Patents

Literature

117 results about "Salt-wasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

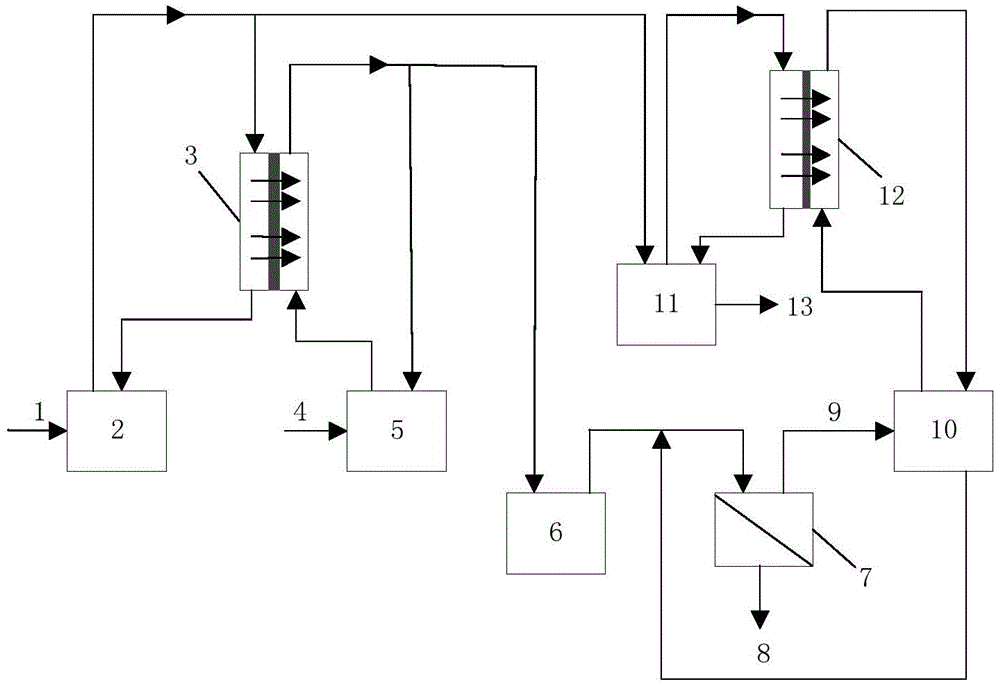

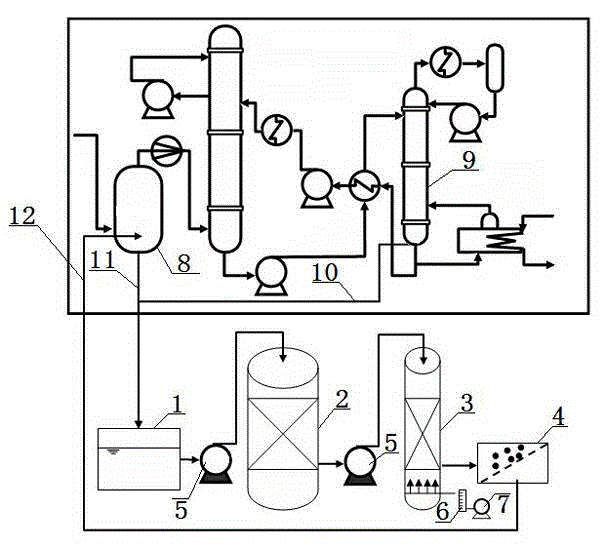

A treatment system for high-salt waste water

InactiveCN104787951ARealize resource utilizationEfficient separationMultistage water/sewage treatmentSalt-wastingSmall footprint

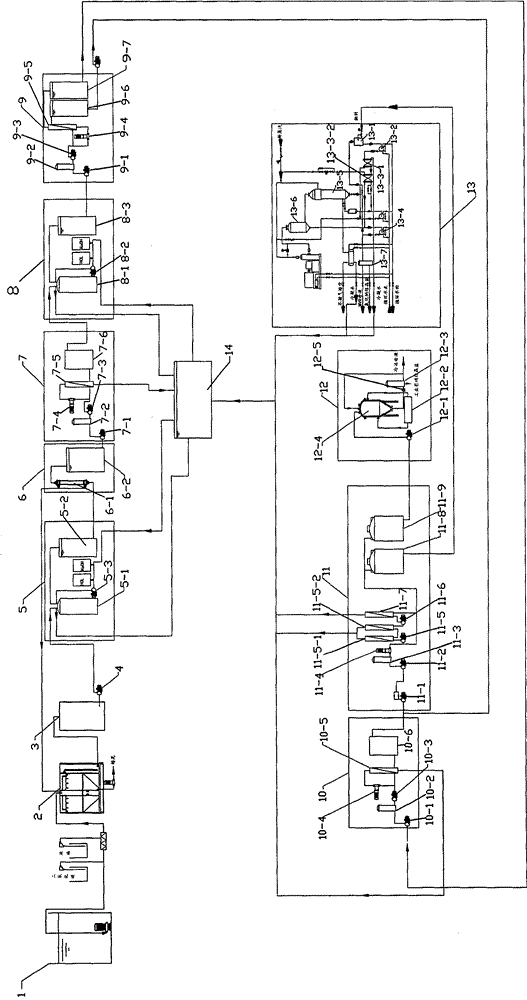

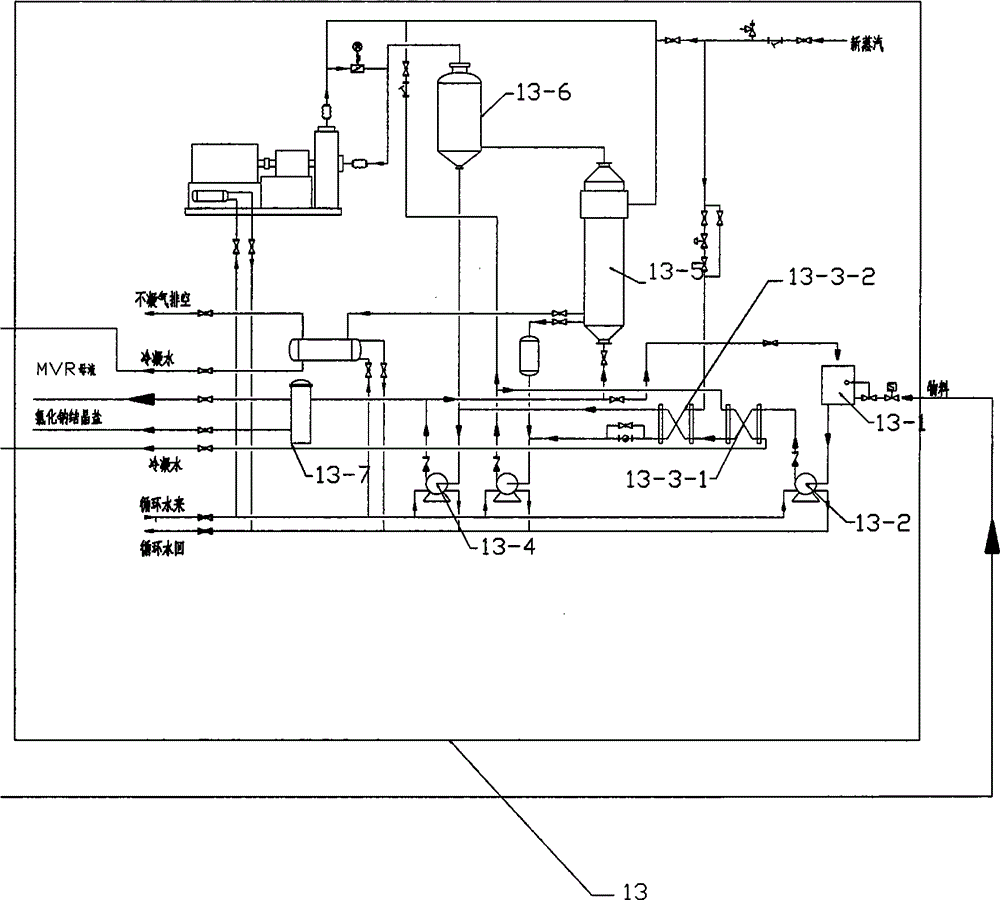

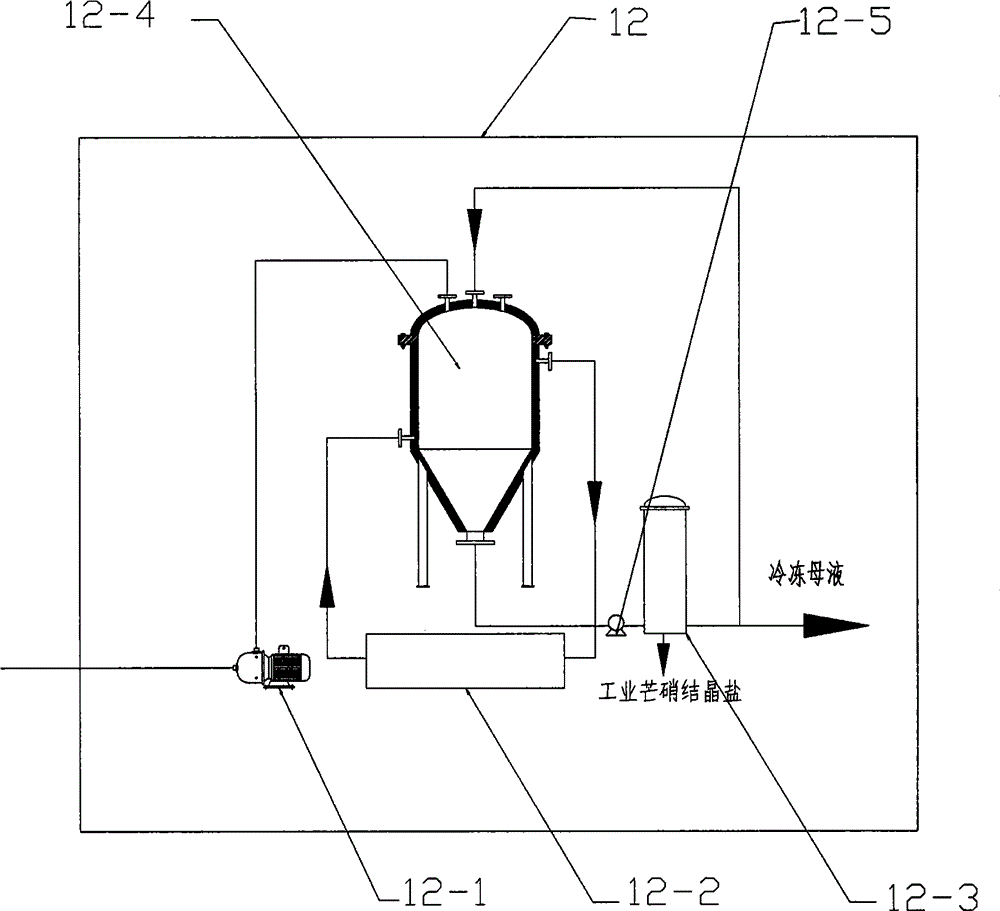

The invention relates to a treatment system for high-salt waste water, and belongs to water treatment techniques. The treatment system comprises an adjusting tank, a high-density sedimentation tank, a V-type filter tank, a first-section ion exchange resin system, an ultrafiltration system, a first-section reverse osmosis system, a second-section ion exchange resin system, a high-pressure nanofiltration system, a second-section reverse osmosis system, a high-pressure flat sheet membrane system and an MVR system in order. The high-pressure nanofiltration system, the high-pressure flat sheet membrane system and a freezing crystallization system are connected in order. The ultrafiltration system is connected to the high-density sedimentation tank. The treatment system reasonably coupling ultrafiltration, nanofiltration, reverse osmosis and a high-pressure flat sheet membrane method and combining MVR crystallization and freezing crystallization techniques is adopted to treatment of the high-salt waste water, and is low in cost, low in running cost, free of secondary pollution, safe, compact in structure, small in occupied space and high in economic value.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

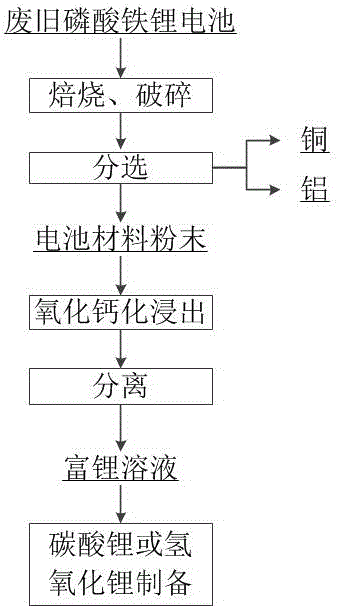

Method for recovering lithium in waste and old lithium iron phosphate batteries

ActiveCN106848472AHigh purityImprove recycling efficiencyWaste accumulators reclaimingBattery recyclingWater insolubleLithium hydroxide

The invention provides a method for efficiently recovering lithium in waste and old lithium iron phosphate batteries. The method comprises that waste and old lithium iron phosphate batteries are roasted and sorted to form lithium-containing positive pole powder, lithium-containing positive pole powder and a calcium-containing alkaline solution undergo a reaction under conditions of oxidation so that iron and phosphate radical are converted into a water-insoluble compound and lithium is converted into water soluble lithium hydroxide, and the reaction products are filtered so that a lithium hydroxide solution is obtained and can be used for further preparation of lithium hydroxide or lithium carbonate products. The method replaces the conventional wet acid leaching method in waste and old lithium iron phosphate battery recovery and is free of a strong acid so that production of a large amount of high-salt waste water is avoided. The method realizes selective leaching of lithium, prevents iron impurities from entering the leaching liquid from the source, can produce a high-purity lithium product, has simple processes, utilizes chemical agents having wide sources, has simple process conditions, can prepare a high-purity lithium product through a one-step method, greatly improves recovery efficiency of waste and old lithium iron phosphate batteries and has a good industrial application prospect.

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

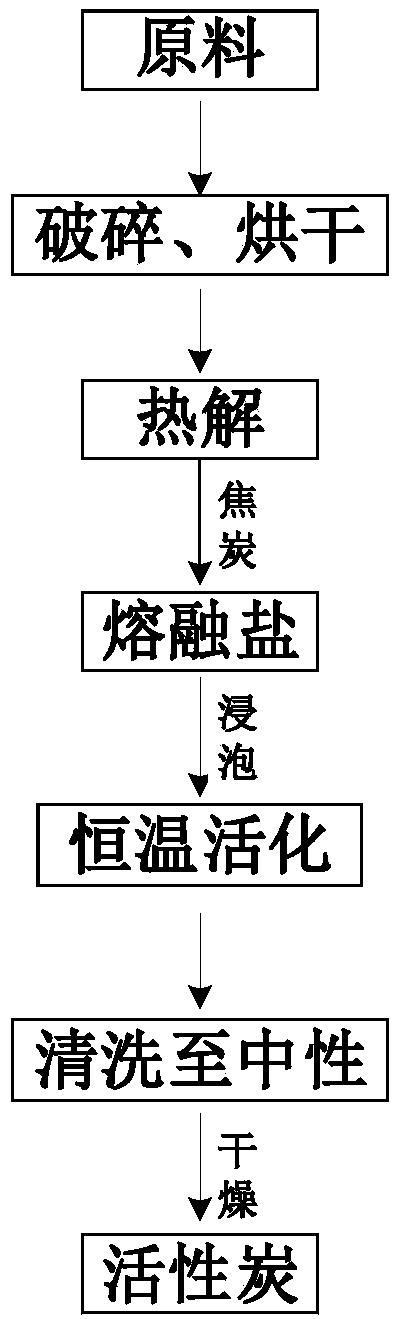

Method utilizing melt salt activation to prepare active carbon

The invention discloses a method utilizing melt salt activation to prepare active carbon. The method comprises the following steps: grinding and drying raw materials, placing the grinded and dried raw materials in a heating furnace, carrying out constant temperature pyrolysis under a certain temperature condition, adding the coke generated during the pyrolysis process into melt salts to carry out constant temperature reactions for a while, heating the coke in an inert gas atmosphere to a certain temperature, carrying out constant temperature activation at the temperature for a while, cooling the coke to the room temperature, soaking the coke in a hydrochloric acid solution with a certain concentration, washing the coke with water until the coke becomes neutral, and finally drying so as to obtain the active carbon. The preparation method can obtain high quality active carbon, utilizes the good permeability of melt salts at a high temperature to reduce the salt waste and volatilization in the preparation process and the pyrolysis process, shortens the preparation time, greatly reduces the production cost of active carbon, and promotes the technology innovation of active carbon production.

Owner:DALIAN UNIV OF TECH

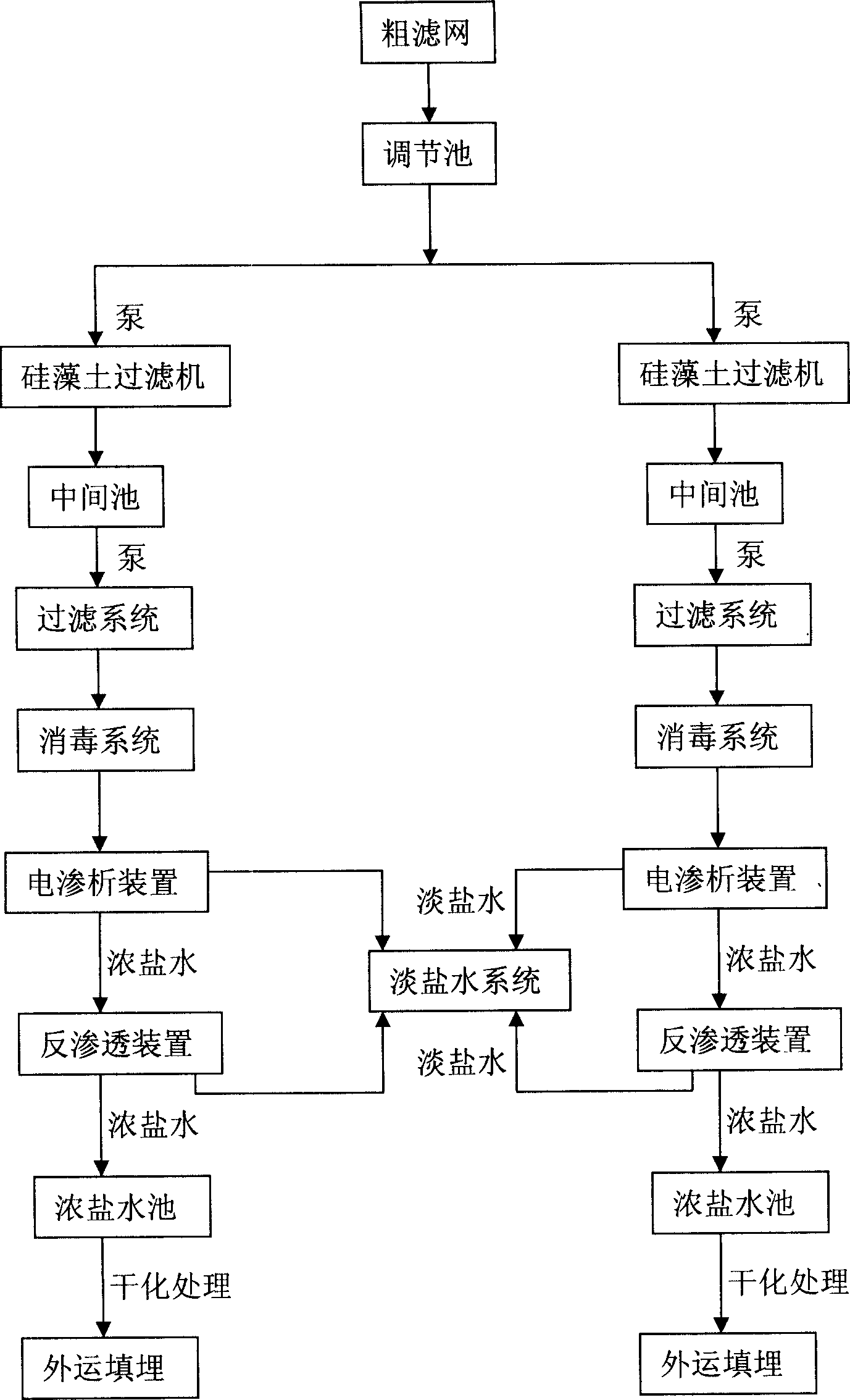

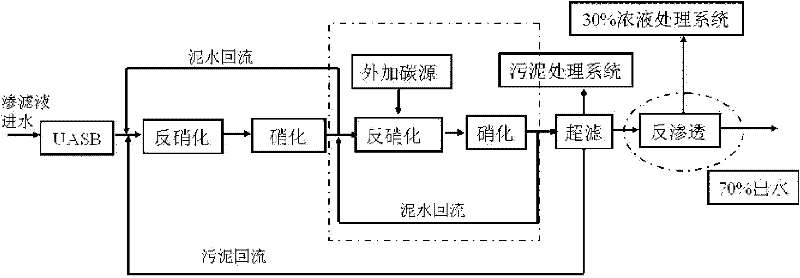

Treatment technology of spirulina waste water

ActiveCN1903751ALow bulk densityImprove stabilityDispersed particle separationMultistage water/sewage treatmentSalt-wastingSludge

The present invention relates to a water, salt-contained waste water, sewage and sludge treatment method. In particular, it relates to a treatment method of high-salt waste water produced in spirulina prince production process. Said method includes the following steps: making the waste water be fed into the inlet of regulation tank, recovering spirulina princes by utilizing filtering screen, then making the waste water be fed into regulation tank, regulating water quality and water quantity, pumping said waste water into diatomite filter to remove solid matter, then making the waste water be fed into intermediate tank, pumping said waste water into filtering system to farther remove smaller solid and living beings, then making the filtered waste water be fed into the disinfection system to kill microorganism and algal single spore, and making the waste water be flowed into electrodialysis device so as to obtain weak brine and strong brine. The weak brine is flowed into weak brine system, the strong brine is flowed into strong brine tank, and is undergone the process of drying solidification, then its residuum is buried.

Owner:银发环保股份有限公司

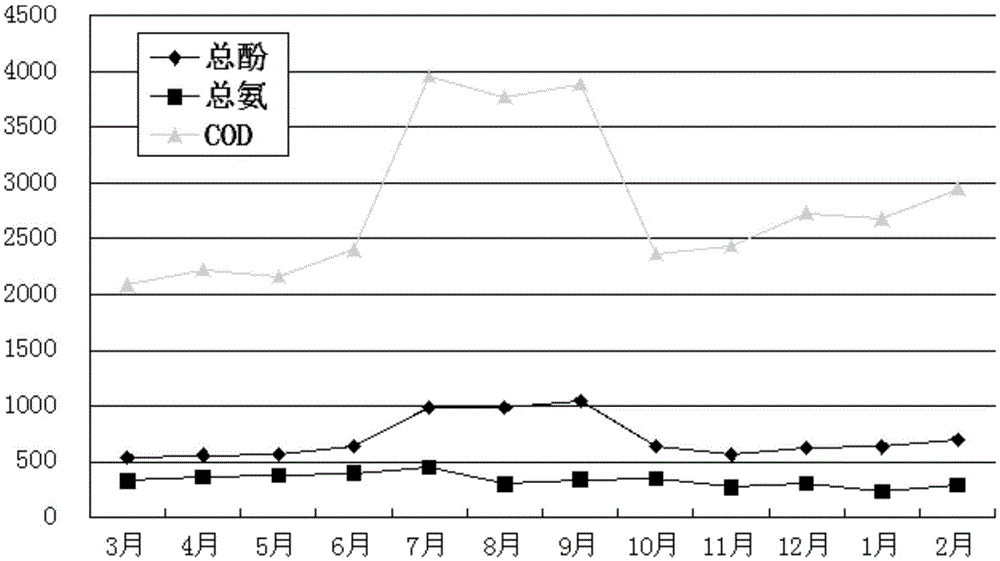

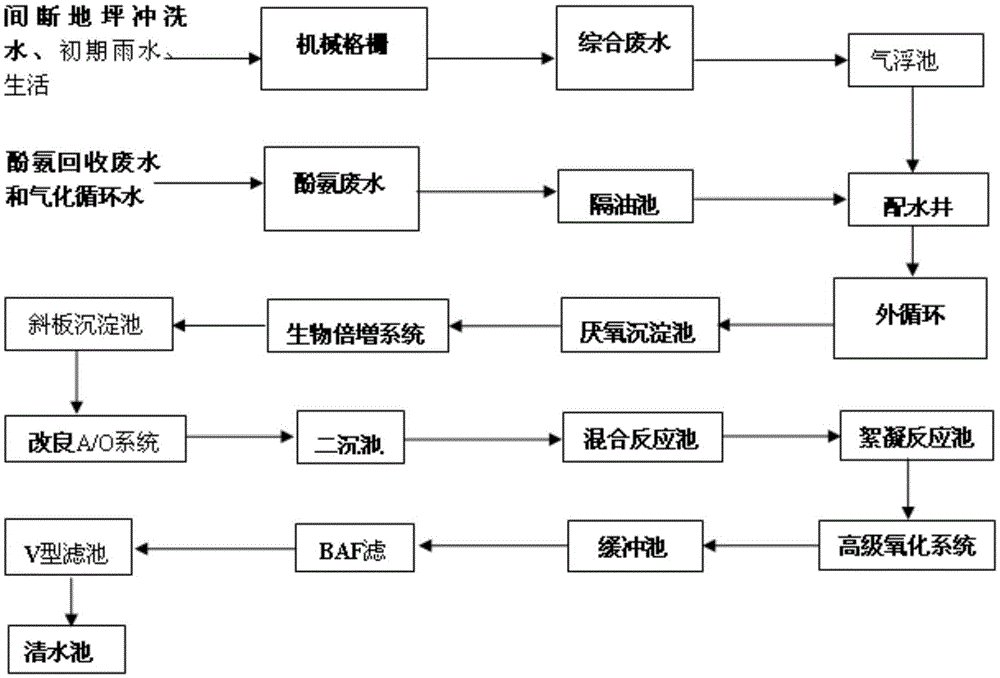

Coal chemical industry waste water treatment technology

ActiveCN106116011AAvoid stagnationReduce usageTreatment using aerobic processesTreatment involving filtrationSalt-wastingTreatments water

The invention provides a coal chemical industry waste water treatment technology. The coal chemical industry waste water treatment technology comprises the following steps of firstly performing an ammonia-phenols removal treatment technology on organic waste water in coal chemical industry waste water so as to obtain treated waste liquid; then performing a biochemical treatment technology on the treated waste liquid obtained in the above step so as to obtain biochemical treatment water; then performing a concentrating treatment technology on the biochemical treatment water obtained in the above step and salt-containing waste water so as to obtain reuse water and high-salt waste water; and finally performing a strong brine treatment technology on the high-salt waste water obtained in the above step so as to obtain salt-containing materials, wherein the ammonia-phenols removal treatment technology comprises a deacidification and ammonia removal working procedure, an extraction working procedure, a solvent removal working procedure, a solvent reclaiming working procedure, a waste liquid separation system, a solvent storage working procedure and an alkali liquid preparation working procedure. According to the coal chemical industry waste water treatment scheme provided by the invention, through gradient utilization and repeated utilization of the waste water, the use of fresh water resources is furthest reduced, so that the water consumption of projects can be fully reduced, and zero drainage of polluted water is realized.

Owner:CHINA COAL ORDOS ENERGY CHEM COP LTD

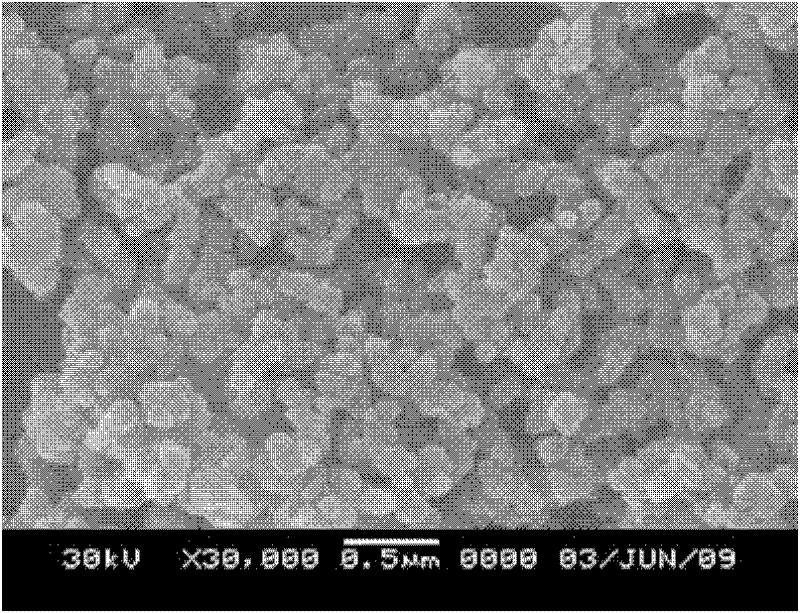

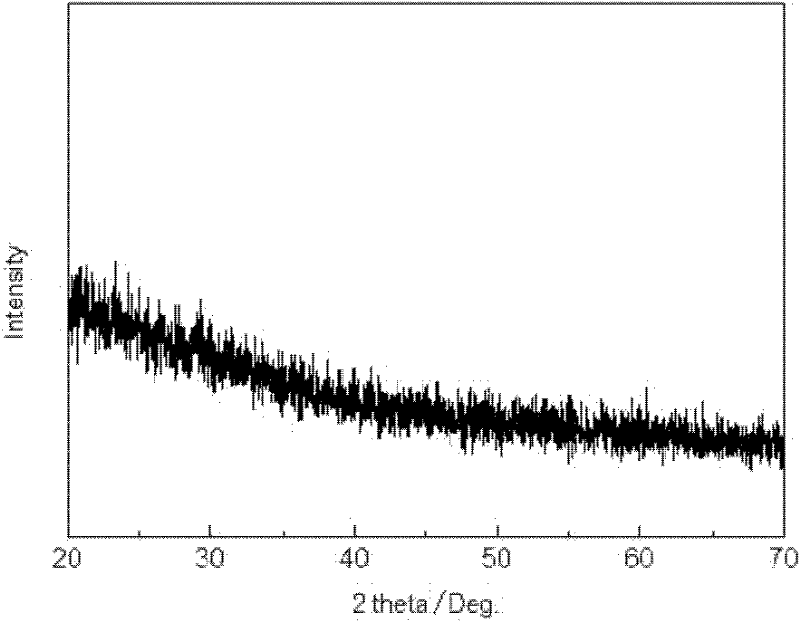

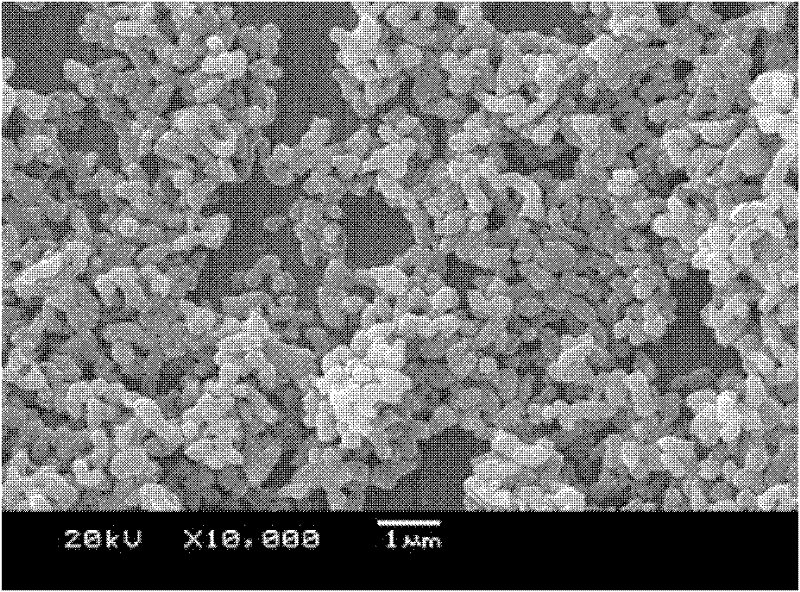

Preparation method of lithium iron phosphate/carbon composite material

The invention relates to a preparation method of a lithium iron phosphate / carbon composite material. The preparation method comprises the following steps: preparing amorphous iron phosphate through a coprecipitation method from a soluble ferrous iron source, a phosphorus source and an oxidant used as raw materials, and synthesizing the lithium iron phosphate / carbon cathode material on the basis of amorphous iron phosphate through a gel method by using oxalic acid and citric acid as carbon sources and lithium hydroxide as a lithium source, wherein by adjusting the ratio of the oxalic acid to the citric acid, the carbon content can be controlled, and ion doping can be easily carried out. The prepared lithium iron phosphate has the advantages of small particle size and narrow particle size distribution, thus reducing the ion diffusion path and maintaining high capacity and good rate performance of the product. In the preparation method provided by the invention, inexpensive ferrous sulfate is used as a raw material to synthesize amorphous ferric phosphate without preventing Fe<2+> from oxidation, thereby simplifying the process; ammonium salt waste liquid can be recycled as fertilizer, thereby reducing the cost; and water is used as the solvent in the preparation process, thereby generating no harmful gas. Thus, the preparation method is environmentally friendly, low in energy consumption, low in cost and suitable for industrial mass production.

Owner:DALIAN JIAOTONG UNIVERSITY

Method for treating waste water in production of para-hydroxyphenyl hydantoin

InactiveCN1884144AGood environmental benefitsThe principle is simpleWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentHydantoin derivativesSalt-wasting

The invention discloses a disposing method of waste water in the p-hydroxybenzene hydantoin manufacturing course, which comprises the following steps: salting waste water with phenol mother liquid through soluble salt; stewing to divide water-phase; blending salted water phase and waste water according to 1:1-8; adsorbing the composite liquid in the resin adsorbing column under normal temperature at 0.1-2 BV per h flow; desorbing the adsorbed saturated resin; preparing for next adsorbing disposal. The invention removes p-phenolsulfonate by over 99 percent, which doesn't pollute environment.

Owner:NANJING UNIV

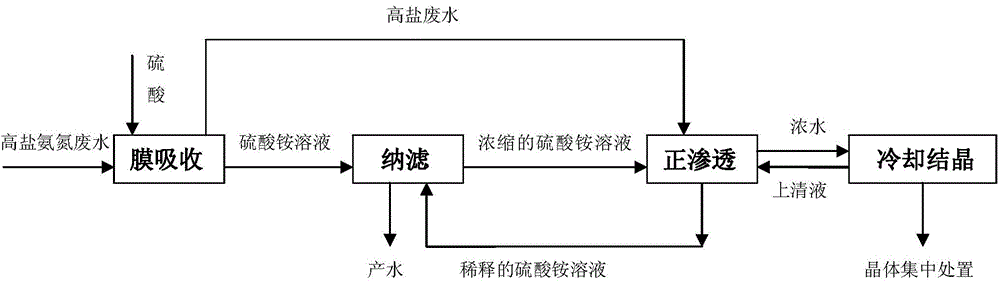

Zero release method of high-salt high-ammonia-nitrogen waste water

ActiveCN104609587ASolve processing problemsHigh recovery rateWater contaminantsMultistage water/sewage treatmentSalt-wastingWater quality

The invention discloses a treatment method of high-salt high-ammonia-nitrogen waste water. The treatment method comprises steps of membrane absorption, nanofiltration, forward osmosis, and cooling crystallization. According to the treatment method, a sulfuric acid solution is taken as an absorption liquid, ammonia nitrogen in waste water is changed into ammonium sulfate via membrane absorption; obtained ammonium sulfate solution is concentrated further via nanofiltration; the concentrated ammonium sulfate solution is taken as a driving liquid of forward osmosis, a high-salt waste water obtained after ammonia nitrogen removing via membrane absorption is taken as a feed liquid of forward osmosis, and forward osmosis concentration is carried out; the ammonium sulfate solution is diluted, and a part of the diluted ammonium sulfate solution is recycled to a nanofiltration unit for concentration of a second time; after a plurality of forward osmosis concentration, concentrated water of a forward osmosis unit is subjected to cooling crystallization; and an obtained supernate is recycled for circulating concentration, and obtained crystal is dried and is subjected to concentrated disposal. The treatment method is used for treatment of high-salt high-ammonia-nitrogen waste water, almost no concentrated water is discharged, problems of high-salt high-ammonia-nitrogen waste water treatment are solved effectively, water recovery rate is high, quality of obtained water is high, and recovery of water resource of high-salt high-ammonia-nitrogen waste water is realized as far as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-salt waste water treatment method

ActiveCN104609621AEfficient use ofSimple methodSeawater treatmentWater/sewage treatment bu osmosis/dialysisSalt-wastingEvaporation

The invention discloses a high-salt waste water treatment method. According to the high-salt waste water treatment method, concentration of high-salt waste water is carried out via membrane distillation; an obtained membrane distillation concentrated water is taken as a driving liquid of forward osmosis; the membrane distillation concentrated water is diluted via continuous concentration of forward osmosis feeding liquid collateral circulation raw water, when the concentration of the diluted membrane distillation concentrated water is equal to a certain concentration, the membrane distillation concentrated water is recycled to a membrane distillation unit for concentration treatment; and the above steps are repeated, so that deep concentration of the high-salt waste water is realized, and water of the high-salt waste water and forward osmosis raw water is recycled as far as possible. The high-salt waste water treatment method can be used for processing high-salt waste water, and can also be used for concentration treatment of river water, brackish water, seawater, surface water, municipal wastewater, petrochemical wastewater, landfill leachate, and solutions containing medicines and protein. No impressed pressure or little impressed pressure is needed for treatment; the high-salt waste water treatment method is simple and convenient; operation is simple; and operation cost is low compared with multiple-effect evaporation.

Owner:CHINA PETROLEUM & CHEM CORP +1

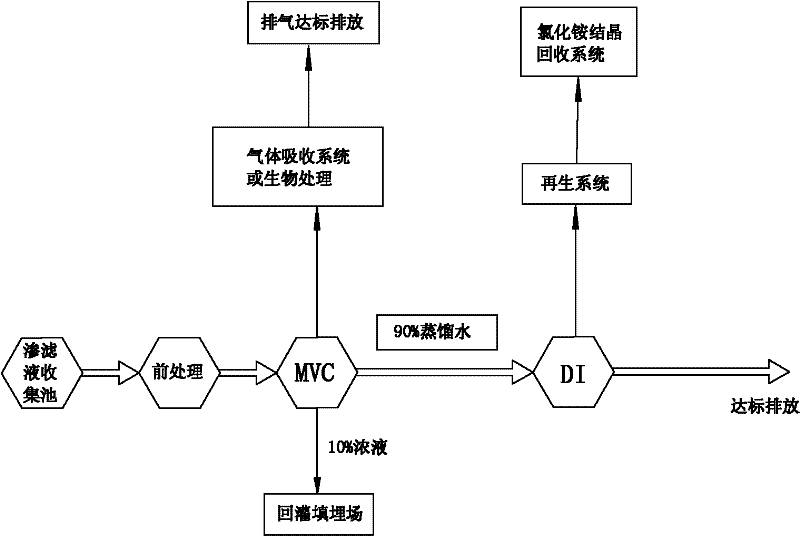

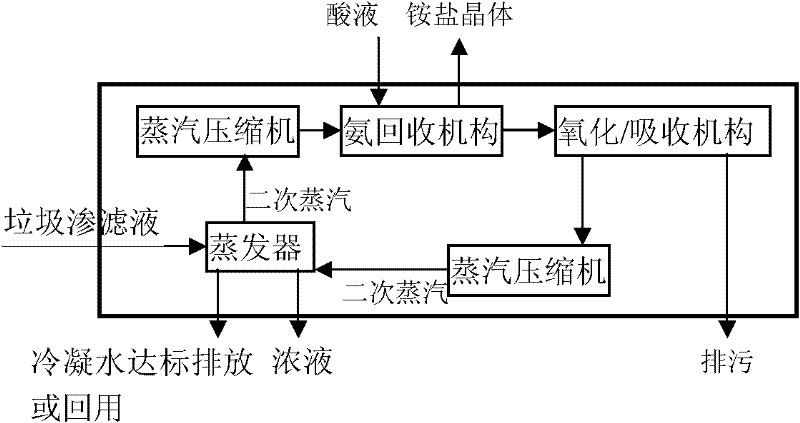

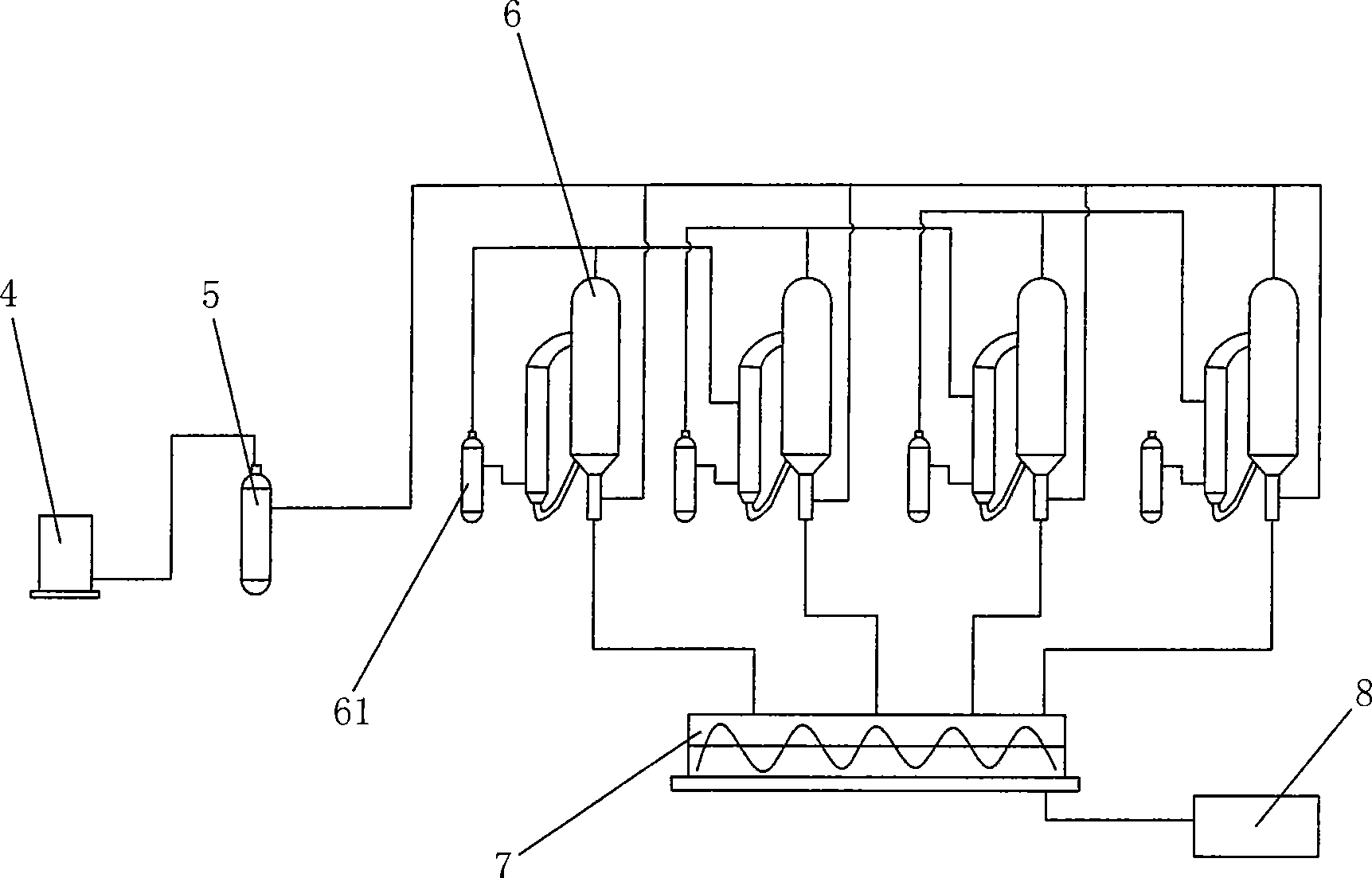

Garbage-percolate evaporating and concentrating processing method capable of recycling ammonia and device thereof

ActiveCN102358625AControllable water qualityEasy to handleAmmonium nitratesPhosphatesWater vaporSalt-wasting

The invention discloses a garbage-percolate evaporating and concentrating processing method capable of recycling ammonia, which comprises the following steps that: (1) garbage percolate is sent into a heating chamber of an evaporator to be evaporated and concentrated to form secondary steam and dischargeable concentrated liquid; (2) ammonia recycling treatment is undertaken for the secondary steam produced in the step (1); and (3) the secondary steam after the ammonia recycling treatment is sent into a heating tube in the evaporator in the step (1) through a pipeline to be used as a heat source for evaporating the garbage percolate. The invention also discloses a garbage-percolate evaporating and concentrating processing device for realizing the above method. Due to the method, the garbage percolate or high-ammonia high-organism high-salt waste water is evaporated, so the ammonia and volatile organisms in the waste water can be evaporated to form secondary steam with the vapor, the ammonia is recycled and the organisms are removed during the flowing process of the secondary steam, and further the method also has the characteristics of thorough absorption and easiness in implementation under the situation that the processed distilled water conforms to relevant emission standards.

Owner:陈伟雄 +1

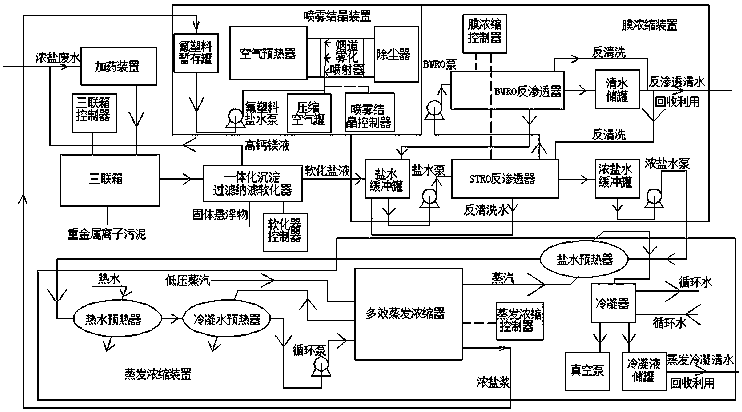

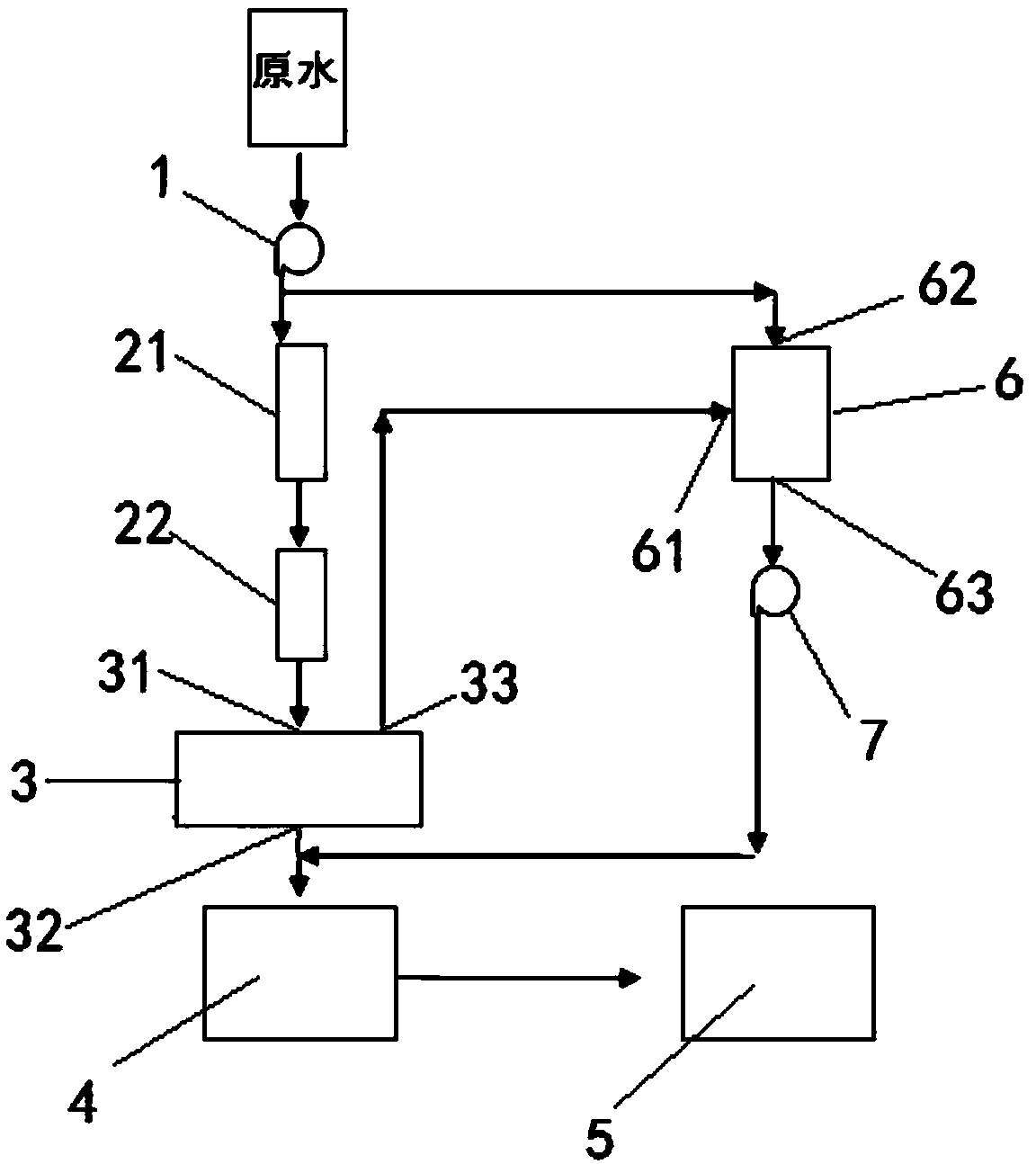

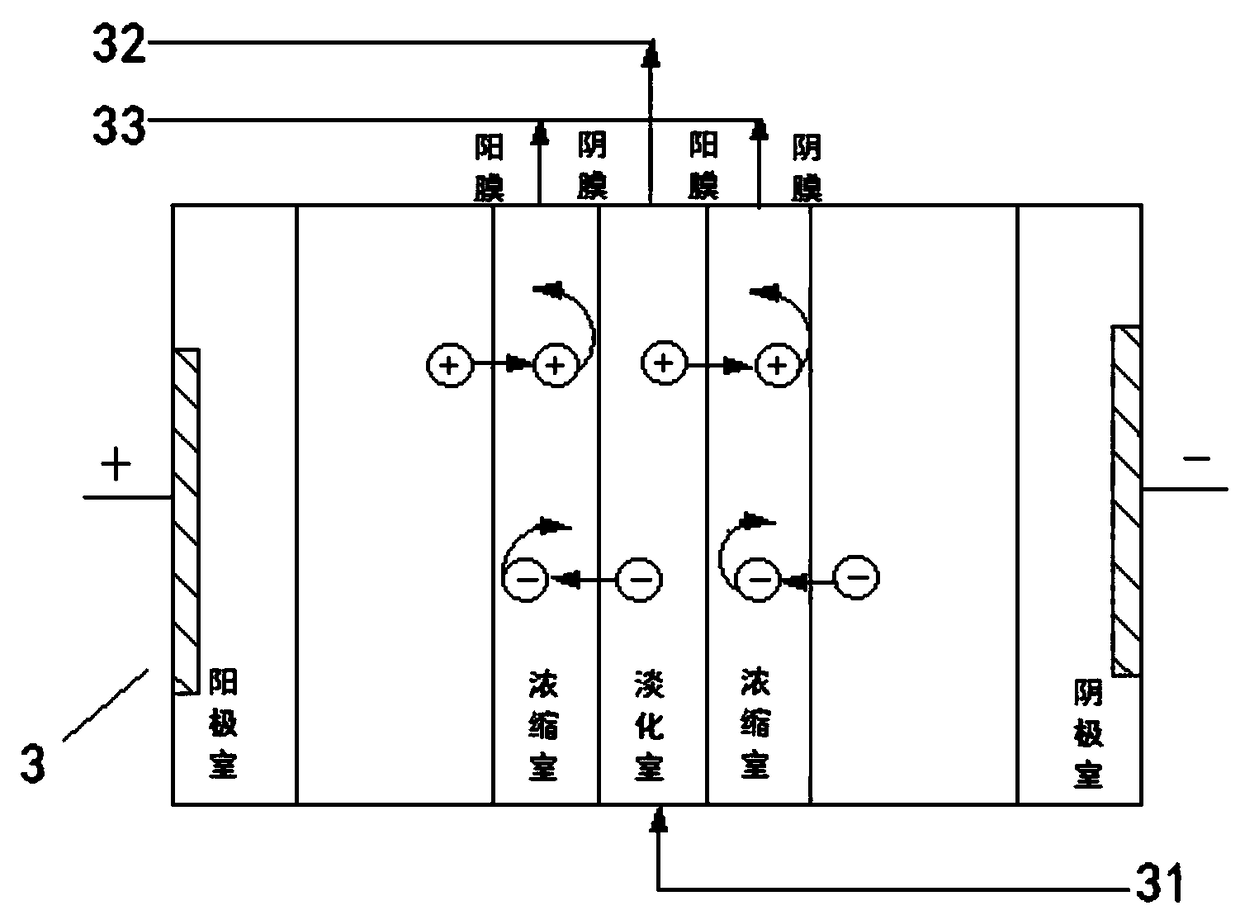

Concentrated salt waste water composite zero discharge system and process

PendingCN108275823AReduce energy consumptionLess investmentTreatment involving filtrationMultistage water/sewage treatmentSalt-wastingSoft water

The invention belongs to the technical field of water treatment and particularly relates to a concentrated salt waste water composite zero discharge system and a concentrated salt waste water composite zero discharge process. The concentrated salt waste water composite zero discharge process is characterized by comprising the following steps: (1) reducing the hardness of calcium and magnesium ionsof to-be-treated concentrated salt waste water; (2) performing softening treatment on the concentrated salt waste water; (3) performing twice membrane concentration crystallization treatment on the soft water part of the treated water; (4) performing evaporation crystallization treatment on the concentrated salt water subjected to the first-time membrane concentration crystallization treatment; and (5) performing spraying crystallization on concentrate salt slurry and recovering the crystal salt after spraying crystallization into smoke. The system and the process have the following beneficial effects: the system is low in energy consumption, low in system investment, reliable in operation, low in treatment cost and small in sewage quantity, the operation of the subsequent dust-removing equipment is not influenced, mixed salt products are not generated, the crystal salt does not need to be subjected to one-step treatment, and the operation stability of the whole system is guaranteed.

Owner:SHANDONG AONENG ELECTRIC POWER SCI & TECH

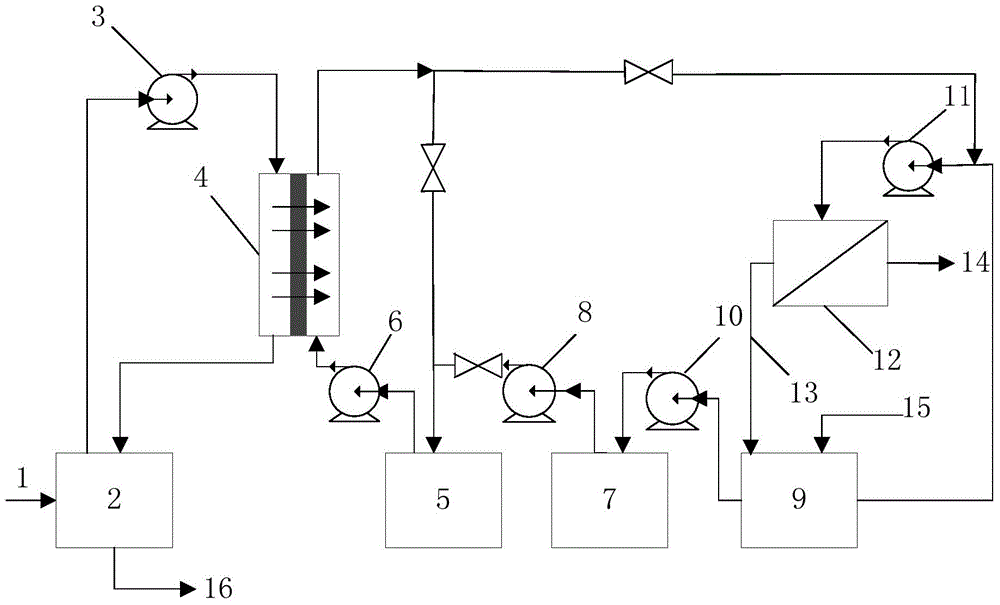

Method used for processing high-salt high-ammonia-nitrogen waste water via membrane coupling

ActiveCN104609588AHigh recovery rateSolve processing problemsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater dischargeSalt-wasting

The invention discloses a method used for processing high-salt high-ammonia-nitrogen waste water via membrane coupling. The method comprises steps of membrane absorption, reverse osmosis, and forward osmosis coupling. According to the method, an acid solution is taken as an absorption liquid, ammonia nitrogen in waste water is changed into ammonium salts via membrane absorption; obtained ammonium salt solution is concentrated further via reverse osmosis; the concentrated ammonium salt solution is taken as a driving liquid of forward osmosis, a high-salt waste water obtained after ammonia nitrogen removing via membrane absorption is taken as a feed liquid of forward osmosis, and forward osmosis concentration is carried out; the driving liquid ammonium salt solution is diluted, and a part of the ammonium salt solution is recycled to a reverse osmosis unit for recycling concentration. The method is capable of solving processing problems of high-salt high-ammonia-nitrogen waste water, water recovery yield is high, and quality of obtained water is excellent. The method is used for recycling concentration of high-salt high-ammonia-nitrogen waste water, concentrated water discharge amount is extremely low, and recovery of high-salt high-ammonia-nitrogen waste water is realized as far as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

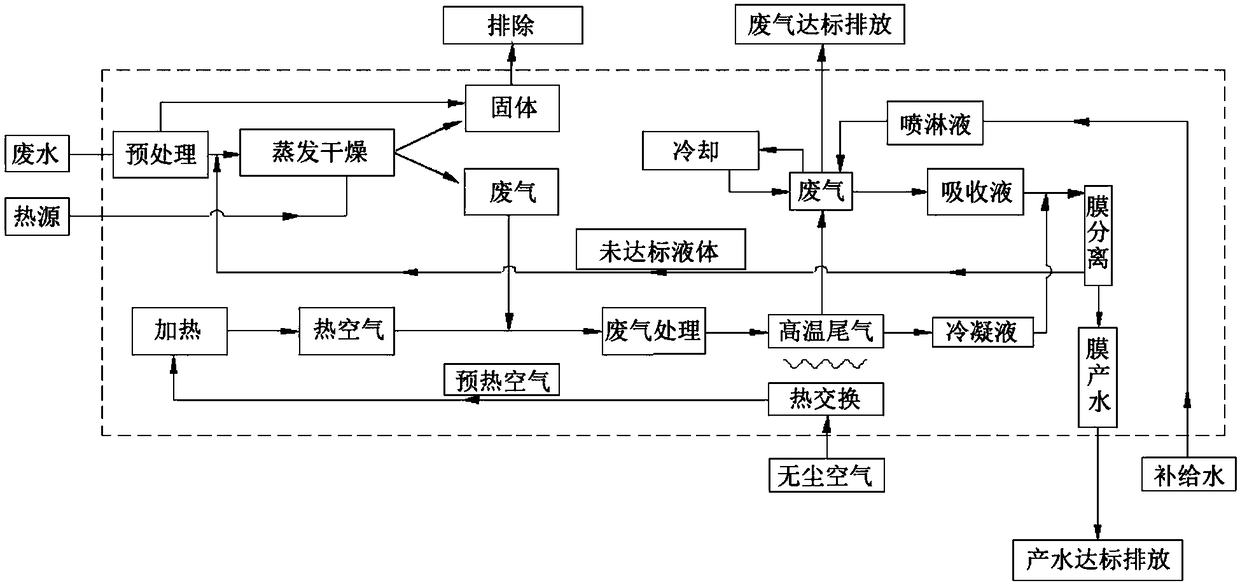

Wastewater treatment method

InactiveCN108558101AImprove processing efficiencyShorten the timeGas treatmentDispersed particle filtrationSalt-wastingPre treatment

The invention relates to a wastewater treatment method. The method comprises the following steps of: the pre-treatment on high-salt wastewater is carried out, the liquid-solid separation of the pre-treated high-salt waste water is carried out; the separated solid impurities are removed, and the separated waste water is gasified and treated to form an exhaust gas; the waste gas and the heating airare mixed and sent to an exhaust gas treatment system for incineration to generate high-temperature tail gas; the cooling treatment is carried on the high-temperature tail gas to form liquid and gaseous substances, then the liquid and gaseous substances are treated successively or simultaneously as follows: the liquid substances are separated by membrane, and the water produced by the membrane isdischarged directly after standard separation, the remaining non-standard parts are returned to continue processing; the gaseous substances are further cooled, and then is washed by the spray liquid to become an absorption liquid, and the liquid substances are separated by membrane, and the water produced by the membrane is discharged directly after standard separation, the remaining non-standardparts are returned to continue processing. According to the wastewater treatment method, the organic substances can be efficiently degraded, and meanwhile, the organic substances can be efficiently desalted.

Owner:内蒙古苏德环保科技有限公司

Recovery utilization method of furfuran amine salt waste gases

The invention relates to a treatment method for nitric oxide gas generated in production of furan amine salt. In the invention after nitric oxide is oxidized into nitric dioxide it enters into adsorption system. By adopting multi-step adsorption method nitric acid with the more than 30% content is obtained. At the same time partial sodium nitrate, partial sodium nitrite (tail gas is adsorbed by alkali solution)or ammonium nitrate solution (tail gas is adsorbed by ammonia)are obtained. The outgrowth can be sale or recycled. The content of nitrogen oxide gas in final discharging tail gas (air and nitrogen oxide gas)is under 0.05mg / m3. The content can achieve the discharging standard of environmental protection country and waste gas pollution problem in production of furan amine salt is solved thoroughly. Before treatment, when 1 ton of furan amine salt is produced about 450 kg of nitrogen oxide gas are produced.

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD

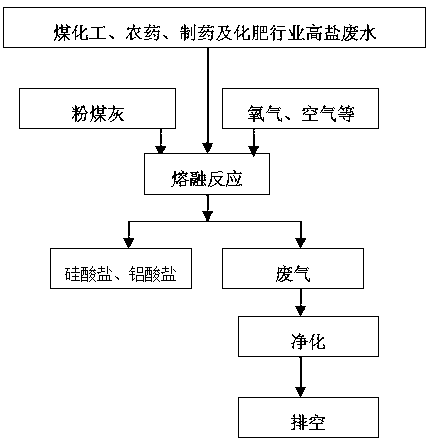

Method for harmlessly treating high-salt wastewater by using fly ash as additive

InactiveCN108571736AEasy complex conversionEasy to burn and gasifyIndirect carbon-dioxide mitigationIncinerator apparatusMelting tankChemical industry

The invention relates to a method for harmlessly treating high-salt wastewater by using fly ash as an additive, and belongs to the field of harmless treatment of dangerous waste and environment protection and the industries of coal chemical industries, fertilizer industries, agricultural chemicals industries and pharmaceutical industries. The invention provides a novel approach of harmlessly treating the high-salt wastewater by using the fly ash as the additive. The high-salt wastewater is placed in an electric stove to heat materials, a certain amount of the fly ash is added to the materialsafter the materials are in a melted state, oxidation gas is added to a melting pool through a jetting gun to perform oxygen enriched combustion of organic pollutants and the like to achieve oriented conversion of sodium salt and potassium salt in harmlessly treated organic pollutants and the like in the high-salt waste water, and purifying processing is conducted on generated fumes enriched with harmful substances such as HCL, NOX, SOX and the like to finally achieve the harmless treatment of the high-salt wastewater of the coal chemical industries, the fertilizer industries, the agriculturalchemicals industries and the pharmaceutical industries. The process of the method is simple to operate and has better industrial application prospect.

Owner:泫龙(北京)环保科技有限公司

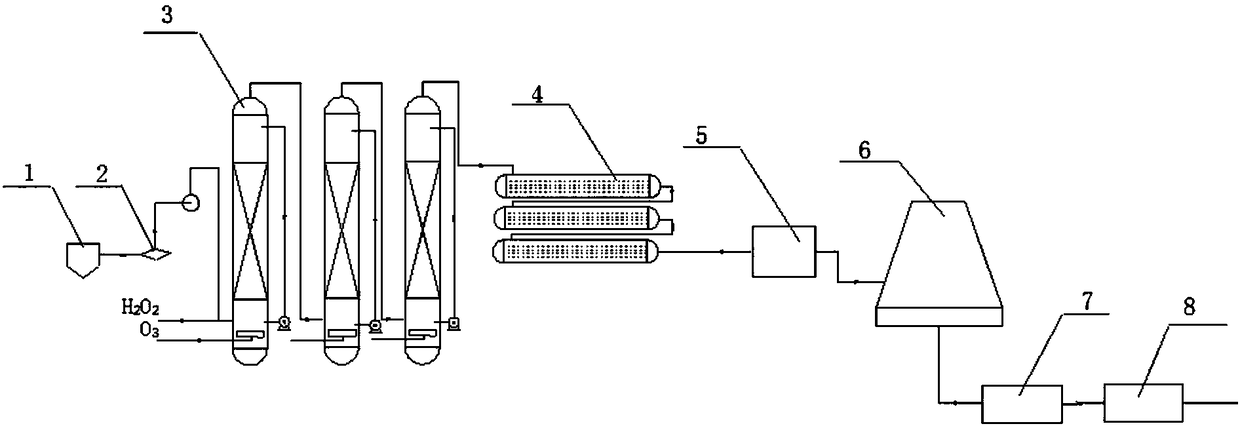

Process method and device for using high-grade oxidization and electrolysis catalysis in combined way on organic matter in high-salt waste water

PendingCN108558146AEnsure removalEnsure efficiencyWater treatment parameter controlWater/sewage treatment by irradiationElectrolysisSalt-wasting

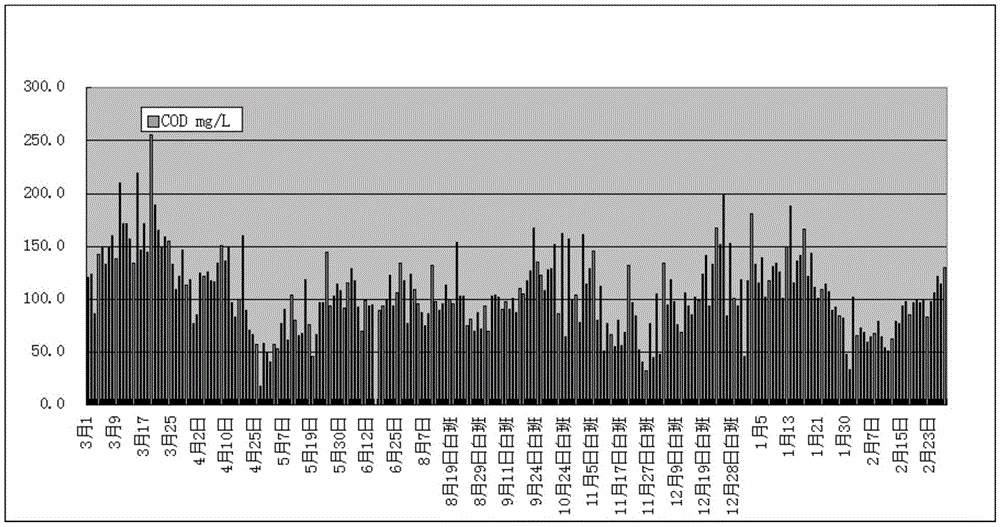

The invention discloses a process method and device for using high-grade oxidization and electrolysis catalysis in a combined way on organic matters in high-salt waste water. The method comprises thefollowing steps that the industrial waste water is subjected to oil removal and filtering by a coarse filter; suspended matter and colloid substances in the waste water are cleared; the industrial waste water subjected to coarse filtering is fed into a high-grade oxidization device; hydrogen peroxide and ozone are introduced; the high-grade catalysis oxidization reaction is performed; then, the waste water subjected to the high-grade oxidization treatment is fed into an electrolysis catalysis oxidization device; under the effect of a catalyst filling material, the voltage being 5 to 24V is exerted; under the ultraviolet light irradiation, difficult-to-degrade organic matters in the waste water are degraded through electrolysis oxidization; the COD content of the waste water in a sampling outlet is detected; the water is discharged when the preset index is reached; the waste water subjected to the electrolysis catalysis oxidization is fed into a crystallizing evaporator for evaporationconcentration crystallization recovery to obtain industrial salt capable of being used as resources; waste water subjected to evaporation condensation is continuously fed into a biochemical device forbiochemical treatment; the discharge or recovery utilization is performed after the discharge standard is met.

Owner:JIANGSU HUDA CHEM TECH CO LTD

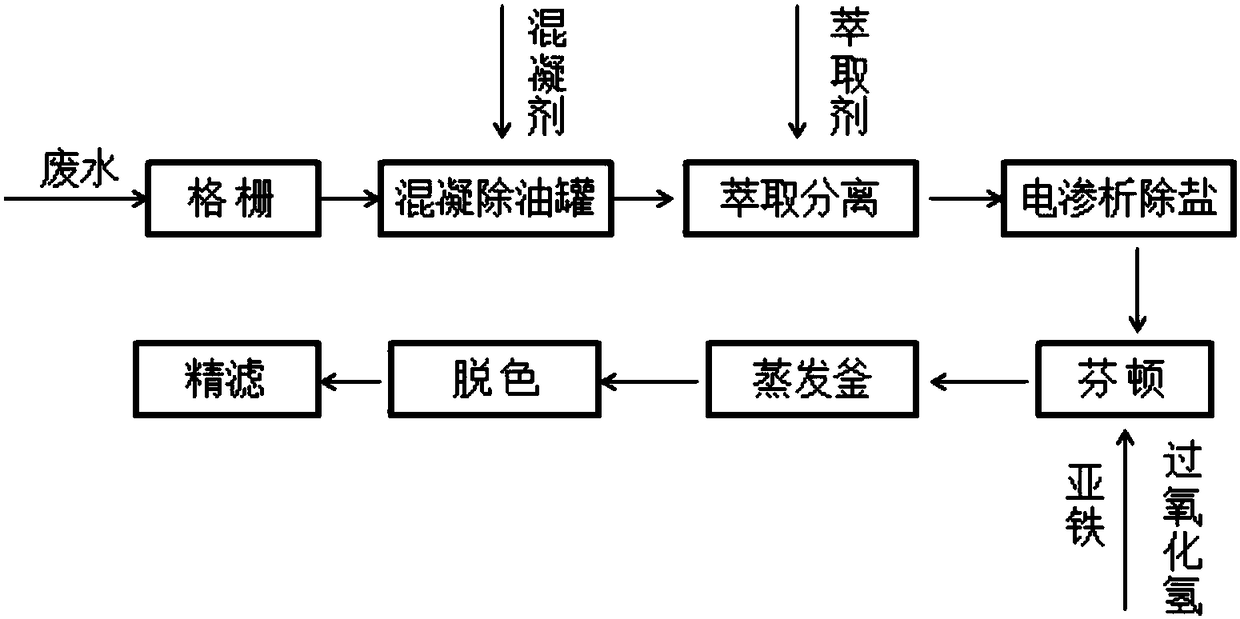

Treating method of epoxy resin generated waste water

ActiveCN108341536AGood coagulation and degreasing effectEasy to handleFatty/oily/floating substances removal devicesWater treatment compoundsEpoxySalt-wasting

The invention belongs to the technical field of sewage water treating, and particularly relates to a treating method of epoxy resin generated waste water. The method comprises the steps that large suspended matter impurities in the epoxy resin generated waste water are removed by grilles, through the combination of physical and chemical methods of coagulation, extraction, electrodialysis desalination, fenton oxidation, flashing, decolorizing and refined filtration, salt water is directly recycled and reused after organics in high-salt waste water are removed, the cost is saved, and the treating method has the advantages of being low in energy consumption, high in removing loading, good in water quality of purified output water and the like.

Owner:武汉弘康本环保新材料有限公司

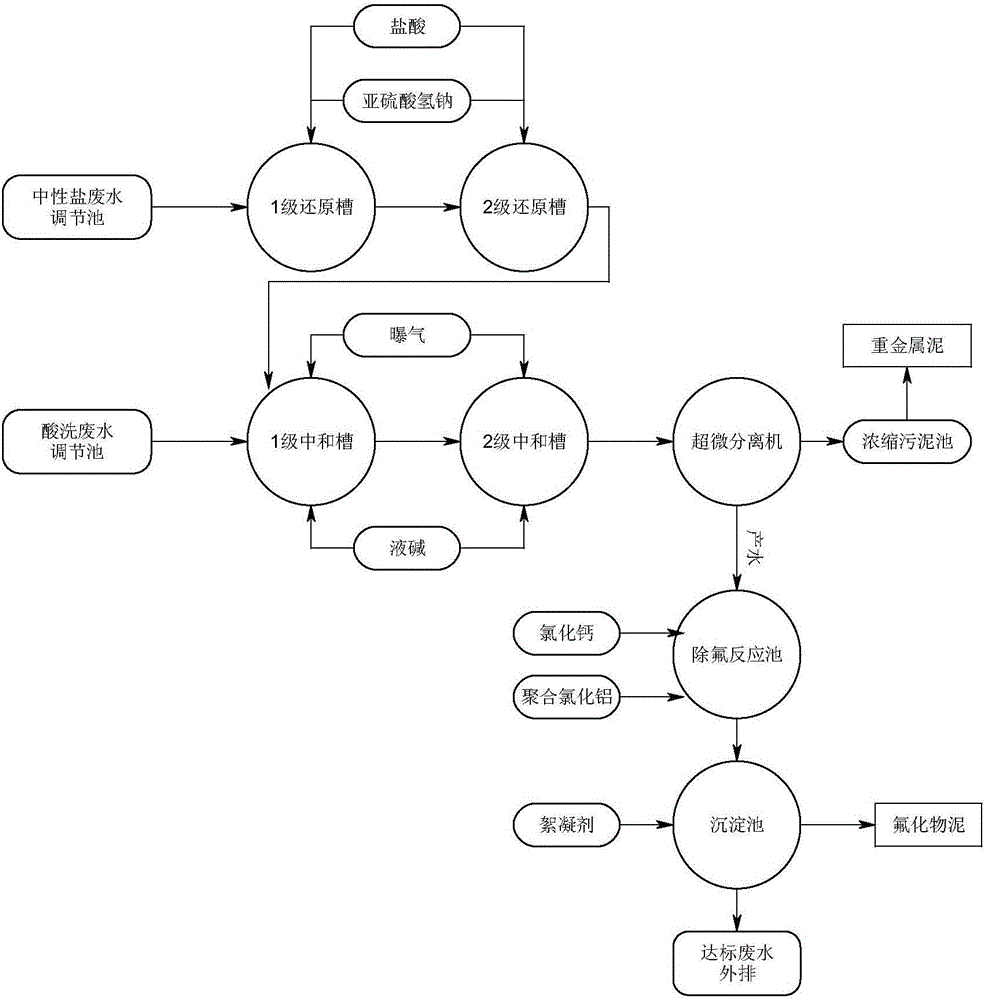

Technology for treating stainless steel nitrate-free pickling waste water

InactiveCN105923840ASolve the problems that still exist in the treatment processSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processNitrateSalt-wasting

The invention relates to a technology for treating stainless steel nitrate-free pickling waste water. The technology comprises the following steps: respectively leading the pickling waste water and neutral salt waste water into corresponding adjusting tanks; adjusting the pH value of the neutral salt waste water and reducing hexavalent chrome; leading the reduced neutral salt waste water and the pickling waste water into a neutralizing tank together, and neutralizing the waste water by using caustic soda liquid; after carrying out aeration treatment on the neutralized waste water, carrying out solid-liquid separation by using a superfine separator, concentrating and dehydrating sludge obtained by separation to form heavy metal mud, leading the waste water obtained by separation into a defluorination reaction tank, and carrying out fluorine removal treatment; and continuing leading the waste water subjected to the fluorine removal treatment to a settling pond for mud-water separation to obtain fluoride mud and supernatant which conforms to the emission standard. Compared with the prior art, the technology has the advantages that the waste water treated by the technology reaches requirements of a chart 2 of GB13456-2012, the heavy metal mud and the fluoride mud are obtained step by step, wherein the heavy metal mud has re-melting and reusing value, and the fluoride mud which is lower than the requirements of the standard of GB5085.3-2007 can be treated as common solid wastes after being identified.

Owner:NINGBO BAOXIN STAINLESS STEEL

Synergistic biological treatment method for washing waste water and amine salt waste liquor produced by capturing CO2 in smoke of coal-fired power plant

InactiveCN103145244ASimple structureRealize resource utilizationTreatment with aerobic and anaerobic processesWaste water treatment from gaseous effluentsLiquid wasteSulphur reducing bacteria

The invention relates to a synergistic biological treatment method for washing waste water and amine salt waste liquor produced by capturing CO2 in smoke of a coal-fired power plant. Waste amine salt in amine salt waste liquor produced by a regenerating tower in a flue gas CO2 capturing process is taken as one organic carbon source in a biological treatment process, an anaerobic and aerobic two-stage biotreatment is adopted for treating the washing waste water and the amine salt waste liquor, the washing waste water and the amine salt waste liquor are pumped into an anaerobic biological reaction column by a water pump, nitrate is converted into N2 under the action of denitrifying bacteria, sulphate is converted into S<2-> under the action of Desulfovibrio, organic carbon in organic amine salt is taken as a partial organic carbon source for sulphate reduction bacteria, and amine is converted into ammonia nitrogen. Waste water after anaerobic treatment enters an aerobic biological reaction column, nitration and denitrification of ammonia nitrogen are realized by carrying out intermittent aeration by an air pump, and finally ammonia nitrogen is released into the air in the form of N2; S<2-> generates sulphur under the action of thiobacillus thioparus, simple substance sulphur is recycled by a sulphur separator, and separated waste liquor returns to a washing tower to be recycled; and no pollution is produced in a CO2 capturing process.

Owner:CHINA PETROLEUM & CHEM CORP +2

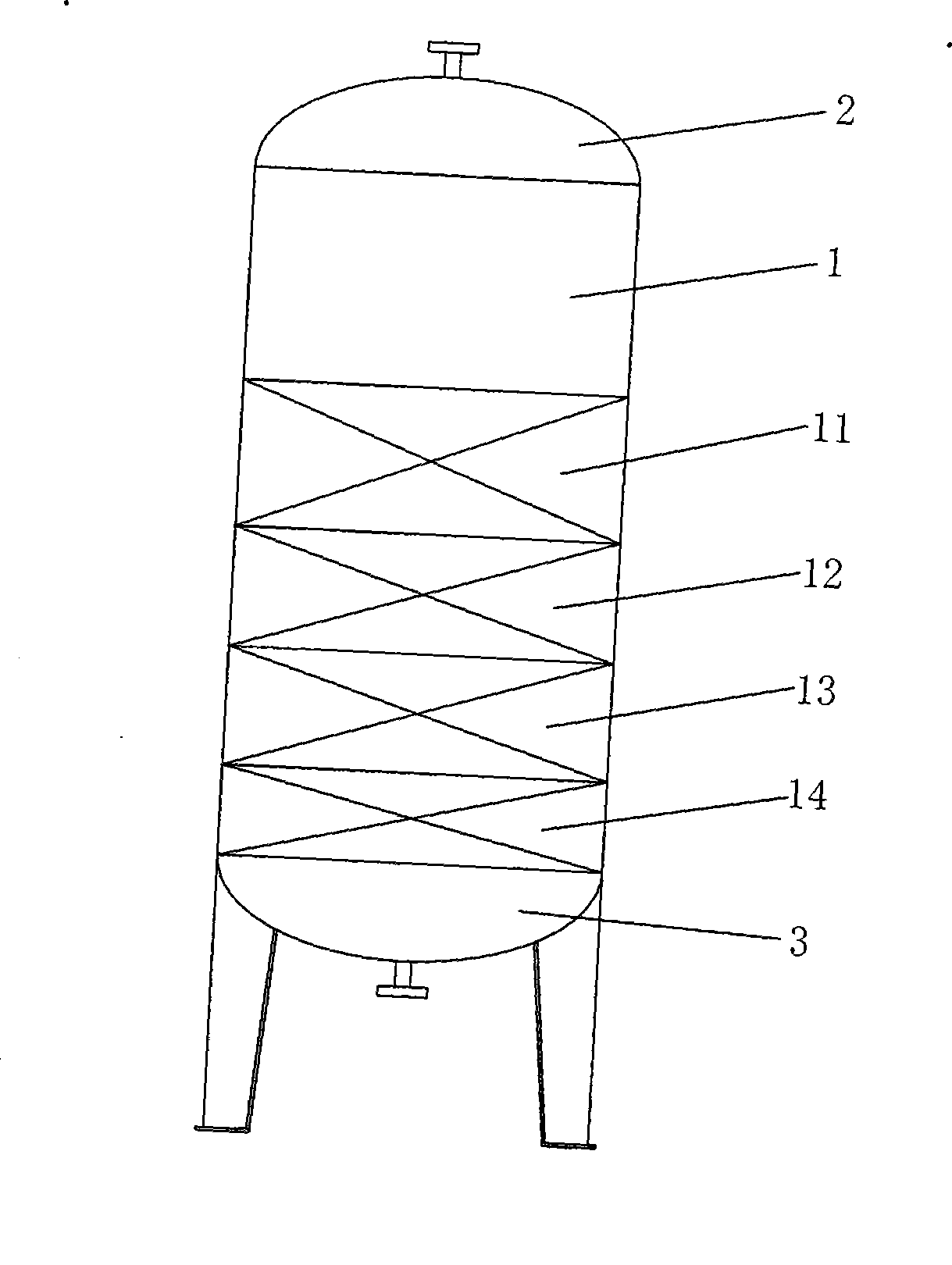

Circulating reuse method of pickling depleted brine and apparatus thereof

InactiveCN101381172AKeep drySolve the problem of secondary moistureMultistage water/sewage treatmentSaline waterSocial benefits

The present invention discloses a method for circulating and reusing preserving salt waste water and a device thereof. A multilayer complex filter is adopted to remove the mechanical impurities and malignant bacteria in the preserving depleted brine. A water soluble macromolecule substance is then selected to be mixed with and dissolved in the preserving depleted brine so as to prepare a mixed solution and a suspensoid. Finally, the mixed solution or the suspensoid is poured into a vacuum salt producing device to produce a powdered refined salt. A quadruple effect evaporating pot is adopted to pressurize under a vacuum condition, and thus not only the manufacturing cost is saved, but also the production efficiency is high and the product quality is good. The multilayer complex filter which is adopted to filter the salt waste water is low in energy dissipation, long in service life, low in cost, and easy to operate and control. The water soluble macromolecule substance is selected to be mixed with and dissolved in the preserving depleted brine, and thus the problems that the saline solution is not easy to dry and is easy to wet twice and agglomerate are solved, and the device has extraordinary significant economic benefits and social benefits.

Owner:ZHEJIANG YUQUAN ENVIRONMENTAL ENG

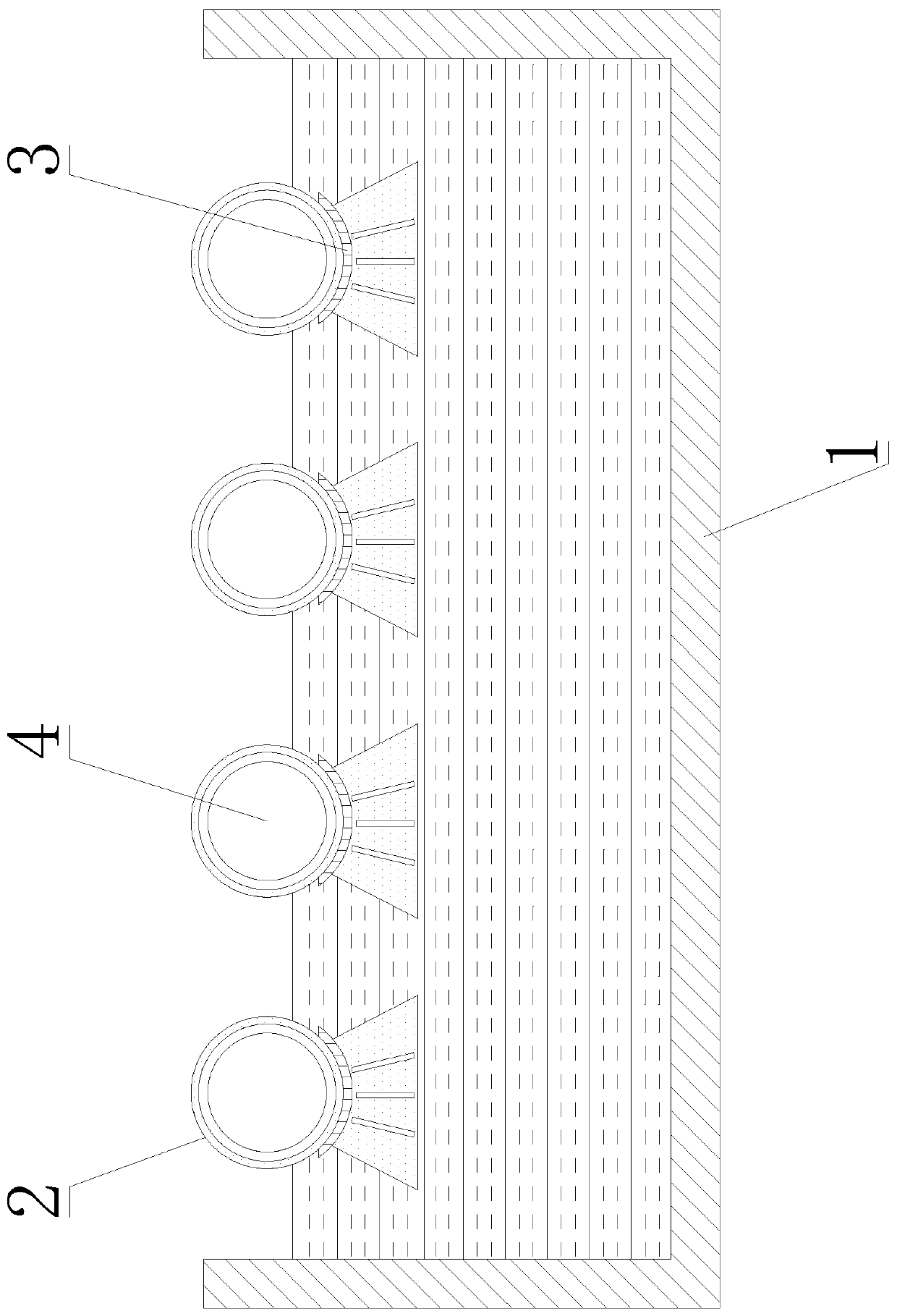

Method and device for accelerating salt obtaining by evaporating brine

PendingCN110040801AHydrophilicPorousWater/sewage treatment by heatingAlkali metal chloridesSalt-wastingEvaporation

The invention provides a device for accelerating salt obtaining by evaporating brine. The device comprises a light-heat conversion part, a buoyancy ball and a locking part, wherein the light-heat conversion part wraps the buoyancy ball, and the locking part fastens the light-heat conversion part. The invention further provides a method for accelerating salt obtaining by evaporating brine. The method comprises the following steps that an aqueous solution to be treated is added, accessories are selected and assembled, the light-heat conversion part wraps the buoyancy ball and is fastened by using the locking part, the device is placed in a water pool, the buoyancy ball floats in the water pool, the remaining part of the light-heat conversion part stretches into the water pool to carry out light absorption and light-heat conversion so as to quickly evaporate water absorbed by the light-heat conversion part, the light-heat conversion part carries out capillary action to quickly supply water. The device and method disclosed by the invention have the beneficial effects that the use effect is excellent, the water evaporation efficiency can be improved, the production period of salt obtaining by evaporating brine in the open air can be shortened, and the treatment time of multiple sewage such as high-salt waste water, heavy-metal sewage and printing and dyeing sewage can be shortened,so that large economic benefit and social benefit can be brought.

Owner:江苏金羿射日新材料科技有限公司

Method for zero discharge recycling of high-salt waste water with electromagnetic forward osmosis reactor

ActiveCN104649502ANo secondary pollutionReduce processing costsMultistage water/sewage treatmentFiltrationSalt-wasting

The invention discloses a method for zero discharge recycling of high-salt waste water with an electromagnetic forward osmosis reactor, and relates to waste water treatment. The method comprises the steps that after the high-salt waste water is subjected to turbidness removal and pH is adjusted to 7, the high-salt waste water enters a raw water adjusting pool for stabilization of water quantity and water quality; an effluent of the raw water adjusting pool enters an electromagnetic crystallization reactor for crystallization; a supernatant fluid effluent of the electromagnetic crystallization reactor is filtered by a membrane filtration reactor, and enters the forward osmosis reactor for concentration; solid residues in the electromagnetic crystallization reactor are scraped regularly; back flushing water of the membrane filtration reactor flows back to the raw water adjusting pool; waste water concentration liquor concentrated by the forward osmosis reactor flows back the electromagnetic crystallization reactor; drawing liquor of the forward osmosis reactor absorbs pure water in the waste water, and then enters a membrane distillation unit for separation between the drawing liquor and the pure water; a pure water effluent of the membrane distillation unit is recycled; and drawing liquor of the membrane distillation unit is subjected to vapor condensation and flows back to the forward osmosis reactor. The method is used under normal temperature and pressure conditions; no chemical agent is required; no secondary pollution is exerted; the treatment cost is low; the efficiency is high; and the floor area of treatment equipment is small.

Owner:XIAMEN NAVDY MEMBRANE TECH

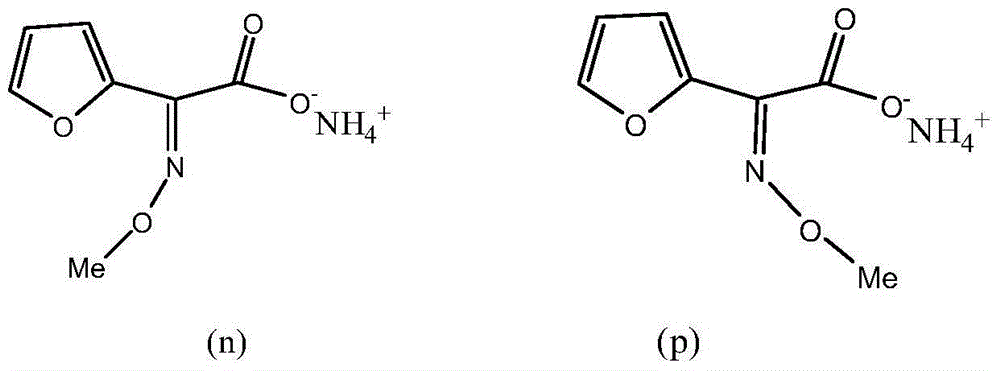

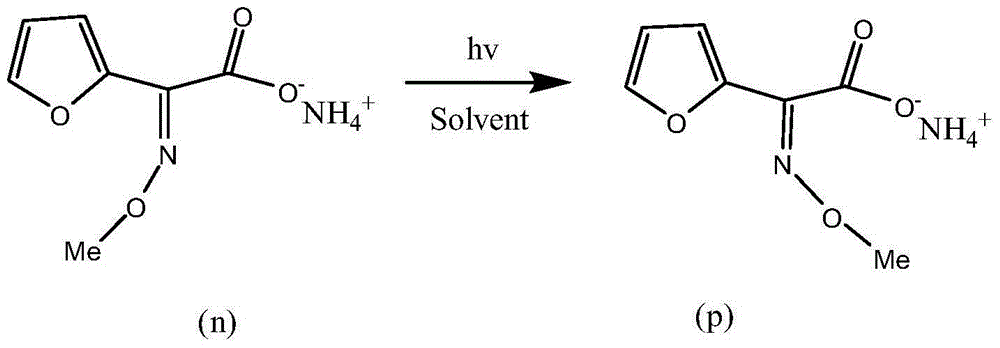

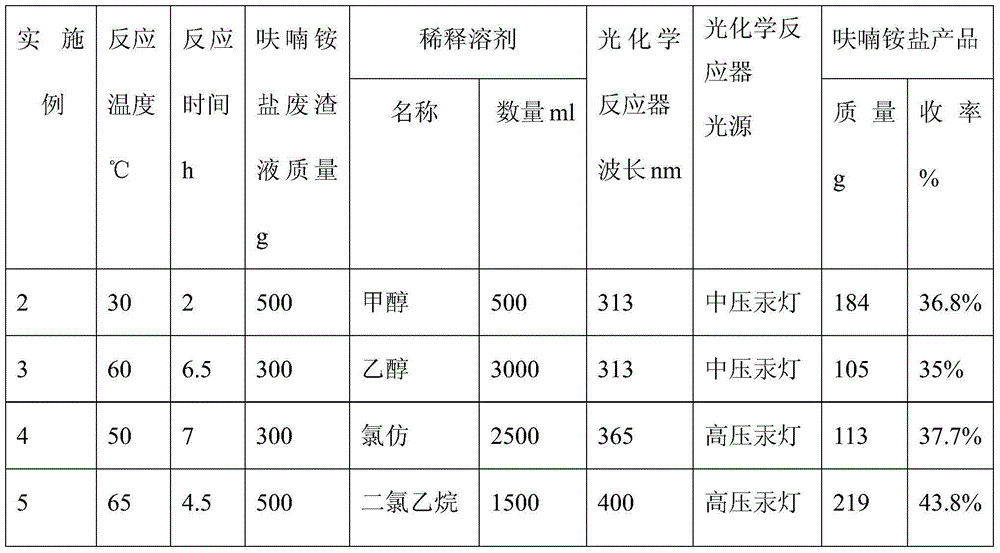

Method for recovering furan ammonium salt from furan ammonium salt waste residue

The invention belongs to the field of preparation of medical intermediates, and specifically relates to a method for recovering a furan ammonium salt from furan ammonium salt waste residue. The method comprises the following steps: dissolving furan ammonium salt waste residue in a solvent, and then adding into a photochemical reactor to react, wherein the wavelength of a light source of the photochemical reactor is 254-540nm, and a medium pressure mercury lamp or a high pressure mercury lamp is used as the light source in the photochemical reactor. According to the method provided by the invention, trans-form byproducts in the furan ammonium salt waste residue are fully converted into cis-form products by ultraviolet irradiation in appropriate bands through a photo-isomerization principle, thereby realizing effective utilization of waste to the maximum extent. Not only is the pollution reduced, but also the yield of the product is further increased. The cis-form products in the reaction process are not damaged and can be fully recovered in a reaction system, so that the yield of the product is high. The reaction process is simple, no other reaction raw materials are consumed in the reaction process, and the production cost is low.

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD +1

Process of comprehensively recovering rare earth from electrolytic fused salt waste residues of rare earth

InactiveCN110453098AReduce processing stepsReduce pollutionRare earth metal compoundsLithium halidesElectrolysisSalt-wasting

The invention relates to a process of comprehensively recovering rare earth from electrolytic fused salt waste residues of rare earth and relates to the technical field of rare earth preparation. Theprocess comprises the following steps: S1, raw material classification: classifying to-be-recovered electrolytic fused salt residues according to different contents of impurities and total amounts ofrare earth; S2, raw material crushing: roughly and intermediately crushing the raw materials classified in the S1, and then grinding the intermediately crushed raw materials by a ball mill till the granularity is greater than 130 meshes to prepare powder I; and S3, proportioning: proportioning the powder prepared in the S2 and sodium hydroxide in a weight ratio of 1: 0.27, and mixing the mixture for 10-15 min in a material mixer fully and uniformly to prepare powder II. The process of comprehensively recovering rare earth from electrolytic fused salt waste residues of rare earth is simple to operate, low in cost and environmental-friendly. Fluorides added for part of common fused salt electrolysis can be obtained by the process. The fluorides processed by a dry method or a wet method are reduced, hydrogen fluoride pollution is reduced, the fluorinating energy consumption is saved and the process is energy-saving and environmental-friendly.

Owner:SUICHUAN QUNXIN MAGNETIC NEW MATERIAL CO LTD

Coal slime argillization inhibition method based on adjustment and control of solution chemical properties

InactiveCN105903547AImprove settlement performanceImprove filtering effectSolid separationCyclic processMagnesium salt

The invention discloses a coal slime argillization inhibition method based on adjustment and control of solution chemical properties. Inorganic salt is utilized to change the chemical properties of water body solution during the coal washing process so as to inhibit clay argillization and coal slime argillization in coal. The coal slime argillization inhibition method comprises the following step: adding an argillization inhibitor, along with supplementary water, in a coal washing system, wherein the adding site of the argillization inhibitor is a water tank of supplementary water of a coal preparation plant; the argillization inhibitor is one selected from natural gypsum, halogen piece or halogen powder of magnesium salt, or industrial high-salt waste water; the adding amount of the argillization inhibitor ensures that the conductivity of coal slime water is greater than or equal to 1.5*10<3> [mu]s / cm during the entire cyclic process. The argillization inhibitor added during the coal washing process can effectively prevent clay particles in coal from hydration swelling and dispersion and has the effects that the argillization process of coal slime is blocked, and the settling property of coal slime water and the dehydration property of coal slime are improved. The coal slime argillization inhibition method has the following advantages: clay and coal slime in coal are prevented from argillization from source; the method is simple and practicable, remarkable in effect, and suitable for washing of coal containing expansive clay.

Owner:CHINA UNIV OF MINING & TECH

Slightly bitter salt water desalting irrigating system

InactiveCN108408994AFlexible structure designEasy maintenance and operationSpecific water treatment objectivesTreatment involving filtrationHigh concentrationWater source

The invention discloses a slightly bitter salt water desalting irrigating system. An electric desalting component is arranged, an anisotropic ionic membrane technology is applied to an agricultural water-saving irrigating project, slightly bitter salt water is desalted by utilizing an electrochemical principle of ions in water repel one another, and opposite ions in the water attract one another,and treated water can be used for providing a new water source for agricultural irrigating water; the slightly bitter salt water desalting irrigating system overcomes the defect that the existing reverse osmosis water treatment system has high requirement on raw water, has wide range of requirements on the hardness of the raw water and does not require water quality softening and activated carbonadsorption; a mechanical filter and a precise filter have wide range of requirements on the content of suspended matters in the raw water; a filter element replacement period is long; the overall system can operate normally with the working water pressure of 0.5 to 2 kilograms; pressure potential safety hazard is avoided; the system is flexible in structural design and convenient to operate and maintain; high-efficiency recycling and utilizing of high-salt waste liquid can be realized through a regulating water tank; the recovery rate of high-concentration bitter salt water can reach 80 percent or more, and the slightly bitter salt water desalting irrigating system is beneficial to saving a resource system.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

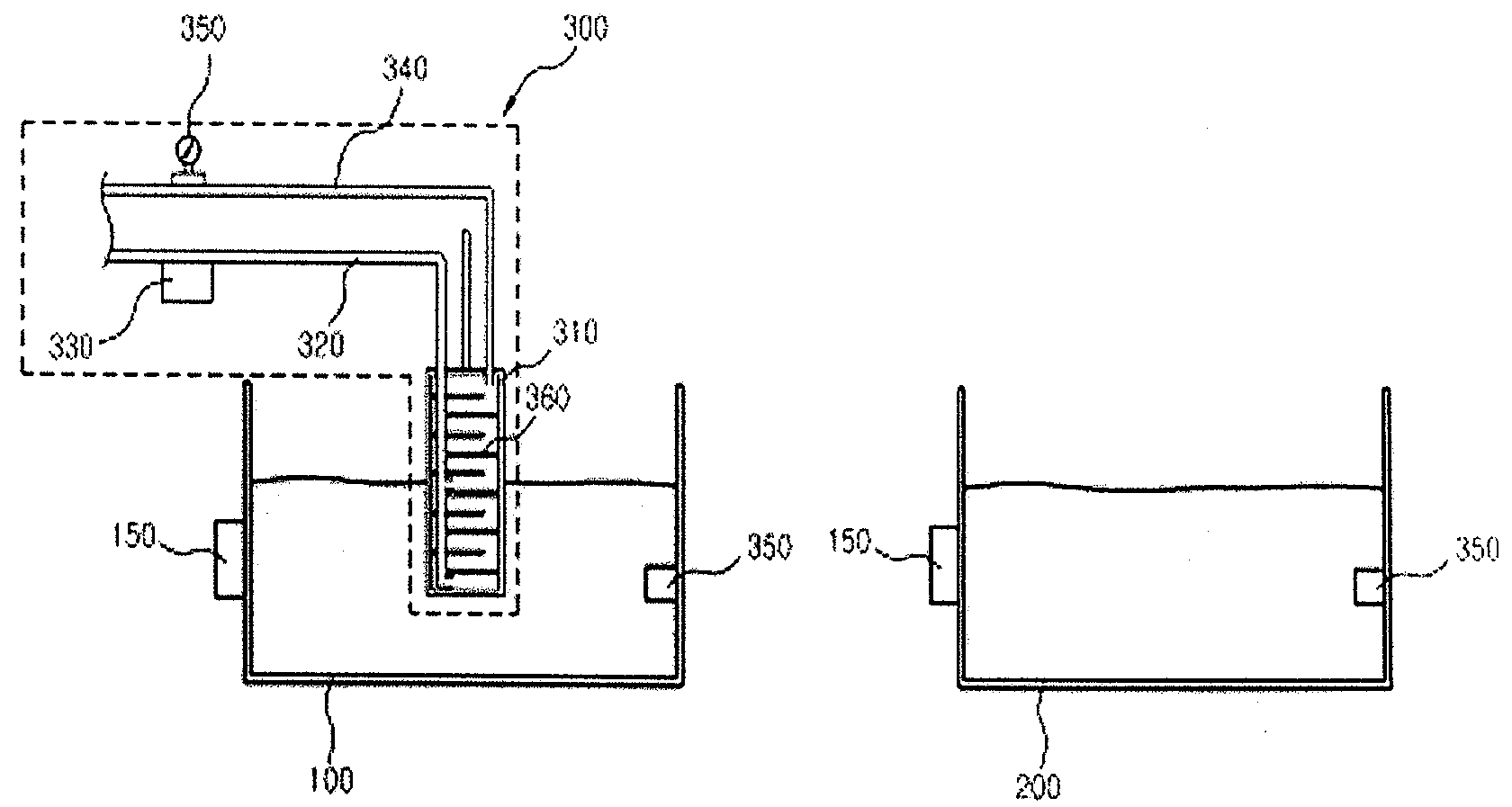

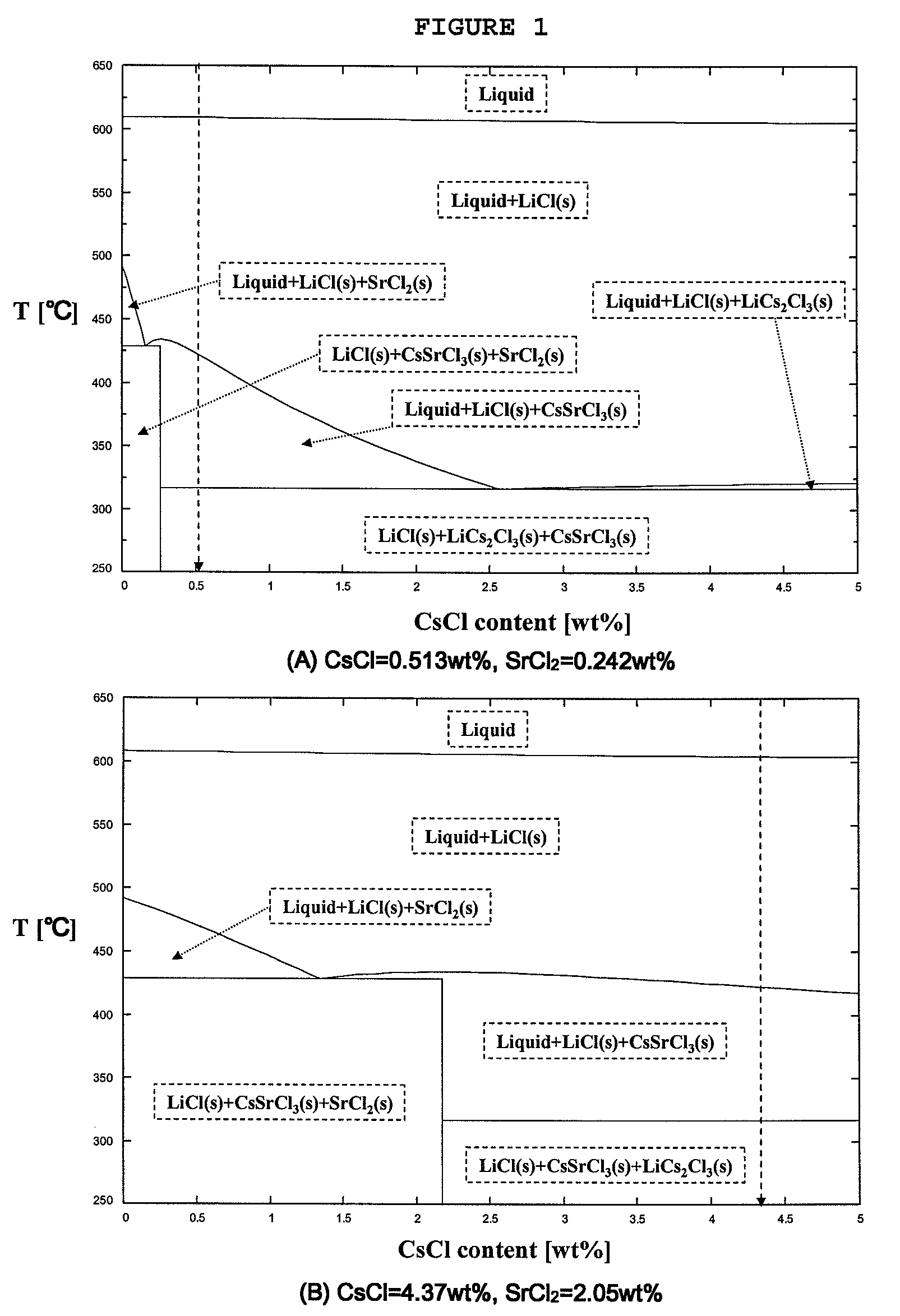

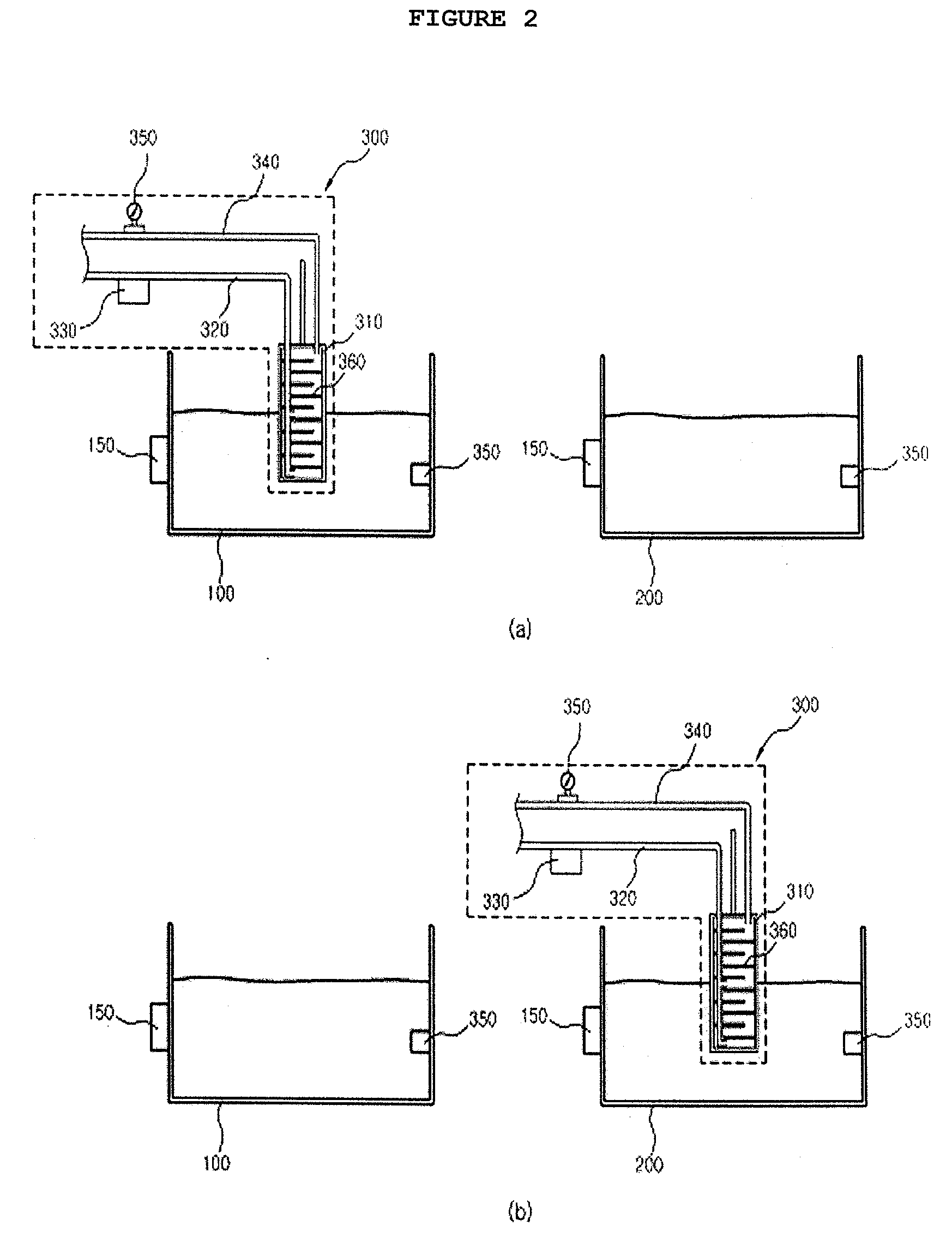

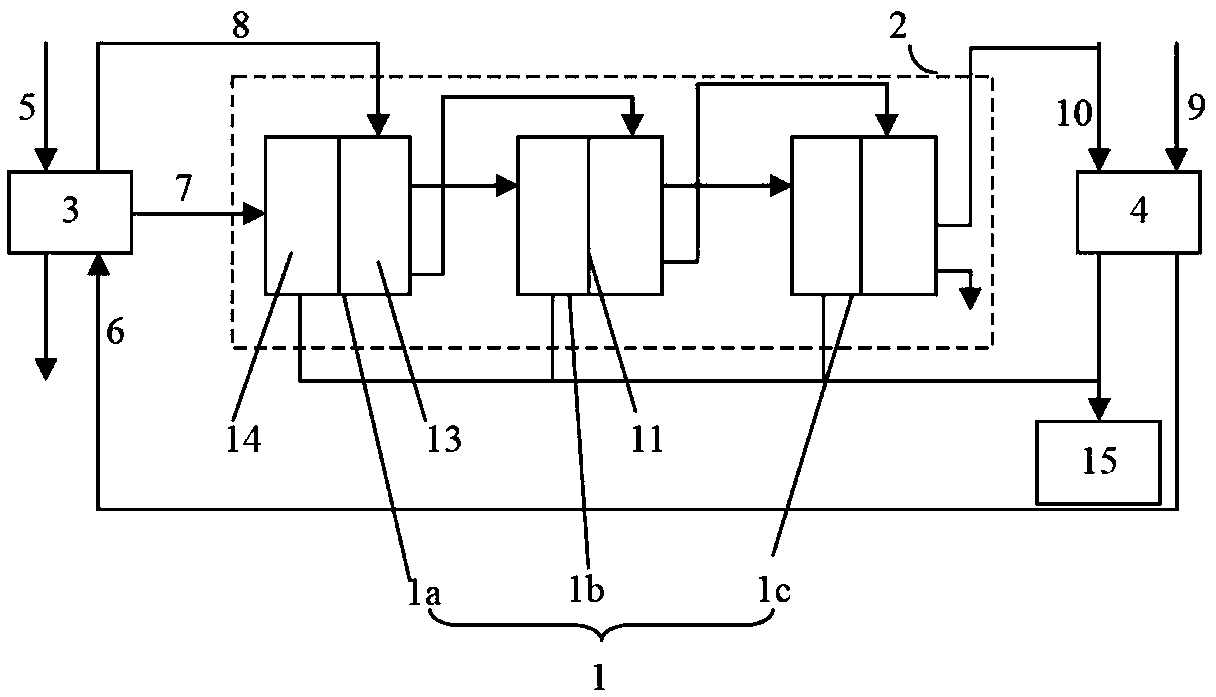

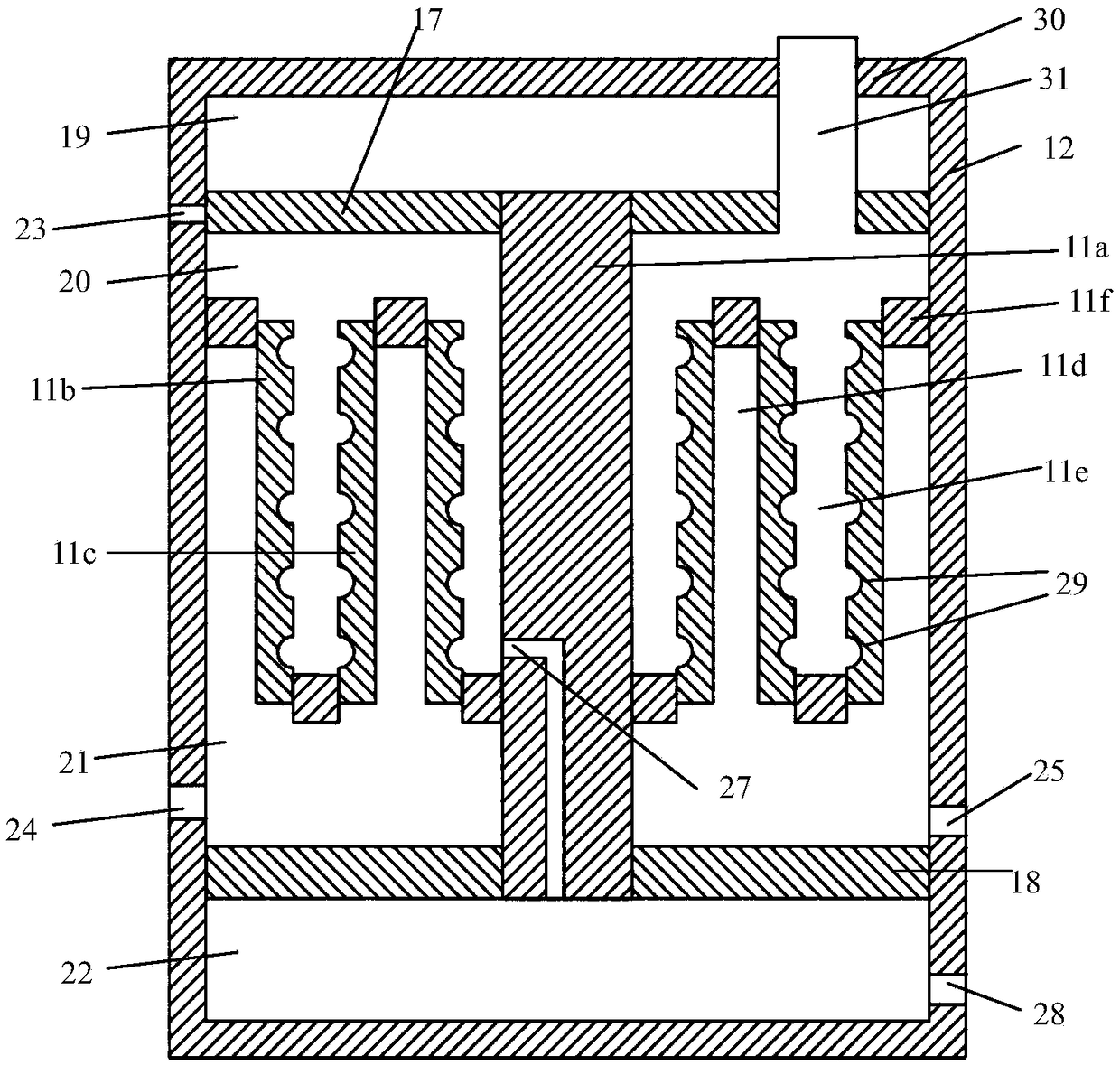

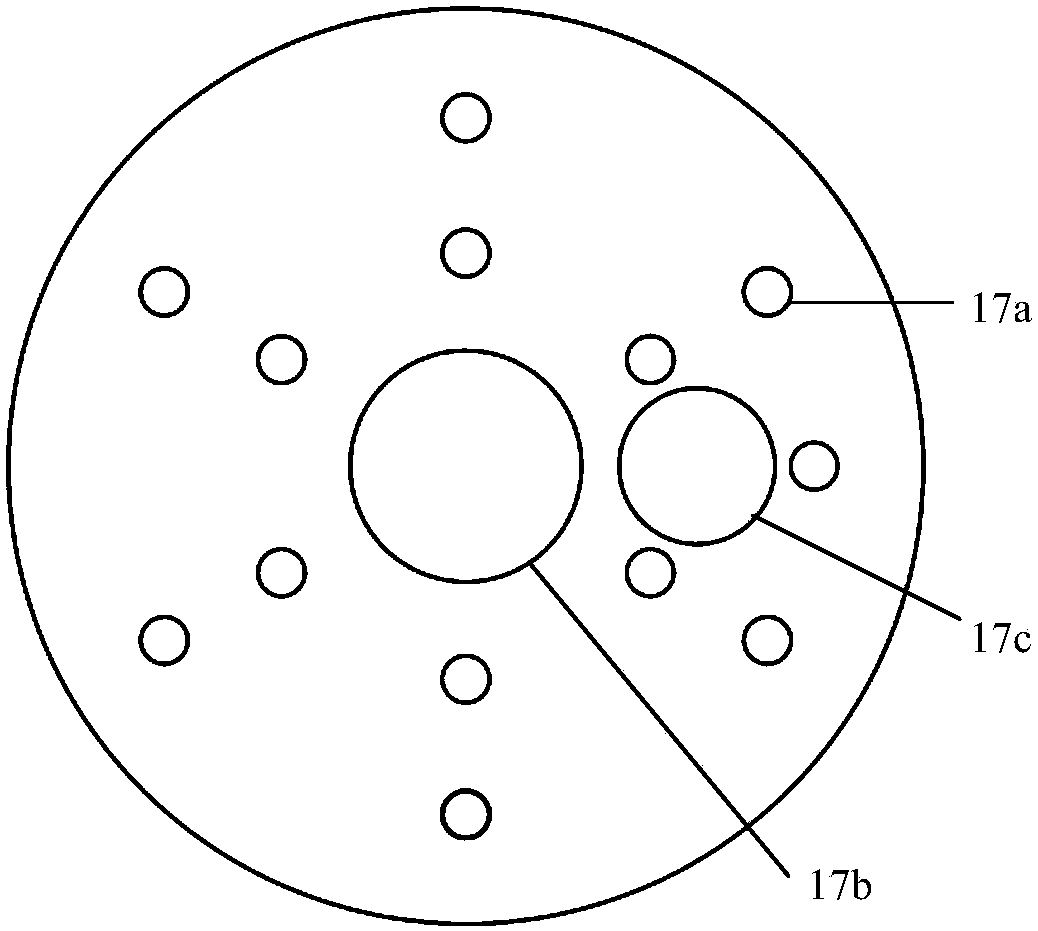

METHOD OF RECYCLING LiCl SALT WASTES BY USING LAYER CRYSTALLIZATION AND APPARATUS FOR THE SAME

InactiveUS20100071408A1Simple processShort processing timeLighting and heating apparatusSolution crystallizationSalt-wastingLiquid state

Disclosed herein are a method of recycling LiCl salt wastes comprising radionuclides and an apparatus using the same. The method includes a) solidifying a LiCl salt contained in the LiCl salt wastes and contacting the outer wall of a housing, by charging a crystallizer comprising the housing having an internal accommodating space and an air cooler in the internal accommodating space into a crystallizing furnace accommodating the LiCl salt wastes comprising the radionuclides, and by cooling the housing to a temperature of two-phase region where the liquid state and the solid state of the LiCl salt waste coexist, b) separating the crystallizer where the LiCl salt is solidified from the crystallizing furnace, c) recycling the LiCl salt by heating the separated crystallizer to melt the solidified LiCl salt.

Owner:KOREA ATOMIC ENERGY RES INST +1

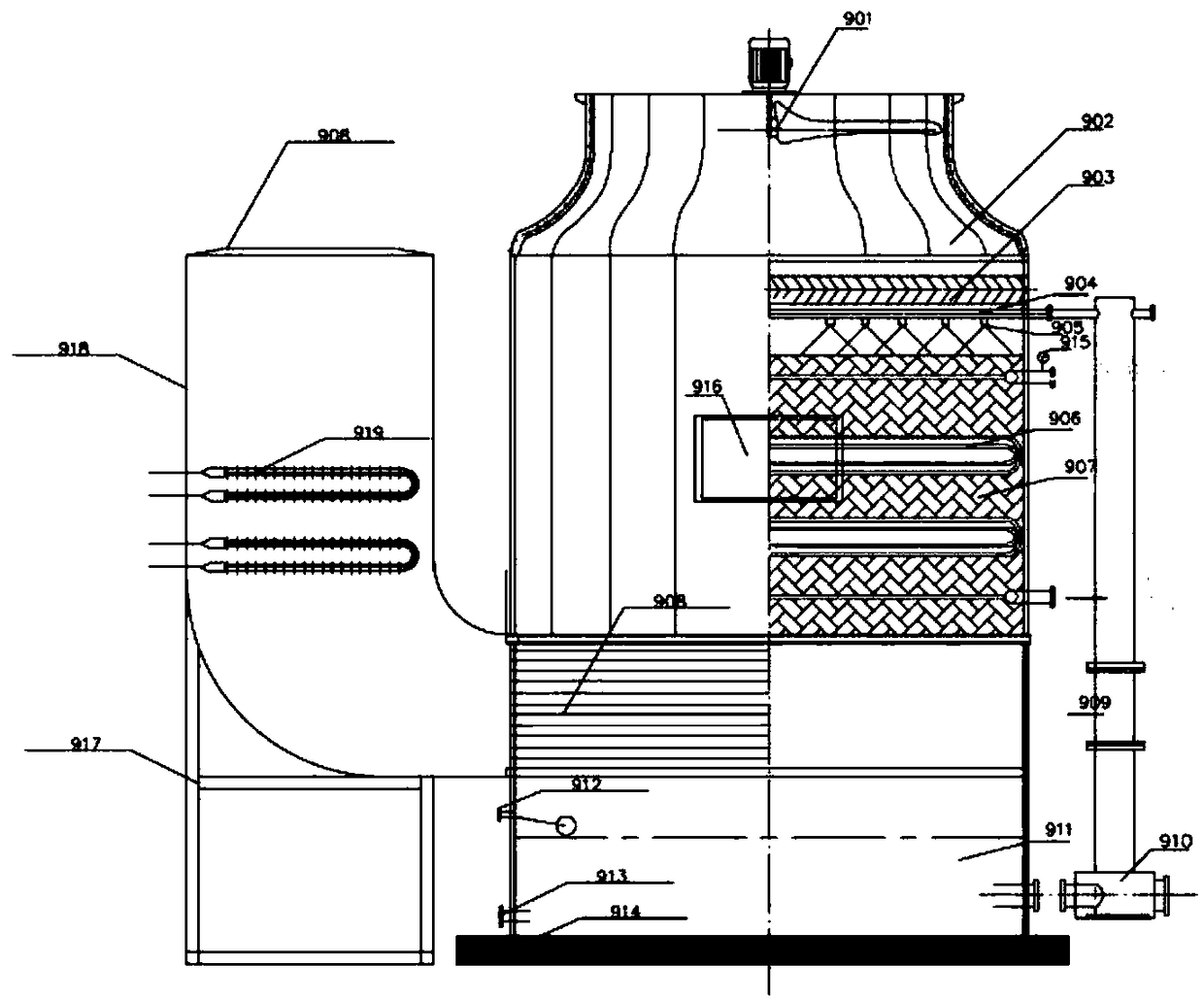

Crystal salt separation purification system based on high-salt-containing high salt waste water

ActiveCN109011668AIncreased flow distanceEvaporative condensation compact structureWater/sewage treatment by heatingMultiple-effect evaporationSalt-wastingWastewater

The invention provides a crystal salt separation purification system based on high salthigh-salt-containing waste water. An outer case of an evaporator is separated into a first cavity and a second cavity through an evaporation-condensationevaporative condenser structure which is arranged inside the outer case of the evaporator and at least comprises a body, a first plate body and a second plate body; in the radial direction of the outer case, the first plate body and the second plate body are respectively connected to the body and the outer case through the respective first end parts and thesecond end parts and are distributed in a separated wayat an interval in a spiral bent form so as to form a first space and a second space which are not mutually communicated, wherein at least one groove which is communicated with the first end part and the second end part in a way of being not parallel to the radial direction of the outer case all the time according to the extending direction isarranged on the surface of each of the first plate body and the second plate body. The evaporator provided by the invention has the advantages that the evaporator has the longer flowing distance through being comparedin comparison with that of the vertically downward flowing process; in addition, the structure is compact; the larger heat exchange contact surface area is largerrealized; the secondary steam quantity generated by the evaporator can be obviously increased.

Owner:ZHENGZHOU JIANGHE ENVIRONMENTAL PROTECTION TECH

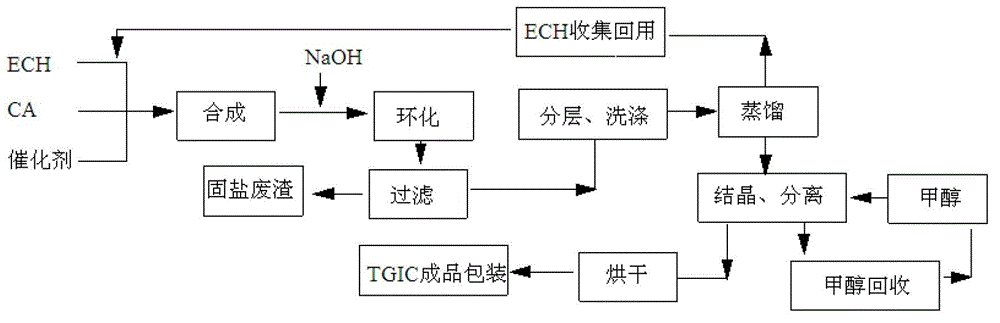

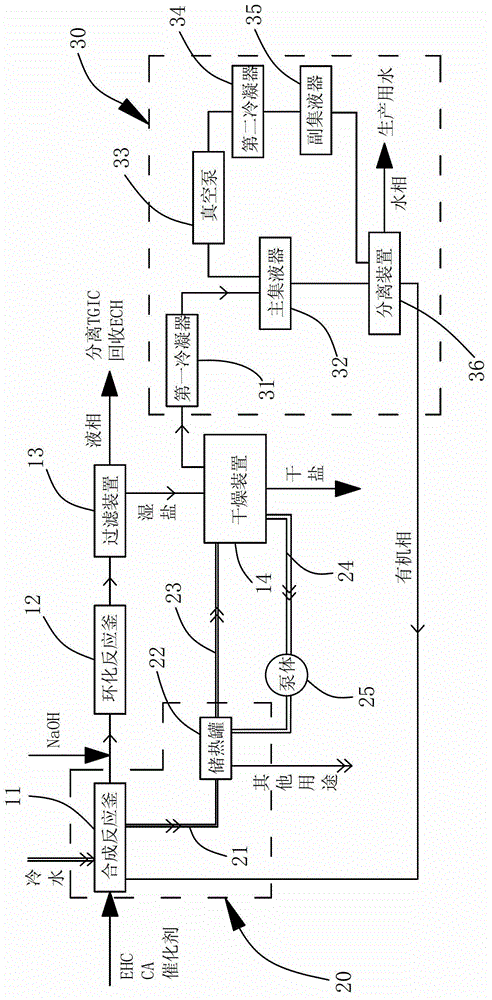

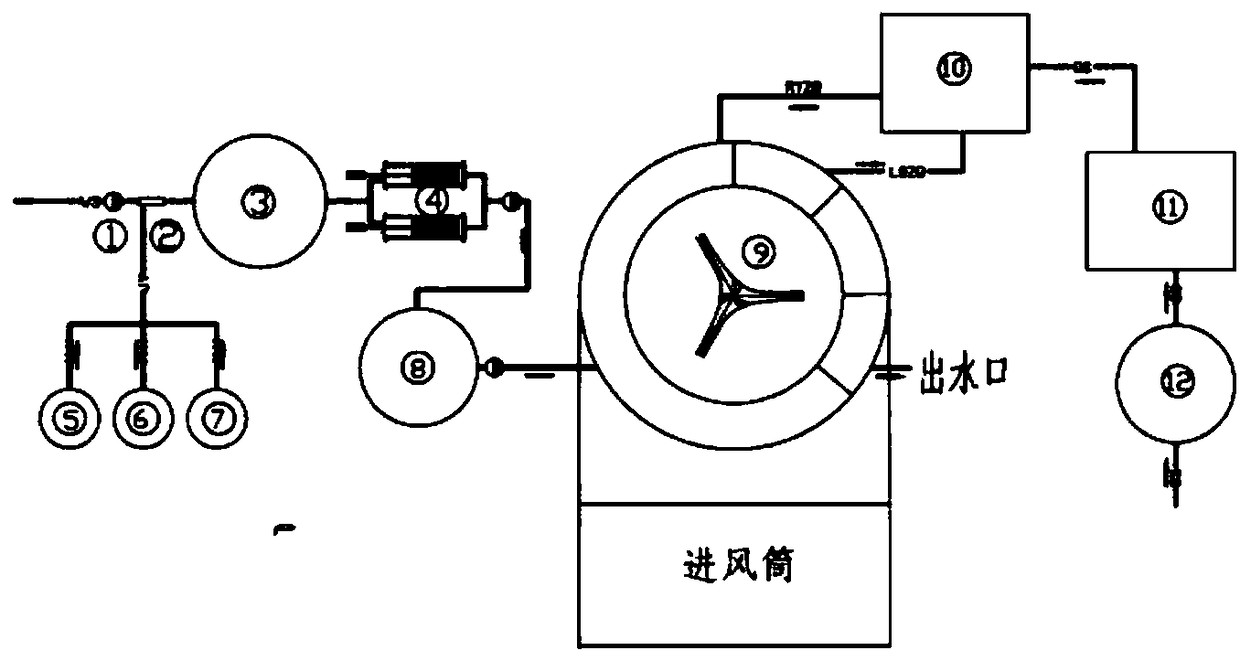

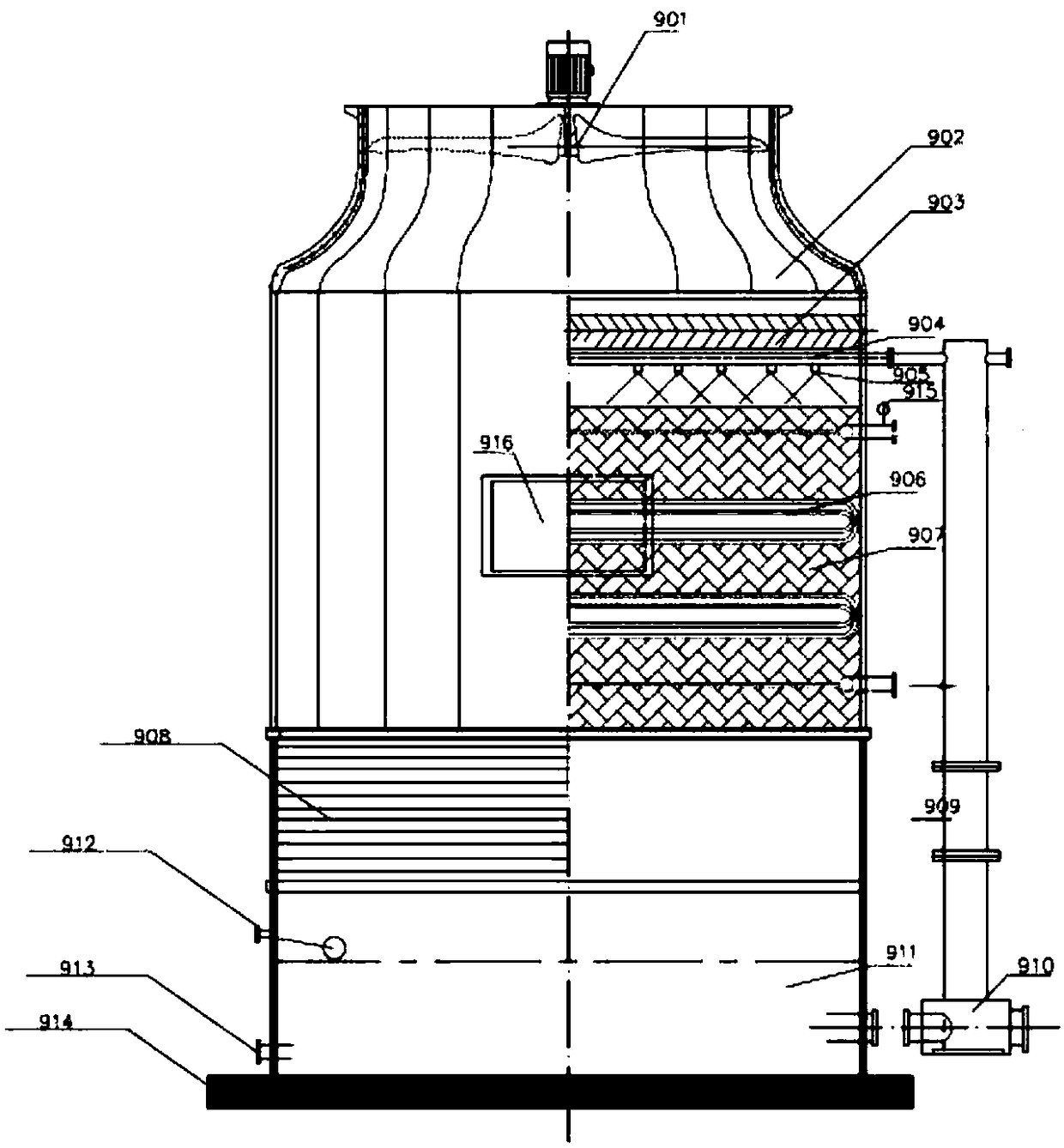

Treatment system for solid salt waste in triglycidyl isocyanurate production

The invention discloses a treatment system for solid salt waste in triglycidyl isocyanurate production. The treatment system comprises a filtering device, a drying device and an organism recycling unit, the filtering device is used for filtering mixture after reaction is finished in a cyclization reaction kettle, the drying device is used for heating remaining solid salt waste after filtering of the filtering device, and the organism recycling unit is used for condensing and recycling gas escaping when the solid salt waste is heated. The mixture is filtered to obtain the solid salt waste, and the solid salt waste is heated in the drying device, so that organisms and moisture in the solid salt waste are heated and evaporated, salt and other components in the solid salt waste can be separated, the organisms escaping by evaporating are recycled and are used respectively, and the solid salt waste is effectively treated.

Owner:HUANGSHAN JINFENG INDAL

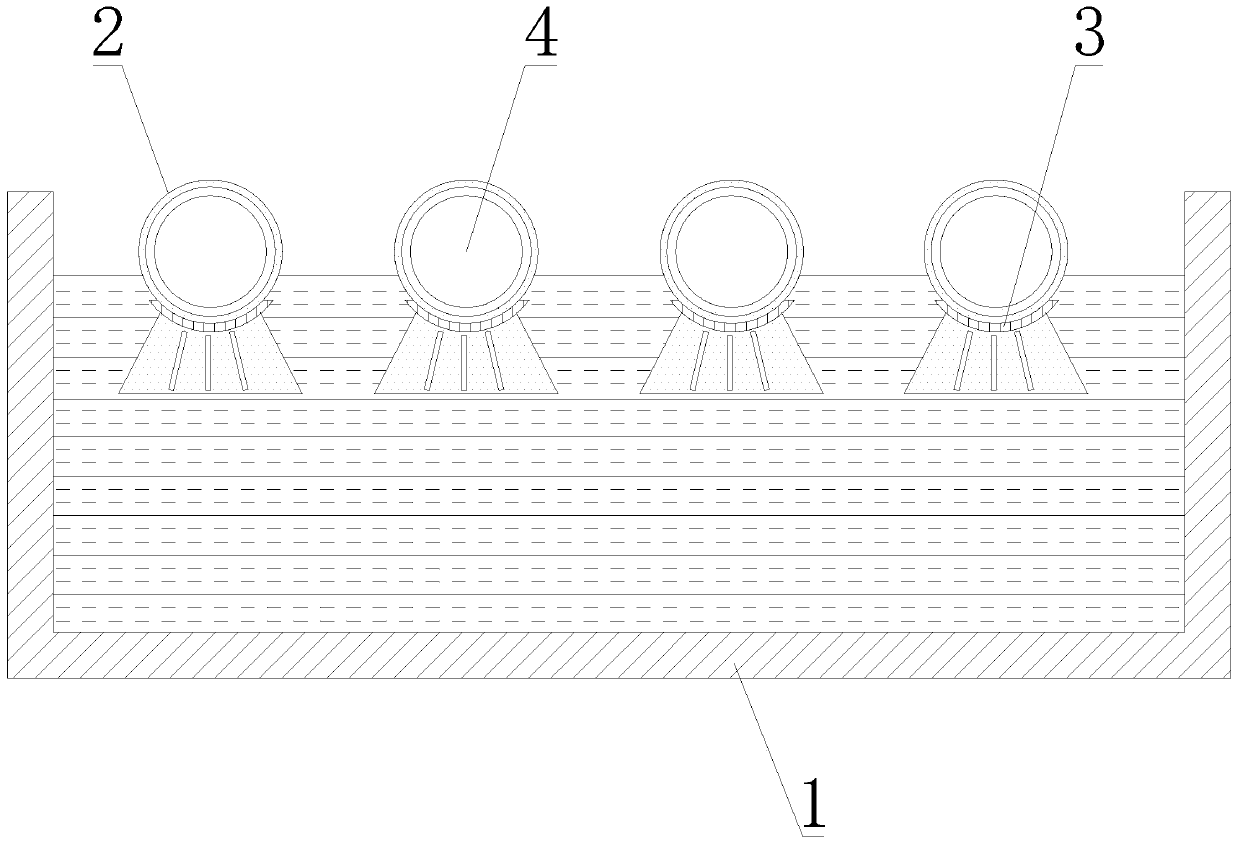

High-salt waste water circulating row pipe atmospheric evaporation reduced treatment method and equipment

PendingCN108117215AEfficient removalImprove evaporation efficiencyTreatment involving filtrationMultistage water/sewage treatmentWater treatmentSalt-wasting

The invention discloses a high-salt waste water circulating row pipe atmospheric evaporation reduced treatment method and equipment. Chemical coagulation, physical filtration and circulating row pipeatmospheric evaporation concentrated treatment steps are adopted. In particular, an atmospheric evaporation tower fulfills the aim of increasing the evaporation quantity of the circulating waste waterto realize concentration by enabling dry air with high enthalpy value to enter the tower under the action of a high-power axial flow fan, transmitting heat to the waste water in the tower by the gas,providing part of heat required by evaporation of the waste water and then extracting the air with low enthalpy value and high humidity by a fan. By adoption of the method and the equipment, which are provided by the invention, the problem about high-salt waste water treatment can be effectively solved economically and technologically.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com