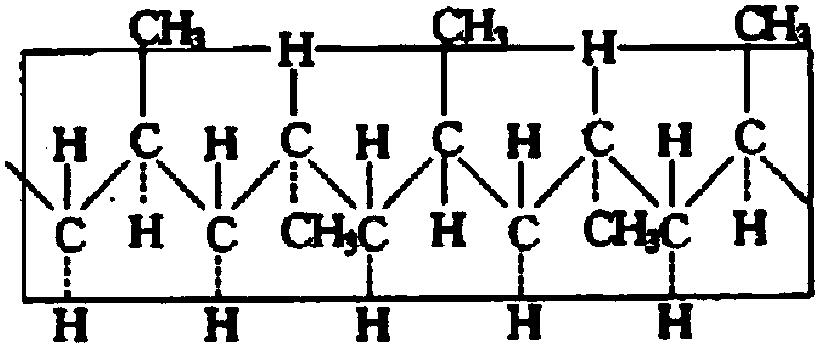

Low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material and preparation method

A composite material, polypropylene technology, applied in the field of modified polypropylene composite material and its preparation, can solve the problems of poor low-temperature impact resistance, high polyamide warpage, limited application, etc., to achieve good mechanical properties, good Effects of impact resistance, low warpage, and low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]

[0035] A kind of preparation method of modified polypropylene composite material, it comprises the following steps:

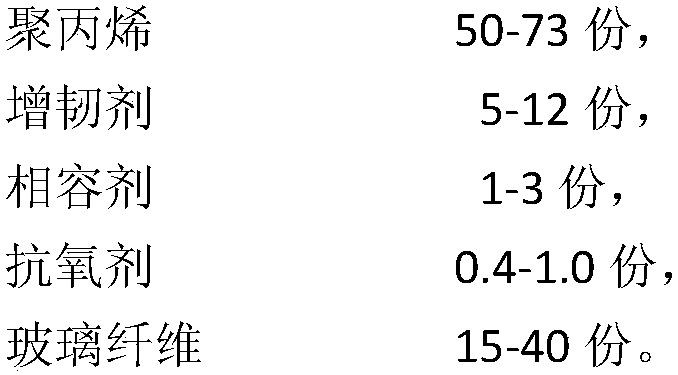

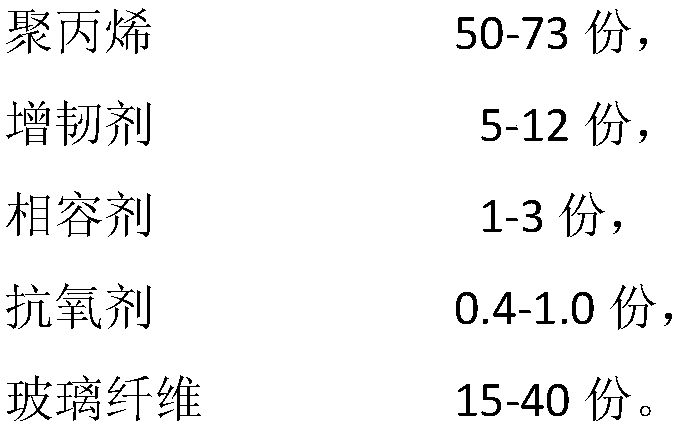

[0036] (1), weigh 50-73 parts of polypropylene, 5-12 parts of toughening agent, 1-3 parts of compatibilizer and 0.4-1.0 part of antioxidant, and mix them uniformly in a high-speed mixer to obtain a mixture;

[0037] (2), the compound is added in the screw extruder, and pelletized by the strands of the screw extruder to obtain a polypropylene resin semi-finished product in the form of pellets;

[0038] (3) Feed the polypropylene resin semi-finished product into the impregnation mold at a certain speed and make it reach a molten state, so that the glass fiber is immersed in the molten polypropylene resin semi-finished product while pultruding, by controlling the drawing of the glass fiber The extrusion speed and the feeding speed of the polypropylene resin semi-finished product are adjusted to the content of glass fiber to 15-40 parts, and the modified...

Embodiment 1

[0044] This embodiment provides a kind of modified polypropylene composite material, and its production raw material comprises the following components:

[0045]

[0046]

[0047] Present embodiment also provides a kind of preparation method of modified polypropylene composite material, it comprises the following steps:

[0048] (1), weigh 73 parts of polypropylene, 10 parts of toughening agent (POE), 2 parts of compatibilizer (PP‐g‐MAH), 0.5 part of antioxidant (0.2 part of antioxidant 1330 and 0.3 part of antioxidant agent ST300), mixed in a high-speed mixer to obtain a mixture; the speed of the high-speed mixer is 800-1000rpm, the mixing temperature is 40°C, and the mixing time is 10min;

[0049] (2) Pour the mixture into a twin-screw extruder, control the temperature of each zone to 190-210°C, and cut into pellets through the strands of the twin-screw extruder to obtain a semi-finished polypropylene resin in the form of pellets;

[0050] (3) Feed the polypropylene r...

Embodiment 2

[0052] This embodiment provides a kind of modified polypropylene composite material, and its production raw material comprises the following components:

[0053]

[0054] Present embodiment also provides a kind of preparation method of modified polypropylene composite material, it comprises the following steps:

[0055](1), Weigh 70 parts of polypropylene, 7 parts of toughening agent (5 parts of POE and 2 parts of MBS), 3 parts of compatibilizer (PP‐g‐GMA), 1.0 part of antioxidant (0.2 part of antioxidant 1330, 0.3 part of antioxidant ST300 and 0.5 part of antioxidant DSTDP), mixed in a high-speed mixer to obtain a compound; the speed of the high-speed mixer is 800-1000rpm, the mixing temperature is 50°C, and the mixing time is 3min;

[0056] (2) Pour the mixture into a twin-screw extruder, control the temperature of each zone to 190-210°C, and cut into pellets through the strands of the twin-screw extruder to obtain a semi-finished polypropylene resin in the form of pellet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com