Patents

Literature

39 results about "Calcium tartrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium tartrate, exactly calcium L-tartrate, is a byproduct of the wine industry, prepared from wine fermentation dregs. It is the calcium salt of L-tartaric acid, an acid most commonly found in grapes. Its solubility decreases with lower temperature, which results in the forming of whitish (in red wine often reddish) crystalline clusters as it precipitates. As E number E354, it finds use as a food preservative and acidity regulator. Like tartaric acid, calcium tartrate has two asymmetric carbons, hence it has two chiral isomers and a non-chiral isomer (meso-form). Most calcium tartrate of biological origin is the chiral levorotatory (–) isomer.

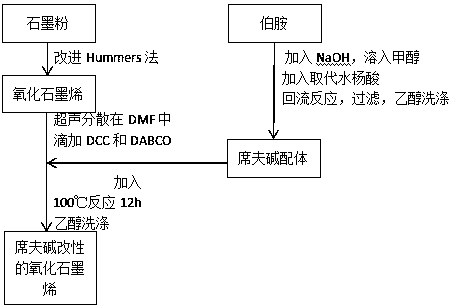

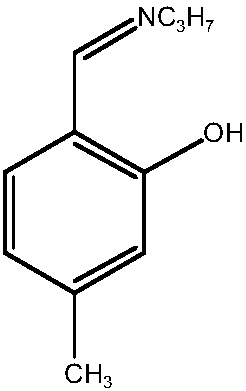

Schiff base modified graphene oxide cement-based permeable crystallization type waterproof material as well as preparation and application thereof

InactiveCN108585711APromote hydrationStable formationCarbon compoundsOrganic chemistry methodsSulfite saltPotassium sodium tartrate

The invention discloses a Schiff base modified graphene oxide cement-based permeable crystallization type waterproof material which comprises a composite concrete admixture, an active anionic catalyst, cement, fine aggregate, a rubber powder, a coupling agent, Fe2O3, CaO and MgO, wherein the active anionic catalyst is Schiff base modified graphene oxide; the composite concrete admixture comprisesa water reducing agent and a retarder; the water reducing agent refers to one or several in NC, ESJ, lignosulfonate, methyl naphthalene sulfonate condensate and polyalkyl aryl sulfonate condensate; the retarder refers to one or several of potassium sodium tartrate, fluosilicate, ferrous sulfate, phosphoric acid, sodium sulfite, lactic acid, calcium tartrate gluconate, sodium lignosulfonate, calcium lignosulphonate and magnesium lignosulfonate; the cement is high-alumina cement or Portland cement; the fine aggregate is quartz sand, silica powdr or natural river sand; the coupling agent is a silane coupling agent. The waterproof material disclosed by the invention has excellent properties such as good effect, simple construction, low environmental requirement, excellent waterproof property,excellent durability and the like.

Owner:苏州太星新材料科技有限公司

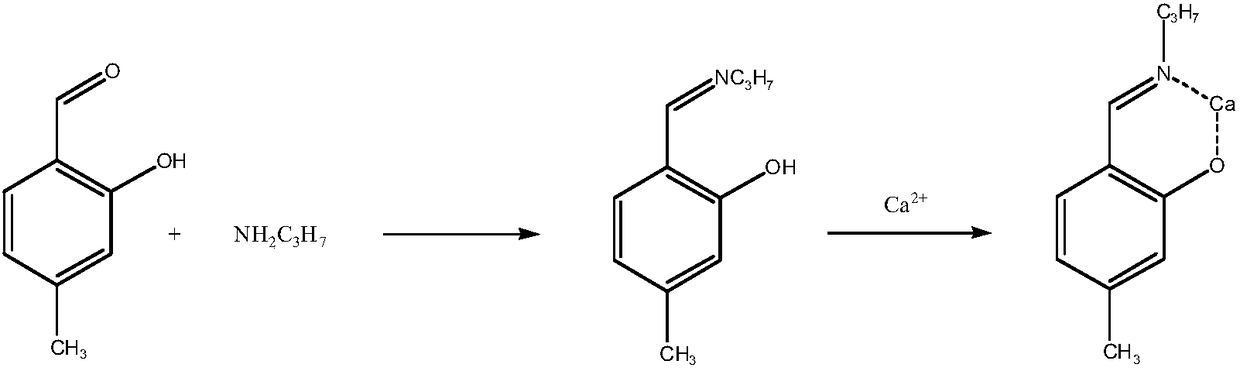

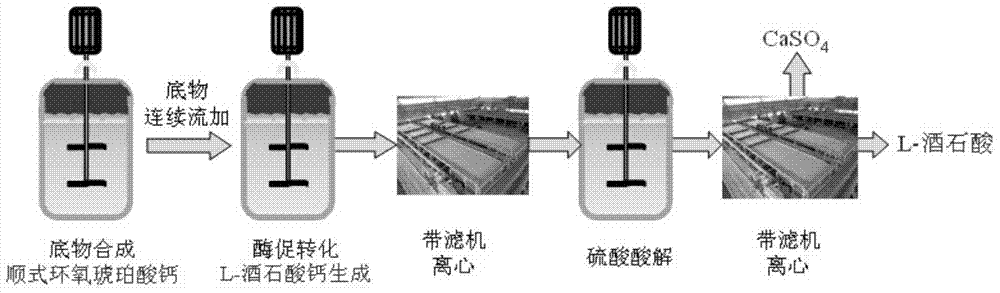

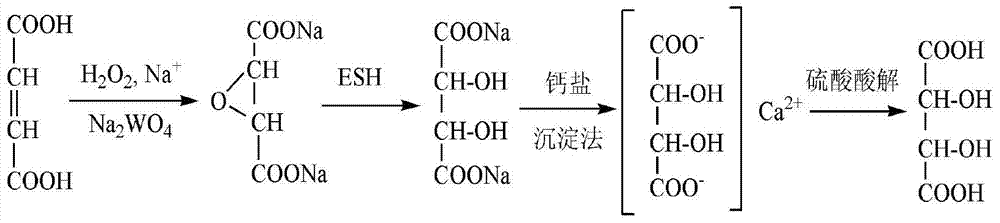

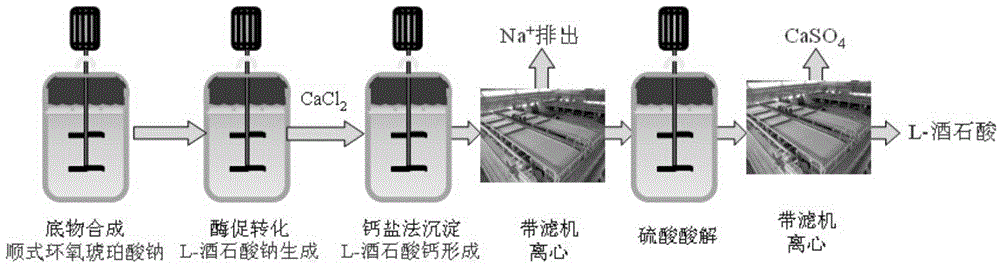

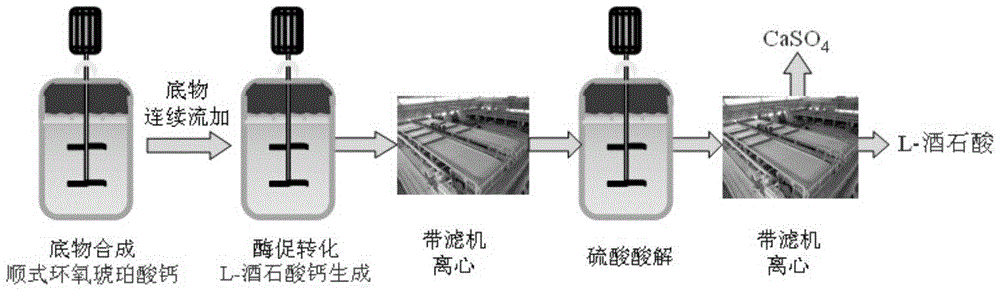

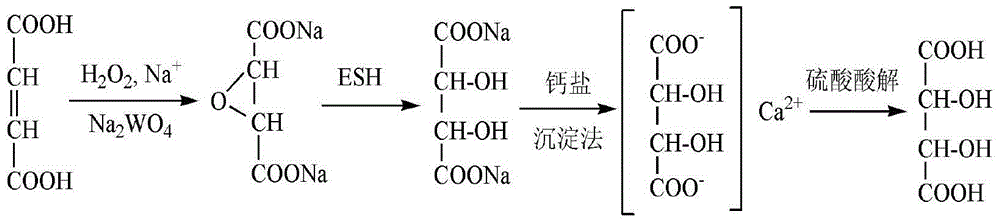

Method for synthesizing calcium epoxysuccinate suspension and method for producing l‑(+)‑tartaric acid

The invention discloses a method for synthesizing cis-epoxy calcium succinate. The method uses maleic anhydride, calcium carbonate and hydrogen peroxide to react under the catalysis of sodium tungstate, and then uses calcium hydroxide to adjust the pH. The invention also discloses a method for producing L-(+)-tartaric acid, wherein cis-epoxysuccinate calcium utilizes enzyme catalysis to produce L-(+)-calcium tartrate, and the solid L-(+) ‑Calcium tartrate crude product, then hydrolyzed with sulfuric acid, then separated to remove calcium sulfate, and then purified to obtain the final product L‑(+)‑tartaric acid. The present invention can replace the current conversion process of cis-epoxysodium sodium succinate, directly generate L-(+)-calcium tartrate, save the calcium salt precipitation operation unit, reduce the emission of sodium ions at the same time, reduce the consumption of raw materials, and have significant advantages Industrial application value and environmental benefits.

Owner:THE GREAT WALL BIO CHEM ENG CO LTD

Aluminum alkali-washing corrosion inhibitor, and preparation method and application thereof

ActiveCN104372362AHigh corrosion inhibition efficiencyGood corrosion inhibitionCalcium tartrateSodium silicate

The invention discloses an aluminum alkali-washing corrosion inhibitor, and a preparation method and application thereof, belonging to the field of aluminum alloy corrosion inhibition. The corrosion inhibitor is composed of water, sodium silicate, sodium gluconate, benzotriazole, calcium tartrate, acridine and phthalate diethylene glycol diacrylate (PDDA). The preparation method comprises the following steps: (1) uniformly mixing the PDDA, calcium tartrate and water to obtain a solution A; (2) uniformly mixing the sodium silicate, benzotriazole and water to obtain a solution B; (3) uniformly mixing the sodium gluconate, acridine and water to obtain a solution C; and (4) adding the solution B and solution C into the solution A, and stirring uniformly to obtain the corrosion inhibitor. The corrosion inhibitor has the advantages of favorable effect, environment friendliness, simple preparation technique and mild conditions, is suitable for corrosion inhibition protection of the aluminum alloy material in the alkali washing process, and is easy to manufacture.

Owner:马鞍山市鸿伟环化有限公司

Method for synthesizing calcium epoxy succinate suspension and method for producing L-(+)-tartaric acid

ActiveCN105753818AIncrease productivityLow costOrganic chemistryMicroorganism based processesEpoxyRaw material

The invention discloses a method for synthesizing calcium cis-epoxy succinate. According to the method, maleic anhydride, calcium carbonate, and hydrogen peroxide are adopted for a reaction in the presence of sodium tungstate as a catalyst, and calcium hydrate is used for adjusting the pH value. The invention further discloses a method for producing L-(+)-tartaric acid. According to the method, calcium cis-epoxy succinate is used for producing calcium L-(+)-tartrate in the presence of an enzyme as a catalyst; a solid coarse calcium L-(+)-tartrate product is separated; sulfuric acid is adopted for acidolysis; separation is carried out to remove calcium sulfate; and purification is carried out to produce the final L-(+)-tartaric acid product. Instead of a current sodium cis-epoxy succinate conversion process, according to the method, calcium L-(+)-tartrate is directly produced, so that a calcium salt precipitation operating unit is saved; discharge of sodium ions is reduced; and consumption of raw materials is decreased. The methods have significant industrial application value and environmental benefit.

Owner:THE GREAT WALL BIO CHEM ENG CO LTD

Preparation method for phosphorus-free compound corrosion and scale inhibitor

ActiveCN104556426ANo pollution in the processNo harmScale removal and water softeningEnergy based wastewater treatmentMethacrylateMeth-

The invention discloses a preparation method for a phosphorus-free compound corrosion and scale inhibitor, and belongs to the field of water treatment. The corrosion and scale inhibitor is composed of 20-30 parts of calcium tartrate dihydrate, 10-20 parts of octadecyl glucoside, 8-12 parts of benzotriazole, 3-5 parts of double (hydroxymethyl) imidazole alkyl urea, 15-20 parts of methyl silanol, 10-15 parts of allantoin, 12-15 parts of a hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, 8-10 parts of glyceryl polymethacrylate and 60-70 parts of water. The corrosion and scale inhibitor is free of organic or inorganic phosphorus, is the compound corrosion and scale inhibitor which is formed by combining a high molecular polymer and inorganic salt, has the advantages of being less in dosage, hazard-free on the environment, humans and crops and the like, and is an environment-friendly corrosion and scale inhibitor; the preparation method is simple in technique, reasonable in design, mild in conditions, easy to operate and suitable for industrialized application.

Owner:广州市清顺环保科技有限公司

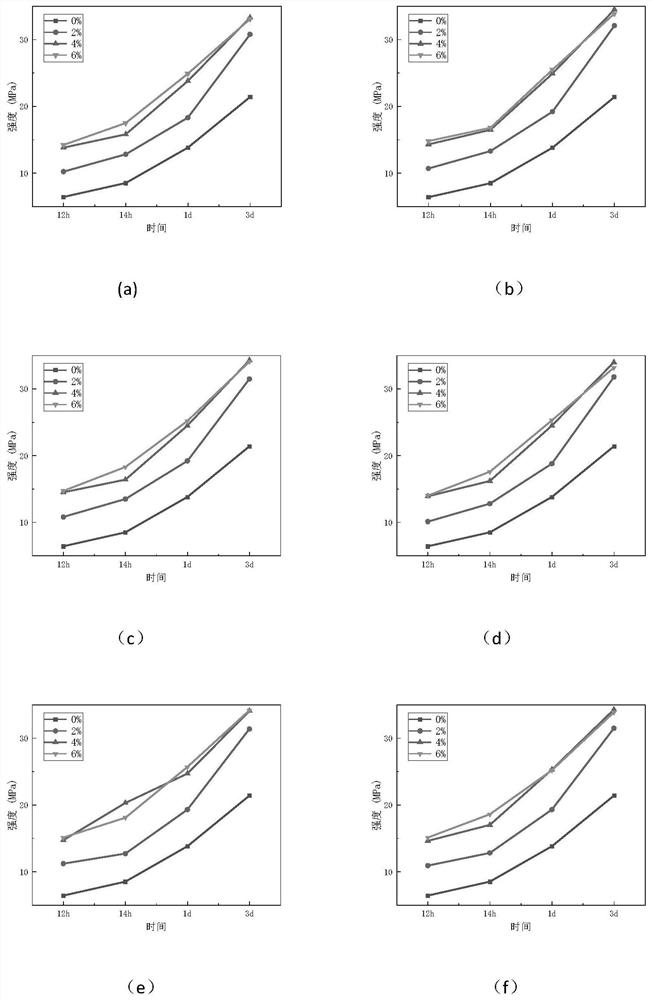

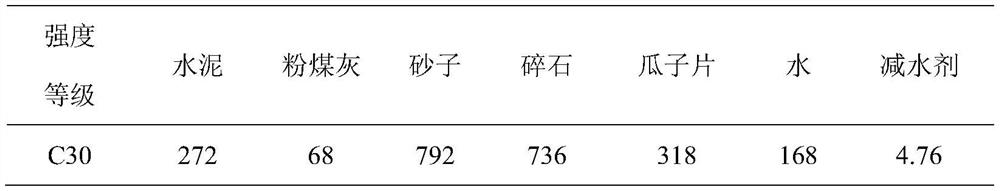

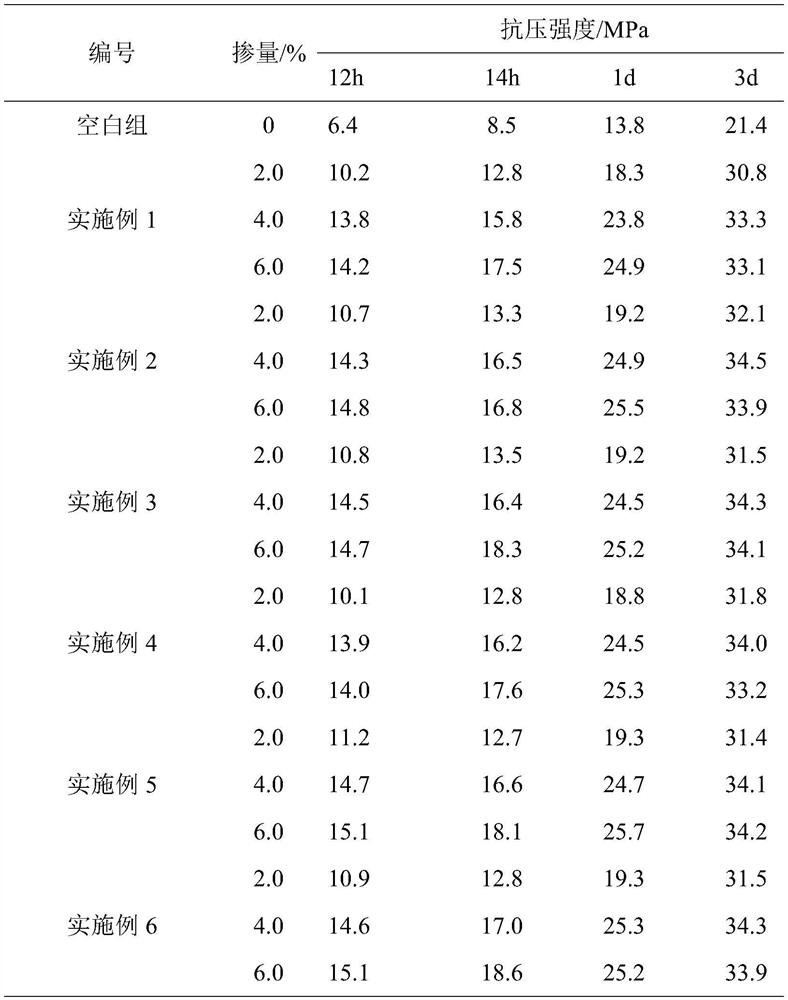

Concrete early strength agent, early strength concrete and preparation method of early strength concrete

The invention discloses a concrete early strength agent, an early strength type concrete and a preparation method of the early strength concrete. The concrete early strength agent is prepared from, by mass, 70-80% of a component A and 20-30% of a component B, the component A is a liquid mixture and comprises, by weight, 10-24 parts of silica sol dispersion liquid, 10-15 parts of siloxane emulsion, 2-4 parts of a surfactant, 8-15 parts of soluble calcium salt and 4-5 parts of alcamines; the silica sol dispersion liquid is a dispersion liquid of three substances, namely nanoscale silicon dioxide, a dispersing agent and a suspending agent, in water, and the dispersing agent accounts for 0.5-2% of the solvent water; the suspending agent accounts for 0.5-1% of the solvent water, and the nanoscale silicon dioxide accounts for 55-70% of the solvent water; and the component B is a solid mixture and comprises,s by weight, 30-40 parts of meta-aluminate, 20-30 parts of silicate, 20-30 parts of lithium salt, 2-10 parts of calcium tartrate and 0.5-1 part of methyl cellulose ether. The superposition effect of different early strength components can be exerted, the setting and hardening speed of cement is accelerated, the precipitation of hydration products is promoted, and the early strength of concrete can be obviously improved in a low-temperature environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

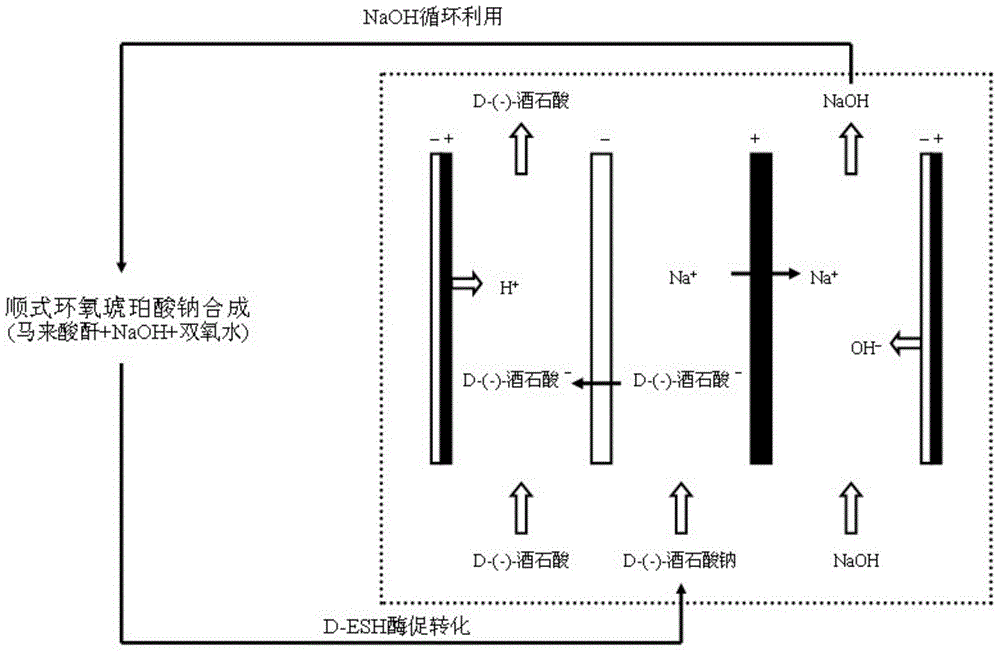

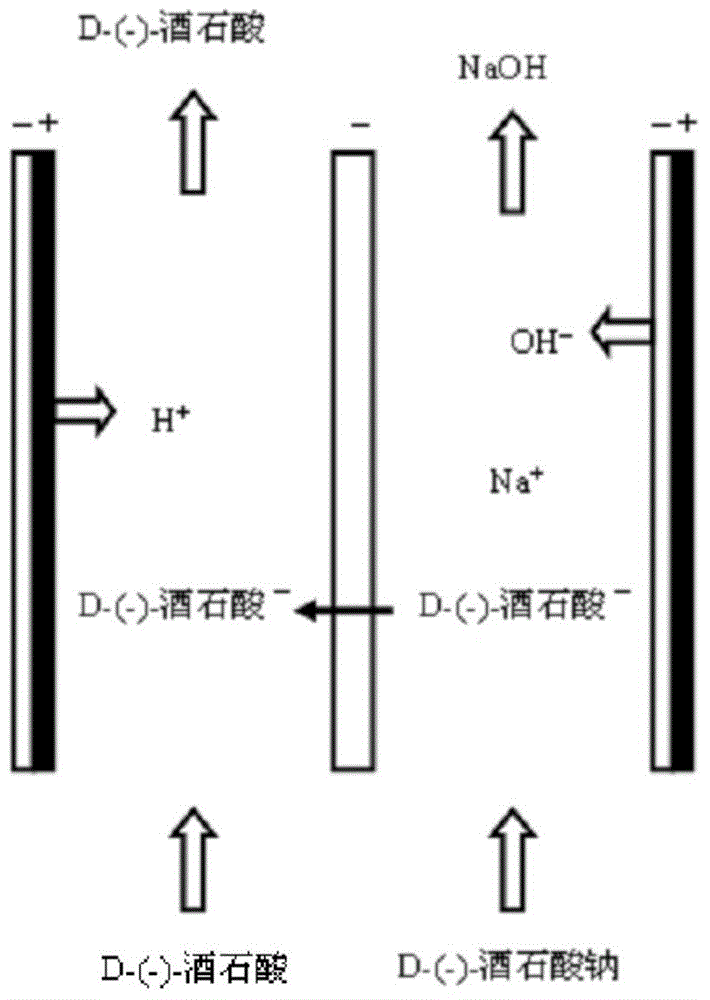

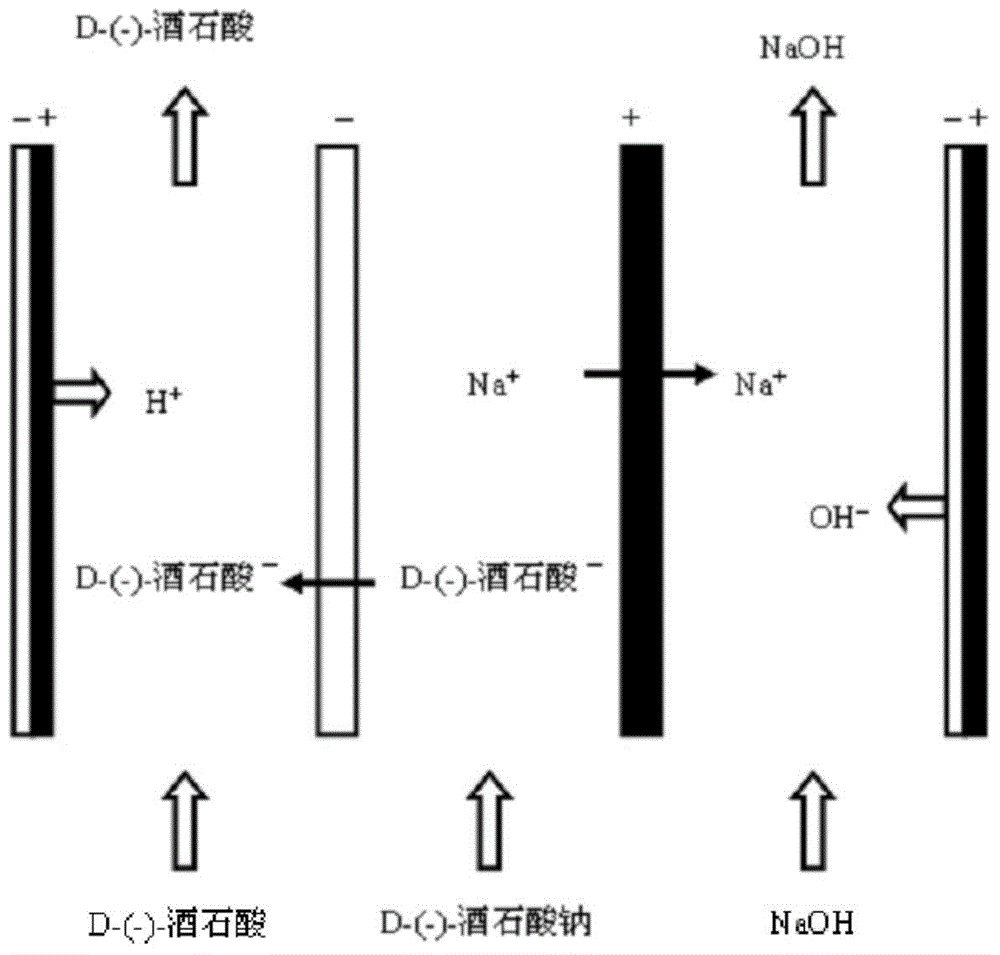

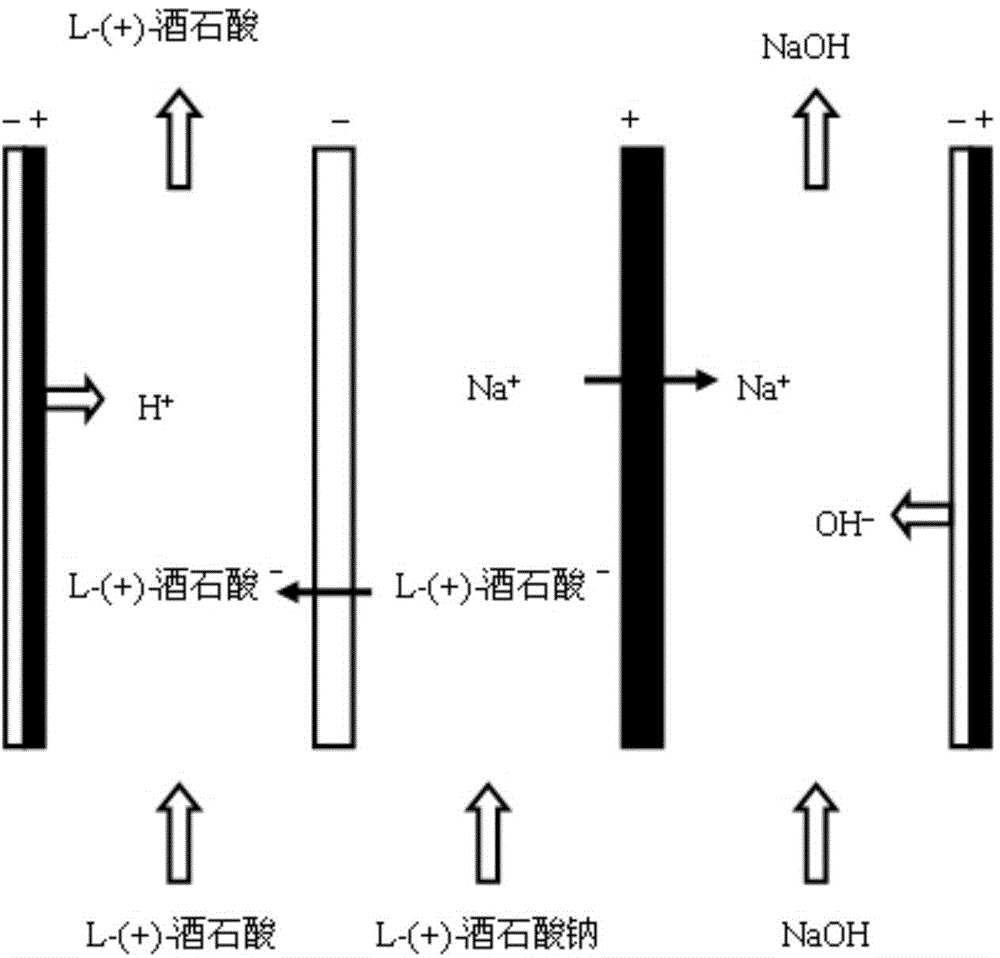

D-(-)-tartaric acid clean production process based on bipolar membrane electroosmosis technology

InactiveCN105087677AInevitableAchieve recyclingPreparation from carboxylic acid saltsFermentationEpoxySalt-wasting

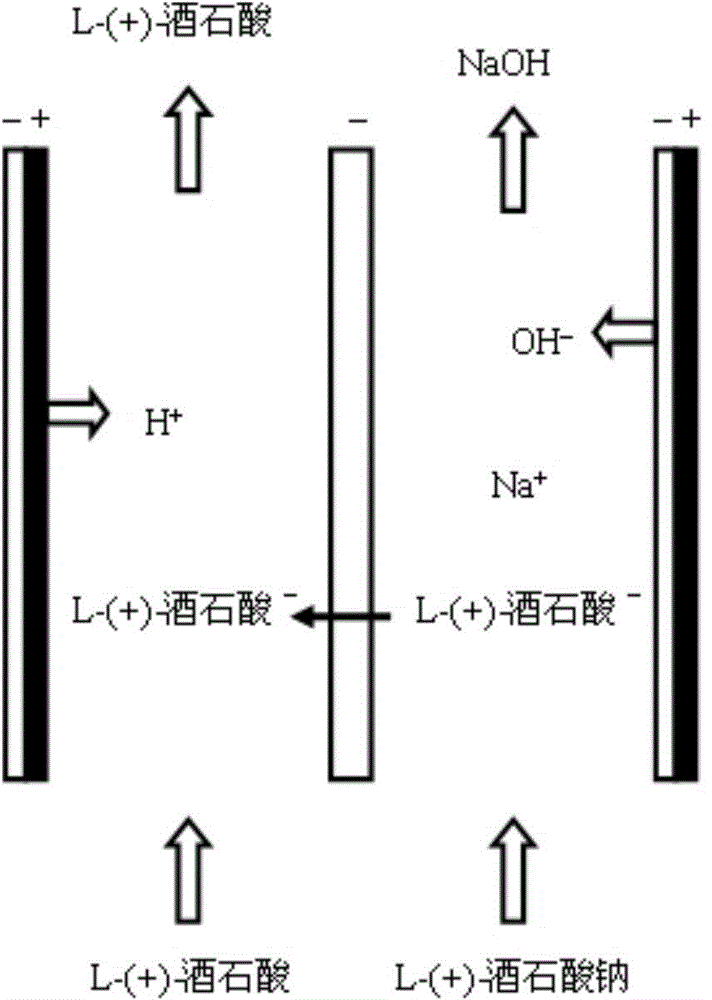

A purpose of the present invention is to provide a D-(-)-tartaric acid clean production process based on a bipolar membrane electroosmosis technology. The process comprises that: a cis-epoxy succinic acid sodium salt is hydrolyzed with D-type cis-epoxy succinic acid hydrolase (D-ESH) to obtain a D-(-)-sodium tartrate conversion solution; and the D-(-)-sodium tartrate contained in the D-(-)-sodium tartrate conversion solution is converted into D-(-)-tartaric acid through a bipolar membrane electordialyzer. According to the present invention, the current D-(-)-calcium tartrate acidification process can be replaced, the D-(-)-tartaric acid yield achieves more than or equal to 95%, and the additional acid is not required to provide H<+>; the generated NaOH solution can be used for synthesizing the precursor cis-epoxy sodium succinate, and the whole production process does not produce acid, alkali and salt waste solutions; and the production process has characteristics of environmental pollution reducing, raw material consumption reducing, significant industrial application values, and significant environmental benefits.

Owner:THE GREAT WALL BIO CHEM ENG CO LTD

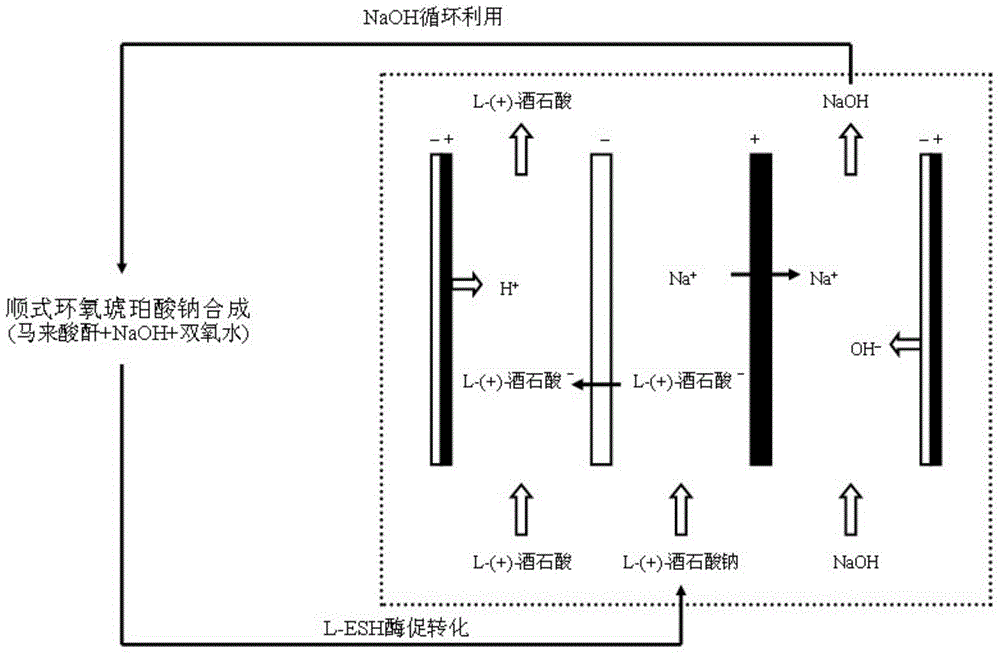

L-(+)-tartaric acid clean production process based on bipolar membrane electroosmosis technology

InactiveCN105087676AAchieve recyclingIncrease productivityPreparation from carboxylic acid saltsFermentationCalcium tartrateChemistry

A purpose of the present invention is to provide a L-(+)-tartaric acid clean production process based on a bipolar membrane electroosmosis technology. The process comprises that: a cis-epoxy succinic acid sodium salt is hydrolyzed with L-type cis-epoxy succinic acid hydrolase (D-ESH) to obtain a L-(+)-sodium tartrate conversion solution; and the L-(+)-sodium tartrate contained in the L-(+)-sodium tartrate conversion solution is converted into L-(+)-tartaric acid through a bipolar membrane electordialyzer. According to the present invention, the current L-(+)-calcium tartrate acidification process can be replaced, the L-(+)-tartaric acid yield achieves more than or equal to 96%, and the additional acid is not required to provide H<+>; the generated NaOH solution can be used for synthesizing the precursor cis-epoxy sodium succinate, and the whole production process does not produce acid, alkali and salt waste solutions; and the production process has characteristics of environmental pollution reducing, raw material consumption reducing, significant industrial application values, and significant environmental benefits.

Owner:THE GREAT WALL BIO CHEM ENG CO LTD

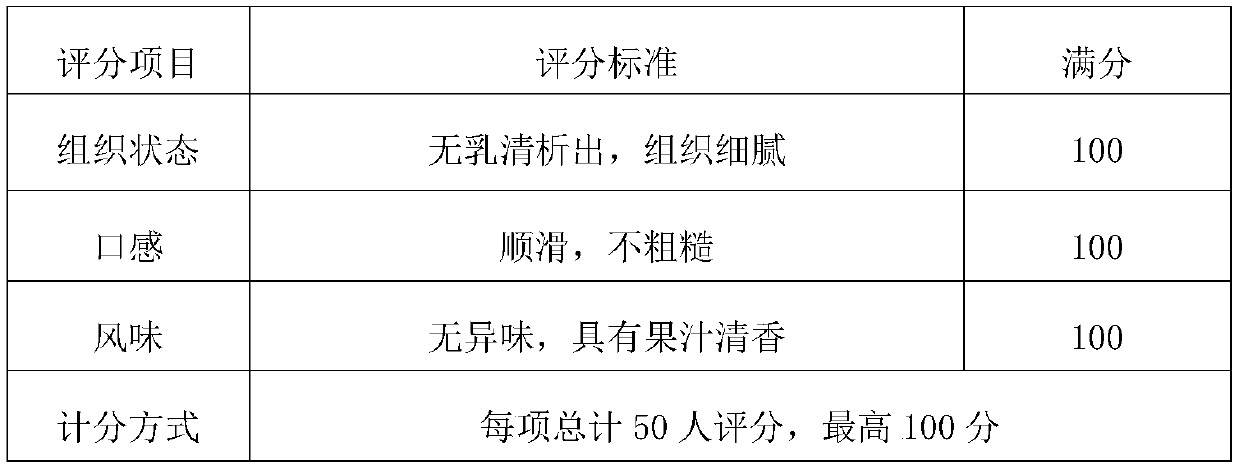

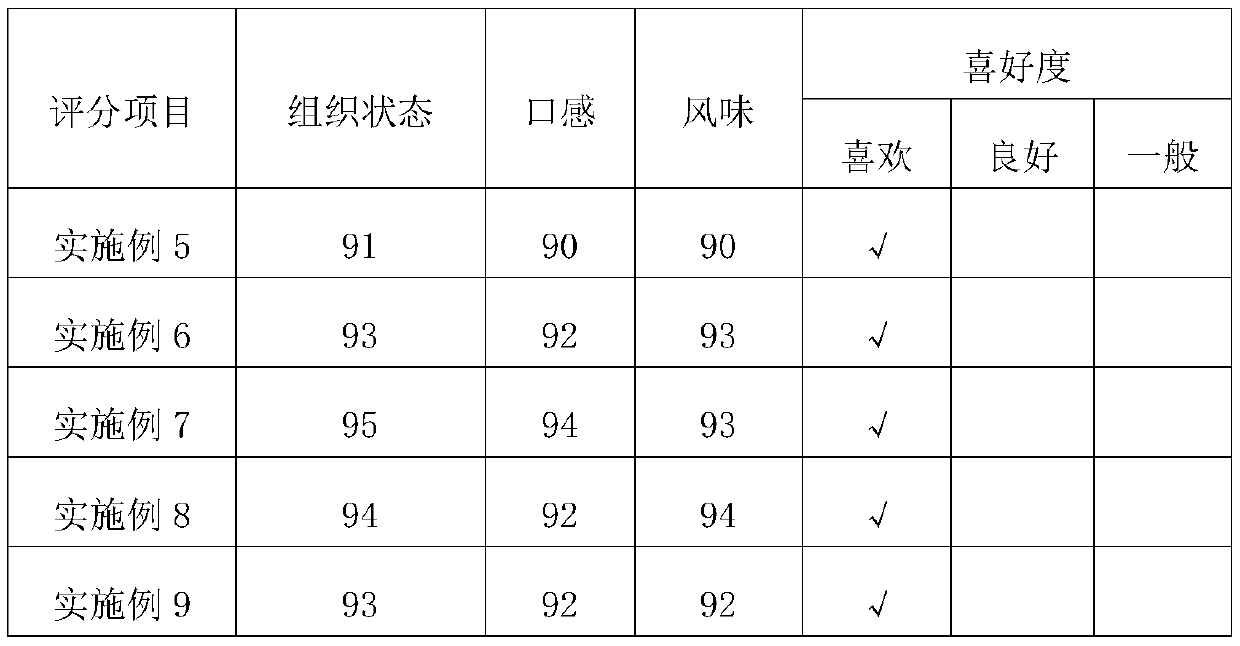

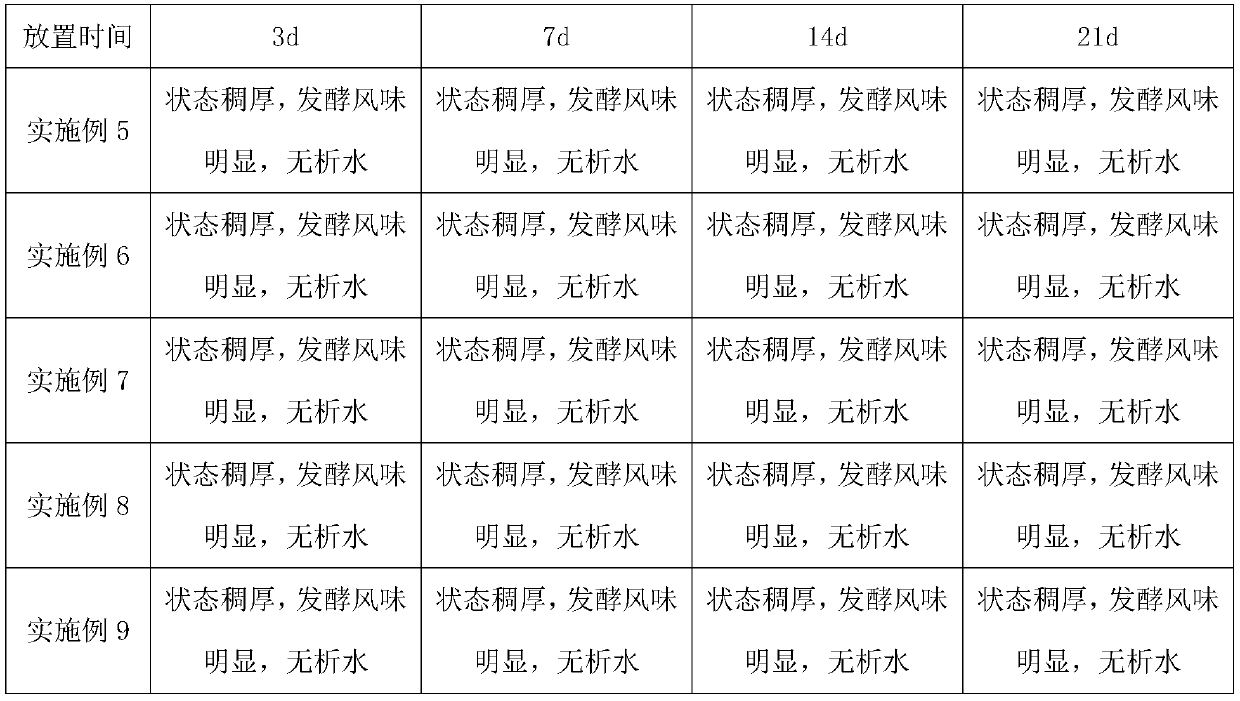

Red grape cheese jam, red grape yogurt and preparation methods of red grape cheese jam and red grape yogurt

ActiveCN110973552AOvercoming the technical difficulty of easy calcium crystallizationAdd funMilk preparationFood scienceBiotechnologyLocust bean gum

The invention discloses red grape cheese jam, red grape yogurt and preparation methods of the red grape cheese jam and the red grape yogurt. The red grape cheese jam is prepared by the following steps: mixing sodium alginate, pectin, xanthan gum, locust bean gum and a sweetener, adding the mixture into water to obtain a colloid mixture, pulping red grapes, and performing mixing with the colloid mixture to obtain a red grape composite; continuously and dropwise adding the red grape composite into an aqueous solution containing CaCl2, performing soaking, then performing filtering, and performingwashing with sterile water to obtain red grape colloidal particles; cutting cheese into dices, mixing the dices with a sweetener, modified starch, pectin and water, adding essence and edible pigment,and performing uniform mixing to obtain cheese paste; and uniformly mixing the red grape colloidal particles with the cheese paste, and performing filling and sterilizing to obtain the red grape cheese jam. The red grape cheese jam and the yoghourt containing the jam overcome the problems that in the prior art, red grapes are easily combined with milk products to form calcium tartrate, taste of products is influenced, and applications of red grape fruits in milk products is greatly limited.

Owner:BRIGHT DAIRY & FOOD

Cold treatment technology for grape wine

InactiveCN107586688AIncrease cold stabilityImproved cold stabilityAlcoholic beverage preparationFlavorCold treatment

The invention discloses a cold treatment technology for grape wine. The cold treatment technology comprises the steps of freezing, extracting, mixing and dissolving, suction filtering, cold storing and filling. The cold treatment technology disclosed by the invention is characterized in that in a cold treatment process, mannose protein extracted from wine lees yeast is added into the grape wine; thus, a separating-out rate of potassium bitartrate and calcium tartrate crystalline is reduced, the potassium bitartrate and calcium tartrate crystalline can be slowly separated out, and cold stability of the grape wine is improved. The mannose protein not only can improve a lateral stability effect of the grape wine, but also can make the grape wine keep a style and a feature of a natural productand reduce a later chemical and physical treatment frequency and a later chemical and physical treatment degree. By means of performing cold treatment on the grape wine by the method disclosed by theinvention, not only is ageing of new wine is accelerated, but also raw color and acor taste of the wine are reduced, the taste is coordinated and palatable, and wine quality is improved; furthermore,stability of the grape wine is improved, and original taste and flavor of the wine are kept.

Owner:贵州神授酒业有限公司

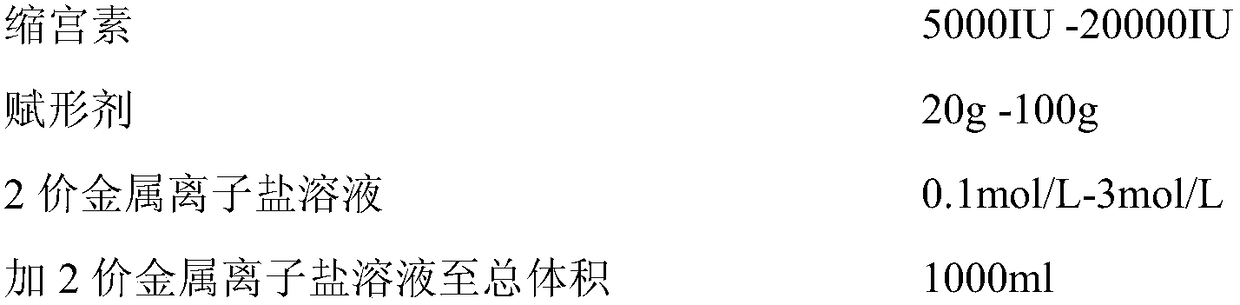

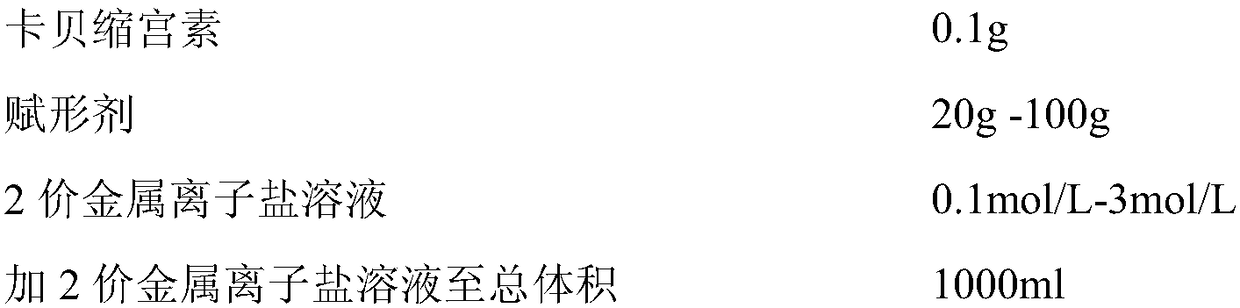

Medicinal composition containing oxytocin analogue, as well as preparation method and application thereof

InactiveCN108236716AEliminate sensitivity differencesReduce generationPowder deliveryPeptide/protein ingredientsGluconic acidDivalent metal ions

The invention relates to a medicinal composition containing an oxytocin analogue, as well as a preparation method and application thereof. The medicinal composition is prepared from the oxytocin analogue, excipient and divalent metal ion salt, wherein the divalent metal ion salt is a solution of one or combination of two or more than two of calcium chloride, calcium acetate, calcium citrate, calcium tartrate, zinc chloride, zinc gluconate, calcium gluconate, calcium sulfate, zinc sulfate, zinc acetate and zinc citrate. The medicinal composition can be used for eliminating the uterine sensitivity difference and is stable in long-time storage at 30 DEG C.

Owner:HYBIO PHARMA

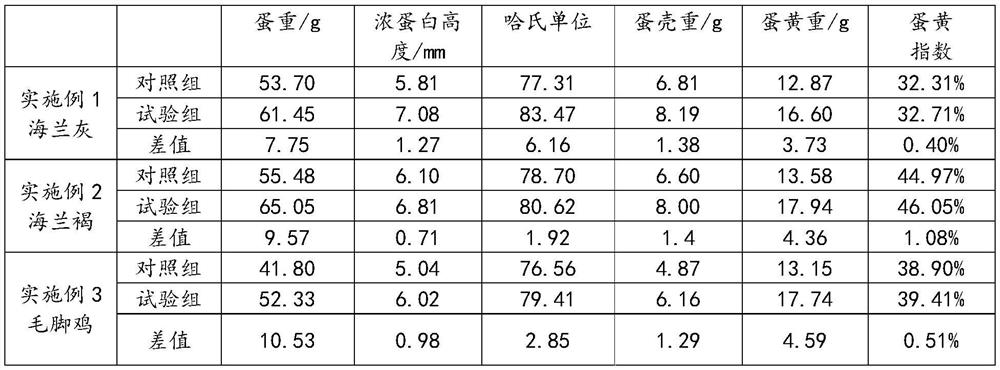

Special micro-ecological preparation for laying hens and preparation method of special micro-ecological preparation

Owner:FUJIAN DAFENG MOUNTAIN POULTRY DEV CO LTD +1

Corrosion and scale inhibition method for aluminum plate type cooling-heat transfer equipment

InactiveCN104591411AWill not polluteNo harmEnergy based wastewater treatmentTreatment using complexing/solubilising chemicalsMethacrylateMeth-

The invention discloses a corrosion and scale inhibition method for aluminum plate type cooling-heat transfer equipment, which belongs to the field of water treatment. A corrosion and scale inhibitor used in the invention is composed of 20-30 parts of calcium tartrate, 10-20 parts of octadecyl glucoside, 8-12 parts of benzotriazole, 3-5 parts of bis(hydroxymethyl) imidazolidinyl urea, 15-20 parts of methyl silanol, 10-15 parts of allantoin, 12-15 parts of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, 8-10 parts of glyceryl polymethacrylate and 60-70 parts of water. The corrosion and scale inhibitor does not contain organic or inorganic phosphorus, and is a compound corrosion and scale inhibitor compounded by using a high-molecular polymer and an inorganic salt, so that the inhibitor has the advantages of small application amount, and no harm to the environment, human bodies and crops, and the like, and the inhibitor is an environmental-friendly corrosion inhibitor, and has an excellent corrosion inhibition effect on the aluminium plate type cooling-heat transfer equipment, therefore, the inhibitor has a good application prospect.

Owner:HARBIN UNIV OF SCI & TECH

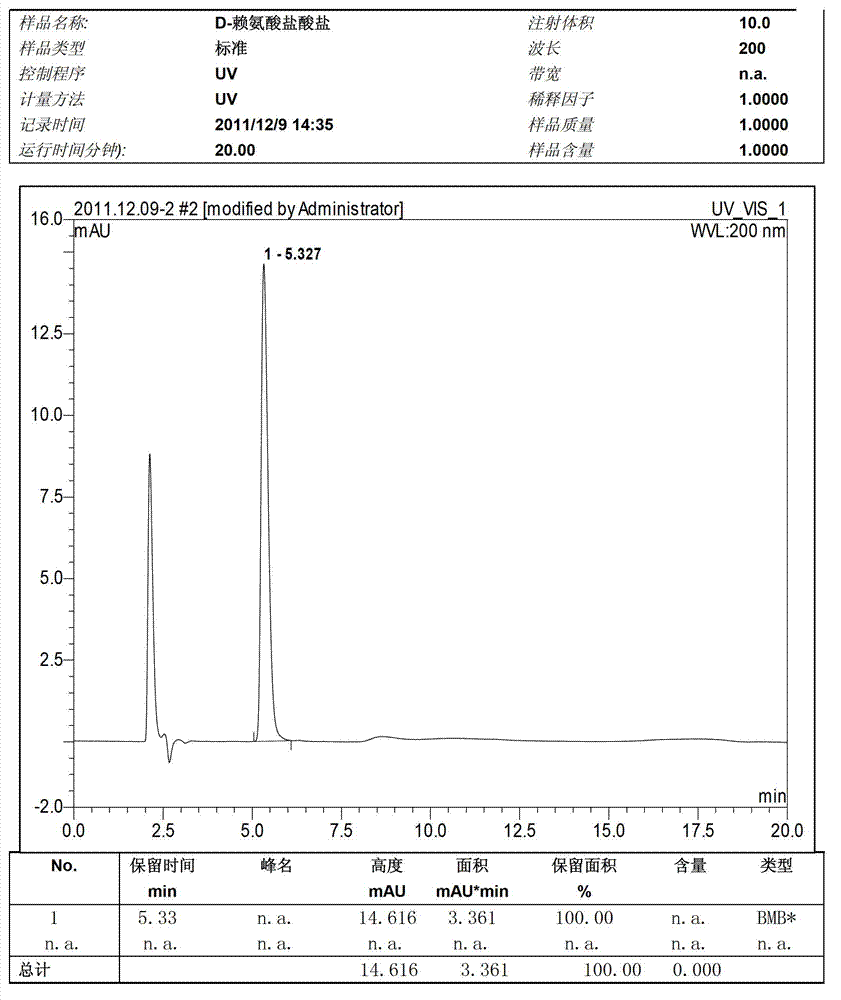

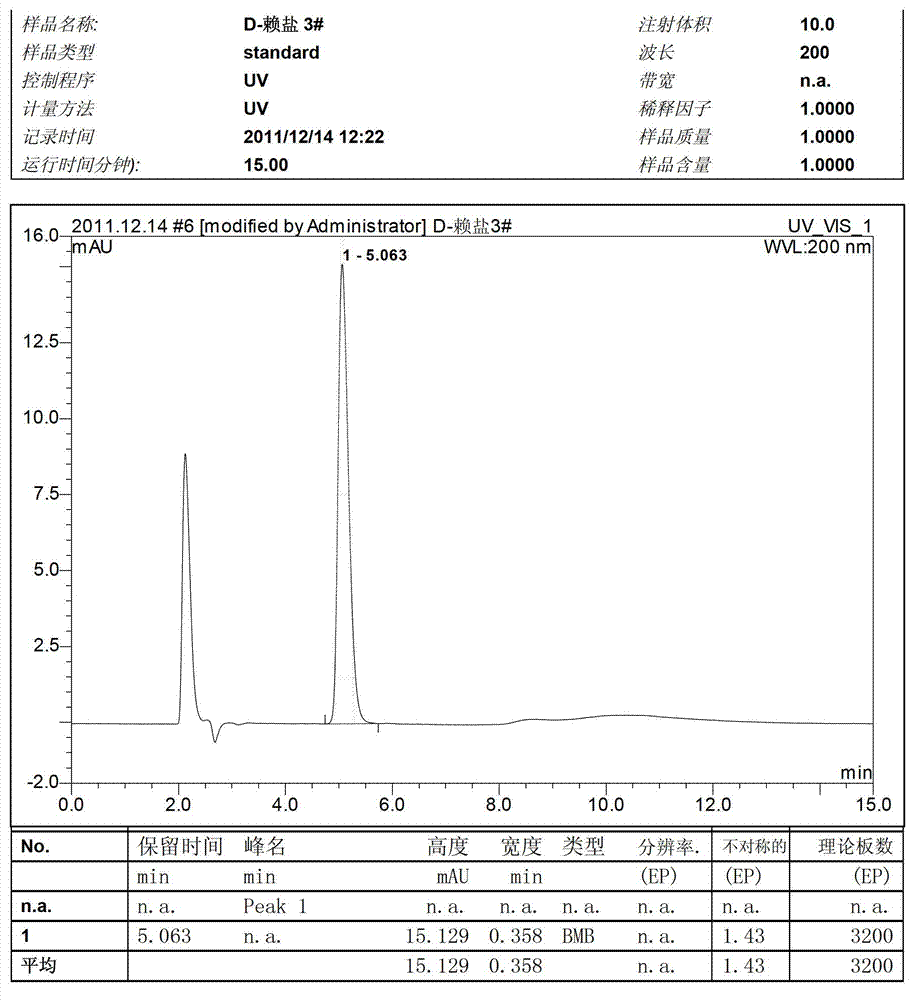

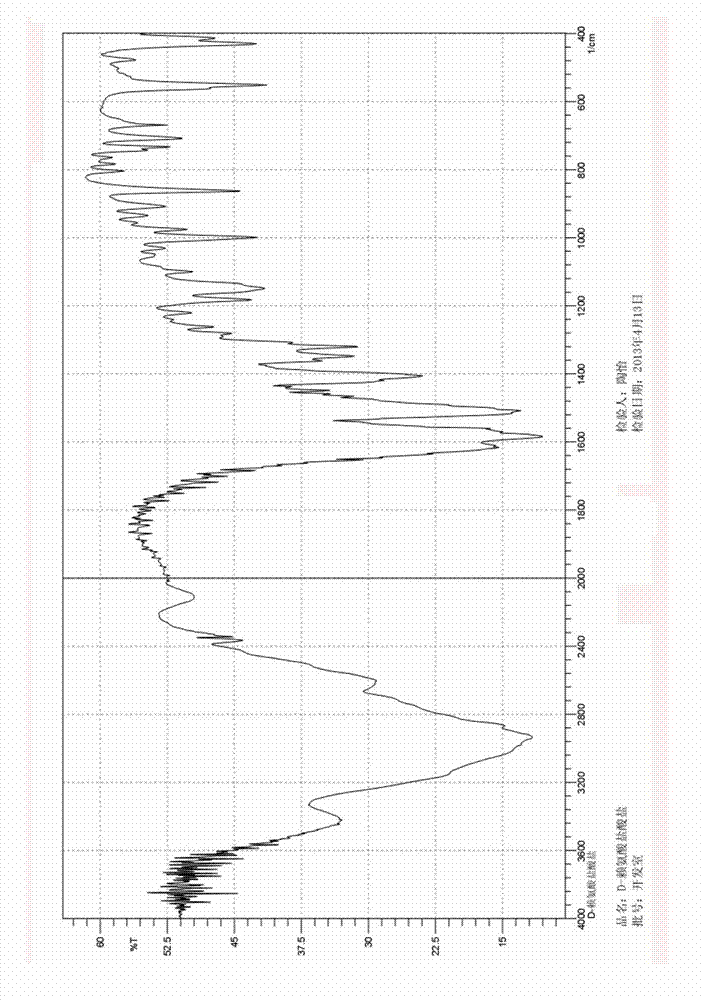

Preparation method of D-lysine hydrochloride

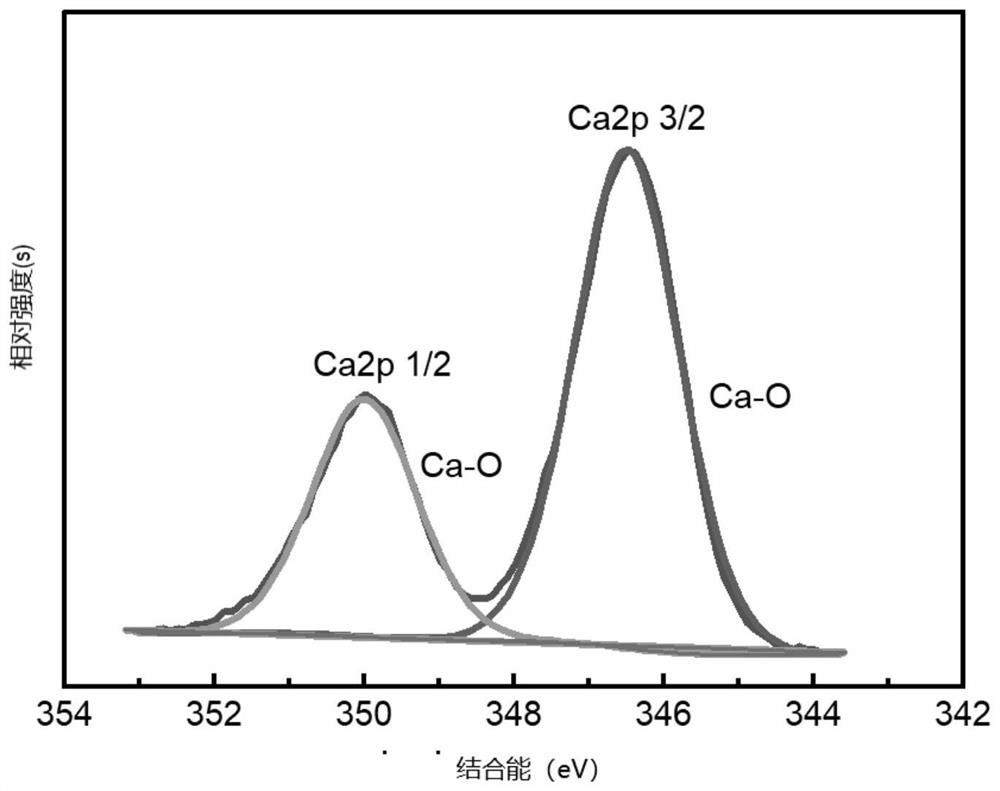

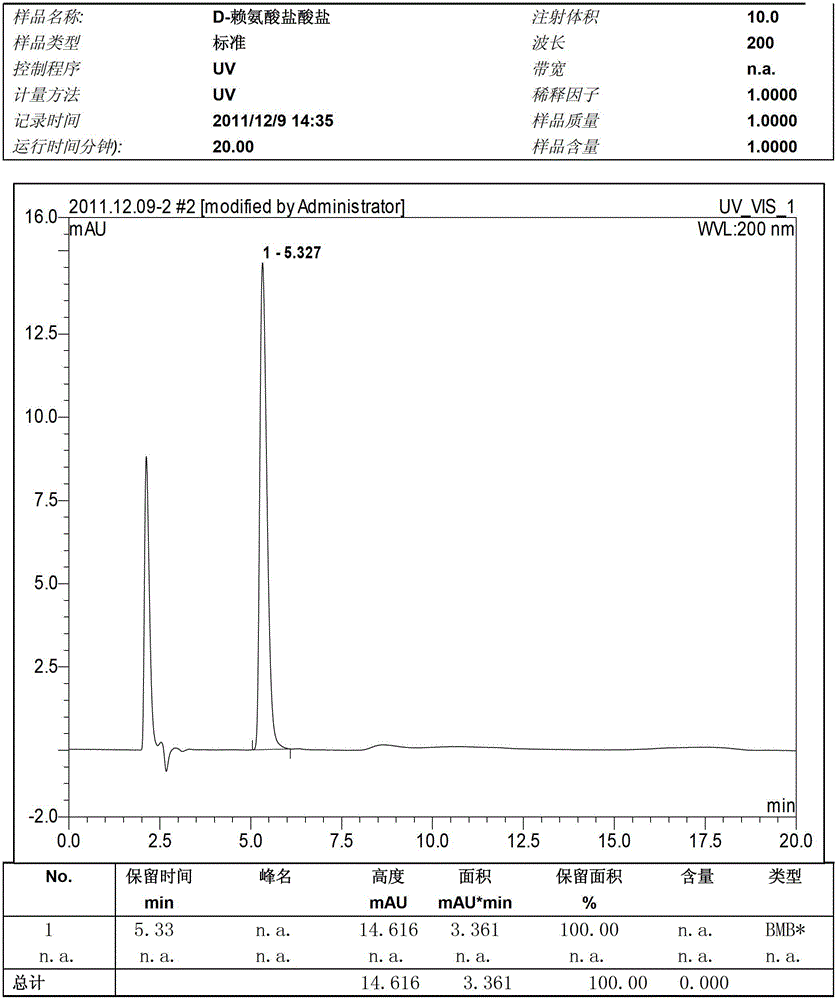

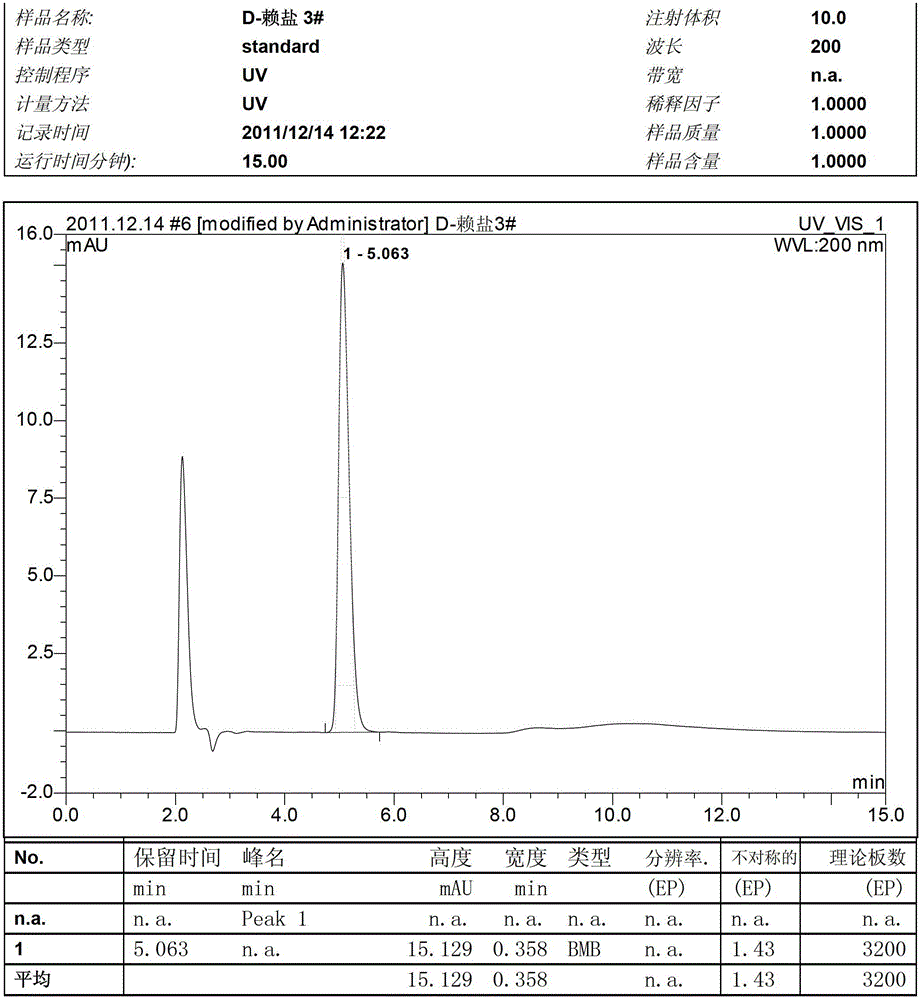

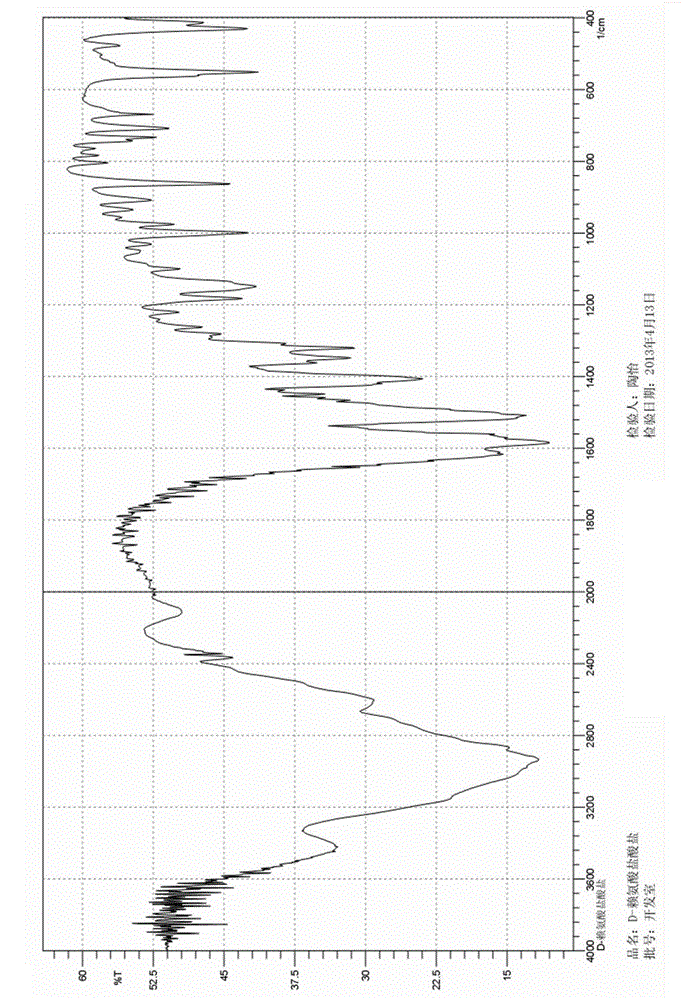

InactiveCN103204783AEasy to separateLow priceOrganic compound preparationAmino-carboxyl compound preparationIon exchangeCalcium tartrate

The invention relates to a preparation method of D-lysine hydrochloride. The method comprises the following steps of: by taking DL-lysine as a raw material, after purification, reacting at 30-70 DEG C with L-tartaric acid to generate diastereomer salt; then, performing inorganic calcium salt with diastereomer salt to generate a calcium tartrate precipitate, while maintaining D-lysine in a liquid; adjusting pH, decoloring, concentrating and crystallizing the D-lysine liquid through hydrochloric acid to obtain D-lysine hydrochloride crude crystalline; and purifying the D-lysine hydrochloride crude crystalline to obtain the D-lysine hydrochloride. The content of DL-lysine in the D-lysine hydrochloride is below 0.5%. According to the method provided by the invention, a simple neutralization precipitation method replaces a complex ion-exchange resin method to the benefit of simplifying the production method and stabilizing the product quality. Meanwhile, the method further has the advantages of no special devices and reduction of environmental pollution, and is easy to popularize and apply industrially.

Owner:ZHANGJIAGANG HUACHANG PHARMA

A kind of production method of l (+) tartaric acid

ActiveCN102093208BSolve pollutionReduce pollutionPreparation from carboxylic acid saltsCalcium tartrateMother liquor

The invention discloses a method for producing an L (+) tartaric acid. The method for producing the L(+) tartaric acid comprises the following steps of: (1) adding cis-epoxy sodium bisuccinate into aqueous solution of frozen mother solution to prepare mixed solution, adjusting the pH value, and adding red rhodococcus to hydrolyze; (2) adding calcium sulfate to perform calcification, filtering to obtain L(+) calcium tartrate solid and calcified mother solution, freezing the calcified mother solution, performing centrifugal separation to obtain sodium sulfate decahydrate solid and frozen mother solution, and returning the frozen mother solution to the step (1); and (3) performing acidolysis on the L(+) calcium tartrate solid by using sulfuric acid, filtering to obtain aqueous solution of the L(+) tartaric acid, passing through cation and anion exchange resins sequentially, concentrating, crystallizing, separating and drying to obtain the L(+) tartaric acid. The calcified mother solution and calcium sulfate generated in the production process can be recycled, so the problem of environmental pollution is solved; and a small amount of product L(+) calcium tartrate dissolved in the calcified mother solution and unreacted cis-epoxy sodium bisuccinate are recovered, so the product yield is increased.

Owner:CHANGMAO BIOCHEMICAL ENG CO LTD

Method for recycling tartaric acid in tilmicosin production wastewater

InactiveCN108609767AReduce dosageReduce contentOrganic compound preparationWater contaminantsHydrogenWastewater

The invention relates to a method for recycling tartaric acid in tilmicosin production wastewater. The method comprises the following steps: (1) delivering the tilmicosin production wastewater containing sodium tartarate into a treatment kettle, slowly adding calcium chloride of which the molar ratio is 1 to (0.9 to 1.1) into the treatment kettle, stirring for 20 to 40 minutes, and carrying out plate frame filtering, thus obtaining calcium tartarate precipitate; (2) preparing and delivering a sulfuric acid solution of which the concentration is 2 to 4 percent to a reaction kettle, starting thereaction kettle for stirring, slowly putting calcium tartarate filtered and obtained in step (1) in the reaction kettle, reacting for 30 to 50 minutes under the situation that stirring is started, sampling, and controlling pH (Potential of Hydrogen) of a reaction solution to be 1.2 to 1.6 by regulating the adding amount of calcium tartarate; (3) carrying out the plate frame filtering on the reaction solution obtained in step (2), wherein filtrate (a tartaric acid solution) is used for production of tylosin tartarate. According to method disclosed by the invention, not only can the problem ofwastewater treatment during tilmicosin production be solved, but also the recycled tartaric acid can be used for preparing tylosin tartarate; the problem of environment protection is solved, meanwhile, the production cost of tylosin tartarate is also reduced, and the purposes of cyclic economy, comprehensive treatment as well as energy conservation and emission reduction are achieved.

Owner:SHANDONG DONGYAO PHARMACEUTICAL CO LTD

Method for recovering L-tartaric acid from D-cysteine conversion hydrolysate

InactiveCN113277941AHigh recovery rateLow volume of mother liquorPreparation from carboxylic acid saltsOrganic compound preparationHydrolysateSulfate

The invention provides a method for recovering L-tartaric acid from D-cysteine conversion hydrolysate. The method comprises the following steps of: 1, hydrolysis and neutralization of double salt, specifically, separating L-tartaric acid from the D-cysteine conversion hydrolysate by using calcium oxide as a precipitator; 2, acidizing treatment, specifically, namely acidizing the L-calcium tartrate with sulfuric acid, performing concentrating, performing filtering to remove calcium sulfate, and cooling and crystallizing filtrate to obtain L-tartaric acid; and 3, product preparation, ,specifically, preparing D-cystine by taking liquid obtained after the L-tartaric acid is recycled as the raw material and adopting a D-cysteine asymmetric synthesis process in the prior art. According to the method, the L-tartaric acid in the D-cysteine conversion hydrolysate is separated by using the calcium oxide as a precipitator. Compared with a method in the prior art, the method has a higher recovery rate which can reach 76%; the application of the L-tartaric acid in the process is realized; the process route for preparing the D-cystine is optimized; the purpose of recovering and recycling the L-tartaric acid is achieved; and the production cost is reduced.

Owner:湖北新生源生物工程有限公司

Scale inhibitor for inhibiting formation of calcium carbonate scale and preparation method thereof

PendingCN113249107AImprove high temperature resistanceEasy to useDrilling compositionGlycosidePhysical chemistry

The invention discloses a scale inhibitor for inhibiting formation of calcium carbonate scale. The scale inhibitor is prepared from the following raw materials in parts by weight: 10-20 parts of calcium tartrate, 4-6 parts of glyceryl polymethacrylate, 20-30 parts of a first component, 50-60 parts of deionized water, 5-7 parts of octadecyl glycoside, 6-8 parts of benzotriazole and 20-30 parts of a second component, the preparation method comprises the following steps: 1, preparing the first component and the second component; and 2, mixing calcium tartrate, glyceryl polymethacrylate, the first component and deionized water, then adding octadecyl glycoside, benzotriazole and the second component, uniformly stirring, heating to 40-50 DEG C, and stirring to react for 1-2 hours, thereby obtaining the scale inhibitor for inhibiting the formation of calcium carbonate scale. The component A is connected to a main chain of a polymer of the first component, so that the high-temperature resistance of the first component is improved, and the second component has better dispersion stability and synergistically promotes the scale inhibition effect.

Owner:上绍同烯达(绍兴)新材料科技有限公司

Building additive material and preparation method thereof

The invention discloses a building additive material and a preparation method thereof. The building additive material is prepared from the following raw materials in percentage by weight: 0.003 to 0.005 percent of sulfuric acid, 0.14 to 0.19 percent of calcium tartrate, 18 to 26 percent of tartaric acid, 0.3 to 0.6 percent of oxalic acid, 0.6 to 1.3 percent of calcium sulfate, 35 to 40 percent ofzinc oxide composite powder materials, 13 to 18 percent of cuprous oxide / zinc oxide composite body materials and the balance of zinc oxide. In a preparation process, the processes of roasting, grinding, secondary tempering and the like are used, so that good waterproof performance is realized by the invention; meanwhile, high stability and practicability are realized; the building additive material can be widely applied to the building fields and the like. The cuprous oxide / zinc oxide composite body materials are favorable for improving the intensity of the loose acicular structure; the wholeanti-seepage capability of the structure is greatly improved by the zinc oxide composite powder materials. The secondary cracking and seepage due to instability of ordinary concrete structure volume is fundamentally improved by the building additive material provided by the invention.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

A method of recovering tartaric acid from calcium tartrate using interfacial reaction

InactiveCN110606802AReduce dosageReduce pollutionPreparation from carboxylic acid saltsInterfacial reactionOrganic solvent

The invention discloses a method for recovering tartaric acid from reaction of calcium tartrate and inorganic acid by using interface reaction, which comprises the following steps: by using an inert organic solvent as a reaction medium system, performing acidifying precipitation, carrying out reduced pressure distillation to recover the solvent, and drying the material to obtain the target productwith the yield of 93-96% and the purity of more than 98%. The method is simple in process (recrystallization is not needed, and the organic solvent is easy to recover), high in recovery rate, easy tocontrol reaction conditions and free of wastewater generation, and overcomes the problems of high energy consumption and high cost of an existing tartaric acid recovery process.

Owner:上海清研新材料科技有限公司

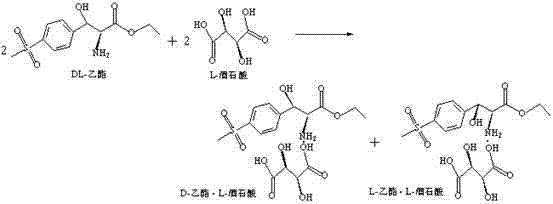

Method for recovering and mechanically applying L-(+)-tartrate in D-ethyl ester production

ActiveCN104326901AChances of avoiding side effectsImprove qualityPreparation from carboxylic acid saltsOrganic compound preparationBiochemical engineeringCentrifugation

The invention discloses a method for recovering and mechanically applying L-(+)-tartrate in D-ethyl ester production, which comprises the following steps: 1)obtaining a L-(+)-tartrate solution; 2)recovering L-(+)-calcium tartrate dehydrate; 3)acidifying; 4)performing pressure reduction and condensation; and 5)crystallizing, separating and drying. The method of the invention employs an inertia organic solvent, takes a solvent method to replace a water phase method to recover L-(+)-tartrate, key points of control temperature, time, centrifugation and vacuum degree are realized, the product yield is high, the purity and specific rotation of the recovered L-(+)-tartrate product accord with quality requirement, quality standard of the L-(+)-tartrate raw material can be reached, and the method can be used for chiral resolution of D-ethyl ester, recovery and mechanical application of L-(+)-tartrate can be realized, production cost is reduced, and the method is suitable for industrial production.

Owner:兰州鑫隆泰生物科技有限公司

Compound slow-release scale inhibitor

PendingCN109942101AReduce dosageNo harmScale removal and water softeningPolyaspartic acidPolyphosphate

The invention discloses a compound slow-release scale inhibitor. The compound slow-release scale inhibitor specifically comprises the following preparation steps that 1, calcium tartrate, benzotriazole, polyaspartic acid, polyacrylamide, diethanolisopropanolamine, water, a starch matrix, 1-hydroxyethylidene-1,1-diphosphonic acid, modified chitosan and polyphosphates are weighed by corresponding weight for use; 2, the 1-hydroxyethylidene-1,1-diphosphonic acid, the starch matrix and an initiator in step 1 are added into a reaction kettle to be stirred uniformly, then heating is conducted to reach 80-90 DEG C, and heat preservation is conducted for 15-18 minutes; 3, the calcium tartrate, the benzotriazole, the polyaspartic acid, the polyacrylamide and water in step 1 are stirred and dissolveduniformly, and an water phase of the non-phosphorus compound slow-release scale inhibitor is obtained. According to the compound slow-release scale inhibitor preparation method, the process is simple, energy conservation and environmental friendliness are achieved, the manufacturing cost is low, the practicability is high, and the method is suitable for wide application and popularization.

Owner:南京广全环保技术服务有限公司

Method for recycling waste nickel-cadmium cell

ActiveCN108118155AImprove dissolution rateHigh dissolution rateProcess efficiency improvementNickel oxides/hydroxidesNickel oxide hydroxideNickel cadmium

The invention provides a method for recycling a waste nickel-cadmium cell. The method comprises the following steps: mixing the waste nickel-cadmium cell material, an HCl solution and a compound to obtain a metal ionic mixed solution, wherein the compound is tartaric acid and / or sodium tartrate; regulating pH to be 4-7; filtering to obtain a pre-treated solution; regulating the pH of the pre-treated solution to be 8-11; filtering to obtain cadmium hydroxide and filtrate; regulating the pH of the filtrate to be 5-7; mixing with calcium nitrate; reacting to obtain a nickel nitrate solution and calcium tartrate; and regulating the pH of the nickel nitrate solution to be 7-12 to obtain nickelous hydroxide. According to the method, a recovery device used in the method is simple, and convenientto operate; the nickel and cadmium are separated and recovered based on different pH; the method is simple; the recovery rate and the purity are high; general agents are adopted; tartaric acid or sodium tartrate are recyclable, so that the cost is low; toxic agents such as sulfide are not used, so that secondary pollution is not caused; tartaric acid or sodium tartrate is capable of increasing themetal dissolution speed and rate.

Owner:GUANGDONG UNIV OF TECH

A method for resource utilization of waste nickel-cadmium batteries

ActiveCN108118155BImprove dissolution rateHigh dissolution rateNickel oxides/hydroxidesProcess efficiency improvementNickel cadmiumNickel oxide hydroxide

The invention provides a method for recycling a waste nickel-cadmium cell. The method comprises the following steps: mixing the waste nickel-cadmium cell material, an HCl solution and a compound to obtain a metal ionic mixed solution, wherein the compound is tartaric acid and / or sodium tartrate; regulating pH to be 4-7; filtering to obtain a pre-treated solution; regulating the pH of the pre-treated solution to be 8-11; filtering to obtain cadmium hydroxide and filtrate; regulating the pH of the filtrate to be 5-7; mixing with calcium nitrate; reacting to obtain a nickel nitrate solution and calcium tartrate; and regulating the pH of the nickel nitrate solution to be 7-12 to obtain nickelous hydroxide. According to the method, a recovery device used in the method is simple, and convenientto operate; the nickel and cadmium are separated and recovered based on different pH; the method is simple; the recovery rate and the purity are high; general agents are adopted; tartaric acid or sodium tartrate are recyclable, so that the cost is low; toxic agents such as sulfide are not used, so that secondary pollution is not caused; tartaric acid or sodium tartrate is capable of increasing themetal dissolution speed and rate.

Owner:GUANGDONG UNIV OF TECH

Method for producing natural tartaric acid from wine leftovers

ActiveCN112010745AReduce acidityImprove solubilityPreparation from carboxylic acid saltsOther chemical processesCalcium tartrateGrape wine

The invention discloses a method for producing natural tartaric acid from wine leftovers. The method comprises the following steps: adding crushed wine leftovers into pure water, adding sodium carbonate, stirring, neutralizing, and filtering to obtain a leftover filtrate; adding excessive calcium chloride into the leftover filtrate, filtering to obtain a primary precipitate, washing the primary precipitate with water, and drying to obtain a calcium tartrate precipitate; adding the calcium tartrate precipitate into a dilute sulfuric acid solution, uniformly stirring and mixing, filtering to obtain a secondary precipitate, washing the secondary precipitate with water, combining the filtered and washed solutions, adding a decolorizing agent for decolorizing, and filtering the decolorized solution; filtering to obtain filtrate; evaporating and crystallizing the filtrate to obtain primary tartaric acid; recrystallizing the primary tartaric acid, and drying to obtain natural tartaric acid; according to the method, the defects in the prior art are overcome, the process steps are few, the production process is simple, the raw material cost is low, and the purity of the produced natural tartaric acid is larger than 99.8%.

Owner:安徽皖晶生物科技有限公司

Method for recovering and applying l-(+)-tartaric acid in the production of d-ethyl ester

ActiveCN104326901BChances of avoiding side effectsImprove qualityPreparation from carboxylic acid saltsOrganic compound preparationSpecific rotationSolvent

The invention discloses a method for recovering and mechanically applying L-(+)-tartrate in D-ethyl ester production, which comprises the following steps: 1)obtaining a L-(+)-tartrate solution; 2)recovering L-(+)-calcium tartrate dehydrate; 3)acidifying; 4)performing pressure reduction and condensation; and 5)crystallizing, separating and drying. The method of the invention employs an inertia organic solvent, takes a solvent method to replace a water phase method to recover L-(+)-tartrate, key points of control temperature, time, centrifugation and vacuum degree are realized, the product yield is high, the purity and specific rotation of the recovered L-(+)-tartrate product accord with quality requirement, quality standard of the L-(+)-tartrate raw material can be reached, and the method can be used for chiral resolution of D-ethyl ester, recovery and mechanical application of L-(+)-tartrate can be realized, production cost is reduced, and the method is suitable for industrial production.

Owner:兰州鑫隆泰生物科技有限公司

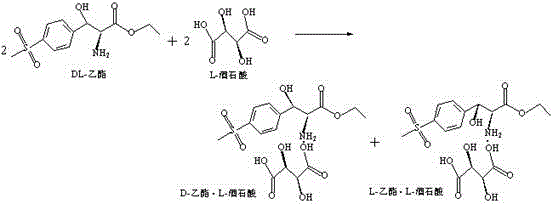

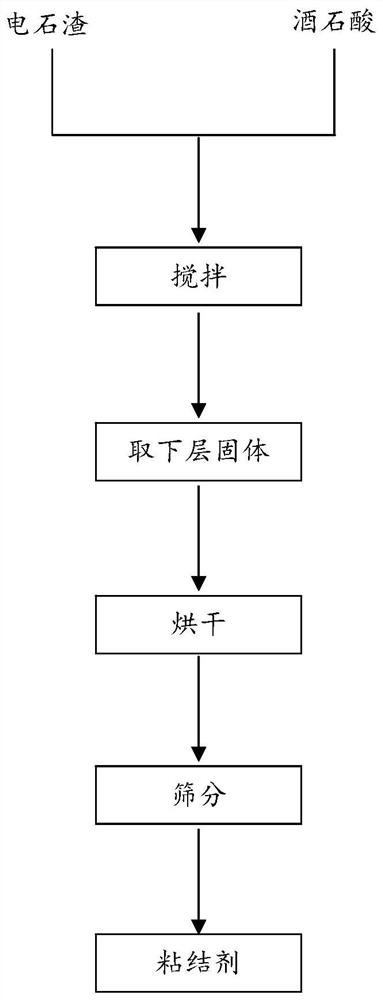

Binder as well as preparation method and application thereof

ActiveCN113403474AImprove adhesionEnable recyclingManufacturing convertersProcess efficiency improvementChemical reactionPhysical chemistry

The invention belongs to the technical field of binder material preparation, and particularly relates to a binder as well as a preparation method and an application thereof. The preparation method comprises the following steps: mixing carbide slag with a tartrate solution, uniformly stirring, taking a lower-layer solid product, and drying to obtain the binder; and wherein the pH value of the tartrate solution is greater than or equal to 13. According to the method provided by the invention, tartaric acid radicals can be adsorbed on the surface of the carbide slag under a strong alkali condition, the tartaric acid and the carbide slag have relatively good complexing ability and adsorption performance, the obtained binder has a good binding effect, when the pH value is lower than 13, the tartaric acid and the carbide slag are subjected to a chemical reaction to generate calcium tartrate, the binder cannot play a binding role, and the bonding effect is poor. According to the preparation method provided by the invention, the carbide slag and the tartrate are used as raw materials, and the pH value of the tartrate solution is controlled, so that the binder with good binding property can be obtained, and the recycling of the carbide slag can be realized.

Owner:广西三秋树环保科技有限公司

A Phosphorus-free Composite Corrosion and Scale Inhibitor

InactiveCN104528964BProduce pollutionNo harmScale removal and water softeningEnergy based wastewater treatmentMethacrylateMeth-

Owner:艾思伟 +2

A kind of preparation method of d-lysine hydrochloride

InactiveCN103204783BEasy to separateLow priceOrganic compound preparationAmino-carboxyl compound preparationIon exchangeCalcium tartrate

The invention relates to a preparation method of D-lysine hydrochloride. The method comprises the following steps of: by taking DL-lysine as a raw material, after purification, reacting at 30-70 DEG C with L-tartaric acid to generate diastereomer salt; then, performing inorganic calcium salt with diastereomer salt to generate a calcium tartrate precipitate, while maintaining D-lysine in a liquid; adjusting pH, decoloring, concentrating and crystallizing the D-lysine liquid through hydrochloric acid to obtain D-lysine hydrochloride crude crystalline; and purifying the D-lysine hydrochloride crude crystalline to obtain the D-lysine hydrochloride. The content of DL-lysine in the D-lysine hydrochloride is below 0.5%. According to the method provided by the invention, a simple neutralization precipitation method replaces a complex ion-exchange resin method to the benefit of simplifying the production method and stabilizing the product quality. Meanwhile, the method further has the advantages of no special devices and reduction of environmental pollution, and is easy to popularize and apply industrially.

Owner:ZHANGJIAGANG HUACHANG PHARMA

Preparation method of high-adhesive-force conductive silver powder used for conductive silver paste

InactiveCN106112004ALow costRealize comprehensive utilizationCable/conductor manufactureWater bathsEvaporation

The invention discloses a preparation method of high-adhesive-force conductive silver powder used for conductive silver paste and belongs to the technical field of conductive silver powder preparation. The preparation method comprises the steps that grape residues after brewing serve as raw materials, and dried calcium tartrate is prepared; the dried calcium tartrate is added with deionized water and sulfuric acid and is filtered, filtrate is subjected to rotary evaporation, and dried crystals are obtained; the dried crystals are mixed with the deionized water, polyethylene glycol, hexadecyl trimethyl ammonium bromide and tea polyphenol and subjected to water-bath heating; after heating is finished, then silver nitrate is added into the dried crystals, centrifugal separation is conducted, and precipitates are washed through absolute ethyl alcohol and the deionized water; and after drying, cooling and grinding are conducted, the high-adhesive-force conductive silver powder used for the conductive silver paste can be obtained. Examples prove that the preparation method is simple in process, low in equipment investment and relatively low in raw material cost; and the prepared powder-like silver powder has the characteristics of being low in photocuring energy, exquisite in line surface and small in filling quantity and resistance, so that the stability and the conductivity of the conductive silver paste are greatly improved, and the conductive silver paste is suitable for industrial large-scale production.

Owner:赛浪车联汽车科技(北京)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com