Patents

Literature

59results about How to "Accurate opening control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

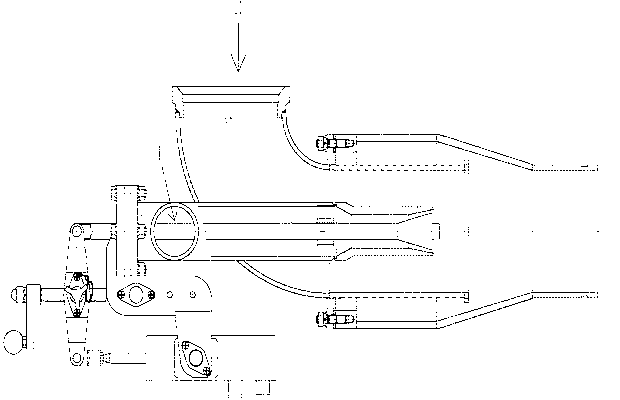

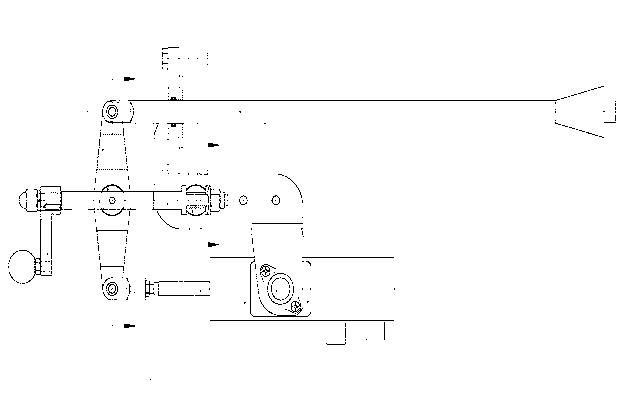

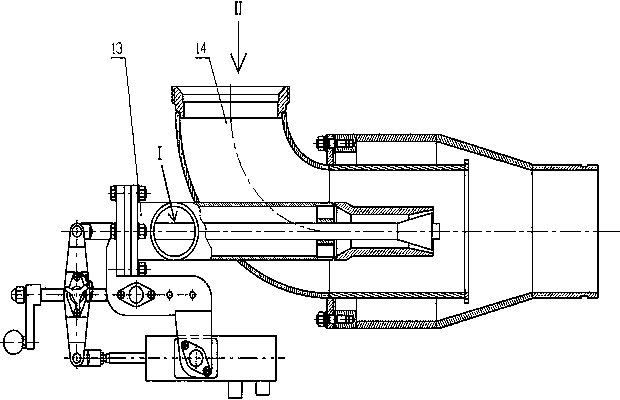

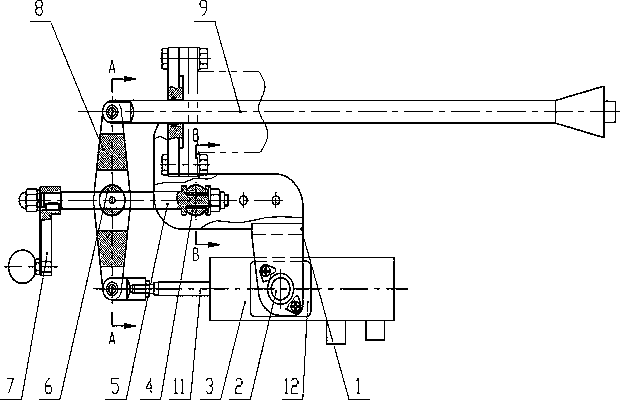

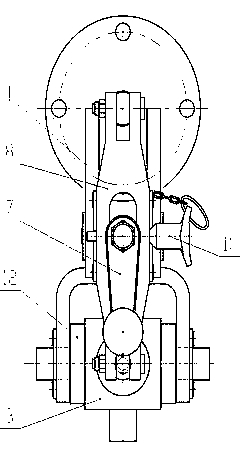

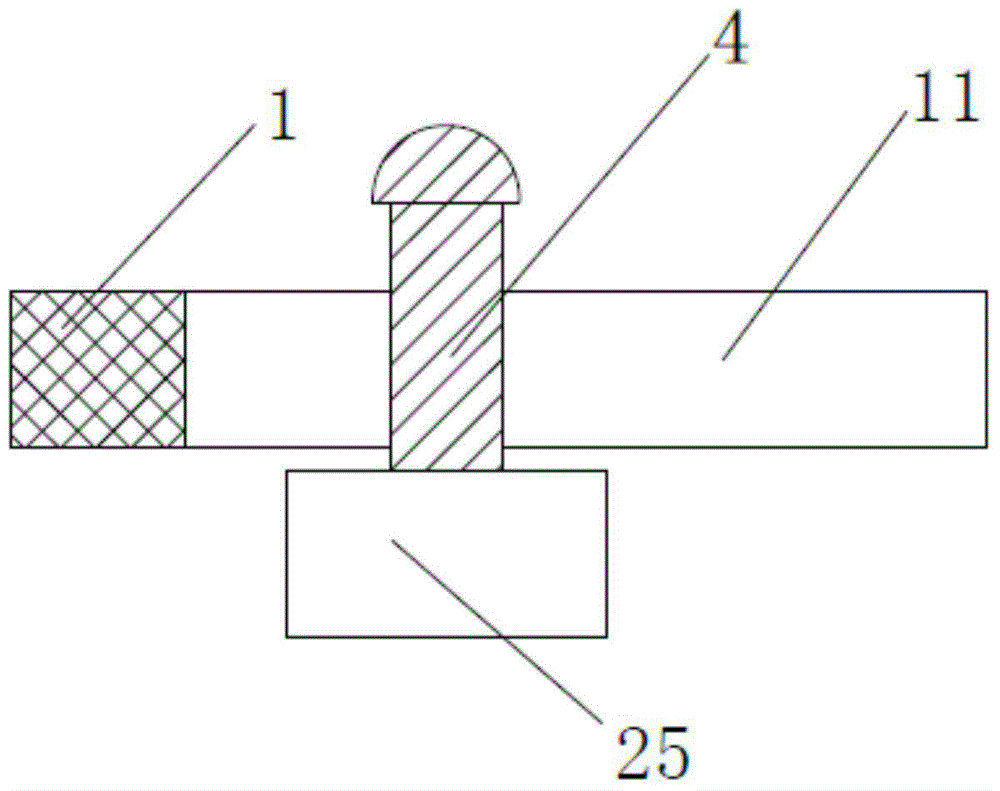

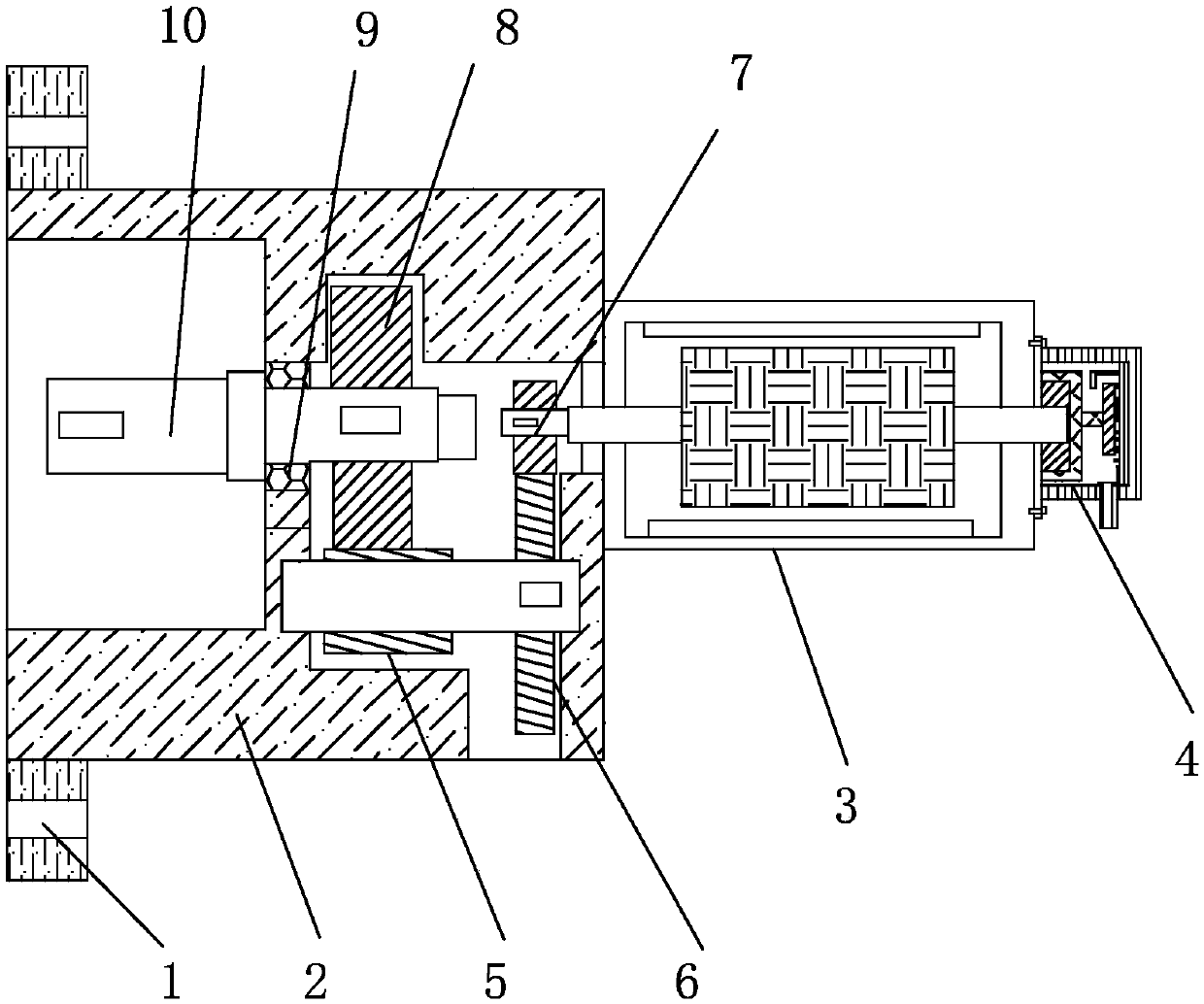

Clear water controlling device for high-energy mixer and high-energy mixer

ActiveCN102729335APrecise position controlGuaranteed nonlinear compensationFlow mixersMixing operation control apparatusHigh energyEngineering

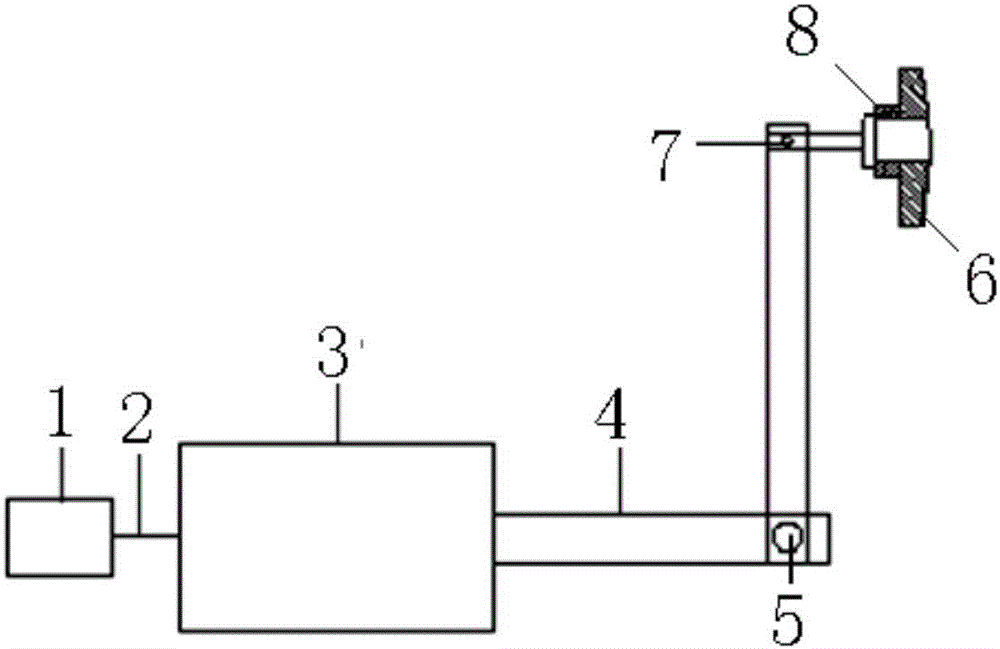

The invention relates to cementing equipment and mixing equipment for oil and gas field and provides a clear water controlling device for a high-energy mixer and the high-energy mixer. The clear water controlling device comprises a soleplate, a linear actuator, a hinge shaft, a rocking arm, a leading screw, a manual rocking handle, a thread spindle and a valve rod, and is characterized in that the soleplate is hinged with a mounting base of the linear actuator; the hinge shaft is inserted in a central shaft hole of the soleplate; one end of the leading screw is fixed on the hinge shaft; the central portion of the leading screw forms a sleeve joint with the thread spindle, which is inserted in a central hole of the rocking arm; the upper end of the rocking arm is hinged with the valve rod; the lower end of the rocking arm is hinged with a push rod of the linear actuator; a through hole is arranged at the junction of the thread spindle and the leading screw; and a pin is disposed inside the trough hole. According to the invention, automatic and accurate control of the valve rod feed can be conveniently realized such that the slurry mixing effect of the high-energy mixer is more excellent than that in the prior art and the high-energy mixer can be used in both automatic and manual modes.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Clear water controlling device for high-energy mixer and high-energy mixer

ActiveCN102729335BControl openingAccurate opening controlFlow mixersTransportation and packagingHigh energyEngineering

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

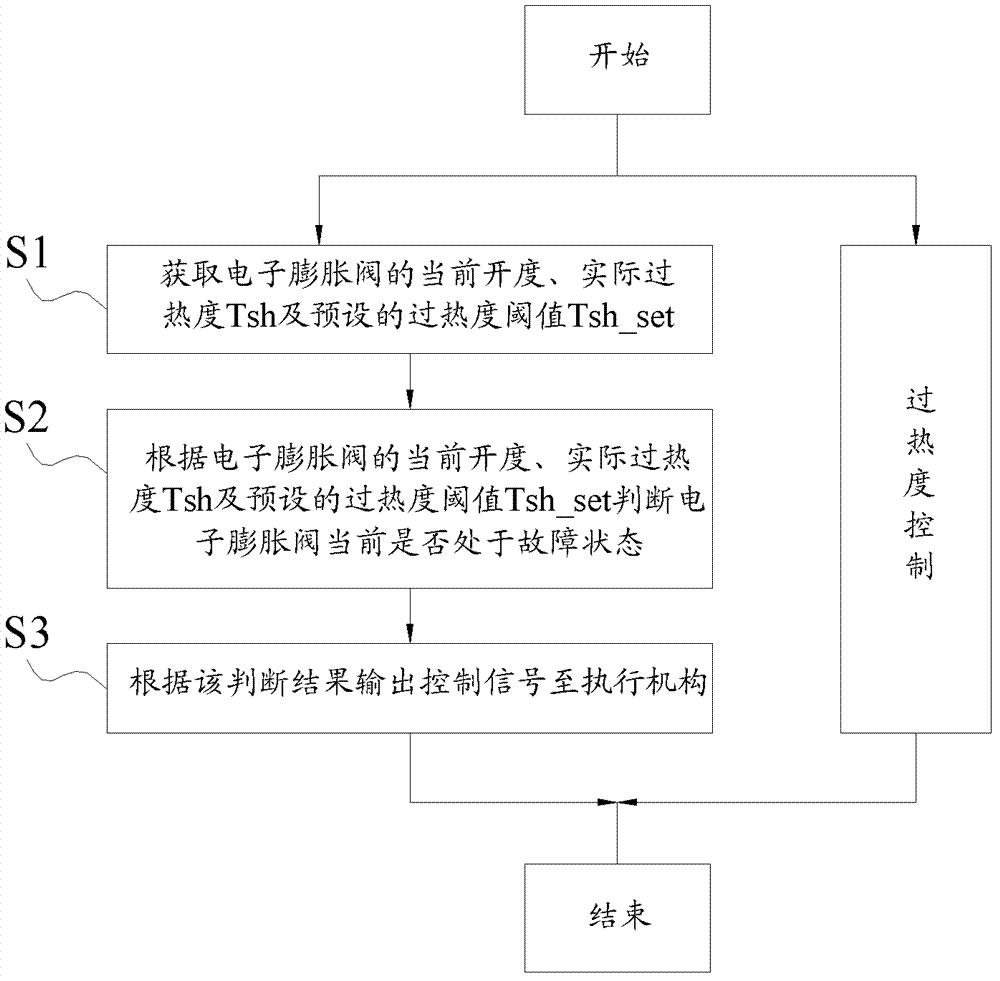

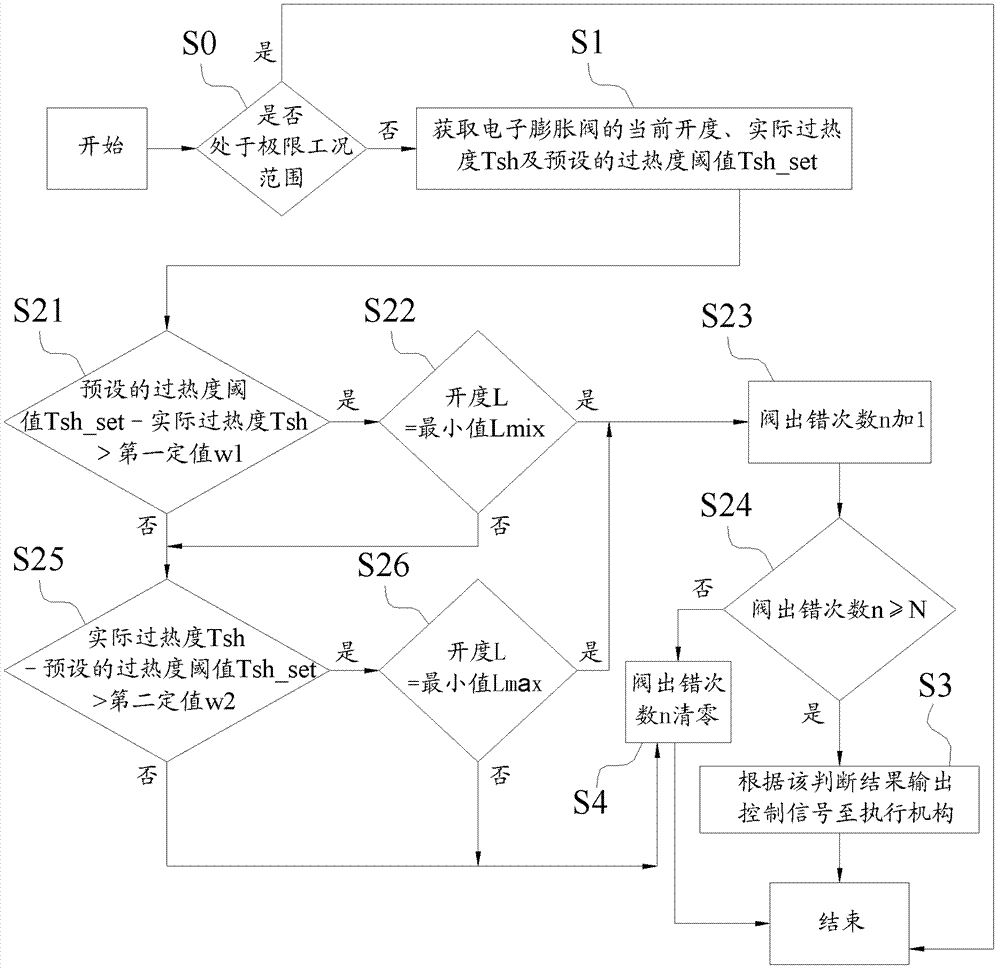

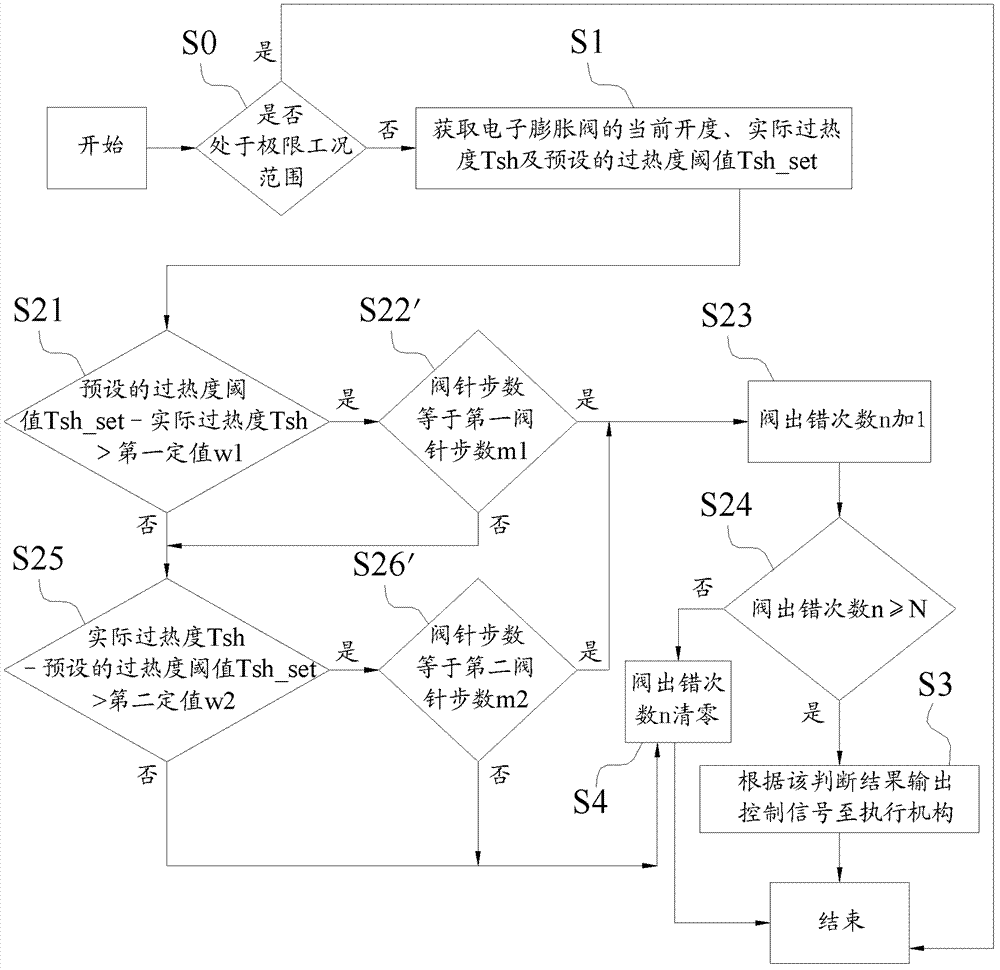

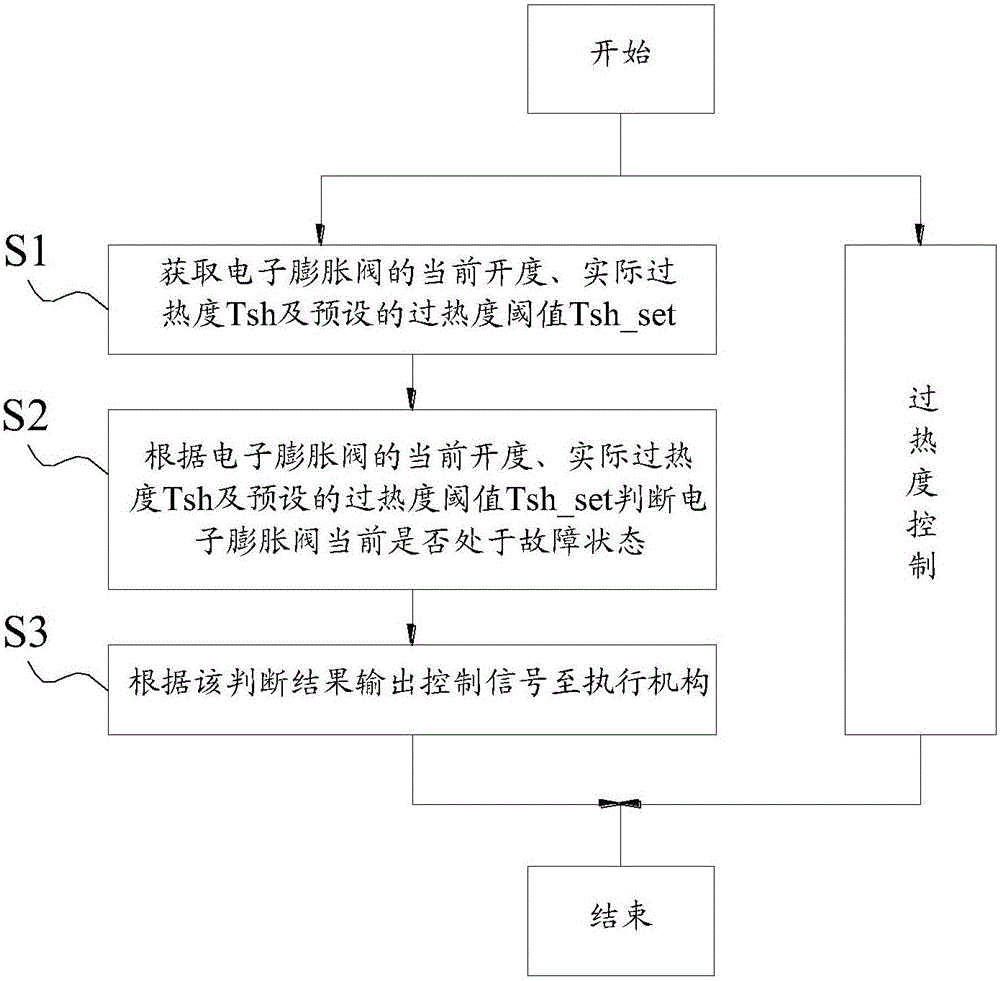

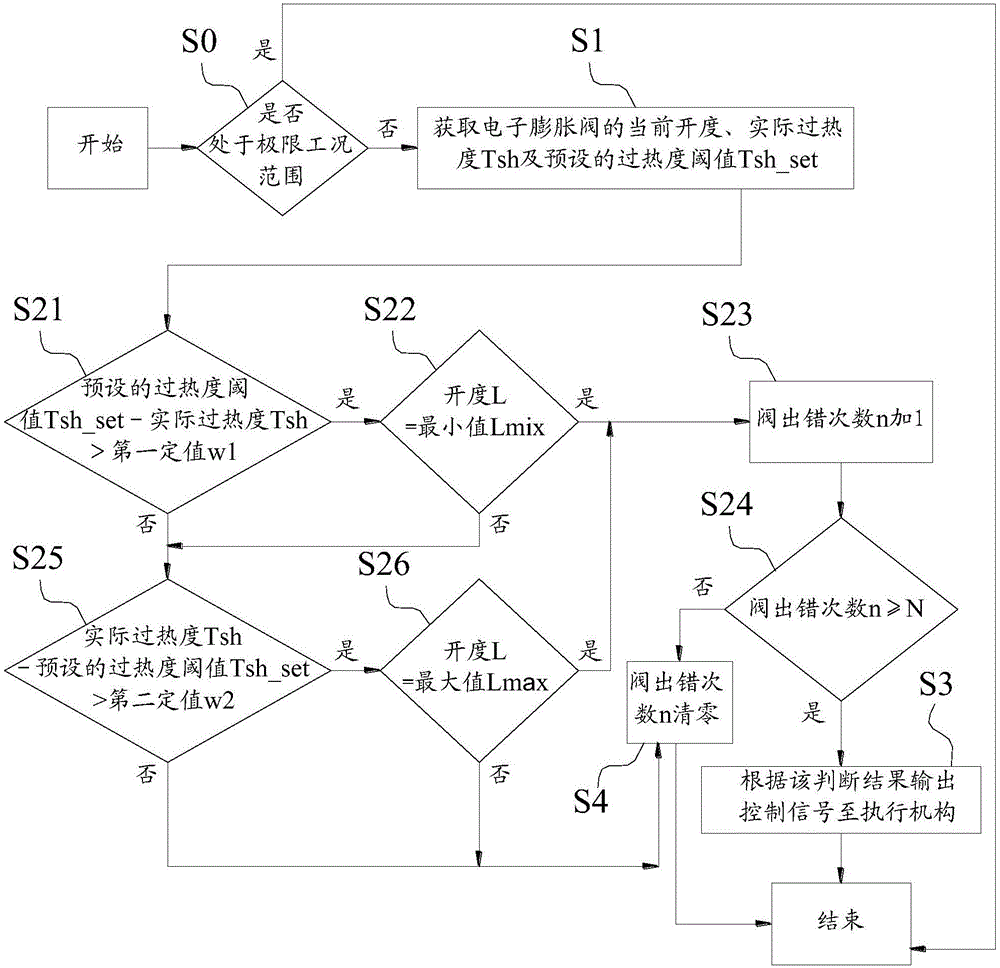

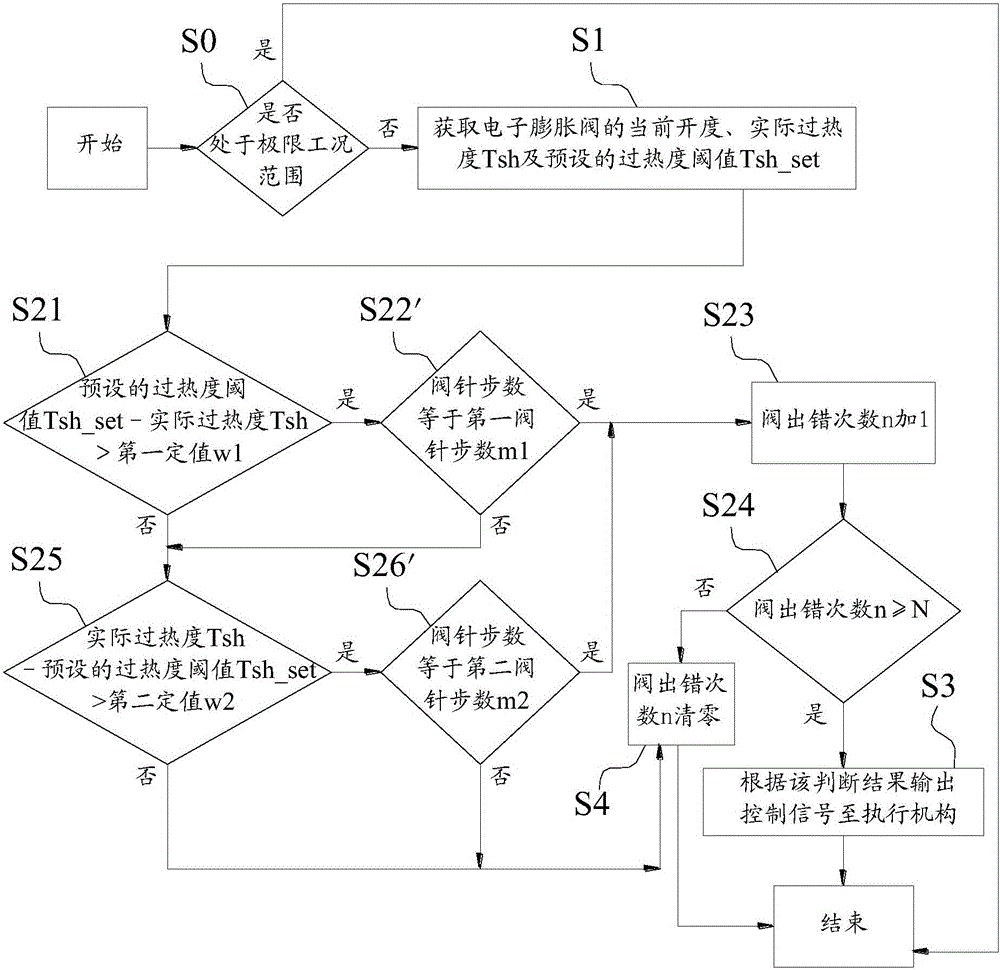

Control method of electronic expansion valve of automobile air conditioner system

ActiveCN103245154AAvoid damage to refrigeration system equipmentImprove safety and reliabilityRefrigeration safety arrangementDevice breakageElectronic expansion valve

The invention discloses a control method of an electronic expansion valve of an automobile air conditioner system. The method includes acquiring a result of the judgment of whether the electronic expansion valve is currently in the fault state or not according to the acquired current openness, actual overheat degree Tsh and preset overheat threshold Tsh_set of the electronic expansion valve while conducting overheating degree control and outputting a control signal to an execution mechanism according to the result of the judgment. By means of the control method, effective fault diagnosis can be conducted on the electronic expansion valve in real time. When the overheat degree is mistakenly controlled, the control signal is output to the execution mechanism to stop work of the system by controlling a compressor to shut down and / or remind operators to conduct fault overhauling by controlling a fault indicator lamp to be turned on, so that accidents of refrigeration system device damage caused by mistaken control can be completely avoided, and system running safety and reliability can be improved.

Owner:SHAOXING SANHUA NEW ENERGY AUTOMOTIVE COMPONENTS CO LTD

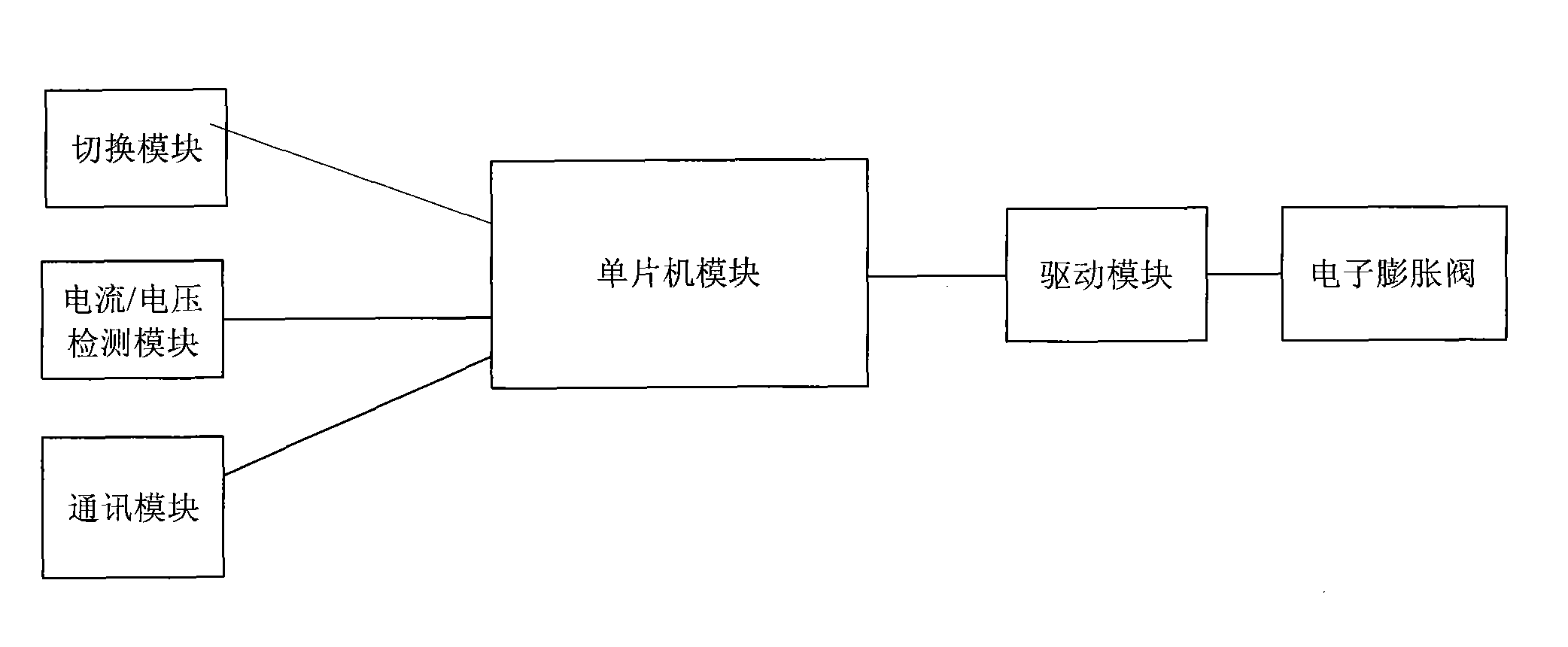

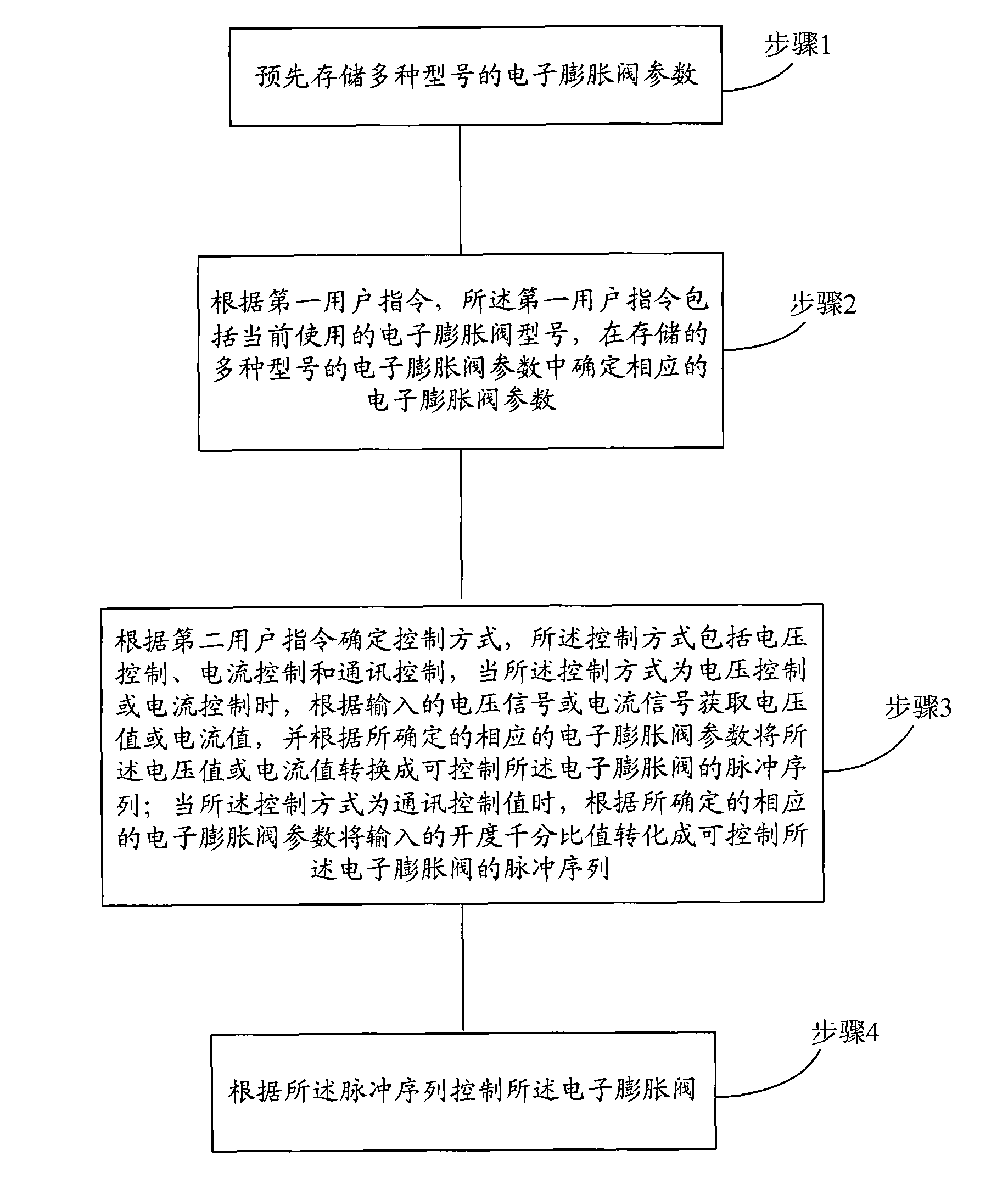

Driving system and method of electronic expansion valve

ActiveCN101989077AVersatilityTo achieve the function of controlling the openingProgramme controlOperating means/releasing devices for valvesPulse sequenceCommunication control

The invention provides a driving method of the electronic expansion valve. The method comprises the following steps: the parameters of various types of electronic expansion valves are prestored; according to a first user instruction which contains the type of the current electronic expansion valve, the corresponding parameters in the stored parameters are determined; a control mode is determined according to a second user instruction, wherein the control mode contains voltage control, current control and communication control; when the control mode is voltage control or current control, a voltage value or current value is obtained according to the input voltage signal or current signal, the voltage value or current value is converted to a pulse sequence capable of controlling the electronic expansion valve, according to the corresponding determined parameters of the electronic expansion valve; when the control mode is communication control, the input opening per mille is converted to a pulse sequence capable of controlling the electronic expansion valve according to the corresponding determined parameters of the electronic expansion valve; and the electronic expansion valve is controlled according to the pulse sequence. By prestoring the parameters of electronic expansion valves, the driving method can be used for different types of electronic expansion valves, thus the driving method has universality; and the corresponding setting can be performed to the prestored parameters of electronic expansion valves according to the required opening and the opening control parameter can be set according to the required opening, thus the function of controlling the opening can be realized.

Owner:GREE ELECTRIC APPLIANCES INC

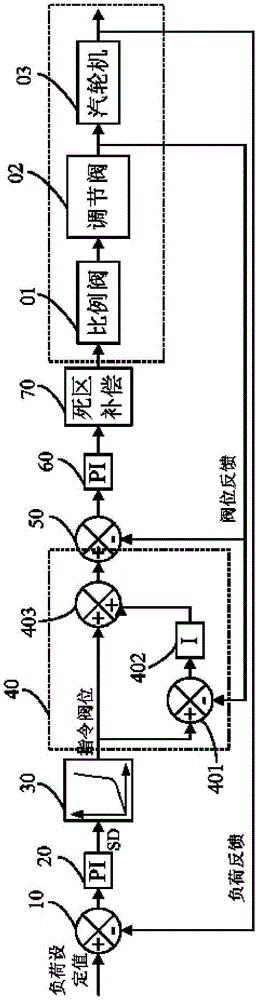

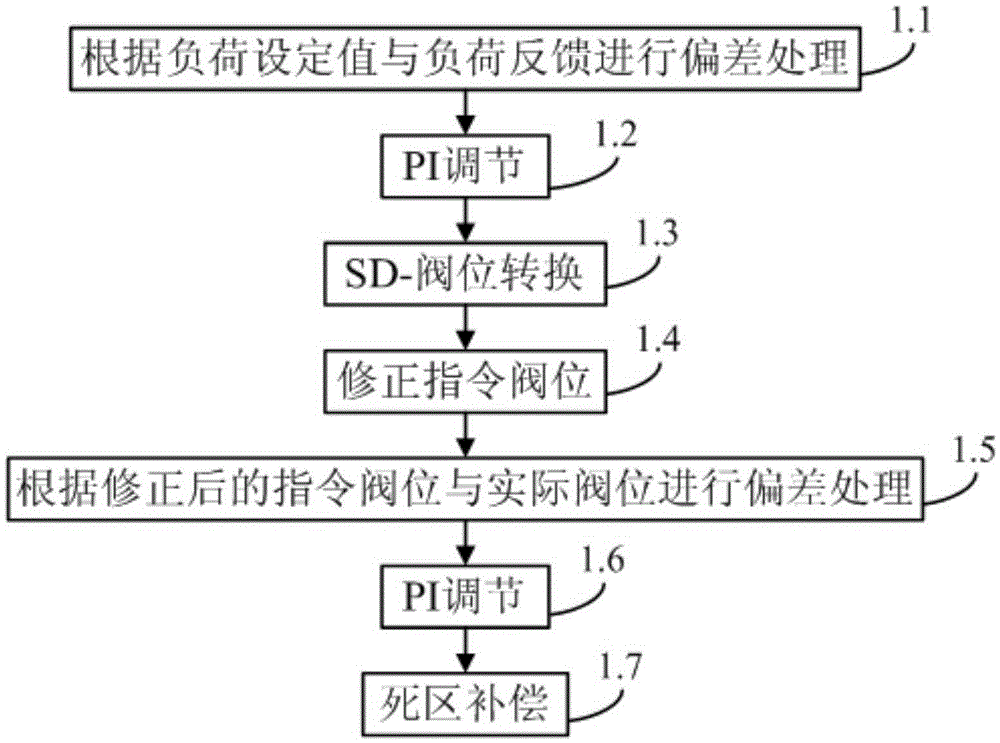

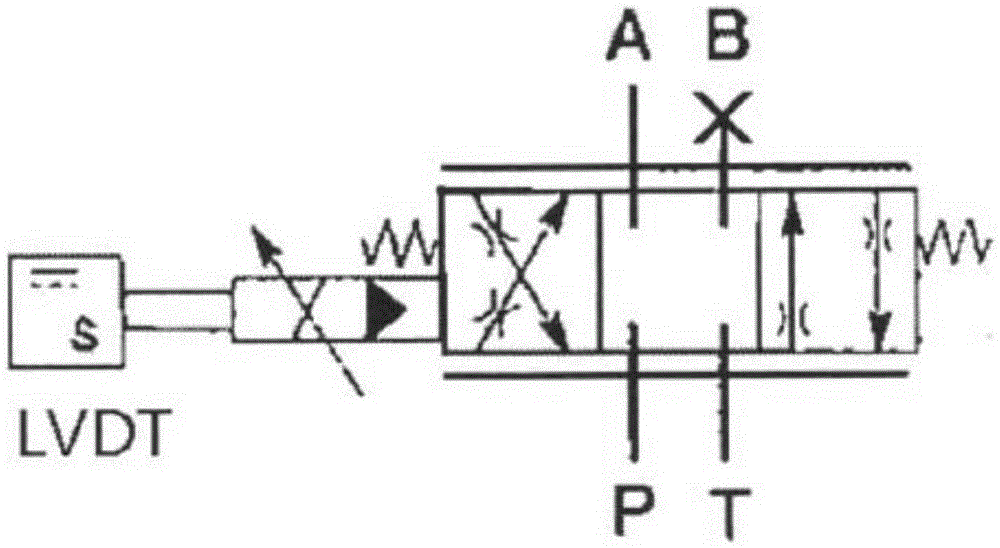

Control device and method for steam turbine regulating valve

ActiveCN106555620AAccurate opening controlEasy to controlMachines/enginesEngine componentsPower stationNuclear power

The invention discloses a control device and method for a steam turbine regulating valve. The device comprises a load control loop and a valve position control loop. The load control loop comprises a load feedback deviation unit, a first PI regulating unit and a converting unit. The valve position control loop comprises a valve position correction unit, a valve position deviation unit, a second PI regulating unit and a dead-zone compensation unit. The control device and method for the steam turbine regulating valve optimize control, and are used for accurately controlling the opening degree of the regulating valve and capable of reducing risk of oil pressure impact and eliminating abnormity. Accordingly, fully loaded running of a steam turbine set of an electric power station can be achieved, power reduction running is avoided, the electric power generating efficiency of the electric power station is improved, normal running of the electric power station is guaranteed, and great economic value is created for the electric power station. In addition, the control device and method can be applied to construction and daily running of a ling'ao nuclear power station (phase II) and other nuclear power stations and make great contribution to optimization of power station construction.

Owner:DAYA BAY NUCLEAR POWER OPERATIONS & MANAGEMENT +3

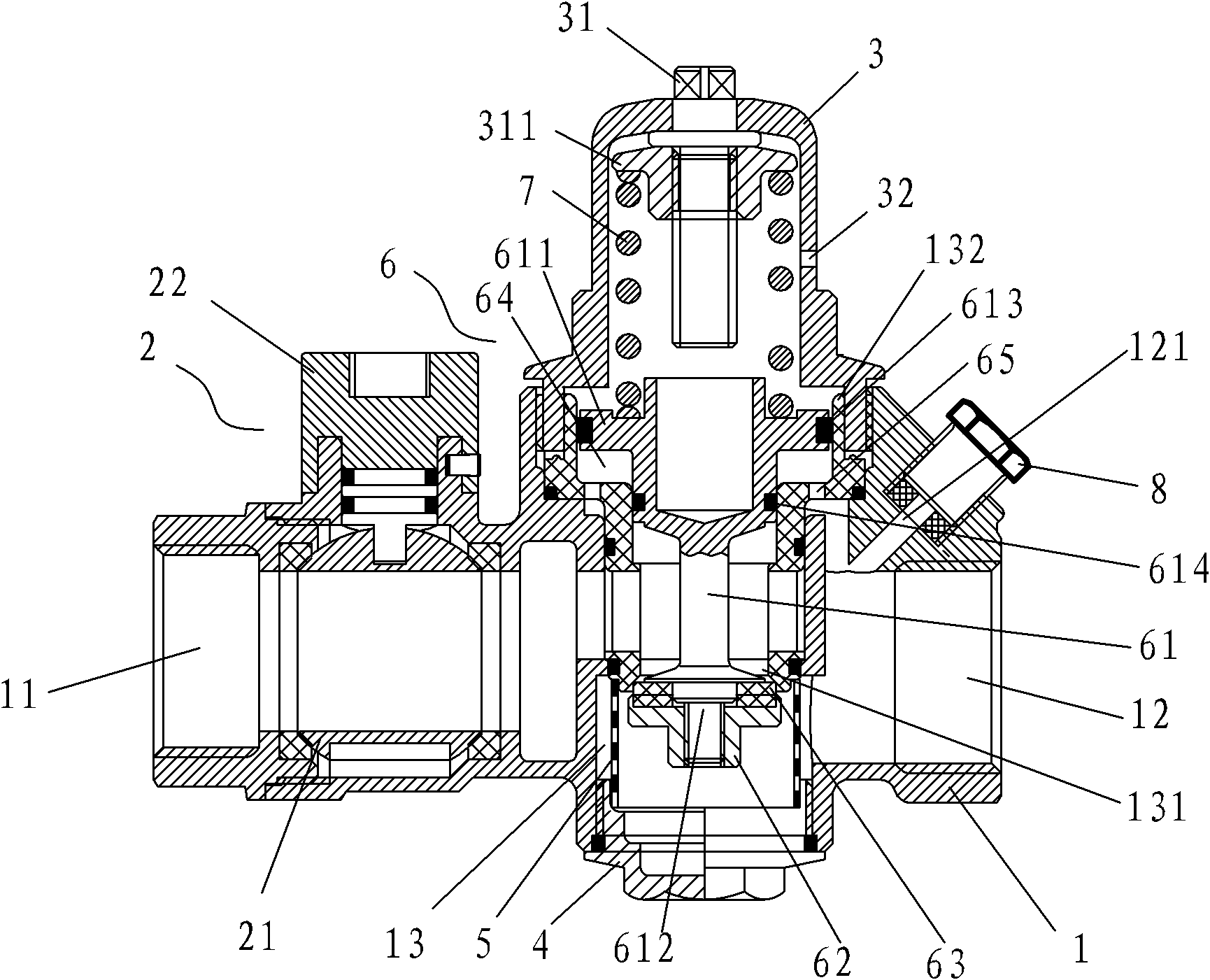

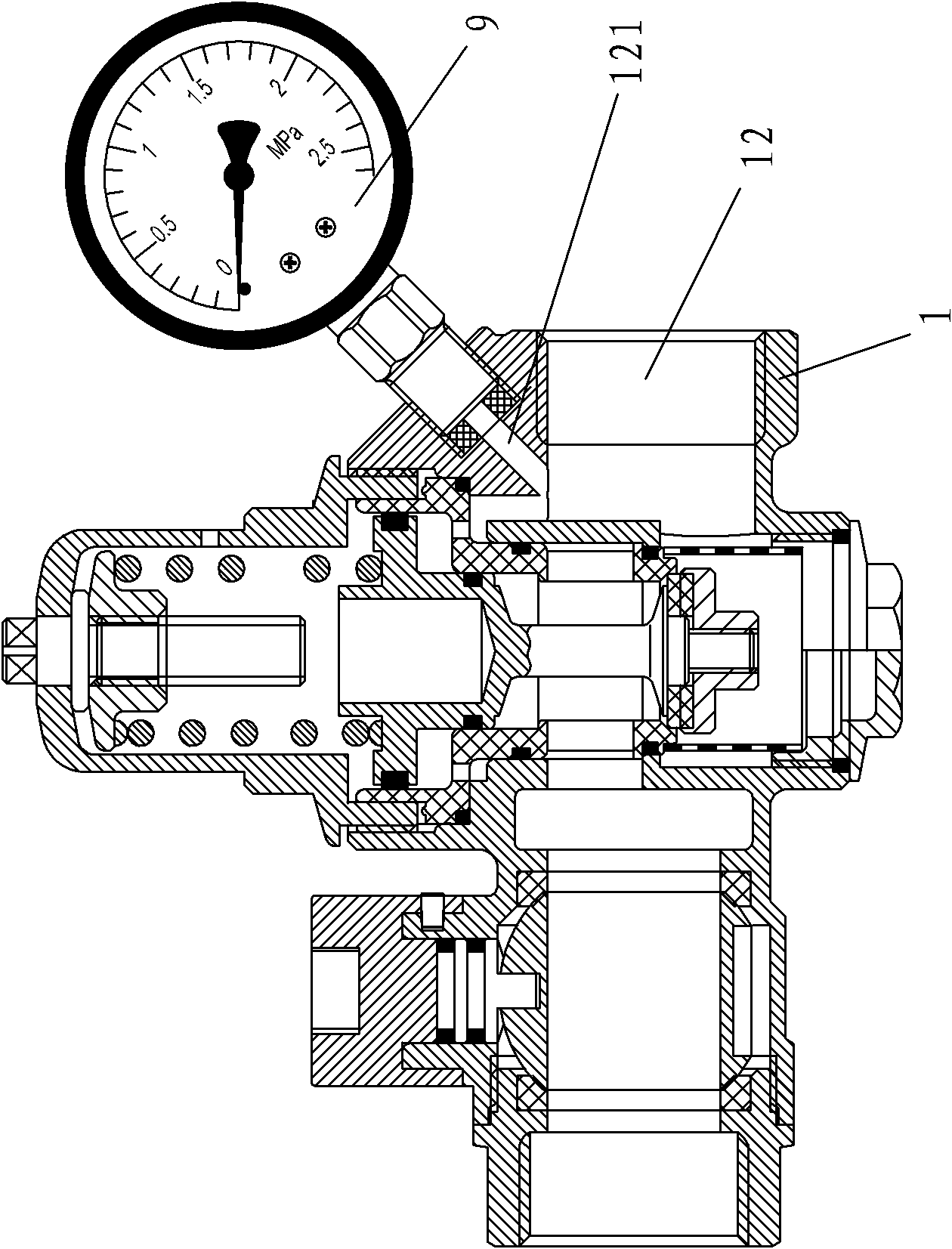

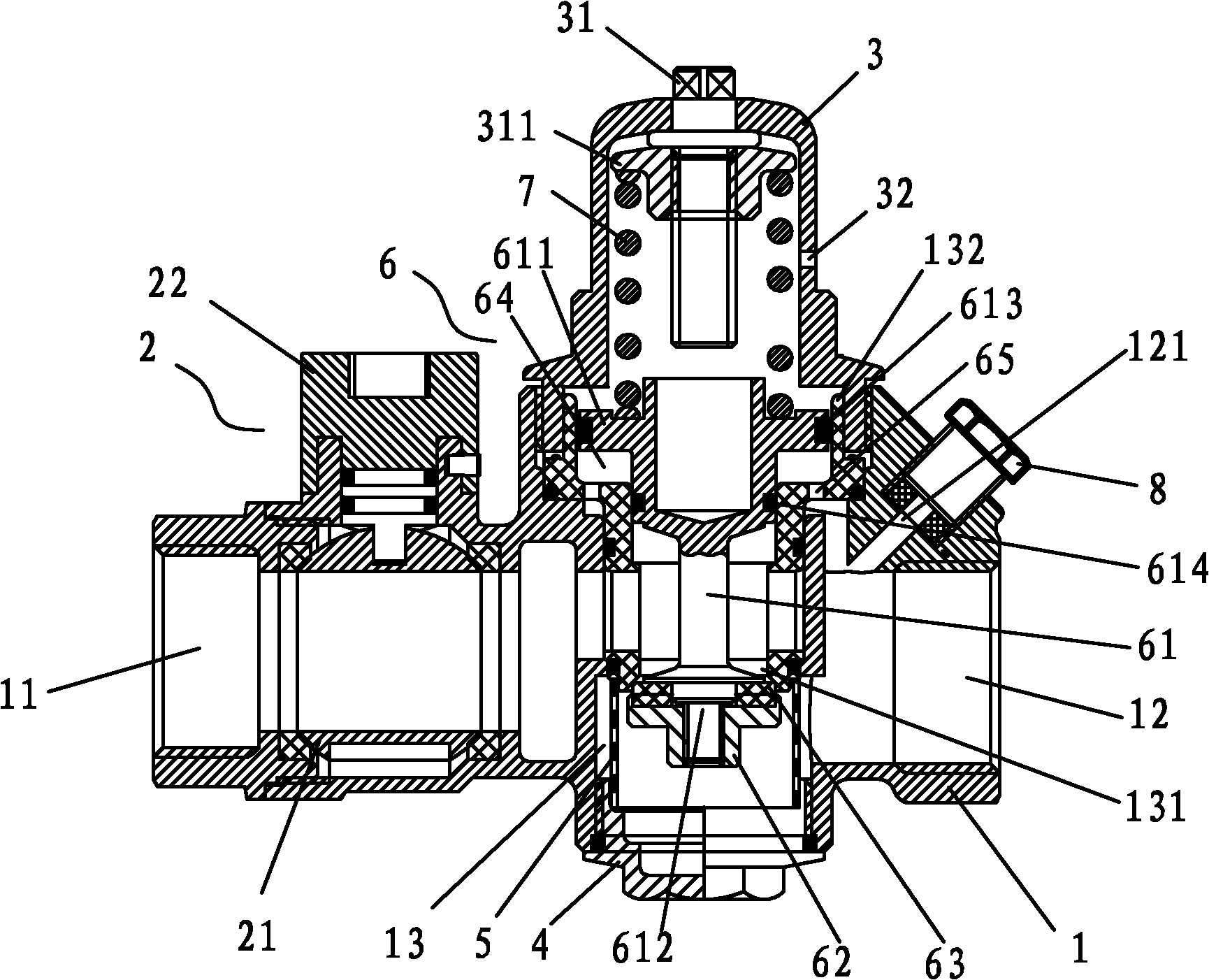

Integrated pressure reducing valve

InactiveCN102278503AMove up and down without jammingReliable mobilityEqualizing valvesSafety valvesInlet channelWater flow

The invention discloses an integrated pressure reducing valve, comprising a valve body, the valve body is provided with a horizontal water inlet passage and a water outlet passage, a ball valve is arranged on the water inlet passage, and a vertical valve connecting the water inlet passage and the water outlet passage is arranged on the valve body. To the water flow control channel, the upper part of the water flow control channel is equipped with an upper valve cover, and the lower part is equipped with a lower valve cover. The upper part of the stem is a piston structure, the lower part of the valve stem is equipped with a valve disc and a valve disc gasket, and the valve stem is installed in the water flow control channel in a movable manner up and down, and the upper part of the valve stem cooperates with the upper part of the water flow control channel to form a The control air chamber has a through hole connecting the control air chamber and the water outlet channel. The upper valve cover is equipped with an adjusting screw and a spring seat. A spring is provided between the spring seat and the upper end of the valve stem. There is a through hole connected to the atmosphere on the upper valve cover. The invention has high reliability, good maintenance performance, and high pressure control precision of the water outlet channel.

Owner:陈建华

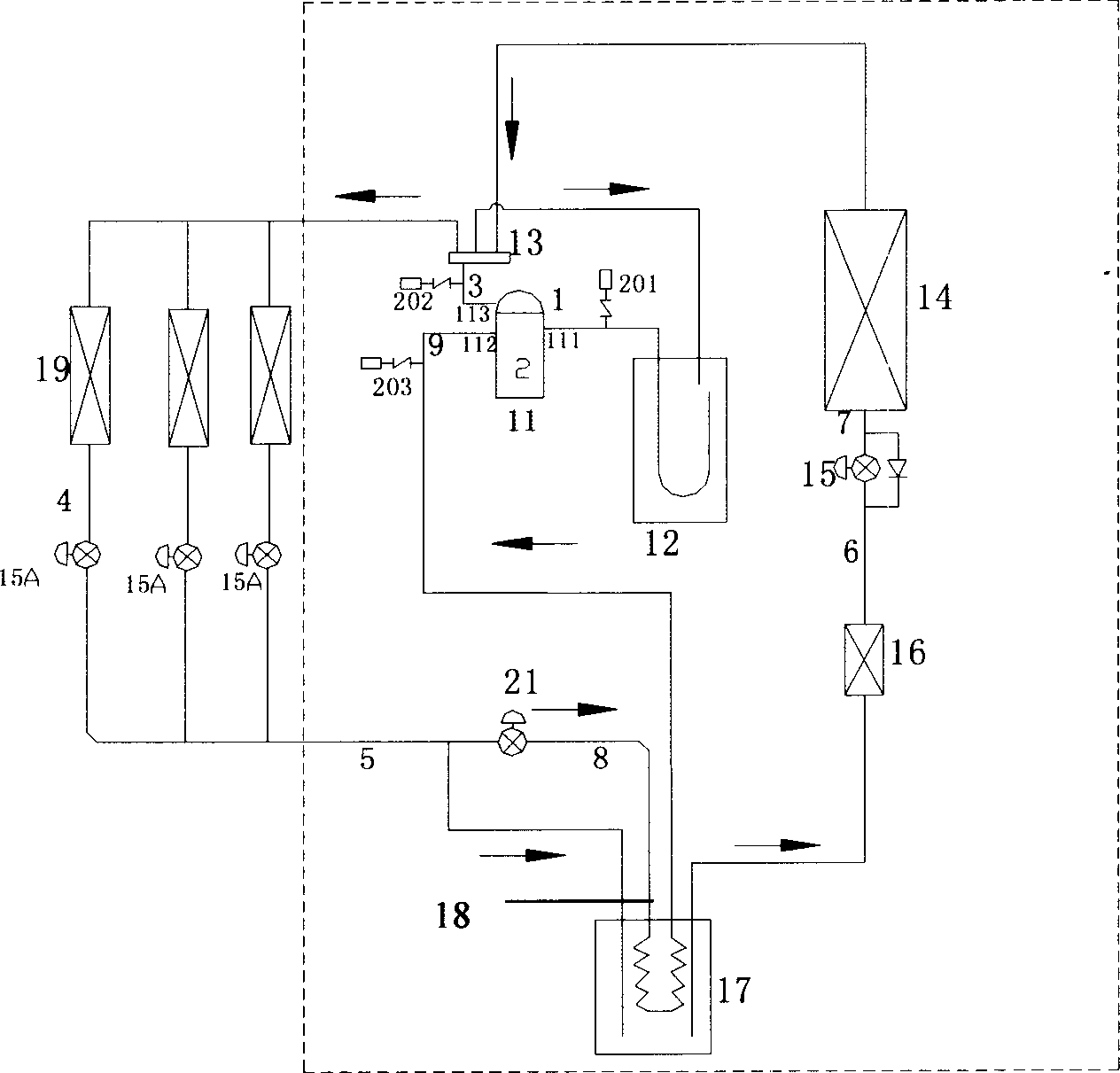

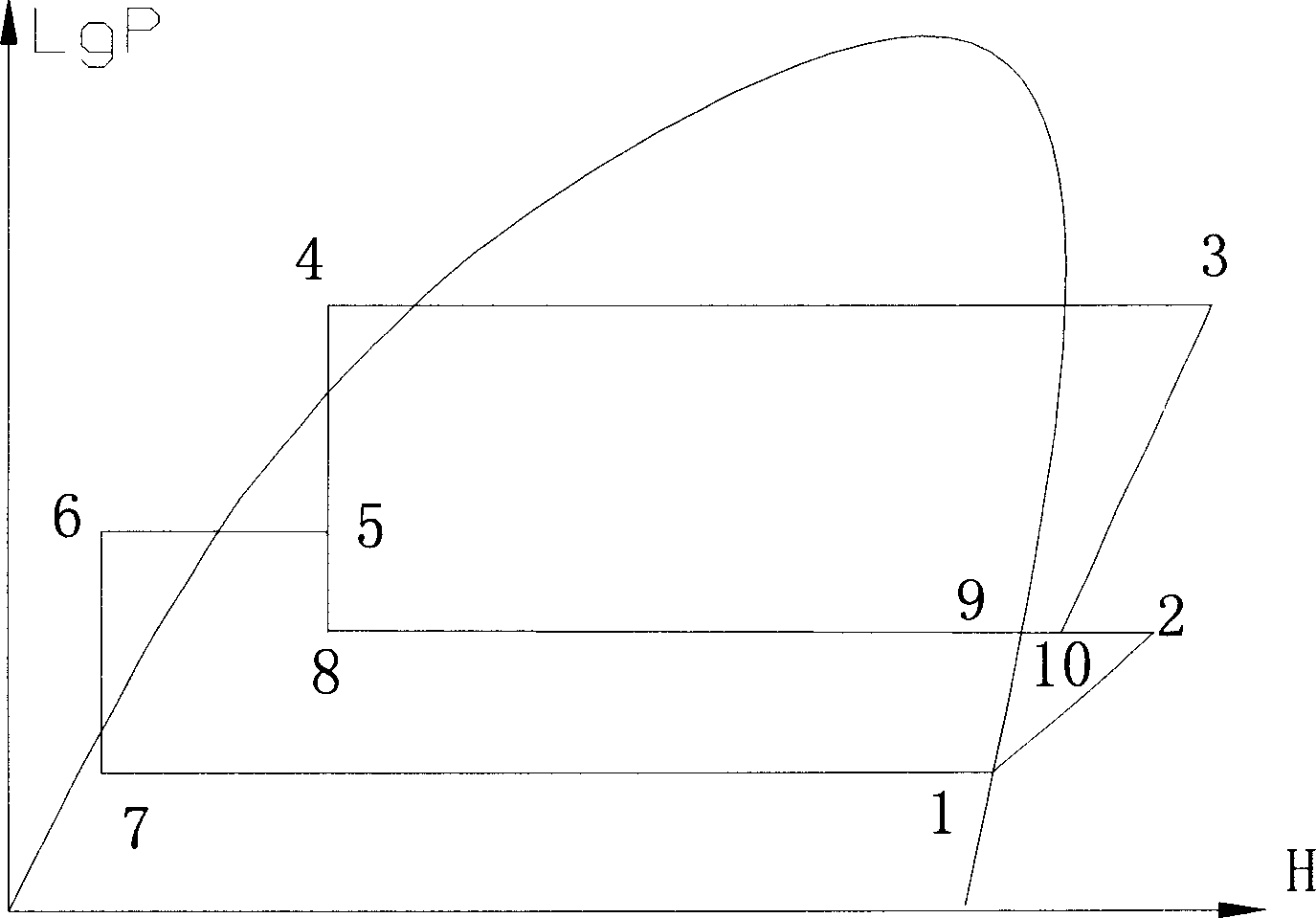

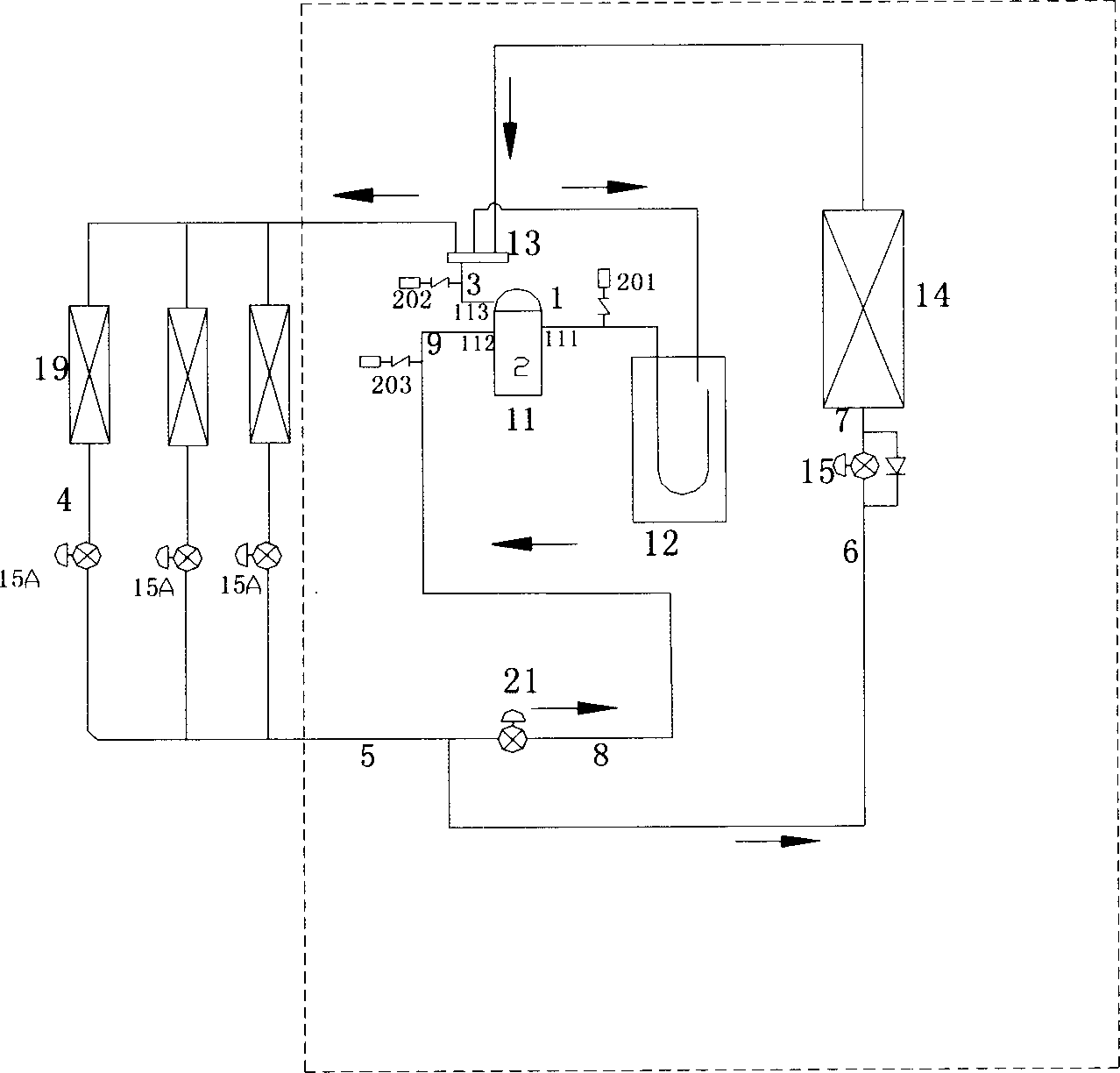

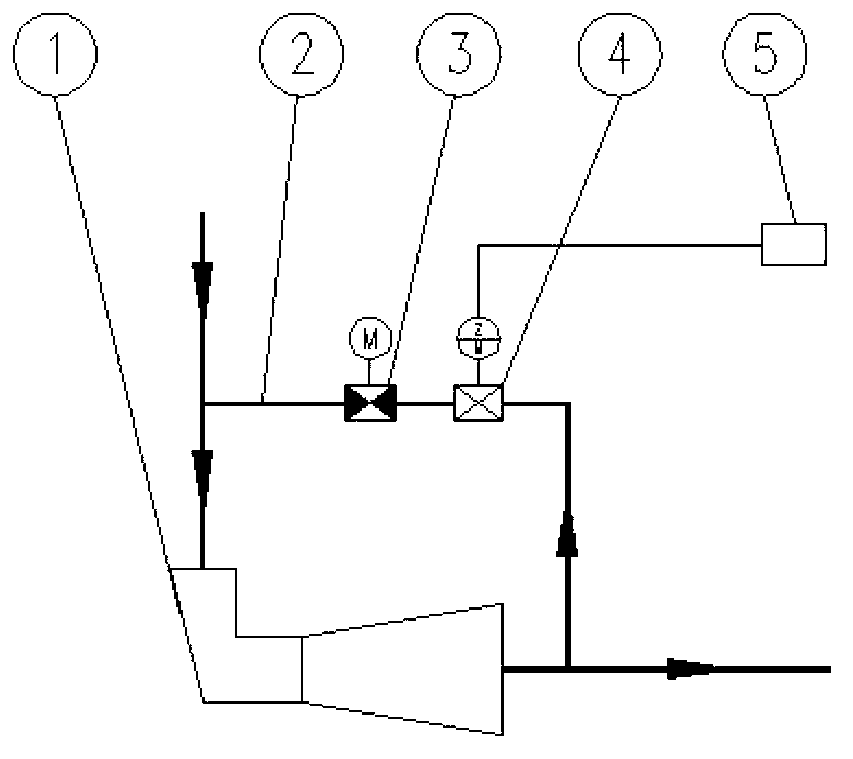

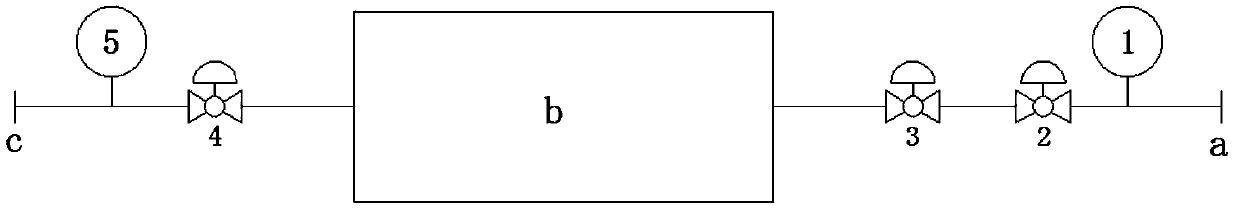

Heat pump air conditioner system and its steam jet control device and method

ActiveCN1828186AGood heating effectIncrease heating capacityHeat pumpsCompression machines with non-reversible cycleFour-way valveBusiness efficiency

The invention relates to a heat pump air conditioner with better heating effect in low-temperature, which comprises a compressor, a four-way valve, indoor and outdoor heat exchangers, and main throat device, which are connected via tubes. Wherein, said compressor has a outlet and two inlets; a bypass tube is arranged at the front and back of main throat device to connect the second inlet of compressor. The invention comprises a steam ejection controller, which at least includes three sensors and one electric expansion valve, while the sensors are at the outlet and two inlets of compressor, and the electric expansion valve is on the by-pass tube. The invention detects the ejector pressure of compressor to control the ejected amount of refrigeration accurately, improve the heating effect and energy / efficiency ratio in lower temperature. it can accurately control the open degree of electric expansion valve, to reduce the vibration of indoor temperature.

Owner:GREE ELECTRIC APPLIANCES INC

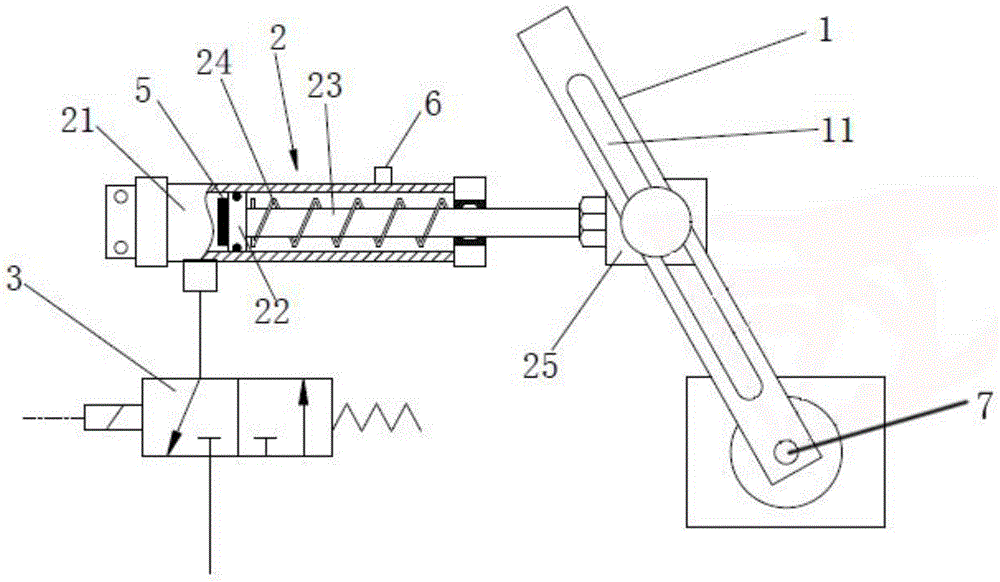

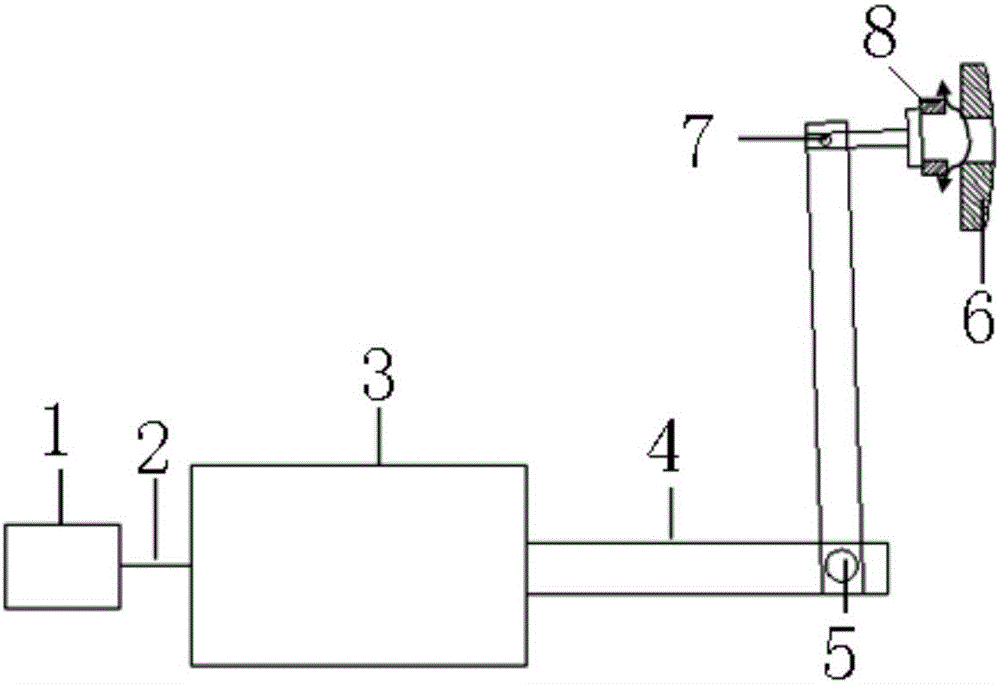

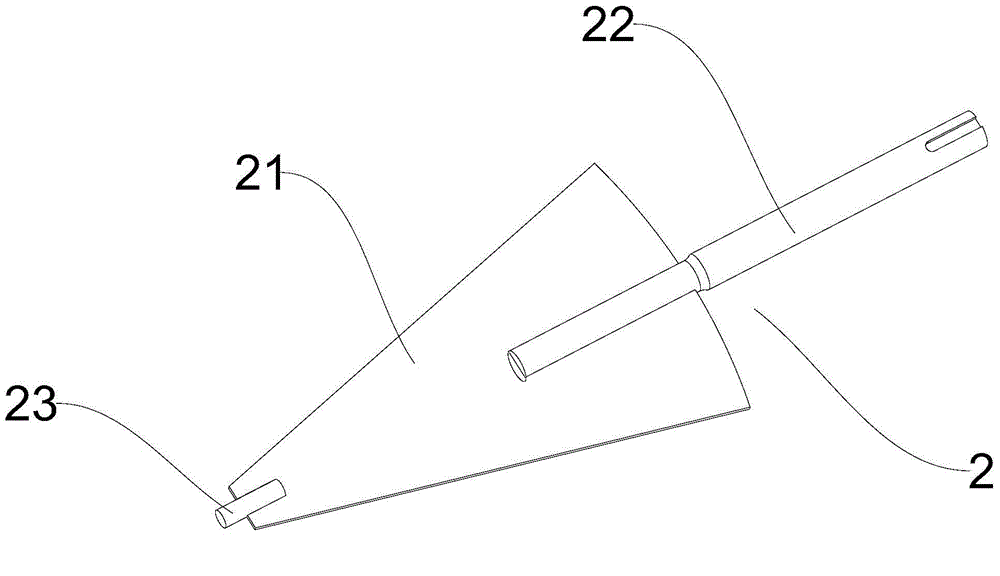

Pneumatic valve control mechanism

InactiveCN104565504ARealize remote controlControl valve openingOperating means/releasing devices for valvesReciprocating motionRemote control

A pneumatic valve control mechanism is characterized by comprising a guide arm, a drive air cylinder and a magnetic reversing valve. An air inlet of the magnetic reversing valve is used for compressed air to be fed, and an air outlet is connected with an air inlet of the drive air cylinder. One end of the guide arm is connected with a valve element drive shaft of the valve, the guide arm can rotate around the valve element drive shaft of the valve and is provided with a chute, a slide shaft is installed in the chute, and the slide shaft is connected with a piston rod of the drive air cylinder to jointly form a connecting rod mechanism. The reciprocating motion of the piston rod drives the slide shaft to slide in the chute of the guide arm so as to form the connecting rod motion mechanism, the guide arm is driven to perform reciprocating rotation around the valve element drive shaft of the valve and further open or close the valve, and remote control of the valve is achieved through the magnetic reversing valve. On the basis, the position required to be reached, of the piston rod can be calculated according to the opening degree of the valve, then the position of a proximity switch sensing end on the drive air cylinder is adjusted, and accordingly accurate positioning during valve opening is achieved.

Owner:JIANGSU MARITIME INST

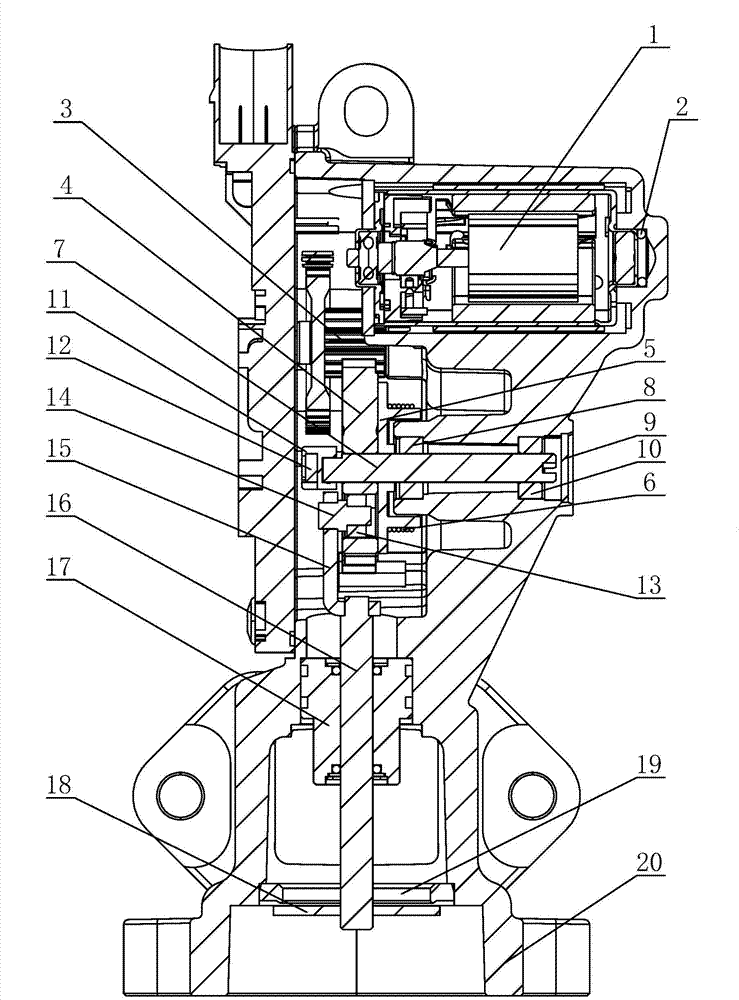

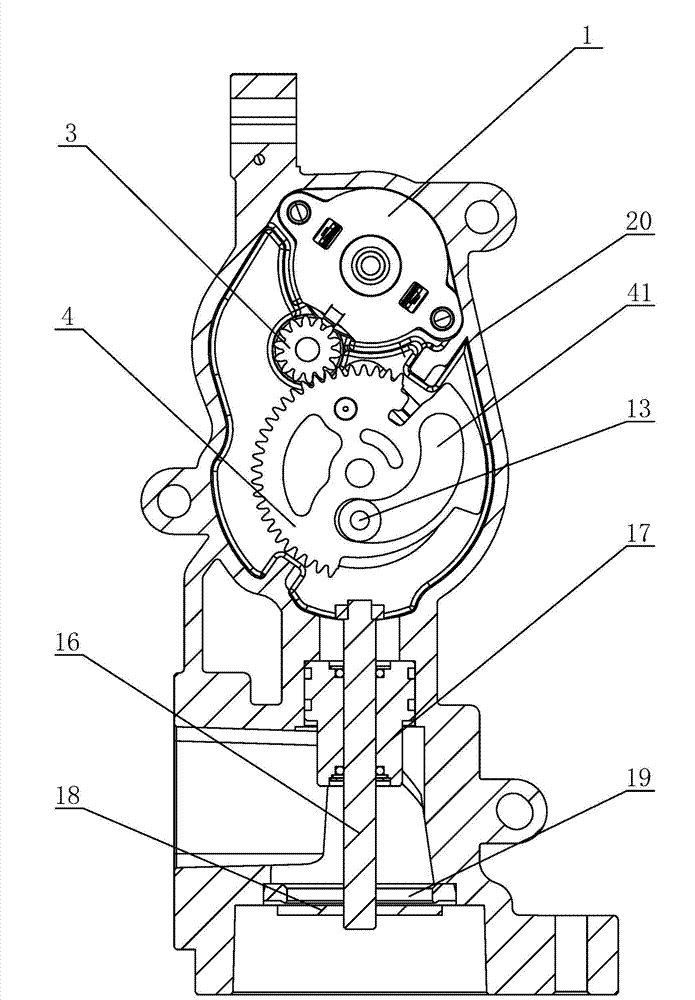

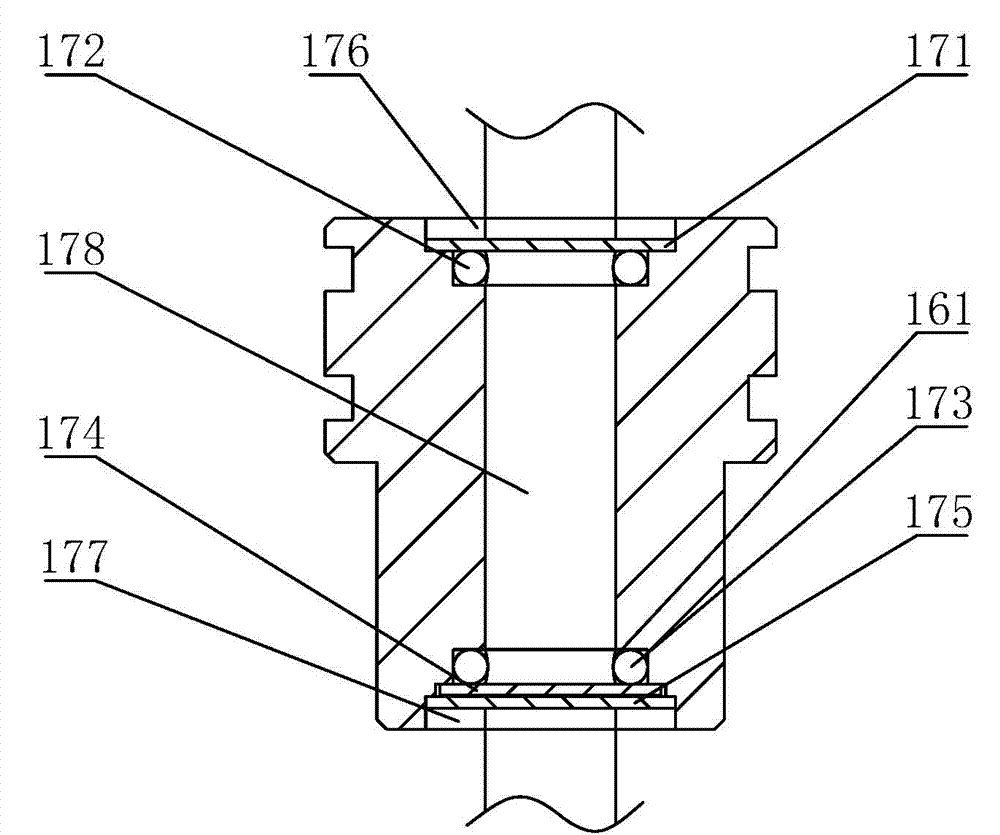

Electric EGR valve

ActiveCN104727989AAccurate opening controlTroubleshoot Signal Transmission DistortionNon-fuel substance addition to fuelInternal combustion piston enginesFailure rateDrive shaft

The invention discloses an electric EGR valve which comprises a shell, a driving motor, a valve rod and a valve block. The driving motor is arranged in the shell, and connected with an intermediate gear, the intermediate gear is meshed with a sector gear, the sector gear is integrally connected with a torsional spring seat, the torsional spring seat is connected with a return torsional spring, the other end of the return torsional spring is fixed to the shell, the sector gear is fixed to a driving shaft, the driving shaft is rotatably arranged in the shell through a rolling bearing and a sliding bearing, an induction magnet is arranged on the driving shaft, and electrically connected with a Hall sensor, a cam groove is formed in the sector gear, a cam bearing is arranged in the cam groove, the cam bearing is connected with a cam bearing shaft and a cam bearing support, the upper end of the valve rod is connected with the cam bearing support, and the lower end of the valve rod is connected with the valve block. The EGR valve is accurate in control, convenient to assemble and low in failure rate.

Owner:KAILONG HIGH TECH

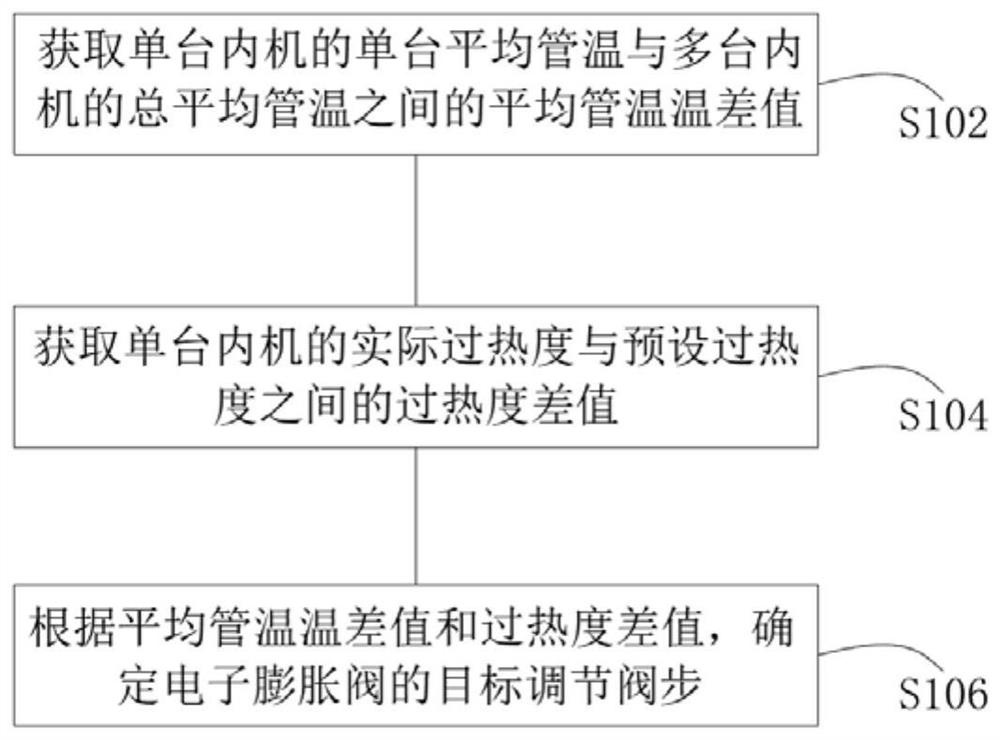

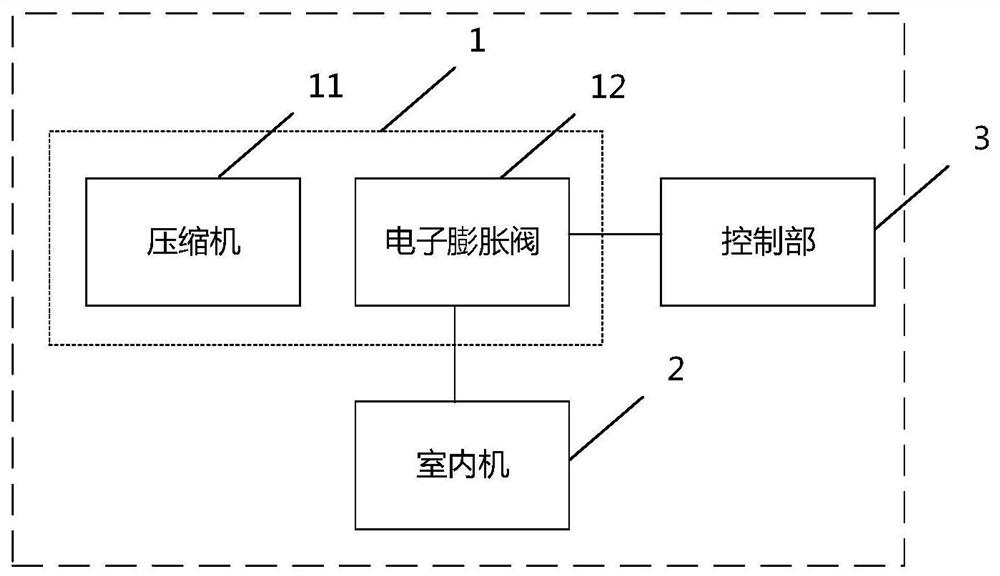

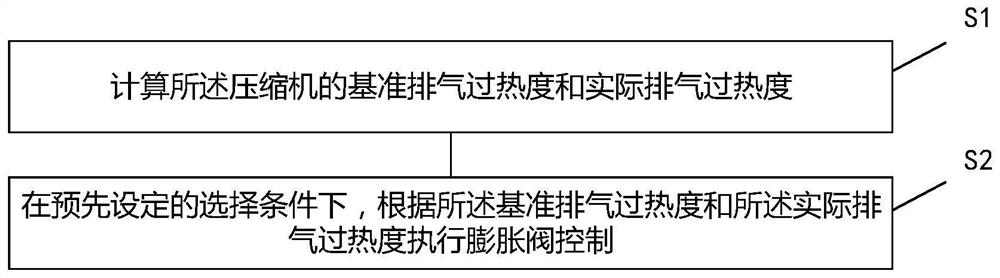

Multi-split electronic expansion valve opening control method, multi-split electronic expansion valve opening adjusting device and air conditioning system

ActiveCN112797599AAccurate judgment of openingAccurate opening controlMechanical apparatusEfficient regulation technologiesEngineeringAir conditioning

The invention relates to the technical field of air conditioners, in particular to a multi-split electronic expansion valve opening control method, a multi-split electronic expansion valve opening adjusting device and an air conditioning system. The multi-split electronic expansion valve opening control method comprises the steps that the average pipe temperature difference value between the single average pipe temperature of a single indoor unit and the total average pipe temperature of multiple indoor units is obtained; the superheat degree difference value between the actual superheat degree and the preset superheat degree of the single indoor unit is obtained; and according to the average pipe temperature difference value and the superheat degree difference value, the target adjusting valve step of the electronic expansion valve is determined. The opening degree of the electronic expansion valve can be accurately controlled, the bias flow phenomenon of the refrigerant amount is reduced or even eliminated, and capacity balance among indoor units is achieved.

Owner:NINGBO AUX ELECTRIC +1

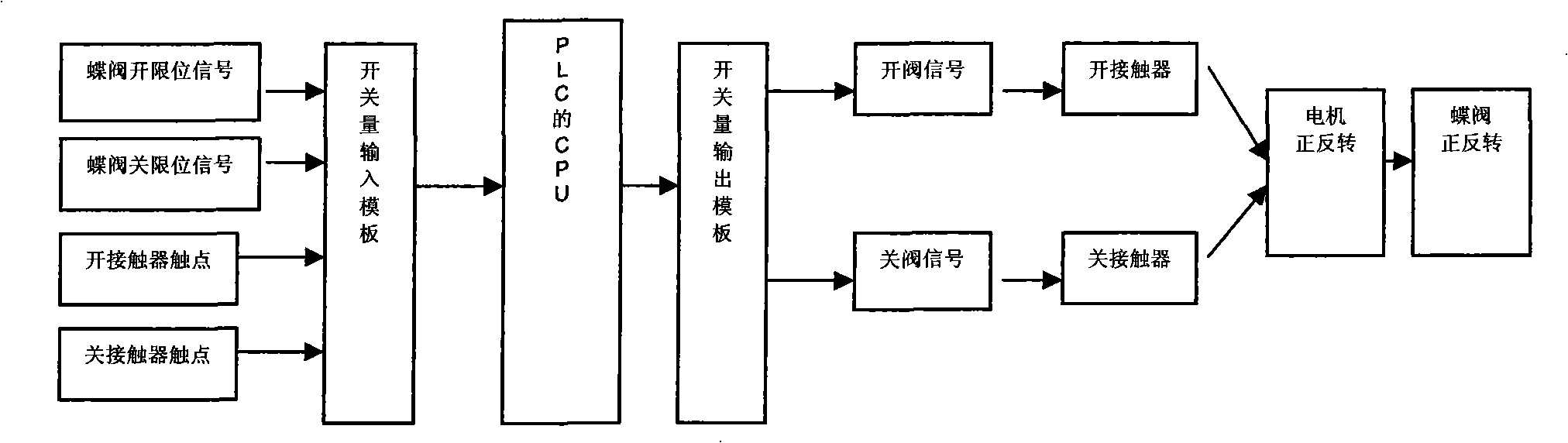

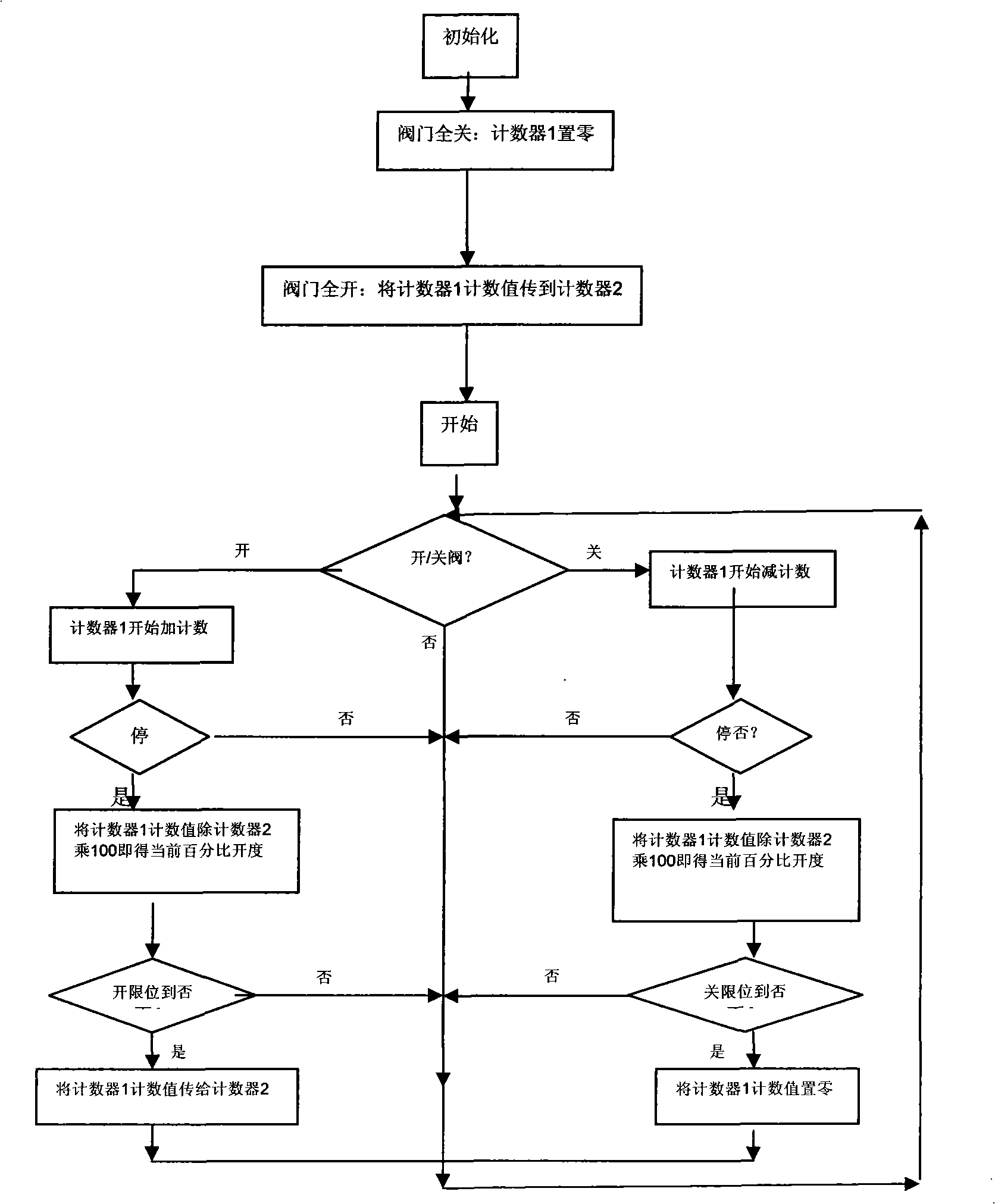

Method and device for displaying and controlling opening of electric butterfly valve

InactiveCN101539191AAccurate opening controlAct as an alternative actuatorGearingEngineeringButterfly valve

The invention relates to a method and a device for displaying and controlling the opening of an electric butterfly valve by using a computer program. A control return circuit which comprises a programmable controller connected with a computer and a driving contactor of the electric butterfly valve is adopted. The method is characterized in that time from starting the electric butterfly valve to thoroughly opening the electric butterfly valve is used as a numerical value that the opening of the electric butterfly valve is 100 percent; time that the electric butterfly valve is opened or closed every time is compared with the time that the opening of the electric butterfly valve is 100 percent, the opening magnitude or the closing magnitude is calculated, and the opening percentage of the electric butterfly valve is obtained; and a counter is set to be zero when the electric butterfly valve is fully closed, which displays 0 percent of the opening. The invention does not require investment in software and hardware, only requires to skillfully use functions, such as the counter of STEP7 software, a passing block, a multiplication block, a division block, and the like to accurately control the opening of the electric butterfly valve instead of a performer, avoids operational errors, and can greatly save engineering cost and maintenance cost when being used in the performer and a system of the electric butterfly valve.

Owner:ELECTRON CO LTD

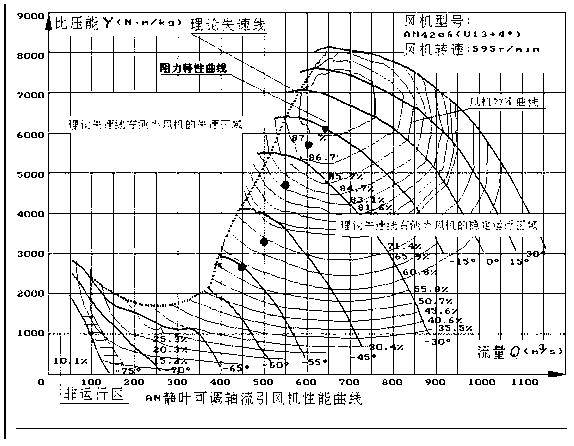

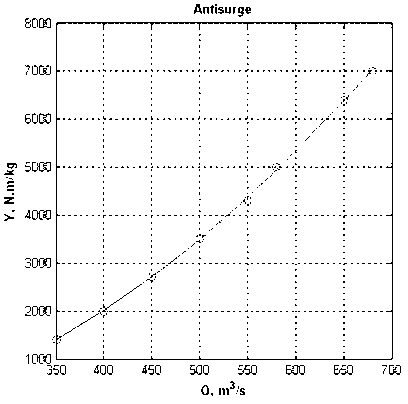

Low-load vibration control method for axial flow fan of thermal power plant and bypass air duct control loop

ActiveCN102840182AGuaranteed not to stallReduce power consumptionPump componentsPump controlLoop controlVibration control

The invention relates to a low-load vibration control method for an axial flow fan of a thermal power plant and a bypass air duct control loop. The vibration control method is characterized by comprising the following steps: 1) arranging the bypass air duct control loop in the axial flow fan of the thermal power plant, so as to regulate the recirculation flow of the fan; 2) using output flow of the fan under a working condition as an original signal, calculating the minimum recirculation flow needed for the working condition by a function operator, and controlling the recirculation flow under the working condition by the bypass air duct control loop, so that the fan works under a stable operating border condition; and 3) using the output flow under each working condition as the original signal, and calculating the minimum recirculation flow needed for each working condition by the function operator, and controlling the recirculation flow under each working condition by the bypass air duct control loop, so that the fan works in a stable operating border condition under each working condition, thereby ensuring the speed of the fan with a low recirculation flow and reducing the recirculation power consumption. The low-load vibration control method has the following beneficial effects of ensuring the speed of the fan with the small recirculation flow, and remarkably reducing the recirculation power consumption.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

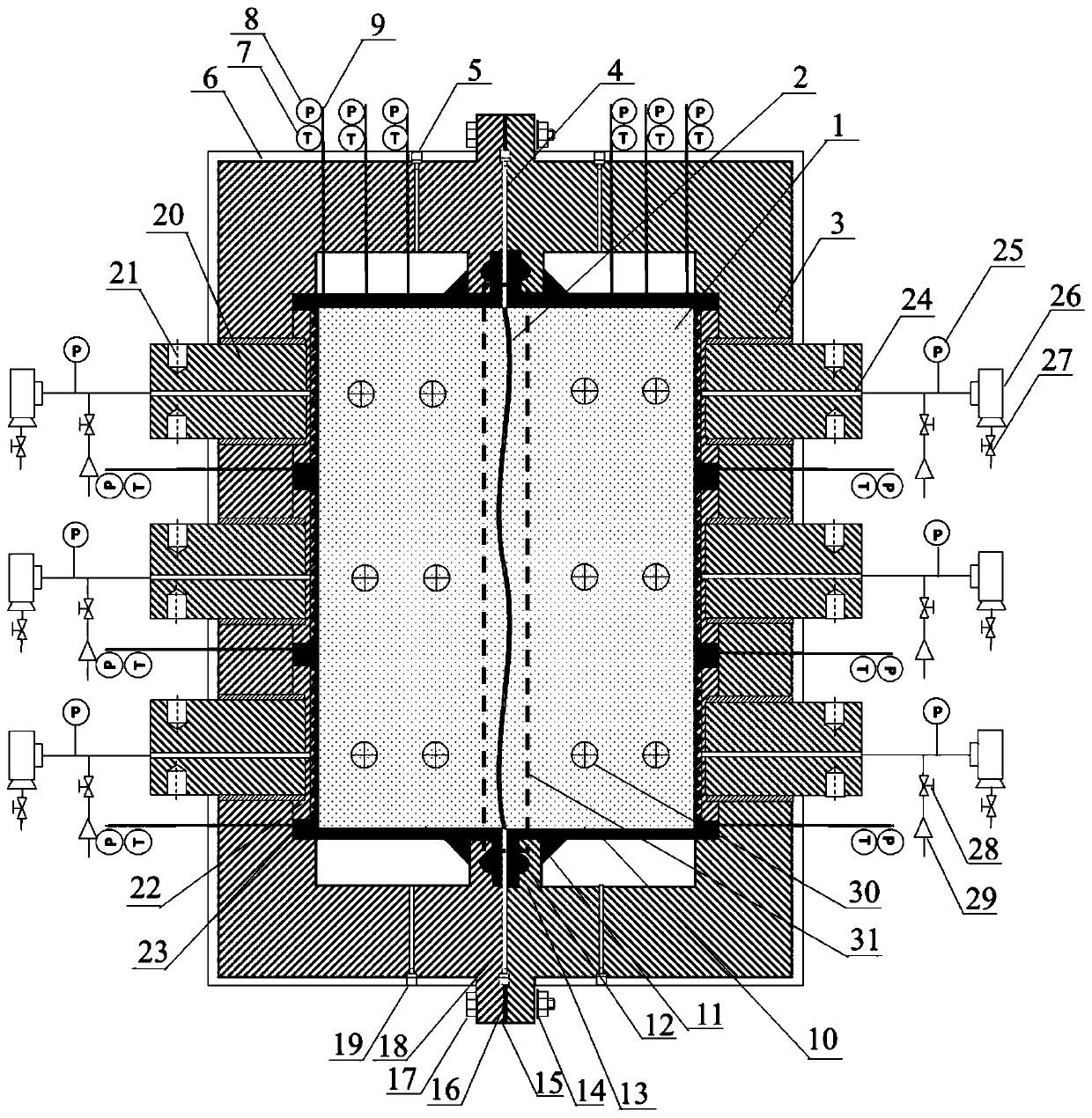

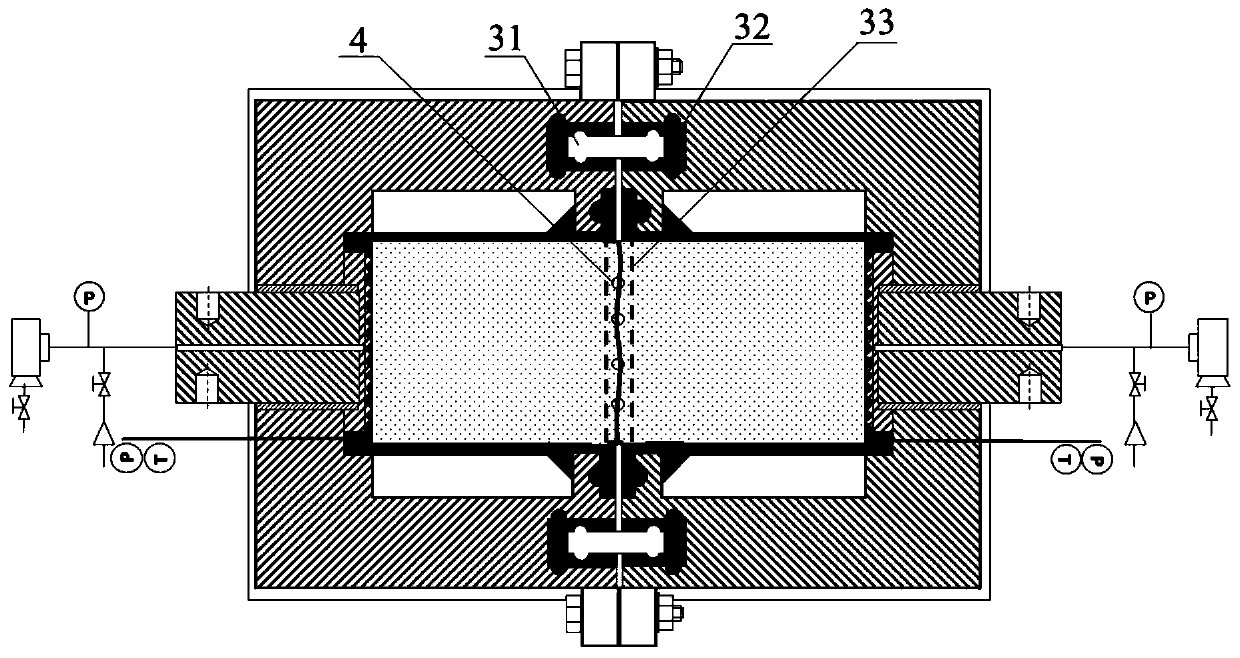

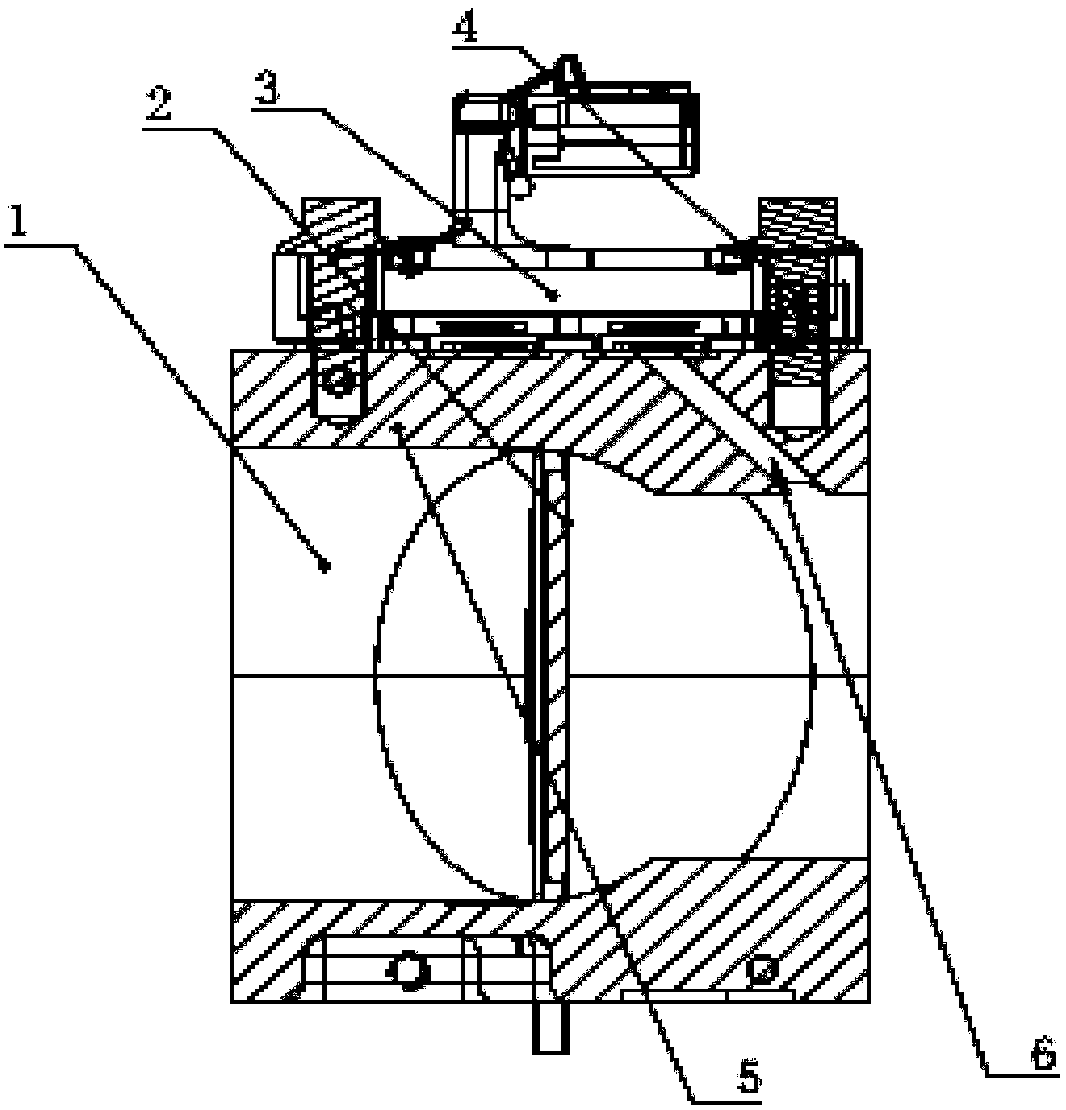

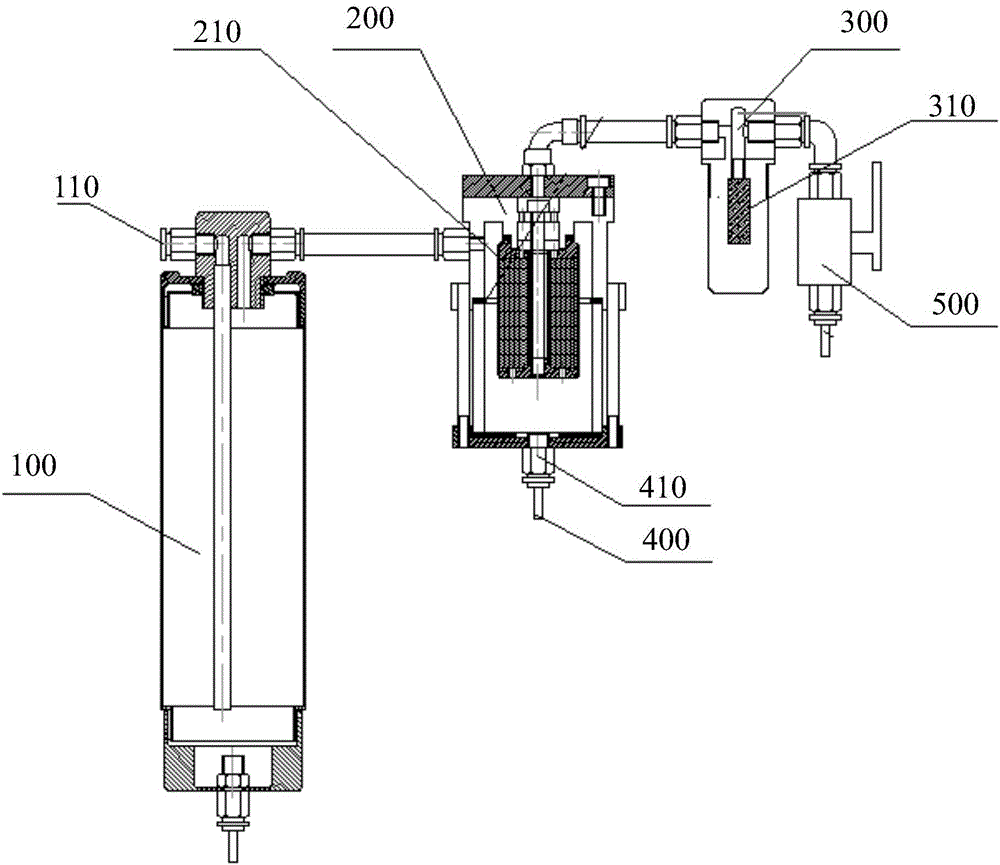

Visualized dynamic filtration loss and discharge and mining simulation device and simulation method for tight gas reservoir fracturing fluid

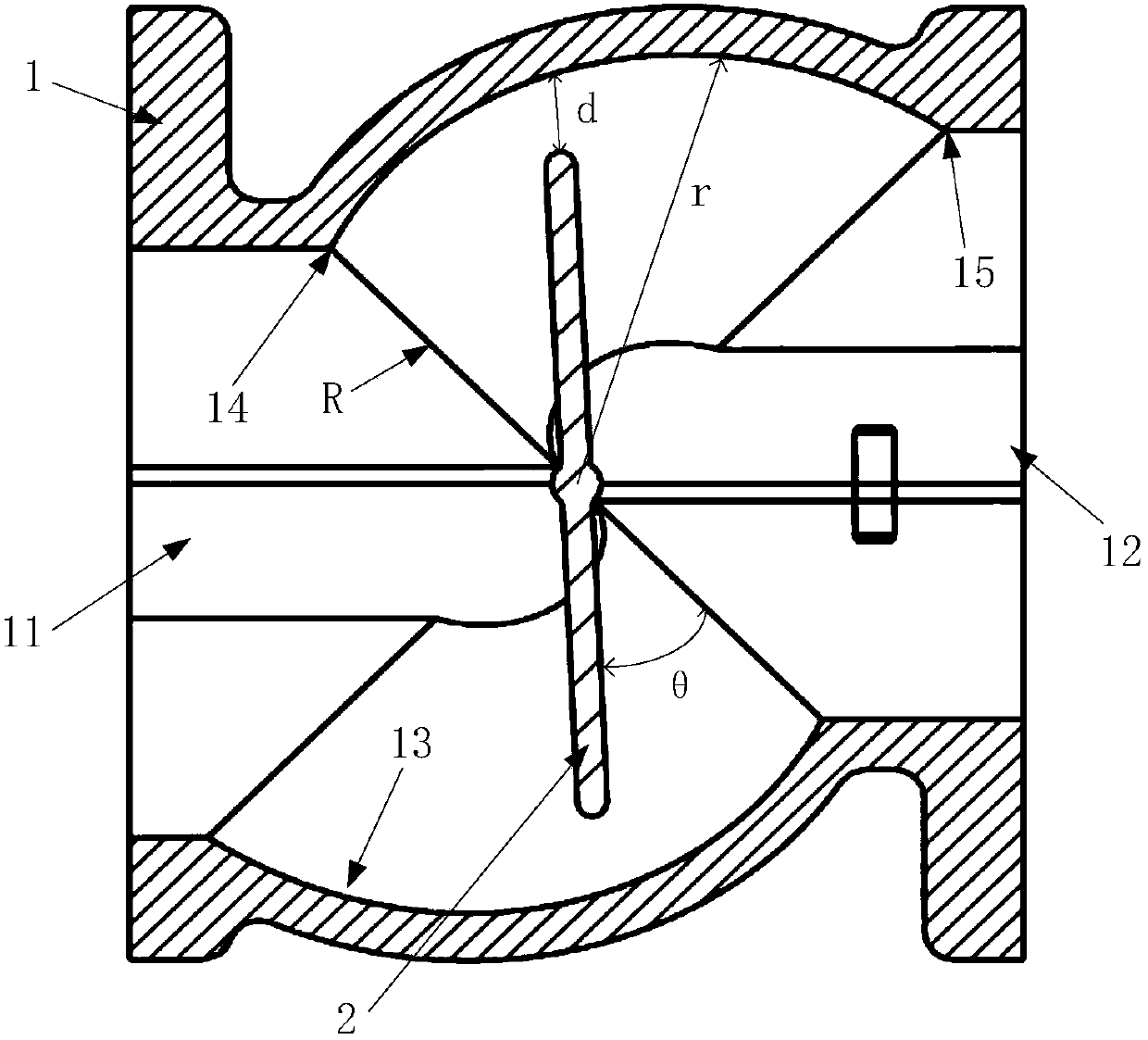

ActiveCN111411930AOvercome the insufficiency of being unable to simulate the real fracture shapeReal-time monitoring of flow statusSurveyConstructionsRock coreFiltration

The invention discloses a visualized dynamic filtration loss and discharge and mining simulation device and simulation method for tight gas reservoir fracturing fluid. The simulation device comprisesa fracture-developed core visualized holder, a fracture morphology controller, a filtrate collection and post-compaction discharge and mining simulator, wherein a square core is arranged in the fracture-developed core visualized holder and has a core crack inside; visualized windows are arranged on the upper side and lower side of the fracture-developed core visualized holder; the fracture morphology controller comprises crack control screwing-in rods and a filtrate collection cushion block; and the filtrate collection and post-compaction discharge and mining simulator comprises a filtrate collection part and a post-compaction discharge and mining simulation part which are connected to center filtrate guide rods of the crack control screwing-in rods through gas-liquid circulating pipelines. The simulation device can adjust and control the angle and opening of a real fracture, and is conductive to researching the dynamic filtration loss law of fractures in unconventional tight gas reservoirs such as shale gas and coalbed methane. The simulation device simulates the long-period discharge and mining process, and is conductive to researching the discharge, mining and development law ofthe unconventional tight gas reservoirs such as the shale gas and coalbed methane after fracturing measures are implemented.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Throttling valve and engine

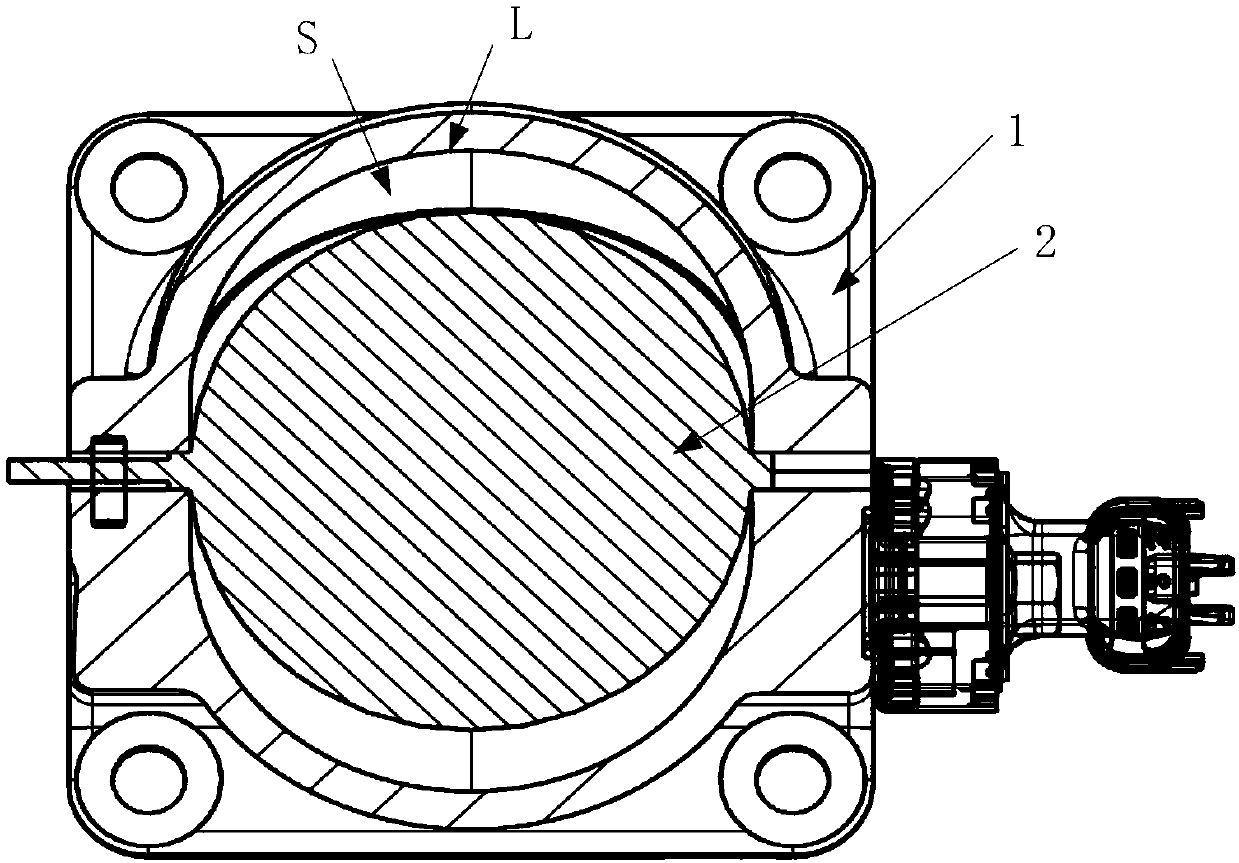

ActiveCN107642418AAvoid throttling instabilityHigh control precisionEngine controllersMachines/enginesEngineeringThrottle control

The invention provides a throttling valve. The throttling valve comprises a throttling valve shell and a valve plate erected inside the throttling valve shell, the throttling valve shell comprises a valve inlet, a valve outlet and a throttling area arranged between the valve inlet and the valve outlet, and the valve plate is erected on the throttling area; a throttling initial point which is in cooperation with the valve plate when the valve plate is closed and a throttling end point which is in cooperation with the valve plate when the valve plate is totally opened are arranged on the inner wall of the throttling valve shell, and a throttling hook face which is in arc transition to the throttling end point from the throttling initial point is further arranged on the inner wall of the throttling valve shell. The throttling hook face which is in arc transition to the throttling end point from the throttling initial point is arranged on the inner wall of the throttling valve shell, alongwith the rotation of the valve plate, the spacing between the end of the valve plate and the throttling hook face is in uniform transition, the opening range control is more accurate, the situation that throttling of the throttling valve is unstable due to sudden change of the throttling area of the valve plate is avoided, the throttling control precision is higher, and the controlling precisionof the throttling valve is improved. The invention further provides an engine provided with the throttling valve structure.

Owner:WEICHAI POWER CO LTD

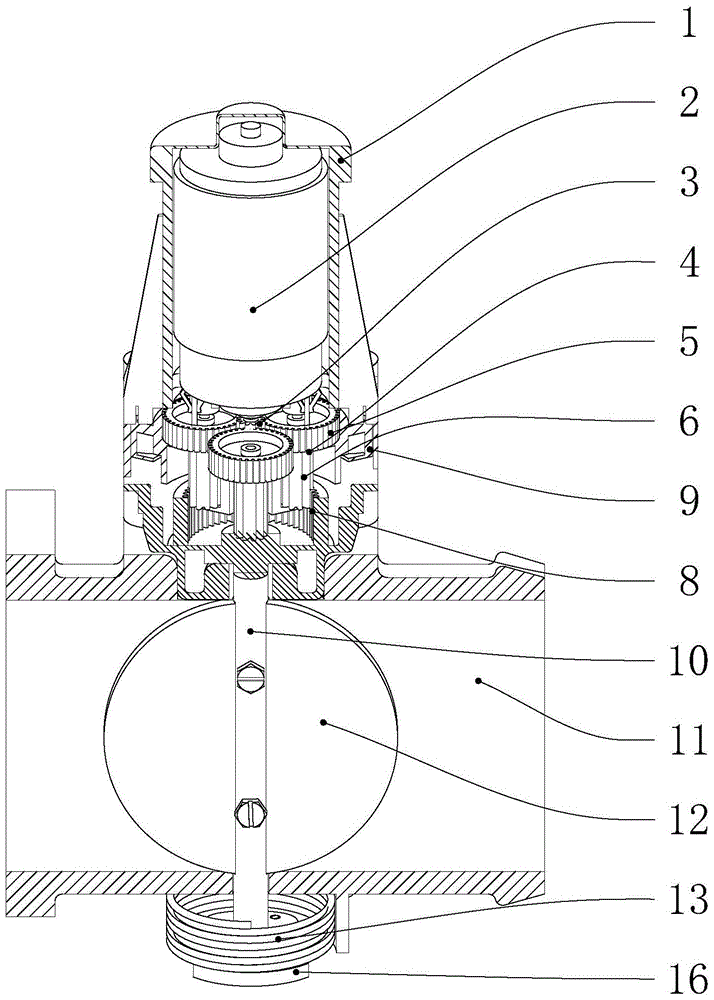

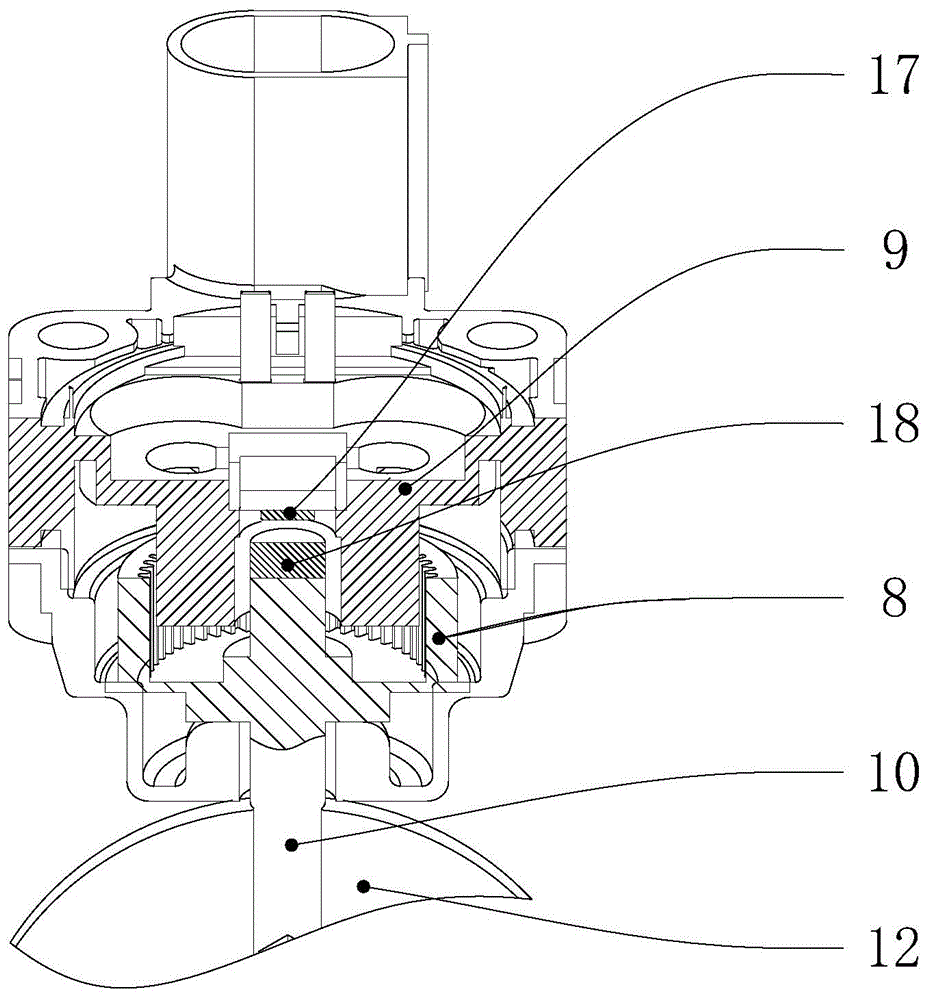

Throttle valve driven by direct-current motor

InactiveCN104454177AImplement the shutdown functionImplement the open functionEngine controllersMachines/enginesCurrent meterElectric machine

The invention discloses a throttle valve driven by a direct-current motor. The throttle valve comprises the direct-current motor (2), a motor gear (3), driven gears (4), a transition gear (8), a valve stem (10), a valve block (12), a sensor (9), a valve body (11), a limit piece (16) and a torsional spring (15), wherein the direct-current motor (2) is fixed on the sensor (9) through a motor shell (1), the motor gear (3) is directly mounted on the direct-current motor (2), a chip (17) on the sensor (9) reads the position signals of the valve block (12) through magnetic steel (18) on the transition gear (8), the transition gear (8) is integrated with the valve stem (10) and the valve block (12), and the transition gear (8) rotates to drive the valve block (12) through the valve stem (10), so that the throttle valve can be opened and closed. The throttle valve has the advantages that the direct-current motor can drive by a simple transmission way to open and close the valve block of the throttle valve, and the throttle valve is small in size, easy to mount and arrange, high in control accuracy and short in response time, and the different opening positions of the valve block can be accurately controlled.

Owner:WUXI LONGSHENG TECH

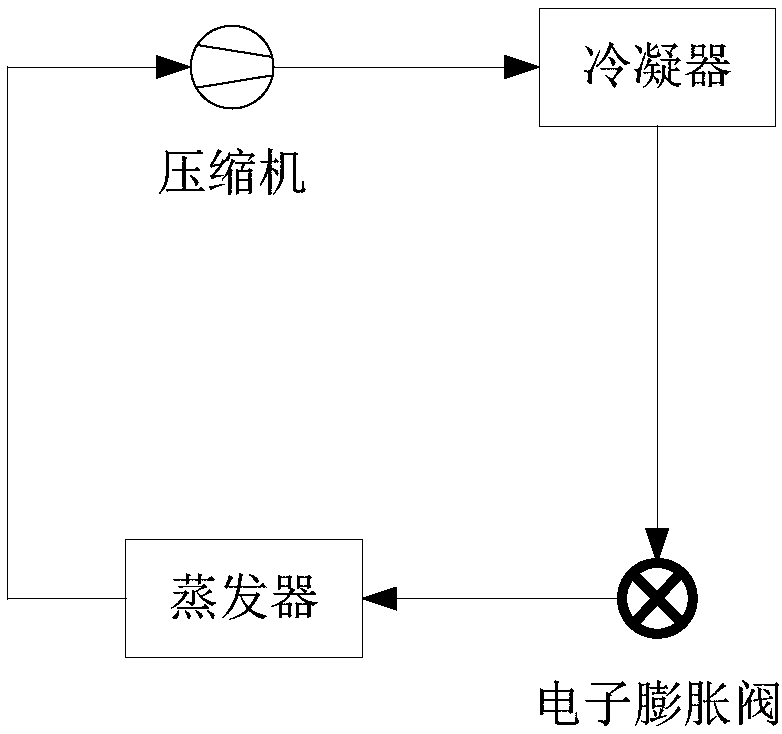

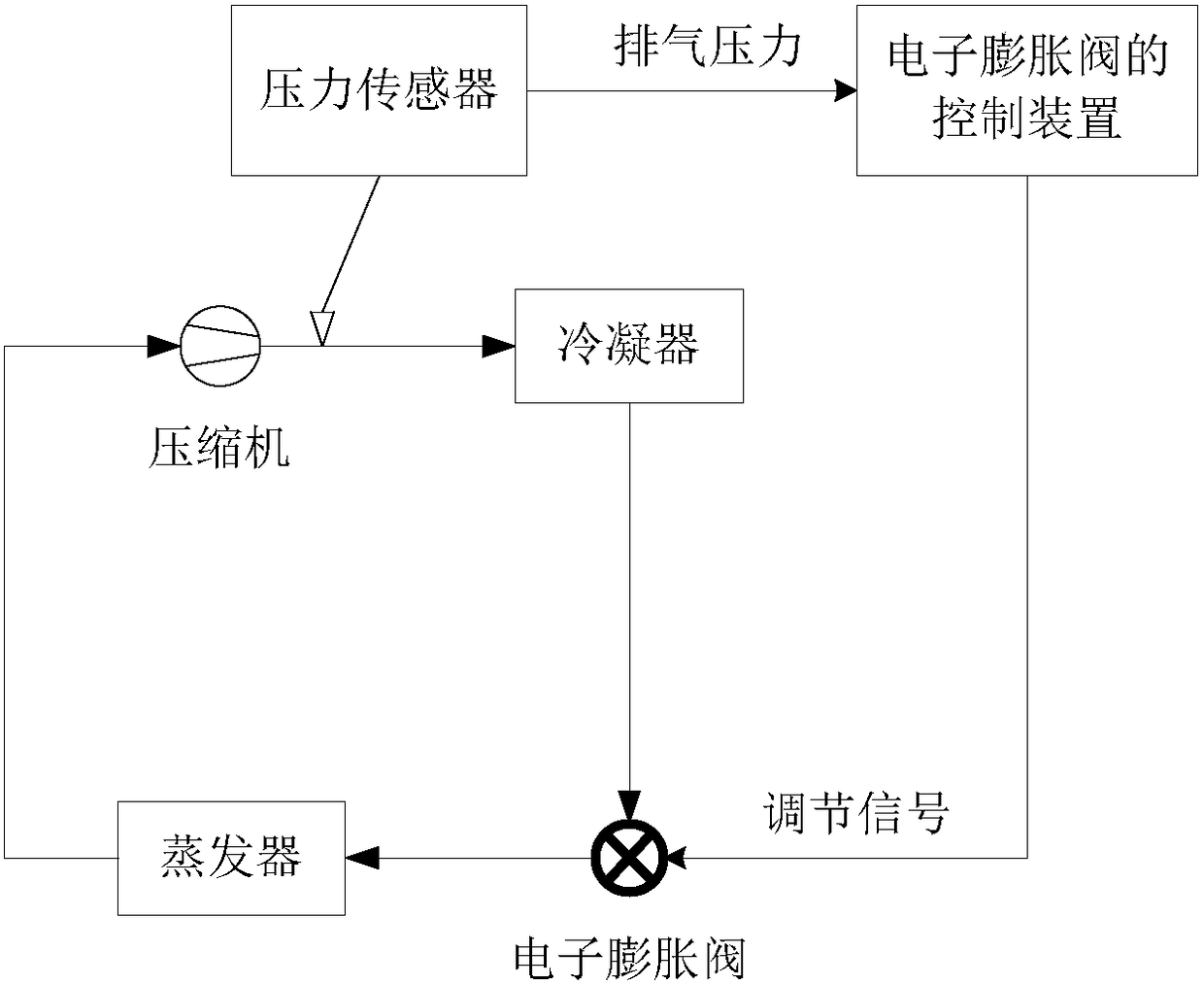

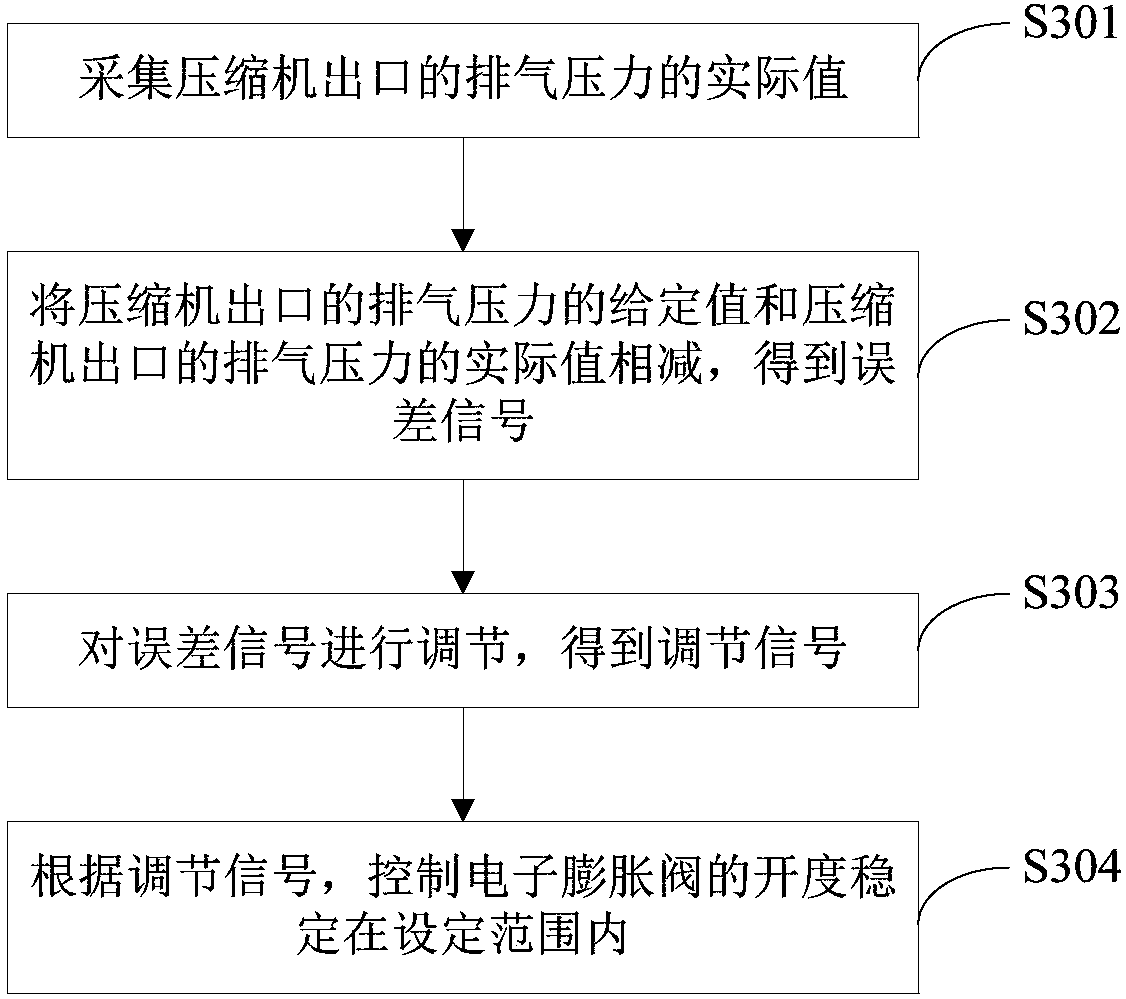

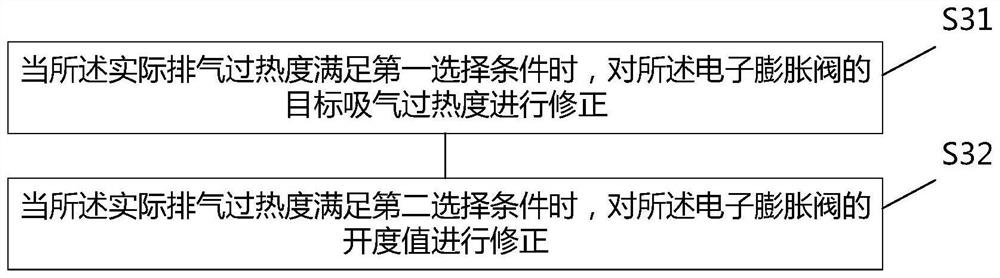

Control method and device for electronic expansion valve, and electronic equipment

InactiveCN108489164AAchieve openingAccurate opening controlMechanical apparatusEfficient regulation technologiesElectronic expansion valveElectric equipment

The invention discloses a control method and device for an electronic expansion valve, and electronic equipment. The control method for the electronic expansion valve comprises the following steps: acquiring the actual value of an exhaust pressure at the outlet of a compressor; subtracting the actual value of the exhaust pressure at the outlet of the compressor by the given value of the exhaust pressure at the outlet of the compressor to obtain an error signal; adjusting the error signal to obtain an adjustment signal; and controlling the opening degree of the electronic expansion valve to stabilize the opening degree of the electronic expansion valve in a set range according to the adjustment signal. According to the embodiment of the invention, the opening degree of the electronic expansion valve is adjusted to be stabilized in the set range according to the error signal between the given value of the exhaust pressure at the outlet of the compressor and the acquired actual value of the exhaust pressure at the outlet of the compressor, so that accurate control for the opening degree of the electronic expansion valve is realized.

Owner:BEIJING ELECTRIC VEHICLE

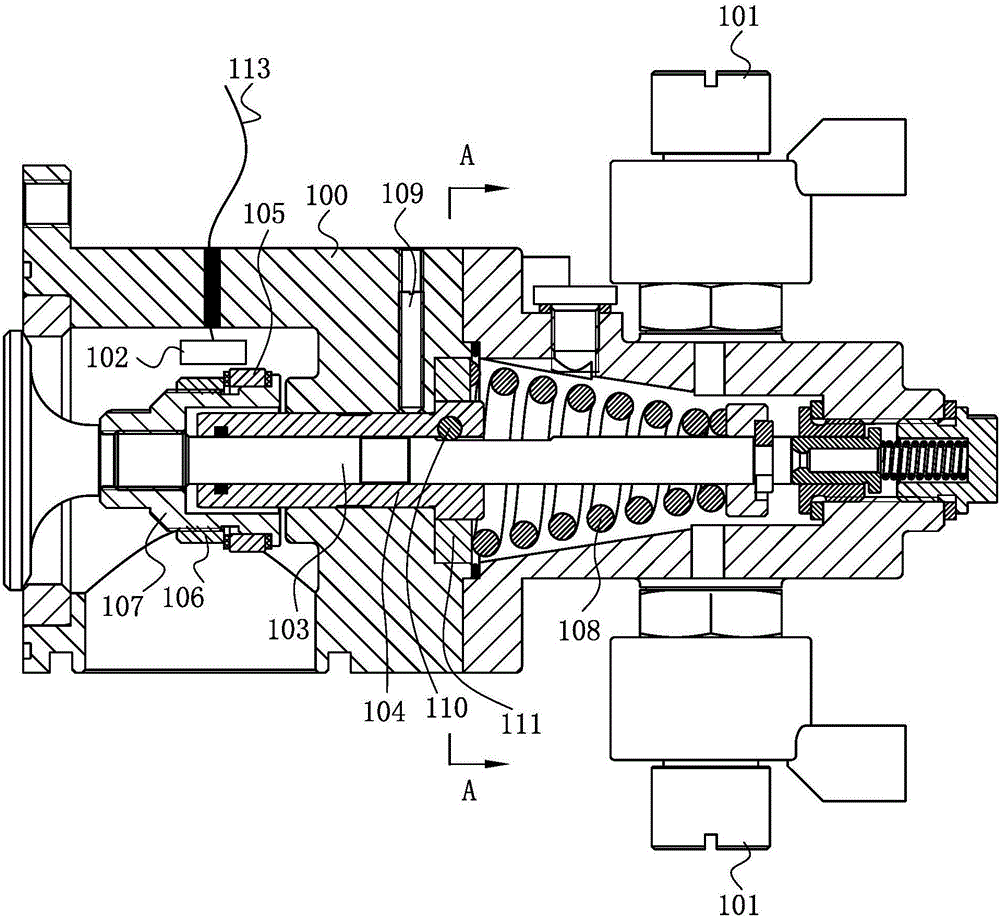

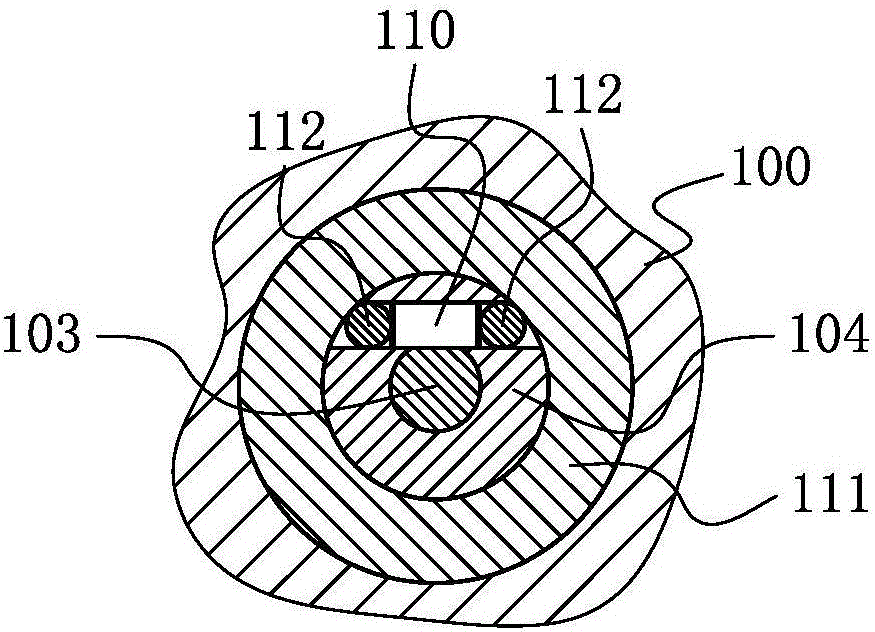

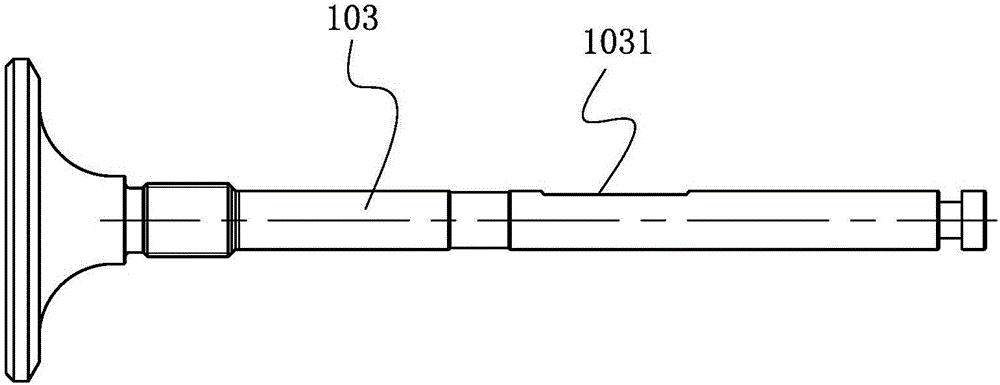

Hydraulically powered gas injection valve

ActiveCN106678426AAccurate opening controlEliminate detection errorsOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringElectromagnetic valve

The invention discloses a hydraulically powered gas injection valve which comprises a valve body and a valve element, wherein a valve bush is arranged in the valve body; an electromagnetic valve communicating with an inner cavity of the valve body is mounted at the external part of the valve body; a valve rod of the valve element and the valve bush are in sliding fit; the valve rod is provided with a first stretching part and a second stretching part stretching out of the valve bush; the first stretching part of the valve rod is fixedly connected with a magnet through a magnet seat; a magnetic field sensor is fixed in the valve body and corresponds to the magnet in position; and a sliding guiding device is arranged between the valve rod and the valve bush. The magnet is fixed with the valve element through the magnet seat and moves along with the valve element, and the magnetic field sensor detects variation of a magnetic field to sense the stroke of the valve element so as to accurately control opening of the valve element; and through the sliding guiding device, the valve element is enabled not to rotate during axial movement, so that detection error brought to the magnetic field sensor by magnetism difference of the magnet in the circumferential direction is eliminated, and measurement accuracy is improved.

Owner:WEIFANG LICHUANG ELECTRONICS TECH

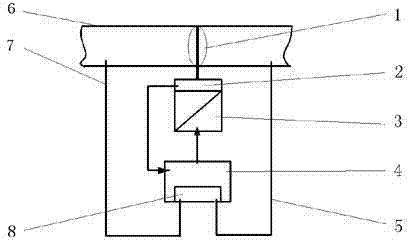

Electromechanical ventilating valve capable of controlling gas pressure inside closed cavity

InactiveCN103569370AReduce structural weightPrecise controlPower plant fuel supplyAirplaneLower limit

The invention discloses an electromechanical ventilating valve capable of controlling gas pressure inside a closed cavity. The electromechanical ventilating valve comprises an electric actuator (3), a valve (1), a controller (4) and a differential pressure sensor (8), wherein the electric actuator (3) is provided with a rotating shaft; the rotating shaft of the electric actuator (3) is sleeved with the valve (1), and the valve (1) is used for connecting or disconnecting a fuel tank and the outside atmosphere; the controller (4) is used for controlling rotation of the rotating shaft of the electric actuator (3); the differential pressure sensor (8) is used for transmitting collected differential pressure values of the gas pressure of the fuel tank and the pressure of the outside atmosphere to the controller (4); and two end values, which are compared with the received differential pressure values of the gas pressure of the fuel tank and the pressure of the outside atmosphere, of the upper limit and the lower limit of an aircraft fuel tank gas pressure limit range are preset in the controller (4). The electromechanical ventilating valve can substitute for two original mechanical ventilating valves and can adjust any gas pressure ranges.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Air conditioning unit and electronic expansion valve control method

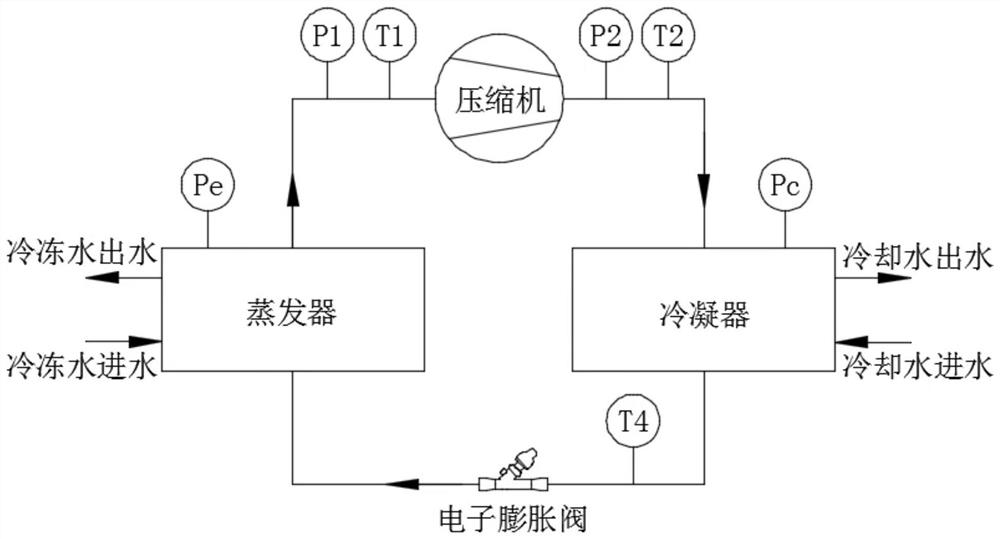

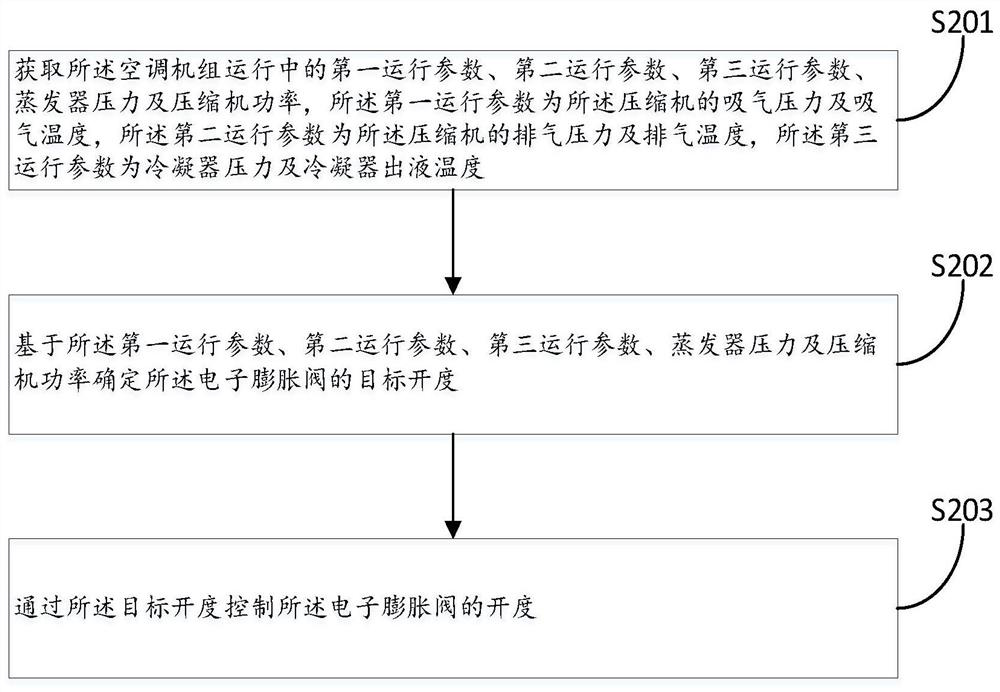

PendingCN112611041AAccurate opening controlReduce frequent movementsMechanical apparatusLighting and heating apparatusEngineeringAir conditioning

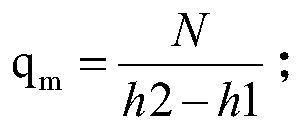

The invention discloses an air conditioning unit and an electronic expansion valve control method. The air conditioning unit comprises a refrigerant circulation loop, a compressor, a condenser, an electronic expansion valve, an evaporator and a controller. The electronic expansion valve control method is configured to obtain first operation parameters, second operation parameters, third operation parameters, evaporator pressure and compressor power in the operation of the air conditioning unit, wherein the first operation parameters are the air suction pressure and the air suction temperature of the compressor, the second operation parameters are the exhaust pressure and the exhaust temperature of the compressor, and the third operation parameters are the condenser pressure and the condenser liquid outlet temperature; and the target opening degree of the electronic expansion valve is determined based on the first operation parameters, the second operation parameters, the third operation parameters, the evaporator pressure and the compressor power; The opening degree of the electronic expansion valve is controlled through the target opening degree, so that the opening degree of the electronic expansion valve is accurately controlled, and lagging actions or frequent actions of the electronic expansion valve are reduced.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Supercharger execution control structure and control method thereof

InactiveCN106246337AImprove responsivenessReduce plumbing componentsInternal combustion piston enginesExecution controlAutomotive engineering

The invention discloses a supercharger execution control structure, which comprises a control unit and a supercharger waste gas vent valve, as well as an electric actuator, wherein the supercharger waste gas vent valve consists of a supercharger waste gas vent valve seat and a waste gas vent valve which are matched with each other, the control unit is connected with the electric actuator through a wiring harness, the waste gas vent valve is connected with the electric actuator through a pull bar. A supercharger execution control method comprises the following control steps: calculating the power of a gas compressor by the control unit according to the required supercharged pressure, and then converting into the power of a turbine according to the energy balance principle, thus being capable of acquiring required waste gas energy; calculating the openness of the waste gas vent valve according to the quantity of the required waste gas energy, and outputting a control command to the electric actuator through the control unit; and executing actions by the electric actuator to drive the pull bar to achieve the required openness value of the waste gas vent valve. The supercharging pressure control precision can be enhanced, and the response speed of the supercharger can be increased.

Owner:CHERY COMML VEHICLE ANHUI

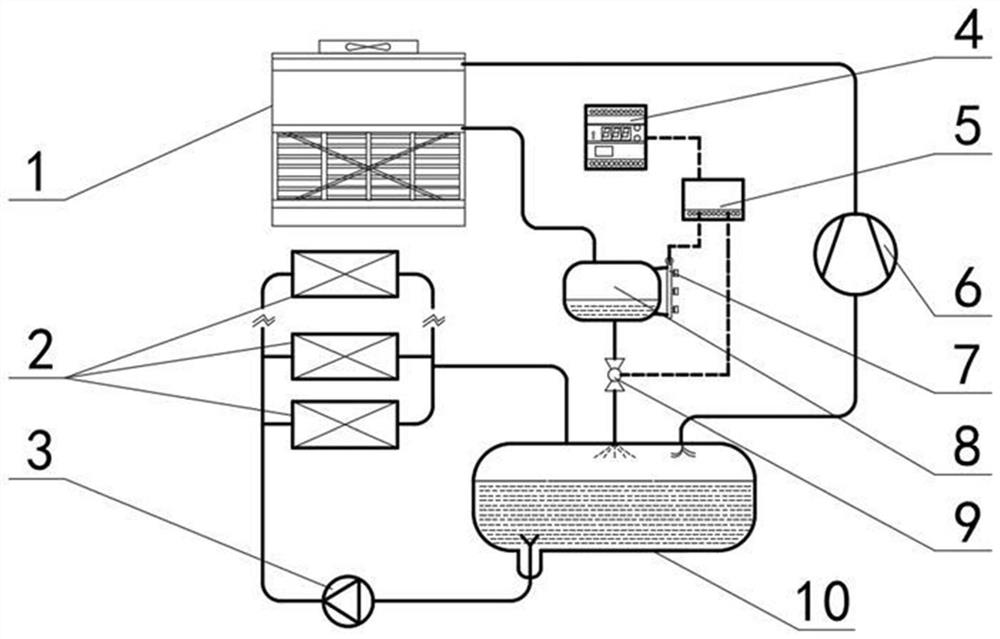

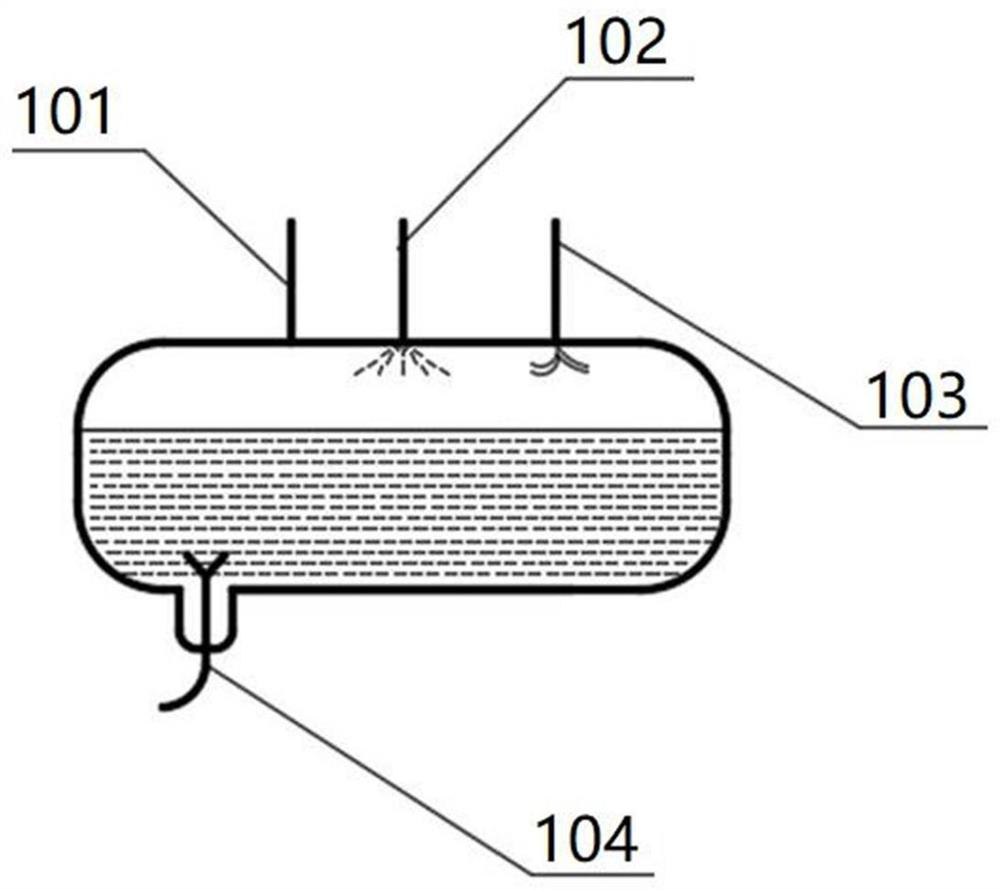

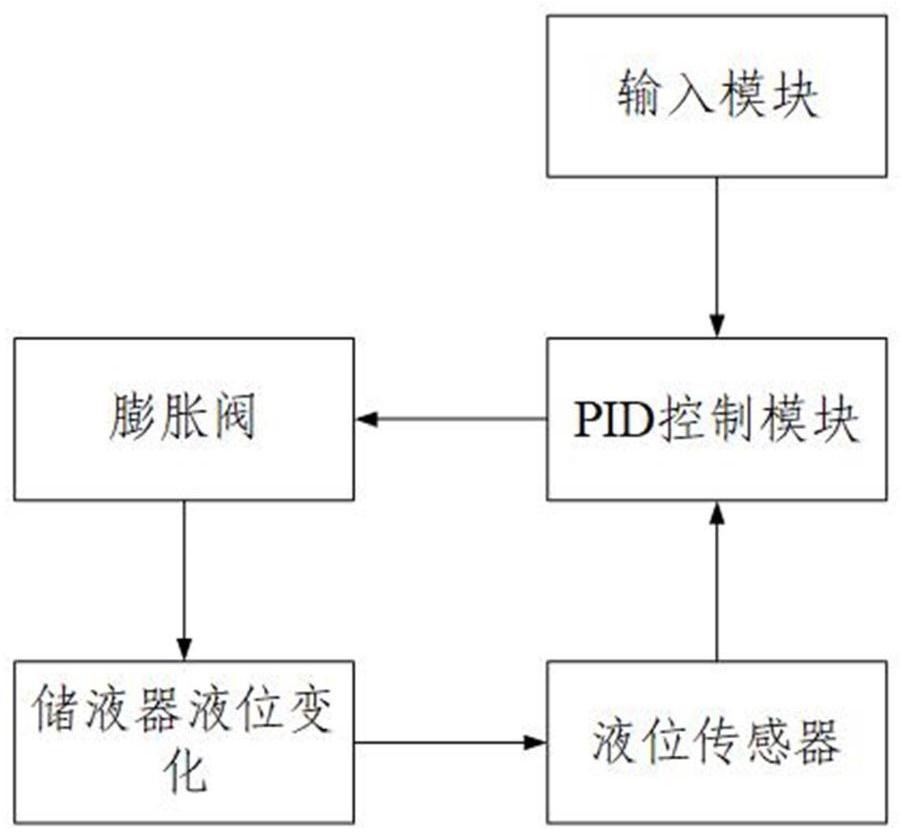

Ammonia pump liquid supply refrigerating system and control method thereof

ActiveCN112146314AReduce overall volume sizeReduce areaFluid circulation arrangementRefrigeration safety arrangementControl systemControl engineering

The embodiment of the invention provides an ammonia pump liquid supply refrigerating system and a control method thereof. The ammonia pump liquid supply refrigerating system involves a compressor, a condenser, a liquid storage device, an expansion valve, a low-pressure circulating barrel, an ammonia pump, an evaporator and a control system. The exhaust end of the compressor is connected with an inlet of the condenser, and an outlet of the condenser is connected with a liquid inlet of the liquid storage device; an outlet of the liquid storage device is connected with an inlet of the expansion valve, and an outlet of the expansion valve is connected with a liquid supply port of the low-pressure circulating barrel; a liquid outlet of the low-pressure circulating barrel is connected with an inlet of the ammonia pump, and an outlet of the ammonia pump is connected with an inlet of the evaporator; an outlet of the evaporator is connected with a flow return port of the low-pressure circulating barrel, and a gas return port of the low-pressure circulating barrel is connected with an air suction port of the compressor; and the control system is connected with the expansion valve and used for controlling an opening degree of the expansion valve so as to adjust a liquid level height in the liquid storage device. The refrigerating system can effectively reduce the probability of ammonia leakage accidents, and the safety and reliability of the refrigerating system are greatly improved.

Owner:华商国际工程有限公司

Air conditioner and control method of electronic expansion valves

ActiveCN111780370AAvoid running state discrepanciesImprove stabilityMechanical apparatusSpace heating and ventilation safety systemsMechanical engineeringElectronic expansion valve

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

VOC automatic processing system used for spray painting operation and optimized adjustment method of VOC processing

InactiveCN109603518AGuaranteed stabilityFast accuracyGas treatmentControlling ratio of multiple fluid flowsAutomatic processingEngineering

The invention discloses a VOC automatic processing system used for spray painting operation and an optimized adjustment method of VOC processing. The system includes an inlet, a front concentration sensor, a regulating valve, a first switching valve, an adsorbent bed agent catalytic bed, a second switching valve, a back concentration sensor, an outlet and a control module; the VOC automatic processing system automatically measures and records concentration values of VOCs of waste gases in the spray painting operation area and the front end and rear end of a system pipeline in real time, processes and calculates measured VOC concentration value data, and controls opening and closing of the valves in the system to realize control of a waste-gas processing cycle; and when the concentration ofthe VOCs in the waste gases in the spray painting operation area or the VOC automatic processing system changes, the system automatically adjusts and controls the valves to ensure reliability of operation of the VOC automatic processing system. The VOC automatic processing system disclosed in the invention can accurately monitor and control the concentration of the VOCs of the waste gases in realtime, the stability of operation of the VOC processing system is improved, and real-time capability and accuracy of monitoring and rapidity, accuracy and stability of control are realized.

Owner:HUDONG HEAVY MACHINERY

A method for controlling an electronic expansion valve of an automobile air-conditioning system

ActiveCN103245154BAvoid damage accidentsImprove safety and reliabilityRefrigeration safety arrangementStopped workFault indicator

The invention discloses a control method of an electronic expansion valve of an automobile air conditioner system. The method includes acquiring a result of the judgment of whether the electronic expansion valve is currently in the fault state or not according to the acquired current openness, actual overheat degree Tsh and preset overheat threshold Tsh_set of the electronic expansion valve while conducting overheating degree control and outputting a control signal to an execution mechanism according to the result of the judgment. By means of the control method, effective fault diagnosis can be conducted on the electronic expansion valve in real time. When the overheat degree is mistakenly controlled, the control signal is output to the execution mechanism to stop work of the system by controlling a compressor to shut down and / or remind operators to conduct fault overhauling by controlling a fault indicator lamp to be turned on, so that accidents of refrigeration system device damage caused by mistaken control can be completely avoided, and system running safety and reliability can be improved.

Owner:SHAOXING SANHUA NEW ENERGY AUTOMOTIVE COMPONENTS CO LTD

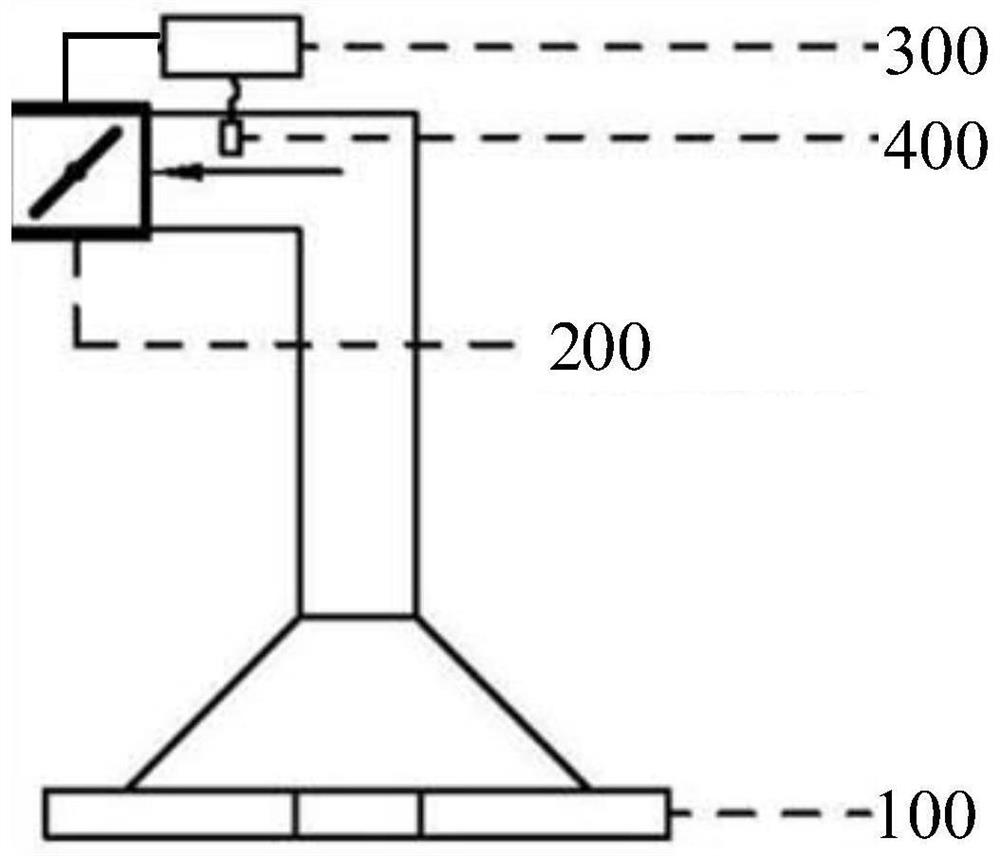

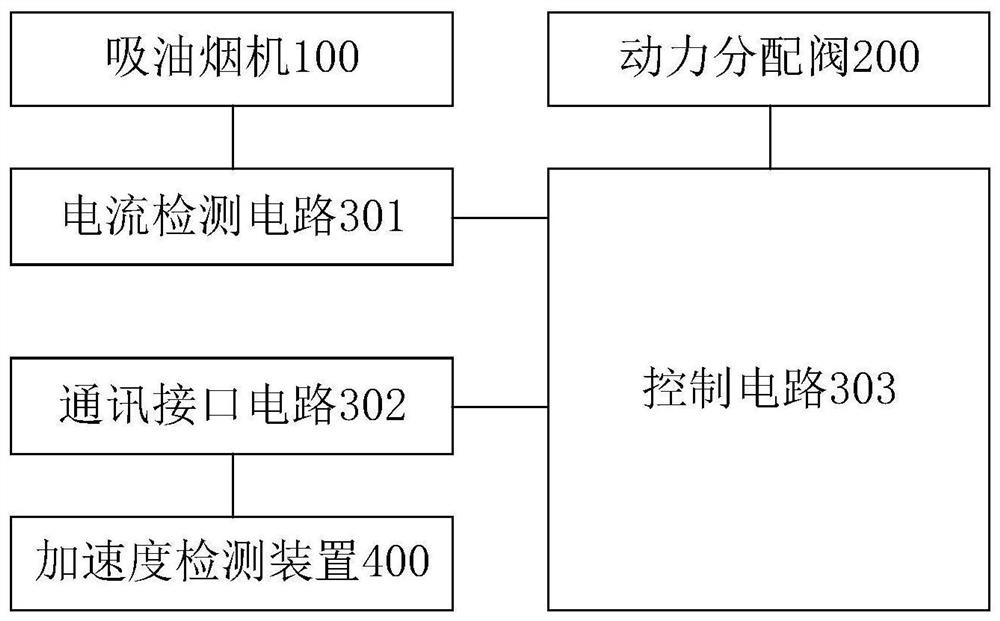

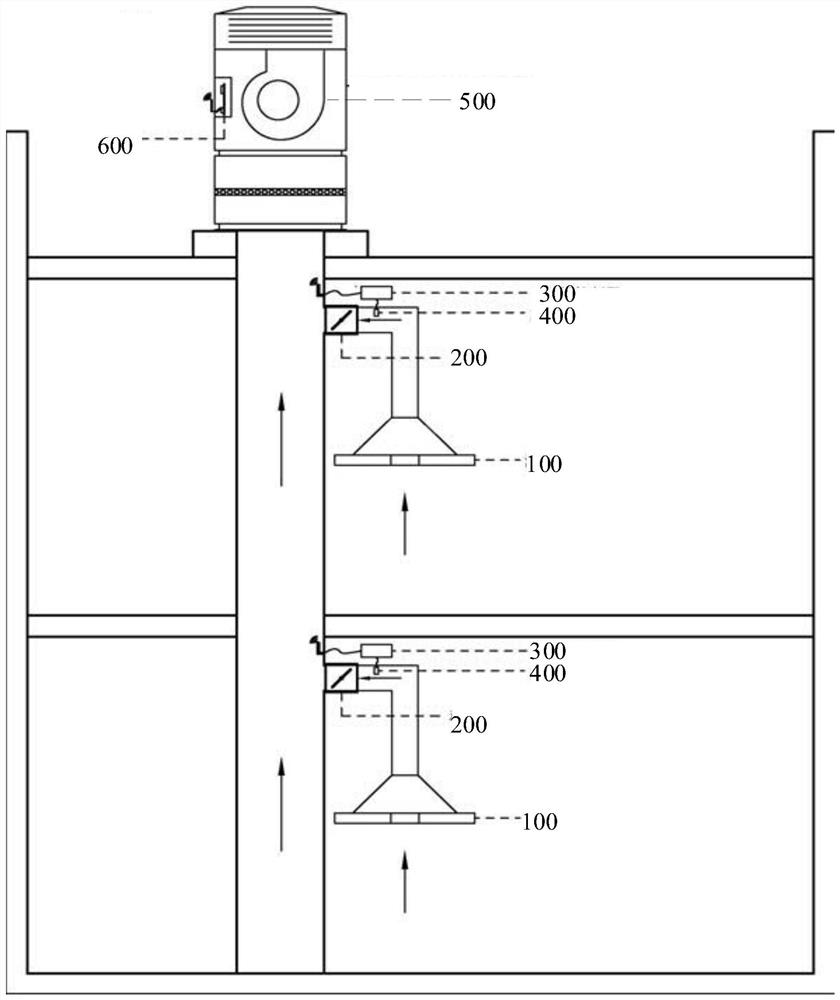

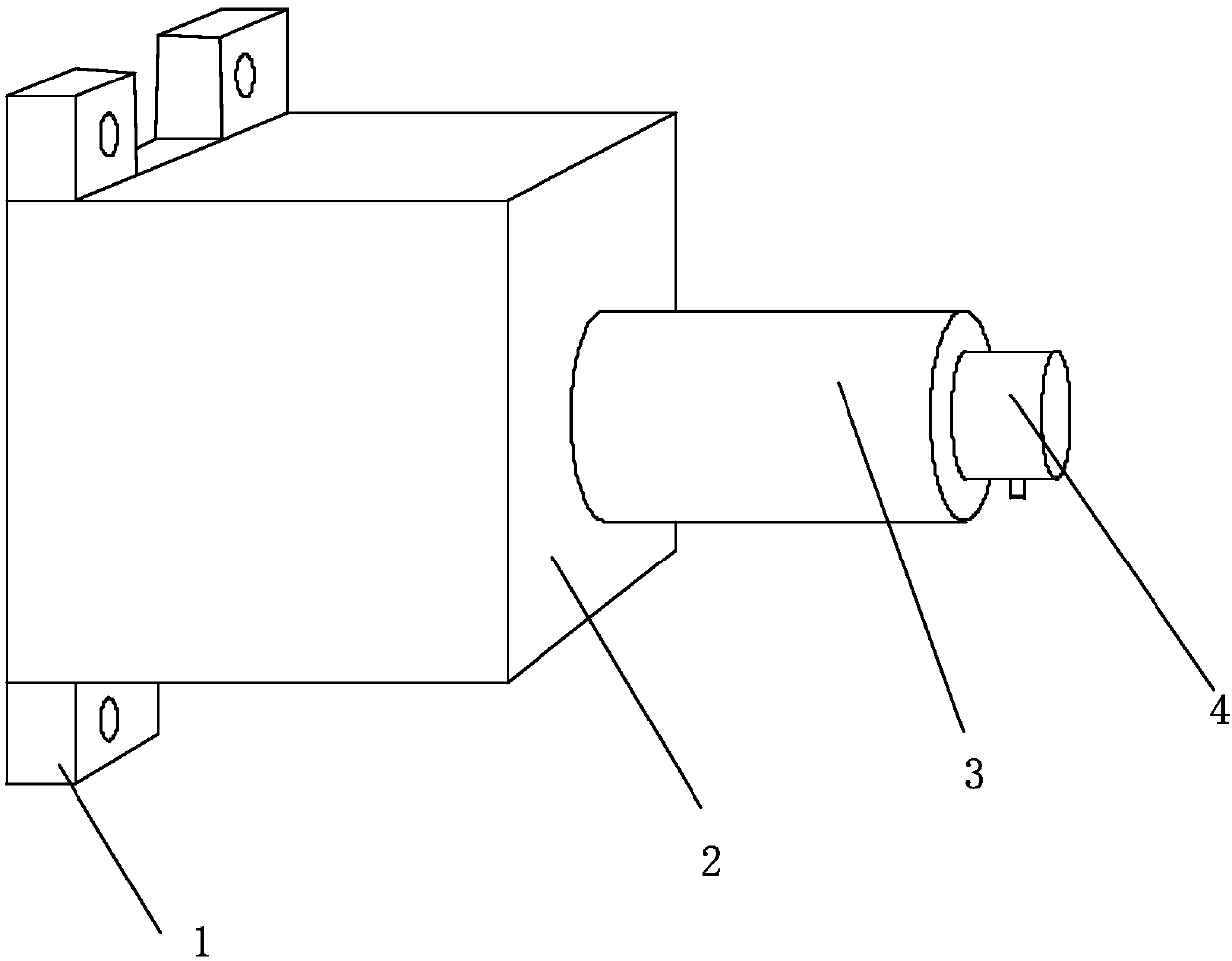

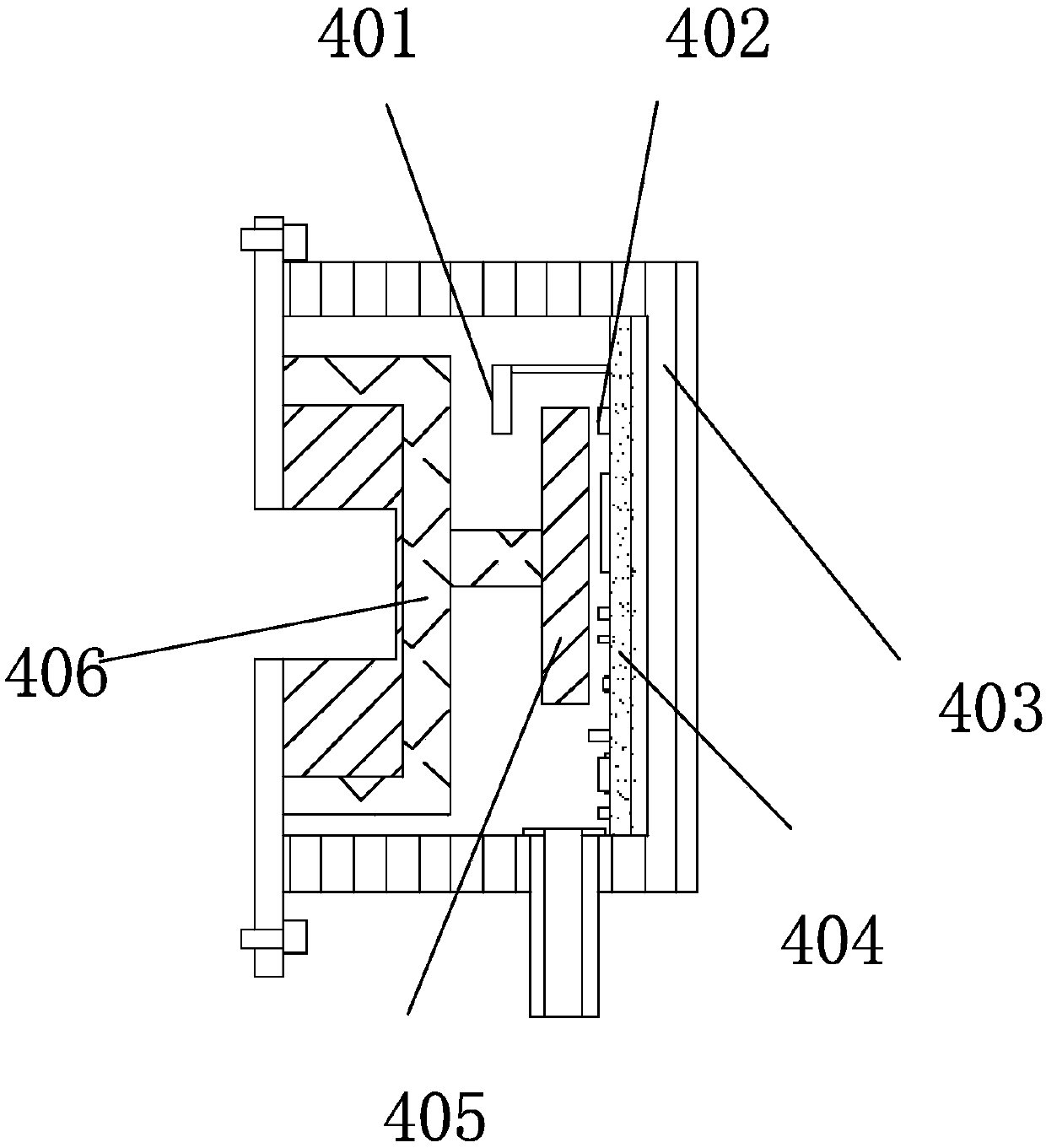

Central range hood, terminal part and air valve control method of range hood

PendingCN113883568ASolve the technical problem of misjudgment of switch stateAccurate opening controlDomestic stoves or rangesLighting and heating apparatusControl theoryMechanical engineering

The invention provides a central range hood, a terminal part and an air valve control method of the range hood, and relates to the technical field of oil smoke removal equipment. The terminal part of the central range hood comprises a range hood, a power distribution valve, an air valve controller and an acceleration detection device; the acceleration detection device detects the self dangling acceleration and sends the self dangling acceleration to the air valve controller; and the air valve controller detects the working current of the range hood and determines the working state of the range hood based on the working current and the dangling acceleration so as to control the opening degree of the power distribution valve. Compared with a terminal part in the prior art, the terminal part has the advantages that the acceleration detection device is additionally arranged in a pipeline, the air valve controller can accurately judge the working state of the range hood by combining the dangling acceleration of the acceleration detection device and the working current of the range hood, then the opening degree of the power distribution valve can be accurately controlled, the technical problem of misjudgment of the on-off state of the range hood is effectively solved, and the kitchen smoke exhaust effect of a user is improved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

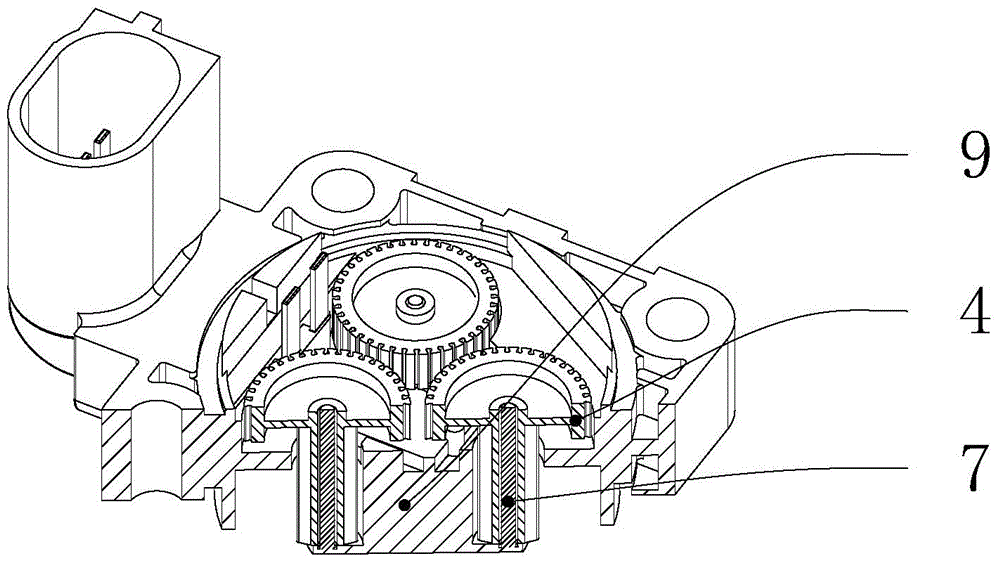

Mechanism for controlling position of variable valve

PendingCN109723882AAccurate opening controlOperating means/releasing devices for valvesInterference fitElectric machinery

The invention discloses a mechanism for controlling a position of a variable valve. The mechanism comprises fixed lugs, a stand, a servo motor, an encoder, a second-grade gear shaft, a first-grade large gear, a first-grade small gear, a second-grade large gear, a bearing and an output shaft; the stand is fixed on the left side of the servo motor, and is connected by adopting a bolt; the encoder ismounted on the right side of the servo motor, and is connected by adopting a bolt; the output shaft is fixed in the stand, and is in clearance fit; four fixed lugs are provided and mounted on the upper and lower sides of the stand, and are fixed by welding; and the first-grade small gear is mounted on the left side of the servo motor, and is in interference fit. The encoder is provided with a photoelectric receiver, a photoelectric emitter, a shell, a circuit board, a coded disc and a connecting shaft; and through the improved prior art, the openness of the valve is detected by adopting the encoder, so that the openness of the valve can be precisely controlled, the magnitude of water currents is not needed to judge if the valve is opened large or small, and the openness range is more precise.

Owner:天津市北方阀门控制设备有限公司

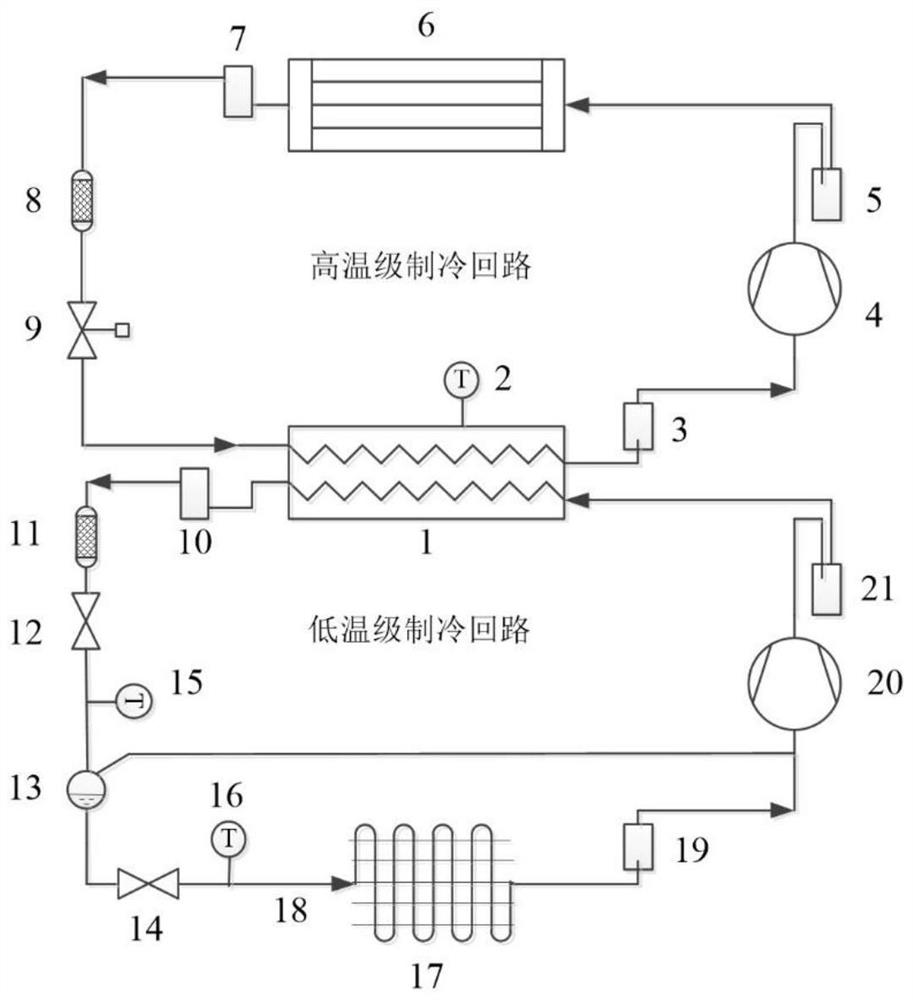

System for preparing solid-gas flow state dry ice based on CO2 cascade refrigeration twice throttling

PendingCN111912130AAccurate opening controlLow costCarbon compoundsEvaporators/condensersTemperature controlDry ice

The invention discloses a system for preparing the solid-gas flow state dry ice based on the CO2 cascade refrigeration twice throttling. The system comprises a high-temperature-stage refrigeration loop, a low-temperature-stage refrigeration loop and a CO2 twice throttling structure; and according to a closed preparation loop disclosed by the invention, solid-gas flow state dry ice is prepared froma small amount of initial CO2 raw material gas, so that the cost is reduced, the production continuity is ensured, the fluidity of a prepared solid-gas flow state dry ice product is better than thatof a dry ice solid, the temperature uniformity of a cooled object is improved, and a cascade refrigeration and twice throttling system with accurate temperature control improves the stability of the solid-gas flow state dry ice product preparation. The system for preparing the solid-gas flow state dry ice based on the CO2 cascade refrigeration twice throttling has the advantages of stability, reliability, high refrigerating capacity, low operation cost, environmental friendliness and the like.

Owner:XI AN JIAOTONG UNIV

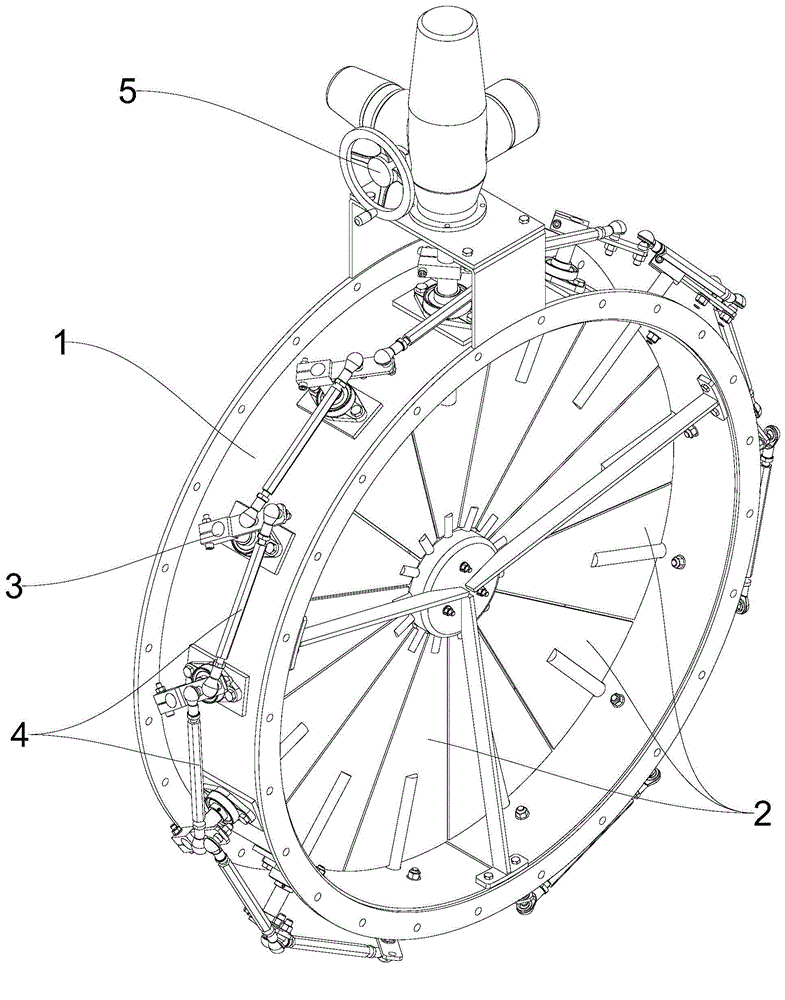

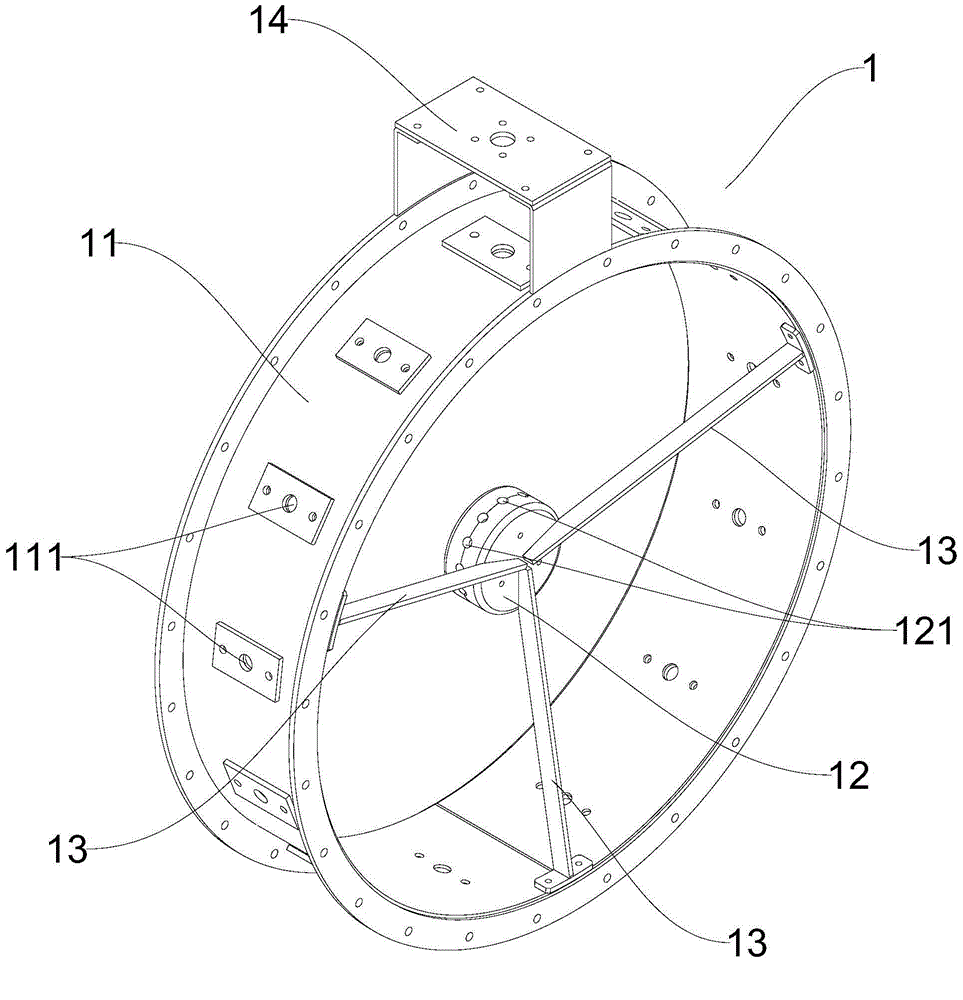

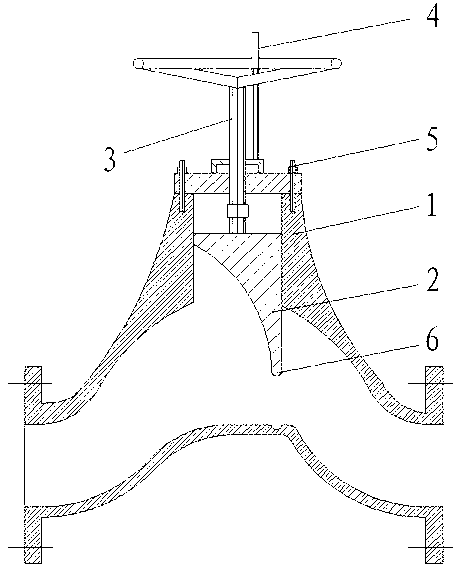

Multi-blade type round valve

InactiveCN106195289AOpen resistance is smallExtended service lifeLift valveMechanical engineeringEngineering

The invention discloses a multi-blade type round valve. The multi-blade type round valve comprises a shell, blade assemblies and a hand wheel assembly. The multi-blade type round valve further comprises rotation arms and connection arms. The shell comprises a connecting cylinder, a center connecting block, three fixing rods and a support. The center connecting block is arranged in the center of the connecting cylinder and fixedly connected with the connecting cylinder through the fixing rods. The support is fixedly connected with the connecting cylinder. First connecting holes are evenly formed in the connecting cylinder, and second connecting holes are evenly formed in the center connecting block. Each blade assembly comprises a sector blade, a first rotating shaft and a second rotating shaft. The multi-blade type round valve has the beneficial effects that the multiple sector blades are arranged, the opening resistance is small, the service life of the blades is long, and labor is saved during operation; and the opening degree of the valve can be better accurately controlled, and using is convenient.

Owner:袁文霞

Low-resistance valve capable of precisely controlling flow rate

InactiveCN103075528AEasy to openPrecise controlSlide valveValve housingsMicrometerBiomedical engineering

The invention discloses a low-resistance valve capable of precisely controlling a flow rate, which belongs to the technical field of fluid conveying. A valve rod 3 is combined with a helical micrometer structure 4, and by utilizing the principle of a helical micrometer instrument, the openness of the valve can be precisely displayed and controlled; fluid of a valve body 1 flows along a C-shaped runner, the fluid is distributed in a linear way, and the runner is smoother; the upper part of a valve clack 2 is in a rectangular shape, and the lower part of the valve clack 2 is in an arc shape; and the valve clack 2 and the valve body 1 are sealed by a semispherical sealing groove 6. The low-resistance valve capable of precisely controlling the flow rate can overcome the defects of the prior art, not only can precisely control the flow rate, but also has the advantages of convenience in opening, precision in controlling, no leakage and small pressure reduction.

Owner:BEIJING UNIV OF CHEM TECH

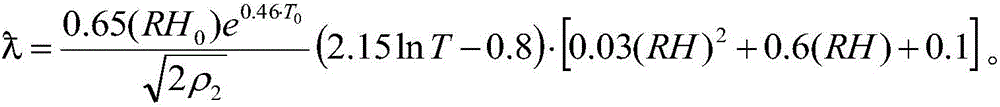

Gas purification device and purification method for degasser

ActiveCN106362540AFully contactedIncrease pipe lengthCombination devicesAdaptive controlDegasserPurification methods

The invention discloses a gas purification device and a purification method for a degasser. The gas purification device comprises a water removal tank, a dirt removal tank and a cleaning tank; the water removal tank comprises a gas inlet pipeline which goes deep into the bottom of a tank body and is used for removing moisture in gas; the dirt removal tank communicates with a gas outlet of the water removal tank, comprises a cleaner arranged inside, and is used for removing impurities in the gas; the cleaning tank communicates with a gas outlet of the dirt removal tank, comprises a cleaning sheet inside the cleaning tank, and is used for further removing the moisture in the dirt removal tank. According to the gas purification device, the impurities in the gas are removed through the dirt removal tank, multi-stage purification parts are connected with one another in a penetrating manner, and thus the purification effect is guaranteed. The invention also provides the gas purification method for the degasser. According to the gas purification method, an evaluation factor is calculated and is input into a fuzzy controller, so that the opening degree of a throttle valve is accurately controlled, and the gas purification effect is guaranteed.

Owner:CHINA FRANCE BOHAI GEOSERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com