Improved guiding and positioning pin for injection mold

A technology of guiding and positioning and injection molding, which is applied in the field of positioning between moving parts that need to be accurately guided. It can solve problems such as single action of guiding and positioning devices, flashing of injection molded parts, complex molds, etc., and achieves reliable fixation, smooth operation, and simplified interior. The effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

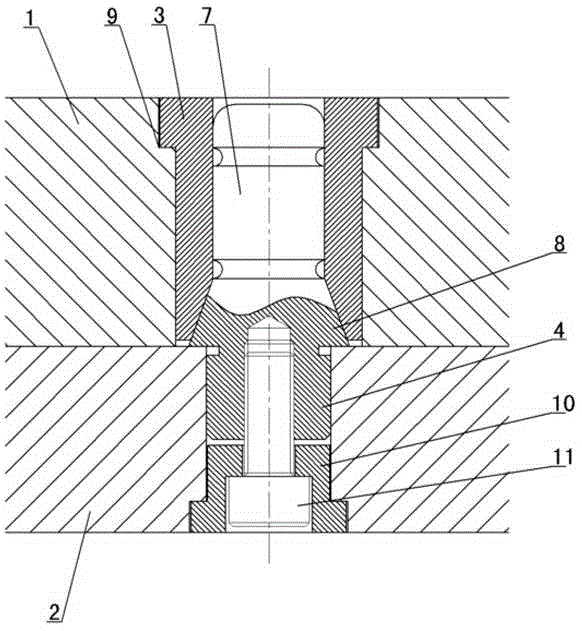

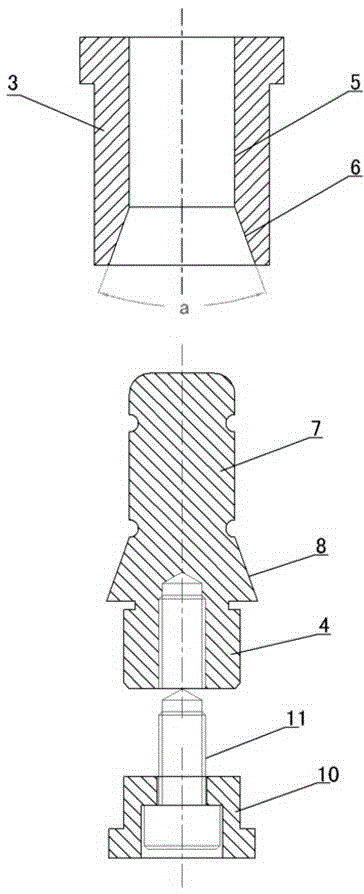

[0009] The invention relates to an improved guide and positioning pin for an injection mold, such as figure 1 , figure 2 As shown, it includes a mold cavity plate 1 and a core plate 2, a positioning sleeve 3 is installed in the cavity plate 1, a positioning pin 4 is installed in the core plate 2, and a straight face is set in the positioning sleeve 3. The guide hole 5 and the tapered lock hole 6, the positioning pin 4 is provided with a straight guide rod 7 and a tapered lock block 8, the straight guide rod 7 cooperates with the straight guide hole 5, the tapered lock block 8 and the tapered lock Hole 6 matches. When the injection mold is closed, the core plate 2 and the cavity plate 1 are closed, and the direct-facing guide rod 7 extends into the direct-facing guide hole 5, and the gap between the direct-facing guide rod 7 and the direct-facing guide hole 5 is generally 0-0.04mm, so , can precisely guide the closing of the core plate 2 and the cavity plate 1. When the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com