Preparation method and application of grain boundary layer ceramic material and grain boundary layer ceramic substrate

A technology of ceramic substrates and ceramic materials, which is applied in the field of grain boundary layer ceramic materials, can solve problems affecting the repeatability and consistency of electrical properties of ceramic substrates in grain boundary layers, and achieve high repeatability and consistency of electrical properties. The effect of reducing the amount and increasing the degree of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

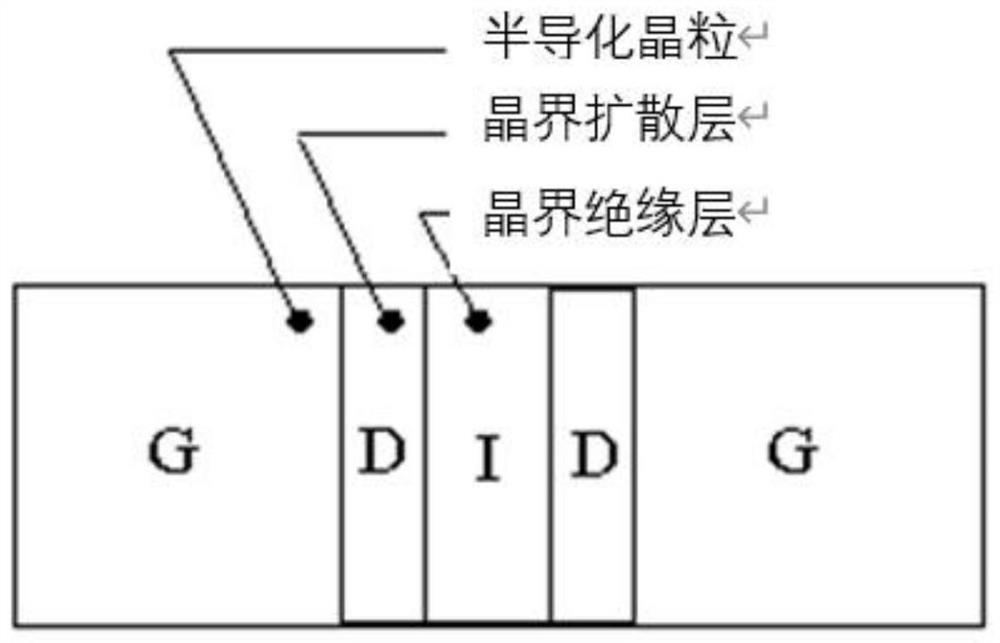

[0036] The invention provides a preparation method of a grain boundary layer ceramic substrate, comprising the following steps:

[0037] Mixing the grain boundary layer ceramic material, the adhesive and the organic solvent described in the above technical solution, and molding to obtain the diaphragm;

[0038] The diaphragm is degummed and reduced fired in one step to obtain a semiconducting grain ceramic substrate;

[0039] coating the oxidant dispersion on the surface of the semiconducting grain ceramic substrate to obtain a semiconducting grain ceramic substrate with an oxide dielectric film attached;

[0040] In a pure oxygen atmosphere, the semiconducting grain ceramic substrate attached with the oxide dielectric film is oxidized and heat-treated to form a grain boundary insulating layer to obtain a grain boundary layer ceramic substrate.

[0041] In the present invention, the grain boundary layer ceramic material described in the above technical solution, adhesive and ...

Embodiment 1

[0058] Grain boundary layer ceramic material preparation: 98.95 parts by weight of SrTiO 3 , 0.38 parts by weight of Nb 2 o 3 , 0.36 parts by weight of SiO 2 and 0.32 parts by weight of Sm 2 o 3 The mixed material is ball milled, dried and sieved in turn to obtain ceramic powder with an average particle size of D 50 0.62μm;

[0059] 57.39 parts of the grain boundary layer ceramic material, 14.51 parts of xylene, 14.51 parts of absolute ethanol, 3.70 parts of PVB B-980 and 3.09 parts of BBP S-1609 were mixed, and formed by casting to obtain a diaphragm (with a thickness of 0.20 mm), cut the diaphragm according to the size required by the product;

[0060] Put the diaphragm into a bowl in the form of a single-piece compartment, put it into an atmosphere furnace, and pass compressed air into the temperature curve of 100-900°C (the heating rate is 0.6°C / min) for debinding, after the debinding is completed After insulated at 900°C for 1 hour, a mixed atmosphere of hydrogen a...

Embodiment 2~4

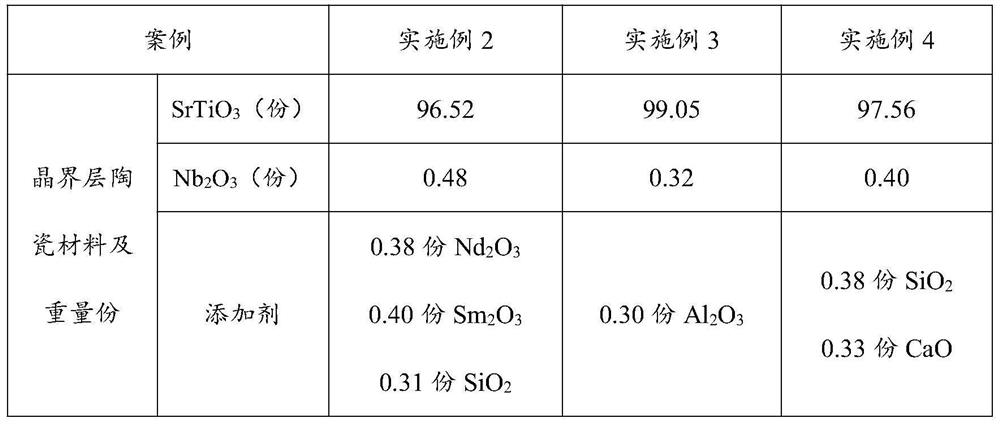

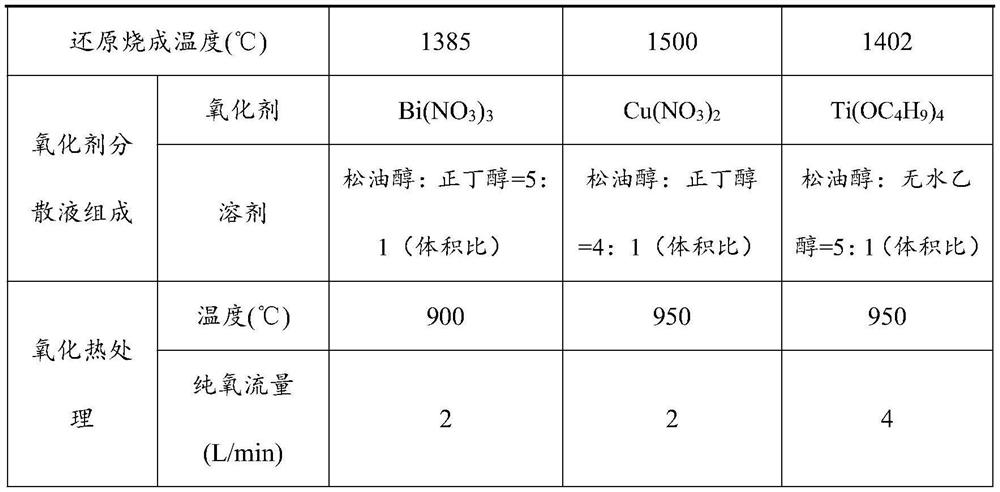

[0065] According to the preparation method of Example 1, adopt the grain boundary layer ceramic material ratio, firing temperature, electrophoresis process parameters and oxidation process as shown in the following table 1 to prepare the grain boundary layer ceramic substrate, the process and reagents not listed in the table Consumption is all identical with embodiment 1.

[0066] The parameter of table 1 embodiment 2~4

[0067]

[0068]

[0069] The grain boundary layer ceramic substrates prepared in the above-mentioned Examples 1 to 4 were cut into 2×2mm through sputtering metal electrodes. 2 Die, measure the electrical properties of the dice. According to K=11.3Ct / S (K is the dielectric constant of calculation, C is the capacitance measured, t is the thickness of the substrate, S is the chip area) calculate the grain boundary layer ceramic substrate sample that embodiment 1~4 prepares the dielectric constant. Take 10 samples from the four corners and the middle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com