Patents

Literature

177results about How to "Low warpage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin composition for production of clad layer, resin film for production of clad layer utilizing the resin composition, and optical waveguide and optical module each utilizing the resin composition or the resin film

InactiveUS20120077401A1Maintain good propertiesImprove stabilitySynthetic resin layered productsAnimal housingEpoxyOrganic solvent

A thermosetting resin composition containing: (A) a resin composition having an unsaturated maleimide group, produced by reacting (a) a maleimide compound having at least two N-substituted maleimide groups per one molecule and (b) an amine compound having at least two primary amino groups per one molecule, in an organic solvent; (B) a thermosetting resin; and (C) a modified imidazole compound, such as an isocyanate-masked imidazole and an epoxy-masked imidazole, and a prepreg, an insulating film with a support, a laminate plate and a printed wiring board, each containing the same.

Owner:HITACHI CHEM CO LTD

Glass fiber-reinforced PBT/PET (Polybutylece Terephthalate/Polyethyleneglycol Terephthalate) composite material and preparation method thereof

The invention discloses a glass fiber-reinforced PBT / PET (Polybutylece Terephthalate / Polyethyleneglycol Terephthalate) composite material and a preparation method thereof. The glass fiber-reinforced PBT / PET composite material consists of the following components in percentage by weight: 10-93.3 percent of PBT, 0.5-20 percent of PET, 0.5-20 percent of low shrink high molecular filler, 0.5-8 percent of compatilizer, 5-60 percent of glass fiber, 0-10 percent of toughening agent and 0.2-5 percent of aids, wherein the low shrink high molecular filler is one or more of an acrylonitrile-styrene-butadiene copolymer, an acrylonitrile-styrene-acrylic rubber copolymer and polycarbonate. The warping rate of glass fiber-reinforced PBT / PET composite material can be lowered effectively, and the performance of the material is improved; and the glass fiber-reinforced PBT / PET composite material can be widely applied to products such as automobile parts, electronic apparatuses and the like, and meets the requirements of large-sized thin-wall parts.

Owner:深圳市欧力隆科技有限公司

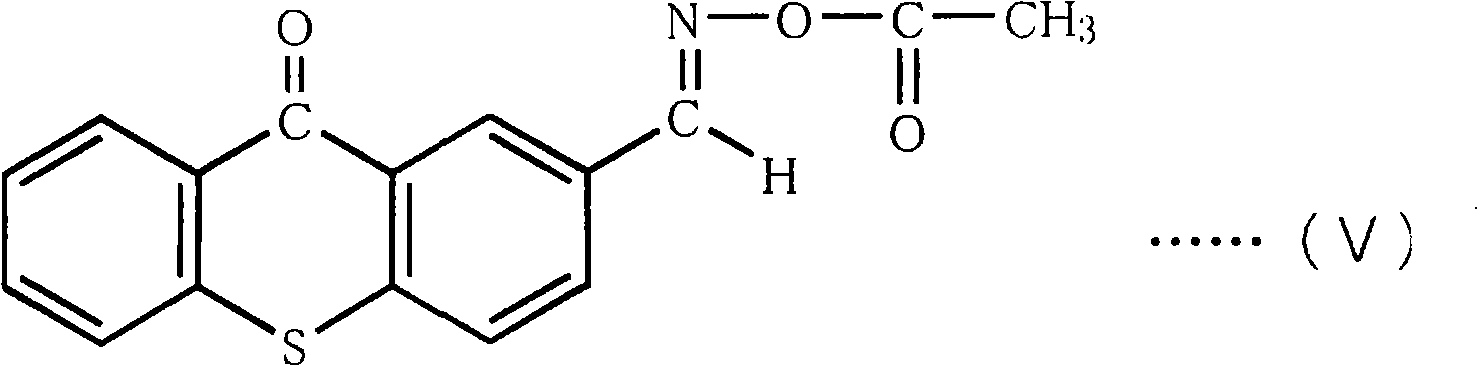

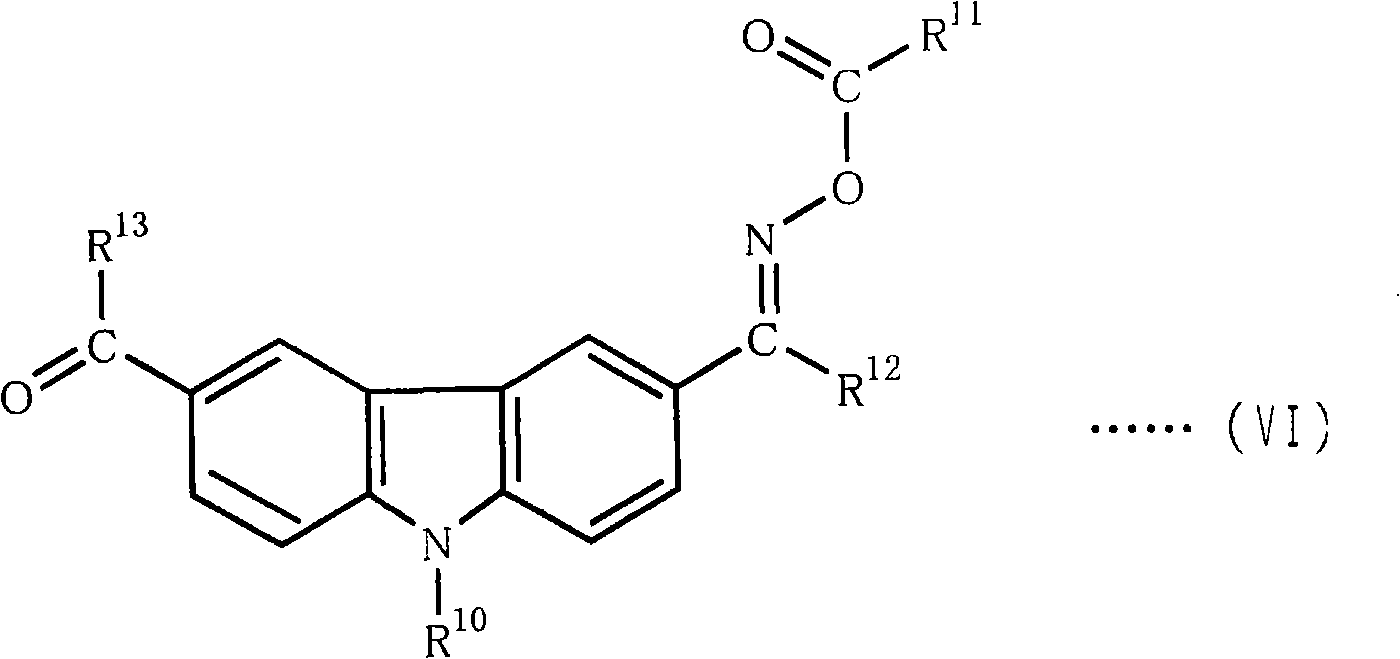

Photosensitive resin composition and curing article thereof

ActiveCN101403859ALow warpageIncreased sensitivityPrinted circuitsPhotosensitive materials for photomechanical apparatusResistPolymer science

The invention provides a light-sensitive polymer composition and condensate thereof, and a printed circuit board with solder resist and the like curing coating formed by the condensate, wherein the light-sensitive polymer composition can inhibit the generation of warping resulting from heating in the process of producing flexible substrates and processes thereafter, and component mounting process, further the invention has high light sensitivity even if adding small quantity of photo-polymerization initiator and the laser can directly exposure. The light-sensitive polymer composition contains: (A) carboxyl-containing resin, (B) proxetil photo-polymerization initiator, and (C)a compound which has more than two ethylenically unsaturated groups in the molecule; and the composition can develop through a dilute alkali water solution, wherein, the composition contains 0.1-1.5 weight parts of the proxetil photo-polymerization initiator (B) relative to 100 weight parts of the carboxyl-containing resin (A).

Owner:TAIYO INK MFG CO LTD

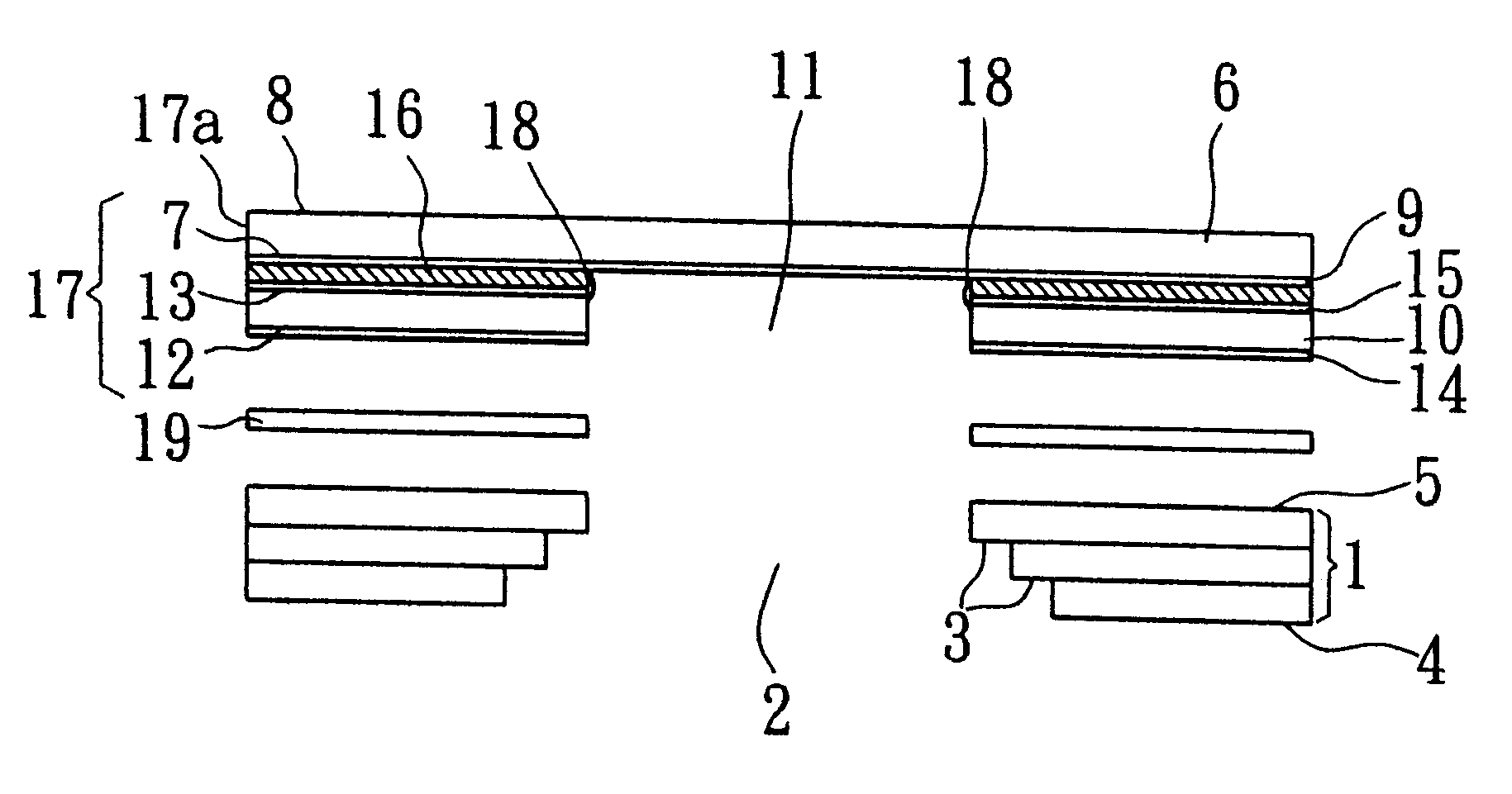

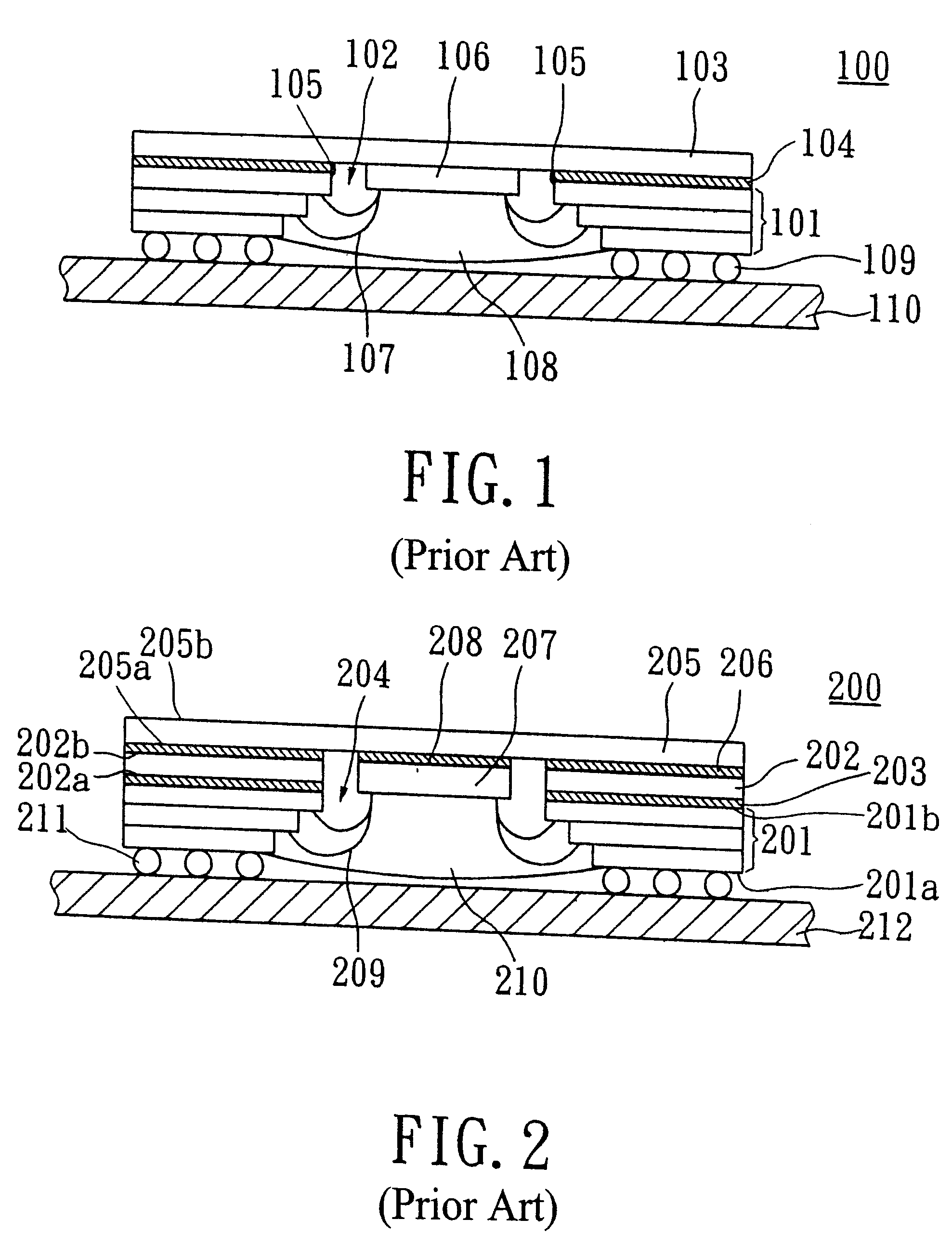

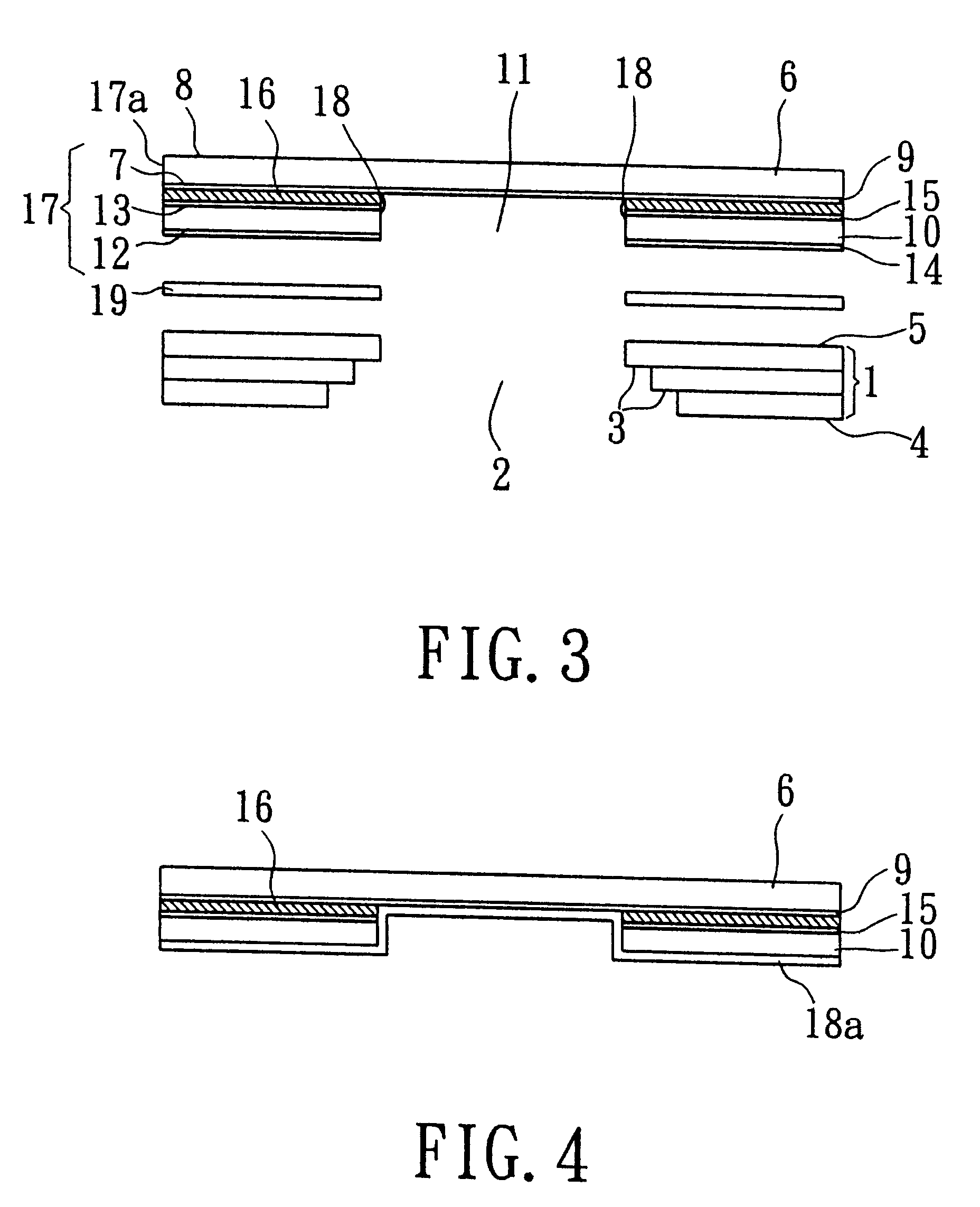

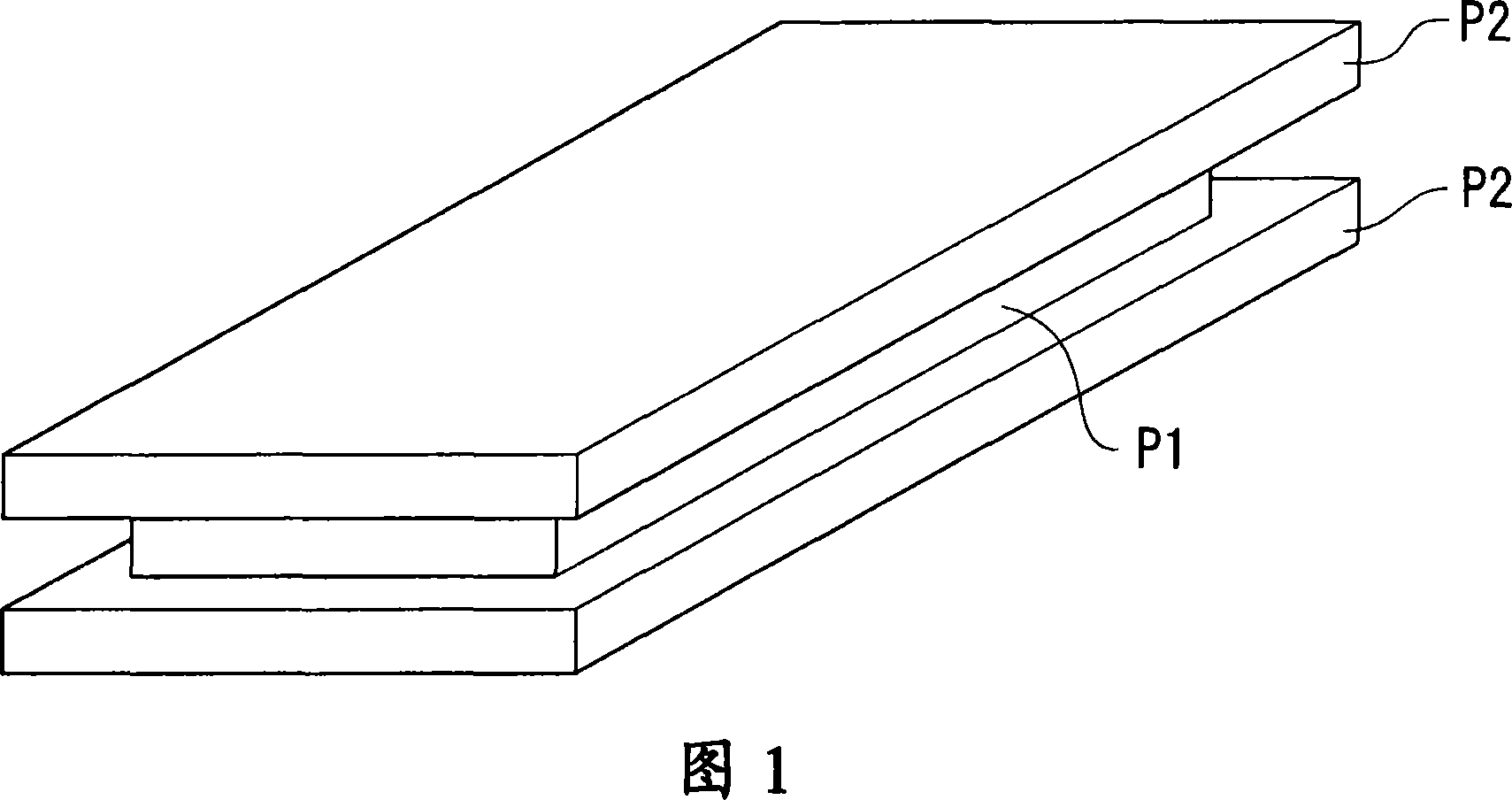

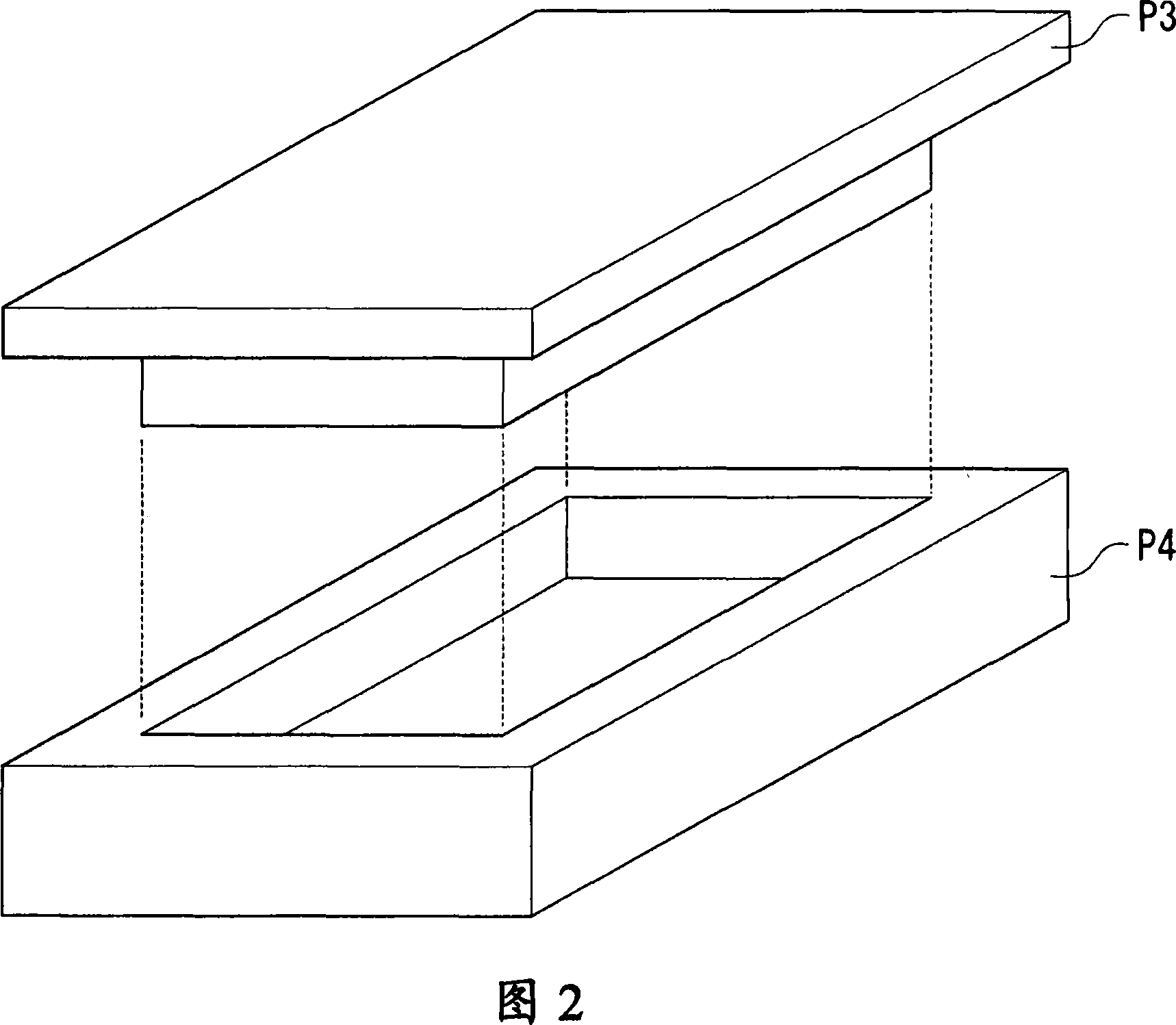

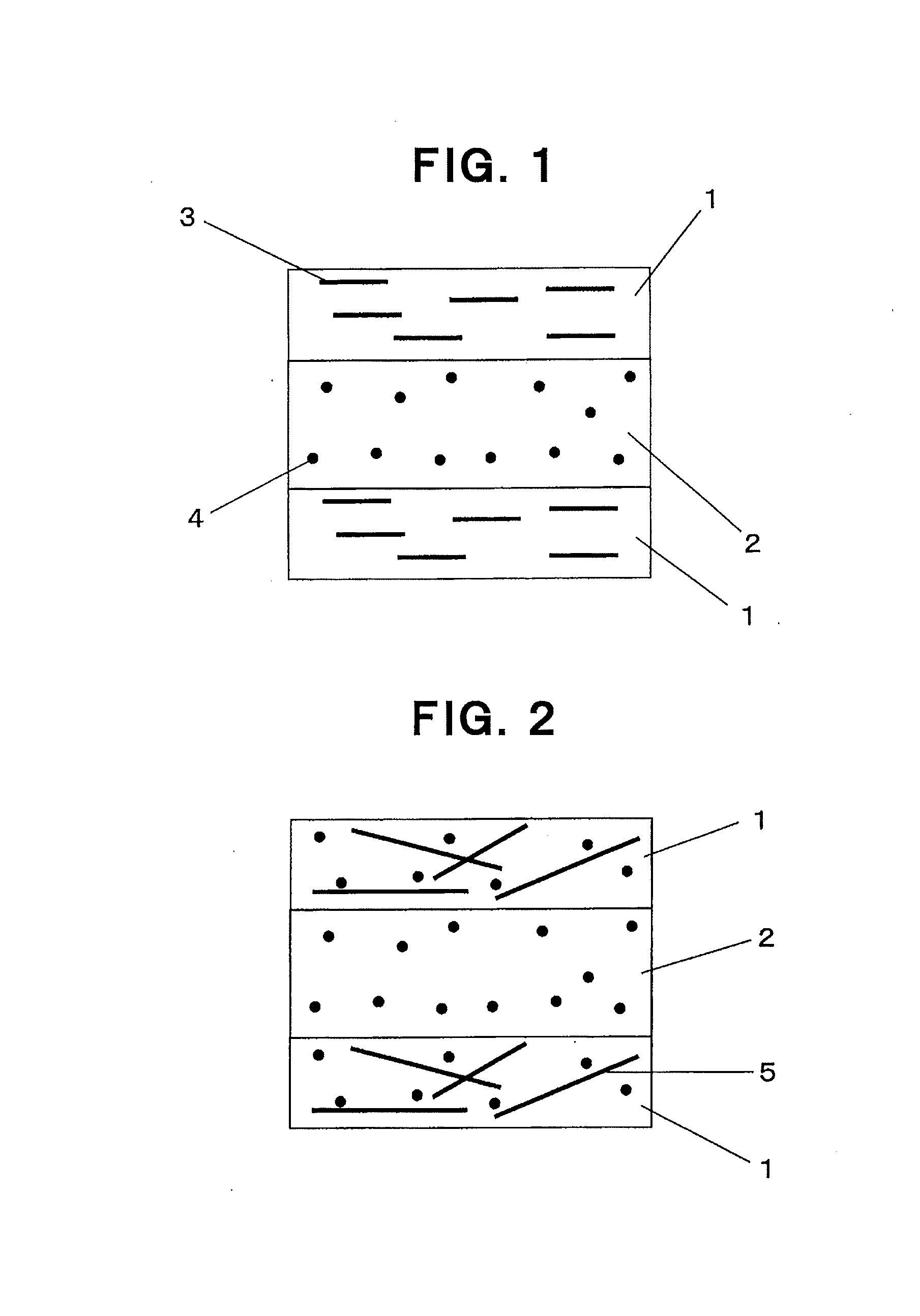

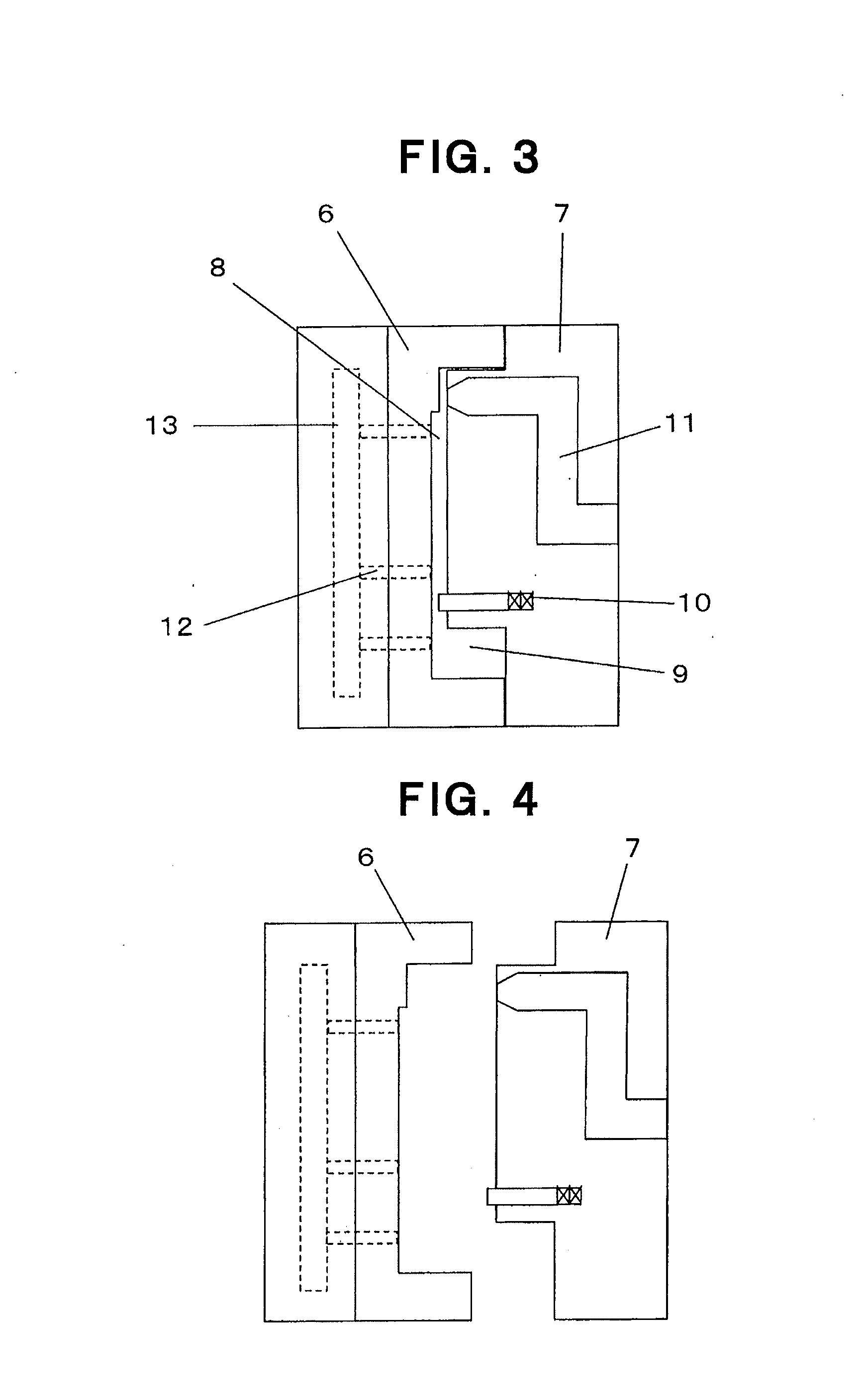

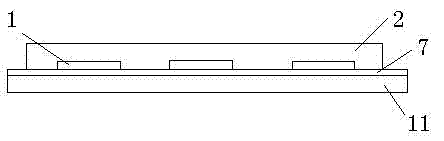

Attachment of a stiff heat spreader for fabricating a cavity down plastic chip carrier

InactiveUS6475327B2Good heat dissipationSmall thicknessSemiconductor/solid-state device detailsAdhesive processes with surface pretreatmentEngineeringElectronic chip

A stiff heat spreader element for making a cavity down plastic chip carrier having benefits of excellent heat dissipation property, low weight, small thickness, low warpage and low twist is disclosed. The stiff heat spreader element is formed by bonding a heat spreader and a thermally conductive sheet with using a first bonding sheet. The first bonding sheet is a prepreg or prepregs made of fiber-reinforced resin. A second bonding sheet is used to bond a circuit substrate and the stiff heat spreader element. The second bonding sheet is made of a single adhesive layer or a stack of adhesive layers. The adhesive layer is made of an adhesive material, or a flake-filled adhesive material, or short fiber-filled adhesive material, or a particle-filled adhesive material. The second bonding sheet is not a prepreg or prepregs. The circuit substrate has an opening to receive an electronic chip.

Owner:PHOENIX PRECISION TECH CORP

High conductivity polycarbonate (PC) composite material and preparation method thereof

The invention provides a high conductivity polycarbonate (PC) composite material and a preparation method thereof. The polycarbonate composite material is prepared from the following components in parts by weight: 40-60 parts of PC resin, 10-30 parts of conductive master batch, 10-30 parts of reinforcing filler, 2-6 parts of toughening agent, 0.08-1.5 parts of first antioxidant and 0.05-3.0 partsof first lubricating agent, wherein the conductive master batch is prepared from the following components in parts by weight: 40-70 parts of thermoplastic resin, 30-50 parts of conductive filler, 0.1-0.6 part of second antioxidant and 0.5-2 parts of second lubricating agent. The PC composite material provided by the invention has very good electrical conductivity, and the volume resistivity of thePC composite material can reach 10<2> omega.m. Furthermore, the addition ratio of the conductive filler material is lower; when the adding amount of the conductive filler is about 10%, the volume resistivity can reach 10<4> omega.m or below, but the composite material can maintain good mechanical properties. In addition, the high conductivity PC composite material also has higher fluidity and lowwarping property, thus being suitable for performing injection molding on large-size workpieces.

Owner:疆合材料科技(苏州)有限公司

Thermal spray metal on low heat resistant substrates

InactiveUS20050025896A1Low shrinkageLow warpageLiquid surface applicatorsMolten spray coatingThermal sprayingAdhesive

Method for thermal spraying a metal stream onto a low heat resistant substrate using an adhesive / release promoted interface with the metal stream and the articles so produced for use in various applications.

Owner:PRAXAIR ST TECH INC

High-temperature-resistant nylon yarn material for 3D printing, preparation method thereof and method for performing 3D printing by applying same

ActiveCN106433108AImprove mechanical propertiesIncrease temperatureAdditive manufacturing apparatus3D object support structuresYarnPolymer science

The invention relates to the technical field of 3D printing, in particular to a high-temperature-resistant nylon yarn material for 3D printing, a preparation method thereof and a method for performing 3D printing by applying the same. The high-temperature-resistant nylon yarn material contains the following raw materials in parts by weight: 90-100 parts of nylon resin, 1-10 parts of a reinforcing agent, 0.3-0.6 part of an antioxidant, and 0.1-0.3 part of a lubricant, wherein the reinforcing agent is organic modified montmorillonite. According to the invention, the high-strength nylon resin is used as a base material, the organic modified montmorillonite, the antioxidant and the lubricant are used for performing physical modification on the nylon resin, and the synergistic action among the components with different proportions is adjusted to improve the contractility and increase the thermal denaturation temperature of the nylon resin, so that the obtained high-temperature-resistant nylon yarn material for 3D printing is high in strength, low in shrinkage rate, low in warping deformation degree, and low in forming accuracy, and is high-temperature-resistant, and a support can be removed easily.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

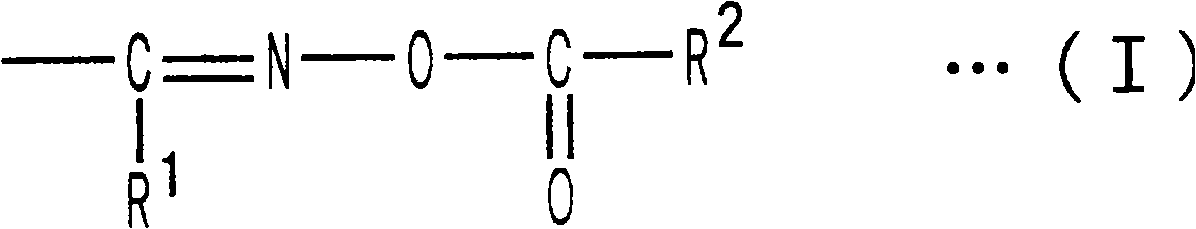

Active energy ray-curable composition for optical material, cured product, and production methods for active energy ray-curable composition and cured product

InactiveCN103237827AExcellent curability with active energy raysLow viscosity propertiesCoatingsOptical elementsCrack resistanceLow temperature curing

Provided are an active energy ray-curable composition for an optical material that has excellent low viscosity, shelf life, low foamability, low-temperature curability, low-warping performance, deep curability, heat-resistant and light-resistant transparency, rubber properties, cracking resistance, moisture permeation resistance and designability; a cured product; and production methods for obtaining the active energy ray-curable composition and the cured product. The active energy ray-curable composition for the optical material comprises (A) a vinyl polymer which has, per molecule, at least one methacryloyl group represented by the general formula (1) -OC(O)C(Ra)=CH2(1) (where Ra is a hydrogen atom or C1-C20 organic group) is produced by living radical polymerization, and has a color difference delta E* of 10 or less; (B) a light-induced radical polymerization initiator; and (C) at least one antioxidant selected from the group consisting of hindered phenol antioxidants, hindered amine antioxidants, and phosphorus antioxidants.

Owner:KANEKA CORP

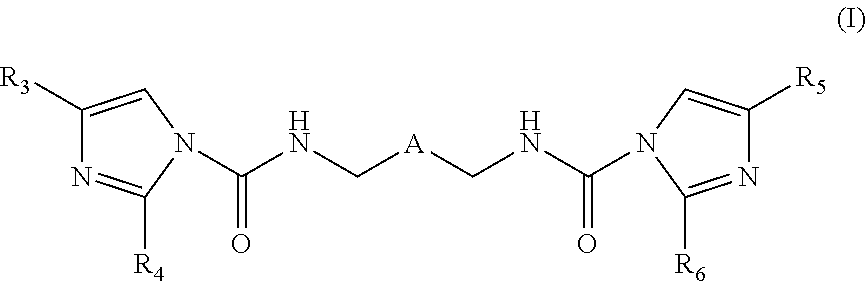

Thermosetting resin composition and uses thereof

InactiveUS20090008138A1Improve reliabilityLow costGroup 5/15 element organic compoundsPrinted circuit aspectsTectorial membraneResist

The thermosetting resin composition and the solder resist ink according to the present invention are characterized by comprising: a thermosetting resin (A) comprising (A1) a compound containing an acid anhydride group and / or a carboxyl group and (A2) a compound having a functional group which reacts with (A1) described above and an organic filler (B) containing a phosphorus atom, wherein the organic filler (B) containing a phosphorus atom has an average particle diameter of 50 Êm or less. According to the present invention, capable of being provided at a low cost and a good productivity are an excellent thermosetting resin composition and solder resist ink capable of forming a cured material which achieves an adhesion to a substrate, a low warping property, a flexibility, a plating resistance, a solder heat resistance and a long term reliability as well as a flame retardancy, and a cured material and a protective film which are excellent in the above characteristics. Further, electronic parts having a protective film which is excellent in a flame retardancy and which has a high reliability can be provided.

Owner:SHOWA DENKO KK

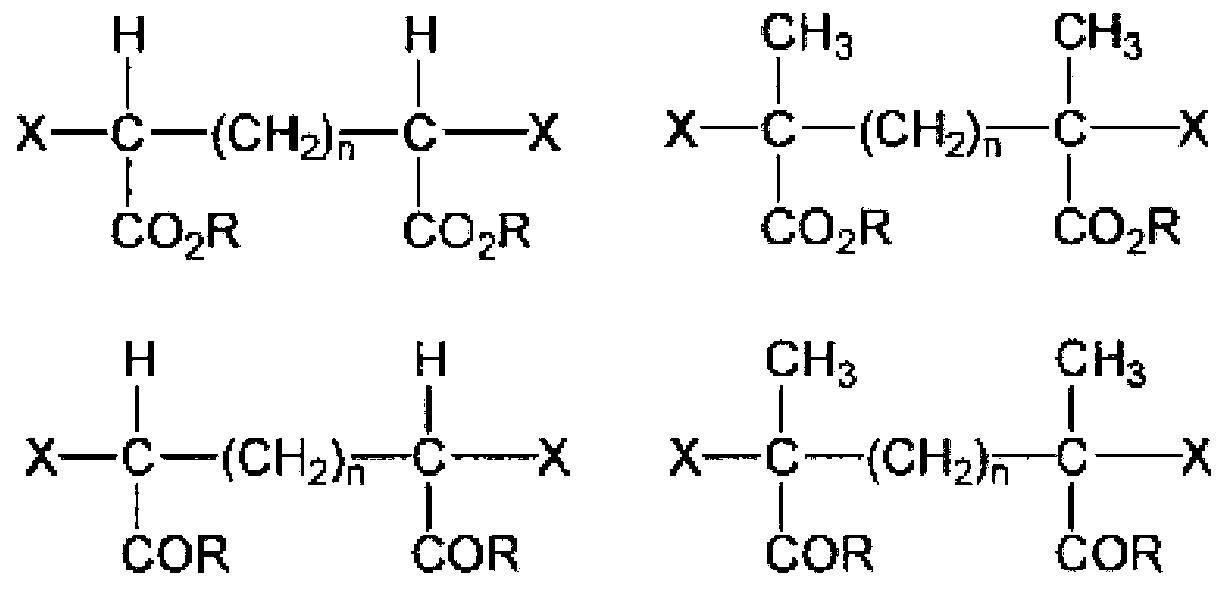

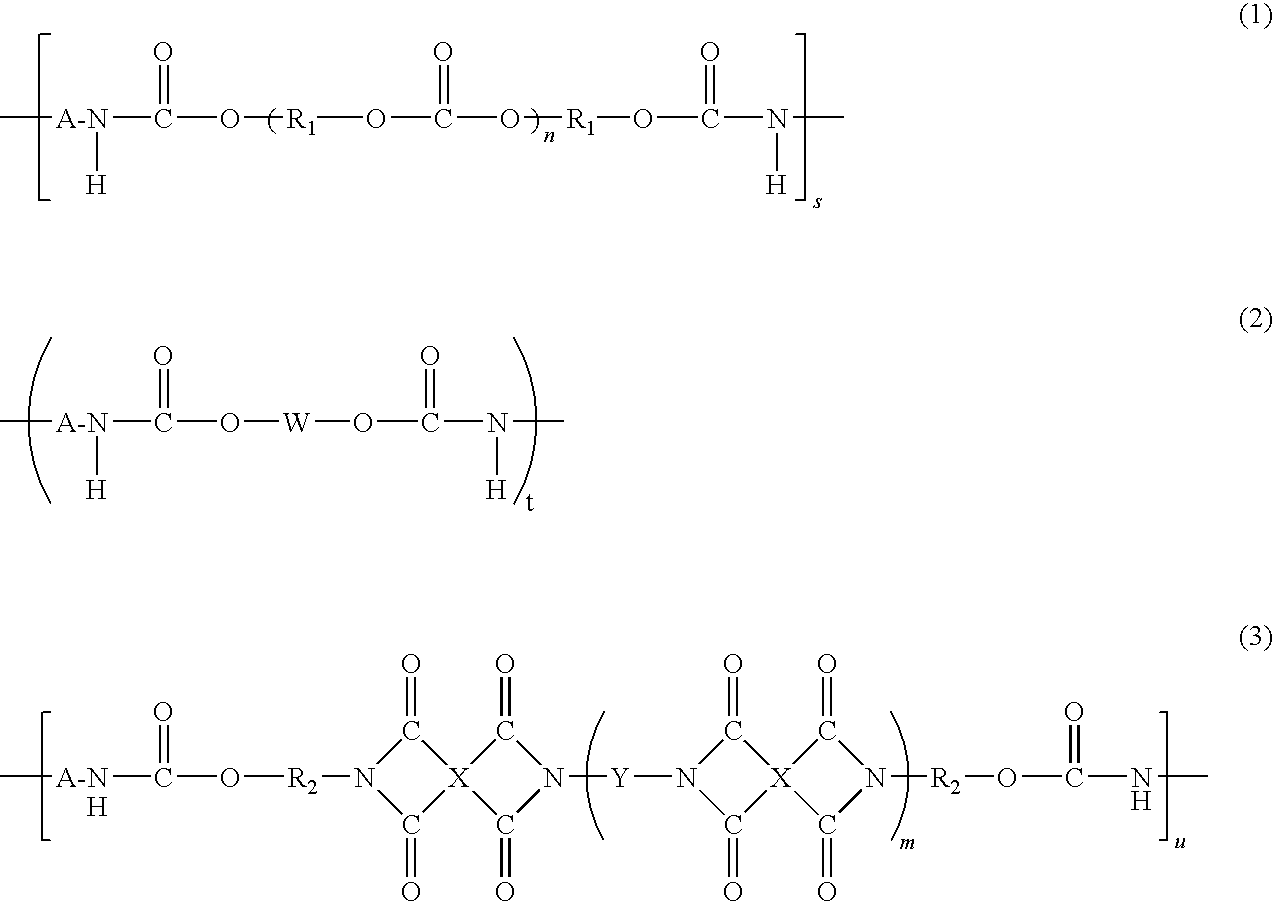

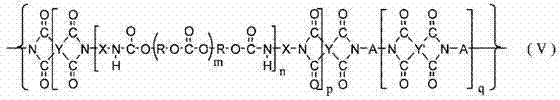

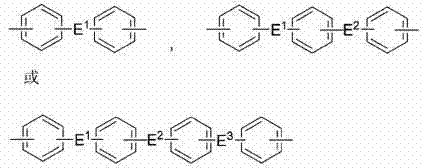

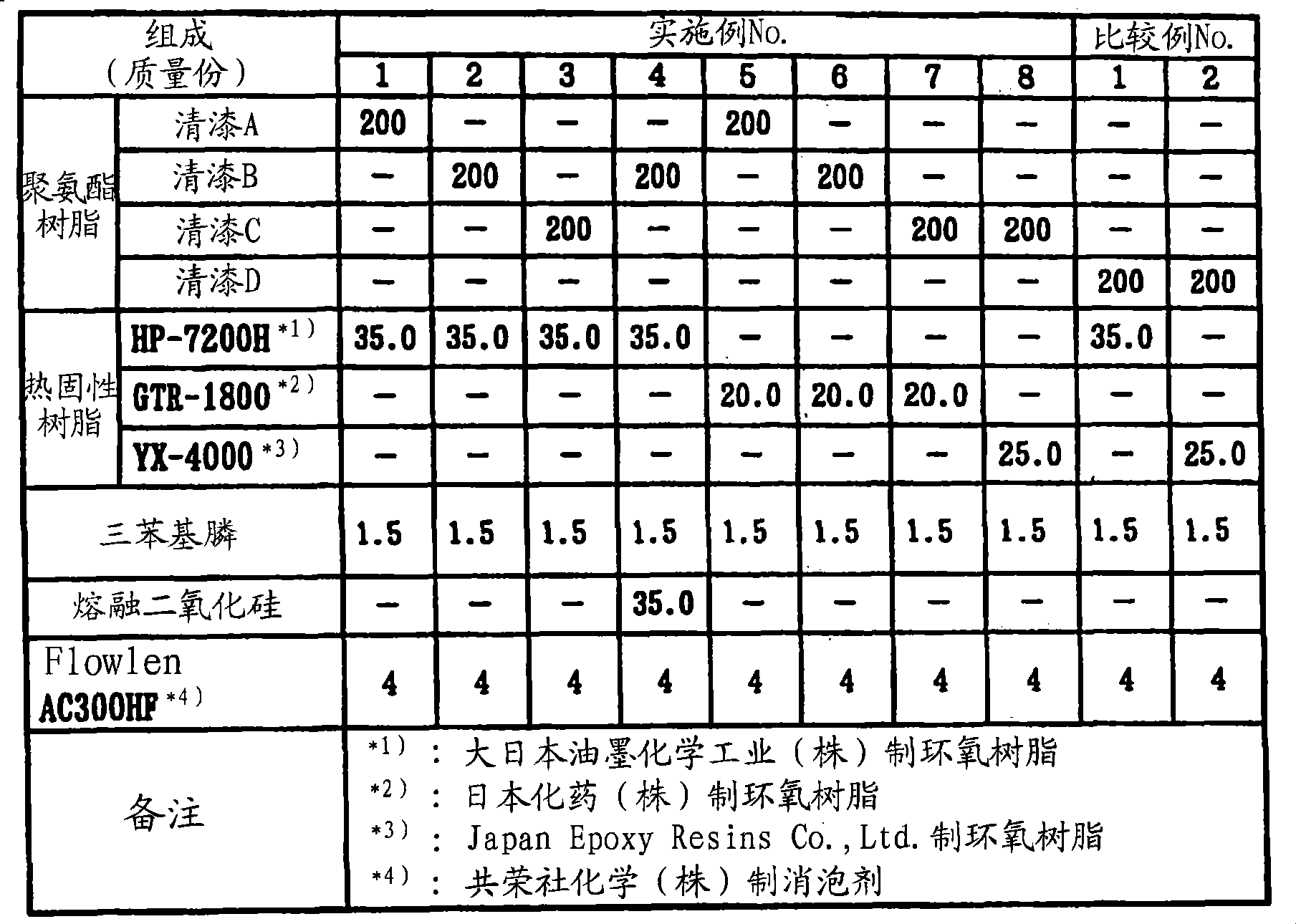

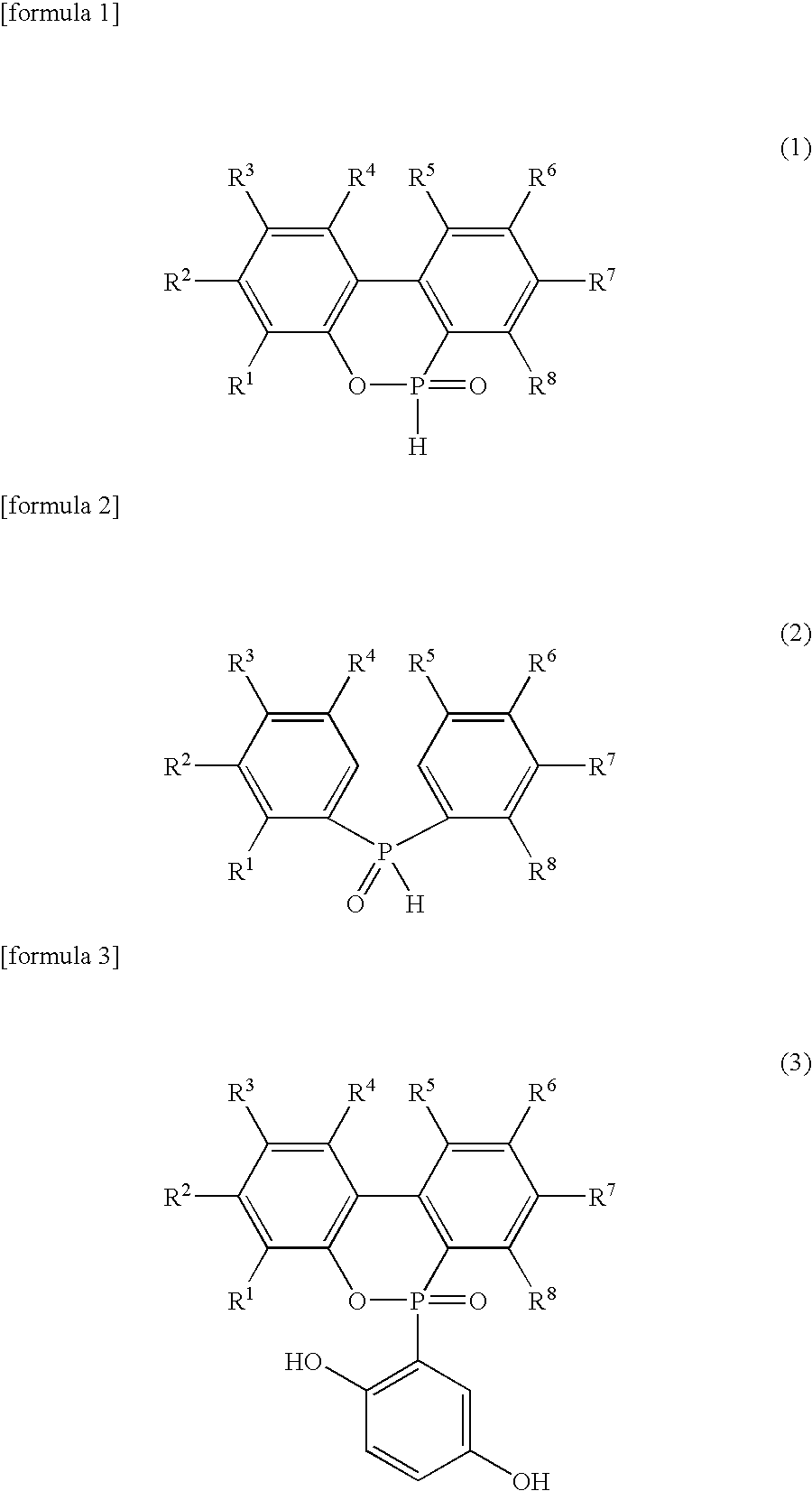

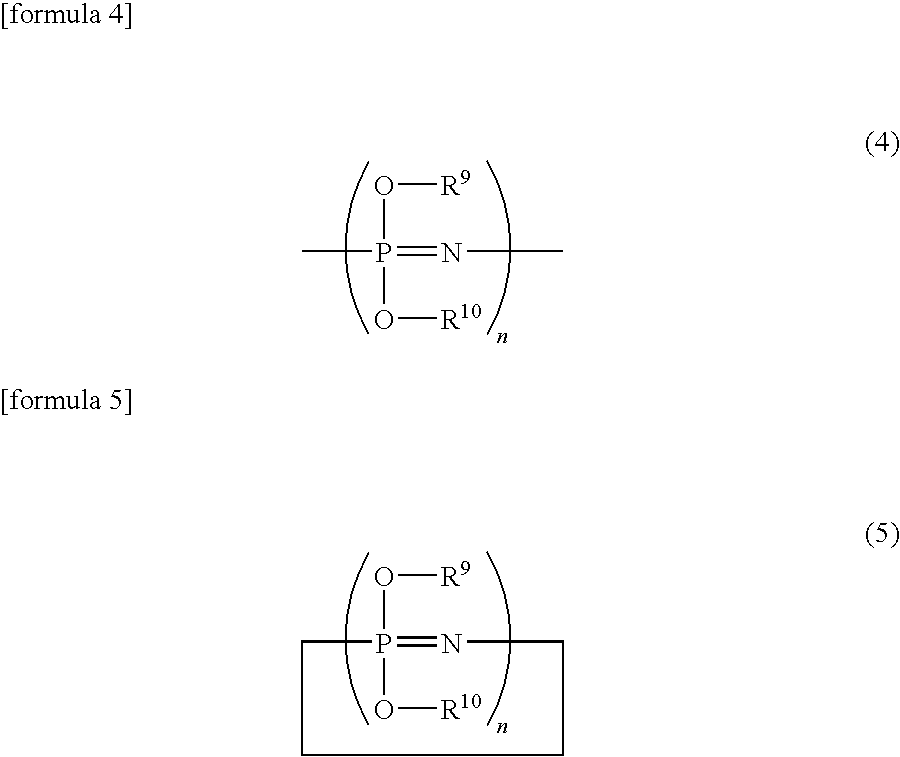

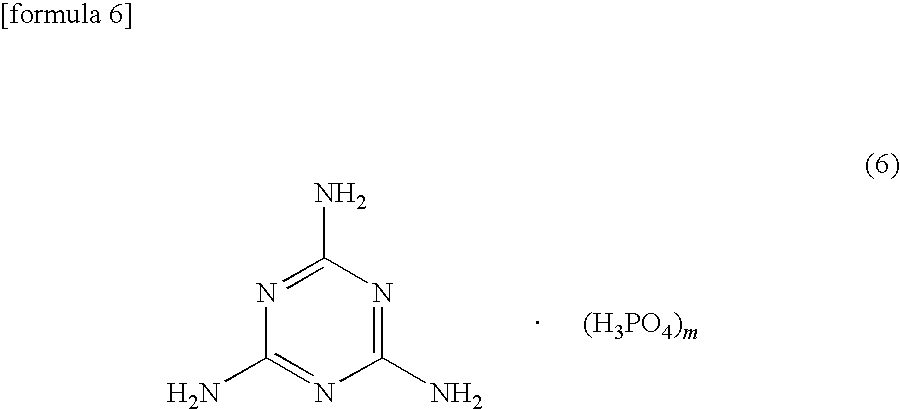

Urethane modified polyimide based flame retardant resin composition

Disclosed is a urethane modified polyimide based flame retardant resin composition having excellent solubility in non-nitrogenous solvents, varnish stability, low temperature drying / curing, low warpage, flexibility, printability, and flame resistance, and also having excellent heat resistance, chemical resistance, electrical properties, and operability, and is low-cost. The urethane modified polyimide based flame retardant resin composition is characterized by containing: (A) a urethane modified polyimide based resin having urethane bonds and generated having as essential components (a) trivalent and / or 4-valent polycarboxylic acid derivatives having an acid anhydride group, (b) diol compounds, and (c) aliphatic polyamine residue derivatives and / or aromatic polyamine residue derivatives; (B) an epoxy resin having two or more epoxy groups per molecule; (C) an organic or inorganic filler; and, (D) a non-halogen-based flame retardant, wherein the non-halogen-based flame retardant (D) contains two essential components (D-1 and D-2), wherein, in an air atmosphere at 350 DEG C, the rate of weight reduction of one component (D-1) is greater than or equal to 50% and less than or equal to 90%, and that of the other component (D-2) is greater than or equal to 0% and less than or equal to 20%.

Owner:TOYOBO CO LTD

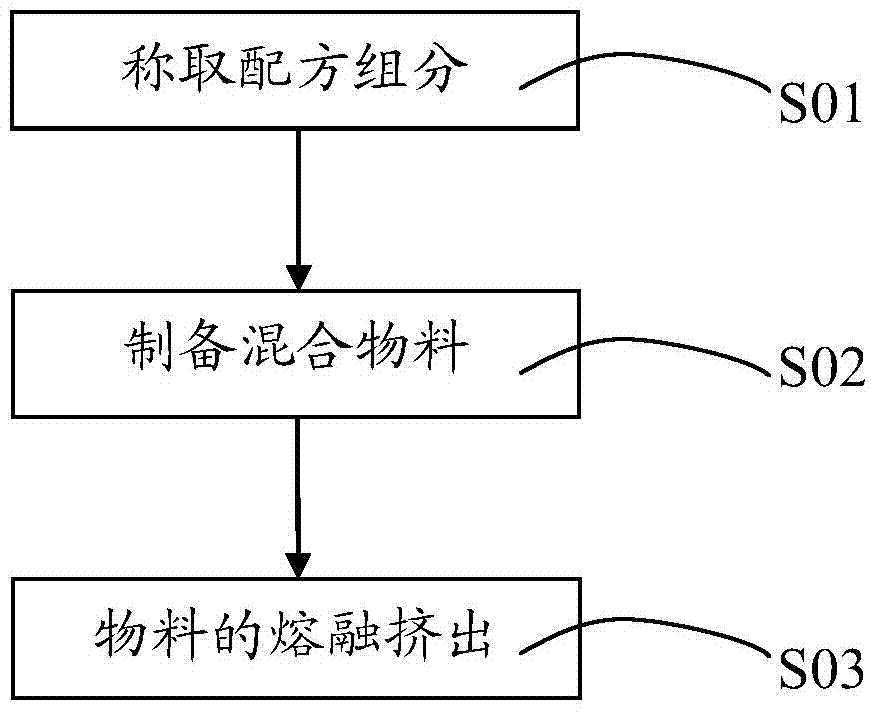

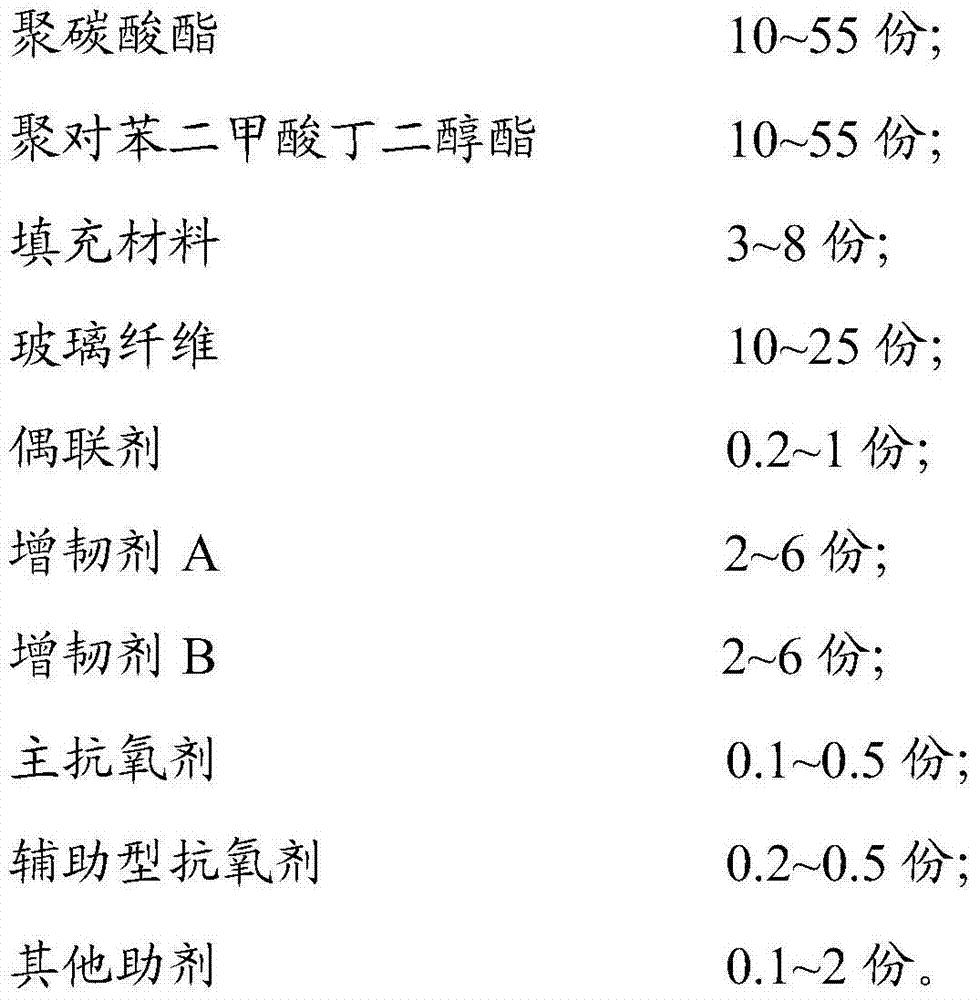

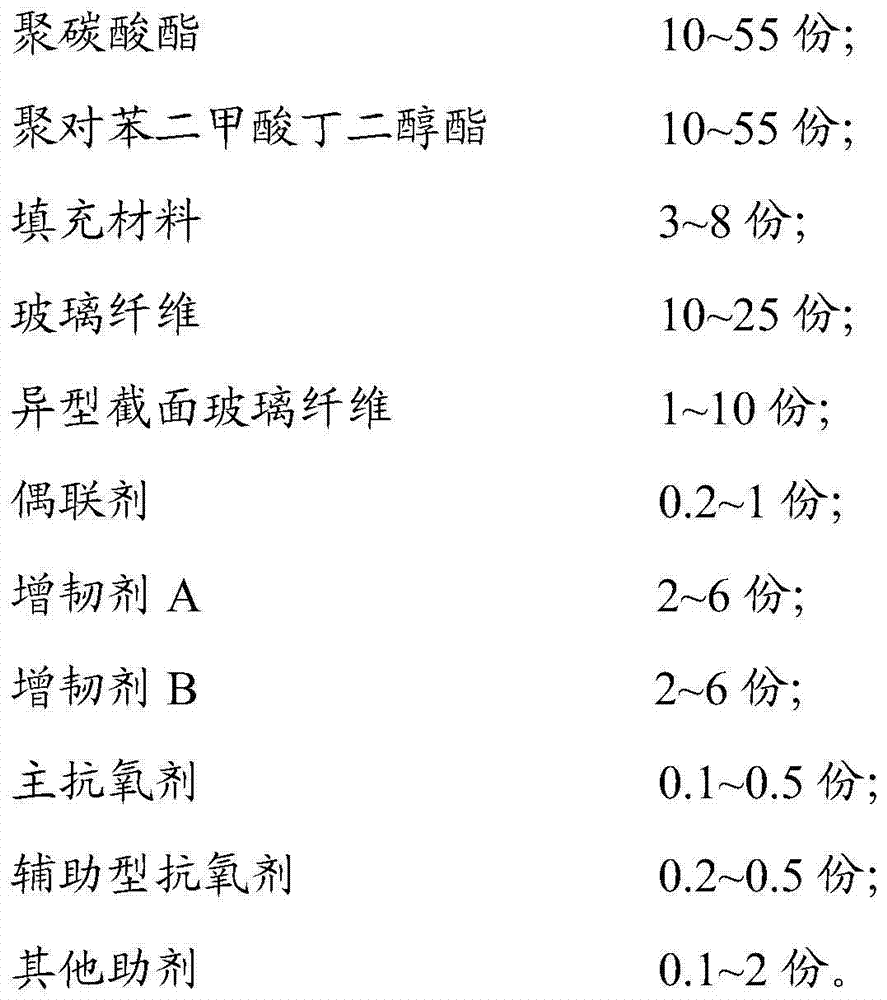

PC/PBT alloy material and preparation method thereof

The invention is suitable for the technical field of modified plastic alloys, and provides a PC / PBT alloy material and a preparation method thereof. The PC / PBT alloy material comprises, by weight, 10-55 parts of polycarbonate, 10-55 parts of polybutylene telephthalate, 3-8 parts of a filler, 10-25 parts of a glass fiber, 1-10 parts of an irregular-section glass fiber, 0.2-1 part of a coupling agent, 2-6 parts of a flexibilizer A, 2-6 parts of a flexibilizer B, 0.1-0.5 parts of a main antioxidant, 0.2-0.5 parts of an auxiliary antioxidant, and 0.1-2 parts of other assistants. The PC / PBT alloy material has the advantages of good mechanical performances, low temperature resistance, impact resistance, warp resistance and processability. The preparation method of the PC / PBT alloy material has the advantages of simple flow, reasonable and controllable technological conditions, and suitableness for the industrial production.

Owner:SHENZHEN WOTE ADVANCED MATERIALS

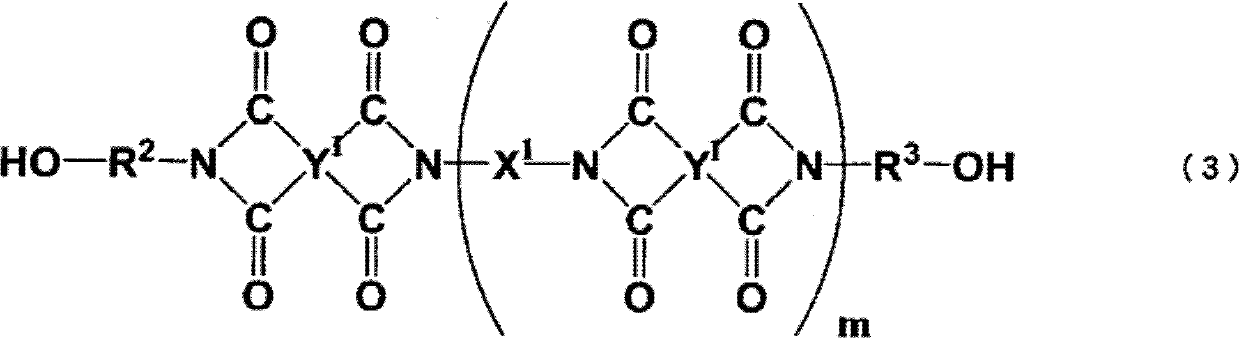

Polyimide Resin and Curable Resin Composition

InactiveUS20100113689A1Improve heat resistanceIncrease flexibilityPrinted circuit manufactureImideDiol

A curable polyimide resin composition containing a polyimide resin obtainable from by a reaction of a reaction mixture containing a diisocyanate compound, a carbonate group-containing diol compound and an imide compound having two terminal hydroxyhydrocarbyl groups gives a cured insulation film having improved characteristics.

Owner:UBE IND LTD

Process for producing foam

InactiveCN101031610AInhibition mechanical strength is lowSmall shrinkageMechanical apparatusLight guides for lighting systemsChemical compoundAmount of substance

The present invention relates to a foam body with a plurality of separate bubbles and / or a plurality of successive bubbles and a method for producing the foam body, in particular to a method for producing a foam body of micro bubbles in diameter equal to or smaller than 10 Mu m with expected thickness, shape, and foamy structure. The present invention provides a method for producing a foam body through the following procedures: an irradiation procedure: irradiate beams with active energy on a foam compound, wherein, the foam compound contains acid generator that can produce acid or alkali generator that can produce alkali under the beams with active energy, and a chemical compound that can react with acid or alkali and decompose and release decomposed functional groups of one or more low boiling point volatile matters; and, a foaming procedure: the foam compound generate foams under pressure control within the temperature range in which the low boiling point volatile matters are released.

Owner:OJI PAPER CO LTD

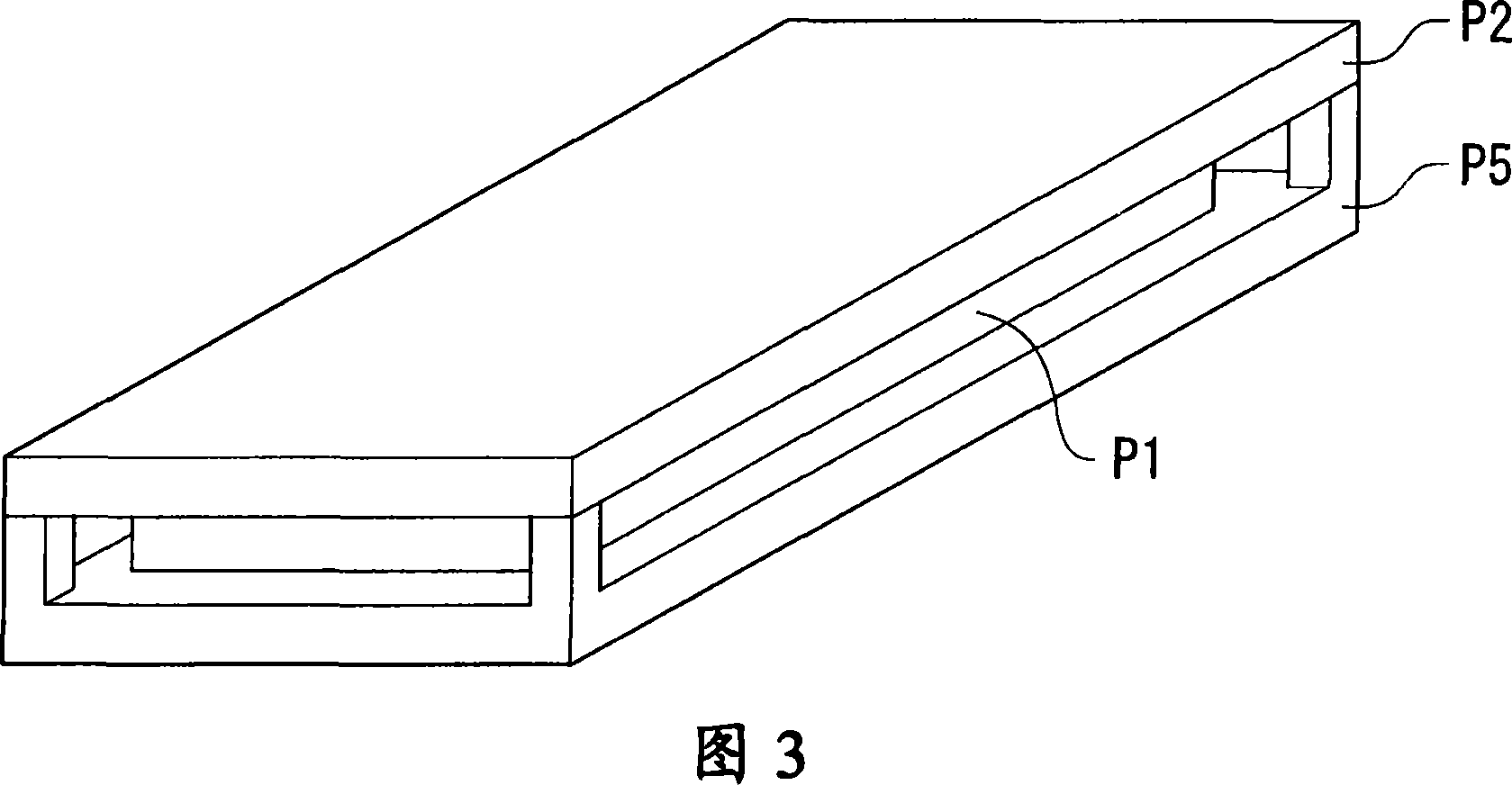

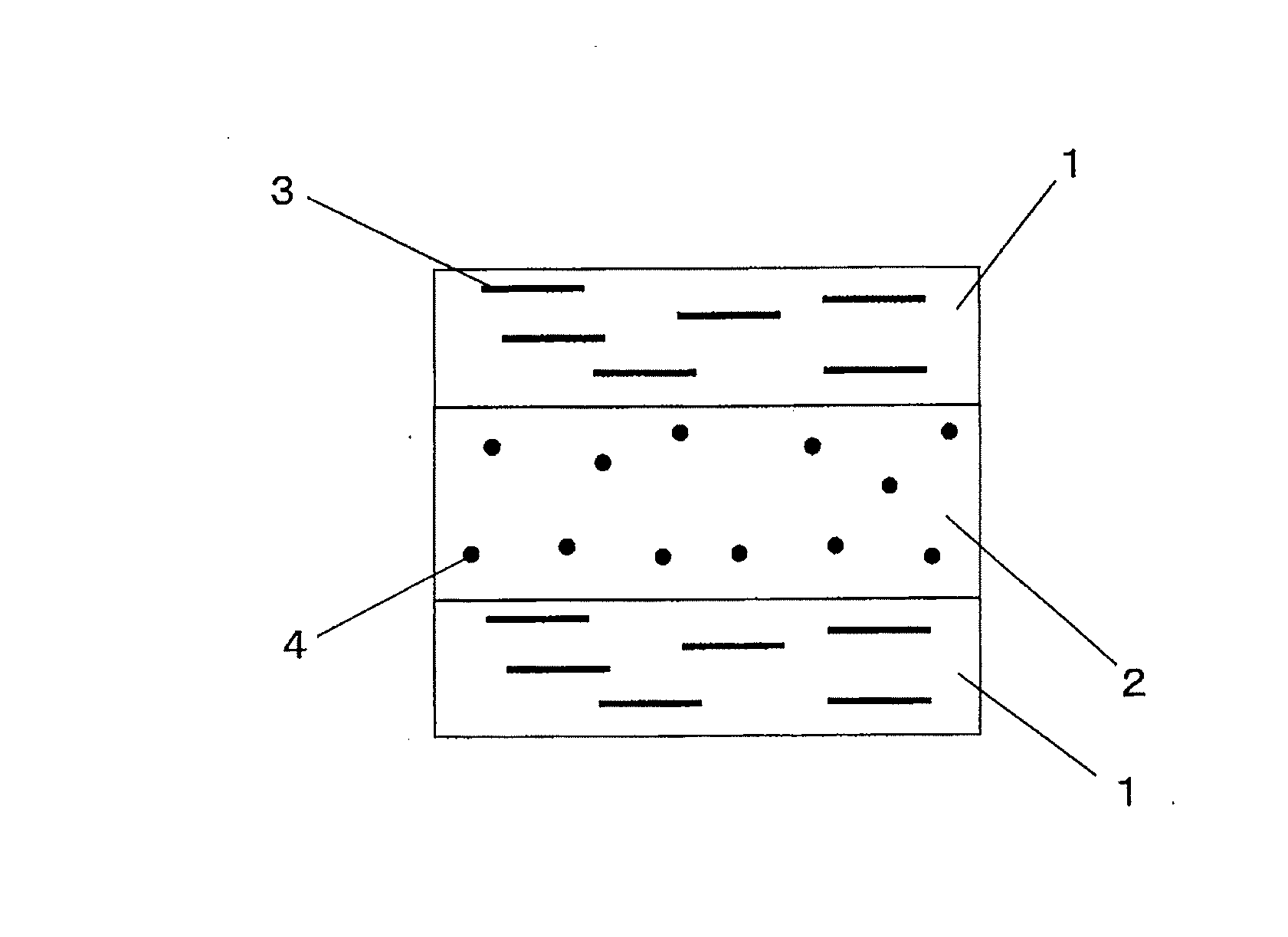

Injection molded body and method for producing same

ActiveUS20130337253A1Low warpageSuitable for useSynthetic resin layered productsThin material handlingInjection mouldingFiber reinforcement

An injection molded body includes a fiber reinforced thermoplastic resin composition formed by combining fibrous filler with thermoplastic resin so that the weight average fiber length in the injection molded body is 300 μm or more, and the injection molded body has a skin layer, a core layer and a skin layer in this order in the thickness direction. The thickness of the core layer, in which the primary orientation direction of the fibrous filler is 40° or less when the direction perpendicular to the flow direction of the resin composition at the time of injection molding is set at 0°, is 20% or less relatively to the thickness of the injection molded body.

Owner:TORAY IND INC

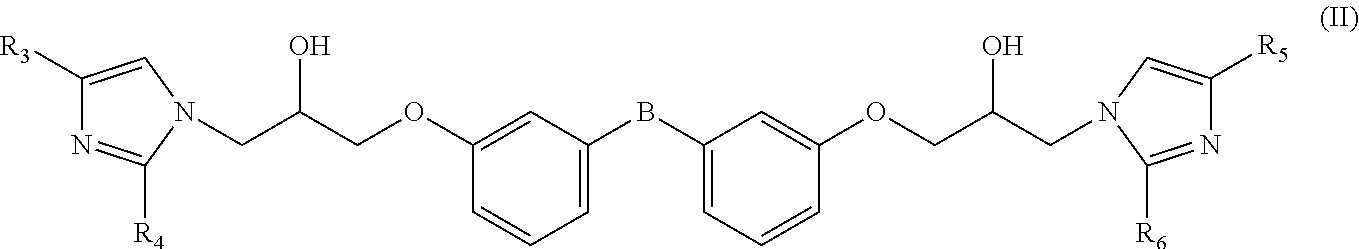

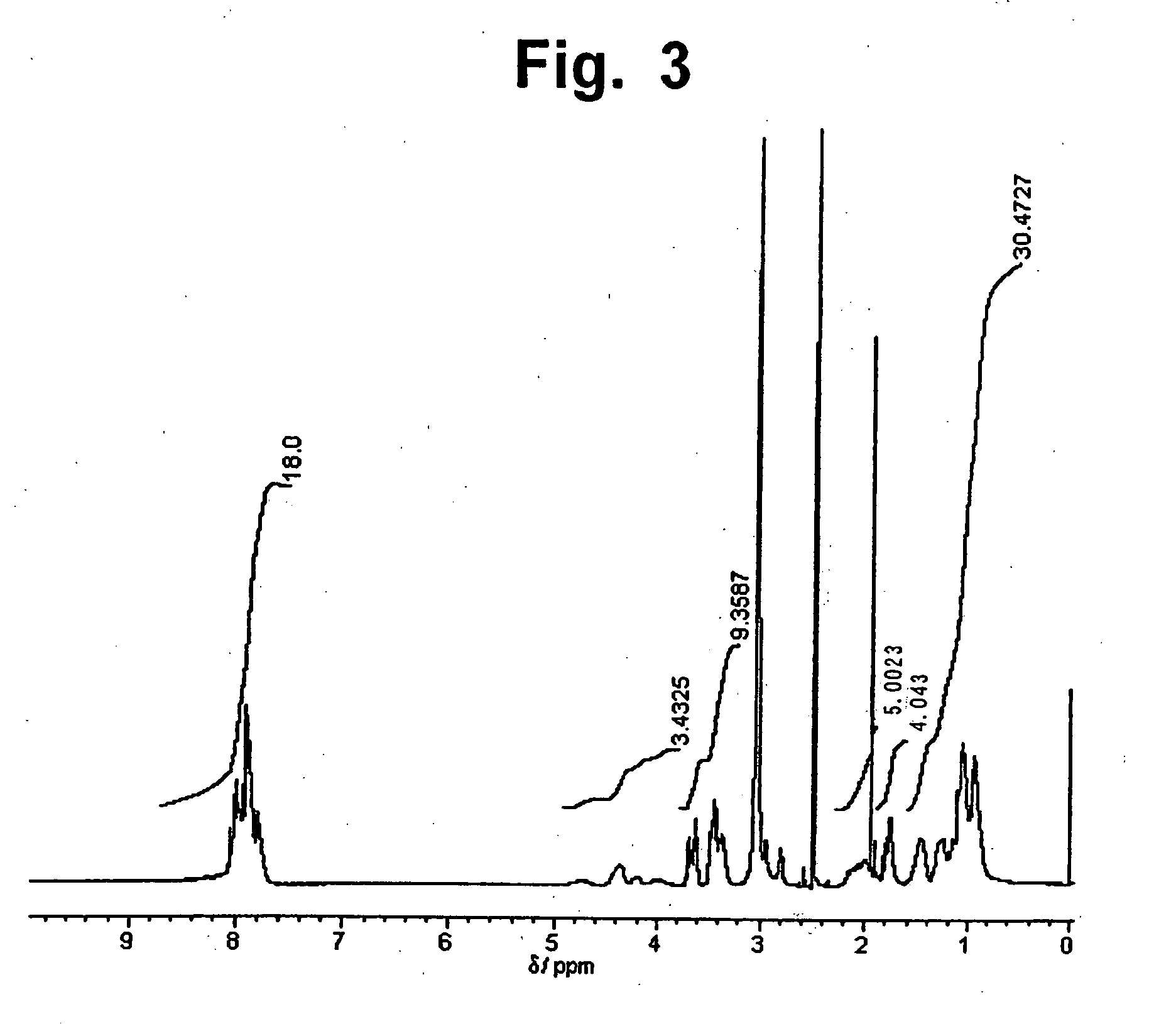

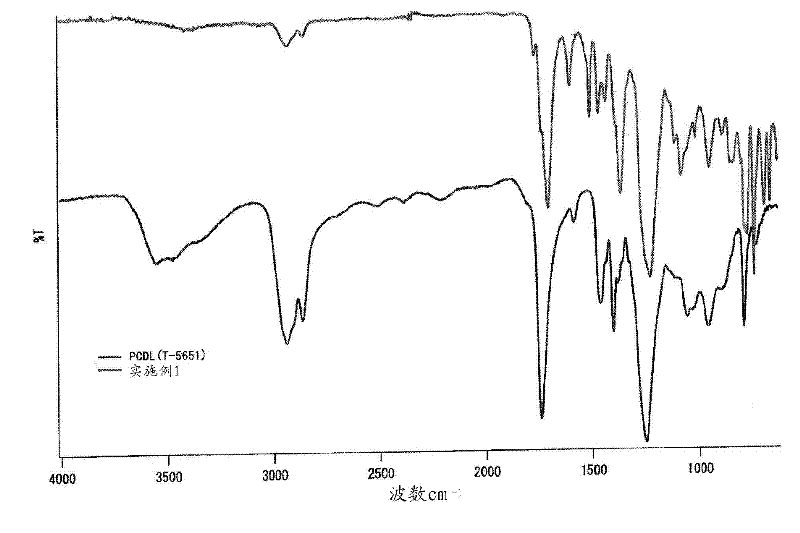

Modified polyimide and method for producing modified polyimide

ActiveCN102459417AGood flexibilityImprove flexibilityPrinted circuit aspectsCoatingsImidePolymer science

Provided is a method for producing a modified polyimide containing a polycarbonate, and having excellent electrical characteristics and adhesiveness, and excellent heat resistance, flexibility, flexion, chemical resistance, storage stability, and low warpage. Also disclosed are said modified polyimide, a composition containing said polyimide, and applications therefor. In this method, tetracarboxylic dianhydride oligomer containing a polycarbonate component is synthesized by reacting tetracarboxylic dianhydride with an isocyanate-terminated oligomer containing a polycarbonate component and having excellent flexibility. Subsequently, this oligomer is reacted with an aromatic diamine and an aromatic tetracarboxylic dianhydride to form a polyimide block copolymer.; According to this method, a broad range of aromatic diamines can be selected, and by appropriately selecting the aromatic diamine, it is possible to produce an excellent modified polyimide which is capable of simultaneously satisfying the aforementioned characteristics.

Owner:HEFEI HANZHIHE MATERIAL SCI & TECH CO LTD

Extension pin Fan-out Panel Level ball grid array (BGA) package part and manufacture process thereof

ActiveCN103094234AFlexible wiring positionSolve cross problemsSemiconductor/solid-state device detailsSolid-state devicesInsulation layerPunching

The invention discloses an extension pin Fan-out Panel Level ball grid array (BGA) package part and manufacture process thereof. The package part is mainly composed of a chip, a plastic package material, an insulation layer, metal copper, nickel porpezite, a solder ball, a soldering disk, a second insulation layer, a reversely-bonded chip, secondary metal copper distribution wires and a third insulation layer. The manufacture process comprises the following steps of thinning a wafer, scratching a wafer, reversely bonding a chip, plastically packing, tearing a film, turning, carrying out primary insulation treatment, punching holes first time, distributing copper wires first time, carrying out secondary insulation treatment, punching holes second time, distributing copper wires second time, carrying out third insulation treatment, punching holes third time, plating nickel porpezite, printing, reflow soldering and cutting. The manufacture process solve the wire cross problem, saves cost and improve electric performance and reliability of products.

Owner:HUATIAN TECH XIAN

Carboxyl group-containing polyurethane and uses thereof

InactiveUS20090118422A1Excellent in adhesion with substrateLow warpagePhotomechanical apparatusInksHeat resistanceDiol

Disclosed is a carboxyl group-containing polyurethane containing a structure derived from a polycarbonate diol (B), the polycarbonate diol (B) having: (i) a number-average molecular weight of 500 to 50,000; (ii) an alkylene group of 8 to 18 carbon atoms in its structure; and (iii) hydroxyl groups at both ends. The carboxyl group-containing polyurethane is suitable as materials of cured products that are excellent in adhesion with substrates, low warpage, flexibility, plating resistance, soldering heat resistance and long-term reliability.

Owner:SHOWA DENKO KK

Thermosetting resin composite and cured resin

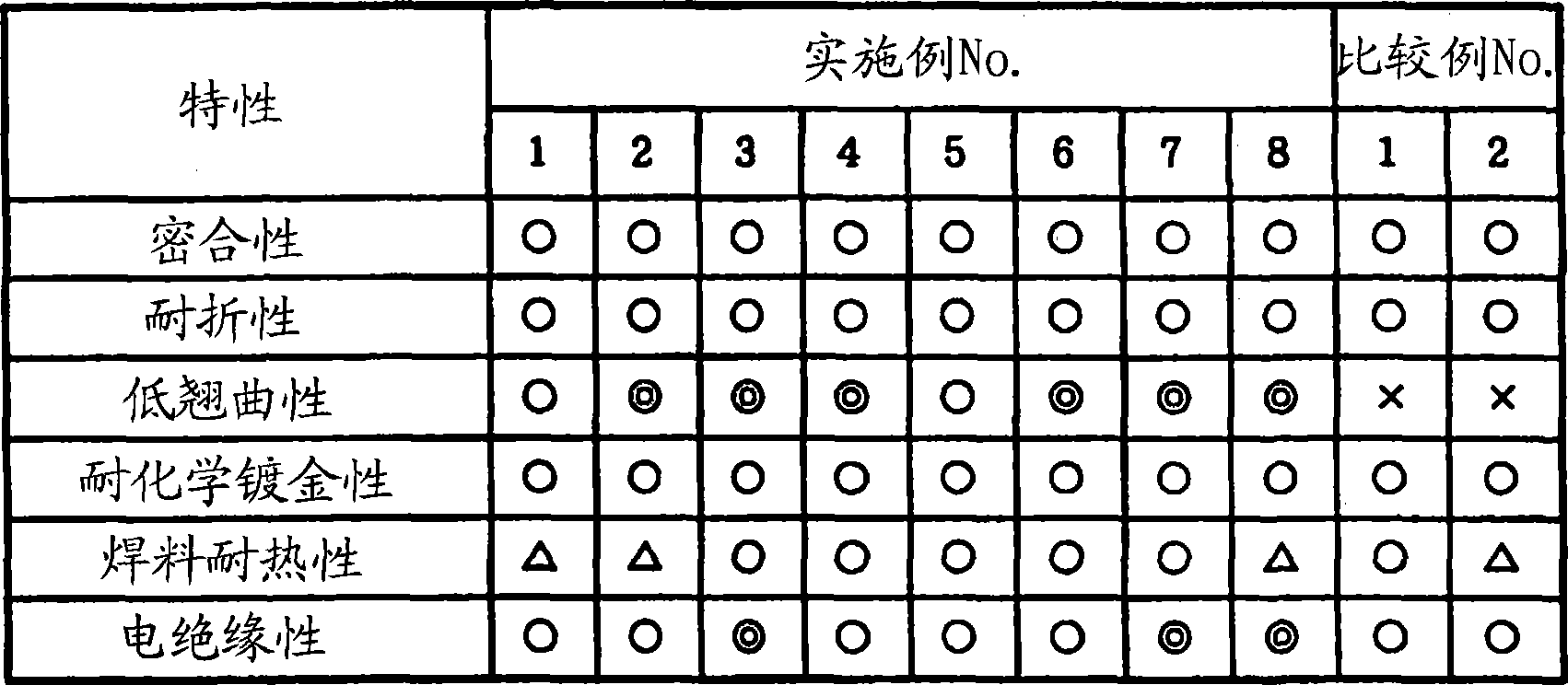

ActiveCN101397402ALow warpageLow costNon-metallic protective coating applicationAlcoholHeat resistance

The present invention provides a thermosetting resin composition and the condensate thereof. The thermosetting resin composition is suitable for forming a flexible film which has excellent sealing property to substrate, excellent flexibility resistance, low warping, excellent heat resistance of solder, excellent chemical coating resistance and excellent chemical insulating property. The thermosetting resin composition comprises the following components: (A) carboxyl-containing polyurethane resin obtained from the compound which has isocyanate group which is not directly connected to aromatic nucleus, and (B) a thermosetting compound. The carboxyl-containing polyurethane resin is preferably a polyurethane resin which is obtained through the reaction of the following components: (a) a compound which has the isocyanate group which is not directly connected to aromatic nucleus, preferably aliphatic isocyanic ester compound or branched chain aliphatic isocyanic ester compound, (b) a compound which has more than two hydroxyl groups in one molecule, and (c) a compound which has one hydroxyl group and more than one phenolic hydroxyl group in one molecule.

Owner:TAIYO HLDG CO LTD

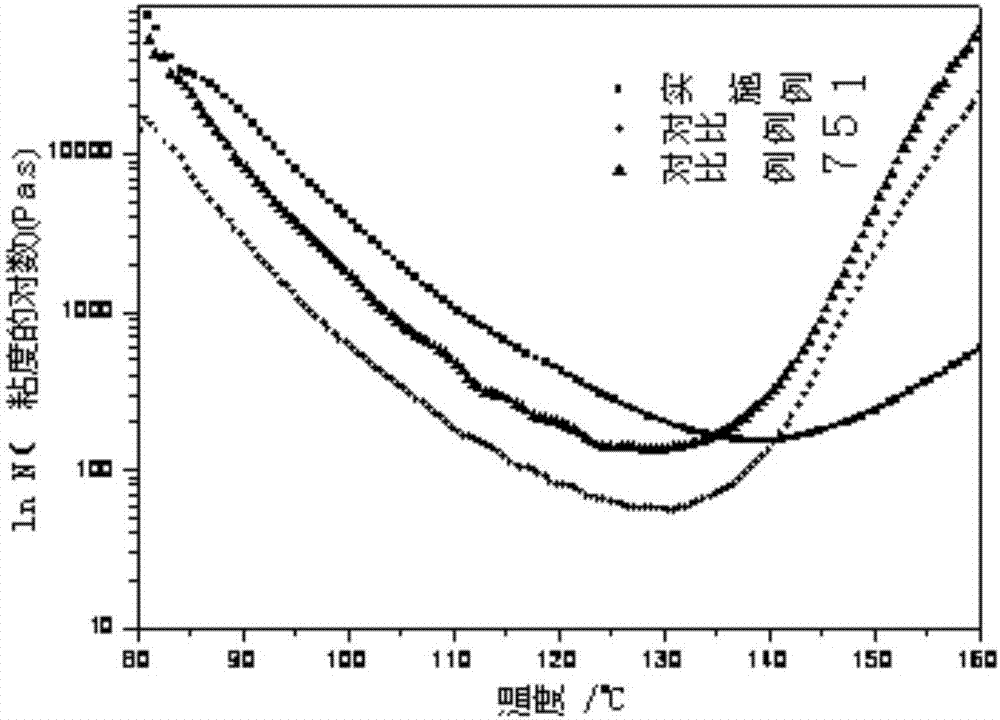

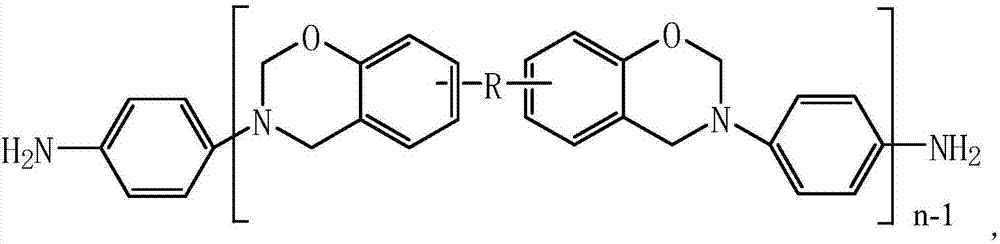

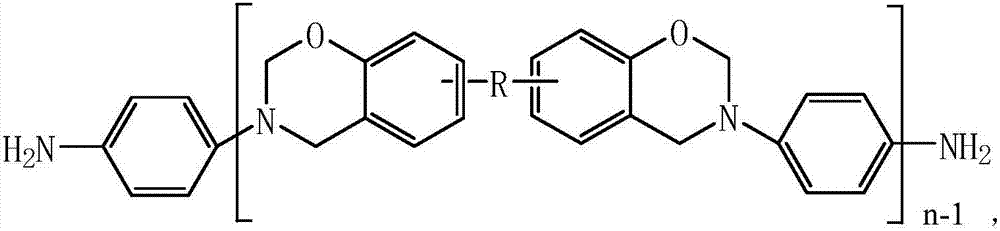

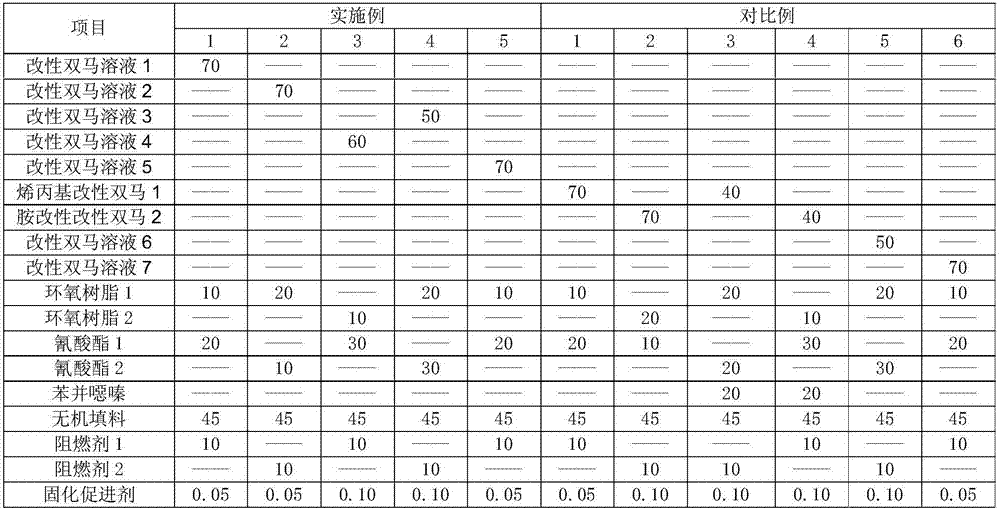

Resin composition, prepreg manufactured by using same, metal foil laminate and interlayer insulating film

ActiveCN107245239AIncrease steric hindranceSlow down reaction rateSynthetic resin layered productsMetal layered productsEpoxyMetal foil

The invention discloses a resin composition which is prepared from the following components (by weight based on solids): (a) 40-80 parts of benzoxazine structure-containing diamine modified bismaleimide resin; (b) 10-50 parts of epoxy resin; (c) 10-40 parts of active ester. As for the resin composition, through preferred pre-reaction of bismaleimide and benzoxazine-containing diamine resin at low temperature, benzoxazine almost does not perform ring-opening reaction at low temperature; by consuming a part of reactive groups through pre-reaction, a prepolymer with certain molecular weight is formed, steric hindrance of benzoxazine ring-opening reaction is improved, the reaction rate of a benzoxazine structure, which is in a resin structure, in a system is slowed down, a rheological reaction window of the resin composition is well regulated, and a risk that defects such as substrate white spots or white textures appear caused by too fast reaction of the resin composition in a pressing process is lowered.

Owner:SHENGYI TECH SUZHOU

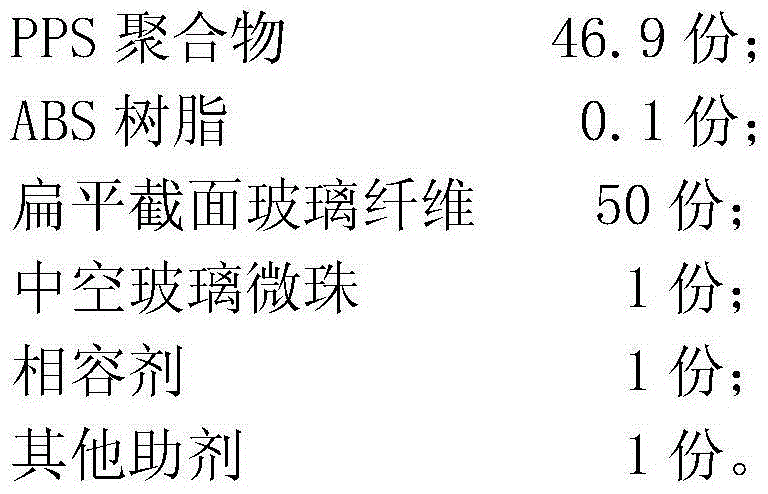

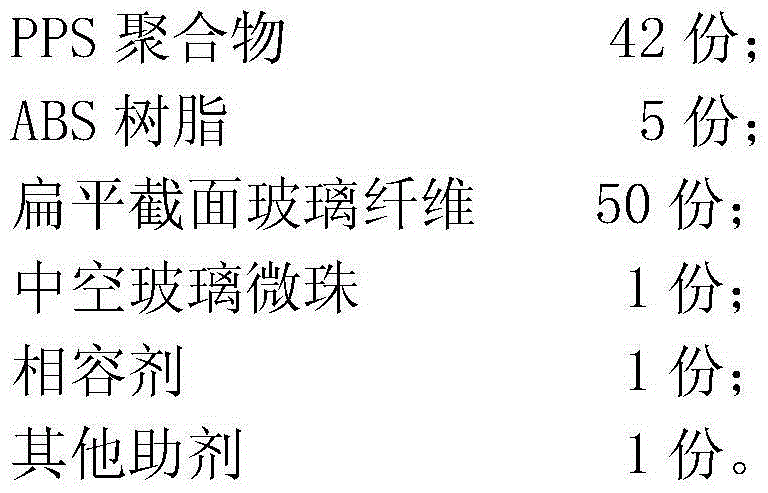

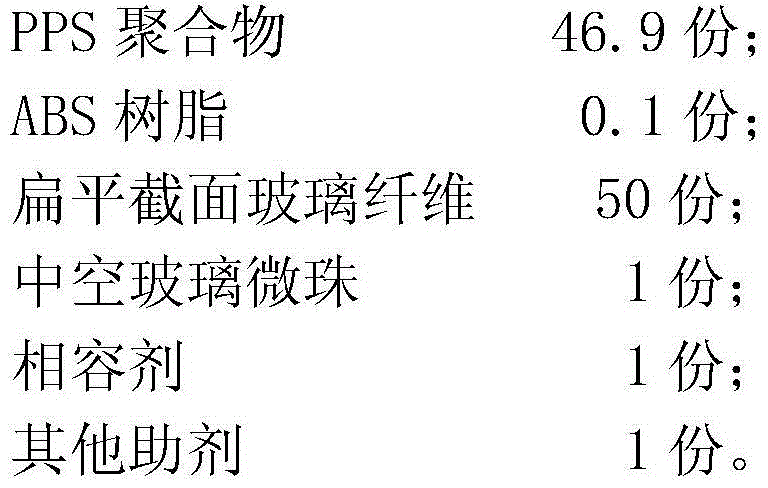

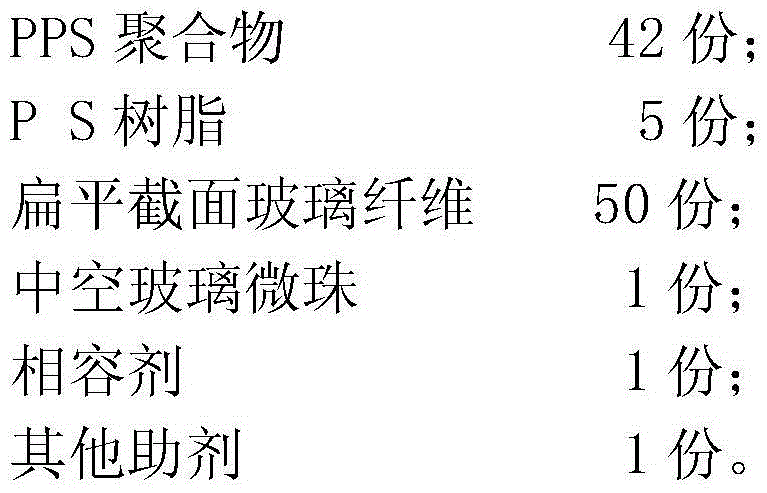

High-fluidity fiber reinforced PPS/ABS composite material and product thereof

The invention discloses a high-fluidity fiber reinforced PPS / ABS composite material and a product thereof. The composite material comprises: by weight, thermoplastic resin comprising 35-50 parts of PPS polymer and 0.1-10 parts of ABS resin; a reinforcing filling material comprising 40-60 parts of flat section glass fiber and 0.5-2 parts of a granular glass filling material; and 0.5-2 parts of a compatilizer. The PPS resin reinforced by the flat section glass fiber and the fibrous filling material except the flat section glass fiber is adopted as a substrate, the ABS resin and hollow glass beads are added, and the compatibilization effect of the added ABS resin with the compatilizer is used to increase the fluidity, the elongation at break and the impact strength, and a reinforced composite resin composition with high mechanical strength, high fluidity and low warp is formed.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Carboxyl group-containing polyurethane and thermosetting resin composition using the same

InactiveCN101133096AExcellent substrate adhesionImprove flexibilityPhotomechanical apparatusPolymer sciencePolycarbonate

The present invention relates to a carboxyl group-containing polyurethane obtained by making (a) a polyisocyanate compound, (b) a polycarbonate diol having a molecular weight of 300 to 50,000, (c) a dihydroxy compound having a carboxyl group and, if necessary, (d) a monohydroxy group. Compounds are reacted to obtain a thermosetting composition using the carboxyl group-containing polyurethane, and a paste for forming a film using the thermosetting composition. The thermosetting compositions of the present invention have excellent substrate adhesion, low warpage, plating resistance and solder heat resistance.

Owner:SHOWA DENKO KK

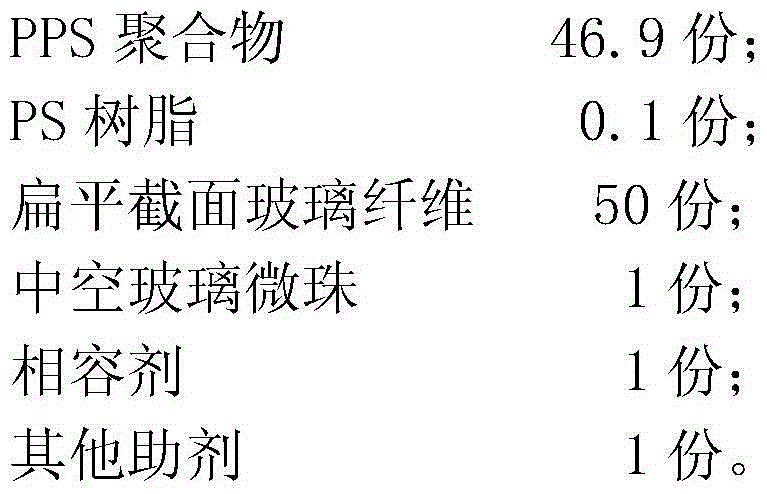

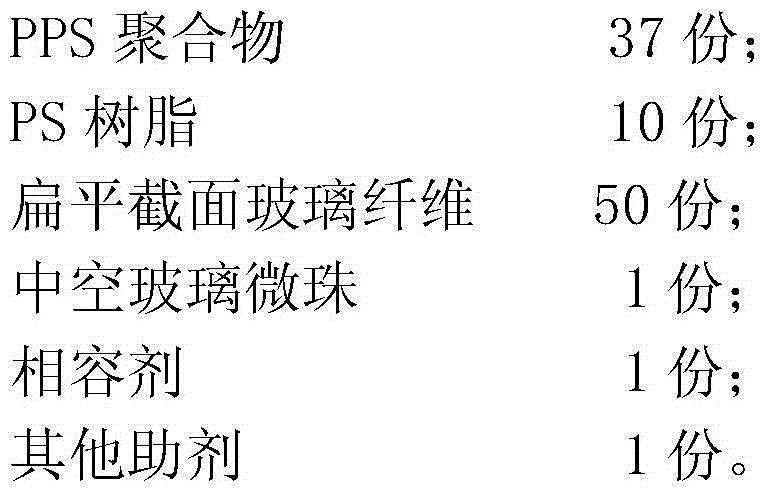

Fiber reinforced PPS/PS composite material and product thereof

The invention provides a fiber reinforced PPS / PS composite material and a product thereof. The fiber reinforced PPS / PS composite material comprises the following materials by weight: thermoplastic resin, which includes 35 to 50 parts of PPS polymer and 0.1 to 10 parts of PS resin; a reinforced filling material, which includes 40 to 60 parts of flat envelope glass fiber and 0.5 to 2 parts of a granular glass filling material; and 0.5 to 2 parts of a compatilizer. According to the fiber reinforced PPS / PS composite material and the product thereof, PPS resin, the flat envelope glass fiber and fibrous filling materials except the flat envelope glass fiber are used as a matrix, the PS resin and hollow glass beads are added, and through addition of the PS resin and compatibilization of the compatilizer, fluidity and impact strength are improved, so a reinforced composite resin composition with higher mechanical strength, higher fluidity and lower warping performance is formed.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Photosensitive thermosetting resin composition and flexible printed circuit board

InactiveUS20100025084A1High-level flame retardancySuperior low warpage propertyFireproof paintsAntifouling/underwater paintsEpoxyPolymer science

There is provided a photosensitive thermosetting resin composition of an alkali development type from which it is possible to form a coating film that is halogen-free yet has high-level flame retardancy, has a superior low warpage property after it is cured, is excellent in plasticity, resolution, soldering heat resistance, chemical resistance, and the like, and a flexible printed circuit board using the same. There is provided a photosensitive thermosetting resin composition of an alkali development type and a flexible printed circuit board using the same, the photosensitive thermosetting resin composition including: (A) a resin component having a (meth)acryloyl group and a carboxyl group in one molecule and soluble in a dilute alkali solution; (B) a phosphorus-containing epoxy thermosetting resin component; (C) a photopolymerization initiator; (D) an organophosphorus compound; and (E) a diluent, and having excellent performance in all the properties comparable to those of conventional photosensitive thermosetting resin compositions using brominated epoxy resin and a halogen-based flame retardant, and having an excellent property of not generating hydrogen bromide which has been a problem at the time of the combustion.

Owner:KYOCERA CORP

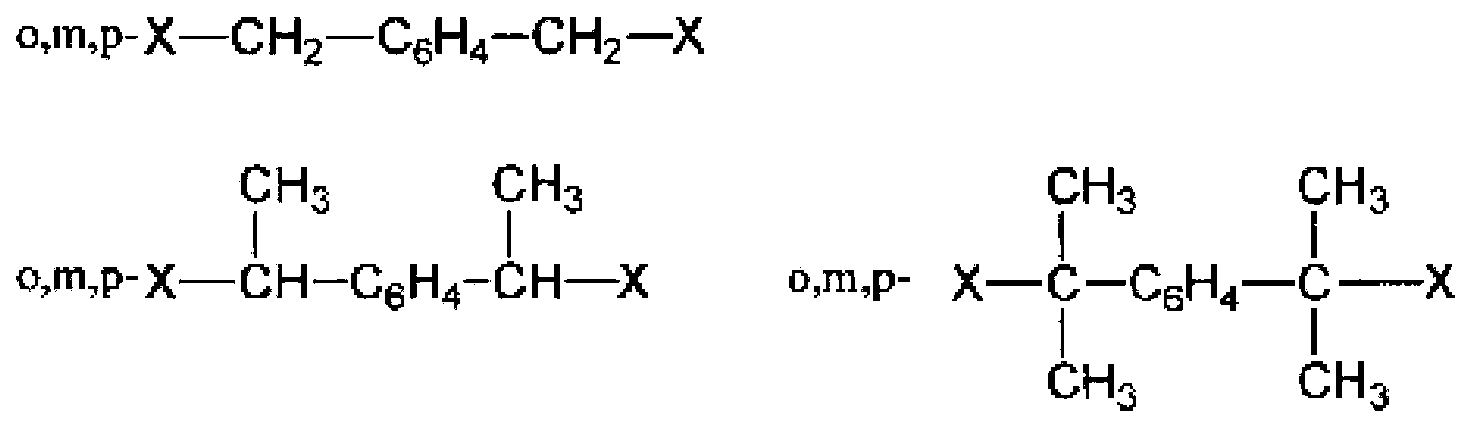

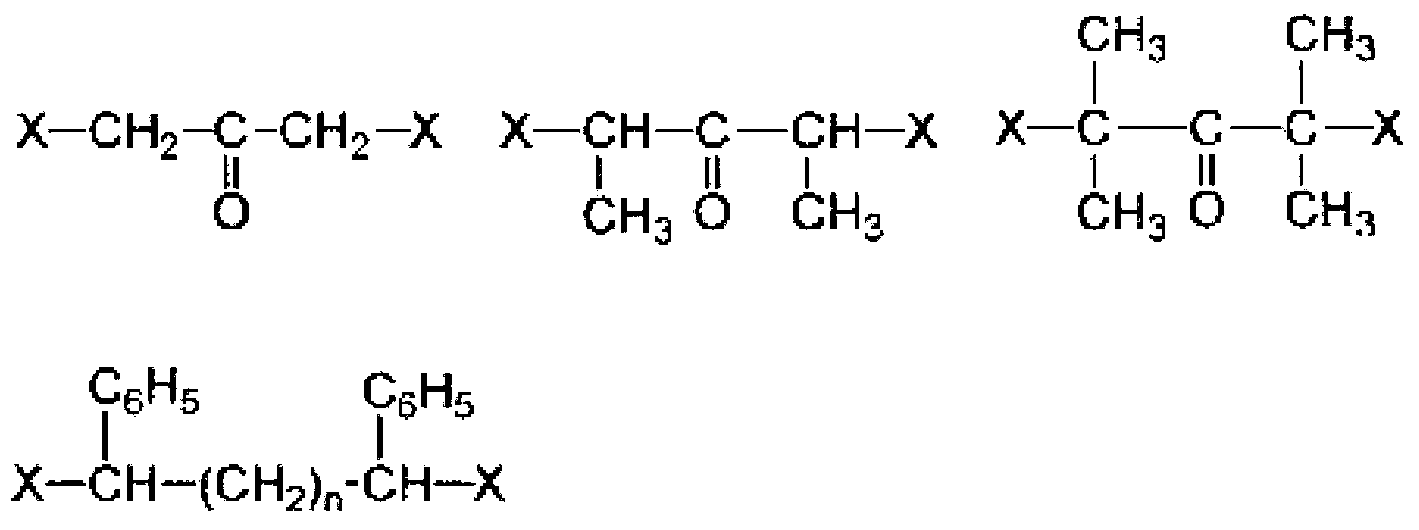

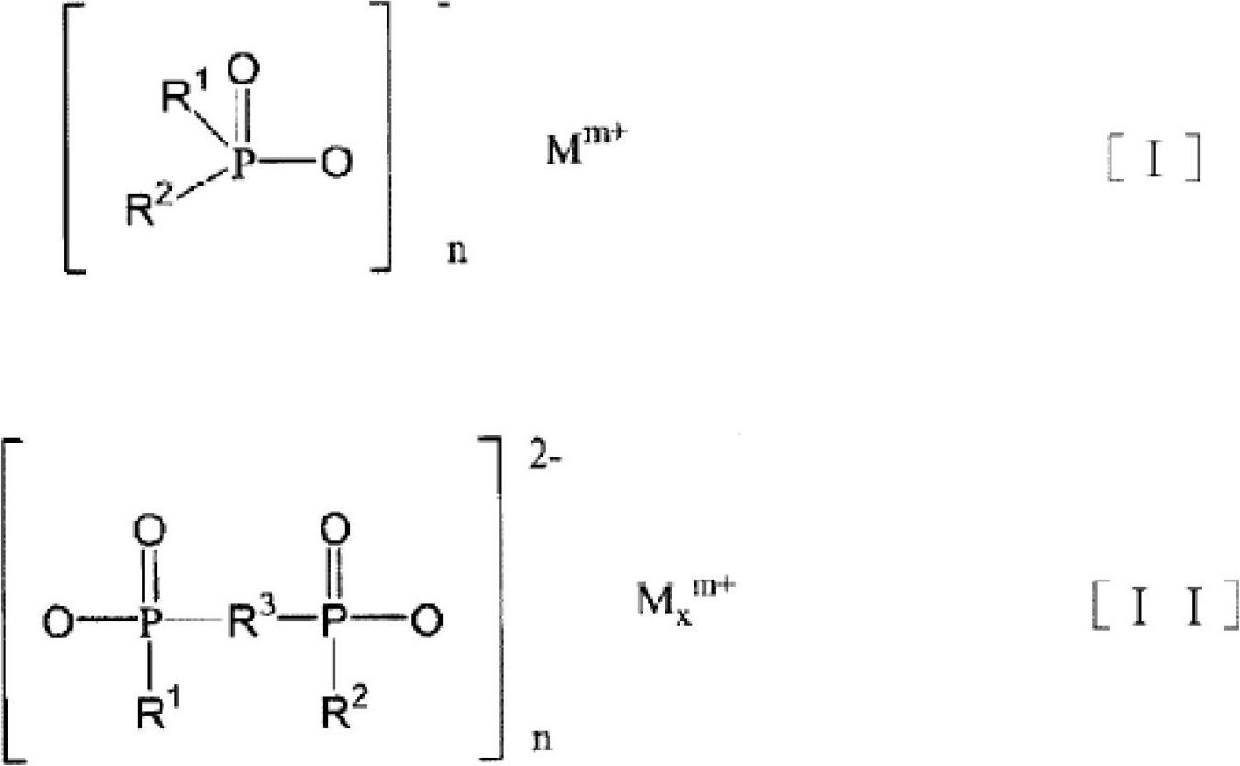

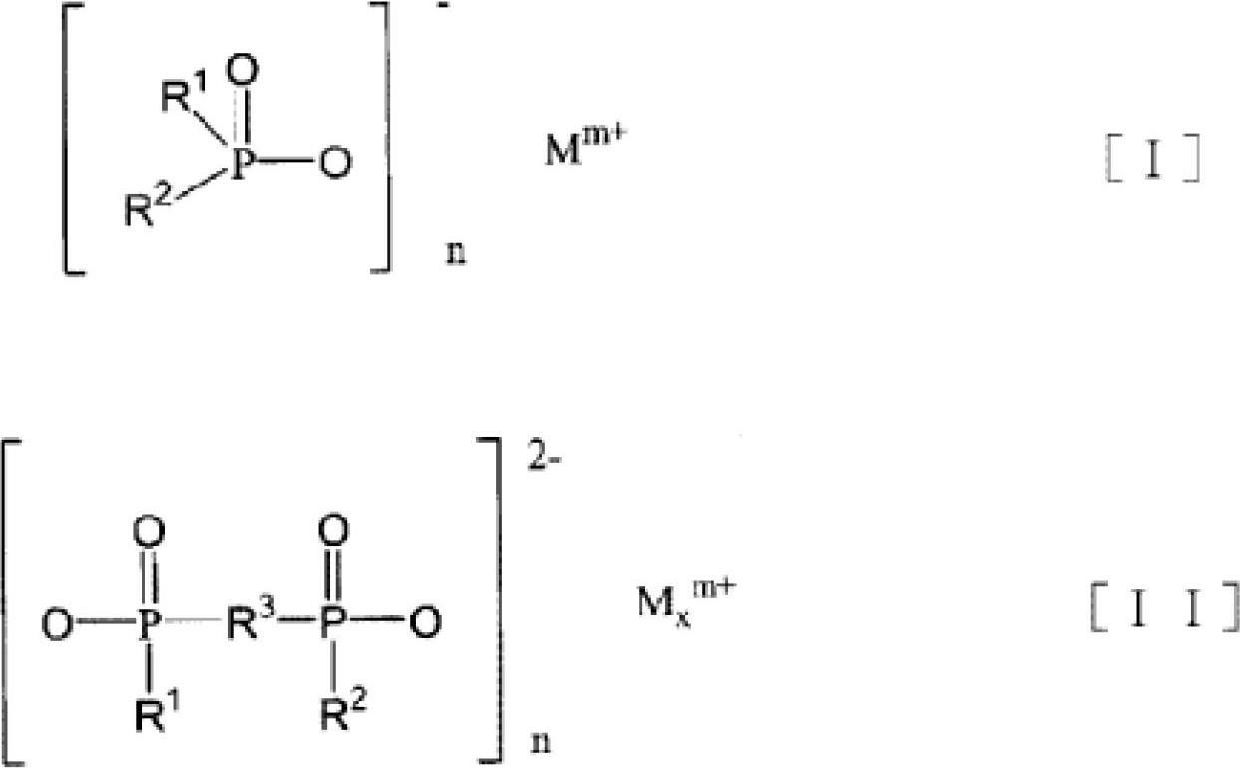

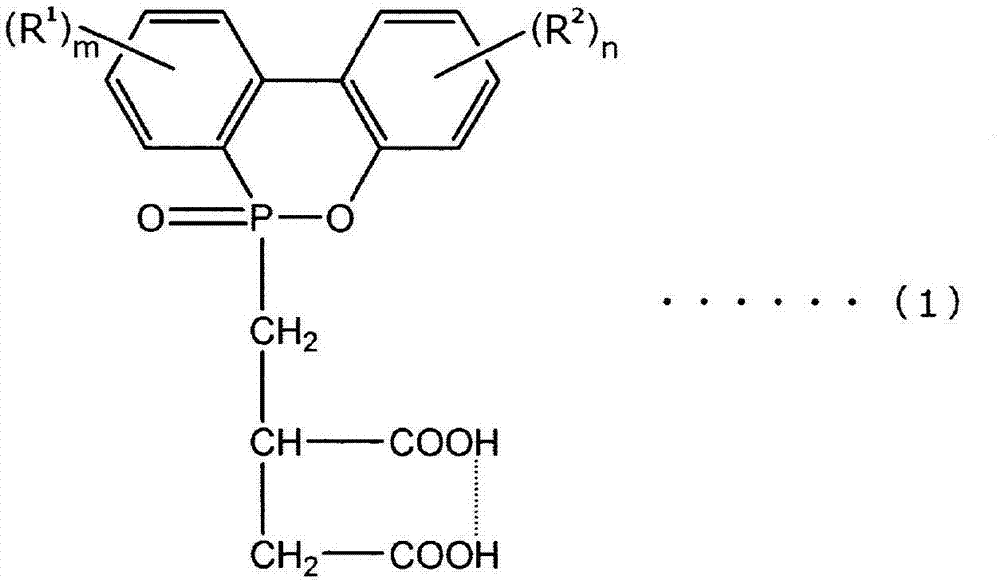

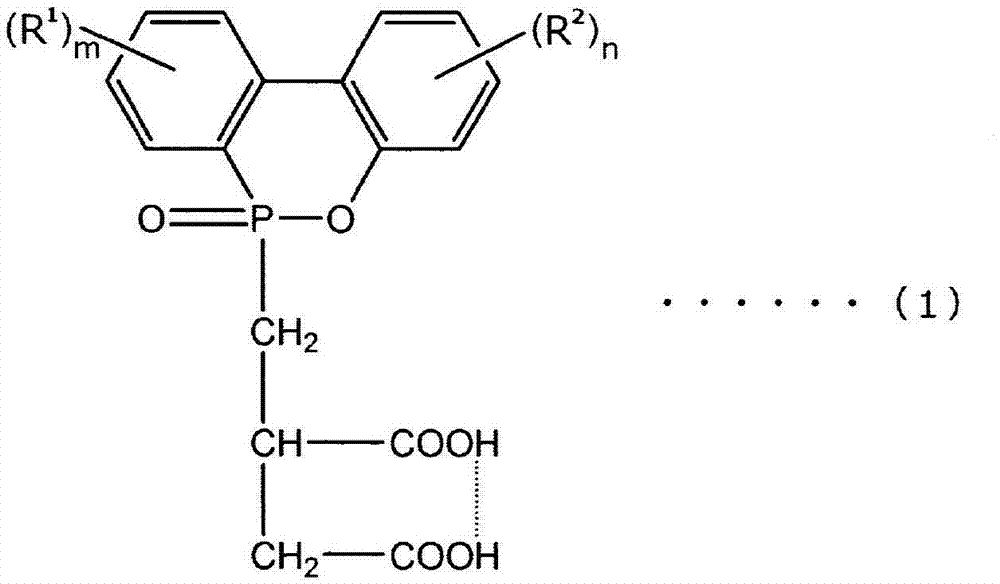

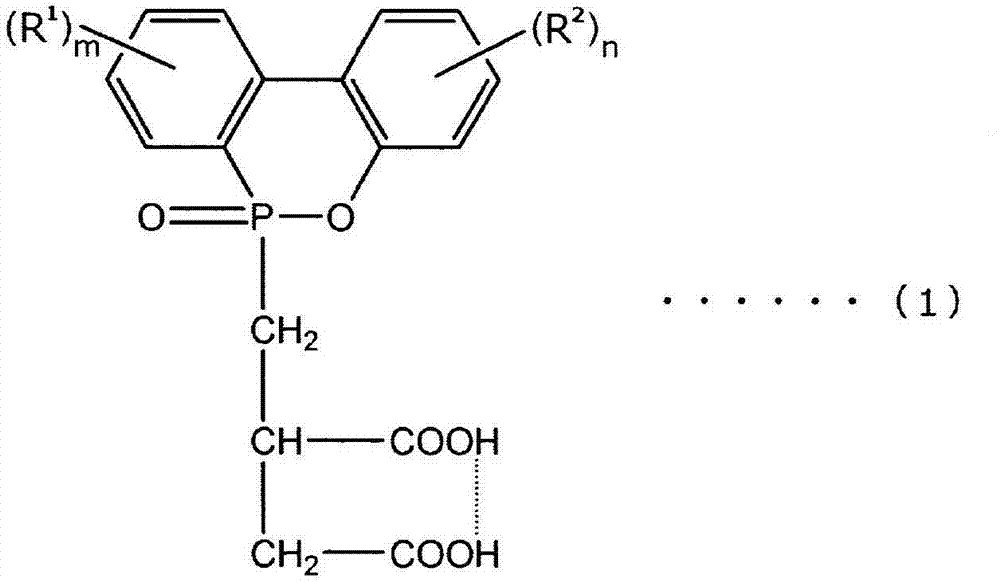

Flame-retardant curable resin composition, dry membrane, flame-retardant covering membrane, and printed circuit board

ActiveCN103365082AReduce environmental loadImprove flame retardant performancePhotosensitive materials for photomechanical apparatusCircuit susbtrate materialsCarboxylic acidPrinted circuit board

The invention provides a flame-retardant curable resin composition, a dry membrane, a flame-retardant covering membrane and a printed circuit board, specifically provides a flame-retardant curable resin composition, a dry membrane and a flame-retardant covering membrane which are free from halogen compositions, have little environmental loads, excellent flame resistance and excellent flexibility, and has no exudation of flame retardant during high-temperature pressing, and a printed circuit board having the flame-retardant covering film. The flame-retardant curable resin composition and the like contain (A) a phosphorus-containing acrylate resin which is obtained by reacting at least one of a phosphorus-containing dicarboxylic acid and an acid anhydride thereof with an acrylic ester, (B-1) a carboxyl-containing resin having partial structures selected from bisphenol A structure and the like, (C) a thermosetting composition and (D) a photo-polymerization initiator. In formula (1), R1 and R2 independently and respectively represent monovalent hydrocarbyl having a hydrogen atom number or a carbon atom number being 1 to 6; m and n respectively and independently represent integers being 0 to 4; the dotted line represents that two carboxyls can form an acid anhydride.

Owner:TAIYO HLDG CO LTD

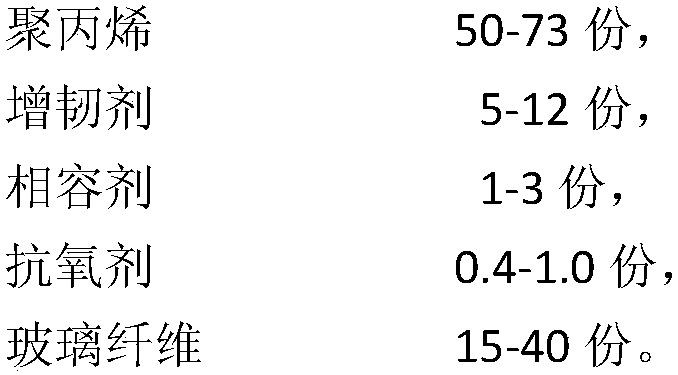

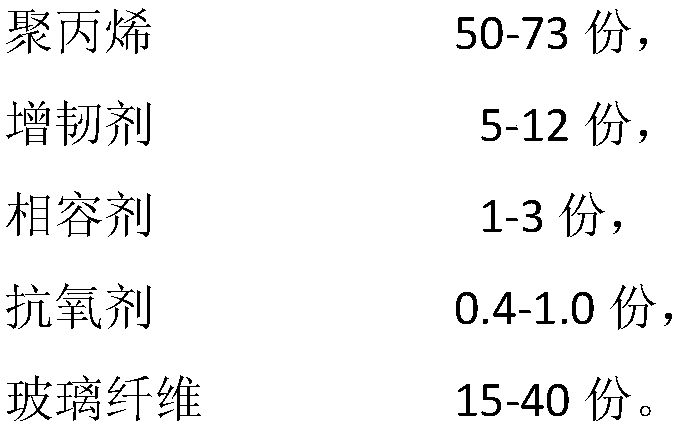

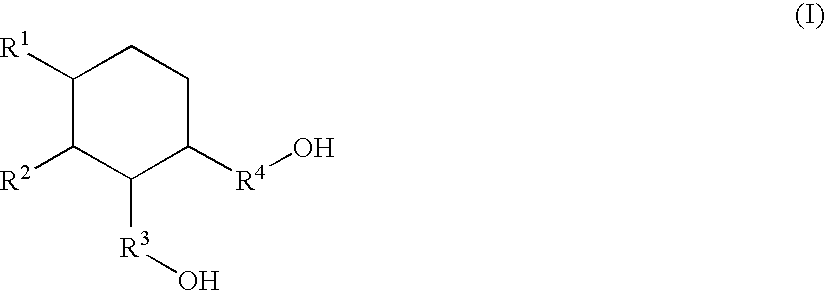

Low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material and preparation method

InactiveCN108219287AIncrease the lengthImprove mechanical propertiesPolypropylene compositesGlass fiber

The invention provides a low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material and a preparation method. A production raw material of the low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material is prepared from the following components: 50 to 73 parts of polypropylene, 5 to 12 parts of a flexibilizer, 1 to 3 parts of a compatilizer,15 to 40 parts of glass fiber and 0.4 to 1.0 part of an antioxidant. A production method of the low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material comprises the following steps: mixing all the components except the glass fiber, bracing and pelletizing the mixture to obtain a polypropylene resin semi-finished product, soaking the glass fiber into the melted polypropylene resin semi-finished product, and bracing and pelletizing the mixture to obtain the low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material. The polypropylenecomposite material disclosed by the invention is relatively low in warpage performance, is also relatively high in low-temperature impact resistance and relatively good in mechanical property, and can be applied to a freezing environment.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Carboxyl group-containing polyurethane and heat-curable polyurethane resin composition

InactiveUS20090156752A1Improve adhesionImprove long-term reliabilitySynthetic resin layered productsInksCarboxyl radicalPolyol

A carboxyl group-containing polyurethane is capable of giving cured products excellent in adhesion with substrates, low warpage, flexibility, plating resistance, soldering heat resistance and long-term reliability. The carboxyl group-containing polyurethane includes a structure derived from a polyol compound having 1 to 10 hydroxyl groups and 18 to 72 carbon atoms per molecule. The carboxyl group-containing polyurethane is produced by reacting: (A) a polyisocyanate compound; (B) a polyol compound having 1 to 10 hydroxyl groups and 18 to 72 carbon atoms per molecule; and (C) a carboxyl group-containing dihydroxy compound (other than the compound (B)).

Owner:SHOWA DENKO KK

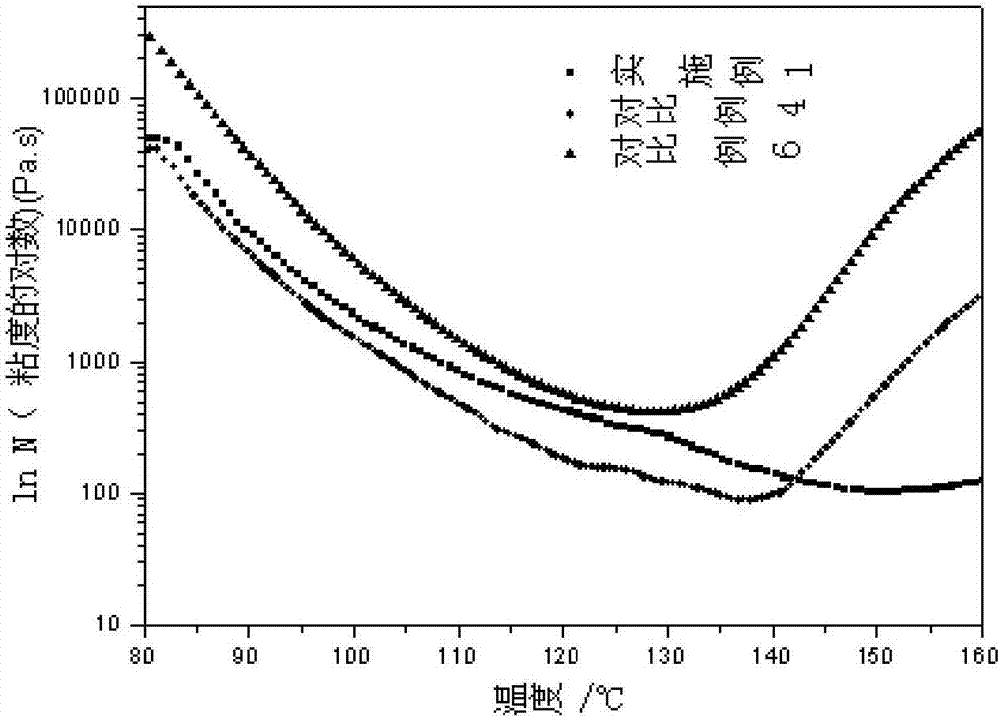

Resin composition and prepreg, metal foil laminated board and interlayer insulating film made therefrom

ActiveCN107353642ASlow down reaction rateTuning the rheological response windowSynthetic resin layered productsElectrical equipmentMetal foilReaction rate

The invention discloses a resin composition. The resin composition comprises the following components by weight: (a) 40-90 parts of diamine modified bismaleimide resin containing a benzoxazine structure; (b) 10-30 parts of epoxy resin; and (c) 10-30 parts of cyanate ester. According to the invention, bismaleimide and diamine resin containing benzoxazine are subjected to pre-reaction at low temperature in priority, ring opening almost does not occur to benzoxazine at low temperature, a part of reaction groups are consumed through the pre-reaction, a prepolymer with certain molecular weight is formed, the steric hindrance of the benzoxazine ring-opening reaction is increased, the reaction rate of the benzoxazine structure in the resin structure is slowed down, the rheological reaction window of the resin composition is well adjusted, and the risk of dry pattern or white stripe defects occurring to the substrate during lamination of the resin composition is lowered.

Owner:SHENGYI TECH SUZHOU

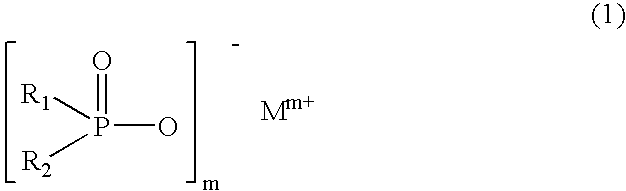

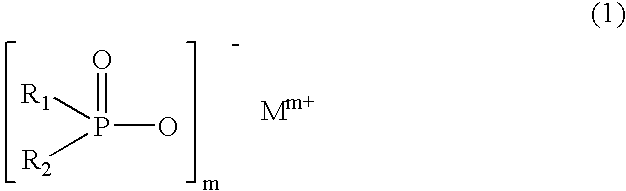

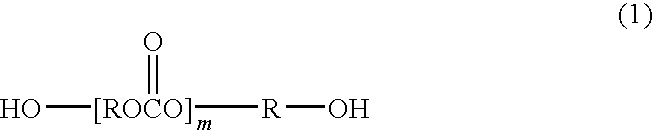

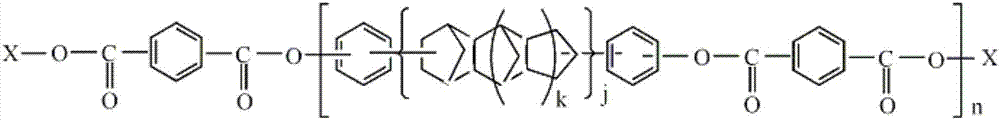

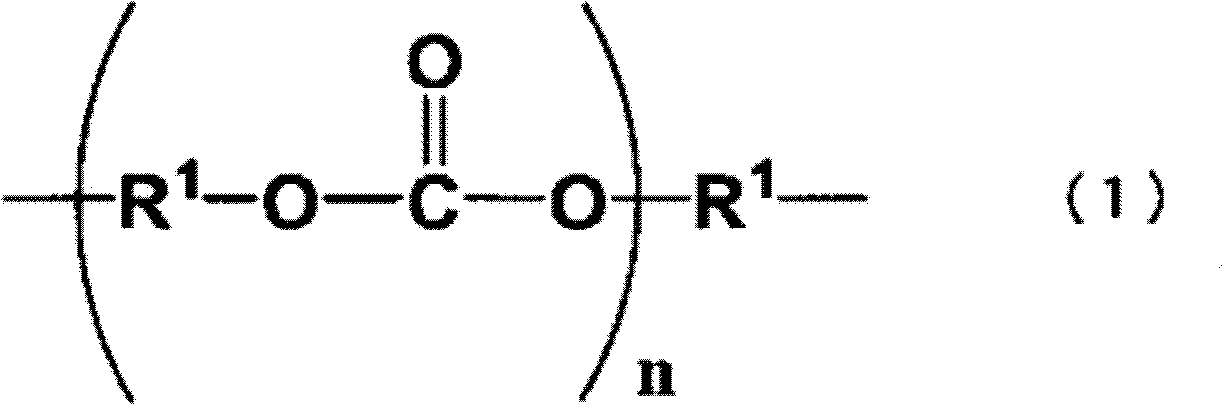

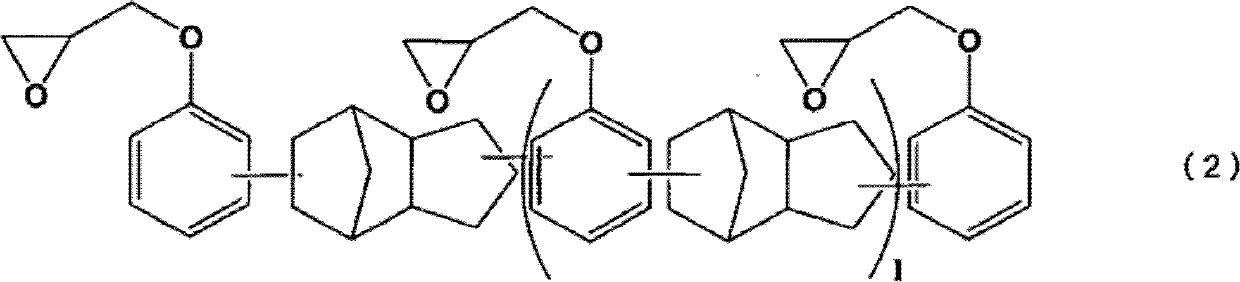

Thermosetting composition for protective film for wiring board

ActiveCN102471460ANo stickinessEasy to operatePolyurea/polyurethane coatingsNon-metallic protective coating applicationTO-18Electricity

Disclosed is a thermosetting composition for a protective film for a wiring board, which has excellent low warpage properties, flexibility, and long-term insulation reliability. The thermosetting composition for a protective film for a wiring board comprises, as essential components, an epoxy group-containing compound having a tricyclodecane structure, polyurethane having a structural unit represented by formula (1) and having a functional group which can react with an epoxy group, and a solvent. In formula (1), R1 represents an alkylene group having 3 to 18 carbon atoms, and n represents an integer of 1 or more. As the epoxy group-containing compound having a tricyclodecane structure, a compound represented by formula (2) is preferably used.

Owner:NIPPON POLYTECH CORP

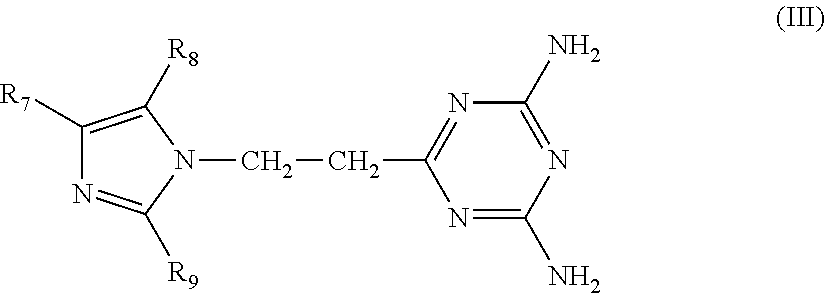

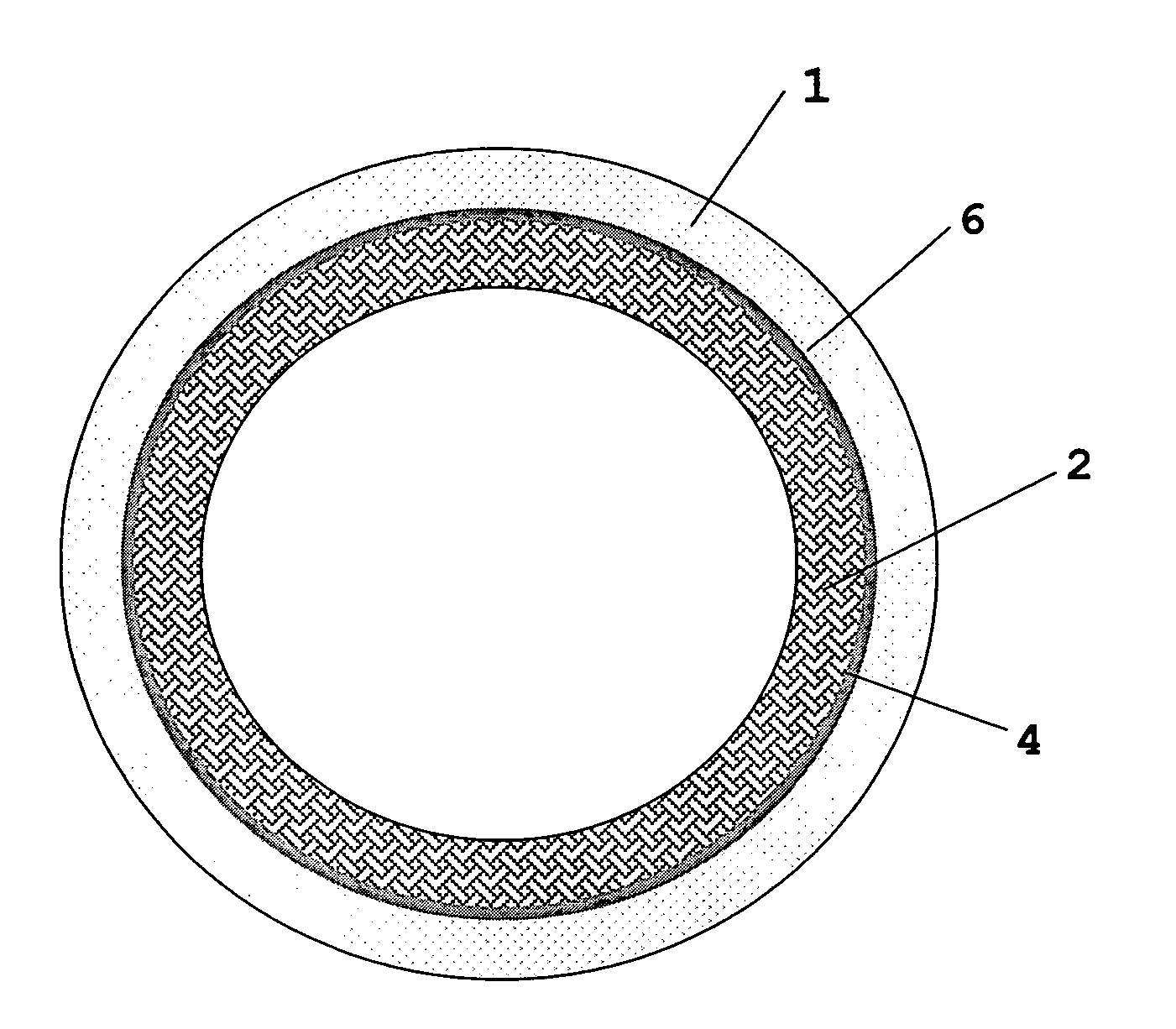

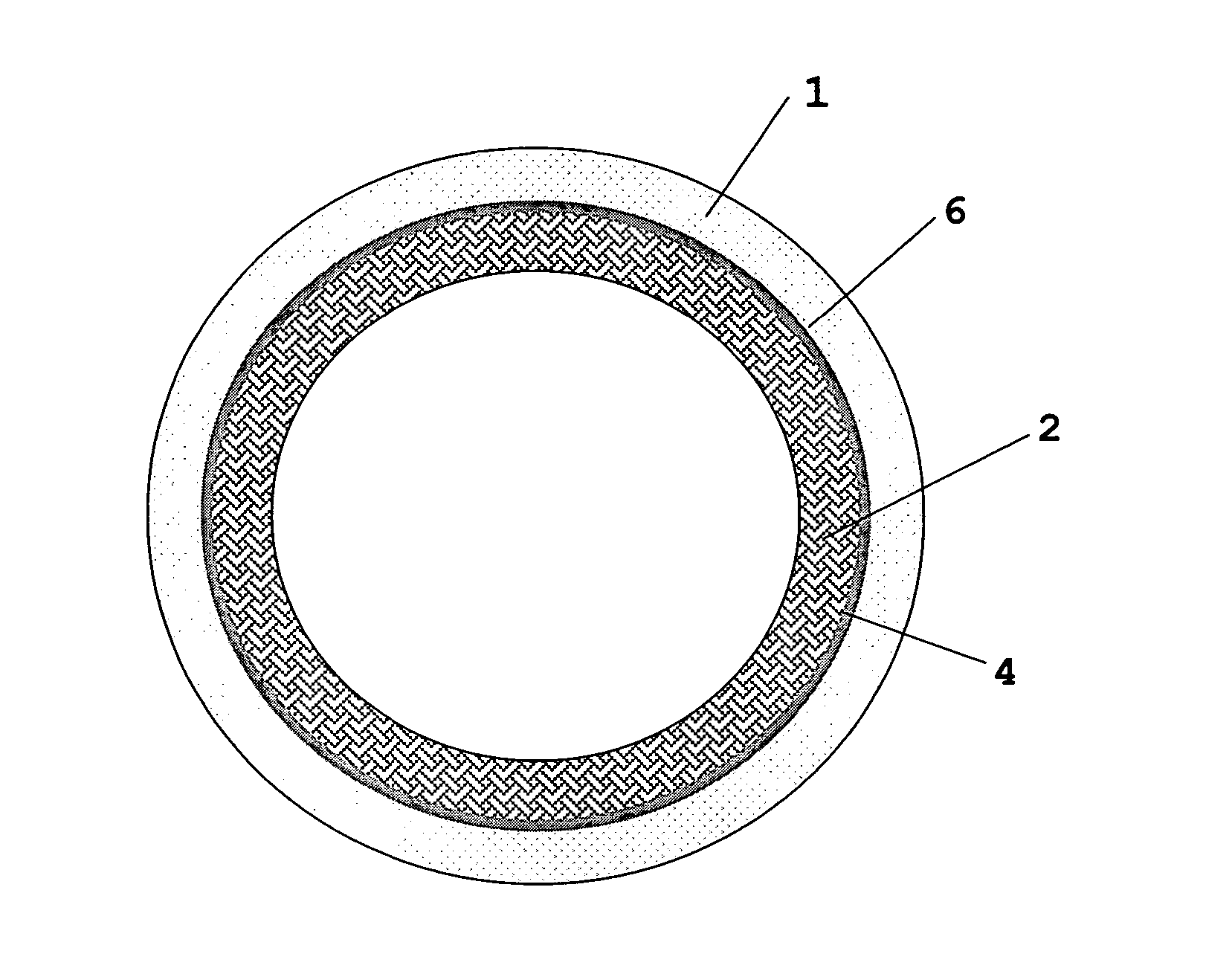

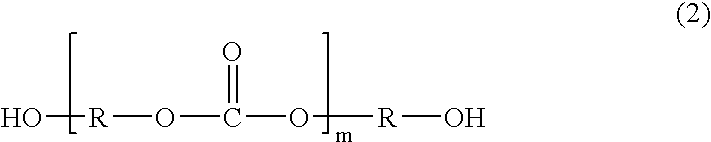

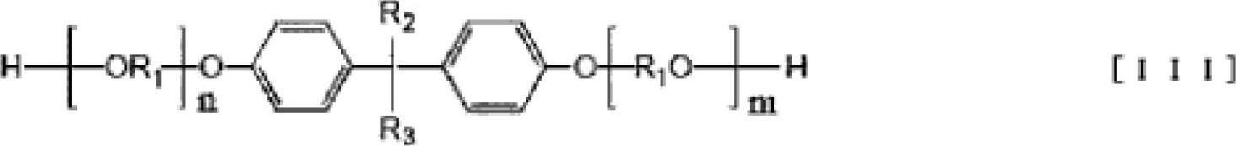

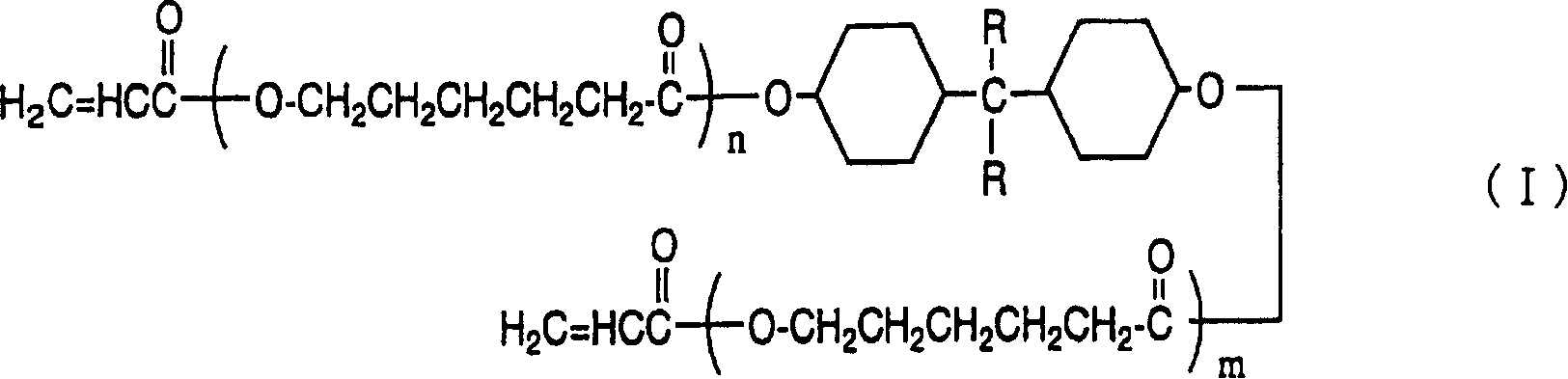

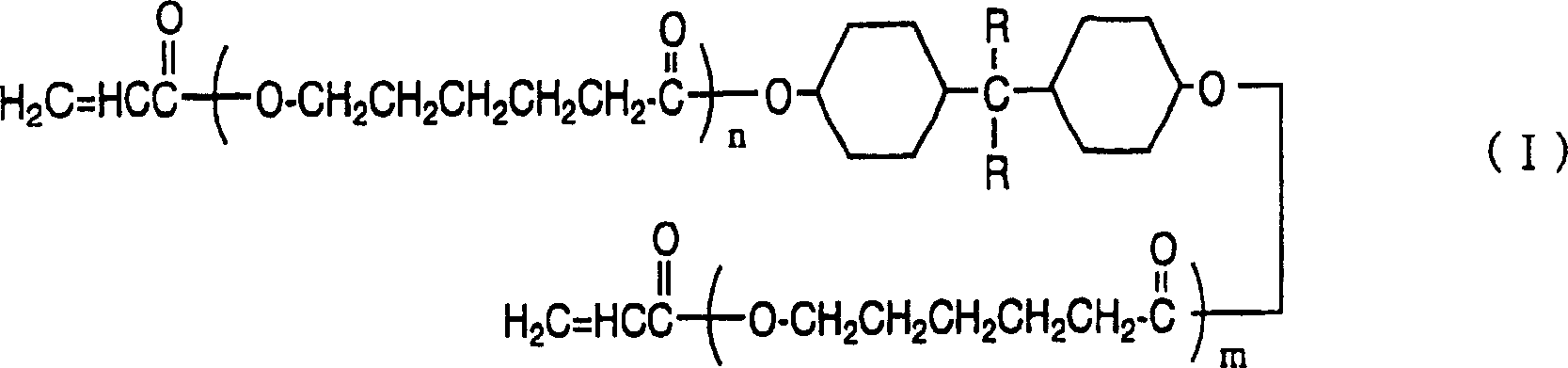

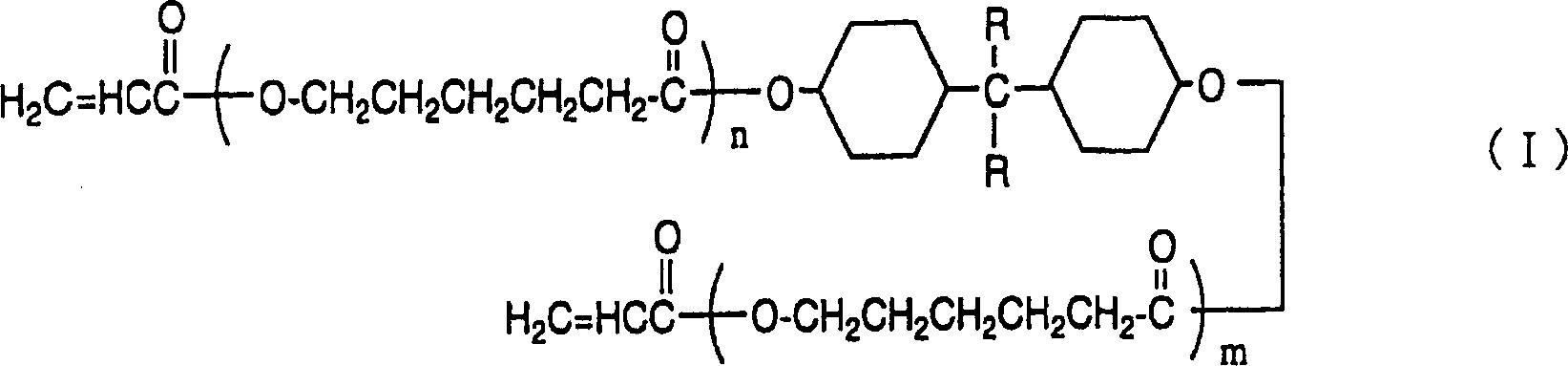

Ultraviolet-curing resin composition and cured product thereof

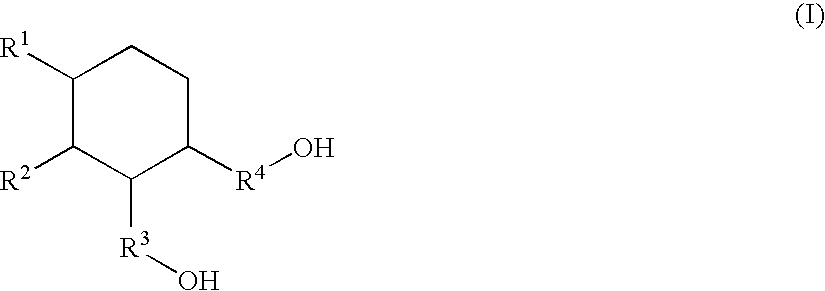

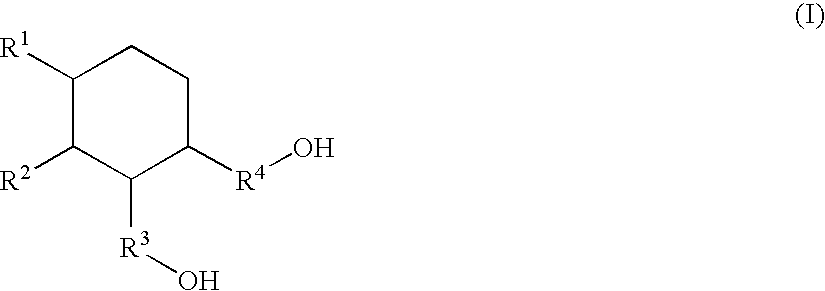

InactiveCN1842550AImprove transmittanceLow transparencyRecord information storageOptical record carriersHydrogen atomUV curing

The present invention enables to provide a highly durable protective coating film or adhesive layer for high-density optical disks with less warp, which is superior in transmission for blue lasers, transparency and low water-absorption, by using an ultraviolet-curing resin composition essentially comprising a compound (A) represented by the following general formula (I) (wherein, R represents each independently a hydrogen atom or a C1-C3 alkyl group, and n and m each represents the number of repetition from 0 to 5) and a photopolymerization initiator.

Owner:NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com