Patents

Literature

38results about How to "Not easy to dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

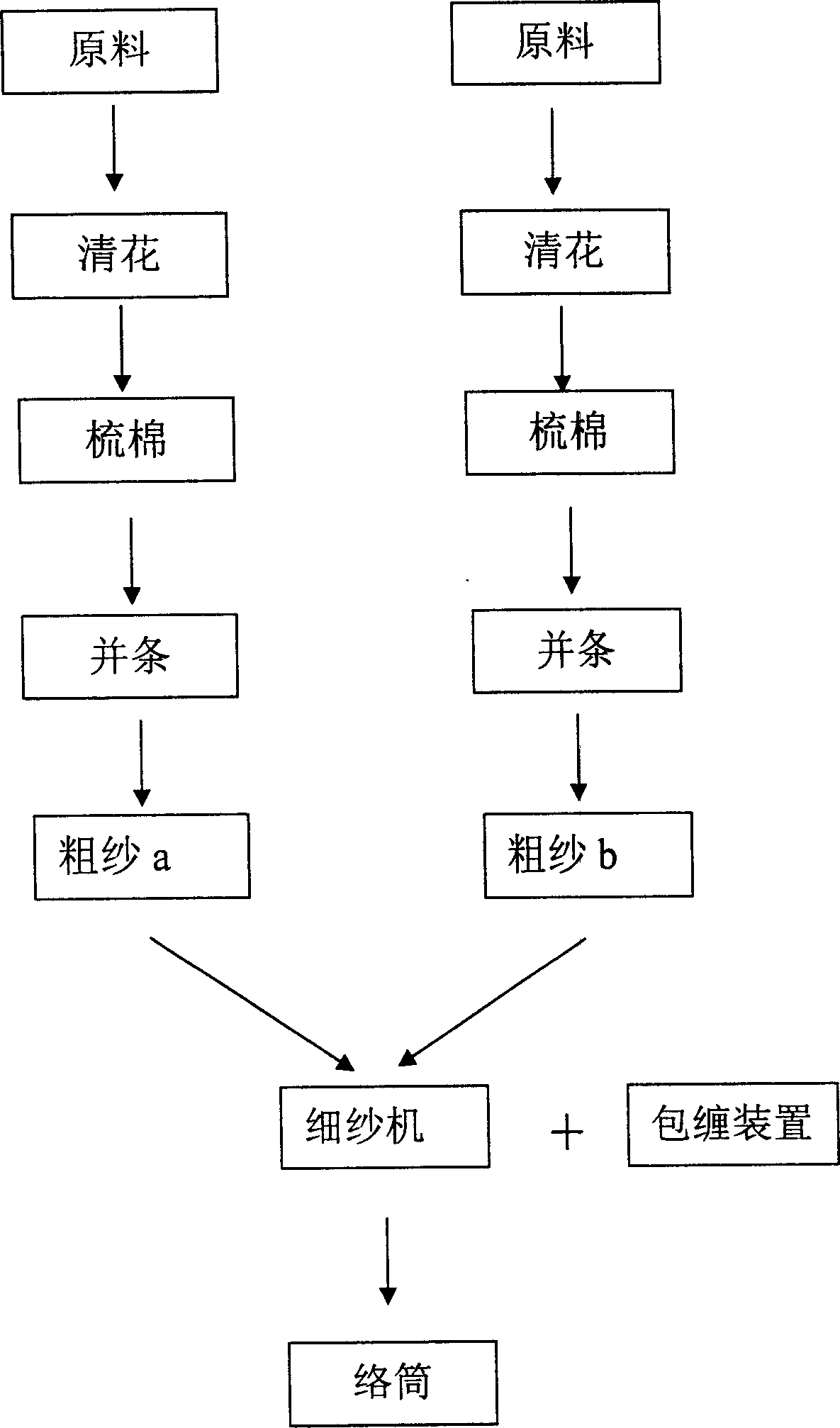

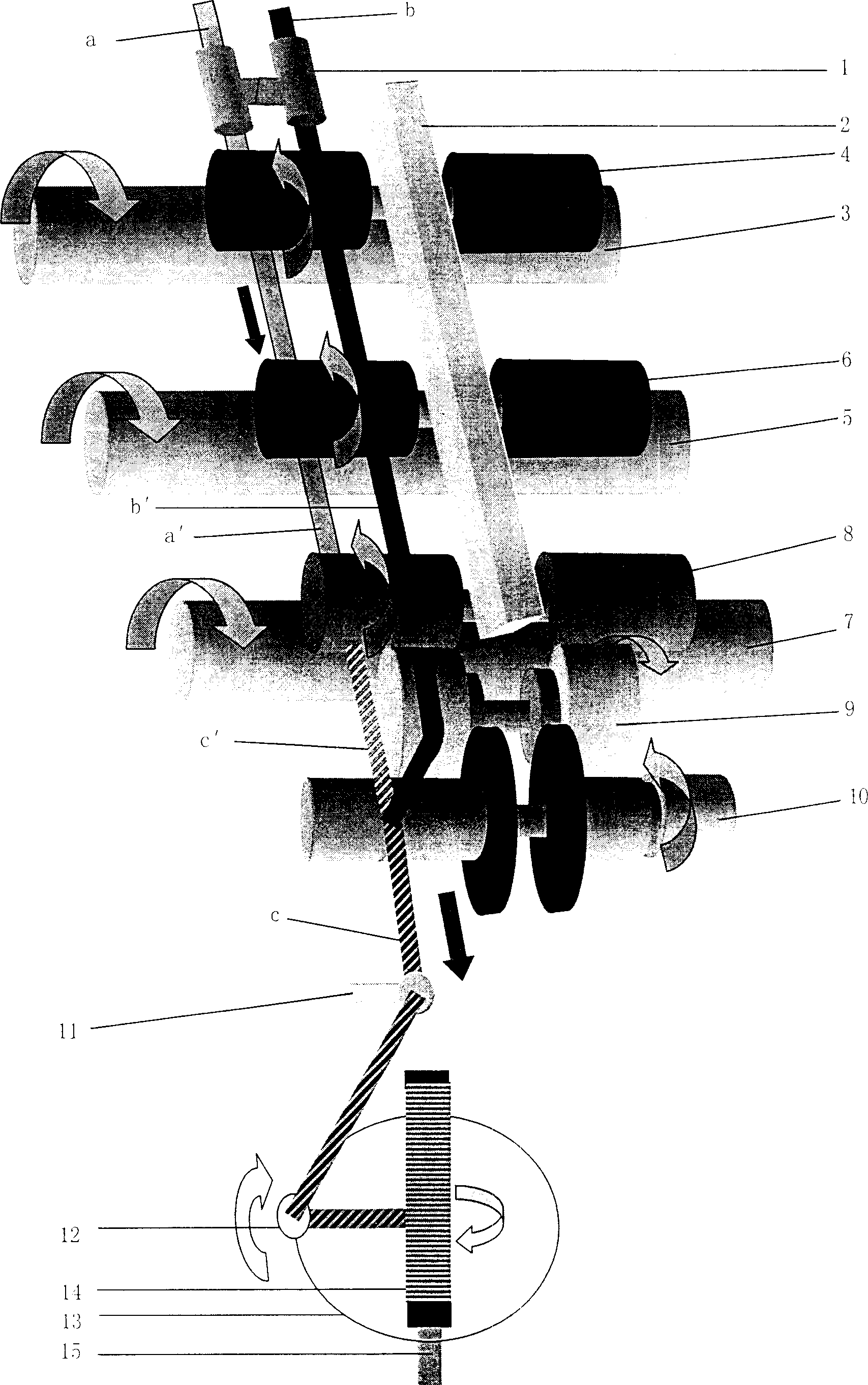

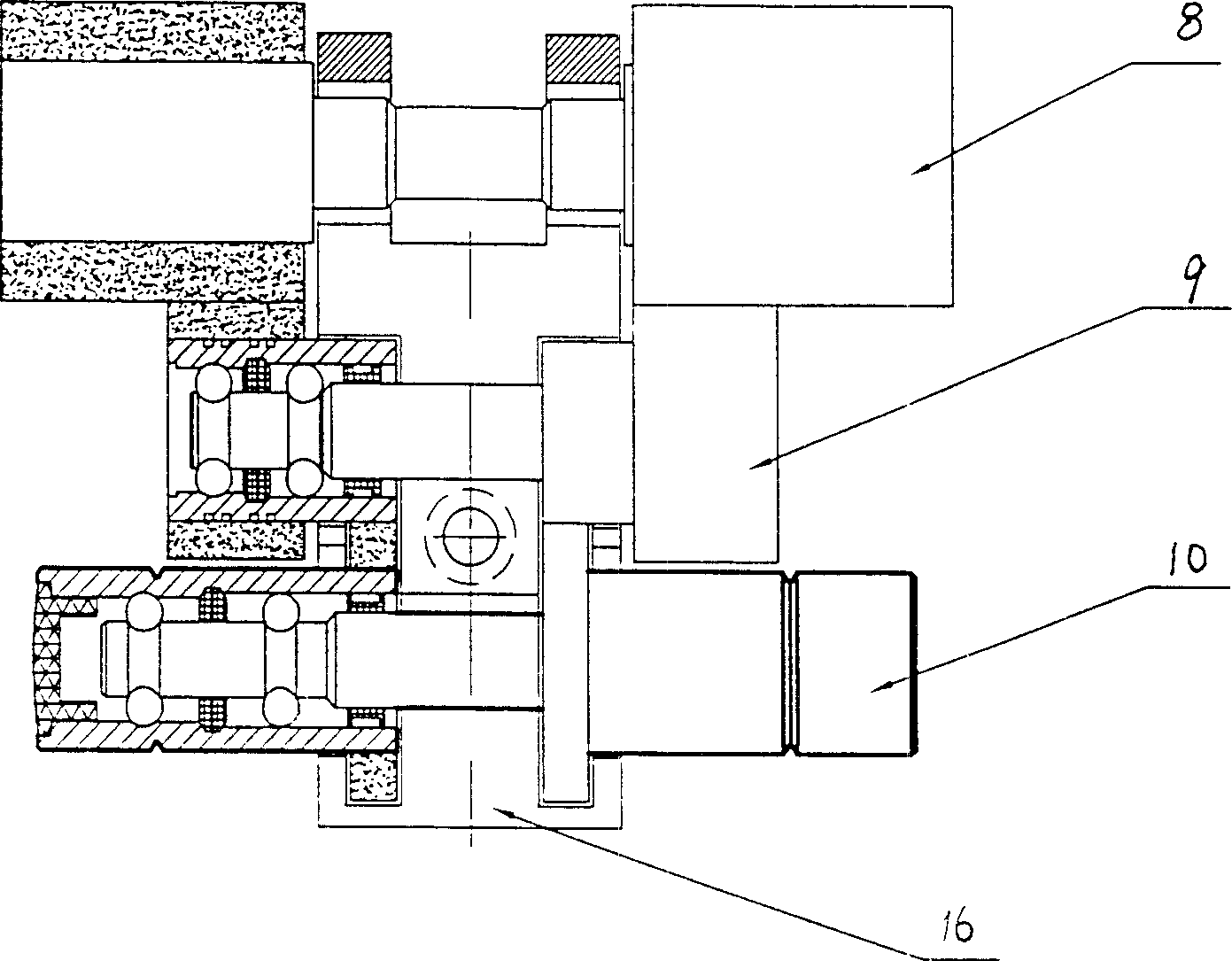

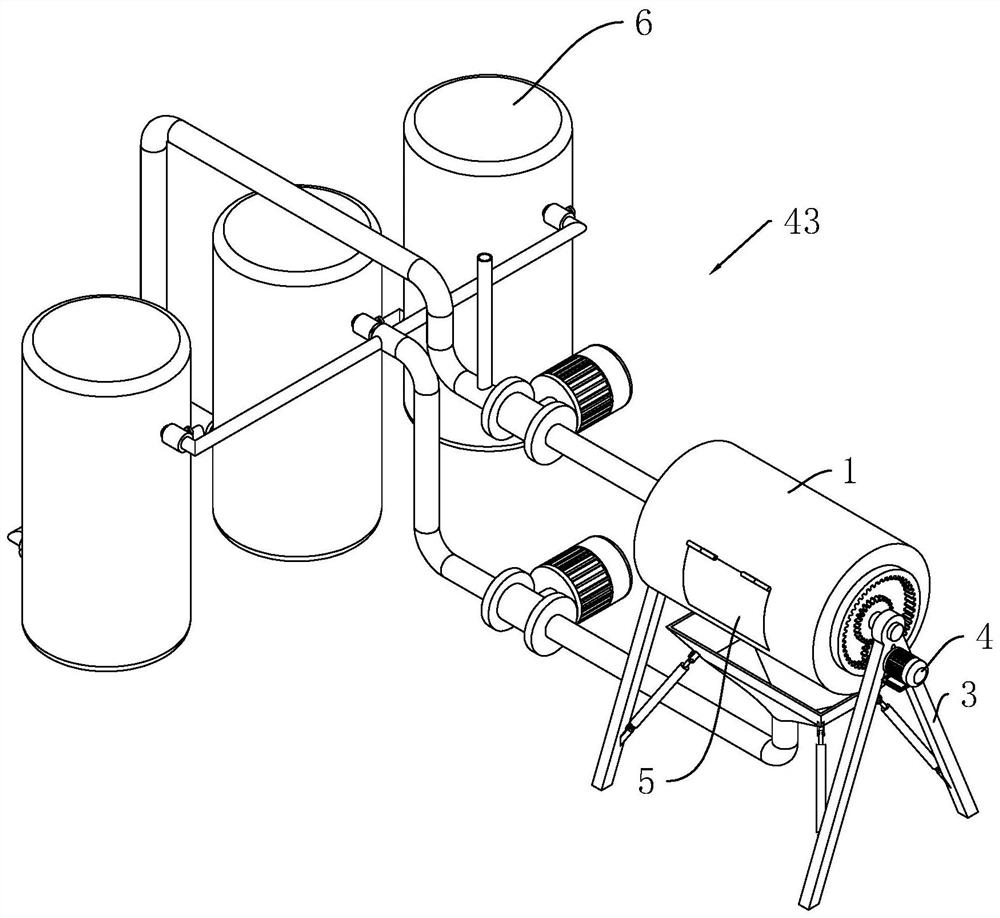

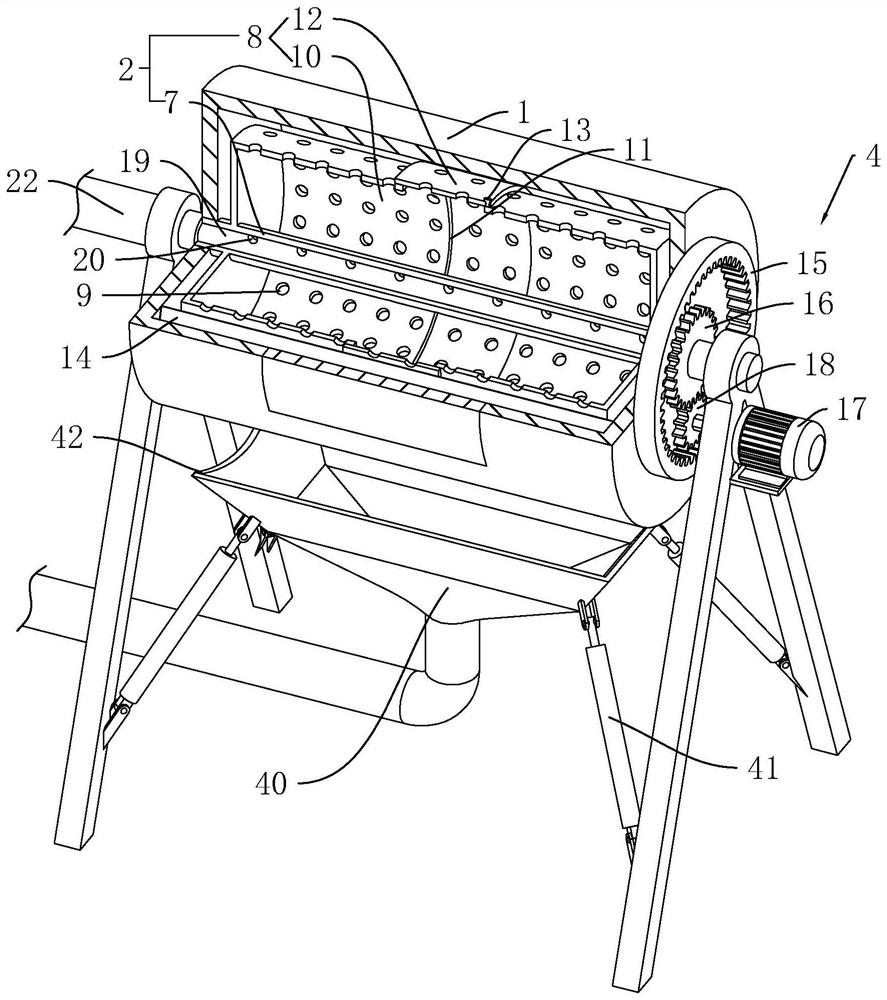

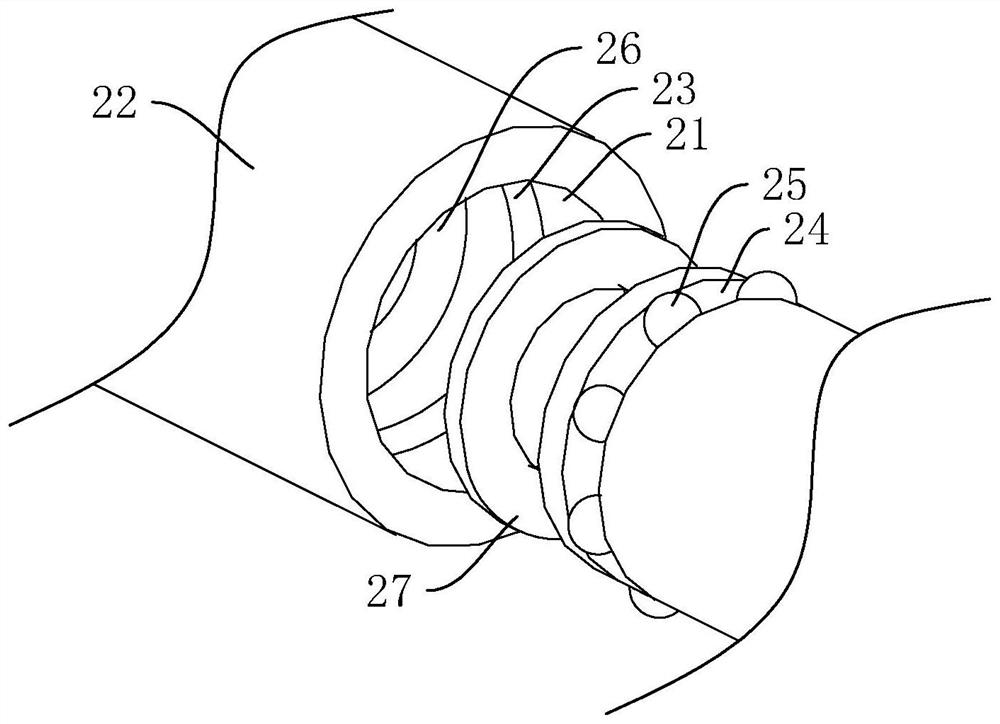

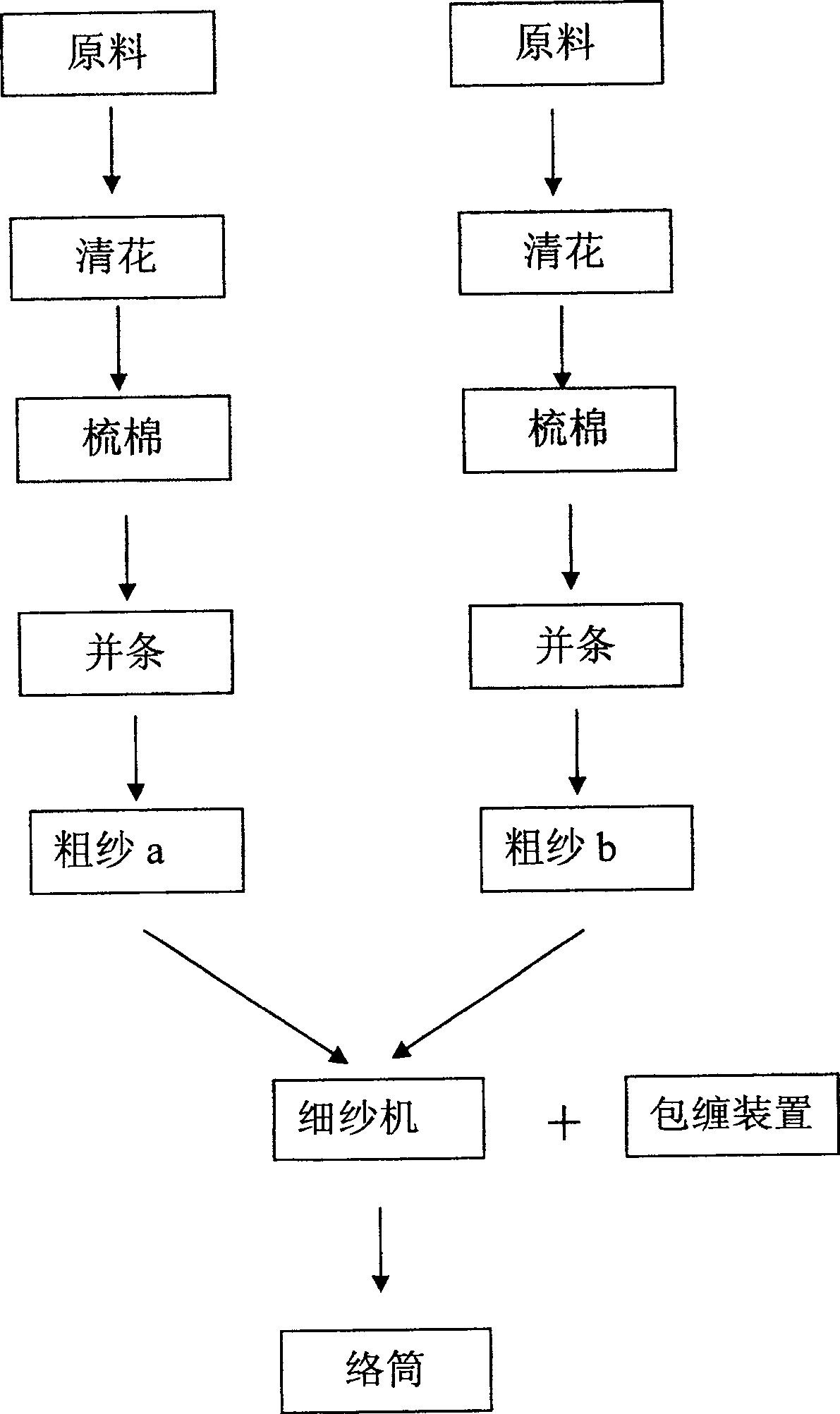

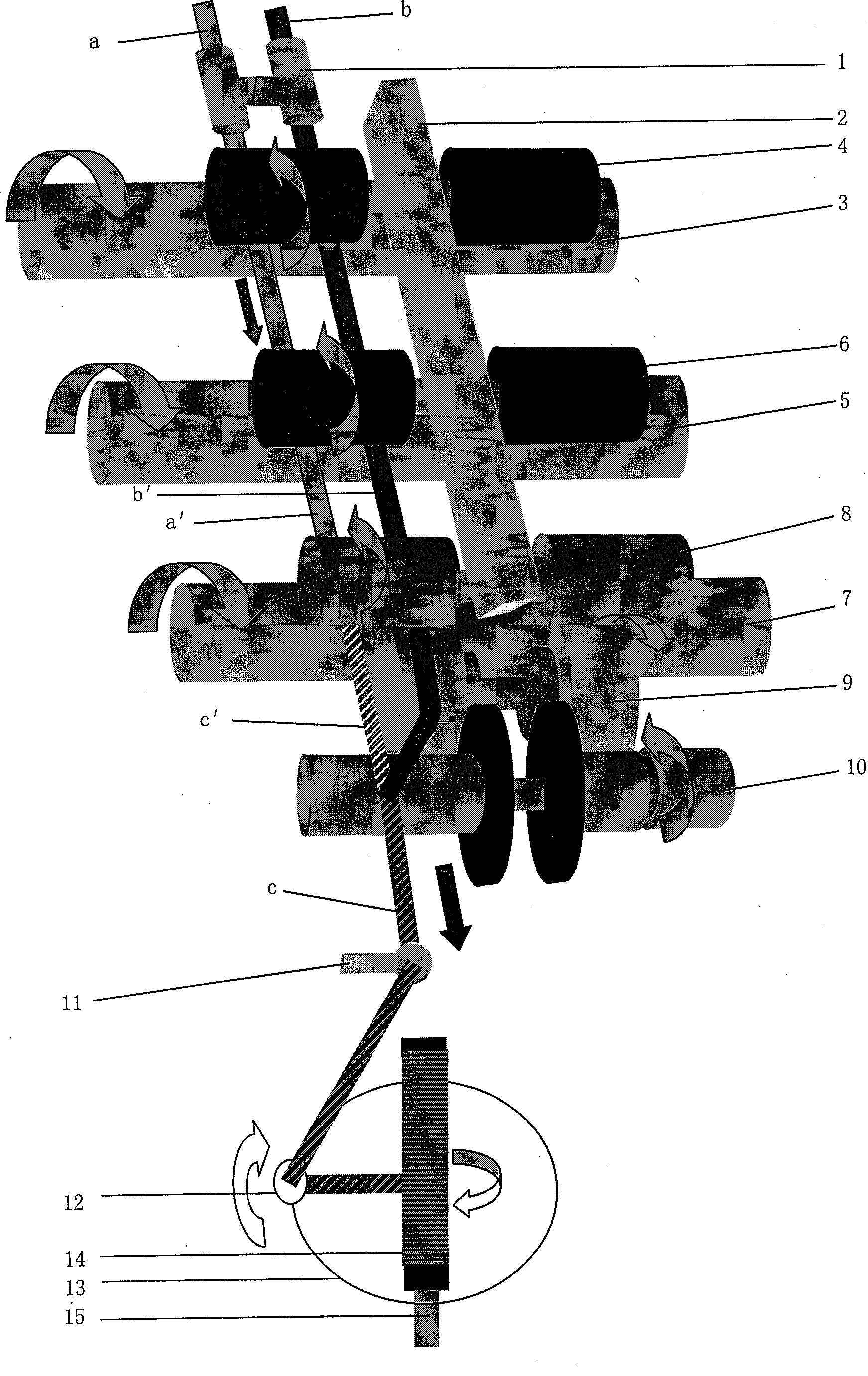

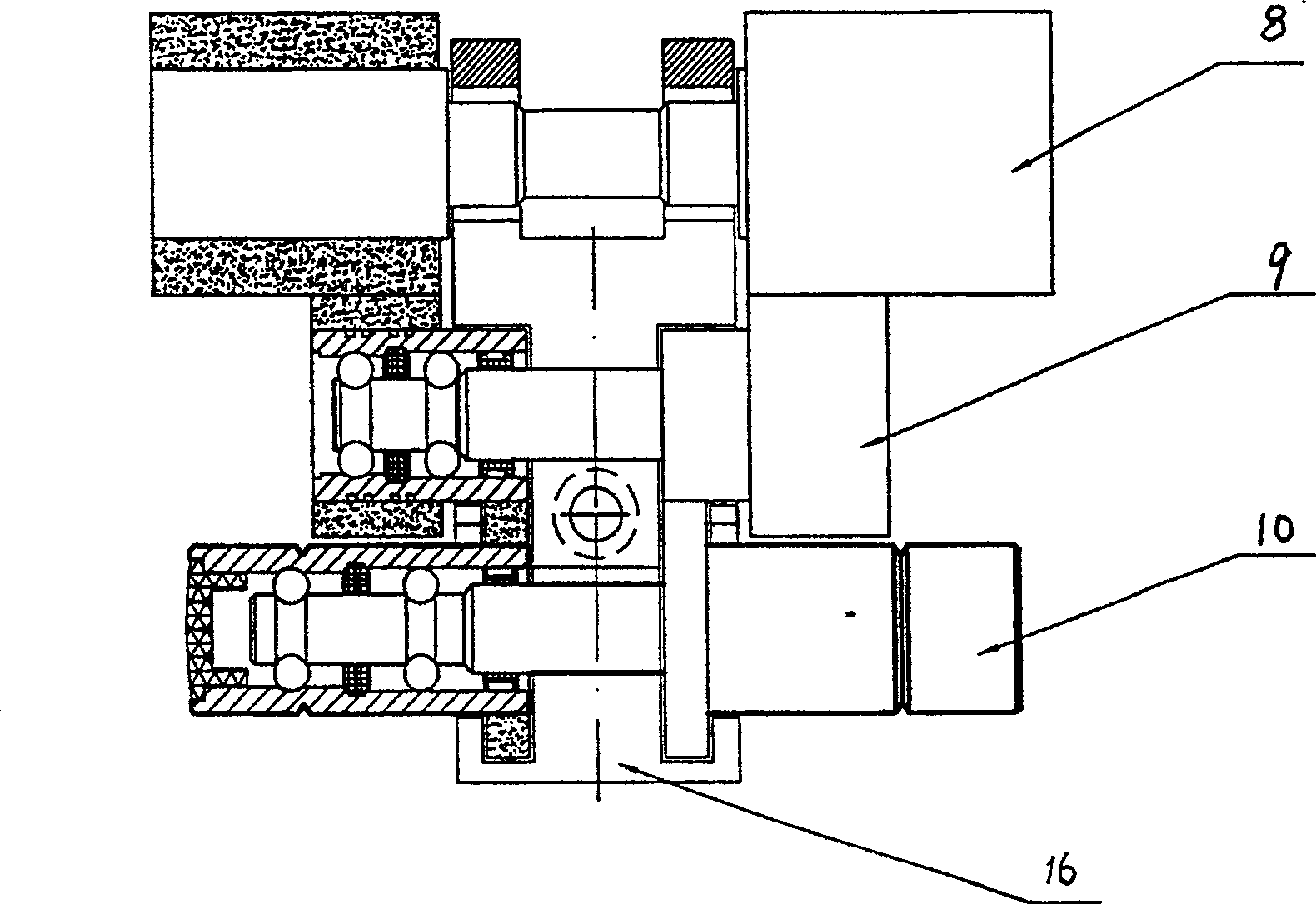

Production method of short staple enveloped composite yarn and its device

The present invention discloses a production method of short fibre wrapped composite yarn and its equipment. Said invention is implemented by using spinning frame and wrapping device, and its production method includes the following steps: raw material, scotching, carding, drawing, roving, spinning and doffing.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

Production technology of viscose flat monofilament

ActiveCN103215679AReduce the blooming effectFully solidifiedFilament/thread formingArtificial filaments from viscoseInlet channelCellulose fiber

The invention relates to a production technology of viscose flat monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose monofilament with the flatness of (10-500):1 through preparation of a spinning solution, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) feeding the spinning solution into a spinning machine and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, an inlet channel of the spinneret orifice is in a parabola shape, the shape of the spinneret orifice is '-', 'C' and 'S', and the length-width ratio of the spinneret orifice is (100-1,500):1; and (C) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the cross section of the prepared viscose flat monofilament strip is in a flat shape, and the viscose flat monofilament has an effect of natural hemp fiber and can be widely applied to weaving.

Owner:YIBIN HIEST FIBER +2

Method for observing embryo sac of paddy rice by using stone peculiar fluorescent dye, and transparent technique of whole ovary

InactiveCN1916609ADifficult to penetrateNot easy to dyePreparing sample for investigationFluorescence/phosphorescenceFluorescenceEmbryo

A method of utilizing nuclear specific fluorescent staining and ovary being made to be completely transparent technique to observe blastocyst of rice includes using certain concentration of sodium hydroxide solution to carry out softening treatment on blastocyst of rice before staining then utilizing specific combination of nucleus fluorescent staining DAPI with nucleus to observe structure of cell and nucleus in blastocyst, enabling to use laser scan confocal microscope to observe internal structure of cell clearly.

Owner:代西梅

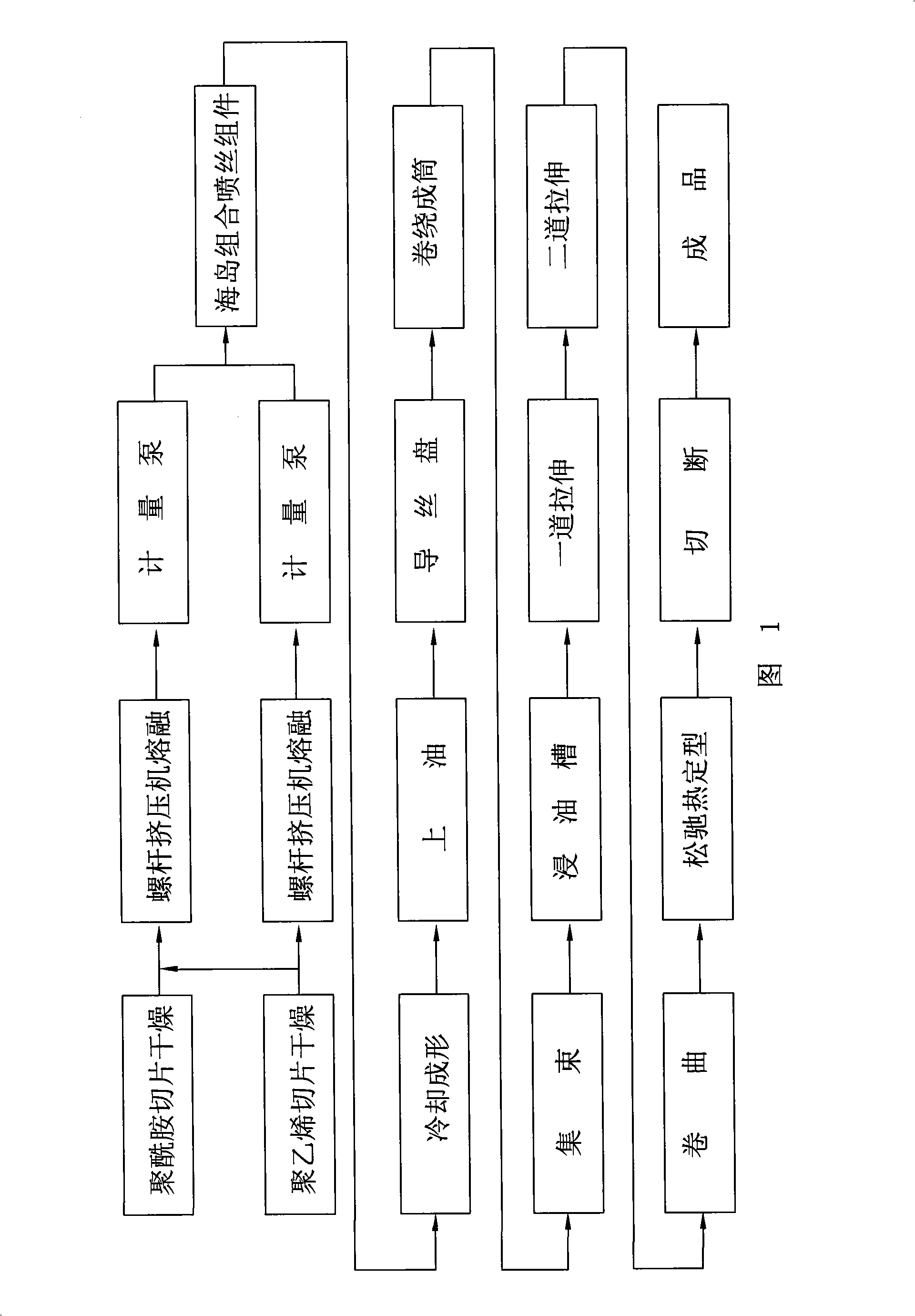

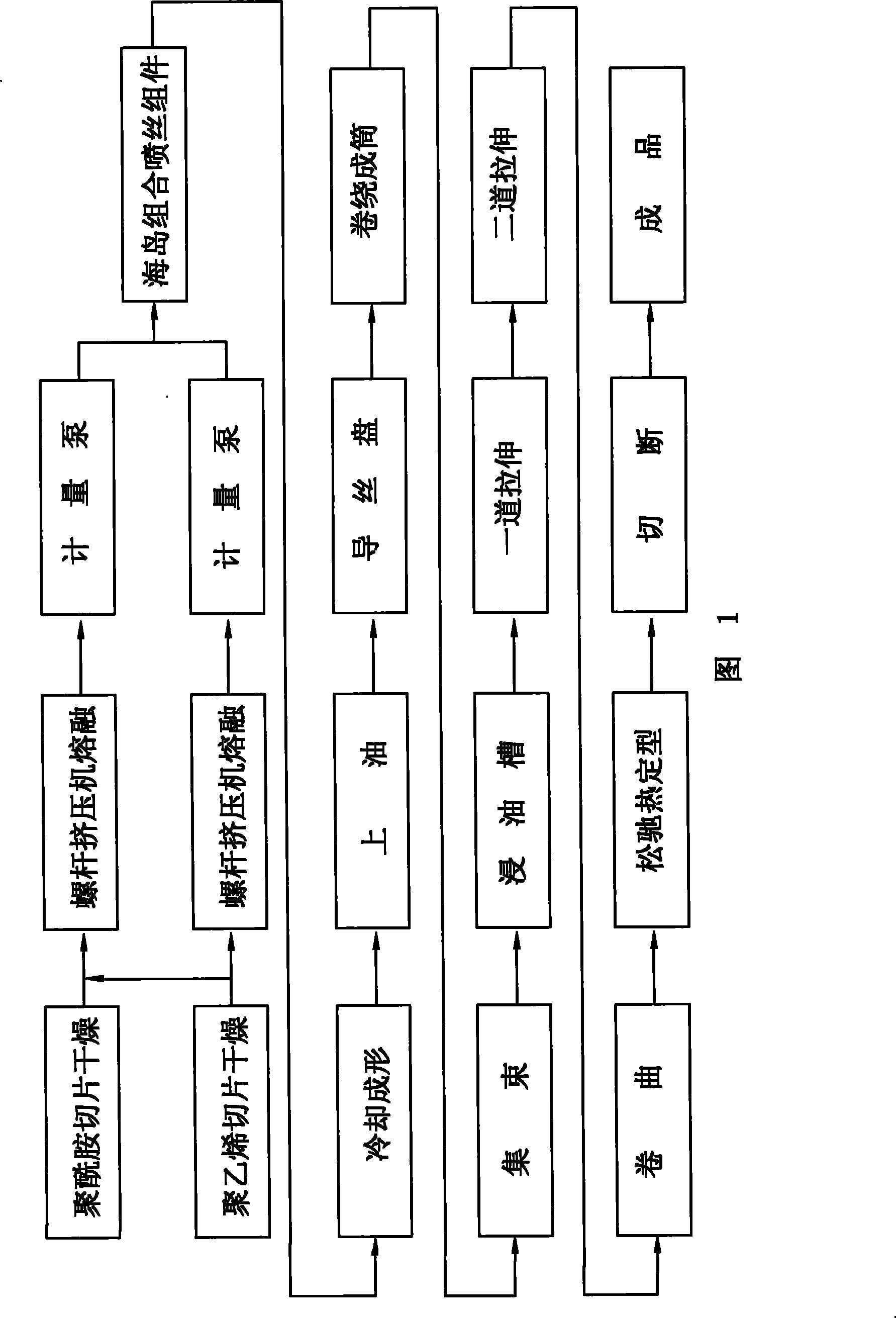

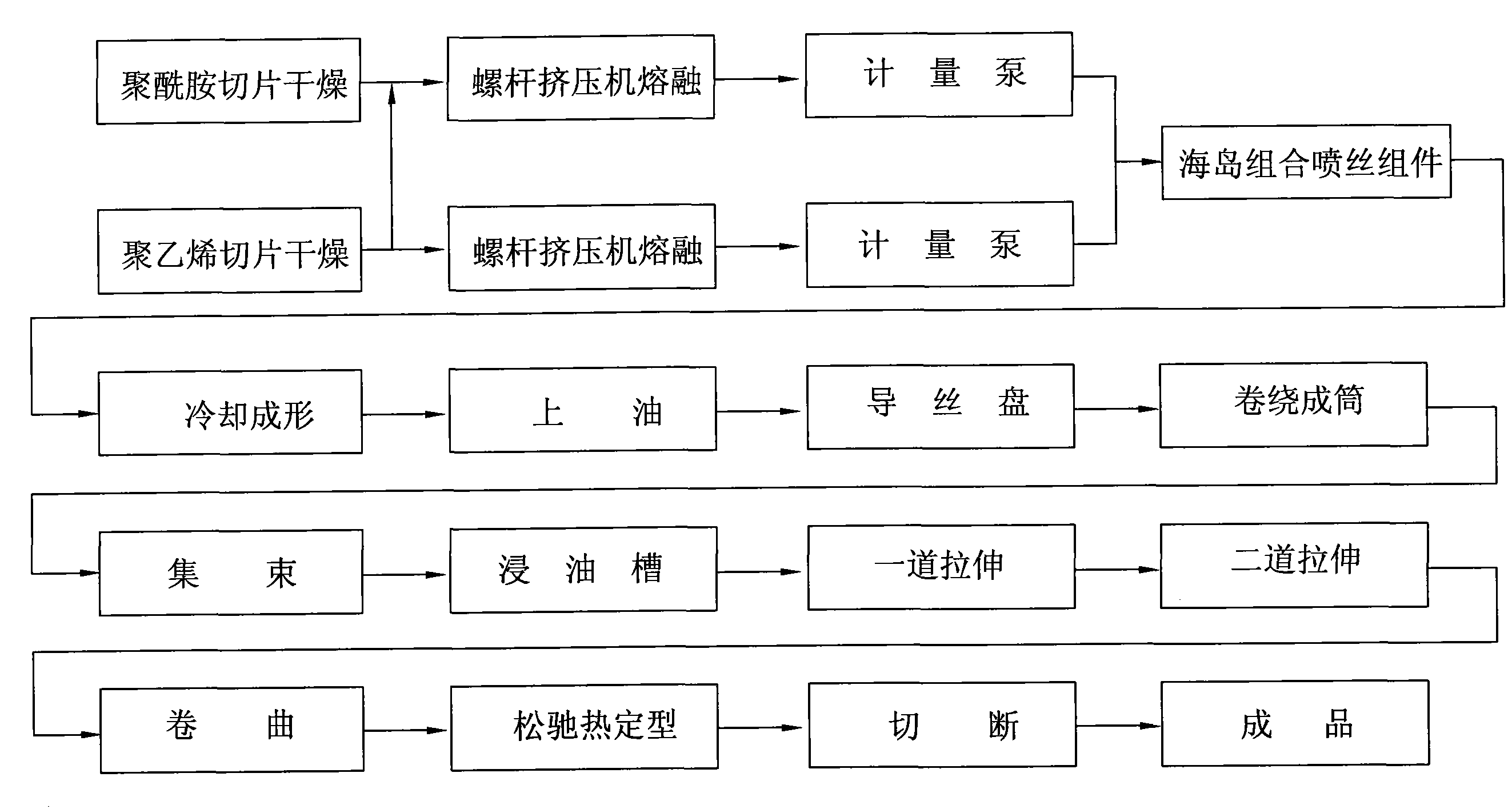

Satellite type superfine denier polyamide short fibre and producing method thereof

ActiveCN101333694AIncrease contentHigh viscosityFilament/thread formingConjugated synthetic polymer artificial filamentsLow-density polyethyleneSpinning

The invention relates to a chemical fiber, in particular to a satellite type superfine denier polyamide short fiber as well as a production method thereof. According to the technical proposal of the invention, the fiber is a sea-island short fiber taking low density polyethylene as a sea component and polyamide as an island component, and is characterized in that: the sea component is a mixture of low density polyethylene and polyamide, the polyamide therein forms a plurality of satellite islands around the island, and the titer of the satellite islands is smaller than that of the island; and the island component and the sea component are in a ratio of 1:0.4 to 2.3, the polyamide and low density polyethylene in the sea component are in a ratio of 1:0.667 to 4, the filament titer ranges from 0.05 to 0.3dtex after the island is separated, and the unit is weight ratio. The chemical fiber can increase the content of effective constituents; and the viscosity of the sea component can make the island difficult to be adhered, and the spinnability in the spinning process is improved, so the sea component and the island component will not be separated easily.

Owner:WUXI DOUBLE ELEPHANT MICRO FIBER MATERIAL

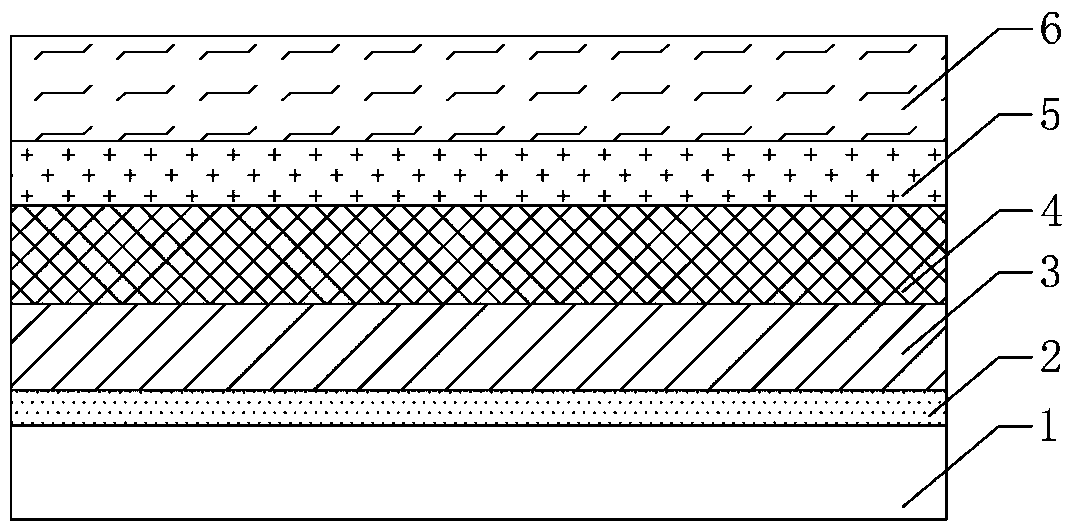

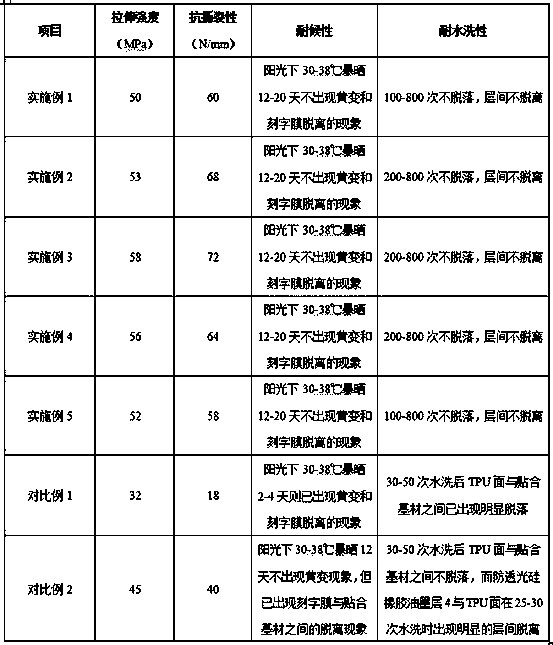

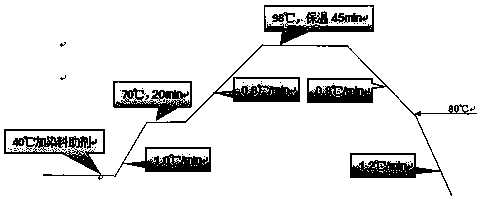

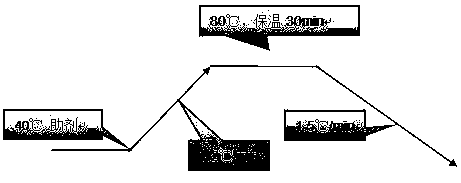

High elasticity silicone rubber heat transfer film and preparation method thereof

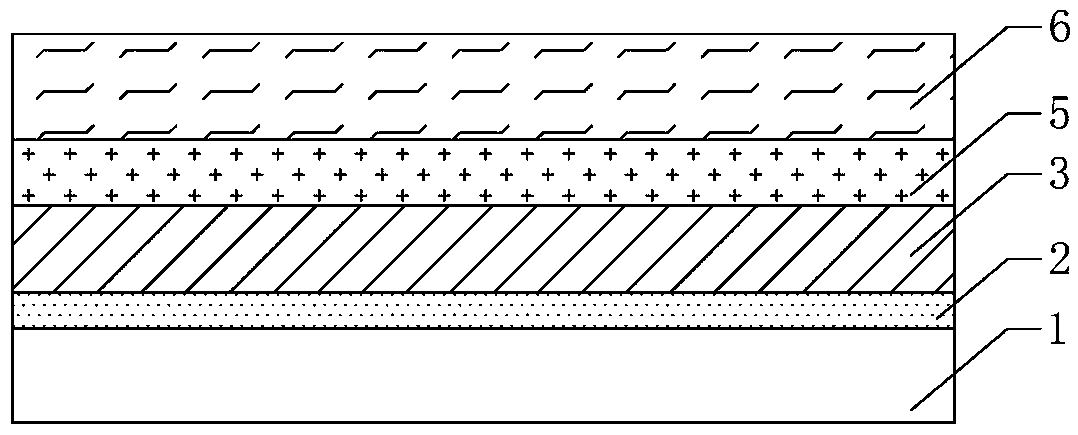

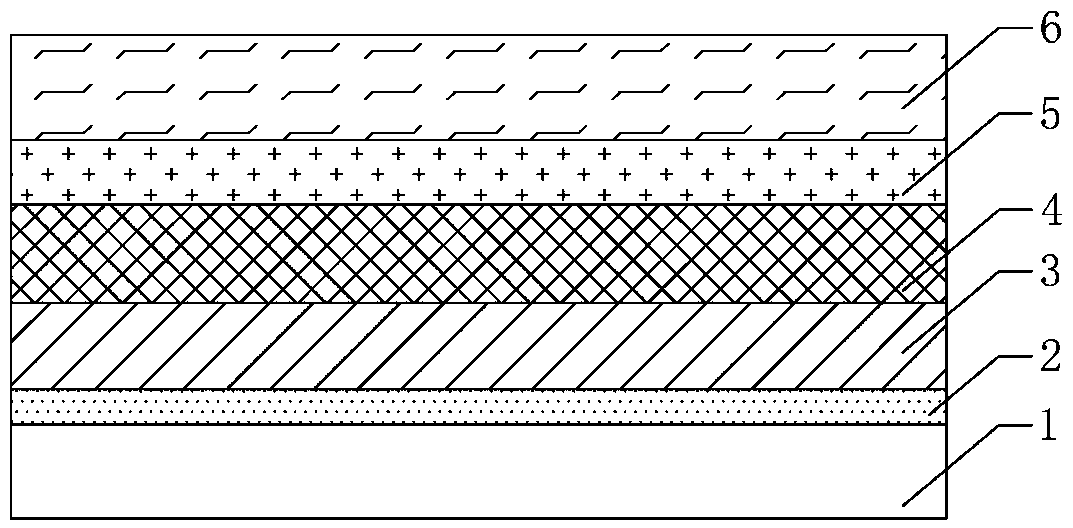

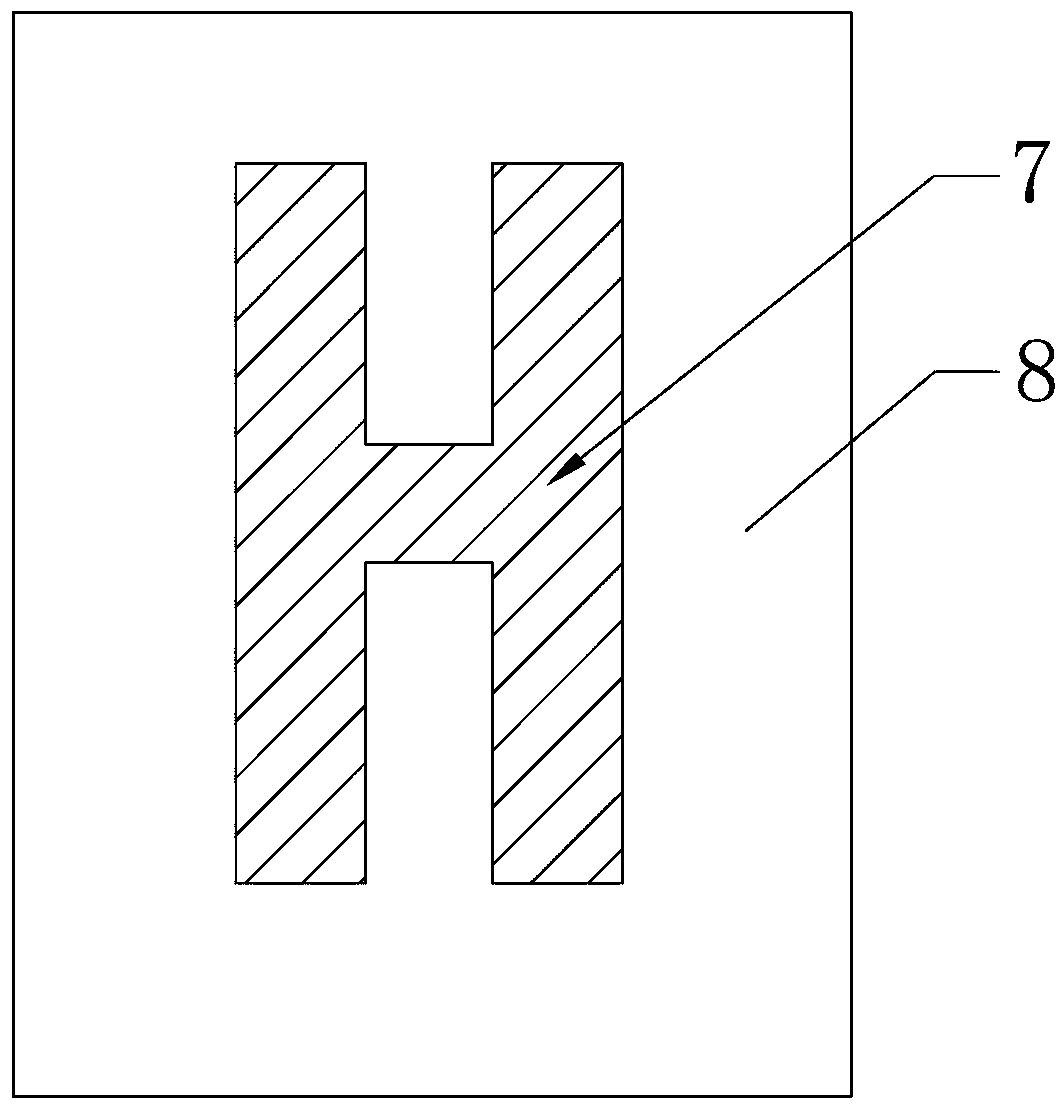

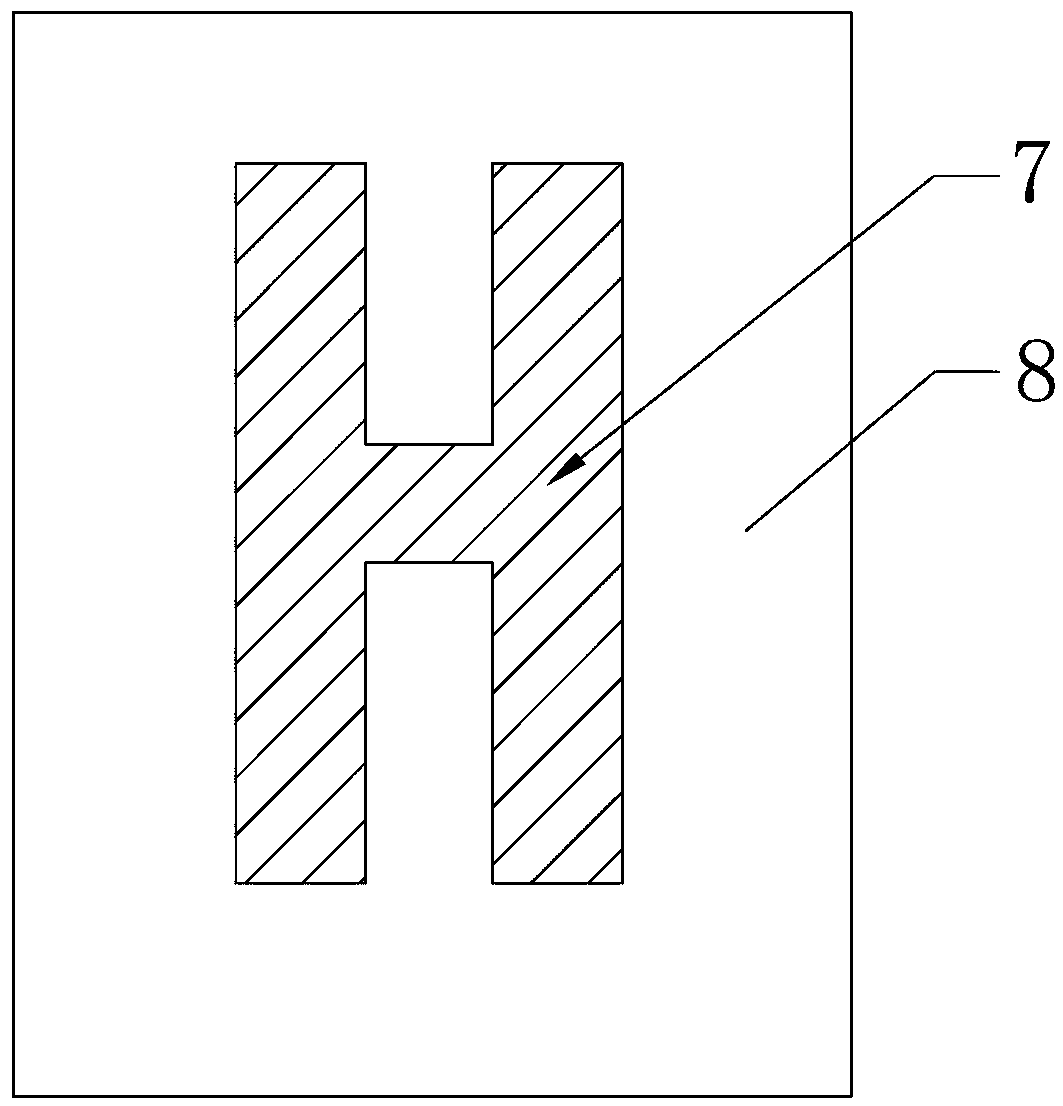

ActiveCN108690515AImprove water resistanceImprove processing efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSurface layer

The invention relates to the technical field of heat transfer films, and specifically relates to a high elasticity silicone rubber heat transfer film and a preparation method thereof. The high elasticity silicone rubber heat transfer film comprises following components from bottom to top: a bearing base material, a release layer, a silicone rubber surface layer, an interface bonding agent layer, and a TPU hot melt adhesive membrane; wherein the interface bonding agent layer is prepared an interface bonding agent, which comprises two resin components. The provided heat transfer film has the advantages of silicone rubber and TPU, such as excellent elasticity, high tearing resistant strength, weatherability, yellowing resistance, washing resistance, and the like. Layering is difficult to happen. Even if the heat transfer film is exposed under the sun, color change or fading is difficult to happen. The water washing fading rate is not more than 0.5%. When the color transfer film is washedwith materials with other colors, other materials will not be dyed easily. The stability is high. The heat transfer film can be easily adhered on multiple materials, the bonding strength is strong, the heat transfer film is not easy to peel off, the stability is good, the hand feeling is fine, the appearance is good, and the service life is long.

Owner:卢汉军

Chitosan modified nylon fabric and manufacturing method thereof

The invention discloses a chitosan modified nylon fabric, which is grafted with 0.1 to 0.2 mass percent of chitosan. The invention also discloses the manufacturing method of the fabric, which comprises: (1) weighing nylon fabric and immersing the nylon fabric in nylon oxidant aqueous solution, heating in a water bath according to a bath ratio ranging from 1:10 to 1:40, and stirring; (2) dissolving the chitosan in 1 to 6 percent of glacial acetic acid, stirring to dissolve the glacial acetic acid to form saturated solution of the glacial acetic acid; (3) weighing chitosan oxidant and adding the chitosan oxidant into the saturated solution of the chitosan prepared in the step (2), stirring uniformly and heating in a water bath; (4) adding the chitosan mixed solution obtained by the step (3)into the nylon oxidant aqueous solution in which the nylon fabric is immersed, heating in a water bath and stirring, wherein the added volume of the chitosan mixed solution is 0.5 to 3 times that of nylon oxidant aqueous solution; and (5) taking finished nylon fabric, washing with a soap, and drying in the air. The modified nylon fabric is smoother and has the effects of inhibiting bacteria, resisting static electricity and the like. The method discloses by the invention is simple, easy to implement and low in cost.

Owner:WUYI UNIV

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

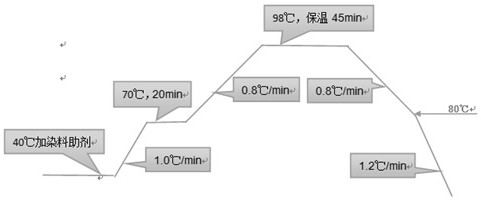

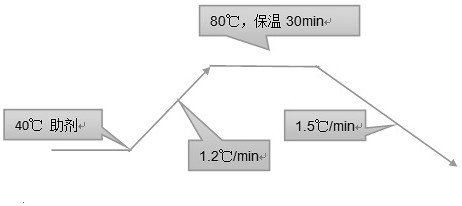

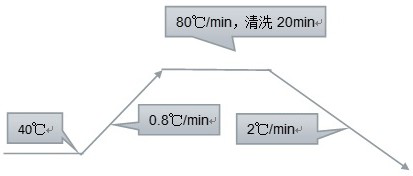

Weaving and dyeing method for unidirectional moisture-conducting elastic fabric

ActiveCN108301234AGood performanceGood effectFibre typesHeating/cooling textile fabricsPolypropyleneWeft yarn

The invention relates to a weaving and dyeing method for a unidirectional moisture-conducting elastic fabric. The weaving and dyeing method includes: warping, sizing and rebeaming, weaving, dyeing, and finished product inspection. Specifically, the dyeing step is carried out according to the process of: cooling piling, loose desizing, pre-setting, dyeing, dehydration drying, and clear water setting. The unidirectional moisture-conducting elastic fabric is a double-layer structure, the surface layer adopts a hydrophilic easily dyeable fiber, and the lining selects polypropylene stock solution colored yarn, the polypropylene stock solution colored yarn is only used as weft yarn, and the yarn matching the polypropylene stock solution colored yarn adopts polyamide spandex coated yarn.

Owner:WUJIANG FUHUA WEAVING

Preparation method of antistatic knitted fabric

InactiveCN108914353AImprove spinnabilityImprove wear resistanceElectroconductive/antistatic filament manufactureWeft knittingPolyesterFiber

The invention discloses a preparation method of an antistatic knitted fabric, and relates to a preparation method for a knitted fabric. The preparation method comprises: a step A: preparing compositeconductive fibers; a step B: selecting polyester and the composite conductive fibers to form a gray fabric; a step C: performing blank pre-shaping on the gray fabric; a step D: dyeing the gray fabric;a step E: dewatering the gray fabric; a step F: drying the gray fabric; and a step J: scutching and shaping the gray fabric. Compared with the prior art, the fabric has a good antistatic effect; thefabric is soft, comfortable and breathable, and has good wearability. The defects that the fabric blended by the traditional conductive fibers and the ordinary fibers is not resistant to friction andwill lose effects due to repeated washing can be overcome.

Owner:NINGBO DAQIAN TEXTILE

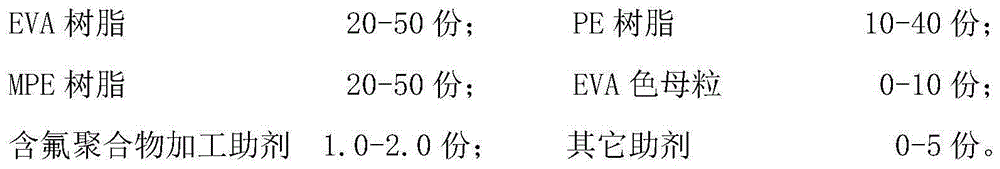

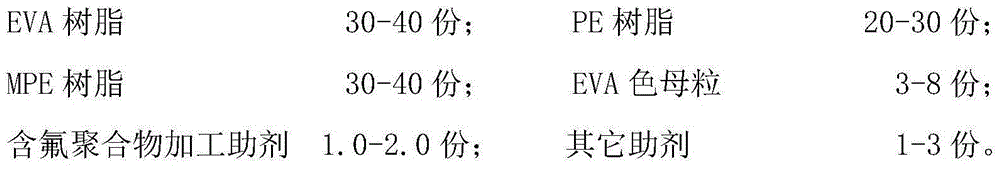

PEVA film for laundry basket and preparation method for PEVA film

The invention relates to the technical field of film materials, in particular to a PEVA film for a laundry basket and a preparation method for the PEVA film. The PEVA film comprises the following components in parts by weight: 20-50 parts of EVA resin, 10-40 parts of PE resin, 20-50 parts of MPE resin, 0-10 parts of EVA color master batch, 1.0-2.0 parts of a fluoropolymer additive and 0-5 parts of other additive. The MPE resin is metallocene-linear polyethylene. The other additive is an ultraviolet stabilizer or an antioxidant. The preparation method comprises the following steps of: 1) weighing the raw materials at the weight part ratio of the components of the PEVA film for the laundry basket, pouring the EVA resin, the PE resin, the MPE resin, the EVA color master batch, the fluoropolymer additive and the other additive into a high-speed mixer for stirring and mixing uniformly, then performing blending melting and extrusion through a casting machine, and performing tape-casting through a flat die head to obtain a semi-finished PEVA film; and 2) performing embossing cooling forming on the semi-finished PEVA film in a molten state in the step 1) to obtain the finished PEVA film. The finished PEVA film for the laundry basket is 0.10-0.50 mm in thickness.

Owner:FUJIAN HUIYIMEI ENVIRONMENTAL PROTECTION MATERIALTECH CO LTD

Chitosan modified nylon fabric and manufacturing method thereof

The invention discloses a chitosan modified nylon fabric, which is grafted with 0.1 to 0.2 mass percent of chitosan. The invention also discloses the manufacturing method of the fabric, which comprises: (1) weighing nylon fabric and immersing the nylon fabric in nylon oxidant aqueous solution, heating in a water bath according to a bath ratio ranging from 1:10 to 1:40, and stirring; (2) dissolving the chitosan in 1 to 6 percent of glacial acetic acid, stirring to dissolve the glacial acetic acid to form saturated solution of the glacial acetic acid; (3) weighing chitosan oxidant and adding the chitosan oxidant into the saturated solution of the chitosan prepared in the step (2), stirring uniformly and heating in a water bath; (4) adding the chitosan mixed solution obtained by the step (3)into the nylon oxidant aqueous solution in which the nylon fabric is immersed, heating in a water bath and stirring, wherein the added volume of the chitosan mixed solution is 0.5 to 3 times that of nylon oxidant aqueous solution; and (5) taking finished nylon fabric, washing with a soap, and drying in the air. The modified nylon fabric is smoother and has the effects of inhibiting bacteria, resisting static electricity and the like. The method discloses by the invention is simple, easy to implement and low in cost.

Owner:WUYI UNIV

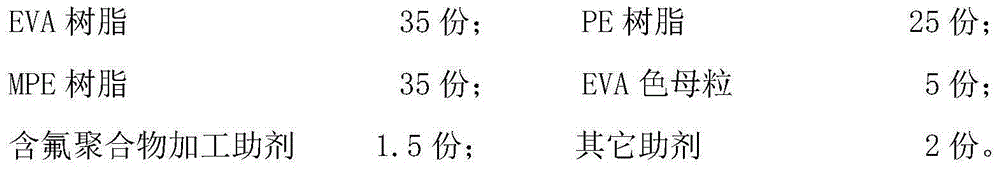

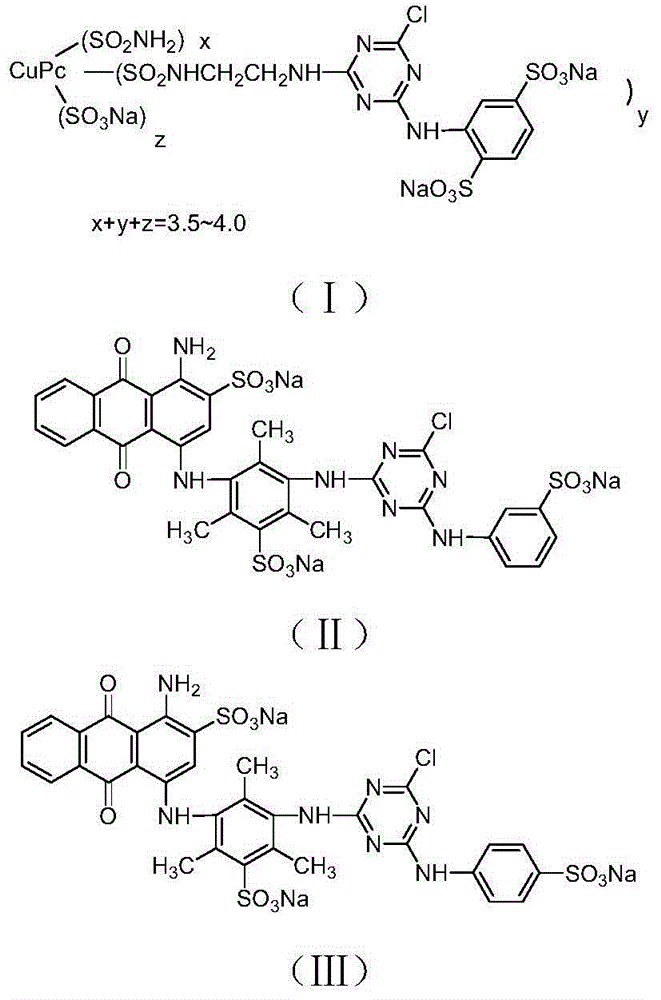

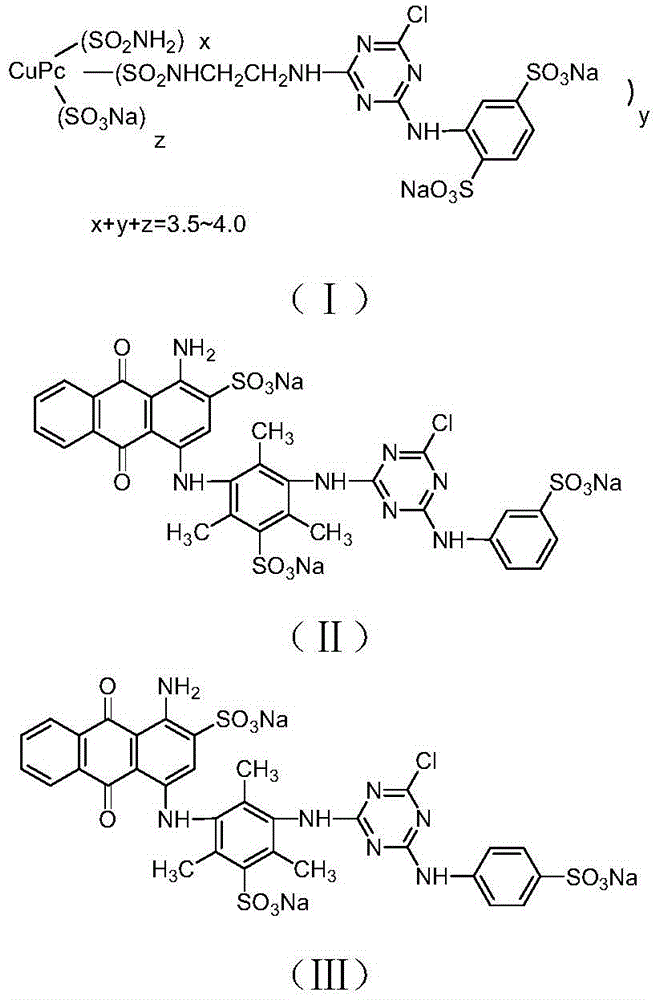

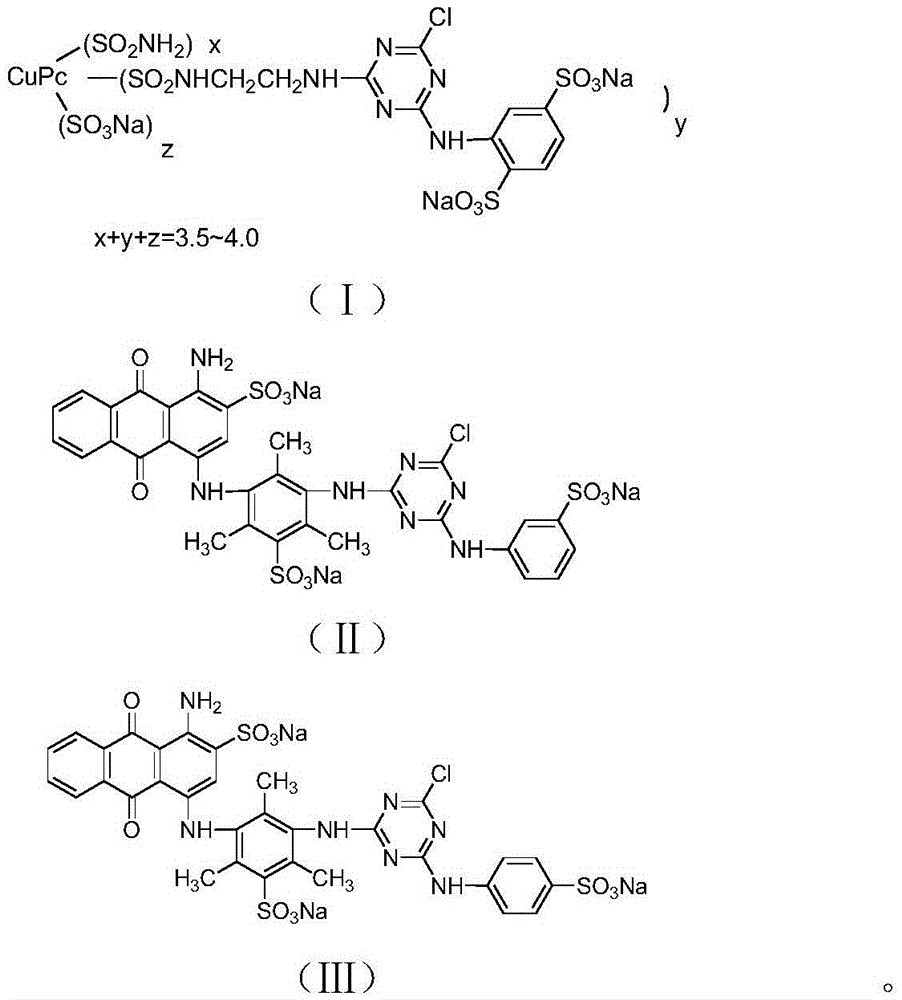

Cobalt blue active dye mixture and application thereof

ActiveCN104650620AOvercome the problem of stainingSolve the problem of greenish colorOrganic dyesDyeing processStainingChemical compound

The invention discloses a cobalt blue active dye mixture which is formed by splicing and mixing compounds shown in a structural formula (I), a structural formula (II) and / or a structural formula (III). The cobalt blue active dye mixture comprises the compounds in percentage by mass: 50-70% of the compound shown in the structural formula (I), 0-50% of the compound shown in the structural formula (II) and 0-50% of the compound shown in the structural formula (III). 65-80% of the cobalt blue active dye mixture, 5-10% of a diffuser, 0.1-0.5% of a dust preventive, 5-15% of anhydrous sodium sulphate and 5-10% of a nonionic levelling agent are mixed to prepare a commercial dye. The commercial dye is used for preventing dyeing and printing for cellulose fiber fabrics and has the advantages of bright in color and luster, no phenomenon of kiss spot of leather, high staining fastness of white cloth and clean and environmental-friendly printing process.

Owner:江苏德美科化工有限公司

Fibre capable of replacing nylon

InactiveCN101294314AMolecular spacing is tightLow priceMonocomponent copolyesters artificial filamentDyeing processPolyesterEther

A fiber capable of substituting for nylon can be selected from PET and PTT fiber, which has lower cost than nylon and can be continuously produced from polyester at reduced energy consumption. The process flow comprises: molten polyester body, transmission of the molten body, spinning box body, metering pump, assembly, cooling (side-blowing air, circular-blowing air), beam gathering and oil addition, processional road, a first heat coil, a second heat coil, a main network, and coiling. The process is characterized in that 5 to 13% ether additive is added during polymerization to improve the molecular structure of polyester, so that the molecular pitch is increased to form amorphous crystal; the spun fiber can be subjected to boiling dyeing under normal pressure in the same bath of nylon using acid dye; and the ultimate elongation of the polyester fiber is improved to above 40%. The polyester fiber with the characteristics of nylon can be used for substituting for nylon at a lower cost than nylon and conserved energy resource than common polyester fiber by 5 to 16%. The common polyester has compact molecular pitch because of the phenyl ring in the polyester molecule, so that the common polyester is not easy to be dyed unless adopting high-temperature high-pressure dyeing.

Owner:周正林

A kind of weaving and dyeing method of unidirectional moisture-conducting elastic fabric

ActiveCN108301234BSolve the problem of coloringNot easy to dyeFibre typesHeating/cooling textile fabricsFiberPolymer science

Owner:WUJIANG FUHUA WEAVING

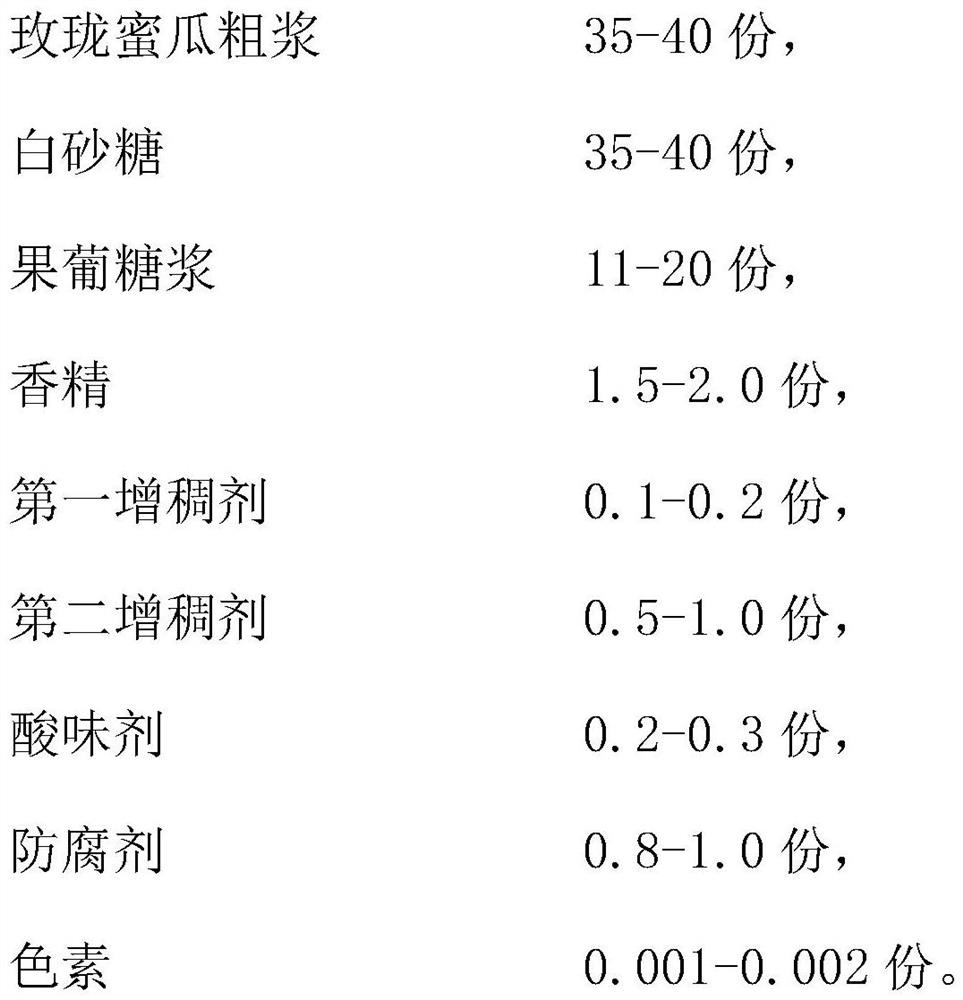

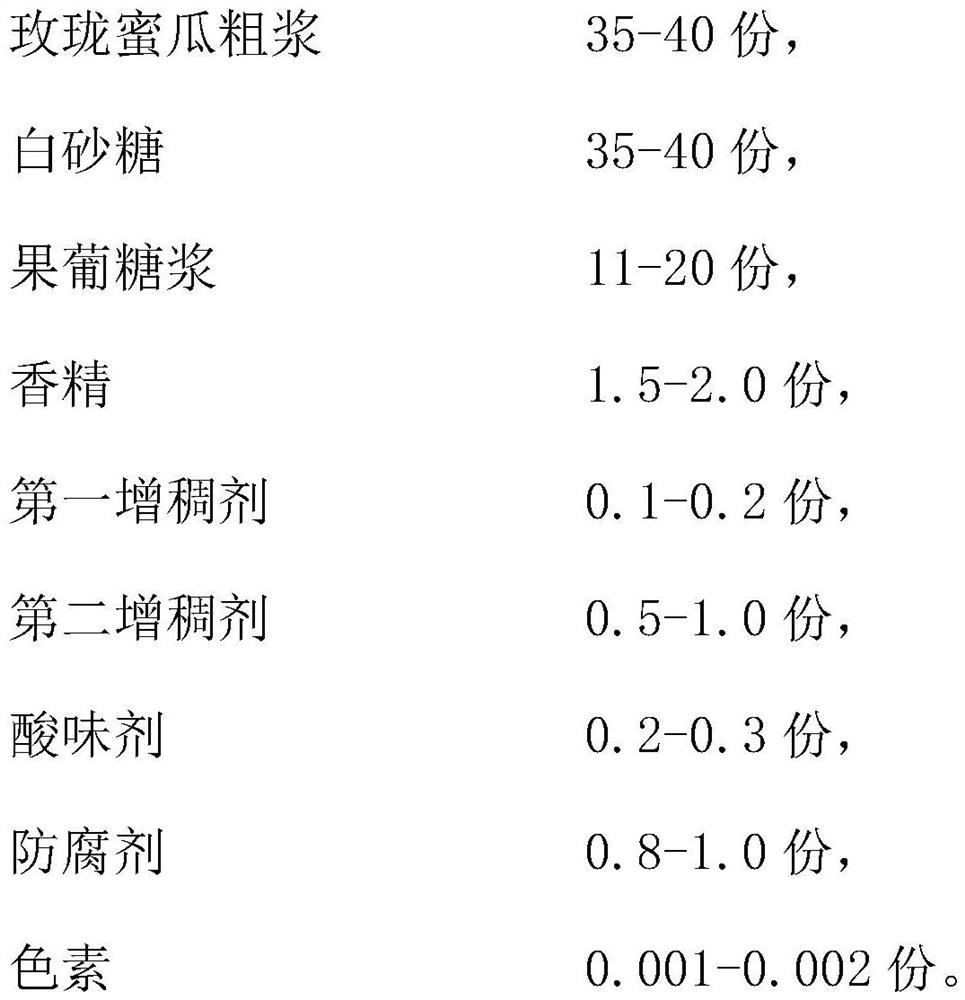

Meilong honeydew melon jam and preparation method thereof

PendingCN113892613ARaw materials are novelGood flavorFood ingredient as thickening agentFood preservationChemistryHoneydew melon

The invention provides Meilong honeydew melon jam. The Meilong honeydew melon jam comprises the following raw materials in parts by weight: 35 to 40 parts of Meilong honeydew melon coarse pulp, 35 to 40 parts of white granulated sugar, 11 to 20 parts of high fructose corn syrup, 1.5 to 2.0 parts of essence, 0.1 to 0.2 part of first thickening agent, 0.5 to 1.0 part of second thickening agent, 0.2 to 0.3 part of acid agent, 0.8 to 1.0 part of preservative and 0.001 to 0.002 part of pigment. According to the preparation method of the Meilong honeydew melon jam, the Meilong honeydew melon pulp is adopted as the raw material, the raw material is novel, has a good flavor, and is nutritional and healthy, the delicious Meilong honeydew melon jam product is prepared on the basis of taking the Meilong honeydew melons as the raw material, supplemented by food additives, and in addition, pasteurization is adopted for the product, and the pasteurization temperature is relatively low and the pasteurization time is short, so that the flavor and nutrient substances of the product can be well reserved.

Owner:GREEN JUICE IND TIANJIN

Satellite type superfine denier polyamide short fibre and producing method thereof

ActiveCN101333694BIncrease contentHigh viscosityFilament/thread formingConjugated synthetic polymer artificial filamentsLow-density polyethyleneFiber

The invention relates to a chemical fiber, in particular to a satellite type superfine denier polyamide short fiber as well as a production method thereof. According to the technical proposal of the invention, the fiber is a sea-island short fiber taking low density polyethylene as a sea component and polyamide as an island component, and is characterized in that: the sea component is a mixture of low density polyethylene and polyamide, the polyamide therein forms a plurality of satellite islands around the island, and the titer of the satellite islands is smaller than that of the island; andthe island component and the sea component are in a ratio of 1:0.4 to 2.3, the polyamide and low density polyethylene in the sea component are in a ratio of 1:0.667 to 4, the filament titer ranges from 0.05 to 0.3dtex after the island is separated, and the unit is weight ratio. The chemical fiber can increase the content of effective constituents; and the viscosity of the sea component can make the island difficult to be adhered, and the spinnability in the spinning process is improved, so the sea component and the island component will not be separated easily.

Owner:WUXI DOUBLE ELEPHANT MICRO FIBER MATERIAL

Viscose monofilament production process

ActiveCN103233289BReduce the blooming effectFully solidifiedSpinnerette packsArtificial filaments from viscoseViscosePulp and paper industry

The invention relates to a viscose monofilament production process. Cellulose fiber pulp is adopted as a raw material, and the steps such as spinning solution preparation, spinning, and post-treatment are carried out, such that the viscose monofilament is obtained. The method specifically comprises the process steps that: (A) cellulose fiber pulp is subjected to impregnation, aging, yellowing, dissolving, defoaming, and filtering, such that the spinning solution is prepared; (B) the spinning solution is delivered into a spinning machine, and passes through a spinning hole with a single-hole nozzle under pressure, such that viscose thin stream is formed, and raw filament strip is formed after coagulation molding, wherein jet nozzle stretch is +60% to +80%, and a spinning hole inlet pore channel is in a parabolic shape; and (C) post-treatment is carried out, wherein the raw filament strip is subjected to desulfurization, bleaching, oiling, and bake-drying, such that the viscose monofilament is obtained. With the production process provided by the invention, produced viscose monofilament has fineness of 50-6000D, and high strength higher than 75CN. With the viscose monofilament, requirements by dyeing, weaving and finished garments can be satisfied.

Owner:YIBIN HIEST FIBER +2

Method for preparing a refreshing wig

The invention discloses a method for preparing a refreshing wig. The method comprises the steps of: using a bleaching agent bleaching hair and apply a brightening agent; processed hair styling beat together, and the upper trim of the same height, the lower end maintain the natural amplitude; finished with a handful of hair into - 70g per 50, the upper end of each hair is coated with an adhesive so abstract adhered to each other; each summarized by filaments are bonded hair knot cover fixed network on the grid, drying; in fixed networks cover the inside of the hair coat binder resin plastic film wrapped refreshing powder connected by the adhesive and cover network; close to the scalp in the caves paste a star magnet sheet. The invention is close to the scalp wig sticking a refreshing film, is conducive to refreshing; and the star point here set a magnet piece of acupressure, liter clear, and refreshing.

Owner:QINGDAO HUAHONGXING PLASTIC

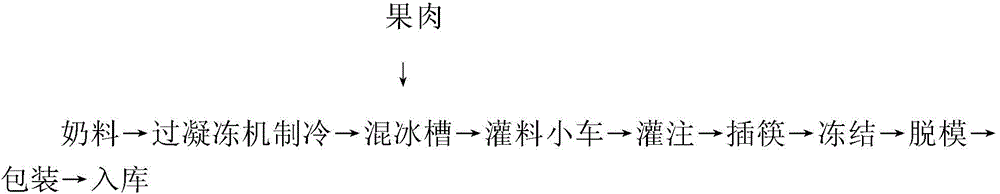

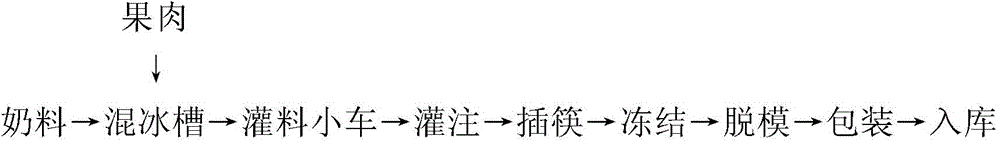

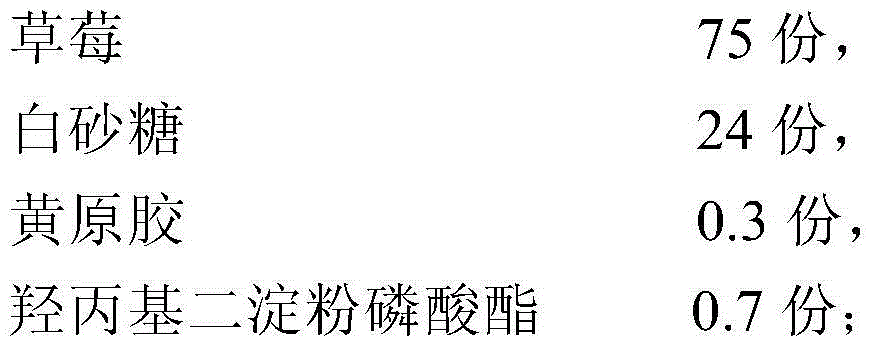

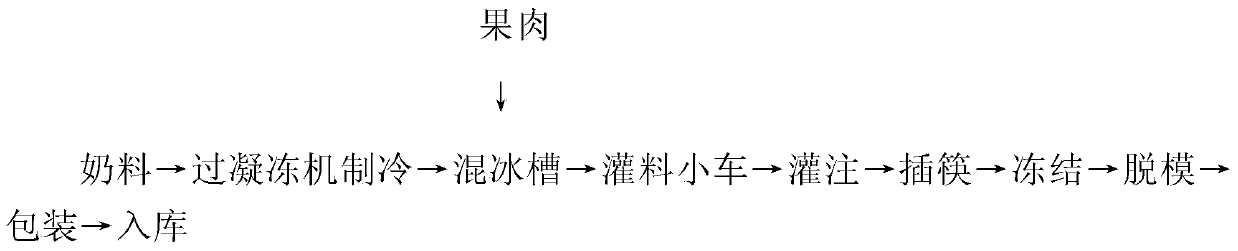

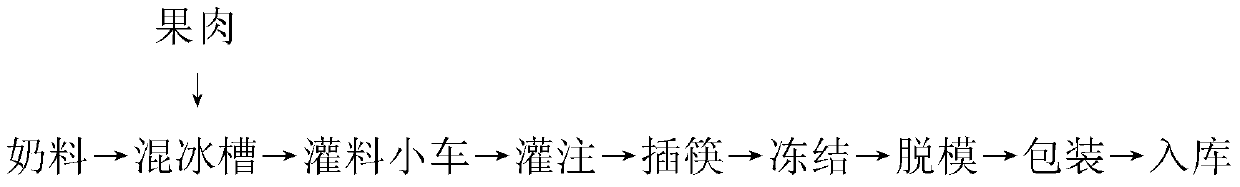

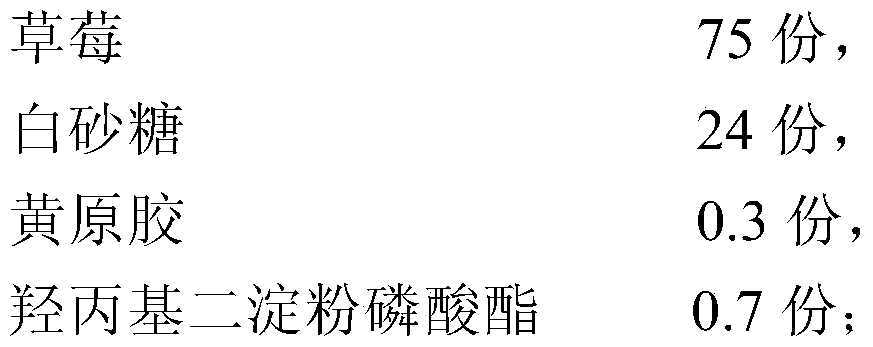

Production technology of strawberry flesh suitable for hard can milk materials and application of the strawberry flesh

The present invention discloses a production technology of strawberry flesh suitable for hard can milk materials and an application of the strawberry flesh in cold drink products. The strawberry flesh comprises the following accessory materials in parts by weight: 70-90 parts of strawberries, 10-30 parts of white granulated sugar and 0.1-1 part of a thickening agent. The production technology comprises the following steps: all the parts by weight of the strawberries are quick-frozen, the quick-frozen strawberries are cut, the cut strawberries are mixed evenly with all the parts by weight of the thickening agent and 5-25% of all the parts by weight of the white granulated sugar to obtain the mixed materials; the mixed materials are put still for at least 30 min; and the left white granulated sugar is added into the mixed materials, and the mixture is mixed evenly, and the mixture is subjected to honey soaking. The strawberry flesh prepared by the production technology can be directly mixed with hard can milk materials at the normal viscosity without using a freezing machine, the fruit flesh is evenly distributed, the suspension is good, the fruit flesh is not easy to sink, so that the excessive precipitation of the fruit flesh soup juice can be avoided, the freshness and granule integrity of the fruit flesh are enhanced, the dyeing of the soup juice separated out by the milk materials can be reduced, and the strawberry flesh is relatively low in sugar content compared with the prior art and more suitable for the consumption of modern people.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

A kind of brilliant blue reactive dye mixture and its application

ActiveCN104650620BOvercome the problem of stainingSolve the problem of greenish colorOrganic dyesDyeing processStainingCobalt blue

The invention discloses a cobalt blue active dye mixture which is formed by splicing and mixing compounds shown in a structural formula (I), a structural formula (II) and / or a structural formula (III). The cobalt blue active dye mixture comprises the compounds in percentage by mass: 50-70% of the compound shown in the structural formula (I), 0-50% of the compound shown in the structural formula (II) and 0-50% of the compound shown in the structural formula (III). 65-80% of the cobalt blue active dye mixture, 5-10% of a diffuser, 0.1-0.5% of a dust preventive, 5-15% of anhydrous sodium sulphate and 5-10% of a nonionic levelling agent are mixed to prepare a commercial dye. The commercial dye is used for preventing dyeing and printing for cellulose fiber fabrics and has the advantages of bright in color and luster, no phenomenon of kiss spot of leather, high staining fastness of white cloth and clean and environmental-friendly printing process.

Owner:江苏德美科化工有限公司

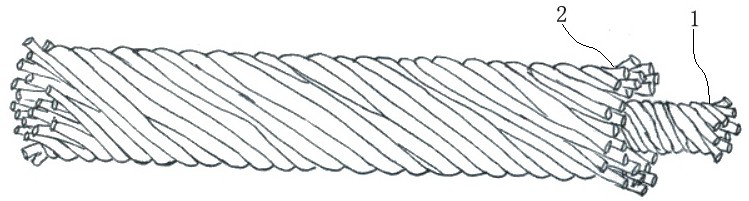

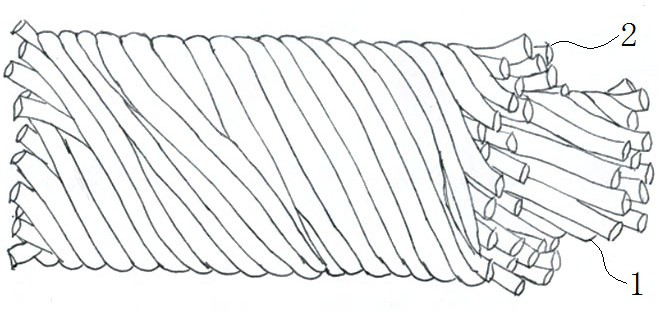

Yarn with controllable white cores

The invention relates to yarn with controllable white cores. The yarn is warp. The warp comprises an inner yarn core and outer yarn wrapped outside the inner yarn core. The inner yarn core is single synthetic fiber staple or blended synthetic fiber staple, and the outer yarn is single cellulose fiber staple or cellulose fiber staple blended. The fineness of the warp yarn is 6-40 counts, and the fineness of the inner yarn core is 40-100 counts. The inner yarn core is spun in Z-twist or S-twist direction, and the outer yarn is wrapped with the inner yarn core and the twist direction is the sameor opposite to the direction of the inner yarn core. The cross-sectional area of the inner yarn core is inversely proportional to the twist factor of the inner yarn core. The larger the twist factor of the inner yarn core is, the smaller the cross-sectional area of the inner yarn core is. As long as the number of inner yarn core and an integral warp is controlled, the dyeing white core degree of the warp can be controlled to a certain extent. The production and economic benefits are improved.

Owner:河北新大东纺织有限公司

Production technology of viscose flat monofilament

ActiveCN103215679BReduce the blooming effectFully solidifiedFilament/thread formingArtificial filaments from viscoseInlet channelCellulose fiber

The invention relates to a production technology of viscose flat monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose monofilament with the flatness of (10-500):1 through preparation of a spinning solution, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) feeding the spinning solution into a spinning machine and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, an inlet channel of the spinneret orifice is in a parabola shape, the shape of the spinneret orifice is '-', 'C' and 'S', and the length-width ratio of the spinneret orifice is (100-1,500):1; and (C) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the cross section of the prepared viscose flat monofilament strip is in a flat shape, and the viscose flat monofilament has an effect of natural hemp fiber and can be widely applied to weaving.

Owner:YIBIN HIEST FIBER +2

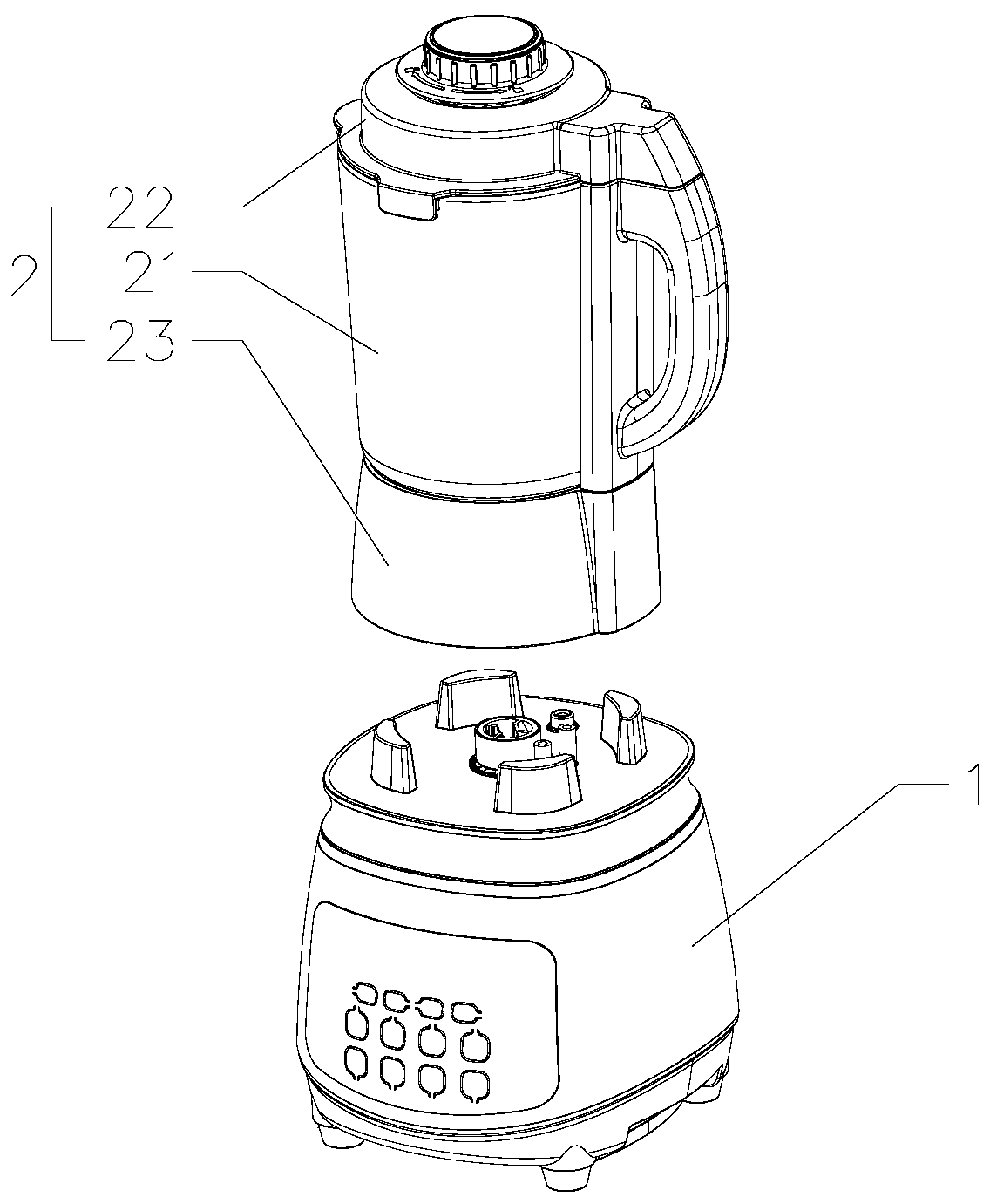

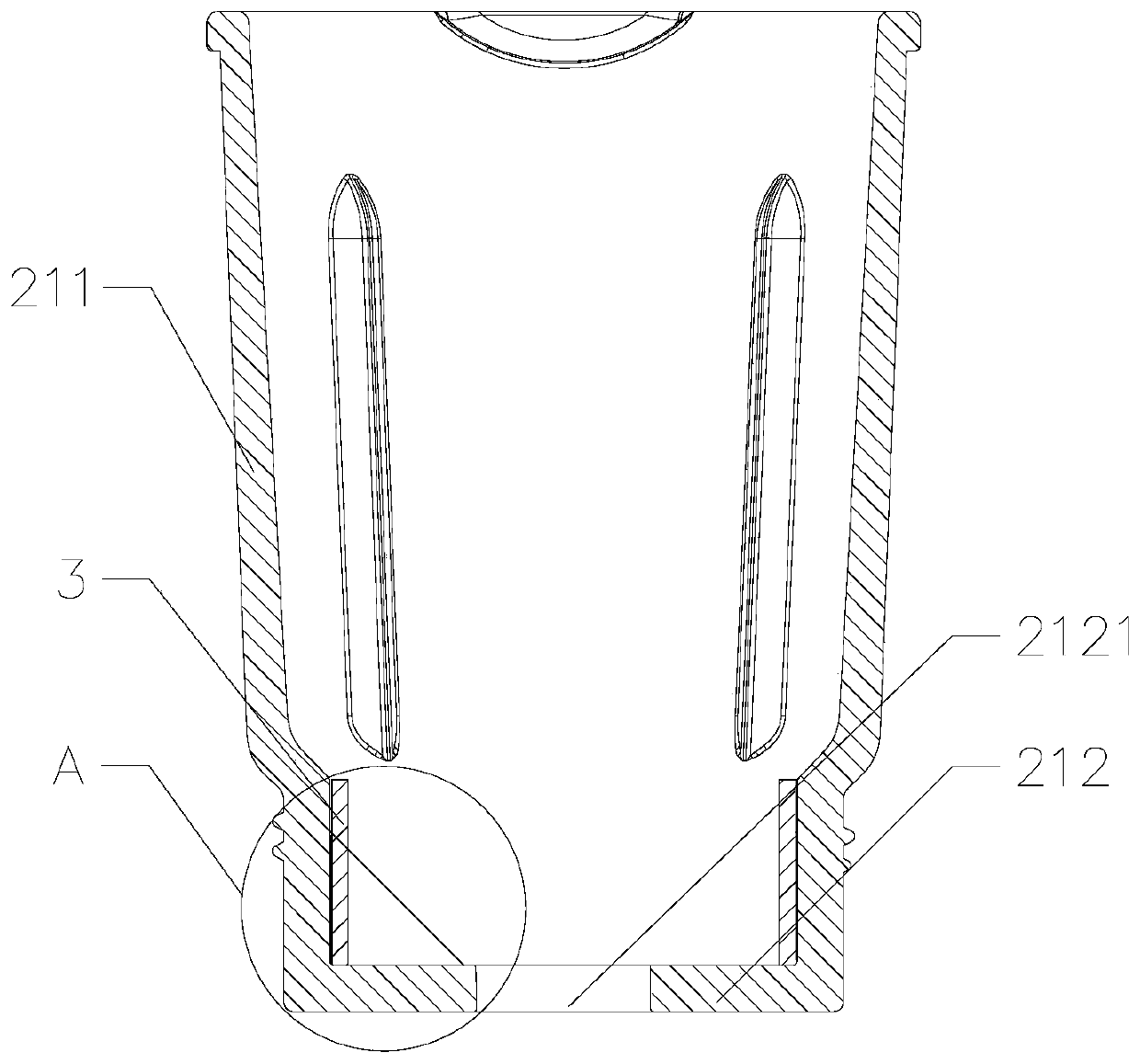

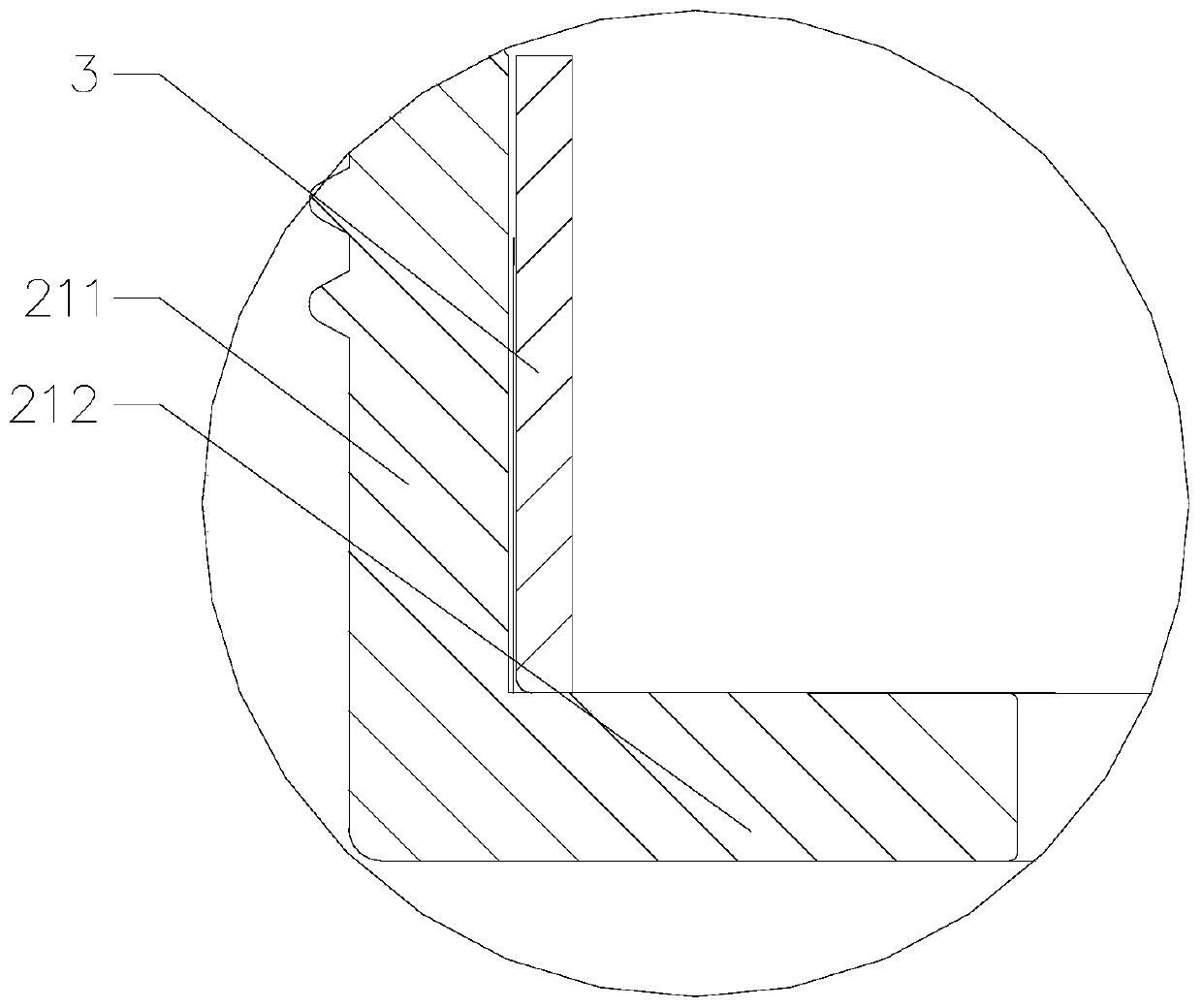

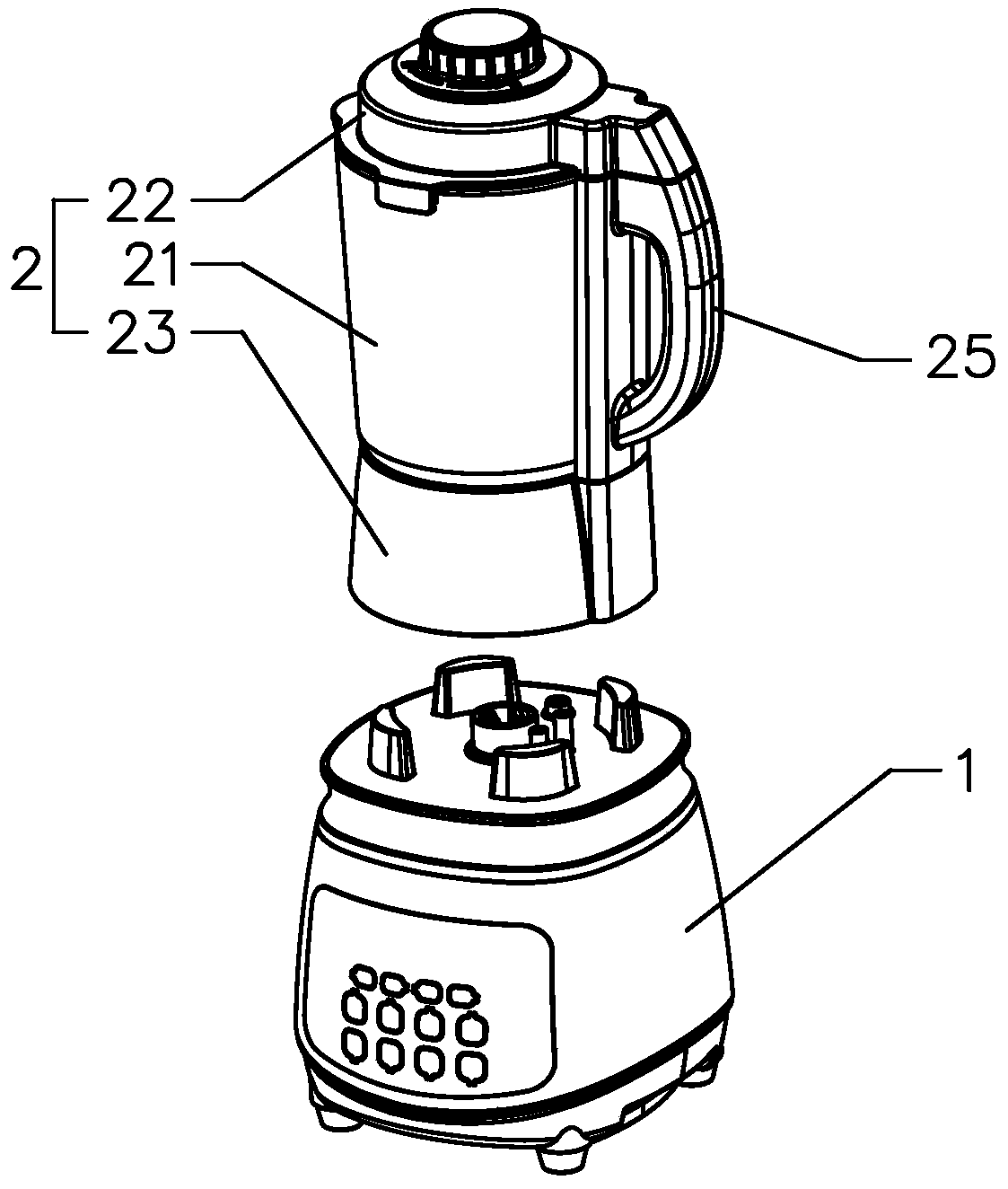

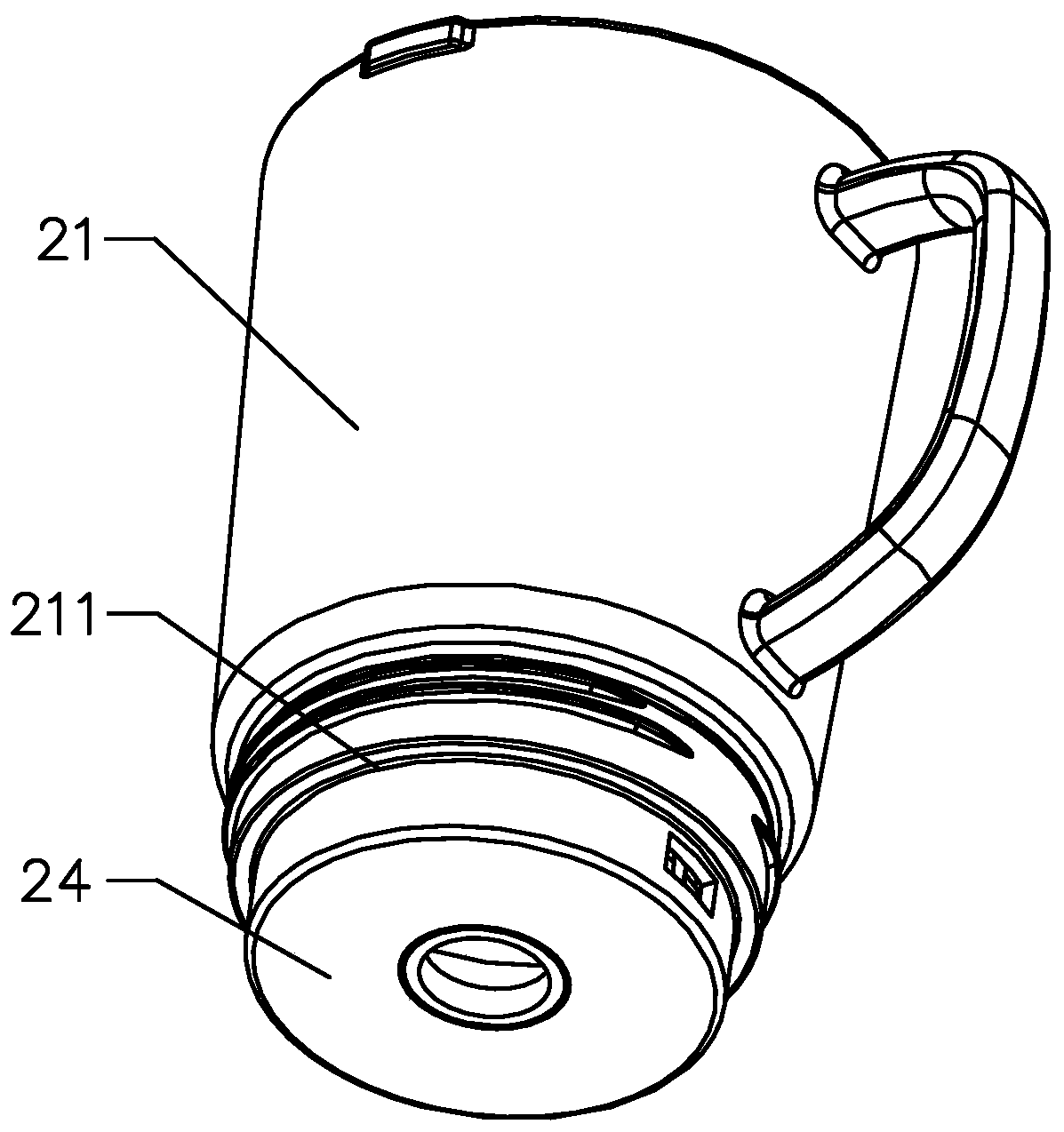

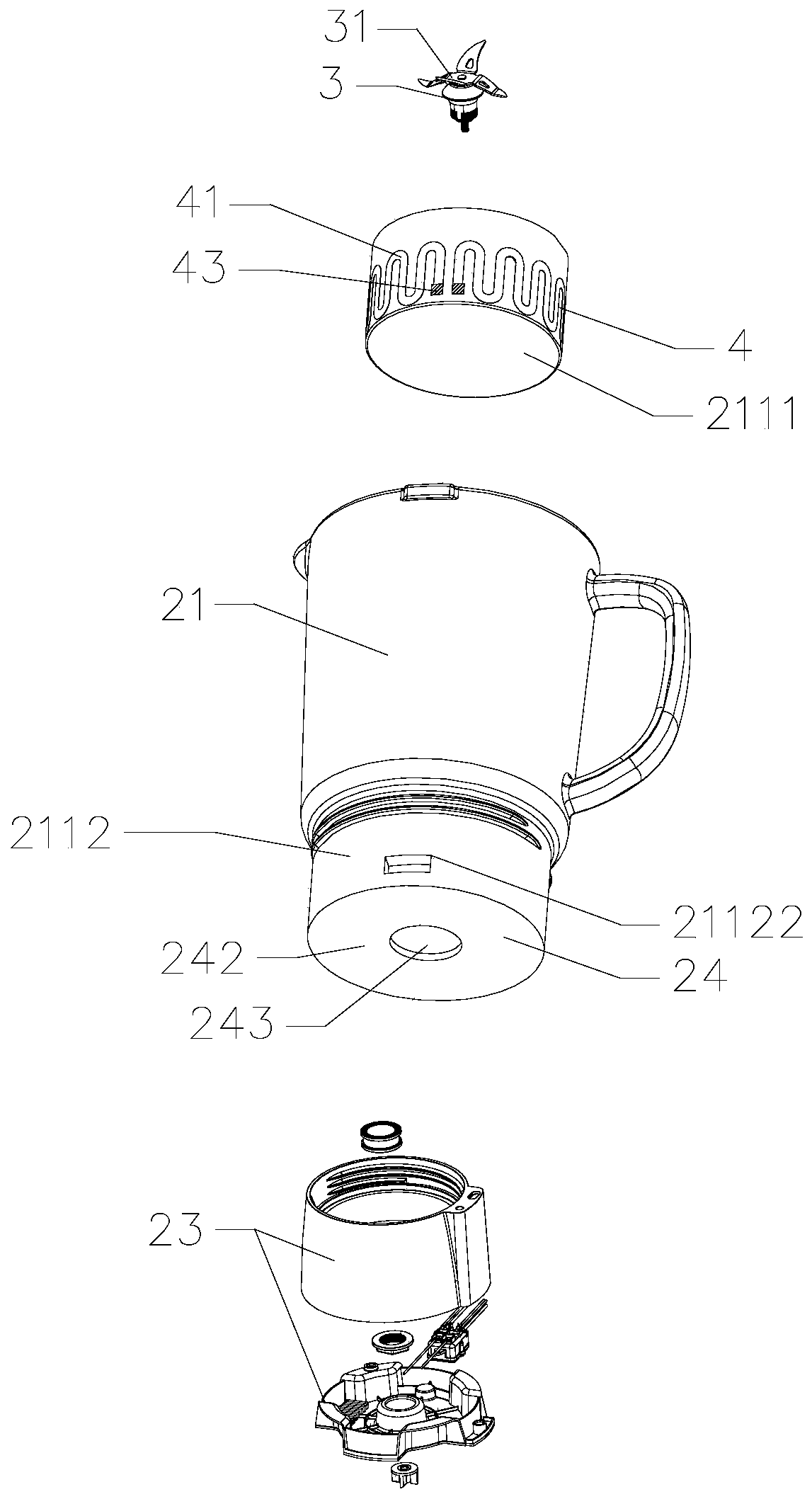

Portable food processor with high heating efficiency

PendingCN111466798ASimple structureGuaranteed insulation performanceVessels with intergral heatingMotor driveElectric machinery

The invention provides a portable food processor, which comprises a base and a stirring cup, wherein a crushing cutter assembly is arranged in the stirring cup; a motor and a control panel are arranged in the base; the motor drives the crushing cutter assembly to rotate; the stirring cup comprises a cup body; the cup body comprises a cup main body and a cup bottom; a mounting hole is formed in thecup bottom, the crushing cutter assembly is rotationally arranged in the mounting hole; a first heating body electrically connected with the control panel is arranged on the inner side wall of the cup body; the first heating body comprises a first insulating film substrate and a first resistance layer coating the inner surface of the first insulating film substrate; the inner surface of the firstinsulating film substrate and the inner side wall of the cup body are attached into a whole in a secondary fixing and sealing mode. In the way, during heating, heat generated by the first resistancelayer can be rapidly transmitted out through the first insulating film substrate, transmission is uniform, heat is not prone to losing, and therefore when water or slurry or food materials are heated,the efficiency is high, and the heating efficiency of the food processor is improved.

Owner:JOYOUNG CO LTD

A production process of strawberry pulp suitable for hard milk feeding and the application of the strawberry pulp

The present invention discloses a production technology of strawberry flesh suitable for hard can milk materials and an application of the strawberry flesh in cold drink products. The strawberry flesh comprises the following accessory materials in parts by weight: 70-90 parts of strawberries, 10-30 parts of white granulated sugar and 0.1-1 part of a thickening agent. The production technology comprises the following steps: all the parts by weight of the strawberries are quick-frozen, the quick-frozen strawberries are cut, the cut strawberries are mixed evenly with all the parts by weight of the thickening agent and 5-25% of all the parts by weight of the white granulated sugar to obtain the mixed materials; the mixed materials are put still for at least 30 min; and the left white granulated sugar is added into the mixed materials, and the mixture is mixed evenly, and the mixture is subjected to honey soaking. The strawberry flesh prepared by the production technology can be directly mixed with hard can milk materials at the normal viscosity without using a freezing machine, the fruit flesh is evenly distributed, the suspension is good, the fruit flesh is not easy to sink, so that the excessive precipitation of the fruit flesh soup juice can be avoided, the freshness and granule integrity of the fruit flesh are enhanced, the dyeing of the soup juice separated out by the milk materials can be reduced, and the strawberry flesh is relatively low in sugar content compared with the prior art and more suitable for the consumption of modern people.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

A scratch-resistant garment dyeing process

ActiveCN109778460BAvoid scratchesMolecular smallLiquid/gas/vapor article treatmentTextile treatment machine arrangementsProcess engineeringDesizing

The invention discloses a scratch-proof dyeing process for finished clothes and belongs to the field of dyeing. The process is technically characterized by mainly comprising the following steps of S1,desizing, wherein padding of the clothes is conducted in a desizing agent; S2, cleaning, wherein clean water is utilized to clean the desized clothes to remove the desizing agent in the clothes; S3,dyeing, wherein the clothes are separately loaded in protective bags with multiple through holes, then the protective bags loading the clothes are placed in a finished-clothes dyeing machine, and water mixed with dyes is introduced into the finished-clothes dyeing machine; S4, washing with water, wherein the clothes and the protective bags are cleaned with water, and then the clothes are taken outfrom the protective bags. The process has the effect of preventing the clothes from being scratched during dyeing.

Owner:嘉兴市腾旺染整有限公司

Portable food processor with good heating effect

InactiveCN111110069ASimple structureImprove oxidation resistanceVessels with intergral heatingFood gradeElectric machinery

The invention provides a portable food processor with high heating efficiency. The portable food processor comprises a base and a stirring cup, a crushing knife is arranged in the stirring cup; a motor and a control panel are arranged in the machine base. Motor-driven crushing knife, the stirring cup comprises a cup body and a cup bottom; wherein a cup cover covers an upper port of the ceramic cupbody; a cup bottom is arranged at the lower end opening of the ceramic cup body; the cup body comprises a heating section, the heating section comprises a food-grade ceramic outer layer and a food-grade ceramic inner layer attached to the food-grade ceramic outer layer. The heating body is embedded between the food-grade ceramic inner layer and the food-grade ceramic outer layer; the heating bodyis electrically connected with the control panel; in this way, during heating, heat generated by the heating body can be quickly transmitted out through the heating section, transmission is uniform,and the heat is not prone to loss, so that when water or slurry or food materials are heated, the efficiency is high, the heating efficiency of the food processing machine is improved, and the overallprocessing efficiency of the food processing machine is also improved.

Owner:JOYOUNG CO LTD

Production method of short staple enveloped composite yarn

The invention discloses a production method of short fiber wrapping composite yarn. The invention realizes wrapping composite spinning of short fiber and short fiber, which is completed by spinning frame and wrapping device. The production steps are as follows: raw material, cleaning Flowers, carding, drawing, roving, spinning, winding. During the spun yarn spinning process, two rovings spun from different raw materials are fed into each drafting zone. After passing through the double-hole bell mouth, they enter the drafting zone at a fixed distance. Output two strands of equal length, one is twisted to become the core yarn, and the other is in the state of free fiber on the surface of the transfer top roller, and is produced by the airflow boundary layer at the groove of the wrapping roller and the core yarn Wrapped to form wrapped yarn. By adopting the present invention, cotton fibers are used to wrap polyester staple fiber for spinning, and the surface of the fabric will be all cotton fibers, and at the same time, it has the inherent characteristics of polyester fibers, thereby solving the problems of poor wrinkle resistance of pure cotton fabrics and difficult dyeing of polyester-cotton fabrics. , the advantages of the two fibers complement each other, the wearability of the fabric is better, and the production cost is low, which is beneficial to environmental protection.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

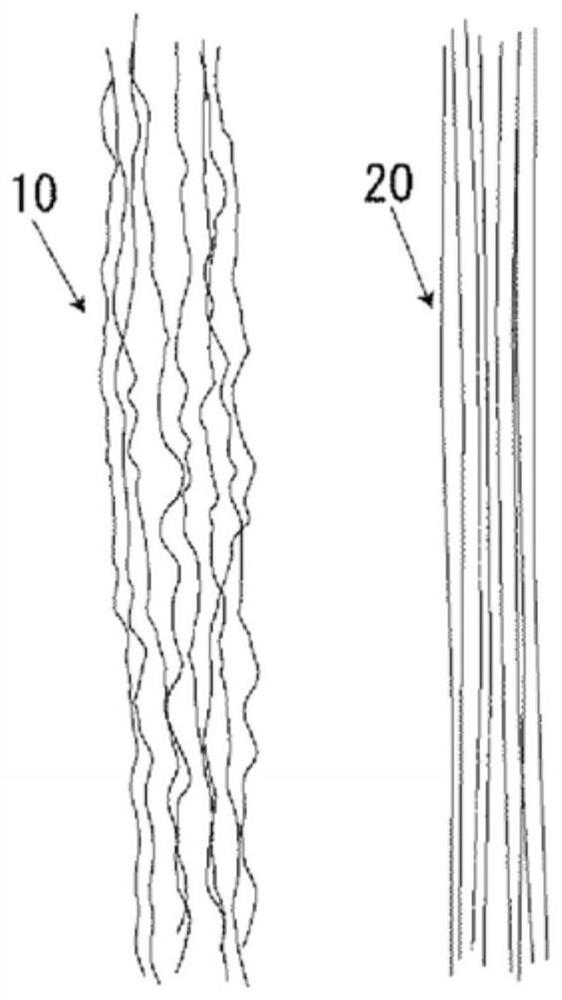

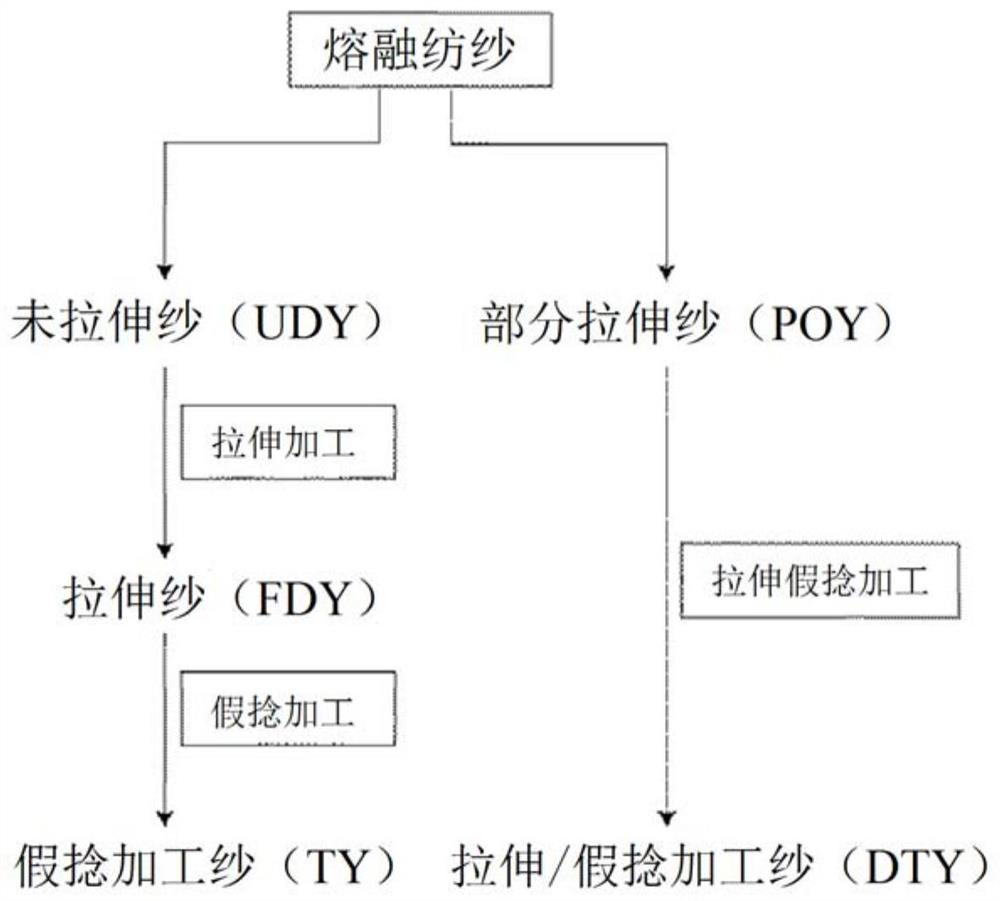

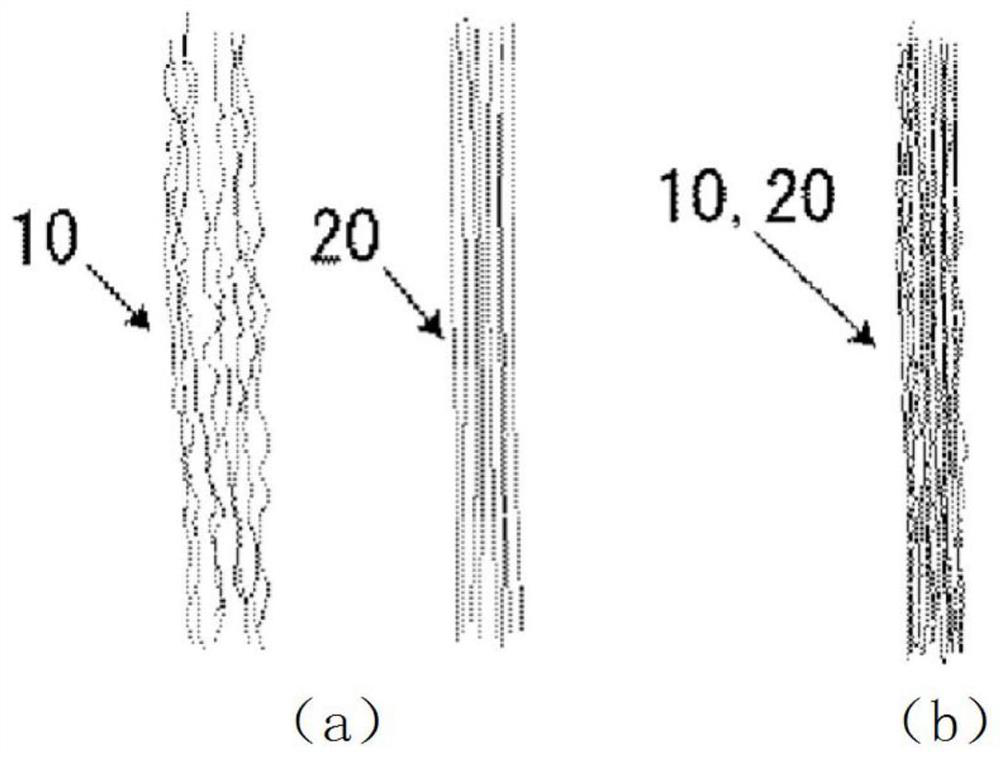

Polyester multifilament blended yarn, fabric, method for manufacturing polyester multifilament blended yarn, and method for manufacturing fabric

The invention provides a polyester multifilament blended yarn that can exhibit a sense of bulkiness and softness like that of natural fibers, a fabric, a method for manufacturing the polyester multifilament blended yarn, and a method for manufacturing the fabric. In a polyester multifilament blended yarn 1 obtained by interlacing at least two types of polyester multifilament yarns having different thermal shrinkage rates, the two types of polyester multifilament yarns include a false-twisted yarn 10 and a partially-drawn yarn 20, and both yarns are subjected to dry thermal shrinkage. Although large shrinkage occurs overall through thermal shrinkage, locations with different shrinkage amounts are mixedly present on a localized manner, and both yarns are unevenly exposed to the outside. Unevenness in the dyeing degree attributed to the differences in the shrinkage amounts in the longitudinal direction of the blended yarn, and unevenness in the dyeing degree attributed to differences in the degrees of orientation of both yarns are combined, and thereby a sense of uneven rippling is formed in the longitudinal direction of the blended yarn after dyeing, and color tones and textures like those of natural fibers are exhibited in the fabric.

Owner:MURASHO TEXTURED CO LTD

Preparation method of plastic cement for transport roller of willow twig peeling machine

The invention discloses a preparation method of plastic cement for the transport roller of a willow twig peeling machine. The preparation method comprises following steps: (1) mixing polyether glycol,polyether triol, and liquefied diphenyl methane diisocyanate, heating the mixture to a temperature of 80-85 DEG C, carrying out reactions for 2-3 hours, cooling to a temperature of 60-65 DEG C, adding 17 to 22 parts by weight of PB-403 water soluble high brightness casein, maintaining the temperature, and keeping on stirring for 40-50 minutes to obtain a polymer solution; and (2) sequentially adding hexamethylene diisocyanate trimer, a chain extender HER, isopropoxyboronic acid pinacol ester, lithionite powder, aluminum silicate fiber cotton, and 1 to 2 parts by weight of dispersant into 40 to 45 parts by weight of polymer solution, continuously stirring for 100-120 minutes, carrying out vacuum degassing, pouring the mixture into a die, and curing the mixture to obtain a finished product.The provided preparation method has the advantages that the generated waste gas, waste solids, and waste water are little, and the preparation method is green and environmentally friendly. The prepared plastic cement has excellent mechanical properties, stable chemical properties, and a strong grasping force on willow twigs. Moreover, the surface energy of the plastic cement is low, and thus theplastic cement is not easily dyed by willow twigs.

Owner:阜南县慧宏柳木工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com