Production method of short staple enveloped composite yarn and its device

A production method and technology of a production device, which are applied in the field of production methods and devices for short fiber-wrapped composite yarns, can solve the problems of affecting the dyeing and wearing properties of fabrics, raw material selection, product application field limitations, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

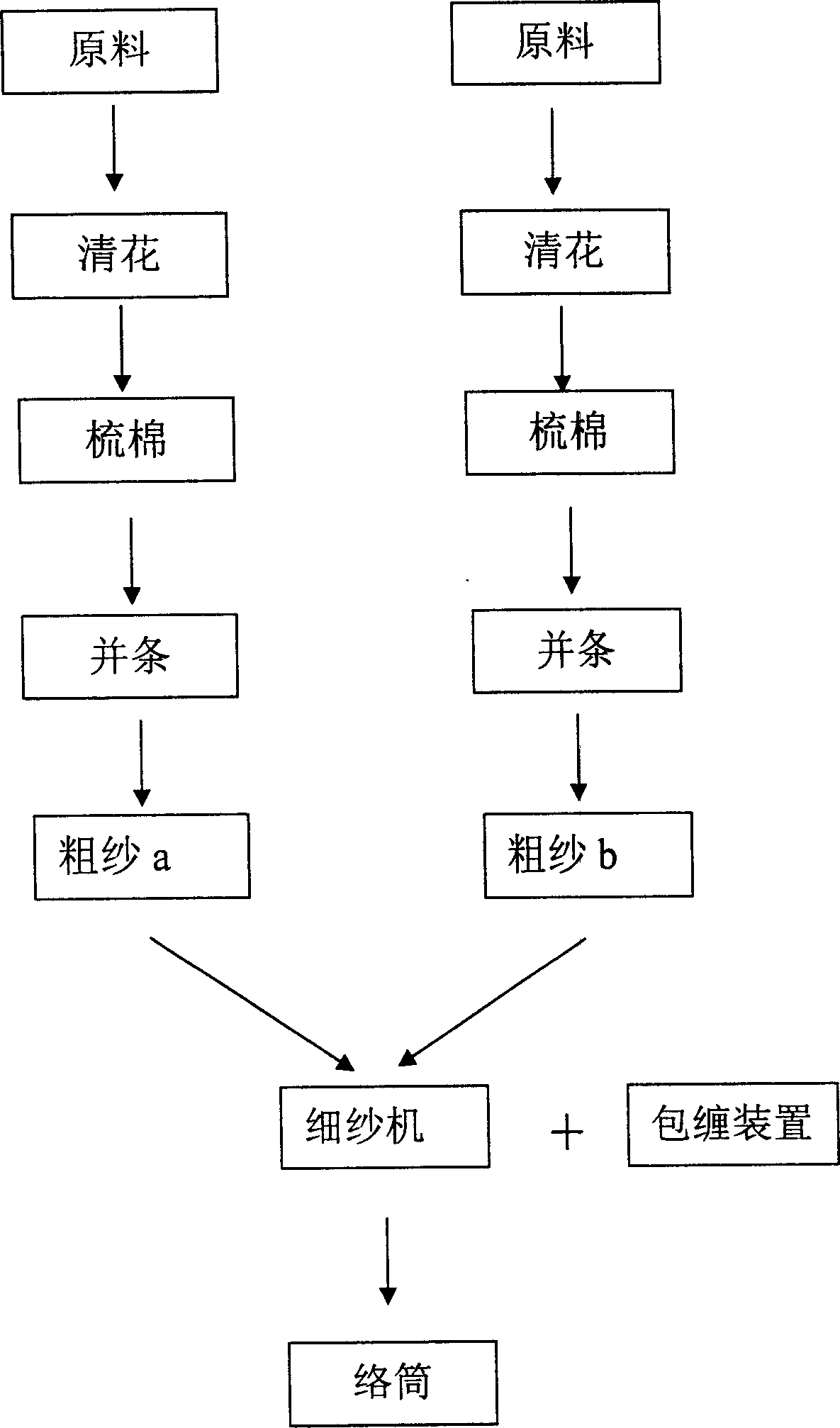

Method used

Image

Examples

Embodiment

[0022] The above indicators can meet the weaving and wearing requirements.

[0023] The quality of wrapped yarn is mainly evaluated by the uniformity of wrapping and yarn strength:

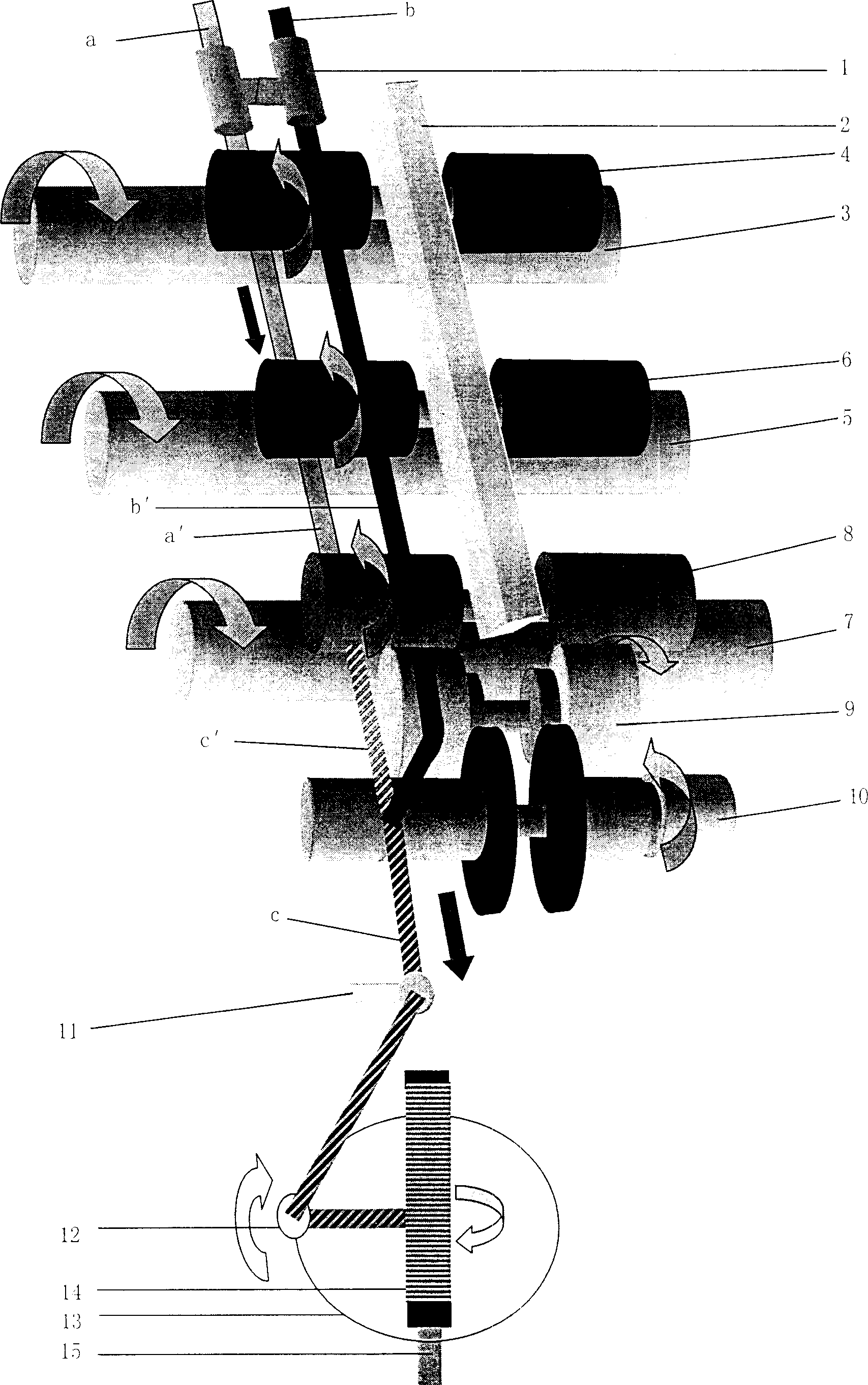

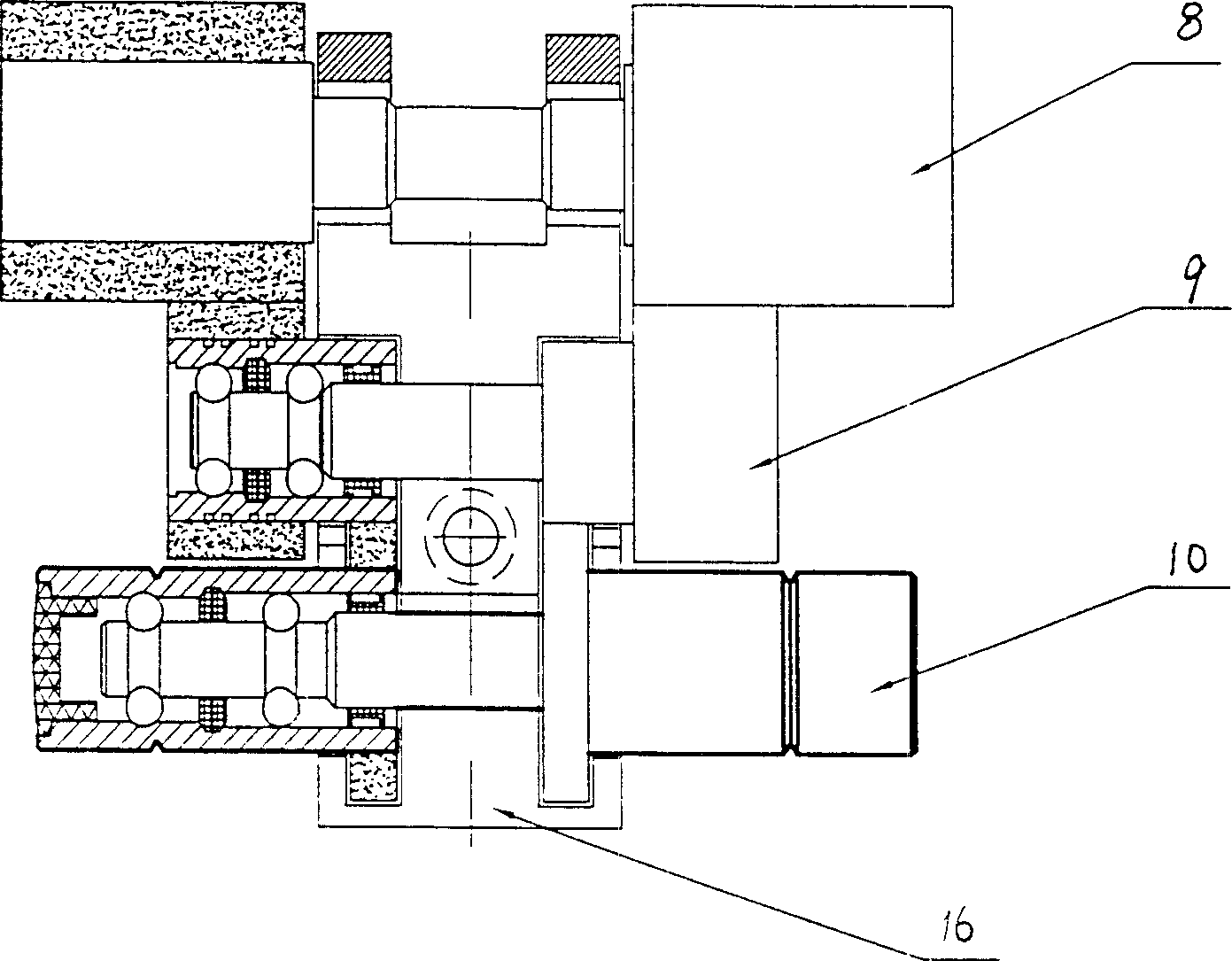

[0024] (1) The wrapping uniformity is mainly determined by the ratio of the outer fiber and the twist of the core yarn. The higher the content of the outer fiber, the better the wrapping uniformity; within a certain range, the higher the design twist, the better the wrapping uniformity ;

[0025] (2) Since the wrapped fiber is wrapped in the outer layer in a spiral shape on the surface of the yarn, the angle between the fiber and the yarn axis is large, the cohesion between the fibers is small, and the contribution to the yarn strength is small, and the strength of the wrapped yarn is mainly It is determined by the cohesion force between the core fibers. The core yarn fiber has high strength, large twist, large cohesion force and high yarn strength.

[0026] Adopt the advantage that the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com