Patents

Literature

123results about How to "Improve low temperature impact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molding composition based on polyetheramides

ActiveUS20050014842A1Increase melt viscosityAdequate long-lasting flexibilityBiocideOrganic active ingredientsEtherDicarboxylic acid

A composition suitable for molding is provided having the following components: I. from 97 to 80 parts by weight of a polyetheramide, having units based on one or more linear aliphatic diamines having from 6 to 14 carbon atoms, one or more linear aliphatic or aromatic dicarboxylic acids having from 6 to 14 carbon atoms, and one or more polyetherdiamines having at least 3 carbon atoms per ether oxygen and having primary amino groups at the chain ends, II. from 3 to 20 parts by weight of a rubber containing one or more functional groups; and where the total of the parts by weight of I and II is 100; and moldings produced therefrom.

Owner:EVONIK OPERATIONS GMBH

Blended material of ethylene-vinyl alcohol copolymer and high-density polyethylene and method for preparing same

InactiveCN101735537AGood compatibilityExcellent gas barrier performanceLow-density polyethyleneAntioxidant

The invention belongs to the technical field of blending processing of copolymers and discloses a blended material of an ethylene-vinyl alcohol copolymer and high-density polyethylene. The blended material comprises the following components in percentage by weight: 50.0 to 80.1 percent of ethylene-vinyl alcohol copolymers, 10.0 to 30.0 percent of high-density polyethylene, 5.0 to 15.0 percent of flexibilizer, 4.8 to 15 percent of compatilizer, and 0.1 to 1.0 percent of antioxidant. The invention also discloses a method for preparing the blended material. The blended material has high gas resisting property of EVOH as well as high moisture resisting property of HDPE; the product cost is effectively lowered; the EVOH / HDPE blended material is good in toughness, the normal-temperature and the low-temperature impact strengths of the EVOH / HDPE blended material are obviously higher than those of the EVOH, and the application range of EVOH is widened.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Process for producing thermoplastic elastomer composition, and air-bag cover

InactiveUS20060199909A1Improve low temperature impact strengthSpecial tyresThermoplastic elastomerMooney viscosity

A process for producing a thermoplastic elastomer composition comprising the step of crosslinking dynamically at least the following components (A) to (C) in the presence of a crosslinking agent: (A) 10 to 50% by weight of an oil-extended ethylene-α-olefin-non-conjugated diene copolymer rubber having a density of 850 to 900 kg / m3, and a Mooney viscosity (ML1+4 100° C.) of 30 to 150, (B) 20 to 60% by weight of an ethylene-α-olefin copolymer having a density of 850 to 910 kg / m3, and a melt flow rate of 0.05 to 80 g / 10 minutes measured at 230° C. under a load of 21.18 N, and (C) 20 to 60% by weight of a propylene resin, the total amount of the components (A) to (C) being 100% by weight; and an air-bag cover comprising a thermoplastic elastomer composition produced according to said process.

Owner:SUMITOMO CHEM CO LTD

Modified polypropylene material for high-performance thin-wall automobile door panel and preparation method thereof

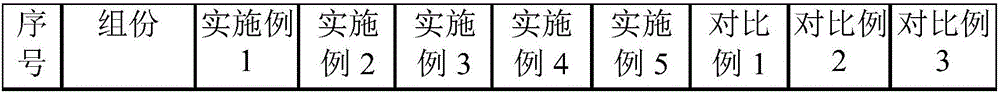

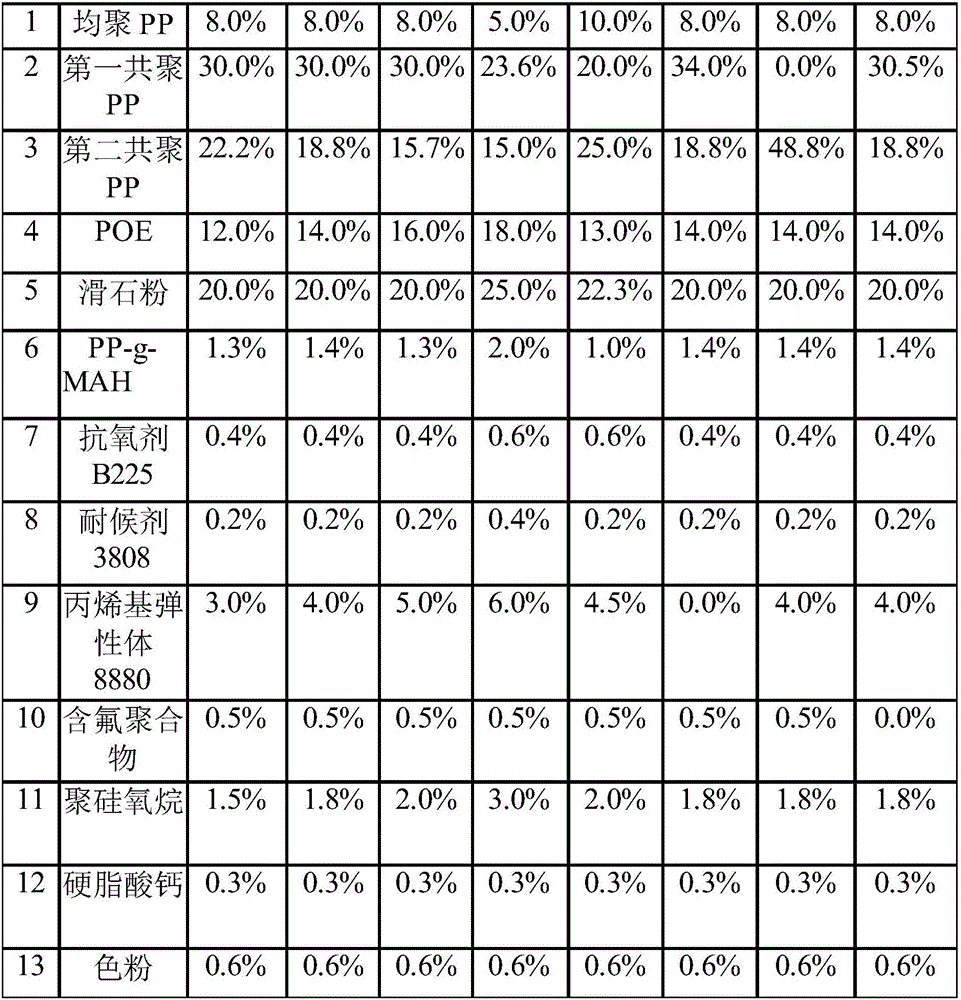

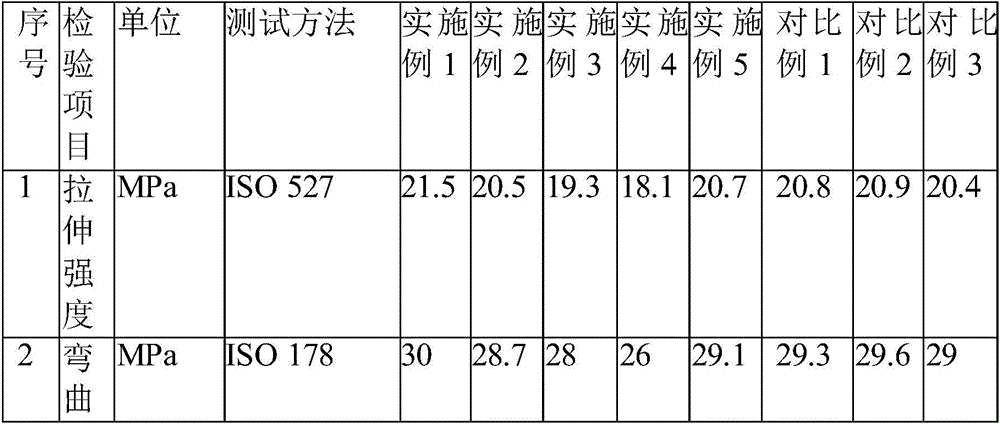

The invention belongs to the technical field of plastics modification and particularly relates to a modified polypropylene material for a high-performance thin-wall automobile door panel and a preparation method thereof. The material is prepared from, by mass, 5%-10% of homopolymerized PP, 20%-30% of first copolymerized PP, 15%-25% of second copolymerized PP, 12%-18% of toughening agent, 1%-2% of compatilizer, 0.4%-0.6% of antioxidant, 0.2-0.4% of weather resistance agent, 3%-6% of melting index regulator, 20%-25% of mineral enhancer, 1.5-3% of scratch resistant agent and 1-2% of other assistants. The preparation method of the modified polypropylene material comprises the steps of mixing, extrusion and granulation. The material prepared by adopting the preparation method has high liquidity, rigidity and toughness, can well meet the usage requirements of the thin-wall automobile door panel and is low in cost. Compared with the prior art, a high-liquidity allyl elastomer is used as the melting index regulator, the liquidity of the material is remarkably improved, and the thin-wall door panel forming requirements are met. In addition, high-liquidity polypropylene and a low surface energy polymer are used in a mixed mode, and the tiger skin stripe defects on the surface of the thin-wall door panel can be basically eliminated.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

Polypropylene composition for automobile enamel-plastic instrument panel frameworks and preparation method thereof

ActiveCN103030884AIncrease surface tensionImprove surface activityManufacturing cost reductionAntioxidant

The invention discloses a polypropylene composition for automobile enamel-plastic instrument panel frameworks and a preparation method thereof. The polypropylene composition comprises the following components in parts by weight: 48-82 parts of polypropylene, 10-30 parts of inorganic filler, 5-15 parts of toughener, 1-4 parts of maleic anhydride graft polymer, 1-5 parts of ethylene-ethyl acrylate, 0.1-2 parts of antioxidant, and 0-3 parts of other assistants. By adding the maleic anhydride graft polypropylene and ethylene-ethyl acrylate polar compound, the polypropylene composition has the following advantages: 1. the polypropylene composition has high surface tension (up to 48 mN / m); 2. the automobile instrument panel framework formed by carrying out injection molding on the polypropylene composition has high surface activity, and can be directly attached to the foam layer without surface pretreatment, thereby enhancing the production efficiency, saving the energy and lowering the manufacturing cost when producing the enamel-plastic foamed soft instrument panel; and 3. the polypropylene composition has obviously higher low-temperature impact strength, and thus, can greatly enhance the safety of the automobile instrument panel.

Owner:SHANGHAI PRET COMPOSITES

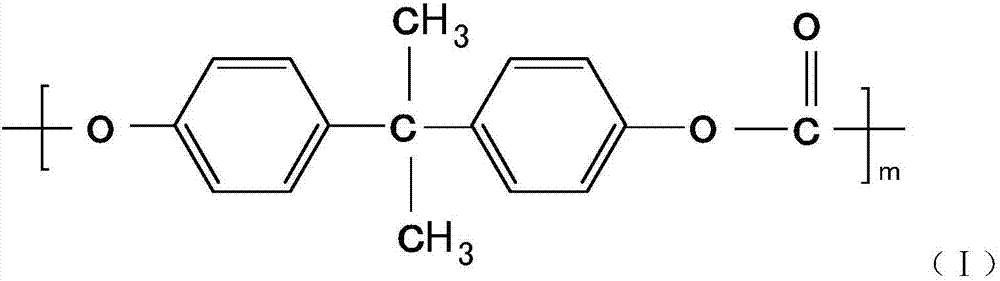

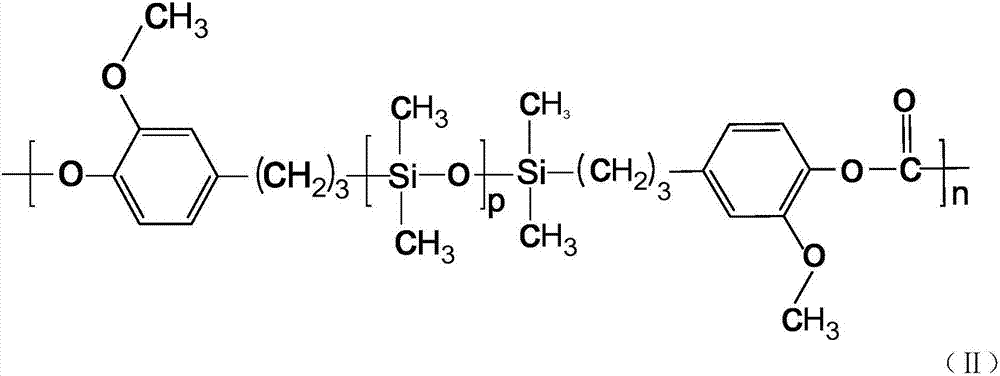

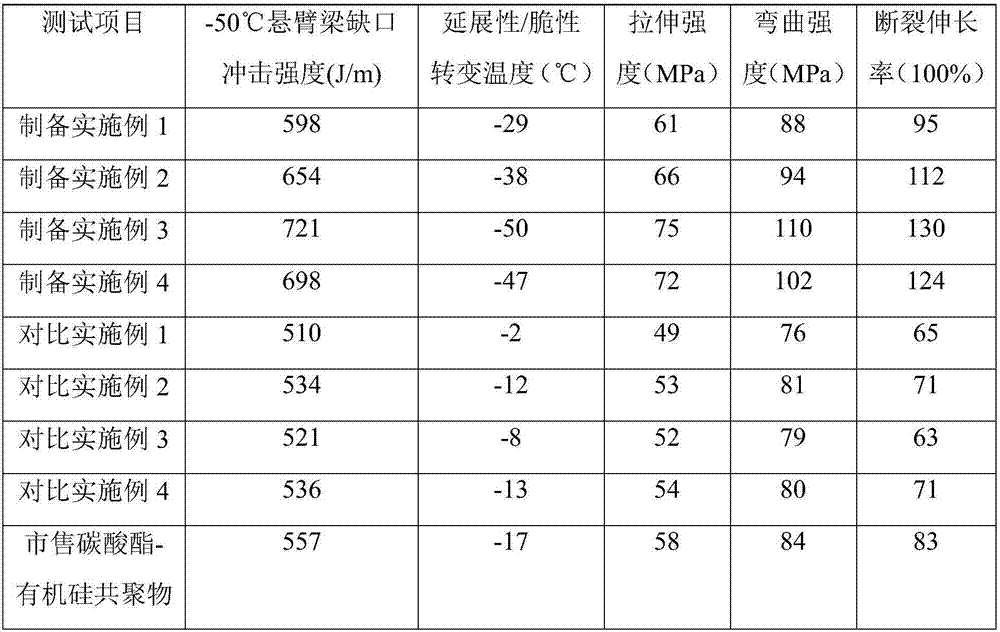

Low temperature resistant non-transparent high-impact random copolymerization polycarbonate, preparation method and application thereof

InactiveCN106928439AImprove low temperature resistanceHigh impact strengthPolycarbonateUltimate tensile strength

The invention discloses low temperature resistant non-transparent high-impact random copolymerization polycarbonate, a preparation method and an application thereof. The random copolymerization polycarbonate is composed of a polycarbonate embedded section and a polysiloxane embedded section. The random copolymerization polycarbonate disclosed by the invention has excellent comprehensive property, excellent low temperature resistance and mechanical property, especially, high shock strength, better low-temperature shock strength, excellent processing property and practical application value.

Owner:广东新通彩材料科技有限公司 +1

Polypropylene modified material for expansion water tank of automobile and preparation method thereof

InactiveCN102775718AImprove low temperature impact strengthImprove high temperature creep resistanceLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polypropylene modified material for an expansion water tank of an automobile and a preparation method thereof and belongs to the technical field of auto part manufacturing. The polypropylene modified material for the expansion water tank for the automobile comprises the following components in percentage by weight: 75-85 percent of propylene-ethylene block polypropylene copolymer, 10-20 percent of linear low density polyethylene (LLDPE) resin, 2-5 percent of ethylene propylene diene monomer (EPDM), 0.1-0.5 percent of nucleating agent and 0.1-0.5 percent of antioxidant. After being mixed according to the proportion, the materials are extruded and granulated by a double screw extruder under the conditions that the processing temperature is 210-240 DEG C, and the screw speed is 210-240 revolutions / minute. The polypropylene modified material has the beneficial effects that polypropylene is modified by the reasonable components according to the mixing proportion, so that the material has higher low-temperature impact strength and higher high-temperature creep resistance; and meanwhile, the hot plate welding performance of the material is improved, the material transparency is improved, and the production processing requirements and the use requirements of the expansion water tank for the automobile are completely satisfied.

Owner:SHANDONG HUA TONG AUTOMOBILE MOLDS PLASTICS TECH

Molding composition based on polyetheramides

ActiveUS7582342B2Extrusion process is simpleAdequate long-lasting flexibilitySynthetic resin layered productsThin material handlingPolymer scienceEther

Owner:EVONIK OPERATIONS GMBH

Polypropylene composition for water-heater inner containers and preparation method thereof

ActiveCN101812201AGood room temperatureImprove low temperature impact strengthFluid heatersSolar heat devicesHeat deflection temperatureProcedure Agents

The invention provides a polypropylene composition for water-heater inner containers, which comprises the following components in portions by weight: (a) 100 portions of homopolymerized polypropylene; (b) 0.01-10 portions of thermal stabilizer; (c) 0.01-10 portions of processing aid; and (d) 0.01-10 portions of alpha-crystal form nucleating agent and / or beta-crystal form nucleating agent. The processing aid is selected from one or a plurality of low-molecular-weight ester compounds, metallic soap compounds, stearic acid-compounded ester compounds and amide compounds. The polypropylene material of the invention overcomes the defect of insufficient rigidity of the common polypropylene, and has the advantage of high heat distortion temperature; and the tensile strength is greater than or equal to 20 MPa, the elongation at break is greater than or equal to 300%, the bending modulus is greater than or equal to 1200 MPa, and the notch impact strength is greater than or equal to 30 Kj / m<2>.

Owner:SHANGHAI KINGFA SCI & TECH

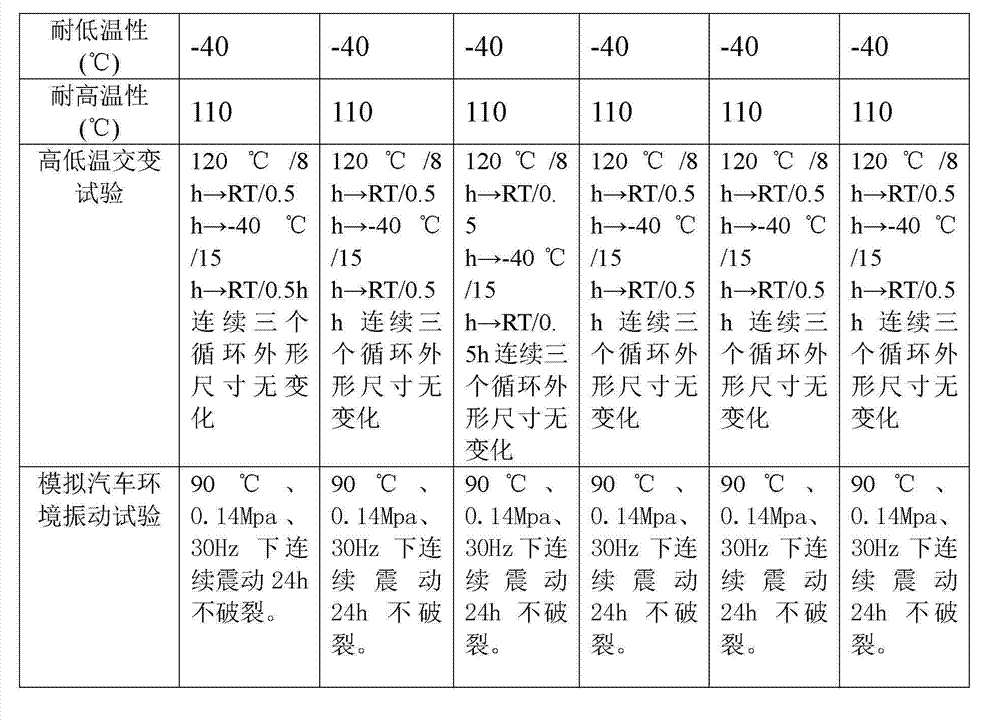

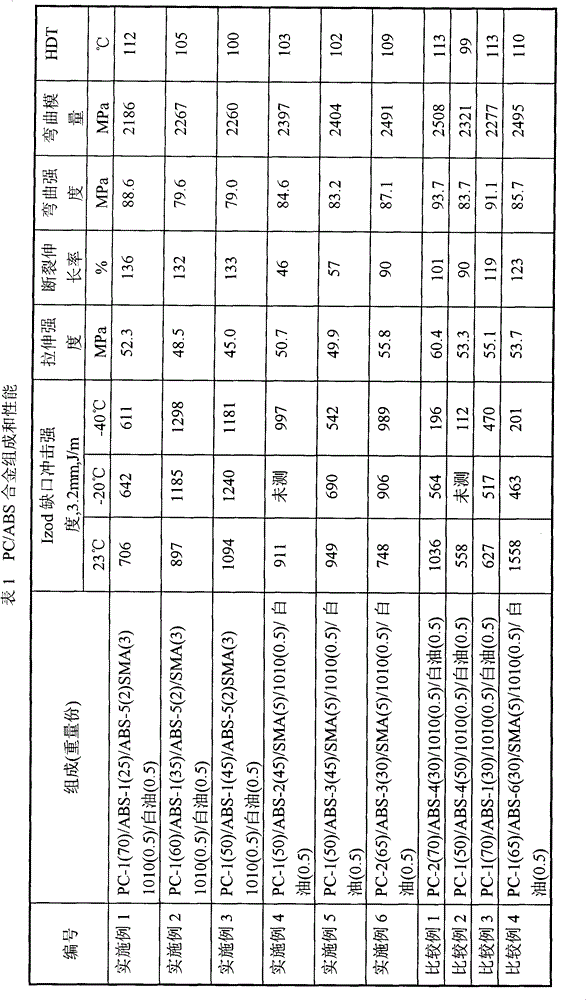

Low temperature impact resistant polycarbonate/ABS (acrylonitrile, butadiene and styrene) resin plastic alloy

ActiveCN102746631AReactive functional groups are goodLarge particle sizeBulk polymerizationEmulsion polymerization

The invention relates to a low temperature impact resistant polycarbonate / ABS resin plastic alloy to mainly solve a problem that polycarbonate / ABS plastic alloys prepared through previous technologies have low temperature impact strengths and cannot satisfy some low temperature application requirements. The problem is well solved through a technical scheme that the plastic alloy comprises a polycarbonate resin with an appropriate molecular weight, a bulk polymerization ABS resin, an emulsion polymerization ABS resin, a compatilizer SMA resin, and auxiliary agents of an antioxidant and the like in the invention. The polycarbonate / ABS resin plastic alloy is especially suitable for the production of some low temperature application plastic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formula of high-impact-resistance polyvinyl chloride (PVC) pipe material

InactiveCN102977506AImprove low temperature impact strengthGood cold bending performanceRigid pipesPlasticizerPolyvinyl chloride

The invention discloses a formula of a high-impact-resistance polyvinyl chloride (PVC) pipe material, which is characterized by consisting of the following raw materials in parts by weight: 60-90 parts of SG-5 type PVC, 5-15 parts of powdery butyronitrile, 3-6 parts of stabilizer, 5-15 parts of light calcium carbonate, 5-10 parts of anti-impact agent, 2-8 parts of titanium, 4-12 parts of lubricant and 1-7 parts of plasticizer. The invention provides a formula of an impact-resistance PVC pipe material with excellent processability, high quality and high safety. According to the formula, the low-temperature anti-impact strength of the finished product is improved, tensile strength and elongation at break of the finished product are increased; the shortcoming that the PVC product made of the chlorinated polyethylene has good ductility but low hardness is overcome; and cold bending property, anti-impact strength and flat pressure of the produced pipe material are remarkably improved.

Owner:QINGDAO XINWANTONG PLASTIC IND

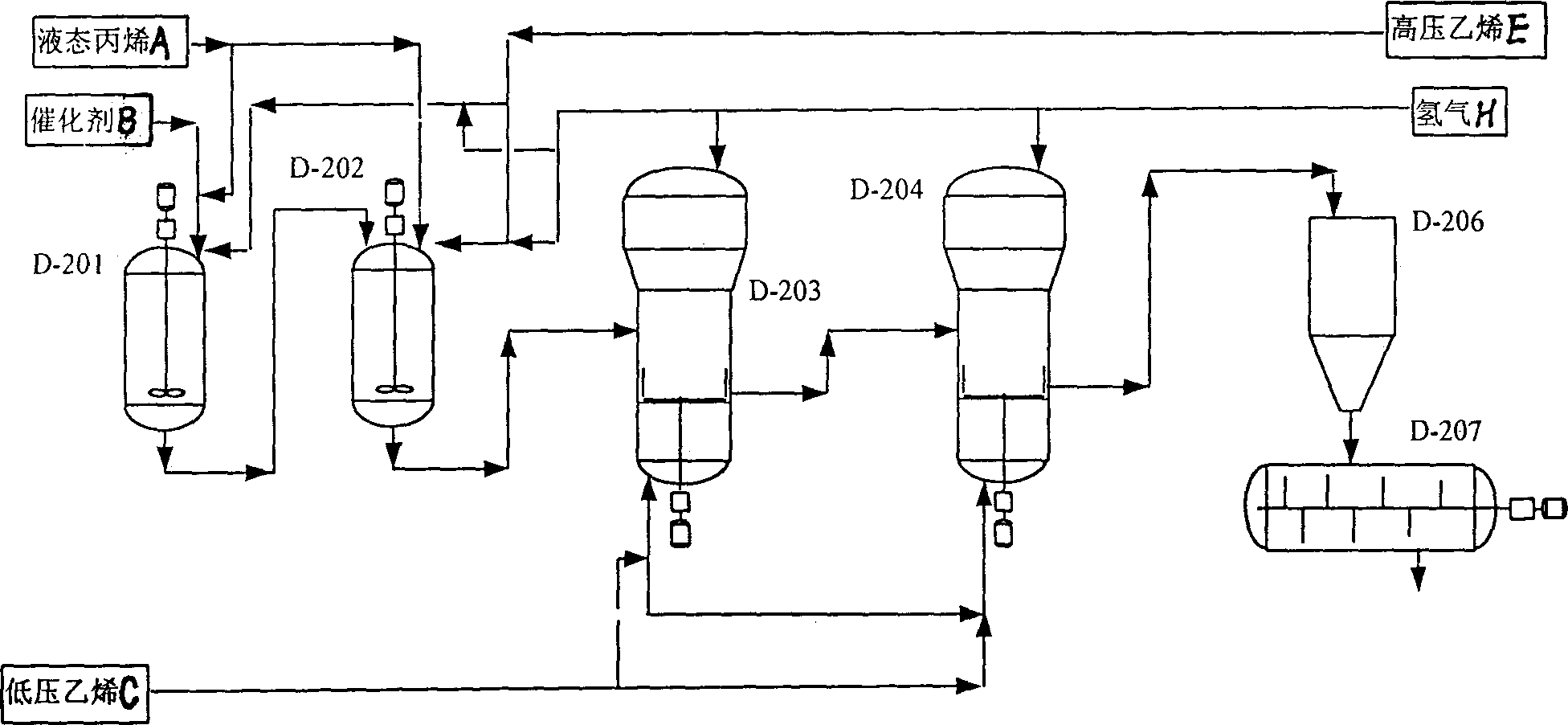

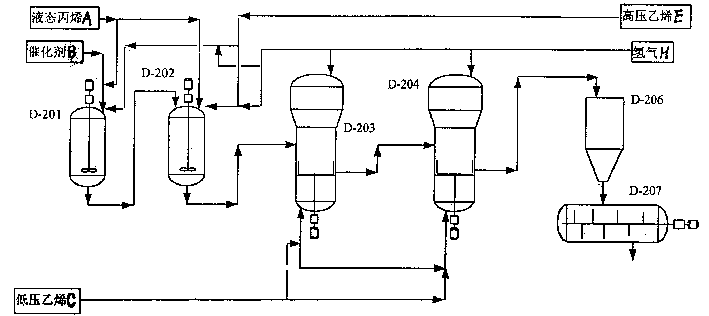

Process for preparing creep-resistant atactic polypropylene copolymer

InactiveCN1379049AImprove performanceImprove low temperature impact strengthPolypropyleneLiquid phase

A creep-resistant atactic polypropene copolymer with optimized structure and performance is prepared through prepolymerizing catalyst; the catalyst entering the first liquid-phase reactor to contact propylene for polymerization, and then copolymerization by introducing ethylene; the materials after reaction, entering the second tiquid-phase reactor to containus copolymerization under the action of hydrogen, propene and ethyene; the above resultant entering the first gas-phase reactor for copolymerization; then entering the second gas phase reactor for copolymerization; entering a separator and then entering a dryer for final drying to obtain the polypropene powder.

Owner:SINOPEC YANGZI PETROCHEM

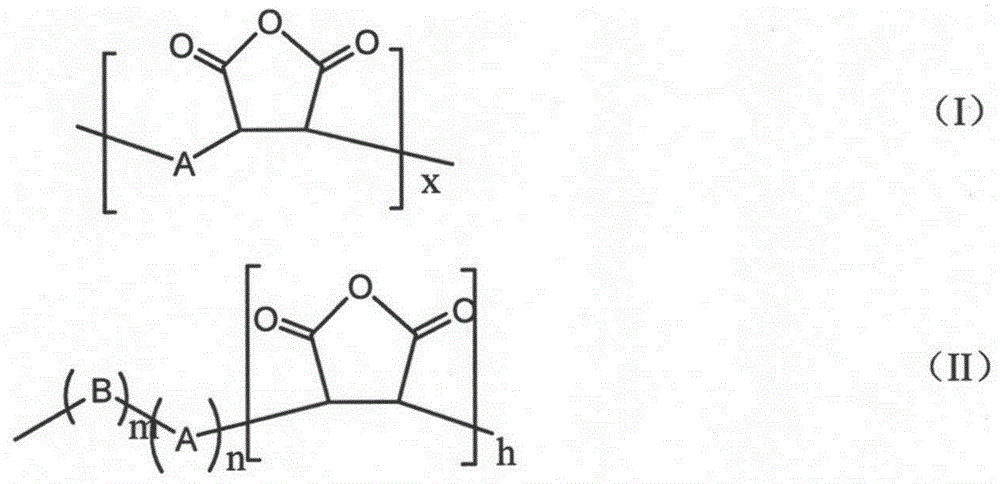

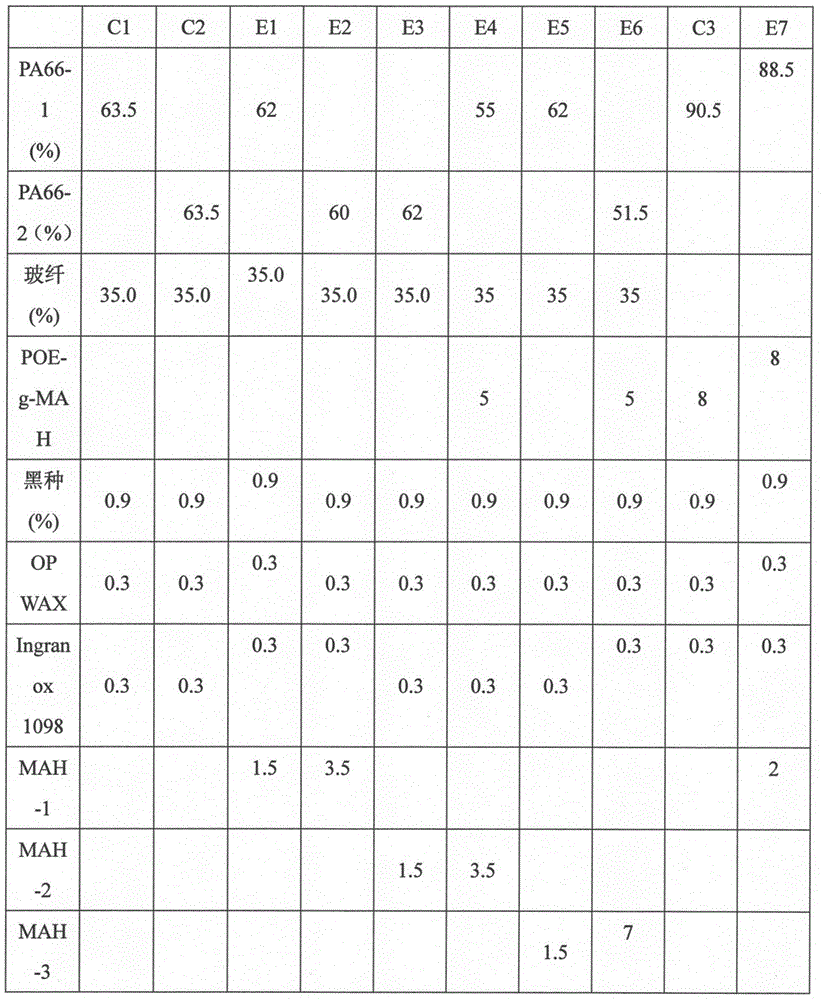

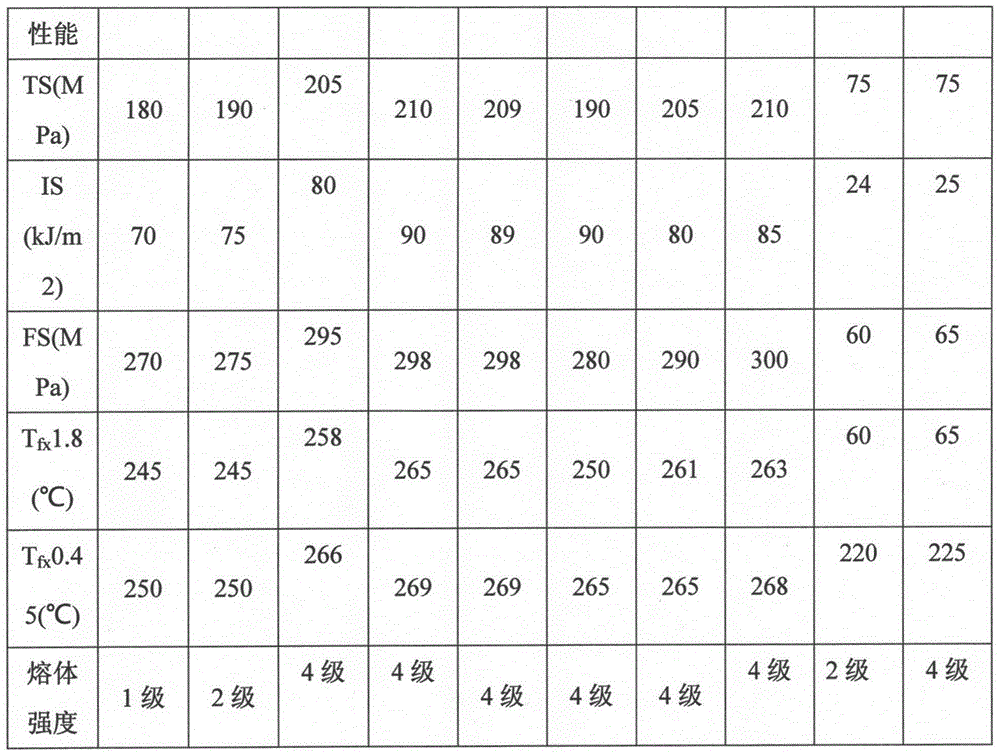

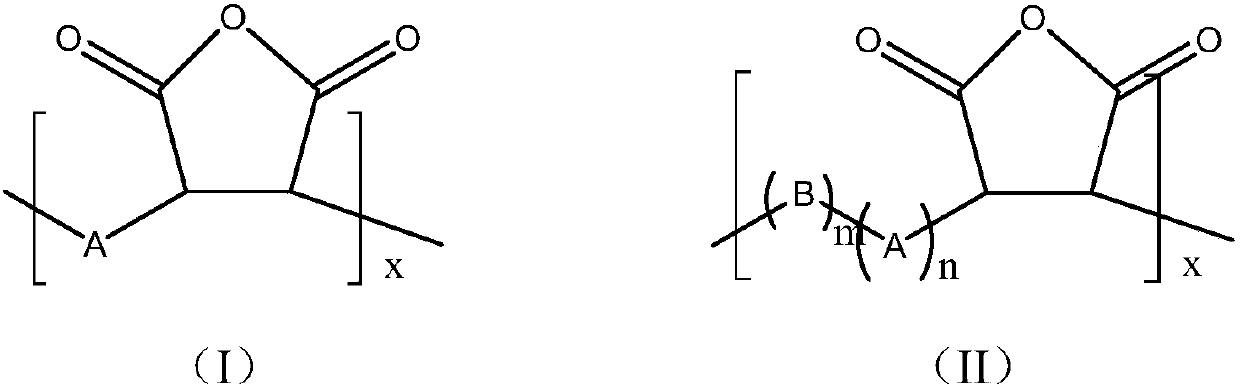

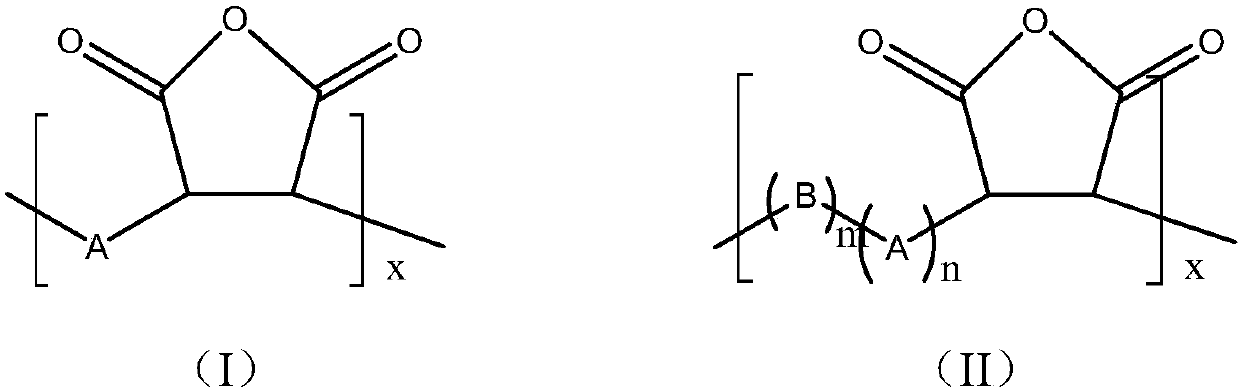

Polyamide composition suitable for extrusion molding, blow molding and foaming multi uses and preparation method thereof

The present invention relates to a polyamide composition suitable for extrusion molding, blow molding and foaming multi uses, the polyamide composition is characterized by comprising 49 to 89% (by weight) of thermoplastic polyamide resin, 0.01 to 10% (by weight) of maleic anhydride copolymer, 0 to 50% (by weight) of filler, 0 to 20% (by weight) of an impact-resistant modifier and 0.1 to 2% (by weight) of an additive, wherein the maleic anhydride copolymer is prepared by alternating copolymerization or block copolymerization of maleic anhydride and one or two alkenyl-containing monomers which contain heteroatom or does not contain heteroatom. The polyamide composition has the advantages of high melt strength increase and significantly enhanced mechanical properties, is suitable for machining or molding process requiring higher melt strength, and is particularly suitable for extrusion molding, blow molding and foaming and the like.

Owner:SHANGHAI KINGFA SCI & TECH

Aging-resistant PC (Polycarbonate) -PBT (Polybutylene Terephthalate) plastic alloy

InactiveCN103351593AImprove heat resistanceImprove wear resistanceCrack resistancePolyethylene terephthalate

The invention discloses an aging-resistant PC-PBT plastic alloy, which is composed of the following components in weight part: 100 parts of PC, 20-40 parts of PBT, 4-8 parts of compatibilizer and 0.5-1.5 parts of age resister. The PC-PBT plastic alloy disclosed by the invention has the advantages of good thermal tolerance, good stress cracking resistance, excellent abrasive resistance, excellent chemical corrosive resistance, high low-temperature impact strength, easiness in machining and good coating property, and is mainly applied to bumpers, chassis and panels of superior quality cars, fenders of motorcycles and the like. The aging-resistant PC-PBT plastic alloy also has excellent thermal aging property, thereby being suitable for use in the extremely high temperature environment.

Owner:深圳市高科塑化有限公司

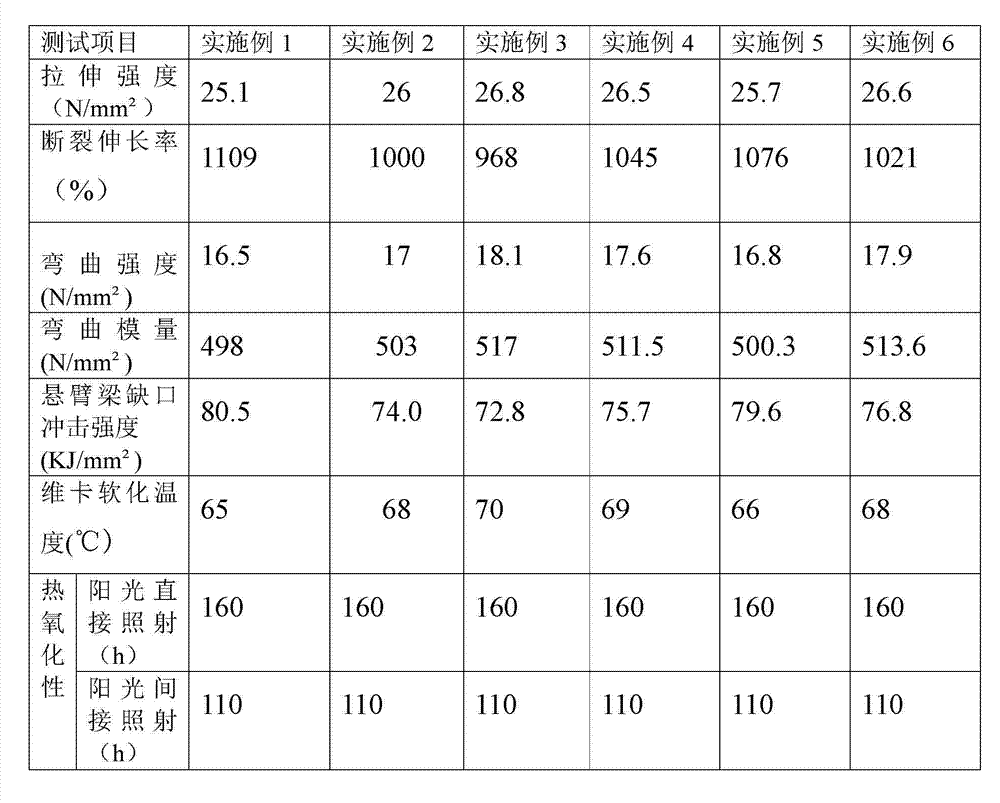

Ultra-low temperature-resistant polycarbonate resin composition

InactiveCN101935443AGood compatibilityLow temperature processing and forming effect is obviousSilica gelPolycarbonate

The invention provides a polycarbonate resin composition which comprises the following components in parts by weight: 100 parts of polycarbonate, 1.5-5 parts of modified silica gel, 0.1-0.5 part of antioxidant and 0.08-0.1 part of flame retardant. All the components in the provided polycarbonate resin composition have good compatibility, so that the polycarbonate resin composition can be used for preparing a polycarbonate resin special product under the environment that the temperature is as low as minus 70 DEG C; simultaneously, a low-temperature impact modifier and the antioxidant produce the synergy, thereby increasing and recovering the original molecular weight and the intrinsic viscosity of the polycarbonate during the low-temperature processing and forming process, increasing the low-temperature impact strength, the bending strength, the tensile strength and other performances, simultaneously enhancing the low temperature resistance, being difficult to produce cracks and giving the performances of fire prevention and flame retardance to the polycarbonate resin composition.

Owner:SHENZHEN XINGYEYUAN SCI & TECH CO LTD

Modified polyvinyl chloride cable material with high cold resistance

InactiveCN104403228AImprove heat resistanceImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsFiberEpoxy

The invention discloses a modified polyvinyl chloride cable material with high cold resistance. The modified polyvinyl chloride cable material is prepared from the following raw materials: polyvinyl chloride, nitrile rubber, maleic anhydride-grafted polypropylene, ethylene-vinyl acetate-carbon monoxide terpolymer, bamboo fiber, modified kaolin, ultra-fine silica dioxide powder, triethyl citrate, acetyl-tri-n-butyl citrate, epoxy sunflower oil, eicosyl dehydroabietate, modified zinc borate, red phosphorus, nanometer aluminum hydroxide, maleopimaric acid lanthanum, methyl tin mercaptide, barium stearate, an antioxidant, and a lubricant. The modified polyvinyl chloride cable material with the high cold resistance disclosed by the invention is high in cold resistance, good in elasticity, good in impact resistance, and excellent in mechanical property; the cable prepared by the modified polyvinyl chloride cable material is long in service life in the cold environment.

Owner:ANHUI DUJIANG CABLE GROUP

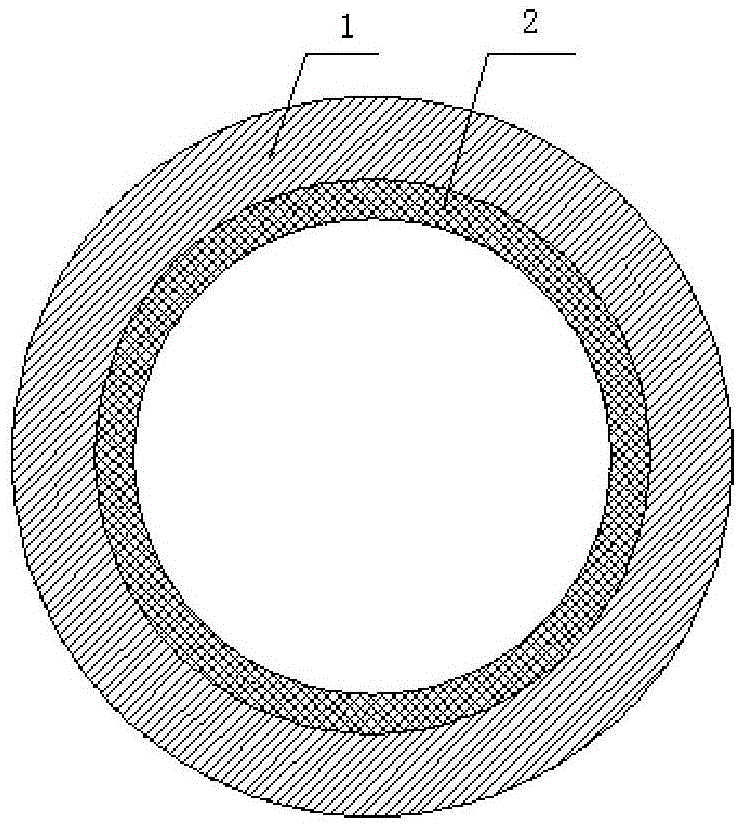

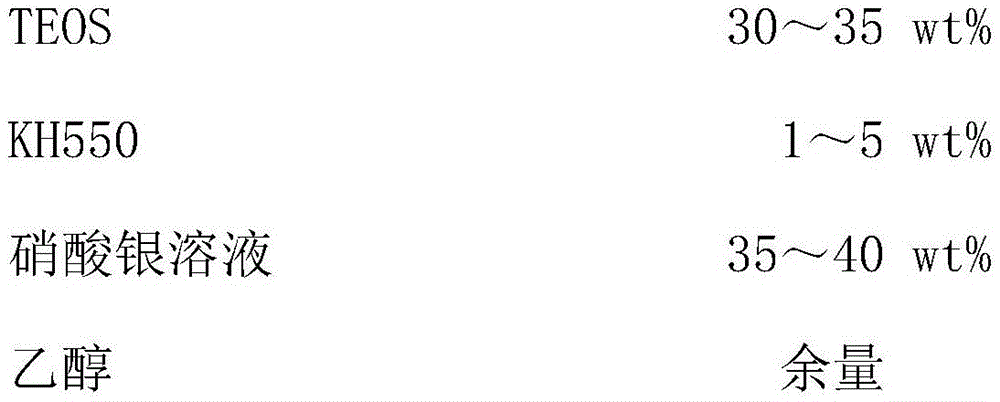

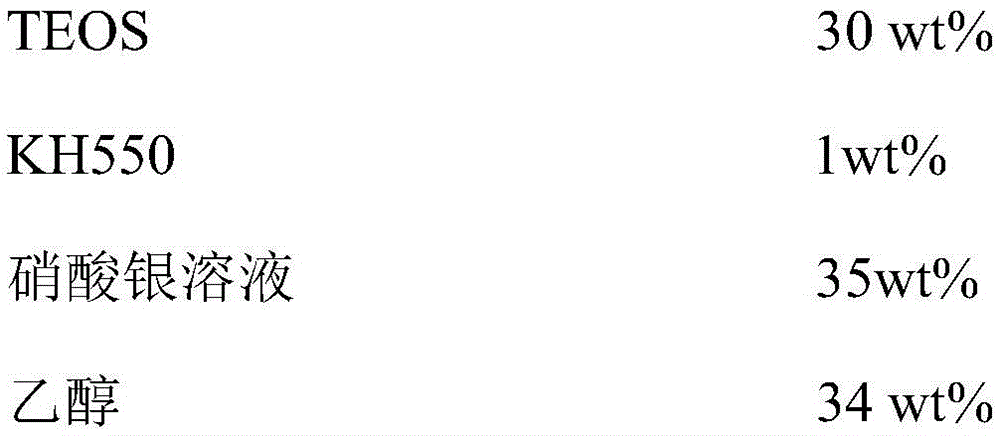

Toughened antibacterial polypropylene pressure pipe

The present invention relates to a toughened antibacterial polypropylene pressure pipe, which are composed of an outer toughening layer and an inner antibacterial layer. The toughening layer is an outer layer of the pipe, and the antibacterial layer is an inner layer of the pipe. The formula of the toughening layer comprises the following ingredients (by weight): 80%-90% of a special material for a polypropylene randon copolymer pipeline, 2%-4% of color masterbatch, 0.05%-0.2% of a beta-nucleating agent for polypropylene, 5%-10% of a compatibilizer and 0.05-0.1% of a heat stabilizer. The above two layers are respectively extruded and pelleted in a twin-screw extruder; and pelleted raw materials are co-extruded by a single screw extruder, cooled, drawn and cut so as to prepare the finished product. The invention has the advantages as follows: the outer layer of the pipe has excellent impact resistance and hydrostatic resistance, and the inner antibacterial layer ensures that a conveying medium will not be polluted by the pipe itself and can have antibiotic and bacteriostatic effects; and in comparison with a common PPR pipe with the same wall thickness, the pressure pipe of the invention has high compression strength and good impact resistance, is green, corrosion-resistant, and has an efficient broad-spectrum antibacterial function.

Owner:SHANGHAI WEIXING NOVEL BUILDING MATERIAL

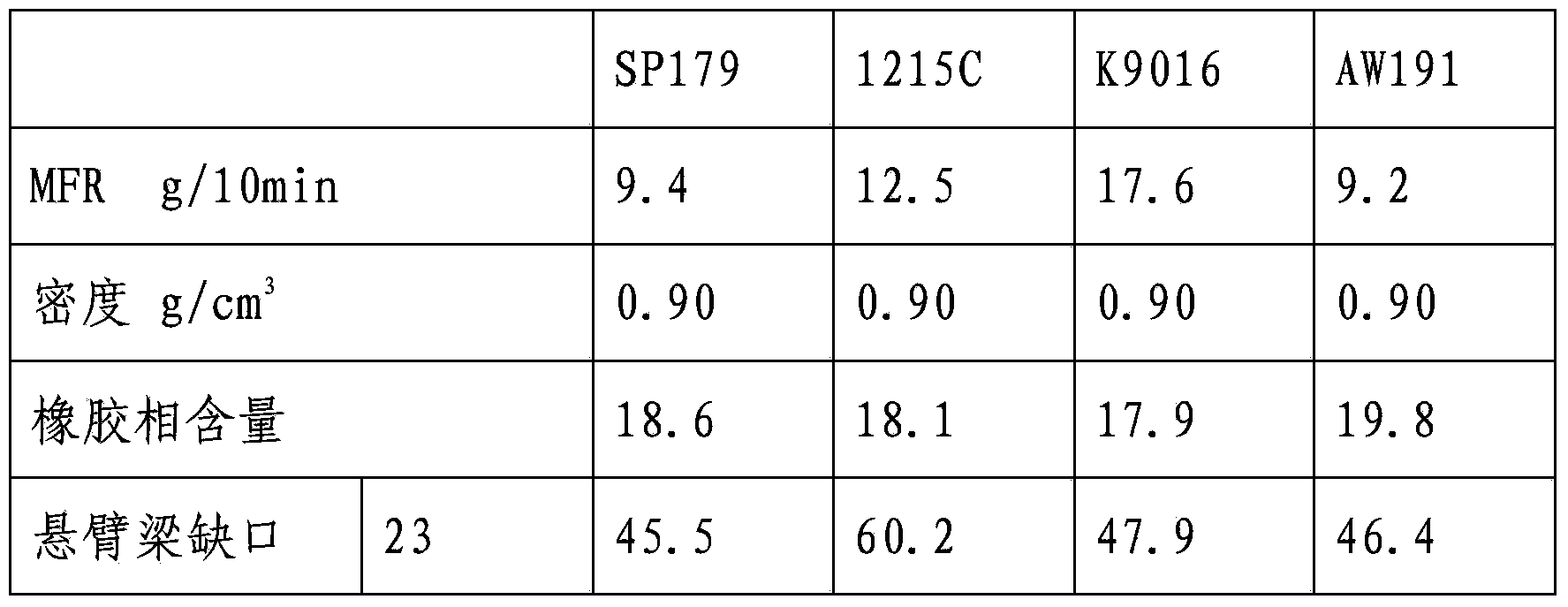

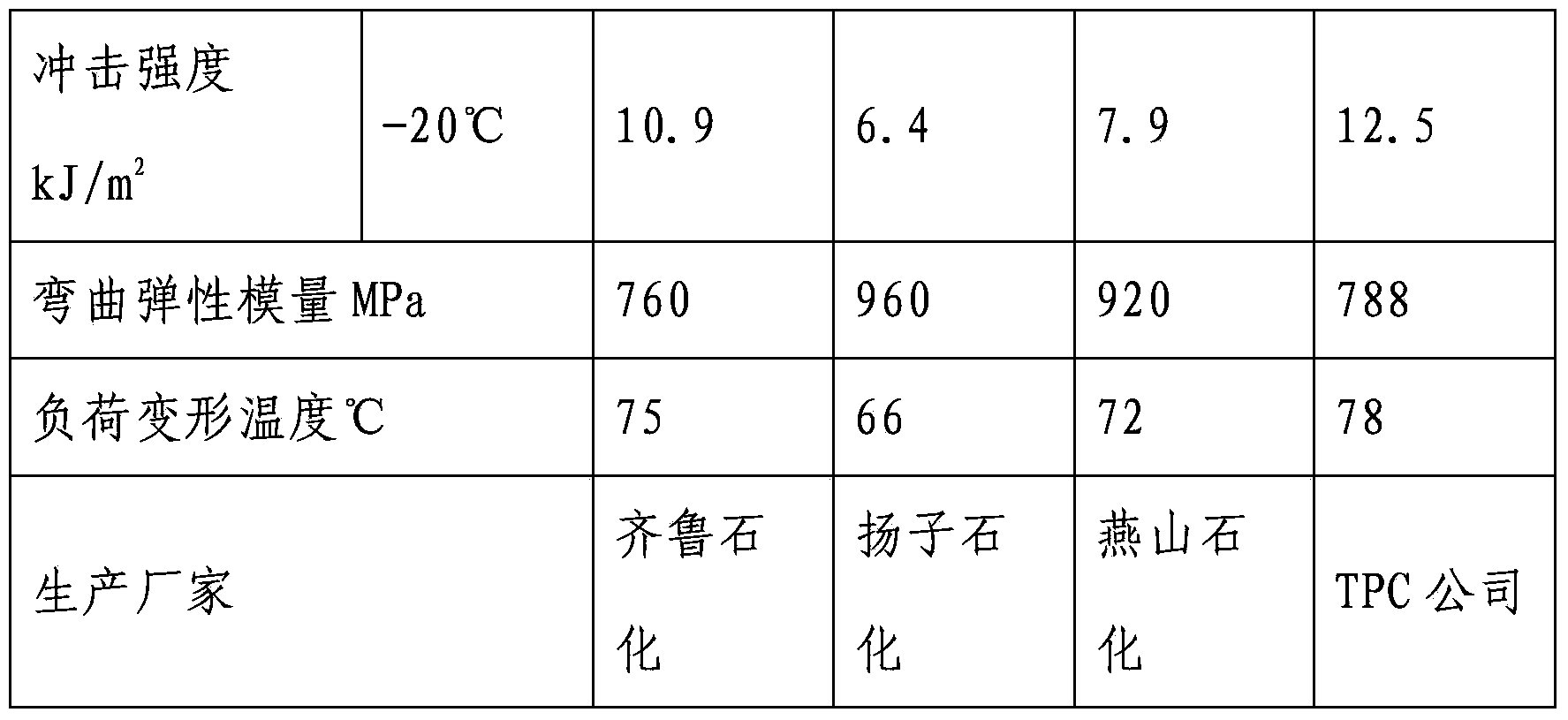

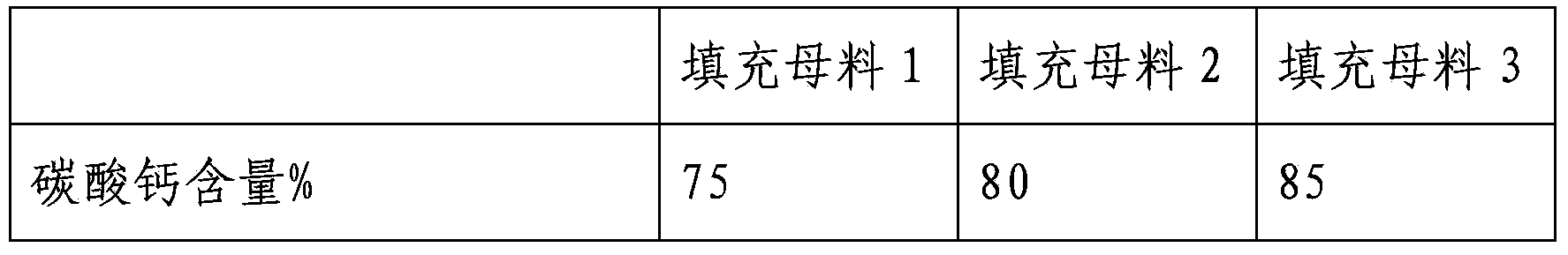

Polypropylene-calcium carbonate filling master batch and preparation method thereof

The invention relates to a polypropylene-calcium carbonate filling master batch and a preparation method thereof. The filling master batch includes: 15-25 parts by weight of high rubber phase content polypropylene; and 75-85 parts by weight of calcium carbonate. The high rubber phase content polypropylene is a propylene-ethylene copolymer with a melt mass flow rate of 8-12g / 10min, and the calcium carbonate is light calcium carbonate treated by a coupling agent. The preparation method includes: fully drying the calcium carbonate in a 120DEG C dryer, then putting the calcium carbonate into a 120DEG C high speed mixer, adding the coupling agent to conduct high speed stirring so as to activate the surface of the calcium carbonate, adding the high rubber phase content polypropylene, mixing them uniformly, and then carrying out extrusion granulation. The polypropylene composite material modified by the filling master batch prepared by the method can have effectively improved low temperature impact strength, flexural modulus, and load deformation temperature. Also, the preparation method provided by the invention is simple and is beneficial to operation. No expensive elastomer material is contained in the components, so that the material cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP

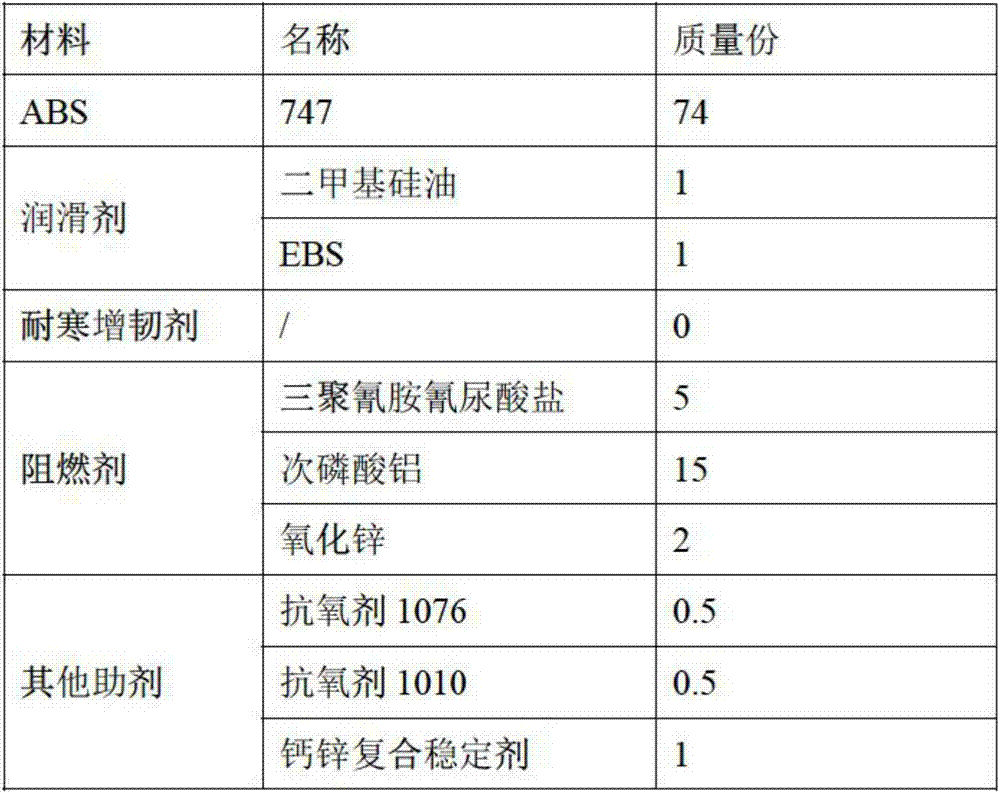

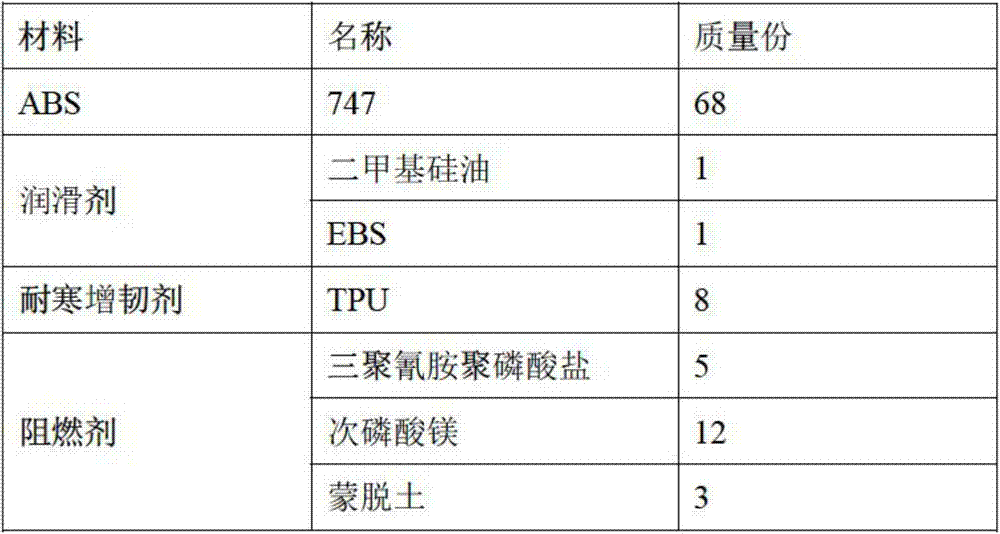

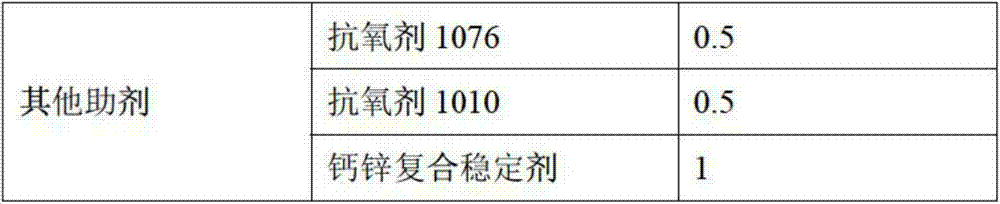

Cold-resisting halogen-free inflaming retarding ABS (Acrylonitrile Butadiene Styrene) and preparation method thereof

InactiveCN103756243AHigh impact strengthImprove low temperature impact strengthHalogenMelamine phosphate

The invention discloses a cold-resisting halogen-free inflaming retarding ABS (Acrylonitrile Butadiene Styrene) material. The cold-resisting halogen-free inflaming retarding ABS material is composed of the following raw materials in parts by mass: 65-85 parts of ABS, 15-25 parts of a halogen-free flame retardant, 0-10 parts of a cold-resisting toughening agent, 0.5-2 parts of a lubricant and 0.5-2 parts of other auxiliary agents, wherein the halogen-free flame retardant is a complex of melamine salt, hypophosphite and a flame retardant synergist; the melamine salt is at least one of melamine cyanurate, melamine phosphate, melamine polyphosphate and melamine pyrophosphate. A preparation method of the cold-resisting halogen-free inflaming retarding ABS material comprises the following steps: (1) uniformly mixing all the raw materials; and (2) fusing and extruding the uniformly-mixed raw materials, cooling by water and dicing to obtain the product. The ABS material prepared by the invention has high impact strength and low-temperature impact strength, has excellent inflaming retarding performance and is free of halogen.

Owner:GUANGDONG JUSHI CHEM CO LTD

Calcium sulfate whisker modified ethylene-vinyl alcohol copolymer and preparation process thereof

ActiveCN102153807ALow temperature impact strength and high bending strengthGood barrier propertiesPlasticizerSeafood fish

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

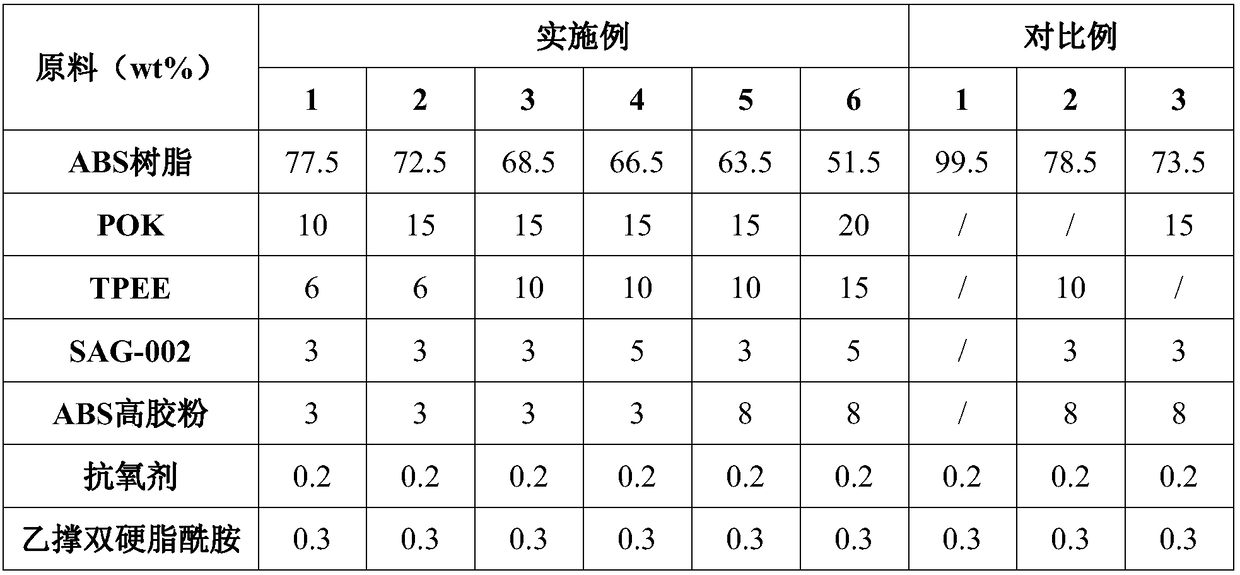

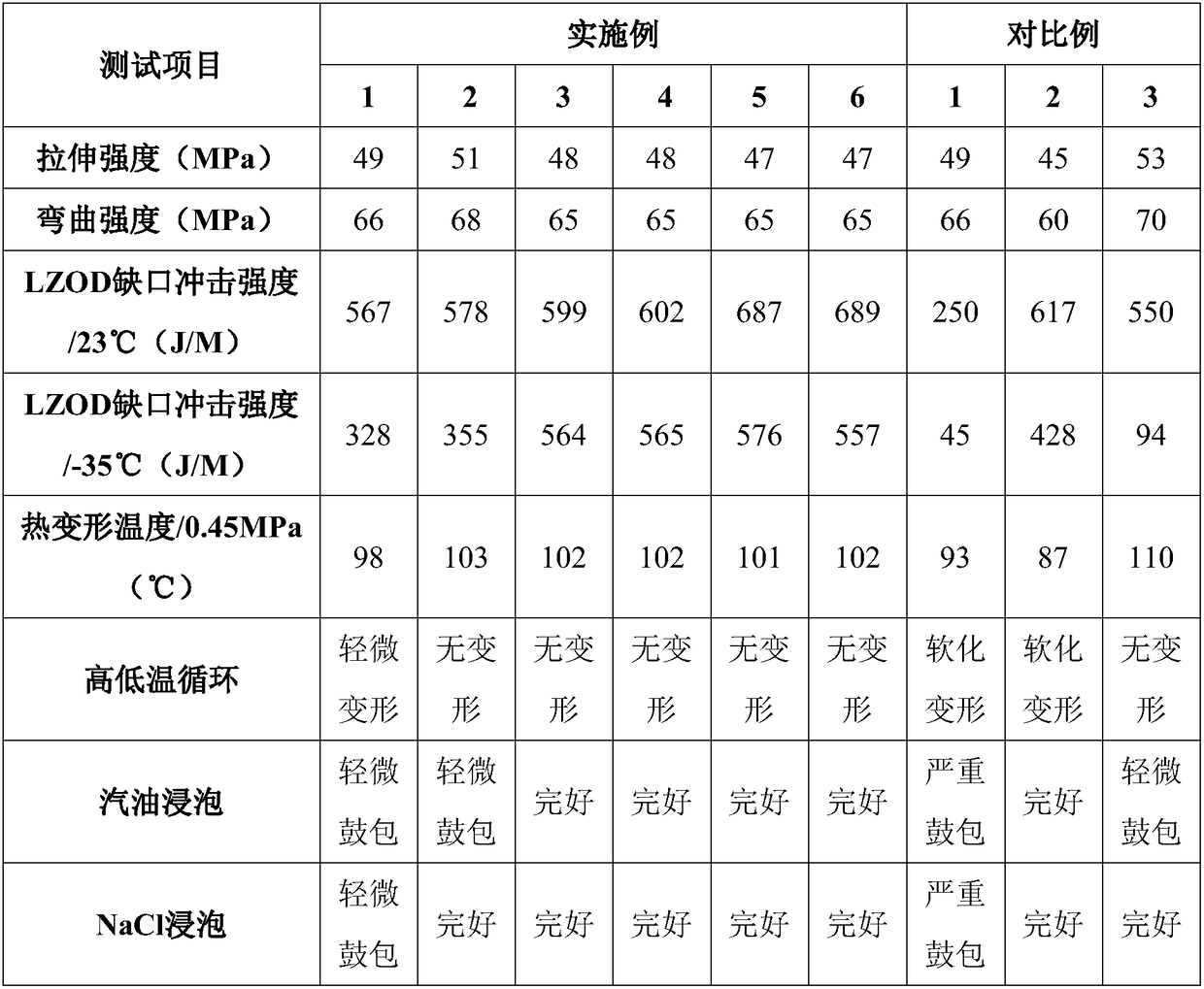

ABS composite resistant to high and low temperatures and chemicals and preparation method of ABS composite

The invention discloses an ABS composite resistant to high and low temperatures and chemicals and a preparation method of the ABS composite. The ABS composite is composed of the following components in percentage by mass: 51%-77.5% of ABS resin, 10%-20% of polyketone resin, 6%-15% of thermoplastic polyester elastomer, 3%-5% of compatilizer, 3%-8% of toughening agent, 0.2%-0.5% of antioxidant and 0.3%-0.5% of lubricant. The preparation method of the ABS composite is as follows: drying all the raw materials, then, adding the raw materials into a high-speed mixer for uniform mixing, then, transferring the mixture into a double-screw extruder, and carrying out extrusion, cooling, granulation and drying. The ABS composite disclosed by the invention is high in low-temperature notch impact strength (higher than 500J / M) and tensile strength and excellent in chemical resistance, has the heat deflection temperature of higher than 100 DEG C and can be widely applied to the fields such as domesticappliance shells, kitchen appliances and automobile materials with severe using environment requirements; and the preparation method is simple and easy to realize large-scale industrial production.

Owner:GUANGDONG JUSHI CHEM CO LTD

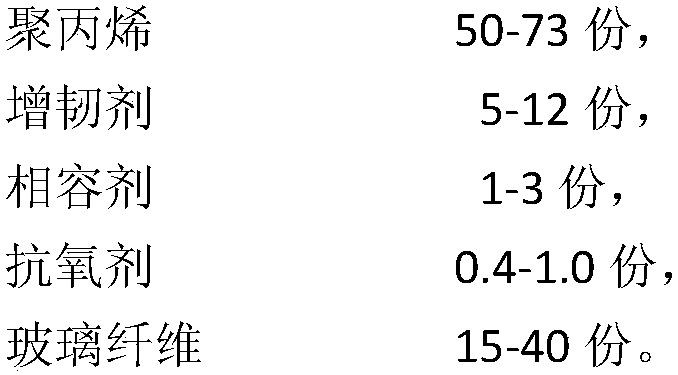

Low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material and preparation method

InactiveCN108219287AIncrease the lengthImprove mechanical propertiesPolypropylene compositesGlass fiber

The invention provides a low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material and a preparation method. A production raw material of the low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material is prepared from the following components: 50 to 73 parts of polypropylene, 5 to 12 parts of a flexibilizer, 1 to 3 parts of a compatilizer,15 to 40 parts of glass fiber and 0.4 to 1.0 part of an antioxidant. A production method of the low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material comprises the following steps: mixing all the components except the glass fiber, bracing and pelletizing the mixture to obtain a polypropylene resin semi-finished product, soaking the glass fiber into the melted polypropylene resin semi-finished product, and bracing and pelletizing the mixture to obtain the low-warpage high-impact-resistance long fiber-enhanced polypropylene composite material. The polypropylenecomposite material disclosed by the invention is relatively low in warpage performance, is also relatively high in low-temperature impact resistance and relatively good in mechanical property, and can be applied to a freezing environment.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Impact strength modifier for chlorine-containing resin, chlorine-containing resin composition and molded body of chlorine-containing resin composition

ActiveUS20160039963A1Improve polymerization stabilityPolymerization speed fasterSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceMeth-

Disclosed is an impact strength modifier (α) for a chlorine-containing resin, comprising a powder of a graft copolymer (A) obtained by graft polymerizing one or more kinds of vinyl monomers (b1) onto a polyorganosiloxane rubber (A1) or a composite rubber (A2) containing a polyorganosiloxane rubber and a polyalkyl(meth)acrylate rubber, wherein the specific surface area of the powder of the graft copolymer (A) measured by a nitrogen gas adsorption method is from 0.6 to 30 m2 / g, and the pH of water used for extraction under conditions, in which (1) in an oven at 180° C., 5.0 g of the powder of the graft copolymer (A) is left to stand still and heated for 15 minutes, and (2) after the heating, the powder is dispersed in 100 ml of heated pure water and extracted for 1 hour at 70° C. while stirring, is from 4 to 11.

Owner:MITSUBISHI CHEM CORP

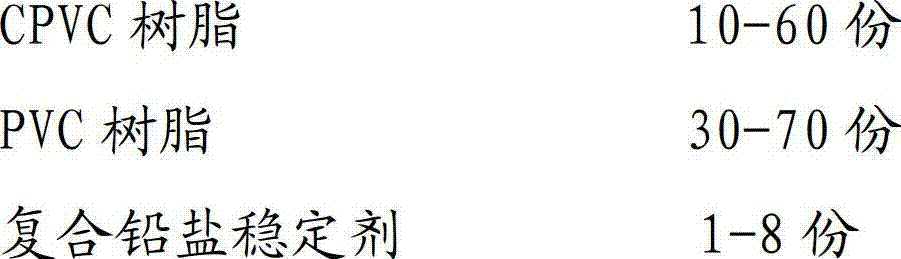

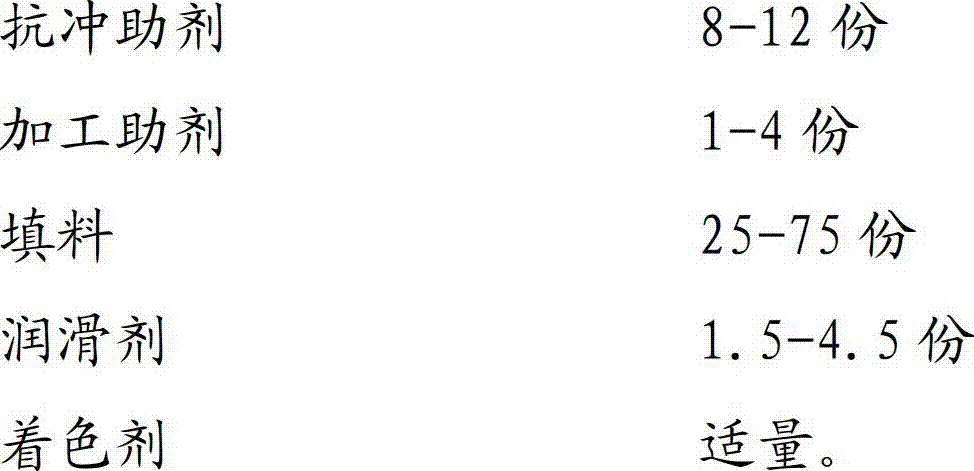

High-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and preparation method of chlorinated polyvinyl chloride (CPVC) corrugated board

ActiveCN102924851AImprove corrosion resistanceReduce thermal conductivity and heat absorptionStabilizing AgentsChemical stability

The invention discloses a high-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and a preparation method of the chlorinated polyvinyl chloride (CPVC) corrugated board. The corrugated board is prepared from the following raw materials by weight: 10-60 parts of CPVC resin, 30-70 parts of PVC (polyvinyl chloride) resin, 1-8 parts of composite lead salt stabilizer, 1-4 parts of processing aids, 8-12 parts of anti-impact aids, 25-75 parts of filler, 1.5-4.5 parts of lubricant, and a reasonable amount of colorant. The corrugated board has the advantages of high mechanical strength, excellent weatherability, high aging resistance and chemical stability and the like, and the formed raised corrugated board has higher thickness uniformity and uniform stress distribution, thereby being not easy to break due to stress concentration.

Owner:山东高信化学股份有限公司

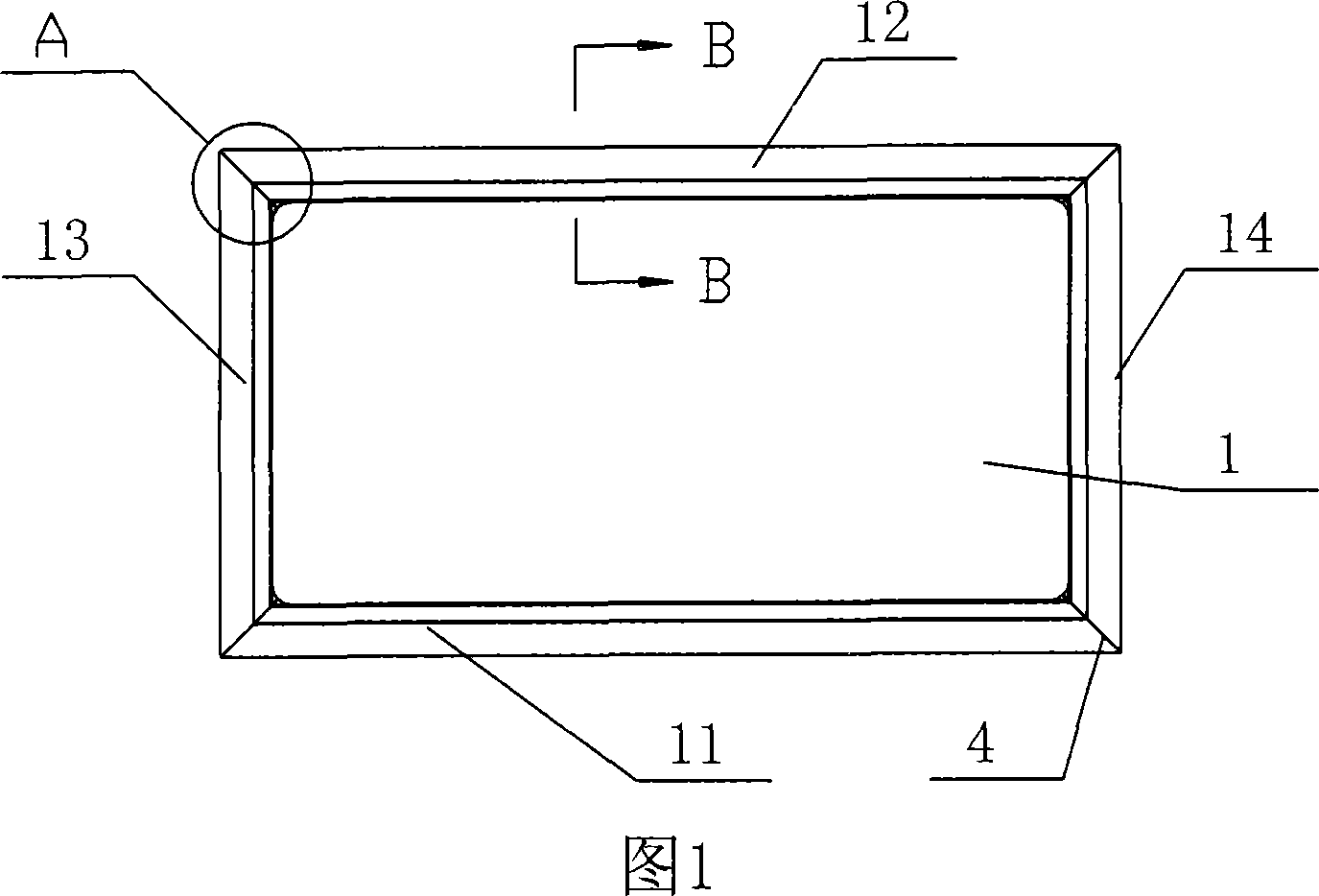

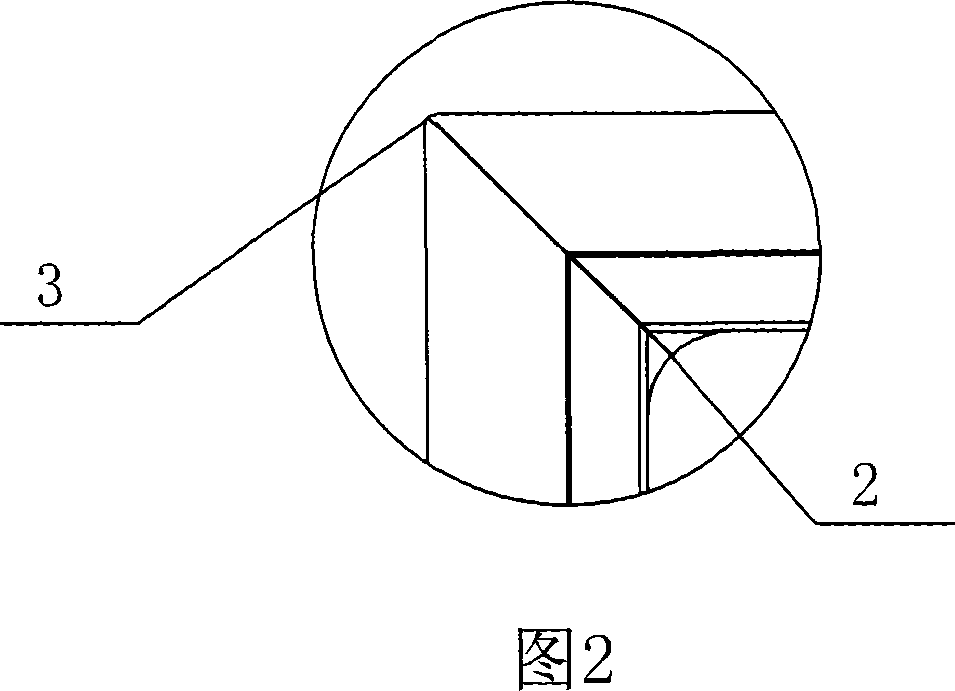

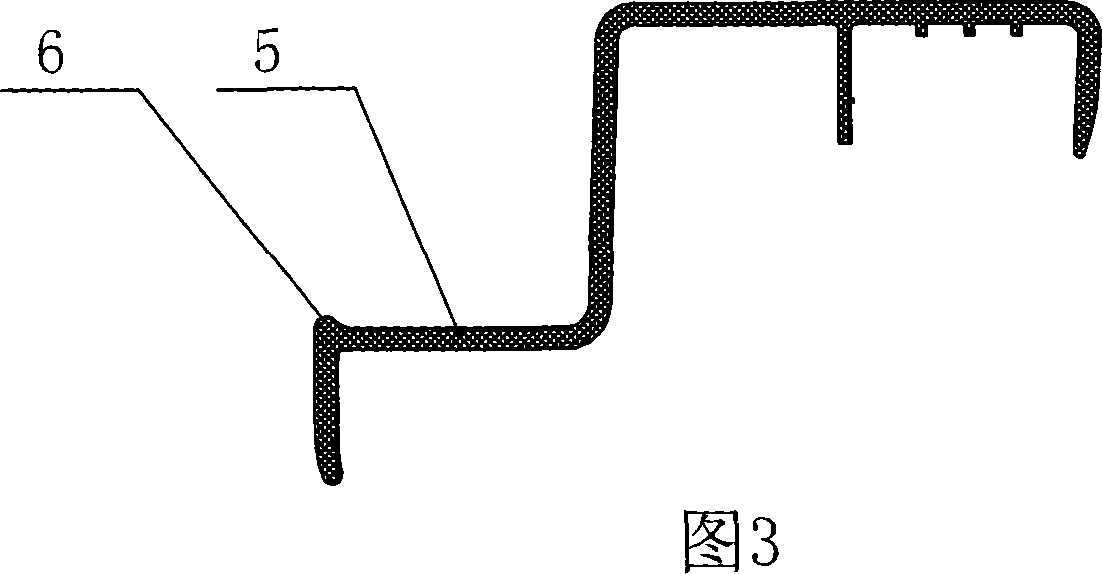

Rectangle ice box frame and producing method thereof

InactiveCN101067533AImprove low temperature impact strengthAvoid crackingDomestic cooling apparatusLighting and heating apparatusDrift angleButt joint

The invention provides a rectangular refrigerator box frame and its manufacture method, the rectangular refrigerator box frame includes the frame body(1) which is composed of the front frame strip(11), the frame strip (12), the left frame strip (13) and the right frame strip (14), the states frame strips is made of the four same section plastics extruding strips, the each extruding strip beginnings and ends is equipped with the drift angle (4), the four extruding strip after the drift angle (4) of two terminal part butt-joint welds form the frame body (1); the interior angle(2) and the outer angle (3) of the four side angle in the rectangular refrigerator box frame body all process rotundity. The refrigerator box frame has low production cost, the strong interchange ability, the simple structure, the small assembly difficulty, the artistic contour, the high intensity of low temperature anti-impact, is not easy cracked under -10 deg-30 deg condition.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

High-flow super-tough cold-resistant material specially used for shells of PC electronic products and preparation method thereof

InactiveCN103665814AGood physical and mechanical propertiesImprove low temperature impact strengthSolventProcessing aid

The invention discloses a high-flow super-tough cold-resistant material specially used for shells of PC electronic products. The material comprises the following raw materials: a PC resin, a flexibilizer, a functional aid, a compatilizer, an anti-oxidant and a processing aid. The invention further discloses a preparation method for the material specially used for the shells. According to the invention, physical and mechanical properties of the material can be substantially improved; the flexibilizer has excellent low temperature impact performance, improves low temperature impact strength of the material and enables the material to have good toughness at a low temperature of -40 DEG C; the functional aid has good fluidity and chemical resistance and can improve fluidity and chemical resistance of the material; the preparation method provided by the invention can rapidly prepare the special material with good fluidity, ultrahigh toughness, cold resistance and chemical solvent resistance, the material can be extensively used in the field of electric products like thin-wall shells of mobile phones and shells of earphones, and the preparation method has simple procedures and is easy to realize.

Owner:DONGGUAN JISU PLASTIC TECH

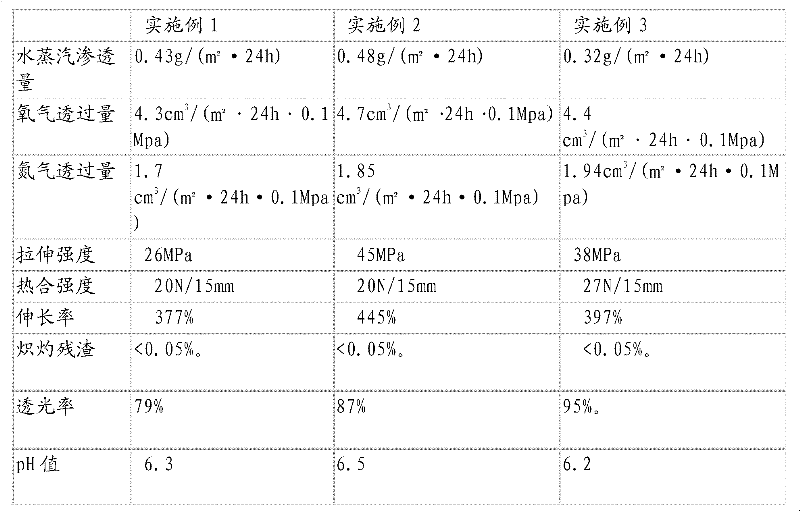

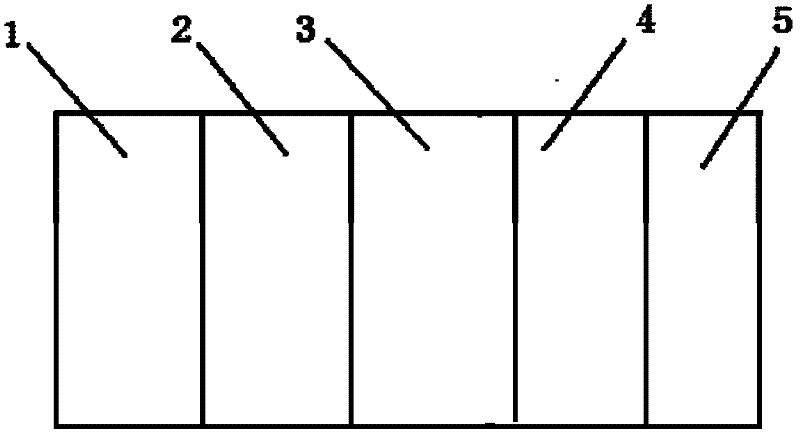

High-barrier multilayer co-extrusion infusion film

The invention relates to a high-barrier multilayer co-extrusion infusion film which is a five-layer composite film with the composition from the outer layer to the inner layer: polyethylene naphthalate modified polyester / ethylene acrylic acid polymer / polypropylene, ethylene- octylene copolymer blending resin / ethylene propylene polymer / modified polypropylene. The advantages of various functional polymer materials are combined by the high-barrier multilayer co-extrusion infusion film, so that not only are the light transmittance, the flexibility, the high barrier performance, the low-temperature thermal sealing property, the thermal bonding strength and the like of the high-barrier multilayer co-extrusion infusion film guaranteed, but also the high-temperature-resistant (121 DEG C and 30min) sterilization performance and the low-temperature-resistant (-30 DEG C) storage performance of the high-barrier multilayer co-extrusion infusion film can be improved; therefore, the matters (including nonvolatile matter, easily-oxidized matter, heavy metal and the like) dissolved out from the infusion film are fewer, a biological or chemical reaction is not caused between the infusion film and liquid medicine after filling sterilization, and toxin is not generated or environmental pollution is not caused when the infusion film is produced, used and recovered. Compared with other similar products, the high-barrier multilayer co-extrusion infusion film has excellent competitive advantages in the aspect of all technical indexes such as production formula, production technique and performances.

Owner:NINGBO HUAFENG PACKAGE

Polypropylene composite material and preparation method thereof

InactiveCN101575433AEffective reinforcementIt has the characteristics of rigidity and toughness balancePolypropylene compositesElastomer

The invention discloses a polypropylene composite material which comprises 100 parts of polypropylene resin, 14 parts to 30 parts of super fine calcium carbonate filler with 6000 meshes to 7000 meshes and 7 parts to 15 parts of materials for elastic body. The surface treatment is carried out on the super fine calcium carbonate filler after the surface coupling treatment of the stearinic acid. Then the polypropylene resin, materials for the elastic body and the super fine calcium carbonate filler are directly put into a high-speed mixer for primary mixing, are mixed evenly at room temperature, and then is moved into a twin-screw extruding machine for even mixing and granulating. Compared with the prior art, the cost of the modified composite material filled by polypropylene equals to the cost of original polypropylene resin. In the invention, the enforcing conditions of the process is ordinary while the modified composite materials is on a par with the popypropylene resin before modification in rigidity and room-temperature impulse strength and low-temperature impulse strength are obviously improved.

Owner:TIANJIN UNIV

Polyamide composition with good appearance

The invention discloses a polyamide composition with good appearance, prepared from, by weight, 49-89% of thermoplastic polyamide resin, 0.01-10% of a maleic anhydride copolymer, 0-50% of a filler, 0-20% of an anti-impact modifier, and 0.01-20% of a polyhydroxy compound, wherein the maleic anhydride copolymer is one of alternating copolymers or block copolymers made by means of mass polymerization. The maleic anhydride copolymer of special structure is added into a polyamide system, so that melt strength and mechanical properties of the polyamide composition are improved; the polyhydroxy compound is introduced, so that the appearance of the polyamide composition is greatly improved, and the mobility worsening due to the introduction of maleic anhydride copolymers is particularly improved;the maleic anhydride copolymer is particularly suitable for processing or forming procedures having high melt strength requirement, especially extrusion molding, blow molding, foaming and the like.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

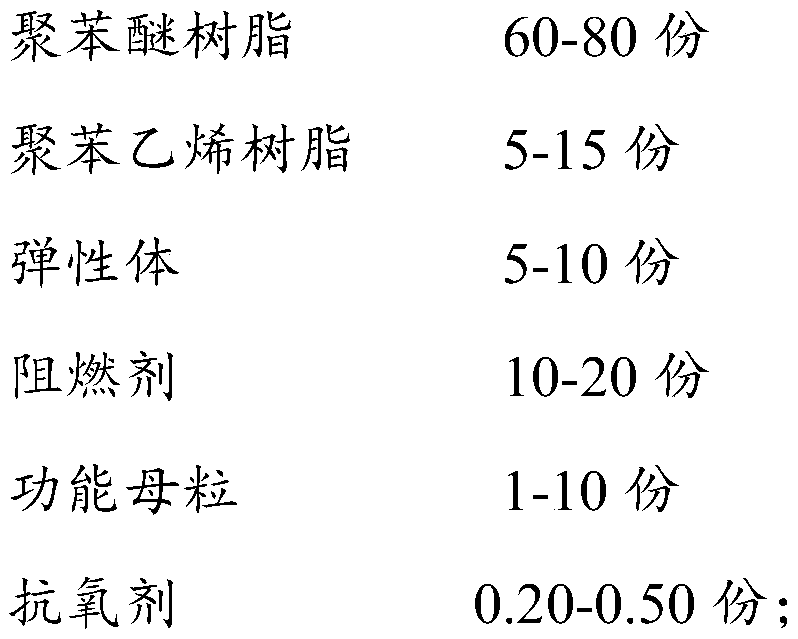

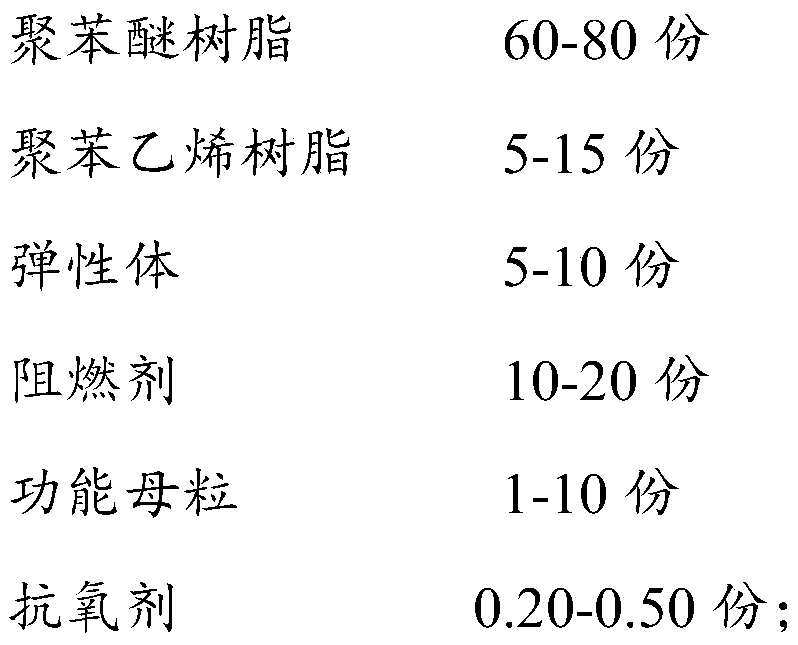

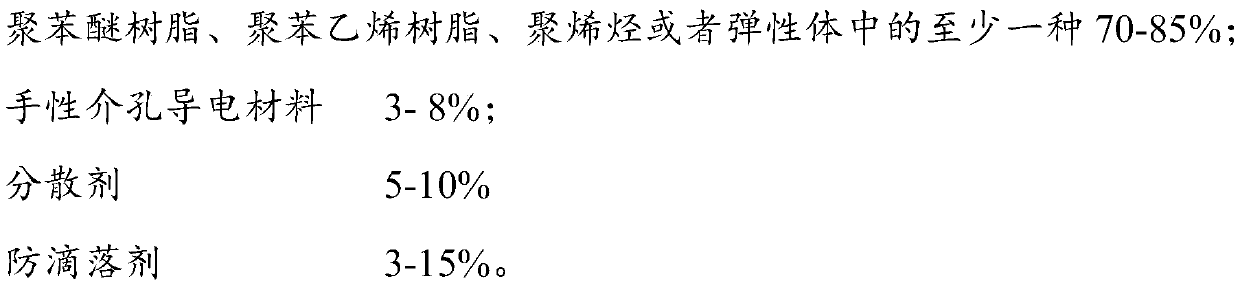

Polyphenyl ether resin alloy material, preparation method thereof and refrigeration compressor

InactiveCN105504767AExcellent stress crack resistance and low temperature impact strengthGood resistance to stress crackingPositive displacement pump componentsPositive-displacement liquid enginesWork performanceFire retardant

The invention discloses a polyphenyl ether resin alloy material, a preparation method thereof and a refrigeration compressor. The polyphenyl ether resin alloy material is prepared from, by weight, 60-80 parts of polyphenyl ether resin, 5-15 parts of polystyrene resin, 5-10 parts of an elastomer, 10-20 parts of fire retardant, 1-10 parts of functional masterbatch and 0.20-0.50 part of antioxygen. The polyphenyl ether resin alloy material has excellent stress cracking resistance, low-temperature impact strength and a flame retardant property, the preparation method is simple in process, and production cost is effectively lowered. A shell of the refrigeration compressor contains the polyphenyl ether resin alloy material, so that the refrigeration compressor is stable in work performance, resistant to low temperature and safe.

Owner:江苏沃特新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com