A carbon-based dielectric elastomer based on core-shell dynamic vulcanization and its preparation method

A dielectric elastomer and dynamic vulcanization technology, which is applied in the fields of carbon-based conductive filler/thermoplastic elastomer composites, carbon-based dielectric elastomers and their preparation, can solve the problems of high dielectric loss and no effective solution, etc. Achieving a high degree of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Polyvinylidene fluoride was selected as the matrix resin (502, Guangzhou Lichang), silicone rubber was used as general foundation silicone rubber (KE571-U, Japan Shin-Etsu), and fluororubber (F2463, Zhonghao Chenguang Chemical Research Institute). Graphene oxide (0.25g) was ultrasonically dispersed in THF for 2h to obtain a graphene oxide suspension;

[0076] Dissolve silicone rubber (15g) in graphene oxide suspension, and disperse evenly by ultrasonication for 2h; evaporate the solvent to dryness at 80°C, and reduce graphene oxide to graphene at 400°C to obtain a graphene / silicone rubber blend thing;

[0077] On an open mill, fluorine rubber (15g), magnesium oxide (0.75g), calcium hydroxide (0.75g) were mixed for 6 minutes to obtain a uniformly mixed fluorine rubber compound;

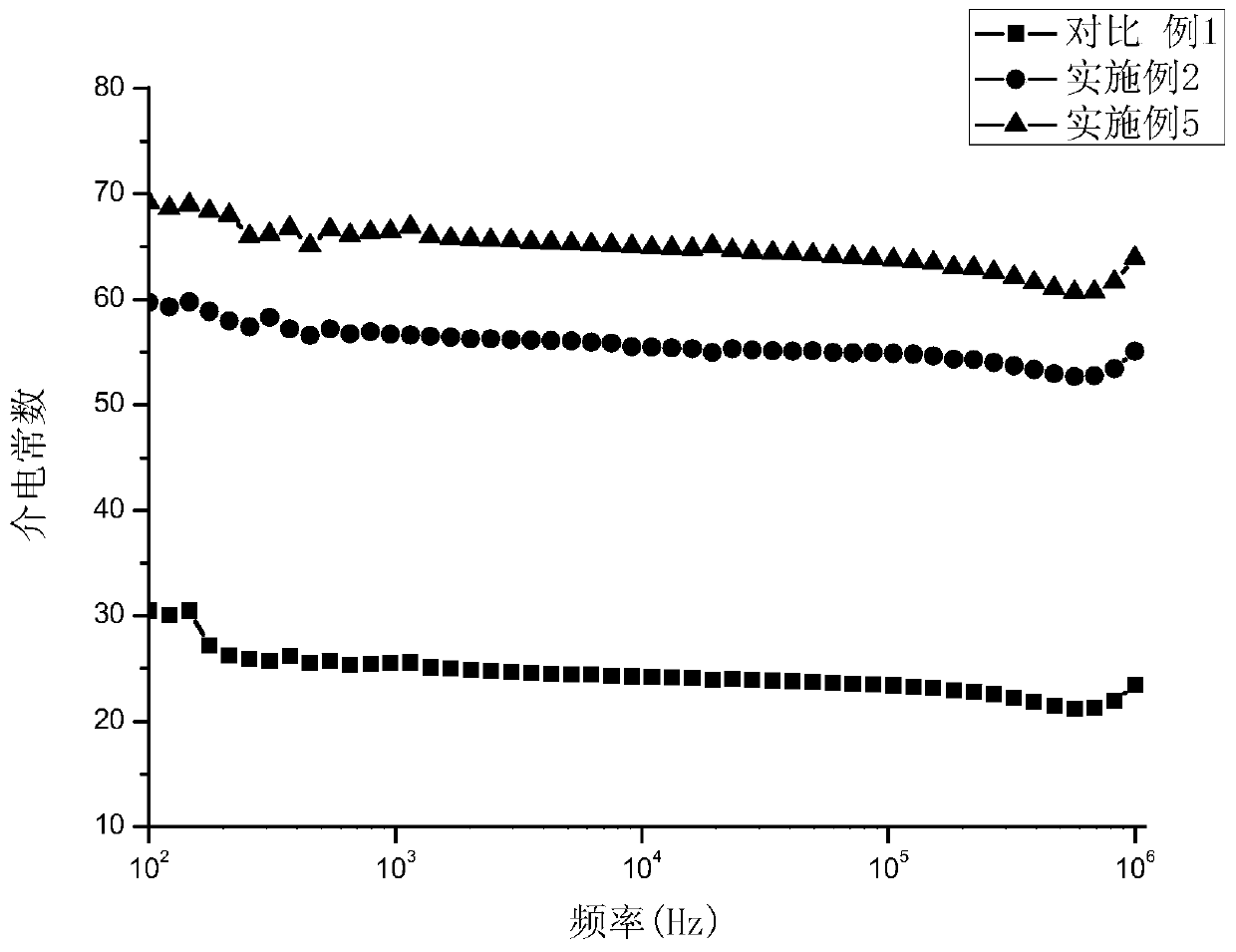

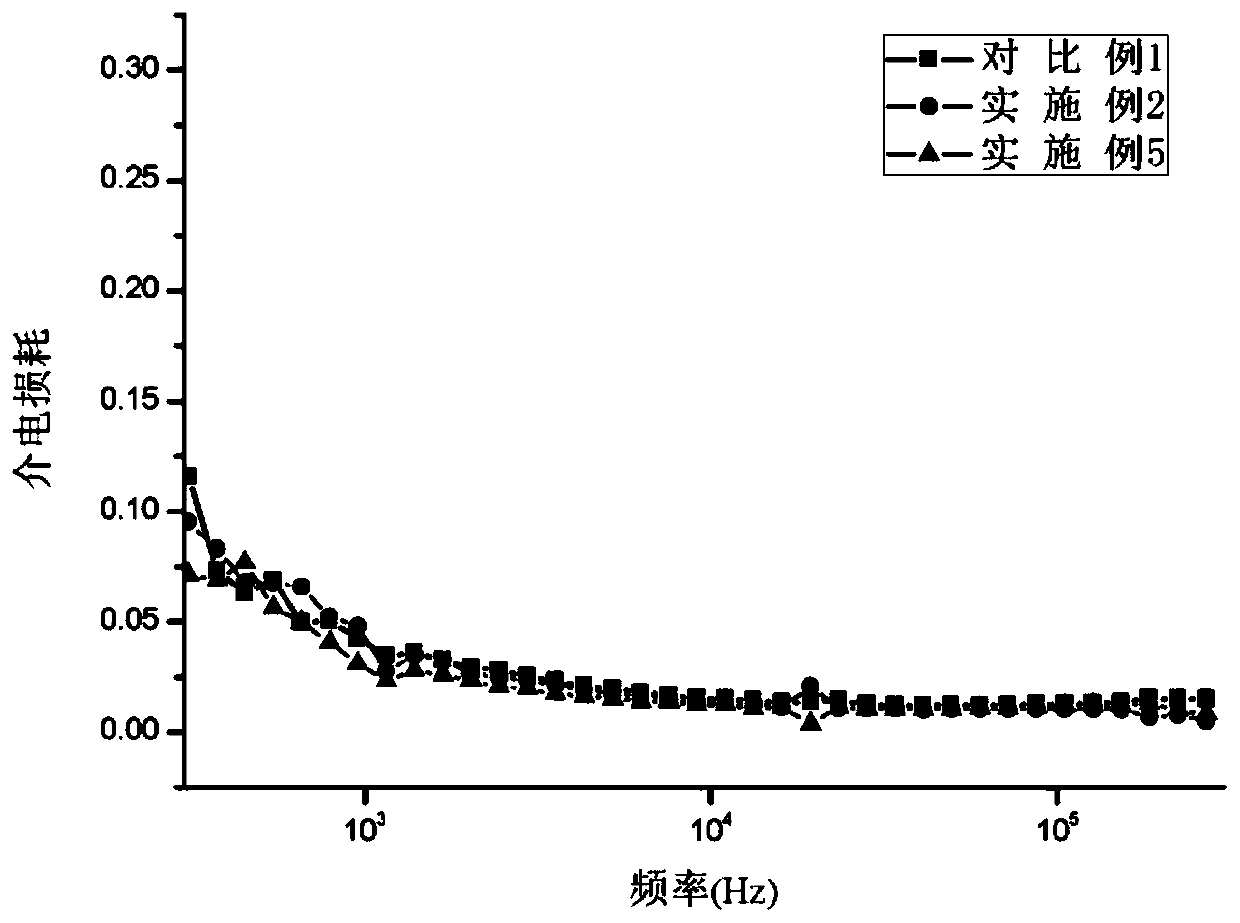

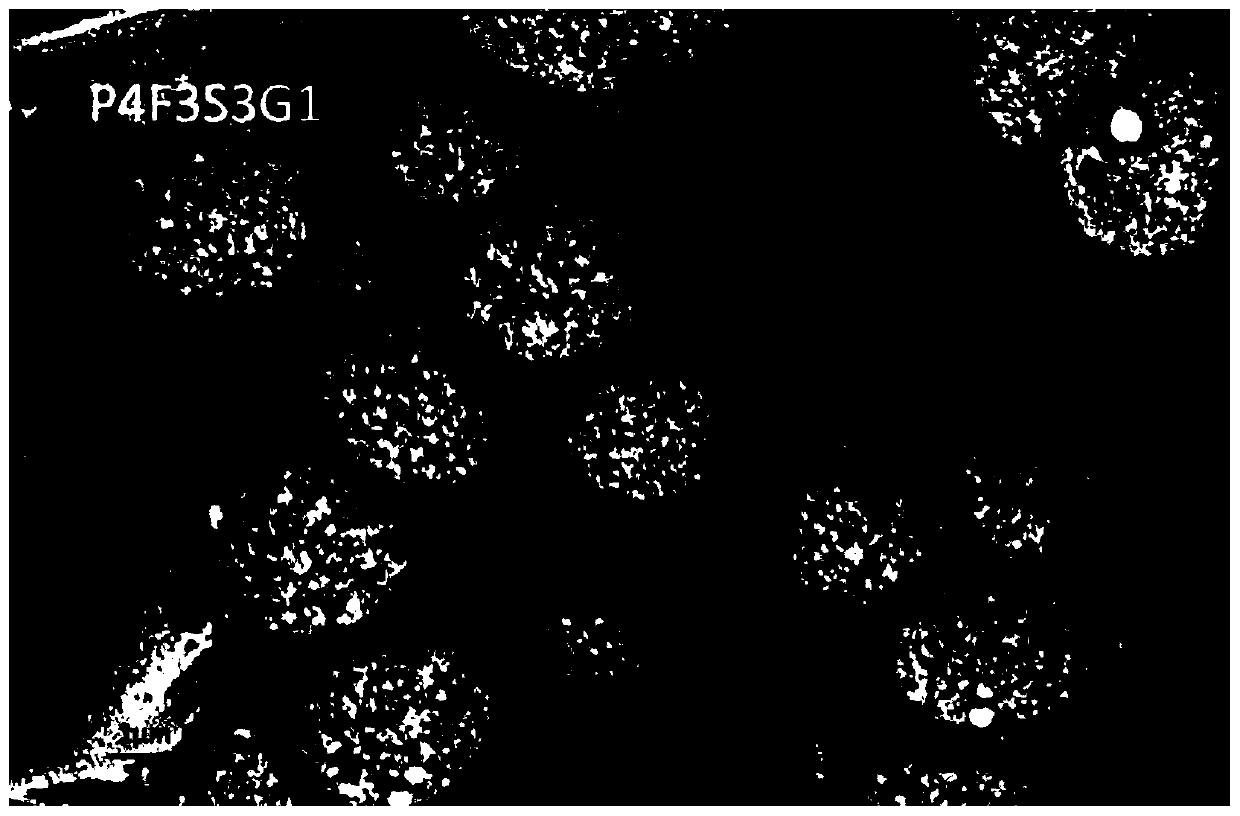

[0078] Add polyvinylidene fluoride (20g) to a Haake torque rheometer with a temperature of 180°C and a rotor speed of 90r / min to completely melt and plasticize the fluoroplastic; add graphene / s...

Embodiment 2

[0081] Polyvinylidene fluoride was selected as the matrix resin (502, Guangzhou Lichang), silicone rubber was used as general foundation silicone rubber (KE571-U, Japan Shin-Etsu), and fluororubber (F2463, Zhonghao Chenguang Chemical Research Institute).

[0082] Graphene oxide (0.5g) was ultrasonically dispersed in tetrahydrofuran for 2h to obtain a graphene oxide suspension; silicon rubber (15g) was dissolved in the graphene oxide suspension, and ultrasonically dispersed for 2h; the solvent was evaporated to dryness at 100°C, Reducing graphene oxide to graphene at 300°C to prepare a graphene / silicone rubber blend;

[0083] On an open mill, mix fluororubber (15g), magnesium oxide (0.75g), and calcium hydroxide (0.75g) for 6 minutes to obtain a uniformly mixed fluororubber compound; polyvinylidene fluoride (20g ) into the Haake torque rheometer with a temperature of 180°C and a rotor speed of 100r / min to completely melt and plasticize the fluoroplastic; add graphene / silicone r...

Embodiment 3

[0086] Polyvinylidene fluoride was selected as the matrix resin (502, Guangzhou Lichang), silicone rubber was used as general foundation silicone rubber (KE571-U, Japan Shin-Etsu), and fluororubber (F2463, Zhonghao Chenguang Chemical Research Institute).

[0087] Graphene oxide (0.75g) was ultrasonically dispersed in tetrahydrofuran for 2h to obtain a graphene oxide suspension; silicon rubber (15g) was dissolved in the graphene oxide suspension, and ultrasonically dispersed for 2h; the solvent was evaporated to dryness at 60°C, Reducing graphene oxide to graphene at 150°C to prepare a graphene / silicone rubber blend;

[0088] On an open mill, mix fluororubber (15g), magnesium oxide (0.75g), and calcium hydroxide (0.75g) for 6 minutes to obtain a uniformly mixed fluororubber compound; polyvinylidene fluoride (20g ) into the Haake torque rheometer with a temperature of 180°C and a rotor speed of 110r / min to completely melt and plasticize the fluoroplastic; add graphene / silicone r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com