PC/PBT alloy material and preparation method thereof

An alloy material and filler material technology, applied in the field of plastic alloys, can solve the problems of not being able to have good mechanical properties, low temperature impact resistance, warpage resistance, processability, etc. at the same time. The effect of high finished product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

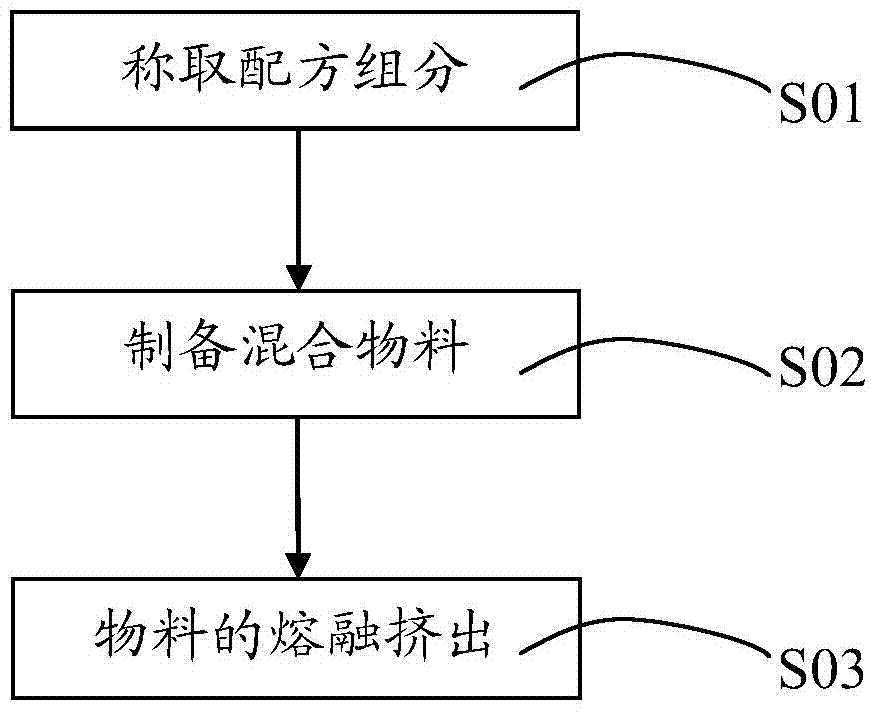

[0037] Correspondingly, the embodiment of the present invention also provides a method for preparing a PC / PBT alloy material, comprising the following steps, such as figure 1 Shown:

[0038] S01. Weighing formula components: weigh each component according to the above-mentioned PC / PBT alloy material formula;

[0039] S02. Preparation of mixed material: mixing each component except glass fiber and special-shaped cross-section glass fiber to form a mixed material, which is added from the main feed;

[0040] S03. Melt extrusion of materials: Add glass fibers and glass fibers with special-shaped cross-sections from the side feeding port for melt extrusion;

[0041] Among them, the specific process of melt extrusion is: the temperature of the first zone is 150±10°C, the temperature of the second zone is 180±10°C, the temperature of the third zone is 225±5°C, the temperature of the fourth zone is 235±5°C, and the temperature of the fifth zone is 245±5°C, the temperature in the six...

Embodiment 1

[0050] A kind of PC / PBT alloy material, the formula component that it comprises and the content of corresponding component are shown in the embodiment 1 in the following table 1, and wherein filling material adopts glass microsphere.

[0051] Preparation method of PC / PBT alloy material:

[0052] (1) Weigh the formula components: weigh each component according to the formula of Example 1 in Table 1;

[0053] (2) Preparation of mixed material: Mix all components except glass fiber to form a mixed material, which is added from the main feed;

[0054] (3) Melt extrusion of materials: Add glass fiber from the side feeding port for melt extrusion;

[0055] Among them, the specific process of melt extrusion is: the temperature of the first zone is 150±10°C, the temperature of the second zone is 180±10°C, the temperature of the third zone is 225±5°C, the temperature of the fourth zone is 235±5°C, and the temperature of the fifth zone is 245±5°C, the temperature in the sixth zone is ...

Embodiment 2

[0057] A kind of PC / PBT alloy material, the formula component that it comprises and the content of corresponding component are shown in the embodiment 2 in the following table 1, and wherein filling material adopts glass microsphere.

[0058] Preparation method of PC / PBT alloy material:

[0059] (1) Weigh the formula components: weigh each component according to the formula of Example 2 in Table 1;

[0060] (2) Preparation of mixed material: Mix all components except glass fiber to form a mixed material, which is added from the main feed;

[0061](3) Melt extrusion of materials: Add glass fiber from the side feeding port for melt extrusion;

[0062] Among them, the specific process of melt extrusion is: the temperature of the first zone is 150±10°C, the temperature of the second zone is 180±10°C, the temperature of the third zone is 225±5°C, the temperature of the fourth zone is 235±5°C, and the temperature of the fifth zone is 245±5°C, the temperature in the sixth zone is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com