Synergistic biological treatment method for washing waste water and amine salt waste liquor produced by capturing CO2 in smoke of coal-fired power plant

A biological treatment, coal-fired power plant technology, applied in the direction of gaseous effluent wastewater treatment, aerobic and anaerobic process treatment, etc., can solve secondary pollution and other problems, achieve low treatment cost, simple reactor structure, and simple engineering construction uncomplicated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

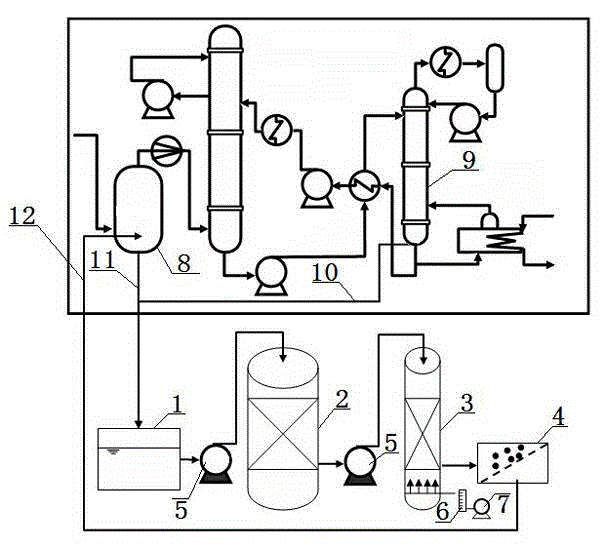

[0014] The invention discloses a coal-fired power plant flue gas CO 2 The water washing wastewater and amine salt waste liquid synergistic biological treatment method produced by capture is characterized in that: the flue gas CO 2 The waste amine salt in the amine salt waste liquid produced by the regeneration tower 9 of the capture process is used as one of the organic carbon sources in the biological treatment process, and the anaerobic and aerobic two-stage biological treatment methods are used to treat the washing wastewater and the amine salt waste liquid; Waste water and amine salt waste liquid first enter the liquid storage tank 1, and are pumped into the anaerobic biological reaction column through the water pump 5, and the nitrate is converted into N under the action of denitrifying bacteria. 2 , sulfate is converted to S under the action of Desulfovibrio 2- , the organic carbon in the organic amine salt is used as part of the organic carbon source for sulfur reducin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com