Patents

Literature

5671results about How to "Increase cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

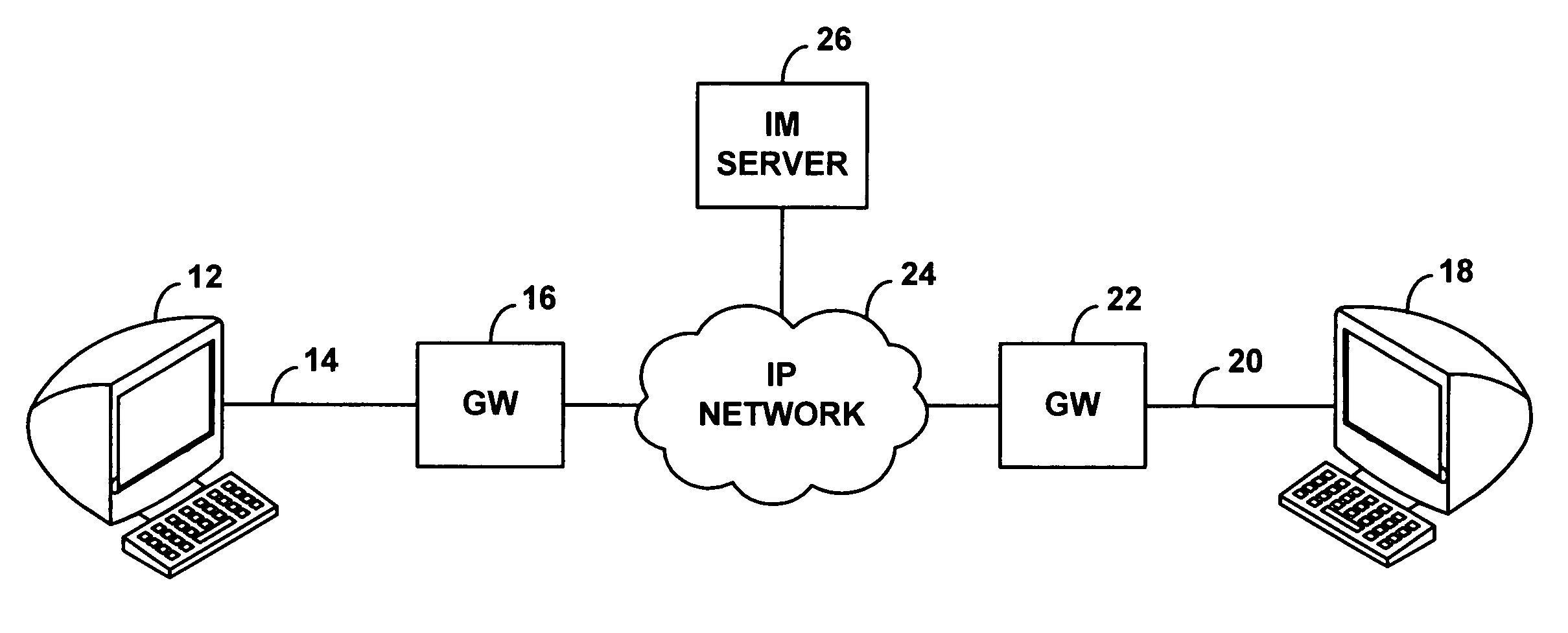

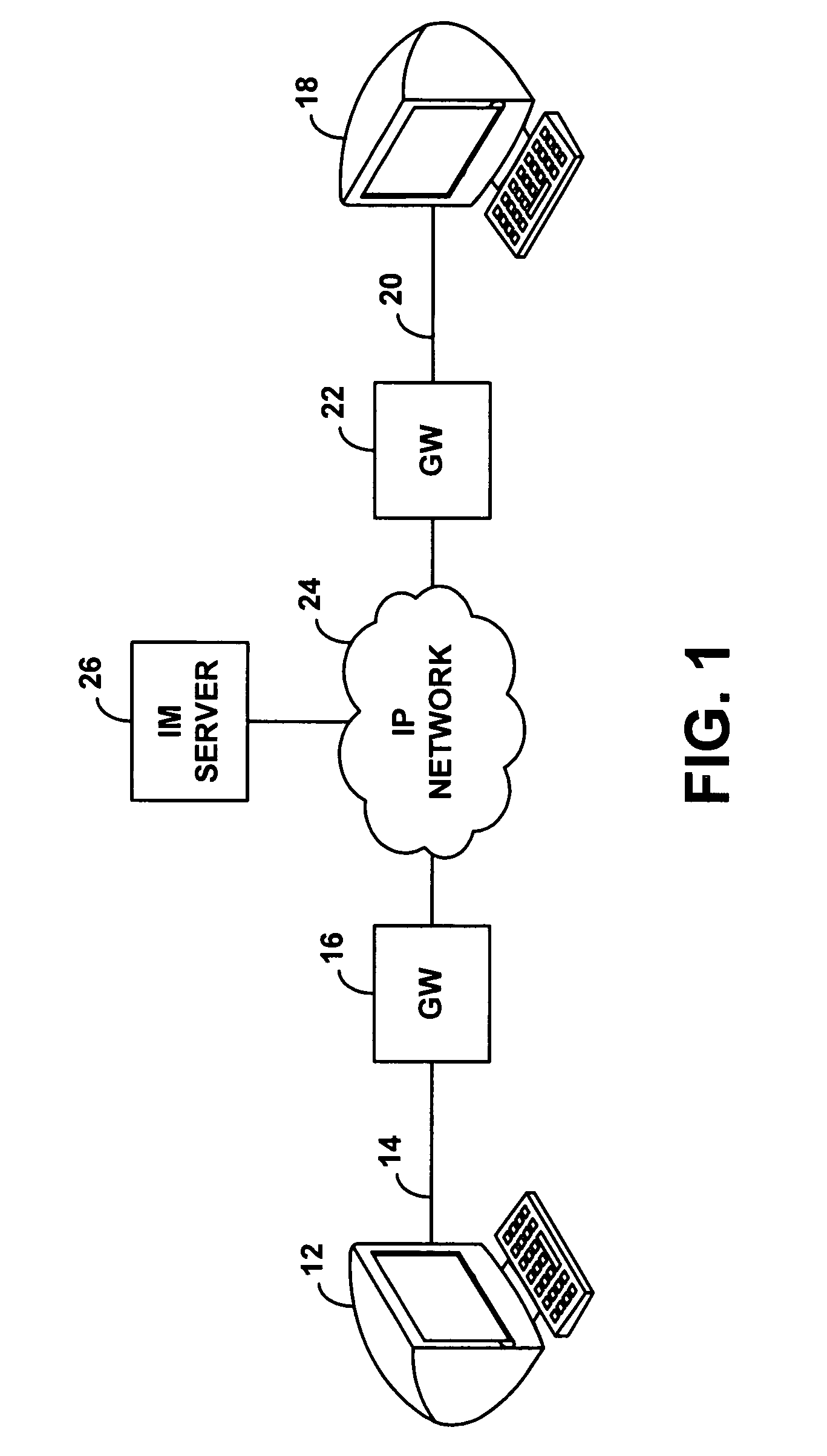

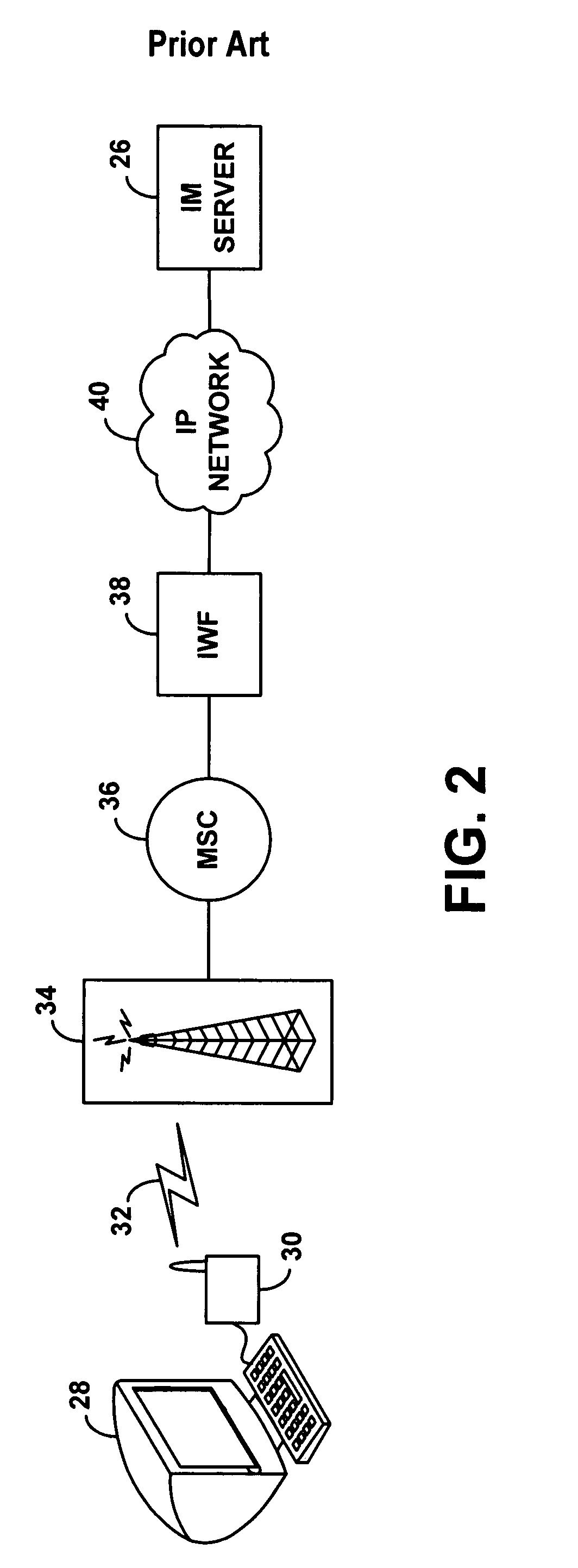

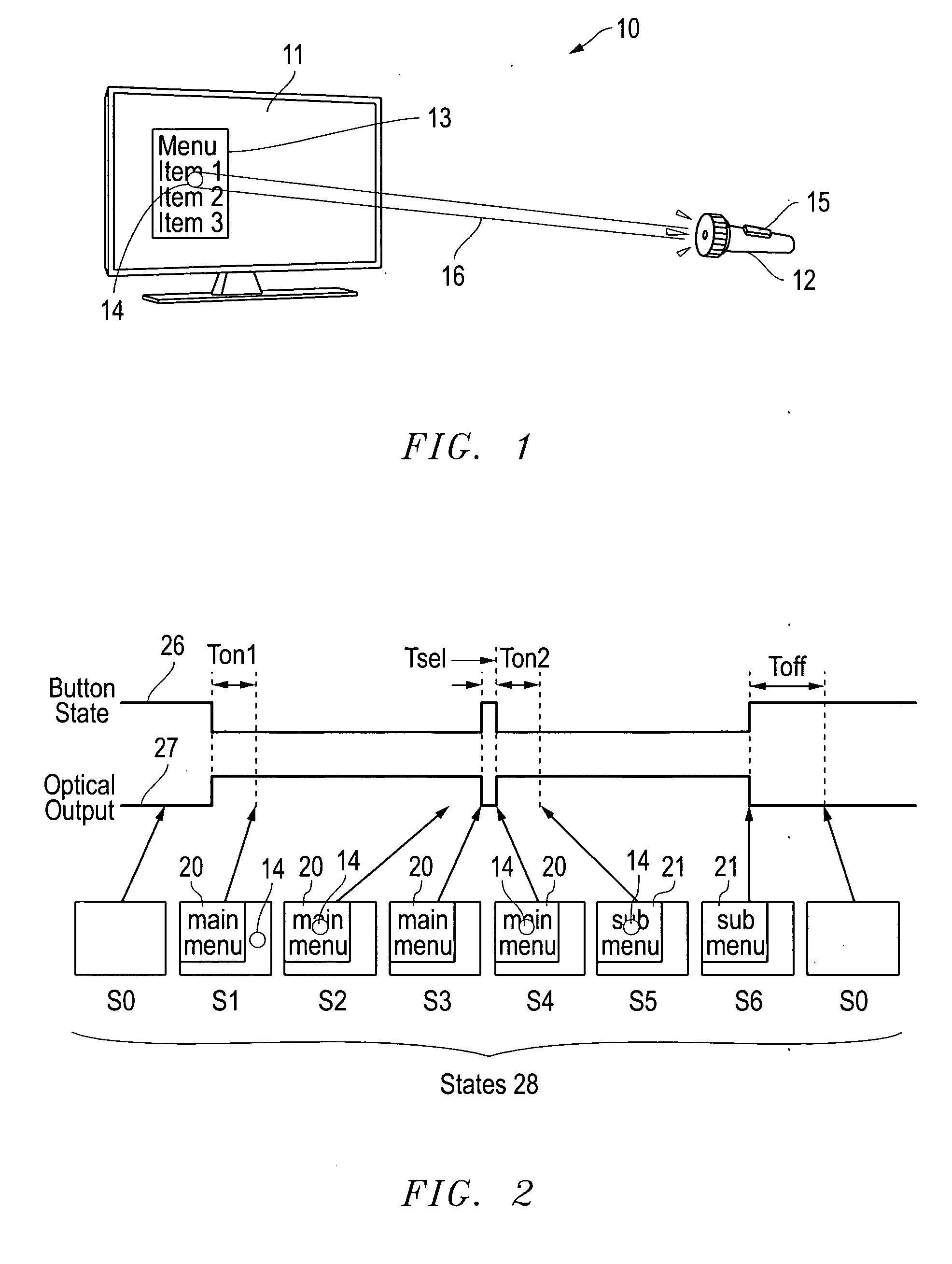

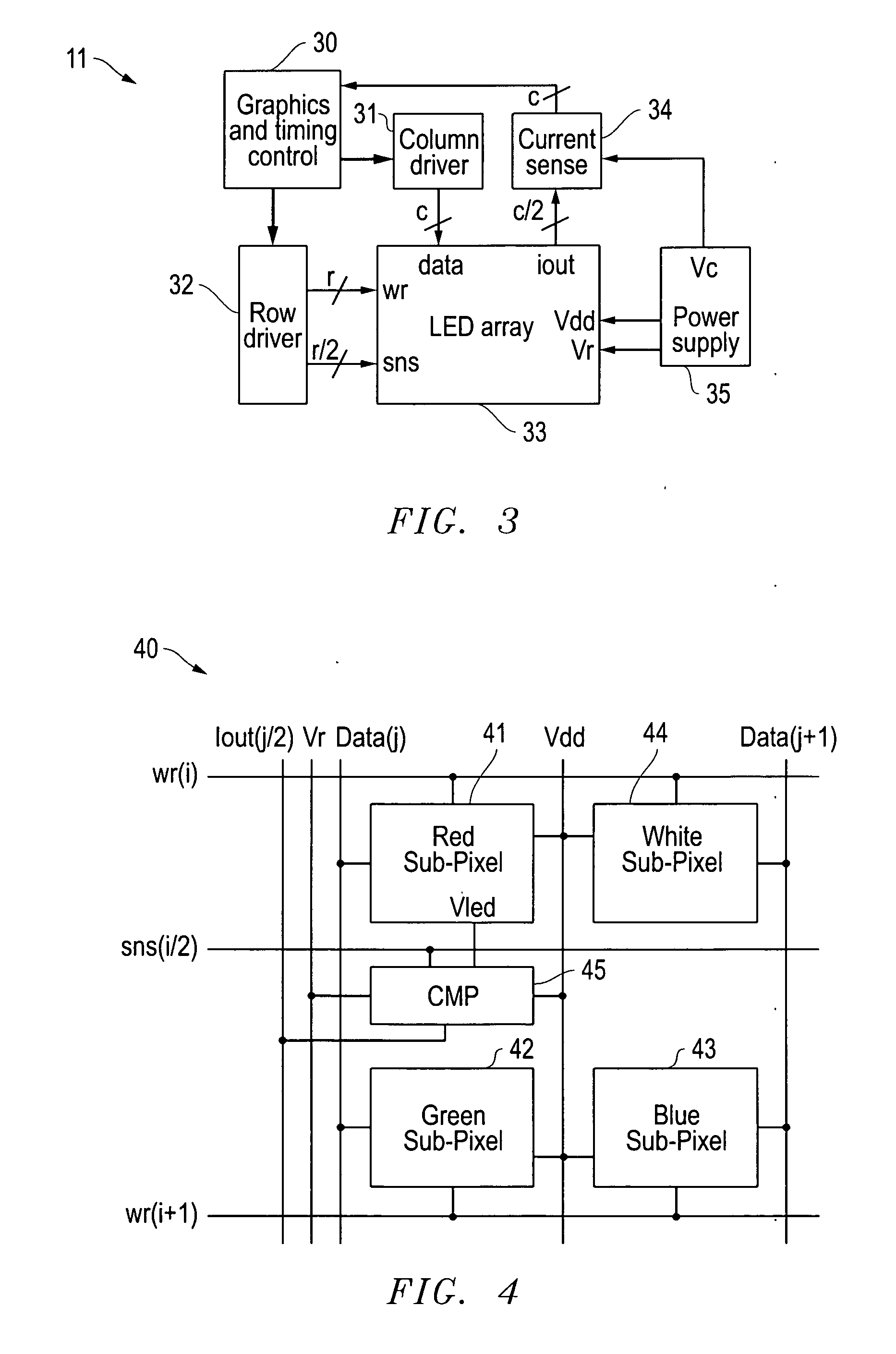

Method and system for wireless instant messaging

InactiveUS7058036B1Increase demandIncreased complexityAutomatic call-answering/message-recording/conversation-recordingData switching by path configurationText entryComputer terminal

A wireless instant messaging system is disclosed. A mobile station (MS), such as a cellular telephone for instance, may be registered with an instant messaging (IM) server as being available to receive instant messages via an IM proxy. A user at an IM client terminal may then send an instant message destined for a user at the MS. The IM server may direct the message to a service node (SN), which may convert the message into an industry standard SMS message and send the SMS message to the MS. At the MS, a user may read the SMS message and engage a callback feature, which will establish a dial-up voice connection between the MS and the SN. The user at the MS may then speak an instant message response, and the SN may record the response as a compressed audio file. The SN may then send the compressed audio file as an attachment to an instant message back to the user at the IM client terminal. The IM client terminal may then play the spoken response message. The invention facilitates robust instant messaging communication, while avoiding the need for a user at the mobile station to engage in cumbersome text entry via a numeric keypad.

Owner:SPRING SPECTRUM LP

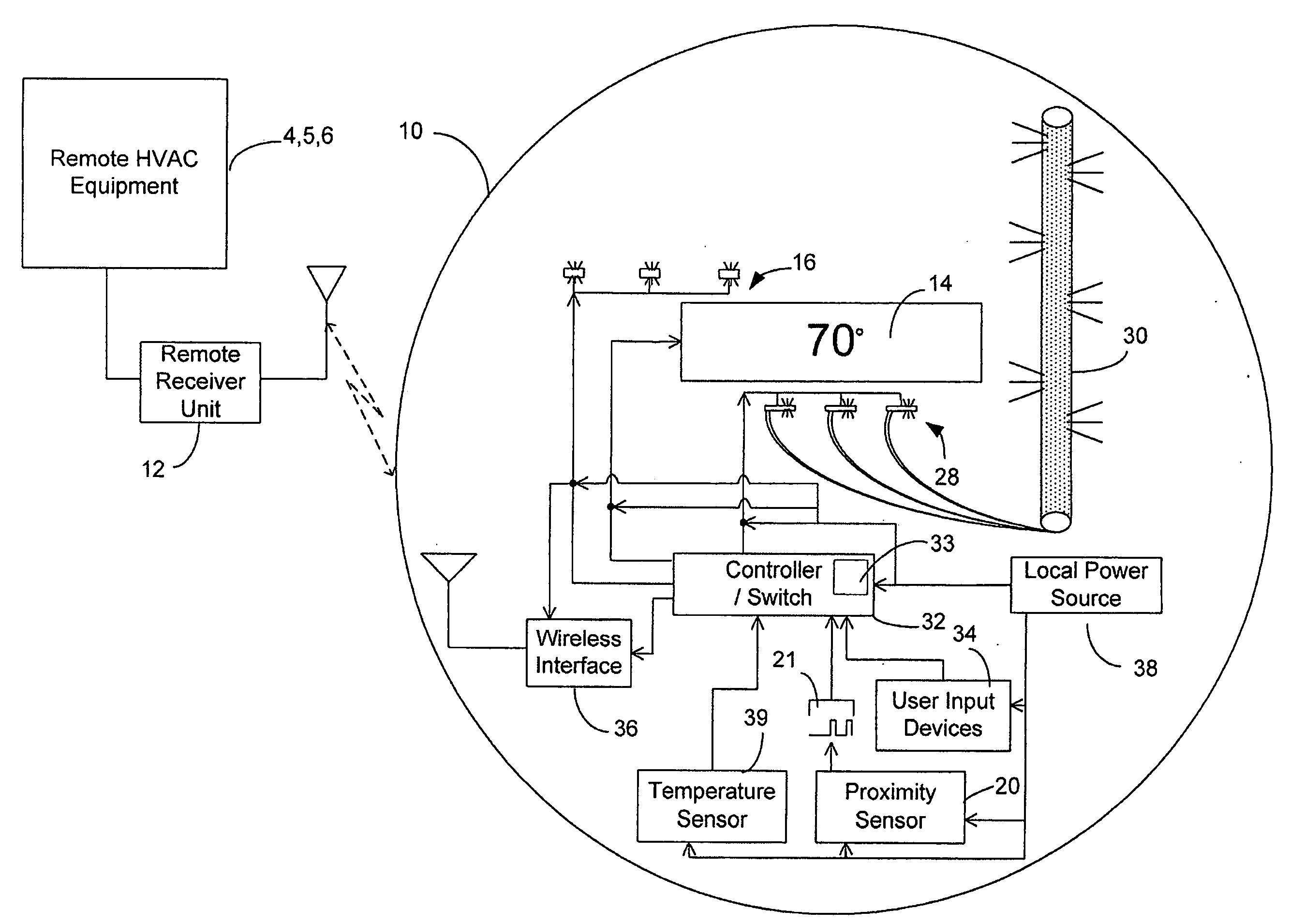

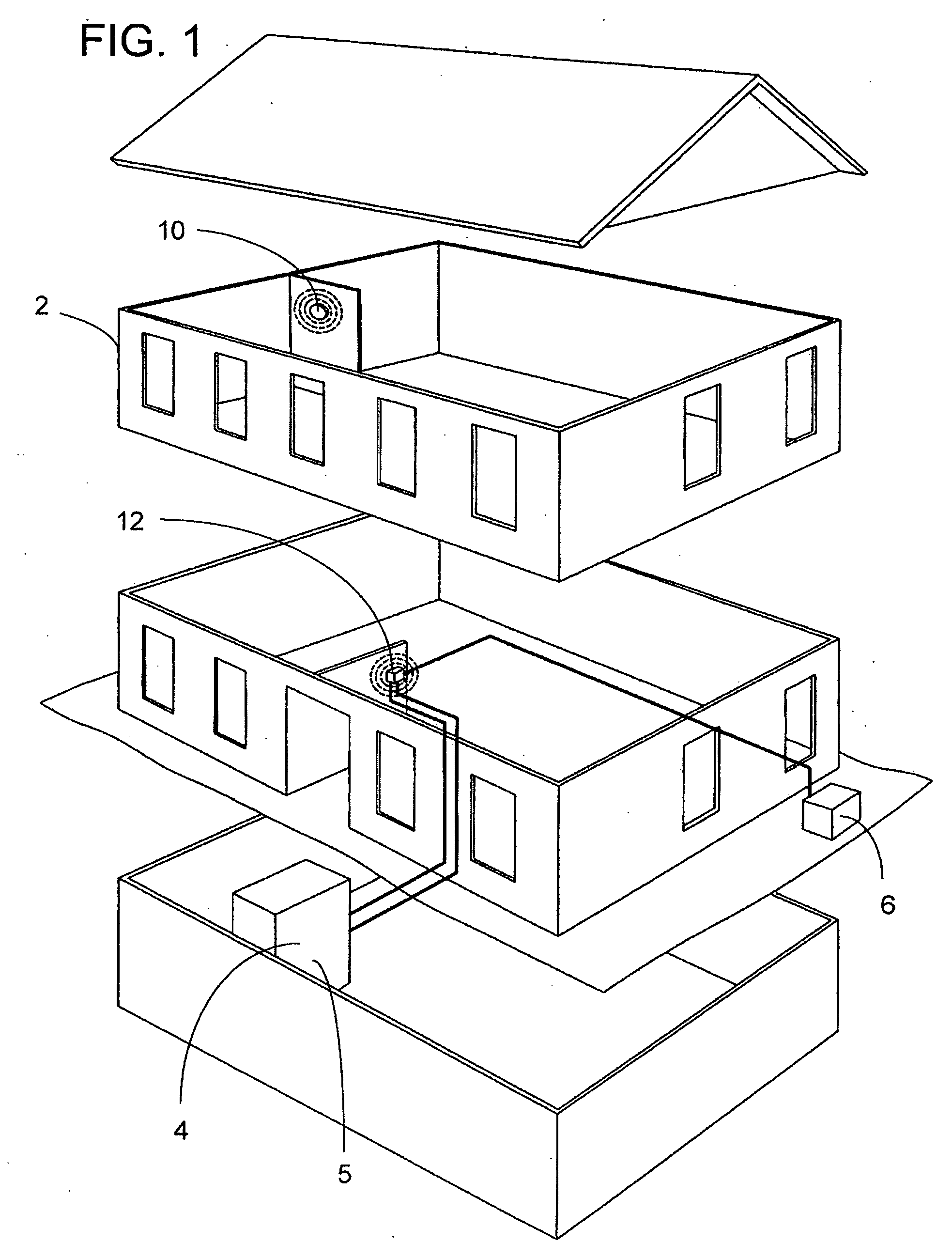

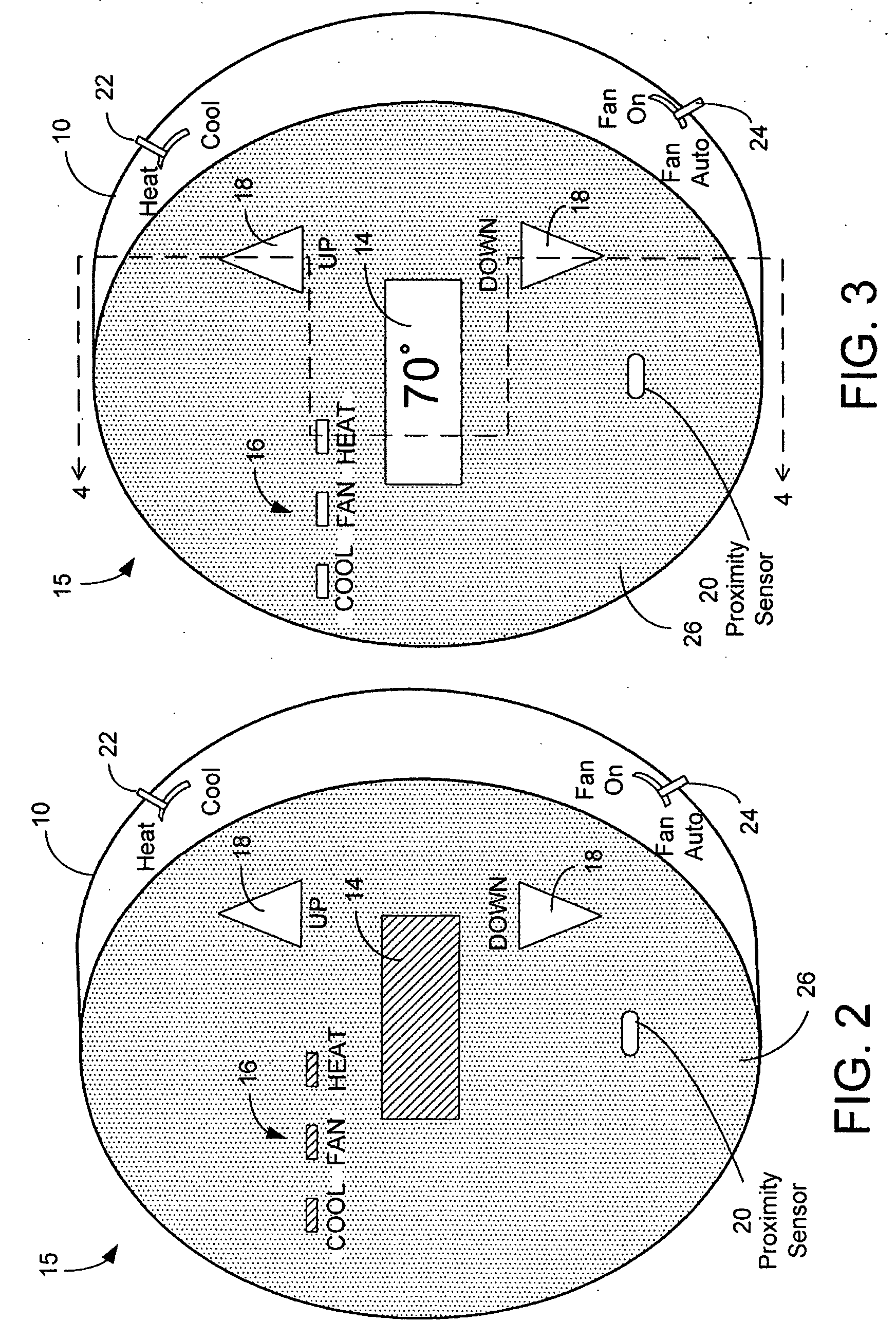

Management of a thermostat's power consumption

InactiveUS20070241203A1Reduce energy consumptionAdditional level of power conservationTemperature control without auxillary powerMechanical apparatusProximity sensorUser input

An HVAC system comprises a programmable wireless thermostat and a remote receiver unit. The thermostat includes a user interface having one or more displays, user input devices, such as buttons, sliders, or a touch screen, and a backlight. The thermostat may include a proximity sensor, wherein the user interface is controlled based on a user's presence near the thermostat. A thermostat controller enters into a reduced energy consumption mode and switches the user interface to an idle state when the proximity sensor indicates a lack of user proximity for a predetermined duration. When the proximity sensor indicates user proximity, the controller exits the reduced energy consumption mode and switches the user interface to an active state. During the reduced energy consumption mode, the user interface may be concealed when the user interface is in a housing which is transparent when backlit but is opaque otherwise.

Owner:RANCO OF DELAWARE

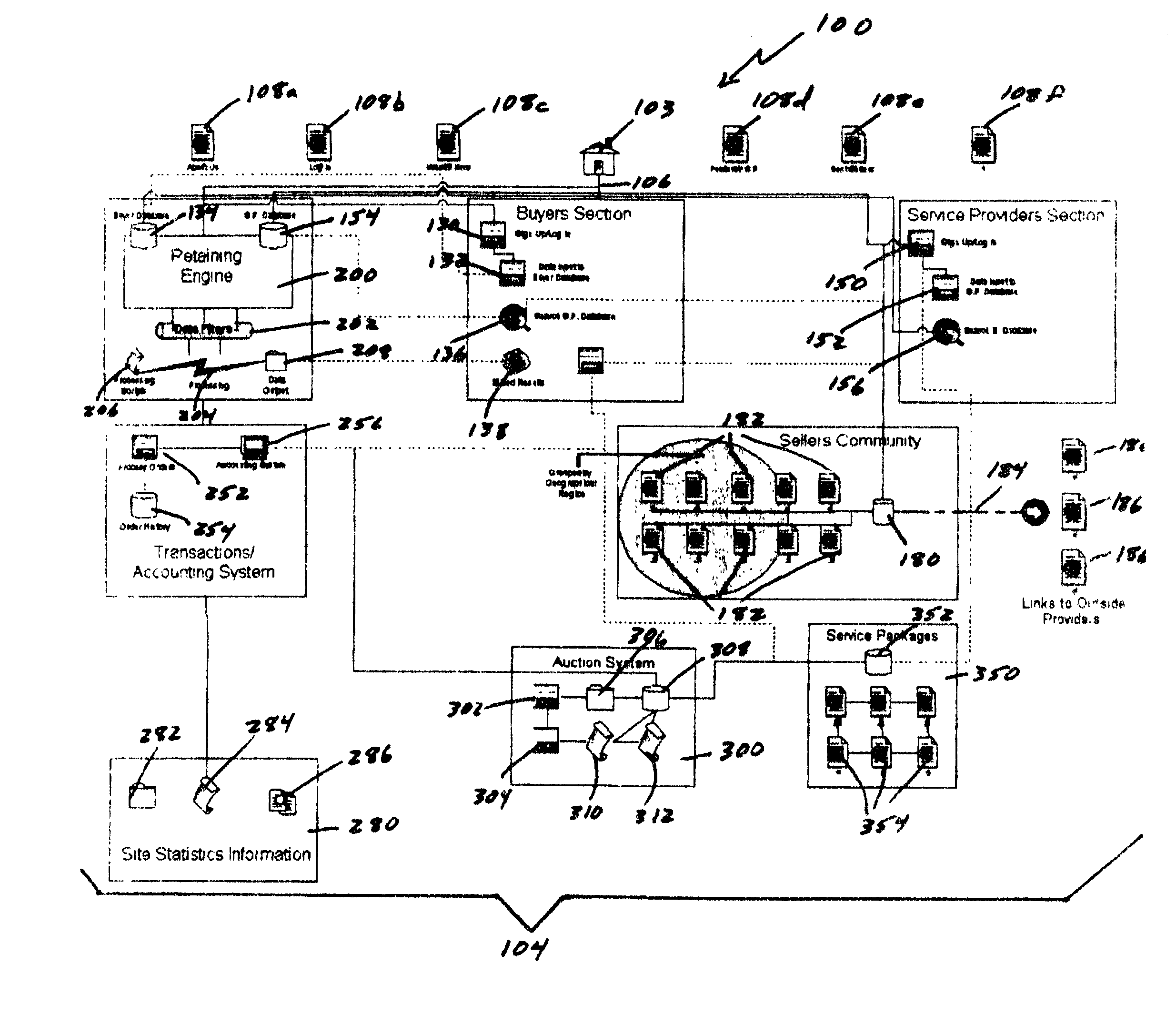

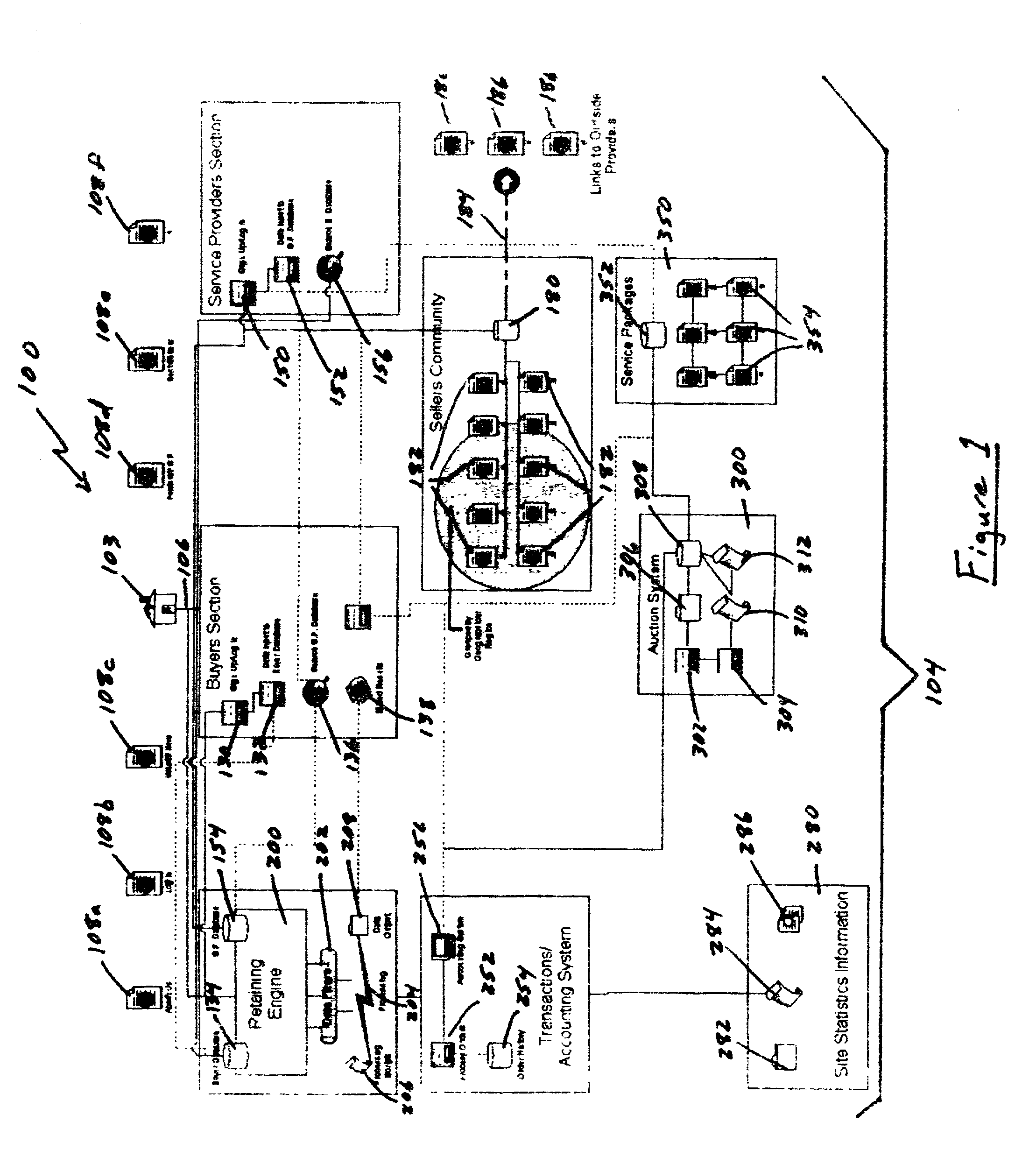

Auction, imagery and retaining engine systems for services and service providers

InactiveUS20020120554A1Facilitates in efficiently accessing latent demandEliminate riskFinancePayment architectureGroup PurchasingService provision

The present disclosure provides a computer-implemented method / system for facilitating communications between service providers and potential customers for services. The computer-implemented method / system provides a marketplace for interactions, both online and off-line, between service providers and potential customers, including purchasing groups, particularly buyer-driven service-related interactions. The marketplace advantageously allows categorization, key word searching, group purchasing, service packaging, data mining, auctions and other commercial features and functionality. The computer-implemented method / system also supports holographic imagery, e.g., in the form of virtual assistants, that facilitates marketplace-related activities. Based on the computer-implemented method / system, service providers are able to efficiently and cost effectively extend the reach of their marketing and promotional activities to a wide range of additional customers, and customers are able to initiate access service providers ideally suited to meet their needs, i.e., buyer-driven commerce, at desirable prices and according to required timeframes.

Owner:VEGA LILLY MAE

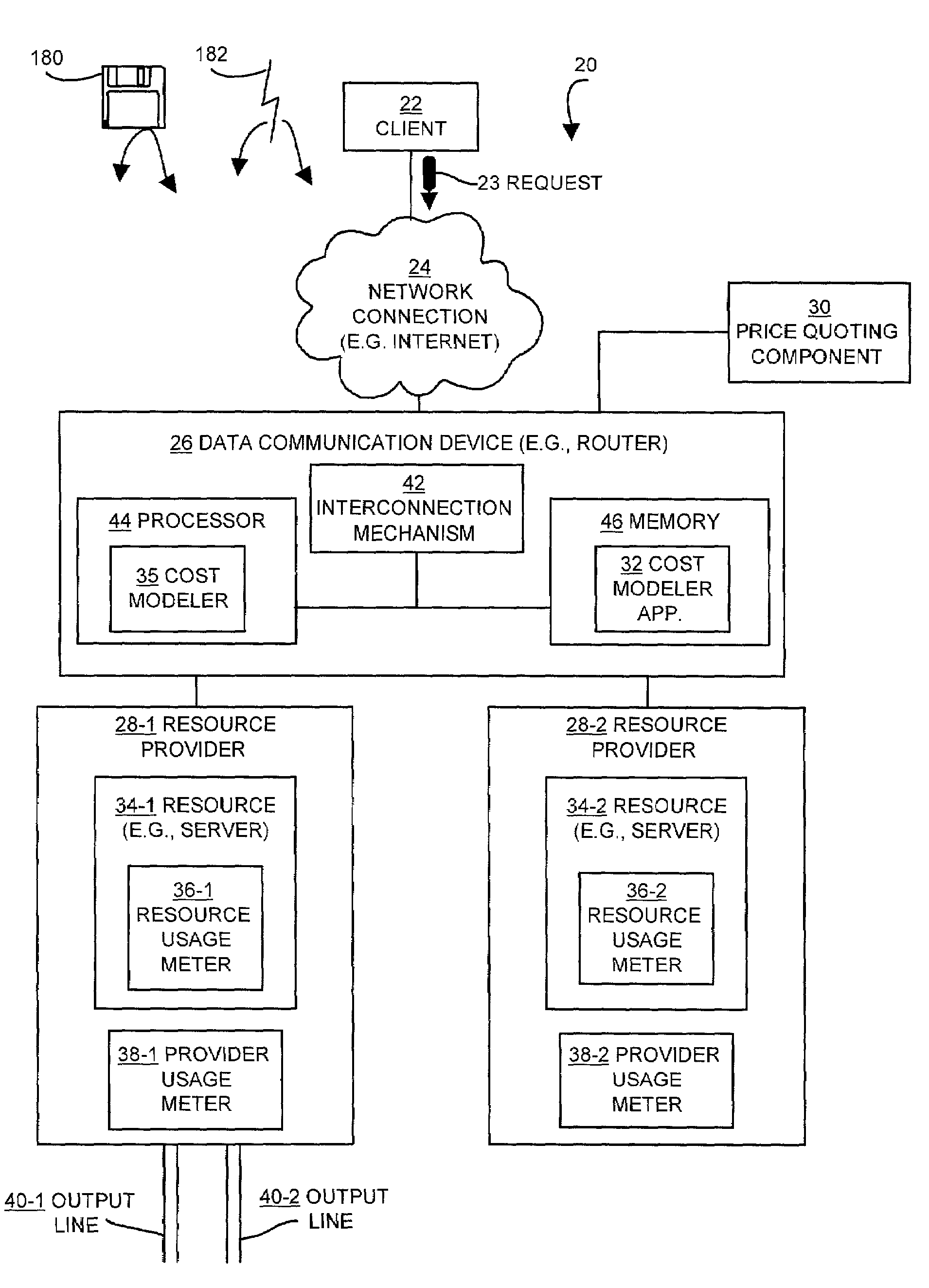

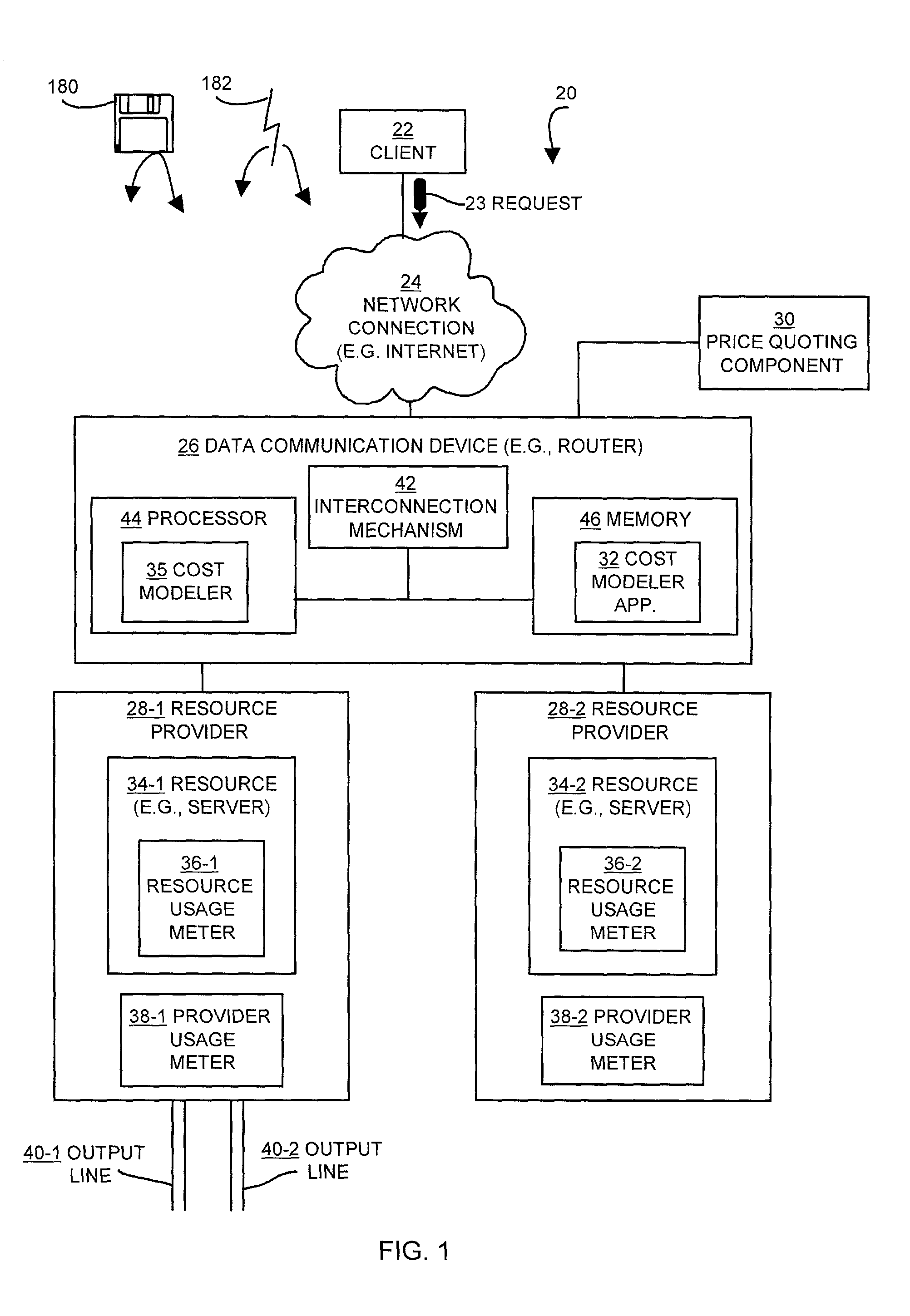

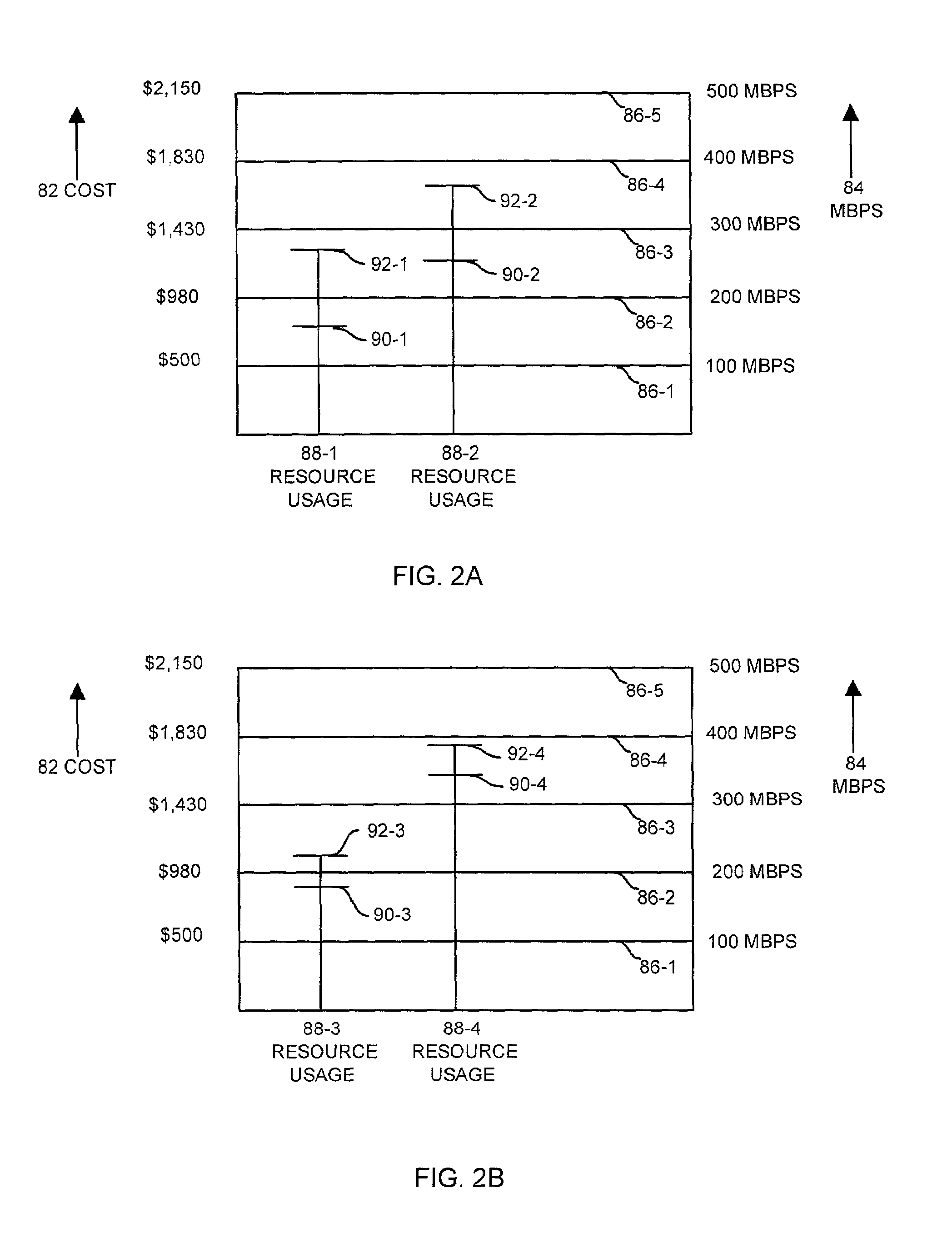

Methods and apparatus for selecting a server to process a request

InactiveUS7320131B1Cost incrementLow costMultiprogramming arrangementsComputer security arrangementsPeak valueClient-side

The invention is directed to techniques for selecting a resource from several resources to process a request from a client. A client sends the request to a data communications device (e.g., network device or switch), which measures usage information from usage meters associated with each resource (e.g., server). The data communications device then makes a usage estimate for each server of the increase in usage required for that server to process the request from the client. Then the data communications device selects one of the servers depending on the usage estimates required to respond to the client's request. The data communications device can consider other factors such as the current level of usage, past usage, and the increased cost of responding to the request. In addition, the data communications device can consider the peak usage level of each resource already established in a current billing period.

Owner:CISCO TECH INC

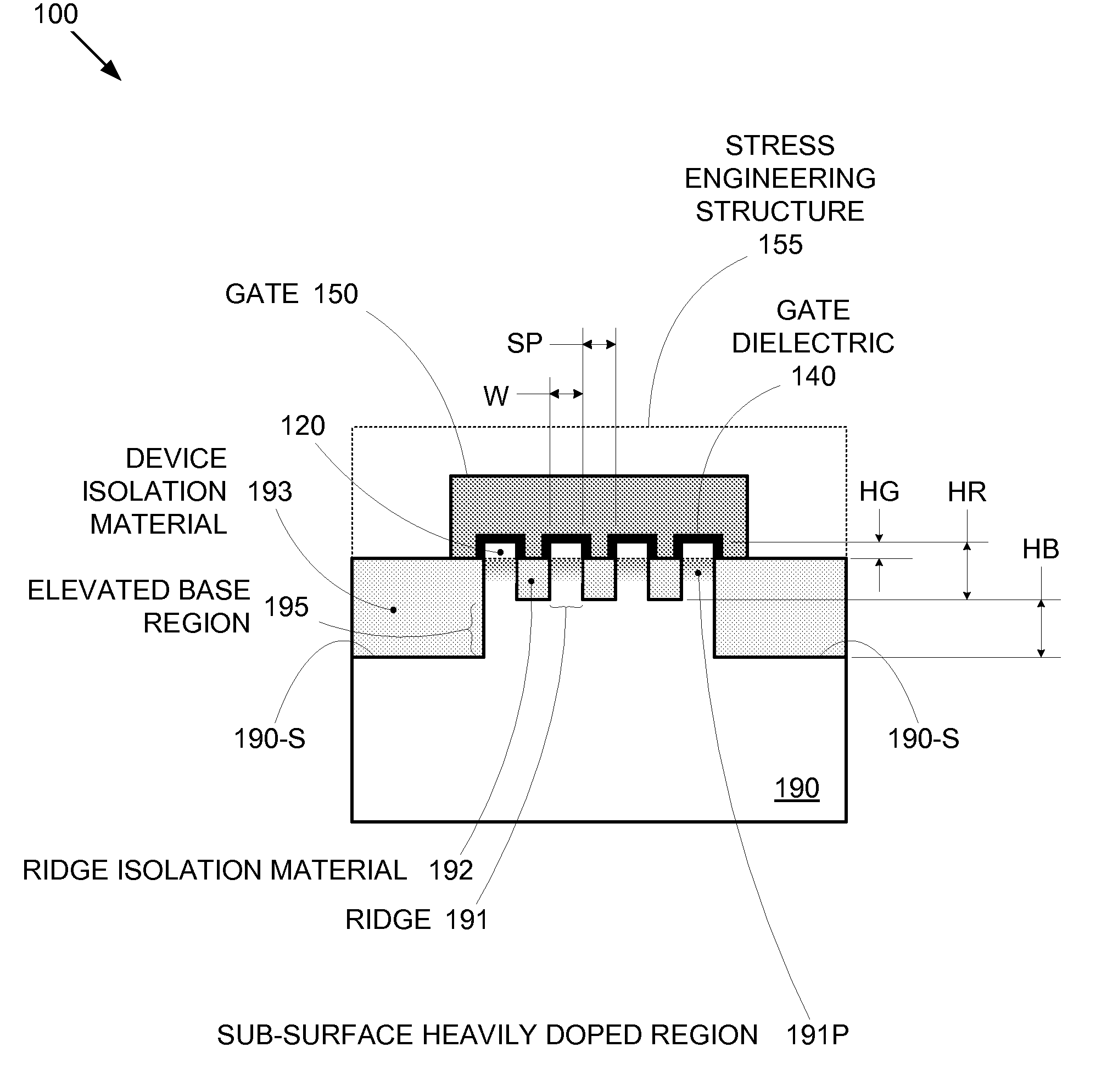

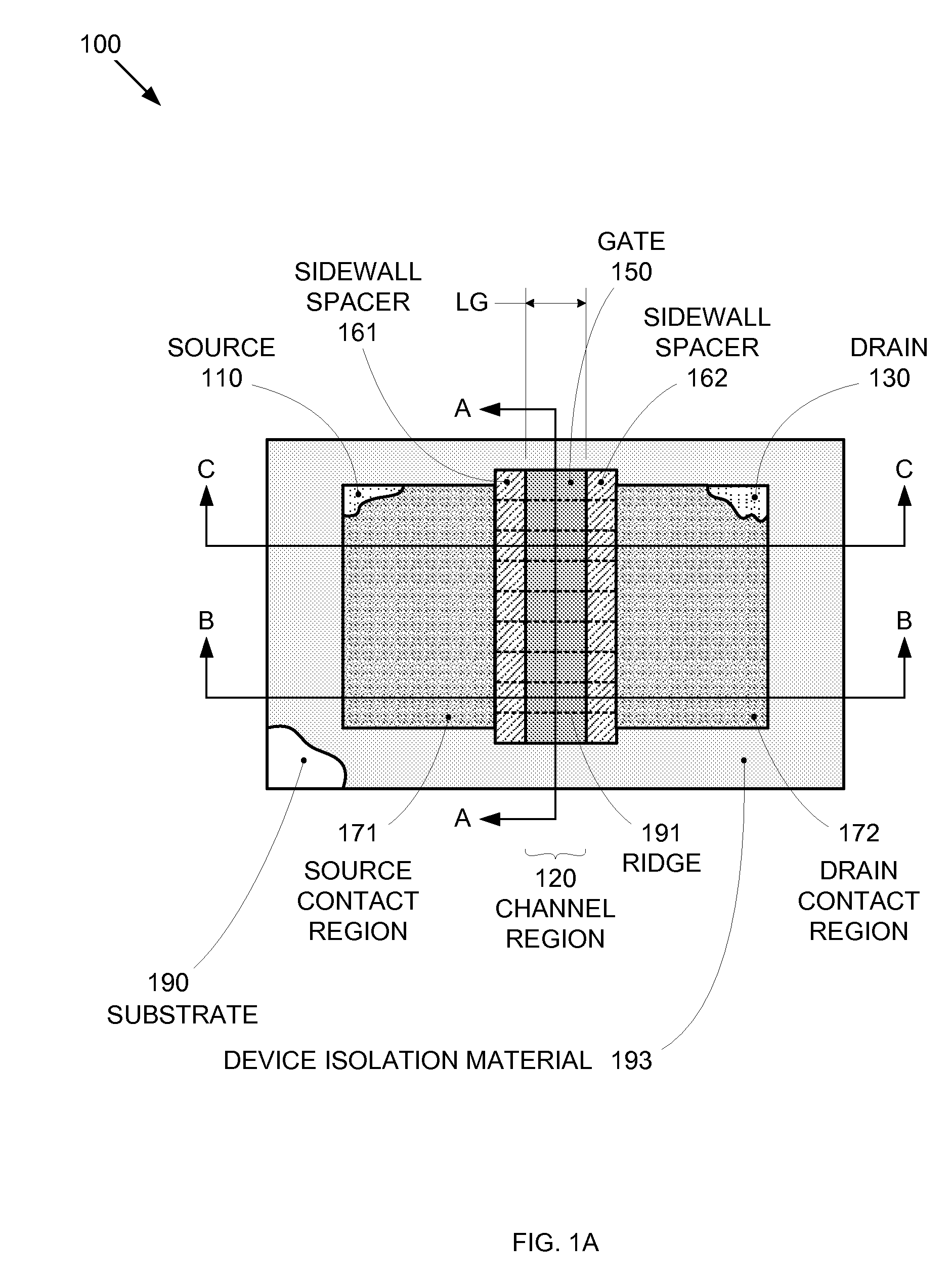

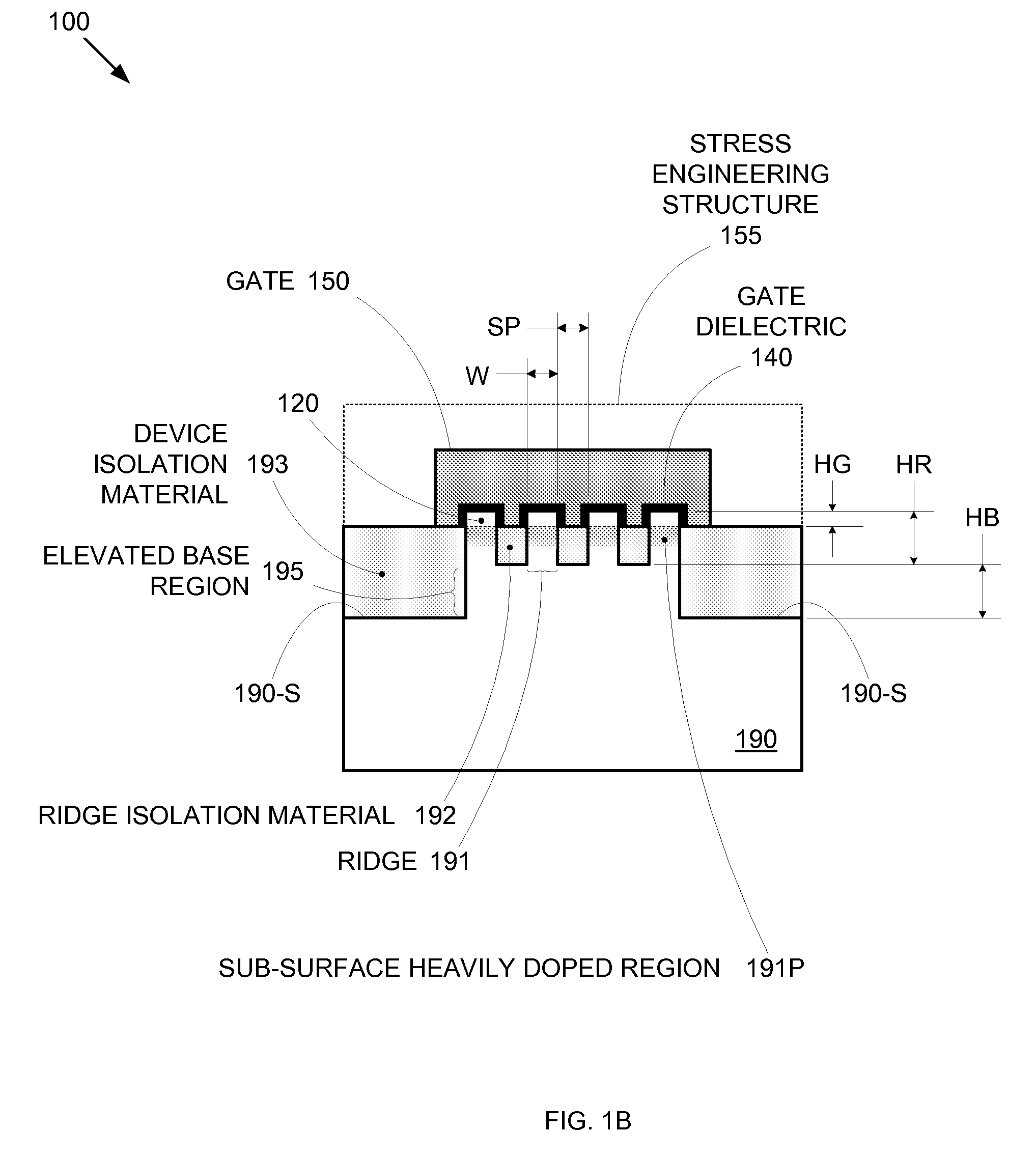

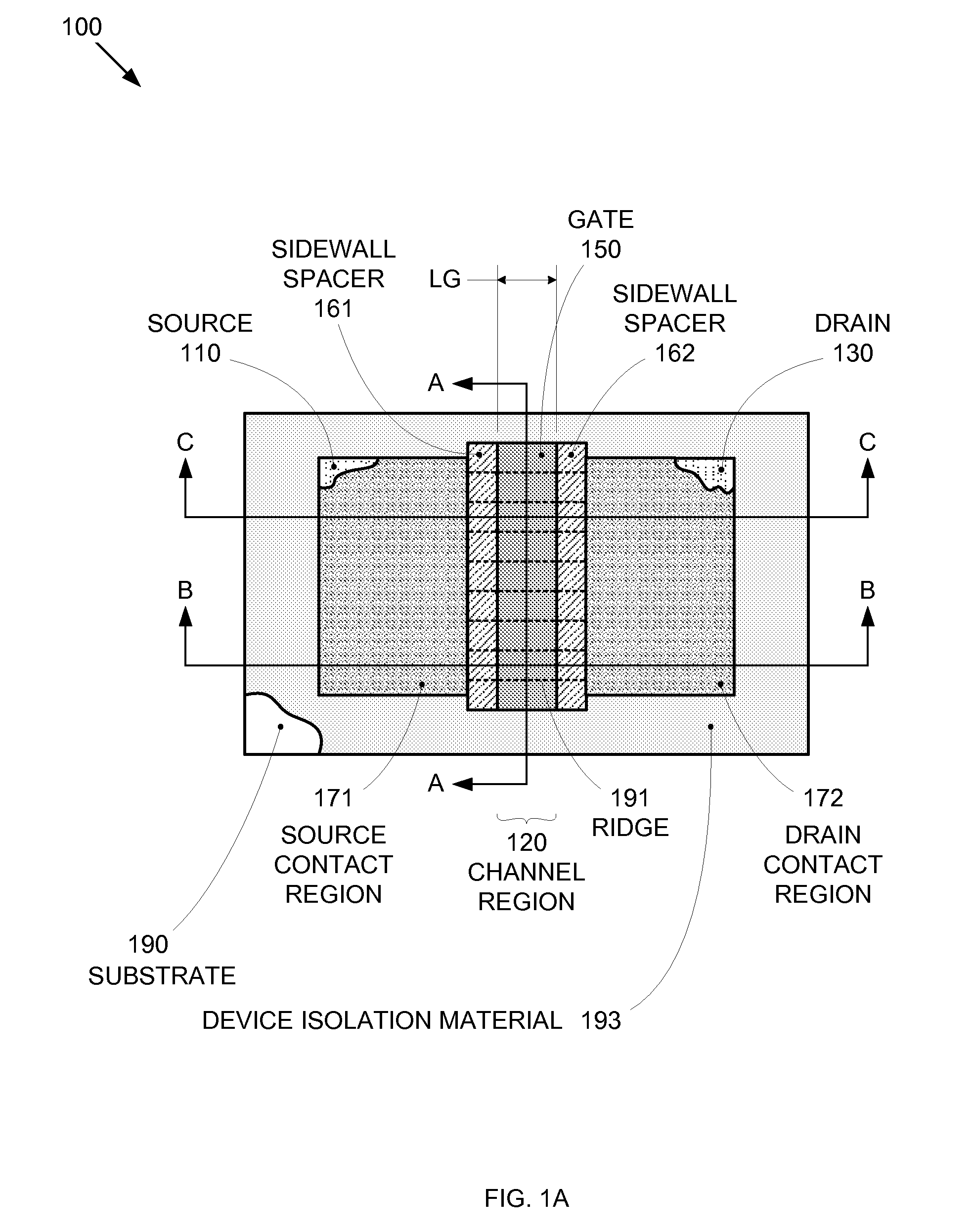

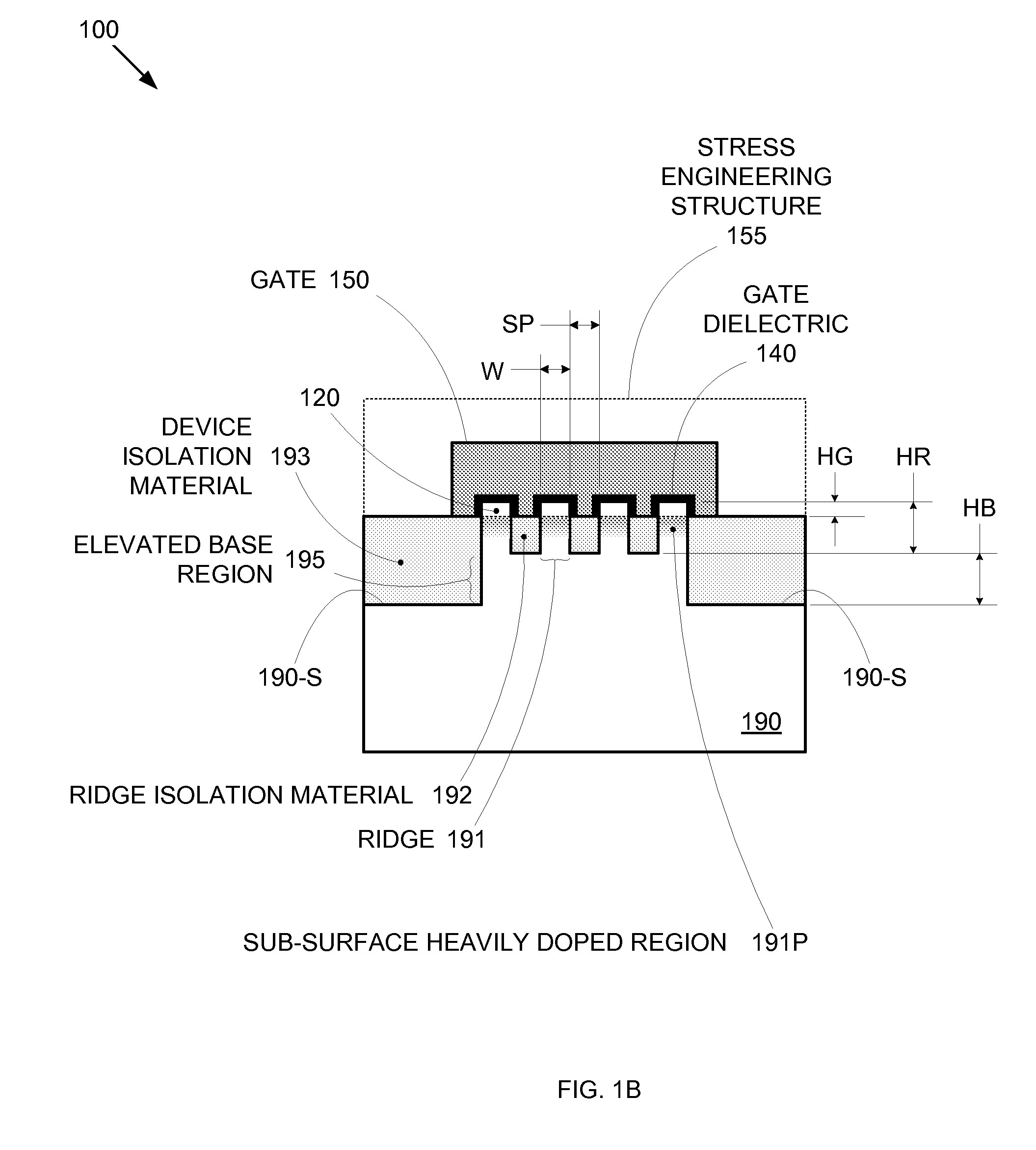

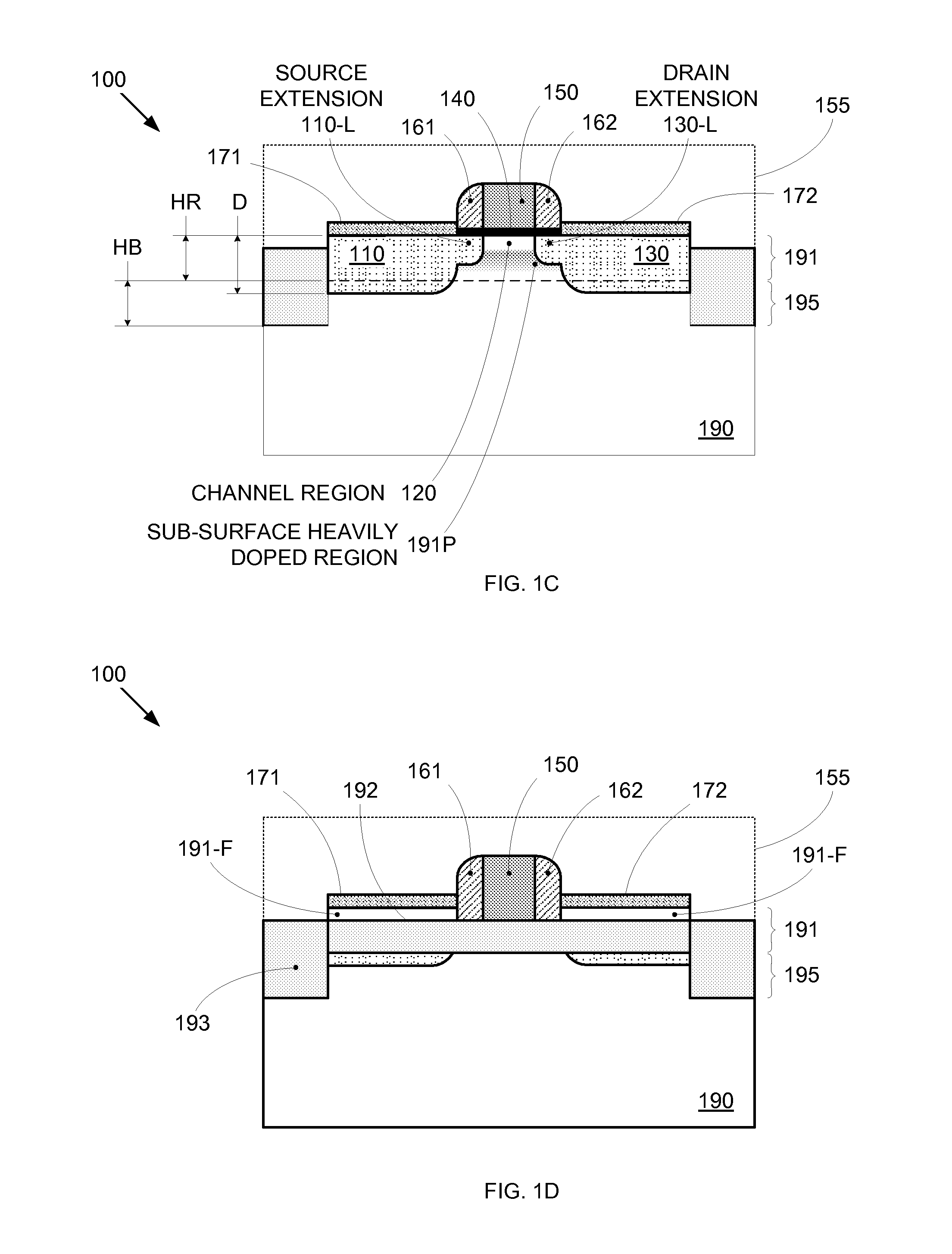

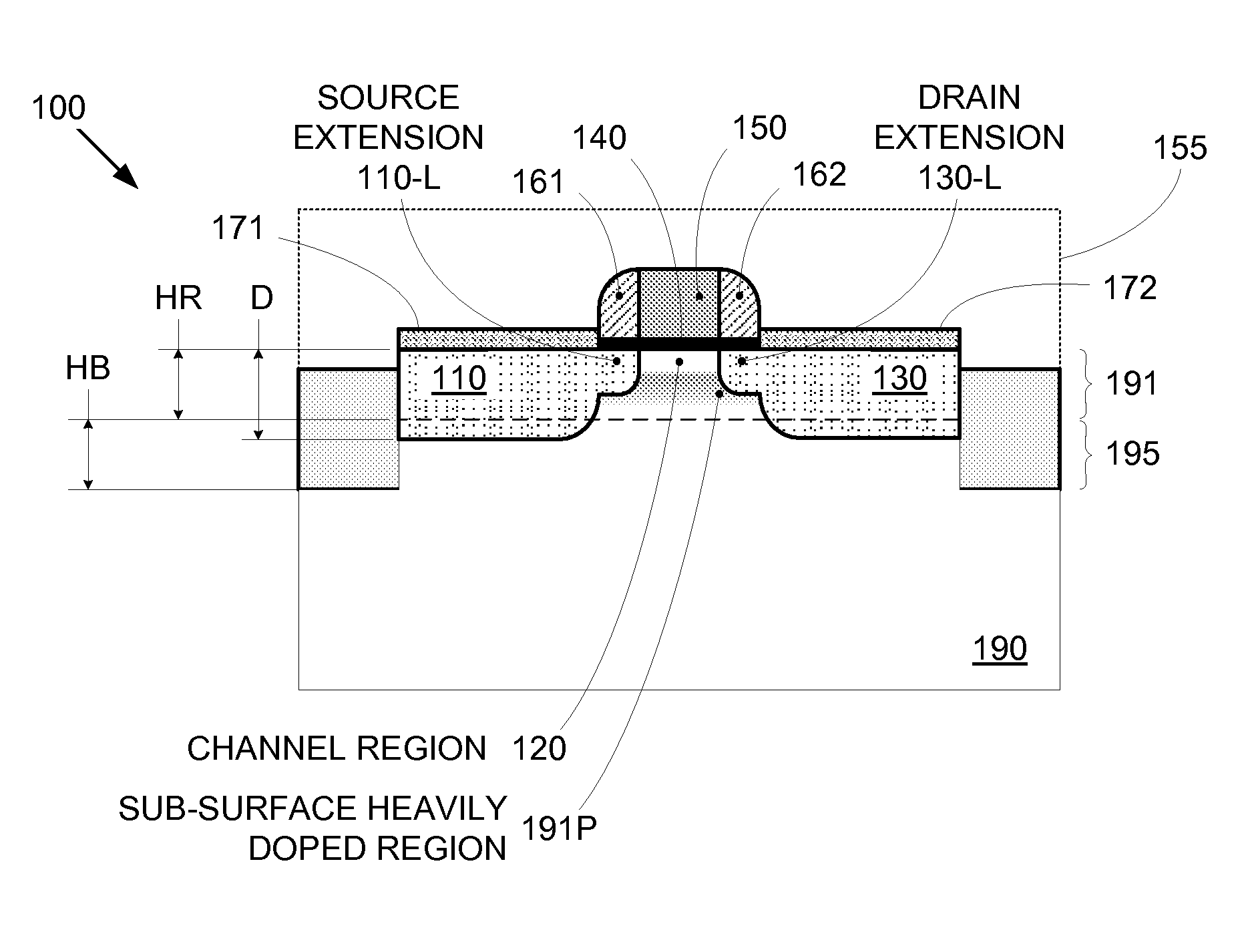

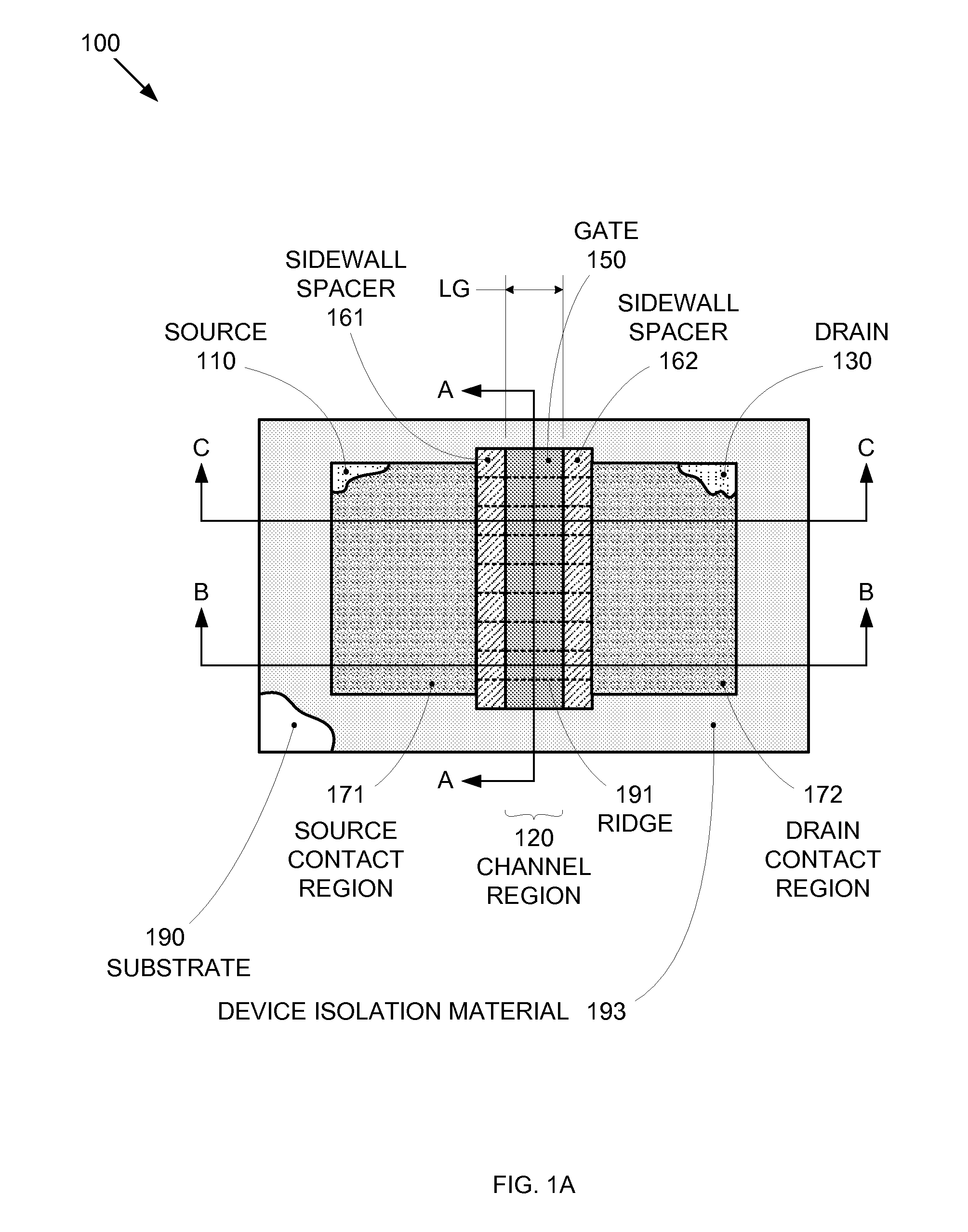

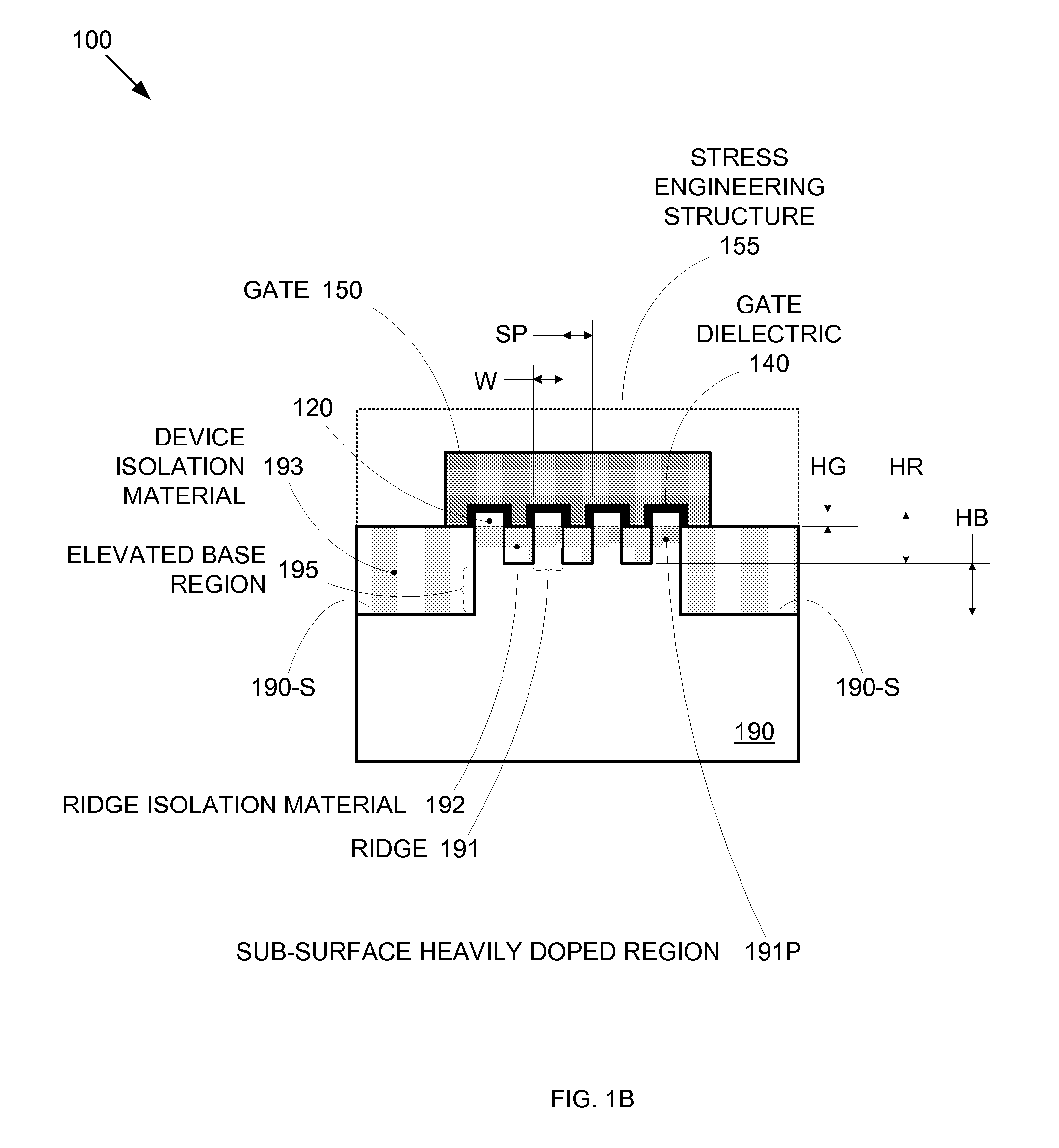

Enhanced Segmented Channel MOS Transistor with Multi Layer Regions

ActiveUS20070120156A1Increase costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Enhanced Segmented Channel MOS Transistor with Narrowed Base Regions

ActiveUS20070128782A1Increase costImprove performanceThyristorSolid-state devicesPre-existingImage resolution

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

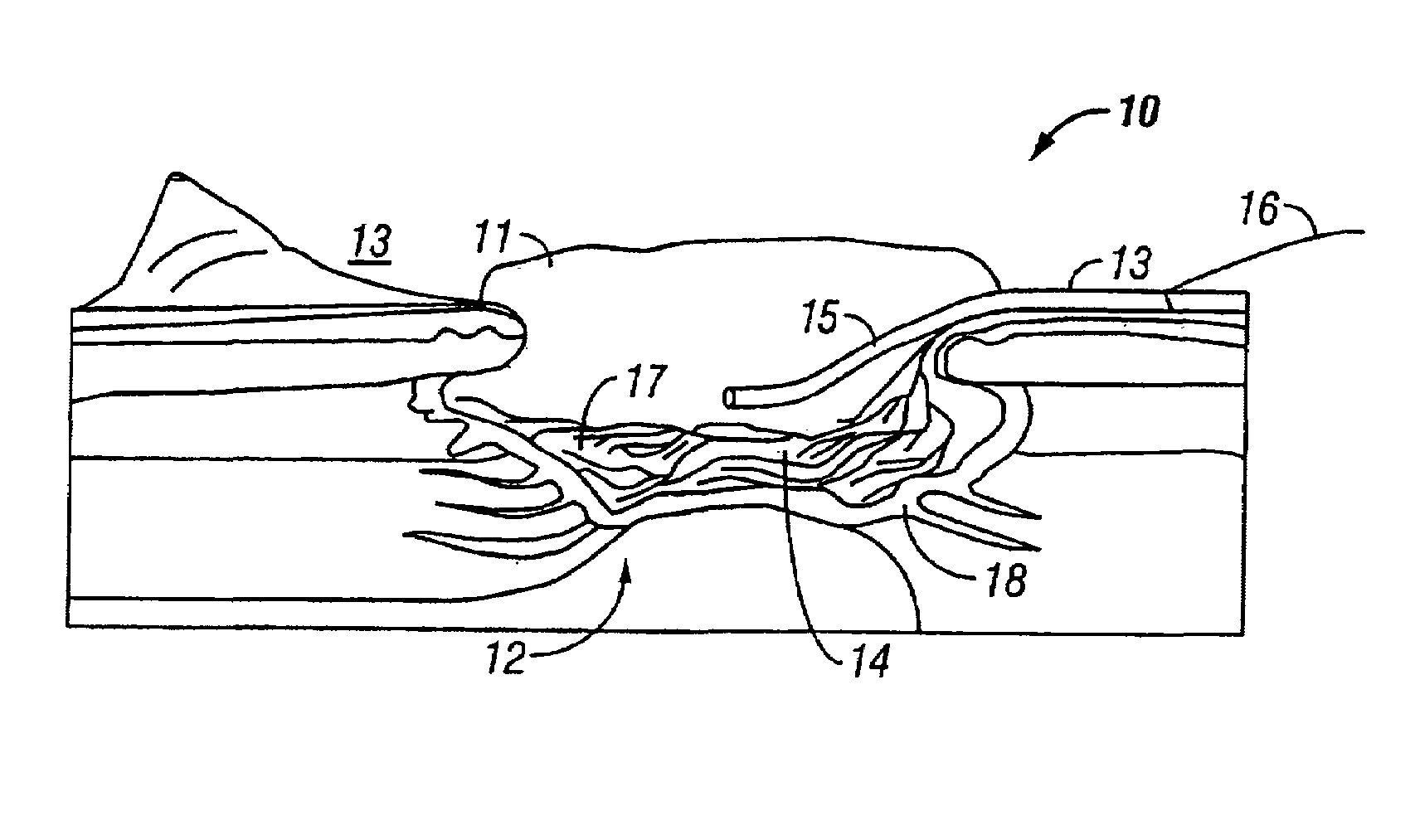

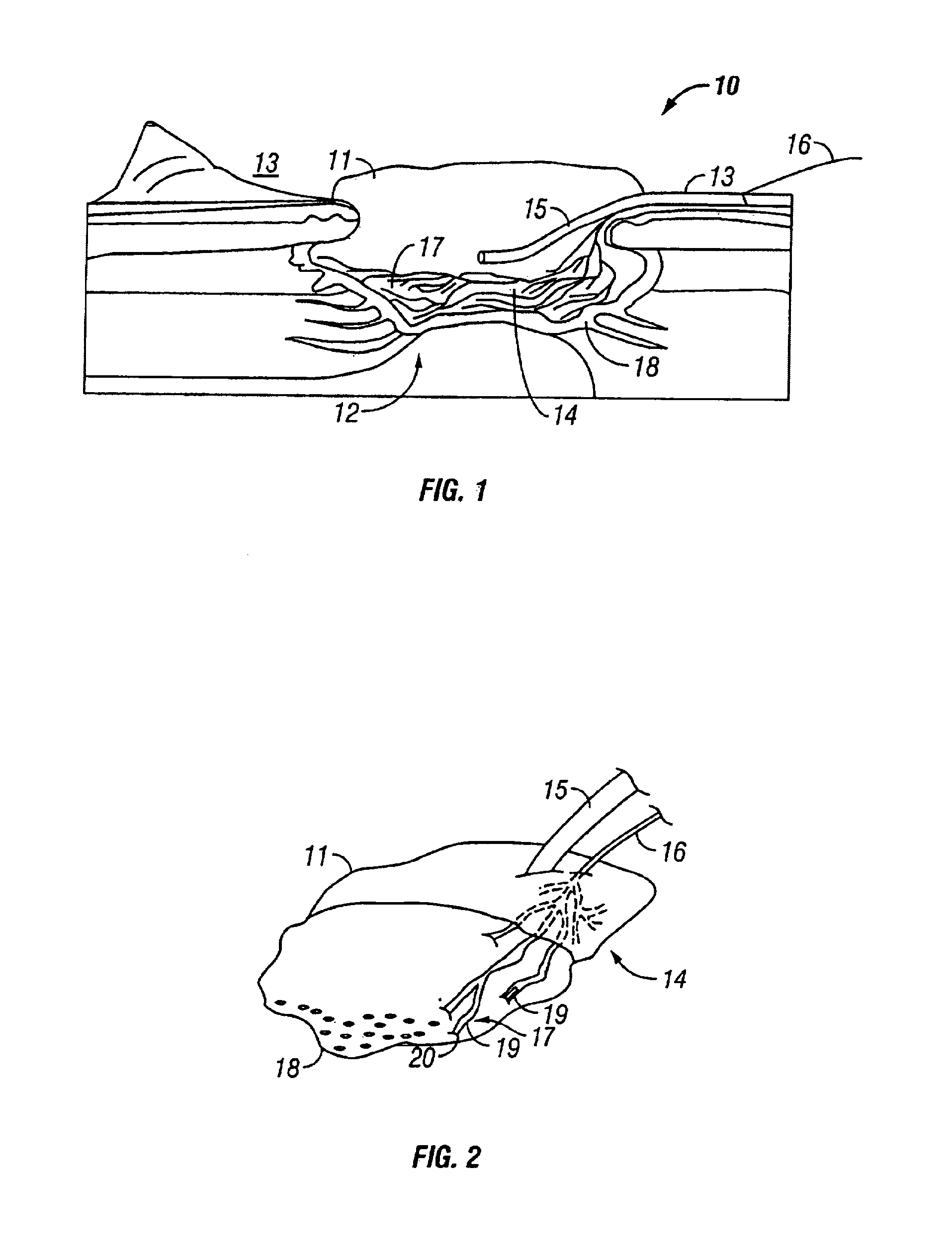

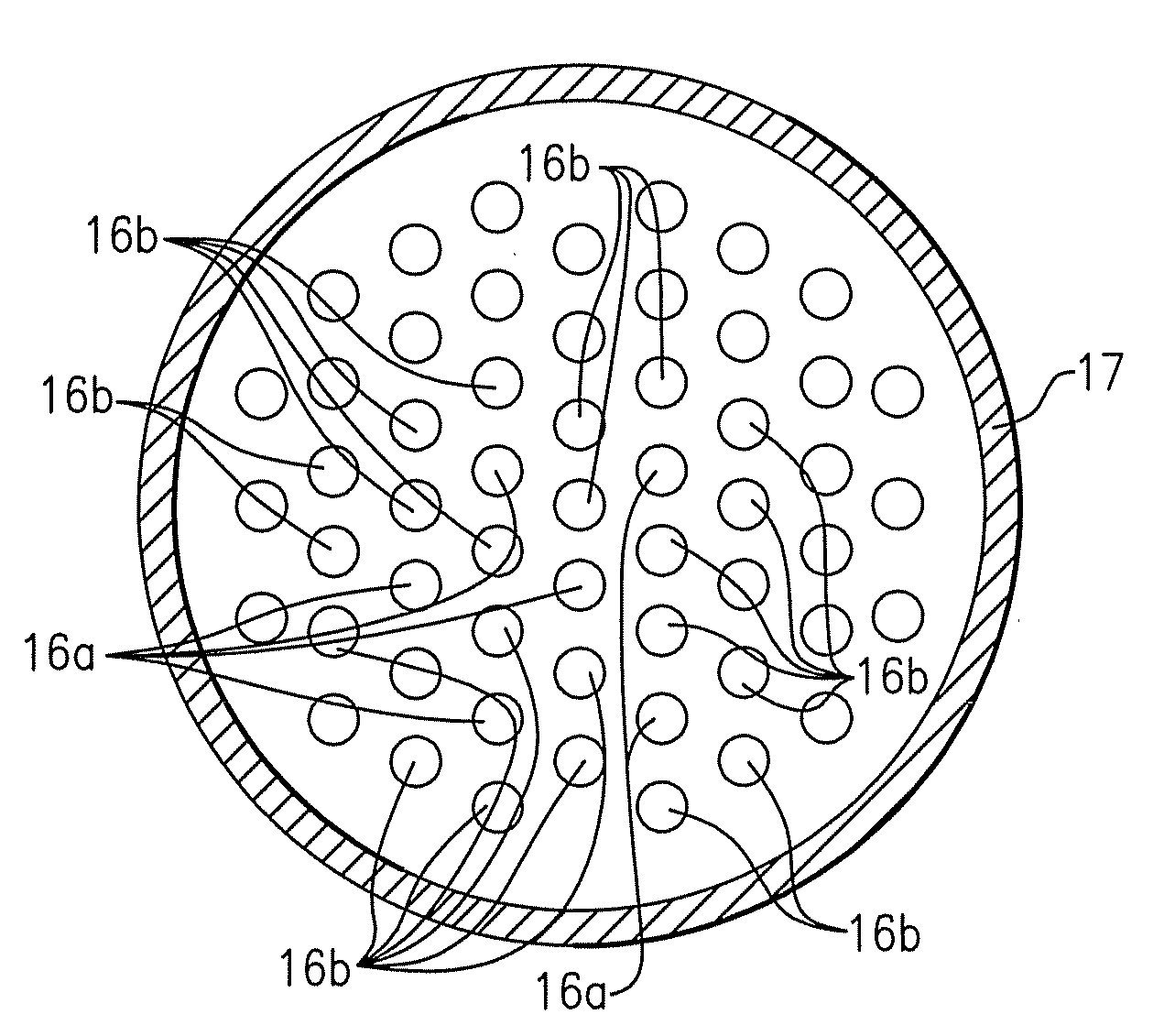

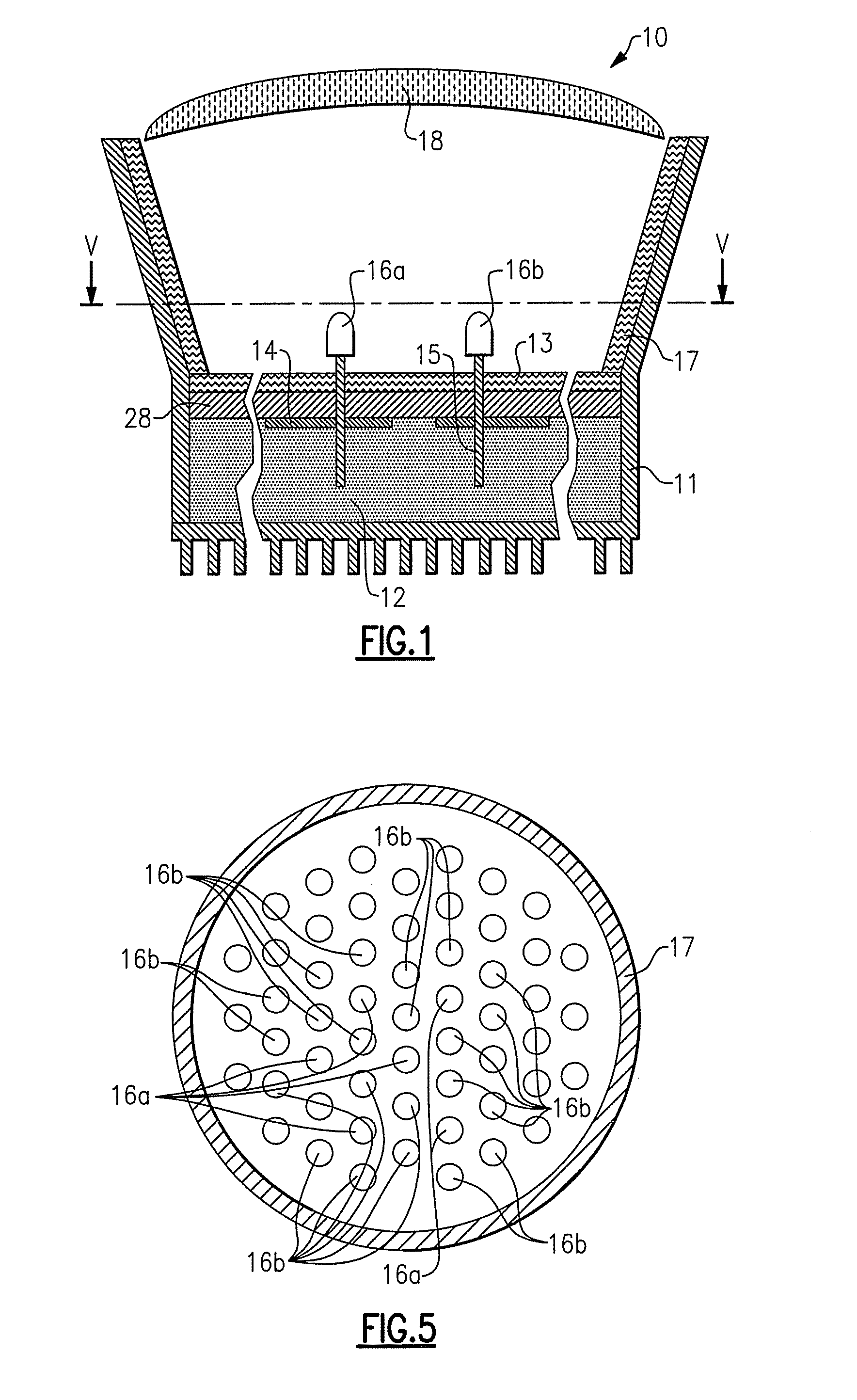

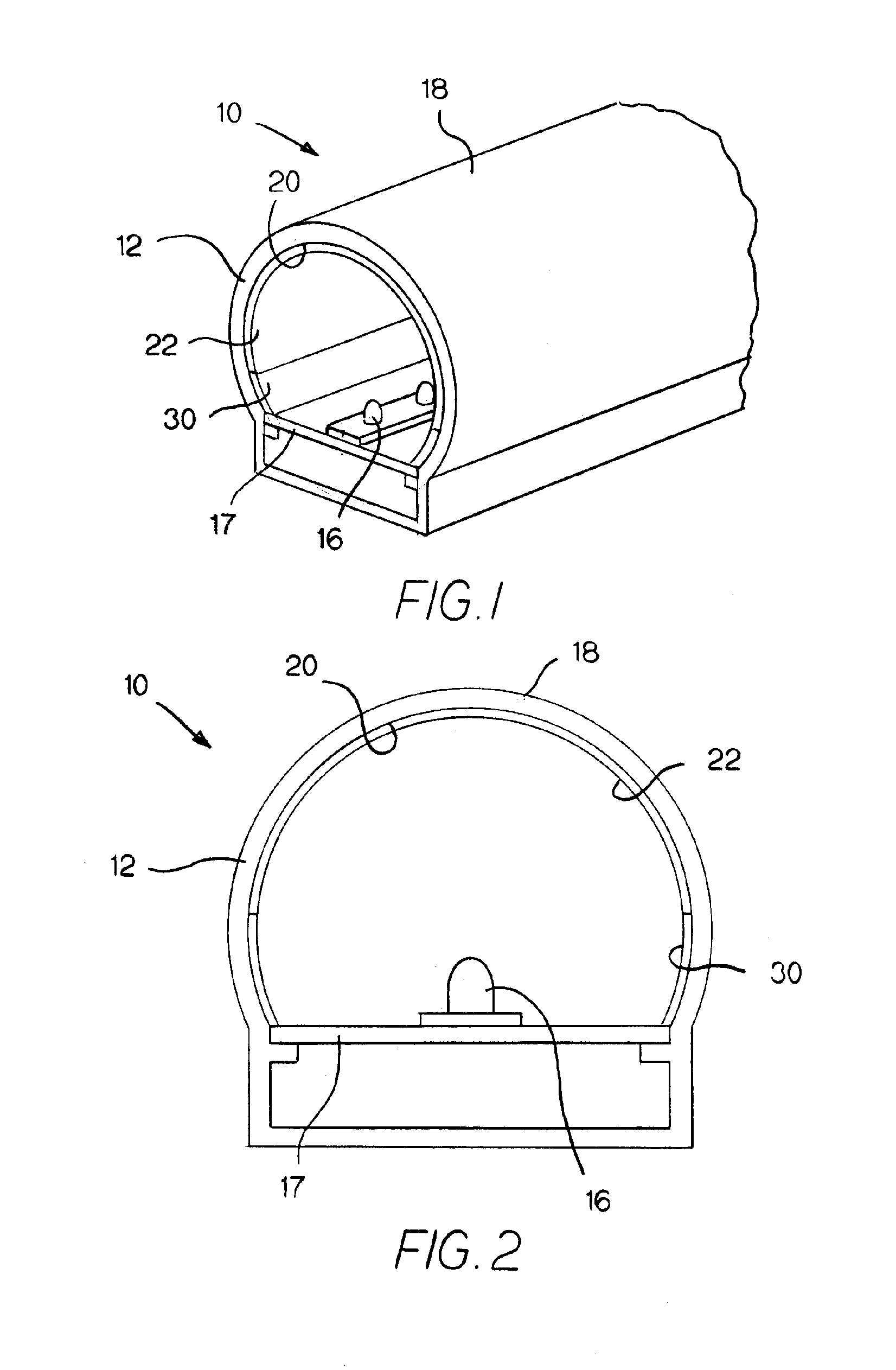

Vacuum assisted closure pad with adaptation for phototherapy

InactiveUS6994702B1Prevent vacuum leakageIncrease costPlastersSurgical instrument detailsFiberVacuum assisted

A modified vacuum assisted wound closure system adapted for concurrent applications of phototherapy having a foam pad for insertion substantially into the wound site and a wound drape for sealing enclosure of the foam pad at the wound site. The foam pad includes an optical pigtail, whereby desired wavelength of light may be directed into and about the wound site. The foam pad is placed in fluid communication with a vacuum source for promotion of fluid drainage. The foam pad is made of a highly reticulated, open-cell polyurethane or polyether foam for good permeability of wound fluids while under suction and is also embedded with an optical pigtail. The optical pigtail comprises an optical fiber that has been formed to fan into a plurality of sections. The fibers of the most distal fanned sections, which are implanted in the foam pad at its base, are provided with tiny optical slots, oriented away from the foam pad and toward the wound site. Each optical slot is made by stripping the cladding from the optical fiber in the desired areas of the fanned sections to form slot radiators. Because it is necessary to trim the foam pad in preparation for therapy, the optical fibers comprise plastics, such as acrylic or styrene. Upon placement of the pad, having the optical pigtail embedded therein, the wound drape is firmly adhered about the VAC therapy suction hose as well as the extending optical fiber to prevent vacuum leakage.

Owner:MORGAN STANLEY

Sequential Selective Epitaxial Growth

ActiveUS20070122954A1Increase costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETCMOS

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. A multi step epitaxial process can be used to extend the ridges with different dopant types, high mobility semiconductor, and or advanced multi-layer strutures. For CMOS integrated circuits a capping layer is formed over the a first region. Epitaxial layers are formed in a second region. Then the capping layer is removed from the first region and a capping layer is formed over the second region. Epitaxial layers can than be formed in the first region.

Owner:SYNOPSYS INC

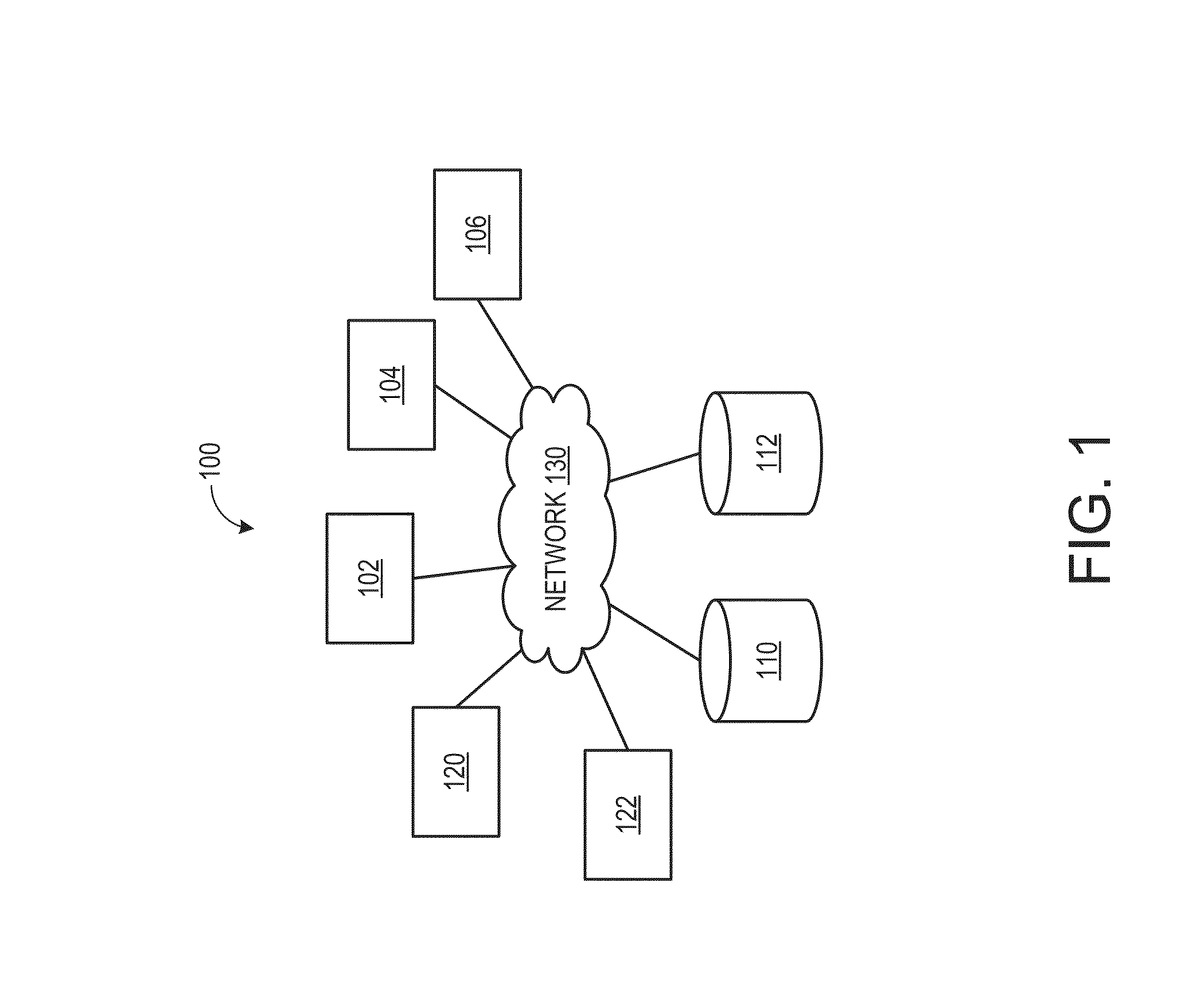

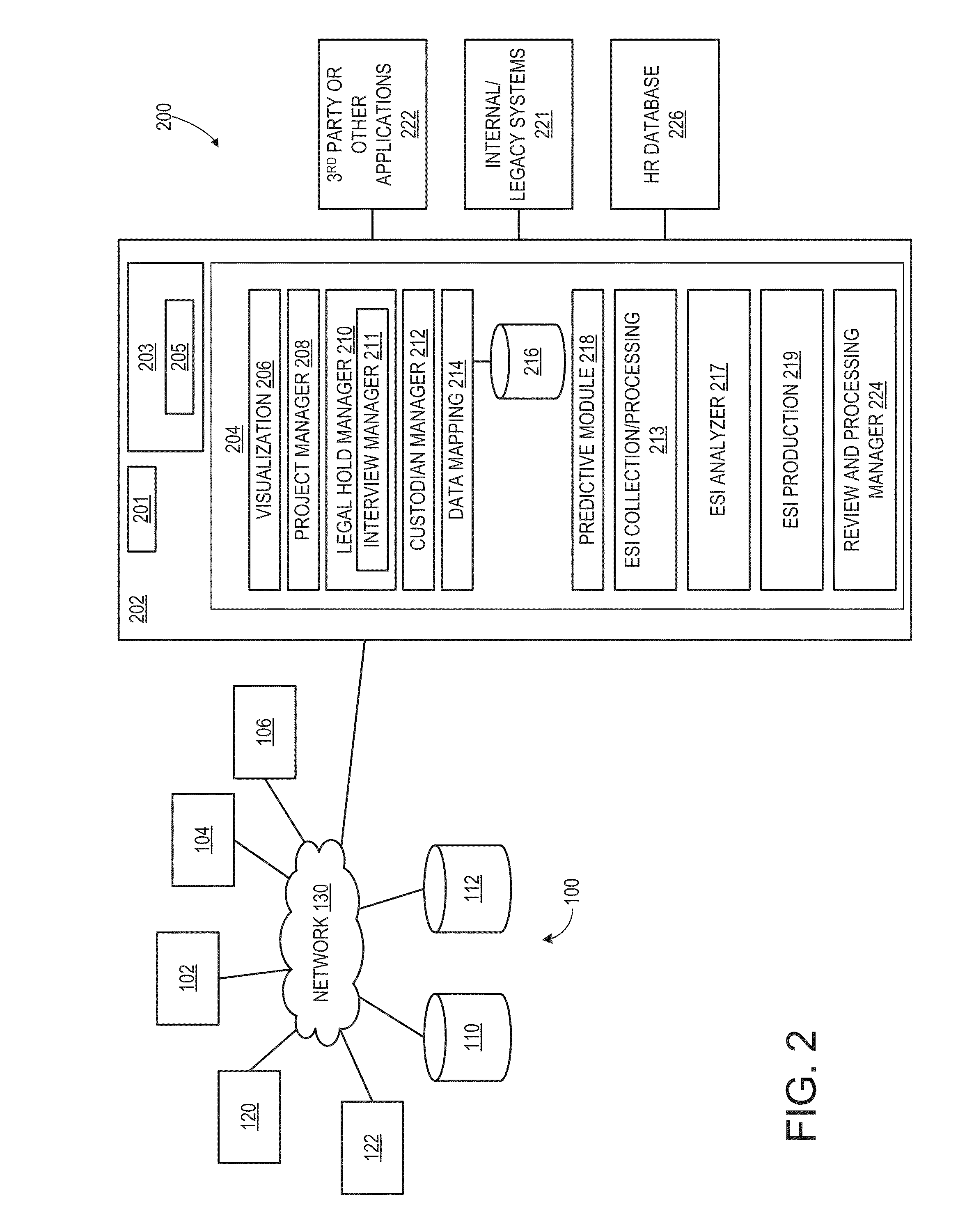

Electronic discovery systems and workflow management method

InactiveUS20140278663A1Reduce in quantityIncrease costResourcesElectronic discoveryKnowledge management

Various systems and methods for managing electronic discovery are provided. In one example, a method for facilitating a cross-team, role-based workflow for task management on a computing device comprises sending a project request to a business coordinator, the project request received from a legal / compliance team member, assigning work required by the project request to a discovery coordinator based on input received from the business coordinator, and performing the work required by the project request by assigning one or more projects to one or more collection / preservation teams based on input received from the discovery coordinator.

Owner:EXTERRO INC

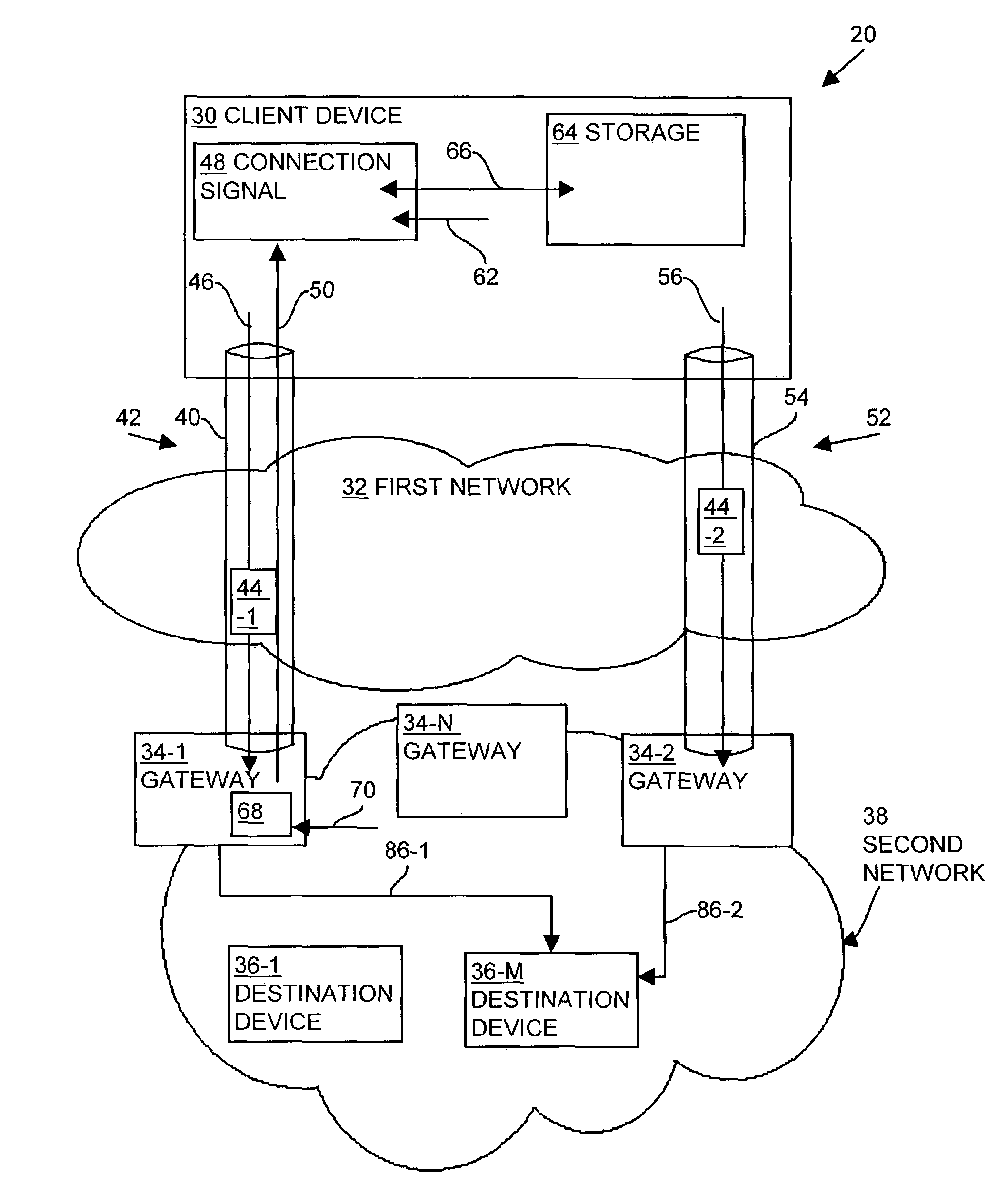

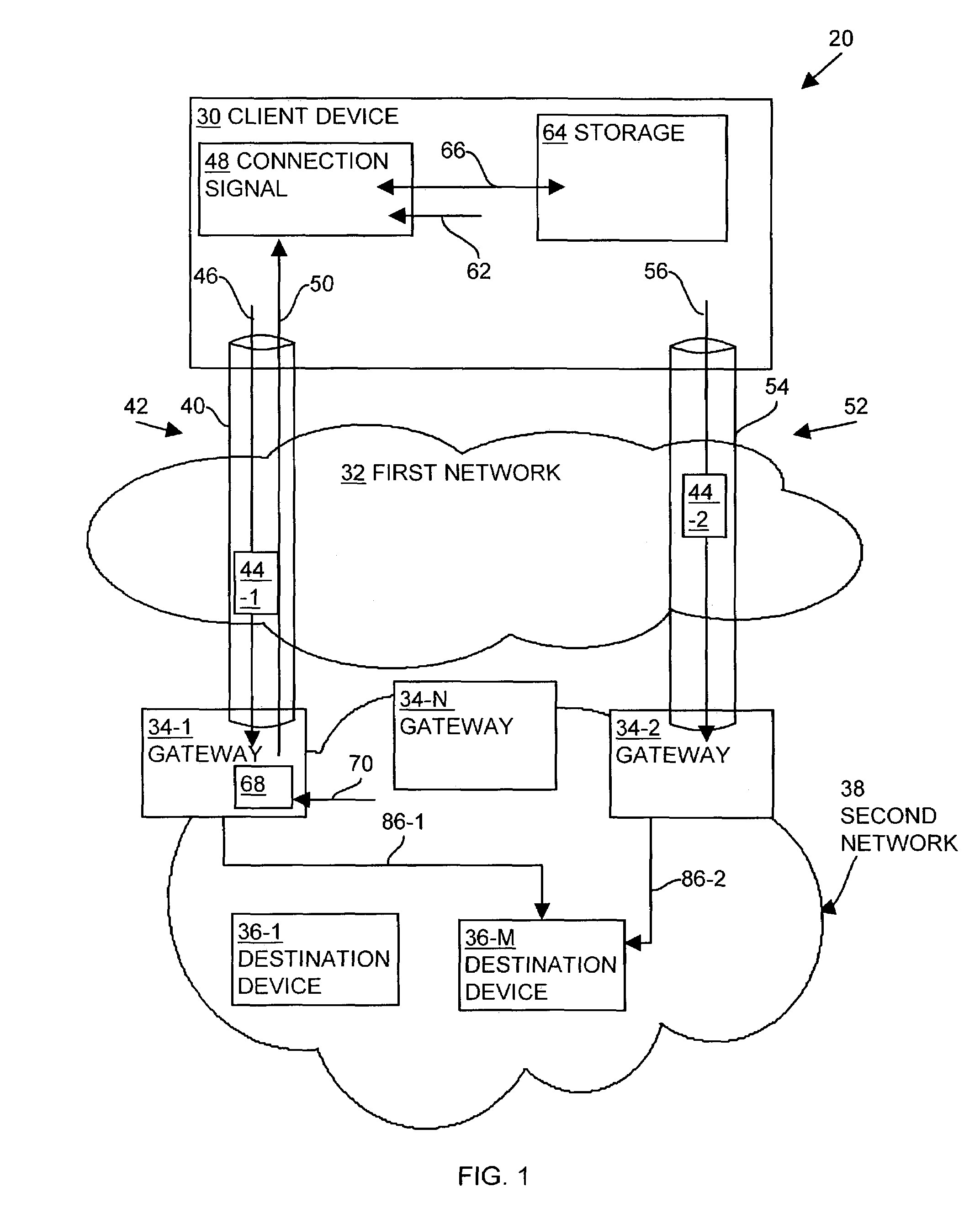

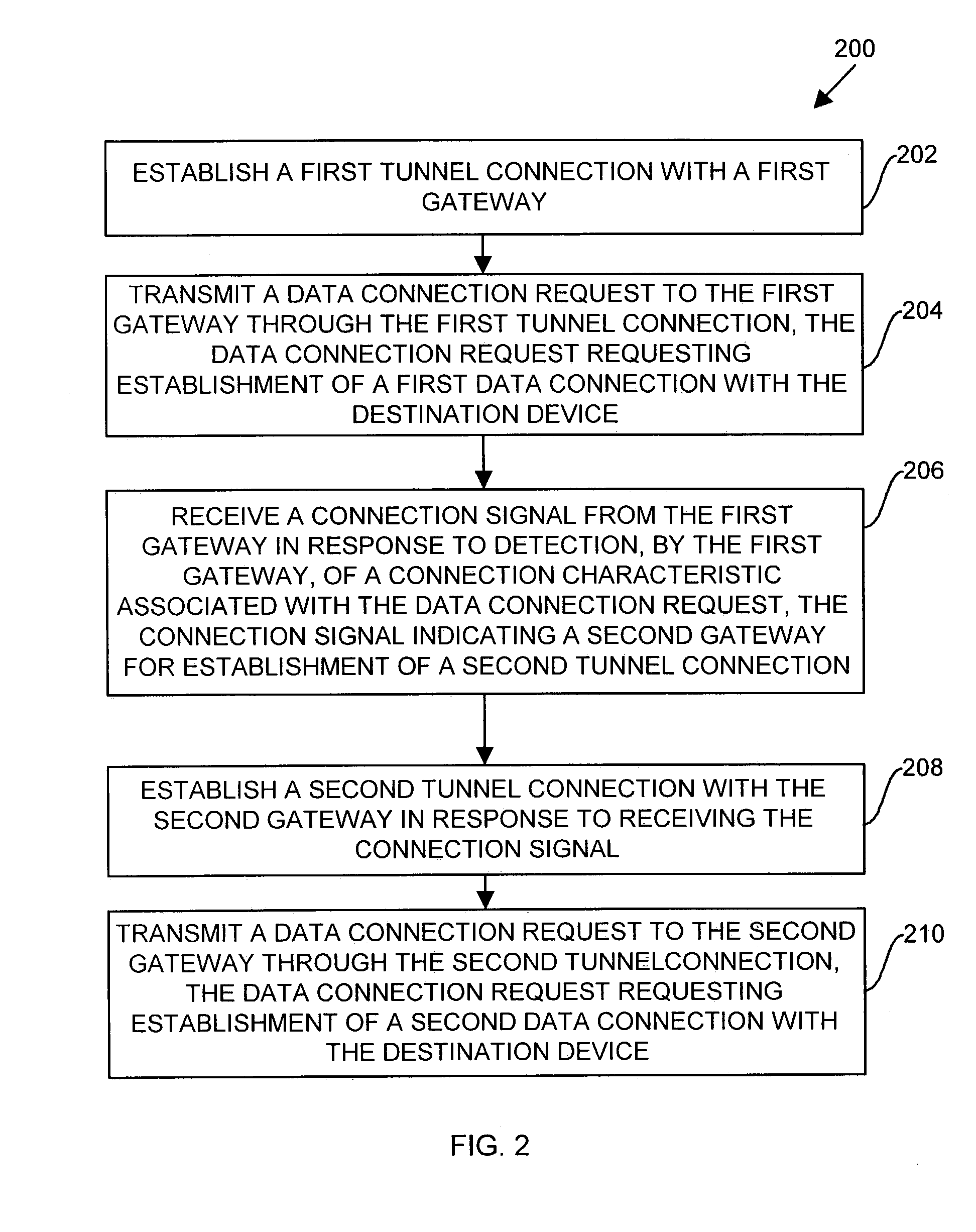

Methods and apparatus for establishing a computerized device tunnel connection

InactiveUS7673048B1Minimize bandwidth utilizationIncrease costError preventionTransmission systemsData connectionTelecommunications

A client device establishes a first tunnel connection or tunnel, through a public network, with a first gateway of a private network and establishes, through the tunnel connection, a data connection with a destination device within the private network. The first gateway monitors or analyzes the geographic locations of the gateways associated with the private network relative to geographic location of the destination device associated with the data connection. Based upon such the monitoring, the first gateway transmits information to the client device relating to establishment of a second tunnel connection or tunnel with a second gateway of the private network. The client device establishes the second tunnel connection with the second gateway and establishes a data connection with the destination device through the second gateway. By establishing the second tunnel connection with the second gateway, the client device utilizes the bandwidth of the public network to exchange data with the destination device, thereby decreasing data transmission costs to the private network and decreasing private network latency.

Owner:CISCO TECH INC

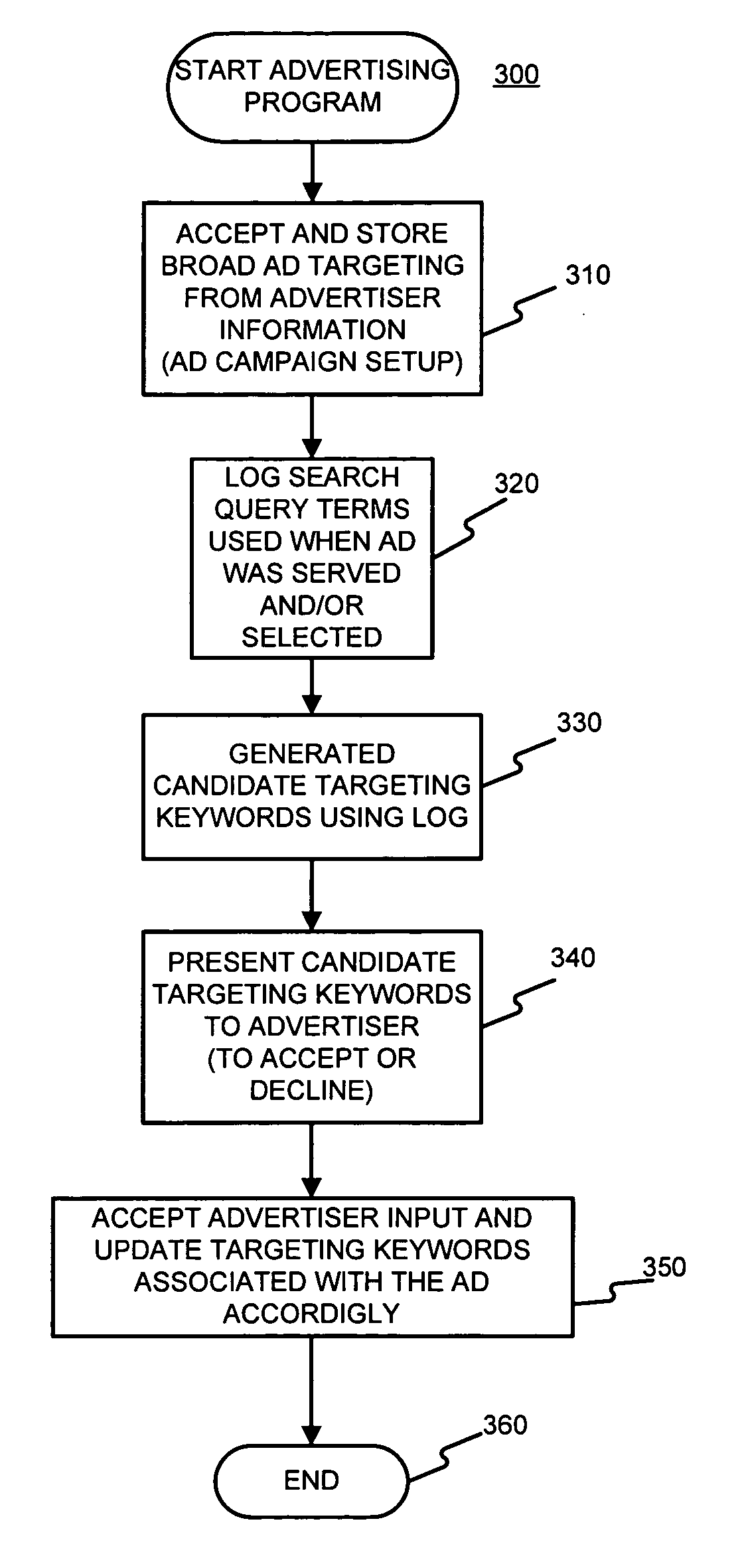

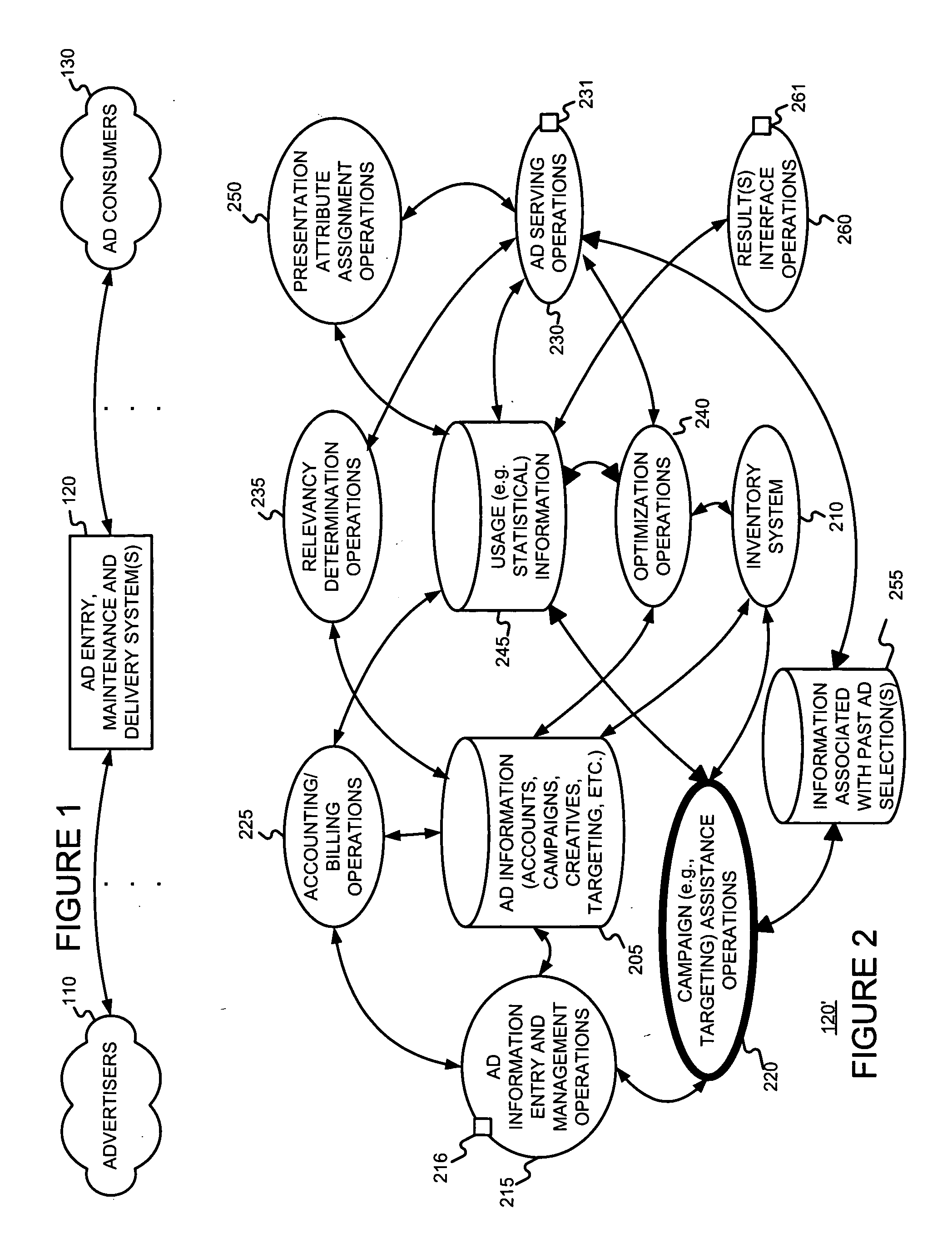

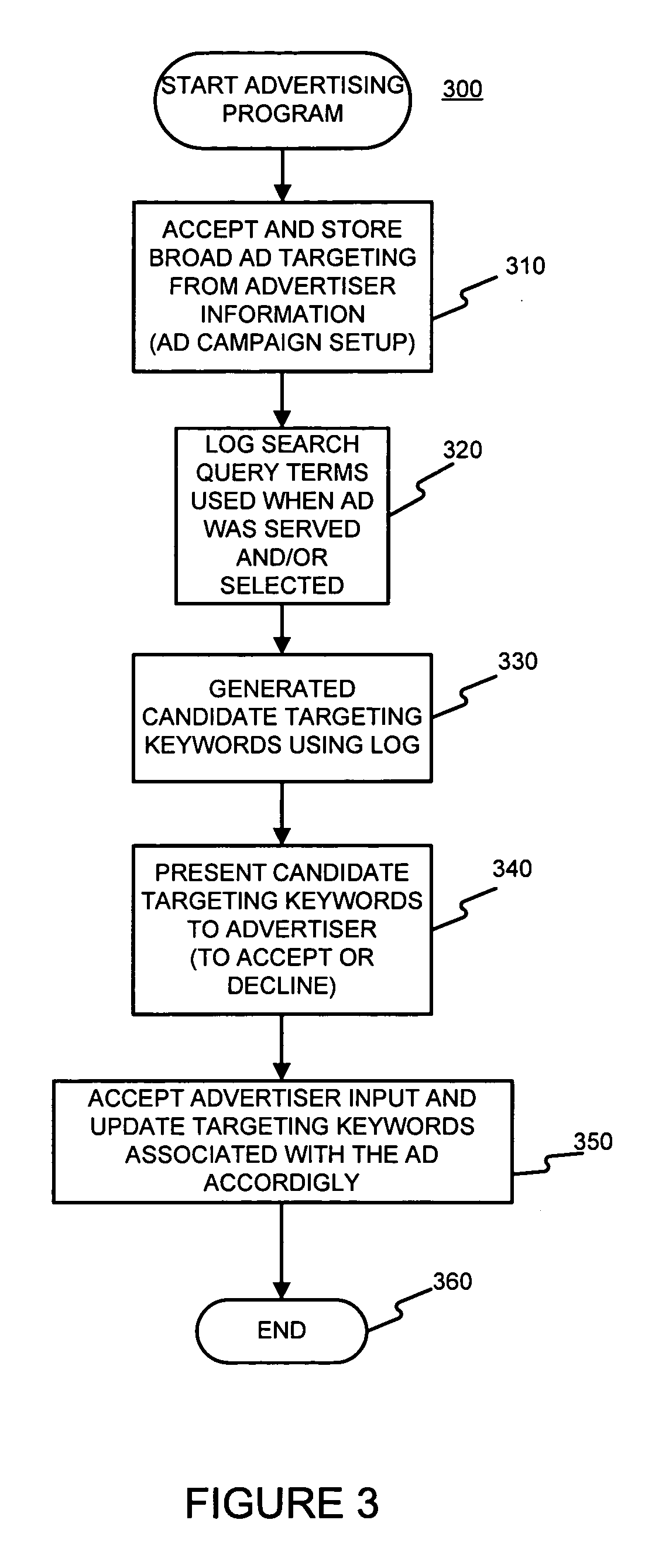

Suggesting and/or providing targeting information for advertisements

InactiveUS20060149625A1Improve performanceSlows sale cycleMarketingInformation provisionInformation retrieval

The relevancy of ads may be increased, and opportunities to serve an ad that might otherwise be missed may be exploited by (i) accepting broad targeting information, to be used for serving an ad, from an advertiser, (ii) serving the ad using the broad targeting information, (iii) logging search query terms (or some other information, such as concepts, concept keywords, etc.) associated with the serving of the ad, and (iv) generating one or more candidate targeting keywords or phrases for the ad using the logged search query terms. At least one of the candidate targeting keywords or phrases may be provided as targeting information for the ad. Alternatively, at least one of the candidate targeting keywords or phrases may be presented to the advertiser. Advertiser input with respect to the candidate targeting keyword(s) or phrase(s) presented may then be accepted. Zero or more of the candidate targeting keyword(s) or phrase(s) may be provided as targeting information for the ad, in accordance with the accepted advertiser input. Cost information (e.g., average cost per selection, average cost per conversion, total costs, etc.) may be presented in association with the candidate targeting information.

Owner:GOOGLE LLC

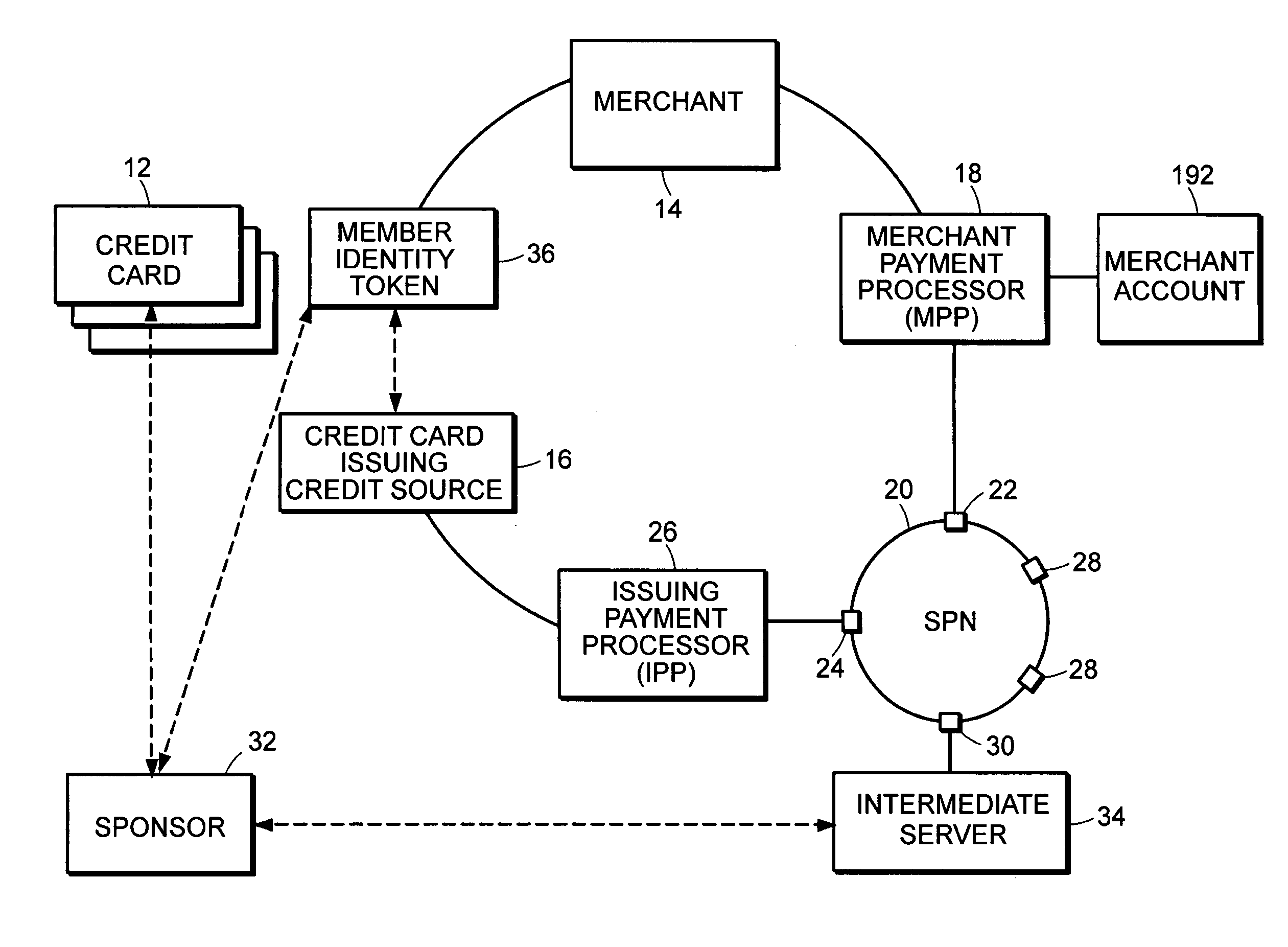

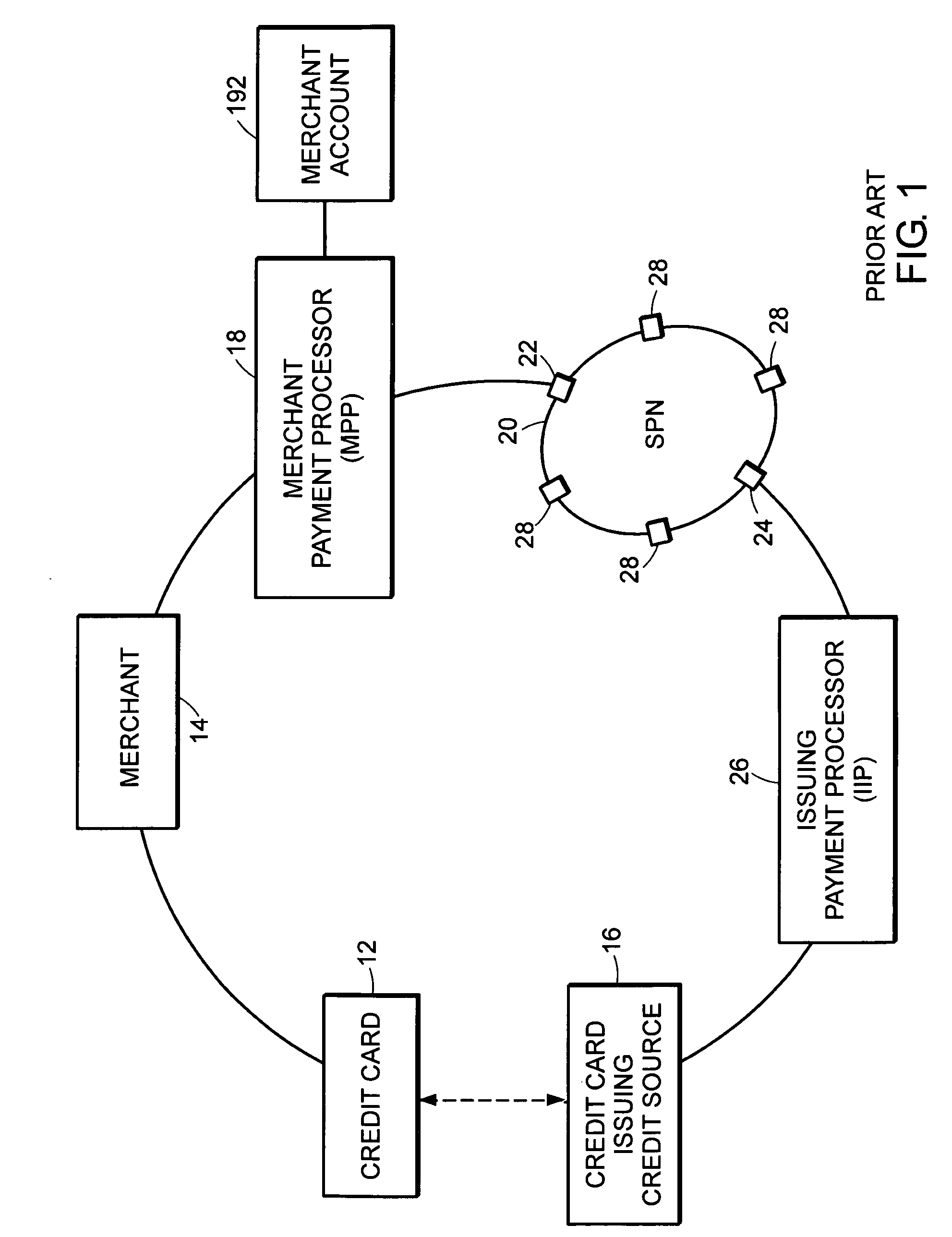

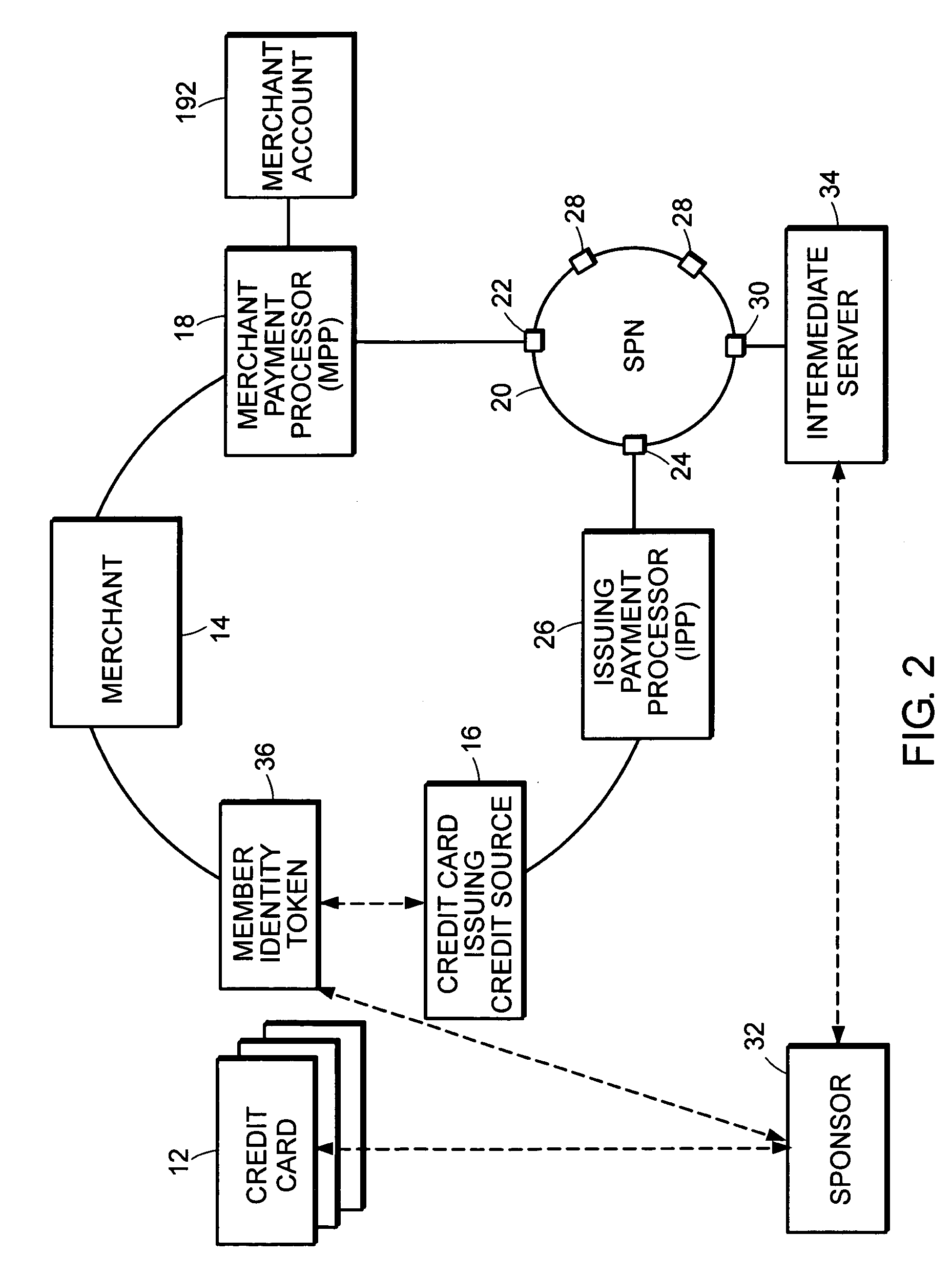

Method and system for processing financial transactions

InactiveUS20060020542A1Protection from disclosureHigh CNP interchange rateFinancePayment architectureCredit cardPayment transaction

A method and system for processing financial transactions by receiving a payment transaction as an Issuing Payment Processor, converting the payment into one or more derivative transactions based on a defined rules set, and then sending, as a Merchant Payment Processor, the resulting derivative transaction or transactions to another Issuing Payment Processor, resulting in real-time settlement, faster and less costly implementation of discount, gift, and loyalty programs, and enhanced member credit card security and privacy.

Owner:PLEJ

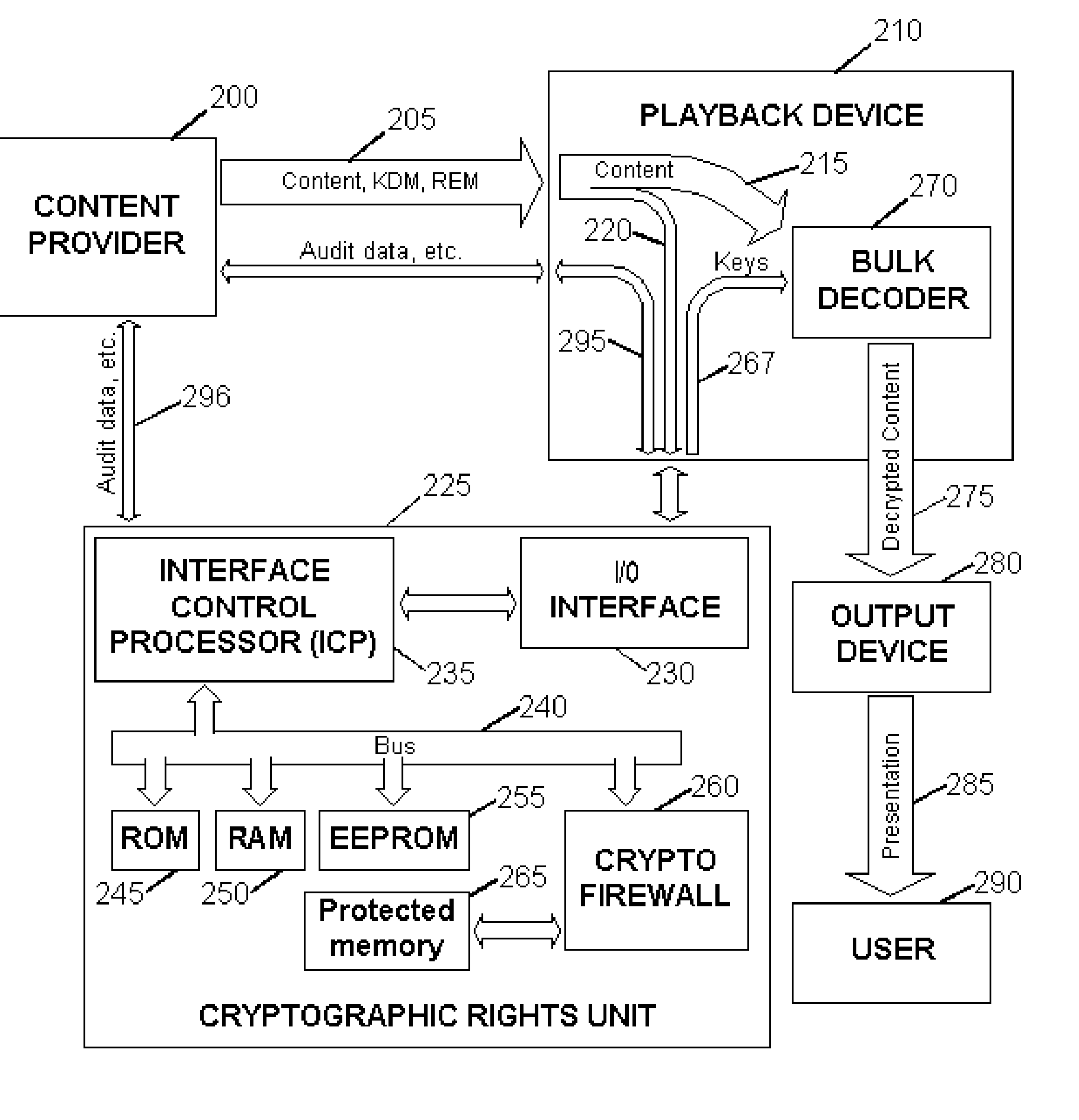

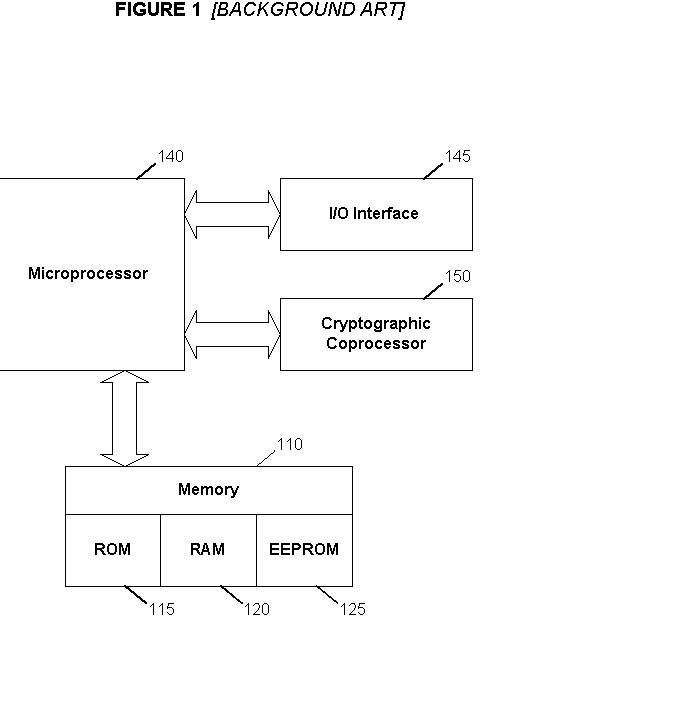

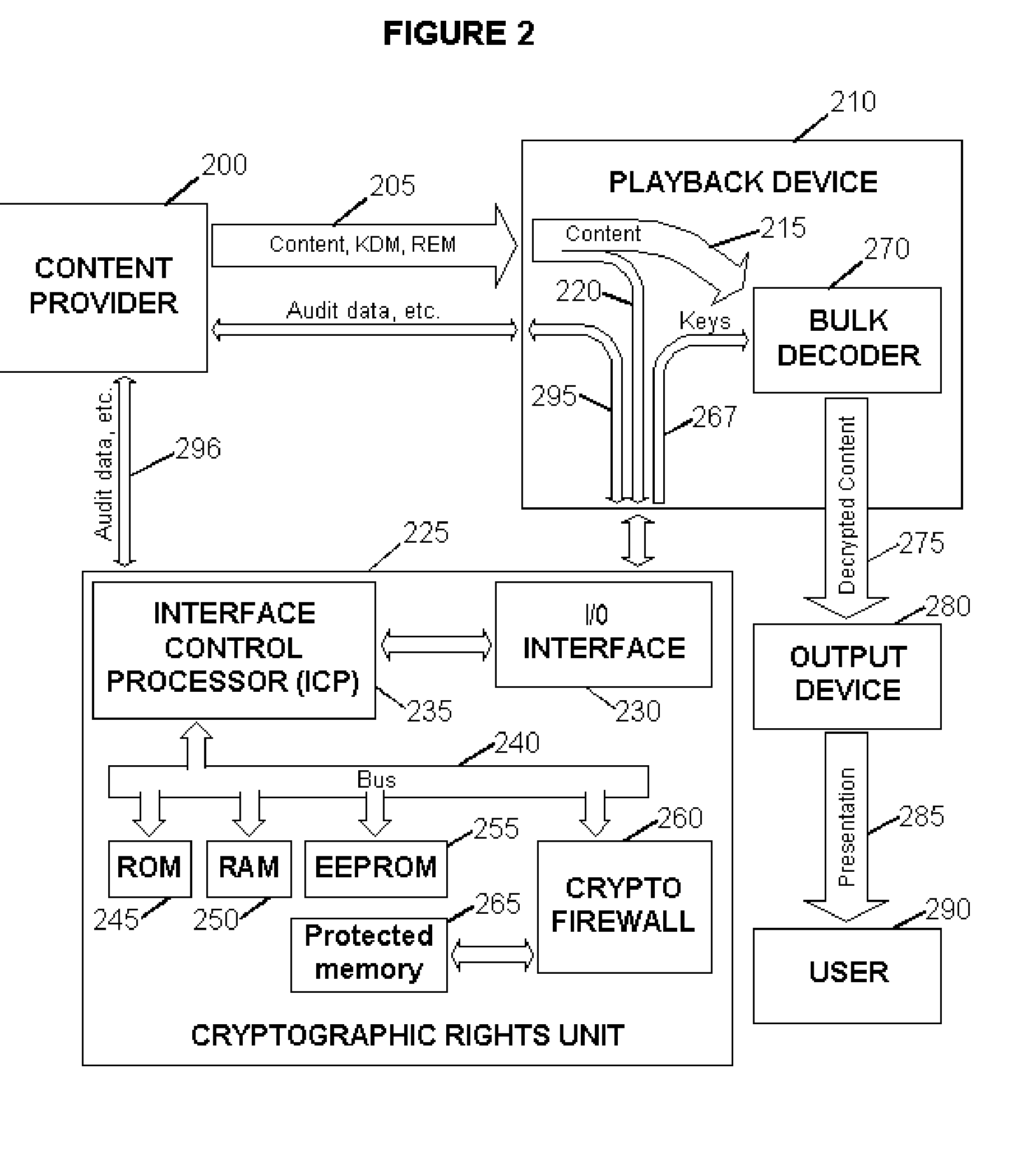

Digital Content Protection Method and Apparatus

InactiveUS20020099948A1Improve securityMinimizes probabilityKey distribution for secure communicationDigital data processing detailsDigital signatureDigital content

<heading lvl="0">Abstract of Disclosure< / heading> Before use, a population of tamper-resistant cryptographic enforcement devices is partitioned into groups and issued one or more group keys. Each tamper-resistant device contains multiple computational units to control access to digital content. One of the computational units within each tamper-resistant device communicates with another of the computational units acting as an interface control processor, and serves to protect the contents of a nonvolatile memory from unauthorized access or modification by other portions of the tamper-resistant device, while performing cryptographic computations using the memory contents. Content providers enforce viewing privileges by transmitting encrypted rights keys to a large number of recipient devices. These recipient devices process received messages using the protected processing environment and memory space of the secure unit. The processing result depends on whether the recipient device was specified by the content provider as authorized to view some encrypted digital content. Authorized recipient devices can use the processing result in decrypting the content, while unauthorized devices cannot decrypt the content. A related aspect of the invention provides for securing computational units and controlling attacks. For example, updates to the nonvolatile memory, including program updates, are supported and protected via a cryptographic unlocking and validation process in the secure unit, which can include digital signature verification.

Owner:CRYPTOGRAPHY RESEARCH

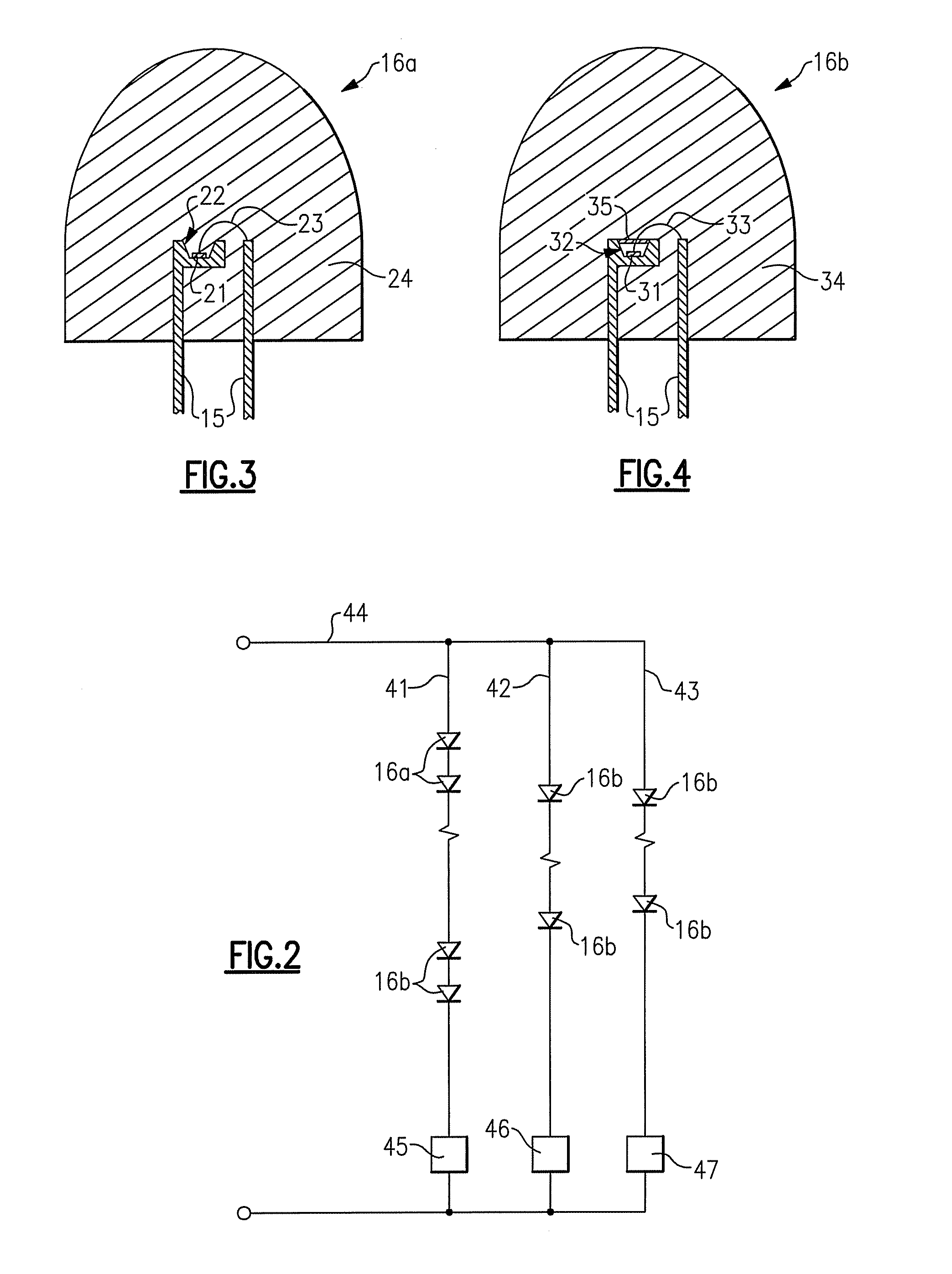

Lighting device and lighting method

ActiveUS20090296384A1Low efficiencyIncreased complexityPoint-like light sourceElectroluminescent light sourcesEffect lightY-Coordinate

There is provided a lighting device that comprises at least one 600-630 nm solid state light emitter and at least one light source emitting light within an area on a 1931 CIE Chromaticity Diagram defined by a first set of points having x, y coordinates of (0.32, 0.40), (0.36, 0.48), (0.43, 0.45), (0.42, 0.42), (0.36, 0.38), or a second set of points having x, y coordinates of (0.29, 0.36), (0.32, 0.35), (0.41, 0.43), (0.44, 0.49), (0.38, 0.53). Some embodiments further comprise at least a first power line. Also provided are methods that comprise illuminating at least one light source to emit light within one of the areas defined above, and illuminating at least one 600-630 nm emitter.

Owner:IDEAL IND LIGHTING LLC

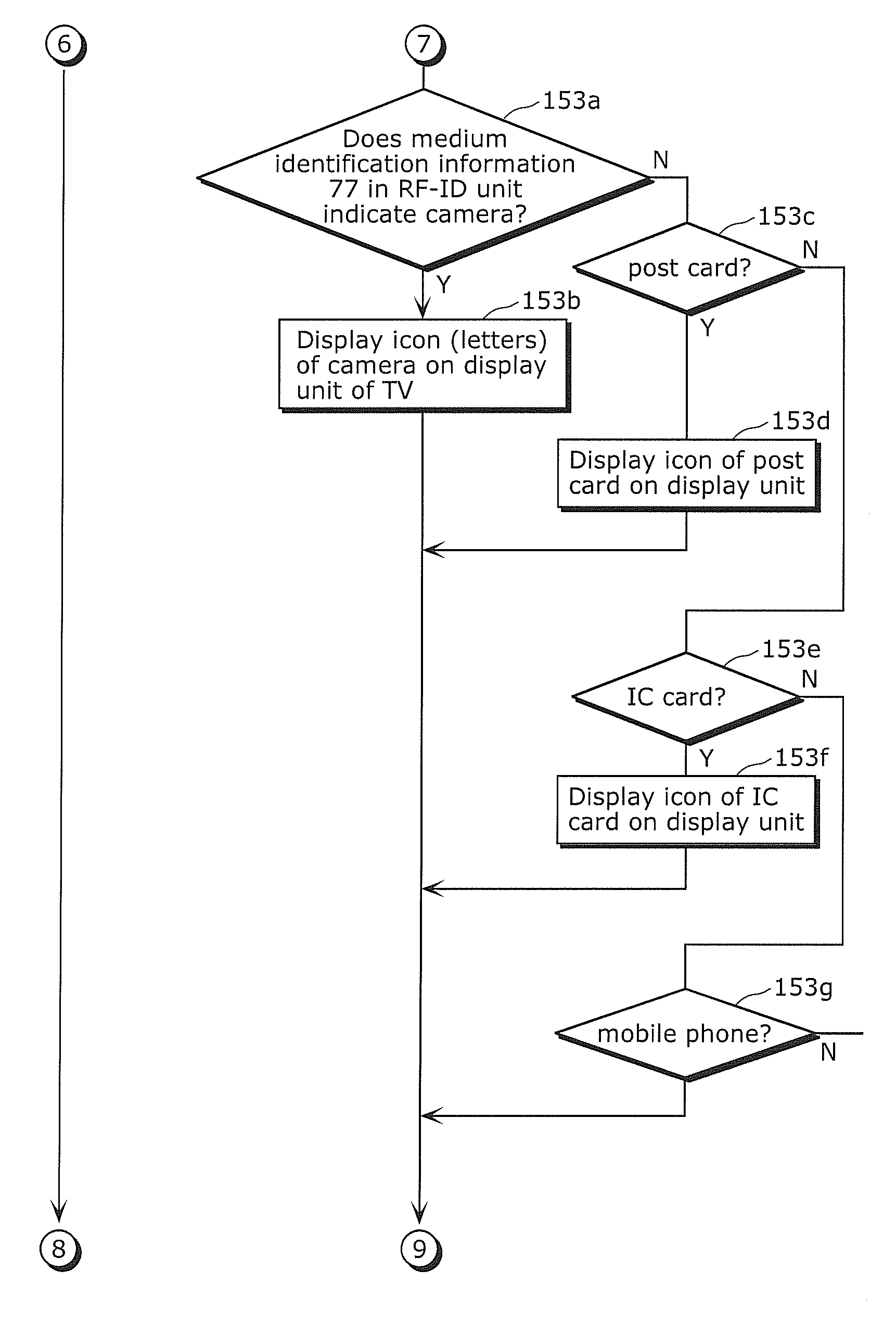

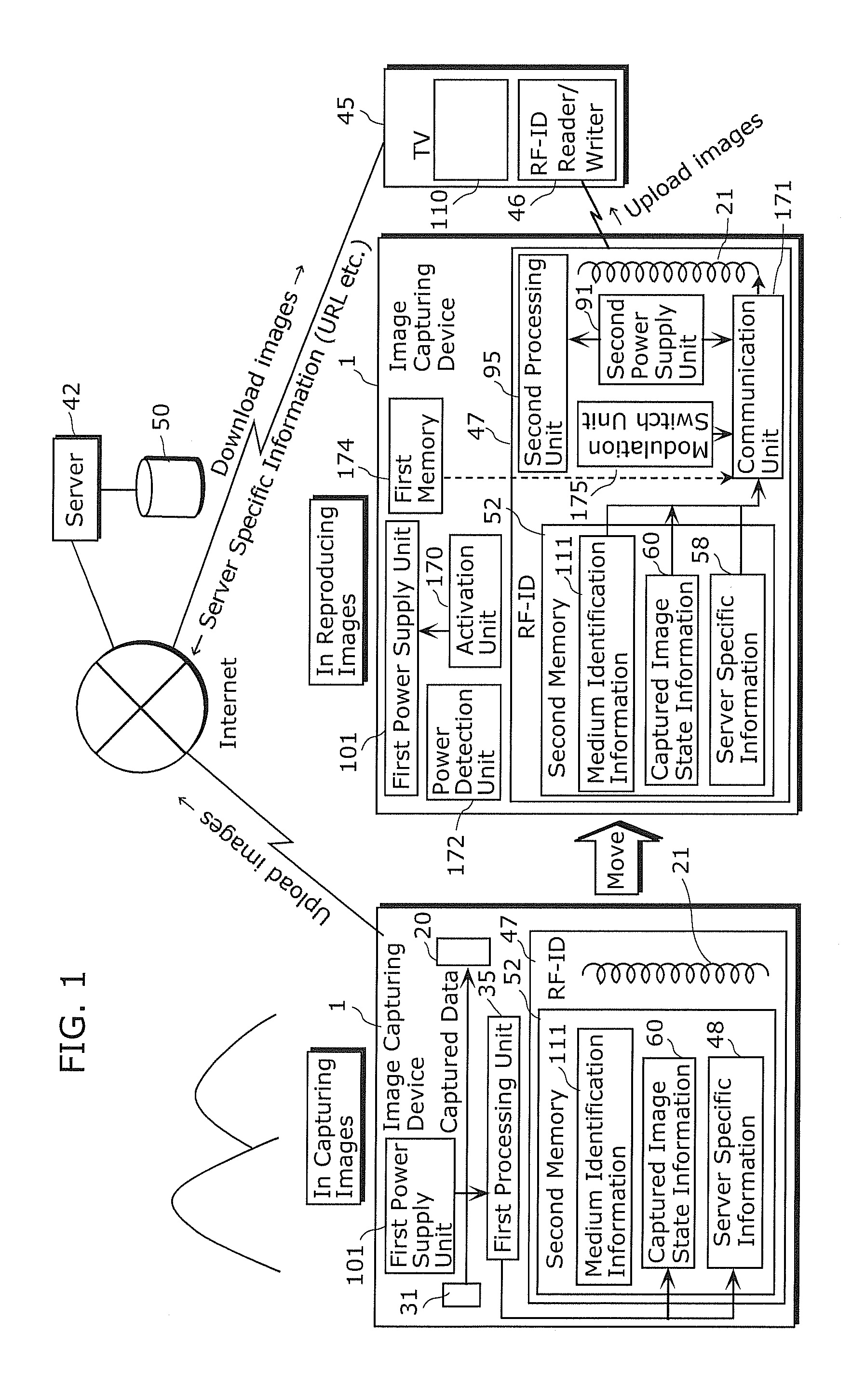

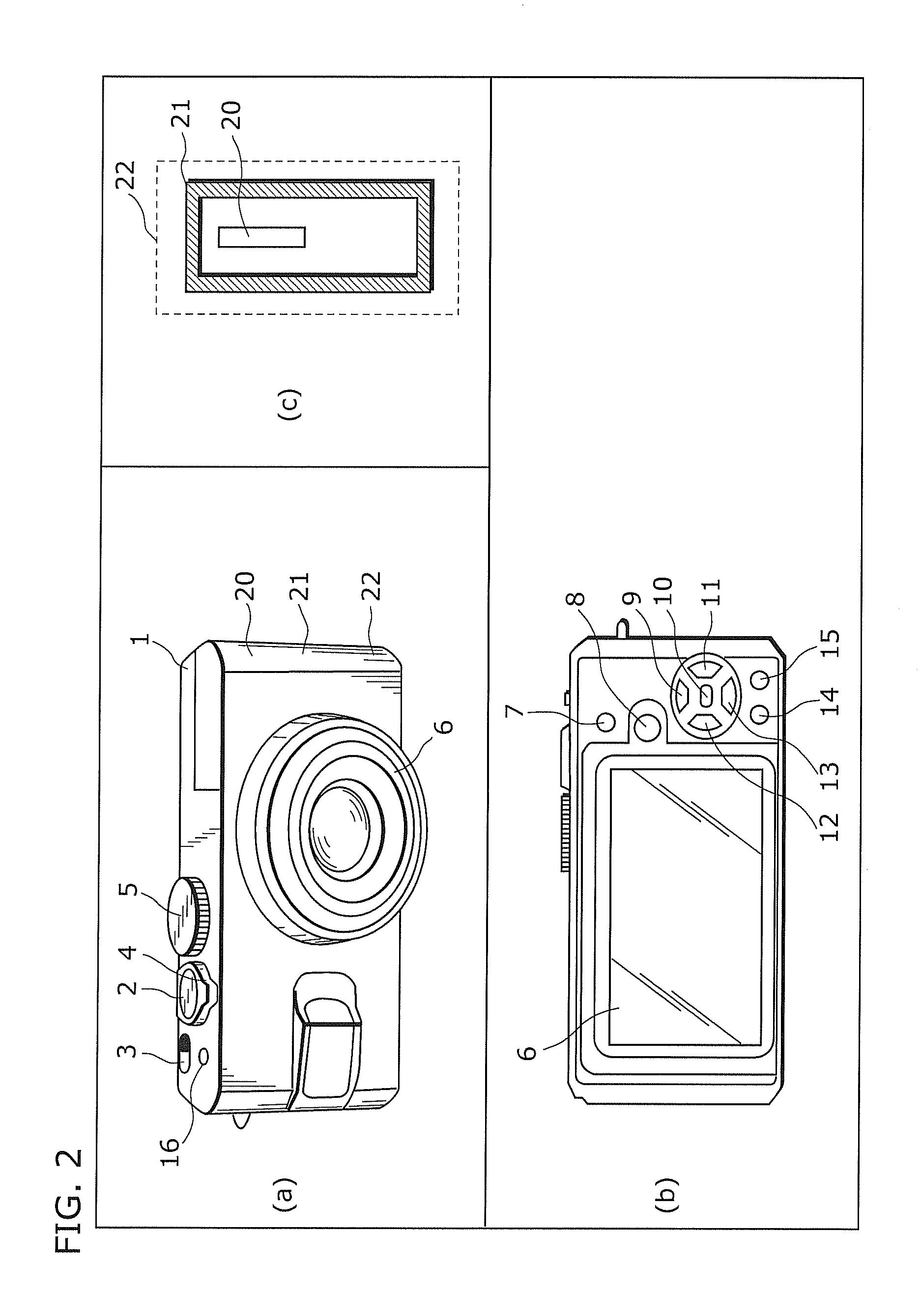

Mobile communication device, communication method, integrated circuit, and program

ActiveUS20110312278A1No action requiredEasy to operateTransmission systemsNear-field in RFIDInformation acquisitionIntegrated circuit

A mobile communication device (98b) includes: an appliance information obtainment unit (98n) that obtains appliance information (98n1) by proximity wireless communication (98c1) with an appliance (98a) installed in a home (99), the appliance information specifying the appliance (98a); a position information obtainment unit (98j) that obtains position information (98j1) of the mobile communication device when the proximity wireless communication (98c1) is performed; and a transmission unit (98o) that transmits transmission information (98o1) to a server (98c) in the case where the proximity wireless communication (98c1) is performed, the transmission information including the appliance information (98n1) and the position information (98j1).

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

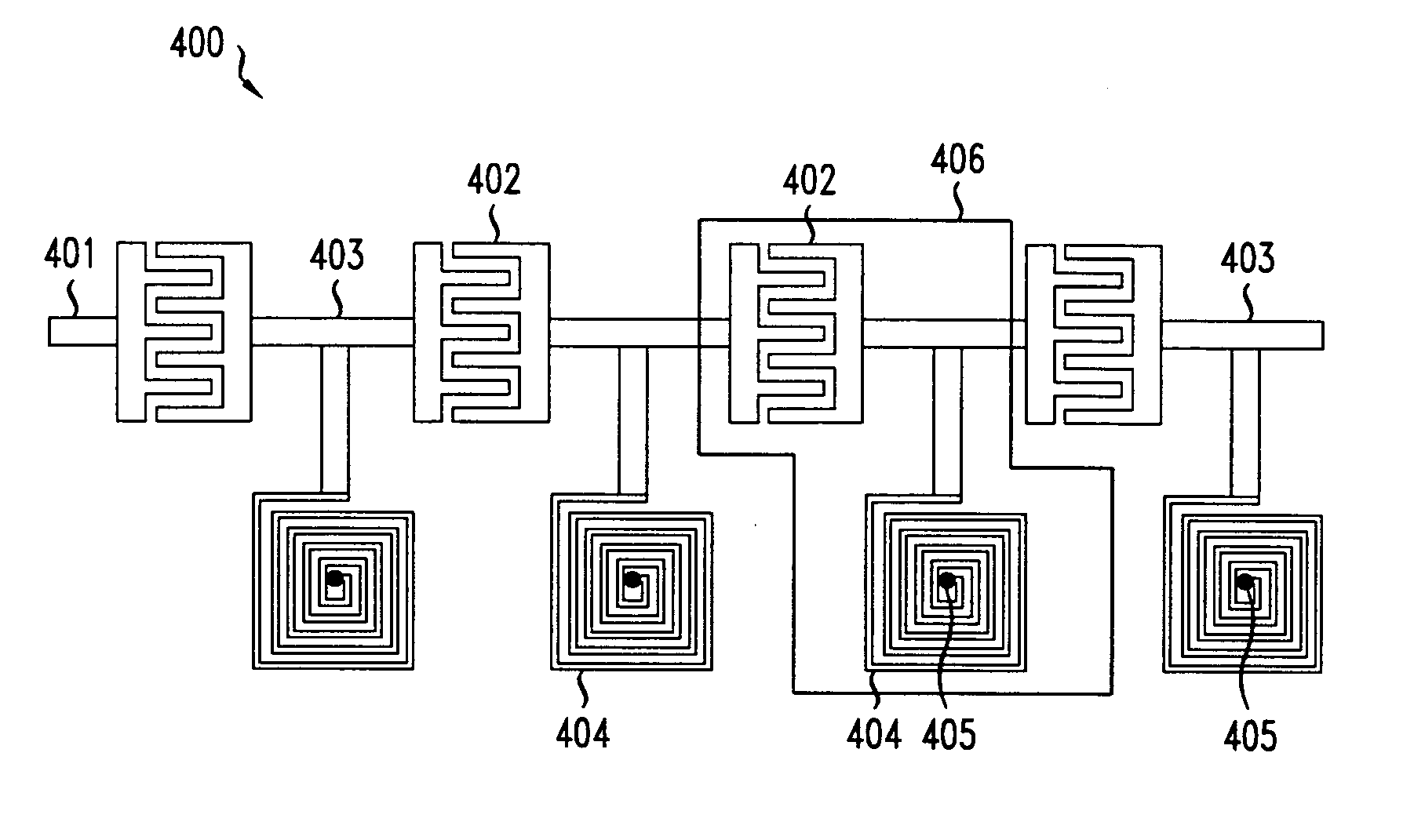

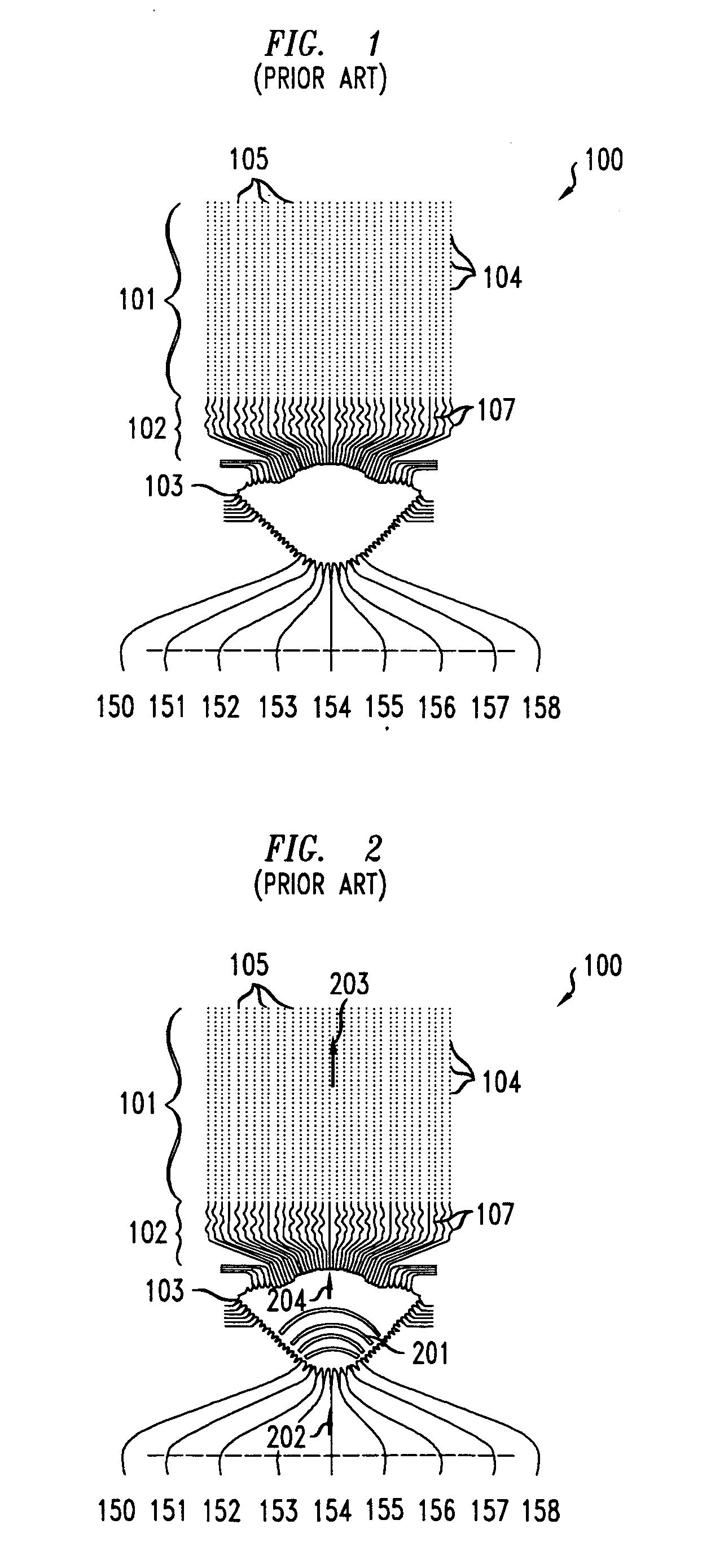

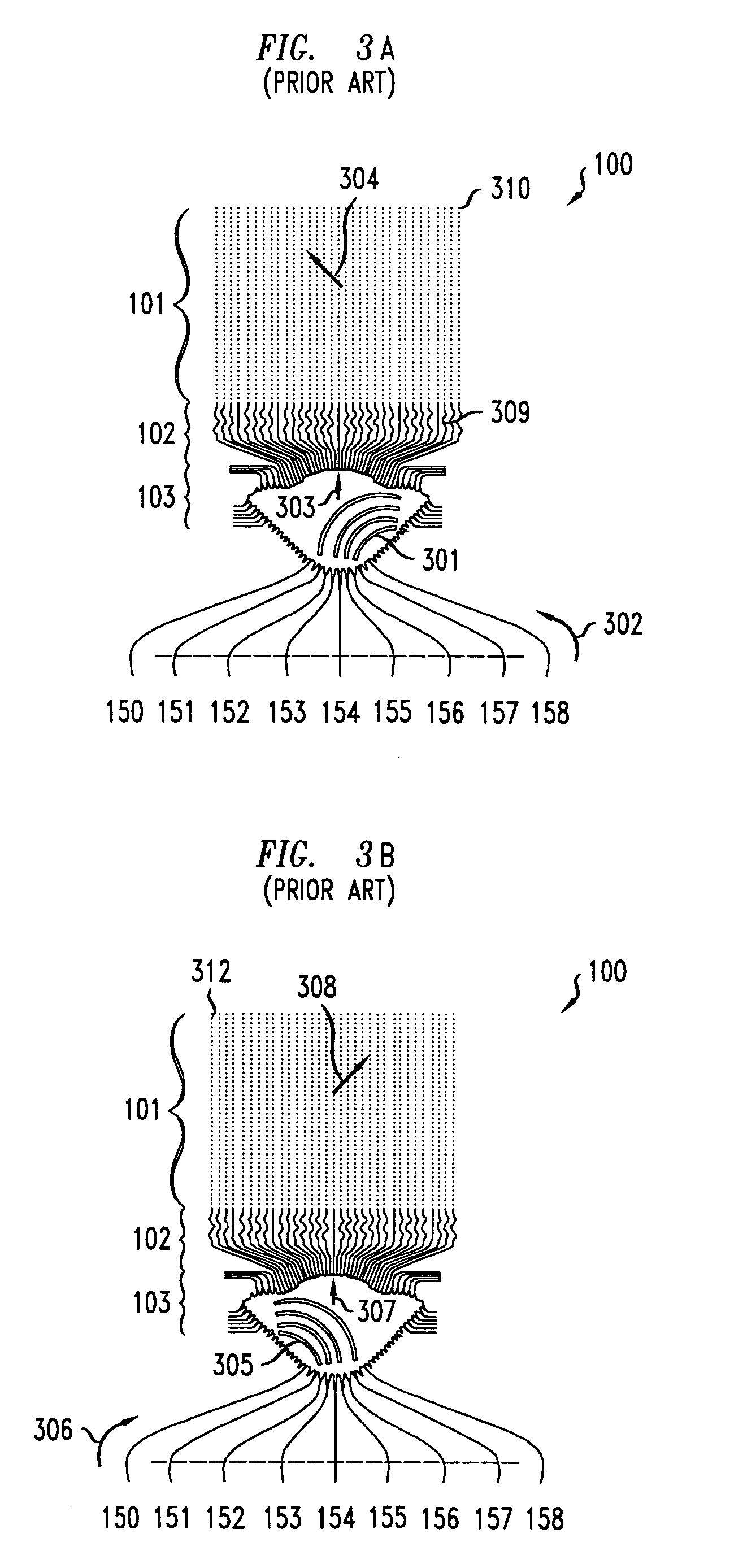

Phased array metamaterial antenna system

ActiveUS20050225492A1Low Sidelobe PerformanceReduce sidelobeRadiating elements structural formsWaveguidesSolid substratePhased array

An efficient, low-loss, low sidelobe, high dynamic range phased-array radar antenna system is disclosed that uses metamaterials, which are manmade composite materials having a negative index of refraction, to create a biconcave lens architecture (instead of the aforementioned biconvex lens) for focusing the microwaves transmitted by the antenna. Accordingly, the sidelobes of the antenna are reduced. Attenuation across microstrip transmission lines may be reduced by using low loss transmission lines that are suspended above a ground plane a predetermined distance in a way such they are not in contact with a solid substrate. By suspending the microstrip transmission lines in this manner, dielectric signal loss is reduced significantly, thus resulting in a less-attenuated signal at its destination.

Owner:LUCENT TECH INC

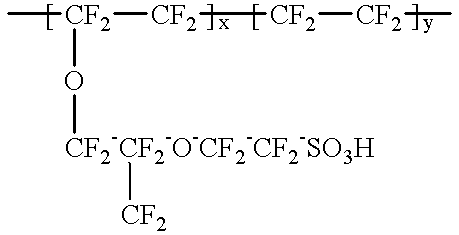

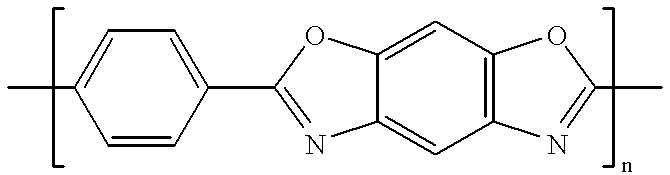

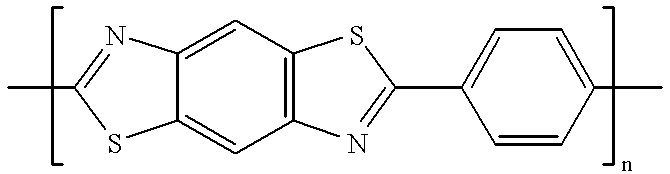

Composite solid polymer elecrolyte membranes

InactiveUS20020045085A1Optimize swellingOptimize fuel crossover resistanceElectrolyte holding meansFinal product manufacturePolymer electrolytesPolymer science

The present invention relates to composite solid polymer electrolyte membranes (SPEMs) which include a porous polymer substrate interpenetrated with an ion-conducting material. SPEMs of the present invention are useful in electrochemical applications, including fuel cells and electrodialysis.

Owner:FOSTER-MILLER

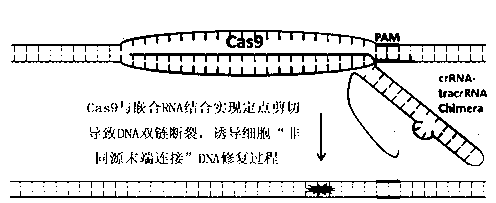

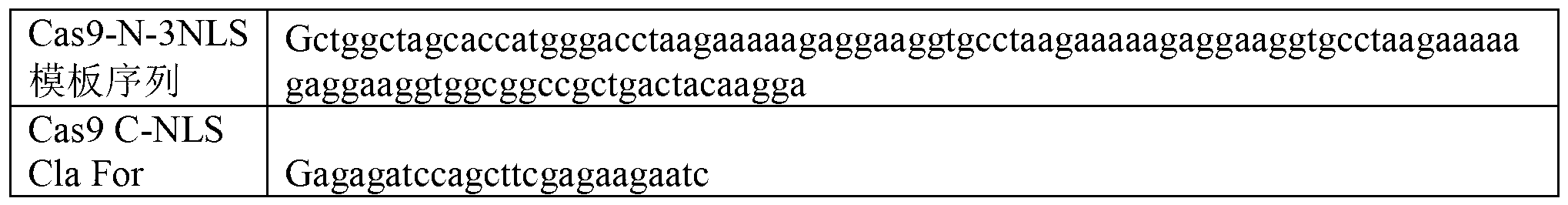

Specie limitation-free eucaryote gene targeting method having no bio-safety influence and helical-structure DNA sequence

ActiveCN103233028AUnable to cutImprove accuracyFermentationVector-based foreign material introductionDNA repairEucoenogenes

The invention discloses a specie limitation-free eucaryote gene targeting method having no bio-safety influence and a helical-structure DNA sequence, and belongs to the field of gene engineering. The specie limitation-free eucaryote gene targeting method comprises the following steps of 1, designing and constructing CRISPR / Cas9 and chimeric RNA, and 2, carrying out Cas9mRNA internal translation so that Cas9 nuclease and the chimeric RNA are bonded, carrying out fixed point clipping so that DNA double-chain cleavage is realized after the clipping, and introducing an exogenous DNA by induction of a natural DNA restoration process which is a non-homologous end bonding process of cells so that cell endogenous gene modification is realized. The specie limitation-free eucaryote gene targeting method has simple processes, realizes flexible site recognition and has low energy consumption.

Owner:NANJING SYNC BIOTECH

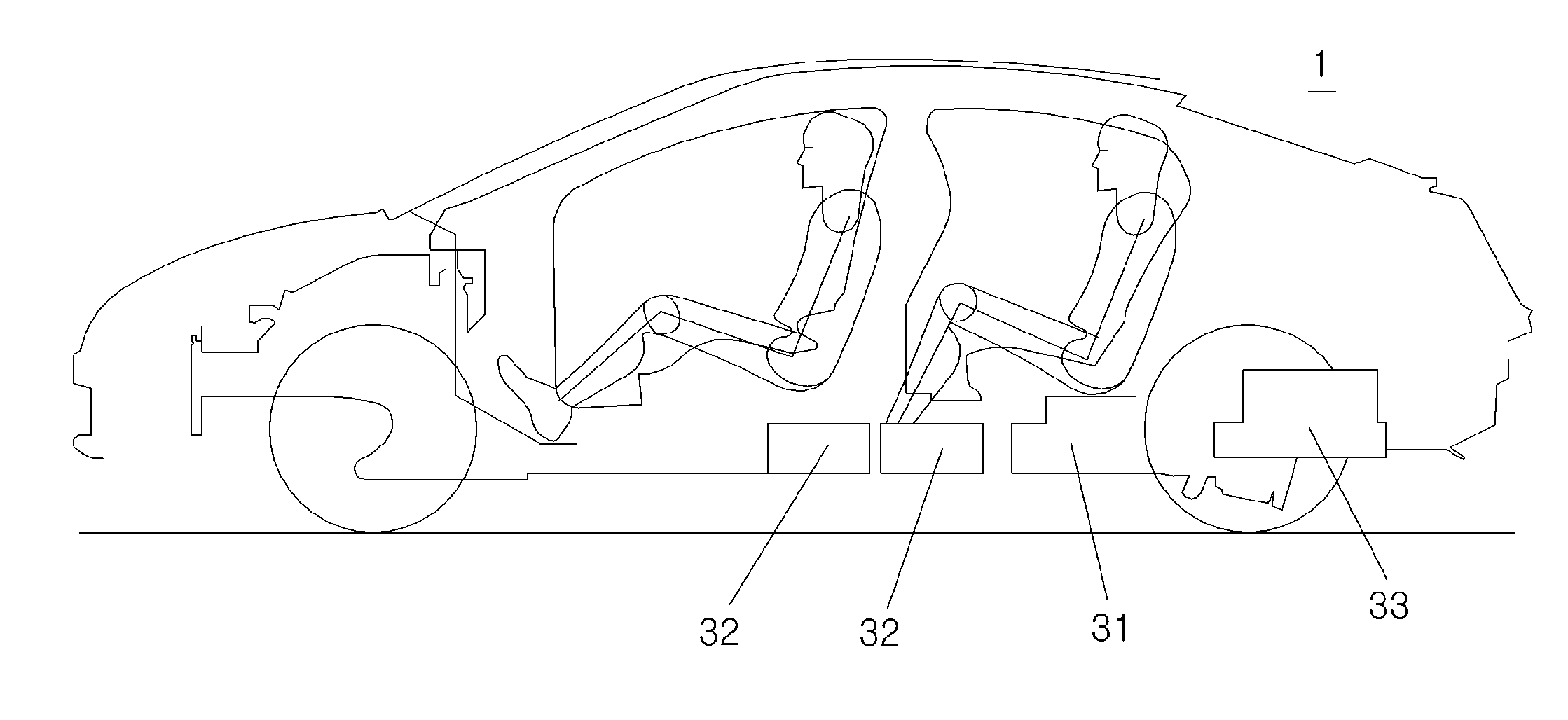

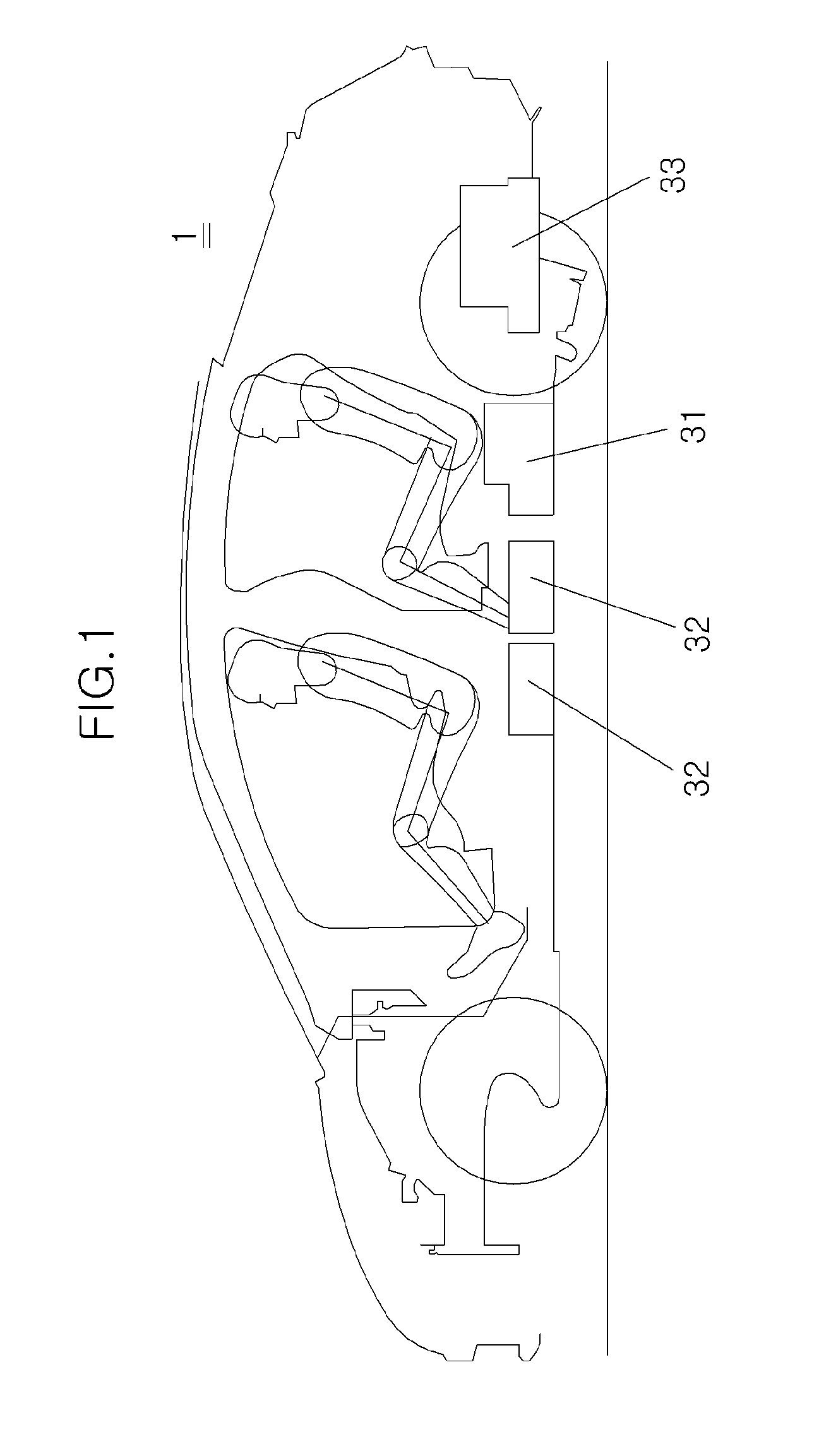

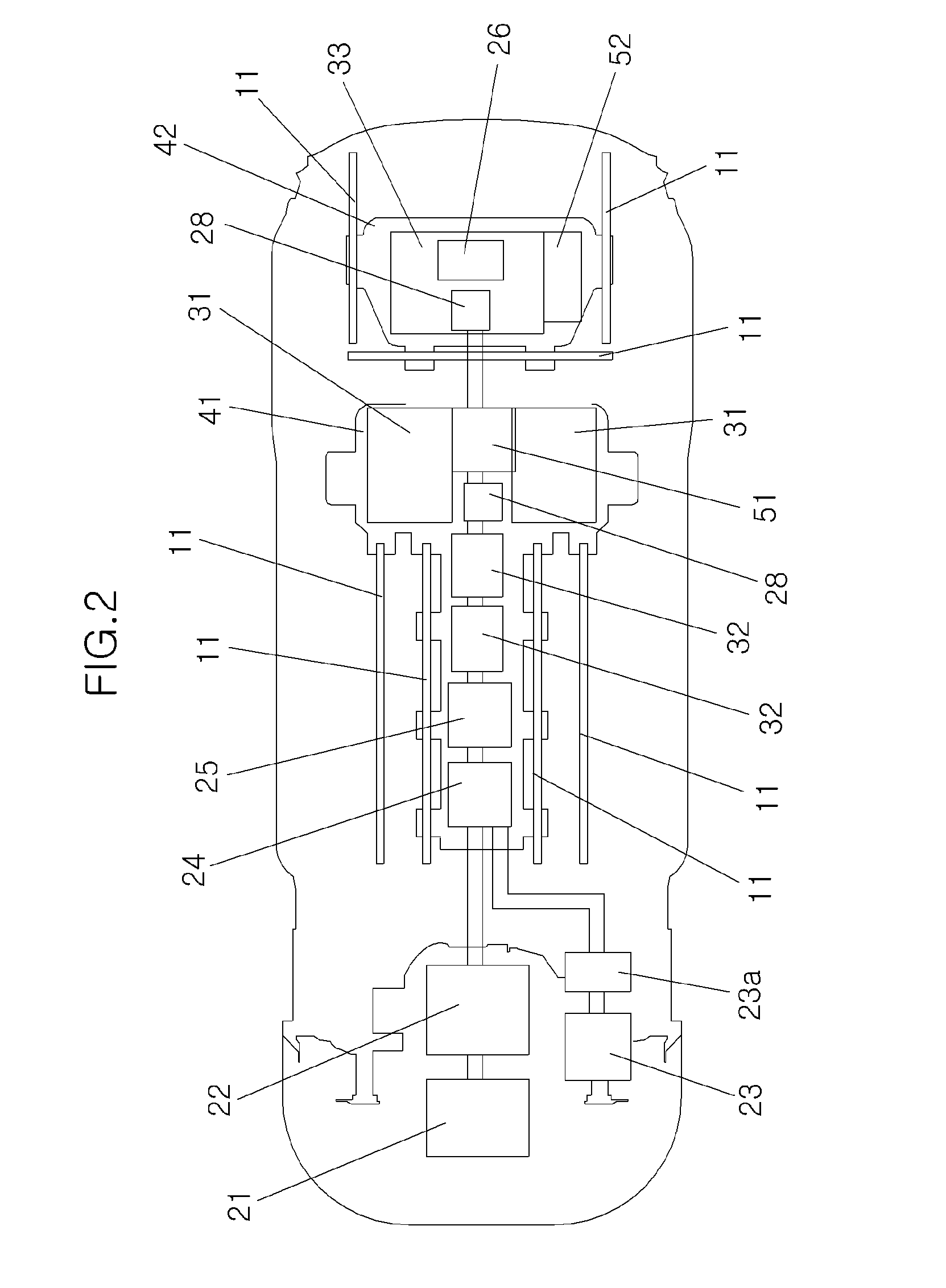

Mounting structure for battery in electric vehicle

InactiveUS20130020139A1Maximize useIncrease costElectric propulsion mountingGas pressure propulsion mountingElectricityElectrical battery

Provided is a mounting structure for a battery in an electric vehicle capable of increasing a driving distance of the electric vehicle by mounting a plurality of battery modules in an existing vehicle body of en electric vehicle. The mounting structure for a battery in an electric vehicle according to an exemplary embodiment of the present invention includes a main relay box electrically connected with an inverter, a plurality of first battery modules mounted beneath the rear seats of the electric vehicle, and a main housing positioned between a pair of front seats in the electric vehicle and below the rear seat. More specifically, the main housing is configured to house the main relay box and first battery modules therein, and is fixed to the vehicle body of the electric vehicle.

Owner:HYUNDAI MOTOR CO LTD +1

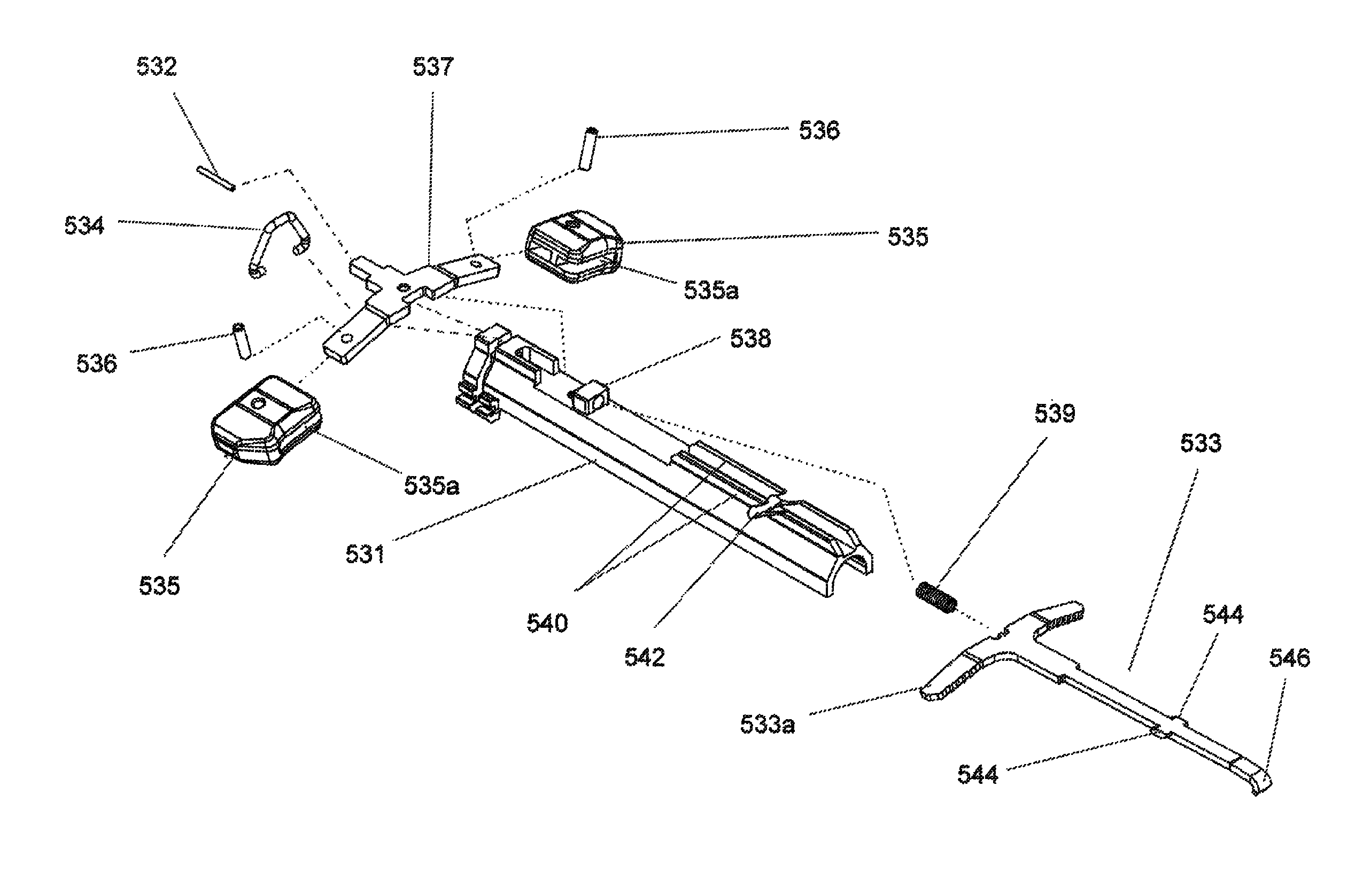

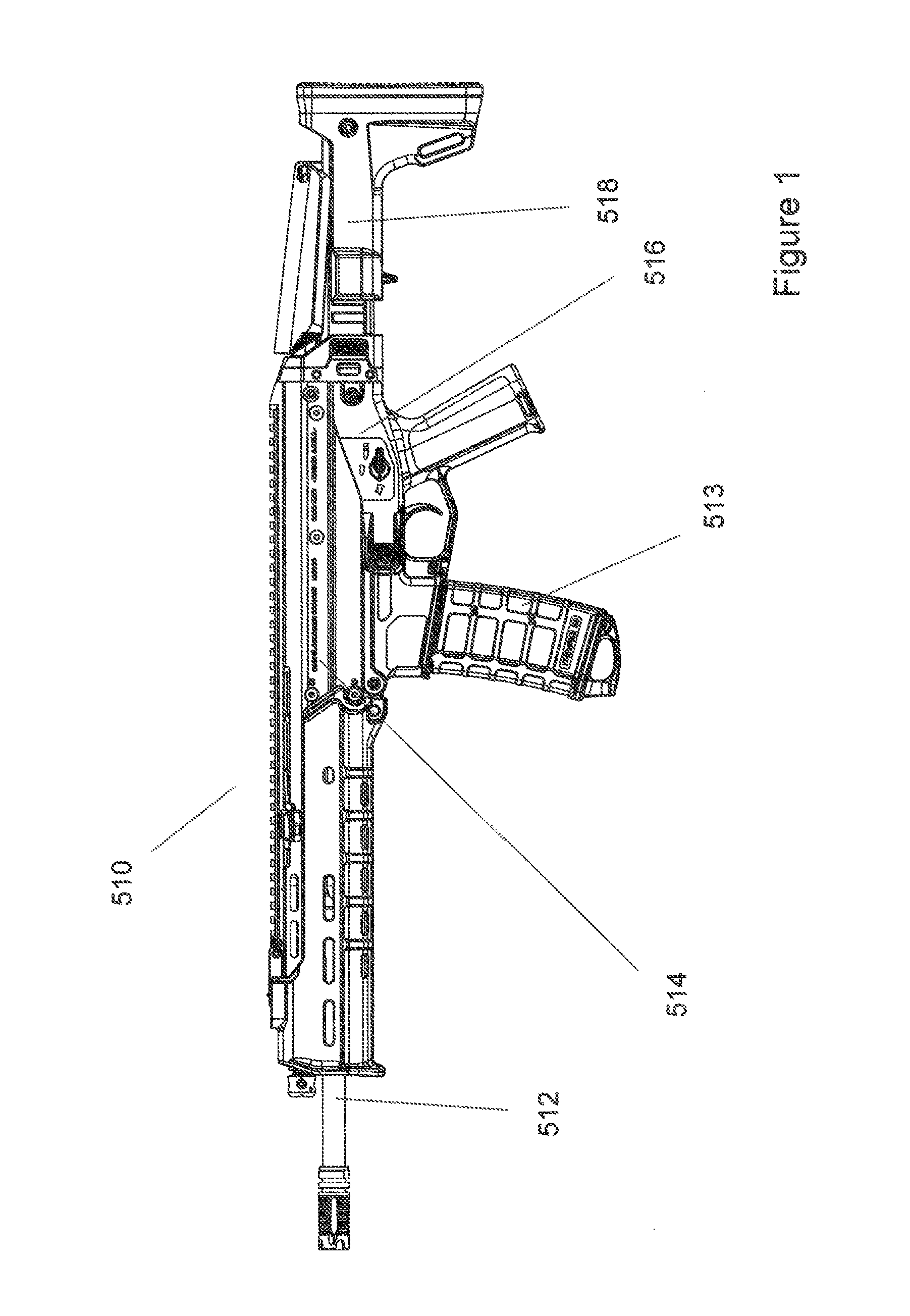

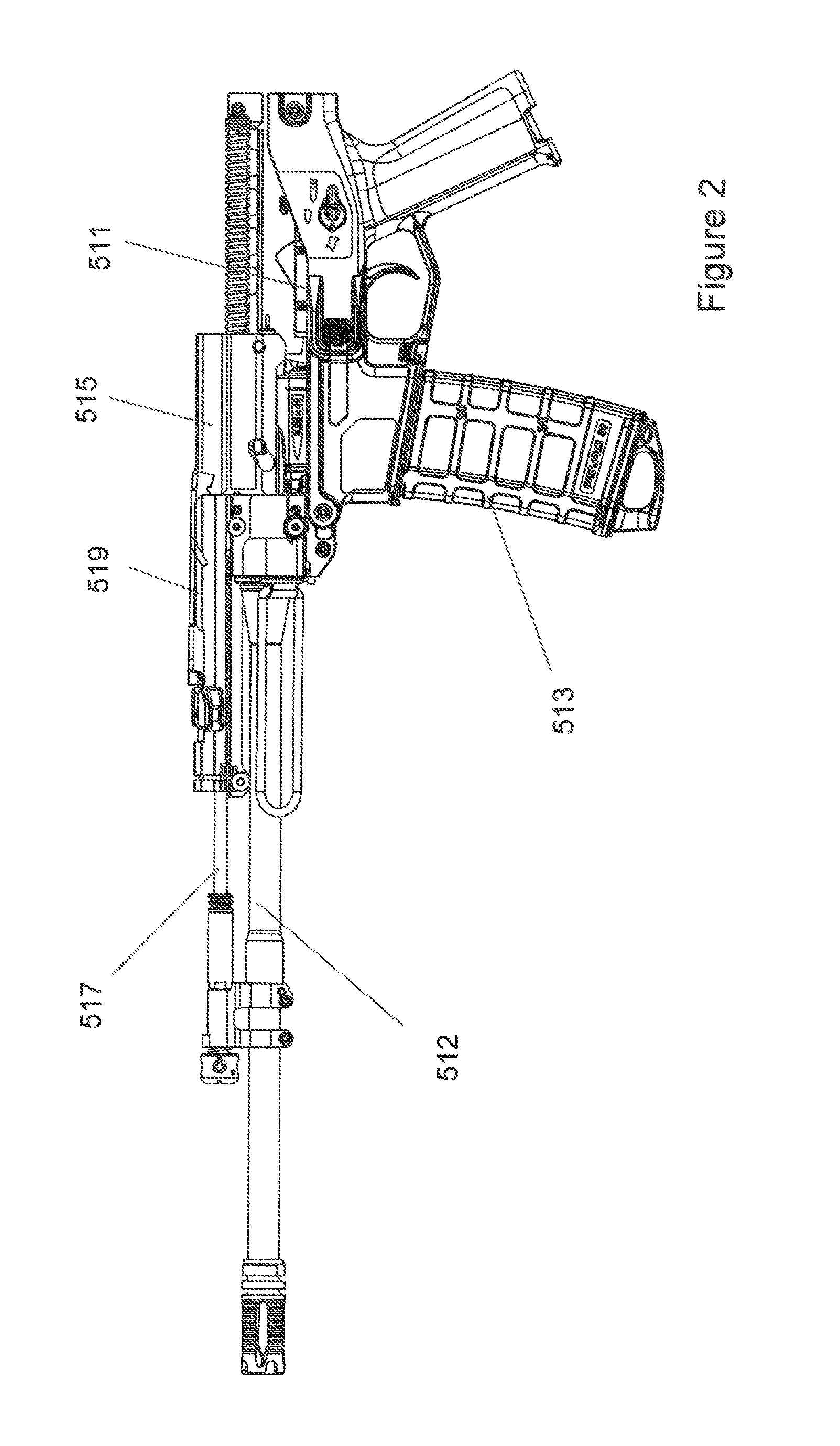

Charging handle with forward assist function

ActiveUS7798045B1Increase costIncrease profitBreech mechanismsBarrel mountingReciprocating motionDetent

The present invention is an improved charging handle for a firearm. The handle is generally non-reciprocating and features a user activated forward assist. The major components are an actuator to provide charging function and upon which other components are mounted, a spring biased lever with a hook which biases downward so that the hook may interface a bolt carrier when the lever is activated, and a blade upon which handle structure is mounted. In the preferred embodiment, the handle is ambidextrous and features a spring detent to keep it in stowed position until the user desires use. The handle will only reciprocate when the lever is activated, which in turn requires intentional user action, thereby providing a relatively safer weapon to operate.

Owner:MAGPUL INDUSTRIES

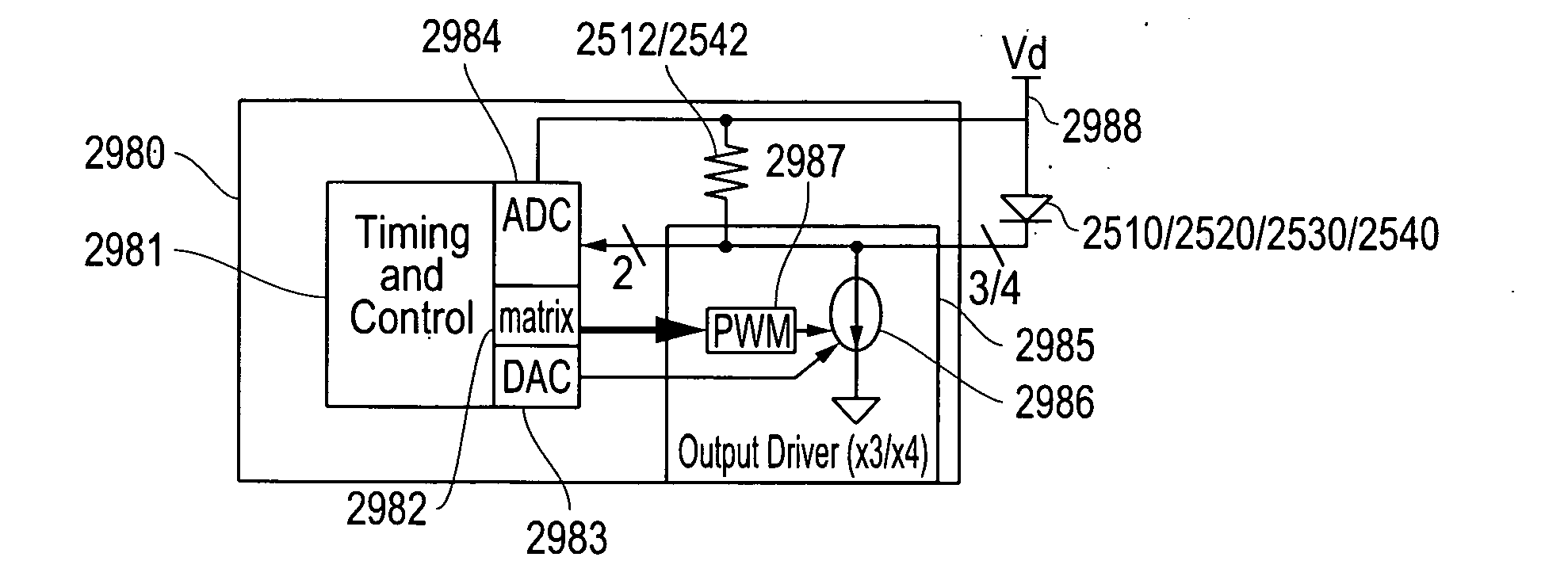

Systems and methods for visible light communication

ActiveUS20110069960A1Low additional costIncreased complexityVehicle testingInstruments for road network navigationLight equipmentPhysical layer

Systems and methods for visible light communication are disclosed. In part, illumination devices and related systems and methods are disclosed that can be used for general illumination, lighting control systems, or other applications. The illumination devices synchronize preferentially to the AC mains to produce time division multiplexed channels in which control information can be communicated optically by the same light source that is producing illumination. Such illumination devices preferentially comprise LEDs for producing illumination, transmitting data, detecting ambient light, and receiving data, however, other light sources and detectors can be used. The physical layer can be used with a variety of protocols, such as ZigBee, from the Media ACcess (MAC) layer and higher.

Owner:LUTRON TECH CO LLC

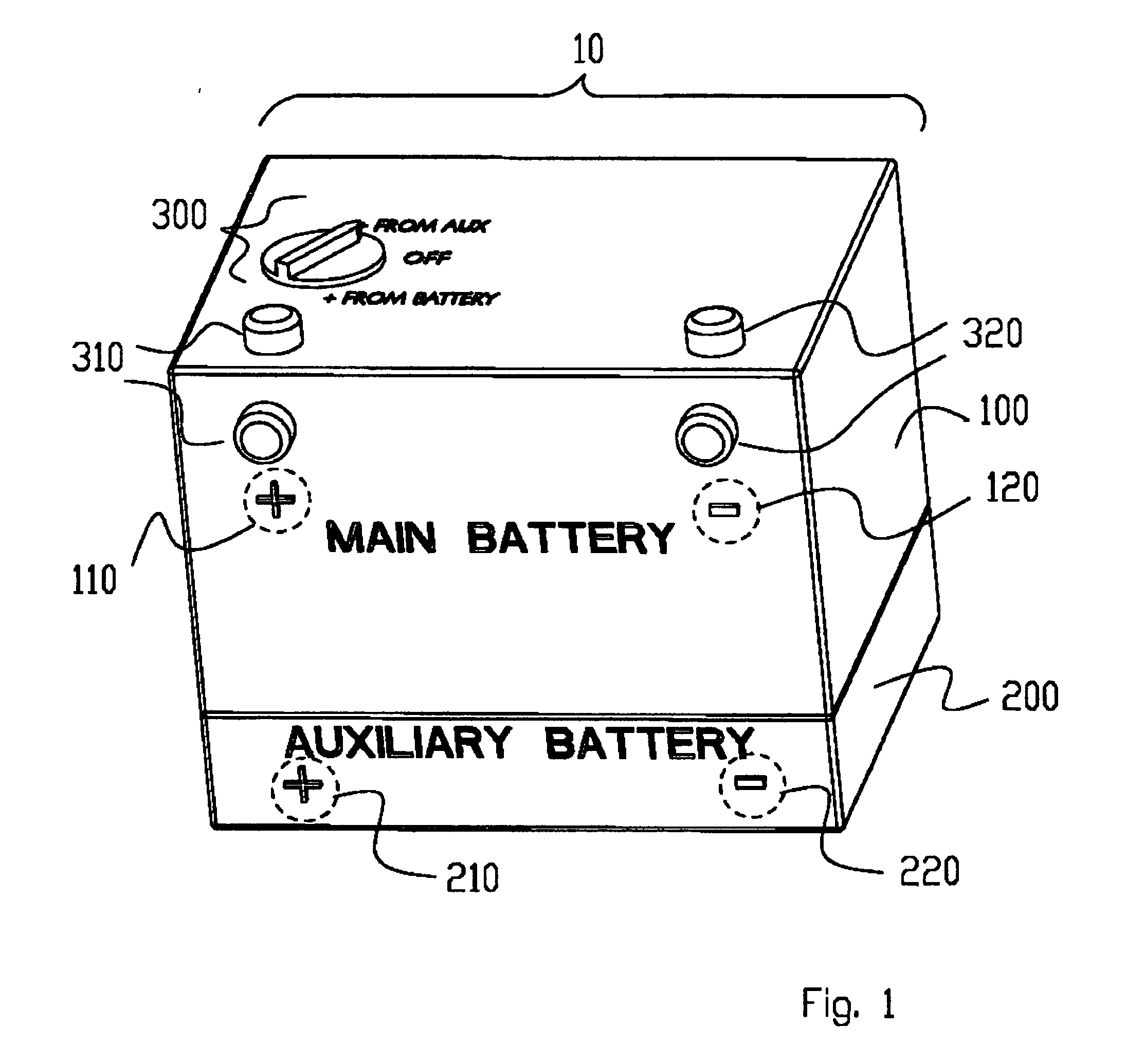

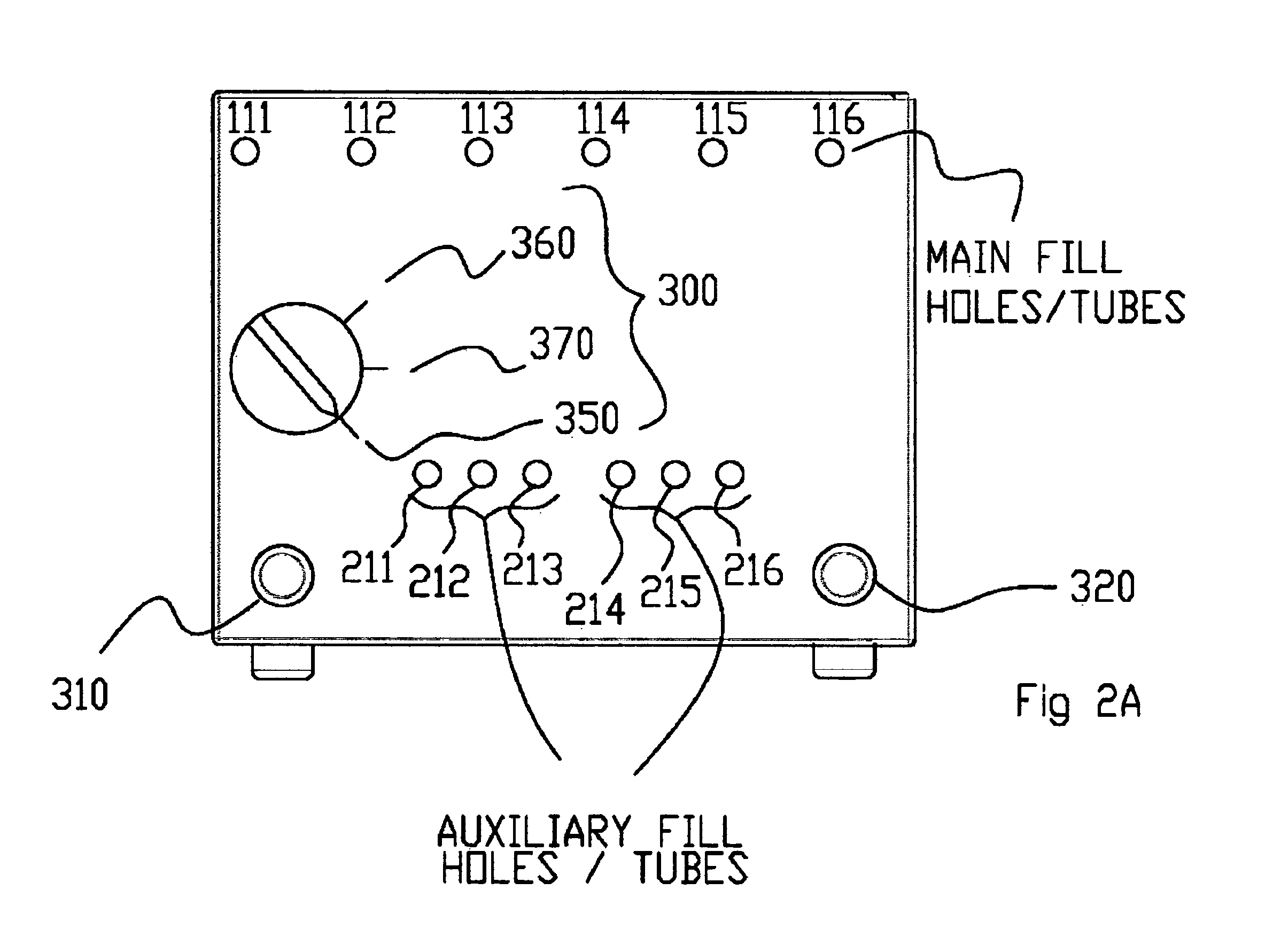

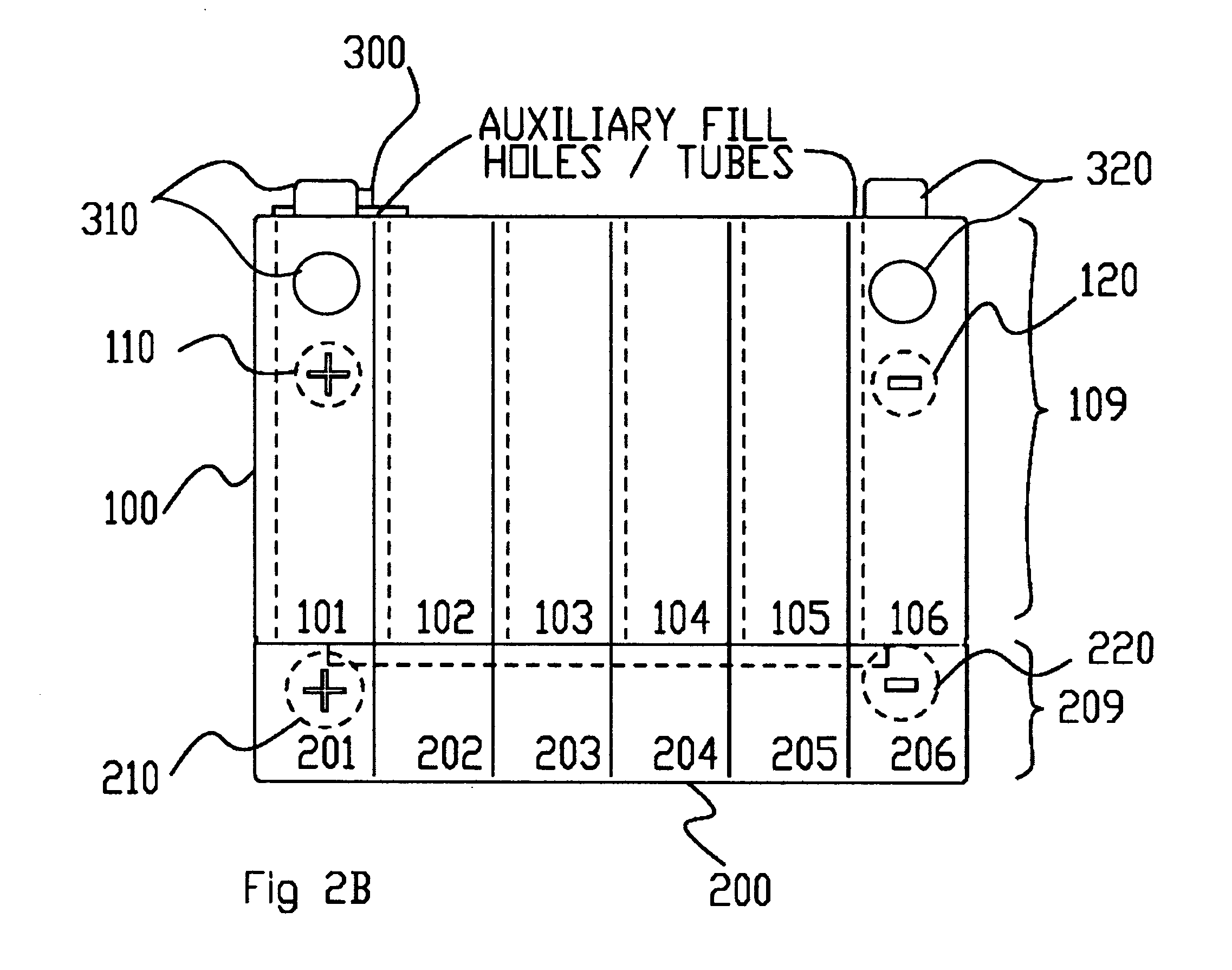

Multiple battery management system, auxiliary battery attachment system, and network controlled multiple battery system

InactiveUS20050035741A1Start fastIncrease costCharge equalisation circuitElectric devicesNetwork controlEngineering

The instant invention is directed to a multiple battery system and network controlled multiple battery system. A main battery having a main positive output and a main negative output is also provided, together with an at least one auxiliary battery having an at least one auxiliary positive output and an at least one auxiliary negative output. A main electrical circuit having an at least one switching device is provided with at least two operating positions. The two operating positions selectively couple the main and at least one auxiliary battery to the common positive terminal. In the first of the at least two operating positions electrical charge is provided to both the main battery and the at least one auxiliary battery. A controller is also provided and coupled to the main electrical circuit and switches the at least one switching device based on input from an at least one sensor.

Owner:RESERVE POWER CELL

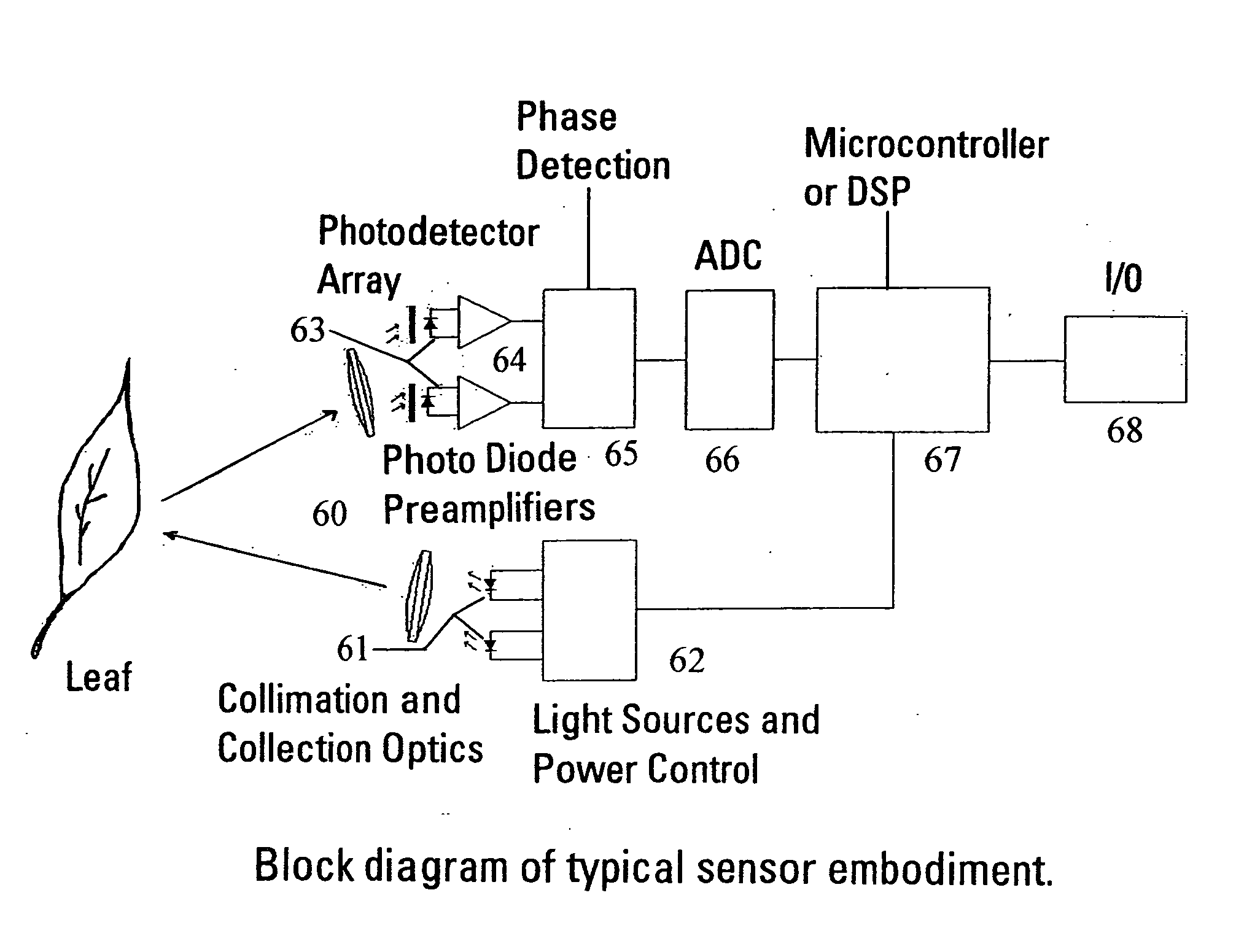

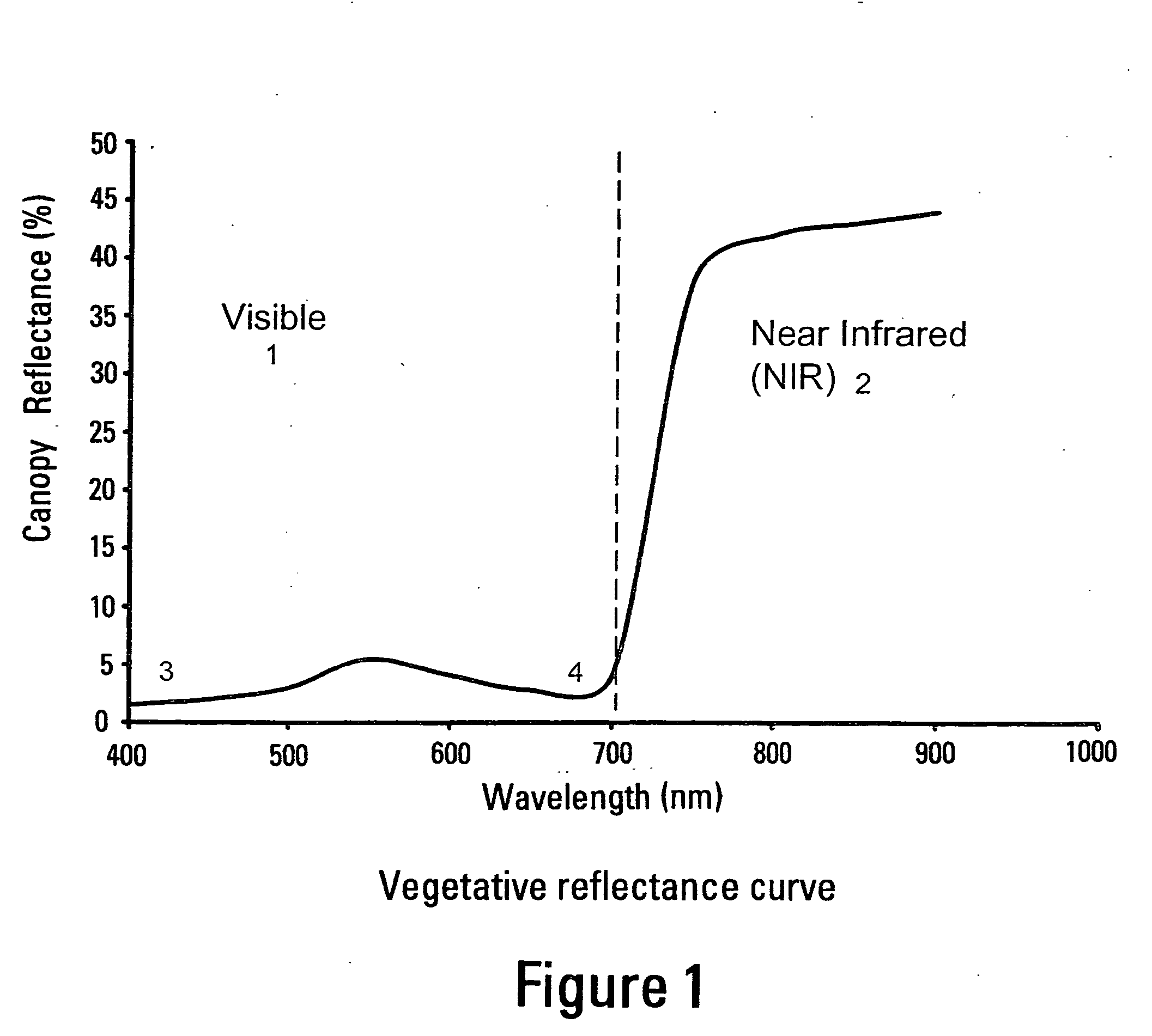

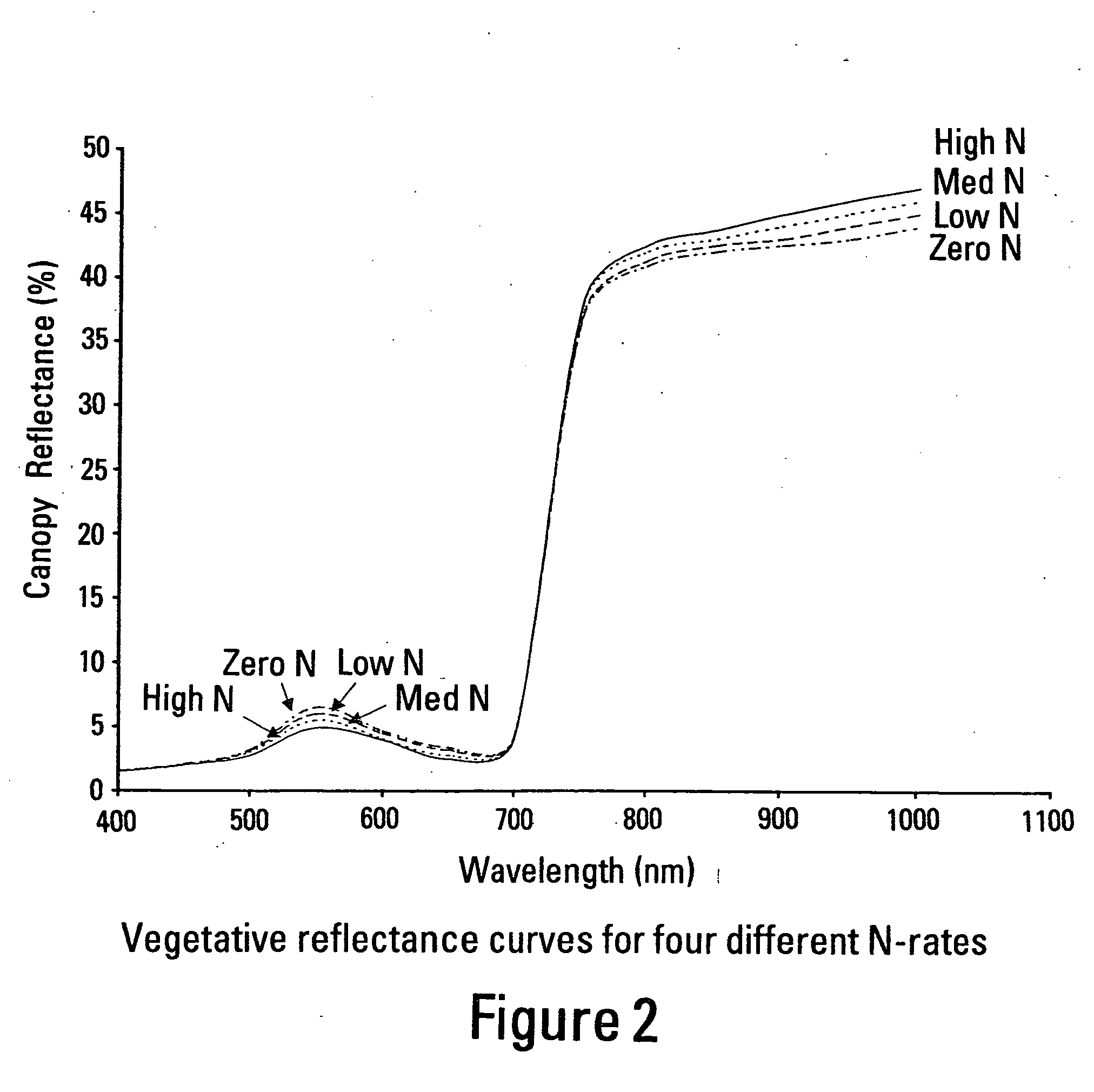

Light sensor with modulated radiant polychromatic source

ActiveUS20050098713A1Increase costImprove performancePhotometry using reference valueRadiation pyrometryDetector arrayAnalytical control

An apparatus is described for assessing plant status using biophysical and biochemical properties of the plant remotely sensed by the invention thereby allowing selective monitoring, elimination or treatment of individual plants. In a preferred embodiment, a single polychromatic emitter provides coincident light beams; one beam substantially in the visible portion of the spectrum (400 nm to 700 nm) and the other in the near infrared (NIR) portion of the spectrum (700 nm to 1100 nm). This light beam illuminates a small surface area on the ground, which may be bare ground, desired plants or undesired weeds. The beam of light may be focused, collimated or non-focused. A detector array, usually composed of a visible detector and a NIR detector, detects portions of this polychromatic light beam reflected by the surface area and provides a signal indicative of whether the detected light was reflected by a plant or by some non-plant object such as soil. A controller analyzes this signal and, assuming a plant is detected, responds by activating a device to take some action with respect to the plant or stores the analyzed signal with corresponding DGPS position in the controller's memory for later analysis. A number of actions may be taken by the controller. For instance, if the plant is a weed, the desired action might be to spray herbicide on the weed. Or, if the plant is a crop that is determined to be lacking in nutrient, the desired action may be to apply fertilizer. Additionally, if the plant under test is a turf landscape, such as found on golf courses and sporting fields, plant biomass may be mapped and geo-located using GPS for later, comparative analysis.

Owner:KYLE H HOLLAND TRUSTEE OF THE MARANATHA TRUST DATED JULY 30 2013

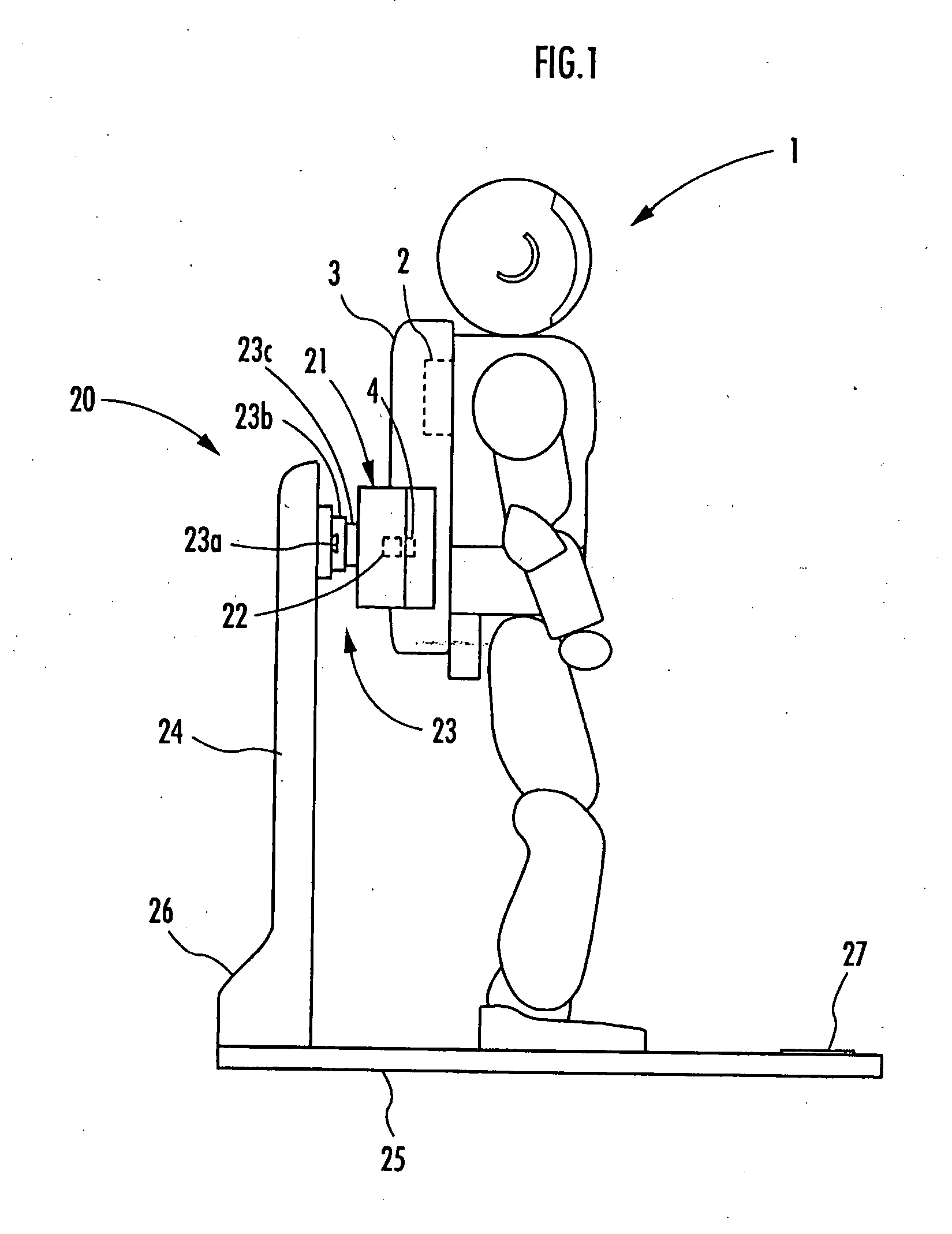

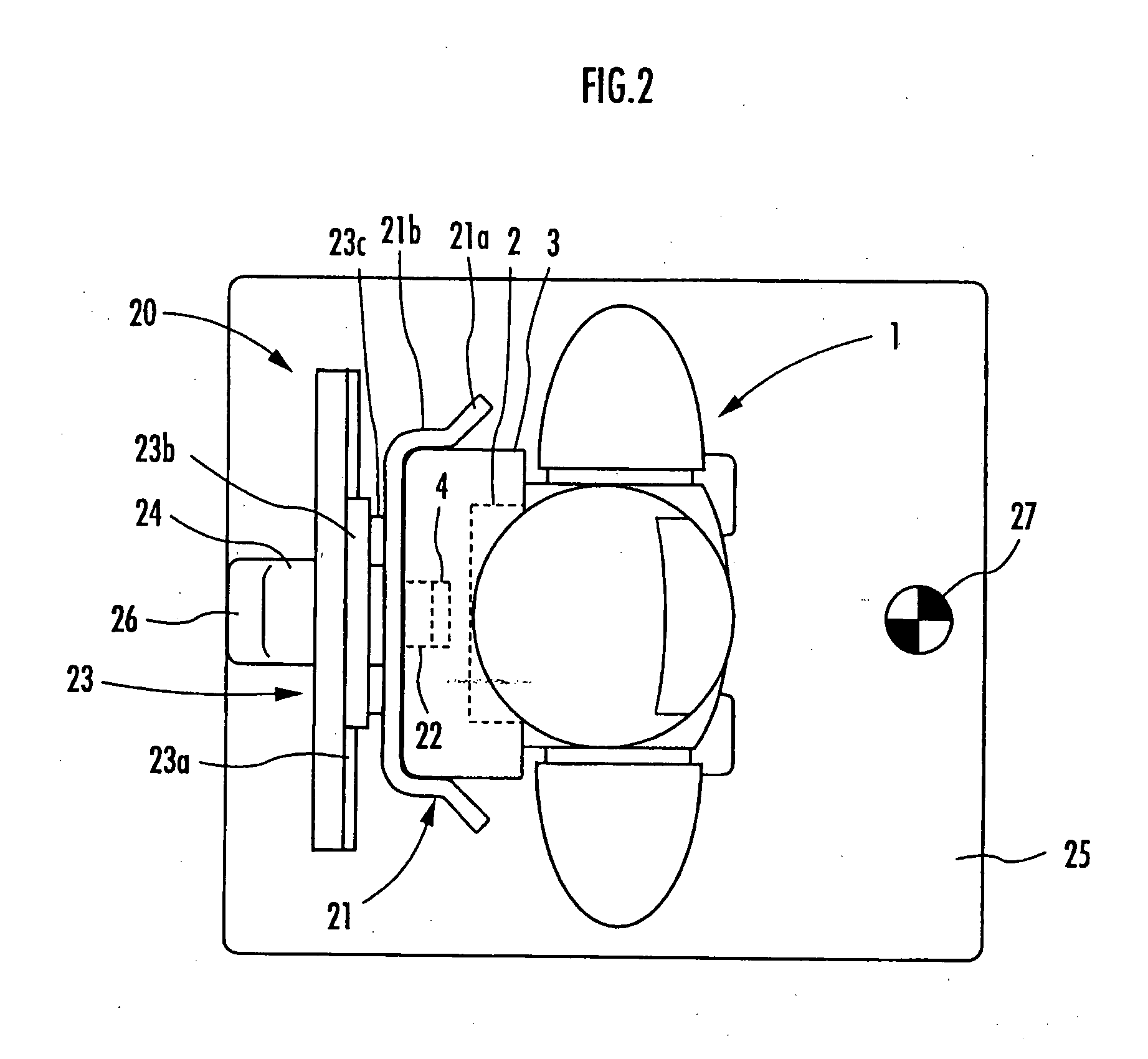

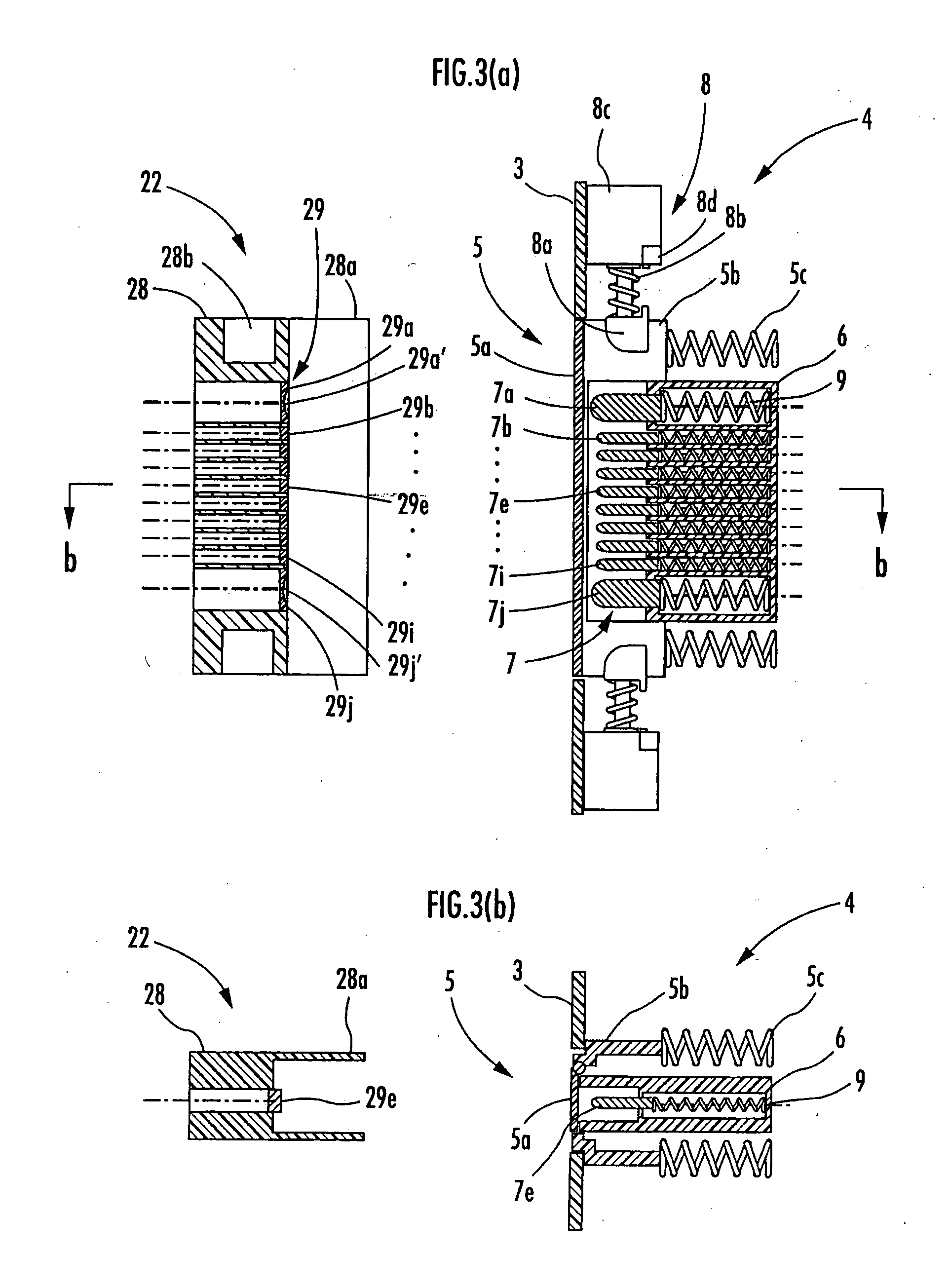

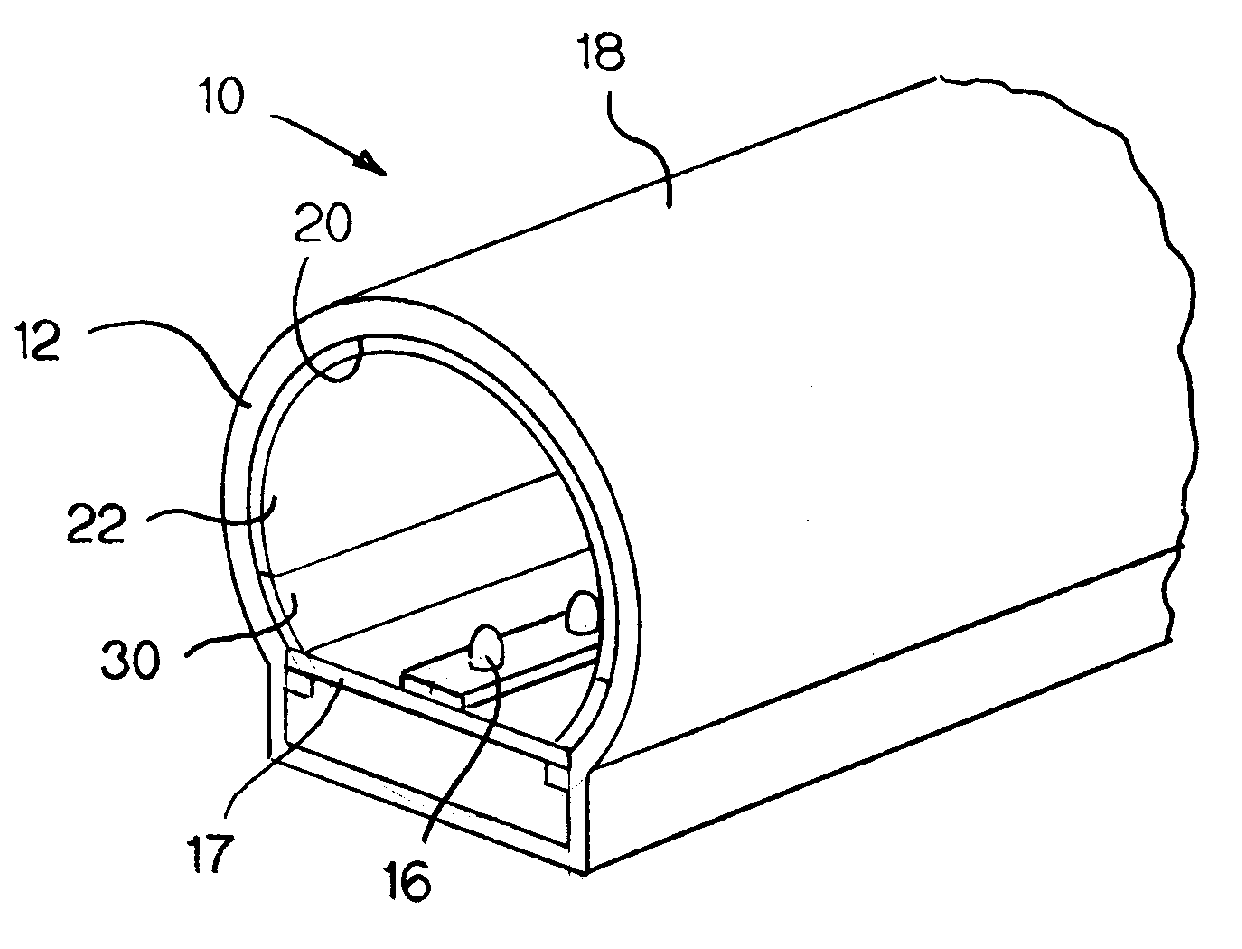

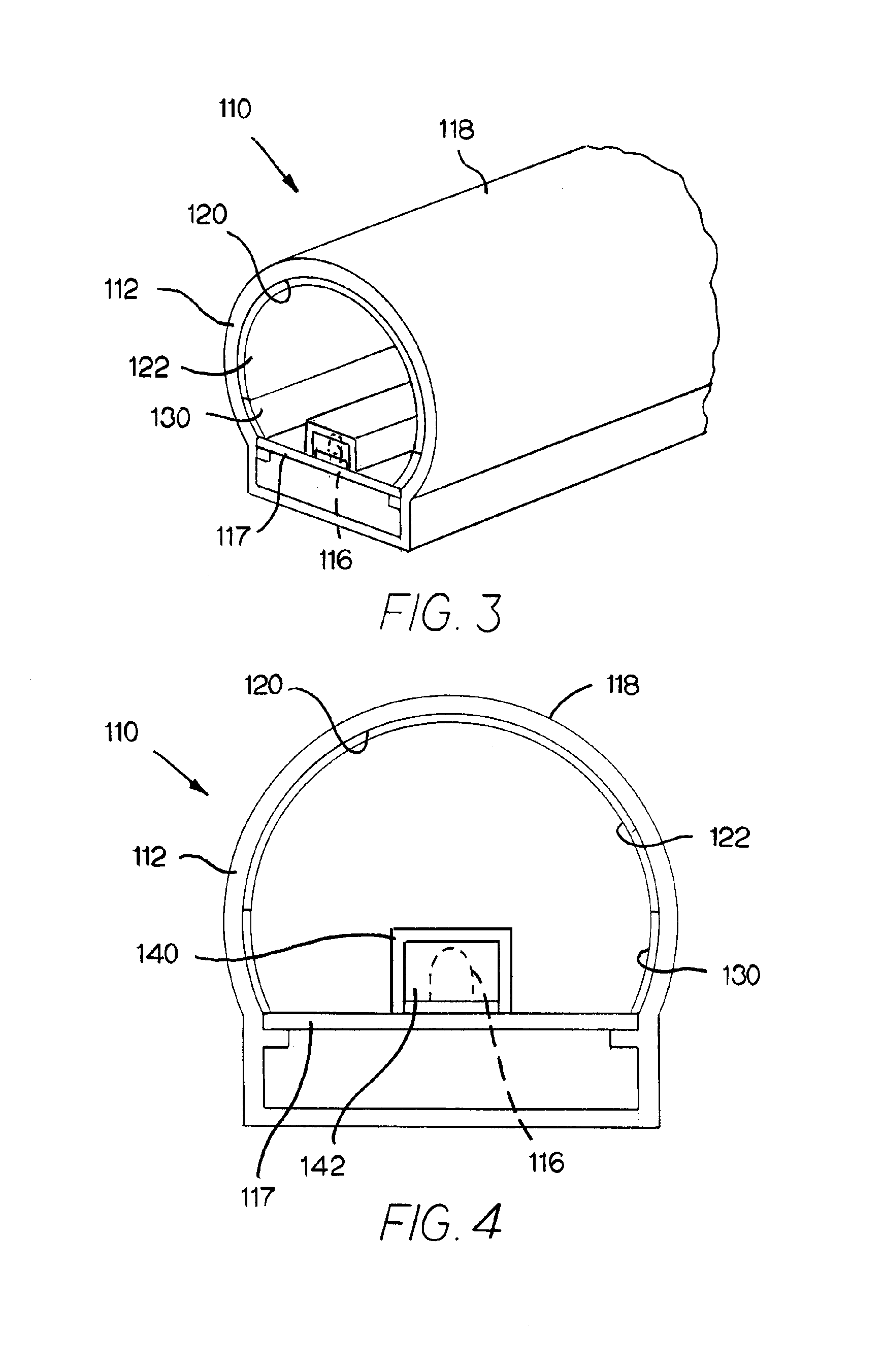

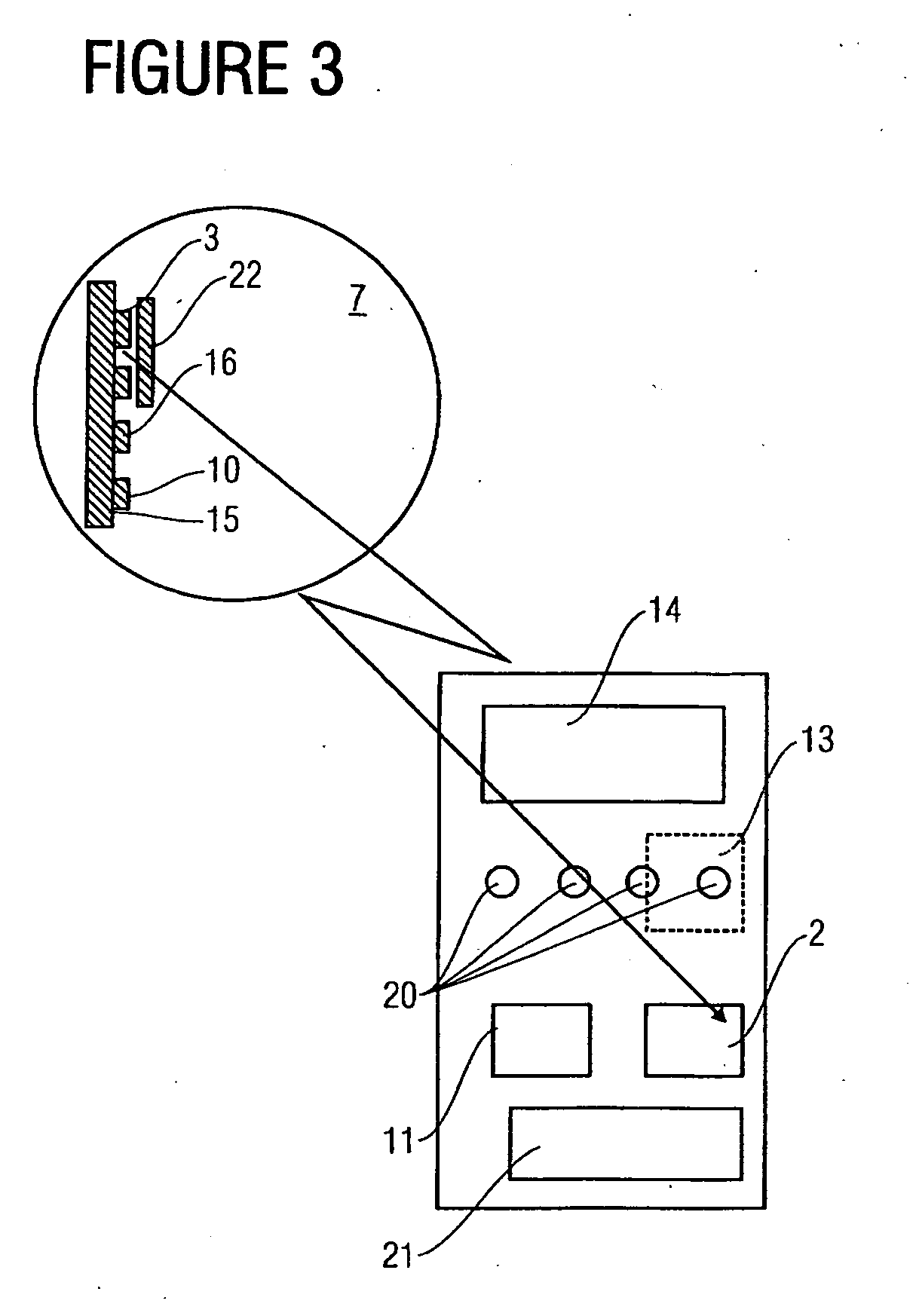

Charging system for legged mobile robot

InactiveUS20070216347A1Increase costHelp positioningBatteries circuit arrangementsCharging stationsCharging stationElectrical and Electronics engineering

A charging system for a legged mobile robot that facilitates positioning of a robot to be charged and does not put a load on the robot is provided. The charging system includes a battery 2, a power receiving connector 4 and a movable shutter member 5 capable of being opened and closed on a rear cover 3, which are provided on a robot 1, and a holder 21, a power supplying connector 22, a slide mechanism 23, a base plate 25, a charging power supply 26 and the like, which are provided on a charging station 20. The robot 1 performs a predetermined positioning on the base plate 25 and then moves the center of gravity rearward to connect the power receiving connector 4 to the power supplying connector 22. In this step, when the rear cover 3 of the robot 1 is guided by a first guide section 21a of the holder 21, the slide mechanism 23 allows the holder 21 to move horizontally. Thus, even if the robot 1 and the charging station 20 are slightly misaligned with each other, the robot 1 can be easily positioned correctly.

Owner:HONDA MOTOR CO LTD

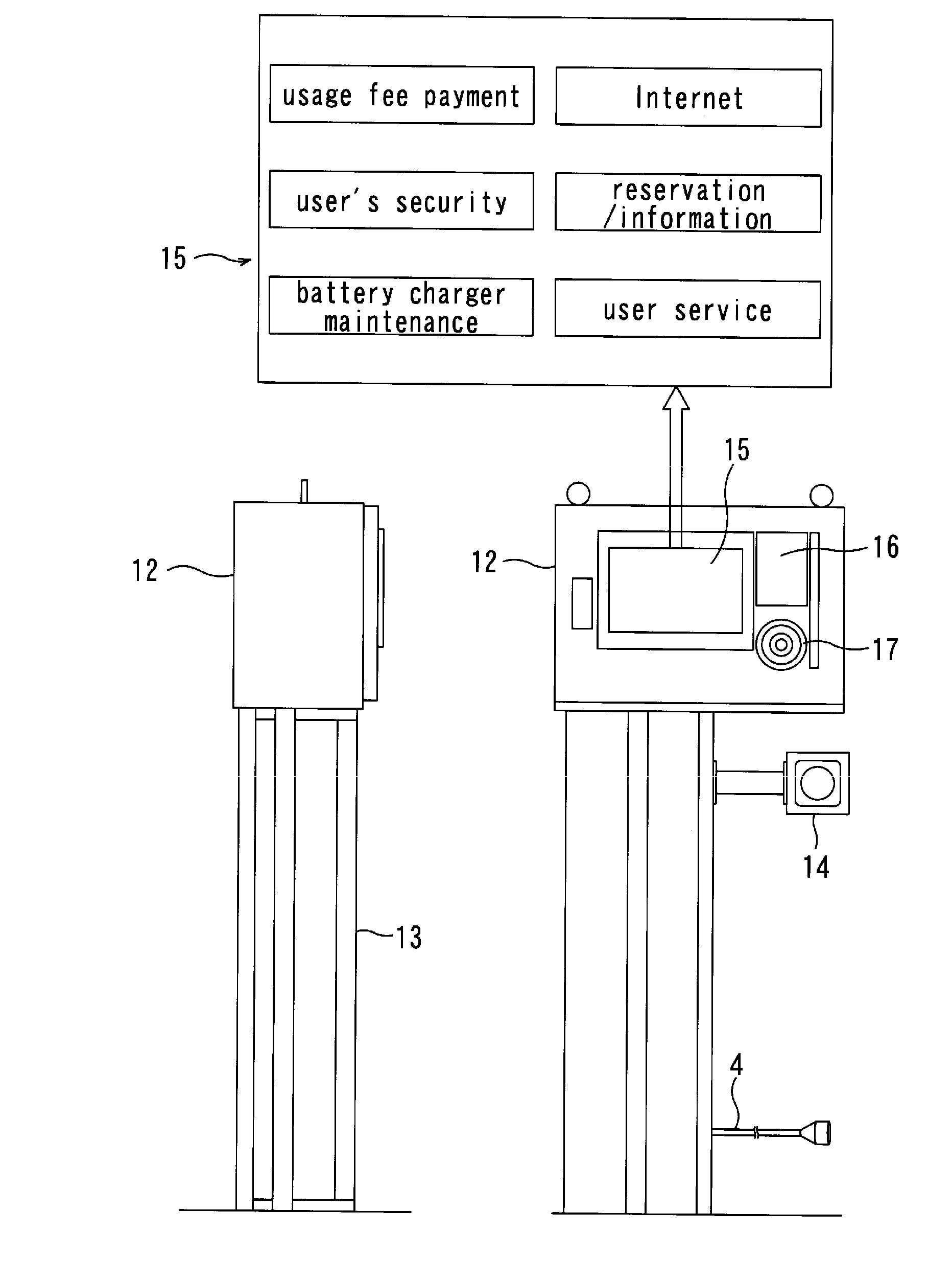

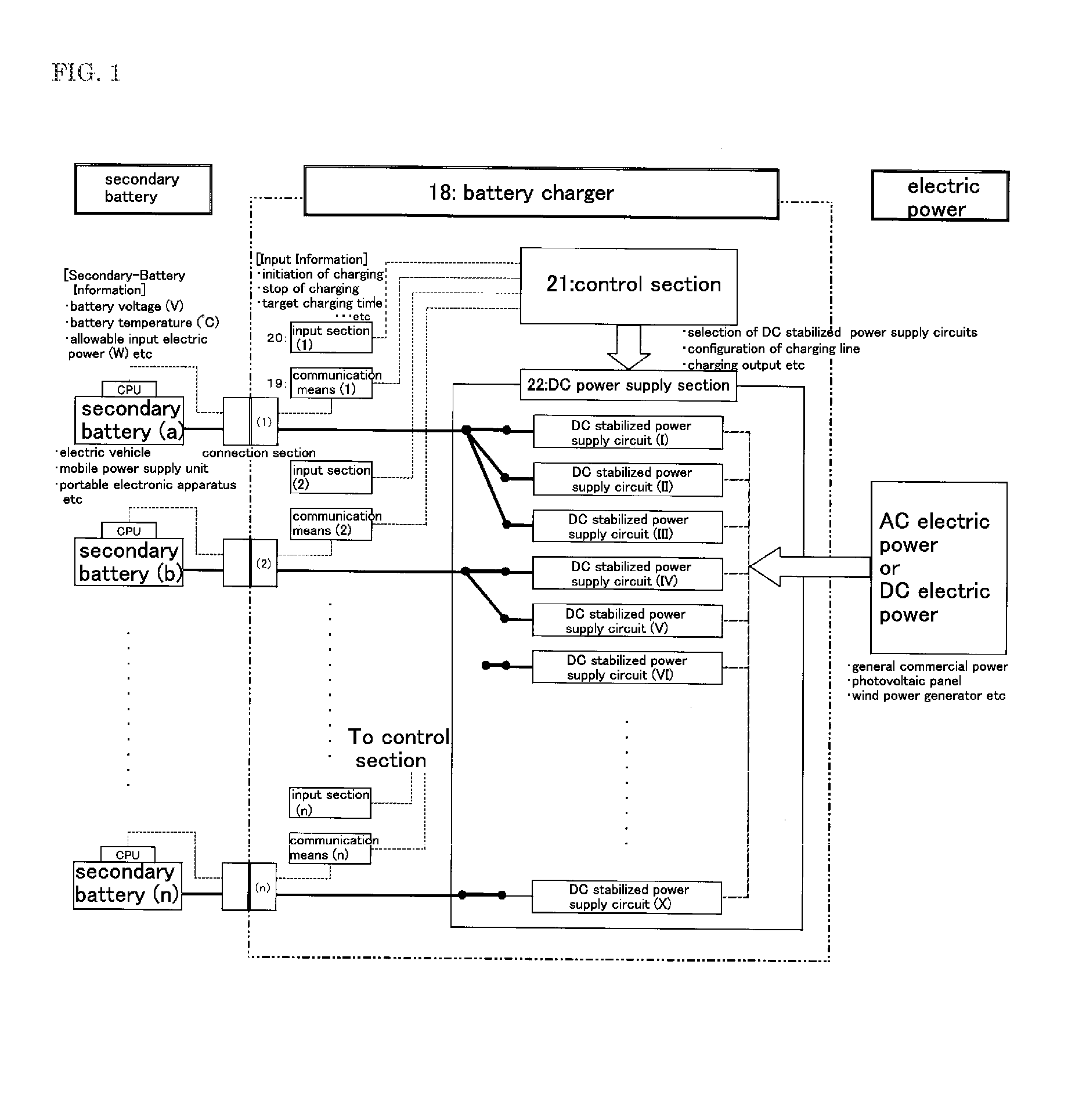

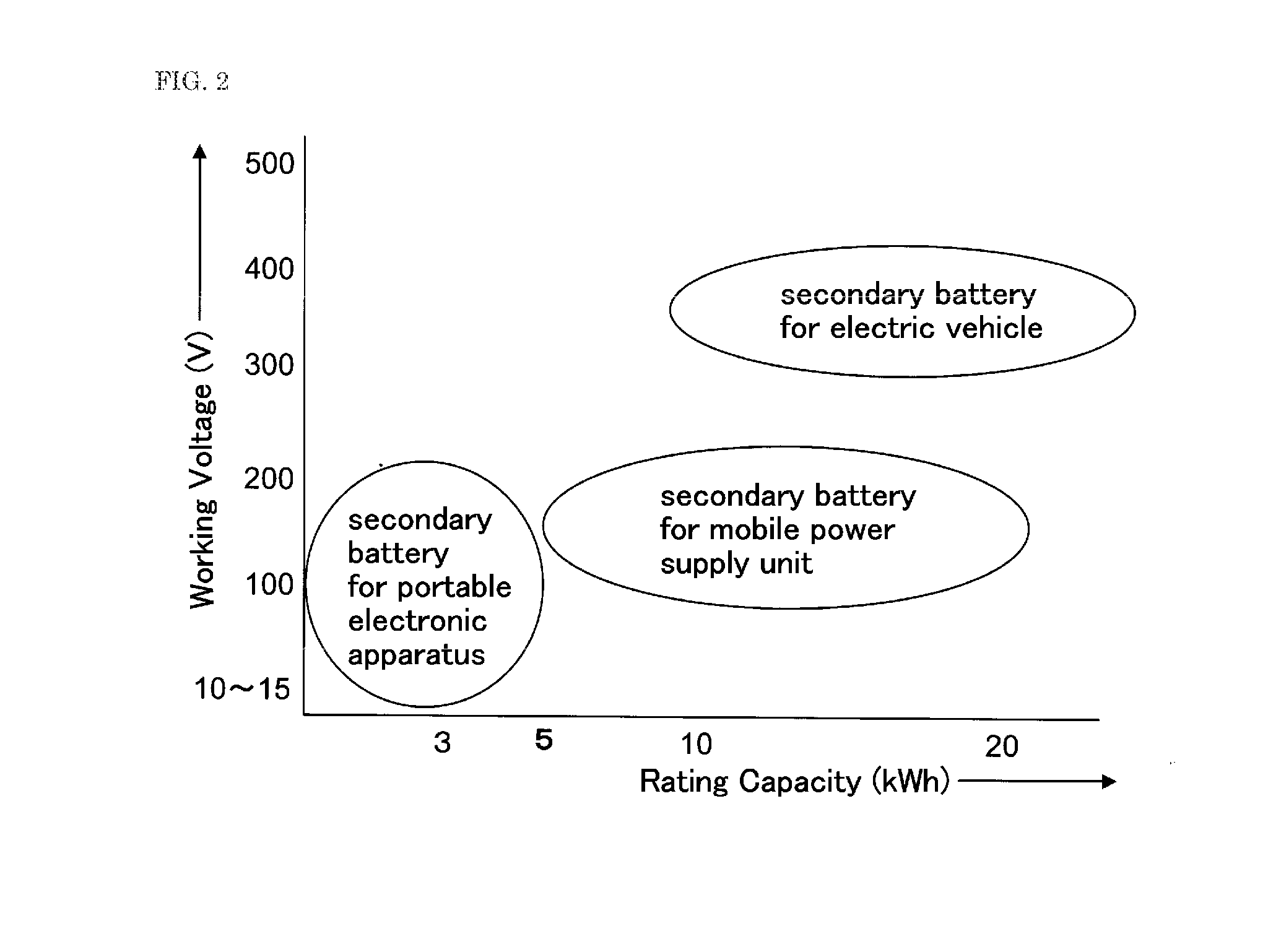

Battery charger

InactiveUS20100106631A1Increase costHigh outputHybrid vehiclesSecondary cells charging/dischargingElectrical batteryElectric power system

The present invention provides a battery charger capable of charging a plurality of secondary batteries which are used in different types of apparatuses, such as an electric vehicle and a mobile power supply unit, in a simultaneous or concurrent manner without largely occupying an installation space on the ground. A DC power supply section 22 includes a plurality of DC stabilized power supply circuits each operable to supply an output according to required electric power, therefrom in an independent manner. Specifically, based on information from each of a plurality of secondary batteries, and information set up / input through a setup / input section, one of or a combination of two or more of the DC stabilized power supply circuits is selected for each of the secondary batteries. Then, an electric power supply line between the selected one of or the selected combination of two or more of the DC stabilized power supply circuits and each of the secondary batteries to be charged is configured, and an output of the selected one of or the selected combination of two or more of the DC stabilized power supply circuits is adjusted. This makes it possible to configure respective electric power supply lines for the secondary batteries to allow the secondary batteries to be concurrently charged, and adjust respective electric power amounts to be supplied to the secondary batteries, individually.

Owner:KYUSHU ELECTRIC POWER CO INC

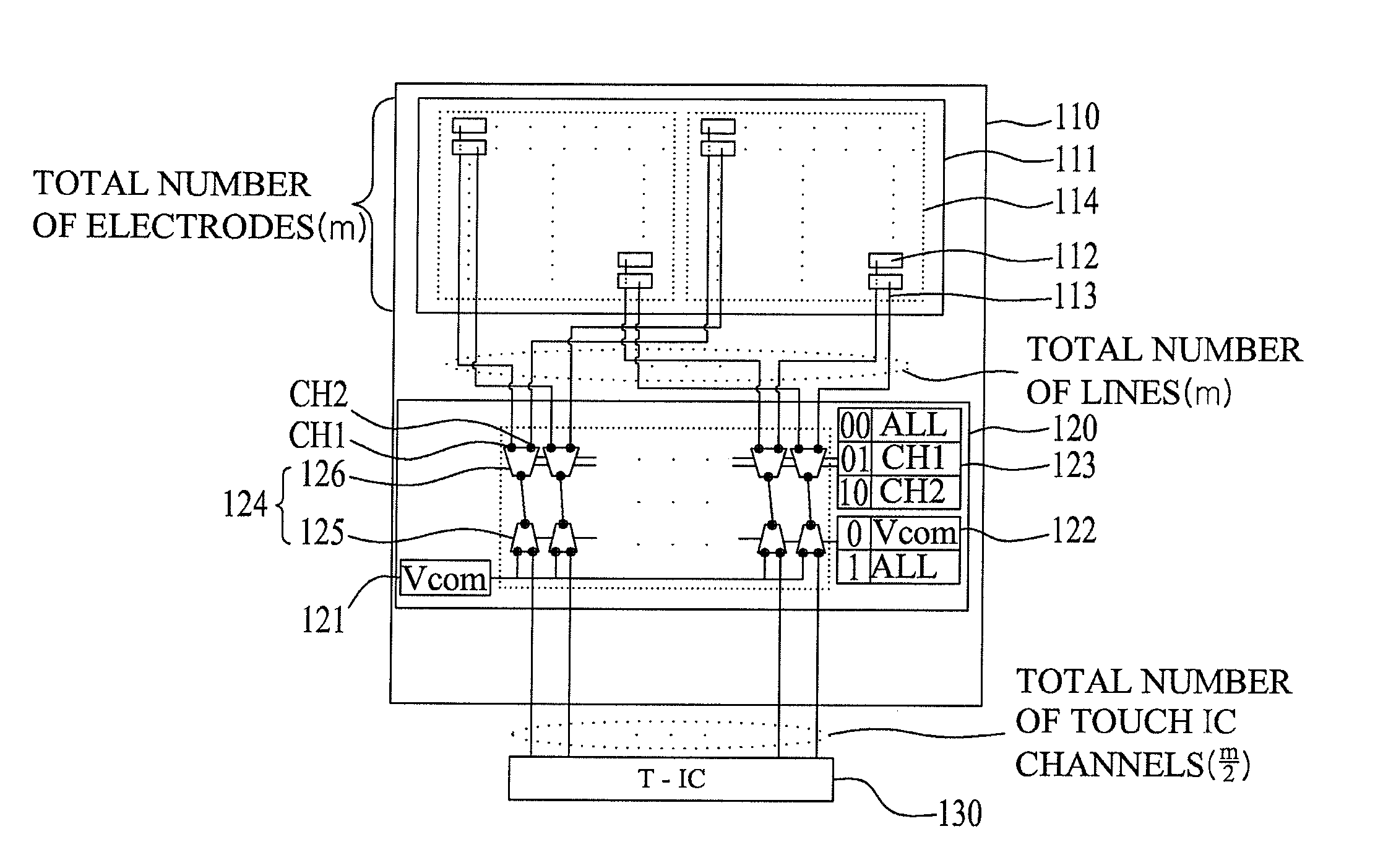

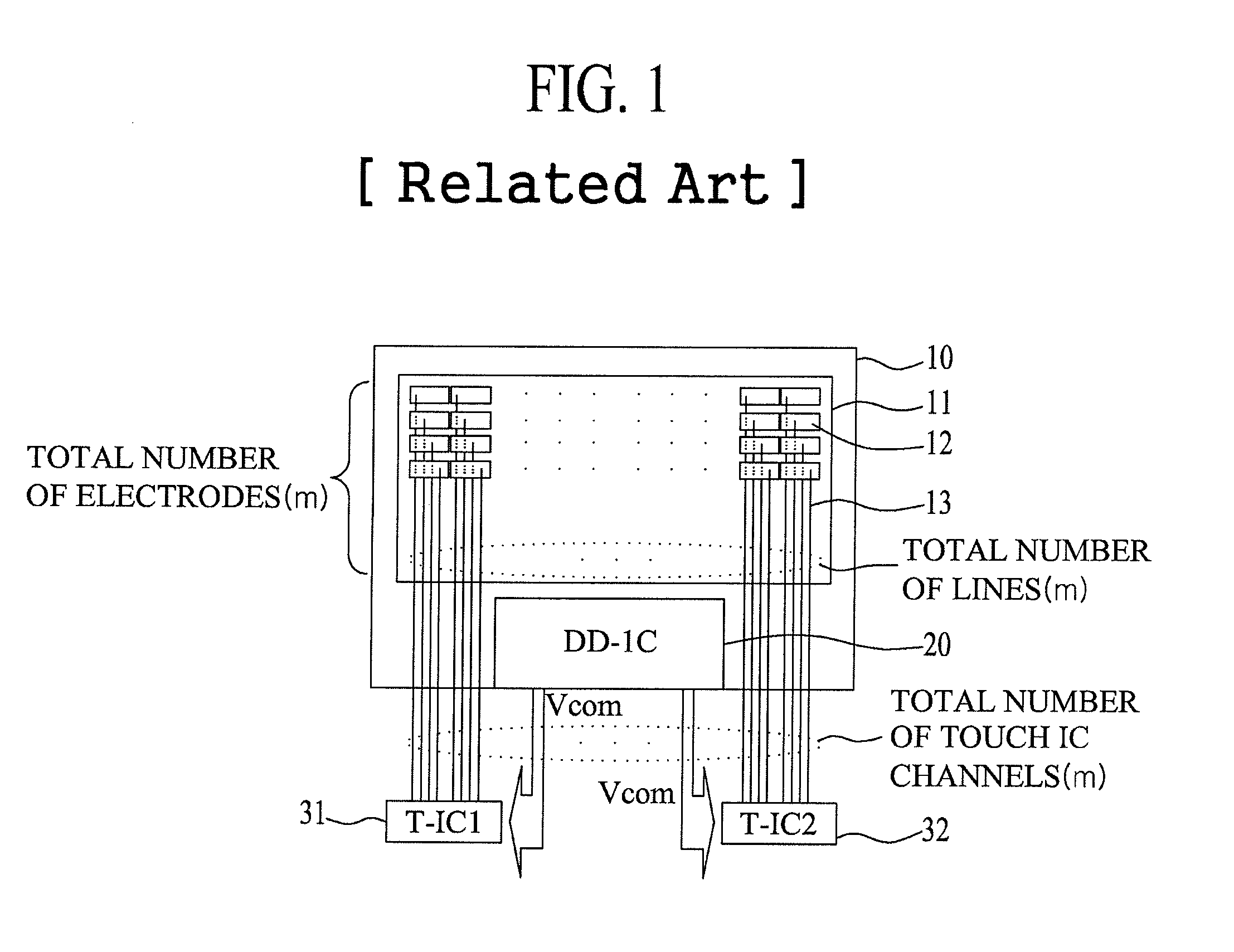

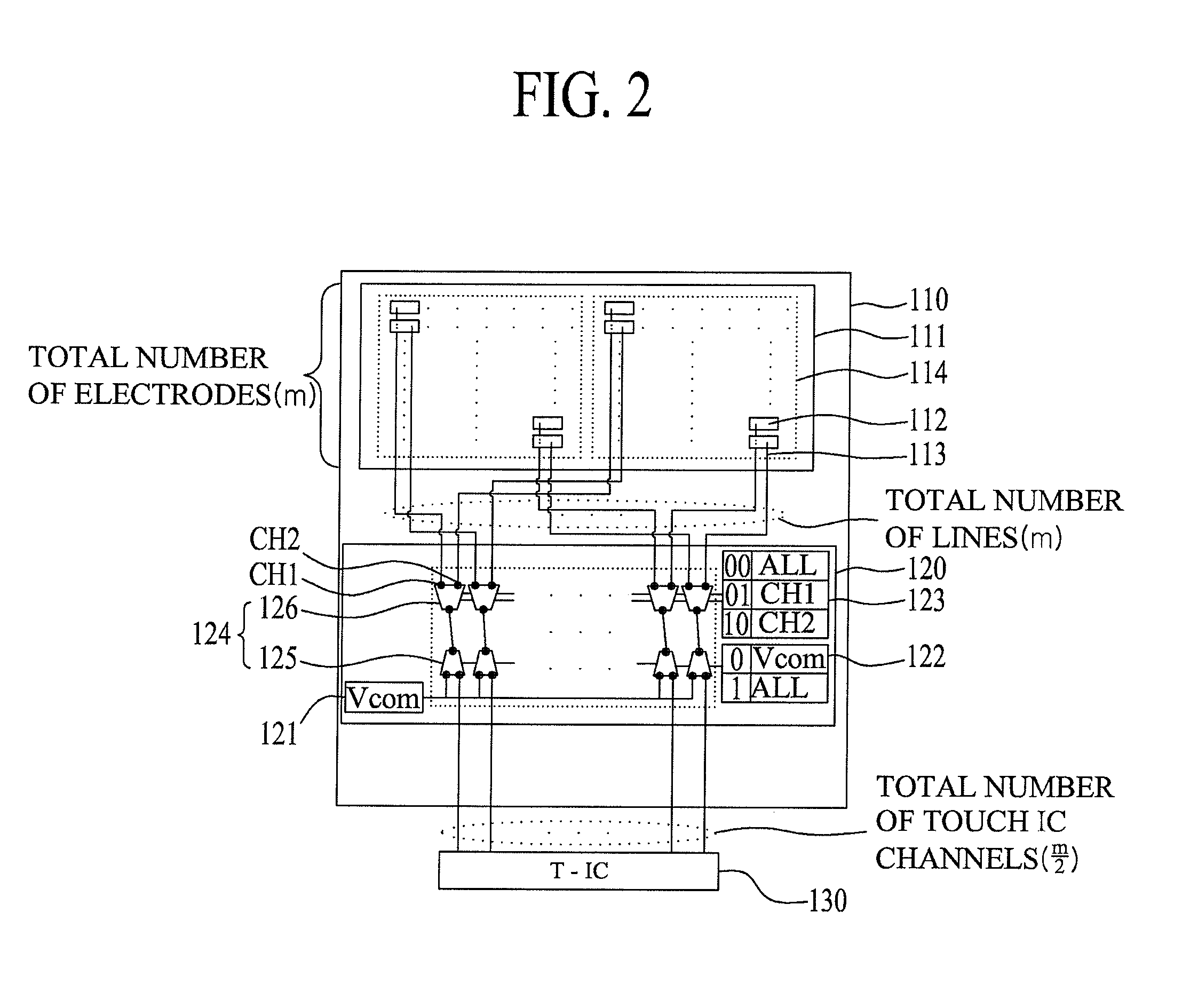

Display device with integrated touch screen and method for driving the same

ActiveUS20130215075A1Increase costReduce in quantityStatic indicating devicesNon-linear opticsComputer scienceDriving mode

Discussed are a display device with an integrated touch screen and a method of operating the same. The display device according to an embodiment includes a display panel including a plurality of pixel electrodes; a touch screen including m number of electrodes which are formed to overlap with the plurality of pixel electrodes, wherein m is a multiple of n, and n is an integer equal to or greater than two, and wherein the m electrodes are divided into n number of electrode groups; a touch driver configured to generate a touch scan signal and to supply the generated touch scan signal to a display driver; and the display driver configured to apply a common voltage or the touch scan signal to one or more of the m electrodes depending on a driving mode of the display device.

Owner:LG DISPLAY CO LTD

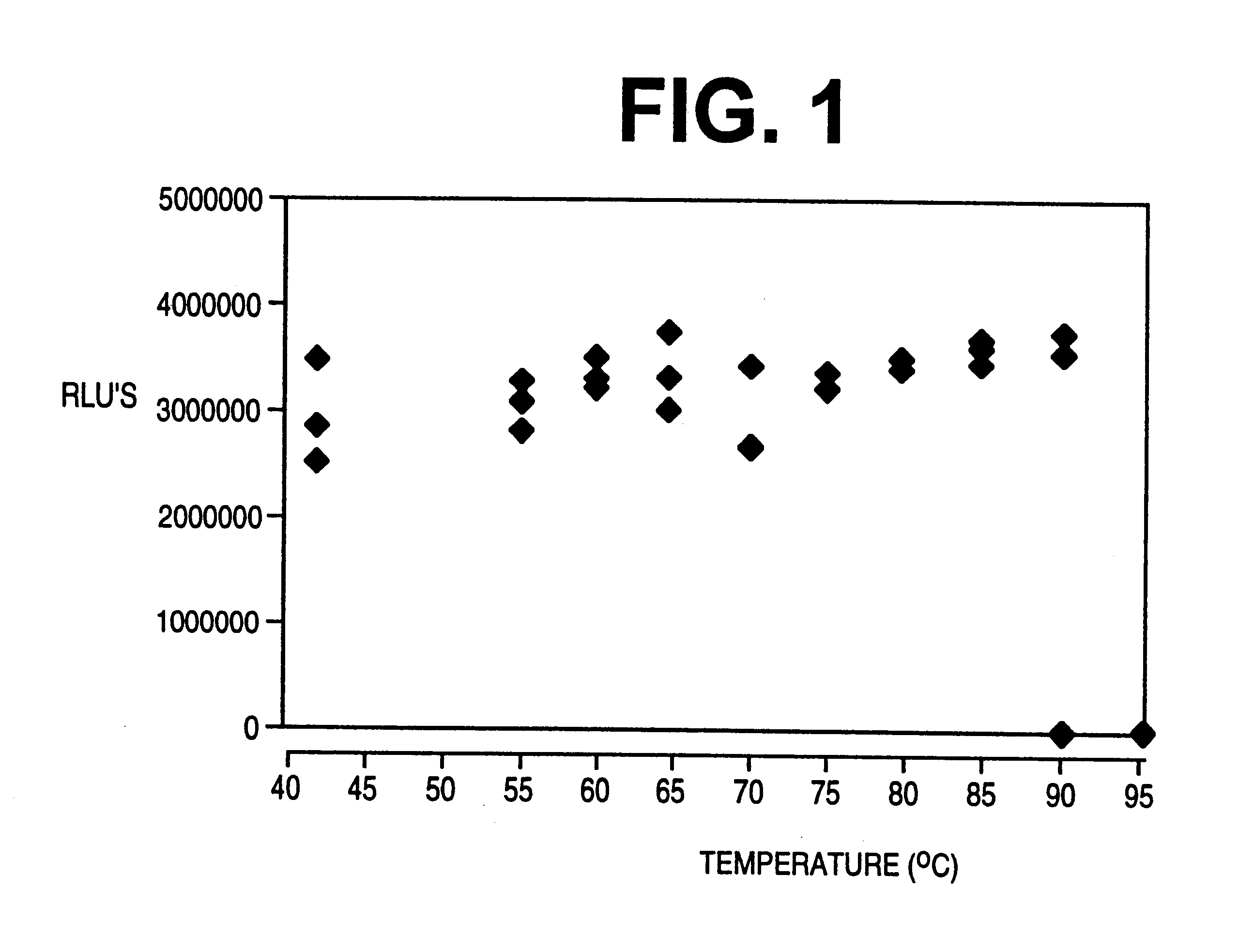

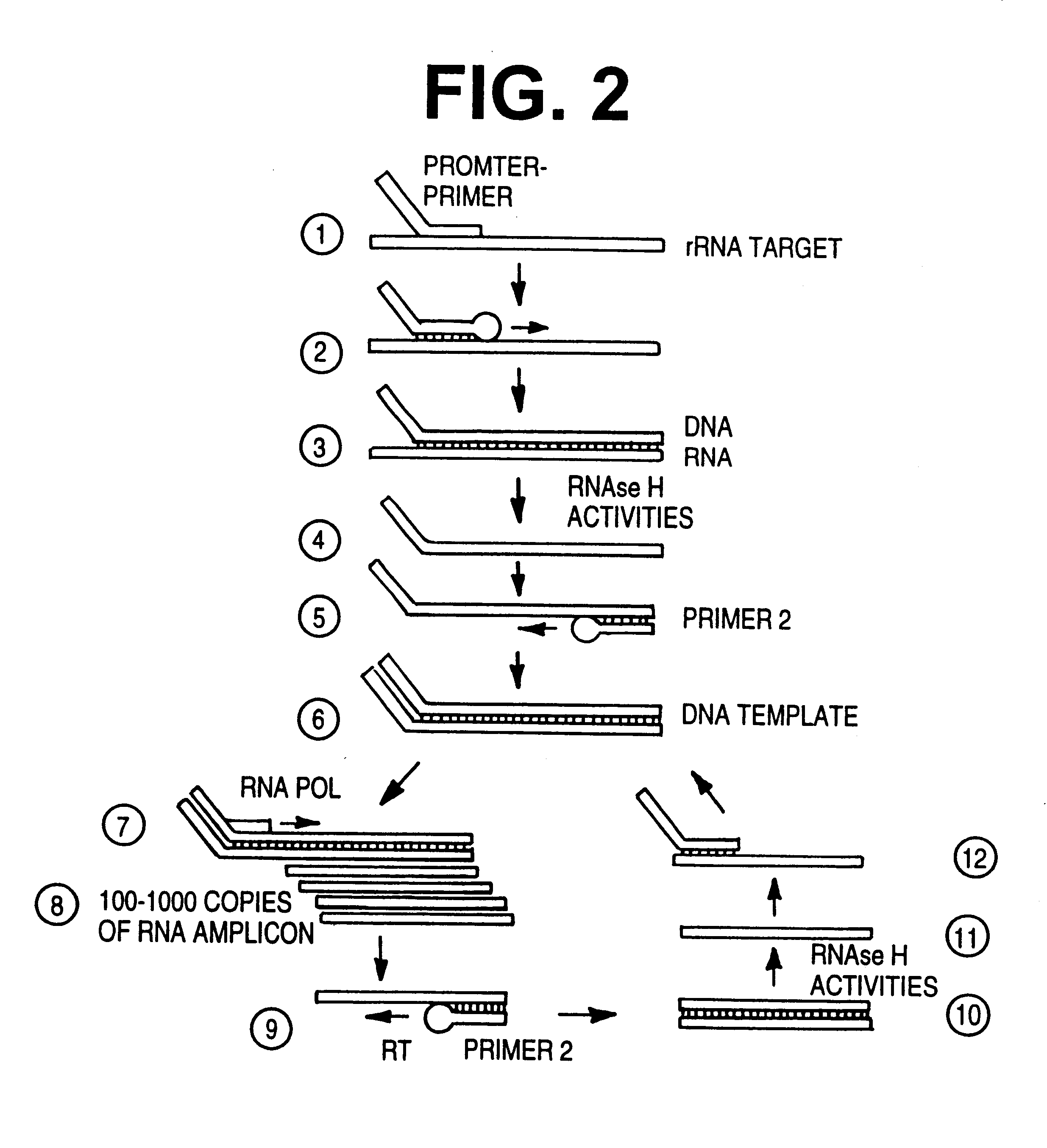

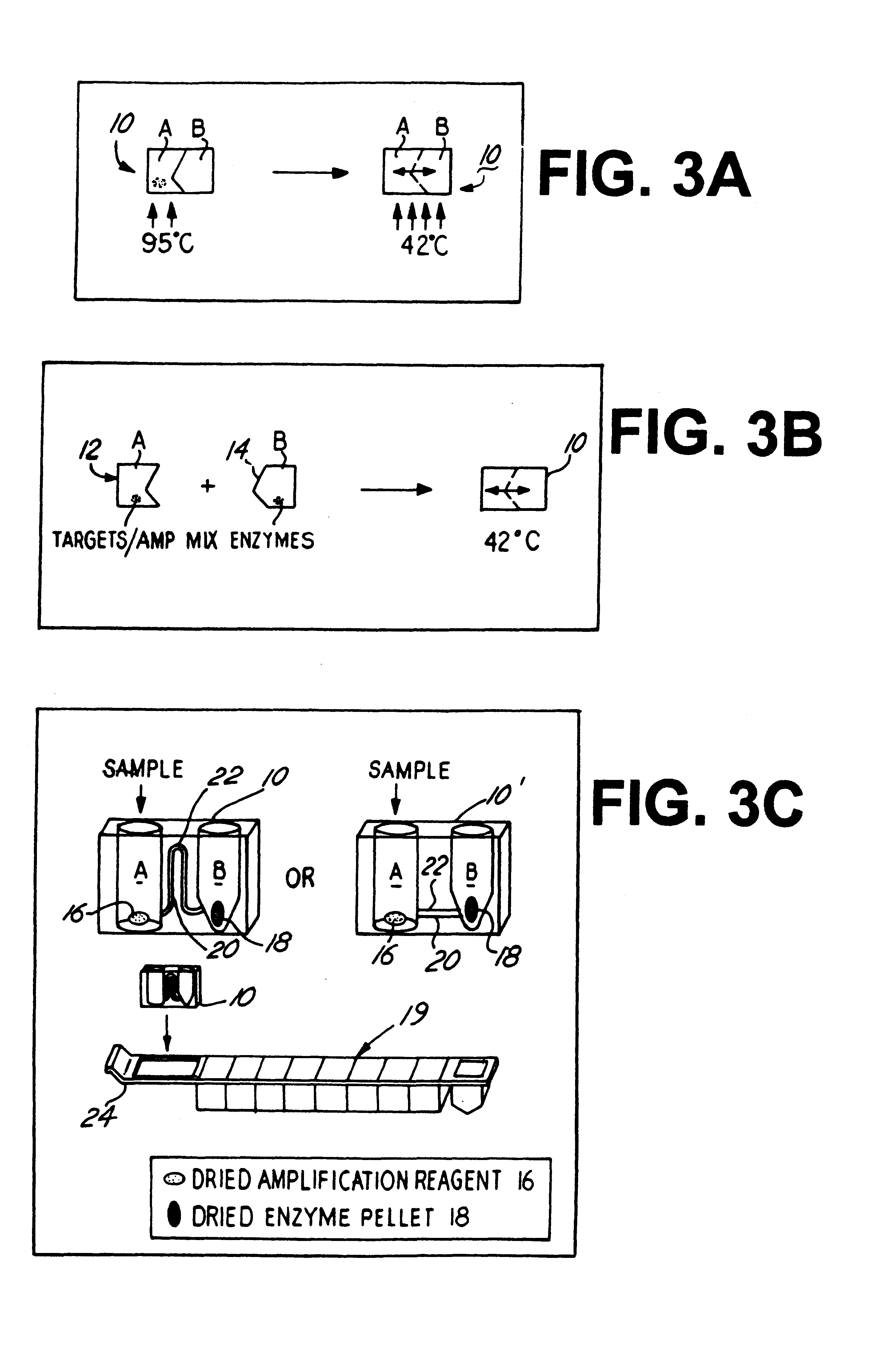

Nucleic acid assays

InactiveUS6300068B1Increase costExtension of timeMicrobiological testing/measurementMicroorganism based processesNucleic acid sequencingBiology

The present invention relates to the detection of specific nucleic acid sequences after an amplification process, or directly without amplification. In particular, the invention provides for the automation of the amplification and detection process, the amplification and detection of one or more specific nucleic acid sequences, the use of internal controls, reduced potential for contamination caused by the manual manipulation of reagents, and improved reagent compositions to better control assay performance and provide for further protection against contamination.

Owner:BIOMERIEUX VITEK

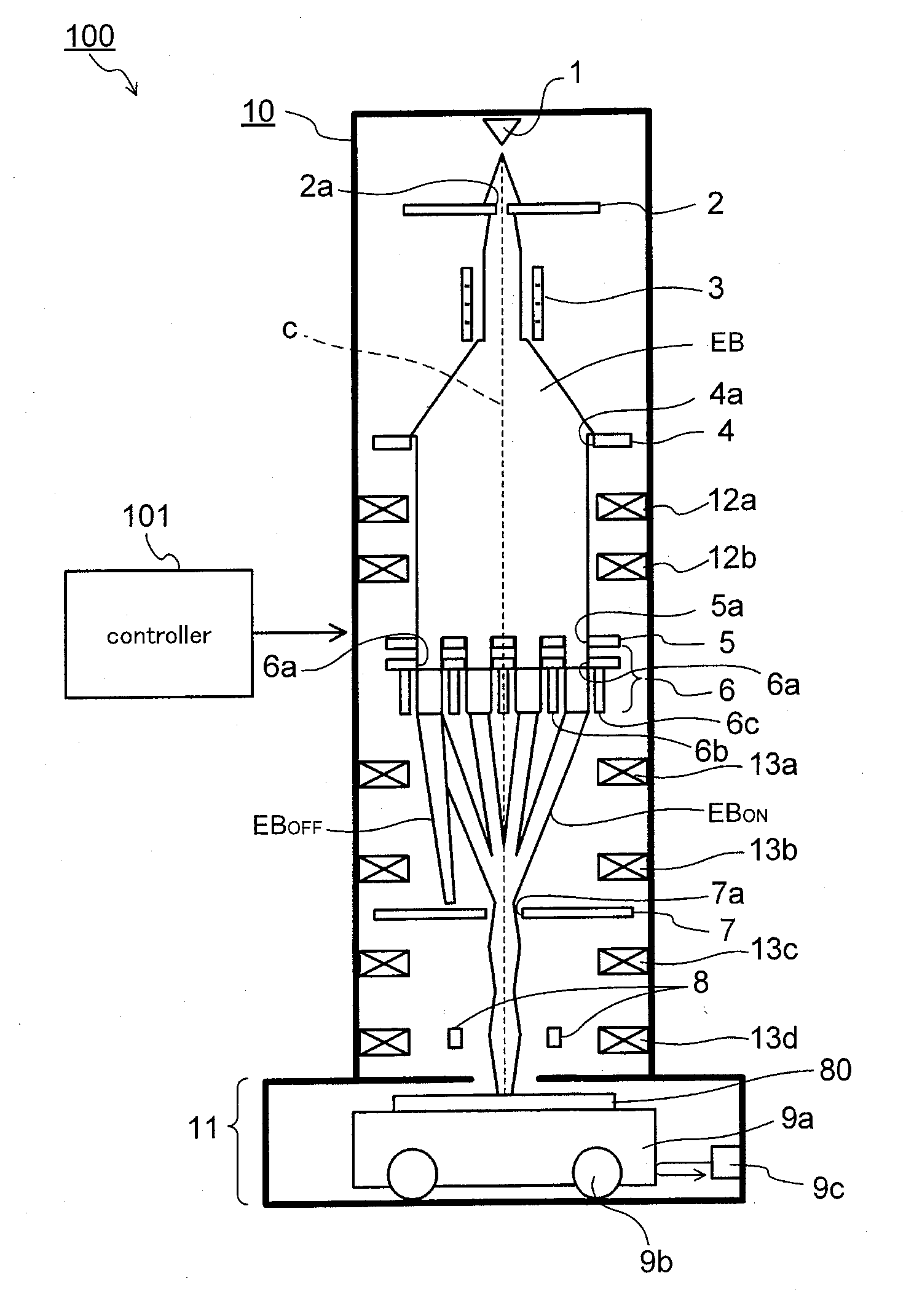

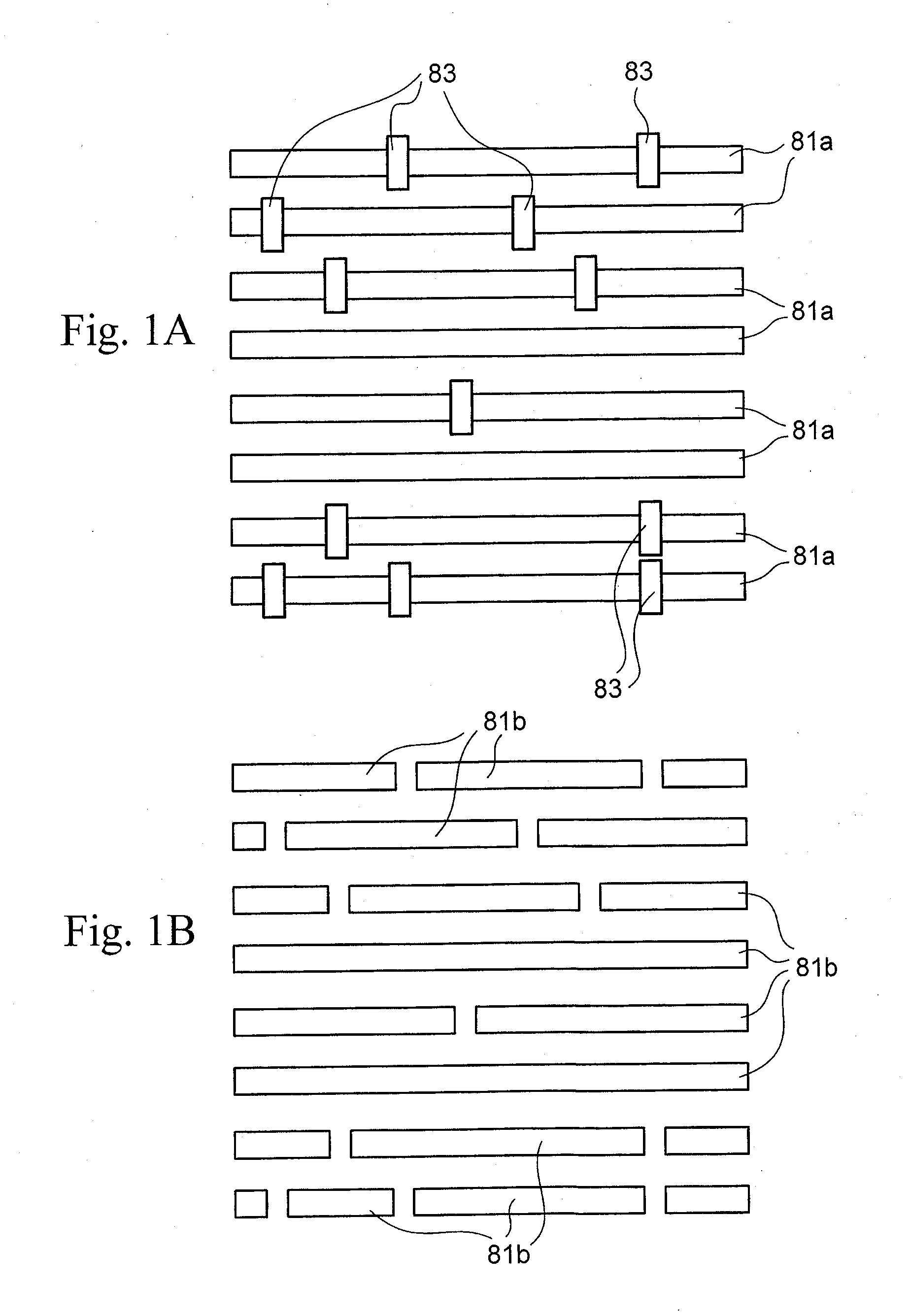

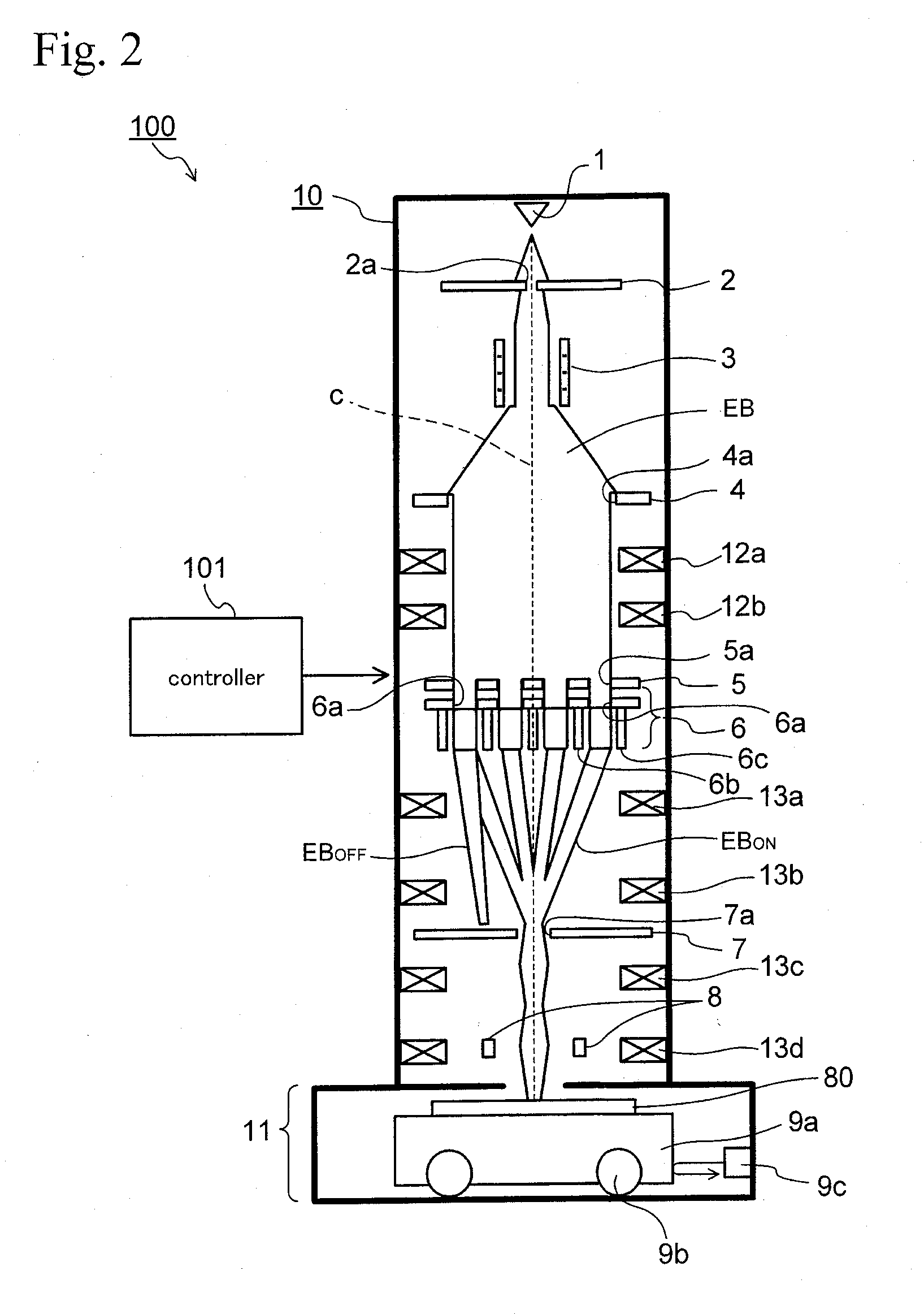

Charged particle beam exposure apparatus and method of manufacturing semiconductor device

ActiveUS20150243480A1Increase costEasy to useElectric discharge tubesSemiconductor/solid-state device manufacturingDevice materialLight beam

The invention relates to a charged particle beam exposure apparatus configured to expose cut patterns or via patterns on a substrate having a plurality of line patterns 81a arranged on an upper surface of the substrate at a constant pitch by irradiating the substrate with a plurality of charged particle beams B1 to Bn while moving a one-dimensional array beam A1 in an X direction parallel to the line patterns 81a, the one-dimensional array beam A1 being a beam in which the charged particle beams B1 to Bn are arranged in an Y direction orthogonal to the line patterns 81a.

Owner:ADVANTEST CORP

Fluorescent illumination device

InactiveUS7192161B1Increased complexityIncrease costPoint-like light sourceElongate light sourcesFluorescenceEffect light

An illumination device for simulating neon or similar lighting uses fluorescent dyes, thus allowing for emission of light in colors that cannot ordinarily be achieved by use of LEDs alone. Such an illumination device is generally comprised of an elongated diffusing member enclosing a string of continuously mounted LEDs. An intermediate light-transmitting medium including a predetermined combination of one or more fluorescent dyes is interposed between the light source and the diffusing member, such that light from the LEDs is partially absorbed by each of the fluorescent dyes, and a lower-energy light is then emitted from each of the fluorescent dyes and into the light-receiving surface of the diffusing member, producing a substantially uniform light along the light-emitting surface of the diffusing member with perceived a color different than that of the LEDs.

Owner:LUMINII PURCHASER LLC

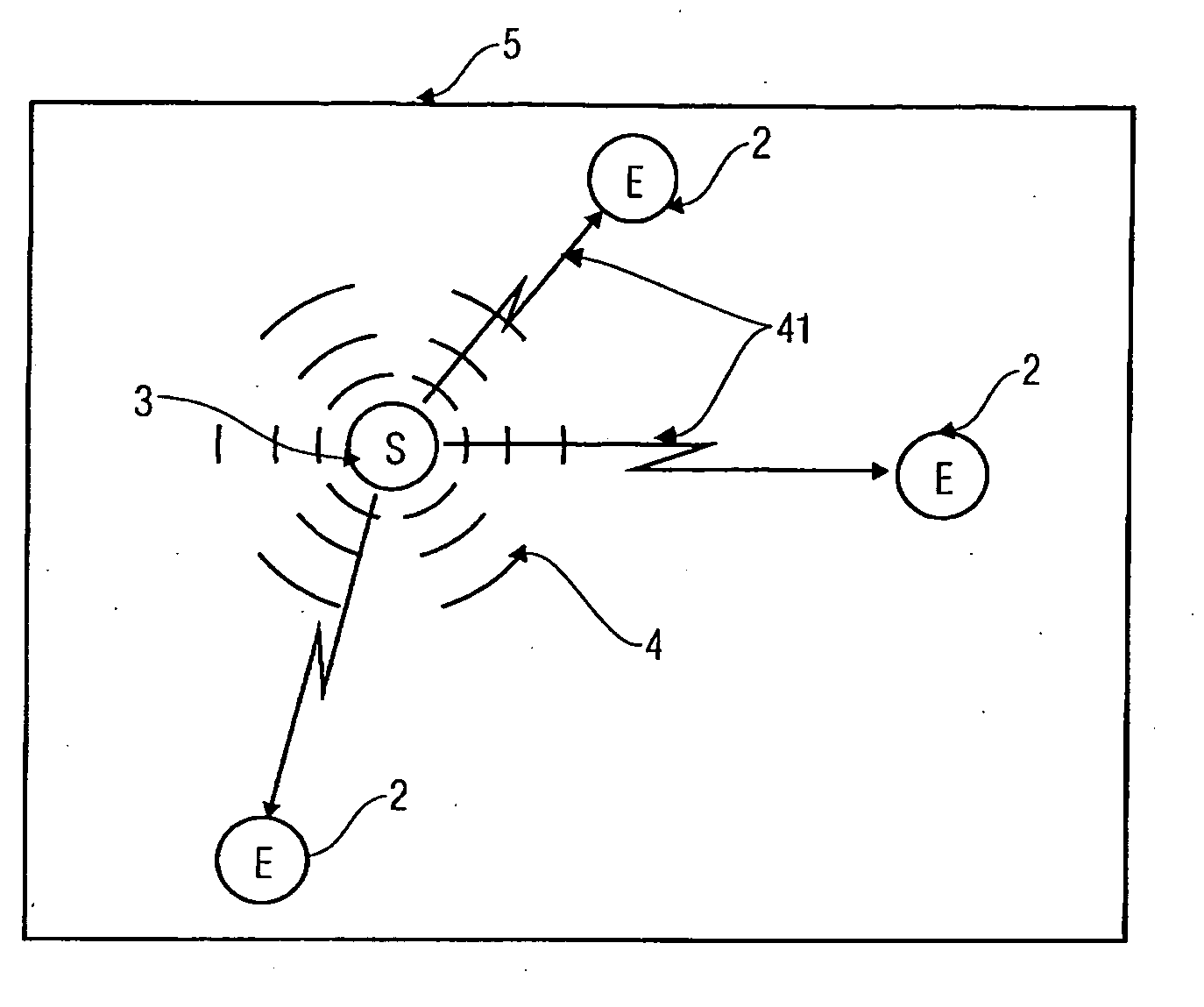

Device and method for measuring a rotational frequency of a movable game device

InactiveUS20070059675A1Low-cost and efficientEasy to useCosmonautic condition simulationsHollow inflatable ballsLow frequency modulationRadio signal

For measuring the rotational frequency of a movable game device, one resorts to an existing radio signal in the form of a broadcast signal or mobile communication signal within the framework of an open system, or to a radio signal of an evaluation unit within the framework of a closed system, so as to obtain, by means of an antenna having a directivity characteristic, a time-varying radio antenna receive signal which has a low-frequency modulation portion, the frequency of which corresponding to the rotational frequency of the movable game device.

Owner:CAIROS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com