Binder as well as preparation method and application thereof

A binder and red mud technology, which is applied in the field of binder and its preparation, can solve the problems of high energy consumption and limited products, and achieve good adsorption performance, good bonding effect, and sustainable development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

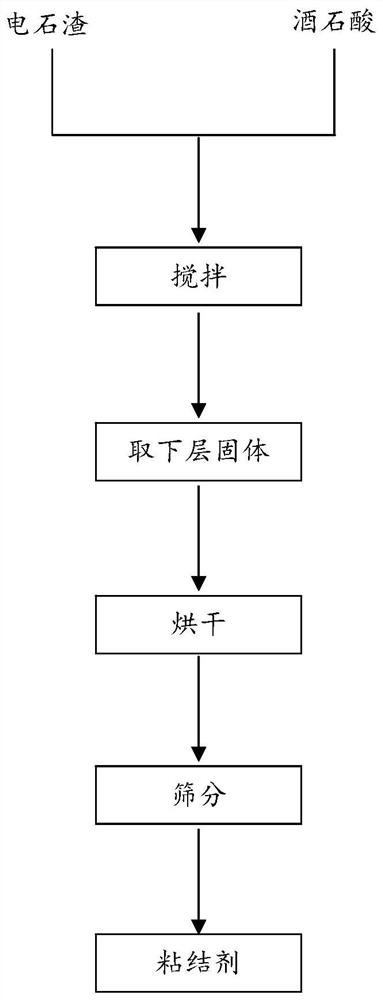

[0040] This embodiment provides a kind of binder and its preparation method, and the preparation process is shown in figure 1 , the preparation method includes the following steps,

[0041] Add sodium hydroxide aqueous solution to 10wt%, 800kg tartaric acid aqueous solution to adjust the pH to 13, after adjusting the pH, stir and mix with 80kg calcium carbide slag passing through a 200 mesh sieve, take the lower layer solid product, dry at 70°C, and pass through a 200 mesh sieve , to get the binder.

[0042] This embodiment also provides a red mud pellet and a preparation method thereof, the preparation method comprising the following steps,

[0043] Crush the red mud to obtain red mud particles, pass through a 3mm sieve, and crush the oversize material again, so that the proportion of red mud particles smaller than 2mm reaches at least 90%. Mix 1000kg of undersize material with 50kg of the above binder evenly, Spray 100kg of water on the material and send it to the feed por...

Embodiment 2

[0047] This embodiment provides a kind of binder and preparation method thereof, and preparation method comprises the following steps,

[0048]Add sodium hydroxide aqueous solution to 6.67wt%, 360kg tartaric acid aqueous solution to adjust the pH to 13, after adjusting the pH, stir and mix with 60kg calcium carbide slag passing through a 200 mesh sieve, take the lower layer solid product, dry it at 80°C, pass through 200 mesh Sieve to get the binder.

[0049] This embodiment also provides a red mud pellet and a preparation method thereof, the preparation method comprising the following steps,

[0050] Crush the red mud to obtain red mud particles, pass through a 3mm sieve, and crush the oversize material again, so that the proportion of red mud particles smaller than 2mm reaches at least 90%. Mix 1000kg of undersize material with 50kg of the above binder evenly, Spray 80kg of water on the material and send it to the feed port of the briquetting machine for cold pressing treat...

Embodiment 3

[0052] This embodiment provides a kind of binder and preparation method thereof, and preparation method comprises the following steps,

[0053] Add sodium hydroxide aqueous solution to 6.25wt%, 560kg tartaric acid aqueous solution to adjust pH to 13, after adjusting pH, stir and mix with 70kg calcium carbide slag passing through 200 mesh sieve, take the lower layer solid product, dry at 60 ℃, pass through 200 mesh Sieve to get the binder.

[0054] This embodiment also provides a red mud pellet and a preparation method thereof, the preparation method comprising the following steps,

[0055] Crush the red mud to obtain red mud particles, pass through a 3mm sieve, and crush the oversize material again, so that the proportion of red mud particles smaller than 2mm reaches at least 90%. Mix 1000kg of undersize material with 50kg of the above binder evenly, Spray 80kg of water on the material and send it to the feed port of the briquetting machine for cold pressing treatment. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com