Steel with high toughness and ultrahigh strength

An ultra-high-strength steel and high-toughness technology, applied in the field of high-toughness ultra-high-strength structural steel, can solve the problems of poor hardenability, high cost, and high cost of ultra-high-strength steel, and achieve high fracture toughness and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

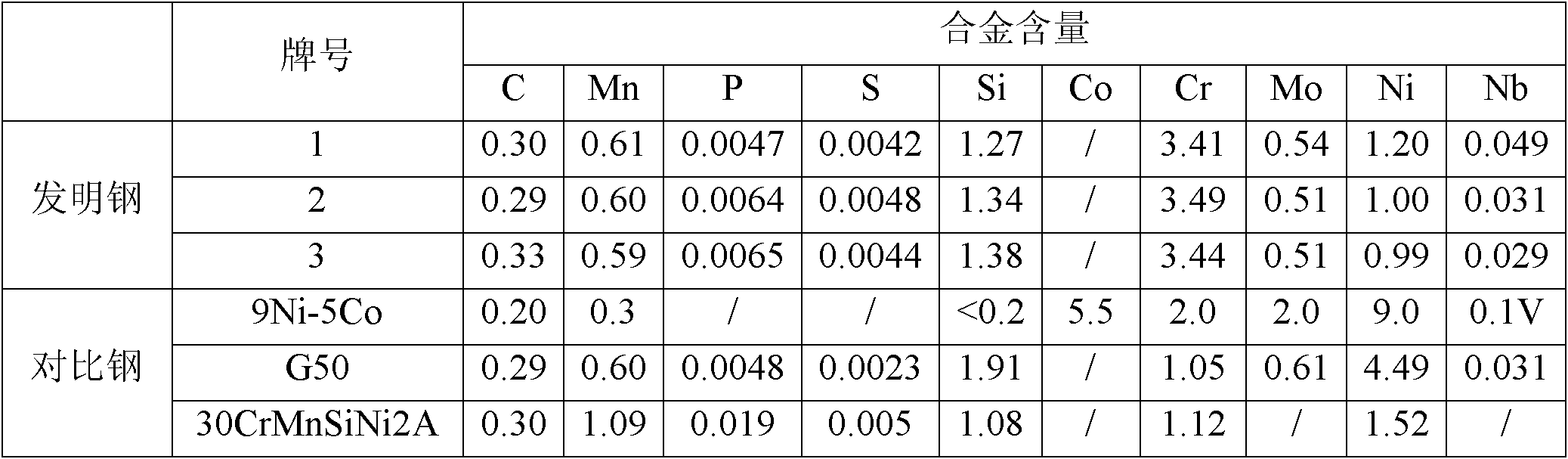

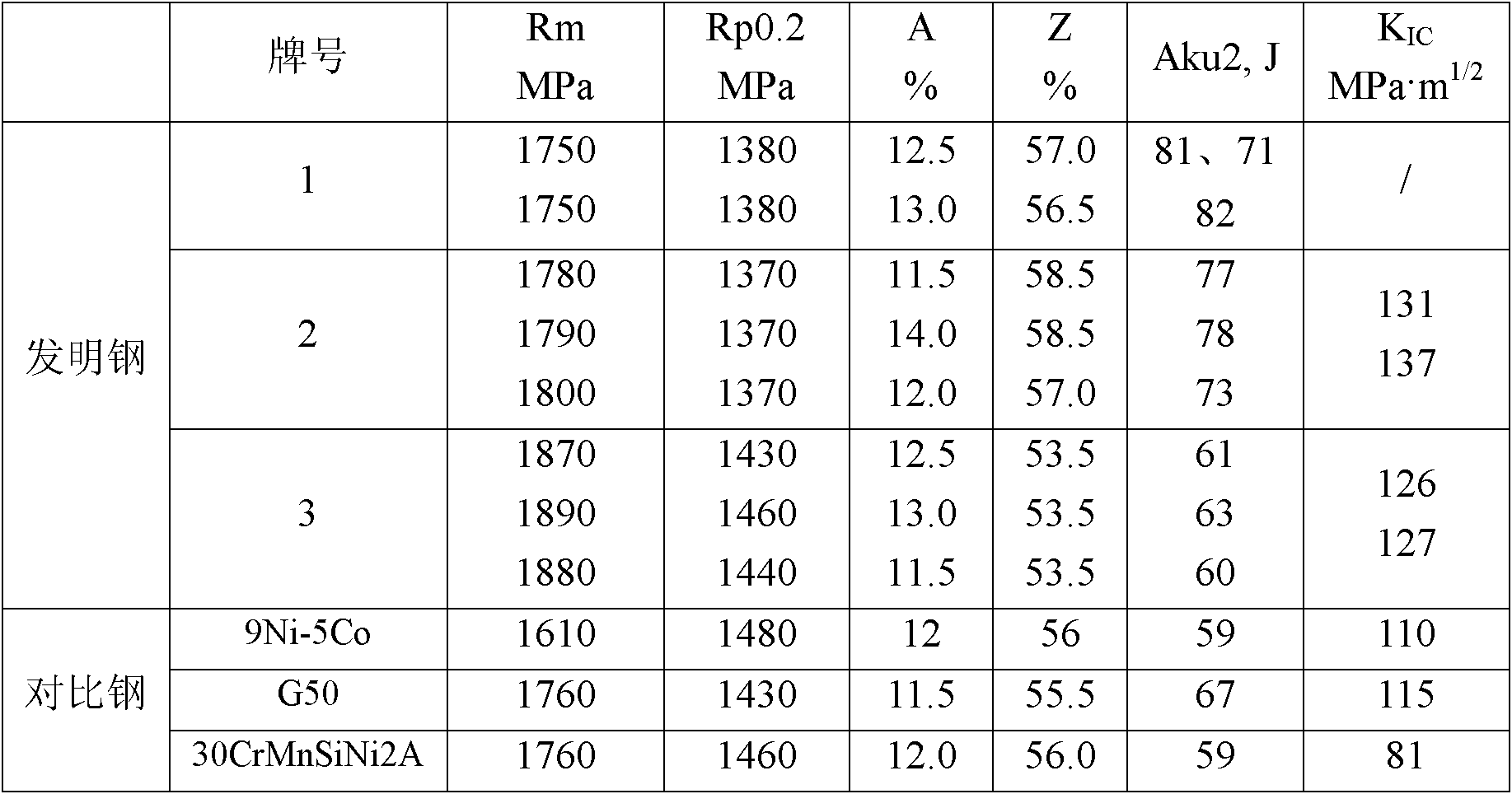

[0019] The steel of the present invention has been smelted in a vacuum induction furnace, and the chemical composition is shown in Table 2. The tensile properties, impact toughness and fracture toughness have been measured with smooth tensile specimens, U-shaped notch impact specimens and three-point bending specimens, and compared with The mechanical properties of the steels were compared, and the relevant results are shown in Table 3.

[0020] It can be seen that the strength and toughness level of the invention steel is significantly higher than that of the high-cost 9Ni-5Co (F175), and even higher than that of the double vacuum smelting (vacuum induction furnace smelting + vacuum self-consumption remelting) G50 steel, which is particularly noteworthy What is remarkable is that the cost of the steel material of the invention is equivalent to that of 30CrMnSiNi2A, but its strength and toughness are significantly higher than that of 30CrMnSiNi2A ultra-high strength steel, espe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com