Clear water controlling device for high-energy mixer and high-energy mixer

A technology of control device and mixer, which is applied in the directions of mixed operation control device, mixed operation control, fluid state mixer, etc. The structure is simple and flexible, meeting the requirements of use, and the effect of good use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

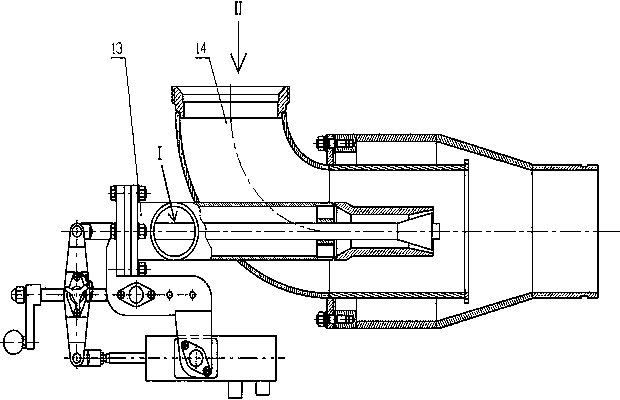

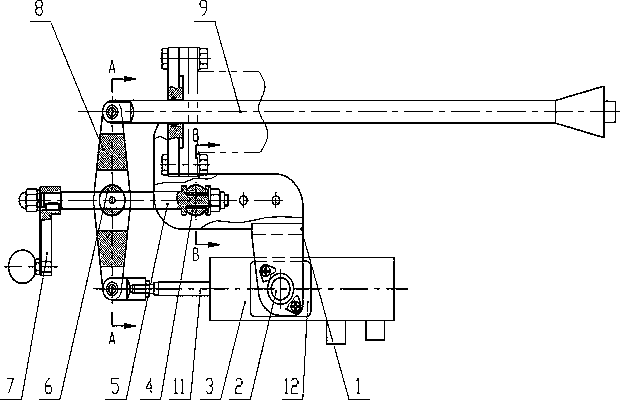

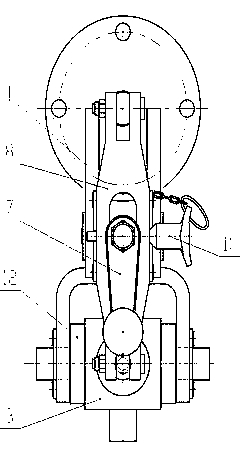

[0023] Such as Figure 1-Figure 5 As shown, a clean water control device for a high-energy mixer includes a mounting base 1, a shaft 2, a linear actuator 3, a hinge shaft 4, a lead screw 5, a threaded shaft 6, a manual crank 7, a rocker arm 8, a valve stem 9, The pin shaft 10 and the fixing seat 12 are characterized in that: the upper part of the mounting seat 1 is equipped with a flange, and is fixedly connected with the end flange of the clear water pipe 13 of the high-energy mixer, and the lower end of the mounting seat 1 and the There are shaft holes in the middle, and the hinge shaft 4 is inserted into the middle shaft hole of the mounting seat 1. The linear actuator 3 is equipped with a fixing seat 12, and shafts 2 are arranged on both sides of the fixing seat 12. , the shaft 2 is inserted into the shaft hole at the lower end of the mounting base 1 .

[0024] The middle part and both ends of the rocker arm 8 are provided with shaft holes, the upper end of the rocker arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com