Patents

Literature

213results about How to "Avoid abnormal growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrimidine antitumor compound with Hedgehog antagonist activity

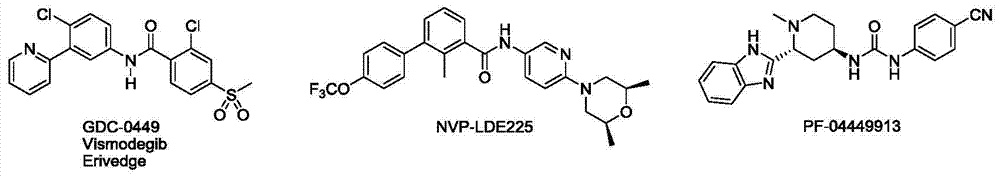

ActiveCN103588771AInhibit abnormal cell growthBlock metastatic regenerationOrganic chemistryAntineoplastic agentsPyrimidineSmoothened Receptor

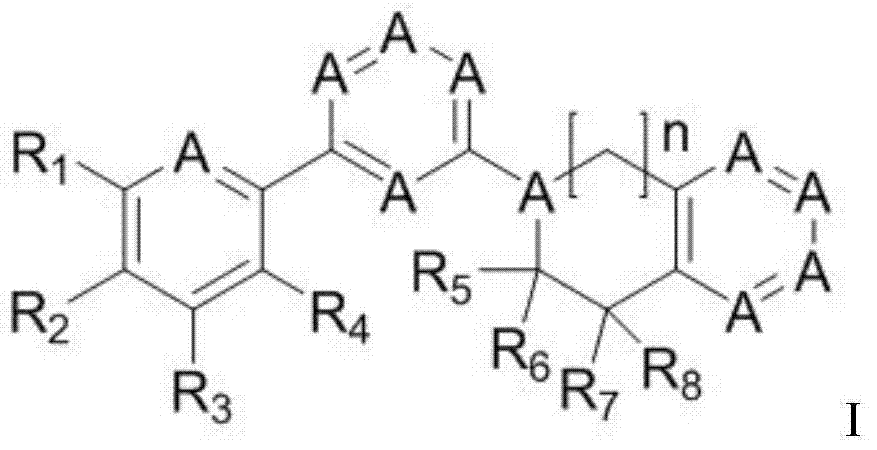

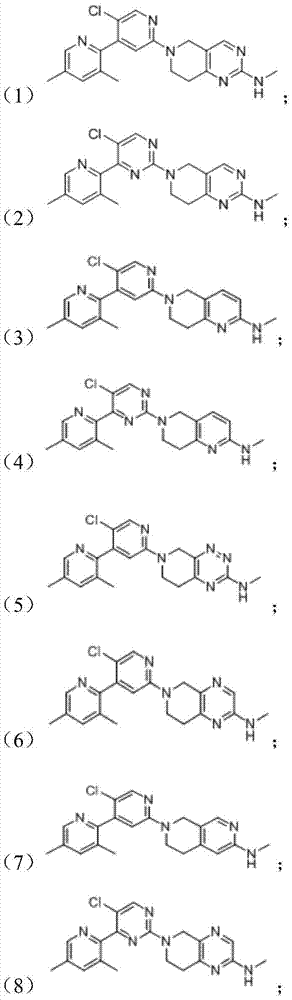

The invention discloses a pyrimidine antitumor compound with Hedgehog antagonist activity, comprising the compound and pharmaceutically acceptable salts, various isotopes, various isomers or various crystal structures thereof. The pyrimidine antitumor compound has the structure shown as the general formula I, wherein, A refers to nitrogen atom or C-R9, n is 0, 1, 2, 3, 4, 5 or 6; the R1, R2, R3, R4, R5, R6, R7, R8 and R9 are independently selected from hydrogen atom, alkyl, alkenyl, alkynyl, aromatic ring group, heterocyclic radical or heteroatom functional group-containing substituent group, respectively. The antitumor compound provided by the invention can block Hedgehog through blocking an SMO (Smoothened receptor) so as to inhibit cell abnormal growth and block tumor cell migration generation, and has an obvious antitumor effect.

Owner:SUZHOU KINTOR PHARMA

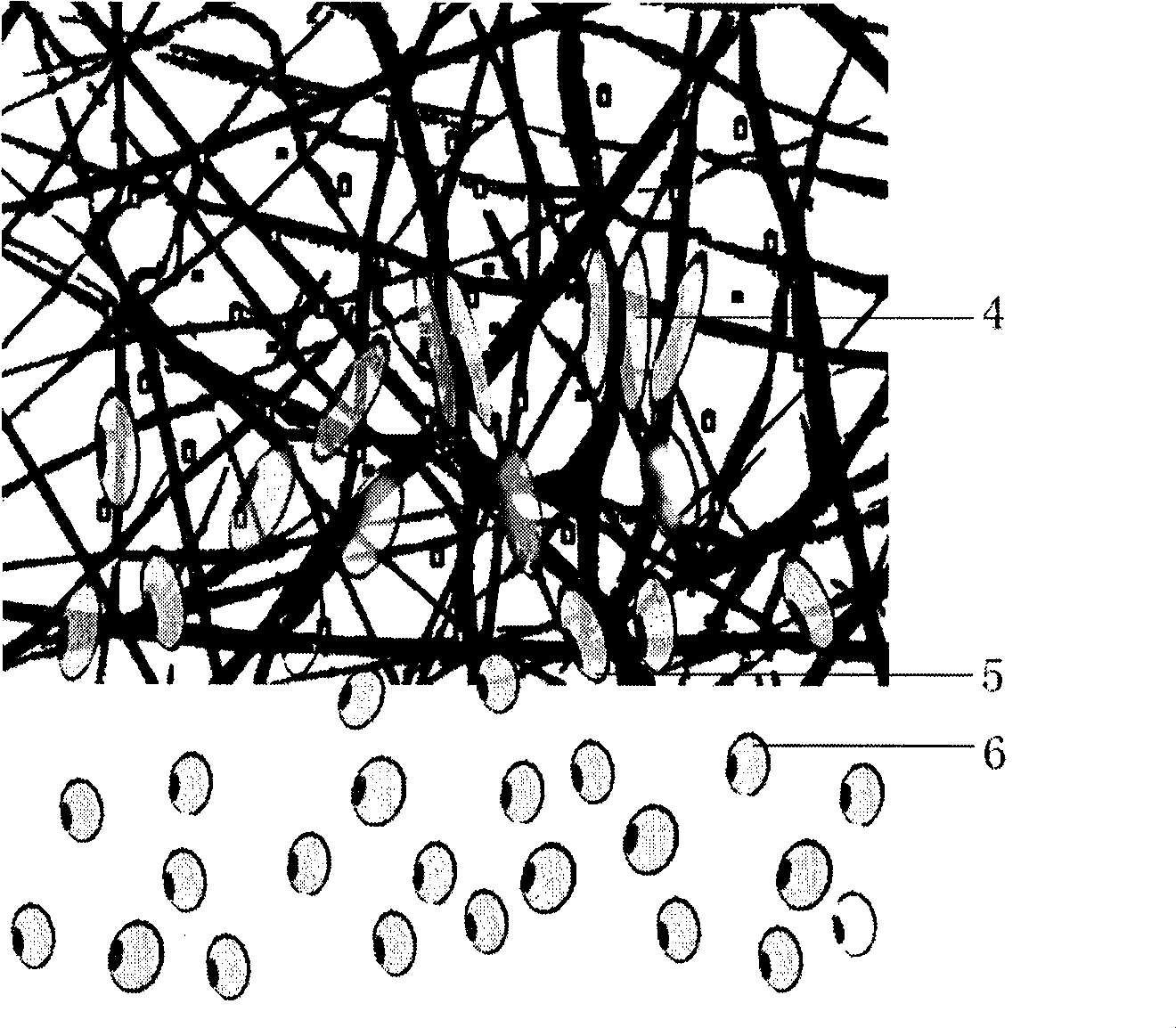

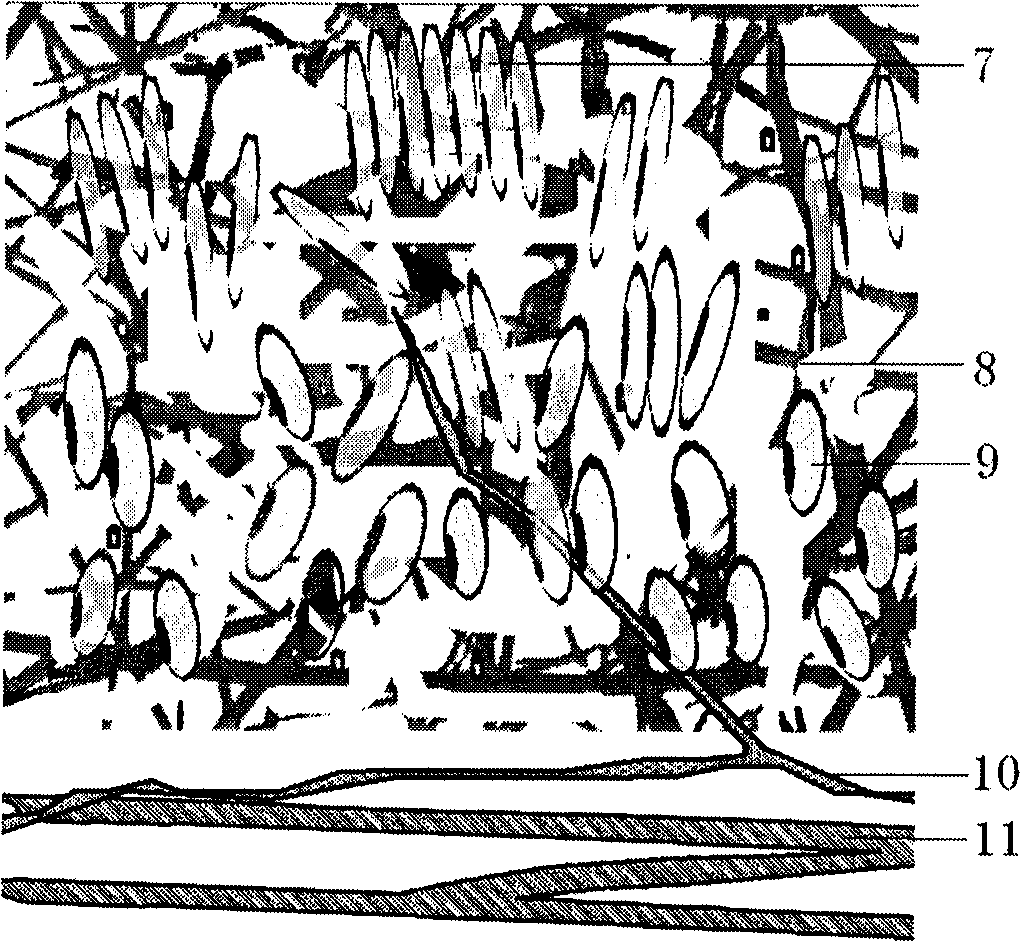

Nano bionic wound-surface cover and preparation method thereof

ActiveCN101507835AAddress barriers to developmentAvoid inconvenienceProsthesisElectrospinningEngineering

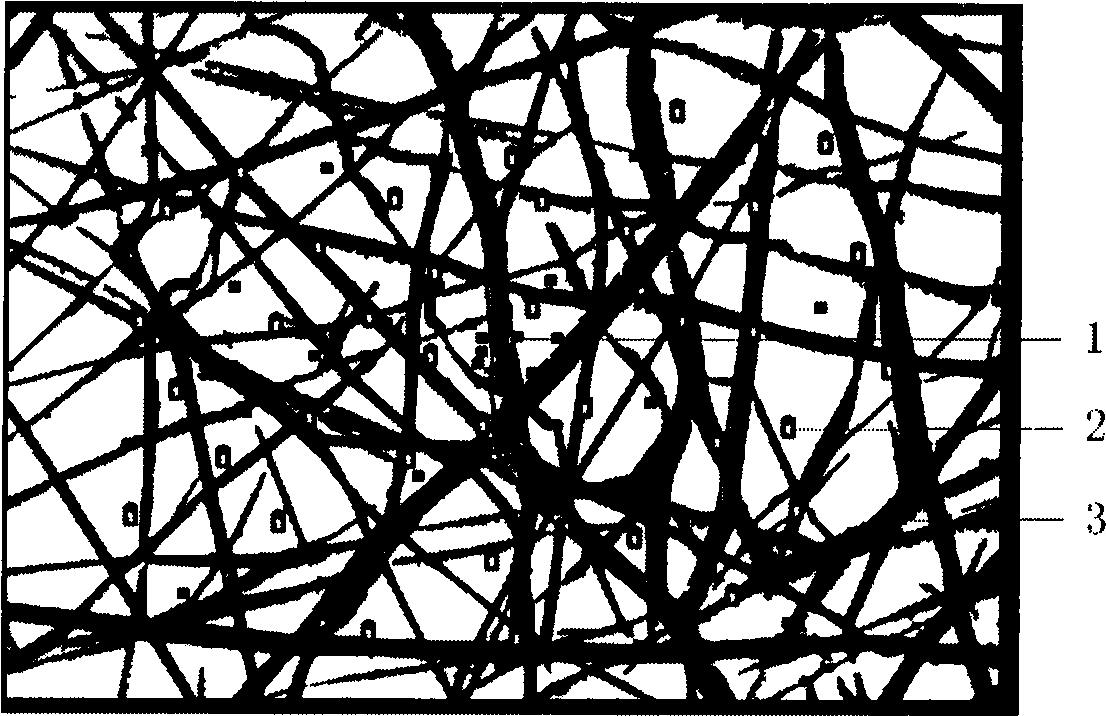

The invention provides a nanometer bionic wound-surface cover and a preparation method thereof. The nanometer bionic wound-surface cover comprises a nanometer bionic bracket and hydrosol attached to the bracket, wherein the hydrosol covers one or a plurality of cytokines. The preparation method for the nanometer bionic wound-surface cover provided by the invention comprises the steps of preparingan electrostatic-spinning solution, a cytokine-containing hydrosol solution and a crosslinker solution, preparing the nanometer bionic bracket by use of electrostatic spinning, using an ink-jet printer to print the cytokine-containing hydrosol solution onto the nanometer bionic bracket, and the like, wherein electrostatic spinning and printing can be repeated so as to form the wound-surface covers different in thickness. The preparation method adopts an in-situ autologous stem-cell engineering technique and adopts stem-cell chemotactic factors to attract autologous stem cells to directionally migrate, enter a wound surface and be differentiated according to designed requirements, thereby avoiding inconvenience caused by using viable cells, achieving rehabilitation effects the same with orbetter than that of using the viable cells and having broad application prospects.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Preparation method of high-coercivity sintered Nd-Fe-B and product

InactiveCN104505206AIncrease profitImprove liquidityInorganic material magnetismInductances/transformers/magnets manufactureRare earthNitrogen

The invention discloses a preparation method of high-coercivity sintered Nd-Fe-B. The preparation method comprises the following steps: preparing a main phase alloy powder and a grain boundary phase alloy powder; protecting the prepared main phase alloy powder and the grain boundary phase alloy powder by using nitrogen or argon in a protective medium, and uniformly mixing, wherein the mass percent of the added grain boundary phase alloy powder accounts for 0.1-10 percent; carrying out orientation profiling and cold isostatic pressing on the mixed alloy powder; in a vacuum sintering furnace, sintering a profiled magnet block for 2-4h at the temperature of 1000-1100 DEG C, then carrying out primary tempering for 2-4h at the temperature of 800-950 DEG C, and carrying out secondary tempering for 2-4h at the temperature of 450-650 DEG C to prepare the sintered Nd-Fe-B. The invention also discloses the high-coercivity sintered Nd-Fe-B. According to the preparation method disclosed by the invention, by virtue of low melting point auxiliary alloy, the wetting temperature between a grain boundary phase and a main phase is lowered, the wetting time is prolonged, the utilization ratio of heavy rare earth is increased, the used amount of rare earth is lowered, the process is simple, the cost is low, and the high-coercivity sintered Nd-Fe-B is suitable for mass production.

Owner:ZHEJIANG UNIV

High saturated flux low consumption MnZn power ferrite and its preparation method

ActiveCN101090017AHigh resistivityAvoid abnormal growthInorganic material magnetismControl materialPower loss

This invention relates to an MnZn power ferrite of high saturated flux density and low loss and its preparation method, which develops a MnZn power ferrite with less than or equal to 260mW / cm3 power loss under the valley temperature of 90deg.C and 100KHz and 200mT, the saturated flux density greater than or equal to 530mT under 25deg.C, 1000A / m and 50Hz and the saturated flux density greater than or equal to 420mT at 100deg.C under the condition of 1000A / m and 50Hz.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

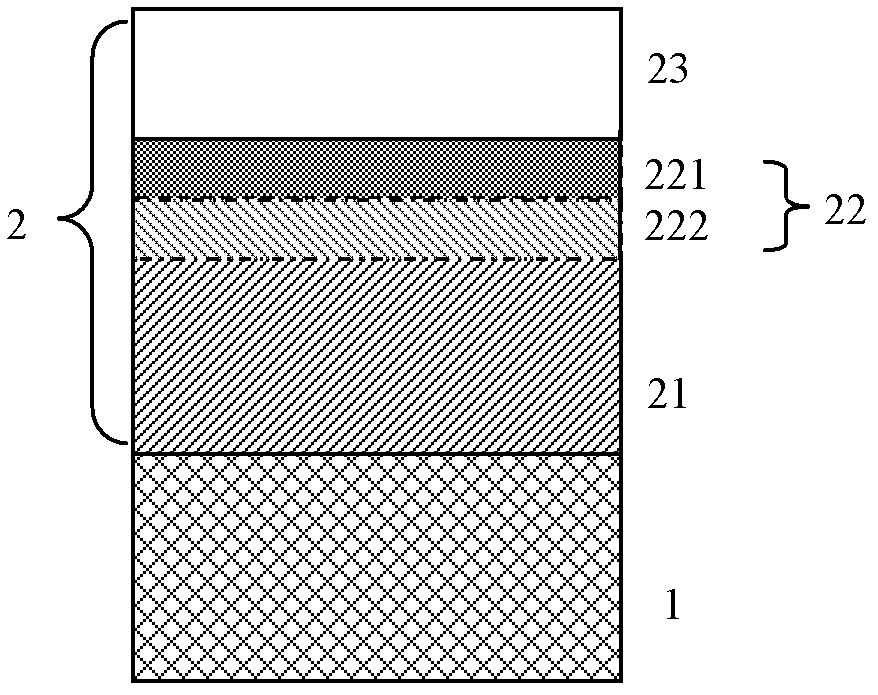

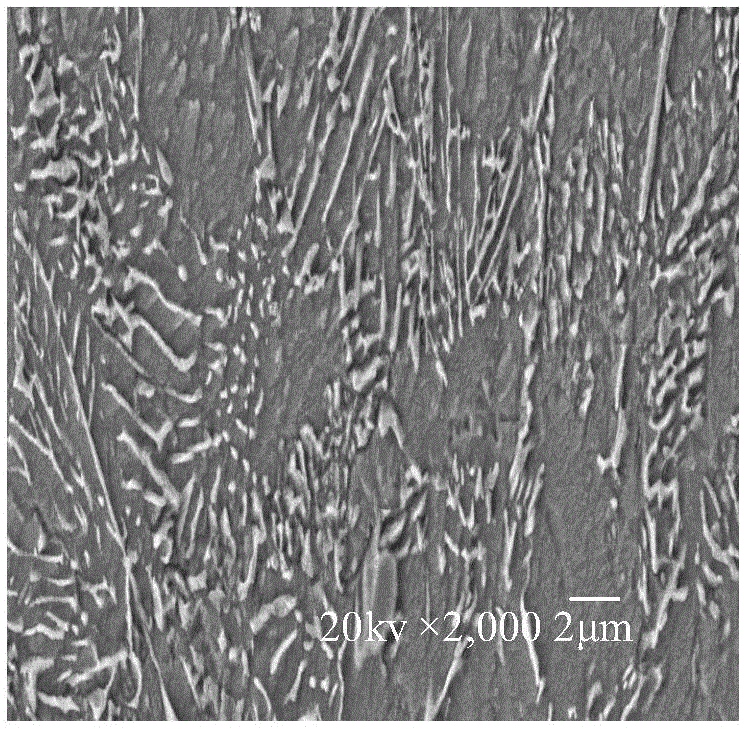

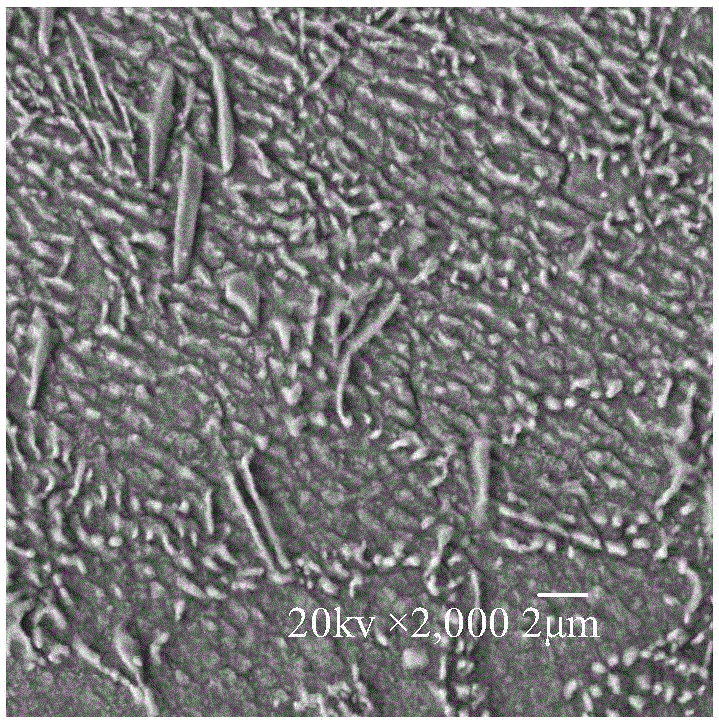

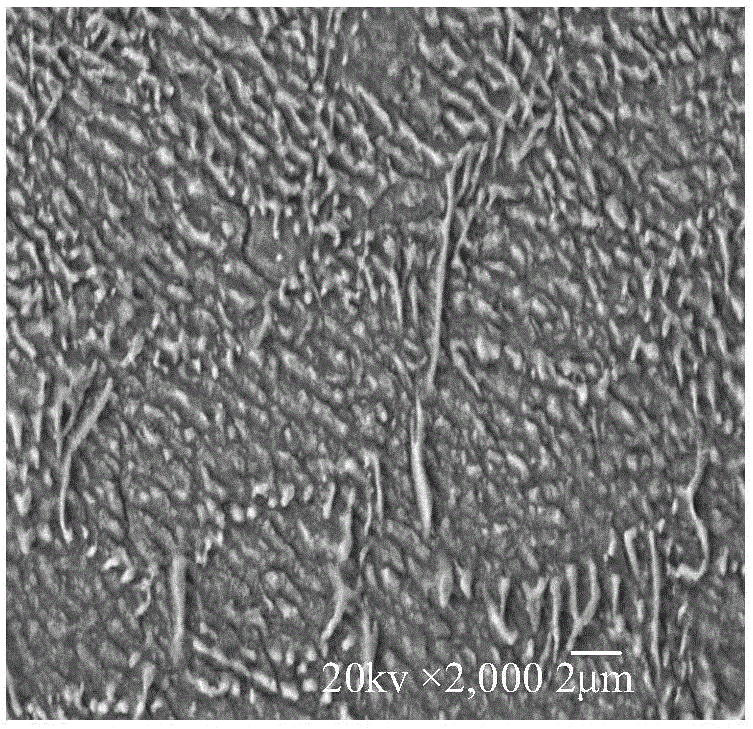

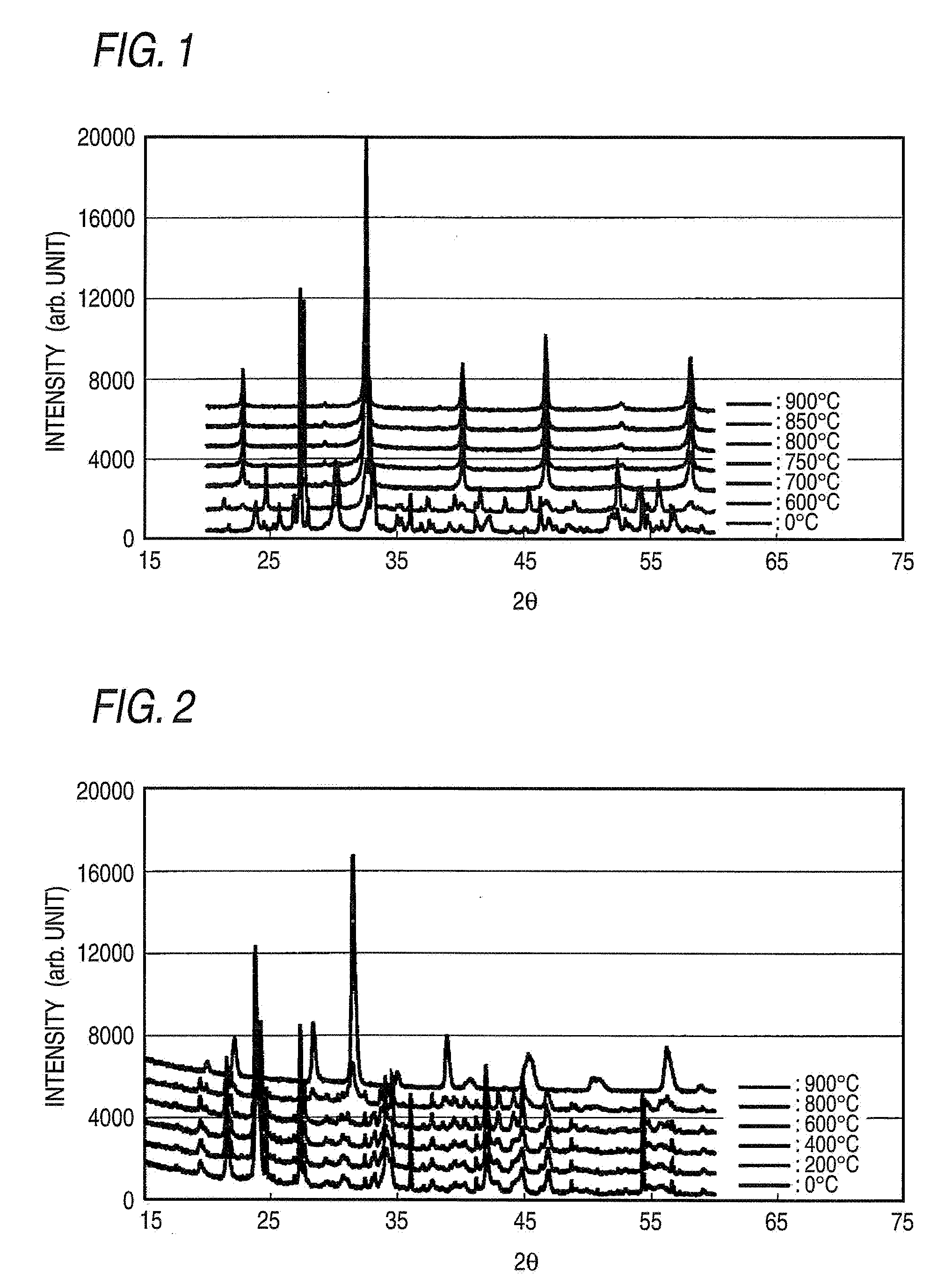

Cutting tool for improving coating structure and preparation method thereof

ActiveCN103173761AExcellent oxidation and crater wear resistanceImprove uniformityTurning toolsSuperimposed coating processSingle phaseCast iron

The invention discloses a cutting tool for improving a coating structure. The cutting tool comprises a matrix and a coating covering the matrix. The coating comprises an inner layer B, a transitional layer C and an outer layer D from inside to outside. The inner layer B consists of transitional elements and nonmetal compounds. The transitional layer C comprises a transitional layer C1 and / or a transitional layer C2. The transitional layer C1 and C2 are mainly formed by carbon oxynitride with titanium. The outer layer D has a single phase alpha-Al2O3 structure. The thickness d of the outer layer D is 0.5-4 mu m. The mean grain size S is greater than or equal to 0.2 mu m but less than or equal to 0.5 mu m. The preparation method comprises the following steps of: first, preparing the tool matrix; then, sequentially depositing the inner layer B, the transitional layer C2, the transitional layer C1 and the outer layer D in a same coating period; and then, performing surface treatment to manufacture the cutting tool. The cutting tool provided by the invention is high in hardness and good in wear resistance, and has excellent cutting performance in cutting materials such as steel, stainless steel and cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

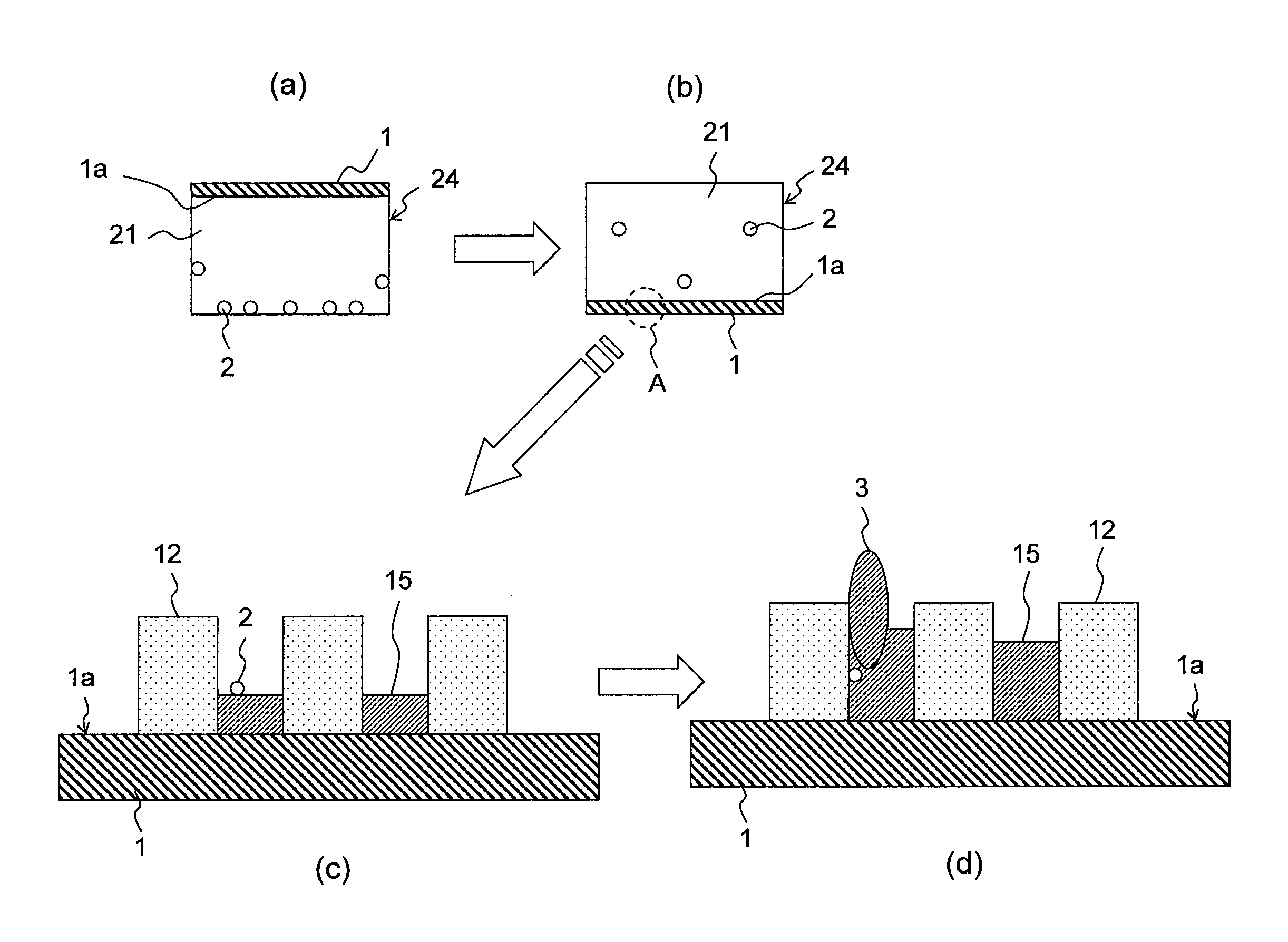

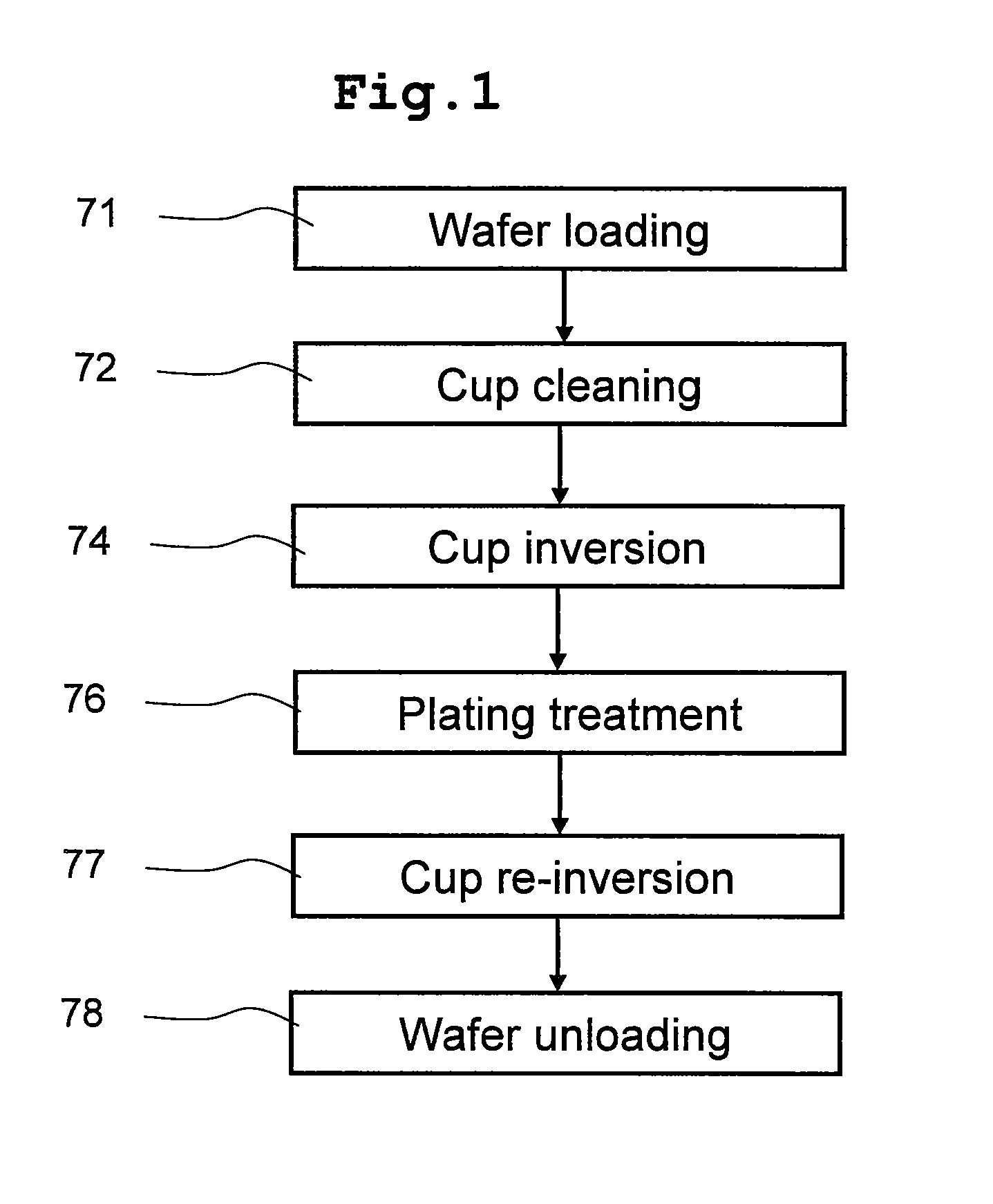

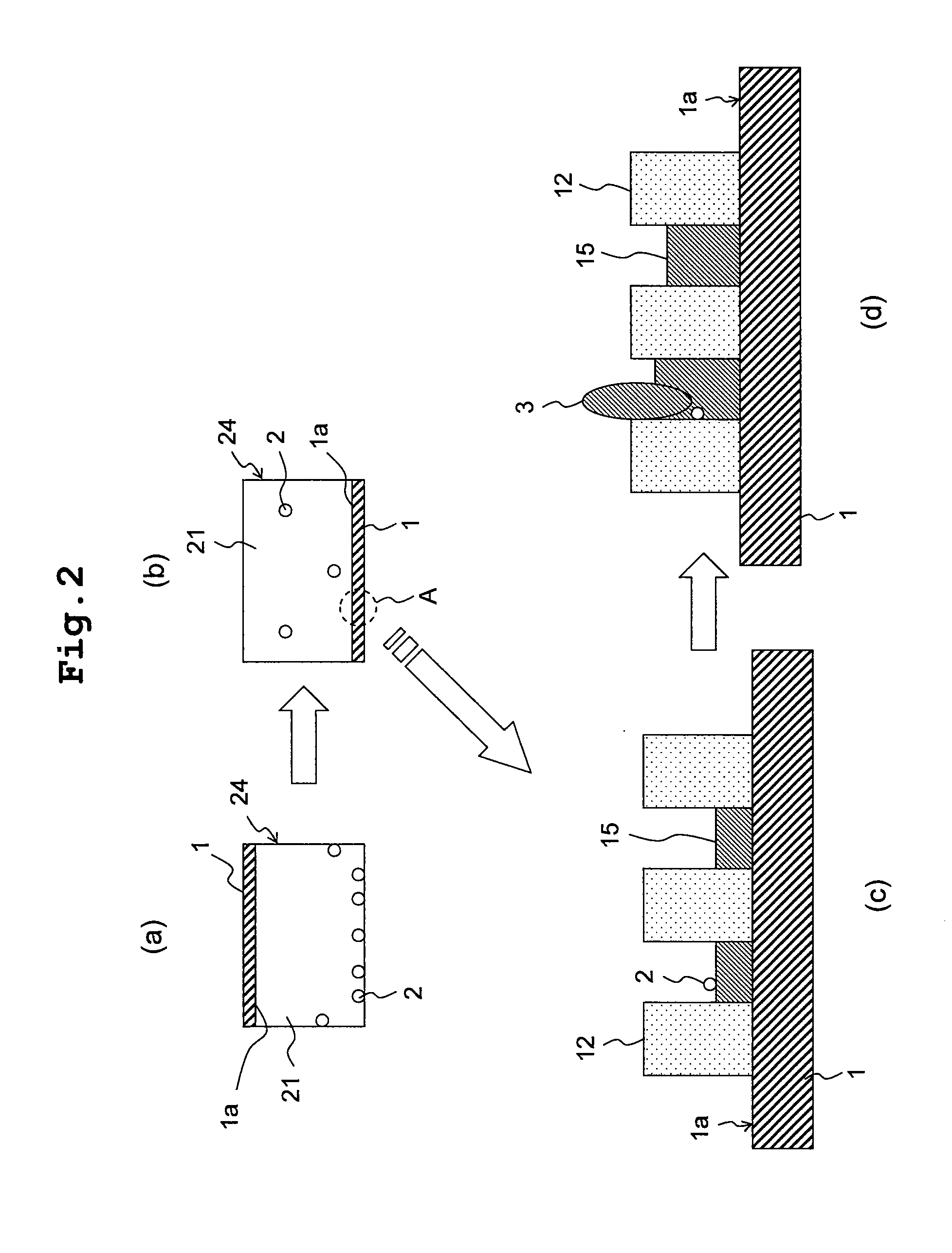

Manufacturing method of semiconductor integrated device

InactiveUS20090117730A1Avoid abnormal growthHighly uniform thicknessCellsAnodisationAbnormal growthsEngineering

Manufacture of semiconductor products such as LCD driver requires a bump plating step for forming a gold bump electrode having a size of from about 15 to 20 μm. This bump plating step is performed by electroplating with a predetermined plating solution, but projections intermittently appear on the bump electrode during a mass production process. In the invention, abnormal growth of projections over the gold bump electrode is prevented by adding, prior to the gold bump plating step, a step of circulating and stirring a plating solution while erecting a plating cup and efficiently dissolving / discharging a precipitate. This step is performed for each wafer to be treated.

Owner:RENESAS ELECTRONICS CORP

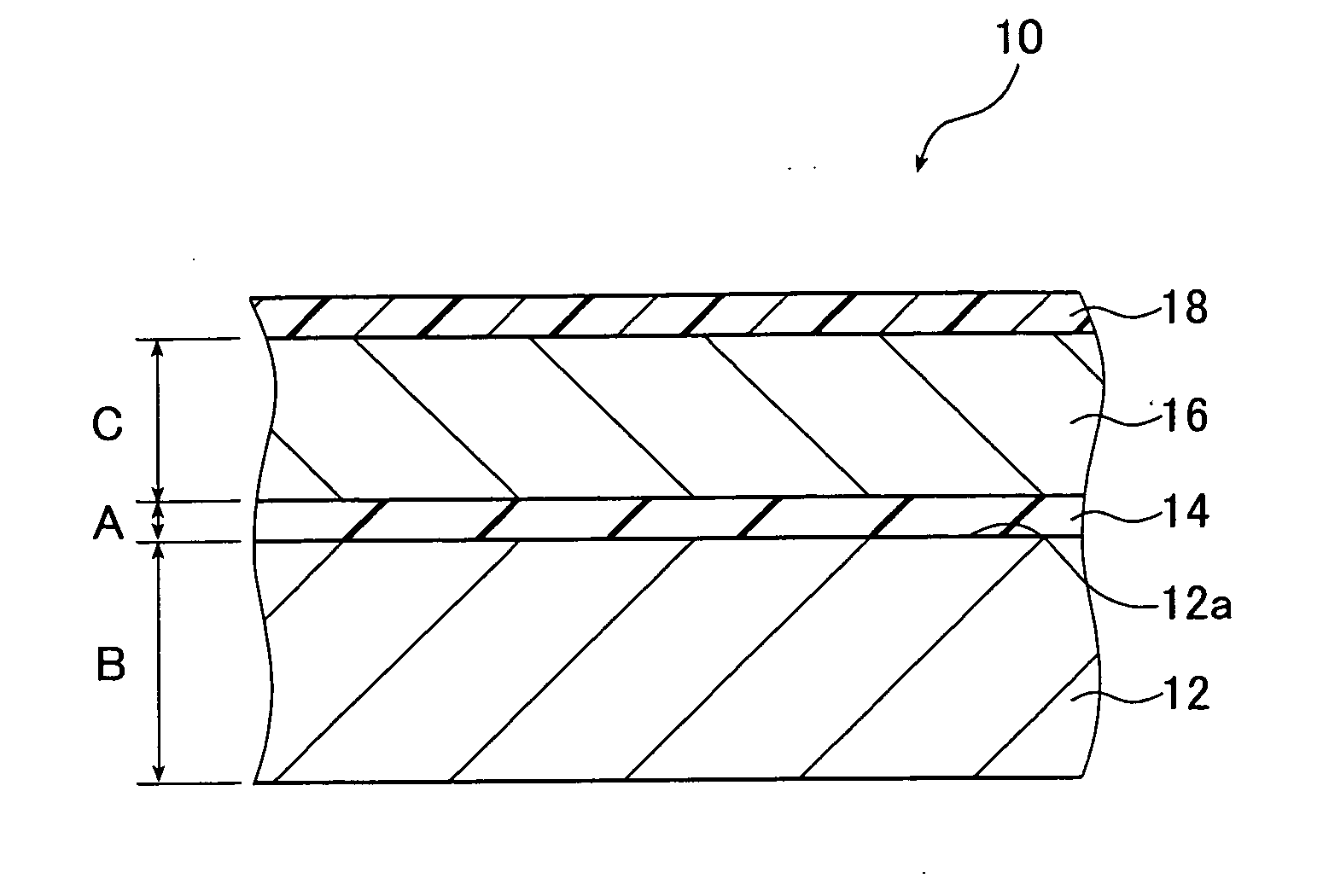

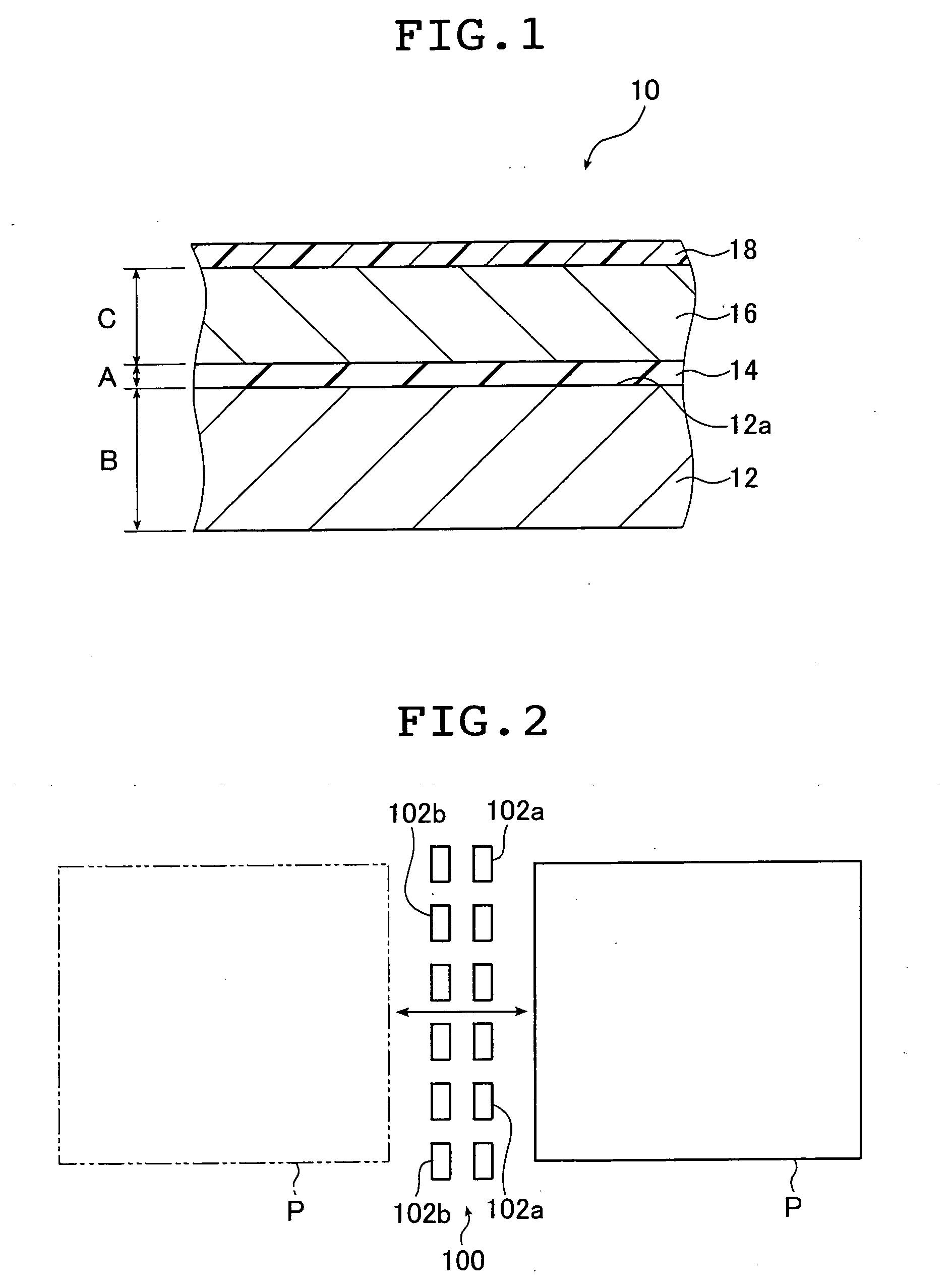

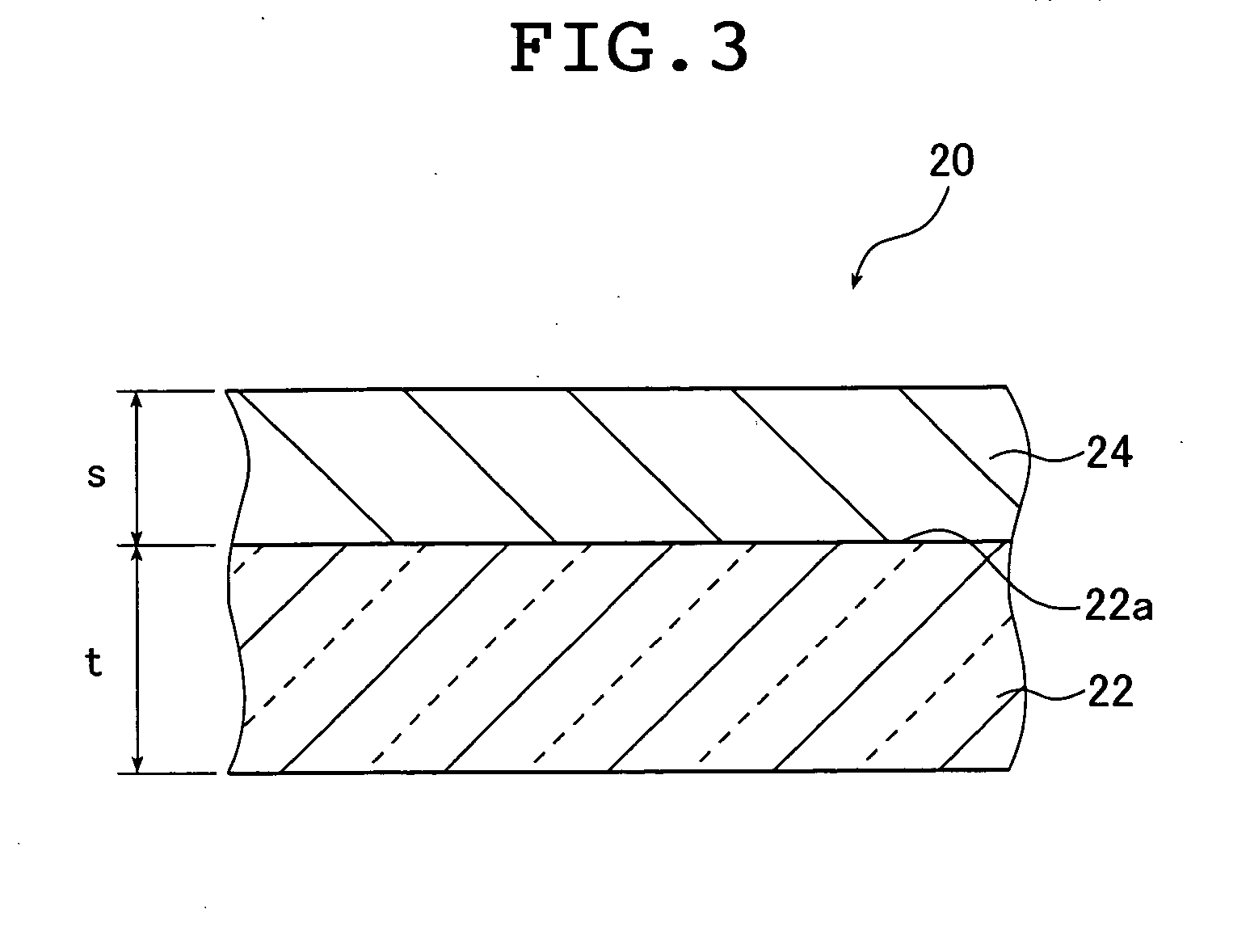

Radiographic image conversion panel and method of manufacturing the same

InactiveUS20060060792A1Highly uniform thicknessWithout deteriorationPhotometryFluorescence/phosphorescenceGas phaseFluorescence

There is provided a radiographic image conversion panel having a substrate made of a metal or an alloy, an oxide layer formed on the substrate by a vapor deposition technique such as sputtering, ion plating or ion beam assisted deposition, and a phosphor layer formed on the oxide layer by the vapor deposition technique. A method of manufacturing the radiographic image conversion panel is also provided. The radiographic image conversion panel is capable of suppressing for a long time corrosion of the surface of the substrate due to a reaction between a stimulable phosphor and the substrate through moisture and also capable of providing a radiographic image without any deterioration of the characteristics.

Owner:FUJIFILM CORP +1

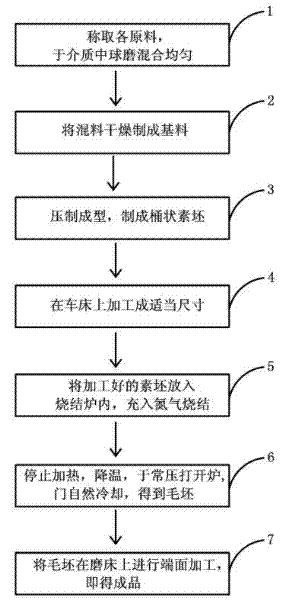

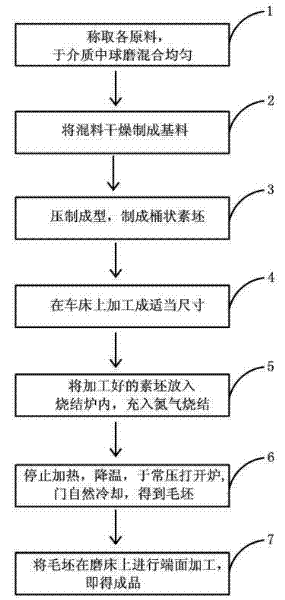

Silicon nitride material and preparation method of heat insulating disc cover prepared from same

The invention relates to a silicon nitride material and a preparation method of a heat insulating disc cover prepared from the same. The silicon nitride material consists of the following raw materials in percentage by weight: 65-87.5 percent of silicon nitride, 5-15 percent of nano-silicon nitride, 8-15 percent of a sintering aid and 0.5-5 percent of tungsten carbide; and the preparation method of the heat insulating disc cover prepared from the silicon nitride material comprises the following steps of: weighing the silicon nitride, nano-silicon nitride, sintering aid and tungsten carbide according to the percentage by weight, performing ball milling and mixing uniformly; drying a mixed material to obtain a substrate; performing press molding to obtain a cylindrical biscuit; processing to a proper size on a lathe; putting the processed biscuit into a sintering furnace, and charging nitrogen gas for sintering; stopping heating, cooling, opening a furnace door under the normal pressure, and cooling naturally to obtain a blank; and performing end face processing on the blank on a grinding machine to obtain a finished product.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD

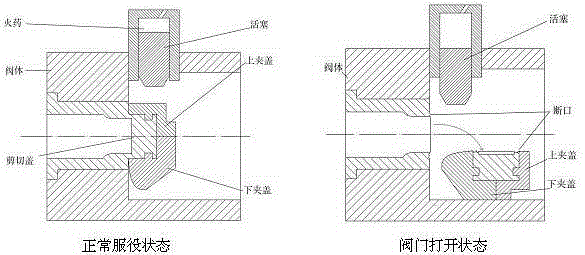

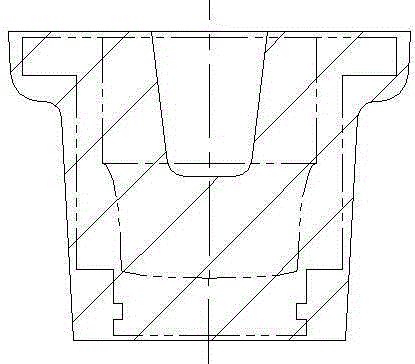

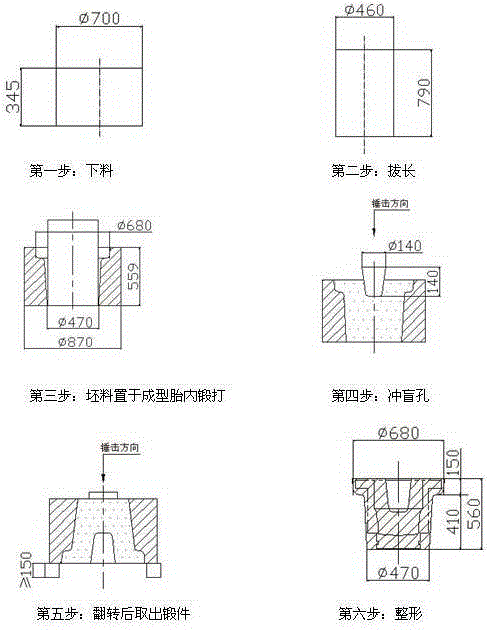

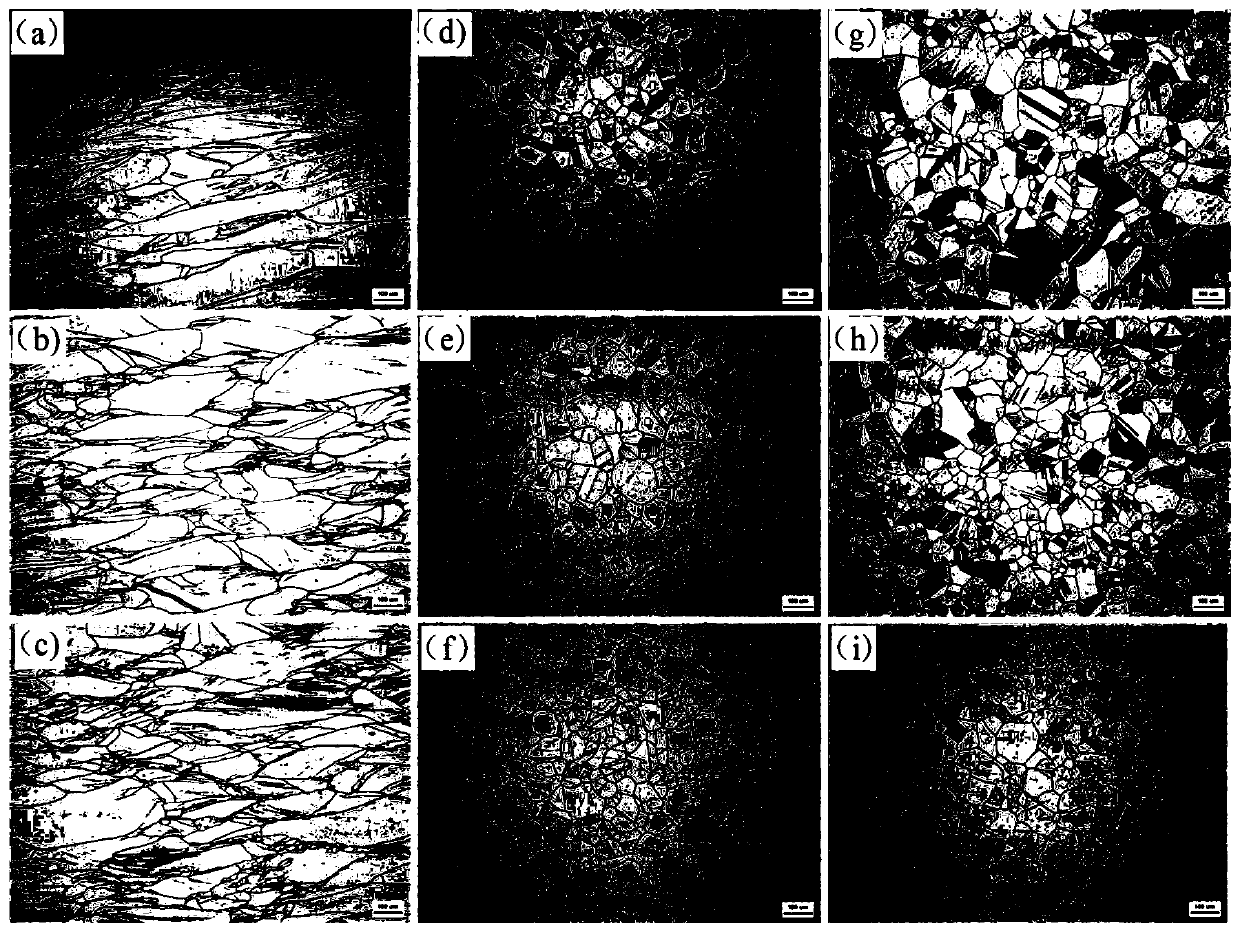

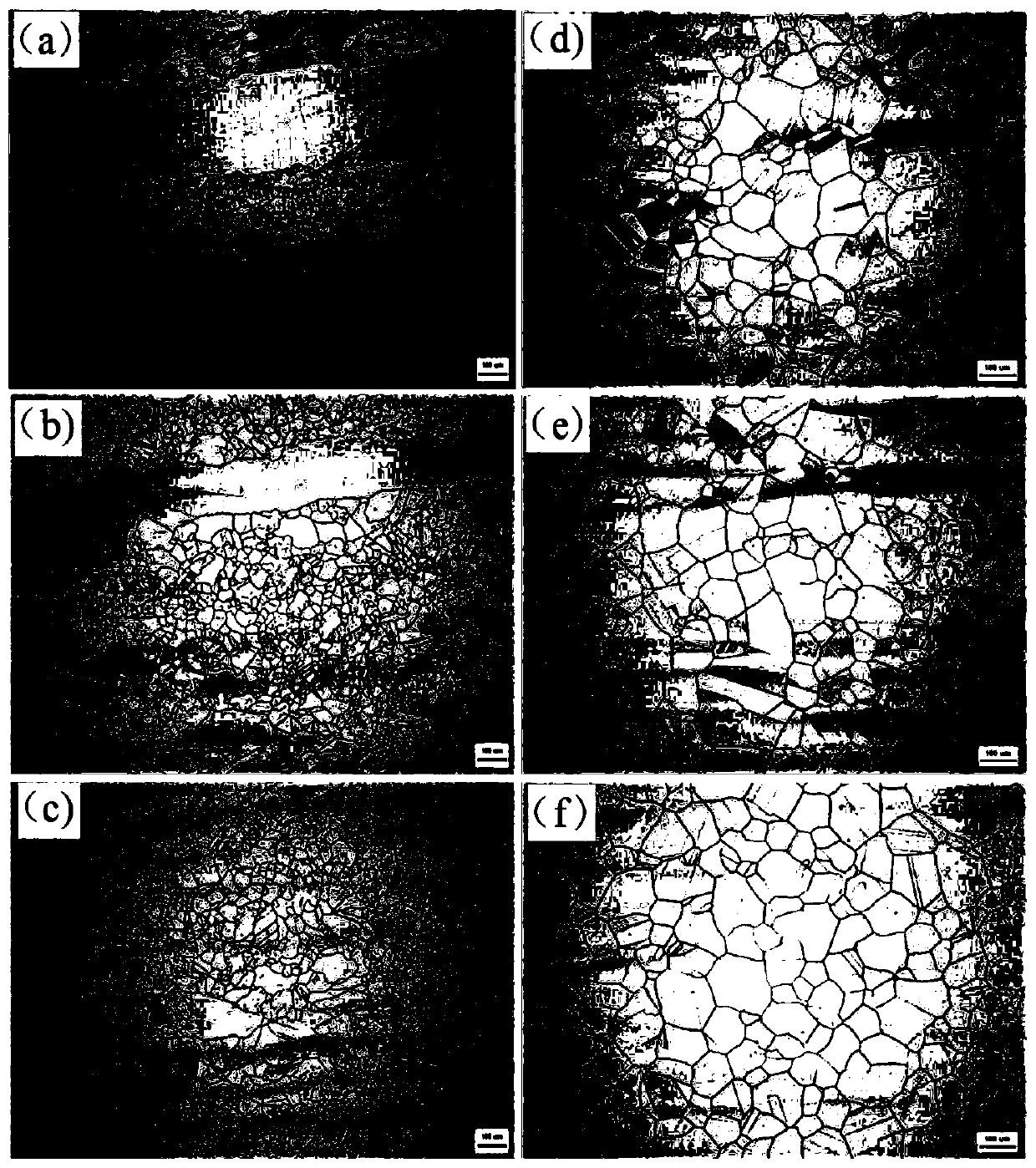

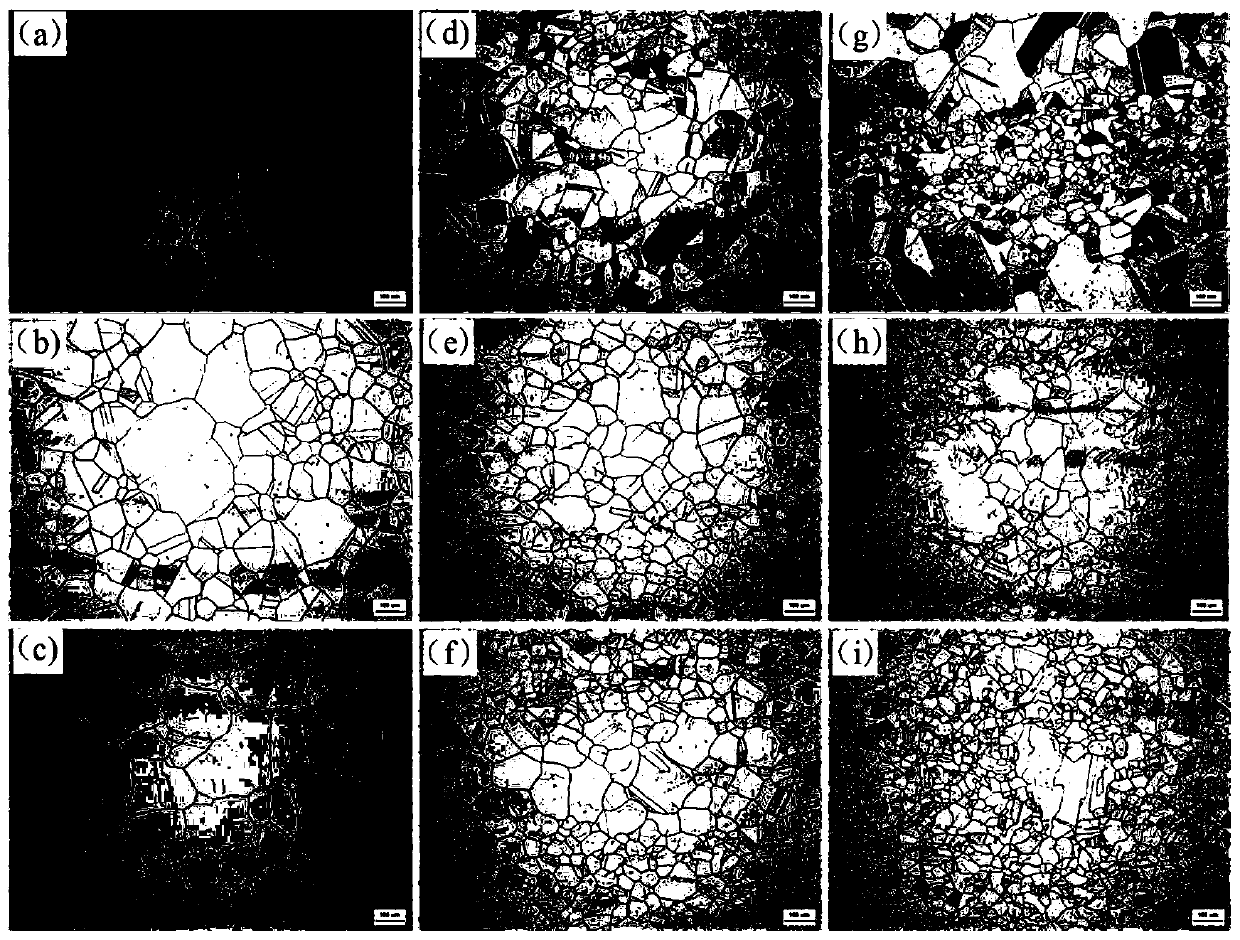

Crystalline grain control method for GH690 alloy shear cover of explosion valve

ActiveCN105170865AAddressing inhomogeneitySolve the problem of abnormal grain growthValve arrangementsMetal-working apparatusAlloyMaterials processing

The invention discloses a crystalline grain control method for a GH690 alloy shear cover of an explosion valve and belongs to the technical field of material machining. The method aims to solve the problems that the structure of a forge piece of the GH690 alloy material shear cover of the explosion valve is not even, and crystalline grains abnormally grow up. A heat treatment machining is organically combined with a forging machining, and the machining method that large deformation free forging is implemented at a high temperature (1020 DEG C to 1150 DEG C), small deformation foetal die forging is implemented at a medium temperature (710 DEG C to 850 DEG C), and the inhibition function of carbide second-phase particles on moving of a grain boundary is used for restraining the abnormal growth of the crystalline grains in forging machining of the shear cover in an auxiliary mode is provided. According to the crystalline grain control method for the GH690 alloy shear cover of the explosion valve, the forging piece forming and crystalline grain refinement are conducted synchronously, and the shear cover forge piece is obtained through heating twice; the machining limitation that a forging piece with the simple structure is subjected to high-temperature multiple-time hierarchical forging machining at present is overcome; the forging heating number is reduced; the follow-up heating treatment of the forging piece of the GH690 nickel-based alloy sheer cover is avoided. The structure with even carbides and refined crystalline grains of the GH690 alloy shear cover of the explosion valve forged through the method can be obtained.

Owner:DALIAN UNIV OF TECH +1

Method for preparing small-particle-size cerium-activated yttrium aluminum garnet (YAG) florescent powder

ActiveCN105062482AImprove luminous efficiencyCrystallization perfectEnergy efficient lightingLuminescent compositionsCeriumCrystallinity

The invention discloses a method for preparing small-particle-size cerium-activated yttrium aluminum garnet (YAG) florescent powder. According to the method, first, in fused salt, a wrapping structure of nanometer yttrium oxide (cerium oxide) @ aluminum oxide particles is obtained through controlled synthesis, then the aggregate of small-particle YAG florescent powder particles is generated through reaction in high-temperature fused salt, and finally the small-particle-size YAG: Ce florescent powder is obtained through weak ball milling. It is avoided that in the reaction process, the aluminum oxide particles and intermediate-phase particles abnormally grow, and while the high crystallinity of the particles is kept, final YAG is effectively controlled; the particle size of the Ce florescent powder has important significance for improving light-color quality of white-light LEDs, lowering the complexity of a white-light LED packaging technology and increasing the yield.

Owner:SOUTHEAST UNIV

Transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic

ActiveCN105198443AConducive to initial sintering densificationFacilitate the realization of initial sintering densificationCeramic sinteringBoron nitride

The invention discloses a transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic and relates to a sintering method of boron nitride multi-phase ceramic. The invention aims at solving the problems that the crystal grains of the prepared multi-phase ceramic are coarse and the mechanical performance is poor for a reason that the sintering temperature of the existing boron nitride multi-phase ceramic. The method comprises the following steps: 1) preparing composite sintering assistant powder; 2) preparing composite powder; 3) increasing the temperature of the composite powder under a vacuum or inert atmosphere condition, increasing pressure and then decreasing the temperature to obtain the boron nitride multi-phase ceramic. The compactness of the boron nitride multi-phase ceramic prepared by adopting the method disclosed by the invention can reach more than 95 percent, the crystal grains of the material are fine and the comprehensive mechanical performance is excellent. The invention belongs to the field of preparation of boron nitride multi-phase ceramics.

Owner:HARBIN INST OF TECH

Control method of local loading and shaping equiaxial alpha content of titanium alloy

InactiveCN101603163AAvoid abnormal growthReduce uneven deformationHeat treatment process controlLoad stepTitanium alloy

The invention discloses a control method of local loading and shaping equiaxial alpha content of titanium alloy. After a blank is changed to forge and is pre-shaped, a shaped forging piece is obtained by isothermal local loading and shaping, finishing and heat treating. Local loading is finished by two passes, and each pass is finished by two loading steps. A mould is divided into two to three modules, and the relative position of different modules can be adjusted. In each loading step in the same pass, different modules are used for carrying out deforming on the blank; after all loading steps in the pass are finished, the next step is started, the loading method in the last step is repeated to finish the forging piece deformation; the equiaxial alpha phase volume fraction effectively controlling the local loading and shaping of the forging piece is obtained, and is controlled within 10-20%; the equiaxial alpha phase volume fraction of different positions on the forging piece differs within 5%; equiaxial alpha crystal and beta crystal are both even and small, have no phenomena of coarsing, unevenness and extraordinary growth, and have favourable mechanical property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Novel potassium sodium niobate-based leadless piezoelectric ceramics and preparation method thereof

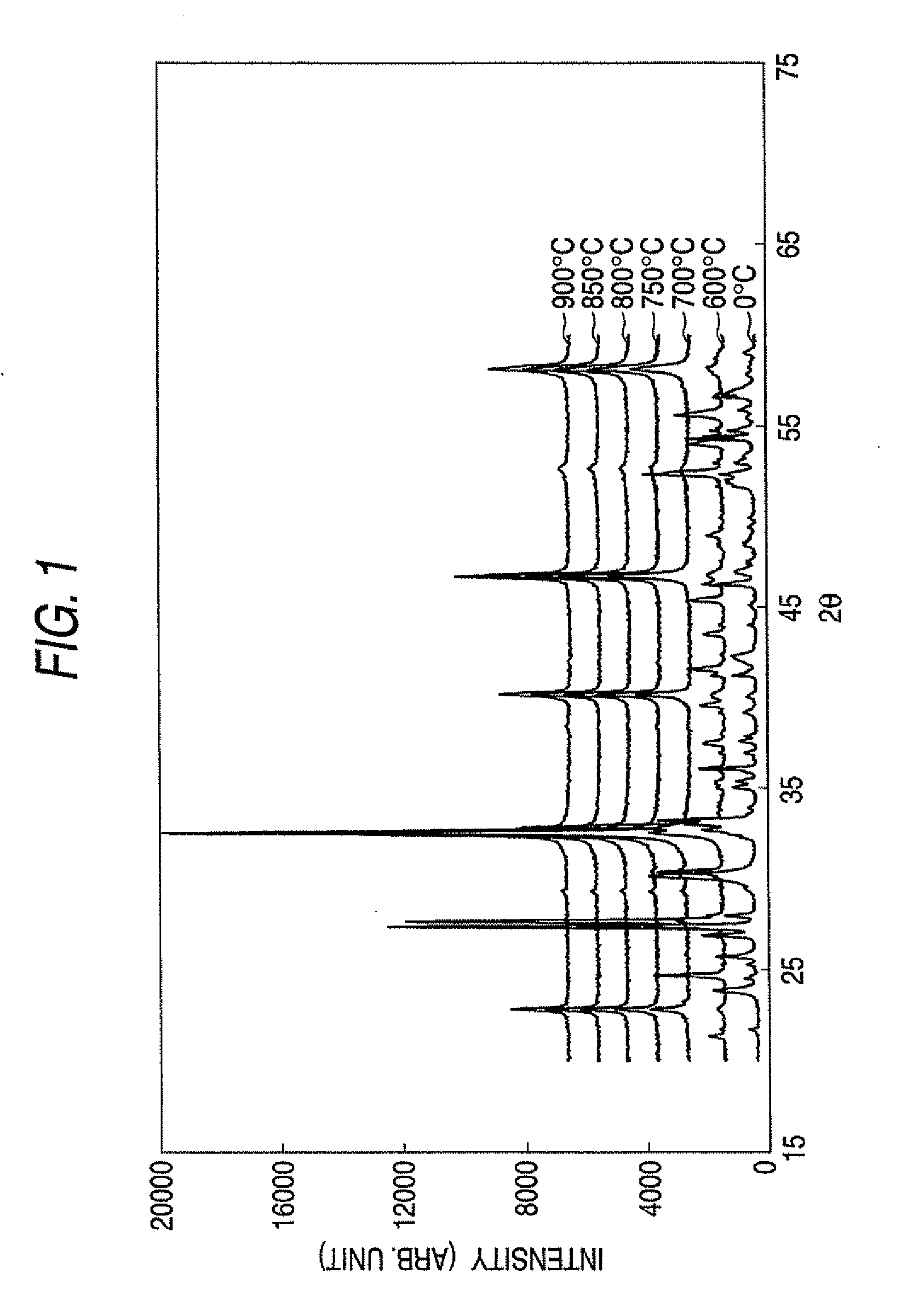

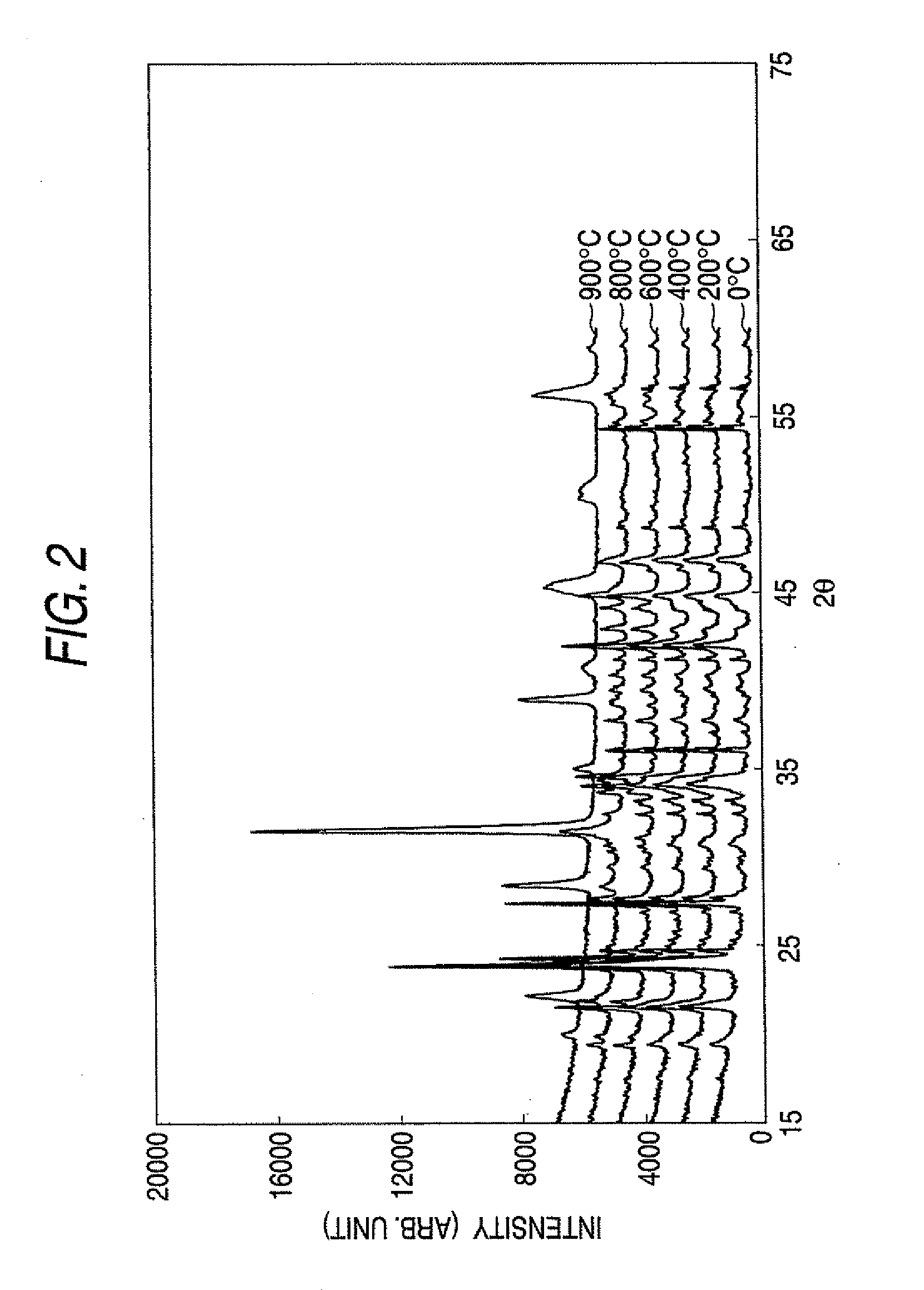

InactiveCN103467096AGuarantee structureLower sintering temperaturePhysical chemistryMicrowave sintering

The invention discloses a novel potassium sodium niobate-based leadless piezoelectric ceramics and a preparation method thereof. The potassium sodium niobate-based leadless piezoelectric ceramics which is higher in density, excellent in piezoelectric property and environment-friendly is prepared by adjusting the components of the potassium sodium niobate-based leadless piezoelectric ceramics and adopting the technologies such as microwave sintering, silver roasting, polarization, etc. The novel potassium sodium niobate-based leadless piezoelectric ceramics is prepared from the raw materials of chemical pure Na2CO3, K2CO3, Li2CO3, Nb2O5, Ta2O5 and Sb2O3, and the additives of chemical pure ZnO, ZnCO3 or 5ZnO.4CO2.6H2O; the composition of the leadless piezoelectric ceramics is expressed as the chemical formula: (Na 0.52 K0.46 Li 0.06) (Nb 0.86 Tb 0.08 Sb 0.06) O(3+x) ZnO, wherein x is equal to 0.00-0.05.

Owner:HENAN UNIV OF SCI & TECH

Method for manufacturing high-performance NdFeB rare earth permanent magnetic device

ActiveUS20150243416A1High energyImprove propertiesTransportation and packagingMetal-working apparatusFiberHydrogen

A method for manufacturing a high-performance NdFeB rare earth permanent magnetic device which is made of an R—Fe—Co—B-M strip casting alloy, a micro-crystal HR—Fe alloy fiber, and TmGn compound micro-powder, includes steps of: manufacturing the R—Fe—Co—B-M strip casting alloy, manufacturing the micro-crystal HR—Fe alloy fiber, providing hydrogen decrepitating, pre-mixing, powdering with jet milling, post-mixing, providing magnetic field pressing, sintering and ageing, wherein after a sintered NdFeB permanent magnet is manufactured, machining and surface-treating the sintered NdFeB permanent magnet for forming a rare earth permanent device.

Owner:SHENYANG GENERAL MAGNETIC

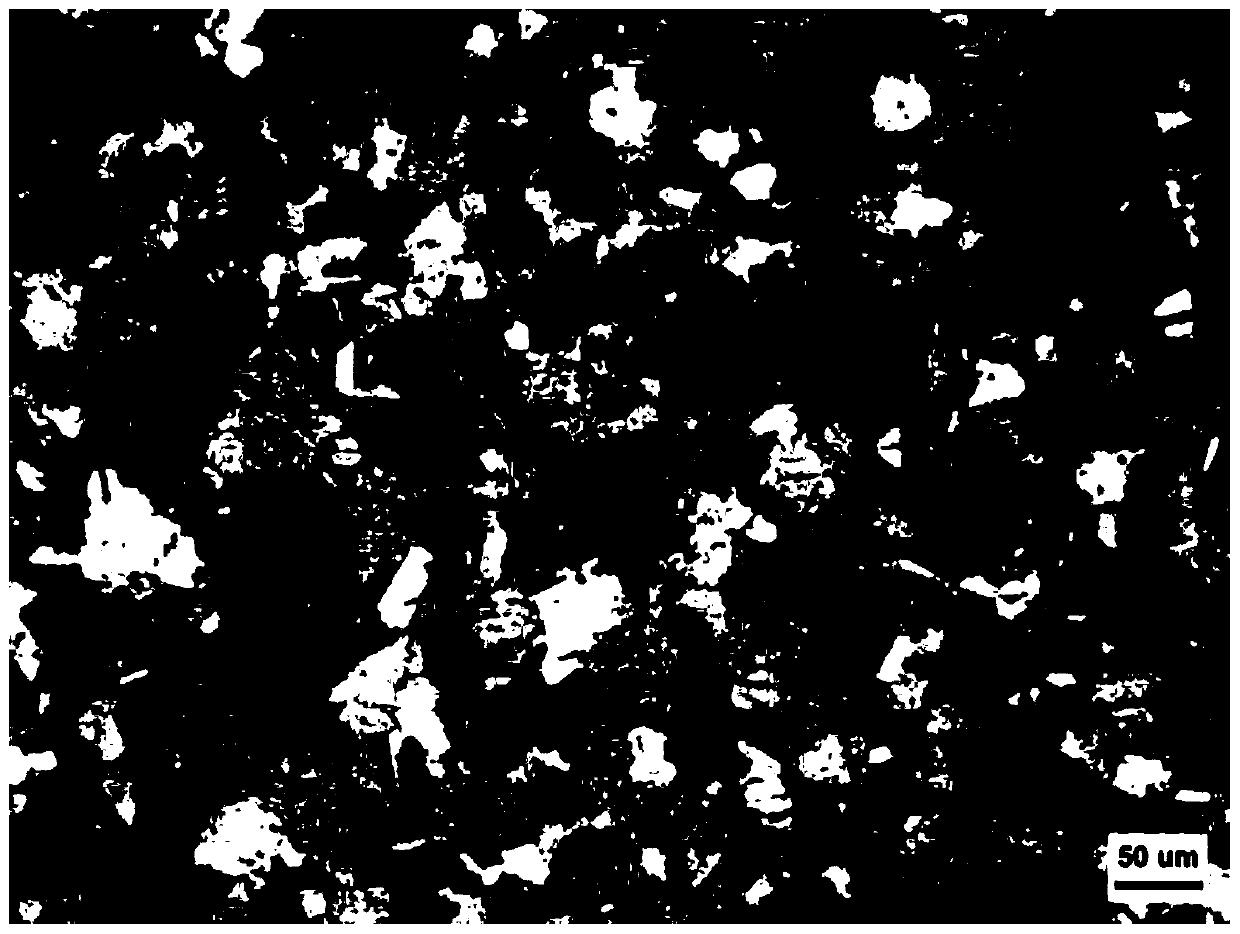

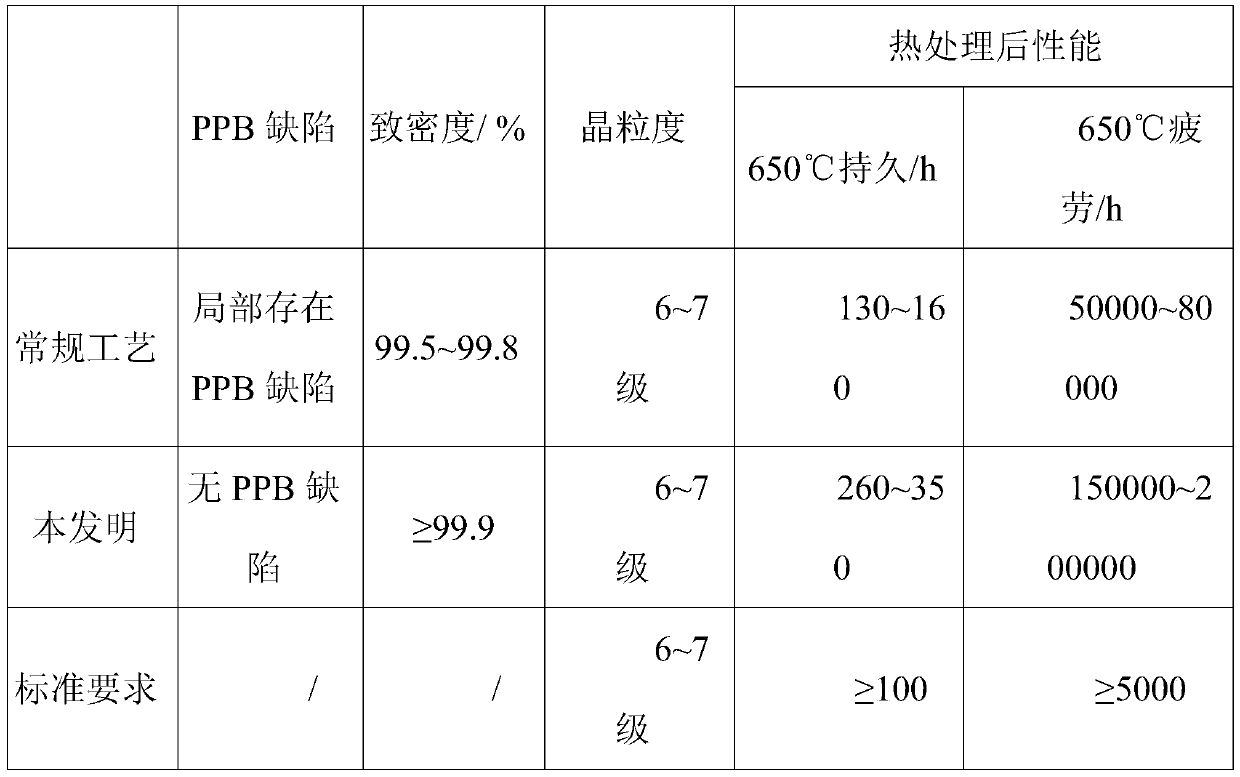

Hot isostatic pressing forming method of nickel-based high-temperature alloy powder disc

ActiveCN110666175AAvoid abnormal growthInhibition formationTurbinesOther manufacturing equipments/toolsSuperalloyMelting temperature

The invention discloses a hot isostatic pressing forming method of a nickel-based high-temperature alloy powder disc, and specifically discloses a hot isostatic pressing forming method of nickel-basedhigh-temperature alloy powder. The method is suitable for preparing a powder high-temperature alloy disc piece subjected to direct hot isostatic pressing forming. The hot isostatic pressing forming method is characterized in that high-temperature alloy powder prepared by a plasma rotating electrode method is used as a raw material, wherein the powder is packaged and sealed and welded under a vacuum condition and then subjected to hot isostatic pressing; the temperature of the first hot isostatic pressing is 10-30 DEG C greater than the gamma' melting temperature, the pressure is not less than100MPa, and the time is not greater than 1h; after the first step is finished, the material is heated to reach 50-100 DEG C below the liquidus temperature, wherein the pressure is more than or equalto 100MPa, and the time is less than or equal to 30min; and after the second step is finished, the temperature is reduced to 10-20 DEG C below the melting temperature of the low-melting-point phase, the pressure is more than or equal to 100MPa, the temperature is kept for 30min, and the furnace is cooled. The method can effectively inhibit the generation of PPB defects in the hot isostatic pressing process and improve the density of the alloy, thereby preparing the high-temperature alloy powder disc with uniform and compact tissues.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

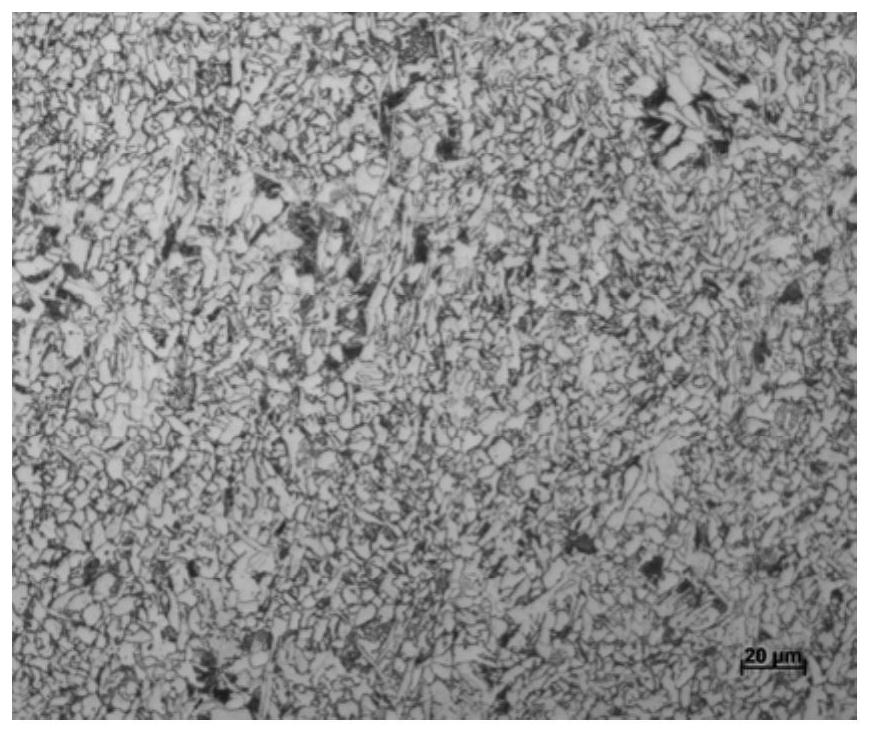

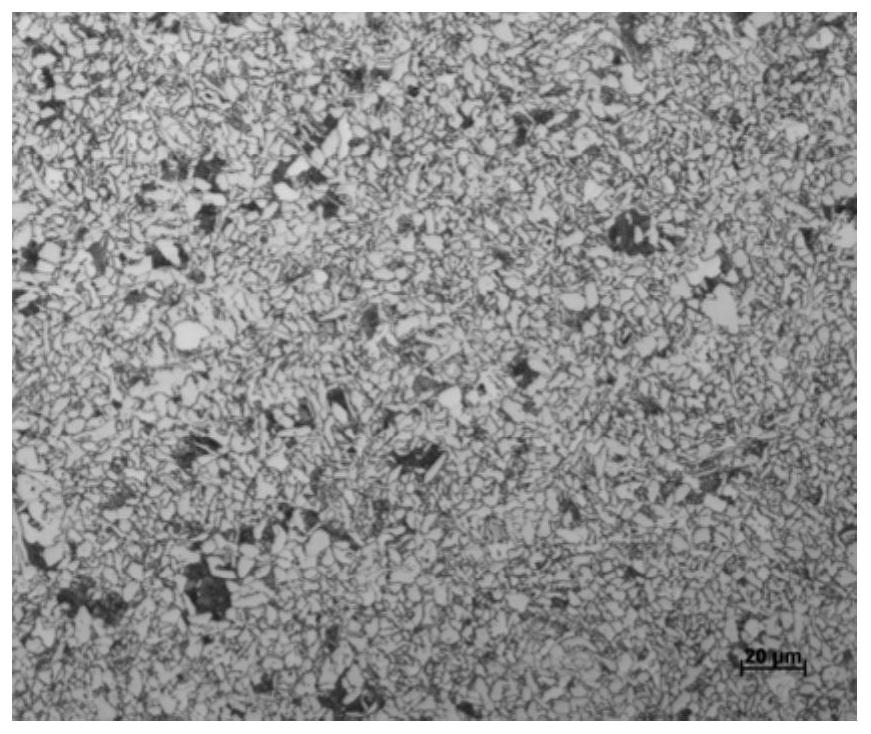

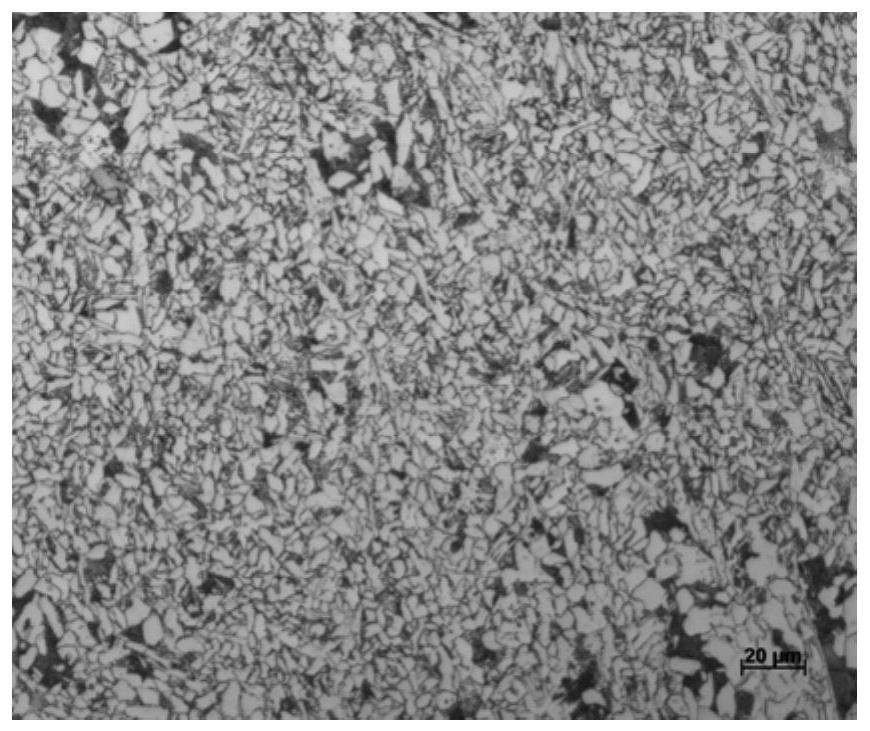

Method for controlling size uniformity of hot rolled high-carbon austenitic stainless steel grains

ActiveCN110724809APrevent precipitationAvoid abnormal growthFurnace typesHeat treatment furnacesSolution treatmentSS - Stainless steel

The invention discloses a method for controlling the size uniformity of hot rolled high-carbon austenitic stainless steel grains. The method comprises the following steps: 1, preparing a high-carbon austenitic stainless steel hot rolled medium plate; 2, putting the medium plate in a heating furnace of 900-920 DEG C for preheating, wherein the preheating time t1 is equal to 0.4-0.6 hour; 3, raisingthe temperature of the preheated plate to 1000-1010 DEG C along with the furnace for recrystallization treatment, or taking the preheated plate out for slow cooling, warming the heating furnace to 1000-1010 DEG C, and then putting the preheated plate in the heating furnace for recrystallization treatment; 4, raising the temperature of the recrystallization plate by 50-100 DEG C along with the furnace for solution treatment, or taking the recrystallization plate out for slow cooling, raising the temperature of the heating furnace by 50-90 DEG C, and then putting the recrystallization plate inthe heating furnace for solution treatment; and 5, carrying out water quenching on a solid solution plate to the normal temperature. According to the method, the recrystallization kinetics and the thermodynamics are taken as the acting points, the multi-stage stepped type annealing technology is adopted to release deformation stored energy step by step, the medium plate with uniform grains and adjustable and controllable grain size is obtained, the maneuverability is high, and industrial application can be realized.

Owner:NORTHEASTERN UNIV

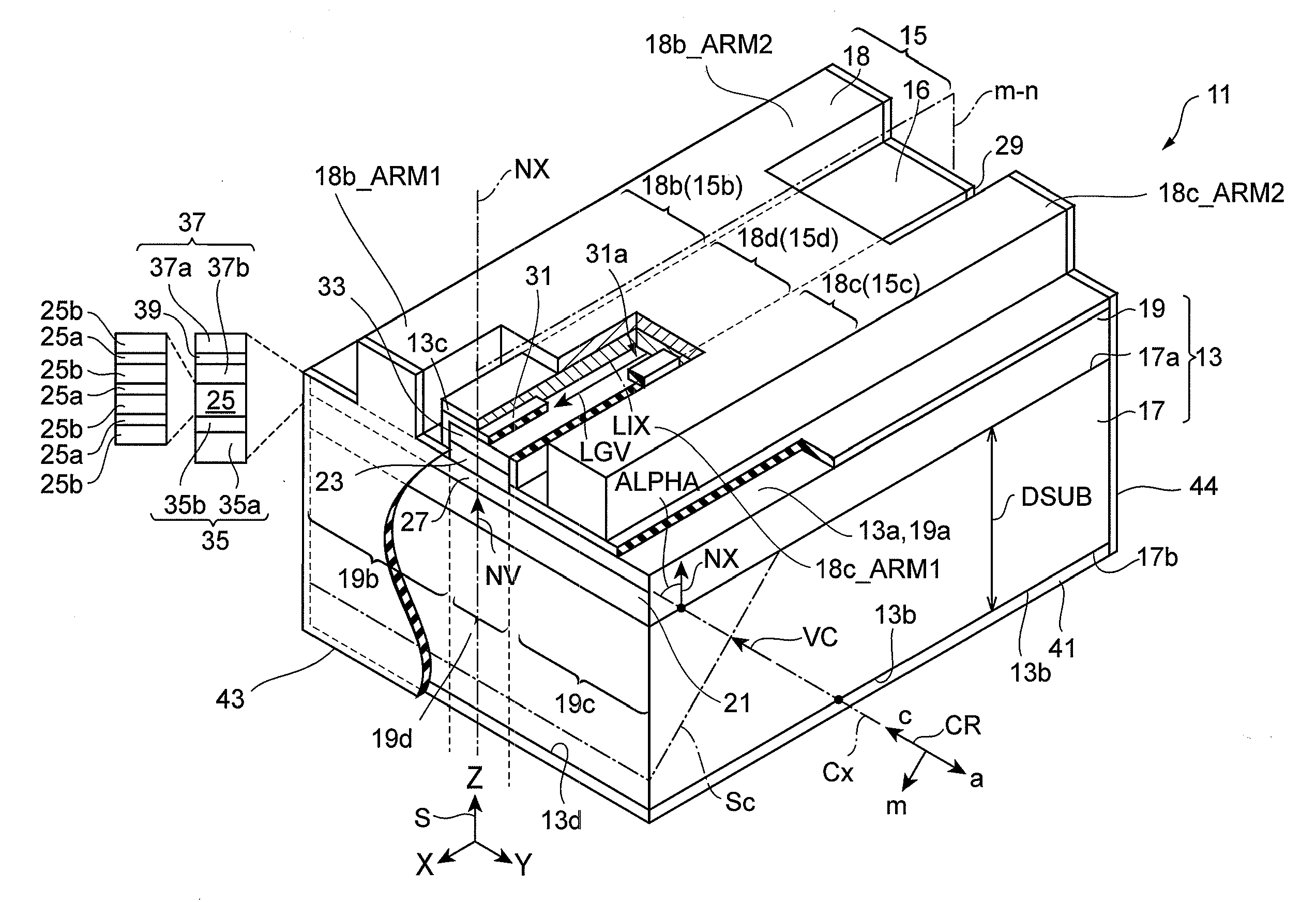

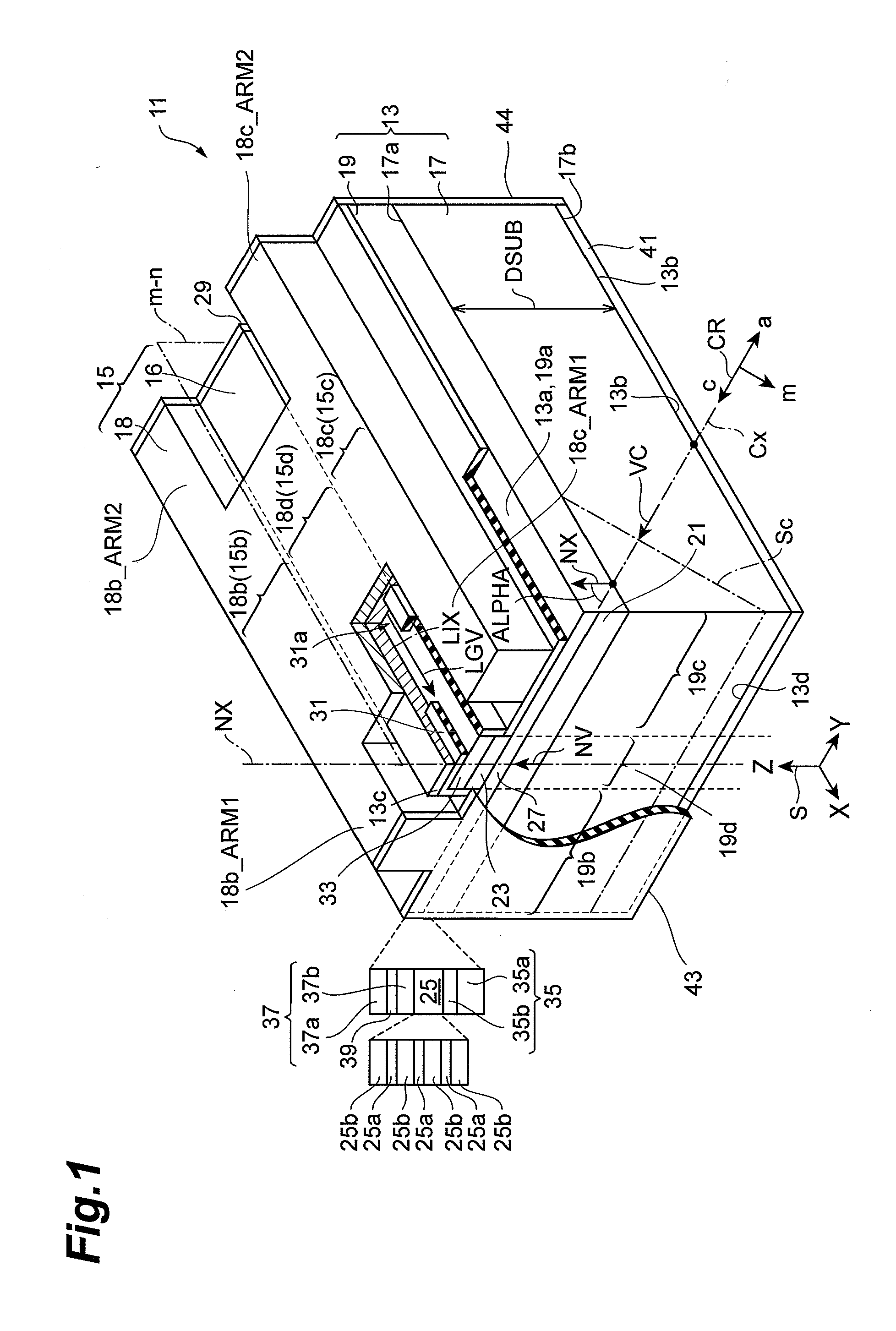

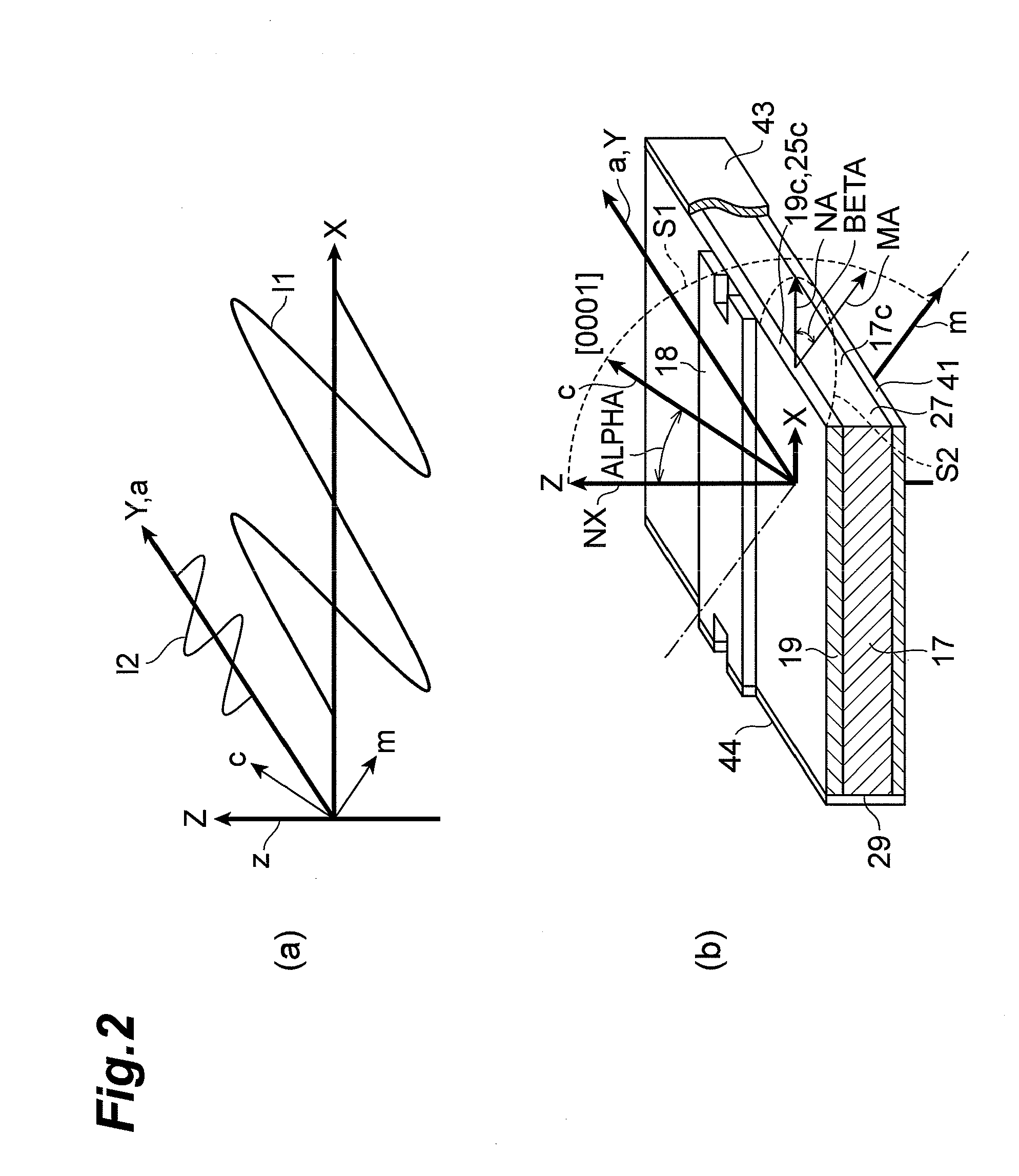

Group iii nitride semiconductor light emitting device

A group III nitride semiconductor laser device includes a laser structure, an insulating layer, an electrode and dielectric multilayers. The laser structure includes a semiconductor region on a semi-polar primary surface of a hexagonal group III nitride semiconductor support base. The dielectric multilayers are on first and second end-faces for the laser cavity. The c-axis of the group III nitride tilts by an angle ALPHA from the normal axis of the primary surface in the waveguide axis direction from the first end-face to the second end-faces. A pad electrode has first to third portions provided on the first to third regions of the semiconductor regions, respectively. An ohmic electrode is in contact with the third region through an opening of the insulating layer. The first portion has a first arm, which extends to the first end-face edge. The third portion is away from the first end-face edge.

Owner:SUMITOMO ELECTRIC IND LTD +1

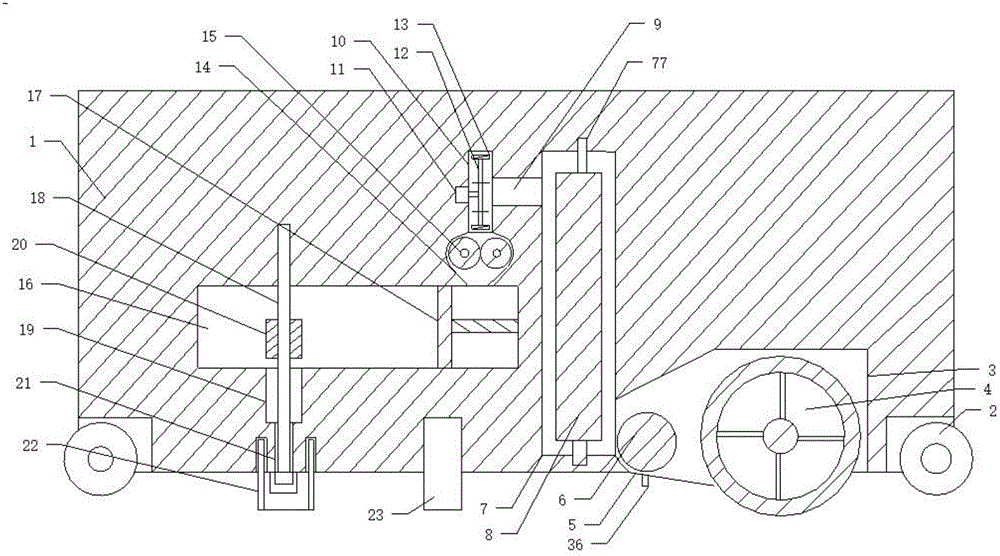

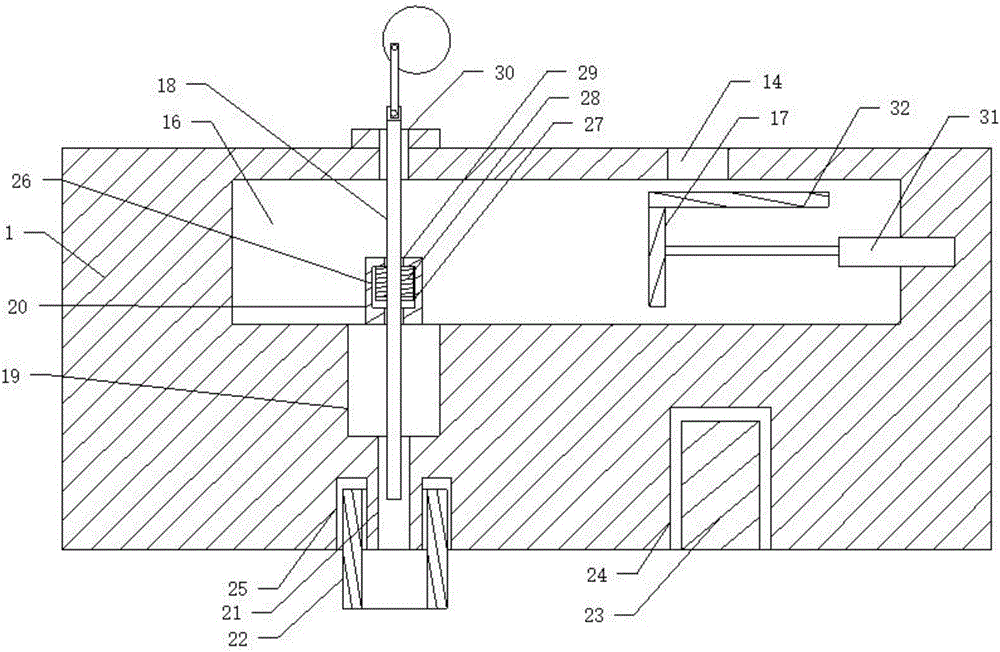

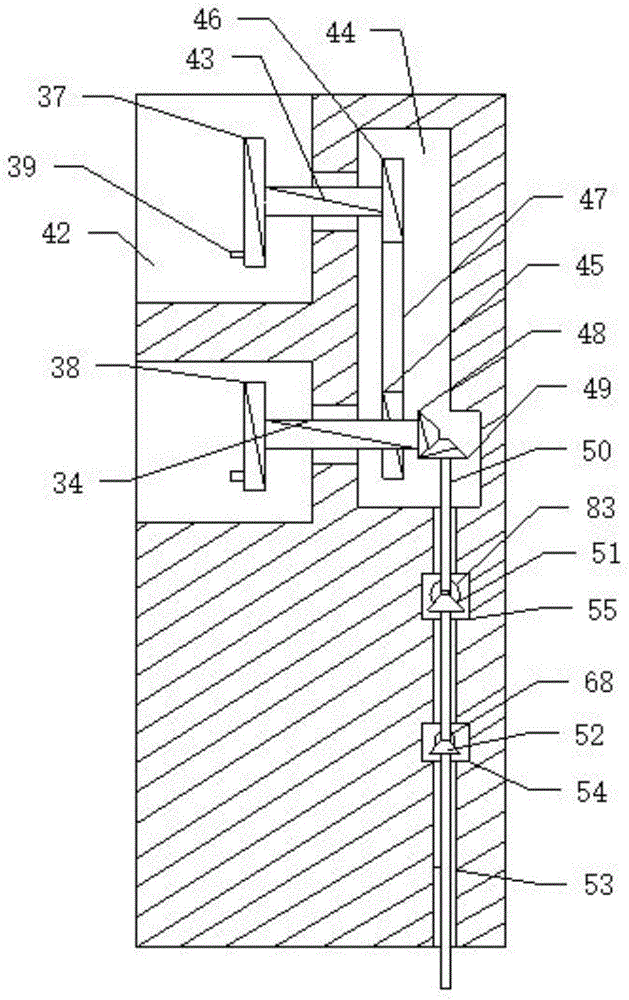

Agricultural weeding plunger type grass treating extruder

ActiveCN106576609AIncrease productionImprove germination ratePlantingCrop conditionersEngineeringOrganic matter

The invention discloses an agricultural weeding plunger type grass treating extruder. A first conveying disc which rotates corresponding to a weeding rolling wheel is also arranged in a weeding bottom groove; a feeding cavity which correspondingly communicates with the weeding bottom groove is also arranged in a machine body and is internally provided with a second conveying disc corresponding to the first conveying disc; a first extrusion cavity which correspondingly communicates with a crushing cavity is also arranged in the machine body; an extrusion plate slides in the first extrusion cavity; a sliding first top pressure rod and a sliding second top pressure rod are also arranged in the machine body; and the second top pressure rod is connected with a top pressure head. According to the agricultural weeding plunger type grass treating extruder, the first top pressure rod can be further utilized to discharge grasses through a discharge hole, the top pressure head can be utilized to punch holes in the ground, the grasses can be extruded into the holes punched by the top pressure head, and thus the effect of converting the grasses to an organic matter is further improved, and the utilization value of the grasses is increased.

Owner:YANCHENG SYNERGY MASCH CO LTD

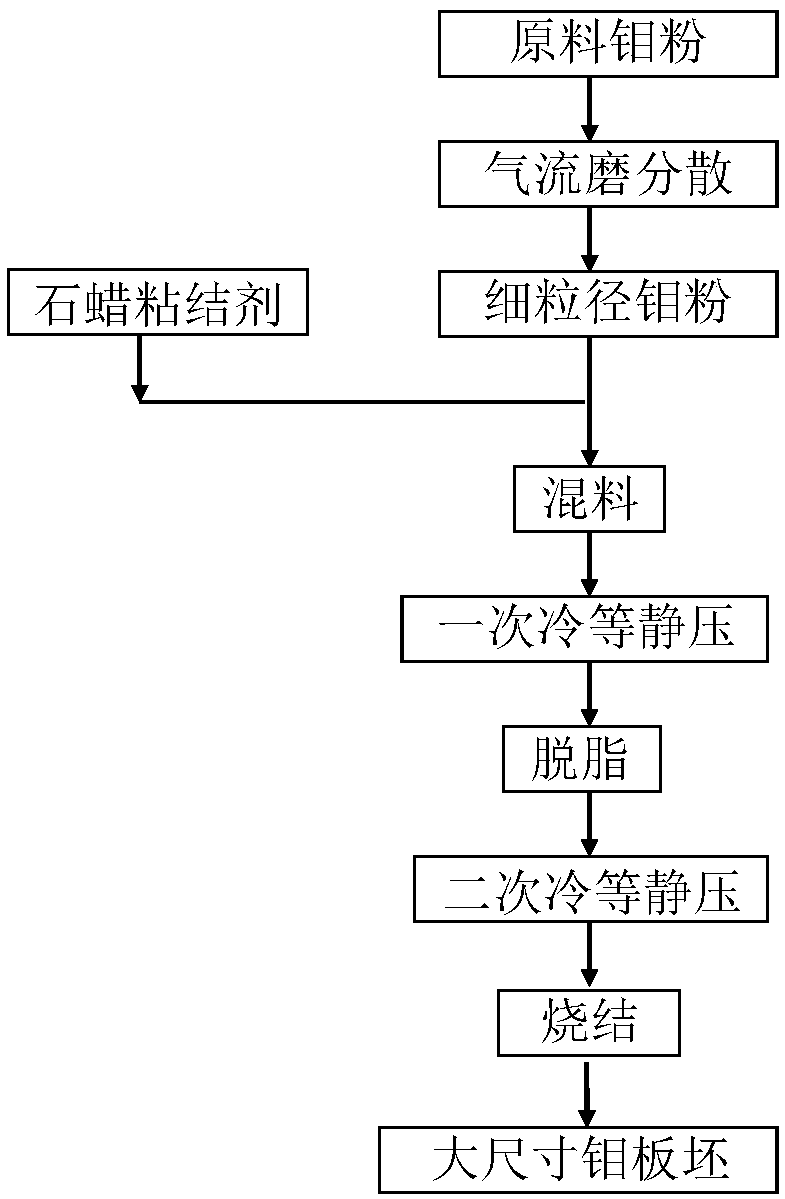

Method for preparing large-size molybdenum plate blank

ActiveCN108907211AGood dispersionUniform particle size distributionTransportation and packagingMetal-working apparatusHigh pressureMaterials science

The invention provides a method for preparing a large-size molybdenum plate blank, and belongs to the technical field of powder metallurgy. The method includes the steps that reducing molybdenum powder serves as a raw material, and small-granularity molybdenum powder which is evenly dispersed, has narrow granularity distribution and is nearly spherical is obtained through airflow milling treatment; then the small-granularity molybdenum powder and a paraffin binder are evenly mixed, and a mixture is obtained; and then by the adoption of a secondary isostatic cool pressing forming process, a degreased blank is isostatically pressed into a secondary blank under high pressure intensity. A sintering method of low-temperature slow heating and high-temperature rapid heating is adopted, specifically, slow heating is carried out at a low-temperature sintering stage, the blank is fully reduced in order to reduce the oxygen content in a blank body, and therefore the sintering activity of the blank is kept; and rapid heating is carried out at a high-temperature sintering stage, grain growth can be reduced, and after sintering is completed, the thick molybdenum plate blank with high density andhigh tissue uniformity can be obtained. By means of the preparation method, the problems that local looseness and cracks are easily generated in former large-size thick molybdenum plates are solved,the density of the prepared molybdenum plate blank reaches 99% or above, and the uniformity and the consistency of tissue of the surface and the center position of the plate blank can be guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

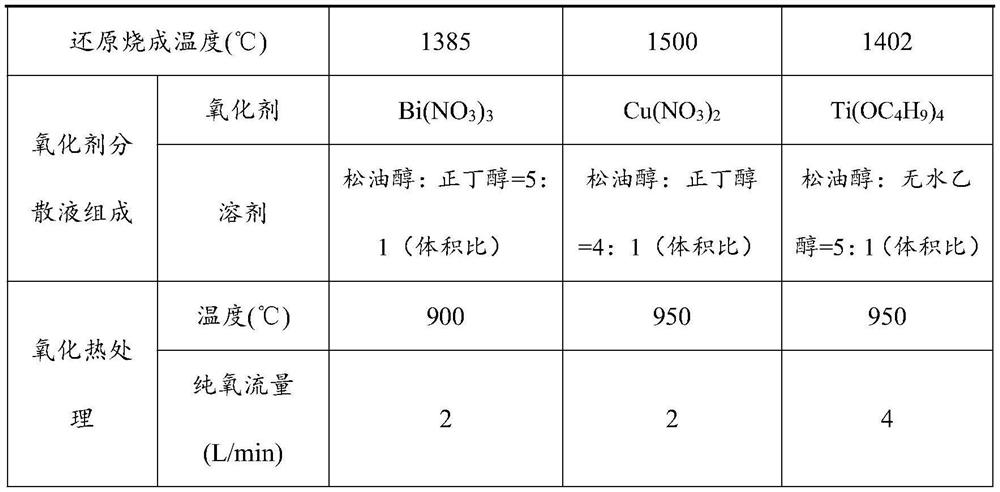

Semiconductor Porcelain Composition and Method of Producing the Same

InactiveUS20080170977A1Avoid abnormal growthFacilitate to control resistivityAlkaline earth titanatesConductive materialDopantRoom temperature

To provide a semiconductor porcelain composition in which a portion of Ba of BaTiO3 is substituted by Bi-Na, which is capable of inhibiting evaporation of Bi in a calcining step, inhibiting the formation of secondary phases by preventing a compositional shift of Bi-Na, further reducing a resistivity at room temperature, and inhibiting a scattering in a Curie temperature, and a method of producing the same. By separately preparing a composition of (BaQ)TiO3 (Q is a semiconductive dopant) and a composition of (BiNa)TiO3, and calcining the composition of (BaQ)TiO3 at a comparatively high temperature and calcining the composition of (BiNa)TiO3 at a comparatively low temperature to thereby calcine the compositions at their respective optimum temperatures, evaporation of Bi in the composition of (BiNa)TiO3 can be inhibited, formation of secondary phases can be inhibited by preventing a compositional shift of Bi-Na; and by mixing, forming and sintering the calcined powders, a semiconductor porcelain composition having a small resistivity at room temperature and being inhibited from a scattering in the Curie temperature can be provided.

Owner:HITACHI METALS LTD

Low-cost 460MPa-grade hot-rolled H-shaped steel with excellent low-temperature toughness and production method thereof

ActiveCN112410666AImprove mechanical propertiesImprove surface qualityMetal rolling arrangementsToughnessWeldability

The invention discloses low-cost 460MPa-grade hot-rolled H-shaped steel with excellent low-temperature toughness and a production method thereof, and belongs to the technical field of steel smelting.The H-shaped steel comprises the following components of, in percentage by weight, 0.03%-0.06% of C, 0.20%-0.40% of Si, 1.40%-1.60% of Mn, less than or equal to 0.01% of P, less than or equal to 0.005% of S, 0.07%-0.09% of V, 0.10%-0.25% of Ni, 0.10%-0.25% of Cr, 0.008%-0.010% of N and the balance Fe and inevitable impurities, wherein the content ratio of V to N is 8:1-10:1. According to the low-cost 460MPa-grade hot-rolled H-shaped steel with excellent low-temperature toughness and the production method thereof, based on actual production of the hot-rolled H-shaped steel, the 460MPa-grade hot-rolled H-shaped steel with flange thickness of 30mm-50mm, high strength, high-low-temperature toughness, excellent weldability and thickness direction performance is developed through a reasonable component proportion and a full-flow TMCP technology.

Owner:MAANSHAN IRON & STEEL CO LTD

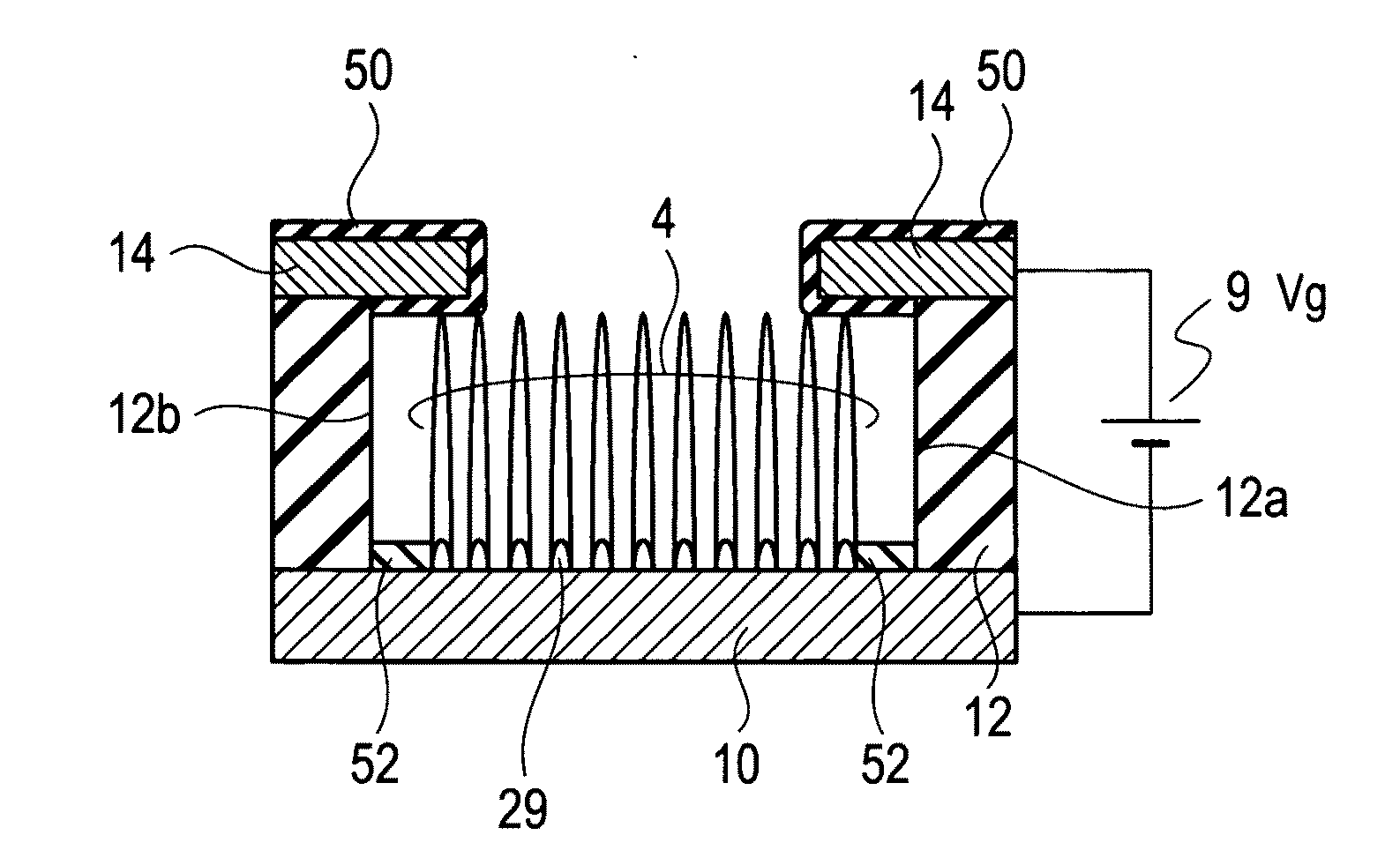

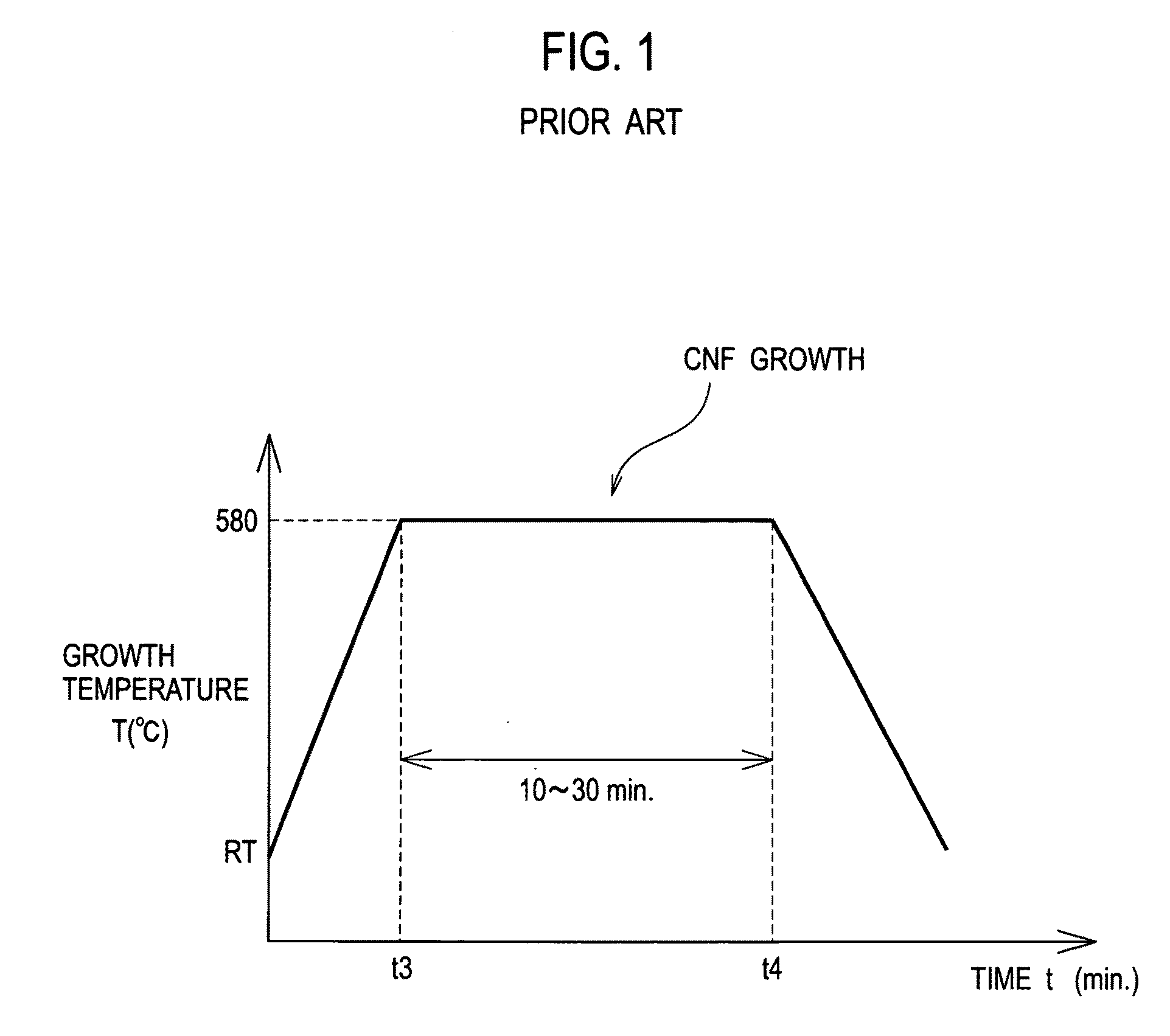

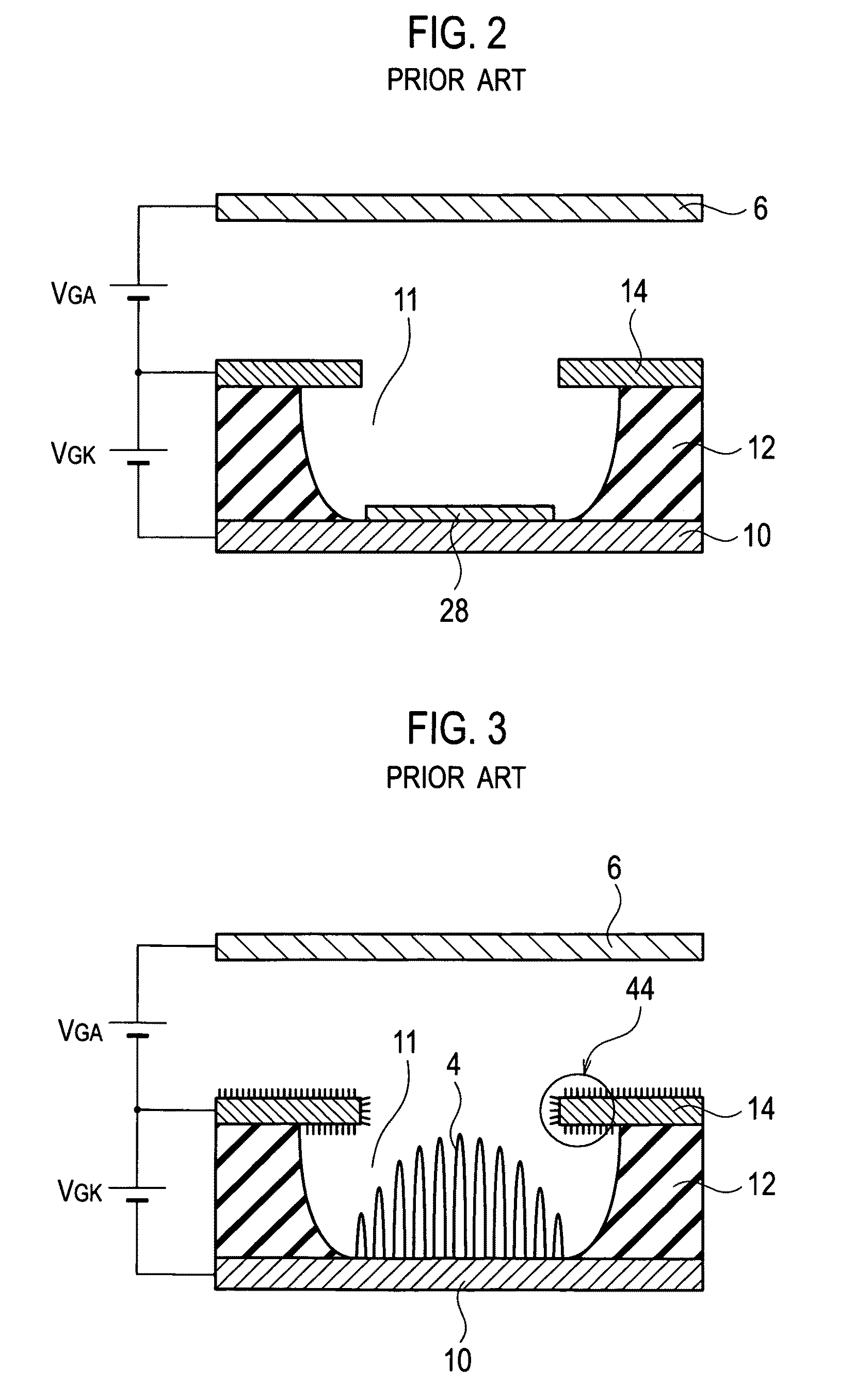

Fabrication method for carbon fiber, carbon fiber electron source, and field emission display device

InactiveUS20090051267A1Reduce abnormal growthSimple processDischarge tube luminescnet screensLamp detailsHigh current densityFiber

A fabrication method for carbon fiber which can prevent abnormal growth from electrode wiring metal, and can be formed a carbon nano-tube with high-density and uniform, by a simple and cheap method and the fabrication method includes process steps: forming a cathode electrode on a substrate; forming a first insulating film on the cathode electrode; forming a gate electrode on the first insulating film; forming a hole which reaches to the cathode electrode surface into the first insulating film; forming a catalyst crystallite nucleus on a bottom of the hole; oxidized forming a second insulating film on the gate electrode surface; and forming a carbon nano-tube on the catalyst crystallite nucleus; a carbon fiber electron source of high-output current density; and FED device which has high-intensity and large capacity with high current density, are provided.

Owner:ROHM CO LTD

Tin-silver-copper composite solder paste enhanced by titanium dioxide nanoparticles and preparation method thereof

InactiveCN105057911AGrowth inhibitionAvoid abnormal growthWelding/cutting media/materialsSoldering mediaTin-silver-copperComposite solder

The invention belongs to the technical field of welding materials and discloses tin-silver-copper composite solder paste enhanced by titanium dioxide nanoparticles and a preparation method thereof. The composite solder paste is obtained by blending tin-silver-copper lead-free solder paste and the titanium dioxide nanoparticles. The preparation method includes the following steps that the titanium dioxide nanoparticles are added into the tin-silver-copper lead-free solder paste with the mass ratio being 96.5:3:0.5, the titanium dioxide nanoparticles are evenly distributed in the tin-silver-copper lead-free solder paste through mechanical stirring, and accordingly the tin-silver-copper composite solder paste enhanced by the titanium dioxide nanoparticles is obtained. According to the tin-silver-copper composite solder paste, by adding the titanium dioxide nanoparticles, growth of an Ag3Sn phase in the solder paste is restrained, microhardness and mechanical property of the composite solder paste are improved, and growth of intermetallic compounds of a solder joint interface can be effectively restrained, crystal grains of the intermetallic compounds of the solder joint interface are refined, soldering reliability is improved, and the application prospect is good.

Owner:SOUTH CHINA UNIV OF TECH

Normal-pressure solid-phase sintered silicon carbide ceramic profiled part and manufacture method thereof

InactiveCN106904974AExtended service lifeLarge particle sizeSlip casting mouldsBoron trioxideHigh pressure

The invention discloses a normal-pressure solid-phase sintered silicon carbide ceramic profiled part and a manufacture method thereof. A compact silicon carbide ceramic profiled part product is obtained by material preparation, material mixing through ball milling, high pressure grouting, drying in shade and low temperature drying and high temperature sintering. Through optimized matching of silicon carbide particles at different levels and effective design of channels of a resin die, micrometer powder is introduced to overcome obstruction of die channels, thereby obviously prolonging the service life of the die. The micrometer powder is large in size and small in specific surface area, thereby preventing loss of components, and through matching of particles with different size, sub-micrometer powder is uniformly dispersed in micrometer powder, thereby overcoming low grouting efficiency and nonuniform components. The density of a blank obtained from matching of particles with different size is obviously increased, so that the contraction is reduced and the blank is beneficial for preventing sintering deformation and cracking of a solid-phase sintered silicon carbide ceramic profiled part. Boric acid or / and diboron trioxide is adopted as a sintering aid and is dissolved in a thick liquid, so that the sintering aid is uniformly dispersed, and the density distribution of high-temperature-sintered silicon carbide ceramic profiled part is uniform.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Semiconductor ceramic composition and process for producing the same

InactiveUS20100012905A1Avoid abnormal growthImprove sintering performanceConductive materialOxide conductorsDopantEvaporation

It is intended to provide a semiconductor ceramic composition in which a part of Ba in BaTiO3 is substituted with Bi—Na, which is capable of restraining the evaporation of Bi in the calcination step, is capable of restraining the compositional deviation of Bi—Na thereby suppressing the formation of different phases, is capable of further reducing the resistivity at room temperature, and is capable of restraining the fluctuation of the Curie temperature; and to provide a production process of the same. When a calcined Ba(TiM)O3 powder (M is a semiconductor dopant) and a calcined (BaNa)TiO3 powder are separately prepared and the Ba(TiM)O3 powder is calcined at a relatively high temperature while the (BaNa)TiO3 powder is at a relatively low temperature, both at the most suitable temperatures for them, then the evaporation of Bi may be retarded and the compositional deviation of Bi—Na may be thereby suppressed to inhibit the formation of different phases; and when these calcined powders are mixed, formed and sintered, then a semiconductor ceramic composition which has a low resistivity at room temperature and is capable of restraining the fluctuation of the Curie temperature can be obtained.

Owner:HITACHI METALS LTD

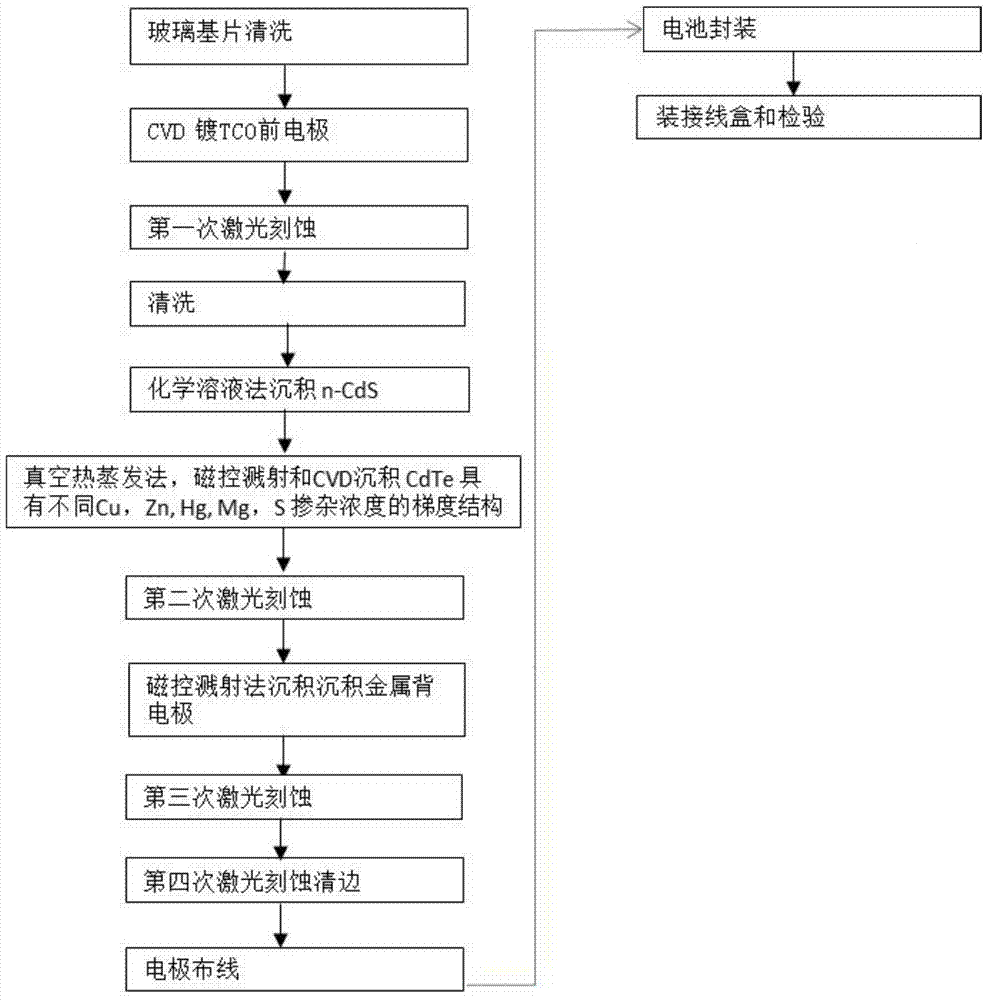

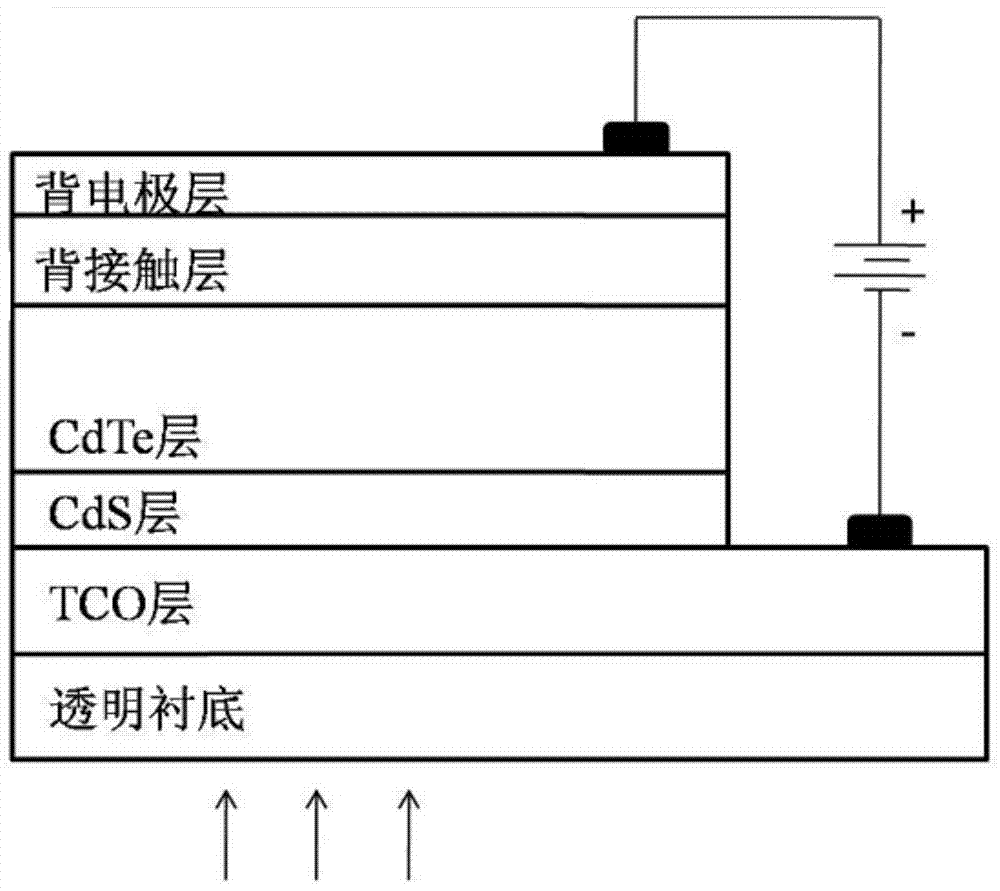

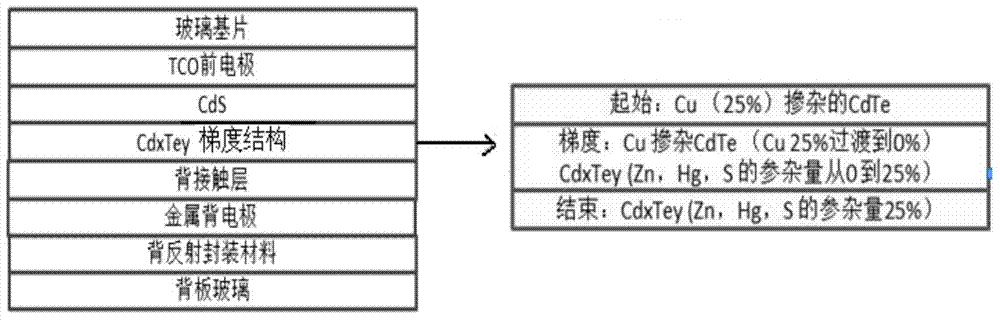

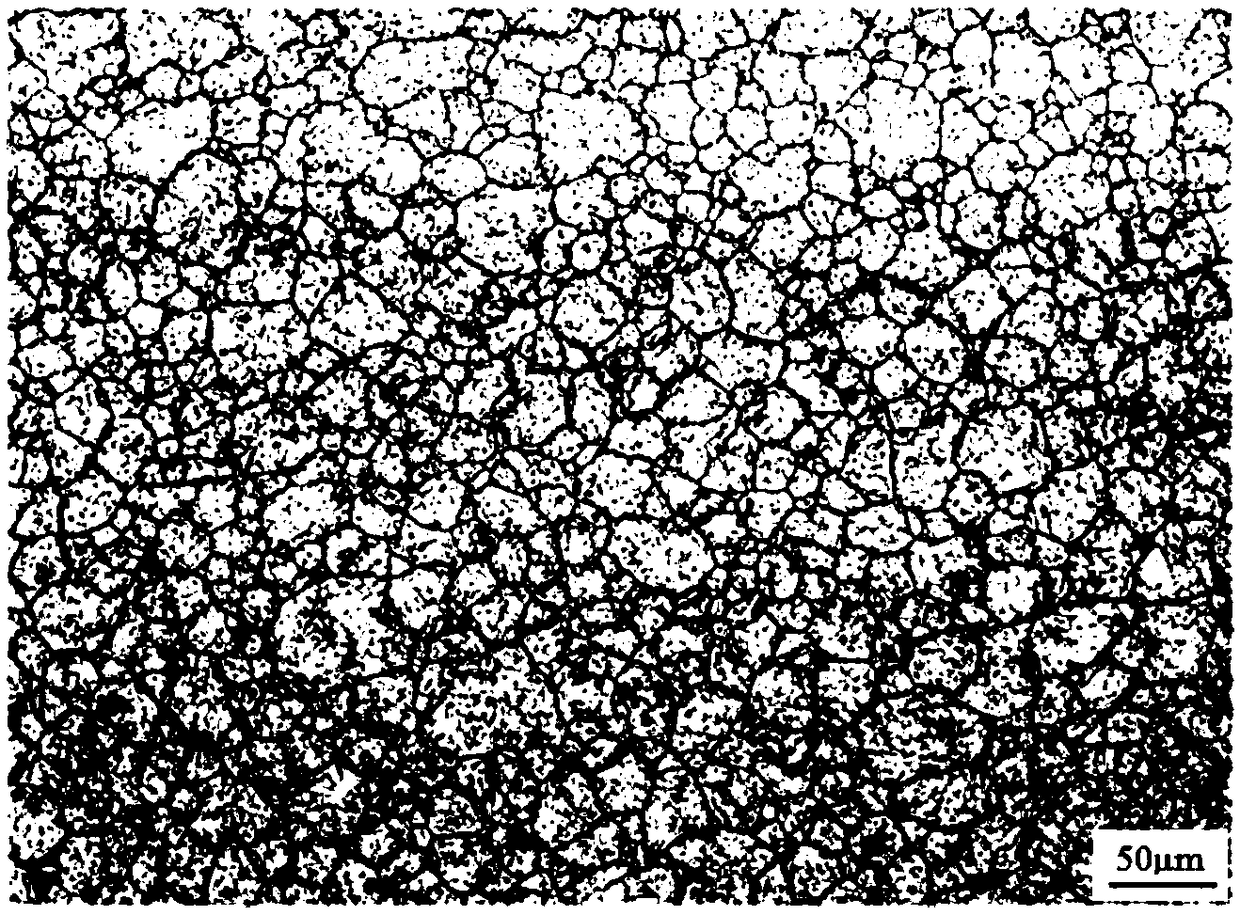

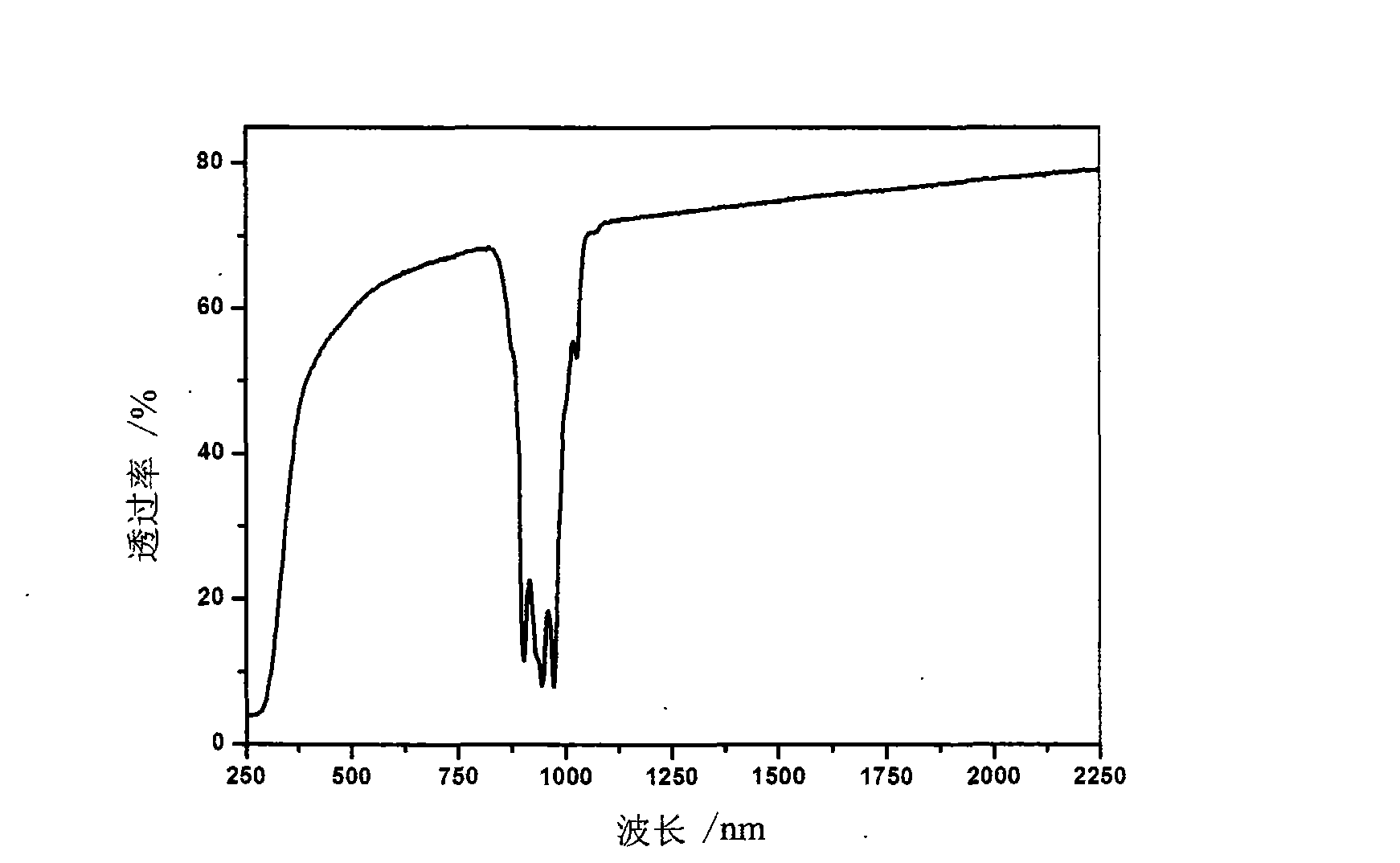

Cadmium telluride thin-film solar cell with gradient structure and manufacture method thereof

ActiveCN104851931AImprove photoelectric conversion efficiencyImprove efficiencyPhotovoltaic energy generationSemiconductor devicesAbnormal growthsPower flow

The invention discloses a cadmium telluride thin-film solar cell with gradient structure and a manufacture method thereof. The cadmium telluride thin-film solar cell comprises a pn junction formed by a CdTe absorbing layer and a CdS window layer. The CdTe absorbing layer of the pn junction of the cadmium telluride thin-film solar cell is a Cd<x>Te<Y> multilayer gradient structure with an energy gap gradient, wherein x is more than or equal to 0 but is less than or equal to 1 and y is more than or equal to 0 but is less than or equal to 1. The gradient structure has a relatively wide energy spectrum range, may separate and capture ionized electrons, and generateS heavy current under the excitation of the sun so as to improve the efficiency of the thin-film solar cell. The gradient structure prevents abnormal growth of crystal grains and generation of holes and cracks and produces a compact high-quality film with uniform crystal grain sizes and matched energy gaps. Further, the gradient structure is beneficial to the full absorption of sunlight so as to further improve the efficiency of the cadmium telluride thin-film solar cell.

Owner:湖南共创光伏科技有限公司

Heat treatment technology for improving tissue uniformity of H13 hot working die forged steel

The invention discloses a heat treatment technology for improving the tissue uniformity of H13 hot working die forged steel. The technology comprises following steps: loading forged H13 steel into a heating furnace, wherein the heating temperature is 860 to 880 DEG C, cooling the H13 steel in the air to the room temperature; then loading the forged steel into the heating furnace, heating to a temperature of 1030 to 1050 DEG C, cooling the forged steel to a temperature of 300 to 400 DEG C in the air; filling the forged steel into the heating furnace for a third time, heating to a temperature of1080 to 1100 DEG C, cooling the forged steel to a room temperature in the air; filling the forged steel into the heating furnace for a fourth time, heating to a temperature of 870 to 890 DEG C, maintaining the temperature for 4 to 6 hours, cooling to a temperature of 720 to 740 DEG C, maintaining the temperature for 6 to 8 hours, secondarily cooling to a temperature not higher than 500 DEG C, taking out the forged steel out of the heating furnace, and cooling the forged steel in the air. Compared with a conventional forging stock annealing treatment, the horizontal impact energy is not less than 12J; the ratio of horizontal impact energy to vertical impact energy is not less than 0.8; the size of grains in tissues is uniform; the mixed crystal tissue is avoided, banded segregation is reduced or eliminated; and horizontal impact toughness and isotropy are enhanced.

Owner:HEBEI IRON AND STEEL

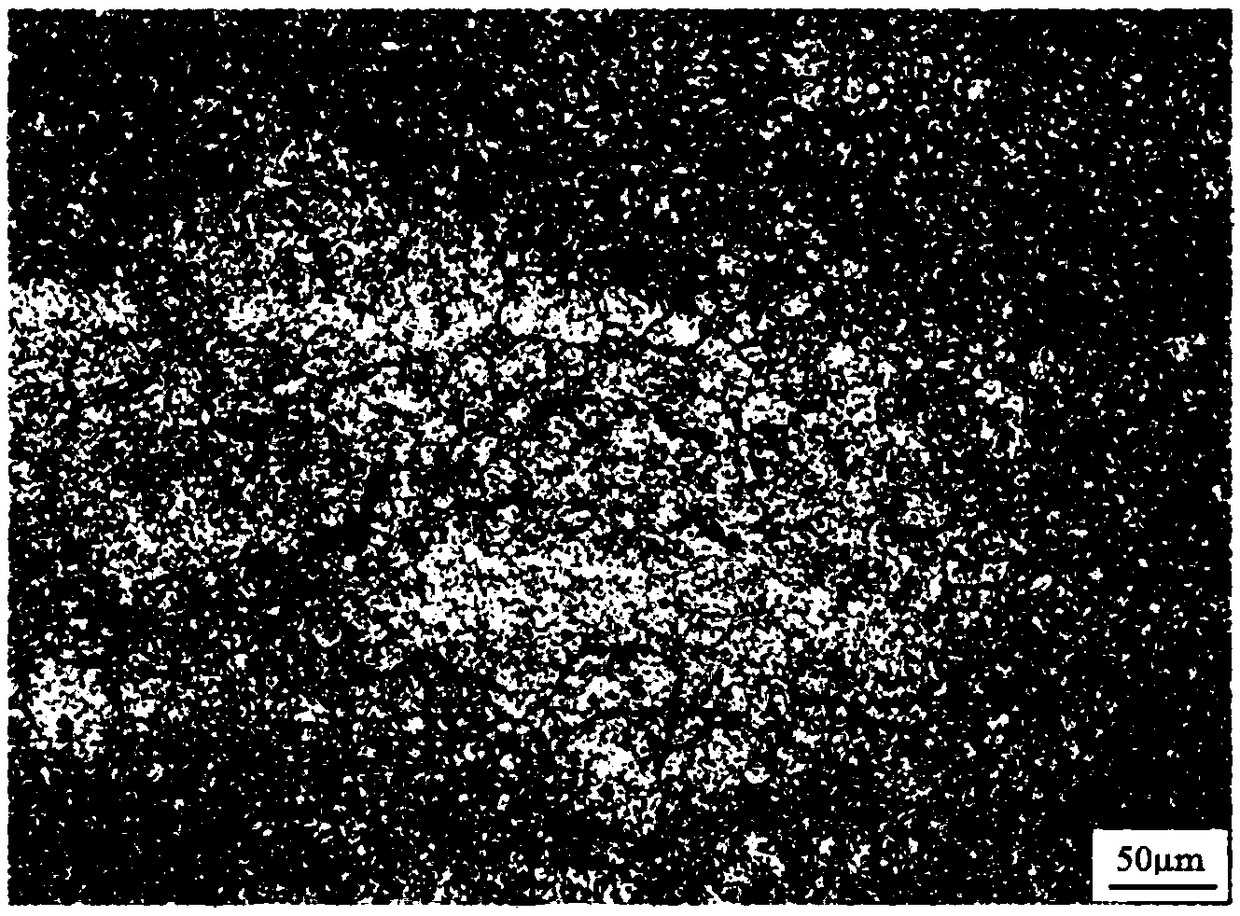

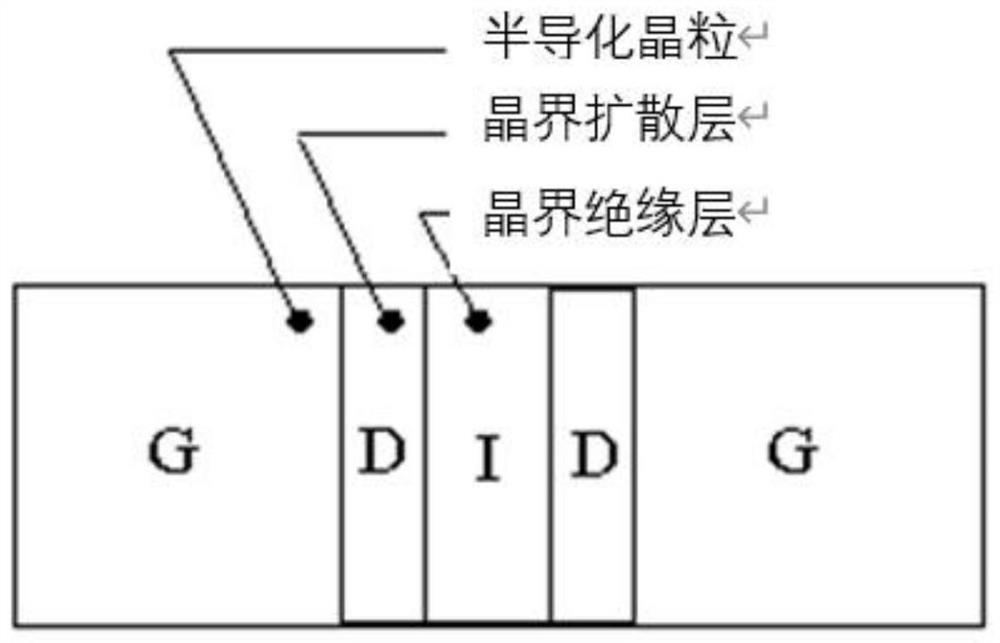

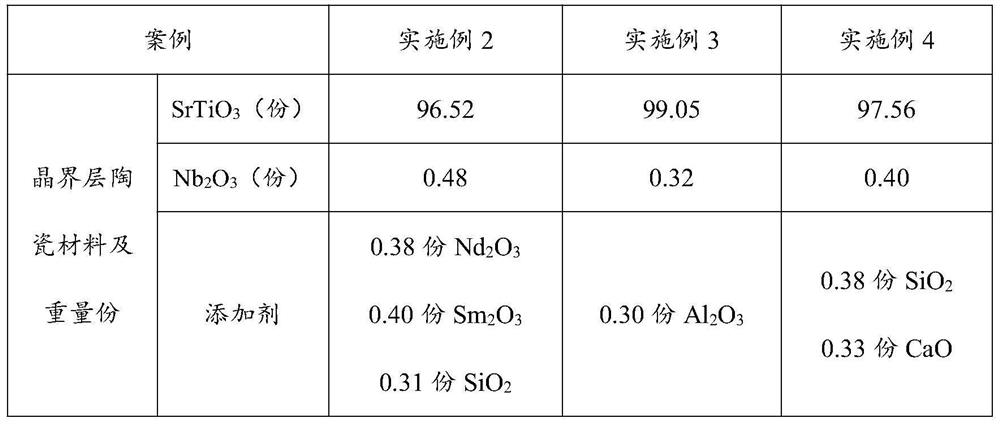

Preparation method and application of grain boundary layer ceramic material and grain boundary layer ceramic substrate

The invention provides a preparation method and application of a grain boundary layer ceramic material and a grain boundary layer ceramic substrate, and belongs to the technical field of chip capacitors. The grain boundary layer ceramic material provided by the invention is prepared from the following preparation raw materials in parts by mass: 95.35 to 99.30 parts of SrTiO3, 0.30 to 0.55 part ofNb2O3 and 0.30 to 5.00 part of a modification additive comprising one or more of BaCO3, Nd2O3, CaO, Sm2O3, Al2O3 and SiO2. The grain boundary layer ceramic material has excellent electrical propertiesand controllability, and a grain boundary layer ceramic substrate prepared from the grain boundary layer ceramic material has excellent repeatability and consistency.

Owner:GUANGZHOU AURORA TECHNOLOGIES CO LTD +1

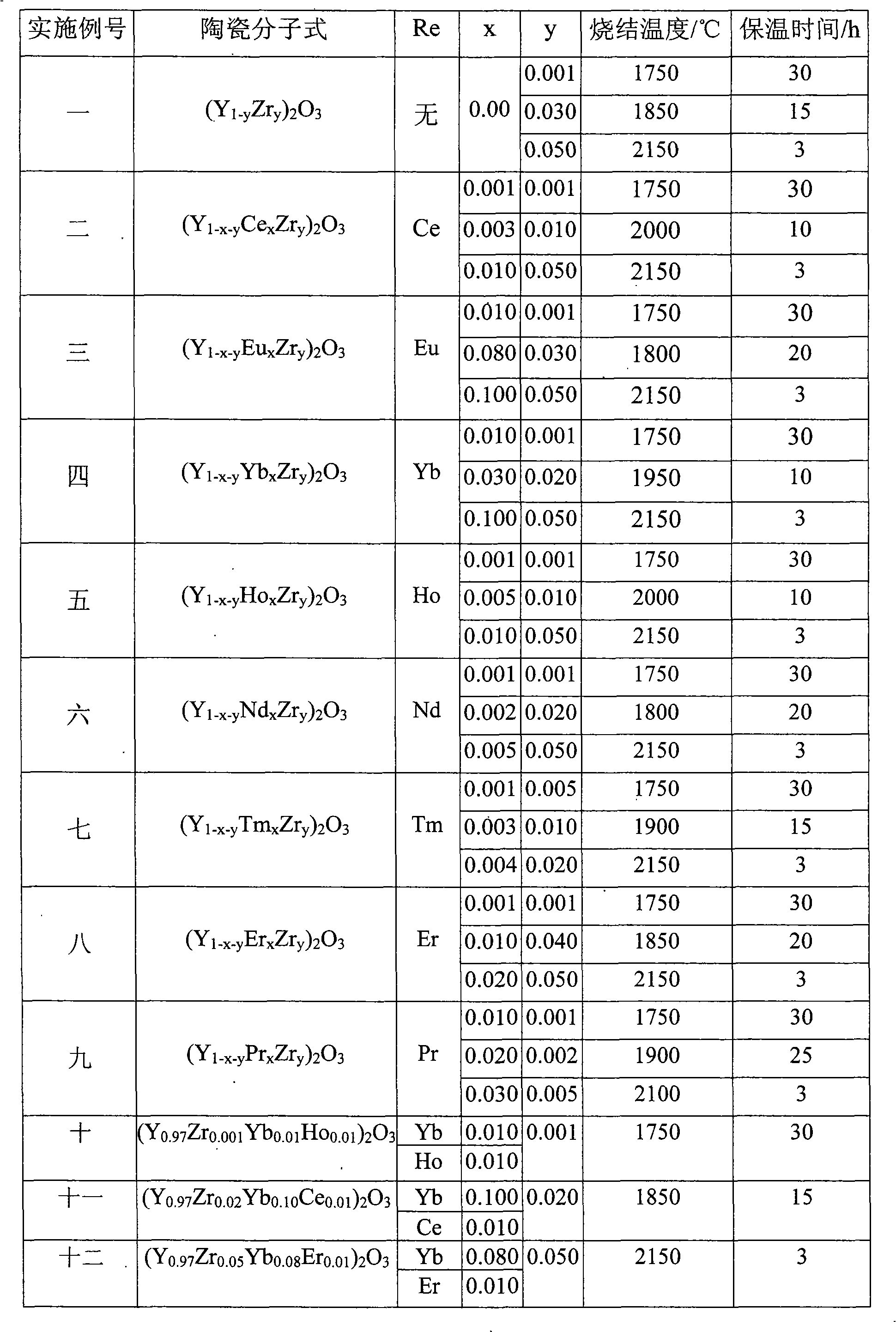

Zirconium-doped yttria base transparent ceramic and preparation method thereof

The invention relates to zirconium-doped yttria base transparent ceramic and a preparation method thereof. The structural formula of the ceramic is (Y(1-x-y)RexZry)2O3, wherein Re is a rare earth element selected from Yb, Nd, Tm, Ho, Ce, Er, Pr and Eu, or double-elements of Yb doped with Ho, Ce, Er, Pr and Eu; x is more than or equal to 0.00 and is less than or equal to 0.10, and y is more than orequal to 0.001 and is less than or equal to 0.05. The zirconium-doped yttria base transparent ceramic prepared by the method has higher transparency and compactness.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

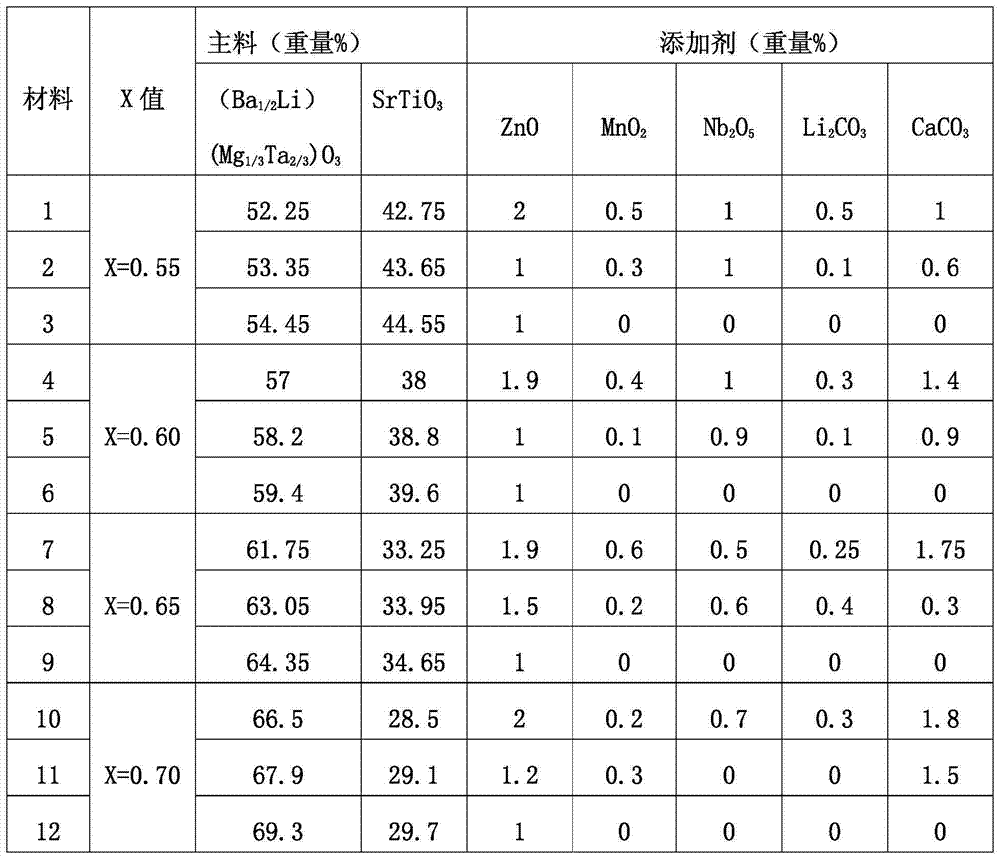

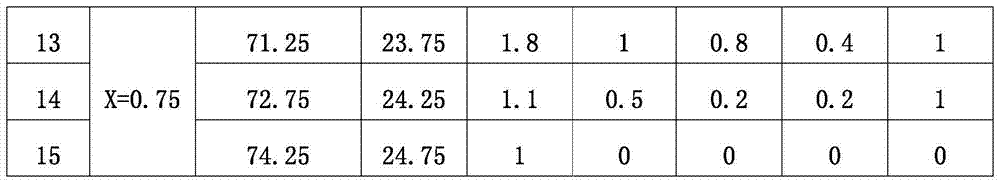

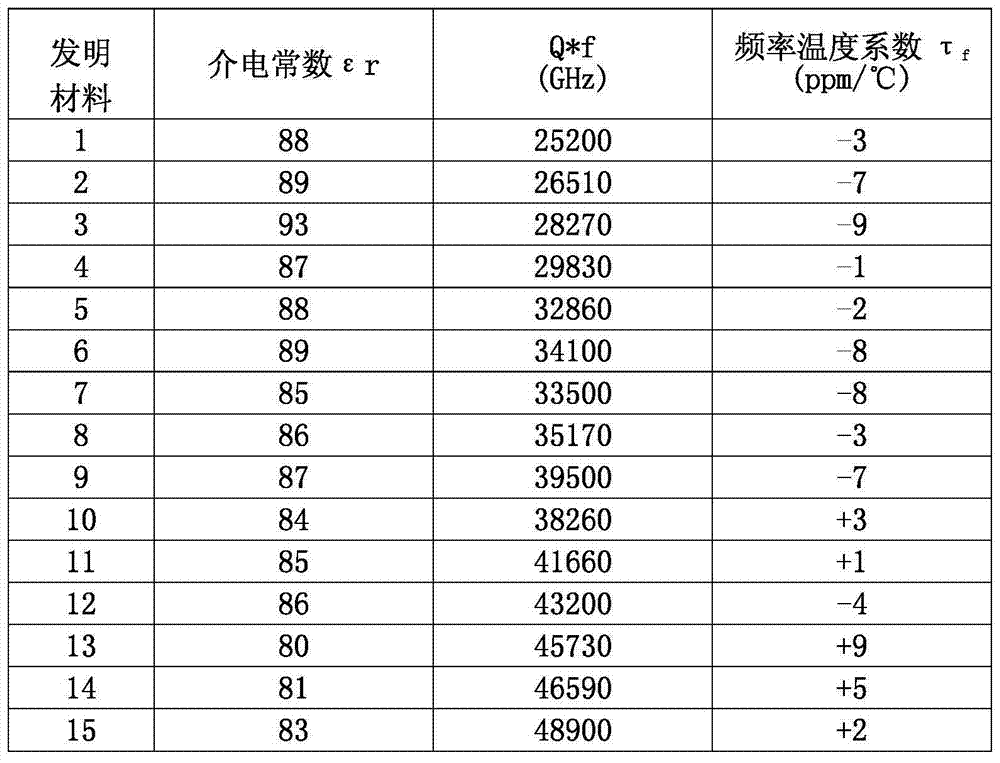

High-dielectric microwave ceramic dielectric material, and preparation method and use thereof

The invention discloses a high-dielectric microwave ceramic dielectric material, and a preparation method and an application thereof. The high-dielectric microwave ceramic dielectric material is composed of a main material and an additive and is characterized in that the main material has a structural formula of X(Ba1 / 2Li)(Mg1 / 3Ta2 / 3)O3-(1-X)SrTiO3, wherein 0.55<=X<=0.75; the additive is one or more of ZnO, MnO2, Nb2O5, Li2CO3 and CaCO3. The weight percentage of the main material is 95-99%, and the weight percentage of the additive is 1-5%. The main material compound is prepared by a chemical co-precipitation method, a calcining synthetic temperature is lower than that of a traditional solid phase method, and the method has the characteristics of low energy consumption, high material purity, uniform composition and high surface activity. Microwave ceramic devices after sintering are good in consistency and dense in ceramic bodies, and can better adapt to application requirements of high-quality microwave devices.

Owner:XIAMEN WANMING ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com