Patents

Literature

213results about How to "Control flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

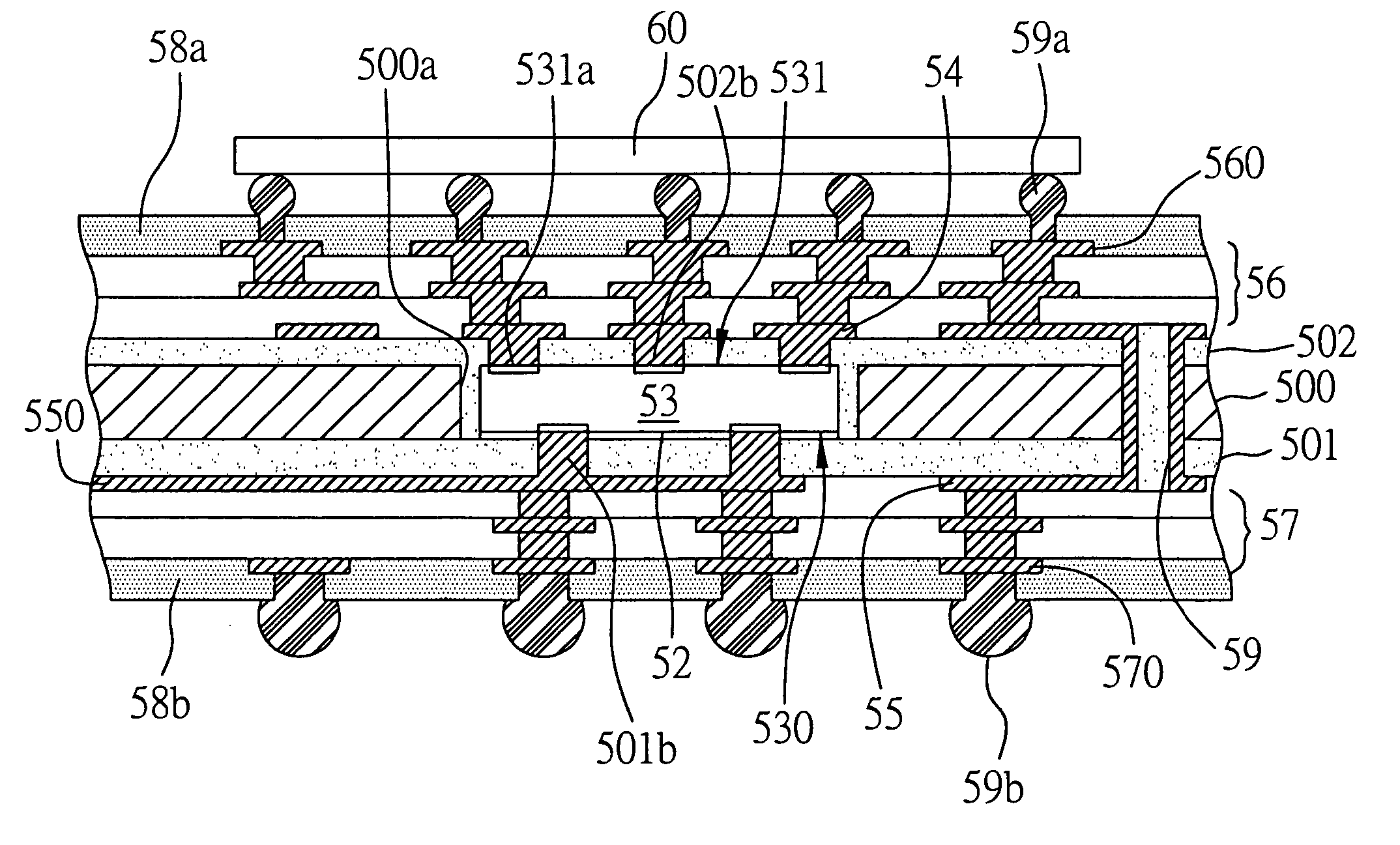

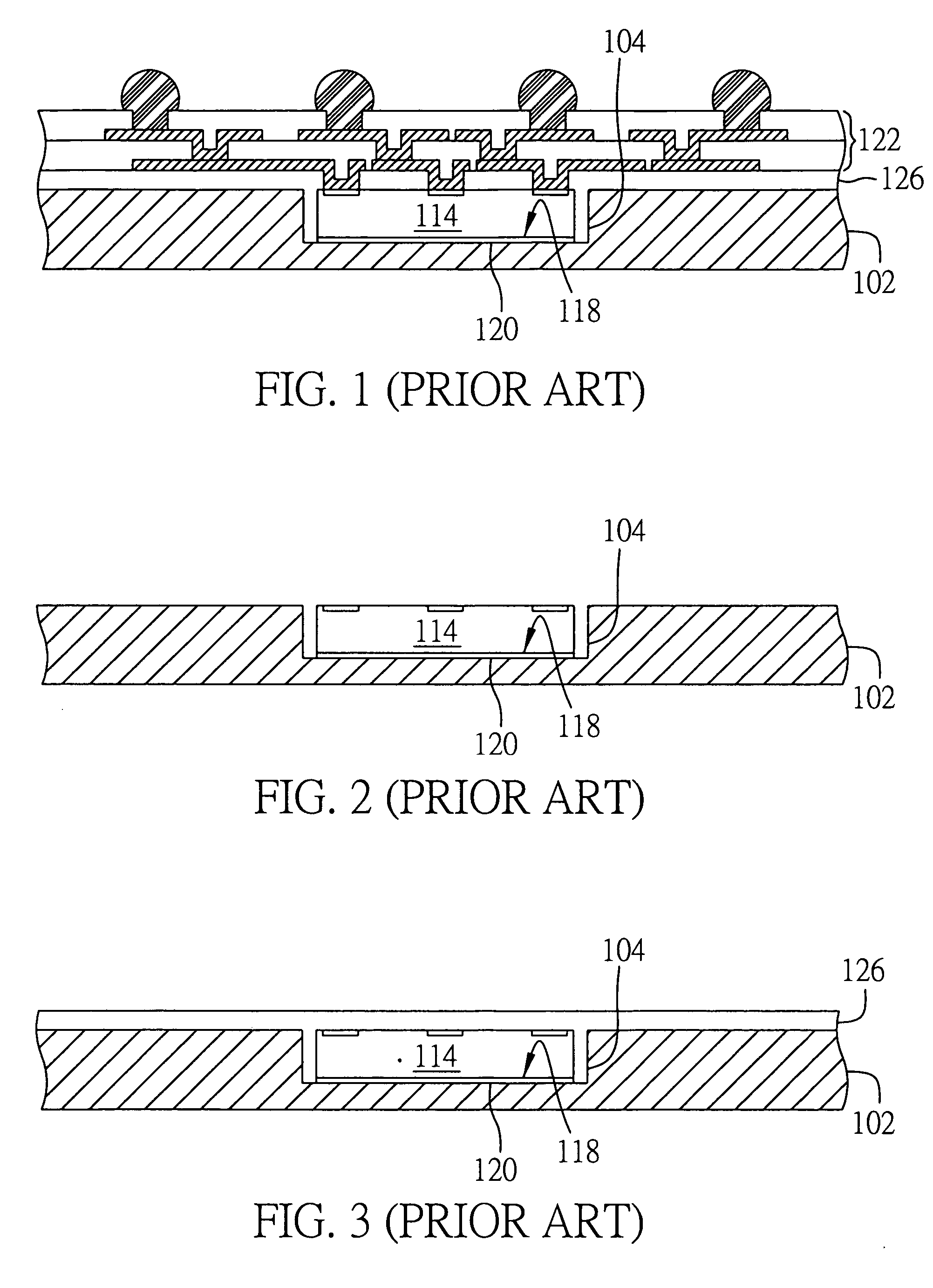

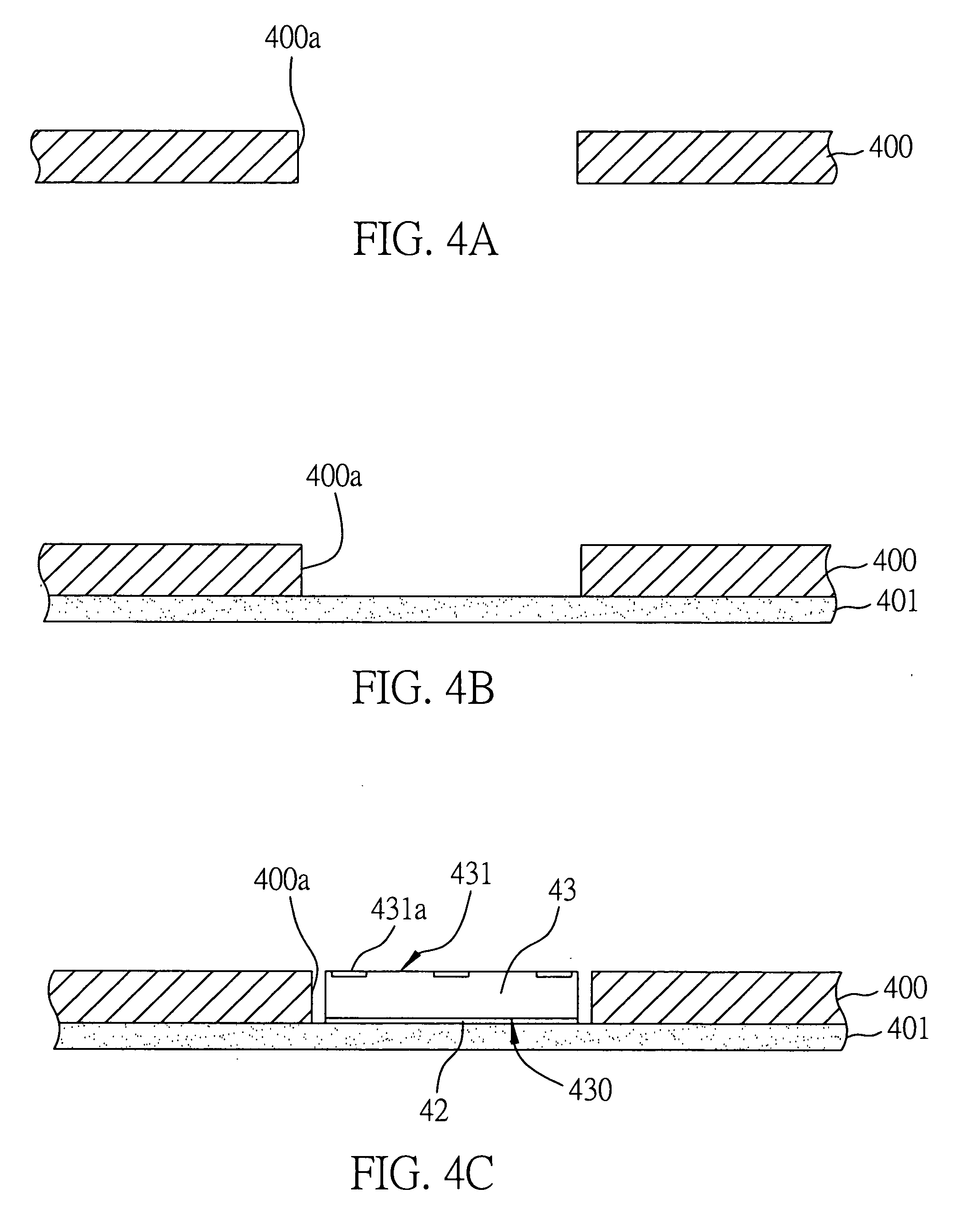

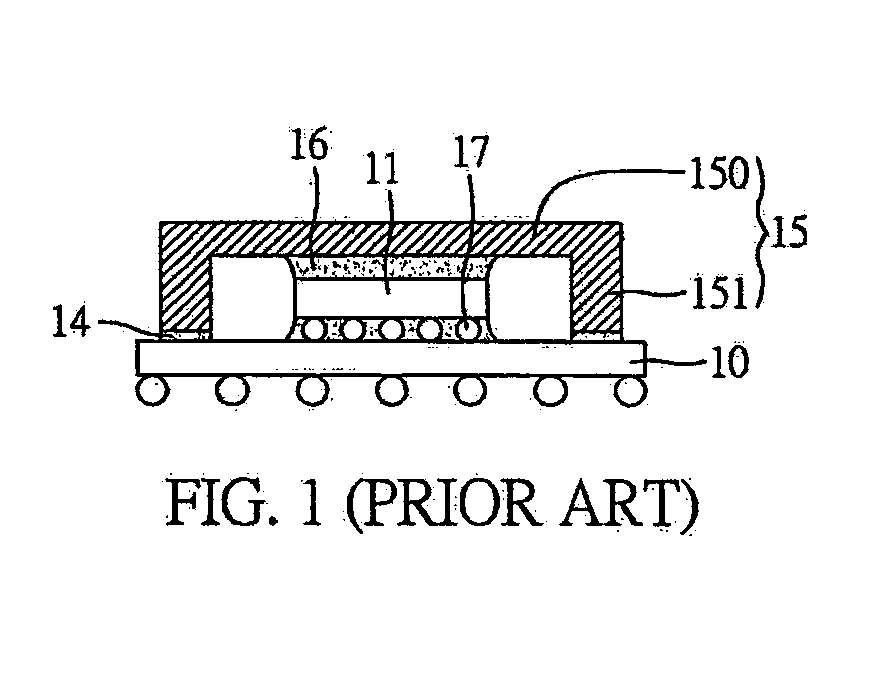

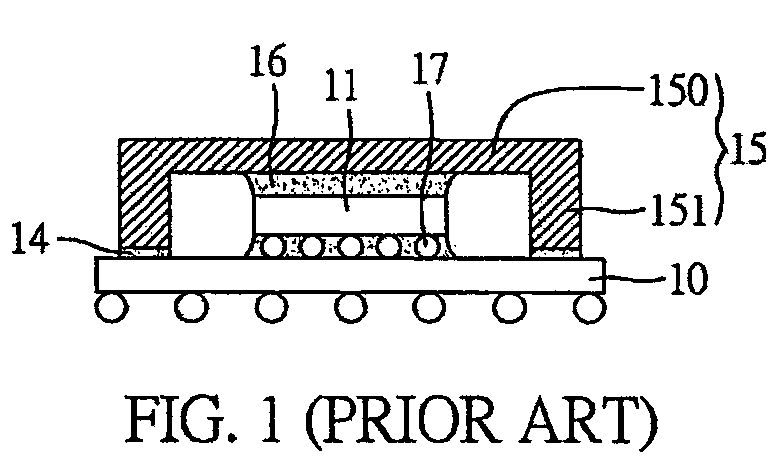

Three dimensional package structure with semiconductor chip embedded in substrate and method for fabricating the same

InactiveUS20060145328A1Avoid disadvantagesImprove cooling effectSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipEngineering

A three dimensional package structure with semiconductor chip embedded in substrate and a method for fabricating the same are proposed. A carrier with at least one cavity is mounted on a first insulating layer, and at least one semiconductor chip is mounted on the first insulating layer and received in the cavity of the carrier. A second insulating layer is formed on the carrier and the semiconductor chip. By performing a pressing process on both of the first insulating layer and the second insulating layer, a gap between the carrier and the semiconductor chip is filled. A circuit layer may be formed on the second insulating layer and is electrically connected to the semiconductor chip. Heat dissipating vias are formed in the first insulating layer and are connected to the semiconductor chip and a heat dissipating circuit so as to facilitate dissipation of heat generated from the semiconductor chip.

Owner:PHOENIX PRECISION TECH CORP

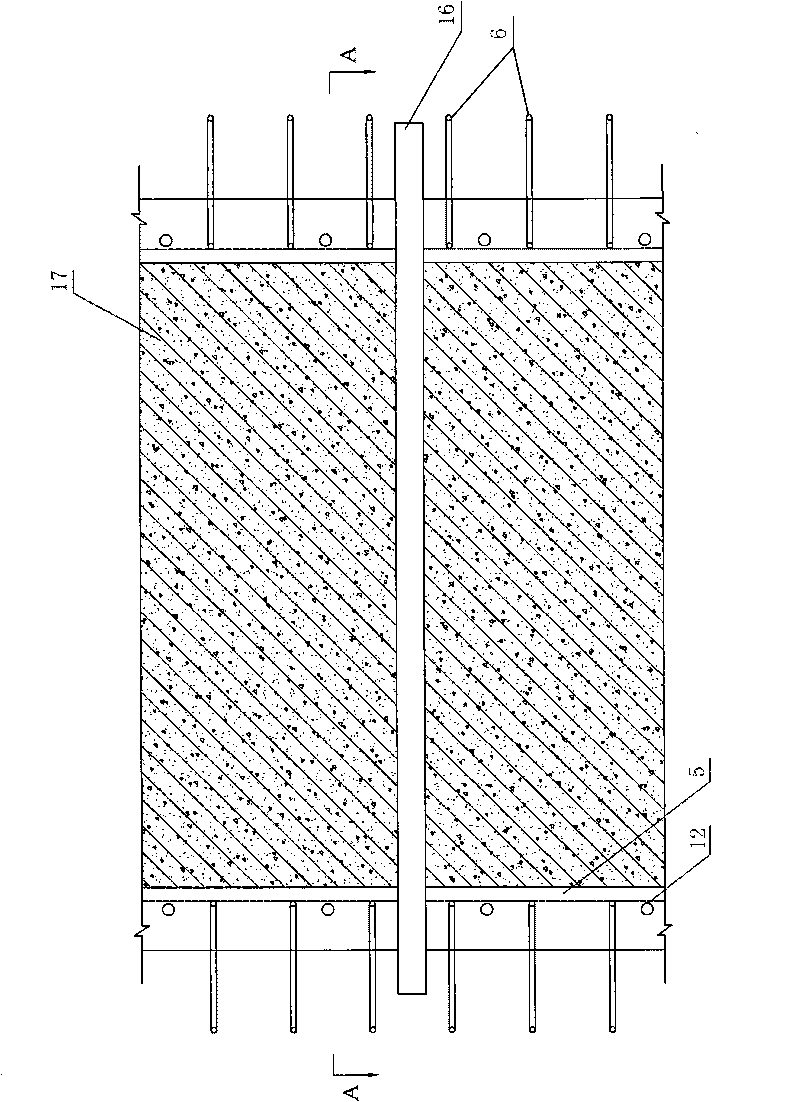

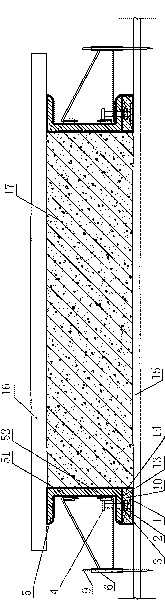

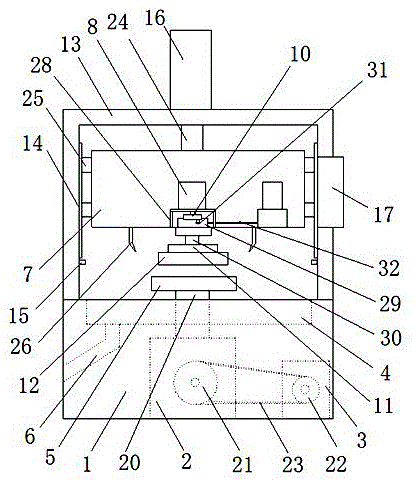

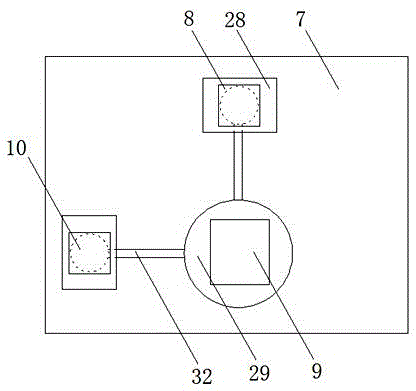

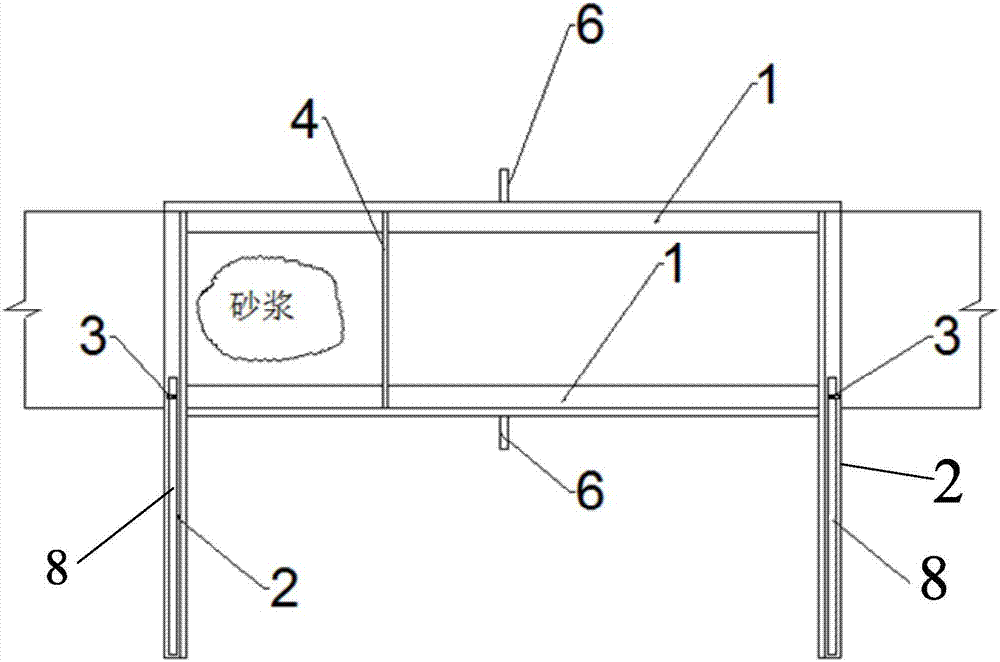

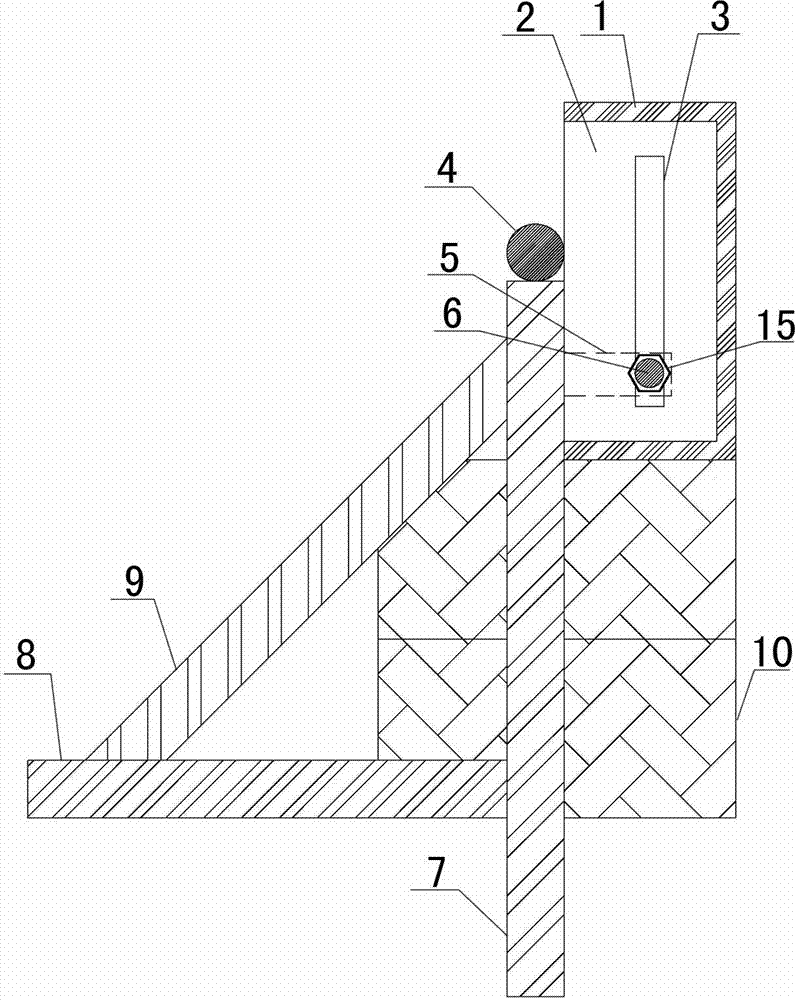

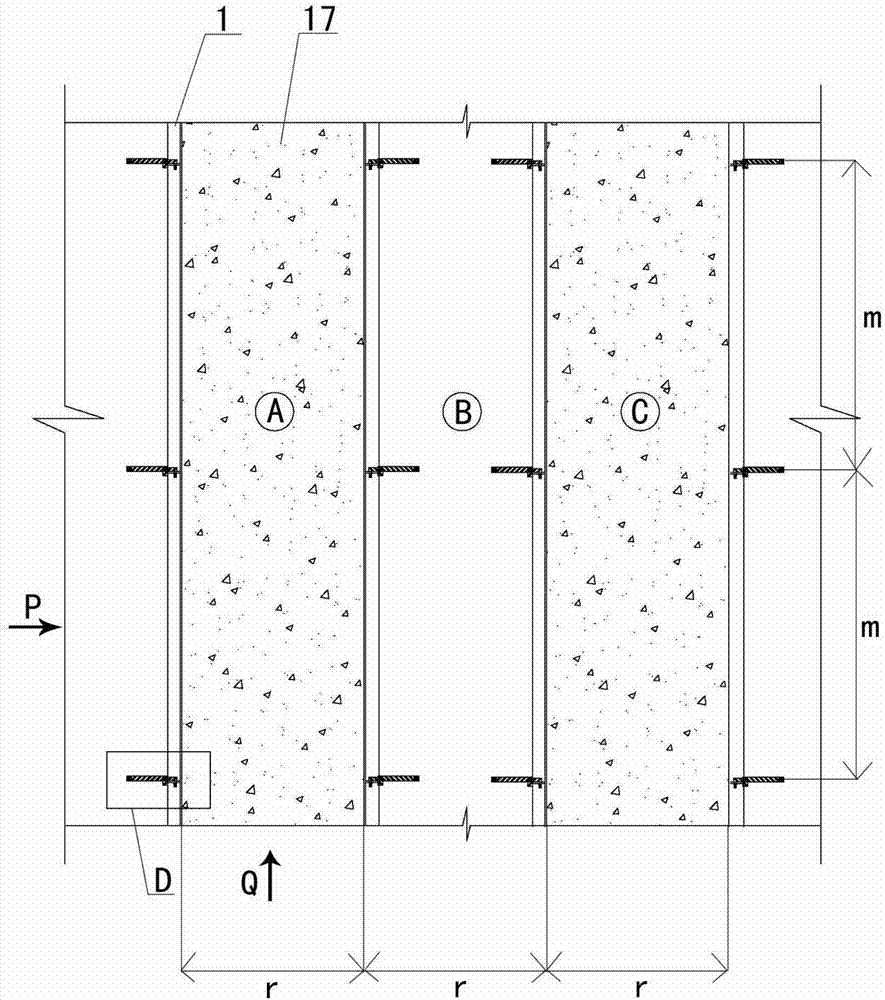

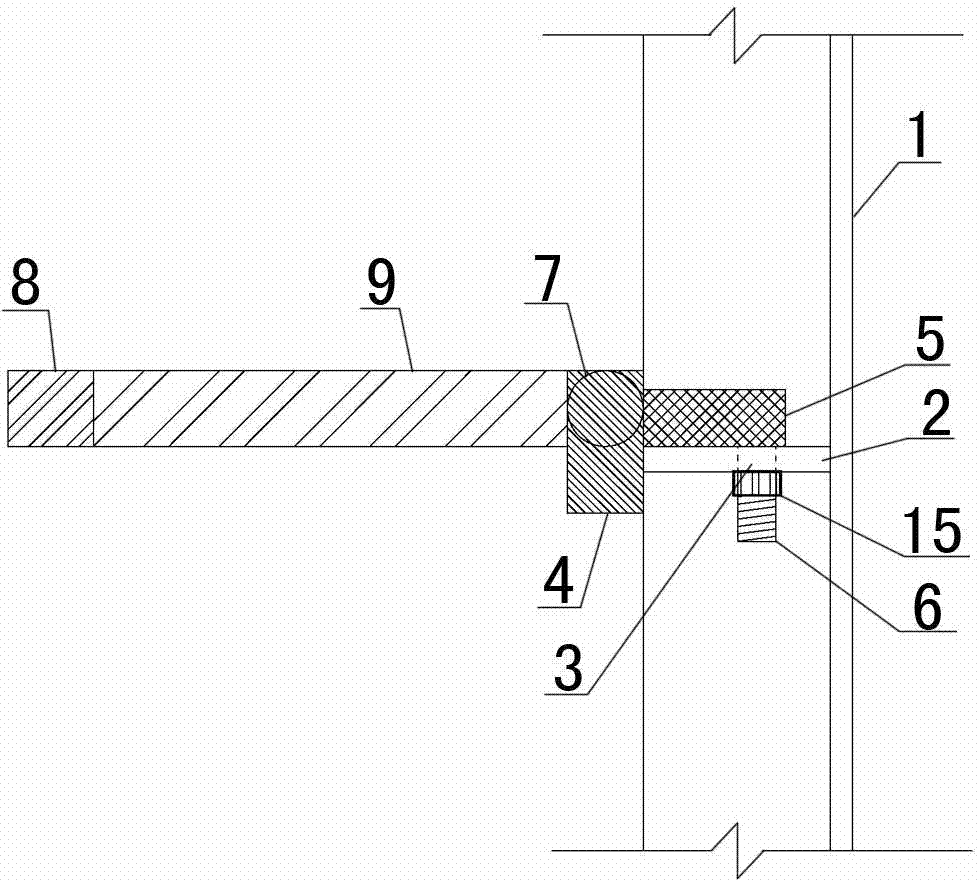

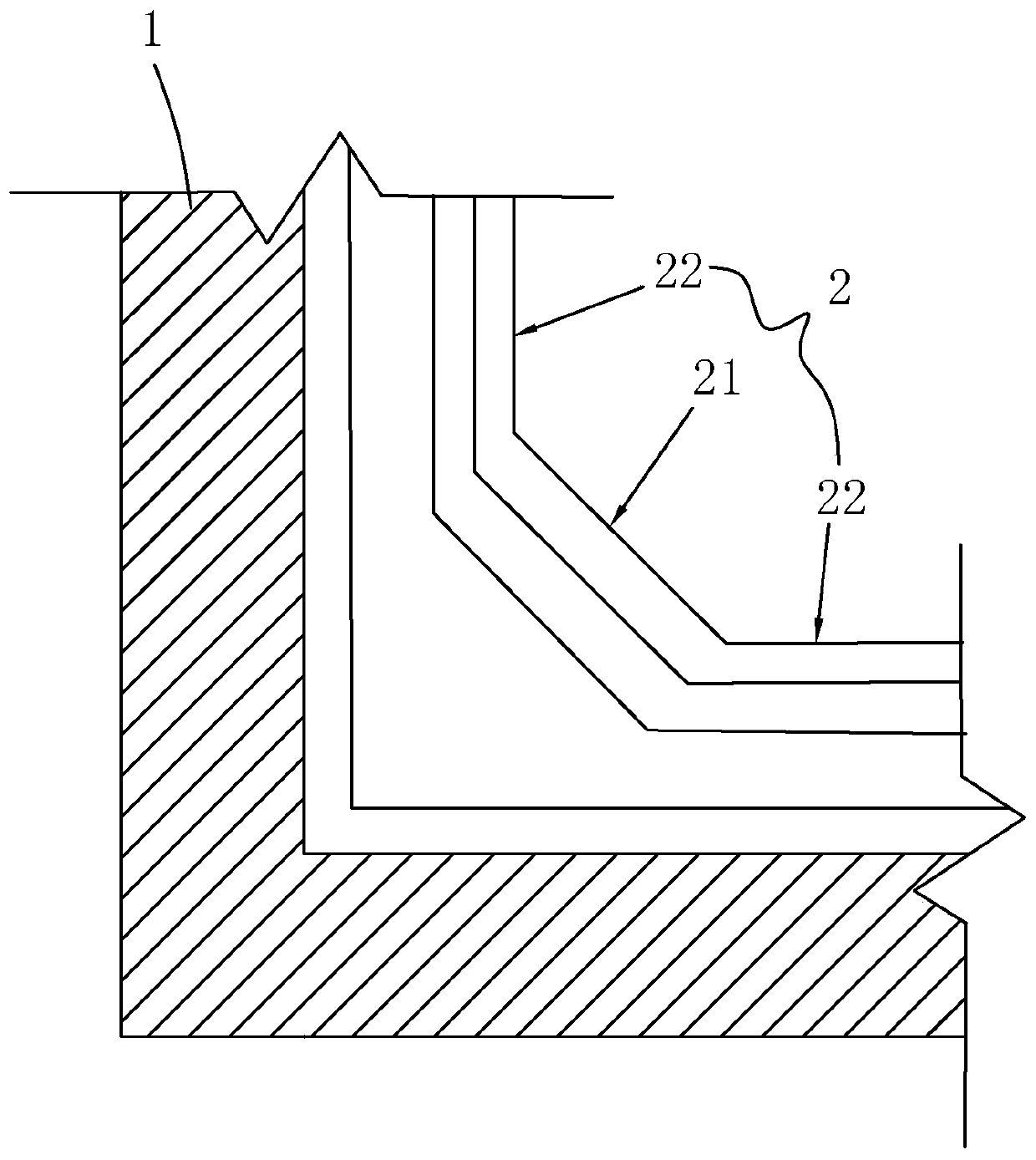

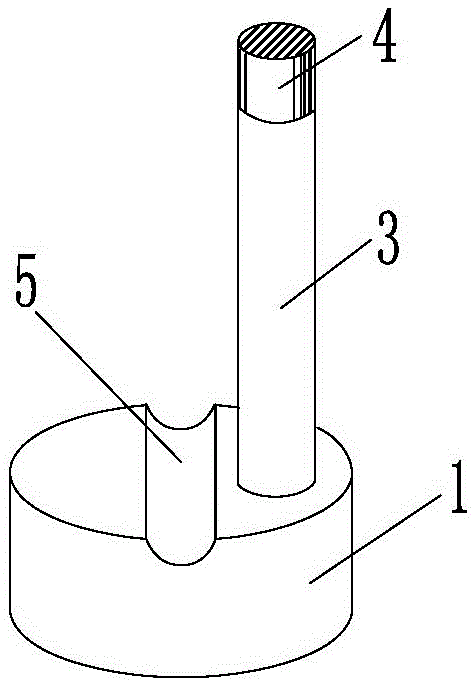

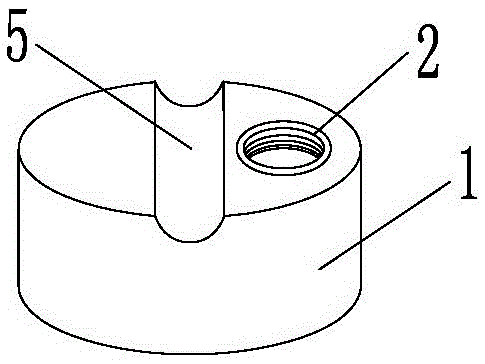

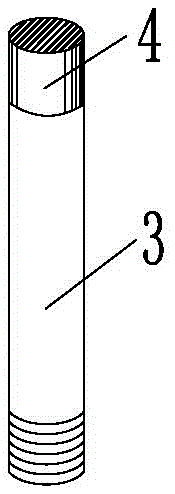

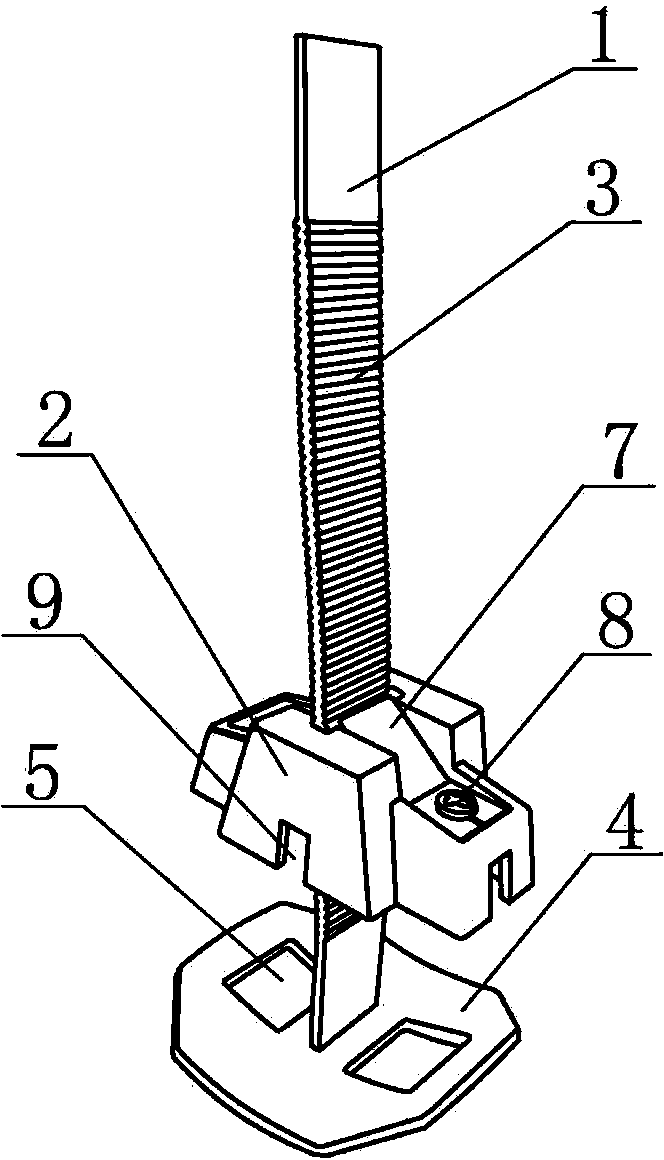

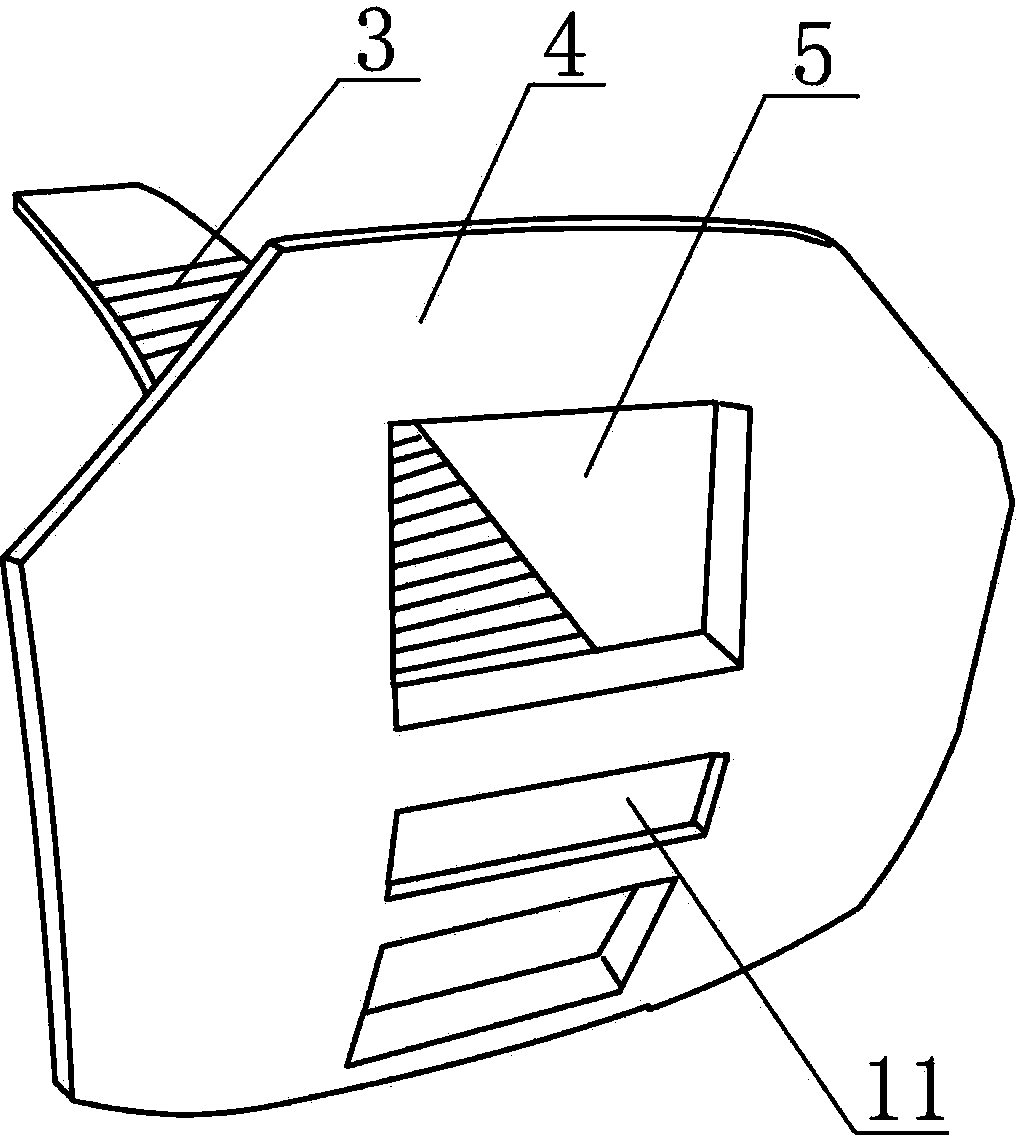

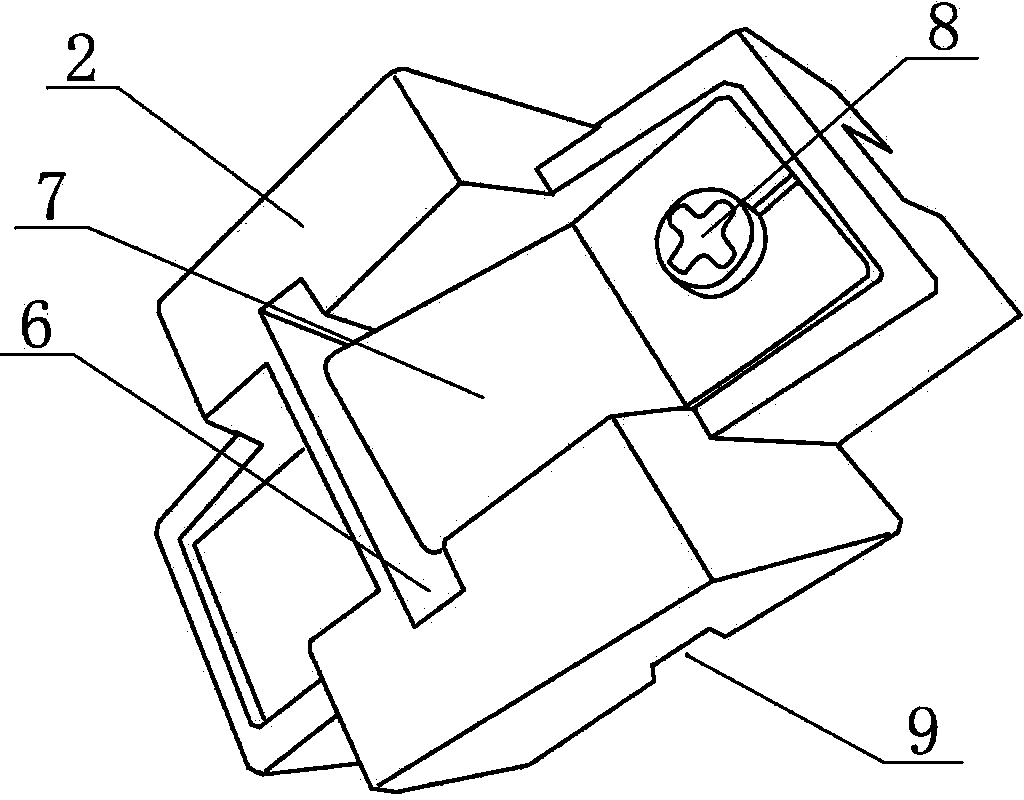

Control device of flatness and elevation of cast-in-place concrete ground surface and method for construction

InactiveCN101748896AEffective control of flatnessMeet construction requirementsRoads maintainenceBuilding material handlingEngineeringCushion

The invention relates to a control device of the flatness and the elevation of a cast-in-place concrete ground surface, which comprises a master groove steel mould, a mater groove steel bracket for fixing the master groove steel mould, and a bracket fixing piece, wherein the master groove steel mould is provided with n groups of module elevation adjusting mechanisms; each group of the module elevation adjusting mechanism comprises a support cushion plate and a set of adjusting bolt which consists of a support screw rod, a fastening cushion ring and an adjusting screw cap; and the support cushion plate is put into a gap between the master groove steel mould and the foundation. The method for controlling the flatness and the elevation of the cast-in-place concrete ground surface with the control device comprises the following steps: installing n groups of the module elevation adjusting mechanisms on the master groove steel mould; measuring the elevation of the top of a supporting and baffling concrete mould, and adjusting the elevation of the supporting and baffling concrete mould with the module elevation adjusting mechanisms; and locking the master groove steel mould to guarantee the flatness and the elevation of the cast-in-place concrete ground surface. The control device has simple structure, convenient construction method, and can effectively control the precision of the flatness and the elevation of the cast-in-place concrete ground surface, wherein n equals to 2-150.

Owner:广西建工第五建筑工程集团有限公司

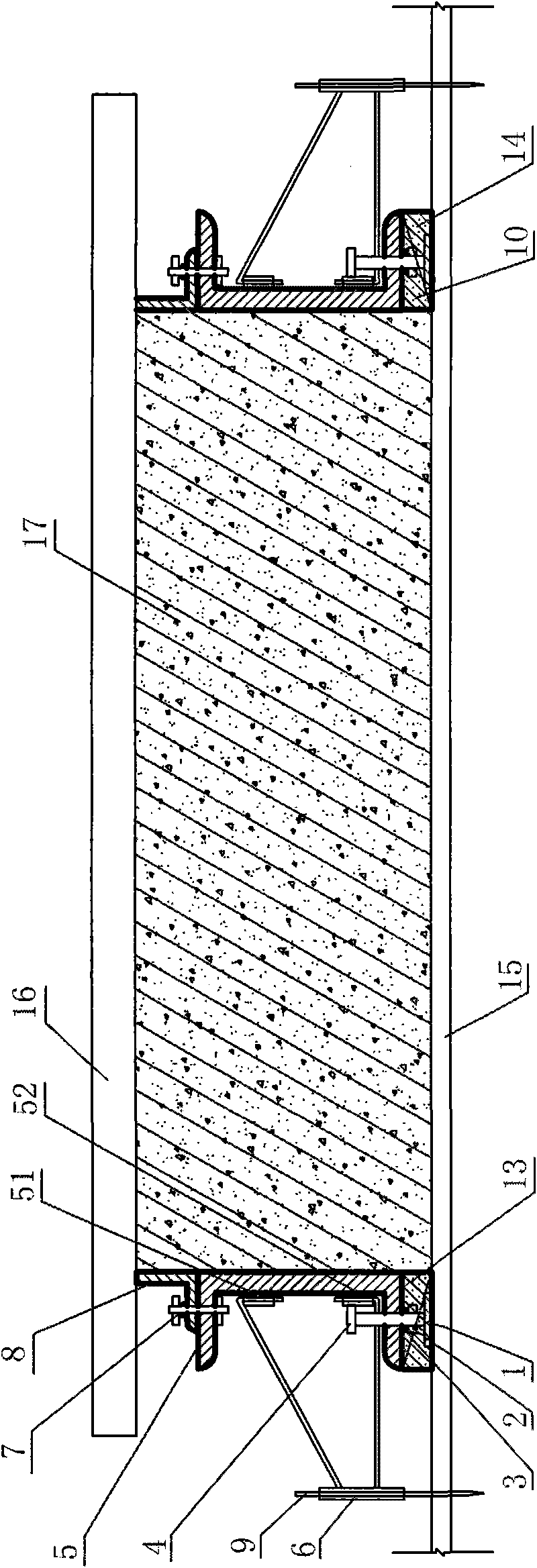

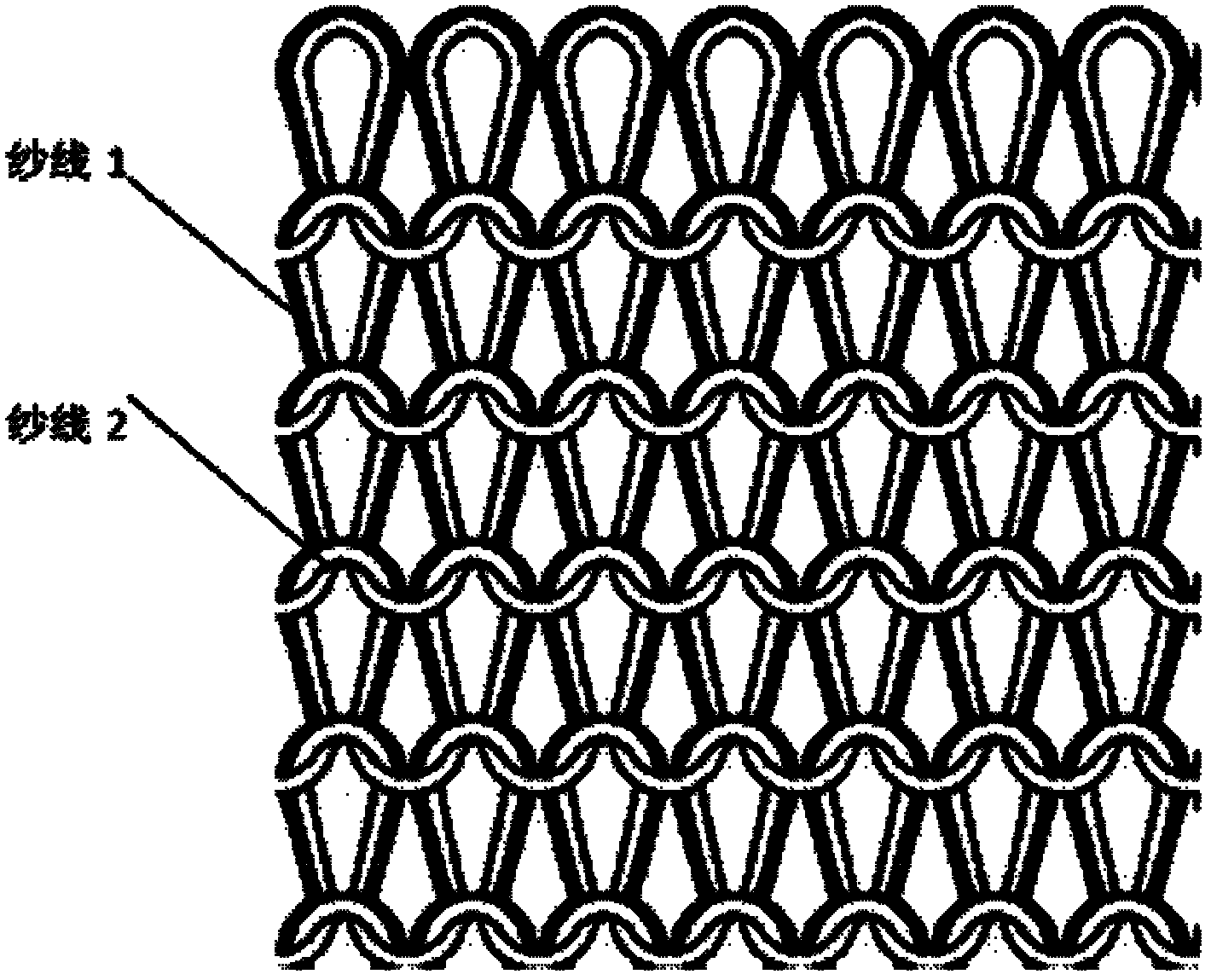

Imitated silk high-elasticity knitted underwear fabric and preparation method thereof

ActiveCN102631030AControl flatnessGuaranteed weightWeft knittingBleaching apparatusYarnBursting strength

The invention relates to imitated silk high-elasticity knitted underwear fabric and a preparation method thereof. The fabric is formed by interweaving fine-denier copper ammonia / nylon bi-component filament and spandex yarn, wherein the fine-denier copper ammonia / nylon bi-component filament is located on the front of the fabric and completely covers the spandex yarn. The preparation method comprises the following steps of: sequential weaving, fabric pre-sizing, pretreatment, copper ammonia dyeing, aftertreatment, nylon dyeing, soaping, soft finish, dehydration and re-sizing. The imitated silk high-elasticity knitted underwear fabric provided by the invention has smooth handfeel, brightness, full appearance, soft handfeel, antibacterial property, comfort and the like; the problems of low bursting strength and insufficient elasticity of the single copper ammonium imitated silk fabric are solved; and the problems of non-uniform blend dyeing of copper ammonium and chemical fiber, color yellowing and rough cloth cover are solved.

Owner:NINGBO DAQIAN TEXTILE

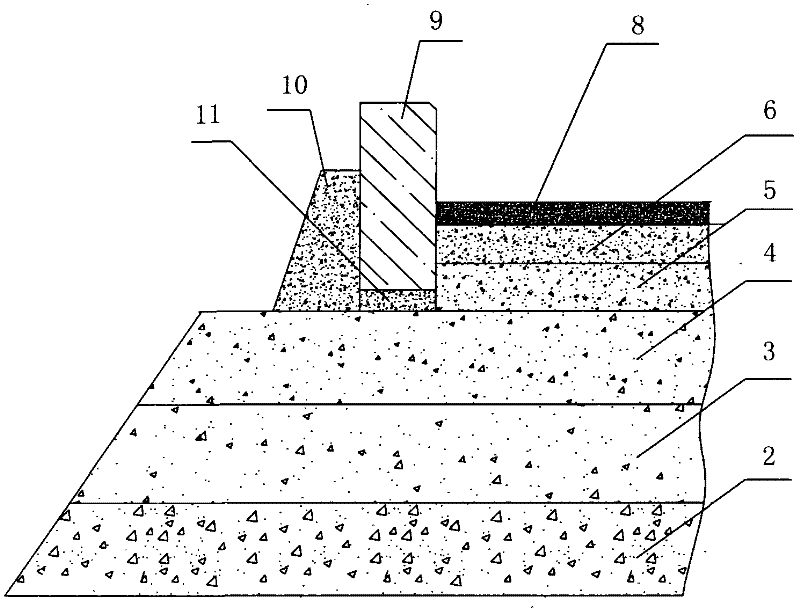

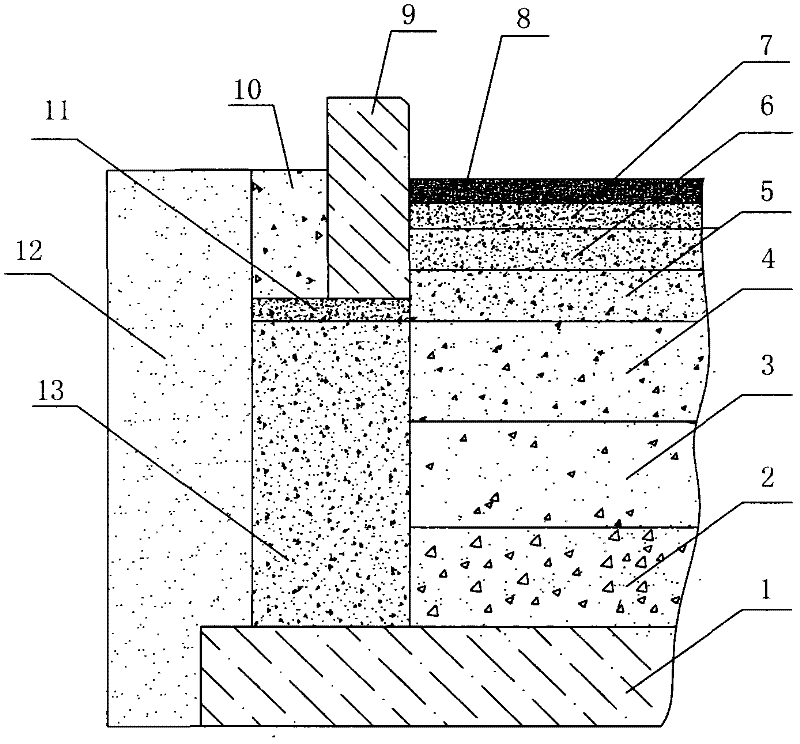

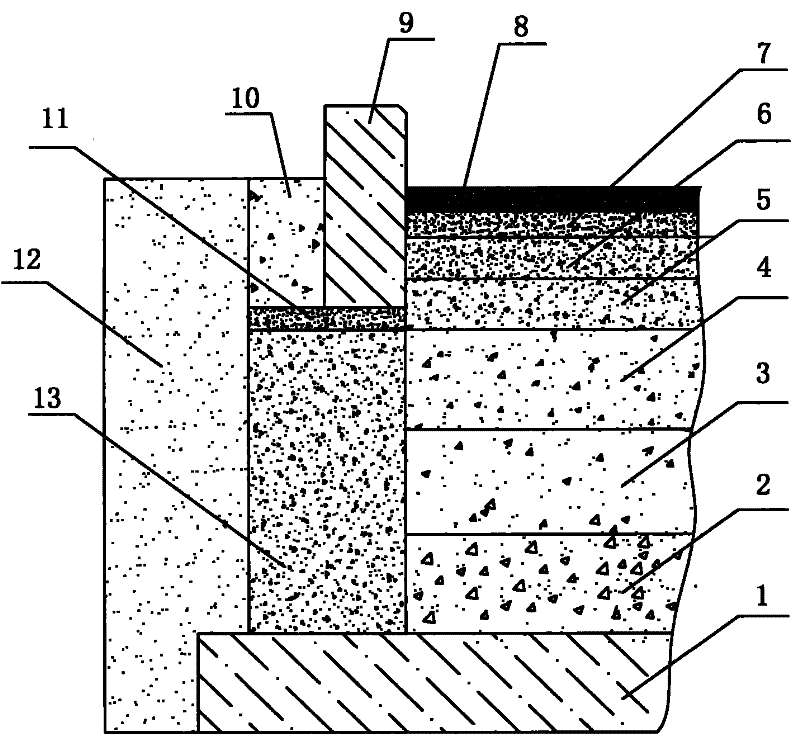

Construction method for road base concrete side mold

The invention provides a construction method for road base concrete side molds. Construction steps are as follows: 1) laying of a sub-layer; 2) measuring and arranging of sidelines of vertical curbstones; 3) installation of templates; 4) pouring of concrete side molds; 5) laying of a lower base of lime-fly ash stabilized aggregate, an upper base of lime-fly ash stabilized aggregate and a cement stabilized crushed rock layer; 6) laying of vertical curbstone concrete foundation; 7) installation of vertical curbstones on the vertical curbstone concrete foundation; 8) pouring of vertical curbstone reinforced concrete at external sides of vertical curbstones; 9) laying of an asphalt sealing layer, a coarse-grained asphalt layer, a medium-grained asphalt layer and a fine-grained asphalt pavement layer at internal sides of vertical curbstones. When the road base concrete side molds are poured, the sidelines are arranged accurately, a straight degree and top elevation of the road base concrete side molds are strictly controlled, and paving width and thickness of the road bases are effectively controlled. The concrete side molds are used as an elevation control reference surface for pavingof the road bases and installation of vertical curbstones, which enables flatness of the road bases, straightness of the vertical curbstones and a qualified rate of top elevation to be greatly improved.

Owner:JINAN URBAN CONSTR GRP

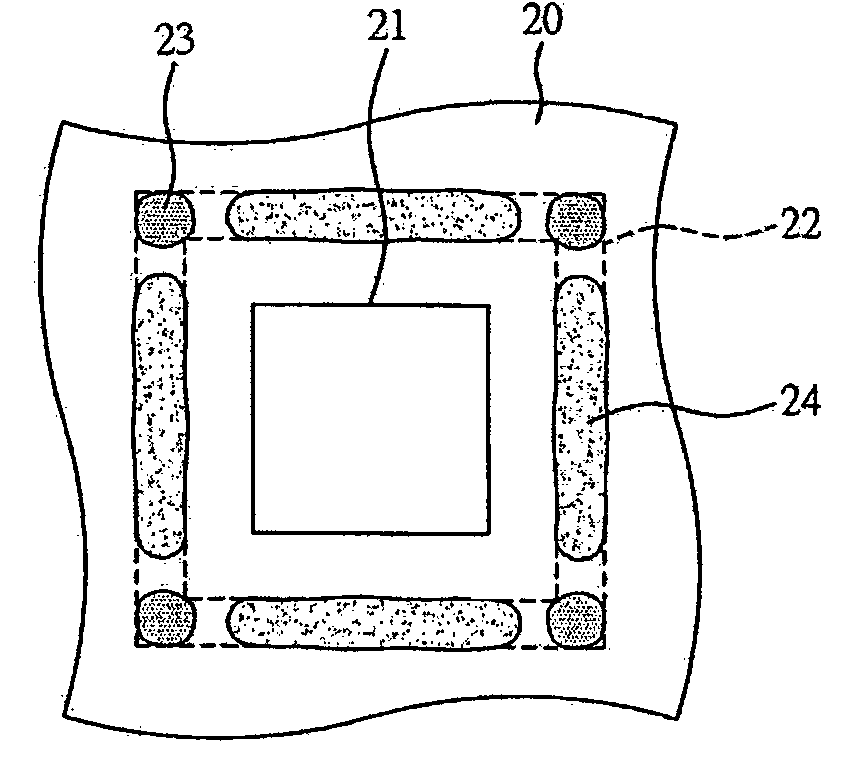

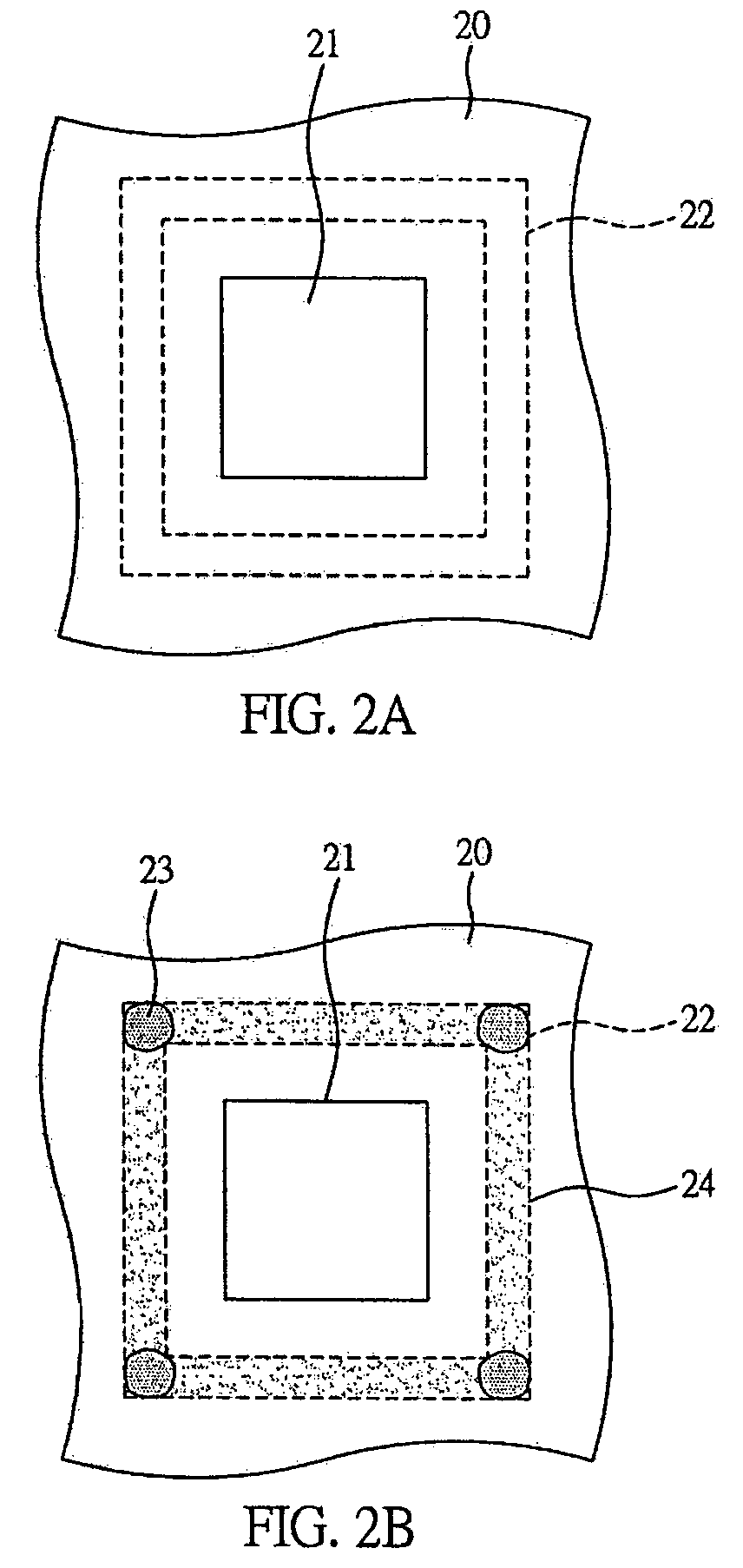

Semiconductor device package with a heat sink and method for fabricating the same

InactiveUS20070235861A1Reduce warpagePrevent disengagementSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor package

A semiconductor package with a heat sink and a method for fabricating the same are proposed. A first adhesive of a low Young's modulus is disposed on a corner region of a heat sink mounting area of a substrate. A second adhesive of a high Young's modulus is disposed on the heat sink mounting area except the corner region. The heat sink is mounted on the heat sink mounting area and thereby secured in position to the substrate, by the first and second adhesives. The disposition of the first and second adhesives of different Young's moduli not only prevents detachment of the heat sink from the substrate, but also controls the flatness of the heat sink. The prevent invention does not affect the appearance of the semiconductor package and its ensuing assembly process.

Owner:SILICONWARE PRECISION IND CO LTD

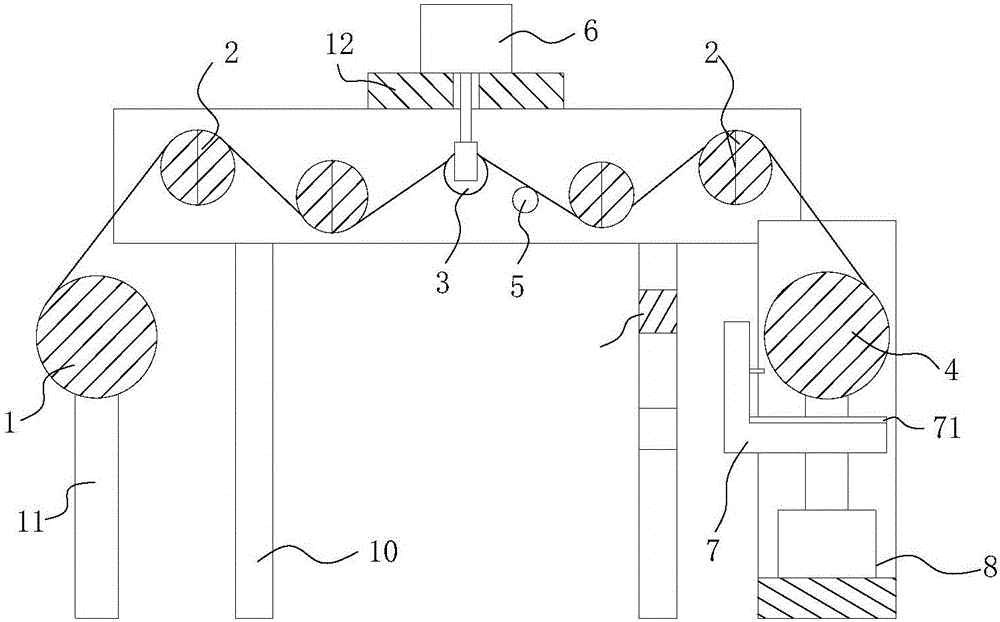

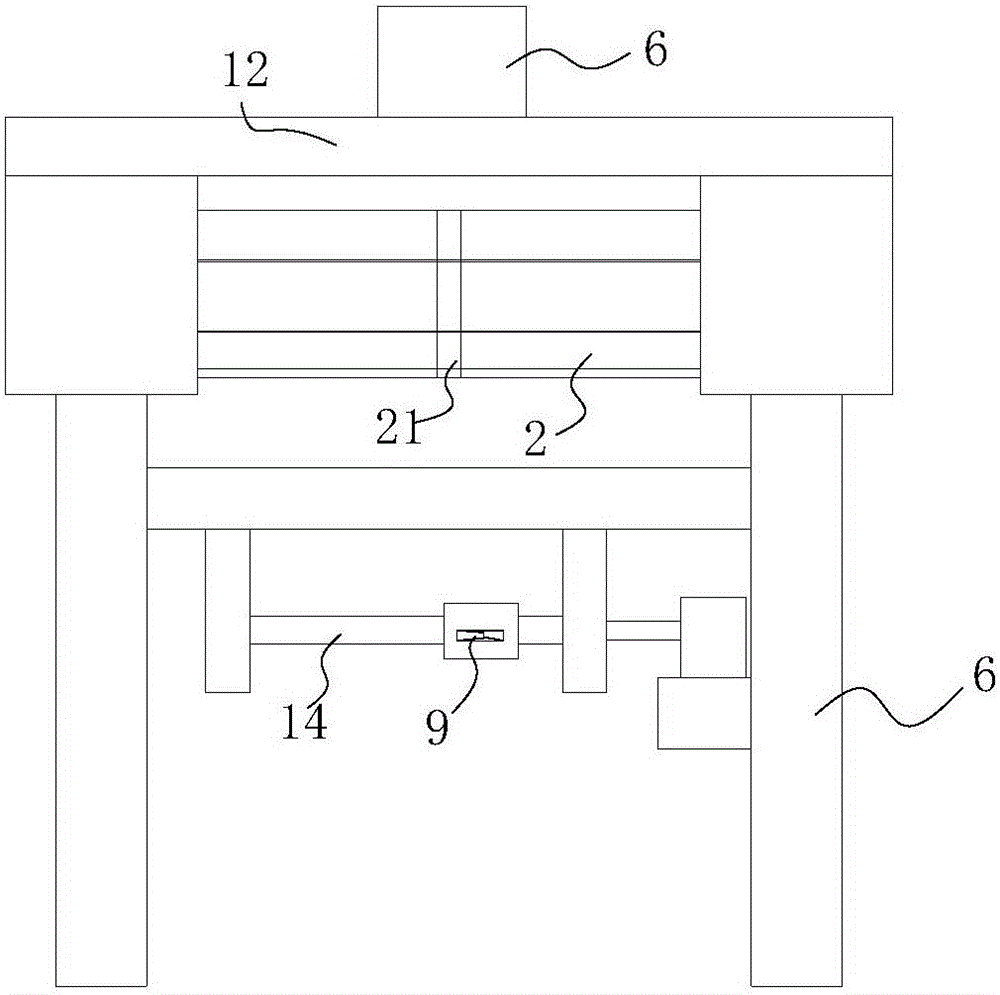

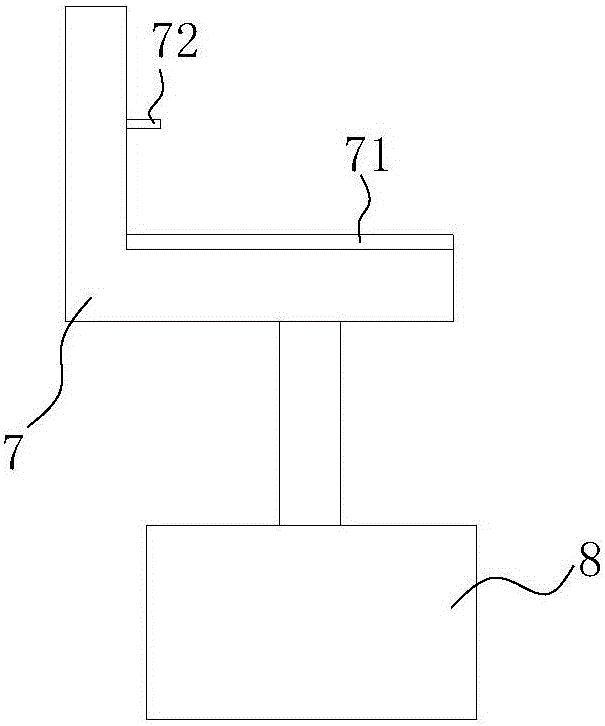

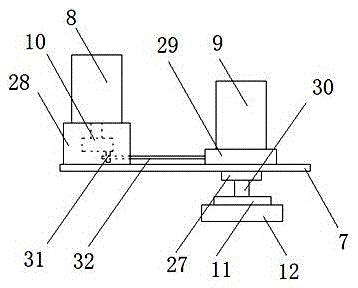

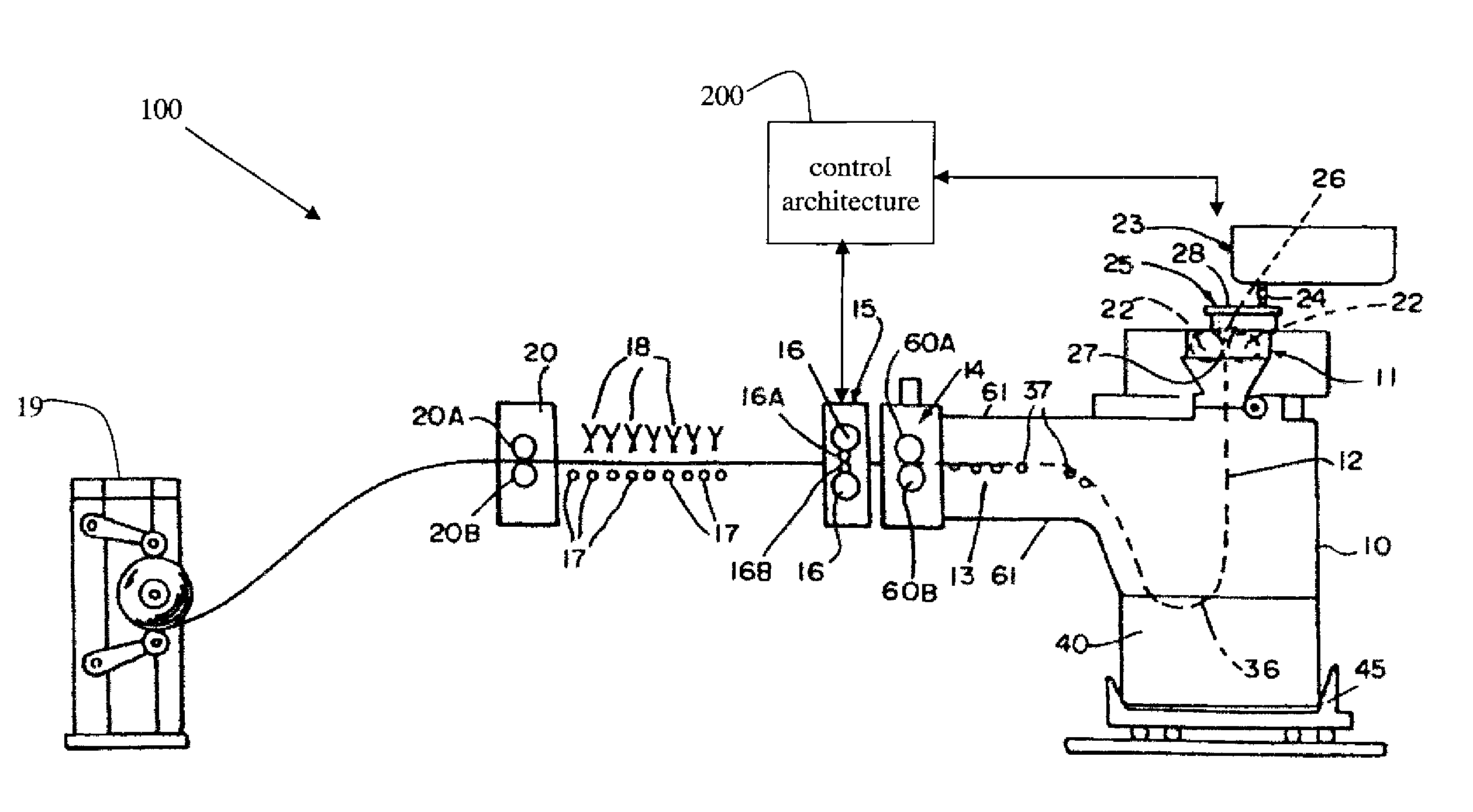

Electromagnetic wire winding device

InactiveCN105742053AGet tension in real timeControl flatnessFilament handlingInductances/transformers/magnets manufactureConductor CoilMechanical engineering

The invention relates to the technical field of electric reactors, in particular to an electromagnetic wire winding device for electric reactor winding. The electromagnetic wire winding device comprises an electromagnetic wire coil rack, a rack, a winding clamp, a tension adjusting roller and a controller, wherein the electromagnetic wire coil rack is used for supporting an electromagnetic wire coil; the rack is provided with a driving roller and a tension detector; the winding clamp is used for clamping a winding reel; a gap adjusting mechanism is also arranged at the lower part of the winding clamp; the tension adjustment roller is arranged at the upper part of the rack; a first adjusting air cylinder for adjusting the height of the tension adjusting roller is arranged at the upper part of the rack; and the controller is used for receiving a tension detector signal and controlling the first adjusting air cylinder and the gap adjusting mechanism to act. The tension detector is arranged in the electromagnetic wire winding device and can obtain the winding tension in real time; the controller controls the first adjusting air cylinder to stretch; the first adjusting air cylinder drives the tension adjusting roller to move up and down and to adjust the winding tension; and the gap adjusting mechanism can control the winding distance and the winding flatness, so that the production efficiency is improved.

Owner:JIANGSU LTEC ELECTRIC CO LTD

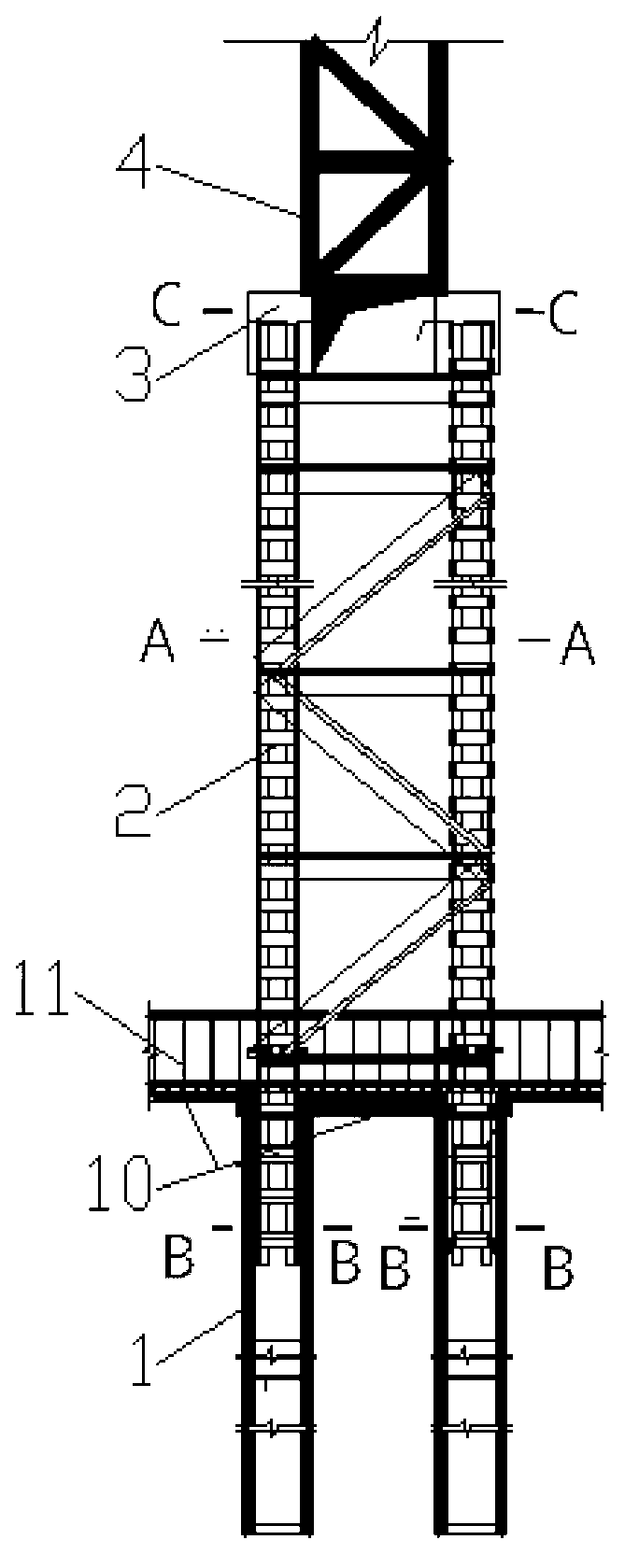

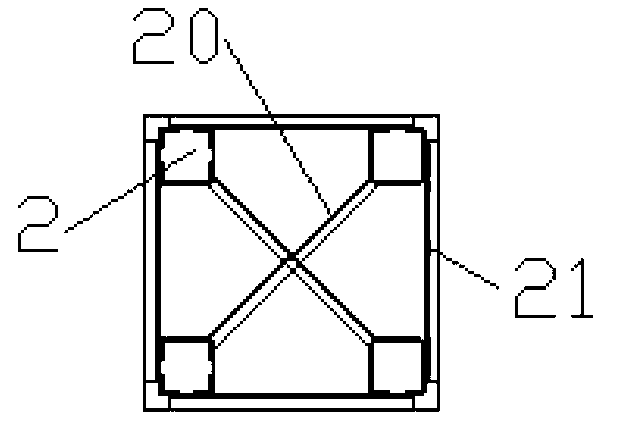

Steel latticed column homocentric-square-shaped concrete bearing platform combination type tower crane base structure and construction method

InactiveCN103132537AMeet the installation requirementsSolve the problem of early insertion of construction vertical transportationArtificial islandsUnderwater structuresBasementTower crane

The invention discloses a steel latticed column homocentric-square-shaped concrete bearing platform combination type tower crane base structure. The base structure comprises four steel latticed columns vertically distributed in a rectangle. A horizontal diagonal bracing and a vertical diagonal bracing are arranged between the steel latticed columns, the bottoms of the steel latticed columns are inserted in a drilling pouring pile arranged under a base plate of a basement, a concrete structure bearing platform is poured under the base plate of the basement, a homocentric-square-shaped concrete bearing platform is poured at the top of the steel latticed columns, and the bottom of the tower crane is installed on the homocentric-square-shaped concrete bearing platform. Effect of self gravity of the concrete bearing platform on the steel latticed columns is considered, the concrete bearing platform is made to be homocentric-square-shaped to form a steel latticed column homocentric-square-shaped concrete bearing platform combination type tower crane base, tower crane construction safety can be ensured by adopting the base, and the problem of in-advance insertion in deep base pit construction vertical transportation is well resolved. Further, concrete smoothness can be well controlled to meet requirement of the tower crane for installation.

Owner:ZHONGTIAN CONSTR GROUP

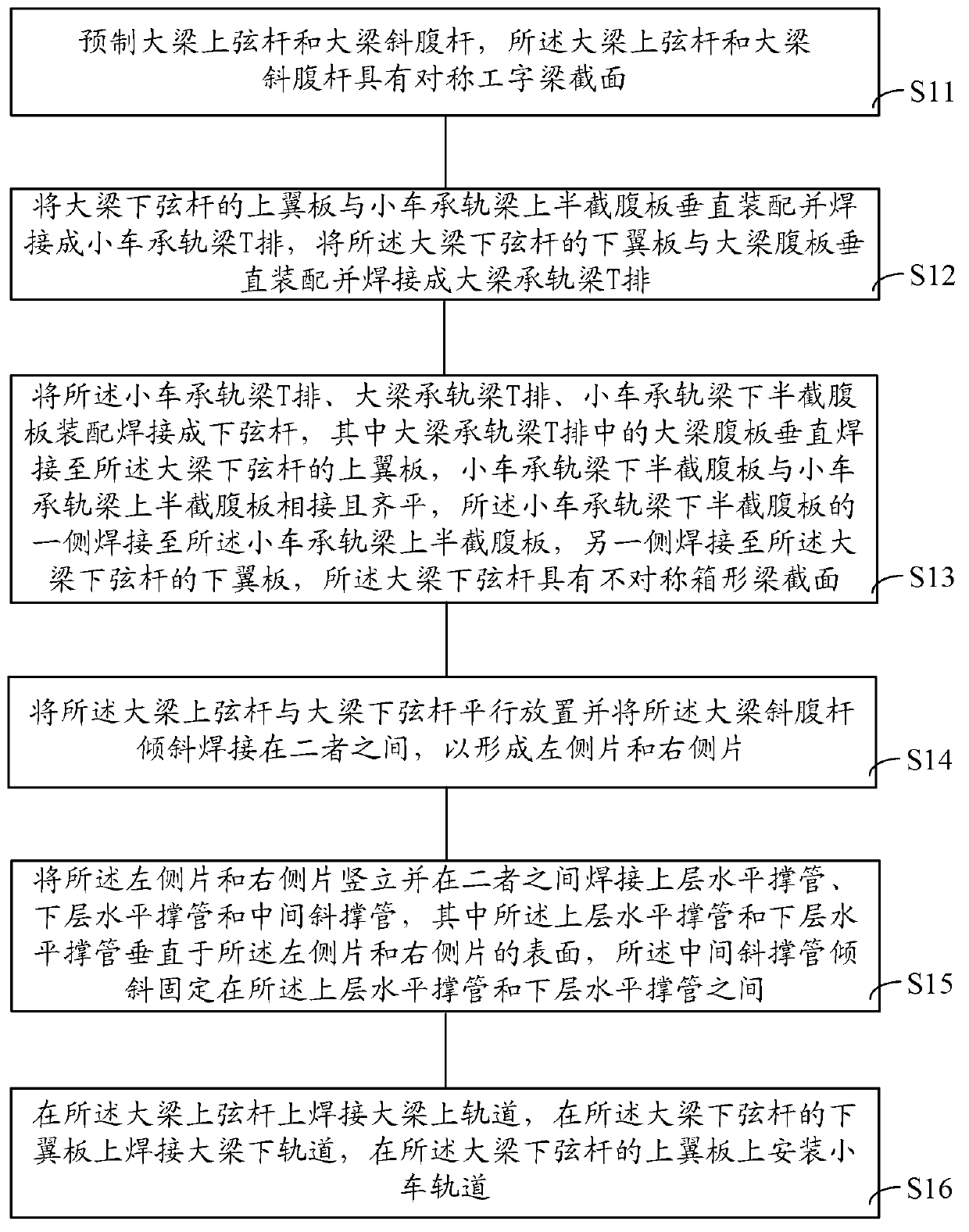

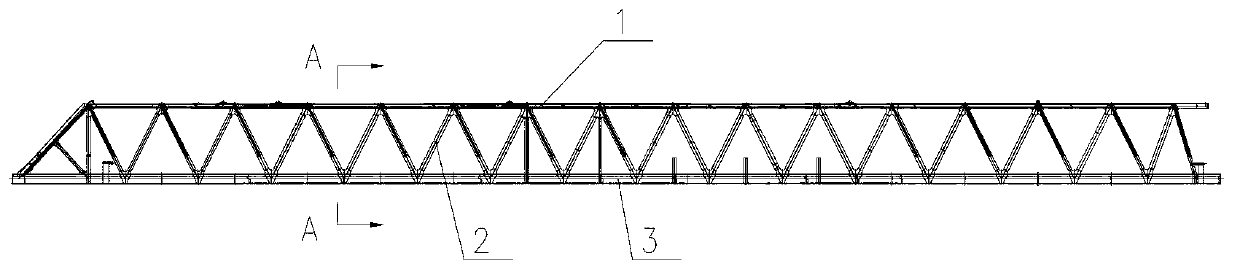

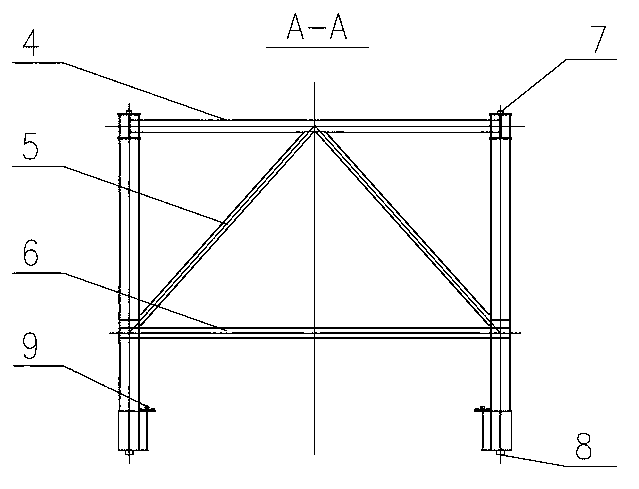

Telescopic truss crossbeam and manufacture method thereof

ActiveCN103321152AMeet the installation technical requirementsAvoid errorsTruss-type bridgeBridge erection/assemblyEngineeringLower wing

The invention provides a telescopic truss crossbeam and a manufacture method thereof. The manufacture method comprises the following steps: a crossbeam upper chord and a crossbeam diagonal web member are prefabricated; T-shaped trolley support rail beams and T-shaped crossbeam support rail beam are assembled and welded; a crossbeam lower chord is formed through the assembly and welding of the T-shaped trolley support rail beams, the T-shaped crossbeam support rail beams and a section of web member at the lower parts of the trolley support rail beams; the crossbeam upper chord and the crossbeam lower chord are placed parallelly, and the crossbeam diagonal web member is obliquely welded between the crossbeam upper chord and the crossbeam lower chord, so that a left lateral plate and a right lateral plate are formed; the left lateral plate and the right lateral plate are erected, and an upper-layer horizontal bracing tube and a lower-layer horizontal bracing tube and a middle inclined bracing tube are welded between the left lateral plate and the right lateral plate; crossbeam upper rails are welded on the crossbeam upper chord, crossbeam lower rails are welded on a lower wing plate of the crossbeam lower chord, and trolley rails are mounted on an upper wing plate of the crossbeam lower chord. According to the method, the sidewise bending and flatness of the crossbeam, the new game start of the rail and the like can be controlled in a precision range.

Owner:SHANGHAI ZHENHUA HEAVY IND

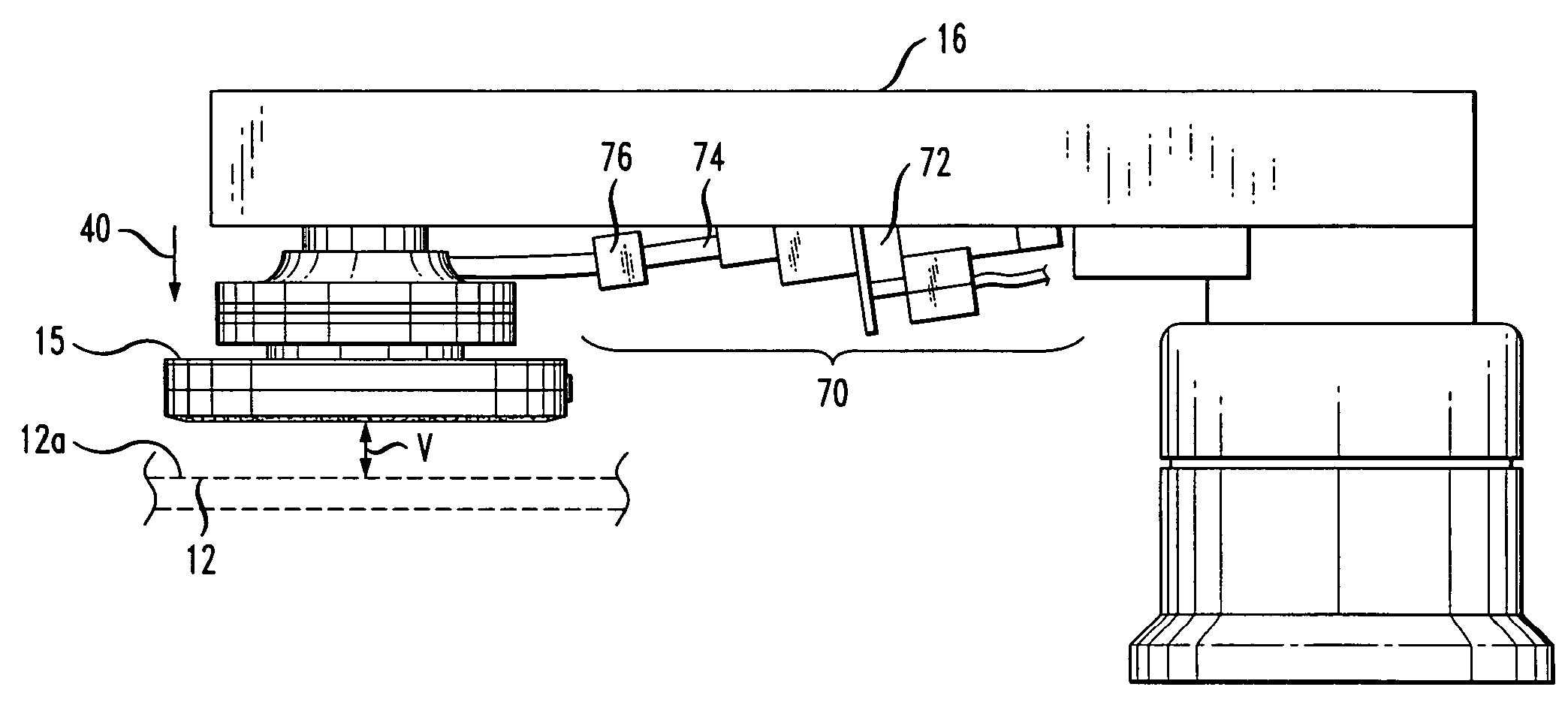

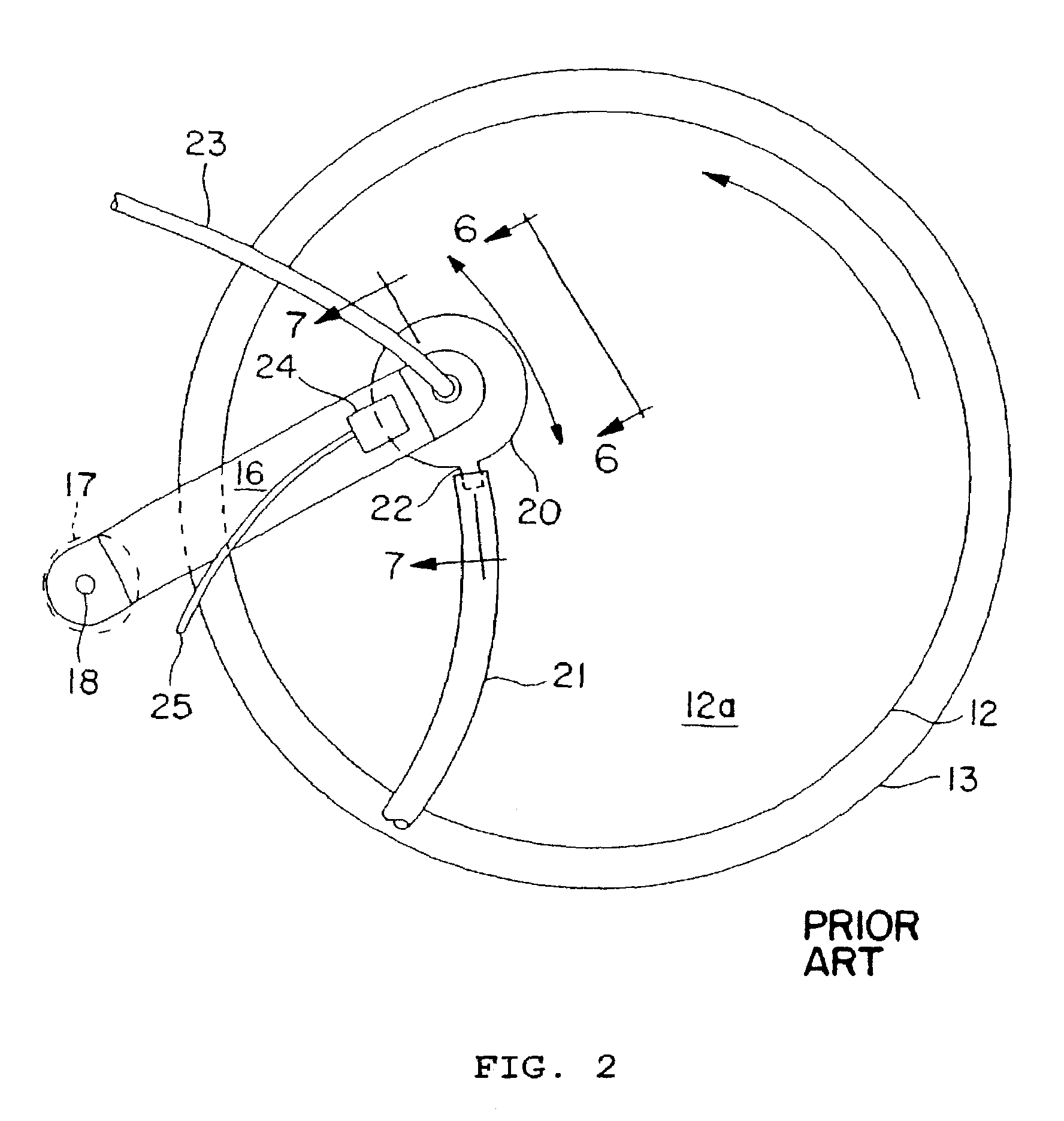

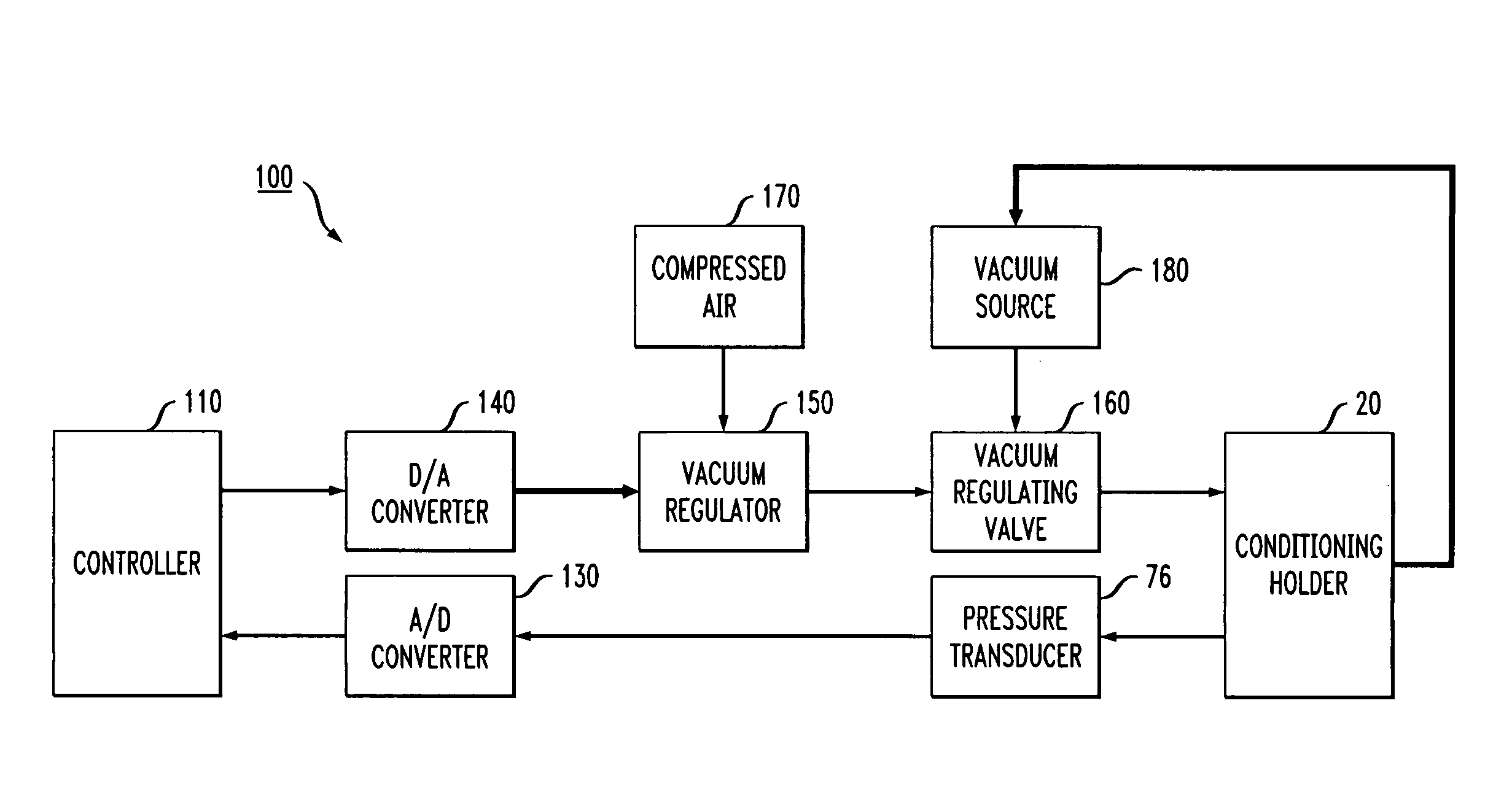

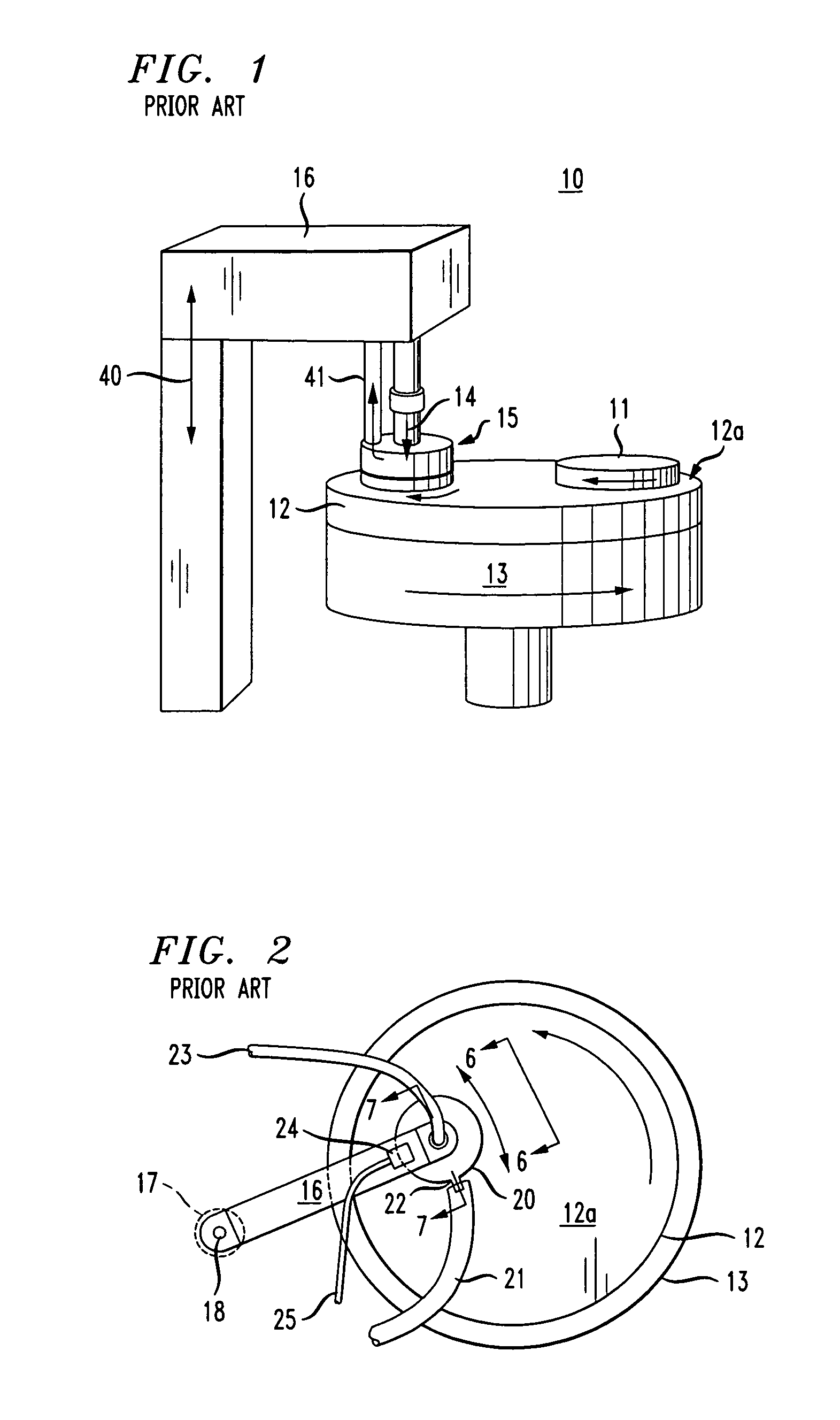

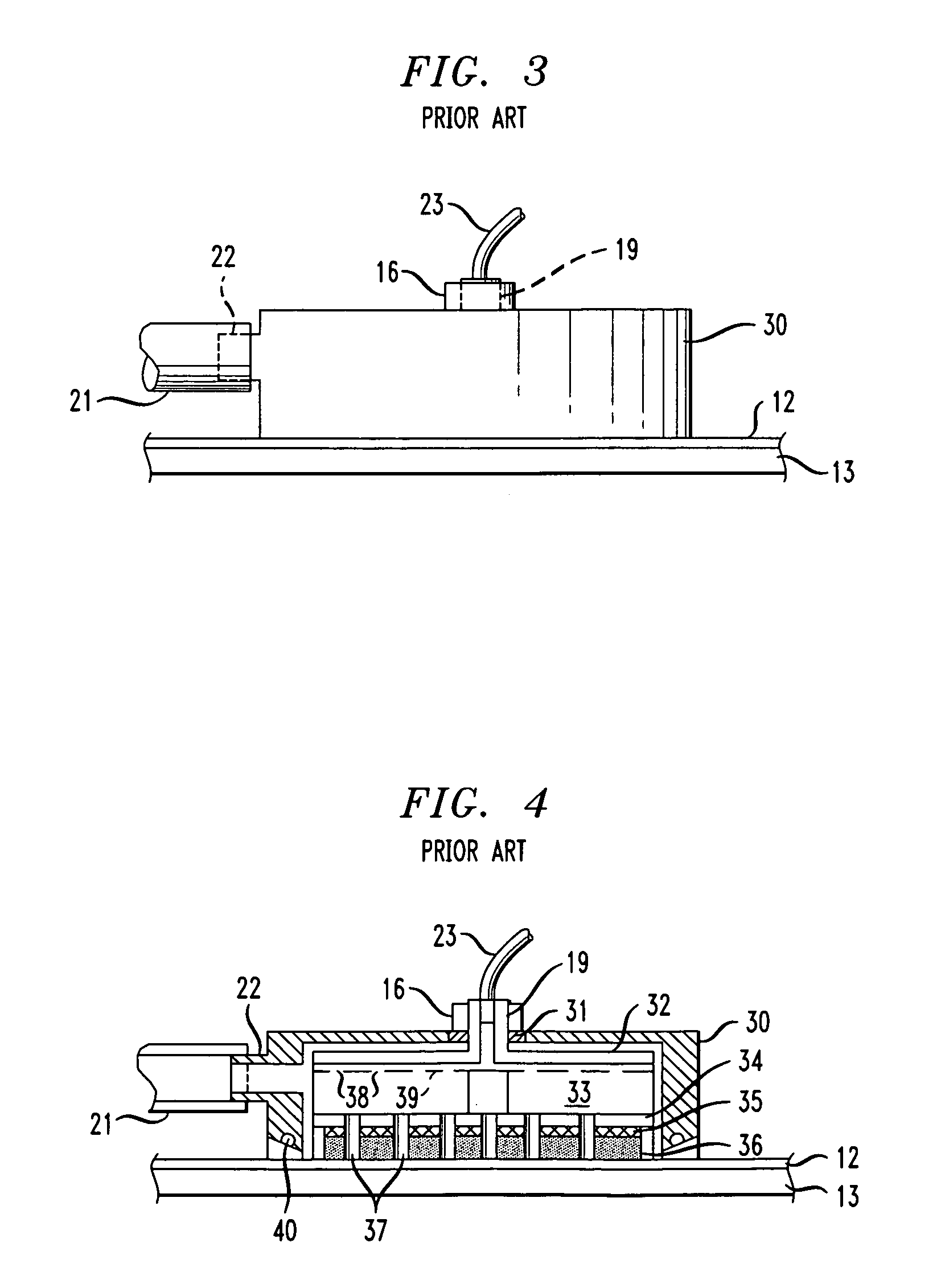

Apparatus for controlling the forces applied to a vacuum-assisted pad conditioning system

InactiveUS7544113B1Quick changeoverControl flatnessEdge grinding machinesGrinding drivesVacuum assistedEngineering

An apparatus for conditioning polishing pads that utilizes an apertured conditioning disk for introducing operation-specific slurries, without the need for additional tooling, platens, and materials handling. The apparatus utilizes a vacuum capability to pull waste material out of the polishing pad and through the apertured conditioning disk to evacuate the apparatus through an outlet port. The apparatus also includes a force adjustment system for providing measurement and control of the force applied by the conditioning disk to the polishing pad.

Owner:TBW IND INC

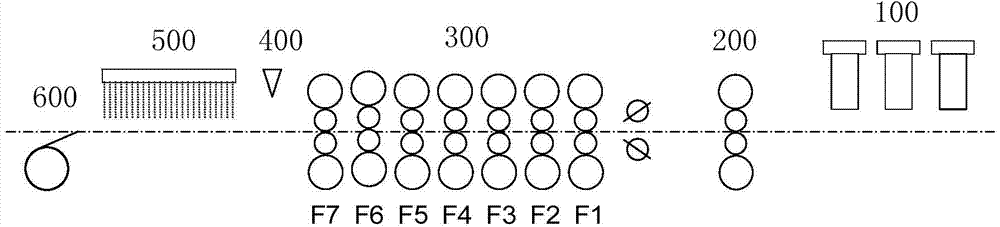

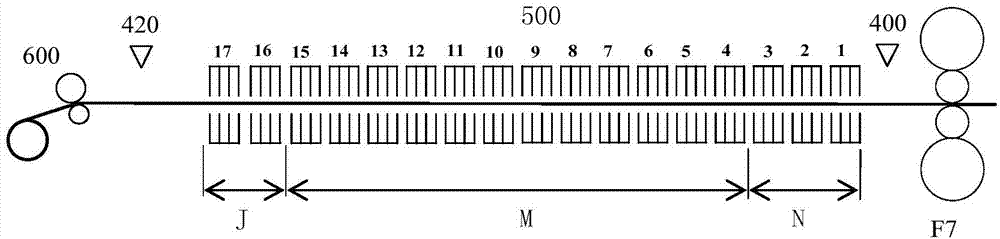

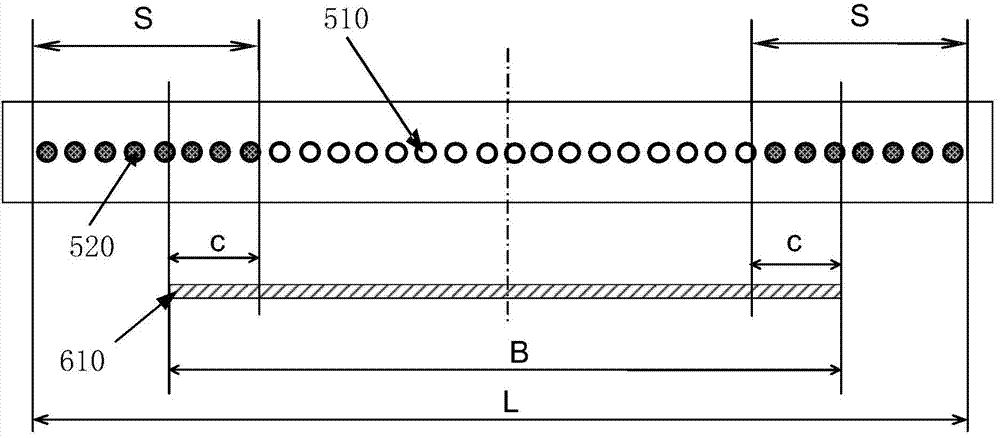

Method for controlling straightness of hot-rolling strip steel by changing spraying width of cooling water

ActiveCN104741389AChange spray widthControl flatnessWork cooling devicesProfile control deviceStrip millStrip steel

The invention discloses a method for controlling straightness of hot-rolling strip steel by changing the spraying width of cooling water, and relates to control equipment or a control method special for a metal rolling machine or a machined product of the metal rolling machine. The method is used for a laminar flow cooling system of a hot rolling line. The method comprises the following steps: according to the width B (unit mm), the edge wave width c (unit mm) and the equipment total cooling width L (unit mm) of a strip steel product, on the basis of a formula that S is equal to L-b+c, a single-side shelter width S is determined, and the spraying width of the cooling water is changed by blocking header nozzles of a corresponding cooling header. According to the method, nozzles on the two sides of the cooling header within a certain range are blocked, and the spraying width of the cooling water is changed; the straightness of the hot-rolling strip steel can be effectively controlled, and the method can adapt to changes of a product width; and the strip shape quality and the product yield are improved. The method is used for transformation of an existing hot rolling line, strip steel transverse temperature uniformity in the cooling process can be effectively improved, meanwhile, a heater or a baffle device can be omitted, and transformation cost of the hot rolling line is saved.

Owner:BAOSHAN IRON & STEEL CO LTD

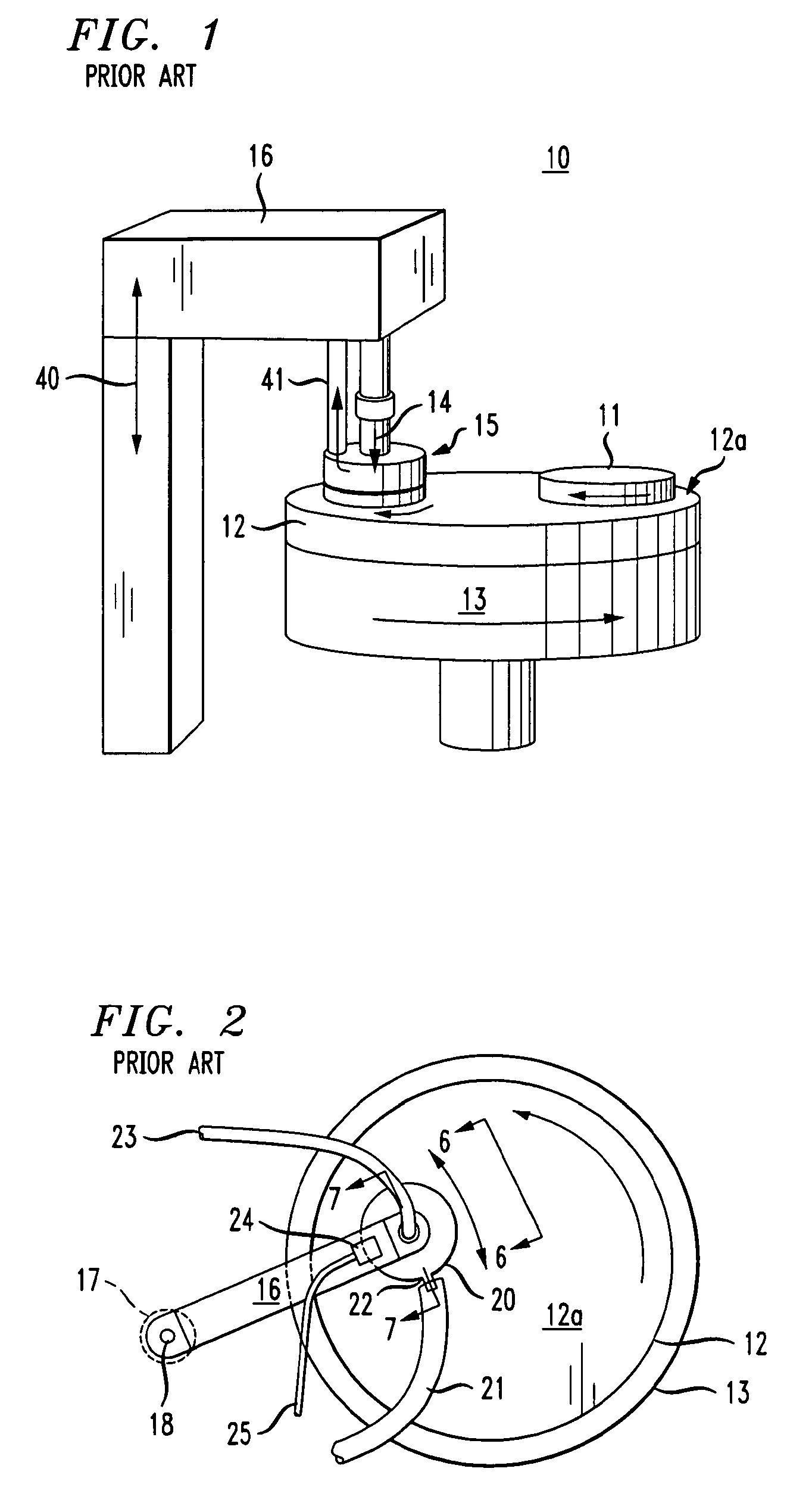

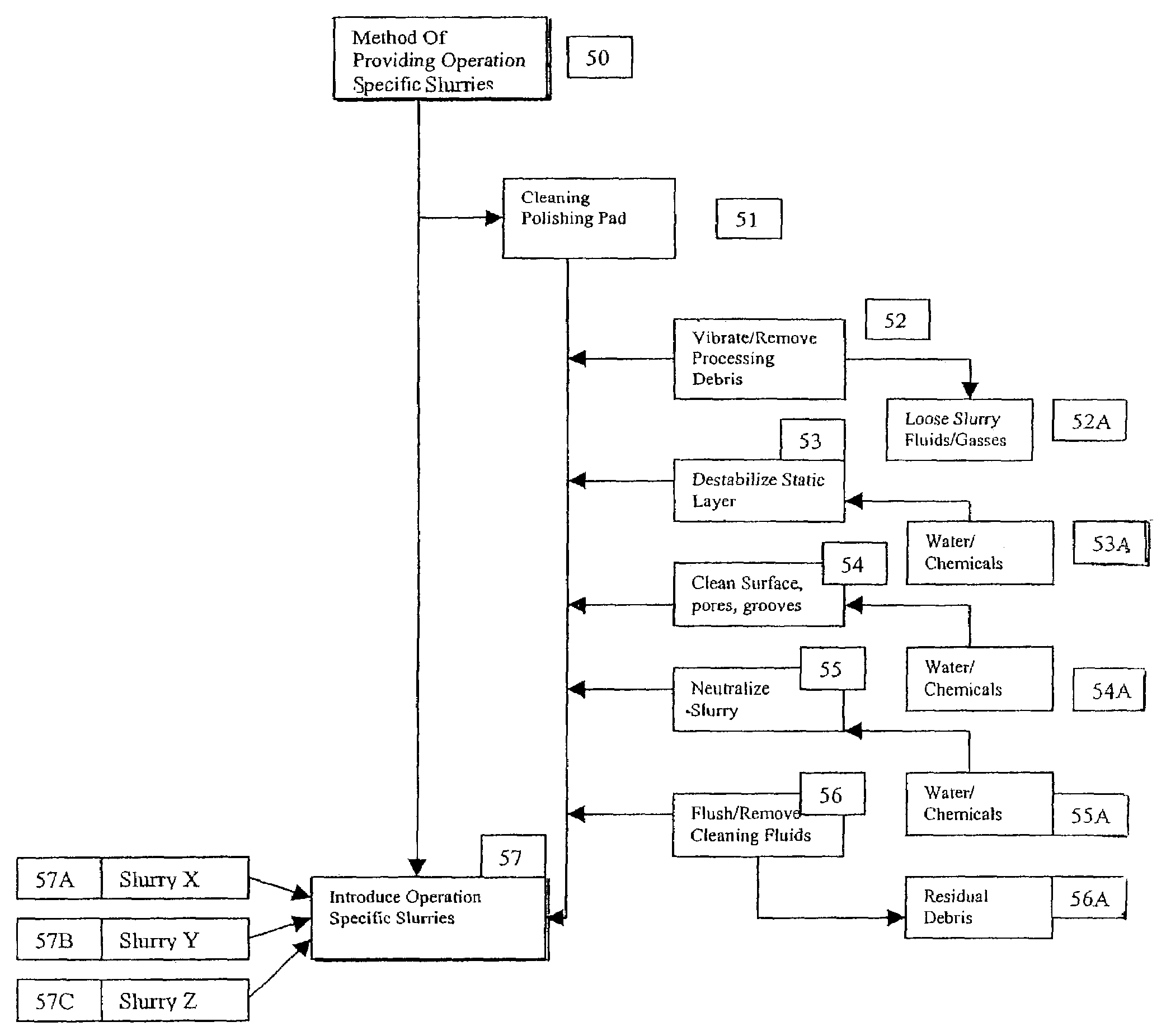

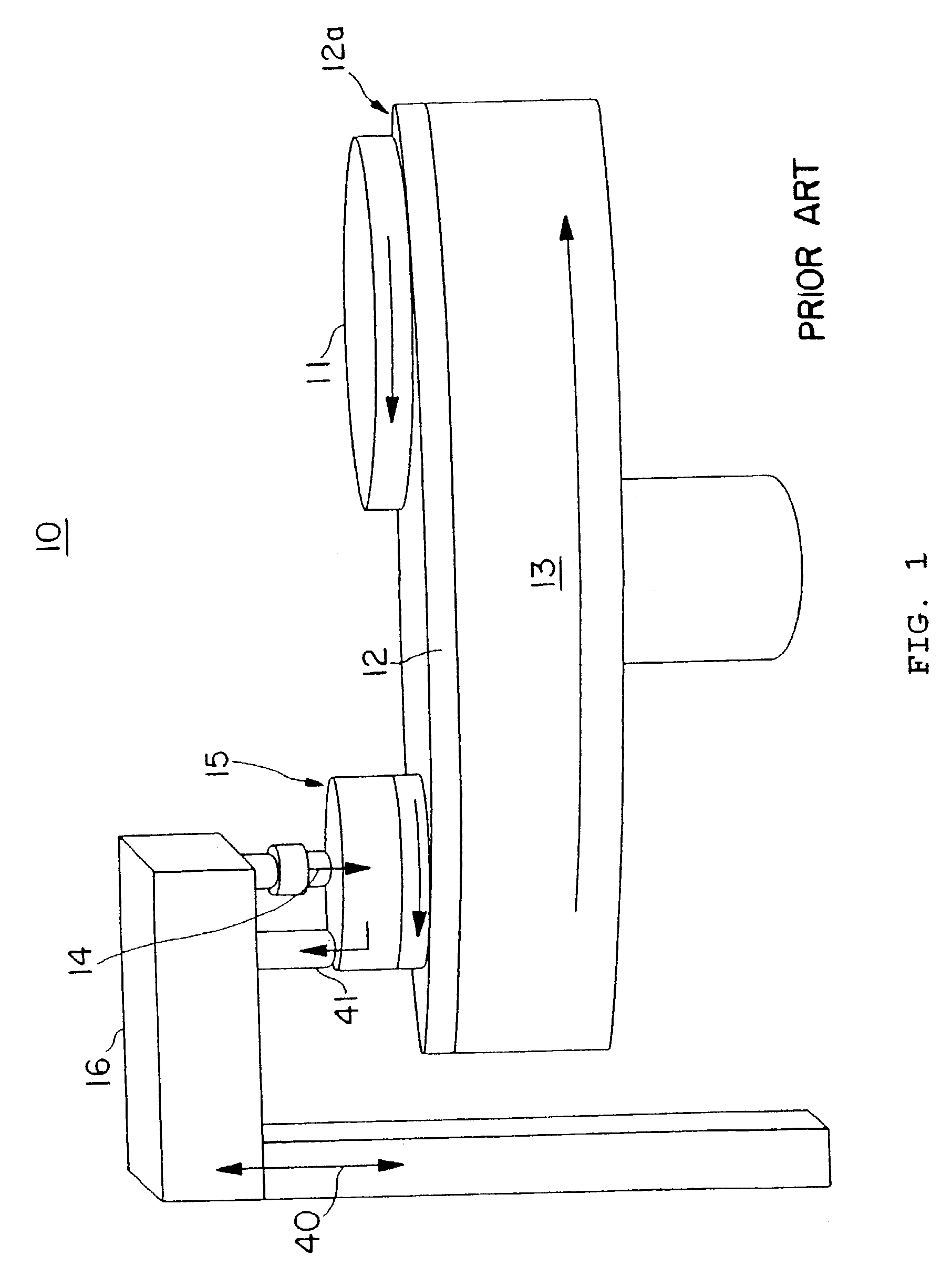

Vacuum-assisted pad conditioning system and method utilizing an apertured conditioning disk

InactiveUS7052371B2Clean thoroughlyControl flatnessEdge grinding machinesGrinding drivesVacuum assistedSlurry

A method and apparatus for conditioning polishing pads that utilize an apertured conditioning disk for introducing operation-specific slurries, without the need for additional tooling, platens, and materials handling. The a method and apparatus utilize a vacuum capability to pull waste material out of the conditioning pad and through the apertured conditioning disk to evacuate the apparatus through an outlet port, the apparatus may also include self-contained flushing means and a piezo-electric device for vibrating the pad conditioning apparatus.

Owner:TBW IND INC

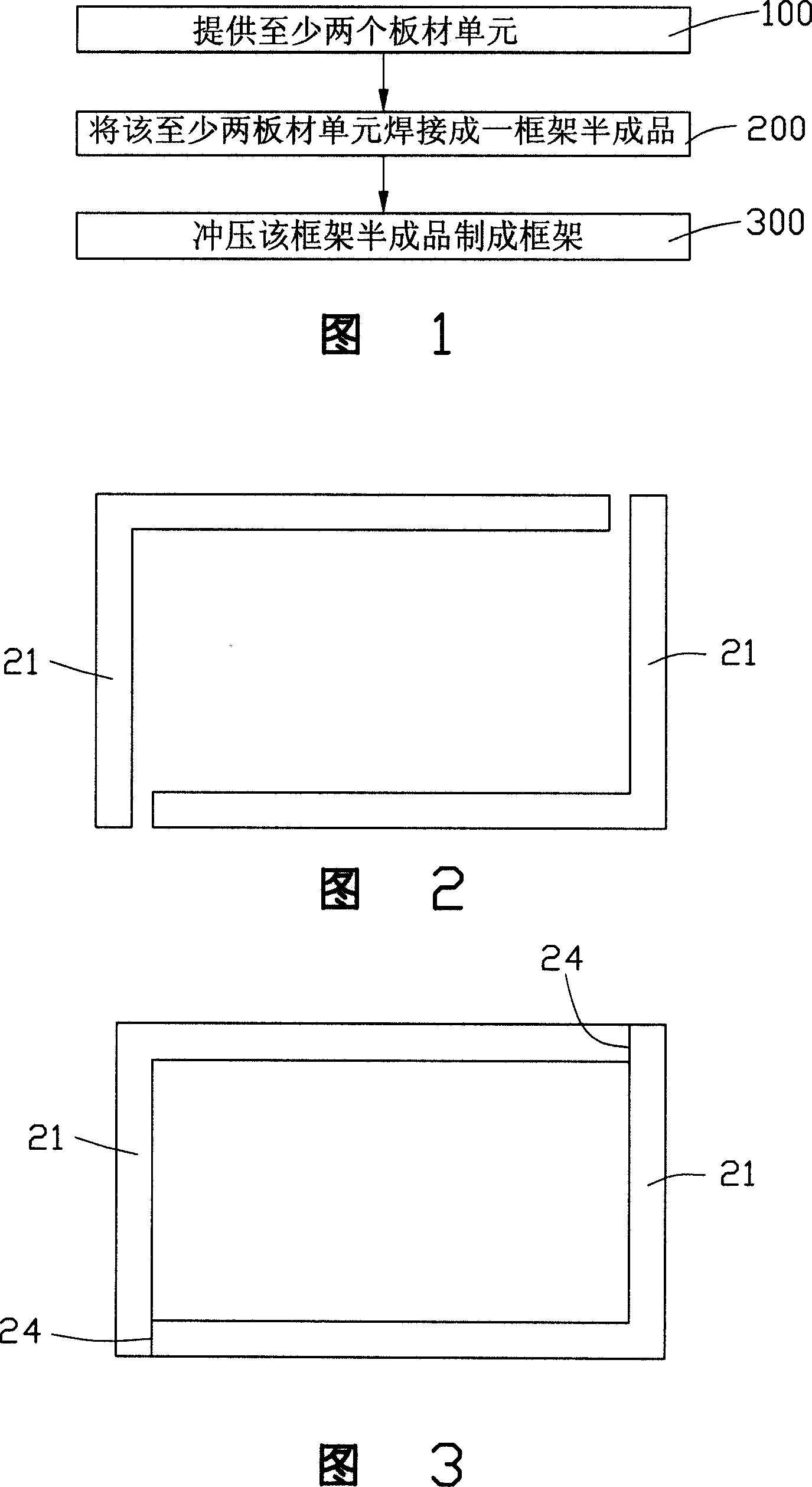

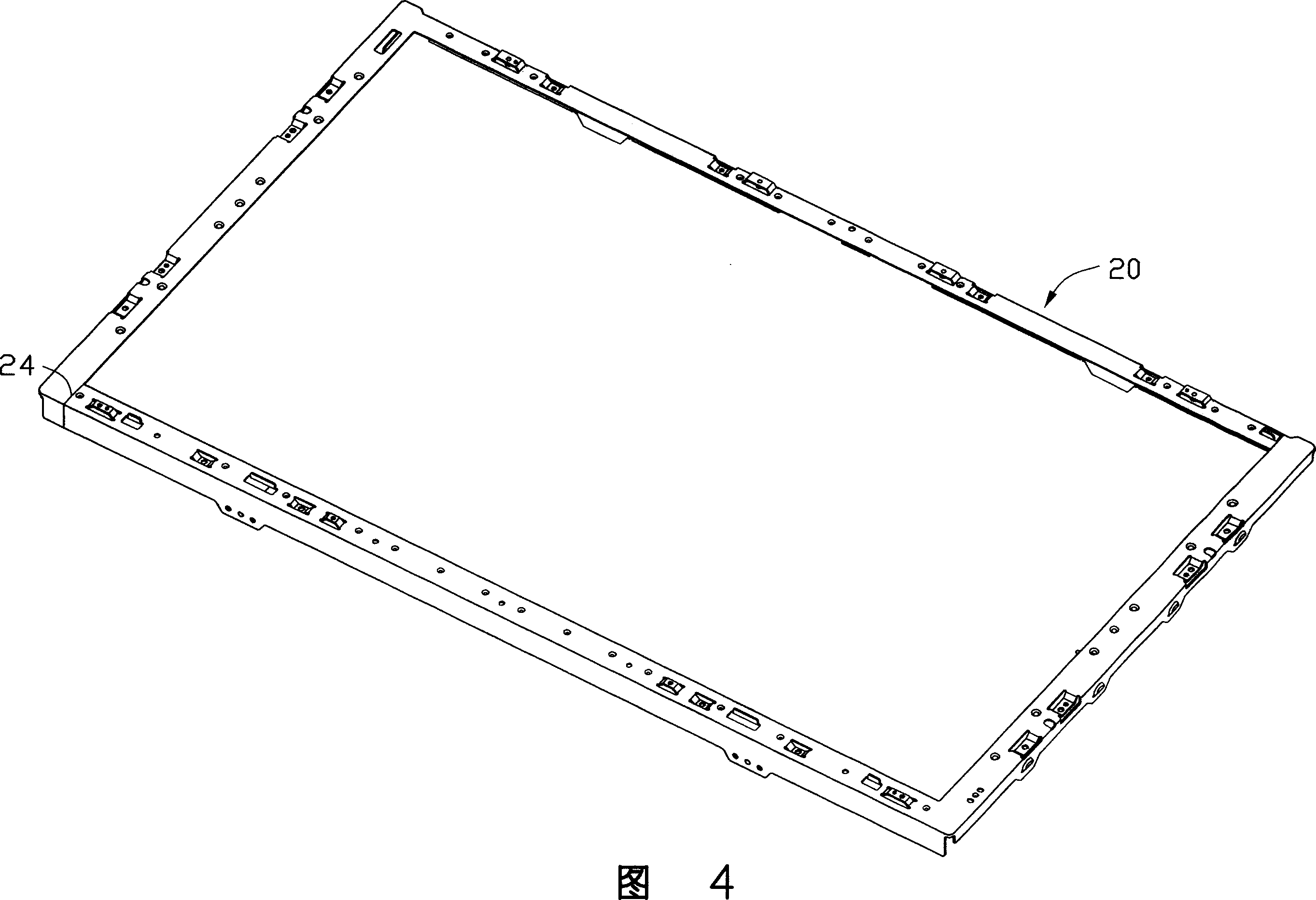

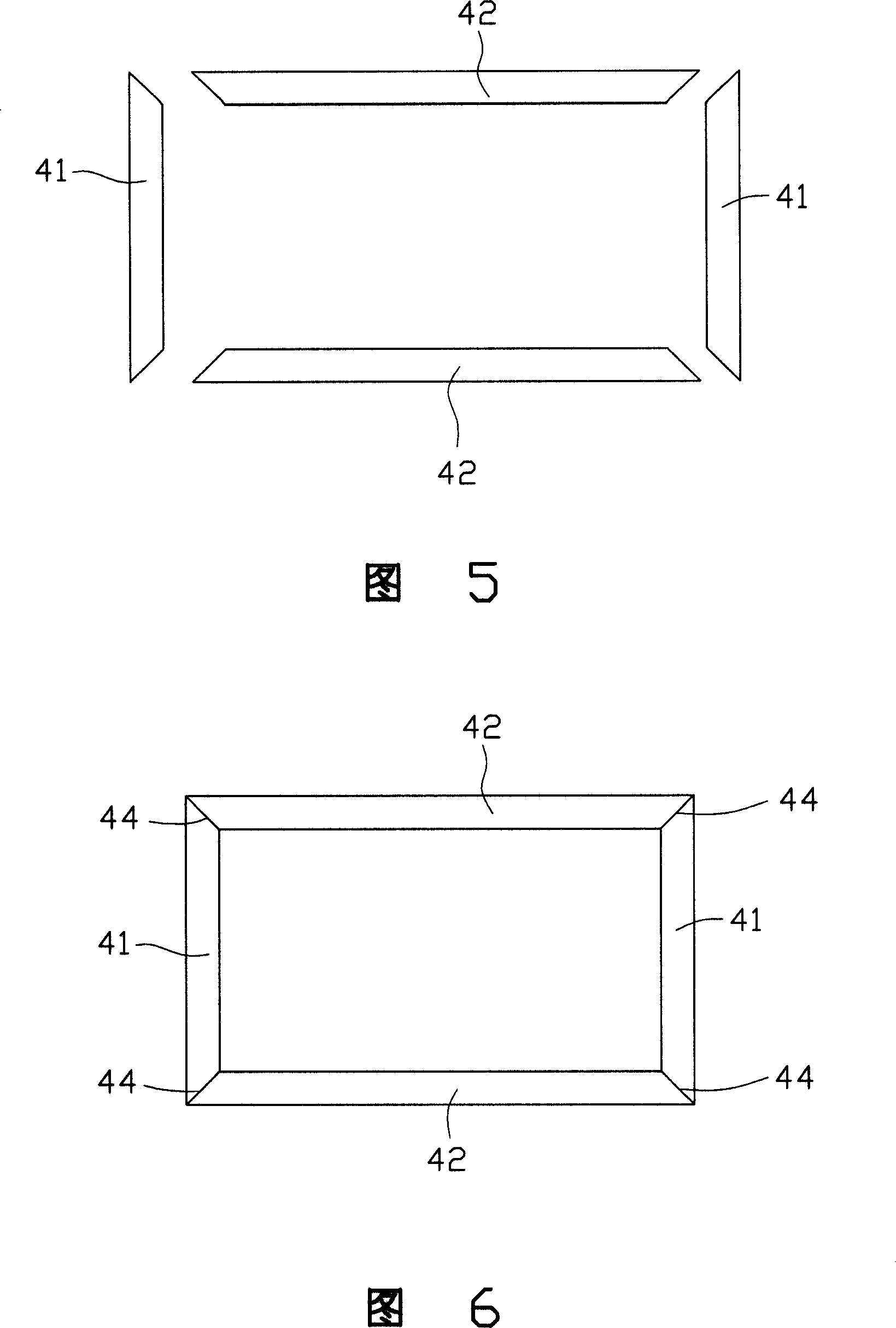

Backlight module frame preparation method

InactiveCN1970219AControl precisionControl FlatnessOther manufacturing equipments/toolsNon-linear opticsWork in processEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

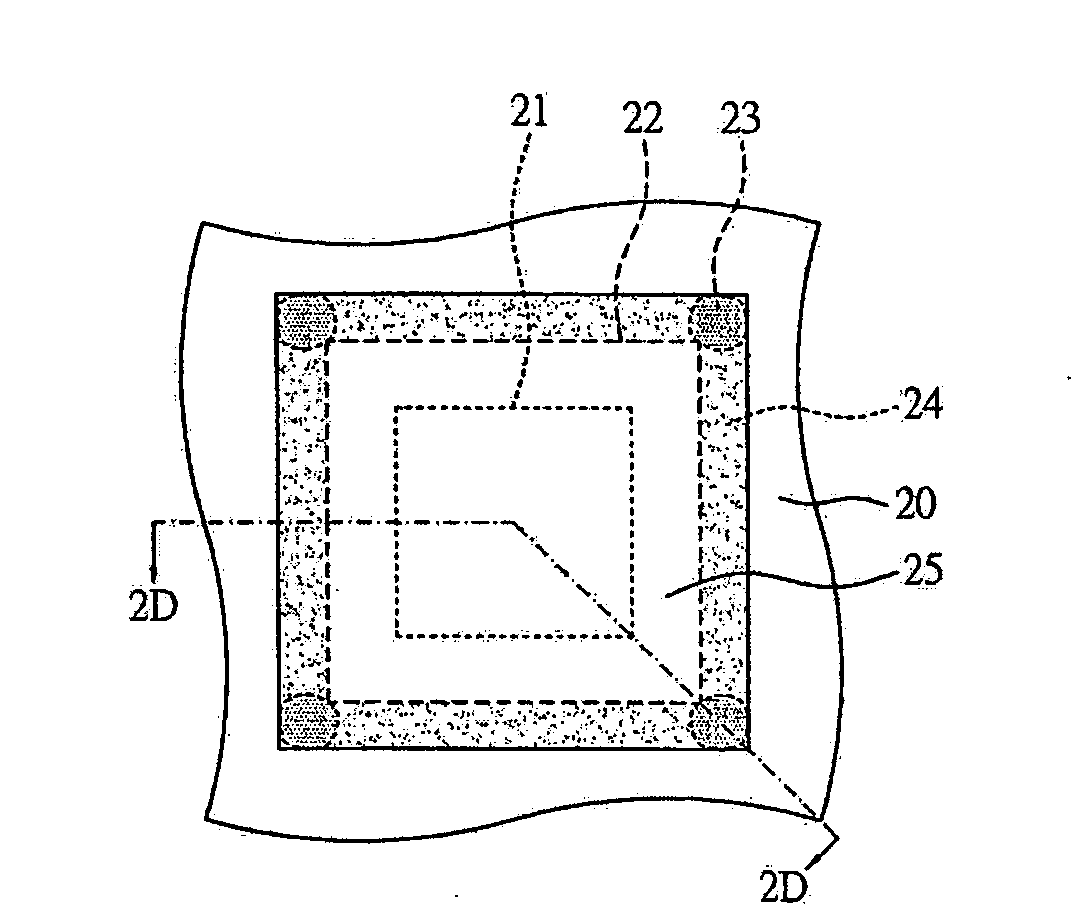

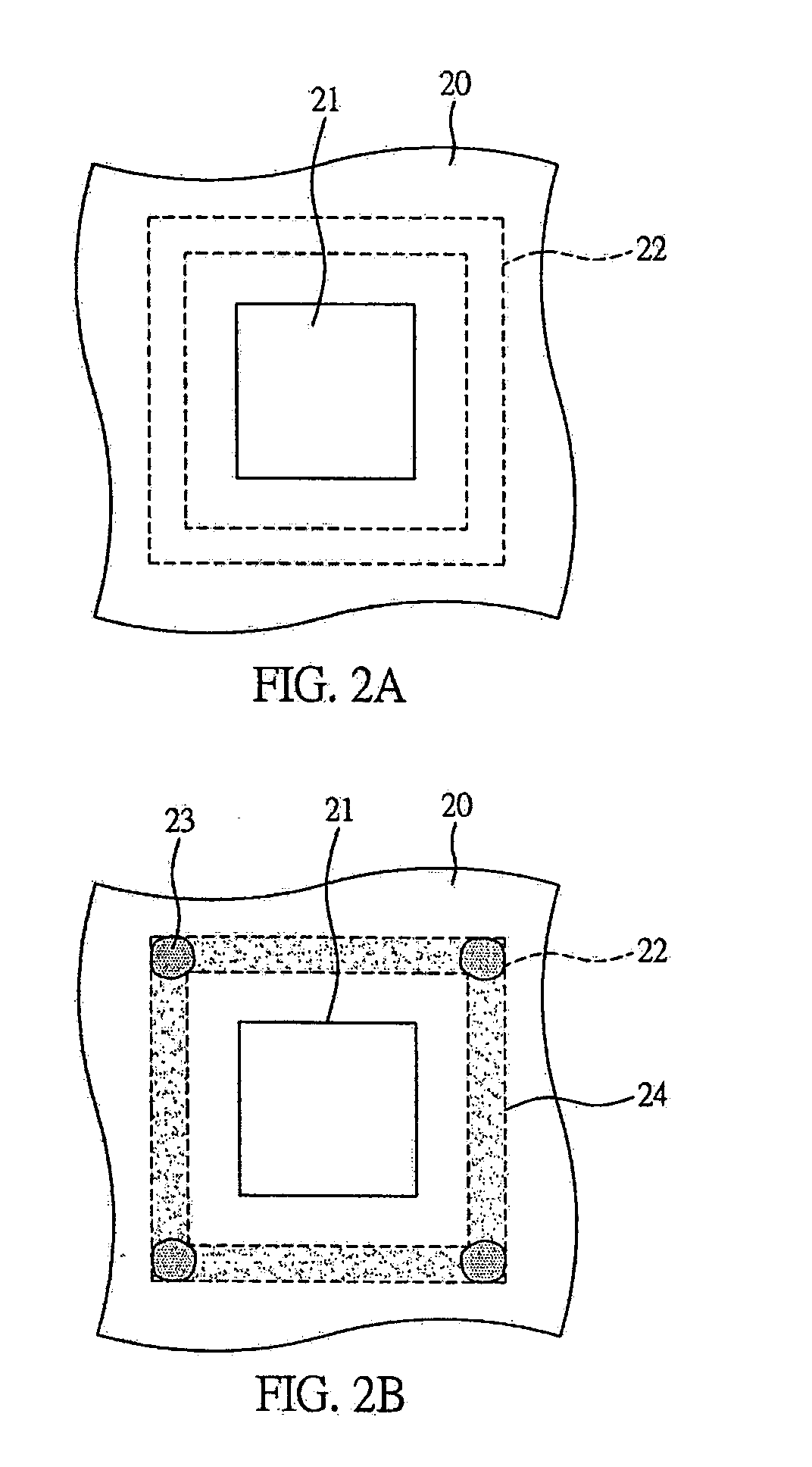

Semiconductor device package with a heat sink and method for fabricating the same

InactiveUS7485496B2Prevent disengagementEffective supportSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor package

A semiconductor package with a heat sink and a method for fabricating the same are proposed. A first adhesive of a low Young's modulus is disposed on a corner region of a heat sink mounting area of a substrate. A second adhesive of a high Young's modulus is disposed on the heat sink mounting area except the corner region. The heat sink is mounted on the heat sink mounting area and thereby secured in position to the substrate, by the first and second adhesives. The disposition of the first and second adhesives of different Young's moduli not only prevents detachment of the heat sink from the substrate, but also controls the flatness of the heat sink. The prevent invention does not affect the appearance of the semiconductor package and its ensuing assembly process.

Owner:SILICONWARE PRECISION IND CO LTD

Precise grinding and polishing machine for sealed end face of airplane engine

ActiveCN105598824AControl FlatnessControl parallelismSeat surface grinding machinesLapping machinesJet aeroplaneElectric machinery

The invention discloses a precise grinding and polishing machine for the sealed end face of an airplane engine. The precise grinding and polishing machine comprises a shell, a gearbox, a first motor, a grinding liquid tank, a bearing plate, a liquid discharge pipe, a bearing box, a second motor, a third motor, a rotating wheel, a grinding plate installation plate and a grinding plate, and is characterized in that a supporting beam is arranged on the shell and provided with a guide rail, a sensor, a cylinder and a controller, the bearing box is connected with the cylinder through a lifting rod, a slide block, a spray nozzle and a stabilizer are arranged on the outer wall of the bearing box, a cushion block and a movable block are arranged in the bearing box, the second motor is arranged on the cushion block, and the third motor is arranged on the movable block. The grinding plate grinds a workpiece according to the track shaped like the Arabic number '8' under the effect of the second motor and the third motor, the grinding plate is prevented from making complete contact with the workpiece, the ground workpiece can be rapidly cooled, and meanwhile the grinding precision of the workpiece can be improved.

Owner:ANHUI GENAN MULLERS

Method for paving and constructing floor tiles with elevation cushion blocks

ActiveCN105256973ALow technical requirementsReduce dosageFlooringUltimate tensile strengthGrounding line

The invention discloses a method for paving and constructing floor tiles with elevation cushion blocks. The method comprises the following steps of (1) ground line snapping and laying out, (2) prearrangement of the elevation cushion blocks, (3) adhesion of the elevation cushion blocks, (4) pulp smearing, and (5) pavement. By the method for paving and constructing the floor tiles with the elevation cushion blocks, technical requirements on the paved floor tiles can be reduced, the amount of labor and materials is reduced, labor intensity is reduced, decoration load is also reduced by means of saving pavement labor and materials, and the integral flatness of the ground of the floor tiles can be controlled effectively.

Owner:苏州水木清华设计营造有限公司

Overlaying process of drilling tool for petroleum extraction

InactiveCN102343471AIncrease depth of fusionGuaranteed service lifeArc welding apparatusAutomatic controlTungsten

The invention provides an overlaying process of a drilling tool for petroleum extraction. Primarily, an overlaying region of the drilling tool is electrically welded by an automatic control carbon dioxide welding machine by using a carbon steel welding wire; pure tungsten powder which is preheated to 200 DEG C is sprayed to an electrical welding position by a powder spraying mechanism during the electrical welding to perform facing; and finally, a tungsten carbide-containing thickening wear-resistant belt is formed by performing facing at the overlaying region of the drilling tool. By adopting the overlaying process of the drilling tool for petroleum extraction, the forming of a weld joint and the fusion depth of a welding wire and a parent metal are effectively increased, and the hardness of a welding layer is improved; and thus, the wear resistance of the drilling tool and the anti-friction quality of the drilling tool to a bushing are improved, and the service life of the drilling tool is prolonged by more than two times.

Owner:SHANGHAI TUBE COTE PETROLEUM PIPE COATING +1

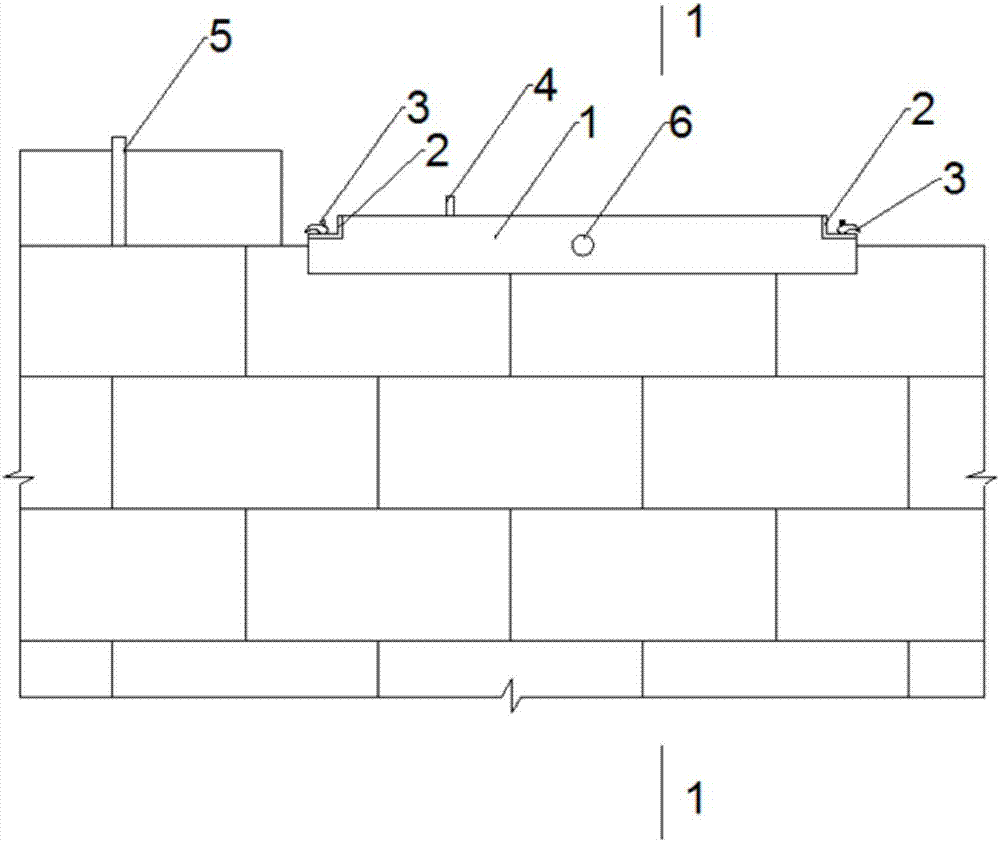

Laying device and using method thereof

ActiveCN106894640AControl flatnessControl the fullness of gray jointsBuilding material handlingEngineeringScratching

The invention provides a laying device and a using method thereof. The laying device comprises a horizontal mortar joint device and vertical mortar joint devices. The horizontal mortar joint device comprises two oppositely-arranged sliding rails, two first adjusting frames, two first fastening pieces and a mortar scratching plate. The bottoms of the two sliding rails can slide relative to a laying body along the horizontal direction. Sliding grooves are formed in the inner sides of the two sliding rails. The mortar scratching plate can slide in the sliding grooves in the horizontal direction. One sides of the two first adjusting frames are fixedly connected with the two ends of one of the sliding rails in a clamping mode. The two first fastening pieces are arranged in two first positioning grooves in a penetrating mode and fixedly connected with the other sliding rail. The vertical mortar joint devices are arranged on the upper side and the left and right sides of the vertical face of the laying body in a surrounding mode. A mortar filling groove is formed between the inner wall of each vertical mortar joint device and the vertical face of the laying body. The heights of the mortar filing grooves are the standard thicknesses of a vertical mortar joint. The flatness, mortar joint fullness and thickness of the laying body can be effectively controlled to be uniform, technological dependence on an operator is little, and the blank of the field of laying body construction equipment is filled.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD +1

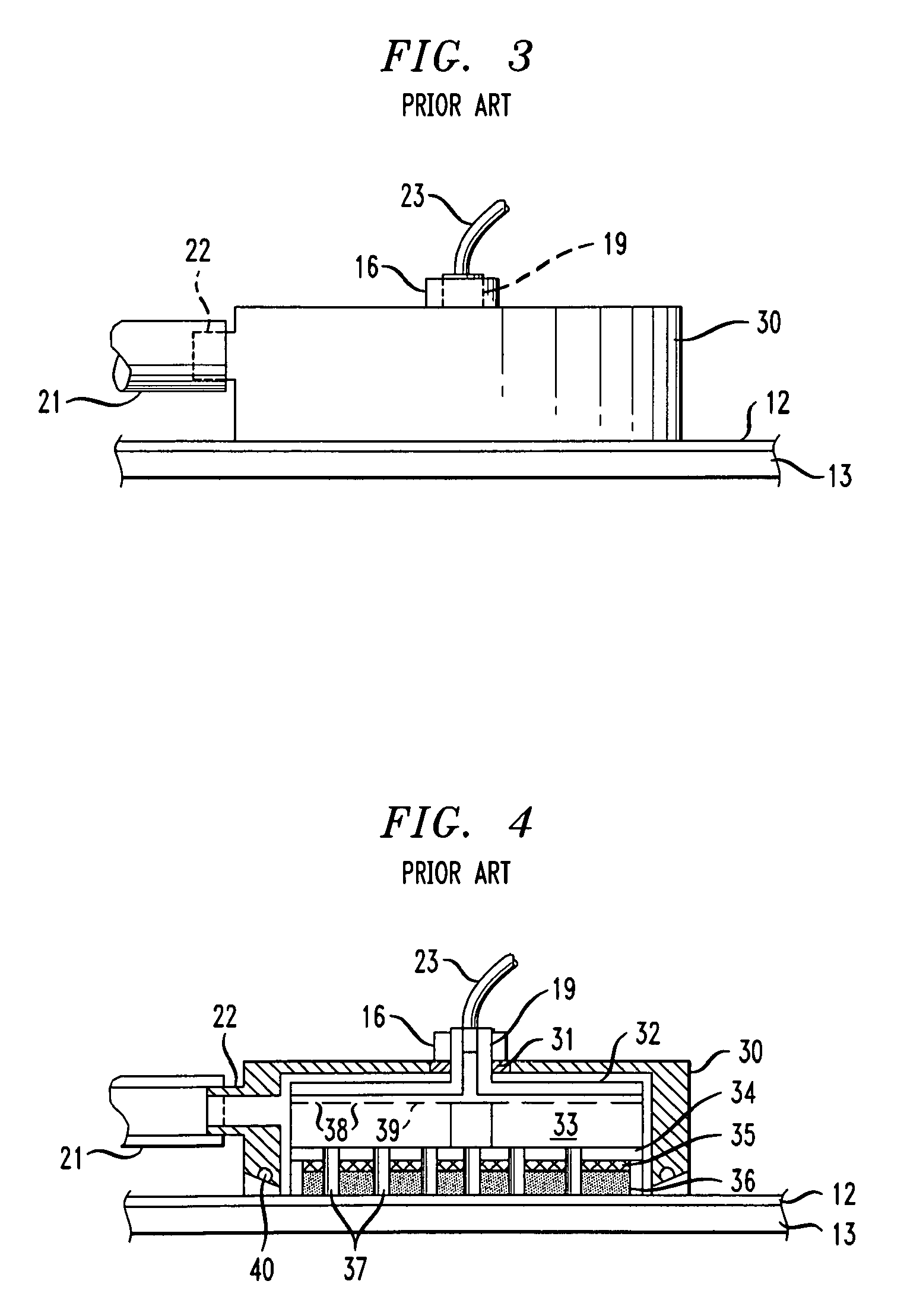

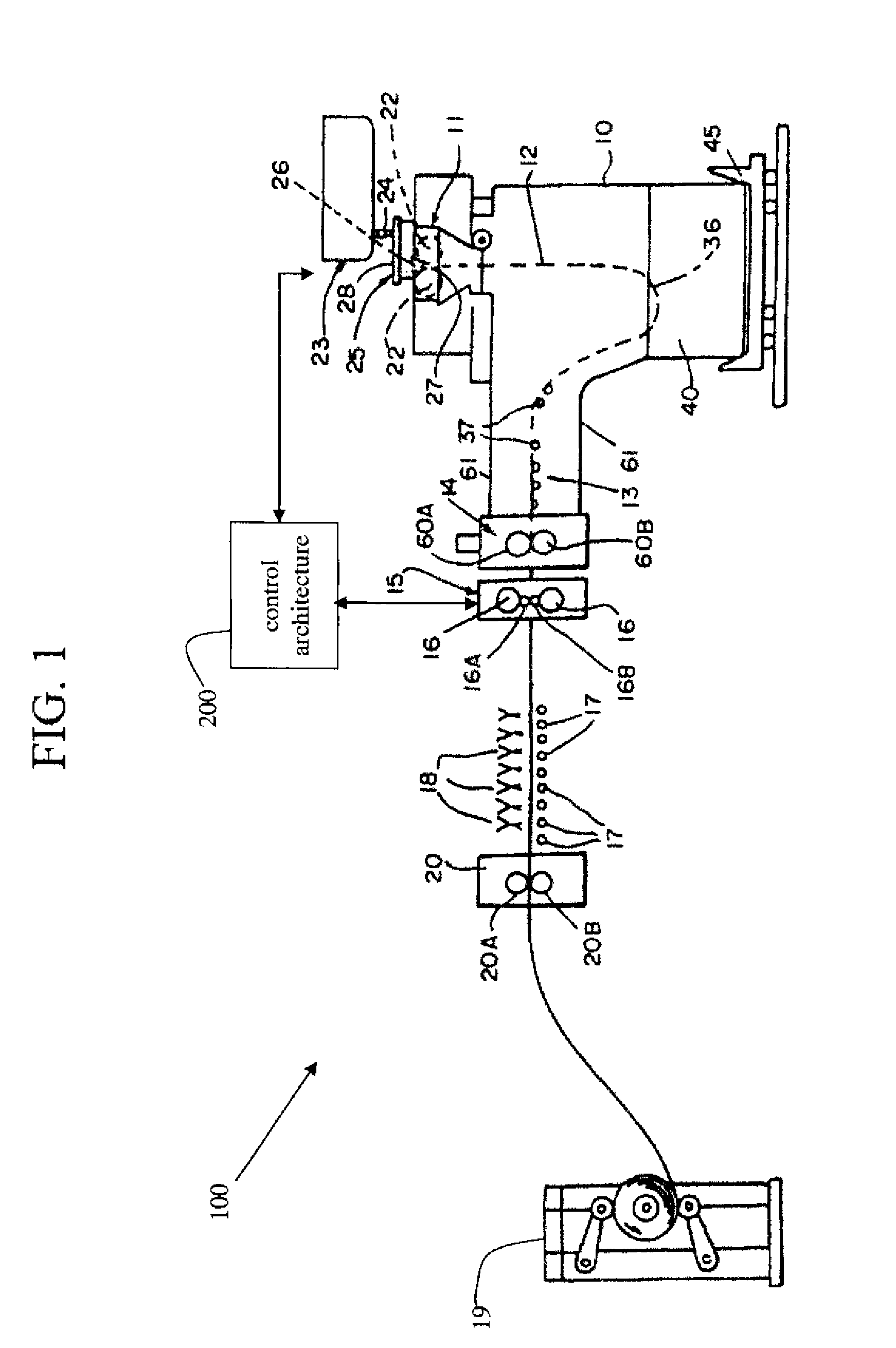

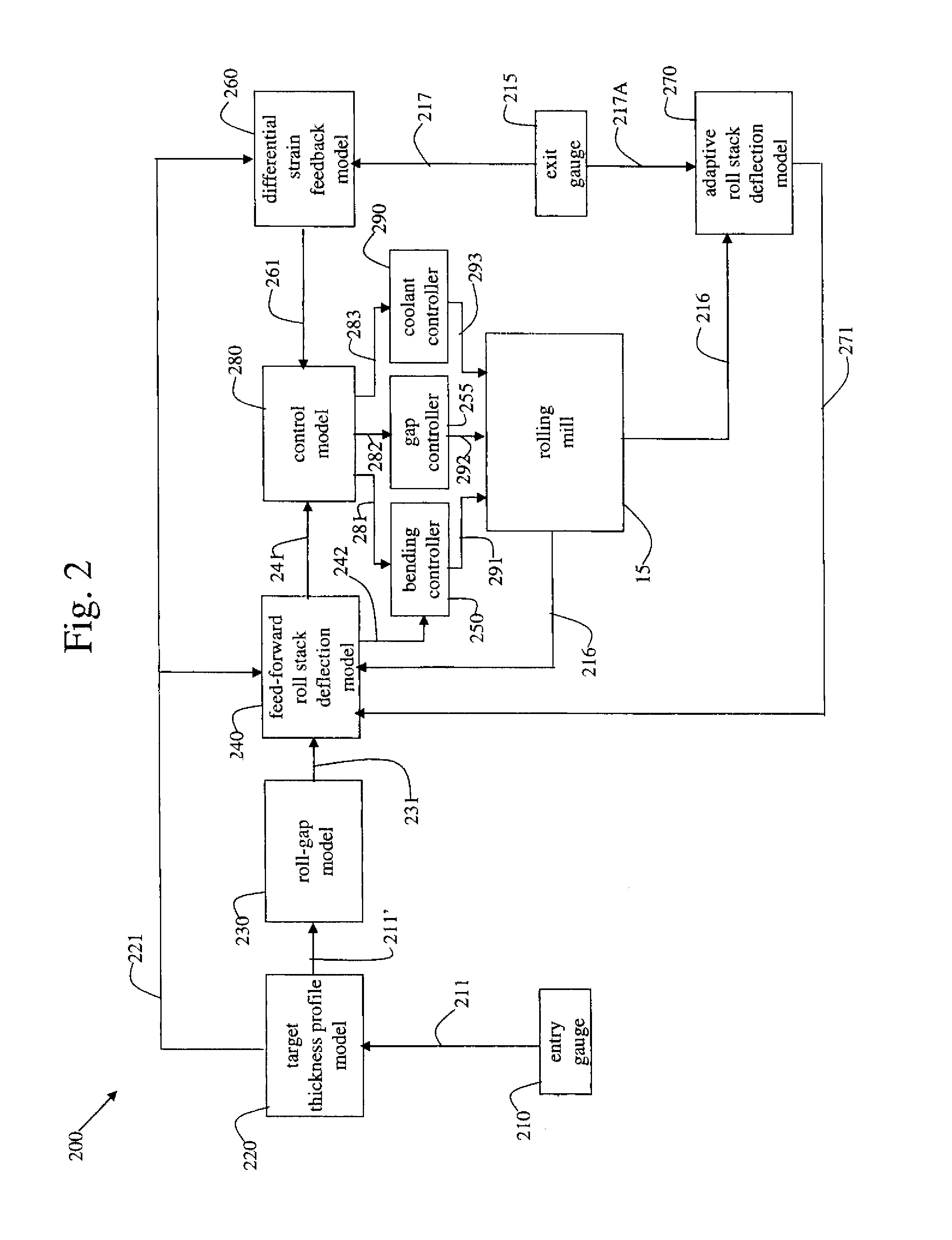

Method and plant for integrated monitoring and control of strip flatness and strip profile

ActiveUS20070220939A1Reduce tensionSusceptible to bucklingRoll force/gap control deviceMetal rolling stand detailsIntegrated monitoringControl signal

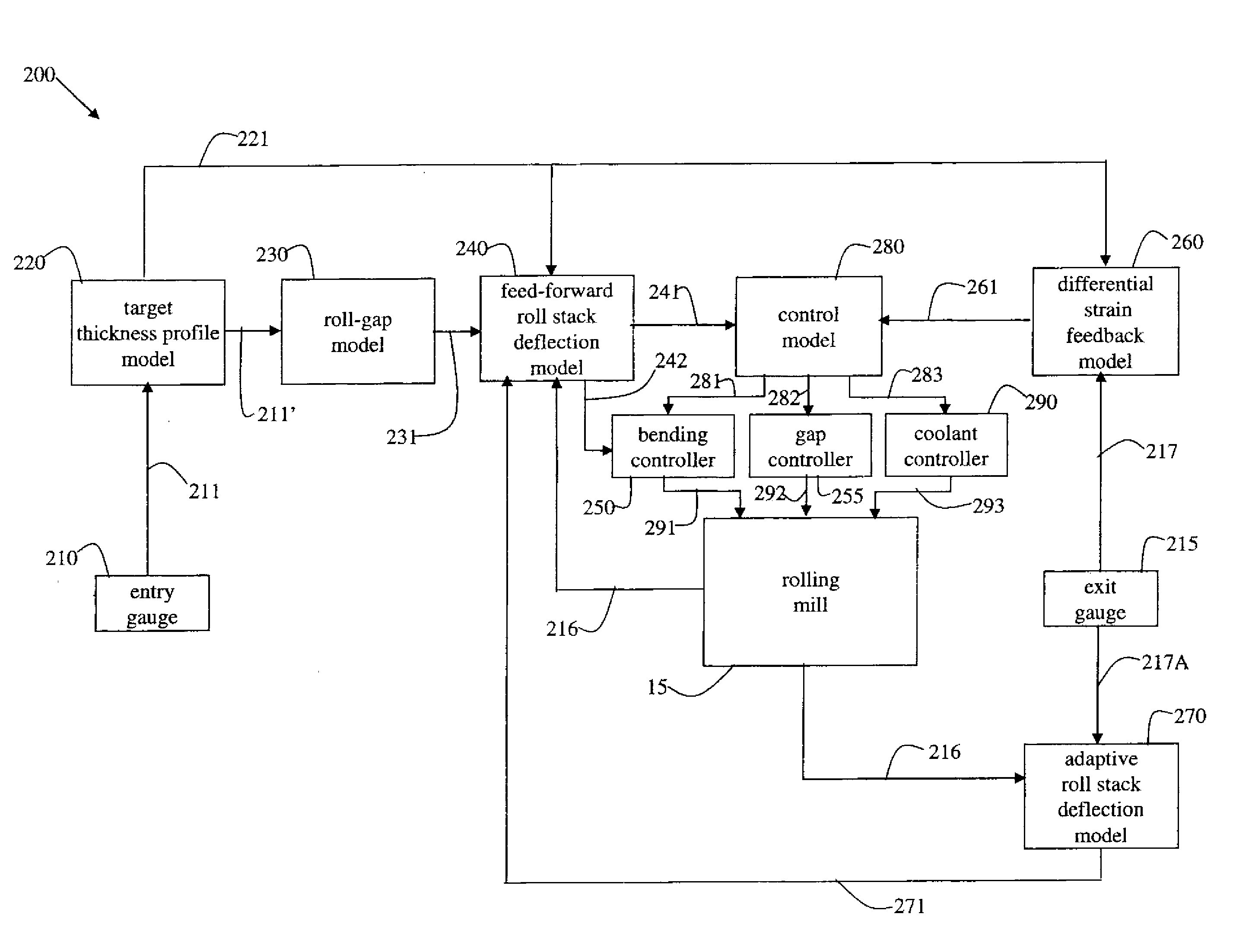

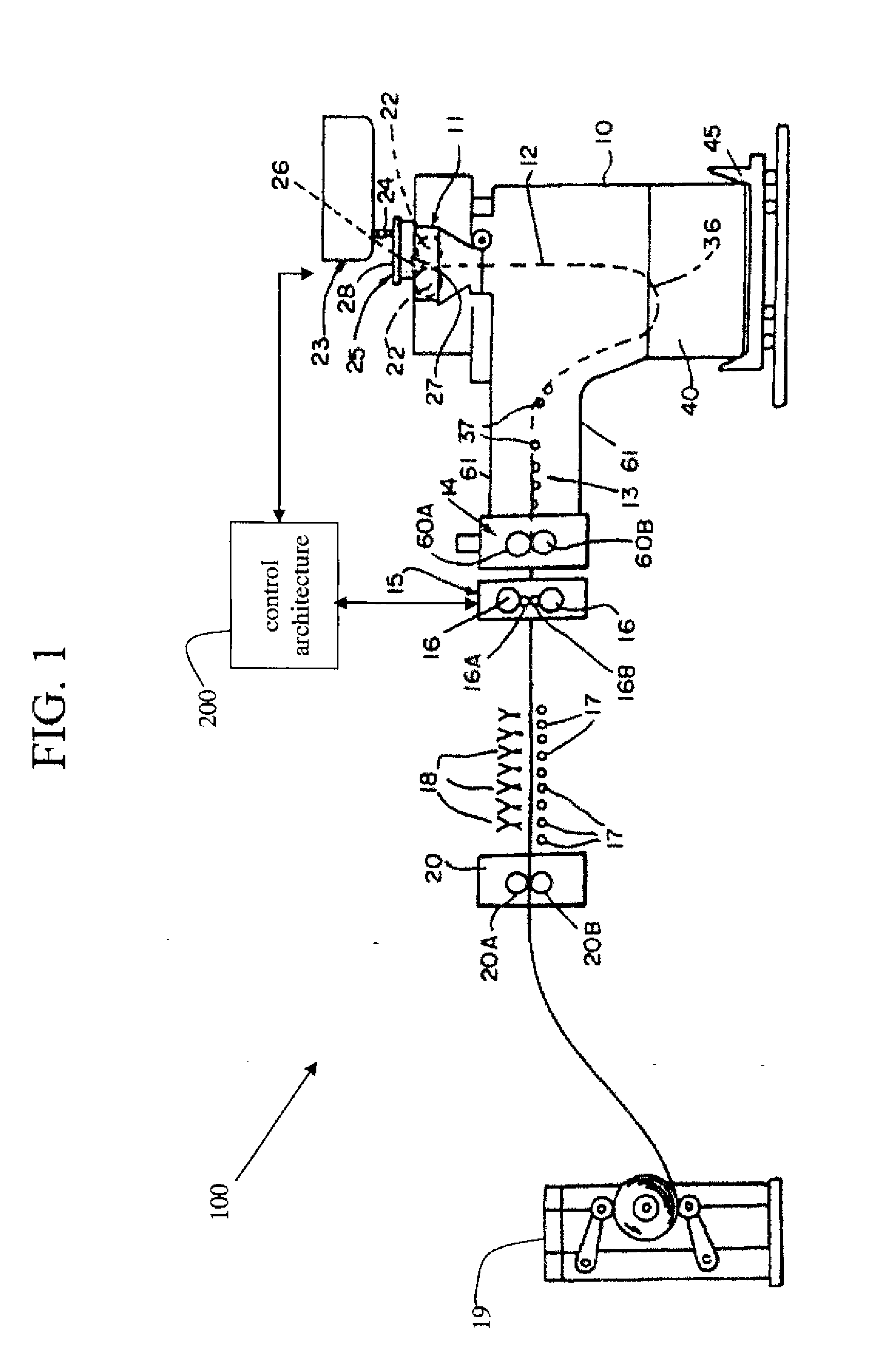

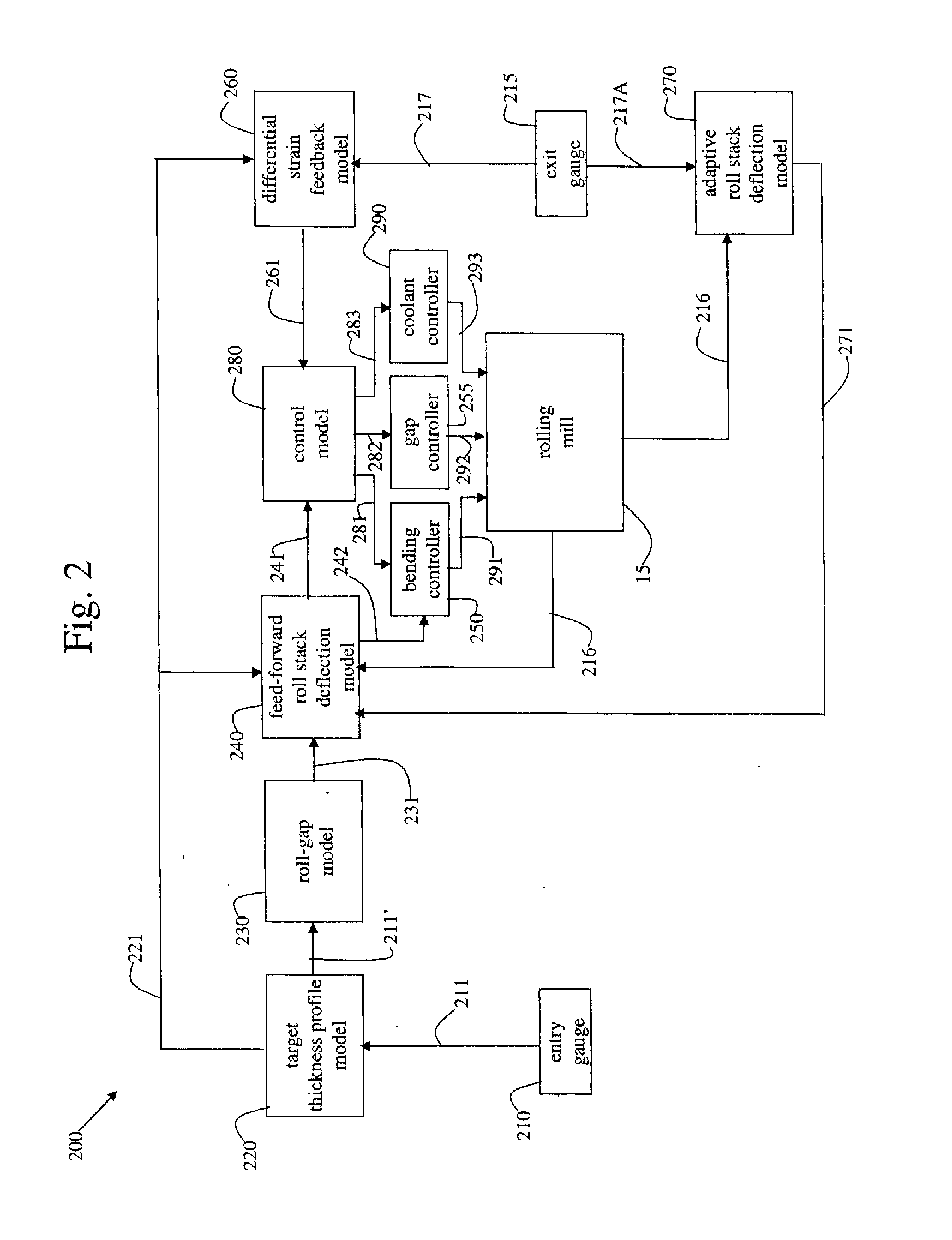

Apparatus and method of controlling strip geometry in casting strip having a rolling mill. A target thickness profile is calculated as a function of the measured entry thickness profile of the strip while satisfying profile and flatness operating requirements. A differential strain feedback from longitudinal strain in the strip is calculated by a control system by comparing the exit thickness profile with the target thickness profile, and a control signal is generated to control a device capable of affecting the geometry of the strip processed by the hot rolling mill. A feed-forward control reference and / or sensitivity vector may also be calculated as a function of the target thickness profile, and used in generating the control signal sent to the control device. The control device may be selected from one or more of the group consisting of a bending controller, gap controller and coolant controller.

Owner:NUCOR CORP

Adjustable large-area floor steel channel formwork system and construction method thereof

InactiveCN103498555AIncrease stiffnessAvoid lateral inward tippingForms/shuttering/falseworksSurface layerThreaded rod

The invention relates to an adjustable large-area floor steel channel formwork system and a construction method of the adjustable large-area floor steel channel formwork system. The system comprises a steel channel formwork, a supporting frame and a batten side mold, and a plurality of stiffening plates with vertical adjusting slot holes are welded in a groove of the steel channel formwork. The supporting frame is composed of vertical rods, horizontal rods and inclined rods, the upper portions of the vertical rods are connected with horizontal connecting parts which are parallel to the horizontal rods and extend into the groove of the formwork, threaded rods connected to the horizontal connecting parts penetrate through the vertical adjusting slot holes and are connected with the stiffening plates in an adjustable mode through nuts, and the top ends of the vertical rods are welded with transverse formwork stopping parts which are perpendicular to and tightly attached to the outer sides of the stiffening plates. The adjustable large-area floor groove steel formwork system further comprises a demolding threaded rod and a rotary hand shank. The construction method includes formwork installing and formwork removing. The adjustable large-area floor groove steel formwork system solves the technical problems that due to the fact that the formwork is not firmly supported and reinforced in an existing large-area floor formwork system, errors of elevation of concrete poured subsequently and flatness of a surface layer are large, formed large-area floor concrete is poor visually, and use functions are affected.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Method for controlling the forces applied to a vacuum-assisted pad conditioning system

InactiveUS7901267B1Clean thoroughlyControl flatnessSemiconductor/solid-state device manufacturingGrinding feed controlVacuum assistedSlurry

A method and apparatus for conditioning polishing pads that utilizes an apertured conditioning disk for introducing operation-specific slurries, without the need for additional tooling, platens, and materials handling. The method and apparatus utilizes a vacuum capability to pull waste material out of the polishing pad and through the apertured conditioning disk to evacuate the apparatus through an outlet port. The apparatus also includes a force adjustment system for providing measurement and control of the force applied by the conditioning disk to the polishing pad.

Owner:TBW IND INC

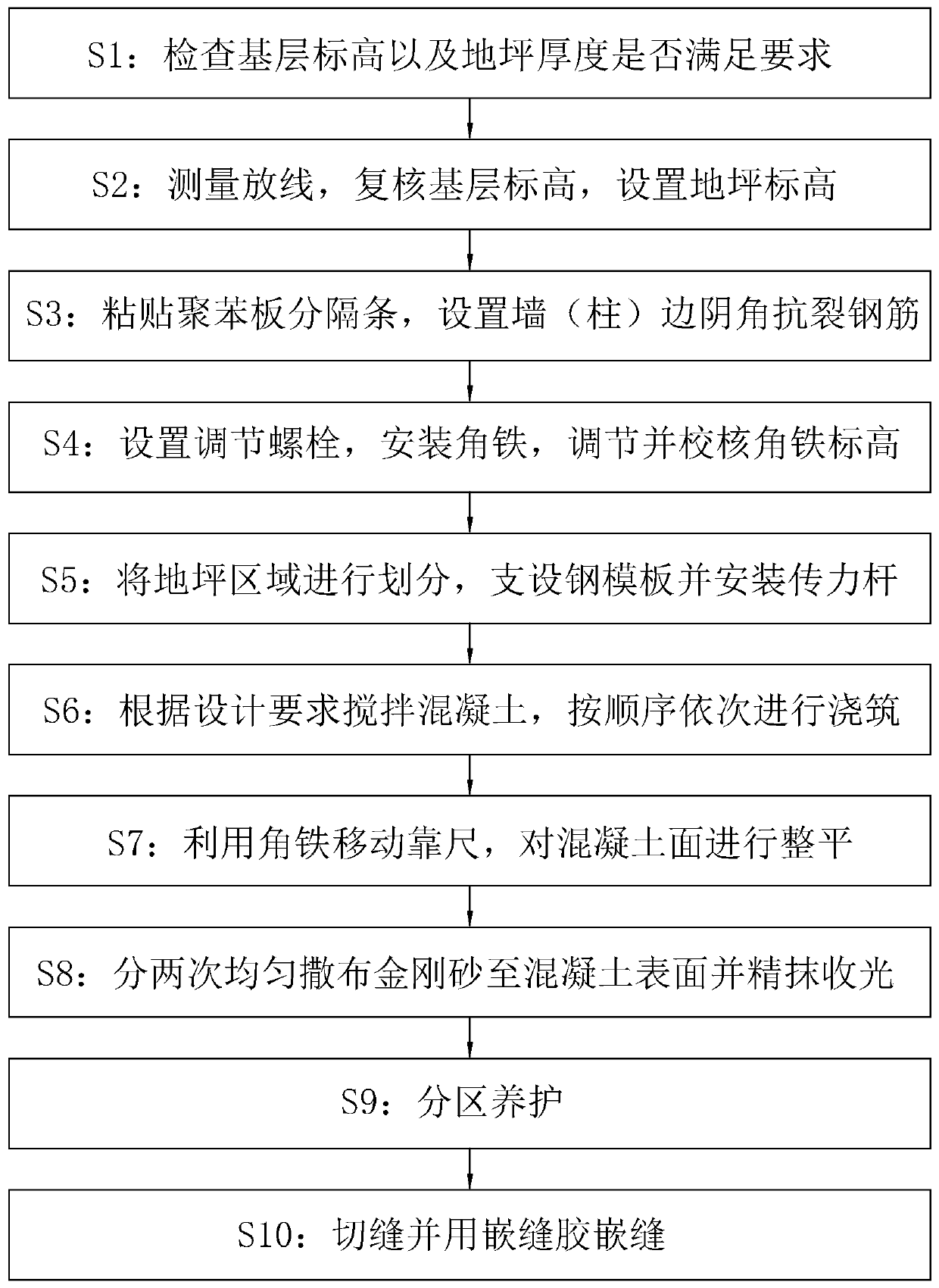

Wear-resistant floor construction process

The invention relates to a wear-resistant floor construction process, and belongs to the field of building construction The wear-resistant floor construction process comprises the following steps thatwhether base level elevation and floor thickness meet requirements is checked; surveying and setting out is carried out, the base level elevation is re-checked, and a floor elevation is set; polystyrene board partition bar pasting is carried out, and anti-cracking reinforcing steel bars are arranged at a wall (column ) internal corner; adjusting bolts are arranged, angle iron is installed, and the elevation of the angle iron is adjusted and checked; a floor area is divided, a steel form is erected, and a force transfer rod is installed; concrete is stirred according to design requirements, and pouring is carried out sequentially according to the sequence; the angle iron is used for moving a guiding ruler, and the concrete surface is leveled; emery is evenly spread twice on the concrete surface, and the concrete surface is subjected to fine grinding and polishing; the subareas are maintained; and seams are formed through cutting and caulked with caulking glue. According to the process,the floor flatness is improved, and the deviation of the floor elevation is reduced.

Owner:中恒辉建设有限公司

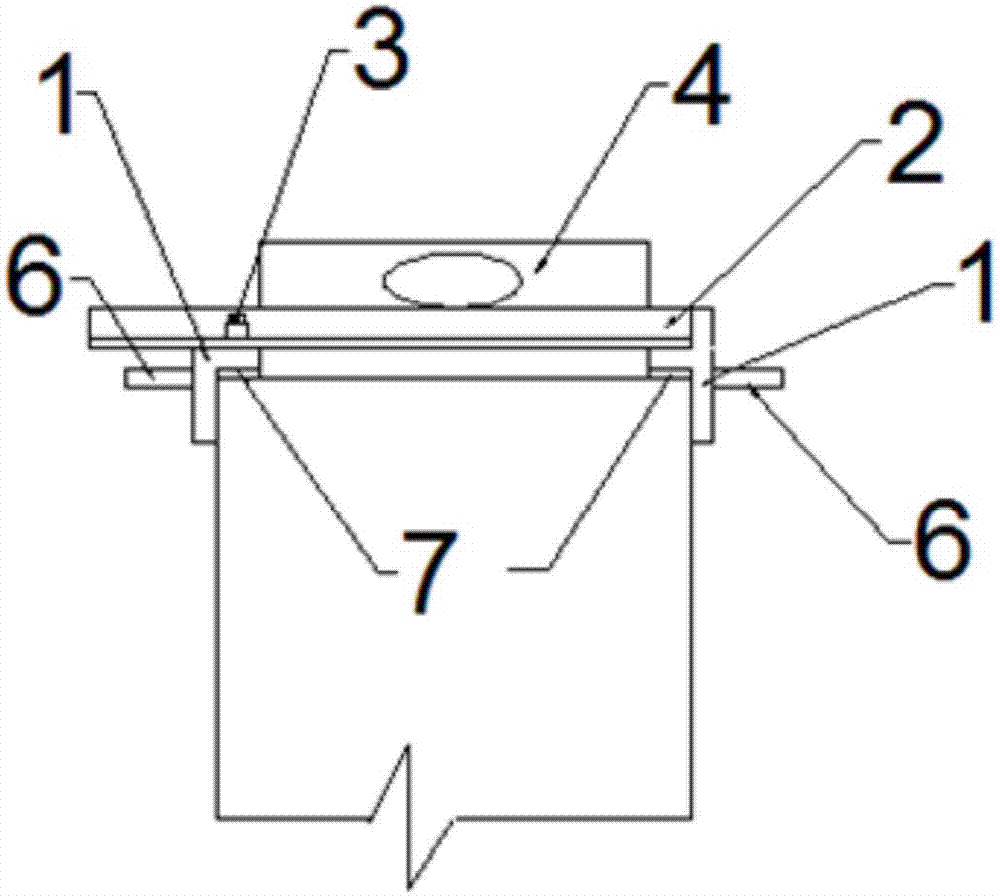

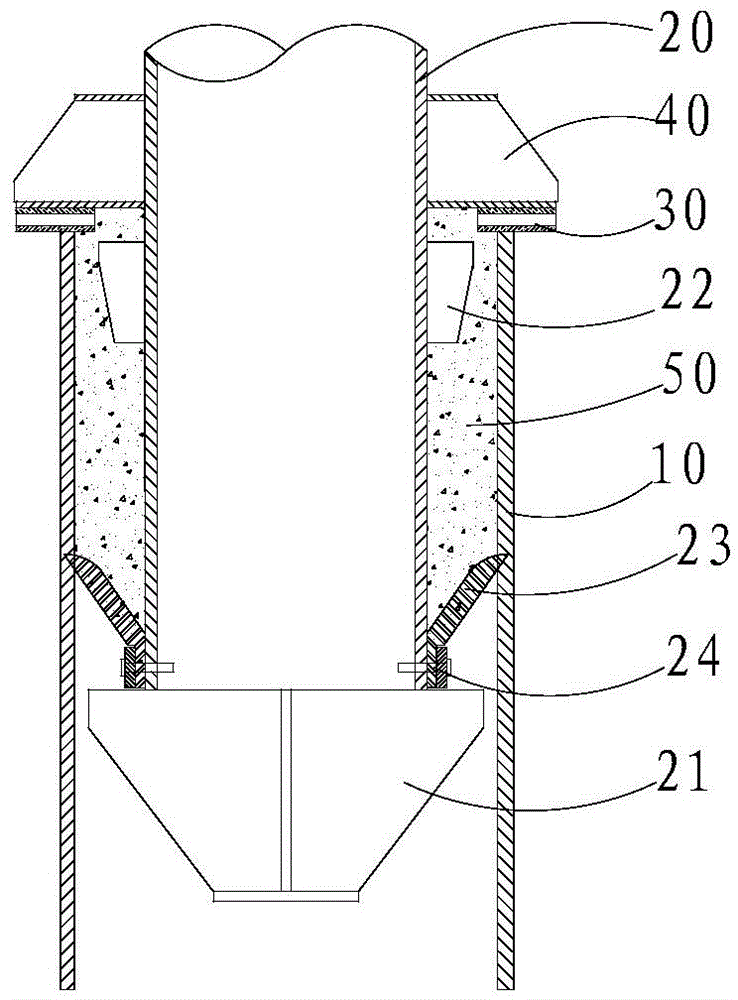

Cushion block for controlling floor thickness

InactiveCN106639166AGuaranteed thicknessControl elevationBuilding reinforcementsFloor slabEngineering

The invention relates to a cushion block for controlling floor thickness. The cushion block for controlling floor thickness effectively overcomes the problems of great consumption of labor and energy and long construction period since the elevation and flatness of floors in construction are difficult to control and subsequent operation like making of a leveling layer is needed in the prior art. According to a technical scheme in the invention, a totally through hole is arranged in a concrete cushion block; a nut is embedded in the through hole; the nut is nested with the lower end of a bolt; the upper end of the bolt is arranged above the nut and coated with a reflecting paint layer; and a groove located at the outer side of the through hole is formed in the center of the top surface of the concrete cushion block. The cushion block for controlling floor thickness in the invention is simple in structure, low in manufacturing cost, practical and convenient; the height of the cushion block can be adjusted at will to fit floors with various thicknesses; floor thicknesses of both plane roofs and sloping roofs can be effectively guaranteed; and the elevation and flatness of cast-in-situ concrete slabs can be controlled in one shot, so the construction procedure for making a leveling layer for a floor is omitted.

Owner:李侠

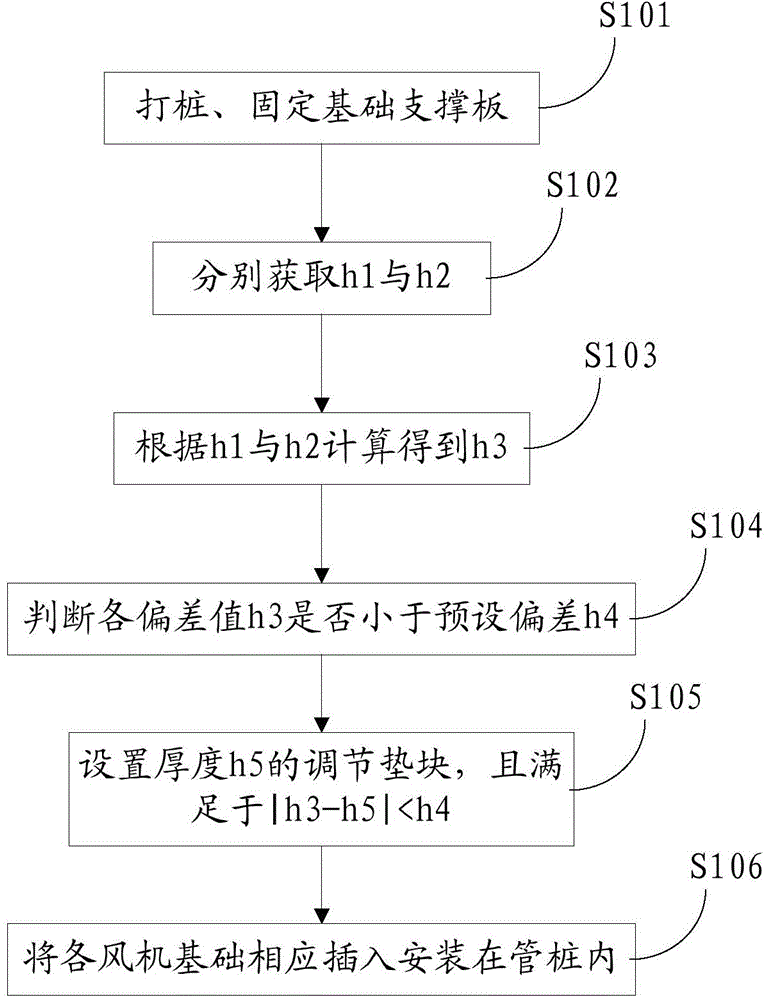

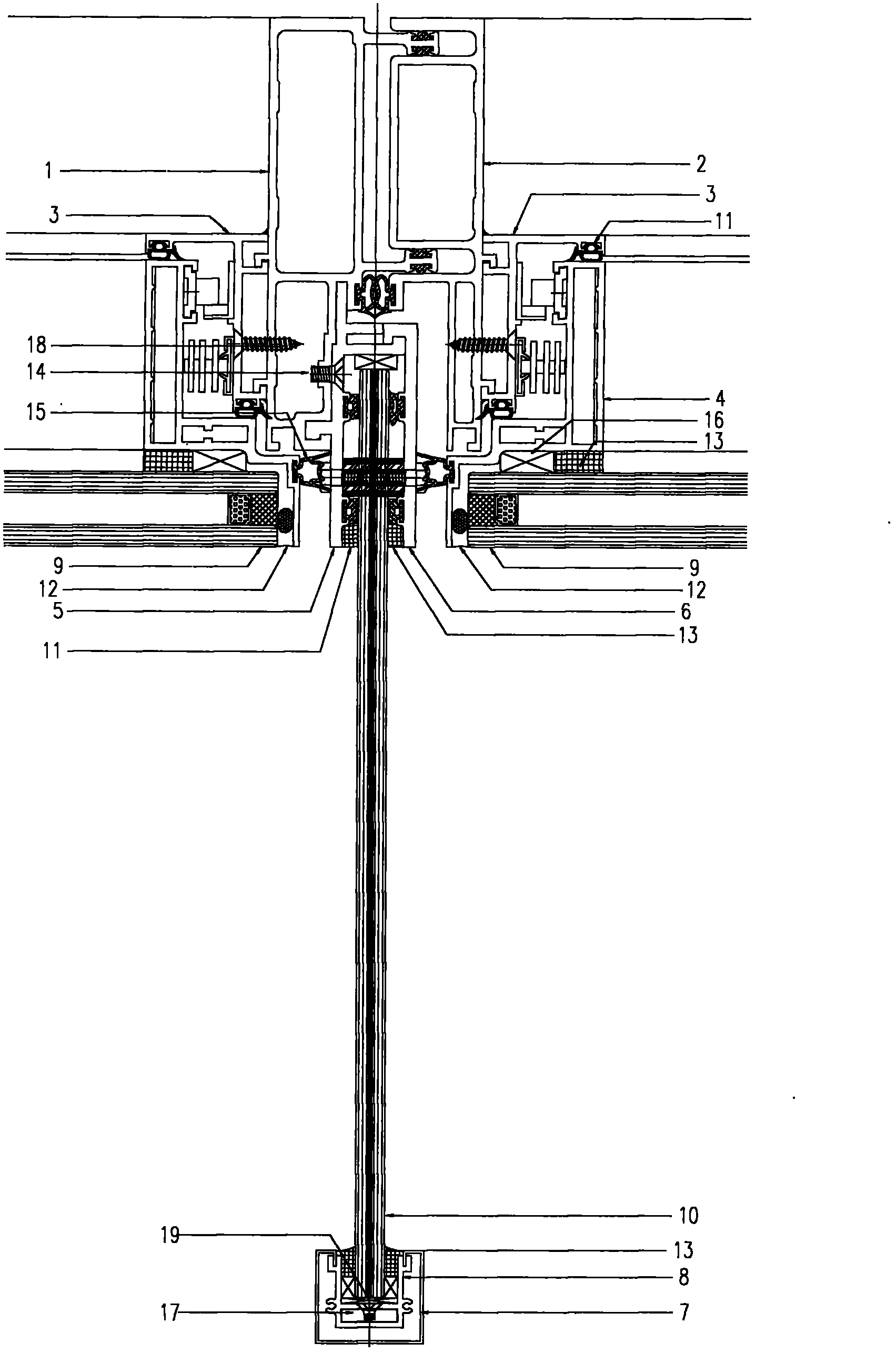

Leveling structure and leveling method for sea fan foundations

The invention relates to a leveling structure and leveling method for sea fan foundations. The leveling structure for the fan foundations comprises two or more than two pipe piles, wherein the pipe piles are fixedly mounted at the bottom of the sea, the pipe piles are connected with the fan foundations, each fan foundation is fixedly connected with a foundation supporting plate, and adjusting cushion blocks are arranged between the foundation supporting plates and the pipe piles. Through the adoption of the leveling structure for the sea fan foundations, each fan foundation is correspondingly inserted into each pipe pile so as to mount and fix each fan foundation. Besides, the adjusting cushion blocks are arranged between the fan foundations and the pipe piles, deviation between the fan foundations and the pipe piles is counteracted by changing the thickness of the adjusting cushion blocks, so that the foundation supporting plates of each fan foundation are ensured to be positioned on the same plane, and better flatness is supplied to sea fans and anemometer towers. As known, the method disclosed by the invention replaces an existing method which uses a hydraulic lifting system to improve the flatness of the fan foundations. Compared with the prior art, the leveling structure disclosed by the invention has the advantages of simpler structure, stronger operability, and higher cost performance.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

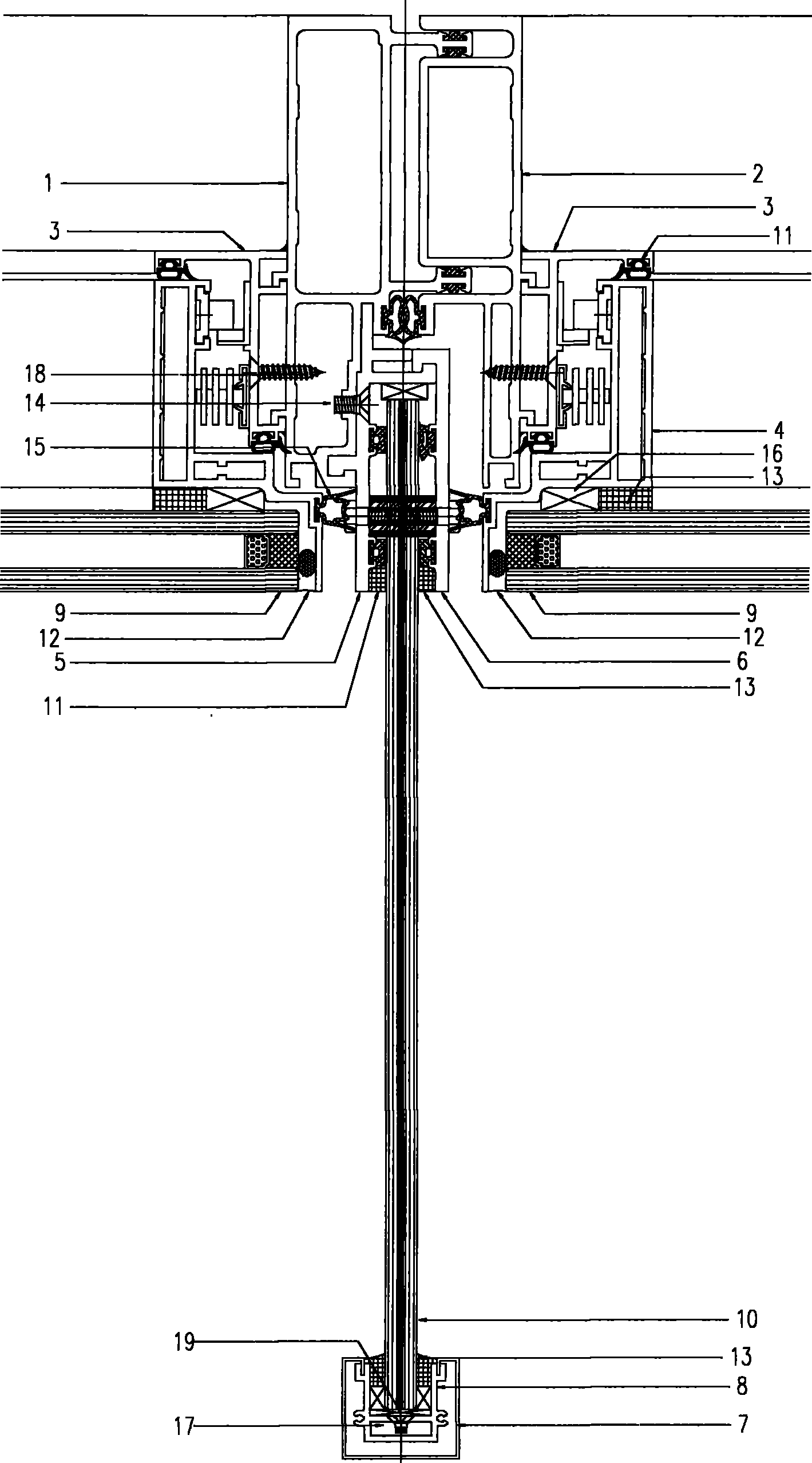

Unit curtain wall system with cantilevered glass flank and opening window

The invention relates to a unit curtain wall system with a cantilevered glass flank and an opening window. The system comprises a unit male column, a unit female column, aluminium alloy window frame materials, aluminium alloy window sash materials, an aluminium alloy connecting piece, an aluminium alloy buckle plate, glass protective edges, curtain wall glass, cantilevered glass and an aluminium alloy insert core, wherein the aluminium alloy window frame materials are buckled on the unit male column and the unit female column and are connected with the unit male column and the unit female column through fastening; the aluminium alloy connecting piece is buckled on the unit male column and is fixedly connected with the unit male column; the aluminium alloy buckle plate is buckled on the aluminium alloy connecting piece; the glass protective edges are fixedly connected at the front end of the cantilevered glass; the aluminium alloy insert core is fixedly arranged in the cavity of the glass protective edges; the cantilevered glass is fixedly inserted in the notch of the glass protective edges; and seal plates are fixedly connected at the upper and lower openings of the glass protective edges. The system has the following beneficial effects: all the processing procedures are completed in the plant; field installation is convenient; the processing flatness is good; the precision is high; and the problem of large deviation after field installation of the cantilevered glass before is solved.

Owner:SUZHOU KELIDA BUILDING & DECORATION CO LTD

Construction electric switch box construction method once and for all

ActiveCN101392597AThe installation position is accurateReduce construction proceduresBuilding constructionsTape measureReinforced concrete

The invention discloses a one-time completed construction method for a building electrical distribution box. The method is to embed the box in place at a time before the concrete is cast during the construction process. The box on a wall takes the level control line on the layer as a reference, and the accurate position of the box is measured by a water level gauge, a steel measuring tape and a track level bar; lines are drawn on the surface of the box to determine the position for entering a pipeline and open an opening on the position by an opener; the box on a reinforced concrete wall is fixed on a steel mesh by a steel bar in a shape of a Chinese character 'jing'; the box on a brick wall or a light partition is connected and fixed with a matched pipeline before construction; the pipeline entering the box corresponds a hole, and the arrangement is orderly; and cut polystyrene foam plates are filled in the box and the periphery of the box is sealed by adhesive tapes. The aim of the method is to ensure the accuracy of the position of the box.

Owner:陕西建工第三建设集团有限公司

Method and plant for integrated monitoring and control of strip flatness and strip profile

ActiveUS7849722B2Reduce tensionSusceptible to bucklingRoll force/gap control deviceMetal rolling stand detailsIntegrated monitoringControl system

Apparatus and method of controlling strip geometry in casting strip having a rolling mill. A target thickness profile is calculated as a function of the measured entry thickness profile of the strip while satisfying profile and flatness operating requirements. A differential strain feedback from longitudinal strain in the strip is calculated by a control system by comparing the exit thickness profile with the target thickness profile, and a control signal is generated to control a device capable of affecting the geometry of the strip processed by the hot rolling mill. A feed-forward control reference and / or sensitivity vector may also be calculated as a function of the target thickness profile, and used in generating the control signal sent to the control device. The control device may be selected from one or more of the group consisting of a bending controller, gap controller and coolant controller.

Owner:NUCOR CORP

Vertically-inserting-type ceramic tile locating horizontal mounting device

The invention discloses a vertically-inserting-type ceramic tile locating horizontal mounting device in the field of building decoration, wherein the vertically-inserting-type ceramic tile locating horizontal mounting device brings convenience to ceramic tile paving. The device is composed of a locating seat and a compressing block. The locating seat is vertically connected to the center of a hexagonal base plate through a rectangular rack, a rectangular shallow groove is formed in the position, perpendicular to the rack, of the bottom face of the base plate, the area of the rectangular shallow groove is equal to the area of the cross section of the rack, and the two ends of the base plate turn upwards, are arc-shaped and have elasticity. The compressing block is composed of two pairs of trapezoid bodies and is cross-shaped either looked downward or upward. A rectangular hole is formed in the upper end of the compressing block, the rectangular hole is matched with the rack of the locating seat, a metal pressing plate is arranged on one side of the compressing block, and one end of the pressing plate is meshed with the rack. According to the vertically-inserting-type ceramic tile locating horizontal mounting device, the size of a gap between two tiles can be controlled, and the flatness of the surface between the tiles can also be controlled. In addition, the vertically-inserting-type ceramic tile locating horizontal mounting device has the advantages of being convenient to use, greatly improved in working efficiency, simple in structure and low in production cost, and lowering use cost due to the fact that the compressing block can be used repeatedly.

Owner:SHANGHAI WONENG INDAL

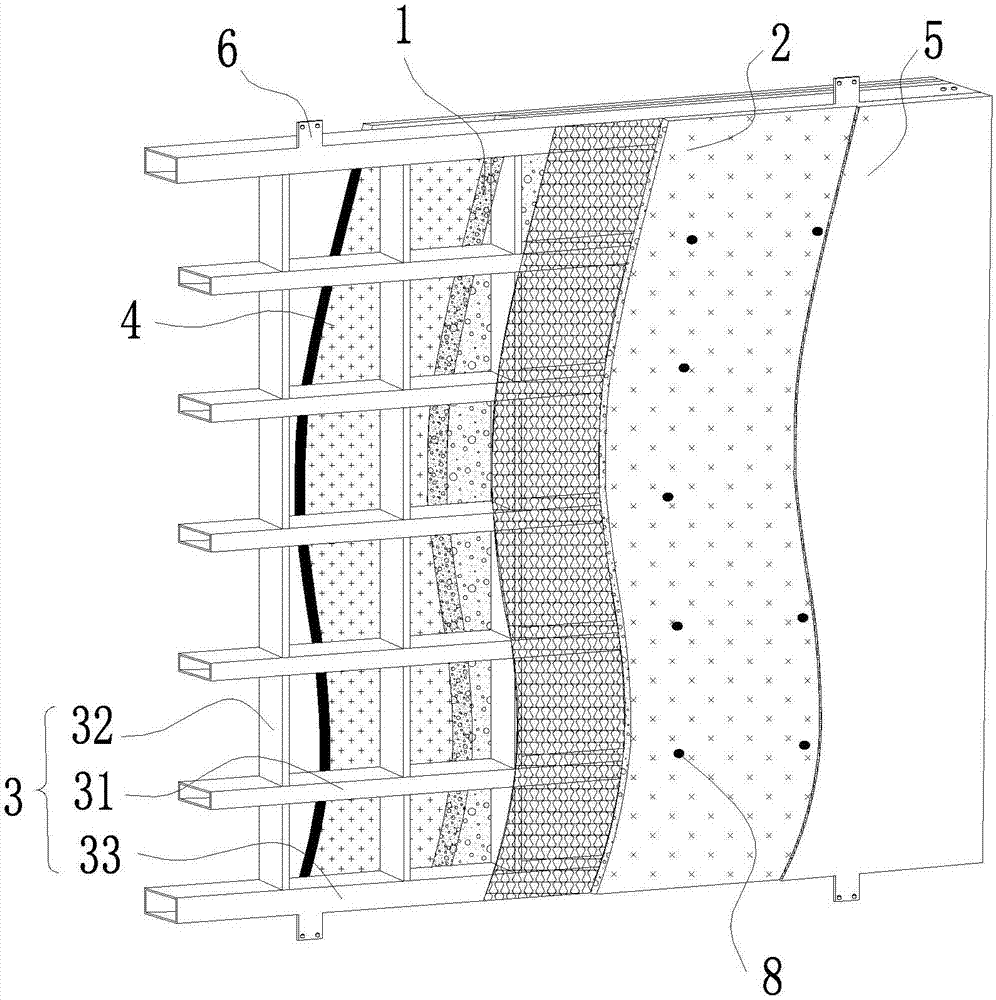

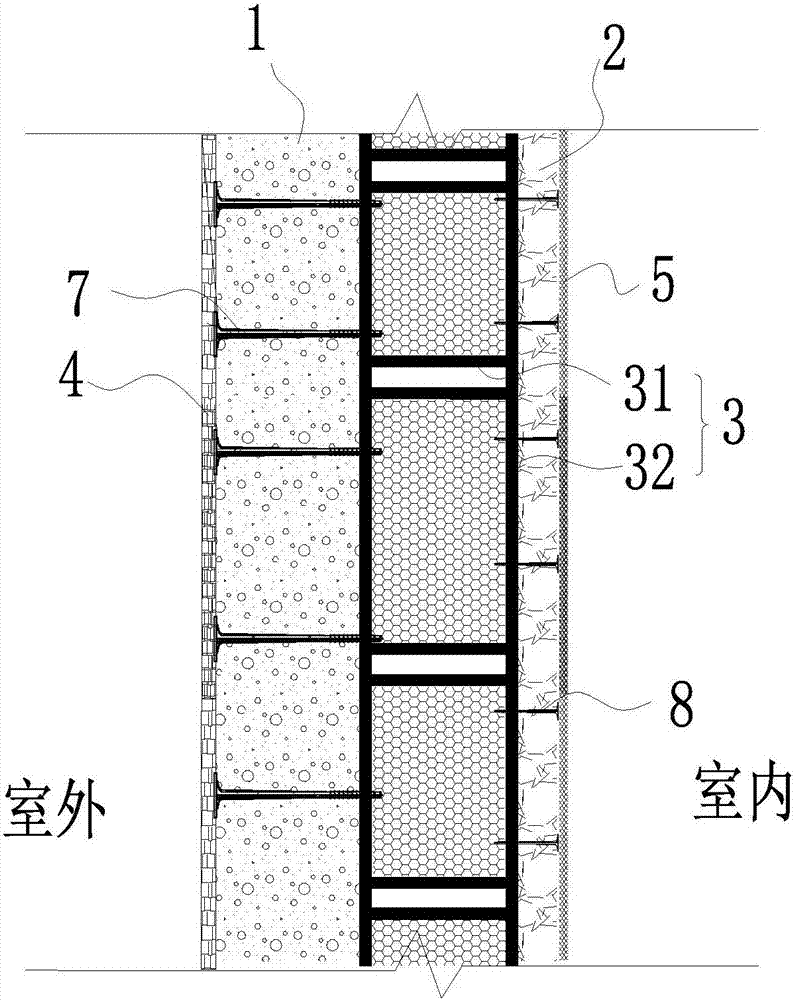

Assembled external wall plate and preparation method thereof

PendingCN107254935ALower requirementAvoid crackingCovering/liningsLayered productsBuilding materialWall plate

The invention relates to the field of a building material, in particular to an assembled external wall plate. The assembled external wall plate comprises an outer side plate, an inner side plate and a multifunctional structure layer, wherein the multifunctional structure layer is arranged between the outer side plate and the inner side plate; one side of the outer side plate is connected with one side of the multifunctional structure layer; an outer decoration layer is compounded at the other side of the outer side plate; one side of the inner side plate is connected with the other side of the multifunctional structure layer; an inner decoration layer is compounded at the other side of the inner side plate; the multifunctional structure layer comprises a force bearing frame; and waterproof heat insulation and heat preservation materials are filled in gaps between the outer side plate and the force bearing frame and gaps between the inner side plate and the force bearing frame. The quality can be ensured; the construction and the hoisting are easy; the construction efficiency is improved; the integral performance is stable; the impact resistant performance is good; the conventional common quality faults of wall plate cracking and deformation, edge missing, corner falling and the like can be avoided; after once installation completion, the veneer construction is not needed; and the engineering manufacturing cost and the construction period are reduced.

Owner:重庆佳良建筑设计咨询有限公司

Titanium boride-based coating composite material for aluminum electrolysis, preparation method and coating method thereof

ActiveCN103194101ALower sintering temperatureReduce manufacturing costCoatingsGraphite carbonAluminium electrolysis

The invention discloses a titanium boride-based coating composite material for aluminum electrolysis, a preparation method and a coating method thereof. The composite material consists of the following raw materials in percentage by weight: 55%-70% of titanium boride-oxide composite particles, 8%-15% of a carbon additive, 15%-30% of an organic resin adhesive and 0.5%-2% of a reinforcing agent. The coating method comprises the following steps: (1) putting a graphite base material into a coating mould, and then, pouring the obtained slurry into a mould; (2) curing the base material coated with the slurry at 15 DEG C-35 DEG C for 24h-48h, and then, curing the base material at 80 DEG C-150 DEG C for 12h-24h; and (3) putting the base material coated with the slurry into a graphite crucible, filling graphite carbon powder into the graphite crucible, and carbonizing and sintering the graphite crucible in an inert gas atmosphere or in vacuum, wherein the carbonizing and sintering temperature is 850-1050 DEG C, and the carbonizing and sintering time is 80-120 hours. The titanium boride-based coating composite material for aluminum electrolysis has high combination degree with a base and good tensile strength high up to 8-10MPa; and a coating structure is dense and has strong anti-scouring property.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

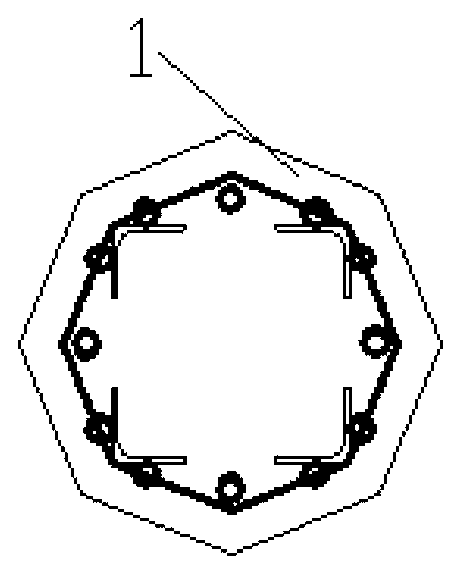

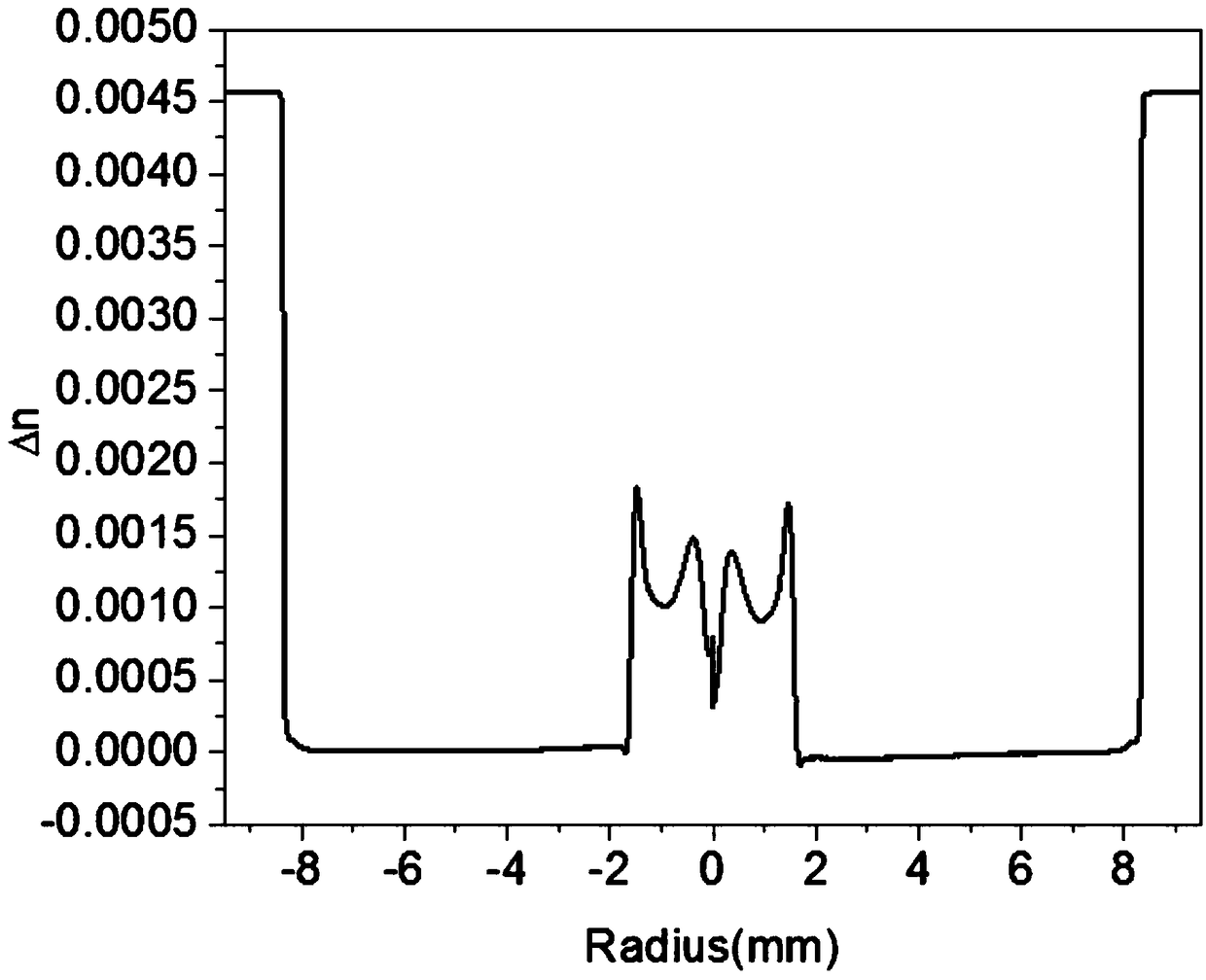

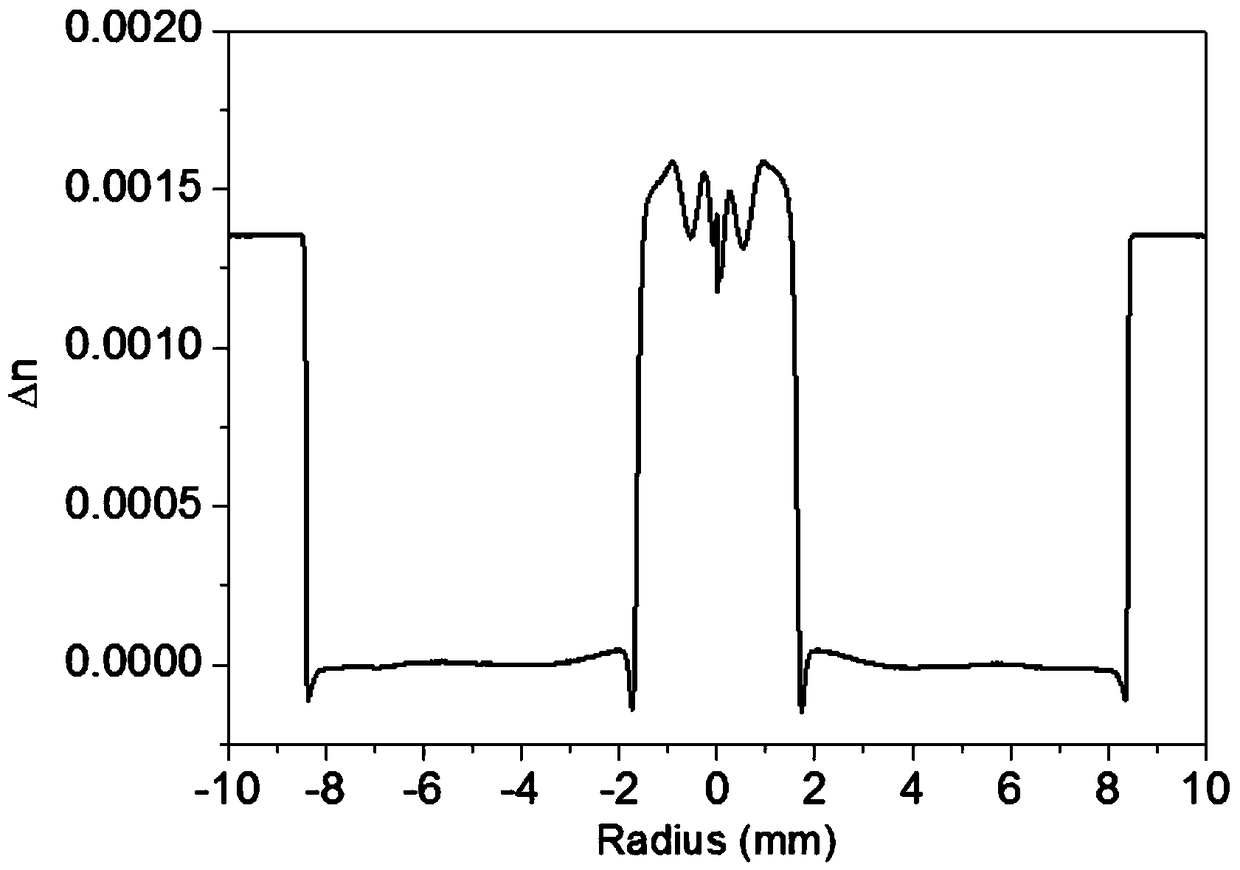

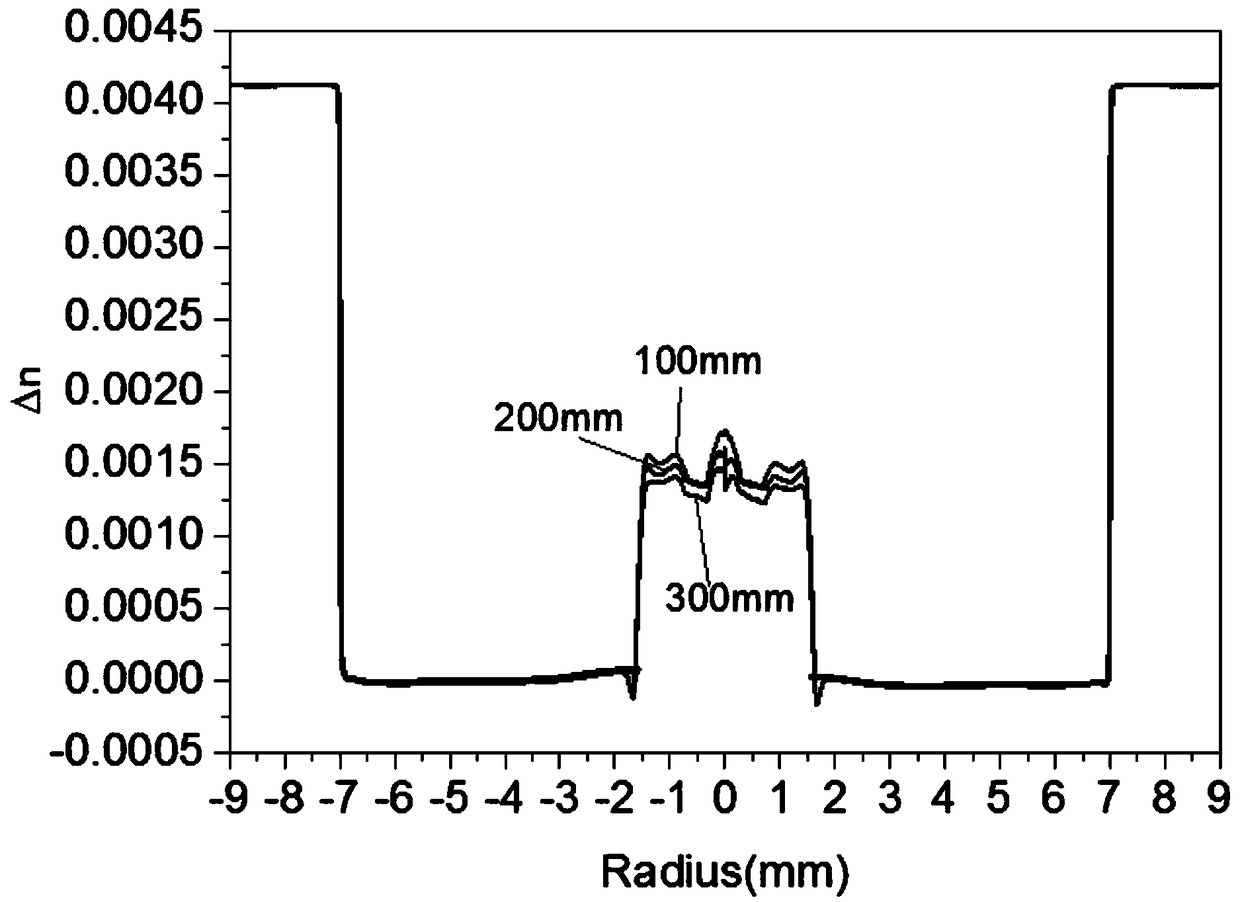

Optical fiber preform and manufacturing method of optical fiber

InactiveCN109293249AControl flatnessIncrease the doping concentrationGlass making apparatusRare earth ionsGas phase

The invention relates to an optical fiber preform and a manufacturing method of an optical fiber, in particular to a manufacturing method of the optical fiber preform with a large core diameter and acorresponding low loss optical fiber, the method solves the problem of the optical fiber preform with a small core diameter prepared in the prior art. The manufacturing method of the optical fiber preform includes, adopting an improved chemical vapor deposition (MCVD) combined with a rare earth ion gas phase doping method; depositing all materials under a gas phase condition; and then obtaining the optical fiber preform with a large core diameter through sintering and tube shrinkage processes, wherein components of the manufactured optical fiber preform core are SiO2, Al2O3, Yb2O3, Ce2O3 and F, the diameter of the preform core > 3 mm. The manufacturing method of the optical fiber includes, selecting an appropriate sleeve process to sleeve the manufactured optical fiber preform to enable the core-to-package ratio to meet the requirements of the optical fiber; processing the sleeved preform into an octagonal structure; and performing wire drawing at a temperature of 2050 + / -20 DEG C to draw into the optical fiber.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com