Patents

Literature

496results about How to "Improve warpage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

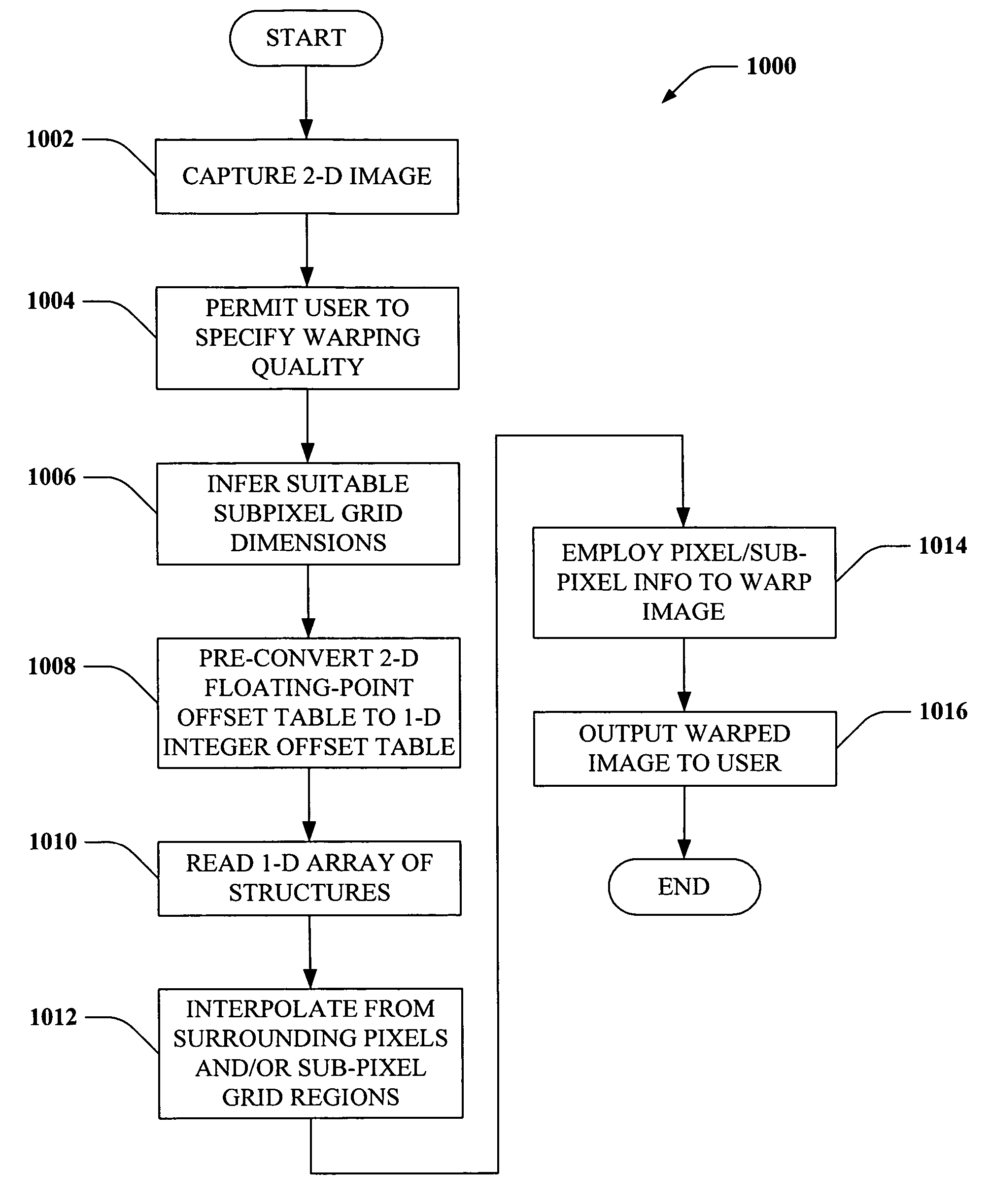

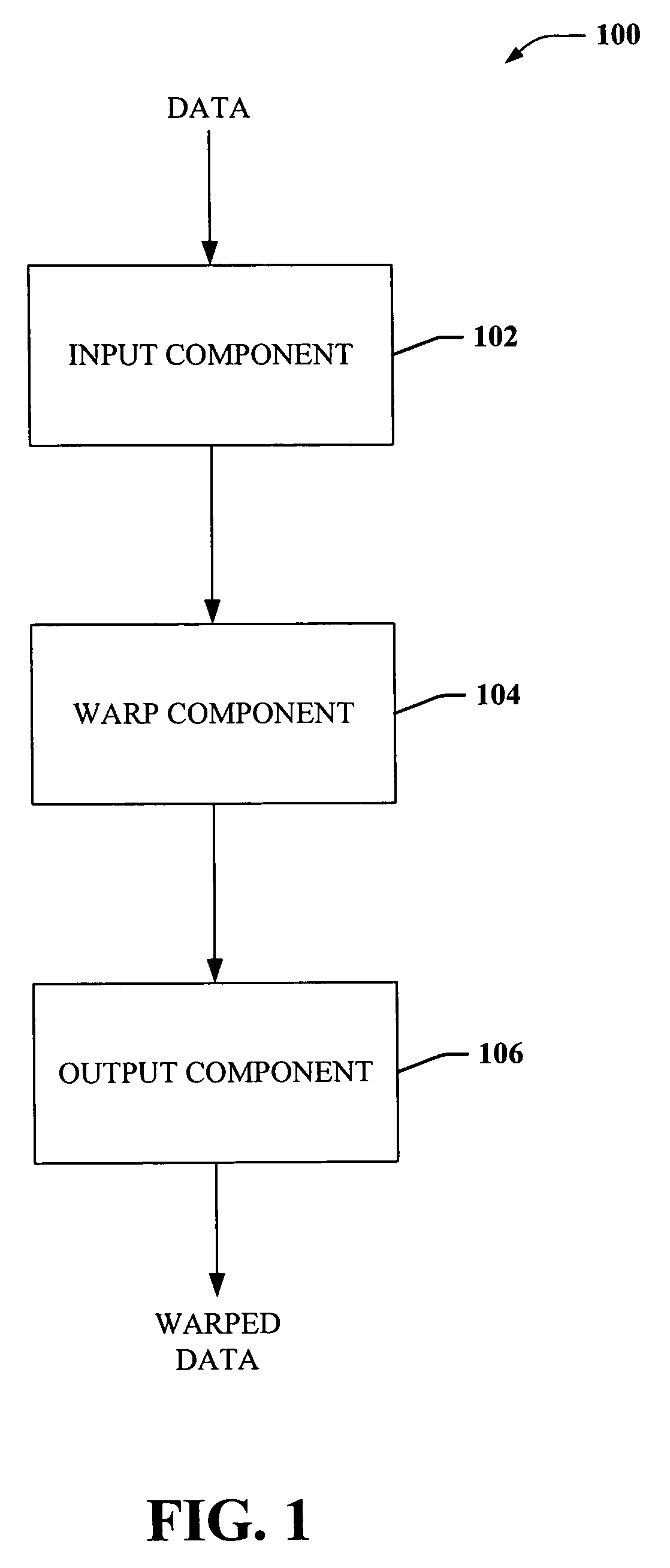

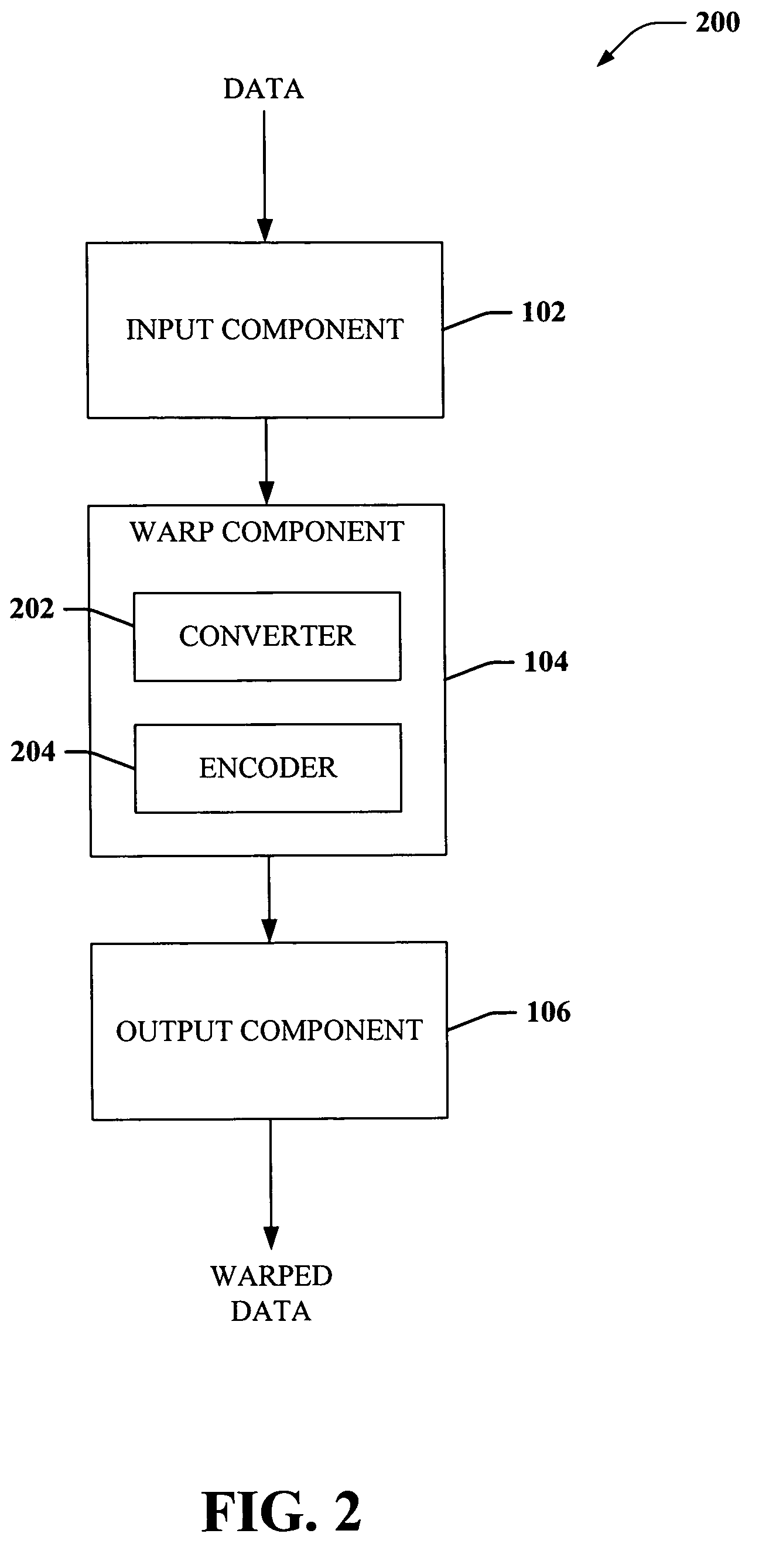

Novel method to quickly warp a 2-D image using only integer math

InactiveUS20050243103A1Good reliefEnhance the imageColor signal processing circuitsGeometric image transformationComputer graphics (images)Floating point

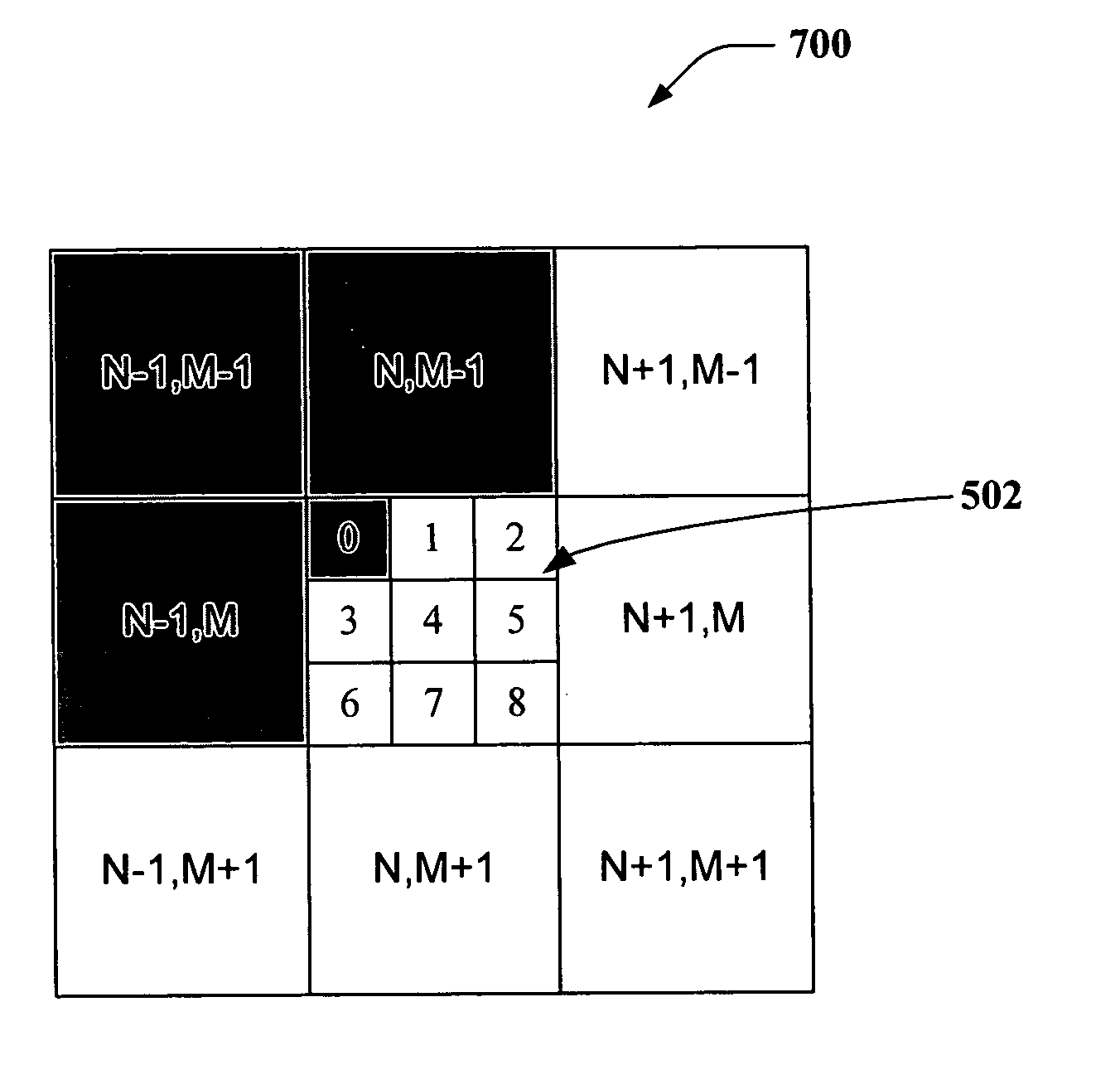

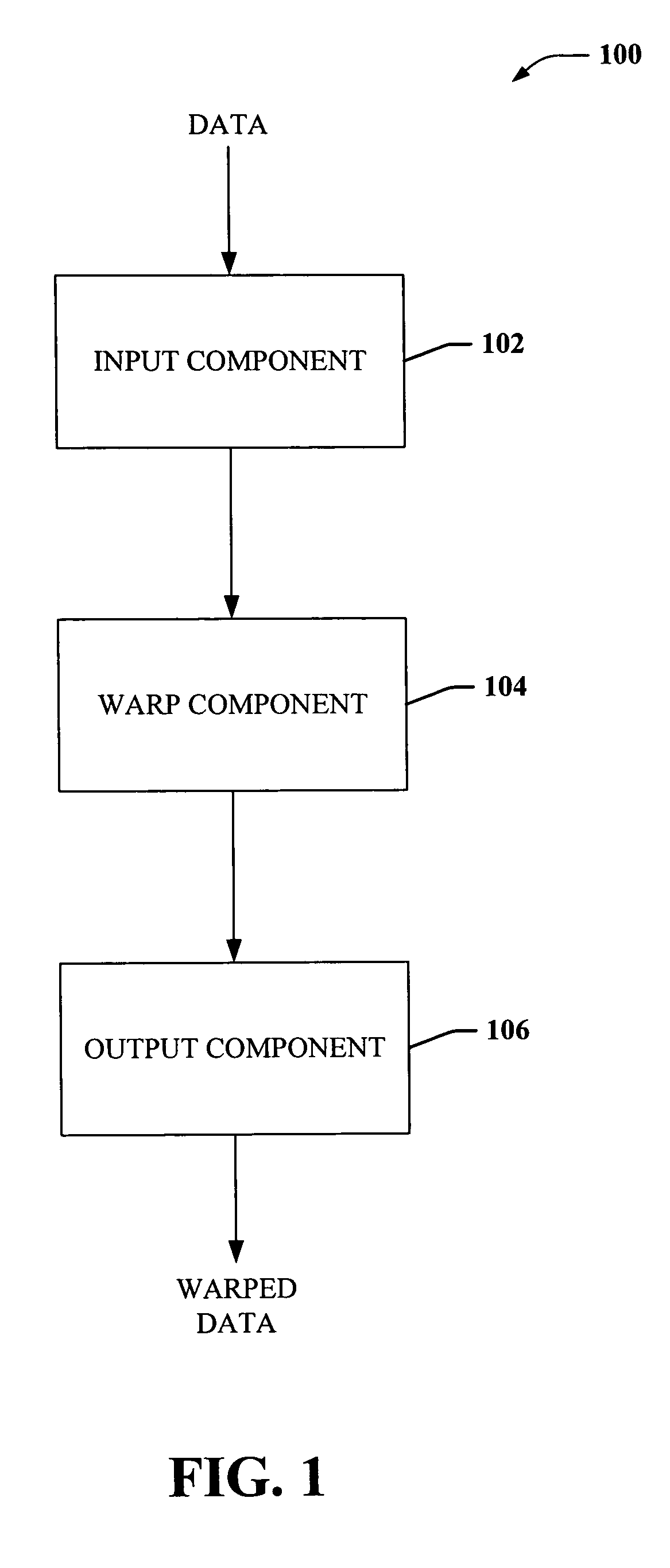

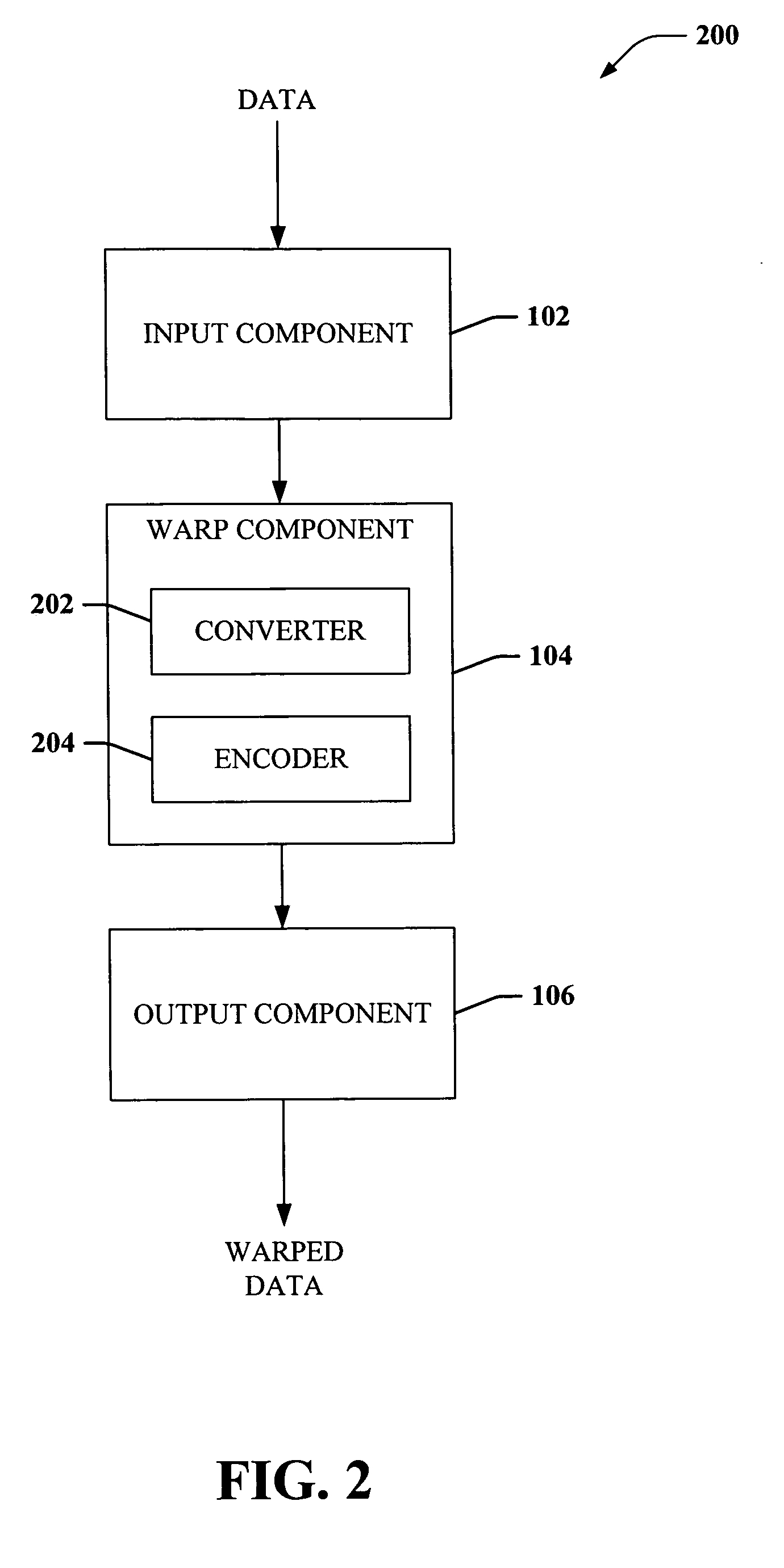

Systems and methods are disclosed that facilitate rapidly warping a two-dimensional image using integer math. A warping table can contain two-dimensional floating point output pixel offset values that are mapped to respective input pixel locations in a captured image. The warping table values can be pre-converted to integer offset values and integer grid values mapped to a sub-pixel grid. During warping, each output pixel can be looked up via its integer offset value, and a one-dimensional table lookup for each pixel can be performed to interpolate pixel data based at least in part on the integer grid value of the pixel. Due to the small size of the lookup tables, lookups can potentially be stored in and retrieved from a CPU cache, which stores most recent instructions to facilitate extremely rapid warping and fast table lookups.

Owner:MICROSOFT TECH LICENSING LLC

Amorphous polyaryletherketone and blends thereof for use in additive manufacturing

ActiveUS20170096576A1High melt flowHigh viscosityAdditive manufacturing apparatusAdditive manufacturing with liquidsFused filament fabricationAdditive layer manufacturing

A material for use in a fused filament fabrication (FFF) printer comprises a polyaryletherketone (PAEK) having an amorphous morphology. In some embodiments, the material also includes a PAEK having a semi-crystalline morphology.

Owner:AREVO INC

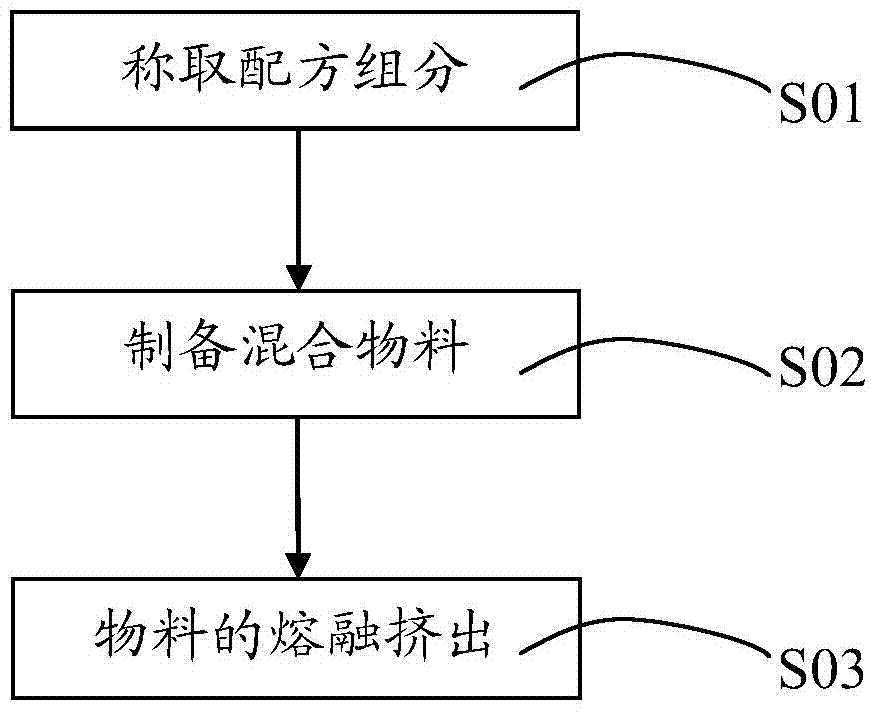

Polyamide material and its preparing process

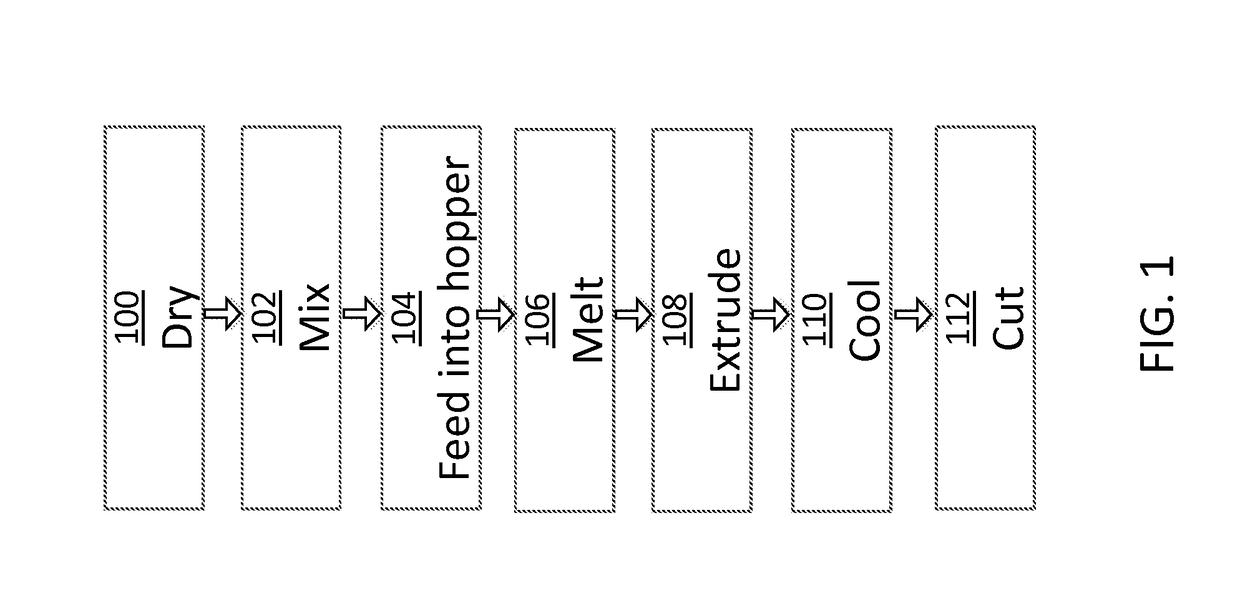

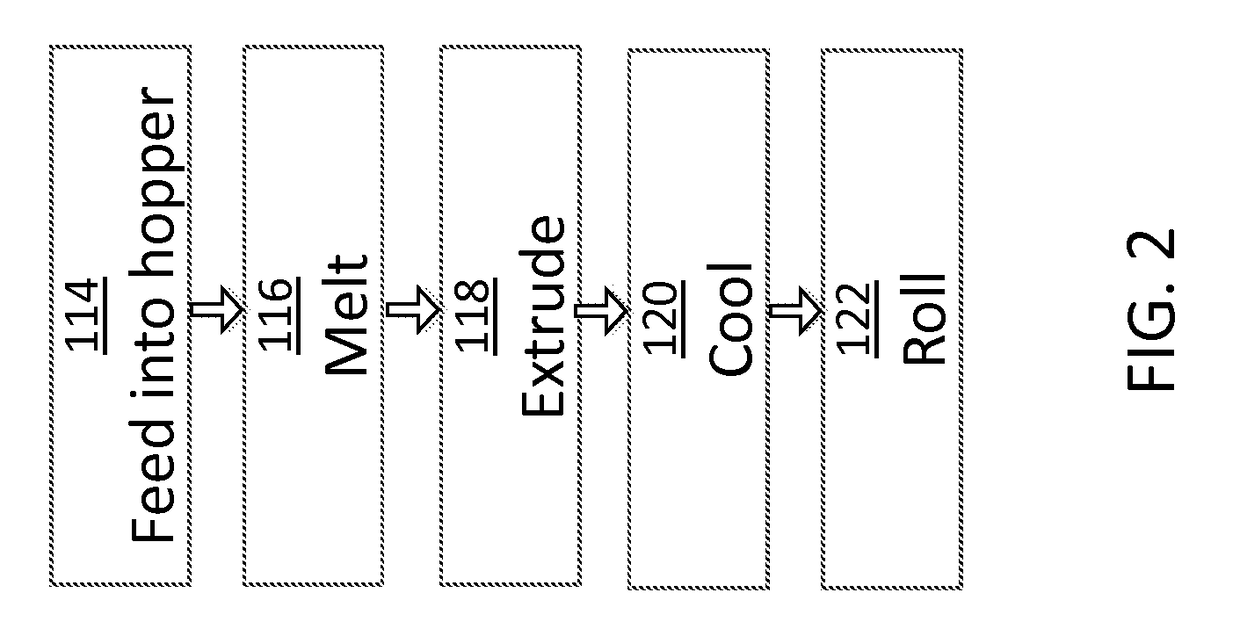

The invention discloses a polyamide material and making method, which comprises the following parts: 45-65% PA, 10-40% glass fiber, 2-10% compatible flexibilizer, 5-25% mineral fill, 0.2-2% antioxidant and 0.1-2% heat stabilizer. The making method comprises the following steps: weighing raw material; disposing the surface of glass fiber through gamma-amphotaethoxy silane; blending polyamide, compatible flexibilizer, heat stabilizer, anti-oxidant and mineral fill in the high-speed blender for 1-4min; placing glass fiber and mixed raw material in the double-screw squeezer to mix; fusing; squeezing; graining.

Owner:SHENZHEN KEJU NEW MATERIAL

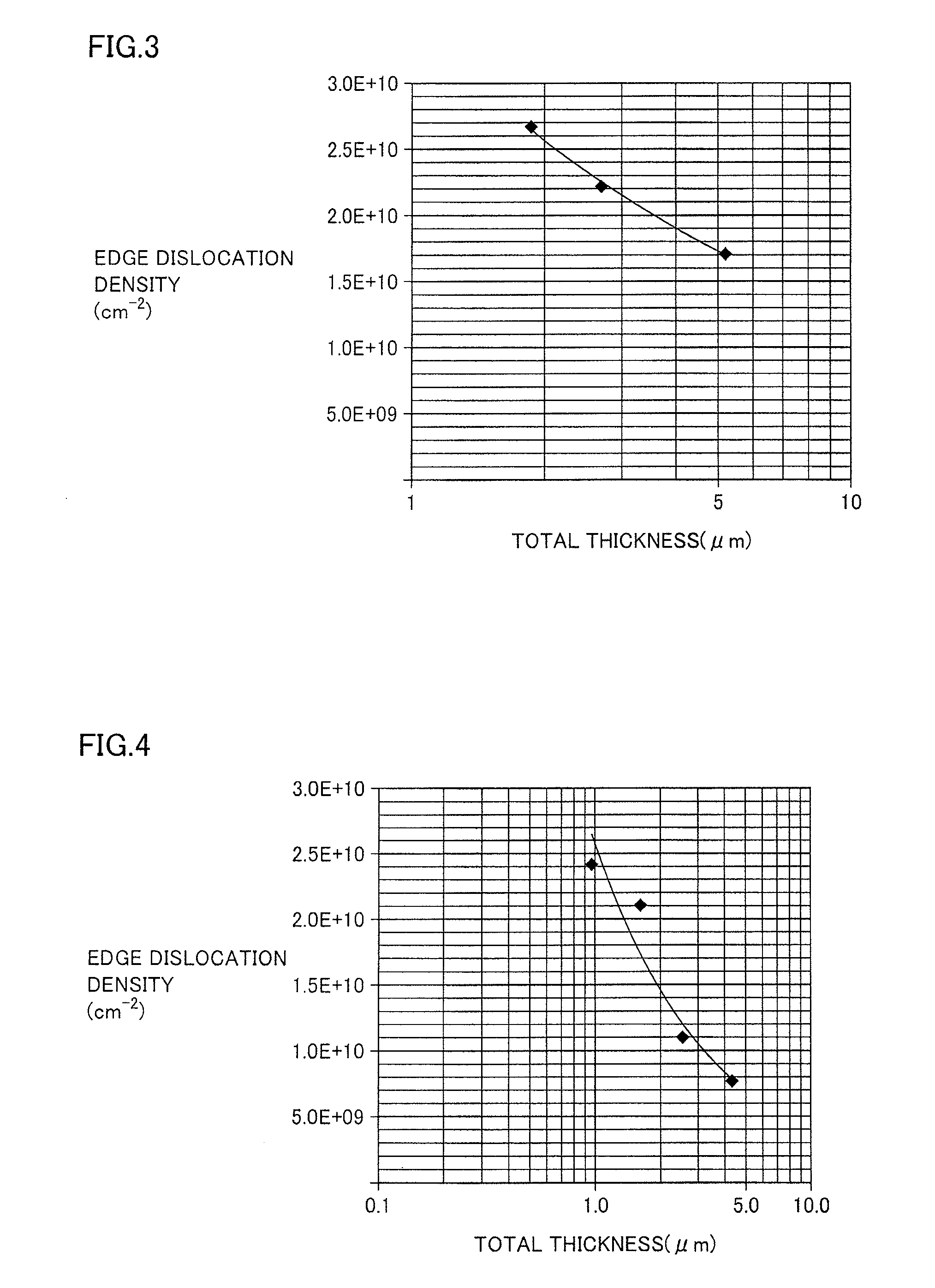

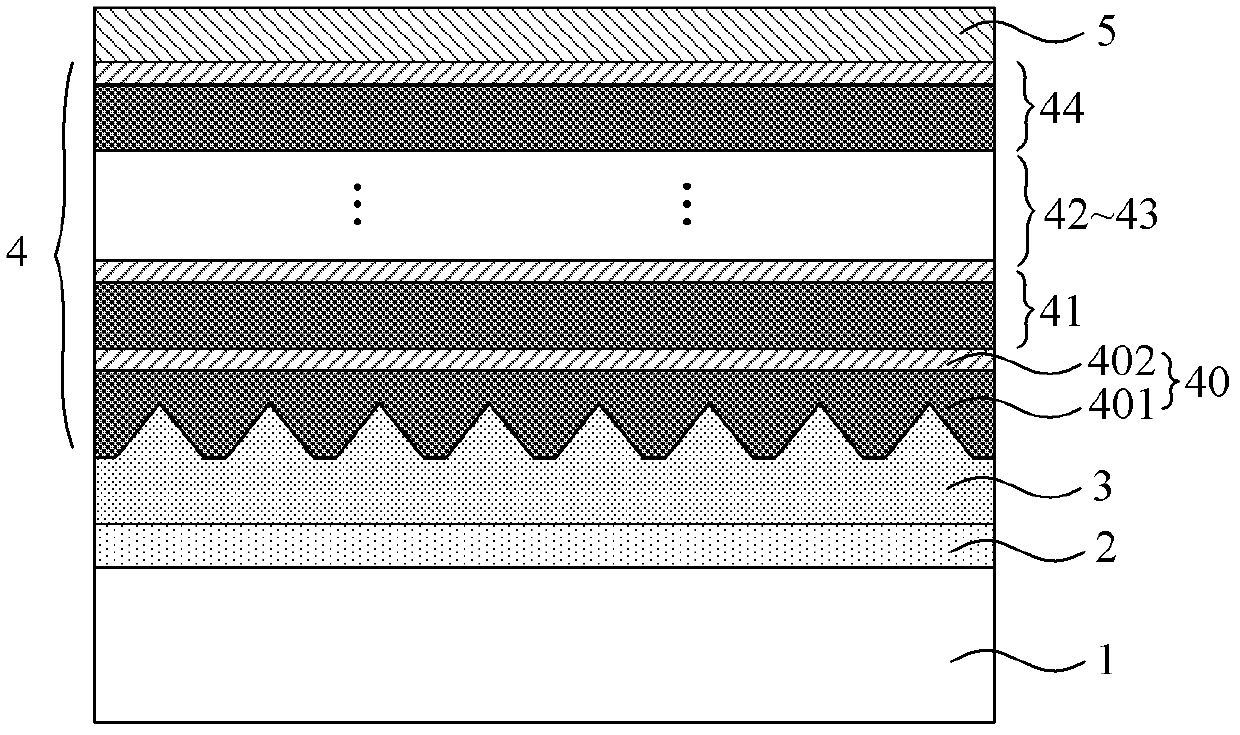

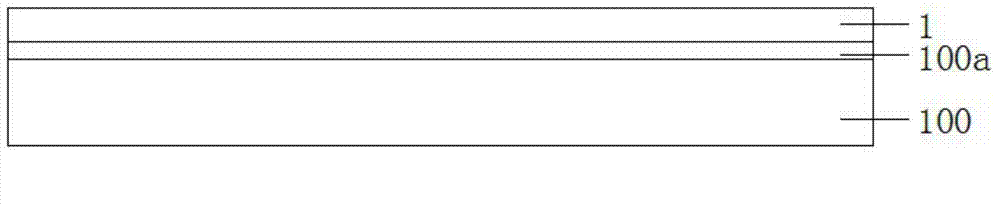

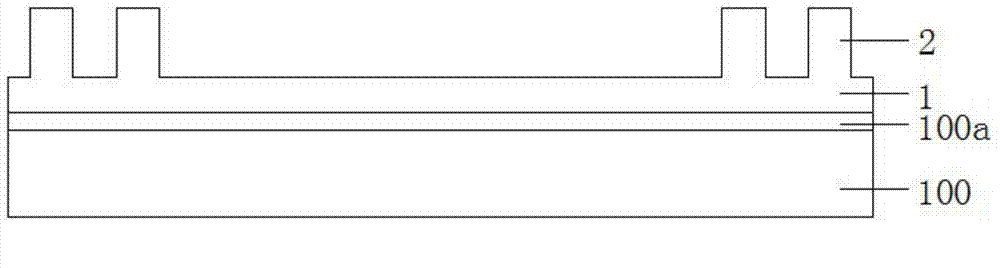

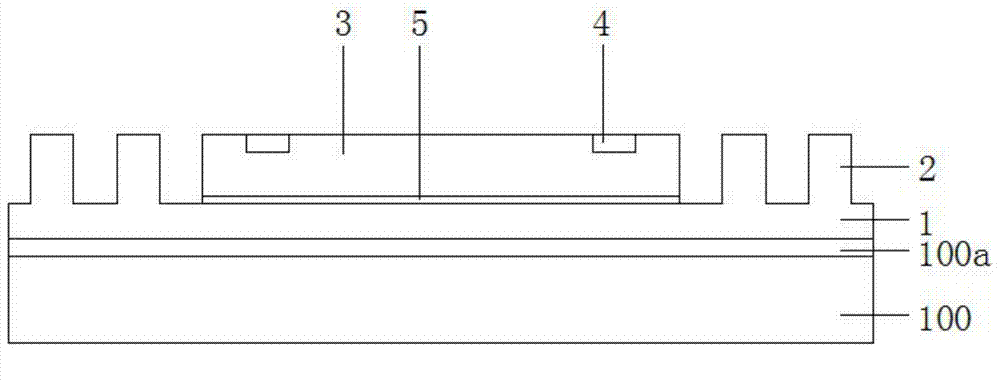

Epitaxial wafer including nitride-based semiconductor layers

InactiveUS20130020581A1Improve warpageHigh crystallinitySemiconductor/solid-state device manufacturingSemiconductor devicesNitrideSemiconductor

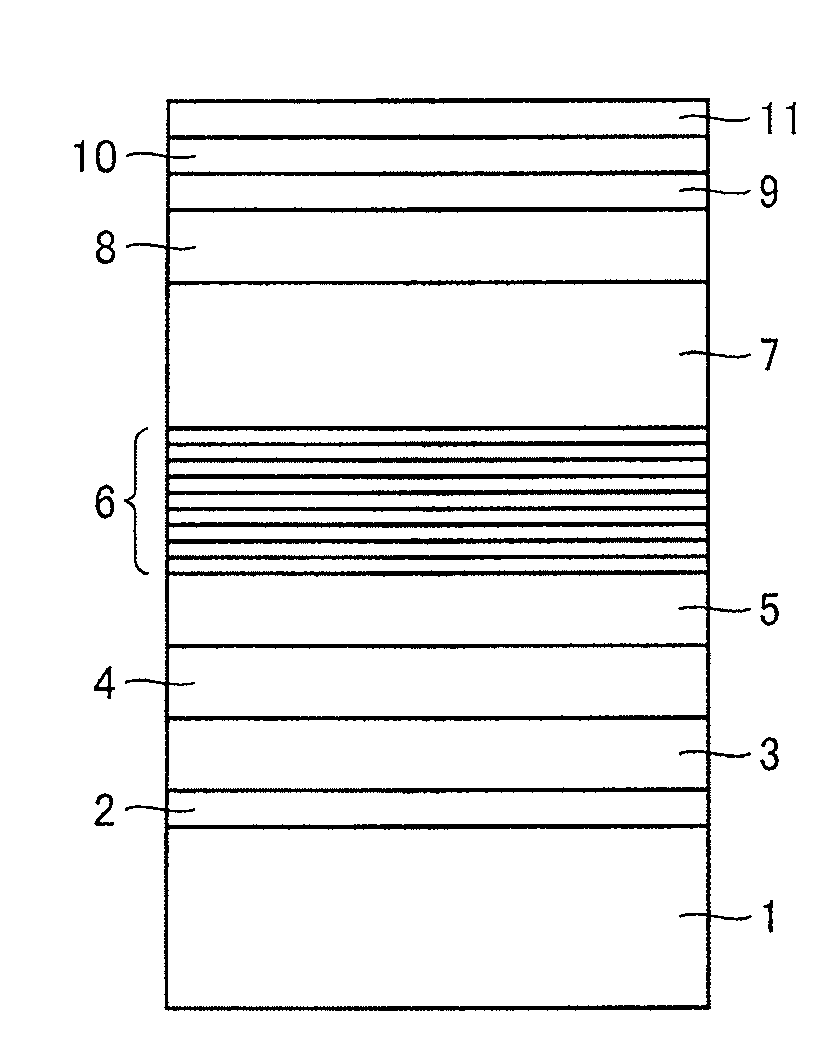

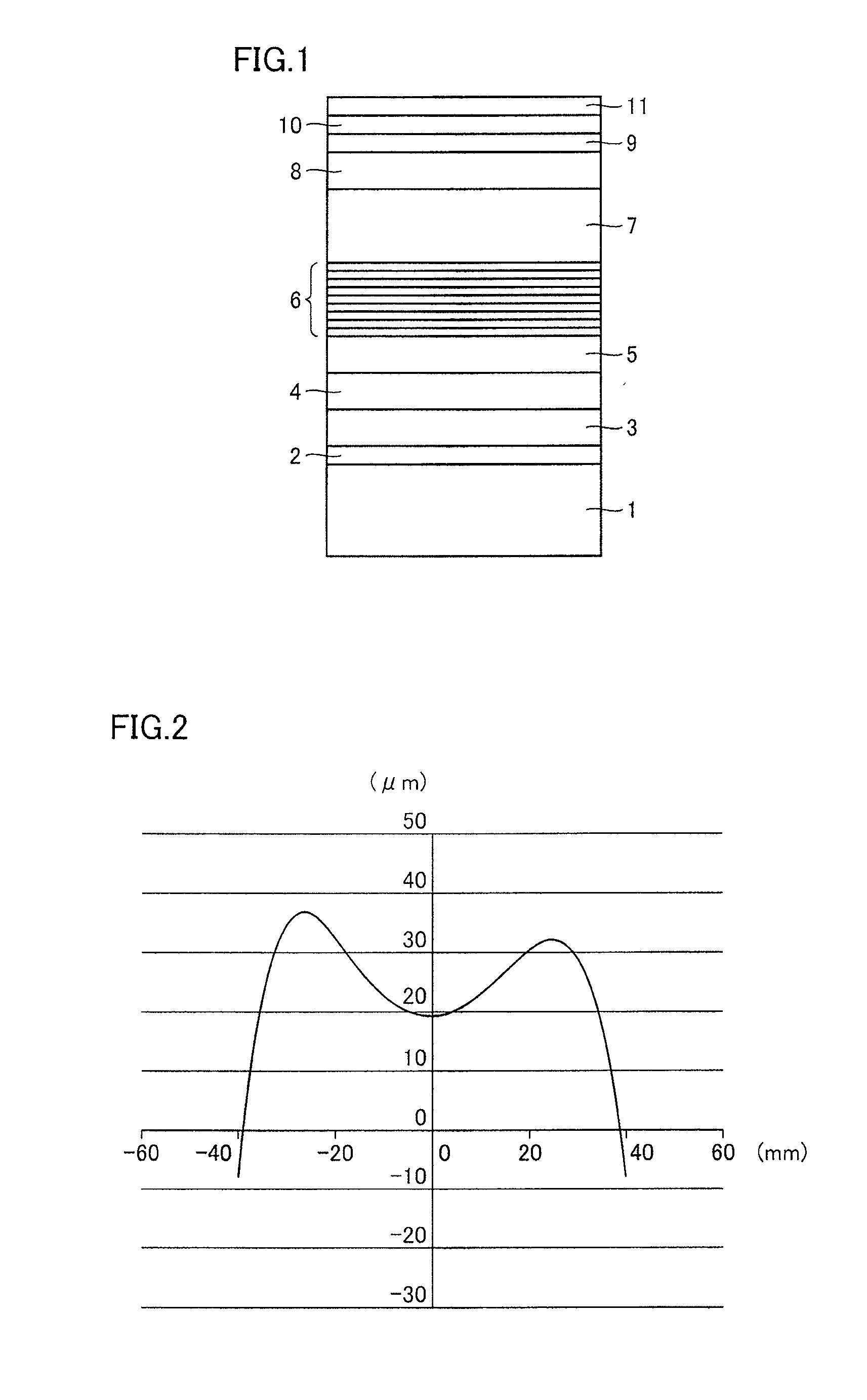

An epitaxial wafer including nitride-based semiconductor layers usable for a hetero-junction field effect type transistor, includes a first buffer layer of AlN or AlON, a second buffer layer of AlxGa1-xN having its Al composition ratios decreased in a stepwise fashion, a third buffer layer including a multilayer of repeatedly stacked AlaGa1-aN layers / AlbGa1-bN layers disposed on the second buffer layer, a GaN channel layer, and an electron supply layer in this order on a Si substrate, wherein the Al composition ratio x in the uppermost part of the second buffer layer is in a range of 0≦x≦0.3.

Owner:SHARP KK

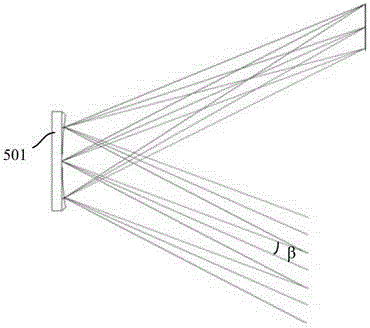

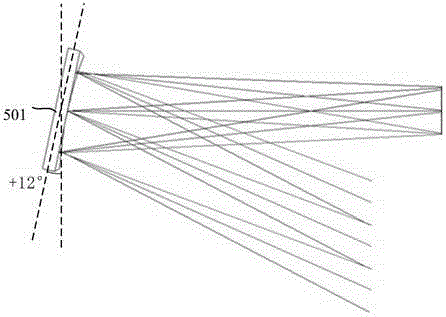

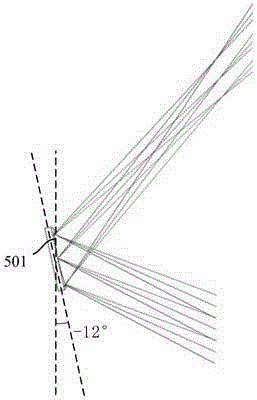

Light curing 3D printing equipment and image exposure system

ActiveCN104802400AHigh-resolutionHigh precisionAdditive manufacturing apparatusCeramic shaping apparatusCamera lensSpatial light modulator

The invention relates to an image exposure system of 3D printing equipment. The image exposure system comprises a spatial light modulator, a light source, a projection lens, a micro-displacement driving mechanism and a controller. The spatial light modulator has multiple micro-mirrors and is used for adjusting reflection direction of light irradiated on the micro-mirrors according to control signals, and each micro-mirror is a concave mirror and is used for converging light irradiated on the micro-mirror into micro-spot with the size being less than corresponding pixel size of the micro-mirror. The light source generates a light beam irradiated on the spatial light modulator. The projection lens is directed at a first direction of the spatial light modulator to make the light source to be projected onto the surface of a light-sensitive material through a micro-spot array formed by the micro-mirrors. The micro-displacement driving mechanism is connected with the spatial light modulator and can drive the spatial light modulator to move in a third direction and a fourth direction, which are perpendicular to each other, so as to fine-tune the position of the micro-spot array projected on the surface of the light-sensitive material. The controller is used for ordering the light source to expose more than once and ordering the micro-displacement driving mechanism to move during each exposure so as to project the exposed micro-spot array to different positions on the surface of the light-sensitive material.

Owner:PRISMLAB CHINA +1

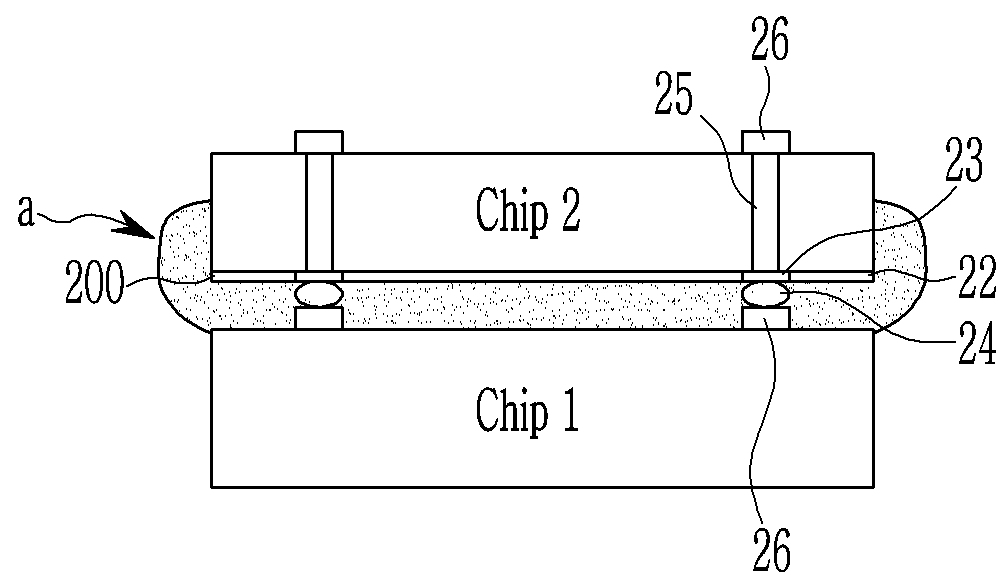

Three-dimensional fan-out type PoP packaging structure and manufacturing process

ActiveCN103887291AImprove slip misalignmentImprove warpageSemiconductor/solid-state device detailsSolid-state devicesEngineeringFiller metal

The invention relates to a three-dimensional fan-out type PoP packaging structure and a manufacturing process. Metal layers are manufactured on a carrying sheet through the process with the front faces of chips facing upwards, grooving is conducted according to the arrangement positions of the chips, and electrodes connected with other packaging units are manufactured according to the requirements. Rerouting layers are manufactured on the front faces of the chips after plastic package, and bonding pads of the chips are fanned out to form first layer chip circuits. Second layer chips are manufactured by repeating the process with the front faces of the chips facing upwards, and the corresponding chip and the corresponding metal layer are pasted on the first packaging unit so that the first packaging unit can be connected with the previous packaging unit. Plastic package, drilling and metal filling are then conducted, and RDL manufacturing is conducted on the second layer chips. Multiple layers of chips are stacked by repeating the stacking process, or lower bump metal layer manufacturing and ball planting are conducted on RDL layers. The carrying sheet is removed after ball planting is completed, a back face rerouting layer is arranged on the back face of each first layer chip, the corresponding packaging unit is obtained, and the packaging units are stacked to form the PoP packaging structure. According to the three-dimensional fan-out type PoP packaging structure and the manufacturing process, slip dislocation caused by warping and expansion and contraction of plastic package materials can be effectively reduced.

Owner:江苏中科智芯集成科技有限公司

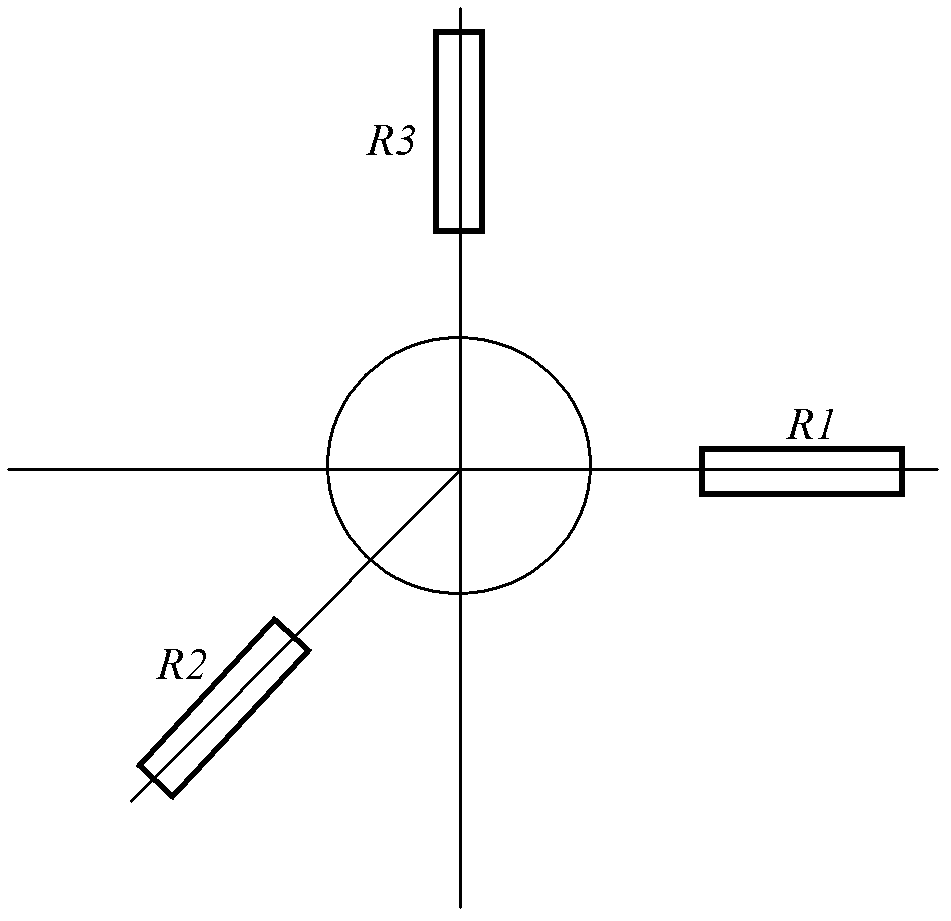

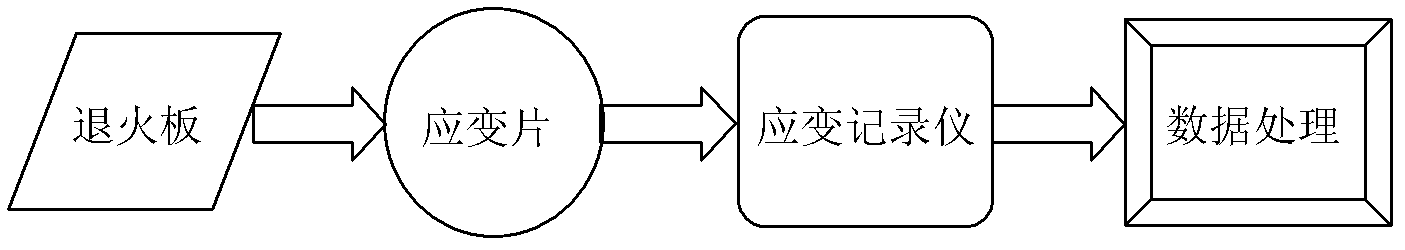

Method for determining precision of blind-hole method residual stress testing system

InactiveCN102608169AEasy to get materialsSimple heat treatmentApparatus for force/torque/work measurementMaterial resistanceStrain gaugeEnvironmental geology

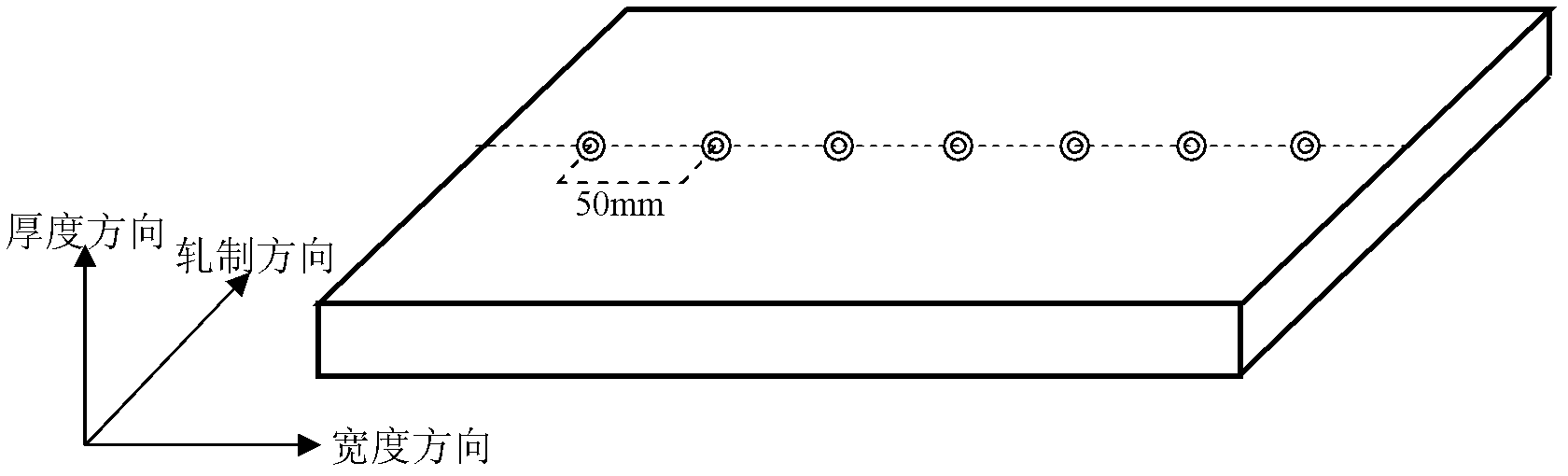

The invention belongs to the technical field of precision determination, and relates to a method for determining the precision of a blind-hole method residual stress testing system. The method comprises the specific technologies of sample plate sampling, stress-relieving annealing, sample surface preparing and strain gauge adhering, data line connection, testing parameter configuring, hole drilling, data collecting, data processing, and precision determining. The method is advantaged in stable technology and accurate result. With the method, deviations of a testing system can be visually, rapidly, and quantitatively determined. Therefore, testing errors caused by influencing factors such as strain gauge quality, hole drilling eccentricity, and additional strain can be conveniently adjusted. Thus, the accuracy of the residual stress testing before and after hot rolled coil decoiling can be ensured.

Owner:SHOUGANG CORPORATION

Method for reducing warping stress of LED epitaxy

InactiveCN103296151AImprove wavelength uniformityImprove wavelength yieldSemiconductor devicesLength waveSapphire substrate

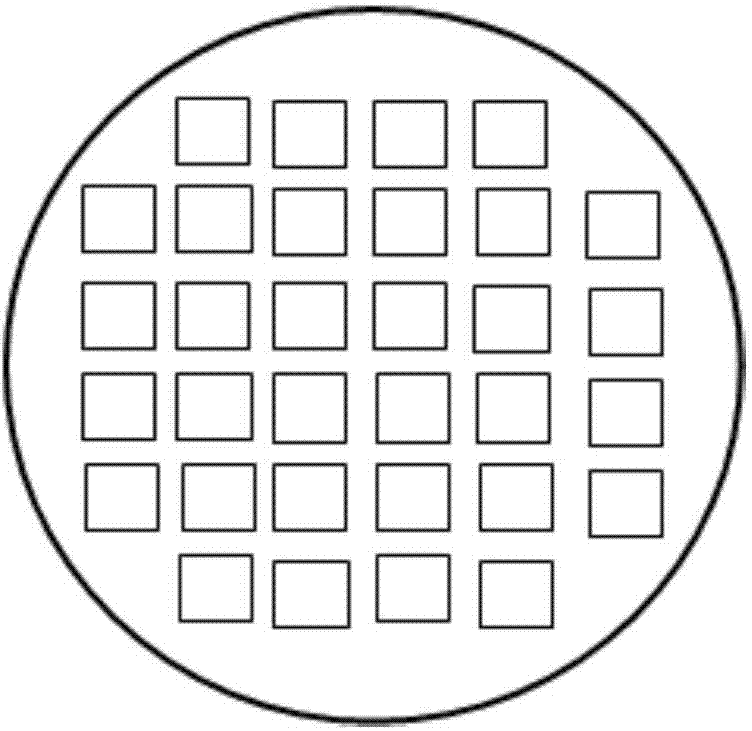

The invention provides a method for reducing warping stress of LED epitaxy. The method comprises the steps of forming a GaN buffer layer on a sapphire substrate in an epitaxial mode, then growing a GaN layer on the GaN buffer layer in a three-dimensional mode, and forming a GaN epitaxial wafer which is provided with an island-shaped surface; after cooling is conducted, forming a double-layer thin film on the GaN epitaxial wafer provided with the island-shaped surface in an epitaxial mode, wherein the double-layer thin film comprises the GaN layer and an All-xGaxN layer, and forming double-layer thin films repeatedly in the epitaxial mode so as to form a superlattice on the GaN epitaxial wafer provided with the island-shaped surface; growing the GaN layer on the superlattice in a two-dimensional mode, and finishing preparation of a GaN base layer on the sapphire substrate. A superlattice inserting layer structure is adopted to adjust and release the warping stress between the GaN epitaxial layer growing in the two-dimensional mode and the sapphire substrate, accordingly, the warping degree when a light-emitting layer is grown on the epitaxial wafer is improved, wavelength difference between the central part and the edge part of the epitaxial wafer after the light-emitting layer is grown can be reduced, uniformity of the wavelength of the epitaxial wafer is improved, and accordingly the wave length yield of the epitaxial wafer is improved.

Owner:EPILIGHT TECH

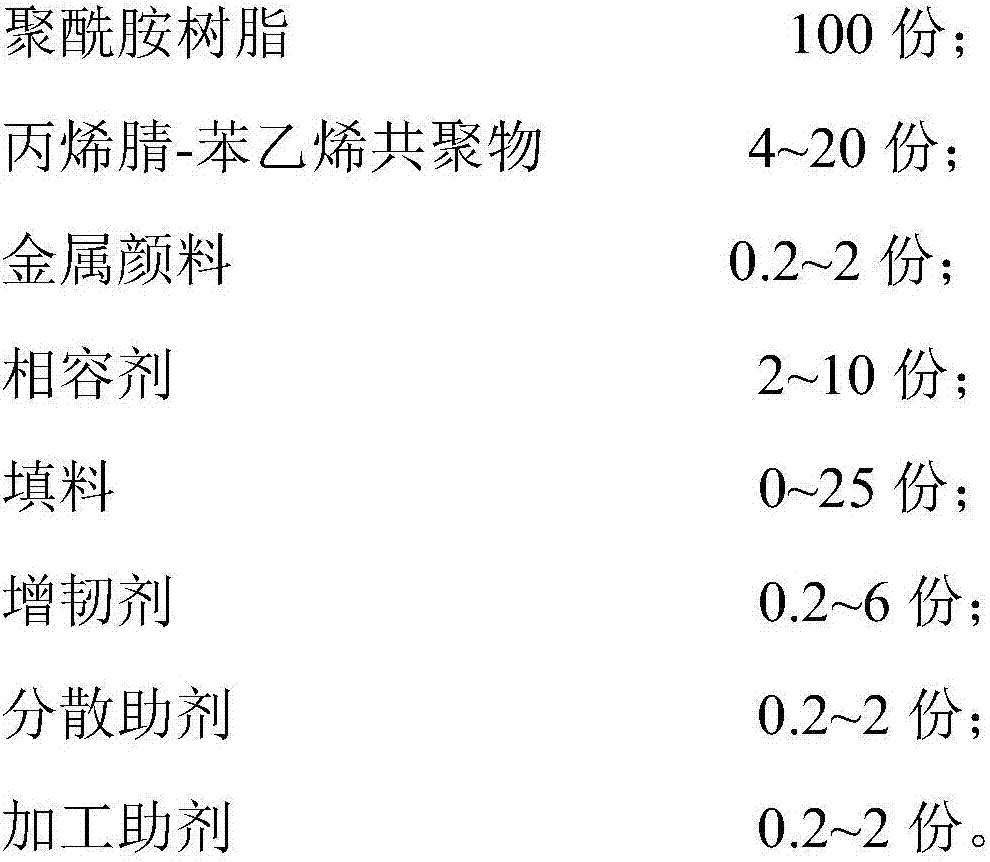

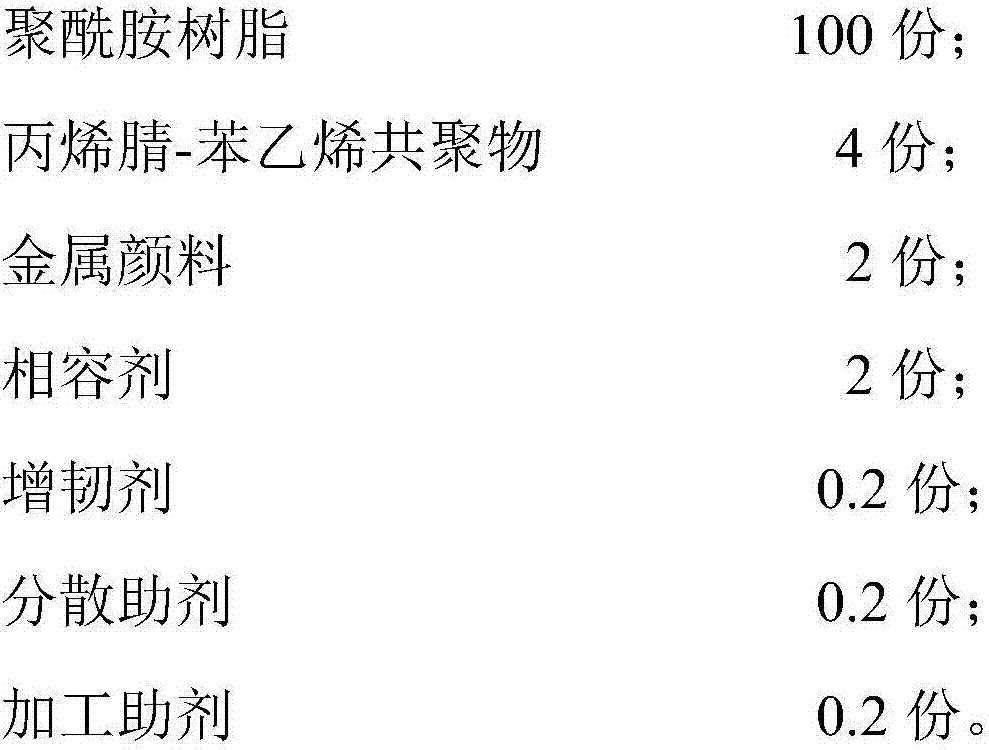

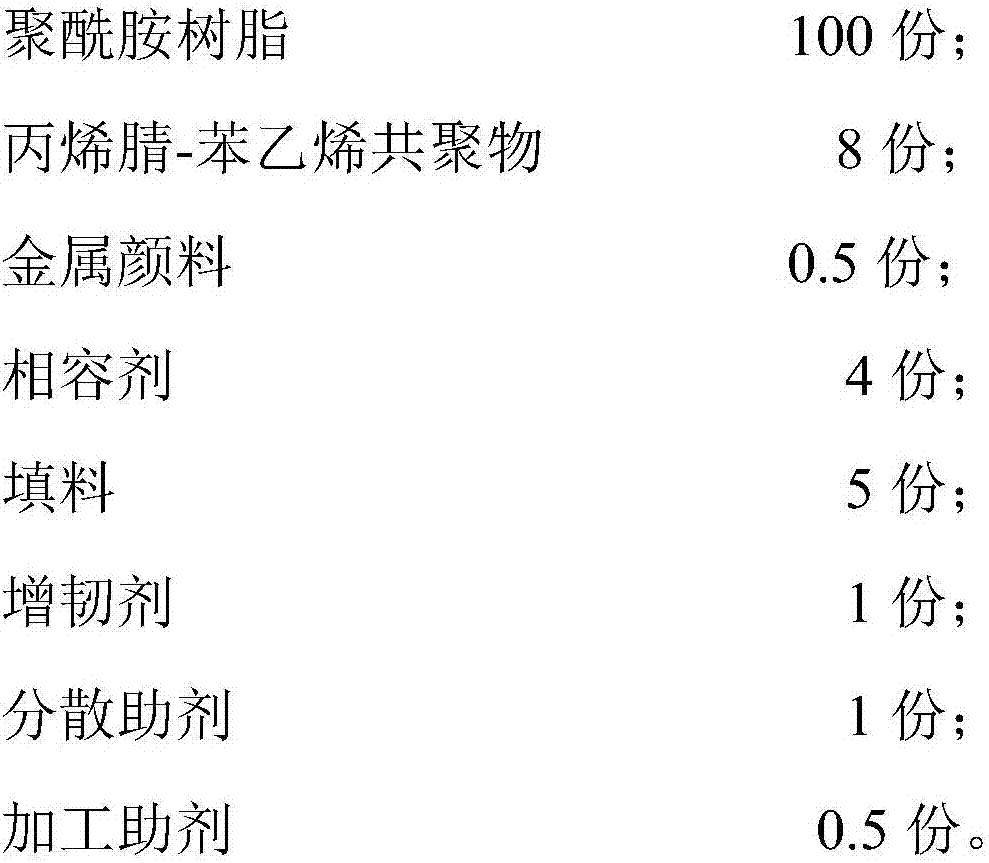

Spray-free polyamide compound with metallic luster and preparation method thereof

The invention discloses a spray-free polyamide compound with metallic luster. The spray-free polyamide compound is prepared from the following raw materials in parts by weight: 100 parts of polyamide resin, 4-20 parts of acrylonitrile-styrol copolymer, 0.2-2 parts of metallic pigment, 2-10 parts of compatilizer, 0-25 parts of filler, 0.2-6 parts of flexibilizer, 0.2-2 parts of dispersing auxiliary and 0.2-2 parts of processing agent. According to the invention, the acrylonitrile-styrol copolymer used as a modifier and the polyamide resin are compounded as a matrix resin of the compound, and meanwhile, the other raw material components are adjusted and the compatilizer, the dispersing auxiliary and the flexibilizer at a specific ratio are supplemented, so that the processing performance of the polyamide compound and the mechanical property and appearance effect of the formed polyamide compound are optimized.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

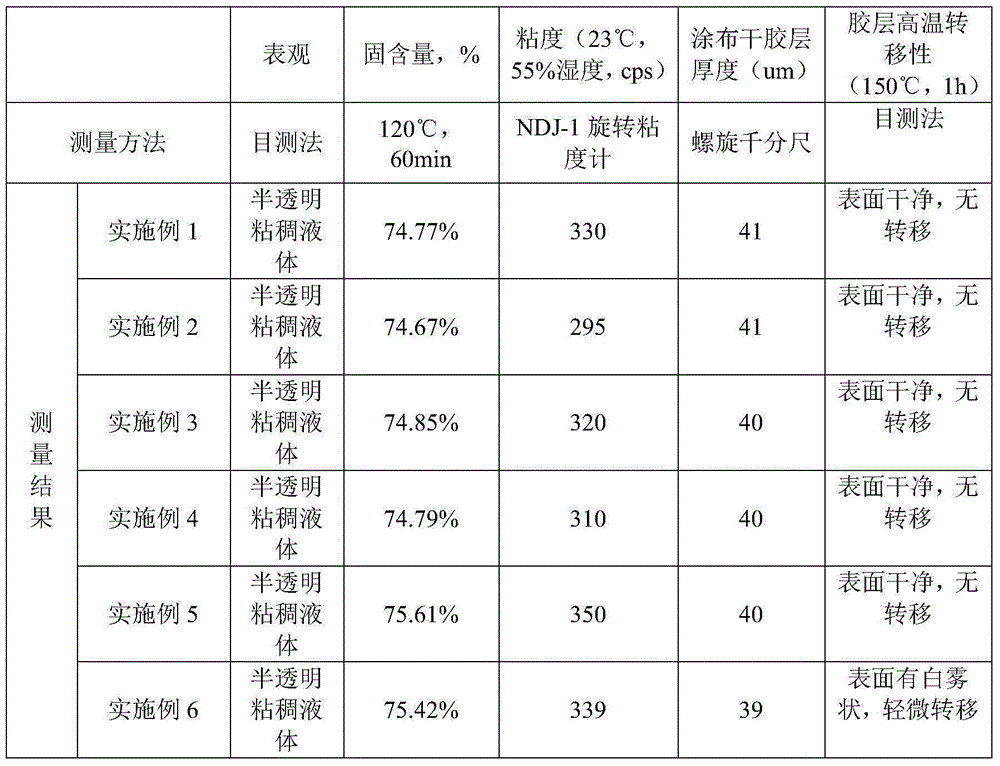

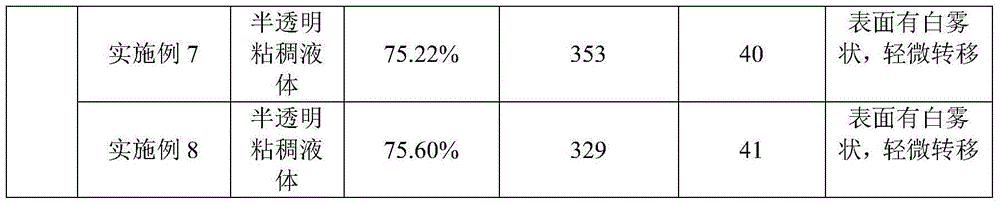

Peelable glue coating composition and peelable glue coating as well as preparation method and application of peelable glue coating

The invention provides a peelable glue coating composition and a peelable glue coating as well as a preparation method and an application of the peelable glue coating. The peelable glue coating composition comprises the following components in parts by weight: 80-120 parts of an acrylate type oligomer, 8-20 parts of a dilutive monomer, 0.1-1.5 parts of a peeling force modifying agent, 2-12 parts of a triggering agent and 30-50 parts of an organic solvent. The peelable glue coating composition is relatively high in transparency and relatively high in light transmittance and relatively low in haze after film formation. Meanwhile, a coating formed by curing the peelable glue coating composition is relatively high in high temperature resistance and relatively high in peelability. By the high temperature resistance, the coating is good in adhesion property on the surface of a functional hardened layer, and the problems of air bubbles and warping can be effectively improved. By the peelability, the problem of glue layer residues caused during peeling of the coating can be reduced.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

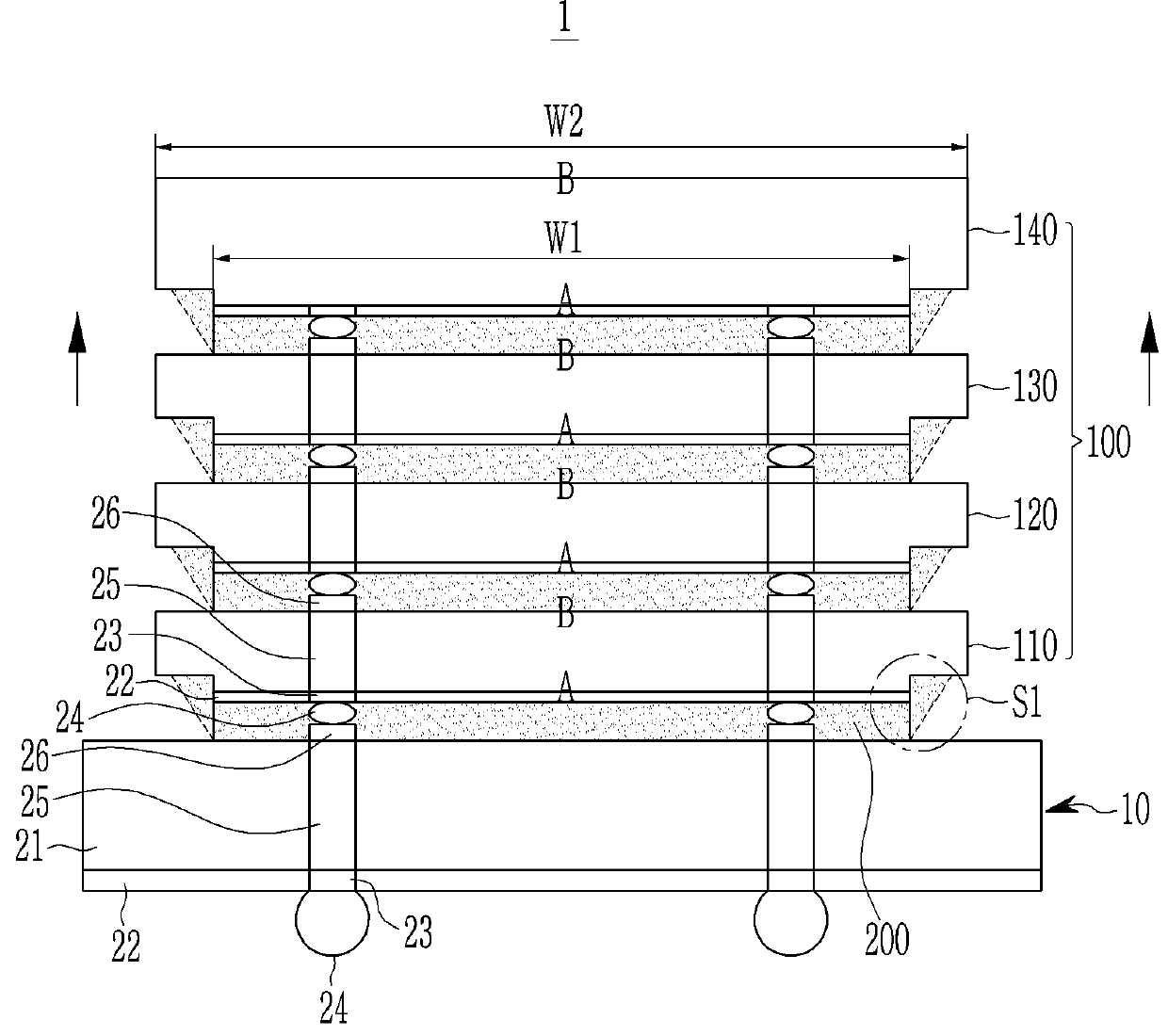

Semiconductor package and fabrication method thereof

ActiveUS20180166420A1Increase process marginImprove warpageSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package includes a semiconductor chip in which a side step or a side slope formed toward an inactive surface from an active surface is included and a width of the active surface is smaller than a width of the inactive surface, and an underfill which is disposed on the active surface and positioned at an inner side of the edge of the semiconductor chip.

Owner:SAMSUNG ELECTRONICS CO LTD

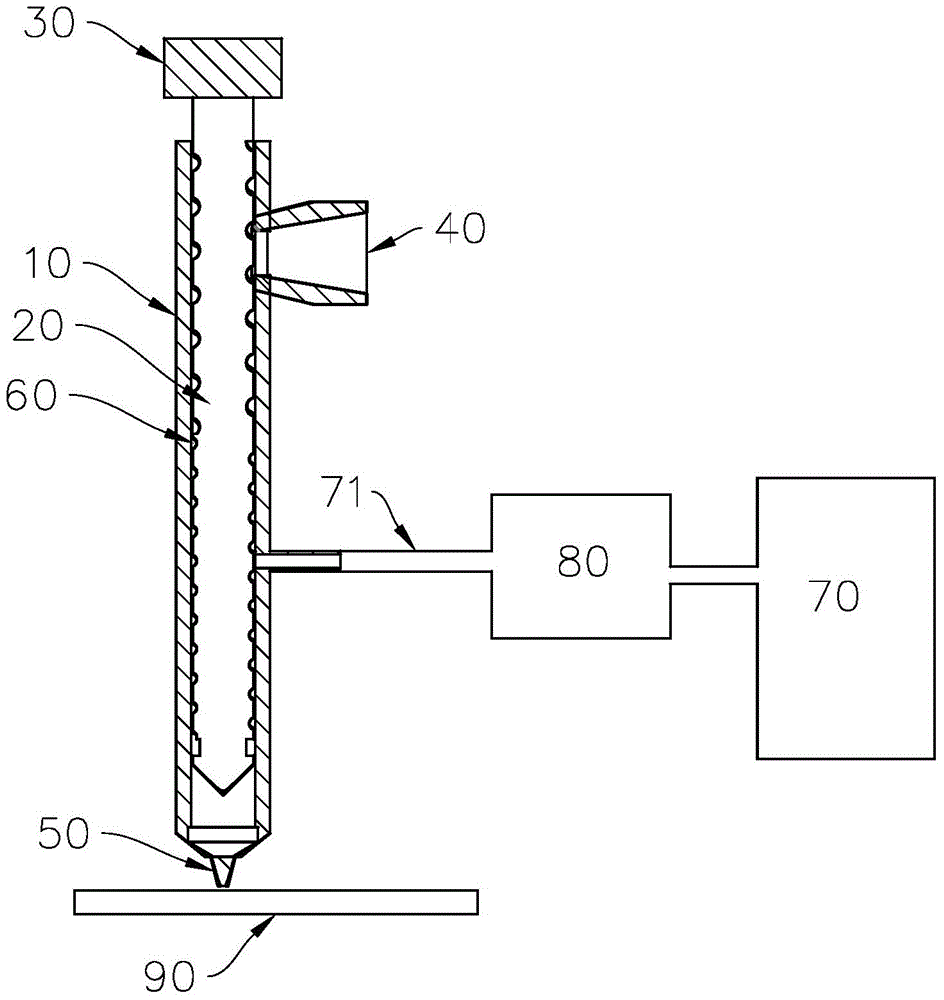

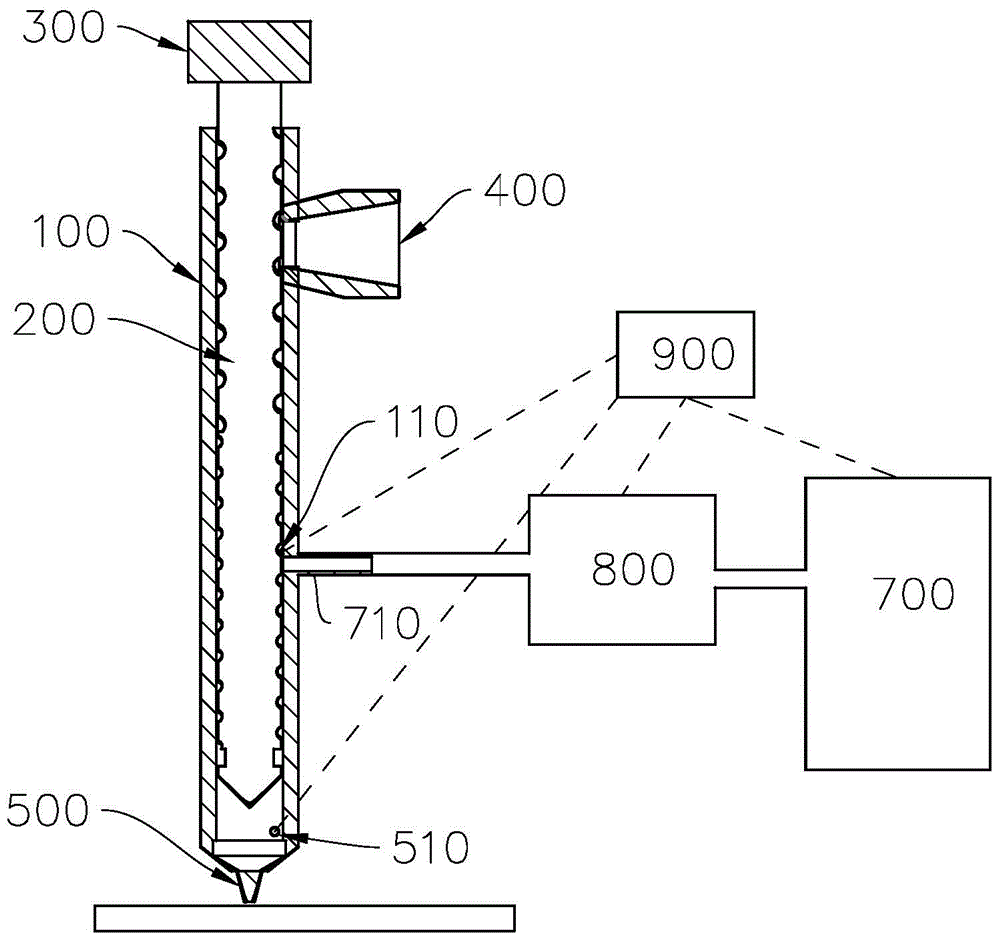

Three-dimensional printer and printing method and three-dimensional printing head

ActiveCN104875389ALow densityReduce the density valueAdditive manufacturing apparatusEngineeringVolumetric Mass Density

The invention relates to a three-dimensional printer, a three-dimensional printing head and a printing method. The three-dimensional printing head comprises a material volume cavity, wherein a screw rod is arranged in the material volume cavity, a motor is connected with the screw rod, a material supply device is communicated with the material volume cavity, a printing nozzle is arranged on the end part of the material volume cavity, a heater is arranged on the material volume cavity and positioned between the material supply device and the printing nozzle, and a supercritical fluid supply system is communicated with the material volume cavity. A molten printing material is mixed with supercritical fluid to generate a single-phase molten mixture under the mixing and stirring effect of the screw rod, and a uniform microporous bubble formation effect is formed, so that the density value of a printing object can be reduced, the size deviation of the three-dimensional printing object can be alleviated, the flatness and straightness of the three-dimensional printing object can be improved by more than 50 percent, the temperature for printing the molten printing material is effectively lowered, the energy is saved, and the operation personnel is prevented from being scalded.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

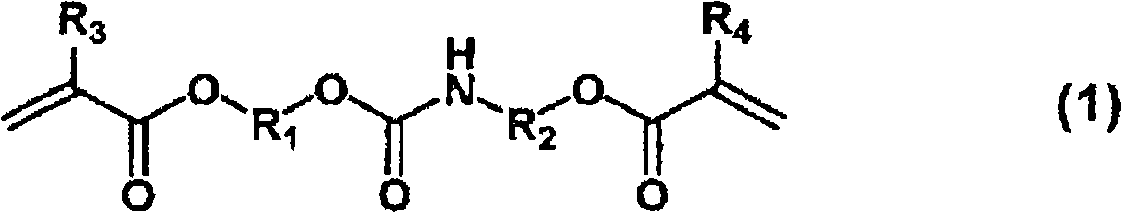

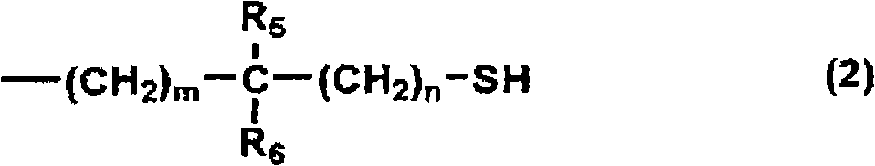

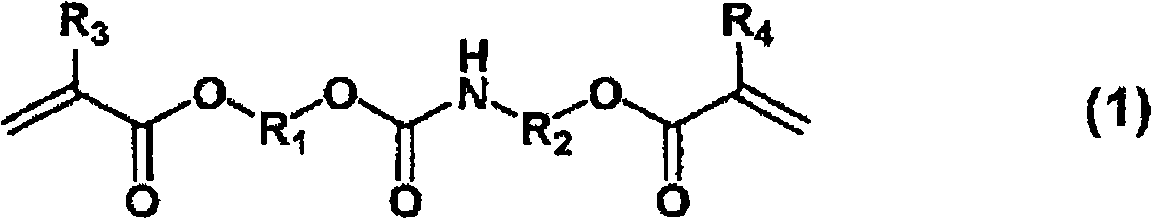

Curable composition and cured product thereof

InactiveCN101679635AExcellent surface hardnessImprove scratch resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceCarbamate

Owner:SHOWA DENKO KK

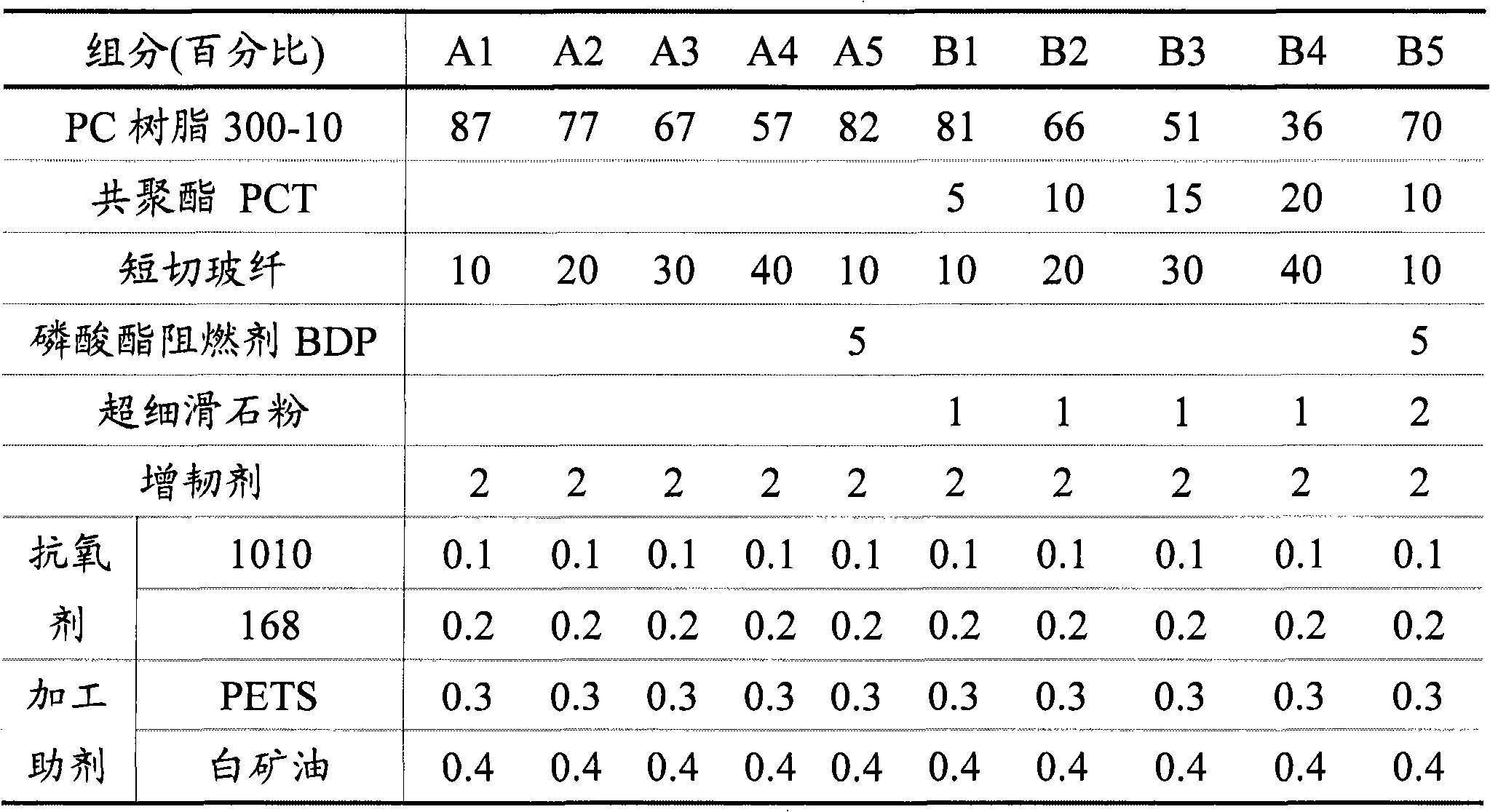

Anti-warp glass fiber reinforced polycarbonate composition with high rigidity and toughness and good appearance

The invention discloses an anti-warp glass fiber reinforced polycarbonate composition with high rigidity and toughness and good appearance, which comprises the following components by weight percentage: 30 to 89.5 percent of polycarbonate resin, 5 to 20 percent of copolyester resin, 5 to 40 percent of alkali-free glass fiber and the balance of assistant. The composition has high rigidity and toughness, has effects on obviously improving the warping degree of injection-molded parts and the surface appearance and can be applied to the fields of precision machinery parts, office equipment parts, computer socket connectors, automobile bracket structural members, and the like.

Owner:KINGFA SCI & TECH CO LTD +1

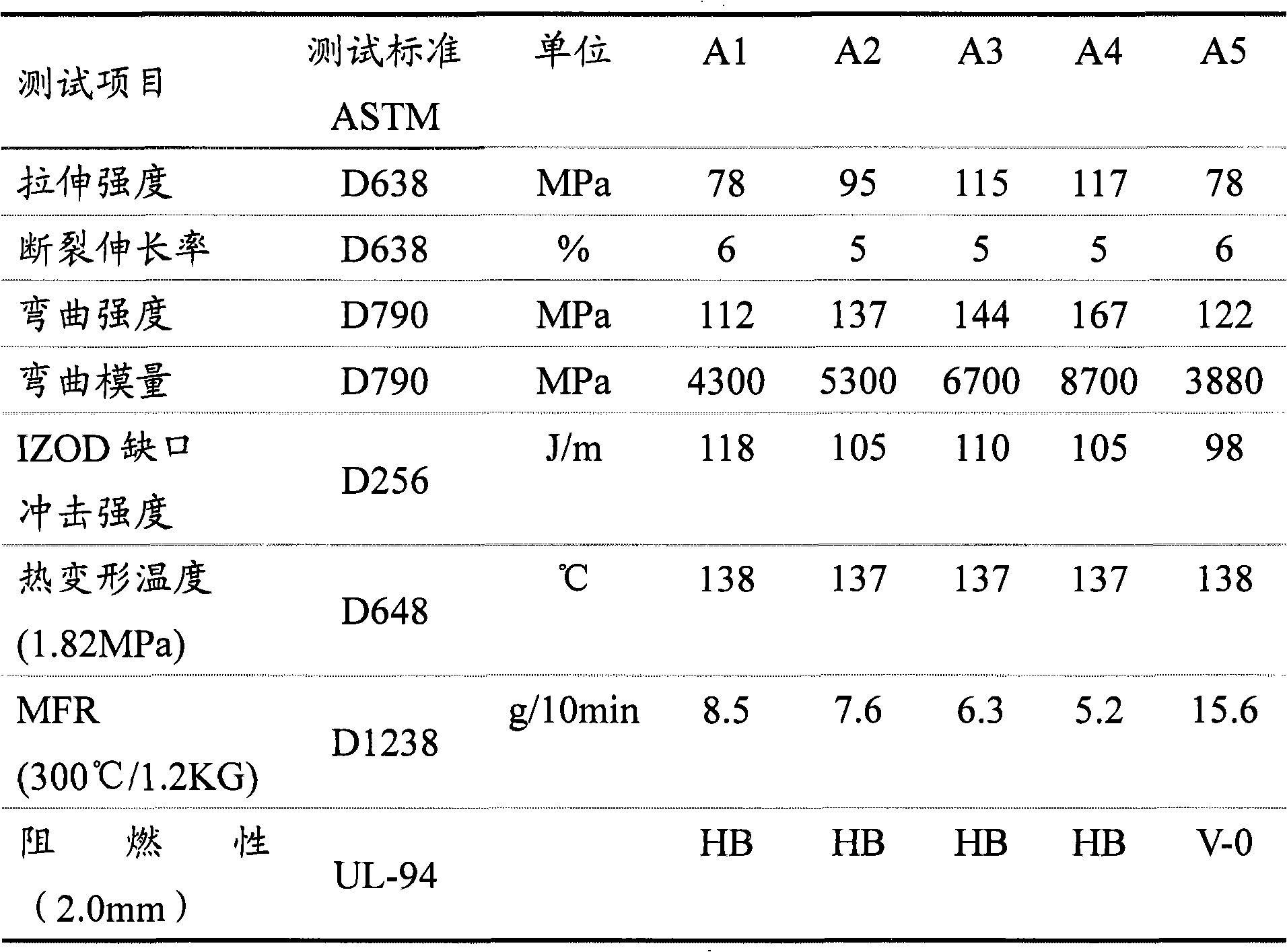

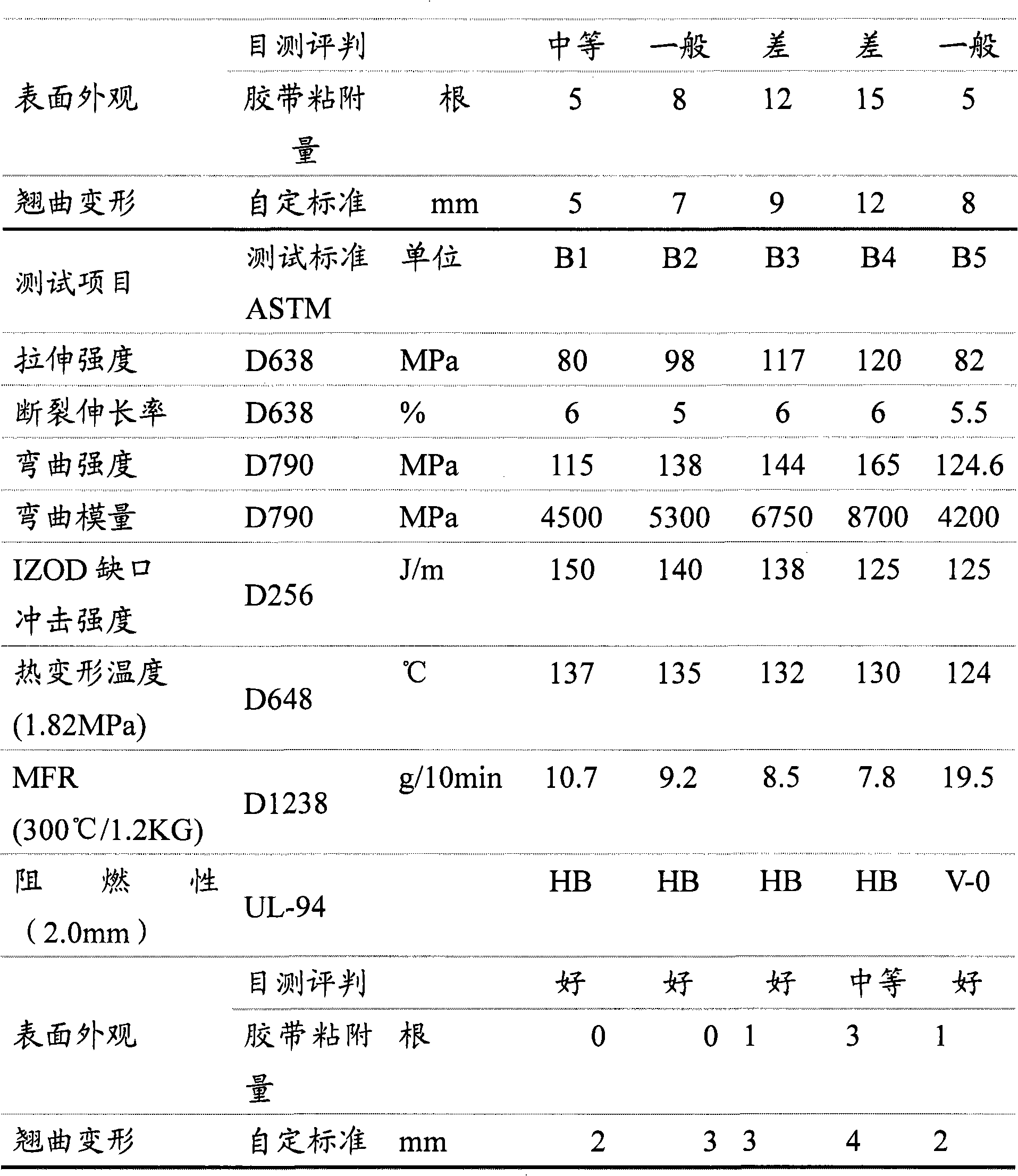

Low-fiber-emergence low-warping high-tenacity flame-retardant PET/PETG composite material and preparation method

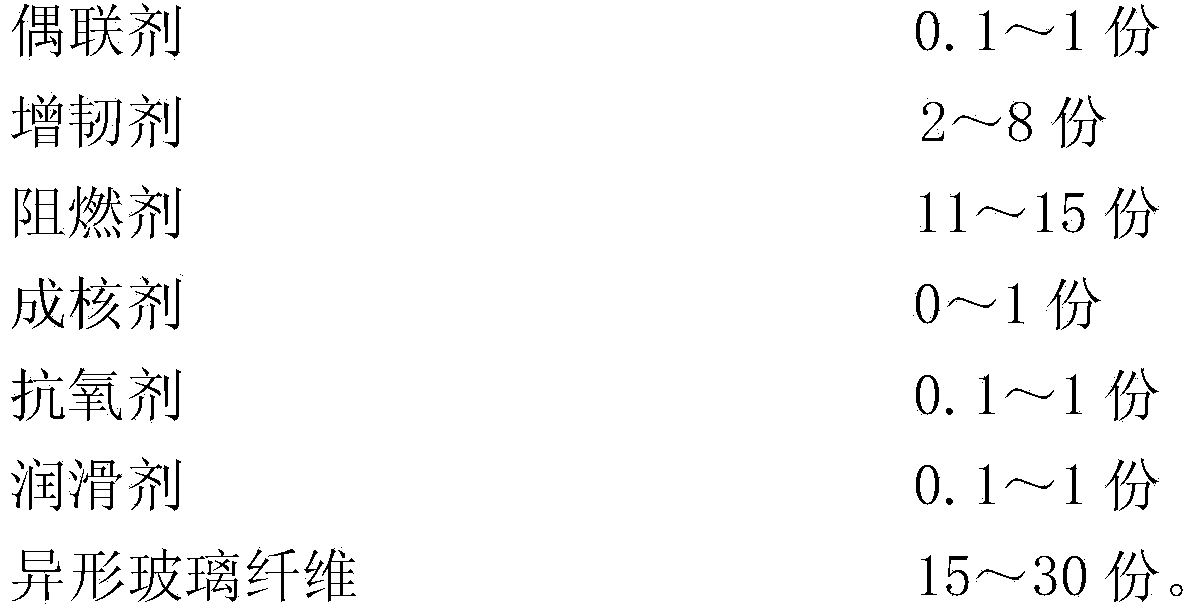

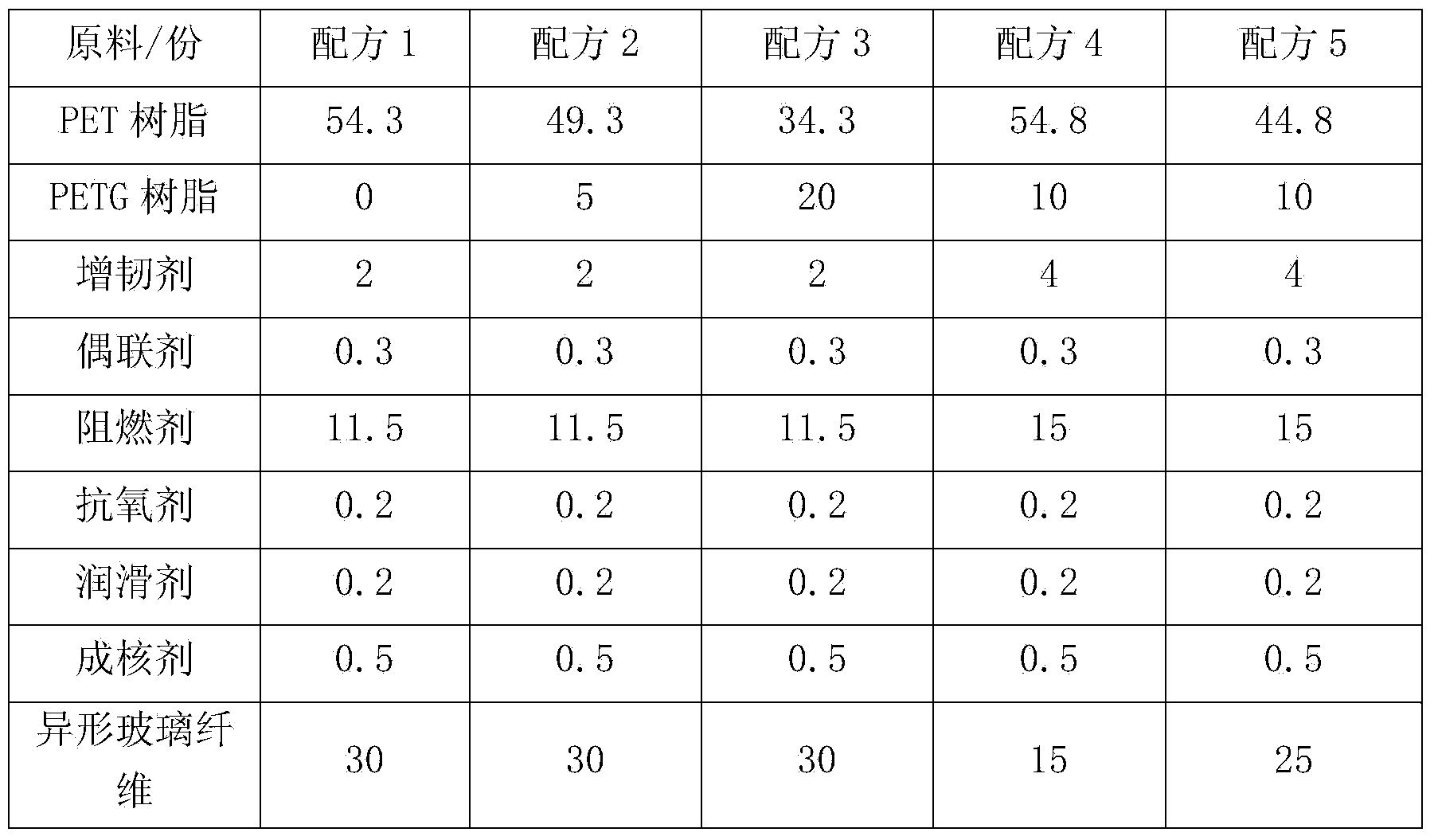

The invention discloses a low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material and a preparation method, and relates to the field of high polymer materials. The composite material is prepared by mixing 30-50 parts of PET resin, 5-20 parts of PETG resin, 0.1-1 part of a coupling agent, 2-8 parts of a flexibilizer, 11-15 parts of a fire retardant, 0-1 part of a nucleating agent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricating agent, adding 15-30 parts of irregular-shaped glass fibers during the extrusion process of a twin-screw extruder, extruding, and pelletizing to obtain. The preparation method of the low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material disclosed by the invention utilizes the characteristic that the PETG resin is well compatible with the PET resin; the addition of the flame-retardant system PETG, the flexibilizer and the nucleating agent greatly improves the processing performance, the surface performance and the impact performance of the composite material, while influencing the other performances a little; meanwhile, the addition of the PETG and the irregular-shaped glass fibers reduces the crystallization temperature and the crystallization rate of the material, and lowers the warping degree.

Owner:古道尔工程塑胶(深圳)有限公司

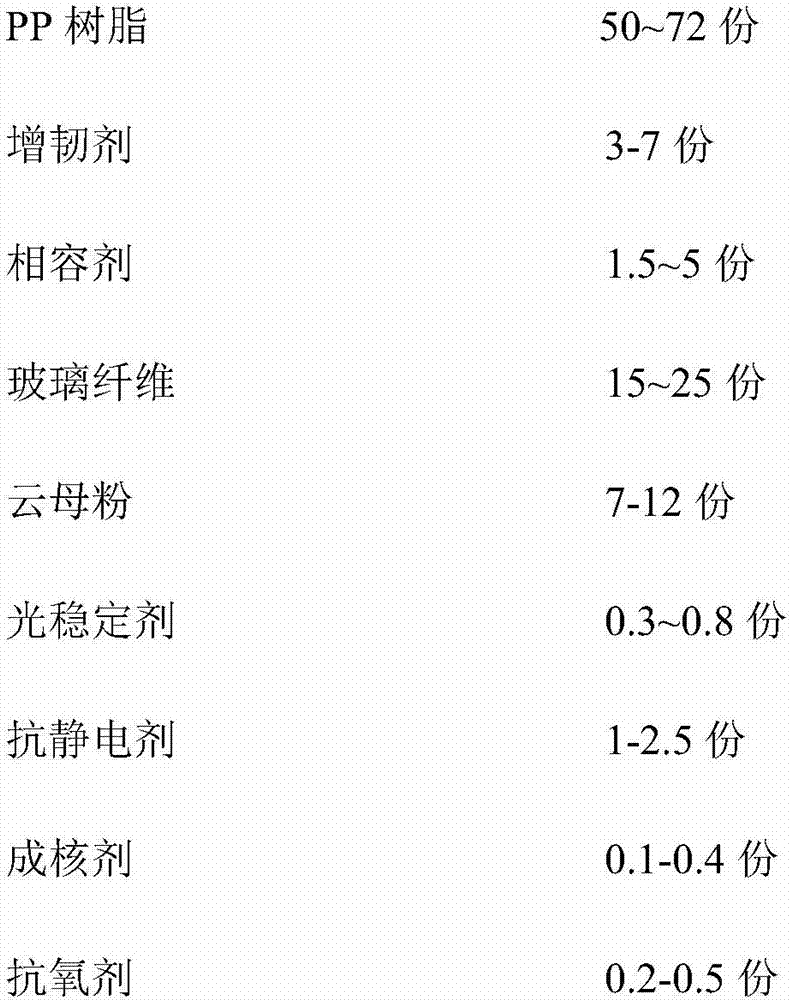

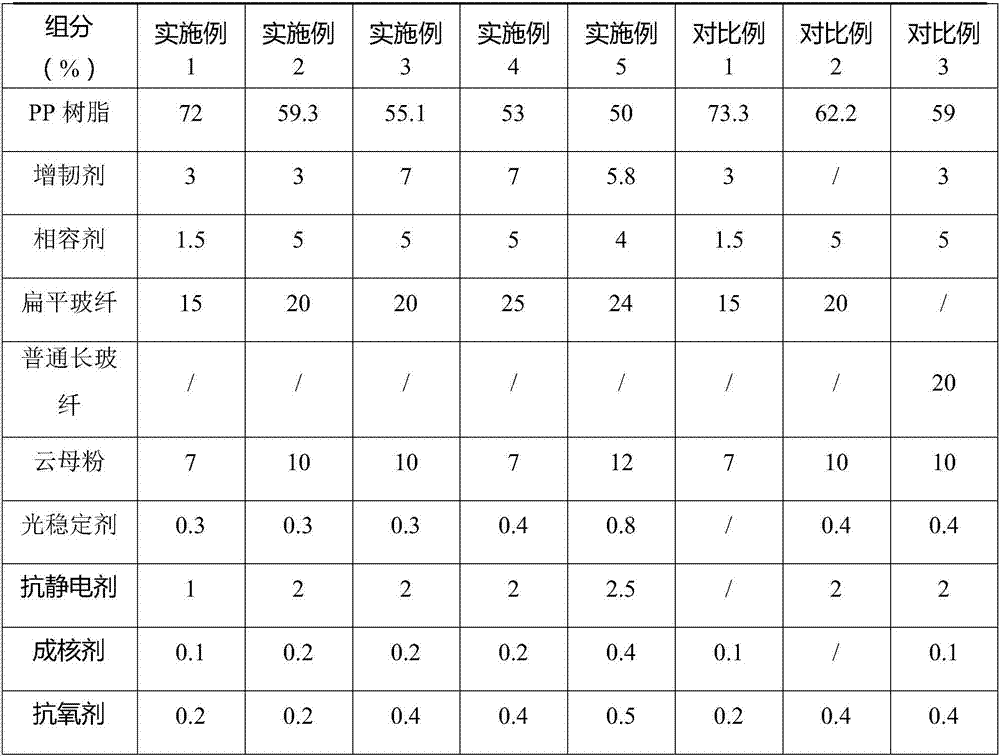

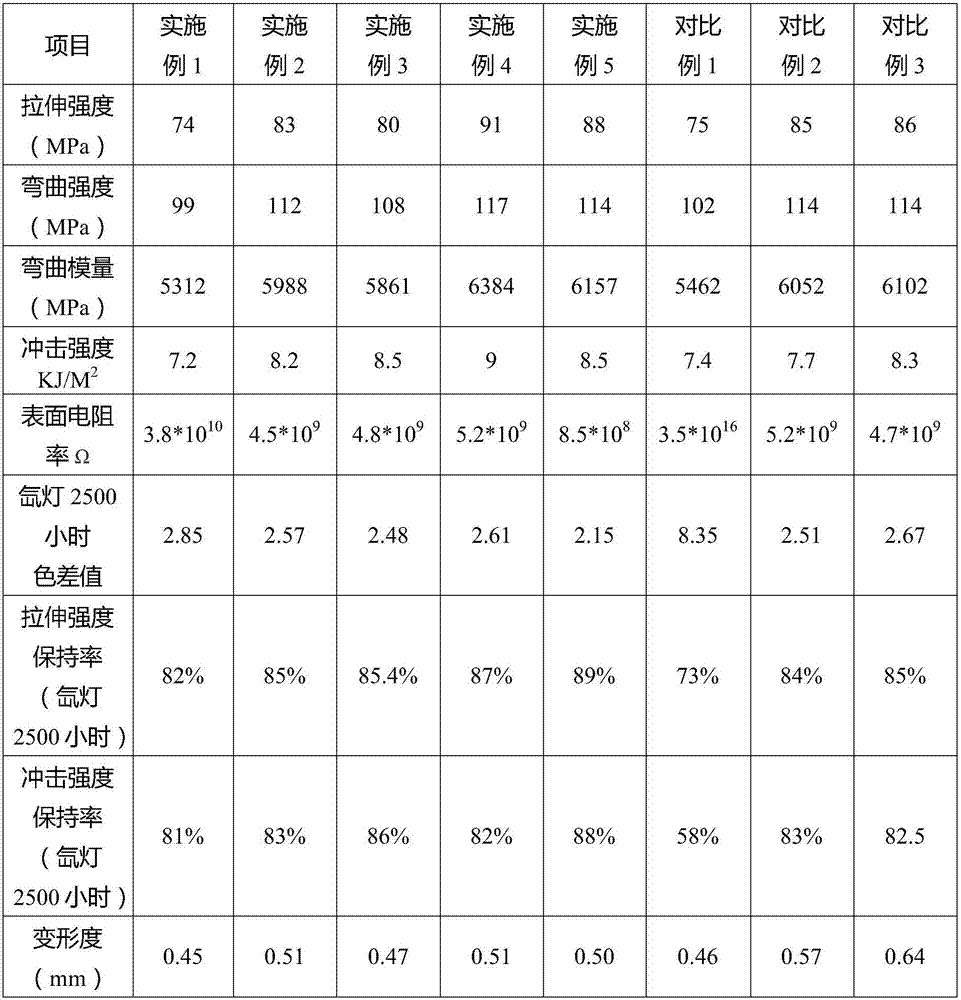

Antistatic low-warping glass-fiber-reinforced weatherproof PP material and preparation method thereof

The invention discloses an antistatic low-warping glass-fiber-reinforced weatherproof PP material and a preparation method thereof, belonging to the field of modification of high polymer materials. The antistatic low-warping glass-fiber-reinforced weatherproof PP material comprises, by mass, 50 to 72 parts of PP resin, 3 to 7 parts of a flexibilizer, 1.5 to 5 parts of a compatilizer, 15 to 25 parts of glass fibers, 7 to 12 parts of mica powder, 0.3 to 0.8 part of a light stabilizing agent, 1 to 2.5 parts of an antistatic agent, 0.1 to 0.4 part of a nucleating agent and 0.2 to 0.5 part of an anti-oxidant. The antistatic low-warping glass-fiber-reinforced weatherproof PP material prepared in the invention has low warping, high strength and antistatic performance and can effectively prevent dust; due to high weatherability of the material, the performance retention rate of the material can be maintained at 80% or more under the condition of high-temperature high-humidity xenon lamp aging; through usage of the flat glass fibers, low warping performance of the material is guaranteed on the prerequisite that high strength of the material is ensured; since propenyl elastomer and the nucleating agent are used, buckling deformation of the material can be effectively improved; and the material has good application prospects in the fields of fan blades of wind wheels, motors and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

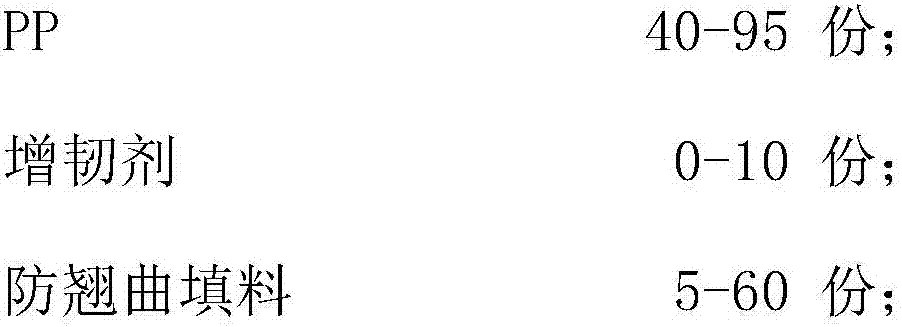

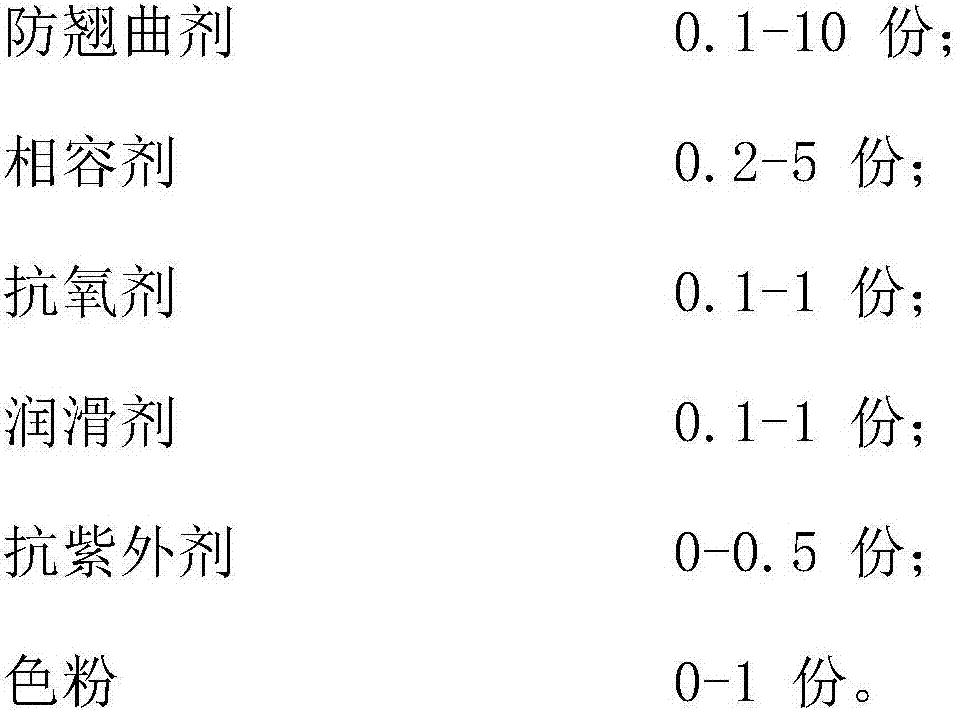

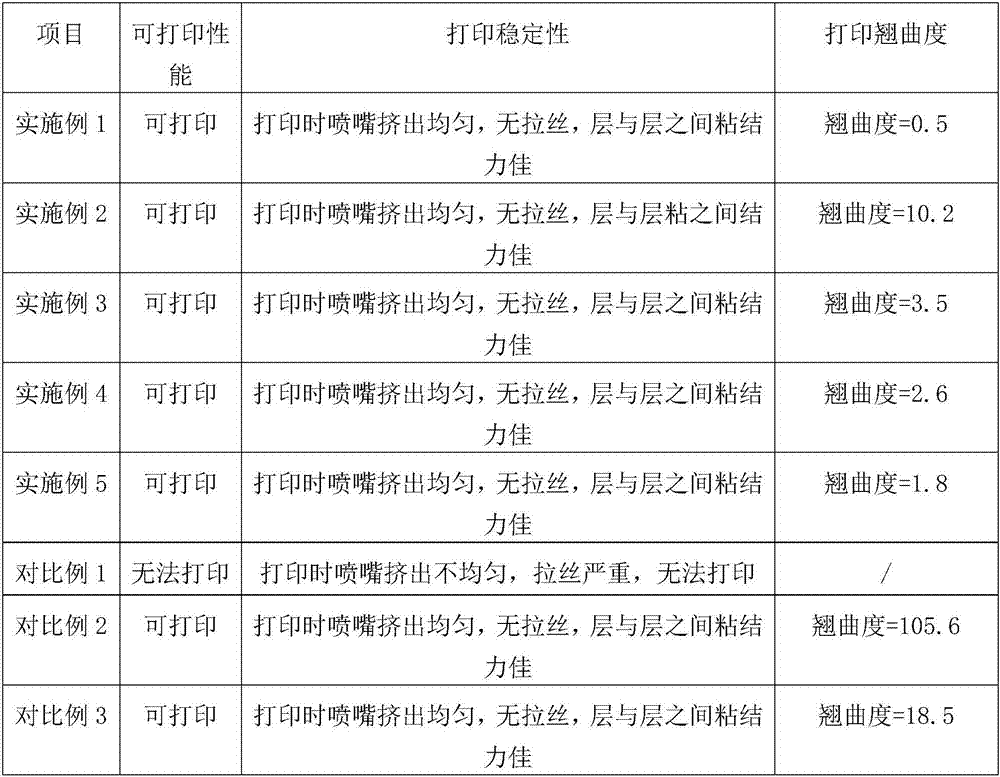

Low warping PP (propene polymer) material for 3D (three-dimensional) printing and preparation method thereof

InactiveCN106977809AControl printingRealize printingAdditive manufacturing apparatusAntioxidantThinning

The invention discloses a low warping PP (propene polymer) material for 3D (three-dimensional) printing and a preparation method thereof. The low warping PP material is prepared from the following components in parts by weight: 40 to 95 parts of PP, 0 to 10 parts of a flexibilizer, 5 to 60 parts of warping resistant filler, 0.1 to 10 parts of a warping resistant agent, 0.2 to 5 parts of a compatilizer, 0.1 to 1 part of an antioxidant, 0.1 to 1 part of a lubricant, 0 to 0.5 part of an anti-ultraviolet agent and 0 to 1 part of toner. The shrinking percentage, weight-average molecular weight, molecular weight distribution and melt index of the PP are strictly controlled, so that the printing of the PP is realized; the printing stability of the PP is improved; and meanwhile, the warping during printing is controlled to some extent. The addition of the warping resistant filler having a relatively high degree of sphericity not only reduces the shrinking percentage of the PP but also can effectively eliminate the stress of a material; accordingly, the warping generated during printing is effectively prevented. The grain size of the warping resistant filler is controlled, so that not only is the filler dispersion facilitated, but also a nozzle of a 3D printer cannot be blocked. In addition, the warping resistant agent can thin the crystal form of the PP; crystal form thinning is conducive to lowering the internal stress of the PP, so that the warping of the PP during printing is ameliorated.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

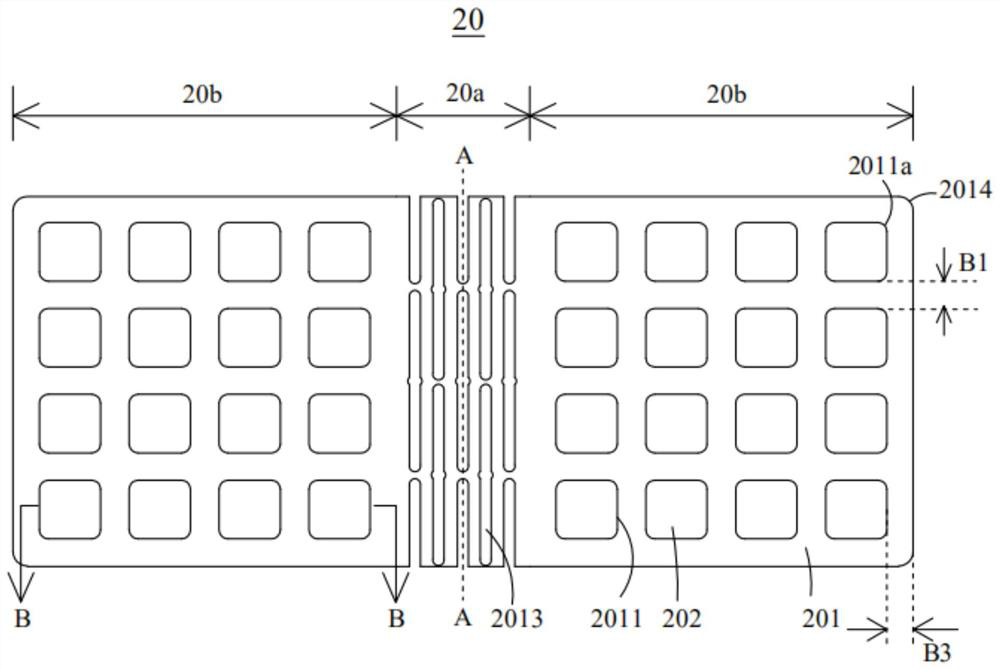

Supporting piece and foldable display module

ActiveCN112164318AReduce weightImprove warpageDetails for portable computersSupport structure mountingStructural engineeringMechanical engineering

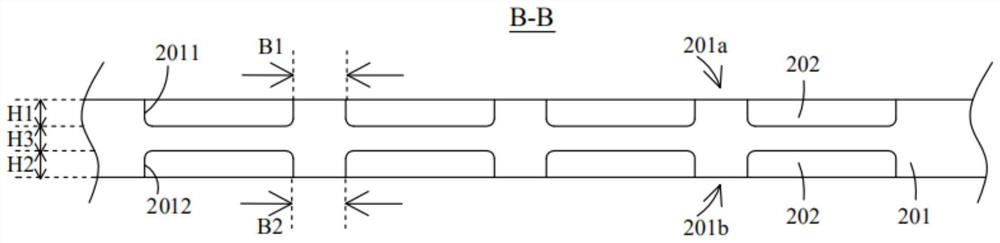

The invention provides a supporting piece and a foldable display module, the supporting piece is provided with at least one bending area and a plurality of non-bending areas, each bending area is connected between two opposite non-bending areas, the supporting piece comprises a supporting framework, and the supporting framework is provided with a first surface and a second surface which are oppositely arranged in the thickness direction of the supporting piece; a plurality of first grooves are formed in the first surface of the part, corresponding to the non-bending area, of the supporting framework, and a plurality of second grooves are formed in the second surface of the part, corresponding to the non-bending area, of the supporting framework. The two opposite surfaces of the part, corresponding to the non-bending area, of the supporting framework are provided with the first groove and the second groove in the thickness direction of the supporting piece respectively, the weight of the supporting piece is reduced, and meanwhile the warping phenomenon of the supporting piece caused by uneven stress distribution of the supporting framework is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Laminated body, circuit board including laminated body, semiconductor package and process for manufacturing laminated body

InactiveUS20100078201A1Minimize warpageReduce misalignmentAdhesivesThin material handlingFiberSemiconductor package

Owner:SUMITOMO BAKELITE CO LTD

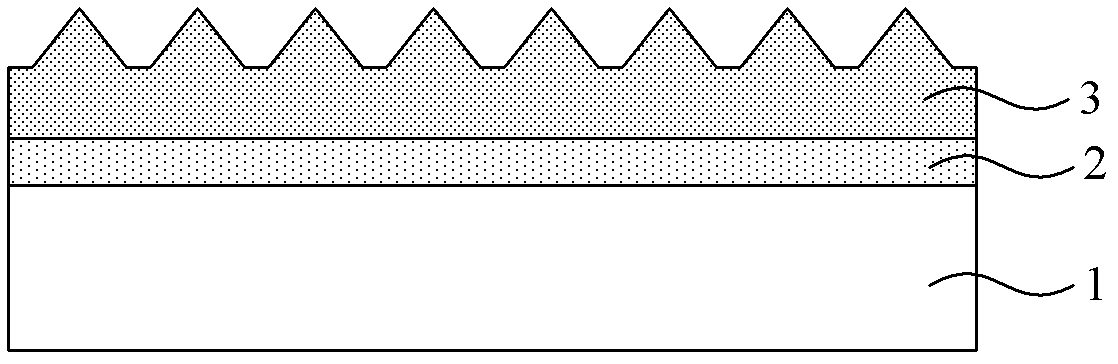

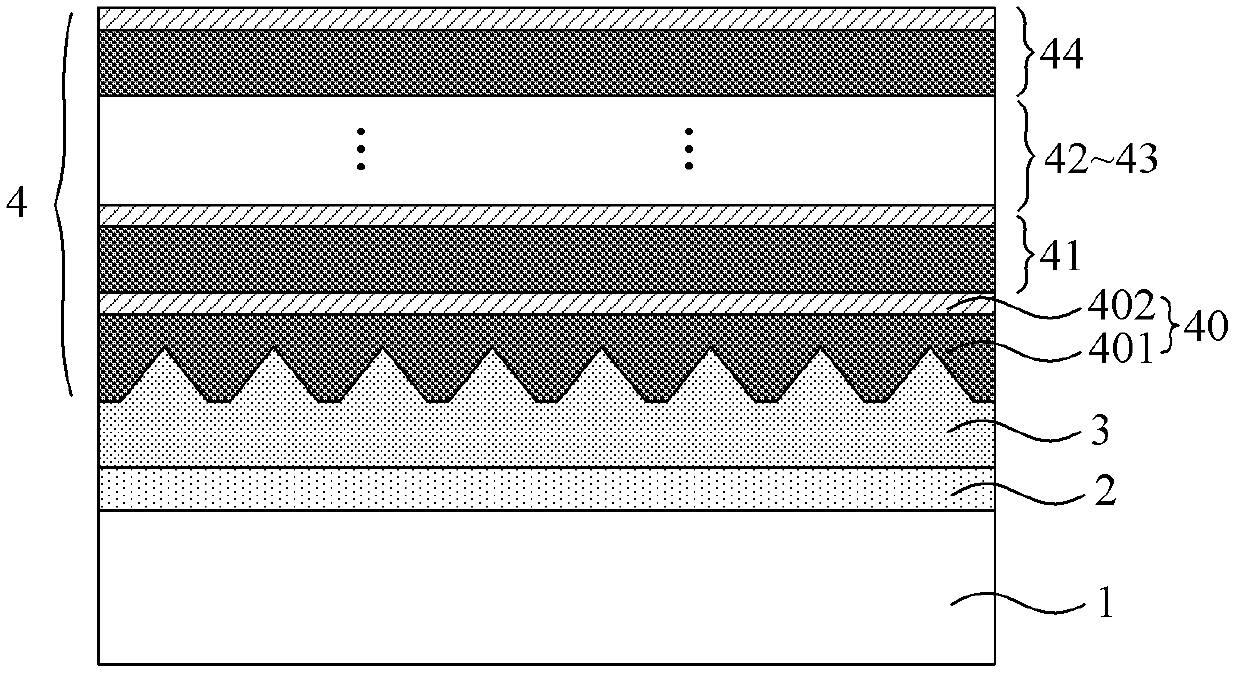

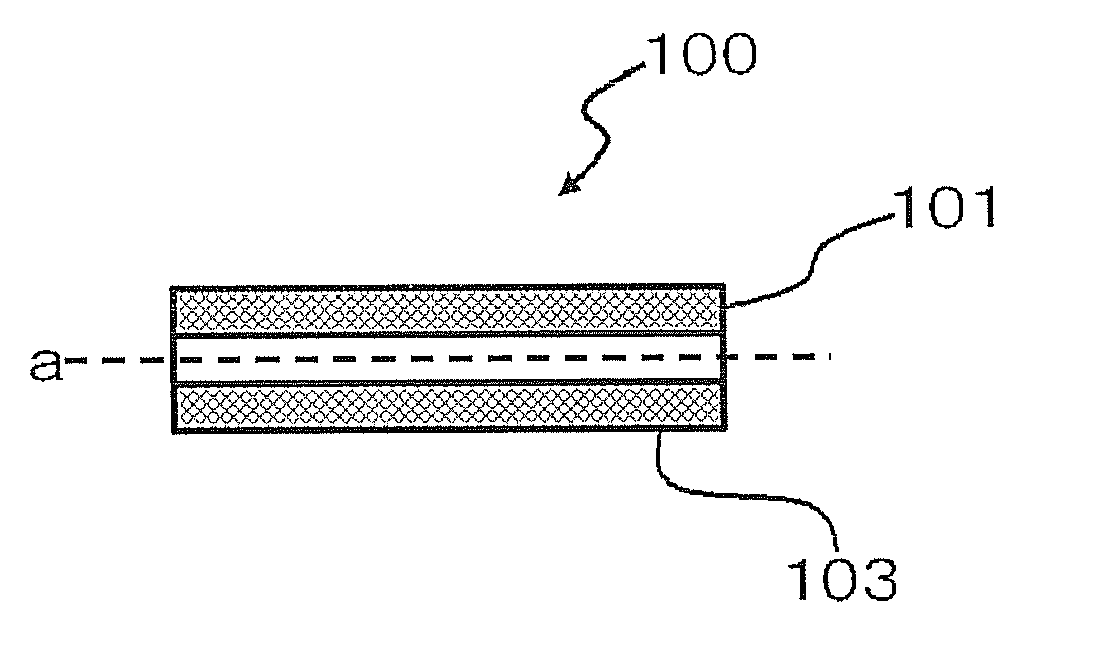

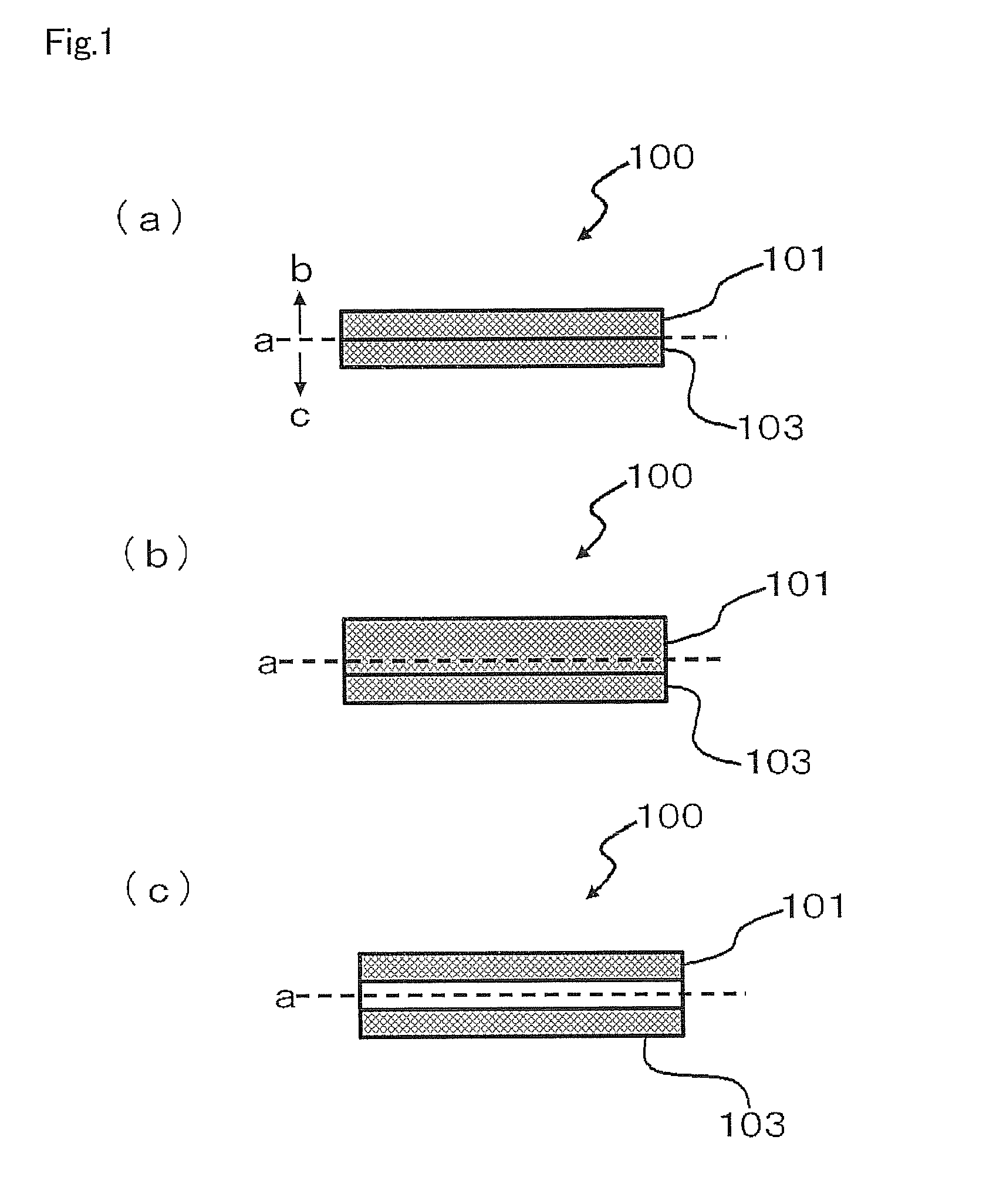

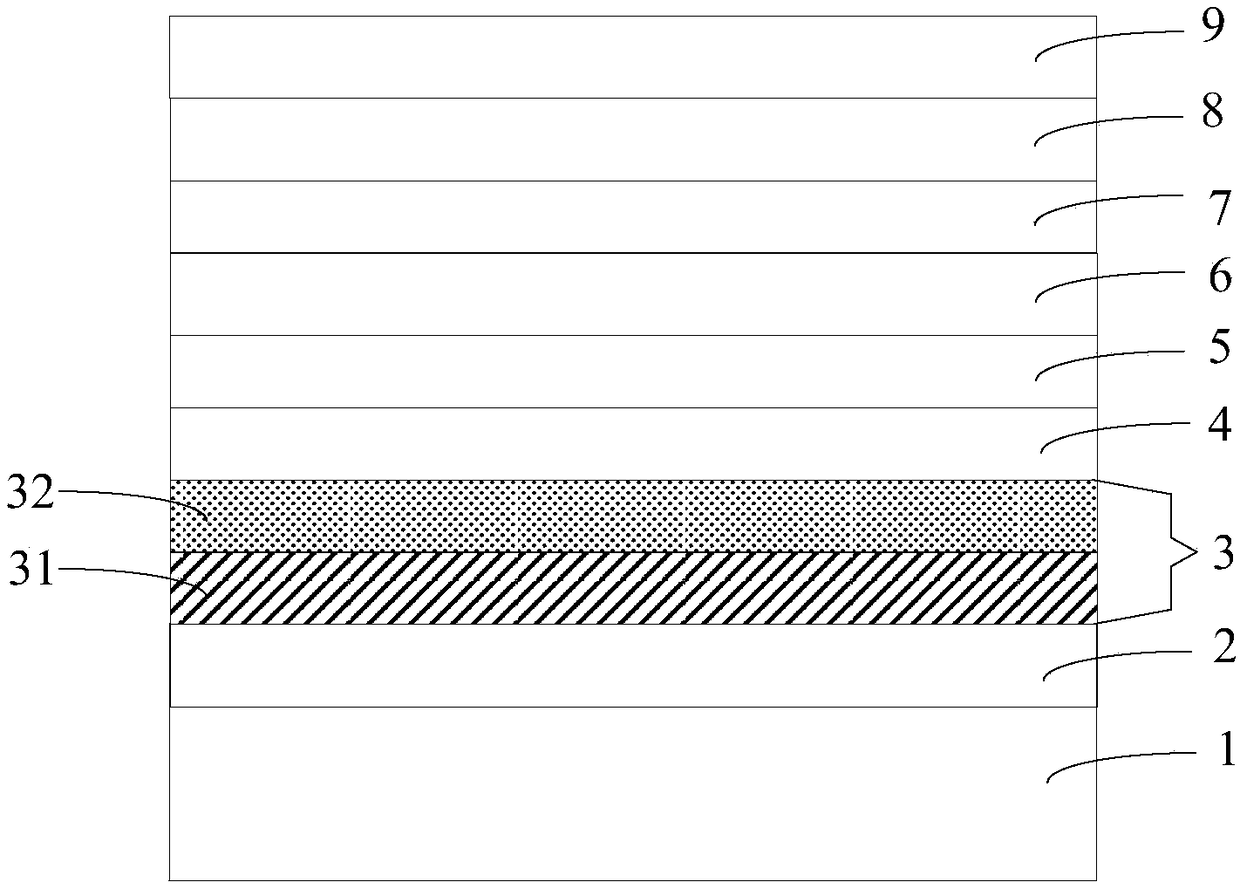

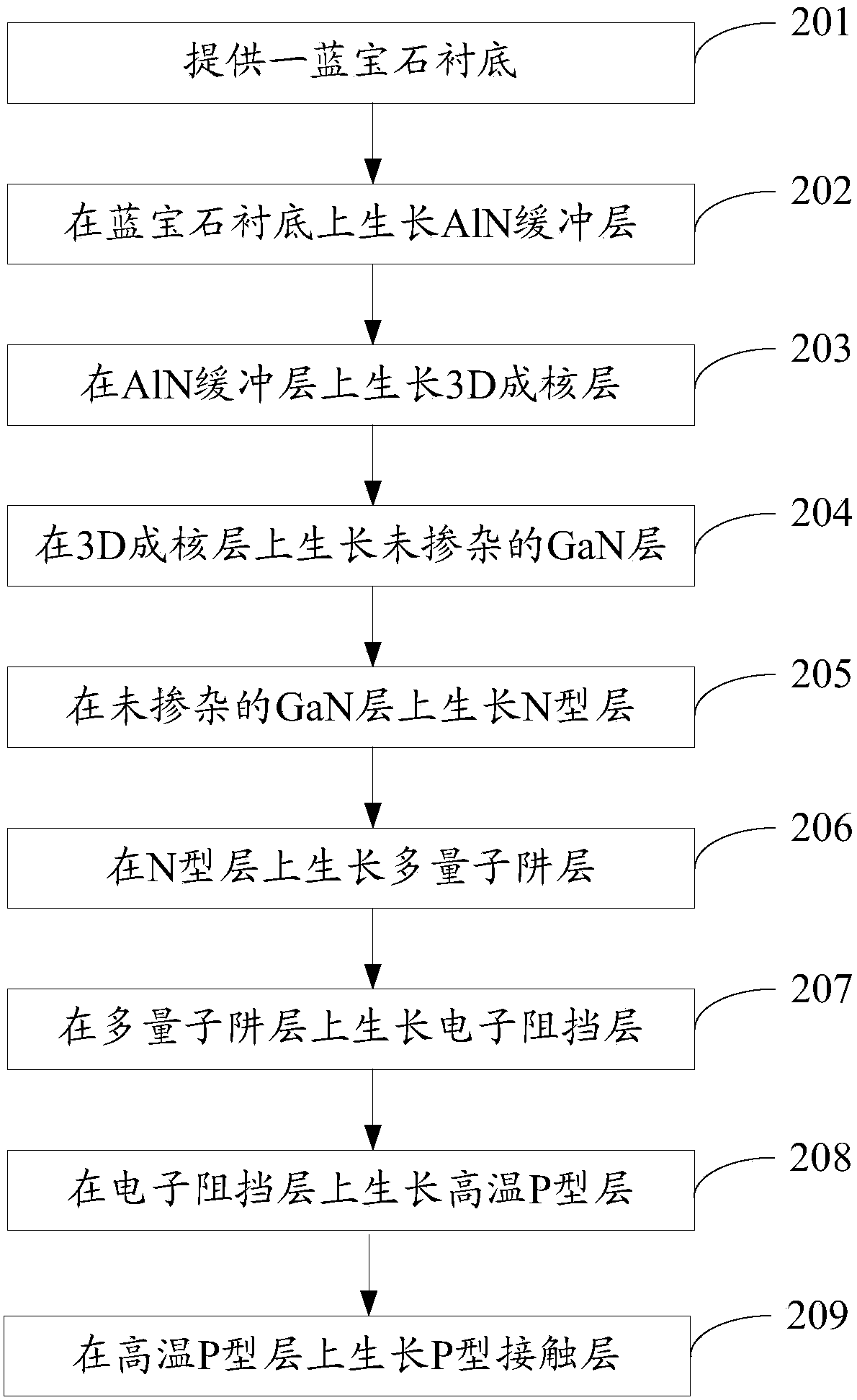

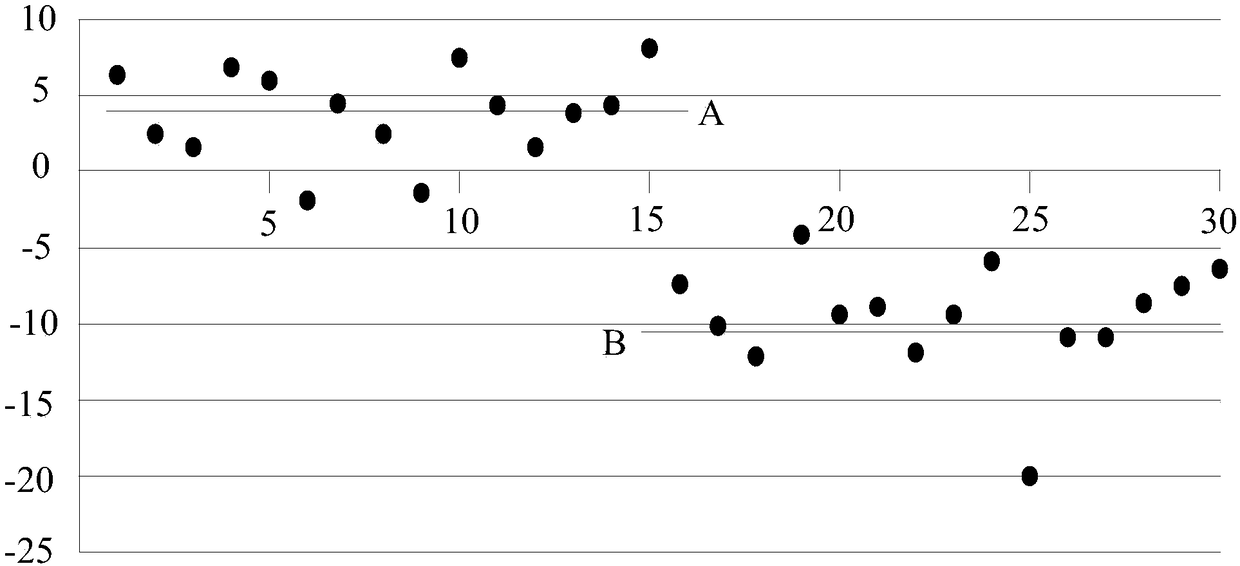

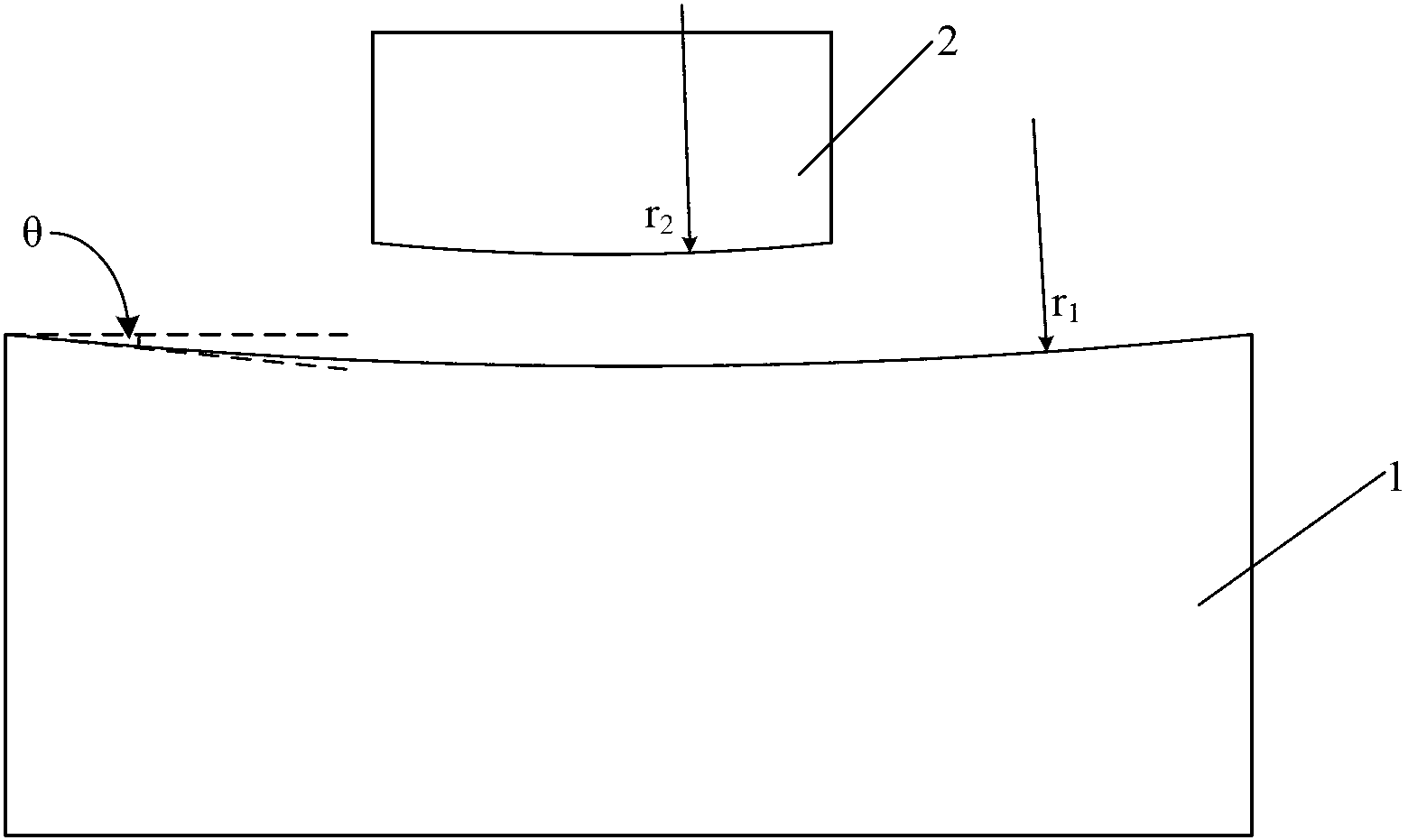

Gallium nitride-based light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN108336203ALow growth temperatureImprove warpageSemiconductor devicesQuantum wellGallium nitride

The invention discloses a gallium nitride-based light emitting diode epitaxial wafer and a manufacturing method thereof, and belongs to the field of a semiconductor technology. The gallium nitride-based light emitting diode epitaxial wafer comprises a sapphire substrate, and an AlN buffer layer, a 3D nucleating layer, a non-doped GaN layer, an N type layer, a multi-quantum-well layer, an electronbarrier layer and a high-temperature P type layer which are laminated on the sapphire substrate in sequence; the 3D nucleating layer comprises a first sub layer and a second sub layer; the first sub layer is a GaN layer grown at a temperature of 800-1,100 DEG C; and the second sub layer is a GaN layer grown at a temperature of 1,000-1,200 DEG C. The lower the growth temperature of the first sub layer is, the formed crystal particles are smaller and more intensive; the crystal particles are stretched and deformed to close gaps to lower surface energy, so that tensile stress is generated, and the epitaxial wafer is to be concave, thereby improving warping and improving wavelength concentration degree; and the temperature of the second sub layer is higher, the surface energy of the crystal particles is lower, so that it is ensured that warping of the whole epitaxial wafer is not caused, thereby improving the photoelectric performance of the LED chip.

Owner:HC SEMITEK SUZHOU

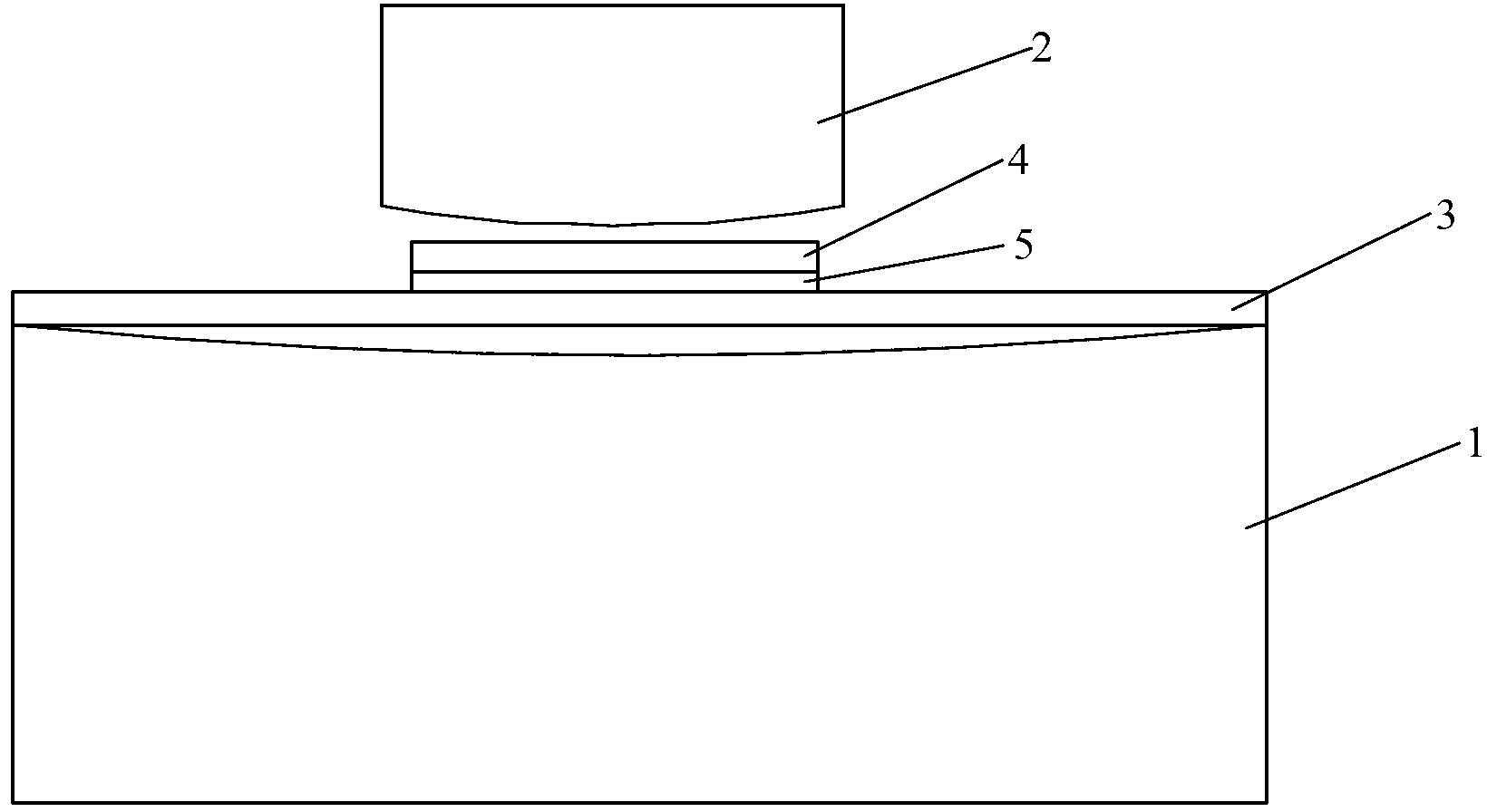

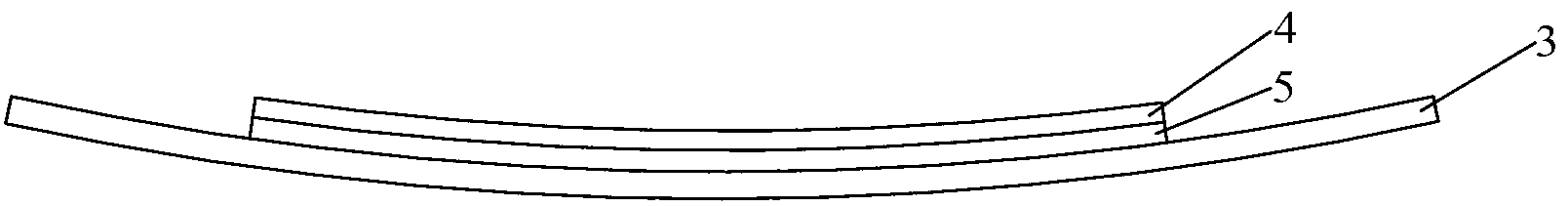

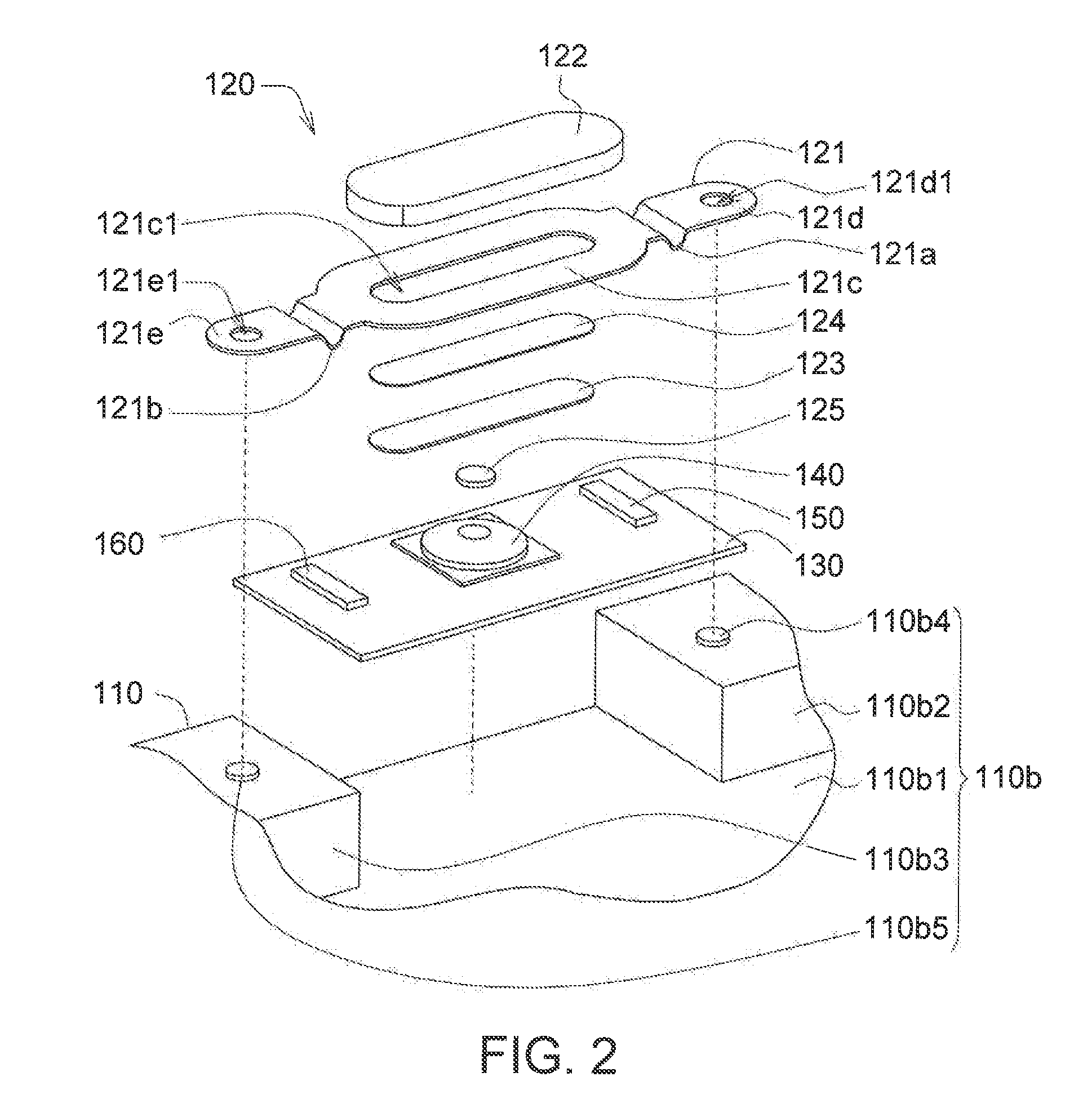

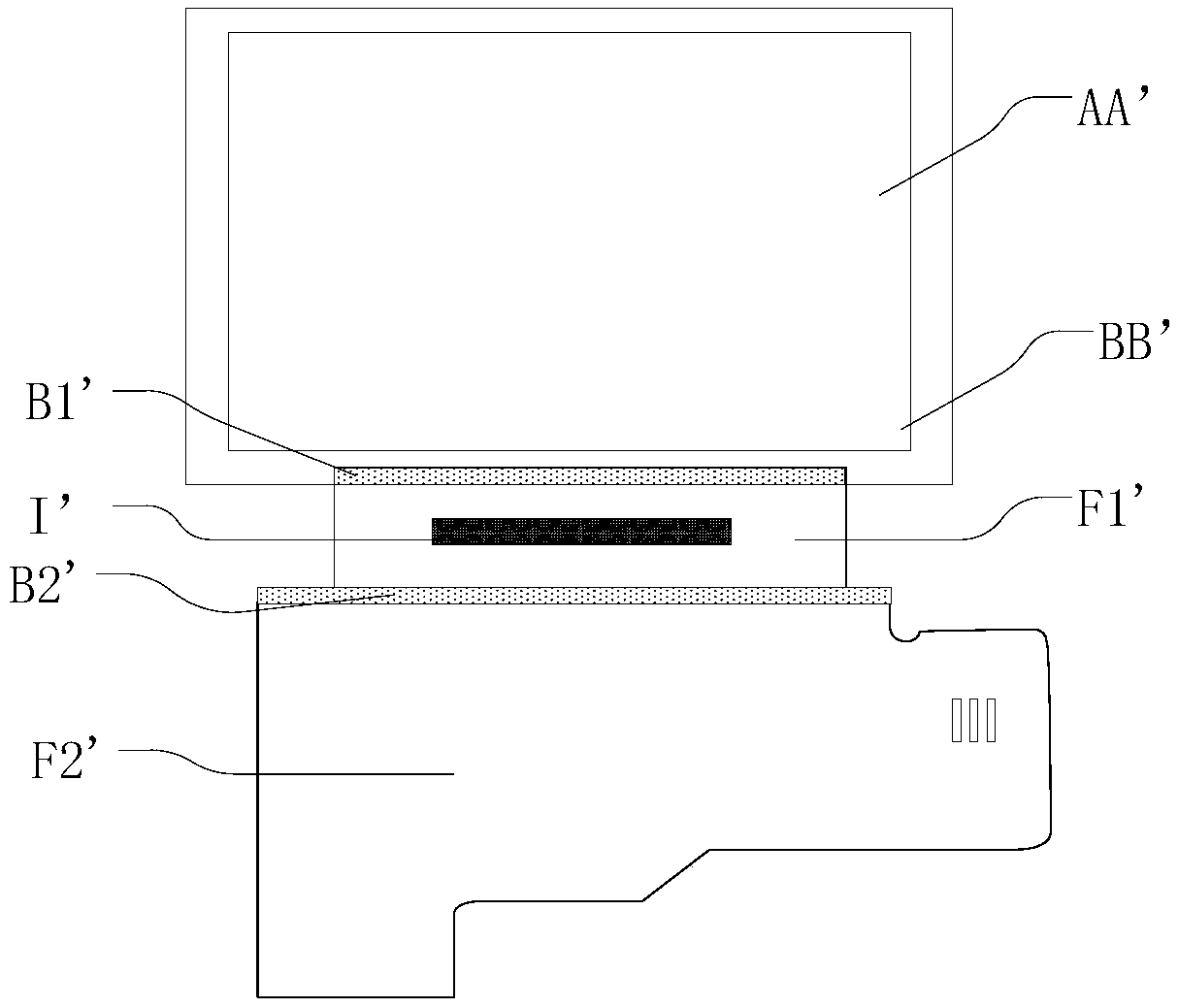

Binding equipment and binding method of chip

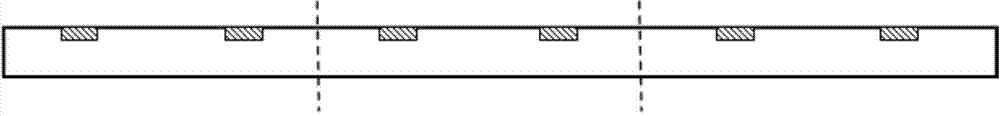

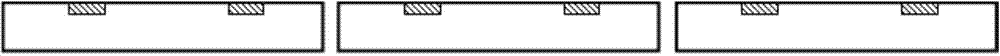

InactiveCN103295937AReduce stressAvoid warpingSolid-state devicesSemiconductor/solid-state device manufacturingLiquid crystalBiochemical engineering

An embodiment of the invention discloses binding equipment and a binding method of a chip, relates to the field of production technique of liquid crystal displaying equipment, and can solve the problem of warping after the chip and a substrate are bound. The binding equipment of the chip comprises a base platform and a pressure head, one surface, used for bearing a substrate, of the base platform has a first downward arc, one surface, in contact with the chip, of the pressure head has a second downward arc, and the base platform with the first arc is matched with the pressure head with the second arc.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

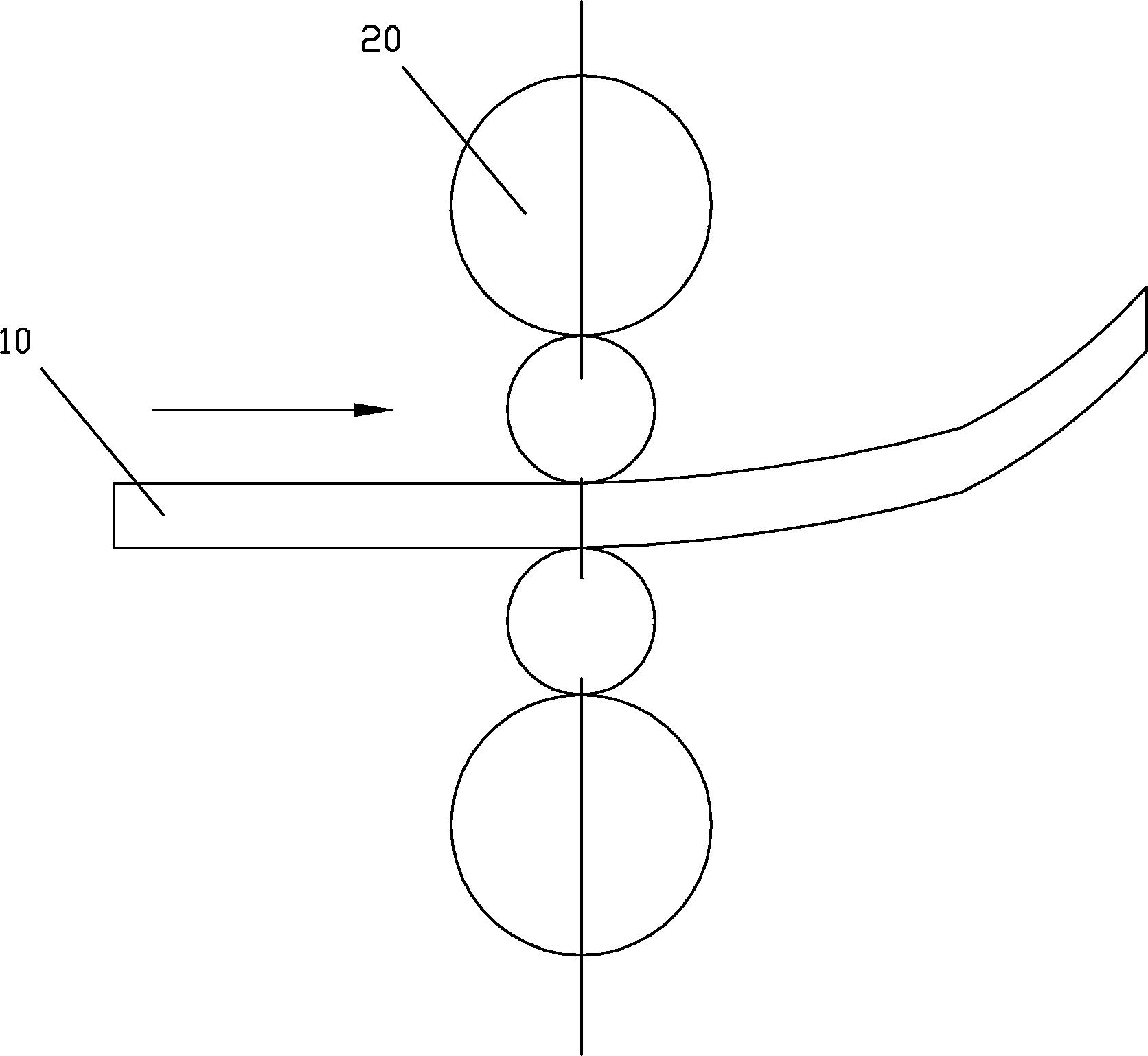

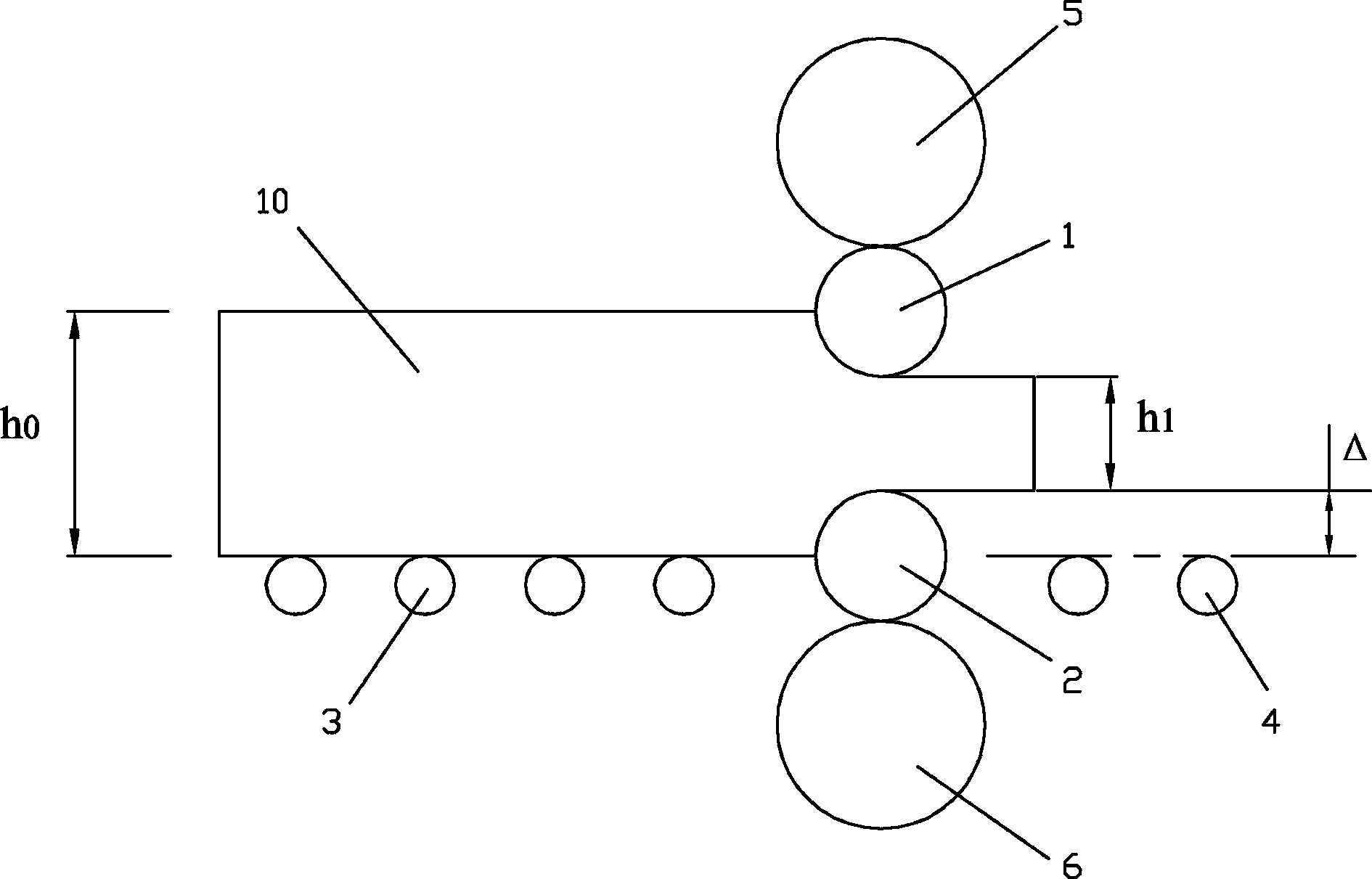

Head warping control method for rough rolling in production of hot-rolled steel strips

Disclosed is a head warping control method for rough rolling in production of hot-rolled steel strips. Firstly, a lower-rollers electric pressing-up mechanism is adopted, and a rolling line height Delta, namely the height difference between the upper roller face of a lower operating roller of a roller mill and the upper roller faces of the roller beds of the inlet and outlet, is set as (img file = 'DDA00002978950300011.TIF' wi = '318' he = '112' / ) in millimeters; h0 and h1 represent the rolled member inlet and the outlet thicknesses respectively in millimeters, and the delta is a rolling line height additional value and ranges from 2 to 10mm; meanwhile, the speed difference between an upper operating roller and the lower operating roller is adjusted, the roller mill speed increment is acquired as (img file = 'DDA00002978950300012.TIF' wi = '462' he = '172' / ), d omega is a rotating speed increment in rad / s, and the DW is the diameter of rollers in millimeters. The method has the advantages that the problem of head warping for rough rolling during hot rolling production is optimized, damage to production equipment by head warping is reduced, and production stability is improved.

Owner:BAOSTEEL STAINLESS STEEL +1

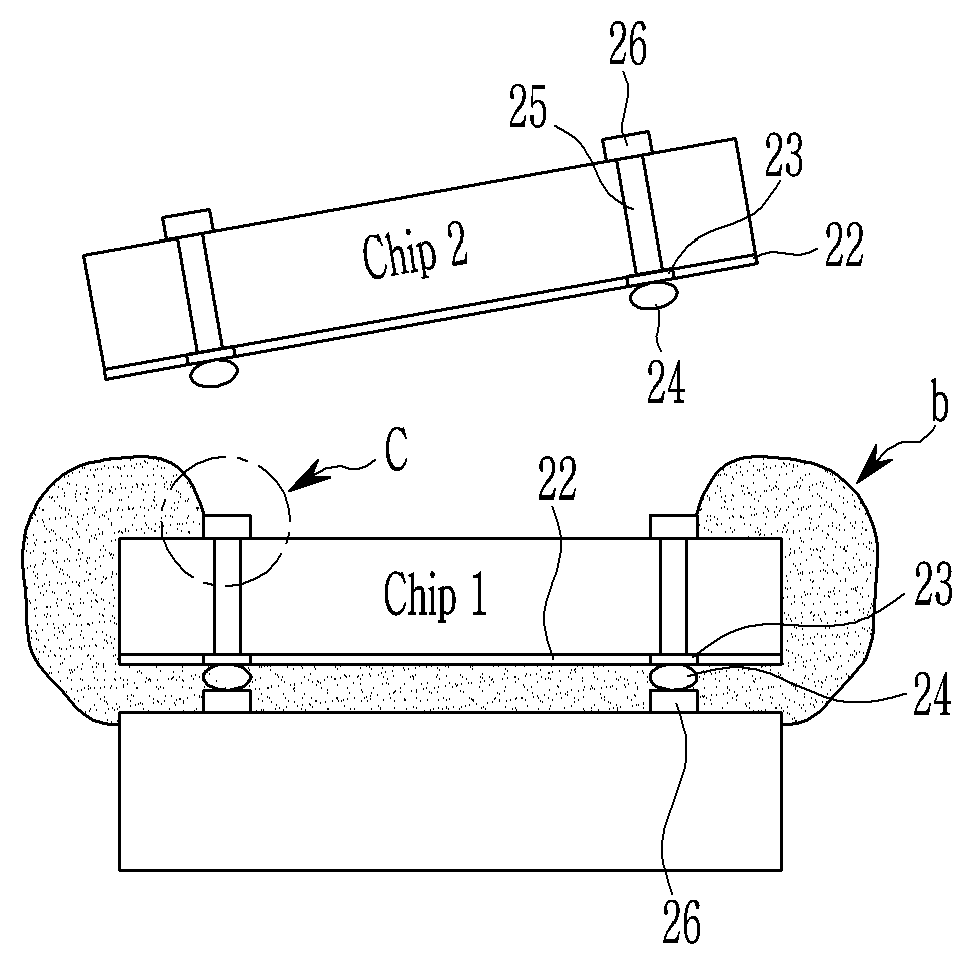

Wafer-level fan-out PoP encapsulation structure and making method thereof

InactiveCN104505382AImprove warpageReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesInterconnectionMetallic substrate

The invention discloses a wafer-level fan-out PoP encapsulation structure and a making method thereof. The wafer-level fan-out PoP encapsulation structure is formed by stacking at least one fan-out PoP encapsulation units, each two adjacent fan-out PoP encapsulation units are connected through a second welding ball and coated and sealed by adopting a second plastic sealing material, each fan-out PoP encapsulation unit comprises an IC chip, a first plastic sealing material, a second binding material, a metal salient point structure, a first metal layer, a second metal layer, a first rewiring metal routing layer, a first dielectric material layer, a second rewiring metal routing layer, a second dielectric material layer, a first welding ball and the second welding ball, a bonding pad of each IC chip is connected with the corresponding first rewiring metal routing layer, each metal salient point structure forms a molded plastic through hole, and three-dimensional integrated interconnection between an upper encapsulating body as well as a lower encapsulating body in each fan-out PoP encapsulation unit and an external structure is realized through the corresponding molded plastic through hole. The making method mainly includes arranging a metal substrate wafer on a first carrier wafer; making the metal salient point structure on the surface of the metal substrate wafer; feeding the chip; plastically sealing, making the first rewiring metal routing layer; arranging a second carrier wafer, removing the first carrier wafer, etching the lower surface of the metal substrate wafer to form the second rewiring metal routing layer; performing stacking and reflow soldering; removing the second carrier wafer; forming the fan-out PoP encapsulation unit after ball placing and reflow soldering processes; performing stacking and reflow soldering on the fan-out PoP encapsulation units; and forming the wafer-level fan-out PoP encapsulation structure after plastic sealing. By the wafer-level fan-out PoP encapsulation structure and the making method, the problems of encapsulating density, cost and reliability of existing PoP encapsulation technology are solved.

Owner:HUATIAN TECH XIAN

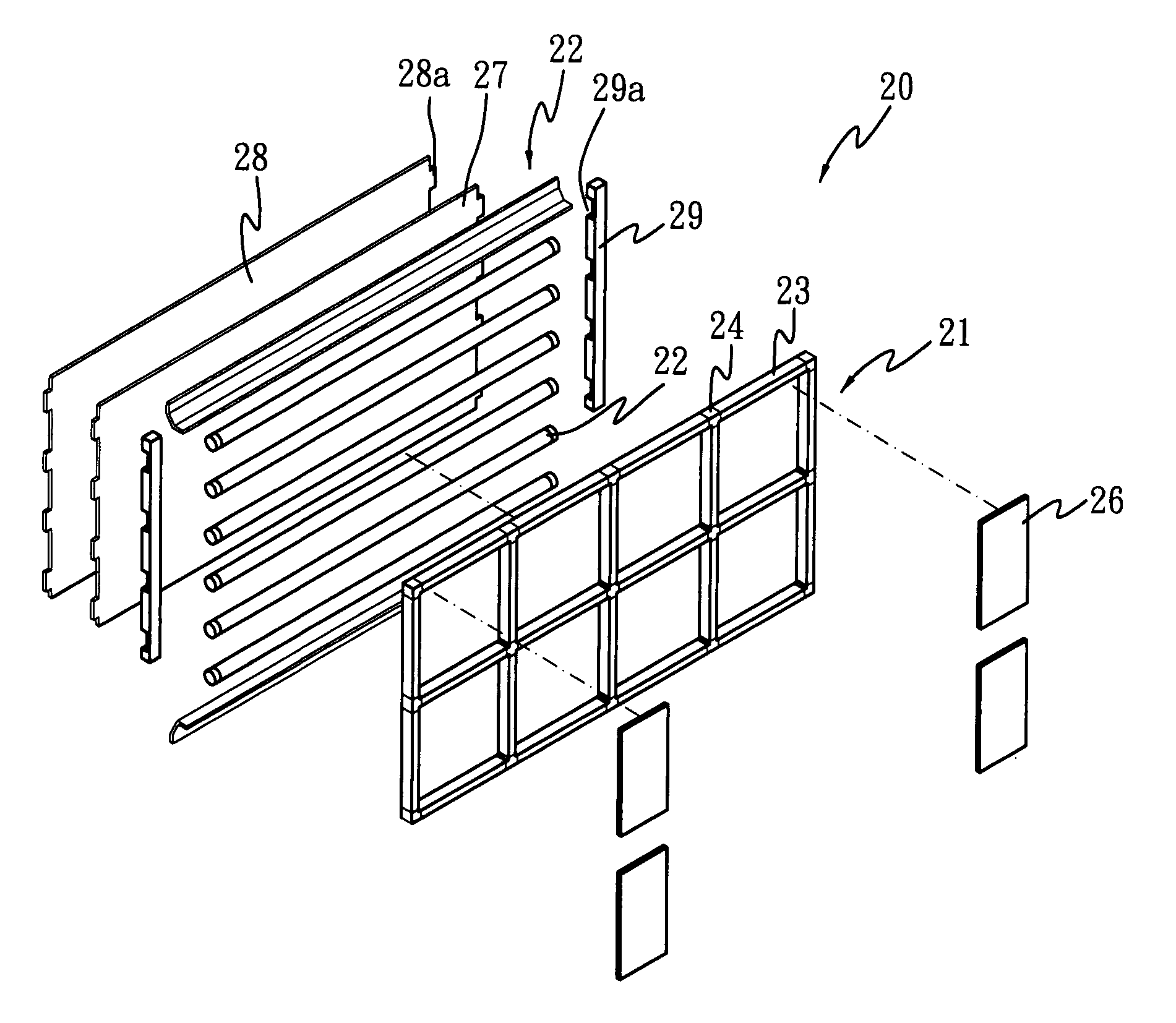

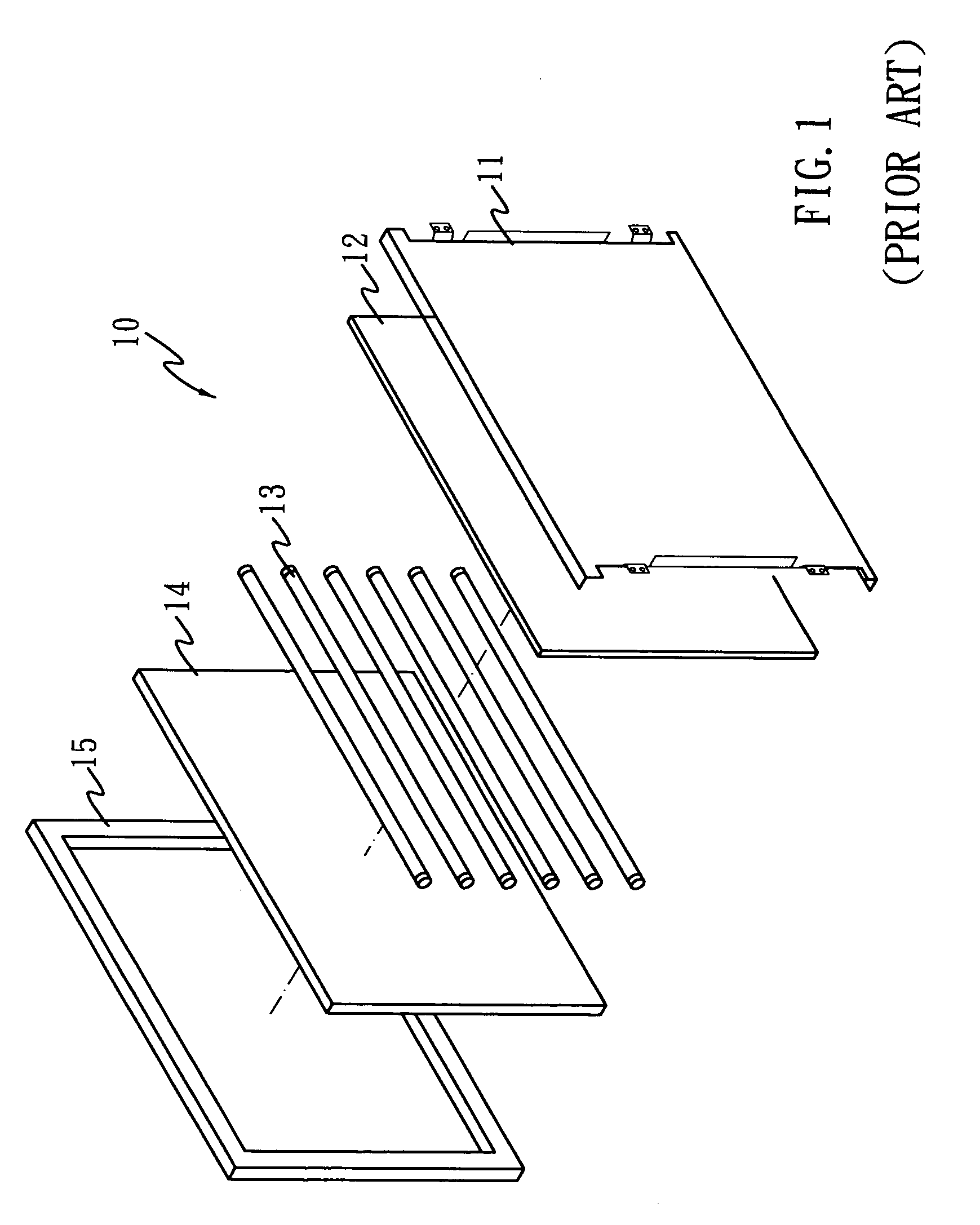

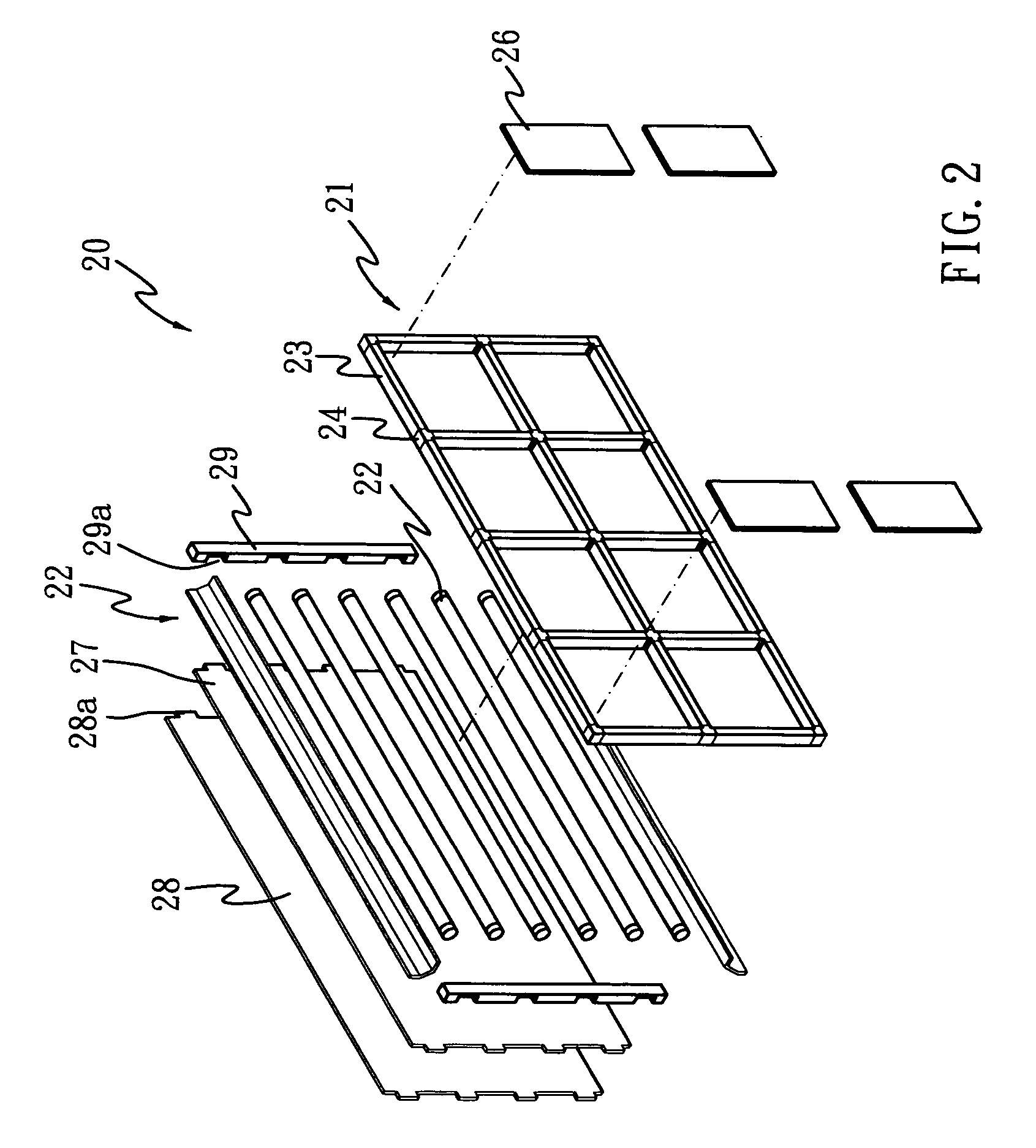

Backlight module having a truss type structure

ActiveUS20060193120A1Reduce weightImprove bending strengthNon-electric lightingPoint-like light sourceLiquid-crystal displayEngineering

A backlight module having a truss type structure comprises a plurality of truss type members, a reflector and at least a light source. The truss members and the light source positioned on the truss type structure. In a liquid crystal display (LCD) panel, the truss type structure disclosed in this invention is used as a main structure of such backlight module. Compared to those of the prior art, backlight modules that utilize the truss type structure of this invention have the advantages of reduced weight and better bending strength.

Owner:HANNSTAR DISPLAY CORPORATION

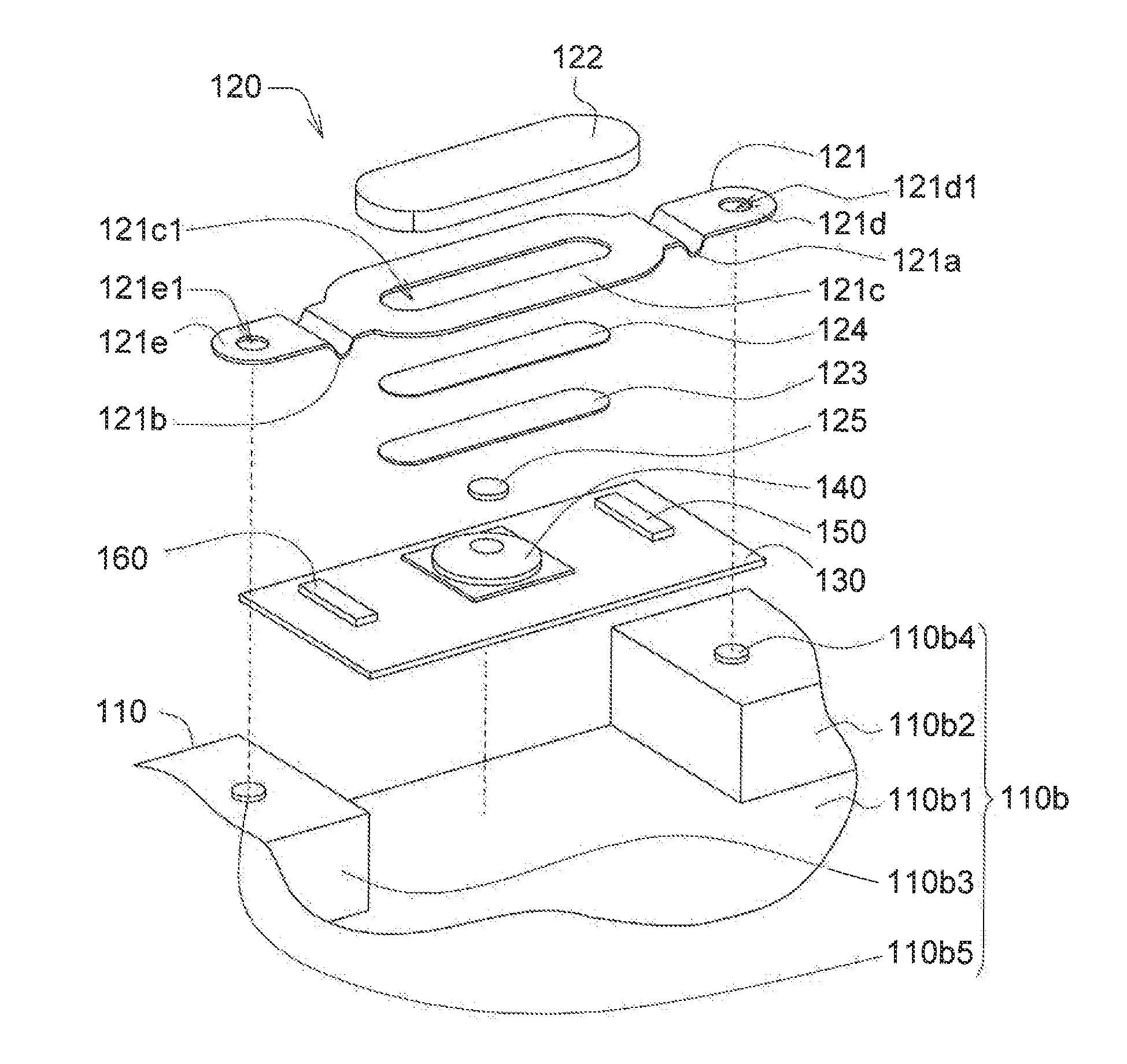

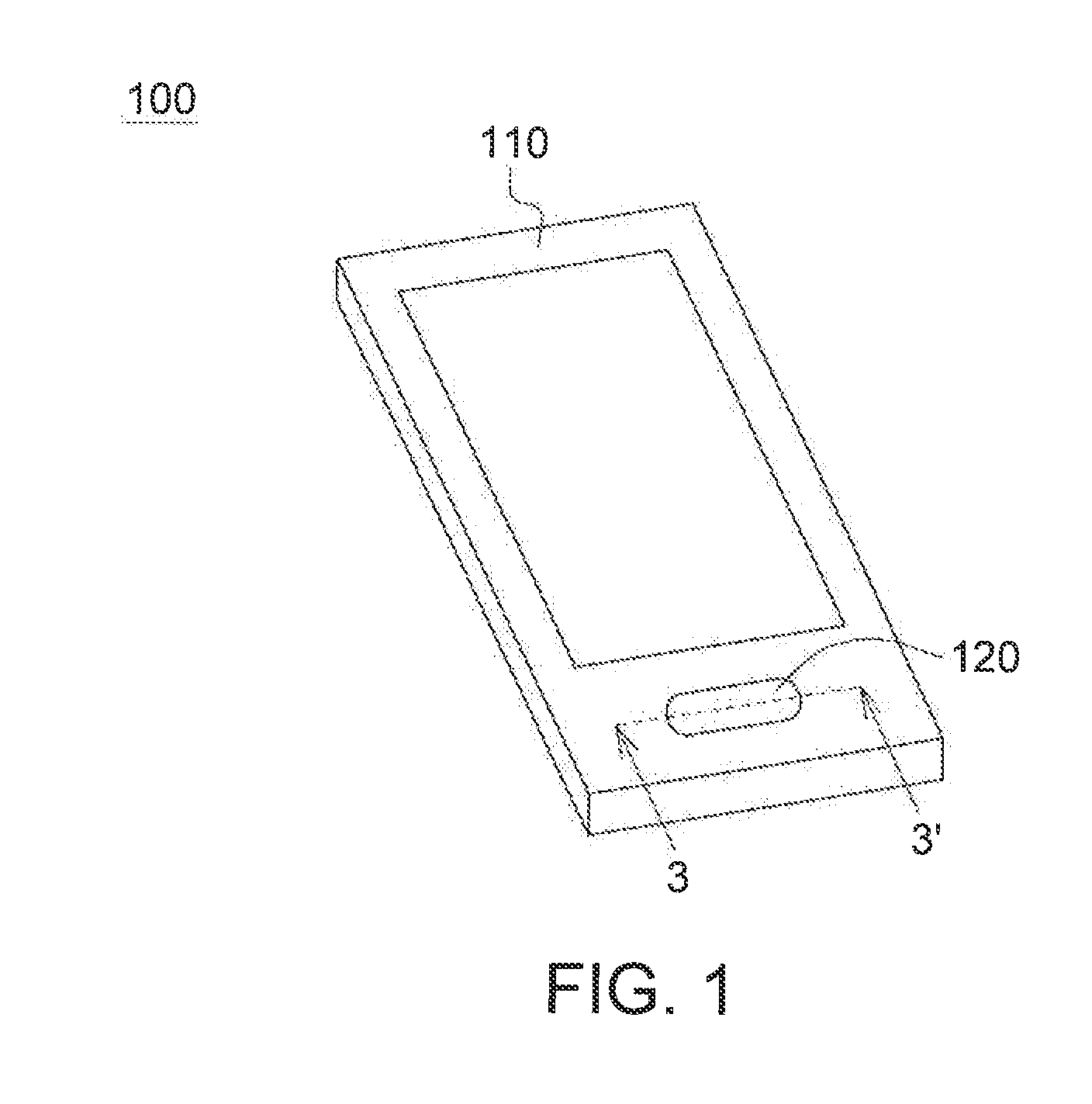

Button structure and electronic device using the same

InactiveUS20120250273A1Improve warpageEmergency actuatorsEmergency casingsEngineeringElectric devices

Owner:INVENTEC CORP

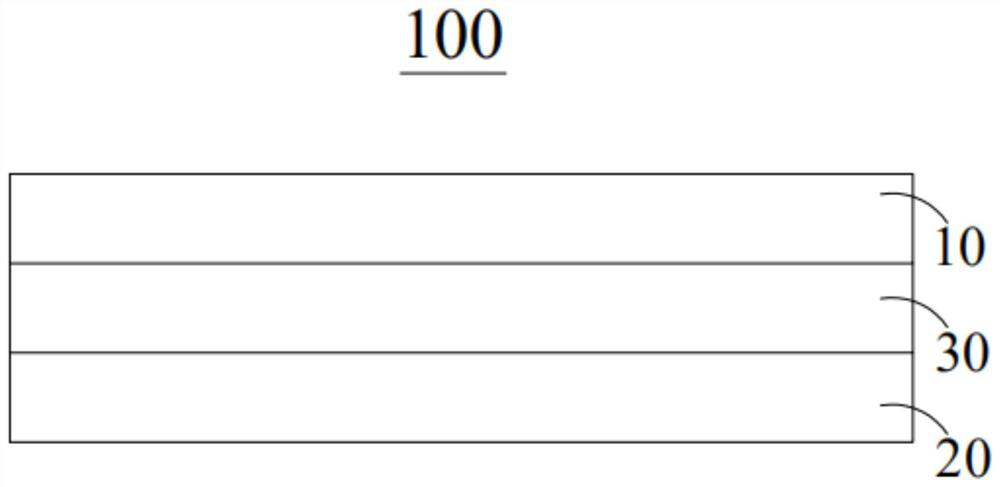

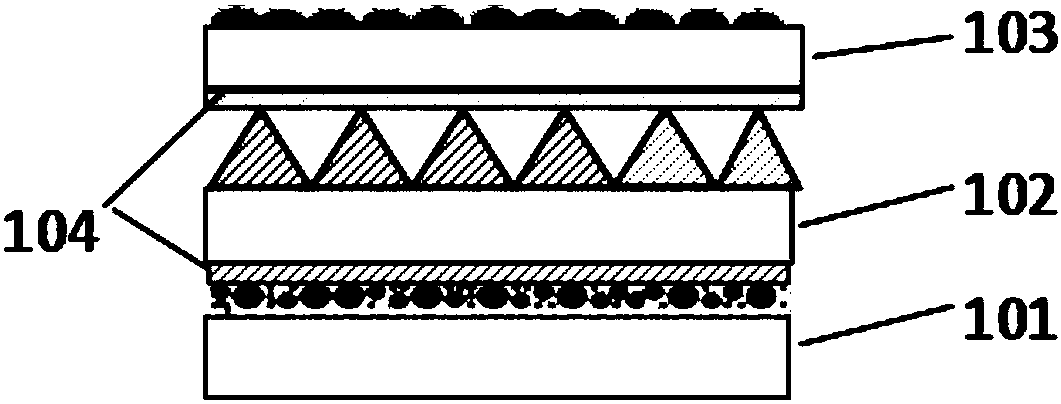

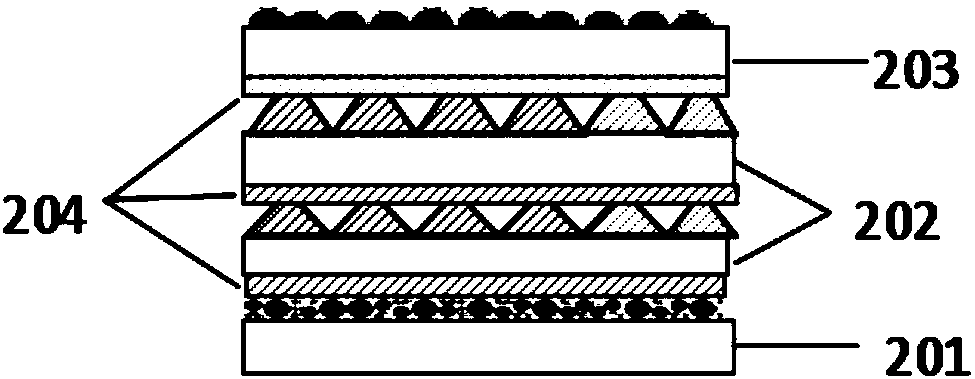

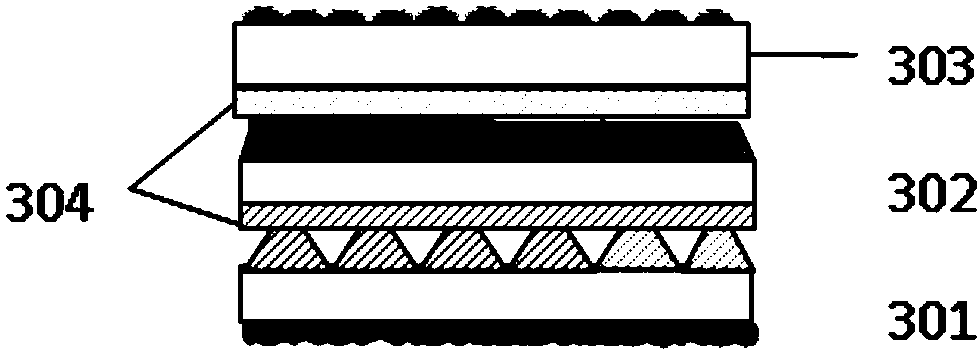

Novel multifunctional optical composite membrane and preparing method thereof

PendingCN107831620ALow costImprove stiffnessNon-linear opticsOptical elementsLiquid-crystal displayOptical Module

The invention belongs to the technical field of liquid crystal display optical modules, and discloses a novel multifunctional optical composite membrane which is composed of a lower layer, a middle layer and an upper layer. The lower layer is a brightening membrane or diffusing membrane, the middle layer is one or two overlapped brightening membranes, and the upper layer is a diffusing membrane ormicro-lens membrane. The lower layer, the middle layer and the upper layer are combined through adhesives. The total thickness of the optical composite membrane can be reduced by 40% or above, and acorresponding backlight module is lighter and thinner; cost is reduced by 10% or above; when the backlight module is assembled, only one-time operation needs to be conducted on the combined optical membrane, and the assembling efficiency is effectively improved; the stiffness of the membrane is effectively improved, the warping property of the membrane can be improved, and the assembling yield isimproved.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

Method to quickly warp a 2-D image using only integer math

InactiveUS7379623B2Good reliefEnhance the imageColor signal processing circuitsGeometric image transformationComputer graphics (images)Floating point

Systems and methods are disclosed that facilitate rapidly warping a two-dimensional image using integer math. A warping table can contain two-dimensional floating point output pixel offset values that are mapped to respective input pixel locations in a captured image. The warping table values can be pre-converted to integer offset values and integer grid values mapped to a sub-pixel grid. During warping, each output pixel can be looked up via its integer offset value, and a one-dimensional table lookup for each pixel can be performed to interpolate pixel data based at least in part on the integer grid value of the pixel. Due to the small size of the lookup tables, lookups can potentially be stored in and retrieved from a CPU cache, which stores most recent instructions to facilitate extremely rapid warping and fast table lookups.

Owner:MICROSOFT TECH LICENSING LLC

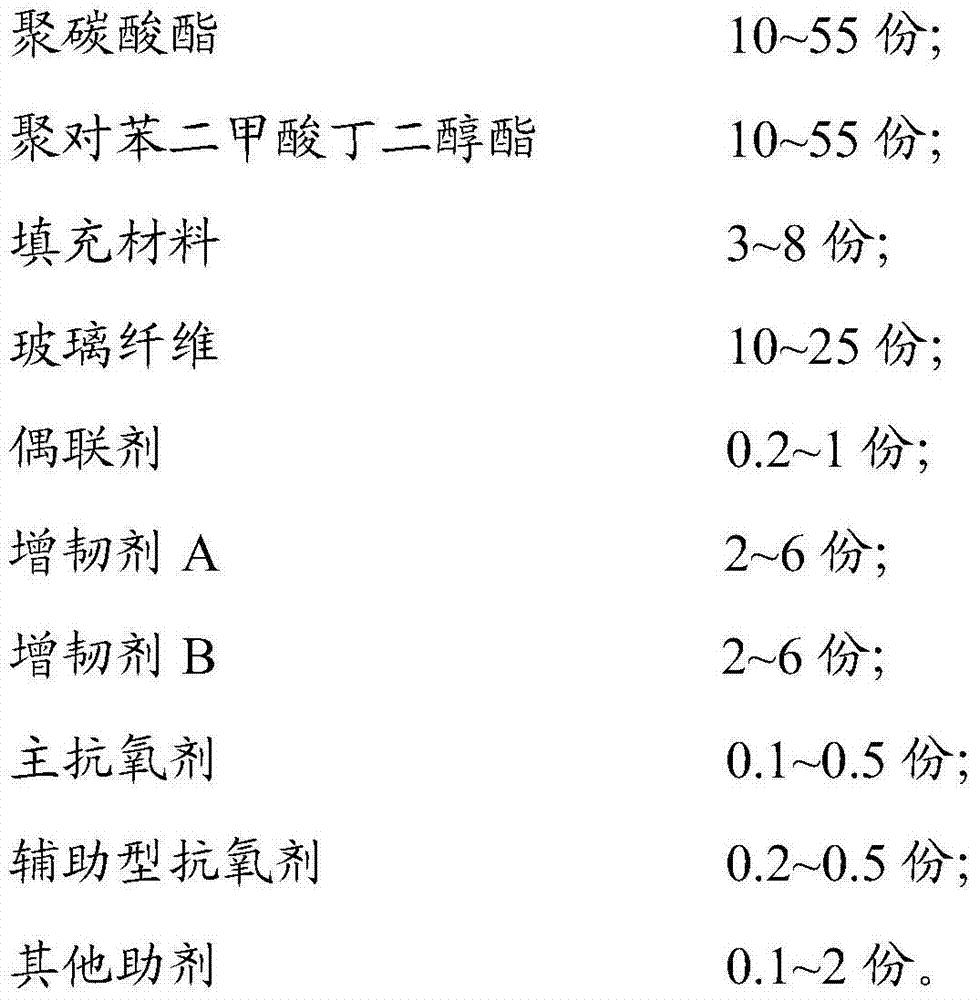

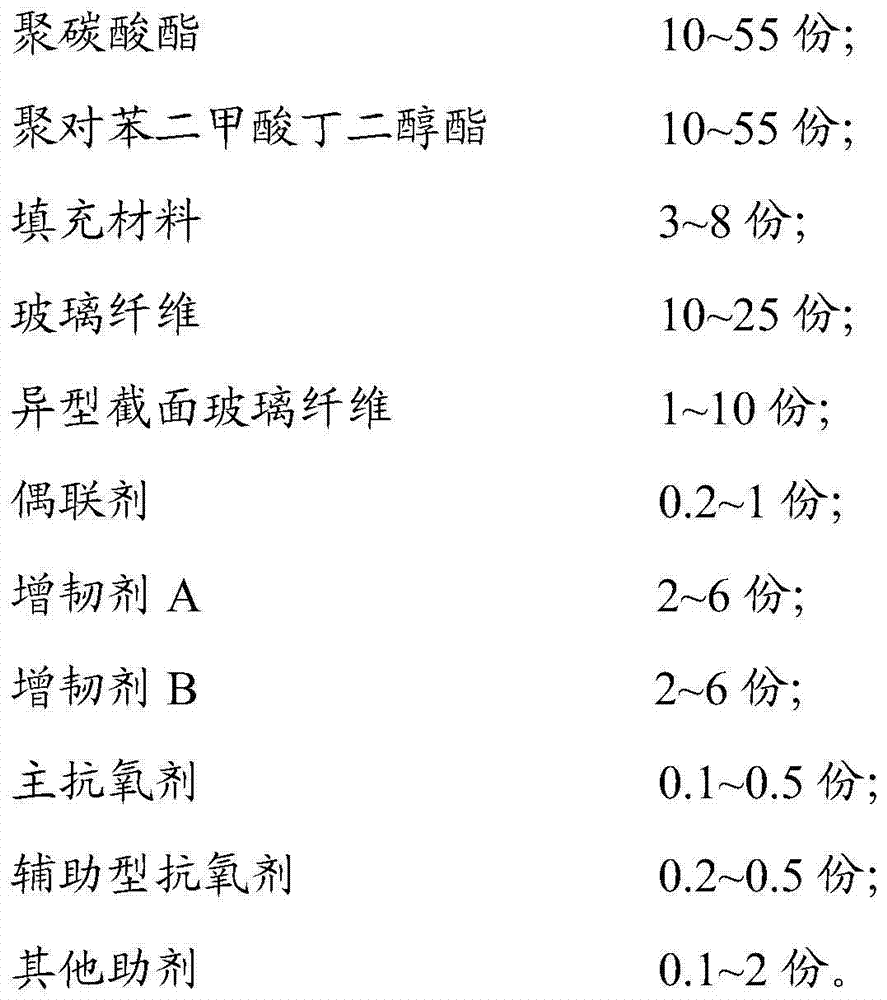

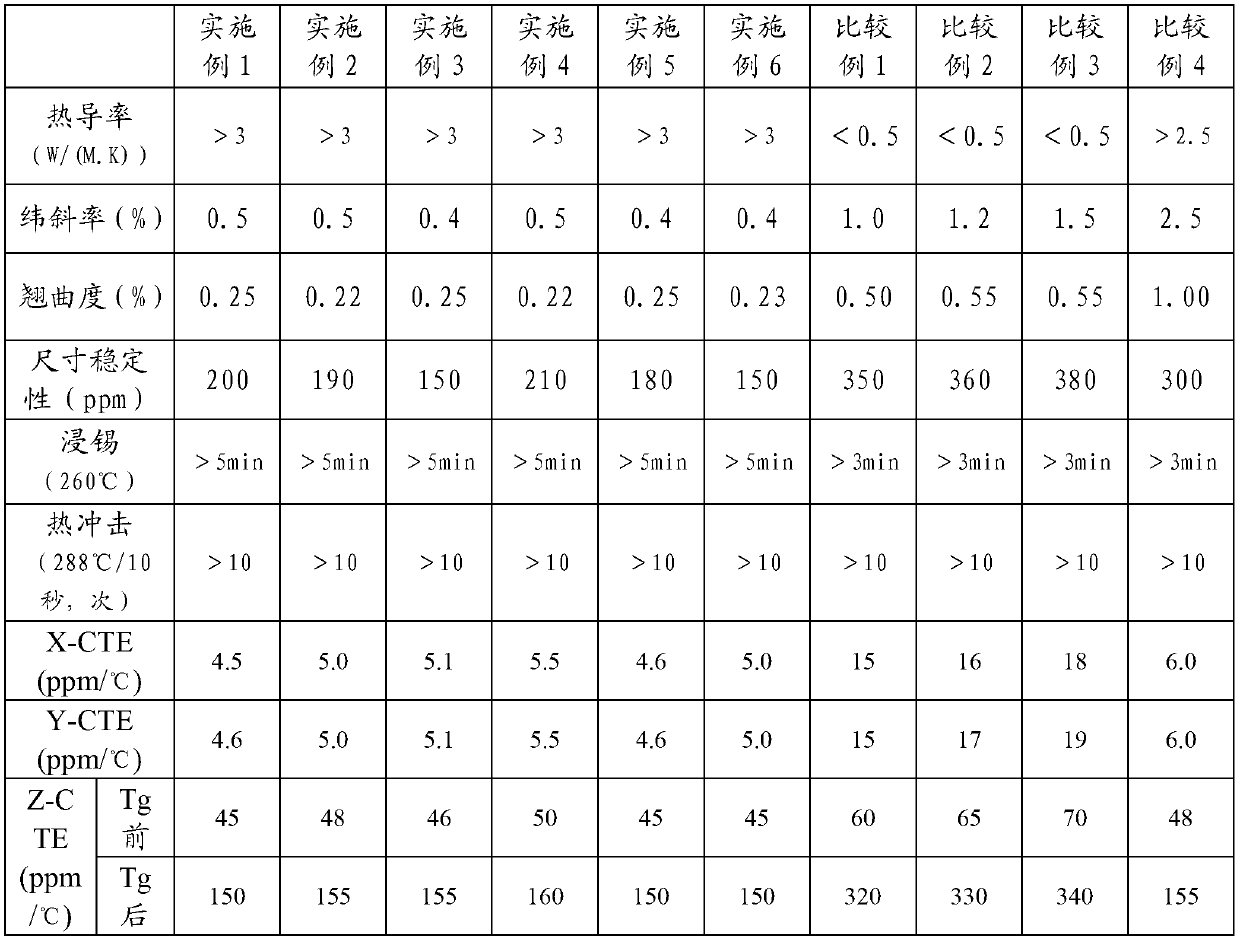

PC/PBT alloy material and preparation method thereof

The invention is suitable for the technical field of modified plastic alloys, and provides a PC / PBT alloy material and a preparation method thereof. The PC / PBT alloy material comprises, by weight, 10-55 parts of polycarbonate, 10-55 parts of polybutylene telephthalate, 3-8 parts of a filler, 10-25 parts of a glass fiber, 1-10 parts of an irregular-section glass fiber, 0.2-1 part of a coupling agent, 2-6 parts of a flexibilizer A, 2-6 parts of a flexibilizer B, 0.1-0.5 parts of a main antioxidant, 0.2-0.5 parts of an auxiliary antioxidant, and 0.1-2 parts of other assistants. The PC / PBT alloy material has the advantages of good mechanical performances, low temperature resistance, impact resistance, warp resistance and processability. The preparation method of the PC / PBT alloy material has the advantages of simple flow, reasonable and controllable technological conditions, and suitableness for the industrial production.

Owner:SHENZHEN WOTE ADVANCED MATERIALS

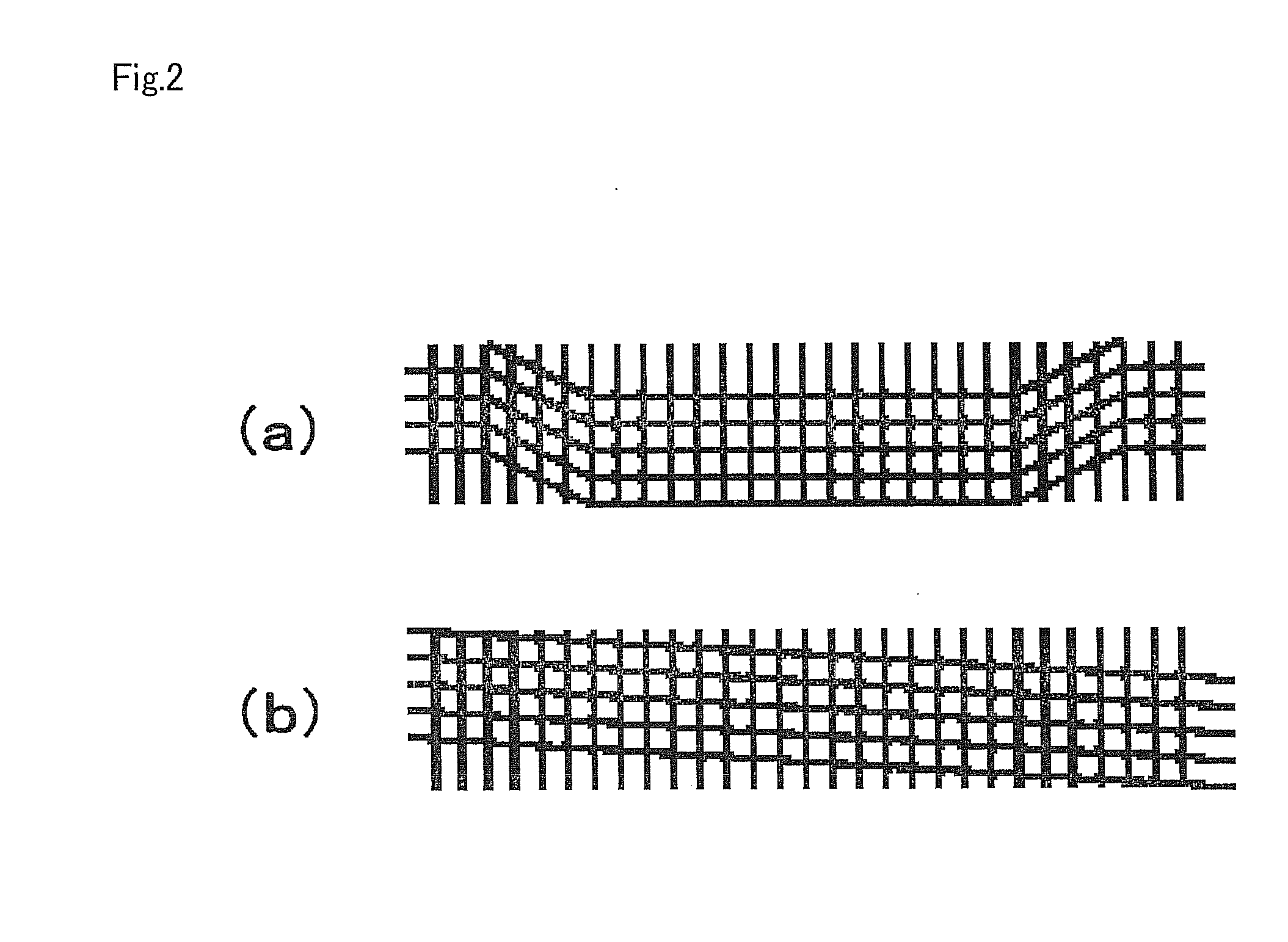

Carbon fiber base fabric composite material and preparation method and application thereof

ActiveCN103129042AAvoid problems such as falling apart or even breakingMeet needsLaminationLamination apparatusFiberCarbon fibers

The invention relates to the technical field of printed circuit boards, in particular to a carbon fiber base fabric composite material. The carbon fiber base fabric composite material comprises at least one layer of carbon fiber base fabric and adhesive layers. The adhesive layers are one layer more than the carbon fiber base fabric. The composite material is formed by the carbon fiber base fabric and the adhesive layers through alternately laminating in a press fit mode. The carbon fiber base fabric is made of carbon fiber through knitting in the warp and weft direction. Compared with a glass fabric base fabric bonding sheet, the carbon fiber base fabric composite material has better thermal conductivity, overcomes the defects that weft skewing can easily happen to a carbon fiber sheet and production operations of the carbon fiber sheet is hard, greatly improves warping of products, and particularly improves the stability of the sizes of the products.

Owner:GUANGDONG SHENGYI SCI TECH

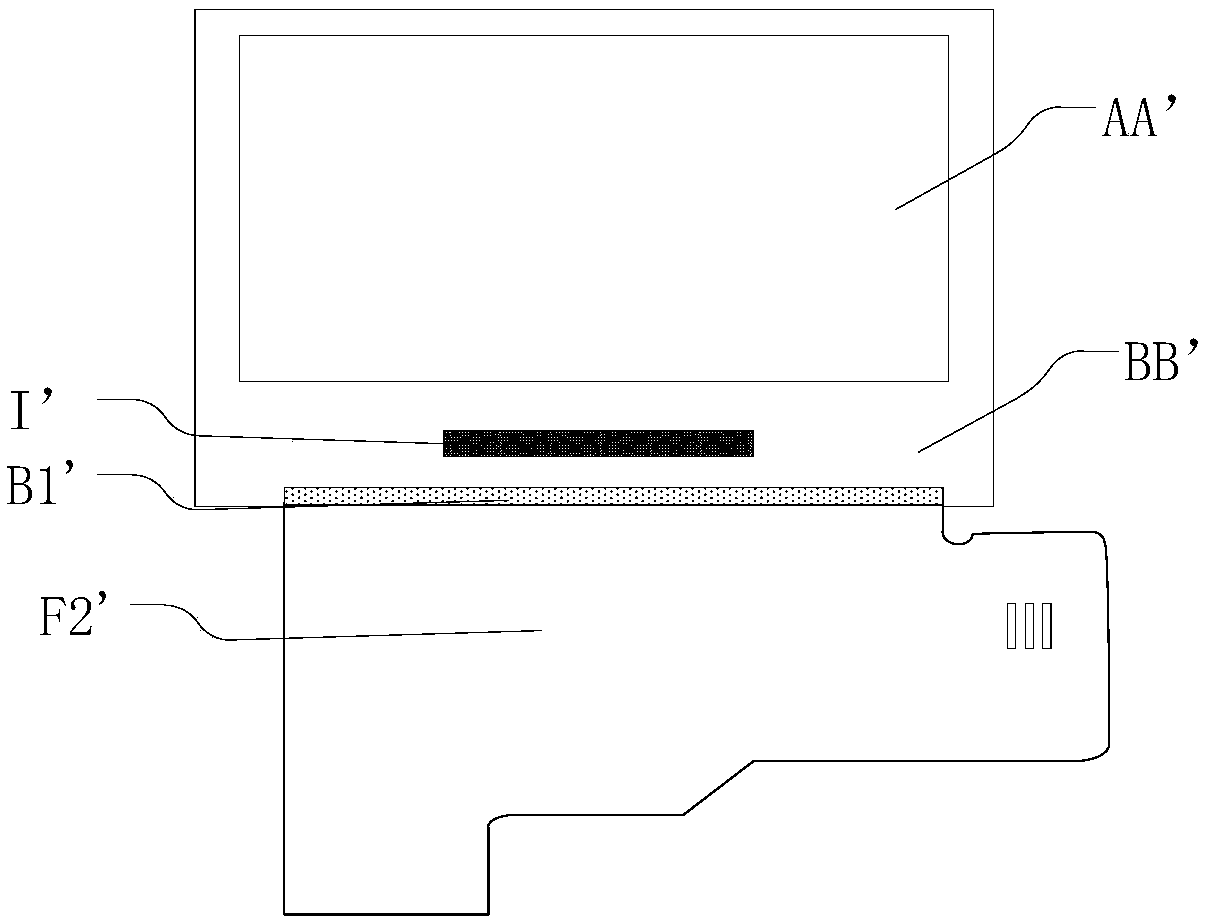

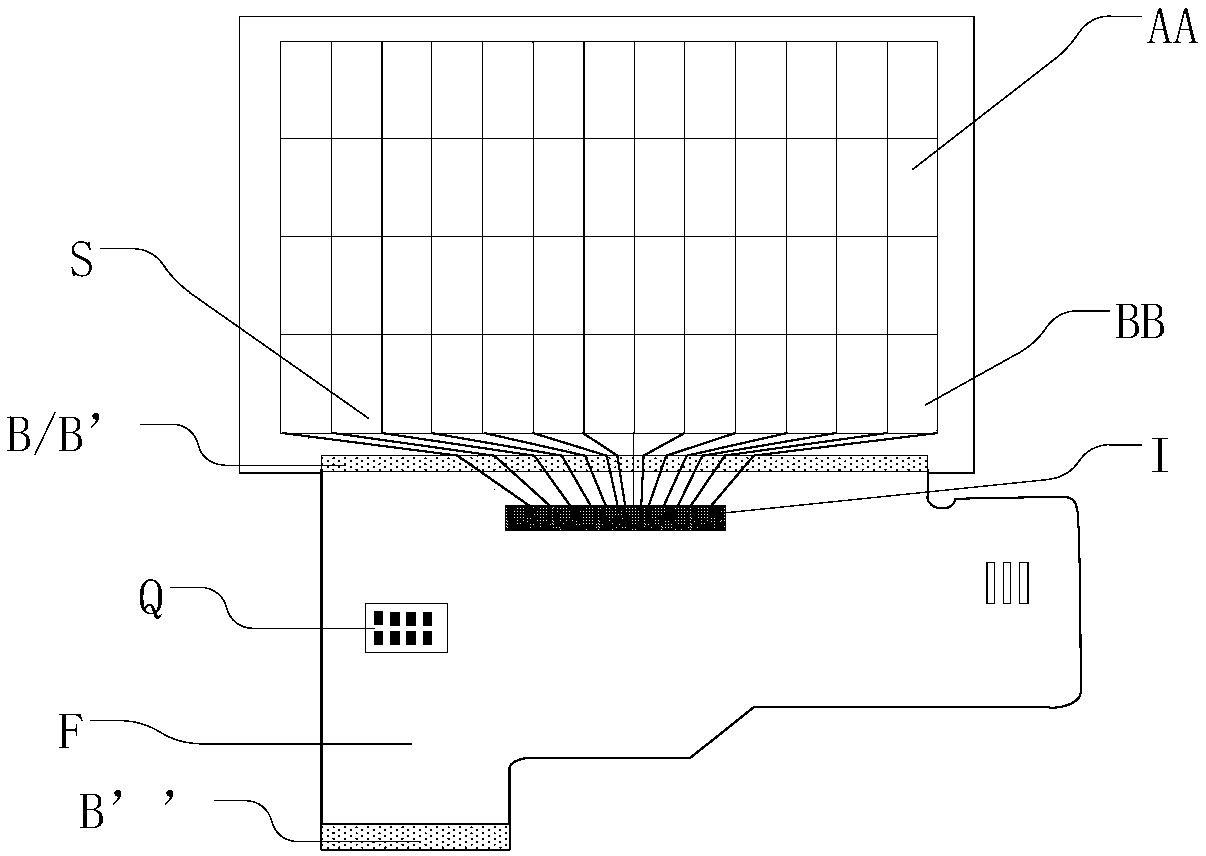

Liquid crystal display module and liquid crystal display device

InactiveCN109597252AIncrease productivityImprove warpageNon-linear opticsPrinted circuit non-printed electric components associationLiquid-crystal displayElectricity

The present invention provides a liquid crystal display module and a liquid crystal display device. The liquid crystal display module comprises: a display panel; a flexible circuit board and an integrated circuit chip, wherein the flexible circuit board comprises a first end and a second end; the first end comprises a second binding terminal; the second binding terminal of the first end is connected to a first binding terminal of a non-display area; the flexible circuit board comprises at least two conductive layers; the flexible circuit board further comprises at least two rows of bonding pads between the first end and the second end; each row of the bonding pads comprises a plurality of sub-bonding pads; the conductive layers are exposed by the sub-bonding pads; the flexible circuit board further comprises a component group; and the integrated circuit chip is electrically connected to the sub-bonding pads through conductive adhesive. The module provided by the invention has the technical effects that the production efficiency can be improved; the cost is reduced; the risk of pressing deviation is reduced; the product yield is increased; the problem that the integrated circuit chip is easy to break is improved; and the package reliability of the integrated circuit chip is increased.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com