Patents

Literature

142results about How to "Reduce cost investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

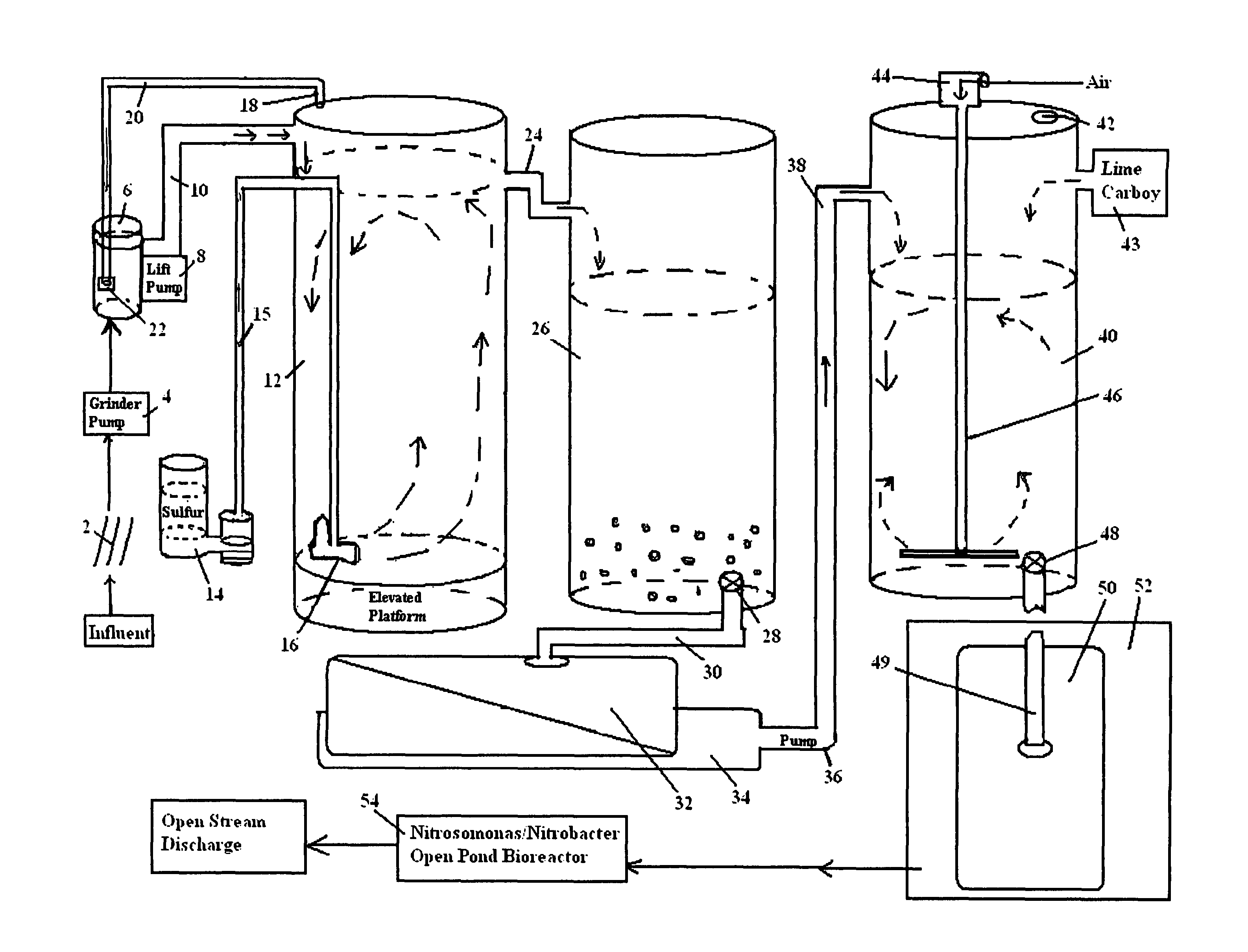

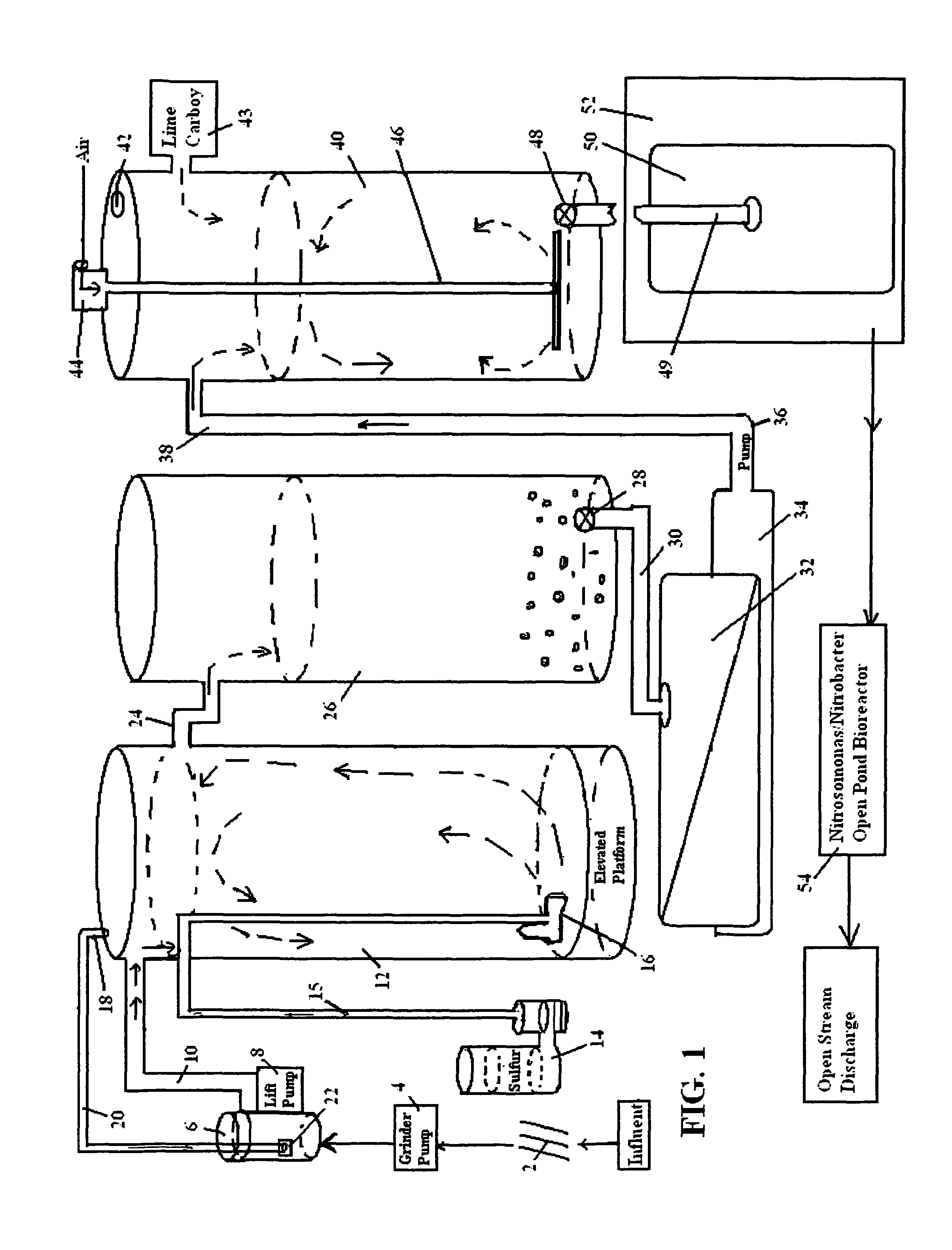

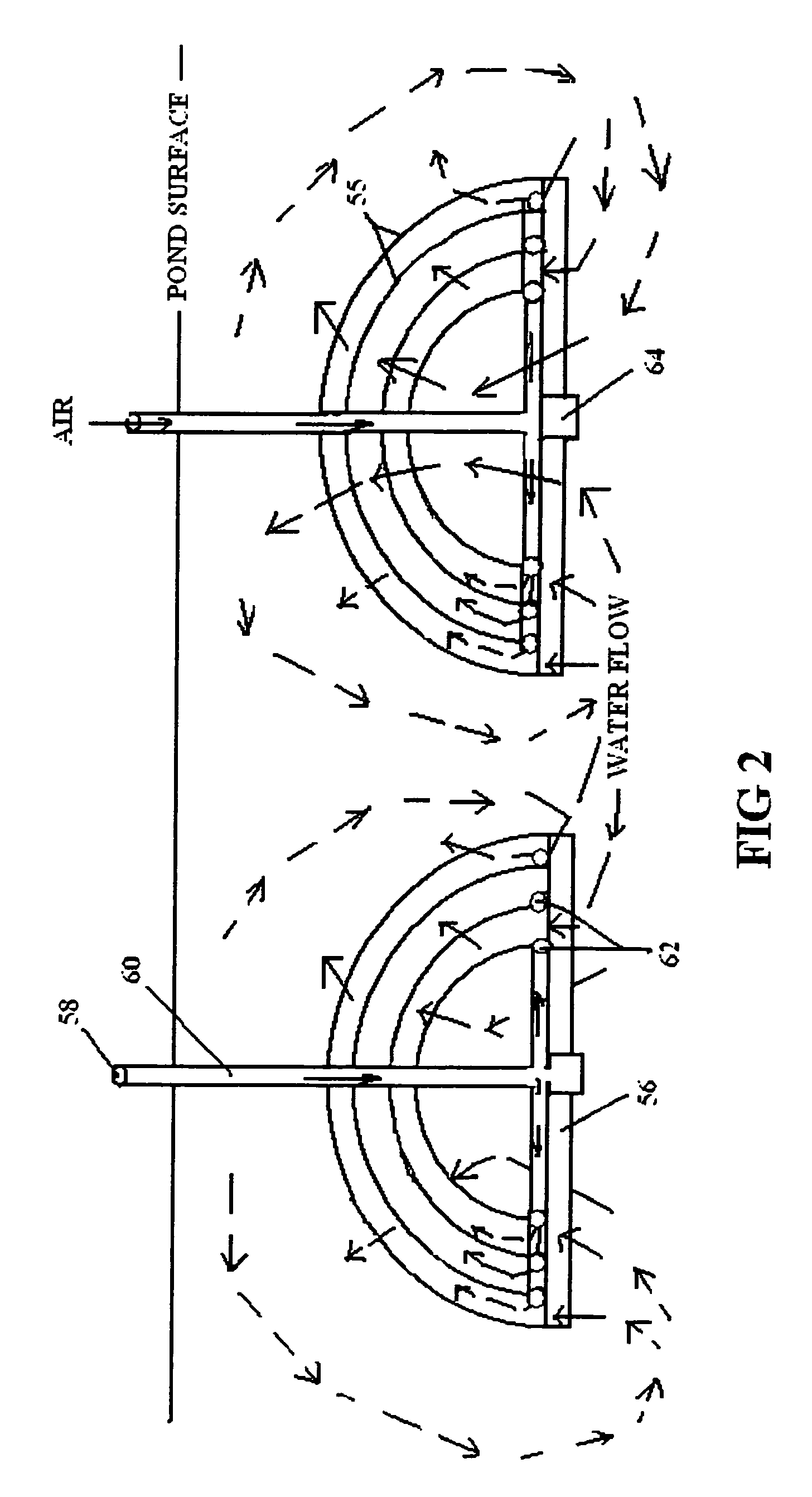

Wastewater chemical/biological treatment method for open water discharge

ActiveUS20120085705A1Surface areaSufficient supplyTreatment using aerobic processesUnicellular algaePhosphateNitrobacter

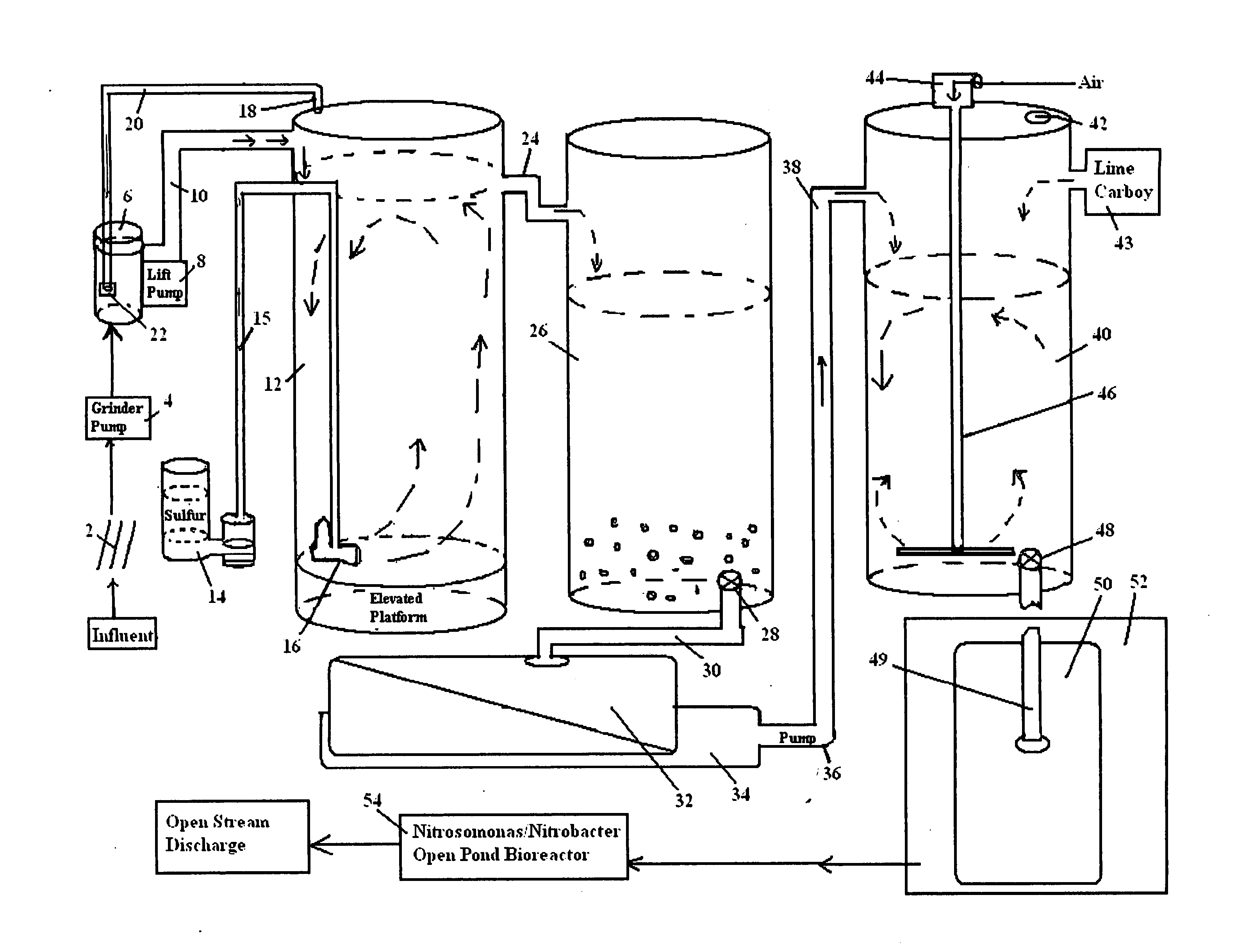

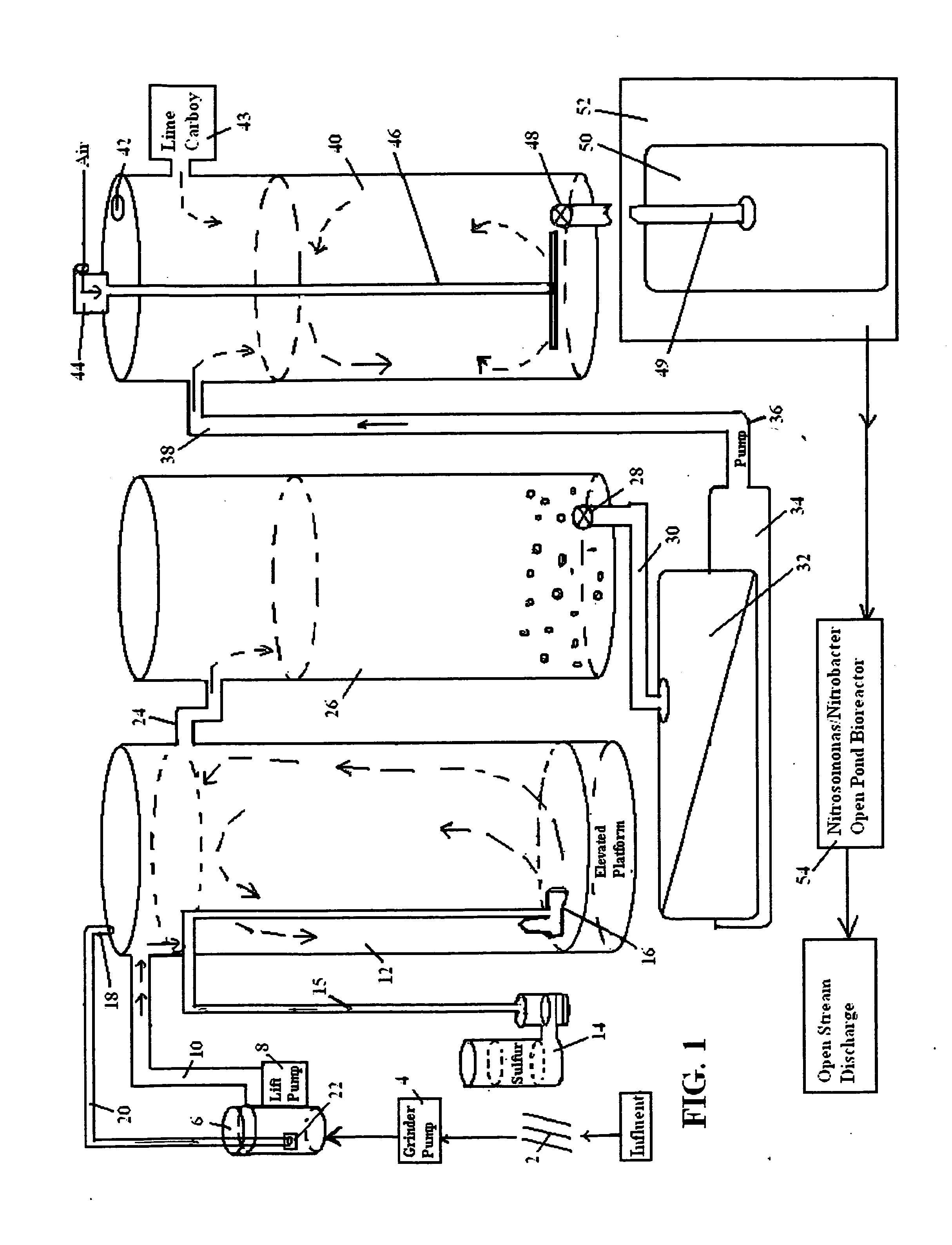

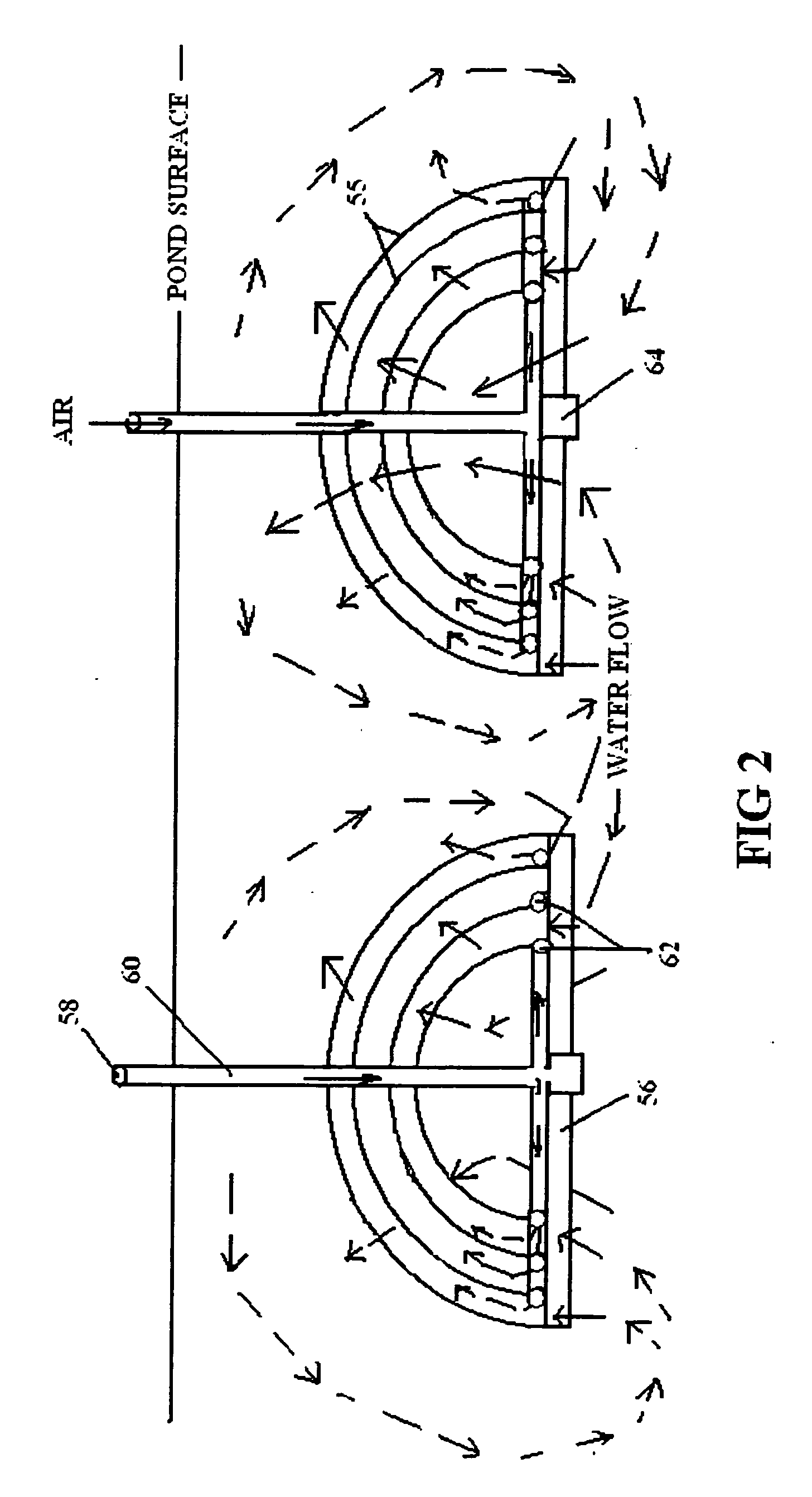

A wastewater treatment method employing chemicals for disinfection, and precipitation of suspended solids, heavy metals and phosphates before subsequent aerobic bacterial biological treatment using Nitrosomonas and Nitrobacter bacteria to remove ammonia and nitrates / nitrites and BOD compounds to produce recovered treated wastewater suitable for open water discharge.

Owner:EARTH RENAISSANCE TECH

Field track and production operation main unit operated thereon and rain type watering machine

ActiveCN101473717AOvercoming the inability to work on the groundShorten the timeAgricultural machinesWatering devicesButt jointTrackway

The invention relates to a filed track, comprising primary tracks and auxiliary tracks, wherein, the primary tracks are a plurality of longitudinal tracks which are arranged in parallel at the filed with equal row space, the auxiliary tracks are a plurality of tracks which are arranged at the two ends of the filed in parallel, and the end face distances of the auxiliary tracks and the primary tracks are constant; shifters are arranged at the auxiliary tracks, the bottom of each shifter is provided with shifting wheels capable of traveling on the auxiliary tracks, and the upper part of each shifter is provided with a transitional track which is in butted joint with the primary tracks; the height of the transitional tracks is equal to the height of the primary tracks, and the structure of the transitional tracks is the same as the structure of the primary structure. The invention also provides a production operation mainframe capable of operating on the field tracks and a water spray type watering machine. A bracket type agricultural manufacturing machine mainframe is formed by arranging various functional machines at the production operation mainframe scientifically and reasonably. The water machine has even and dense water amount, thereby avoiding the defects that the growth of crops is affected by decreased temperature of the ground, and fertilizer leaks and is lost with the water and can not be absorbed by crops due to broad irrigation.

Owner:尹树林

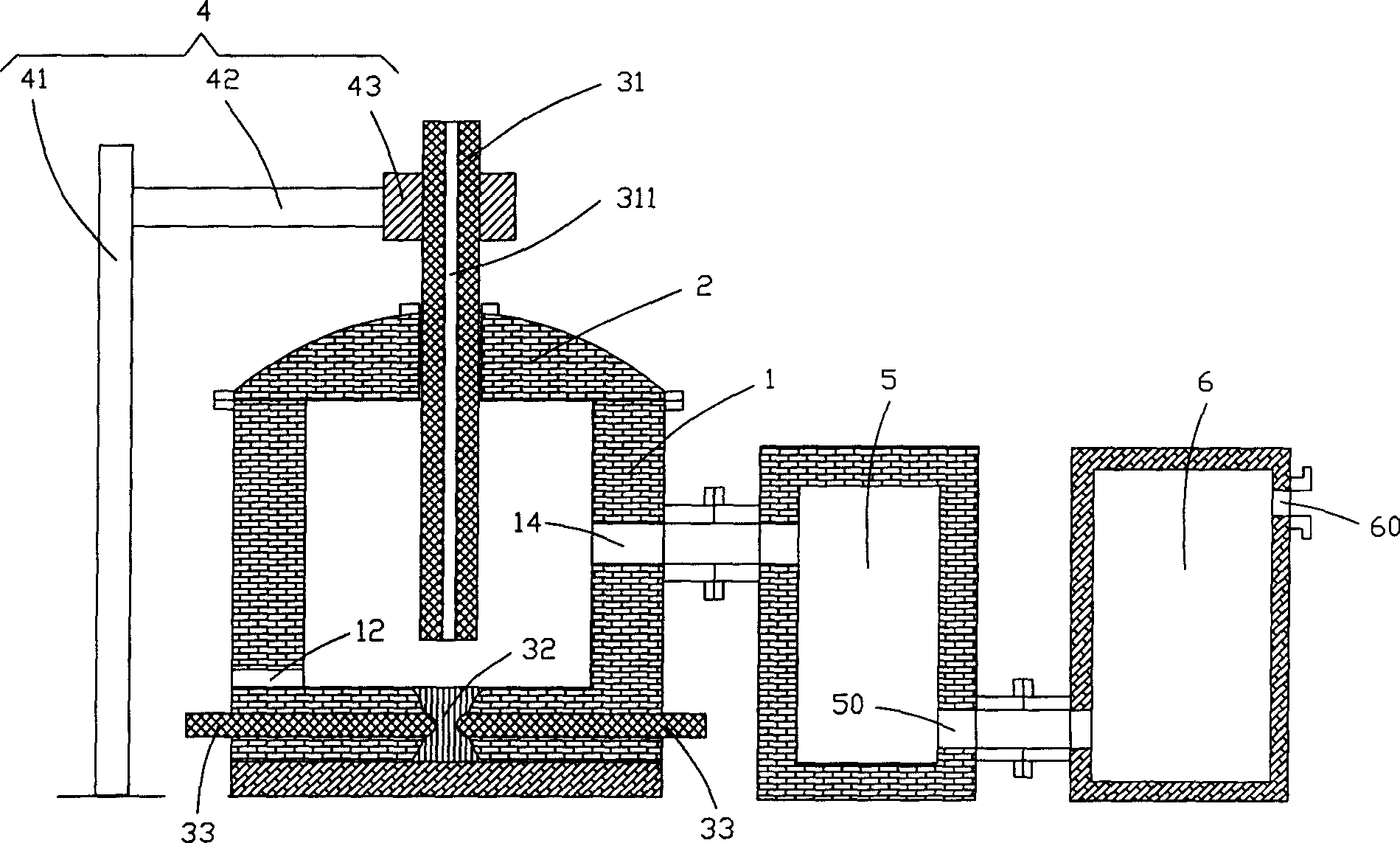

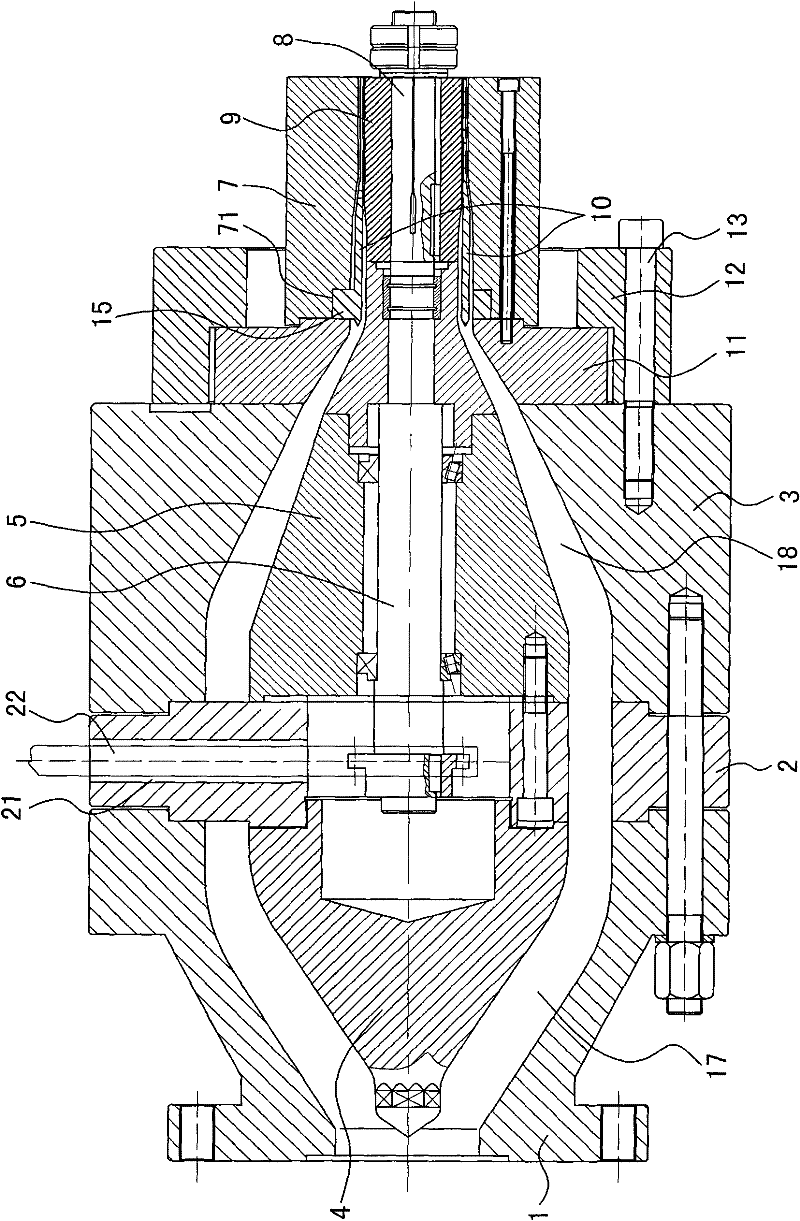

Plasma reaction furnace for processing waste

InactiveCN1825042AIncrease profitImprove processing efficiencyIncinerator apparatusBell type furnacesGraphite electrodeRefractory

The invention comprises a furnace body and a furnace lid. There is a refractory furnace liner and a thermal-protective insulating layer inside of the furnace body. A molten mass portal is disposed on the side of the hearth bottom. An air outlet is disposed on the furnace wall. A hollow graphite electrode disposed in the center of the furnace lid extends into the furnace. In the hollow graphite electrode there is a passageway. A second electrode against the hollow graphite electrode and a graphite lead-out electrode connected with the second electrode are disposed at the bottom of the furnace body. An arc zone is formed between the hollow graphite electrode and the second electrode to generate hot plasma.

Owner:黄建军

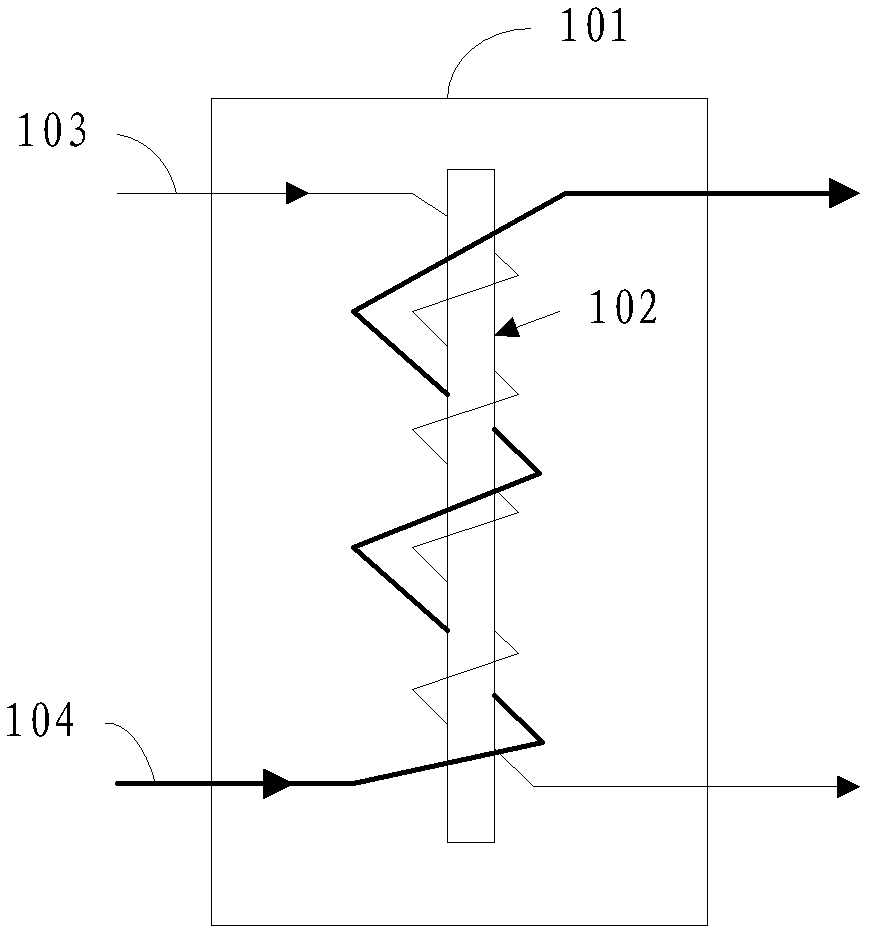

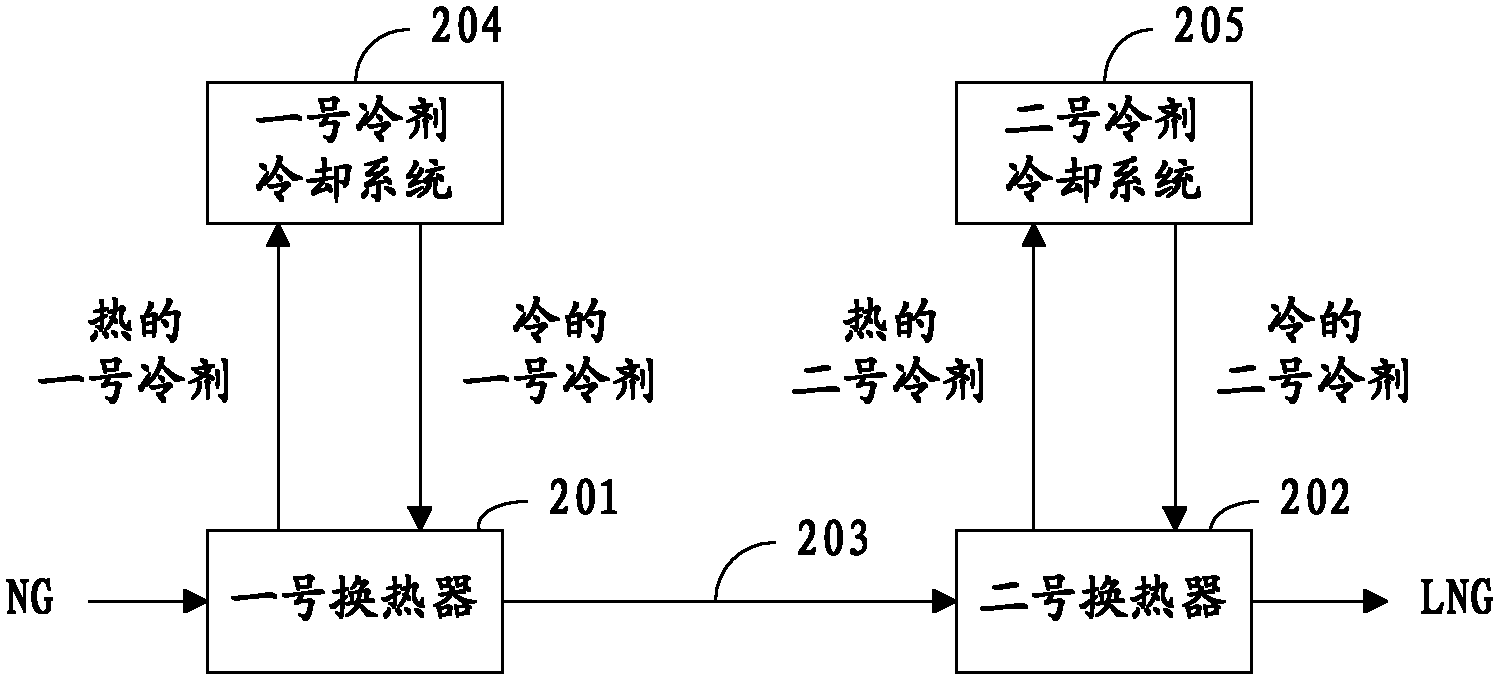

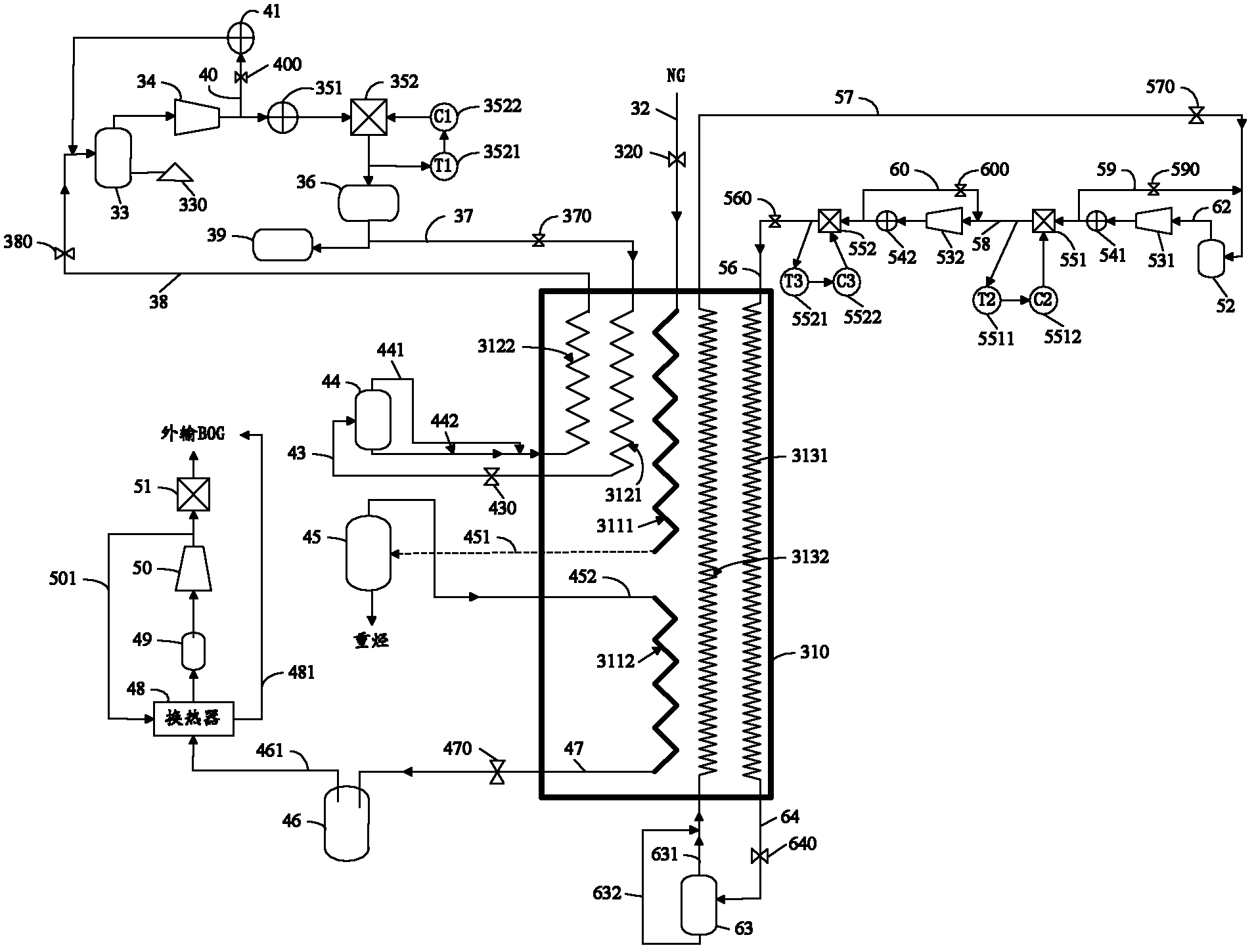

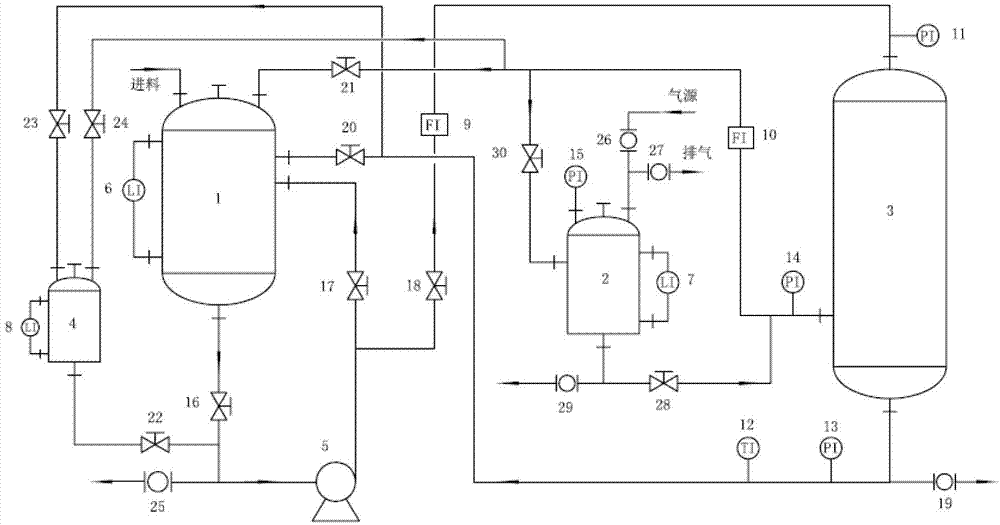

Liquefaction system and method for NG (Natural Gas)

ActiveCN103075868AImprove utilization efficiencyImprove cooling efficiencySolidificationLiquefactionEngineeringHigh pressure

The invention relates to a liquefaction system and a liquefaction method for NG (Natural Gas). The system comprises a cold box, a supply pipe for supplying the NG to the cold box, a No.1 refrigerant liquefaction subsystem, a No.2 refrigerant liquefaction subsystem, a No.1 refrigerant cooling subsystem, a No.2 refrigerant cooling subsystem, a heavy hydrocarbon separation tank which is used for conducting gas-liquid separation to liquid heavy hydrocarbon and gas light hydrocarbon, and an LNG (Liquefied Natural Gas) storage tank which is used for storing LNG obtained through liquefaction, wherein the cold box comprises an NG precooling passage which is connected with the heavy hydrocarbon separation tank and is used for supplying the NG; an NG deep cooling passage which is connected with the LNG storage tank and is used for supplying the gas light hydrocarbon; a No.1 refrigerant precooling passage and a No.2 refrigerant precooling passage which are used for respectively supplying and cooling high-pressure No.1 refrigerant and high-pressure No.2 refrigerant which are respectively supplied by the No.1 refrigerant liquefaction subsystem the No.2 refrigerant liquefaction subsystem, and are used for respectively supplying the cooled high-pressure No.1 refrigerant and the cooled high-pressure No.2 refrigerant to the No.1 refrigerant cooling subsystem and the No.2 refrigerant cooling subsystem; and a No.1 refrigerant cooling passage and a No.2 refrigerant cooling passage which are used for respectively supplying low-temperature No.1 refrigerant and low-temperature No.2 refrigerant which are respectively supplied by the No.1 refrigerant cooling subsystem and the No.2 refrigerant cooling subsystem to cool the NG, high-temperature No.1 refrigerant and high-temperature No.2 refrigerant. By adopting the technical scheme, the complexity and the energy consumption of the system can be reduced.

Owner:PETROCHINA CO LTD +1

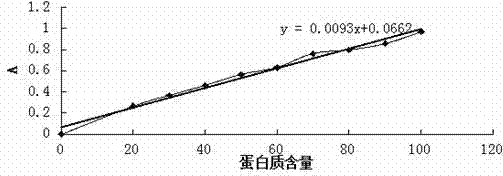

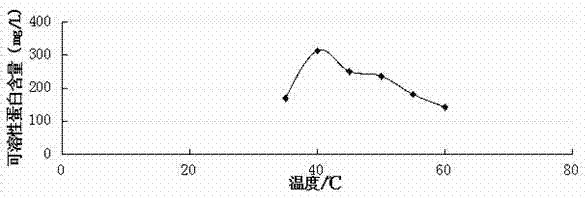

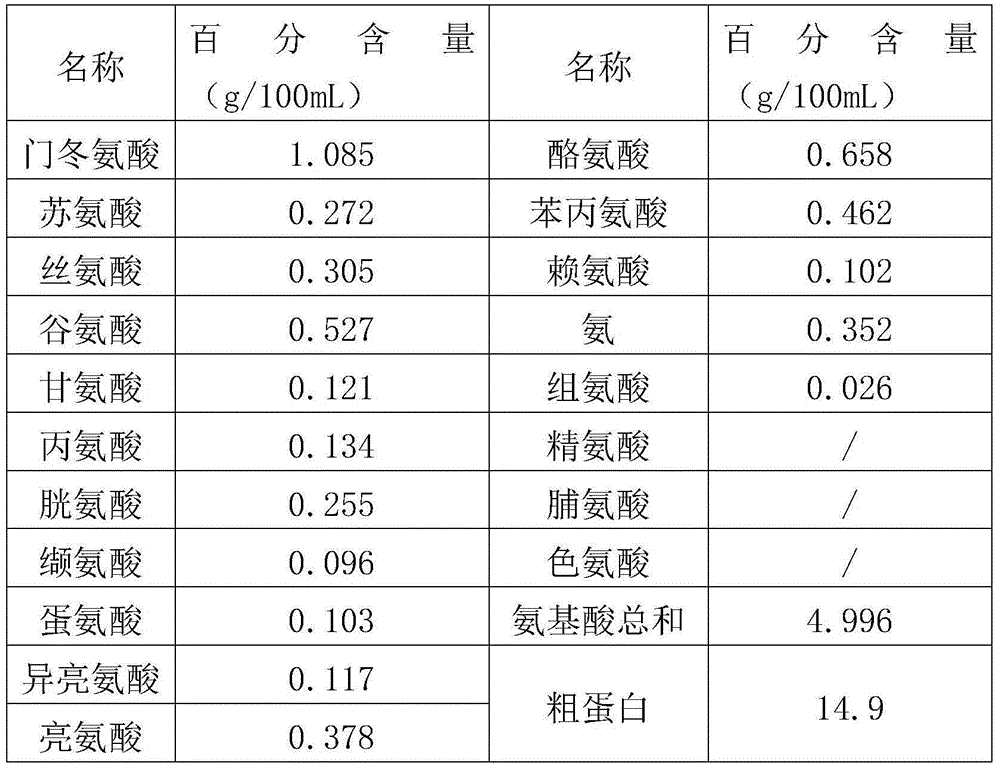

Preparation method of feather protein powder

InactiveCN104286372AThe process steps are simpleReduce cost investmentAnimal feeding stuffAnimal feedPre treatment

The invention relates to the technical field of animal feed processing, and particularly discloses a preparation method of feather protein powder. The preparation method of the feather protein powder takes chicken feathers as a raw material, and is characterized by comprising the steps of carrying out pretreatment on the chicken feathers, and grinding into feather powder; putting the feather powder into a container, and feeding distilled water into the container, wherein 0.015-0.0525g of keratinase or 0.050-0.175g of neutral protease is fed into 1g of feather powder; adjusting the pH value to be 6-8.5, and carrying out enzymolysis for 4-48 hours at the temperature of 35-60 DEG C; and filtering enzymolysis reaction liquid, and taking out the filtrate which is the product. The preparation method is simple in processing steps and less in cost and investment; the product is high in purity; the product can be processed into amino acid products and feed additive protein, thus being relatively wide in application and suitable for wide popularization and application.

Owner:QILU UNIV OF TECH

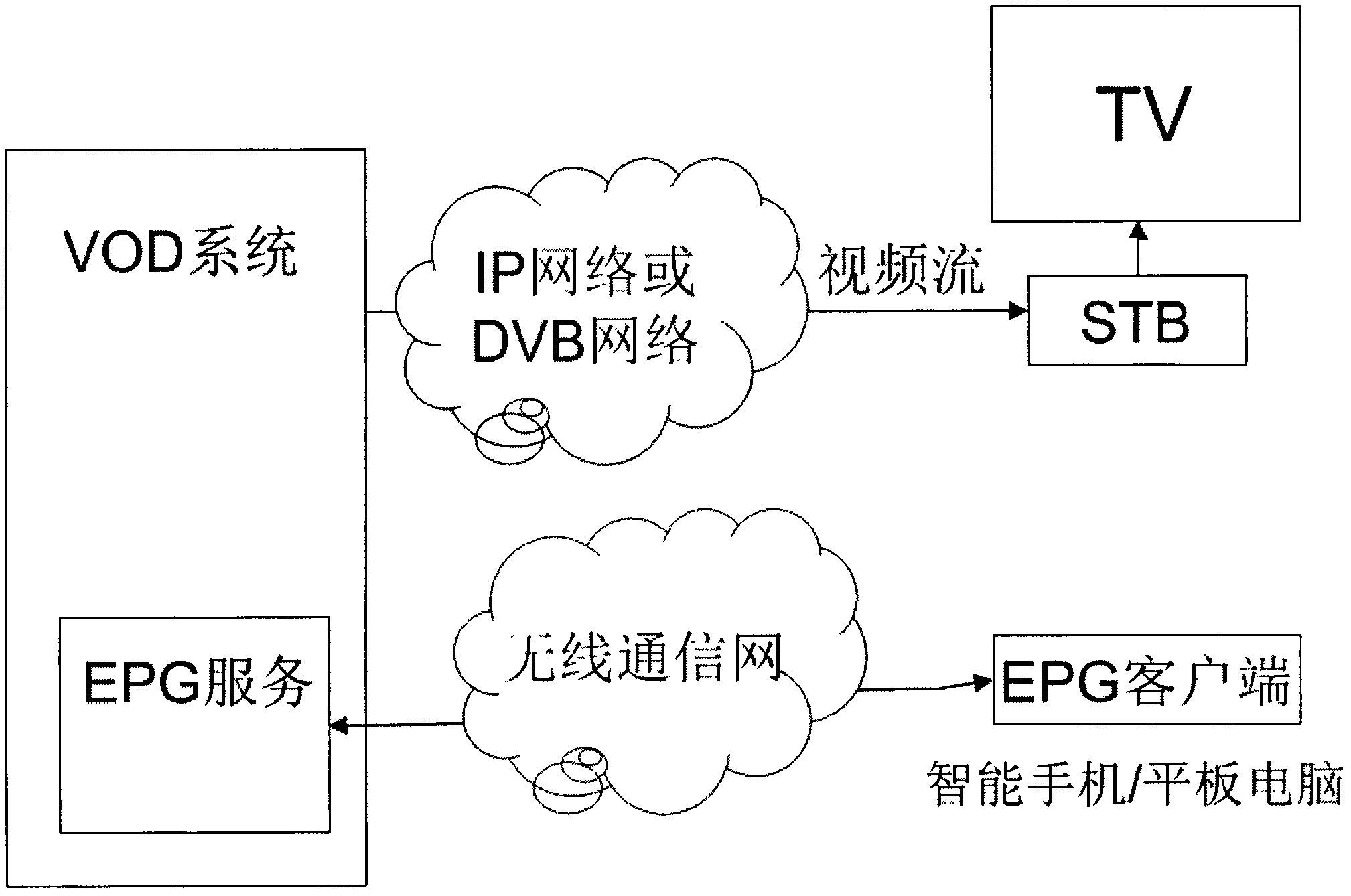

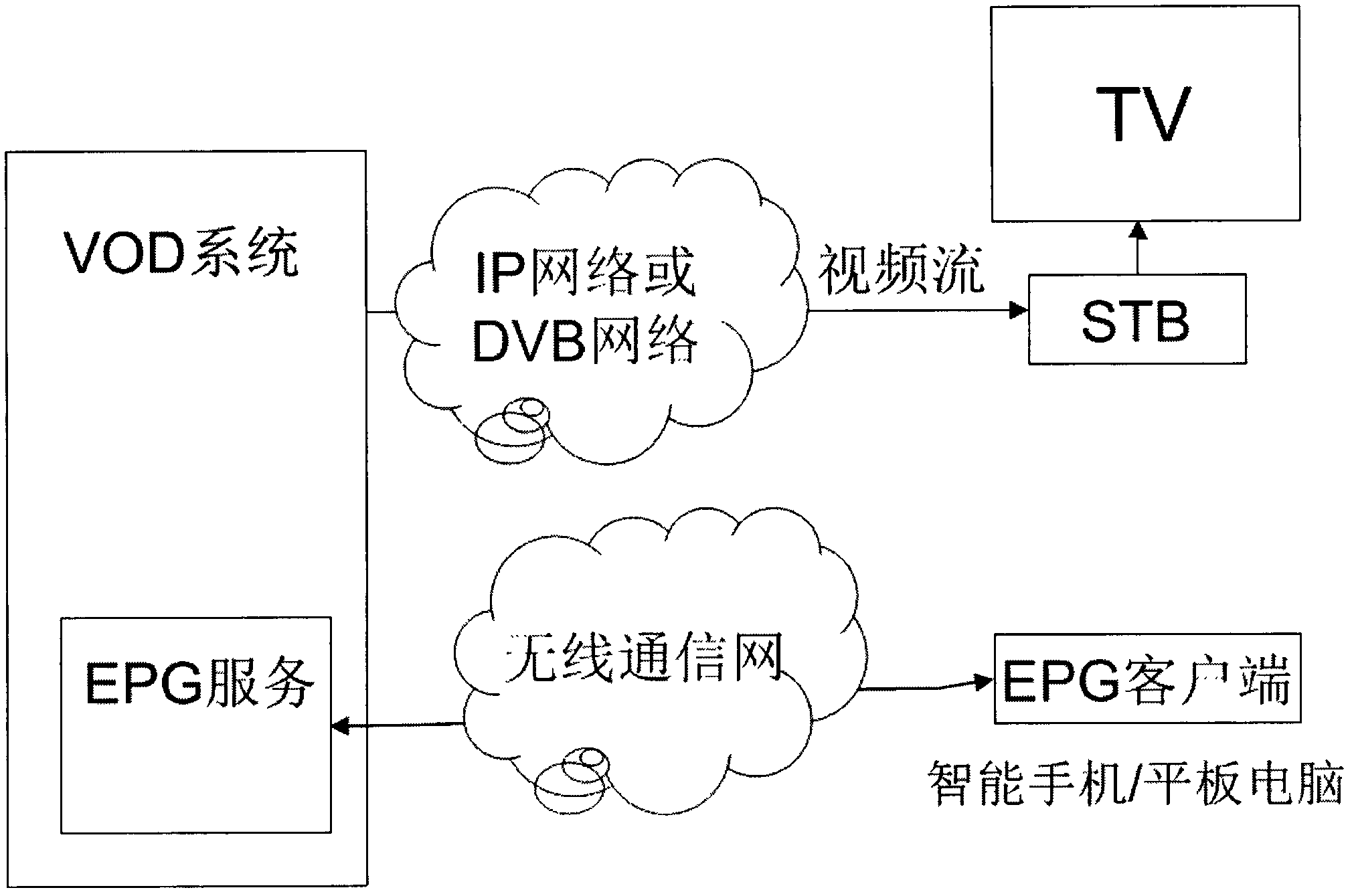

Video-on-demand method

InactiveCN102630047AGood experiencePowerful human-computer interfaceSelective content distributionData connectionTerrestrial television

The invention provides a video-on-demand method. The video-on-demand method sequentially comprises the following steps: a wireless handheld terminal such as a smart phone or a panel personal computer and the like is used by a television user for establishing bidirectional communication data connection through wireless communication network and a video-on-demand (VOD) system, and on-demand request information is transmitted to the VOD system through the data connection; the VOD system transmits requested television programs and VOD authorized instructions to a terminal set top box or a terminal television all-in-one machine by using IP (Internet Protocol) network or DVB (Digital Video Broadcasting) network; and the terminal set top box or the terminal television all-in-one machine plays television programs on a television according to the VOD authorized instructions. The video-on-demand method has the advantages of providing a more powerful human-computer interaction function for video-on-demand business and solving the unidirectional problem of digital video broadcasting network, thereby the video-on-demand business can be supplied without needing bidirectional network transformation and replacing the set top box.

Owner:SUZHOU DAOWEI INFORMATION TECH

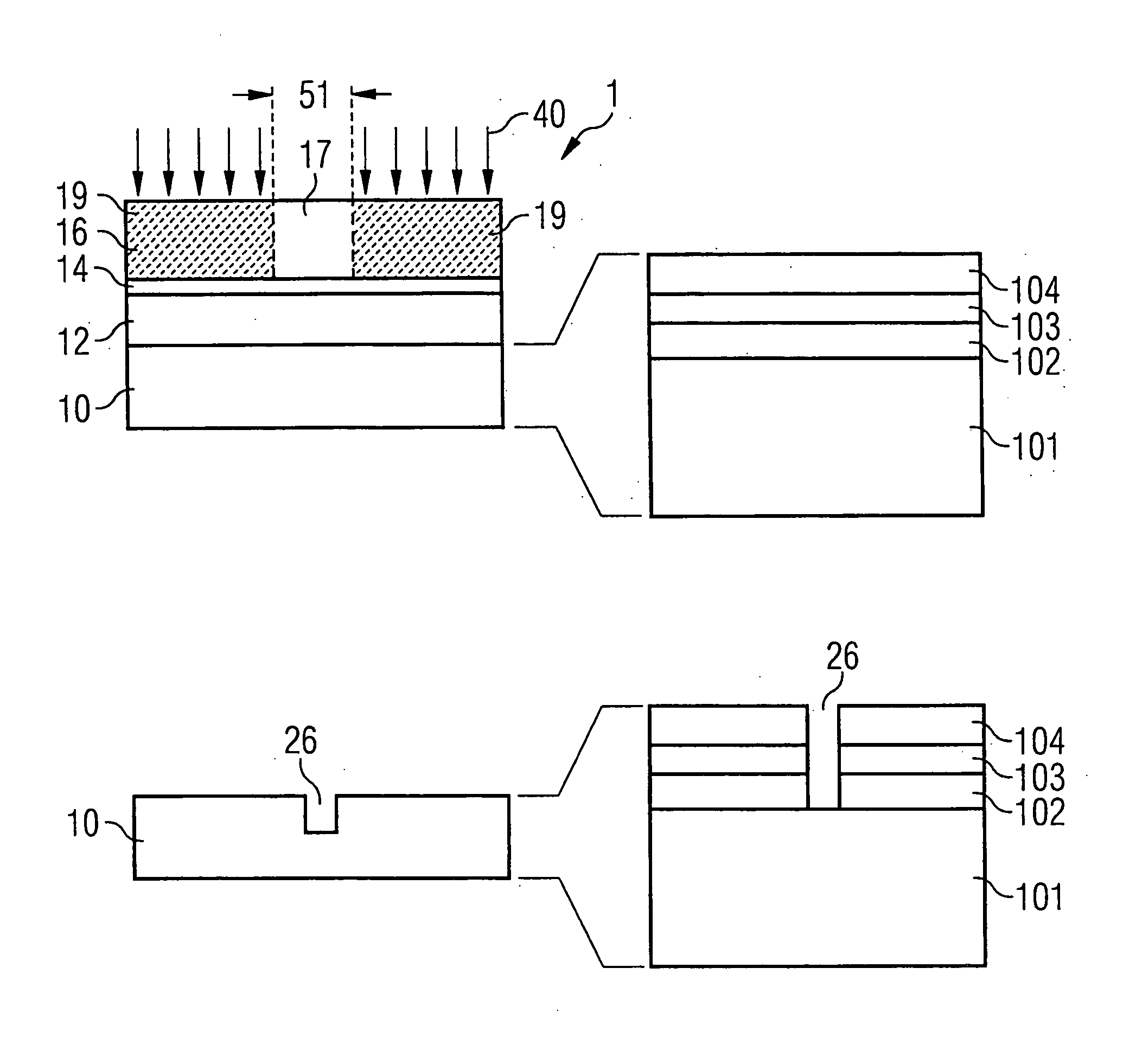

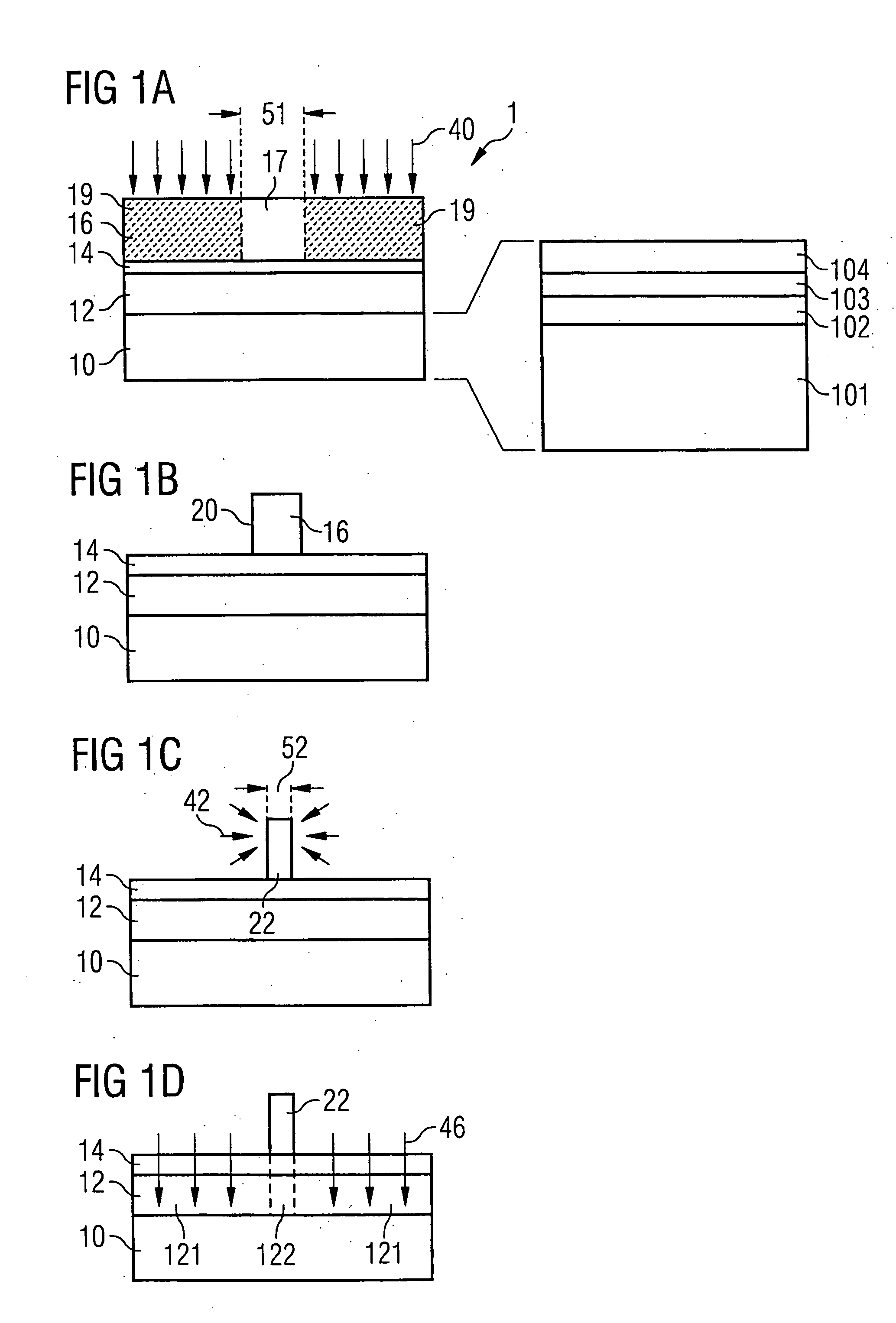

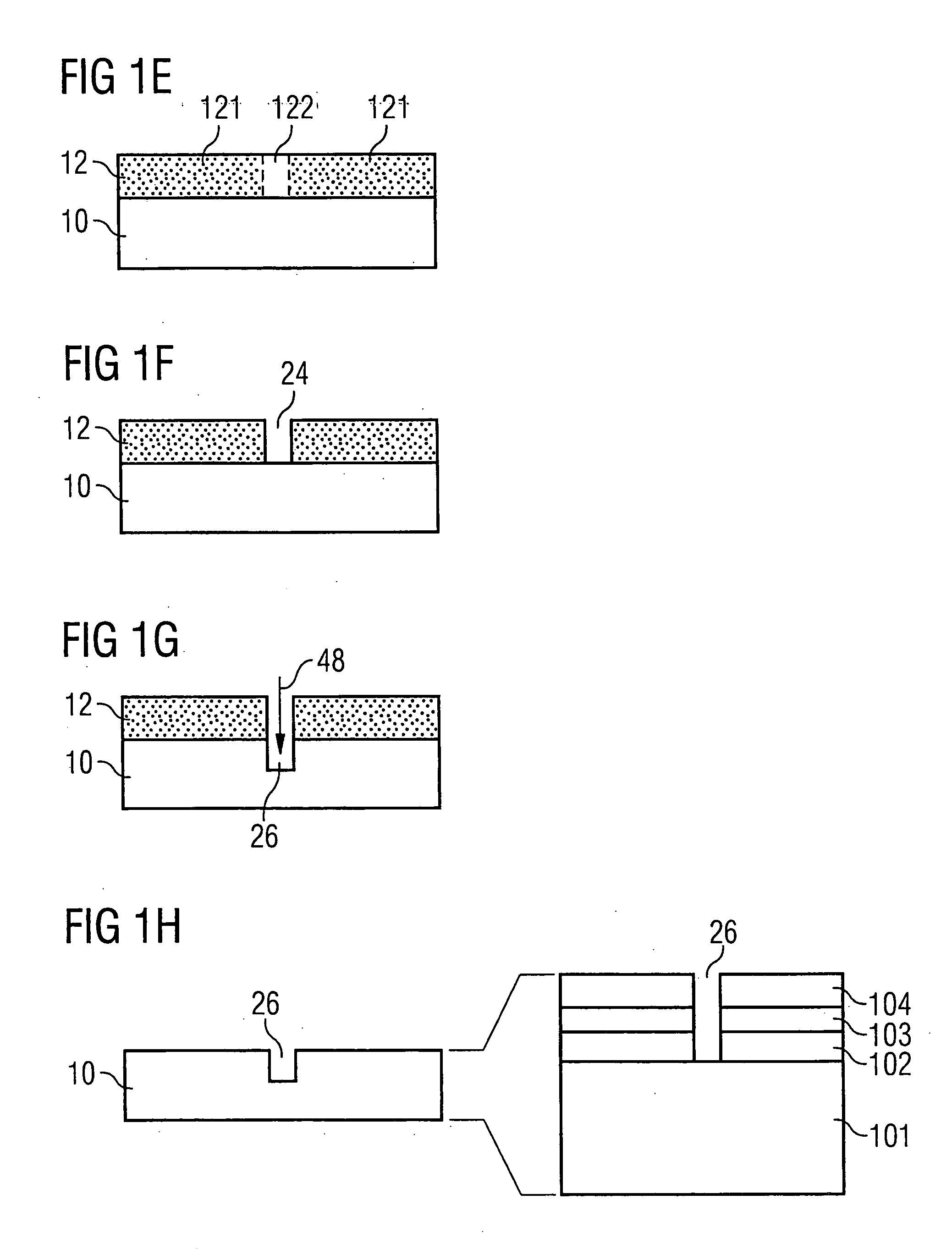

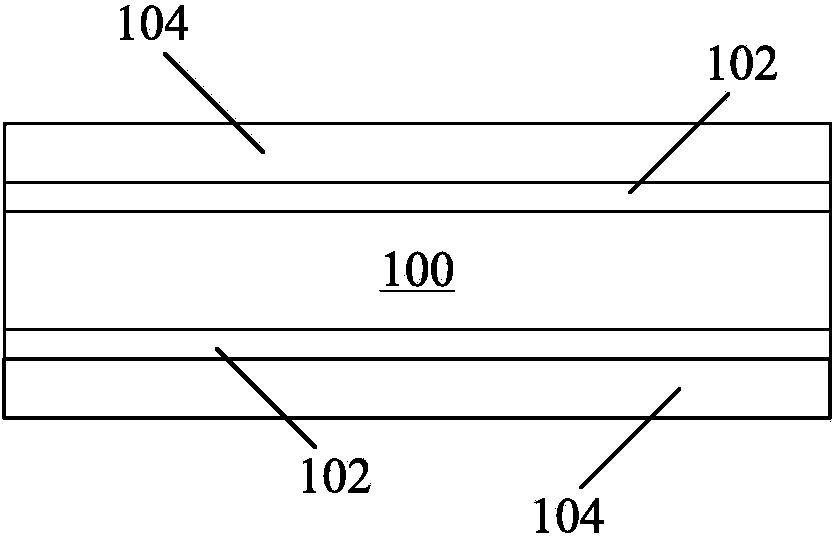

Method for forming a trench in a layer or a layer stack on a semiconductor wafer

InactiveUS20050106890A1High degree of uniformityReduce cost investmentSolid-state devicesSemiconductor/solid-state device manufacturingResistSemiconductor

Preferably using a positive resist, a resist ridge (20) is formed in a photosensitive resist (16) applied on a semiconductor wafer (1) above a hard mask layer (12). The resist ridge (20) serves as a mask for a subsequent implantation step (46). This makes use of an effect whereby the material of the hard mask layer (12), in a part (122) shaded by the resist ridge (20), can be etched out selectively with respect to the implanted part (121). The consequently patterned hard mask layer is used as an etching mask with respect to an underlying layer or layer stack (102-104) that is actually to be patterned. From the resist ridge (10) that has been formed as a line in the photosensitive resist (16), in a type of tone reversal, an opening (24) has been formed in the hard mask layer and a trench (26) has been formed in the layer / layer stack (102-104). According to the invention, the width (51, 52) of the resist ridge (20) is reduced by exposing the resist ridge (20) to an oxygen plasma (42). As a result, it is possible to form a trench (26) in the hard mask layer (12) and in the layer / layer stack (102-104) the width (52) of which trench is smaller than the lithographic resolution limit during the lithographic patterning of the resist (16).

Owner:POLARIS INNOVATIONS

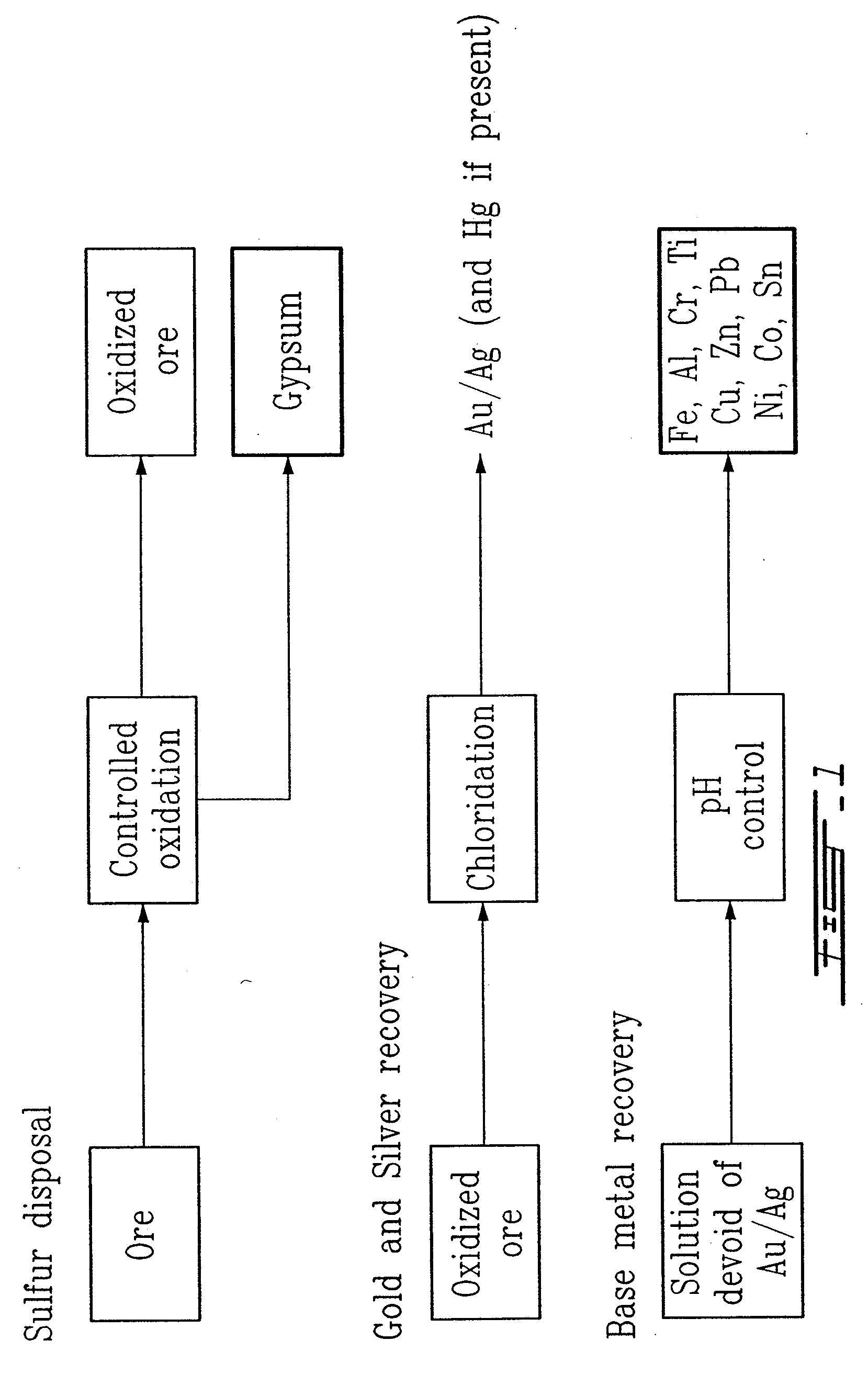

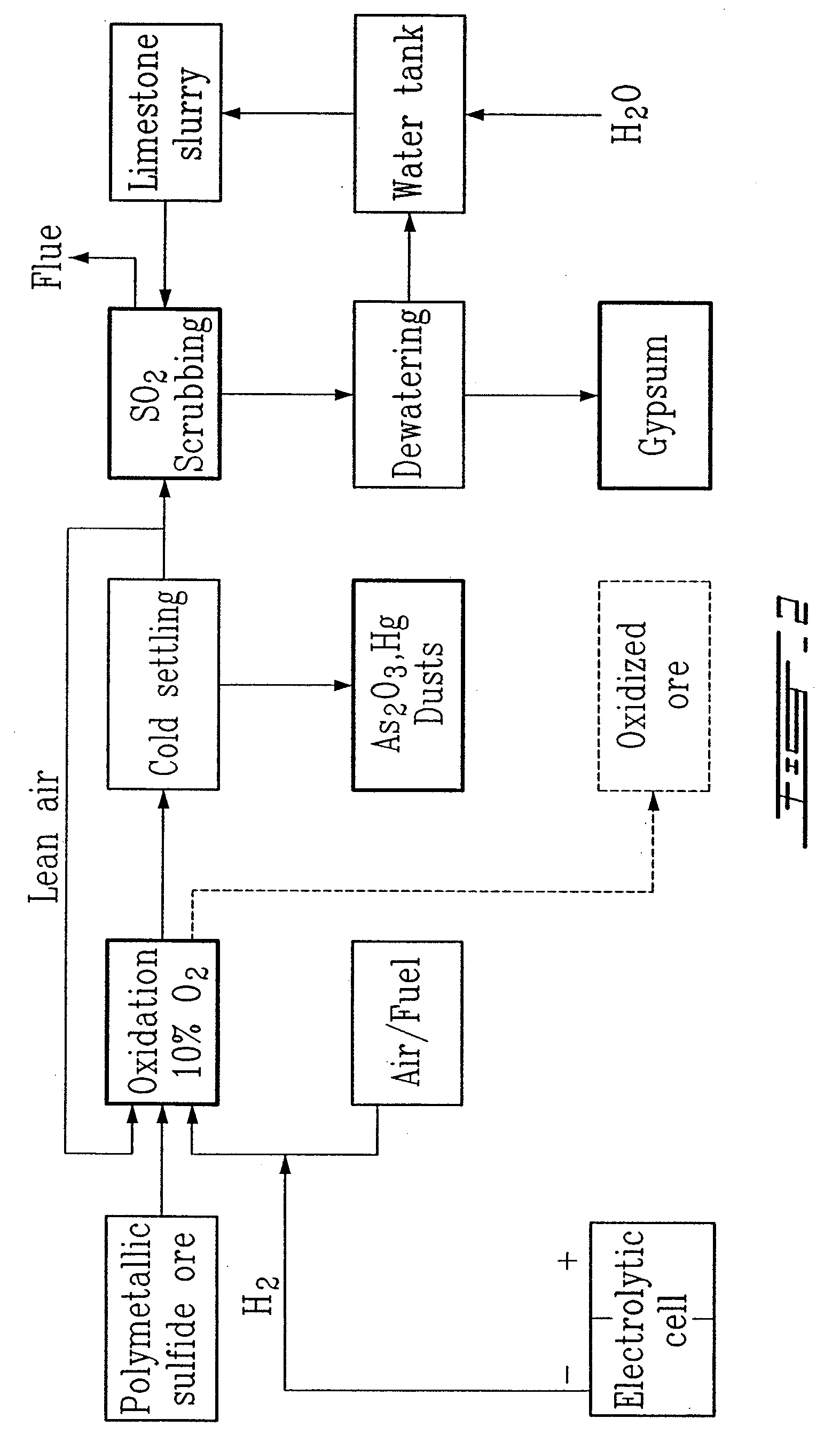

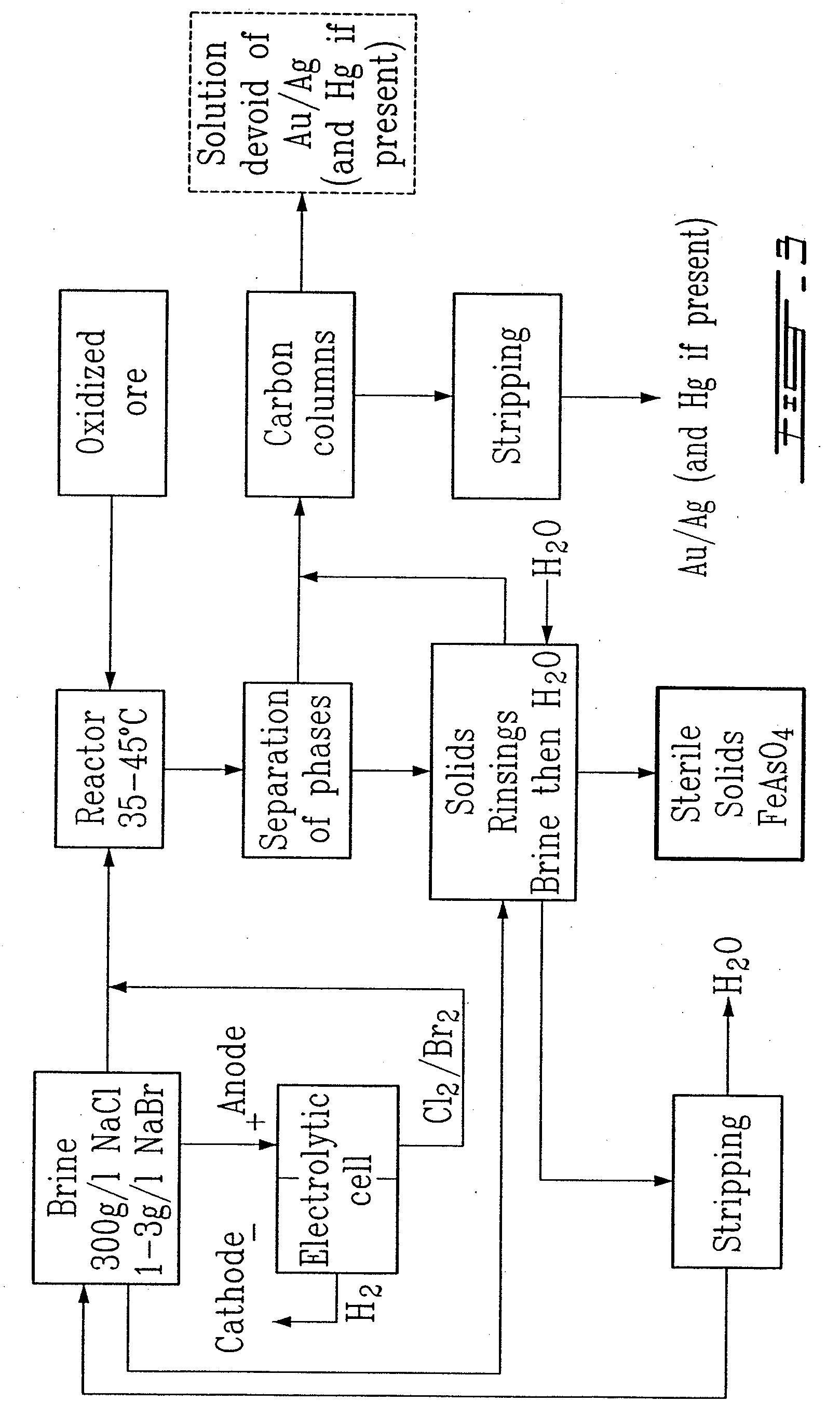

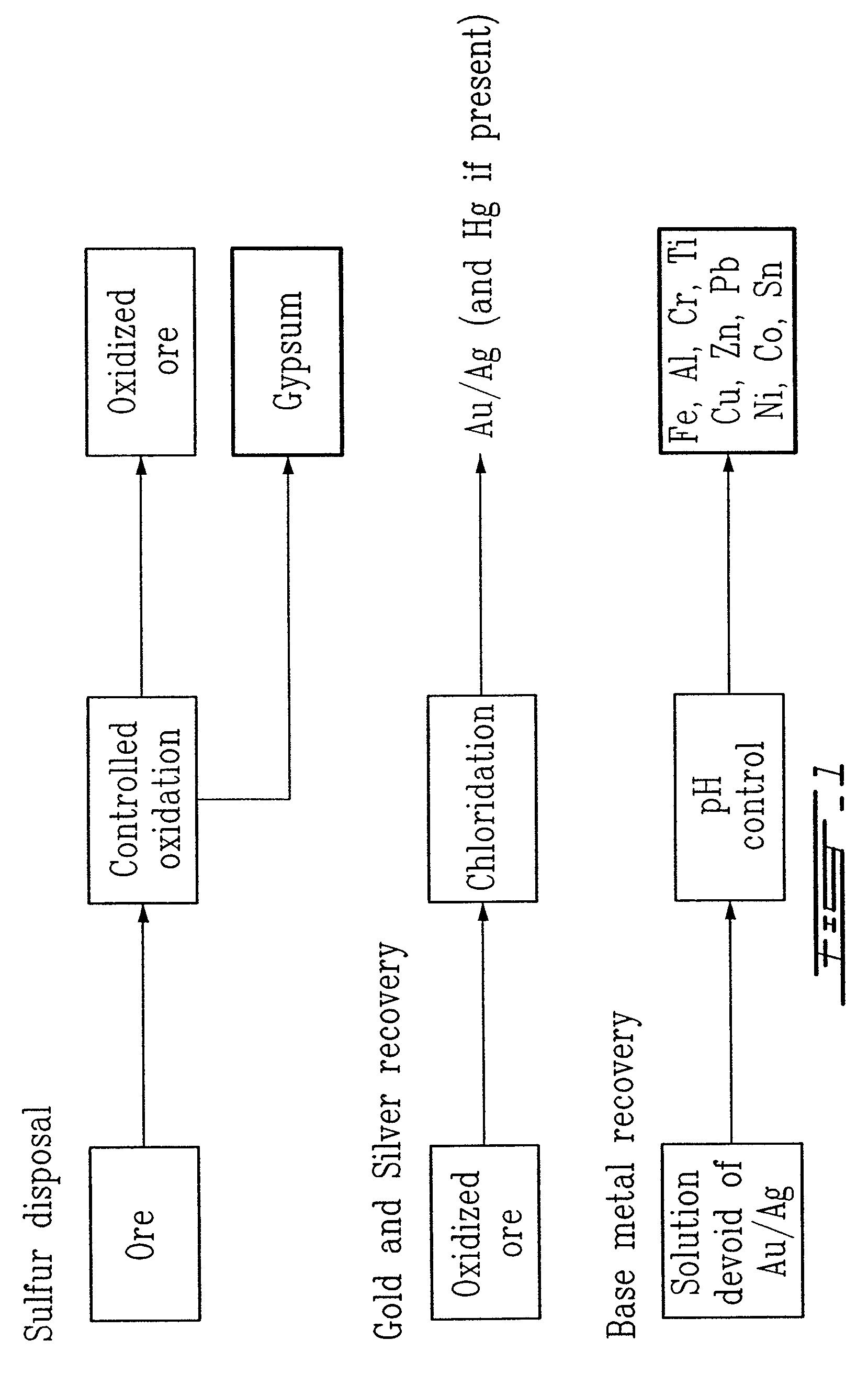

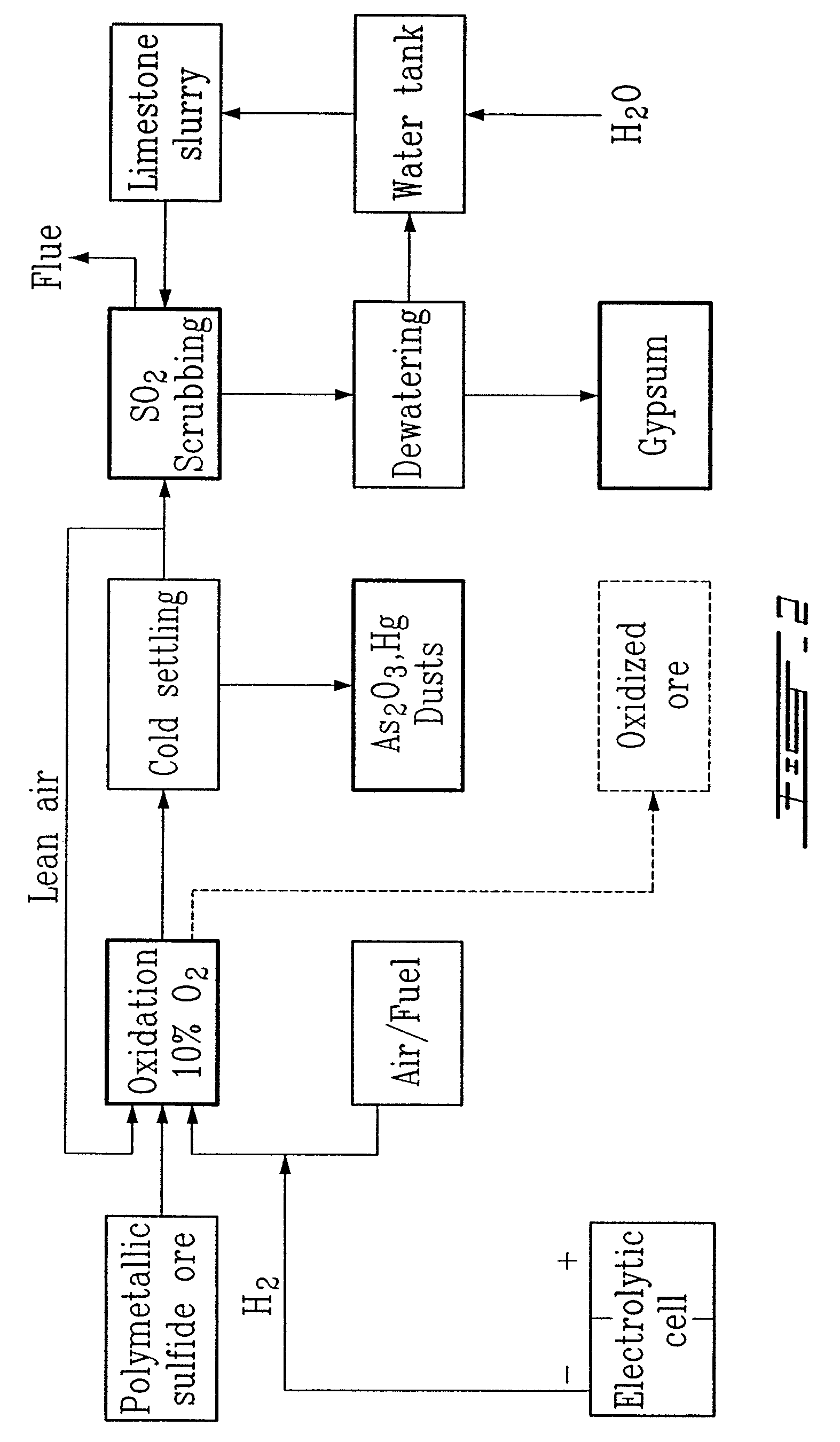

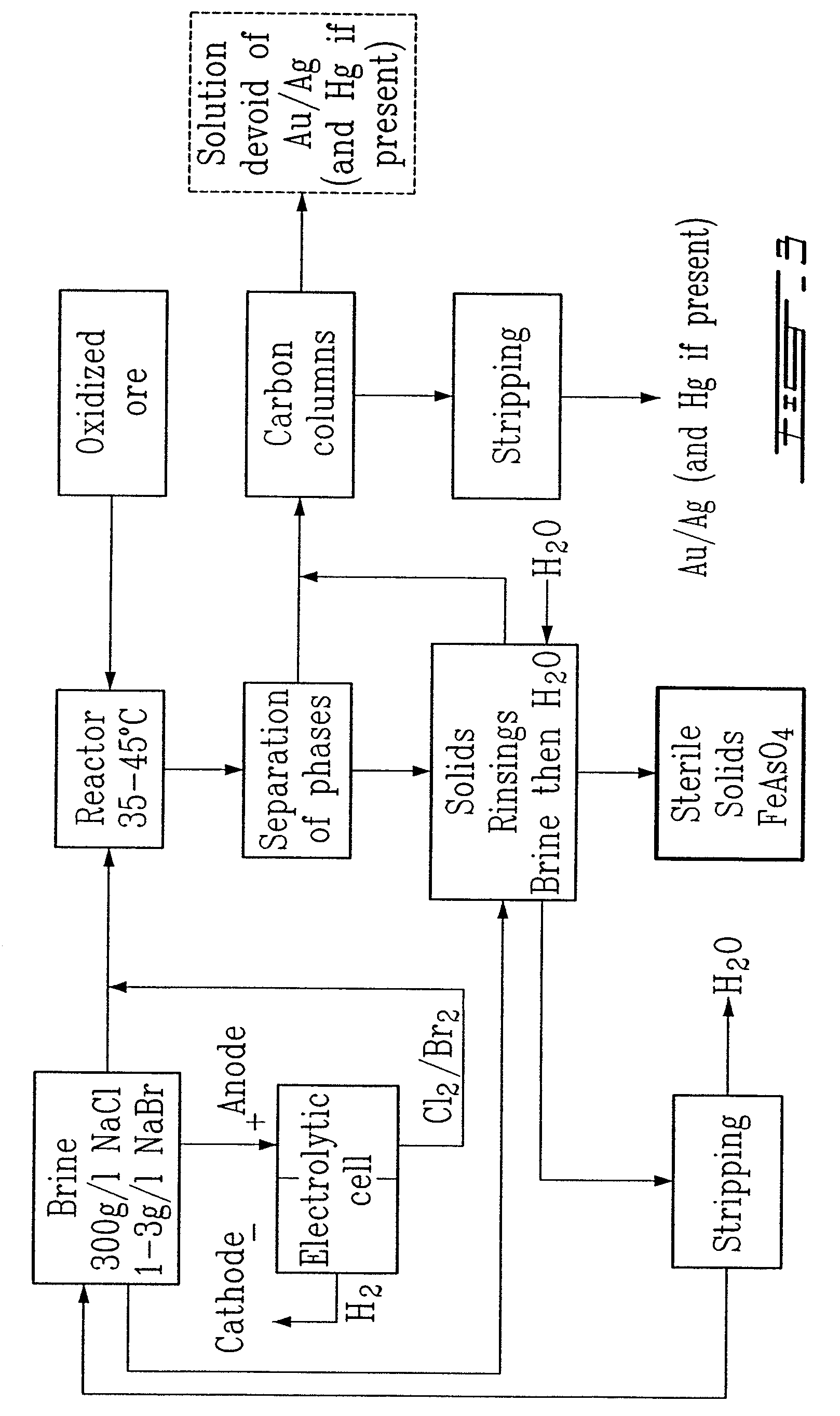

Gold and silver recovery from polymetallic sulfides by treatment with halogens

ActiveUS20080112864A1Quick responseHigh treatment rateAluminium compoundsSolvent extractionMetallic sulfideTitanium

A method for treating a polymetallic sulfide ore containing gold and / or silver, and further containing base metals selected from the group consisting of iron, aluminum, chromium, titanium, copper, zinc, lead, nickel, cobalt, mercury, tin, and mixtures thereof, is disclosed. The method comprises the steps of grinding the polymetallic sulfide ore to produce granules, oxidizing the granules to produce oxidized granules, and chloride leaching the granules using a brine solution including dissolved halogens, as well as chloride and bromide salts.

Owner:DUNDEE SUSTAINABLE TECH

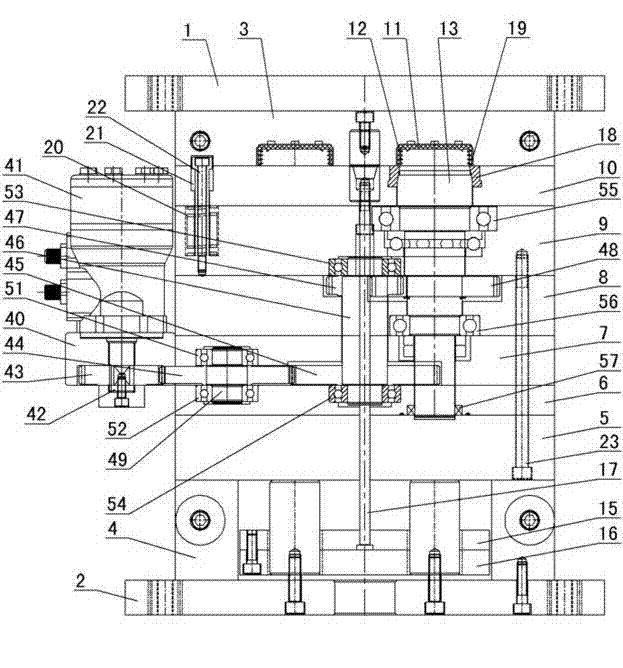

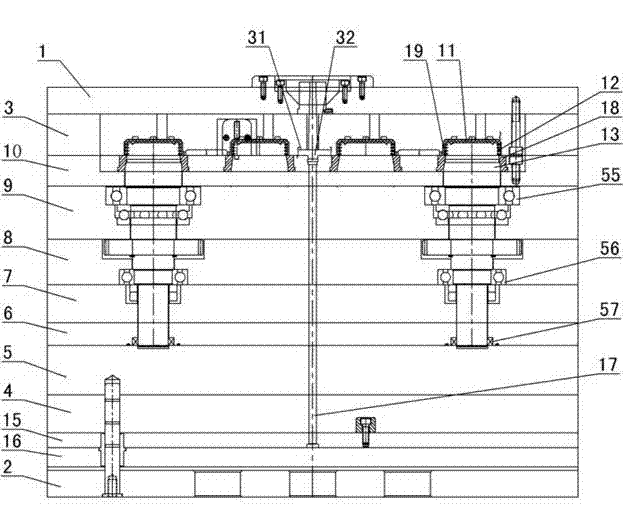

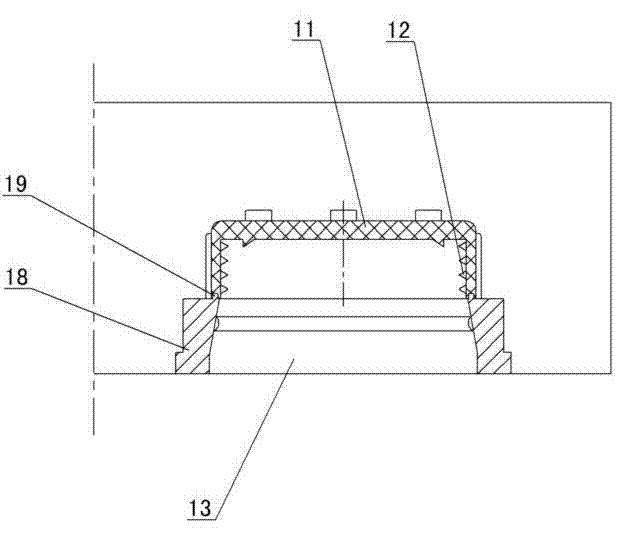

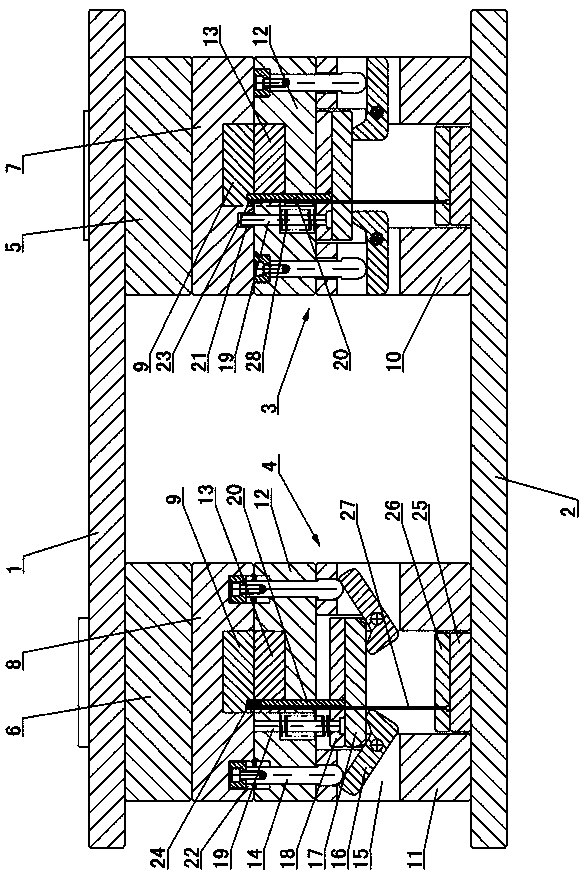

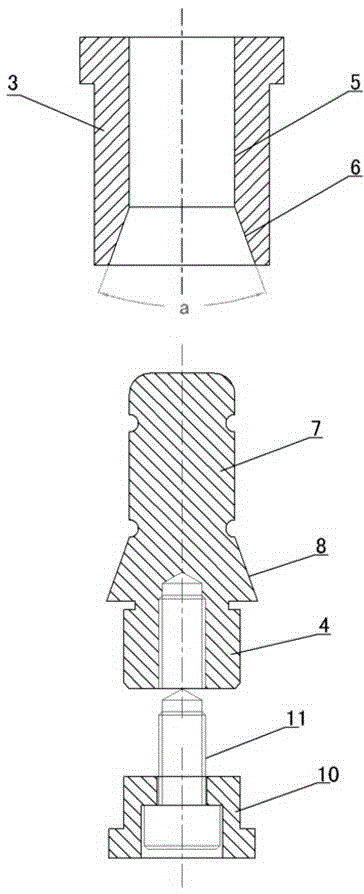

Plastic mold internal screw thread floating stopping demolding mechanism

Provided is a plastic mold internal screw thread floating stopping demolding mechanism. The mechanism comprises an upper doubling plate and a lower doubling plate. A fixed mold plate is arranged under the upper doubling plate. Support blocks are arranged on the lower doubling plate. A movable mold bottom plate, a lower gear fixing plate, an upper gear fixing plate, a transition gear fixing plate and a movable mold clamping plate are arranged on the support blocks. A movable platen is arranged on the movable mold clamping plate. There is a mold cavity between the movable platen and a fixed mold plate. A product is arranged in the mold cavity. Internal screw threads are arranged in the inner wall of the product. A screw thread core is arranged on the movable mold bottom plate. The head of the screw thread core is matched with the internal screw threads. The screw thread core is driven to rotate by power through a gear drive assembly. An upper top plate, a lower top plated and an ejector pin are arranged between the support blocks. The head of the ejector pin contacts a material handle after injection molding. A stopping insert block is arranged on the outer wall of the screw thread core. A stopping pin is arranged on the stopping insert block. The stopping insert block is embedded into the bottom of the wall body of the product. A floating spring is arranged on the movable mold clamping plate. A stop slot is arranged in the movable mold plate. A stop screw is arranged in the stop slot. The stop screw goes through the floating spring and is connected with the movable mold clamping plate.

Owner:TAIZHOU HUANGYAN WEIDA PLASTIC MACHINERY

Cultivating method of dragon fruits

InactiveCN104303783AReduce cost investmentIncrease productionCultivating equipmentsPlant cultivationMagnesiumInsect disease

The invention relates to a cultivating method of dragon fruits. The cultivating method includes S1, choosing sandy soil lands with PH (potential of hydrogen) value 6.5-8; S2, growing seedlings, to be specific, performing transplanting when height of the seedlings reaches 5cm or above; S3, performing transplanting, to be specific, planting supports on the land where the dragon fruits are planted, 3-5 dragon fruit seedlings are transplanted around each support with planting density of 300-350 / mu; S4, performing daily management including the steps of 1, uniformly fertilizing before flowering, and adding potash fertilizer and magnesium fertilizer during flowering period and fruit setting period; 2, keeping soil wet; 3, covering the peripheries of roots with dry glasses; 4, pruning branches; S5, performing insect disease prevention. The cultivating method has the advantages that the dragon fruits are natural and pollution-free, investment cost is low, and economic and practical effect is achieved.

Owner:CHONGQING DILONG AGRI

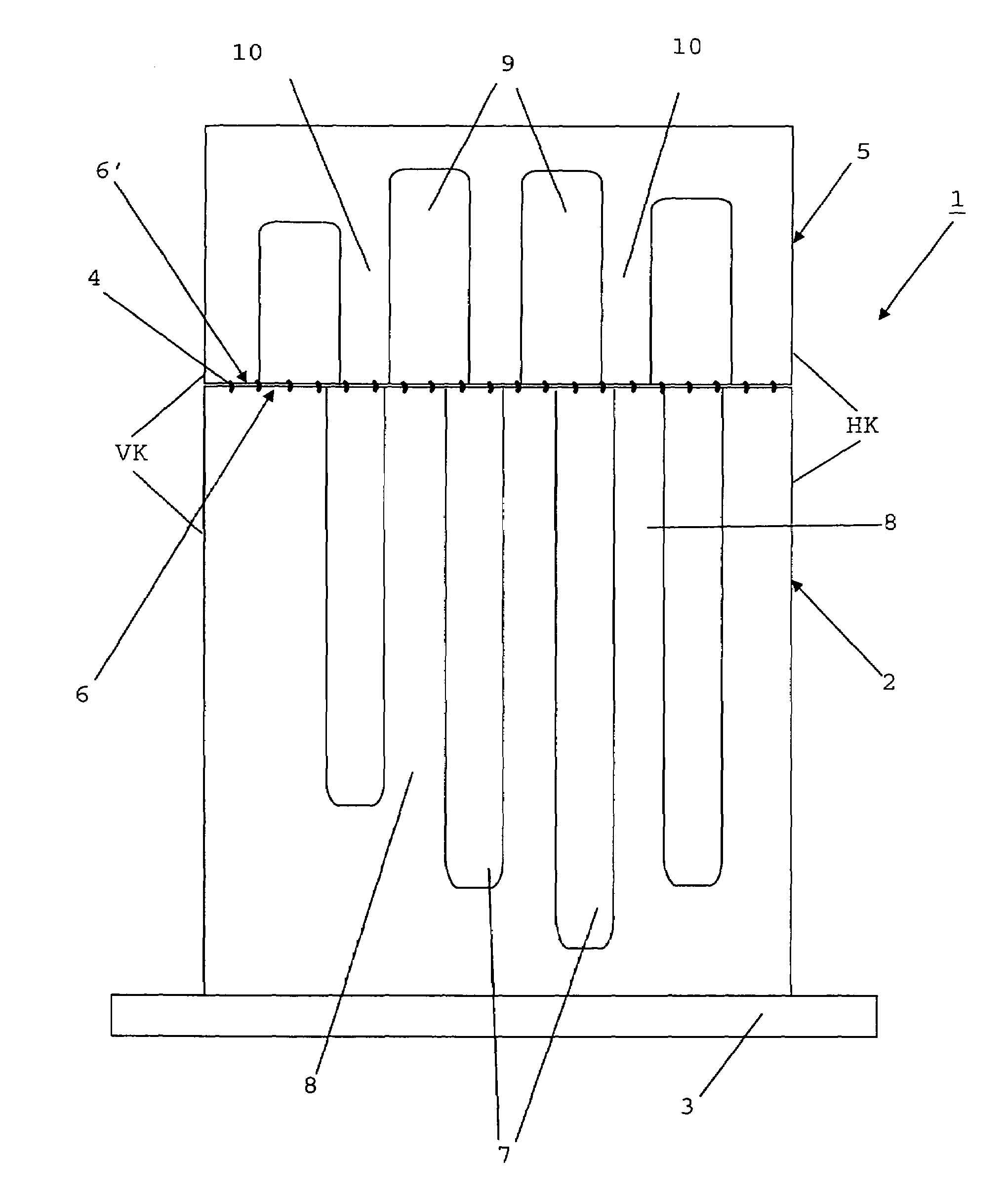

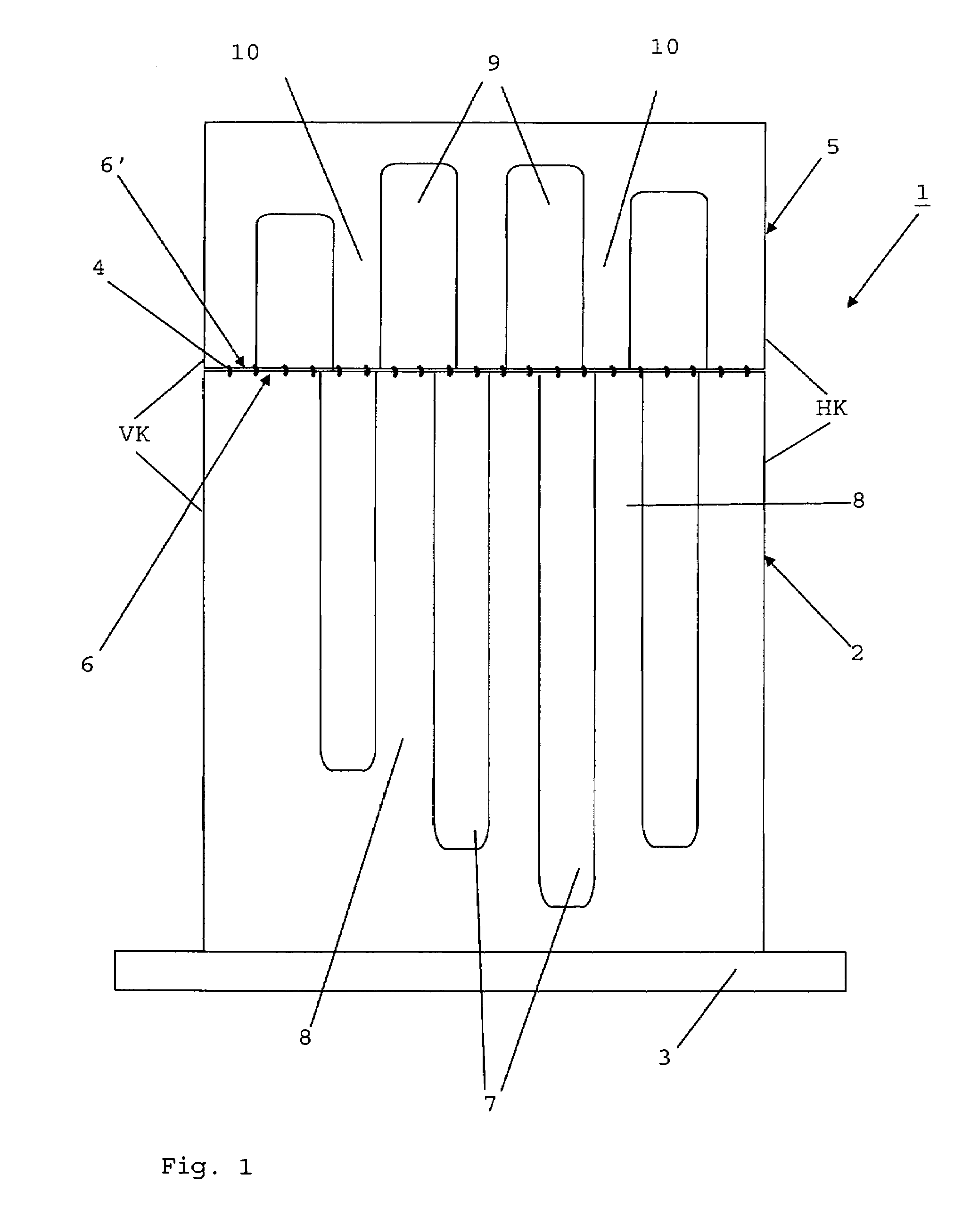

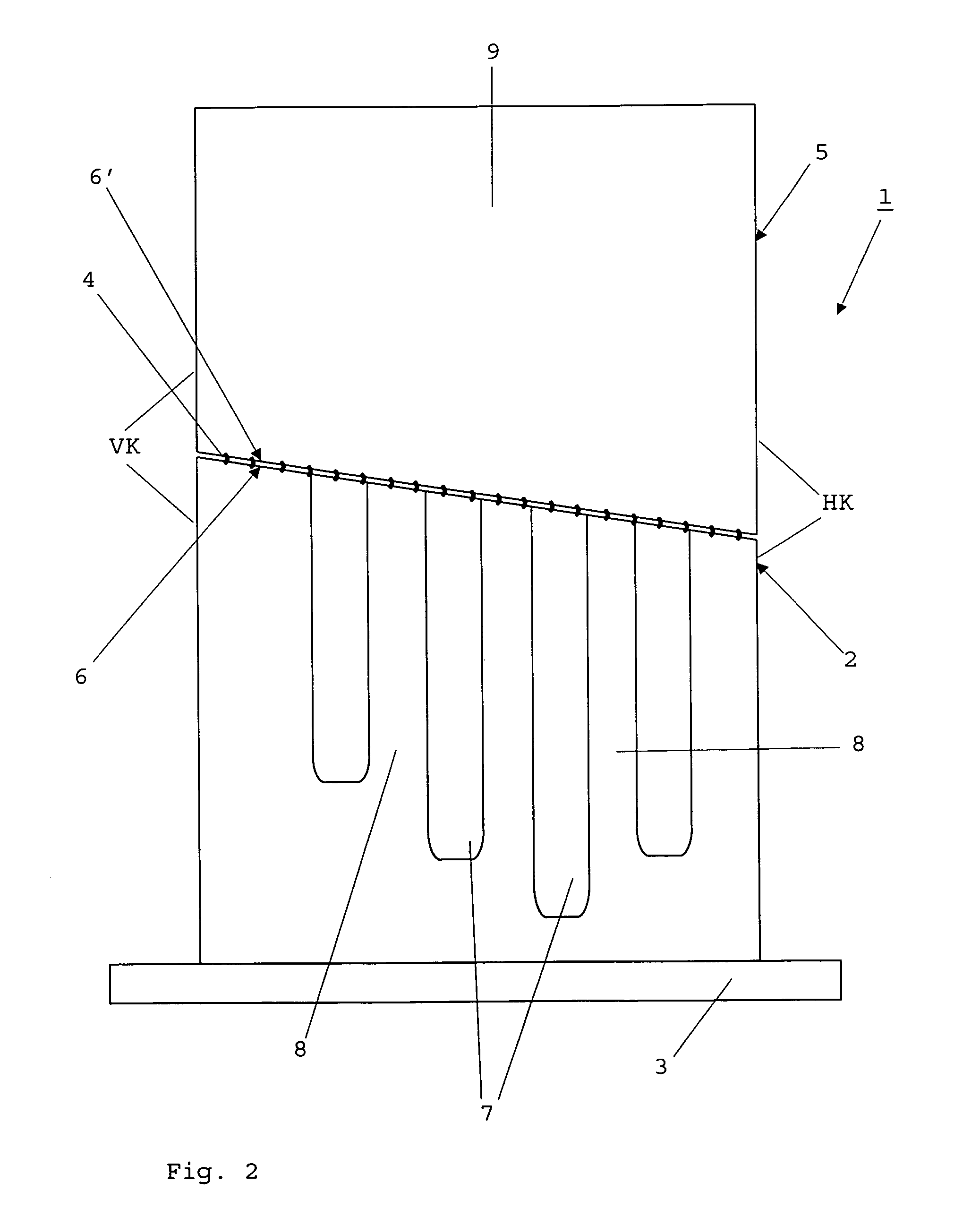

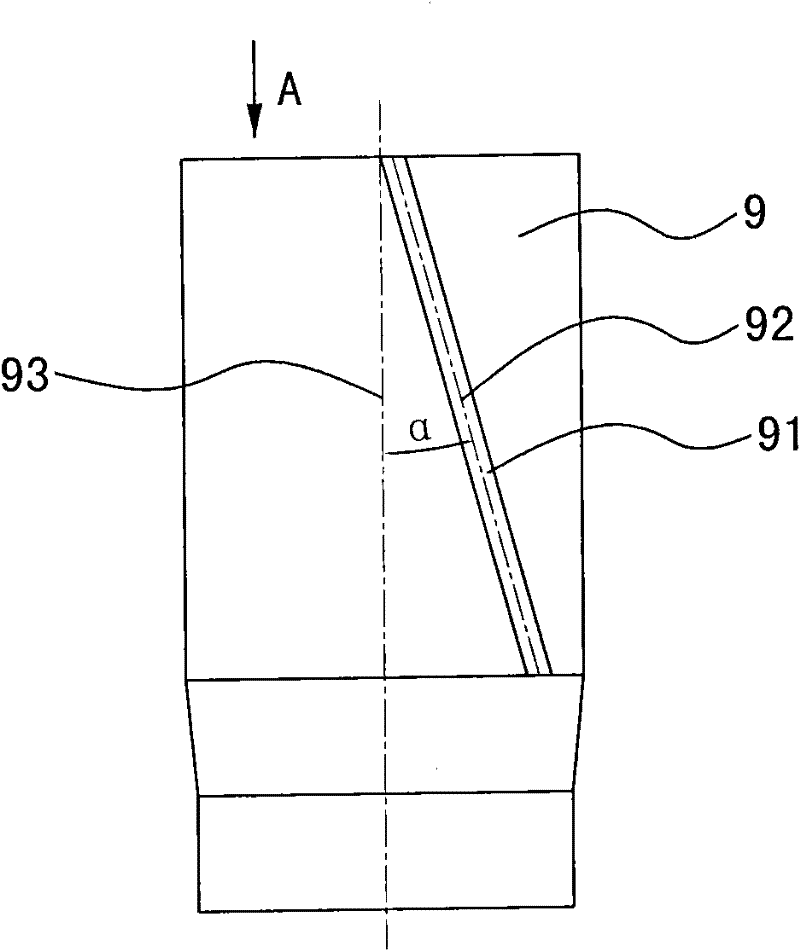

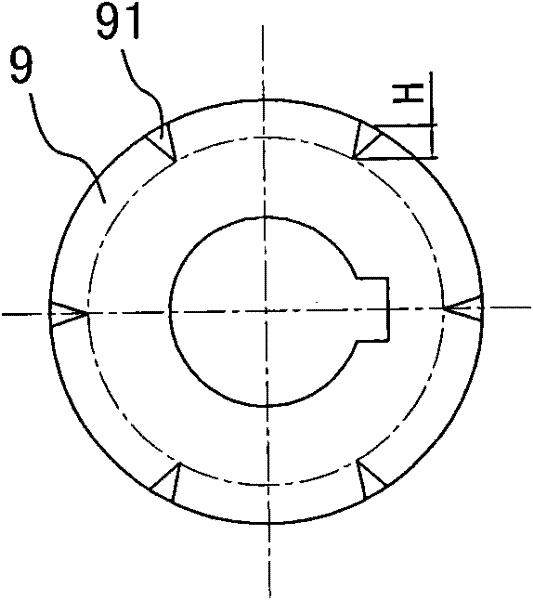

Hollow fan blade for aircraft engines and method for its manufacture

A hollow fan blade for the fan of an aircraft engine includes a blade base section (2) and a blade tip section (5) which are assembled at opposing faying surfaces (6, 6′) by a joining process. Starting from the respective faying surface, cavities (7, 9) are produced in the two blade portions (2, 5) which are dimensioned in accordance with the loads occurring in the respective blade areas. The joining weld (4) is in a low-loaded area. The blade base section and the blade tip section can be constructed of solid material with formed-in cavities. The blade tip section can also be a sheet-metal structure.

Owner:ROLLS ROYCE DEUT LTD & CO KG

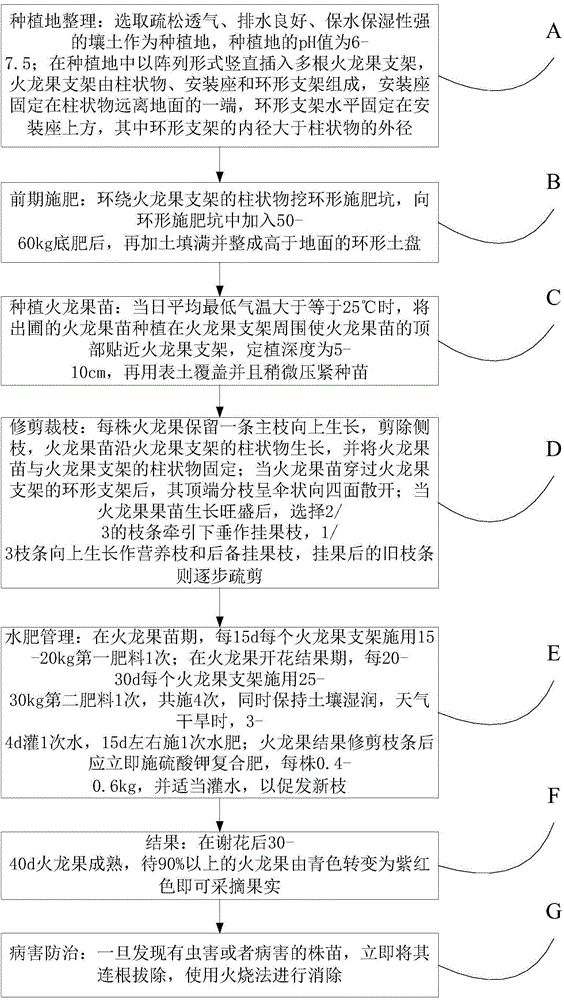

Pitaya planting method

InactiveCN104871757AReduce cost investmentIncrease productionHorticultureFertilizer mixturesComing outEngineering

The invention discloses a pitaya planting method which includes the steps of A, selecting loose and breathable soil with good draining performance and high water and moisture retention as a planting field; vertically inserting a plurality of pitaya supports in the planting field in an arrayed manner, wherein each pitaya support comprises a column, a mounting seat and an annular support, the mounting seat is fixed at one end, away from the ground, of the column, the annular support is horizontally fixed above the mounting seat, and the inner diameter of the annular support is larger than the outer diameter of the column; B, digging a fertilizing pit around the column of each pitaya support, applying 50-60kg of base fertilizer in each fertilizing pit, and then filling each fertilizing pit with soil to form an annular soil plate higher than the ground; C, planting pitaya seedlings coming out nursery around the pitaya supports and allowing the tops of the pitaya seedlings to be close to the pitaya supports, wherein the planting depth of the pitaya seedlings is 5-10cm; D, pruning; E, managing water and fertilizer; F, fruiting; G, controlling diseases.

Owner:广德县菁菁果业专业合作社

Gold and silver recovery from polymetallic sulfides by treatment with halogens

InactiveUS7537741B2Reduce cost investmentHigh treatment rateAluminium compoundsSolvent extractionMetallic sulfideTitanium

A method for treating a polymetallic sulfide ore containing gold and / or silver, and further containing base metals selected from the group consisting of iron, aluminum, chromium, titanium, copper, zinc, lead, nickel, cobalt, mercury, tin, and mixtures thereof, is disclosed. The method comprises the steps of grinding the polymetallic sulfide ore to produce granules, oxidizing the granules to produce oxidized granules, and chloride leaching the granules using a brine solution including dissolved halogens, as well as chloride and bromide salts.

Owner:DUNDEE SUSTAINABLE TECH

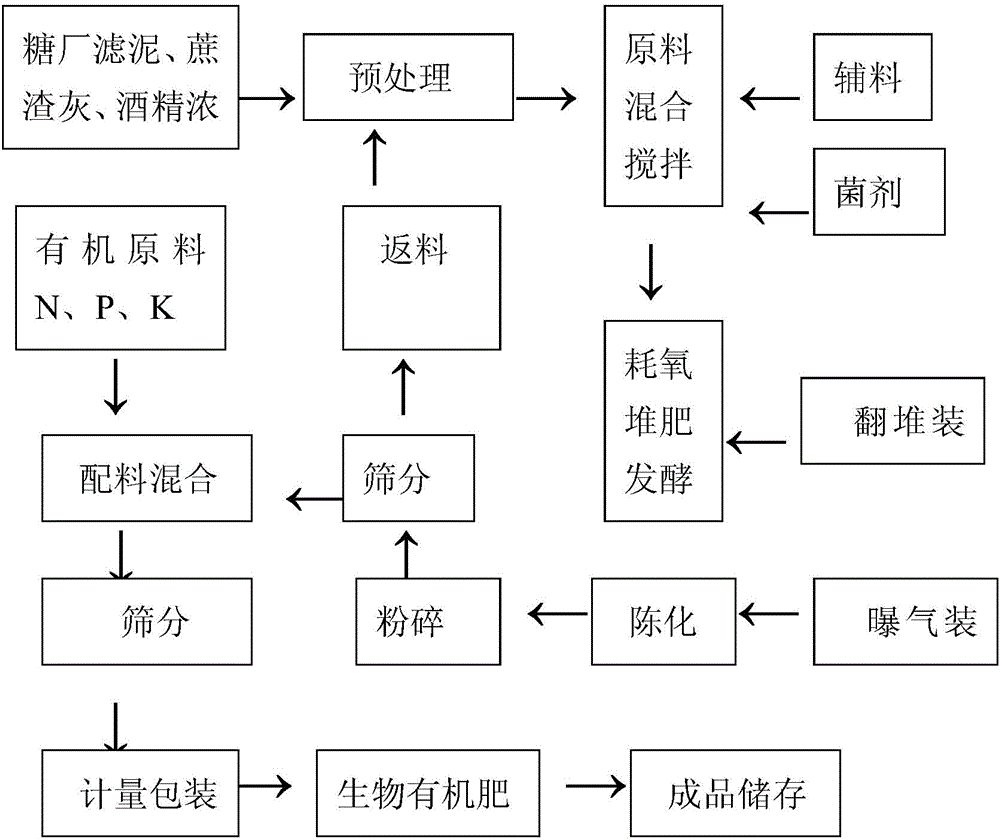

Bio-organic fertilizer and production method thereof

ActiveCN104045385AAccelerate the lossEasy to sieveBio-organic fraction processingOrganic fertiliser preparationFiltrationMoisture

The invention discloses bio-organic fertilizer. Through fermentation, the bio-organic fertilizer is prepared from 6-26wt% of filter mud produced by a sugar refinery, 55-75wt% of bagasse ash and 10-30wt% of ethanol concentrate. The production method comprises the following steps of 1, carrying out mixing stacking on filter mud produced by a sugar refinery, bagasse ash and ethanol concentrate, 2, removing moisture by filtration, 3, stacking the raw material mixture in a strip-shaped stack way, adding bifidobacterium, lactic acid bacteria, bacillus, saccharomycetes, actinomycetes and acetic bacteria into the stacked mixture, and carrying out fermentation, 4, keeping the primary fermented stack temperature above 60 DEG C and keeping material moisture content in a range of 40-45%, 5, increasing the height of the primary fermented stack, and carrying out secondary fermentation for aging until material moisture content is in a range of 30-35%, 6, adding the aged material into organic raw materials of N, P and K and carrying out mixing and 7, packaging the mixture to obtain the product. The bio-organic fertilizer has good fertilizer efficiency and is conducive to absorption by crops. The production method utilizes simple production equipment, has simple production processes and can be operated easily. The production method reduces a cost and has high income.

Owner:广西凭祥桂商现代农业投资有限公司

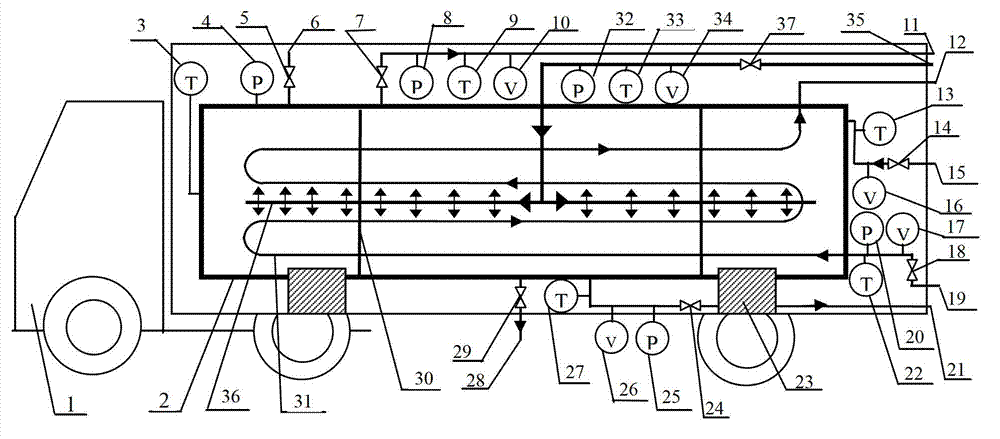

Multifunctional mobile heat storing and discharging method and mobile heat supplying device

ActiveCN103090455AAdaptableImprove water cleanlinessLighting and heating apparatusSpace heating and ventilation detailsWater storage tankSpray nozzle

The invention belongs to the technical field of mobile heat supplying, and particularly relates to a multifunctional mobile heat storing and discharging method and a mobile heat supplying device. The mobile heat supplying device comprises a water storage tank and a transporter, wherein the water storage tank is fixed on the transporter, a heat exchanging pipe is arranged in the water storage tank, and an inlet and an outlet of the heat exchanging pipe are both located outside the water storage tank, a distribution pipe is further arranged in the water storage tank, multiple spray nozzles are evenly formed in the distribution pipe, and a feeding pipe used for feeding steam or hot water is connected on the distribution pipe. A cold water feeding pipe is connected on the water storage tank, a first pressure gage, a first thermometer and a pressure reducing valve are connected on the water storage tank, a steam outlet pipe is connected with the top portion of the water storage tank, and a hot water outlet pipe is connected with the bottom portion of the water storage tank. The mobile heat supplying device is strong in heat storage capacity, has two heat exchanging modes, namely a direct heat exchanging mode and an indirect heat exchanging mode, can use waste heat and waste gas in various industries widely, and is especially suitable for using the waste heat in the industries to prepare clean saturated water with certain pressure at a certain temperature.

Owner:QINGDAO AOHUAN NEW ENERGY GRP CO LTD

Method for processing micro-electromechanical systems (MEMS) sensor

ActiveCN103832967AReduce risk of debrisReduce cost investmentDecorative surface effectsChemical vapor deposition coatingPhotoresistContact hole

The invention provides a method for processing a micro-electromechanical systems (MEMS) sensor. The method comprises the following steps: providing a silicon substrate, and sequentially forming an etching barrier layer and a first electrode layer on the positive and reverse sides of the silicon substrate; patterning the first electrode layer on the positive side of the substrate; respectively and sequentially forming a sacrificial layer and a second electrode layer on the substrate; patterning the second electrode layer on the positive side of the substrate; etching the sacrificial layer to form a contact hole through the patterned second electrode layer, and respectively forming metal contact at the bottom of the contact hole and the second electrode layer; sequentially etching the second electrode layer, the sacrificial layer, the first electrode layer and the etching barrier layer from the reverse side of the substrate, continuously etching the substrate so as to reach the etching barrier layer on the positive side and stopping, and forming a deep groove with a downward opening; coating photoresist above the front side of the substrate to protect, and reserving a subsequent area in which the sacrificial layer needs to be etched; and etching the sacrificial layer through the patterned second electrode layer, and removing the etching barrier layer at the bottom of the deep groove. According to the method, the process steps are simplified, a smooth flow is guaranteed, and high yield is realized.

Owner:ADVANCED SEMICON MFG CO LTD

Hollow sound attenuation spiral pipe extrusion mold

InactiveCN102189662AReduce the impactTo achieve the purpose of silenceUltrasound attenuationWater flow

The invention discloses a hollow sound attenuation spiral pipe extrusion mold, which comprises a connecting seat arranged on a machine head of an extrusion machine, wherein the connecting seat is connected with a machine head body; an opening mold is arranged on the outer wall of the machine head body; a core shaft and a hollow loose core strip are arranged in the opening mold; a flow distribution spine is arranged in the connecting seat and the machine head body, and is connected with a flow combination spine through a flow distribution plate; a flow distribution cavity is formed between the flow distribution spine and the connecting seat; and a flow combination cavity is formed between the flow combination spine and the machine head body. The mold is characterized in that: a rotating shaft is arranged in the flow combination spine, is driven by power and is connected with the core shaft; a spiral core rod is arranged on the outer wall of the core shaft; and a spiral rib groove is formed on the spiral core rod. In the scheme, a spiral rib strip is formed on the inner wall of an extruded pipe, water flow flows downward along the spiral rib strip, the impact of the water flow on the wall of the pipe is reduced, and the noise generated when the water flow impacts the wall of the pipe is reduced, so that the aims of sound attenuation is fulfilled; and the extrusion mold has extremely prominent advantages. Therefore, the spiral core rod is used and the spiral rib groove is formed on the spiral core rod, so that the mold has ingenious concepts and a reasonable structure, and can be used for extruding a practical pipe out when driven by the power.

Owner:YONGGAO CO LTD

Membrane device for treating oilfield produced water for reinjection and treating method

ActiveCN103030193AGuaranteed qualityHD Liquid Side FluxFatty/oily/floating substances removal devicesUltrafiltrationWater qualityFilter system

The invention relates to a membrane device for treating oilfield produced water for reinjection and a treating method. The device comprises a feed liquid tank, a series of separator main bodies, built-in membrane separation elements of the separator main bodies, a backlash tank, a cleaning tank and a pump. The oilfield produced water with oil spots enters separating devices through a precipitation tank and the pump; a clear liquid after membrane separation is in accordance with a reinjection index of oilfield reinjection water, and used for the reinjection; and waste water with the oil spots on the concentrated liquid side returns to the precipitation tank. When a permeating flux decline of a filtering unit module is set to be 80% of an initial value, the backlash course is started. A whole system is totally enclosed so as to prevent the water from being contacted with the outside to bring in new pollution; the quality of dischargws products on the clear liquid side can be ensured; the products are high-temperature resistant and acid and alkali resistant; the clear liquid side of a ceramic membrane is high in flux; the treating capacity is high; the separating effect is good; the effluent quality is stable; a ceramic membrane filtering system is easy to operate, short in technological process and high in automation degree, and lowers the cost and investment; a cleaning period is long; and a flux restoration ratio can reach above 90% after cleaning.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

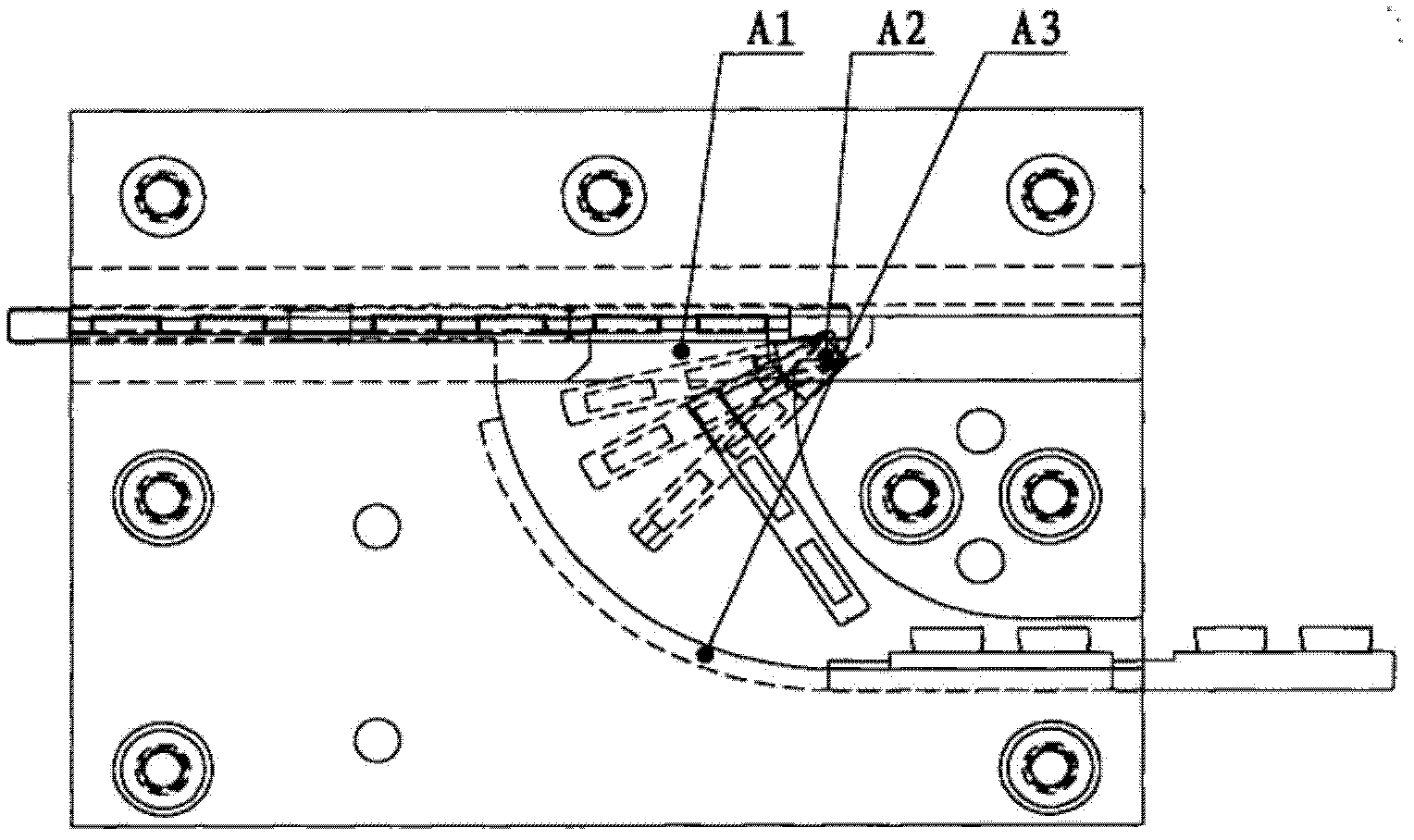

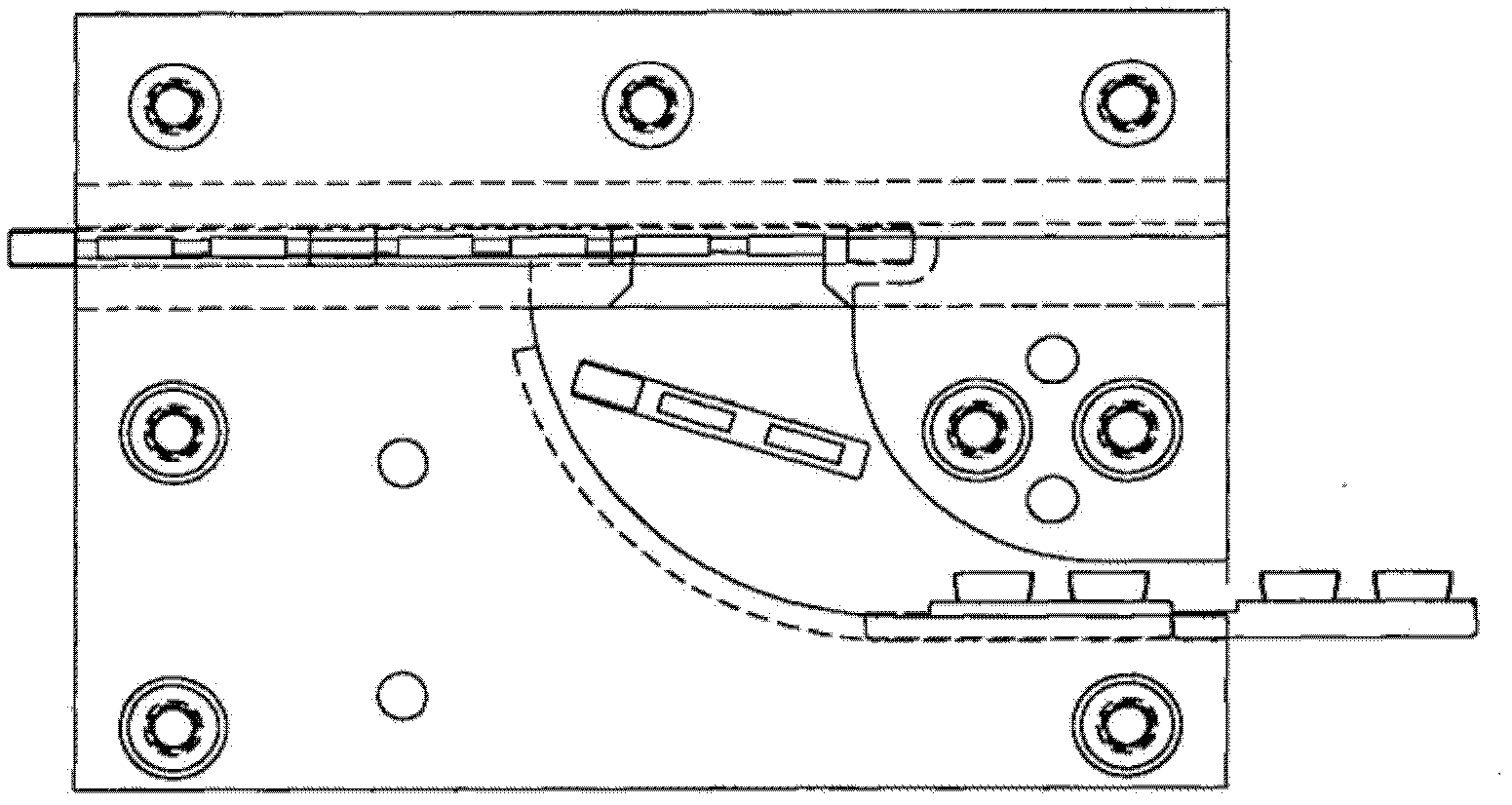

Double-color injection mold for pipe clamp of automobile circuit wire

The invention discloses a double-color injection mold for a pipe clamp of an automobile circuit wire. The double-color injection mold comprises an upper mold plate and a lower mold plate, wherein a first injection mold and a second injection mold are arranged between the upper mold plate and the lower mold plate and comprise a first fixed mold plate and a second fixed mold plate which are respectively internally provided with a fixed mold insert; the lower mold plate is respectively provided with first mold feet and second mold feet; the first mold feet and the second mold feet are respectively provided with a movable mold plate; the movable mold plates are respectively internally provided with a movable mold insert and a pressing column; the first mold feet and the second mold feet are respectively internally provided with an avoiding groove which is internally provided with a prying rod; each prying rod is provided with a lower pushing plate and an upper pushing plate; each upper pushing plate is provided with a top column and an insert rod; the first fixed mold plate is provided with a top-column concave opening; the second fixed mold plate is provided with a pressing-column concave opening; the top column is matched with the top-column concave opening; one insert rod, the corresponding fixed mold insert and the corresponding movable mold insert form a first injection mold cavity; the pressing column is matched with the pressing-column concave opening; after the insert rods are withdrawn, the formed space is a second injection mold cavity, and by secondary injection molding with a mold blank, the complete product is formed.

Owner:浙江正立塑模有限公司

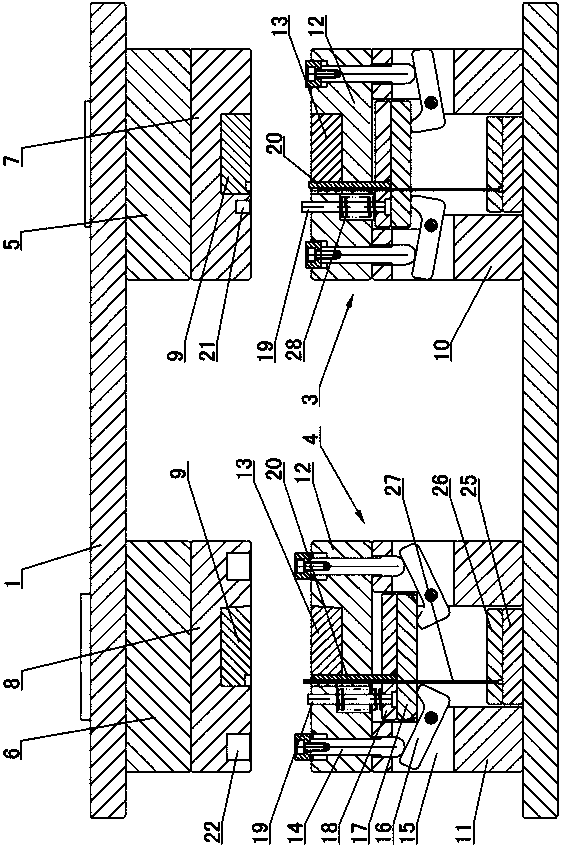

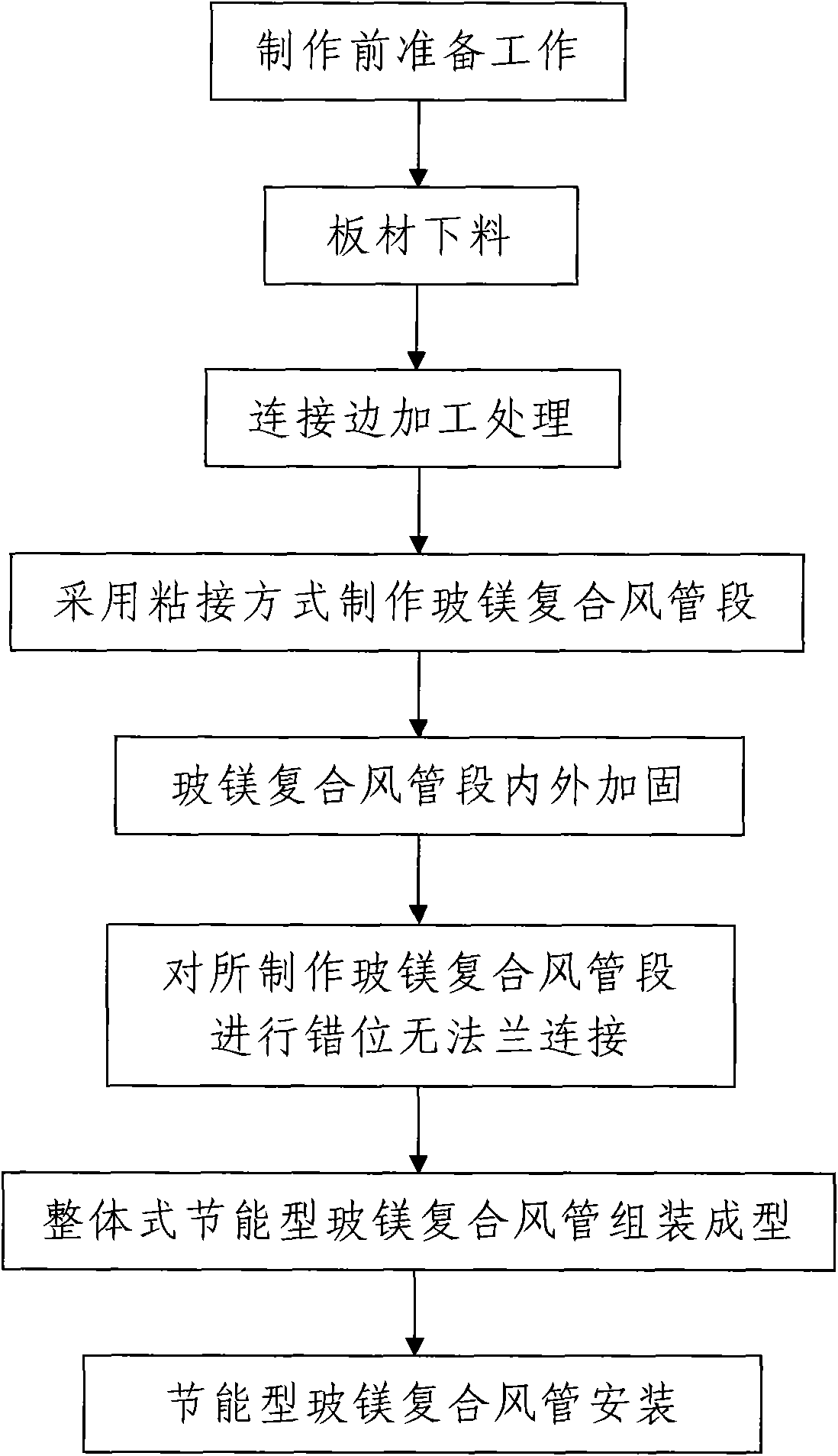

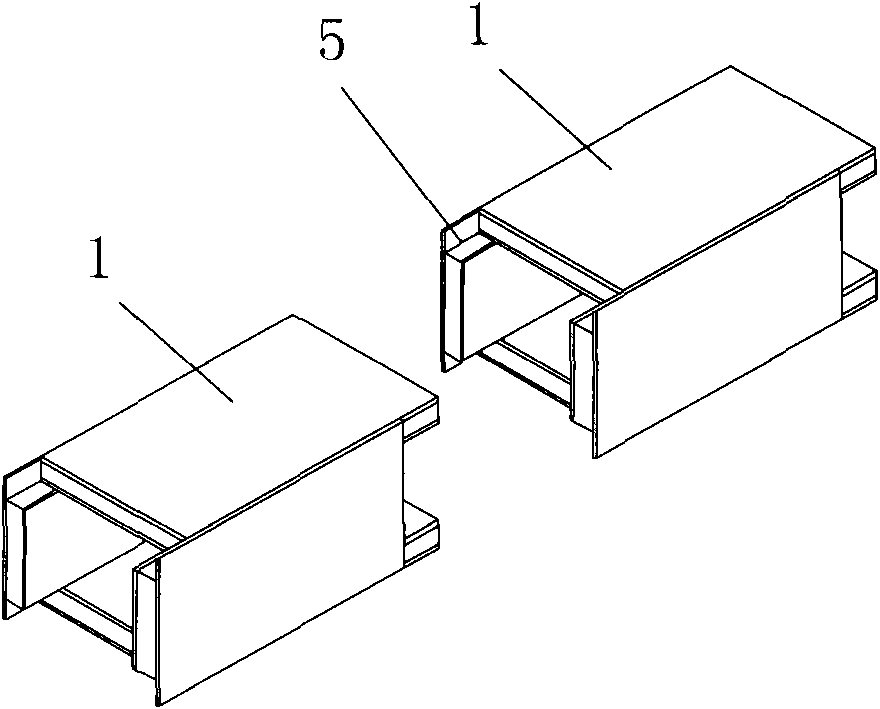

Energy-saving glass fiber and magnesium composite air duct manufacture and installation method

The invention discloses an energy-saving glass fiber and magnesium composite air duct manufacture and installation method. An energy-saving glass fiber and magnesium composite air duct is manufactured by assembling a plurality of sections of glass fiber and magnesium composite air duct sections. The method comprises the following steps of: 1, preparing before manufacturing; 2, manufacturing glass fiber and magnesium composite air duct sections, manufacturing a plurality of sections of glass fiber and magnesium composite air ducts in which upper plates and lower plates as well as left plates and right plates are malposed by adopting the glass fiber and magnesium composite air ducts and adhering glue; and 3, assembling and installing the energy-saving glass fiber and magnesium composite air duct: assembling all finished glass fiber and magnesium composite air duct sections and obtaining the integral energy-saving glass fiber and magnesium composite air duct. The invention has the advantages of simple manufacture process, convenient construction, low labor intensity and high construction speed; and the manufactured energy-saving glass fiber and magnesium composite air duct has the advantages of reliable connection among all members and easy insurance of quality. Meanwhile, the investment of used machinery equipment during the construction is less, the cost input is low, the manufacture process greatly reduces adverse factors of noise, vibration, and the like, thus the method can be used for manufacturing various shapes and structures of glass fiber and magnesium composite air ducts.

Owner:SHAANXI CONSTR ENG GRP CO LTD THE FIRST BUILDING

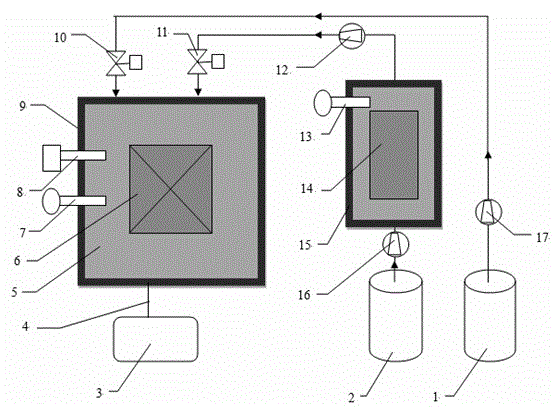

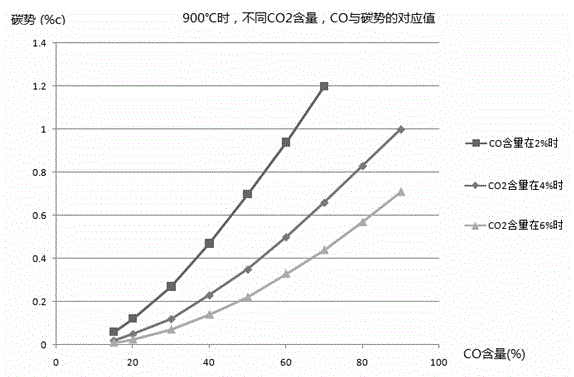

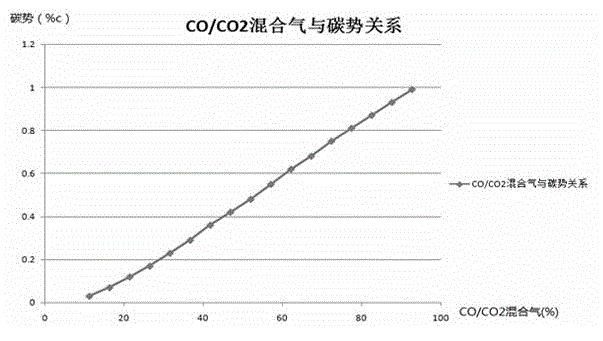

No-hydrogen atmosphere protection heat treatment process completely without decarburization for steel

The invention discloses a no-hydrogen atmosphere protection heat treatment process completely without decarburization for steel. CO2 is fed in a gas generation furnace with activated carbons, and is chemically reacted with the activated carbons; a reaction product a is fed in a sealing atmosphere furnace with workpieces to be thermally treated; then, N2 is fed in the sealing atmosphere furnace to dilute the reaction product a; the contents of the reaction product a and N2 in the sealing atmosphere furnace are adjusted through comparing a set value of a carbon controller with a carbon potential measurement value in the atmosphere in the sealing atmosphere furnace to form a no-hydrogen protection atmosphere; the workpieces can be located in the no-hydrogen environment in the heating and insulation process of the heat treatment; the carbon potential in the atmosphere is always kept the same with the carbon content of the workpieces in the furnace; the workpieces generate no decarburization or recarburization through long-time stop under high temperature; the complete protection of the steel in the no-hydrogen environment is realized; and the decarburization problem of large and ultralarge workpieces manufactured by high-strength steel and ultrahigh-strength steel in the heat treatment in the field of aerospace is solved.

Owner:XIAN BEIHENG IND CO LTD

Active carbon and modification method as well as application thereof in processing water containing endocrine disrupters

InactiveCN101513999AChange surface chemistryBest adsorption interfaceWater/sewage treatment by sorptionPerturbateurs endocriniensAbsorption capacity

The invention provides active carbon and modification method as well as application thereof in processing water containing endocrine disrupters. The active carbon is arranged in a muffle furnace silica tube; under the room temperature, hydrogen is pumped into the muffle furnace at first for 0.5 to 1.5 hours; the hydrogen flowing speed is 40 to 60ml / minute; then under the protection of the same hydrogen flow, the temperature of the muffle furnace is raised to 500-900 DEG C by the speed of 10 DEG C / minute and then the temperature is maintained for 1 to 5 hours; after the temperature is reduced to 30 DEG C, hydrogen pumping is stopped; then the air is pumped continuously for one hour by the flux of 40 to 60ml / minute; then the active carbon is taken out, and is added into a container together with muriatic acid with a volume by volume concentration of 35 percent according to a weight percentage of 10 percent for boiling and reflowing for 2 to 4 h; then de-ionized water is used for leading the sample of the active carbon to be detected without chloridion to obtain the modified active carbon. The modified active carbon prepared by the invention is used as a sorbent in the treatment process and has larger absorption capacity and renewable performance than that of raw carbon, and can realize to completely remove the endocrine disrupters under lower carbon inputting amount.

Owner:HARBIN ENG UNIV

Modified active carbon and preparation method application thereof

InactiveCN101774576AImprove adsorption capacityExtended service lifeWater/sewage treatment by sorptionHigh concentrationPerturbateurs endocriniens

The invention provides a modified active carbon and a preparation method application thereof. The method comprises the following steps of: placing active carbon into a quartz pipe of a muffle furnace; filling nitrogen in the muffle furnace at room temperature for 1-2 hours, wherein the gas flow rate is 80-120ml / min; then heating the muffle furnace to 400-800 DEG C at the speed of 10 DEG C / min under the protection of the same nitrogen flow and maintaining for 1-4 hours; after the temperature is reduced to 25 DEG C, stopping filling the nitrogen; continuously filling air at the flow rate of 80-120ml / min for 1hour and taking out to obtain the modified active carbon. The modified active carbon is used as an adsorbent and used for removing organic pollutants in the process of water treatment, has the advantages of high purifying ability and long service life and particularly can solve the problem of poor maneuverability on high-concentration phenol endocrine distributing object polluted water by the traditional water treatment method.

Owner:HARBIN ENG UNIV

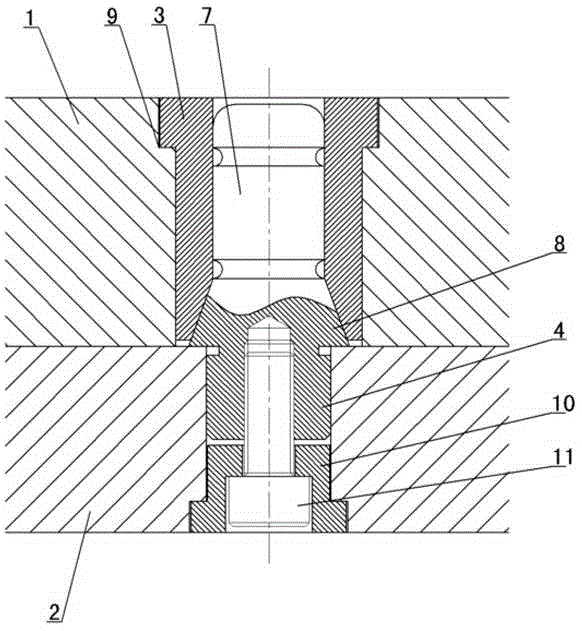

Improved guiding and positioning pin for injection mold

The invention discloses an improved guiding and positioning pin for an injection mold. The modified guiding and positioning pin comprises a mold cavity plate and a core plate, wherein a positioning sleeve is mounted in the cavity plate, and a positioning pin is mounted in the core plate; a straight surface guiding hole and a conical surface locking hole are formed in the positioning sleeve, a straight surface guiding rod and a conical surface locking block are arranged on the positioning pin, the straight surface guiding rod and the straight surface guiding hole are matched, and the conical surface locking block and the conical surface locking hole are matched. Through the adoption of the scheme disclosed by the invention, two functions of straight surface guiding and conical surface positioning are combined into one component, so that double functions of guiding and positioning between two moving components of the injection mold are realized, the modified guiding and positioning pin is simple in structure, convenient to process and low in cost, the internal structure of the mold is simplified, and the investment cost of the mold is reduced.

Owner:YONGGAO CO LTD +1

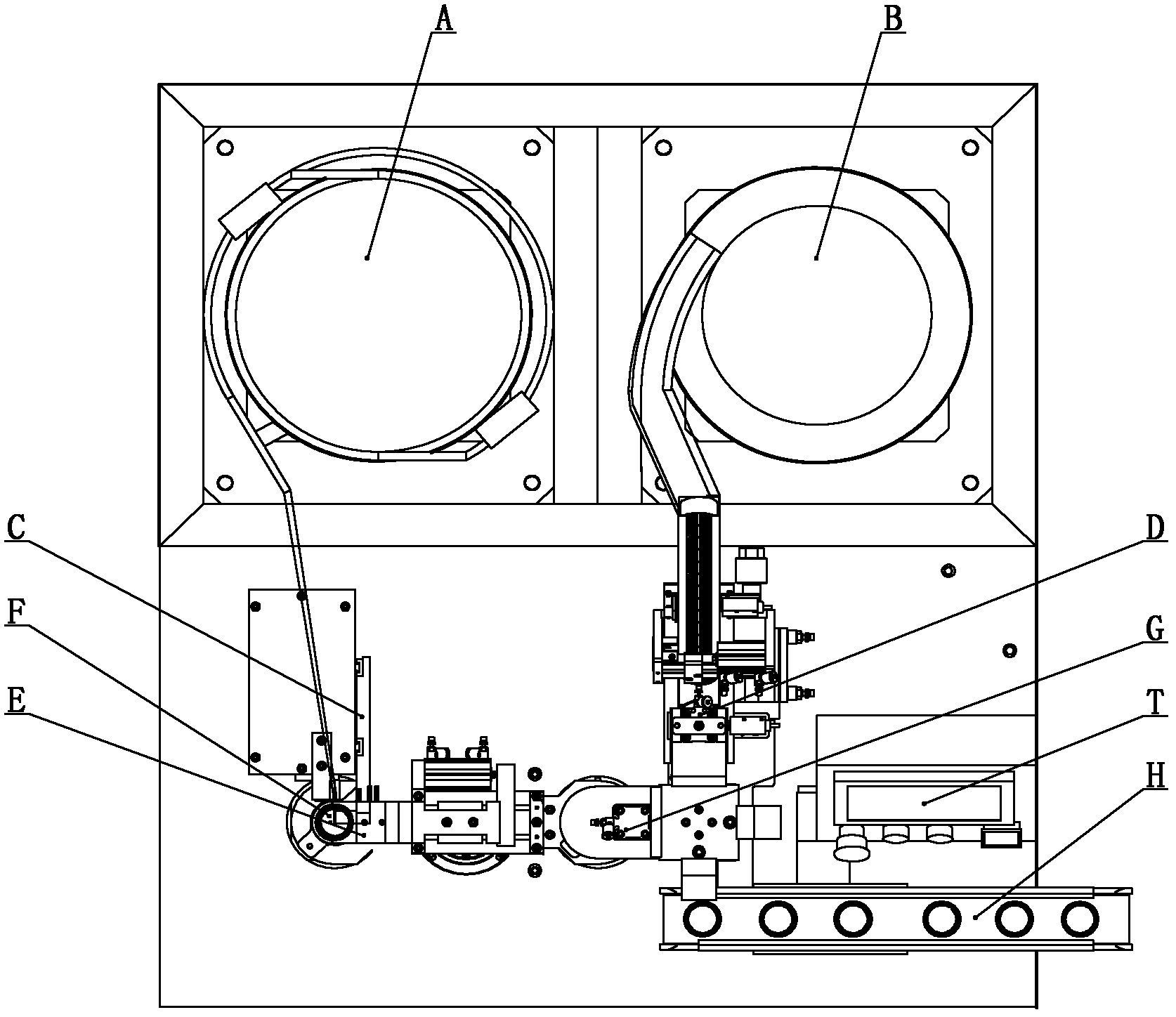

Full-automatic commutator bar assembly machine of rubber sleeve commutator

InactiveCN102496830AAutomate assemblyReduce management costsCommutators manufactureMechanical equipmentOutput device

The invention provides a full-automatic commutator bar assembly machine of a rubber sleeve commutator. The machine comprises a commutator bar part screening vibration feeder, a rubber sleeve part screening vibration feeder, a commutator bar inserting device, a rubber sleeve loading device, a rubber sleeve heating device, an indexing transfer device, a finished product clamping device and a finished product output device. In the technical scheme provided by the invention, manual operation is replaced by the work of mechanical equipment, the benefit and yield of the assembly worker post in the commutator (motor commutator) industry are met, automatic commutator assembly is realized, the working efficiency is greatly improved, the commutator insertion is simplified due to the mechanical operation, the whole manufacturing level is ensured, and the benefits of the product are increased naturally; and moreover, since the manual operation is replaced by mechanical equipment, the labor amount in enterprises is reduced, the cost investment of the enterprises is lowered, the fund is saved, and the administrative cost of the post is lowered therewith.

Owner:WENZHOU K Q B W AUTOMATIC EQUIP

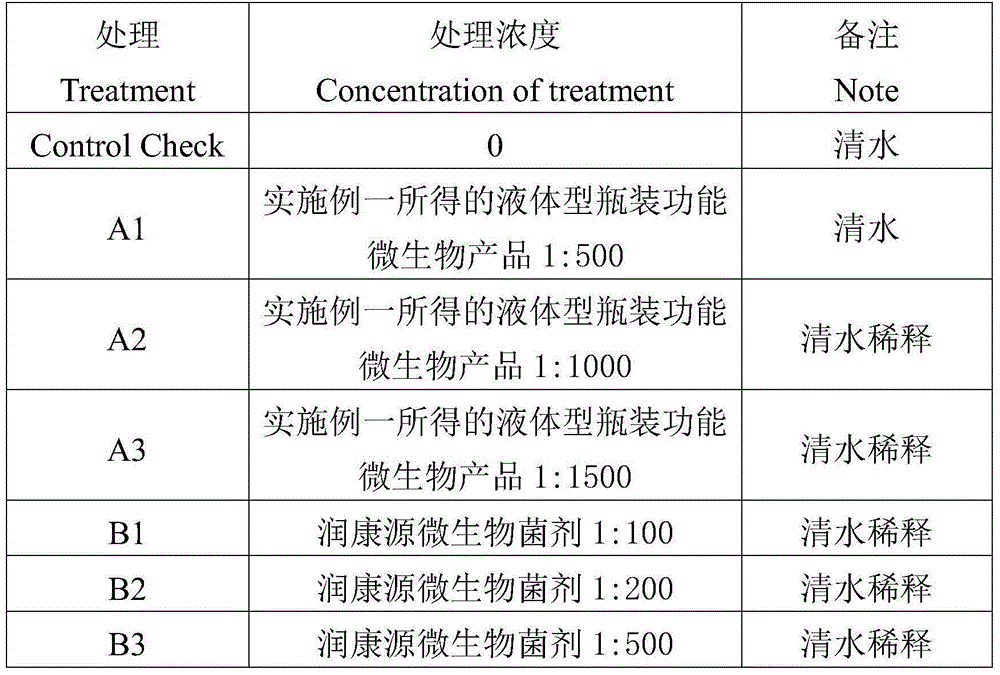

Method for producing functional microbes with glutathione waste liquid

The invention discloses a method for producing functional microbes with glutathione waste liquid and belongs to the field of microbes. The method includes: a, respectively subjecting bacillus licheniformis seed solution, candida utilis seed solution, lactobacillus acidophilus seed solution, lactobacillus acidophilus seed solution and bacillus subtilis seed solution to seeding tank culture by taking the glutathione waste liquid as an effective ingredient of a seed culture medium; b, performing fermentation in a fermentation tank by taking the glutathione waste liquid as an effective ingredient of a fermentation tank culture medium to obtain functional fermentation broth. Compared with the prior art, the method has the advantages that the functional microbes are produced with the glutathione waste liquid, and the method is low in cost, diversified in product, high in economic value, high in waste recycling rate and the like and has extensive application value.

Owner:山东君德生物科技有限公司

Wastewater chemical/biological treatment method for open water discharge

ActiveUS8192626B2Improve scalabilityFast injectionTreatment using aerobic processesUnicellular algaePhosphateNitrobacter

A wastewater treatment method employing chemicals for disinfection, and precipitation of suspended solids, heavy metals and phosphates before subsequent aerobic bacterial biological treatment using Nitrosomonas and Nitrobacter bacteria to remove ammonia and nitrates / nitrites and BOD compounds to produce recovered treated wastewater suitable for open water discharge.

Owner:EARTH RENAISSANCE TECH

Winter jujube culture method

InactiveCN104381074ABreeding method is simpleReduce cost investmentCultivating equipmentsInsect pestPlastic film

The invention relates to a winter jujube culture method, which comprises the following steps of S1, land selection: sandy loam or clay loam with irrigation and drainage convenience and thick soil layer is selected; S2, field planting: the tree seedling is soaked in clear water for 15 to 20 hours before the field planting; farm manure is applied before planting, then, the field planting is carried out, and the field planting depth does not exceed 3 to 4cm of the original ground plane; the sufficient water is watered in time after the field planting, and then, the tree disc is covered by a plastic film; S3, soil management: grass coverage and grass growth are carried out in a winter jujube orchard; S4, fertilizer application: fertilizers are applied for one to three times in each year, and the applied fertilizers include farm manure, urea, phosphate fertilizers and potash fertilizers; S5, disease and insect pest prevention and control. Winter jujubes obtained by the method are natural and pollution-free, the culture method is simple, the cost investment is low, and the yield of the winter jujubes is higher.

Owner:CHONGQING DILONG AGRI

Large mulberry cultivating method

The invention relates to a large mulberry cultivating method which comprises soil selecting, cultivating, core picking, daily management and disease and insect prevention. The obtained large mulberry is good in taste, the large mulberry tree is strong in vitality, and the cultivating method is simple, green, environment-friendly, low in cost investment and high in yield.

Owner:CHONGQING DILONG AGRI

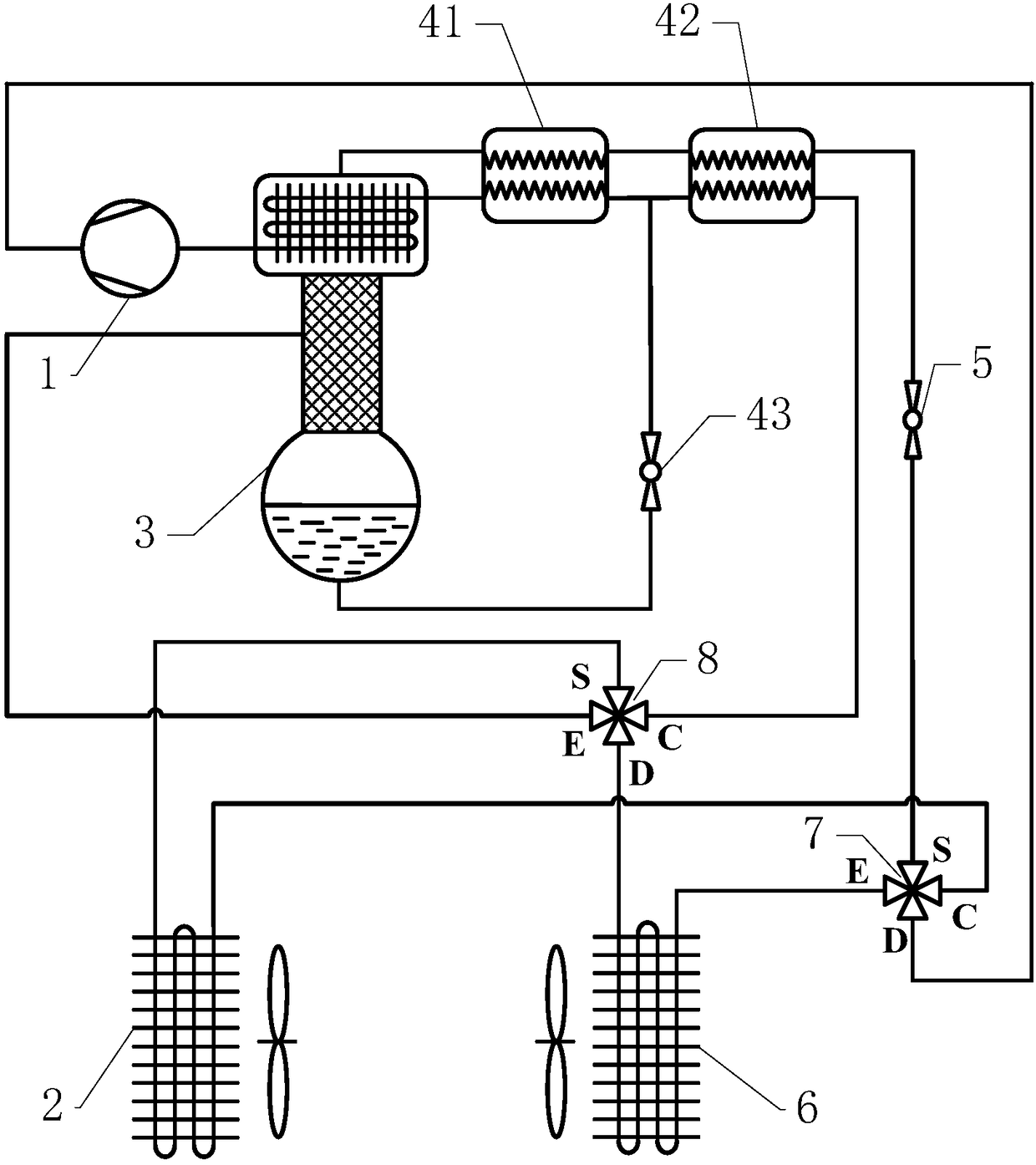

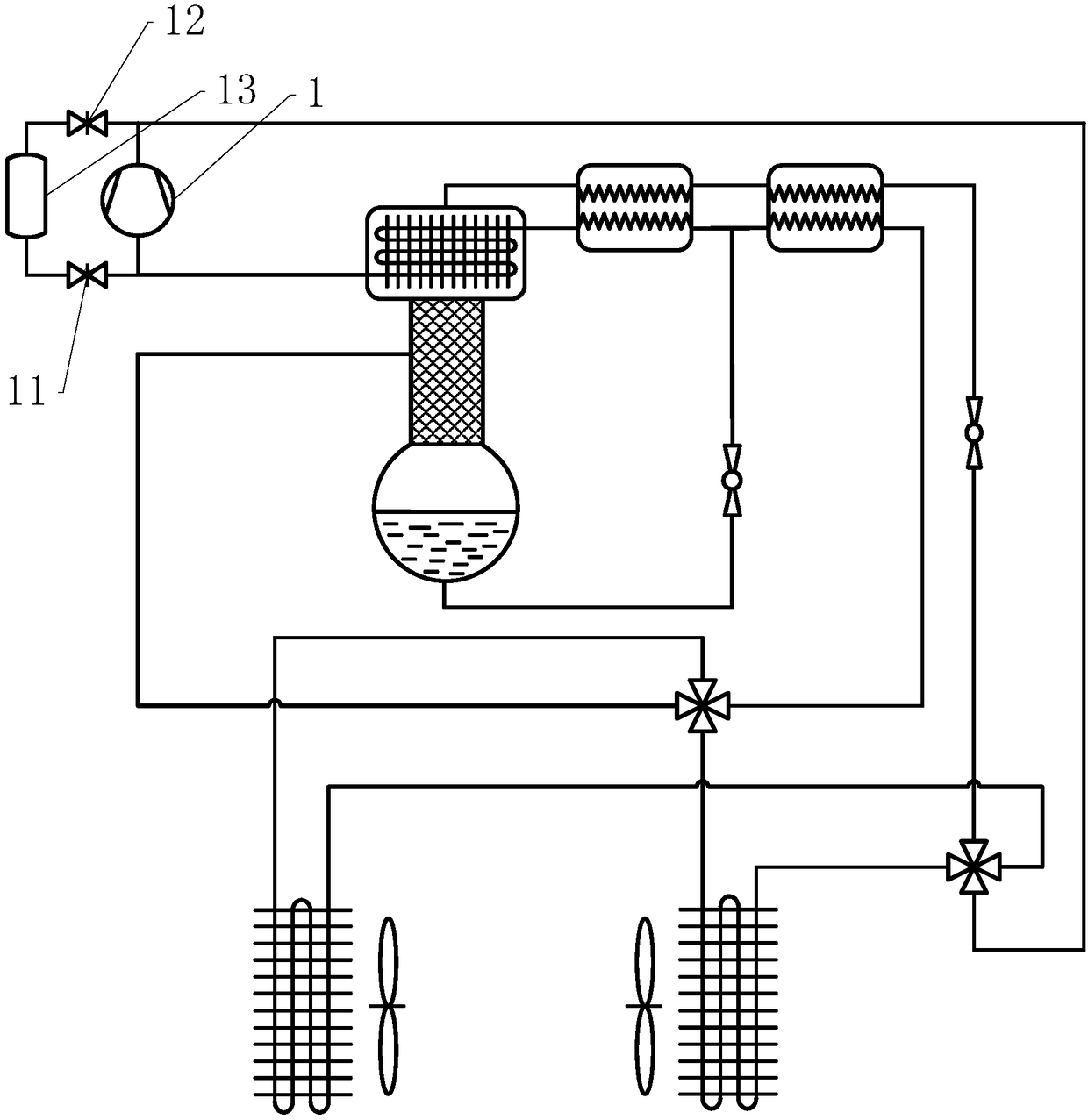

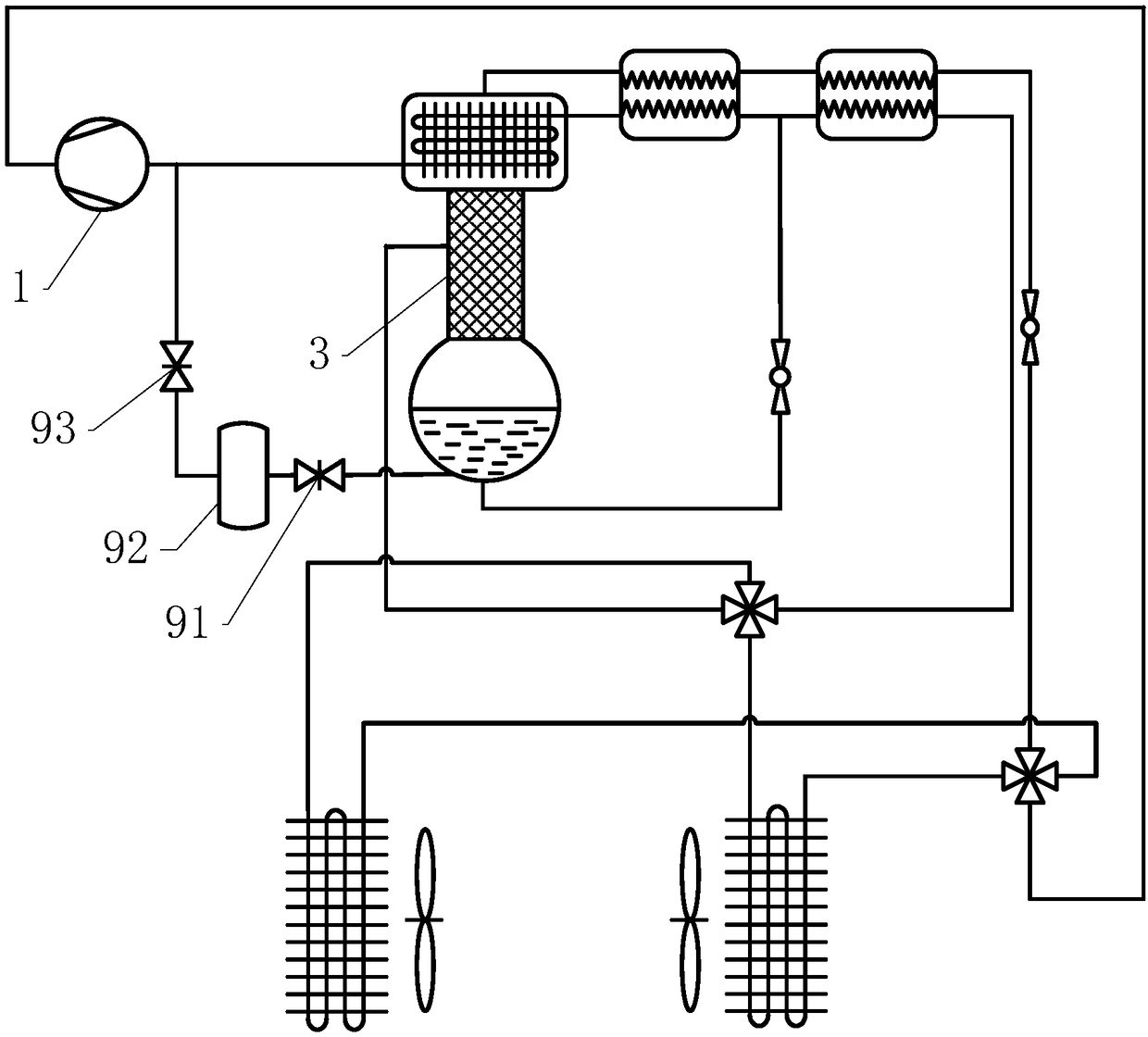

Bidirectional auto-cascade heat pump system

InactiveCN108061403AImprove operational efficiencyReduce cost investmentHeat pumpsCorrosion preventionEngineeringThrottle

The invention relates to a bidirectional auto-cascade heat pump system, and belongs to the technical field of heating. The bidirectional auto-cascade heat pump system comprises a compressor, an indoorheat exchanger, a rectification column, a first heat regenerator, a second heat regenerator, an auxiliary throttle device, a main throttle device, an outdoor heat exchanger, a first four-way valve and a second four-way valve. Through the combination of the ports of the double four-way valves in a communication state, the compressor, the indoor heat exchanger, the rectification column, the first heat regenerator, the second heat regenerator, the auxiliary throttle device, the main throttle device and the outdoor heat exchanger are combined into a heating loop and a defrosting loop which are anauto-cascade flow path separately, so that defrosting can be carried out when the running efficiency of the system is influenced due to frosting of the outdoor heat exchanger; moreover, heating witha high temperature difference of greater than 75 DEG C can be realized; and the bidirectional auto-cascade heat pump system can be widely applied to the technical field of heating.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com