Patents

Literature

1303results about How to "Make up for deficiencies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

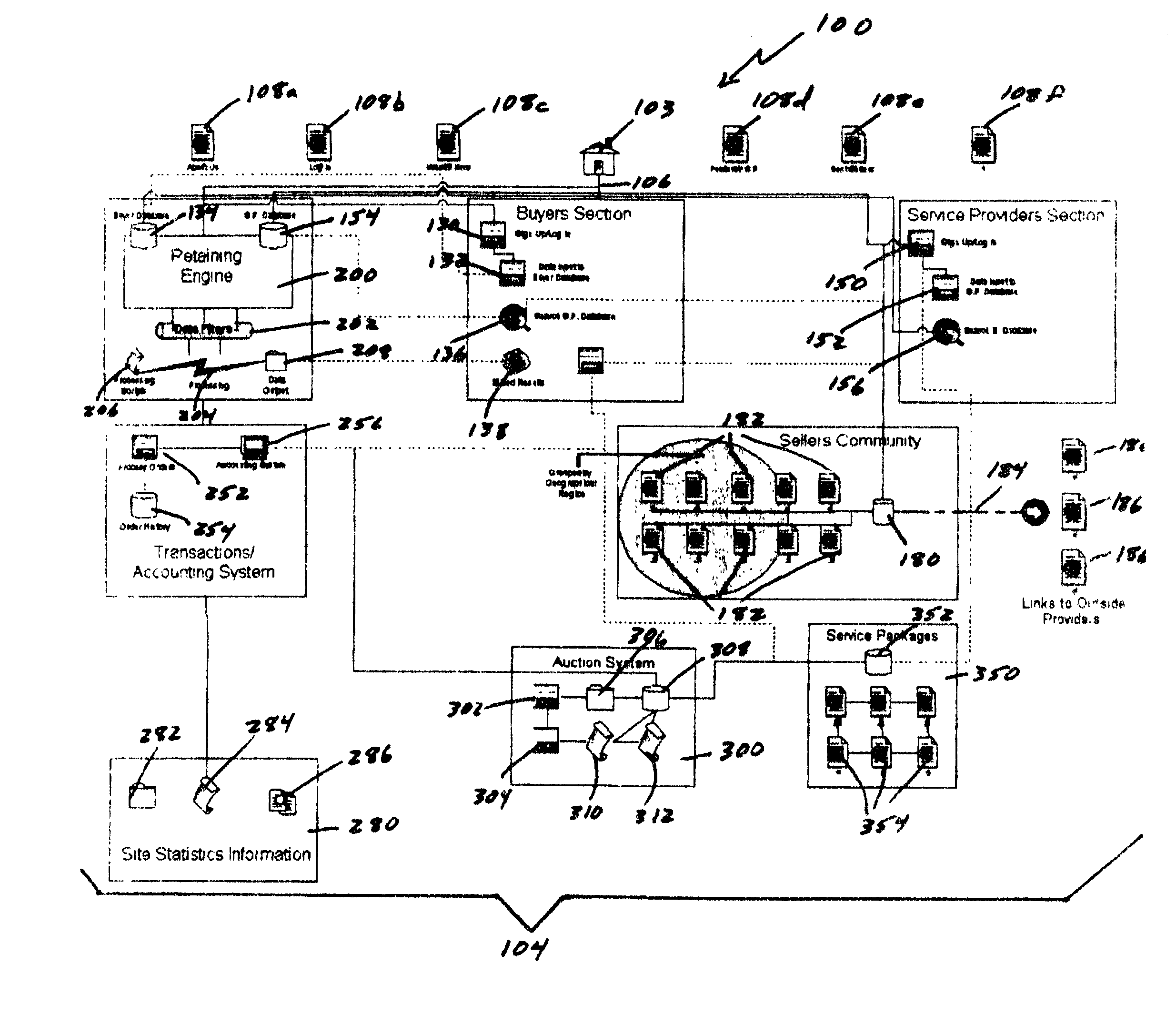

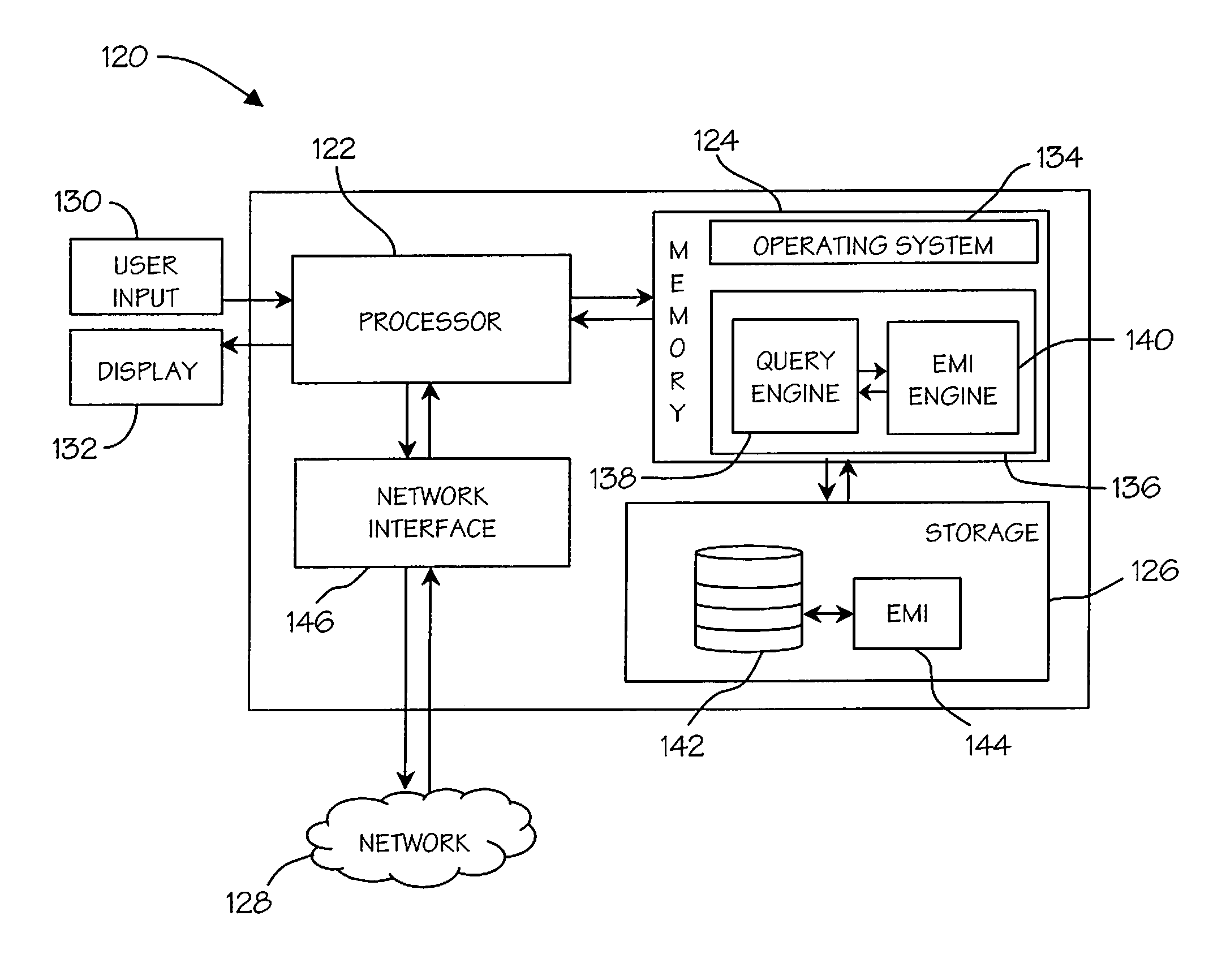

Auction, imagery and retaining engine systems for services and service providers

InactiveUS20020120554A1Facilitates in efficiently accessing latent demandEliminate riskFinancePayment architectureGroup PurchasingService provision

The present disclosure provides a computer-implemented method / system for facilitating communications between service providers and potential customers for services. The computer-implemented method / system provides a marketplace for interactions, both online and off-line, between service providers and potential customers, including purchasing groups, particularly buyer-driven service-related interactions. The marketplace advantageously allows categorization, key word searching, group purchasing, service packaging, data mining, auctions and other commercial features and functionality. The computer-implemented method / system also supports holographic imagery, e.g., in the form of virtual assistants, that facilitates marketplace-related activities. Based on the computer-implemented method / system, service providers are able to efficiently and cost effectively extend the reach of their marketing and promotional activities to a wide range of additional customers, and customers are able to initiate access service providers ideally suited to meet their needs, i.e., buyer-driven commerce, at desirable prices and according to required timeframes.

Owner:VEGA LILLY MAE

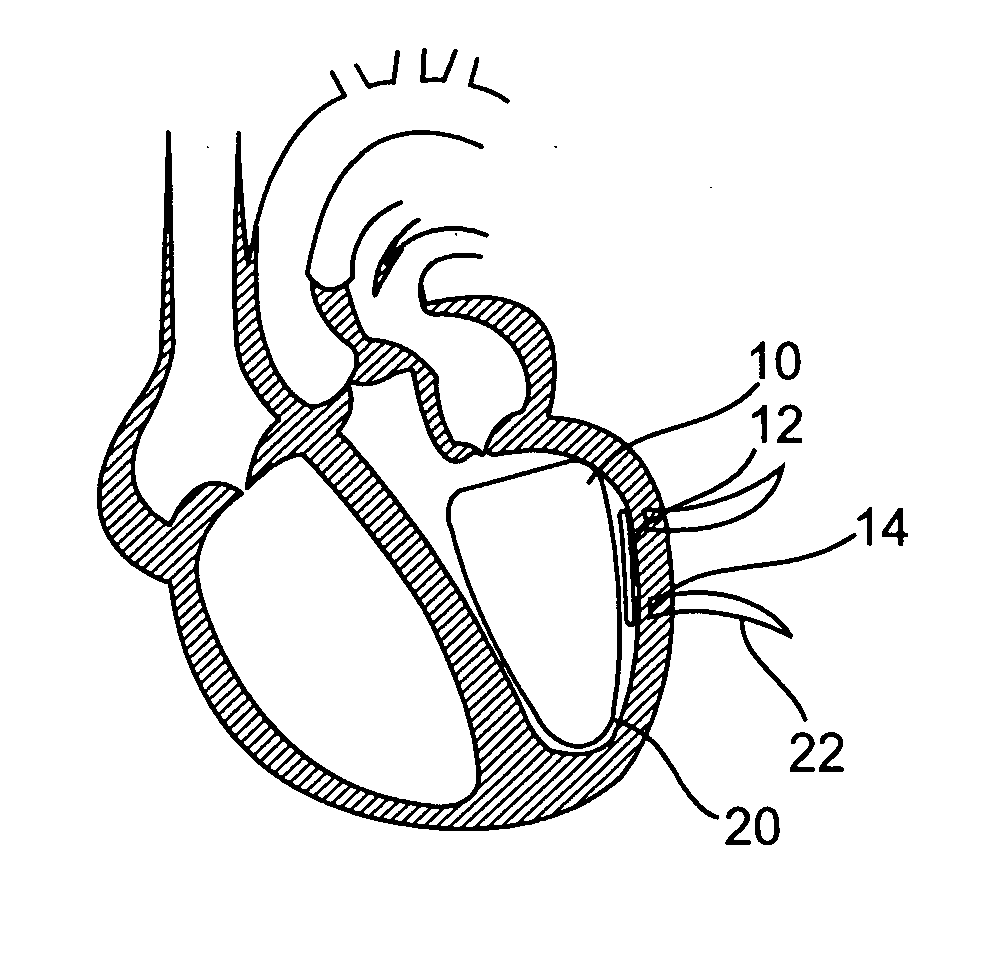

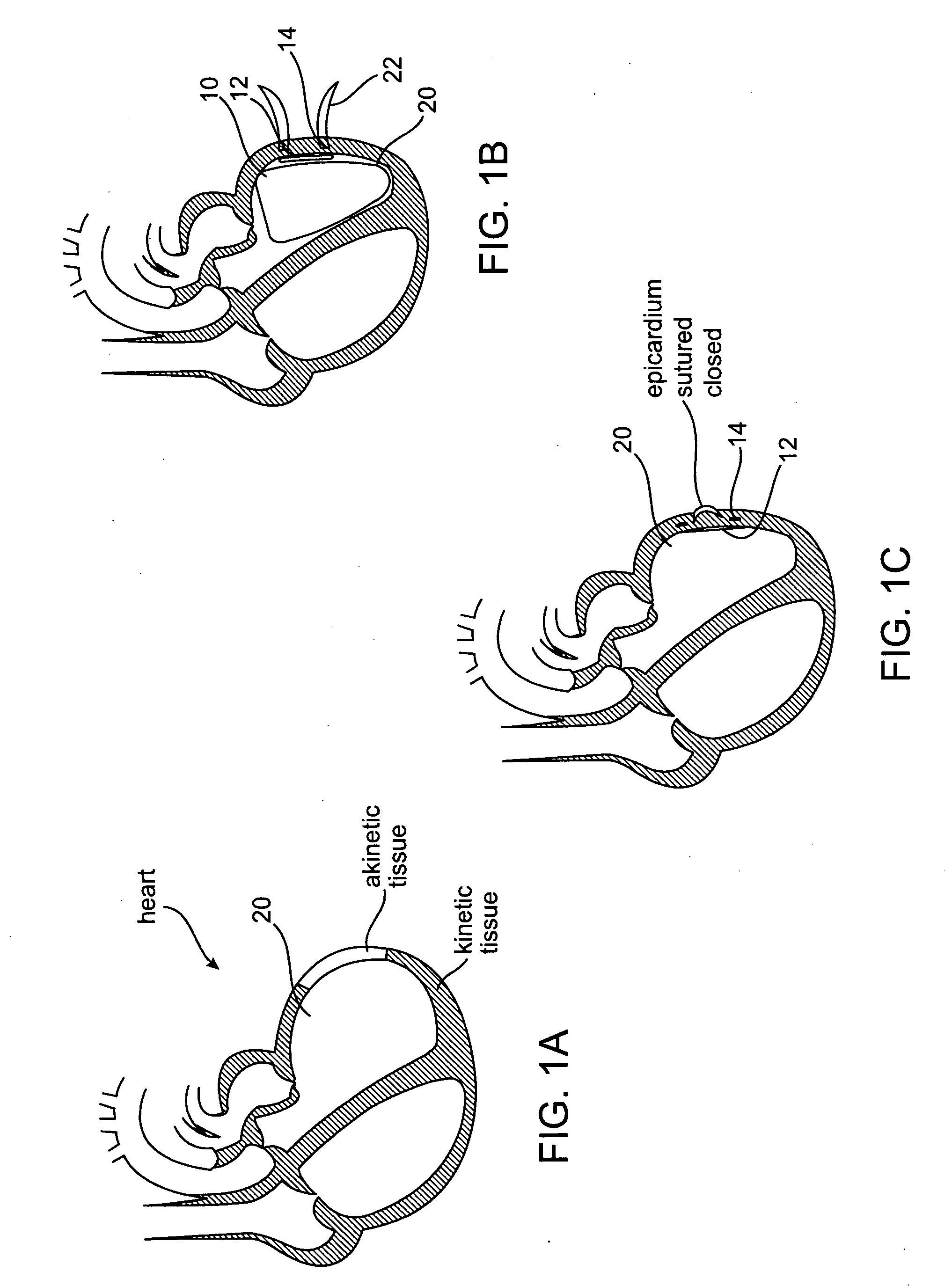

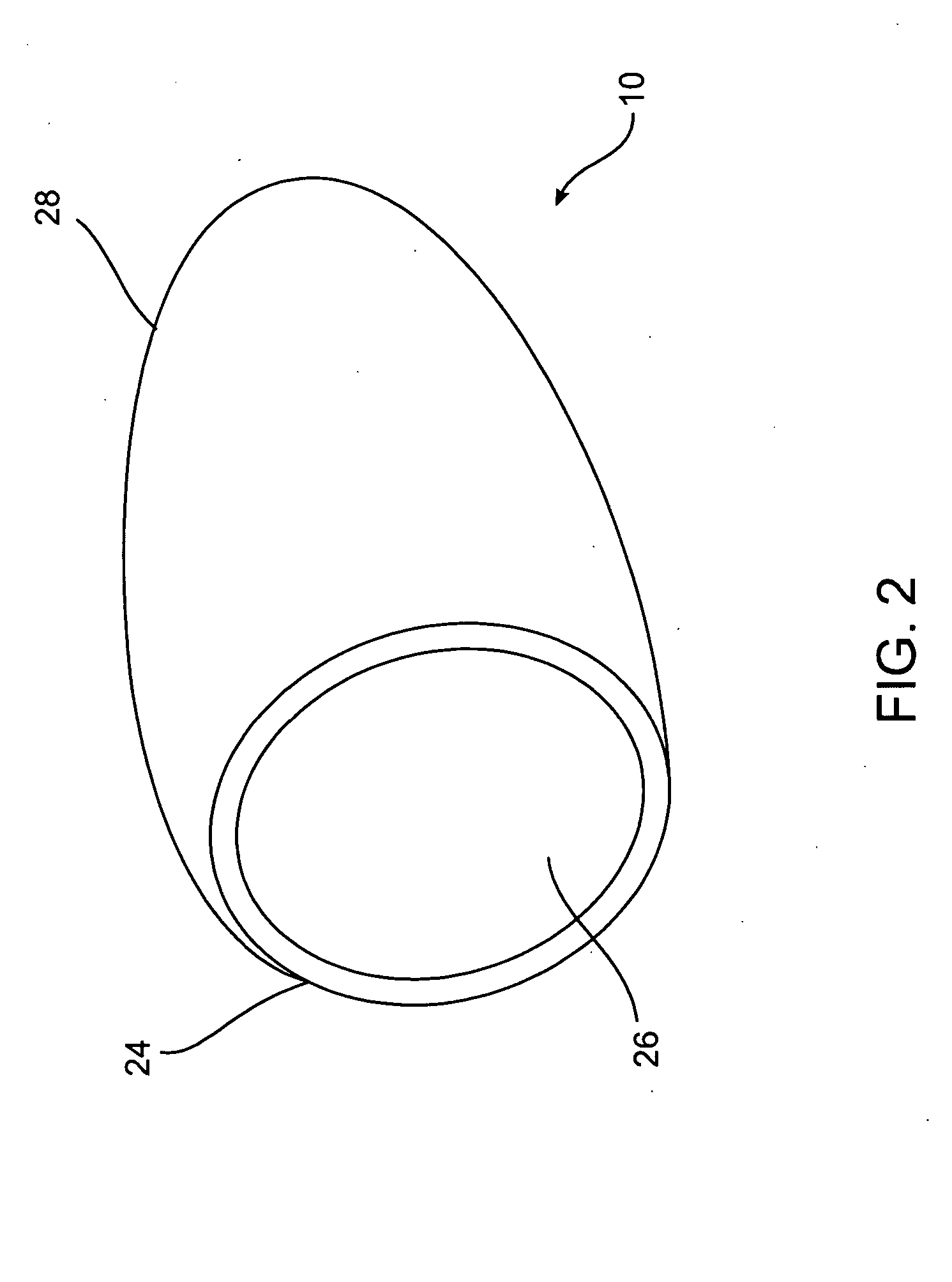

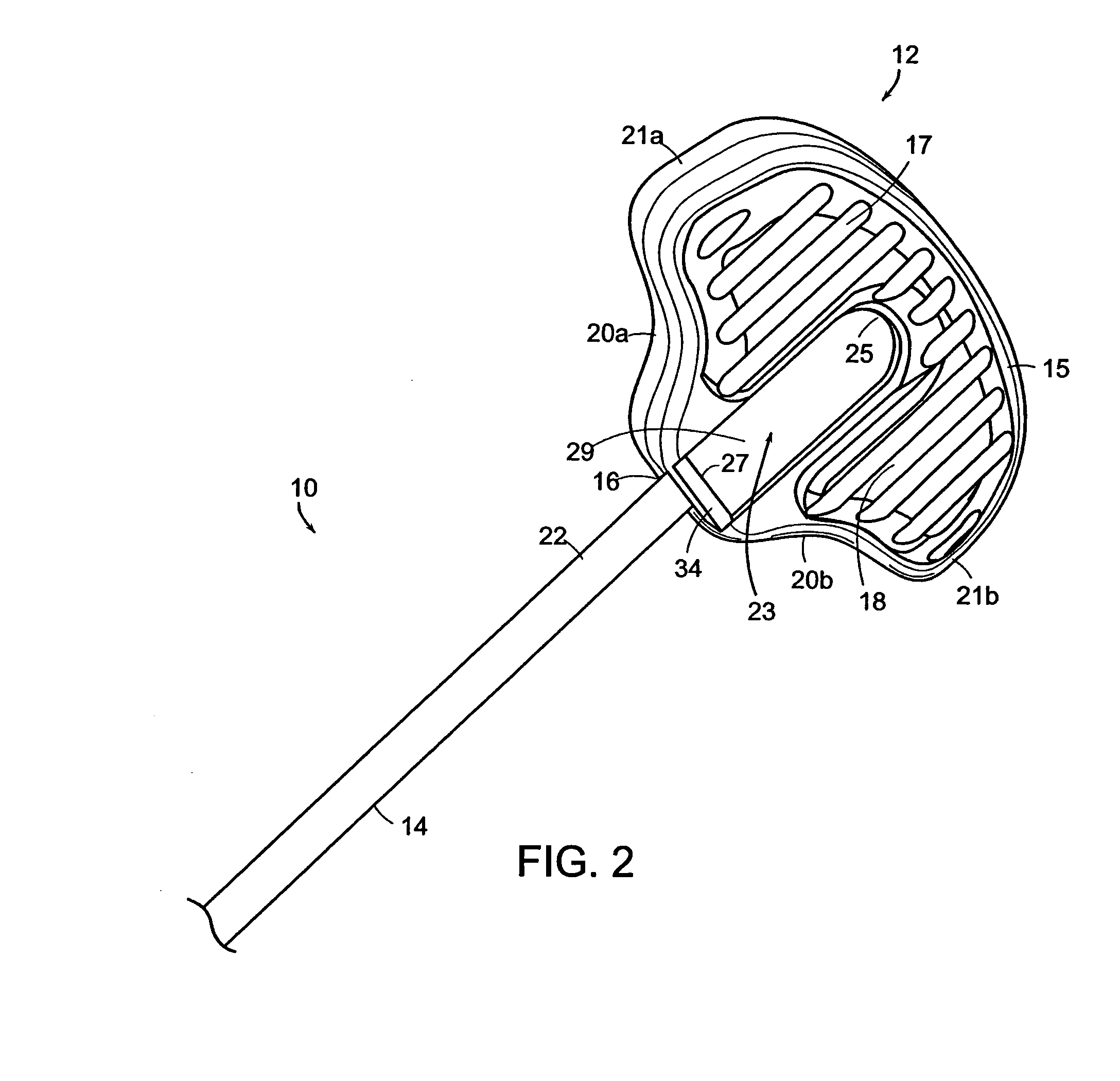

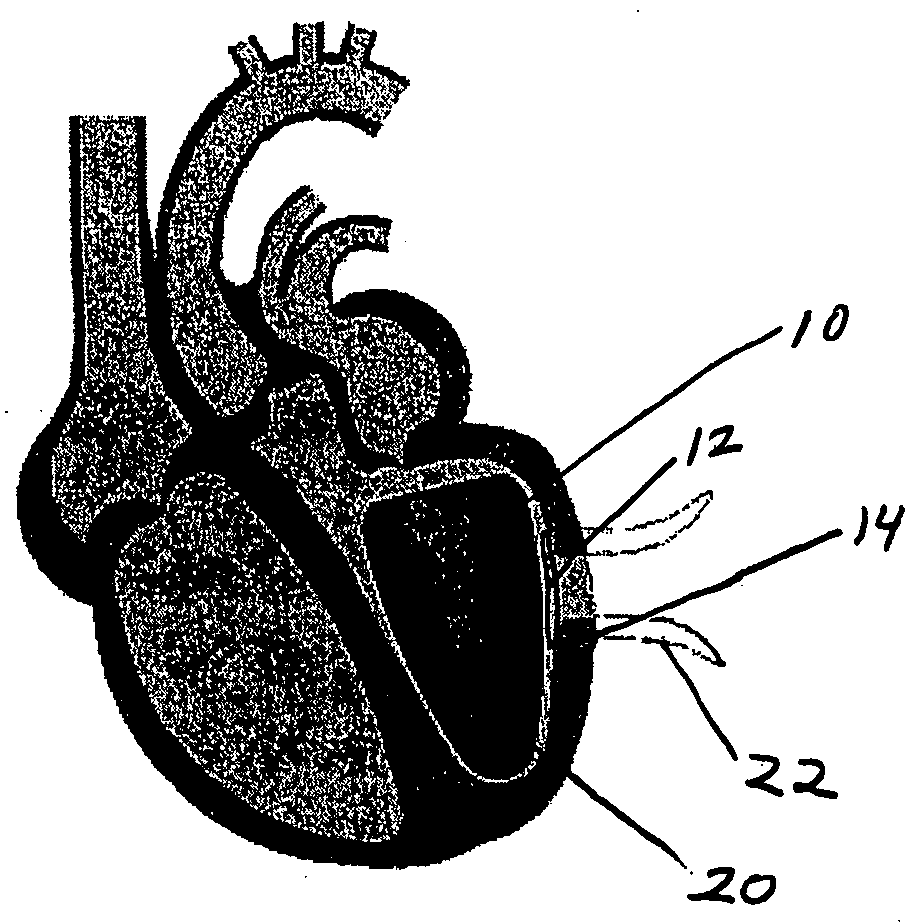

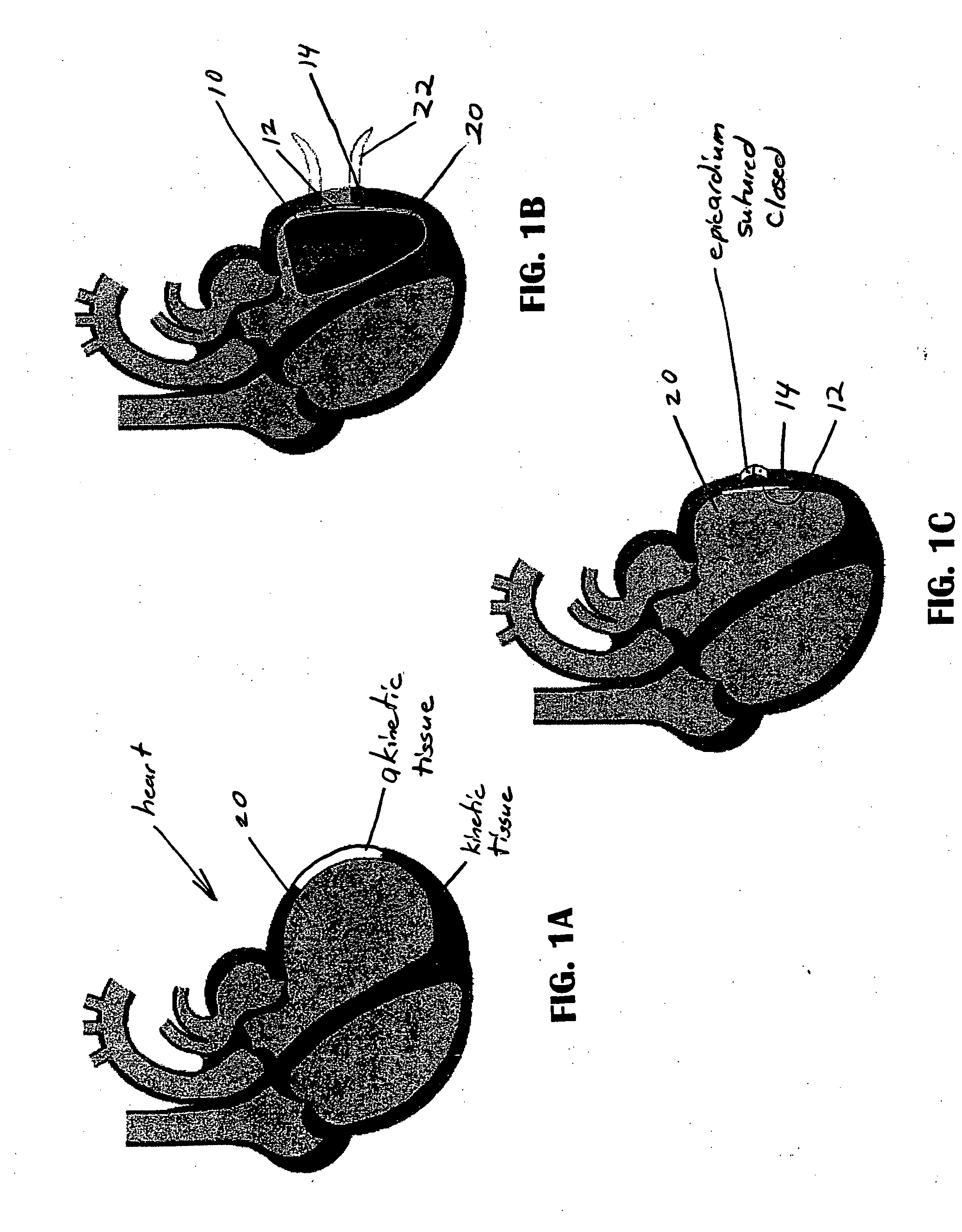

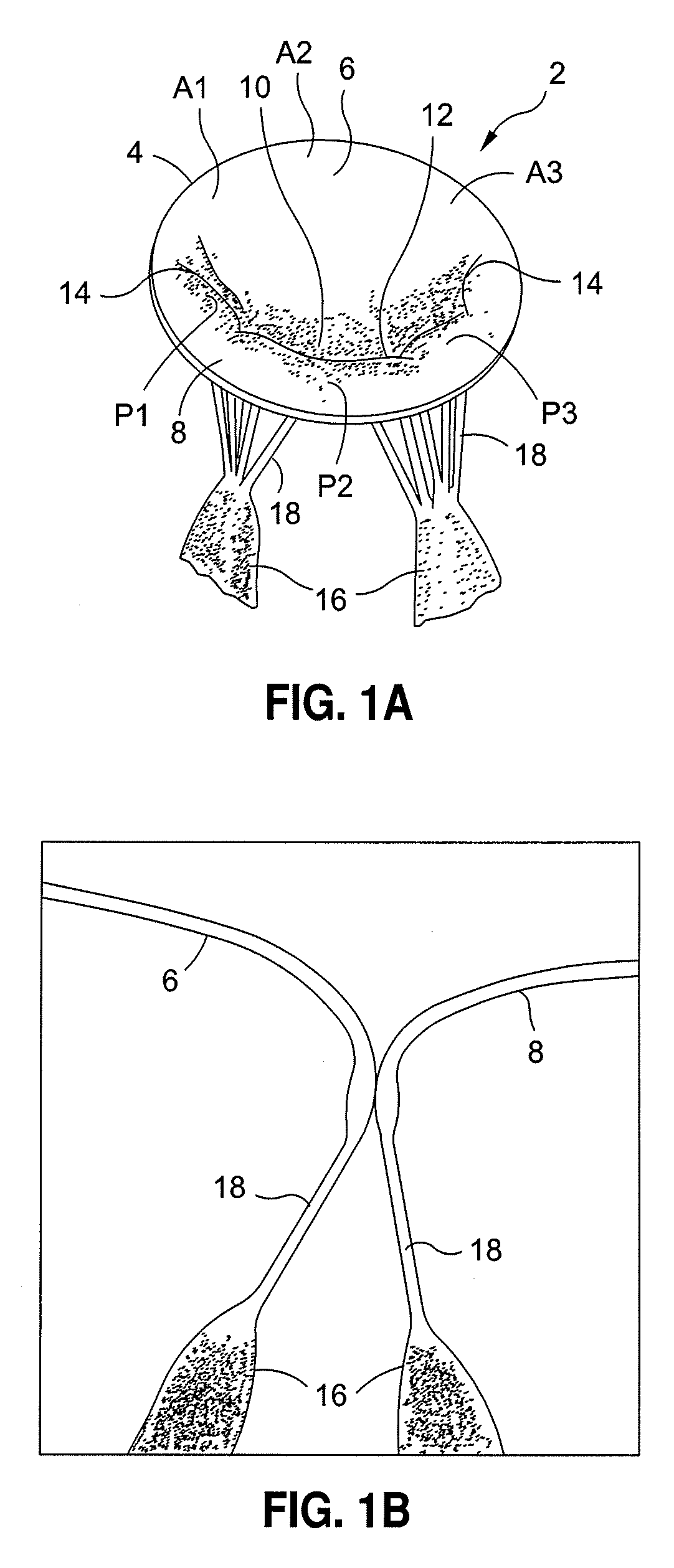

Sizing and shaping device for treating congestive heart failure

InactiveUS20050096498A1Improve and enhance overall treatmentMake up for deficienciesDiagnosticsSurgeryCongestive heart failure chfSurgery

A kit and method are described for treating congestive heart failure. The kit may comprise multiple components including a shaping device, deployment tool, patch, and suture. The method may utilize one or more of these components.

Owner:CHF TECH A CALIFORNIA CORP

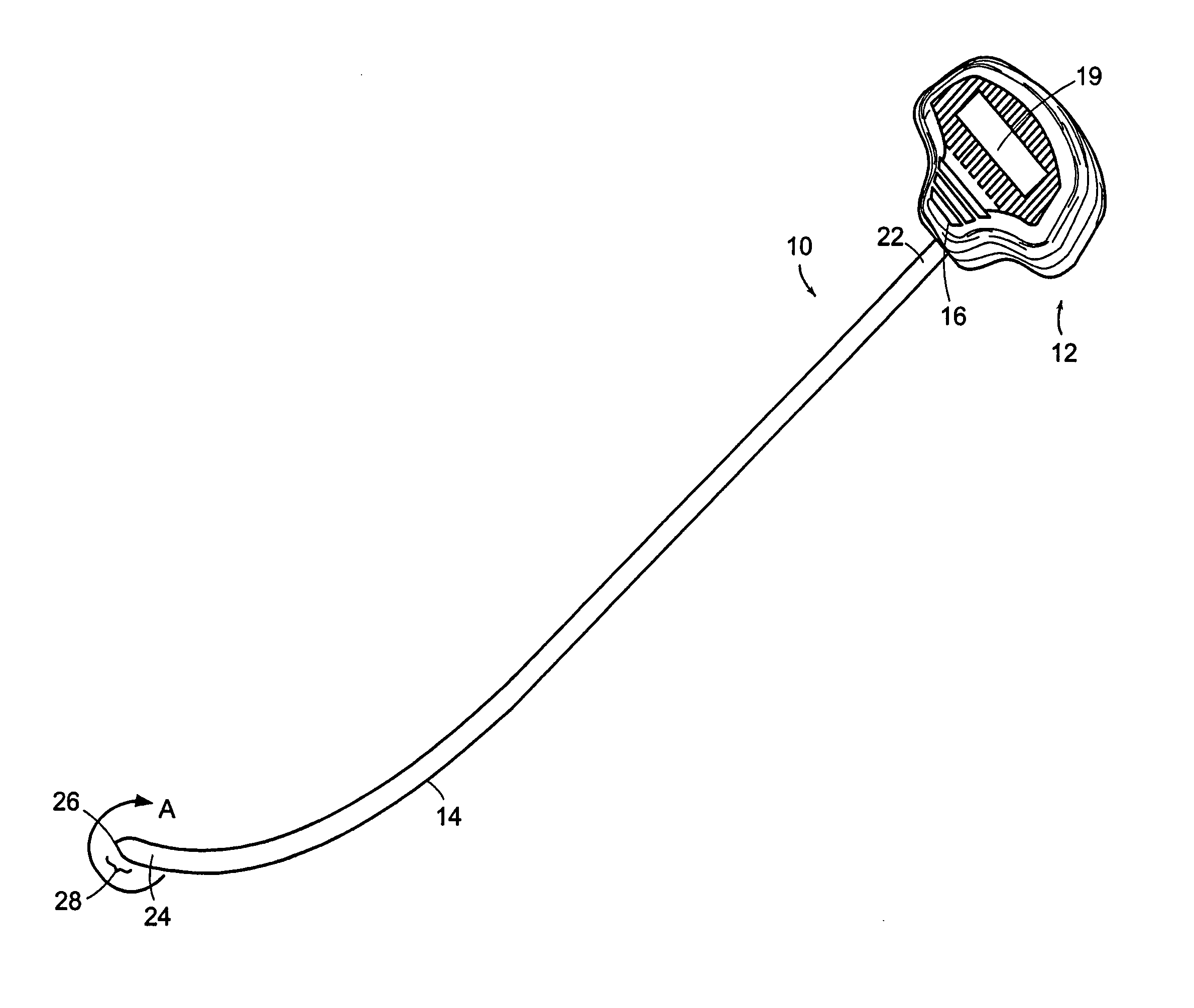

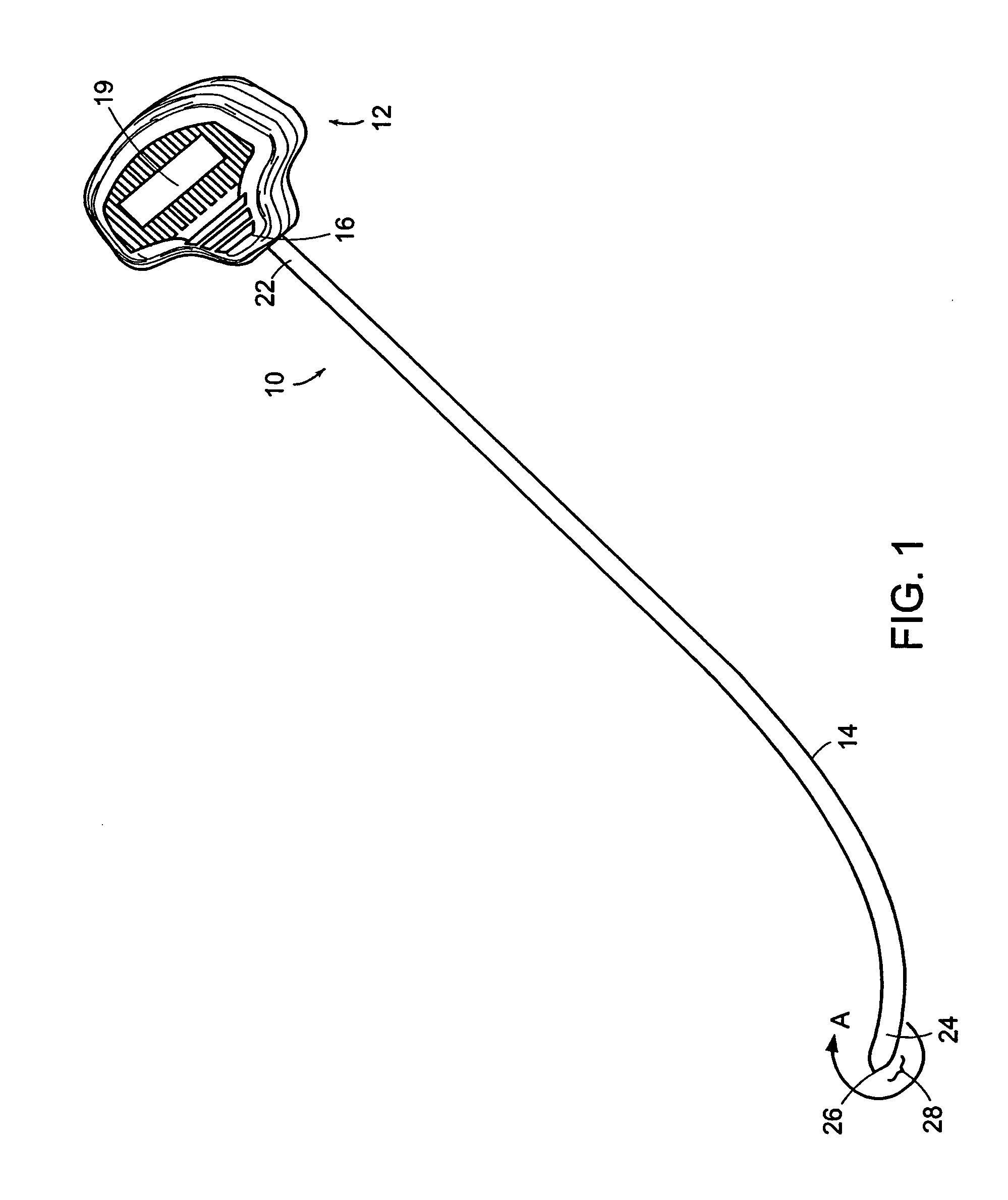

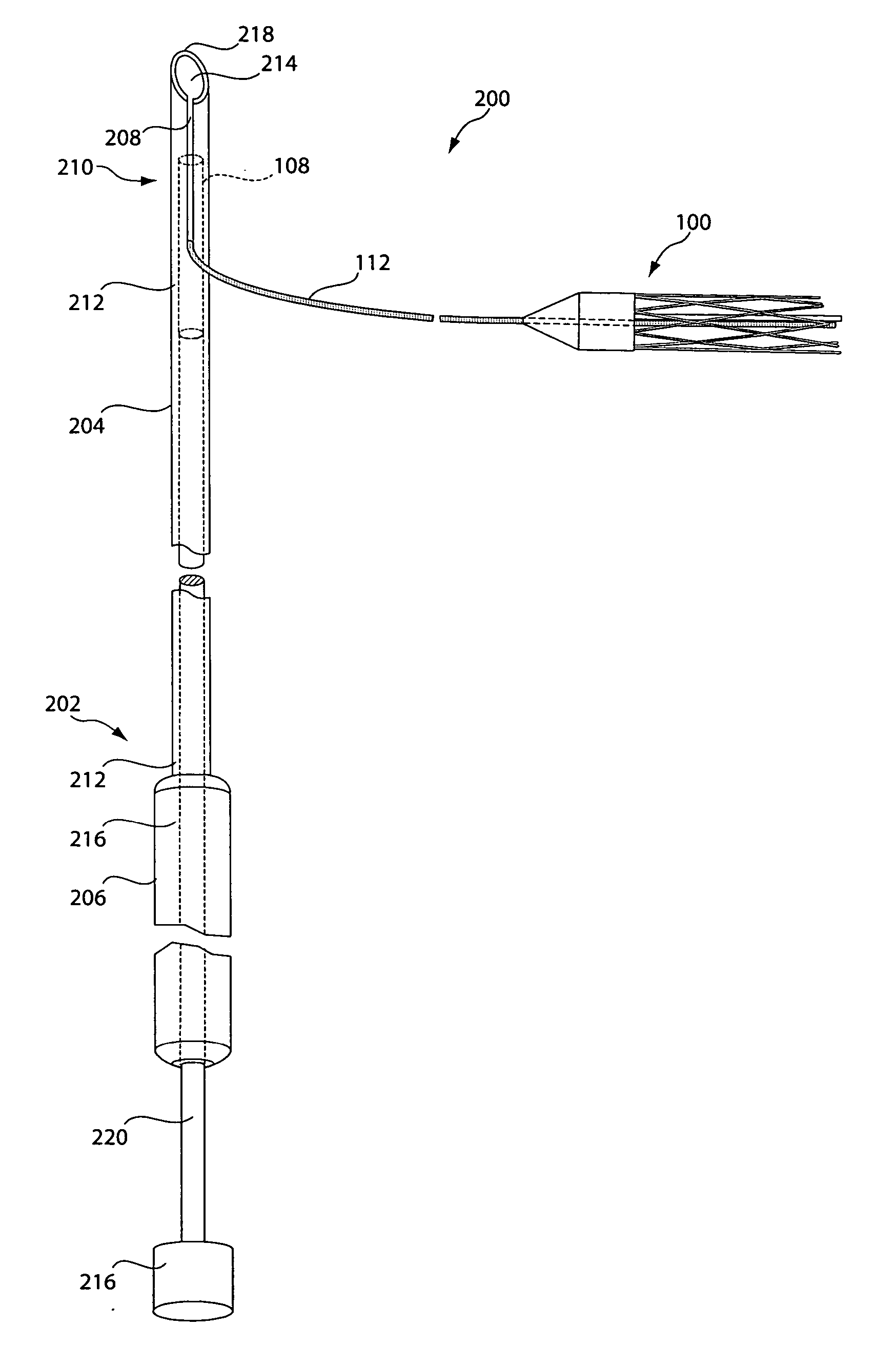

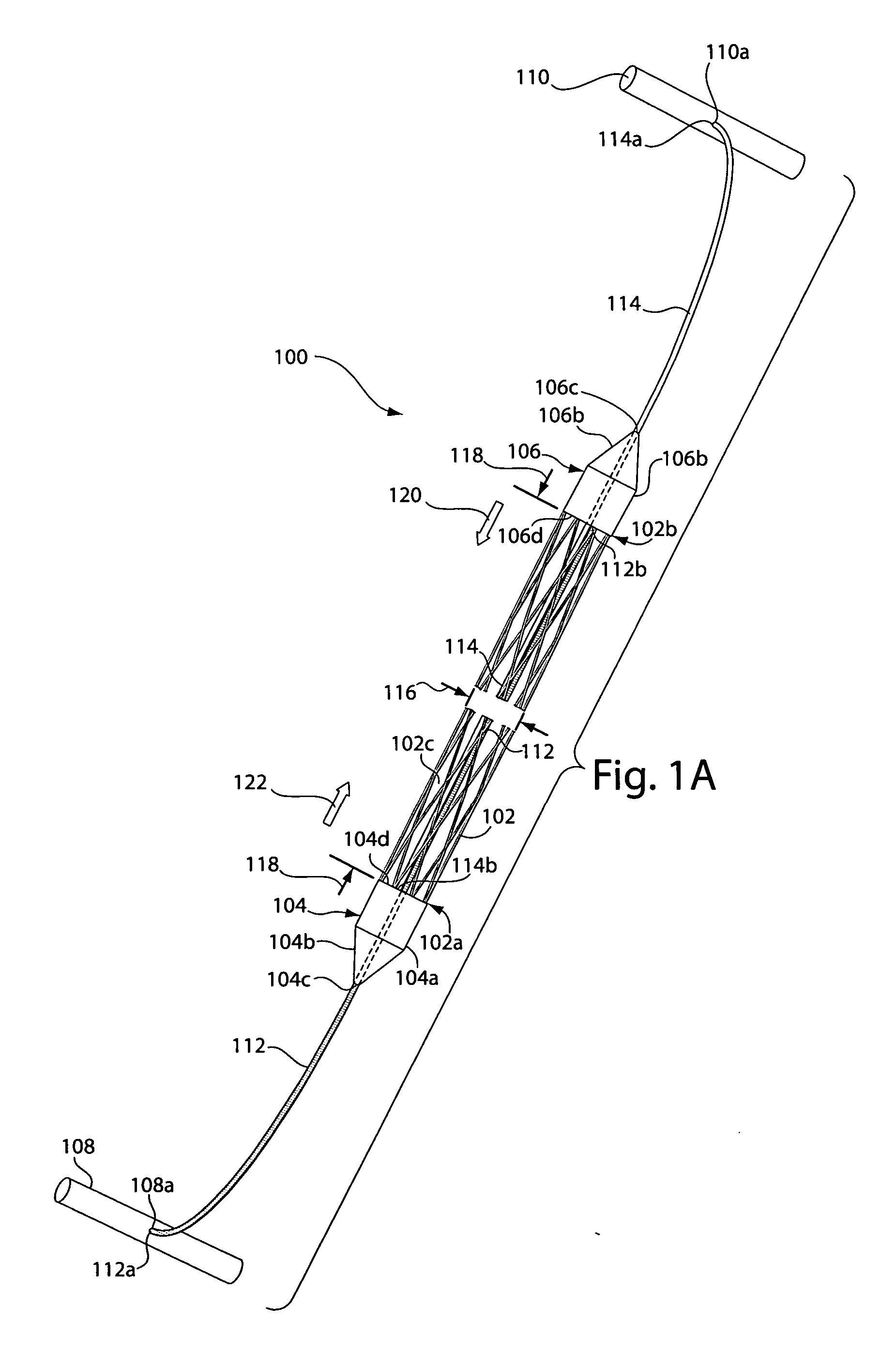

Systems, methods and devices relating to delivery of medical implants

ActiveUS20050131391A1Simple deliveryMinimal damageSuture equipmentsAnti-incontinence devicesBiomedical engineeringSystems approaches

Owner:BOSTON SCI SCIMED INC

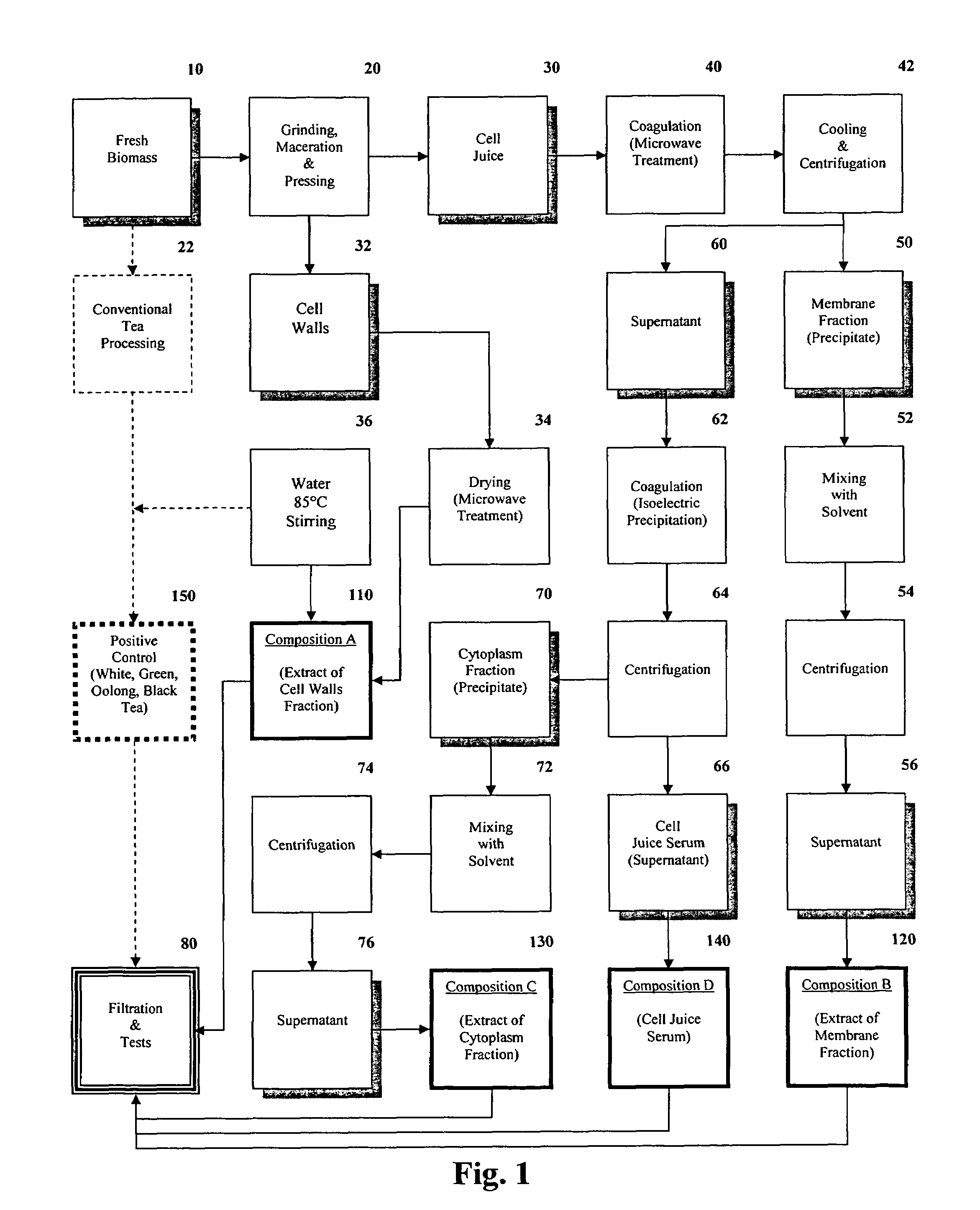

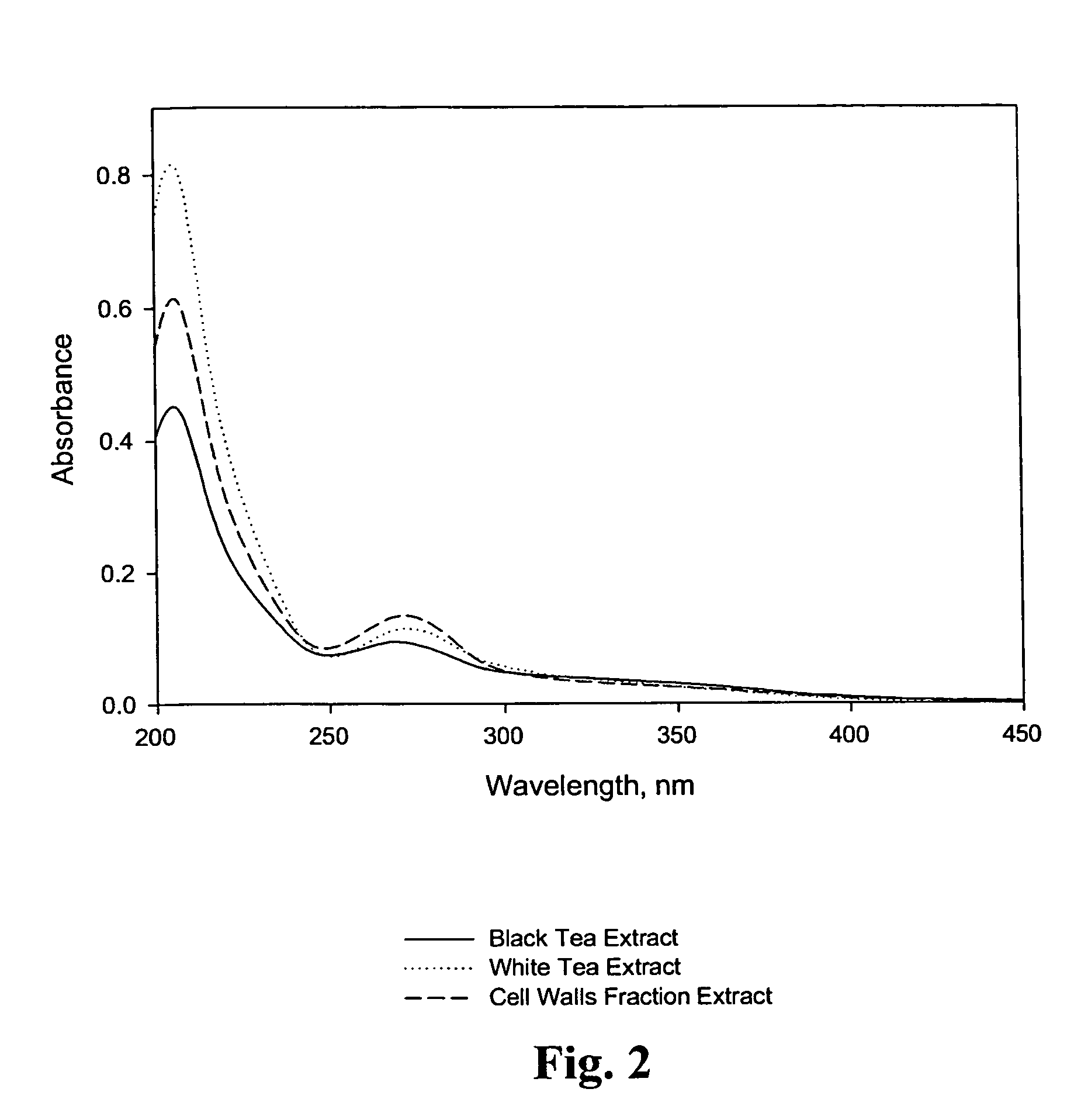

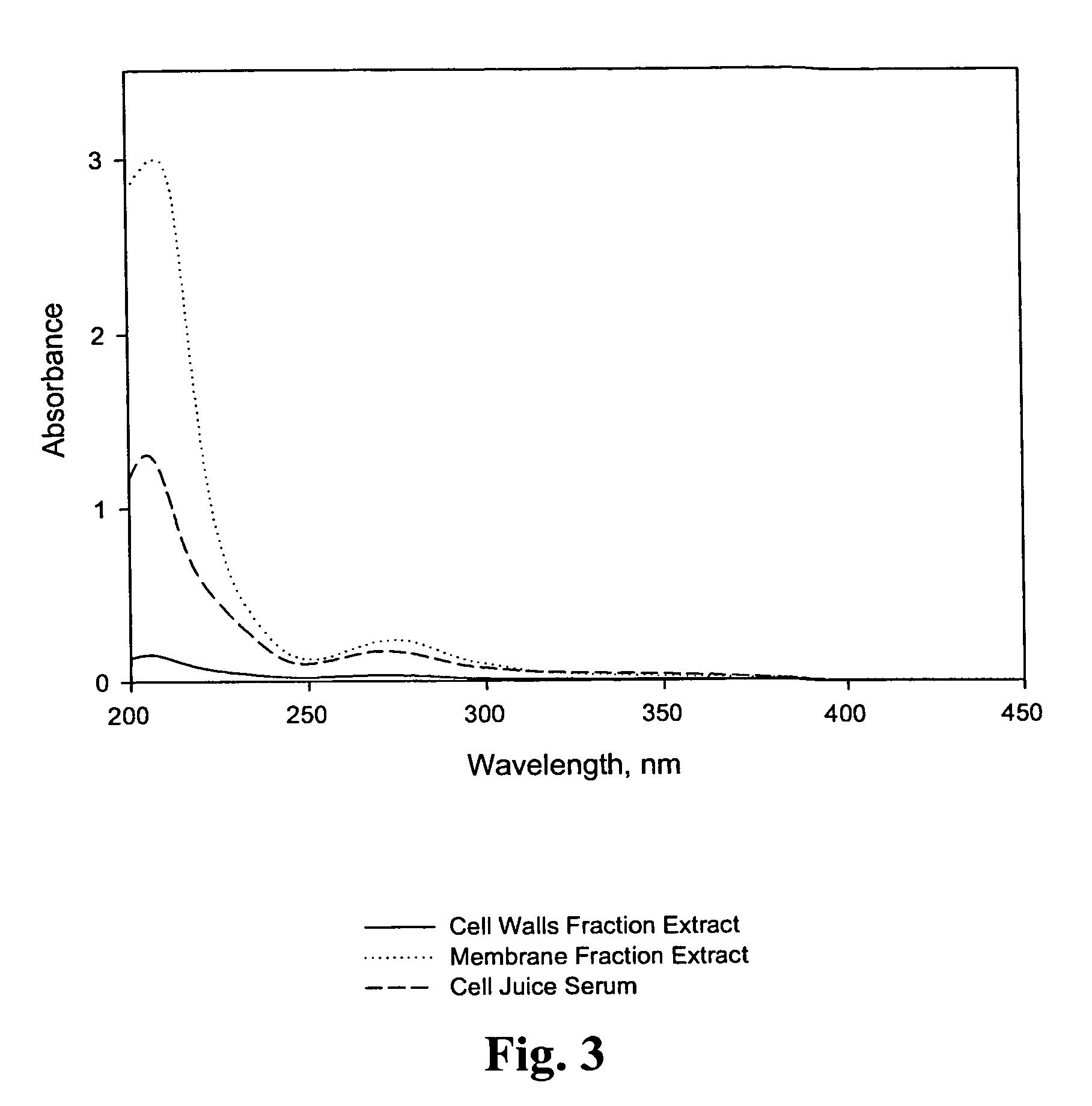

Bioactive compositions from Theacea plants and processes for their production and use

ActiveUS7473435B2Reduce ultraviolet light-induced damageProtects against oxidative damagePigmenting treatmentOrganic active ingredientsUltraviolet lightsCell wall

The present invention relates to isolated bioactive compositions containing bioactive fractions derived from Theacea plants. The present invention also relates to bioactive topical formulations containing the bioactive compositions. The present invention further relates to methods of using the bioactive compositions of the present invention, including, for example, methods for inhibiting inflammatory activity in skin tissue of a mammal, for protecting skin tissue of a mammal from ultraviolet light-induced damage, and for normalizing skin disorders in skin tissue of a mammal. The present invention also relates to methods for isolating bioactive fractions derived from cell juice or a cell walls component a Theacea plant.

Owner:ISP INVESTMENTS LLC

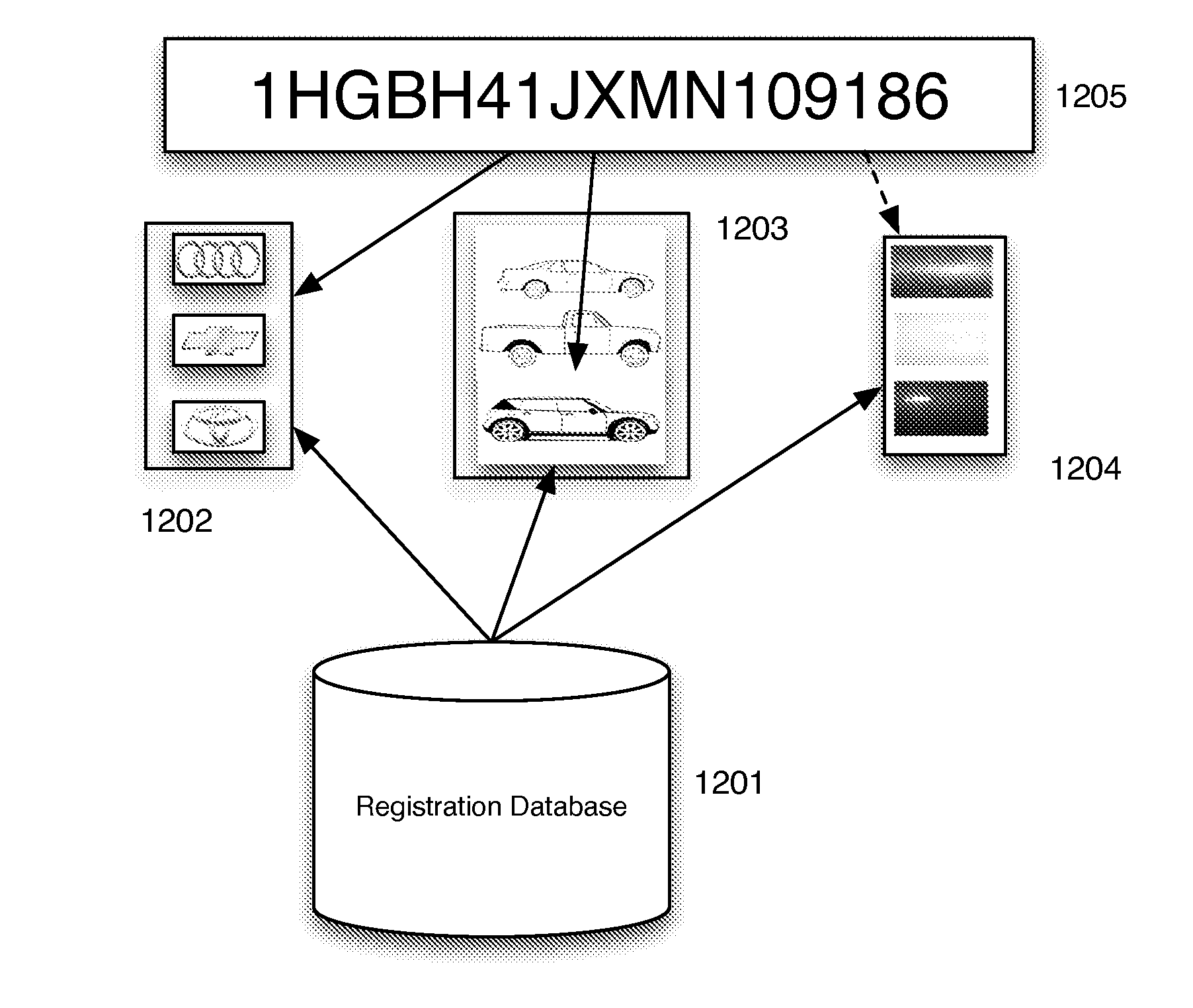

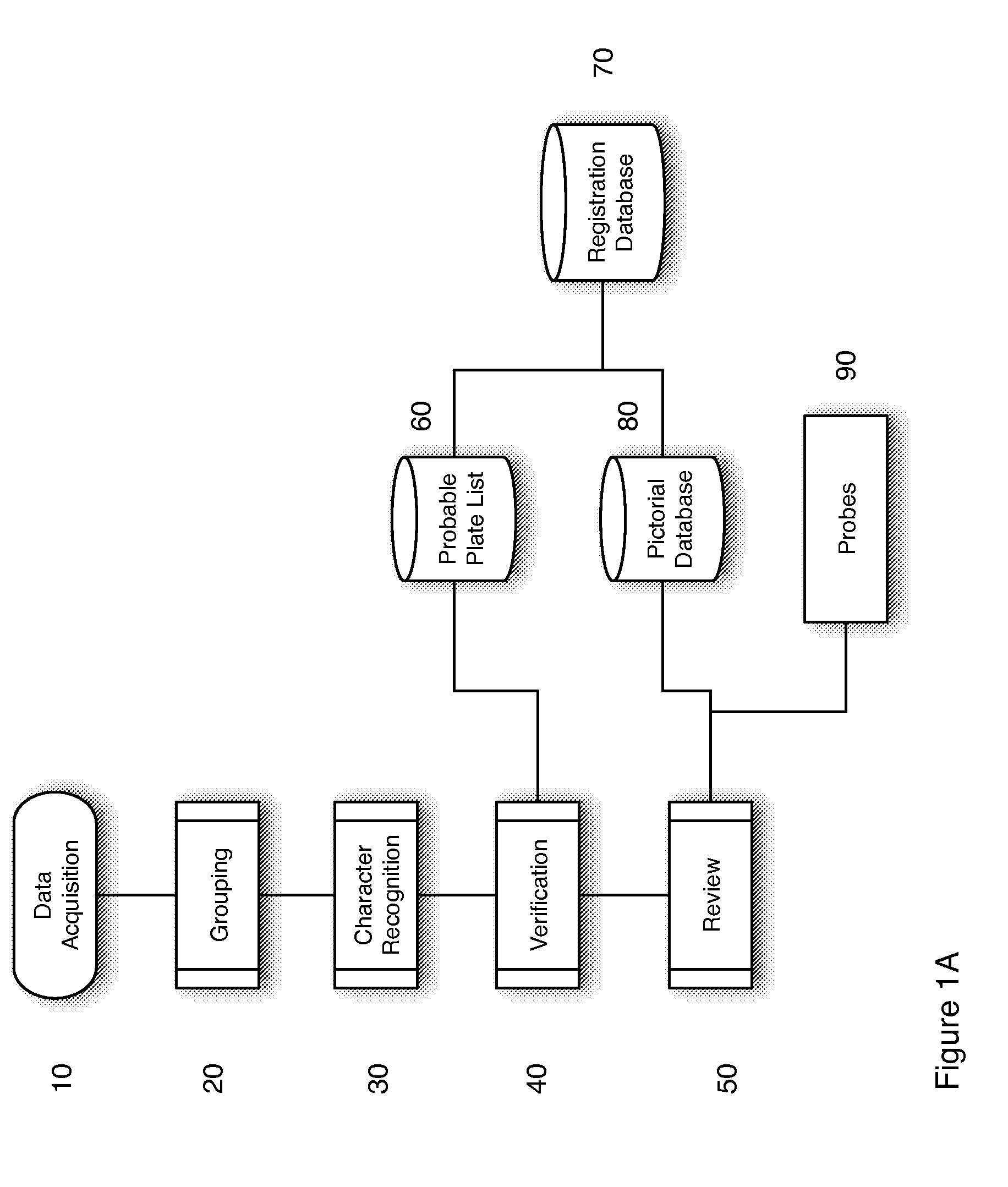

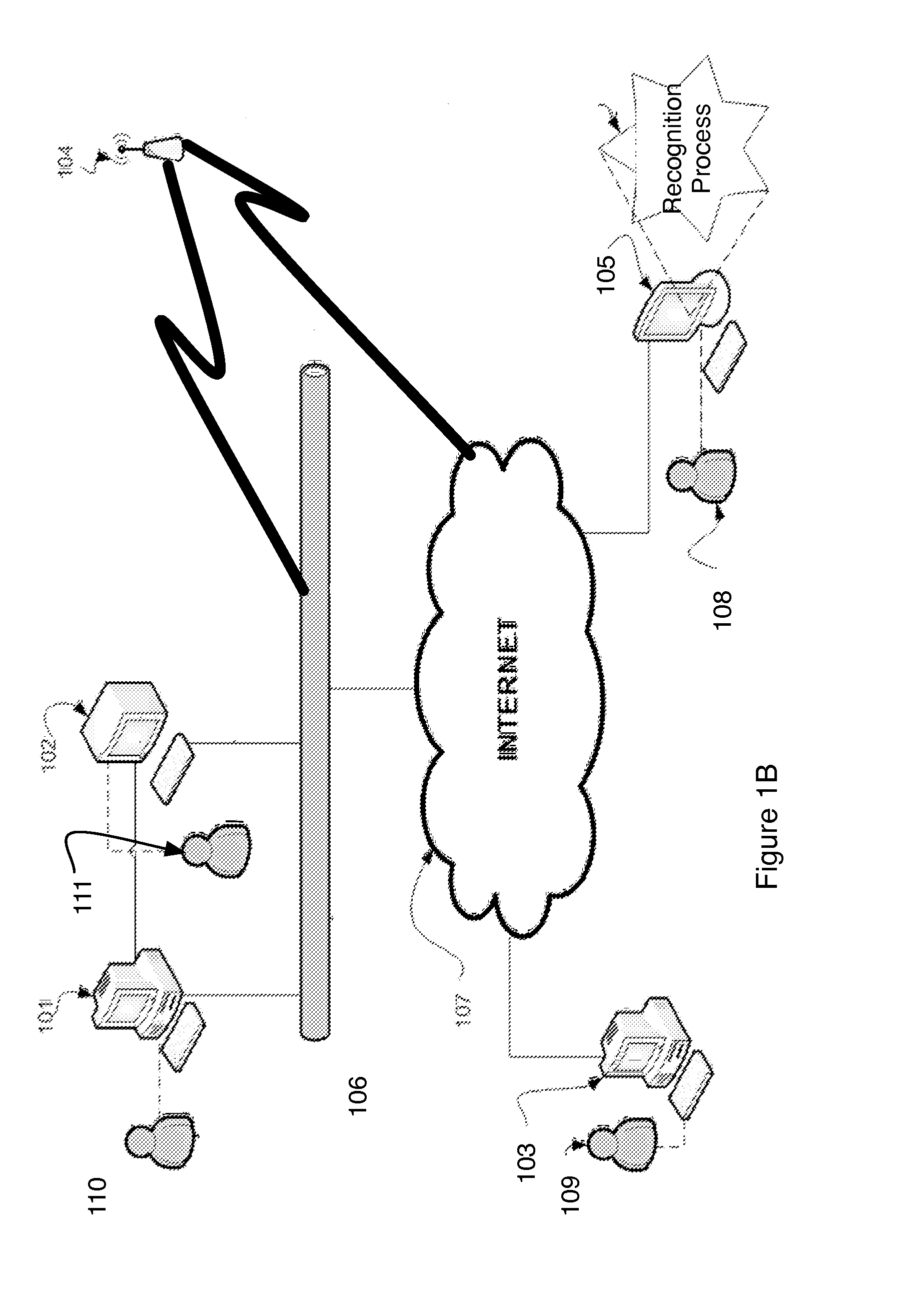

License Plate Recognition

ActiveUS20150049914A1Improve recognition resultsMake up for deficienciesCharacter and pattern recognitionPattern recognitionComputer science

A license plate recognition and image review system and processes are described. The system includes grouping of images that are determined to be of the same vehicle, using an image encoded database such that verification of a license plate read is done through comparison of images of the actual vehicle to images from the encoded database and testing of the accuracy of a manual review process by interspersing previously identified images with real images being reviewed in a batch process.

Owner:ALVES JAMES

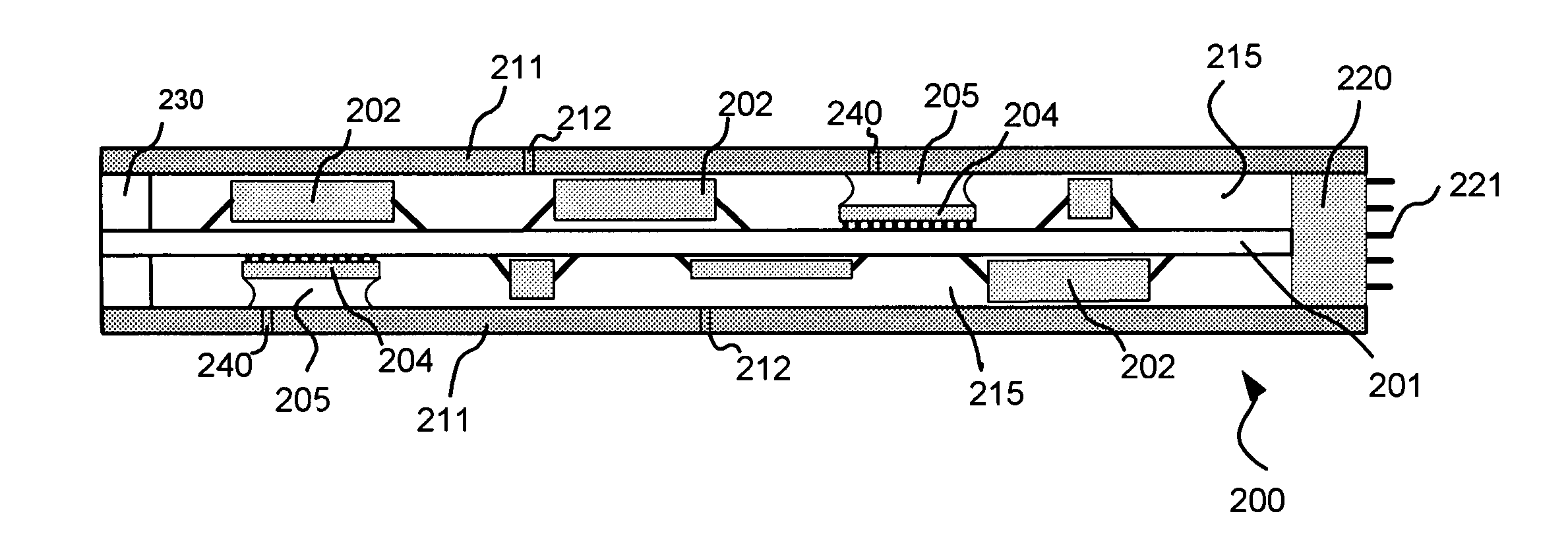

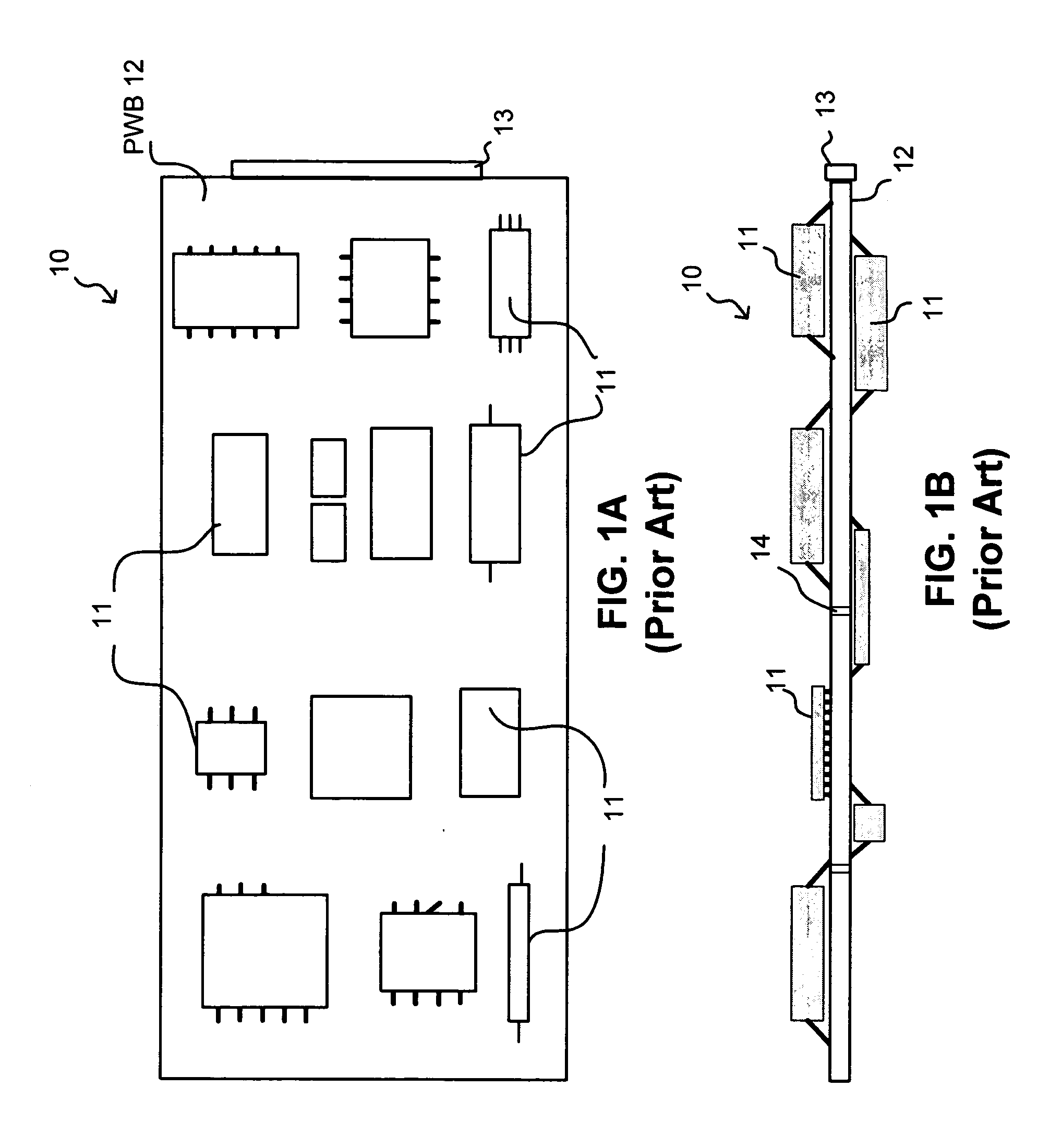

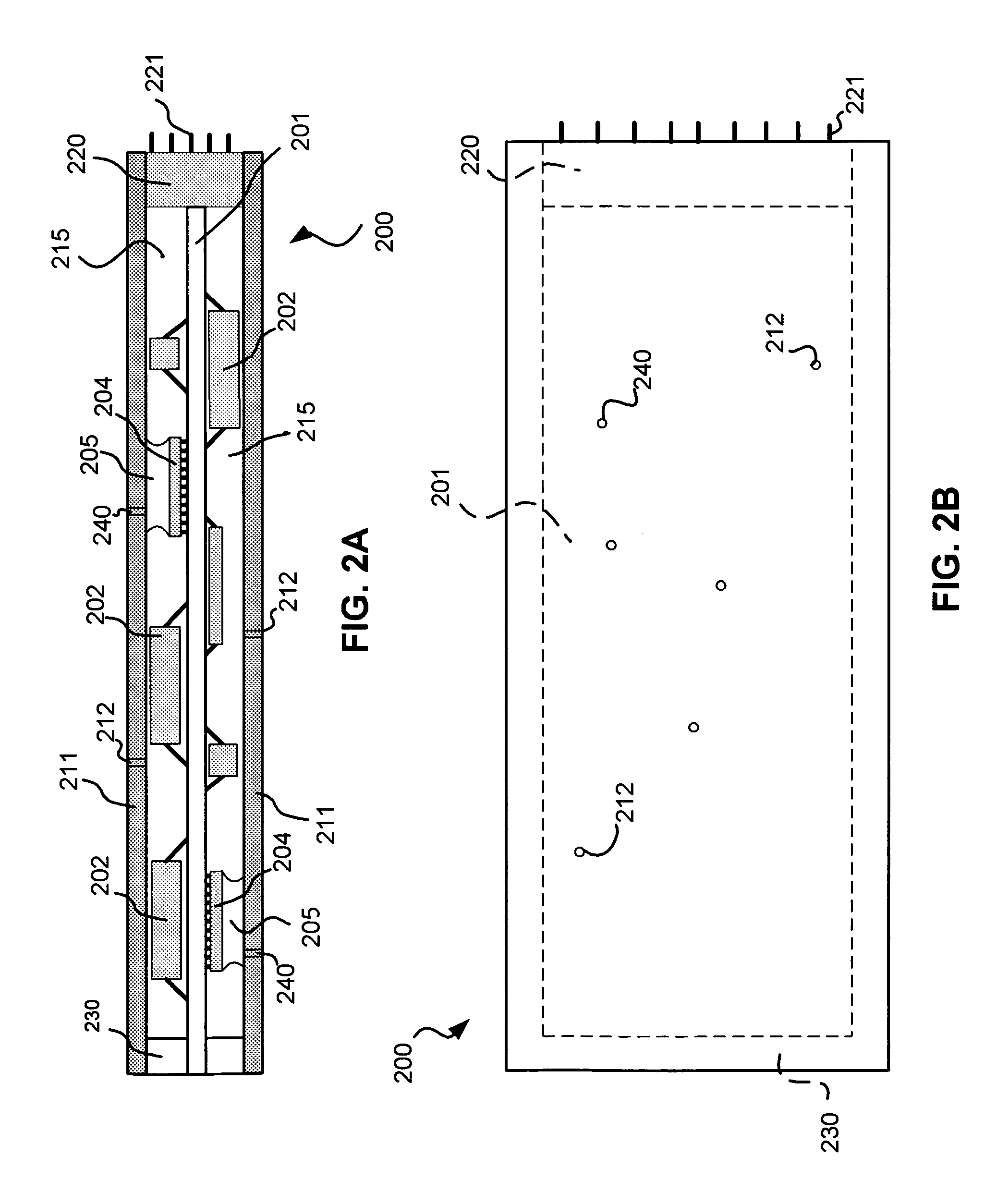

Environmentally tuned circuit card assembly and method for manufacturing the same

InactiveUS7095615B2Make up for deficienciesImprove rigiditySlidable card holdersCard stiffenersFilling materialsElectronic component

A circuit card assembly and a method for manufacturing the circuit card assembly are disclosed. The circuit card assembly includes a printed wiring board with electronic components bonded thereto. The printed wiring board and electronic components are placed in an outer shell made of lightweight stiff material. The spaces or voids between the outer shell and the printed wiring board and the electronic components are filled with lightweight filling material and thermal filler material. The outer shell and the filling material provide increased rigidity to the electronic components and the thermal filler material increases heat transfer from a given electronic component to outside the circuit card assembly.

Owner:HONEYWELL INT INC

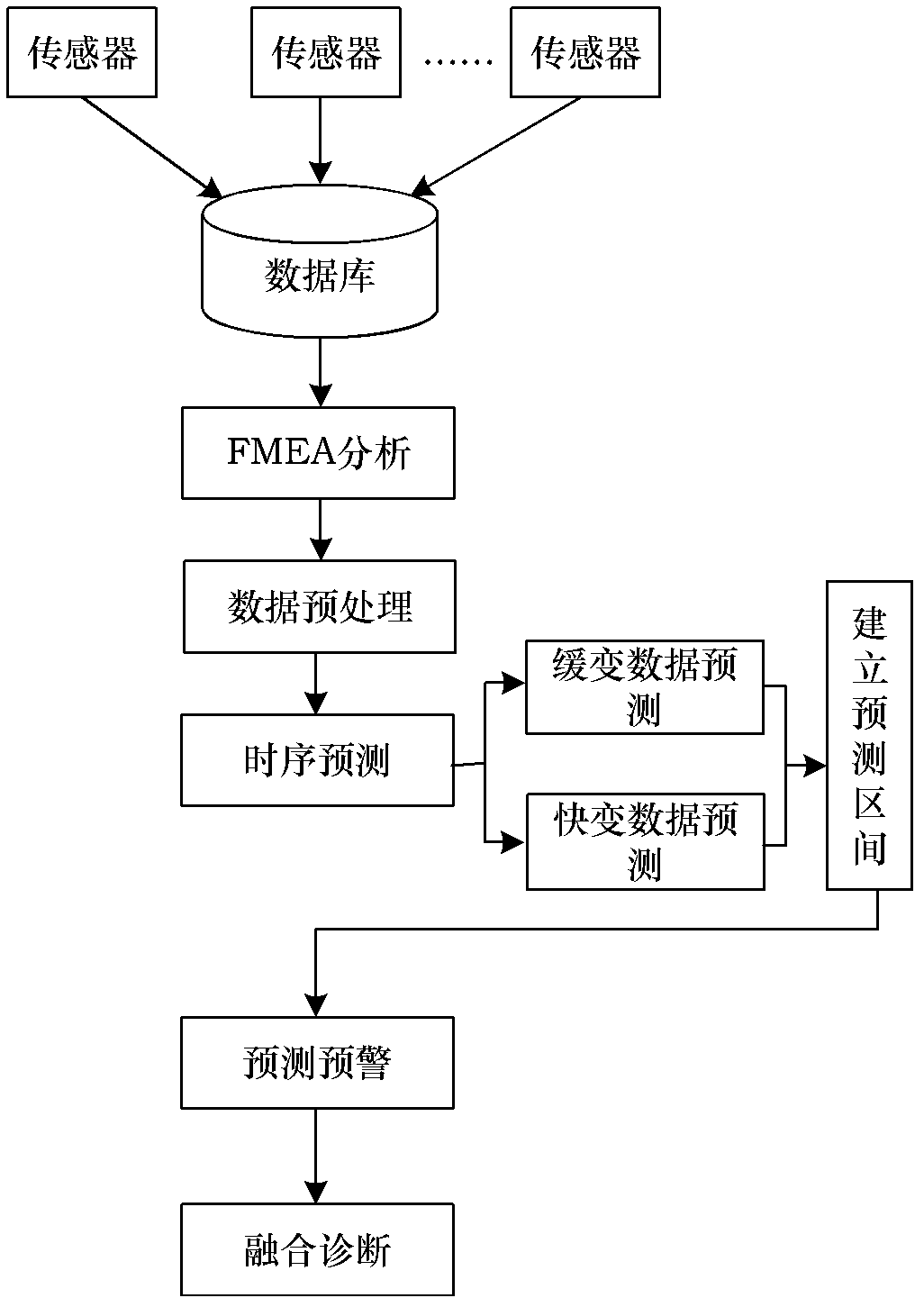

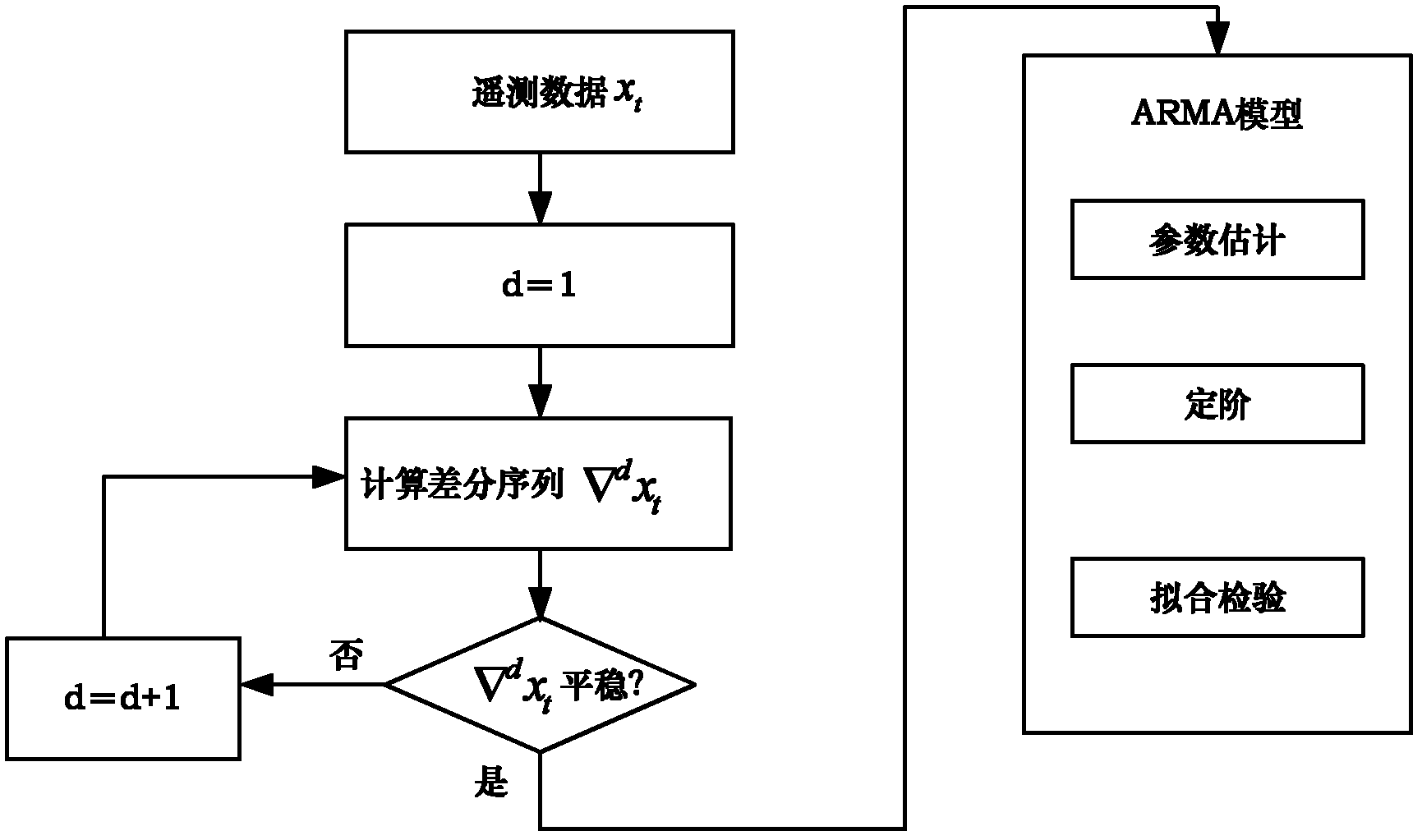

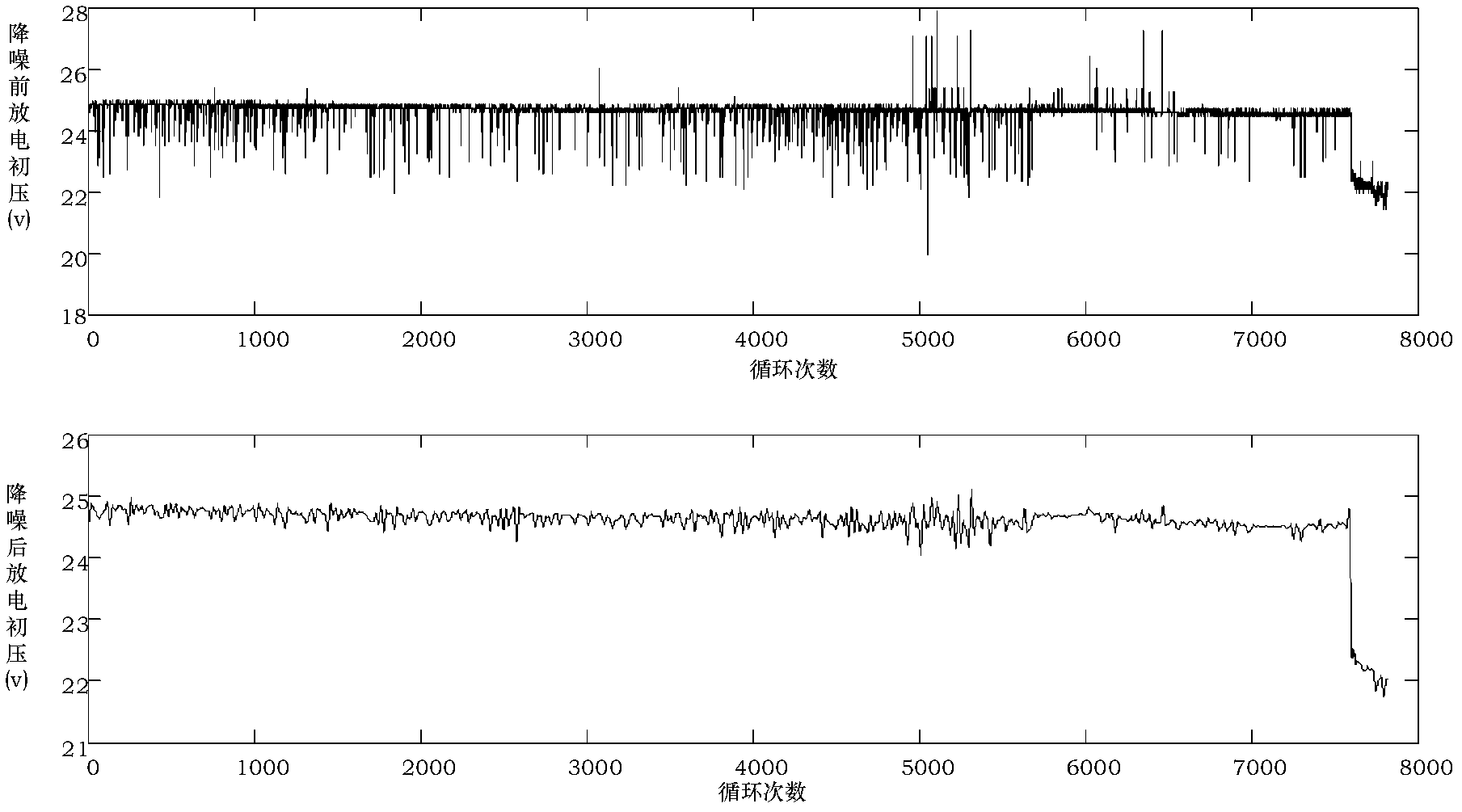

Fault predicting and diagnosing method suitable for dynamic complex system

InactiveCN102208028AOvercome the drawbacks of harsh restrictionsImprove general performanceCharacter and pattern recognitionPrediction intervalSystem failure

The invention provides a fault predicting and diagnosing method suitable for a dynamic complex system. The method can be applied in the field of fault prediction and diagnosis of dynamic complex systems of spacecrafts and the like. The method comprises the following steps of: performing failure mode and effect analysis (FMEA) on the dynamic complex system to obtain a main fault mode and corresponding performance detection parameters, dividing the performance detection parameters into slowly variable data and fast variable data, pre-processing the performance detection parameters, establishingan autoregressive moving average model (ARMA) aiming at the slowly variable data to perform time sequence prediction, establishing a multi-resolution wavelet neural network aiming at the fast variable data to perform time sequence prediction, performing fault early warning on the time sequence prediction results by establishing a prediction interval model, and performing fault diagnosis by establishing a D-S (Dempster-Shafer) evidence theory-based multi-signal fusion model. The method can be used for predicting and diagnosing the faults of the dynamic complex system with high precision, and has strong universality.

Owner:BEIHANG UNIV

Shaping suture for treating congestive heart failure

InactiveUS20050113810A1Improve and enhance overall treatmentMake up for deficienciesProsthesisWound clampsCongestive heart failure chfSurgery

A kit and method are described for treating congestive heart failure. The kit may comprise multiple components including a shaping device, deployment tool, patch, and suture. The method may utilize one or more of these components.

Owner:CHF TECH A CALIFORNIA CORP

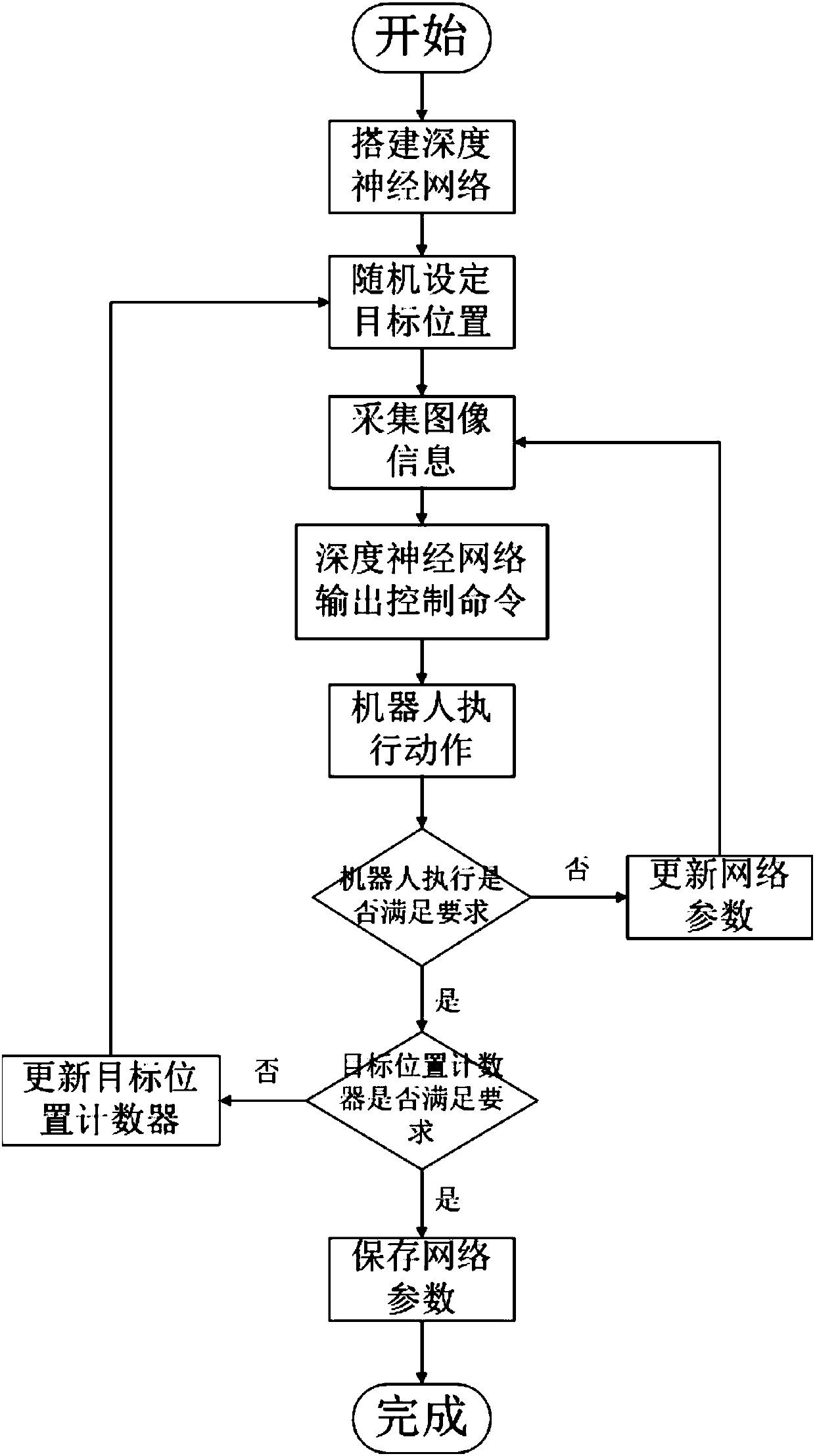

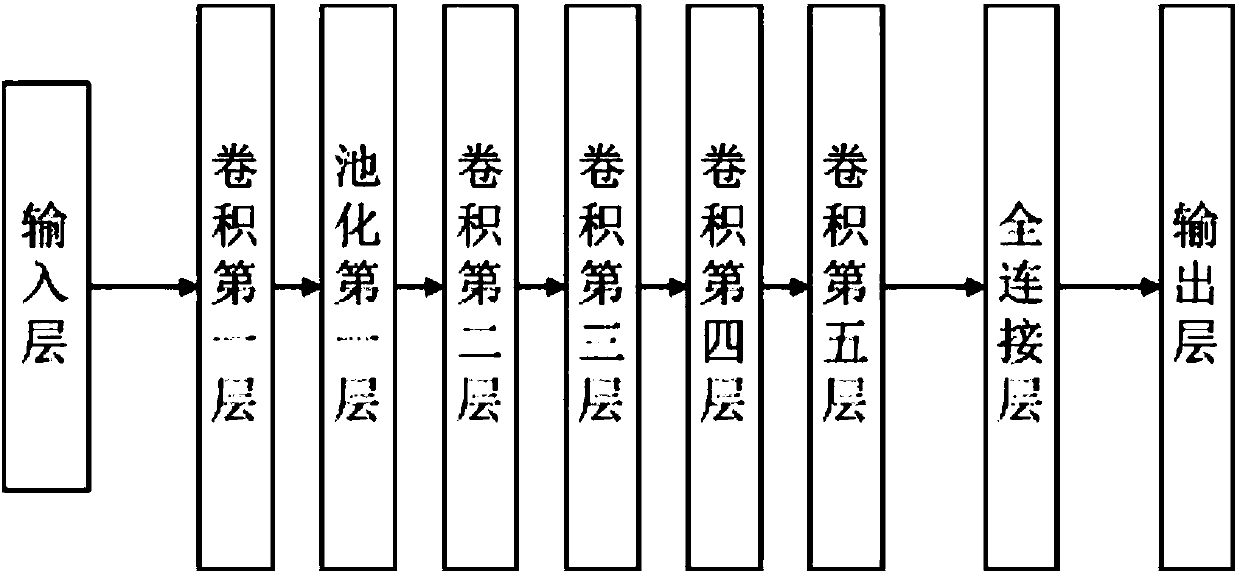

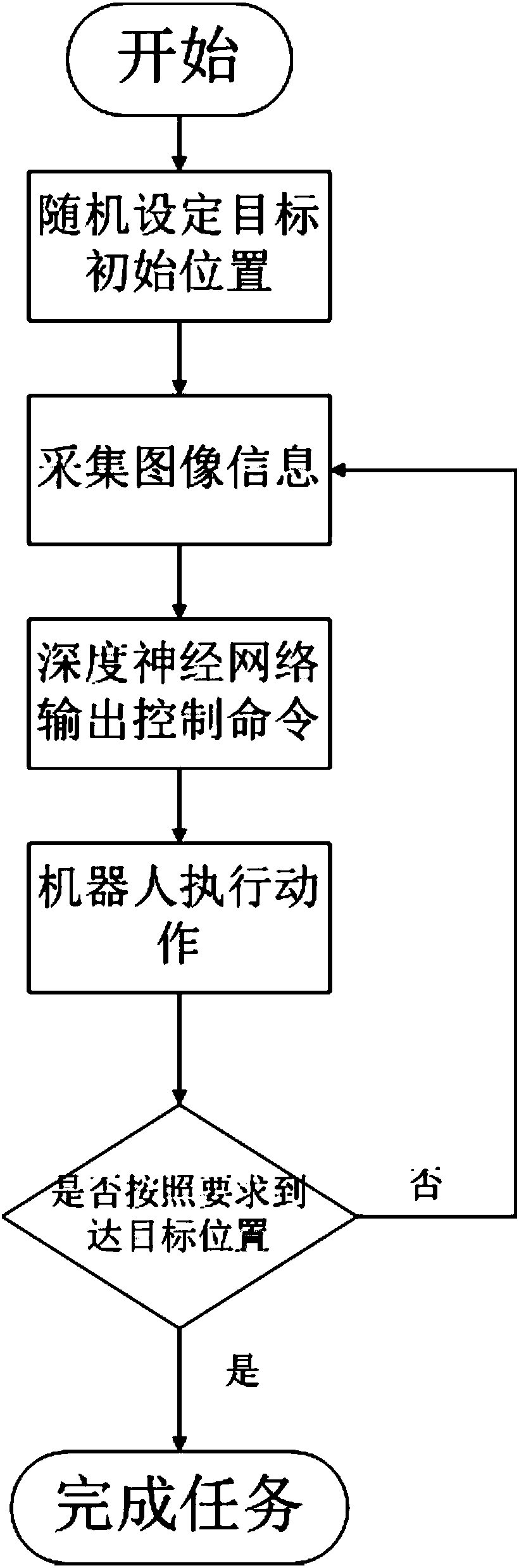

Robot global path planning method based on deeply enhanced learning

ActiveCN107065881AMake up for deficienciesStrong real-timePosition/course control in two dimensionsNerve networkView camera

The invention proposes a robot global path planning method based on deeply enhanced learning, which belongs to the robot learning and global path planning technology fields. The method comprises: in the training session: firstly, installing a top-view camera in a scenario; constructing a deep neural network; after a training path is created, outputting the executing actions by the deep neural network according to the images photographed by the camera; and according to the execution effect of the actions, optimizing the parameters of the deep neural network; then, updating the position of a target; performing different path planning trainings to obtain a final deep neural network; and in the execution session: outputting the executing actions for the robot by the final deep neural network according to the images photographed by the camera so that the robot executes the actions; and if the robot reaches the position of the target after its execution of the actions, then, completing the global path planning by the robot. The method of the invention is very practical in use, does not require manual participation, or the entrance of a scenario for constructing an environment map in advance. The method can be applied to multiple scenarios at a low cost.

Owner:TSINGHUA UNIV

Expanded membership access control in a collaborative environment

InactiveUS20050289234A1Make up for deficienciesComputer security arrangementsMultiple digital computer combinationsWorld Wide WebAccess control list

A method, system and apparatus for expanded membership access control in a collaborative environment. A collaborative application which has been configured for expanded membership access control can include a collaborative space configured to host places, and rooms and sub-rooms within the places. The collaborative space further can include a membership management processor coupled to the collaborative space and programmed both to produce access control lists for the rooms and sub-rooms based upon specified roles for members and to assign the roles to members added to the rooms and sub-rooms separately from the access control lists. Notably, a membership directory also can be included which can be configured to store membership information for the members exclusive of the access control lists.

Owner:TAASERA LICENSING LLC

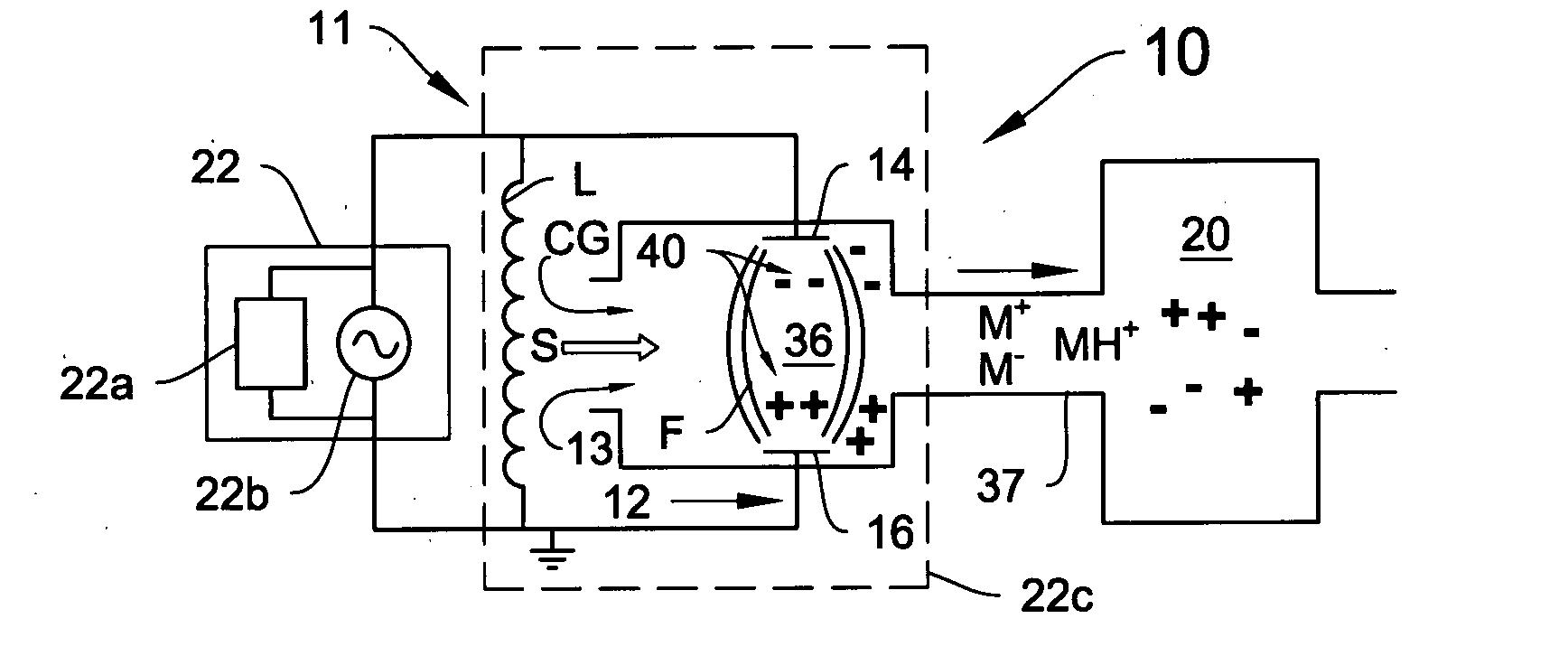

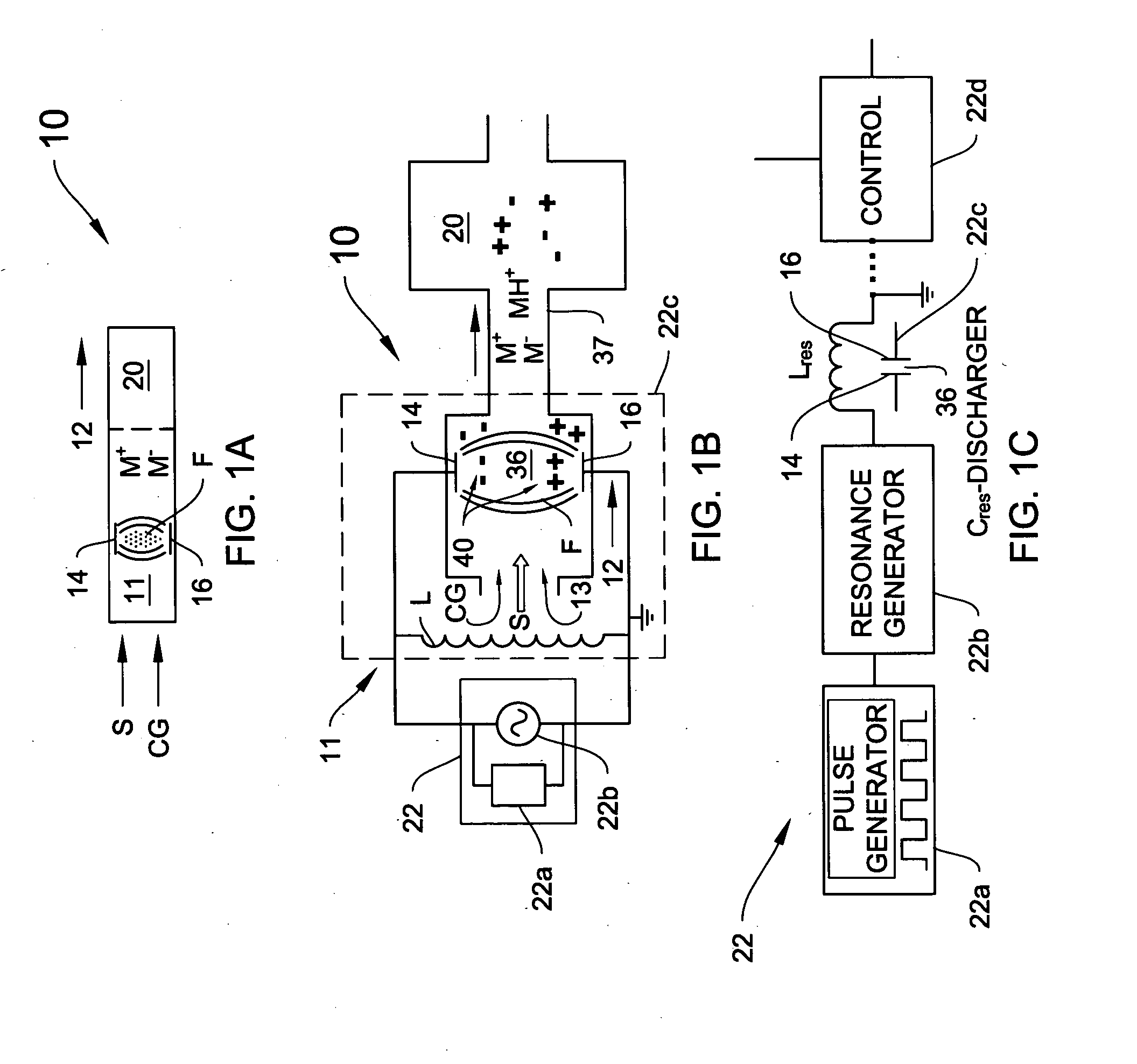

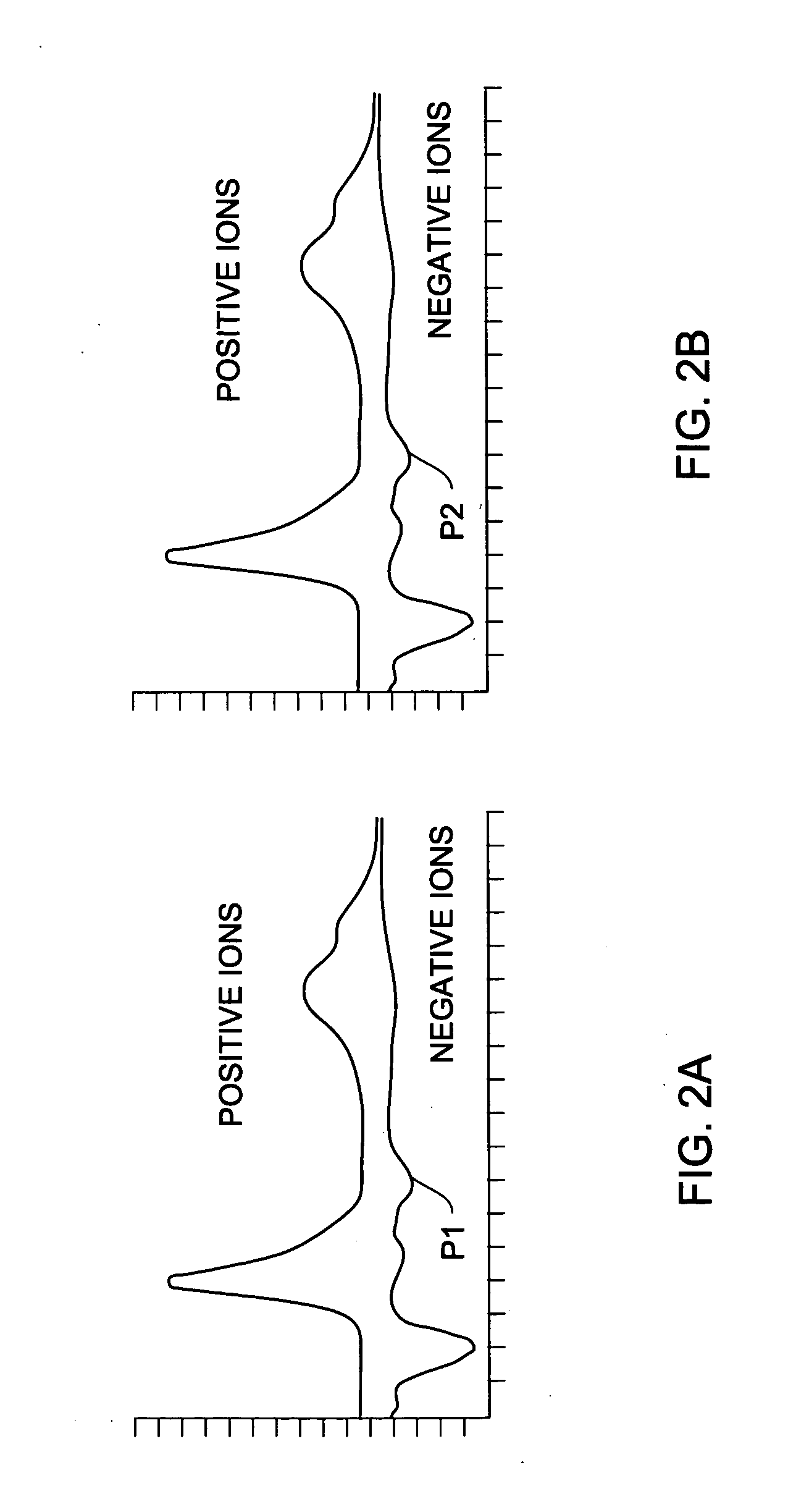

Method and apparatus for plasma generation

InactiveUS20050121607A1Low to moderate ionization energyDegrade device performanceTime-of-flight spectrometersMaterial analysis by electric/magnetic meansRadio frequencyPhoto ionization

An RF-driven plasma source, including a pair of spaced-apart plasma electrodes, wherein the electrodes act as plates of a capacitor, the gas electrically discharges and creates a plasma of both positive and negative ions, in a clean process that enables efficient sample analysis, with preferred isolated sample photo-ionization, reduced-power operation and also including signal detection with modulated drive electronics.

Owner:DH TECH DEVMENT PTE

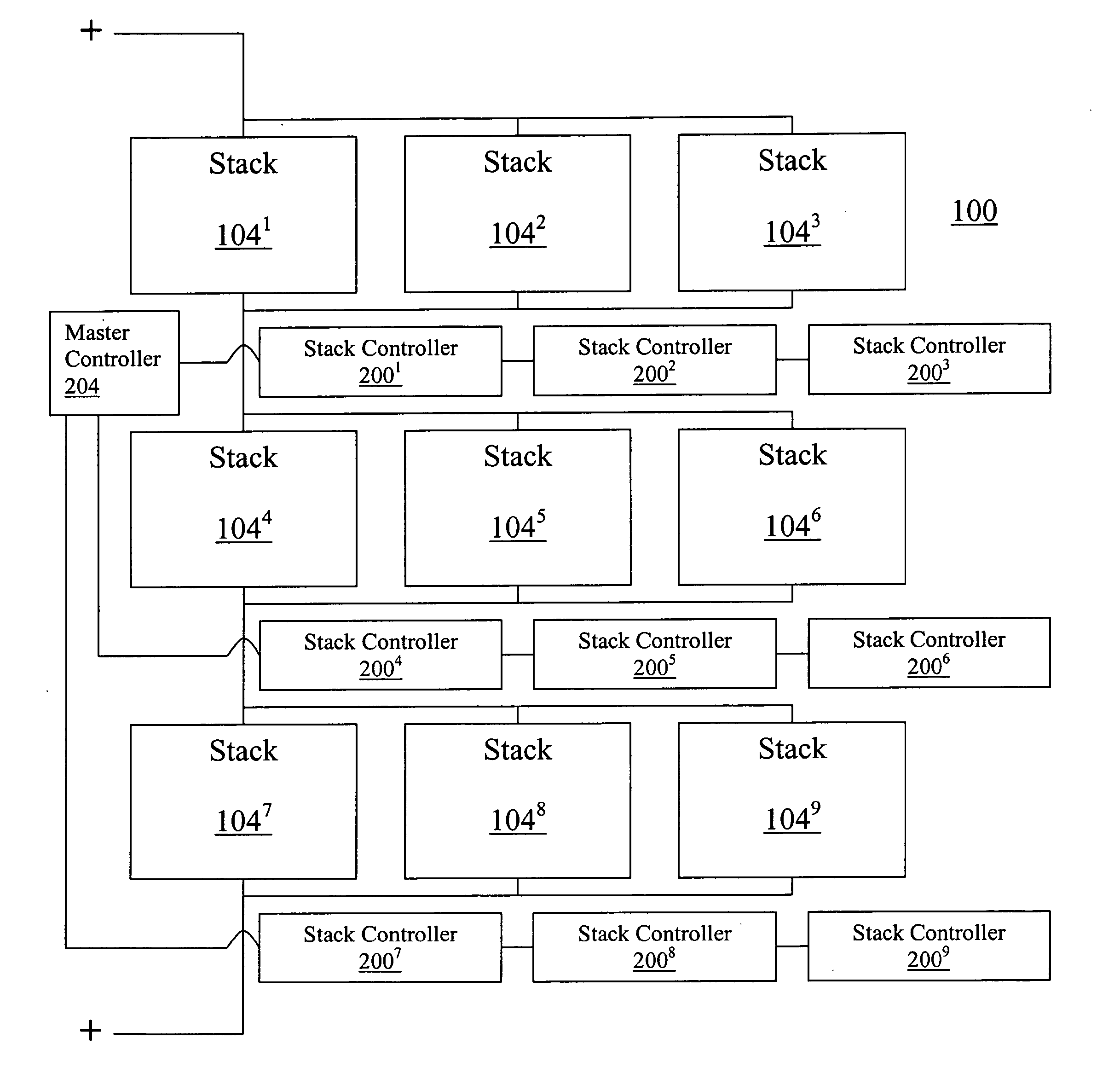

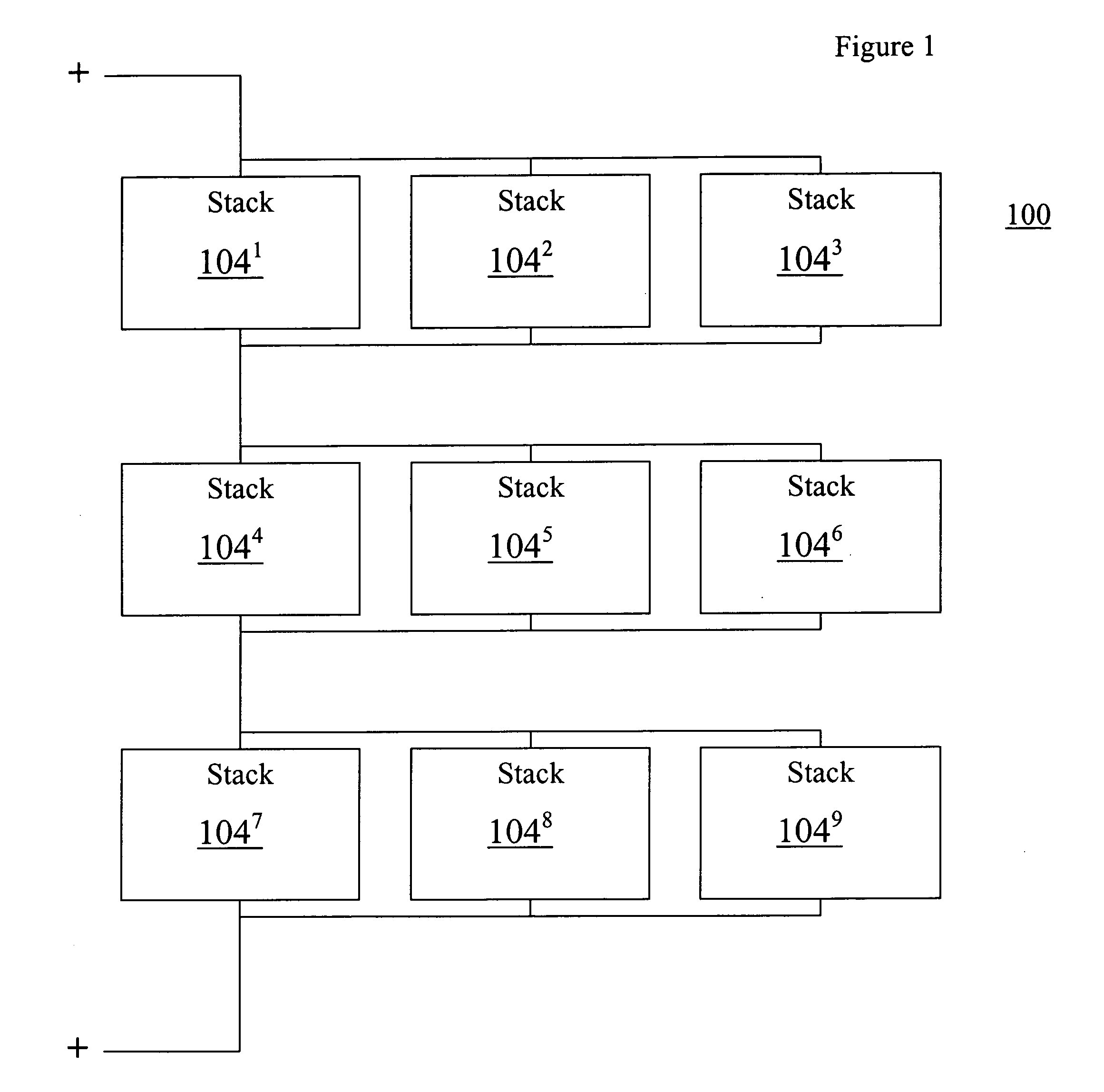

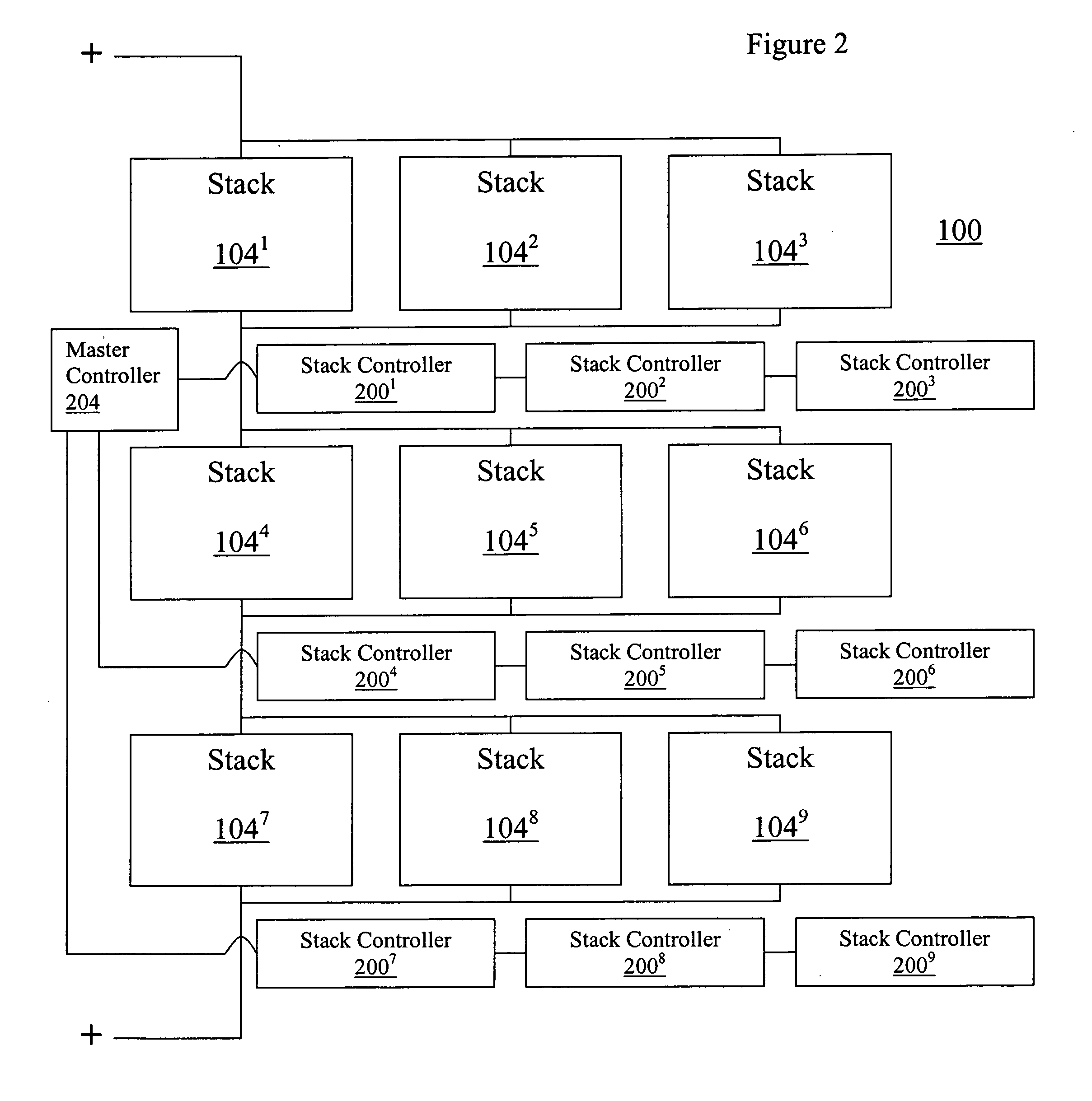

Systems and methods for selective cell and/or stack control in a flowing electrolyte battery

ActiveUS20050084745A1Increase flexibilityReduce riskPrimary cell to battery groupingMechanical power/torque controlEngineeringEnergy storage

The invention provides in various embodiments methods and systems relating to controlling energy storage units in flowing electrolyte batteries.

Owner:LARGO CLEAN ENERGY CORP

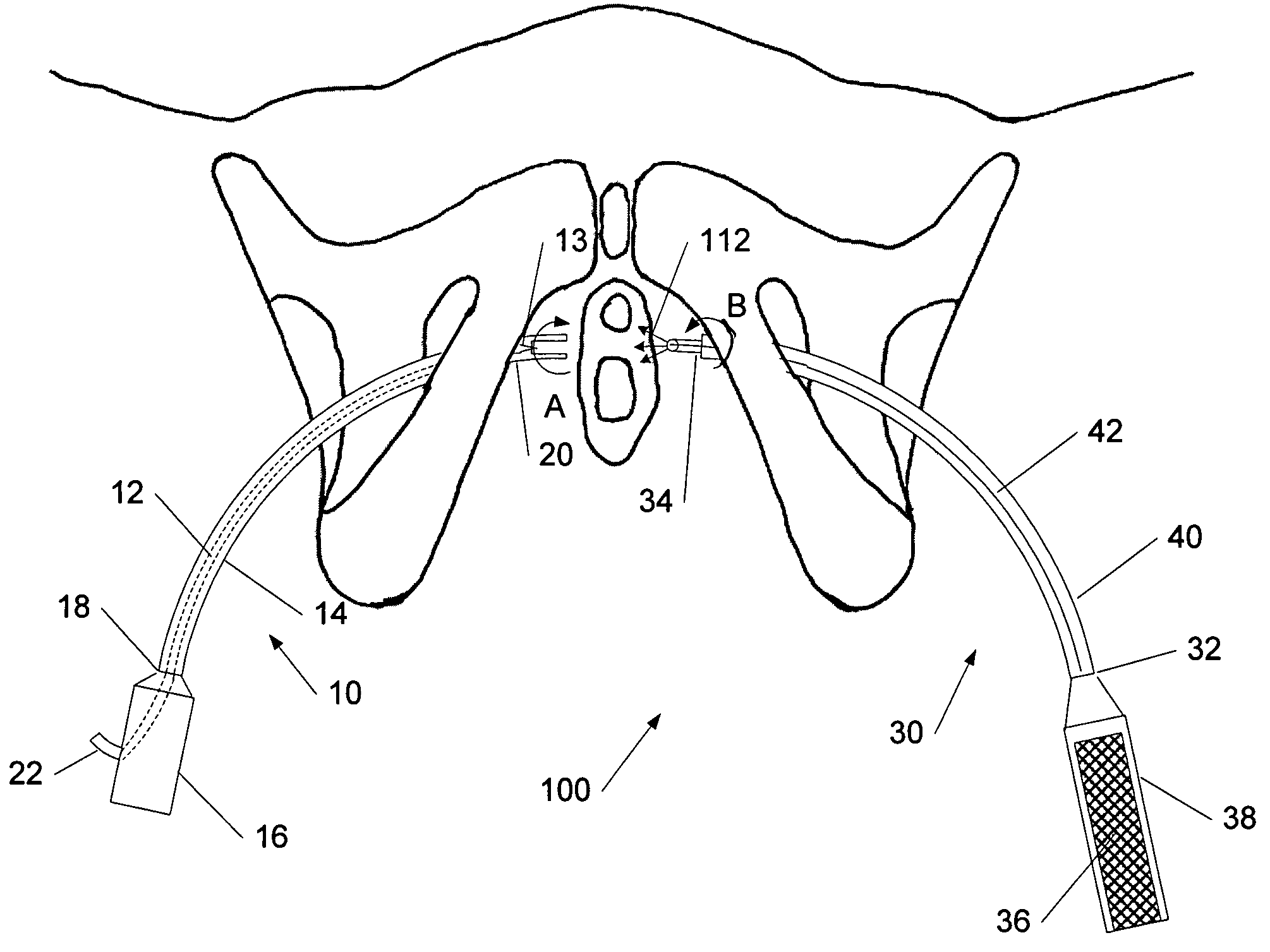

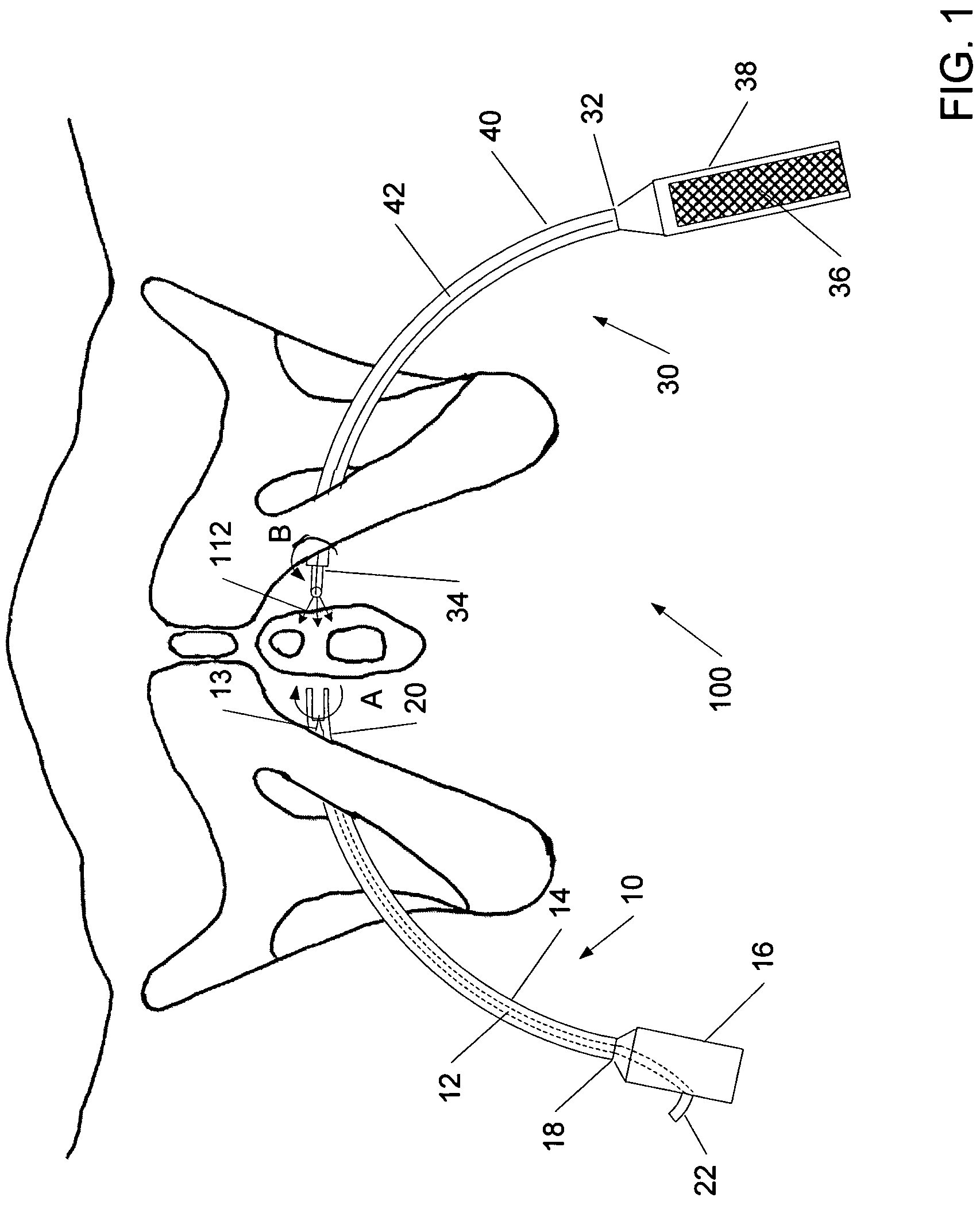

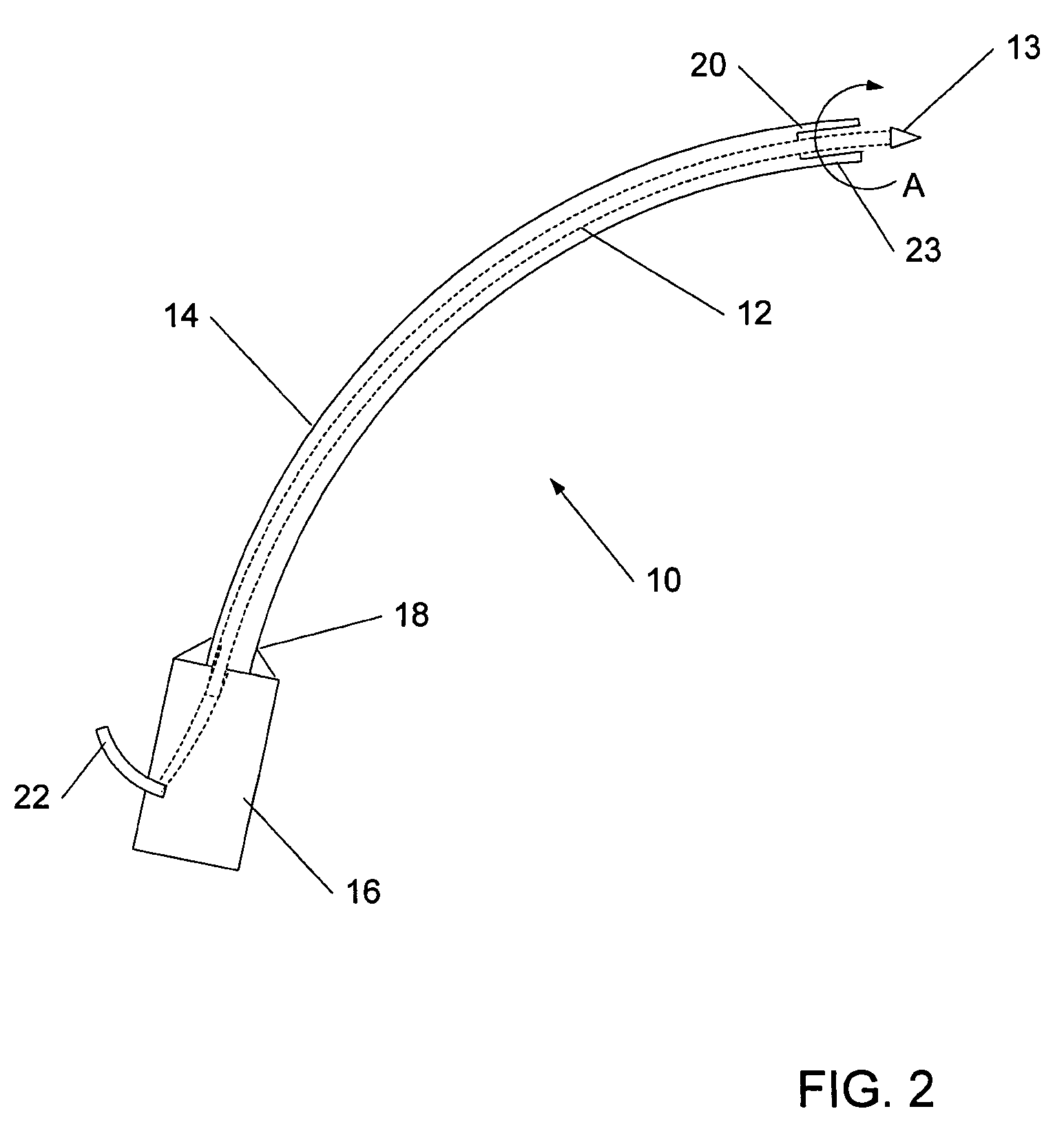

Devices for minimally invasive pelvic surgery

InactiveUS7637860B2Simple deliveryMake up for deficienciesSuture equipmentsDiagnosticsCouplingPelvic surgery

Systems and methods employing a sling delivery assembly having a sling delivery device couplable to a sling assembly to deliver an implant through a transobturator incision point are disclosed. Successful coupling between the sling delivery device and the sling assembly can be verified through changes in an optical or electrical signal produced at the coupling location.

Owner:BOSTON SCI SCIMED INC

Tubular implantable sling and related delivery systems, methods and devices

ActiveUS20070038017A1Large widthIncrease the lengthSuture equipmentsAnti-incontinence devicesMedicineBiomedical engineering

Owner:BOSTON SCI SCIMED INC

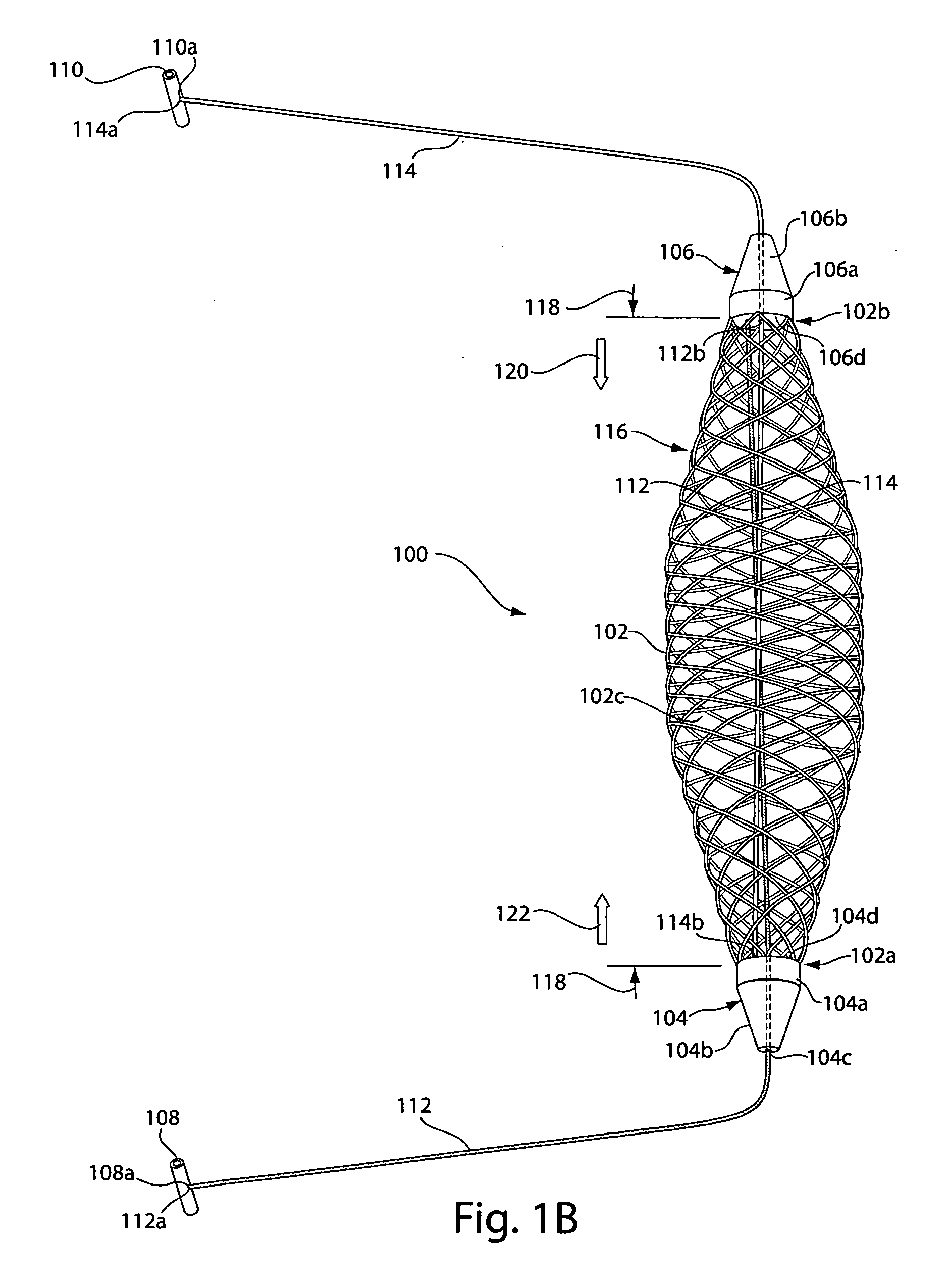

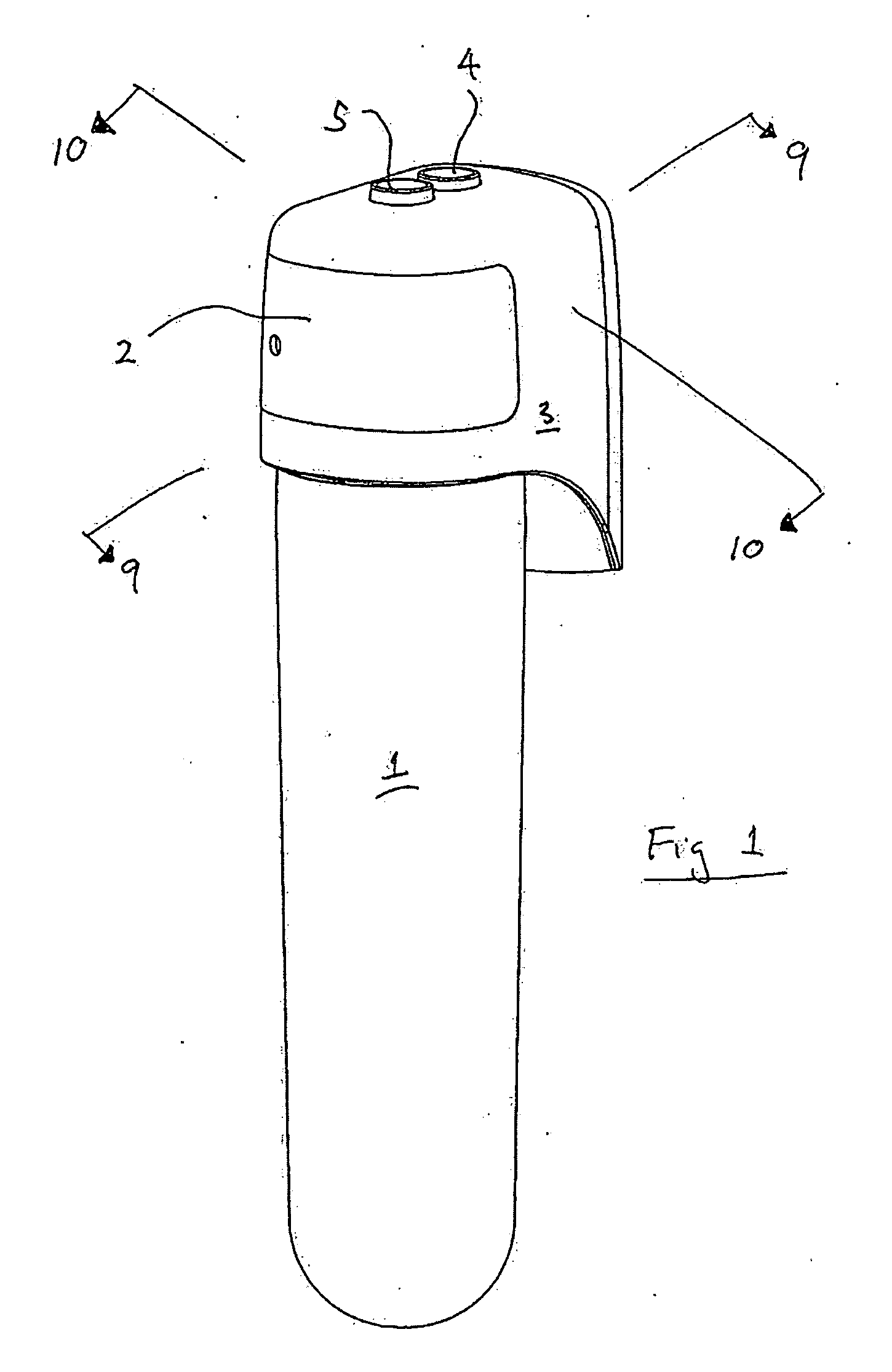

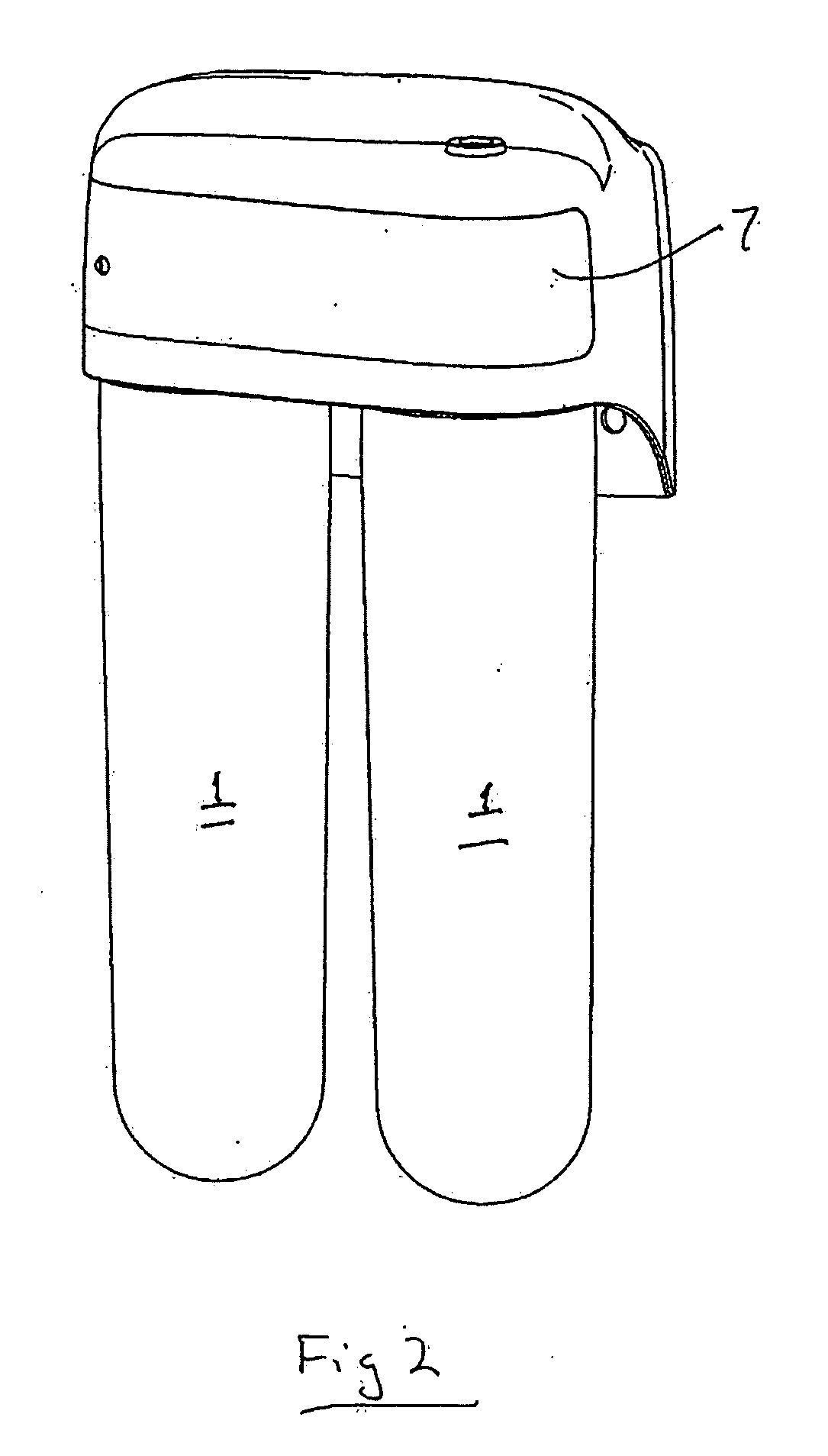

Filter cartridge for use with a filter head assembly

InactiveUS20090321340A1Reduced Possibility of ContaminationPrevent disengagement and unthreadingDialysis systemsMembrane filtersFilter mediaWaste management

A filter cartridge for use with a filter head assembly and for filtering a stream of pressurized fluid. The filter cartridge comprises a housing enclosing filtering media, a retainer to releasably engage a receiver in a filter head assembly, and one or more rotationally engagable locks securing the filter cartridge to the filter head assembly upon the rotational engagement of the filter cartridge with the filter head assembly. The housing includes an upper end having therein entry and exit passages to permit fluid to enter the housing, pass through the filtering media and exit the housing. Rotational engagement of the filter cartridge with the filter head assembly causes the retainer and said the receiver to releasably secure the filter cartridge to the filter head assembly and to thereby permit fluid to travel from the filter head assembly through the entry passage and to permit fluid to pass from the exit passage into the filter head assembly. The locks help to resist the rotational disengagement of the filter cartridge from the filter head assembly.

Owner:ENVIROGARD PRODS

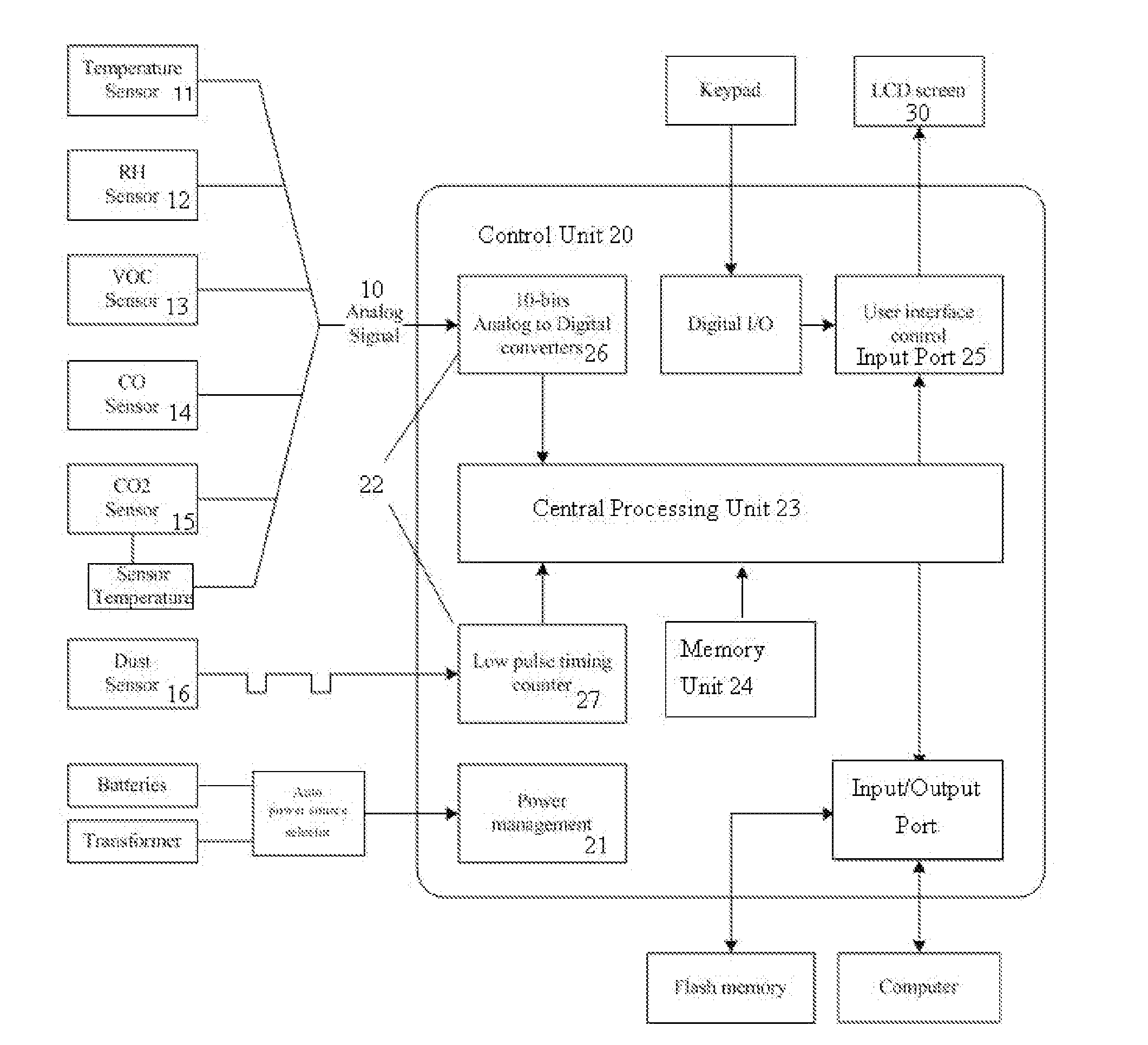

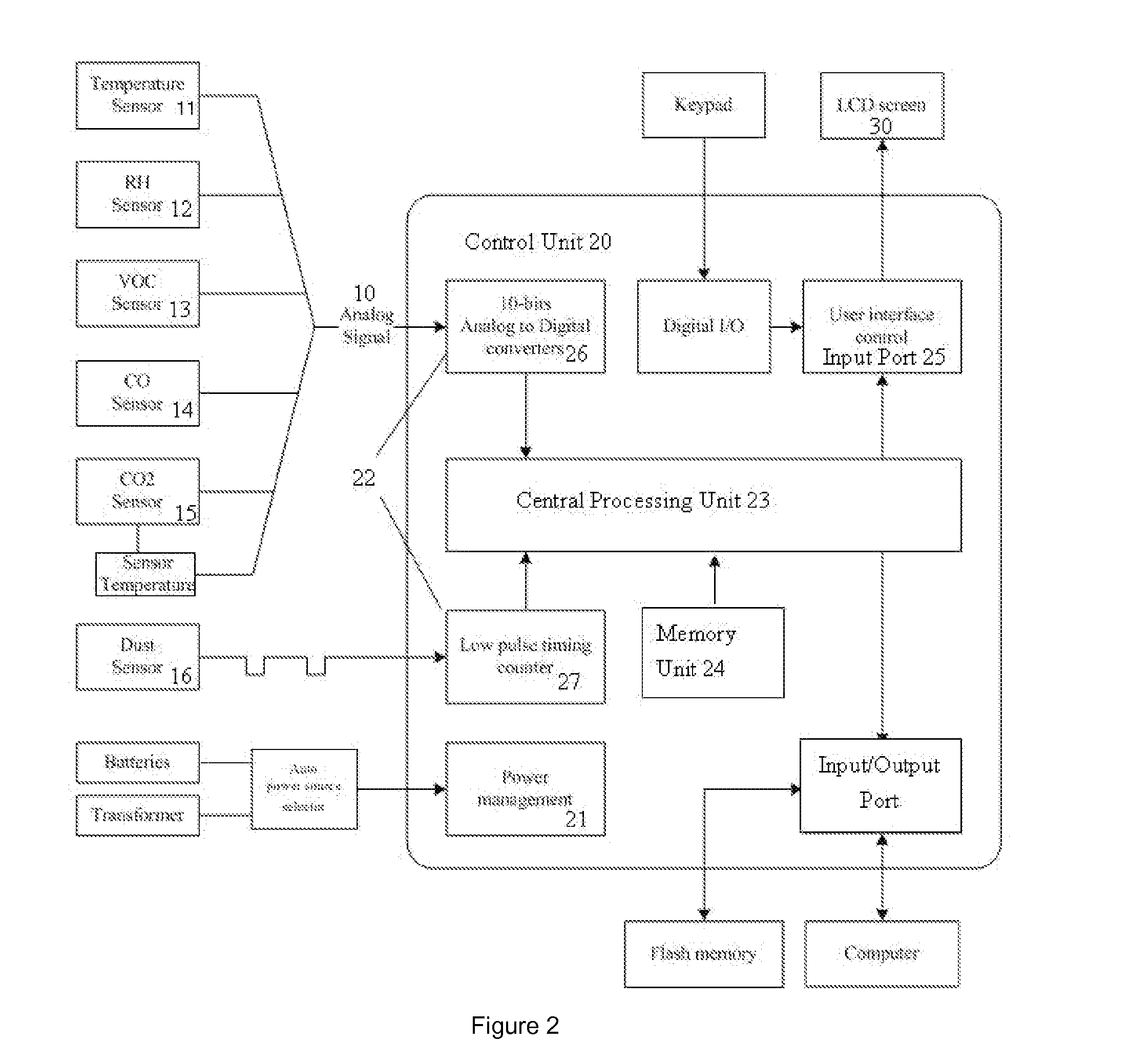

Method and Device for Environmental and Health Monitoring

InactiveUS20150330817A1Improve healthReduce lifeSamplingWeather condition predictionEngineeringEnvironmental monitoring

Owner:LAW SUI CHUN +1

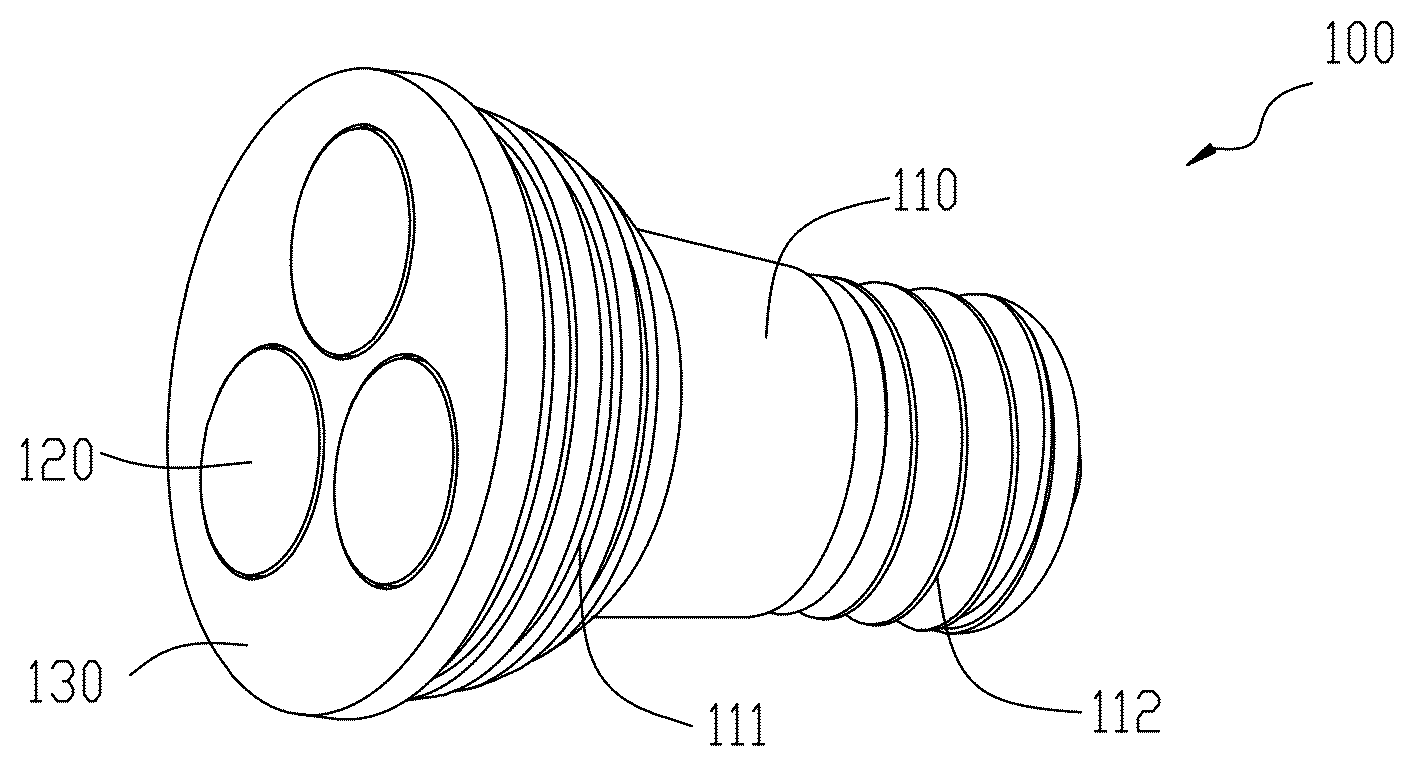

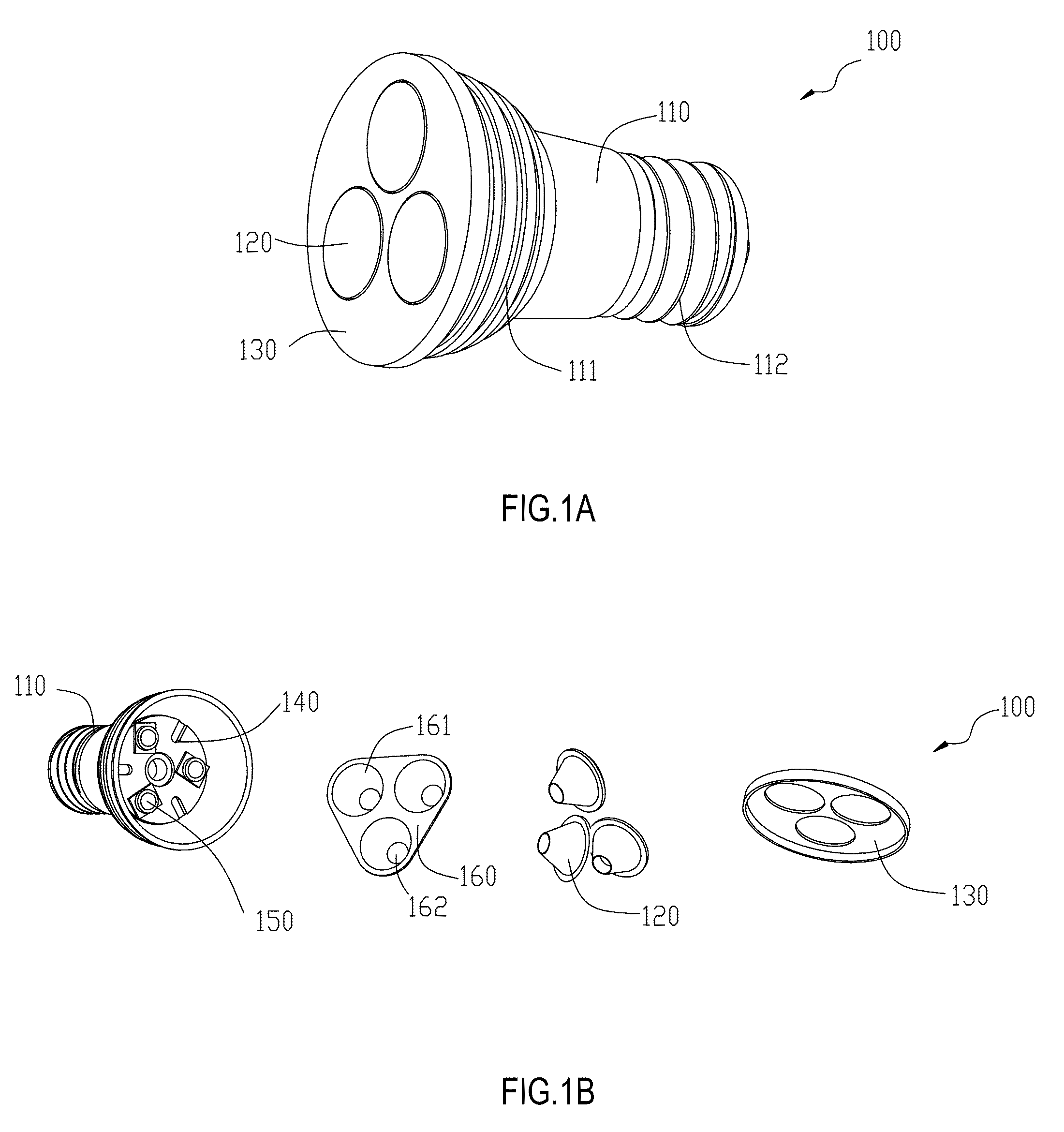

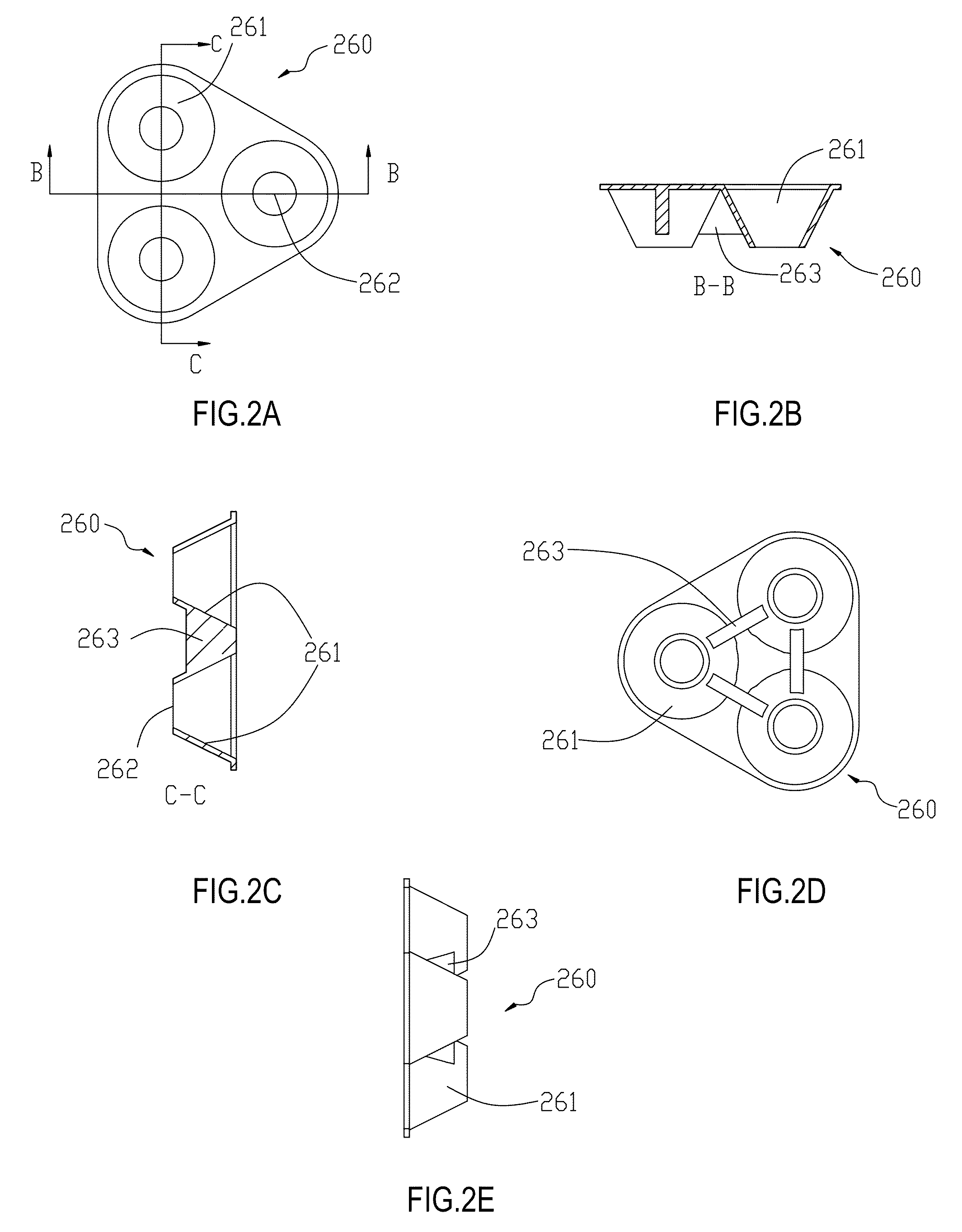

LED lamp assembly

InactiveUS20100046223A1Simple preparation processMake up for deficienciesNon-electric lightingLight source combinationsEffect lightEngineering

The present invention relates to lighting assemblies and more particularly to light emitting diode (LED) light bulbs comprising a support for one or more LED lenses, which can be used to position and support the lenses within the lamp housing and which facilitate assembly of the light bulbs during manufacturing.

Owner:US VAOPTO +1

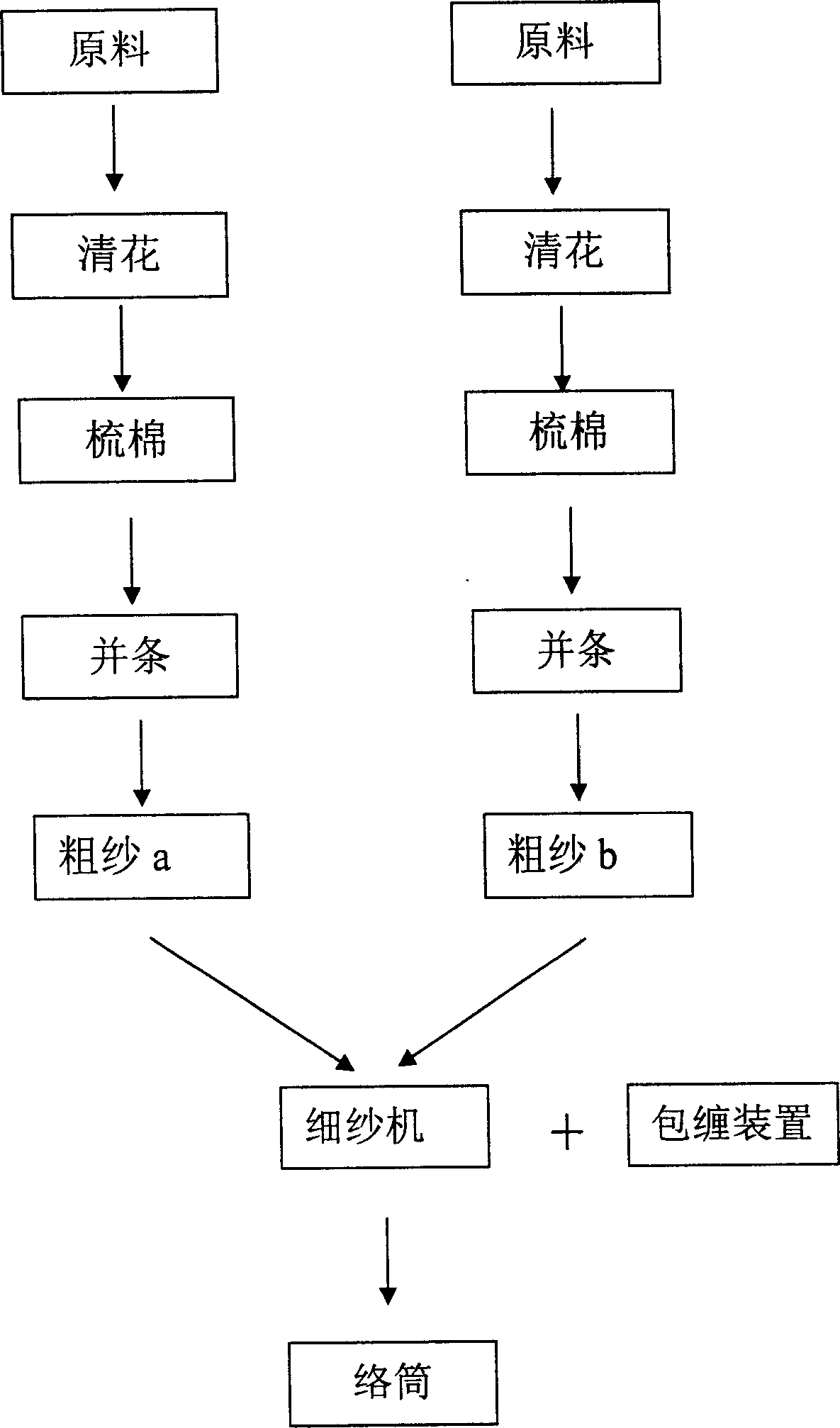

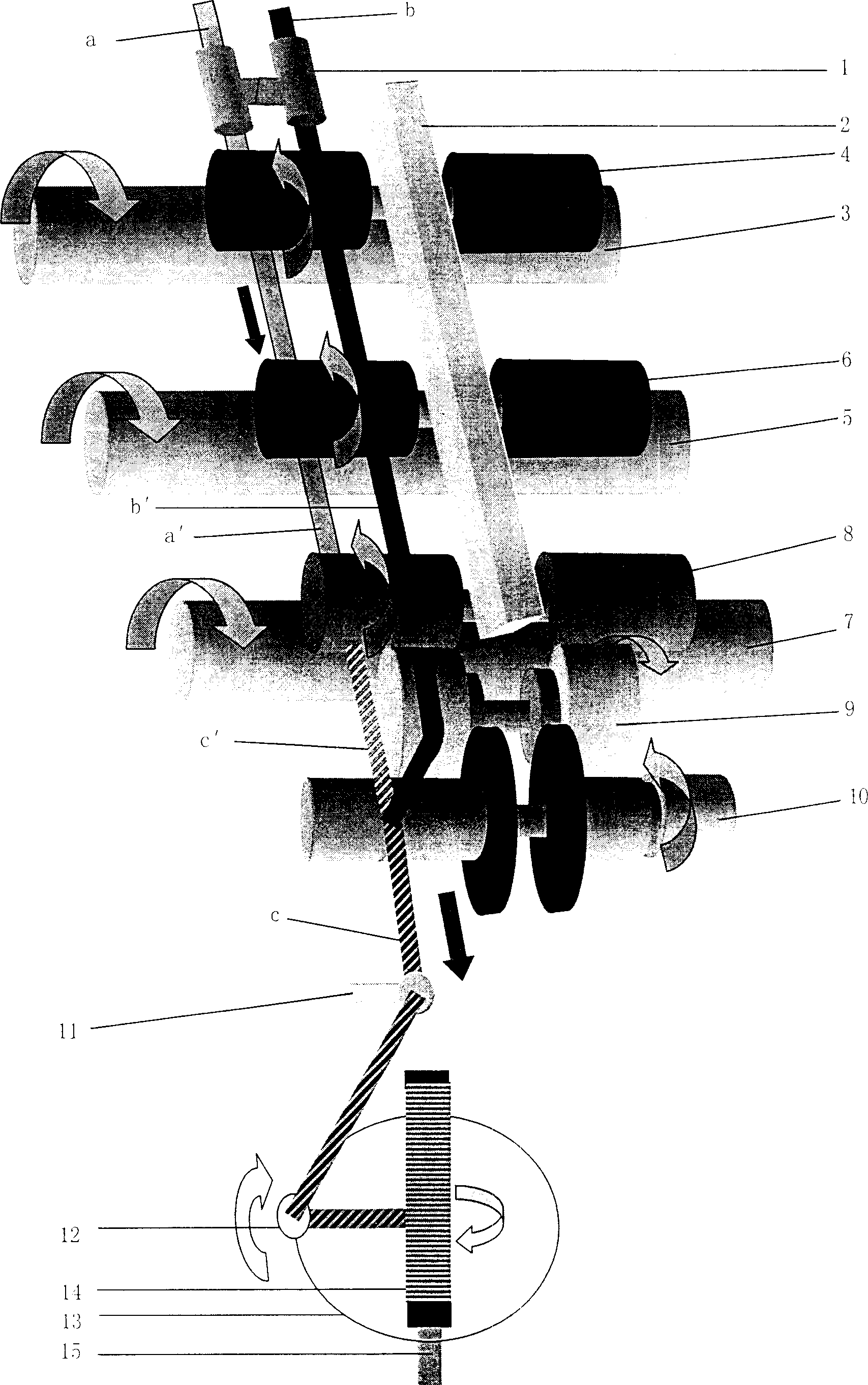

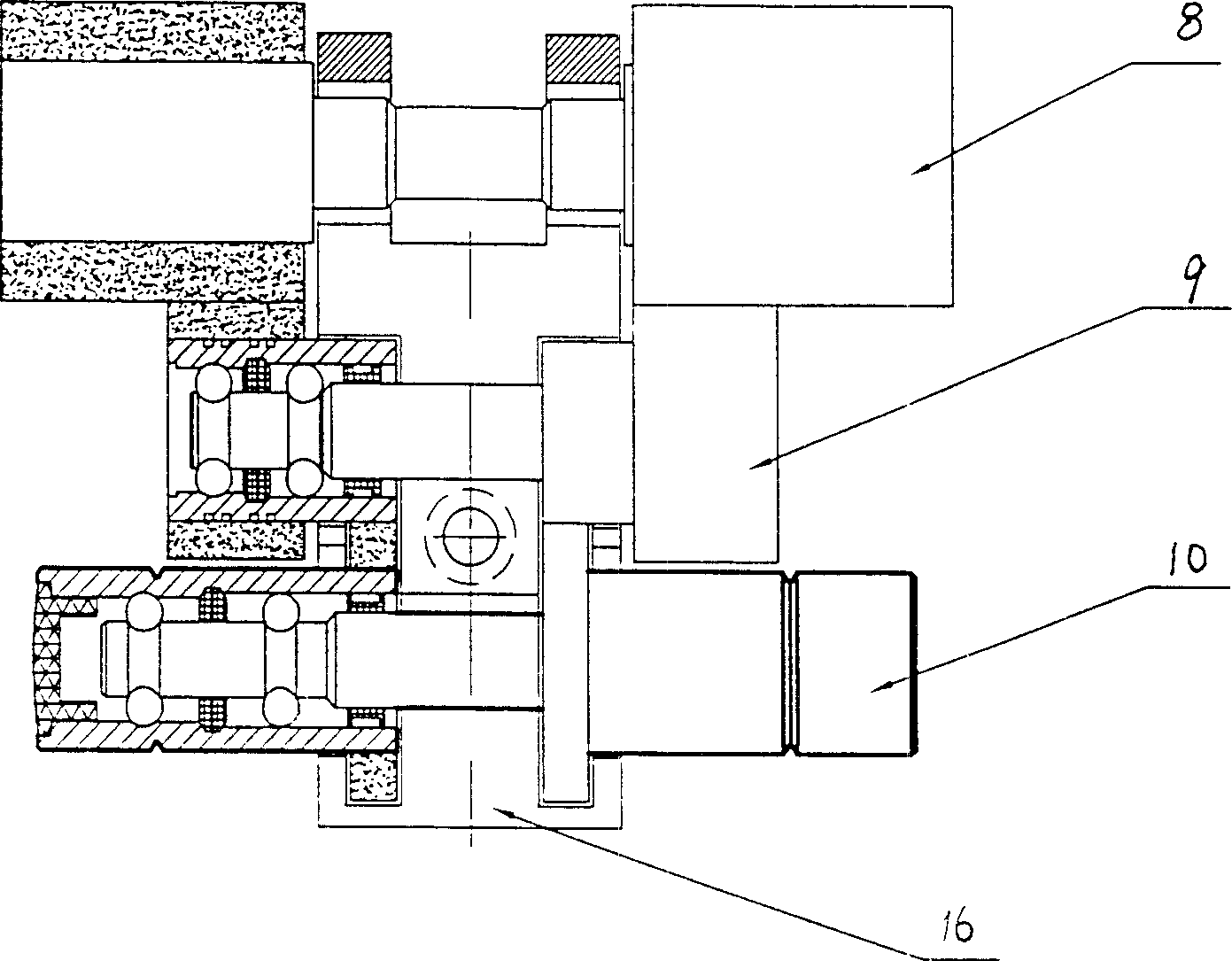

Production method of short staple enveloped composite yarn and its device

The present invention discloses a production method of short fibre wrapped composite yarn and its equipment. Said invention is implemented by using spinning frame and wrapping device, and its production method includes the following steps: raw material, scotching, carding, drawing, roving, spinning and doffing.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

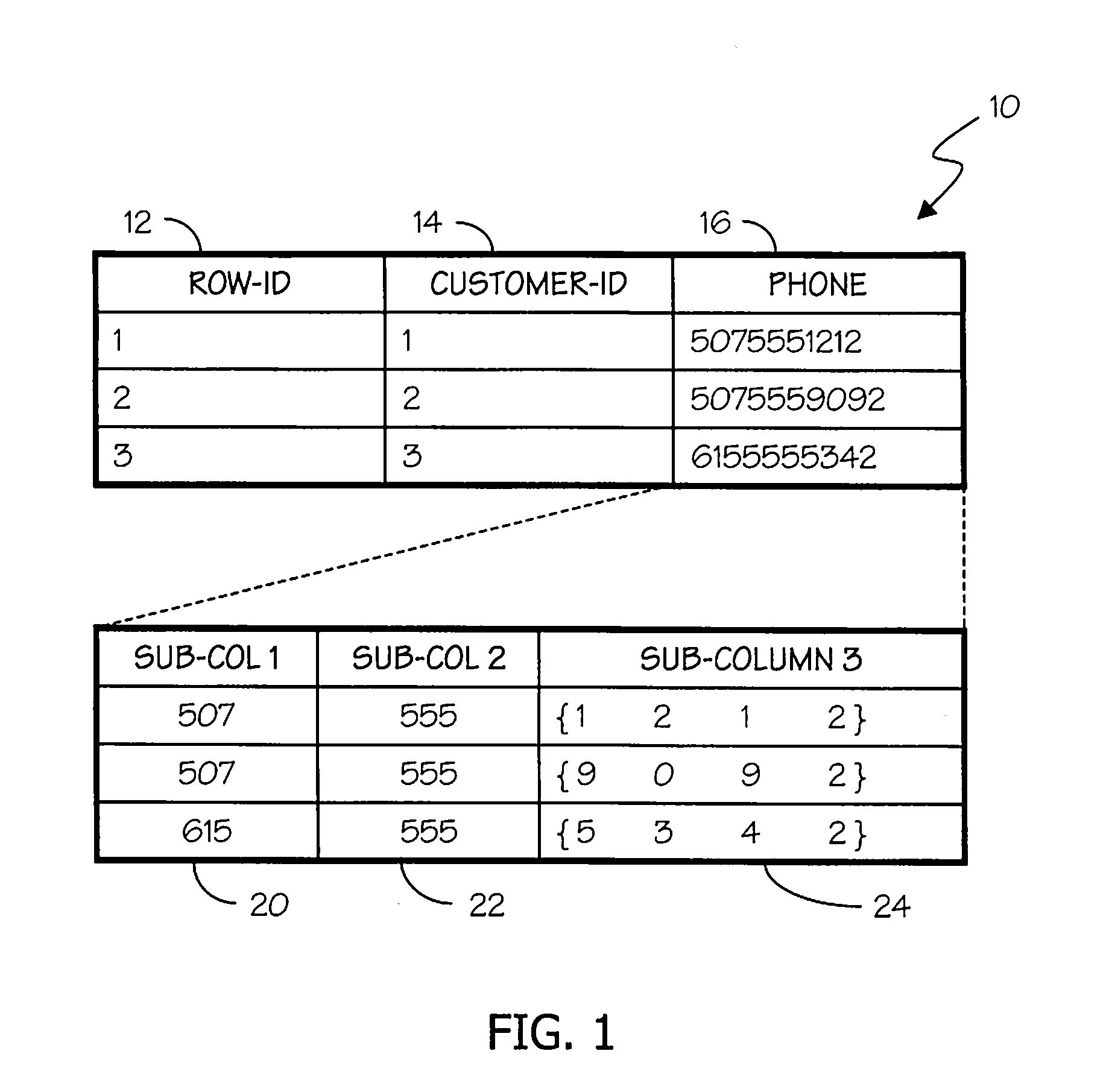

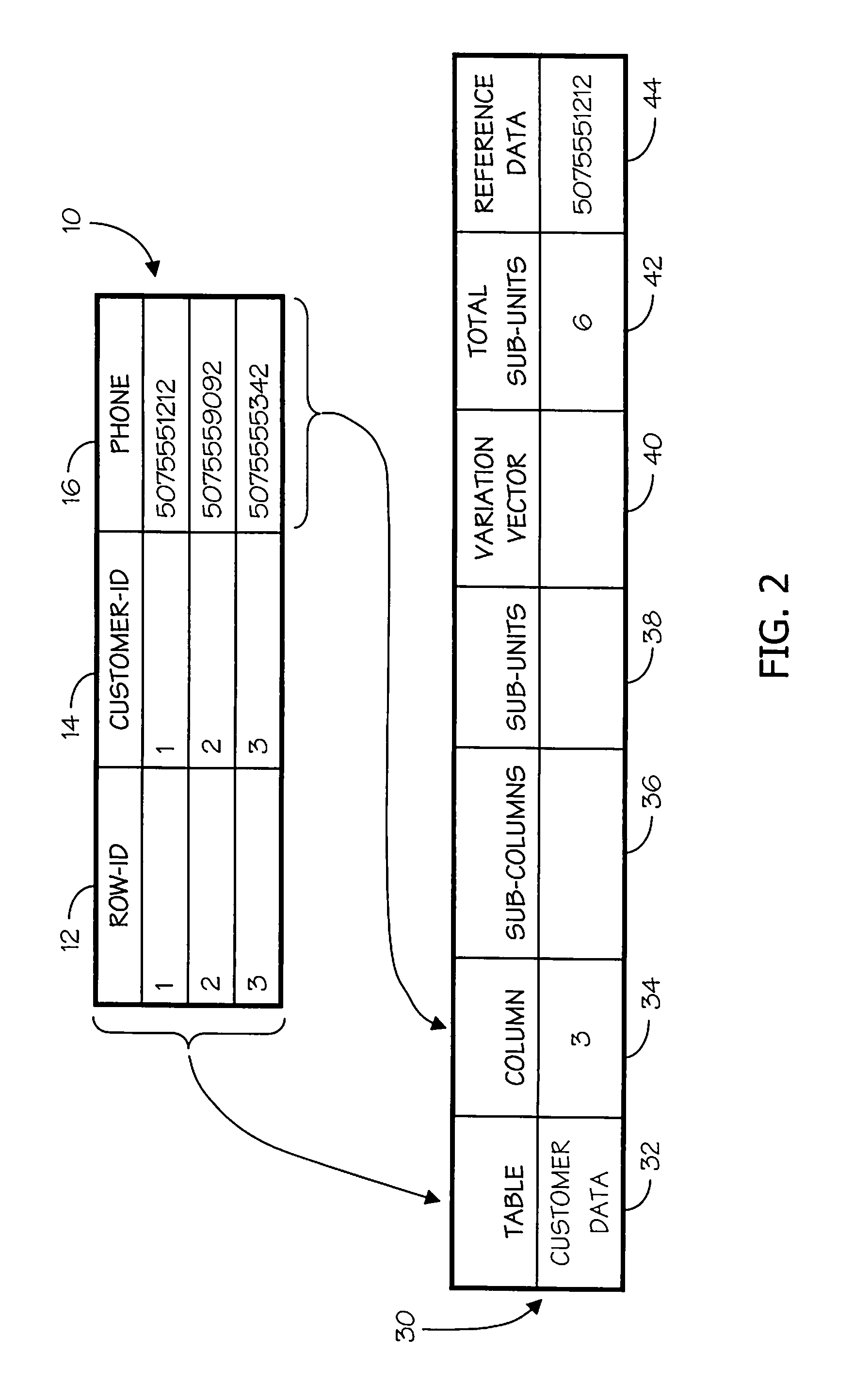

Encoded matrix index

ActiveUS20090313210A1Easy to rebuildReduce the amount of informationDigital data information retrievalDigital data processing detailsDatabaseData structure

A method, apparatus, and program product are provided for creating an Encoded Matrix Index for a column in a database table. An element of the column for all rows in the database table is compared to a corresponding reference value in a reference data structure, and in response to at least one value for the element of the column not matching the reference value, indicating a variation in a variation data structure and creating a value data structure. Queries executed using the Encoded Matrix Index include terms associated with a sub-column defined in a column of a database table. The variation data structure is accessed to determine whether any variation exists between rows belonging to a sub-column of the database table. If no variation exists, a value is accessed from the reference data structure; otherwise, a value for each row of the sub-column is accessed from a value data structure.

Owner:IBM CORP

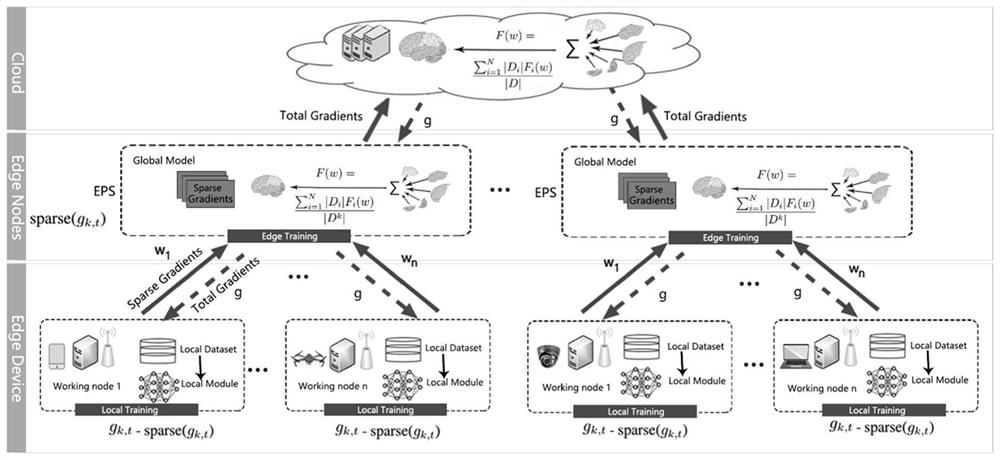

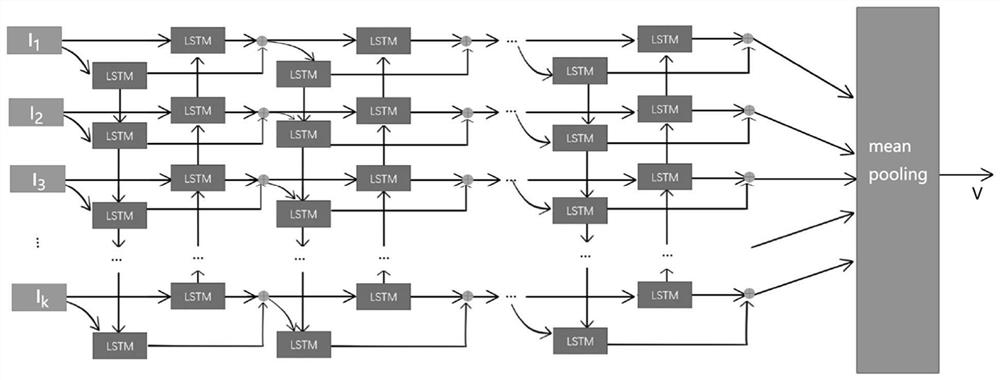

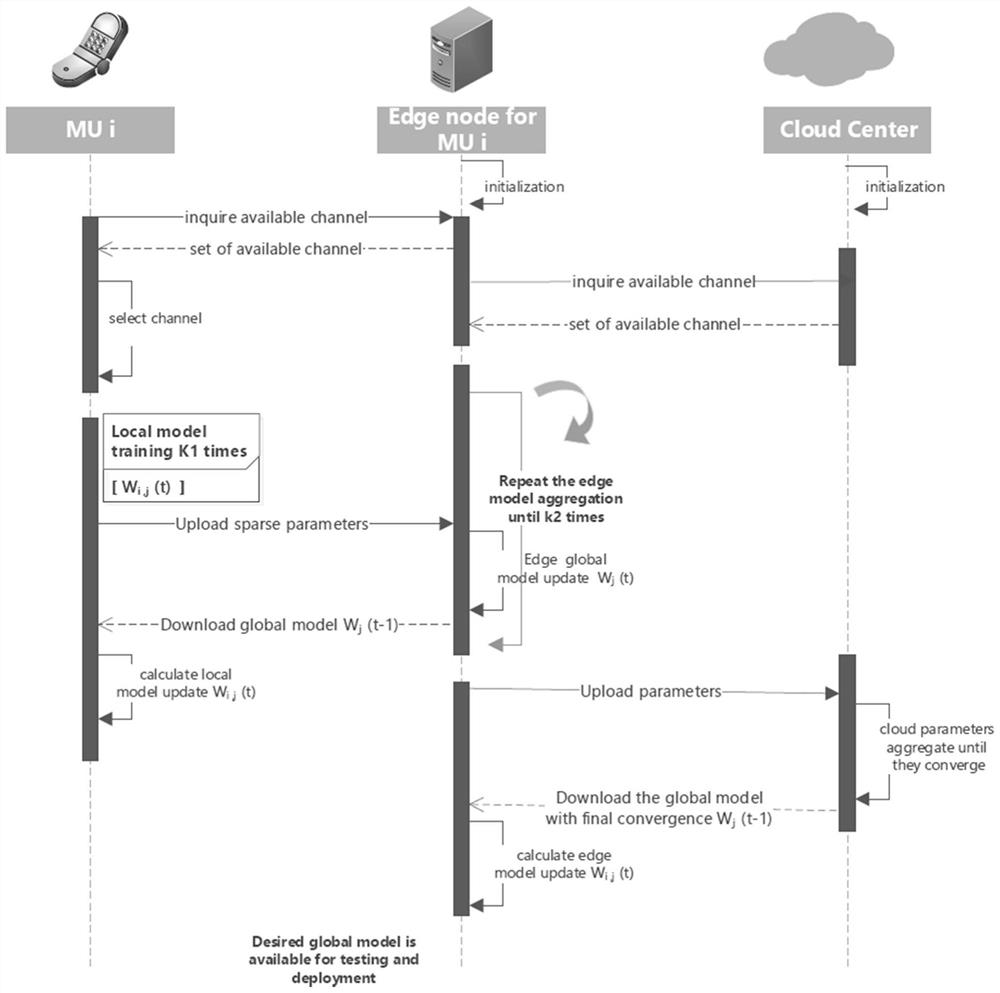

Federal learning computing unloading computing system and method based on cloud side end

InactiveCN112817653AMake up for deficienciesAccurate decisionProgram initiation/switchingResource allocationComputation complexityEdge node

The invention discloses a federated learning computing unloading resource allocation system and a method based on a cloud side end, and aims to make an accurate decision for computing task unloading and resource allocation, eliminate the need for solving a combinatorial optimization problem and greatly reduce the computing complexity. Based on cloud side three-layer federated learning, the adjacent advantage of edge nodes to a terminal is comprehensively utilized, core powerful computing resources in cloud computing are also utilized, the problem that the computing resources of the edge nodes are insufficient is solved, a local model is trained at each of multiple clients to predict an unloading task. A global model is formed by periodically executing one-time parameter aggregation at an edge end, the cloud end executes one-time aggregation after the edge executes the periodic aggregation until a global BiLSTM model is formed through convergence, and the global model can intelligently predict the information amount of each unloading task. Therefore, guidance is better provided for calculation unloading and resource allocation.

Owner:XI AN JIAOTONG UNIV

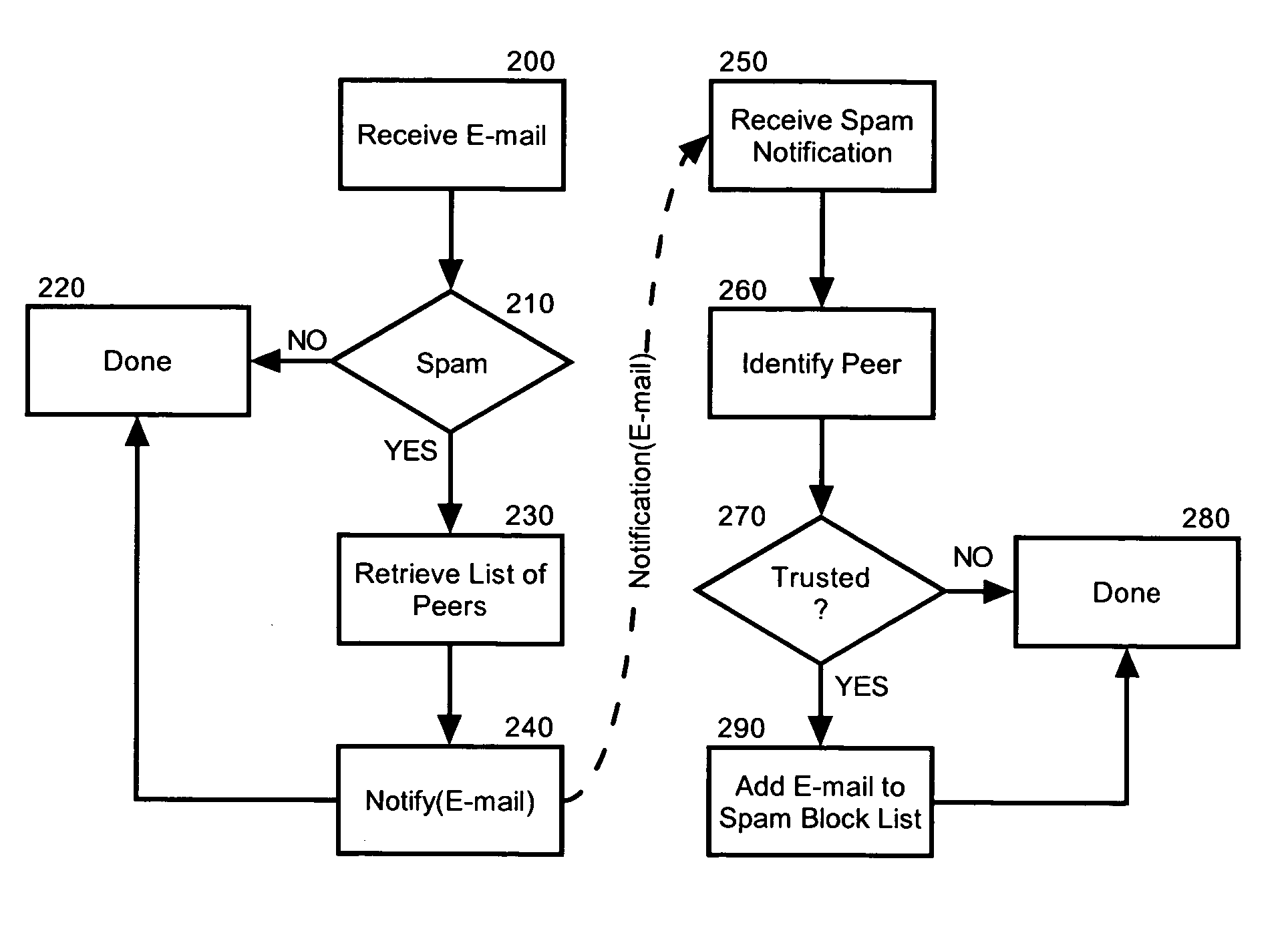

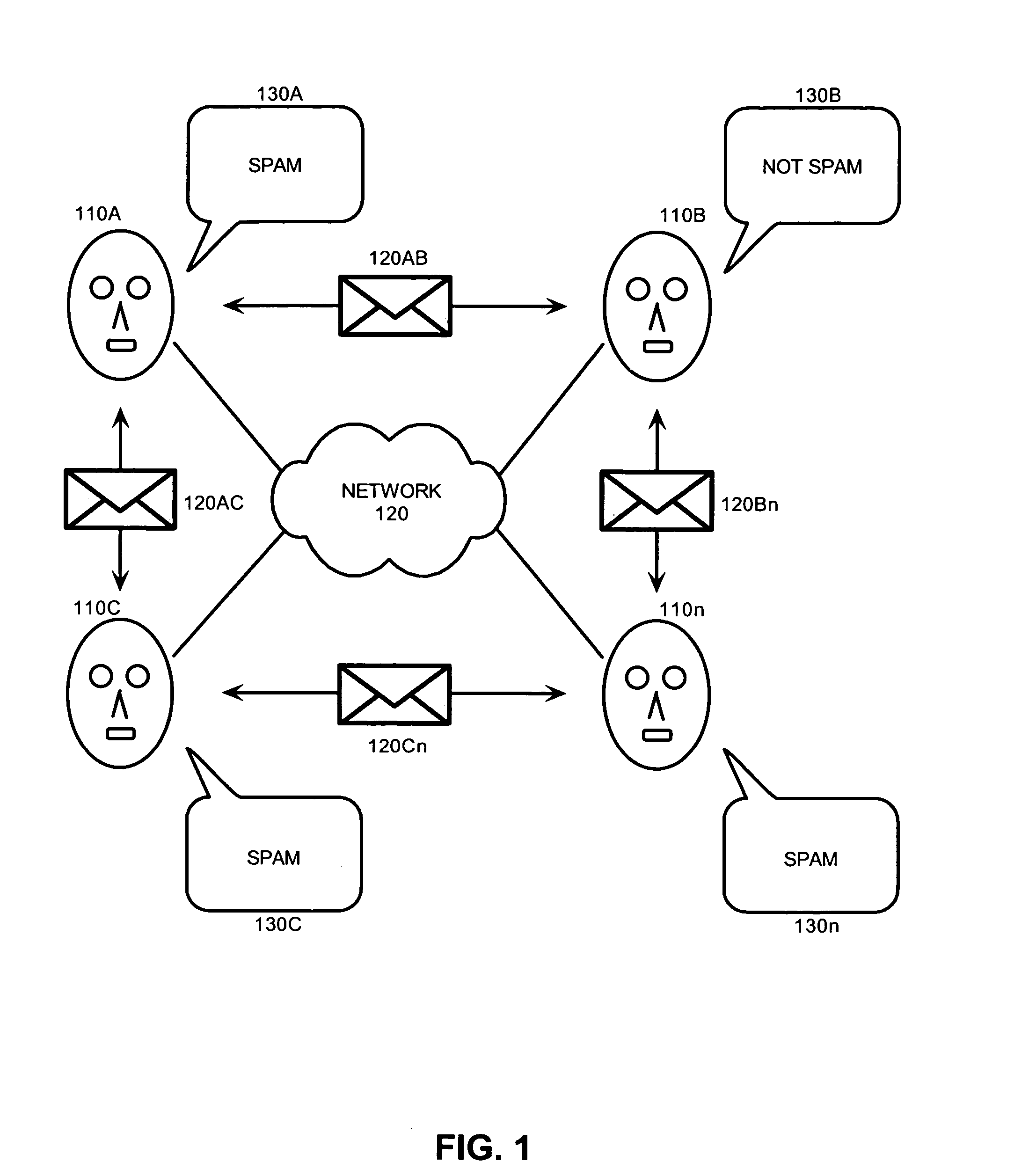

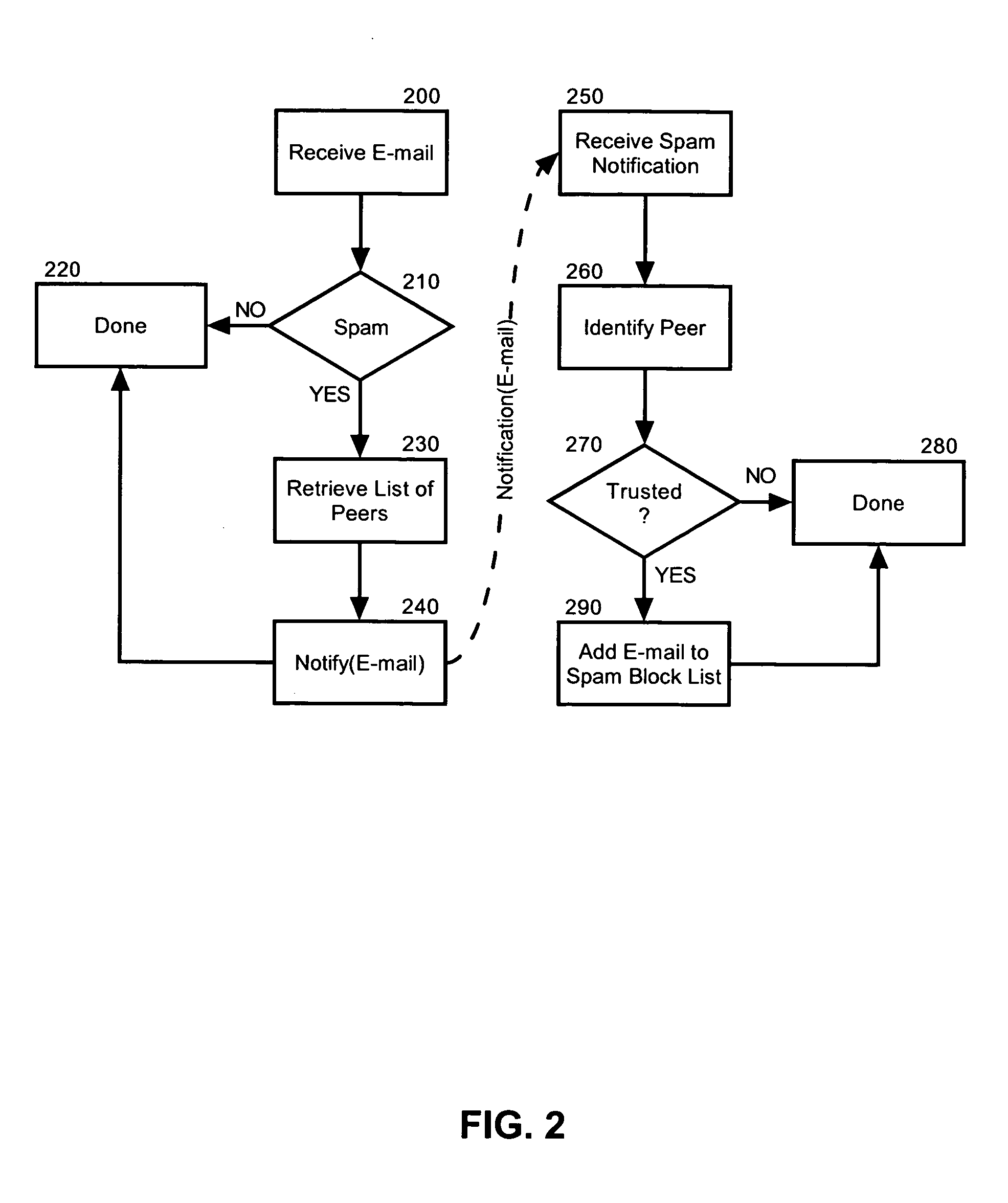

Cooperative spam control

InactiveUS20050223076A1Make up for deficienciesMultiple digital computer combinationsData switching networksSpammingData mining

A method, system and apparatus for cooperative spam control. A cooperative spam control method can include the step of accepting an electronic spam notification received from a peer e-mail recipient in a common computing group identifying a spam message received by the peer e-mail recipient. The method further can include the step of storing the notification. Finally, if an e-mail is subsequently received which corresponds to the identified spam message, the received e-mail can be processed as spam. In a preferred aspect of the invention, the method also can include the steps of determining that a received e-mail is spam; and, communicating an electronic spam notification identifying the received e-mail determined to be spam to other peer e-mail recipients in the common computing group.

Owner:IBM CORP

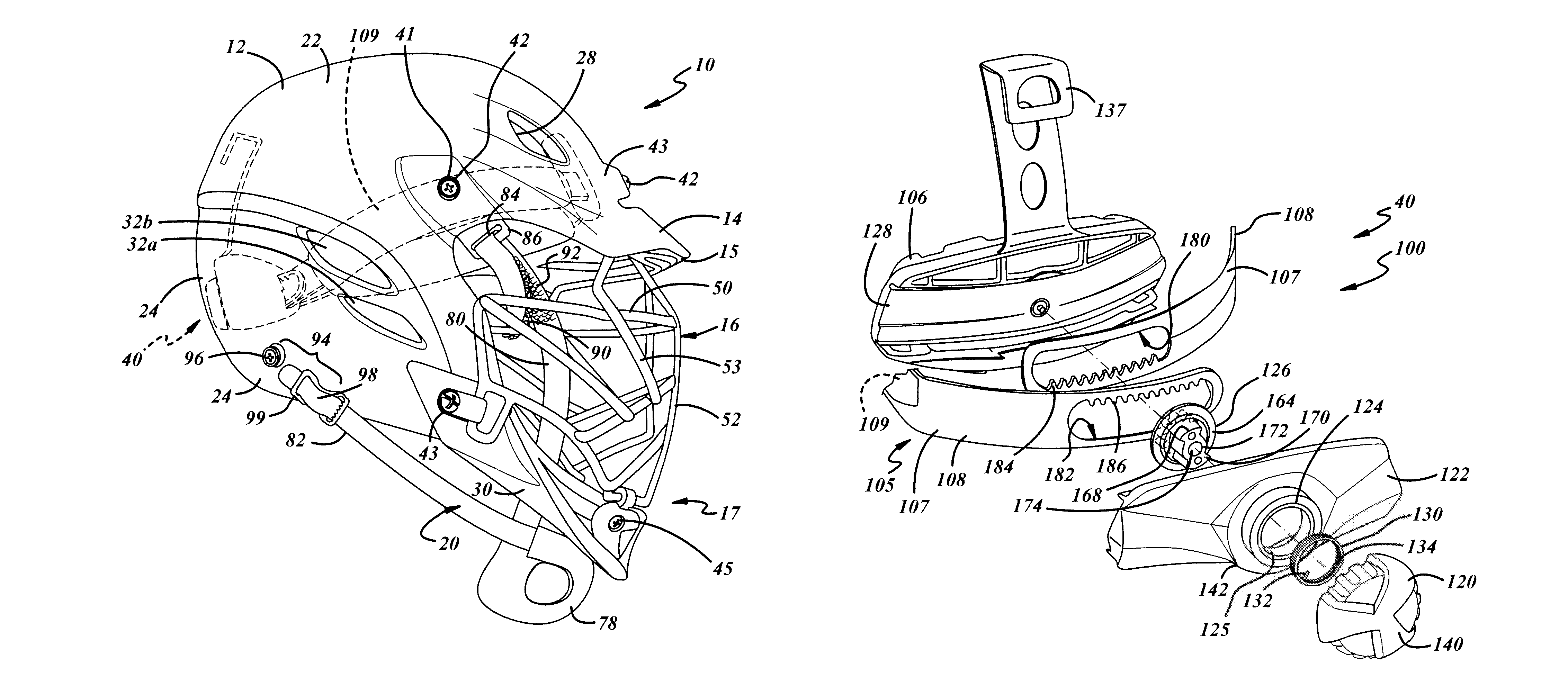

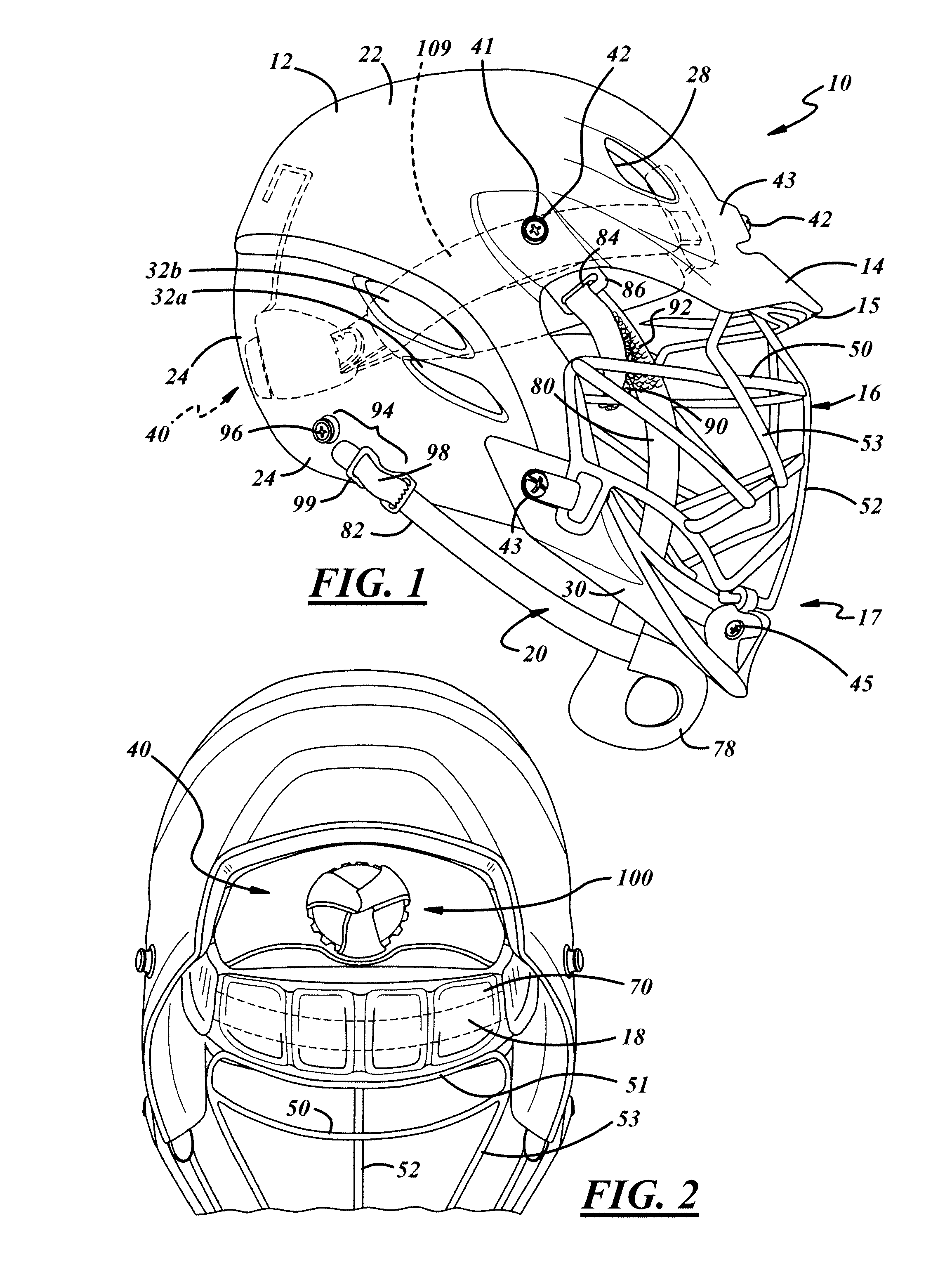

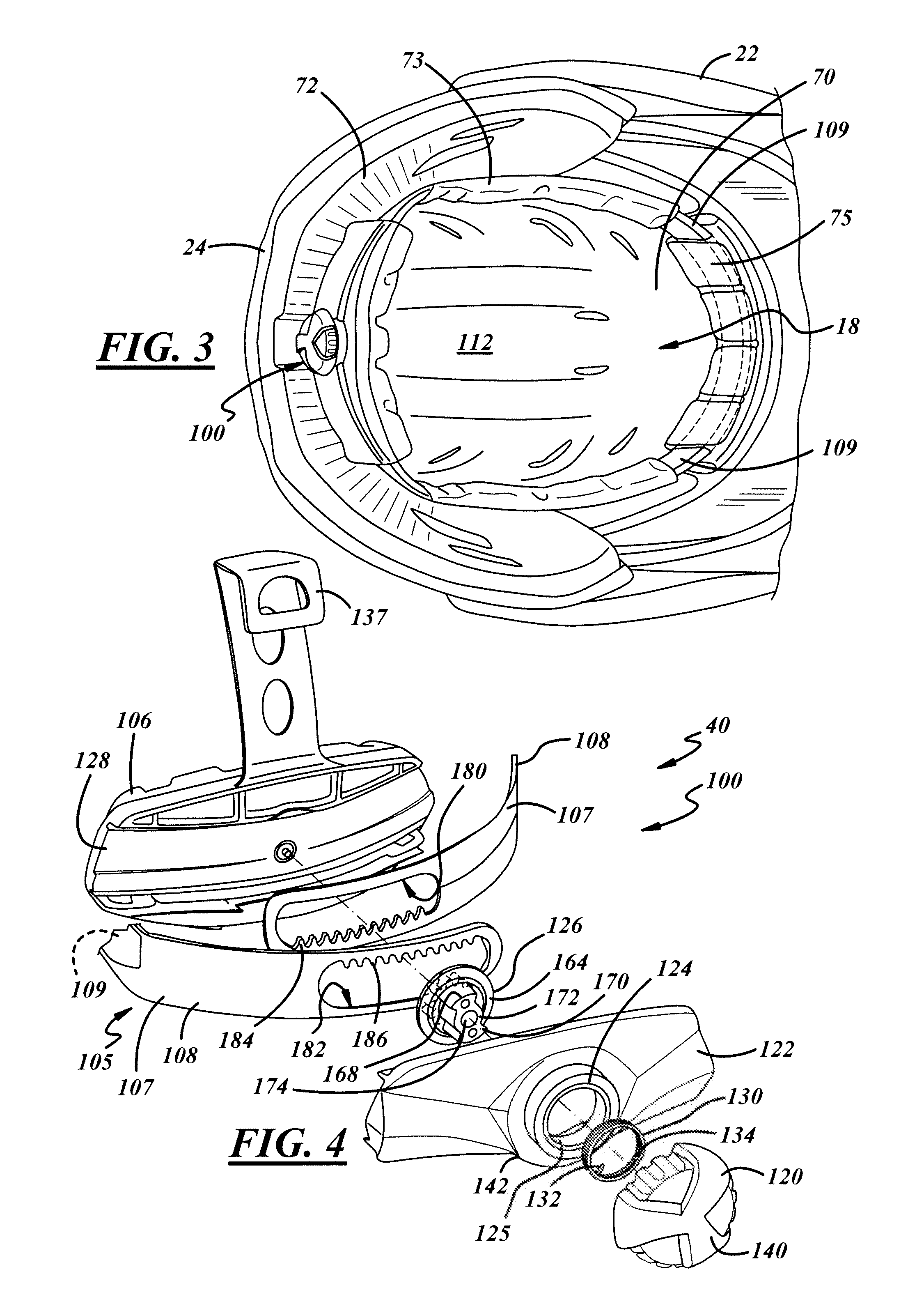

Helmet adjustment system

A protective sport helmet, such as for lacrosse, includes a hard shell portion, a lining portion, and an adjustment mechanism. The inner side of the adjustment mechanism includes an adjustment protective pad. Together, the lining portion and the inner surface of the adjustment protective pad define an interior region of the helmet wherein the user's head is introduced. The adjustment mechanism includes a lower rear shell portion having a clutching mechanism that allows the user to manually adjust the size of the interior region via a strapping system of the helmet to couple snugly around the user's head. The clutching mechanism also prevents the interior region from being easily altered in the absence of manual adjustment to the adjustment mechanism. The strap includes a hard end material that engages the adjustment mechanism and a flexible, durable and tough material that conforms to a wearer's head.

Owner:WARRIOR SPORTS INC

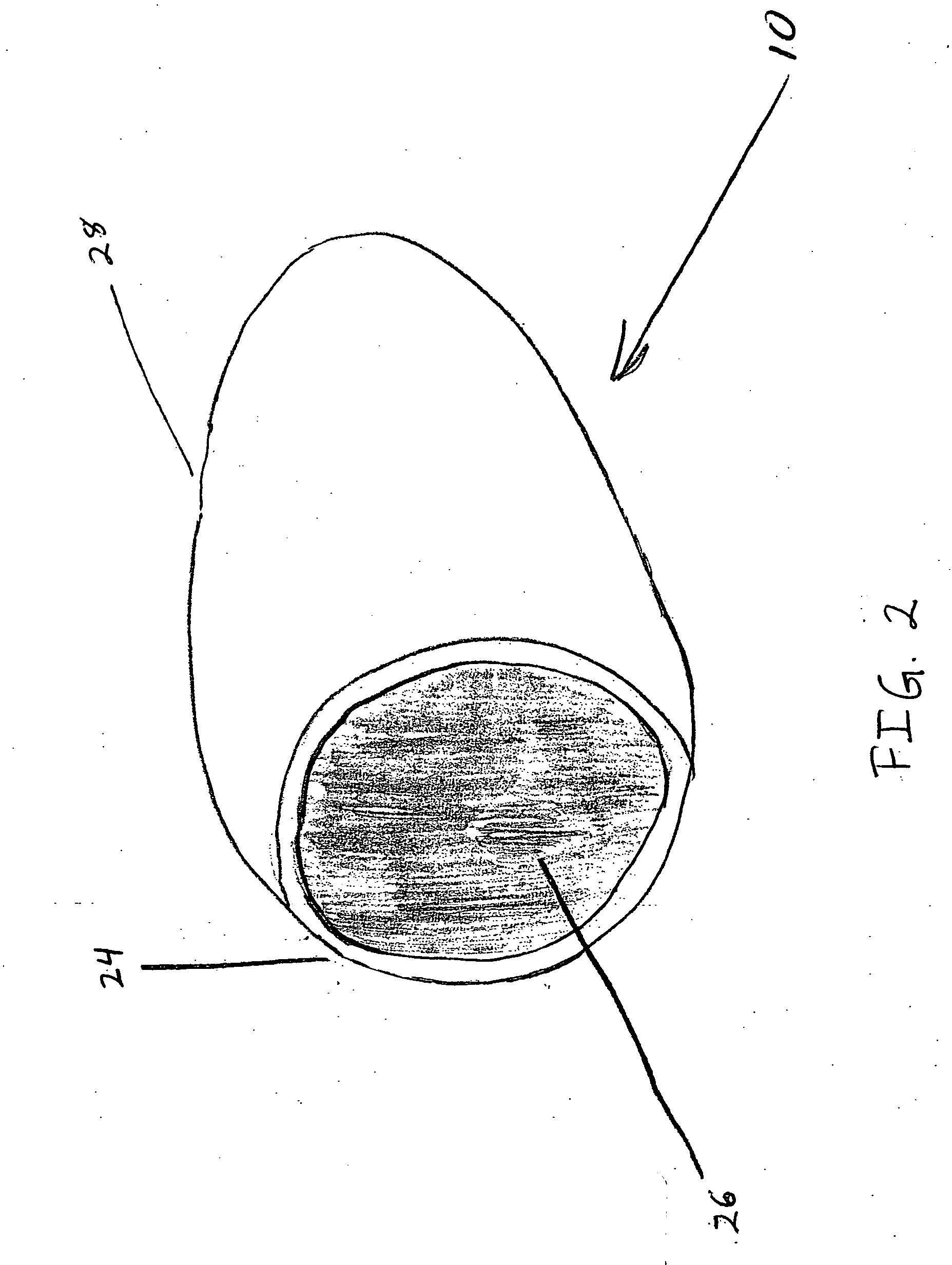

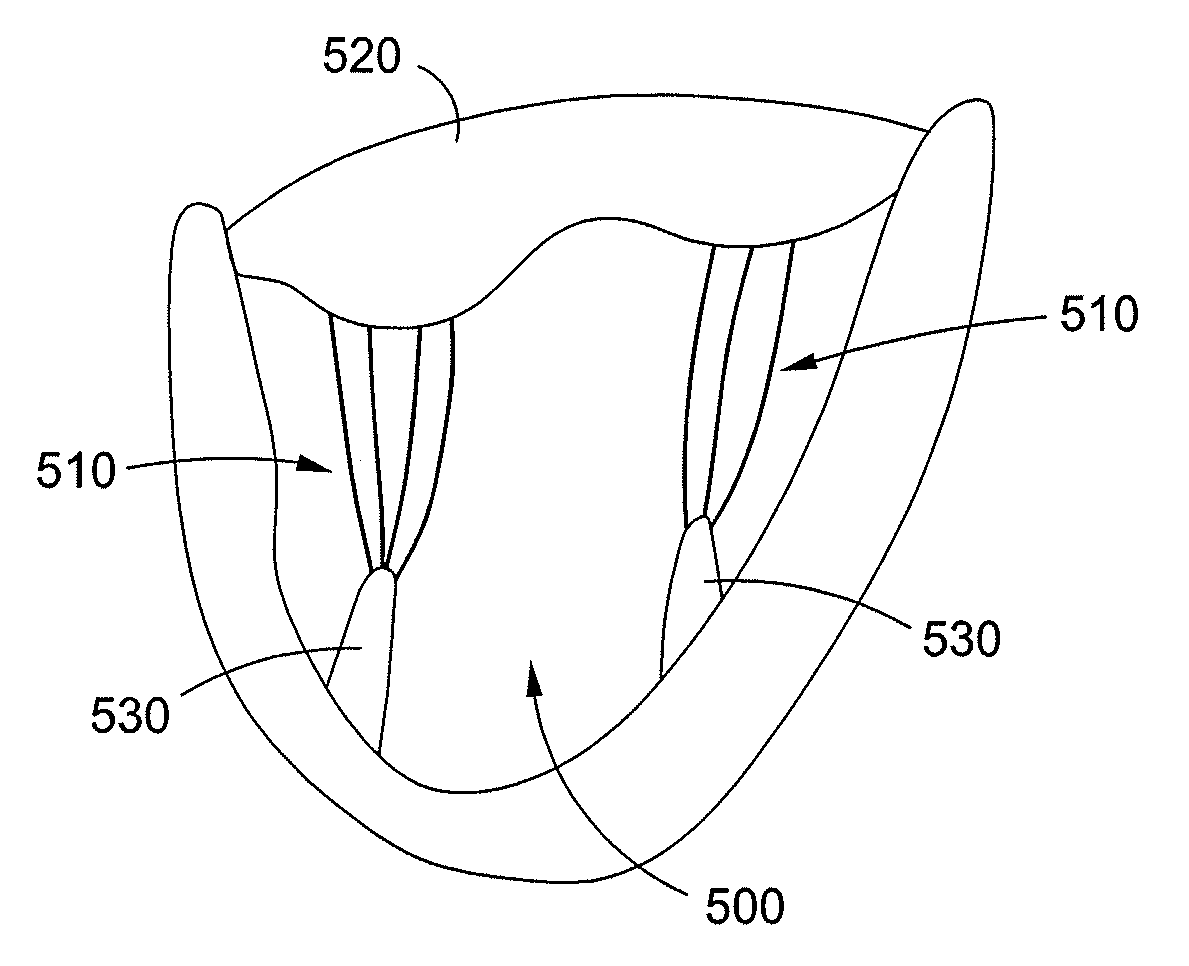

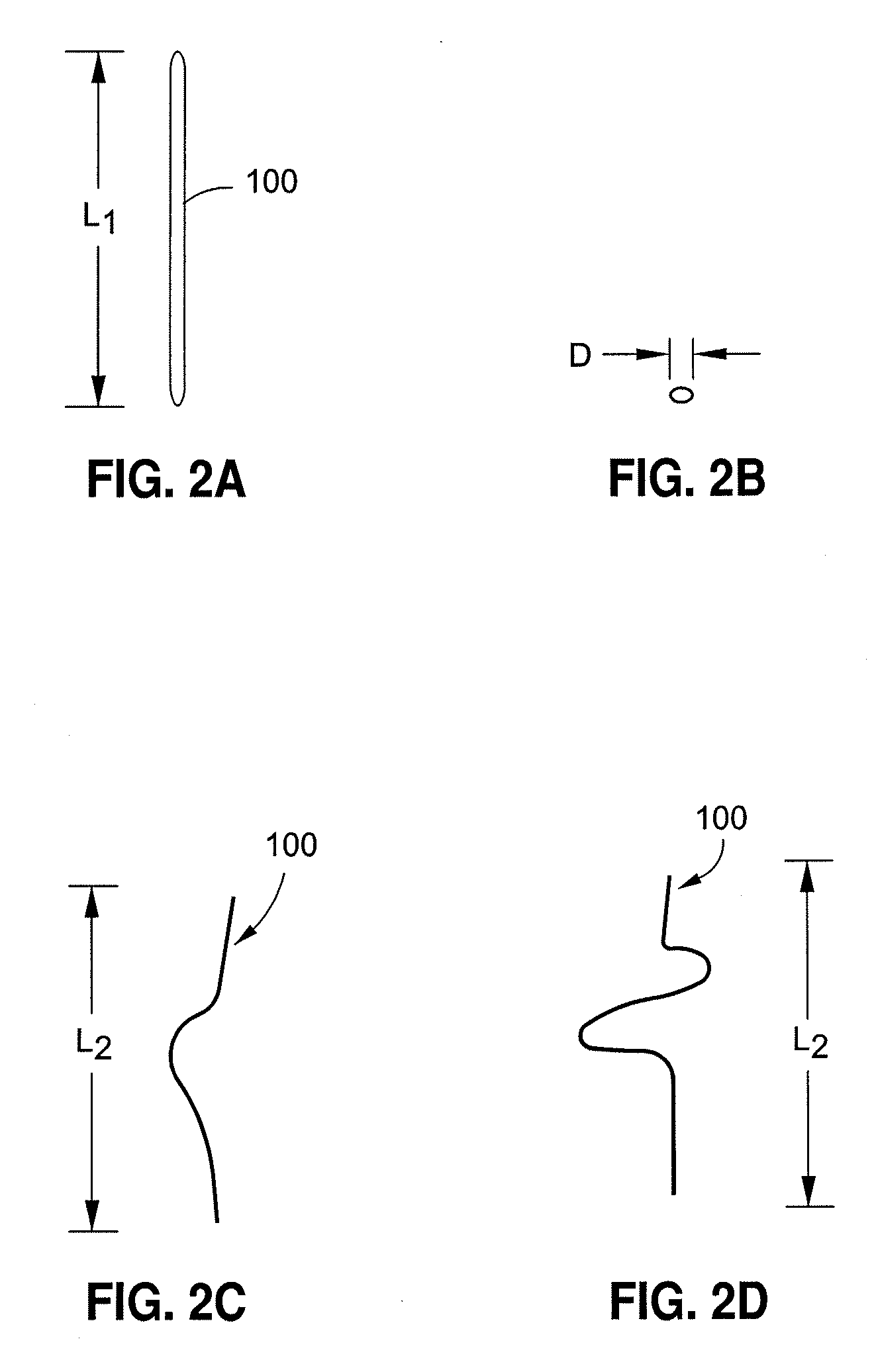

Dynamically adjustable suture and chordae tendinae

InactiveUS20080228272A1Lower activation energyIncreased riskHeart valvesLigamentsThermal energyLight energy

Embodiments of a dynamically adjustable artificial chordae tendinae implant are described. In some embodiments the implant includes a body portion, including an adjustable portion. In some embodiments, the implant includes a plurality of adjustable portions. In some embodiments the adjustable element can include a shape memory material. The adjustable portion can be configured to transform from a first conformation to a second conformation in response to an activation energy. In some embodiments, the activation energy can be one of electromagnetic energy, acoustic energy, light energy, thermal energy, electrical energy, mechanical energy, or a combination of energies. The implant couples a heart valve leaflet to a papillary muscle. Activation of the shape memory material regulates tension between the muscle and valve leaflet improving coaptation of heart valve leaflets, and reducing or eliminating regurgitation.

Owner:MICARDIA CORP

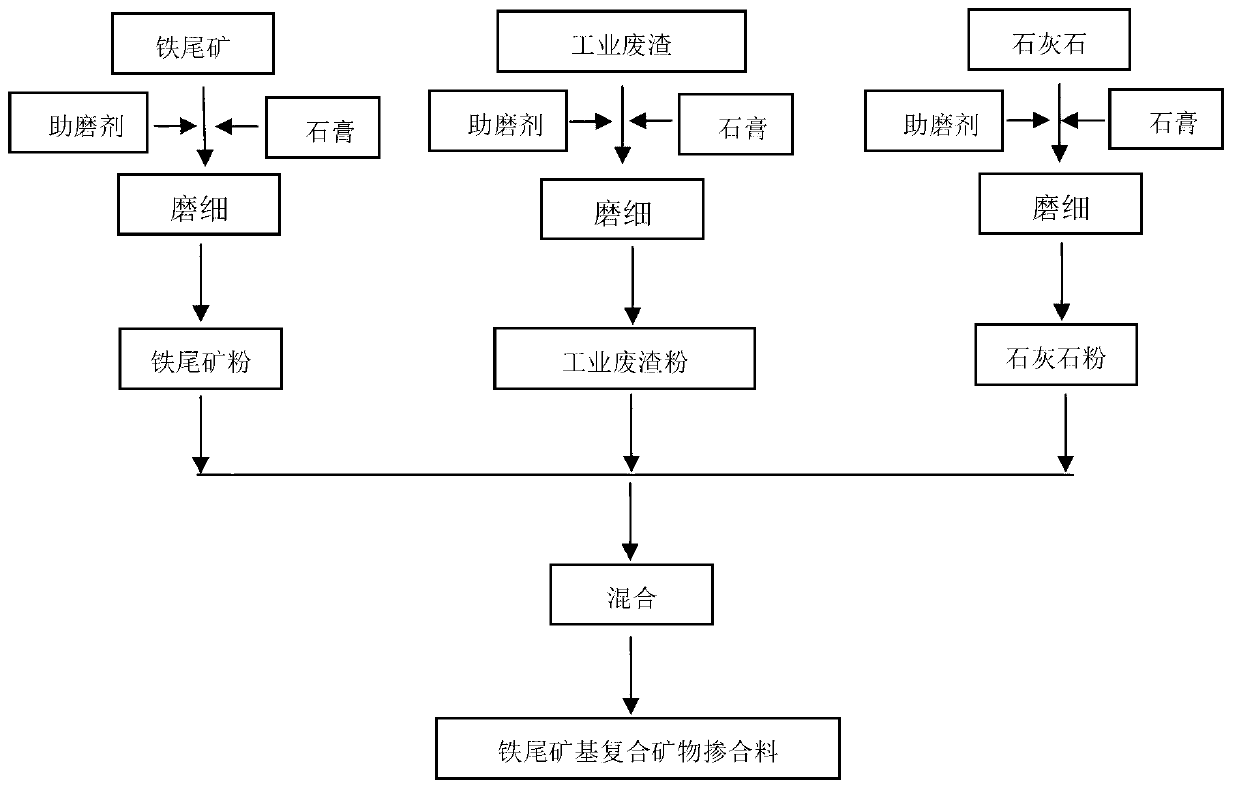

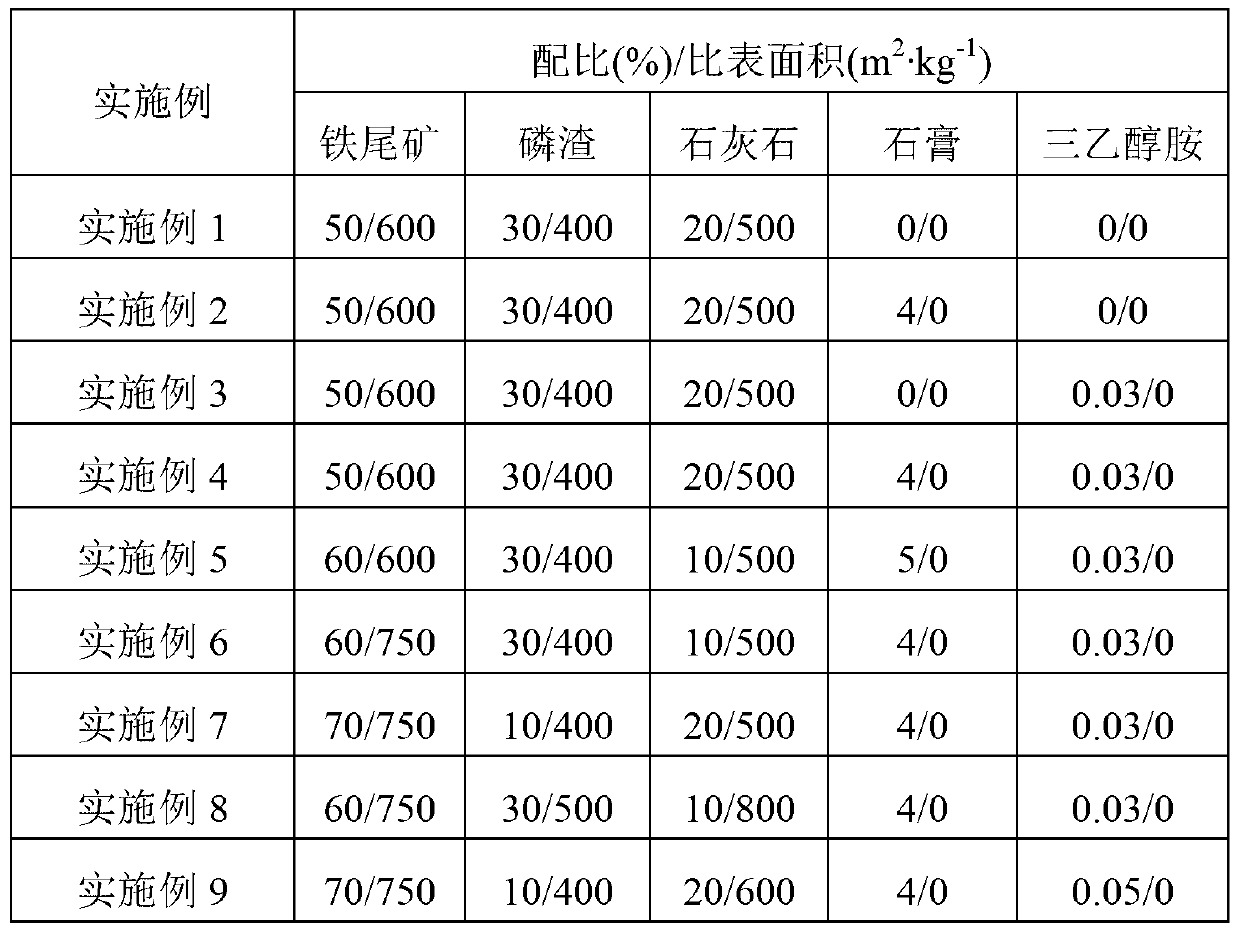

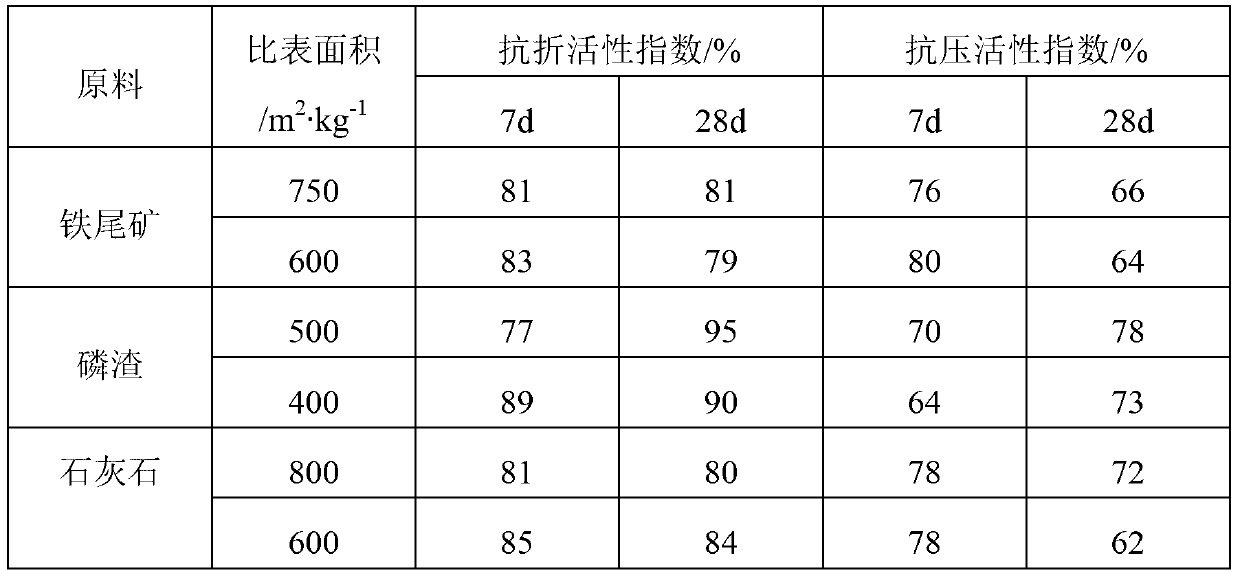

Iron tailing-based complex mineral admixture and preparation process thereof

InactiveCN103342491AExcellent performanceImprove pore structureSolid waste managementWater contentSlag

The invention relates to an iron tailing-based complex mineral admixture and a preparation process thereof. The preparation process comprises the following steps of: respectively drying iron tailing sand, industrial waste slag and limestone till water content is not more than 1% for later use; adding gypsum to match with iron tailings, the industrial waste slag and the limestone after drying, then sending into a ball grinding machine to perform powder grinding, and adding grinding aids during the powder grinding process; and uniformly mixing the obtained iron tailing powder, industrial waste slag powder and limestone powder to obtain the iron tailing-based complex mineral admixture. The iron tailing-based complex mineral admixture disclosed by the invention has the beneficial effects that 1) the iron tailings are matched with other industrial waste slag, the admixture for concrete is prepared by simple mechanical fine grinding, and the performance is better; 2) the performance is good, and the iron tailing-based complex mineral admixture can be used for preparing the concrete with the strength grade of C50-C80; 3) a variety of industrial wastes are scientifically and effectively compounded, the activity and particle size synergy of each component against cement and the concrete can be fully exerted to enable the advantages of all the components to complement each other, and the over-superimposed effect is further realized; and 4) the production process is simple and conductive to industrial production, popularization and application.

Owner:WUHAN UNIV OF TECH

Constructing method for in tunnel weak soil layer by freezing method horizontally

InactiveCN1614152AStrong targetingMake up for deficienciesArtificial islandsUnderwater structuresSoil scienceSoil horizon

A horizontal freezing method for constructing the tunnel in soft stratum includes such steps as determining the saline temp in active freezing period and maintaining freezing period, the average temp of frozen earth wall and the strength of frozen earth, designing and arranging the freezing hole, calculating the cold needed by freezing, excavating the horn-shaped portal tunnel segments at both ends, excavating middle segments, and enlarging the tunnel.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

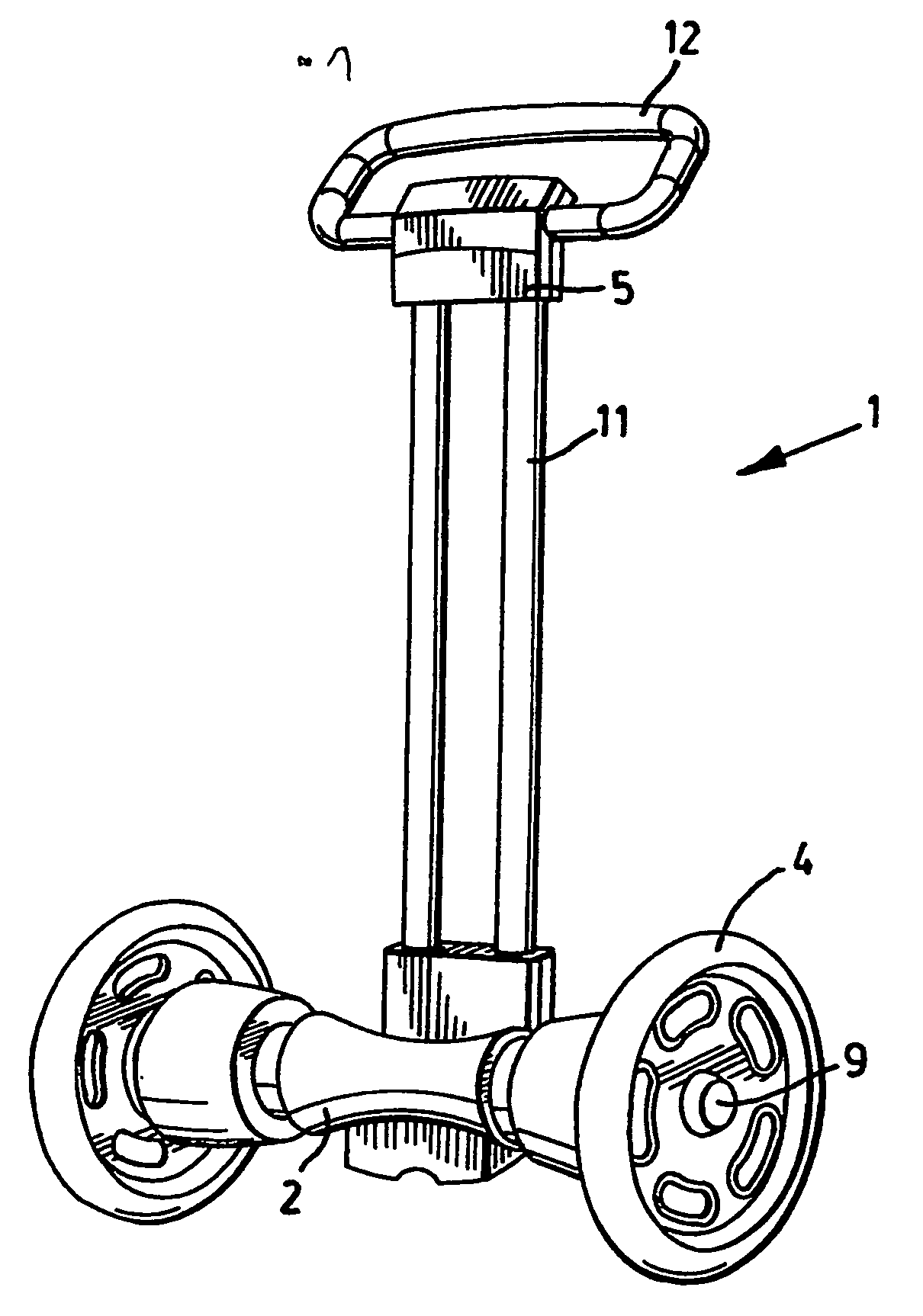

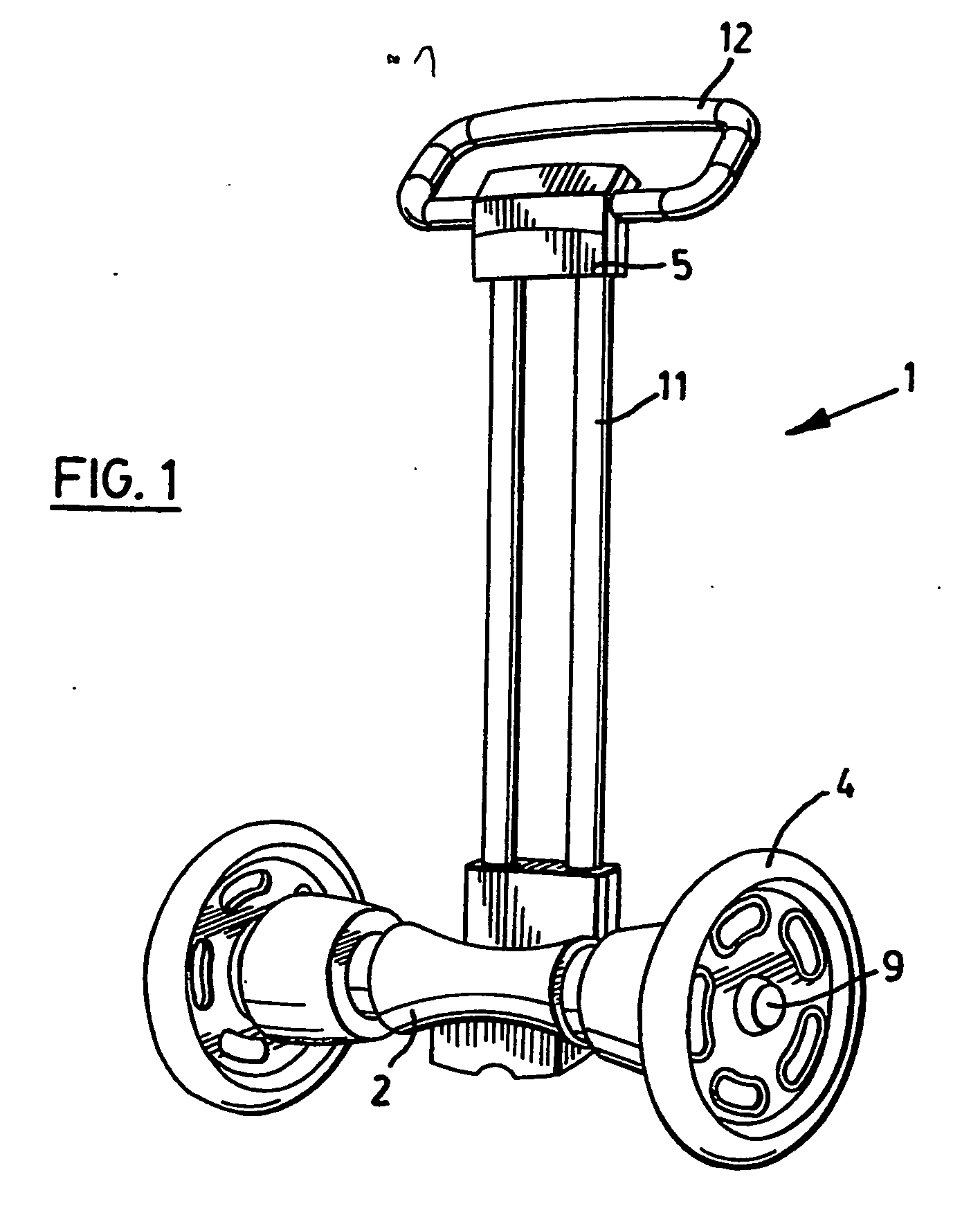

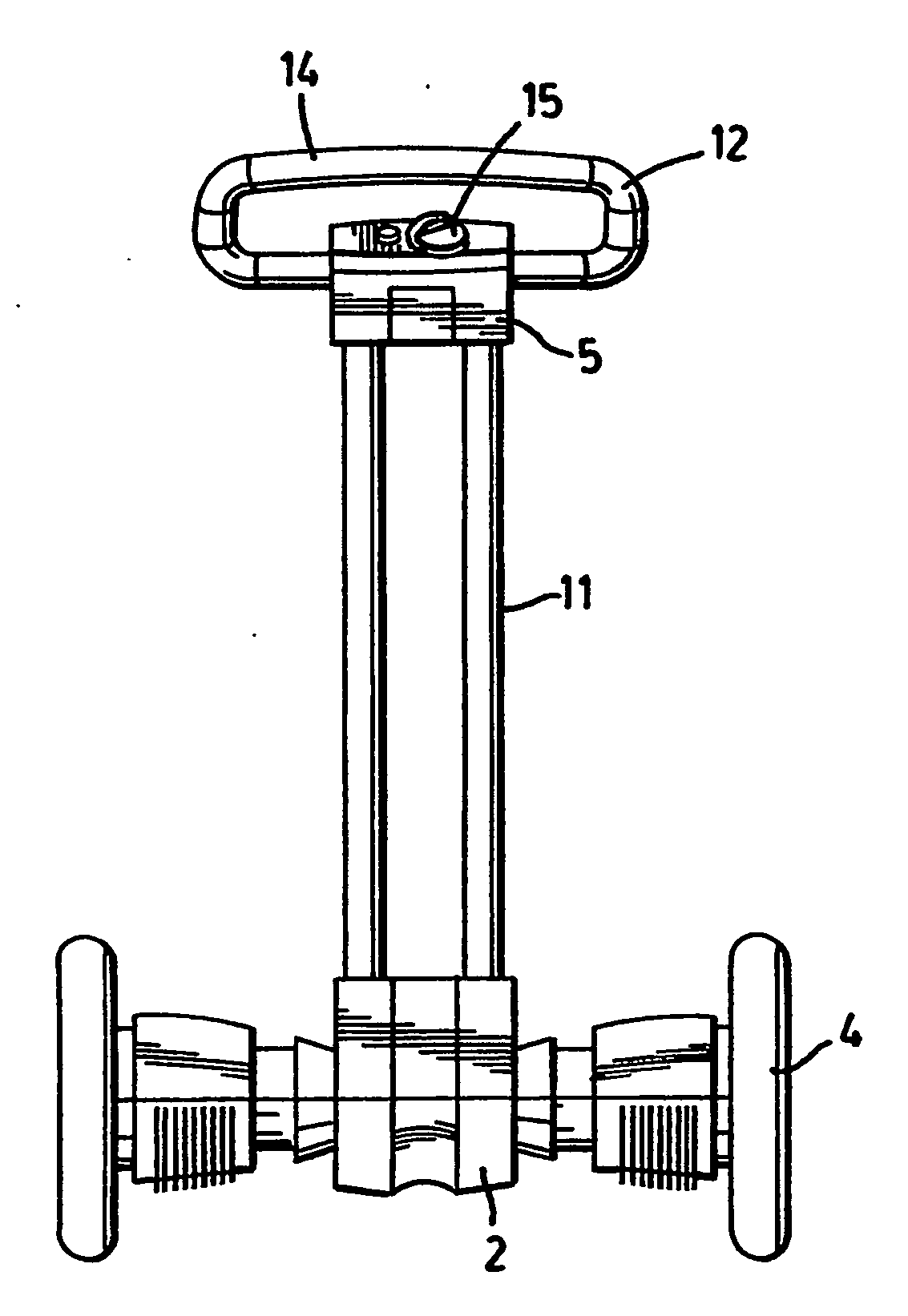

Motorized towing device

InactiveUS20070131461A1Quickly and easily attachFacilitate large volumeTractor-trailer combinationsHand cart accessoriesElectric machineryEngineering

A motorized towing device comprising a chassis, at least one motor, at least two wheels, a controller, and a quick release attachment mechanism. The controller operates the motor to cause the rotation of the wheels and the movement of the chassis over a surface. The quick release attachment mechanism releaseably secures the chassis to an object desired to be towed or moved while permitting rotational movement of the device relative to the object about a generally horizontal plane.

Owner:1498456 ONTARIO

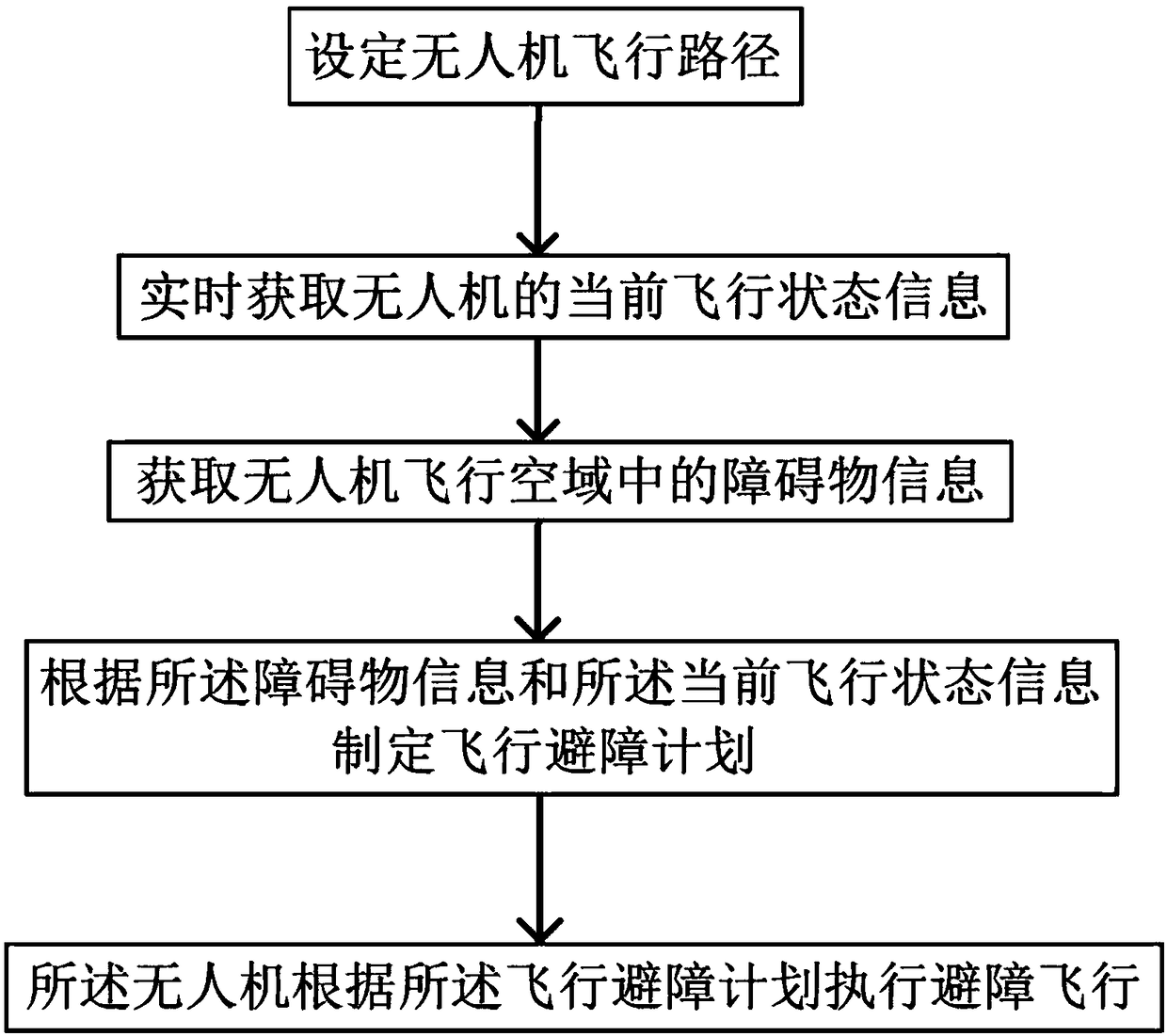

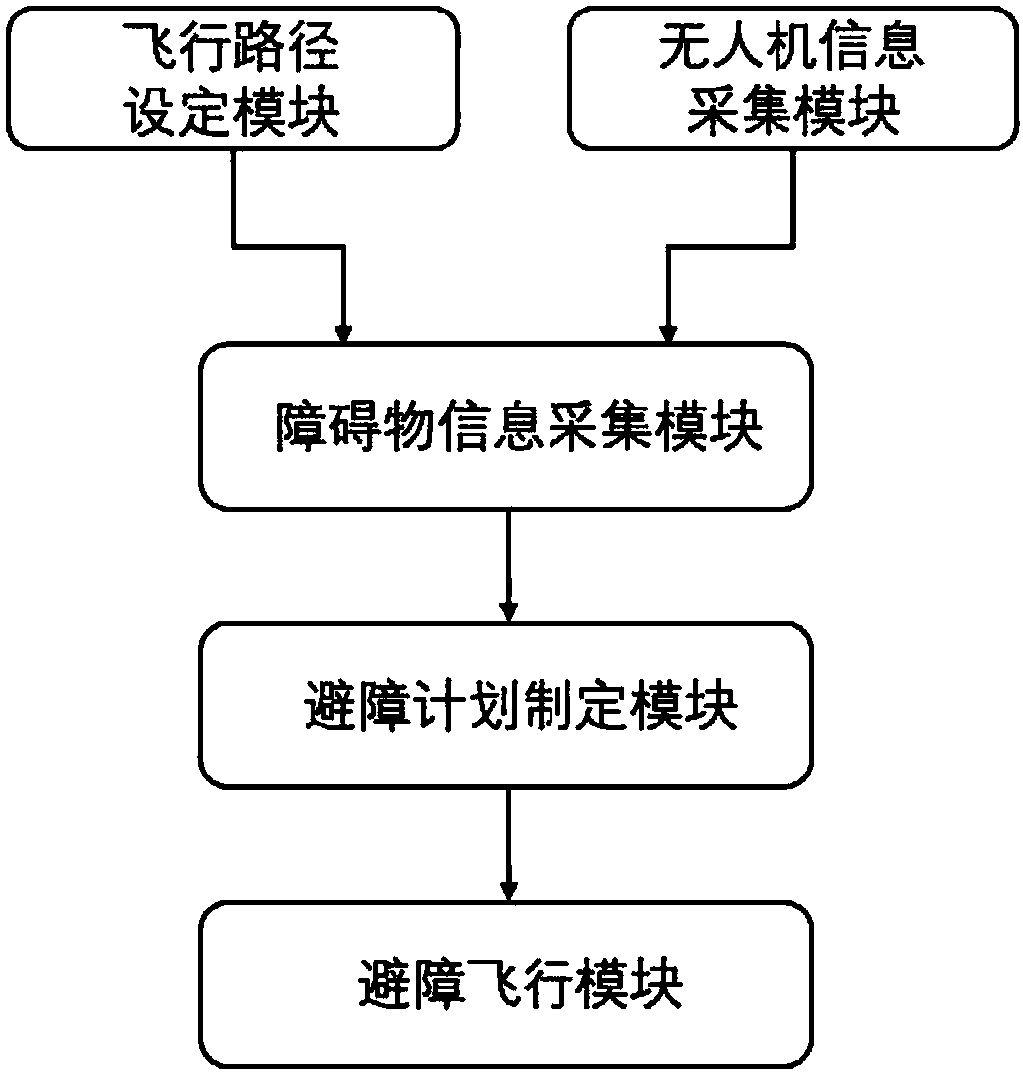

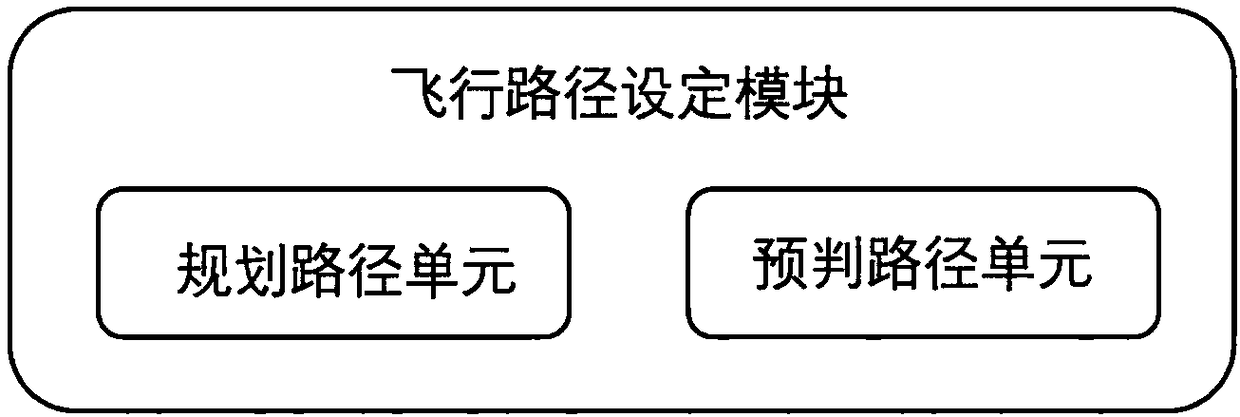

Unmanned aerial vehicle multi-distance obstacle avoidance method and obstacle avoidance system

ActiveCN108334103AFlight safetyMake up for deficienciesInternal combustion piston enginesPosition/course control in three dimensionsShortest distanceFlight vehicle

The invention relates to the technical field of aircrafts, and particularly provides an unmanned aerial vehicle multi-distance obstacle avoidance method and an obstacle avoidance system. According tothe invention, firstly, a flight path of the unmanned aerial vehicle is set. Secondly, the obstacle information on a plurality of distance levels in the flight space of the unmanned aerial vehicle isacquired. At the same time, the current flight state information of the unmanned aerial vehicle is acquired in real time. Thirdly, a flight obstacle avoidance plan is formulated according to the obstacle information and the current flight state information. Finally, the unmanned aerial vehicle performs the obstacle avoidance flight according to the flight obstacle avoidance plan. According to theinvention, a plurality of obstacle avoidance mechanisms are applied in parallel, wherein the predictive obstacle avoidance can be realized especially for large barriers such as buildings existing on flight paths, as well as moving barriers within the range of a moderate distance. The defects caused by purely relying on a short-distance obstacle avoidance mechanism are fully overcome.

Owner:GUANGZHOU EHANG INTELLIGENT TECH

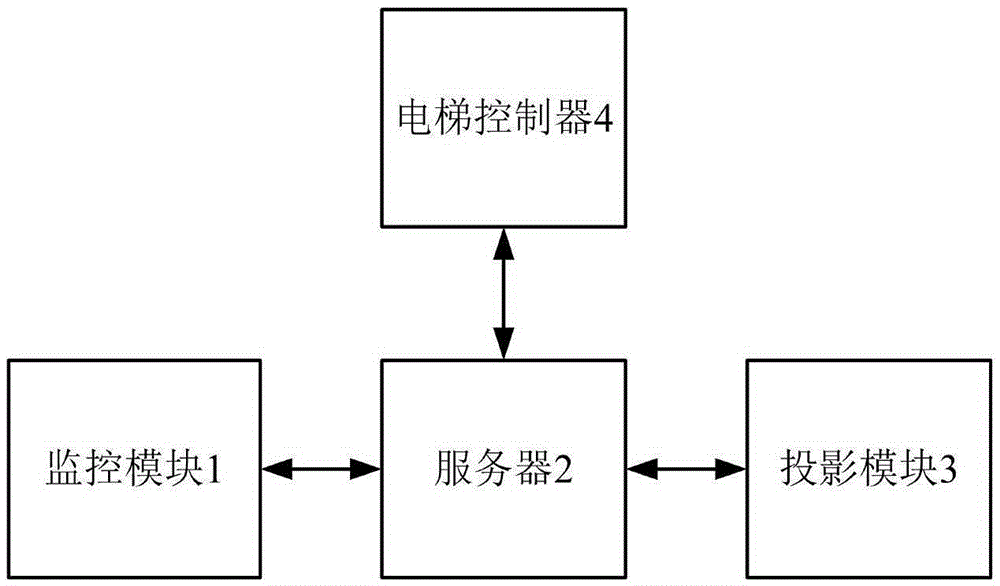

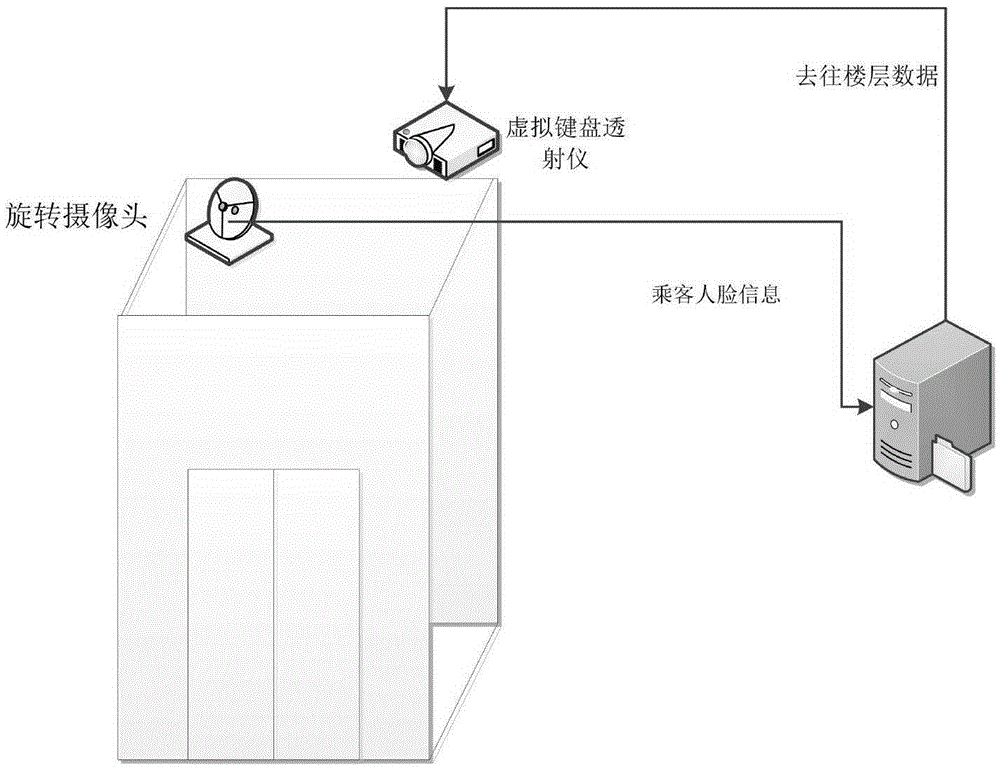

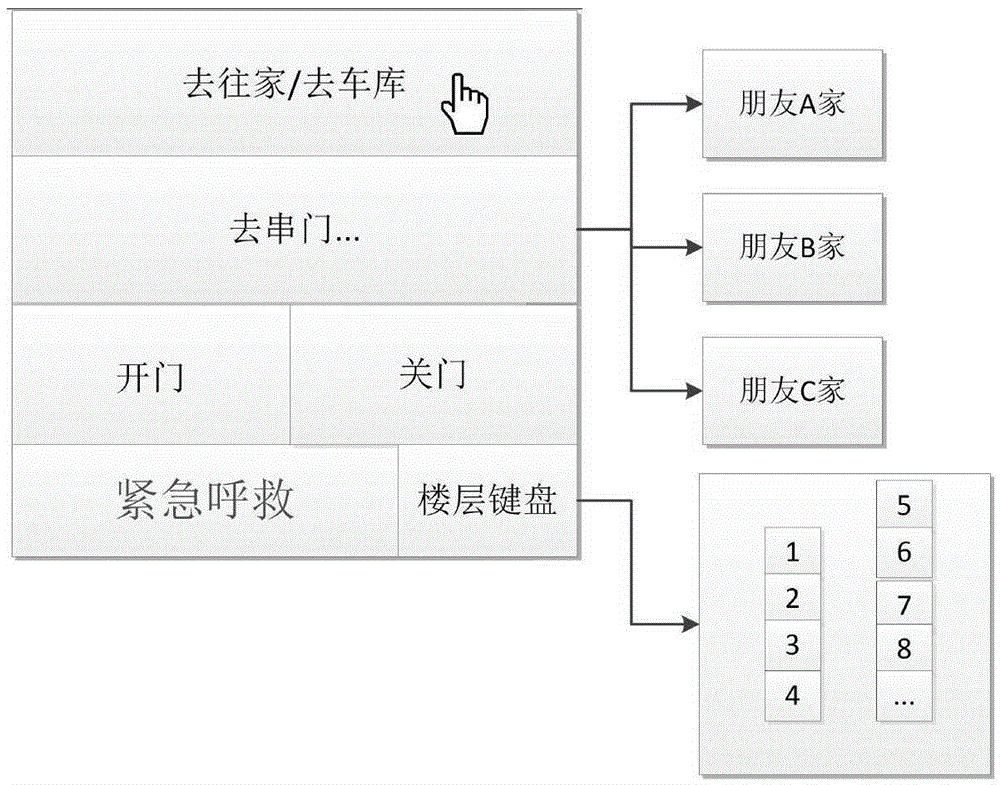

Elevator control system based on human face recognition and intelligent recommendation

The invention provides an elevator control system based on human face recognition and intelligent recommendation. The elevator control system comprises a monitoring module, a projection module and a server, wherein the monitoring module and the projection module are respectively connected with the server; the monitoring module comprises a camera and communication equipment, and is used for acquiring human face information of passengers at an elevator door and in a car; the human face information is sent to the server through the communication equipment; the server is used for comparing the human face information with locally stored customer information and training user elevator taking history data according to a machine learning method to obtain corresponding judgment results; and the judgment results are sent to the projection module; and the projection module is used for projecting elevator keys to corresponding positions in the car according to the judgment results to provide more precise floor recommendation to the users. Like that, the defects of traditional elevator buttons are made up, and the elevator application is more intelligent.

Owner:SUZHOU UNIV

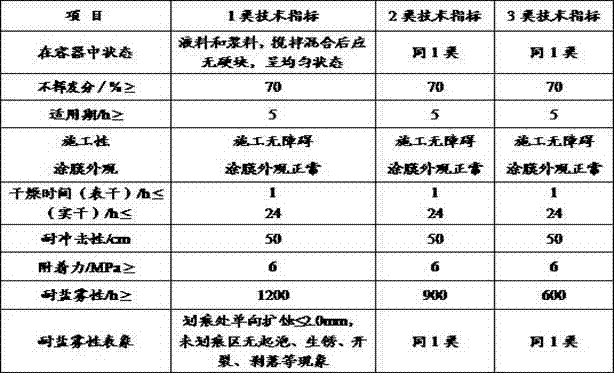

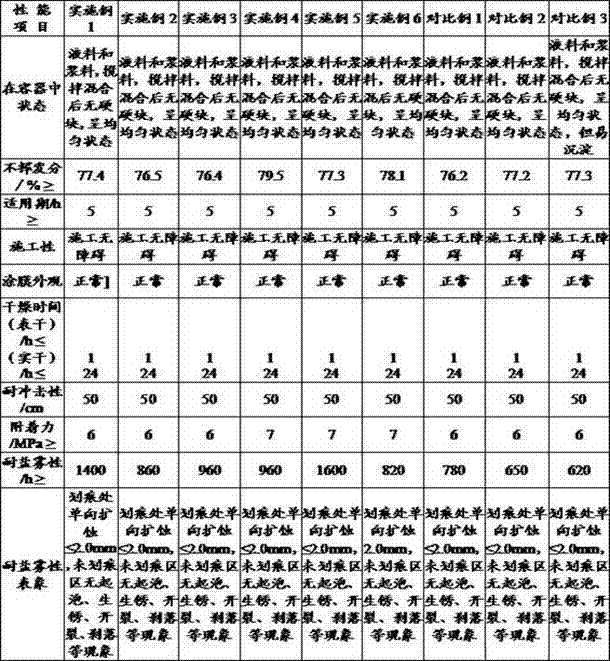

Zinc-graphene heavy-duty anti-corrosive coating and preparation method thereof

ActiveCN103897556AReduce contentHigh mechanical strengthAnti-corrosive paintsEpoxy resin coatingsAluminium powderOrganosolv

The invention relates to a zinc-graphene heavy-duty anti-corrosive coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component B contains a curing agent; the component A contains the following components in percent by mass: 10-20% of a graphene epoxy resin solution, 0.5-2% of an anti-settling agent, 15-30% of zinc powder, 2-10% of aluminum powder, 35-50% of an antirust pigment filling material and 5-10% of an organic solvent; the graphene epoxy resin solution comprises the following components in percent by mass: 1-10% of graphene, 80-90% of an epoxy resin solution, 5-10% of an organic solvent and 1-2% of an additive. Graphene is added into the coating, so that the zinc content is reduced, zinc oxide smog generated during welding is reduced, and the coating is super-strong in water resistance and corrosion resistance. When the coating is prepared, graphene is subjected to pre-soaking treatment to be uniformly dispersed on epoxy groups of epoxy resin, so that the defect that graphene is easy to agglomerate is overcome, the excellent performance of graphene is fully played, and an intermediate with the combination of the advantages of zinc and graphene is obtained. The salt-fog resistance time of the coating prepared by the intermediate is more than 1200 hours.

Owner:江苏道蓬科技有限公司

Method for making PH value-sensitive polyvinylidene fluoride hollow fibre intelligent film and products thereby

InactiveCN1594405ASimple processEase of industrial implementationSemi-permeable membranesWater bathsHollow fibre

Disclosed is a method for making pH sensitive PVDF hollow fiber intelligent film and products made thereby, wherein the making process comprises the steps of, (1) steeping the film in pure water for 24 hours, (2) preparing 10-20% alkali solution, and charging 3-4gl / L of tetrabutylammonium bromide, charging immersed film in alkali solution, heating by water bath, (3) preparing 1-2 mol / L of AAC solution, charging dimethyl formamide solution by 40-50ml / L, mixing uniformly, charging alkali-treated film in the mixed solution, steeping 10-20 minutes at room temperature, preparing solution of crosslinking agent 0.01-0.09mol / L and K2S2O3 0.1-0.3g, charging the readily made film into the solution, filling N2 and sealing, water-bathing, heating and washing with deionized water, the crosslinking agent is MBAA or diacrylic acid ethylene glycol ester.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com