Patents

Literature

551results about How to "Guaranteed Density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

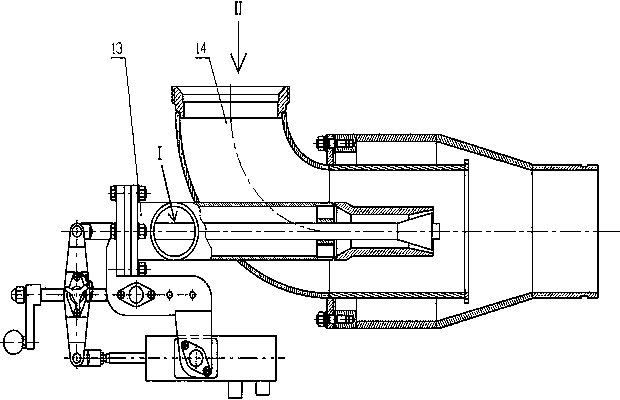

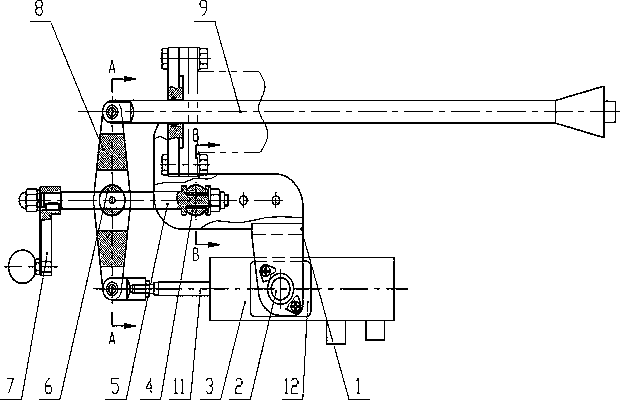

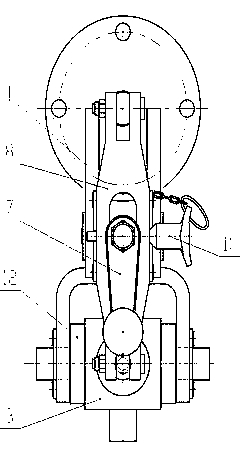

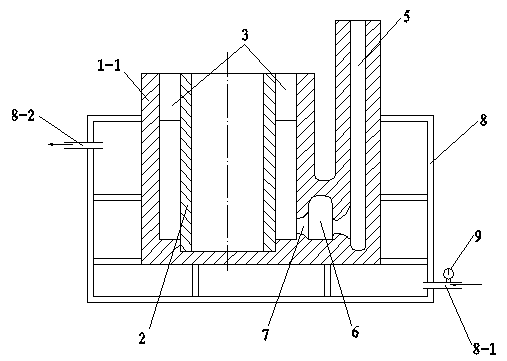

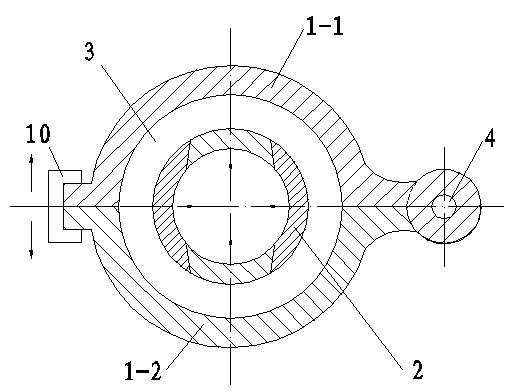

Clear water controlling device for high-energy mixer and high-energy mixer

ActiveCN102729335BControl openingAccurate opening controlFlow mixersTransportation and packagingHigh energyEngineering

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

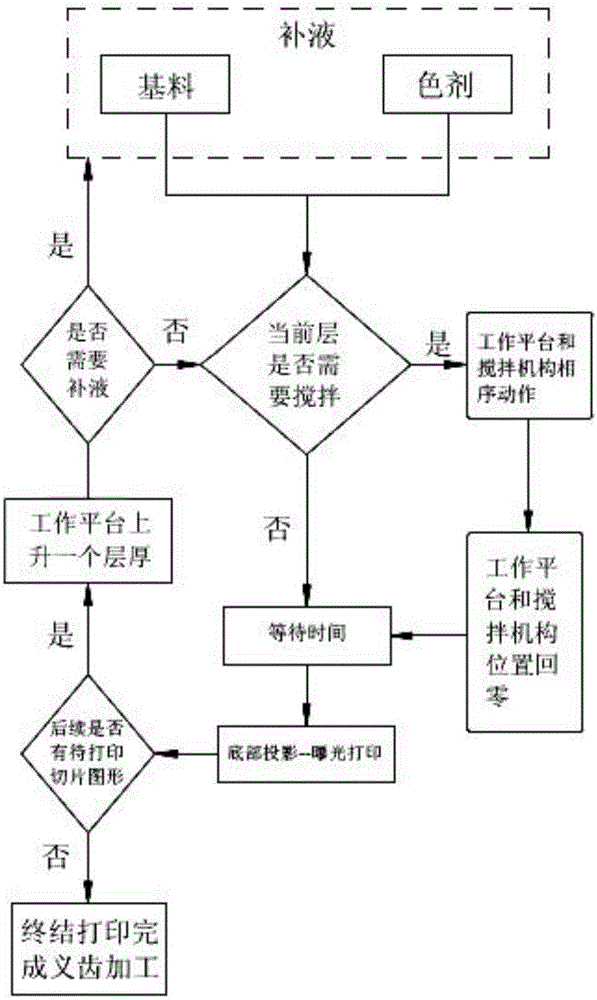

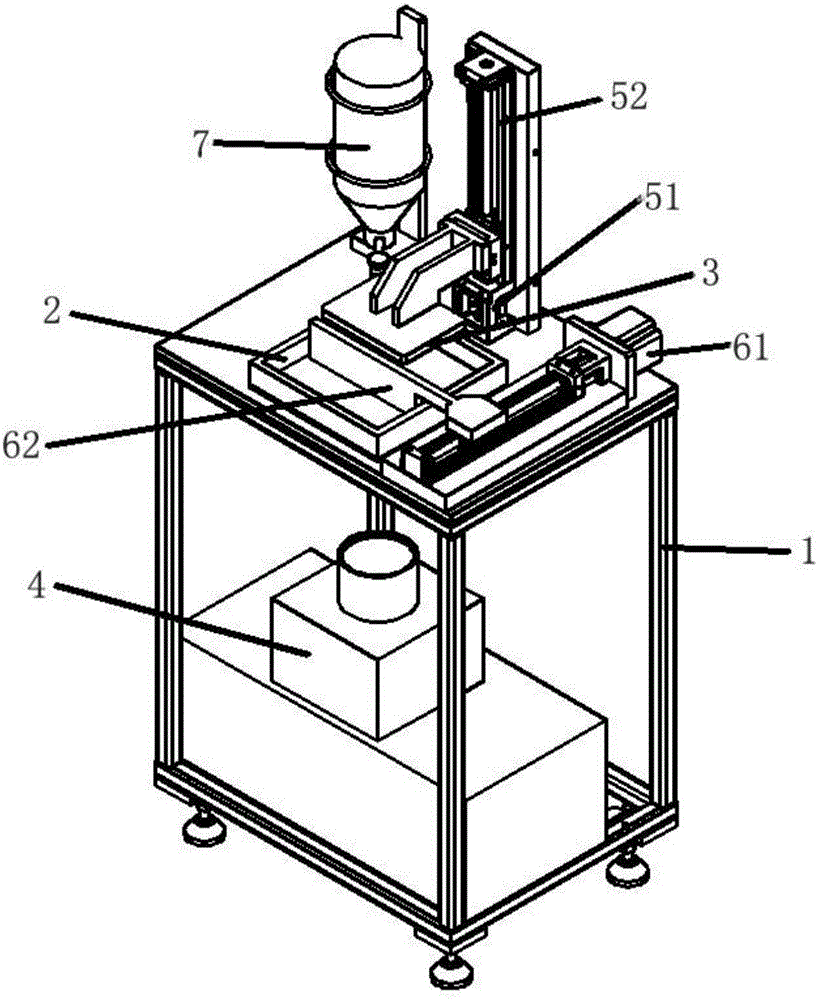

Method and device for ceramic denture 3D printing suitable for light curing molding

ActiveCN106217882AGuaranteed accuracyGuaranteed to mix evenlyAdditive manufacturing apparatusCeramic shaping apparatusData modelLight source

The invention relates to a method and device for ceramic denture 3D printing suitable for light curing molding and belongs to the technical field of tooth making. According to the method, through scanned tooth data and data processing, data of each layer of image after a data model to be printed is sliced are obtained and transmitted to a control system, a liquid supplementing action is controlled through the control system so that the liquid level of a base material can be always kept at the preset height, the base material is configured by photosensitive resin and ceramic powder according to the ratio, and the control system controls completion of stirring of supplemented liquid after liquid supplementing; and a bottom projection manner is adopted for printing, slice images of each layer of image are projected successively, light source exposure is conducted, and curing is completed layer by layer. The method and device have the beneficial effects that the making process is simple, the making efficiency is high, the consumption of materials is low, the making precision is high, and the match is good.

Owner:SHANGHAI UNION TECH

Comprehensive restoration method for salt-alkali degraded marsh wetland in plain area

InactiveCN102845156AEasy maintenanceGood consolidationClimate change adaptationHorticultureMarshRestoration method

The invention relates to a comprehensive restoration method for a salt-alkali degraded marsh wetland in a plain area, in particular to a restoration method for the salt-alkali degraded marsh wetland, and solves the problem that a satisfactory effect cannot be achieved as a land leveling technology, a hydrologic control technology or a wetland plant cover restoration technology is singly used in the conventional restoration process for the salt-alkali degraded marsh wetland in the plain area. The comprehensive restoration method comprises the steps as follows: 1, leveling land; 2, hydrologically controlling the salt-alkali degraded marsh wetland to be restored in the plain area; and 3, carrying out plant cover technology treatment on the salt-alkali degraded marsh wetland in the plain area. The comprehensive restoration method can be applied to the field of a restoration project for the salt-alkali degraded marsh wetland in the plain area.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

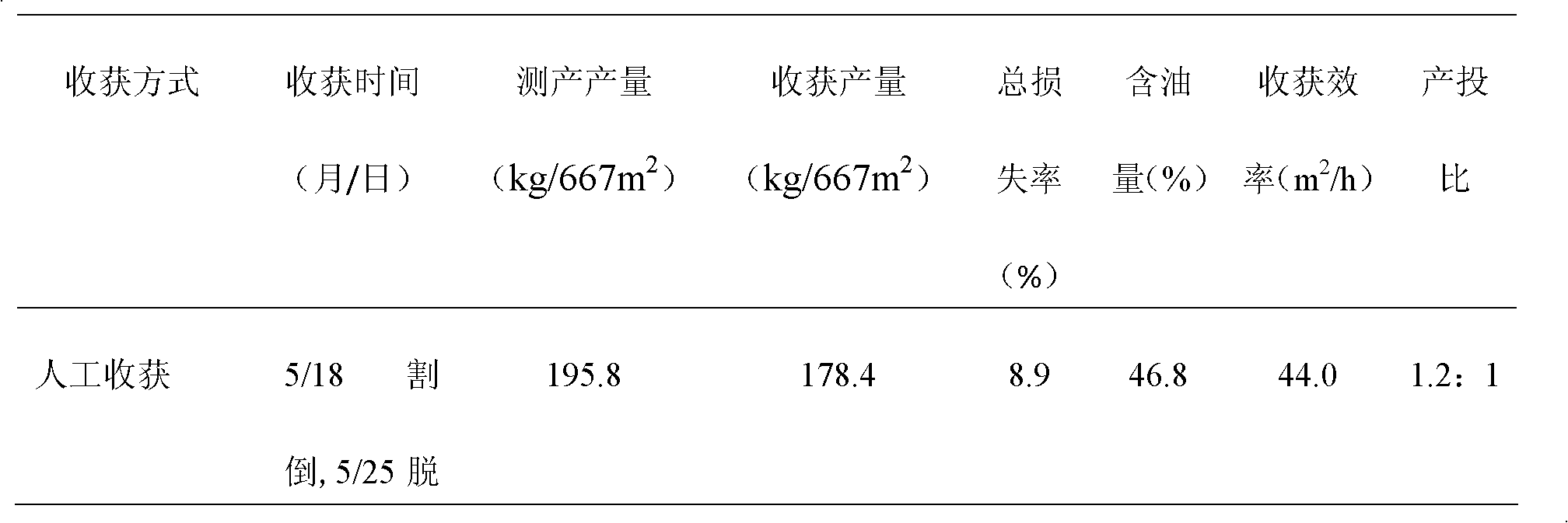

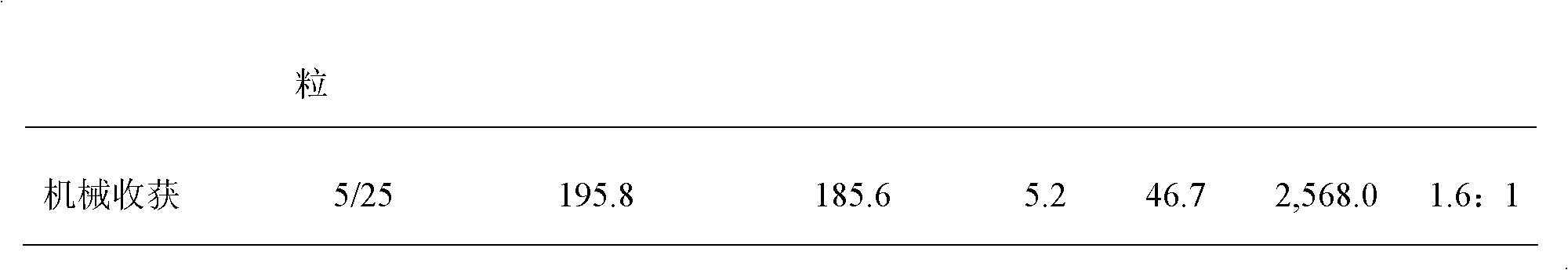

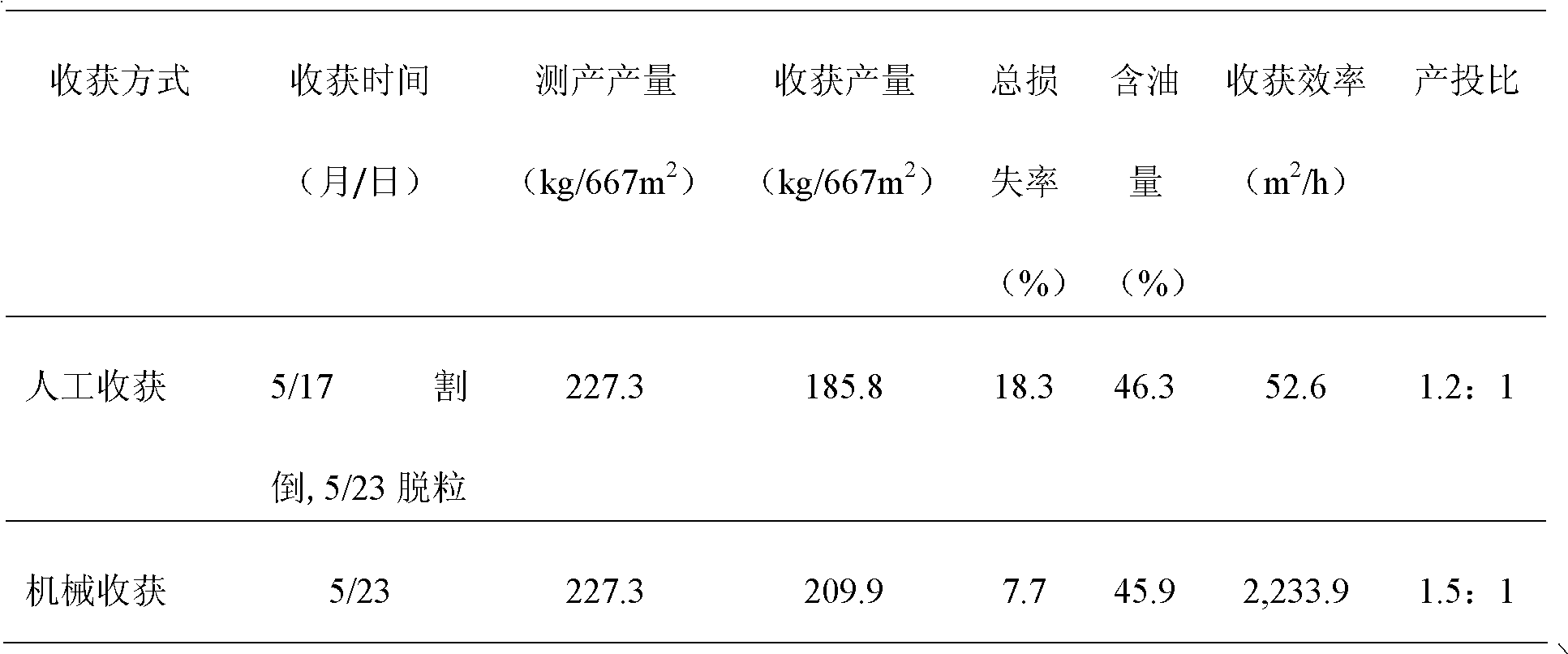

Method for mechanically harvesting winter rape efficiently with low power consumption

InactiveCN102124898AIncrease harvest yieldAvoid pollutionSeed and root treatmentCrop conditionersDiseaseLoss rate

The invention discloses a method for mechanically harvesting winter rape efficiently with low power consumption. The method comprises the following steps of: A, constructing a rape group suitable for mechanical harvest: selecting the variety suitable for mechanical production, performing mechanical precise-quantity direct seeding when the soil water content is 30 to 40 percent, and constructing an ideal group and a plant type by fertilizer and water application and disease inset pest and weed control; B, adjusting a mature period: spraying a ripener two to three days before the harvest of rape seed ripening stage in the regions of contradictory seasons; C, harvesting at right time: observing and measuring the morphological physiological index of the plant before the harvest of the rape, wherein more than 95 percent of siliques, namely yellow loquat fruits in the cropland are suitable for mechanical harvest; D, mechanically harvesting and measuring loss rate: harvesting by a special rape harvesting mechanism in a combining way in the period suitable for harvest; E, smashing and returning rape straw to the cropland: flooding the straw in water immediately after the harvest of rape, decaying and returning to the cropland. The method is easy and convenient to operate, improves a one-time efficient branch height, reduces the branch number, reduces the thickness of the pod layer, solves the problems of high harvest loss rate, and improves the yield.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

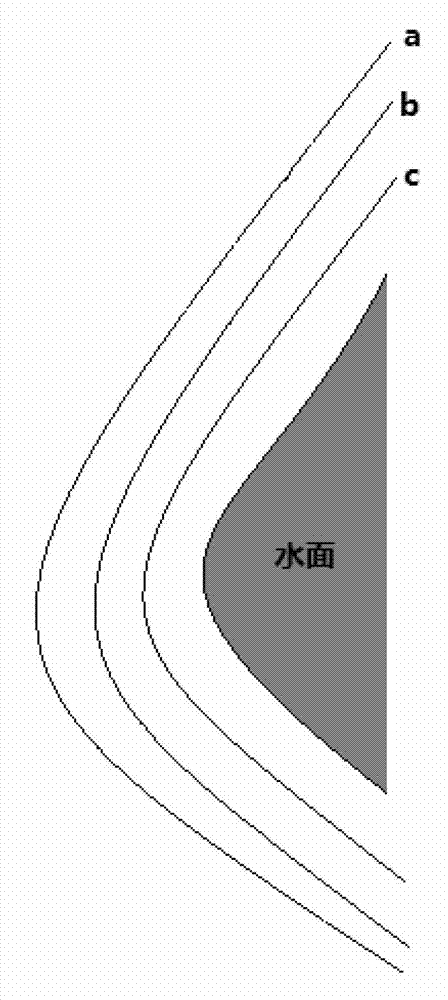

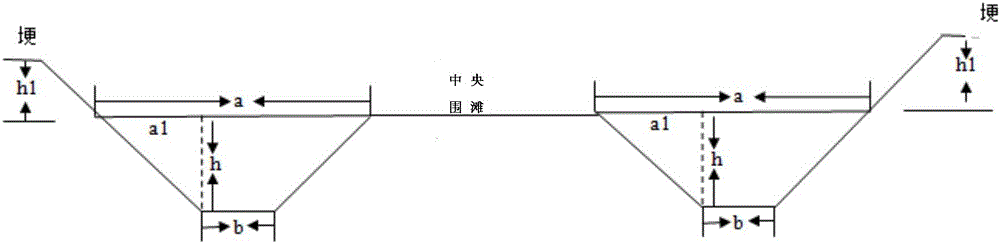

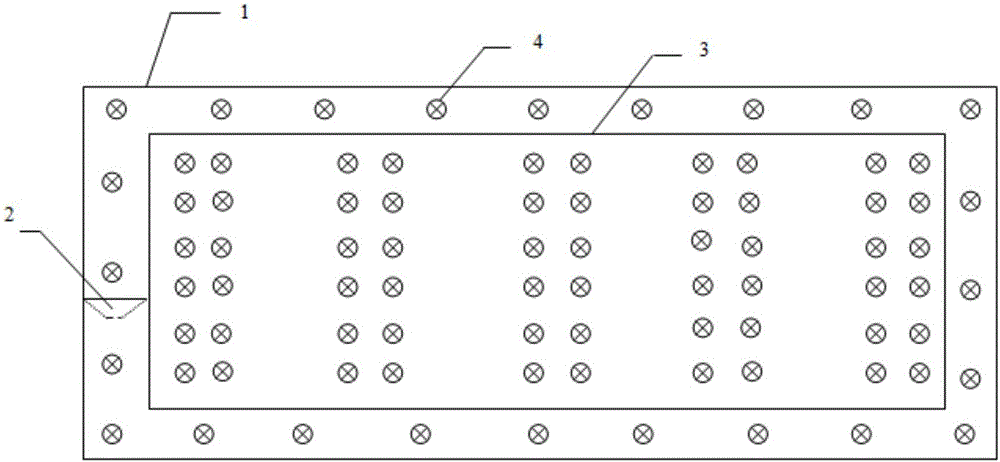

Breeding method and pond for improving commercial specification and yield of procambarus clarkii in pond

ActiveCN105994027AEasy plantingIncrease coverageClimate change adaptationPisciculture and aquariaShrimpProcambarus clarkii

The invention provides a breeding method and a pond for improving the commercial specification and the yield of procambarus clarkii in the pond. The breeding method comprises the following steps: drying the pond under the sun; putting young procambarus clarkii into the pond for the first time; performing catch rotation on commercial procambarus clarkii for the first time; putting young procambarus clarkii into the pond for the second time; performing catch rotation on commercial procambarus clarkii for the second time; and thoroughly draining water of the pond, and catching all commercial procambarus clarkii. The pond comprises a circular groove which is digged along the periphery of the pond, wherein the circular groove has an upper bottom width of 6 to 10 meters, a lower bottom width of 1 to 5 meters, a depth of 0.8 to 1 meter, a ridge height of 0.8 to 1 meter and a slope ratio of 1: 3; the area of the circular groove accounts for 20 to 30% of the total area of the pond; the a region, located at the inner side of the circular groove, of the pond is piled with a central enclosed beach; and the distance between the water level of the pond and the central enclosed beach is in a range of 10 to 70 cm. The invention has the following beneficial technical effects: by adopting the method provided by the invention, 200 to 250 kg of commercial procambarus clarkii can be harvested in two seasons, wherein the proportion of the commercial procambarus clarkii with a specification of 40 g or more reaches 60 to 70%.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

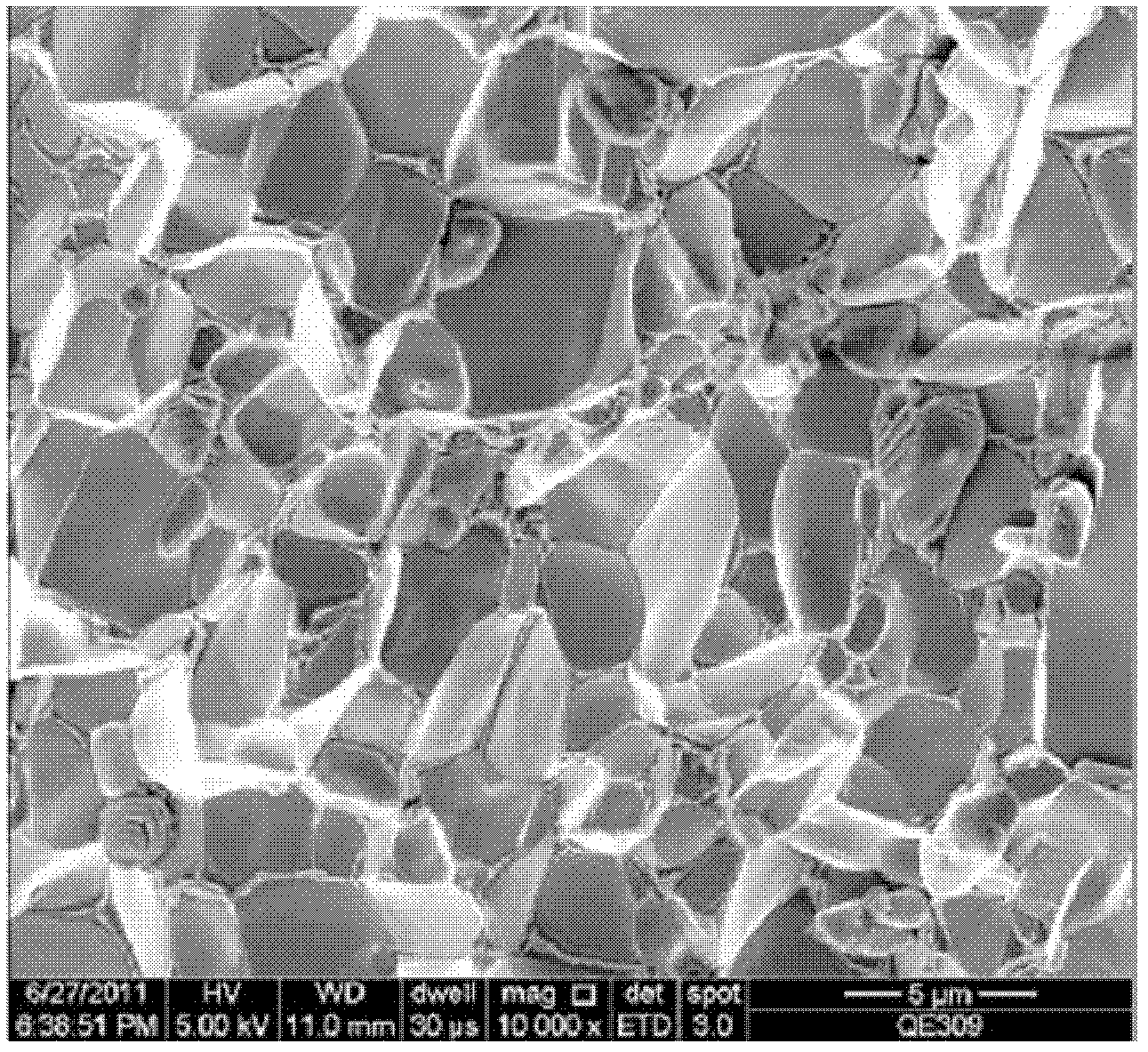

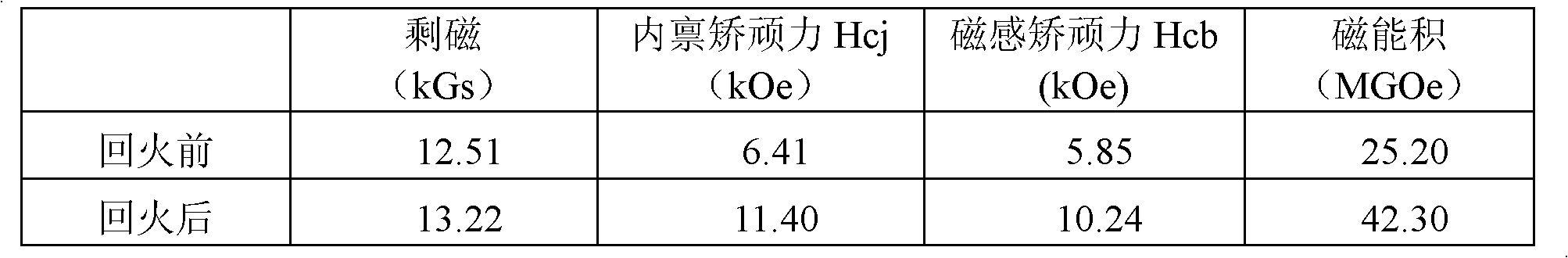

Preparation method for fine grain anisotropy densified neodymium iron boron permanent magnet

ActiveCN103123843ASmall sizeNo grain growth occurredPermanent magnetsInductances/transformers/magnets manufactureHydrogenGranularity

The invention relates to a preparation method for a fine grain anisotropy densified neodymium iron boron permanent magnet. The preparation method comprises the steps: traditional firing neodymium iron boron technology is adopted; a magnetic blank with small grains and loose texture is obtained by means of low-temperature presintering after rapid hardening, hydrogen breaking, air-stream milling and orientation forming; then the blank is hot-pressed and densified; and the anisotropy neodymium iron boron magnet with the small grains and densified is obtained after tempering is performed to the blank. According to the method, the grains in sintering process of magnet can be prevented from being larger effectively, the prepared magnet has a fine grain structure and is high in densification and the grain size of the fine grain anisotropy densified neodymium iron boron permanent magnet is close to air-stream milling powder granularity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

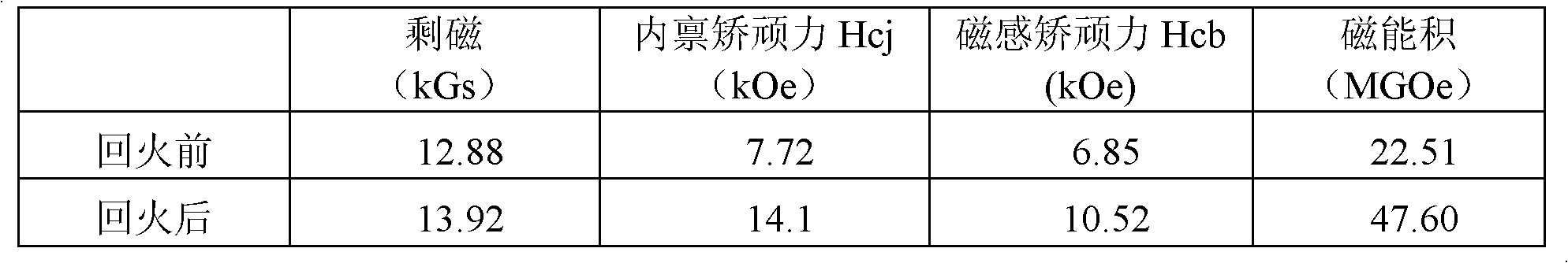

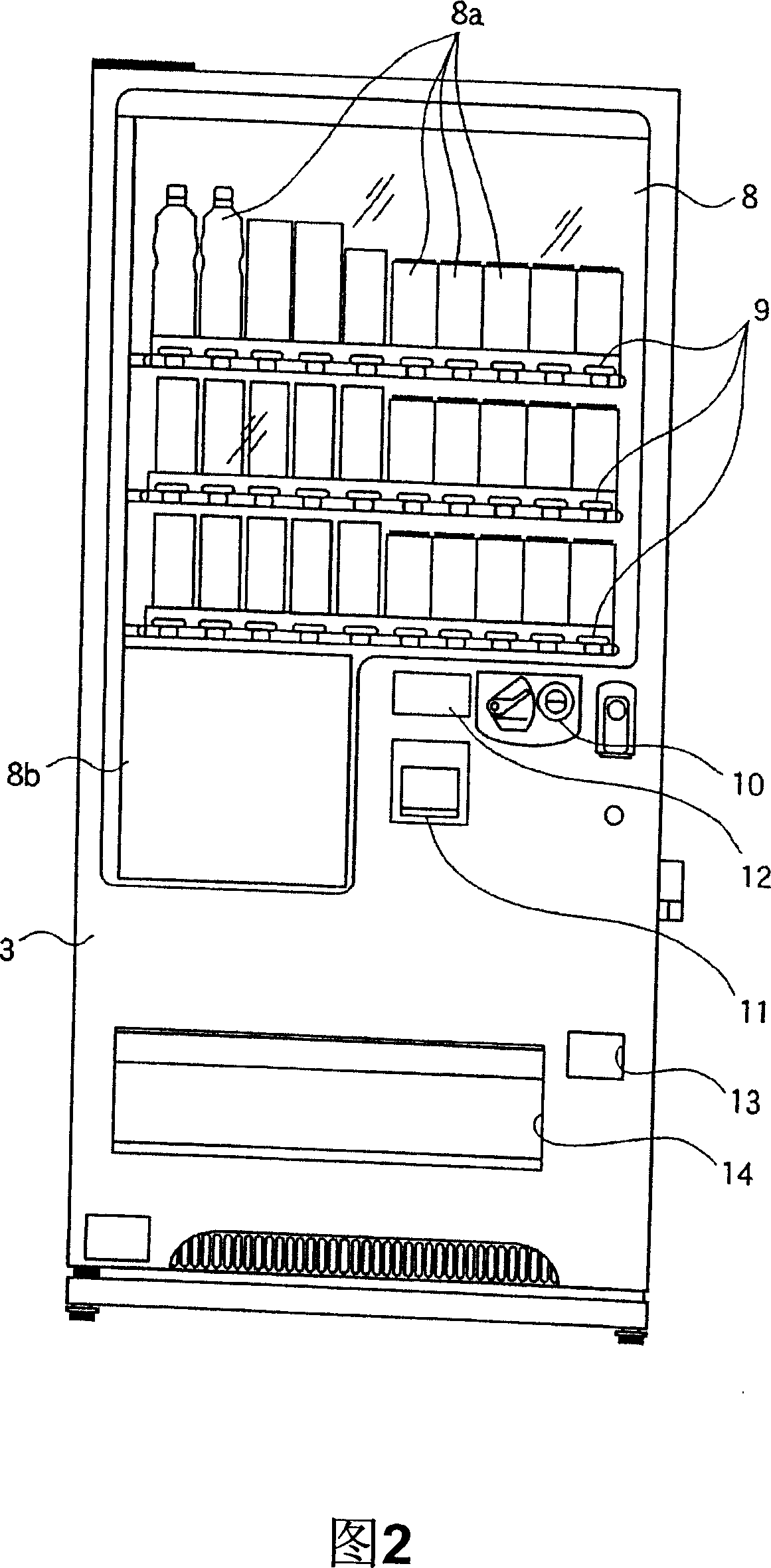

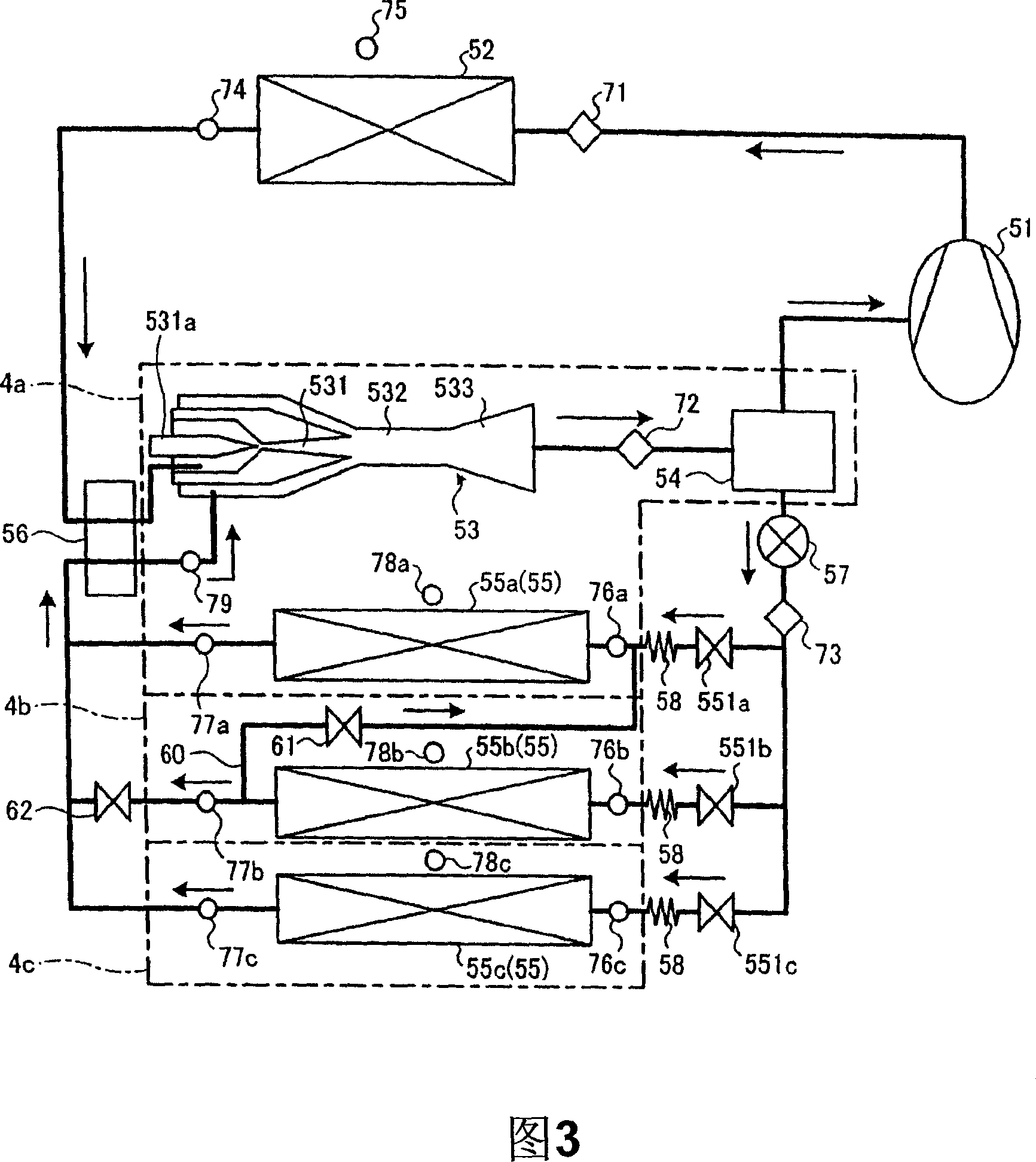

Cold-producing medium loop

The invention discloses a cooling agent circuit, which is characterized by the following: comprising compressor of compression refrigerating agent, gas cooler, evaporator to evaporate cooling agent, ejector and inner heat exchanger; depressing high pressure cooling agent from gas cooler; absorbing in the low pressure cooling agent from the evaporator; mixing; increasing the pressure for mixed cooling agent; discharging with the ejector; separating the mixed cooling agent to gas phase cooling agent and liquid phase cooling agent; turning the gas phase back to the compressor; providing the liquid phase cooling agent to the gas-liquid separator of the evaporator; paralleling the multiple evaporator; connecting multiple strips of cooling agent cycling passage through switch valve; proceeding heat exchange for the high pressure cooling agent and the low pressure cooling agent with the inner heat exchanger. This invention can prevent increasing of high pressure side, which can make the cycling state to reach optimum.

Owner:FUJI ELECTRIC RETAIL SYST CO LTD

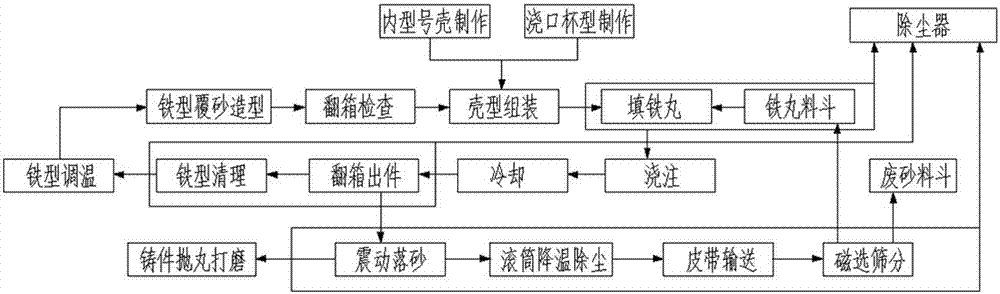

Novel casting technique of semitrailer brake drum

InactiveCN103286279AGuaranteed not to deformBack-off guaranteeCasting plantsFoundry mouldsBrakeDust control

The invention relates to a novel casting technique of a semitrailer brake drum. The novel casting technique of the semitrailer brake drum comprises the following steps of: manufacturing an inner mold shell and a pouring cup; regulating the temperature of an iron mold, covering with sands, and modeling; checking by turning over a mold; assembling a shell mold; filling iron shots; pouring and cooling; turning over the mold, discharging elements, assembling the elements, and recovering; carrying out magnetic separation, and screening; dedusting and cleaning. No deformation of the brake drum is ensured fully; the steel shots are filled in an internal mold sand shell; poured steel liquids generate pressure inward; firstly, because of the 'arch bridge principle', the internal mold sand shell has great support force; and then the steel shots also can block the pressure by steel liquids, and the internal mold sand shell cannot be cracked or deformed absolutely. Before cast elements are condensed and contracted, the internal mold sand shell is scattered, the filled steel shots are at the scattered state, the deformability of the cast elements in contraction is ensured fully, so that free contraction instead of hindered contraction is formed; a bottom-pouring-type pouring mode is adopted, air is discharged smoothly; the cracking possibility at the crossed part is reduced; air holes of the cast elements caused by dampness of a sand mold are prevented; the novel casting technique of the semitrailer brake drum is an environment-friendly casting technique.

Owner:FUDI PRECISION CASTING

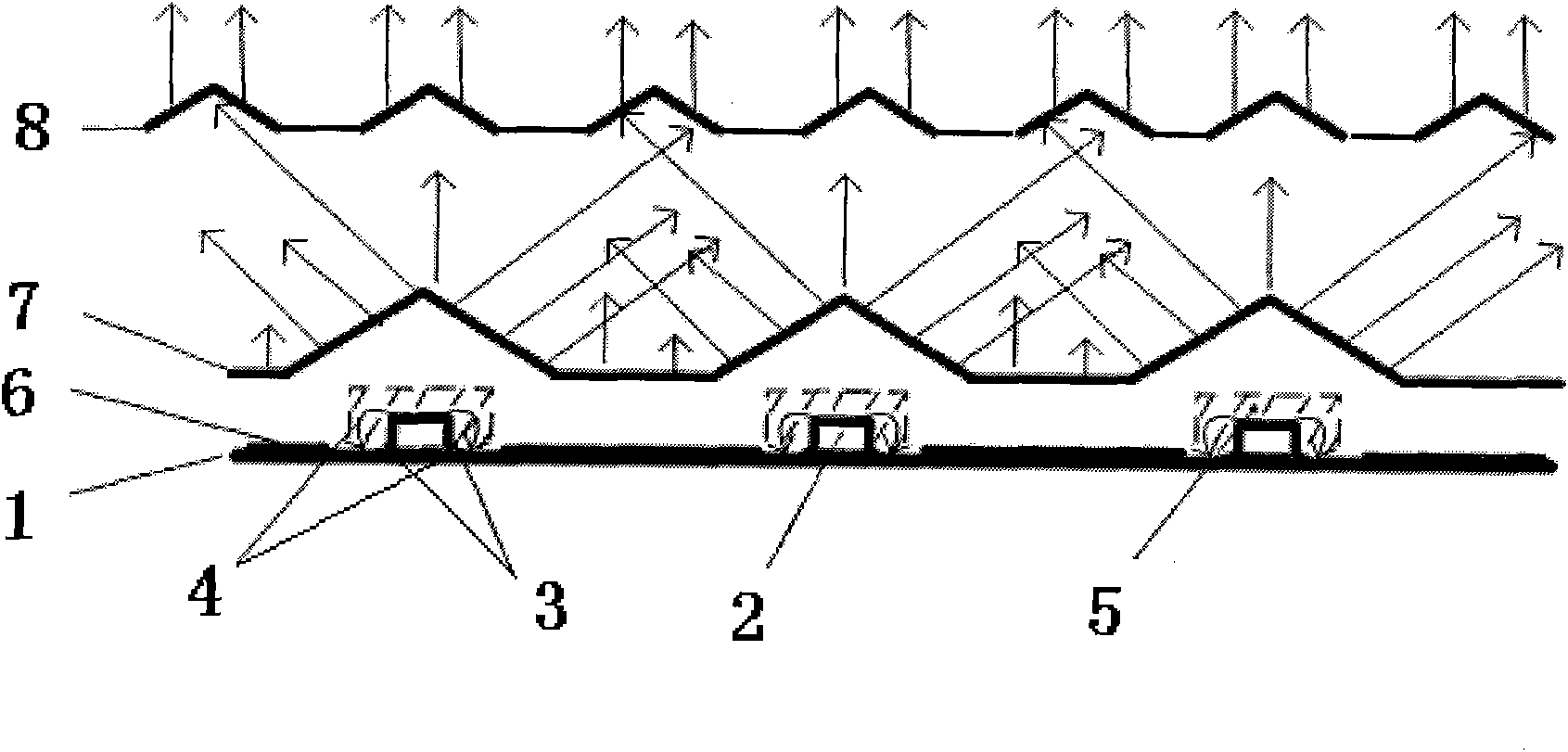

LED backlight integration and encapsulation structure and encapsulation method

InactiveCN101783340ASolve the cooling problemSolve the costSolid-state devicesSemiconductor devicesEpoxyHeat conducting

The invention relates to an LED backlight integrating encapsulation structure and encapsulation method. The encapsulation structure comprises a substrate (1) and a reflecting layer (6) arranged on the substrate (1), wherein a light-guiding diffusion plate (7) and a prism plate (8) are arranged on the substrate (1) successively provided with the reflecting layer (6) from bottom to up. The encapsulation structure is characterized in that LED blue dies are arranged on the substrate (1) in an array mode. The encapsulation method comprises the following steps: embedding the LED blue dies, coating solder paste on high conductivity substrate material, bonding dies through reflow soldering, fixing the LED blue dies on the substrate, and adopting ultrasonic wire bonding technology to connect the LED and a circuit board. The LED blue dies are covered with yellow fluorescent powder and epoxy resin and the reflecting layer is plated on the heat-conducting substrate so that the luminous efficiency and heat dissipation effect of the LED are increased and the rays are parallel and uniform. The encapsulation method is used to reduce power consumption, increase luminous efficiency, prolong the life of the device and save energy. The volume of the encapsulation structure is reduced and the backplane becomes lighter and thinner.

Owner:SHAANXI UNIV OF SCI & TECH

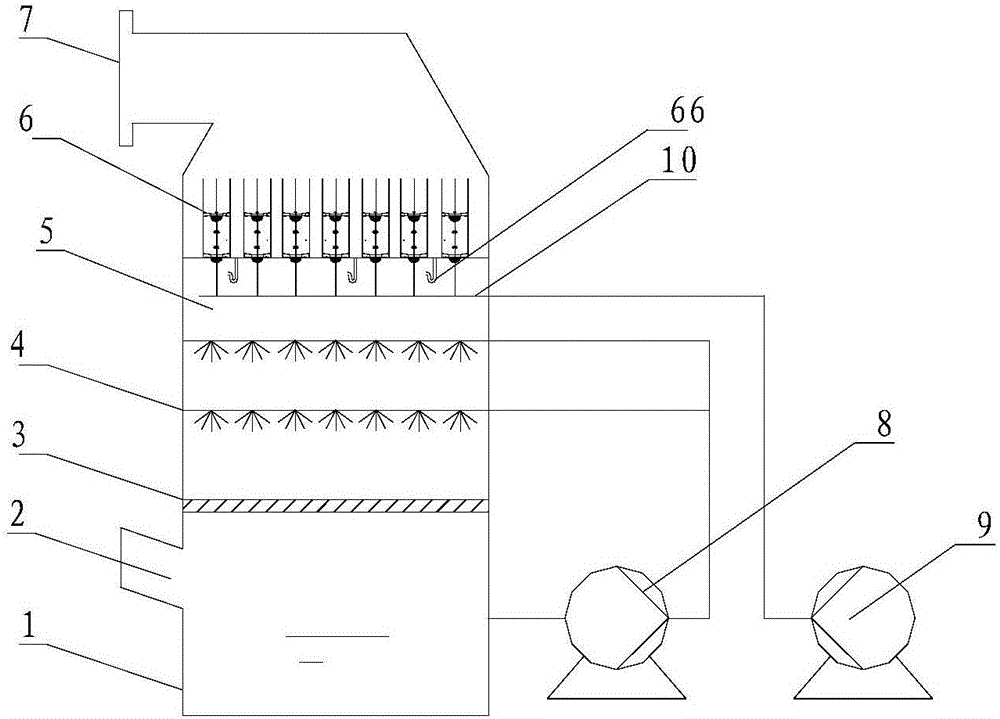

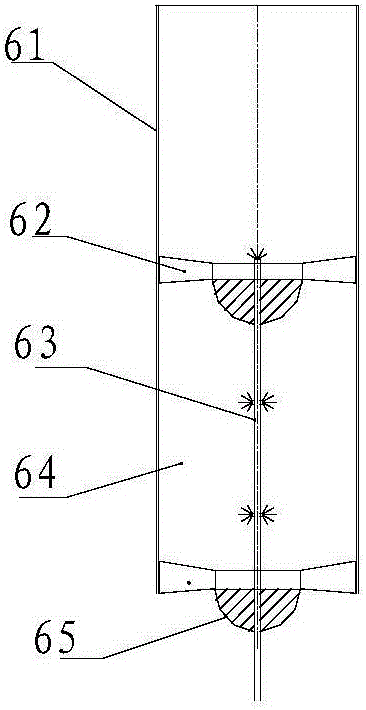

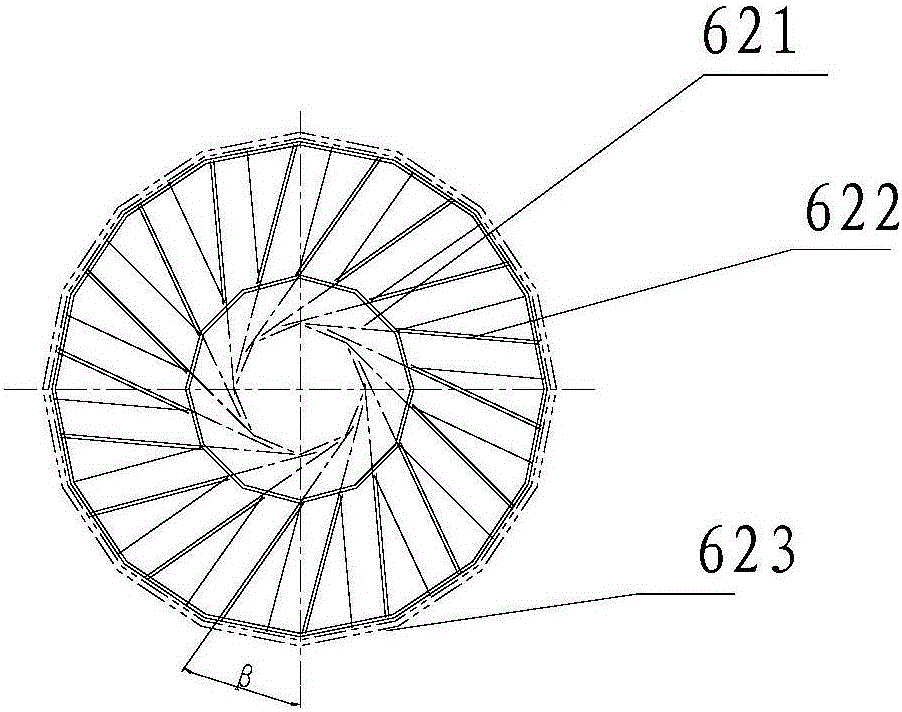

Device and process for coordinative treatment of smoke desulfuration and dedusting

ActiveCN105854561AIncreased chance of impactImprove dust removal efficiencyDispersed particle separationCycloneLiquid layer

The invention discloses a device and a process for coordinative treatment of smoke desulfuration and dedusting. The process includes that crude smoke enters an absorption tower and sequentially pass through a tray layer, a spray layer, a sedimentation and cooling area and an efficient demisting layer and out of the outlet of the absorption tower, the smoke entering the absorption tower in the tray layer is reshaped and rises up at uniform speed over the section of the absorption tower, SO2 in the smoke and size in the accumulative liquid layer and the sprayer layer above the tray can be effectively removed, saturated smoke with small size drops and dust can be settled through the cooling area after desulfurized, and size drops and dust may be abundantly settled. The size drops and dust unsettled can enter a cyclone demister layer along with airflow and be removed through cyclone and collision, and clean smoke treated can be discharged from the outlet of the absorption tower. By the process of reshaping the smoke and sequentially spraying, absorbing and efficiently removing dust and mist, desulfurization, and demisting and dedusting efficiency of the wet-method desulfurization device is improved, and operation energy consumption is lowered.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorus and low-carbon alumina-magnesia unburned brick for a stainless steel ladle and a manufacturing method of the brick. The non-phosphorus and low-carbon alumina-magnesia unburned brick comprises the following components by mass percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 10-15% of bauxite less than or equal to 1mm in particle size, 10-15% of 3-1mm fused magnesite, 5-10% of fused magnesite less than or equal to 1mm in particle size, 10-15% of emery powder, 15-20% of spinel powder, 2-5% of aluminum oxide micropowder less than or equal to 25 micrometers, 0.1-2% of silicon carbide additive, 0.1-2% of wetting agent and a phenolic resin binding agent. Compared with the prior art, the brick and the method have the prominent advantages that a burning technology in the conventional method is omitted, energy sources are saved, the brick is free from phosphorus; aluminum and magnesium perform spinel reaction at the high temperature; and the brick is subjected to machine molding in the absence of the phosphorus, has higher density, avoids pollution of molten stainless steel, and has a longer service life.

Owner:长兴南冶冶金材料有限公司

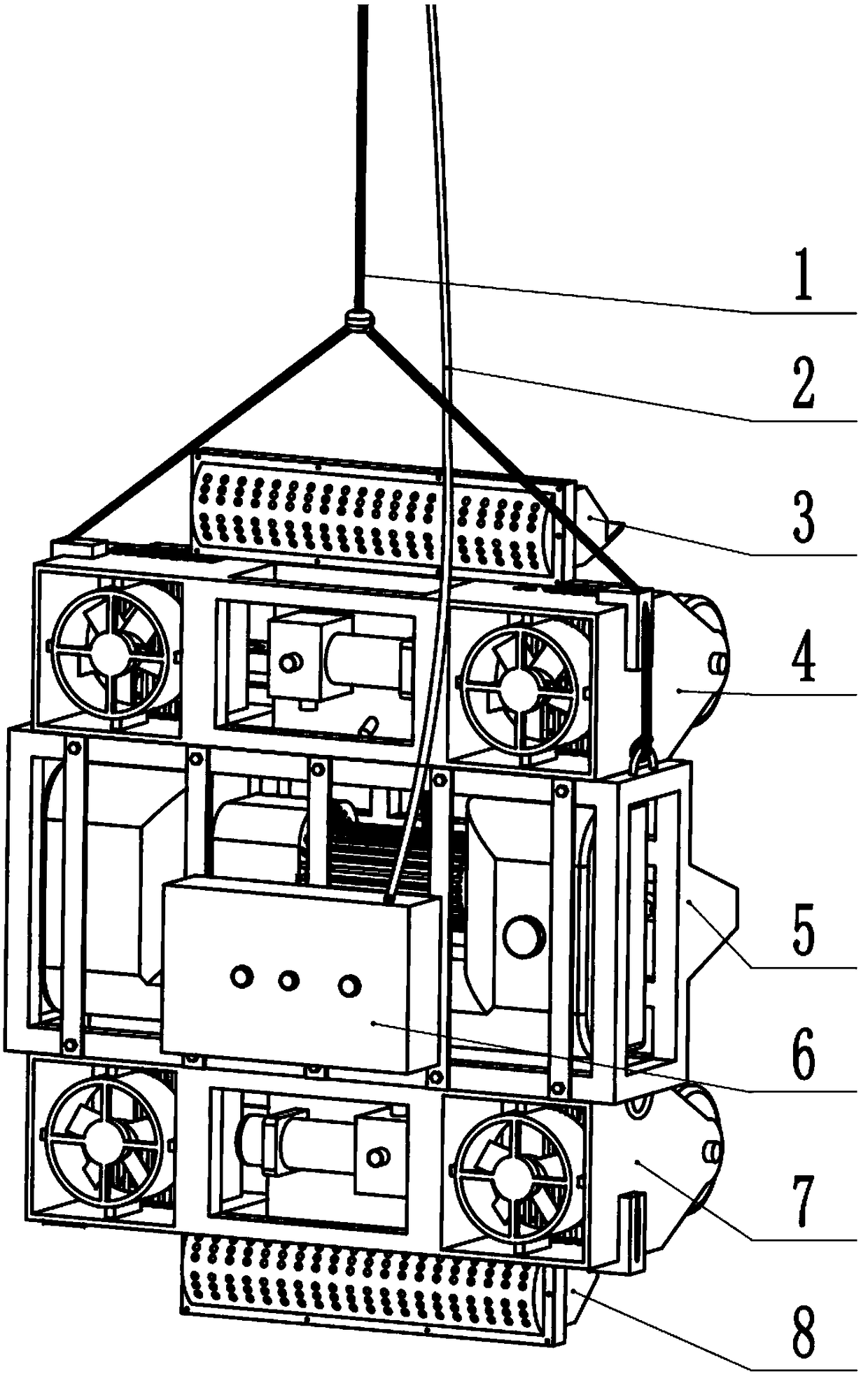

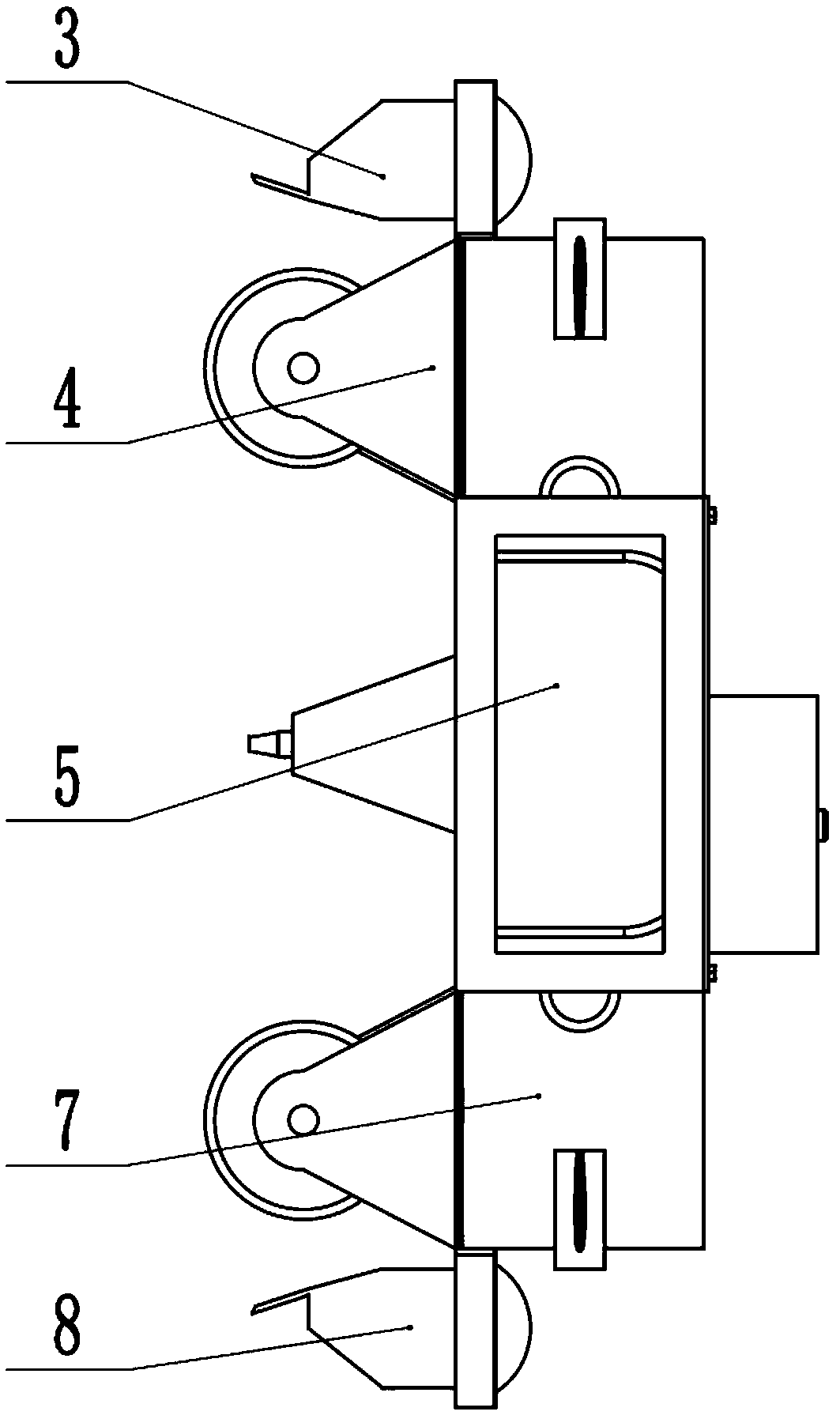

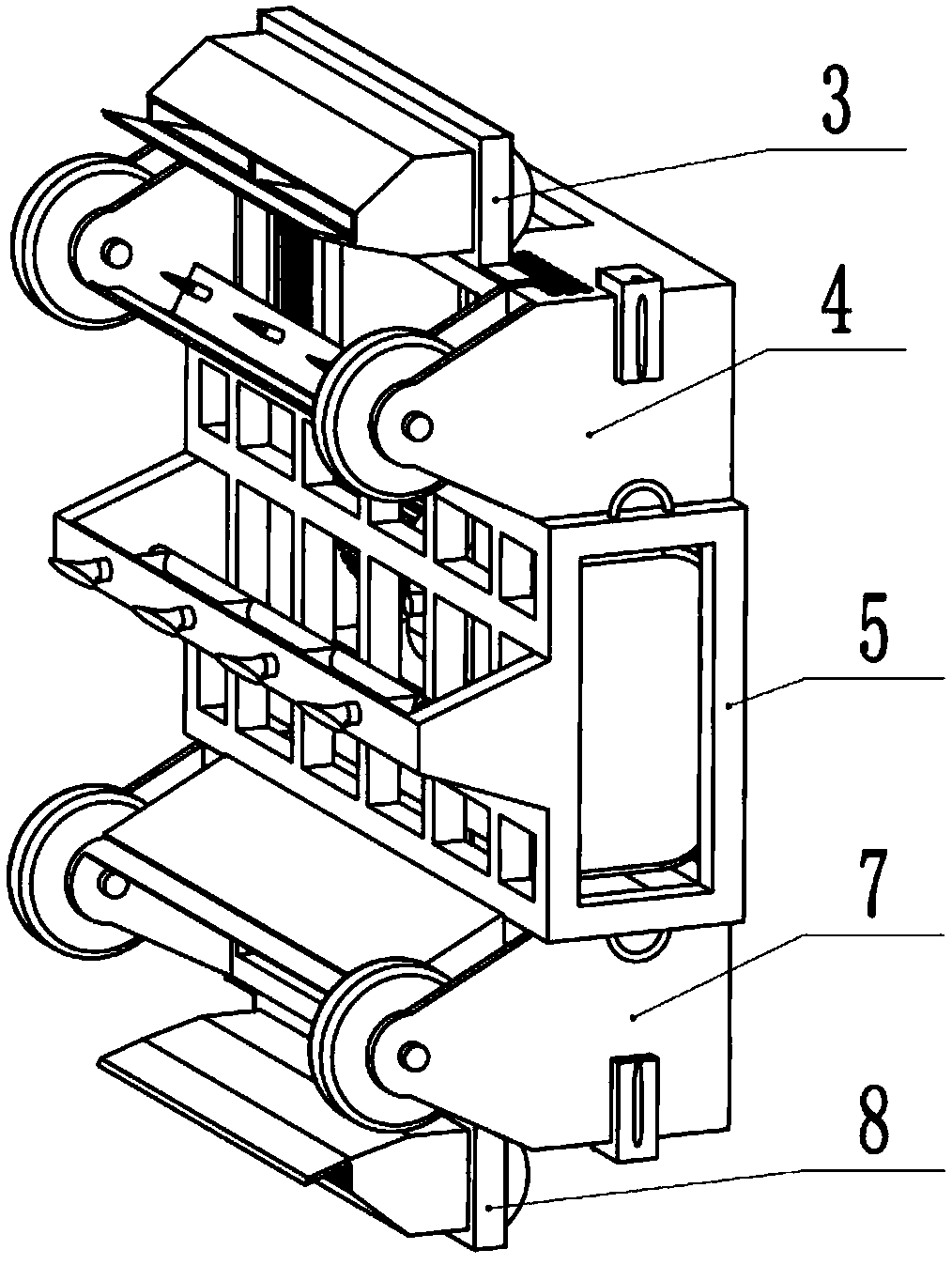

High-rise wall spraying robot

ActiveCN109162431AFully automatedGuaranteed uniformityBuilding constructionsRemote controlControl system

The invention discloses a high-rise wall spraying robot and relates to the technical field of high-rise wall surface spraying. The high-rise wall spraying robot comprises a hoist, an electric cable pay-off and take-up device, a roof moving crane, a panoramic camera, an anemometer, a remote control device, a steel wire rope and a cable line. The roof moving crane is parked on a side close to a wallto be painted. The high-rise wall spraying robot also includes a hot air drying device I, a dust cleaning device I, a spraying device, a control system device, a dust cleaning device II, and a hot air drying device II. The anemometer is also arranged on the mobile crane. The hoist is connected to the spraying device through the steel wire rope. The spraying device is provided with the control system device and the panoramic camera. An upper side of the spraying device is sequentially connected to the dust cleaning device I and the hot air drying device I, and a lower side of the spraying device is sequentially connected to the dust cleaning device II and the hot air drying device II. According to the invention, the automation of the wall surface spraying is realized, the spraying efficiency is improved, the uniformity of the spraying density is ensured, the labor cost is reduced, an artificial high-altitude operation is substituted, and the danger is reduced.

Owner:冠品机具(深圳)流体科技有限公司

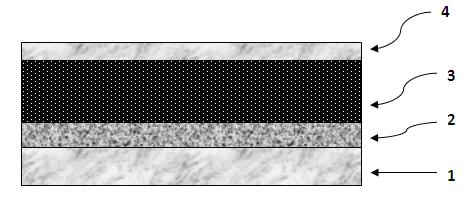

A mipm type internal field emission cathode

InactiveCN102280332AGuaranteed Emission EfficiencyGuaranteed DensityDischarge tube/lamp detailsPower flowAlternating current

A cathode of the invention belongs to the field of vacuum electronics and the materials science, and in particular relates to an MIPM (multum in parvo mapping)-type internal field emitting cathode. The MIPM-type internal field emitting cathode is composed of a bottom electrode layer, an insulating layer, an electronic storage transmission layer and a top electrode layer; the emitting cathode is mainly characterized in that the electronic storage transmission layer adopts a porous silicon film material. In an alternating current AC driving mode, a functional layer not only can transport electrons, but also can store the electrons so as to improve the emitting efficiency. Compared with the prior art, the MIPM-type internal field emitting cathode has the advantages of great emitting current and good stability; and due to the strong environment adaptability, the cathode not only can work in the gas, but also can work in the liquid.

Owner:SICHUAN UNIV

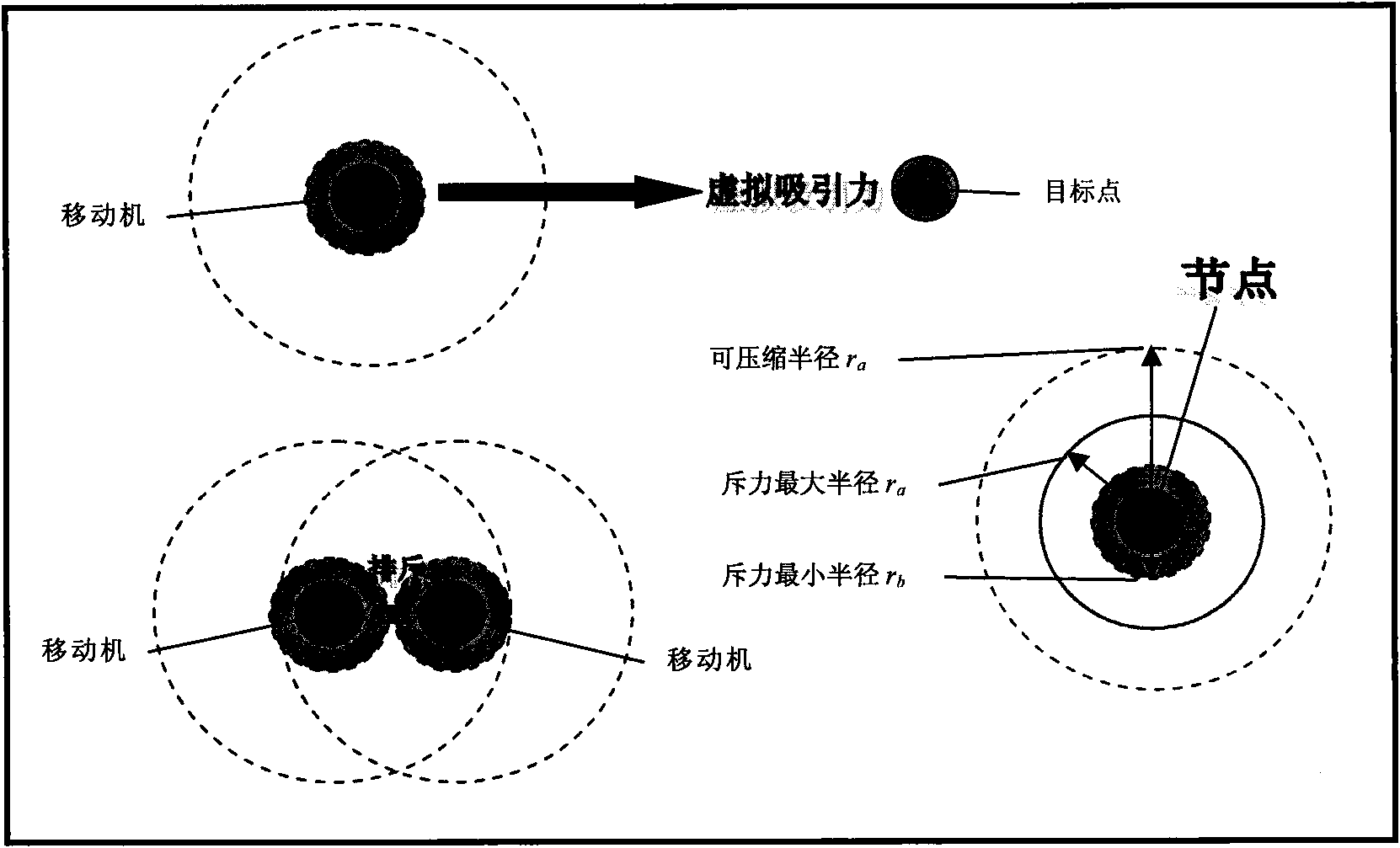

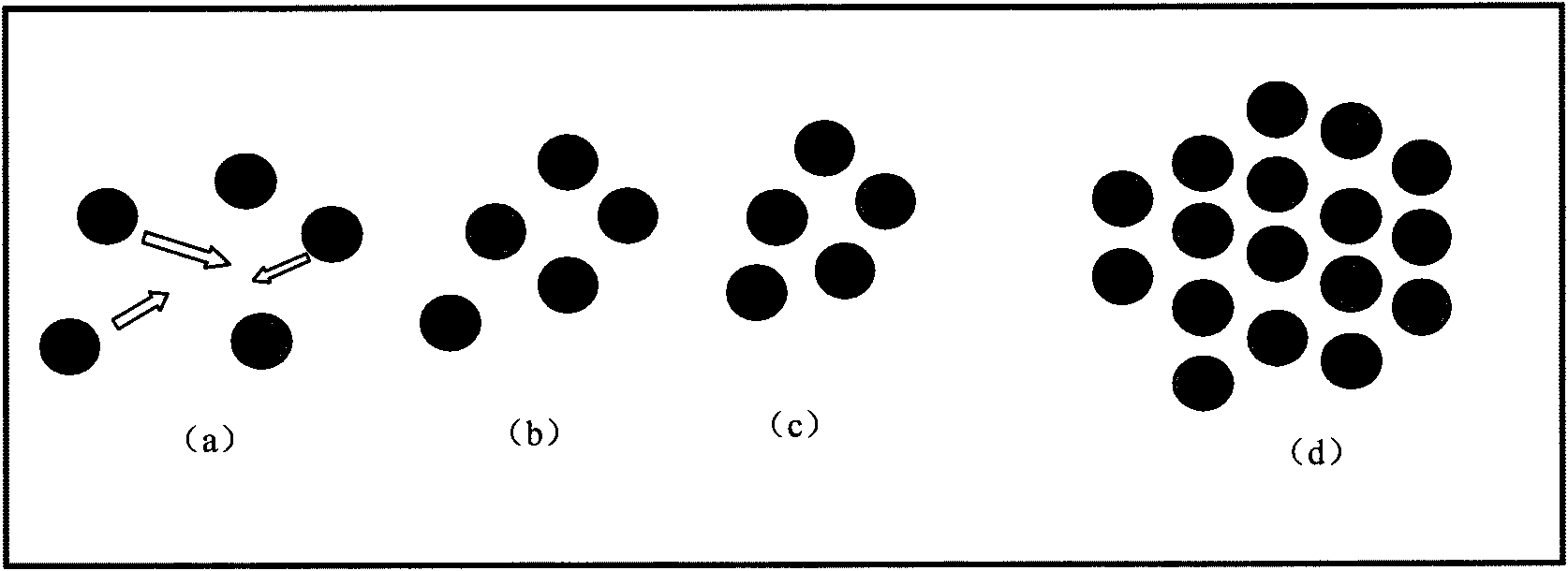

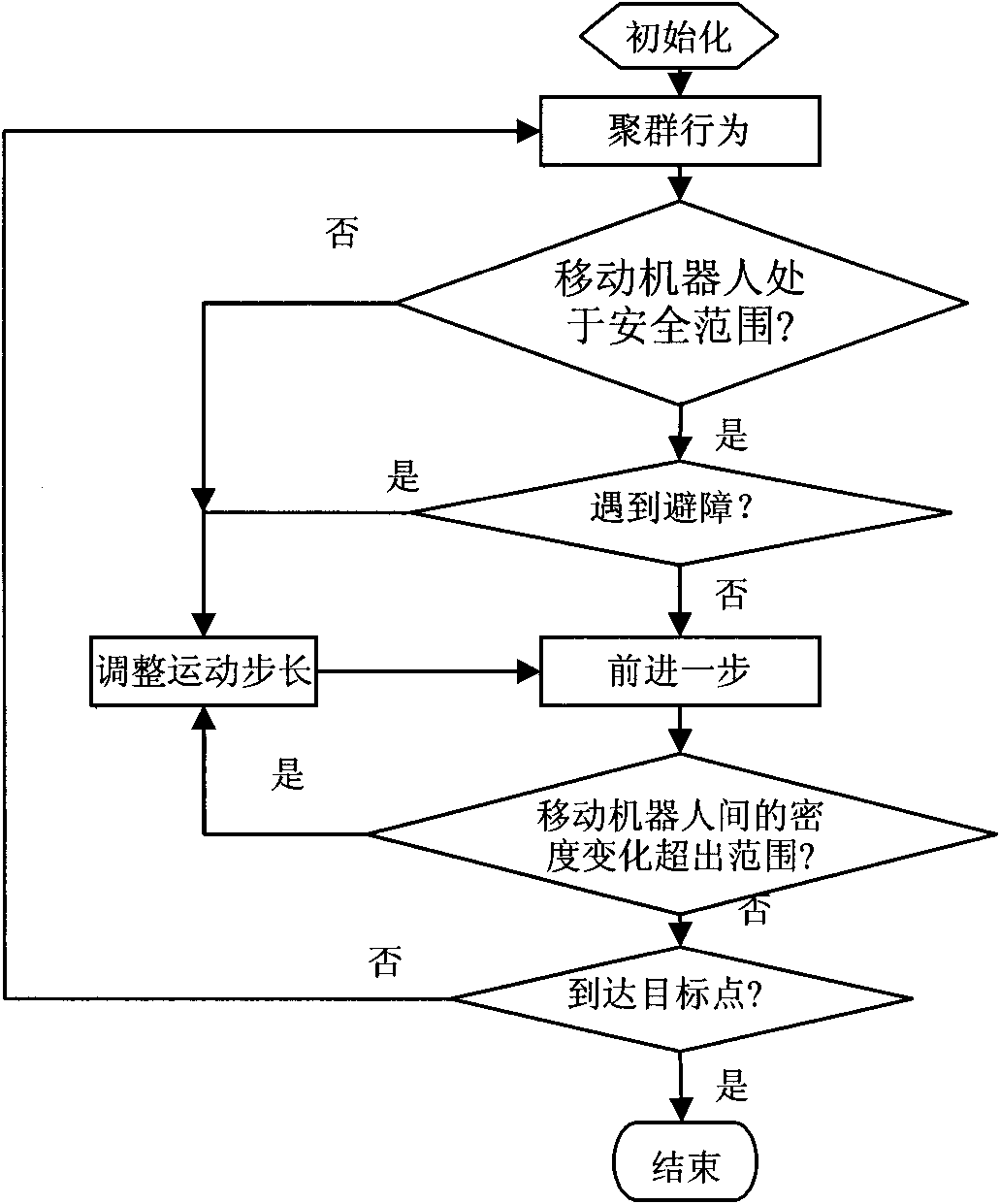

Method for controlling density of group mobile robots in any formation

InactiveCN102053621AUniform densityFacilitate communicationVehicle position/course/altitude controlPosition/direction controlSimulationCrowds

The invention discloses a method for controlling the density of group mobile robots in any formation, and belongs to the technical of mobile multiple robots. The method includes steps of grouping mobile robots, setting an advance destination point for the group mobile robots, and performing ground mobile adjustments to the robots till the destination is achieved. The invention adjusts the problem that the robots are too dispersive through a crowded factor, and adjusts the safety distance to solve the problem that the robots are too crowded or barriers are too close and cause collisions easily, through a robot spring model with a compressible range; and the formation of the group mobile robots is changed, but the method can efficiently ensure the communicating and sensing range of the group mobile robots, and overcome the phenomenon that one robot falls behind easily. The method enables the group mobile robots to be highly automated, the density of the group mobile robots can be controlled, and any formation can be formed according to movement environments, so that the method has the characteristics of keeping the density of the group mobile robots in an unknown environment and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Casting method for copper bush with high lead bronze content

InactiveCN103742536AImprove quality requirementsImprove the authenticity rateFoundry mouldsBearing componentsCasting moldBronze

The invention relates to a casting method for a copper bush with high lead bronze content. The casting method is characterized in that a metal mould taking a parting surface of a casting and a pouring gate system as a half folding structure is used as an external casting mould; a metal mould core with a multi-piece parting structure is used as an internal casting mould; the copper bush with high lead bronze content comprises the following chemical components in percentage by weight: 18-23% of Pb, 4-6% of Sn and the balance of Cu; a water cooling device arranged at the periphery of the casting mould is used as a cooling means of the casting; and the casting method comprises the concrete casting steps: copper alloy smelting; deoxidation treatment; casting mould preheating; casting pouring; casting cooling; and casting head removal to obtain the copper bush with high lead bronze content. The casting method has the advantages of reasonable process, low production cost and the like and the quality of the produced copper bush is high.

Owner:JIANGSU RECODE RAIL TRANSIT TECH CO LTD

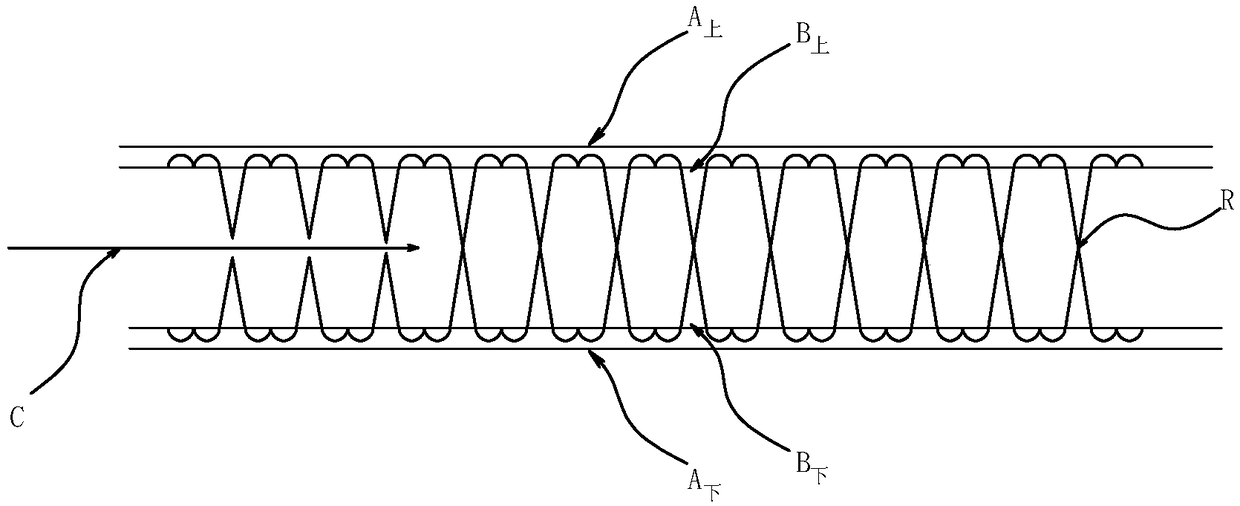

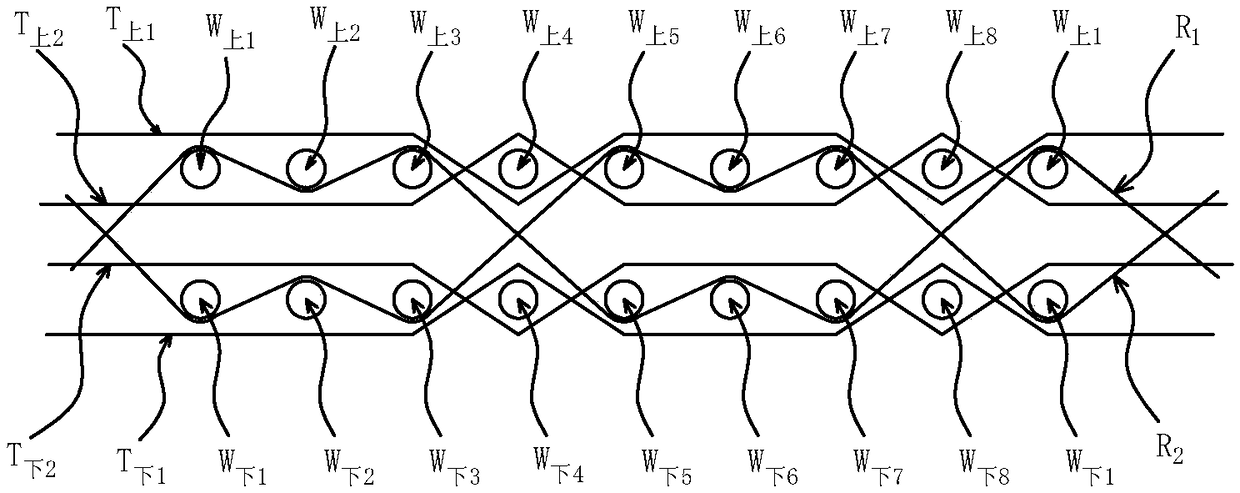

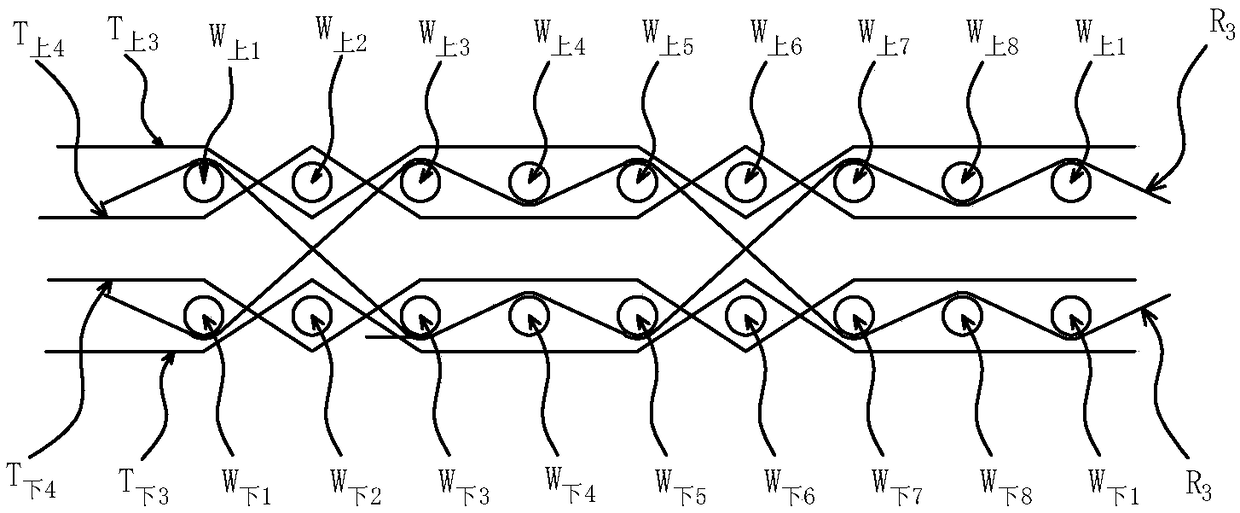

Production process of home textile velvet

ActiveCN109023664AExtrusion stabilityExtruded and consolidated firmlyMulti-ply fabricsNatural fiberFineness

The invention discloses a production process of home textile velvet. The home textile velvet is formed by subjecting a double cloth comprising an upper base fabric, a lower base fabric and a pile warpto velvet pile and arrangement. The pile warp is connected with the upper base fabric and the lower base fabric, and is W consolidated through the upper base fabric and the lower base fabric. The pile warp is a natural fiber yarn. An upper base fabric weft yarn and a lower base fabric weft yarn are both functional yarns. An upper base fabric warp yarn and a lower base fabric warp yarn use naturalfiber yarns and functional yarns. The fineness of the ground warp is not restricted by the fineness of the pile warp. The fineness of the ground warp can be less than that of the pile warp, or can begreater than the fineness of the pile warp. The home textile velvet is very suitable for mass production. The production process can reduce the fineness of the pile warp to achieve a light and elegant purpose while ensuring the density of pile is not exposed to the ground. The home textile velvet comprises all natural fibers contacted by the human body, and functional yarns that are imparted by modern technology and cannot be contacted by the human body, which satisfies people's needs.

Owner:ZHEJIANG INNOVATION TEXTILE CO LTD

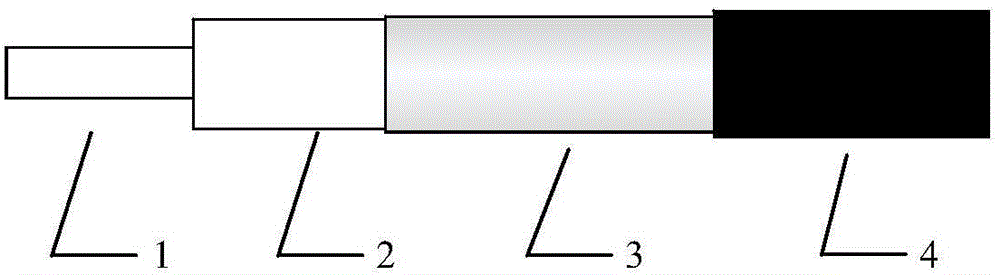

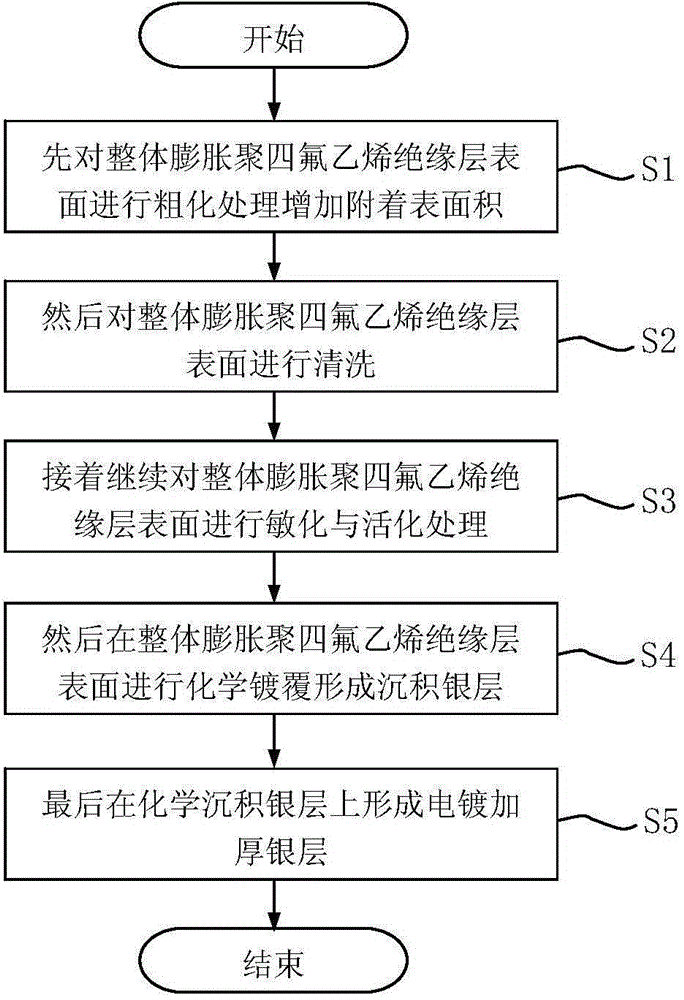

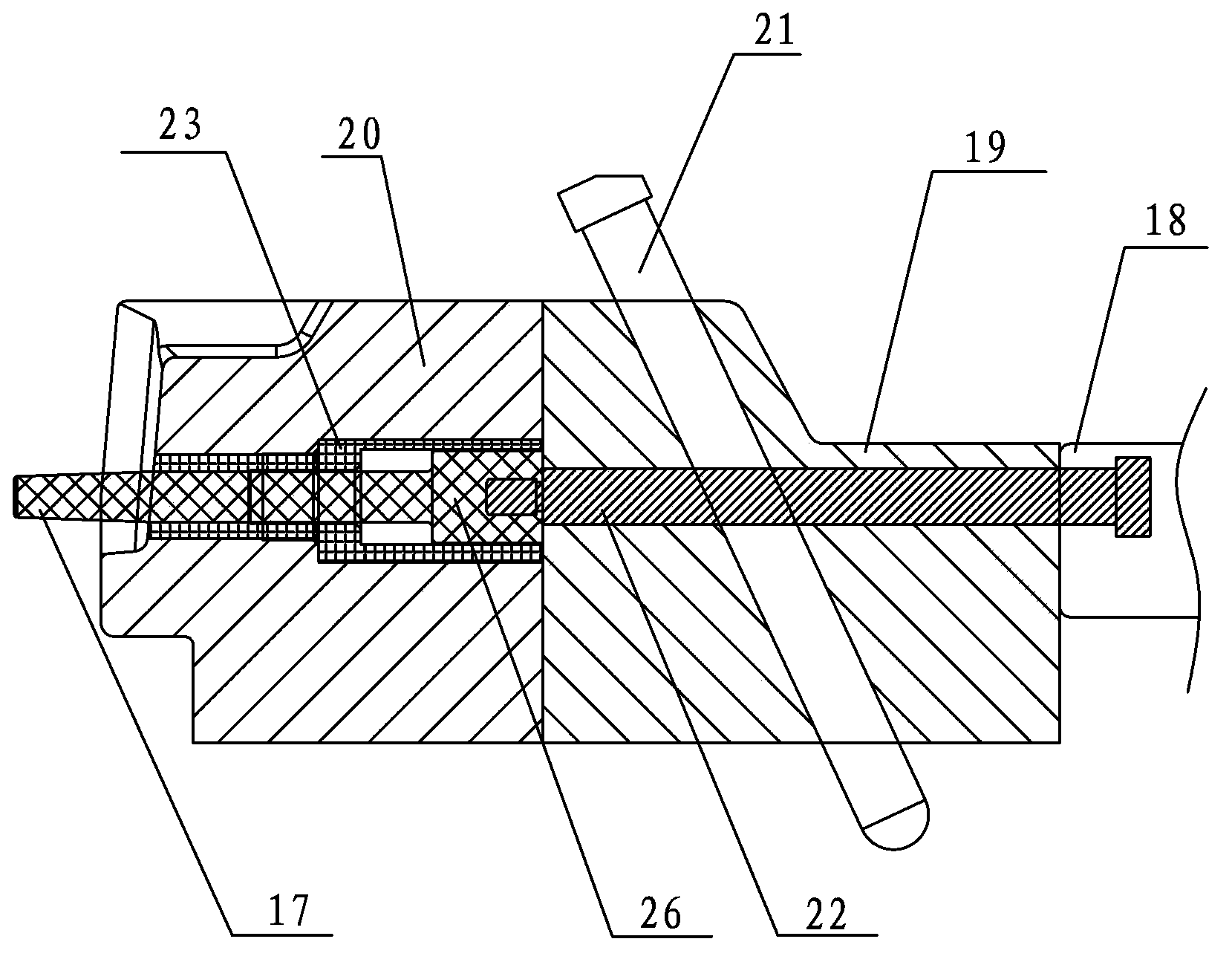

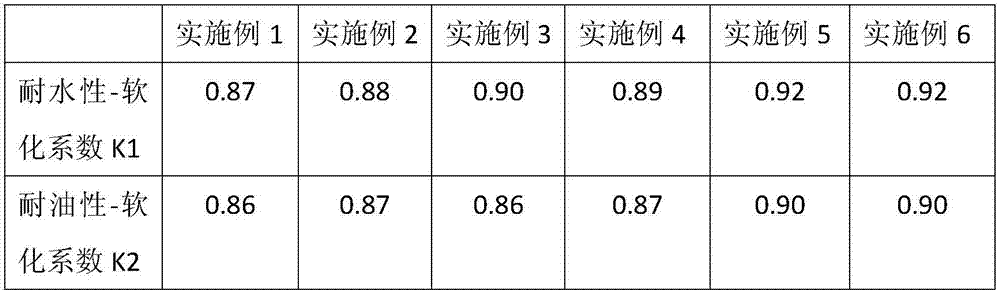

Radio frequency cable with integrated polytetrafluoroethylene insulating surface silver-plating outer conductor, and machining method for radio frequency cable

ActiveCN104681907AGuaranteed DensityGuaranteed continuityWaveguidesAdhesion forceElectrical conductor

The invention discloses a radio frequency cable with an integrated polytetrafluoroethylene insulating surface silver-plating outer conductor, and a machining method for the radio frequency cable. The machining method comprises the following steps: a) firstly, performing roughening treatment on the surface of an integrated expansion polytetrafluoroethylene insulating layer to increase the adhesion surface area; b) secondly, cleaning the surface of the integrated expansion polytetrafluoroethylene insulating layer; c) thirdly, performing sensitizing and activating treatment on the surface of the integrated expansion polytetrafluoroethylene insulating layer; d) fourthly, forming a chemical deposition silver layer on the integrated expansion polytetrafluoroethylene insulating layer; e) finally, forming an electroplating thickening silver layer on the chemical deposition silver layer. According to the radio frequency cable and the machining method thereof, an integrated expansion polytetrafluoroethylene insulating core cable is subjected to surface roughening, surface cleaning, surface sensitizing and activating treatment, and an integrated pure-silver outer conductor is formed by utilizing the chemical deposition silver layer and the electroplating thickening silver layer, so that the density, the continuity, the uniformity and the adhesion force of the integrated pure-silver outer conductor are ensured; the conductive performance and the firmness of the integrated pure-silver outer conductor are improved; therefore, the radio frequency cable has the characteristics of light weight, small size, and high bendability and flexibility.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

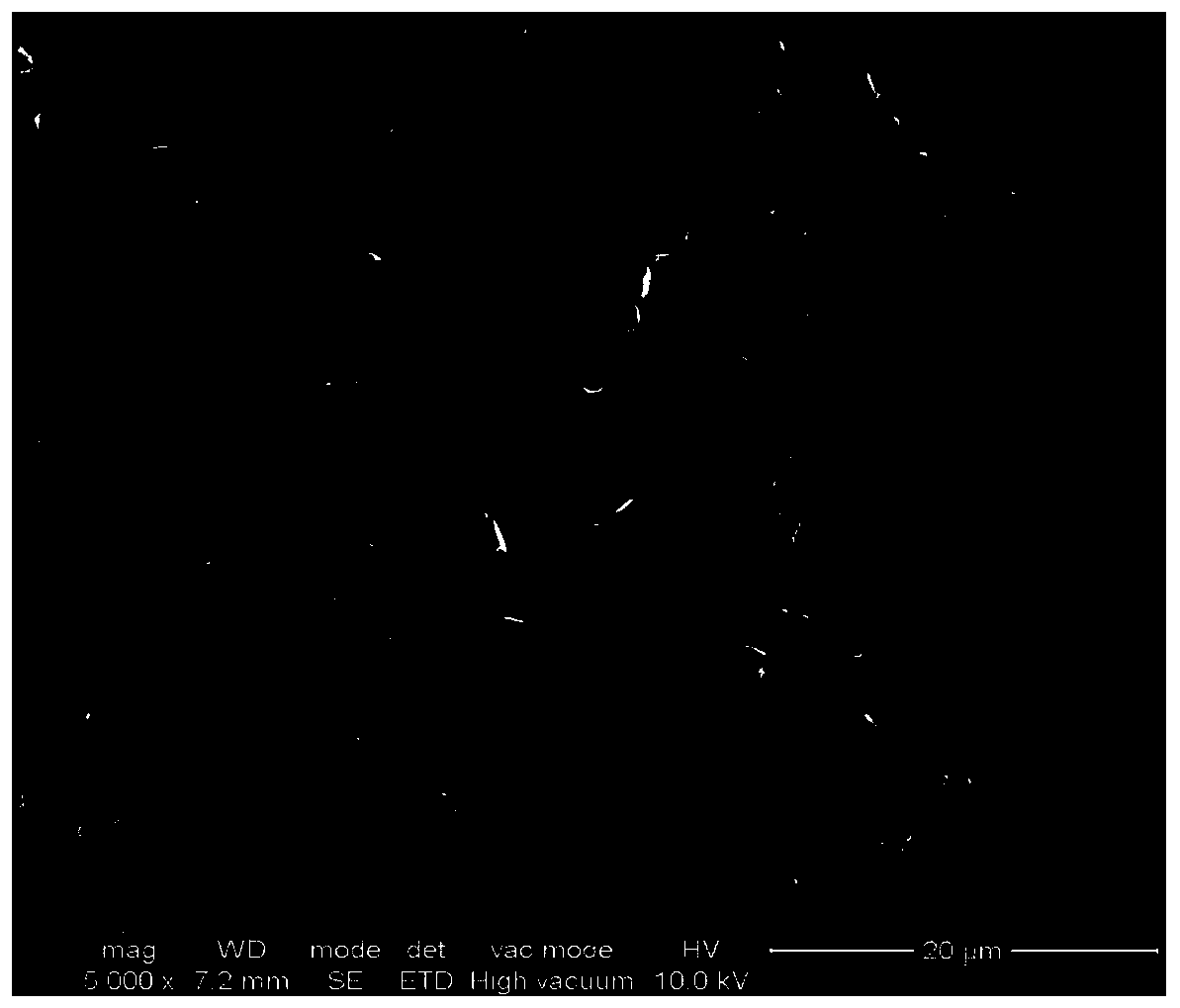

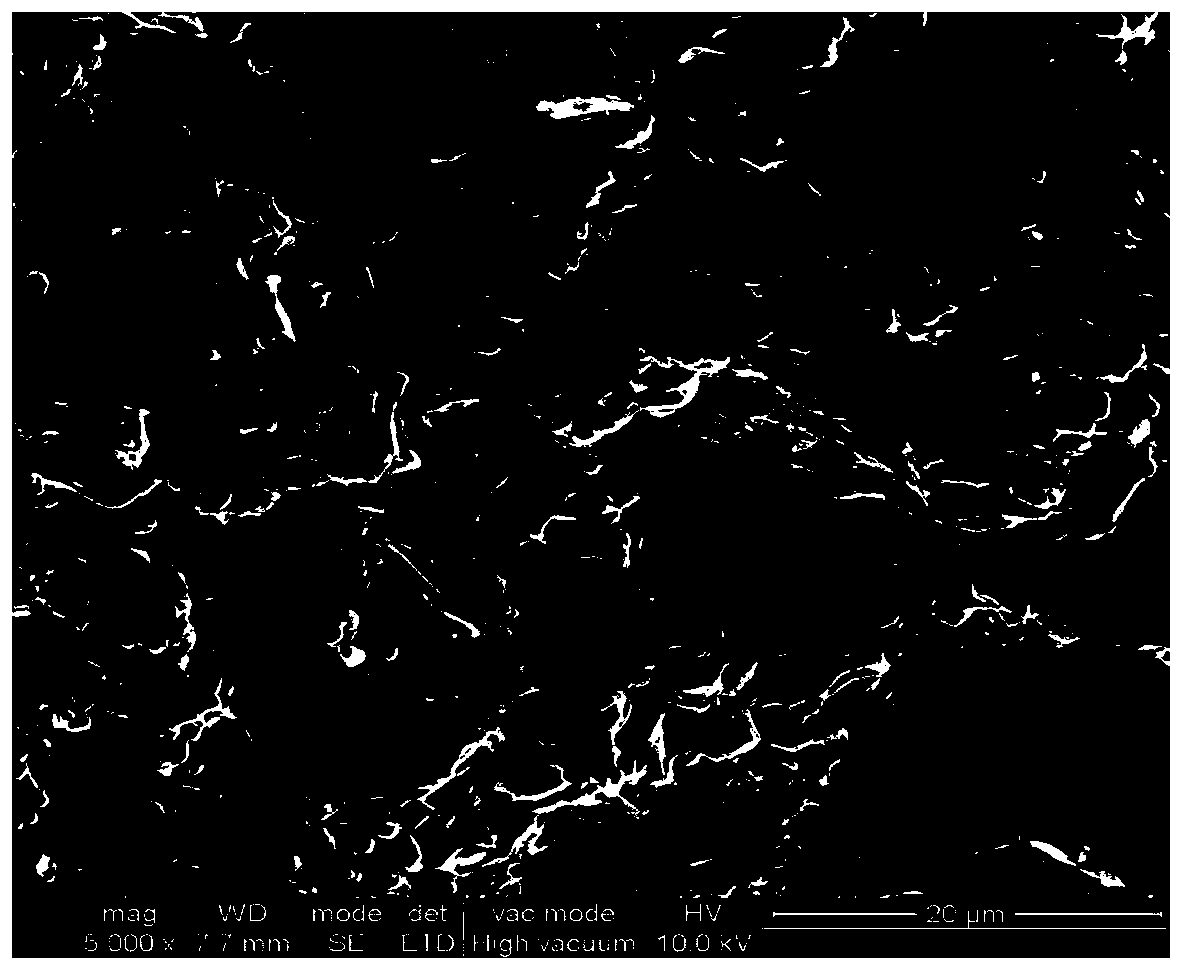

Composite papermaking nano reinforced aramid paper and preparation method thereof

PendingCN112609493AImprove dispersion compatibilityImprove evennessPulp beating methodsDryer sectionAdhesivePapermaking

The invention belongs to the technical field of papermaking, and particularly relates to composite papermaking nano reinforced aramid paper and a preparation method thereof. By utilizing the characteristics of easy dispersion, large specific surface area and the like of the para-aramid nanofibers in a solution, the para-aramid nanofiber composite wet paper sheet replaces the traditional pulp wetting agent and adhesive, and the para-aramid nanofiber composite wet paper sheet is prepared from the traditional chopped fibers and pulp or fibrids. Then the para-aramid nanofiber dispersion liquid is subjected to spraying sizing treatment on the surface of the aramid wet paper sheet, then compounding and drying forming are carried out, and the sprayed and compounded paper sheet can significantly improve the uniformity, dielectric property and mechanical strength of aramid paper, improve the forming thickness of finished aramid paper, improve the production efficiency and the like; and the negative influence on the performance of the paper sheet due to the introduction of a third adhesive or a wet strength agent is avoided.

Owner:山东聚芳新材料股份有限公司

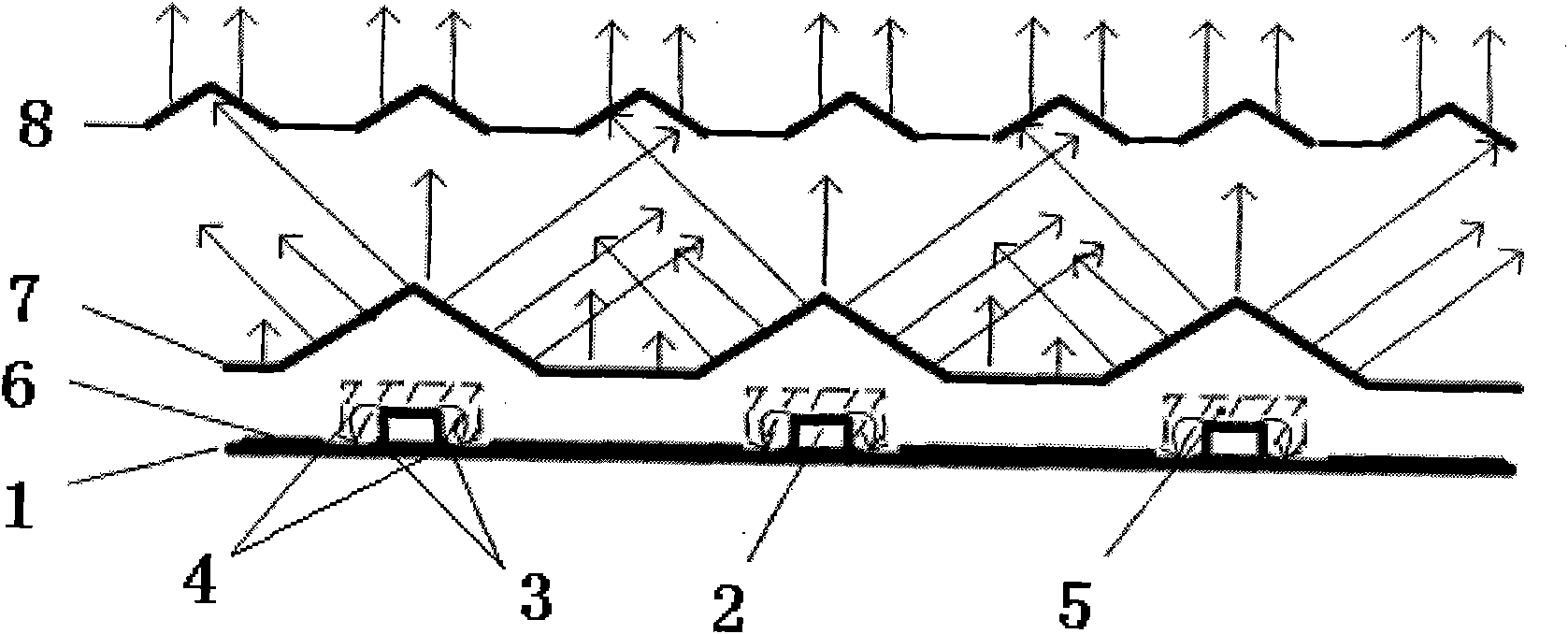

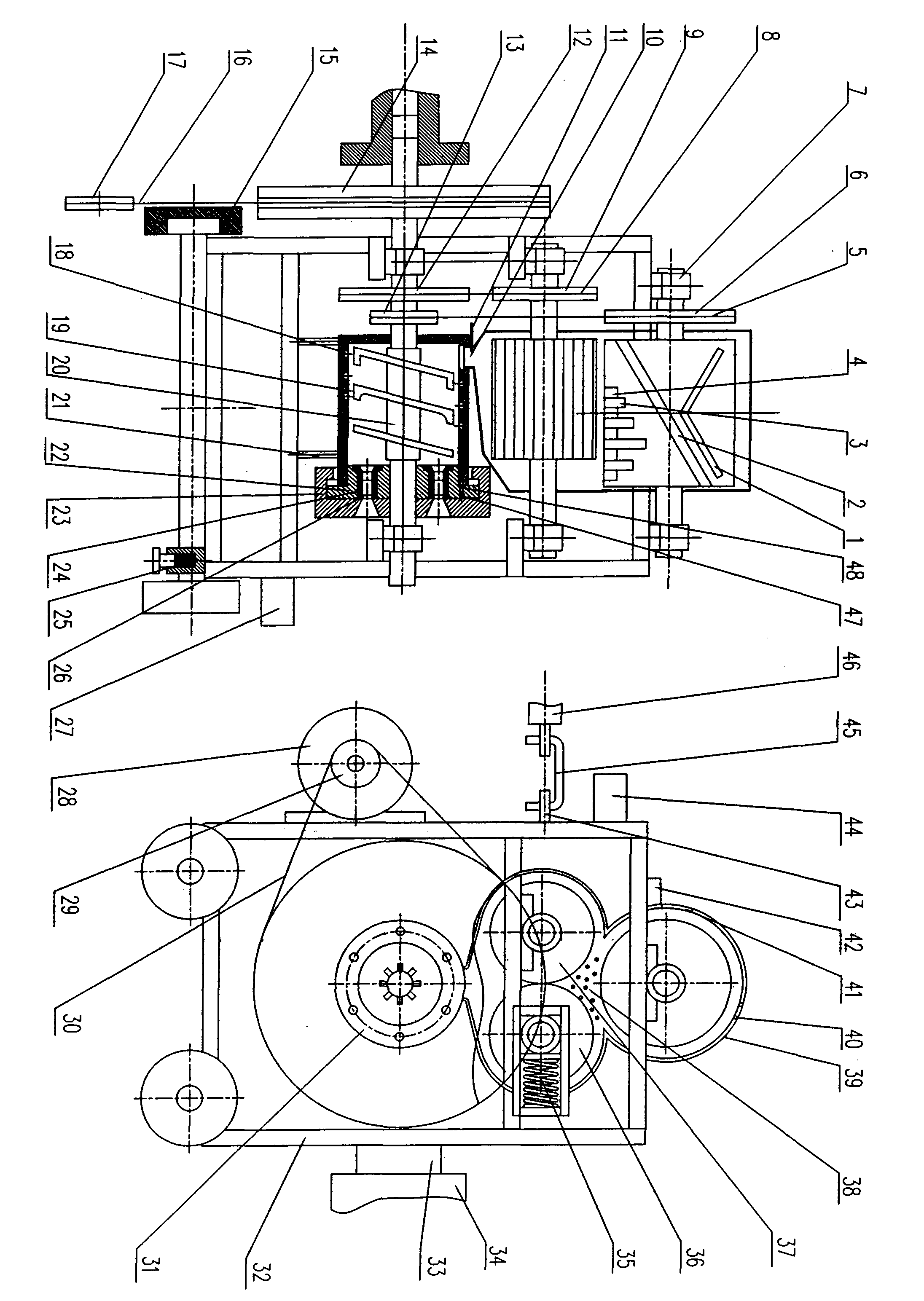

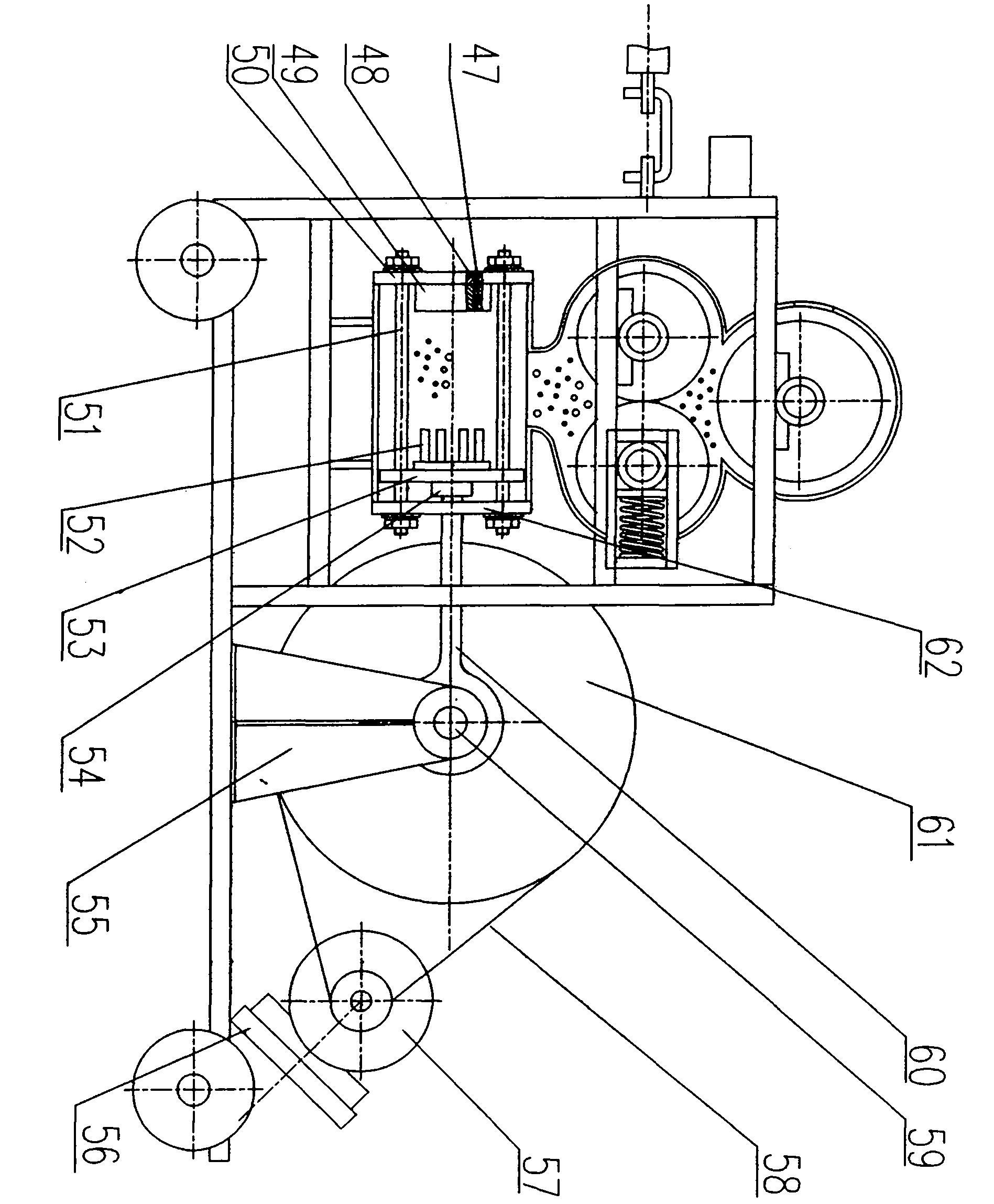

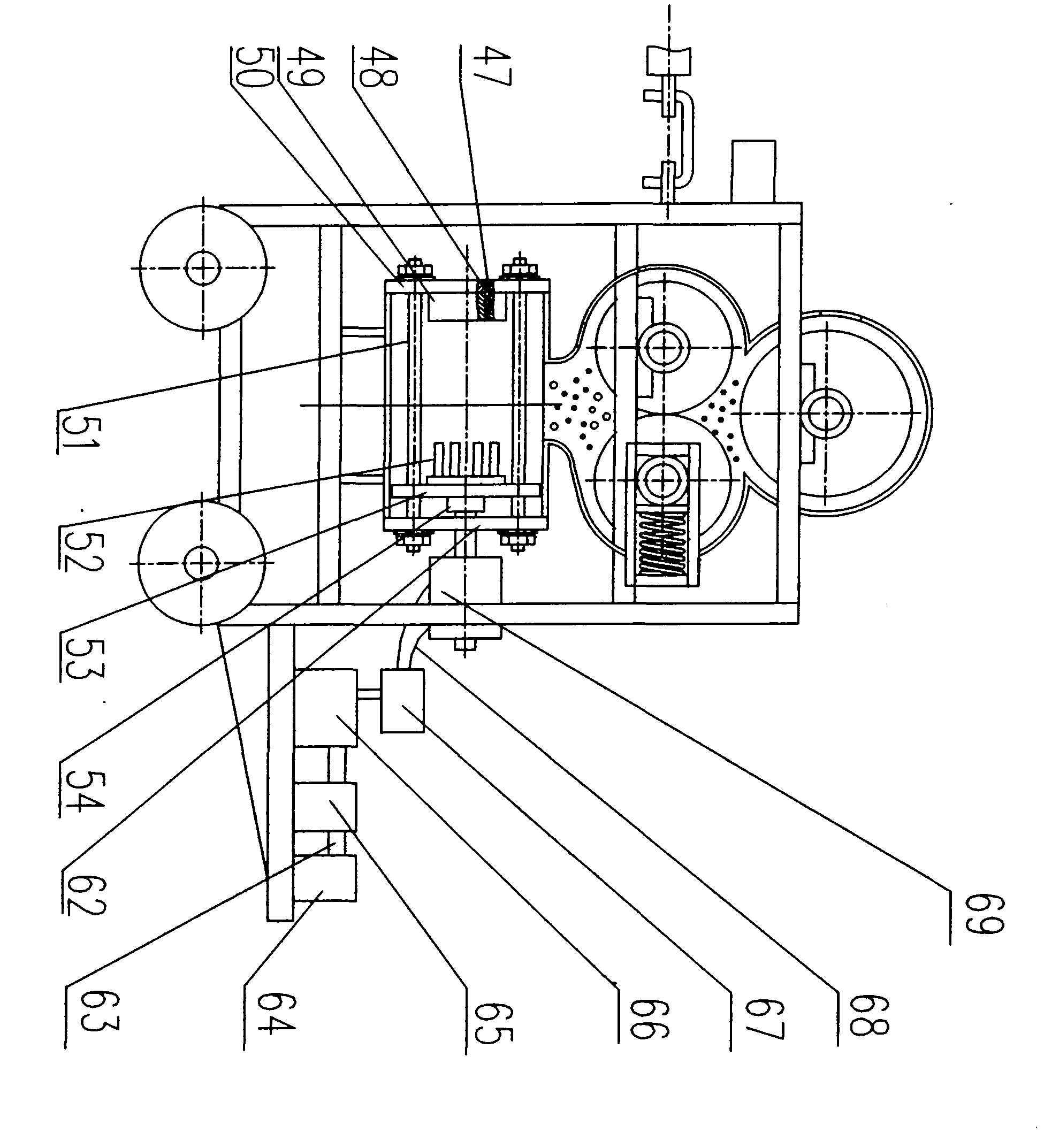

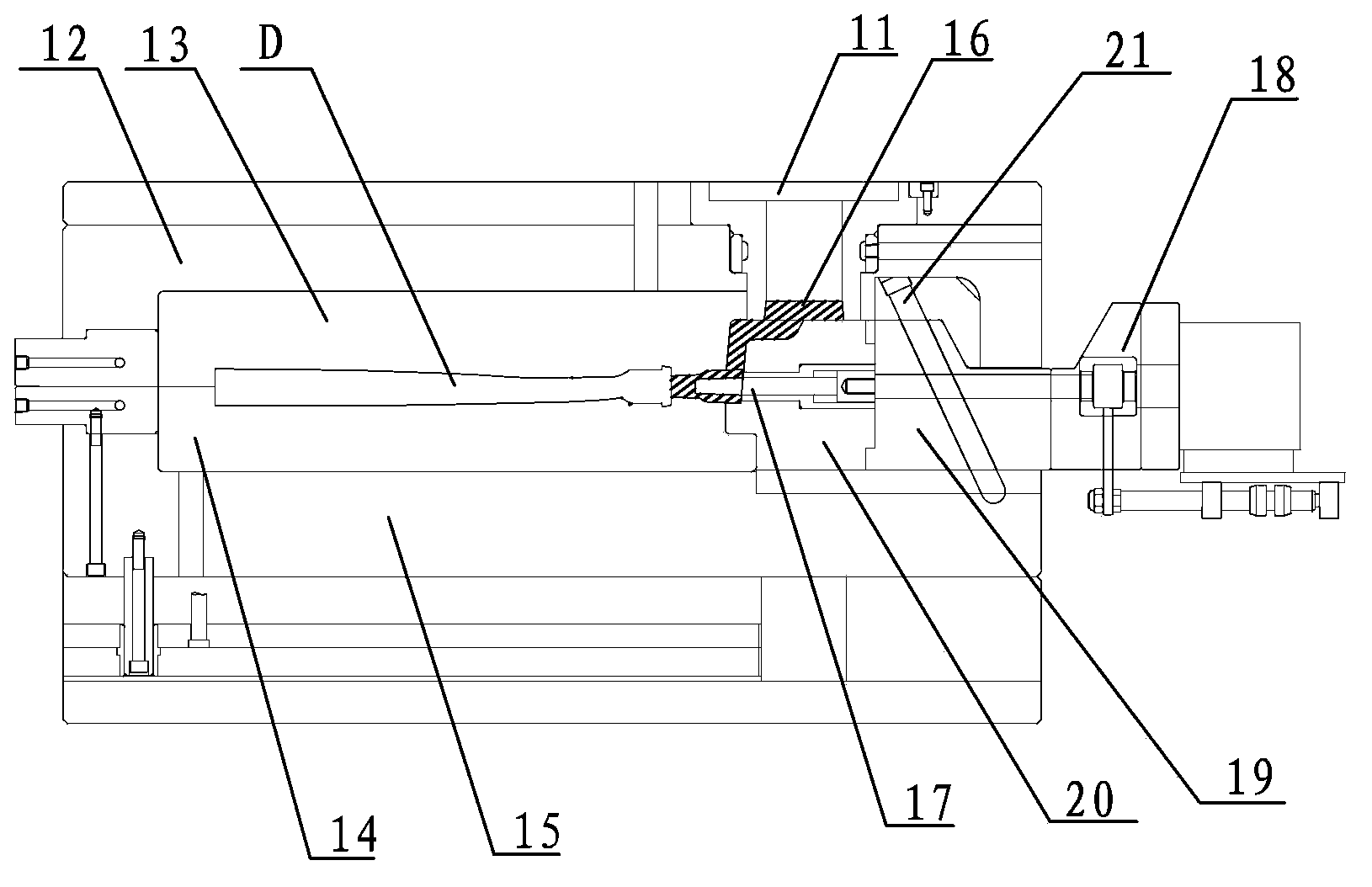

Biomass extruding and molding combined unit

The invention relates to a biomass extruding and molding combined unit which is formed by a power device, an operation control device, a cutting device, a rolling device, an extruding and molding device, a finished-product squeezing and cutting-off device and a weighing and packaging mechanism device and is mounted on the same rack. The biomass extruding and molding combined unit can continuously make biomasses including fine and soft rice and wheat straws, rough and hard bamboo, wood, cotton and bean stalks, palms, sugarcanes, rattans, potato rattans, corn cores, stalks and the like into molded products. Particularly, a gear pair is used for carrying out repeated S-shaped rolling on the materials after the materials pass through a gear top, a gear surface and a gear root to be cracked in a radial direction, so that elastic stress is degraded, and a gap is manufactured for contained sugar and lignin to be thermalized and smelted until a thin-sheet-wire net shape is formed and the softening is realized; and in a squeezing process, residual elastic stress can be degraded, a porous hollow molded block in a single-hole pipe shape or a coal ball shape can be extruded by sufficient and uniform yielding and deformation, and dense adhesion, or a spiral and straight convex rib is extruded or a circular and non-circular molded block of a groove is extruded. Particularly, the invention provides the biomass extruding and molding combined unit which is mounted on a combined harvesting machine and takes power to link or walk along with the combined harvesting machine.

Owner:吴昊

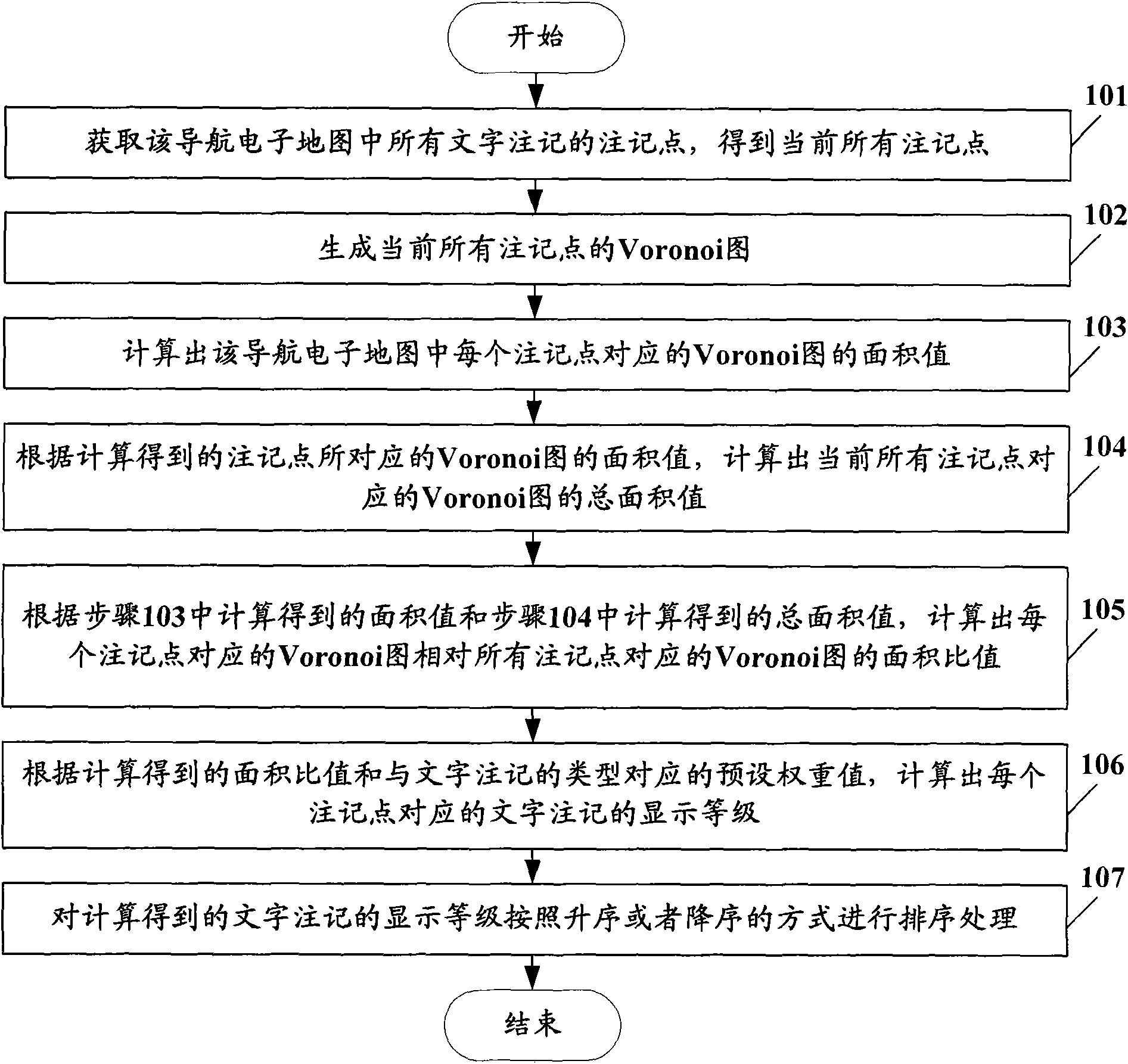

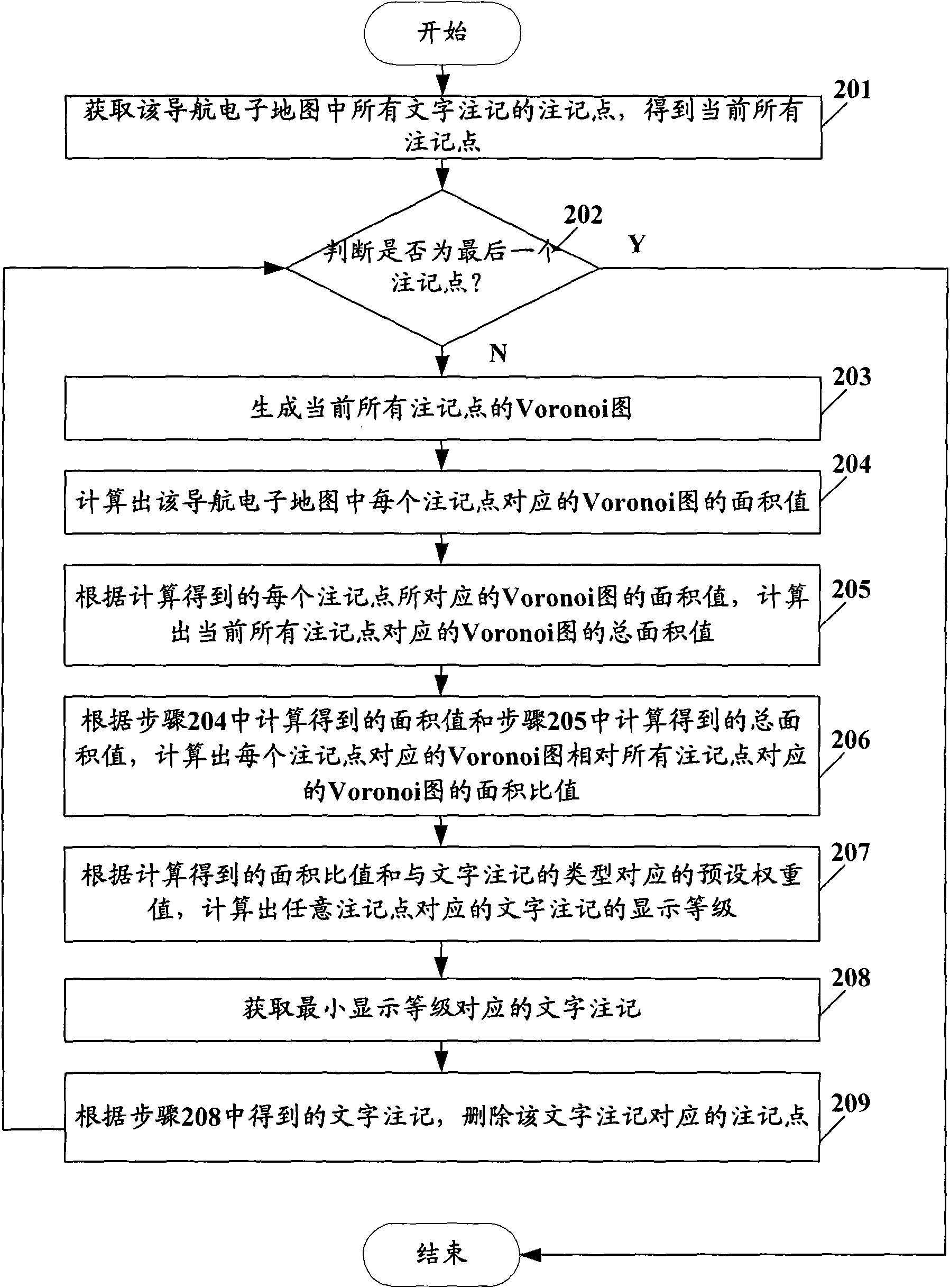

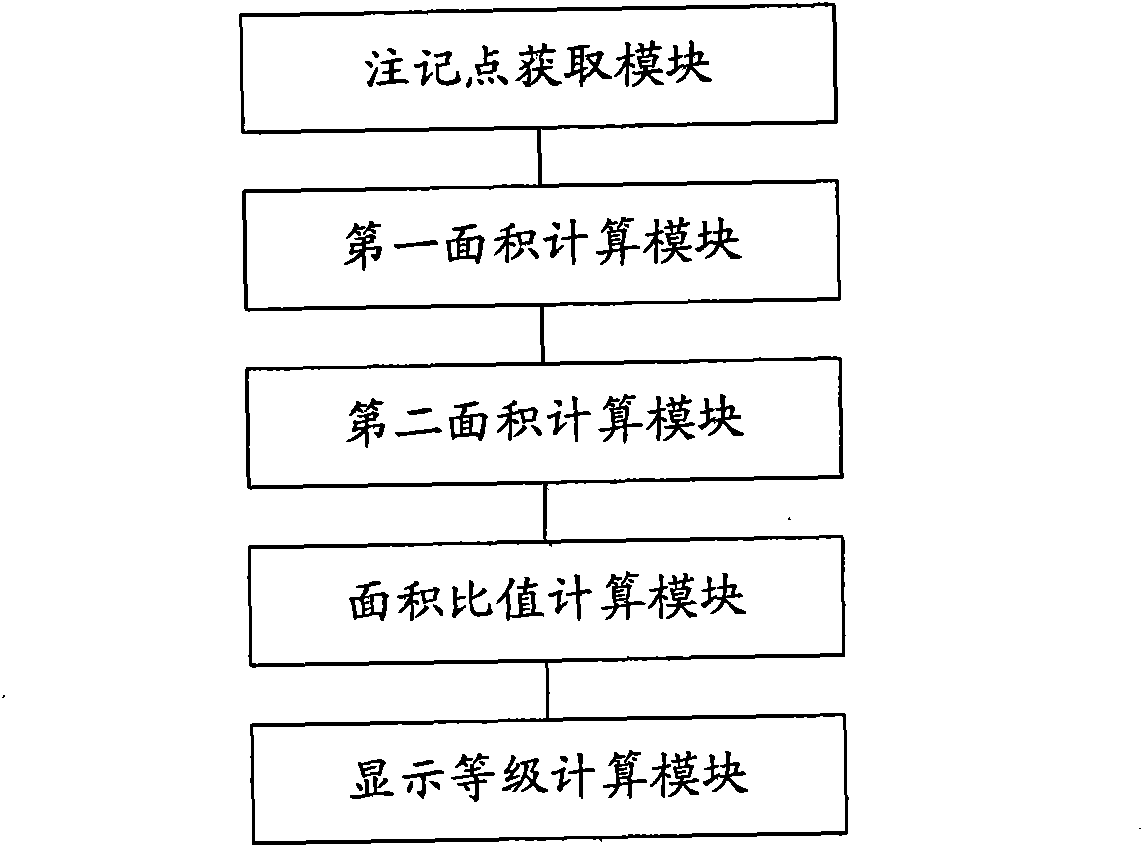

Method for automatically dividing display level of character marks in navigation electronic map and device thereof

ActiveCN101655375AMaintain information loadGuaranteed DensityInstruments for road network navigationElectronic mapMarine navigation

The invention provides a method for automatically dividing the display level of character marks in a navigation electronic map and a device thereof, belonging to the field of a digital drawing technology. The method comprises the following steps: obtaining mark points of all the character marks in the navigation electronic map to obtain all the current mark points; generating the voronoi maps of all the current marking points, and computing the area value of the voronoi maps corresponding to each marking point; according to the computed area value of the voronoi maps corresponding to each marking point, computing the gross area value of the voronoi maps corresponding to all the marking points; according to the area value and the gross area value, computing the area ratio of the voronoi maps corresponding to all the marking points relative to the voronoi maps corresponding to the each marking points; and according to the computed area ratio and the preset weighting value corresponding to the type of the character marking, computing the display level of the character marks corresponding to the each marking point, thereby being capable of automatically ensuring the display level of the character marks in a multi-level scale map.

Owner:NAVINFO

Anti-hair loss hair-growing liquid and preparation method thereof

InactiveCN109498537AIncrease nutritionImprove toughnessCosmetic preparationsHair cosmeticsEcological environmentGINSENG EXTRACT

The invention relates to anti-hair loss hair-growing liquid. The anti-hair loss hair-growing liquid is prepared from the following raw materials by percentage: 0.5 to 5 percent of radix ginseng extract, 0.5 to 5 percent of cacumen platycladi extract, 0.5 to 5 percent of radix angelicae sinensis extract, 0.5 to 5 percent of radix polygoni multiflori extract, 0.3 to 3 percent of radix rehmanniae extract, 0.3 to 3 percent of radix scutellariae extract, 0.3 to 3 percent of rhizoma zingiberis recens extract, 0.05 to 0.8 percent of tripeptide-1copper, 1 to 8 percent of palmitoyl tripeptide-1, 0.5 to5 percent of myristoyl pentapeptide-4, 15 to 30 percent of edible alcohol, 0.2 to 0.5 percent of hexanediol, 0.1 to 0.35 percent of phenoxyethanol, 0.05 to 0.30 percent of sodium citrate, 0.02 to 0.2percent of citric acid, 0.005 to 0.02 percent of essence and the balance of deionized water. The anti-hair loss hair-growing liquid disclosed by the invention has the advantages that the problems ofscalp hair loss and less hair can be solved, and the ecological environment of the scalp can be improved due to high active ingredients; a good role in hair fixation and hair growth is played, so thatthe hairs are thicker.

Owner:广州蜜妆生物科技有限公司

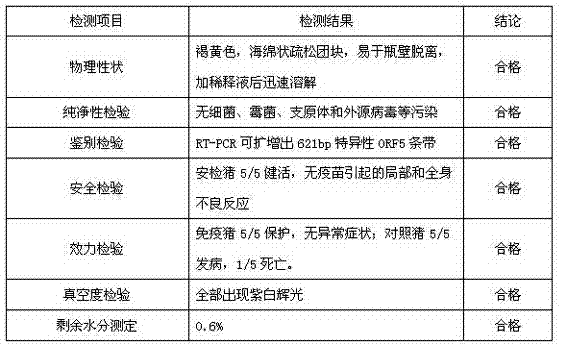

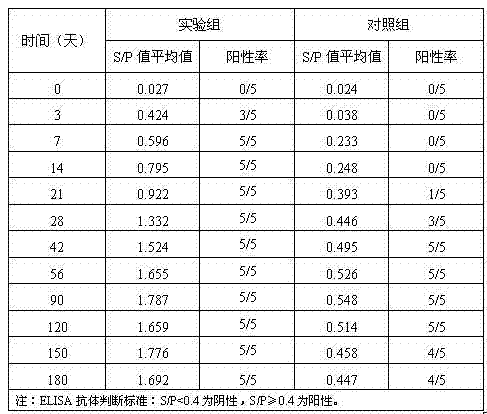

Preparation method of complex live vaccine for porcine reproductive and respiratory syndrome

ActiveCN103495166AReduce incubation timeReduce operating proceduresViral antigen ingredientsAntibody ingredientsAntigenSide effect

The invention discloses a preparation method of a complex live vaccine for porcine reproductive and respiratory syndrome, belonging to the technical field of veterinary biological products. The preparation method comprises the following steps: (1) culturing master cells; (2) performing suspension culture on vaccine preparation cells; (3) culturing and harvesting viruses; (4) performing mixed adsorption on the harvested full-suspension virus solution and chicken anti-porcine reproductive and respiratory syndrome virus egg yolk antibody; (5) adding the adsorbed antigen-antibody compound into an immunoenhancer-containing freeze-drying protecting agent, sub-packaging and then performing freeze vacuum drying to prepare the complex live vaccine for the porcine reproductive and respiratory syndrome. The method is used for preparing the vaccine, and has the characteristics that the production period can be shortened, the personnel allocation is reduced, the pollution probability is low, the floor area is small, the virus titer is high, the difference between the prepared vaccine batches is small, the product has stable and high-efficiency quality, the side effect is small and the quality of the vaccine can be completely improved.

Owner:浙江美保龙生物技术有限公司

Aluminum oxide reinforced high-entropy boride ceramic as well as preparation method and application thereof

The invention belongs to the field of ceramic cutting tools, and discloses aluminum oxide reinforced high-entropy boride ceramic as well as a preparation method and application thereof. The alumina-reinforced high-entropy boride ceramic is prepared by the following steps: carrying out ball milling and mixing on high-entropy boride ceramic powder (A<0.2>B<0.2>C<0.2>D<0.2>E<0.2>) B2 and a reinforcing phase Al2O3; drying the mixture to obtain mixed powder; heating the mixture powder to 900-1200 DEG C in vacuum; then under argon protection and axial pressurization of 30-50 MPa, heating the mixed powder to 1700-1900 DEG C; and performing spark plasma sintering, wherein the A, B, C, D, and E are different elements selected from Ti, Zr, Hf, V, Nb, Ta, Cr, Mo or W. The alumina-reinforced high-entropy boride ceramic has the advantages of high hardness, favorable chemical stability, favorable wear resistance and favorable cutting property, and can be applied to the field of cutting tools for difficult-to-machine materials.

Owner:GUANGDONG UNIV OF TECH

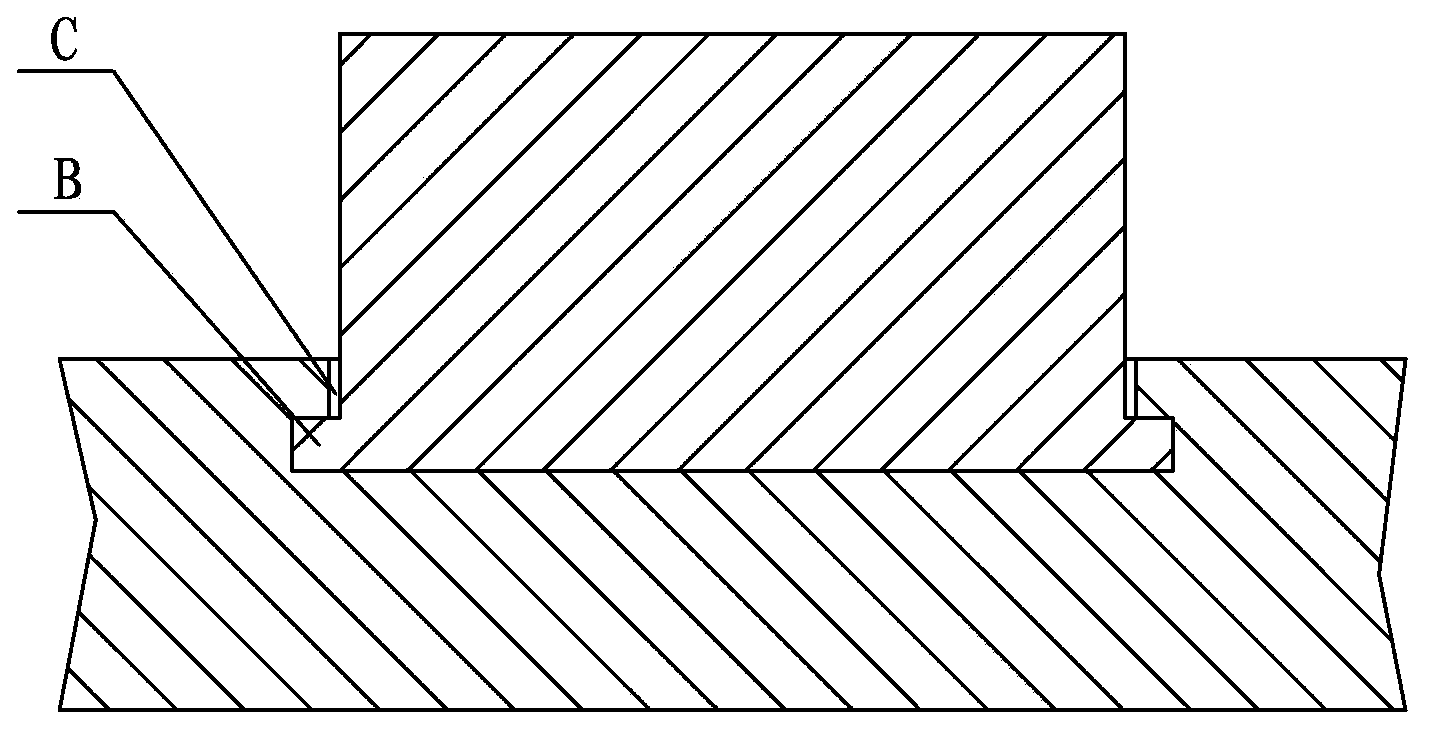

Die casting mold for manufacturing fan blades

The invention discloses a die casting mold for manufacturing fan blades. The die casting mold comprises a sprue gate, a fixed mold plate, a fixed mold core, a movable mold core and a movable mold plate. The fixed mold core and the movable mold core are combined with each other to form a cavity, a runner which is communicated with the cavity is arranged at the end, which corresponds to the cavity, of the sprue gate, a sprue spreader is arranged in the runner, an extrusion device is arranged between the fixed mold core and the movable mold core and comprises an extrusion pin and a cylinder, the cylinder provides extrusion power for the extrusion pin, and one end of the extrusion pin is positioned in the runner; a slider core pulling mechanism which can drive the extrusion pin to be pulled out of the runner is arranged between the fixed mold plate and the movable mold plate. The die casting mold has the advantages that after the die casting mold is closed, the fan blades can be primarily extruded by a pressure cylinder of a die casting machine, then secondary pressurization feeding and pressing compensation can be carried out by the extrusion pin on the basis of primary extrusion, accordingly, the density of the fan blades can be guaranteed, defects such as air holes, loosening and sinking can be prevented, and the forming quality of the fan blades can be effectively improved.

Owner:SUZHOU GUANGXING MOLD

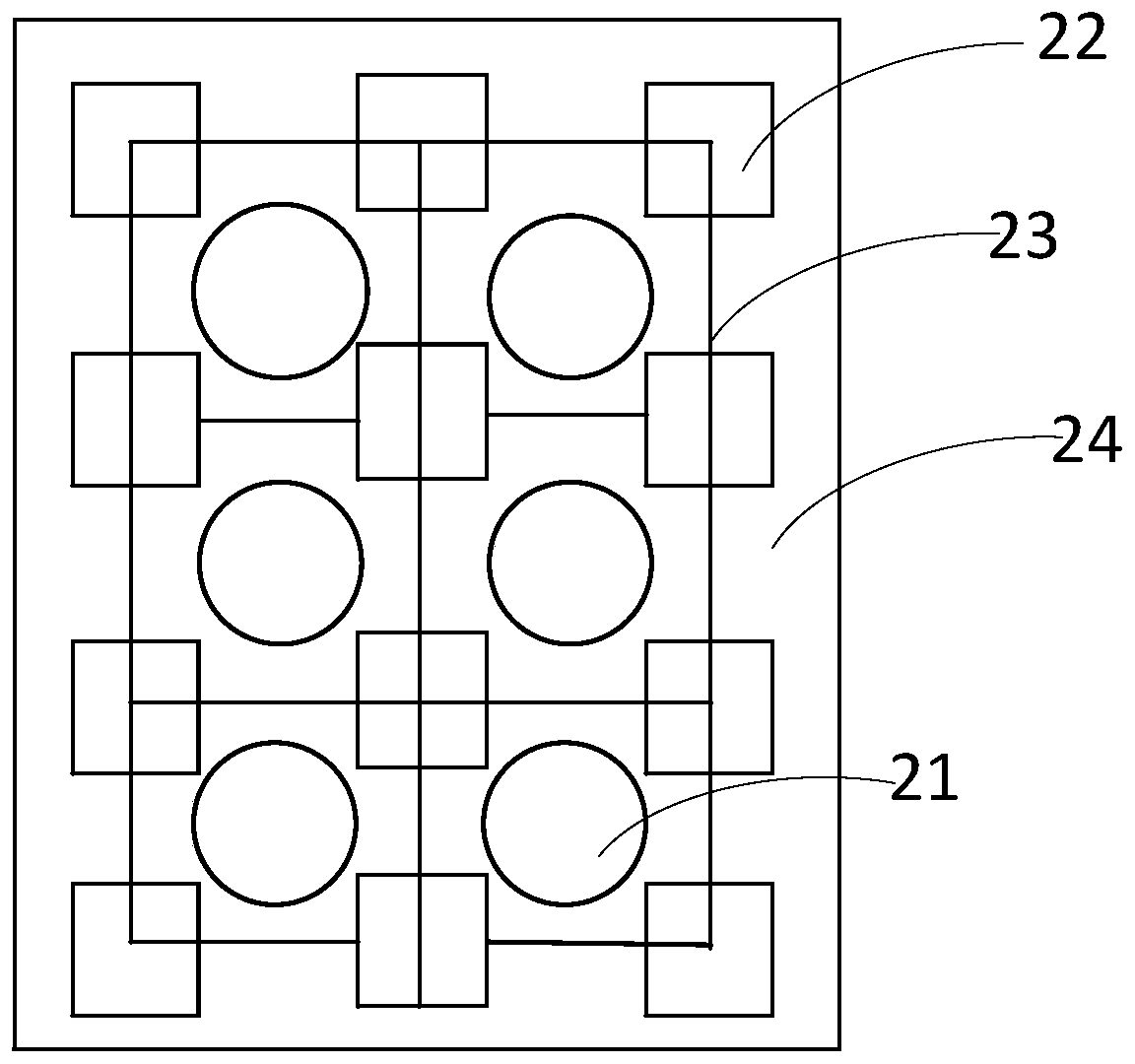

Display panel and display device

ActiveCN111162105ADiffraction reductionEvenly distributedSolid-state devicesSemiconductor devicesImaging qualityDisplay device

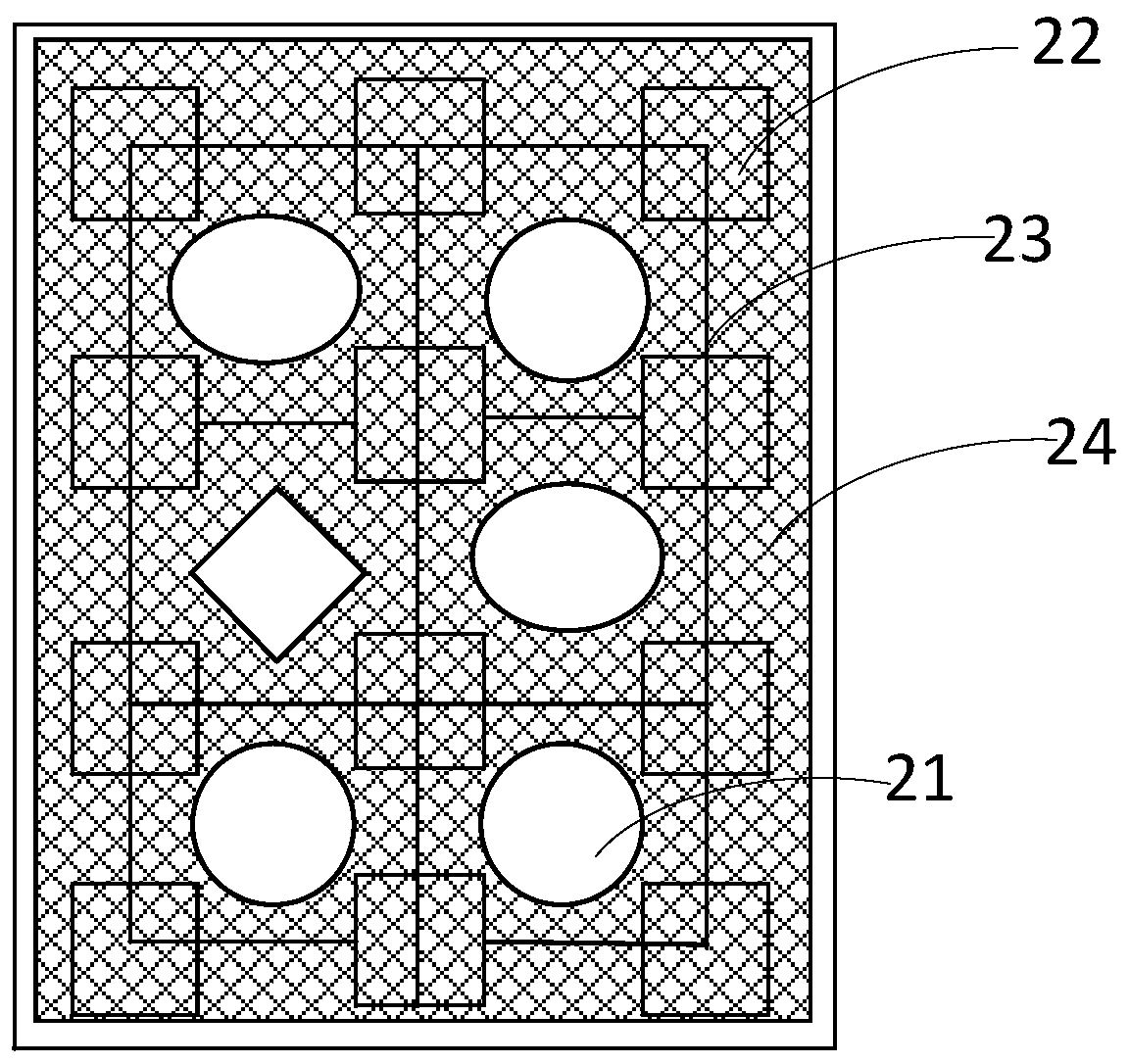

The invention relates to the technical field of display, and discloses a display panel and a display device. The display panel comprises a normal display area and a semitransparent display area, the normal display area is adjacent to the semitransparent display area, and the semitransparent display area corresponding to a camera is arranged to correspond to an optical acquisition element. The display panel further comprises a diffraction elimination layer arranged in the semitransparent display area, and the diffraction elimination layer comprises a semitransparent area which comprises a plurality of light-transmitting holes distributed in an array mode and a non-light-transmitting area, wherein the light-transmitting holes in each row comprise at least two light-transmitting holes with different shapes, the light-transmitting holes in each column comprise at least two light-transmitting holes with different shapes, and the non-light-transmitting area is provided with a plurality of pixel units. According to the display panel disclosed by the invention, the diffraction and interference phenomena occurring during light transmission are reduced, the phase superposition is avoided asmuch as possible, and the light distribution is uniform, so that the influence of the diffraction and interference effects on the light uniformity is reduced, the image quality is improved, and the photographing effect is also ensured.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

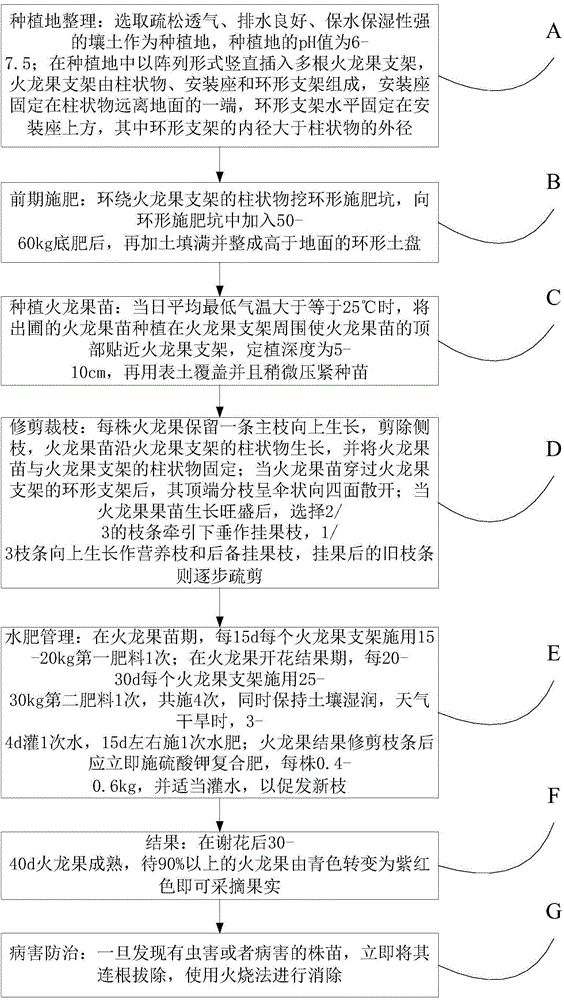

Pitaya planting method

InactiveCN104871757AReduce cost investmentIncrease productionHorticultureFertilizer mixturesComing outEngineering

The invention discloses a pitaya planting method which includes the steps of A, selecting loose and breathable soil with good draining performance and high water and moisture retention as a planting field; vertically inserting a plurality of pitaya supports in the planting field in an arrayed manner, wherein each pitaya support comprises a column, a mounting seat and an annular support, the mounting seat is fixed at one end, away from the ground, of the column, the annular support is horizontally fixed above the mounting seat, and the inner diameter of the annular support is larger than the outer diameter of the column; B, digging a fertilizing pit around the column of each pitaya support, applying 50-60kg of base fertilizer in each fertilizing pit, and then filling each fertilizing pit with soil to form an annular soil plate higher than the ground; C, planting pitaya seedlings coming out nursery around the pitaya supports and allowing the tops of the pitaya seedlings to be close to the pitaya supports, wherein the planting depth of the pitaya seedlings is 5-10cm; D, pruning; E, managing water and fertilizer; F, fruiting; G, controlling diseases.

Owner:广德县菁菁果业专业合作社

Solid-state fermentation method for feeding bacillus subtilis with high germination rate and high stress resistance

InactiveCN104388347AGuaranteed DensityIncreased spore yieldBacteriaMicroorganism based processesTemperature resistanceGermination

The invention discloses a solid-state fermentation method for feeding bacillus subtilis with a high germination rate and high stress resistance. The solid-state fermentation method comprises the following steps: selecting the bacillus subtilis CICC 10453; fermenting and culturing the bacillus subtilis CICC 10453 in a solid culturing medium by adopting a segmented temperature control method, wherein the main component of the solid culturing medium is wheat bran; directly collecting without the necessity of drying, and then smashing and sieving to obtain a solid finished product. Every 1g of bacillus-subtilis preparation contains 1.0*10<10>CFU effective bacillus subtilis, and more than 95% of the bacillus subtilis can germinate, so that the bacillus-subtilis preparation has good acid, cholate and high temperature resistance. If the bacillus-subtilis preparation is used as a feed additive, the unnecessary loss caused in the process of processing a feed can be reduced to a great extent. In addition, the bacillus-subtilis preparation can pass the harsh strong-acid environment in the stomach of an animal to play a beneficial role in the intestine.

Owner:ANYOU BIOTECH GRP

Cereal-based edible tableware and making method thereof

ActiveCN106954663AIncrease gelatinization temperature and gelatinization viscosityPromote aggregationDough treatmentBakery productsMillet flourRice flour

The invention discloses cereal-based edible tableware and a making method thereof. The cereal-based edible tableware comprises cereal powder and auxiliary materials, wherein the cereal powder comprises the following components in parts by weight of 60-80 parts of whole wheat flour, 5-20 parts of sorghum flour, 5-15 parts of rice flour, 0-10 parts of millet flour and 0-10 parts of purple sweet potato flour; and the auxiliary materials comprise the following components in parts by mass: 30-40 parts of water, 3-5 parts of butter and 0-5 parts of seasonings. The making method comprises the following steps of mixing the cereal powder which is subjected to microwave-assisted treatment and then roasting and precooking treatment or dry heat precooking treatment with the auxiliary materials to make dough; putting the made dough in a mold, performing heat-preservation shaping, conveying the shaped dough into an oven, performing roasting, and in the roasting process, performing pressurization for 1-2 times; and performing roasting until shaped dough is 90% cooked, performing film painting with rice flour dextrinization fluid or starch dextrinization fluid of which the concentration is 2-5%, and continuing roasting for 1-2 min so as to obtain finished products. According to the cereal-based edible tableware and the making method thereof disclosed by the invention, used raw materials are natural cereals, are rich in nutrition and can be directly eaten, so that environmental pollution is avoided; the used technology is simple, industrial production is easy to realize, and the cost is low; and the cereal-based edible tableware is compact in texture and is not deformed.

Owner:QINGDAO AGRI UNIV

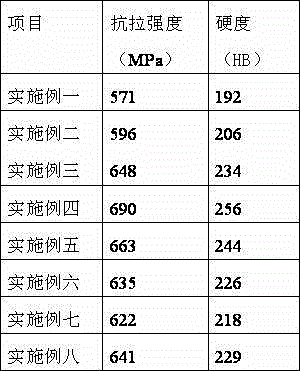

Medium silicon molybdenum nodular cast iron and production method thereof

The invention discloses a medium silicon molybdenum nodular cast iron. The medium silicon molybdenum nodular cast iron comprises the following components in percentage by mass: 3.1-3.3% of C, 3-5% of Si, 0-0.3% of Mn, 0-0.07% of P, 0-0.02% of S, 0.5-1.2% of Mo, 0.025-0.045% of Mg, and the balance of Fe and inevitable microelements. The invention also discloses a production method of the medium silicon molybdenum nodular cast iron: putting the prepared materials into an electric furnace for smelting, and adding a nodulizing agent and a nucleating agent during ladle casting to improve the properties of the nodular iron. The production method of the medium silicon molybdenum nodular cast iron is capable of eliminating a chilling tendency caused by nodulized elements and thus obtaining a cementite-free carting, and further increasing graphite cores and the quantity thereof; besides, the production method has the advantages of reduction of a nodular diameter, uniform distribution, round shape, high graphite grade, refining of eutectic cells, reduction of segregation, improvement of mechanical properties of the casting; as a result, the quality of products is guaranteed.

Owner:西峡飞龙特种铸造有限公司

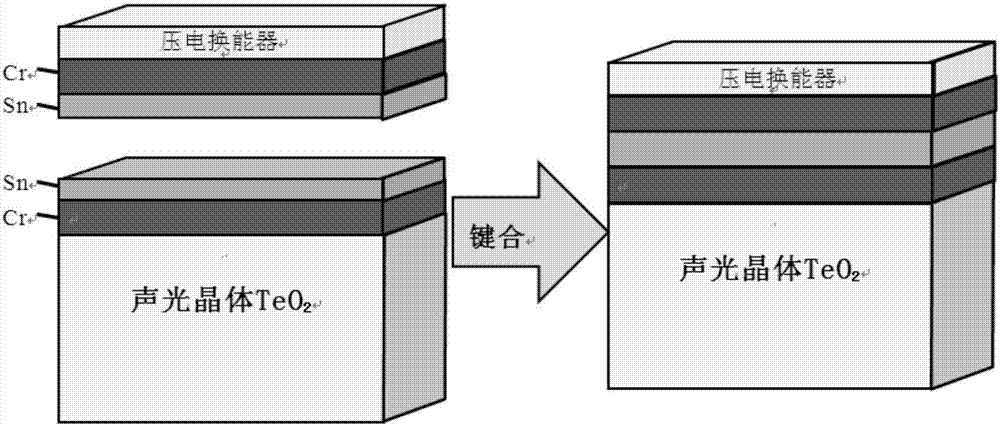

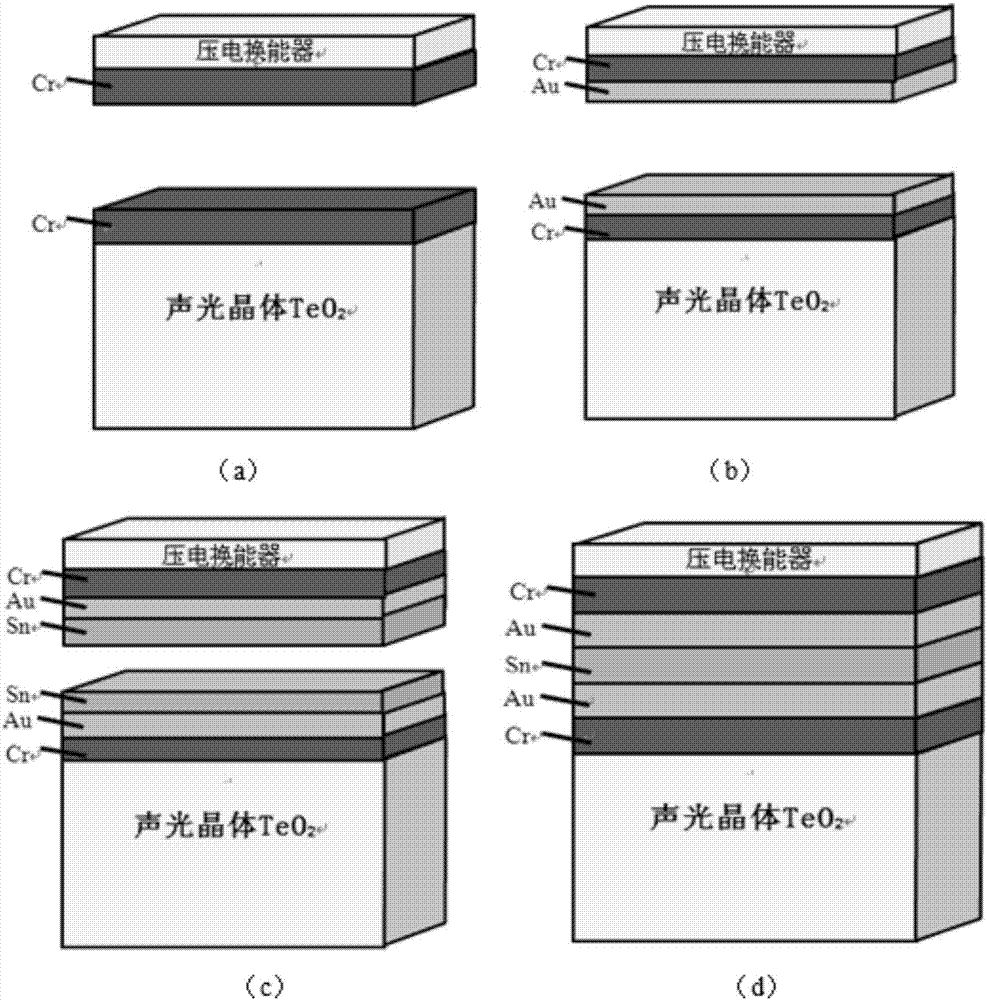

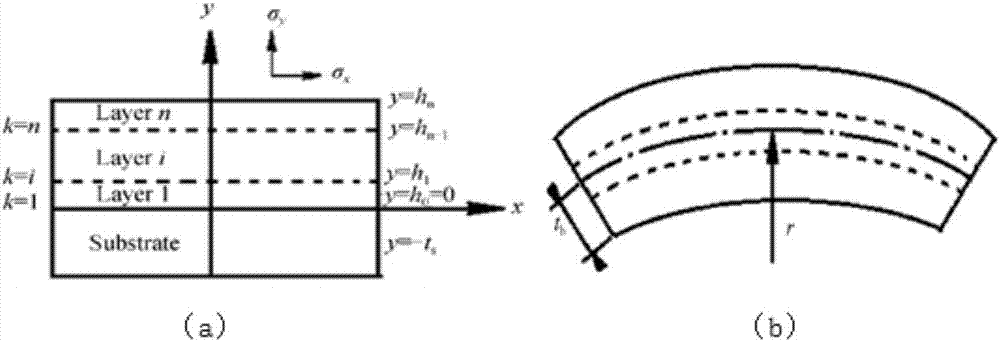

Acoustooptic crystal and transducer bonding structure

The invention discloses an acoustooptic crystal and transducer bonding structure. A bottom electrode layer and a welding layer are sequentially plated on the surface of each of an acoustooptic crystal and a transducer; the welding layer of the acoustooptic crystal is bonded with the welding layer of the transducer together; metal transition layers are arranged between the bottom electrode layer and the welding layer of the acoustooptic crystal as well as between the bottom electrode layer and the welding layer of the transducer respectively; after each welding layer is adhered to the corresponding bottom electrode layer through the corresponding metal transition layer, the adhesive force between the bottom electrode layer and the acoustooptic crystal is larger than that between the bottom electrode layer and the acoustooptic crystal when the welding layer is directly adhered to the corresponding bottom electrode layer; and the thickness of each metal transition layer enables a bonding layer to meet the acoustic impedance matching requirement of a device wholly. As for the acoustooptic crystal and transducer bonding structure, after bonding, the surface of the transducer does not have the phenomenon of cracking any more, the strength and the adhesive force of the transducer are strengthened, and the thermal stress of the device is obviously lowered.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com