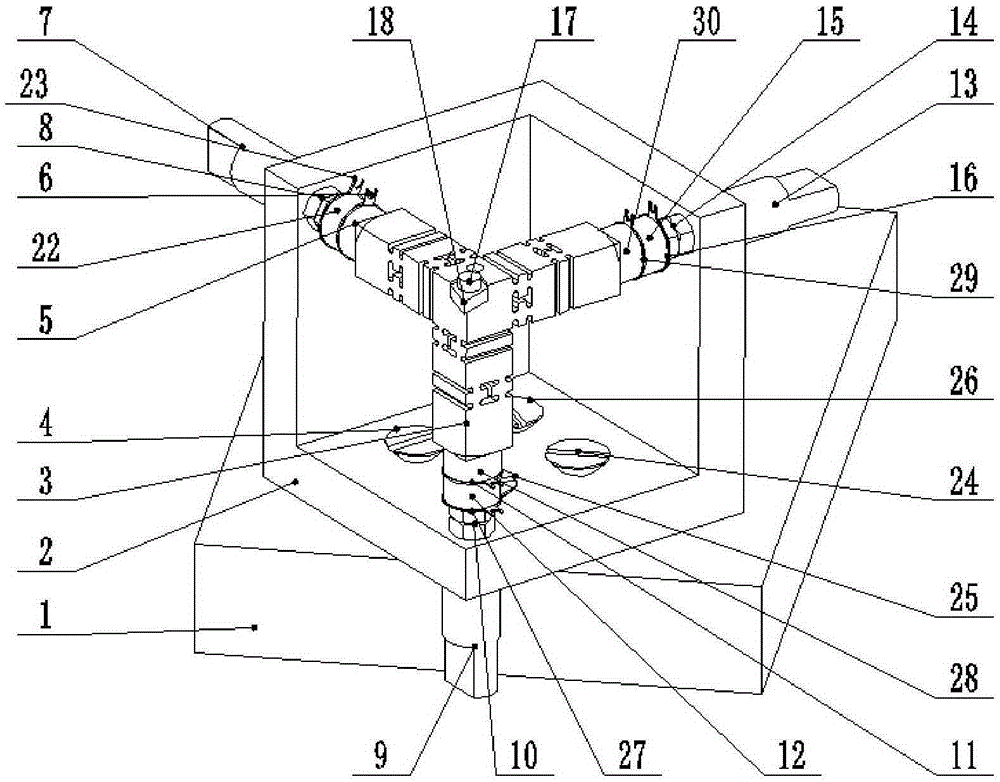

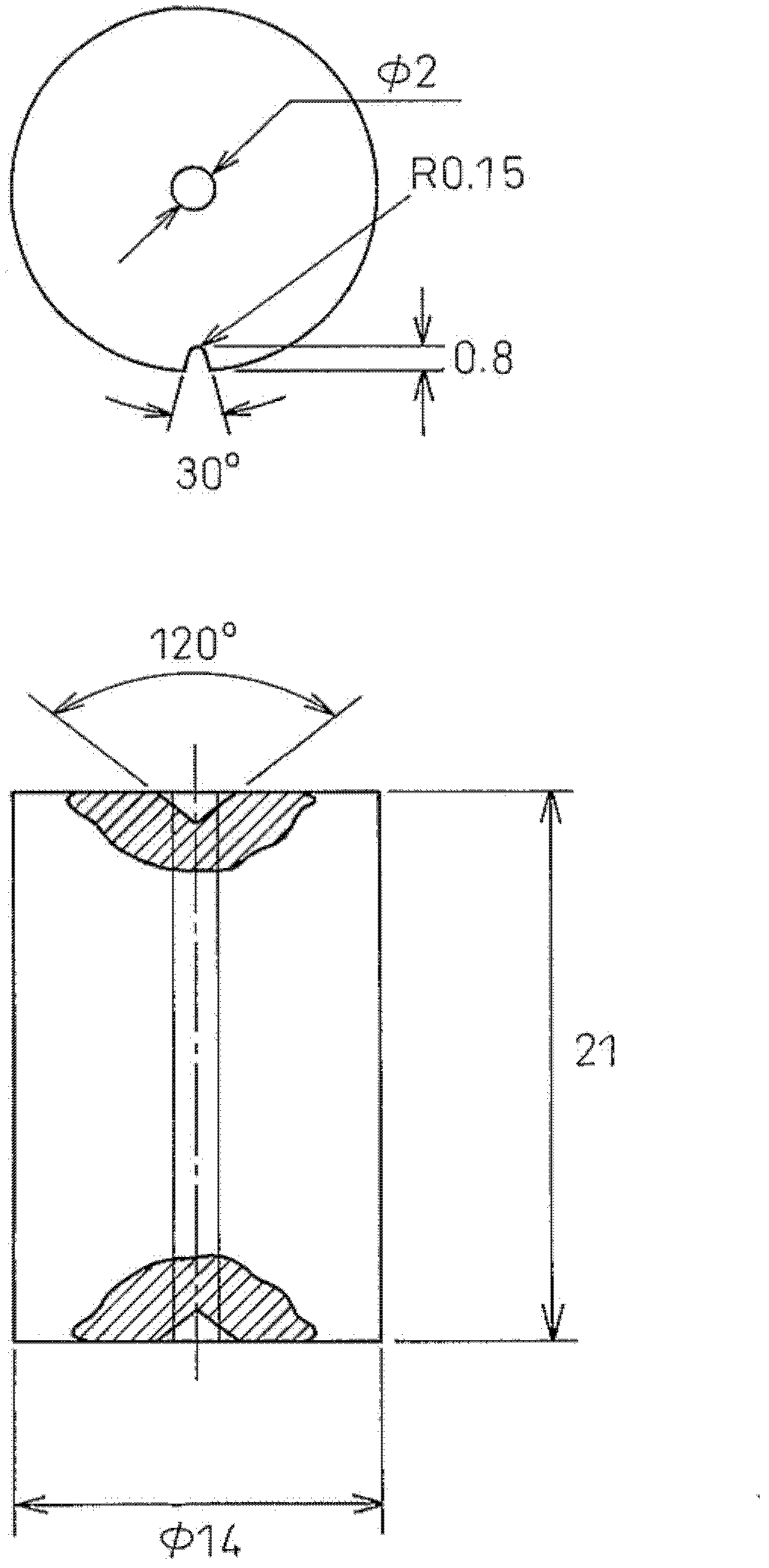

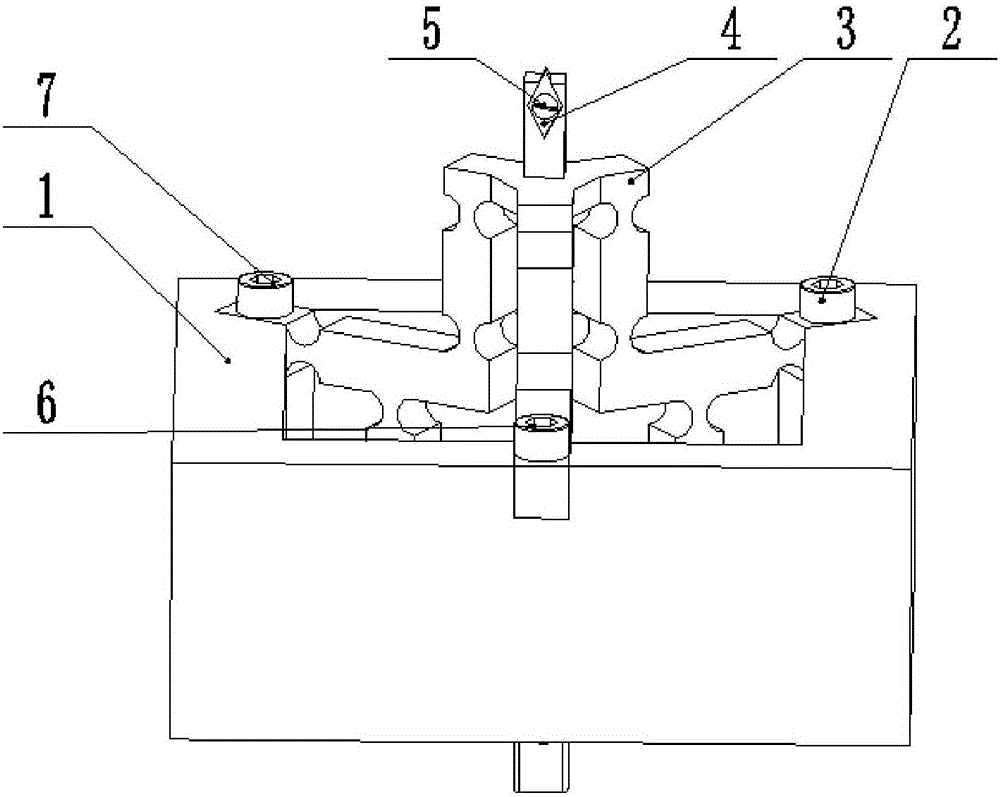

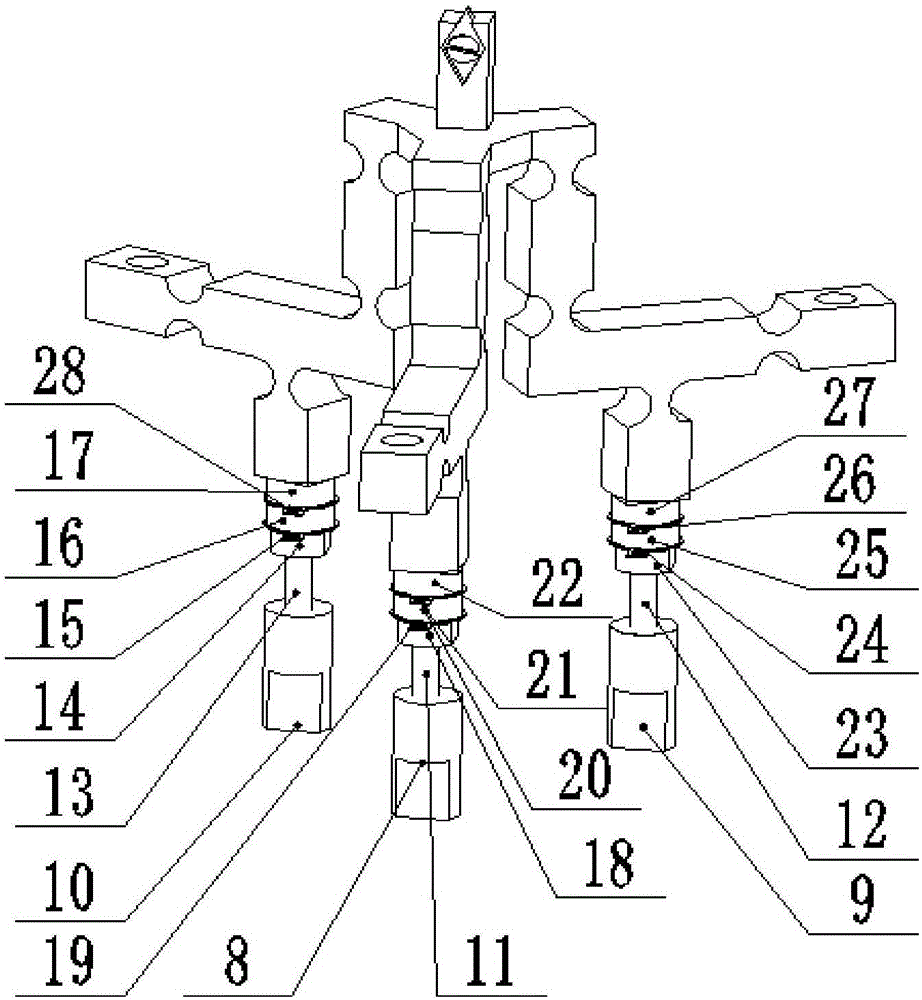

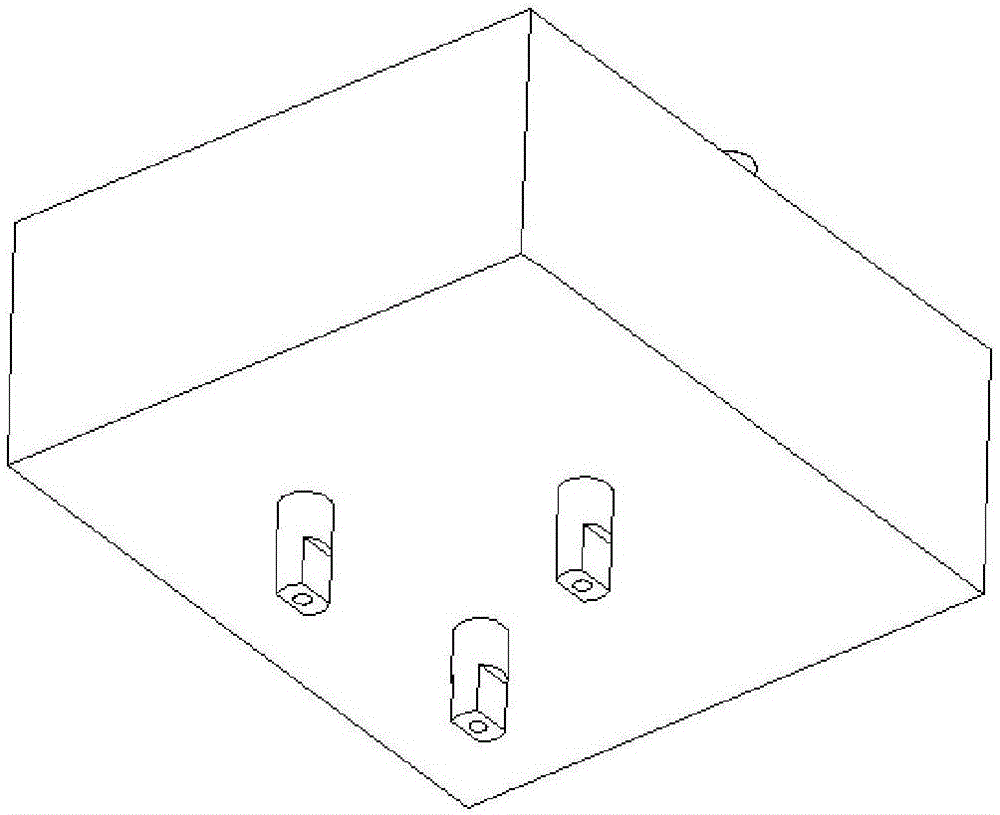

Three-dimensional ultrasound elliptical vibration assisted cutting device and elliptical orbit generation method

InactiveCN105312679AExcellent machinabilityFacilitates the realization of decoupled inputNumerical controlElectricity

The invention discloses a three-dimensional ultrasound elliptical vibration assisted cutting device and an elliptical orbit generation method thereof, and belongs to the field of numerical control machining. The device is composed of a multi-shaft flexible hinge, a base, a cutter pre-tightening screw, a connecting screw and a pedestal as well as piezoelectric ceramic plates, electrode plates, double-nut structures, connecting shafts and vibration frequency trimmers in the X direction, the Y direction and the Z direction. The multi-shaft flexible hinge is composed of three subchains perpendicular to one another and a cutter mounting frame. Each subchain is provided with a first flexible hinge unit and a second flexible hinge unit which are of the same structure and different in arrangement direction. A cutter is fixed to the cutter mounting frame. Displacement inputs are generated on all the subchains through the piezoelectric ceramic plates in the X direction, the Y direction and the Z direction, and after displacement amplification and superposition in the three directions, the multi-shaft flexible hinge is driven to generate an elliptical motion orbit in a three-dimensional space at the point of the cutter. The device is simple in structure, the inputs are mutually decoupled, the three-dimensional elliptical motion orbit is generated easily, and the device can be conveniently and directly integrated with a numerically-controlled machine tool for assisted precision machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

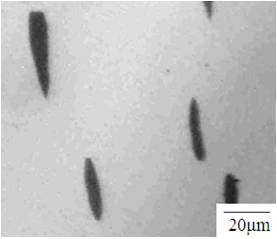

Low-carbon high-sulfur free-cutting steel with excellent cutting performance and manufacturing method thereof

The invention discloses low-carbon high-sulfur free-cutting steel with excellent cutting performance and a manufacturing method thereof, and belongs to the technical field of free-cutting steel. the free-cutting steel contains the following ingredients by mass percentage composition: 0.05 to 0.2 percent of C, 0.6 to 2.0 percent of Mn, 0.04 to 0.1 percent of P, 0.2 to 0.45 percent of S, 0.005 to 0.02 percent of O, less than or equal to 0.02 percent of N, less than or equal to 0.005 percent of Si and less than or equal to 0.001 percent of Al. Generated MnS impurities have the following characteristics: (1) over 95 percent of MnS impurities in as cast steel are Class I MnS, and the proportion of single-phase MnS impurities is equal to or larger than 80 percent; (2) the length of at least 70 percent of MnS impurities in the rolling direction is equal to or larger than 5 micron, and the length-width ratio is lower than or equal to 6; and (3) the average area of MnS impurities in 1 square mm in the rolling direction is no less than 50 square micron. C is adopted for deoxygenation, the cooling rate of ingoting is controlled to range from 2 to 4 mm / min, the roll opening temperature is controlled to range from 1200 to 1250 DEG C, and the roll closing temperature is controlled to be equal to or larger than 1050 DEG C. The low-carbon high-sulfur free-cutting steel has excellent cutting performance. After cutting, the surface fineness of parts is improved. The low-carbon high-sulfur free-cutting steel is generally close to or matches the lead-containing low-carbon free-cutting steel, and is suitable for high-speed cutting.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

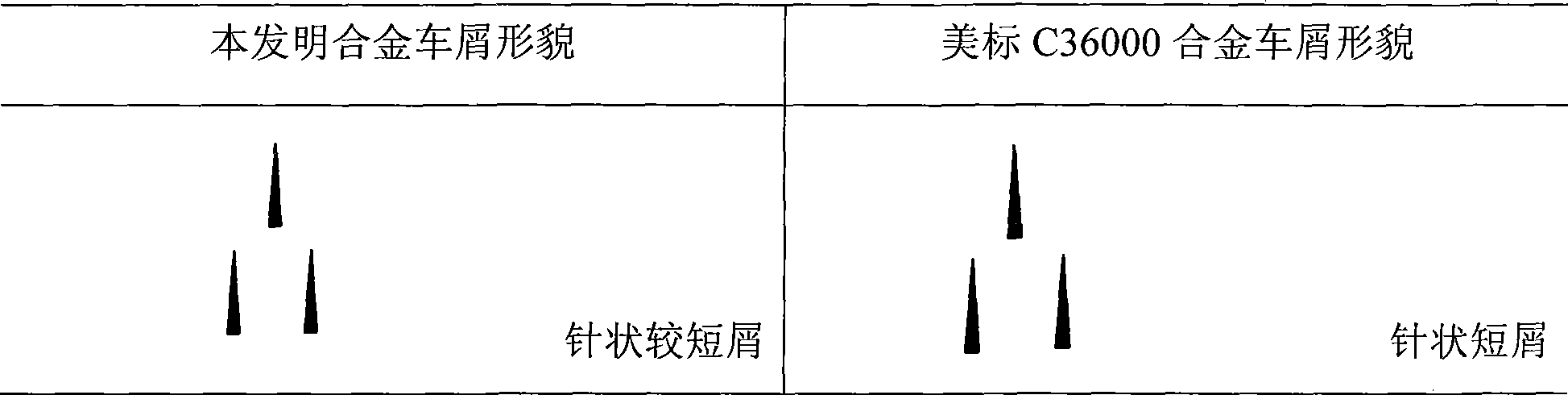

Leadless and free-cutting phosphorus-brass alloy and manufacturing method thereof

The invention provides a lead-free cutting-free alloy and a preparation method thereof. The components (weight percentage) of the alloy are: more than 97.0 but not equal to 99.5 of (copper + zinc), more than 35.0 of zinc, 0.4-1.6 of phosphor and 0.005-0.6 of at least two other elements selected from aluminum, silicon, antimony, stannum, lanthanon, titanium and boron, the balance being zinc and impurities, wherein, the zinc content is more than 35.0 (weight percentage). The invention also provides a preparation method for the lead-free cutting-free high phosphor brass alloy. The alloy of the invention has excellent machinability, castibility, welding property, dezincification corrosion resisting property, formability and mechanical property, and is particularly suitable for forged pieces and low-pressure cast castings needing cutting processing, grinding processing (polish), welding and plating, such as hydrants, valve bodies and bushings in a water supply system.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

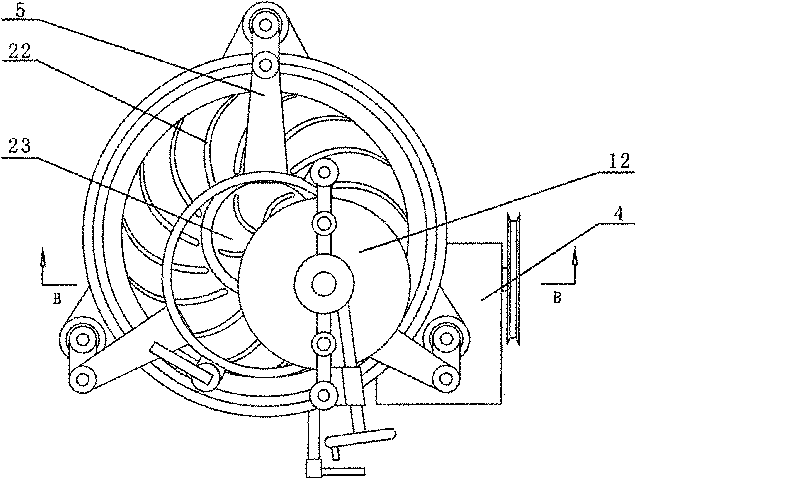

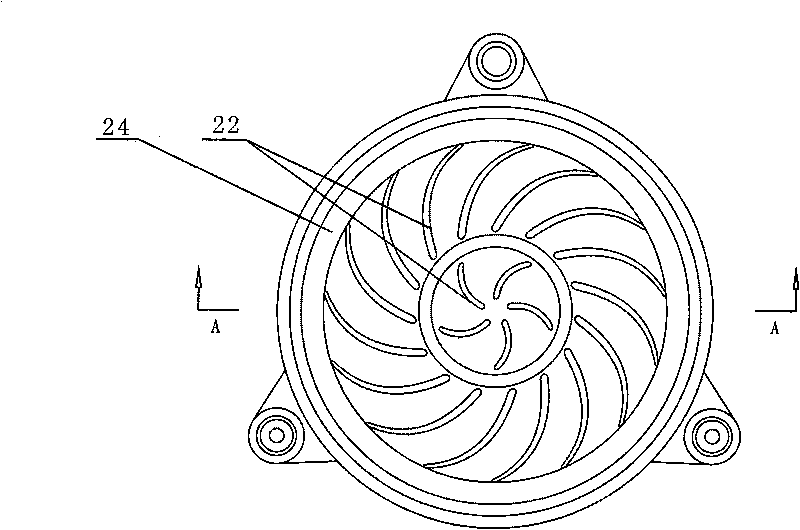

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

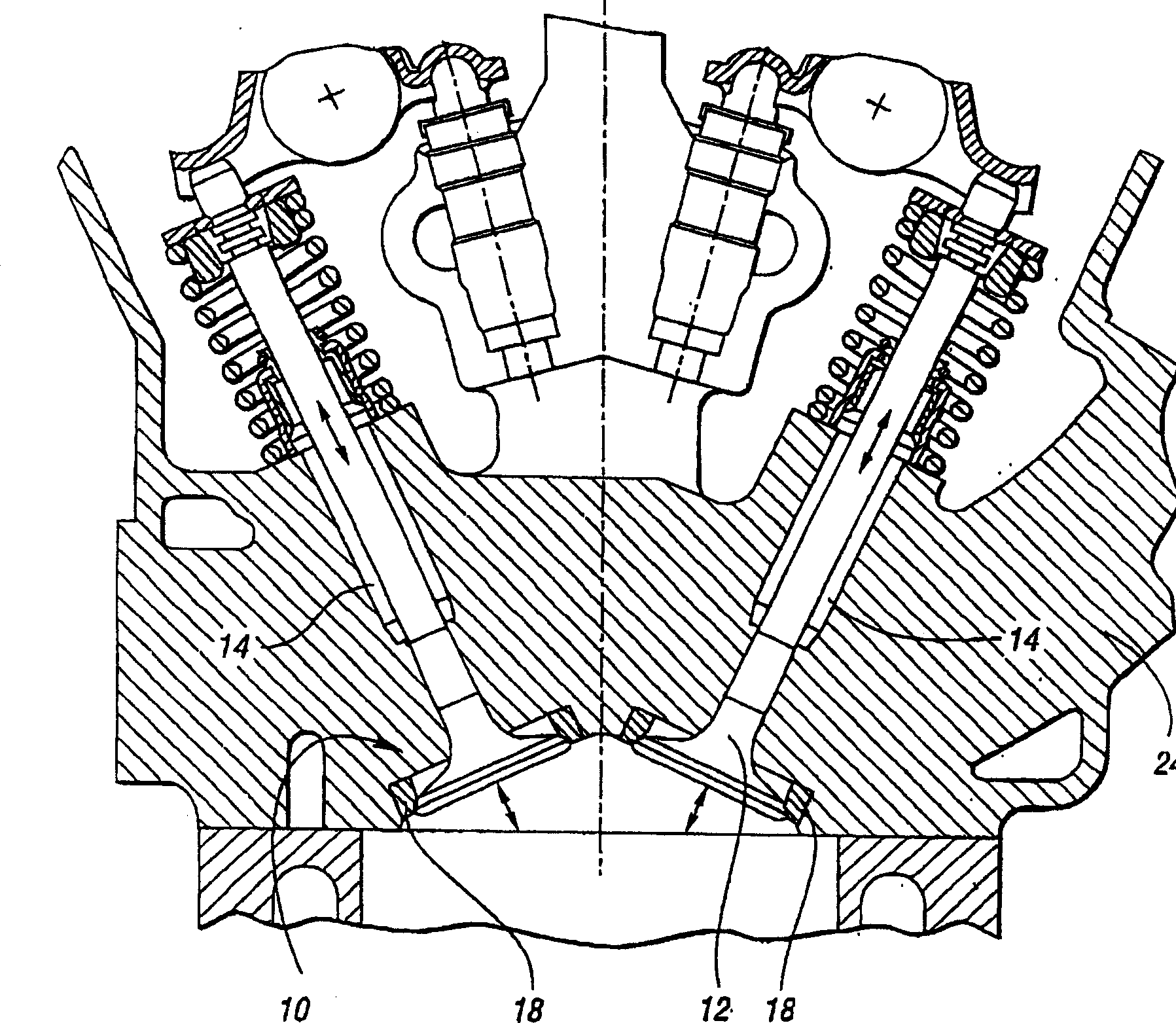

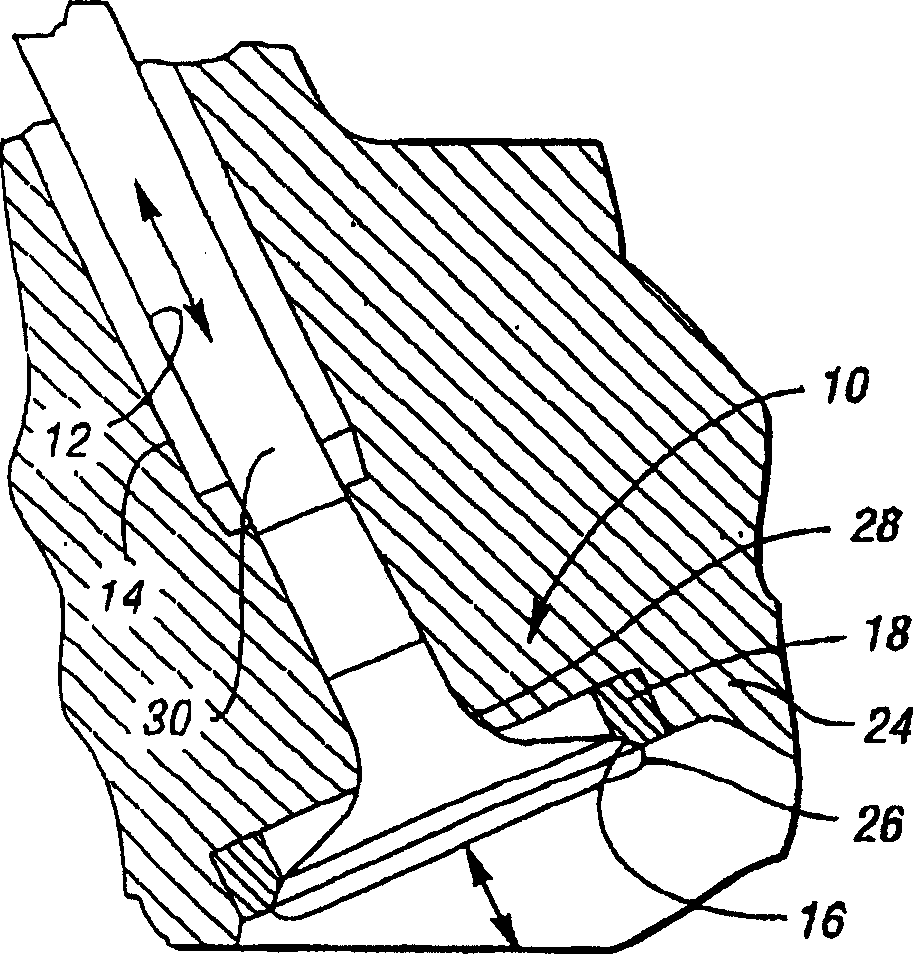

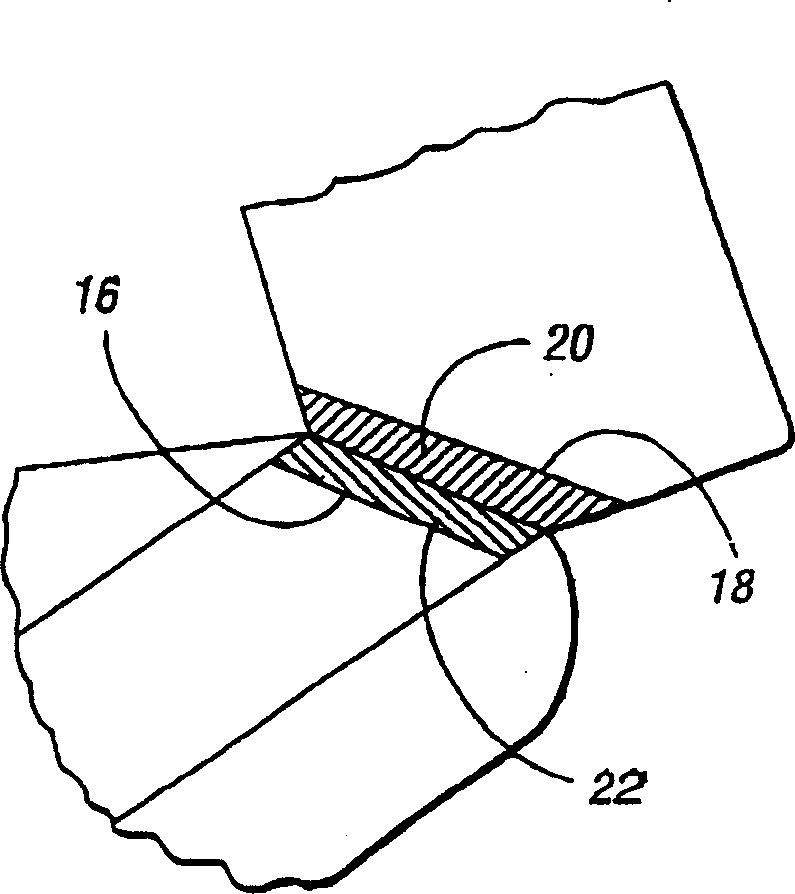

Power-matallurgy valve seat inserts

InactiveCN1438350AHigh temperature resistanceExcellent machinabilityTransportation and packagingMetal-working apparatusVALVE PORTValve seat

A powdered metal blend mixture for making a powdered metal part especially a valve seat insert. The mixture includes 15 to 30 wt.% of a valve steel powder, 0 to 10 wt.% nickel, 0 to 5 wt.% copper, 5 to 15 wt.% of a ferro-alloy powder, 0 to 15 wt.% of a tool steel powder, 0.5 to 5 wt.% of a solid lubricant, 0.5 to 2 wt.% graphite, 0.3 to 1.0% of a temporary lubricant, and the balance being substantially a low alloy steel powder containing 0.6 to 2.0 wt.% molybdenum, 0 to 5 wt.% nickel, and 0 to 3.0 wt.% copper. The present invention provides improved high temperature wear and corrosion resistance over prior art materials as well as improved machinability. The blend of the present invention provides a relatively high density material that allows for a single press and sinter technique.

Owner:EATON CORP

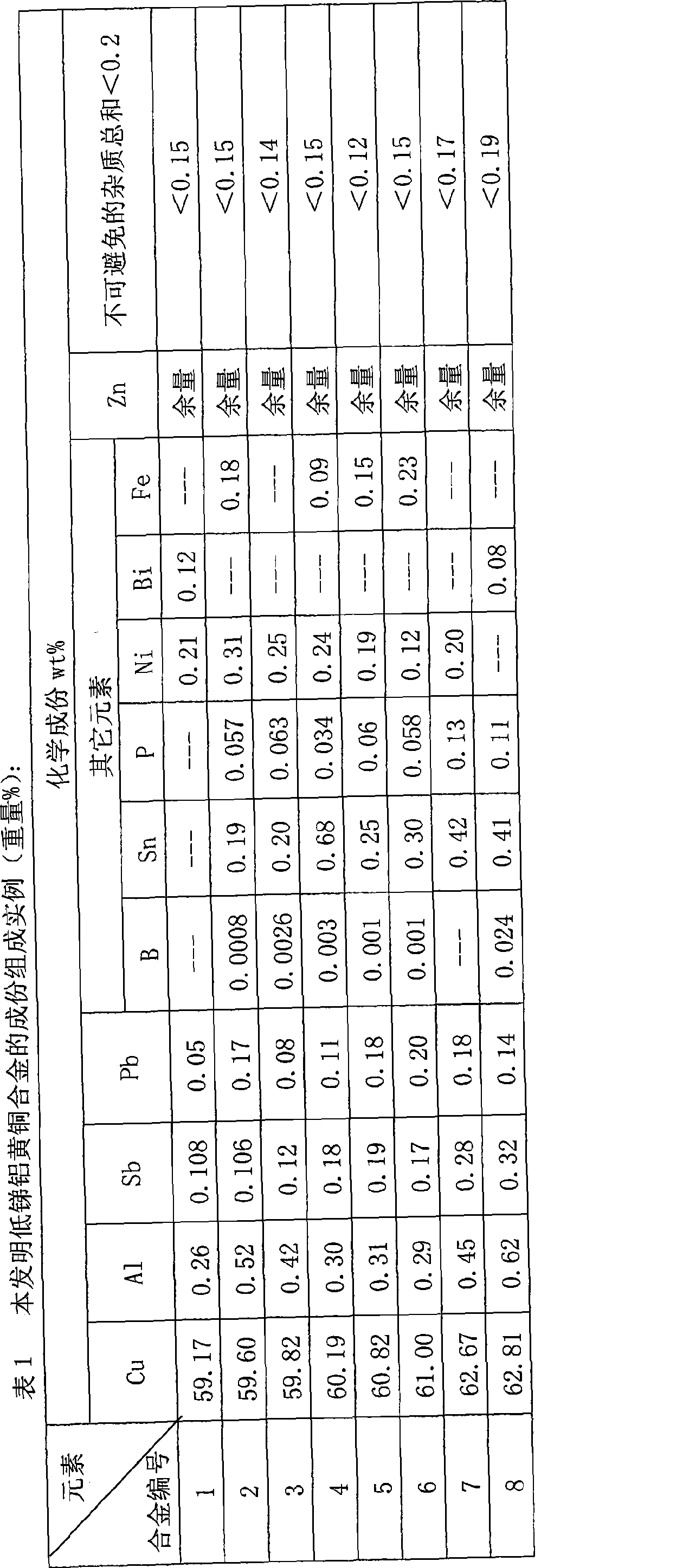

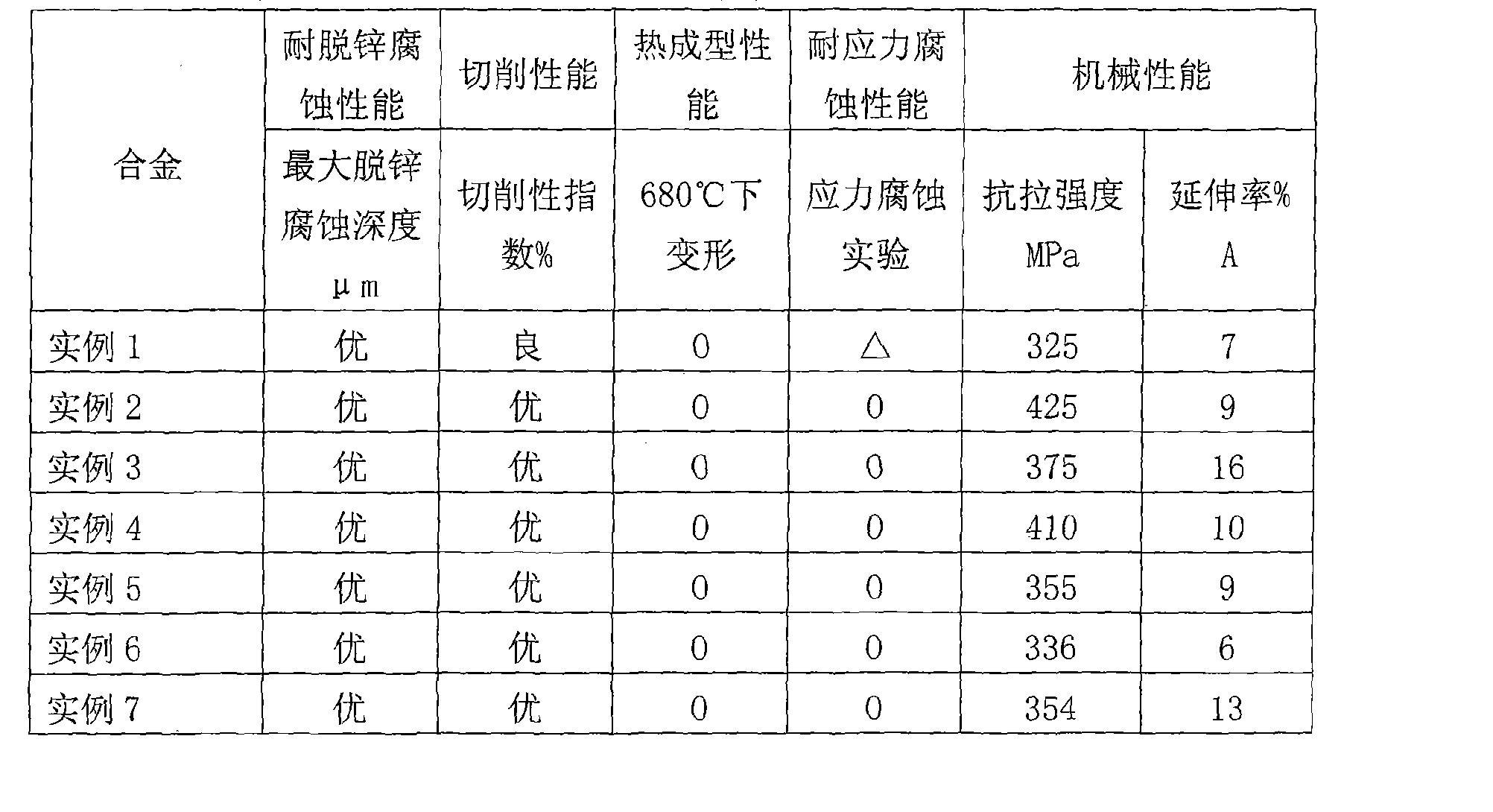

Dezincification corrosion resistant low-stibium aluminum yellow brass alloy and manufacturing method thereof

InactiveCN101440443AExcellent resistance to dezincificationImprove mechanical propertiesMechanical propertyImpurity

The invention discloses a low-stibium aluminum-brass alloy with dezincification corrosion resistance and a preparation method thereof. The alloy comprises the following chemical components: 58.8 to 63 weight percent of copper, 0.25 to 0.65 weight percent of aluminum, 0.105 to 0.35 weight percent of stibium, 0.03 to 0.25 weight percent of lead, 0.04 to 1.5 weight percent of other element, and the balance being zinc and inevitable impurities, wherein the weight percentage of the copper, the zinc, the aluminum, the stibium and the lead is more than 98.2 weight percent, and the other element is at least one element selected from boron, tin, phosphorus, nickel, bismuth and iron. The preparation method comprises: adopting methods of alloying treatment, covering, protecting, dreg removing, purifying and refining, casting the low-stibium aluminum-brass alloy by fusion, thermally processing the alloy at a temperature of between 680 and 740 DEG C; and then carrying out cold processing and intermediate thermal treatment on the alloy, and carrying out stress relieving annealing at a temperature of lower than 380 DEG C after a finished product is subjected to cold processing. The alloy product has the advantages of excellent dezincification corrosion resistance, thermal forming property, mechanical property and easy polishing and plating properties, good cutting property, remarkably excellent hygienic safety, simple manufacturing technique, low cost and easy recycling.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Smelting method for modifying sulfide inclusions in non-quenched and tempered steel or pinion steel

The invention discloses a smelting method for modifying sulfide inclusions in non-quenched and tempered steel or pinion steel. A modification process is mainly realized by the following step: feedinga silicon-magnesium-calcium composite core-spun yarn into refined molten steel, or respectively feeding a silicon-magnesium core-spun yarn and a silicon-calcium core-spun yarn into the refined moltensteel, so that the content of magnesium in the steel is 4-25ppm, and the content of calcium in the steel is 5-25ppm. According to the method, by optimizing the contents of oxygen, sulfur, manganese, calcium, magnesium and aluminum in the steel in a refining process, the sulfide inclusions in the non-quenched and tempered steel and the pinion steel are modified effectively, so that the form, size and distribution of sulfide are controlled, the inclusions in the non-quenched and tempered steel and the pinion steel are transformed into 'internal hard oxide particle and external covered sulfide' composite inclusions, and the quality of special steel is enhanced.

Owner:SHANGHAI UNIV

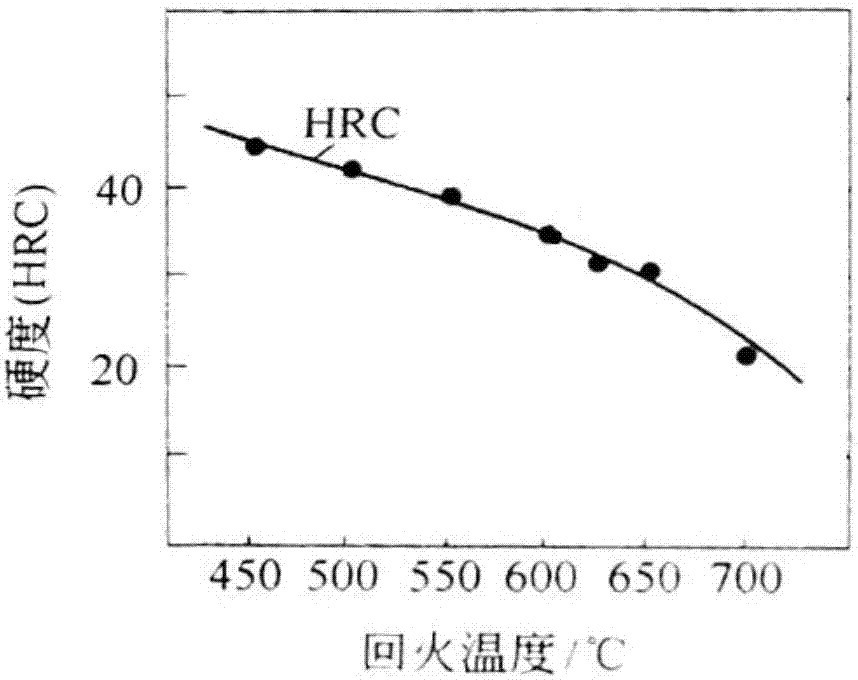

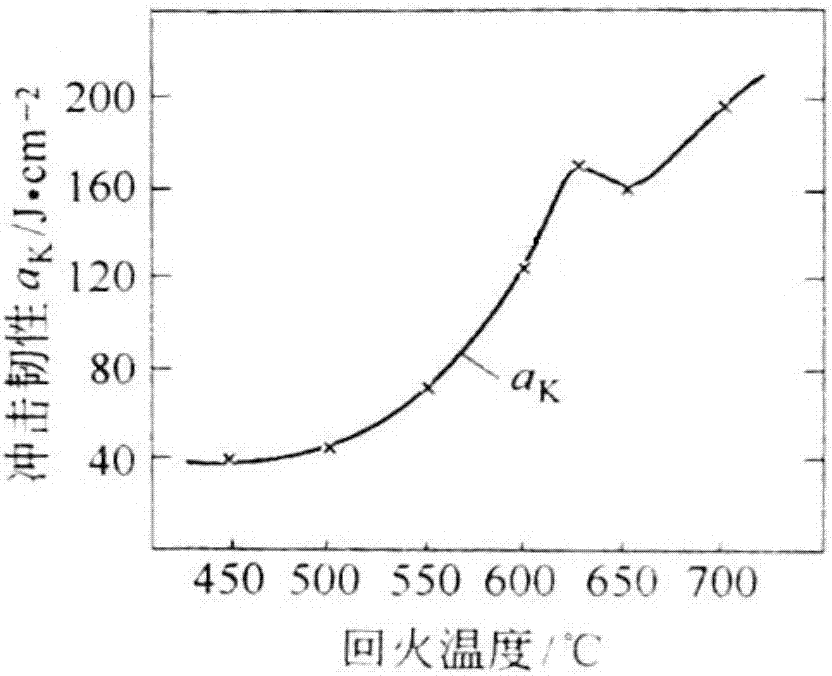

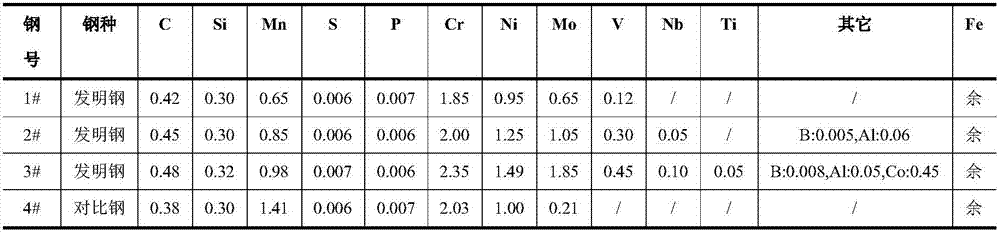

High-hardness high-hardenability pre-hardening plastic mould steel and preparation method thereof

The invention discloses a high-hardness high-hardenability pre-hardening plastic mould steel and a preparation method thereof and belongs to the technical field of tool and mould steels. To be specific, the steel comprises, by weight percentage, 0.40-0.50% of C, 0.2-0.5% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, 0.6-1.0% of Mn, 0.8-1.5% of Ni, 0.6-2.0% of Mo, 1.6-2.5% of Cr, 0.1-0.5% of V and the balance Fe and inevitable impurities. The high-hardness high-hardenability pre-hardening plastic mould steel has the beneficial effects that compared with the priorart, the steel is higher in pre-hardening hardness, toughness and hardenability; the comprehensive performance is more excellent; and the steel can be used for producing a high-hardness large-size pre-hardening plastic mould steel module more easily, so that user requirements are met.

Owner:CENT IRON & STEEL RES INST

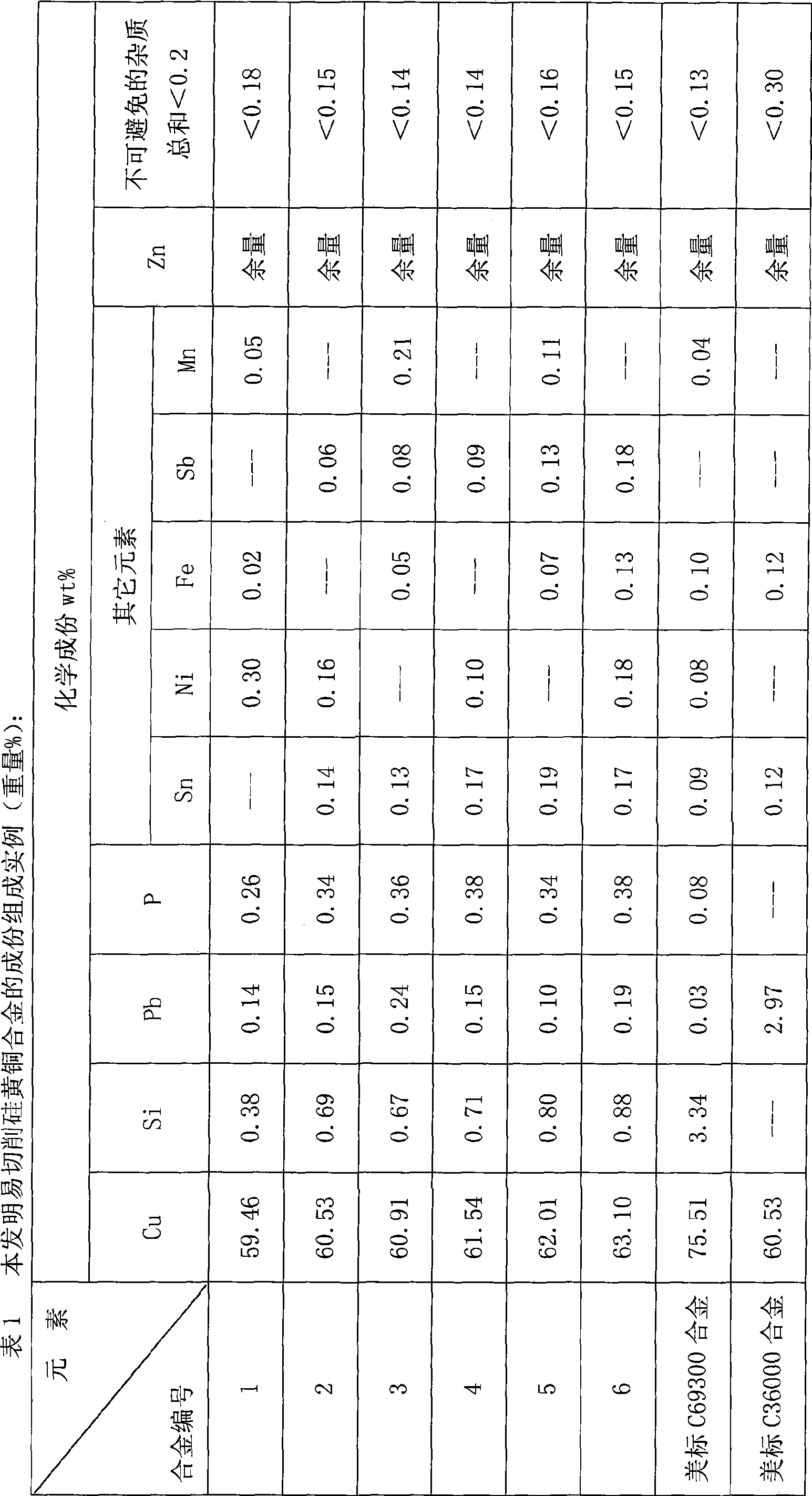

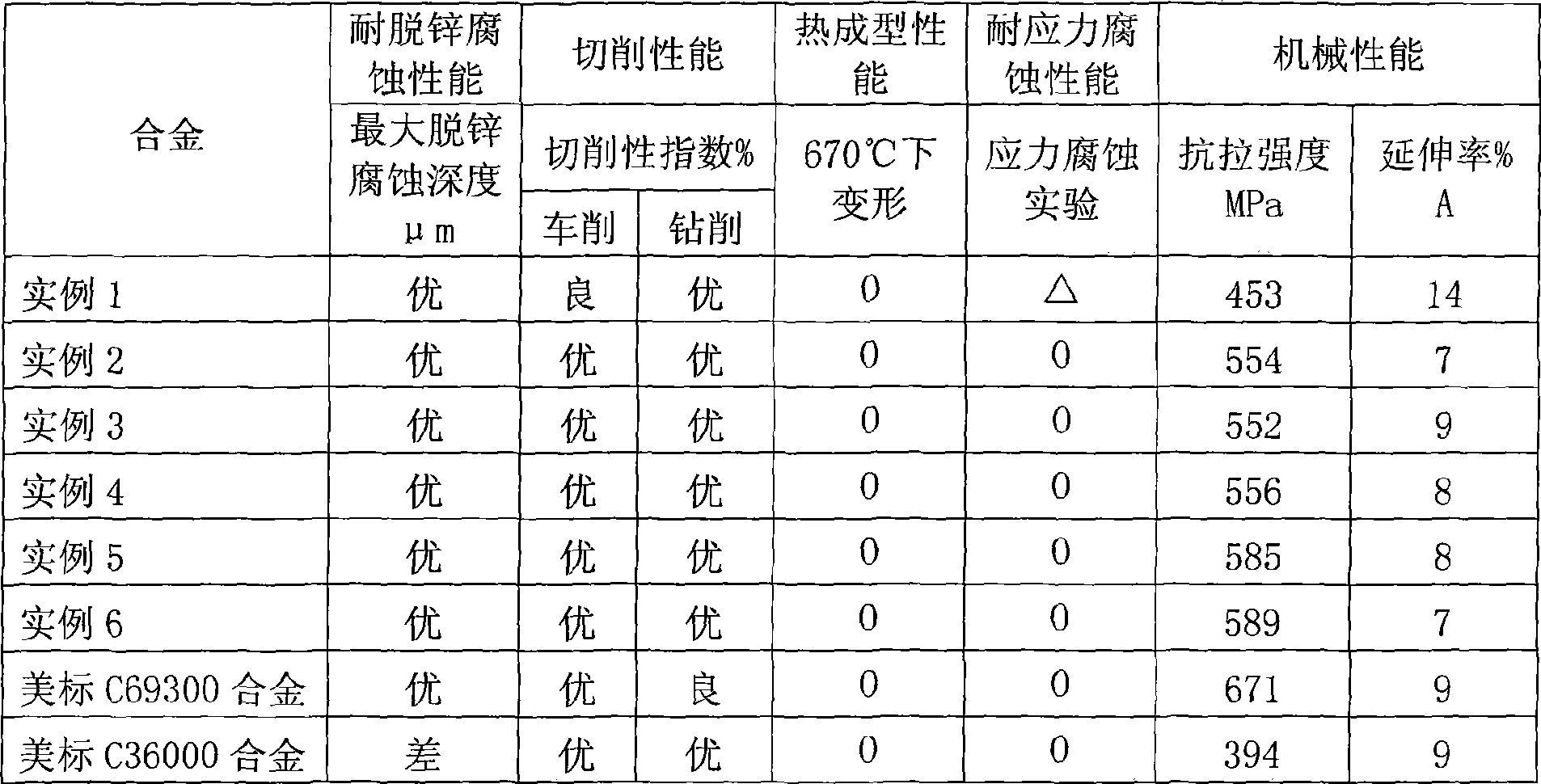

Easily-cut silicon brass alloy and preparation method thereof

ActiveCN101445885AExcellent machinabilityExcellent resistance to dezincificationManganeseStress relief

The invention discloses an easily-cut silicon brass alloy and a preparation method thereof. Chemical components of the silicon brass alloy include 59.2-63.5wt% of copper, 0.35-0.9wt% of silicon, 0.04-0.25wt% of lead and 0.22-0.38wt% of phosphor, other elements account for 0.005-1.1wt%, and the rest include zinc and inevitable impurities, wherein, the total amount of the copper, the zinc, the silicon, the lead and the phosphor is larger than 98.7wt%, and the other elements include at least one element selected from a group consisting of tin, nickel, iron, stibium and manganese. The preparation method is as follows: a method for alloying and for purifying and refining a covered and protected alterative scarfing cinder is adopted for smelting the easily-cut silicon brass alloy, then intermediate heat treatment is carried out at a temperature of 560-660 DEG C after coldworking with a working rate ranging from 4 percent to 25 percent, and a final finished product resulting from the working undergoes stress relief annealing at a low temperature of 380 DEG C. The invention has the advantage that the easily-cut silicon brass alloy has high tensile strength, excellent thermal formability, dezincing resistance, safe and sanitary performance and remarkable excellent cutting performance; meanwhile, the preparation process of the easily-cut silicon brass alloy is simple, the cost is low, and the easily-cut silicon brass alloy can be easily recycled.

Owner:NINGBO POWERWAY ALLOY MATERIAL

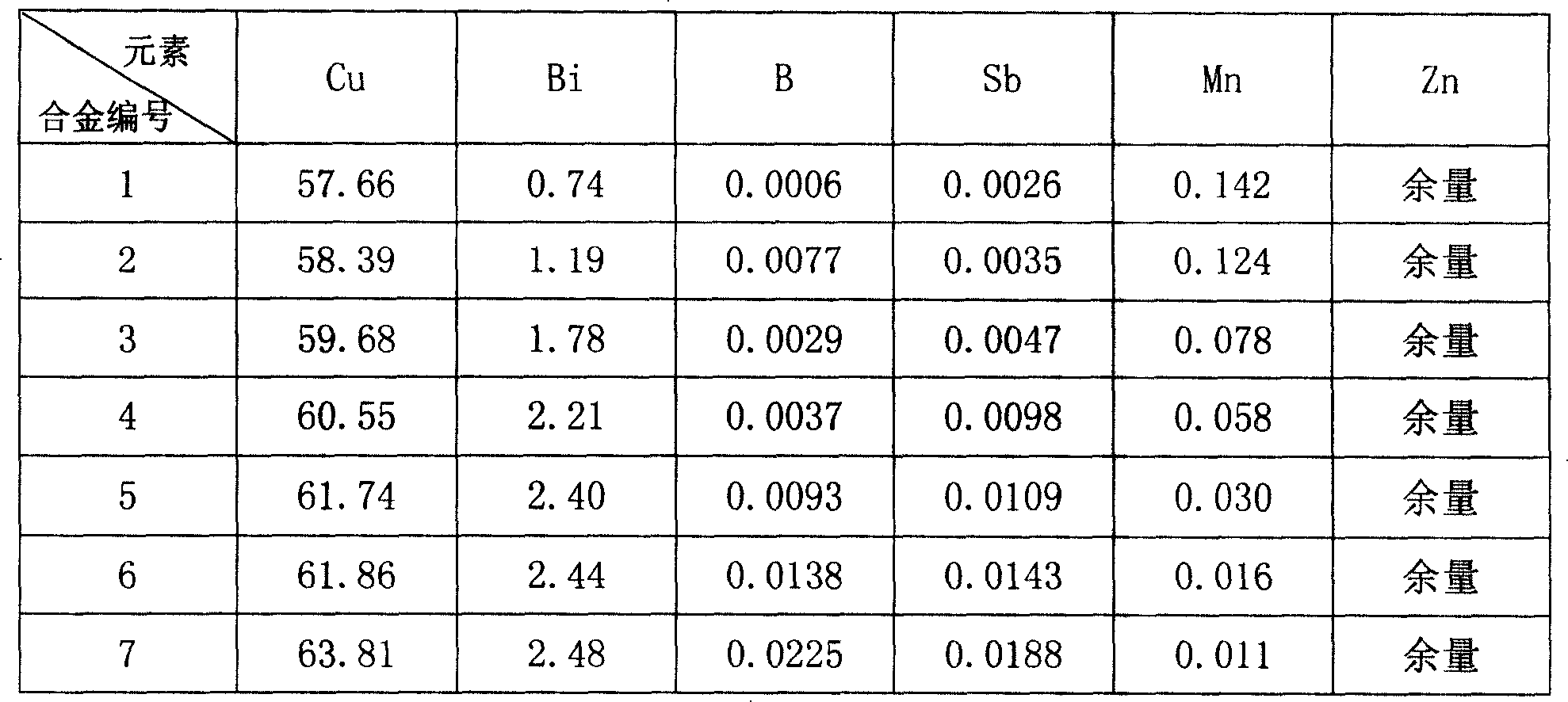

Free-cutting anticorrosive brass alloy and its prepn process

The present invention discloses one kind of free-cutting anticorrosive brass alloy and its preparation process. Chemically, the brass alloy consists of Cu 57-64 wt%, Bi 0.6-2.5 wt%, B 0.0003-0.025 wt%, Mn 0.01-0.2 wt%, Sb 0.002-0.02 wt% and Zn and inevitable impurities for the rest. The inevitable impurities has content within 0.3 wt%, and includes Pb within 0.1 wt% and Cd within 0.001 wt%; and the alloy contains Cu+Zn over 97 wt%. The brass alloy has high anticorrosive performance, excellent cutting performance and good welding performance.

Owner:NINGBO POWERWAY ALLOY MATERIAL

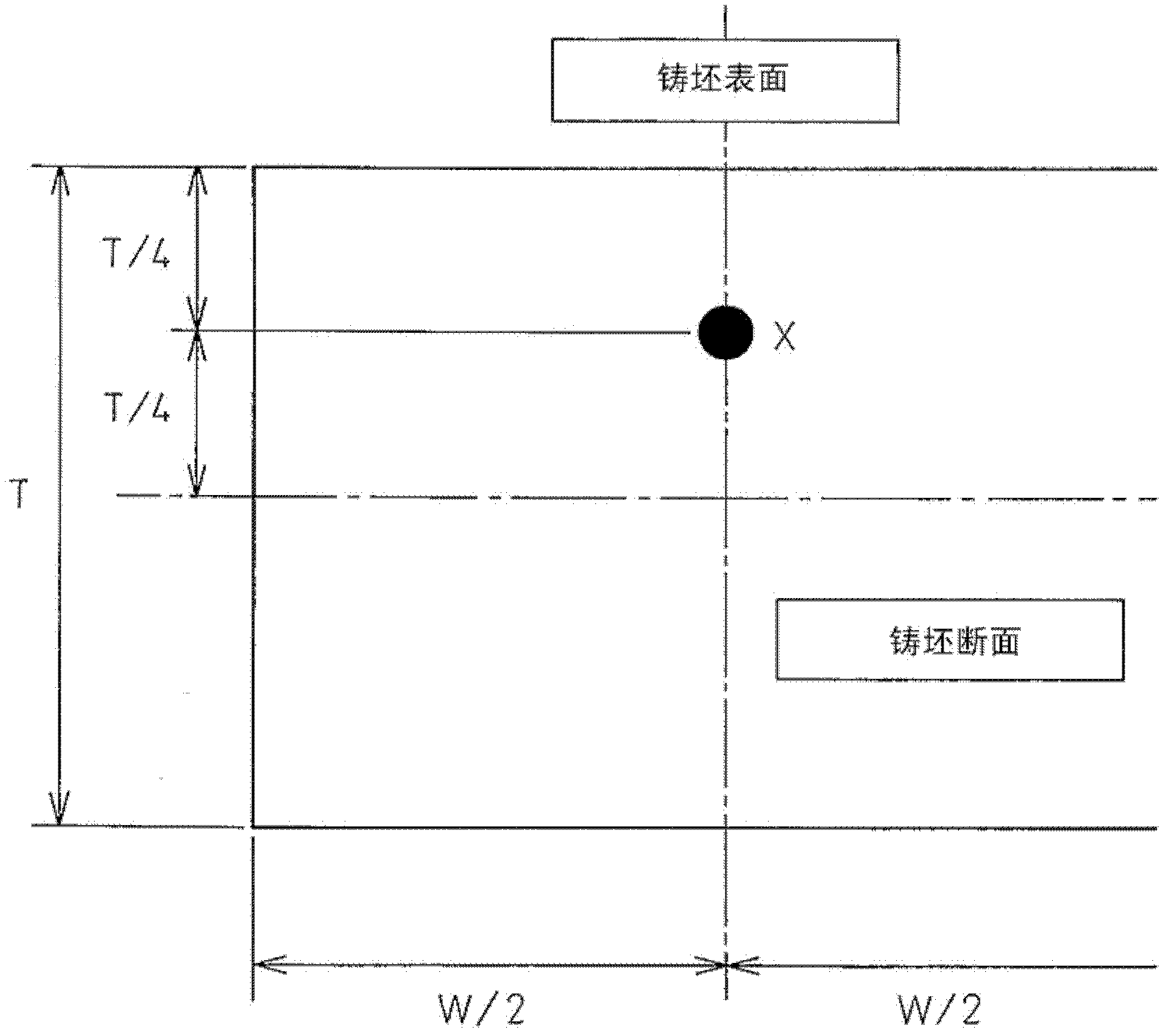

Rolled material for fracture split connecting rod excelling in fracture splittability, hot forged part for fracture split connecting rod excelling in fracture splittability, and fracture split connect

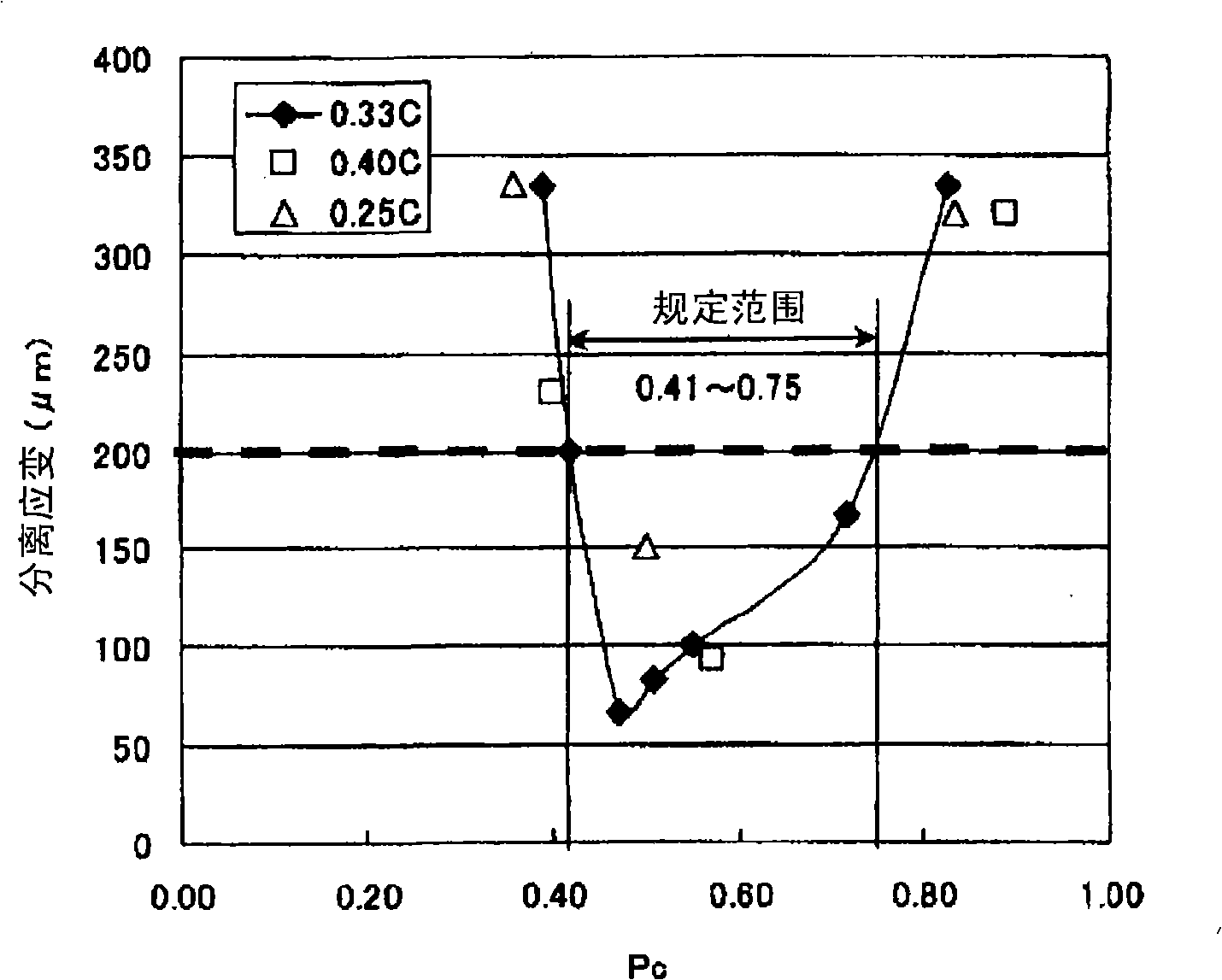

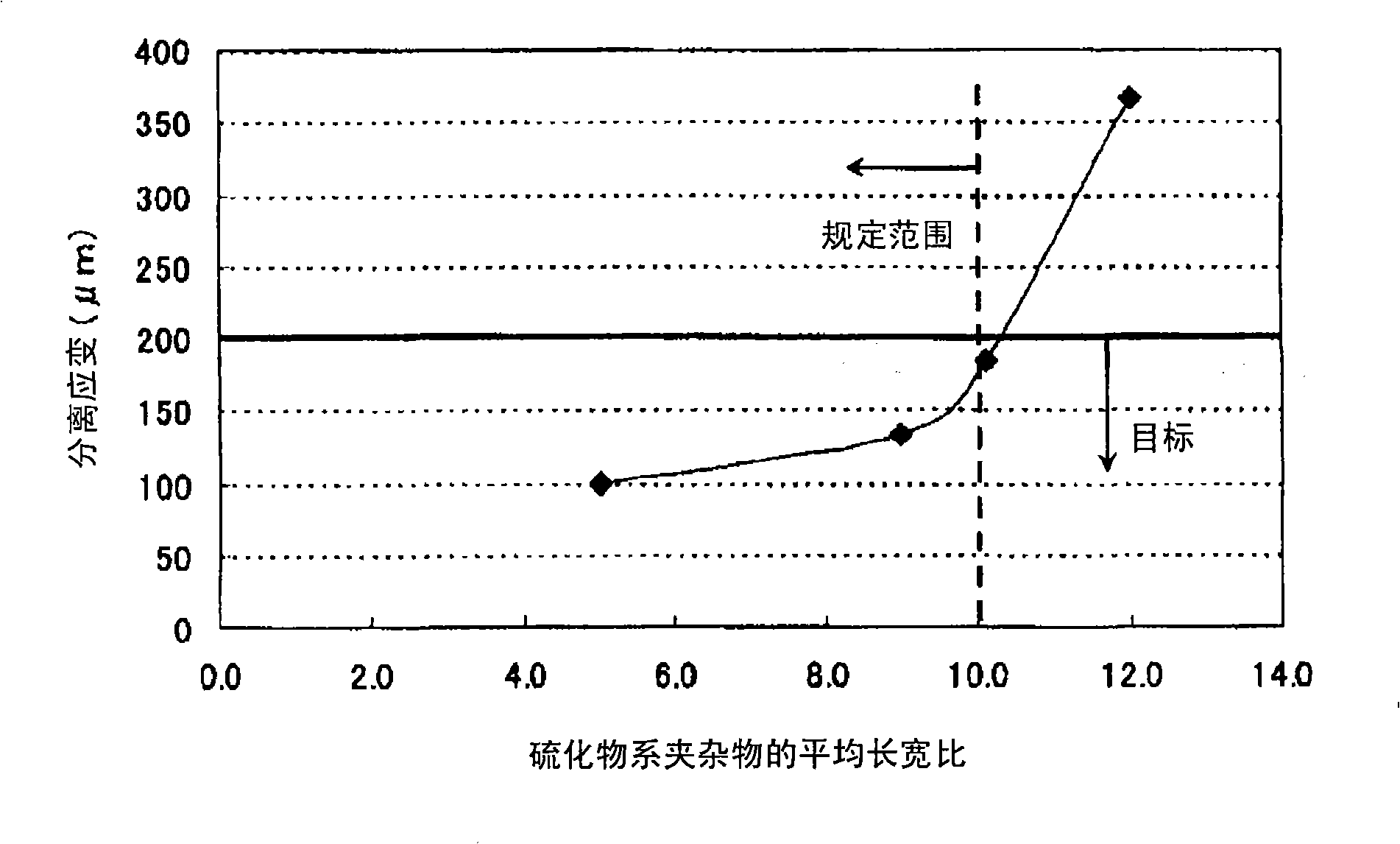

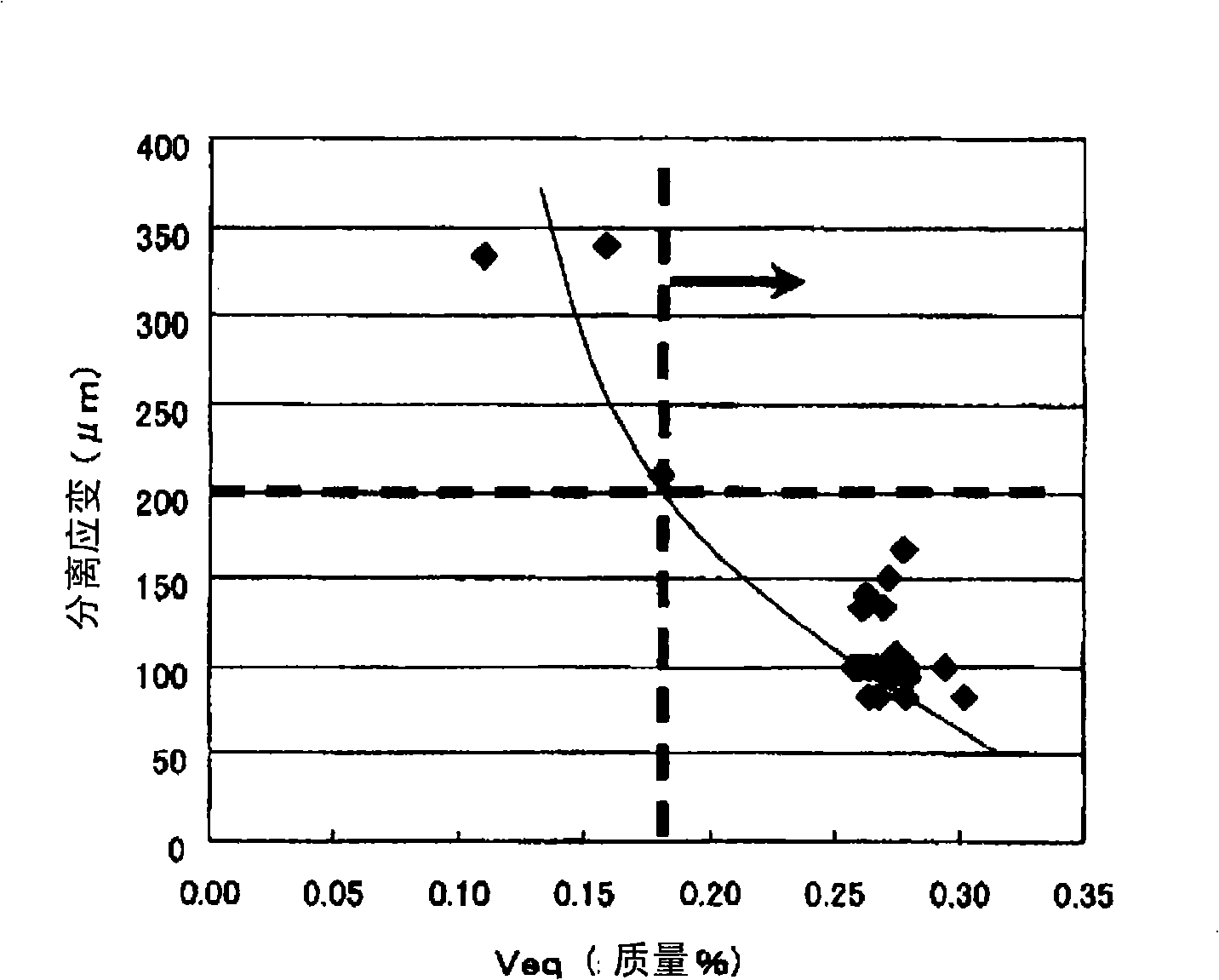

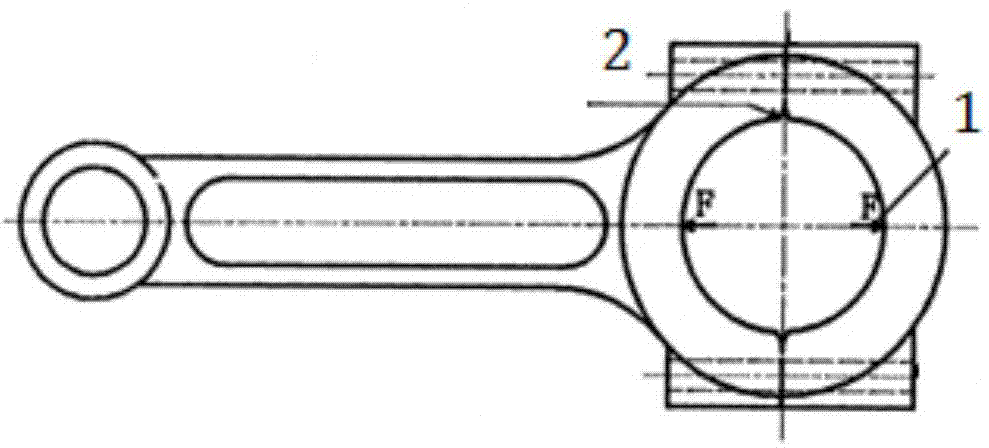

The present invention provides a rolled material having excellent fracture splitting characteristics and suitable for the manufacture of a connecting rod in which a through-hole section for assembly in a crankshaft is fracture split in substantially semicircles. Prescribed components are contained, an average aspect ratio of a sulfide-based inclusion as observed in a D / 4 portion (D is the diameter of the rolled material) in a cross-section parallel to a longitudinal direction of the rod-shaped rolled material is not more than 10.0, a Pc indicated in Equation (1) below is between 0.41 and 0.75, and a Veq indicated in Equation (2) below is not less than 0.18 mass %. Pc=C(1-alpha / 100) (1) {In Equation (1), C represents the carbon content in steel (mass %) and alpha represents the ferrite fraction (area ratio %)}; Veq=V+Ti / 2+Si / 20 (2) {In Equation (2), V, Ti and Si represent the content of each element in steel (mass %)}.

Owner:KOBE STEEL LTD

High-carbon non-tempered steel for breaking connecting rod and manufacturing method thereof

InactiveCN104775081ANo obvious plastic deformationMeet breakout requirementsHigh carbonChemical element

The invention discloses high-carbon non-tempered steel for breaking a connecting rod and a manufacturing method thereof. The high-carbon non-tempered steel comprises the following chemical elements in percentage by weight: 0.65%-0.85% of C, 0.15%-0.25% of Si, 0.50%-0.60% of Mn, 0.010%-0.045% of P, 0.060%-0.070% of S, 0.10%-0.20% of Cr, 0.55%-0.80% of Ni, 0.03%-0.04% of V, 010%-0.20% of W, 0.0120%-0.0160% of N, 0.0001%-0.0004% of Re and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: electric furnace primary smelting; ladle refining and vacuum degassing; die casting or continuous casting; and steel bar rolling. The high-carbon non-tempered steel has relatively high strength and good breaking performance.

Owner:BAOSHAN IRON & STEEL CO LTD

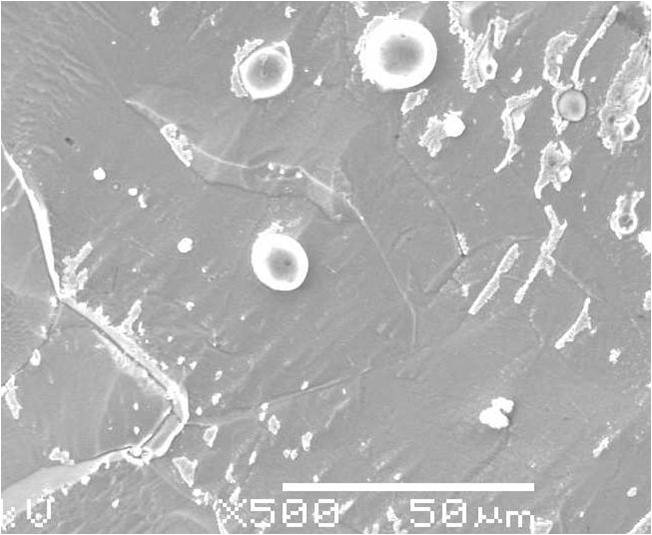

Cutting tip of metal ceramic based on titanium carbonitride toughened by crystal whisker, and preparation method

This invention relates to a method for preparing SiC whiskers toughened Ti(CN)-based metal ceramic tool blade. The tool blade is composed of Ti (CN) as the major phase, SiC whiskers as the toughening agent, and metal binding phase and carbide hard phase as the additives. The method comprises: mixing the above components, molding, and sintering in vacuum to obtain a high compactness. Compared with traditional TN metal ceramic tool blade, the SiC whiskers toughened Ti(CN)-based metal ceramic tool blade has such advantages as high strength, high toughness, high wear resistance, high heat resistance, and high cuttability, and can be used for high speed milling, finish turning or semi-finish turning of carbon steel, stainless steel, hardened steel, wear-resistant cast iron and high-strength steel.

Owner:SECTION OF SCI & TECH DEV

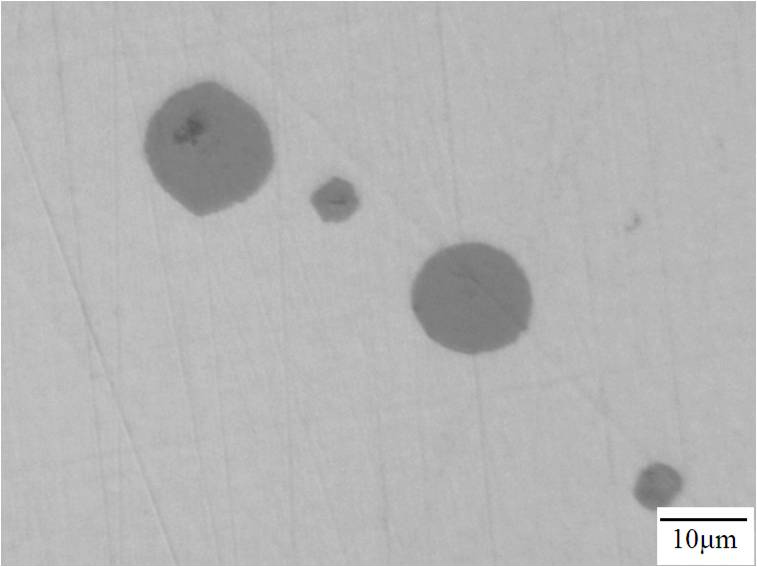

Steel for case hardening which has excellent cold workability and machinability and which exhibits excellent fatigue characteristics after carburizing and quenching, and process for production of same

ActiveCN102378822AOptimizing Forging PerformanceExcellent machinabilitySolid state diffusion coatingSulfideCase hardening

Provided is a steel for case hardening, which is to be subjected to cold working, machining, and carburizing and quenching, and in which the occurrence of coarse particles is prevented. The steel for case hardening has excellent cold workability and machinability and further exhibits excellent fatigue characteristics after carburizing and quenching. The steel for case hardening is characterized by: containing, by mass, 0.001 to 0.15% of S, 0.05 to 0.2% of Ti, at most 0.04% of Al, at most 0.0050% of N, and specific amounts of other specific components, and further containing at most 0.003% of Mg, and / or at most 0.01% of Zr, and / or at most 0.005% of Ca; having a content of precipitated AlN of 0.01% or less; and satisfying the relationship: d = 1700[S]+20 [wherein d is the density (particles / mm2) of sulfides which have equivalent circle diameters exceeding 20[mu]m and aspect ratios exceeding 3; and [S] is the content (mass%) of S].

Owner:NIPPON STEEL CORP

Easy-cutting lead-free brass alloy for forging and preparation method thereof

The invention discloses an easy-cutting lead-free brass alloy for forging and a preparation method thereof. The alloy comprises the following components in percentage by mass: 55-68 percent of copper, 0.1-0.8 percent of bismuth, 0.05-0.3 percent of calcium, 0.05-0.3 percent of lithium, 0.05-0.15 percent of sulfur, 0.001-0.1 percent of aluminum, 0.001-0.05 percent of boron, 0.001-0.08 percent of mixed rare-earth elements (one or more lanthanum, cerium and neodymium) and the balance of zinc and unavoidable impurity. The preparation method comprises the following steps: smelting copper-zinc alloy at 1,150 DEG C-1,300 DEG C; after fusant sprays fire, sequentially adding bismuth and zinc rare-earth medium alloy; after the mixture stands and preserves the temperature for 10 minutes, sequentially adding zinc-calcium medium alloy, copper-sulfur medium alloy, the aluminum, copper-boron medium alloy, the zinc and zinc-lithium medium alloy; stirring and deslagging the mixture; preserving the mixture at 1100 DEG C for 15 minutes-20 minutes and casting the mixture at the casting temperature of 1,000 DEG C-1,050 DEG C; preparing an alloy casting blank; and finally casting and molding the obtained casting blank so as to obtain a part blank. An alloy product obtained by the invention has thin crystalline grain, high hot processing performance as well as favorable cutting performance and is suitable for forging.

Owner:XIAMEN LOTA INT CO LTD

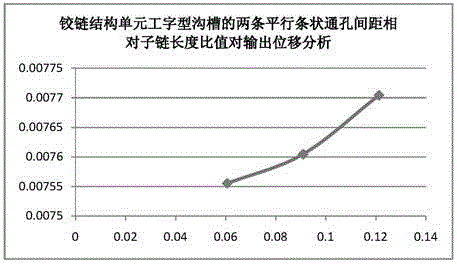

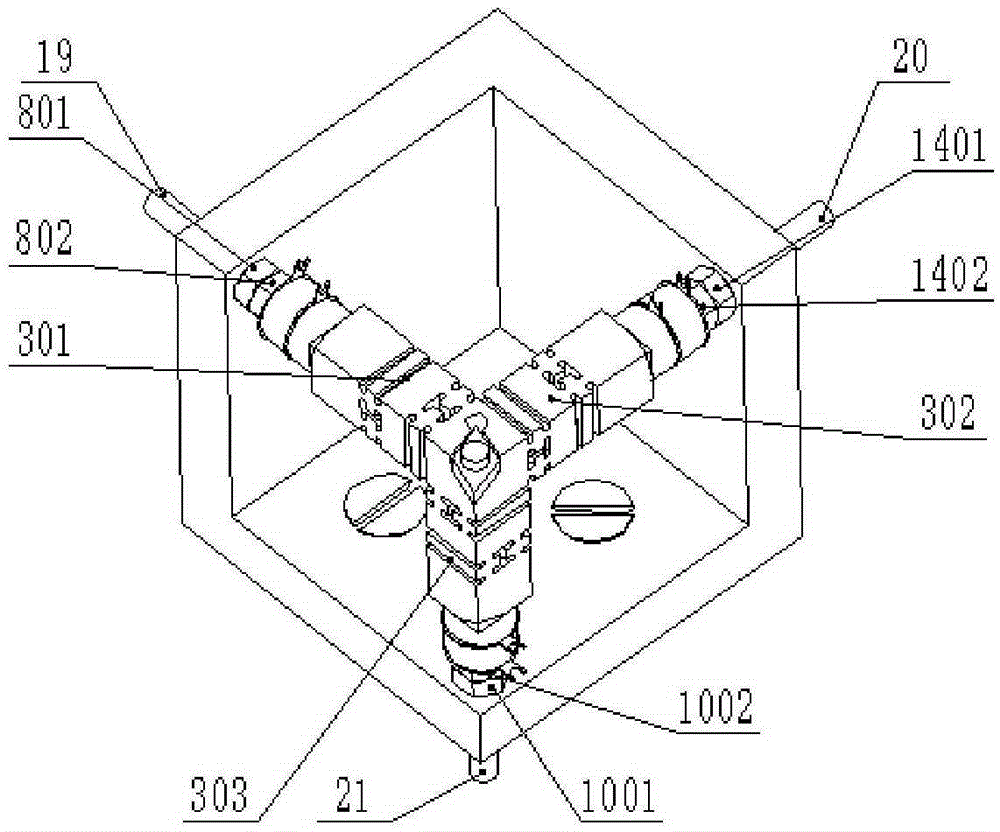

Three-dimensional ultrasonic elliptical vibration cutting device of parallel structure and track generating method

ActiveCN106141761AWith output displacement amplificationExcellent machinabilityGeometric CADMechanical vibrations separationNumerical controlSonification

The invention discloses a three-dimensional ultrasonic elliptical vibration cutting device of a parallel structure and a track generating method and belongs to the field of elliptical vibration assisted cutting machining. The device outputs the space three-dimensional ultrasonic elliptical vibration track by using design in a form of a flexible hinge parallel structure. The device comprises a flexible hinge parallel structure, a fixed base, a cutter pre-tightening bolt, pretensioners, piezoelectric ceramics, electrode plates, thread shafts and resonant frequency regulators. The flexible hinge parallel structure comprises tree branch hinges and a cutter mounting table; the tree branch hinges are uniformly distributed at the periphery with intervals of 120 degrees; displacement is simultaneously input into the three branch hinges and finally forms an elliptical track at a cutter point through transmission and amplification actions of the flexible hinge parallel structure. The device is simple in structure and rapid in response, is capable of easily generating the three-dimensional elliptical motion track, and can be conveniently and directly integrated with a numerically-controlled machine tool to carry out auxiliary precision machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

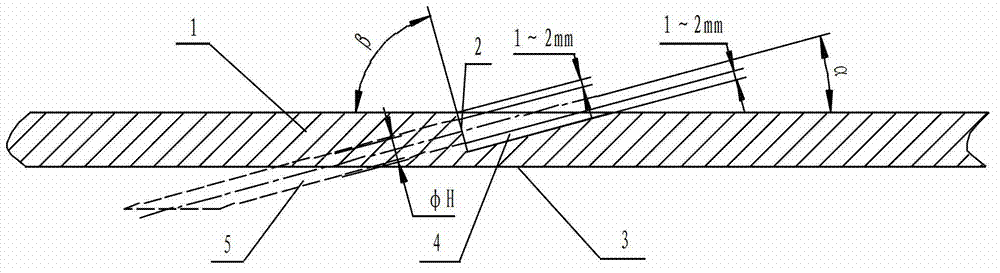

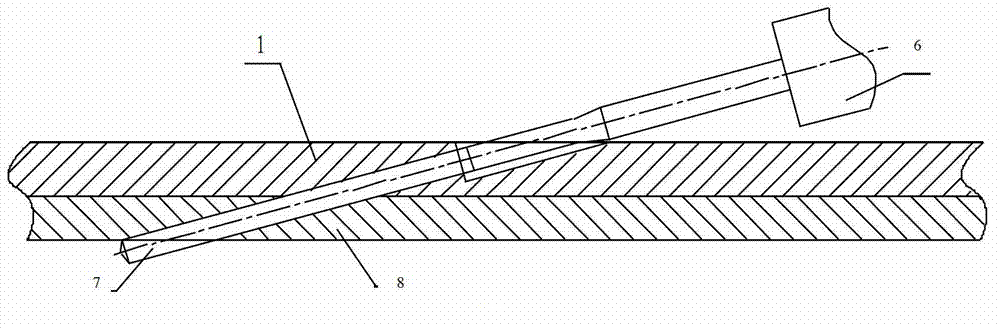

Method for processing deep minipore with large gradient on difficult-to-process material

The invention provides a method for processing a deep minipore with large gradient on a difficult-to-process material. The method comprises the following steps of: adding and fixing a cutting force balancing guide plate with reasonable thickness, excellent cutting performance and good locating cooperation and firm adhesion with a workpiece on the workpiece, milling an inclined plane vertical to the central axis of the hole on the guide plate through a large diameter milling tool, and converting deep inclined minipore processing into common minipore processing to solve the problems of large gradient of the difficult-to-process material, chip breaking, chip discharge, chip removal, cutter back-off, cutter vibration and cutter striking in the deep minipore cutting processing and the problem that the surface roughness and the length dimension of an entrance cannot meet the demand in direct processing, and the method provides reliable technical support for integral surface processing and anti-fatigue manufacturing and provides guarantee for improving the service life and safety of the parts.

Owner:AECC AVIATION POWER CO LTD

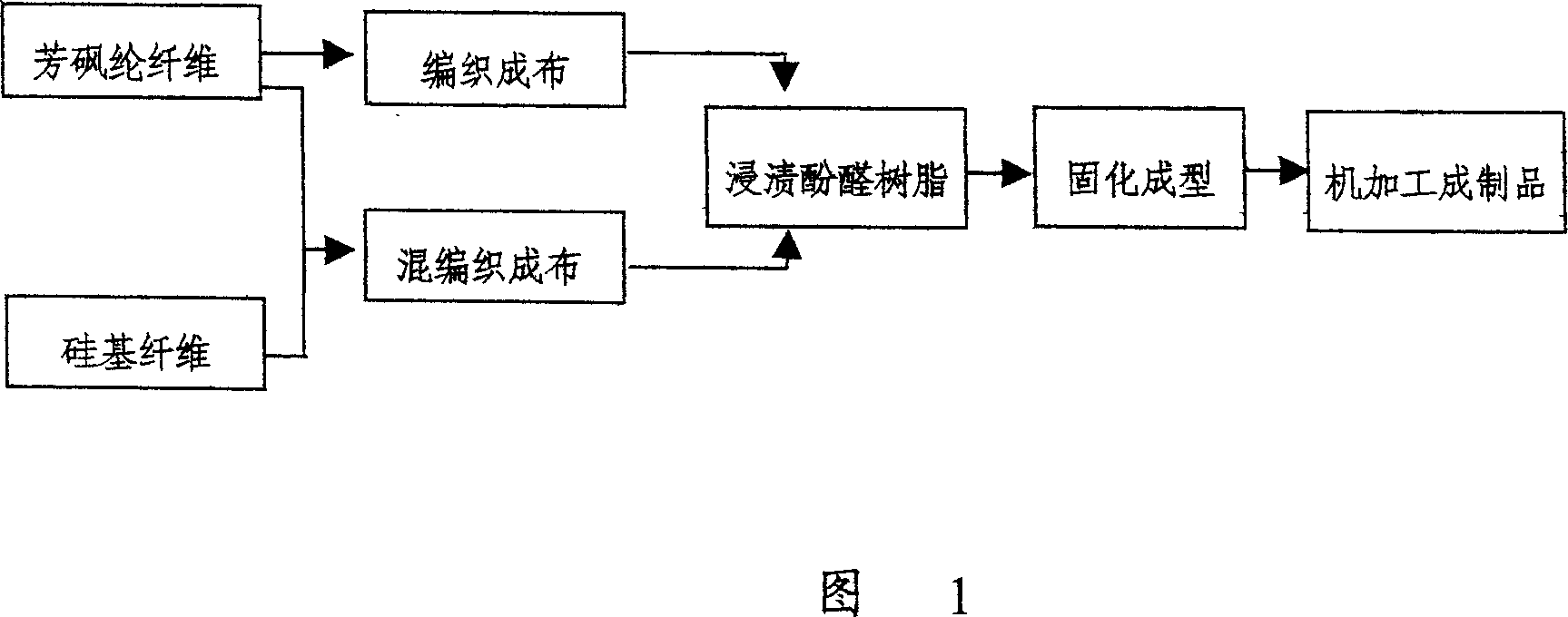

Enhancement ablation thermal protection composite material and preparation method thereof

ActiveCN1990920AGood strengthImprove heat resistanceFibre treatmentWoven fabricsThermal insulationFiber

The invention relates to a thermal protective composite with enhancing ablation and the manufacturing method. It is the novel heat insulation composite, whose manufacturing technology is that PSA fabric cloth or / and Si-based fiber mixed weaved cloth is dipped in phenolic resin and is solidified to mould. The composite in invention is widely applied in the structuring with heat insulation and protection and is provided with better intensity, stability of dimension and machining technology. It breaks through the demand that prior material can not be ablated for a long time and can not insulate heat. It finds a better solved path for realizing integration of ablative heat protection and heat insulation of material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

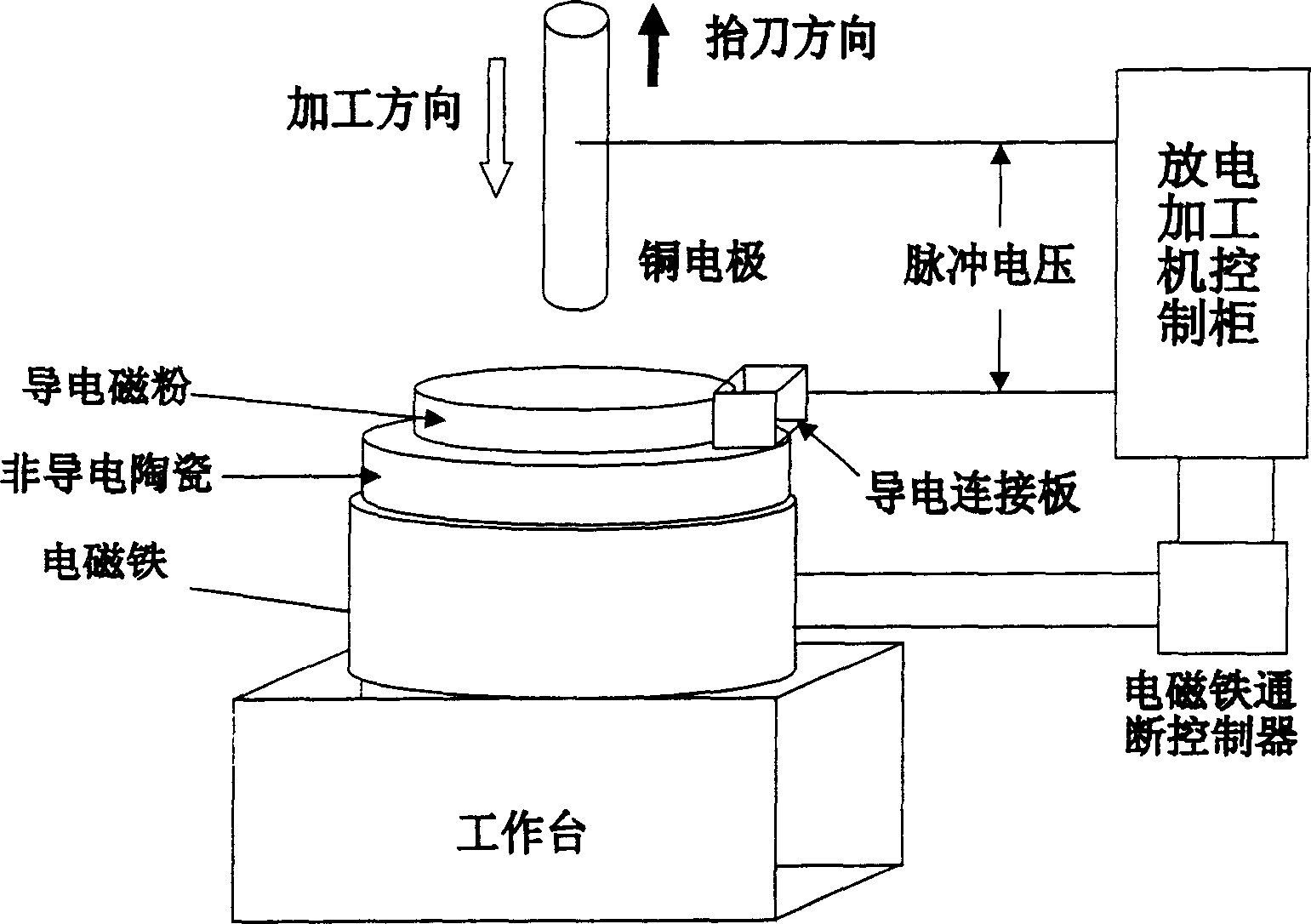

Electrodischarge machining method for working non-conductive ceramic utilizing conductive magnetic powder

InactiveCN1775441AEasy to operateExcellent machinabilityElectrical-based auxillary apparatusCeramicSurface spreading

The electro-discharge machine method for preparing nonconducting ceramics by utilizing conductive magnetic powder includes the following steps: (1) placing electromagnetic iron device on working table of electro-discharge machining machine, form of electromagnetic iron is identical to that of workpiece; (2) on the electromagnetic iron mounting and holding nonconducting ceramics; (3) on said ceramics surface spreading conductive magnetic powder; (4) using conductive magnetic powder as one end of electrode and making it and metal electrode be formed into electrode pair; (5) switching on the power supply of electromagnetic iron, the conductive magnetic powder can be adsorbed on the ceramics surface; (6) setting main electro-discharge machining parameter; and (7) making electro-discharge machining process.

Owner:SHANGHAI JIAO TONG UNIV

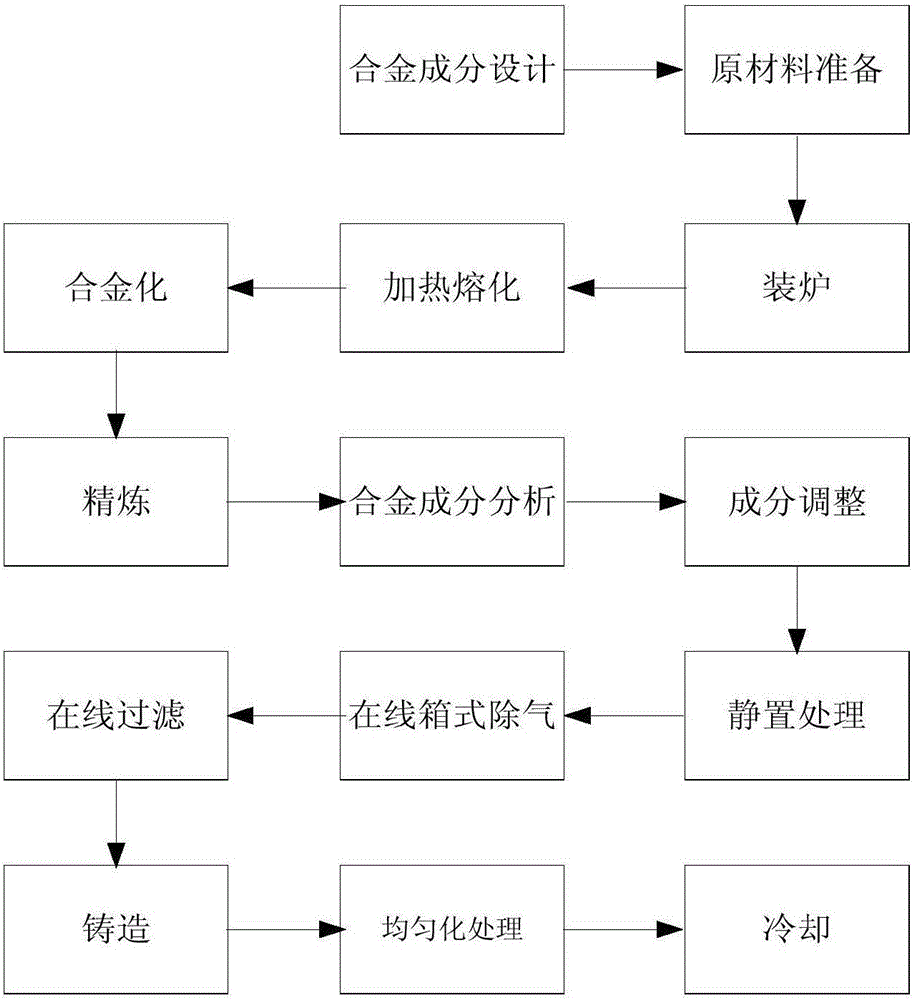

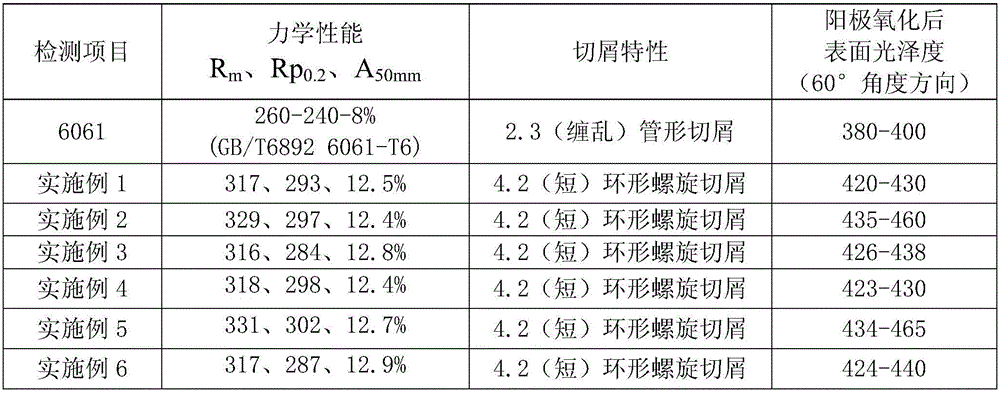

Al-Mg-Si-Cu alloy and preparation method and application thereof

The invention discloses Al-Mg-Si-Cu alloy and a preparation method and application thereof. The Al-Mg-Si-Cu alloy comprises, by mass, 0.6%-0.8% of Si, 1.0%-1.2% of Mg, 0.25%-0.5% of Fe, 0.2%-0.4% of Cu, 0.1%-0.15% of Mn, 0.1%-0.2% of Cr, 0.10%-0.20% of Zn, 0-0.10% of Ti, smaller than 0.15% of other impurities, and the balance Al. The Al-Mg-Si-Cu alloy has high strength and excellent anodic oxidation performance, meanwhile also has great chip cutting performance and can be used for manufacturing industrial aluminum alloy materials, such as electronic equipment structural connecting pieces, with high-quality requirements for high strength, decorative surfaces and a large quantity of CNC processing.

Owner:中山瑞泰铝业有限公司

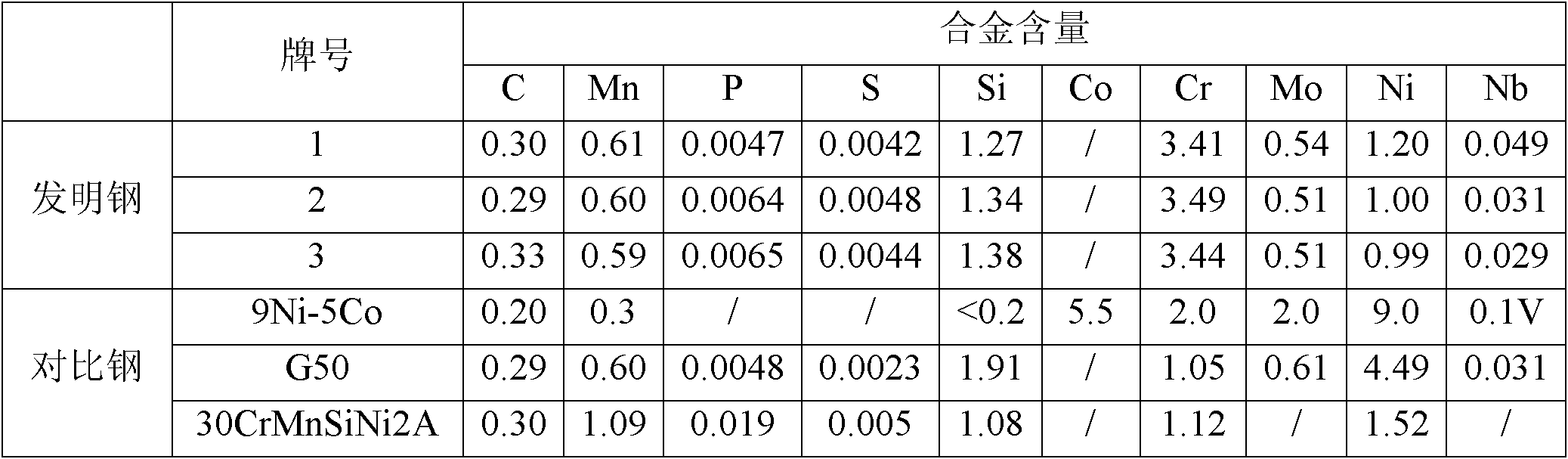

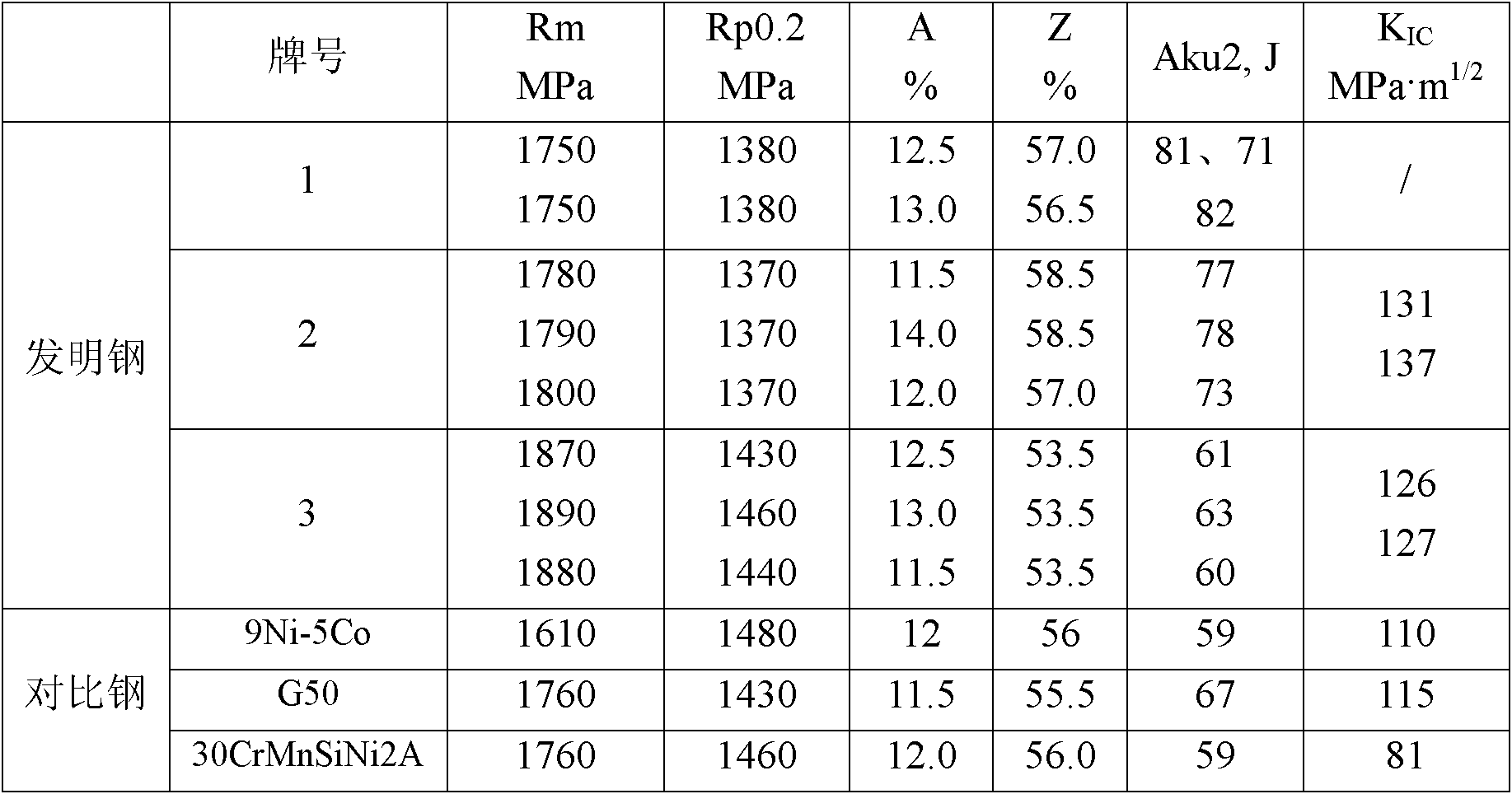

Steel with high toughness and ultrahigh strength

The invention discloses steel with high toughness and ultrahigh strength, and belongs to the technical field of alloy steels. The steel comprises the following chemical components in percentage by mass: 0.20 to 0.35 percent of C, 0.5 to 2.0 percent of Mn, 1.25 to 2.25 percent of Si, 2.0 to 5.0 percent of Cr, 0.5 to 2.5 percent of Ni, 0.3 to 0.8 percent of Mo, 0.01 to 0.10 percent of Nb, 0.05 to 0.3 percent of V, less than or equal to 0.005 percent of S, less than or equal to 0.01 percent of P, and the balance of Fe. Compared with the conventional steel with ultrahigh strength, the steel has the advantages of ultrahigh strength, high fracture toughness, high hardening property and low cost.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com