Crystal salt separation purification system based on high-salt-containing high salt waste water

A technology of crystalline salt and high salt content, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of not fully utilizing the effect of steam liquid film formation, etc., and achieve easy Effects of demolition, long flow distance, and increased recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

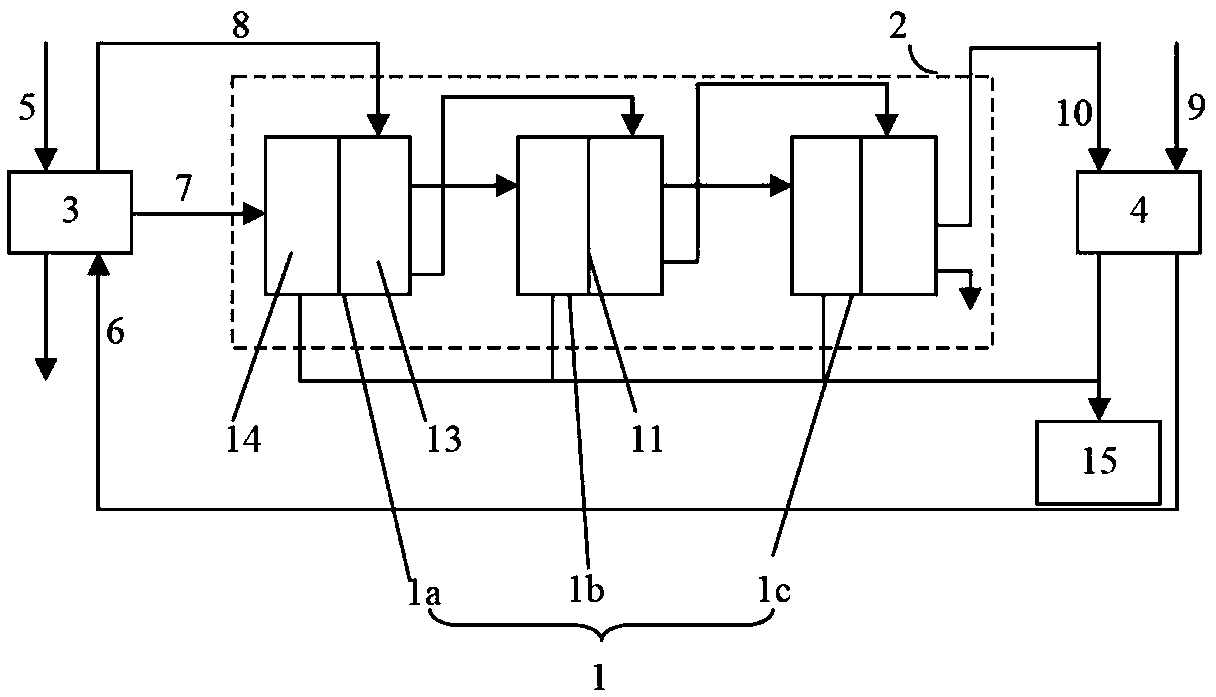

[0058] The invention provides an evaporation and concentration treatment unit for high-salt wastewater. The evaporative concentration treatment unit is used to perform evaporative concentration treatment on the saline wastewater that has been pretreated or pre-concentrated to obtain a higher concentration of salt solution, crystallized salt and / or distilled water. The evaporation and concentration treatment unit includes at least a multi-effect evaporation unit 2 formed by connecting several evaporators 1 in series, wherein the evaporation and concentration treatment unit also includes a first heat exchanger 3 and a second heat exchanger 4 for heat exchange.

[0059] figure 1 An evaporation concentration treatment unit with three evaporators is shown, and the number of evaporators can be selected and designed according to the treatment capacity of the evaporation concentration treatment unit or the type of waste water. For example, in order to achieve higher wastewater treatm...

Embodiment 2

[0067] Embodiment 2 is a further improvement on Embodiment 1, and repeated content will not be repeated here.

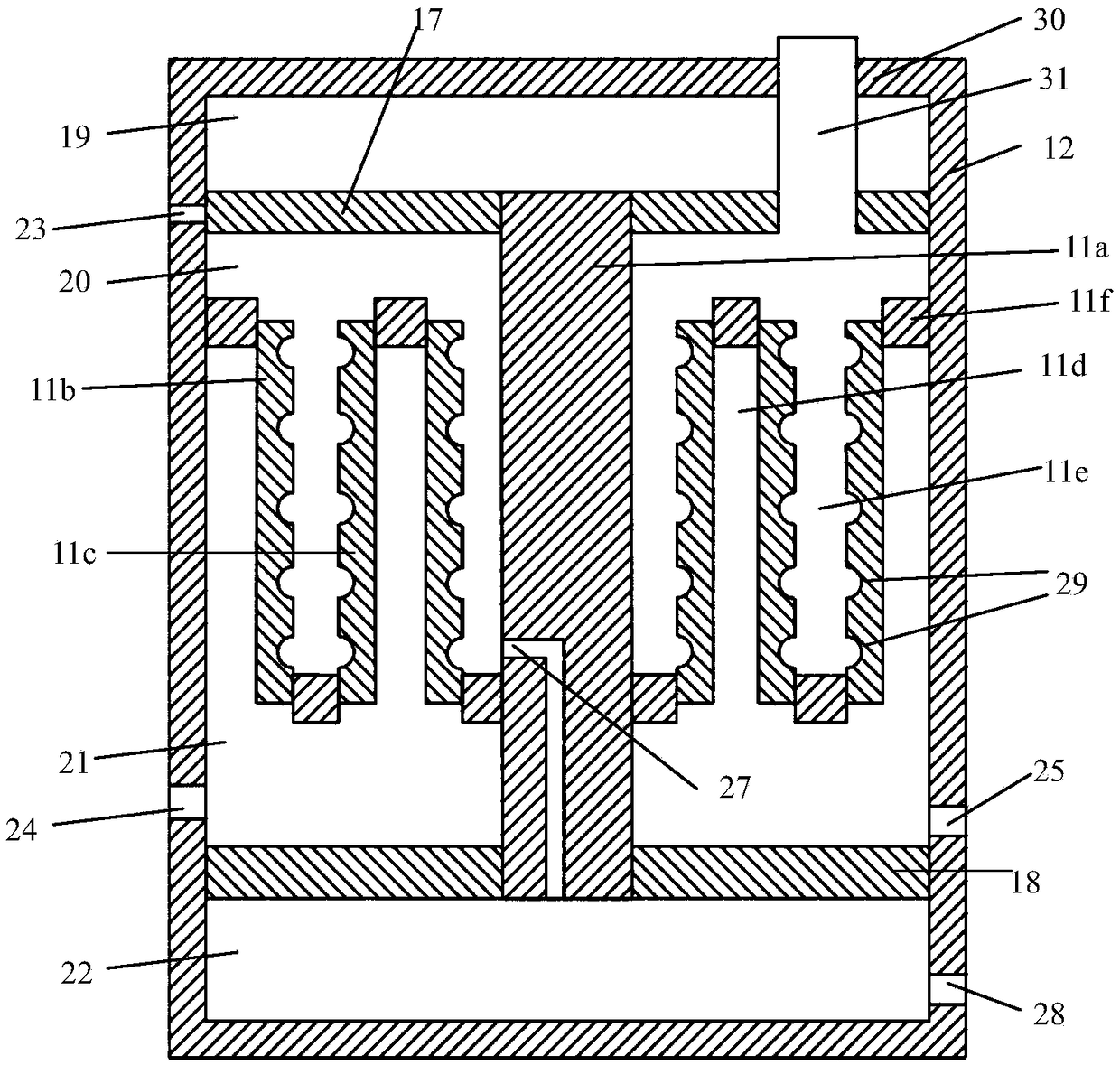

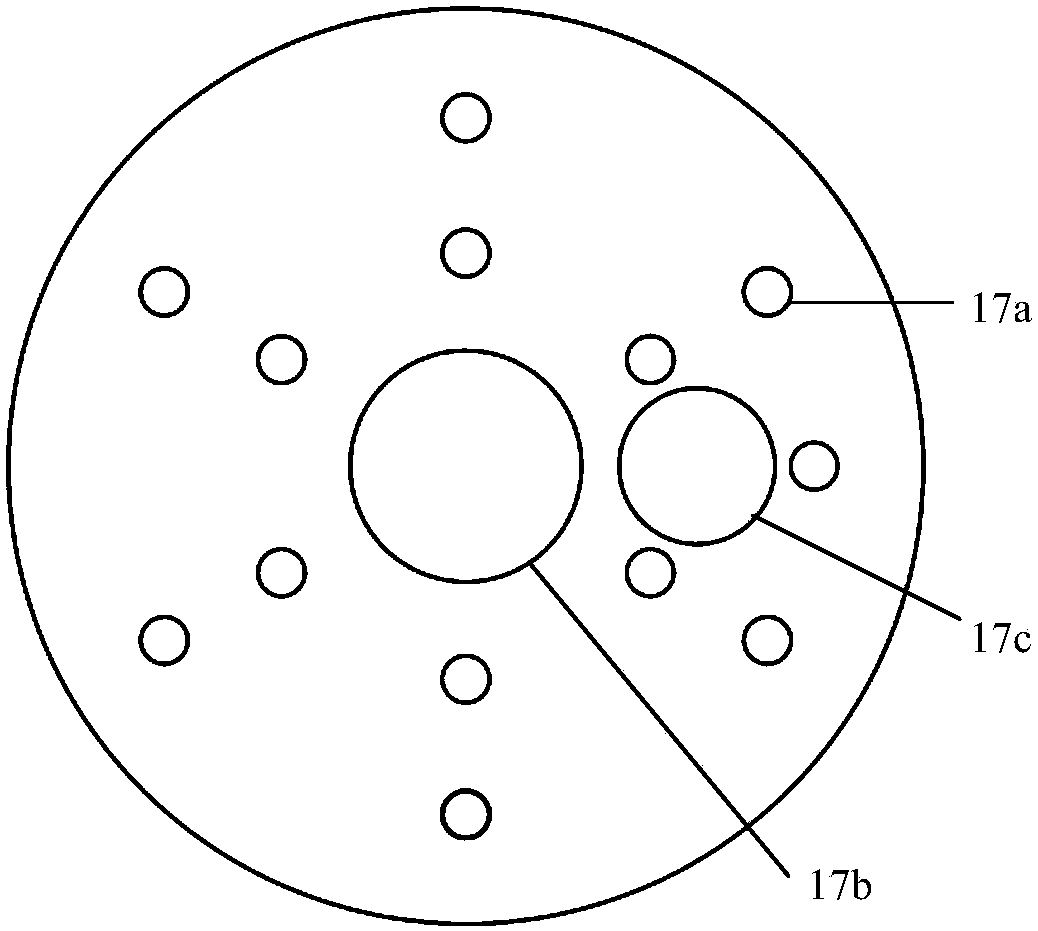

[0068] figure 2 A schematic diagram of the structure of the evaporator is shown. like figure 2 As shown, the shape of the housing 12 is defined by a hollow cylinder with one end open. In the axial direction parallel to the casing, the casing 12 is divided into four compartments by the distributor 17, the evaporation and condensation structure 11 and the installation web 18, wherein the distributor is installed on the inner wall of the casing near its open end Above, the installation web is installed near the other end of the housing 12 corresponding to its open end, and the evaporation and condensation structure 11 is installed on the area of the housing corresponding between the distributor and the installation web. In the direction along the open end of the shell towards its closed end, a first compartment 19, a second compartment 20, a third compartment 21 ...

Embodiment 3

[0080] This embodiment is a further improvement on Embodiment 1 and Embodiment 2, and repeated content will not be repeated here.

[0081] Preferably, the evaporator of the present invention can be used alone or in series. For example, when three evaporators are connected in series to form a multi-effect evaporation unit, the structures of the first effect evaporator, the second effect evaporator and the third effect evaporator are exactly the same, and the only difference is that the first effect evaporator The air pressure in the third compartment of the evaporator, the second effect evaporator and the third effect evaporator is different from each other, wherein the air pressure in the third compartment of the first effect evaporator, the second effect evaporator and the third effect evaporator Set in steps of gradual reduction.

[0082] Preferably, the exhaust pipe of the first effect evaporator communicates with the second opening of the second effect evaporator, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com