Patents

Literature

426results about How to "The installation position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

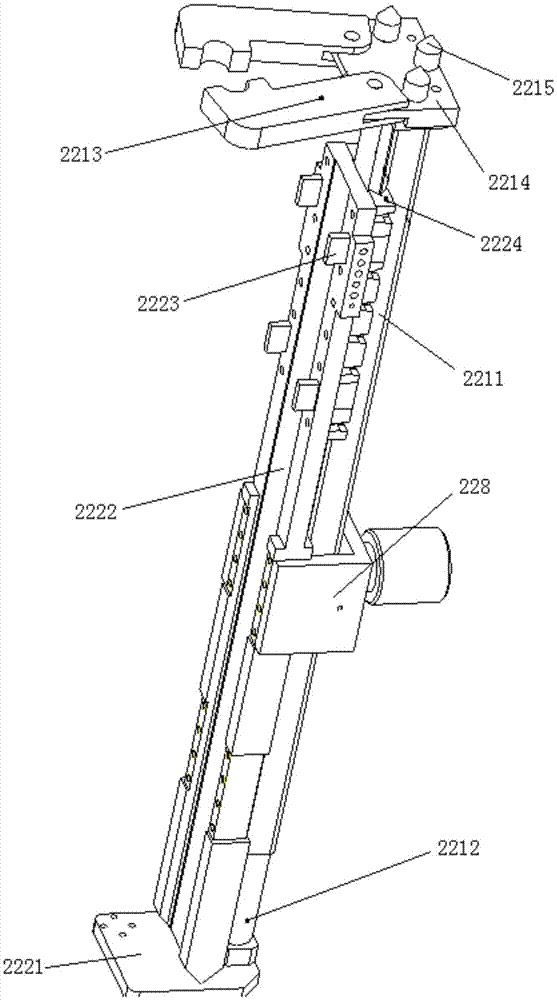

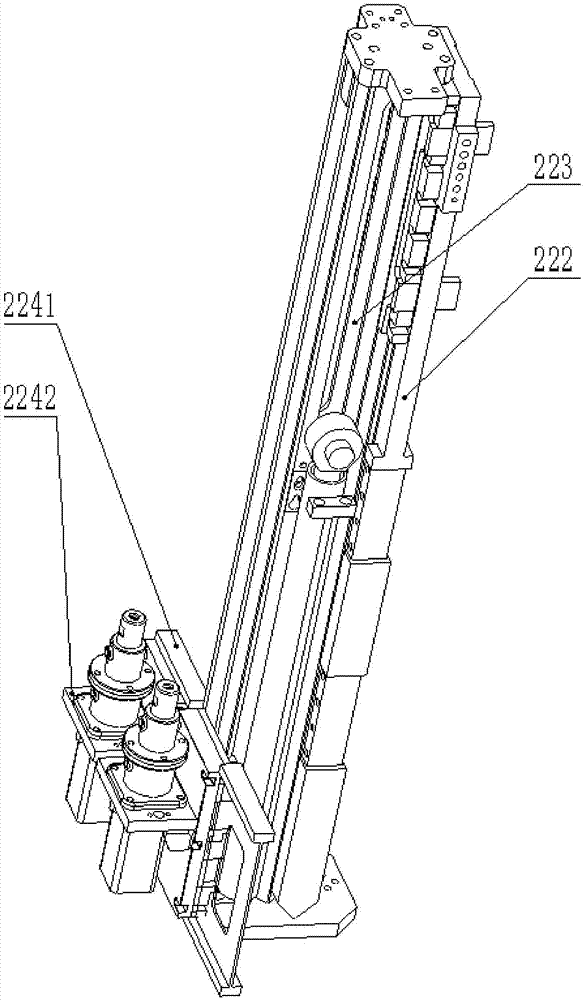

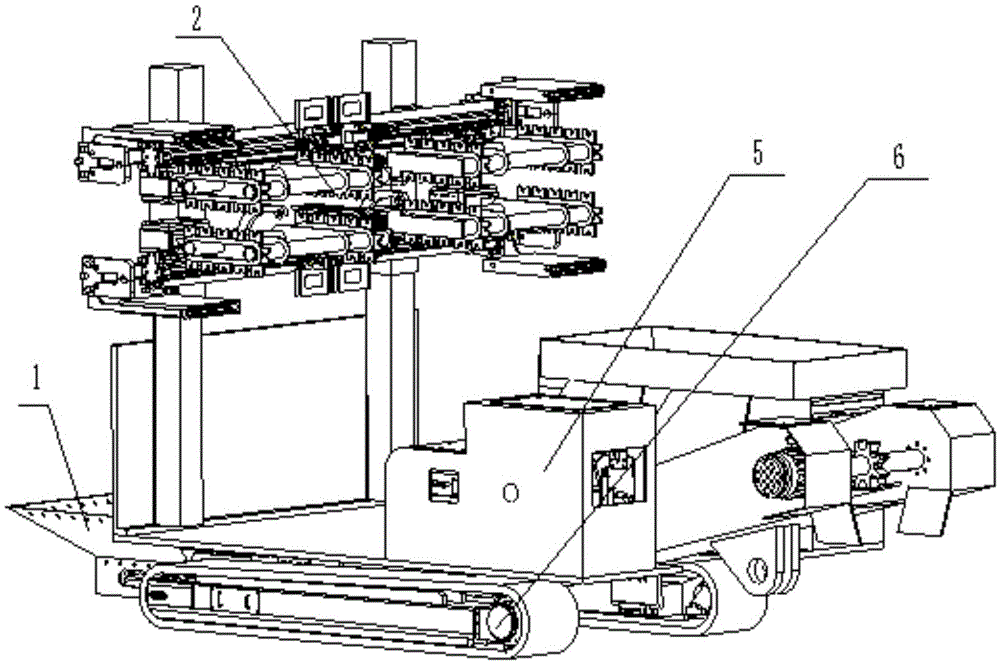

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

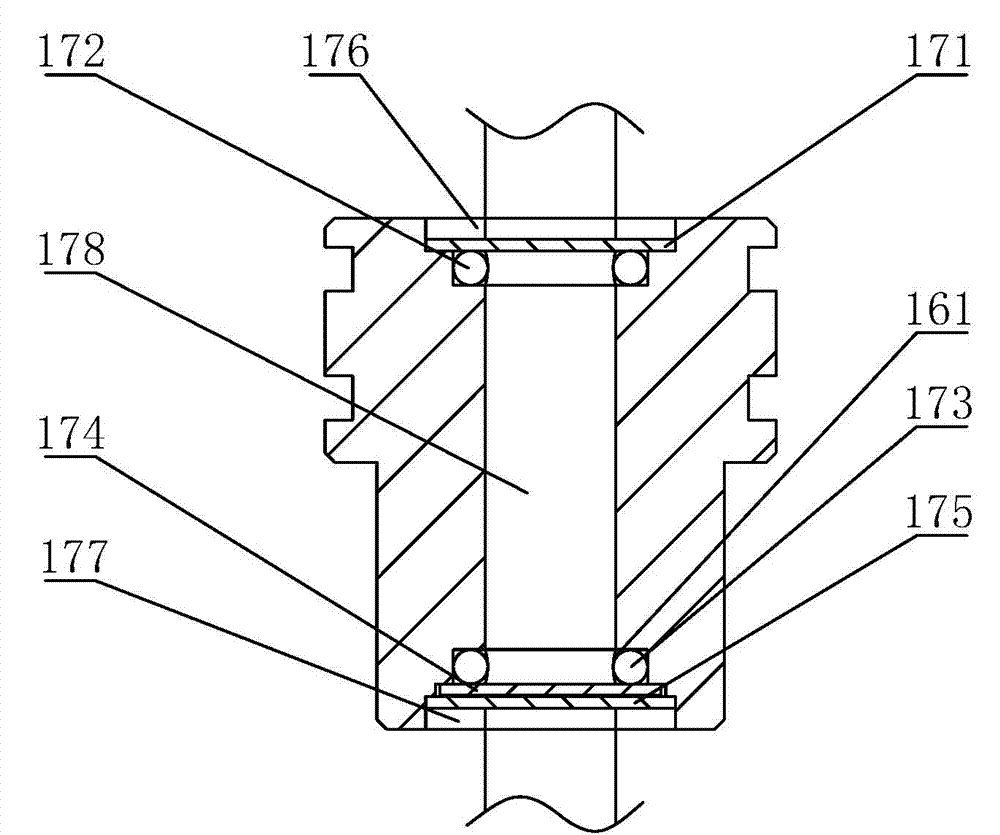

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

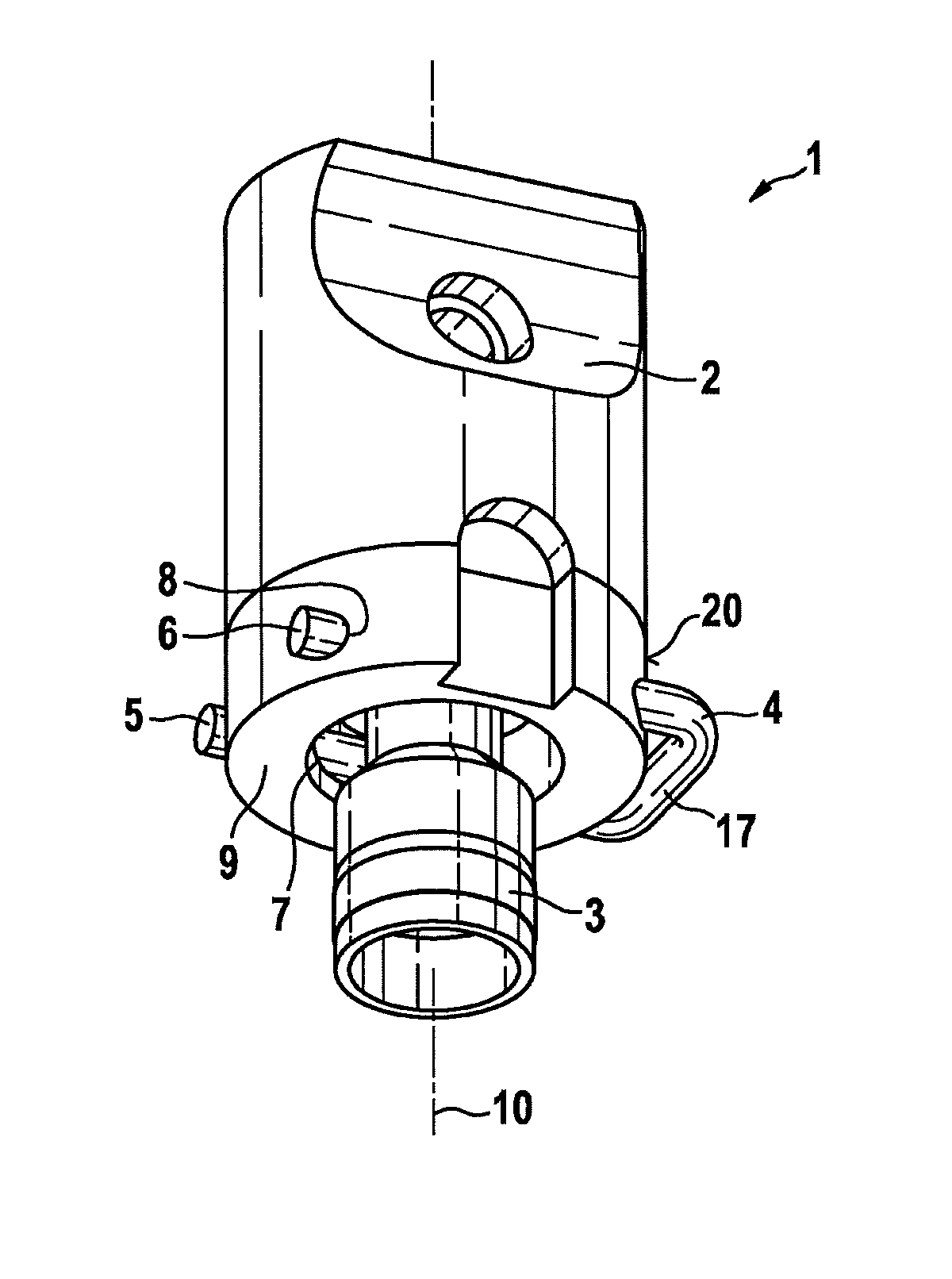

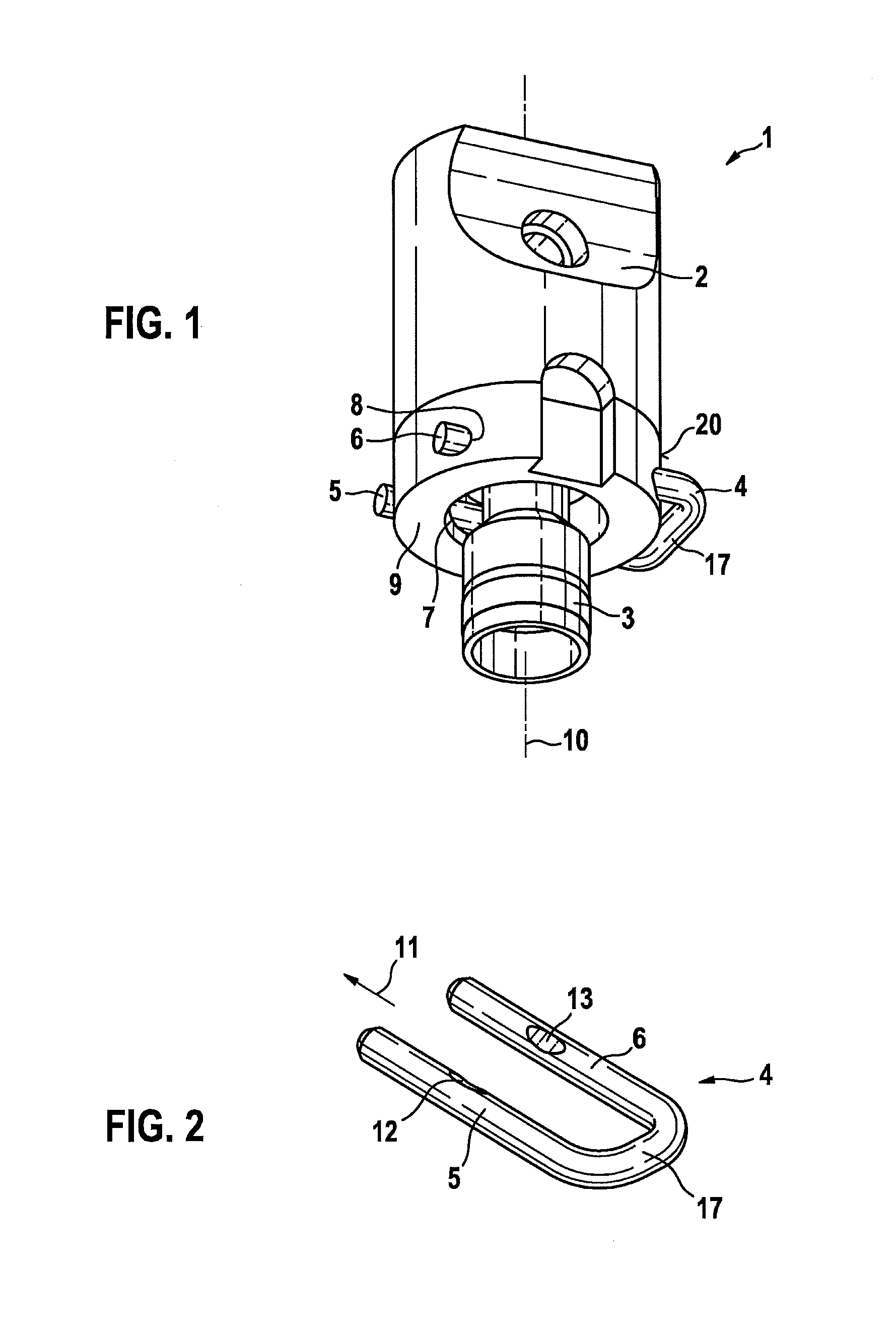

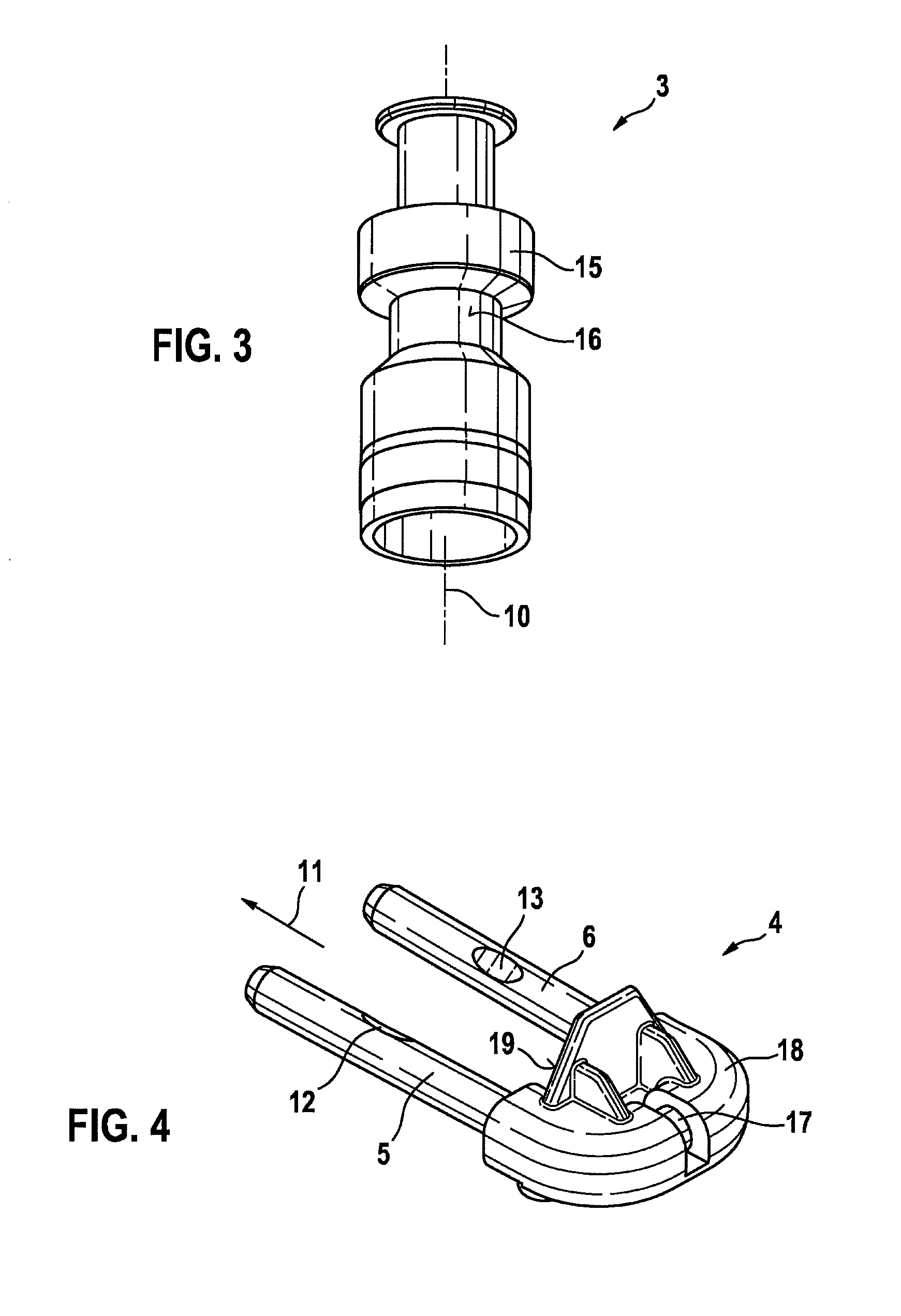

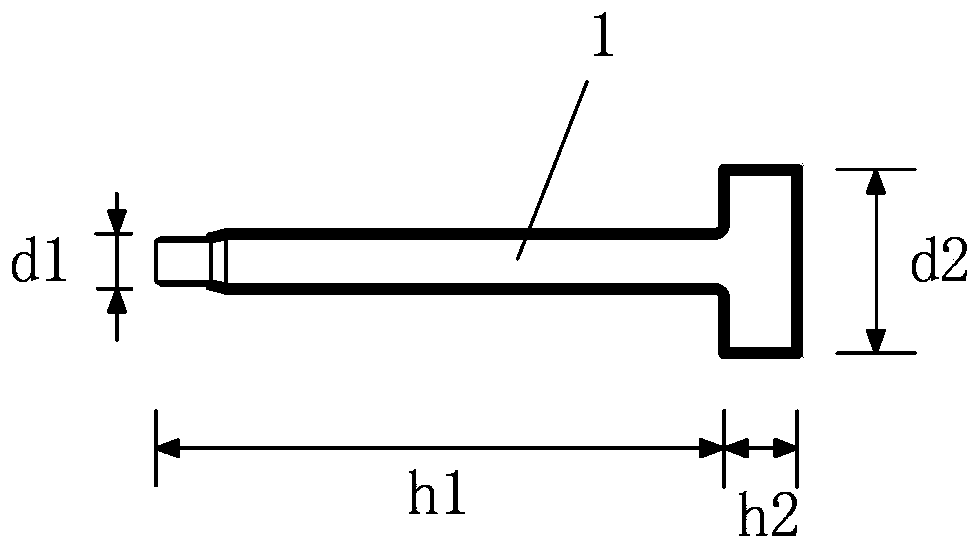

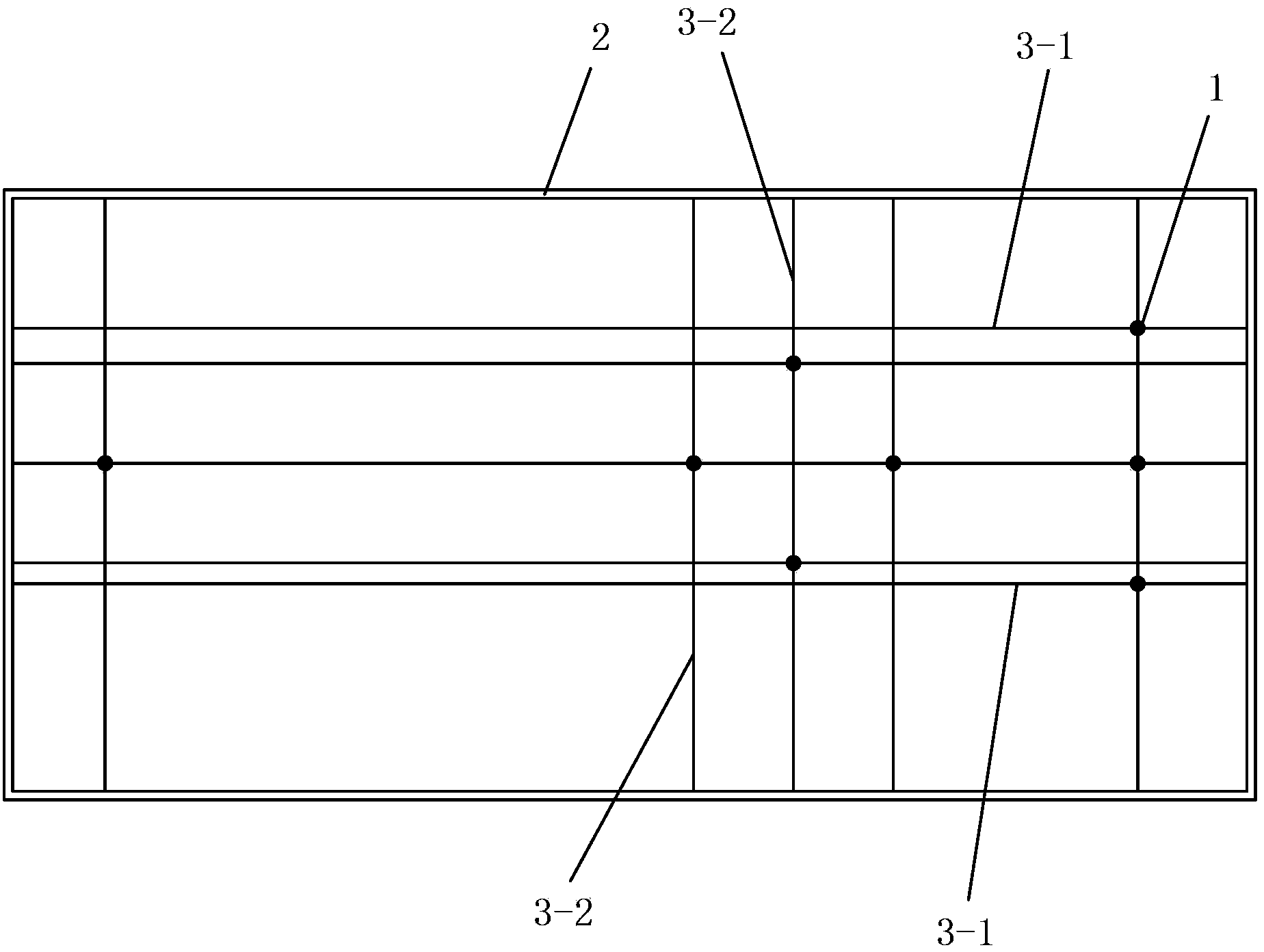

System having a fuel distributor and multiple fuel injectors

ActiveUS20150330347A1Improve load effectHigh work pressureInternal combustion piston enginesSpecial fuel injection apparatusCombustionEngineering

A system, which is used especially as a fuel injection system for the high-pressure injection in internal combustion engines, includes a fuel distributor and a plurality of fuel injectors. Each fuel injector is situated on a cup of the fuel distributor. At least one of the fuel injectors is fastened to the associated cup by a holding element. The holding element has an at least essentially straight first leg and an at least essentially straight second leg. The cup includes at least one recess, which extends through a wall of the cup. The first leg and the second leg are guided through the at least one recess. Furthermore, the connection sleeve of the fuel injector has a collar, which is braced on the first leg of the holding element and on the second leg of the holding element in order to secure the fuel injector on the cup. This makes it possible to fasten the fuel injector on the cup in a reliable manner.

Owner:ROBERT BOSCH GMBH

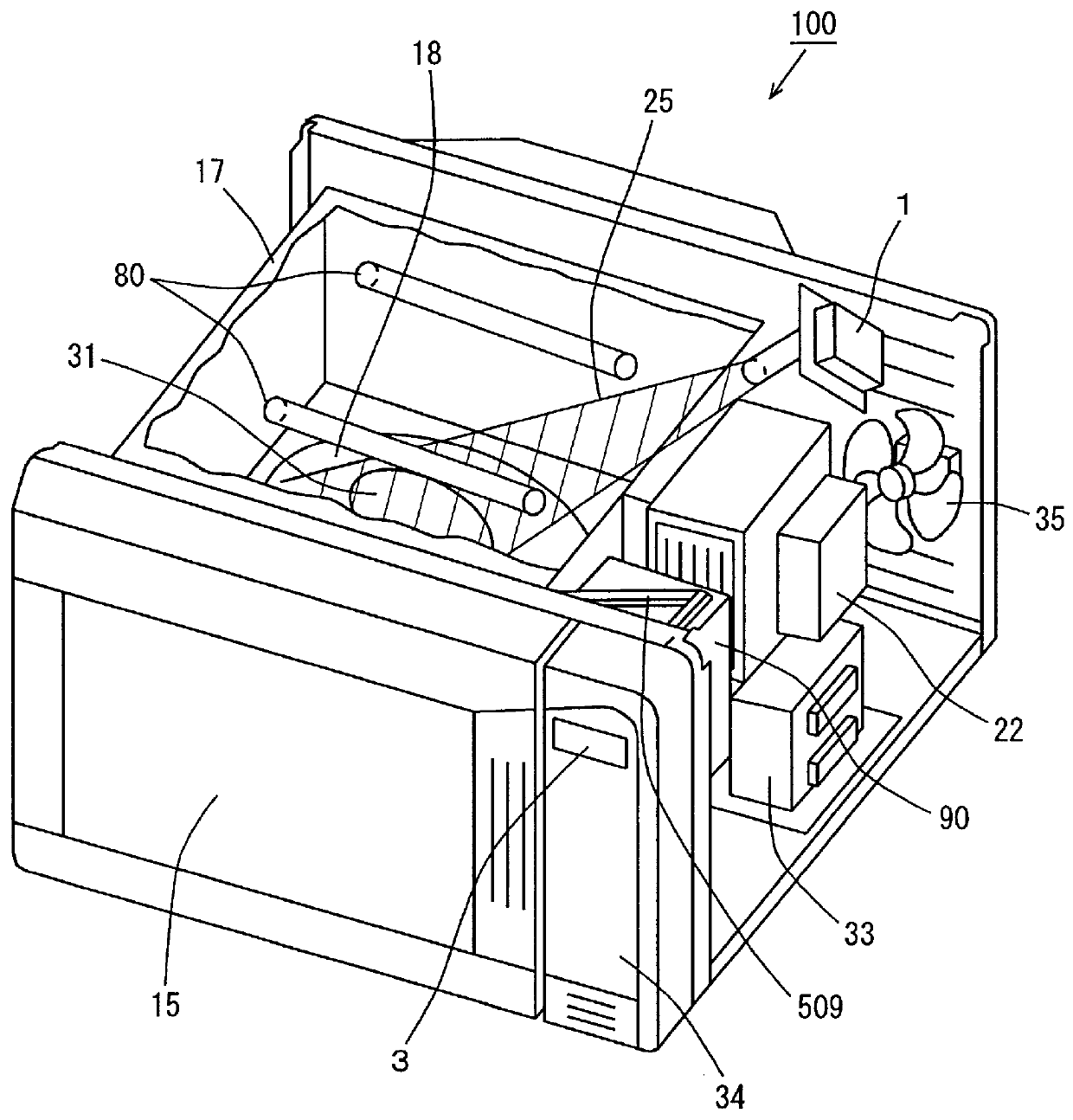

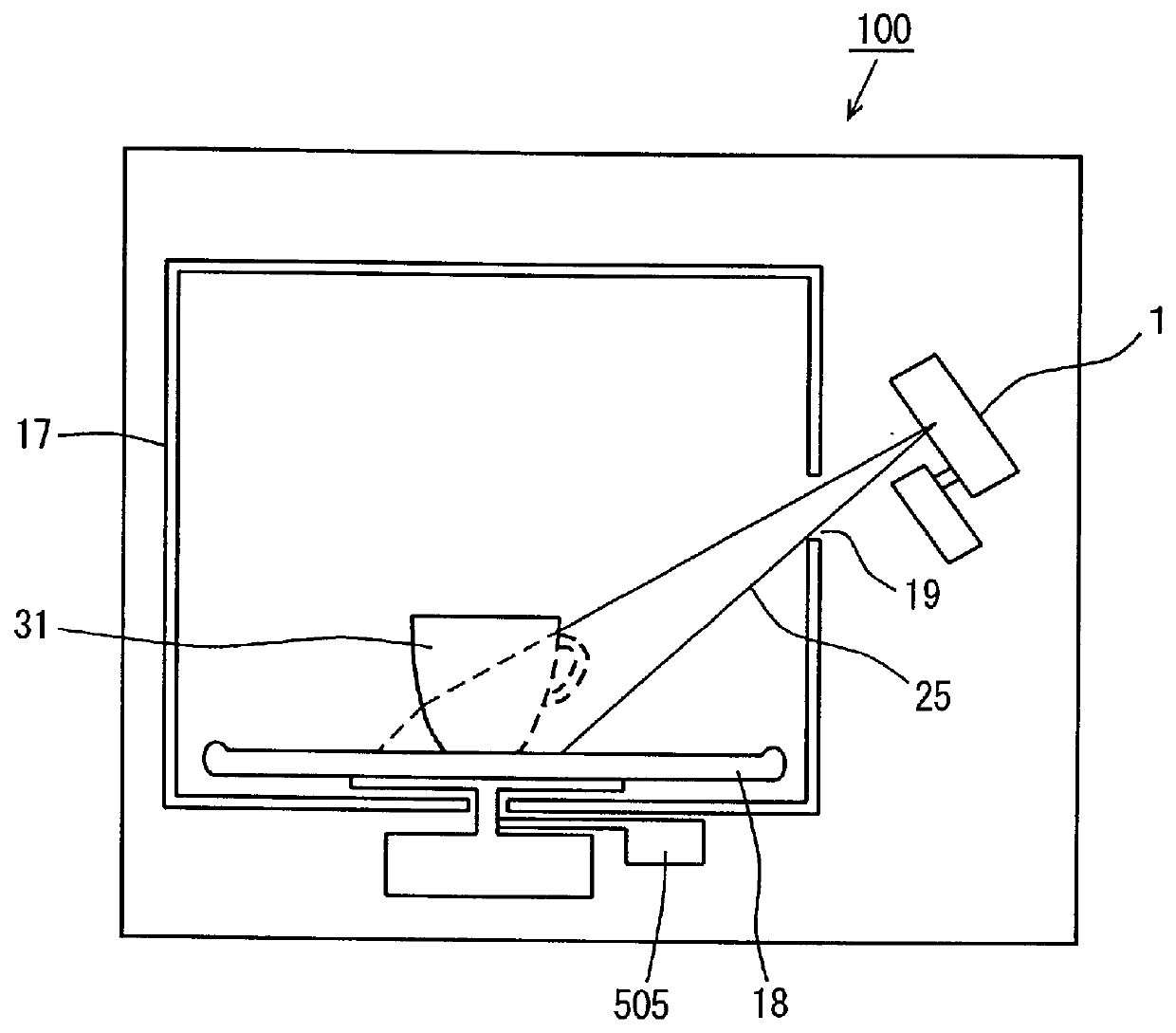

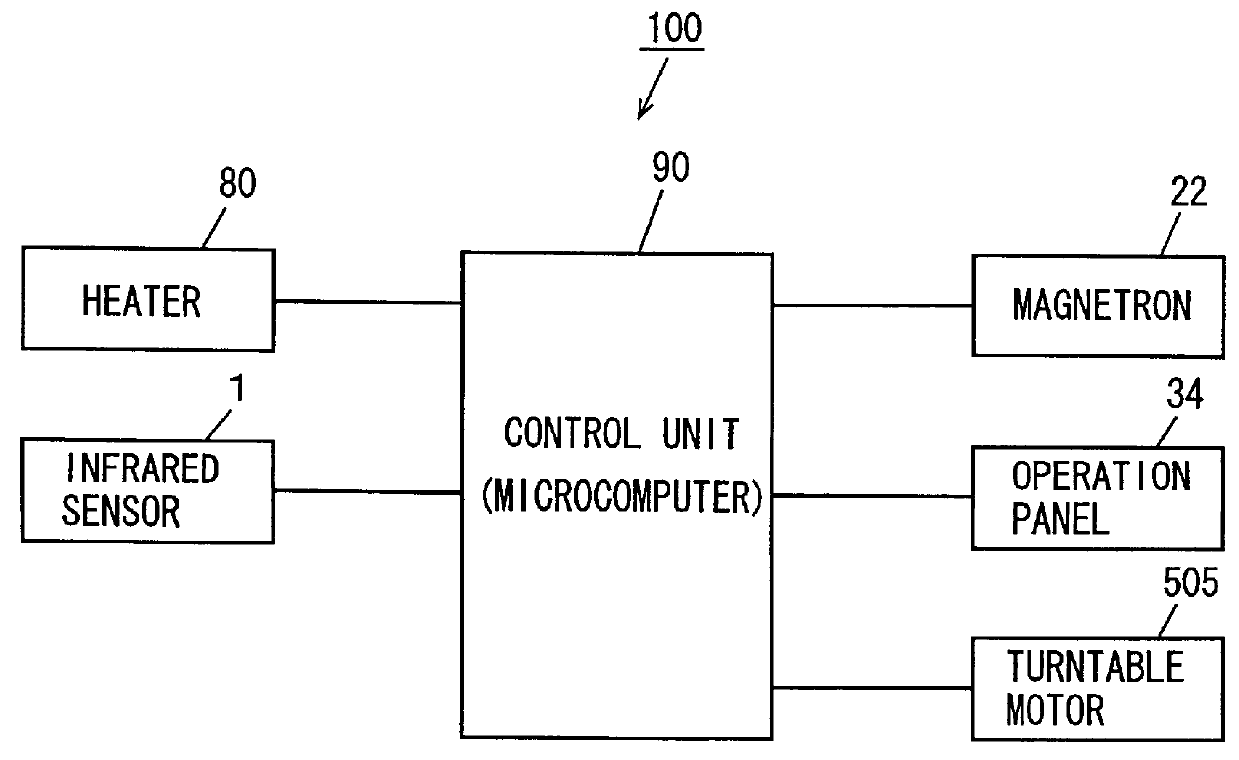

Cooking appliance that can detect temperature of foodstuff using infrared sensor

InactiveUS6121596AStable temperatureAccurate detectionThermometer detailsDomestic stoves or rangesEngineeringControl unit

In a cooking appliance, the foodstuff is placed on a turntable in a heating chamber. Infrared radiation emitted from the foodstuff is sensed by an infrared sense unit. The cooking appliance obtains the number of extrema of the amount of infrared radiation sensed over the period of one cycle of the turntable. The number of foodstuffs is determined according to the number of maxima. A control unit drives a heat unit according to the determined number of foodstuffs.

Owner:SANYO ELECTRIC CO LTD

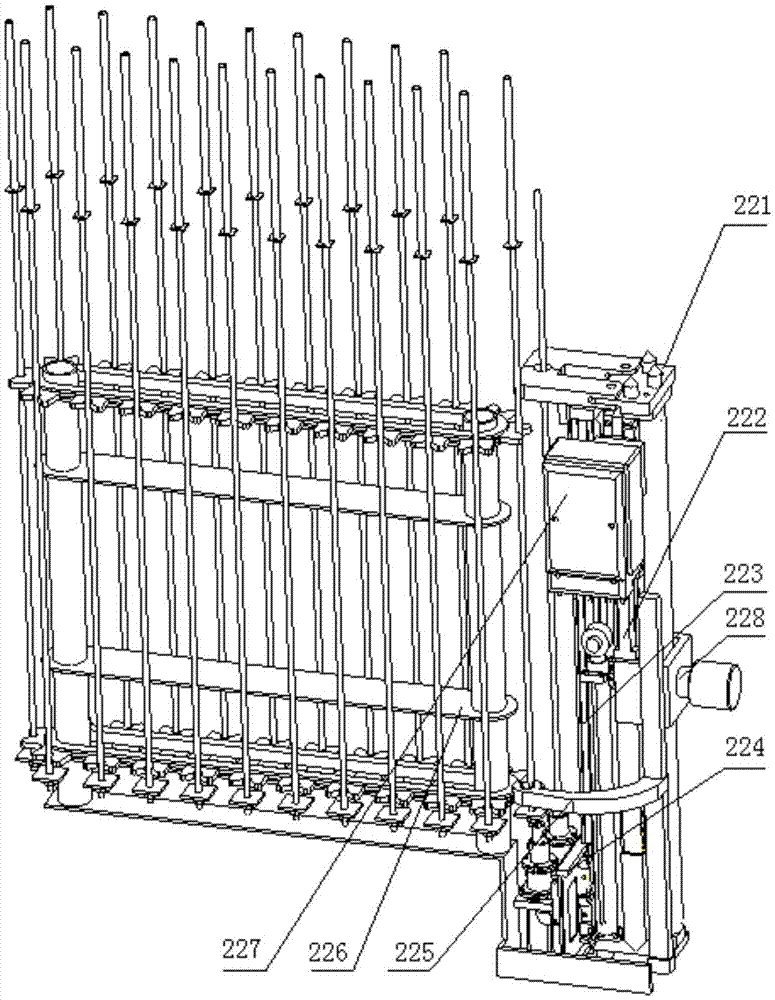

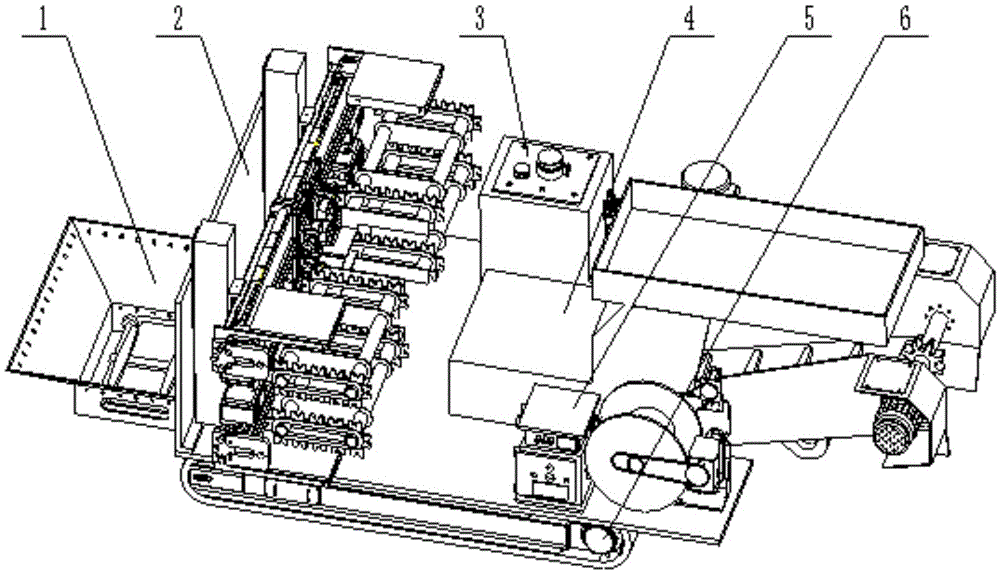

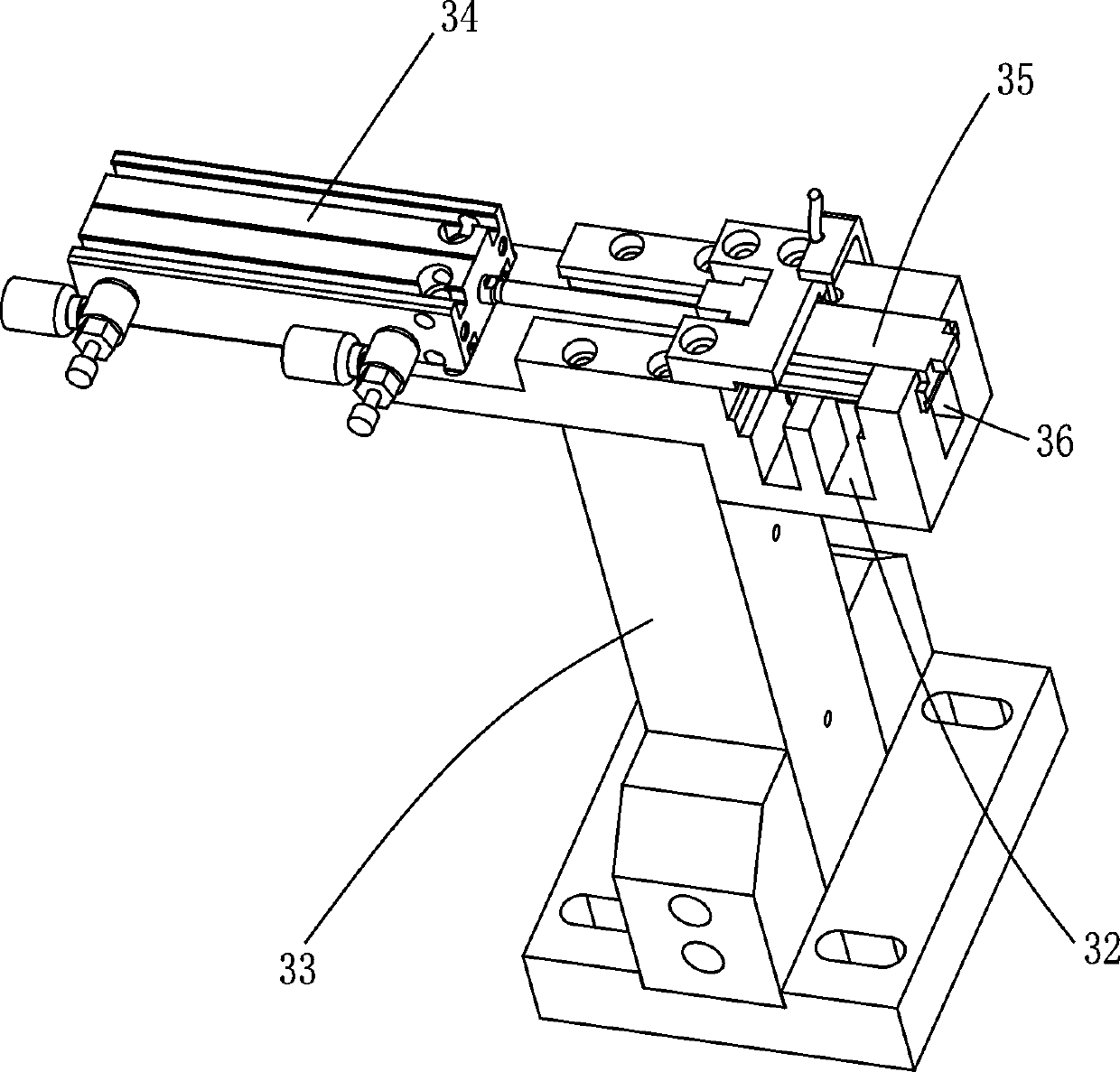

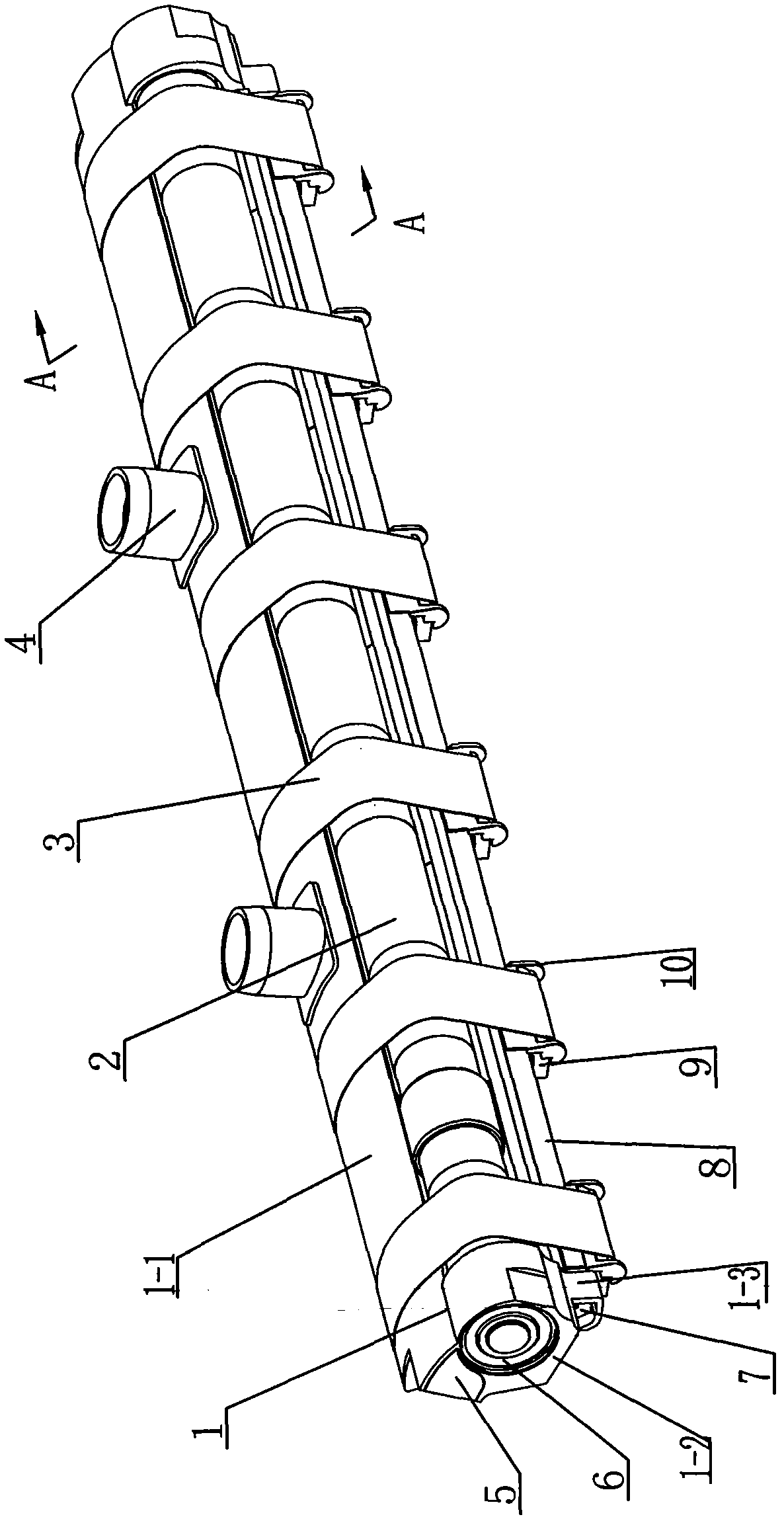

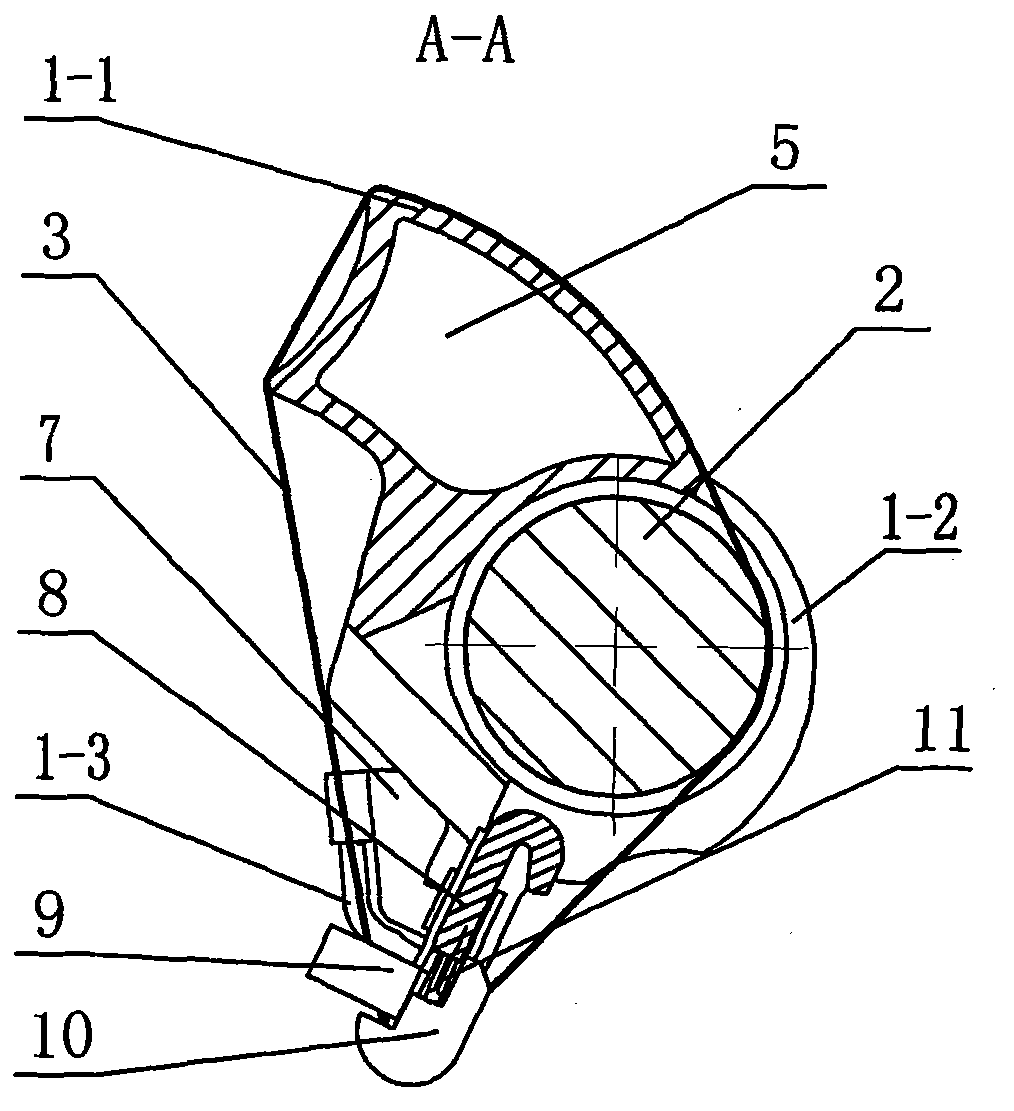

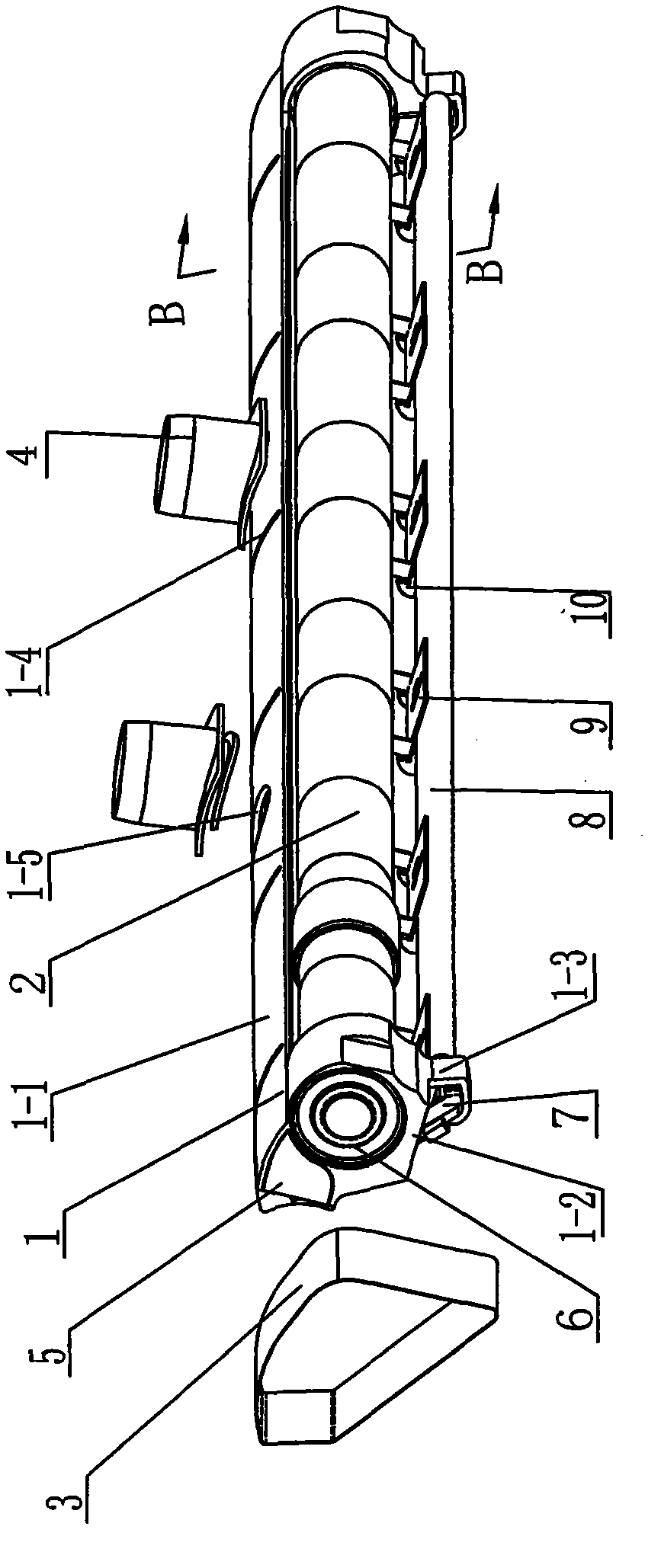

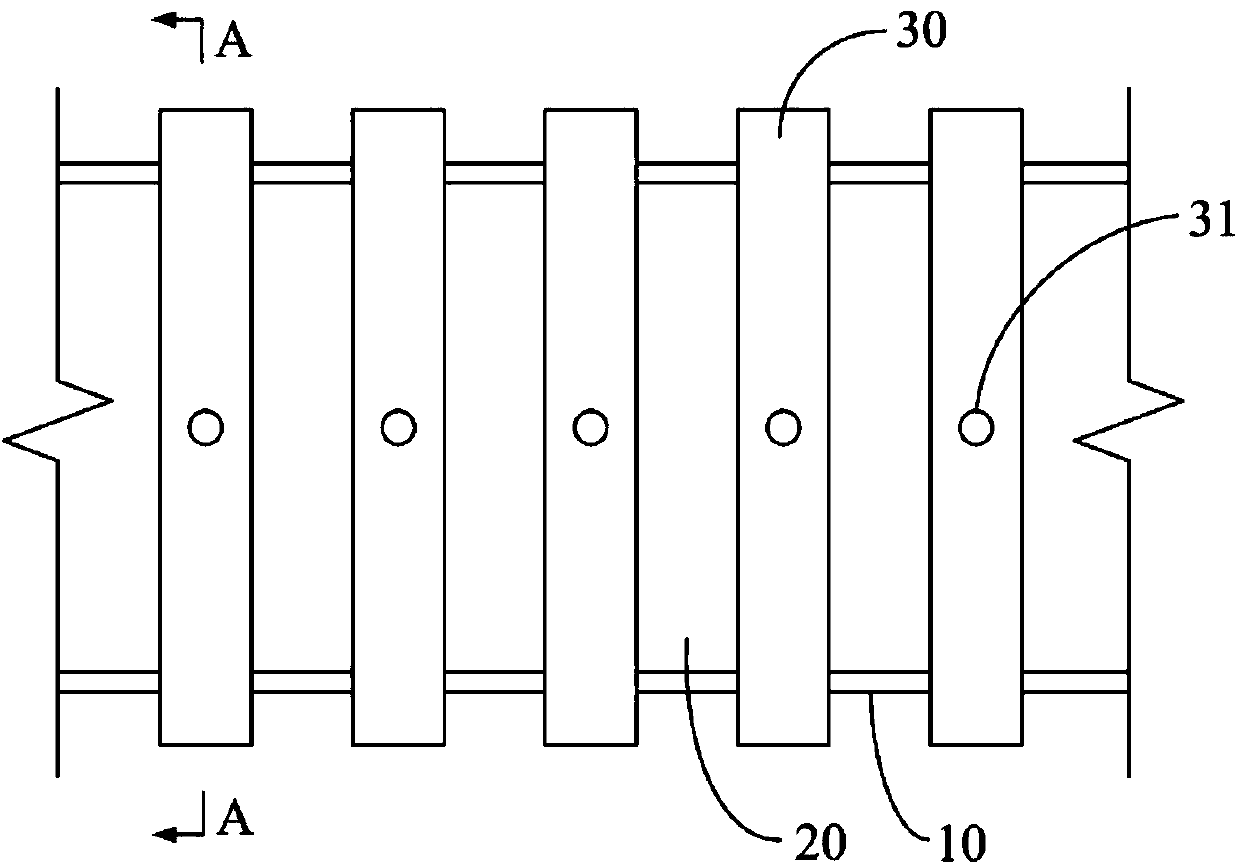

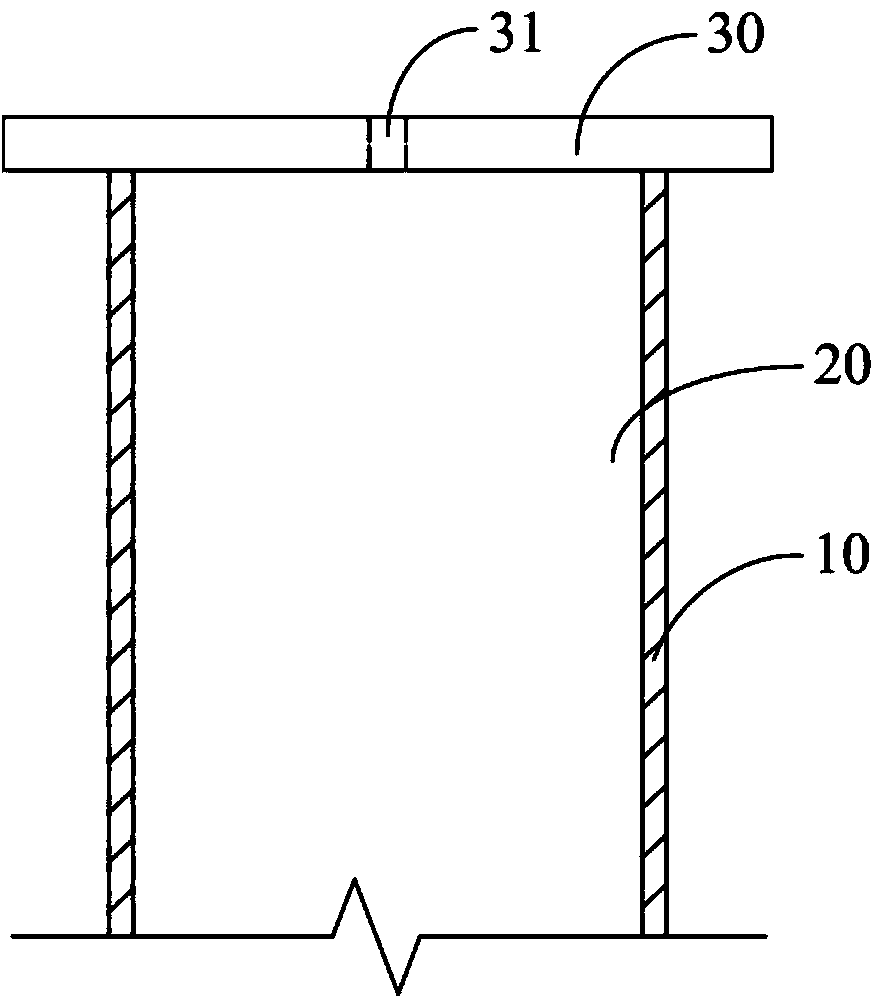

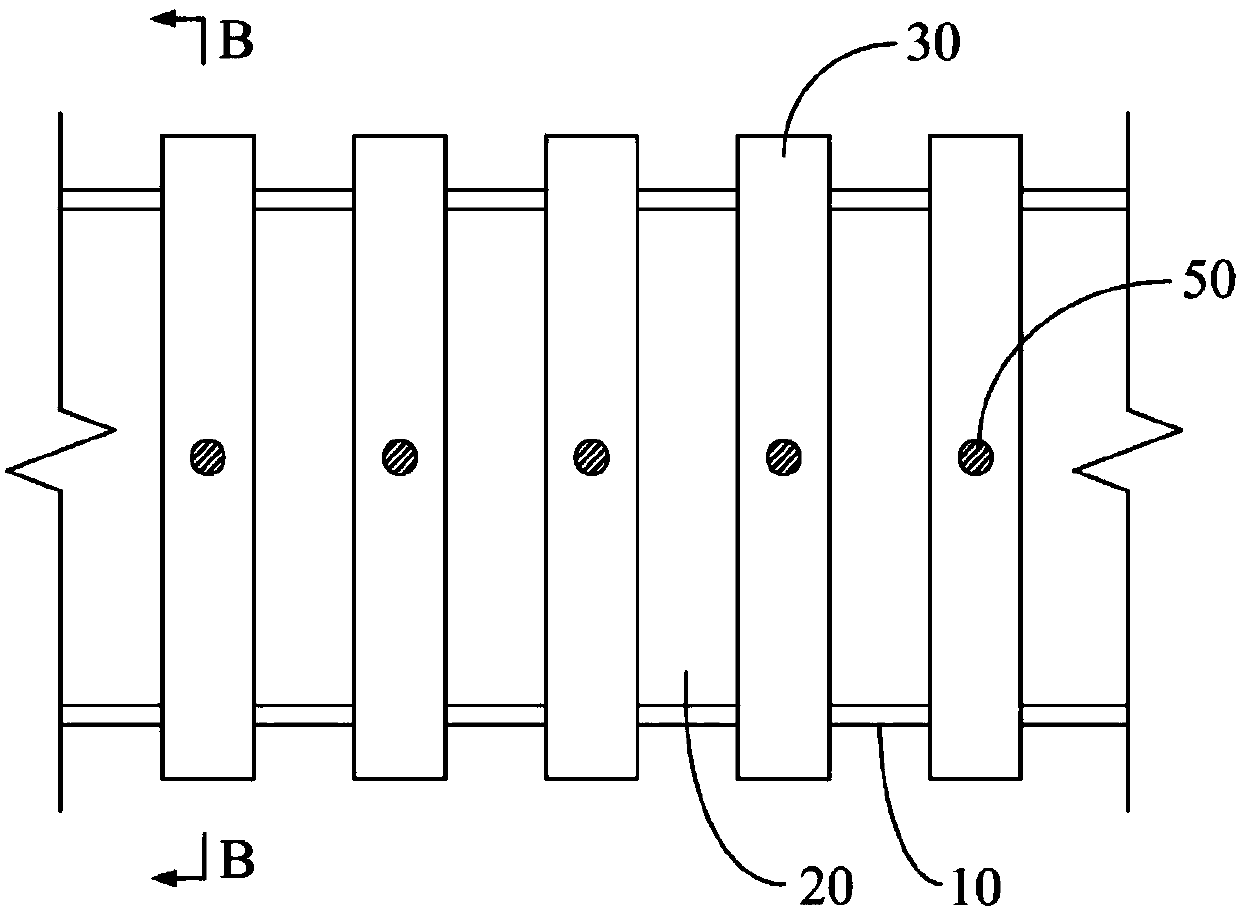

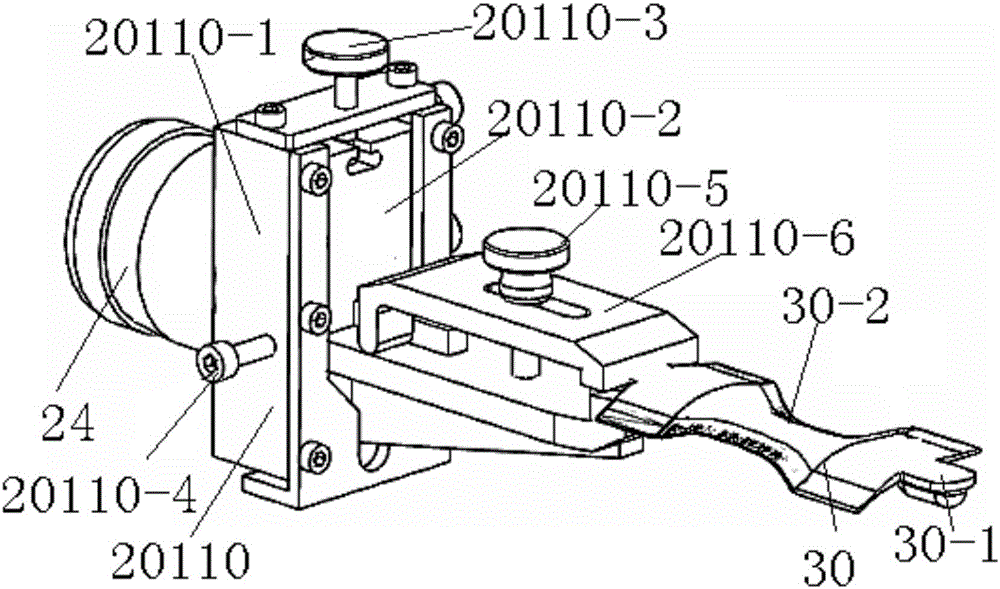

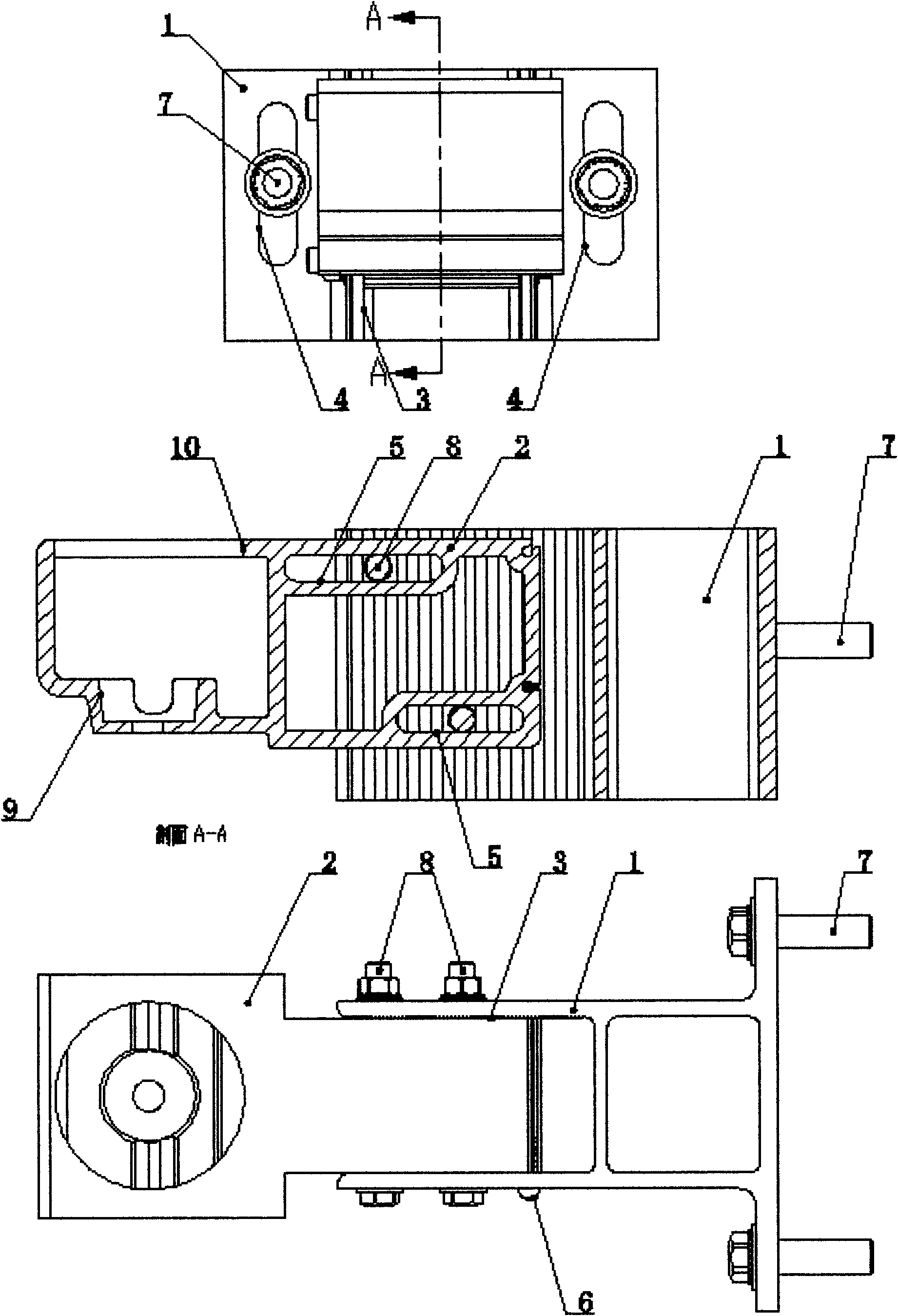

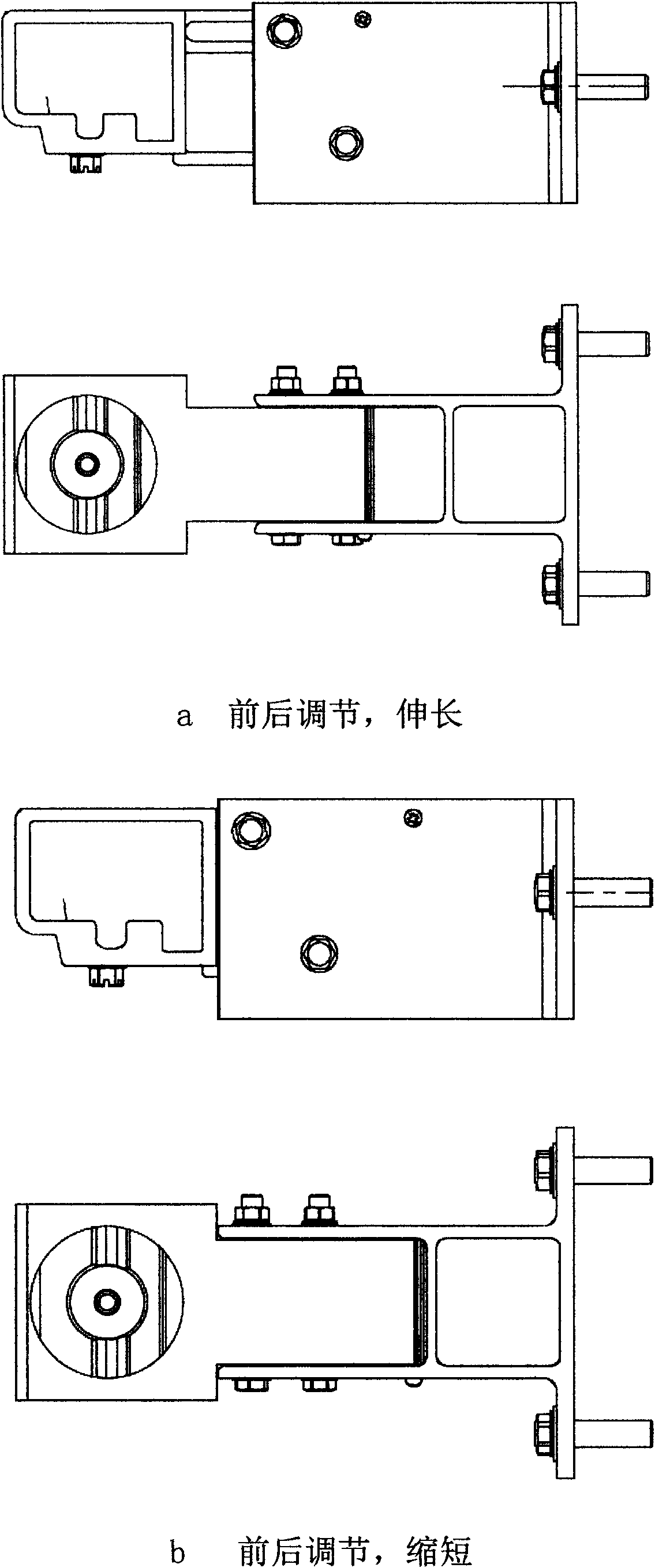

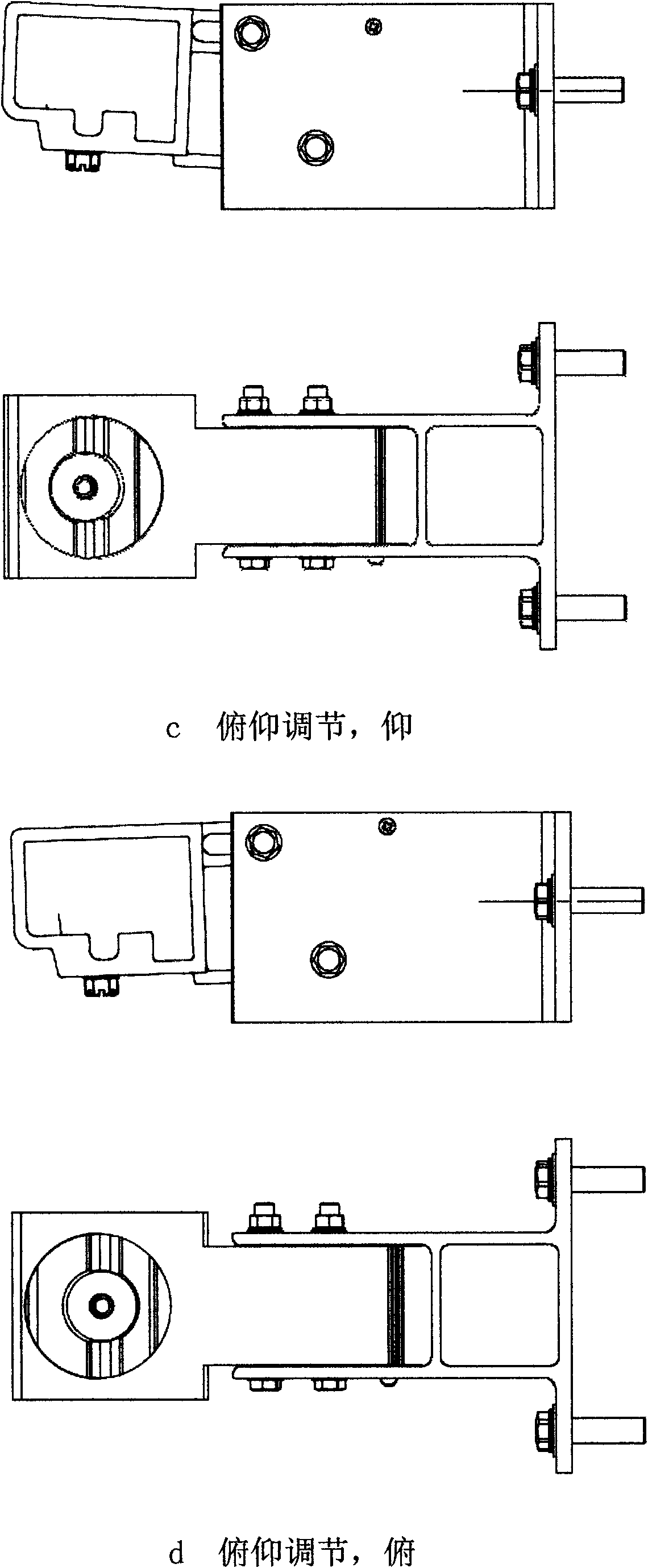

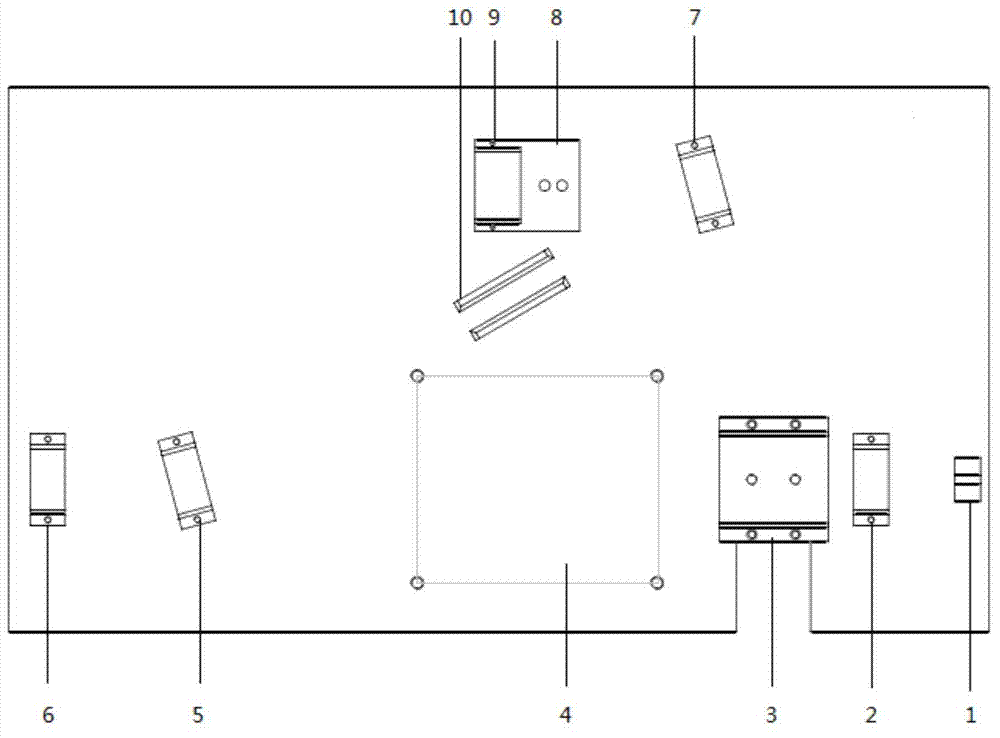

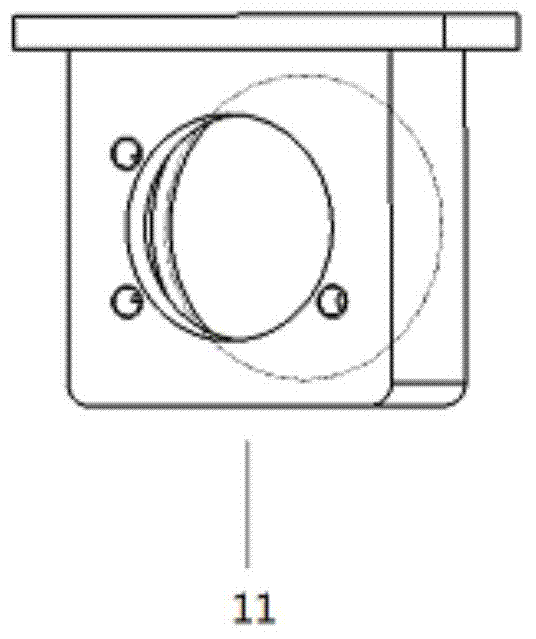

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

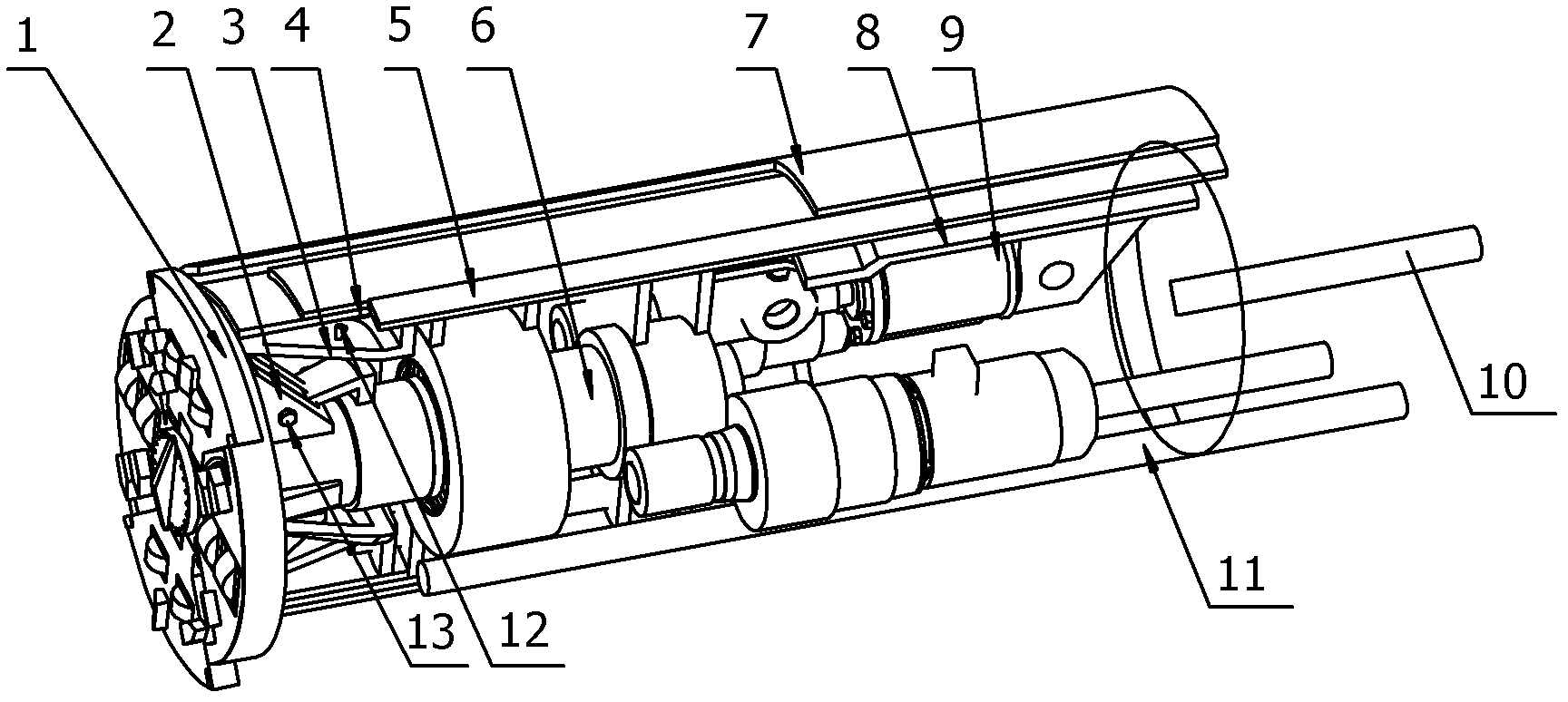

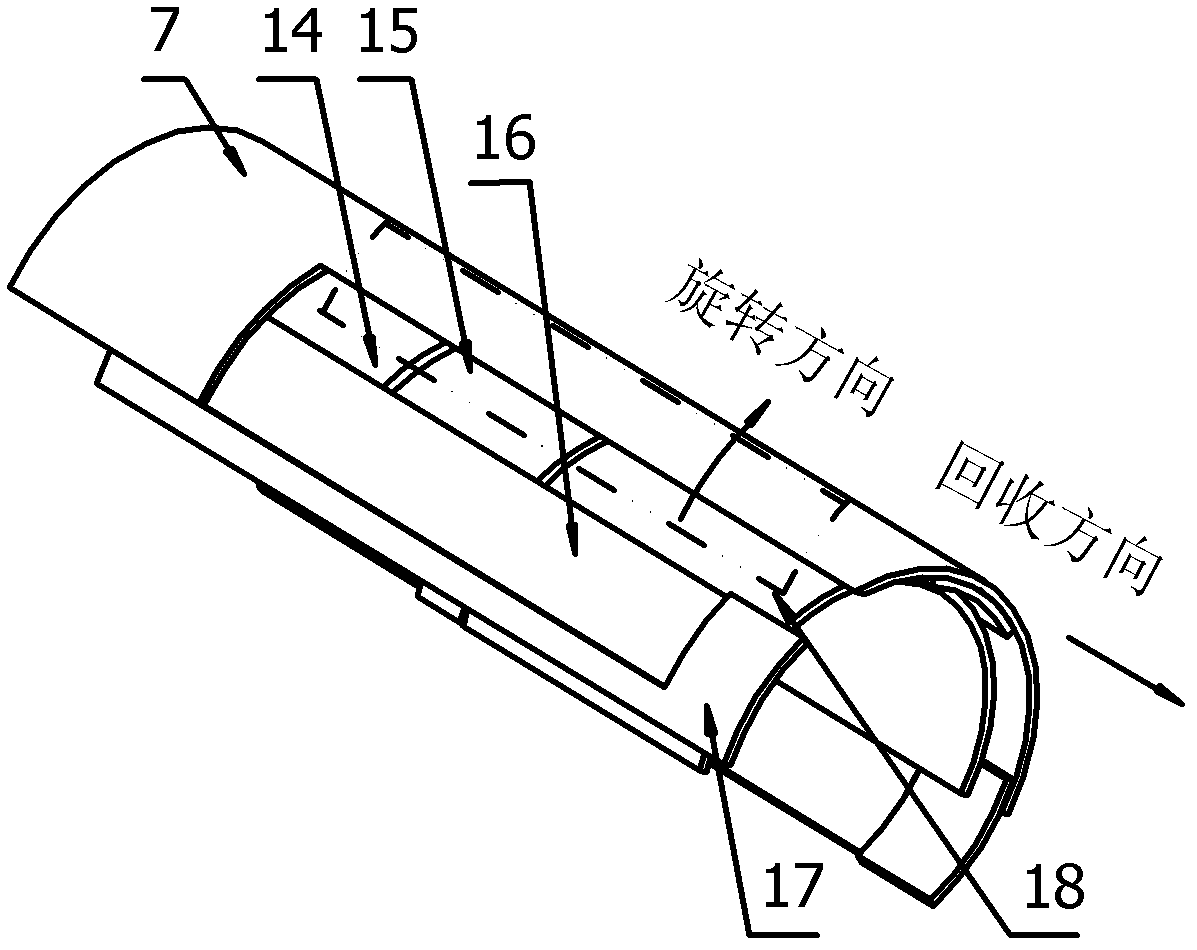

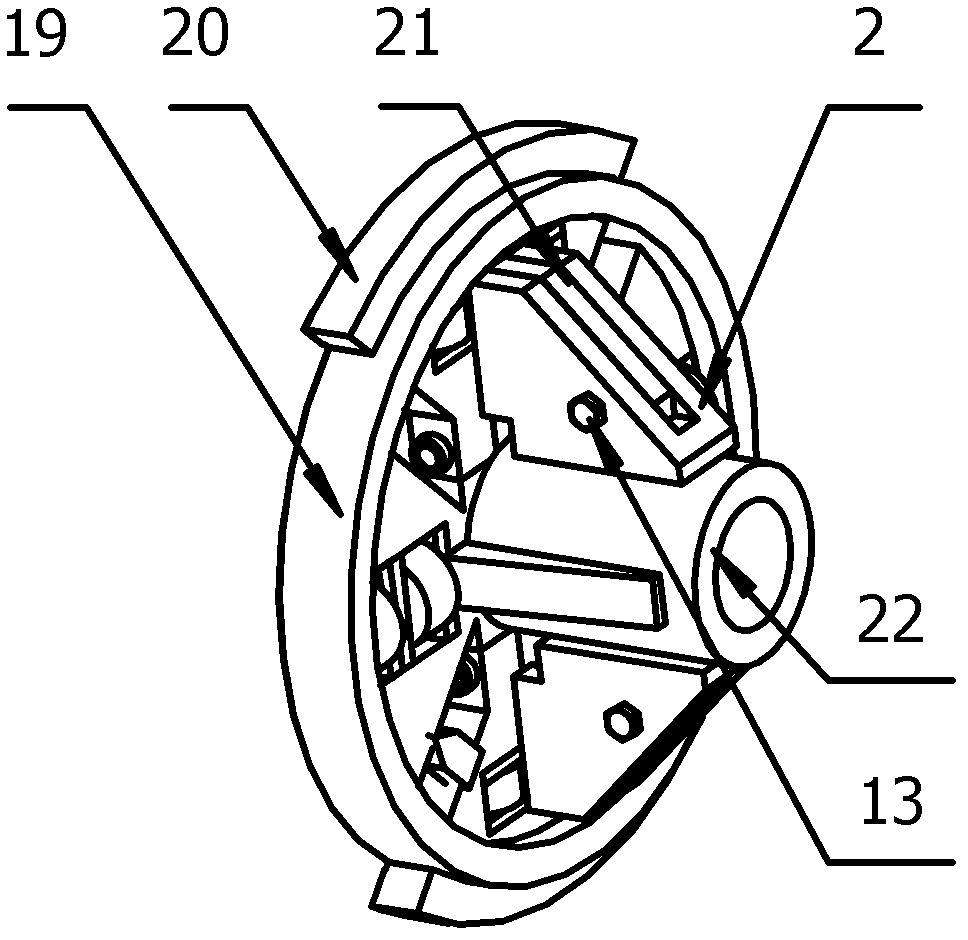

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

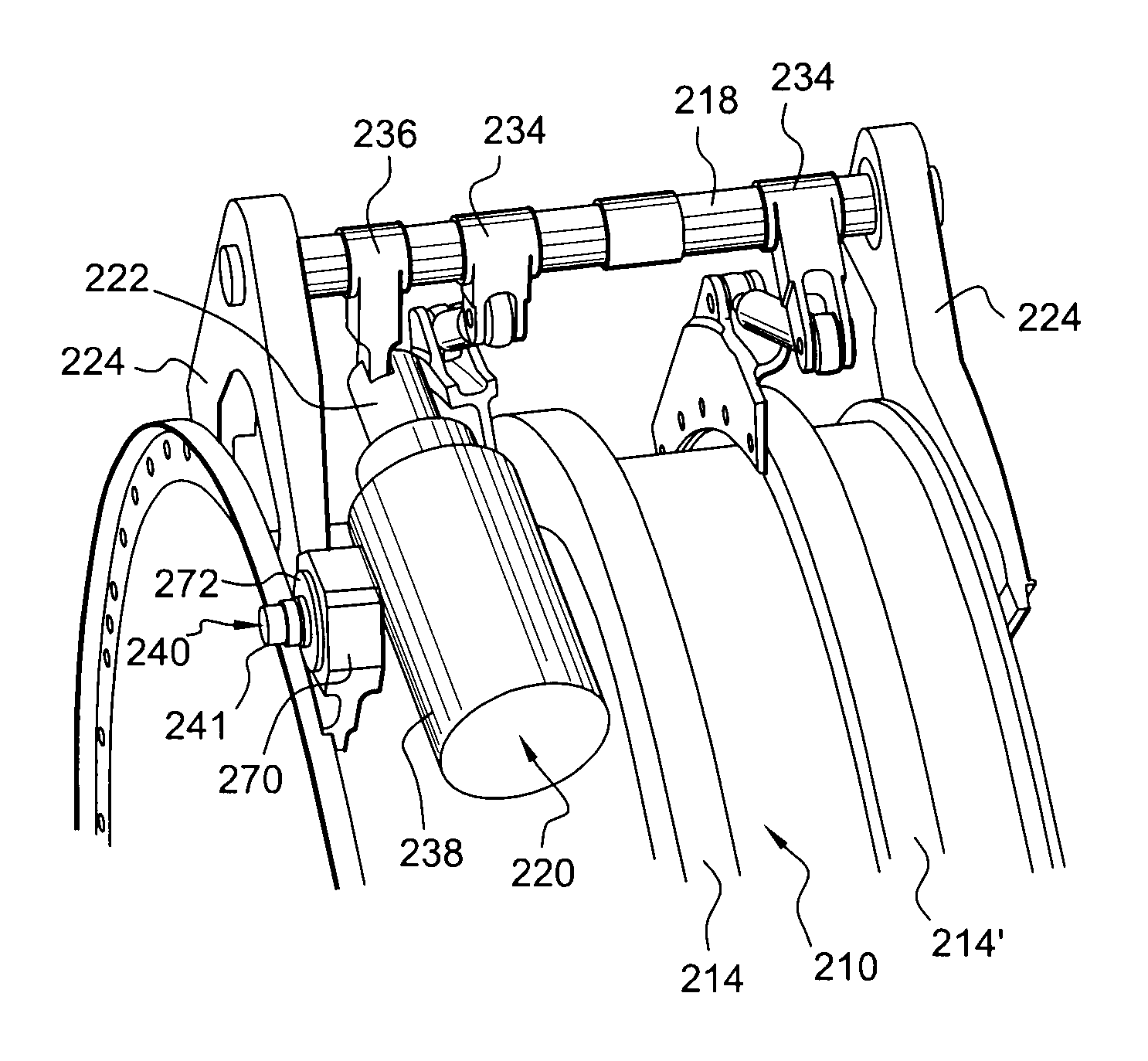

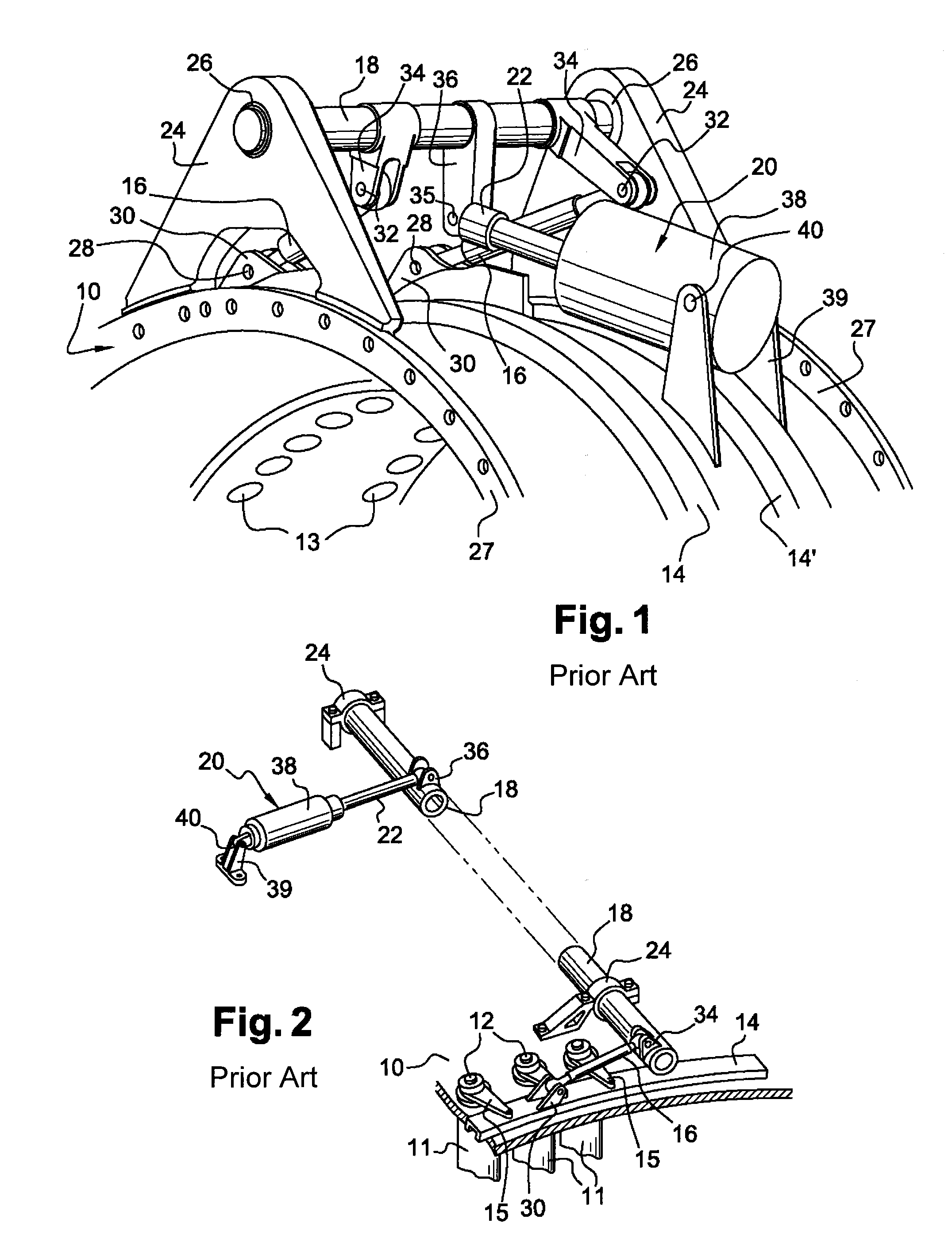

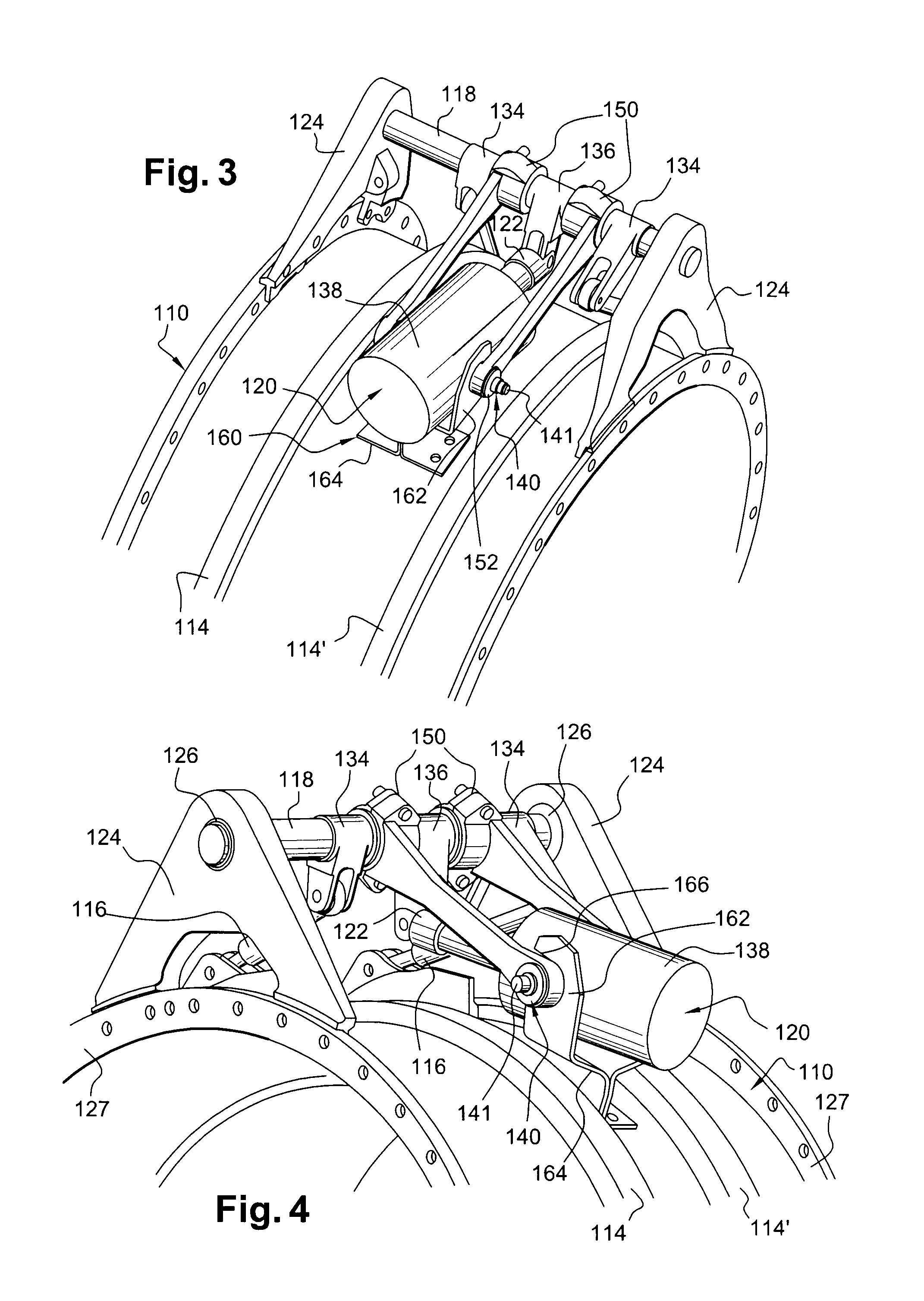

Device for controlling variable-pitch blades in a turbomachine compressor

ActiveUS8784043B2Compensate for misalignmentThe installation position is accuratePropellersPump componentsEngineeringActuator

A device for controlling variable-pitch blades in a turbomachine compressor, including at least one control ring surrounding an external casing of the compressor, and a control shaft connected to the ring and to the rod of an actuator, the body of which is mounted such that it can pivot about an axle borne by a support mechanism of the control shaft so as to guarantee a precise relative positioning of the axis of pivoting of the actuator with respect to the control shaft.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

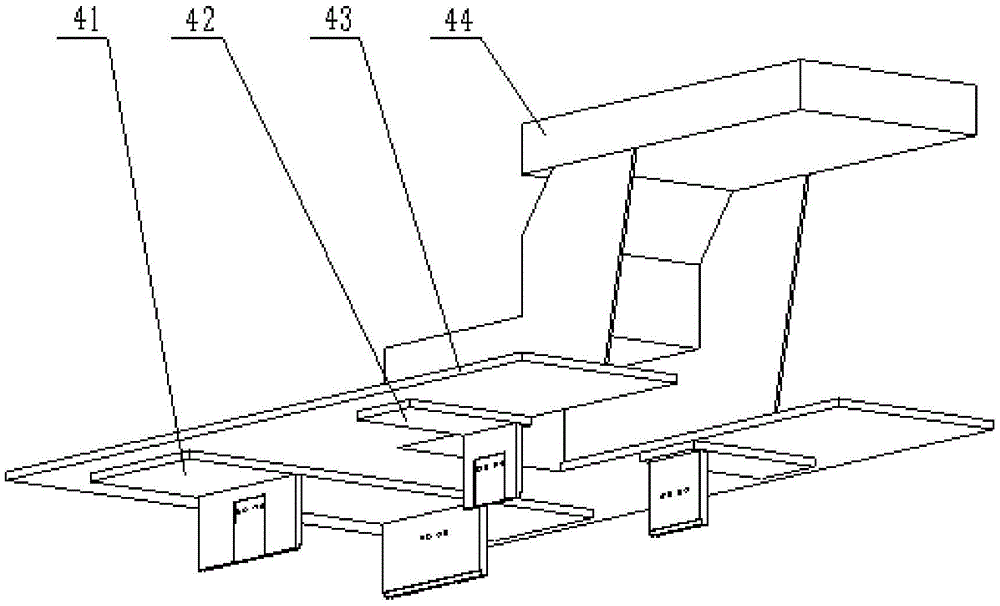

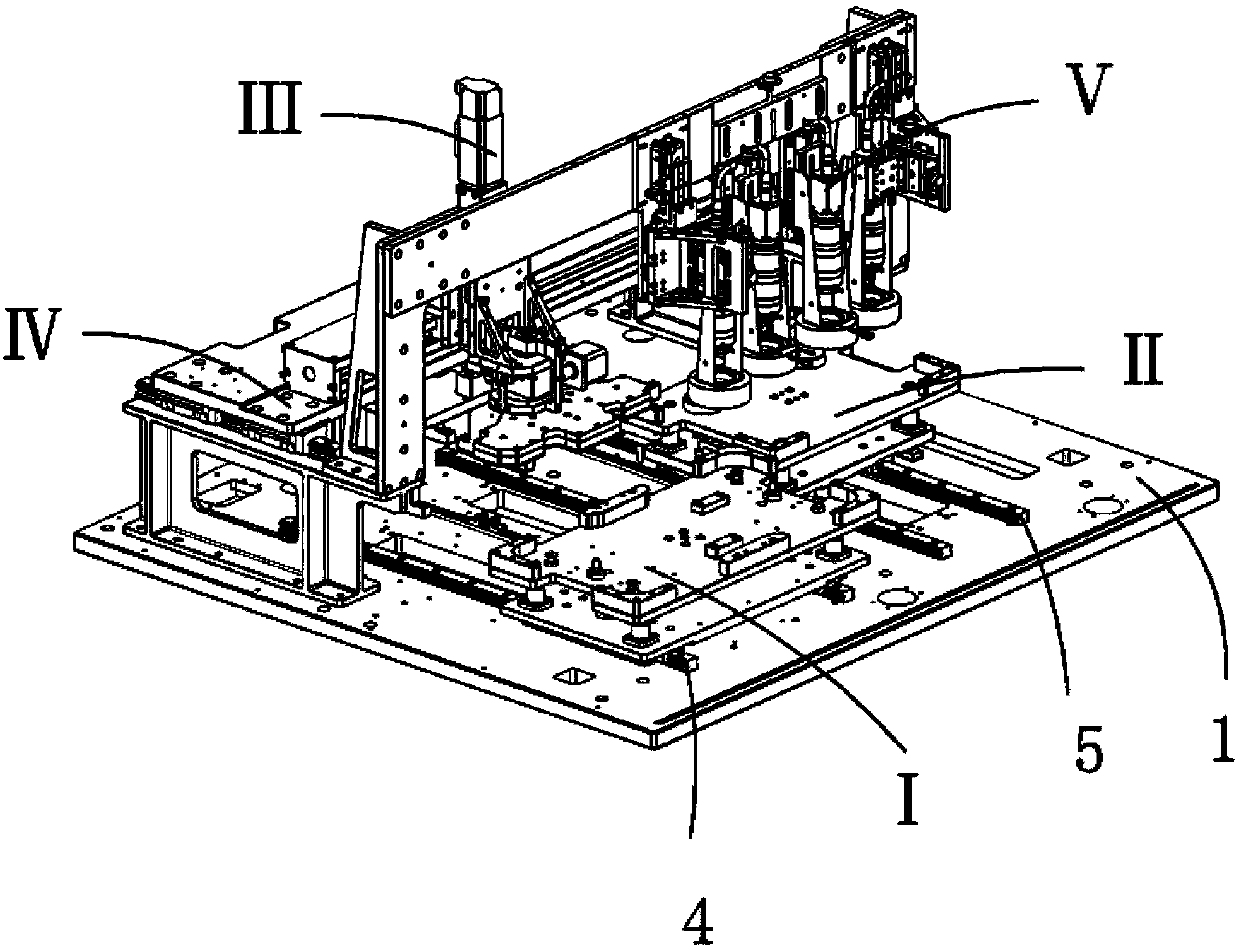

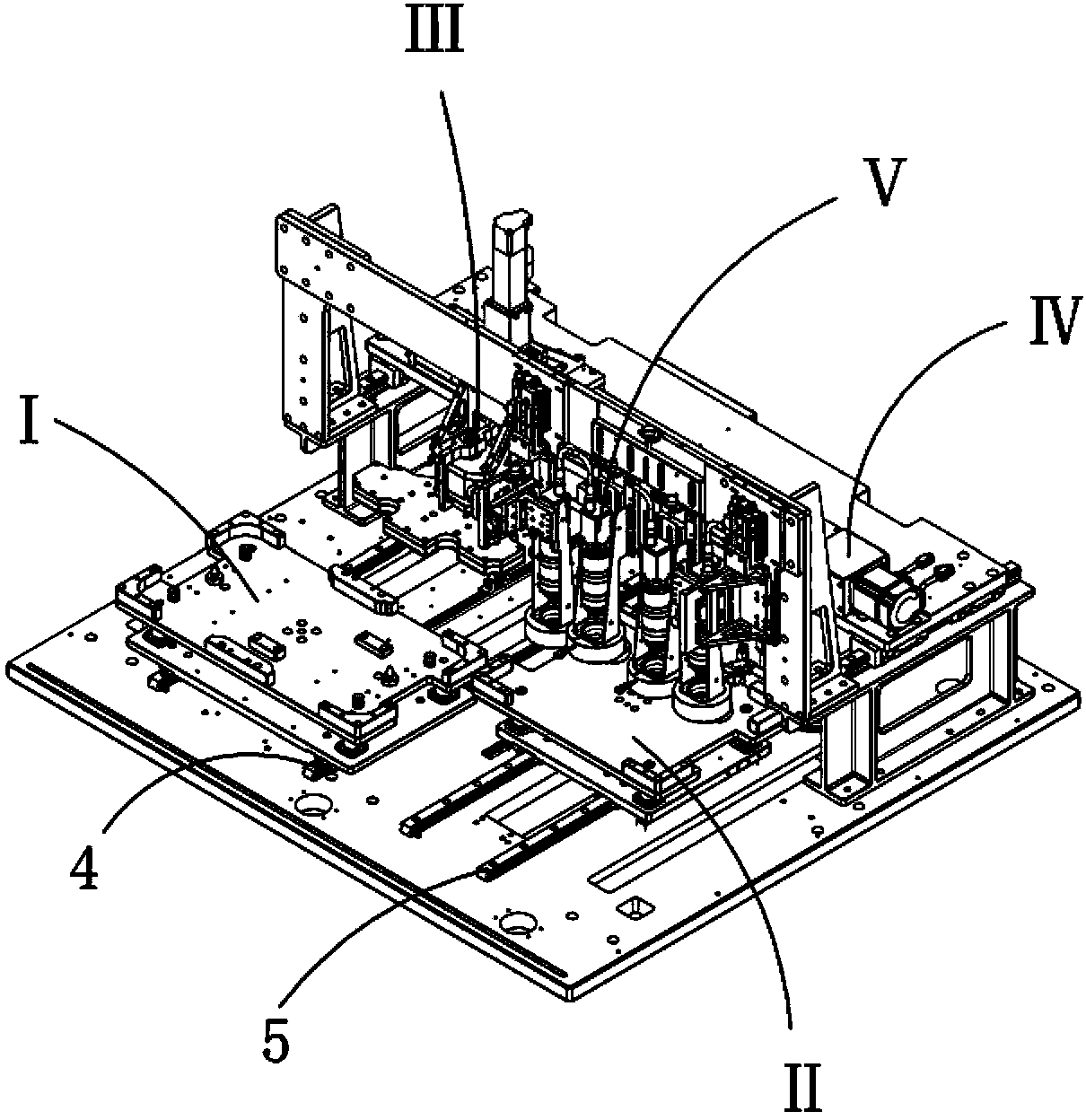

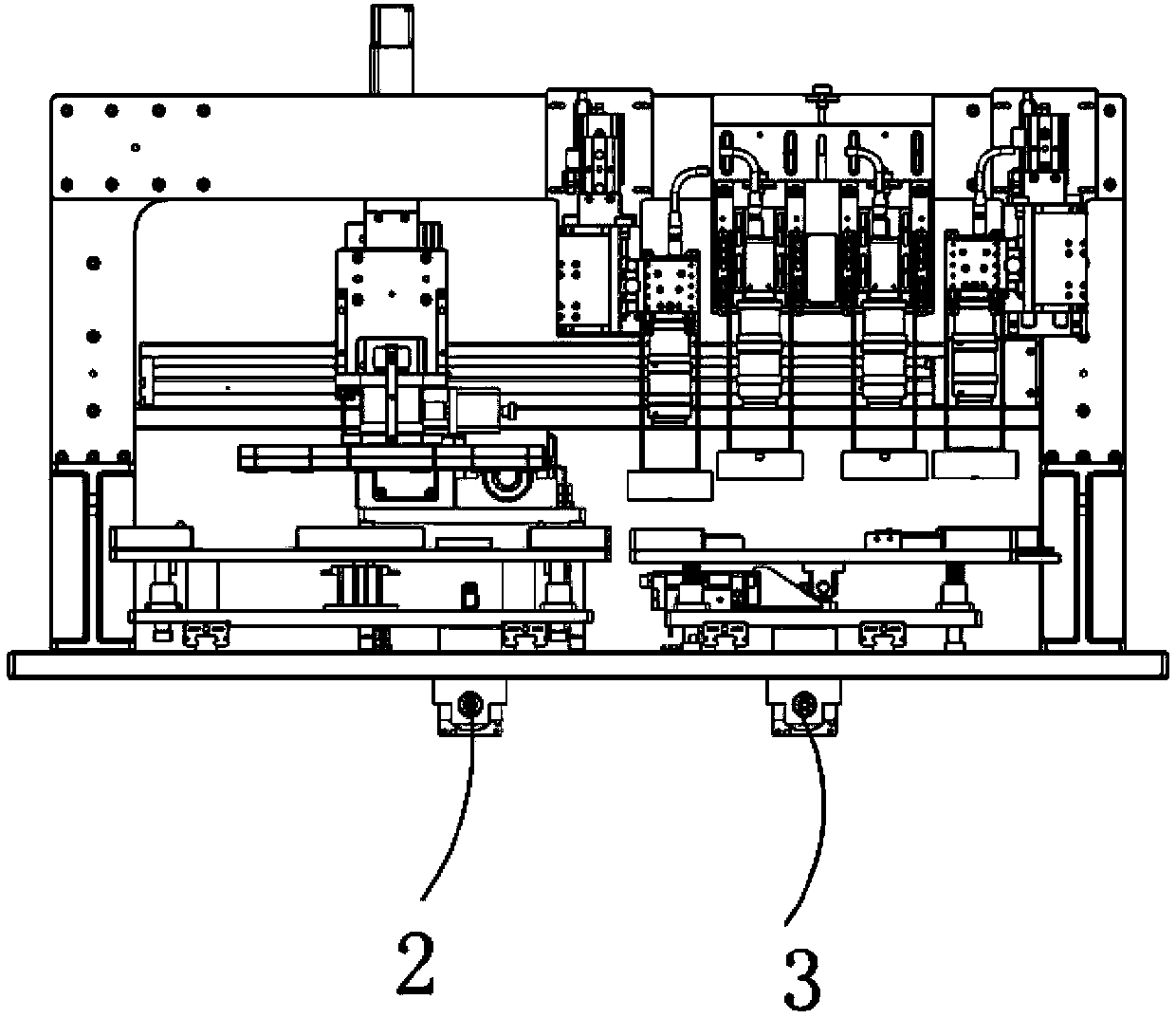

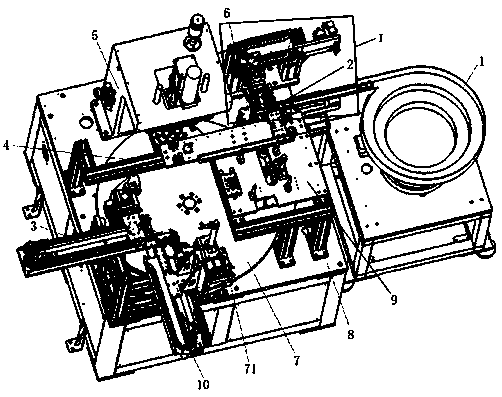

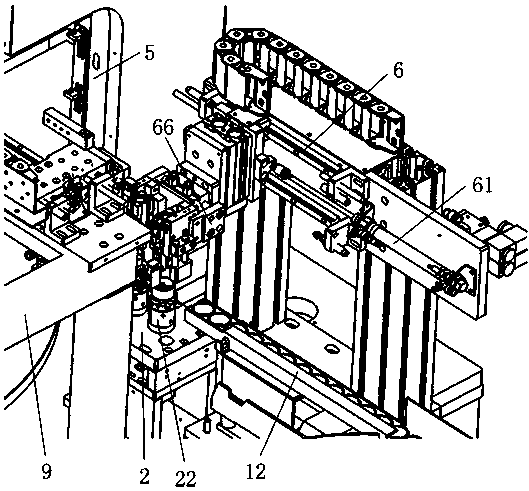

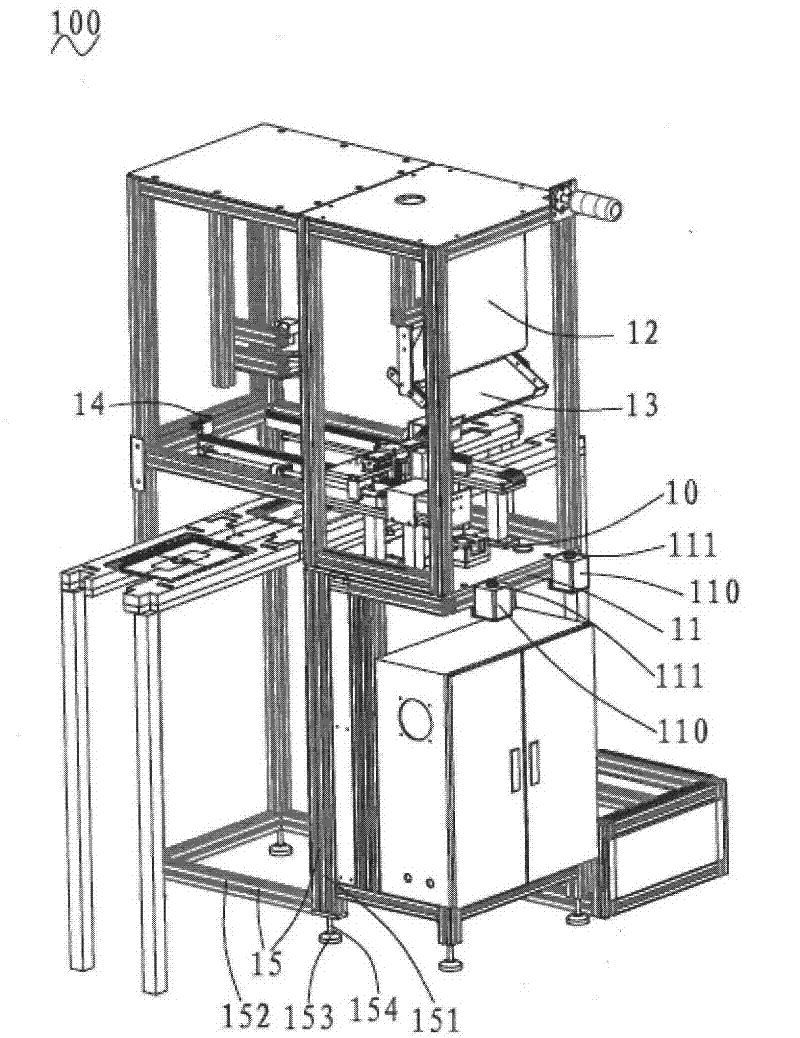

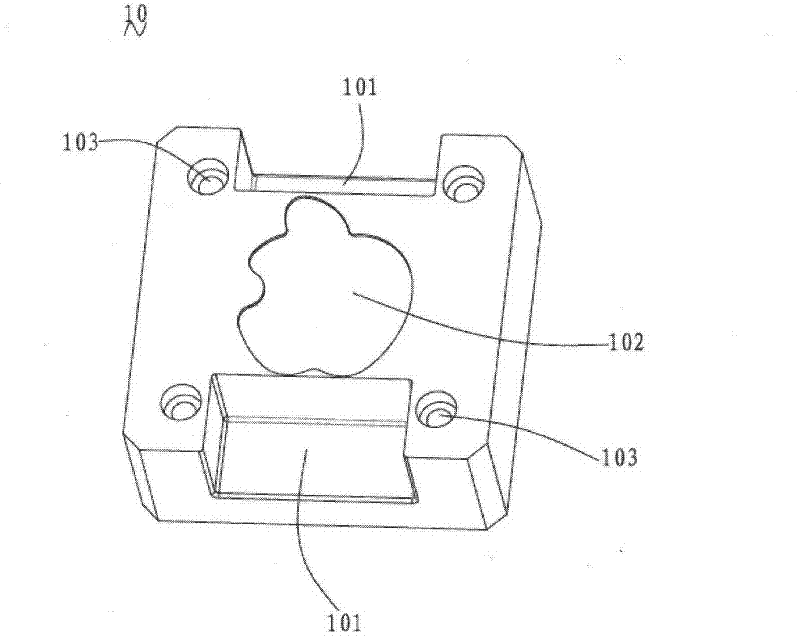

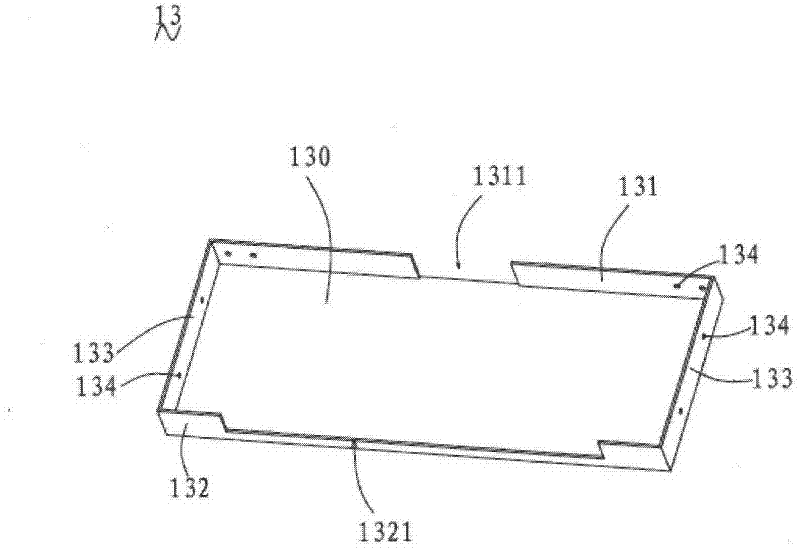

Laptop batter assembling machine

ActiveCN103419014APrecise positioningThe positioning column is firmly fixedMetal working apparatusElectrical and Electronics engineeringLaptop

The invention relates to a laptop battery assembling machine. The laptop battery assembling machine comprises a big base plate, a carrier mechanism, a carrier conveying mechanism, a suction plate mechanism, a conveying mechanism, a correcting mechanism and a battery. A motor a and a motor b are installed at the bottom of the big base plate. A sliding rail assembly a and a sliding rail assembly b are installed on the big base plate. The carrier mechanism is installed on the sliding rail assembly a. The carrier mechanism is connected with a lead screw of the motor a. The carrier conveying mechanism is installed on the sliding rail assembly b. The carrier conveying mechanism is connected with a lead screw of the motor b. The conveying mechanism is installed on the big base plate through an installation base. The suction plate mechanism is installed on the conveying mechanism. The correcting mechanism is installed on the front portion of the installation base. According to the laptop battery assembling machine, the battery is placed on the carrier mechanism, a laptop is placed on the carrier conveying mechanism, the battery is sucked by the suction plate mechanism and conveyed to the portion above the carrier conveying mechanism through the conveying mechanism, the suction plate mechanism rotates so that the position can be adjusted, the battery is installed in the standard operation position, and then the correcting mechanism conducts shooting and correcting.

Owner:BOZHON PRECISION IND TECH CO LTD

Burying method of inclination measuring pipes in soil body

InactiveCN102787616AThe installation position is accurateEasy to buryFoundation testingSoil scienceSlurry

The invention discloses a burying method of an inclination measuring pipes in a soil body. The burying method comprises the following steps that (a) holes are drilled; (b) slurry is continuously filled in drilled holes for hole washing after the hole drilling completion; and (c) after the hole washing completion, a prepared inclination measuring pipe is inserted into the drilled hole, the bottom end of the inclination measuring pipe with an end cover is firstly downwards placed into the drilled hole, clean water is fully filled in the inclination measuring pipe, the upper section of inclination measuring pipe is connected, the insertion is continuously carried out after the connection completion, the operation is repeated in such a way until the inclination measuring pipe is inserted into the hole bottom, the rest inclination measuring pipe is cut off, the distance from a pipe opening of the inclination measuring pipe to the ground is 200 to 500mm, the pipe opening of the inclination measuring pipe is sealed and covered by a top cover, and the gap of the drilled holes outside the inclination measuring pipe is filled by sand or bentonite. The burying method has the advantages that the inclination measuring pipe burying is convenient, the construction speed is high, the cost is low, the inclination measuring pipe and the surrounding soil body can be enabled to form a whole after the burying, the inclination measuring pipe can deform along with the horizontal displacement of the soil body, and the horizontal displacement of the soil body at the position is analyzed and obtained through measuring the horizontal deformation of different positions of the inclination measuring pipe.

Owner:CHINA CONSTR SIXTH ENG DIV CORP +2

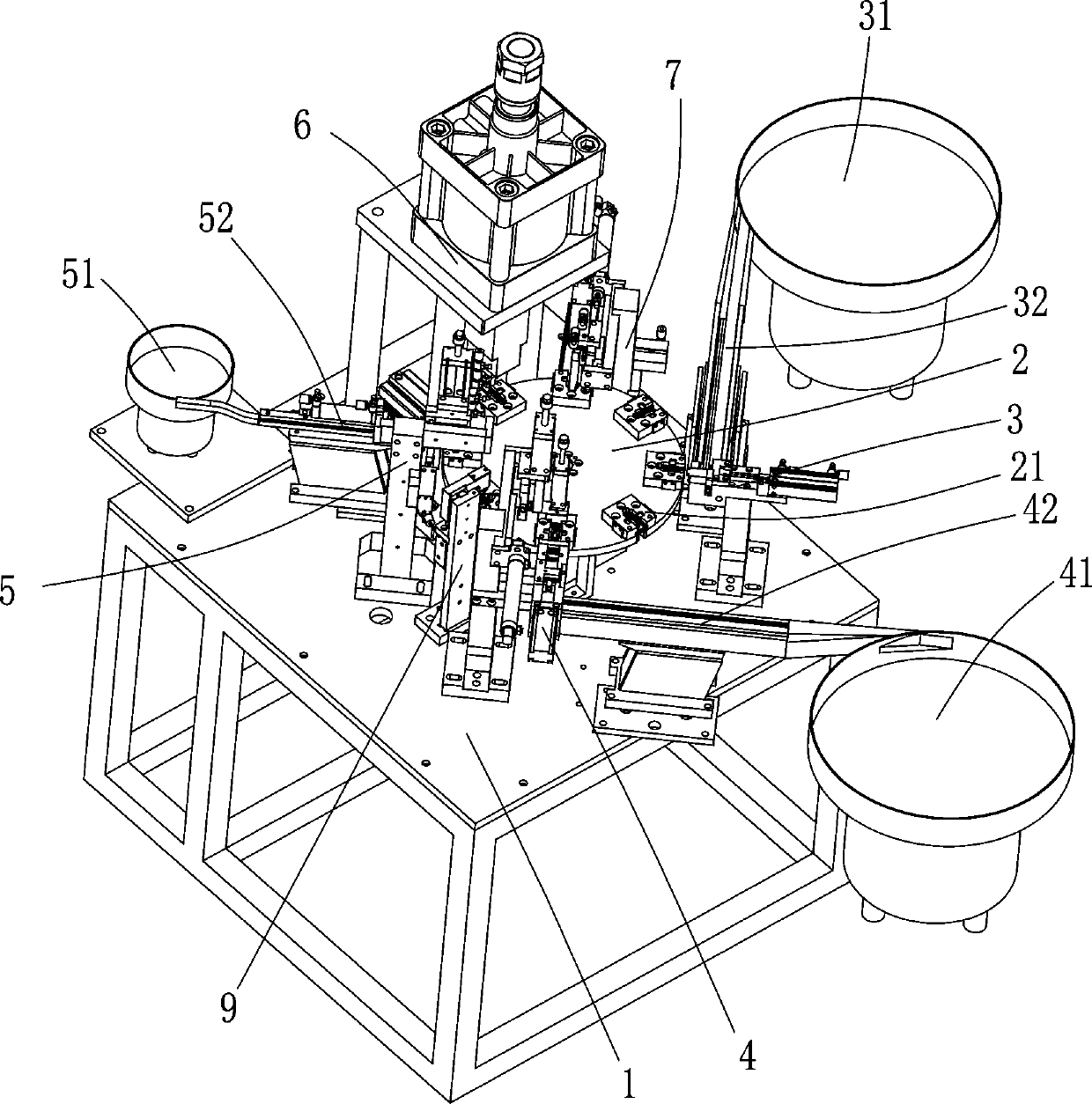

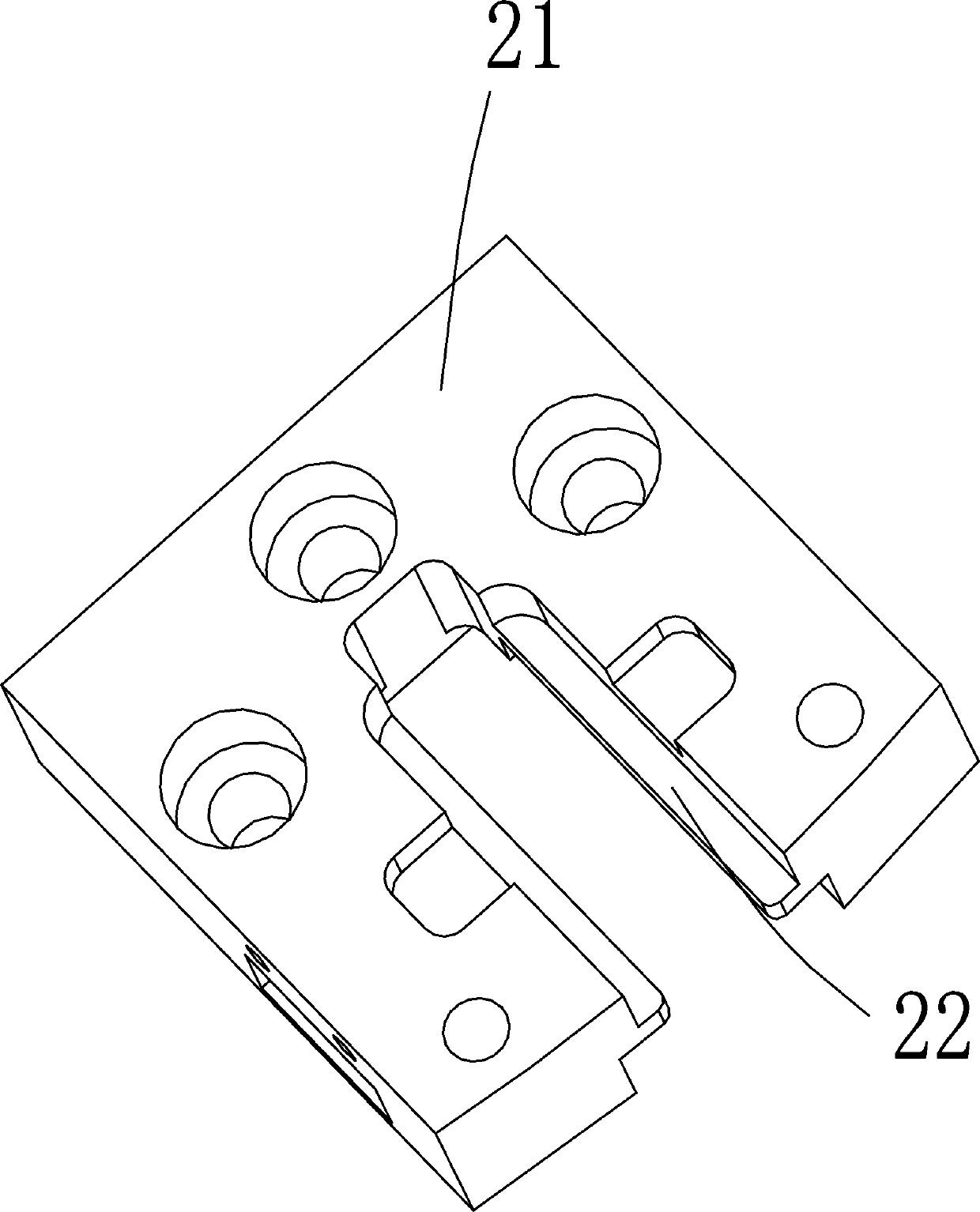

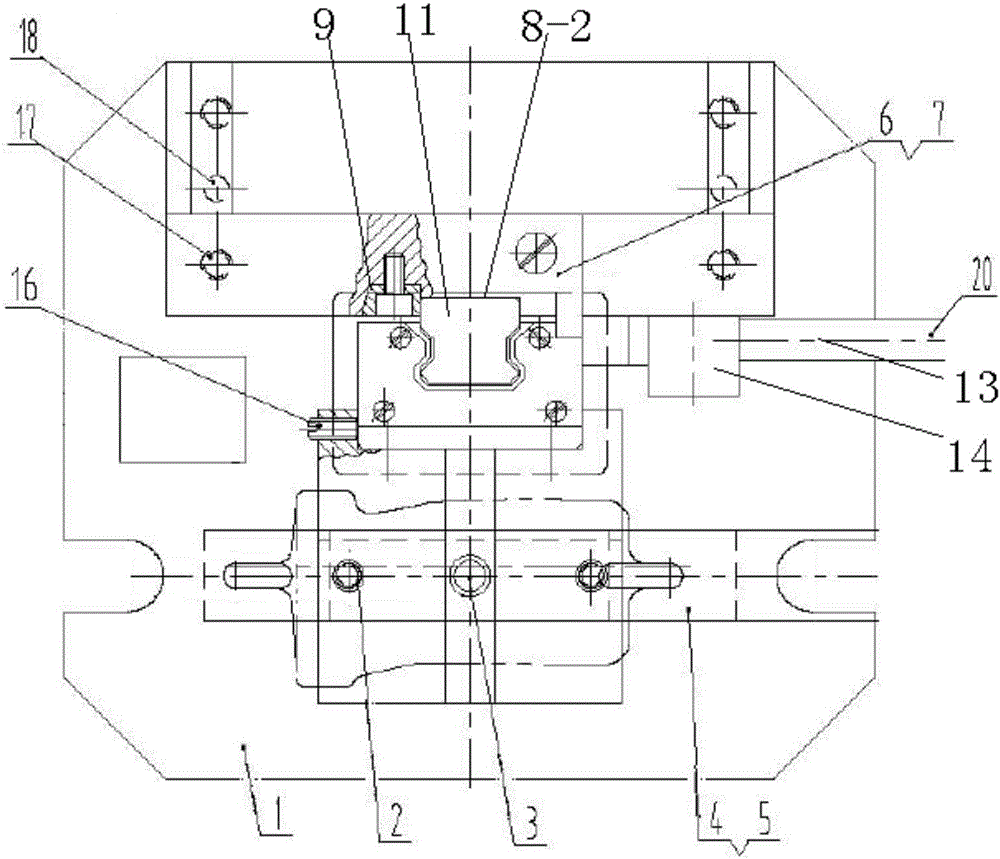

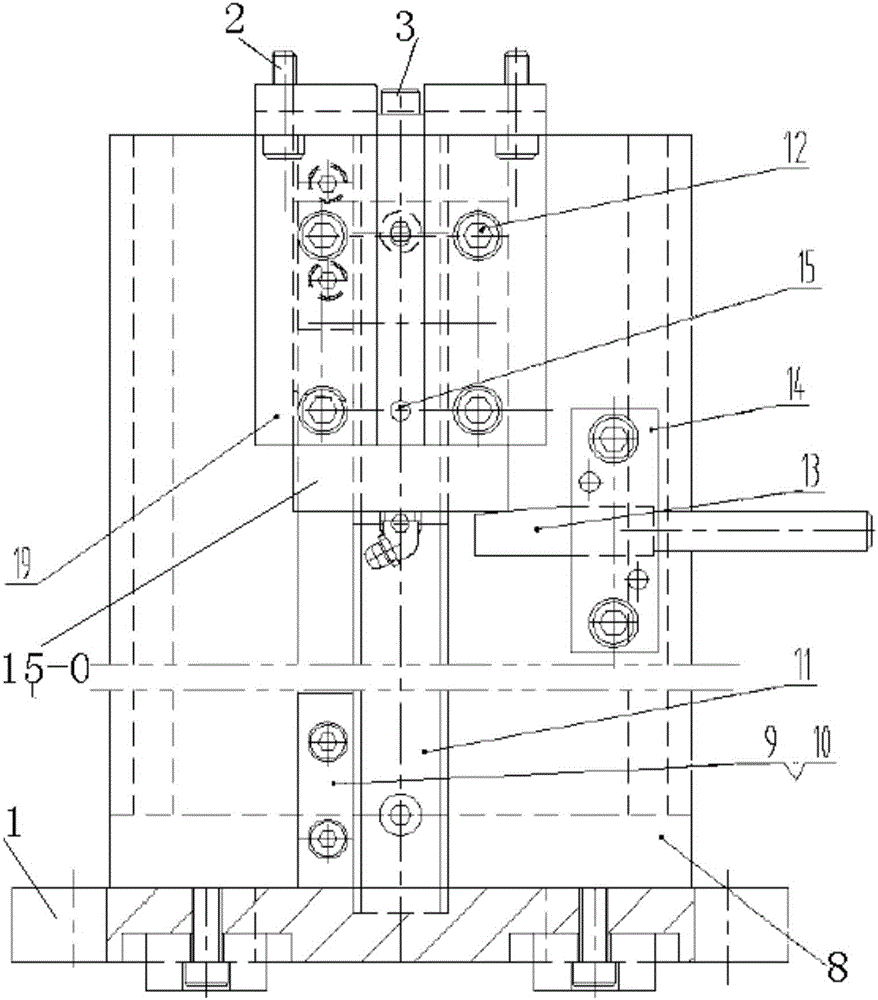

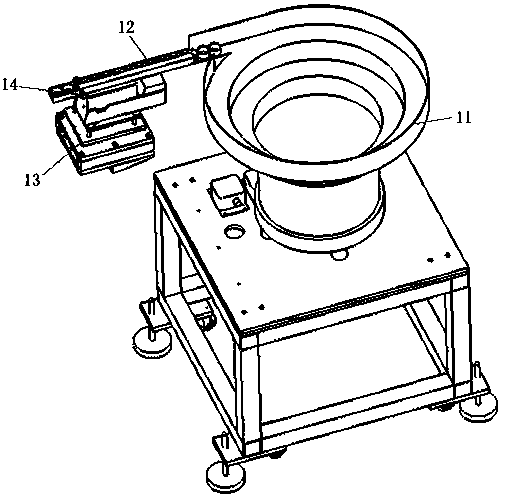

Temperature control switch automatic assembly riveting machine

PendingCN109559921AThe installation position is accurateImprove work efficiencyElectric switchesMetal working apparatusEngineeringTemperature control

The invention discloses a temperature control switch automatic assembly riveting machine comprising a base and a rotating disc, wherein the rotating disc is rotatably disposed on the base; a temperature control switch base loading device, a thermo-sensitive metal sheet loading device, a riveting sheet loading device, a riveting device and a unloading device are successively arranged on the base and around the rotating disc; a plurality of positioning seats are uniformly disposed on the rotating disc; and each positioning seat is provided with a discharging groove having an opening facing the outside of the rotating disc. The automatic assembly riveting machine can realize automatic assembly and automatic riveting of the temperature control switch base, the thermo-sensitive metal sheet andthe riveting sheet, not only improves work efficiency, but also ensures the accurate installation position of the thermo-sensitive metal sheet, and is less likely to cause personal injury.

Owner:宁波友信电器有限公司

Multifunctional split bolt and application thereof

ActiveCN103061505AImprove performanceReliable functionAuxillary members of forms/shuttering/falseworksBuilding reinforcementsArchitectural engineeringUsability

The invention discloses a multifunctional split bolt and application thereof. Steel plates are penetratingly mounted at two ends of a bolt bar. The bolt bar is fixedly connected one steel plate by means of welding. A pair of positioning clamps for fixing rebar positions is welded on the bolt bar between the two steel plates. Fastening nuts are fitted at two ends of the bolt bar. When the split bolt is used in a composite structure with building prior to pouring, construction speed is increased, construction efficiency is improved, bonding degree and tightness of interfaces of different materials are enhanced, overall performance of a structure is improved, usability of the structure is more reliable, maintenance is reduced, service life of a project is prolonged, accuracy and reliability of rebar protective layer control are higher, soakage resistance and erosion resistance of concrete is guaranteed to be more reliable, formwork mounting and strengthening are more convenient and faster, influence of building verticality and evenness can be eliminated, construction accuracy is higher, common signal side formwork lateral supports can be reduced, construction difficulty can be lowered, cost is saved, and the split bolt is suitable for double-side formwork construction and embedded part positioning mounting of walls and board components.

Owner:河北省第四建筑工程有限公司

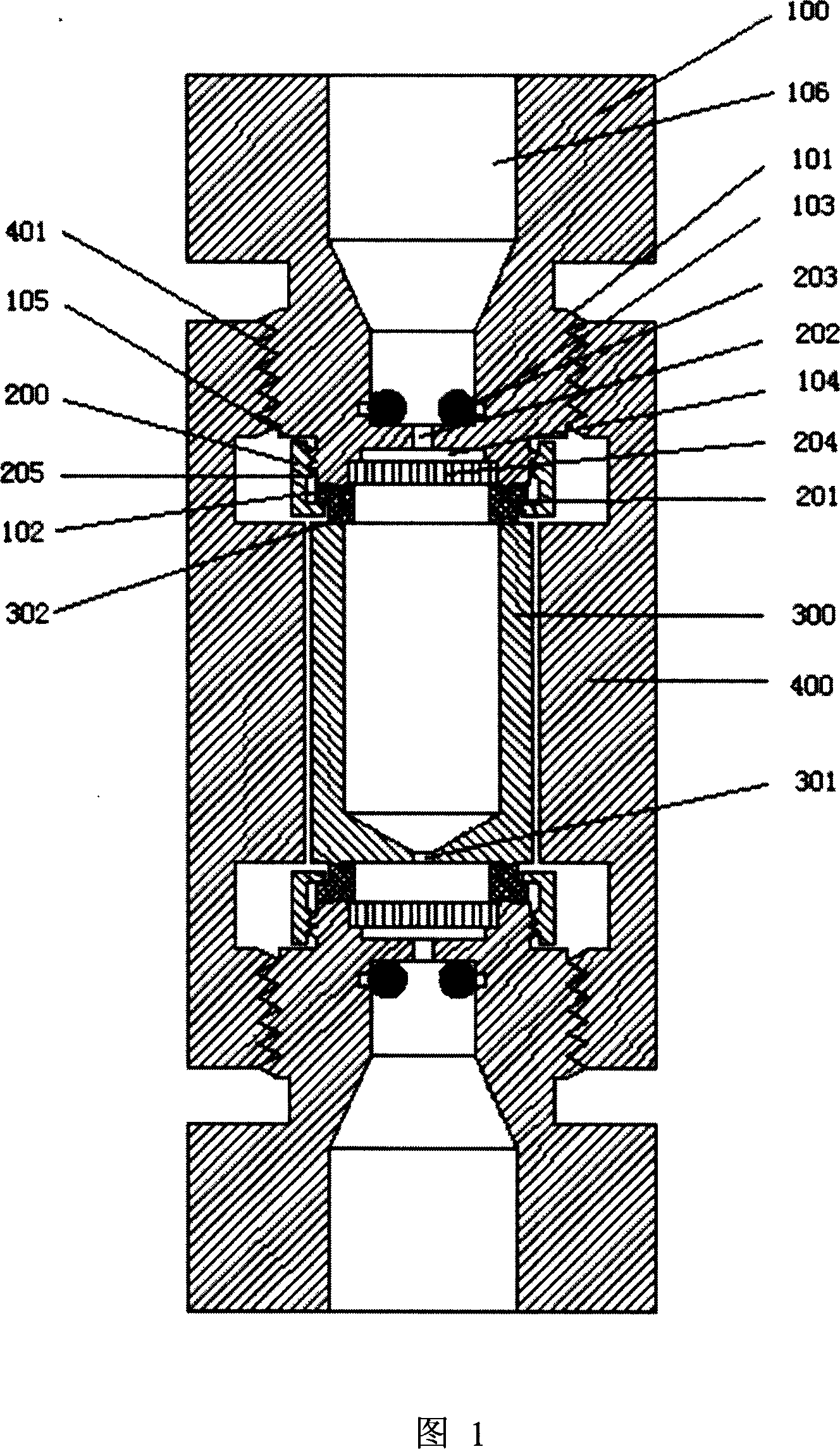

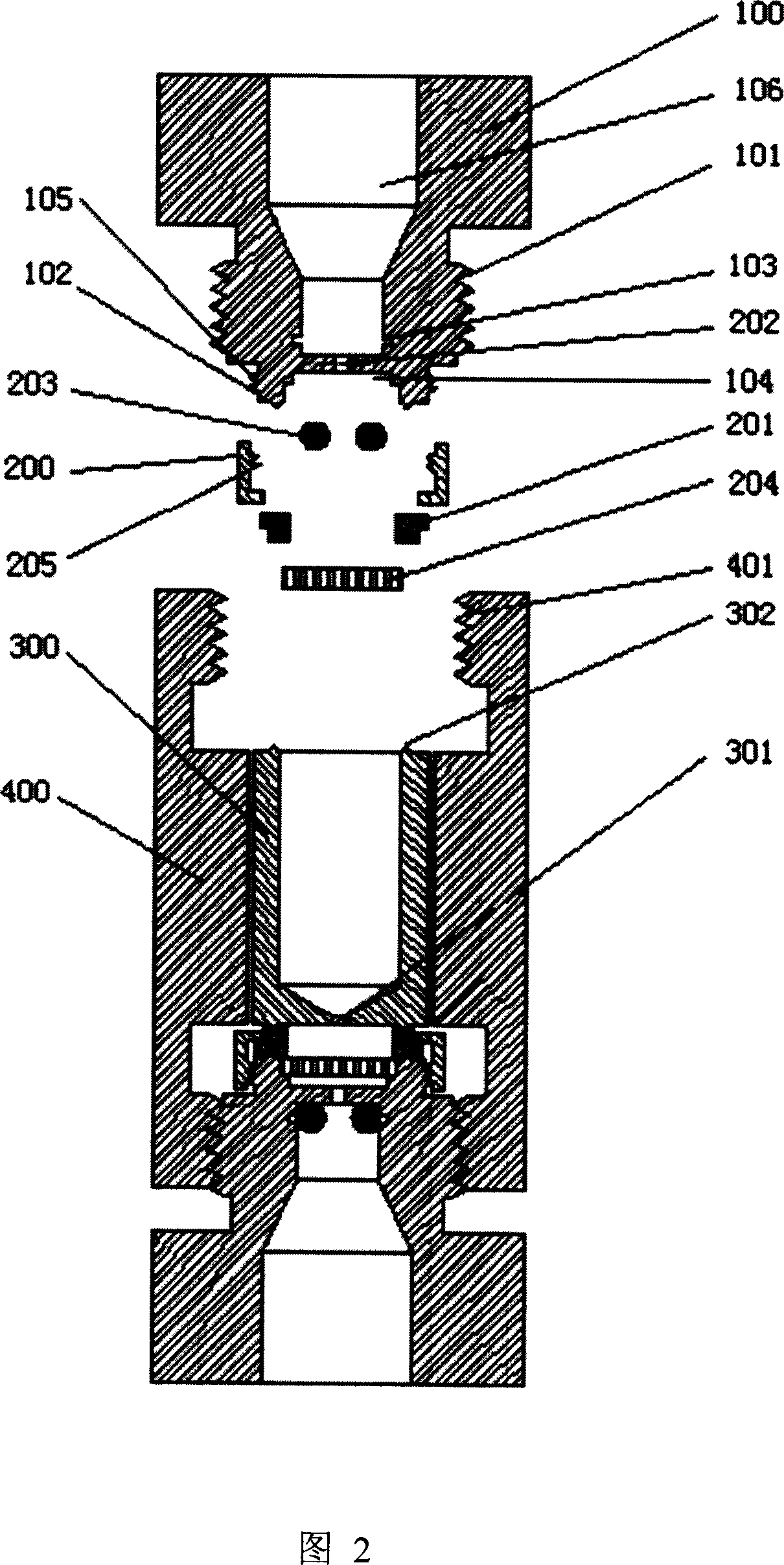

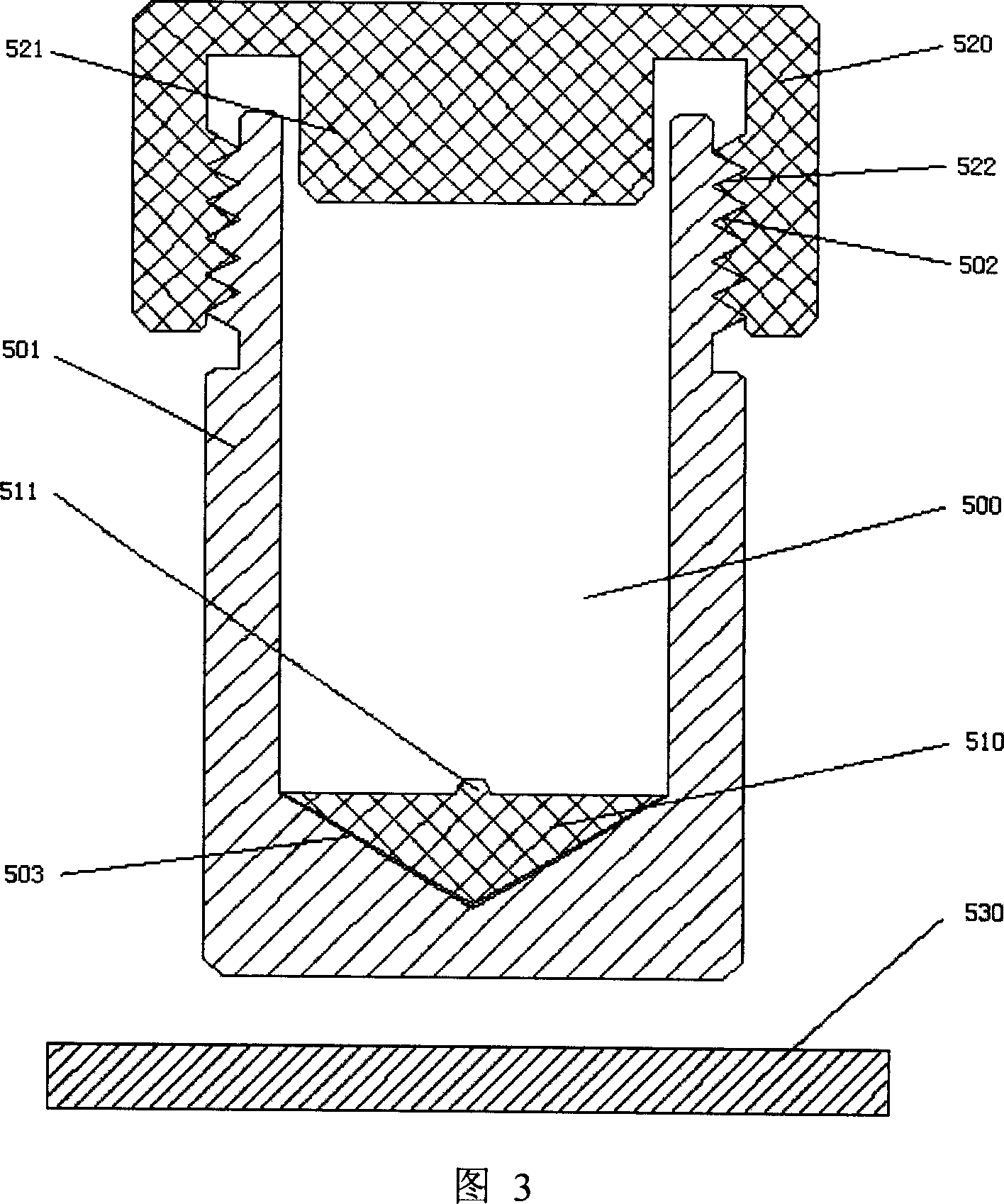

Sleeve type high-temperature and high-pressure resistant extracting pool and external member used for solvent extraction

The invention relates to a sample extraction device which is a sleeve typed high temperature and high pressure resistance extraction tank used for solvent extraction. The invention contains an extraction tank pressure cap, a sealing ring pressure cap, a sample tank, a sample tank fixed sleeve, a sealing ring, a porous filter and so on. The sample tank is in a pot structure. One end of the cavity of the sample tank is a close typed conical structure. The sample tank fixed sleeve is sheathed outside of the sample tank. The two ends of the sample tank fixed sleeve are separately connected with extraction tank pressure cap in screw-threaded connection. The sealing ring pressure cap is arranged between the two ends of the sample tank fixed sleeve and the extraction tank pressure cap. The sealing ring is arranged inside the sealing ring pressure cap. The porous filter is arranged on the sealing ring. A convex sealing knife edge is arranged on the two end faces of the sample tank. Correspondingly, a convex pressure cap sealing knife edge is arranged on the pressure cap. The sealing ring is arranged between the sealing knife edge and the pressure cap sealing knife edge. The invention is convenient to be used and has low manufacture cost and use-cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

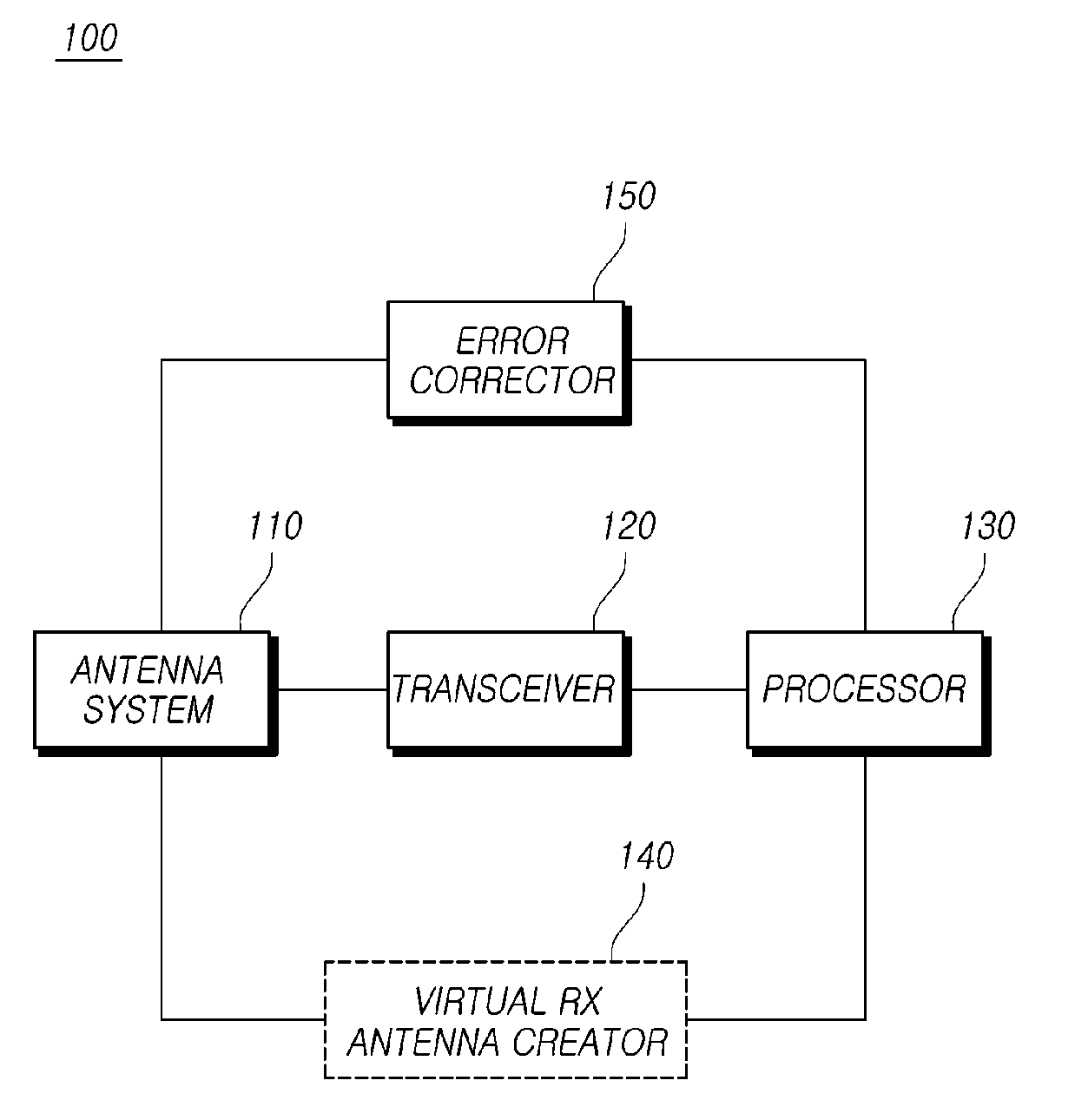

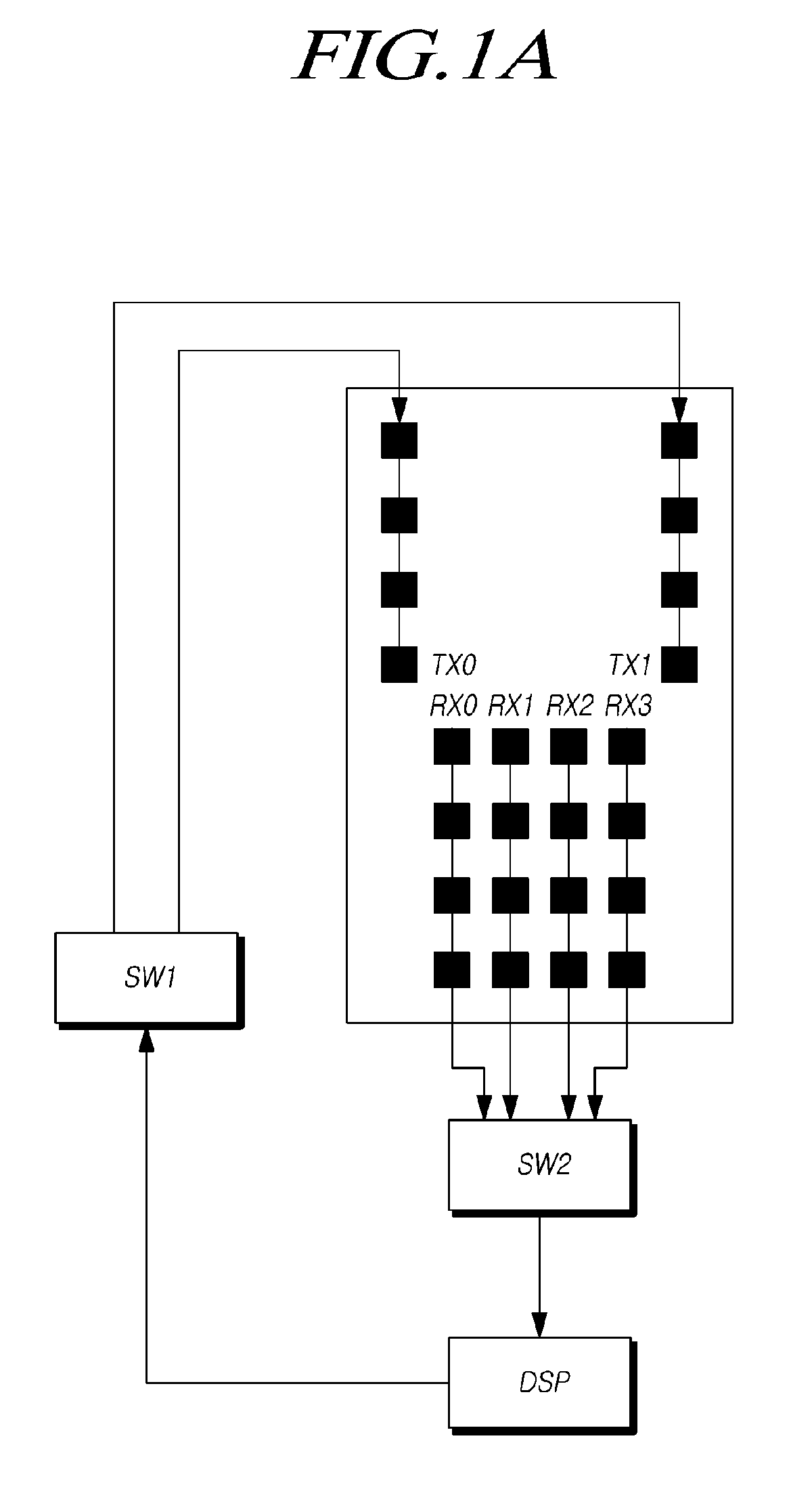

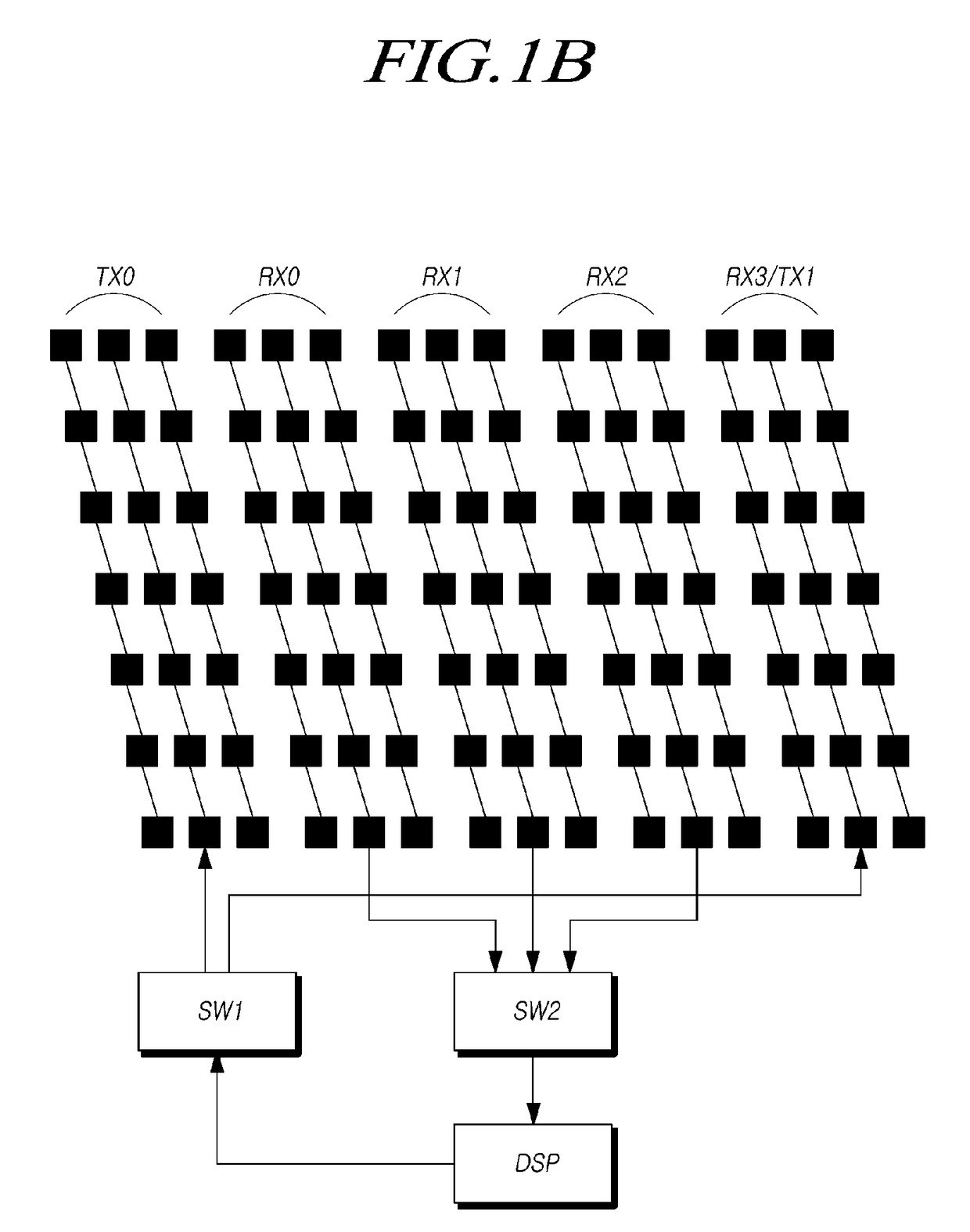

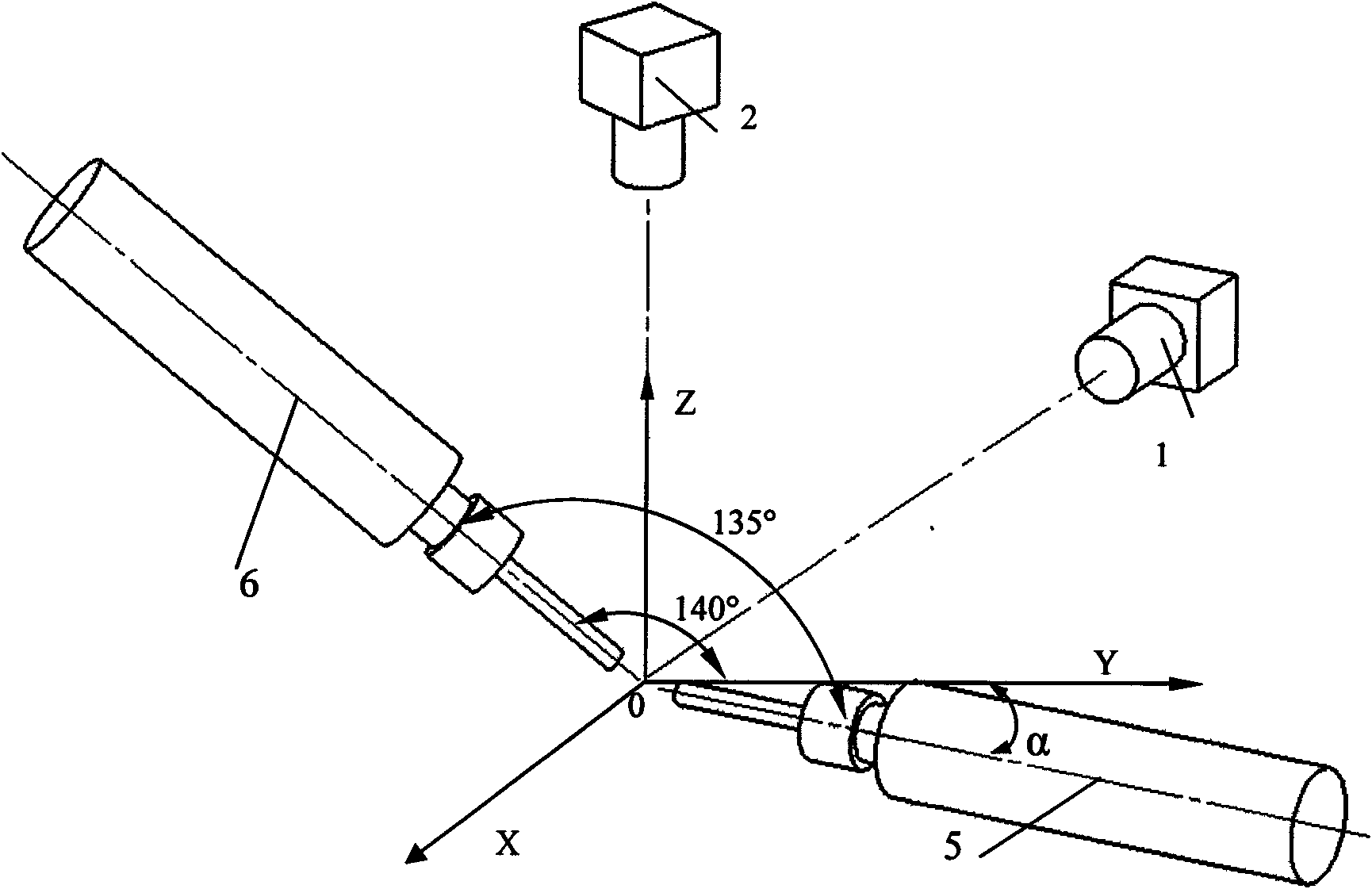

Radar apparatus and error correction method thereof

ActiveUS20180151958A1Accurate measurementCorrection errorParticular array feeding systemsAntenna adaptation in movable bodiesRadarCorrection method

The present disclosure provides a radar apparatus and a method of correcting an error of the radar apparatus. According to the present disclosure a first transmitting antenna group and a first receiving antenna group are constituted by elongating some of a plurality of transmitting antennas and a plurality of receiving antennas in a first direction of vertical directions, a second transmitting antenna group and a second receiving antenna group are constituted by elongating the other antennas in a second direction opposite to the first direction, and one or more of transmitting antennas that transmit transmission signals and one or more of receiving antennas that receive reflection signals are included in different groups, thereby being able to measure elevation information of an object and correct a mounting position of the radar apparatus on the basis of the information.

Owner:HL KLEMOVE CORP

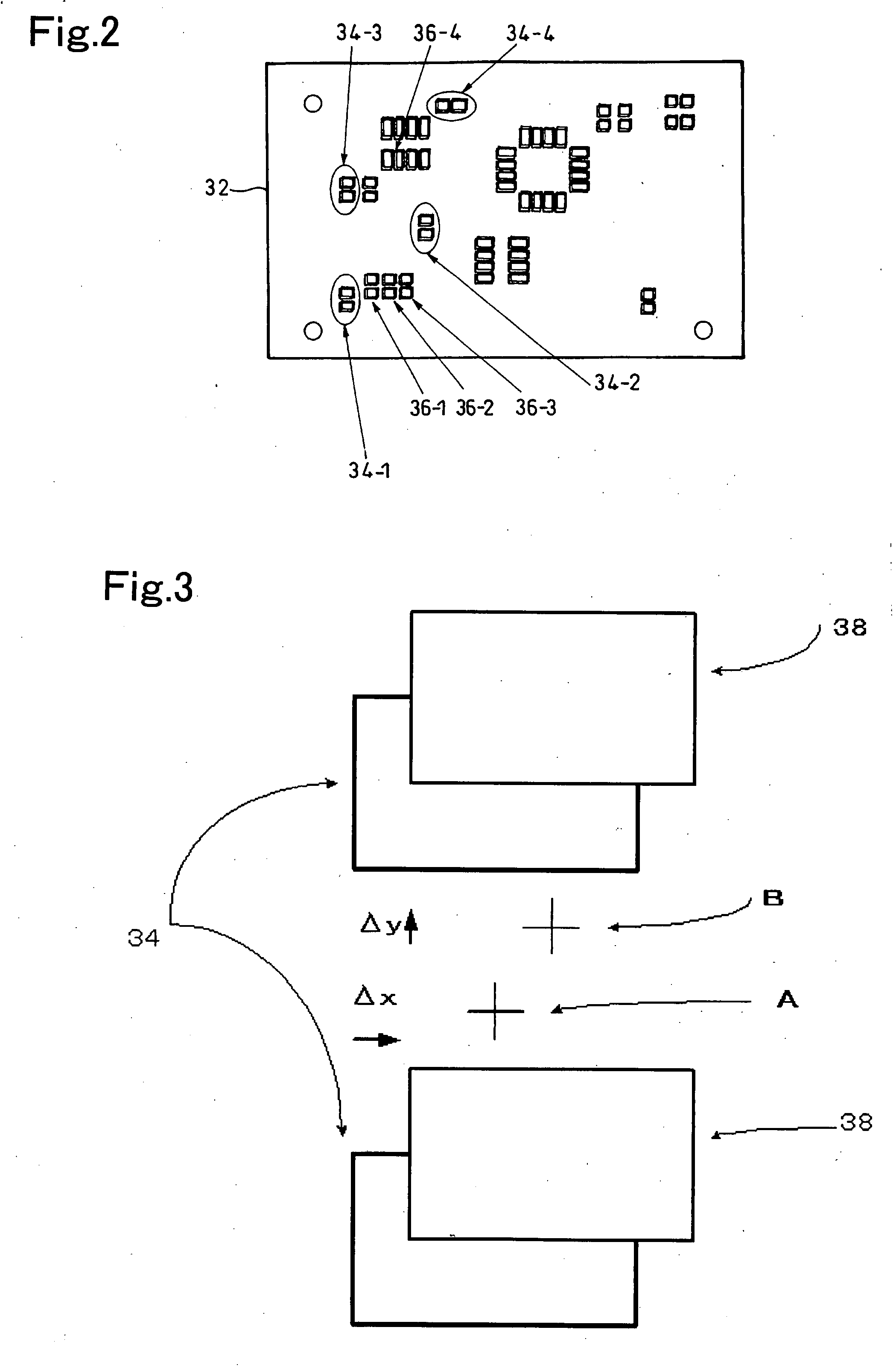

Component mounting position correcting method and component mouting apparatus

InactiveUS20080014772A1Small stretchShorten detection timeFinal product manufactureInspection/indentification of circuitsEngineeringElectrode

A component mounting position is corrected in accordance with a printing misalignment amount of a solder with respect to an original mounting position on a board at which a component is to be mounted. More specifically, a mounting position of a predetermined correction object component is corrected in accordance with the printing misalignment amount of the solder printed on a predetermined detection object electrode.

Owner:JUKI CORP

Integrated composite spinning device of ring spinning frame

The invention relates to an integrated composite spinning device of a ring spinning frame. The device comprises a special-shaped tube, a grid ring, an integrated composite roller and a tension supporting mechanism; negative pressure integrated composite tubes are positioned at two ends of a front tube wall on one side of a fiber whisker outlet line and provided with two extended roller supporting seats with closed peripheries, tension supporting seats are arranged below the two roller supporting seats, and the negative pressure integrated composite tubes are provided with more than two positioning surfaces; the tension supporting mechanism comprises a tension supporting frame and two positioning spring plates; the tension supporting frame comprises a tension rod and more than three limit sliding seats arranged transversely at intervals along the tension rod; the limit sliding seats are propped on the lower part of the tension rod by adjusting springs, and the bottom of each limit sliding seat is provided with a stop block; and the connecting surfaces of the two positioning spring plates are connected with the two tension supporting seats respectively, and the adjusting and installation surfaces of the two positioning spring plates are in pressing connection with two ends of the tension rod respectively. The device can improve the assembly precision, adjust the axial position of the grid ring in time and conveniently adjust the tension of the grid ring.

Owner:常州市同和纺织机械制造有限公司

Method for fixedly connecting embedded bars in assembly-type structure and cast-in-place structure

ActiveCN103590510AFirmly connectedEasy to get materialsWallsBuilding reinforcementsReinforced concreteButt joint

The invention provides a method for fixedly connecting embedded bars in an assembly-type structure and a cast-in-place concrete structure and relates to the technical field of building structure connection. The problems that according to an existing connecting method of a prefabricated shear wall, steel bars are not positioned accurately by a steel bushing plate, so that butt joint mismatch of sleeves and the steel bars is large, and therefore the phenomenon that accurate butt joint of the prefabricated shear wall and a lower-layer wall body can not be achieved is caused are solved. The method comprises the steps that firstly, a wooden bushing board provided with a plurality of base holes is provided and the base holes can correspond to the positions of bushings in an assembly-type reinforced concrete structure; secondly, template supporting is conducted on the position where the concrete structure needs to be cast in place so that a chamber can be formed, the wooden bushing board is fixed to the top end of the chamber, and the embedded bars penetrate through the wooden bushing board and are implanted in the chamber so that positioning can be achieved; thirdly, concrete is poured to the chamber, and after the concrete is hardened, the wooden bushing board is detached, so that the cast-in-place concrete structure is manufactured; fourthly, the assembly-type reinforced concrete structure and the cast-in-place concrete structure are in butt joint and are fixed; fifthly, a gap of the connection portion of the wall body is plugged so that assembly construction can be accomplished.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD +1

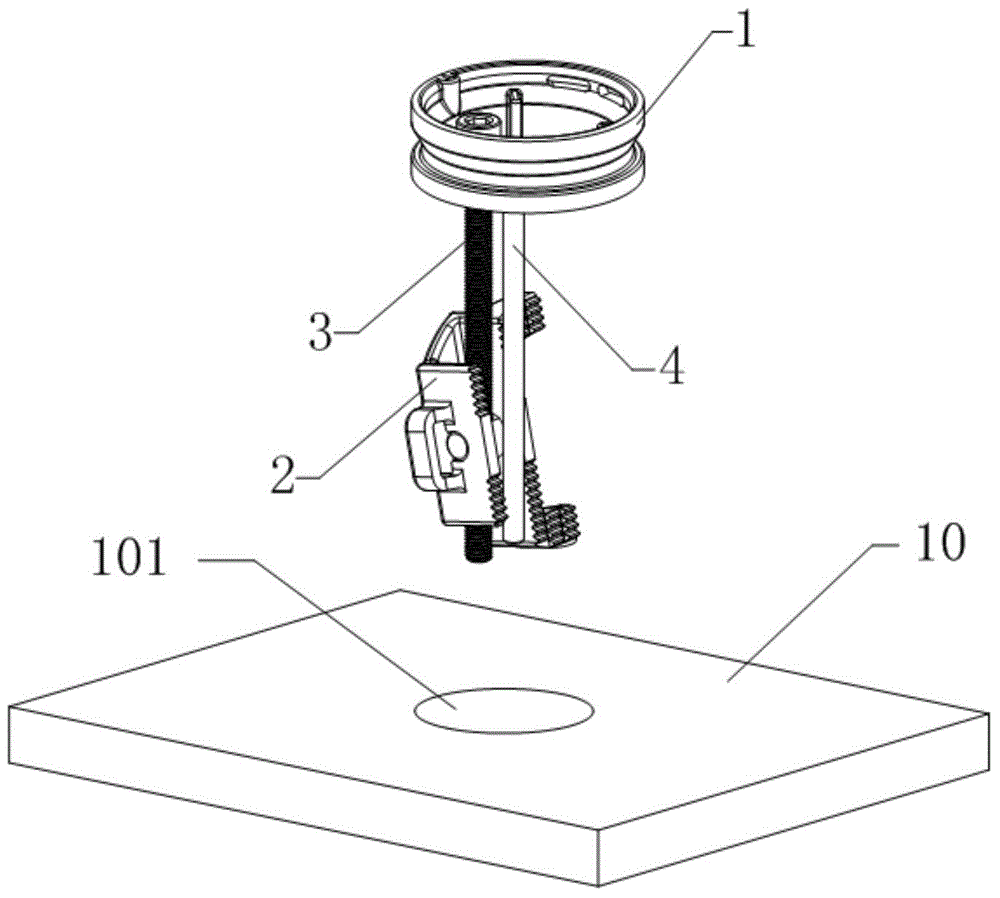

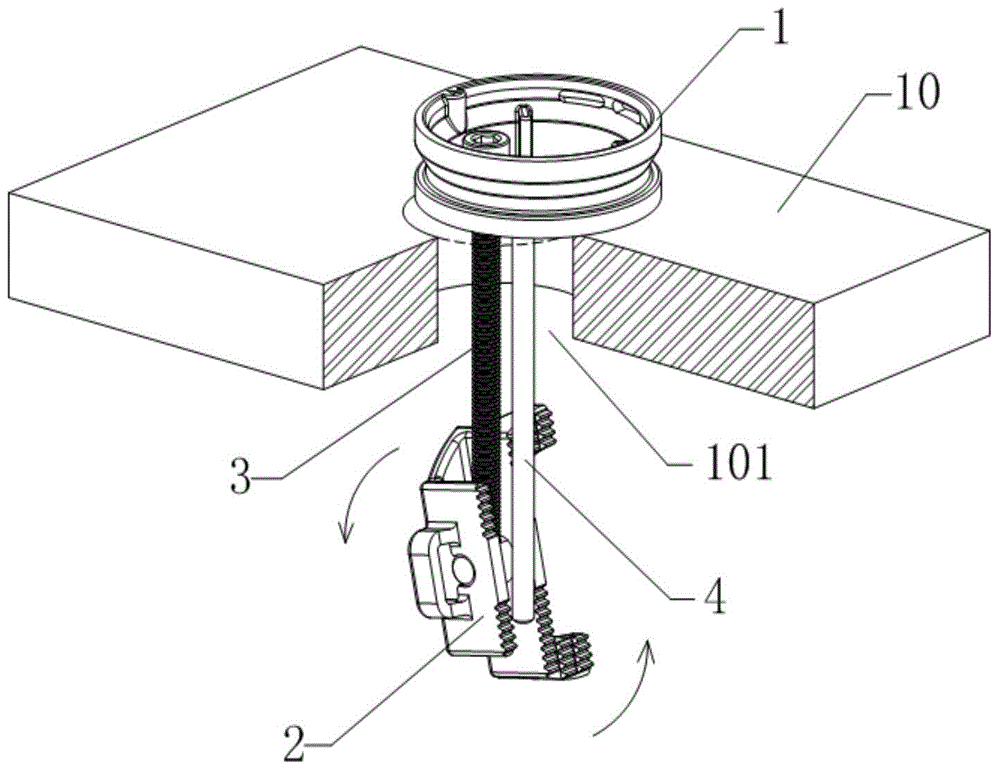

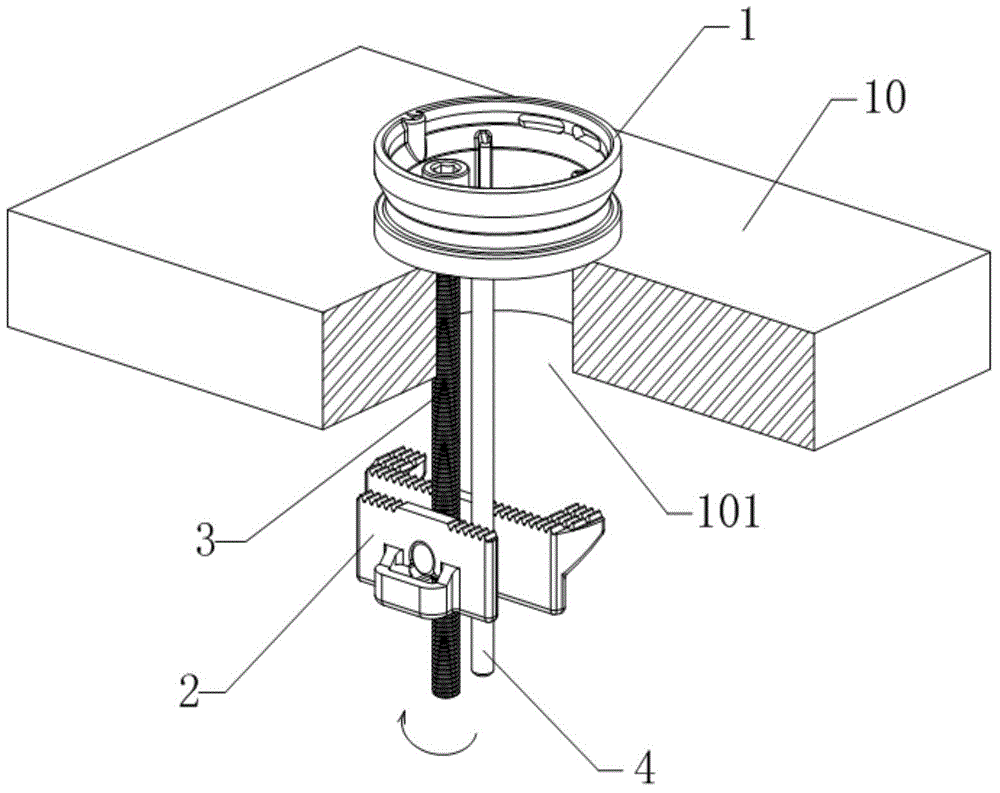

Faucet connecting mechanism facilitating deck mounting

ActiveCN104674904AEasy to installThe installation position is accurateDomestic plumbingEngineeringMechanical engineering

The invention discloses a faucet connecting mechanism facilitating deck mounting. The faucet connecting mechanism can be mounted on a sink deck provided with a mounting hole and comprises a base, a locking device as well as a thread rod assembly and a limiting stop lever which are arranged between the base and the locking device. When a faucet is mounted, the thread rod assembly is screwed above the sink deck to be rotated, the rotation of the locking device is limited by the limiting stop lever, the locking device moves in the direction of the sink deck and is propped against the bottom wall surface of the sink deck, meanwhile, a propping end at the bottom of a surrounding wall is propped against the top surface of the sink deck, so that the propping end at the bottom of the surrounding wall and the locking device are clamped at the upper end and the lower end of the sink deck, the faucet connecting mechanism is fixed, and then the faucet is connected with the connecting mechanism. Therefore, the mounting is convenient, and the problem that mounting cannot be finished independently in order to guarantee both correct mounting position of the faucet and firm mounting of the faucet due to narrow operation space, limited reach of arms and limited angle of view of eyes is solved.

Owner:PRIMY CORP LTD

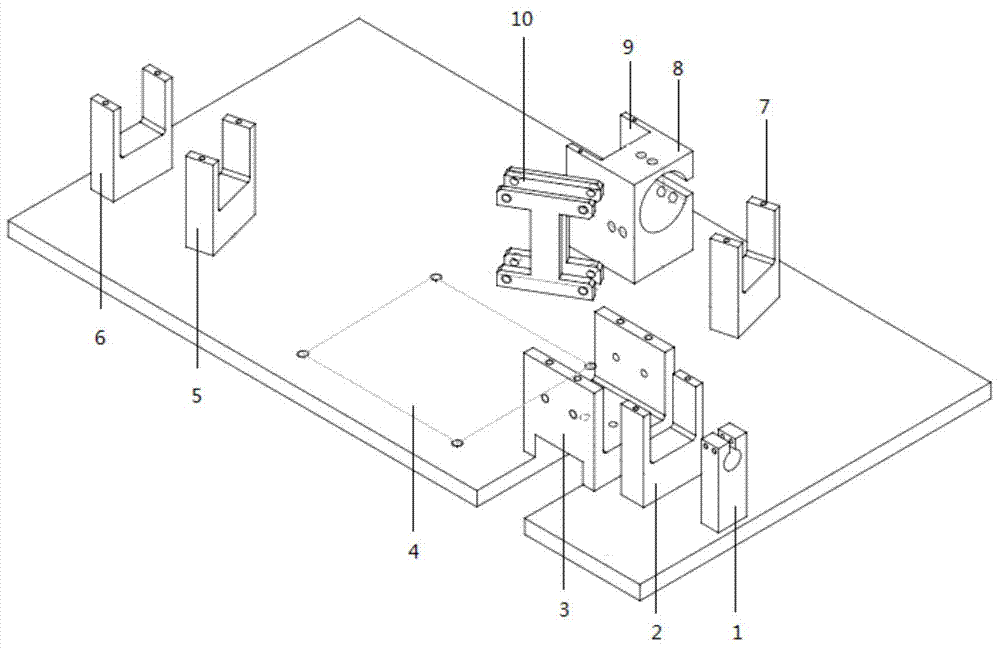

Numerical control abrasive belt grinding tooling for intake and exhaust edges of precise forged stator blade of aircraft engine

ActiveCN106425734AAchieve positioningGuaranteed positioning accuracyEdge grinding machinesBelt grinding machinesNumerical controlBelt grinding

The invention relates to a numerical control abrasive belt grinding tooling for intake and exhaust edges of a precise forged stator blade of an aircraft engine. The numerical control abrasive belt grinding tooling comprises fixtures used for clamping technological bosses at the two ends of the blade, a molded surface locating block used for locating a blade molded surface, and a fixture base, wherein the molded surface locating block is arranged on the fixture base; the fixture base comprises a bottom plate; a bracket is arranged on the bottom plate; a vertical linear guide rail is arranged on the bracket; a movable sliding block which can move up and down along the linear guide rail is arranged on the linear guide rail; a support is fixed to the movable sliding block; the molded surface locating block is fixed to the upper end of the support; a limiting device is further arranged on the bracket; the limiting device is used for fixing the support at a preset height; locating pins are arranged at the upper end of the molded surface locating block; and during locating, second locating pins are in contact with the blade molded surface of the blade, and first locating pins are in contact with the side surfaces of the blade technological bosses of the blade. According to the numerical control abrasive belt grinding tooling, the tooling structure adopts split design, the molded surface and a locating point are separated, and parts are clamped at one time.

Owner:AECC AVIATION POWER CO LTD

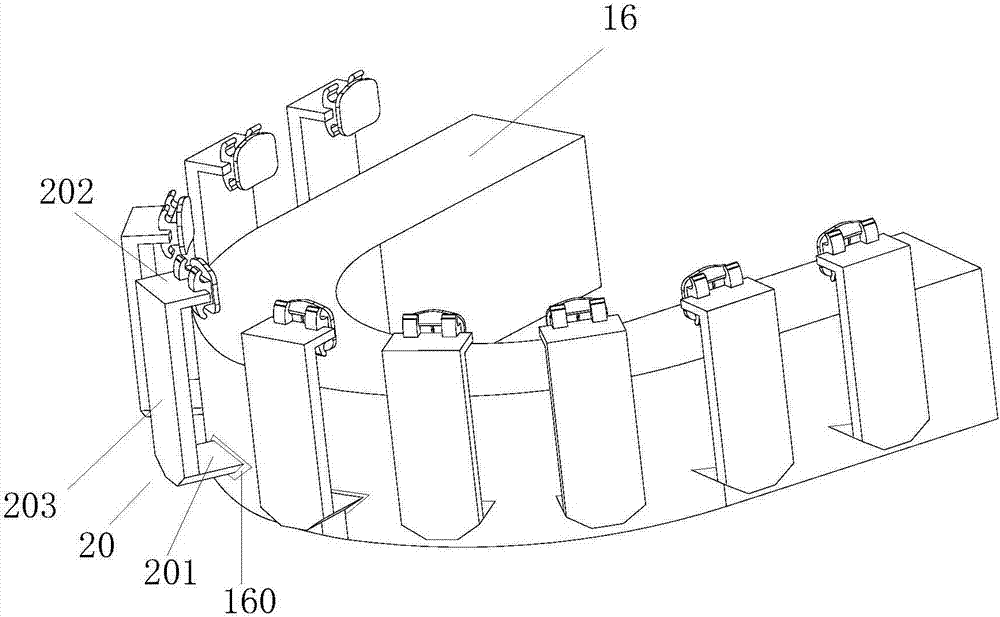

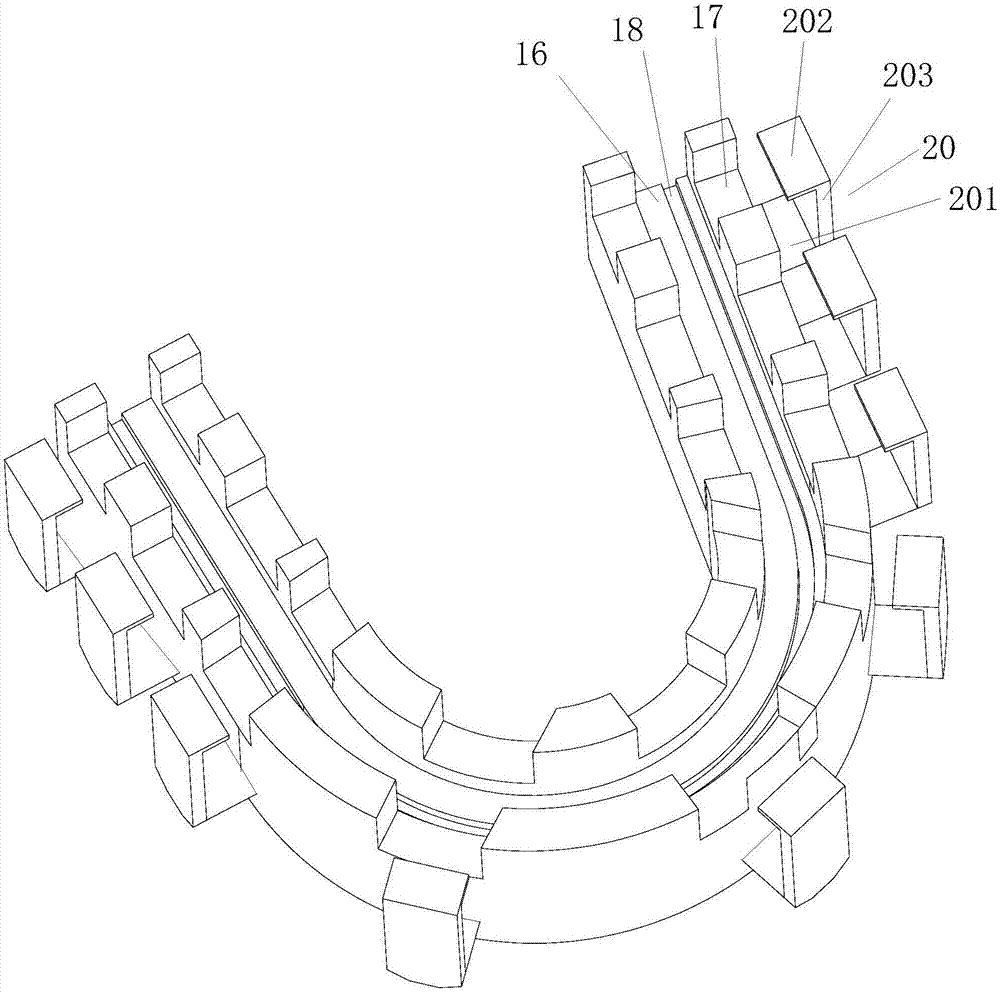

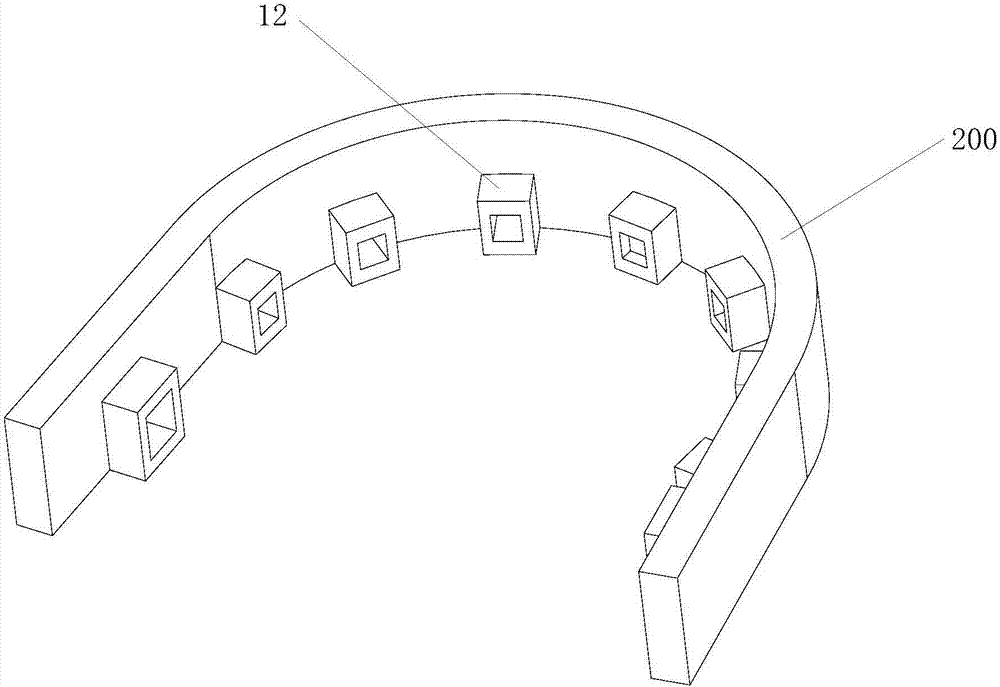

Bracket bonding locator, manufacturing method thereof and bracket locating method

ActiveCN107874849AReduce discomfortImprove the treatment environmentArch wiresBracketsCorrosionEngineering

The invention relates to the field of orthodontics and discloses a bracket bonding locator, a manufacturing method thereof and a bracket locating method. The bracket bonding locator comprises an occlusion plate (16) used for occluding upper and lower oral teeth, wherein a bracket locating rack (20) used for transferring the bracket is arranged on the occlusion plate (16); the bracket locating rack(20) is inserted into the occlusion plate (16); and the bracket locating rack (20) slides in the occlusion plate (16) to transfer the bracket to be bonded onto the tooth surface. Simulated creation of a personalized bracket bonding locator and an acid etching locating plate is performed by utilizing a computer, so that the personalized acid etching locating plate is matched with the teeth, accurate bonding of the bracket is ensured, and the operation is convenient and simple. Meanwhile, the bracket bonding locator disclosed by the invention has the advantages of being high in acid etching synchronicity, low in tooth corrosion, simple in operation and the like.

Owner:浙江日盛医疗科技股份有限公司

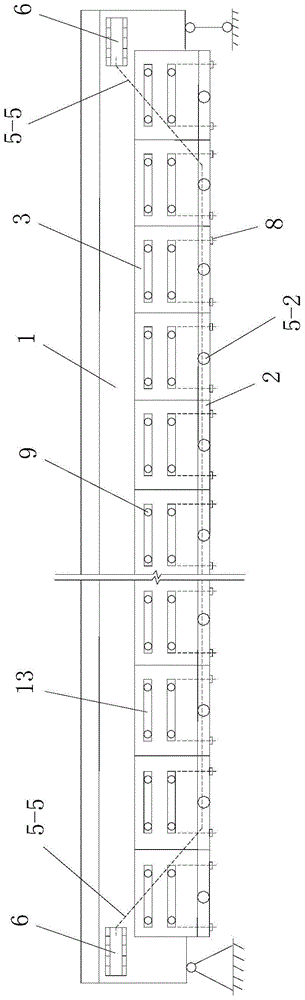

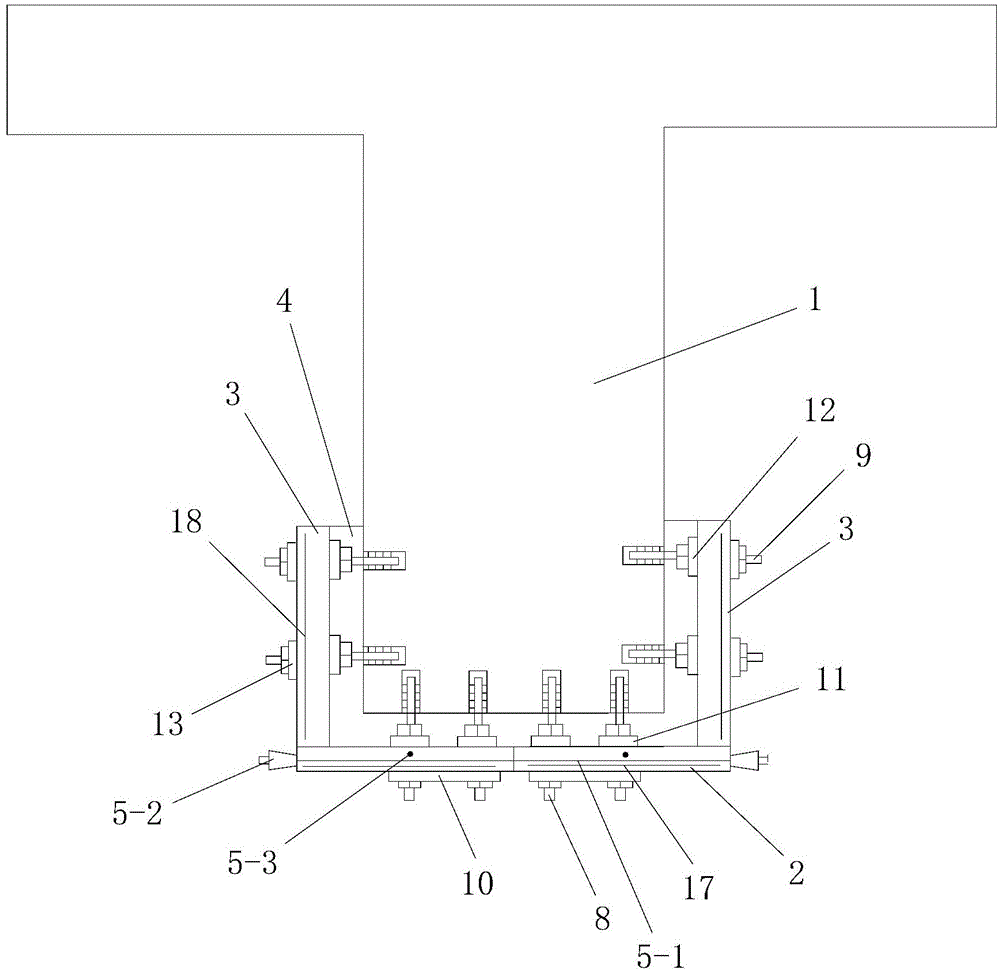

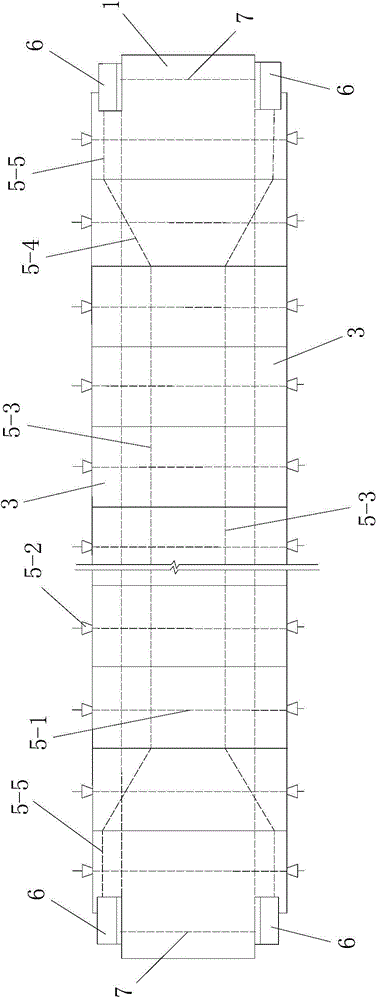

Integral-type settlement plate installation device of soil mass layered settlement monitoring equipment

InactiveCN103266589AThe installation position is accurateAvoid breakingIn situ soil foundationEngineering

The invention discloses an integral-type settlement plate installation device of soil mass layered settlement monitoring equipment. The integral-type settlement plate installation device of the soil mass layered settlement monitoring equipment comprises a guide pipe (1) and a plurality of settlement plates (2), wherein a bearing supporting plate (3) is arranged on each settlement plate (2), a guide hole (4) is formed in each bearing supporting plate (3), a plug pin (5) is arranged inside each guide hole (4) in a sliding matched mode, and the length of each plug pin (5) is smaller than the depth of each guide hole (4). An air bag (6) is fixed on the outer wall of the guide pipe (1), a plurality of layers of jacking rods (8) are fixed on the air bag (6), the jacking rods (8) are as high as the bearing supporting plates (3) one to one, a plurality of passing holes (11) are formed in an outer sleeve barrel (9), and the outer end of each jacking rod (8) of each layer penetrates each passing hole (11) of the outer sleeve barrel (9), and is inserted into the inner end of the guide hole (4) of the bearing supporting plate (3) of the same height. The integral-type settlement plate installation device of the soil mass layered settlement monitoring equipment enables the settlement plates (2) to be accurately, conveniently and reliably installed on the hole wall of a measuring hole.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

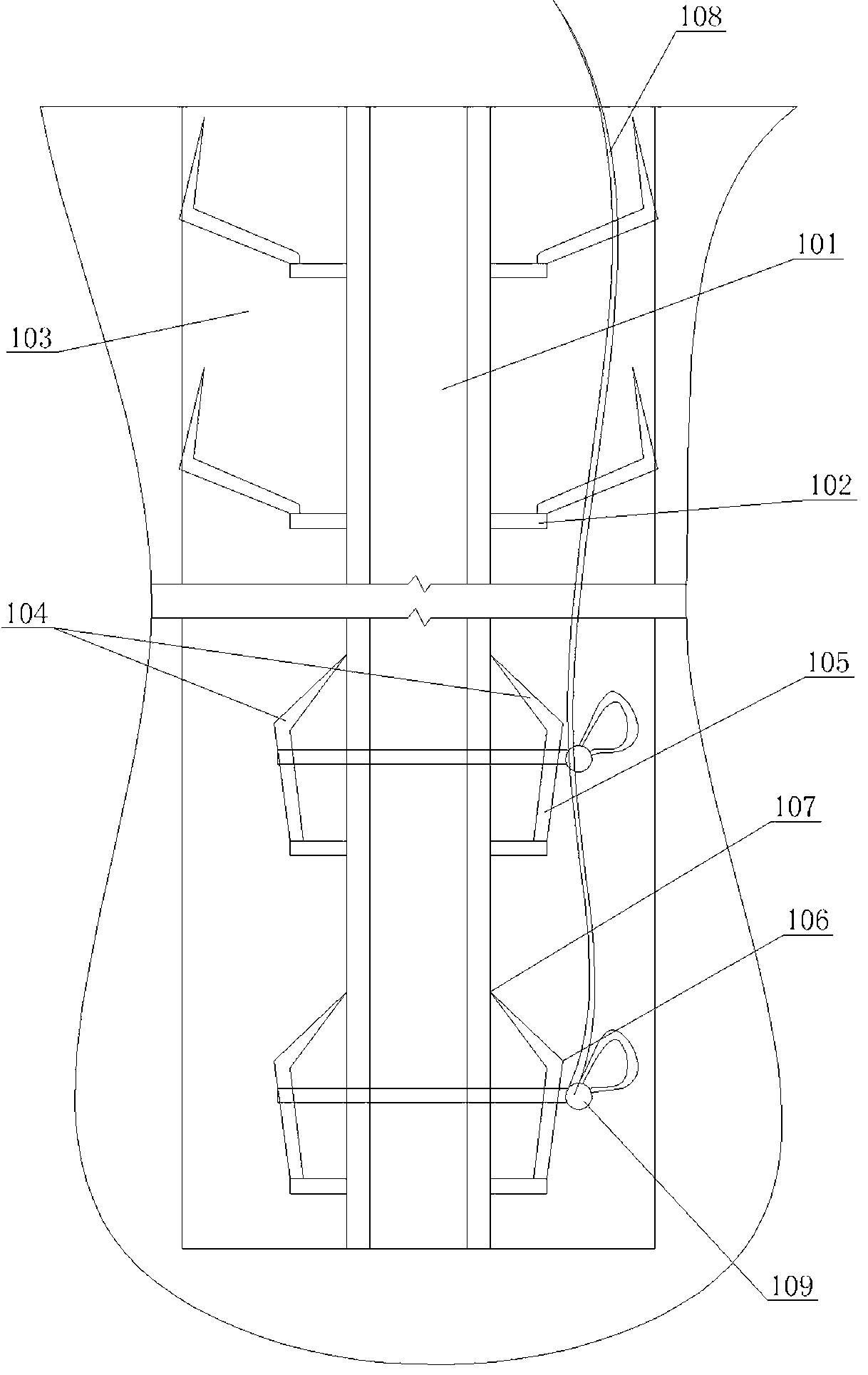

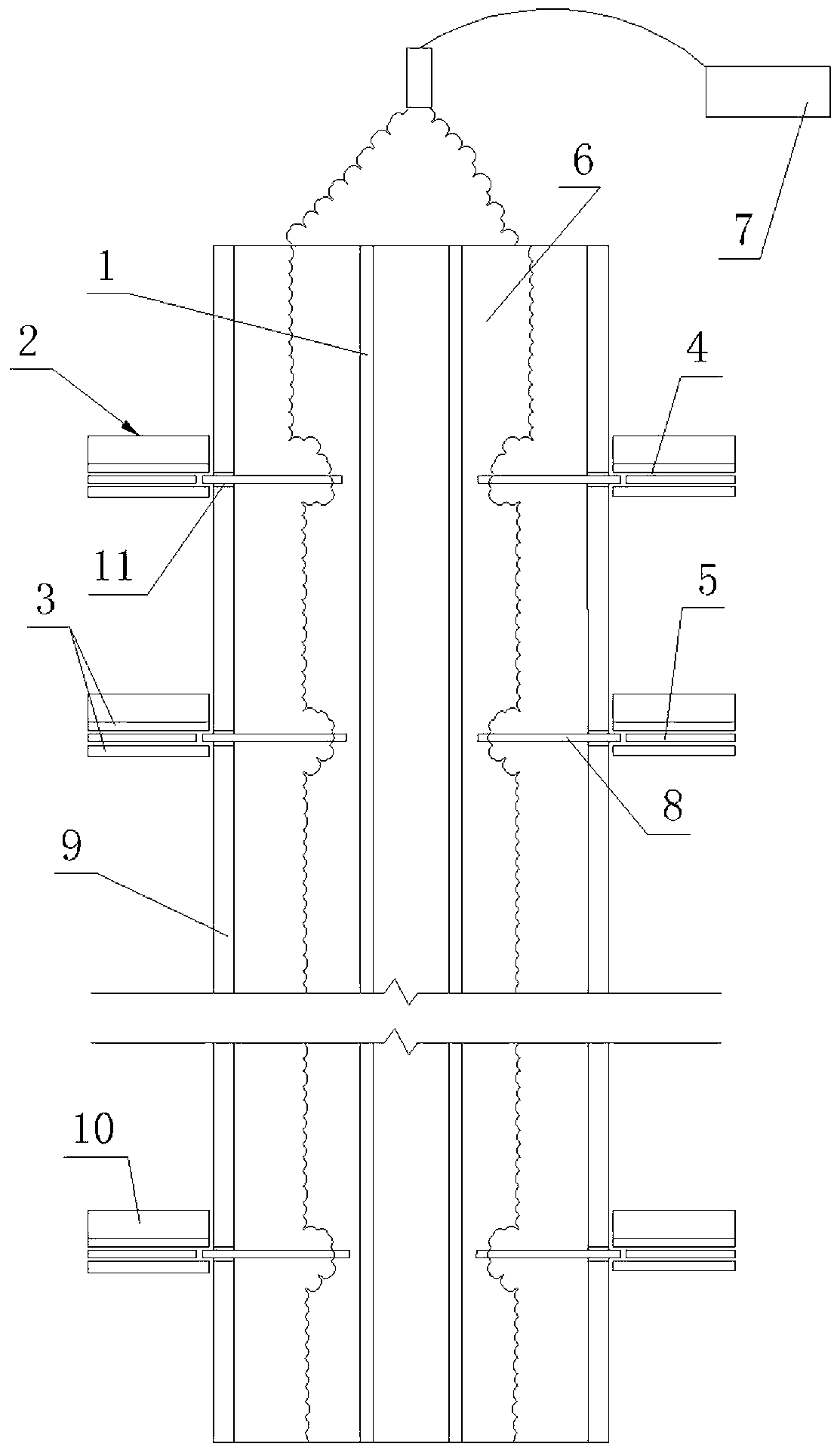

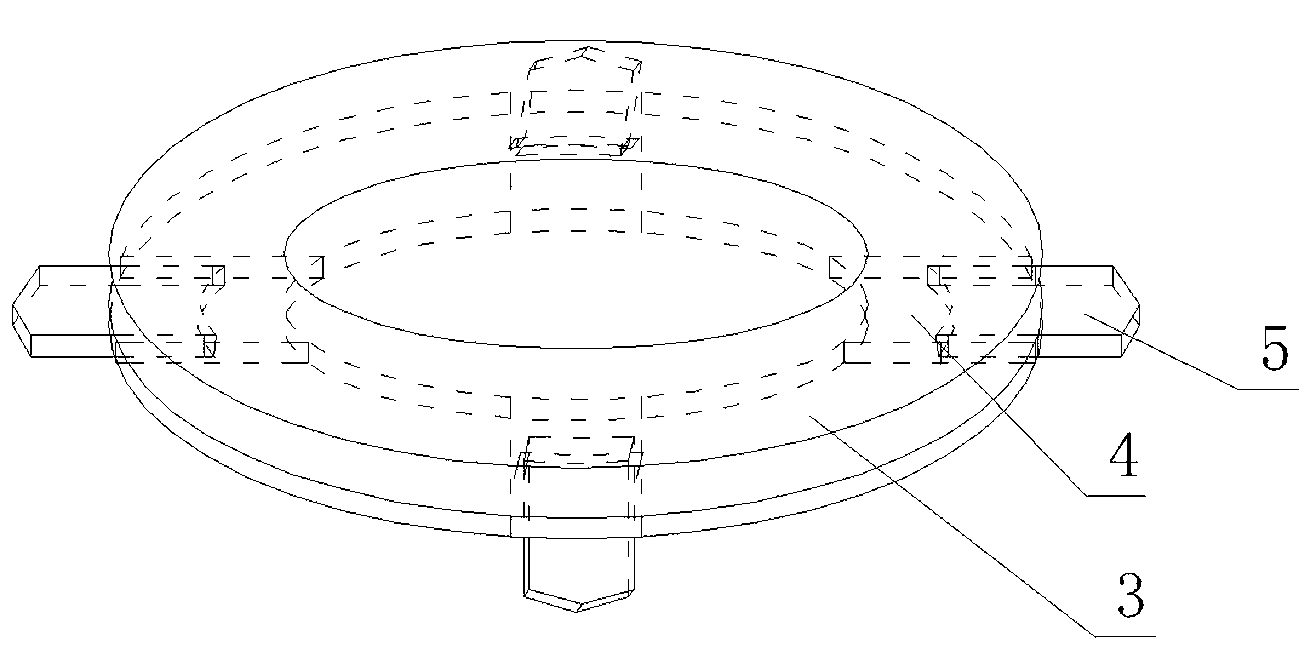

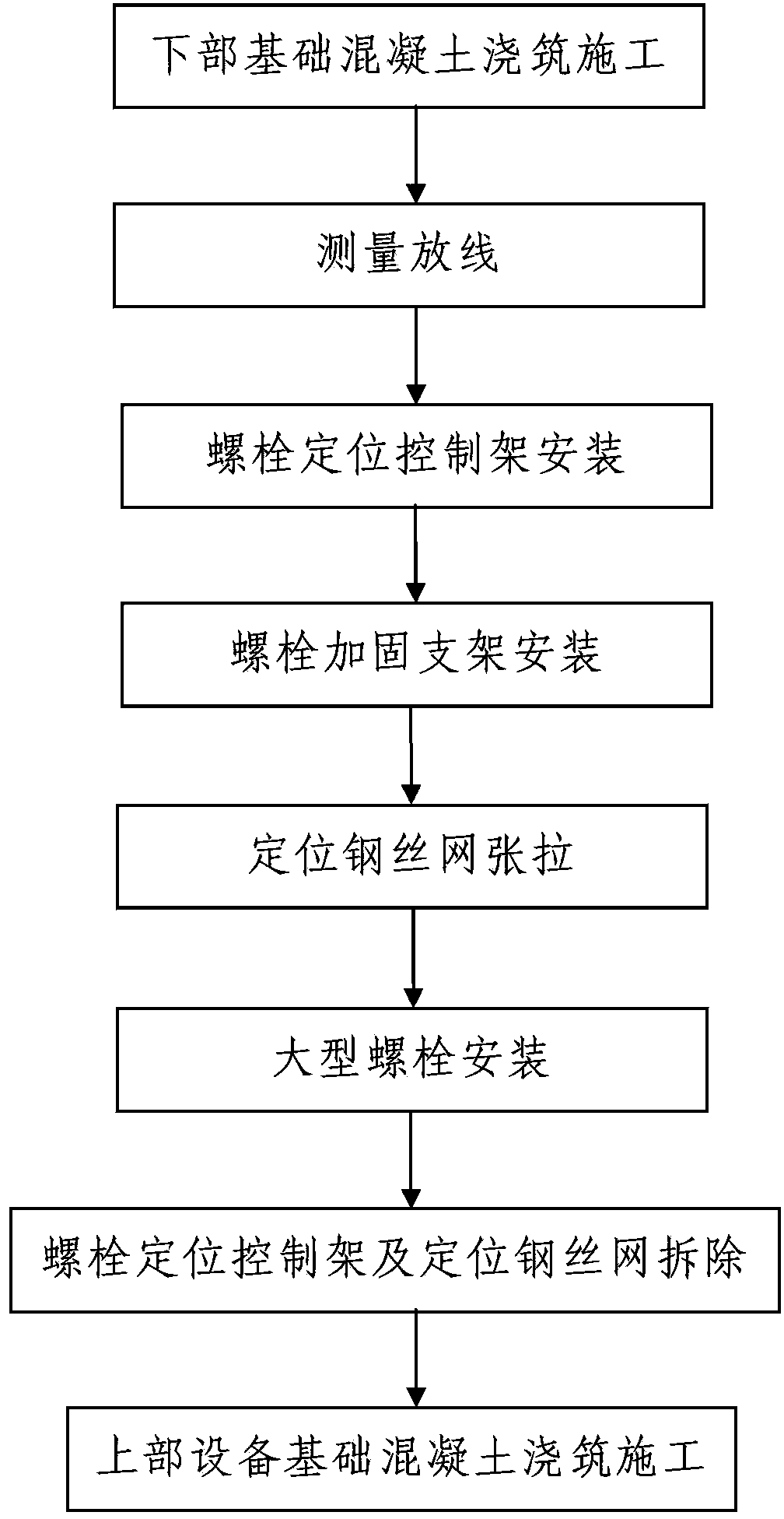

Large-scale bolt high-precision pre-burying construction method

ActiveCN103352476ASimple structureReasonable designFoundation engineeringCushionBuilding construction

The invention discloses a large-scale bolt high-precision pre-burying construction method. The number of pre-buried large-scale bolts is N, all the large-scale bolts are pre-buried in a construction device foundation, the large-scale bolts comprise screw rods and bases, external threads are arranged at the top ends of the screw rods, the bases are arranged on the bottom portions of the screw rods, and the device foundation is divided into a lower foundation cushion layer and an upper device foundation with the plane where the bottom portions of the bases of the large-scale bolts are located as a boundary. The method comprises a first step of carrying out concrete pouring construction on the lower foundation cushion layer, a second step of carrying out measurement and paying off, a third step of mounting a bolt locating control rack, a fourth step of mounting a bolt reinforcing support, a fifth step of tensioning a locating steel wire net, a sixth step of mounting the large-scale bolts, a seventh step of removing the bolt locating control rack and the locating steel wire net, and an eighth step of carrying out concrete pouring construction on the upper device foundation. The method is simple in process, reasonable in design, convenient to achieve, good in using effect, and capable of simply, conveniently and fast achieving the high-precision pre-burying process of the large-scale bolts in the device foundation in high quality.

Owner:陕西建工第十一建设集团有限公司

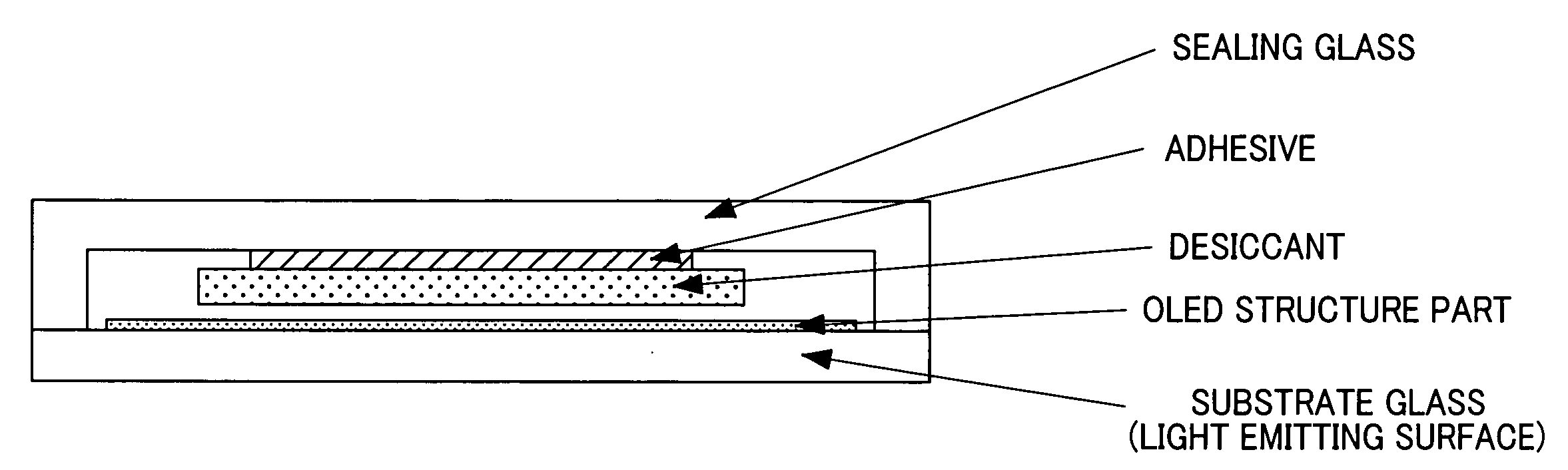

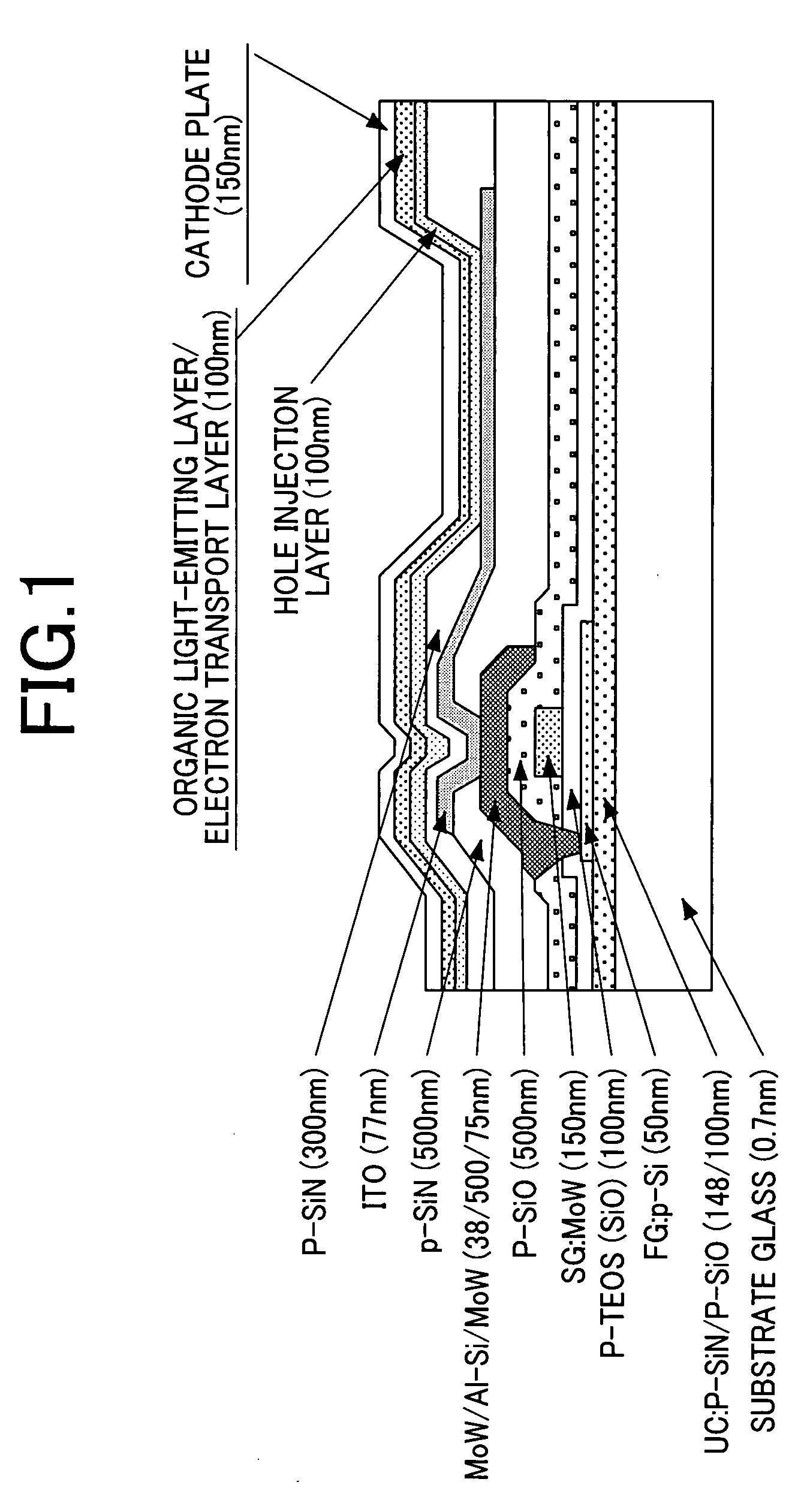

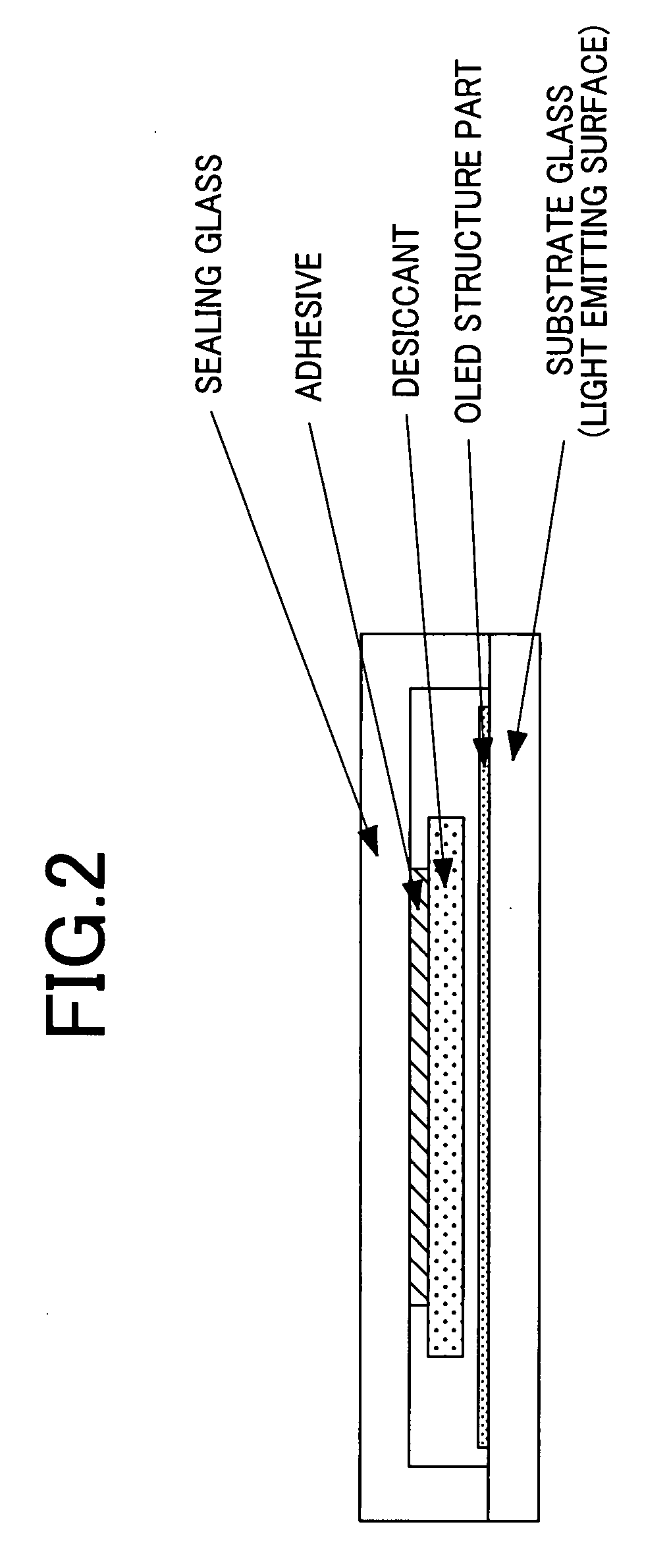

Organic electroluminescence display device

ActiveUS20070200497A1Improve cooling effectHigh impact strengthDischarge tube luminescnet screensLamp detailsDiffusion functionDisplay device

The strength of the whole OLED is increased by proposing a new method of fixing OLED panels. To address the problem, an OLED element is formed on a substrate, and a sealing substrate of a structure by which the substrate is sealed is fixed to a lower metallic frame via an elastic sheet. Silicon resin is preferably used as the sheet, and use of a sheet having a heat diffusion function based on radiation is more desirable.

Owner:HITACHI DISPLAYS +1

Reinforced concrete girder bridge girder reinforcing structure and method

ActiveCN104947603ASimple structureReasonable designBridge erection/assemblyBridge strengtheningReinforced concretePre stress

The invention discloses a reinforced concrete girder bridge girder reinforcing structure and method. The reinforcing structure comprises a reinforcing form board, a concrete structure located in a cavity between the reinforcing form board and a to-be-reinforced girder and a prestress system arranged on the reinforcing form board, wherein the reinforcing form board includes a girder-bottom form board and two girder-side form boards; the prestress system comprises two longitudinal prestress steel strands penetrating the reinforcing form board and a plurality of first transverse prestress steel strands penetrating the girder-bottom form board, four steel anchor boxes are disposed on the to-be-reinforced girder, and the two longitudinal prestress steel strands, two second transverse prestress steel strands and the four steel anchor boxes form the annular prestress system. The reinforcing method includes the steps of firstly, prefabricating the reinforcing form board; secondly, arranging anchor parts; thirdly, hoisting and fixing the reinforcing form board; fourthly, pouring concrete; performing prestress tension. The reinforcing structure and method is reasonable in design, simple in construction, good in reinforcing effect and capable of solve various problems of existing reinforcing methods.

Owner:XIAN UNIV OF SCI & TECH

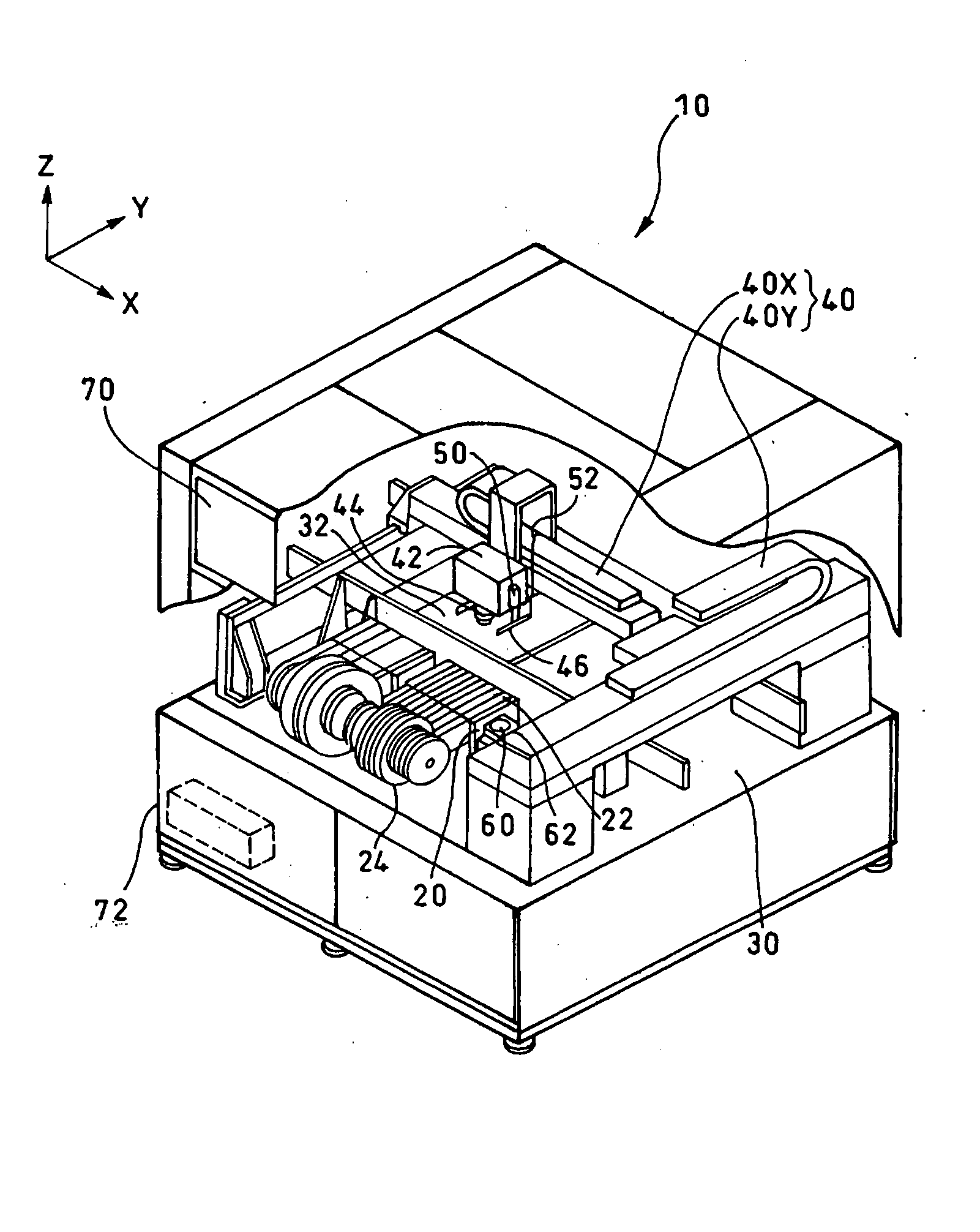

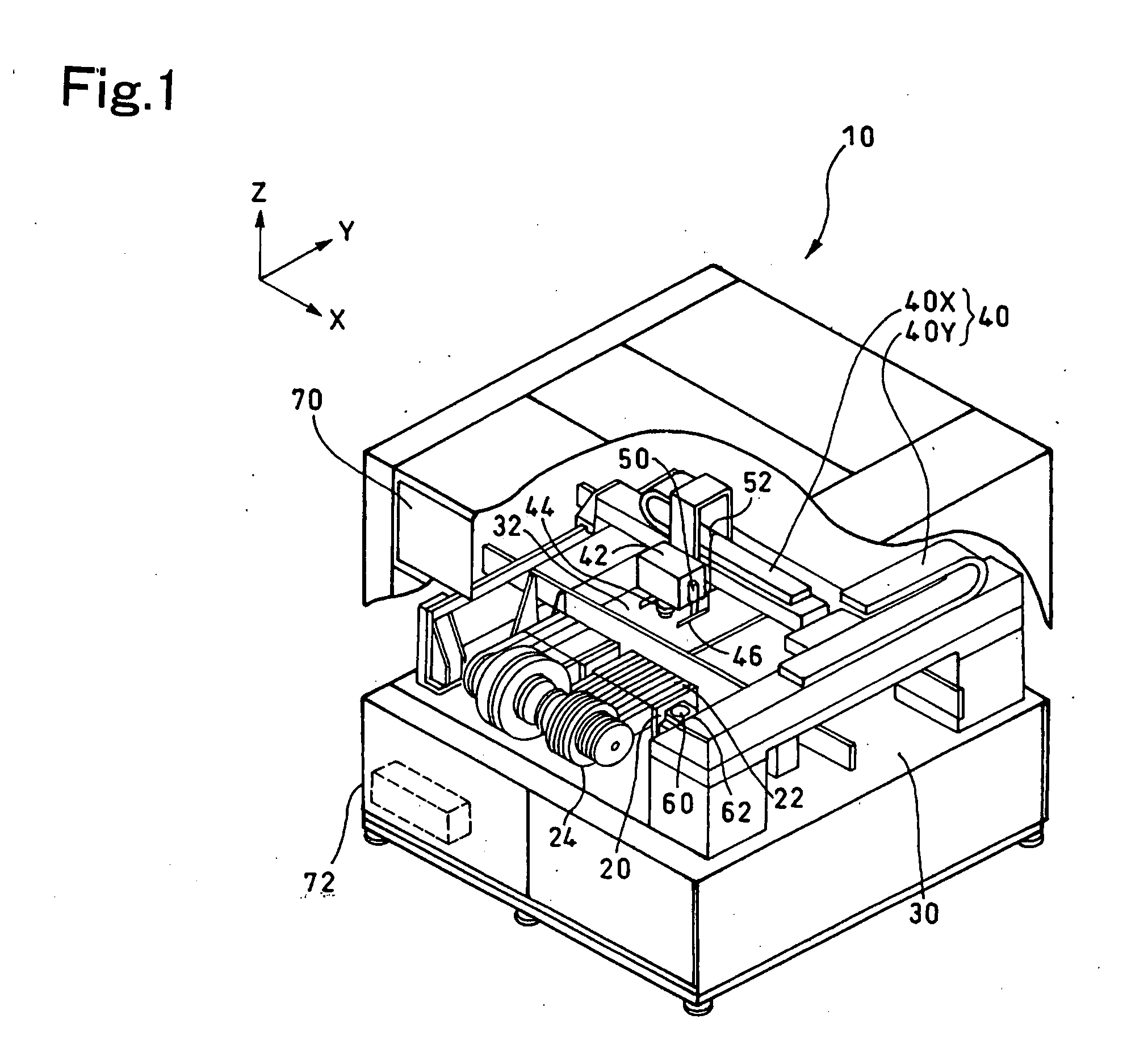

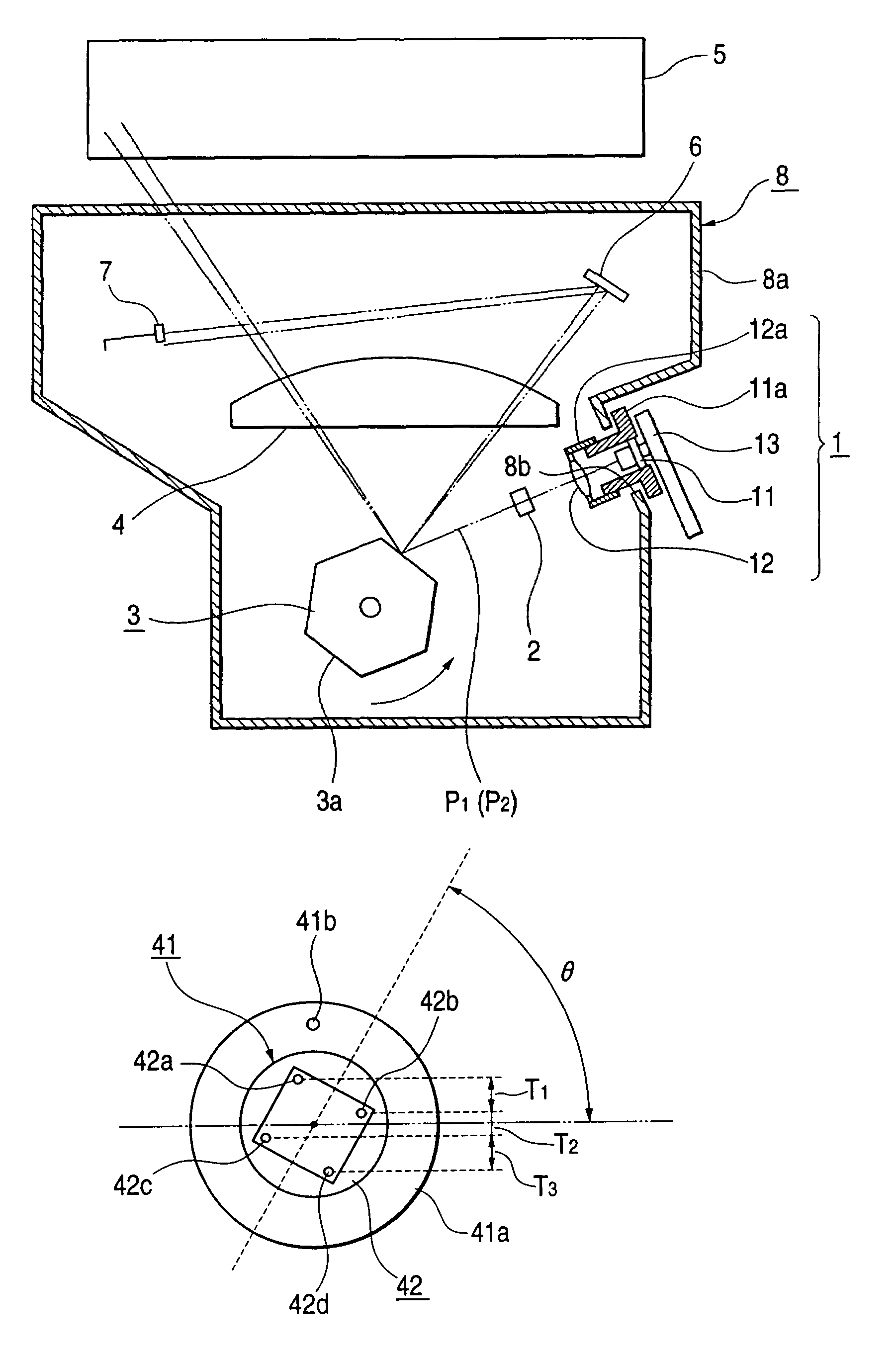

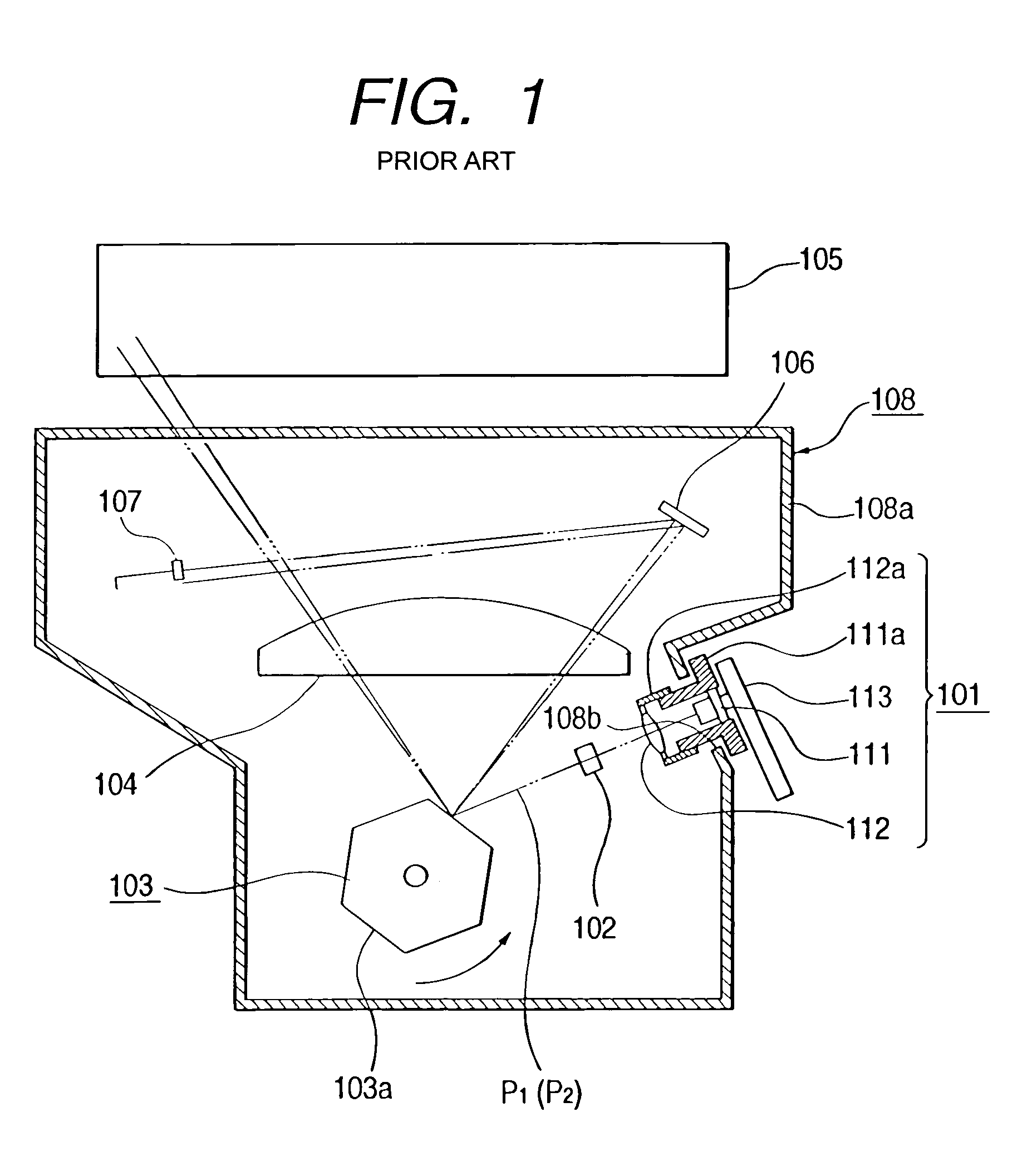

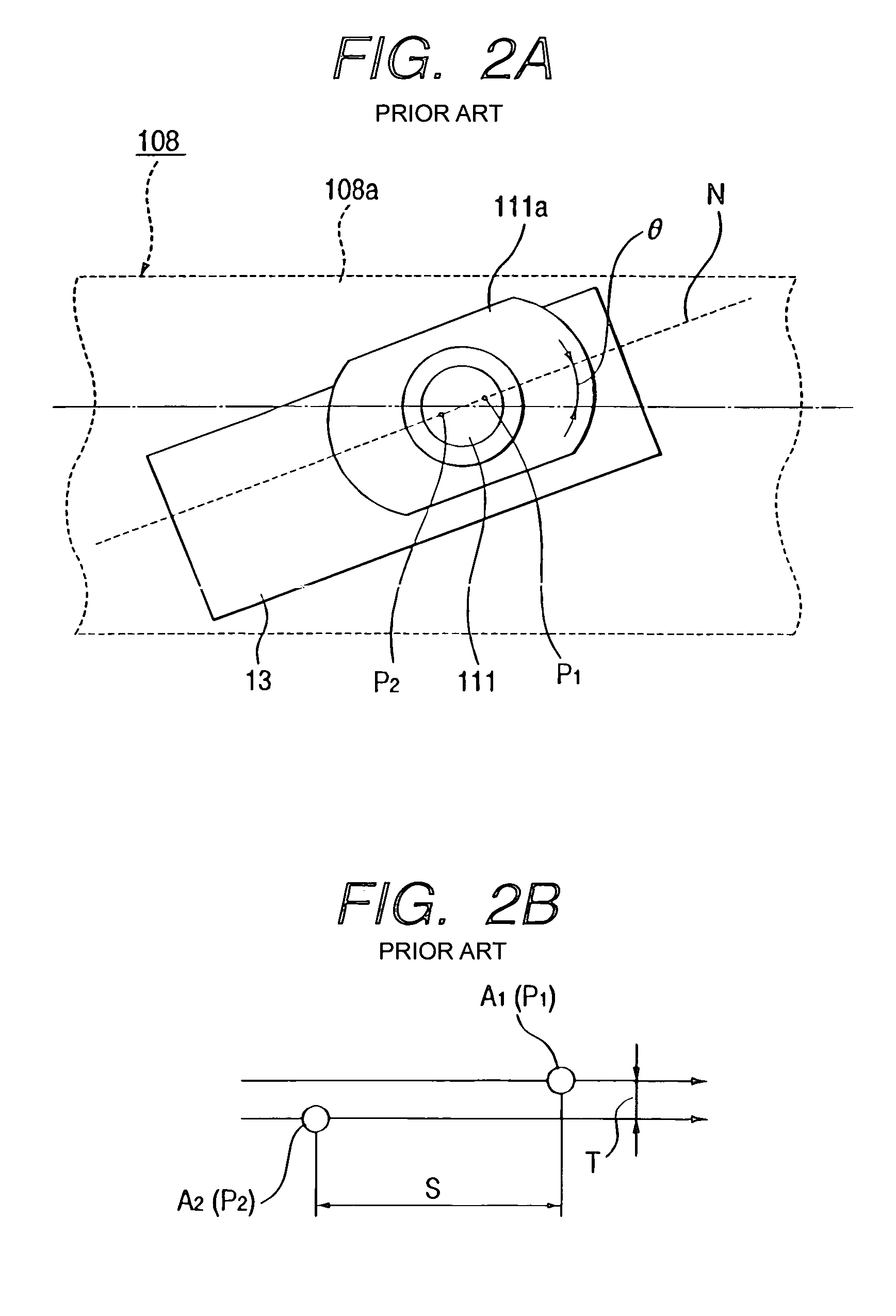

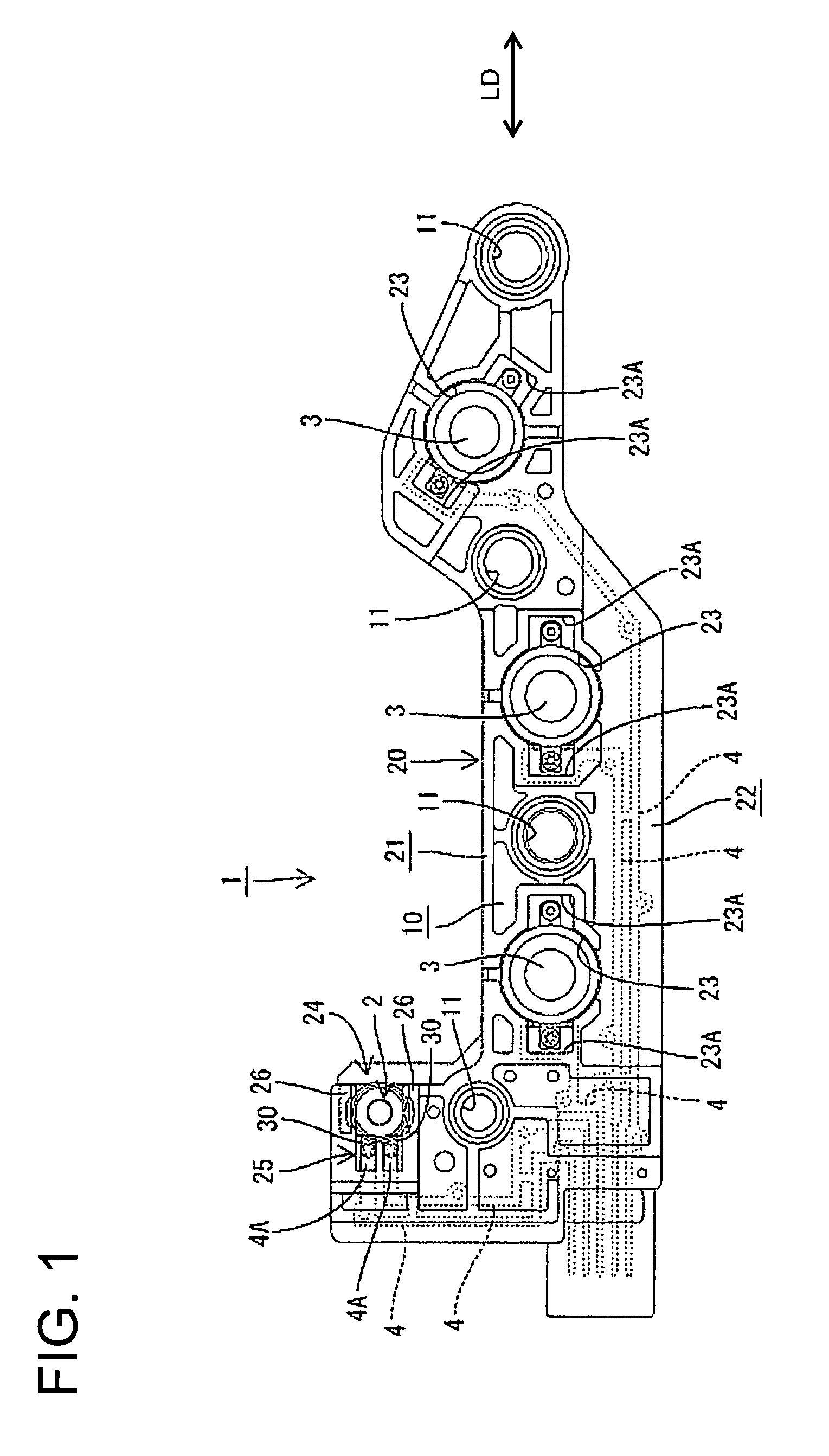

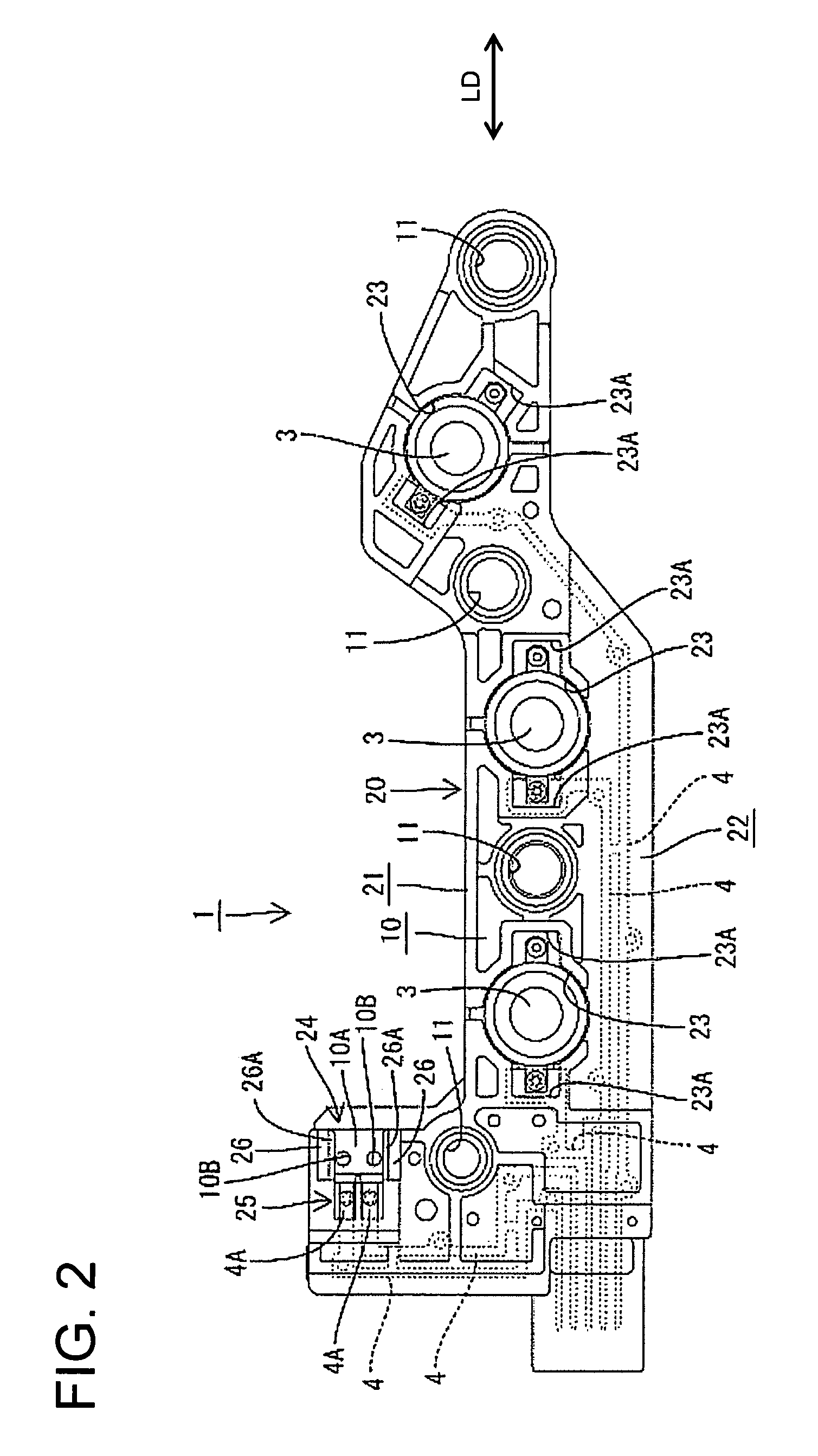

Multi-beam scanning apparatus

A multi-beam scanning apparatus has a multi-beam semiconductor laser which emits a plurality of laser beams, a laser holder holding the multi-beam semiconductor laser, a multi-beam light source unit having the multi-beam semiconductor laser and the laser holder, scanning imaging unit for scanning a plurality of laser beams emitted by the multi-beam semiconductor laser to form an image on a surface to be scanned, and a housing supporting the scanning imaging unit and the multi-beam light source unit. The multi-beam semiconductor laser is fixed to the laser holder with an inclination at or near a predetermined rotational angle for adjusting a beam interval between the plurality of laser beams.

Owner:CANON KK

Automatic press fitting equipment for oil pump cooper sleeve

ActiveCN110977399APress fit correctlyEfficient pressingEdge grinding machinesMetal working apparatusEngineeringTransfer mechanism

The invention relates to the technical field of oil pump component assembly, and discloses automatic press fitting equipment for an oil pump cooper sleeve. The automatic press fitting equipment comprises a cooper sleeve feeding mechanism, a cooper sleeve gap recognition mechanism, an end cover feeding mechanism, a cooper sleeve discharging mechanism, a press fitting mechanism for pressing cooper sleeves into end covers, a transferring mechanism for transferring the cooper sleeves from the cooper sleeve feeding mechanism to the cooper sleeve gap recognition mechanism and a rotary disc mechanismfor undertaking material transferring in the whole press-fitting process; a plurality of end cover positioning jigs are arranged on the rotary disc mechanism, the transferring mechanism transfers twocooper sleeves each time, and the copper sleeve gap recognition mechanism carries out gap recognition on the two copper sleeves at the same time; and the copper sleeve discharging mechanism is used for transferring the two copper sleeves on the copper sleeve gap recognition mechanism to the end cover positioning jigs to be pre-assembled for press-fitting by the press fitting mechanism, and the press fitting mechanism simultaneously presses the two copper sleeves into two copper sleeve mounting holes of an end cover correspondingly. Gaps of the two copper sleeves are effectively detected at the same time, and the two copper sleeves are pressed in at a time by the press fitting mechanism, so that the copper sleeve press-fitting process is carried out efficiently and continuously without errors.

Owner:ZHUZHOU TORCH SPARK PLUG CO LTD

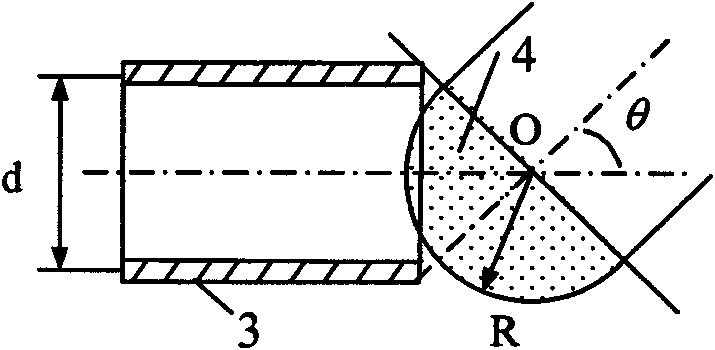

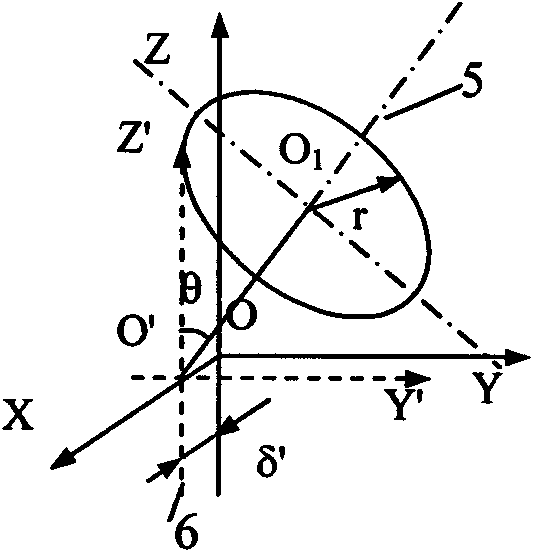

Diamond ball head grinding wheel electric sparkle dressing cutter adjustment method based on two-time cutter adjustment process

InactiveCN101623847AImprove surface accuracyMeet the surface accuracy requirementsAbrasive surface conditioning devicesGrinding wheelFace shape

The invention discloses a diamond ball head grinding wheel electric sparkle dressing cutter adjustment method based on two-time cutting tool process, and relates to a ball head grinding wheel electric sparkle dressing cutter adjustment method. The purpose of the invention is to improve the accuracy of cutter adjustment in dressing a grinding wheel, so as to improve the surface shape accuracy of the diamond ball head grinding wheel which is dressed. The main technical core of the invention is: firstly, the relative mounting positions of a grinding wheel spindle and a electrode spindle are precisely adjusted before grinding wheel dressing, so that the axial lines of the grinding wheel spindle and the electrode spindle form an angle of to 45 degrees and intersect at a point; secondly, first-time cutter adjustment is performed on a small-diameter diamond ball head grinding wheel, and the grinding wheel is dressed for the first time; finally, two newly formed edge feature points of the grinding wheel are selected to realize the second cutter adjustment of the small-diameter diamond ball head grinding wheel. The second cutter adjustment after the first cutter adjustment can effectively eliminate the influence of manufacturing errors of the grinding wheel and judgment errors of the edge feature points on the cutting tool accuracy; under the same conditions, the two-time cutter adjustment process can reduce cutter adjustment errors by 30% to 70%.

Owner:HARBIN INST OF TECH

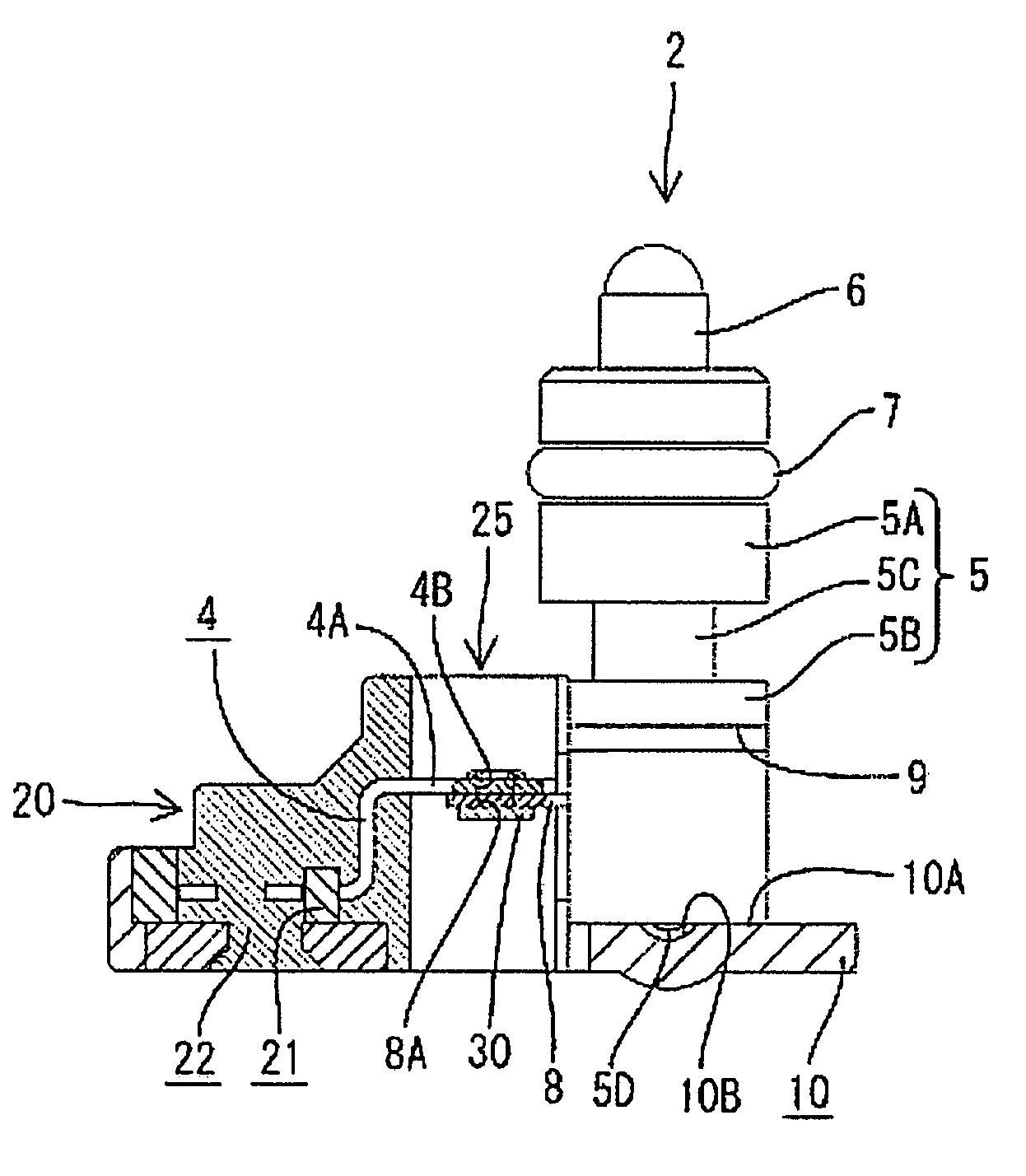

Resin molded component fitted with a metal plate and molding method therefor

ActiveUS7488904B2Increase chancePrecise positioningDigital data processing detailsSemiconductor/solid-state device detailsShell moldingEngineering

A sensor unit (1) has a metal plate (10), a resin molded portion (20) and an oil temperature sensor (2). Busbars (4) made of a metal are arranged in the resin molded portion (20). Since the busbars (4) are insert-molded while having the exposed ends (4A) thereof tightly held by a pair of forming dies, a distance between the exposed ends (4A) and the placing surface 10A is held constant. Further, gate marks (5D) of the oil temperature sensor (2) are accommodated in recesses (10B) of the placing surface (10) and engaging grooves (9) and engaging projections (26A) are engaged. Thus, the oil temperature sensor (2) can be held in a proper posture. Additionally, the oil temperature sensor (2) can be held on the placing surface (10A) by riveting the exposed end (4A) and a terminal (8) of the oil temperature sensor (2).

Owner:SUMITOMO WIRING SYST LTD

Insulator mounting bracket

The invention discloses a bracket system used for mounting and fixing a conductor-rail insulator. The system is of a two-section structure formed by two section bars having mutually vertical penetrating directions, wherein a bracket 2 is held in a support base 1, and the bracket is fastened and connected with a holding side 3 through a bolt 8. By using the insulator mounting bracket provided by the invention, the space adjustment in wide range can be realized on the basis of construction error in a smaller space, the positioning and locking are precise, and the positioning is convenient, quick, stable and reliable.

Owner:HUNAN HUAPIN RAIL TRANSIT CO LTD

Integral positioning device for multi-device solid laser resonant cavity

InactiveCN103701013AThe installation position is accuratePrecise positioningLaser constructional detailsResonant cavityTemperature control

The invention discloses an integral positioning device for a multi-device solid laser resonant cavity. The integral device can be used for accurately positioning the installing positions of an endoscope, a switch Q, a laser crystal, a non-linear crystal and a temperature control furnace of the laser resonant cavity and can be used for finely adjusting each optical element at the same time; the device is processed integrally, so that the installing position and angle positioning of optical components are accurate, and a solid laser resonant cavity can be realized. The integral device has the advantages that the installing position of each optical element in the solid laser resonant cavity is directly positioned by using the device, and the elements are finely adjusted via adjusting jackscrews, so that the position and angle of each element in the cavity are more accurate.

Owner:BEIJING UNIV OF TECH

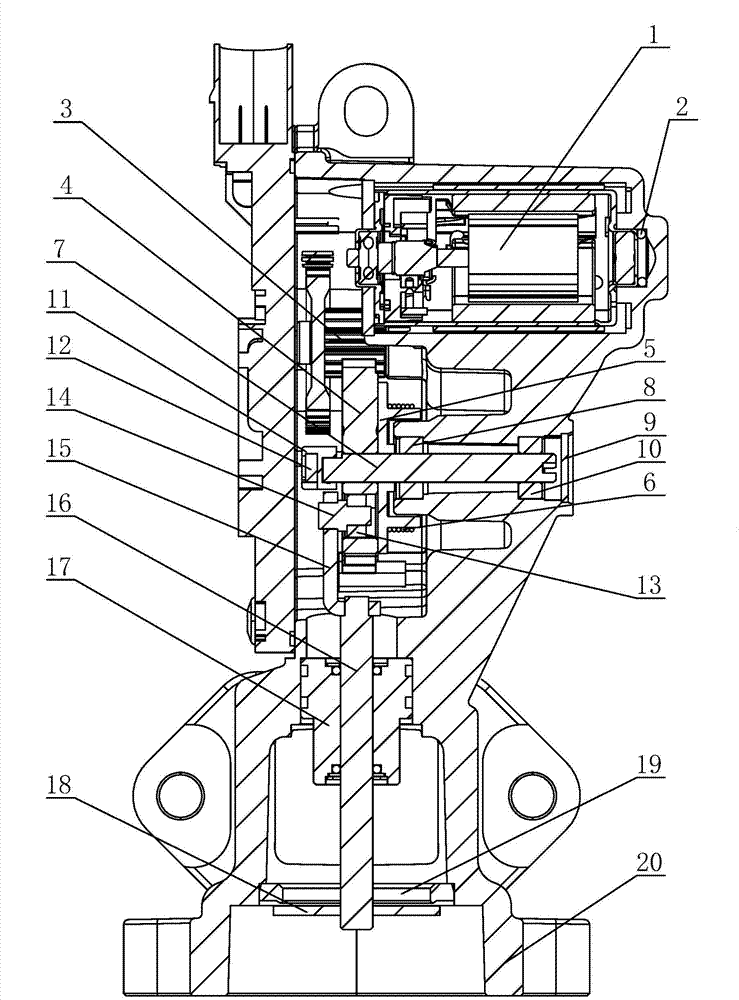

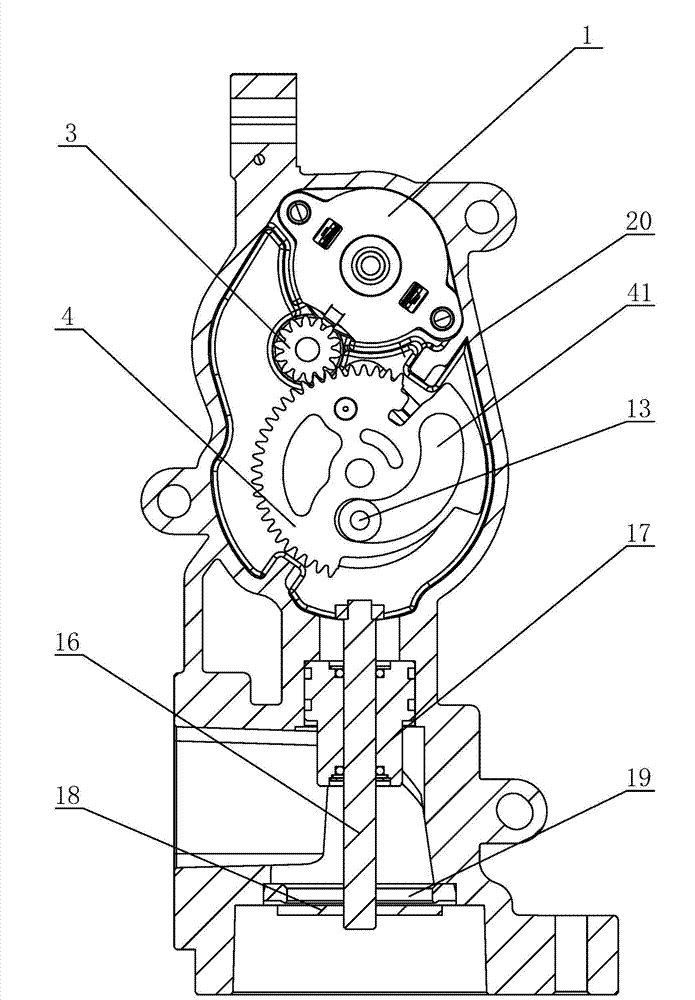

Electric EGR valve

ActiveCN104727989AAccurate opening controlTroubleshoot Signal Transmission DistortionNon-fuel substance addition to fuelInternal combustion piston enginesFailure rateDrive shaft

The invention discloses an electric EGR valve which comprises a shell, a driving motor, a valve rod and a valve block. The driving motor is arranged in the shell, and connected with an intermediate gear, the intermediate gear is meshed with a sector gear, the sector gear is integrally connected with a torsional spring seat, the torsional spring seat is connected with a return torsional spring, the other end of the return torsional spring is fixed to the shell, the sector gear is fixed to a driving shaft, the driving shaft is rotatably arranged in the shell through a rolling bearing and a sliding bearing, an induction magnet is arranged on the driving shaft, and electrically connected with a Hall sensor, a cam groove is formed in the sector gear, a cam bearing is arranged in the cam groove, the cam bearing is connected with a cam bearing shaft and a cam bearing support, the upper end of the valve rod is connected with the cam bearing support, and the lower end of the valve rod is connected with the valve block. The EGR valve is accurate in control, convenient to assemble and low in failure rate.

Owner:KAILONG HIGH TECH

Flexible tunneling machine for installing sleeve

ActiveCN102587833AReasonable structural designThe installation position is accurateDrilling machines and methodsAgricultural engineeringSlurry

The invention discloses a flexible tunneling machine for installing a sleeve, belonging to the technical field of underground oil-gas reservoir exploitation. The tunneling machine comprises a flexible cutter head, a cutter head supporting plate, a conical crushing device, a front shell, a fixing device, a dynamic system, a rear shell, oil cylinders, a recovery system, a slurry inlet / outlet pipe, a slurry nozzle and a cutter head positioning pin, wherein the flexible cutter head is connected with the cutter head supporting plate through the cutter head positioning pin; the flexible cutter head is connected with a rotary main shaft of the conical crushing device; the rotary main shaft of the conical crushing device is connected with the main shaft of the dynamic system; the conical crushing device is welded in the front shell; the recovery system is arranged at the tail part of the rear shell; the oil cylinders are arranged on the front shell and the rear shell through fixing seats; the slurry inlet / outlet pipe is fixed below the inner part of the rear shell; and the slurry nozzle is arranged on the conical crushing device. The flexible tunneling machine for installing the sleeve is reasonable in structural design, correct and efficient in steel sleeve mounting position, free of end part sinking phenomenon, simple and reliable in recovery scheme and free of clamping phenomenon.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Installation method of trademark

InactiveCN102514783AAutomate installationThe installation position is accurateLabelling machinesTrademarkEngineering

The invention provides an installation method of a trademark, which concretely comprises the following steps: manually putting a trademark into an accommodating groove of a workpiece table, pressing a double-switch button and starting equipment; adsorbing the trademark by using a vacuum suction nozzle; carrying out destaticizing treatment on the trademark adsorbed on the vacuum suction nozzle by using an ion air nozzle; driving the trademark subjected to destaticizing treatment by using the vacuum suction nozzle; photographing the trademark and a case by a dual-vision system, respectively, and calibrating the pictures of both, and adjusting the position of the trademark if the trademark and the case have a position difference until there is not any position difference between the trademark and the case; adhering the trademark at a corresponding position of the case, and blowing by the vacuum suction nozzle so as to break the vacuum; and pressing the trademark by using a pressing device to tightly adhere the trademark on the case. The installation method of the trademark has the advantages that not only the automatic installation of the trademark can be realized, but also the installation position of the trademark is accurate and the installation quality is improved.

Owner:SIP GOLDWAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com