Injectable biological calcium salt compound bone cement and preparation method thereof

A technology of bone cement and biological calcium, used in tissue regeneration, medical science, prosthesis, etc., to achieve the effects of easy extrusion, convenient injection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

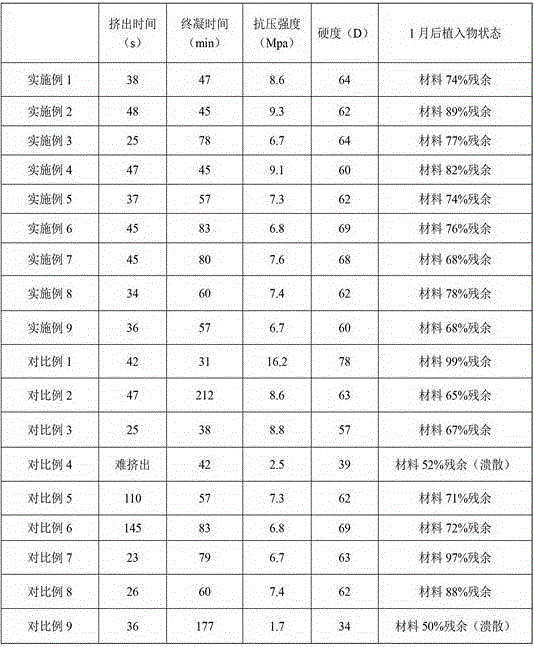

Examples

Embodiment 1

[0041] Put 65 parts of pharmaceutical grade α-calcium sulfate hemihydrate, 8 parts of calcium phosphate and 2 parts of anhydrous calcium citrate enhancer in absolute ethanol, grind for 40 minutes at room temperature, and obtain component A after drying; 20 parts of powder Cancellous bone extracellular matrix (particle size: 0.1-0.2 mm) and 0.5 parts of calcium stearate are directly ground and blended in a dry state to obtain component B. When in use, first add component A to an appropriate amount of sterile water for injection (the solid-liquid ratio of components A and B to sterile water for injection is 2.5g / mL) under stirring, and stir continuously for 1-2 minutes to make a uniform paste shape, then add component B, stir for 30-60 seconds, and transfer to the bone cement delivery equipment for injection delivery and solidification.

Embodiment 2

[0043] Put 70 parts of pharmaceutical grade α-calcium sulfate hemihydrate, 10 parts of calcium phosphate and 1 part of anhydrous calcium tartrate enhancer in absolute ethanol, grind for 60 minutes at room temperature, and obtain component A after drying; 10 parts of powdered pine Bone extracellular matrix (particle size: 0.05-0.1 mm) and 0.1 part of magnesium stearate are directly ground and blended in a dry state to obtain component B. When in use, add component A into an appropriate amount of normal saline (the solid-to-liquid ratio of components A and B to normal saline is 2.0g / mL) under stirring, keep stirring for 1-2 minutes to make it into a uniform paste, and then Add component B, stir for 30-60 seconds, and transfer to the bone cement delivery equipment for injection delivery and solidification.

Embodiment 3

[0045] Put 60 parts of pharmaceutical grade α-calcium sulfate hemihydrate, 5 parts of calcium phosphate, and 5 parts of anhydrous calcium tartrate in absolute ethanol, grind for 50 minutes at room temperature, and obtain component A after drying; 30 parts of powdered cancellous bone The extracellular matrix (particle size: 0.1-0.25 mm) and 3 parts of calcium stearate are directly ground and blended in a dry state to obtain component B. When in use, add component A into an appropriate amount of sterilized PBS physiological buffer (the solid-liquid ratio of components A and B to the buffer is 3.0g / mL) under stirring, and stir continuously for 1min to make it into a uniform paste. Then add component B, stir for 30-60 seconds, and transfer to the bone cement delivery equipment, which can be injected, delivered and solidified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com