Patents

Literature

39results about How to "Fully solidified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

Solidification method for preparing para-aramid by adopting dry jet-wet spinning

InactiveCN104451935AIncrease productivityIncrease production speedArtificial filament washing/dryingWet spinning methodsUltimate tensile strengthAramid

The invention provides a solidification method for preparing para-aramid by adopting dry jet-wet spinning. The method is characterized by comprising the following specific steps: extruding a PPTA-H2SO4 spinning solution from a spinneret plate; enabling liquid flow extruded from the spinneret plate to vertically pass through an air layer and feeding to a solidification bath; leading out through a godet wheel, so as to obtain a nascent fiber; and washing, winding and drying, so as to obtain a para-aramid fiber precursor, wherein the solidification bath is sulfuric acid solution and is formed by sulfuric acid and water; the mass fraction of the solidification bath is 2.0%-15.0%; and the temperature of the solidification bath is 1-12 DEG C. The fineness of the fiber can be significantly reduced under the condition of the solidification bath; the strength of the para-aramid fiber is improved; the apparent defects of the fiber can be reduced; and the fiber quality is improved, thus the stability of a spinning process and the quality of a fiber product can be effectively improved.

Owner:DONGHUA UNIV

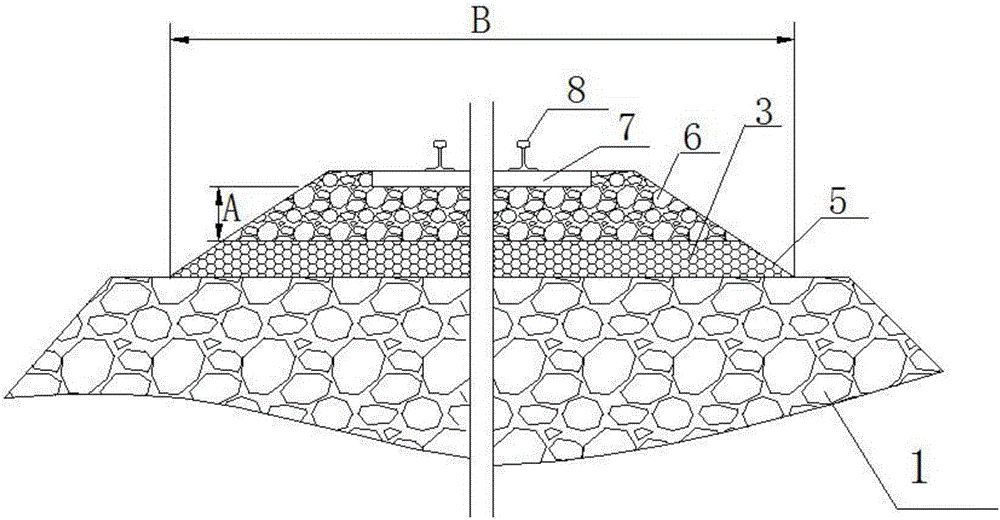

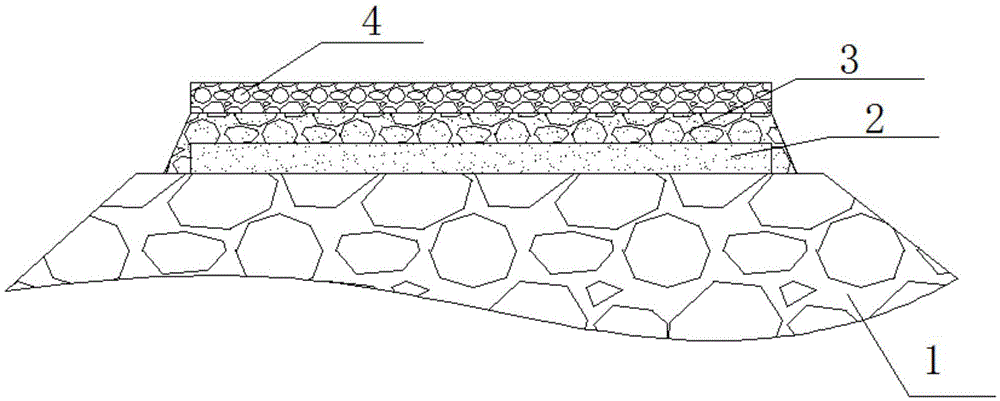

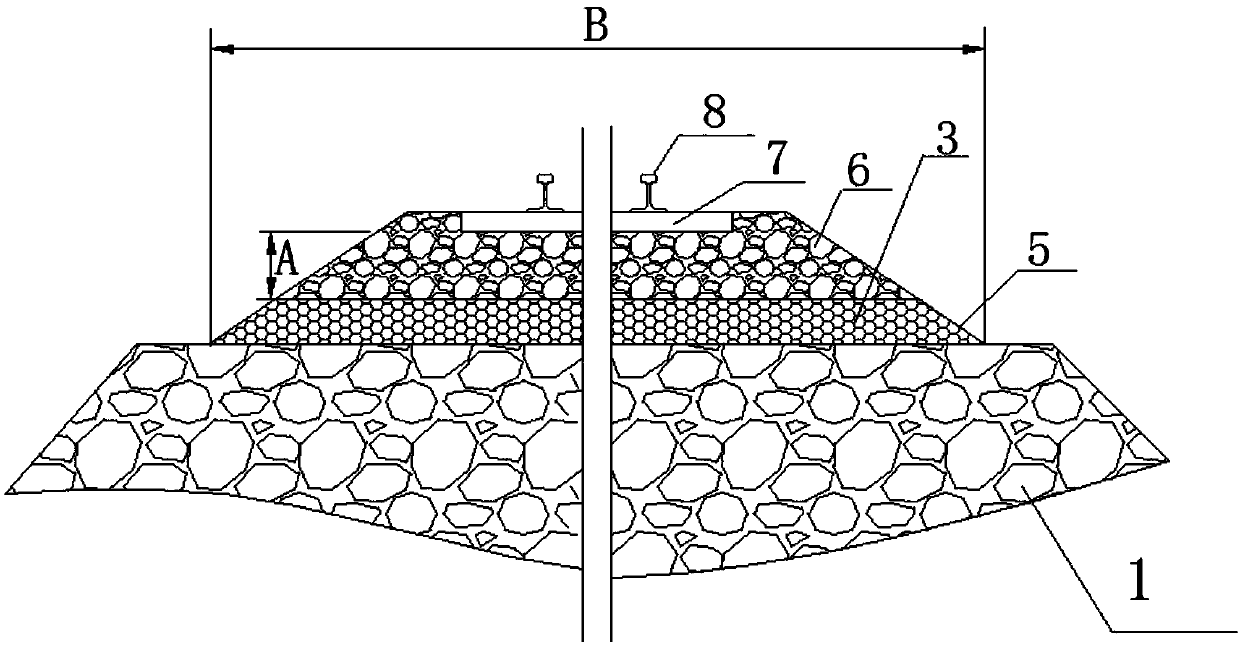

Structure capable of preventing railroad bed mud pumping and paving method thereof

The invention discloses a structure capable of preventing railroad bed mud pumping and a paving method thereof. The structure is positioned between a railroad bed and a rail roadway ballast and comprises a first protective layer and a second protective layer. The paving method of the structure comprises the following steps of: 1) paving sand aggregate with an average grain diameter of 0.05-5mm on the surface of the railroad bed so as to form a sand cushion with the a the thickness of 4-6cm; 2) paving the broken stone with an average grain diameter of 5-7mm on the surface of the sand cushion, wherein the a the paving thickness of the broken stone is 3-6cm; 3) filling broken stone clearances with a polymer waterproof coating, wherein thea first protective layer is obtained after the polymer waterproof coating is solidified; 4) spraying a polyurea waterproof coating onto the surface of the first protective layer so as to form thea second protective layer with the thickness of 2-4 mm. Water infiltrating to the second protective layer is discharged through a dewatering slope of the first protective layer; ascending mud is isolated by the first protective layer, and the second protective layer forms thea second protection, so that the mud is effectively prevented from being pumped and extruded towards the railway railroad ballast or towards the outside through the railway ballast.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

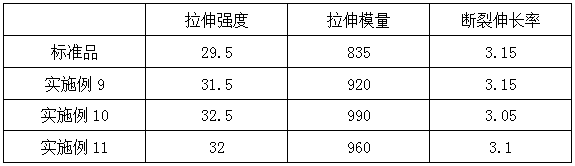

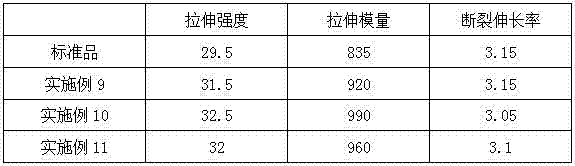

Multistage stretching technology for manufacture aramid fiber III

ActiveCN102797061AImprove mechanical propertiesImprove product qualityArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceAramid

The invention relates to a multistage stretching technology for manufacture aramid fiber III, which belongs to the technical field of chemical fiber. The multistage stretching technology comprises a negative stretching technology, plasticizing stretching treatment, water washing and plasticizing stretching treatment again to obtain final products. The multistage stretching technology can obviously improve the mechanical property of aramid fiber III, the multifilament stretching strength is increased to 32cN / dtex from 30cN / dtex, and the stretching modulus is increased to 950cN / dtex from 850cN / dtex. High-strength and high-modulus fiber obtained can be applied to applicable fields with higher market requirements.

Owner:中蓝晨光化工有限公司

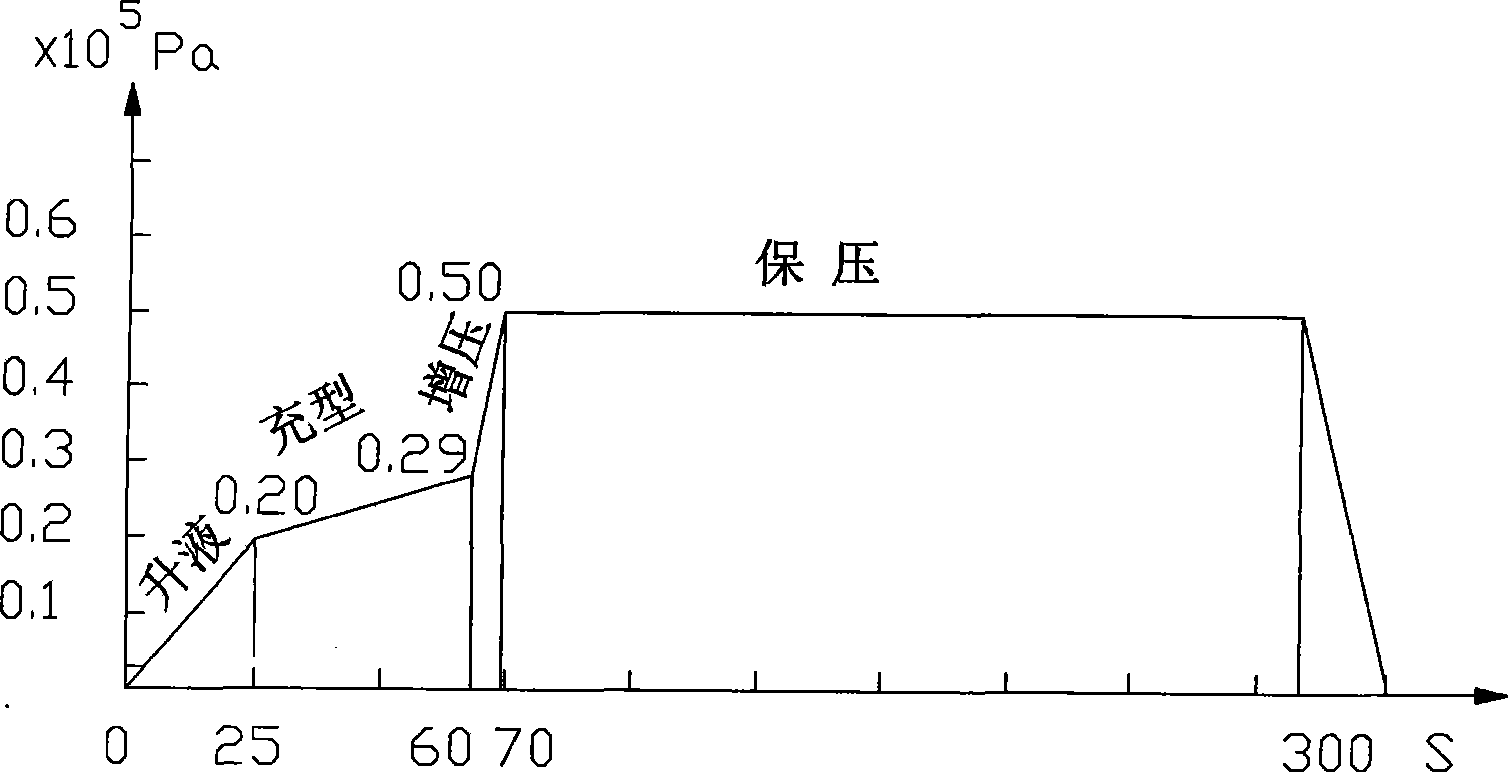

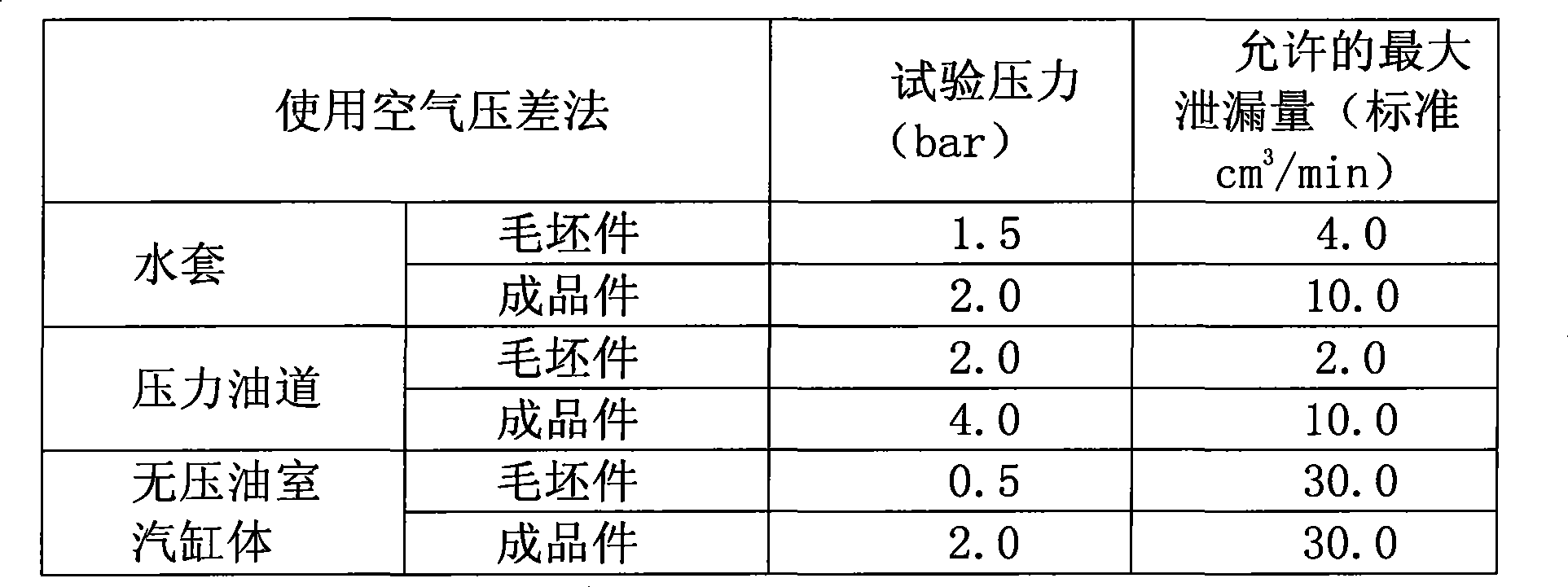

Pressurizing method of diesel motor aluminium alloy cylinder metal mould low-pressure casting

The invention discloses a pressurizing method for metal mold low-pressure casting of an aluminum alloy cylinder of a diesel engine, which comprises the following steps: step one, performing liquid-raising and pressurizing operations on an aluminum liquid; step two, performing filling type pressurizing operations on the aluminum liquid obtained in the step one; step three, pressurizing a cast obtained in the step two; step four, performing pressure-maintaining operations on the cast obtained in the step three; and step five, performing depressurizing operations on the cast obtained in the step four. The pressurizing method adopts a reasonable pressurizing specification to make the cast filled and molded smoothly and solidified sufficiently so that the structure of the cast is compact without generating hole defects to satisfy the sealing requirement, thus the method can make a high-compactness and high-strength aluminum alloy and a diesel engine cylinder body which is provided with a closed water-cooling cast-in cylinder sleeve.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

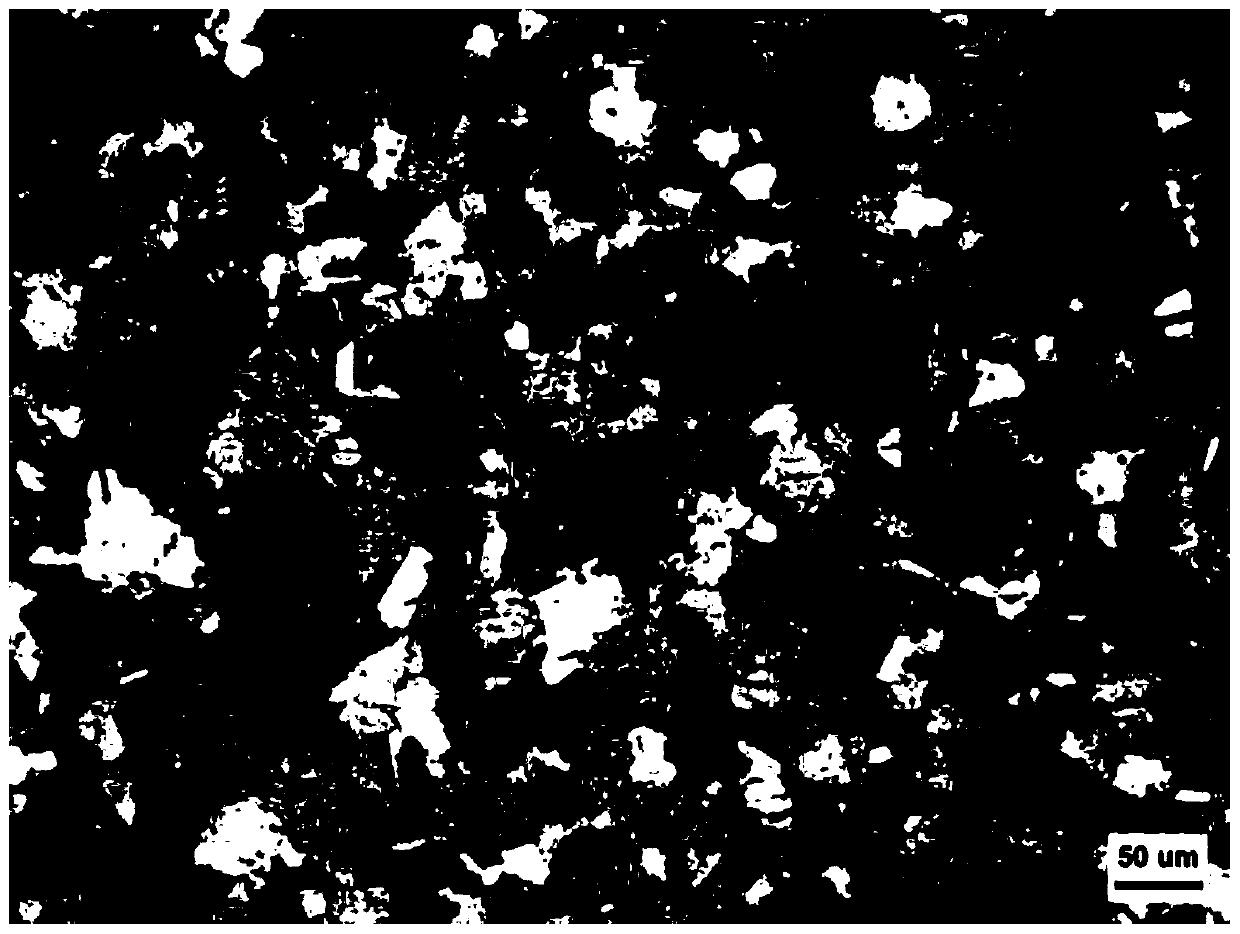

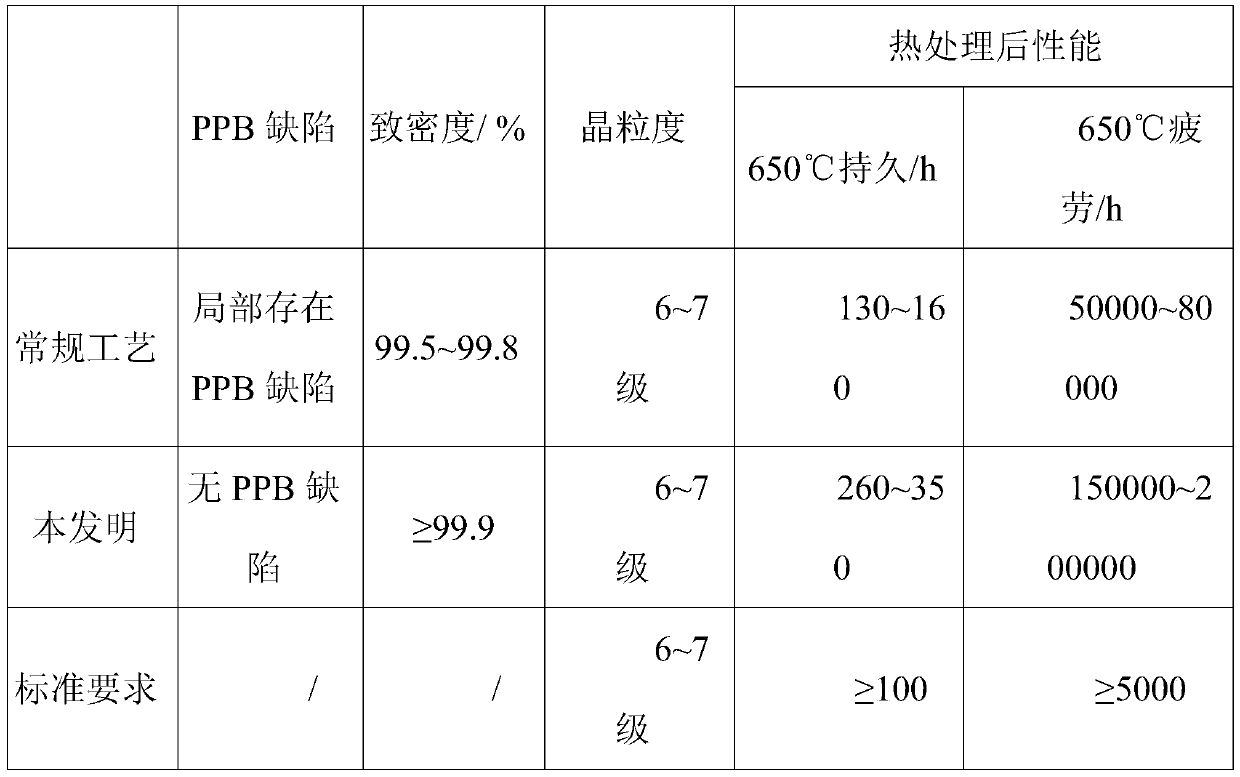

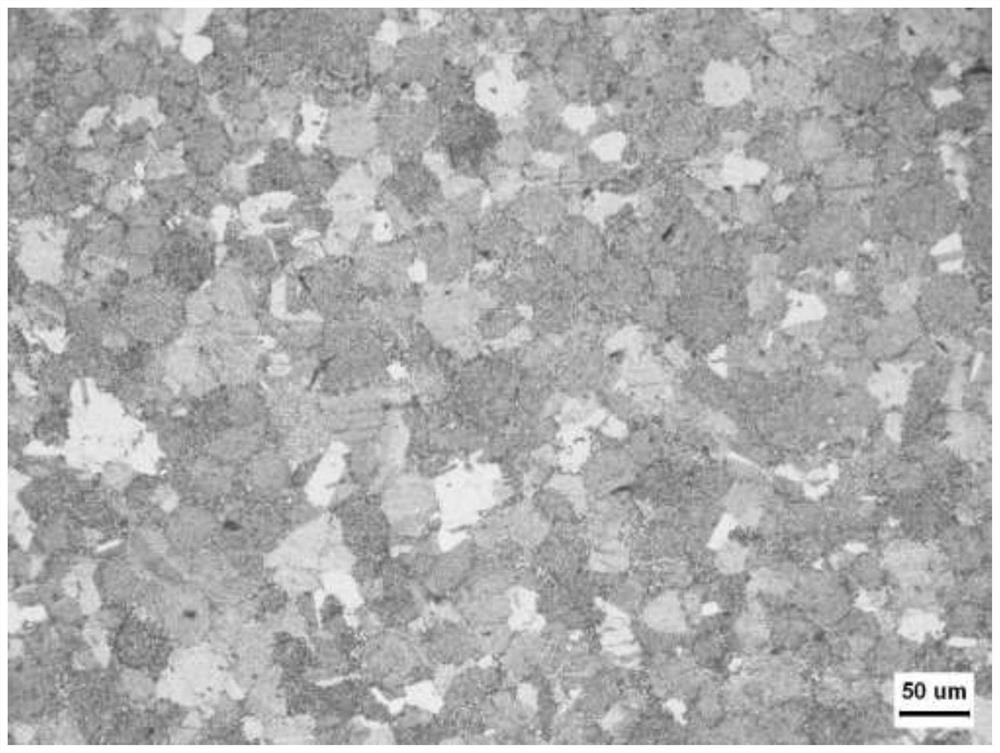

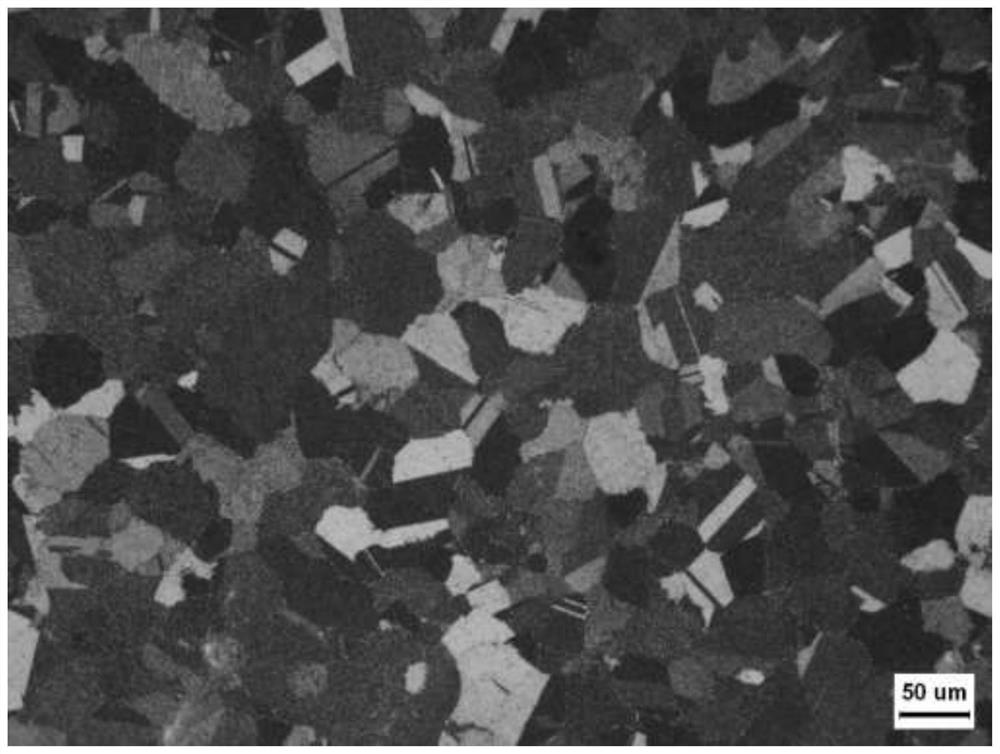

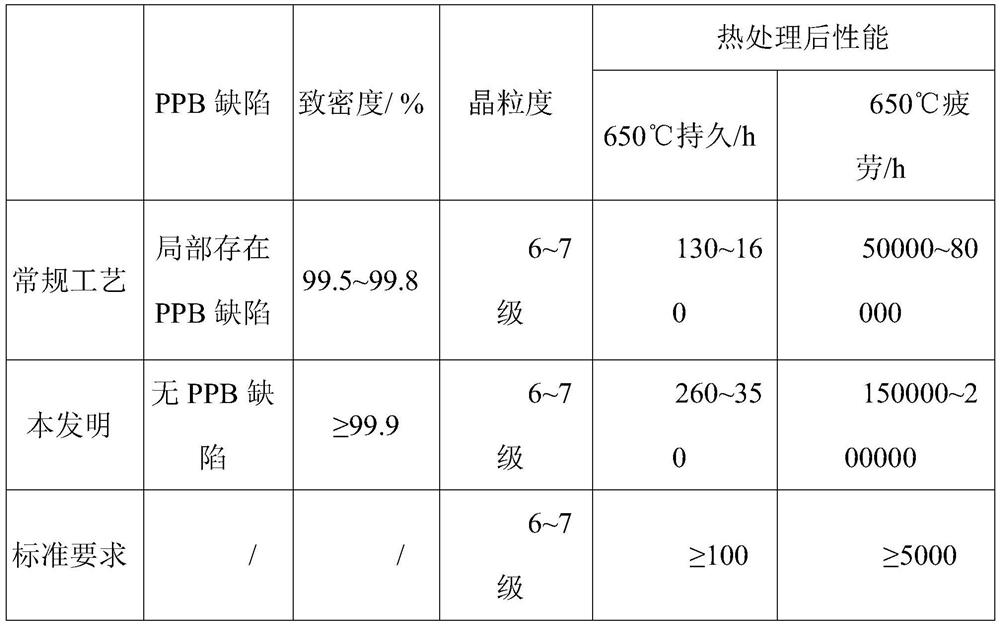

Hot isostatic pressing forming method of nickel-based high-temperature alloy powder disc

ActiveCN110666175AAvoid abnormal growthInhibition formationTurbinesOther manufacturing equipments/toolsSuperalloyMelting temperature

The invention discloses a hot isostatic pressing forming method of a nickel-based high-temperature alloy powder disc, and specifically discloses a hot isostatic pressing forming method of nickel-basedhigh-temperature alloy powder. The method is suitable for preparing a powder high-temperature alloy disc piece subjected to direct hot isostatic pressing forming. The hot isostatic pressing forming method is characterized in that high-temperature alloy powder prepared by a plasma rotating electrode method is used as a raw material, wherein the powder is packaged and sealed and welded under a vacuum condition and then subjected to hot isostatic pressing; the temperature of the first hot isostatic pressing is 10-30 DEG C greater than the gamma' melting temperature, the pressure is not less than100MPa, and the time is not greater than 1h; after the first step is finished, the material is heated to reach 50-100 DEG C below the liquidus temperature, wherein the pressure is more than or equalto 100MPa, and the time is less than or equal to 30min; and after the second step is finished, the temperature is reduced to 10-20 DEG C below the melting temperature of the low-melting-point phase, the pressure is more than or equal to 100MPa, the temperature is kept for 30min, and the furnace is cooled. The method can effectively inhibit the generation of PPB defects in the hot isostatic pressing process and improve the density of the alloy, thereby preparing the high-temperature alloy powder disc with uniform and compact tissues.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

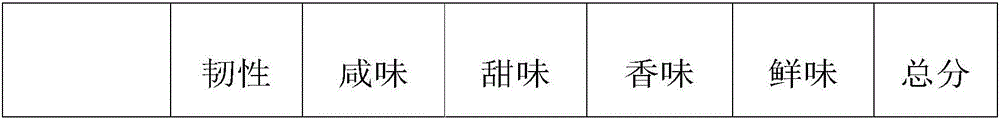

Egg dried tofu and processing method thereof

InactiveCN106578132AReasonable nutritional structureBeautiful and fragrantCheese manufactureFlavorGlutamine transaminase

The invention provides egg dried tofu and a processing method thereof, and relates to the field of food processing. The processing method comprises the following steps: after evenly mixing egg juice and water, then adding soyabean protein powder and chopping; adding salad oil and five-spice oil and then continuing chopping; adding cassava starch and chopping, adding glutamine transaminase and continuing chopping; and then refrigerating the mixture at the temperature of 0-5 DEG C for 4-24 hours to obtain the initial product of the egg dried tofu. According to the method, the dried tofu has special flavor due to the added egg, and is tasty fully in a repeated chopping process, and the processing method is simple in process and easy to operate. The egg dried tofu is obtained by the processing method, tastes good, is chewed easily, and is good in flavor.

Owner:重庆凰巢实业有限公司

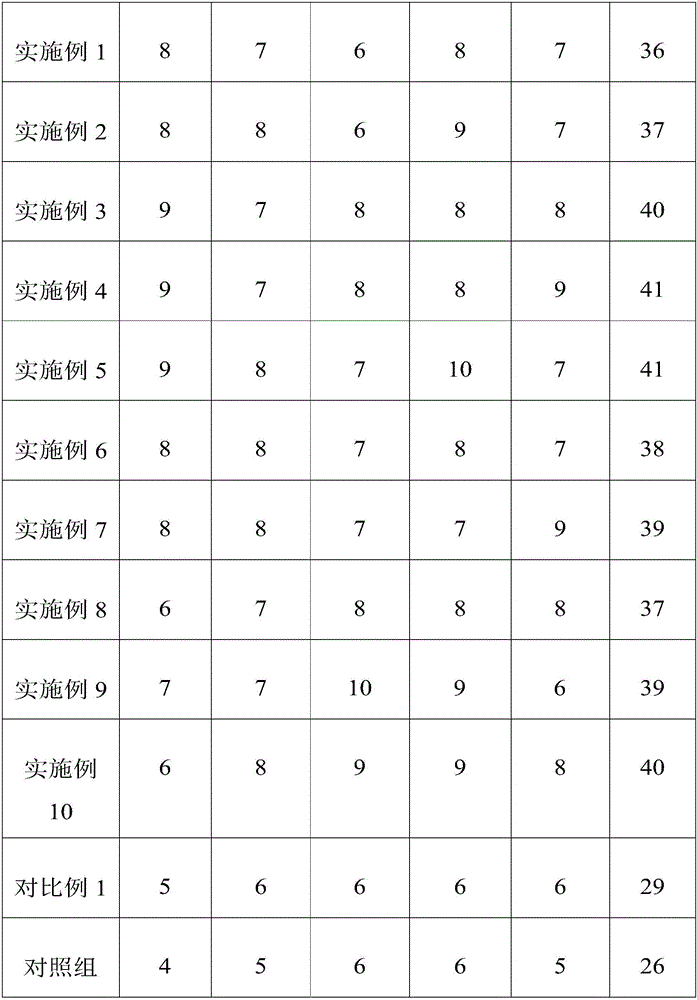

Controllable cement backfilling grouting method

The invention discloses a controllable cement backfilling grouting method. The method comprises the following steps: punching a grouting hole with aperture of 4-8 cm in the tunnel or the stratum; accessing a grouting pipe and a screw type grouting device in the grouting hole; preparing pasty cement grout according to the preparation proportion of cement grout materials; and performing low-pressuregrouting by adopting an intermittent grouting method until filling up the grouting hole. Since the cement grout is added with flocculant and prepared into the pasty cement grout, the intermittent grouting is performed by adopting an intersection grouting method and a circulation grouting method, the problem that the cement grout is wasted since the water-cement ratio in the prior grouting methodis excessively small, the corresponding additive is not added, and the intermittent grouting method is not adopted is solved, and the cost for tunnel construction or rehabilitation is reduced.

Owner:重庆市十八土鑫诚灌浆防水工程有限公司

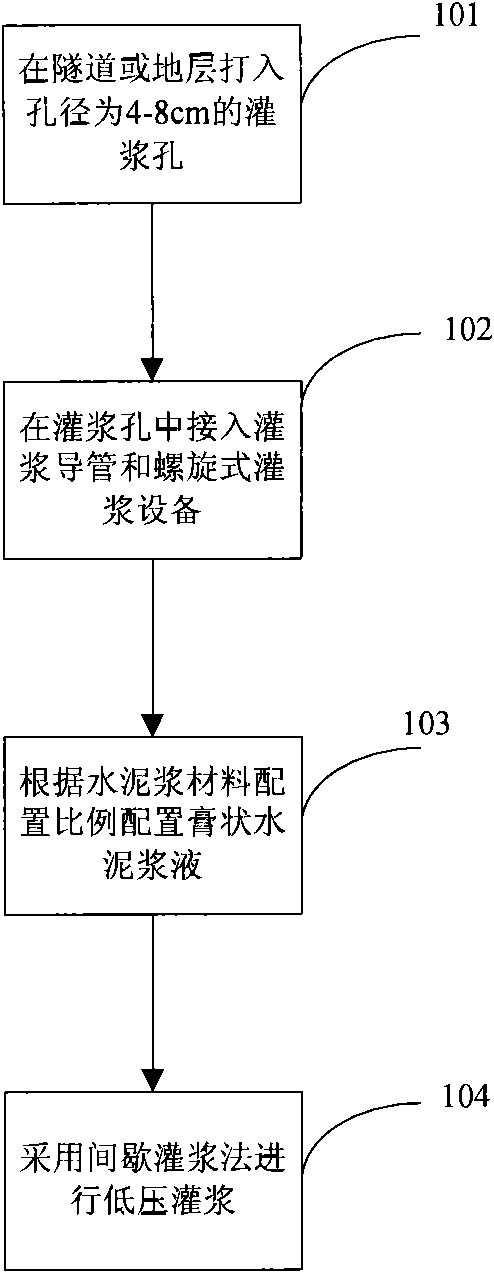

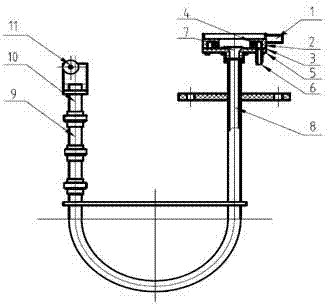

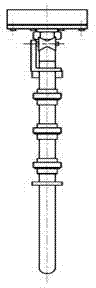

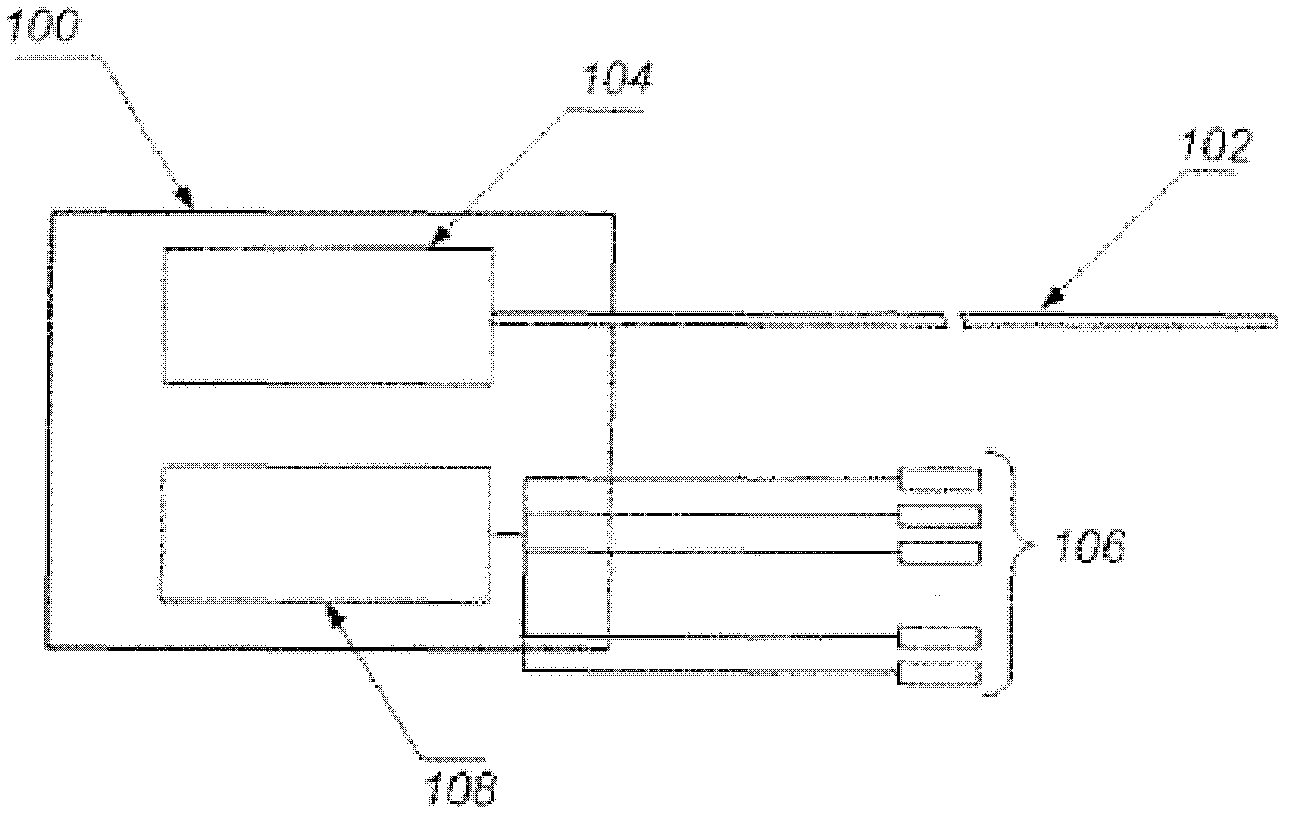

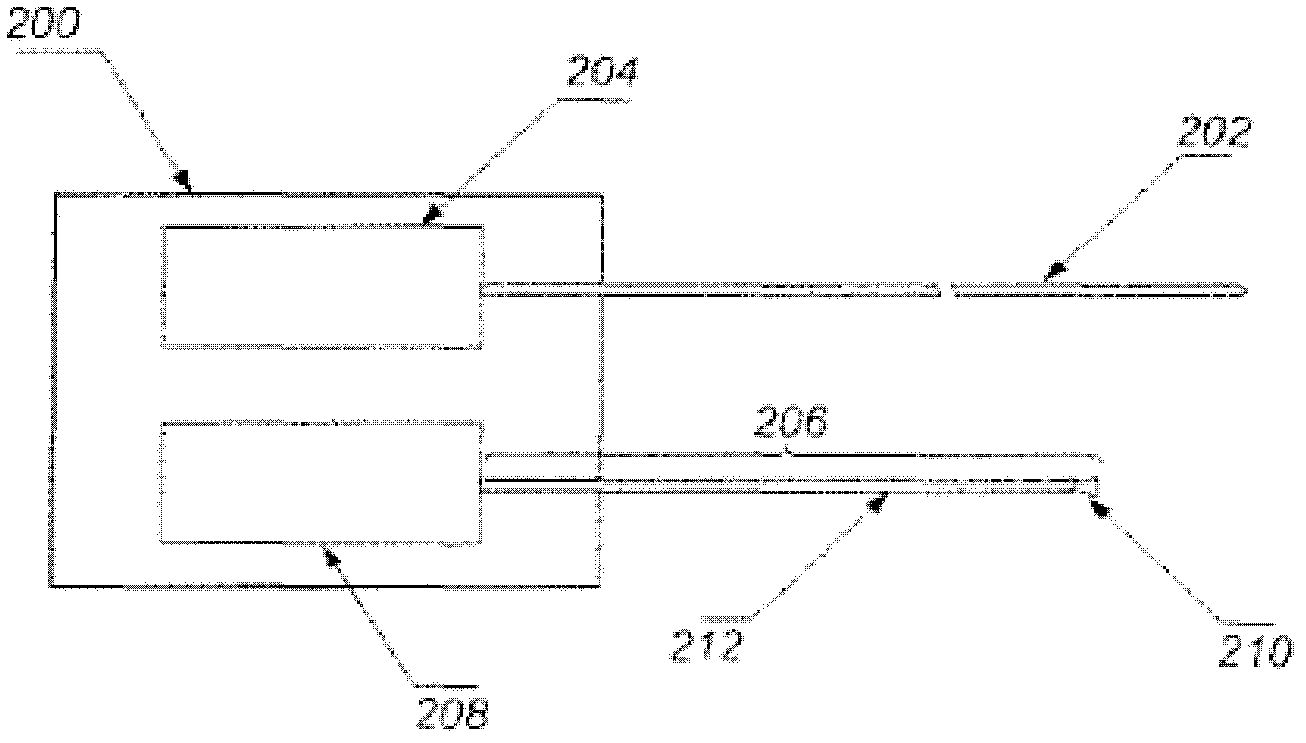

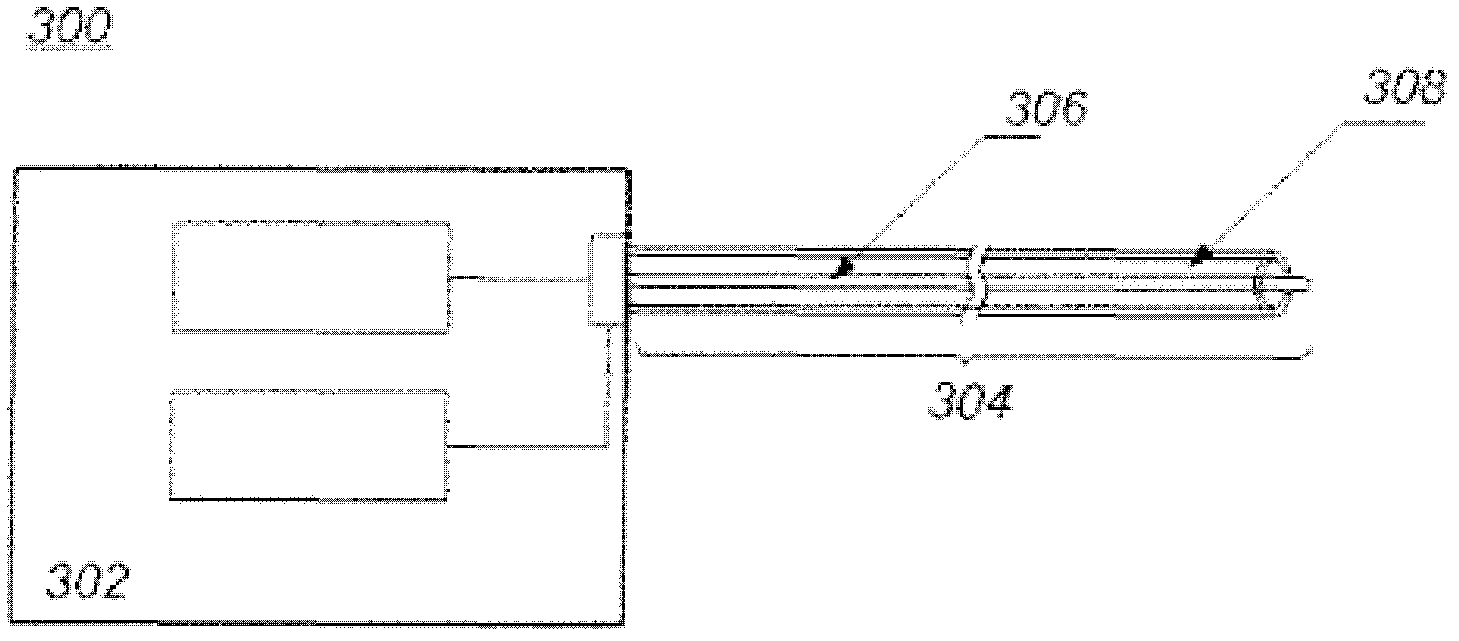

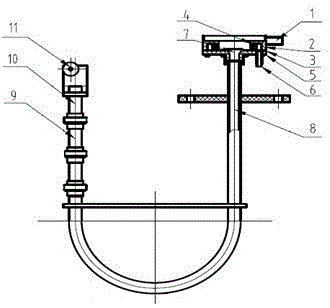

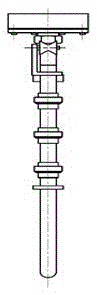

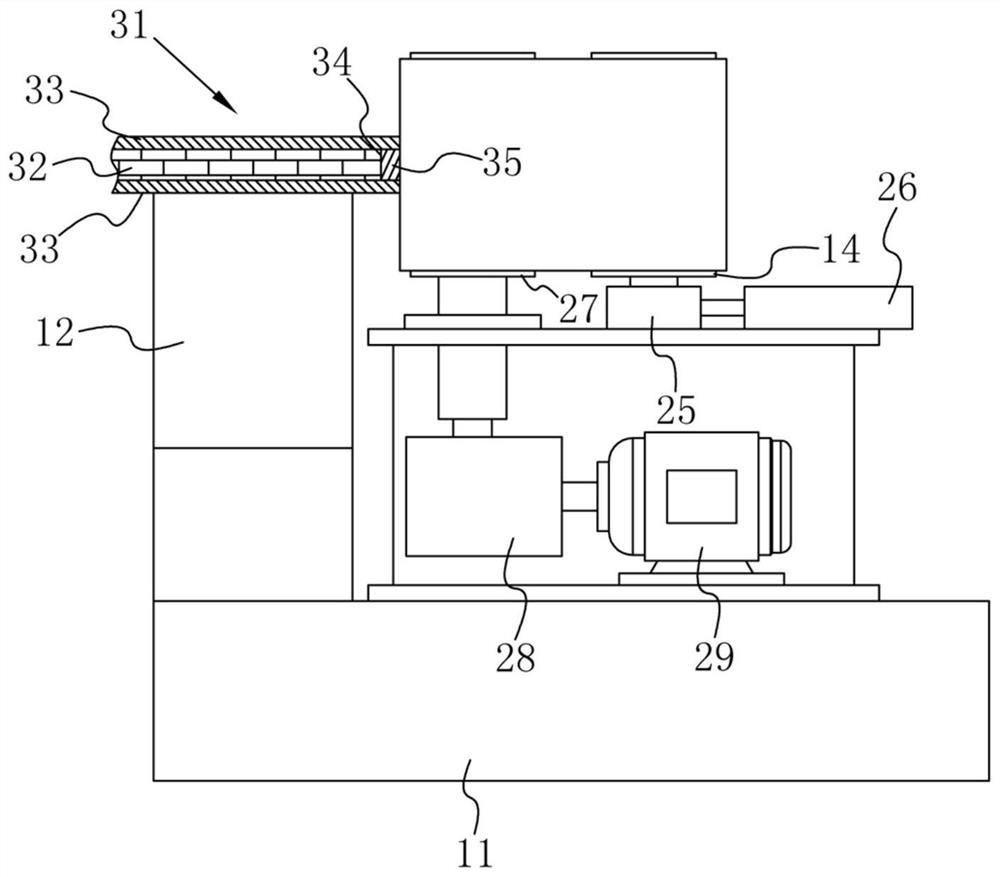

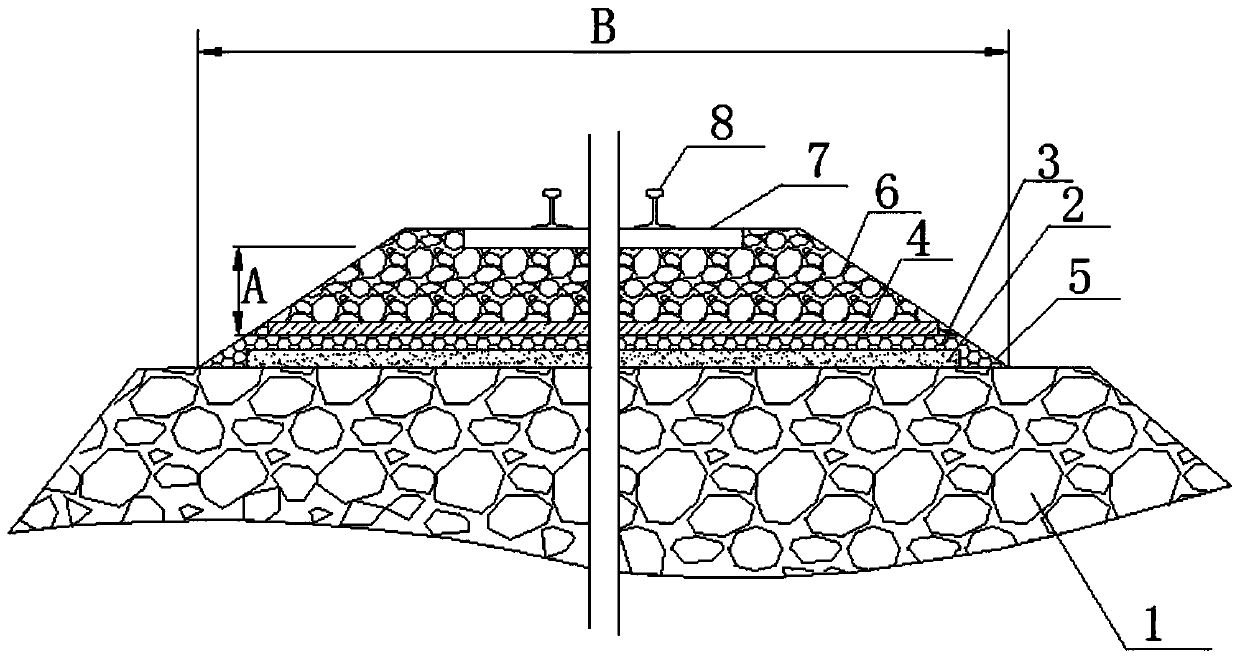

Solidification forming device suitable for manufacturing aramid III fibers through dry jetting and wet spinning method

ActiveCN103498207ASolidify continuously and evenlyUniform and stable solidificationArtificial thread manufacturing machinesWet spinning methodsSpinningAramid

The invention discloses a solidification forming device suitable for manufacturing aramid III fibers through a dry jetting and wet spinning method. The solidification forming device comprises a solidification plate and a U-shaped solidification pipe, wherein the solidification plate is mainly composed of a solidification plate base, a sealing gasket, a solidification liquid distribution net, a solidification plate cover and an overflow tube, the U-shaped solidification pipe is mainly composed of a U-shaped pipe, an adjusting pipe and a fiber outlet pipe, one end of the U-shaped pipe is connected with the solidification plate, and the other end of the U-shaped pipe is movably connected with the adjusting pipe. The height difference between a liquid inlet of the U-shaped solidification pipe and a liquid outlet of the U-shaped solidification pipe can be adjusted according to the requirement for the spinning speed. Rapid and uniform solidification of aramid III nascent fibers can be achieved through the solidification forming device, the spinning speed of the aramid III fibers can be remarkably improved, production efficiency is improved, meanwhile, the manufactured fibers are good in quality, small in the number of burrs and neater in appearance, and due to the fact that the device is small in size and compact in structure, modularized manufacturing and replacement can further be achieved.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

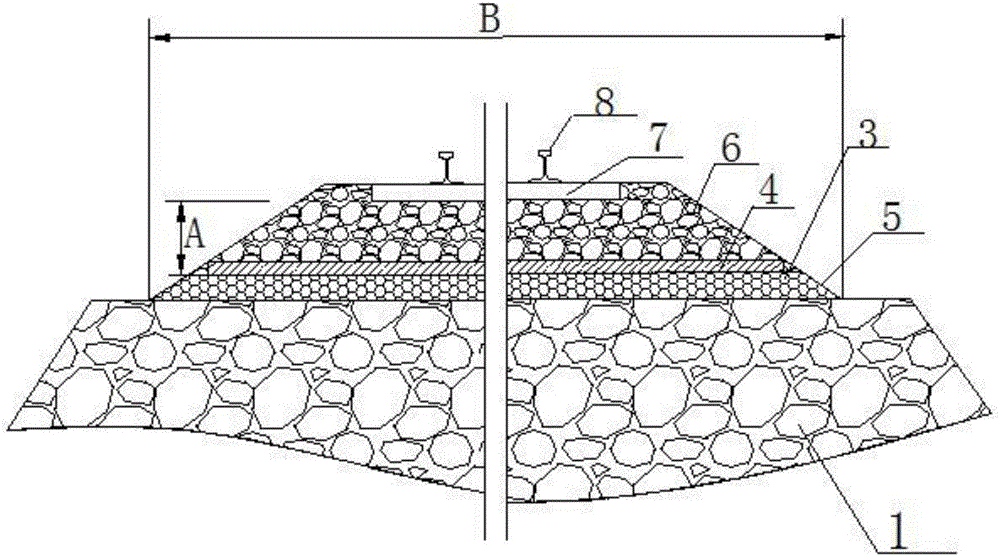

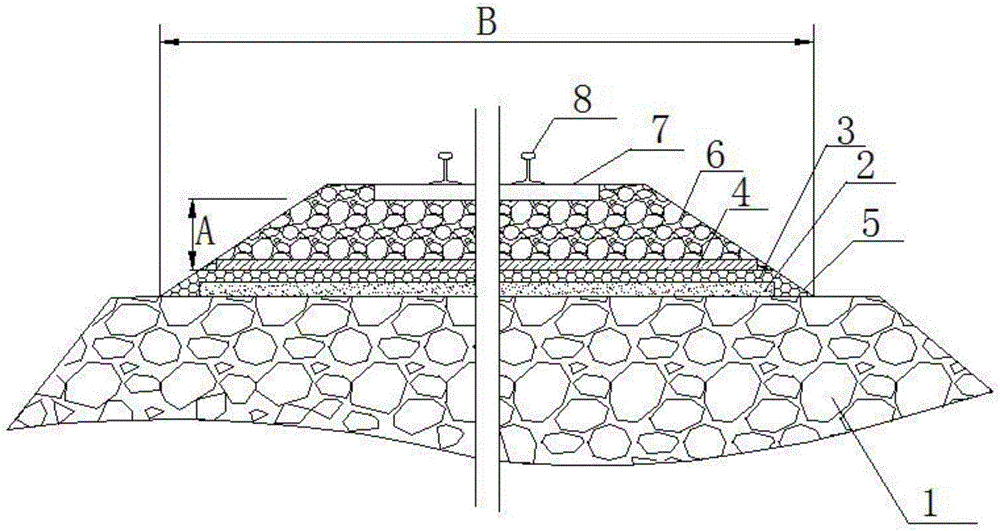

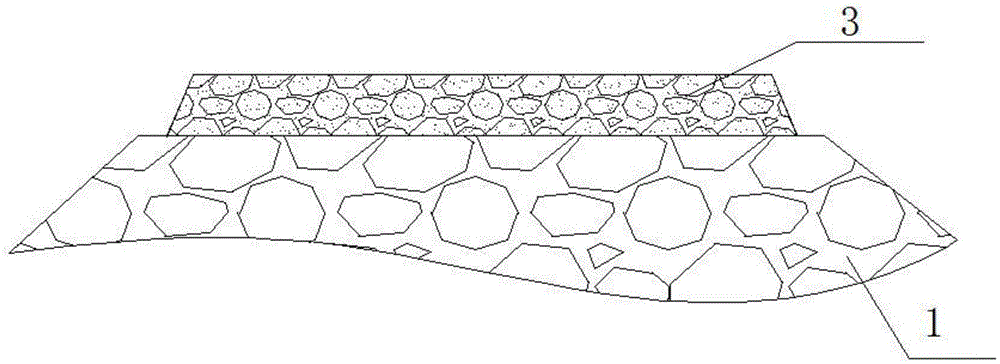

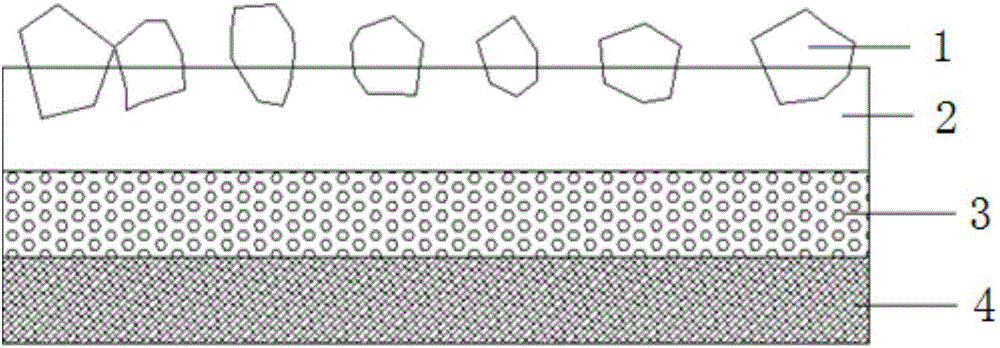

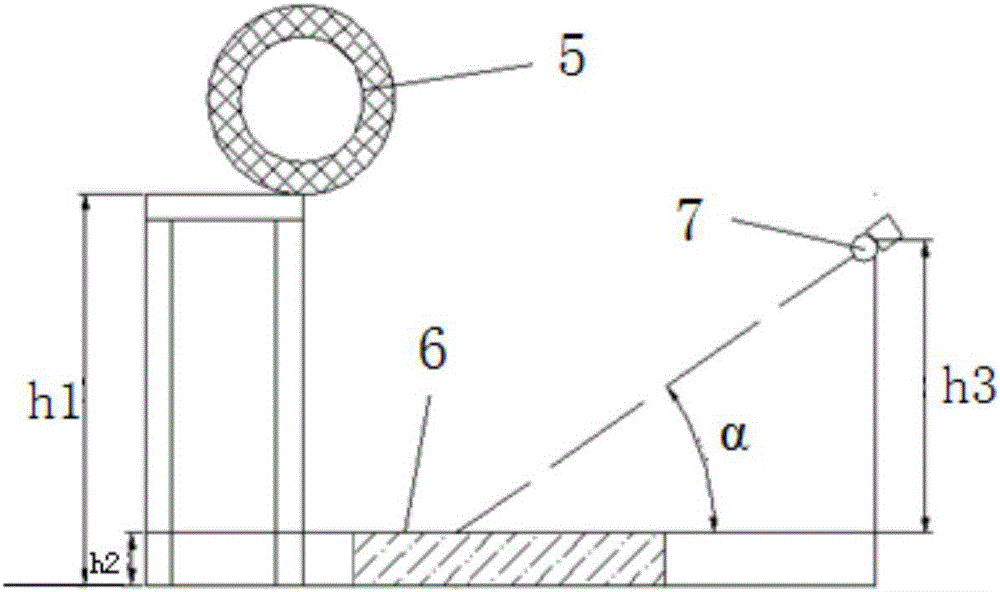

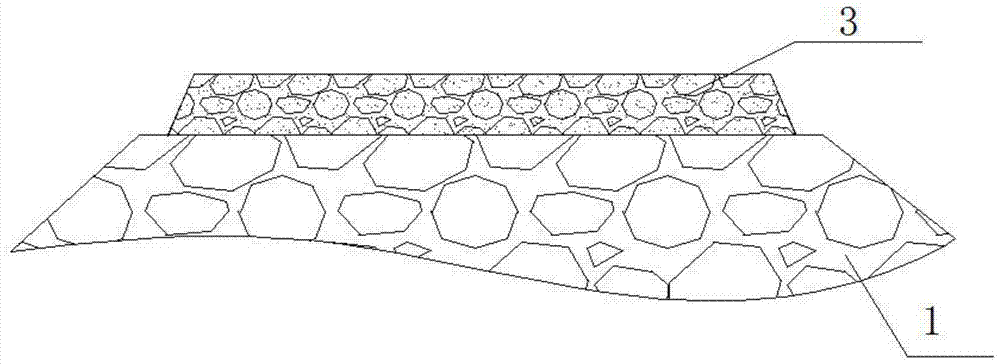

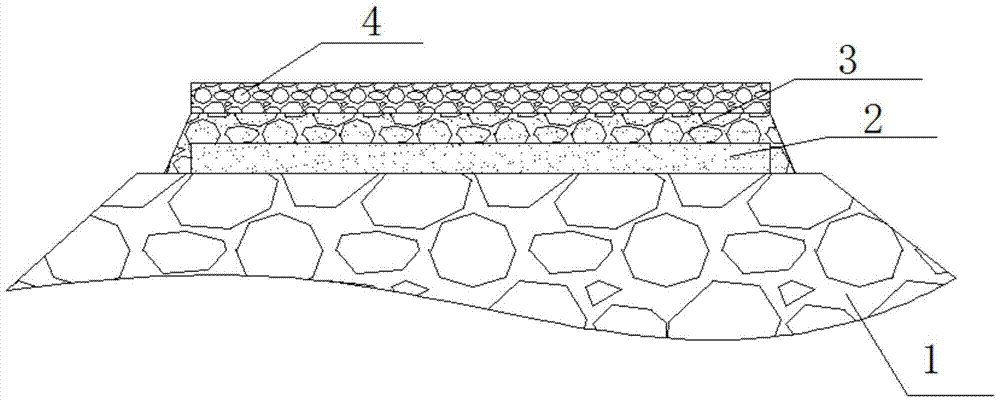

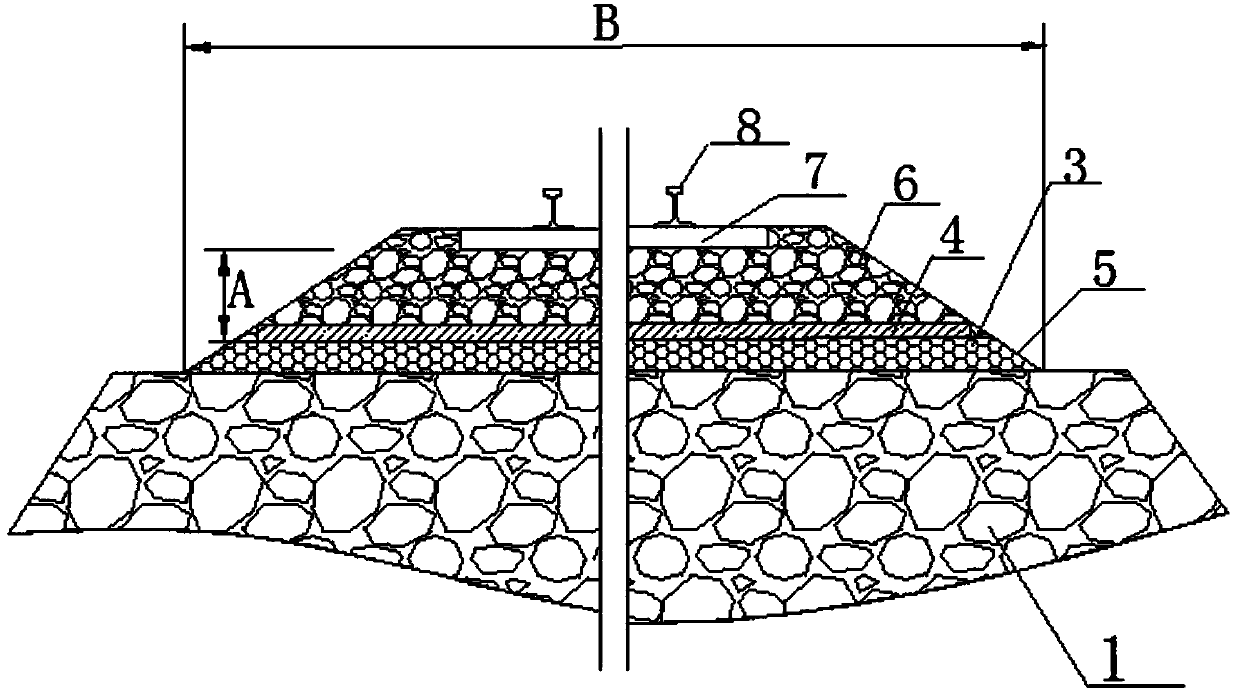

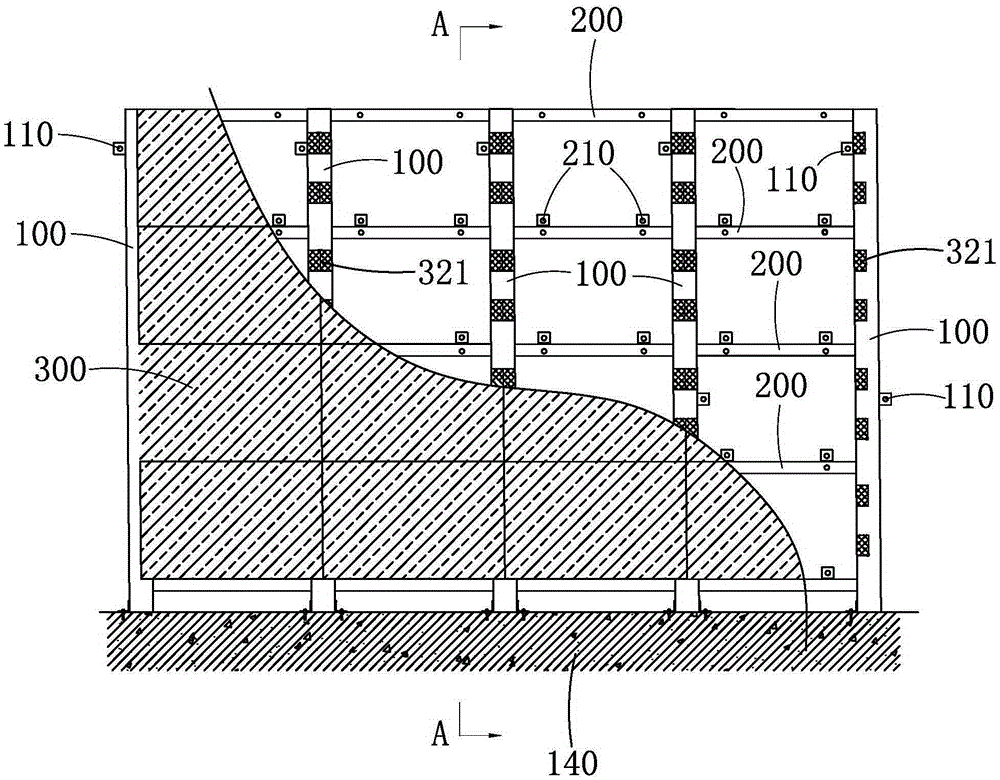

Railroad bed waterproof structure and pavement method thereof

ActiveCN105568779AShorten the setting timeFully solidifiedBallastwayProtective foundationChipsealPolymer coating

The invention discloses a railroad bed waterproof structure and a pavement method thereof. The waterproof structure is located between a railroad bed and railway ballast and comprises a waterproof layer which comprises gravel stacked on the surface of the railroad bed and a waterproof polymer coating arranged in gravel gaps in a filling manner; the waterproof polymer coating is poured or sprayed into the gravel gaps, and the waterproof layer is obtained after solidification of the waterproof coating; the waterproof layer is 3-6 cm thick and is 25-35 cm away from the rail flange, and the horizontal width of a main track is 4-6 m; the average particle size of the gravel is 5-7 mm. With the adoption of the pavement method, the waterproof layers with different thicknesses can be paved according to specific demands, the pavement method is simple and fast; the waterproof structure has excellent waterproof performance and comprehensive mechanical performance; further, the waterproof structure further comprises a sand bed arranged between the railroad bed and the waterproof layer as well as a gravel layer arranged between the waterproof layer and the railway ballast, and the mechanical performance and the waterproof performance of the waterproof structure can be further improved.

Owner:SOUTHWEST JIAOTONG UNIV

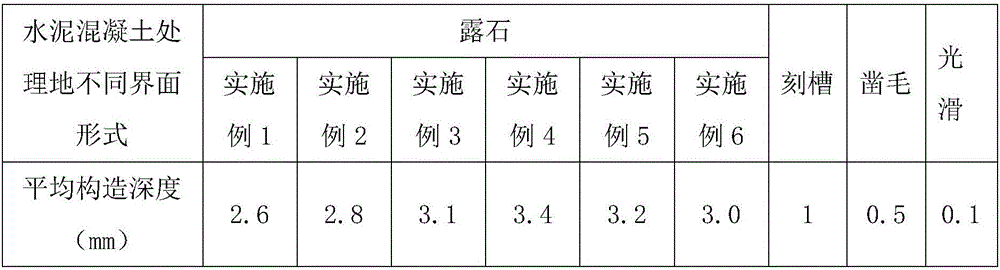

Method for slitting cement concrete pavement

ActiveCN106917338ASolve the lack of cooling capacityFully solidifiedPaving detailsRoad surfaceInternal stress

The invention provides a method for slitting a cement concrete pavement. Slitting is phased, so that the interior of the cement concrete pavement is sufficiently cooled and solidified. Slits are neat with no rough edges and the internal stress can be sufficiently released without extra cracks.

Owner:CCCC THIRD HIGHWAY ENG

Ablative/coagulative urological treatment device and method

InactiveCN102695468AMake sure to removeFully solidifiedElectrotherapyCatheterFiberCombined treatment

A device / system and a method for the treatment of enlarged prostate and other urologic abnormalities are presented. This system enables the simultaneous attachment of several interstitial coaguiative treatment probes as well as an ablative fiber to perform a combined treatment utilizing the intervention time and the time of the localized anesthesia effect in an optimal manner. The amount of tissue removed by the urologist by vaporization can be kept to a minimum, thanks to the (delayed) improvement of the achieved symptom scores resulting from the denaturalizing effect of the interstitial coaguiative fibers. In one preferred embodiment, two or more types of delivery systems are embedded in a single device for achieving optimal tissue ablation and coagulation effects including at least one non-laser source such as microwave energy, capable of producing radiation energy to coagulate tissue and at least one laser source capable of producing radiation to ablate tissue. In another preferred embodiment, device comprises two or more laser sources which emit at adjustable wavelengths controllable by physician according to ablative and coaguiative needs and tissue penetration needs depending on their effective absorption in different tissue components. Wavelengths ranges are chosen such that tissue absorption properties change sensibly with small variations of such wavelengths, based on a steep region of the absorption curve. Radiation may be applied in continuous, semi-continuous or pulsed wave, in different combinations. In another preferred embodiment, optical fiber has a central core for transmitting laser radiation, and a cladding layer about the core that may further transmit other laser radiation of a different or a same wavelength as the core.

Owner:BIOLITEC UNTERNEHMENSBETEILLIGUNGS II AG

A coagulation and forming device suitable for dry-spray-wet-spinning method to manufacture aramid ⅲ fibers

ActiveCN103498207BSolidify continuously and evenlyUniform and stable solidificationArtificial thread manufacturing machinesWet spinning methodsPolymer scienceSpinning

The invention discloses a coagulation forming device suitable for producing aramid III fiber by dry spraying-wet spinning method, which comprises two parts: a coagulation plate and a U-shaped coagulation tube. The U-shaped coagulation tube is mainly composed of a U-shaped tube, a regulating tube, and a wire outlet tube. One end of the U-shaped tube is connected to the coagulation plate, and the other end is flexibly connected to the regulating tube. The height difference between the liquid inlet and the liquid outlet of the U-shaped coagulation tube can be adjusted according to the spinning speed. The coagulation and forming device of the present invention can realize rapid and uniform coagulation of aramid III primary fibers, significantly increase the spinning speed of aramid III fibers, improve production efficiency, and at the same time produce better fiber quality, less burrs, and a more regular appearance. And because the device is small in size and compact in structure, modular manufacturing and replacement can also be realized.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Sliding-resistant colored pavement surface and paving method thereof

The invention discloses a sliding-resistant colored pavement surface and a paving method thereof. The paving method comprises the following steps that (1) cement concrete is subjected to blending, paving, vibrating, excess water removing and plastering, and then paved on a base layer of a pavement; (2) after a surface water film disappears and the surface temperature of the cement concrete is 15-45 DEG C, a retarder is sprayed to the surface of the cement concrete; (3) a plastic film is paved on the cement concrete immediately for primary curing; (4) the plastic film on the surface of the cement concrete is uncovered after the primary curing time is due, and uncondensed cement mortar on the surface of the cement concrete is brushed away; (5) secondary curing is conducted till the cement concrete reaches a certain strength; (6) after the cement concrete reaches the certain strength, dust and chips on the surface of the cement concrete are removed, and colored pigment is smeared; and (7) tertiary curing is conducted, and the whole paving process is completed after the cement strength reaches the final strength. According to the sliding-resistant colored pavement surface and the paving method thereof, the construction depth and friction coefficient of the cement concrete pavement surface are additionally considered, and meanwhile, the pavement is colored.

Owner:CHANGAN UNIV

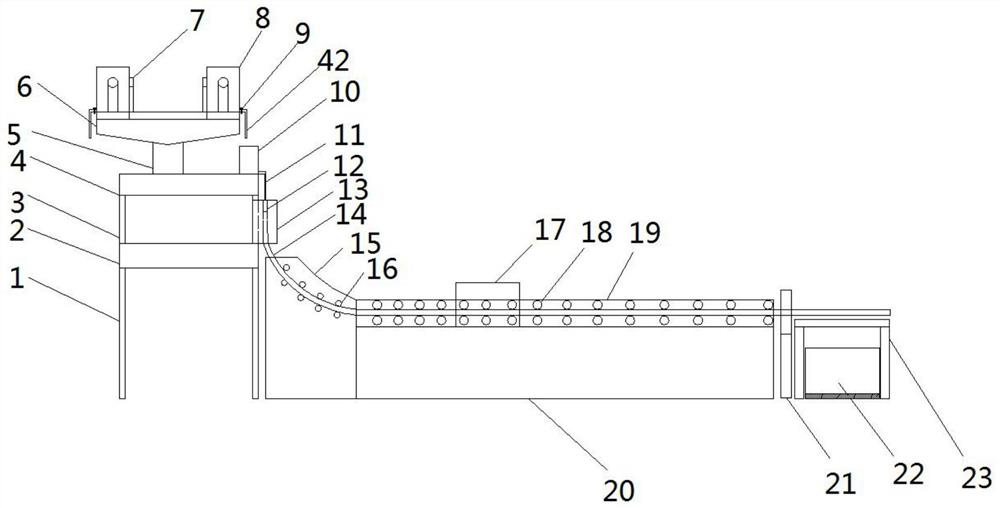

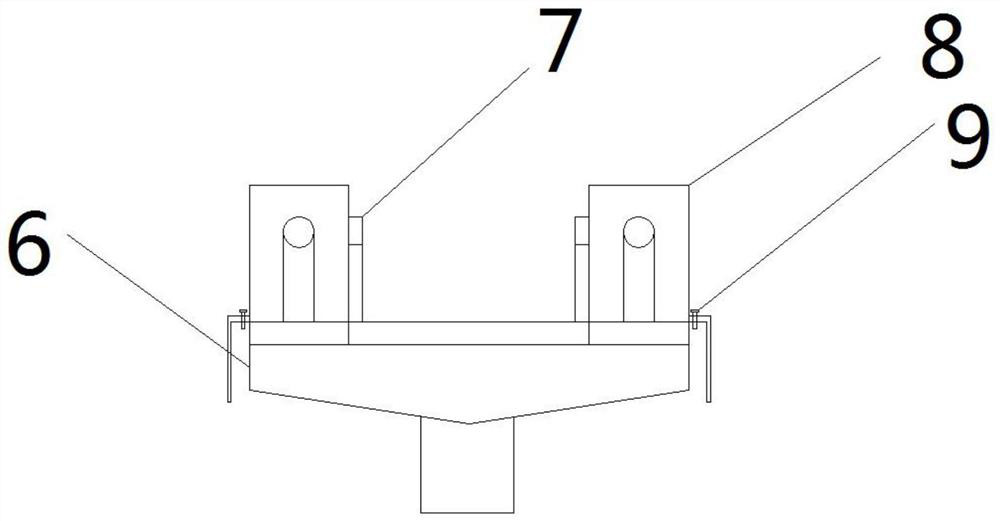

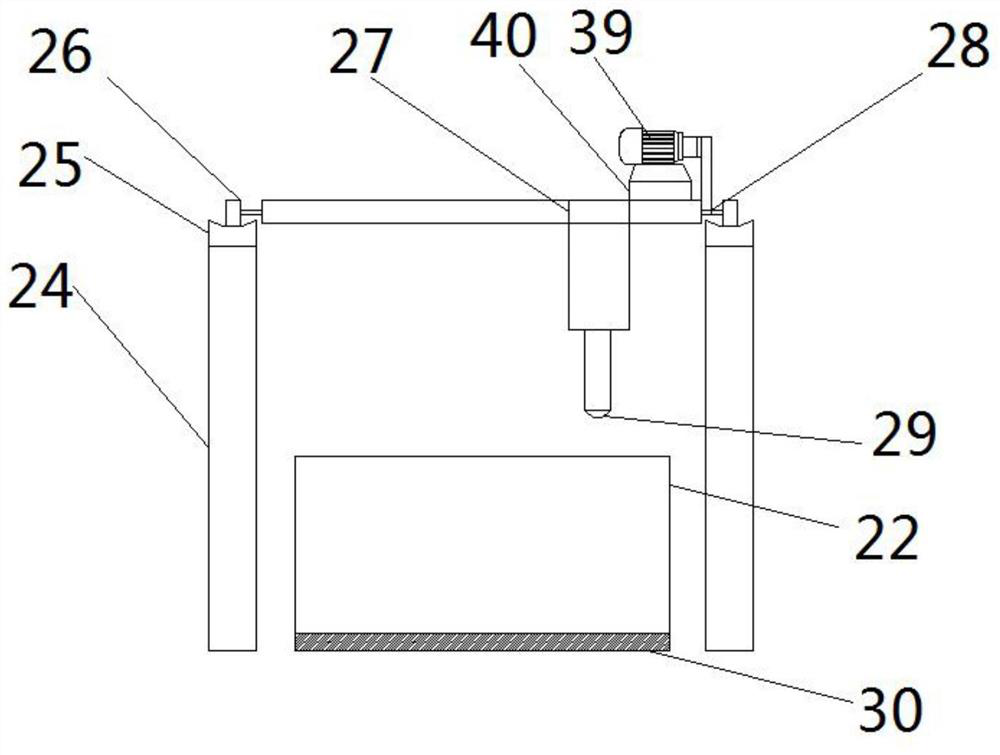

Energy-saving and environment-friendly continuous casting and slicing production equipment for lead storage battery grid

ActiveCN111916760AAdjust the falling speedCondensation forming fullElectrode carriers/collectorsCasting cleaning apparatusReciprocating motionEngineering

The invention discloses an energy-saving and environment-friendly lead storage battery grid continuous casting and slicing production equipment, and the equipment comprises supporting legs and a firstworkbench; the supporting legs are arranged at the bottom end of the first workbench and fixedly connected with the first workbench, the top end of the first workbench is fixedly connected with one end of a connecting rod, and the other end of the connecting rod is fixedly connected with the first workbench; the connecting rods are symmetrically distributed at the four corners of the first workbench, the other ends of the connecting rods are fixedly connected with a second workbench, a rotating shaft is arranged at the top end of the second workbench, one end of the rotating shaft is rotationally connected with the second workbench, and the other end of the rotating shaft is fixedly connected with a rotary table. A steel ladle is mounted at the top end of the rotary table in an embedded manner, and the steel ladle is fixedly connected with the rotary table; the crystallizer can do reciprocating motion in the vibrator, so the crystallizer does arc-imitating motion along the radius of the continuous casting machine according to the given amplitude, frequency and waveform deflection characteristics, the demolding is easier, and molten steel can be solidified more sufficiently througha condensing agent filled in the vibrator.

Owner:JIESHOU HUAYU POWER SUPPLY

Ultrahigh molecular weight polyoxyethylene fiber and preparation method thereof

ActiveCN111206291AHigh retention rateImprove solubilityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberBenzene

The invention discloses an ultrahigh molecular weight polyoxyethylene fiber and a preparation method thereof. The preparation method comprises the following steps of providing a spinning solution containing ultrahigh molecular weight polyoxyethylene, an antioxidant and a spinning solvent, wherein the spinning solvent comprises water, dimethyl sulfoxide, methanol, tetrahydrofuran, toluene, benzene,N,N-dimethylformamide, 1,4-dioxane and the like, and the molecular weight of the dissolved ultrahigh molecular weight polyoxyethylene is more than 70% of the retention rate of a raw material; and injecting the spinning solution into a coagulating bath for coagulation and fixation to obtain gel filaments by adopting a wet spinning method, then carrying out extraction treatment and drying to obtainultrahigh molecular weight polyoxyethylene extracted and dried fibers, and then carrying out hot drawing to obtain the ultrahigh molecular weight polyoxyethylene fibers. The ultrahigh molecular weight polyoxyethylene fiber disclosed by the invention has better mechanical property, higher fiber molecular weight than the raw material retention rate, high molecular weight and high orientation degree, and the preparation method is stable and feasible and is convenient for large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of microorganism solidification gel

InactiveCN107602732AFully solidifiedPlay a toughening and reinforcing roleBacteriaMicroorganism based processesMicroorganismCellulose

The invention discloses a preparation method of microorganism solidification gel and belongs to the technical field of natural high molecular materials. According to the technical scheme, the preparation method comprises the following steps: firstly, mixing cellulose and oxidized acid liquid and reacting; then filtering, washing and drying to obtain cellulose oxide; after mixing and swelling chitosan, gelatin and water, heating, stirring and dissolving; adding casein and mixed strains; after mixing and fermenting, regulating the pH (Potential of Hydrogen) to be neutral to prepare solidification liquid; then mixing the solidification liquid, the cellulose oxide and saturated lime water and continuously introducing carbon dioxide to react, so as to prepare modified solidification liquid; then stirring and mixing the modified solidification liquid, latex and a solidification auxiliary agent, and standing; pressing, granulating and drying to obtain the microorganism solidification gel. Themicroorganism solidification gel disclosed by the invention has relatively high tensile strength, tearing strength and rigidity and has good mechanical properties.

Owner:孙祎

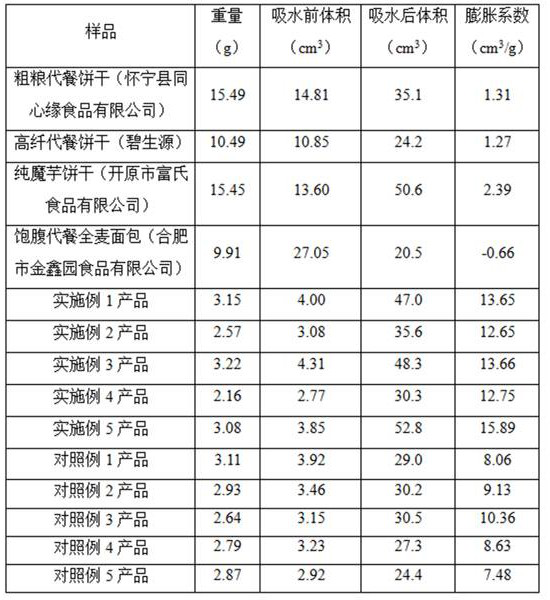

High-expansion-coefficient weight control product and preparation process thereof

The invention belongs to the technical field of food science, and in particular relates to a high-expansion-coefficient weight control product and a preparation process thereof. The product in the invention comprises raw materials including konjac glucomannan, pectin, bran and procyanidine. After being eaten, the product in the invention rapidly expands after absorbing water in the stomach to forma three-dimensional reticulated hydrogel and achieve the occupation purpose in the stomach; therefore, the product makes people feel full to reduce eating; and thus, the purpose of losing weight or controlling weight is achieved.

Owner:菲昂(北京)生物科技有限公司

Ceramic tile adhesive

The invention discloses a ceramic tile adhesive. The ceramic tile adhesive is prepared from, by weight, 15-30 parts of modified polymer resin, 50-75 parts of a filler, 0.2-0.4 part of a thickening agent, 0.4-0.5 part of a defoaming agent, 1.0-1.6 parts of a preservative, 0.5-1.0 part of a stabilizer, 1.0-1.5 parts of a brightening agent and 0-5 parts of a color paste, wherein the modified polymerresin is starch grafted resin. The components of the ceramic tile adhesive are reasonably adjusted, the starch-grafted resin is used for improving the water retention capacity and the bonding force ofthe ceramic tile adhesive, water is inhibited from being too fast lost from the adhesive to a substrate or a tile, and the adhesive has enough water to be comprehensively solidified, so the bonding strength of the ceramic tile adhesive is further improved, and the ceramic tile adhesive has a wide application prospect.

Owner:FOSHAN UNIVERSITY

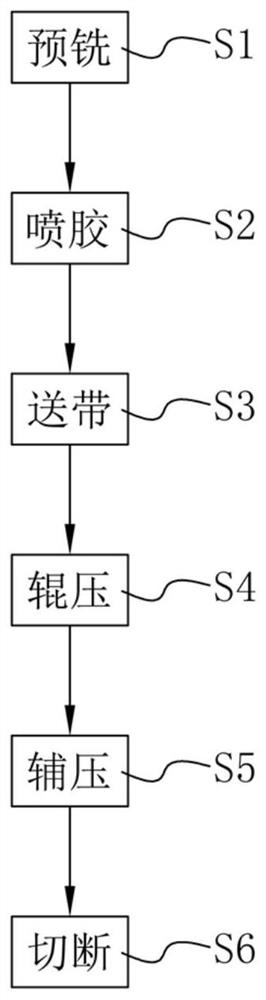

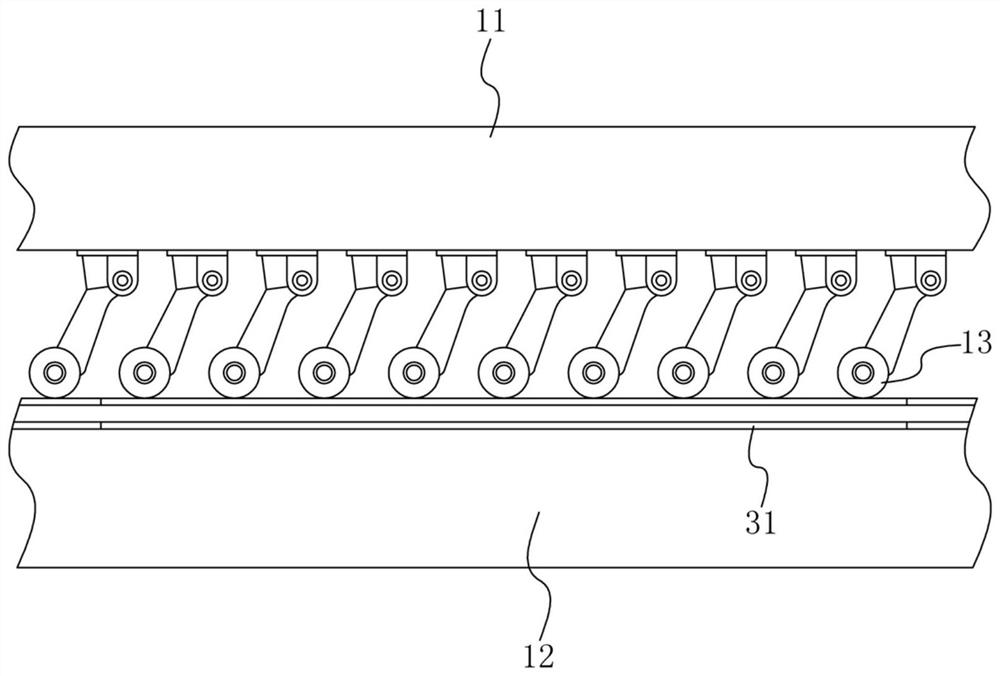

Inner strip edge sealing process method of inner honeycomb plate

PendingCN112848636AAvoid exposureImprove aestheticsLamination ancillary operationsLaminationHoneycombMechanical engineering

The invention discloses an inner strip edge sealing process method of an inner honeycomb plate, and relates to the technical field of edge sealing of inner honeycomb plates. According to the technical key points, the method comprises the following steps: pre-milling; glue spraying; tape conveying; rolling; auxiliary pressing; and cutting. After the edge of a wooden honeycomb plate is milled, a mounting groove is enclosed by a wooden honeycomb plate and two partition plates. A sealing strip is placed in the mounting groove, and the side surface of the sealing strip is attached to the side wall of the mounting groove, so that the wooden honeycomb plate can be blocked through the sealing strip, the effect of protecting the wooden honeycomb plate is achieved, the wooden honeycomb plate can be prevented from being exposed outside, and the effect of improving the attractiveness is achieved.

Owner:舒跃进

Waterproof structure of railway subgrade and its laying method

ActiveCN105568779BShorten the setting timeFully solidifiedBallastwayProtective foundationChipsealPolymer coatings

The invention discloses a railroad bed waterproof structure and a pavement method thereof. The waterproof structure is located between a railroad bed and railway ballast and comprises a waterproof layer which comprises gravel stacked on the surface of the railroad bed and a waterproof polymer coating arranged in gravel gaps in a filling manner; the waterproof polymer coating is poured or sprayed into the gravel gaps, and the waterproof layer is obtained after solidification of the waterproof coating; the waterproof layer is 3-6 cm thick and is 25-35 cm away from the rail flange, and the horizontal width of a main track is 4-6 m; the average particle size of the gravel is 5-7 mm. With the adoption of the pavement method, the waterproof layers with different thicknesses can be paved according to specific demands, the pavement method is simple and fast; the waterproof structure has excellent waterproof performance and comprehensive mechanical performance; further, the waterproof structure further comprises a sand bed arranged between the railroad bed and the waterproof layer as well as a gravel layer arranged between the waterproof layer and the railway ballast, and the mechanical performance and the waterproof performance of the waterproof structure can be further improved.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of structure and laying method for preventing railway subgrade from muddling

ActiveCN105839476BShorten the setting timeFully solidifiedBallastwayRailway embankmentStone clearance

The invention discloses a structure capable of preventing railroad bed mud pumping and a paving method thereof. The structure is positioned between a railroad bed and a rail roadway ballast and comprises a first protective layer and a second protective layer. The paving method of the structure comprises the following steps of: 1) paving sand aggregate with an average grain diameter of 0.05-5mm on the surface of the railroad bed so as to form a sand cushion with the a the thickness of 4-6cm; 2) paving the broken stone with an average grain diameter of 5-7mm on the surface of the sand cushion, wherein the a the paving thickness of the broken stone is 3-6cm; 3) filling broken stone clearances with a polymer waterproof coating, wherein thea first protective layer is obtained after the polymer waterproof coating is solidified; 4) spraying a polyurea waterproof coating onto the surface of the first protective layer so as to form thea second protective layer with the thickness of 2-4 mm. Water infiltrating to the second protective layer is discharged through a dewatering slope of the first protective layer; ascending mud is isolated by the first protective layer, and the second protective layer forms thea second protection, so that the mud is effectively prevented from being pumped and extruded towards the railway railroad ballast or towards the outside through the railway ballast.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

Gold removing and tin coating method and lead tin coating protective agent for lead of connector between gold-plated plates, and preparation method of lead tin coating protective agent

InactiveCN113621282AGuaranteed stabilityGood physical propertiesFireproof paintsHot-dipping/immersion processesCelluloseTinning

A preparation method of a tin coating protective agent for a connector lead between gold-plated plates comprises the following steps: uniformly stirring deionized water and acrylic emulsion, adding ammonium polyphosphate, pentaerythritol, melamine and titanium dioxide, uniformly stirring, grinding the obtained slurry to required fineness, adding cellulose ether and a high-temperature-resistant antioxidant, and stirring to obtain the tin coating protective agent. The tin coating protective agent comprises, by mass,10-15% of the acrylic emulsion, 25-35% of the ammonium polyphosphate, 5-15% of the pentaerythritol, 5-8% of the melamine, 10-15% of the titanium dioxide, 1-3% of the cellulose ether and 3-5% of a high-temperature-resistant antioxidant. A gold removing and tin -coating method for the connector comprises the following steps: immersing a lead part needing to be protected in a protective agent, dipping in the protective agent, airing in the air, standing and drying, cooling to room temperature, and carrying out gold-removing and tin-coating. The connector lead is immersed in deionized water, the protective agent is removed, and airing is performed at room temperature to achieve the effects of removing gold and tinning. The protective agent is reasonable and controllable in component concentration, simple and feasible in preparation method, moderate in viscosity, easy to cure, resistant to high temperature, free of corrosion to a substrate and capable of being stripped after being washed with water.

Owner:XIAN MICROELECTRONICS TECH INST

A hot isostatic pressing method for nickel-based superalloy powder

ActiveCN110666175BAvoid abnormal growthInhibition formationTurbinesOther manufacturing equipments/toolsSuperalloyMelting temperature

The invention discloses a hot isostatic pressing forming method of a nickel-based superalloy powder disc, specifically a hot isostatic pressing forming method of a nickel-based superalloy powder, which is suitable for preparing powdered superalloys directly formed by hot isostatic pressing Disc, the present invention uses the superalloy powder prepared by the plasma rotating electrode method as raw material, puts the powder into the sheath under vacuum conditions and seals and welds the hot isostatic pressing, the temperature of the first hot isostatic pressing should be higher than γ' melting temperature is 10-30°C, pressure ≥100MPa, time ≤1h; after the first step is completed, the temperature is raised to 50-100°C below the liquidus temperature, the pressure is ≥100MPa, and the time is ≤30min; after the second step is completed, the temperature drops to The melting temperature of the low melting point phase is 10-20°C below the melting temperature, the pressure is ≥100MPa, the temperature is kept for 30min, and the furnace is cooled. The invention can effectively suppress the generation of PPB defects in the hot isostatic pressing process and improve the alloy density, thereby preparing a high-temperature alloy powder disk with uniform and dense structure.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

A kind of ultra-high molecular weight polyethylene oxide fiber and preparation method thereof

ActiveCN111206291BHigh retention rateImprove solubilityArtificial filament heat treatmentWet spinning methodsFiberBenzene

The invention discloses an ultra-high molecular weight polyethylene oxide fiber and a preparation method thereof. The preparation method includes: providing a spinning solution comprising ultra-high molecular weight polyethylene oxide, an antioxidant and a spinning solvent, the spinning solvent including water, dimethyl sulfoxide, methanol, tetrahydrofuran, toluene, benzene, N , N-dimethylformamide and 1,4-dioxane, etc., after dissolution, the molecular weight of the ultra-high molecular weight polyethylene oxide is more than 70% compared with the raw material retention rate; using wet spinning method, the spinning The solution is injected into a coagulation bath to coagulate and fix to obtain jelly filaments, which are then extracted and dried to obtain ultra-high molecular weight polyethylene oxide extracted and dried fibers, which are then thermally drawn to obtain ultra-high molecular weight polyethylene oxide fibers. The ultra-high molecular weight polyethylene oxide fiber of the present invention has better mechanical properties, higher fiber molecular weight retention rate than raw materials, high molecular weight and high orientation degree, and the preparation method is stable and feasible, and is convenient for large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Multistage stretching technology for manufacture aramid fiber III

ActiveCN102797061BImprove mechanical propertiesImprove product qualityArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceAramid

The invention relates to a multistage stretching technology for manufacture aramid fiber III, which belongs to the technical field of chemical fiber. The multistage stretching technology comprises a negative stretching technology, plasticizing stretching treatment, water washing and plasticizing stretching treatment again to obtain final products. The multistage stretching technology can obviously improve the mechanical property of aramid fiber III, the multifilament stretching strength is increased to 32cN / dtex from 30cN / dtex, and the stretching modulus is increased to 950cN / dtex from 850cN / dtex. High-strength and high-modulus fiber obtained can be applied to applicable fields with higher market requirements.

Owner:中蓝晨光化工有限公司

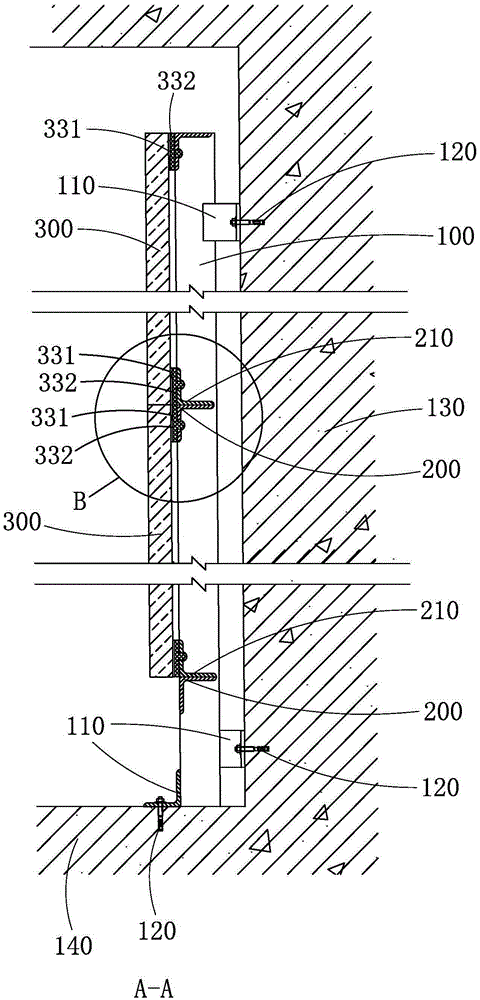

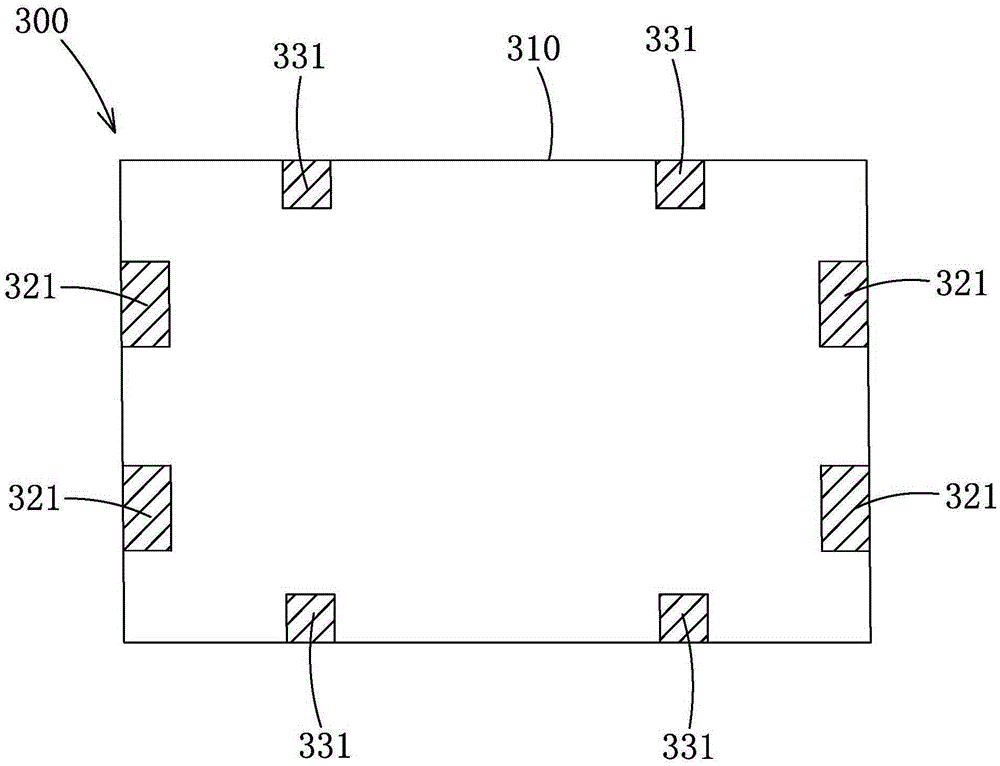

A glass fiber reinforced gypsum board interior wall dry bonded structure and its construction method

The invention provides an inner wall dry bonding structure for a glass-fiber reinforced gypsum plate and a construction method of the inner wall dry bonding structure. The glass-fiber reinforced gypsum plate comprises a rectangular framework, wherein marble adhesive bonding convex plates and structure adhesive bonding convex plates are respectively fixed on the longitudinal side edge and the transverse side edge of the rectangular framework; the marble adhesive bonding convex plates and the structure adhesive bonding convex plates are slightly projected out of the back side of the glass-fiber reinforced gypsum plate; angle steel cross beams are horizontally welded between adjacent steel upright posts; the cross section of the angle steel cross beams is in a reverse L shape; the distance between the center lines of the adjacent steel upright posts is matched with the width of the glass-fiber reinforced gypsum plate; the marble adhesive bonding convex plates of each glass-fiber reinforced gypsum plate are fixed on the steel upright posts through marble adhesives; the structure adhesive bonding convex plates arranged on the top edge of each glass-fiber reinforced gypsum plate are fixed with the angle steel cross beams through structure adhesives; and the structure adhesive bonding convex plates are fixed with L-shaped corner connectors through structure adhesives. The point bonding fixation is adopted; the perforation on the glass-fiber reinforced gypsum plate is not needed; the intensity is improved; and the dust is avoided.

Owner:SDCIC CONSTR GRP CO LTD

Viscose monofilament production process

ActiveCN103233289BReduce the blooming effectFully solidifiedSpinnerette packsArtificial filaments from viscoseViscosePulp and paper industry

The invention relates to a viscose monofilament production process. Cellulose fiber pulp is adopted as a raw material, and the steps such as spinning solution preparation, spinning, and post-treatment are carried out, such that the viscose monofilament is obtained. The method specifically comprises the process steps that: (A) cellulose fiber pulp is subjected to impregnation, aging, yellowing, dissolving, defoaming, and filtering, such that the spinning solution is prepared; (B) the spinning solution is delivered into a spinning machine, and passes through a spinning hole with a single-hole nozzle under pressure, such that viscose thin stream is formed, and raw filament strip is formed after coagulation molding, wherein jet nozzle stretch is +60% to +80%, and a spinning hole inlet pore channel is in a parabolic shape; and (C) post-treatment is carried out, wherein the raw filament strip is subjected to desulfurization, bleaching, oiling, and bake-drying, such that the viscose monofilament is obtained. With the production process provided by the invention, produced viscose monofilament has fineness of 50-6000D, and high strength higher than 75CN. With the viscose monofilament, requirements by dyeing, weaving and finished garments can be satisfied.

Owner:YIBIN HIEST FIBER +2

Rapid paraffin sectioning method for plant tissue

InactiveCN102967493BImprove fixation efficiencyImprove permeabilityPreparing sample for investigationPlant tissueEngineering

The invention discloses a rapid paraffin sectioning method for plant tissue. The method comprises the following steps: sampling, fixation, dehydration and vitrification, paraffin embedding and sectioning, gluing tablets and spreading tablets, and dyeing and cementing. The invention greatly improves fixation efficiency of paraffin sectioning for plant tissue by 10-20 times, compared with a fixation time of one day in traditional paraffin sectioning; tert-butyl alcohol or n-butanol is used as a dehydrating agent and a transparent agent to simplify the dehydration and vitrification step, and the dehydration and vitrification only consumes 6-7h, which has efficiency improved by more than 3 times compared with a traditional dehydration and vitrification; and infiltration efficiency of the plant tissue in paraffin and embedding quality are improved, and the penetration consumes 4-7h, which has efficiency improved by more than one time compared with the traditional paraffin infiltration method, so as to effectively solve problems of tissue hardening and brittleness caused by high temperature during the paraffin infiltration. The invention has the characteristics of simplified experimental procedures, low equipment price, short production cycle, high sectioning quality, safety and environment-friendliness.

Owner:SHANXI AGRI UNIV

Roadbed construction method for soft foundation area

InactiveCN112095382AImprove stabilityRealize the use of fixed supportIn situ pavingsBulkheads/pilesAsphaltStructural engineering

The invention provides a roadbed construction method for a soft foundation area, and relates to the field of roadbed construction. According to the roadbed construction method for the soft foundationarea, a main body is included, side edge layers are arranged on the two sides of the main body correspondingly, stirring piles are arranged in the main body in a penetrating mode, a bonding layer is arranged on the upper end face of the main body, a gravel layer is arranged at the upper end of the bonding layer, and an asphalt layer is arranged at the upper end of the gravel layer. Arc-shaped edges are arranged at the upper ends of the side edge layers and opposite to the two sides of the gravel layer. The stirring piles are effectively used through effective construction, cement and soft soilare fully mixed to form reinforcement, the roadbed is reinforced through the gravel layer and the asphalt layer, the roadbed is waterproof through a waterproof agent with which the asphalt layer is coated, and water is guided through the arc-shaped edges at the side edge layers.

Owner:江苏兴业环境集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com