Optical fiber preform and manufacturing method of optical fiber

A technology of optical fiber preform and equipment, which is applied in the field of low-loss optical fiber preparation, can solve the problems of optical fiber background loss, uneven distribution of core refractive index, and small core diameter of optical fiber preform, so as to reduce loss and reduce clusters” effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

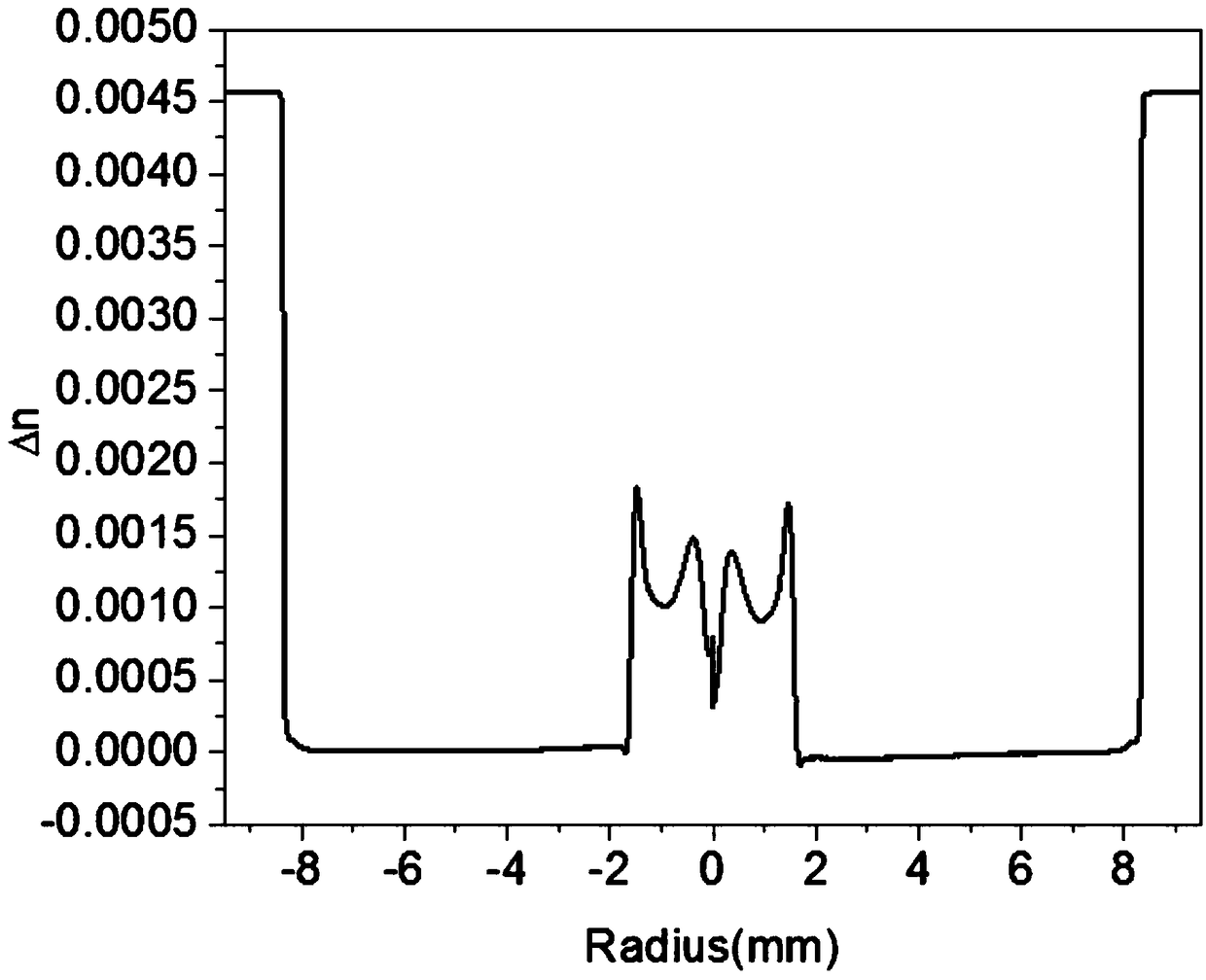

[0058] According to Table 1, the flow rate of each component in each deposition layer is set in the MCVD automatic control software; the quartz tube is connected to the MCVD deposition lathe, and the quartz tube is preheated by the hydrogen-oxygen flame. After the preheating is completed, the SF 6 The gas erodes the inner wall of the quartz tube; after the erosion, the gas material is passed into the quartz tube to start depositing the core layer; The speed is 100mm / min; after the deposition is finished, 5sccm of Cl is introduced 2 Shrunk the quartz tube, after the hollow tube has been shrunk many times and fired into a solid rod, the prefabricated rod was flame-polished at 1600°C, and its refractive index and rod core diameter were tested. The results are as follows: figure 1 and 1 in Table 6 # sample shown, from figure 1 It can be seen that the radial refractive index distribution of the optical fiber preform is not uniform, and it is difficult to meet the requirements of ...

Embodiment 2

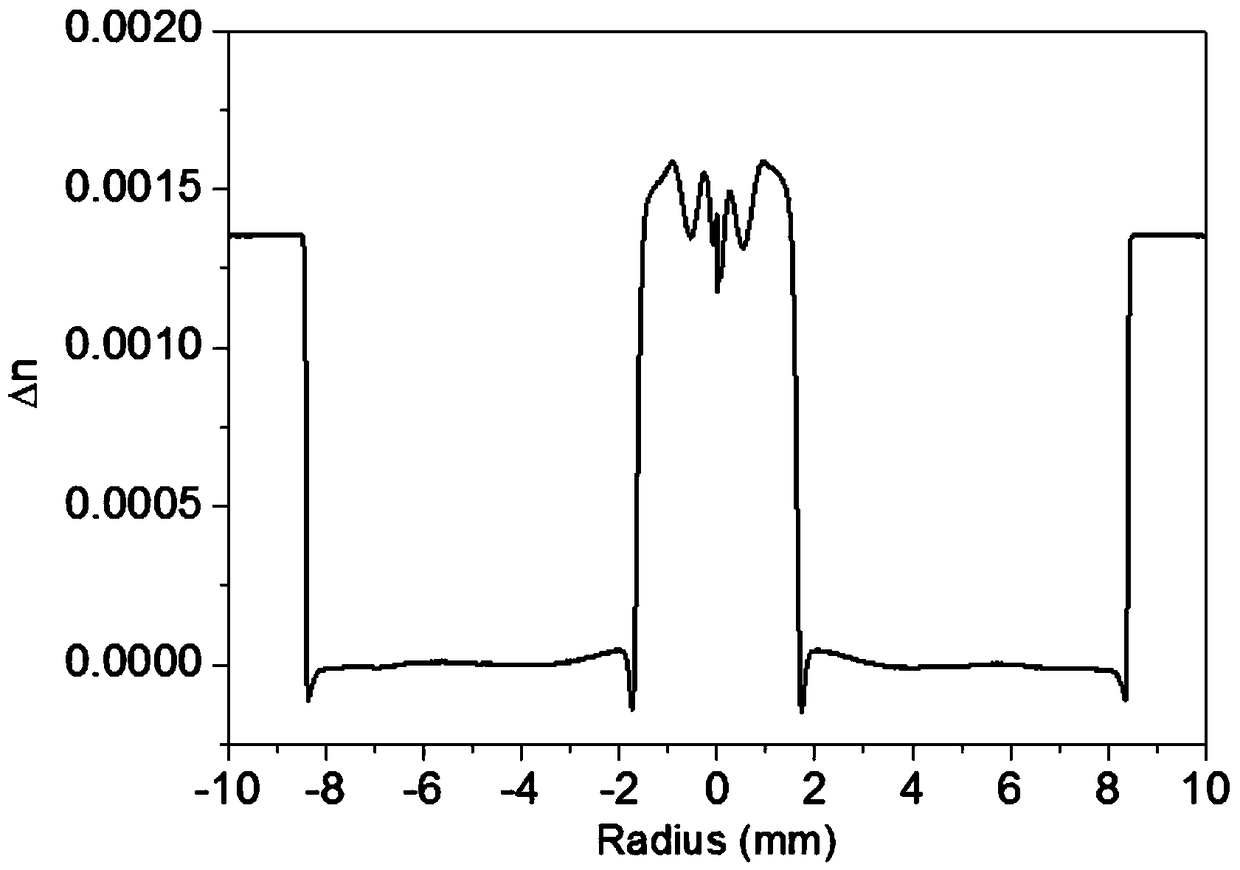

[0062] According to the component flow rate and refractive index distribution diagram of the prefabricated rod in Experimental Example 1, adjust the component Al(acac) in the deposited layer 3 and SiF 4 The flow rate, see Table 2, set the component flow rate in the MCVD automatic control software; connect the quartz tube to the MCVD deposition lathe, preheat the quartz tube through the hydrogen-oxygen flame, and pass it into SF after the preheating is completed 6 The gas erodes the inner wall of the quartz tube; after the erosion, the gas material is passed into the quartz tube to start depositing the core layer; The speed is 100mm / min; after the deposition is finished, 5sccm of Cl is introduced 2 Shrink the quartz tube, and after the hollow tube has been shrunk several times and fired into a solid rod, the optical fiber preform is polished with flame at 1600°C. Test the refractive index of the optical fiber preform and calculate the corresponding numerical aperture, the res...

Embodiment 3

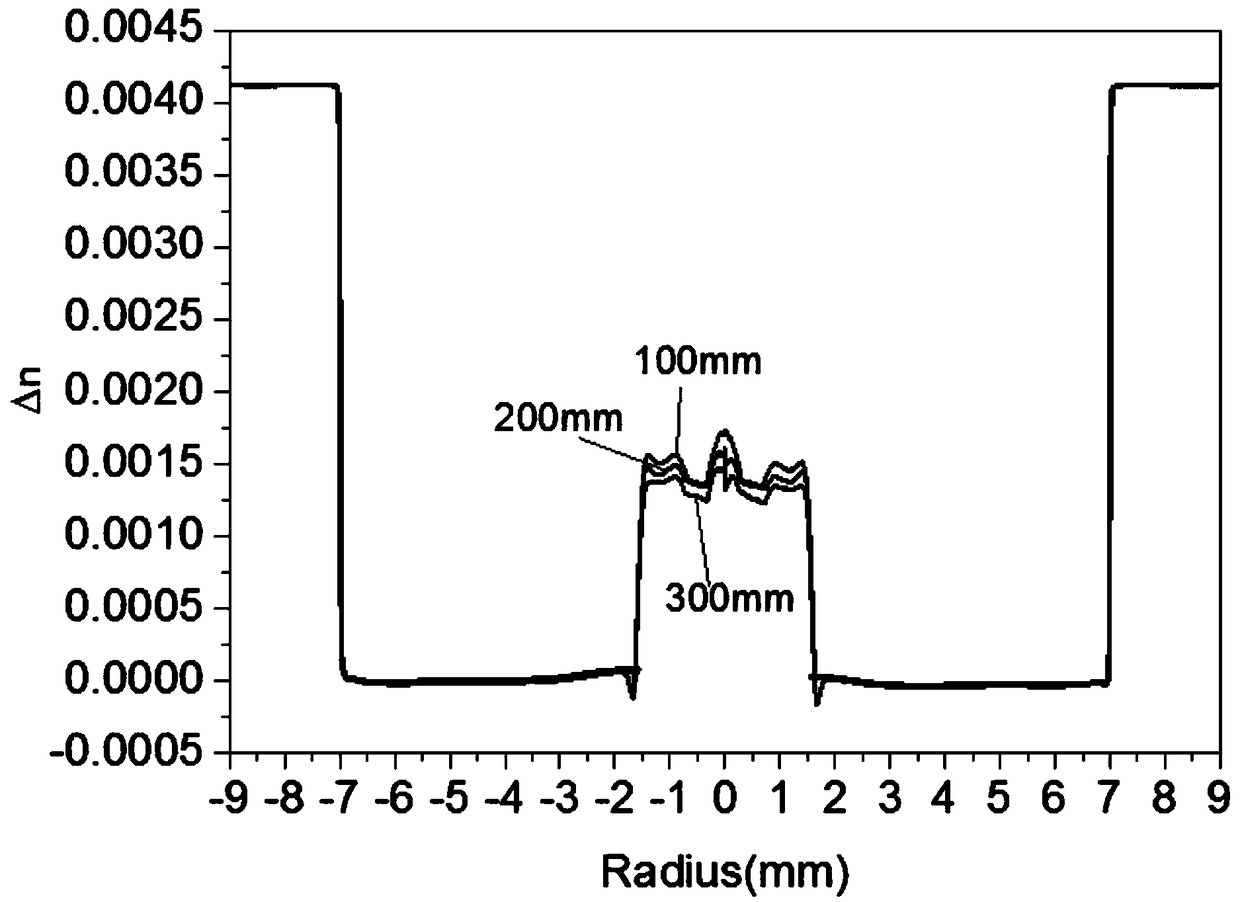

[0067] Adjust the reaction material Al(acac) in the deposition layer according to the component flow rate and the refractive index distribution diagram of the prefabricated rod in Experimental Example 1 3 and SiF 4 The flow rate, see Table 3, set the component flow rate in the MCVD automatic control software; connect the quartz tube to the MCVD deposition lathe, preheat the quartz tube through the hydrogen-oxygen flame, and pass the SF after the preheating is completed. 6 The gas erodes the inner wall of the quartz tube; after the erosion, the gas material is passed into the quartz tube to start depositing the core layer; The speed is 100mm / min; after the deposition is finished, 5sccm of Cl is introduced 2 Shrink the quartz tube, and after the hollow tube has been shrunk several times and fired into a solid rod, the optical fiber preform is polished with flame at 1600°C. Test the refractive index of the optical fiber preform of this embodiment, the results are shown in ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com