Patents

Literature

83results about How to "Simplify internal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

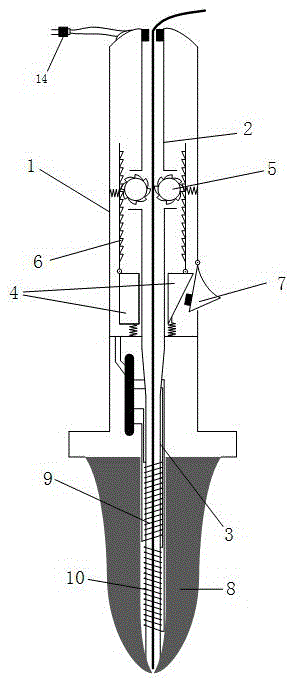

Automatic tin adding electric soldering iron

InactiveCN105598548AEasy to useSimplify internal structureHeating appliancesSoldering ironElectrical conductorConductor Coil

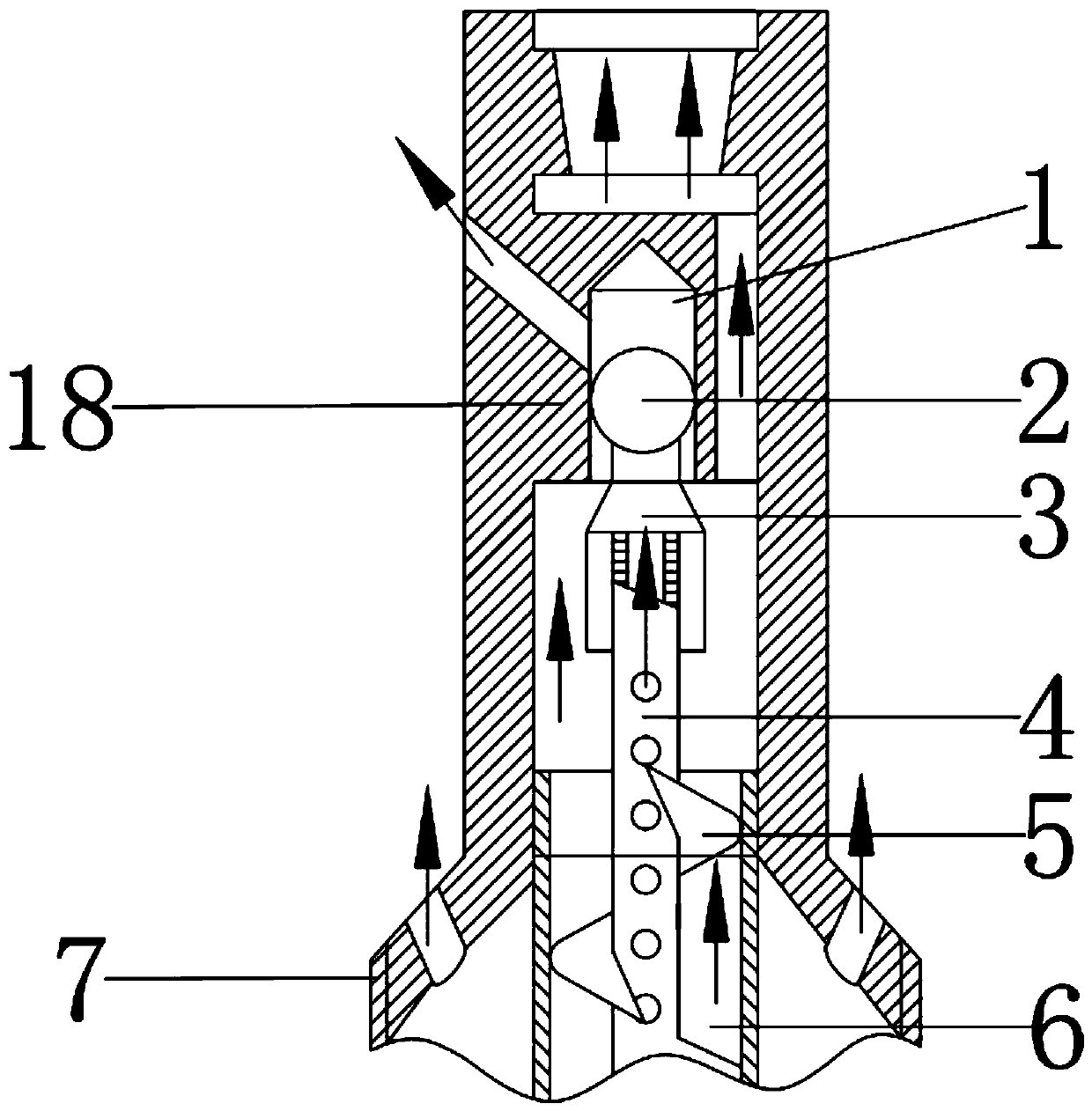

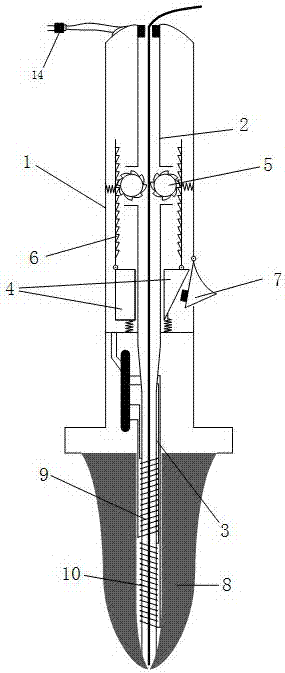

The invention discloses an automatic tin adding electric soldering iron which comprises a transmission module and a heating module. The transmission module comprises a shell, an inner cavity, an inner ceramic cavity, a pushing body and a wire adding button, wherein the upper end of the inner ceramic cavity is sleeved with the pushing body. A pair of one-way rotation circular gears are arranged at the joint of the inner cavity and the inner ceramic cavity. The side faces of the circular gears are provided with meshed straight gears. The lower ends of the straight gears are hinged to the upper end of the pushing body. A spring is arranged at the lower end of the pushing body. One side of the pushing body is in a conical shape with the large top and the small bottom. The wire adding button is hinged to the shell. The wire adding button can just press the conical side of the pushing body when rotating so that the pushing body is made to move upwards. The heating module comprises a heating body with the lower sharp nozzle type end, a conductor winding wire, a heating wire and a control circuit board, the upper end of the heating body is connected with the shell, the conductor winding wire is arranged at the lower portion of the inner ceramic cavity, and the lower portion of the inner ceramic cavity stretches into the heating body till the tip nozzle position, a user can operate the automatic tin adding electric soldering iron with one hand, tin wires are molten during welding, and no dead tin is generated.

Owner:HUBEI UNIV OF TECH

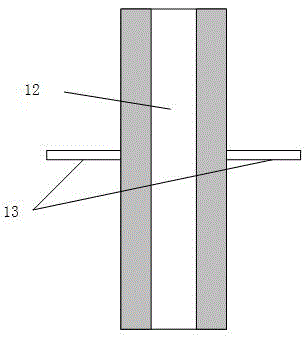

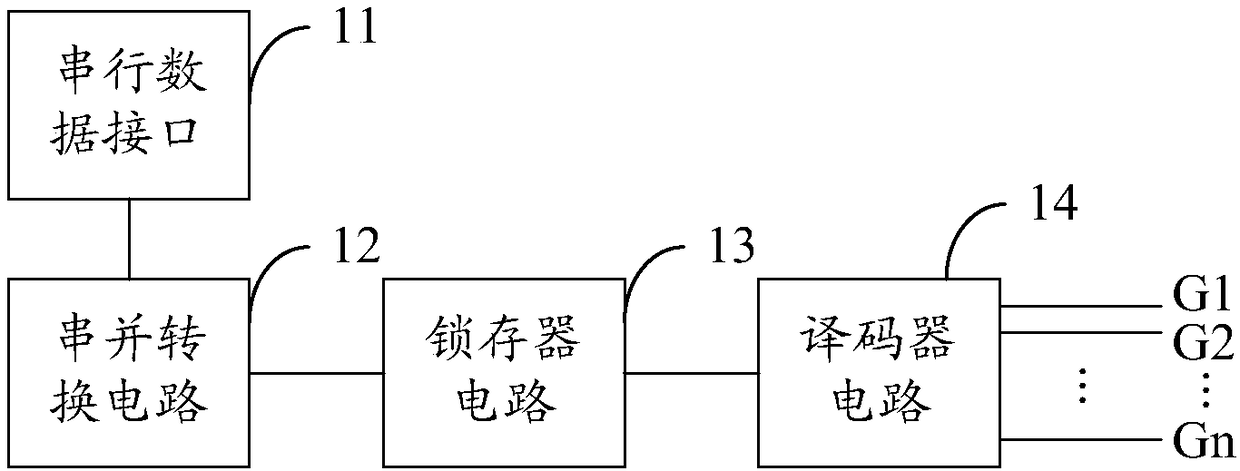

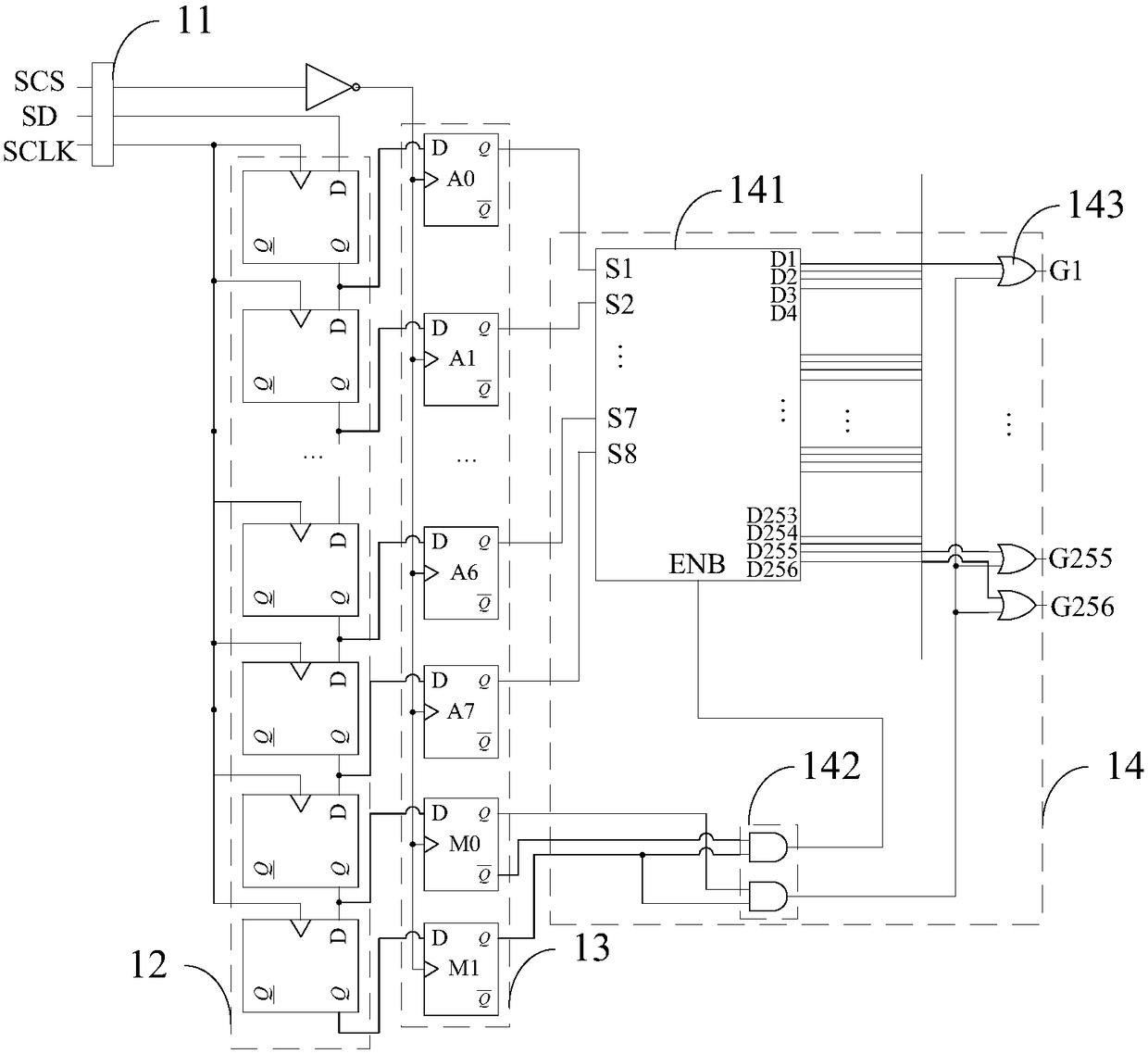

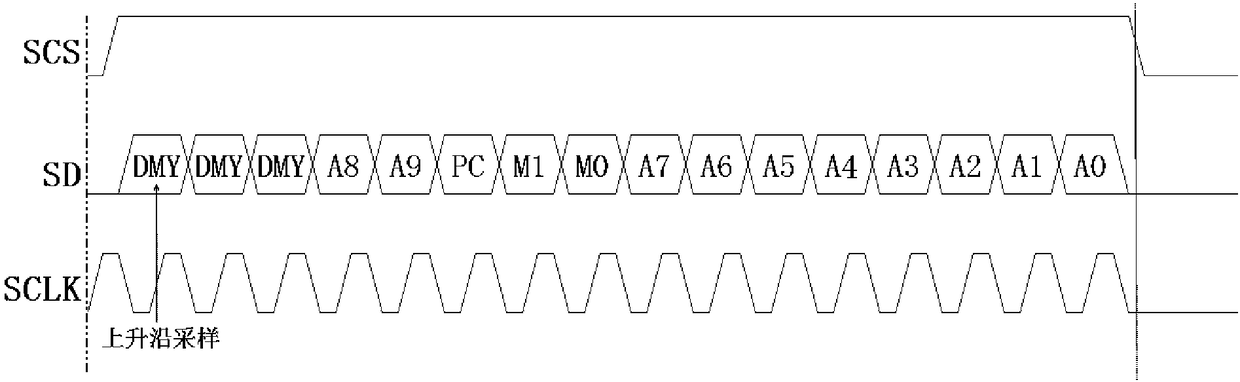

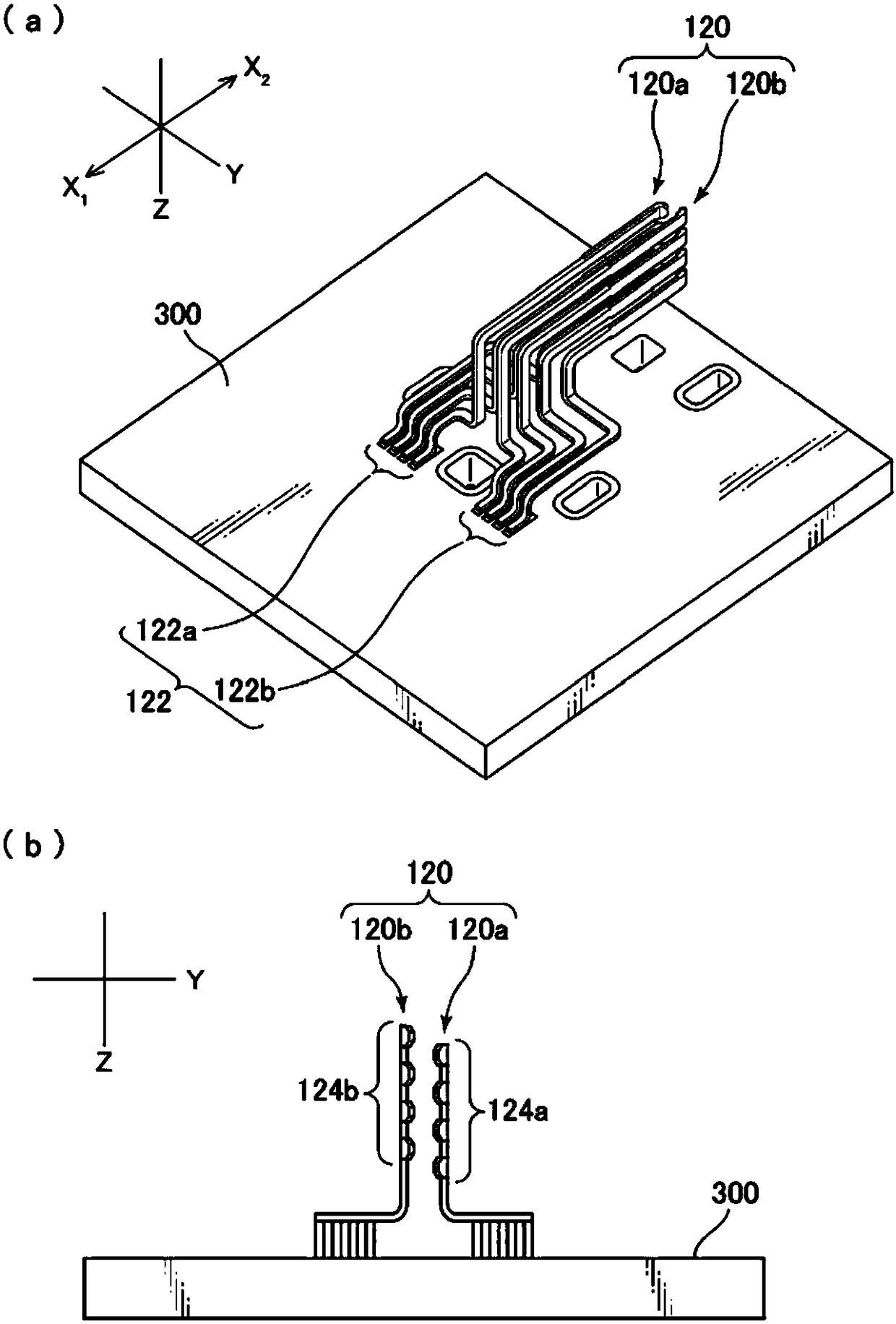

Gate drive circuit and drive method thereof, and display device

InactiveCN108447436AReduce in quantitySimplify internal structureStatic indicating devicesDisplay deviceData interface

The present invention provides a gate drive circuit and a drive method thereof, and a display device. The gate drive circuit comprises: a plurality of scanning output ends; a serial data interface; aserial-to-parallel conversion circuit connected with the serial data interface and configured to receive serial data frames through the serial data interface and convert the serial data frames to parallel data frames; a latch circuit connected with the serial-to-parallel conversion circuit and configured to store and output the parallel data frames when any one data frame is completely received; and a decoder circuit connected with the latch circuit and each scanning output end and configured to output scanning signals at the scanning output ends corresponding to the data frames when the dataframes output by the latch circuit are received. The gate drive circuit and the drive method thereof, and the display device allow the gate drive circuit made on an array substrate to have a functionof flexibly selecting a pixel row to perform data refreshing.

Owner:BOE TECH GRP CO LTD +1

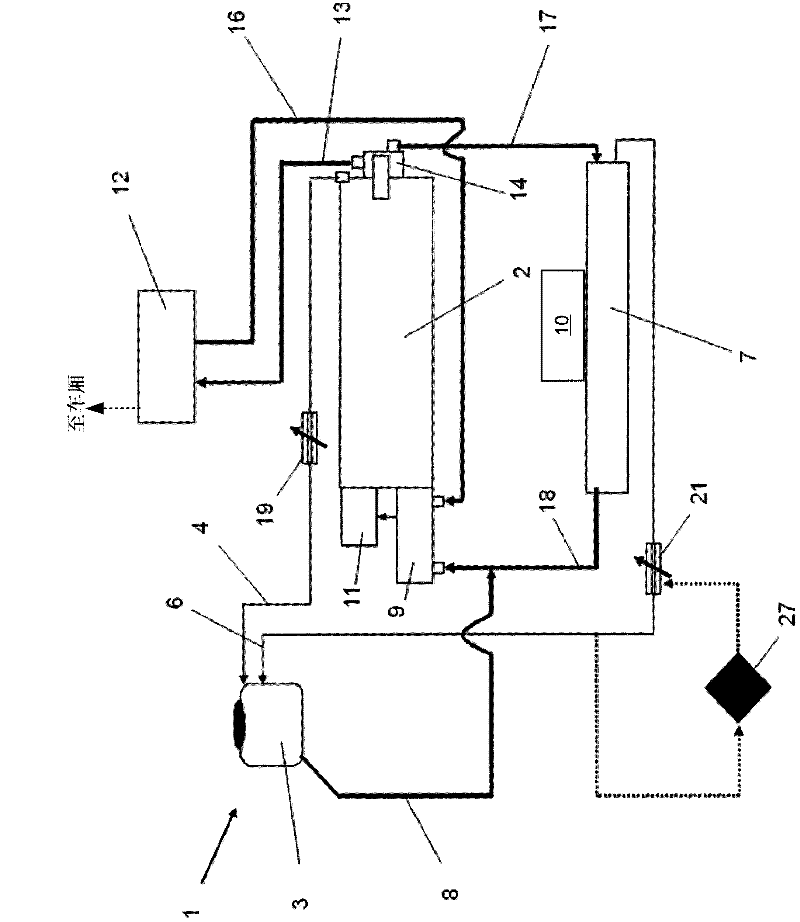

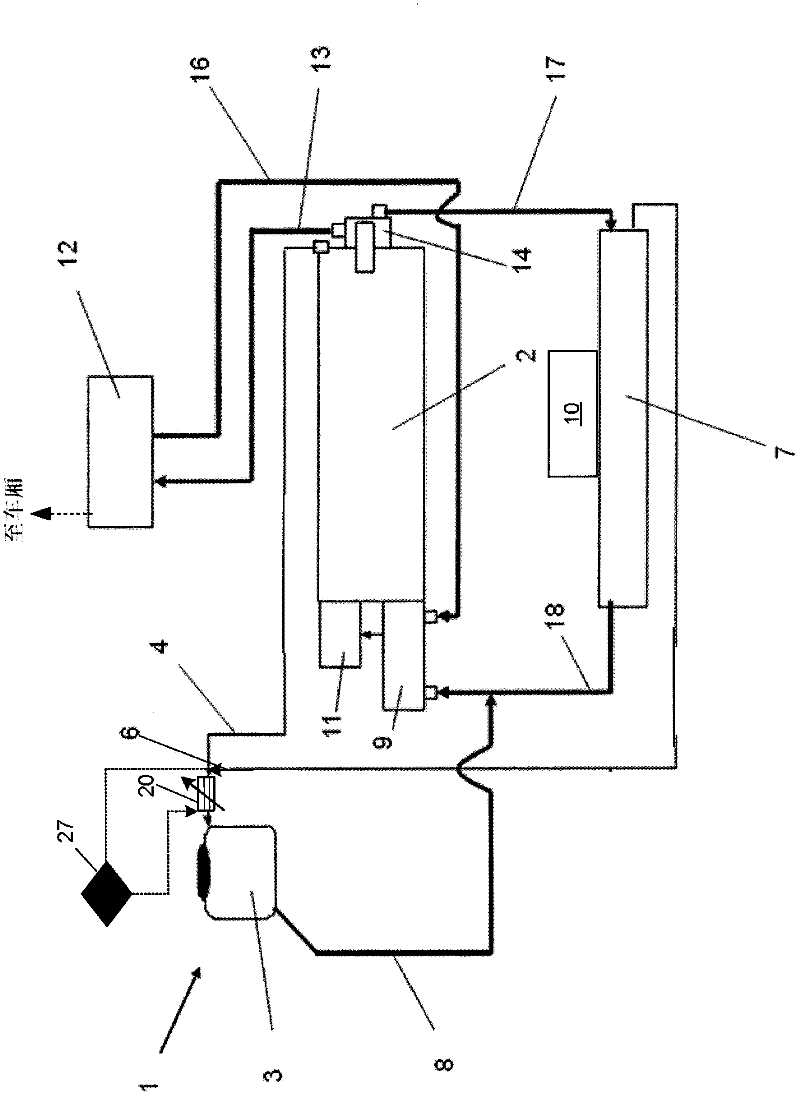

Cooling arrangement for internal combustion engines

InactiveCN102312717ASatisfactory ventilationSatisfaction extensionCoolant flow controlMachines/enginesCombustionExternal combustion engine

A cooling arrangement for an internal combustion engine is described, with a coolant balancing tank which is capable of being filled with coolant and the inlet side of which is connected via a first venting line to an internal combustion engine and / or via a second venting line to a cooler for cooling the coolant, and the outlet side of which is connected via a coolant return line to the inlet side of a pumping device for pumping the coolant through the internal combustion engine. The cooling arrangement has, furthermore, a flow control unit for variably limiting the coolant volume flow in the venting line.

Owner:FORD GLOBAL TECH LLC

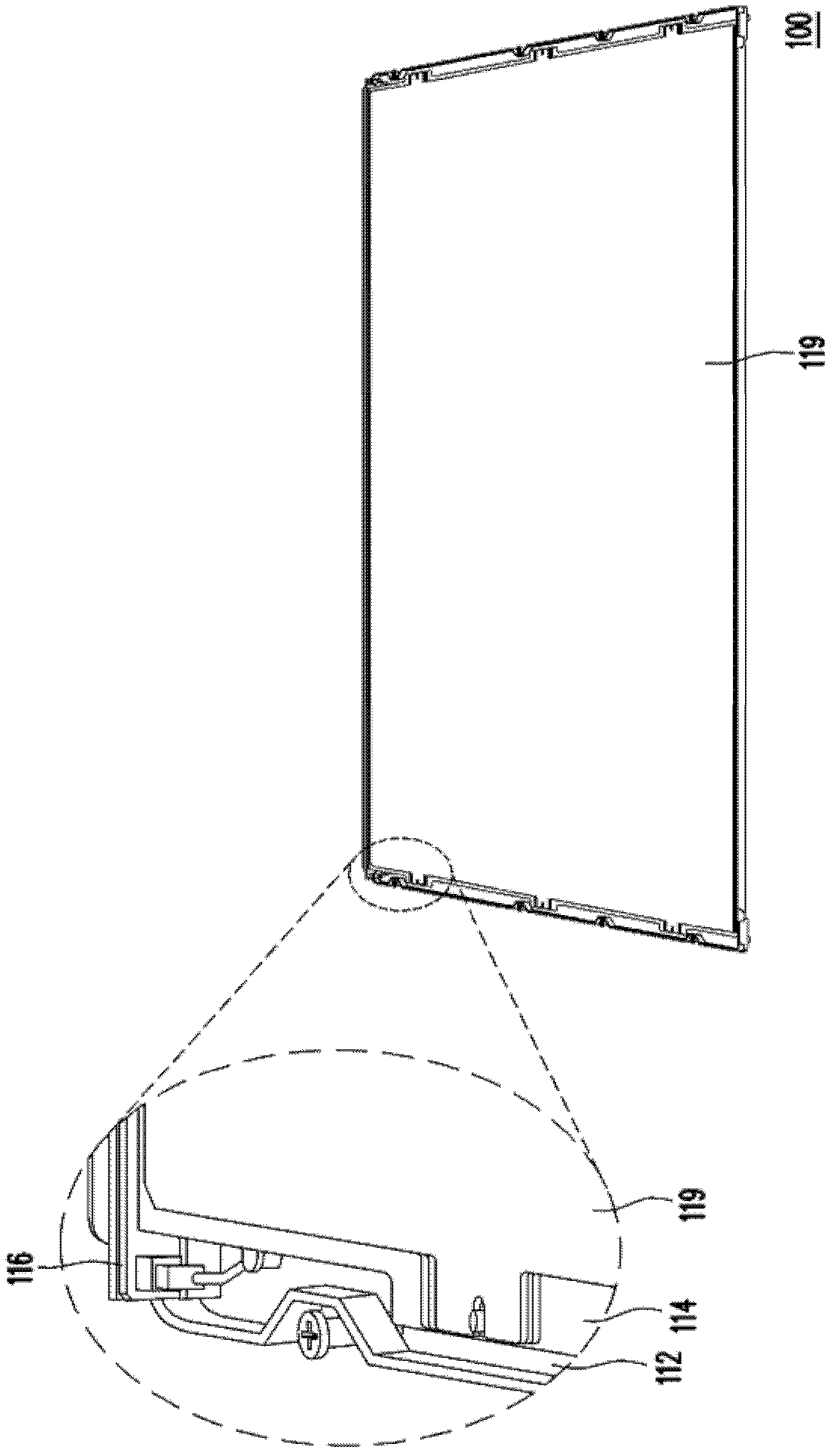

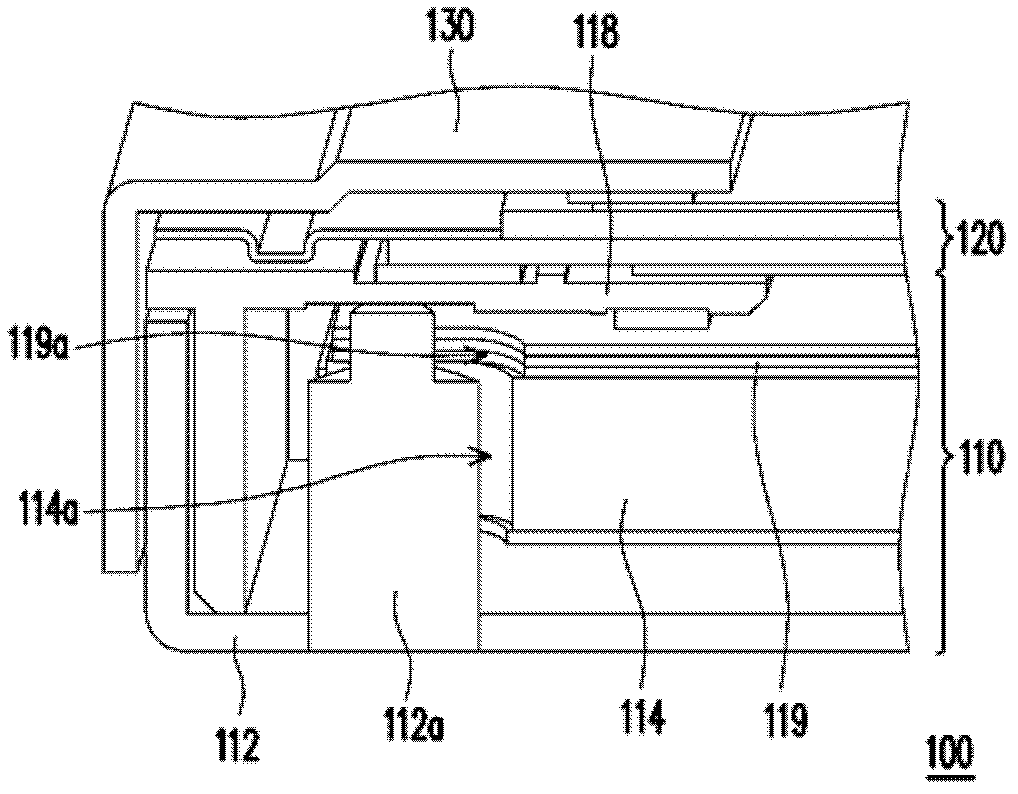

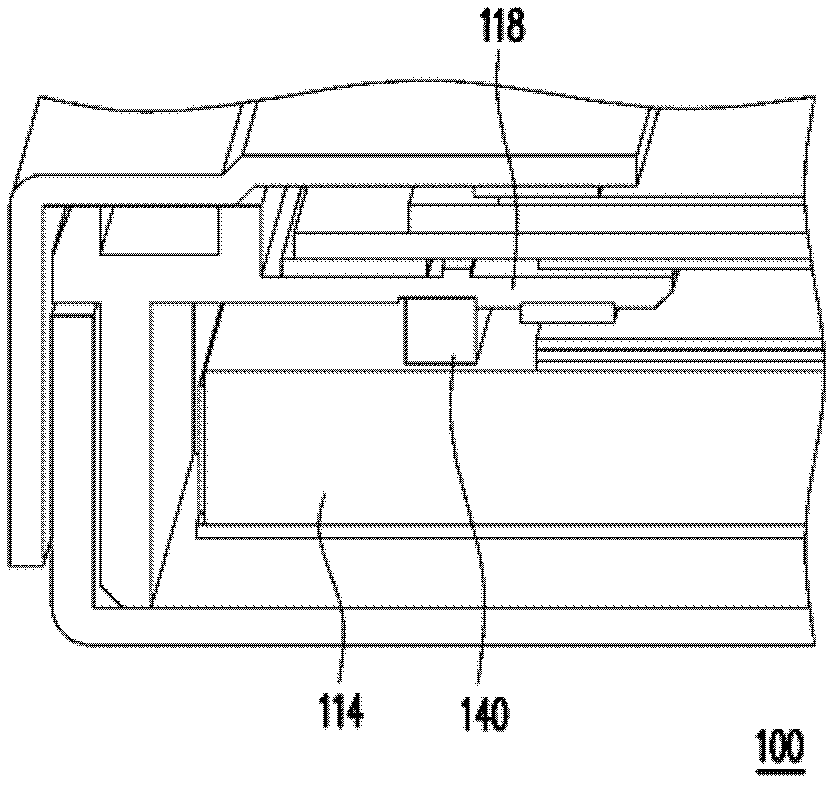

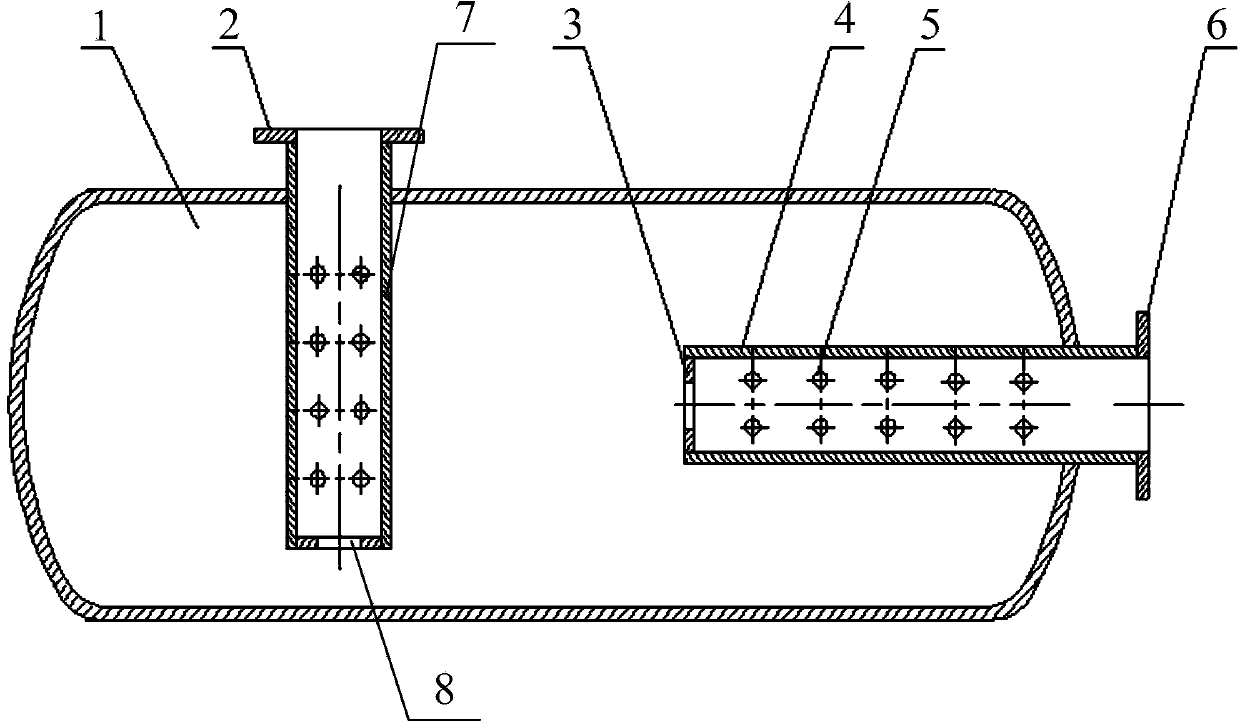

Backlight module and display module

InactiveCN102506358ASimplify internal structureReduce manufacturing costNon-linear opticsLight fasteningsLight guideComputer science

The invention discloses a display module and a backlight module. The display module includes the backlight module and a display panel arranged on the backlight module. The backlight module includes a base plate, a light guide plate, a support frame, a buffer material and a baffle. The light guide plate is arranged on the base plate and includes the top face, the bottom face and a plurality of side faces connecting between the top face and the bottom face. The support frame surrounds the light guide plate. The buffer material is arranged on at least one side of the light guide plate and includes the top wall, the bottom wall and the side wall. The top wall is arranged on the outer periphery of the top face of the light guide plate. The bottom wall leans between the base plate and the bottom face of the light guide plate. The side wall connects with the top wall and the bottom wall and wraps at least one side face of the light guide plate. The baffle is arranged on the base plate vertically and is disposed on at least one side of the light guide plate. The side wall of the buffer material leans between the baffle and at least one side face of the guide plate.

Owner:AU OPTRONICS CORP

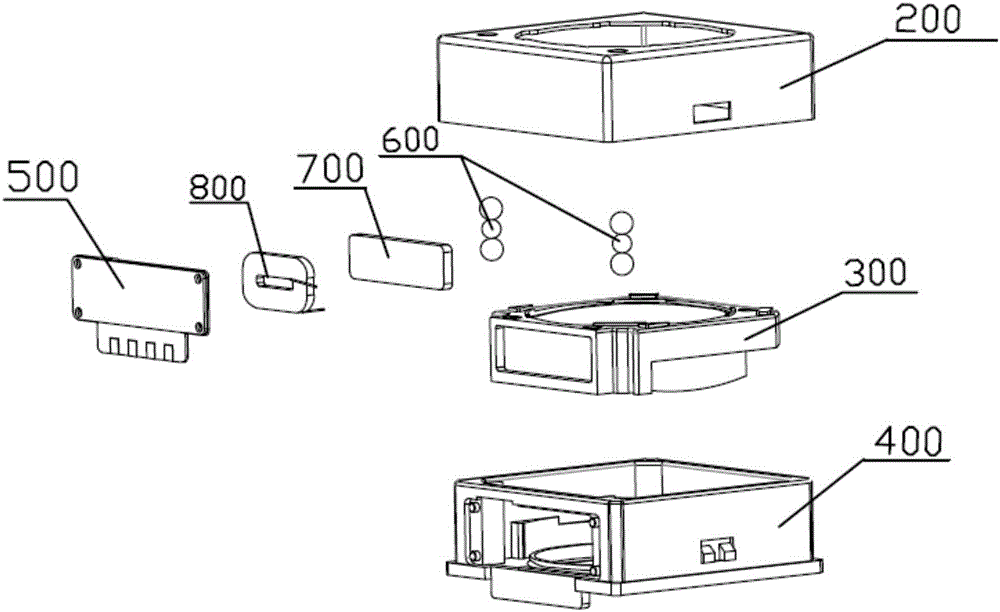

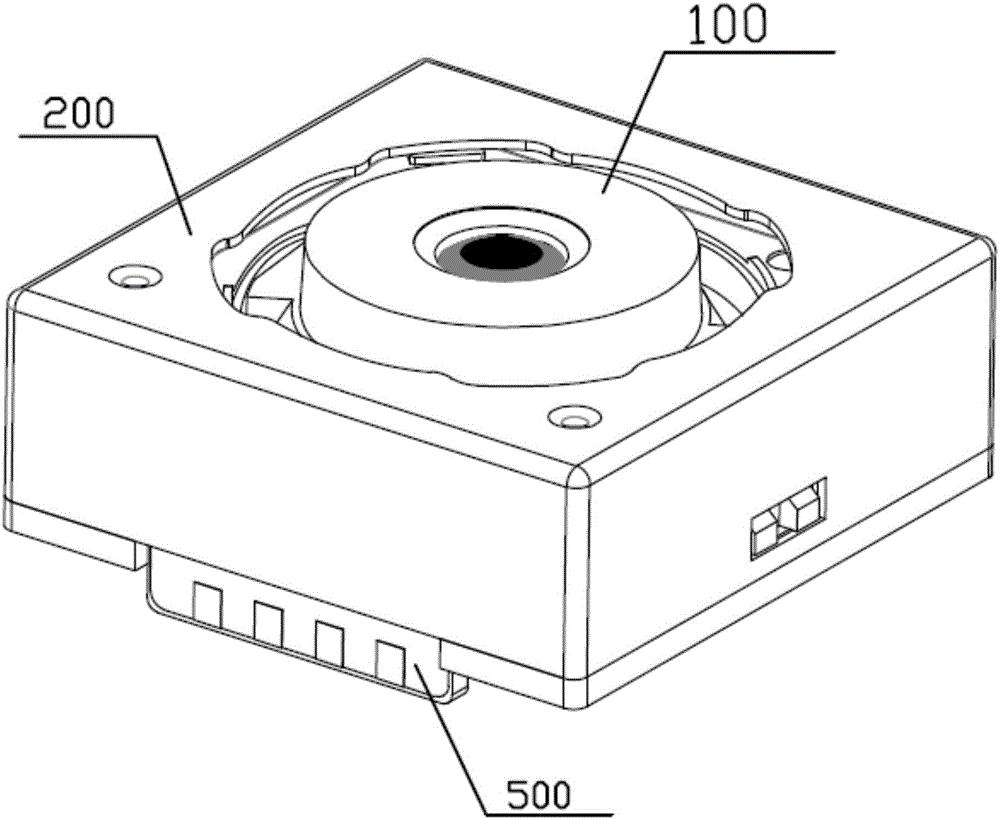

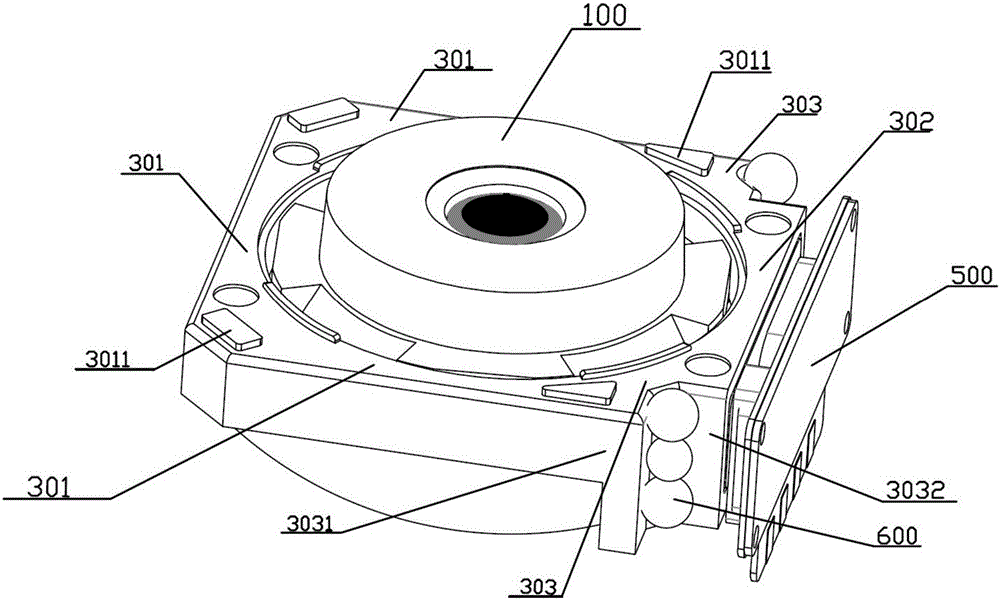

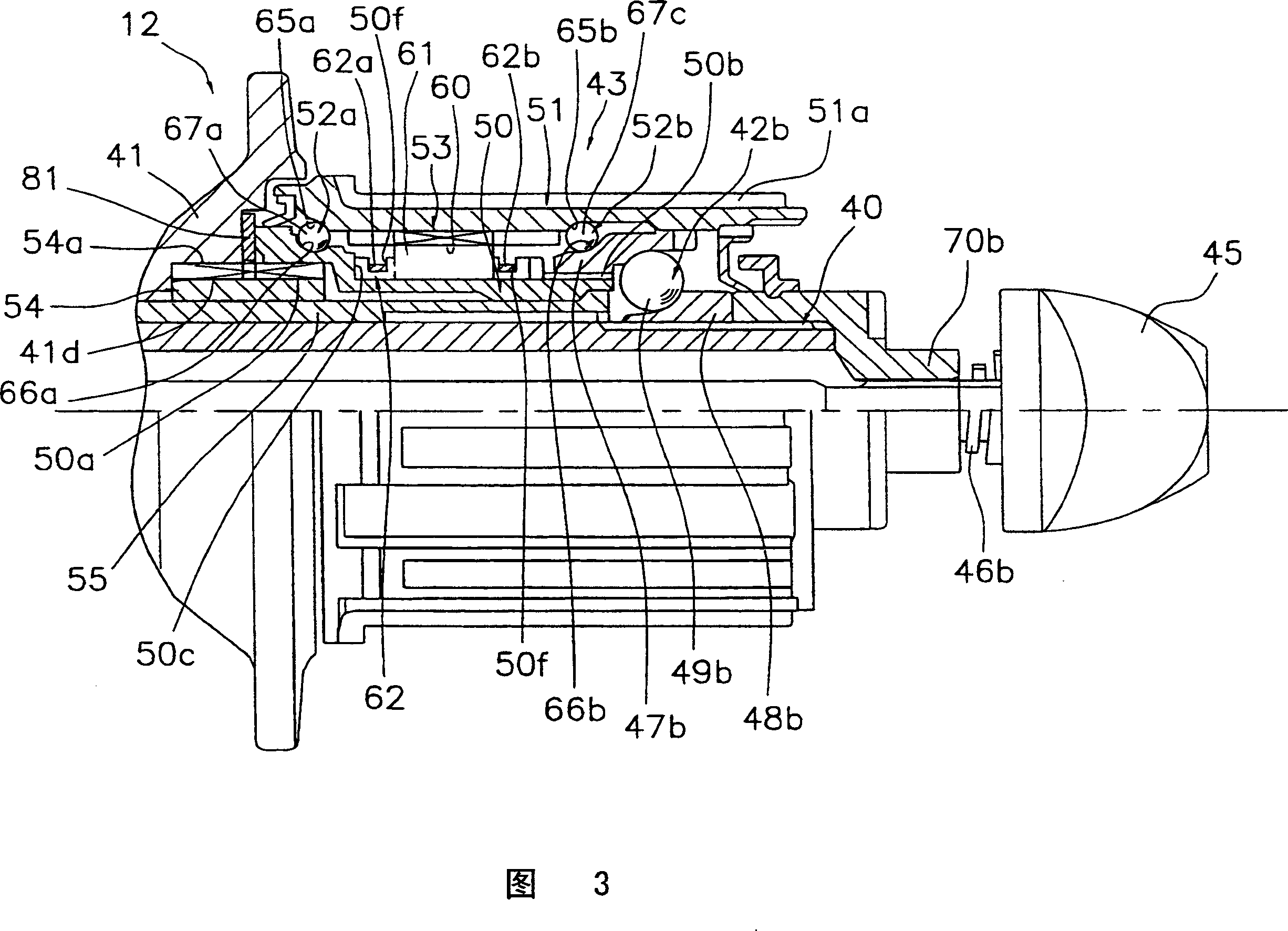

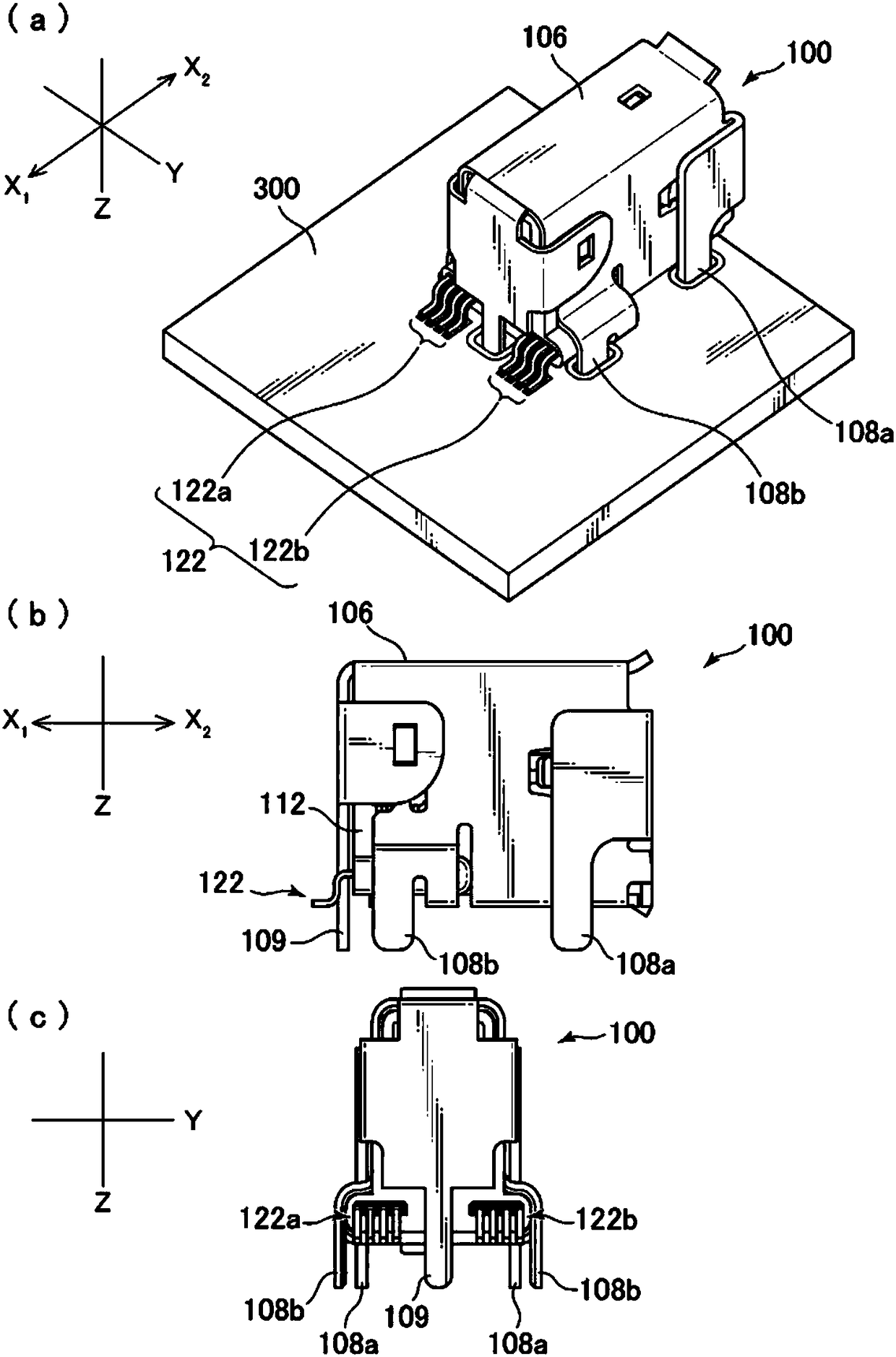

Camera module

InactiveCN106716242ASimple structureTake advantage ofMountingsFocusing aidsCamera lensComputer module

The invention relates to a camera module. The camera module comprises a pedestal (400), a housing (200) which is matched with the pedestal (400), and is hollow and provided with an opening in the top surface, and a camera lens assembly (100) and a carrier (300) which are accommodated in the housing (200). The camera module also comprises at least two sets of moving members (600) arranged between the outer wall of the carrier (300) and the housing (200), and the camera lens assembly (100) is accommodated in the carrier (300) and moves relative to the pedestal (400) through the at least two sets of moving members (600). The camera module has distinctive advantages that the camera module is simple in internal structure, convenient to carry, fast in focusing response speed, stable in focusing performance and good in imaging effect.

Owner:JIANGXI SENYANG TECH

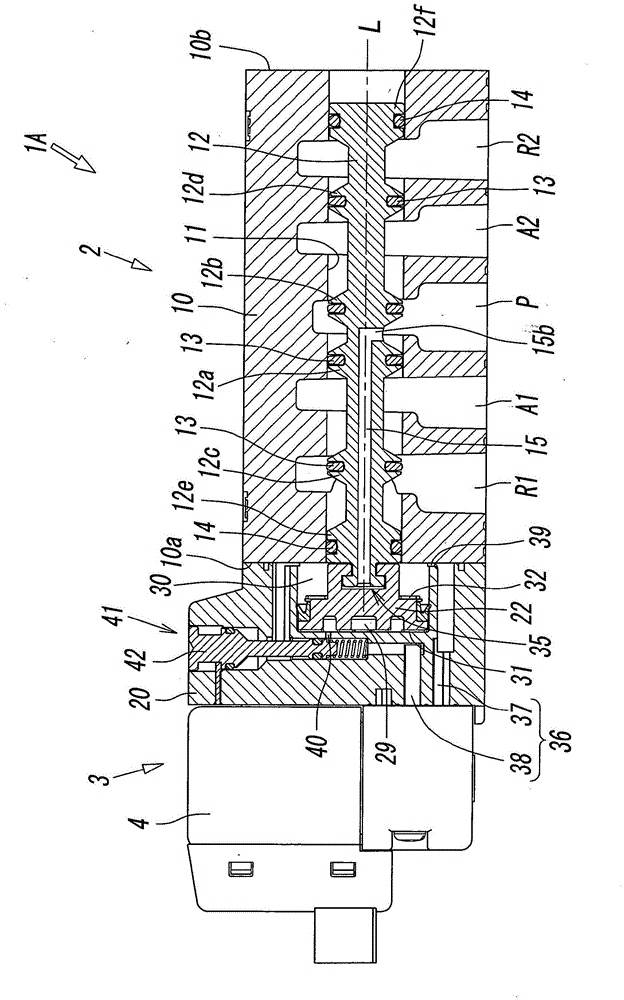

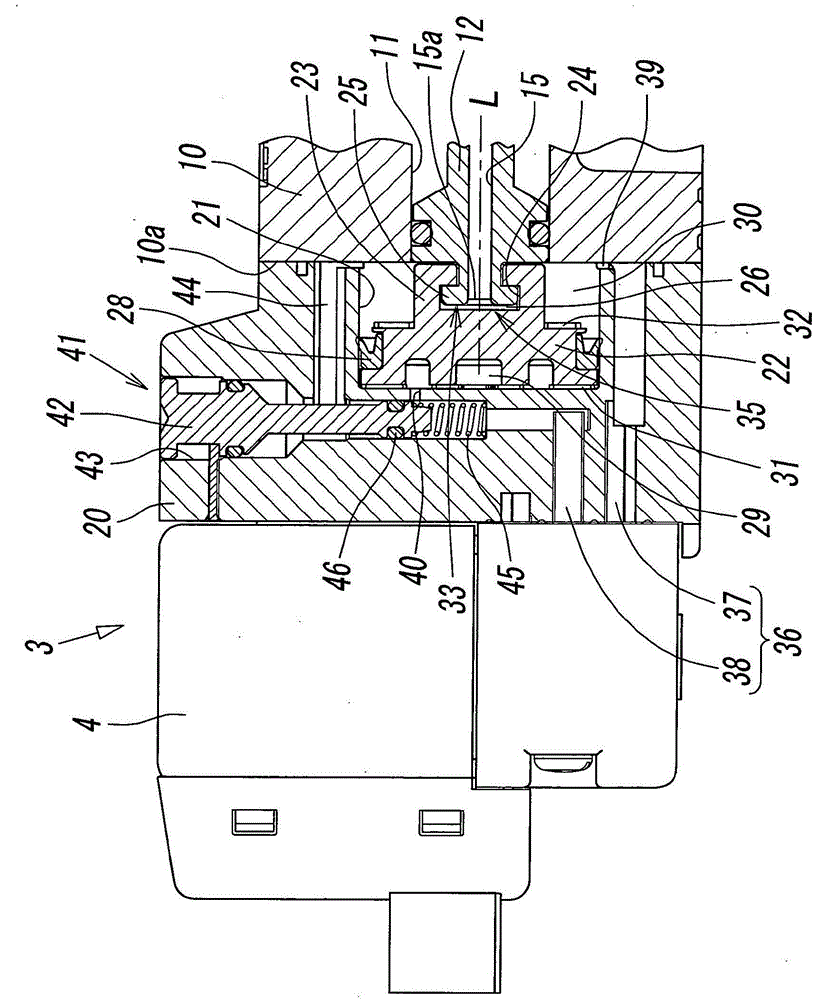

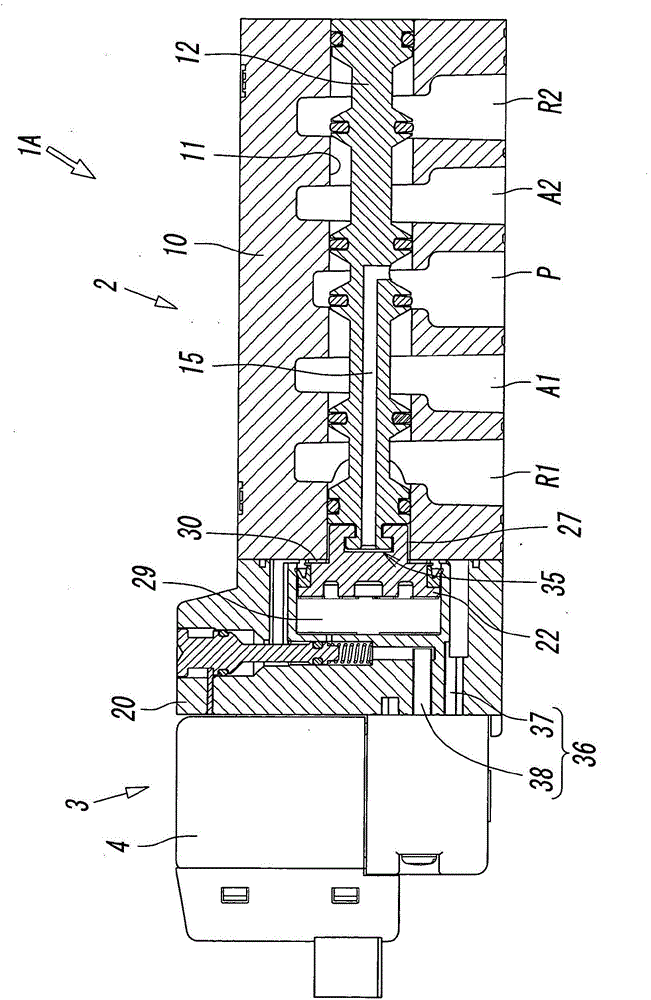

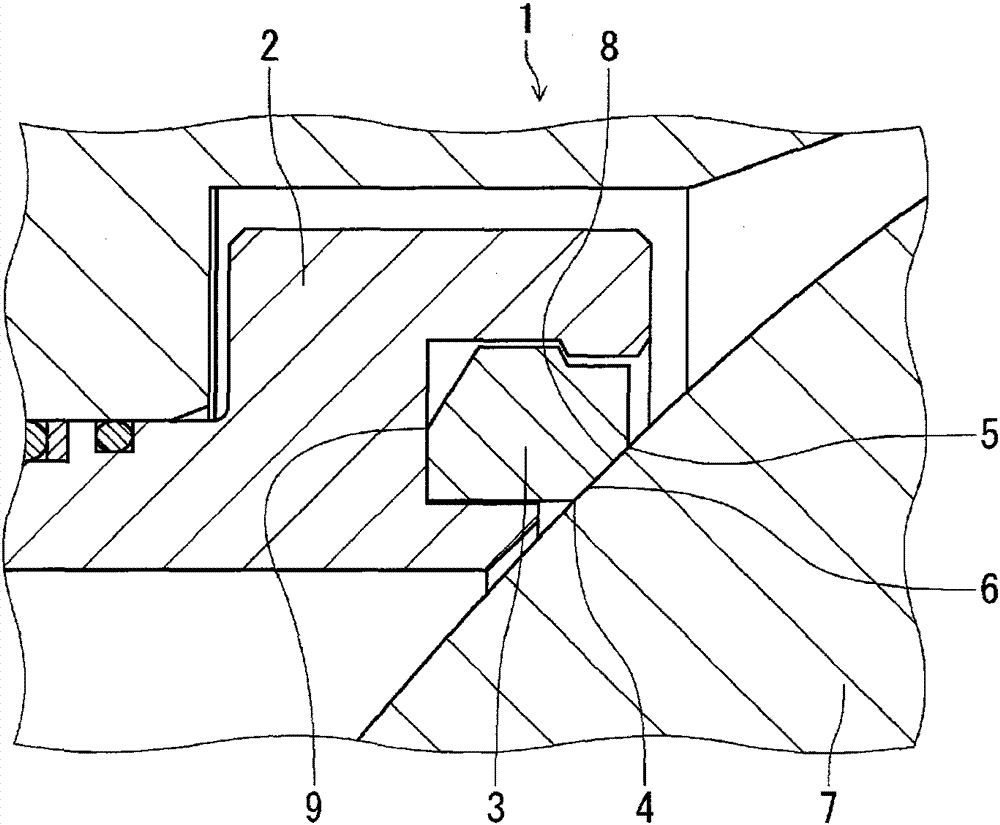

Solenoid-operated pilot type spool valve

ActiveCN104832700ASimplify internal structureEasy to processOperating means/releasing devices for valvesServomotor componentsSpool valvePiston

A pilot passage that is in communication with an input port at all times is formed inside a spool, the pilot passage and a second pressure receiving chamber on one side of a pilot piston are made to be in communication with each other at all times through a constantly open communication passage formed in a continuous portion between the spool and the pilot piston, the second pressure receiving chamber and a first pressure receiving chamber on the other side of the pilot piston are made to be in communication with each other through an opening / closing communication passage that is formed in a piston box and that is opened and closed with a pilot valve, and the pilot piston is driven and the spool is switched by turning the pilot valve on and off to supply / discharge pilot air to / from the first pressure receiving chamber.

Owner:SMC CORP

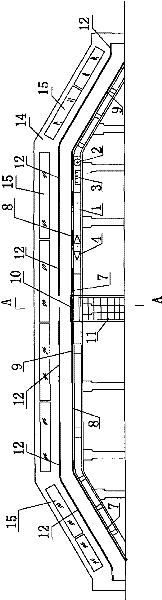

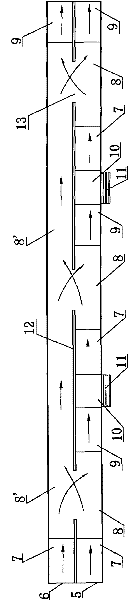

Automatic pedestrian path public transit system

ActiveCN102234055AImprove timelinessGood weather resistanceRoad vehicles traffic controlEscalatorsOperation modePollution

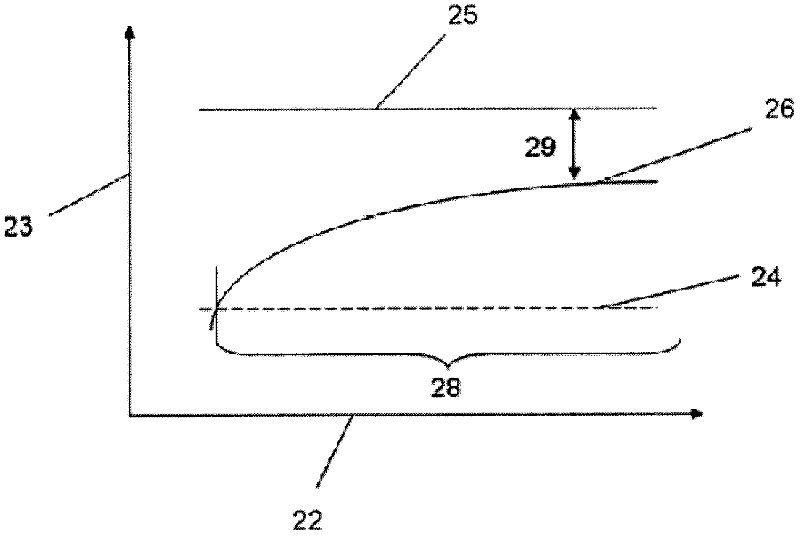

The invention relates to an automatic pedestrian path public transit system, comprising two short-distance boarding and alighting paths which are parallel and operate in the same direction and a long-distance through continuous rapid carrying path, the boarding and alighting processes of the two paths are respectively set to be in gradually varied operation modes such as uniform acceleration, uniform speed and uniform deceleration, multiple platforms which can cause passengers to walk out or get into the short-distance boarding and alighting paths are arranged on the short-distance boarding and alighting paths, and multiple synchronous transfer sections are arranged between the two paths and transfer ports are correspondingly arranged. Pedestrian can go into the carrying path at a leg speed and can freely select to take the continuous rapid carrying path or the short-distance boarding and alighting paths according to the length of a travel; the pedestrian can rapidly and directly arrive at a farther destination by taking the continuous rapid carrying path, can transfer to the short-distance boarding and alighting paths before arriving at a platform destination and can walk out thepaths at the leg speed after uniform deceleration is carried out, thus the pedestrian can arrive at a destination stably. The automatic pedestrian path public transit system provided by the inventioncan be applied to a road at high traffic flow, a traffic jam can not be caused, and continuous, uninterrupted, seamless and pollution-free operation can be realized.

Owner:赵峰

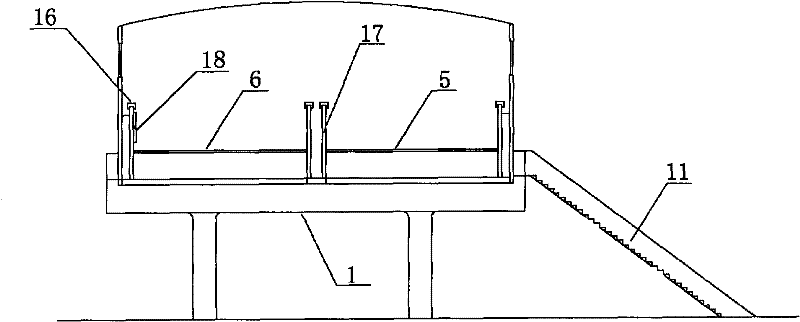

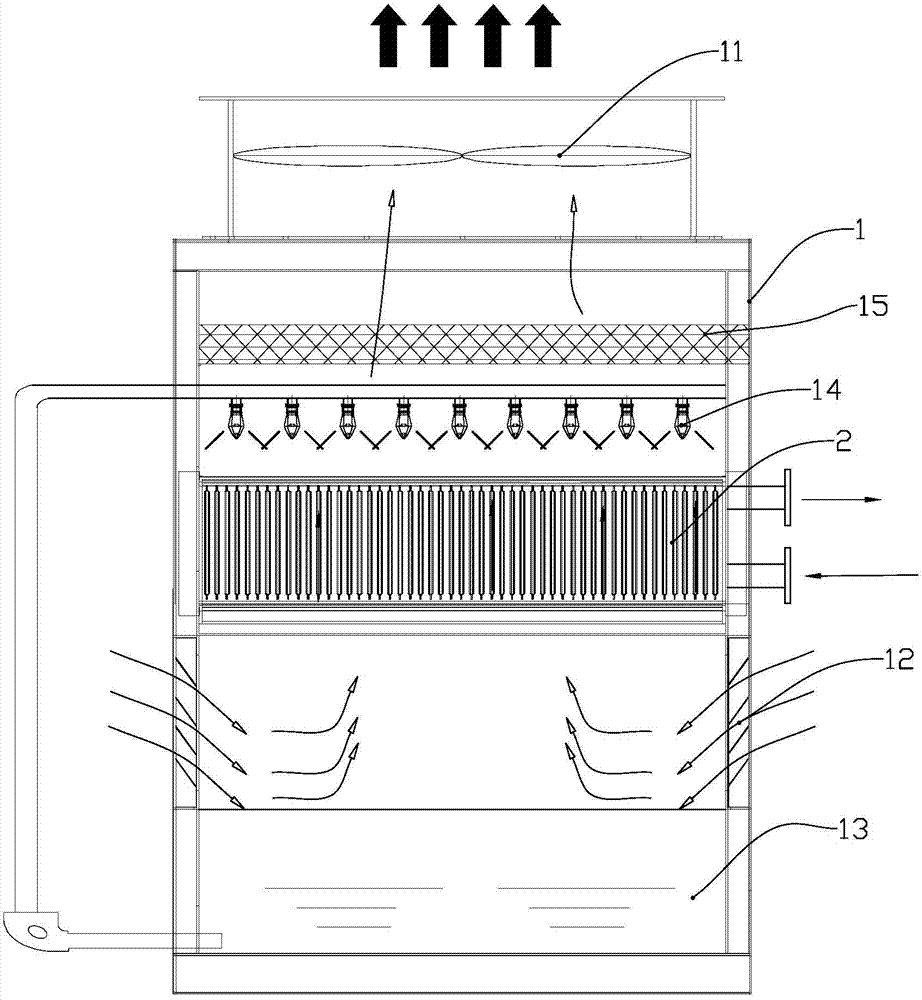

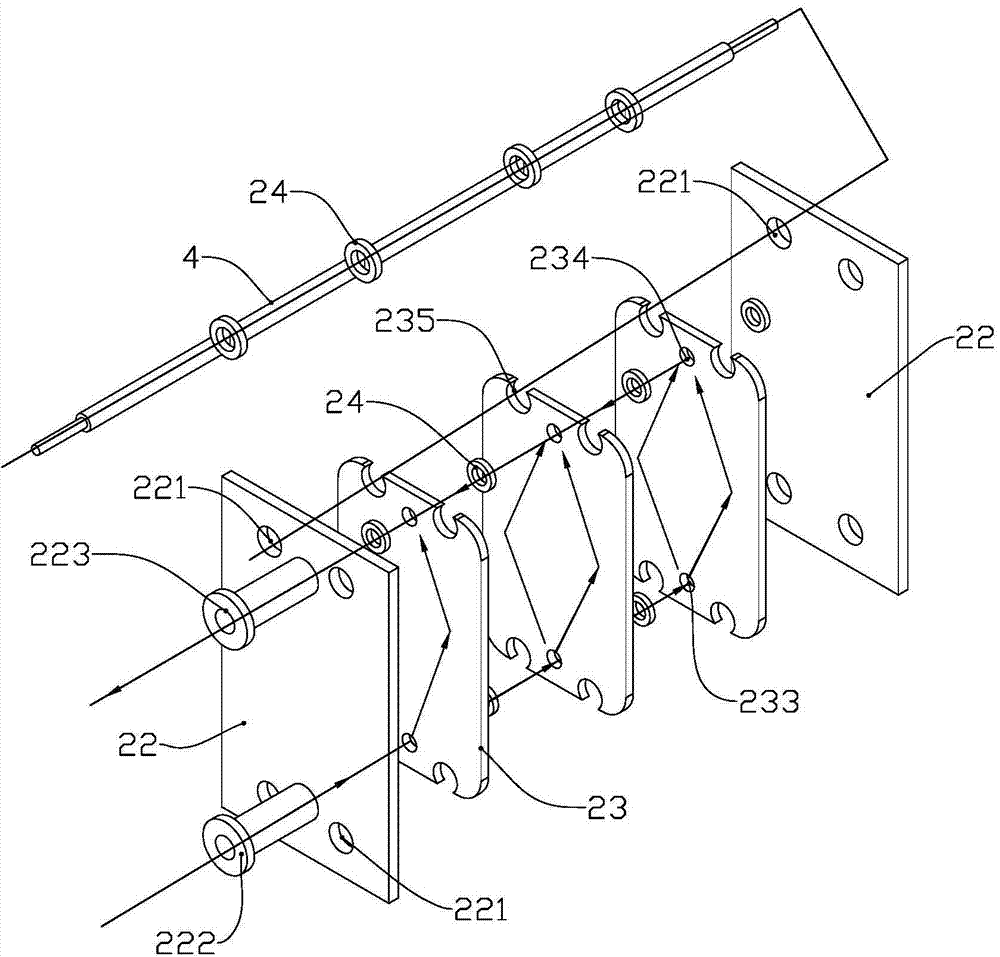

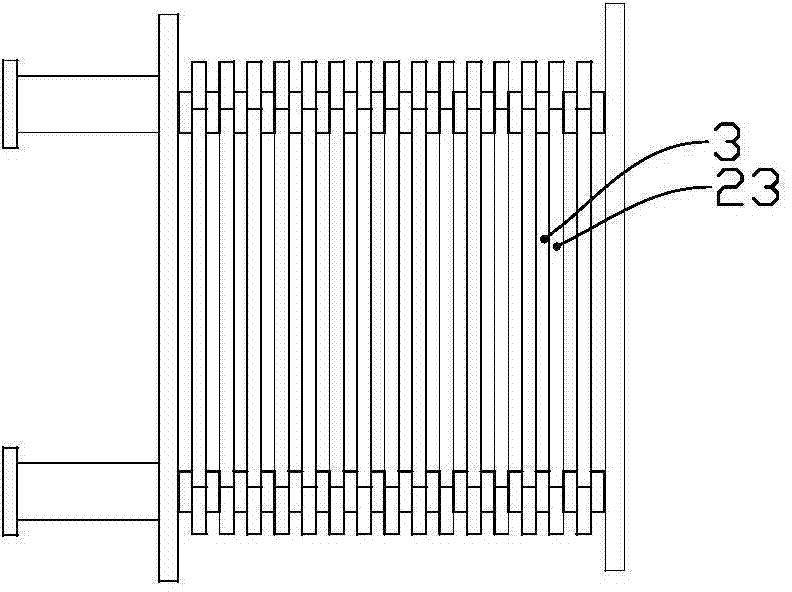

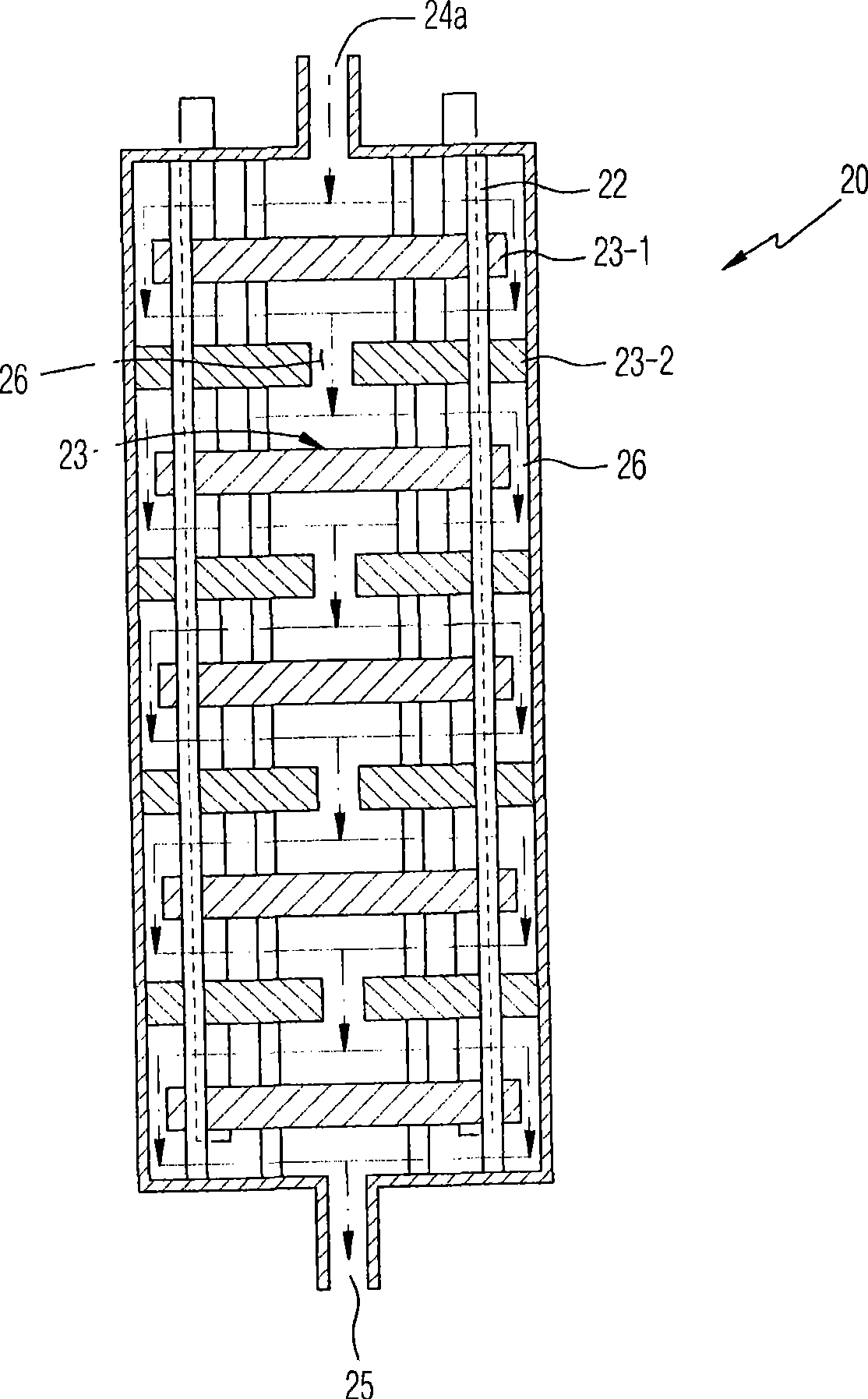

Sealed cooling tower

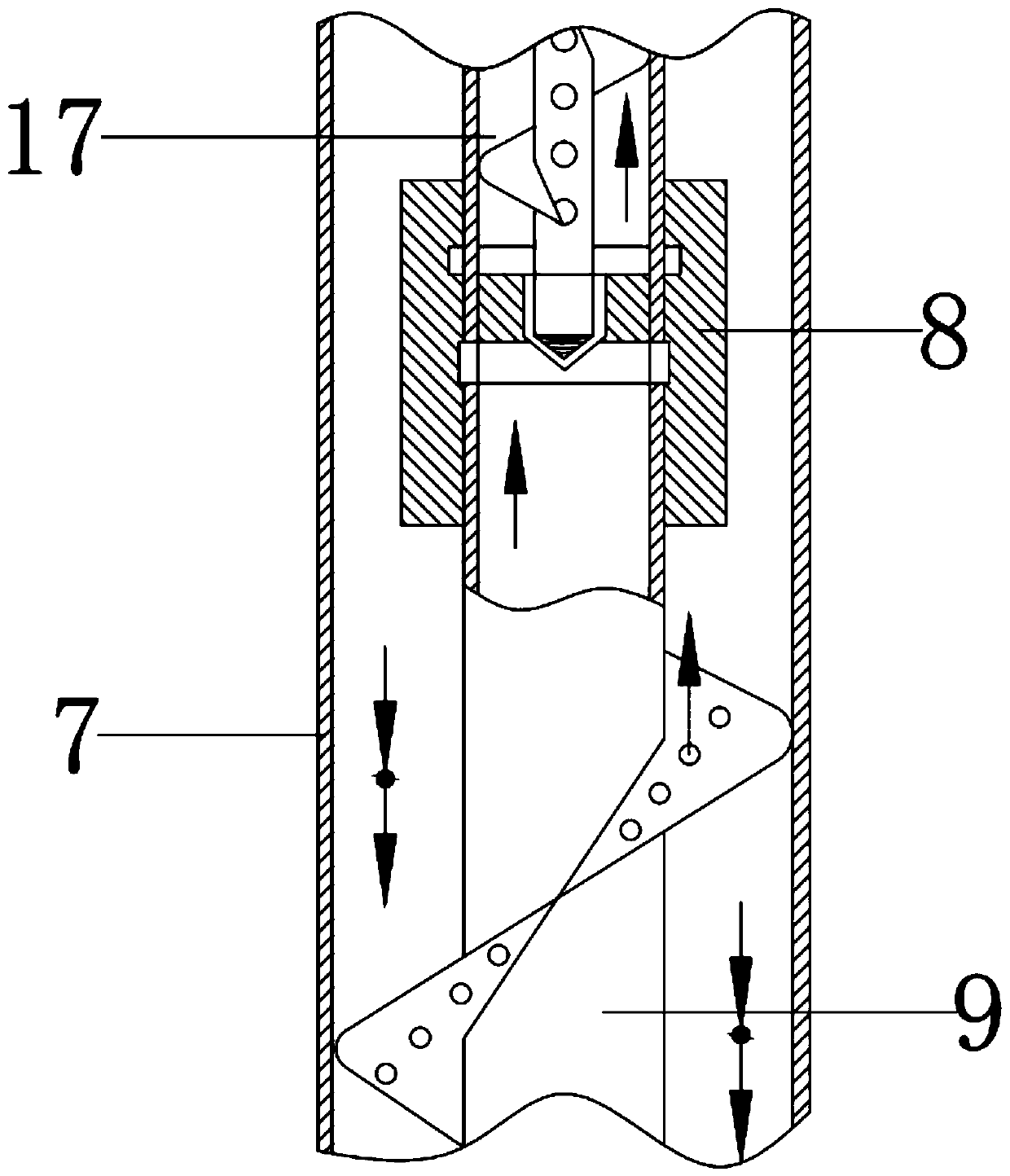

InactiveCN104776729ASolve the installation of polyvinyl chloride fillerSolve efficiency problemsTrickle coolersLiquid mediumCooling tower

The invention discloses a sealed cooling tower and solves the problems that an existing cooling tower is filled with polyvinyl chloride packing and the heat exchange efficiency is low. The sealed tower comprises a tower body, a spraying system, a heat exchange part and a fan, wherein the heat exchange part is a cooler; multiple shell type heat exchange units are vertically arranged in the cooler at intervals; a spraying and air flow channel is formed between the outer walls of two adjacent heat exchange units; at least one inlet and at least one outlet are formed in each heat exchange unit; at least one set of to-be-cooled medium channel penetrating through the inlet and the outlet of each heat exchange unit is formed in the heat exchange unit; the inlets of the heat exchange units are communicated with one another and are converged to form a to-be-cooled liquid medium inlet; the outlets of the heat exchange units are communicated with one another and are converged to form a to-be-cooled liquid medium outlet. The inside structure of the sealed cooling tower is simplified and the cooling efficiency is improved.

Owner:济南秦泰热工技术有限公司

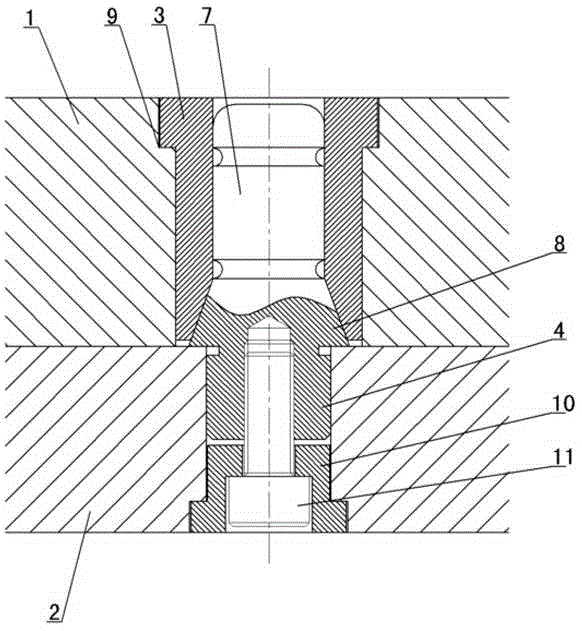

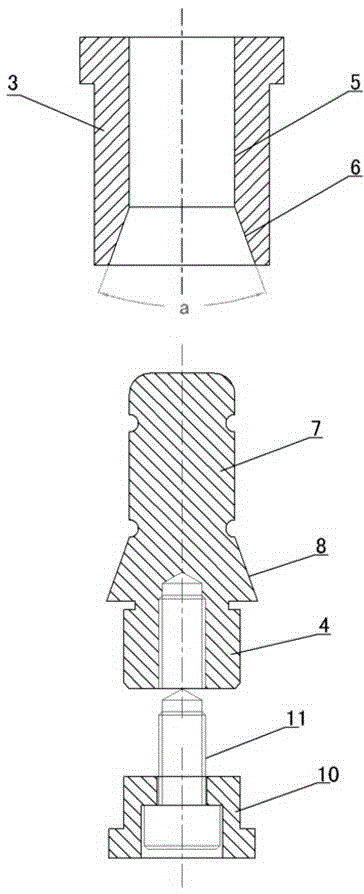

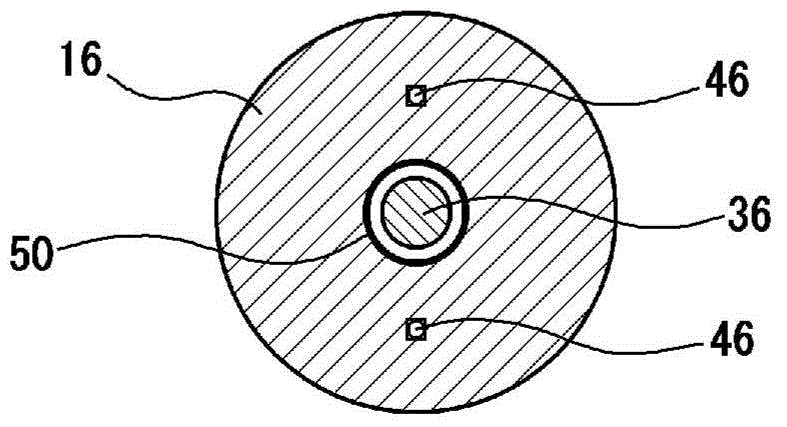

Improved guiding and positioning pin for injection mold

The invention discloses an improved guiding and positioning pin for an injection mold. The modified guiding and positioning pin comprises a mold cavity plate and a core plate, wherein a positioning sleeve is mounted in the cavity plate, and a positioning pin is mounted in the core plate; a straight surface guiding hole and a conical surface locking hole are formed in the positioning sleeve, a straight surface guiding rod and a conical surface locking block are arranged on the positioning pin, the straight surface guiding rod and the straight surface guiding hole are matched, and the conical surface locking block and the conical surface locking hole are matched. Through the adoption of the scheme disclosed by the invention, two functions of straight surface guiding and conical surface positioning are combined into one component, so that double functions of guiding and positioning between two moving components of the injection mold are realized, the modified guiding and positioning pin is simple in structure, convenient to process and low in cost, the internal structure of the mold is simplified, and the investment cost of the mold is reduced.

Owner:YONGGAO CO LTD +1

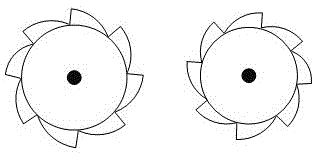

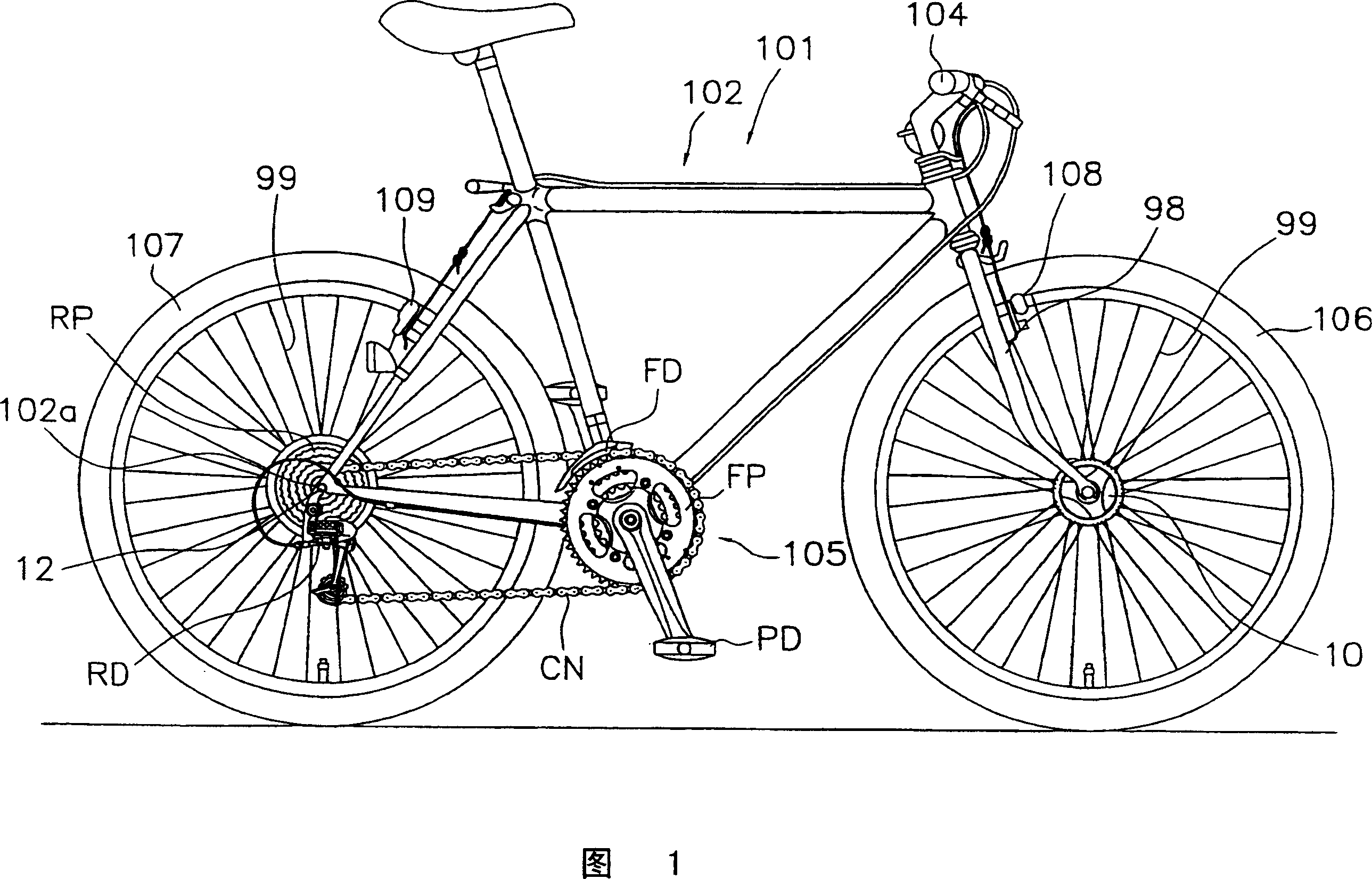

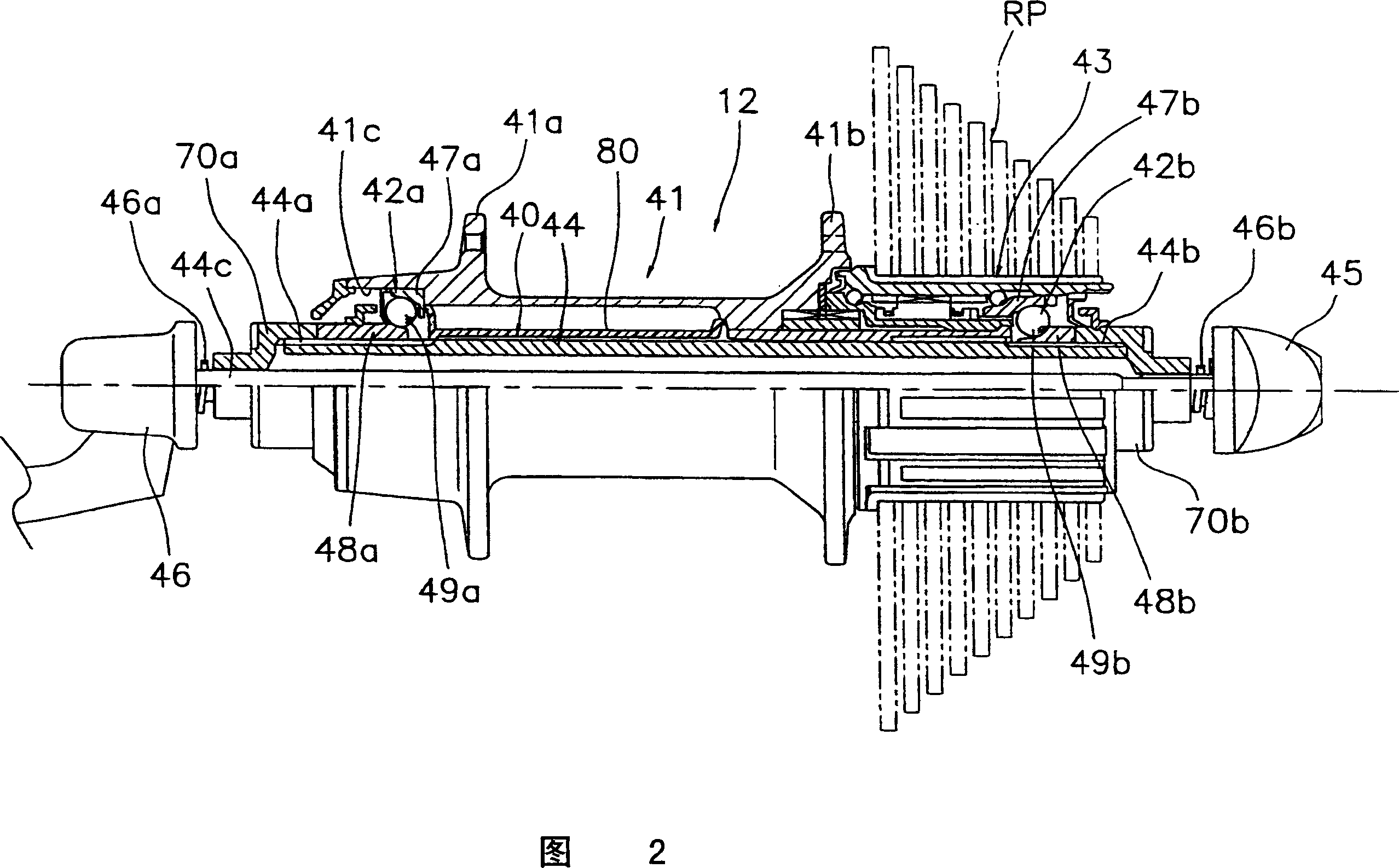

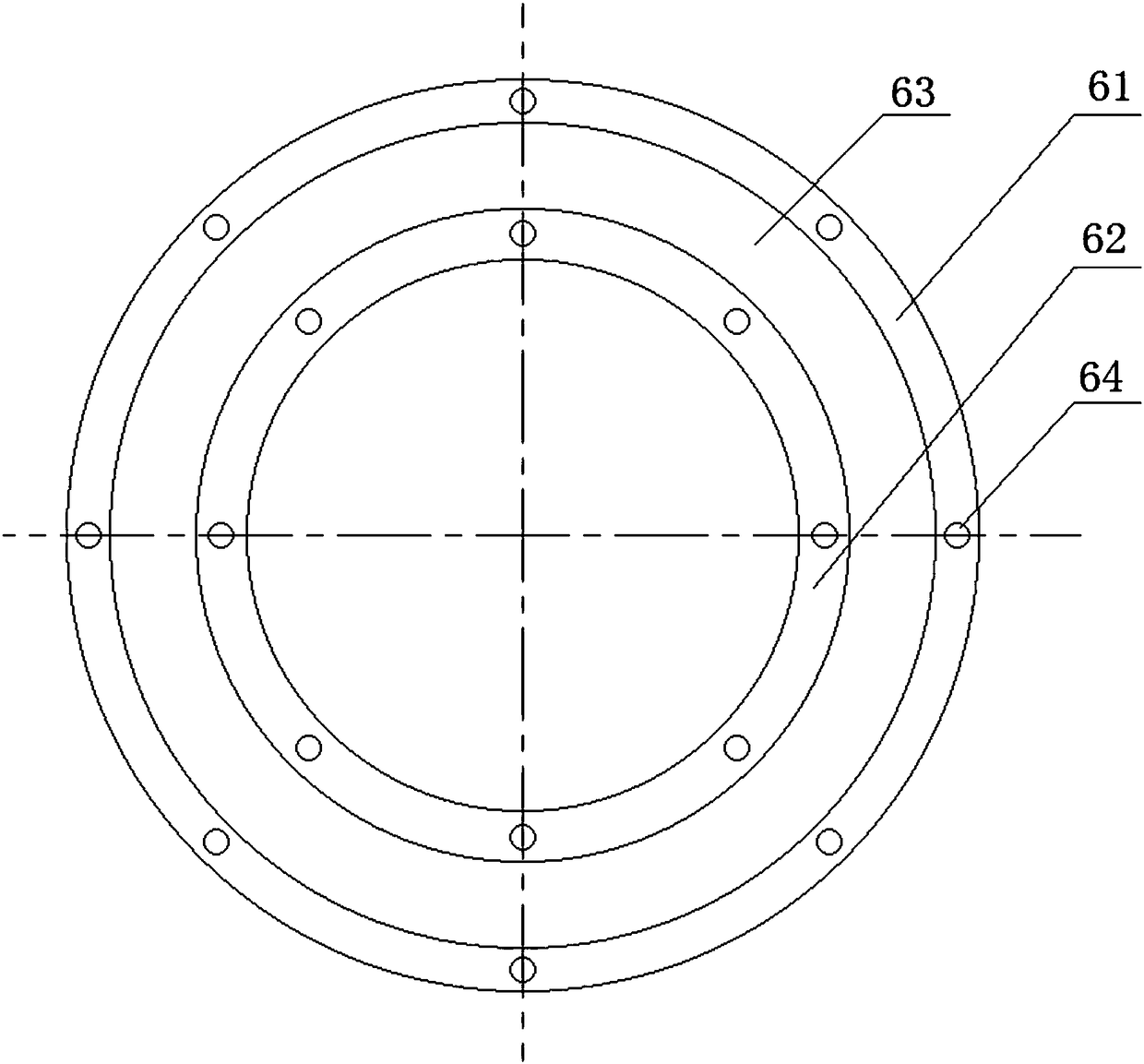

Bicycle freewheel

InactiveCN1952422ASmall clearance angleSimplify internal structureFreewheel clutchesFreewheelEngineering

A freewheel basically has an inner tubular member, and outer tubular member, at least one bearing assembly, and a one-way clutch. The inner tubular member is fixed to a hub body. The bearing assembly is arranged between the inner and outer tubular members to rotatably couple the outer tubular member to the inner tubular member. The one-way clutch has ratchet teeth provided on an internal circumferential surface of the outer tubular member, at least three clutch pawls provided on the outer side circumference of the inner tubular member in a circumferential direction, and at least one force applying member applying forces against at least two of the clutch pawls in a direction oriented away from the outer side circumference of the inner tubular member toward an engagement position. The clutch pawls are arranged such that an angle of lost motion of the freewheel is 10 DEG or less.

Owner:SHIMANO INC

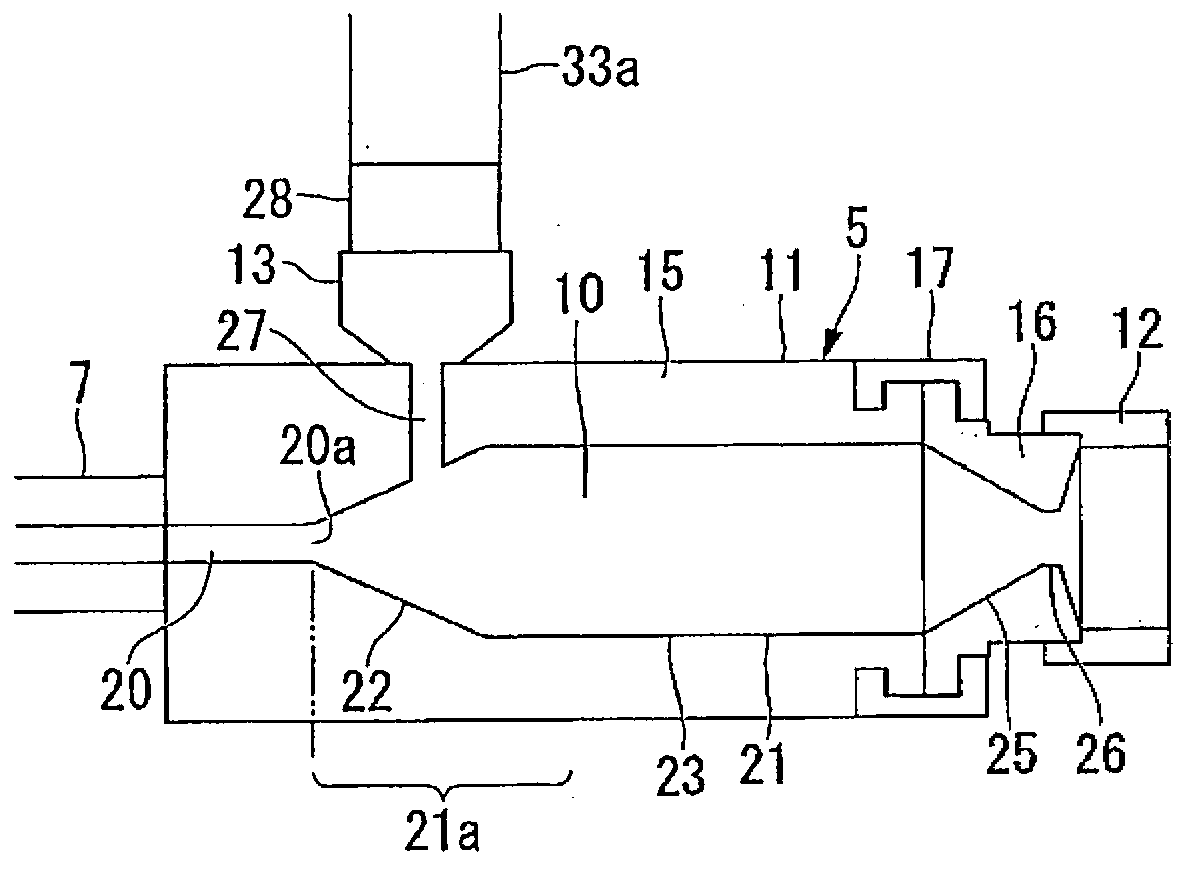

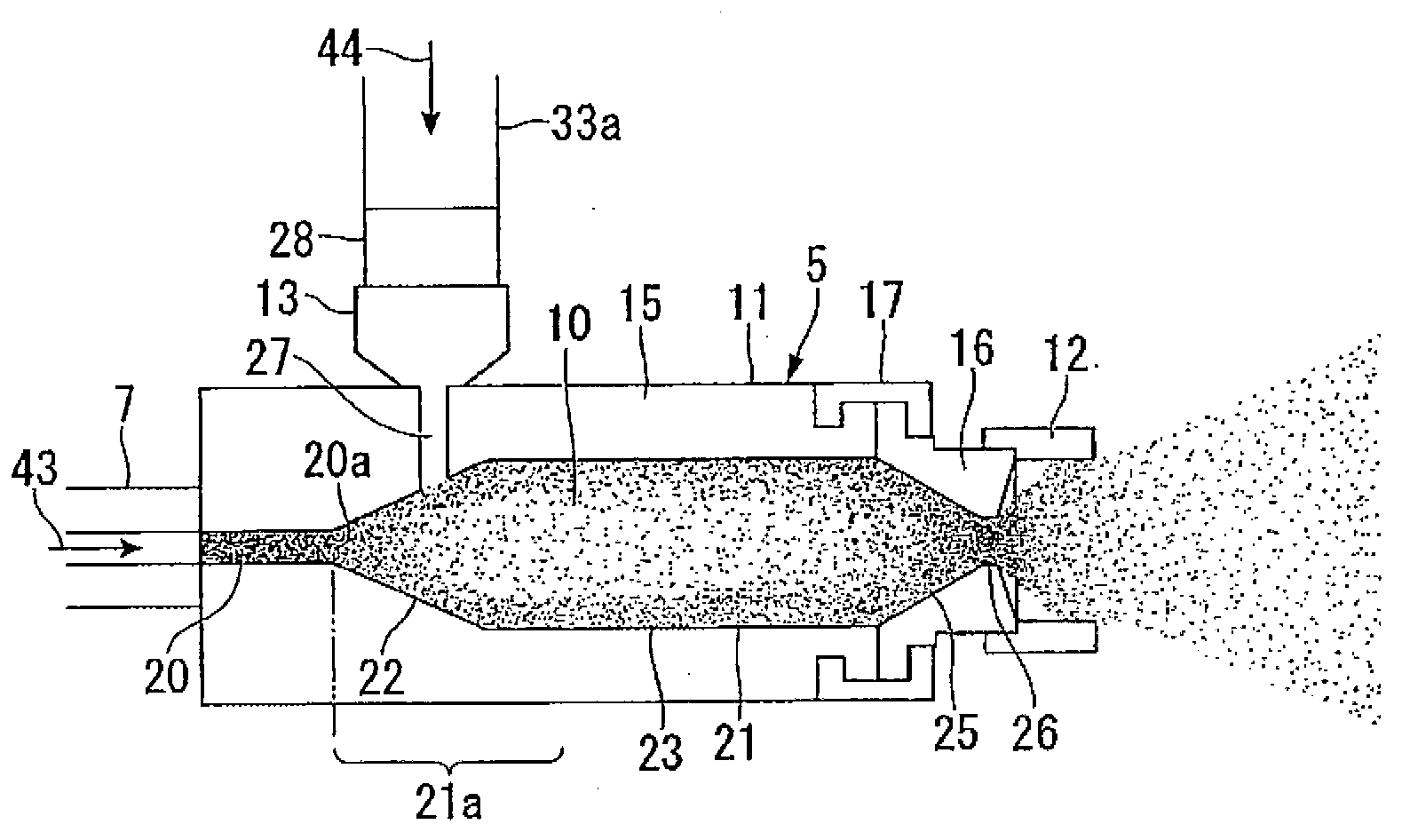

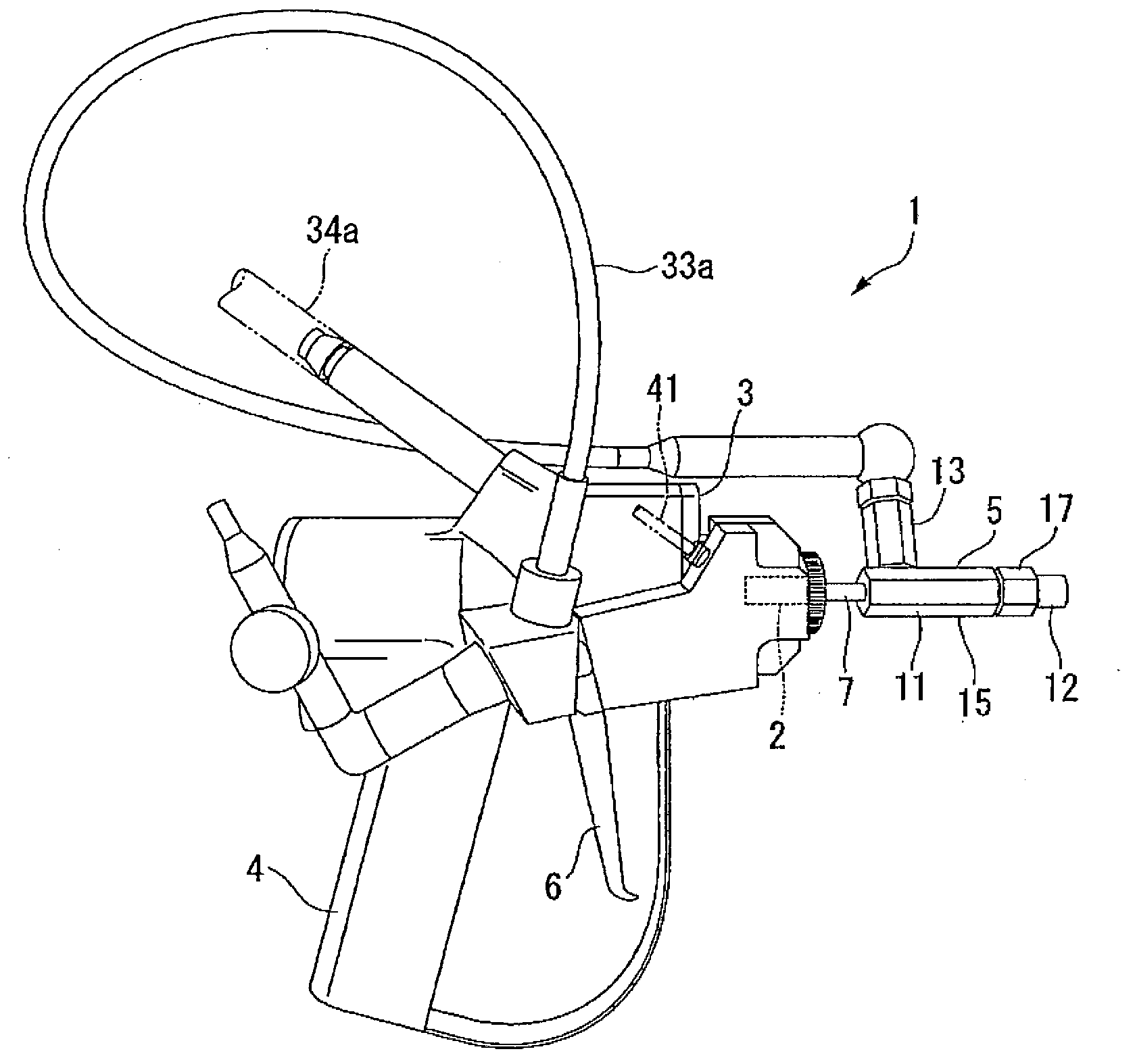

Spray gun, spray coating device, and spray coating method

InactiveCN102858465AIncrease supplyShorten the timeLiquid surface applicatorsBuilding constructionsInterior spaceSpray coating

A spray gun is provided with a nozzle section for mixing gas into a material liquid and spraying the material liquid. The inner space of the nozzle section has an introduction path through which the material liquid is introduced, an open section which has a flow path expanded to a size greater than that of the introduction path and which sprays the material liquid in a fine particle-like form, a reduced-diameter section which has a flow path contracted to a size smaller than that of the open section and which re-collects the fine particle-like material liquid, and a spray opening section which sprays the material liquid to the outside. The nozzle section has formed therein a gas introduction hole for introducing gas to a base end side portion of the open section.

Owner:DYFLEX CORP

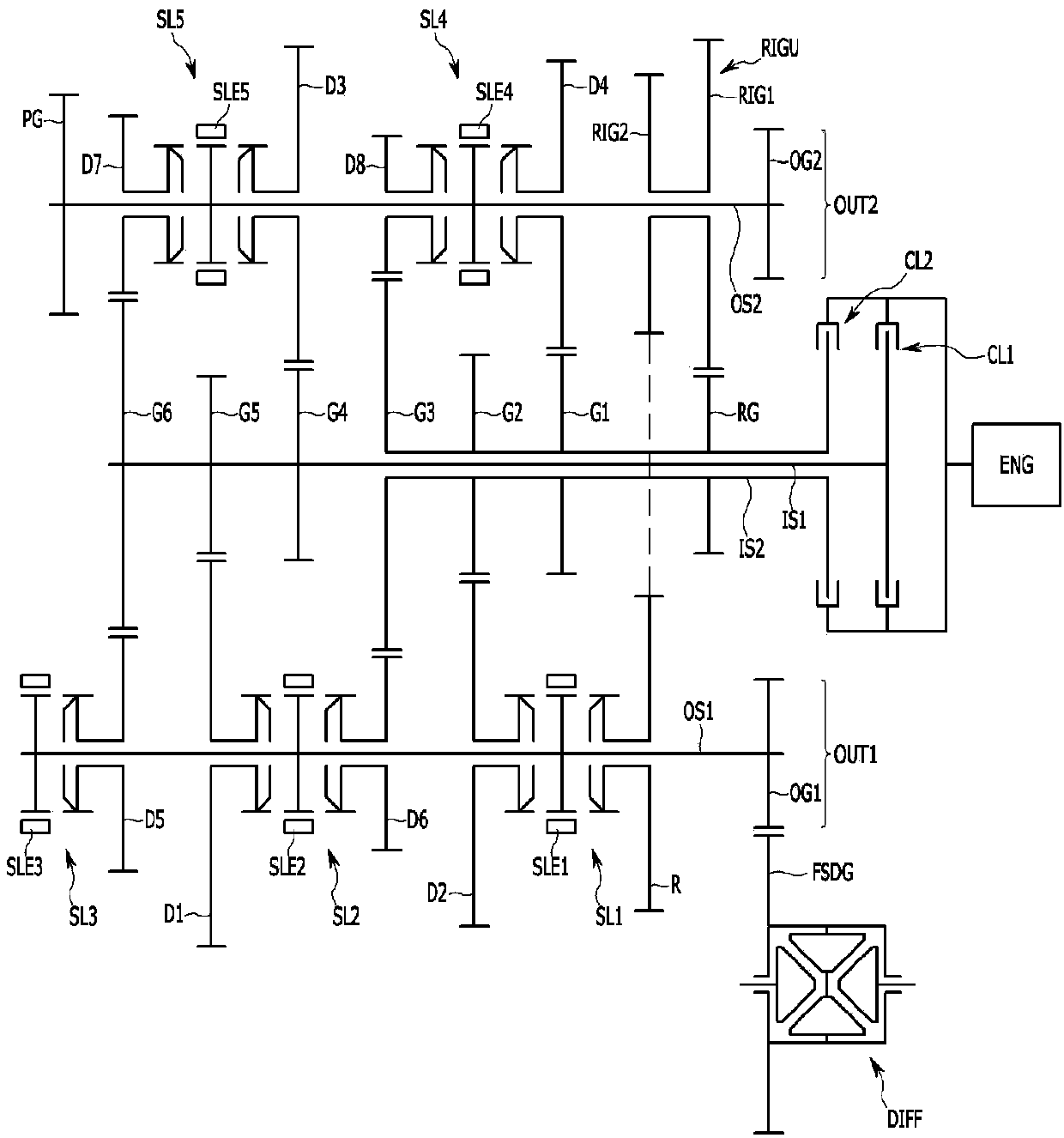

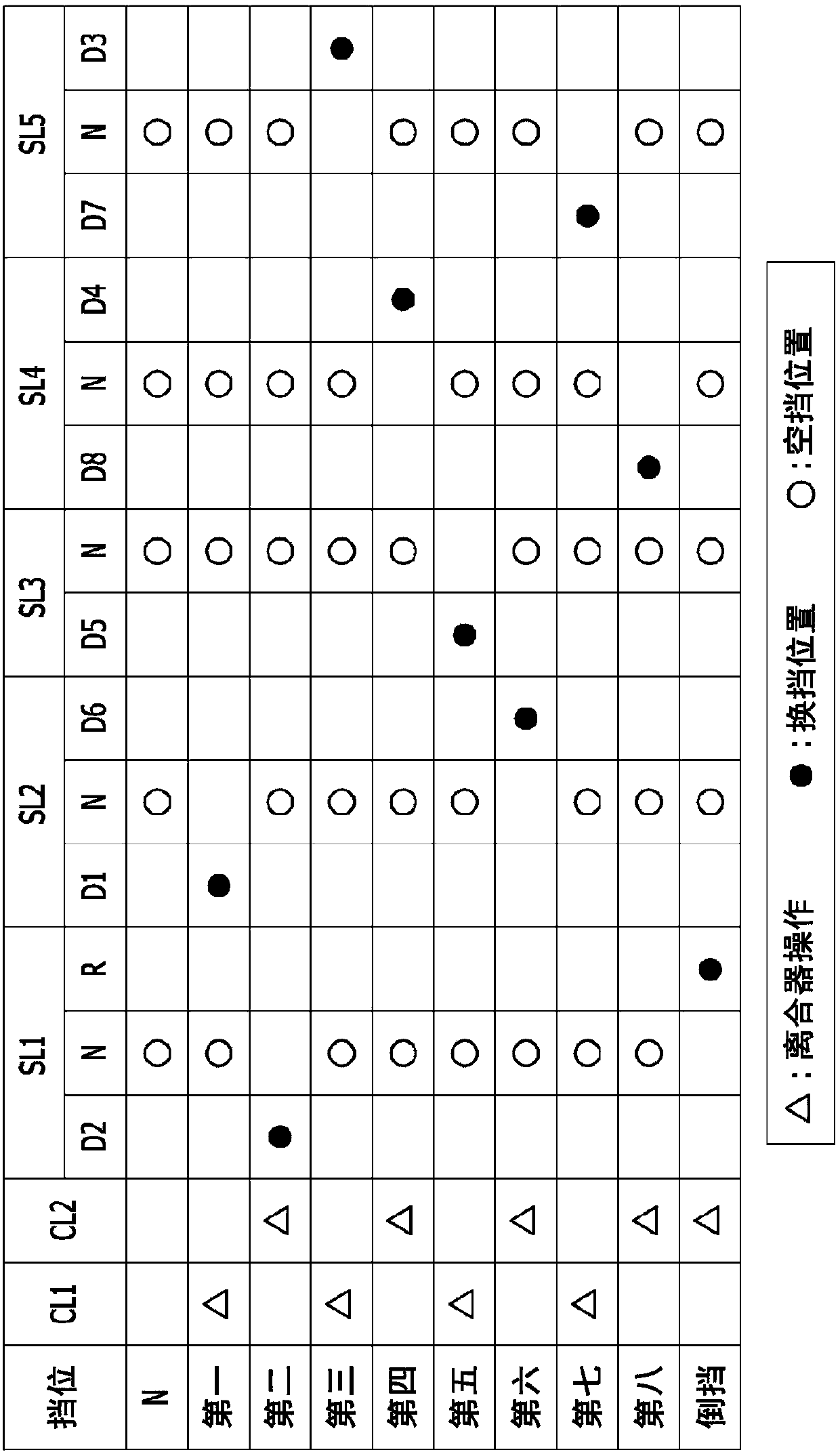

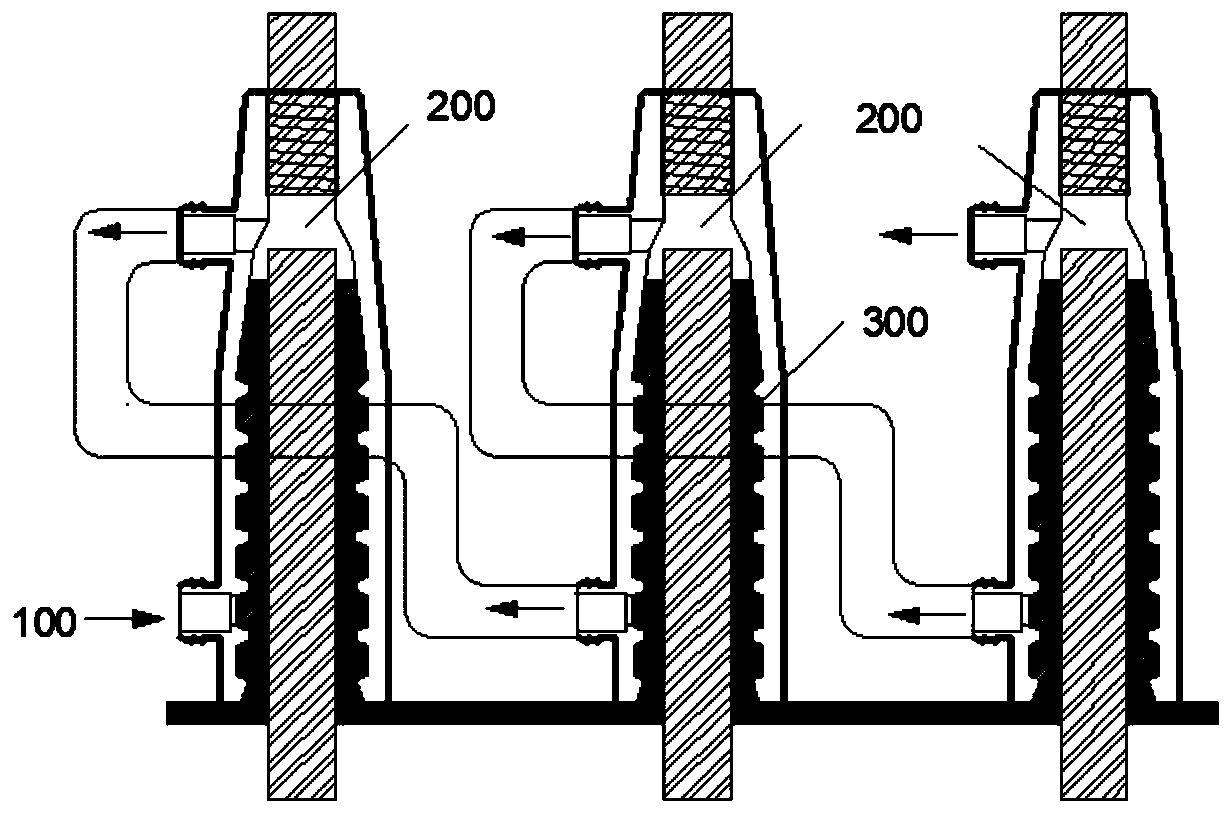

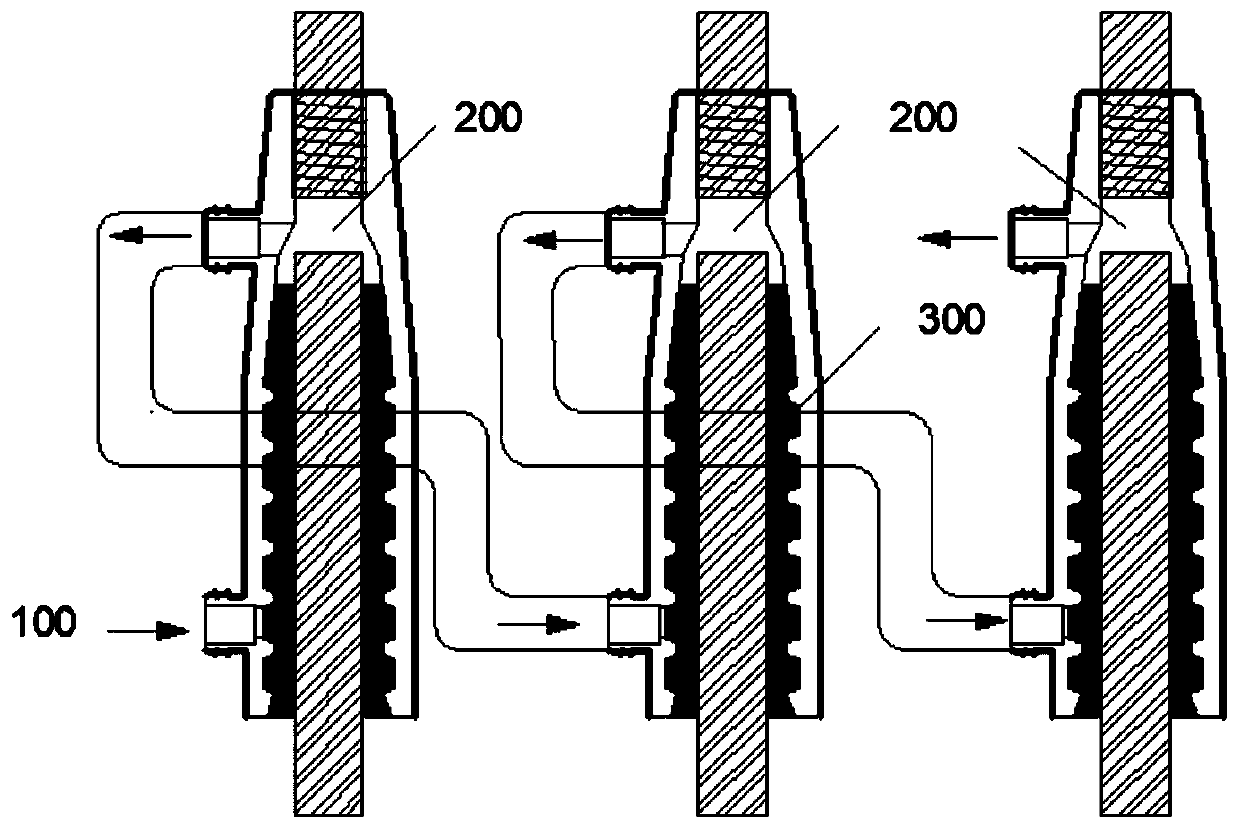

Power Transmission Apparatus for Vehicle

InactiveCN107939916AImprove installabilitySimplify internal structureToothed gearingsGearing controlEngineeringPower control

A power transmission apparatus for a vehicle includes a power control unit constituted by first and second clutches. An input unit is configured by configuring a number of input gears on first and second input shafts overlapped and disposed on the same axis line without rotary interference so that the rotary power of the engine is input through the power control unit. A shift output unit is constituted by first and second output shafts which are disposed in parallel to the first and second input shafts, respectively. A number of synchronization units synchronization-connect the plurality of transmission gears to the first and second output shafts. A reverse shift unit is constituted by a reverse input gear configured in one input shaft of the first and second input shafts, and a reverse transmission gear disposed on an output shaft and synchronization-connected to output shaft by the synchronization unit.

Owner:HYUNDAI MOTOR CO LTD

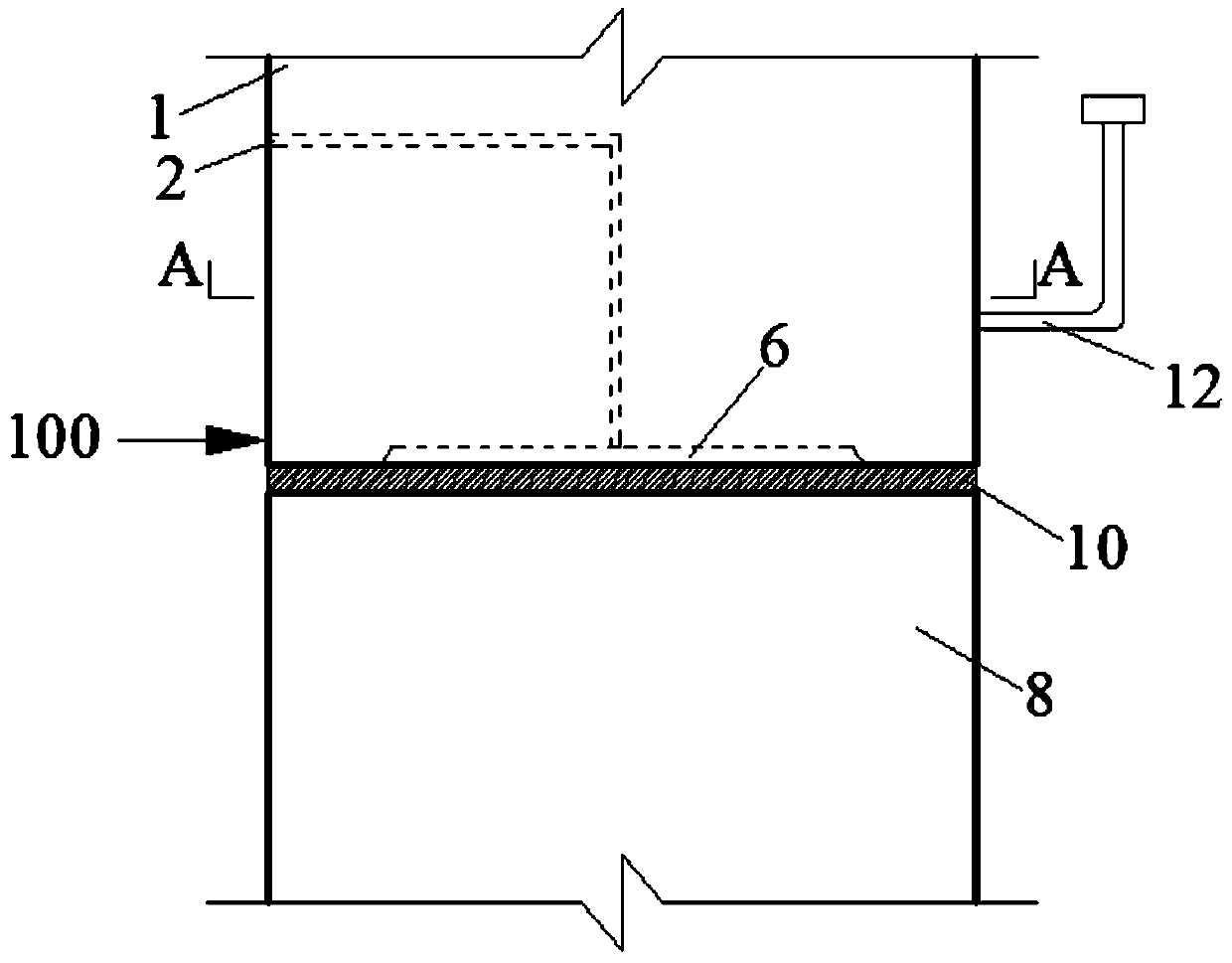

Assembly prefabricated component series-connection sleeve connecting structure and grouting method thereof

PendingCN109853862AEasy constructionSimplify internal structureBuilding reinforcementsSingle pointEngineering

The invention relates to an assembly prefabricated component series-connection sleeve connecting structure and a grouting method thereof, and belongs to the field of residential PC industrialization.The assembly prefabricated component series-connection sleeve connecting structure comprises one or more sets of series-connection sleeves and connecting pipes; a gap is formed between an assembly prefabricated upper component and an assembly prefabricated lower component; each set of series-connection sleeves is formed by a plurality of sleeves which are connected in series through the corresponding connecting pipe, and the two ends of the connecting pipes are connected with upper openings and lower openings of the adjacent sleeves correspondingly; and a shear key forming groove is formed inthe bottom end of the upper component, communicates with the gap between the upper component and the lower component and is poured with a primary grouting material, and the series-connection sleeves are poured with secondary grouting materials. The grouting method of the assembly prefabricated component series-connection sleeve connecting structure comprises the steps: primary pouring, still standing and secondary pouring. The assembly prefabricated component series-connection sleeve connecting structure is improved based on a single-point grouting method, and has the characteristics of beingeasy to construct, excellent in performance and free of grouting defects.

Owner:河北冀科工程项目管理有限公司

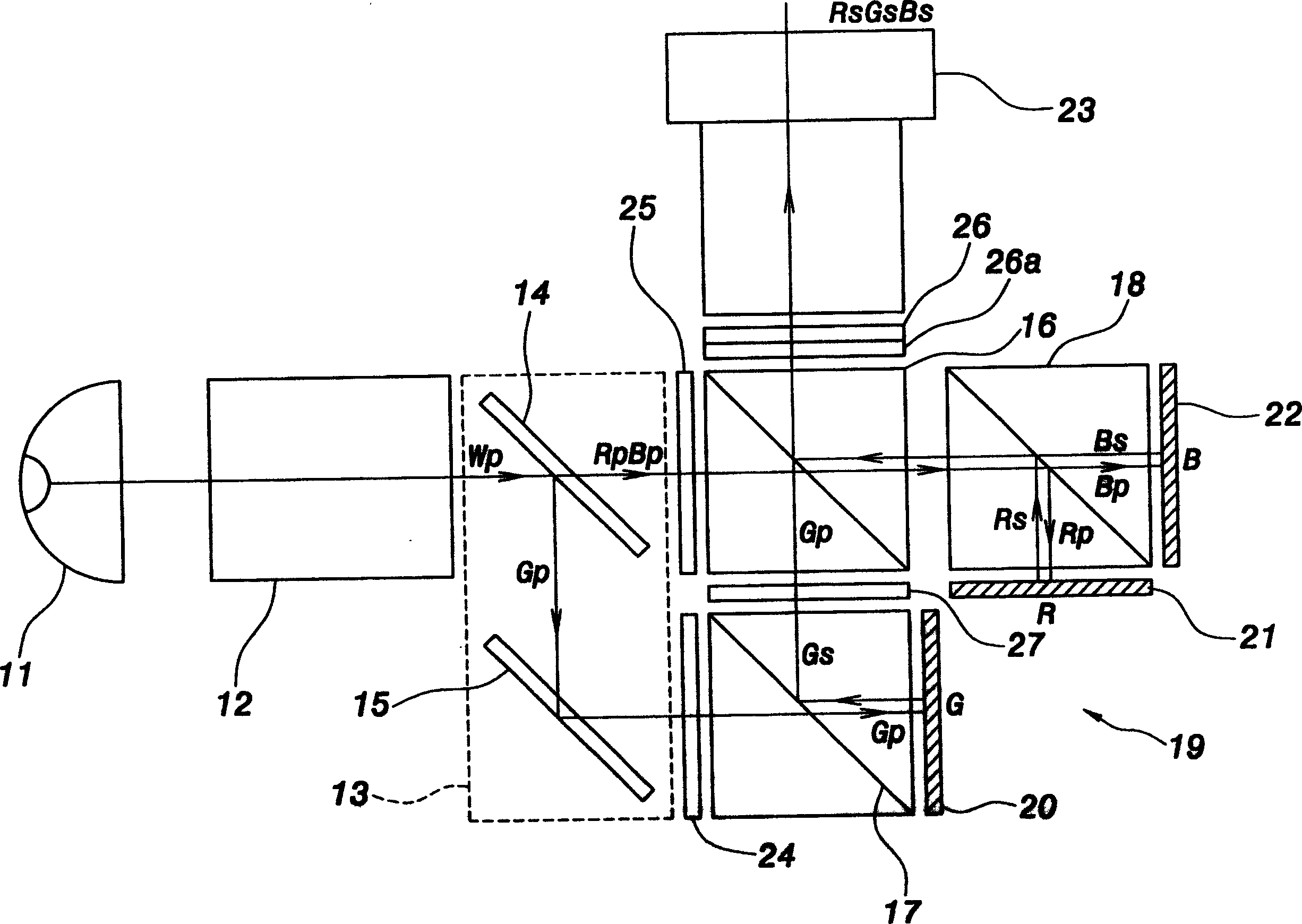

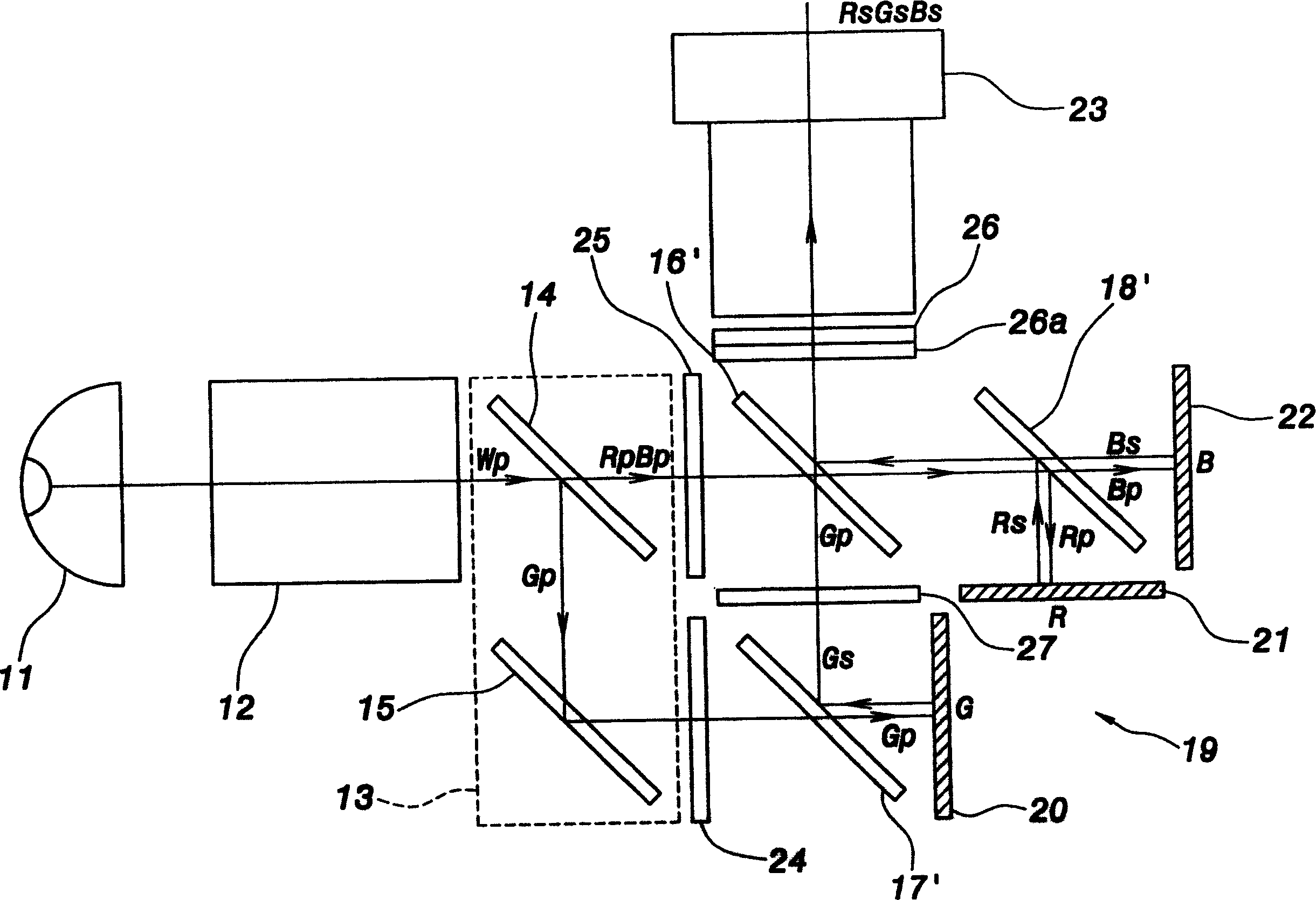

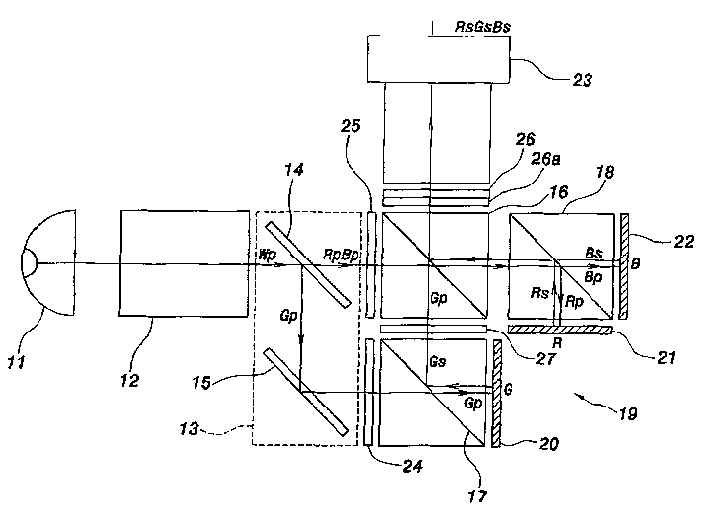

Liquid crystal projection system

InactiveCN1479129AReduce volumeLow costStatic indicating devicesOptical elementsCamera lensElectrical polarity

A liquid crystal projection system is composed of a unit for splitting a polarized light into a dual-prime-color light and a single-prime-color light, two polarizers for polarizing said two light beams, a color separator for separating said dual-prime-color light beam, an offset device for changing said two beams to another polarity and reflecting them out, a delay plate, and a projecting lens.

Owner:示创科技股份有限公司

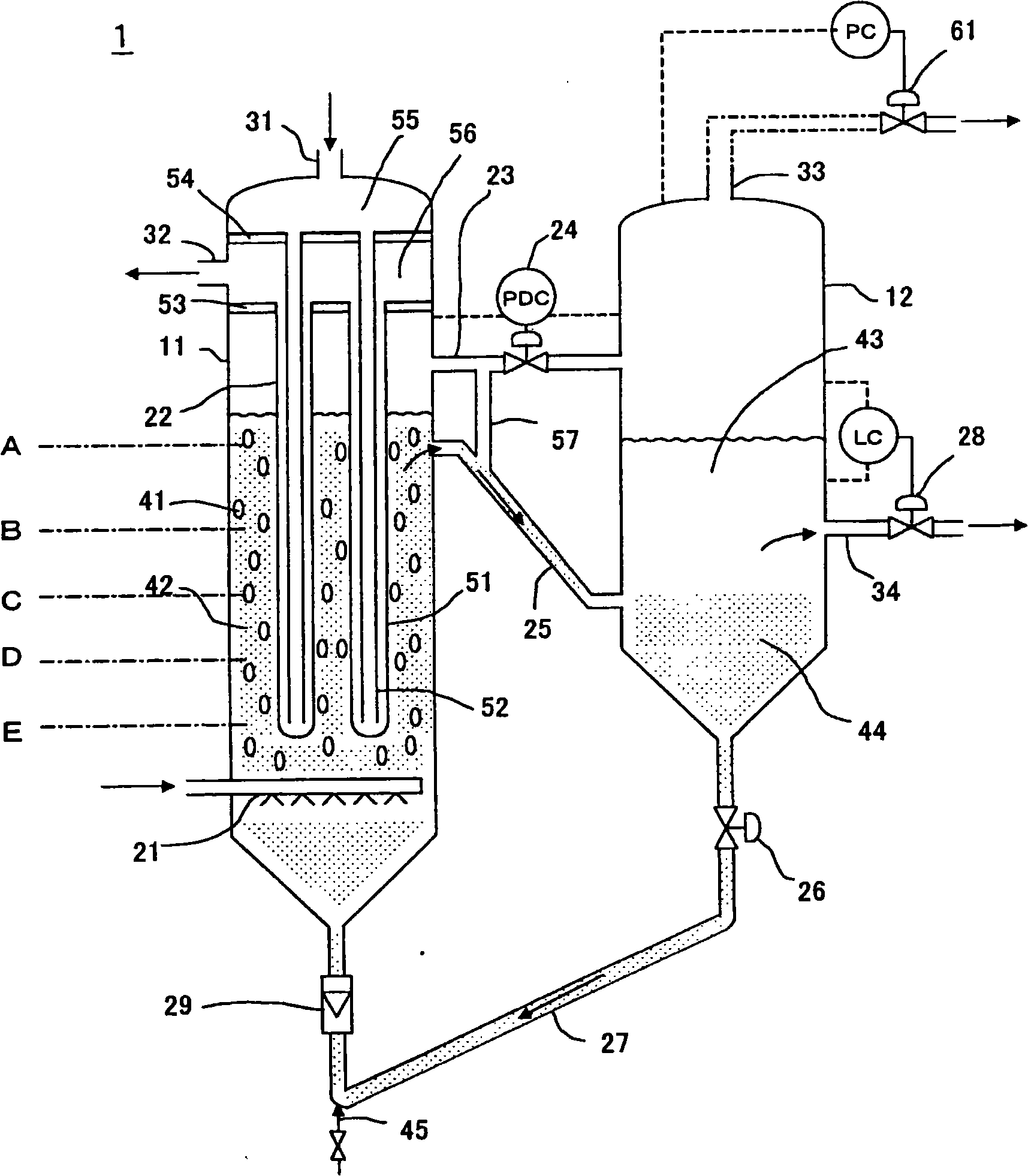

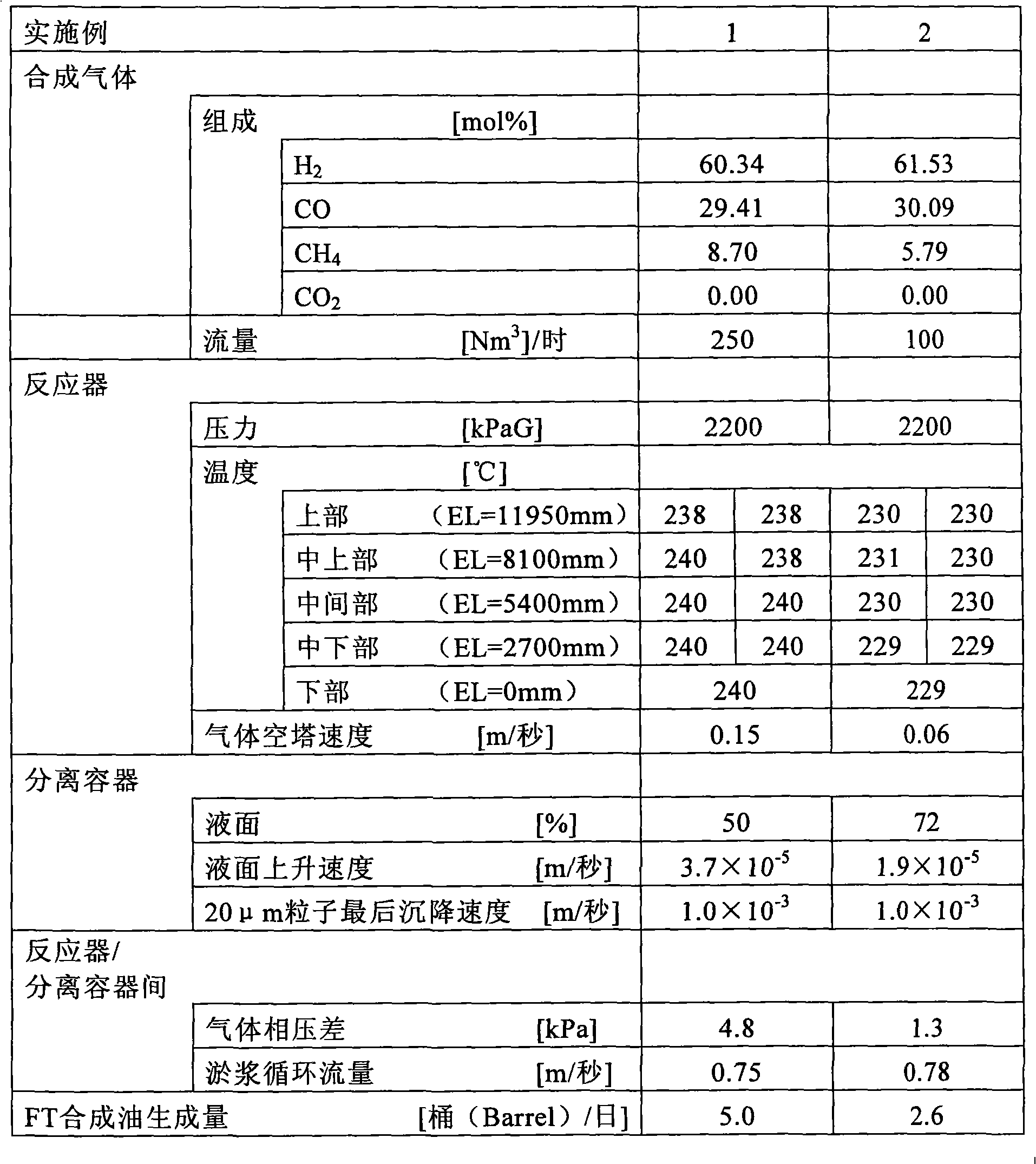

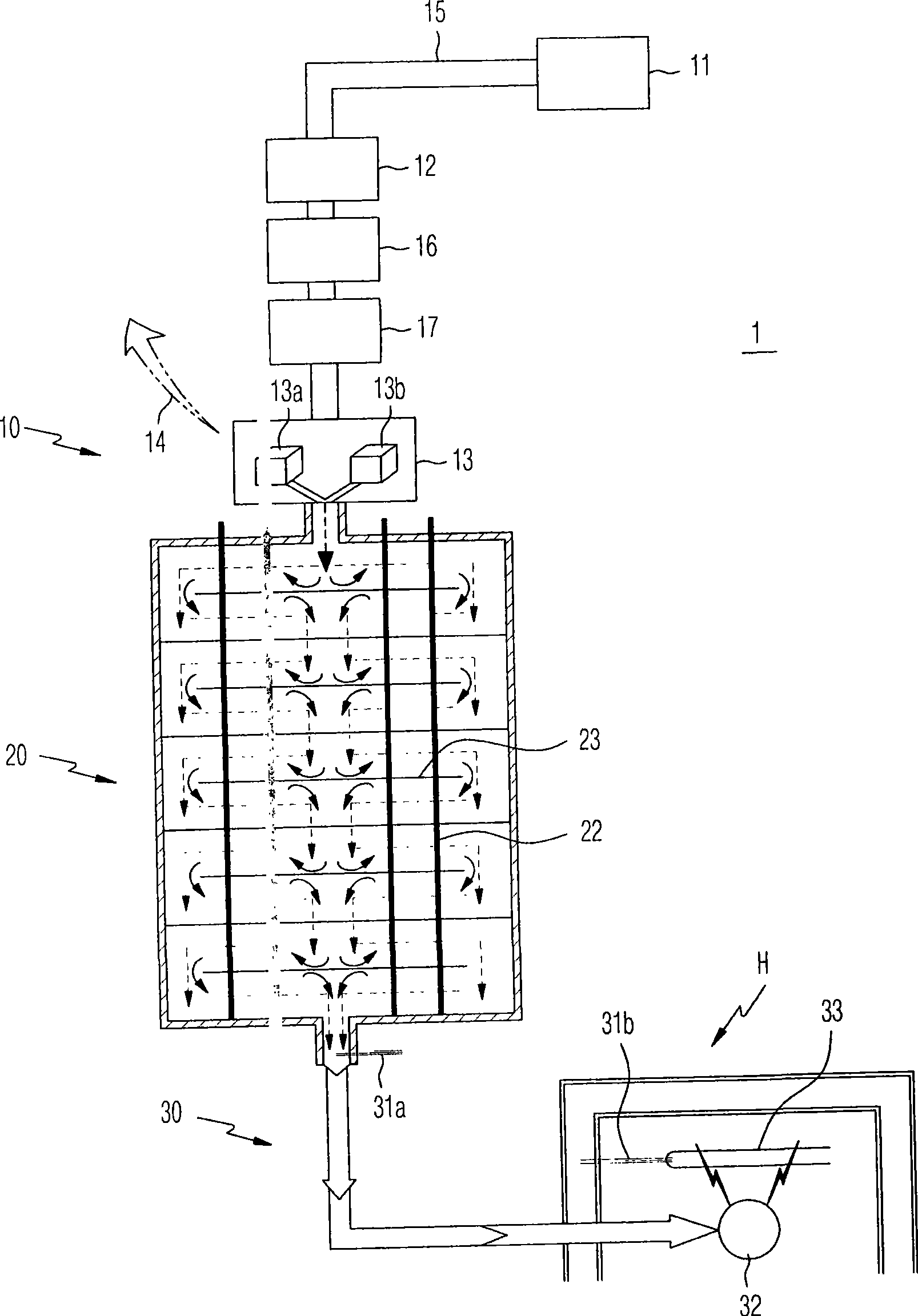

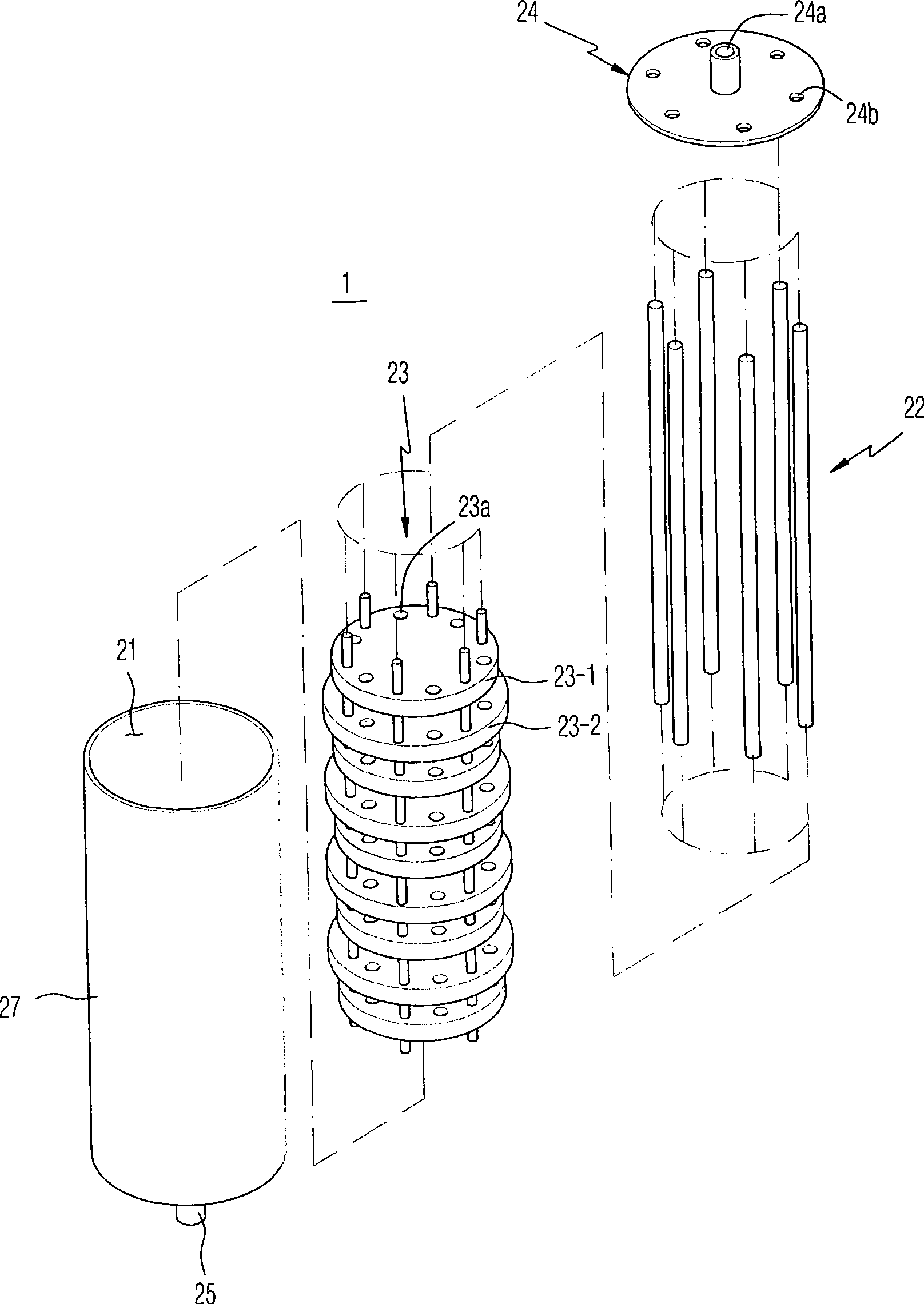

Reaction system for bubbling tower type Fischer-Tropsch synthesis slurry bed

InactiveCN101351526AAvoid performance degradationSimplify internal structureHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionLiquid productForming gas

A Fischer-Tropsch (FT) synthesis system, characterized in that the FT synthesis process of bringing synthesis gas continuously fed from the bottom of a bubble column type slurry-bed reactor into contact with suspended catalyst particles in the reactor to form liquid hydrocarbons, gaseous hydrocarbons, and water, the process of separating the catalyst particles from the liquid product in a separator, the process of transferring the gaseous product to the separator and withdrawing it from the top of the separator, the process of withdrawing the liquid product from the intermediate section of the separator, and the process of withdrawing a concentrated slurry of catalyst particles from the bottom of the separator and circulating it to the bottom of the reactor are conducted by the driving force of synthesis gas which is introduced to the bottom of the reactor and ascends in the reactor.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +4

Heating, sterilizing and drying appliance using superheated steam generator

InactiveCN101378786AHigh temperature efficiencySimplify internal structureSteam cooking vesselsSteam superheatersCombustion chamberLine tubing

Owner:JAEYOUNG SOLUTEC

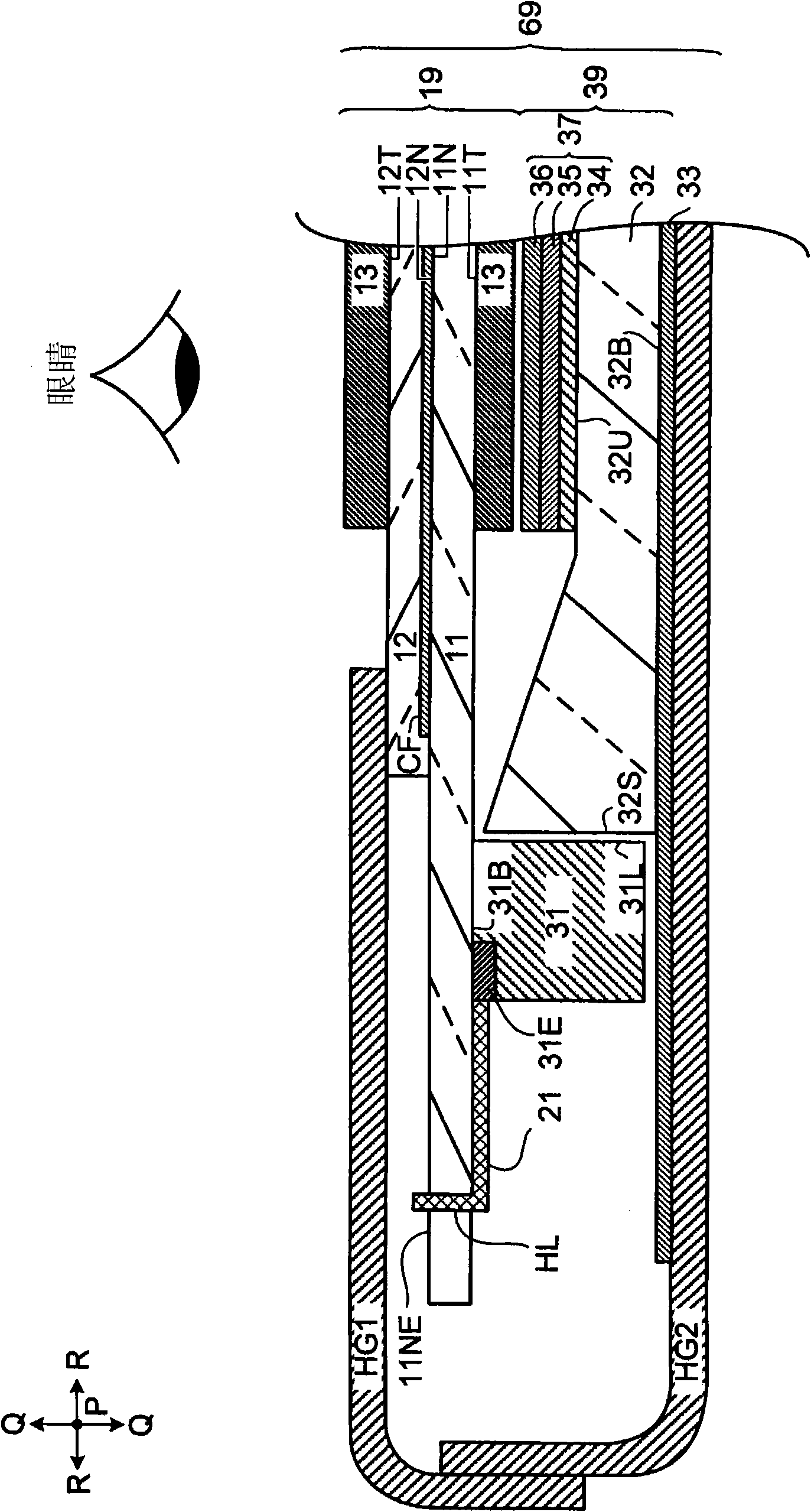

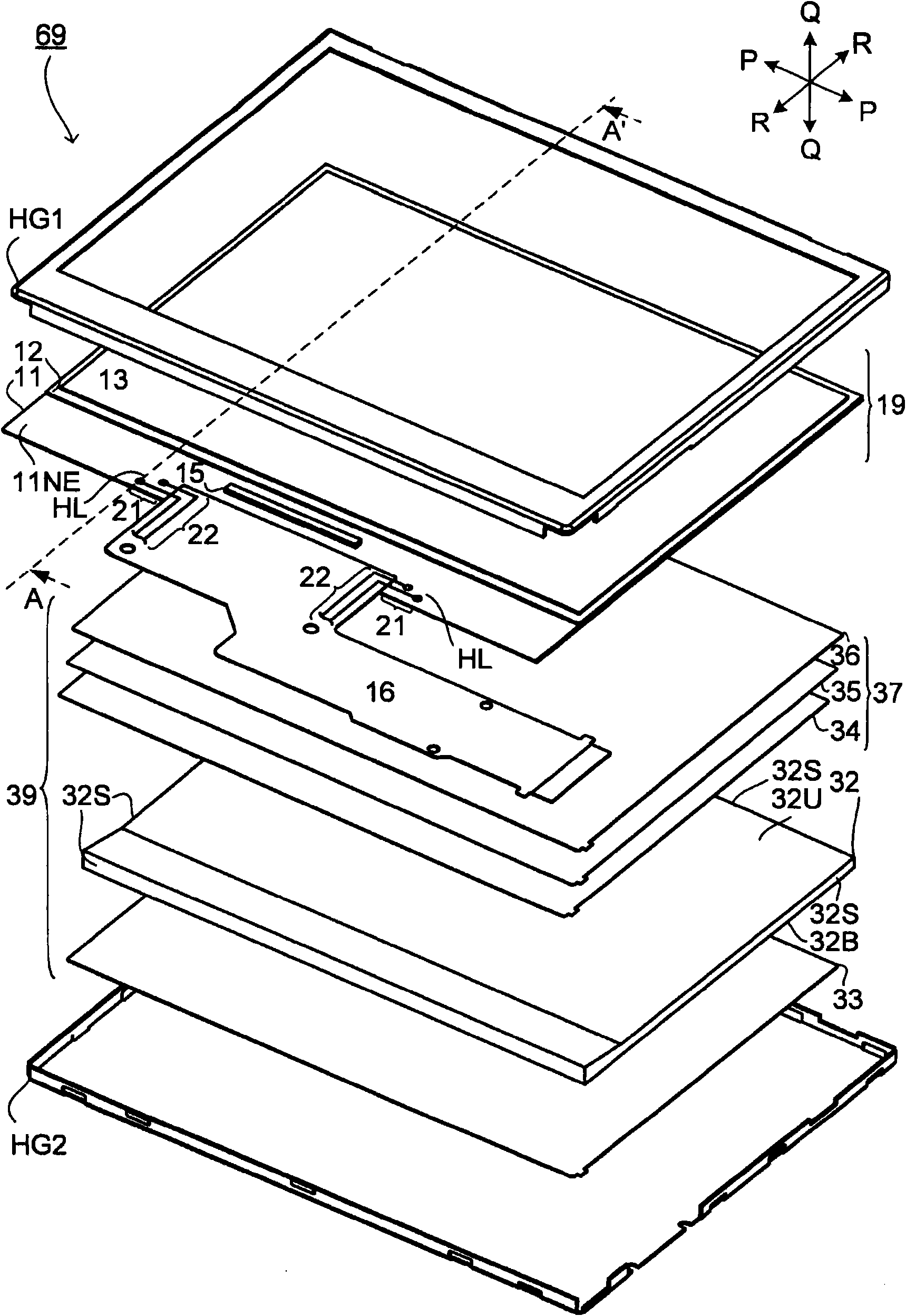

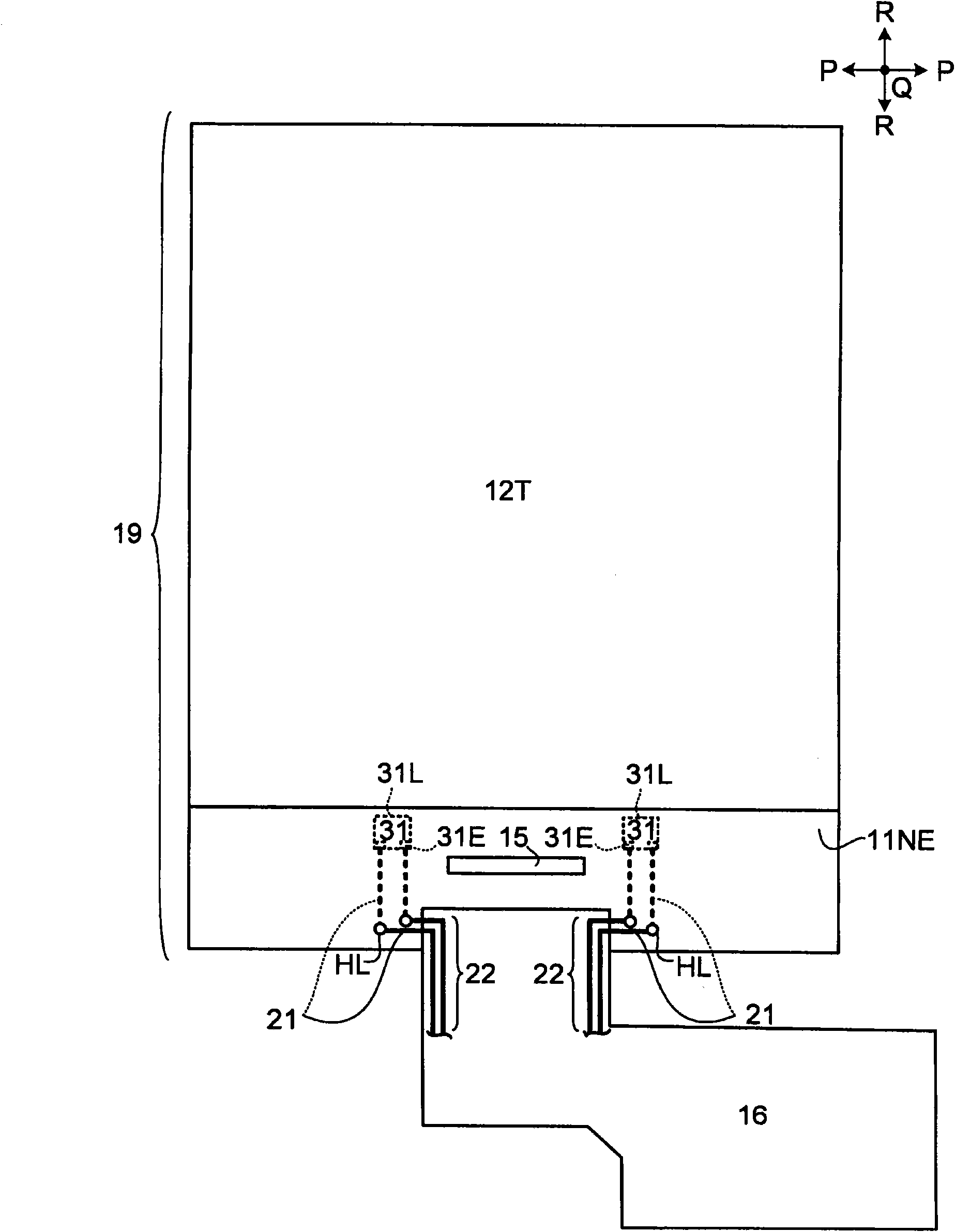

Liquid crystal display device

InactiveCN102067022ASimplify internal structurePlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayEngineering

An LED (31) is mounted on an active matrix substrate (11), and a light-emitting surface (31L) of the LED (31) is on the outer substrate surface (11T) side of the active matrix substrate (11).

Owner:SHARP KK

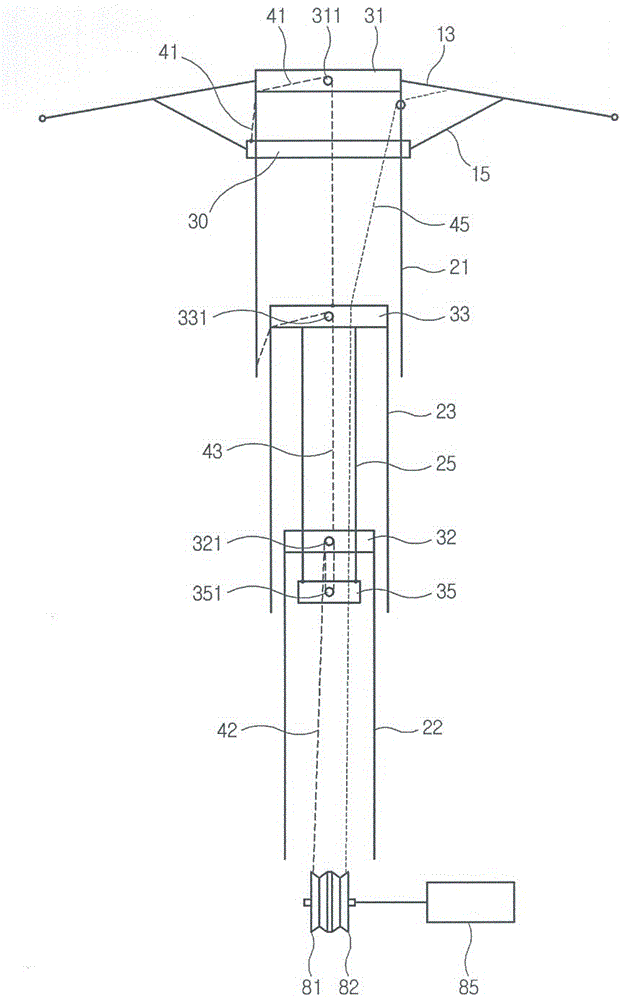

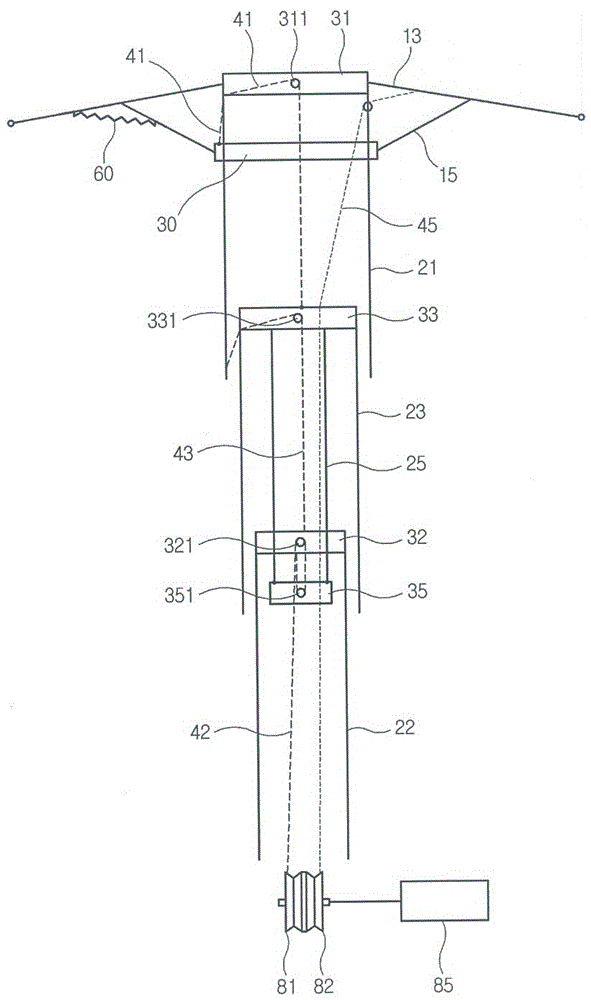

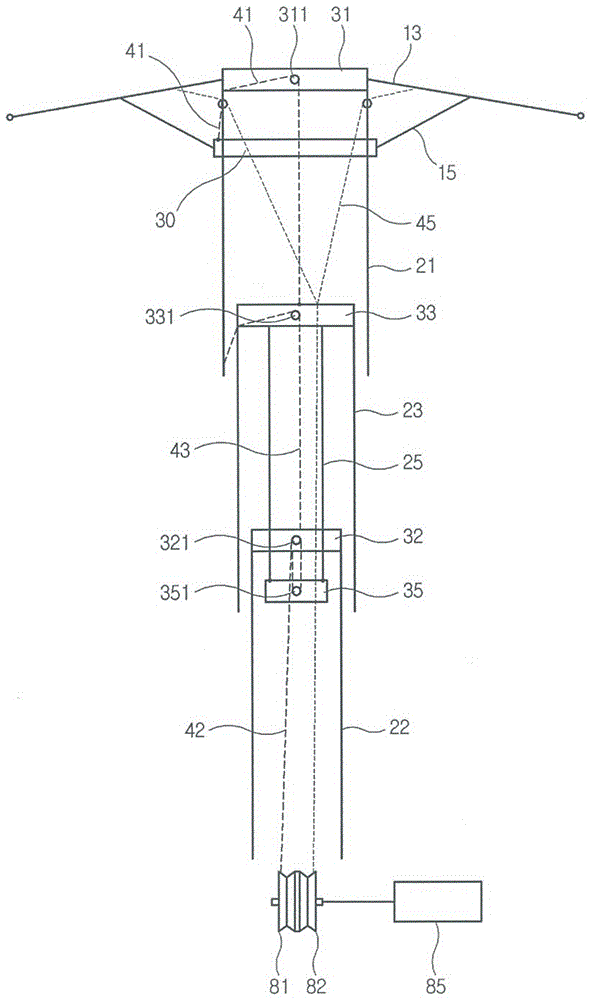

An automatic umbrella

InactiveCN105942686ASimplify internal structureReduce product costWalking sticksUmbrellasEngineeringStructural engineering

The invention relates to an automatic umbrella comprising a middle rod, an umbrella handle, an upper nest, a lower nest, first umbrella ribs with the inner ends connected with the upper nest, second umbrella ribs with the two ends connected with the lower nest and the first umbrella ribs, and an automatic umbrella opening and closing device. The automatic umbrella opening and closing device comprises umbrella opening pull ropes, an umbrella closing pull rope, a first winding wheel and a second winding wheel which are installed in the inner cavity of the umbrella handle, and a drive member. One end of one umbrella opening pull rope is connected with the lower nest and enters the inner cavity of the middle rod after rounding the top of the middle rod; the other end of another umbrella opening pull rope is connected with the first winding wheel; one end of the umbrella closing pull rope is connected with the second winding wheel and the other end is led out from the side wall of the upper portion of the middle rod and connected with one first umbrella rib. The drive member provides rotating force for both the first winding wheel and the second winding wheel or for either the first winding wheel or the second winding wheel. The automatic umbrella is simple in structure, can greatly reduce the torsion required by the drive member, reduce electricity consumption and reduce cost and is more convenient and safer to use.

Owner:陈传扬

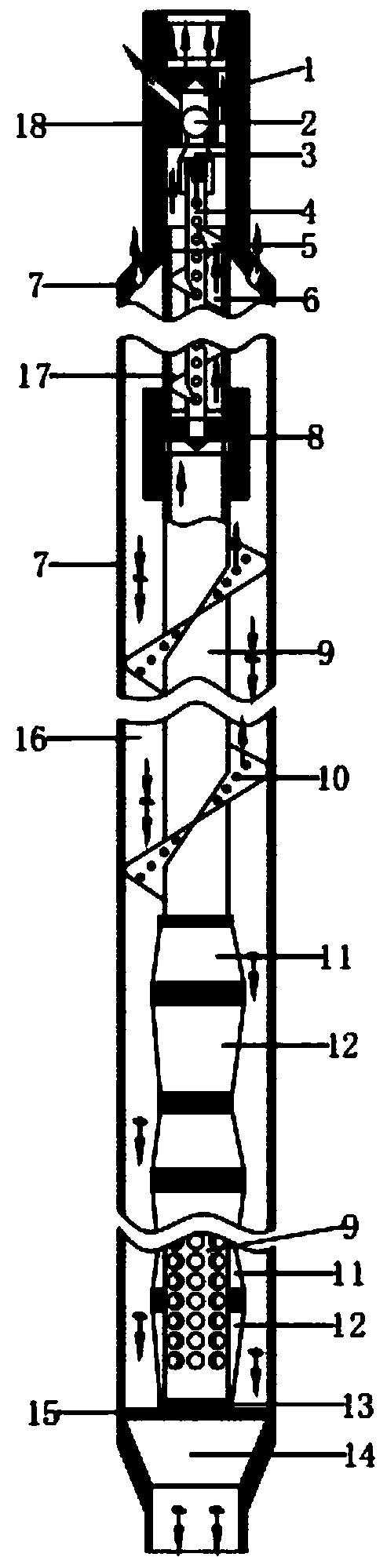

Multistage swing type oil-gas-sand separating device

PendingCN110778303AEasy to separateIncrease productionFluid removalFlash degasificationExhaust valveSand filter

The invention provides a multistage swing type oil-gas-sand separating device and belongs to the field of downhole oil recovery auxiliary tool equipment. The multistage swing type oil-gas-sand separating device comprises a sleeve, and dense and even oil, gas and sand inlet and outlet holes are formed in the upper middle wall of the sleeve. An oil-gas separating mechanism is arranged on the upper portion in the sleeve. An oil-sand separating mechanism is arranged on the lower portion in the sleeve. The lower end of the sleeve is fixedly connected with a sand discharge opening. The oil-gas separating mechanism is formed by connecting a one-way exhaust valve formed by a valve body, a ball element and a valve seat, an inner spiral channel formed by an exhaust pipe, a small spiral guide plate and an oil pipe, a connector and an outer spiral channel formed by an upper half section of an oil pipe with a hole and a large spiral guide plate from top to bottom. The oil-sand separating mechanismis formed by a lower half section of the oil pipe with the hole, multiple flow guide covers and multiple sand filtering screens. The multistage swing type oil-gas-sand separating device provides an ultrastrong separating effect, is convenient to repair, not high in replacing and maintaining cost and not likely to cause long-term halt production of a gas well.

Owner:FUNING COUNTY PETROL MECHANICAL LIMITED

L-type impact air flow attenuator

InactiveCN103438323AReduce couplingExhaust flow requirements guaranteedPipe elementsEngineeringChange positions

The invention discloses an L-type impact air flow attenuator which comprises an air flow buffer cavity. An air inlet pipe and an air outlet pipe are installed on the air flow buffer cavity, wherein the air inlet pipe and the air outlet pipe are communicated with a cavity body inside the air flow buffer cavity, the direction changing position of an evacuation pipeline is communicated with the air outlet pipe through the air inlet pipe on the air flow buffer cavity, the air inlet pipe is perpendicular to the air outlet pipe, and L-type layout is arranged inside the air flow buffer cavity. According to the L-type impact air flow attenuator, the characteristics of impact air flow and the evacuation pipeline are comprehensively considered, the basic principles of an interference type air flow buffer, a perforated plate and a hole plate acoustic filter are fused, and the characteristics of the flow exhaust requirements and of the evacuation pipeline and the small installation site of the attenuator are comprehensively considered. For the evacuation pipeline with pipeline steering at the position of an outlet in a security valve, the L-type impact air flow attenuator achieves the effects of dissipating the impact air flow energy, reducing the pipeline coupling, and ensuring the gas exhaust flow requirements to the greatest extent by arranging the air flow buffer cavity and communicating the direction changing position of the evacuation pipeline by the air inlet pipe and the air outlet pipe of the air flow buffer cavity.

Owner:XI AN JIAOTONG UNIV

An automatic tinning electric soldering iron

InactiveCN105598548BPreventing Dead Tin SituationsSimplify internal structureHeating appliancesSoldering ironElectrical conductorControl circuit

The invention discloses an automatic tin adding electric soldering iron which comprises a transmission module and a heating module. The transmission module comprises a shell, an inner cavity, an inner ceramic cavity, a pushing body and a wire adding button, wherein the upper end of the inner ceramic cavity is sleeved with the pushing body. A pair of one-way rotation circular gears are arranged at the joint of the inner cavity and the inner ceramic cavity. The side faces of the circular gears are provided with meshed straight gears. The lower ends of the straight gears are hinged to the upper end of the pushing body. A spring is arranged at the lower end of the pushing body. One side of the pushing body is in a conical shape with the large top and the small bottom. The wire adding button is hinged to the shell. The wire adding button can just press the conical side of the pushing body when rotating so that the pushing body is made to move upwards. The heating module comprises a heating body with the lower sharp nozzle type end, a conductor winding wire, a heating wire and a control circuit board, the upper end of the heating body is connected with the shell, the conductor winding wire is arranged at the lower portion of the inner ceramic cavity, and the lower portion of the inner ceramic cavity stretches into the heating body till the tip nozzle position, a user can operate the automatic tin adding electric soldering iron with one hand, tin wires are molten during welding, and no dead tin is generated.

Owner:HUBEI UNIV OF TECH

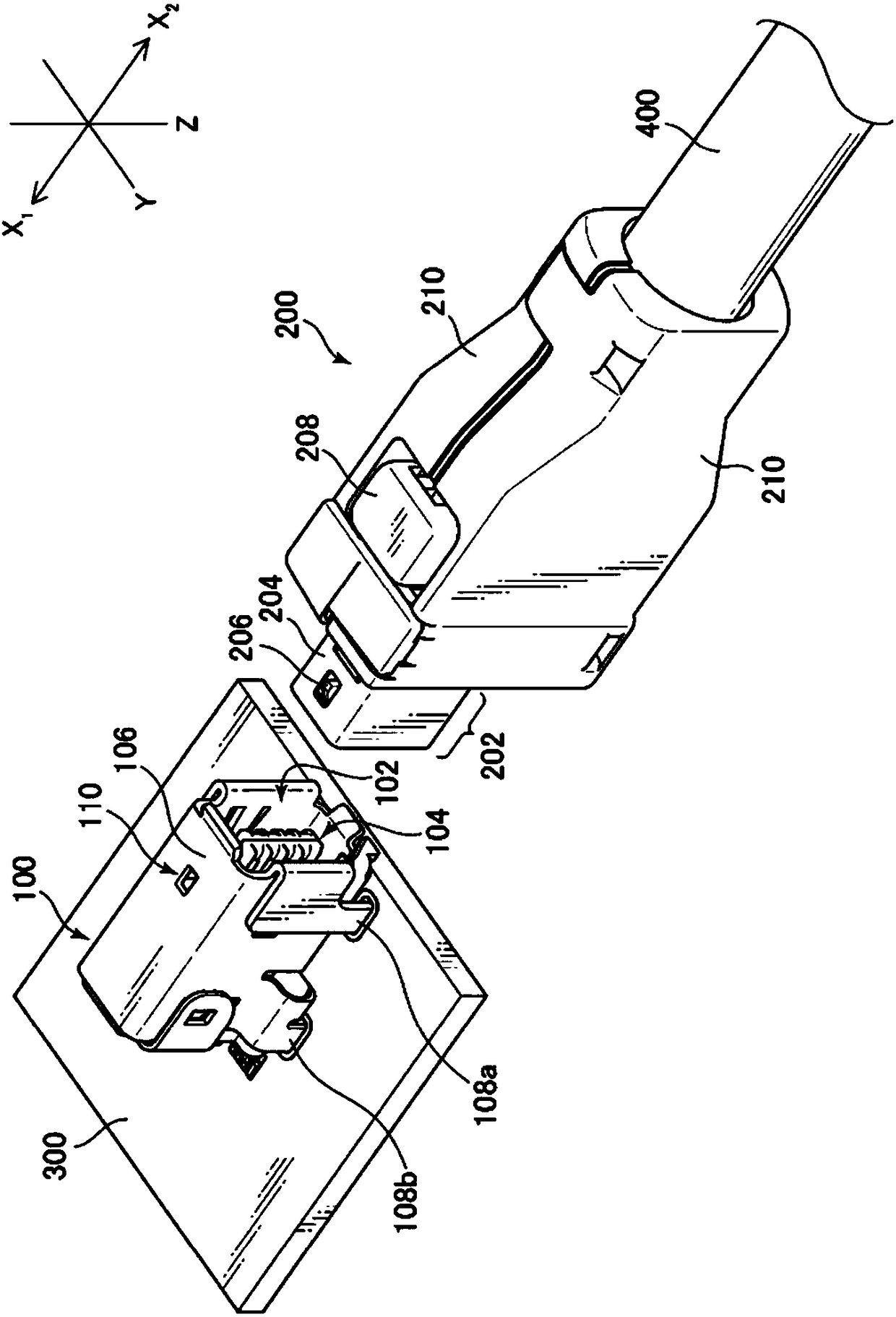

Connector

ActiveCN108352660AReduce the numberGuaranteed high frequency characteristicsCoupling device detailsTwo-part coupling devicesElectrical conductorEngineering

Conventional connectors had the problem that, because in addition to the signal terminals it was necessary to arrange one or more ground terminals between two signal terminal pairs, or between one pair of signal terminals and another pair of signal terminals, the number of components configuring the connector increased, making the internal structure of the connector more complicated. This substrate-side connector is provided with two terminal groups which are arranged so as to face one another along the fitting direction of the connector, an insulator which holds said terminal groups, and an external conductor shell which houses said insulator, wherein a shell mounting unit, for mounting the external conductor shell on the substrate, is passed between the two terminal groups and mounted between a group of terminal mounting units of the terminals included in one terminal group and a group of terminal mounting units of multiple terminals included in the other terminal group, and therebythe shell mounting unit of said external conductor shell can function as a ground terminal.

Owner:HIROSE ELECTRIC GROUP

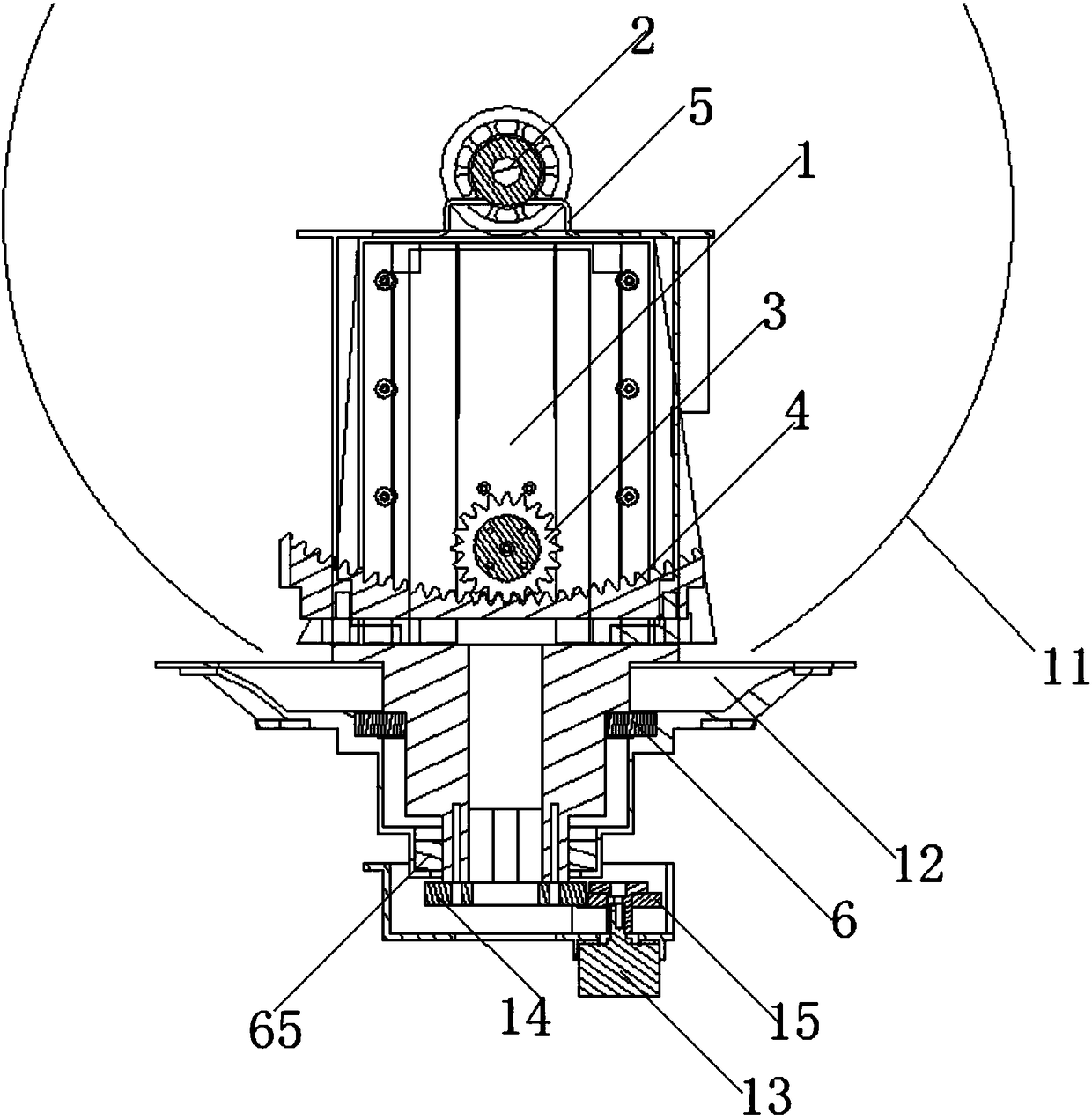

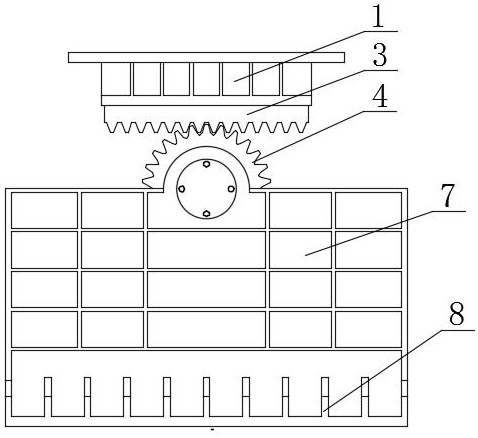

Robotic Head Motion System

The invention discloses a head motion system of a robot. The system comprises a vertical shaft. The upper part of the vertical shaft stretches into a head part, the lower part of the vertical shaft is rotationally fixed to a trunk, and accordingly horizontal rotation of the head part of the robot is achieved. Above the vertical shaft, a cross shaft is arranged in the head part, the head part can rotate around the cross shaft, and accordingly the pitching motion of the head part of the robot is achieved. The vertical shaft is fixed to the trunk of the robot through bearings, a rack fixed to the head part is driven by a gear on the vertical shaft to rotate so as to drive the head part of the robot to rotate, and by means of the motion system, the direction and angle of a projector on the head part of the robot can be adjusted.

Owner:SANGEBABA HOME INTELLIGENT ENVIRONMENTAL TECH BEIJING CO LTD

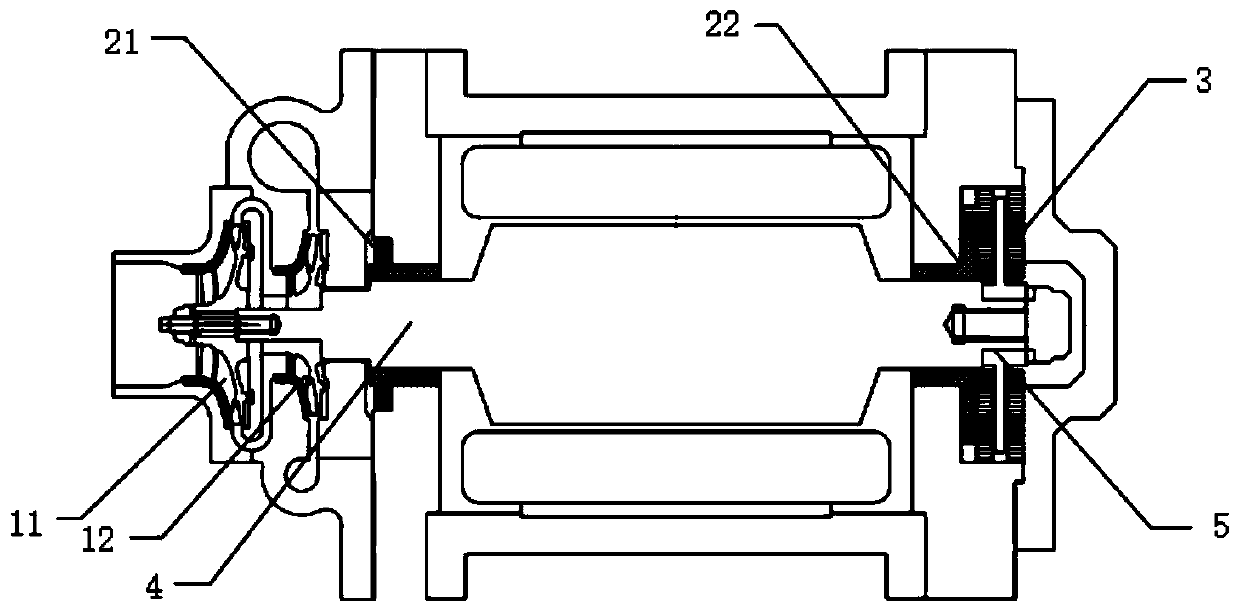

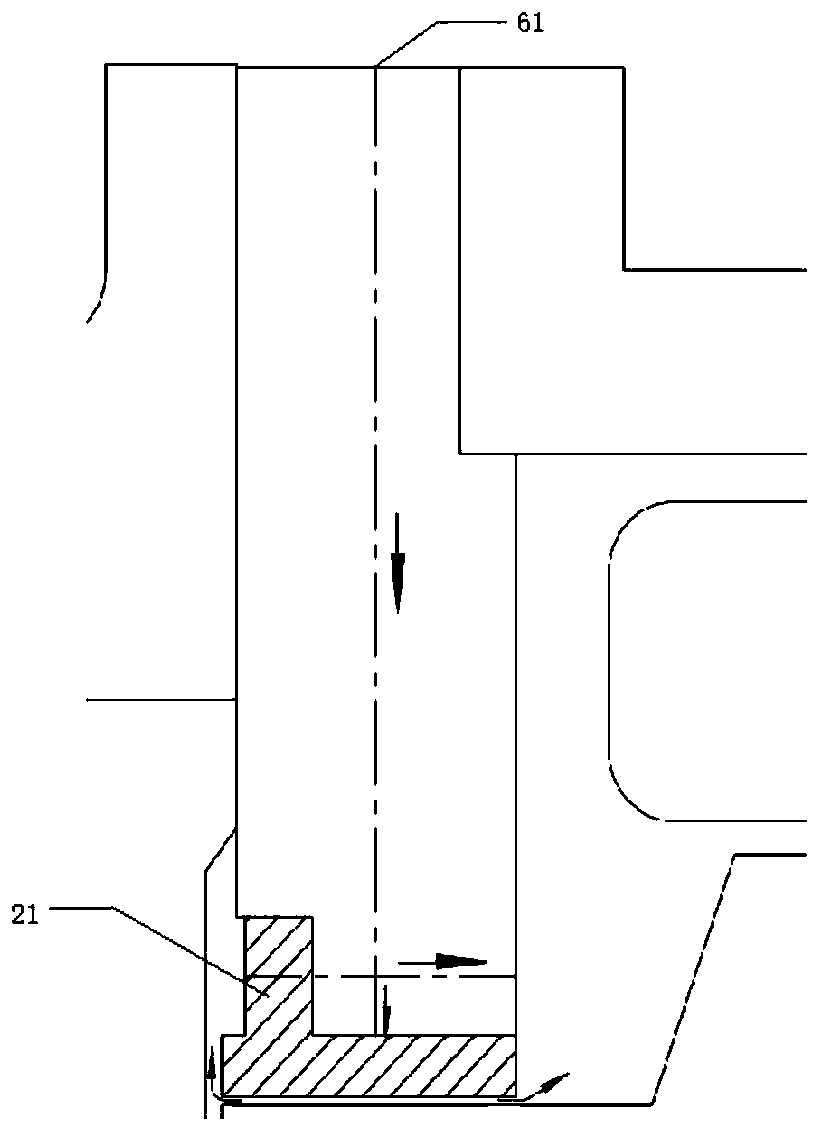

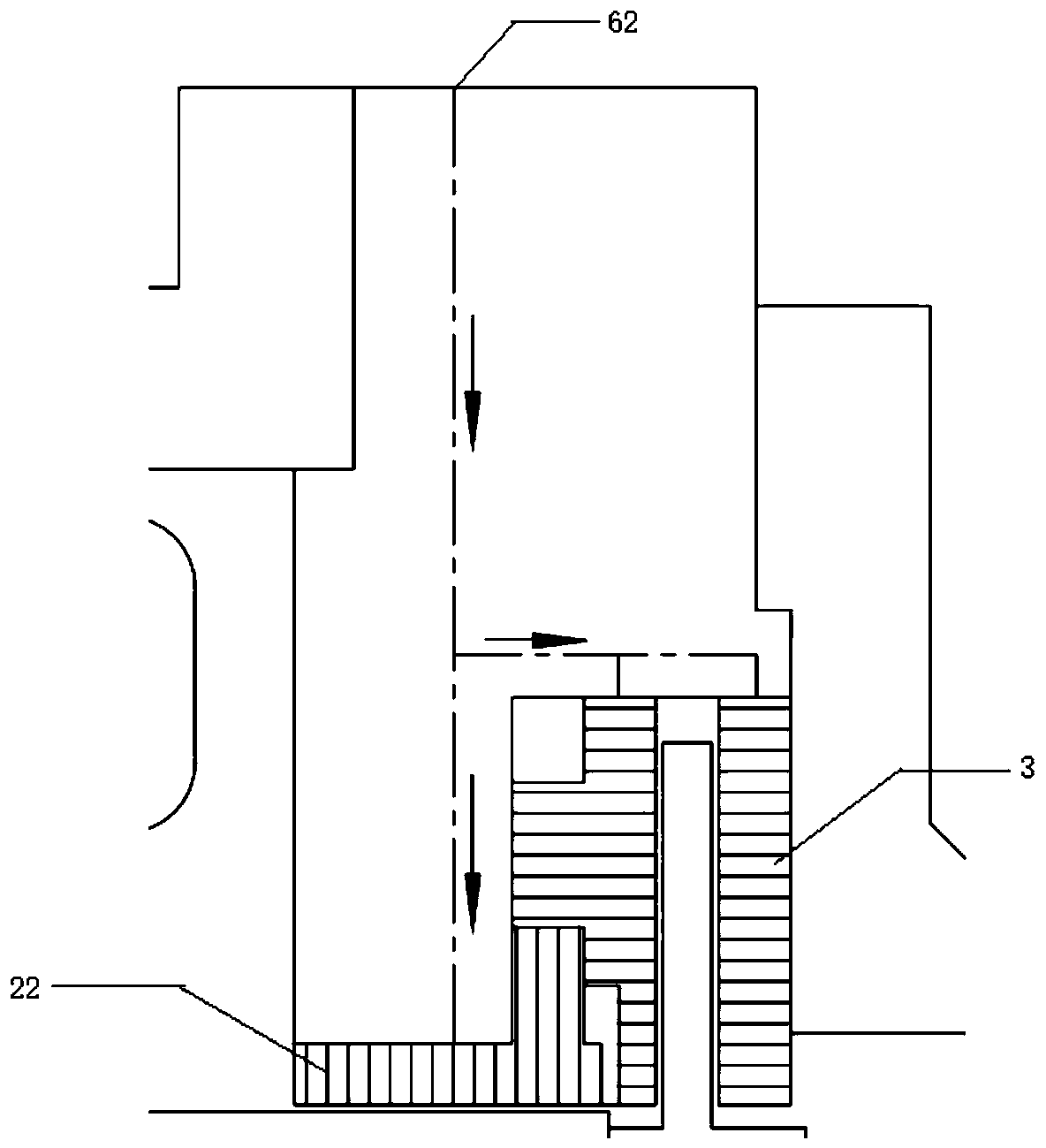

Centrifugal compressor and heat pump system

ActiveCN111486103ASimplify internal structureImprove stabilityPump componentsPump installationsPhysicsElectric machinery

The invention belongs to the field of compressors, and discloses a centrifugal compressor which comprises a shell, an impeller and a motor rotor located in the shell. A thrust disc is arranged on oneside of the motor rotor, the motor rotor is supported through radial static pressure gas bearings, and axial static pressure gas bearings are arranged on the two sides of the thrust disc. A cooling gas passage is arranged in a motor of the centrifugal compressor, bearing seats of the radial static pressure gas bearings and the axial static pressure gas bearings are respectively provided with ventholes, and the vent holes are communicated with the cooling gas passage. The bearings of the centrifugal compressor provided by the invention are all static pressure gas bearings taking gas as a lubricating agent, so that the oil-free property is realized; and meanwhile, gas generated by operation of the gas bearings is used as a cooling agent, an external cooling element is omitted, and the operation procedure of the centrifugal compressor is simplified.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

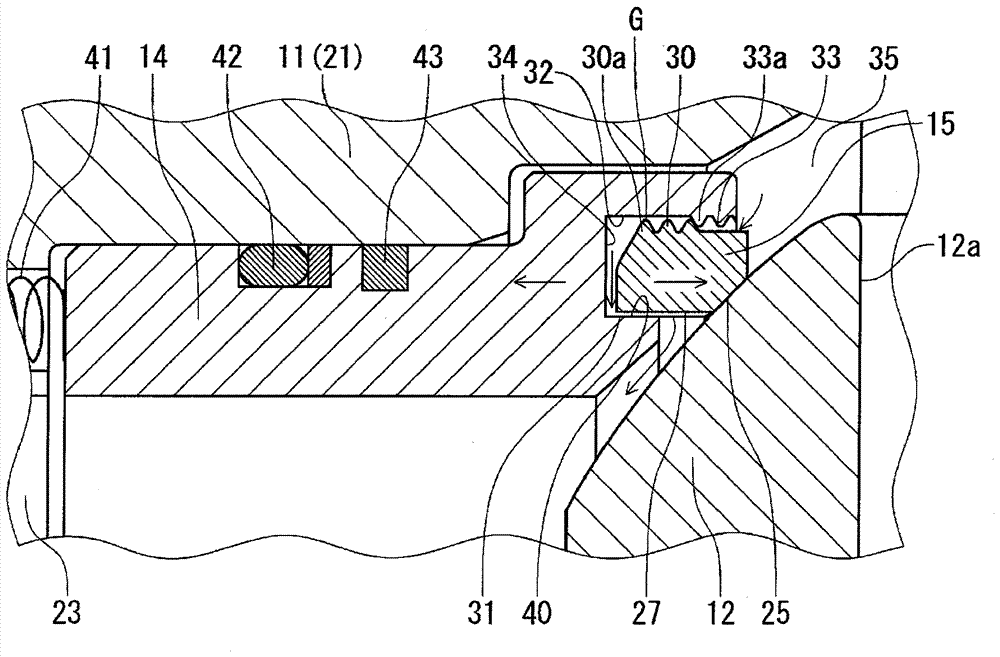

Trunnion-type ball valve

A seat retainer (14) fitted with a ball seat (15) is provided on one or both sides of a ball (12) having a through hole (12a) provided inside a body (11), the ball (12) is provided so as to be rotatable by a stem (13), and the ball seat (15) is prevented from flying out into a fitting groove (32) formed in the seat retainer (14), and is fitted in a free state. Excess pressure due to abnormal pressure increases in a cavity (35) when fully open or fully closed causes the seat retainer (14) to move in an opposite direction from the ball (12) due to a self-sealing force making use of this pressure, and excess pressure that has flowed to the rear surface side of the ball seat (15) inside the fitting groove (32) pushes the ball seat (15) toward the ball (12), and is relieved to a flow channel via a communication part (40) provided between the inner circumferential surface (27) of the ball seat (15) and the fitting groove (32).

Owner:KITZ CORP

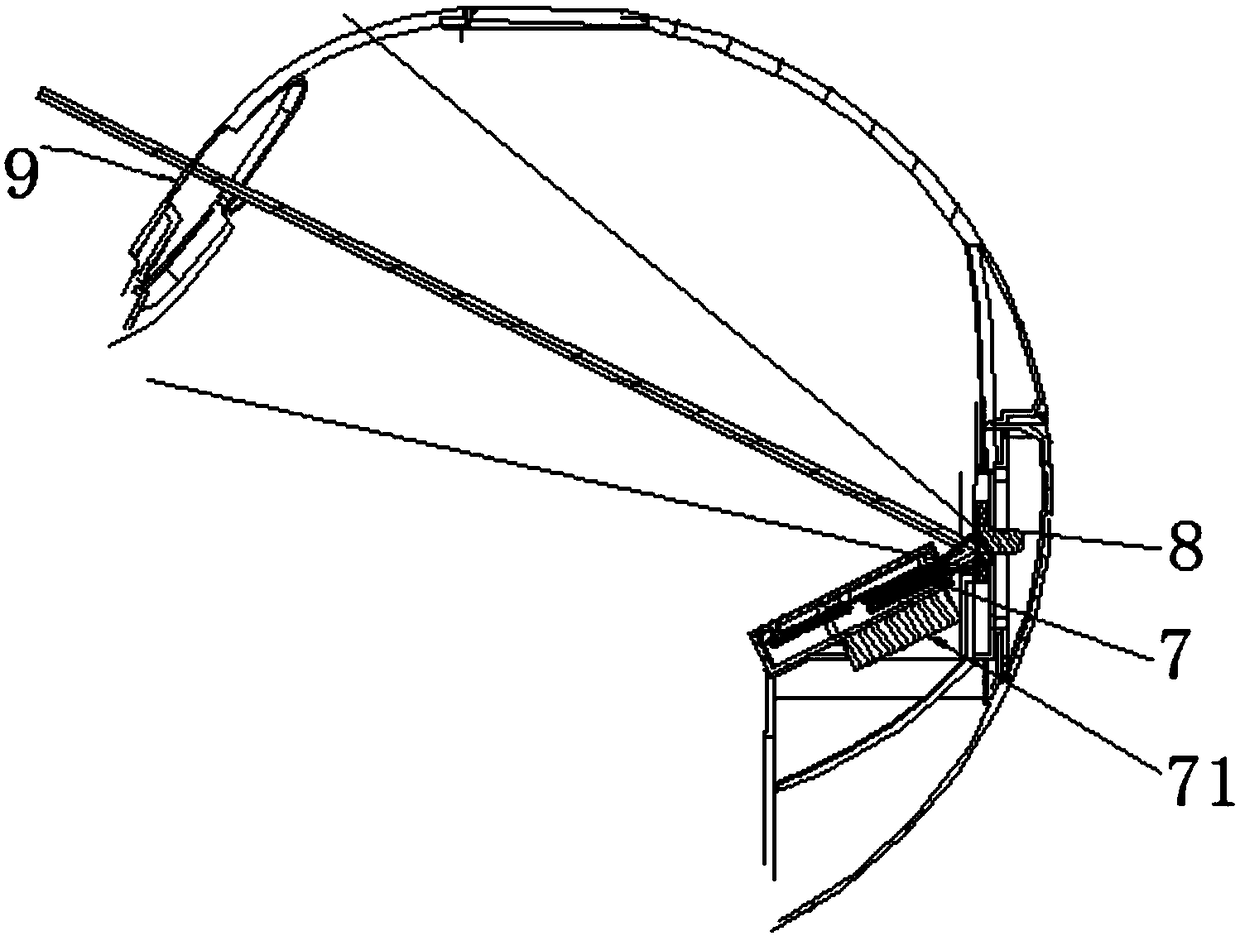

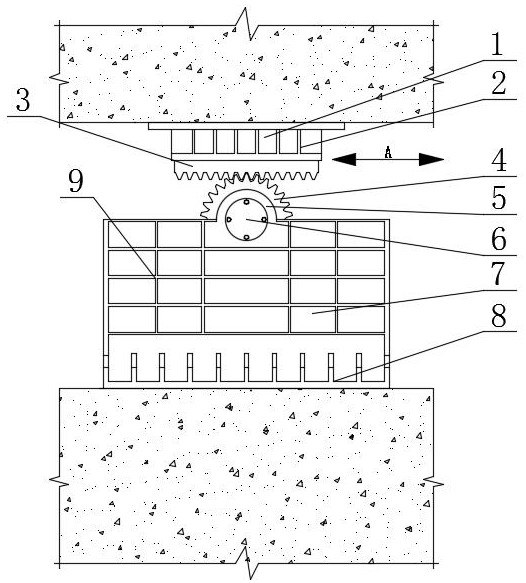

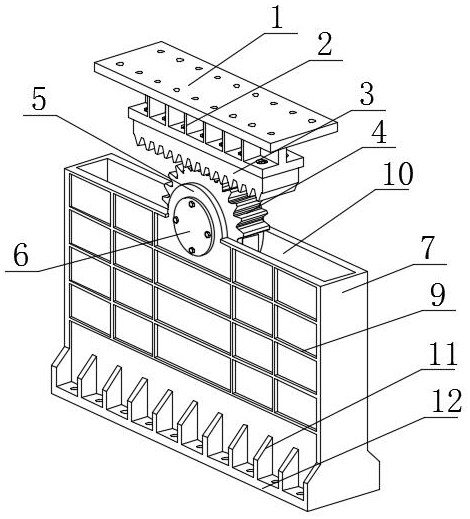

Swing type energy dissipation and shock absorption mechanism suitable for fabricated building

PendingCN113356388AGreat effortMeet the precision requirementsProtective buildings/sheltersShock proofingEngineeringMechanical engineering

The invention provides a swing type energy dissipation and shock absorption mechanism suitable for a fabricated building. The swing type energy dissipation and shock absorption mechanism comprises an upper-layer structure, a lower-layer structure and a buffering mechanism for connecting the upper-layer structure with the lower-layer structure; and the buffering mechanism comprises a damping box connected with the lower-layer structure, a cavity is formed in the damping box, an opening of the cavity is located in the upper end of the damping box, damping liquid is arranged in the cavity, a rotating mechanism is arranged at the upper end of the damping box, a swing part is arranged on the rotating mechanism, the lower portion of the swing part extends into the cavity, a semicircular first transmission part is arranged at the upper end of the swing part, and a second transmission part matched with the first transmission part is arranged at the lower portion of the upper-layer structure. By means of the swing type energy dissipation and shock absorption mechanism, horizontal kinetic energy of the adjacent upper-layer and lower-layer structures can be converted into swing kinetic energy, and the swing kinetic energy is converted into heat energy in the form of shearing the damping liquid so as to achieve the energy consumption and buffering effects.

Owner:信阳学院

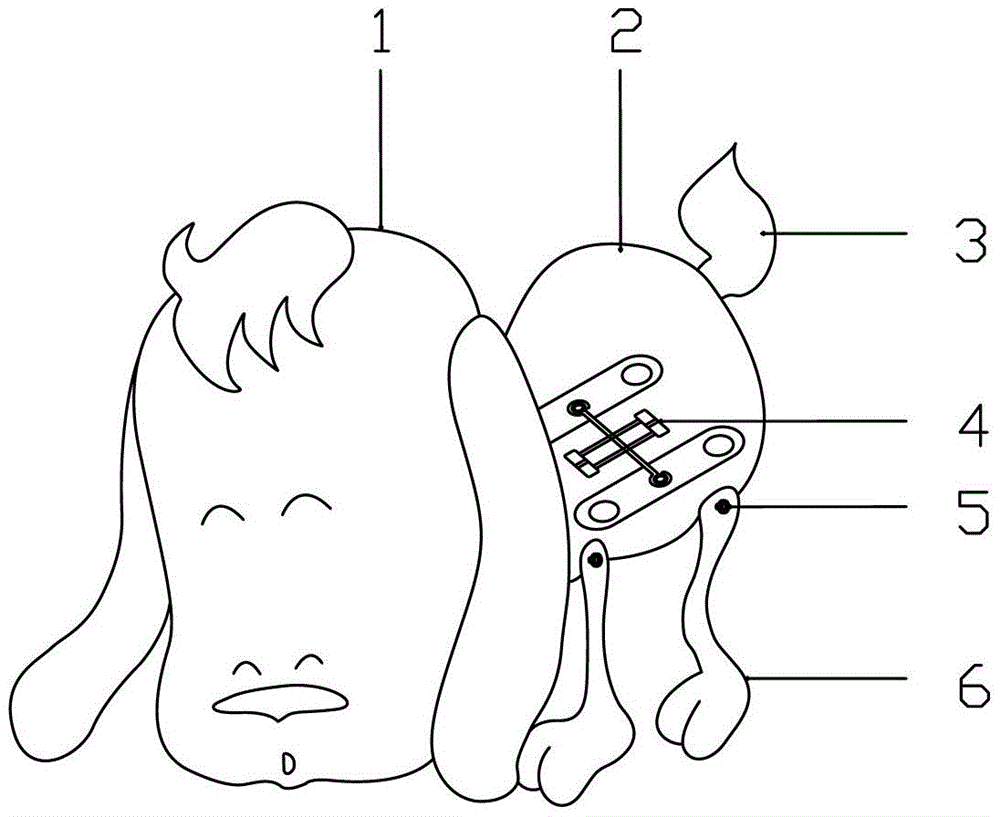

Movable toy dog

InactiveCN102908787AEasy to moveReduce manufacturing costSelf-moving toy figuresEngineeringCanis lupus familiaris

The invention relates to a movable toy dog which belongs to toys for children and mainly solves the problems that the conventional electronic toy is high in manufacturing cost and easy to damage and waste batteries pollute the environment. The movable toy dog comprises a toy dog body; the toy dog body comprises a head part, a body part, a tail part, a power system, hinge pins and four limbs; the power system is arranged in the body part and is respectively connected with the head part, the tail part and the four limbs of the toy body; a flat spring formed by spiral of Archimedes or equally spaced spiral is adopted as the power system, the resilience force of a spring is utilized to drive the four limbs at one side to more forward or backward and drive the head part and the tail part to swing, and the four limbs of the toy dog are hinged with the outside of the body part by the hinge pins and the four limbs extending into the body part are connected with the power system. According to the movable toy dog, a mechanical transmission manner is adopted as a power source, therefore, the movable toy dog is low in manufacturing cost, simple in internal structure and detachable, can develop the intelligence of children and can cultivate the habit of acting and thinking of children.

Owner:林泽鲁

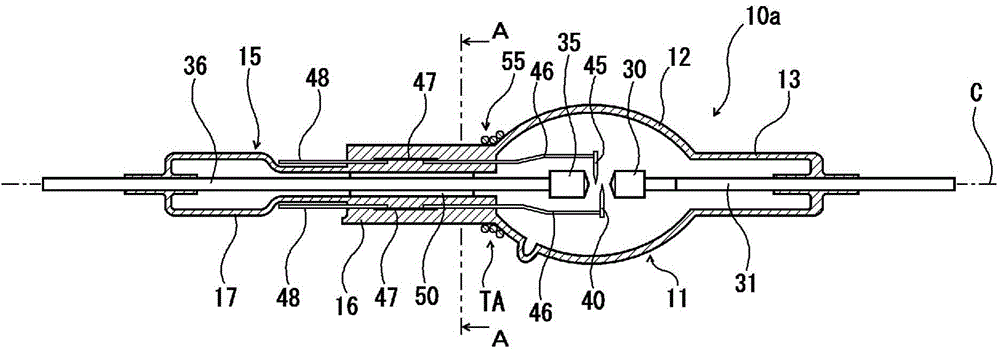

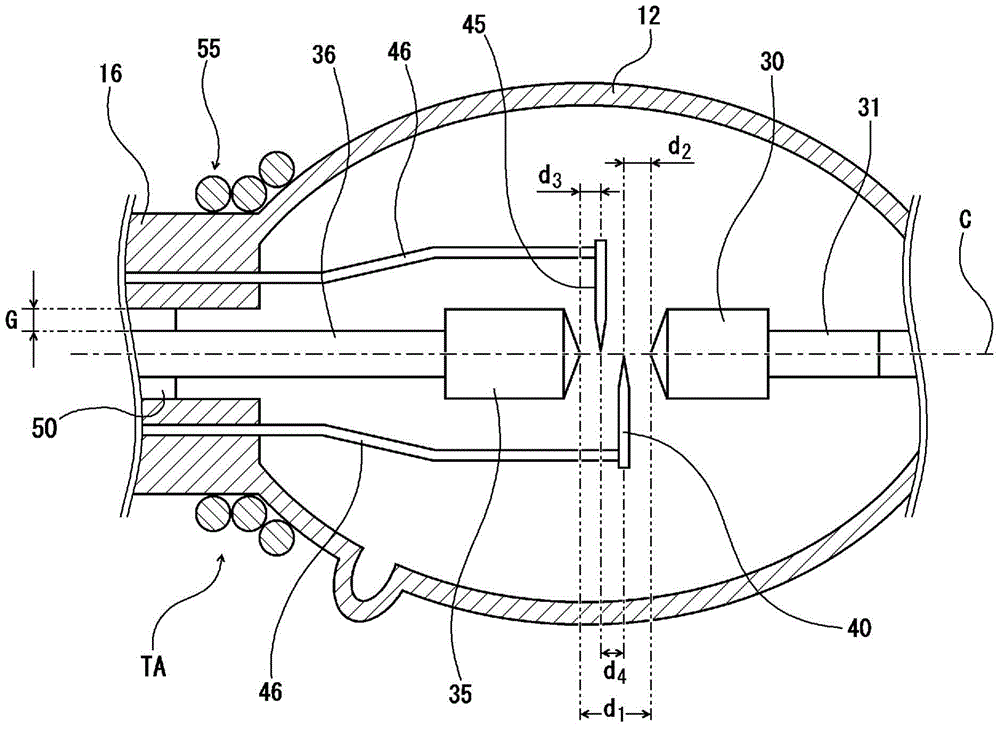

Short Arc Type Flash Lamp And Light Source Device

InactiveCN104882353AImprove starting performanceAvoid situations where light-gathering efficiency decreasesHigh-pressure discharge lampsGas discharge lamp detailsAuxiliary electrodeEngineering

Disclosed herein are a short arc type flash lamp having high lamp starting performance and capable of reducing the diameter of its seal tube part, and a light source device thereof. The flash lamp has an electrode shaft of one of the main electrodes, and an electrode shaft of the other of the main electrodes and leads for starting auxiliary electrodes which are respectively led out from the second seal tube part, and an external trigger is disposed in a state in which it extends in the circumferential direction on the outer peripheral surface of one end side region of the second seal tube part. The light source device is structured by a concave reflection mirror disposed on the second seal tube part side of the flash lamp in a state in which a focal point of the concave reflection mirror coincides with a luminous point of the flash lamp.

Owner:USHIO DENKI KK

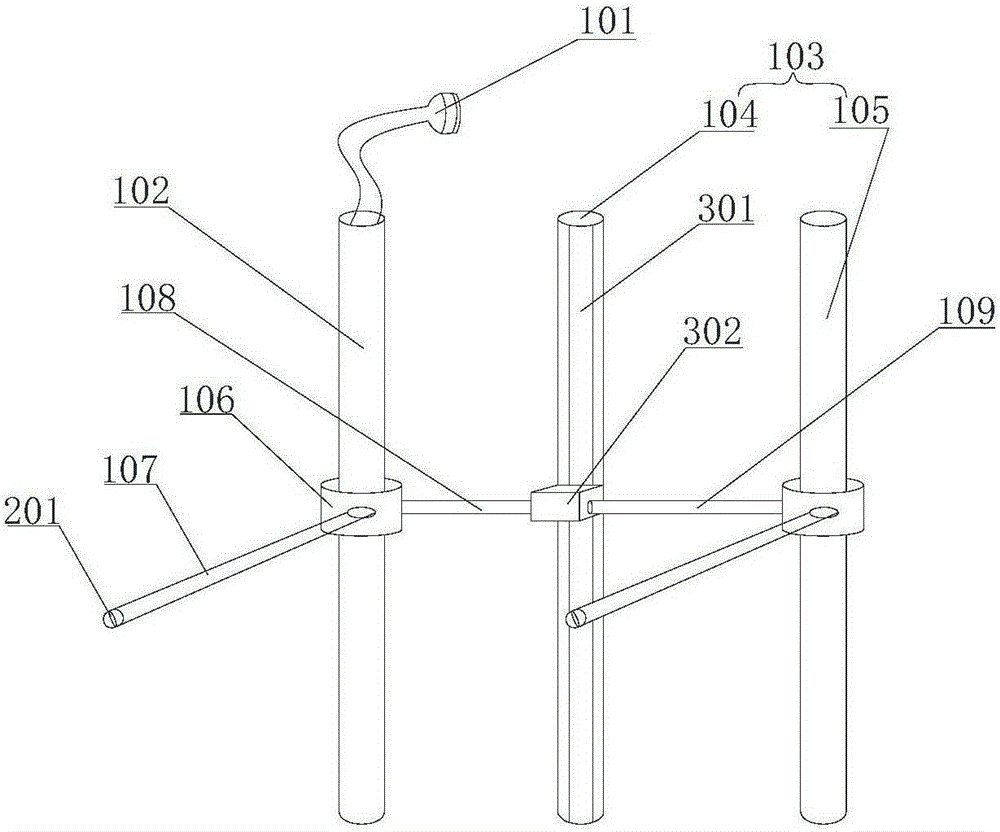

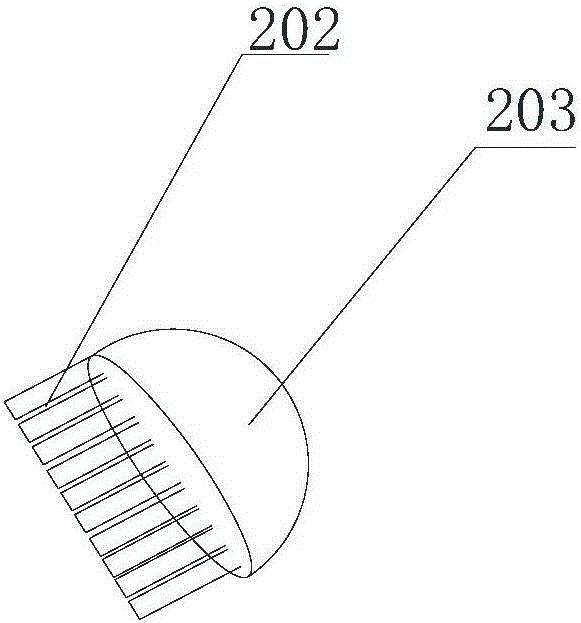

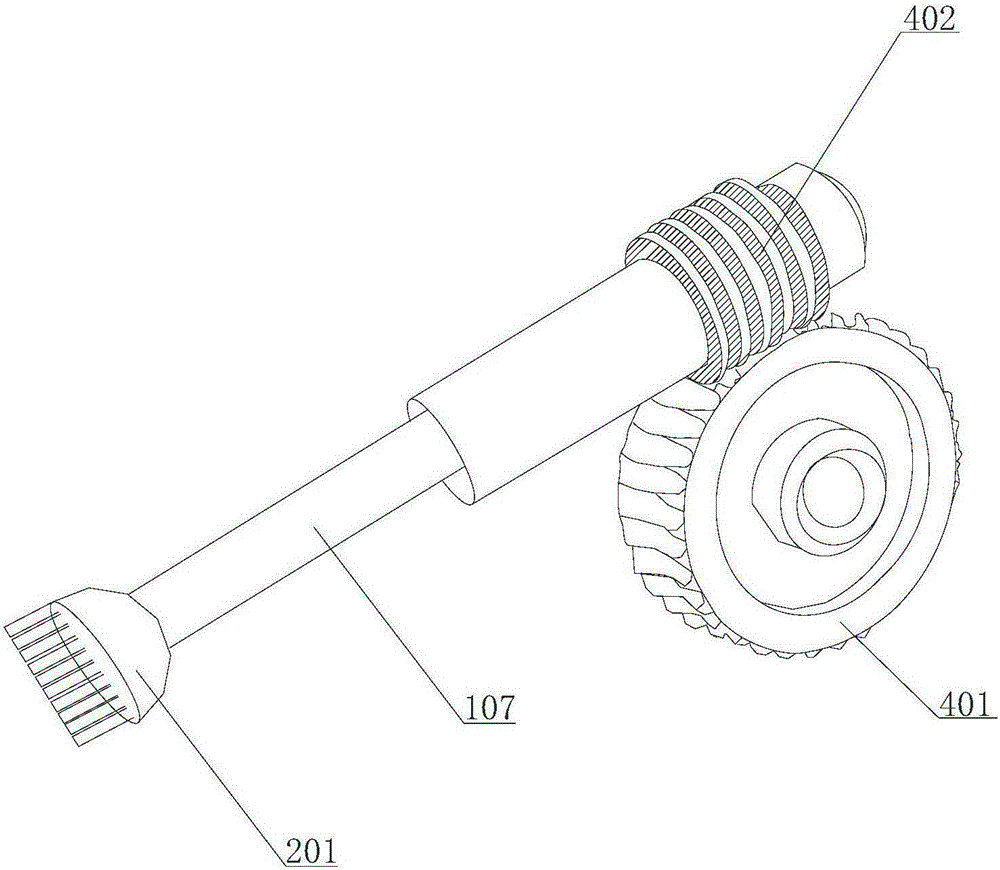

Multifunctional sprinkler

InactiveCN105214864AThere will be no problem that the hands are not long enough to washImprove experienceSpray nozzlesBristleEngineering

The invention provides a multifunctional sprinkler, and belongs to the field of shower goods. The multifunctional sprinkler is provided with a nozzle and a water outlet pipe, wherein the nozzle is communicated with the water outlet pipe. The multifunctional sprinkler further comprises a support frame and a bristle wheel for scrubbing and washing; the support frame is near the water outlet pipe, and is provided with a transmission mechanism; the bristle wheel is connected with the transmission mechanism; and the bristle wheel can vertically slide corresponding to the support frame. As the support frame and the bristle wheel are arranged, the bristle wheel is used for cleaning user bodies; the transmission mechanism on the support frame can drive the bristle wheel to vertically move corresponding to the support frame, so that the condition of incapability of cleaning some parts in place of users in the shower process due to short length of hands is improved; and meanwhile, the position of the bristle wheel is adjusted through the transmission mechanism, so that two hands of the users are liberated to prevent the aching pain of arms due to holding of a washing towel for washing in the shower process, and the experience of the users in the shower process is better.

Owner:肖琪钧

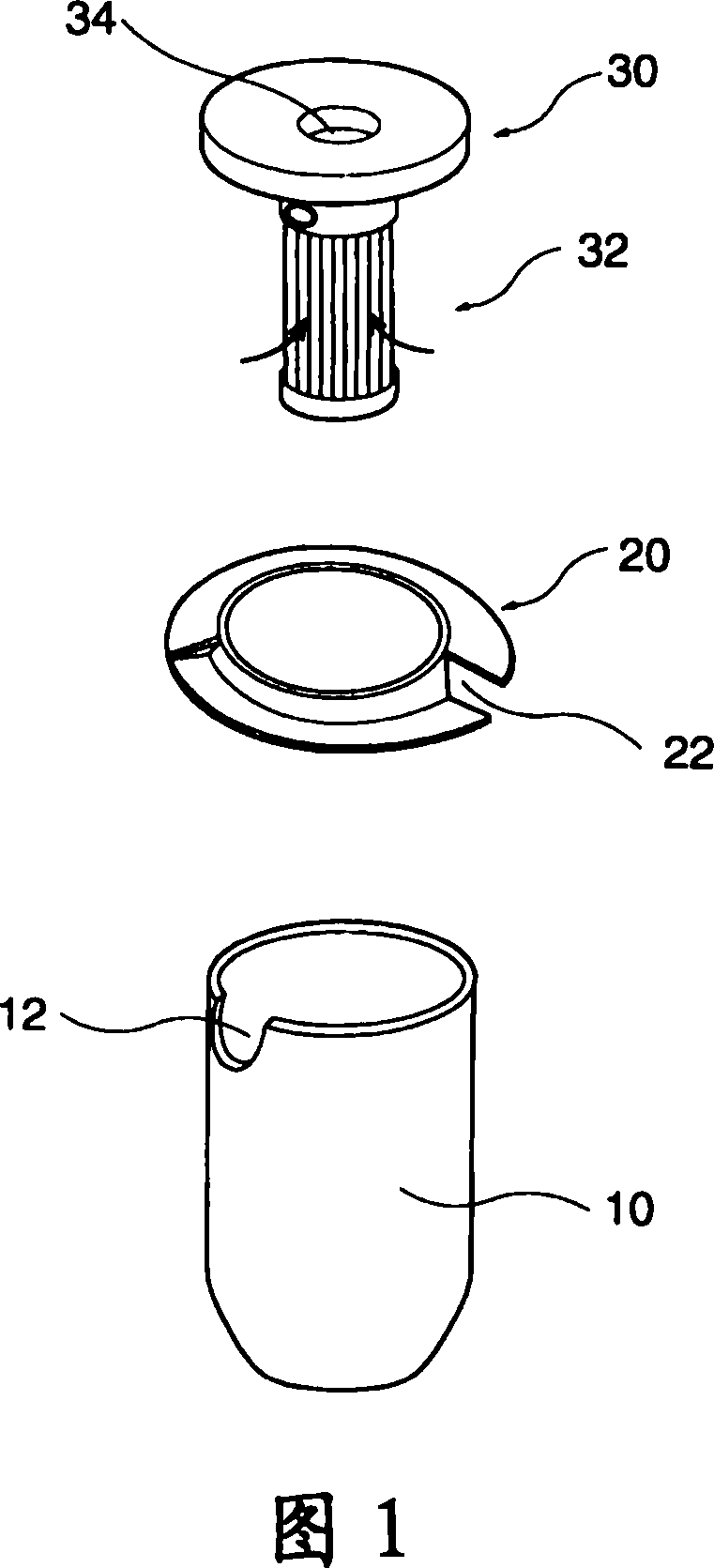

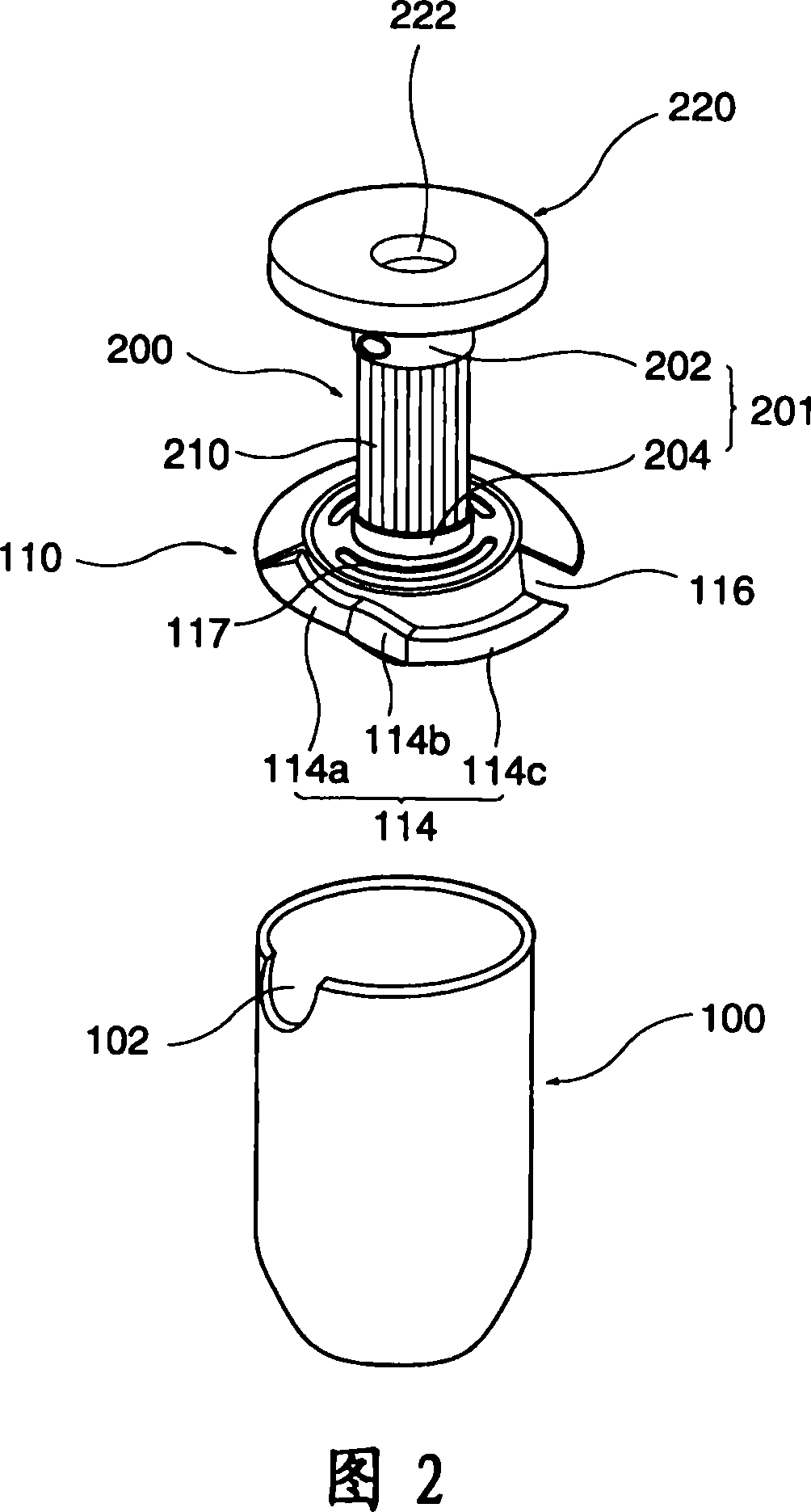

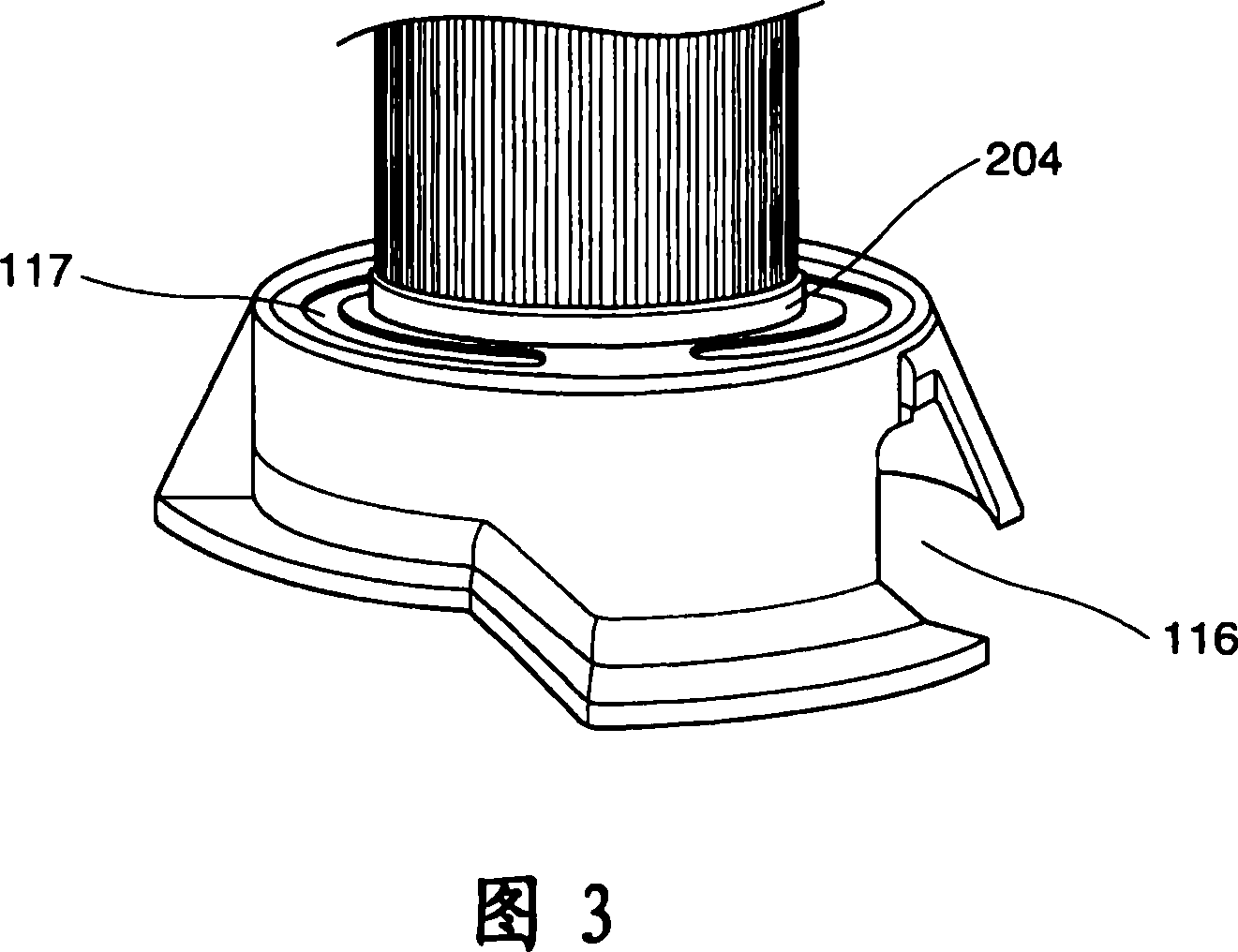

Dust collector special-purpose dust separation type dust collecting component

InactiveCN1303931CSimplify internal structureSimplify the assembly processSuction filtersForeign matterEngineering

The dust-separating dust collecting assembly for dust collector includes dust collecting case with upper opening; case cover capable of being assembled to and disassembled from the upper part of the dust collecting case; filter capable of being assembled to and disassembled from the lower part of the case cover; and partitioning board, which is set in the middle of the dust collecting case, has hole in the edge for foreign matter to fall down and is formed integrally with the lower part of the filter. The partitioning board has downward inclined conic edge, and curved guide part to the hole or air guiding part to the hole, with the guiding part comprising several horizontal planes and connecting slants. Forming the filter and the portioning board can reduce the number of parts, simplify structure and assembling process and raise production efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com