Patents

Literature

464results about How to "Improve assembly yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

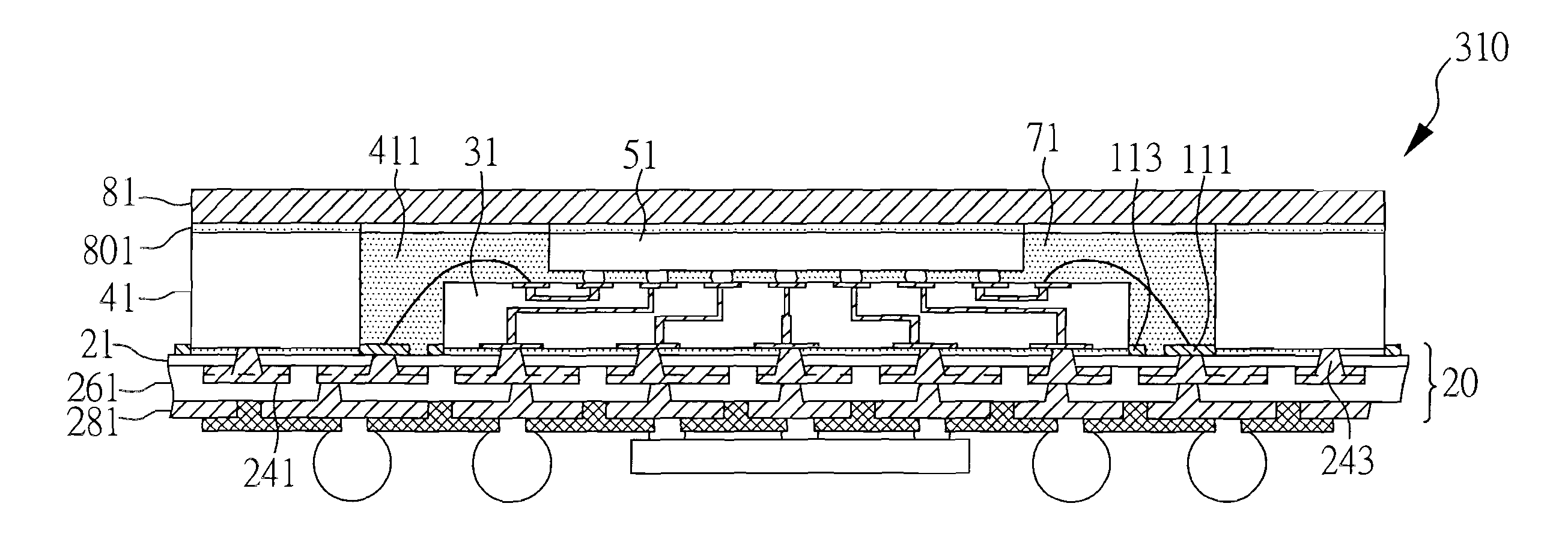

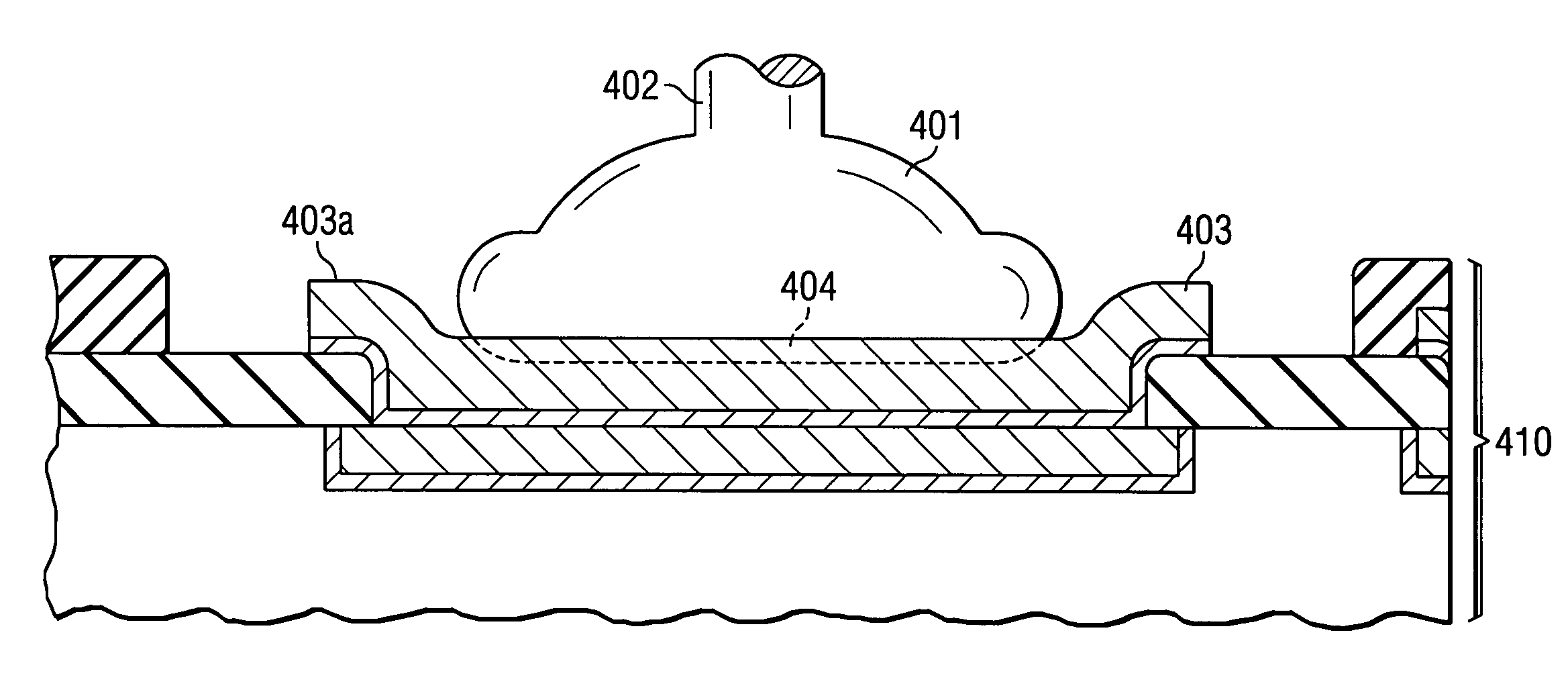

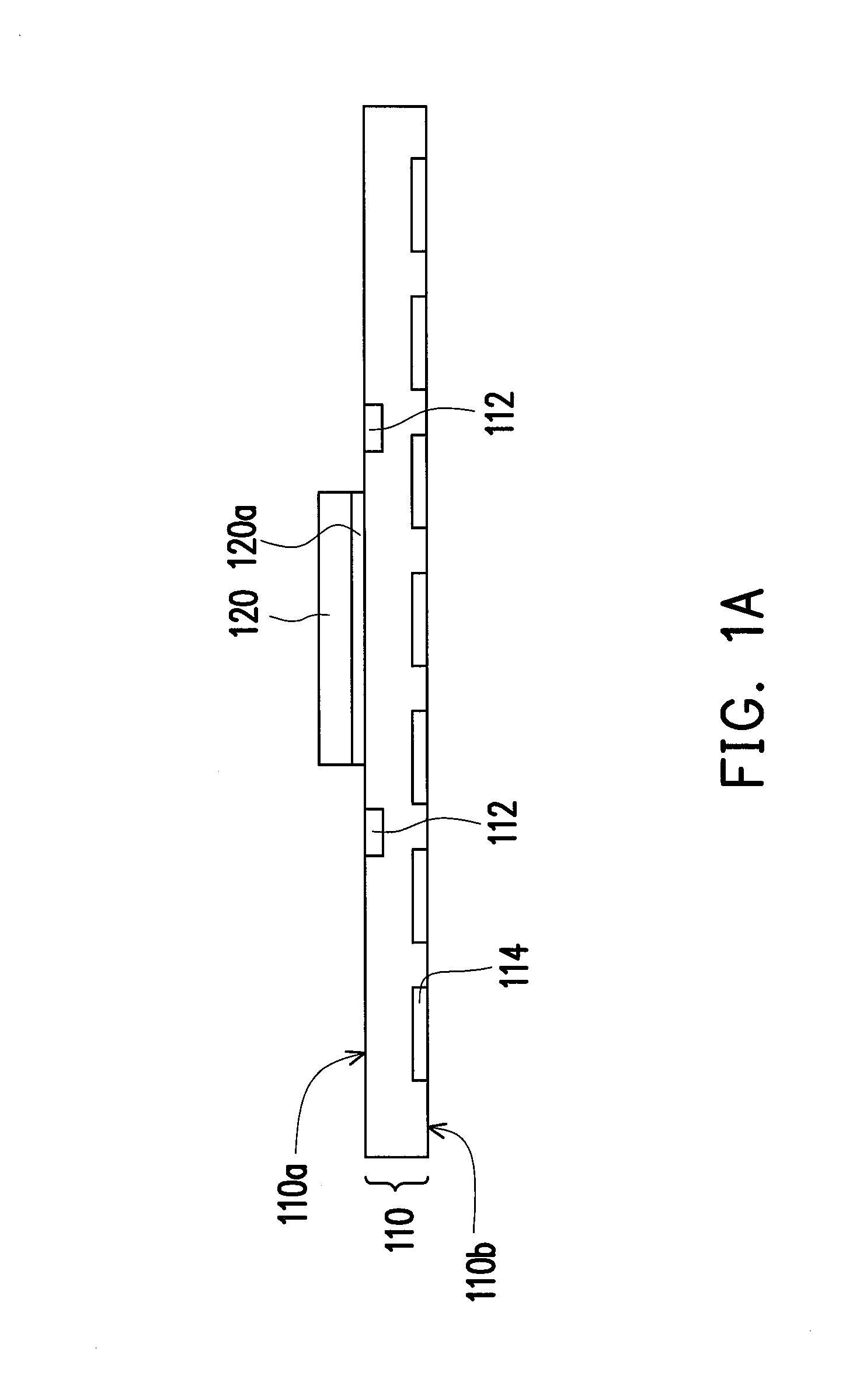

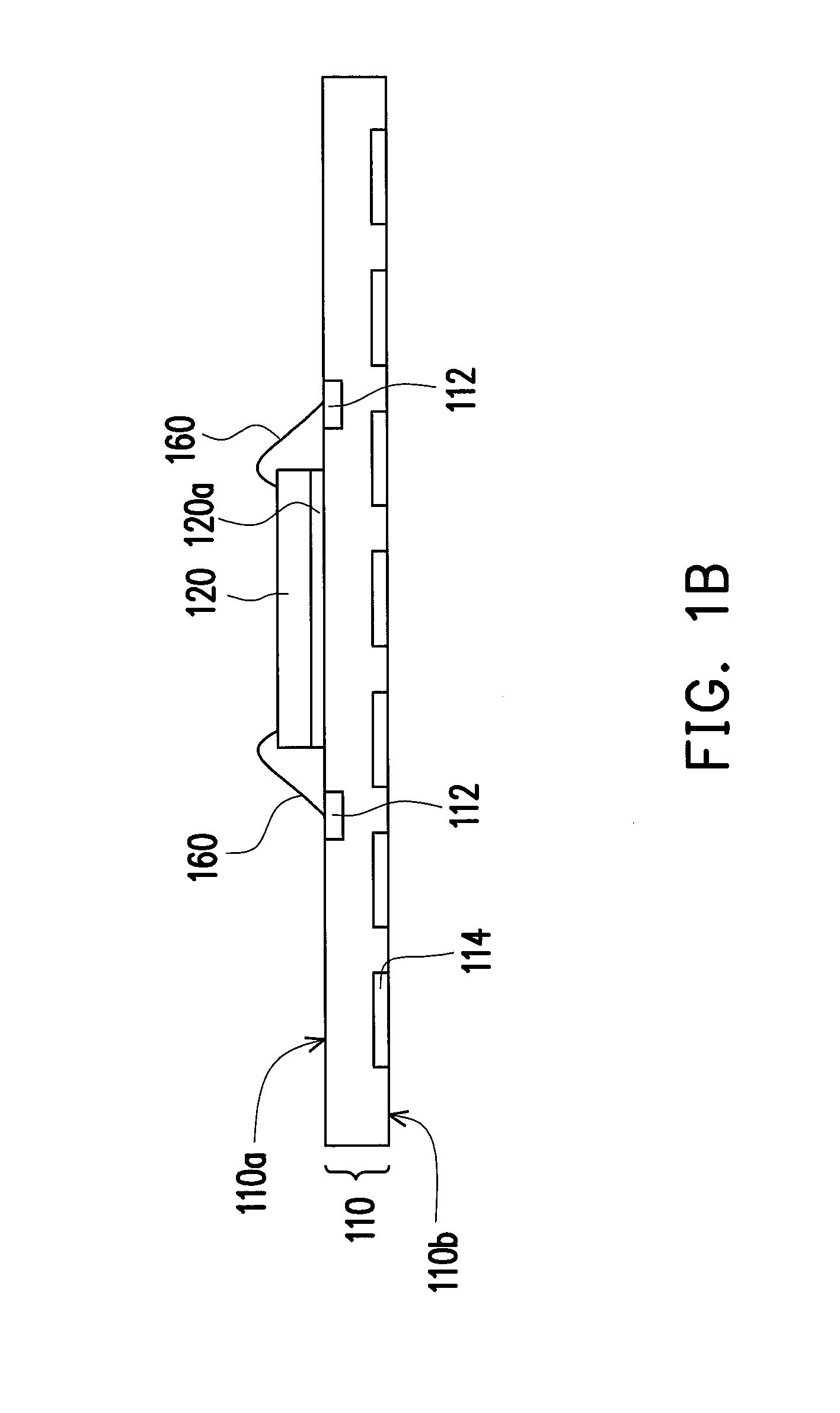

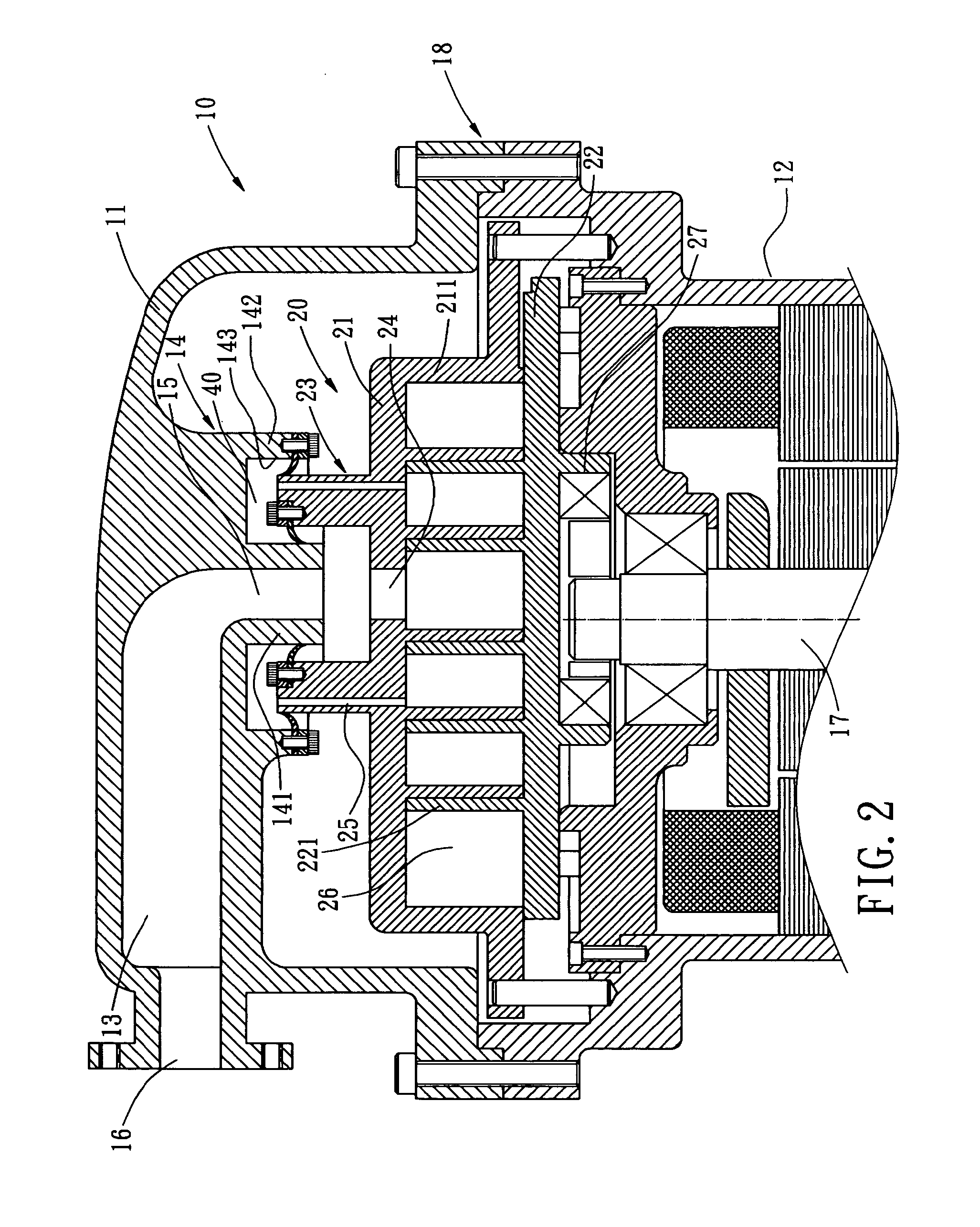

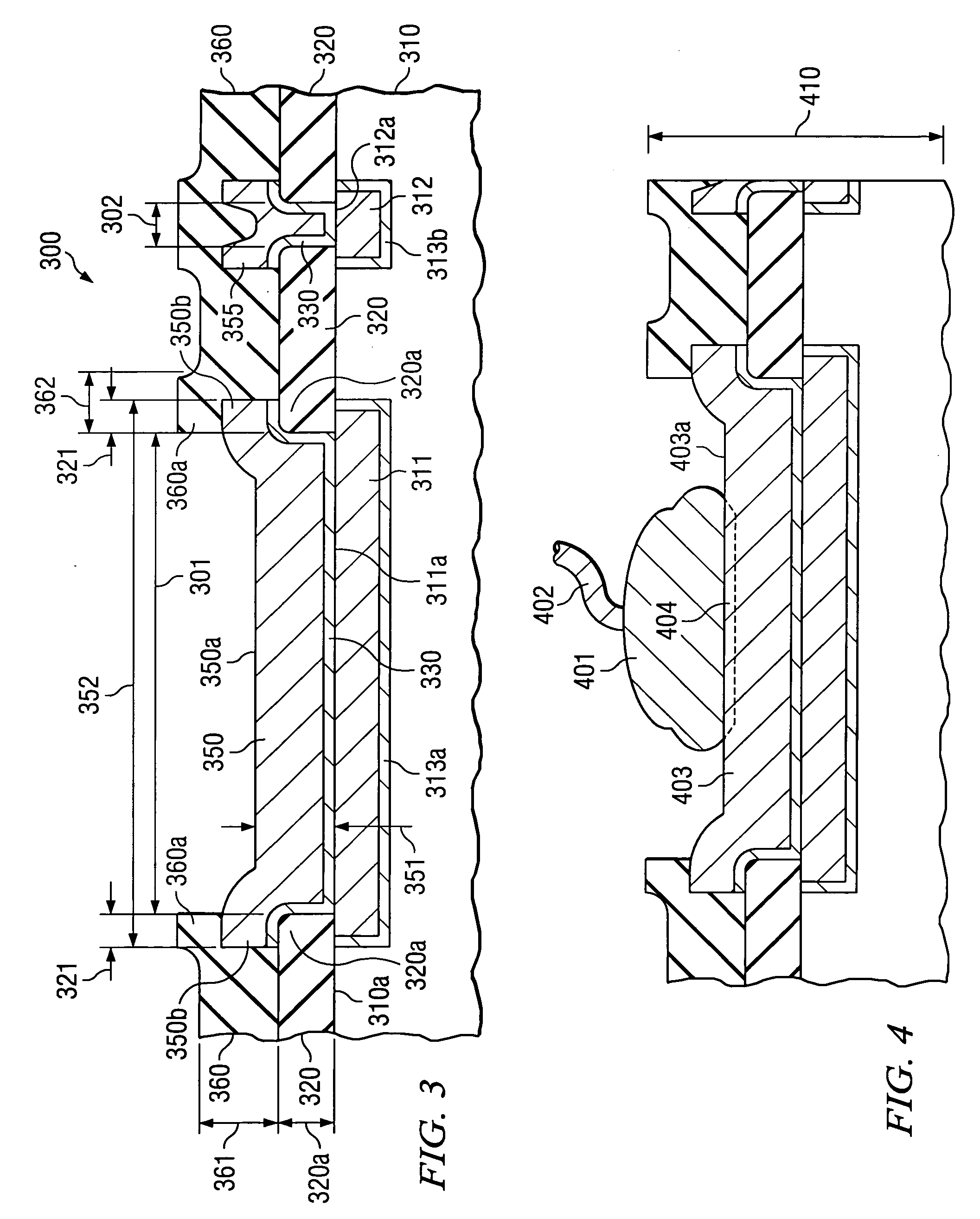

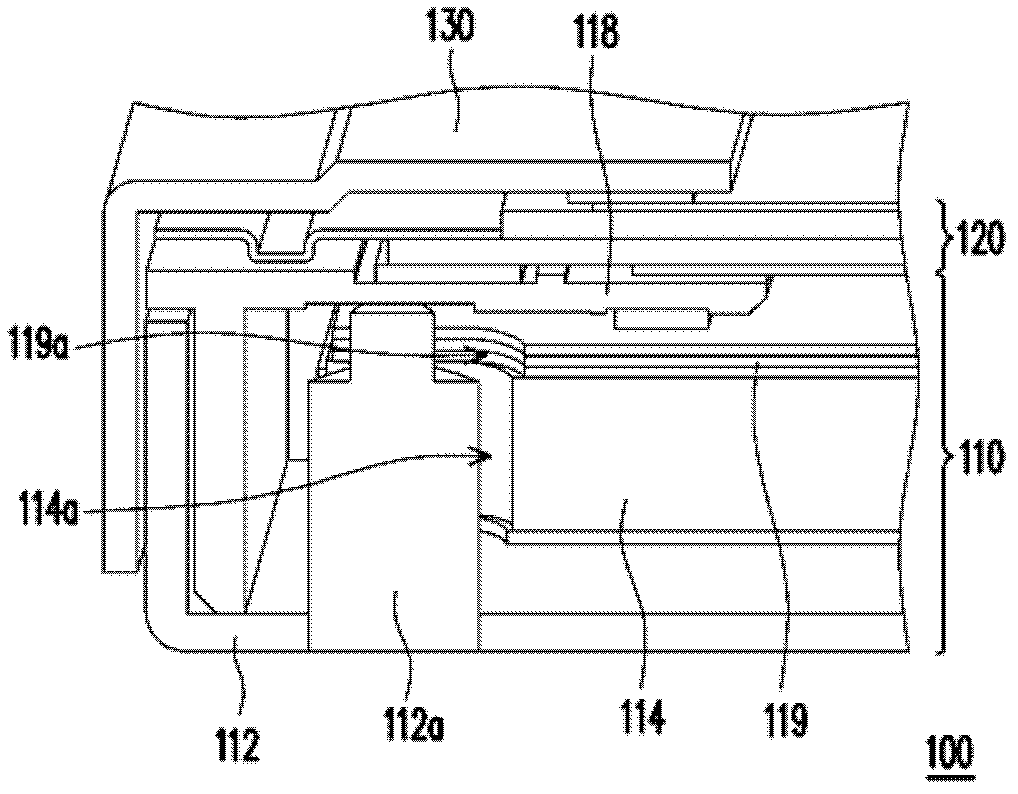

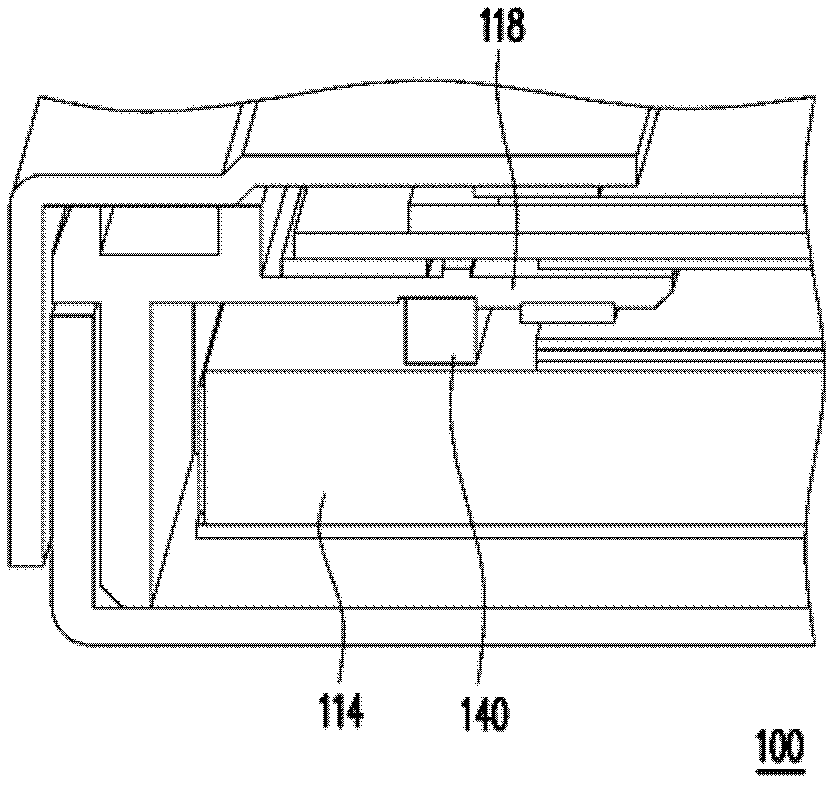

Semiconductor assembly with dual connecting channels between interposer and coreless substrate

InactiveUS20140048951A1Reduce sizeImprove manufacturing yieldSemiconductor/solid-state device detailsSolid-state devicesElectrically conductiveSemiconductor

A semiconductor assembly includes a semiconductor device, a through-via interposer, a coreless substrate and a stiffener. The semiconductor device is flip mounted on the interposer, and the interposer is affixed on the coreless substrate by adhesive and extends into an aperture of a stiffener which provides mechanical support for the coreless substrate. The electrically connection between the interposer and the coreless substrate includes bond wire and conductive micro-via. The coreless substrate can provide fan-out routing for the interposer.

Owner:BRIDGE SEMICON

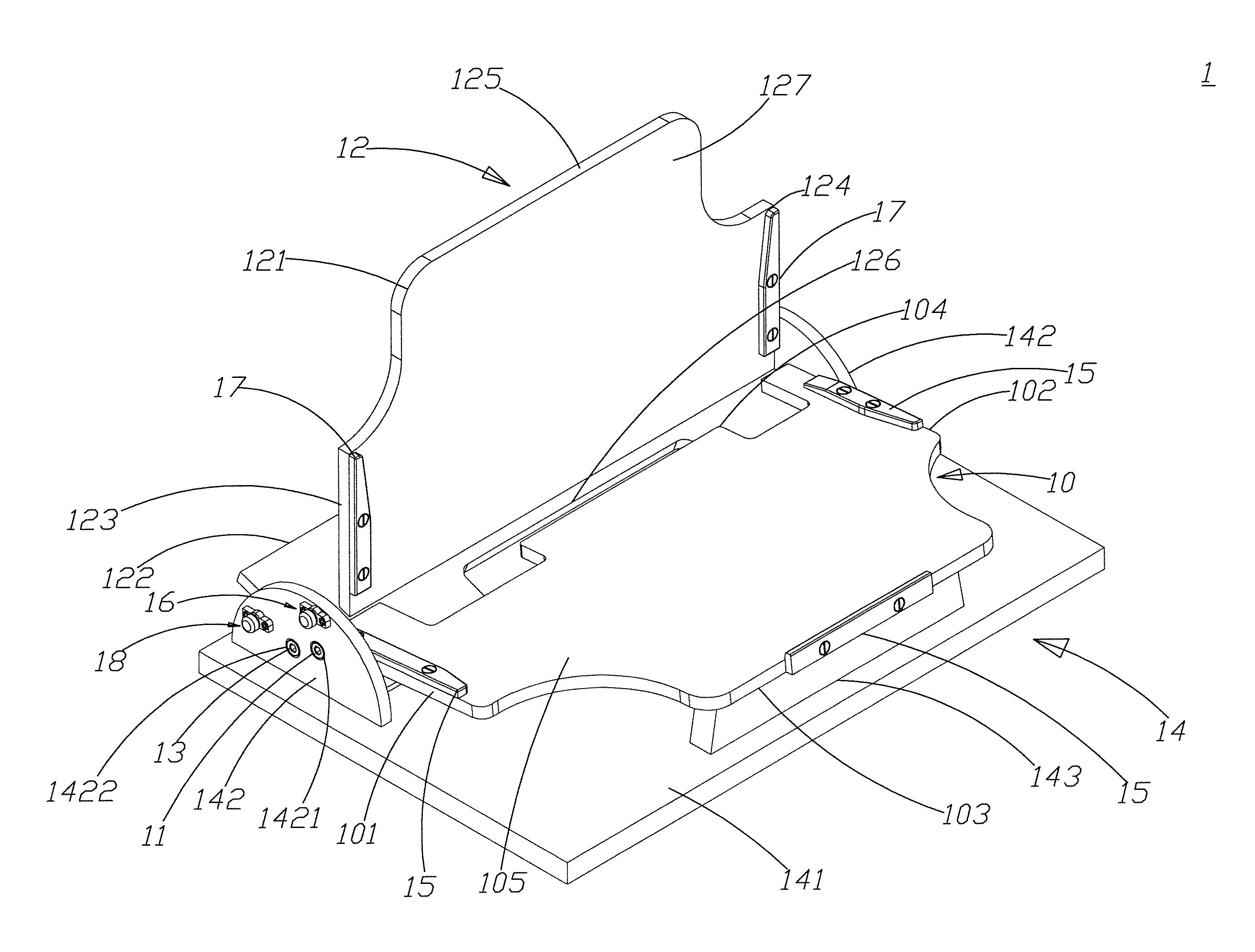

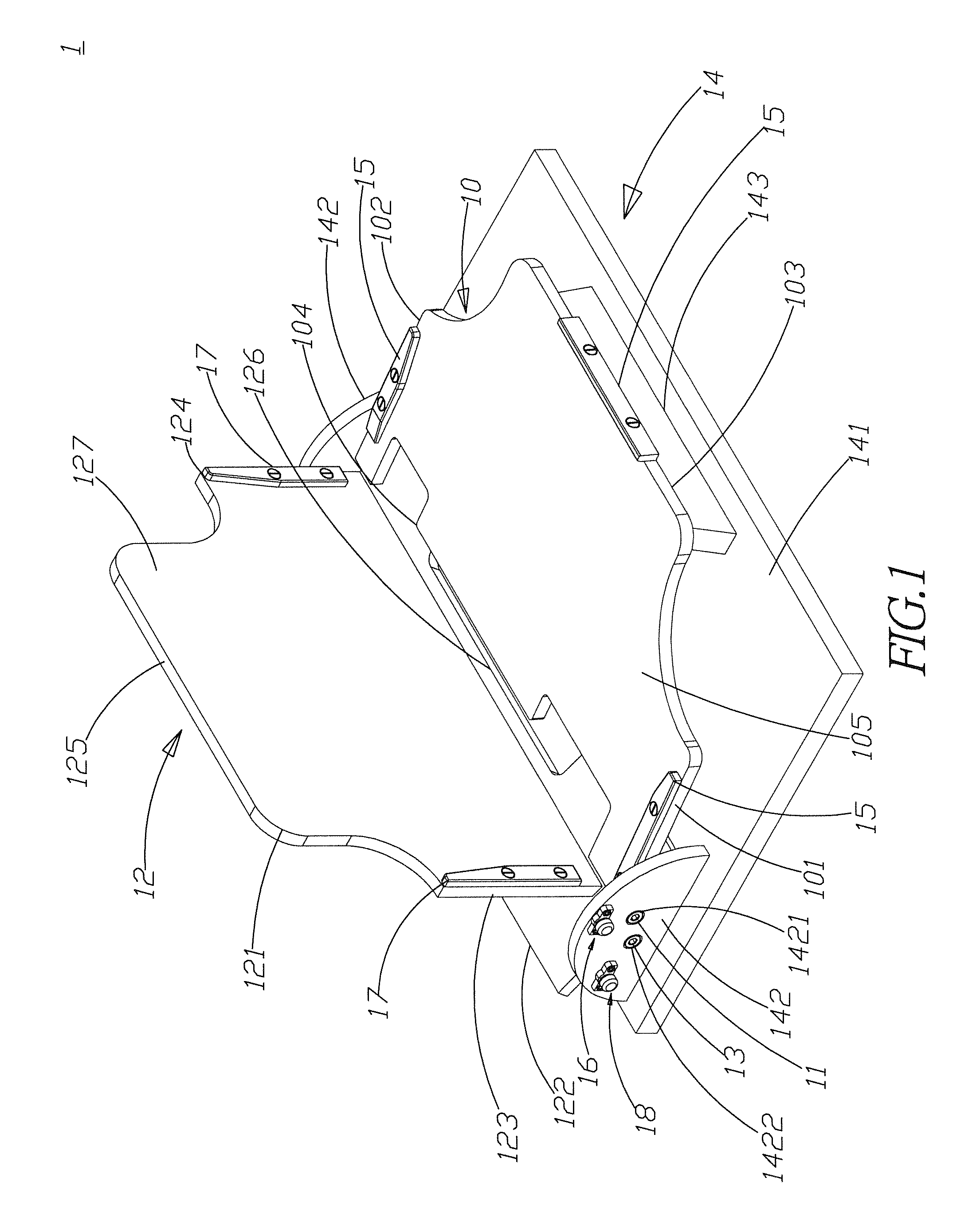

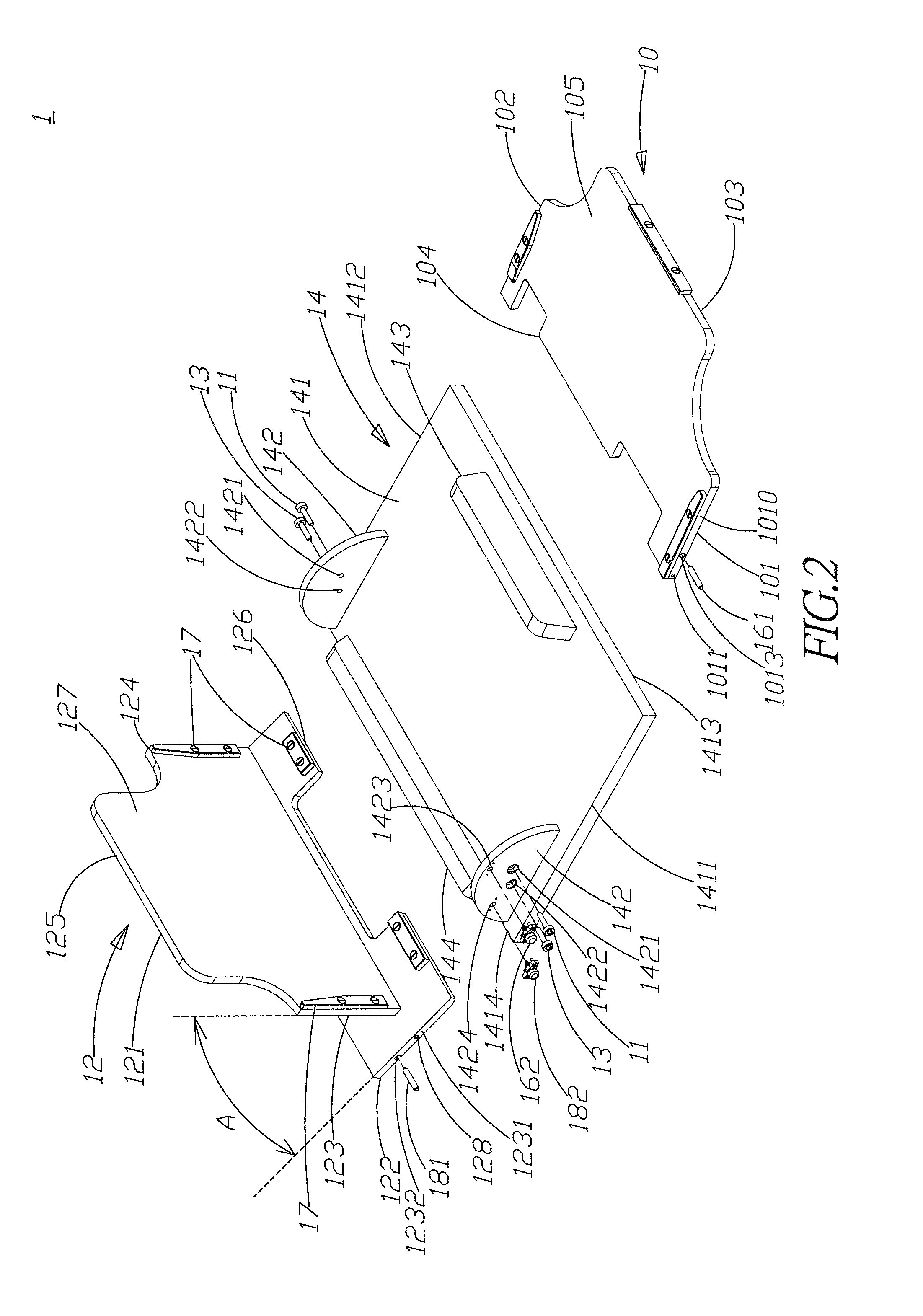

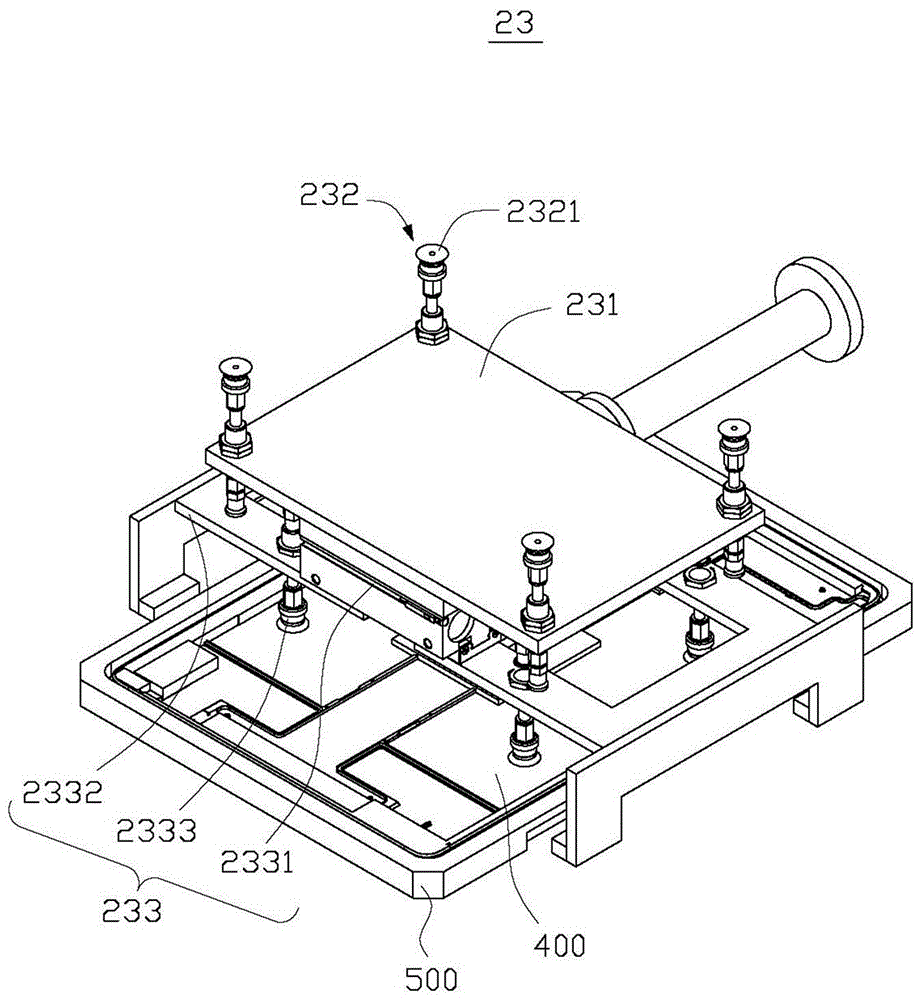

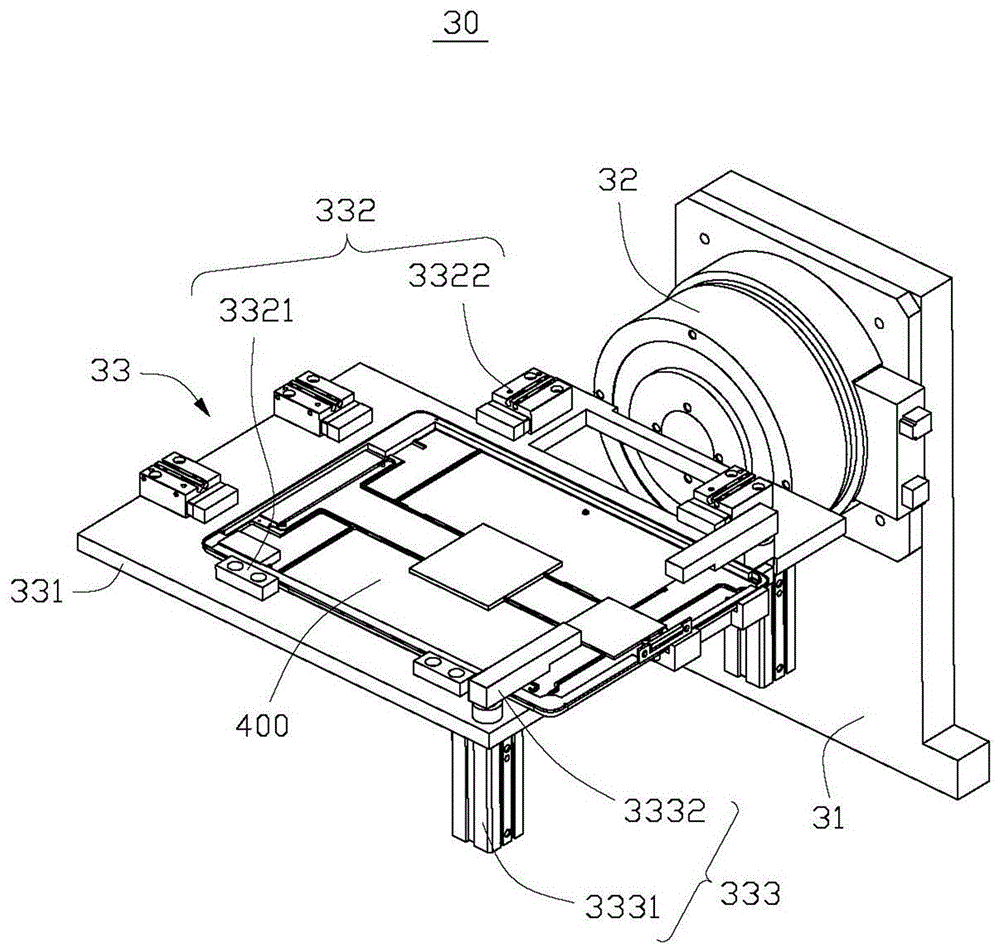

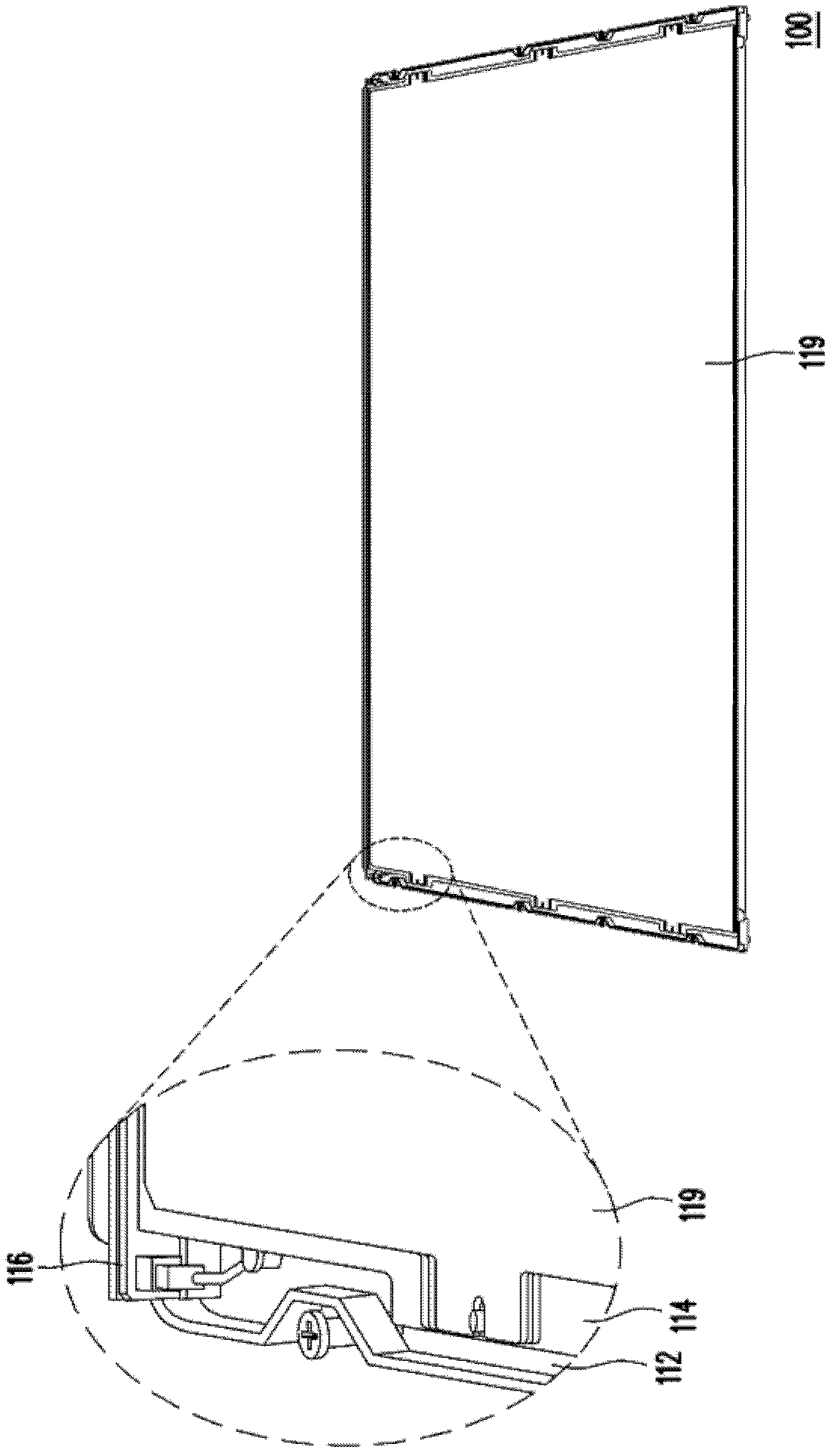

Ancillary fixture for assembling touch display and method for using the same

InactiveUS20150121691A1Reduce labor costsReduce wasteLine/current collector detailsDigital data processing detailsMechanical engineeringEngineering

Owner:WISTRON CORP

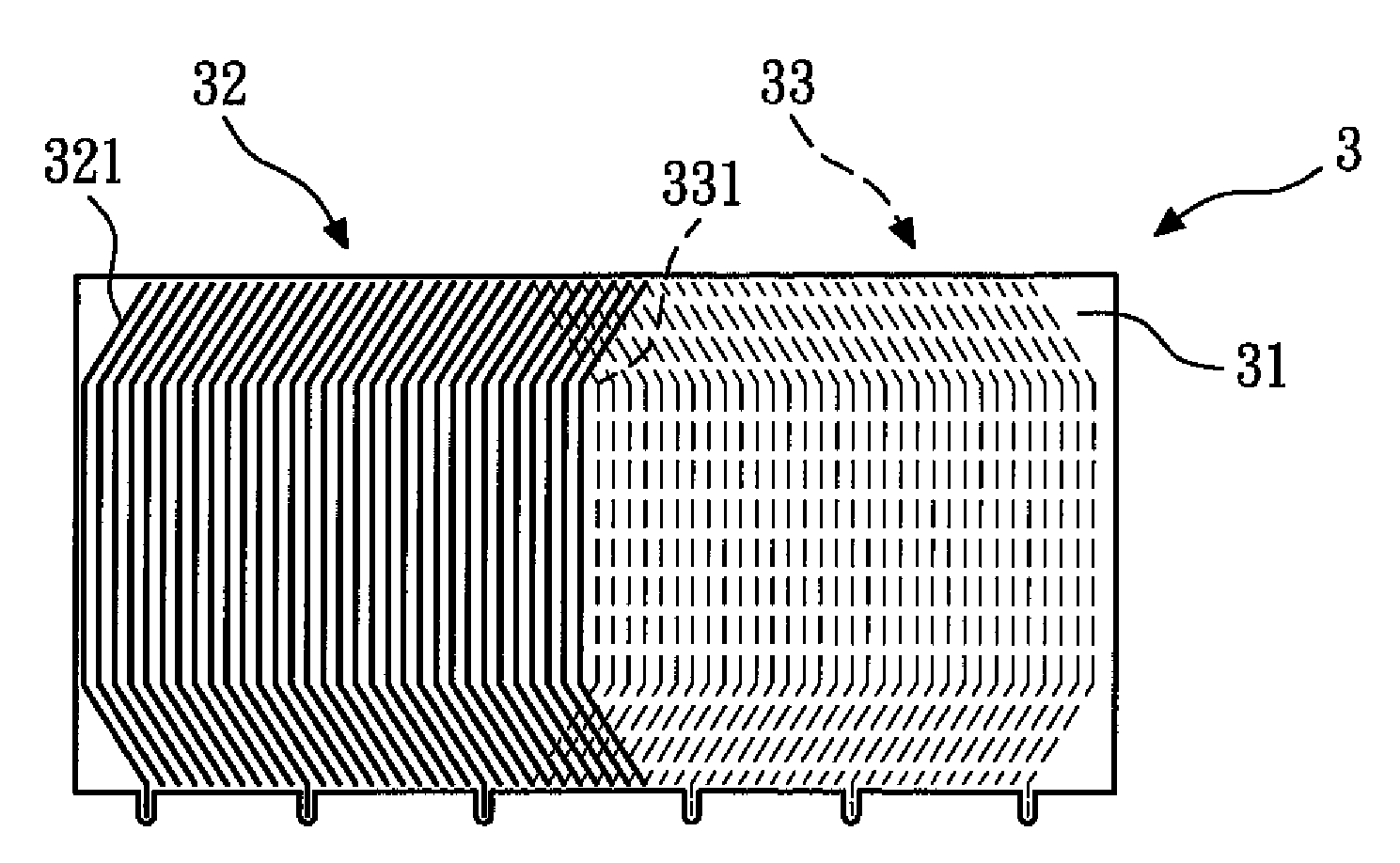

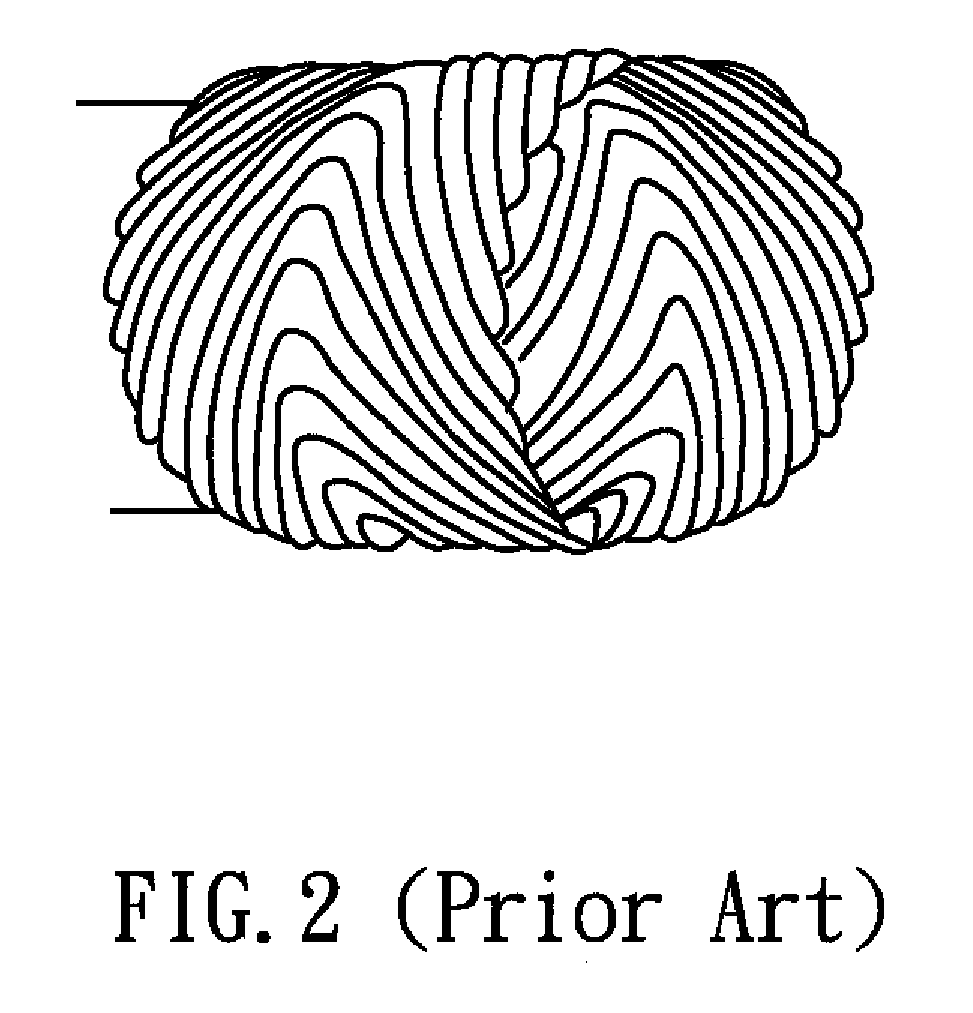

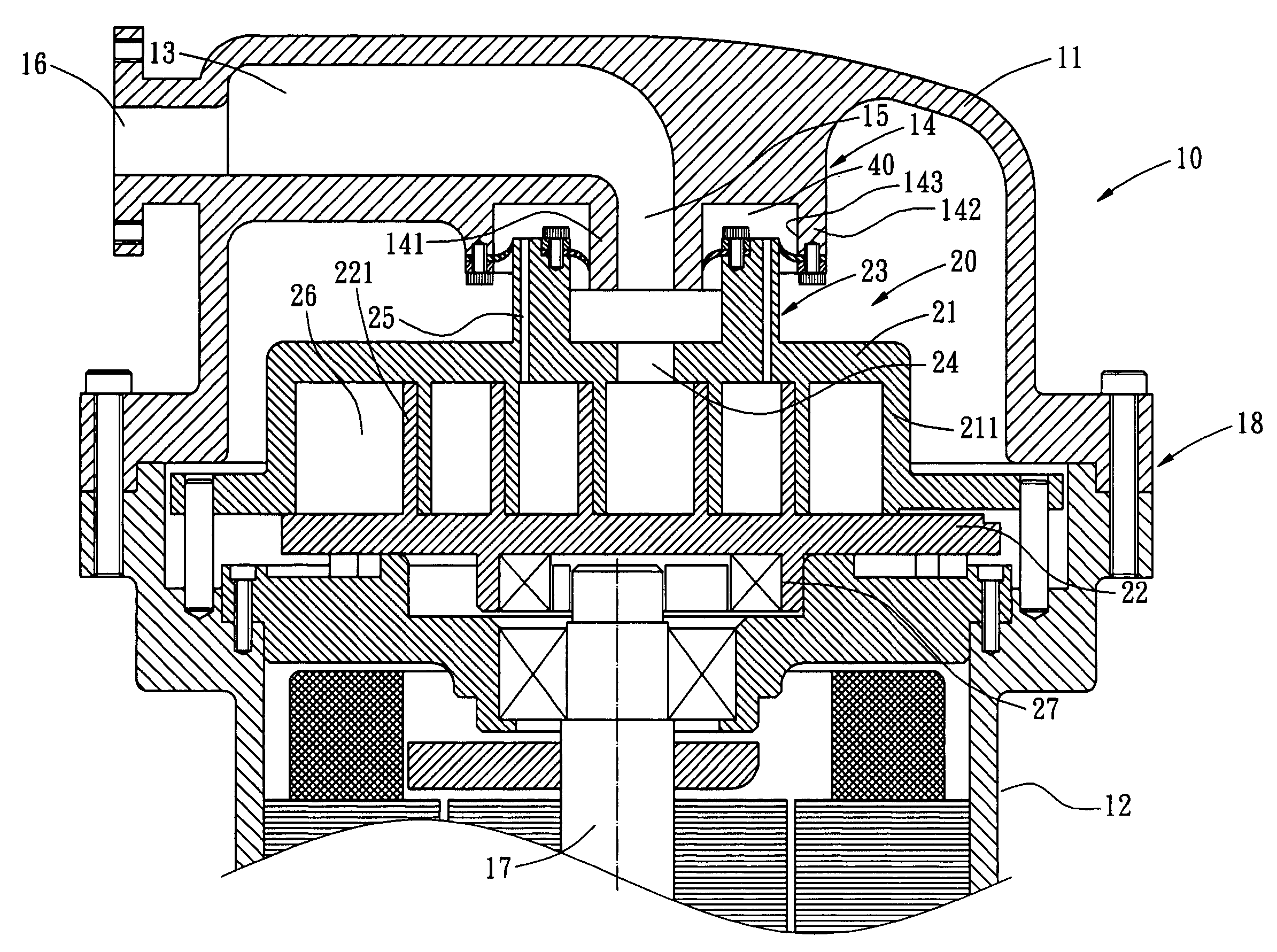

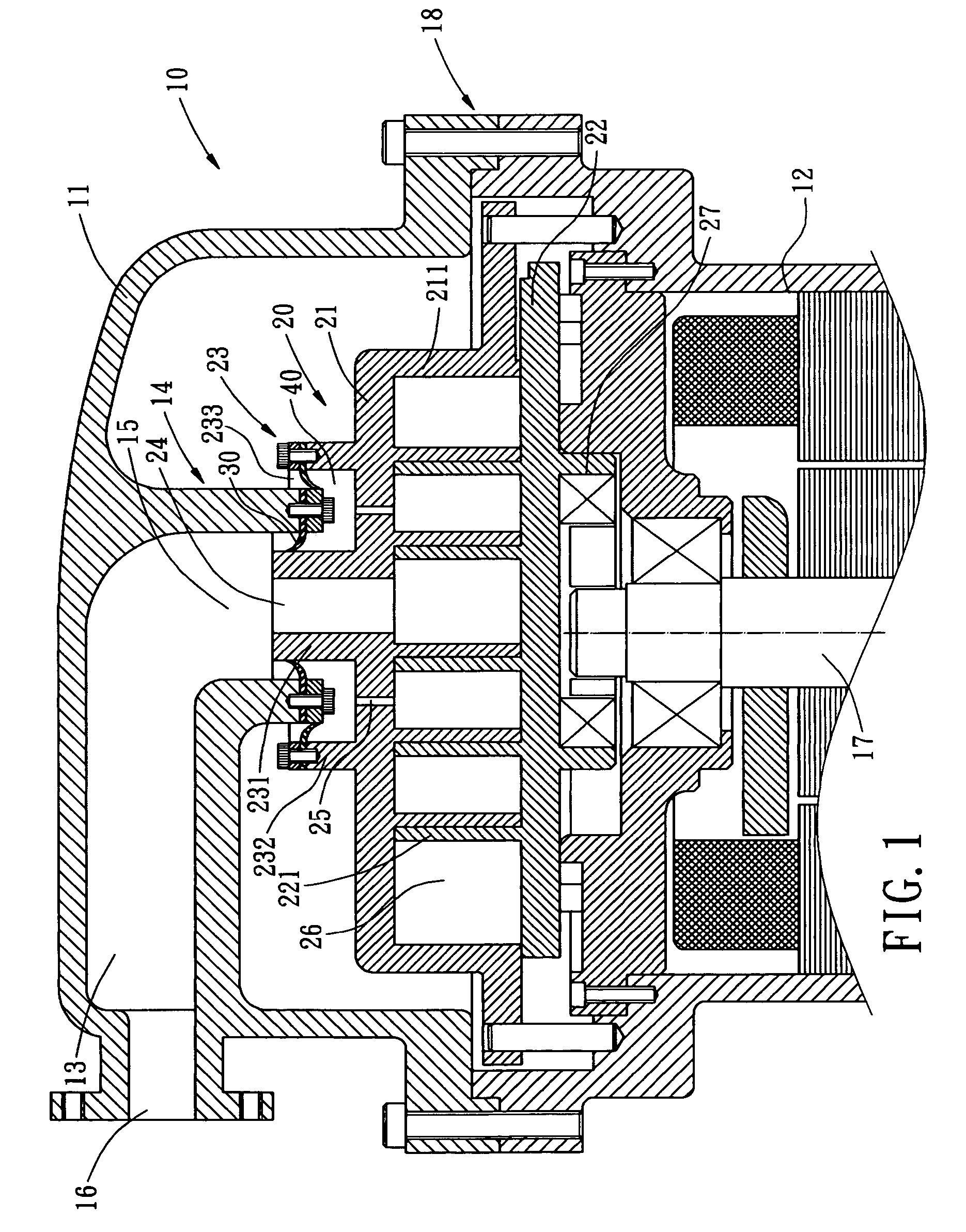

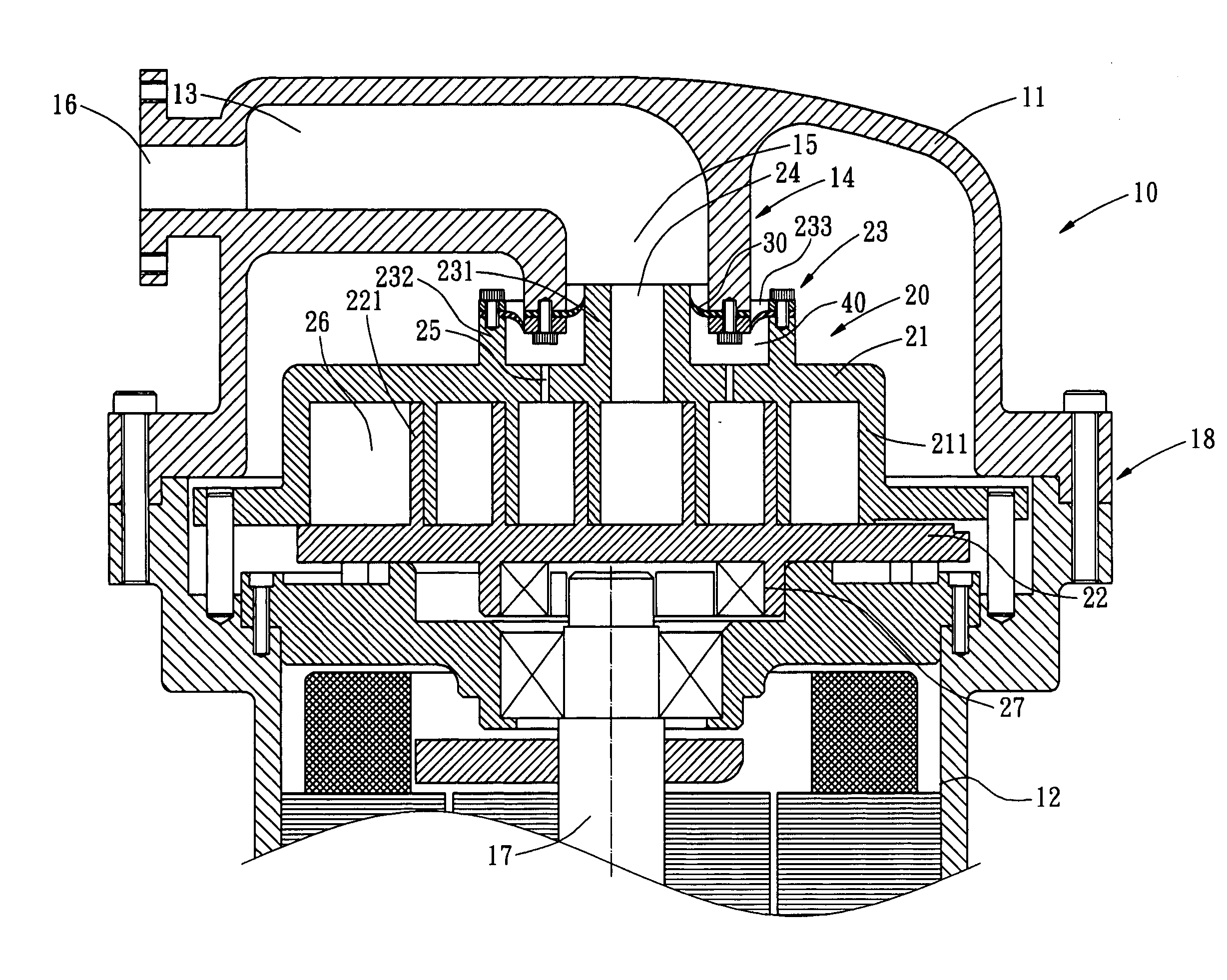

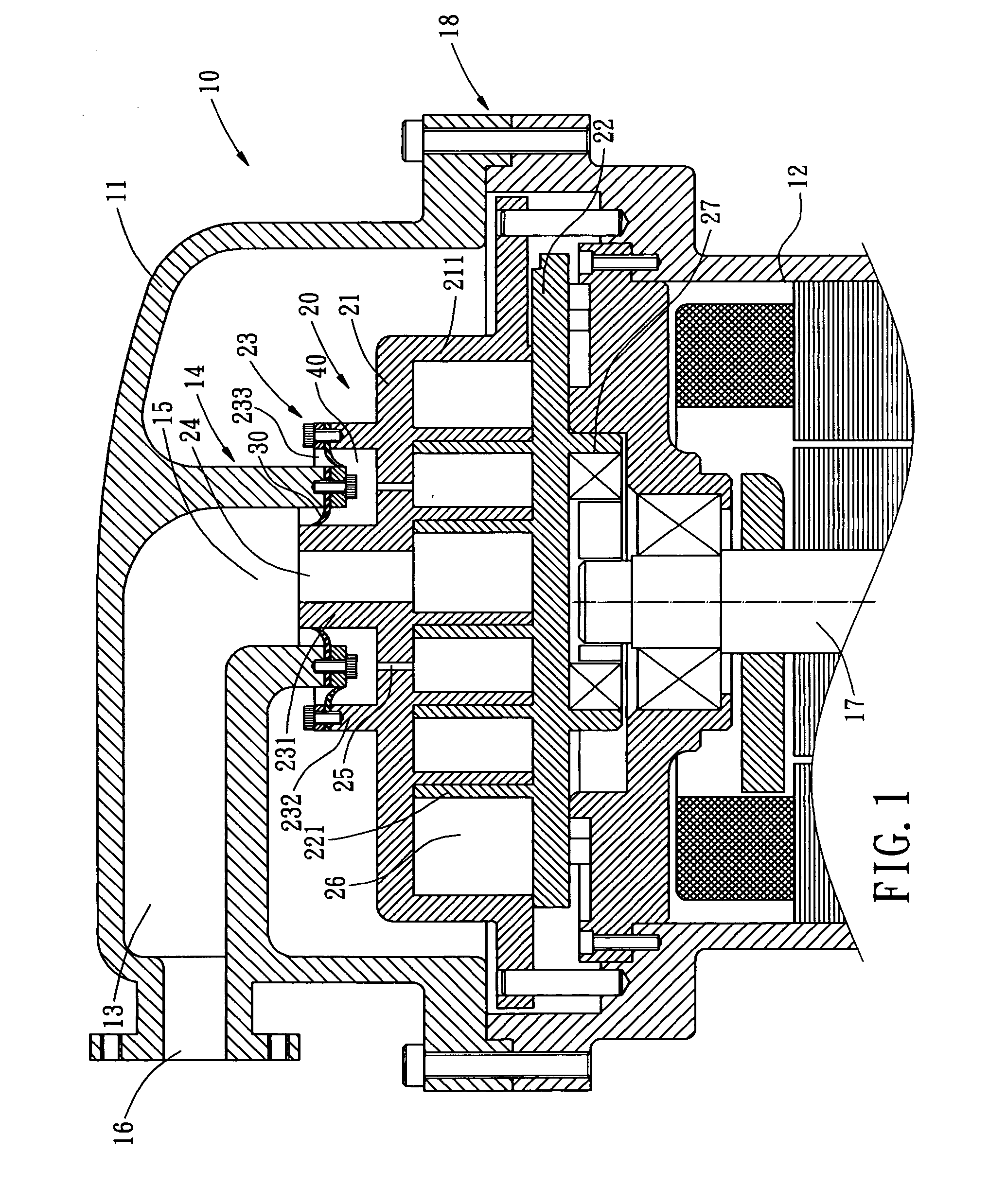

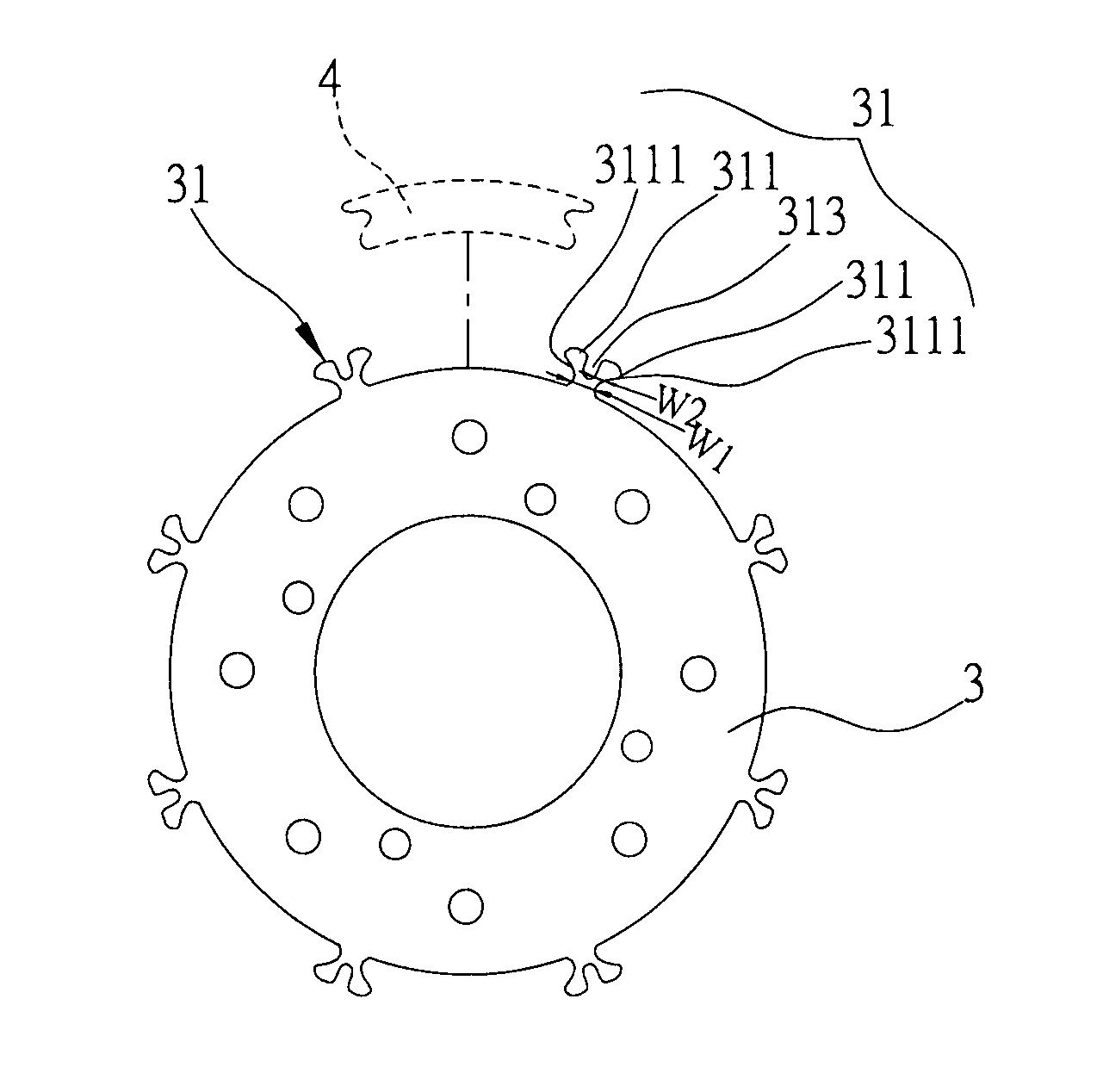

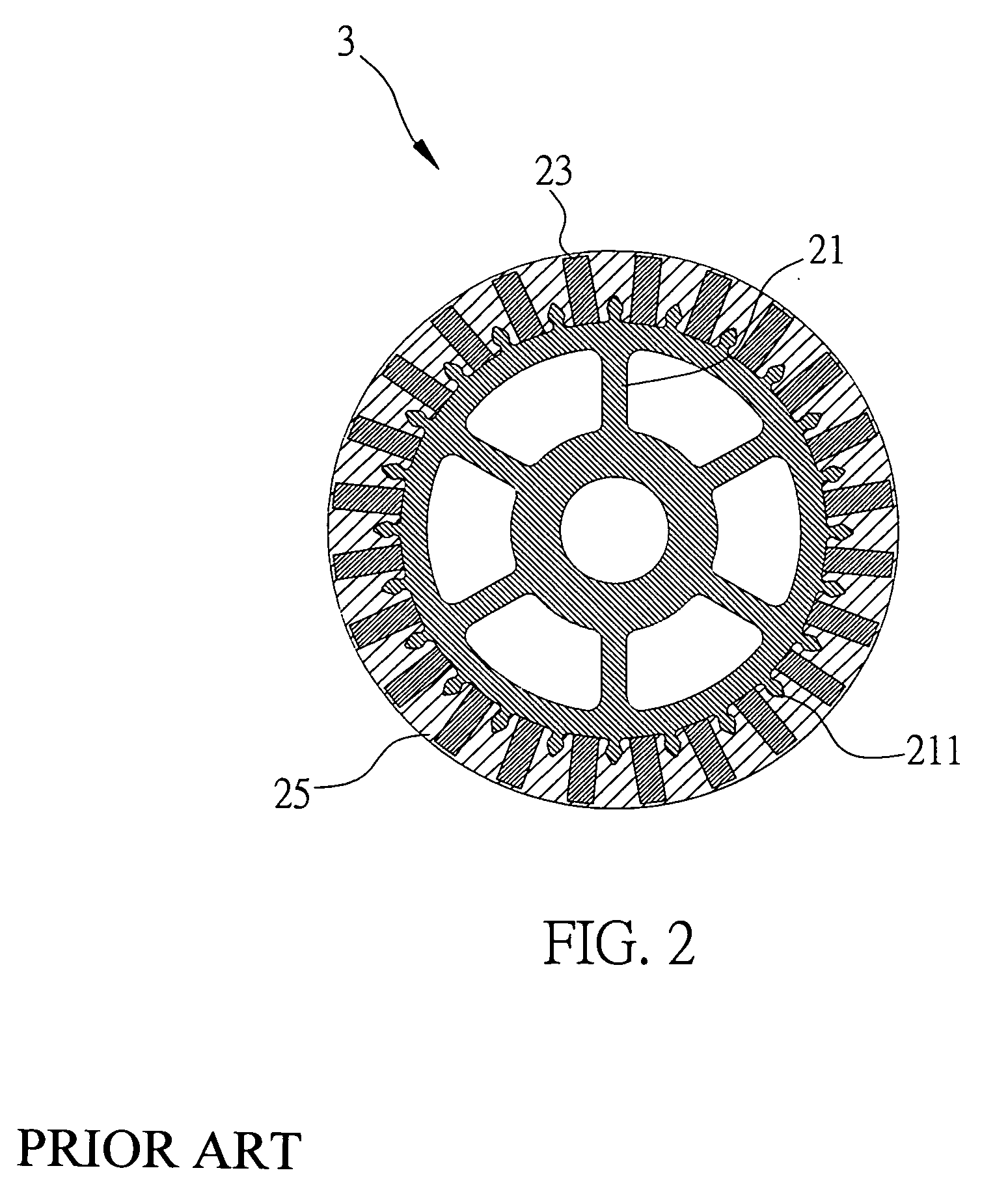

Slotless winding for rotating electric machine and manufacturing method thereof

InactiveUS20090072651A1Improve applicabilityImprove performanceMagnetic circuitTransformers/inductances coils/windings/connectionsElectric machineBarrel Shaped

The present invention relates to a slotless winding for a rotating electric machine and a manufacturing method thereof. The slotless winding includes at least one flexible printed circuit board having at least one circuit, and one piece of flexible printed circuit board(s) is curved or a plurality of pieces of flexible printed circuit board(s) is mutually combined to form a barrel shape, thereby simplifying the procedure of manufacturing the slotless winding, improving production speed and reliability, and enabling diversified designing schemes to meet the demands of the rotating electric machine. In addition, it is not necessary for the coil winding to be cured for assembling, and assembling yield is thus enhanced.

Owner:METAL INDS RES & DEV CENT

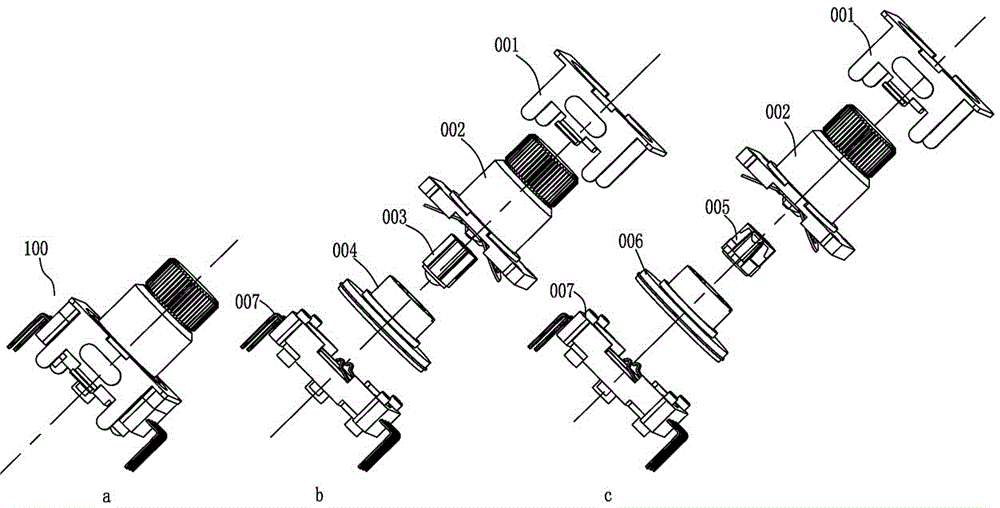

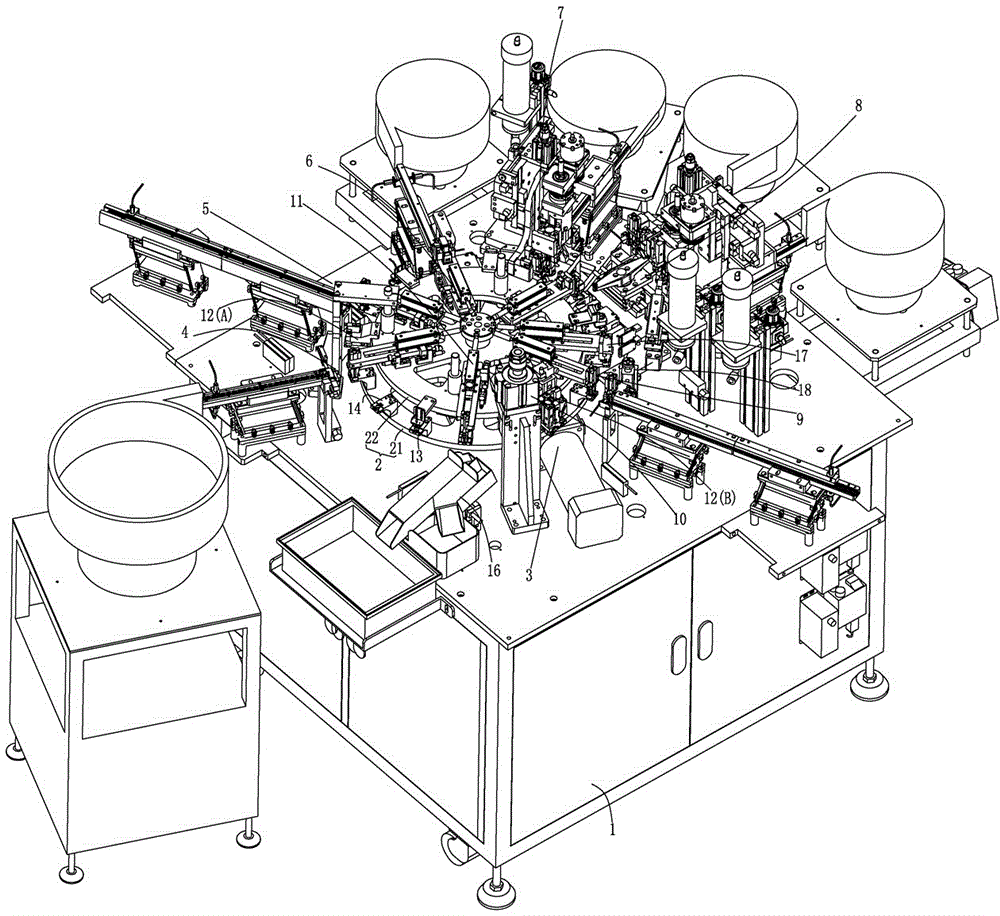

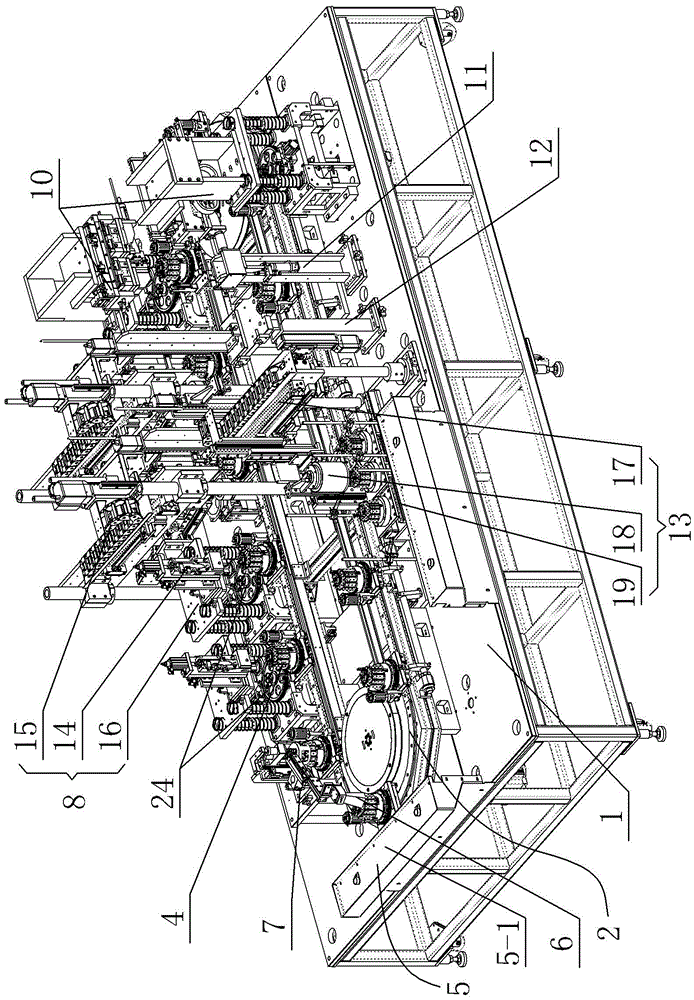

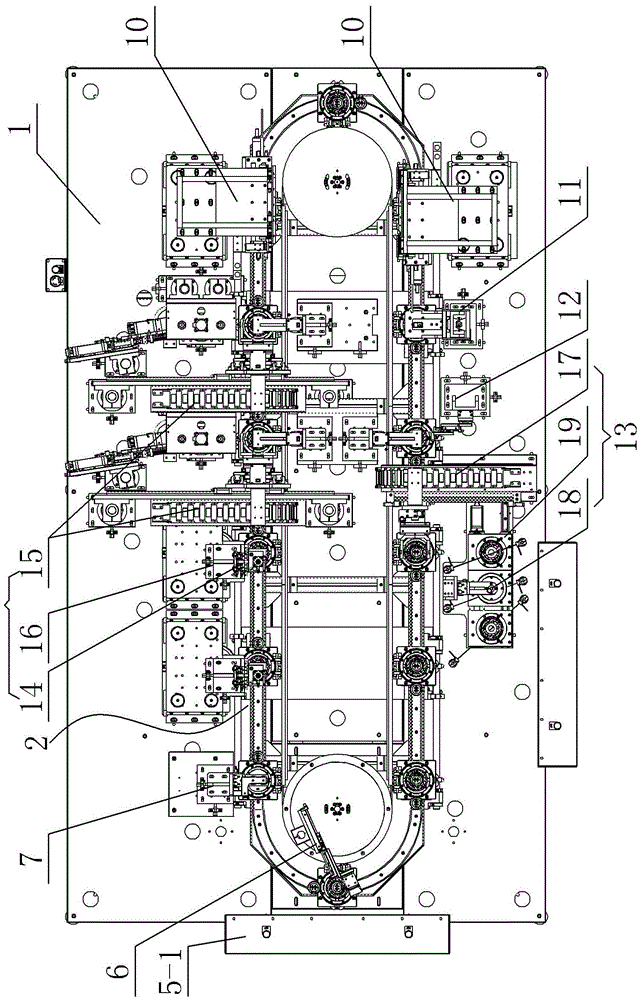

Automatic assembling machine for assembling vehicle-mounted encoder

ActiveCN106736540AImprove assembly yieldHigh degree of automationAssembly machinesMetal working apparatusEngineeringCam

Disclosed is an automatic assembling machine for assembling a vehicle-mounted encoder. The automatic assembling machine comprises a rotating table assembly, a cam indexer assembly, a support feeding mechanism, a manual pendulum shaft core and shaft sleeve feeding mechanism, a first rotor feeding mechanism, a first drive plate feeding mechanism, a second rotor and second drive plate assembling mechanism, a manual pendulum body feeding mechanism, a riveting mechanism and a discharging mechanism, wherein the rotating table assembly, the cam indexer assembly, the support feeding mechanism, the manual pendulum shaft core and shaft sleeve feeding mechanism, the first rotor feeding mechanism, the first drive plate feeding mechanism, the second rotor and second drive plate assembling mechanism, the manual pendulum body feeding mechanism, the riveting mechanism and the discharging mechanism are arranged on the top of a machine box. The automatic assembling machine further comprises two shape trimming assemblies and a plurality of detection assemblies, wherein the shape trimming assemblies are used for shape trimming of supports. A plurality of station clamps are arranged on the circumferential edge of a rotating table of the rotating table assembly in an array mode. A rotating pendulum assembly is further arranged on the top of the machine box in a matched mode. The feeding mechanisms are matched with the movement of the rotating table assembly to conduct feeding in sequence, the riveting mechanism conducts riveting on parts of the encoder to form an encoder finished product, the discharging mechanism enables the encoder finished product to be discharged into a collecting box, the shape trimming assemblies conduct opening shape trimming and inward extrusion shape trimming on the supports, and the rotating pendulum assembly is used for transmitting a second rotor and second drive plate assembly assembled by the second rotor and second drive plate assembling mechanism to the matched station clamp.

Owner:广东钺河智能科技有限公司

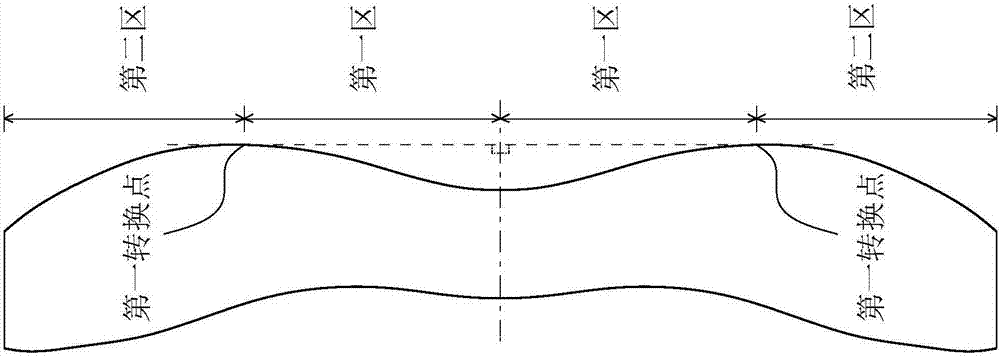

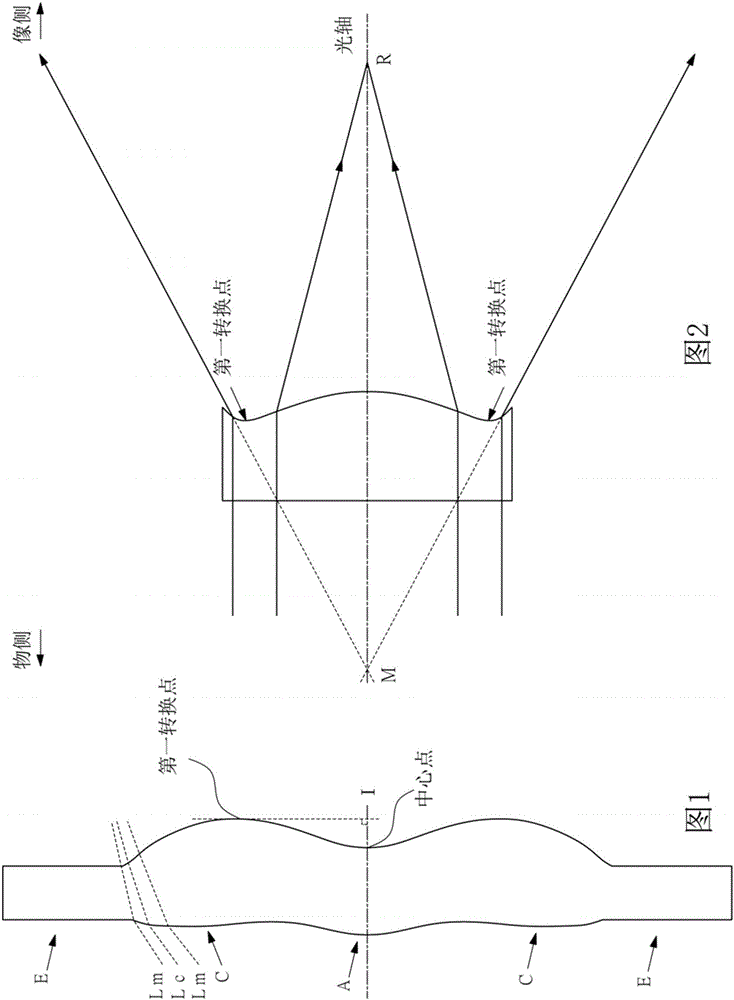

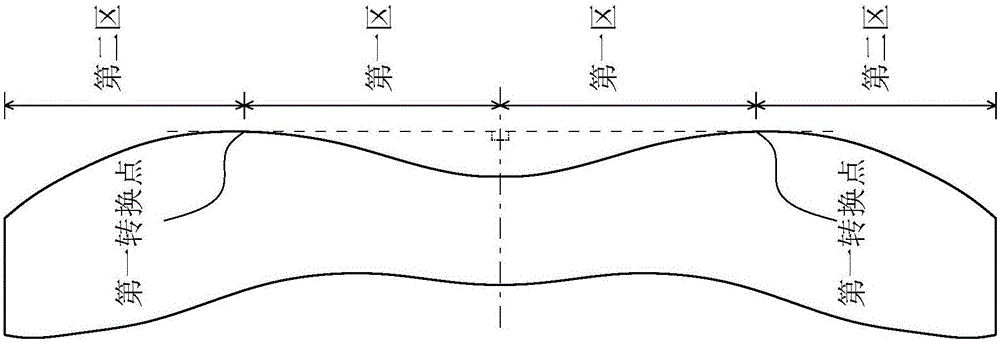

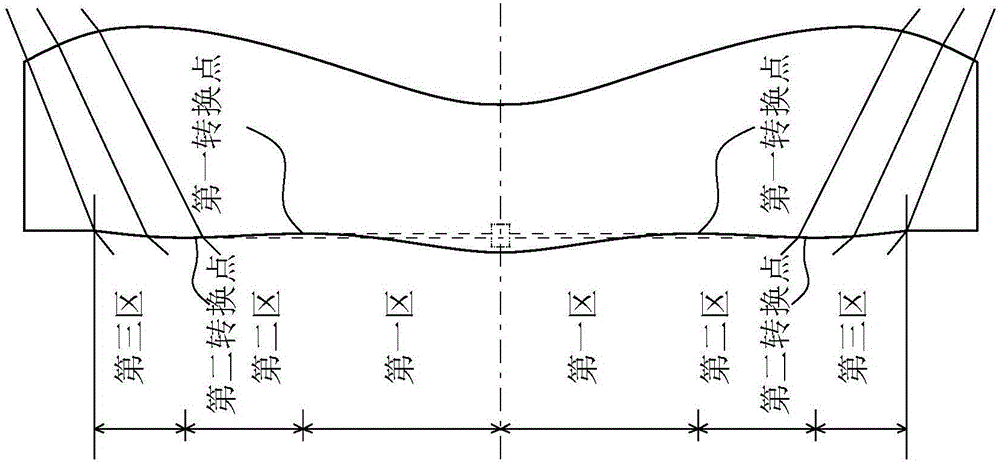

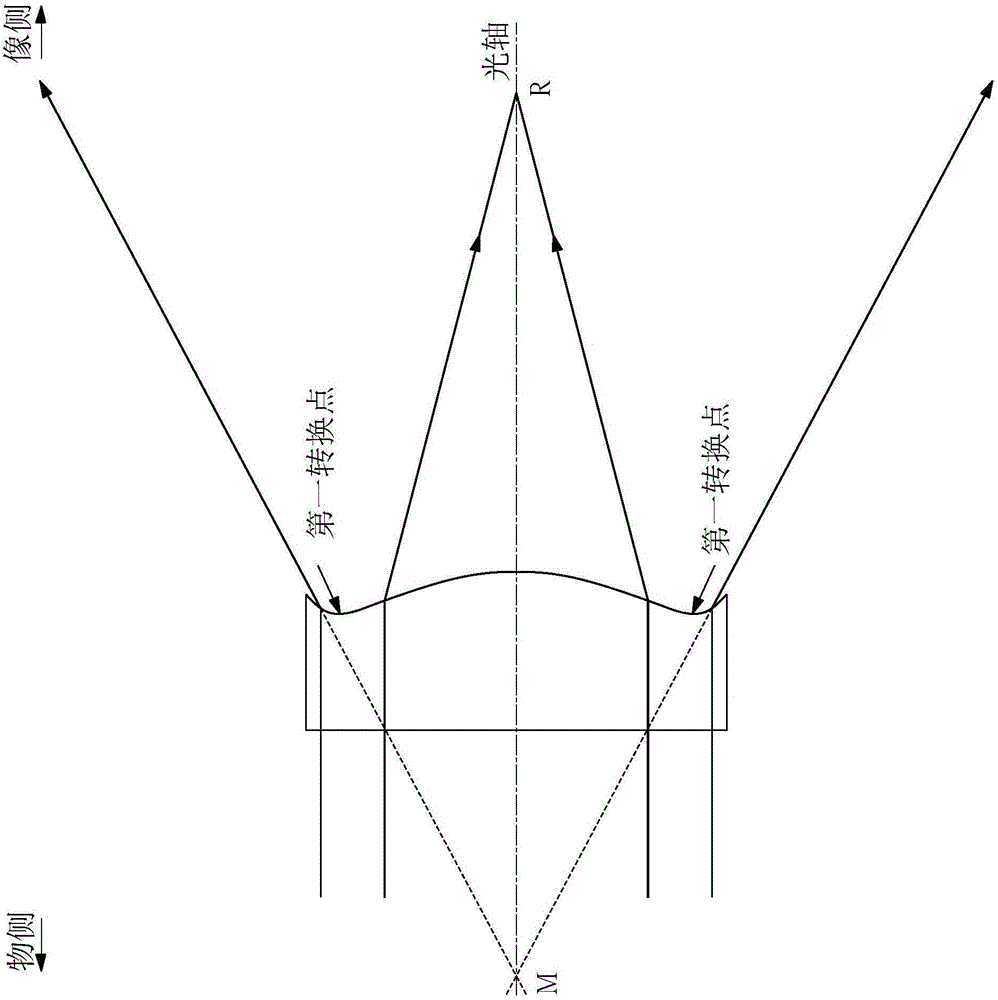

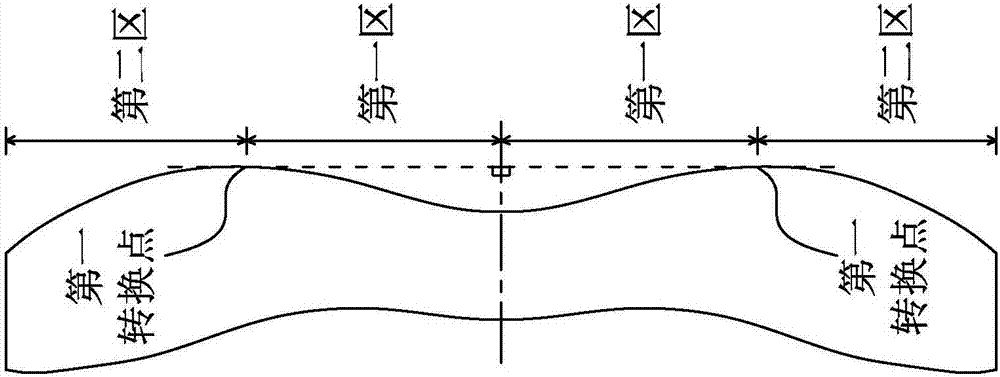

Optical imaging lens

InactiveCN106908932AShorten the lengthExcellent optical propertiesOptical elementsCamera lensImaging quality

The invention discloses an optical imaging lens, which comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens and a seventh lens arranged from an object side to an image side. Through the concave and convex arrangements of the surfaces of the seven lenses, the overall length of the optical imaging lens is shortened, and the imaging quality and optical performances are also considered.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

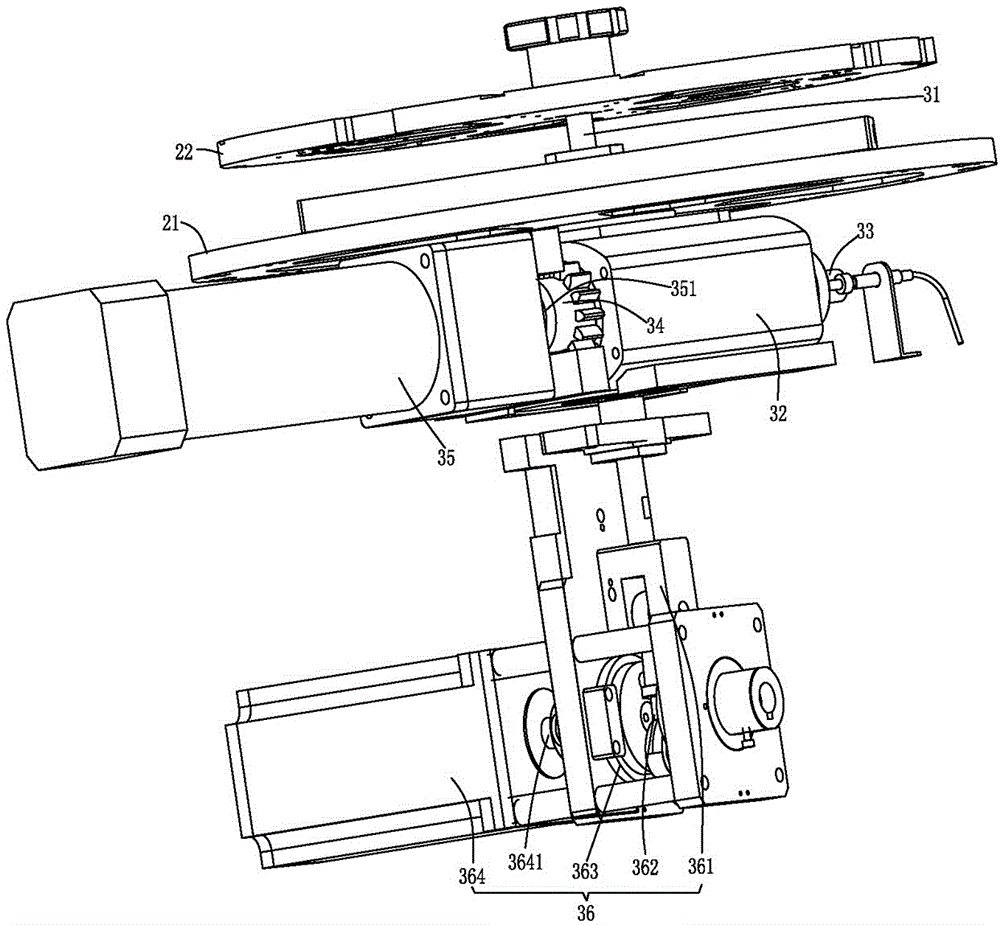

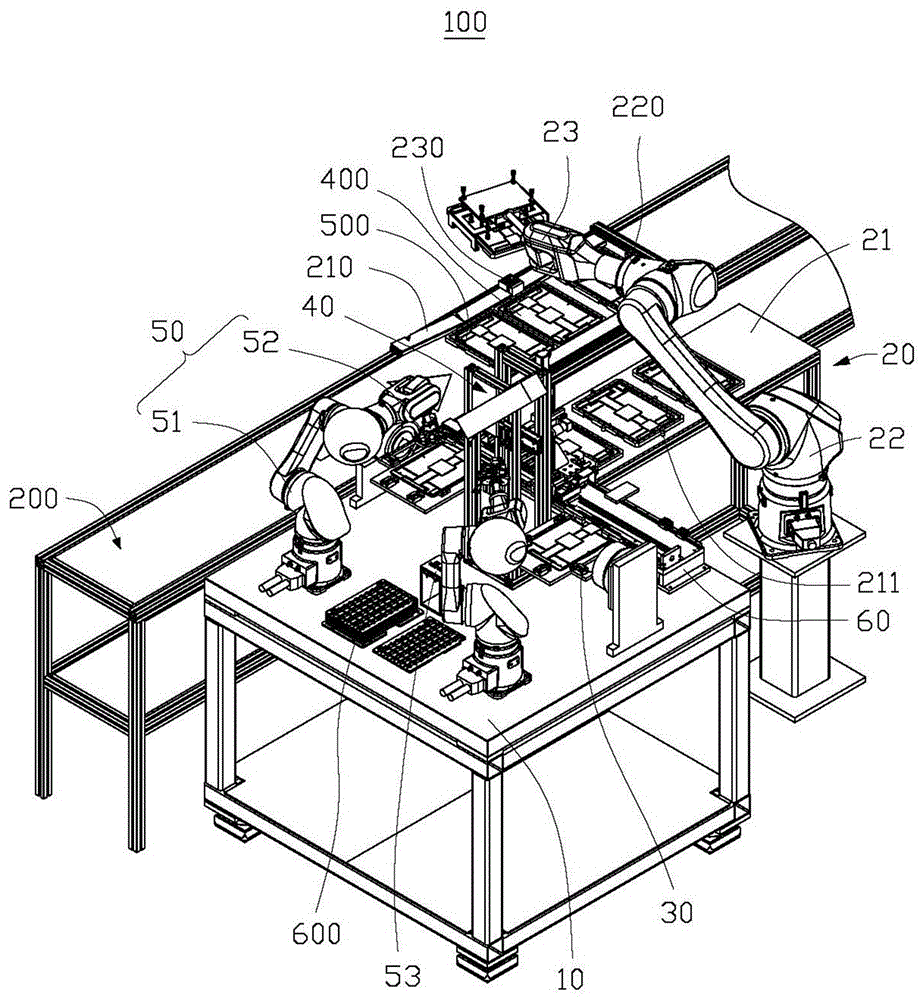

Automatic assembling device

InactiveCN107438357AImprove assembly efficiency and assembly yieldImprove stabilityTotal factory controlElectrical componentsAssembly lineHeating element

The invention provides an automatic assembling device, which is used for being matched with an assembly line to assemble accessories on workpieces. The automatic assembling device comprises a workbench, a loading module, a positioning module, a dispensing module, an assembly module, an electric control module and a detection module fixed on the workbench, wherein the loading module is used for conveying the workpieces to the positioning module; the positioning module, the dispensing module and the assembly module are fixed on the workbench separately; the positioning module is used for positioning the workpieces; the dispensing module is used for carrying out gluing treatment on the accessories; the assembly module is used for mounting the accessories subjected to gluing treatment to the workpieces and comprises a heating element; the heating element is used for carrying out preheating treatment on the accessories; and the detection module comprises two detectors, one detector is used for detecting the deviation when the accessories and the workpieces are assembled and aligned and feeding back the deviation to the assembly module to adjust the assembly positions, and the other detector is used for detecting the offset between the assembled accessories and the corresponding workpieces to screen out unqualified workpieces.

Owner:FU TAI HUA IND SHENZHEN +1

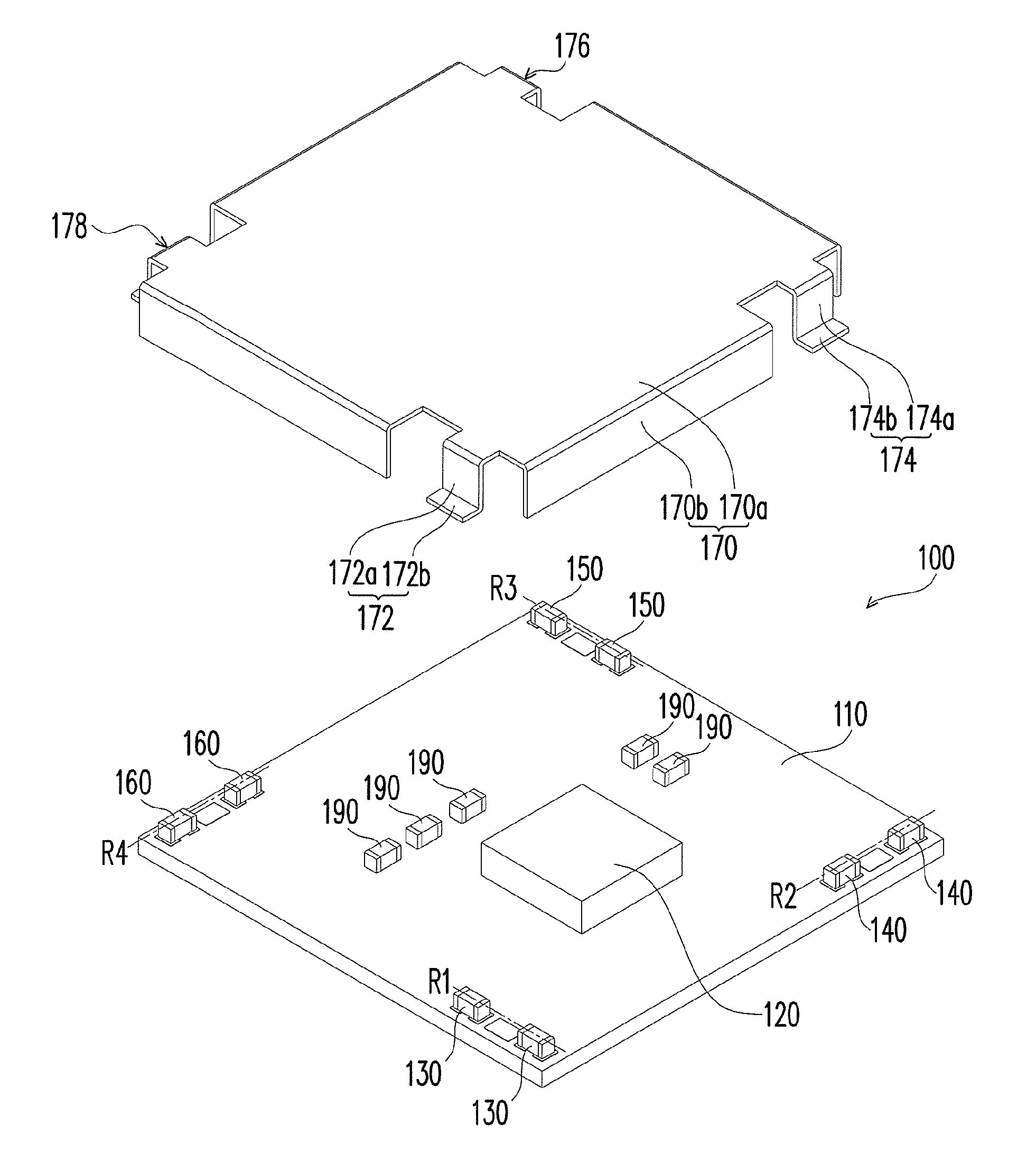

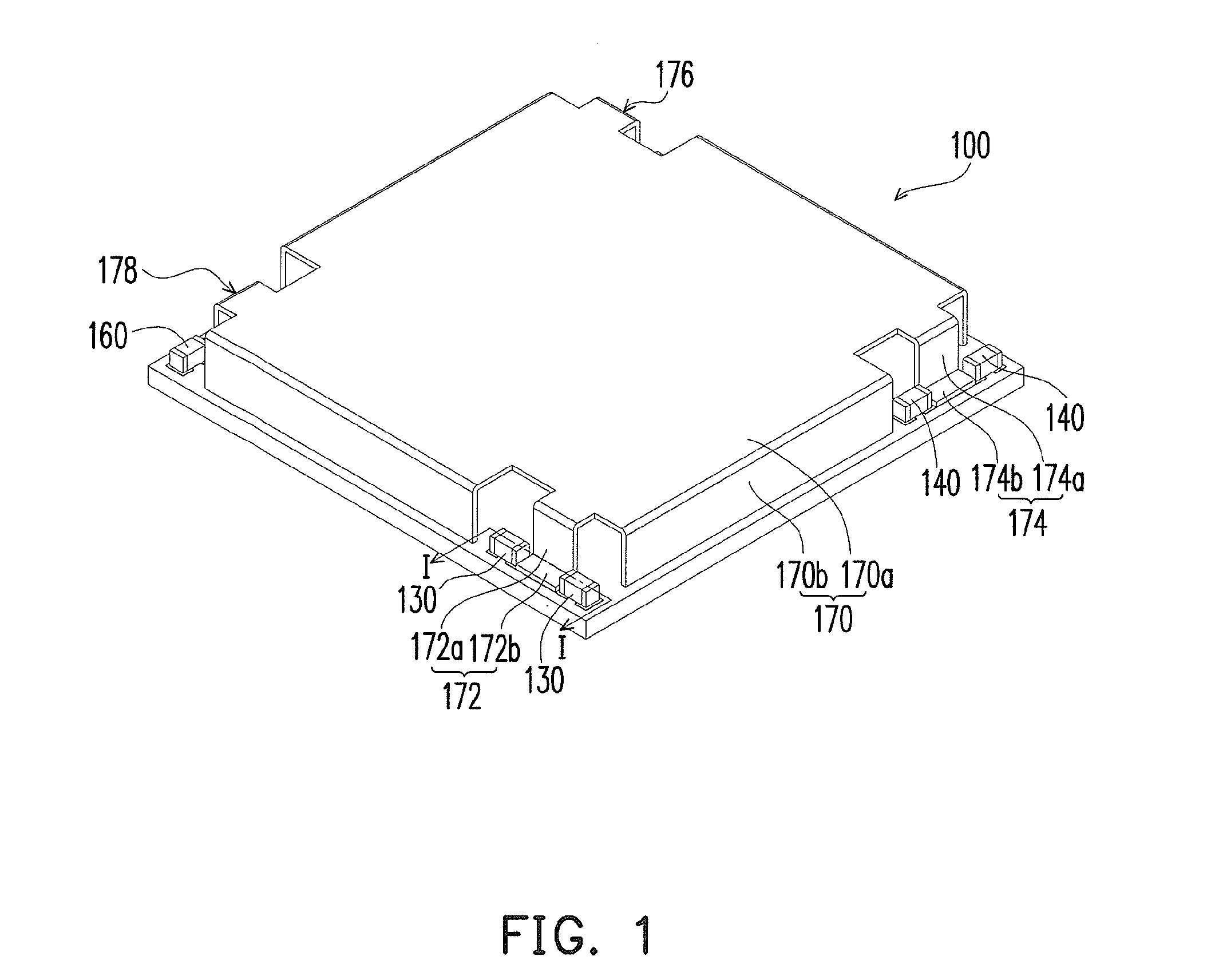

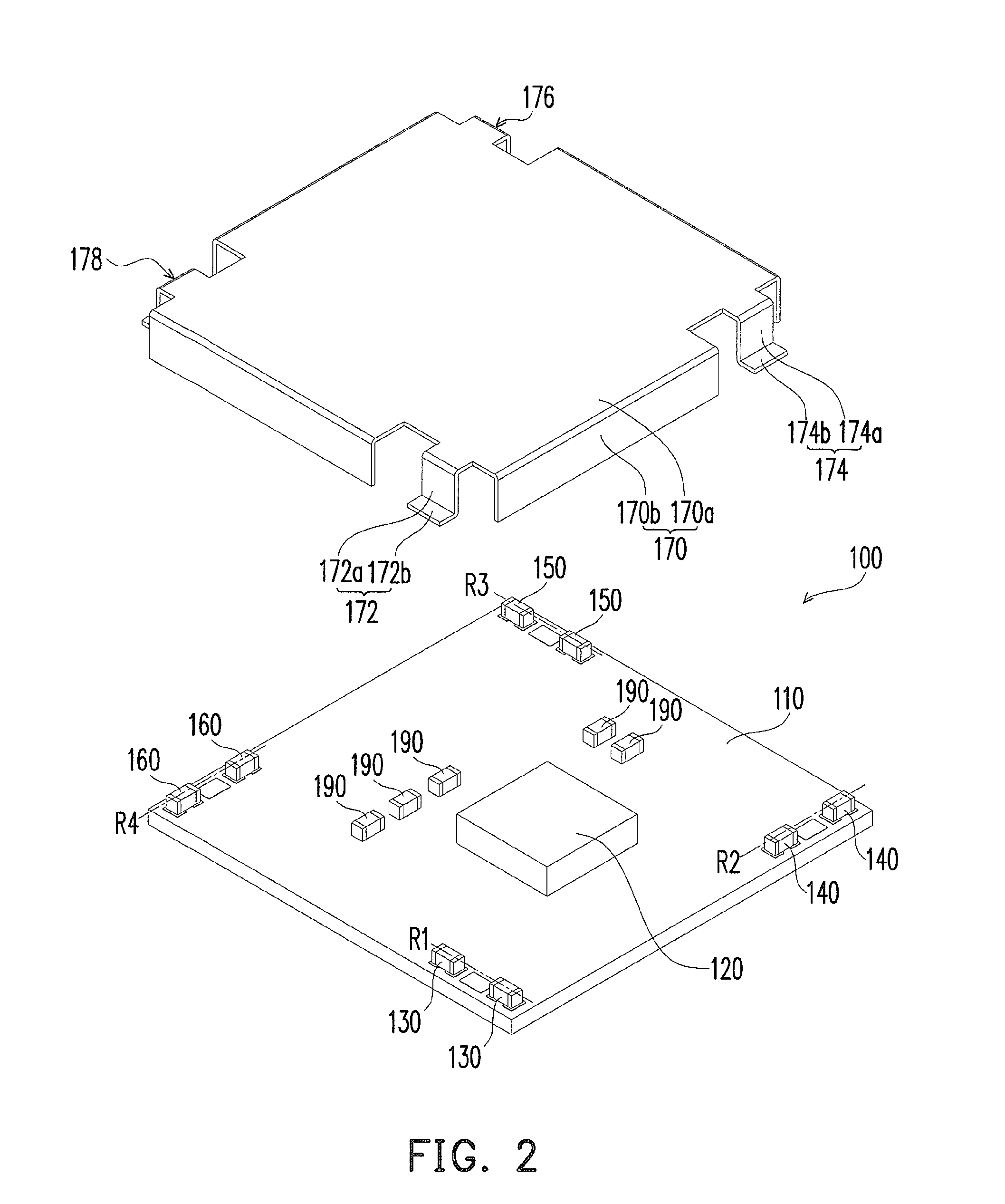

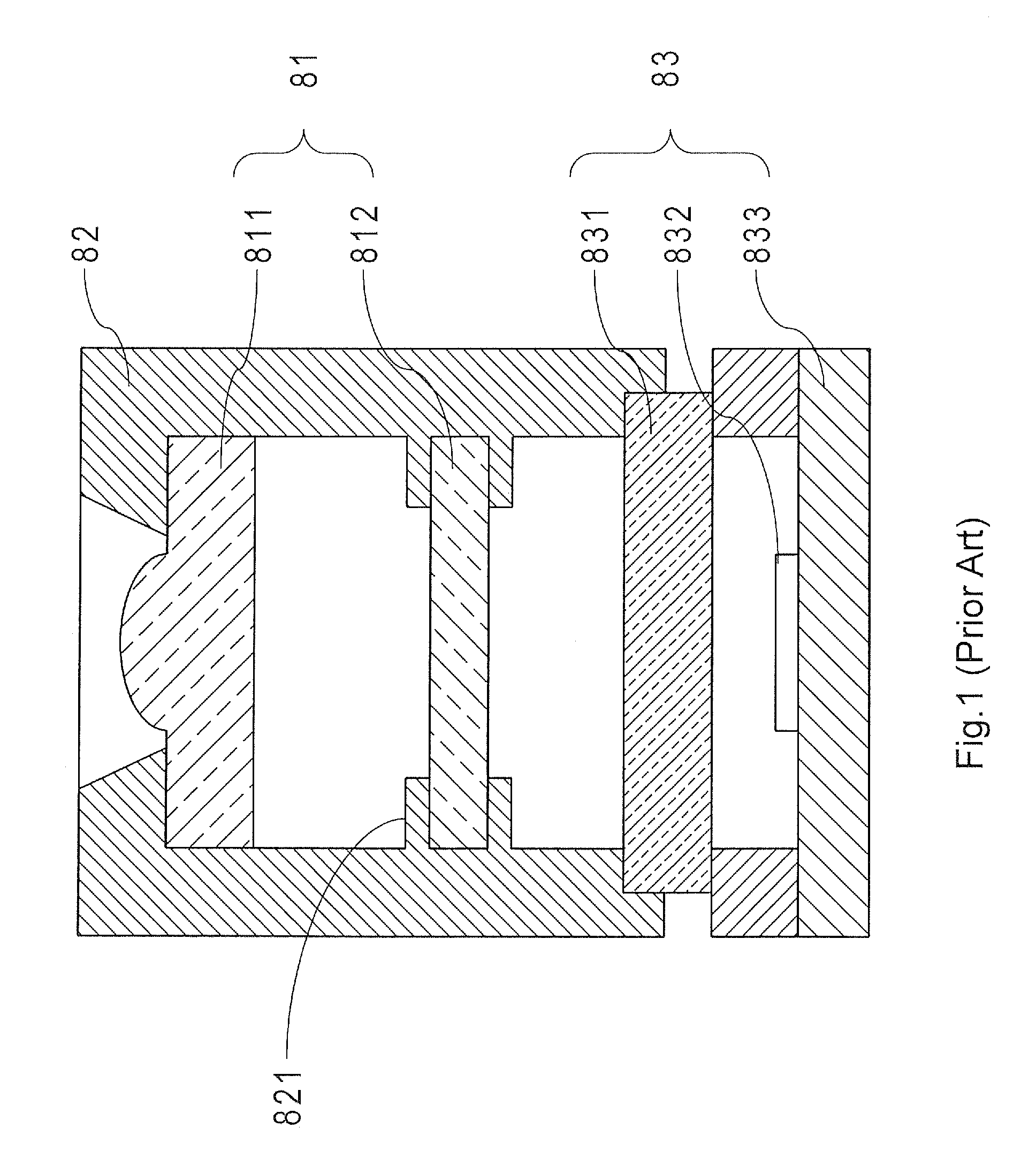

Chip package structure with shielding cover

ActiveUS20100085719A1Improve assembly yieldIncrease productionMagnetic/electric field screeningSemiconductor/solid-state device detailsElectrical and Electronics engineering

A chip package structure with a shielding cover includes a substrate, a chip, a pair of first passive components, a pair of second passive components, and a shielding cover. The chip, the pair of first passive components, the pair of second passive components, and the shielding cover are disposed on the substrate. The chip is electrically connected to the substrate. The shielding cover covers the chip and has leads connected to the substrate. The leads include a first lead and a second lead. The first lead connected to a portion of the substrate is located between the pair of first passive components and arranged along a first axis with the pair of first passive components. The second lead connected to a portion of the substrate is located between the pair of second passive components and arranged along a second axis with the pair of second passive components.

Owner:ADVANCED SEMICON ENG INC

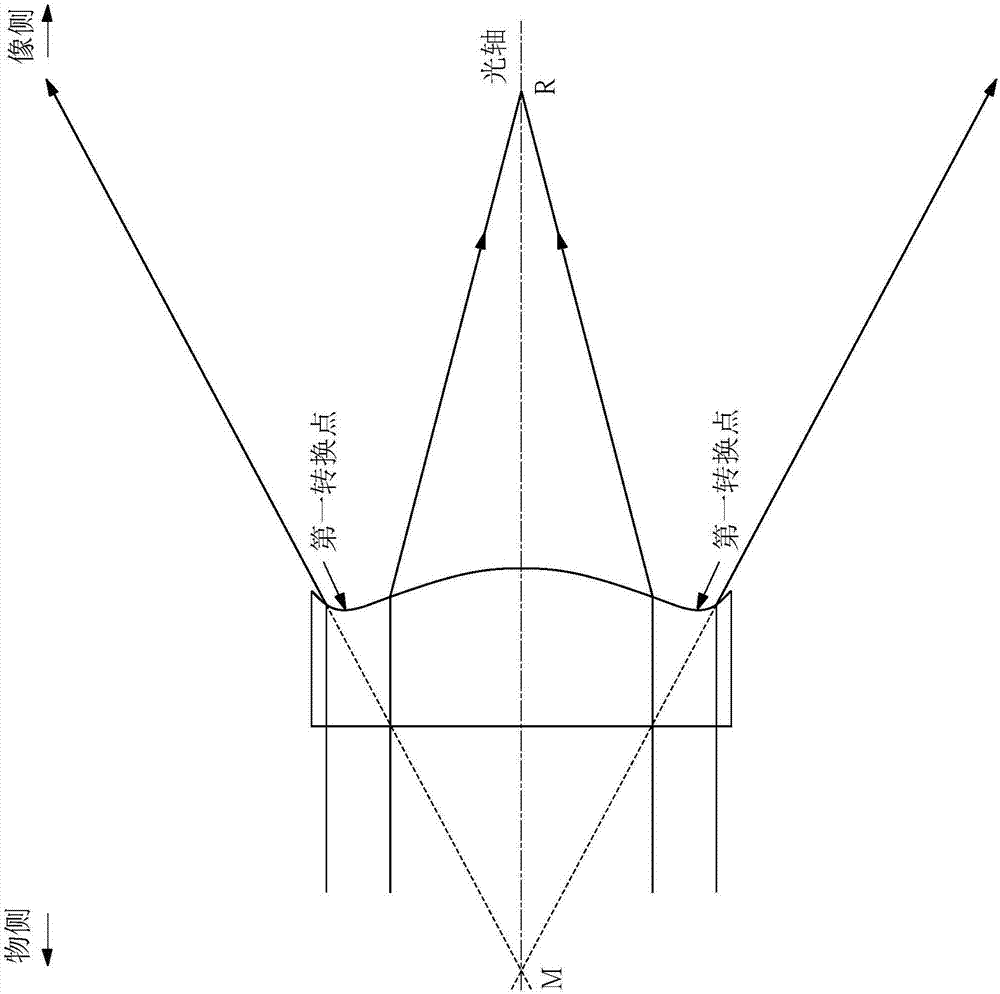

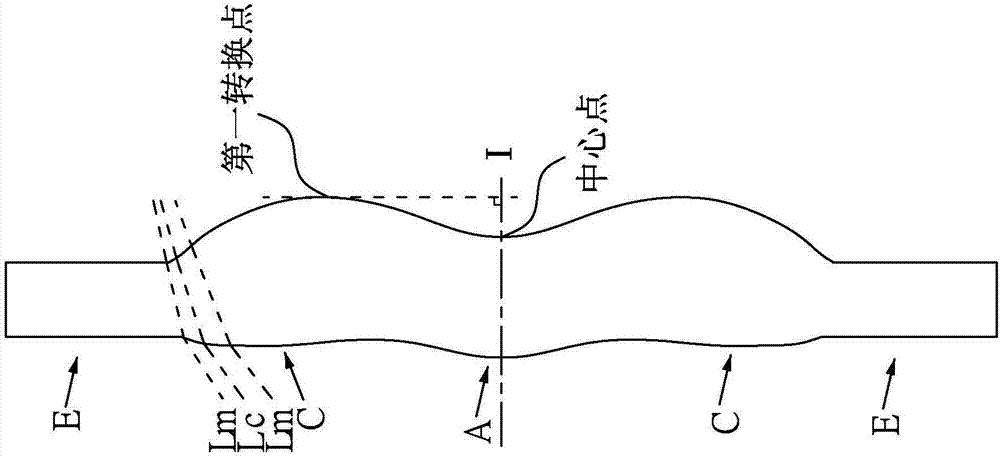

Optical imaging lens

ActiveCN106526789AShorten the lengthAvailable aperture increasesOptical elementsVisual field lossCamera lens

The present invention discloses an optical imaging lens. The optical imaging lens comprises in order from an object side to an image side a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens. The following conditional expressions are satisfied in that: TTL<=6.5mm; TL / (G23+G34+G45)<=2.7; or TTL<=6.5mm; TL / (G23+G34+G45)<=2.7; or TTL<=6.5mm; and TL / (G23+G34+G45)<=2.7. The optical imaging lens is configured for optics photography imaging and performs the control of the concave-convex curved surface arrangement of each lens and the control of the related parameters through adoption of at least two conditional expressions to shorten the length of the lens while maintaining good optical performance, increasing the effective focal length of the system and shortening the angle of the visual field.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

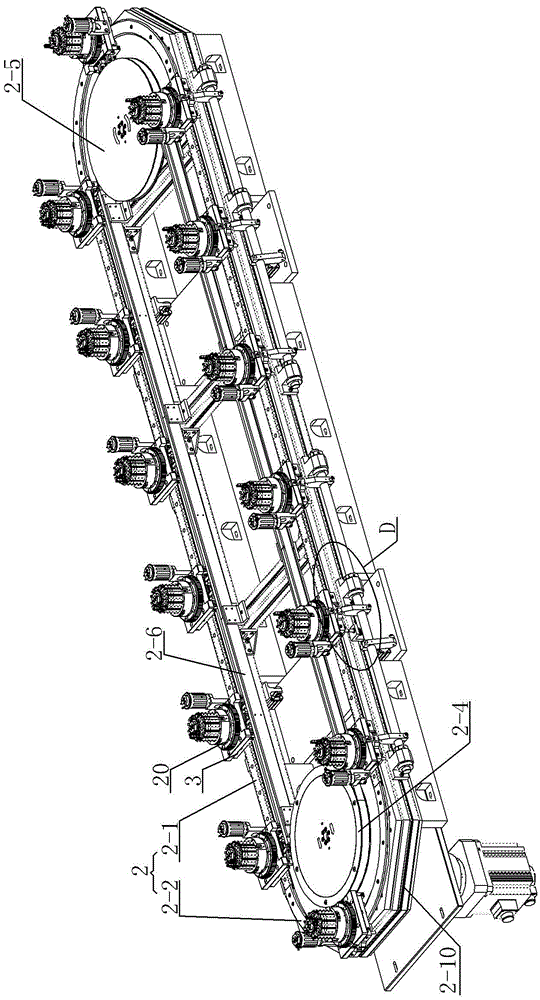

Automatic motor stator end copper wire riveting and welding line

ActiveCN105537969AReduce labor costsImprove pass rateOther manufacturing equipments/toolsManufacturing stator/rotor bodiesCopper wireEngineering

The invention provides an automatic motor stator end copper wire riveting and welding line. A motor stator end cover copper wire can be welded and detected through the riveting and welding line, the assembly efficiency and productivity of motor stators can be improved, and the assembly yield is greatly increased. The riveting and welding line comprises a rack, a runway type track structure is arranged on the rack and comprises two linear tracks in parallel and two arc tracks, and the heads and the tails of the two arc tracks are connected with corresponding sections of the linear tracks at the two ends of the corresponding sides to form the runway type track structure. A feeding station, a code scanning station, a front project height detecting station, a copper wire riveting station, a welding station, a height detecting station, a high-pressure detecting station and an OK product carrying station are sequentially arranged on the runway type track structure in the station direction, the copper wire riveting station comprises a copper wire pressing structure, riveting and carrying mechanical hands and a sweeping device, and shorn copper wires are swept by the sweeping device; the OK product carrying station comprises a carrying and clamping mechanism, an OK product sweeping device and an OK product conveying track.

Owner:SUZHOU LING AUTOMATION EQUIP

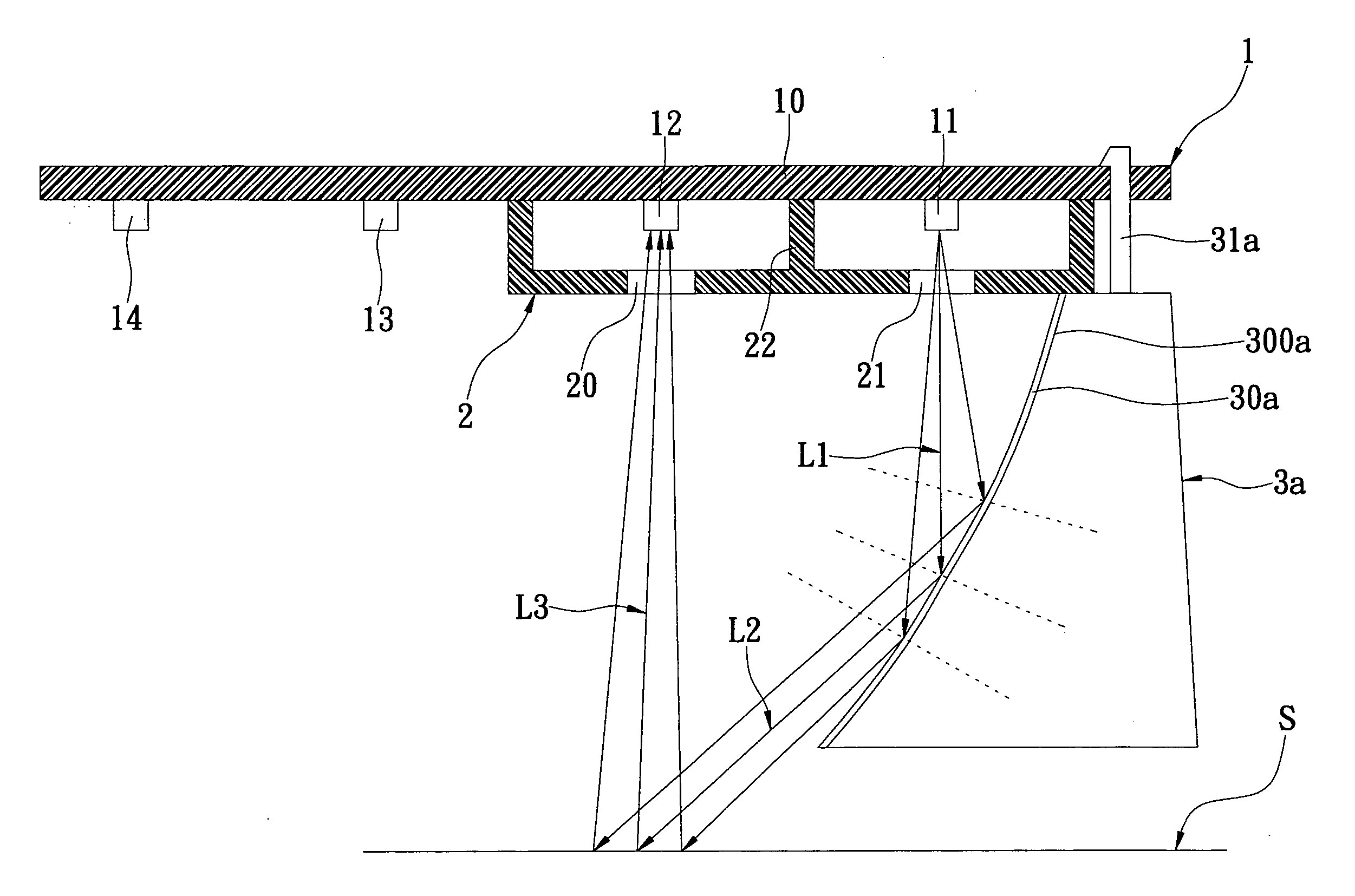

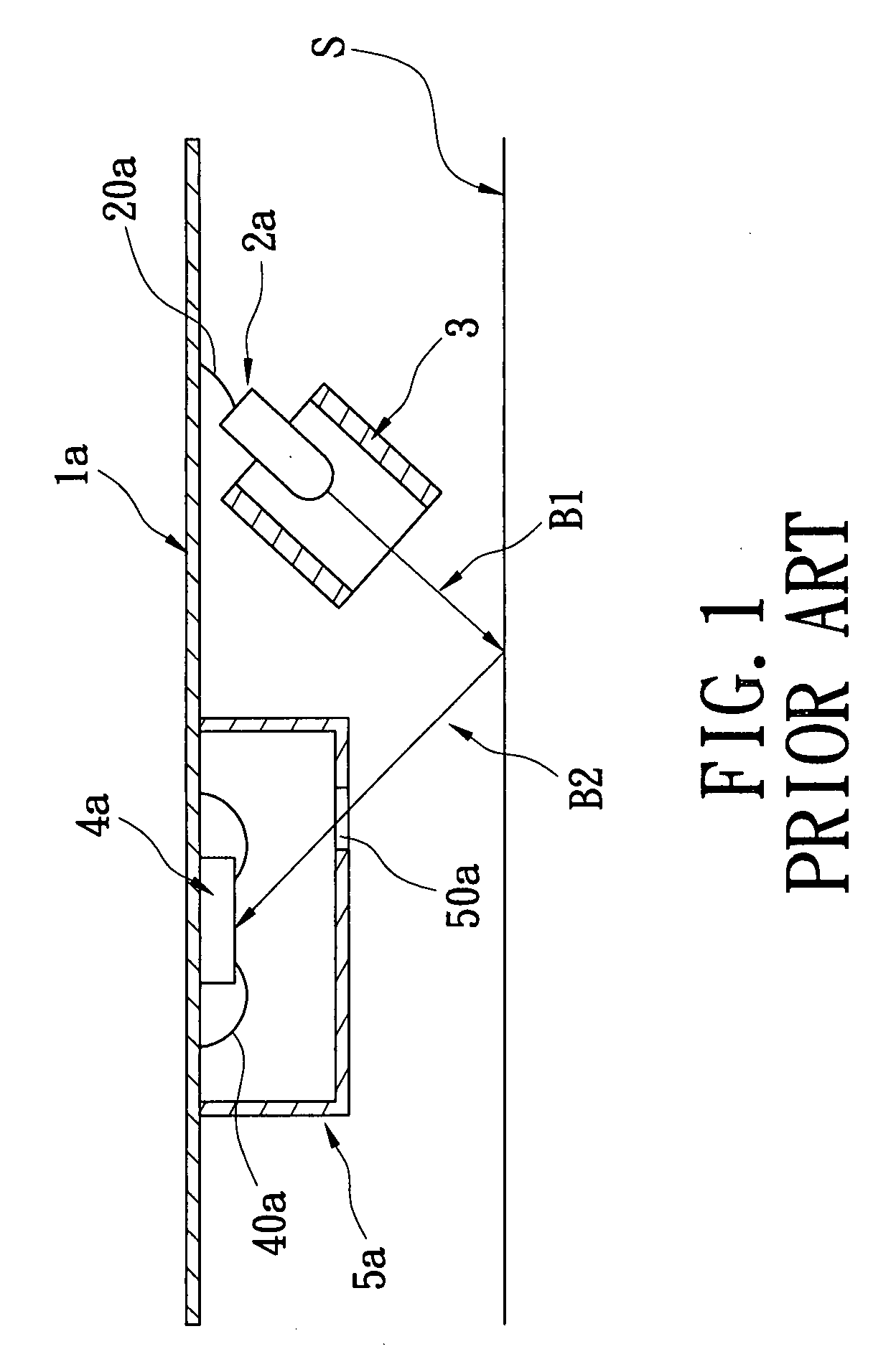

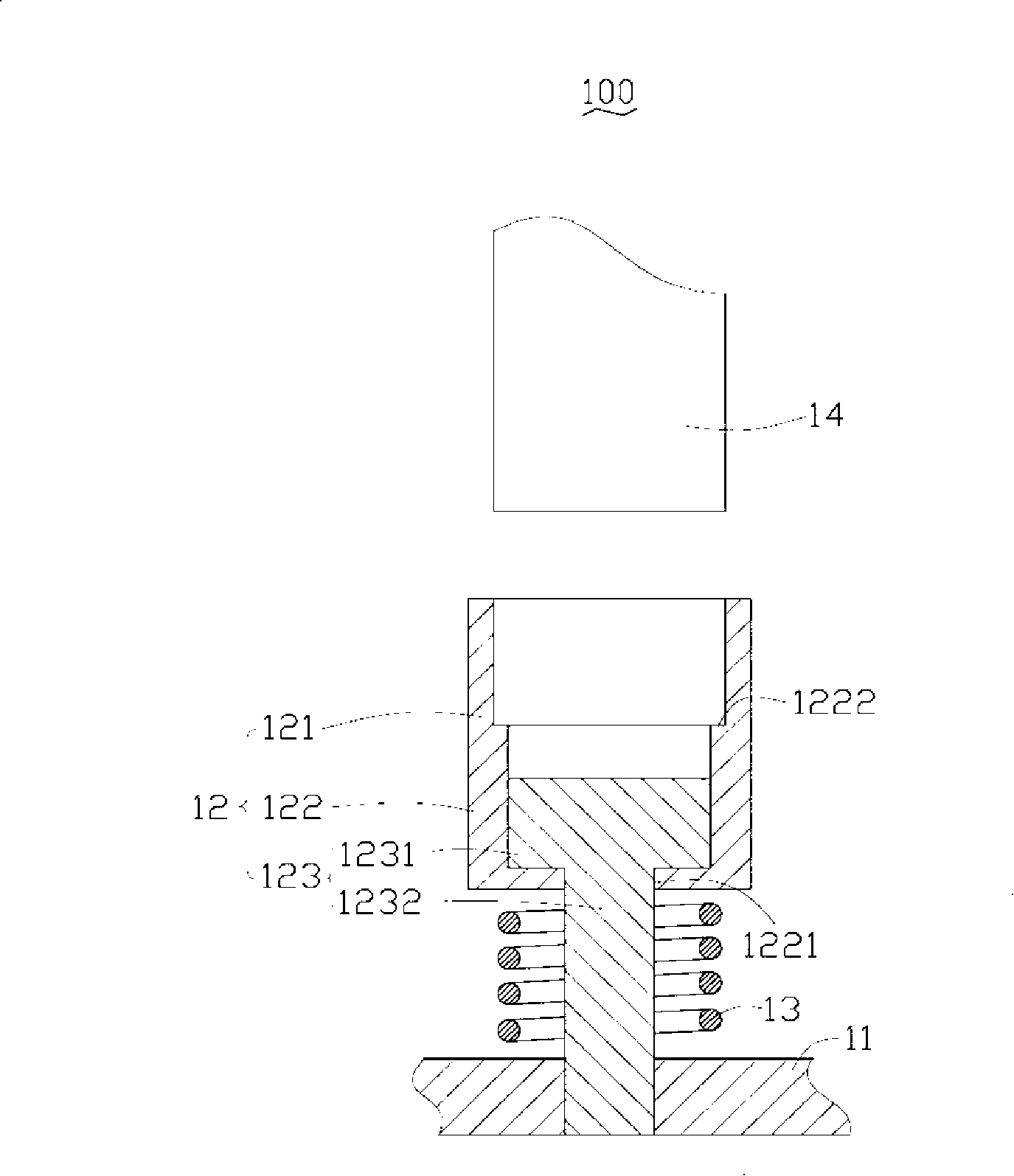

Motion-detecting module with a built-in light source

InactiveUS20080173790A1Manufacturing cost be reduceIncrease assembly yieldMaterial analysis by optical meansOptical detectionEngineeringImage sensing

A motion-detecting module with a built-in light source includes a chip unit, a cover unit, and a light-guiding unit. The chip unit has a PCB, a light-emitting chip, and an image-sensing chip. The light-emitting chip and the image-sensing chip are electrically disposed on the PCB. The cover unit is covered on the image-sensing chip, and the cover unit has a first opening for exposing the image-sensing chip. The light-guiding unit is disposed on a bottom side of the cover unit, and the light-guiding unit has a surface having a reflective layer thereon with a concave structure. The surface and the reflective layer are formed a reflective surface for reflecting and condensing beams generated from the light-emitting chip. Therefore, the beams are reflected via the reflective surface to form first beams, and the first beams are reflected via the object surface to form second beams that project onto the image-sensing chip.

Owner:LITE ON SEMICON

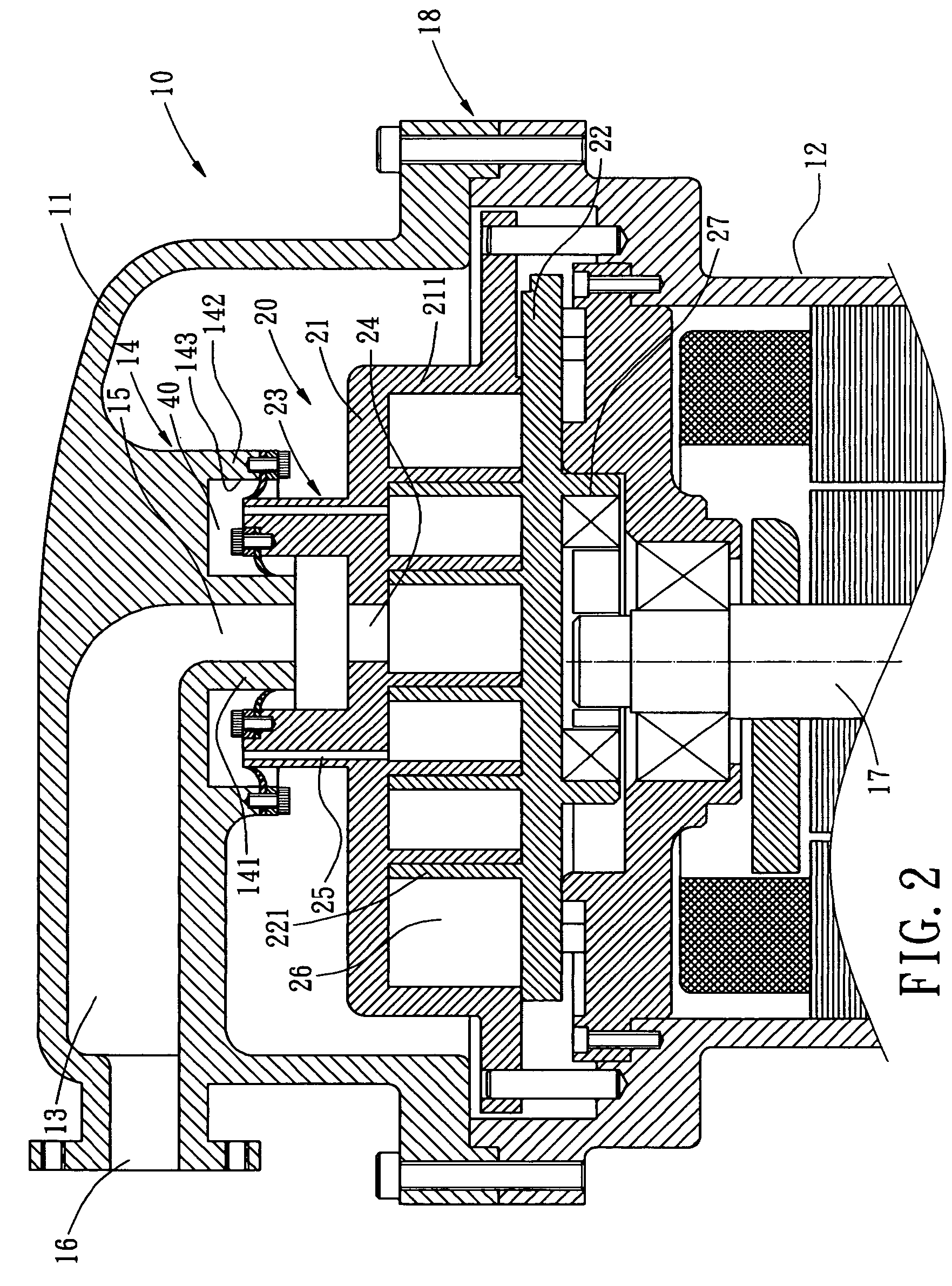

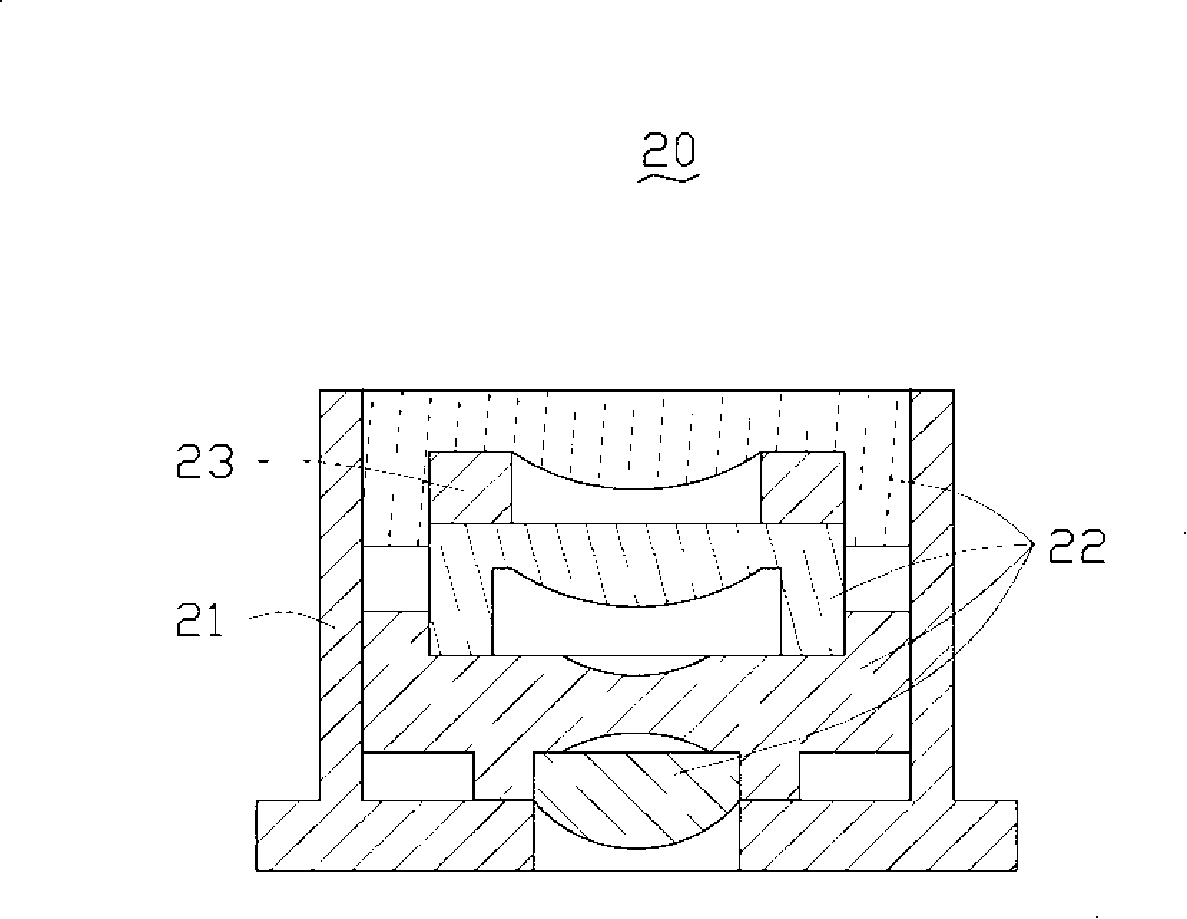

Axial compliance mechanism of scroll compressor

InactiveUS7140851B2Improve volumetric efficiencyEasy to assembleEngine of arcuate-engagement typeOscillating piston enginesWorking fluidEngineering

Owner:FUSHENG IND CO LTD

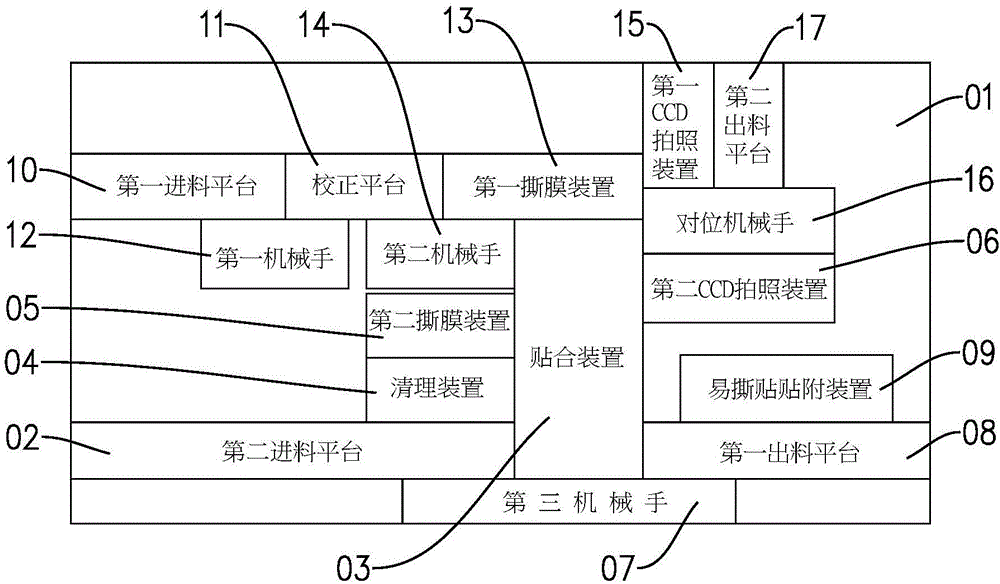

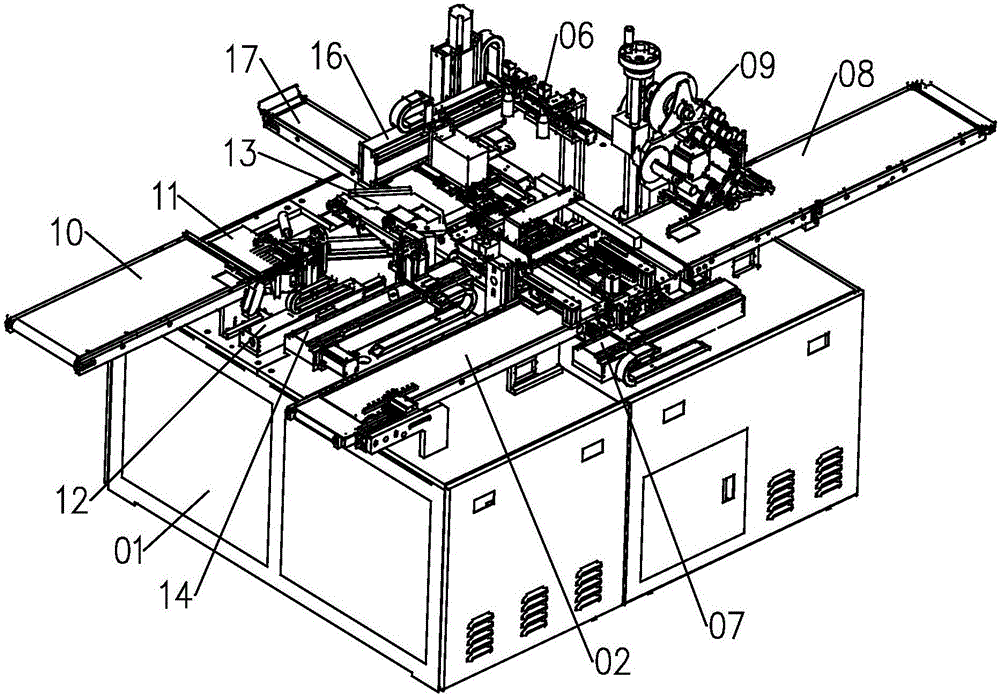

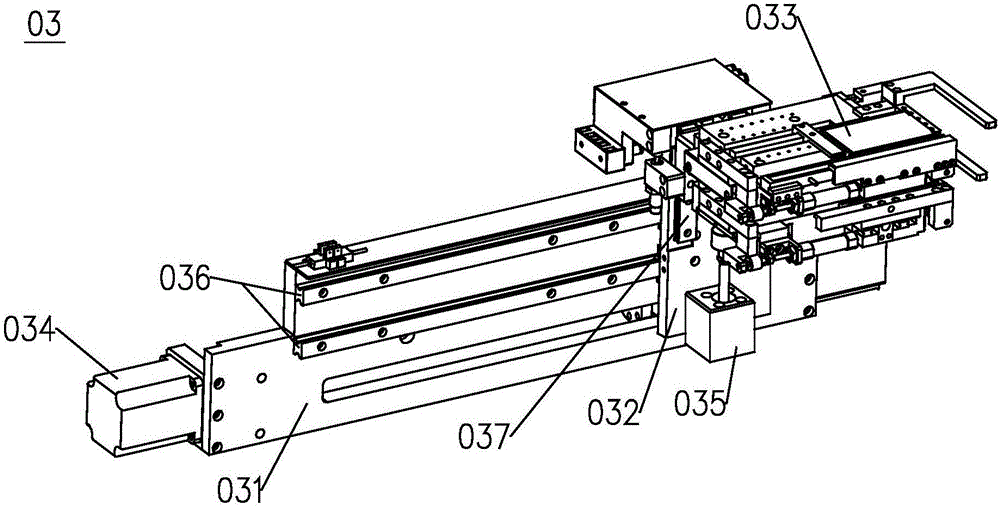

Fully automatic backlight assembly machine

InactiveCN106556942AImprove assembly yieldImprove assembly efficiencyNon-linear opticsFully automaticManipulator

The invention provides a fully automatic backlight assembly machine which comprises a base box. A BLU backlight module processing unit and an FOG glass module processing unit are arranged on the mounting platform of the base box. The fit device of the BLU backlight module processing unit transfers a processed BLU backlight module to a photographing position corresponding to a second CCD photographing device for photographing and records the position information. The assembly robot of the FOG glass module processing unit captures an FOG glass module, and at the same time matches a dyestripping tape to complete dyestripping. A first CCD photographing device photographs the captured FOG glass module and records the position information. A central processor controls the assembly robot to assembly and fit the FOG glass module to the BLU backlight module according to the position information fed back by the second CCD photographing device and the first CCD photographing device. According to the fully automatic backlight assembly machine provided by the invention, the assembly of the FOG glass module and the BLU backlight module can be accurately completed; the assembly yield and efficiency of a display module are greatly improved; and the cost is reduced.

Owner:深圳市凯达扬自动化有限公司

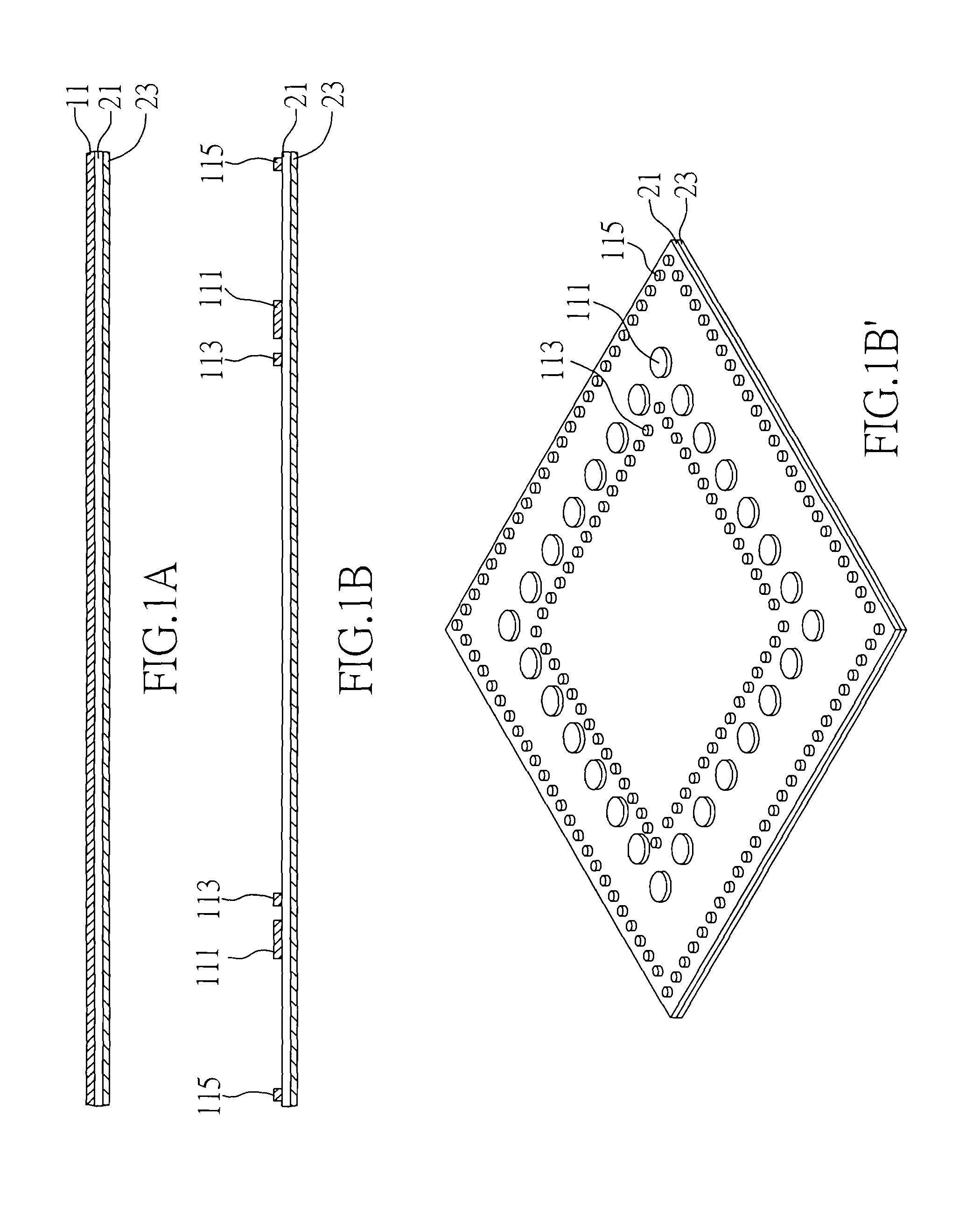

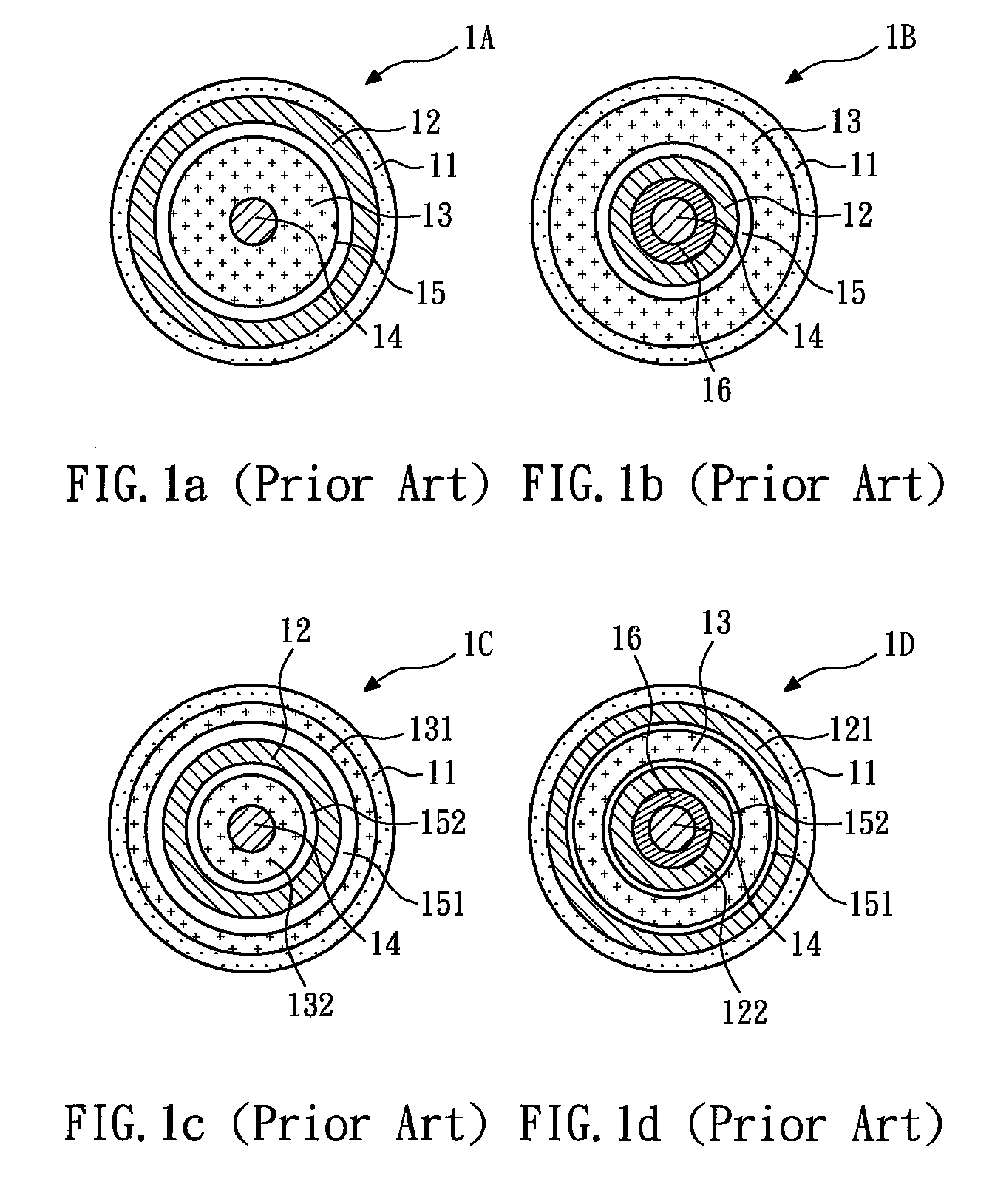

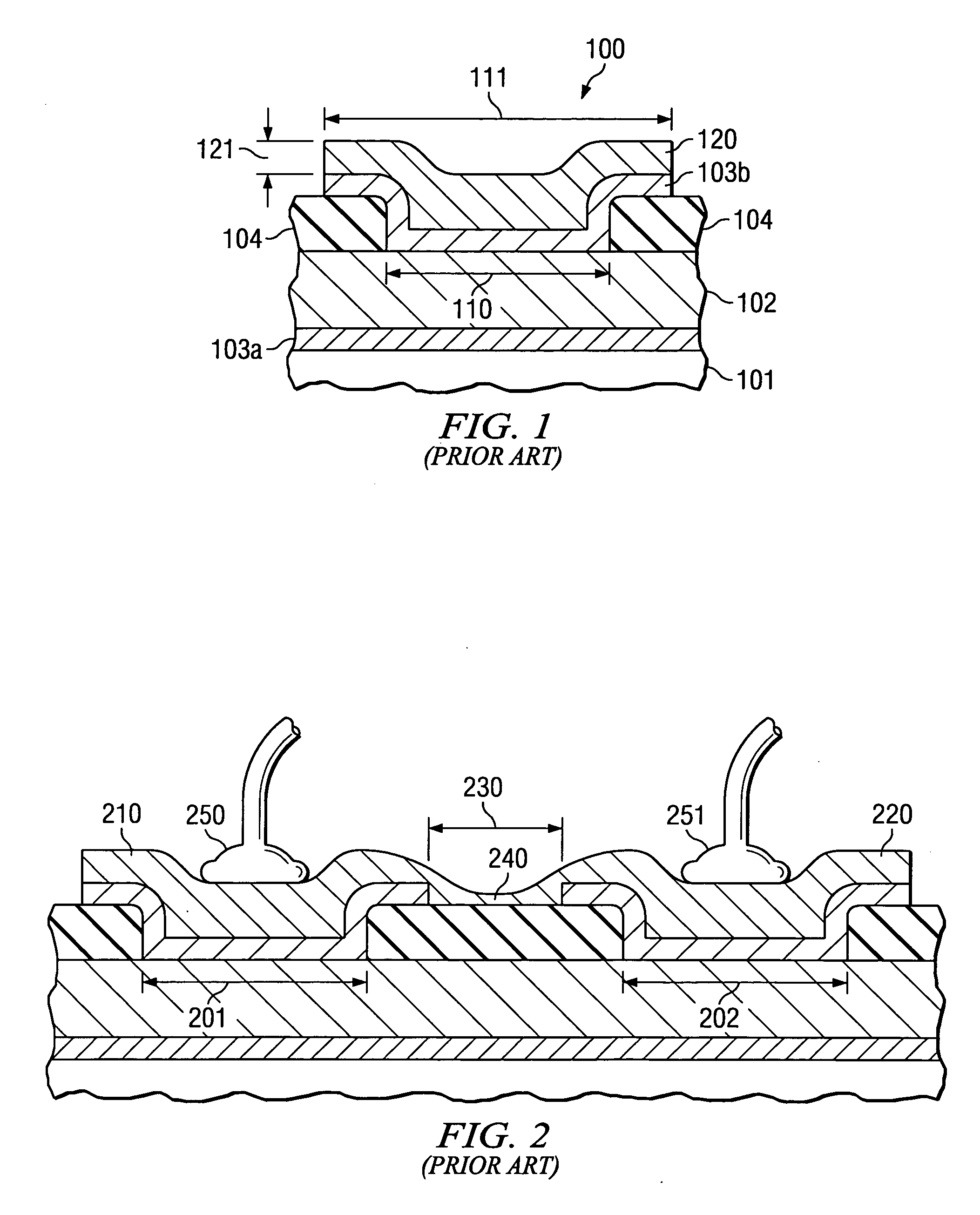

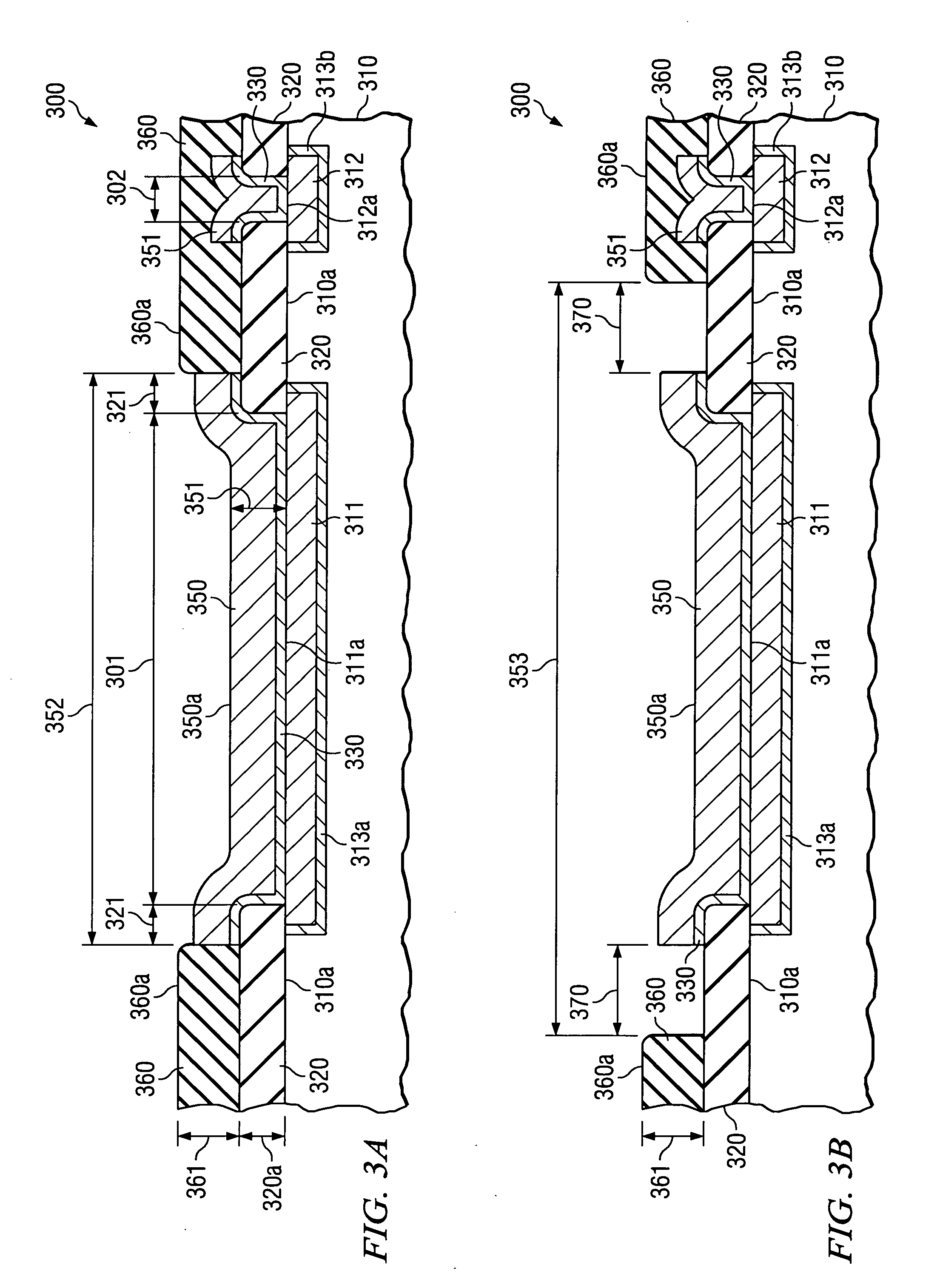

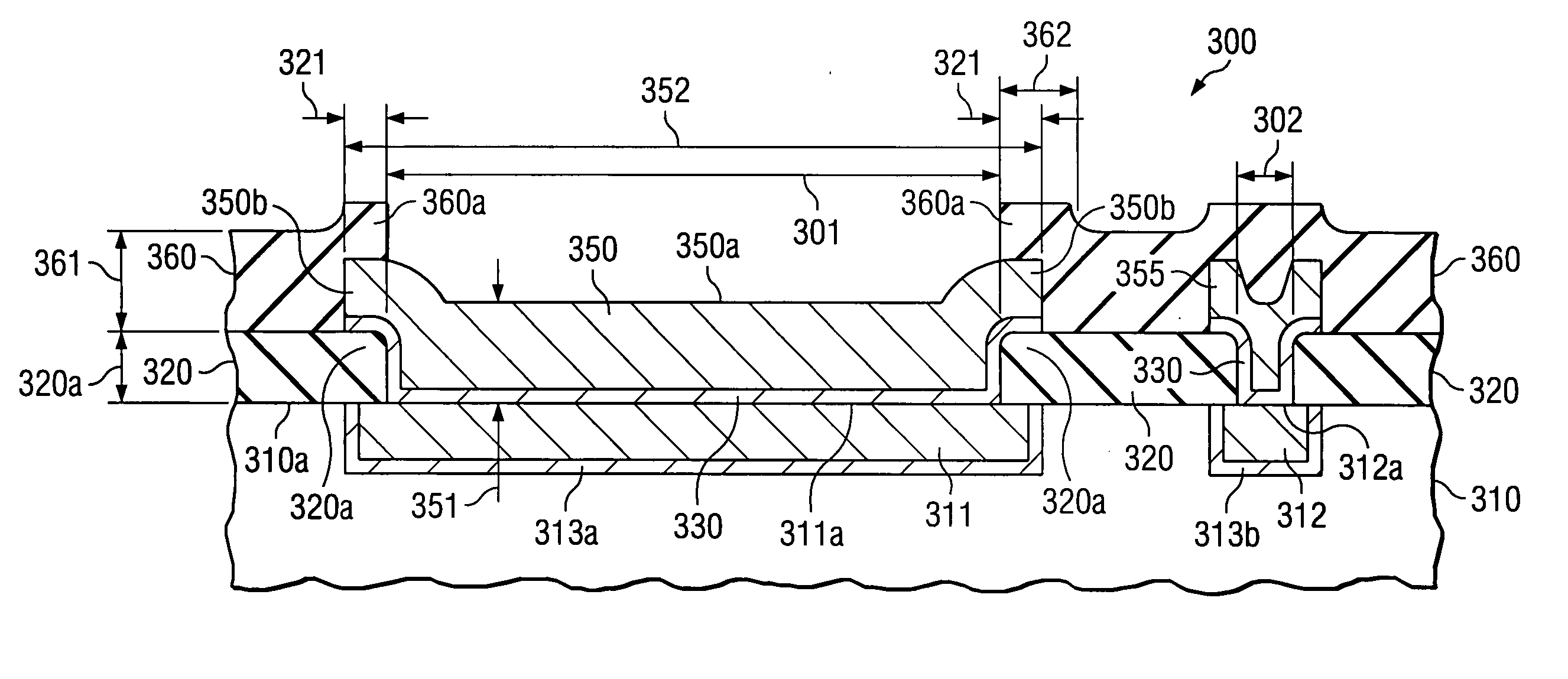

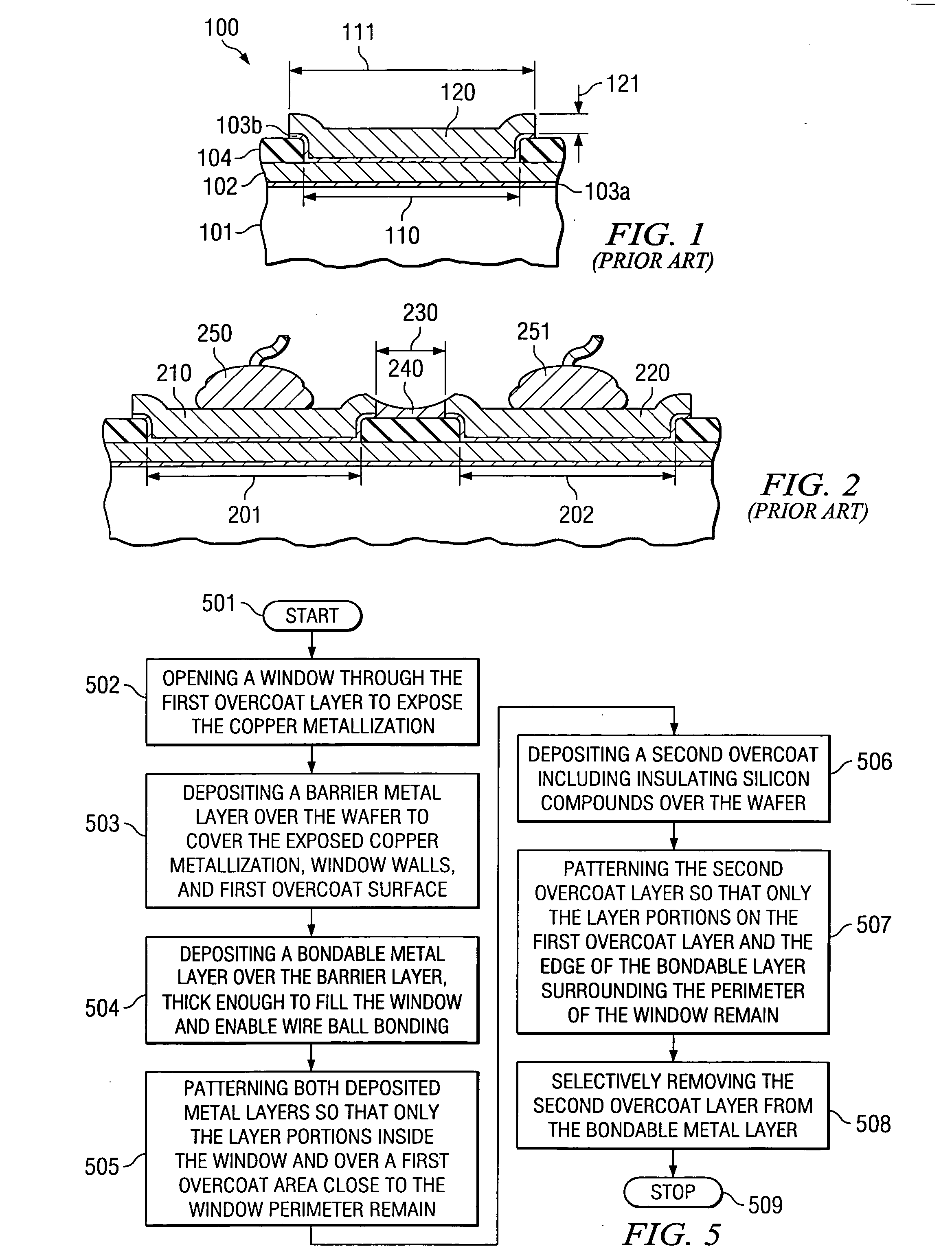

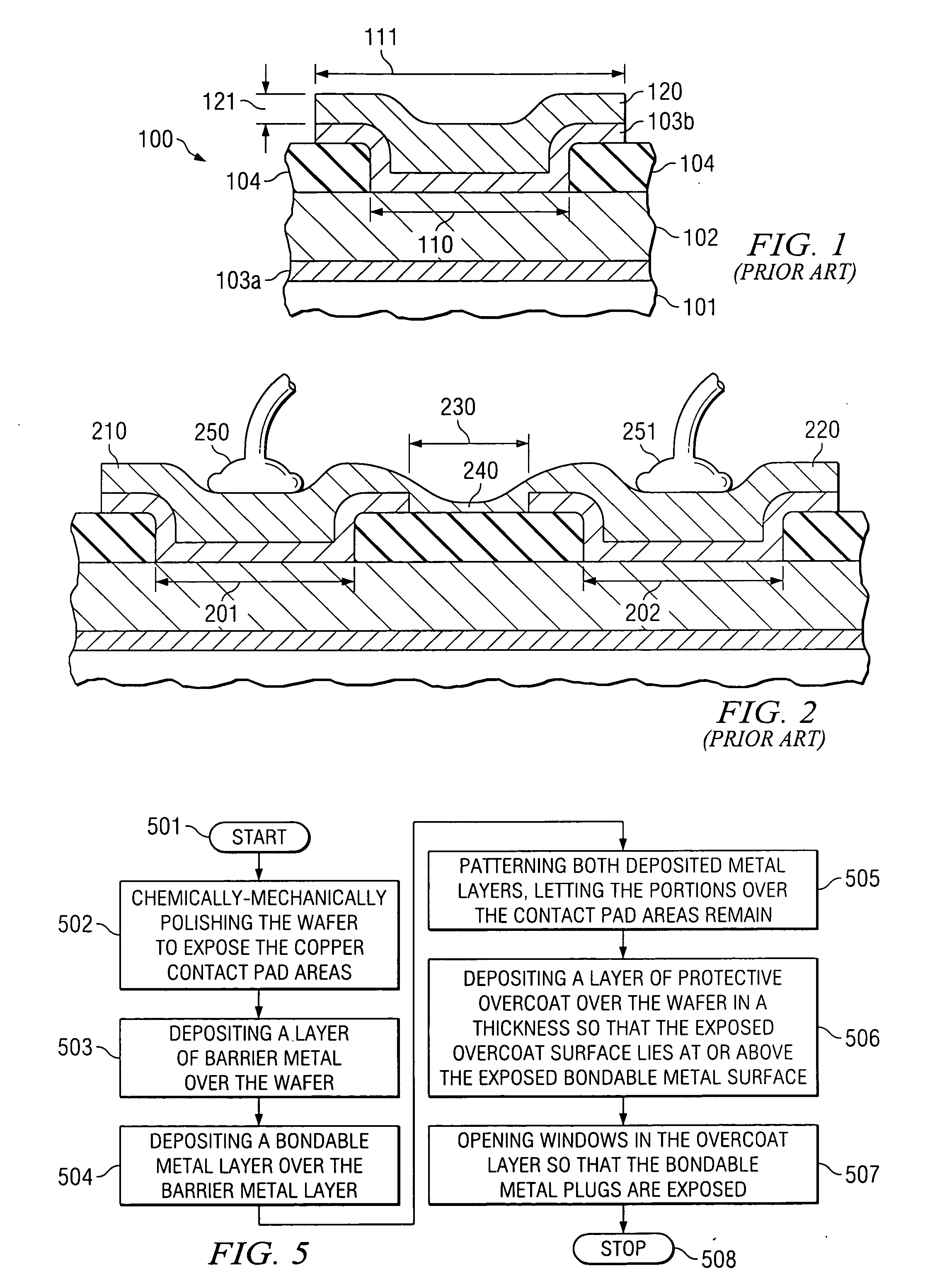

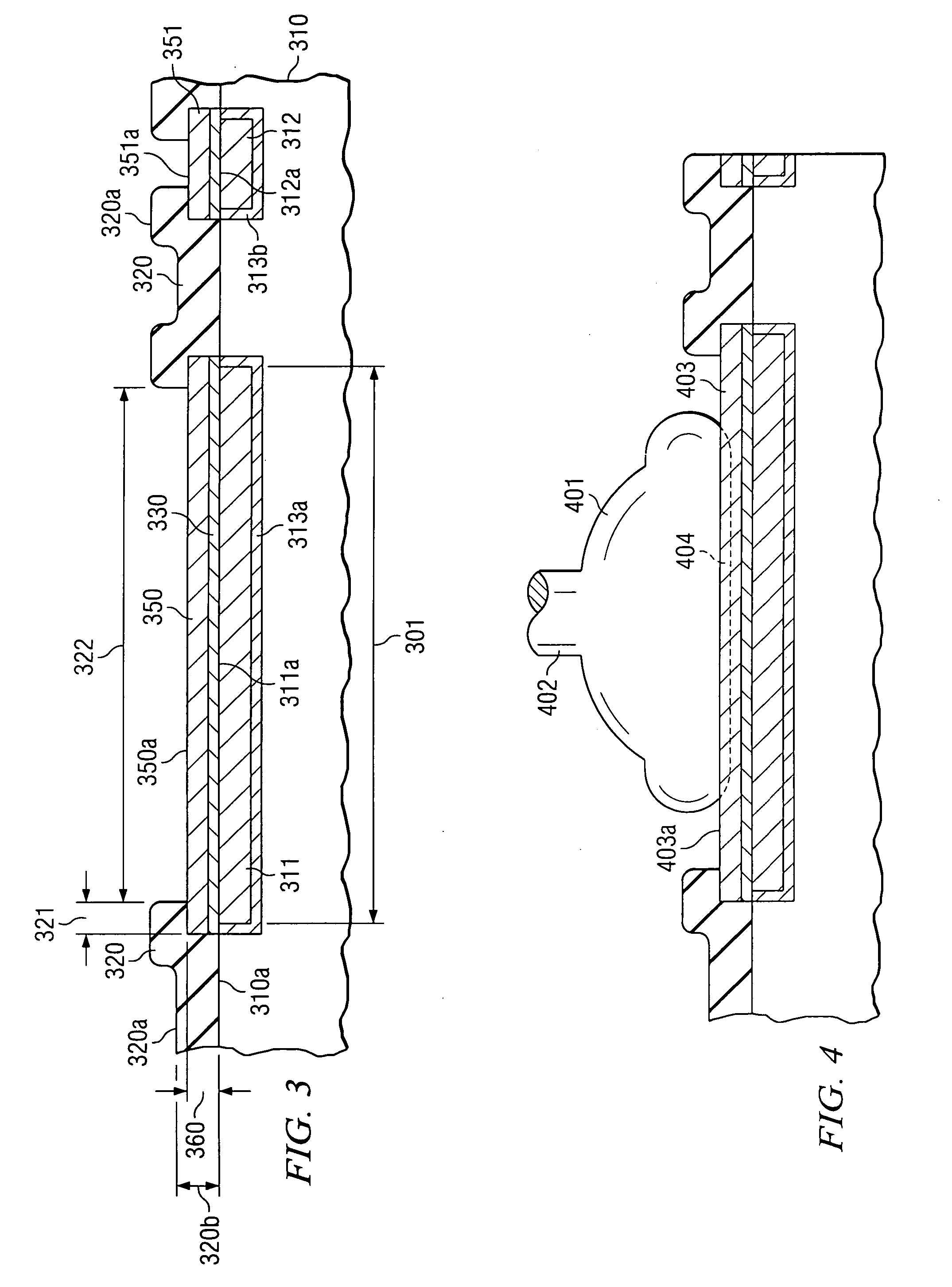

Structure and method for contact pads having a protected bondable metal plug over copper-metallized integrated circuits

ActiveUS20050224984A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

An integrated circuit having copper interconnecting metallization (311, 312) protected by a first, inorganic overcoat layer (320), portions of the metallization exposed in windows (301, 302) opened through the thickness of the first overcoat layer. A patterned conductive barrier layer (330) is positioned on the exposed portion of the copper metallization and on portions of the first overcoat layer surrounding the window. A bondable metal layer (350, 351) is positioned on the barrier layer; the thickness of this bondable layer is suitable for wire bonding. A second, organic overcoat layer (360) is surrounding the window so that the surface (360a) of this second overcoat layer at the edge of the window is at or above the surface (350a) of the bondable layer. The second overcoat layer may be spaced (370) from the edge of the bondable metal layer.

Owner:TEXAS INSTR INC

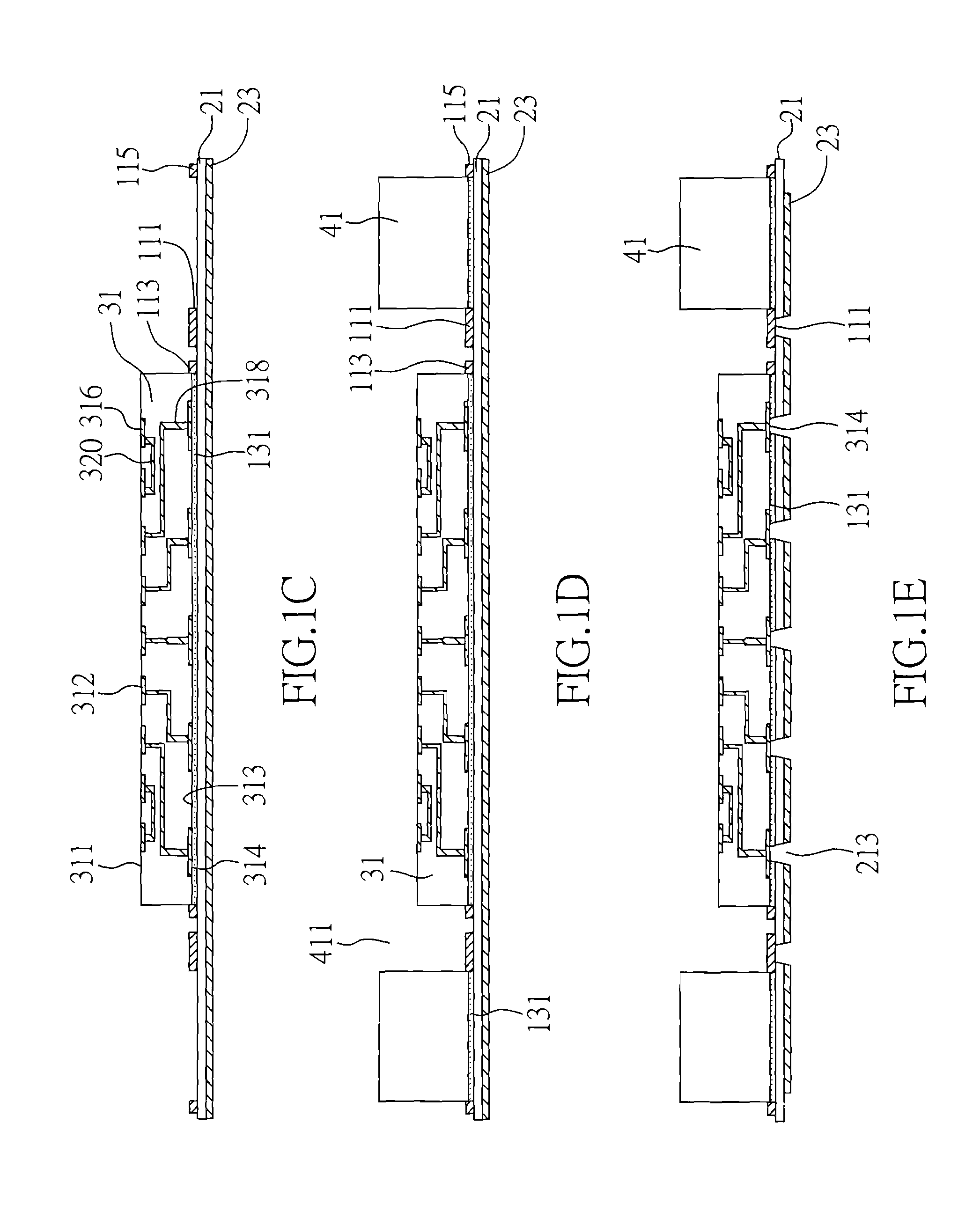

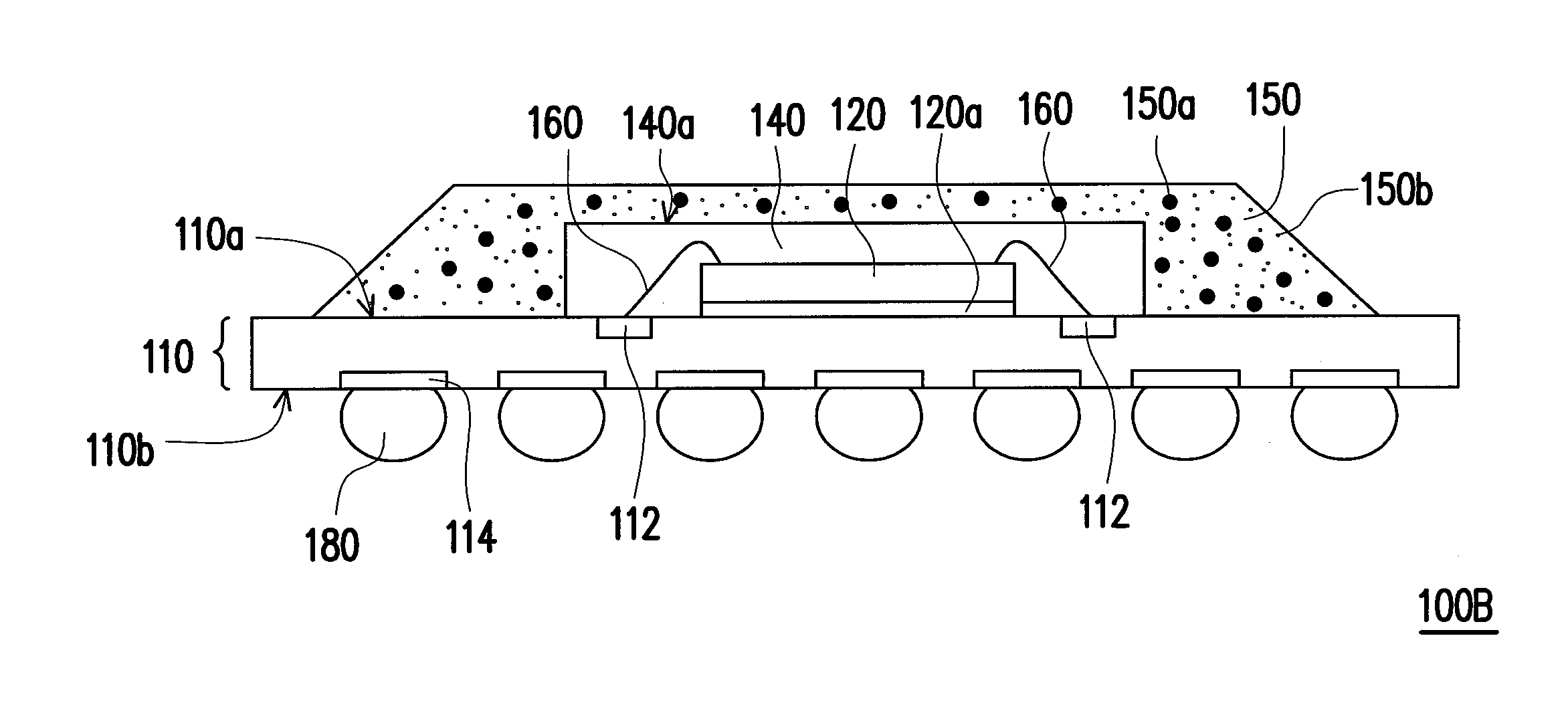

Chip package structure and manufacturing method thereof

InactiveUS20150076670A1Improve assembly yieldReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesElectromagnetic shieldingSealant

A chip package structure and a manufacturing method thereof are provided. The chip package structure includes a substrate, a chip, a plurality of wires, a film layer, a carrier, and an encapsulant. The substrate has an upper surface and a lower surface. The chip is mounted on the upper surface of the substrate. The wires are electrically connected to the chip and the substrate respectively. The film layer is attached to the substrate and entirely encapsulates the chip and the wires. The carrier is adhered on the film layer. The encapsulant is disposed on the upper surface of the substrate, wherein the encapsulant has an electro-magnetic shielding filler. The encapsulant at least partially encapsulates the carrier and the film layer, and the encapsulant covers the chip and the wires.

Owner:CHIPMOS TECH INC

Axial compliance mechanism of scroll compressor

InactiveUS20060051227A1Improve volumetric efficiencyEasy to assembleEngine of arcuate-engagement typeOscillating piston enginesWorking fluidEngineering

An axial compliance mechanism of a scroll compressor is installed between a compressor housing and a scroll. The housing has a first shell and a second shell. The first shell defines a chamber and has a guiding part at one end of and in communication with the interior of the chamber. The scroll has a fixed scroll member and an orbiting scroll member. A plurality of compression pockets is formed between these two scroll members. A rear surface of the fixed scroll member has a protrusion matching the guiding part of the first shell and a venting hole in communication with the compression chambers. A sealing device is installed between the guiding part and the protrusion, and a negative pressure chamber is formed. Thereby, the working fluid is guided into the negative pressure chamber during operation, so as to provide a tight attachment between the fixed scroll member and the orbiting scroll member, such that the volume efficiency of the compressor is enhanced.

Owner:FUSHENG IND CO LTD

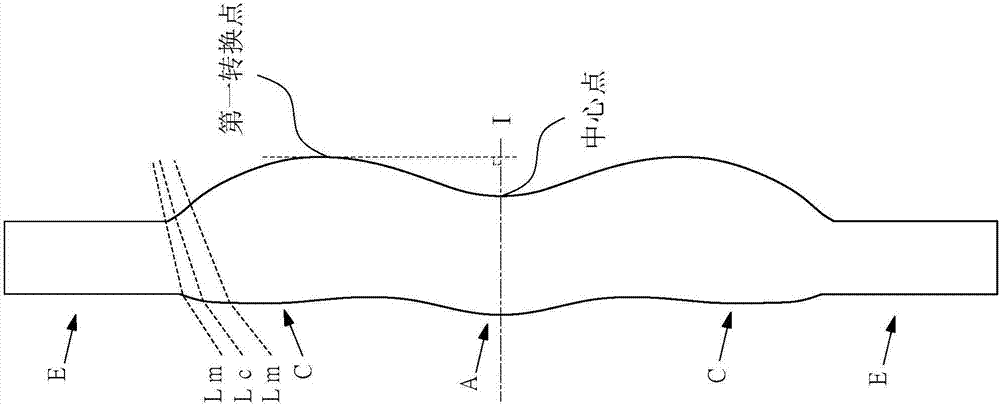

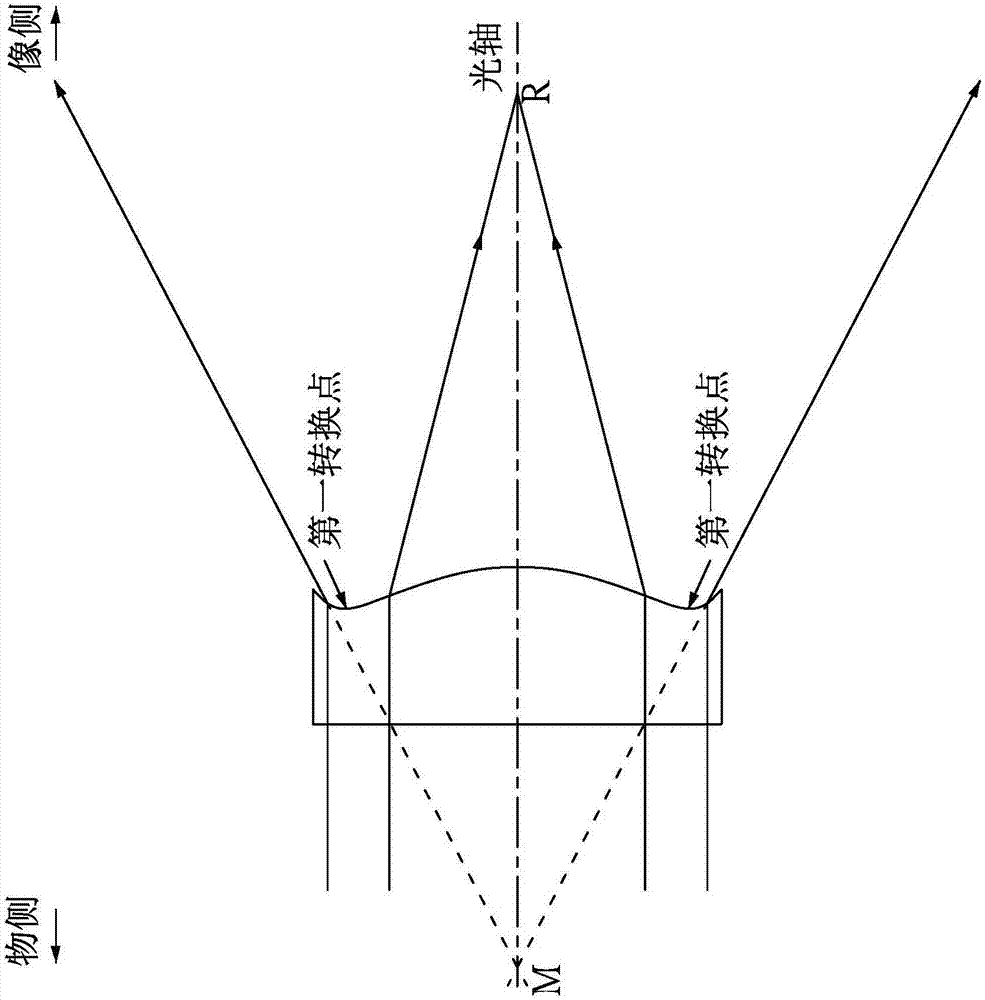

Optical imaging lens

The invention provides an optical imaging lens, which comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens sequentially from the object side to the image side and satisfies the following relational expressions: 1<=EFL / TTL and TTL<=18mm. By controlling the arrangement of the concave and convex surfaces of the lenses and using at least one relational expression to control relevant parameters, the length of the optical imaging lens is shortened under the condition of maintaining good optical performance. The optical imaging lens of the invention is used in optical imaging.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

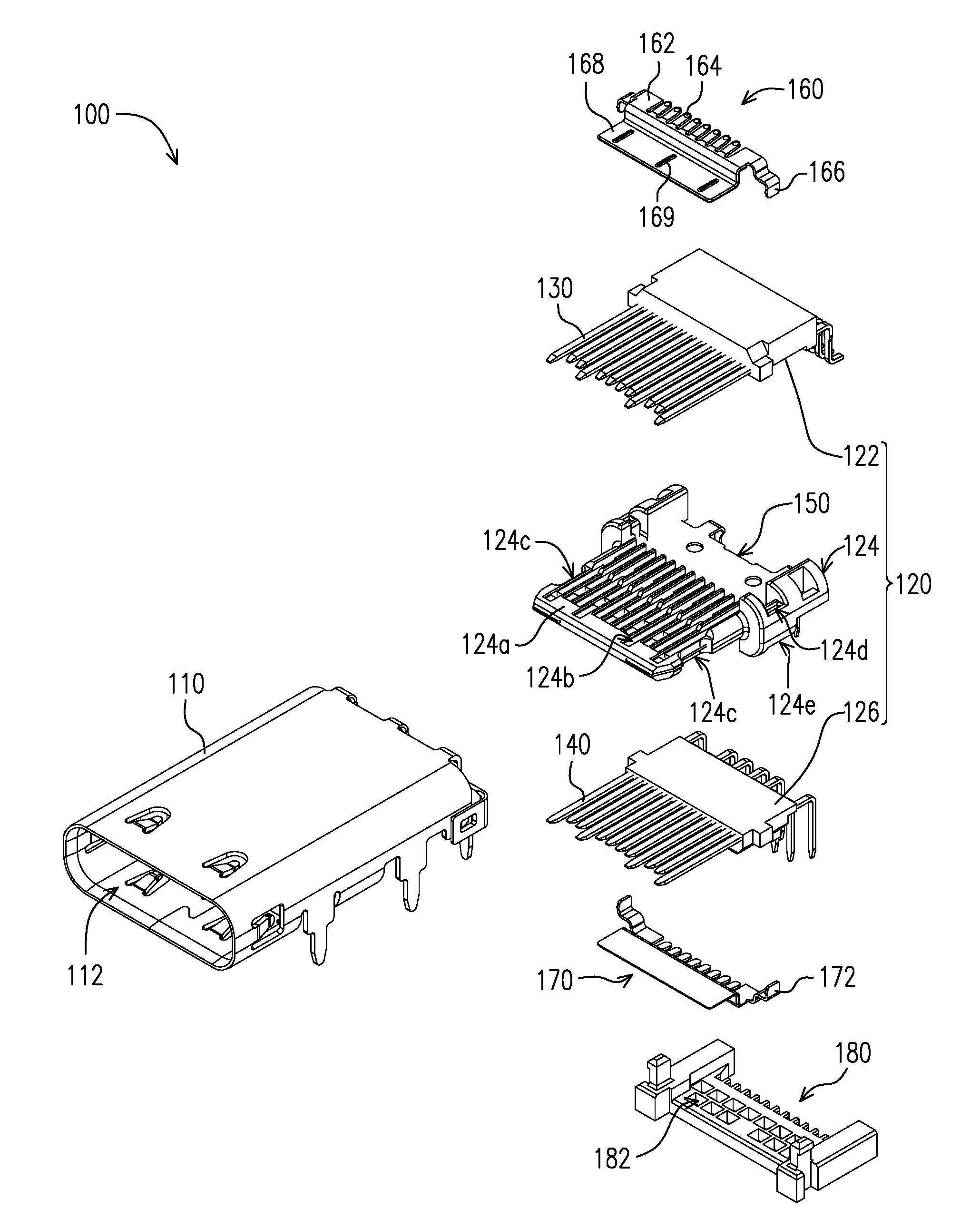

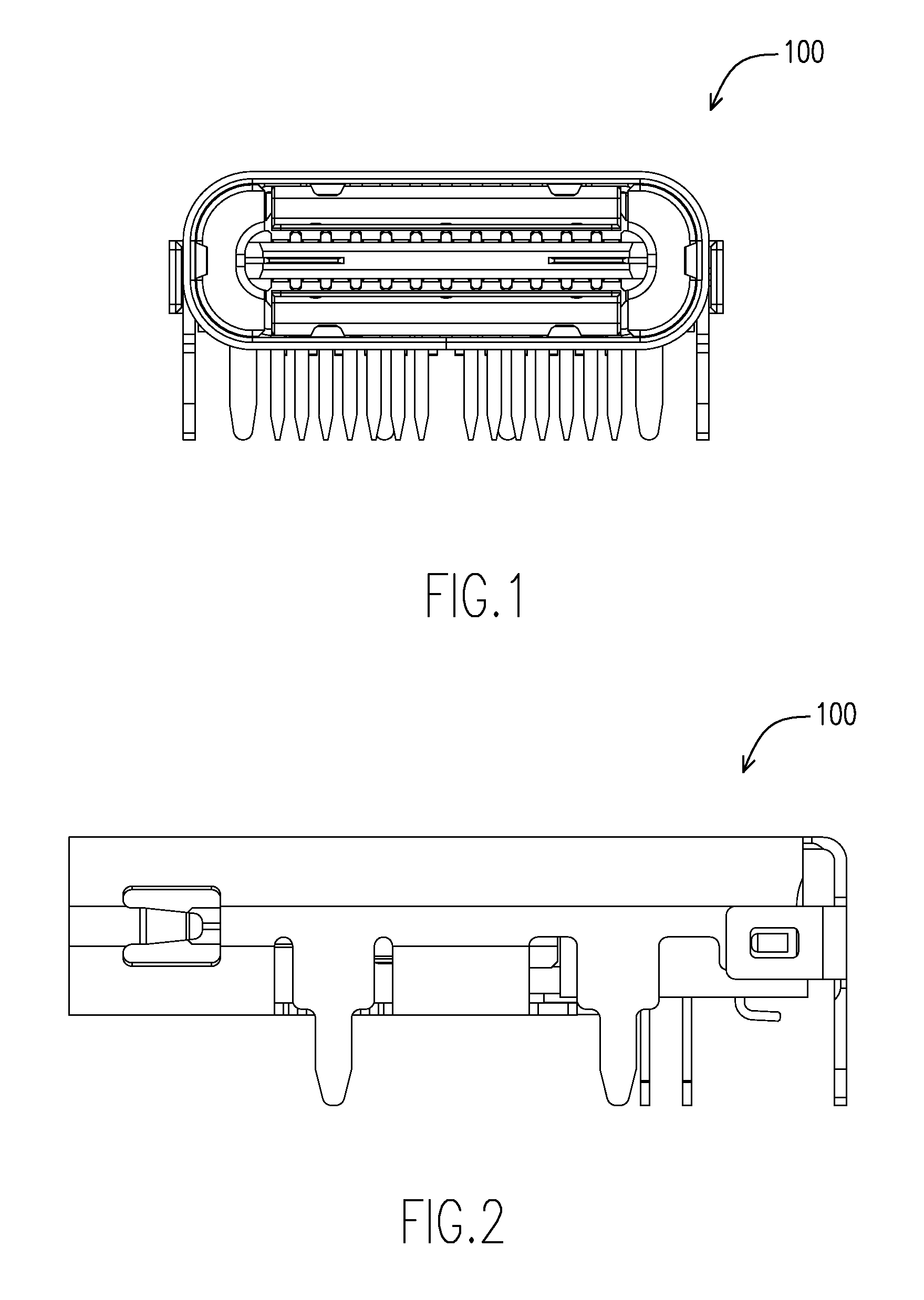

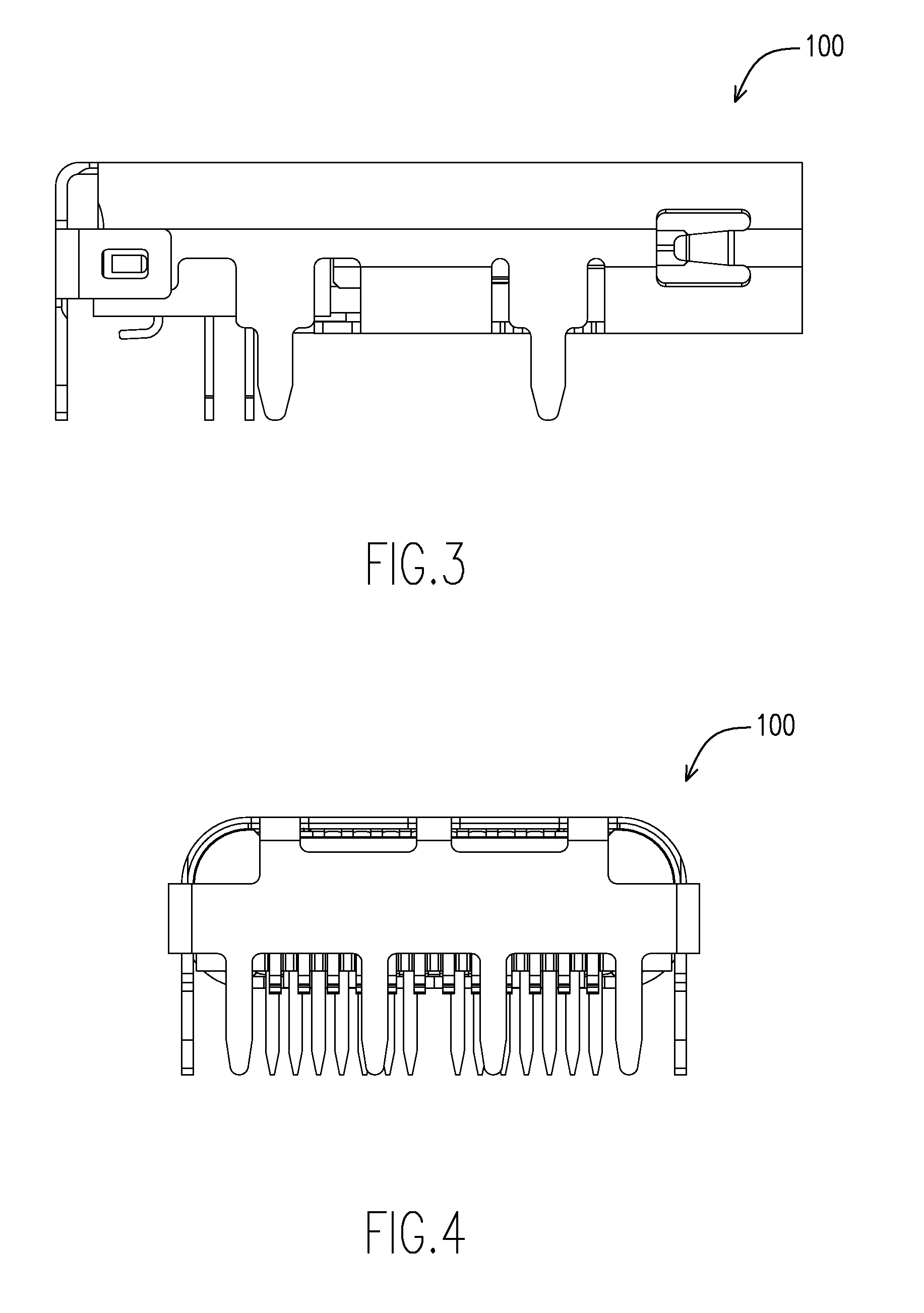

Electrical connector

ActiveUS9356406B2Increase plug strengthImprove the anti-electromagnetic interference effectTwo-part coupling devicesCoupling protective earth/shielding arrangementsEngineeringElectrical connector

An electrical connector comprises an external conductive sheet, an upper internal conductive sheet, a lower internal conductive sheet and the necessary others. An insulative base is disposed within a casing and includes a top complex, a center complex, and a bottom complex in sequential connection. The upper internal conductive sheet and the lower internal conductive sheet are fixed to the insulative base. Thereafter, an improving electrical connector interface is provided.

Owner:CHANT SINCERE CO LTD

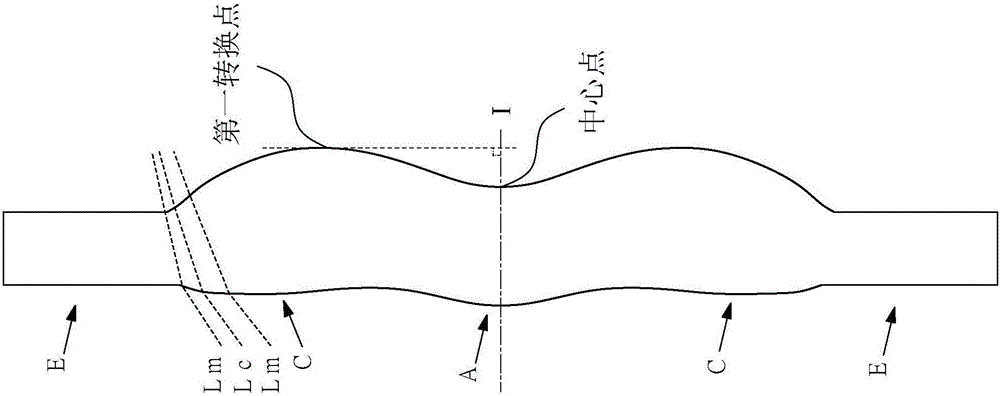

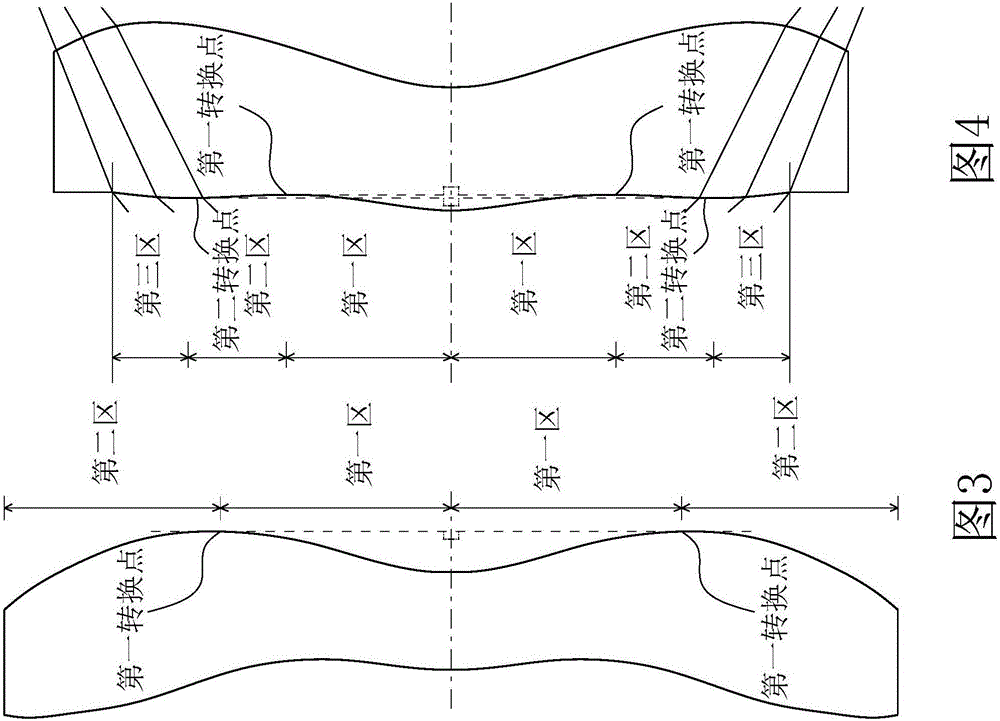

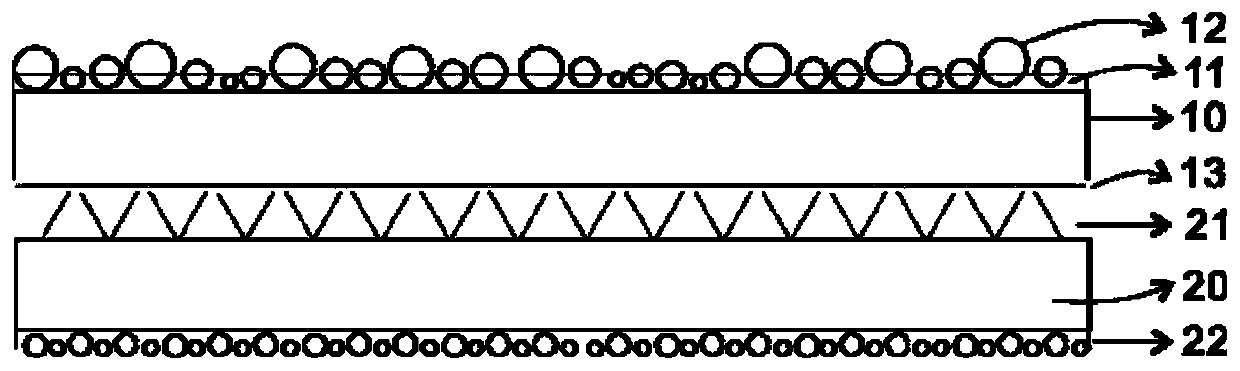

Optical composite film and preparation method thereof

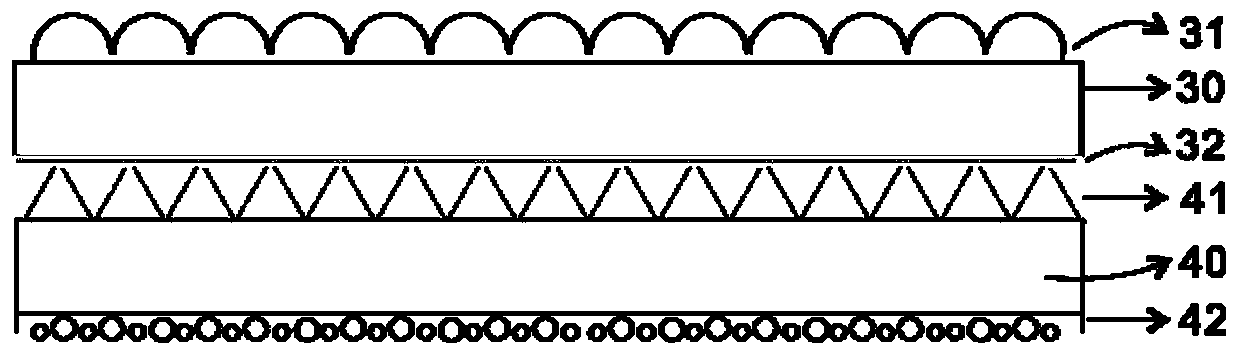

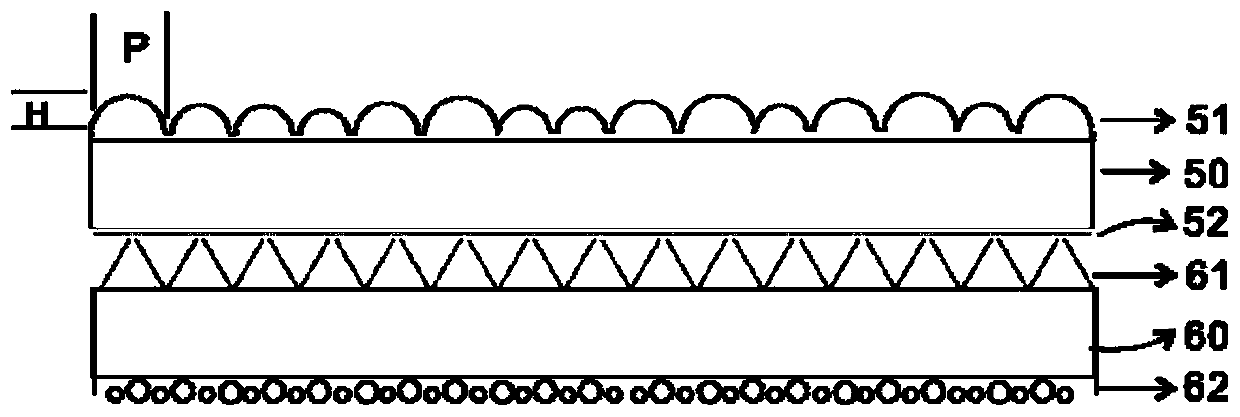

PendingCN111443516AReduce manufacturing costIncreased luminosity gain effectDiffusing elementsNon-linear opticsComposite filmPhysical chemistry

The invention relates to the field of an optical film for a backlight module, in particular to an optical composite film and a preparation method thereof. In order to solve the problem that an existing composite film cannot realize luminance gain, covering performance and interference relieving at the same time, the invention provides the optical composite film and the preparation method thereof.The optical composite film comprises a first layer of optical film and a second layer of optical film, wherein the first layer of optical film is arranged above the second layer of optical film; the first layer of optical film and the second layer of optical film are bonded together through an attaching layer; the first layer of optical film sequentially comprises a micro lens structure layer anda first layer of substrate layer; and the second layer of optical film sequentially comprises a prism layer, a second layer of substrate layer and a back coating layer. The optical composite film provided by the invention has the advantages that the luminance gain effect can be improved; a good covering effect is achieved; and meanwhile, excellent interference relieving performance is realized. Byusing the preparation method of a micro lens film provided by the invention, the production cost of the micro lens structure is greatly reduced.

Owner:NINGBO EXCITON TECH

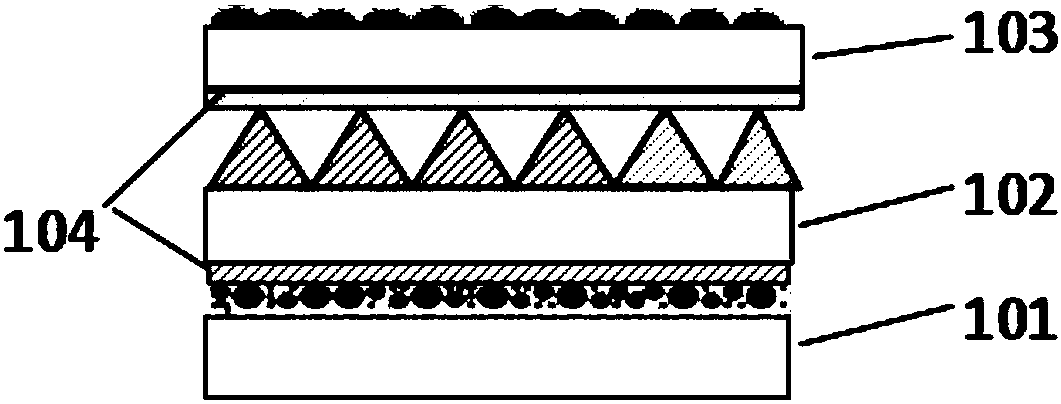

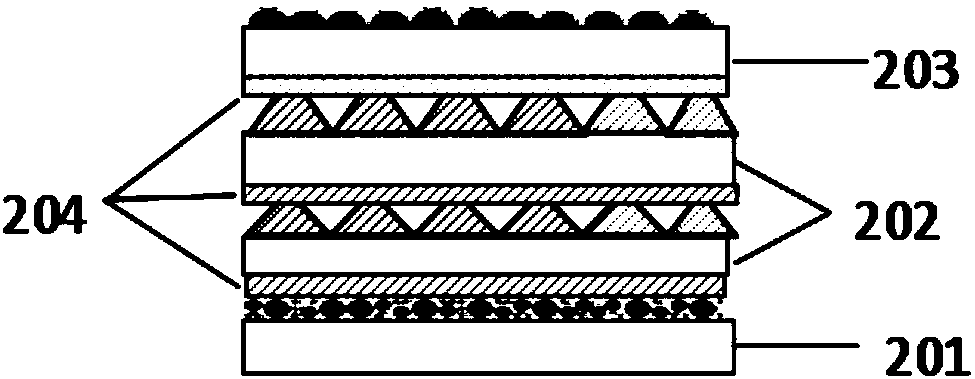

Novel multifunctional optical composite membrane and preparing method thereof

PendingCN107831620ALow costImprove stiffnessNon-linear opticsOptical elementsLiquid-crystal displayOptical Module

The invention belongs to the technical field of liquid crystal display optical modules, and discloses a novel multifunctional optical composite membrane which is composed of a lower layer, a middle layer and an upper layer. The lower layer is a brightening membrane or diffusing membrane, the middle layer is one or two overlapped brightening membranes, and the upper layer is a diffusing membrane ormicro-lens membrane. The lower layer, the middle layer and the upper layer are combined through adhesives. The total thickness of the optical composite membrane can be reduced by 40% or above, and acorresponding backlight module is lighter and thinner; cost is reduced by 10% or above; when the backlight module is assembled, only one-time operation needs to be conducted on the combined optical membrane, and the assembling efficiency is effectively improved; the stiffness of the membrane is effectively improved, the warping property of the membrane can be improved, and the assembling yield isimproved.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

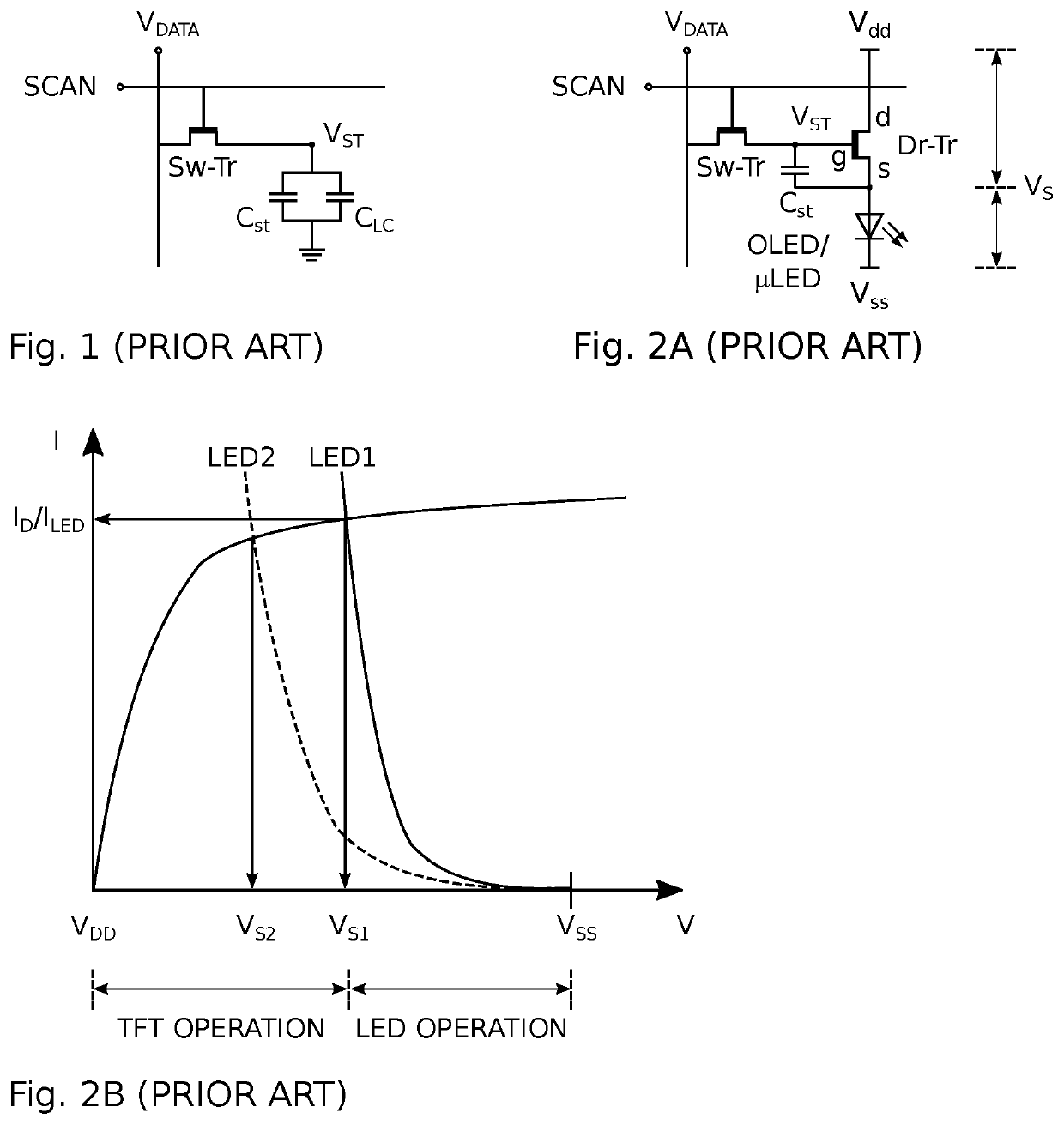

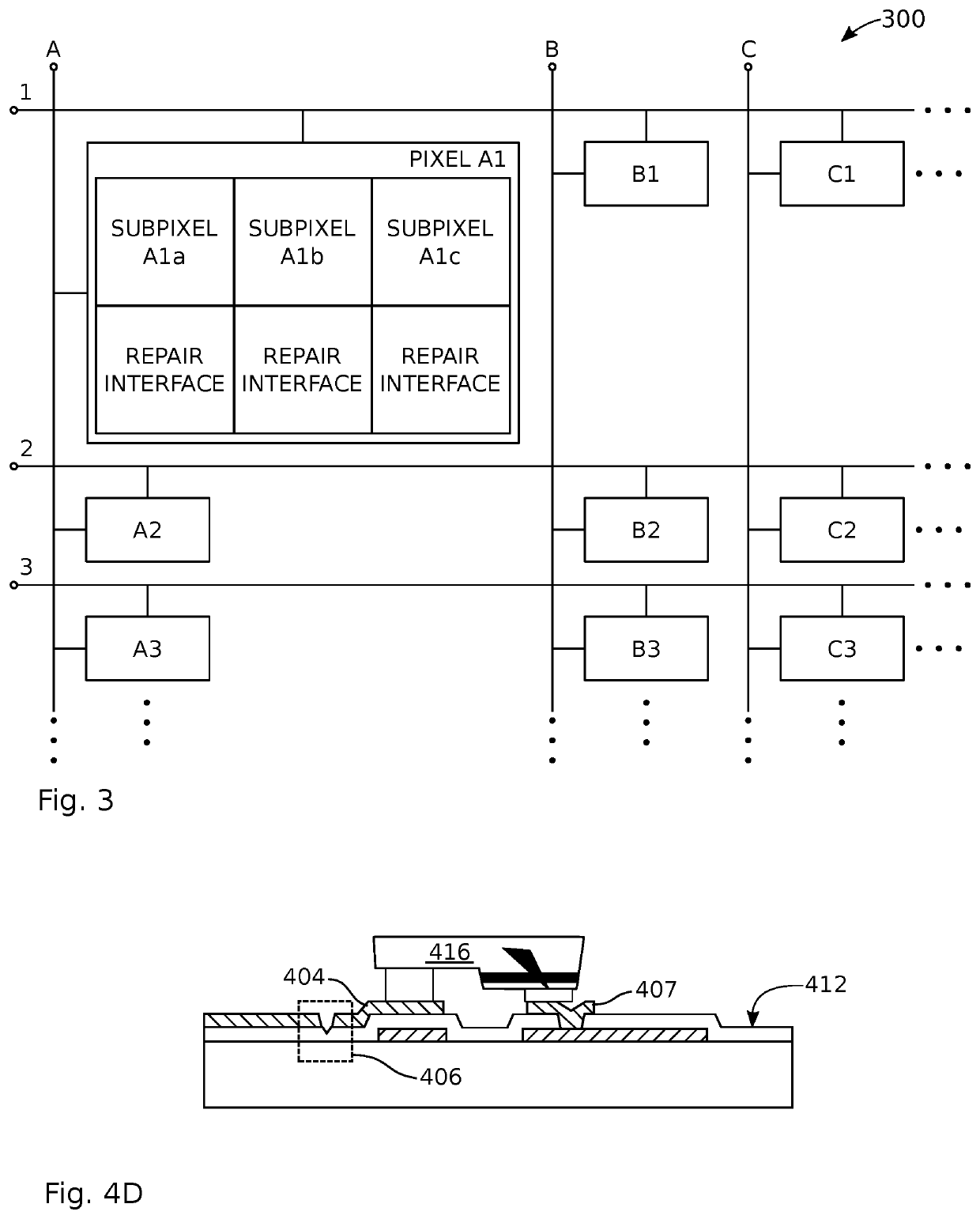

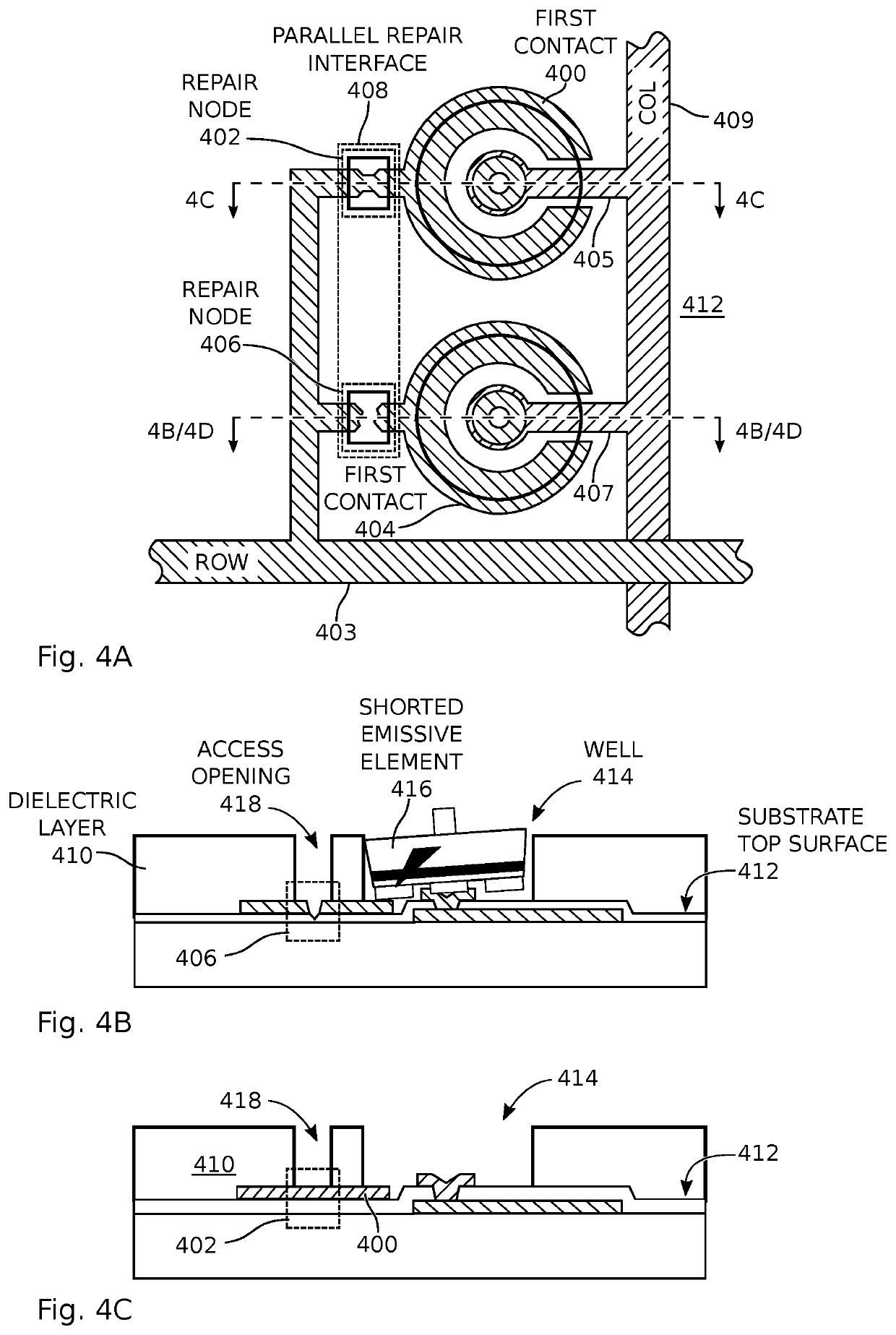

System and Method for Light Emitting Diode (LED) Display Repair

ActiveUS20200152826A1Improve assembly yieldIncrease pixel operating voltageStatic indicating devicesSolid-state devicesDisplay deviceLight-emitting diode

A system and method are provided for repairing an emissive element display. If a defective emissive element is detected in a subpixel, a subpixel repair interface isolates the defective emissive element. The repair interface may be a parallel repair interface with n number of selectively fusible electrically conductive repair nodes, connected in parallel to a control line of the matrix. Alternatively, the repair interface may be a series repair interface with m number of repair nodes, selectively connectable to bypass adjacent (defective) series-connected emissive elements. If the subpixel emissive elements are connected in parallel, and a defective low impedance emissive element is detected, a parallel repair interface fuses open a connection between the defective emissive element and a matrix control line. If the subpixels include series-connected emissive elements, and a high impedance emissive element is detected, a series repair interface forms a connection bypassing the defective emissive element.

Owner:ELUX INC

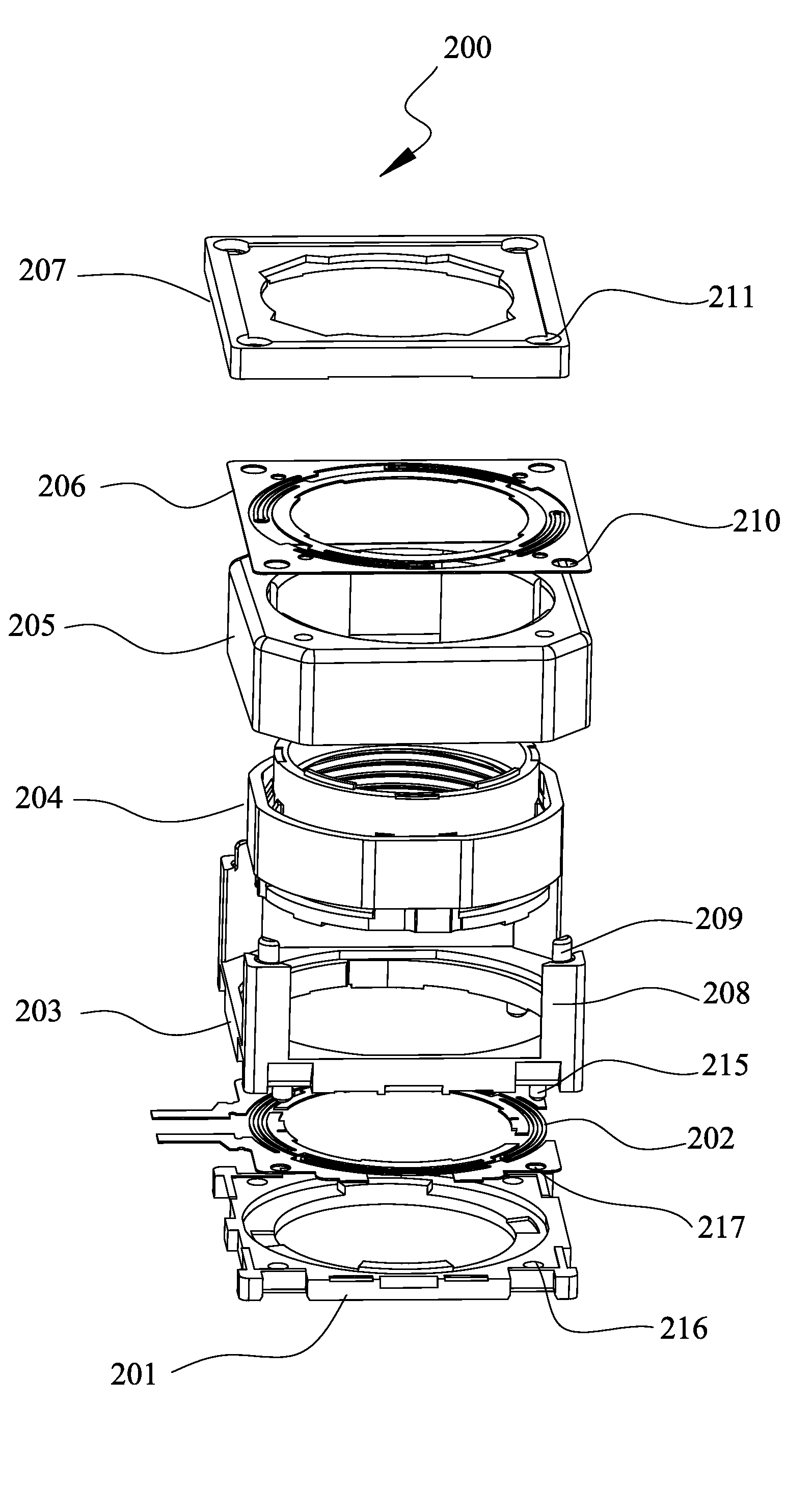

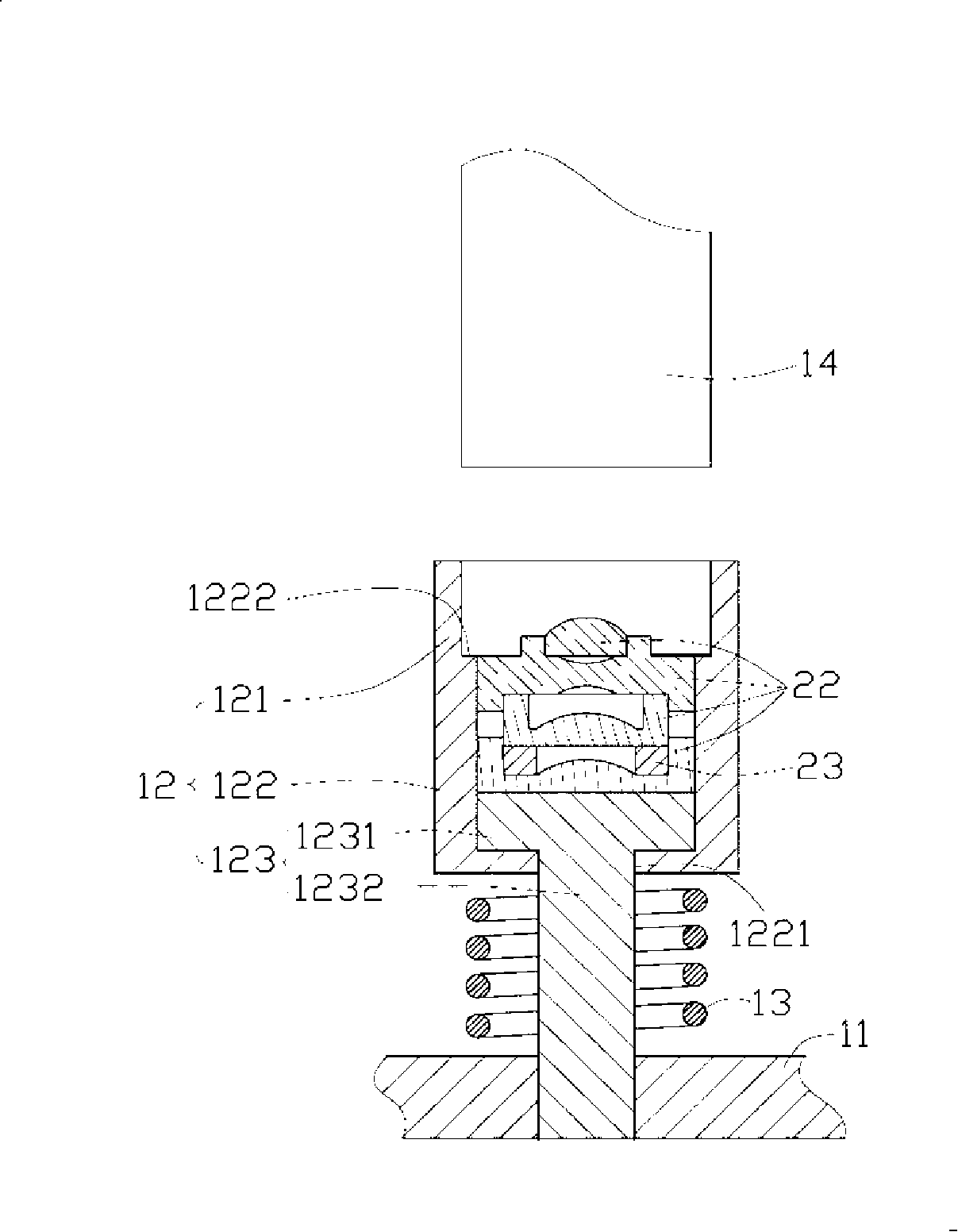

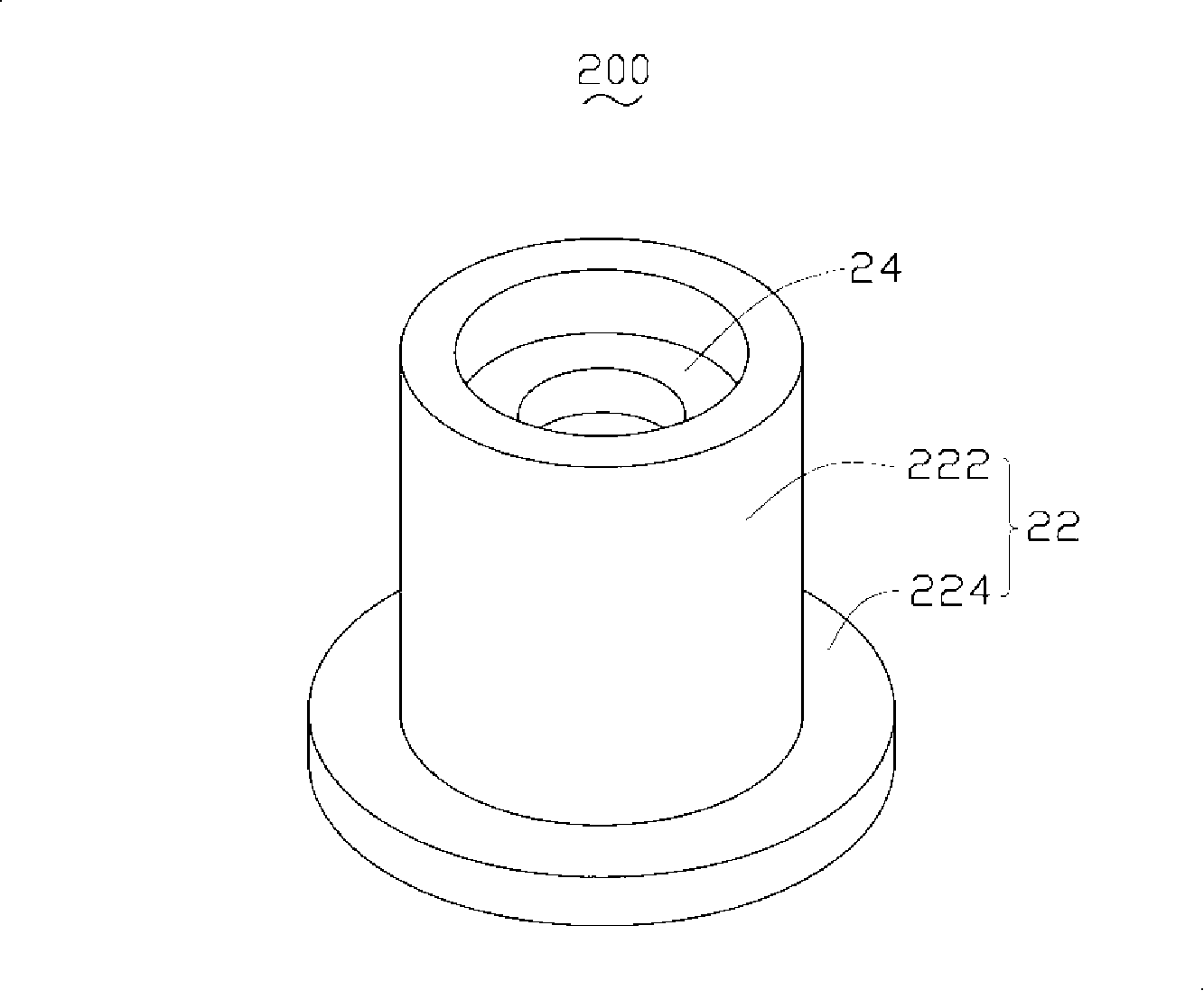

Lens module

A lens module includes a base to be fixed, a second elastic sheet fixed in the base, a lens sleeve sliding according to the base, a limiting member installed on the lens sleeve, a first elastic sheet, and an upper cover. The lens module includes a covering board with a central hole installed between the second elastic sheet and the lens sleeve. The diameter of the central hole is greater than the outer diameter of the lens sleeve. The covering board is connected to the base to fix the second elastic sheet on the base. Because the covering board to connect to the base, the second elastic sheet can be fixed on the base for decreasing time-consumption, reliable fixation, and decreasing the rate which the second elastic sheet rotates and is deformed.

Owner:ASIA OPTICAL INT LTD

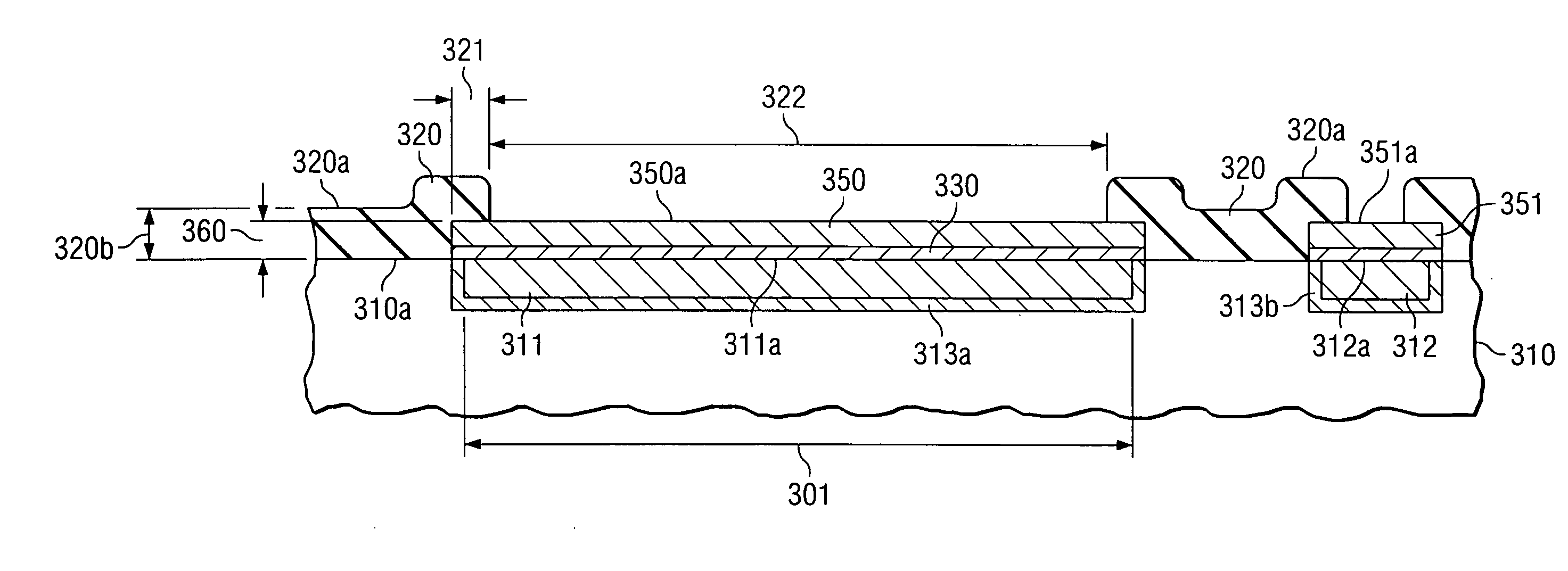

Structure and method for contact pads having double overcoat-protected bondable metal plugs over copper-metallized integrated circuits

InactiveUS20050224987A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

An integrated circuit having copper interconnecting metallization (311, 312) protected by a first overcoat layer (320), portions of the metallization exposed in windows (301, 302) opened through the thickness of the first overcoat layer. A patterned conductive barrier layer (330) is positioned on the exposed portion of the copper metallization and on portions of the first overcoat layer surrounding the window. A bondable metal layer (350, 351) is positioned on the barrier layer; the thickness of this bondable layer is suitable for wire bonding. A second overcoat layer (360) including insulating silicon compounds is positioned on the first overcoat layer so that the edge (362) of the second overcoat layer overlays the edge of the bondable layer positioned on the portions (321) of the first overcoat layer surrounding the window.

Owner:TEXAS INSTR INC

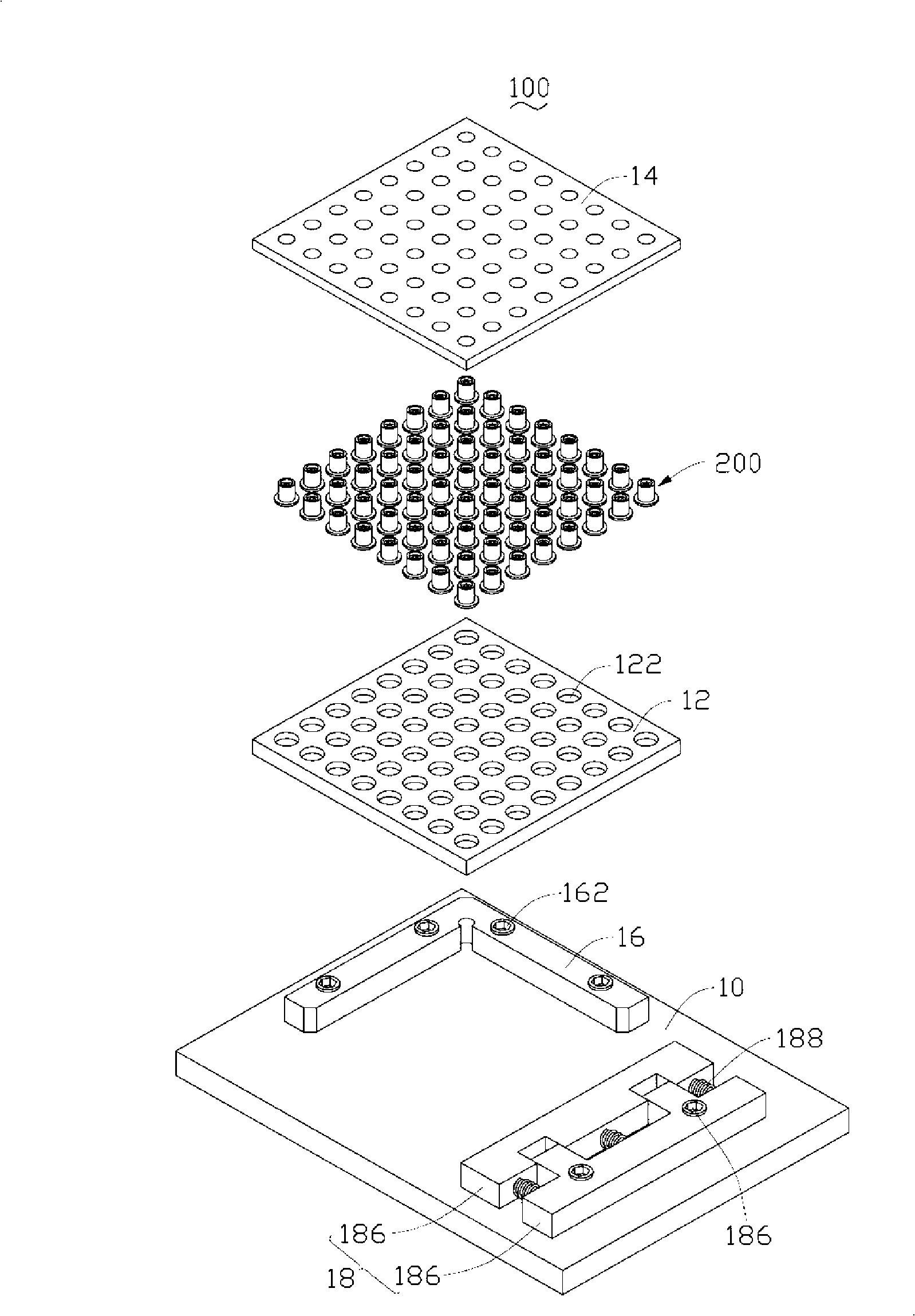

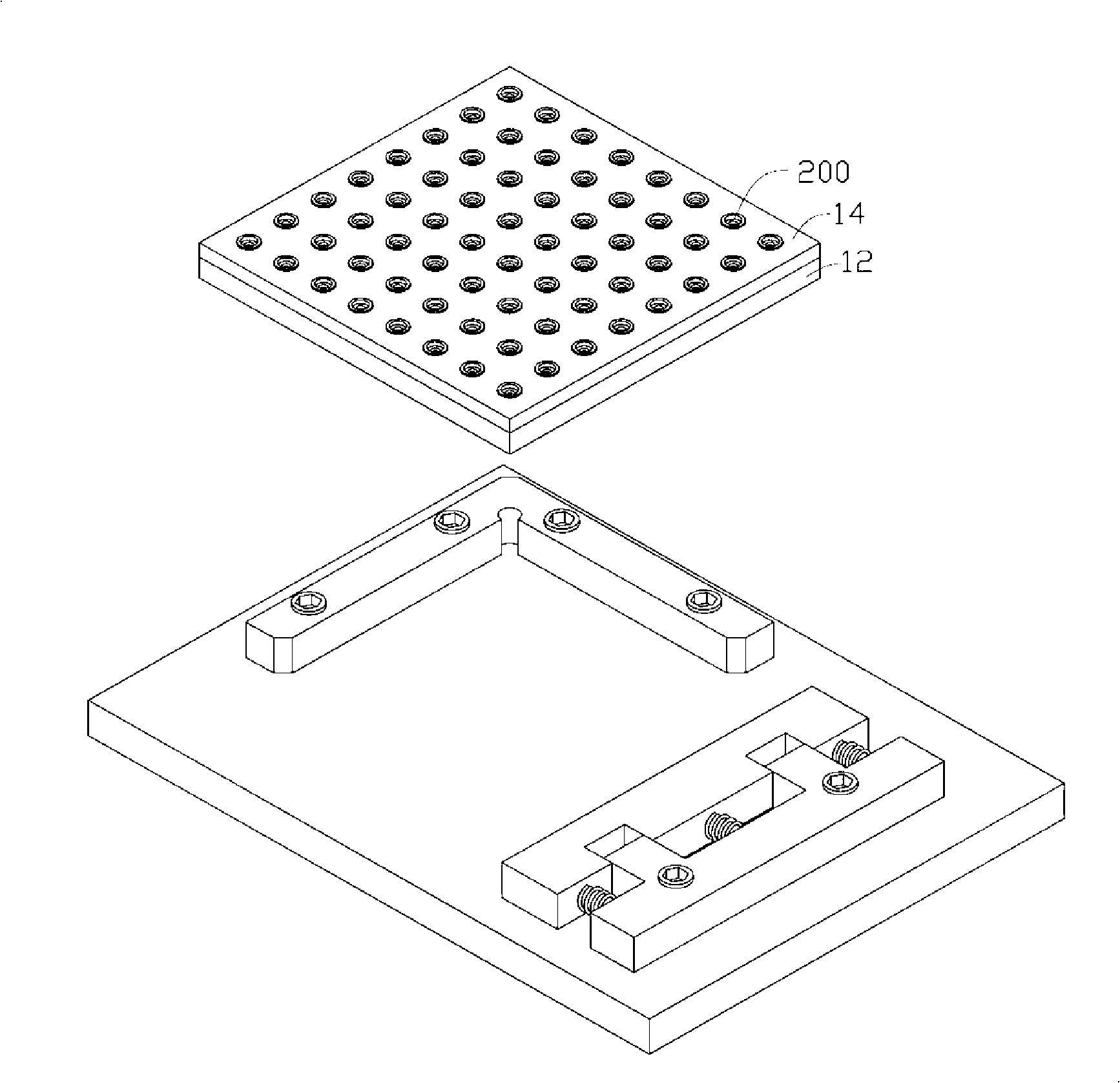

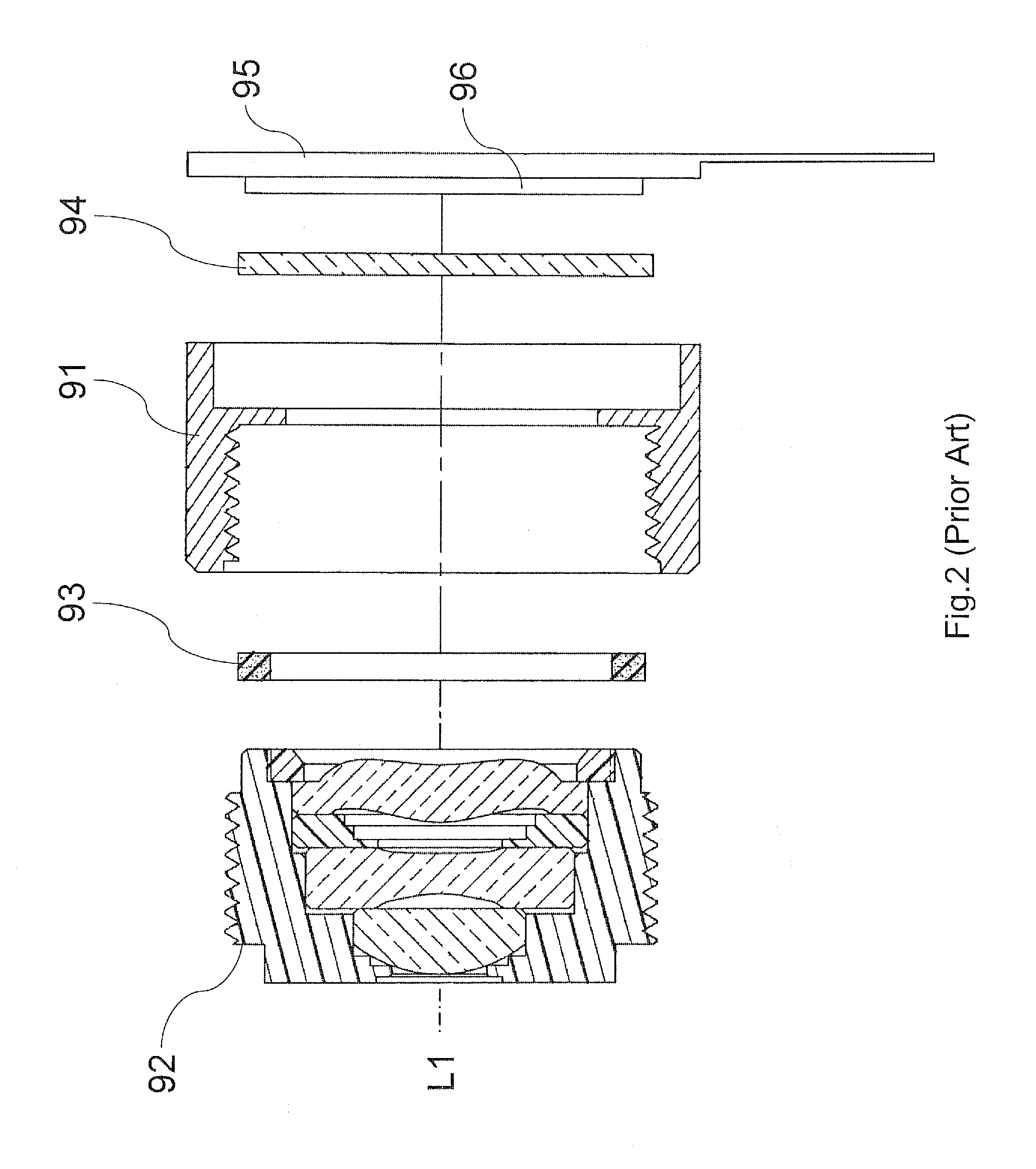

Lens assembled fixture and assembling system possessing same and assembling method

A lens assembly system comprises a holder, a lens assembly fixture on the holder, an elastic element and a push rod. The lens assembly fixture comprises a first shell, a second shell connected with the first shell and a post rod sleeved on the second shell. The first shell is used to contain the drawtube of the lens module. A through hole is provided at one end of the second shell. The post rod is contained with the through hole to push an optical element contained in the second shell out of the second shell and connected with the holder. The push rod is coaxially arranged towards one end of the first shell in interval. The lens assembly system and the assembly fixture make the lens not been sloped so as to improve the nondefective assembly rate. The invention also relates to a assembly method of the lens assembly system.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Optical imaging lens

The invention discloses an optical imaging lens. The optical imaging lens sequentially comprises first, second, third, fourth, fifth and sixth lenses arranged from an object side to an image side, wherein a vignetting stop is arranged between the object side surface of the third lens and the image side surface of the fourth lens; for the optical imaging lens, conditions that Fno is not greater than 2 and TTL / IS is not greater than 1 are satisfied. Or the optical imaging lens sequentially comprises first, second, third, fourth and fifth lenses arranged from an object side to an image side, wherein a vignetting stop is arranged between the object side surface of the third lens and the image side surface of the fourth lens; for the optical imaging lens, conditions that Fno is not greater than 2 and TTL / IS is not greater than 1 are satisfied. The optical imaging lens is used for realizing optical shooting imaging, through forming the vignetting stop and designing optical parameters at least satisfying two conditions, and better optical performance, relatively short effective focal length and relatively large visual angle are realized when integral length of the optical imaging lens is shortened.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Structure and method for contact pads having an overcoat-protected bondable metal plug over copper-metallized integrated circuits

InactiveUS20060094228A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper interconnectContact pad

A metal structure for a contact pad of an integrated circuit (IC), which has copper interconnecting metallization (311). A portion (301) of this metallization is exposed to provide a contact pad to the IC. A conductive barrier layer (330) is positioned on the exposed portion o the copper metallization. A plug (350) of bondable metal, preferably aluminum between about 0.4 and 1.4 μm thick, is positioned on the barrier layer. A protective overcoat layer (320) surrounds the plug and has a thickness (320b) so that the exposed surface (322) of the plug lies at or below the exposed surface (320a) of the overcoat layer. Optionally, a portion (321) of the overcoat layer between about 0.1 and 0.3 μm wide may overlap the perimeter of the plug.

Owner:LI LEI +1

Gluing tool

InactiveCN101271186ASimple structureImprove dispensing accuracy and assembly yieldMountingsBiomedical engineering

The invention relates to a dispensing fixture which is used for positioning a lens module to be dispensed. The dispensing fixture comprises a tray, a cover body, an L-shaped block and a pushing block. The tray is internally provided with a depression for containing the lens module. The cover body is provided with a through hole which is corresponding to the depression, and the cover body is matched with the tray to fix the lens module. The block is used for positioning the tray and the cover body. The pushing block is used for resisting the adjacent two sides of the tray and the cover body at the block for fixation. The dispensing fixture of the invention has simple structure, the pushing block can be matched with the block for positioning the tray and the cover body, thus accurately positioning the lens module and further improving the dispensing accuracy and the assembly yield.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

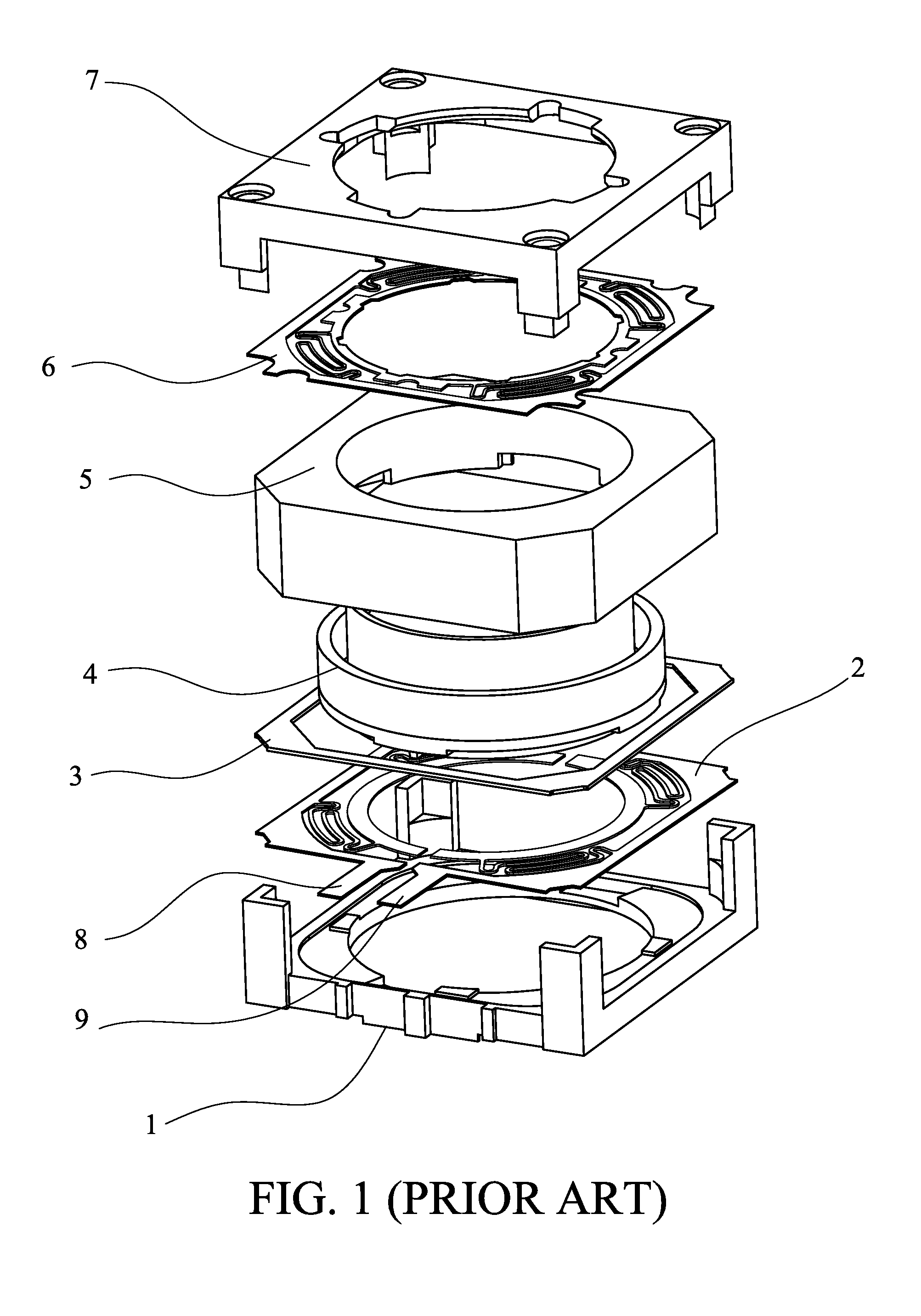

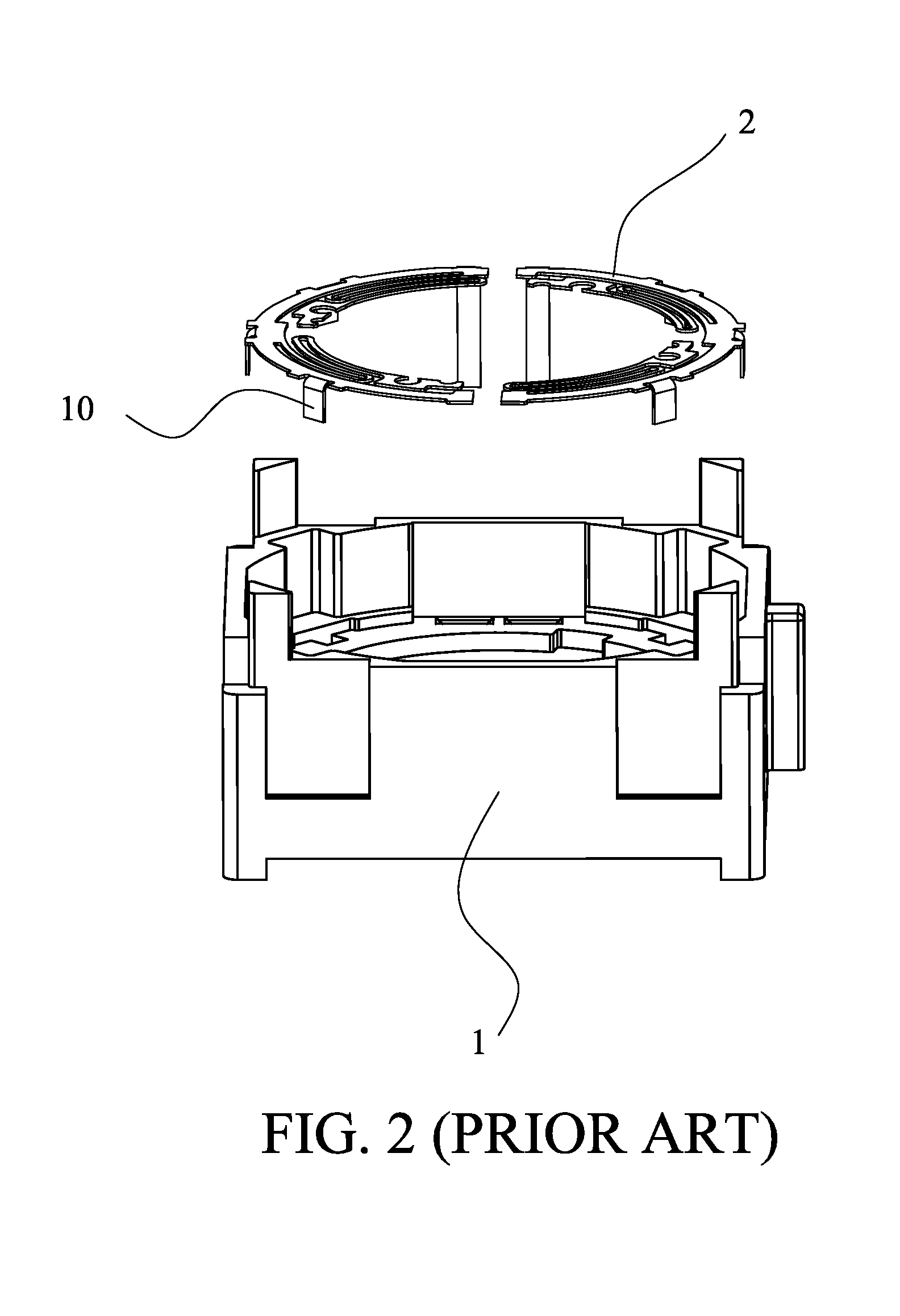

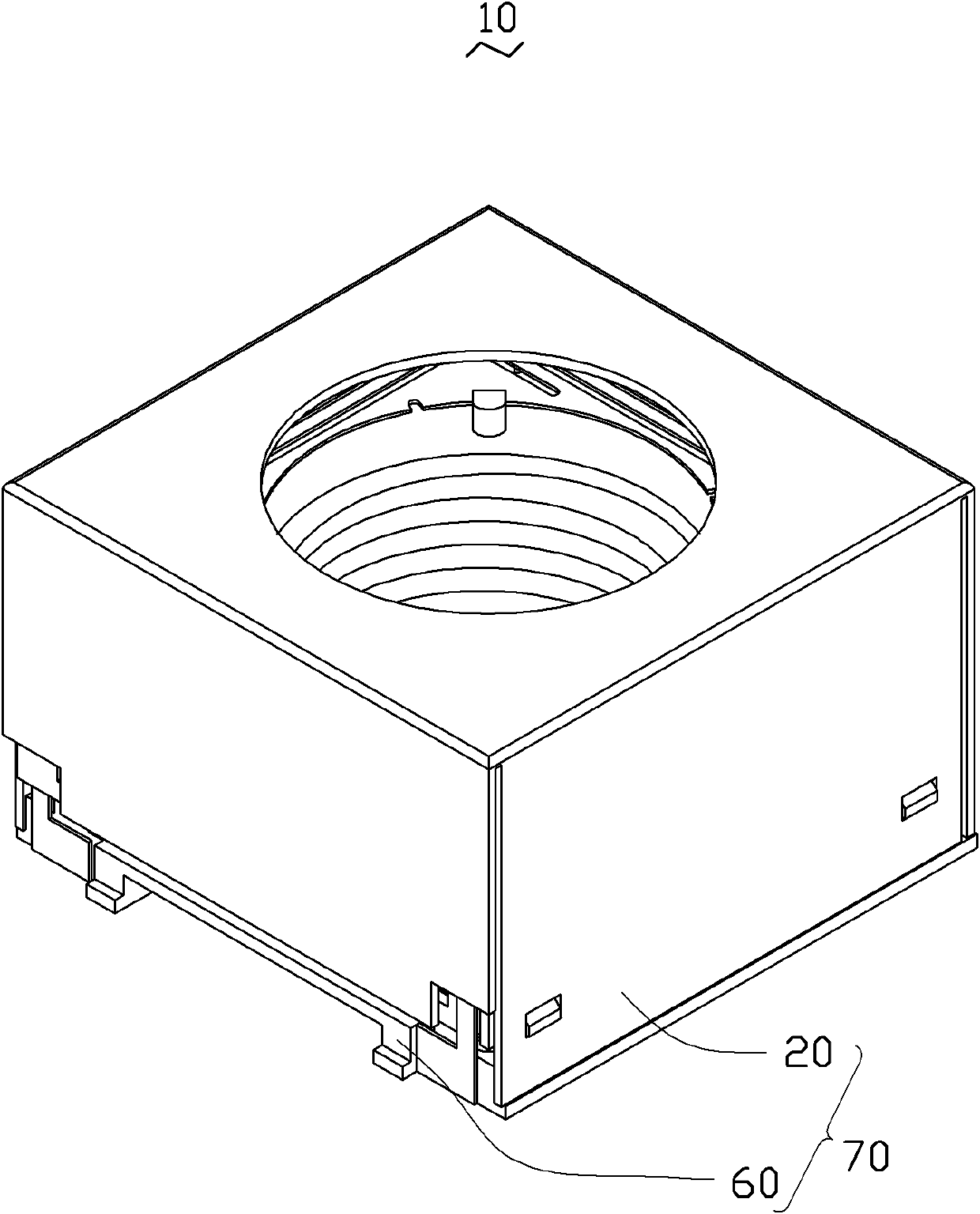

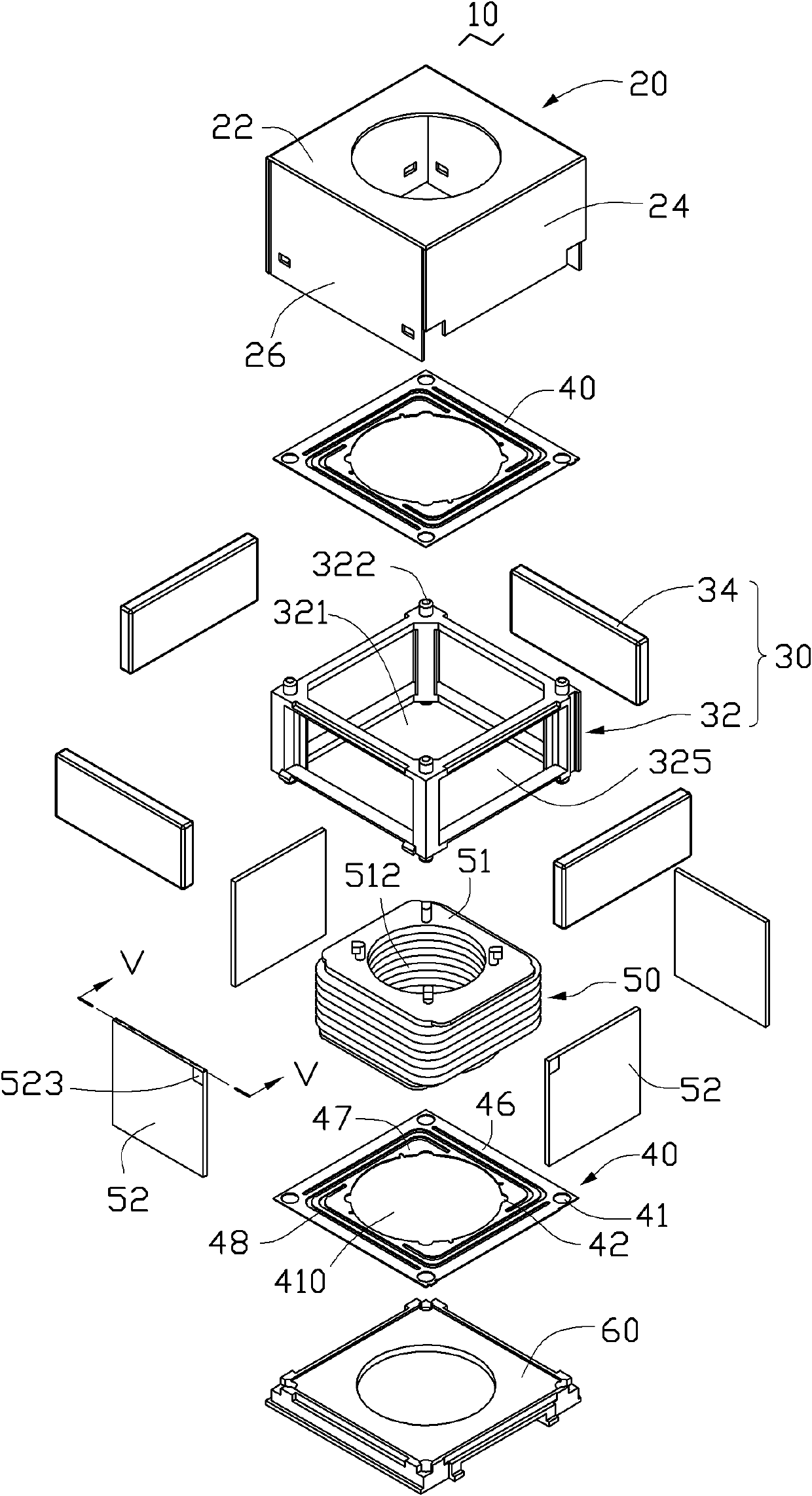

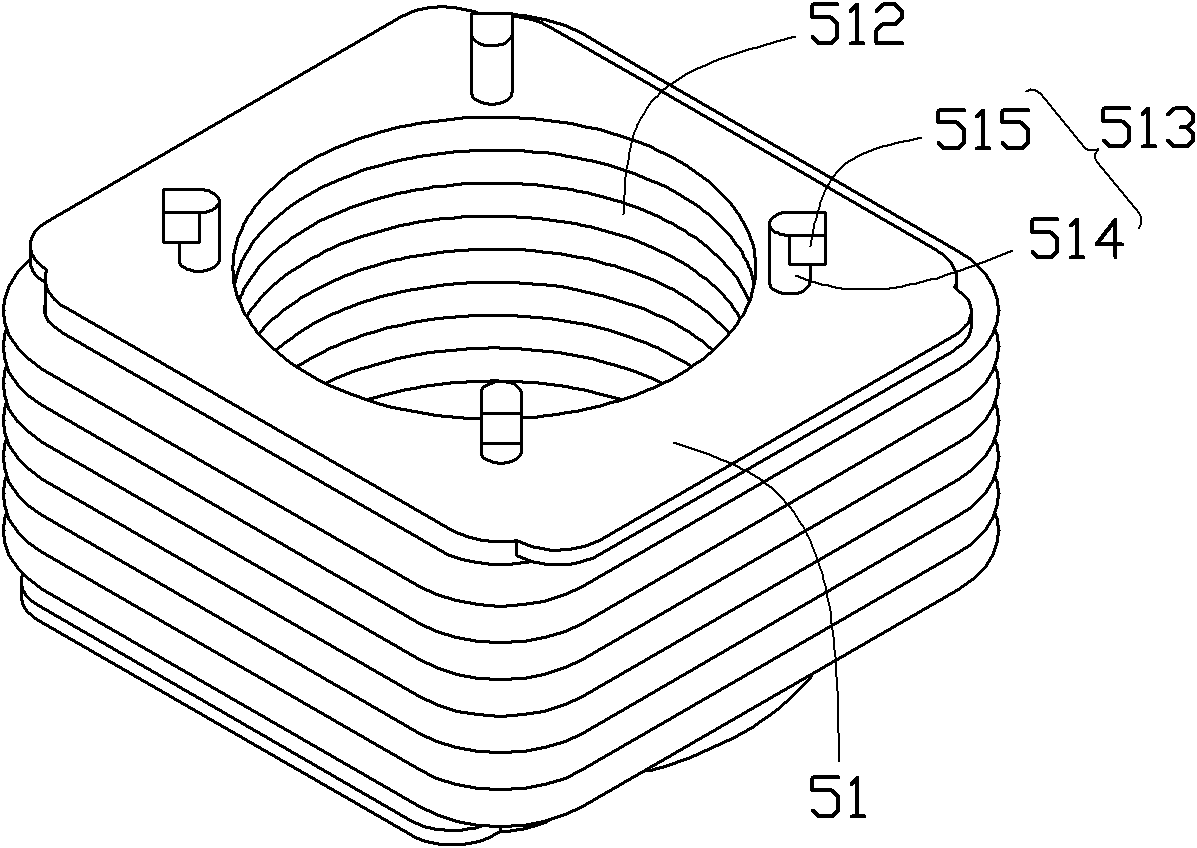

Voice coil motor

InactiveCN102570762AFlexibility to increase the number of slicesIncrease the number of piecesDynamo-electric machinesMountingsPrinted circuit boardVoice coil

The invention relates to a voice coil motor, which comprises a lens cylinder, a magnet, at least one spring plate and a printed circuit board process coil, wherein the lens cylinder is provided with a lateral wall and a first accommodating cavity for accommodating a lens; the magnet surrounds the lateral wall and is separated from the lateral wall; the at least one spring plate is connected with the lens cylinder; and the printed circuit board process coil is fixed on the lateral wall and is opposite to the magnet. The printed circuit board process coil generates a magnetic field force with the magnet after being electrified, to drive the lens cylinder to move along the axis. The at least one spring plate generates deformation when the lens cylinder moves, and applies a restoring force to the lens cylinder, so that the lens cylinder moves to a preset position from an initial position under the actions of the magnetic field force and the restoring force, is then still and restores to the initial position after the current of the printed circuit board process coil is powered off. The voice coil motor is convenient to assemble.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Rotating shaft and motor rotor having the same

InactiveUS7888835B2Simple structureCutting elementMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric motorEngineering

Owner:SEMICON COMPONENTS IND LLC

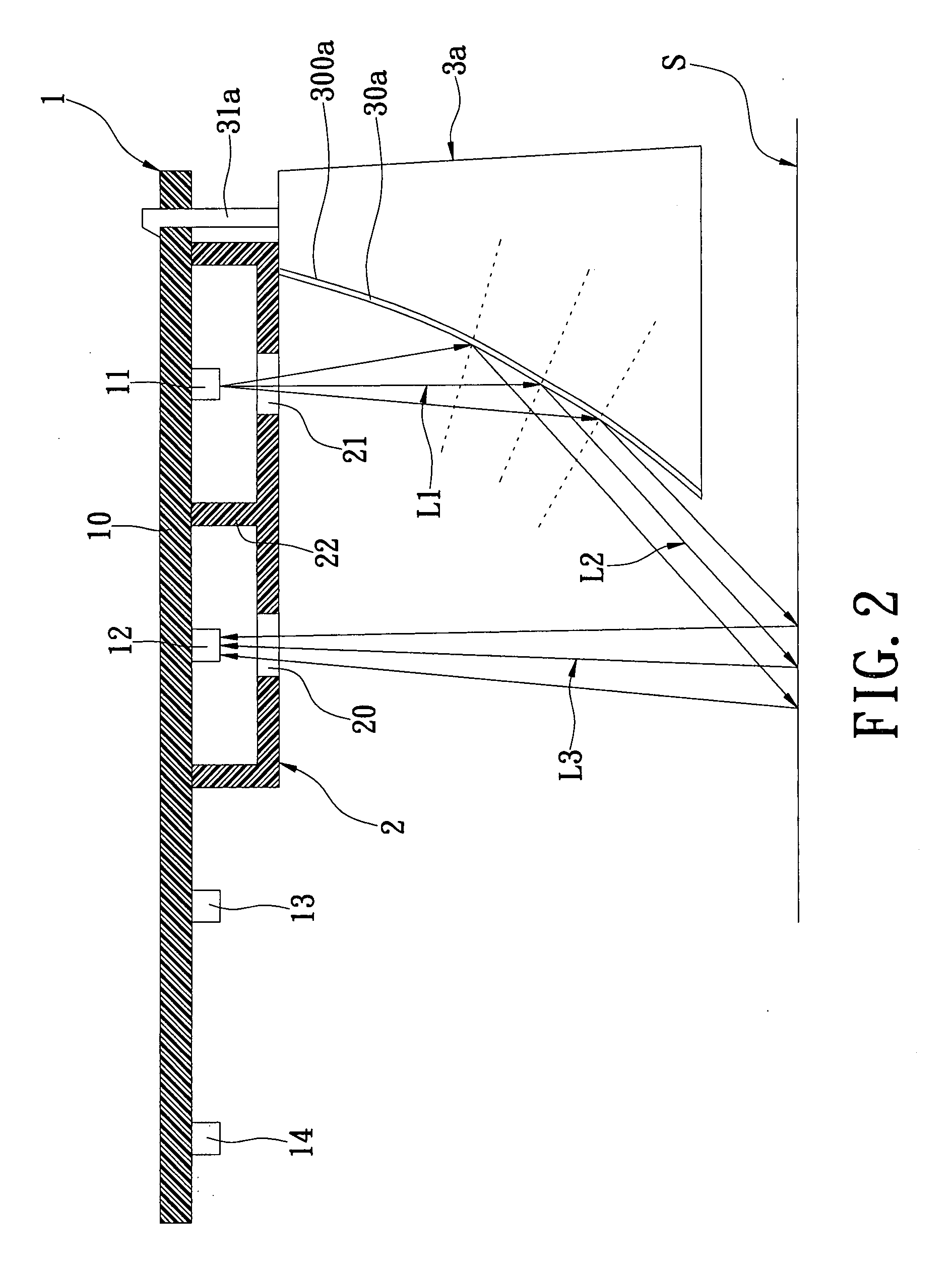

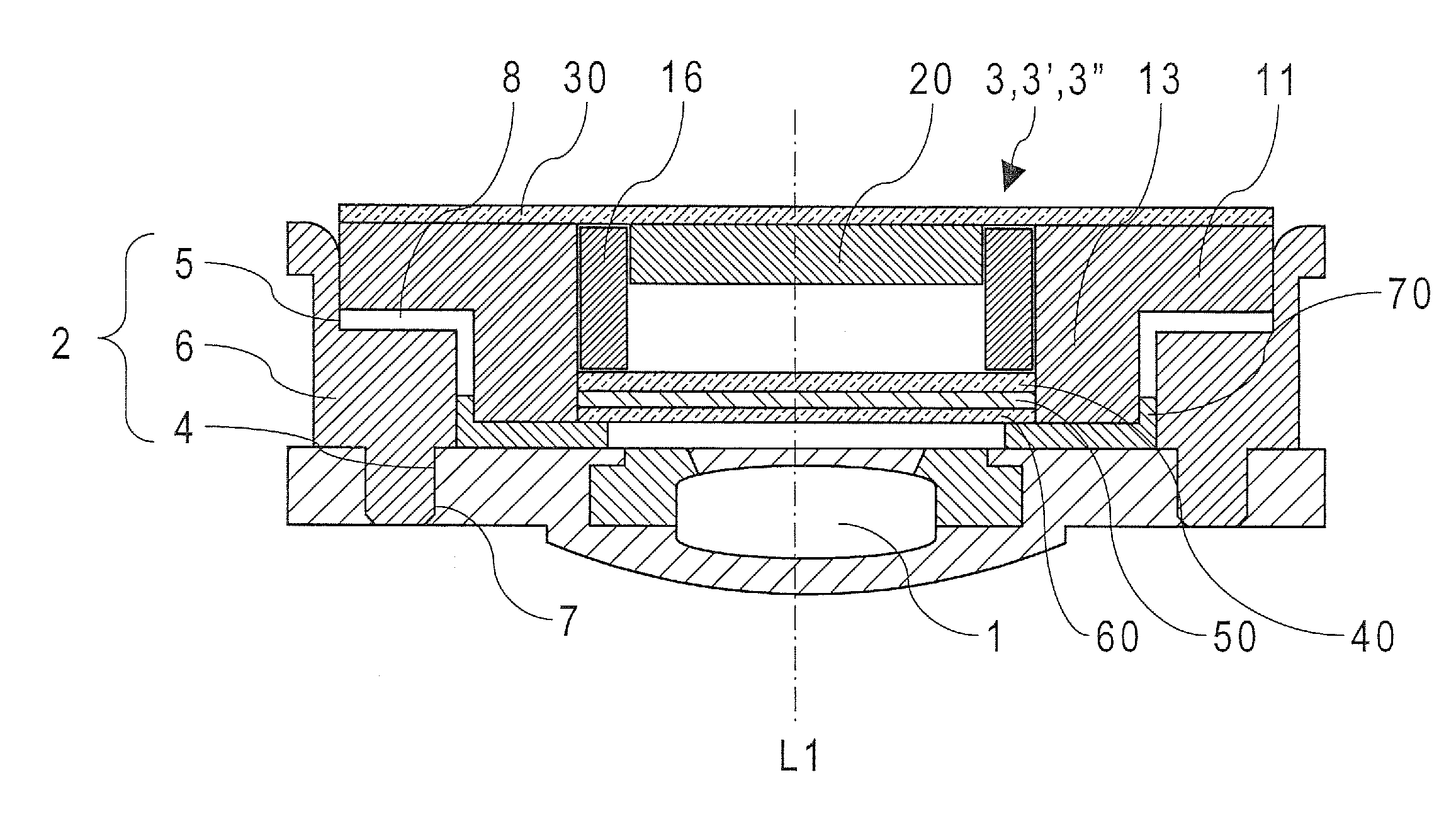

Image Detecting Module and Lens Module

InactiveUS20110102652A1Reduce thicknessImprove assembly yieldTelevision system detailsTelevision system scanning detailsInterior spaceCamera lens

An image detecting module includes a socket, a circuit board, an image sensor, an elastic element, a filter and a holder. The socket comprises an inner circumference wall along a main axis for defining an inner space and a platform that extended from the inner circumference wall. Pluralities of mounting holes are provided on the holder and pluralities of protrusions are provided on the socket; thus the elastic element and the filter could be fixed between the platform and the holder by fitting the protrusions into the mounting holes.

Owner:ABILITY ENTERPRISE CO LTD

Backlight module and display module

InactiveCN102506358ASimplify internal structureReduce manufacturing costNon-linear opticsLight fasteningsLight guideComputer science

The invention discloses a display module and a backlight module. The display module includes the backlight module and a display panel arranged on the backlight module. The backlight module includes a base plate, a light guide plate, a support frame, a buffer material and a baffle. The light guide plate is arranged on the base plate and includes the top face, the bottom face and a plurality of side faces connecting between the top face and the bottom face. The support frame surrounds the light guide plate. The buffer material is arranged on at least one side of the light guide plate and includes the top wall, the bottom wall and the side wall. The top wall is arranged on the outer periphery of the top face of the light guide plate. The bottom wall leans between the base plate and the bottom face of the light guide plate. The side wall connects with the top wall and the bottom wall and wraps at least one side face of the light guide plate. The baffle is arranged on the base plate vertically and is disposed on at least one side of the light guide plate. The side wall of the buffer material leans between the baffle and at least one side face of the guide plate.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com