Novel multifunctional optical composite membrane and preparing method thereof

An optical composite film, multi-functional technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as backlight module overthickness, diaphragm warpage, low assembly efficiency, etc., to improve warpage, improve Stiffness and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

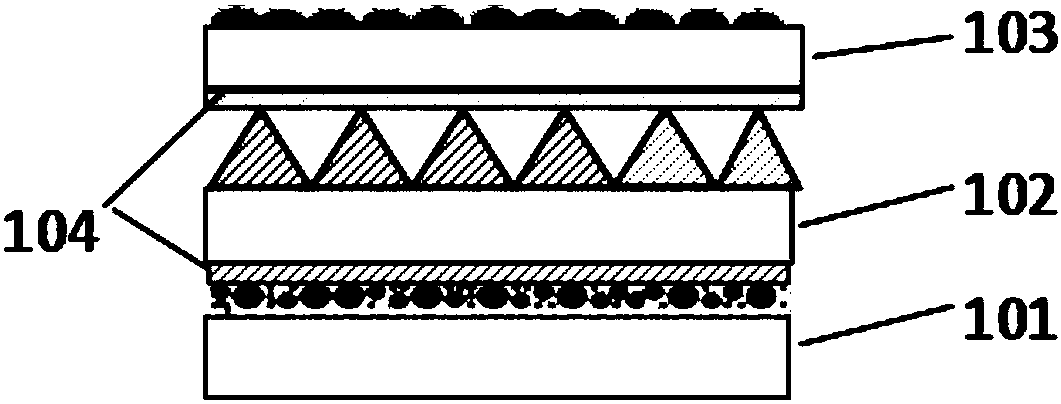

[0028] as attached figure 1 The structure of the optical composite film shown is: lower layer: diffusion film 101 , middle layer: brightness enhancement film 102 , upper layer: microlens film (abbreviated as microlens film) 103 .

[0029] The diffusion film 101 includes a substrate layer and a light diffusion layer, and the light diffusion layer is placed on the upper surface of the substrate layer; the substrate layer of the diffusion film 101 is a PET substrate with a thickness of 100 μm, and the light diffusion layer is a light diffusion layer. Microbead coated haze 95% coating.

[0030] The brightness enhancement film 102 is a prism film, and the prism film includes a substrate layer and a microprism brightness enhancement structure layer, and the microprism brightness enhancement structure layer of the prism film is arranged on the upper surface of the substrate layer; The prism height of the microprism brightening structural layer of the film 102 is 40 μm, and the angle...

Embodiment 2

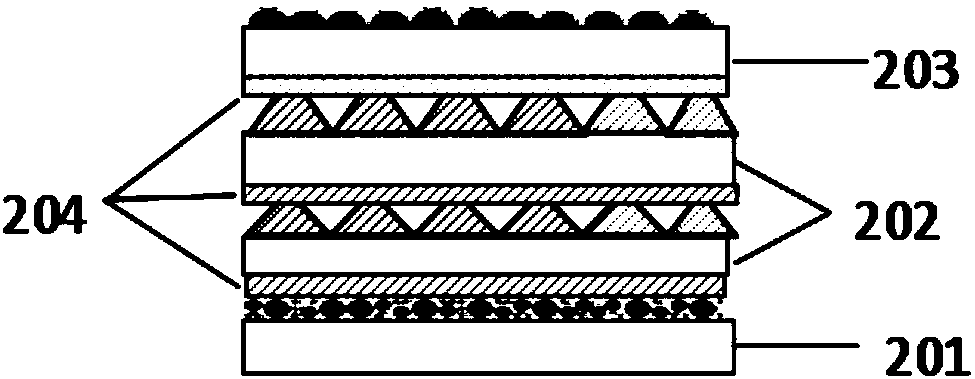

[0034] as attached figure 2 The structure of the optical composite film shown is: lower layer: diffusion film 201 , middle layer: double-layer brightness enhancement film stacked layer 202 , upper layer: microlens film (abbreviated as microlens film) 203 .

[0035] The diffusion film 201 includes a substrate layer and a light diffusion layer, and the light diffusion layer is placed on the upper surface of the substrate layer; the substrate layer of the diffusion film 201 is PET with a thickness of 125 μm, and the light diffusion layer is light-curable acrylate glue Apply a haze 50% coating.

[0036] The brightness enhancement film 202 is a prism film, and the prism film includes a substrate layer and a microprism brightness enhancement structure layer, and the microprism brightness enhancement structure layer of the prism film is arranged on the upper surface of the substrate layer; The included angle between the prism structure array direction of the upper brightness enhanc...

Embodiment 3

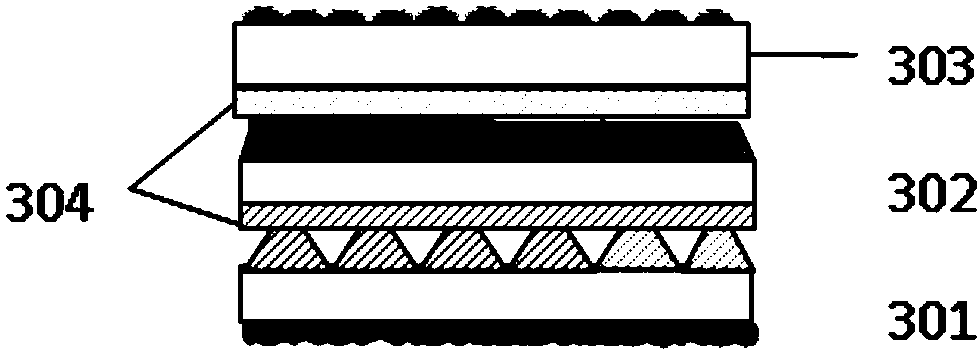

[0040] as attached image 3 The structure of the composite film shown is: lower layer: brightness enhancement film 301 , middle layer: brightness enhancement film 302 , upper layer: microlens film (abbreviated as microlens film) 303 .

[0041] The brightness enhancement film 301 is a prism film, and the prism film includes a substrate layer, a microprism brightness enhancement structure layer and a back coating layer, and the microprism brightness enhancement structure layer of the prism film is arranged on the upper surface of the substrate layer, The back coat layer of the prism film is arranged on the lower surface of the substrate layer; the prism height of the lower brightness enhancement film 301 is 30 μm, the angle is 90°, and the material of the microprism brightness enhancement structure layer is acrylic resin, which is 250 μm thick. PET substrate, back coating haze 60%.

[0042] The brightness enhancement film 302 is a prism film, and the prism film includes a subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com